Page 1

Important

Information

Page 2

Installation

Installation and Operation

Manual

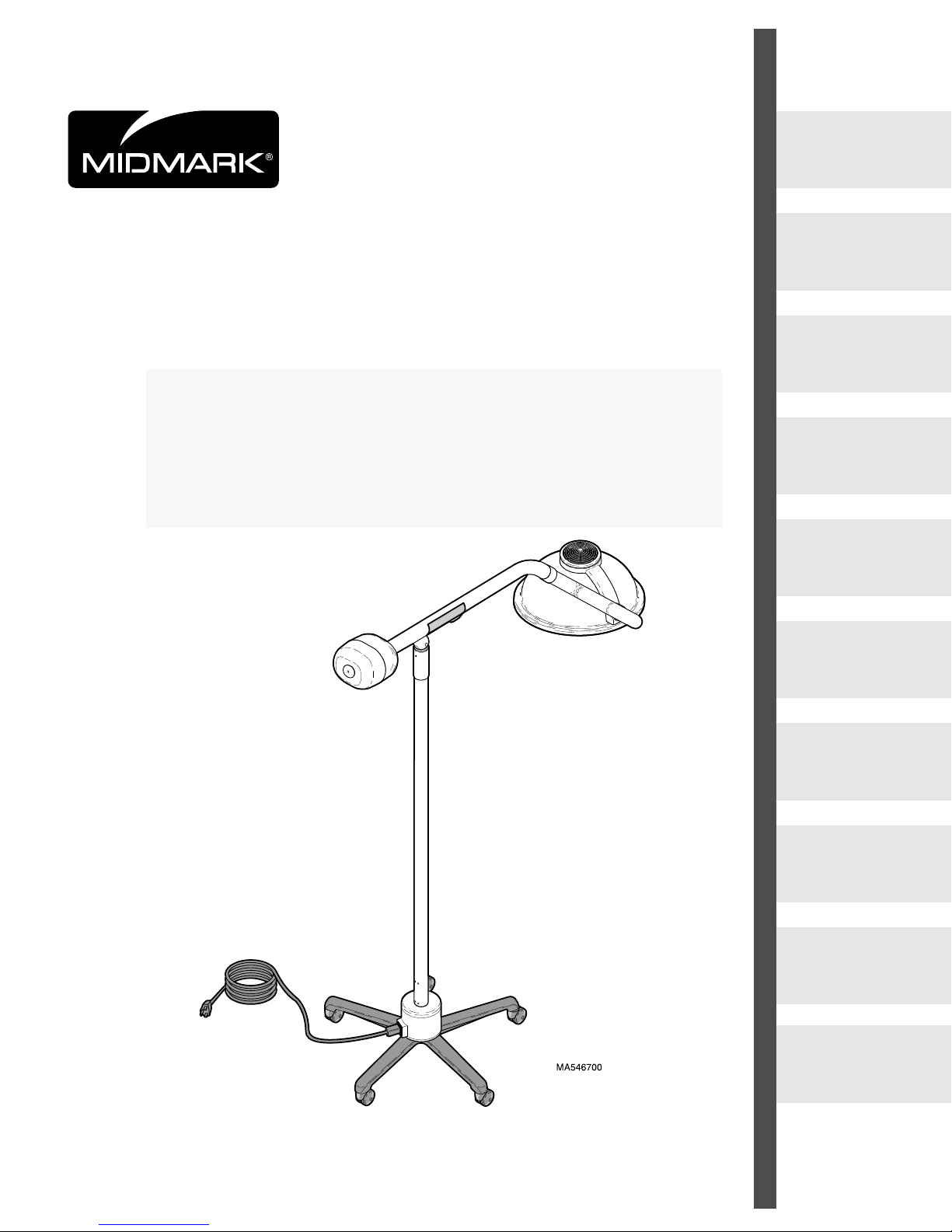

355 Mobile Lighting

System

Page 5

Description

Page 14

Components

Overview

Page 15

Controls &

Indicators

Page 16

Operation

Page 17

Operator

Maintenance

Page 18

Calling For

Service

Page 26

Specifications

Page 27

Limited

Warranty

Page 28

Page 2

MA350400

Owner’s Product Identification

(information that you will need to provide for servicing - key information is highlighted)

Date of Purchase

Serial Number

Model NumberName of Owner / Facility / Department

Name of Authorized Midmark Dealer Telephone # of Authorized Midmark Dealer

Address of Authorized Midmark Dealer

MODEL AND SERIAL

NUMBER LOCATION

MODEL NUMBER /

SERIAL NUMBER

Page 3

CONTENTS

IMPORTANT INFORMATION............................................................................................................................ 2

Scope and Purpose of This Manual ......................................................................................................... 2

Intended Use of Product........................................................................................................................... 2

Safety Instructions ....................................................................................................................................2

Transportation and Storage Conditions .................................................................................................... 2

Explanation of Safety Symbols and Notes................................................................................................ 3

INSTALLATION ................................................................................................................................................. 4

Unpacking................................................................................................................................................. 4

Necessary Tools ....................................................................................................................................... 5

Vertical Tube Installation........................................................................................................................... 6

Counterbalance Assembly Installation......................................................................................................7

Bulb Installation / Replacement Procedure .............................................................................................. 8

Housing Cap Installation........................................................................................................................... 9

Electrical Requirements.......................................................................................................................... 10

Electrical Input Setting............................................................................................................................ 10

Operational Test...................................................................................................................................... 12

DESCRIPTION ................................................................................................................................................ 13

Introduction / Features............................................................................................................................ 13

COMPONENTS OVERVIEW ........................................................................................................................... 14

CONTROLS & INDICATORS .......................................................................................................................... 15

OPERATION.................................................................................................................................................... 16

Electromagnetic Interference .................................................................................................................. 16

Operating Lighthead Assembly............................................................................................................... 16

Moving Mobile Light System ................................................................................................................... 16

OPERATOR MAINTENANCE ......................................................................................................................... 17

Operator Troubleshooting ....................................................................................................................... 17

Preventive Maintenance ......................................................................................................................... 18

Fuse Replacement Procedure................................................................................................................ 19

Ball Pivot Tension Adjustment Procedure...............................................................................................21

Cross Tube Counterbalance Adjustment ................................................................................................ 22

Cleaning and Disinfecting....................................................................................................................... 23

External Cleaning Procedures................................................................................................................ 24

External Disinfecting Procedures ........................................................................................................... 24

Handle Sterilization................................................................................................................................. 25

CALLING FOR SERVICE................................................................................................................................ 25

SPECIFICATIONS........................................................................................................................................... 26

LIMITED WARRANTY..................................................................................................................................... 27

Page 4

Important

Information

IMPORTANT INFORMATION

Scope and Purpose of This Manual

This manual covers complete instructions for the installation, operation, and

normal care of the 355-024, -037 Mobile Light System. It is intended that this

manual be used by any medical personnel responsible for operating the mobile

light system during a medical procedure or performing operator level

maintenance.

Intended Use of Product

This product is intended for use in all medical environments where illumination

is required for external examinations and procedures and where mobility of the

product is desired.

Safety Instructions

The primary concern of Midmark is that this equipment is operated and

maintained with the safety of the patient and staff in mind. To assure safer and

more reliable operation:

• Read and understand this manual before attempting to install or operate the

mobile light system.

• Assure that appropriate personnel are informed on the contents of this

manual; this is the responsibility of the purchaser.

• Assure that this manual is located near the light.

Transportation and Storage Conditions

• Ambient Temperature Range: ...... -30°C to +60°C (-22°F to 140°F)

• Relative Humidity ......................... 10% to 90% (non-condensing)

• Atmospheric Pressure.................. 500hPa to 1060 hPa (0.5 bar to 1.06 bars)

• This product contains glass, so it should be transported and stored with care

to limit vibration and shocks.

2

Page 5

Explanation of Safety Symbols and Notes

Indicates that the unit is rated:

Type B, Applied Part.

Indicates that the operator’s

manual should be consulted for

important information.

Indicates the presence of a

dangerous voltage / shock

hazard.

Indicates a fuse rating

specification.

V

A

Indicates a protective earth

ground.

Indicates product is fragile.

Indicates proper shipping

orientation.

Indicates that the product is

to be kept dry.

Indicates a hot surface.

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. The DANGER

symbol is limited to the most extreme situations.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALERT

Indicates an imminently or potentially hazardous situation which,

if not avoided, will or may result in serious, moderate, or minor

equipment damage.

Important

Information

NOTE

Amplifies an operating procedure, practice, or condition.

3

Page 6

2

1

MA546803i

4

3

7

5

6

#10-24 x 3/8” Button Screw (4a)

1/2-20 Hex Nut (4c)

1/2” Washer (4d)

1/2” Lockwasher (4e)

Spacer Disk (4f)

Housing Cap (4h)

#10-24 x 7/8” Pan Head Screw (4b)

#10-24 x 3/8” Pan Head Screw (4i)

100 Watt Halogen Bulb (4j)

Sterilizable Handle (4k)

1/8” Hex Wrench (4g)

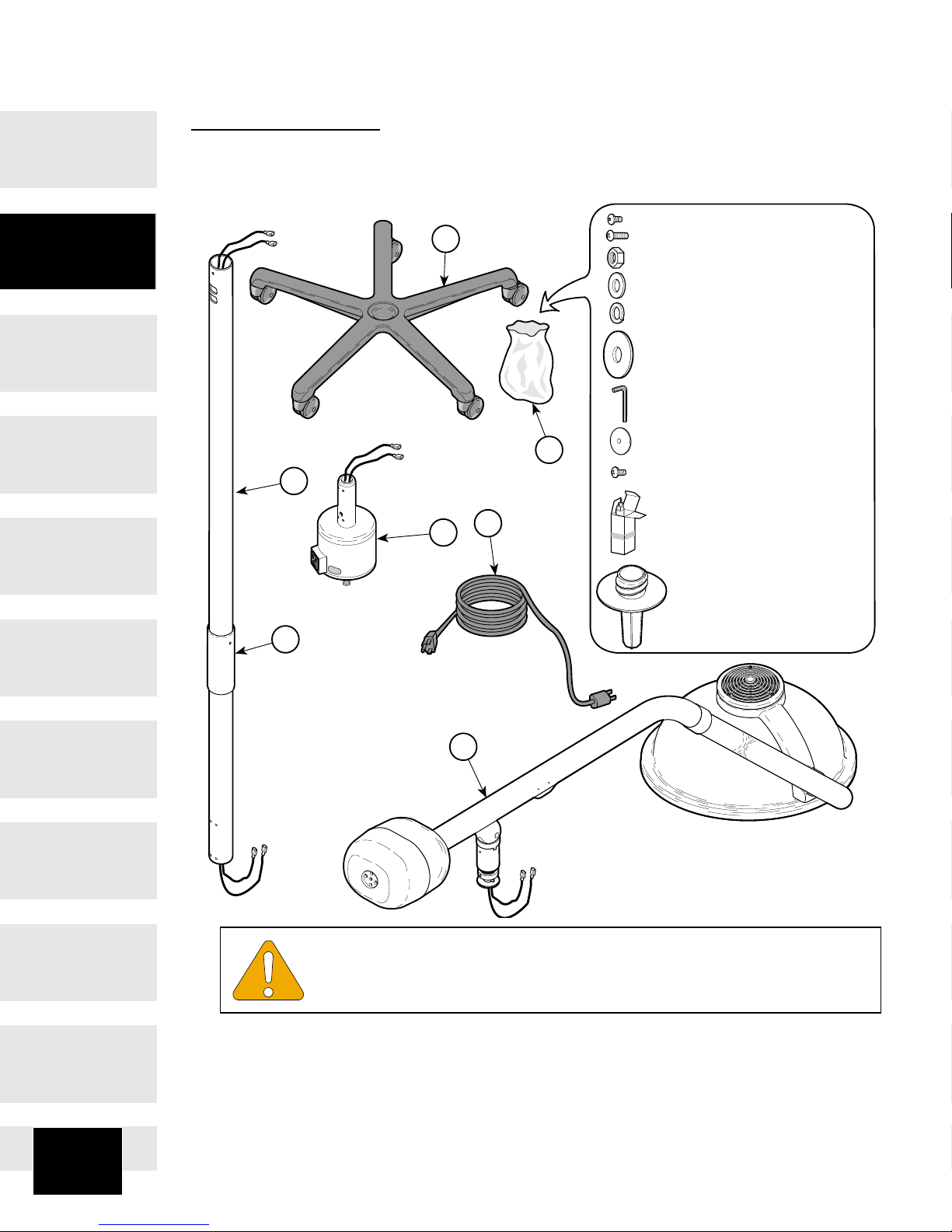

Installation

INSTALLATION

Unpacking

EQUIPMENT ALERT

To avoid damaging the light components, do not use a knife or

other sharp object to open the light’s packaging.

Carefully remove the packaging from the light components. Then inspect the

light components for any shipping damage. Report any damage to the shipping

company and fill out a concealed damage report.

4

Page 7

1. Cut banding and remove box lid from box.

2. Remove one base assembly (1) and inspect for damage. Check each individual caster for damage.

3. Remove one counterbalance assembly (2) and inspect for damage.

4. Remove vertical tube (3) and inspect for damage. Check that pivot sleeve

(6) is present.

5. Remove one bag (4) and inventory contents; the following items should be

included:

4a. Six #10-24 x 3/8” Button Head Screw

4b. One #10-24 x 7/8” Pan Head Screw

4c. One 1/2”-20 Hex Nut

4d. One 1/2” Flat Washer

4e. One 1/2” Lockwasher

4f. One Spacer Disk

4g. One 1/8” Hex Wrench

4h. One Housing Cap

4i. One #10-24 x 3/8” Pan Head Screw

4j. One 100 Watt Halogen Bulb

4k. One Sterilizable Handle (inspect)

6. Remove one transformer housing assembly (5) and inspect for damage.

Installation

7. Remove one power cord (7) and inspect for damage.

Necessary Tools

• 3/4 in. Socket and Ratchet Driver

• Phillips Screwdriver (medium point)

5

Page 8

MA548301i

5

4

6

1

2

8

11

3

7

10

9

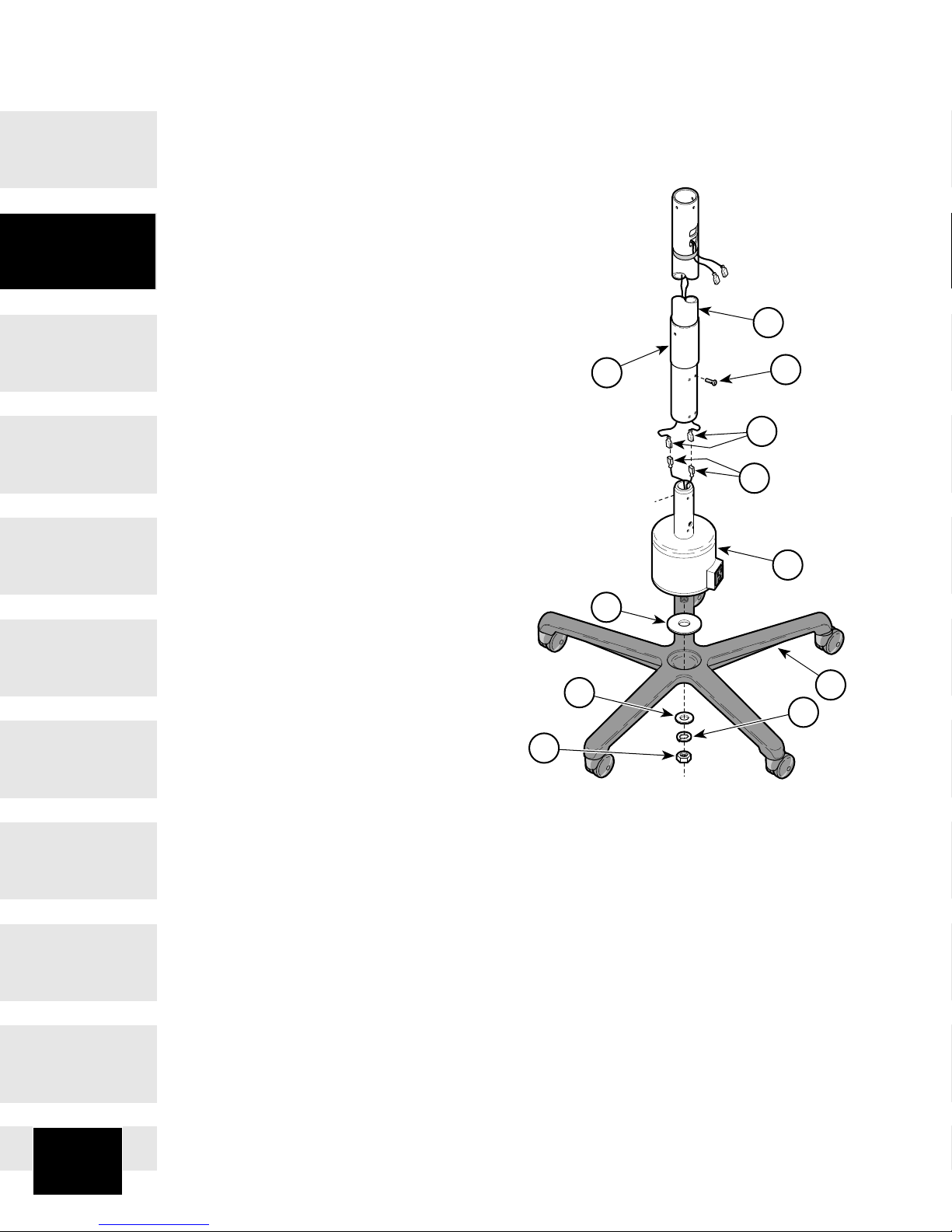

Installation

Vertical Tube Installation

1. Install spacer disk (1) on

center hole of base

assembly (2).

2. Using 3/4 in. socket

and ratchet, install

transformer housing

assembly (3) on base

assembly (2) and

secure with washer

(4), lockwasher (5),

and nut (6). Tighten

nut (6) to 35 - 45 ft-lbs

(47.5 - 61.0 N•m).

3. Remove tape securing wires

(7) to vertical tube (8) then

slide ball pivot sleeve (9) up

onto tube. Connect brown wire

(7) to brown wire (10) and blue

wire (7) to blue wire (10).

3. Using a 1/8 in. hex

wrench (supplied),

install vertical tube (8)

on mounting tube of

transformer housing

assembly (3) and

secure with four

screws (11).

6

Page 9

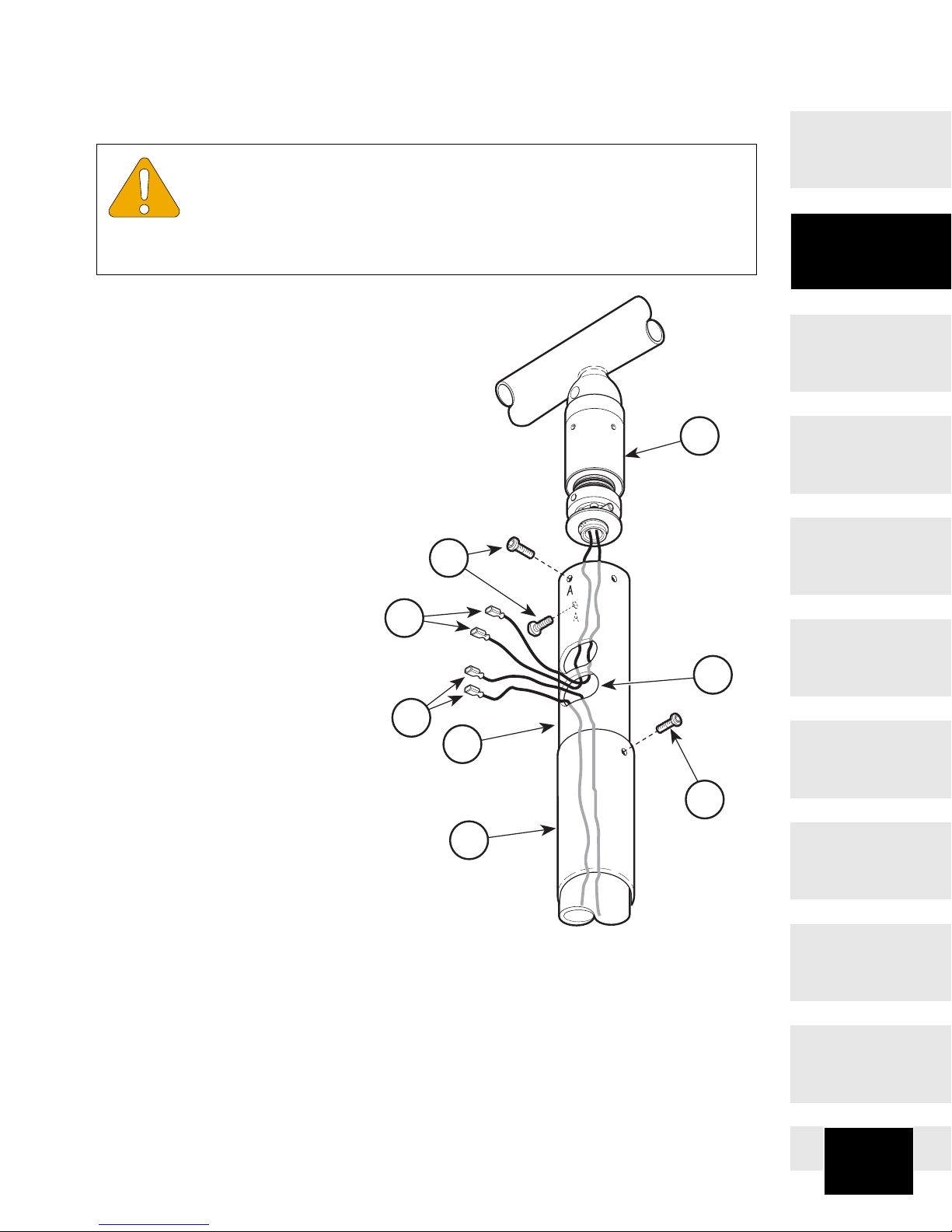

Counterbalance Assembly Installation

7

8

1

4

6

2

5

3

MA350700

EQUIPMENT ALERT

Make sure all three screw holes on the vertical tube (2) are

aligned with the three screw holes on the ball pivot housing of the

counterbalance assembly before installing any screws. Failure to do so could

result in damage to screw threads.

1. Align three screw holes;

then insert ball pivot housing

of counterbalance assembly

(1) into vertical tube (2) and

secure with two #10-24x3/8”

black oxide button head

screws (3), making sure to

install the two screws (3)

into the screw holes marked

with an “A”. Tighten screws

with 1/8 in. hex wrench

(supplied).

Installation

2. Pull two wires (4) from

counterbalance assembly

(1) through the bottom

access window (5).

3. Connect the brown wire (4)

to brown wire (6) and blue

wire (4) to blue wire (6).

Push wires (4 and 6) inside

the bottom access window

(5).

4. Slide ball pivot sleeve (7) up

into position and secure with

one # 10-24 x 3/8” zinc

cadmium oval head phillips

screw (8) (New Units Only,

Refer to Page 6).

7

Page 10

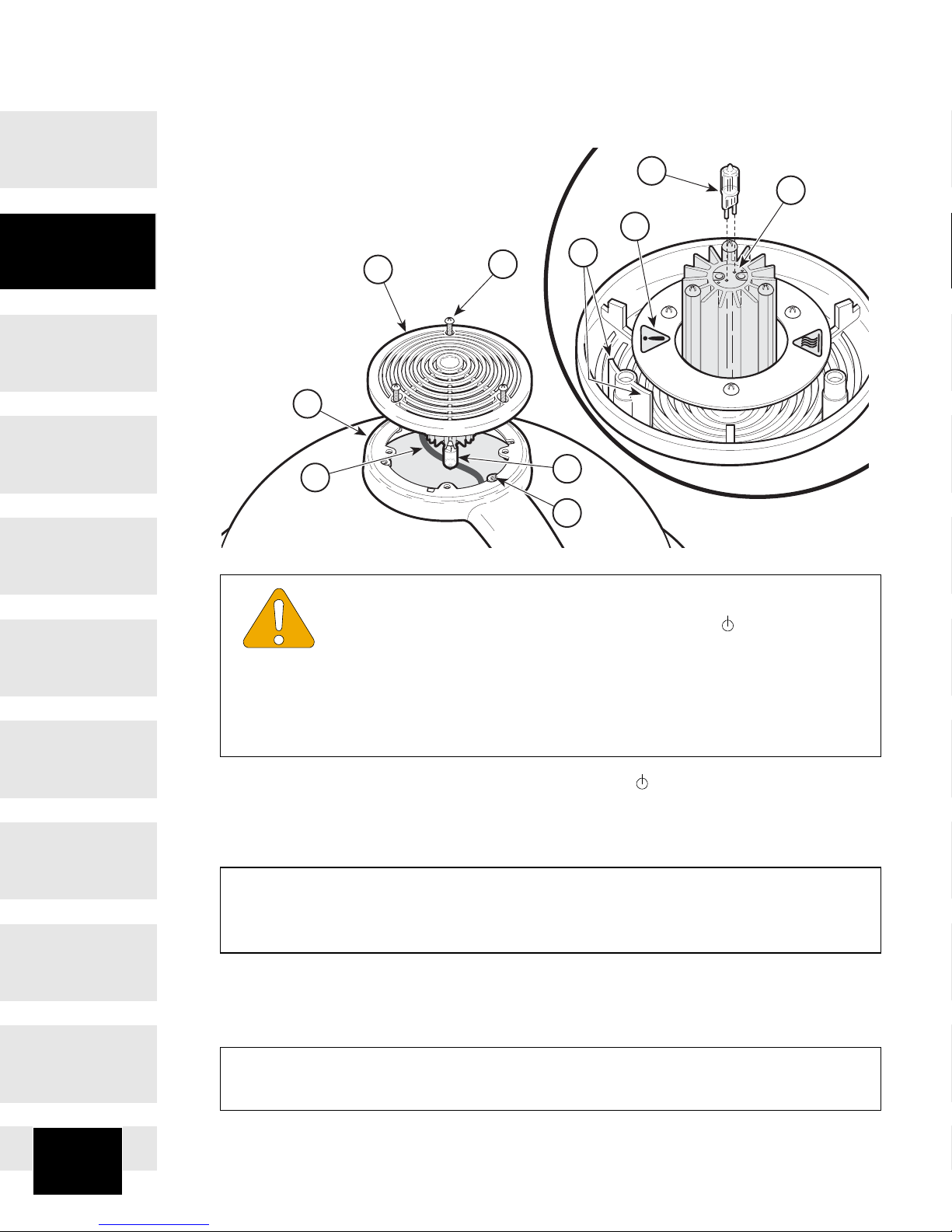

Bulb Installation / Replacement Procedure

4

5

Installation

2

3

6

1

EQUIPMENT ALERT

Turn the ON / STANDBY switch to STANDBY “ “ before

replacing bulb. Otherwise, electrical shock or hand burns could

result. Also, move the lighthead as far as possible from the exam / procedure

site to prevent contaminants from falling onto the exam / procedure site. Do

not try to remove the bulb until the unit is allowed to cool. Otherwise, burns to

hands and fingers will result.

A

4

B

MA381900

*

1. Turn the ON / STANDBY switch to STANDBY “ “. Move lighthead away

from the exam / procedure site. Lower the lighthead to gain access for bulb

removal.

NOTE

Screws (1) are captive screws. Only loosen captive screws; do not try to

remove them.

2. Loosen three captive screws (1) and separate top cap (2) from support arm

pivot (3).

NOTE

If new unit, remove packing material from inside of lighthead.

8

Page 11

3. Allow the bulb (4) to cool (usually for several minutes). Grasp the bulb (4)

and pull the bulb from bulb socket (5). Discard the old bulb while taking care

not to break the glass capsule of the bulb.

WARNING (*)

The maximum allowable bulb wattage which can be used in

this light is 100 Watts. There is a risk of fire or equipment

damage if 100 Watt limit is exceeded. Use Midmark P/N: 015-1357-00.

NOTE

Halogen bulbs are sensitive to body oils. Be sure not to touch the glass

portion of the bulb during relamping or cleaning. Body oils create a hot spot

on the bulb and may cause the bulb to burn out prematurely. If the glass

portion of the bulb is handled, wipe with a clean, soft, lint free cloth. Wipe with

alcohol and pat dry.

4. Using a cotton glove or similar clean cloth, grasp the new bulb (4) (supplied)

and insert the bulb into the bulb socket (5). Push the bulb in until its prongs

bottom out; there should be approximately 1/16 in. [1.6 mm] gap between

bulb socket and glass base of bulb. Forcing the bulb in further will cause

damage.

NOTE

The top cap is keyed which allows it only to be installed in one position.

Installation

5. Align the key (A) of the top cap (2) with key hole (B) in support arm pivot (3).

Then, secure top cap (2) on support arm pivot (3) by tightening three captive

screws (1). Make sure wiring (6) is tucked up above light block as much as

possible and does not hang down into path of light.

Housing Cap Installation

1. Install housing cap (2) on

ballast housing (3) and secure

with # 10-24 x 7/8” button

head screw (1). Tighten screw

using 1/8” hex wrench supplied

1

2

3

MA475300

9

Page 12

Installation

Electrical Requirements

WARNING

Use 220/230/240 VAC, 50/60 HZ alternating current only.

Failure to do so could result in electrical shock to personnel

and will result in damage to mobile light system.

NOTE

Grounding reliability can only be achieved if this equipment is connected to

an equivalent grounded receptacle.

The electrical rating for the mobile light system is 220/230/240 VAC, 50/60 Hz,

0.7 amps. The three-pronged grounding plug on the power cord must be

plugged into a matching three-pronged, grounded, correctly polarized 220/230/

240 VAC receptacle.

Electrical Input Setting

EQUIPMENT ALERT

Failure to properly determine your local voltage and / or failure to

rotate the fuse drawer until your voltage appears in the window of

the fuse drawer may result in equipment damage.

The mobile light system must be set for one of three possible voltages: 220

VAC, 230 VAC, or 240 VAC. Follow the procedure below to ensure the mobile

light system is set to match the voltage level available at your location.

1. Determine the correct voltage (220 VAC, 230 VAC, or 240 VAC) for your

location by consulting the proper local authorities.

10

Page 13

2. While simultaneously pressing inward on two locking tabs (A) with a small

flat bladed screwdriver, pull fuse drawer (1) from AC inlet (2).

4

3

Installation

B

240

230

220

2

4

A

C

1

B

A

EQUIPMENT ALERT

Be very gentle when pulling outward on two locking tabs (B). The

locking tabs are fragile and will break if pulled outward too far.

3. While simultaneously pulling out on two locking tabs (B), pull the fuse/

voltage selector (3) from fuse drawer (1).

4. Rotate the fuse/voltage selector (3) until the correct voltage for your location,

as determined in step 1, is aligned with the window (C) of fuse drawer (1).

MA382200

5. Insert the fuse/voltage selector (3) back into the fuse drawer (1) until it locks

into place. Check to make sure that the correct voltage label for your location

appears in the window (C).

11

Page 14

MA350800

Installation

6. Making sure both fuses (4) are present, insert the fuse drawer (1) into the

AC inlet (2) until it locks into place; you should hear a light clicking sound.

7. Plug one end of the power cord into AC inlet (2) and the other end into the

facility outlet receptacle.

Operational Test

1

540°

580°

35°

4

35°

1

36"

(91.4 cm)

1. Turn the ON / STANDBY switch (1) to ON “I”.

2. Observe. The lighthead (2) should illuminate.

2

3

180°

8"

(20.3 cm)

3. Position the lighthead (2) 36 in. (91.4 cm) from a table and aim the light

beam at the table.

4. Observe. There should be an evenly distributed circular pattern of bright

light, approximately 8 in. (20.3 cm) in diameter, on the table surface.

12

Page 15

5. Rotate the lighthead (2), lamp tube (3), and cross tube (4) through their

range of motions as shown on the illustration. Release the lighthead at

different positions.

6. Observe. The lighthead (2) should be able to be positioned easily through

the entire range of its motion. When the lighthead is released in any position,

no drifting should occur at any axis.

7. Turn the ON / STANDBY switch (1) to STANDBY “ “.

Installation

8. If any problems are discovered, refer to the troubleshooting guide for

adjustment and repair tips.

DESCRIPTION

Introduction / Features

The 355 lighthead assembly is a fixed-focus, faceted reflector lighthead. The

faceted reflector design provides excellent cavity penetrationwith 432 facets,

while also controlling shadows from light-blocking objects. The individual beams

of light are arranged to provide an evenly illuminated 8 in. (20.3 cm) diameter

beam at a distance of 36 in. (91.4 cm). The peak illumination at 36 in. (91.4 cm)

is 4,000 fc (43,000 lux). The optical system also filters out most of the infrared

heat from the prefocused pattern of light. The plastic handle can be easily

TM

removed for sterilization or it accepts a Devon EZ Handle

awkward adapter. The lighthead is made with a color molded, lightweight

polymer resulting in a very lightweight lighthead which is easy to position. The

arm assembly has been precisely designed, assembled, and balanced so that

the lighthead can be positioned with minimal force and no drifting. In addition,

three pivot points make the positioning of the lighthead easy and flexible.

without requiring an

Description

13

Page 16

COMPONENTS OVERVIEW

The illustration below shows the location of the light’s major components and

the chart below provides their descriptive name.

9

8

Components

Overview

5

6

12

7

4

2

11

10

1. Caster Base Assembly 8. Lighthead Assembly

2. Transformer Housing Assembly 9. Top Cap Assembly

3. AC Inlet / Fuse Drawer 10. Support Arm Pivot Assembly

4. Vertical Tube 11. Faceplate Assembly

5. Cross Tube Assembly 12. Ball Pivot Joint

6. Ballast Assembly 13. Power Cord

7. Lamp Tube Assembly

14

13

1

3

DESCRIPTION OF COMPONENTS

Page 17

CONTROLS & INDICATORS

MA382100

The following illustration shows the location of the light’s controls and indicators

and the chart below describes their function.

1

540°

580°

1

35°

35°

2

3

180°

Controls &

Indicators

Ref. Control / Indicator Function

1

2 fuse drawer

3 sterilizable handle allows sterile personnel to move lighthead.

on / standby switch (on

“I” / standby “ “)

turns the light on or off.

can be removed and inspected to determine if

fuse has been blown, indicating a current

surge or problem with light.

15

Page 18

Operation

OPERATION

Electromagnetic Interference

This product is designed and built to minimize electromagnetic interference with

other devices, however, if interference is noticed between another device and

this product, remove the interfering device from the room or plug this product

into an isolated circuit.

WARNING

Risk of fire and/or equipment damage. Do not obstruct the

airflow of the lighthead.

If the 355 mobile light system malfunctions, immediately turn the ON /

STANDBY switch to STANDBY “ ” and unplug the power cord.

Operating Lighthead Assembly

Turn the lighthead on by switching the ON / STANDBY switch to ON “I”. To

adjust the position of the lighthead, grasp the sterile handle (3) and rotate the

arm assembly and lighthead as necessary to obtain correct light position on the

patient (See previous figure for amount of rotation for an axis). To turn off the

lighthead, switch the ON / STANDBY switch to STANDBY “ “.

Moving Mobile Light System

WARNING

The mobile light system is very stable when it is stationary

and when pushed on smooth surfaces. However, when the

mobile light system is being transported, it can become susceptible to

tipping when it is pushed over a threshold or other similar obstruction.

Failure to use care when navigating over thresholds, obstructions, or

carpet could result in the mobile light system tipping and causing

severe personal injury or damage to mobile light system. Grasping the

vertical tube at waist height or lower during movement will help

stability during movement.

To move the mobile light system to a new area or room, simply unplug the light’s

power cord from the outlet receptacle, coil and hold power cord, and then

grasping the vertical tube at approximately waist height or lower, push the

mobile light system to desired area.

16

Page 19

OPERATOR MAINTENANCE

Operator Troubleshooting

Problem Possible Cause Solution

no light from lighthead

no light from lighthead; on /

standby switch is on “ I”

no light from lighthead

although the bulb and fuses

were checked; lighthead

flashes intermittently when

lighthead or arms are moved

lamp tube or lighthead does

not rotate freely or drifts when

released in desired position

lighthead is on standby

““

bulb has burned out or

has not been installed

fuse is blown (open)

no power to the

transformer housing

assembly

transformer is

malfunctioning

circuit or wiring problem

within arm assemblies,

transformer housing

assembly, or other part of

lighting system

brakes for the suspect

axis need adjustment

turn on / standby switch

to on “ I”

refer to bulb installation

procedure in this manual

refer to the fuse

replacement procedure

in this manual

check to make sure

power cord is plugged

in. Then call your

building maintenance

electrician to check for

facility power at the

electrical receptacle.

call Midmark Technical

Support: 1-800-Midmark

call Midmark Technical

Support: 1-800-Midmark

call Midmark Technical

Support: 1-800-Midmark

Operator

Maintenance

cross tube rotates (at ball pivot

joint) too stiffly or drifts when

released in desired position

squeak coming from

movement of the ball pivot.

tension needs to be

adjusted or cross tube

counterbalance needs to

be adjusted

residue build-up on ball

pivot

refer to tension

adjustment procedure in

this manual. If proper

tension cannot be

achieved, call Midmark

Technical Support: 1800-Midmark.

Lower the ball pivot

sleeve. Wipe the ball

pivot with a clean, dry

rag. Reinstall the ball

pivot sleeve.

17

Page 20

Preventive Maintenance

The following preventive maintenance schedule should be followed. If and when

problems are detected, refer to the troubleshooting guide in this manual.

FREQUENCY ACTIVITY

monthly Inspect casters for breaks, cracks, or wear. Replace

casters as necessary.

semiannually Inspect rotation of lighthead. Make sure the lighthead

rotates freely, without noise, and has 180° of rotation at

lamp tube connection. Make sure the lighthead stays positioned at any point (without drifting) with respect to the

lamp tube. See figure in the Controls & Indicators section.

semiannually Inspect the rotation of the lamp tube and cross tube. Make

sure the arm assembly rotates freely and without noise.

Make sure the arm assembly doesn’t drift at any point in

its range of motion. The lamp tube should have 540° of

rotation at cross tube connection. The cross tube should

have 580° of rotation at vertical tube connection and

should also have a vertical range of motion from -35° to

+35°. See figure in the Controls & Indicators section.

Operator

Maintenance

semiannually Turn light ON. Rotate lighthead, lamp tube, and cross

tube while observing lighthead. Lighthead should not

intermittently flicker or stop illuminating while joints are

being rotated.

semiannually Check for excessive joint rotation (more than 540° of

rotation at lamp tube connection or 580° of rotation at

cross tube connection). If there is excessive rotation, the

physical stops for an axis may be broken.

semiannually Inspect faceplate and inside of lighthead for indications of

broken material or other signs of damage. If damage to

any part of lighthead is evident, do not continue to use

lighthead. Using lighthead with a broken IR filter could

result in tissue burns to patients.

semiannually Inspect lighthead for excessive dust or grime buildup in

lighthead interior. Do not attempt to clean or disinfect;

instead call an authorized dealer or service technician.

Semiannually Move the cross tube up and down while listening for

squeaks coming from the ball pivot area. If squeaks are

heard, lower the ball pivot sleeve and wipe the ball pivot

sleeve with a clean, dry rag (wipe even if ball pivot

appears clean). Repeat the test. If no squeaks are heard,

reinstall the ball pivot sleeve.

18

Page 21

Fuse Replacement Procedure

230

240

220

2

3

A

A

1

230

3

MA38510

1. Turn the ON / STANDBY switch to standby “ ” and unplug light power cord

from AC inlet (2).

2. While simultaneously pressing inward on two locking tabs (A) with a small

flat bladed screwdriver, pull fuse drawer (1) from AC inlet (2).

3. Pull two fuses (3) out of fuse drawer (1).

4. Inspect fuses (3) for any indication that they have blown (opened); i.e. burnt

look, discolored, fuse cord melted through, etc. Discard fuse(s).

EQUIPMENT ALERT

Use fuses of the same voltage rating, amperage rating, and type.

Failure to do so could result in damage to the mobile light

assembly.

Operator

Maintenance

19

Page 22

5. Obtain new fuse(s) (3) of the same voltage rating, amperage rating, and

type. Refer to the SPECIFICATIONS section in this manual for the fuse

specification.

6. Insert the fuse drawer (1) into the AC inlet (2) until it locks into place; you

should hear a light clicking sound.

7. Plug light power cord into AC inlet (2), turn ON / STANDBY switch to ON “I”,

and check for light output. If fuse blows again, call for service (see calling for

service in this manual).

Operator

Maintenance

20

Page 23

Ball Pivot Tension Adjustment Procedure

2

ASSEMBLY / DISASSEMBLY

POSITION

LIGHT TENSION

POSITION

MEDIUM TENSION

POSITION

STIFF TENSION

POSITION

CRAFTSMAN

1

3

4

5

MA3509

ASSEMBLY / DISASSEMBLY

POSITION

LIGHT TENSION POSITION

MEDIUM TENSION POSITION STIFF TENSION POSITION

1. Remove screw (1) and slide ball pivot sleeve (2) down out of way.

2. Rotate cross tube (3) until adjustment hole (4) appears in the adjustment

window opening.

NOTE

There are three settings which the ball pivot cam (5) can be set for: light

tension, medium tension, or stiff tension (see above figure). These settings

may be changed according to the operator’s preference.

3. Insert a phillips screwdriver into adjustment hole (4). Then, using the

screwdriver, rotate ball pivot cam (5) to the desired tension setting.

4. Remove the screwdriver and move the cross tube (3) about the ball pivot

joint in a circular motion and up and down motion to ensure the setting is the

one desired. Move the cross tube (3) to a horizontal position and release it.

The cross tube should not drift in any direction. If it does, a higher tension

setting is required or the cross tube counterbalance needs adjusted (see

counterbalance adjustment in this manual). Repeat steps 3 and 4 until the

desired tension adjustment is achieved with no drifting of the cross tube.

Operator

Maintenance

5. Slide ball pivot sleeve (2) up into position and secure with screw (1).

21

Page 24

Cross Tube Counterbalance Adjustment

3

2

1

Operator

Maintenance

4

1. Remove screw (1, see previous figure) and slide ball pivot sleeve (2) down

out of way.

2. Rotate cross tube (3, see previous figure) until adjustment hole (4) appears

in the adjustment window opening.

3. Insert screwdriver into adjustment hole (4, see previous figure). Then, using

the screwdriver, rotate ball pivot cam (5) to the assembly / disassembly

setting. Remove the screwdriver.

4. Remove screw (1, see figure above) and housing cap (2) from ballast

housing (3).

MA351000

NOTE

One way to determine if cross tube is balanced properly is to raise the cross

tube above the horizontal plane, release it, and observe where it stops. Then,

lower the cross tube below the horizontal plane, release it, and observe

where it stops. The cross tube should return to the horizontal position and

remain there; if it does, the cross tube counterbalance is adjusted properly.

Turning screw (4) in clockwise direction will raise the lighthead end of the

cross tube. Turning screw (4) in counterclockwise direction will lower the

lighthead end of cross tube.

22

Page 25

5. Using a 3/16” hex (Allen) wrench, adjust screw (4) until cross tube (5)

balances in a horizontal position.

6. Install housing cap (2) on ballast housing (3) and secure with screw (1).

NOTE

It is recommended that you start with the light setting and then proceed to the

medium or stiff setting only if necessary to prevent drifting.

7. Insert screwdriver into adjustment hole (4, see figure of previous paragraph).

Then, using the screwdriver, rotate ball pivot cam (5) to the light, medium, or

stiff setting as desired by the operator(s). Remove screwdriver.

8. Slide ball pivot sleeve (2) up into position and secure with screw (1).

Cleaning and Disinfecting

EQUIPMENT ALERT

When cleaning or disinfecting the light, remove power from the

light, allow optical unit to cool, and do not touch glass portion of

bulb or inner components of lighthead with bare hand. Clean EXTERNAL

SURFACES ONLY (arm assemblies and lighthead). Prevent fluids from

leaking into interior or onto electrical contacts. DO NOT ATTEMPT to clean

or disinfect interior; instead call an authorized dealer or service technician.

EQUIPMENT ALERT

Use only quaternary disinfectants to disinfect light. Staining,

pitting, discoloration, or softening could occur if phenolic,

iodophor, or glutaraldehyde-based disinfectant is used on plastic surfaces of

the lighthead. Also, use of alcohol or aerosol spray cleaner / disinfectant

containing substantial amounts of alcohol in the formula can damage the

faceplate.

Operator

Maintenance

23

Page 26

External Cleaning Procedures

For general cleaning, use a mild detergent and water solution. Wring excess

solution from sponge or cloth before wiping.

According to your facility’s procedure:

1. Clean faceplate with an antistatic acrylic cleaning solution using a soft, clean

cloth. Do not use alcohol or abrasive compounds on faceplate.

2. Wipe external surface of arm assemblies and lighthead with a mild detergent

and water solution.

3. Rinse all external surfaces with a soft cloth and clear water, wringing excess

from cloth before wiping.

4. Wipe all external surfaces dry.

External Disinfecting Procedures

Operator

Maintenance

According to your facility’s procedure:

1. Use only quaternary disinfectants to disinfect light. Staining, pitting,

discoloration, or softening could occur if phenolic, iodophor, or

glutaraldehyde-based disinfectant is used on plastic surfaces of the

lighthead. Also, use of alcohol or aerosol spray cleaner / disinfectant

containing substantial amounts of alcohol in the formula can damage the

faceplate.

2. Wring excess solution from cloth.

3. Using soft cloth, wipe all external surfaces of arm assemblies and lighthead.

4. Do not rinse or dry external surfaces. Allow germicidal solution to air dry.

24

Page 27

Handle Sterilization

Acceptable Acceptable Unacceptable

• Use only steam sterilization on the handle.

• To sterilize, process the handle in a dynamic air removal steam sterilizer

(sterilizer that uses pressure pulses and / or vacuum purges to remove air

from the chamber) at a temperature of 132°C (270°F) for 4 minutes

minimum. If using a Midmark M9 or M11 sterilizer use the “Pouches” cycle. It

is recommended that the handle be pouched or wrapped for sterilization to

maintain its sterility until placed on the light. When pouching or wrapping the

handle, use only sterilizer pouches or wraps that have been cleared by the

FDA and labeled for use with steam sterilization cycle parameters (e.g.

temperature and exposure time) of the sterilization cycle being used. Place

the handle on the sterilizer tray so steam can enter the opening and air and

any steam condensate can drain from the handle (refer to illustration).

.

CAUTION

The handle is not sterile when shipped so if your application

requires the handle to be sterile, it must be sterilized before initial

use or covered with a sterile protective barrier.

CALLING FOR SERVICE

If you are having a problem or have a question, refer to the inside front cover of

this manual and call your dealer. Make sure that you have the information that is

highlighted on the inside front cover of this manual available. If you can’t resolve

your question or problem with your dealer, call the following number:

1-800-Midmark (1-800-643-6275) or 937-526-3662

8:00 a.m until 5:00 p.m. (Eastern Standard Time in the U.S.)

Monday thru Friday, except for standard U.S. holidays.

Operator

Maintenance

Calling For

Service

25

Page 28

Specifications

SPECIFICATIONS

Model 355 Mobile Light

Beam diameter @ 91 cm:.............. 20 cm (8 in.) (defined by 20% of peak

illumination)

Bulb: ............................................... 24 VAC, 100 W halogen bulb

Color temperature:........................4,200K

Diameter of lighthead: ..................43 cm (17 in.)

Focal length: .................................. 91 cm (36 in.)

Illumination @ 60.9 cm (24 in.):....53,800 lux / 5000 fc

Illumination @ 91.4 cm (36 in.):....36,600 lux / 3400 fc

Refecting facets............................. 432

Electrical requirement: .................220, 230, or 240 VAC, 50 / 60 HZ,

0.7 amps, single phase

“A” Reach of arm assemblies:.....66 cm (26 in.) maximum from centerline of

vertical tube to center of lighthead.

“B” Length of counterbalance: ....122 cm (48 in.)

“F” Diameter of caster base: ........71 cm (28 in.)

“E” Minimum lighthead height:.... less than 112 cm (44 in.)

“D” Maximum lighthead height:... greater than 188 cm (74 in.)

“C” Maximum overall height: .......less than 218 cm (86 in.)

Rotation of lighthead: ...................180° rotation at lamp tube connection

Rotation of lamp tube: .................. 540° rotation at cross tube connection

Rotation of cross tube: .................580° rotation at vertical tube connection

Vertical range of cross tube: ........-35° to +35° vertical movement

Box dimensions:............................154.9 cm “L” x 77.5 cm “W” x 26.7 cm “H”

61in. “L” x 30.5 “W” x 10.5 “H”

Unboxed weight:....26.8 kg (59.0 lbs)

Power cord .............Harmonized cordage,

2.44 m (96 in.) long

with hospital grade

grounding type plug.

Classifications: ......Class 1, Type B

applied part, Ordinary

Equipment,

Continuous Operation

Fuse Rating:...........0.8 amp, 250 VAC,

5 x 20 mm, Type FST

Time Lag IEC 127-2/3

Equipment not suitable for use in the

presence of a flammable anesthetic

mixture with air, oxygen, or nitrous

oxide.

26

Page 29

LIMITED WARRANTY

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original purchaser its new

Alternate Care products and components (except for components not warranted

under “Exclusions”) manufactured by Midmark to be free from defects in material

and workmanship under normal use and service. Midmark’s obligation under this

warranty is limited to the repair or replacement, at Midmark’s option, of the parts or

the products the defects of which are reported to Midmark within the applicable

warranty period and which, upon examination by Midmark, prove to be defective.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original

user, shall be one (1) year for all warranted products and components.

EXCLUSIONS

This warranty does not cover and Midmark shall not be liable for the following: (1)

repairs and replacements because of misuse, abuse, negligence, alteration,

accident, freight damage, or tampering; (2) products which are not installed, used,

and properly cleaned as required in the Midmark “Installation” and or “Installation /

Operation Manual for this applicable product. (3) products considered to be of a

consumable nature; (4) accessories or parts not manufactured by Midmark; (5)

charges by anyone for adjustments, repairs, replacement parts, installation, or other

work performed upon or in connection with such products which is not expressly

authorized in writing in advance by Midmark.

EXCLUSIVE REMEDY

Midmark’s only obligation under this warranty is the repair or replacement of

defective parts. Midmark shall not be liable for any direct, special, indirect,

incidental, exemplary, or consequential damages or delay, including, but not limited

to, damages for loss of profits or loss of use.

NO AUTHORIZATION

No person or firm is authorized to create for Midmark any other obligation or liability

in connection with the products.

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO

IMPLIED WARRANTIES OF ANY KIND INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. THIS

WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF DEFECTIVE

PART S.

SF-1487 REV. A1

Warranty

27

Page 30

NOTES:

28

Page 31

NOTES:

29

Page 32

Midmark Corporation

60 Vista Drive

Versailles, OH 45380 USA

1-800-643-6275

1-937-526-3662

www.midmark.com

Language of origin: English

© Midmark Corporation - 1999

003-1058-00 Rev. K (3/3/12)

Loading...

Loading...