Page 1

409

4

7

U

N

L

O

C

K

L

O

C

K

MIDMARK

Pediatric

409

Service and

-004 thru -007

Pediatric Examination Table

Serial Number Prefixes:

RG, RH, RJ, RK, RL,

RM, & V

Parts Manual

409-004 & 409-005

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

409-006 & 409-007

409

-00

thru

-00

SF-1561 Part No. 004-0070-00 Rev. K (4/04/08)

Page 2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Section/Paragraph Page Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions ...........................................ii

Safety Alert Symbols .....................................................ii

Warranty Instructions .................................................. ii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual .......................................... 1-1

1.2 How to Use Manual ...................................... 1-1

1.3 Description of 409 Pediatric Examination

Table.......................................................... 1-1

1.4 Specifications ............................................... 1-3

1.5 Standard Torque Specifications.................... 1-5

1.6 Parts Replacement Ordering........................ 1-5

1.7 Special Tools ................................................ 1-7

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test (Models 409-004 and

409-005).................................................... 2-1

2.2 Operational Test (Models 409-006 and

409-007).................................................... 2-3

2.3 Troubleshooting Procedures (Models

409-004 and 409-005)............................... 2-4

2.4 Troubleshooting Procedures (Models

409-006 and 409-007)............................... 2-6

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance (Models

409-004 and 409-005).............................. 3-1

3.2 Scheduled Maintenance (Models

409-006 and 409-007).............................. 3-2

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction................................................... 4-1

4.2 Beam Scale Components Removal /

Installation (Mechanical Scale Only)....... 4-1

4.3 Zero Balance Adjustment (Mechanical

Scale Only)............................................... 4-2

4.4 Beam Scale Calibration Check

(Mechanical Scale Only)......................... 4-3

4.5 Platform Components Removal /

Installation or Table Top Locking

Mechanism Access (Mechanical

Scale Only)............................................... 4-4

4.6 Linear Scale Alignment (All Models)........... 4-6

4.7 Digital Display Removal / Installation

(Digital Scale Only) ................................. 4-6

4.8 Platform Scale Components / Load Cell

Assembly Access (Digital Scale

Only)......................................................... 4-7

4.9 Platform Load Cell Removal / Installation

(Digital Scale Only)................................. 4-9

4.10 Platform Assembly Removal / Installation

(Digital Scale Only)................................. 4-9

4.11 Display Board Assembly Removal /

Installation (Digital Sca le Only)............. 4-10

4.12 Digital Scale Calibration............................. 4-12

4.13 Digital Scale Gravitational Compensation

Adjustment.............................................. 4-13

4.14 Display Board Assembly Mode Setting

Procedure (Digital Scale Only) ............. 4-13

4.15 AUTO Power Off / Continuous Use

Selection Procedure (Digital Scale

Only)....................................................... 4-14

SECTION V SCHEMATICS AND DIAGRAMS

None.

SECTION VI PARTS LIST

6.1 Introduction ................................................ 6-1

6.2 Description of Columns................................ 6-1

6.3 Torque Specifications And Important

Assembly Notes........................................ 6-1

Pictorial Index [s/n prefix “JS”] ..................... 6-2

Pictorial Index [s/n prefix “PP”]..................... 6-3

Cabinet Assembly ....................................... 6-4

Upper Wrap [s/n prefix “JS”]:

w/ Mechanical Scale............................... 6-5.*

w/o Mechanical Scale............................. 6-6.*

Table Top Assembly [s/n prefix “JS”]:

w/ Mechanical Scale................................. 6-7

w/o Mechanical Scale............................... 6-8

Upper Wrap [s/n prefix “PP”] ....................... 6-9

Table Top Assembly [s/n prefix “PP”]:

w/ Digital Scale ....................................... 6-10

w/o Digital Scale..................................... 6-11

Tanita Scale Components ........................ 6-12.*

Weight Calibration...................................... 6-13

Key And Lock Assembly............................. 6-14

COMMENTS ............................................................. 7-1

FAX ORDER FORM.................................................. 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1998 SF-1561 Page i Printed in U.S.A.

Rev. 8/02

Page 4

TABLE OF CONTENTS

General Safety Instructions

Safety First: The primary concern of Midmark Corporation is that this table is maintained with the safety

of the patient and staff in mind. To assure that services

and repairs are completed safely and correctly, proceed

as follows:

(1) Read this entire manual before performing any

services or repairs on this table.

(2) Be sure you understand the instructions con-

tained in this manual before attempting to service or repair this table.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure, practice, or condition which, if not correctly followe d,

will result in loss of life or serious personal

injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow the guidelines listed below will

void the warranty and/or render the 409 Pediatric

Examination Table unsafe for operation.

• In the event of a malfunction, do not attempt to

operate the table until necessary repairs have been

made.

• Do not attempt to disassemble table, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components. Use only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure, practice, or condition which, if not correctly followe d,

could result in loss of life or serious personal

injury.

CAUTION

A CAUTION is used for a potentially haz-

ardous operating procedure, practice, or

condition which, if not correctly followed, could result

in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous operating procedure, practice, or condition which, if not

correctly followed, will or could result in serious, moderate, or minor damage to unit.

© Midmark Corporation 1998 SF-1561 Page ii Printed in U.S.A.

Page 5

SECTION I

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for the 409 Pediatric Exam Table. This manual is

intended to be used by Midmark’s authorized service

technicians.

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1 or 3.2).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

B. Manual Use When Table Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on Table (Refer to

para 2.1 or 2.2).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.3 or

2.4).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

1.3 Description of 409 Pediatric Exam

Table

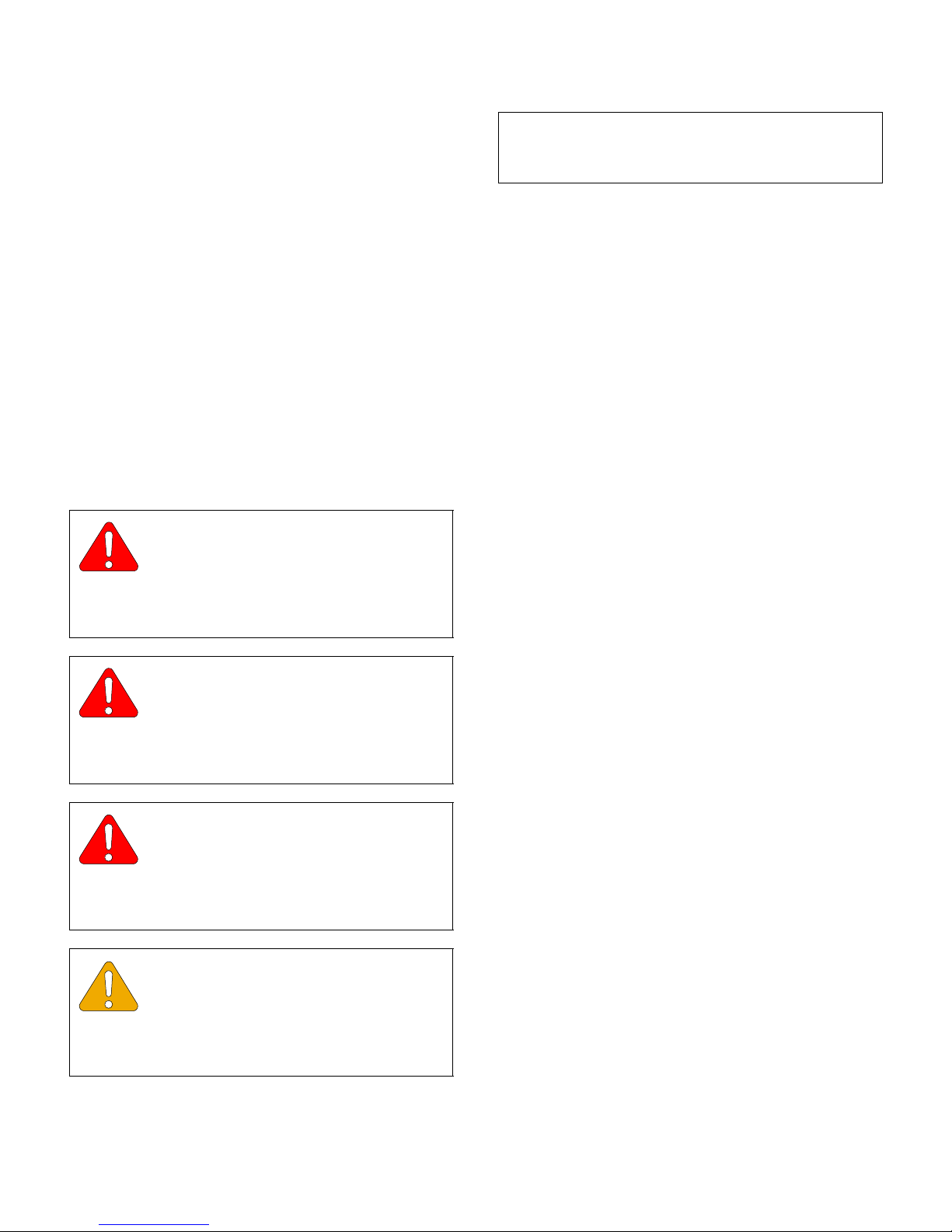

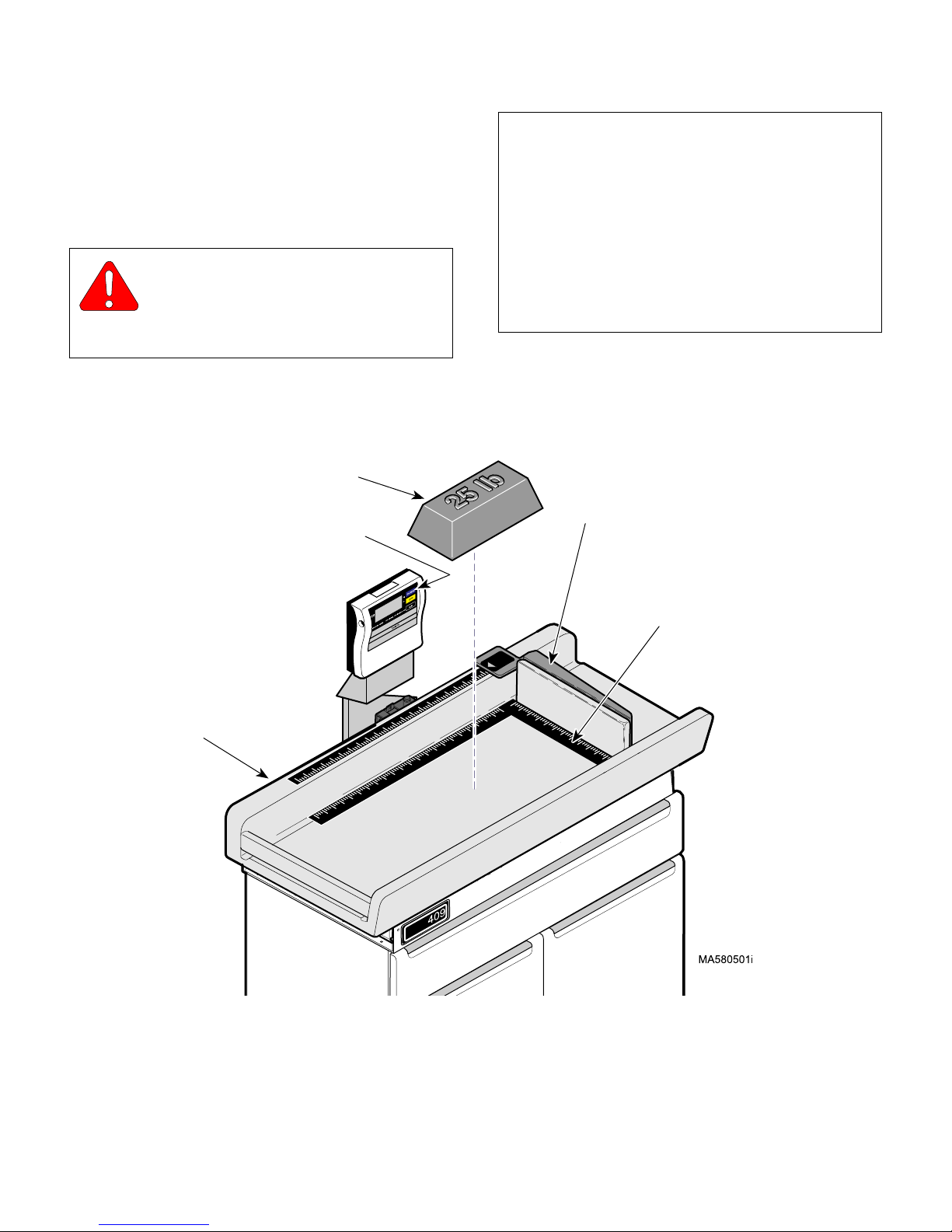

A. General Description (See Figure 1-1).

The 409 Pediatric Examination Table is a table designed

to be used by physicians and office staff to conduct routine medical examinations and measurements on pediatric patients weighing between 7.0 to 40.0 lbs (3.2 to

18.1 kg) and measuring 15.0 to 36.0 in. (38.1 to 91.4

cm) in length. Listed below are the four different models

available:

409-004............. Exam Table with mechanical scale

409-005............. Exam Table without mechanical scale

409-006............. Exam Table with digital scale

409-007............. Exam Table without digital scale

The major serviceable components of the 409-004 table

(table with mechanical scale) are the beam scale components which include the “0” balance screw & weight,

platform components, linear scale, and table top locking

mechanism. The major serviceable component of the

409-005 table (table without mechanical scale) is the

linear scale (See Figure 1-1).

The major serviceable components of the 409-006 table

(table with digital scale) are the digital display (which

includes display board assembly), platform components

(which includes load cell assembly), and linear scale.

The major serviceable component of the 409-007 table

(table without digital scale) is the linear scale (See Figure 1-1).

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with maintenance / service instructions (Refer

to para 4.1).

© Midmark Corporation 1998 SF-1561 Page 1-1 Printed in U.S.A.

Rev. 3/01

Page 6

SECTION I

GENERAL INFORMATION

409-004 and 409-005

409-006 and 409-007

© Midmark Corporation 1998 SF-1561 Page 1-2 Printed in U.S.A.

Rev. 3/01

Figure 1-1. Major Components

Page 7

SECTION I

GENERAL INFORMATION

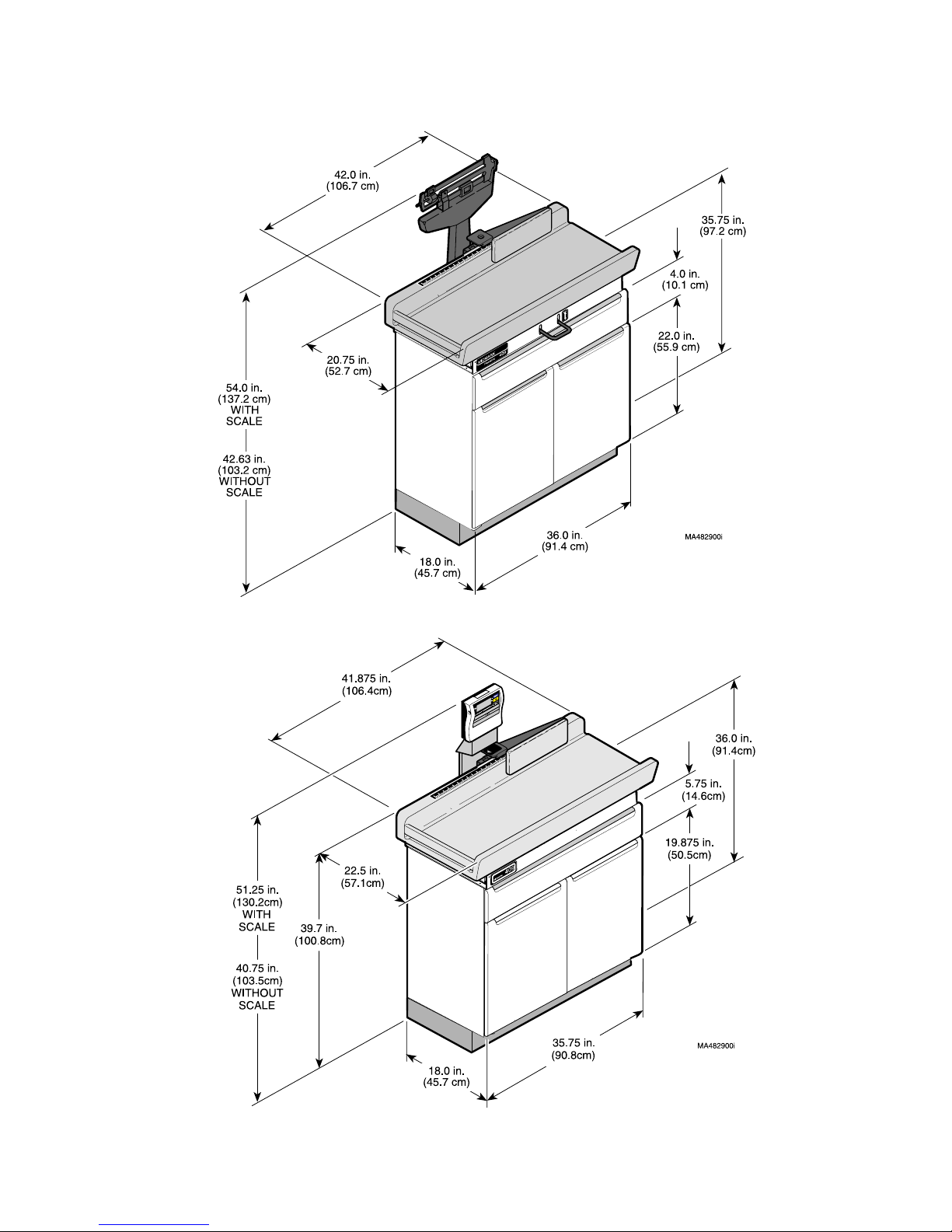

1.4 Specifications

Factual data for the 409 Pediatric Examination Table is

provided in Table 1-1. Also, see Figure 1-2.

Table 1-1. Specifications

Description Data

Patient Weight (409-004/409-005):

Maximum For Examination.................. 40 lbs (18.1 kg)

Maximum For Weighing ...................... 40 lbs (18.1 kg)

Patient Weight (409-006/409-007):

Maximum For Examination.................. 40 lbs (18.1 kg)

Maximum For Weighing ...................... 40 lbs (18.1 kg)

Weight of 409-004 Unit:

Boxed Weight ............................. 242.0 lbs (109.8 kgs)

Unboxed Weight ............................188.0 lbs (85.3 kgs)

Weight of 409-005 Unit:

Boxed Weight .............................. 215.0 lbs (97.5 kgs)

Unboxed Weight ............................161.0 lbs (73.0 kgs)

Weight of 409-006 Unit:

Boxed Weight ............................. 242.0 lbs (109.8 kgs)

Unboxed Weight ............................188.0 lbs (85.3 kgs)

Weight of 409-007 Unit:

Boxed Weight .............................. 215.0 lbs (97.5 kgs)

Unboxed Weight ............................161.0 lbs (73.0 kgs)

Overall Depth (w/o scale)...................... 21.5 (54.6 cm)

Overall Width ..............................41.875 in. (106.4 cm)

Beam Scale Accuracy (409-004):

up to 18.0 lbs (8.2 kg) is: ...................... ±1 oz. (28.3 g)

between 18-40 lbs (8.2 - 18.1 kg) is: ... ± 2 oz. (56.6.g)

over 40.0 lbs (18.1 kg) is:................... ± 4 oz. (113.3 g)

Beam Scale

Readout Increments (409-004):..................... minimum

increment is 1 oz. (20 g)

Digital Scale Accuracy (409-006):

0 - 11 lbs (0 - 5 kg) is: ........................... ±1.75 oz. (50 g)

11 - 40 lbs (5 - 18 kg) is: ....................... ±3.5 oz. (100 g)

[Serial #’s PP1143 thru present only register to 40 lbs]

40 - 100 lbs (18 - 45 kg) is: ................. ±5.25 oz. (150 g)

Digital Scale Readout

Minimum Increments (409-006):

Serial #’s: PP1000 thru PP1142 .............0.2 lb (0.09 kg)

Serial #’s: PP1143 thru present ..................1 oz (.01 kg)

Digital Scale Specifications:

Type Measurement ........ Electrical Resistance Method

Power Source ..................... Six LR6 Alkali Batteries or

AC Adapter - 9V, 300mA or more

center minus plug

Battery Life........................ 100 Hours Continuous Use

Power Consumption.................... 0.25 Watts maximum

Display ...................... LCD with 1 in. (25mm) numerals

Shipping Carton: ........... 45.0 in. "L" x 28.75 in. "W" x

43.0 in. "H"

Linear Scale

Accuracy:......................................... ± 1/8 in. (0.32 cm)

(114.3 cm x 73.0 cm x 109.2 cm)

Linear Scale Readout

Dimensions (409-004/409-005):

Minimum Increments: ...........................1/8 in. (0.5 cm)

Upholstered Top ..............20.75 in. wide x 42.0 in. long

(52.7 cm wide x 106.7 cm long)

Certifications:..................................ISO-9001 Certified

Table Top Work Height ................... 35.75 in. (97.2 cm)

Overall Height (w/scale) .................... 54 in. (137.2 cm)

Overall Height (w/o scale) .......... 40.625 in. (103.2 cm)

Overall Depth (w/scale) .................... 25.5 in. (64.8 cm)

Overall Depth (w/o scale) .................... 21.75 (55.2 cm)

Overall Width.................................. 42.0 in. (106.7 cm)

Dimensions (409-006/409-007):

Upholstered Top ..........20.75 in. wide x 41.875 in. long

(52.7 cm wide x 106.4 cm long)

Table Top Work Height ..................... 36.0 in. (91.4 cm)

Overall Height (w/scale) ............... 51.25 in. (130.2 cm)

Overall Height (w/o scale) ............ 40.75 in. (103.5 cm)

Overall Depth (w/scale) .................... 22.5 in. (57.1 cm)

© Midmark Corporation 1998 SF-1561 Page 1-3 Printed in U.S.A.

Rev. 6/07

Page 8

SECTION I

GENERAL INFORMATION

409-004 and 409-005

409-006 and 409-007

© Midmark Corporation 1998 SF-1561 Page 1-4 Printed in U.S.A.

Rev. 3/01

Figure 1-2. Dimensions

Page 9

SECTION I

GENERAL INFORMATION

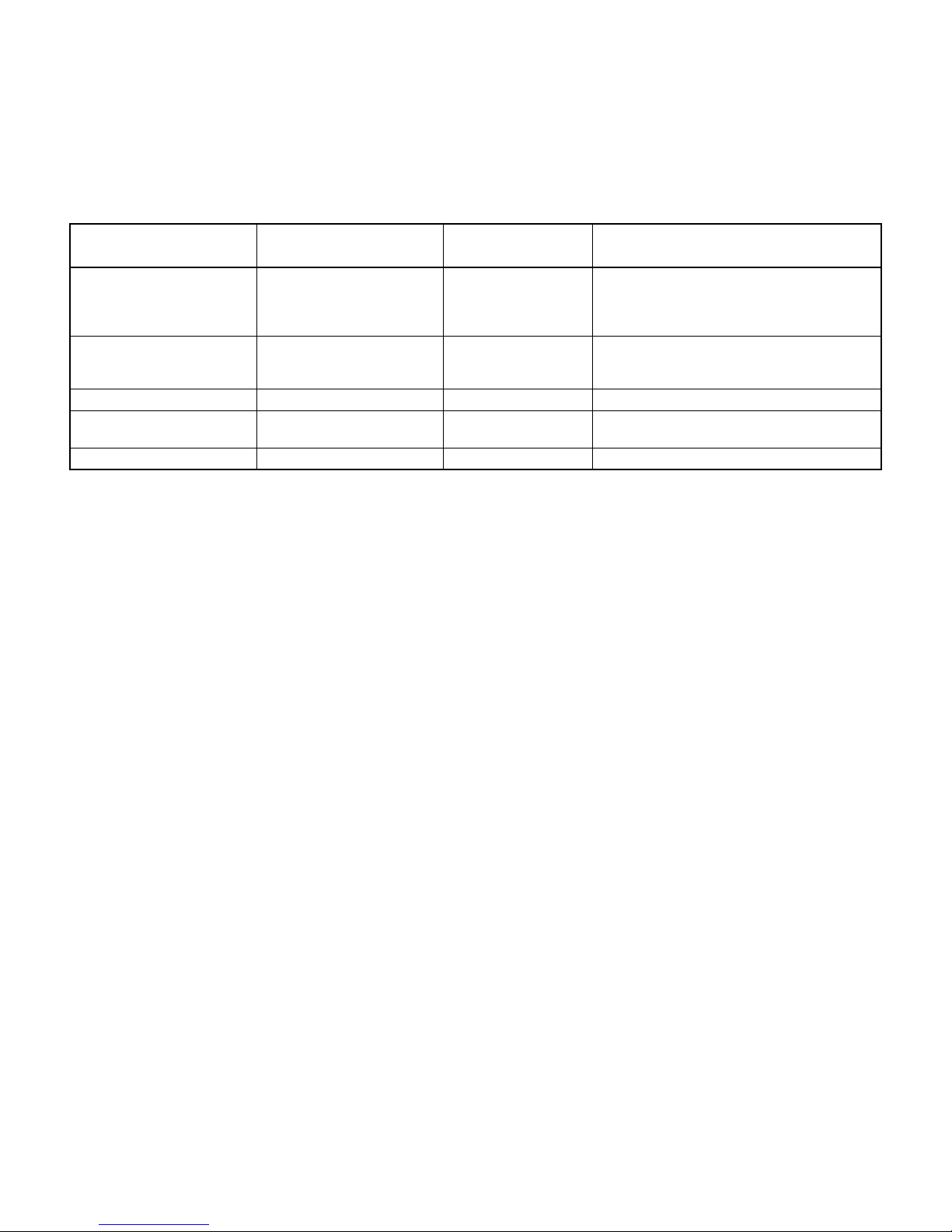

1.5 Standard Torque Specifications

The following standard torque specifications in Table

1-2 apply to the various hardware used on the units

unless otherwise listed elsewhere in service procedures

or parts illustrations:

Table 1-2. Torque Specifications

Hardwa r e S ize Torque Values

#6 ............................11 to 21 inch / lbs. (1.2 to 2.3 N•M)

#8 ............................20 to 30 inch / lbs. (2.2 to 3.3 N•M)

#10 ..........................32 to 42 inch / lbs. (3.6 to 4.8 N•M)

1/4" .........................75 to 85 inch / lbs. (8.5 to 9.6 N•M)

5/16" .....................18 to 22 foot / lbs. (24.4 to 29.8 N•M)

3/8" .......................31 to 35 foot / lbs. (42.0 to 47.5 N•M)

1/2” .......................50 to 60 foot / lbs. (67.8 to 81.4 N•M)

1.6 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

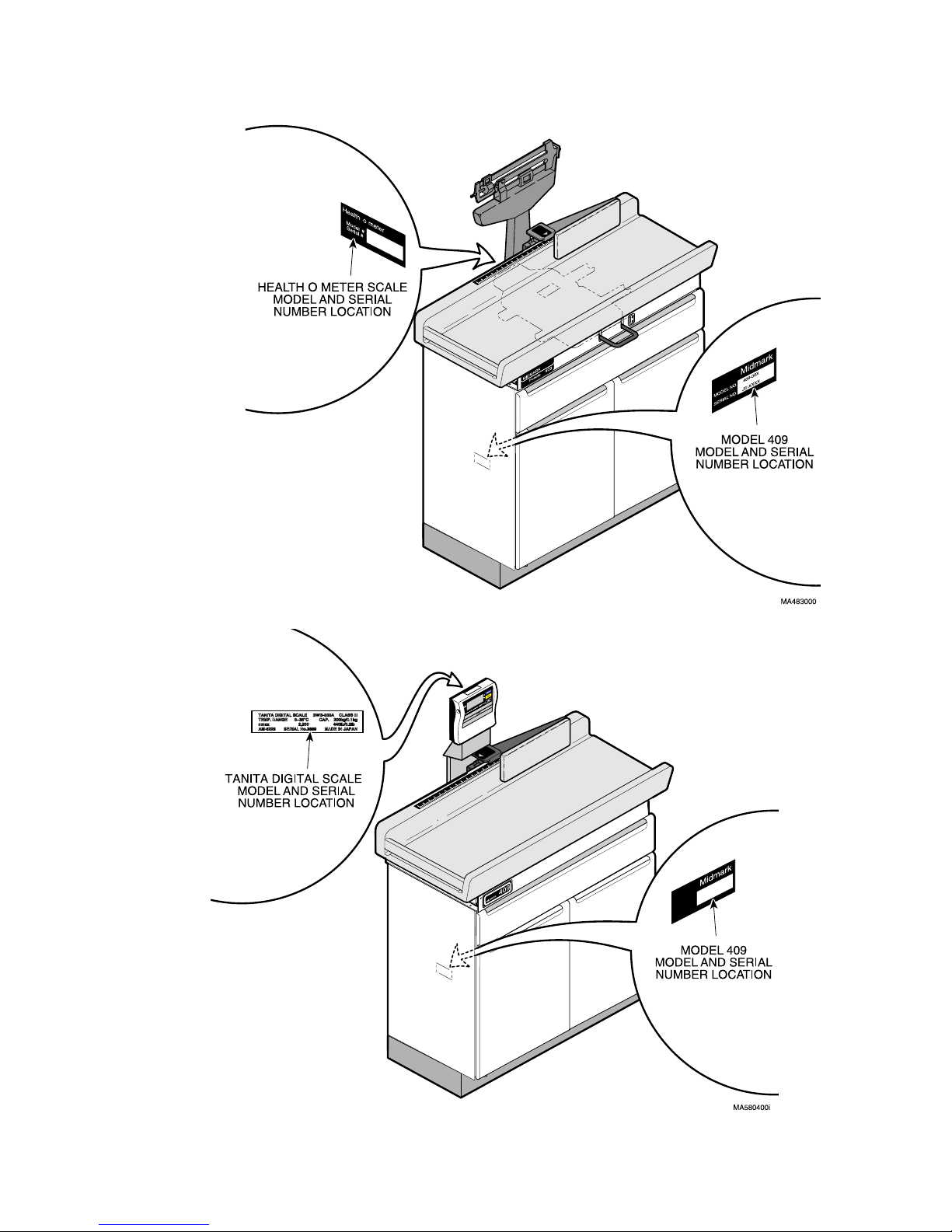

(1) Refer to Figure 1-3 to determine the location of

the model number and serial number of the

table and record this data.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the

parts, descriptions of the parts, and quantities

of parts needed and record this data (Refer to

para 6.1).

NOTE

Ask the Purchasing Department of the company that

owns the unit for this information. Otherwise, this

information may be obtained from the dealer that sold

the unit.

(3) Determine the installation date of the table and

record this data.

(4) Call Midmark with the recorded information and

ask for the Medical Products Technical Services

Department. See back cover of this manual for

the phone number or use the Fax Order Form

(See page 7-2 for Fax Order Form).

© Midmark Corporation 1998 SF-1561 Page 1-5 Printed in U.S.A.

Rev. 3/01

Page 10

SECTION I

GENERAL INFORMATION

409-004 and 409-005

409-006 and 409-007

Figure 1-3. Model Number / Serial Number Location

© Midmark Corporation 1998 SF-1561 Page 1-6 Printed in U.S.A.

Rev. 3/01

Page 11

SECTION I

GENERAL INFORMATION

1.7 Special Tools

the table, how to obtain the special tools, and the purpose of each special tool.

Table 1-3 lists all of the special tools needed to repair

Table 1-3. Special Tool List

Description of Special Tool

Calibrated Test Weight

(included with & applies only to

409-004 table)

200kg or 440 lb Calibrated Test

Weight (applies to 409-006

table)

50 lb Calibrated Test Weight Commercially Available Any Type Used to check digital scale calibration.

Soldering iron & solder Commercially Available Any Type Used to desolder/solder two battery leads to dis-

Torque Wrench Commercially Available Any Type Used to tighten nuts or screws to specified values.

Manufacturer’s

Name / Address / Phone

Midmark Corporation

60 Vista Drive

Versailles, Ohio 45380

937-526-3662

Commercially Available Any Type Used to calibrate digital scale.

Manufacturer’s

Part N umbe r

050-4086-10 Used to calibration of the beam scale. A calibrated

test weight is included with each table from the factory. The test weight should be hanging on the

right rear of the table on a hook.

play board assembly when it is being replaced.

Purpose of Special Tool

© Midmark Corporation 1998 SF-1561 Page 1-7 Printed in U.S.A.

Rev. 3/01

Page 12

SECTION I

GENERAL INFORMATION

© Midmark Corporation 1998 SF-1561 Page 1-8 Printed in U.S.A.

Rev. 3/01

Page 13

TESTING AND TROUBLESHOOTING

SECTION II

TESTING AND TROUBLES HOOTING

SECTION II

2.1 Operational Test (Models 409-004

and 409-005) (See Figure 2-1)

In order to effectively diagnose a malfunction of the 409004 and 409-005 Pediatric Examination Table, it may be

necessary to perform an operational test as follows:

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

table. Failure to do so could result in personal

injury.

NOTE

The Operational Test, for the most part, only

describes what should happen when the table is

operated. If the table does something other than

described, a problem has been discovered. Refer to

the Troubleshooting Guide to determine the cause of

the problem and its correction.

Also, this operational test procedure is based on units

that have a beam scale; some units do not have a

beam scale - For these units skip to step 14.

(6) Remove any items from table top. Set large

poise weight to zero, making sure it is seated in

notch and set small poise weight to zero, making sure small poise weight is pushed firmly

against shoulder of beam.

(7) Observe. The beam pointer should balance in

center of trig square, indicating scale is zeroed.

NOTE

Use the calibrated test weight which should be hanging on a storage hook on the right rear of the table.

The test weight will have a label indicating the calibrated weight of the test weight.

(8) Place the calibrated test weight on center of

upholstered table top.

(9) Using the large poise weight and small poise

weight, set beam scale to a setting which is

equal to calibrated test weight.

(10) Observe. The beam pointer should center in

the trig square indicating beam scale is within

tolerance.

(1) Move table top locking handle to LOCK posi-

tion. Attempt to move table top (See

Figure 2-1).

(2) Observe. The table top should be firmly locked

into a stationary position.

(3) Move table top locking handle to UNLOCK posi-

tion.

(4) Observe. The table top should not be locked

into a stationary position anymore. Look

between table top and base. There should be

approximately a 1/4 in. (6.35 mm) gap between

locking rails and bottom of table top; at the very

least, there should not be any contact.

(5) Push down on center of table top a few times to

align and exercise all internal scale parts.

(11) If beam scale does not center, adjust the small

poise weight and/ or large poise weight as necessary to center beam pointer in trig square.

(12) Determine how much beam scale reading dif-

fers from weight of calibrated test weight. The

allowable tolerance is ±1 oz. (28.3 g).

(13) Hang the calibrated test weight on its storage

hook, located on right rear of table.

(14) Remove any items from table top and then

move table top locking handle to LOCK position.

(15) Extend linear scale fully. Using a carpenter

square, check to see if the linear scale is

square with back of table top when scale is fully

extended.

© Midmark Corporation 1998 SF-1561 Page 2-1 Printed in U.S.A.

Rev. 3/01

Page 14

SECTION II

TESTING AND TROUBLESHOOTING

LARGE POISE

WEIGHT

SMALL POISE

WEIGHT

LOCKING RAILS

(LEFT SIDE SHOWN)

TRIG

SQUARE

BEAM

POINTER

LINEAR

SCALE

CARPENTERS

SQUARE

TABLE

TOP

409

MIDMARK

Pediatric

Figure 2-1. Operational Test (Models 409-004 & 409-005)

TABLE TOP

LOCK/UNLOCK

HANDLE

MA483100

© Midmark Corporation 1998 SF-1561 Page 2-2 Printed in U.S.A.

Rev. 3/01

Page 15

SECTION II

TESTING AND TROUBLESHOOTING

2.2 Operational Test (Models 409-006

and 409-007) (See Figure 2-2)

In order to effectively diagnose a malfunction of the 409006 and 409-007 Pediatric Examination Table, it may be

necessary to perform an operational test as follows:

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

table. Failure to do so could result in personal

injury.

25 lb (11.3 kg)

TEST WEIGHT

ON / ZERO

BUTTON

NOTE

The Operational Test, for the most part, only

describes what should happen when the table is

operated. If the table does something other than

described, a problem has been discovered. Refer to

the Troubleshooting Guide to determine the cause of

the problem and its correction.

Also, this operational test procedure is based on units

that have a digital scale; some units do not have a

digital scale - For these units skip to step 7.

LINEAR

SCALE

TABLE

TOP

MIDMARK

Figure 2-2. Operational Test (Models 409-006 & 409-007)

(1) Press ON / ZERO button to turn digital scale

ON.

CARPENTERS

SQUARE

© Midmark Corporation 1998 SF-1561 Page 2-3 Printed in U.S.A.

Rev. 6/07

Page 16

SECTION II

TESTING AND TROUBLESHOOTING

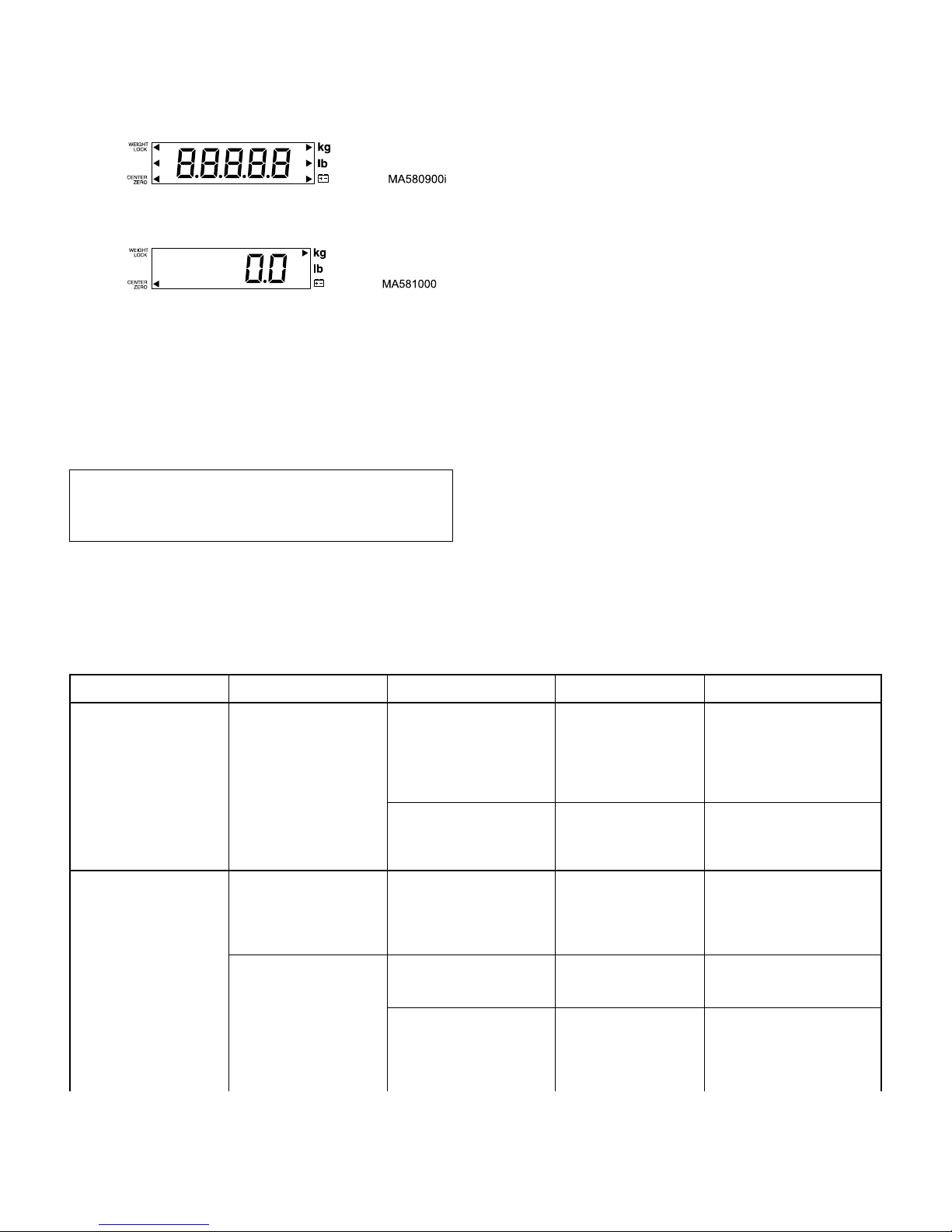

(2) Observe. The display should flash

momentarily and then the display should display

Make sure all LCD segments illuminate properly.

(3) Check all functions of digital display (Reference

TANITA BWB-800 operating Instructions Manual).

(4) Press KG / LB button until display is set to LB.

NOTE

Use the calibrated test weight to perform the following procedure.

(6) Determine how much digital scale reading dif-

fers from weight of calibrated test weight. The

allowable tolerance is ±5.25 oz. (150 g).

(7) Remove calibrated test weight and then press

ON / ZERO to turn digital scale OFF.

(8) Extend linear scale fully. Using a carpenter

square, check to see if the linear scale is

square with back of table top when scale is fully

extended.

2.3 Troubleshooting Procedures

(Applies to 409-004 and 409-005)

Table 2-1 is a Troubleshooting Guide which is used to

determine the cause of the malfunction. This guide covers problems with scale platform components, beam

scale components, and linear scale components which

the model 409-004 has. The model 409-005 does not

have a scale platform or beam scale; it only has a linear

scale. For this model, only use the portion of the guide

which is applicable.

(5) Place a calibrated 25 lb (11.3 kg) test weight on

center of table top.

Table 2-1. Troubleshooting Guide (Models 409-004 & 409-005)

Problem Symptom Probable Cause Check Correction

Table top will not lock into

stationary position properly.

Weight scale does not

measure weight accurately.

When table top locking

handle is moved to the

LOCK position, the table

top is not locked into stationary position (can still be

moved).

The beam pointer will not

center when the large and

small poise weights are set

to zero.

The measured weight of

the patient is inaccurate.

Table top locking mechanism

has bent, broken, or missing

components.

Platform has worn “V” bearings or a broken pivot.

The beam scale is not

zeroed.

Paper roll is interfering with

table top.

Locking rails are not releasing properly when table top

locking handle is moved to

the UNLOCK position.

Check for bent, broken,

or missing components.

Check for worn “V” bearings or a broken pivot.

Check to see if the beam

pointer centers when the

large and small poise

weights are set to zero.

Check to see if paper roll

is in contact with bottom

of table top.

Check for bent or missing

components in table top

locking mechanism. See

why locking rails are

“hanging up”.

Replace any bent, broken, or

missing components on the

table top locking mechanism.

Refer to para 4.5 to gain

access.

Replace platform assembly

and beam scale assembly (are

a factory matched unit). Refer

to para 4.2 and 4.5.

If beam pointer does not center when the large and small

poise weights are set to zero,

perform a zero balance adjustment. Refer to para 4.3.

Reduce thickness of paper roll

or remove paper roll.

Repair or replace any bent,

broken, or missing components on the table top locking

mechanism. Refer to para 4.5

to gain access.

© Midmark Corporation 1998 SF-1561 Page 2-4 Printed in U.S.A.

Rev. 6/07

Page 17

Table 2-1. Troubleshooting Guide (Models 409-004 & 409-005) - Continued

Problem Symptom Probable Cause Check Correctio n

Linear scale seems to be

inaccurate.

Beam pointer does not

move at all during weighing.

Arm of linear scale is not

perpendicular to upholstered top when extended

or height measurements

seem inaccurate.

TESTING AND TROUBLESHOOTING

Table is not level. Check to see if table top

Beam pointer is touching the

the side of the trig square

during its travel.

Patient is not being centered on the table top before

being weighed.

Platform is rocking excessively or touches its base at

any corner as a result of a

worn or broken “V” bearing

or a broken pivot.

Steel connecting rod which

connects beam scale and

weight platform is rubbing

against inside of scale pillar.

Beam scale is out of calibration.

Connection rod is incorrectly connected or has

become disconnected from

linkage rods.

Scale label is not positioned

properly.

Linear scale is out of alignment (not square with back

of table top).

is level.

Press down on the center

of the table top while

observing the beam

pointer.

Check to see if table

operator is positioning

patient properly.

Check for worn or broken

“V” bearings or a broken

pivot.

Check to see if all wire

hooks of steel connecting

rod face toward the right

side of the table.

Check accuracy of scale

with the calibrated test

weight.

Check connection rod

connections.

Use tape measure to

check if scale label is

positioned properly.

Use a carpenter square

to check squareness of

linear scale with respect

to the back of table top.

SECTION II

Adjust four leveling screws,

located on base of table, to

level table.

Replace platform assembly

and beam scale assembly (are

a factory matched unit). Refer

to para 4.2 and 4.5.

Inform operator of correct

patient positioning for weighing.

Replace platform assembly

and beam scale assembly (are

a factory matched unit). Refer

to para 4.2 and 4.5.

Position all wire hooks so they

face the right side of table.

Refer to para 4.2.

Check the calibration of the

beam scale using the calibrated test weight. Refer to

para 4.4. If scale is out of calibration, replace platform

assembly and beam scale

assembly (are a factory

matched unit). Refer to para

4.2 and 4.5.

Connect disconnected connection rod. Make sure all

other linkage is correctly positioned and connected to connection rod.

Reposition scale label or if

necessary, replace with new

scale label.

Align linear scale. Refer to

para 4.6.

© Midmark Corporation 1998 SF-1561 Page 2-5 Printed in U.S.A.

Rev. 3/01

Page 18

SECTION II

TESTING AND TROUBLESHOOTING

2.4 Troubleshooting Procedures

(Applies to 409-006 and 409-007)

Table 2-2 is a Troubleshooting Guide which is used to

determine the cause of the malfunction. This guide covers problems with scale platform components and digital display which the model 409-006 has. The model

Table 2-2. Troubleshooting Guide (Models 409-006 & 409-007)

Problem Symptom Probable Cause Check Correctio n

Digital Scale is malfunctioning.

Nothing is displayed on

digital display when ON /

ZERO switch is pressed.

Digital display acts erratically.

Digital display works, but

measured weight stays at

zero even with weight on

table top.

The measured weight of

the patient is inaccurate.

AC adapter is malfunctioning

or disconnected (applies

only if AC adapter is being

used instead of batteries).

Batteries are too weak to

operate digital scale (applies

only if batteries are being

used instead of AC adapter).

Display board assembly is

malfunctioning.

The mode setting for the digital display has been lost due

to a power surge or replacement of display board

assembly.

Display connector (connects

to underside of digital display) is loose or disconnected from digital display.

Wiring / connector between

display board assembly and

platform scale load cell is

disconnected or torn.

Platform scale load cell

assembly is malfunctioning.

Paper roll is interfering with

table top.

Table is not level. Check to see if table top

Table is located where

excessive vibration occurs.

409-007 does not have a scale platform or digital display; it only has a linear scale. For this model, only use

the portion of the guide which is applicable.

Check the connection of

the AC adapter jack to

the AC jack port and the

connection of AC adaptor

plug to the wall outlet.

Replace suspect batteries with known working

batteries or use an AC

adapter.

Replace suspect display

board assembly with

known working display

board assembly.

Check mode setting for

unit.

Check if display connector is loose or disconnected.

Check for disconnected,

torn, or damaged connector / wiring.

Replace suspect platform

scale load cell with

known working platform

scale load cell.

Check to see if paper roll

is in contact with bottom

of table top.

is level.

Check for signs of excessive vibration at table

location.

Correct bad connection. If

necessary, replace AC

adapter (Call TANITA Corporation @847-640-9241 to order

parts /accessories).

Replace six used batteries

with six new LR6 Alkali batteries (“AA” Batteries).

Replace display board assembly (Call TANITA Cor poration

@847-640-9241 to order parts

/accessories).

Adjust mode setting for digital

scale to code:H8830. This is

the type of scale used on this

table. Refer to para 4.14.

Make sure display connector

is properly connected to digital

display.

Connect loose connector or

replace any torn or damaged

connector / wiring. (Call TANITA Corporation @847-6409241 to order parts /accessories.) Refer to para 4.8.

Replace platform scale load

cell. Refer to para 4.9. (Call

TANITA Corporation @847640-9241 to order parts /

accessories.)

Reduce thickness of paper roll

or remove paper roll.

Adjust four leveling screws,

located on base of table, to

level table.

Accurate measurement may

be impossible if the product is

used where there is excessive

vibration. Try using the table

at another location.

© Midmark Corporation 1998 SF-1561 Page 2-6 Printed in U.S.A.

Rev. 3/01

Page 19

Table 2-2. Troubleshooting Guide (Models 409-006 & 409-007) - Continued

Problem Symptom Probable Cause Check Correctio n

Linear scale seems to be

inaccurate.

Arm of linear scale is not

perpendicular to upholstered top when extended

or height measurements

seem inaccurate.

TESTING AND TROUBLESHOOTING

Digital scale is out of calibration.

Display board assembly is

malfunctioning.

Wiring / connector between

display board assembly and

platform scale regulator is

disconnected or torn.

Platform scale load cell

assembly is malfunctioning.

Scale label is not positioned

properly.

Linear scale is out of alignment (not square with back

of table top).

Check accuracy of digital

scale with a calibrated 50

lb (22.7 kg) test weight.

The allowable tolerance

± 5.25 oz. (150 g).

is

Replace suspect display

board assembly with

known working display

board assembly.

Check for disconnected,

torn, or damaged connector / wiring.

Replace suspect platform

scale load cell with

known working platform

scale load cell.

Use tape measure to

check if scale label is

positioned properly.

Use a carpenter square

to check squareness of

linear scale with respect

to the back of table top.

SECTION II

Check the calibration of the

digital scale using the calibrated test weight. If digital

scale is out of calibration, calibrate digital scale. Refer to

para 4.12.

Replace display board assembly. Refer to para 4.11. (Call

TANITA Corporation @847640-9241 to order parts /

accessories.)

Connect loose connector or

replace any torn or damaged

connector / wiring. (Call TANITA Corporation @847-6409241 to order parts /accessories.) Refer to para 4.8.

Replace platform scale load

cell. Refer to para 4.9. (Call

TANITA Corporation @847640-9241 to order parts /

accessories.)

Reposition scale label or if

necessary, replace with new

scale label.

Align linear scale. Refer to

para 4.6.

© Midmark Corporation 1998 SF-1561 Page 2-7 Printed in U.S.A.

Rev. 3/01

Page 20

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 1998 SF-1561 Page 2-8 Printed in U.S.A.

Rev. 3/01

Page 21

SCHEDULED MAINTENANCE

SECTION III

SCHEDULED MAINTENANCE

SECTION III

3.1 Scheduled Maintenance (Models

409-004 and 409-005)

This guide covers inspections on tables with platform

components, beam scale components, and linear scale

components which the model 409-004 has. The model

Table 3-1 is a Scheduled Maintenance Chart which lists

the inspections and services that should be performed

periodically on the 409-004 & 409-005) Pediatric Exam-

409-005 does not have a platform or beam scale; it has

only a linear scale. For this model, only use the portion

of the guide which is applicable.

ination Table. These inspections and services should

be performed as often as indicated in the chart.

Table 3-1. Scheduled Maintenance

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of table for obvious damage such as: cracks in components, missing com-

Fasteners / hardware Check table for missing or loose fasteners / hardware. Replace any missing hardware and tighten

Warning and instructional

decals

Pivot points / moving

parts / accessories

Table top locking mechanism

Beam scale zero balance Zero the large and small poise weights; the beam pointer should center in the trig square indicating

Beam scale accuracy Check to see if beam scale reading matches the calibrated test weight placed on table top (within

Linear scale Use carpenter square to ensure linear scale is square with back of table top when fully extended. If

Levelness of table Check to see if table is level. If not, level table by adjusting leveling screws; there is one located at

Upholstery Check upholstered table top for rips, tears, or excessive wear. Replace table top if necessary.

Operational Test Perform an Operational Test to determine if the table is operating within its specifications. Refer to

ponents, dents in components, or any other visible damage which would cause the table to be

unsafe to operate or would compromise its performance. Repair table as necessary.

any loose hardware as necessary.

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based lubricant.

Refer to para 4.5 for access.

Check that table top is stationary when table top locking handle is in the LOCK position. Check that

table top floats freely on scale platform when table top locking mechanism is in UNLOCK position.

If not, replace any bent, broken, or missing components on table top locking mechanism. If necessary, replace platform assembly and beam scale assembly (are a factory matched unit). Refer to

para 4.2 and 4.5.

scale is zeroed. If not, perform a zero balance adjustment. Refer to para 4.3.

specified tolerance). Refer to para 4.4. If not, replace platform assembly and beam scale assembly (are a factory matched unit). Refer to para 4.2 and 4.5.

not, align linear scale. Refer to para 4.6. Use tape measure to make sure linear scale label is positioned correctly, indicating the correct patient measurement.

each corner of table.

para 2.1. Replace or adjust any malfunctioning components.

© Midmark Corporation 1998 SF-1561 Page 3-1 Printed in U.S.A.

Rev. 3/01

Page 22

SECTION III

SCHEDULED MAINTENANCE

3.2 Scheduled Maintenance (Models

409-006 and 409-007)

This guide covers inspections on tables with platform

components, digital display, and linear scale components which the model 409-006 has. The model 409-

Table 3-2 is a Scheduled Maintenance Chart which lists

the inspections and services that should be performed

periodically on the 409-006 & 409-007) Pediatric Exam-

007 does not have a platform or digital display; it has

only a linear scale. For this model, only use the portion

of the guide which is applicable.

ination Table. These inspections and services should

be performed as often as indicated in the chart.

Table 3-2. Scheduled Maintenance

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of table for obvious damage such as: cracks in components, missing com-

ponents, dents in components, or any other visible damage which would cause the table to be

unsafe to operate or would compromise its performance. Repair table as necessary.

Fasteners / hardware Check table for missing or loose fasteners / hardware. Replace any missing hardware and tighten

Warning and instructional

decals

Pivot points / moving

parts / accessories

Digital Display

Linear scale Use carpenter square to ensure linear scale is square with back of table top when fully extended. If

Levelness of table Check to see if table is level. If not, level table by adjusting leveling screws; there is one located at

Upholstery Check upholstered table top for rips, tears, or excessive wear. Replace table top if necessary.

Operational Test Perform an Operational Test to determine if the table is operating within its specifications. Refer to

Annually Digital scale calibration Perform a digital scale calibration and then a gravity compensation procedure. Refer to para 4.12

any loose hardware as necessary.

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based lubricant.

Check accuracy of scale using a 50 lb (22.7 kg) test weight. The allowable tolerance is

(150 g). If necessary, calibrate digital scale (Refer to para 4.12). Check all LCD segments to

ensure they are illuminating. If necessary, replace display board (Refer to para 4.11).

not, align linear scale. Refer to para 4.6. Use tape measure to make sure linear scale label is positioned correctly, indicating the correct patient measurement.

each corner of table.

para 2.2. Replace or adjust any malfunctioning components.

and 4.13.

± 5.25 oz.

© Midmark Corporation 1998 SF-1561 Page 3-2 Printed in U.S.A.

Rev. 3/01

Page 23

MAINTENANCE / SERVICE

SECTION IV

MAINTENANCE / SERVICE INSTRUCTIONS

SECTION IV

4.1 Introduction

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

table. Failure to do so could result in personal

injury.

NOTE

Perform an operational test on the table after the

repair is completed to confirm the repair was properly

made and that all malfunctions were repaired.

Also, this guide covers procedures on platform components, beam scale components, and linear scale

components which the model 409-004 has. The

model 409-005 does not have a platform or beam

scale; it only has a linear scale. For this model, only

use the procedures which are applicable.

The following paragraphs contain removal, installation,

repair, and adjustment procedures for the table.

4.2 Beam Scale Components Removal /

Installation (Mechanical Scale Only)

(5) Disconnect lever assembly (7) from wire loop

(D) and remove lever assembly.

(6) Remove four locknuts (8) and pillar assembly

(4) from base assembly (9).

B. Installation

(1) Install pillar assembly (4) on base assembly (9)

and secure with four locknuts (8).

EQUIPMENT ALERT

The open ends of all wire loops must face

the operator’s right side of the table after

being installed. Failure to do so will result in inaccurate readings.

(2) Position lever assembly (7) inside pillar assem-

bly (4); then connect lever assembly to wire

loop (D).

(3) Connect wire loop (B) of connection rod (6) to

lever assembly (7); then connect wire loop (C)

of connection rod (6) to calibrating arm (10).

(4) Install beam scale (5) on pillar assembly (4).

A. Removal

EQUIPMENT ALERT

The serial number labels on both the pillar

assembly (4, Figure 4-1) and platform

base (12, Figure 4-5) must match each other; they

are a factory matched pair. If serial numbers do not

match, do not proceed with beam scale installation,

stop and call Midmark Technical Service at 1-800MIDMARK.

(1) Remove two screws (1, Figure 4-1), front cap

(2), and back cap (3) from pillar assembly (4).

(2) Disconnect wire loop (A) from beam scale (5).

(3) Remove beam scale (5) from pillar

assembly (4).

(4) Disconnect wire loops (B and C) and remove

connection rod (6).

NOTE

Pull upward gently on wire loop (A) to create slack so

wire loop can be connected to beam scale.

(5) Connect wire loop (A) of lever assembly (7) to

beam scale (5).

(6) Install back cap (3) and front cap (2) over beam

scale (5) and secure with two screws (1).

(7) Perform zero balance adjustment (Refer to

para 4.3).

(8) Check beam scale calibration (Refer to

para 4.4).

© Midmark Corporation 1998 SF-1561 Page 4-1 Printed in U.S.A.

Rev. 3/01

Page 24

SECTION IV

A

800600

400

200

800

5

4

600400

200

250 300

200

4

3

7

6

5

2

1

MAINTENANCE / SERVICE

1

5

A

D

2

3

1

D

4

A

MA483300

Figure 4-2. Zero Balance Adjustment

B

6

C

10

7

C

8

Figure 4-1. Beam Scale Components

Removal / Installation

4.3 Zero Balance Adjustment (Mechanical Scale Only)

A. Adjustment

(1) Move the table top locking handle (1, Figure 4-

2) to UNLOCK position.

(2) Push down on center of table top (Point A) a

few times to align and exercise all internal parts.

9

(4) Set large poise weight (3) to zero setting, mak-

ing sure it is seated in notch and set small poise

weight (4) to zero setting by making sure small

poise weight is pushed firmly against shoulder

of beam (all the way to left).

(5) Observe. The beam pointer (5) should center

MA483200

in trig square (6), indicating the beam scale is

zeroed.

(6) If the beam pointer (5) centers, no adjustment is

necessary. If the beam pointer does not center,

go to step 7.

NOTE

If beam pointer touches bottom of trig square or stabilizes below the centerline of trig square, turn zero

adjustment screw in a clockwise direction. If beam

pointer touches top of trig square or stabilizes above

the centerline of trig square, turn zero adjustment

screw in a counterclockwise direction.

(3) Remove any items from upholstered table

top (2).

© Midmark Corporation 1998 SF-1561 Page 4-2 Printed in U.S.A.

Rev. 3/01

(7) Turn zero adjustment screw (7) in or out until

beam pointer (5) centers in trig square (6).

Page 25

4.4 Beam Scale Calibration Check

(Mechanical Scale Only)

A. Calibration Check

SECTION IV

MAINTENANCE / SERVICE

3

CAUTION

This procedure only checks to make sure

the beam scale is still calibrated within tolerance. The beam scale cannot be calibrated in the

field. If the beam scale does not pass the calibration

check (after performing a zero balance adjustment),

the scale platform and beam scale components must

be replaced; the scale platform and beam scale components are factory calibrated and are shipped as a

matched pair.

(1) Move table top locking handle (1, Figure 4-3) to

UNLOCK position.

(2) Remove any items from upholstered table

top (2).

(3) Push down on center of upholstered table top

(A) a few times to align and exercise all internal

parts.

(4) Perform zero balance adjustment (Refer to

para 4.3).

EQUIPMENT ALERT

Use calibrated test weight provided; a label

indicating the calibrated weight is on test

weight. Failure to use calibrated test weight could

result in a faulty calibration check reading.

(5) Remove calibrated test weight (3) from its stor-

age hook, located on right rear of table. Place

calibrated test weight on center of upholstered

table top (A).

7

4

5

6

2

MIDMARK

Pediatric

Figure 4-3. Scale Calibration

(8) If beam pointer (6) centers, beam scale is prop-

erly calibrated. If beam pointer does not center,

adjust small poise weight (5) and / or large

poise weight (4) as necessary to center beam

pointer (6) in trig square (7).

409

A

1

MA483400

(6) Using large poise weight (4) and small poise

weight (5), set beam scale to weight indicated

on calibrated test weight.

(7) Observe. The beam pointer (6) should center

in trig square (7), indicating beam scale is

within tolerance.

© Midmark Corporation 1998 SF-1561 Page 4-3 Printed in U.S.A.

Rev. 3/01

CAUTION

The beam scale cannot be calibrated in

the field. If the beam scale does not pass

the calibration check (after performing a zero balance

adjustment), the scale platform and beam scale components must be replaced; the scale platform and

beam scale components are factory calibrated and

are shipped as a matched pair.

Page 26

SECTION IV

MIDMARK

Pediatric

409

MAINTENANCE / SERVICE

NOTE

The allowable difference listed below is based on a

test weight of 18 lbs (8.2 kgs) or less.

(9) Determine how much beam scale reading dif-

fers from weight of calibrated test weight. The

allowable difference is ±1 oz. (±28.3 g); if the

difference is more than ±1 oz. (±28.3 g), the

scale platform and beam scale components

must be replaced (Refer to para 4.2 and 4.5).

(10) Hang calibrated test weight (3) on its storage

hook, located on right rear of table.

4.5 Platform Components Removal /

Installation or Table Top Locking

Mechanism Access (Mechanical

Scale Only)

A. Removal

EQUIPMENT ALERT

The serial number labels on both the pillar

assembly (4, Figure 4-1) and platform

base (12, Figure 4-5) must match each other; they

are a factory matched pair. If serial numbers do not

match, do not proceed with beam scale installation,

stop and call Midmark Technical Service at 1-800MIDMARK.

(1) Pull drawer (1, Figure 4-4) out until resistance is

felt. Then, on both sides of drawer, pull sides of

drawers outward until locking slots (A) of drawer

are free of tabs (B) on door glides (2). Remove

drawer (1) from table.

(2) Remove four screws (1, Figure 4-5), lockwash-

ers (2), washers (3), and upholstered table top

(4) from base (5).

(3) Lift up slightly on calibrating arm (6) and then

disconnect wire hook (7) from calibrating arm.

(4) Remove four nuts (8) and beam scale assembly

(9) from platform (10).

(5) Remove four screws (11), lockwashers (12),

and platform (10) from upholstered table

top (4).

409

MIDMARK

Pediatric

1

3

A

B

MA483500

Figure 4-4. Drawer Removal / Installation

B. Installation

(1) Install platform (10, Figure 4-5) on upholstered

table top (4) and secure with four lockwashers

(12) and screws (11).

NOTE

If installing a new beam scale, skip steps 2 and 3.

Then, after step 5, install the new beam scale components (Refer to para 4.2).

(2) Install beam scale assembly (9) on platform

(10) and secure with four nuts (8),

(3) Lift up slightly on calibrating arm (6) and then

connect wire hook (7) to calibrating arm.

(4) Install upholstered table top (4) on base (5) and

secure with four washers (3), lockwashers (2),

and screws (1).

(5) Install drawer (1, Figure 4-4) by positioning

drawer on drawer glides (2), making sure rear

of drawer is contained by two hooks (3); then

2

Rev. 3/01

© Midmark Corporation 1998 SF-1561 Page 4-4 Printed in U.S.A.

Page 27

SECTION IV

6

7

MAINTENANCE / SERVICE

pull sides of drawers outward and install locking slots (A) of drawers on tabs (B).

9

10

4

8

12

11

MIDMARK

Pediatric

409

UNLOCK

LOCK

5

3

2

1

Figure 4-5. Platform Components Removal / Installation

© Midmark Corporation 1998 SF-1561 Page 4-5 Printed in U.S.A.

Rev. 3/01

MA483600

Page 28

SECTION IV

MAINTENANCE / SERVICE

4.6 Linear Scale A li gnment (All Models)

A. Alignment

(1) Open measuring arm of linear scale (1, Figure

4-6) to its fully extended position as shown in

illustration.

(2) Using a carpenter square (A), check to see if

the measuring arm of linear scale (1) is square

with back of upholstered table top (2) when linear scale is fully extended.

(3) If measuring arm of linear scale (1) is not

square, use a 3/32 in. Allen wrench to adjust

setscrew (3) until linear scale is square with

back of upholstered table top (2).

4.7 Digital Display Removal / Installation (Digital Scale Only)

A. Removal

(1) Disconnect display connector (1, Figure 4-7)

from digital display (2).

Figure 4-6. Linear Scale Alignment

Figure 4-7. Digital Display Removal / Installation

(2) If using AC adapter, disconnect AC adapter jack

(3) from digital display (2).

(3) Remove two screws (4), spacers (5), and digital

display (2) from scale readout holder (6).

B. Installation

(1) Install digital display (2) on scale readout holder

(6) and secure with two spacers (5) and

screws (4).

EQUIPMENT ALERT

Use locator arrow to ensure display con-

nector is installed in correct orientation.

Also, do not use excessive force to connect. Failure

to do so could result in damage to display connector

or digital display.

(2) Connect display connector (1) to digital

display (2), making sure locator arrow (A) is facing front side of digital display.

© Midmark Corporation 1998 SF-1561 Page 4-6 Printed in U.S.A.

Rev. 3/01

Page 29

SECTION IV

MAINTENANCE / SERVICE

(3) Perform digital scale calibration (Refer to

para 4.12).

(4) Perform digital scale gravitational compensa-

tion adjustment (Refer to para 4.13).

4.8 Platform Scale Components / Load

Cell Assembly Access (Digital Scale

Only)

A. Removal

(1) Disconnect display connector (1, Figure 4-8)

from digital display (2); then remove cord of display connector from cable clamp (3).

(2) If using AC adapter, disconnect AC adapter jack

(4) from digital display (2).

(3) Remove drawer (5) from table as follows: pull

drawer out until it meets resistance. Then, on

both sides of drawer (5), bend sides of drawer

outward until locking slots (6) of drawer are free

of tabs (7) on drawer slides.

(3) If using AC adapter, connect AC adapter jack

(4) to digital display (2).

EQUIPMENT ALERT

Use locator arrow to ensure display con-

nector is installed in correct orientation.

Also, do not use excessive force to connect. Failure

to do so could result in damage to display connector

or digital display.

(4) Connect display connector (1) to digital display

(2), making sure locator arrow (A) is facing front

side of digital display; then secure cord of display connector in cable clamp (3).

(4) Remove four nuts (8) and pediatric top assem-

bly (9) from upper wrap (10).

B. Installation

(1) Position pediatric top assembly (9, Figure 4-8)

on upper wrap (10) and secure with four

nuts (8).

(2) Install drawer (5) in table as follows: position

drawer on drawer slides. Then, slide back of

drawer (5) into rear hooks (A) on each slide and

then snap drawer side slots (6) over slide locking tabs (7).

© Midmark Corporation 1998 SF-1561 Page 4-7 Printed in U.S.A.

Rev. 3/01

Page 30

SECTION IV

MAINTENANCE / SERVICE

Figure 4-8. Platform Scale Components / Load Cell Assembly Access

© Midmark Corporation 1998 SF-1561 Page 4-8 Printed in U.S.A.

Rev. 3/01

Page 31

SECTION IV

MAINTENANCE / SERVICE

4.9 Platform Load Cell Removal / Installation (Digit al Scale Only)

A. Removal

(1) Access platform scale components (Refer to

para 4.8).

(2) Disconnect display harness (1, Figure 4-9) from

load cell harness (2).

(3) Connect display harness (1) to load cell

harness (2).

(4) Install upholstered table top (Refer to para 4.8).

(5) Perform digital scale calibration (Refer to

para 4.12).

(6) Perform digital scale gravitational compensa-

tion adjustment (Refer to para 4.13).

4.10 Platform Assembly Removal / Installation (Digital Scale Only)

A. Removal

(1) Access platform scale components (Refer to

para 4.8).

(2) Disconnect display harness (1, Figure 4-10)

from load cell harness (2).

(3) Remove one screw (3) and cable clamp (4)

from scale mount weldment (5). Remove cable

clamp from display harness (1).

Figure 4-9. Platform Load Cell Removal / Installation

(3) Remove screw (3) and disconnect ground

wire (4) from platform (5).

(4) Remove eight screws (6), lockwashers (7), and

load cell (8) from platform components (5).

B. Installation

(1) Install load cell (8) on platform components (5)

and secure with eight lockwashers (7) and

screws (6).

(2) Connect ground wire (4) to platform (5) with one

screw (3).

(4) Remove four locknuts (6), screws (7), and two

scale mount weldments (5) from Tanita scale

platform (8).

(5) Remove four screws (9) and top scale mount

(10) from pediatric top assembly (11).

(6) Remove four nuts (12), screws (13), and top

scale mount (10) from Tanita scale platform (8).

B. Installation

(1) Install top scale mount (10) on Tanita scale plat-

form (8) and secure with four screws (13) and

nuts (12).

(2) Install top scale mount (10) on pediatric top

assembly (11) and secure with four screws (9).

© Midmark Corporation 1998 SF-1561 Page 4-9 Printed in U.S.A.

Rev. 9/02

Page 32

SECTION IV

MAINTENANCE / SERVICE

4.11 Display Board Assembly Removal /

Installation (Digital Scale Only)

A. Removal

(1) Remove digital display from table (Refer to

para 4.7).

(2) Unscrew thumbscrew (1, Figure 4-11) and pull

battery box (2) from upper housing (3).

(3) Pry upper two rubber pads (4) from lower hous-

ing (5).

(4) Remove two screws (6) and lower housing (5)

from upper housing (3).

(5) Remove two screws (7) and cable port harness

(8) from battery box cover (9).

Figure 4-10. Platform Assembly Removal / Installa-

(3) Install two scale mount weldments (5) on Tanita

scale platform (8) and secure with four screws

(7) and four locknuts (6).

(4) Connect load cell harness (2) to display har-

ness (1).

(5) Wrap cable clamp (4) around display harness

(1); then install cable clamp (4) on platform (5)

with one screw (3).

(6) Install upholstered table top (Refer to para 4.8).

(7) If load cell was replaced, perform digital scale

calibration (Refer to para 4.12).

(8) If calibration is performed, perform digital scale

gravitational compensation adjustment (Refer

to para 4.13).

(6) Remove one screw (10) and battery box cover

(9) from upper housing (5).

(7) Tag and desolder two wires (11) from terminals

of display board assembly (12).

(8) Remove four screws (13) and display board

assembly (12) from upper housing (5).

(9) Disconnect cable port harness (8) from display

board assembly (12).

B. Installation

(1) Connect cable port harness (8) to display board

assembly (12).

(2) Install display board assembly (12) on upper

housing (5) and secure with four screws (13).

EQUIPMENT ALERT

Red wire must be soldered to terminal

TP1+ of display board assembly and black

wire to terminal TP2- of display board assembly. Failure to do so could result in damage to display board

assembly.

© Midmark Corporation 1998 SF-1561 Page 4-10 Printed in U.S.A.

Rev. 3/01

(3) Solder two wires (11) to terminals of display

board assembly (12).

(4) Route cable port harness (8) as necessary;

then install battery box cover (9) on upper housing (5) and secure with one screw (10).

Page 33

SECTION IV

MAINTENANCE / SERVICE

(5) Position cable port harness (8) on battery box

cover (9) and secure in place with two

screws (7).

(6) Install lower housing (5) on upper housing (3)

and secure with two screws (6).

(7) Install two rubber pads (4) on top of two

screws (6).

(8) Insert battery box (2) in upper housing (3) and

secure by tightening thumbscrew (1).

(9) Install digital display on table (Refer to

para 4.7).

(10) Perform digital scale calibration (Refer to

para 4.12).

(11) Perform digital scale gravitational compensa-

tion adjustment (Refer to para 4.13).

Figure 4-11. Display Board Assembly

Removal / Installation

© Midmark Corporation 1998 SF-1561 Page 4-11 Printed in U.S.A.

Rev. 3/01

Page 34

SECTION IV

MAINTENANCE / SERVICE

4.12 Digital Scale Calibration

This procedure must be performed . . . if the digital

scale’s readings appear to be inaccurate, on a yearly

basis, or if a new digital display, display board assembly,

or new scale platform is installed. Also, after the digital

scale calibration is performed, the gravitational compensation adjustment must also be performed.

Tables with serial numbers PP1000 thru PP1142,

use the calibration procedure below:

Calibration Steps Desired

Display Text

While pressing the KG / LB

button, press the ON / ZERO

button to turn display power

ON.

Press and release the ON /

ZERO button until the display

changes to F2.

Press the KG / LB button. 9

Press the ON / ZERO button

to select either [kg] weights 9

or [lb] weights 16.

Press the KG / LB button. 0 --

Gently place a 200 kg [if 9

was selected] or 440 lb

weight [if 16 was selected]

on the center of the pediatric

table top.

Press the KG / LB button. F 1

Remove the weight, then

press the OFF button to turn

display OFF.

88888

to

F 1

F 2

9 or 16

to

2 --

2 --

Tables with serial numbers PP1143 thru present, &

V2200 thru present use the calibration procedure

below:

Calibration Steps Desired

Display Text

Press & hold the KG / LB

button, then press the ON /

ZERO button to turn display

power ON.

Release the KG / LB button

when F 1 appears in display.

Press the ON / ZERO button.

The display will show F 2.

Press the KG / LB button.

Display will show 9 or 16.

If display shows 16, press the

KG / LB button.

If display shows 9, press the

ON / ZERO button then press

the KG / LB button.

The display will show 0 - -

then advance to 2 - -.

Gently place 50 lb of certified

calibration weights on the

center of the table top.

Allow weight to stabilize for

10 seconds, then press the

KG / LB button.

The display will show F 1.

[Calibration is complete]

Remove weights, then press

the OFF button.

Press the ON / ZERO button,

then place >

weights on the center of the

table top.

39 lb. of certified

The weight displayed

should exactly match

the the amount of

calibrated weight on

the table top.

88888

to

F 1

F 2

9 or 16

0 - -

to

2 - -

F 1

-

© Midmark Corporation 1998 SF-1561 Page 4-12 Printed in U.S.A.

Rev. 1/07

Page 35

SECTION IV

MAINTENANCE / SERVICE

4.13 Digital Scale Gravitational

Compensation Adjustment

This procedure must be performed if a digital scale calibration has been performed or if the table has been

moved from the location where it was calibrated.

Gravitational

Compensation Steps

While pressing the KG / LB

button, press the ON / ZERO

button to turn display power

ON.

Press and release the ON /

ZERO button until the display

changes to F3.

Press the KG / LB button. 0.00

Adjust the gravitational compensation error to 0. Press

the ON / ZERO button to

increase the displayed numerical value by 0.1% Press the

OFF button to decrease the

displayed numerical value by

0.1%

Press the KG / LB button. F 1

Press the OFF button to turn

display OFF.

Desired

Display Text

88888

to

F 1

F 3

0.0x

to

0.00

or

-0.0x

to

0.00

4.14 Display Board Assembly

Mode Setting Procedure

(Digital Scale Only)

This procedure must be performed if a new digital display or its display board assembly is replaced.

Mode Setting

Procedure

While pressing the KG / LB

button, press the ON / ZERO

button to turn display power

ON.

Press and release the ON /

ZERO button until the display

changes to F4.

Press the KG / LB button.

NOTE: The mode setting

should be set to H8830 for the

Tanita display on the Midmark

table. If an initial mode setting has not been completed

on board yet, only H will dis-

play.

Press the ON / ZERO button

to change the 1

digit to an 8. Then, press the

OFF button to change the 2

numerical digit to an 8.

Press the KG / LB button. F 1

Press and release the ON /

ZERO button until the display

changes to F5.

Press the ON / ZERO button

to change the 3

digit to a 3. Then, press the

OFF button to change the 4

numerical digit to a 0.

Press the KG / LB button. F 1

Press the OFF button to turn

display OFF.

st

numerical

rd

numerical

nd

th

Desired

Display Text

88888

to

F 1

F 4

H

Hxx

to

H88

F 5

H88xx

to

H8830

© Midmark Corporation 1998 SF-1561 Page 4-13 Printed in U.S.A.

Rev. 8/01

Page 36

SECTION IV

MAINTENANCE / SERVICE

4.15 Auto Power Off / Continuous Use

Selection Procedure

(Digital Scale Only)

The digital display may be set for AUTO POWE R OFF

(in this mode, the digital display will automatically shut

off after 30 minutes of non use) or CONTINUOUS USE

(in this mode, the digital display will remain on continuously).

Mode Setting

Procedure

While pressing the KG / LB

button, press the ON / ZERO

button to turn display power

ON.

Press and release the ON /

ZERO button until the display

changes to F7.

Press the KG / LB button. U 1

Press the ON / ZERO button

to change the far right numerical digit to a 1 or 0.

NOTE: If digit on far right is a

0, mode is set for AUTO

POWER OFF. If digit on far

right is a 1, mode is set for

CONTINUOUS USE.

Press the KG / LB button. F 1

Press the OFF button to turn

display OFF.

Desired

Display Text

88888

to

F 1

F 7

or

U 0

U 1

to

U 0

(AUTO POWER OFF mode)

or

U 0

to

U 1

(Continuous Use mode)

© Midmark Corporation 1998 SF-1561 Page 4-14 Printed in U.S.A.

Rev. 8/01

Page 37

None are required.

SECTION V

SCHEMATICS AND DIAGRAMS

SECTION V

SCHEMATICS AND DIAGRAMS

© Midmark Corporation 1998 SF-1561 Page 5-1 Printed in U.S.A.

Page 38

SECTION V

SCHEMATICS AND DIAGRAMS

© Midmark Corporation 1998 SF-1561 Page 5-2 Printed in U.S.A.

Page 39

SECTION VI

PARTS LIST

SECTION VI

PARTS LIST

6.1 Introduction

The illustrated parts list provides information for identifying and ordering the parts necessary to maintain the

unit in peak operating condition. Refer to paragraph 1.5

for parts ordering information.

6.2 Description of Columns

The Item column of the parts list gives a component its

own unique number. The same number is given to the

component in the parts illustration. This allows a part

number of a component to be found if the technician

can visually spot the part on the illustration. The technician simply finds the component in question on the illustration and notes the item number of that component.

Then, he finds that item number in the parts list. The

row corresponding to the item number gives the technician the part number, a description of the component,

and quantity of parts per subassembly. Also, if a part

number is known, the location of that component can be

determined by looking for the item number of the component on the illustration.

The Part No. column lists the MIDMARK part number

for that component.

The Description column provides a physical description

of the component.

The Qty. column lists the number of units of a particular

component that is required for the subassembly. The

letters “AR” denote “as required” when quantities of a

particular component cannot be determined, such as:

adhesive.

Bullets { • } in the Part No. column and the Description

column show the indenture level of a component. If a

component does not have a bullet, it is a main component of that illustration. If a component has a bullet, it is

a subcomponent of the next component listed higher in

the parts list than itself that does not have a bullet. Likewise, if a component has two bullets, it is a subcomponent of the next component listed higher in the parts list

than itself that has only one bullet.

6.3 Torque Specifications and Important

Assembly Notes

When specific assembly torque specifications, measurements, or procedures have been identified, by our

engineering department, as required to assure proper

function of the unit, those torque specifications measurements, and procedures will be noted on the parts

illustrations. Adherence to these requirements is essential.

© Midmark Corporation 1997 SF-1561 Printed in U.S.A.

Always Specify Model & Serial Number

Page 6-1

Page 40

3

2

1

409

MIDMARK

Pictorial Index Mechanical Scale

SECTION VI

PART S LI ST

MA411800

Used on Units with Serial Numbers JS1000 Thru Present

Item Part No. Description Page Item Part No. Description Page

409-004 Pediatric Examination Table (With

409-005 Pediatric Examination Table (W/O

1 • • Cabinet Assembly - Mechanical

Used on Units with Serial Numbers V2200 Thru Present

2 • • Upper Wrap Assembly (With

Mechanical Scale)

(Serial # Prefix JS) ...........................Ref.

Mechanical Scale)

(Serial # Prefix JS) ...........................Ref.

and Digital Scale ..............................6-4

Always Specify Model & Serial Number

• • Upper Wrap Assembly (W/O

3 • • Table Top Assembly (With

• • Table Top Assembly (Without

4 • • Weight Calibaton (Not Shown) ...... 6-13

5 Key and Lock Assembly (Optional

Mechanical Scale) ........................... 6-5

Mechanical Scale) ........................... 6-6

Mechanical Scale) ........................... 6-7

Mechanical Scale) ........................... 6-8

[Not Shown])..................................... 6-14

© Midmark Corporation 1997 SF-1561 Printed in U.S.A.

Rev. 2/04

6-2

Page 41

Pictorial Index Digital Scale

CENTER

LOAD

BWB-800A CLASS III 200 kg/0.1kg 400lb/02lb

SECTION VI

PARTS LIST

3

ON/ZERO

kg

OFF

lb

kg/lb

max 2.20

n

NITA

NI

TA

2

409

MIDMARK

1

Used on Units with Serial Numbers PP1000 Thru Present

Used on Units with Serial Numbers V2200 Thru Present

MA578900

Item Part No. Description Page Item Part No. Description Page

409-006-***-* Pediatric Examination Table (With

Digital Scale)(Serial # Prefix PP)......Ref.

409-007-***-* Pediatric Examination Table (W/O

Digital Scale) (Serial # Prefix PP).....Ref.

1 • • Cabinet Assembly.............................6-4

2 • • Upper Wrap Assembly (With or

W/Out Digital Scale).........................6-9

3 • • Table Top Assembly

(w/ Digital Scale)..........................6-10

© Midmark Corporation 1997 SF-1561 Printed in U.S.A.

Rev.2/04

3 • • Table Top Assembly

(w/ Digital Scale) ......................... 6-10

• • Tab l e To p A ss em bl y

(w/o Digital Scale) ....................... 6-11

4 Key and Lock Assembly (Optional

[Not Shown])..................................... 6-14

Attnetion:

***-* after model number denotes

upholstery & panel color

Always Specify Model & Serial Number

6-3

Page 42

1

2

4

5

8

9

18

23

7

13

15

17

3

25

26

14

16

27

10

20

24

12

11

12

28

7

6

19

21

22

29

29

Cabinet Assembly

SECTION VI

PART S LI ST

MA412002

15 • 016-0510-00 • Door Hinge .....................................4

16 • 053-0578-02 • Handle............................................2

17 053-0705-00-xxx Vinyl Insert (*Specify Color)..............2

18 053-0627-05 Handle Cover....................................2

19 040-0006-71 Screw ................................................8

20 • 016-0510-02 • Screw .............................................8

21 • 040-0010-157 • Screw .............................................4

22 042-0045-11 Nutsert ..............................................4

23 029-1761-01 Shelf Clip ..........................................2

24 050-2851-10 Shelf Bracket.....................................2

25 050-3935-10 Pediatric Shelf...................................1

26 050-3960-10 Cabinet Bottom .................................1

27 029-2126-00 Base Assembly .................................1

28 040-0010-00 Screw ..............................................10

29 016-0001-00 Leveling Screw..................................4

Used on Units with Serial Numbers JS1000 and PP1000 Thru Present

Used on Units with Serial Numbers V2200 Thru Present

Item Part No. Description Qty Item Part No. Description Qty