Midmark 304 Service manual

-001

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

Style B

thru

304

-021

Examination

Ta ble

Service and

Serial Number Prefixes:

GJ, GK, GL, JE, JF, JG

JH, KV, KW, KX, KZ, LC

& V

Parts Manual

NO LONGER IN PRODUCTION

Some service parts may not

be available for this product-

(Monitor Arm on 304-017

Integrated Patient Exam

Table [IPET] Only)

FOR USE BY MIDMARK

TRAINED TECHNICIANS ONLY

304

-001

thru

-021

SF-1532 Part No. 004-0044-00 Rev. M (03/18/08)

Go To Table Of Contents

TABLE OF CONTENTS

TABLE OF CONTENTS

Section/Paragraph................................................Page Section/Paragraph ............................................... Page

IMPORTANT INSTRUCTIONS

General Safety Instructions ...........................................ii

Safety Alert Symbols .....................................................ii

Warranty Instructions .................................................. ii

SECTION I GENERAL INFORMATION

1.1 Description Of 304 Exam Table.................... 1-1

1.2 Specifications ............................................... 1-3

1.3 Parts Replacement Ordering........................ 1-5

1.4 Special Tools ................................................ 1-6

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test (See Figure 2-1) ................ 2-1

2.2 Troubleshooting Procedures......................... 2-3

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance ............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction................................................... 4-1

4.2 Styled Upholstery Removal /

Installation ................................................ 4-1

4.3 Soft Touch Upholstery

Removal / Installation ............................... 4-2

4.4 Footrest Extension Removal /

Installation ................................................. 4-4

4.5 Step Assembly Removal /

Installation ................................................. 4-5

4.6 Back Lock Assembly Removal /

Installation ................................................. 4-7

4.7 Lift Lever Removal / Installation.................... 4-9

4.8 Heater ON / OFF Switch

Removal / Installation .............................. 4-11

4.9 Heater Plate Removal /

Installation ............................................... 4-12

4.10 Stirrup Components Removal /

Installation ............................................... 4-13

4.11 Electrical Receptacle Removal /

Installation (120 VAC units)..................... 4-14

4.12 Typical Electrical Receptacle Removal /

Installation (220 VAC units)..................... 4-16

4.13 Fuse Removal / Installation

(220 VAC units) ....................................... 4-18

4.14 AC Inlet Removal / Installation

(220 VAC units) ....................................... 4-19

Model 304-017 Maintenance / Service Instructions Only

4.15 Accessing Electrical Components.............. 4-20

4.16 Fuse Holders.............................................. 4-21

4.17 Transformers .............................................. 4-21

4.18 Power Strips............................................... 4-22

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Electrical Schematics /

Wiring Diagrams ..................................... 5-1

SECTION VI PARTS LIST

6.1 Introduction ................................................ 6-1

6.2 Description Of Columns ............................... 6-1

6.3 Torque Specifications And Important

Assembly Notes........................................ 6-1

Pictorial Index ............................................ 6-2.*

Table Top Components

(Vacu-Form upholstery) .......................... 6-3.*

Table Top Components

(Soft Touch upholstery)............................. 6-4

Upperwrap Components ............................ 6-5.*

Stirrup Components ................................... 6-6.*

Cabinet Components

(120 VAC units) ......................................... 6-7

Cabinet Components

(220 VAC units) ......................................... 6-8

Step Assembly ............................................. 6-9

Electrical Components

(120 VAC units) ..................................... 6-10.*

Electrical Components

(220 VAC units) ..................................... 6-11.*

Receptacle Assembly

(220 VAC units) ....................................... 6-12

IPET Components...................................... 6-13

IPET Monitor Arm assembly ...................... 6-14

COMMENTS ............................................................. 7-1

FAX ORDER FORM.................................................. 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1997 SF-1532 Page i Printed in U.S.A.

Rev. 9/04

TABLE OF CONTENTS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark Corporation is that this table is maintained with the safety

of the patient and staff in mind. To assure that services

and repairs are completed safely and correctly, proceed

as follows:

(1) Read this entire manual before performing any

services or repairs on this table.

(2) Be sure you understand the instructions con-

tained in this manual before attempting to service or repair this table.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure, practice, or condition which, if not correctly followed,

will result in loss of life or serious personal

injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow the guidelines listed below will

void the warranty and/or render the 304 Medical Examination Table unsafe for operation.

• In the event of a malfunction, do not attempt to use

the examination table until necessary repairs have

been made.

• Do not attempt to disassemble table, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components. Use only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure, practice, or condition which, if not correctly followed,

could result in loss of life or serious personal

injury.

CAUTION

A CAUTION is used for a potentially haz-

ardous operating procedure, practice, or

condition which, if not correctly followed, could result

in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous operating procedure, practice, or condition which, if not

correctly followed, will or could result in serious, moderate, or minor damage to unit.

© Midmark Corporation 1997 SF-1532 Page ii Printed in U.S.A.

Rev. 7/04

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Description Of Model 304 Medical

Examination Table

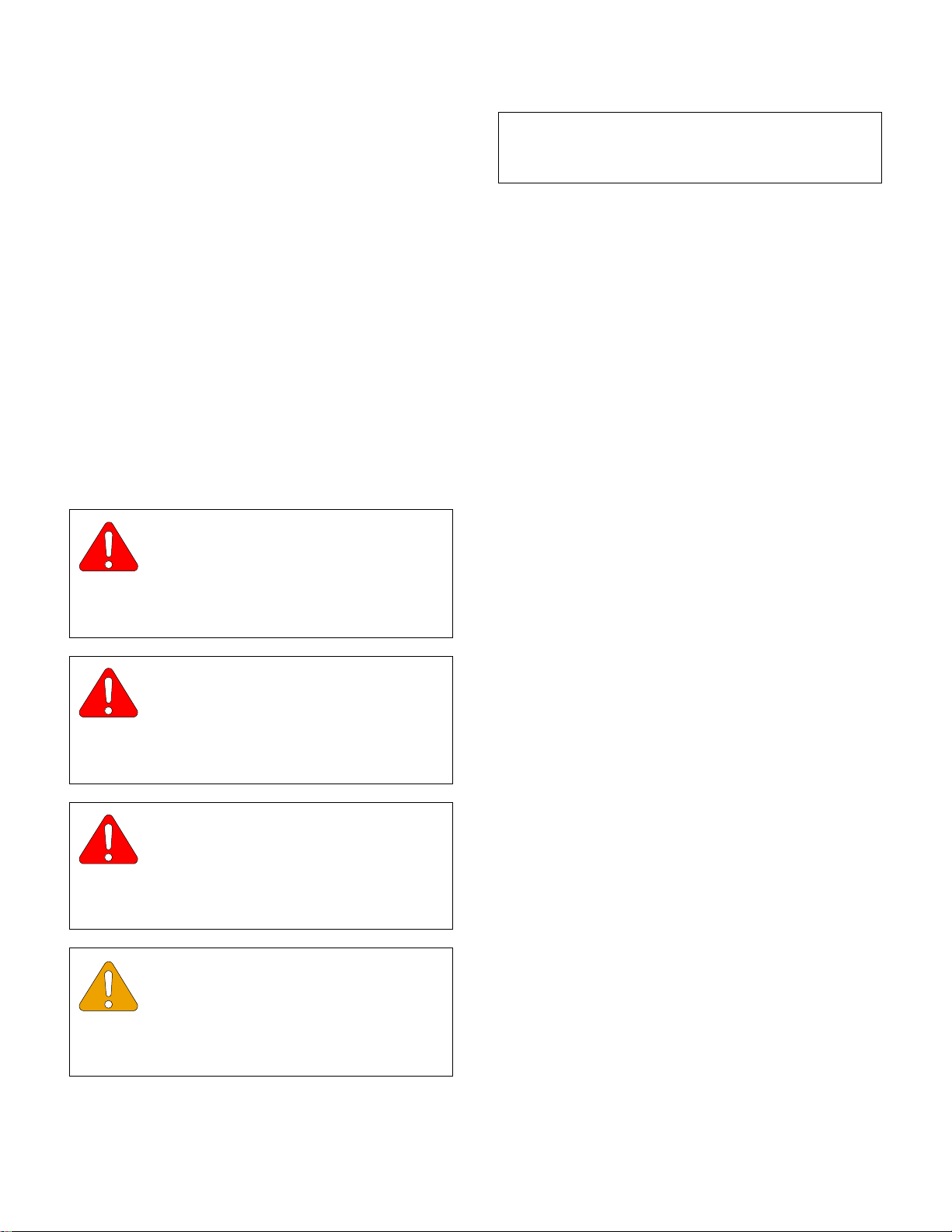

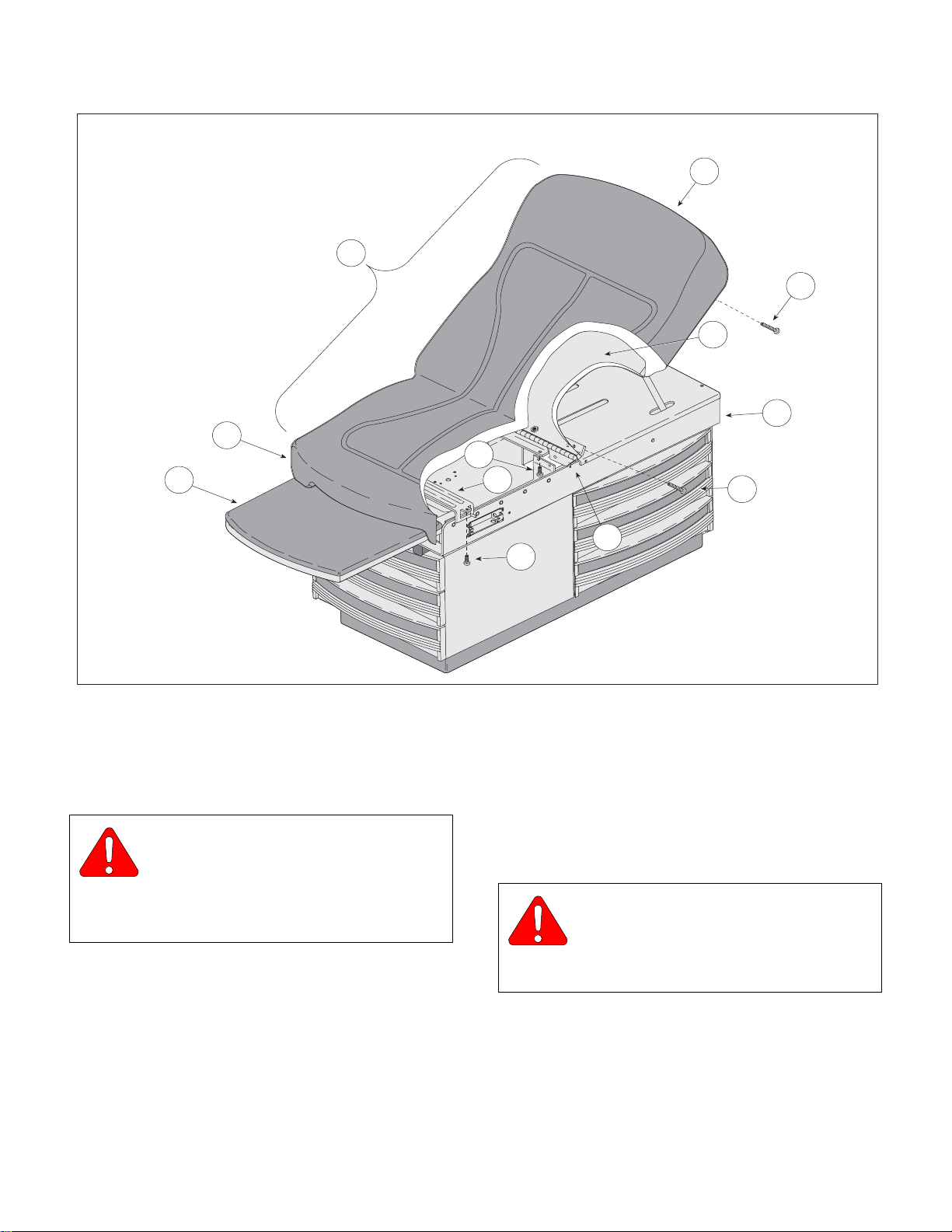

A. General Description (See Figure 1-1).

The Model 304 -001 thru -004 & -007 thru -014 Medical

Examination Table is primarily used in examination

rooms for general examinations and minor procedures.

The table top is adjustable from a full horizontal position

to a chair position. Also, when supported with an

optional pelvic lift bar, the lithotomy position can be

achieved.

Listed below are the models currently available:

304 (-001 thru -004 &

-007 thru -014)................................ 120 VAC units

304 (-018 thru -021 Canadian) .............................. N/ A

304 (-005, -006, -015, -016) .................... 220 VAC units

The components of the table are:

the drawer heater plate (optional) (1, Figure 1-1),

heater ON / OFF switch (optional), electrical receptacle,

back lock assembly, lift assembly, step assembly, and

two stirrup assemblies.

304 (-017)................................................ 120 VAC units

The Model 304 -017 Intergrated Patient Exam Table is

primarily used in examination rooms for general examinations and minor procedures.

It also provides an organized means by which a PC, and

PC-based instruments can be placed nearer to the

patient for more efficient use by the practitioner.

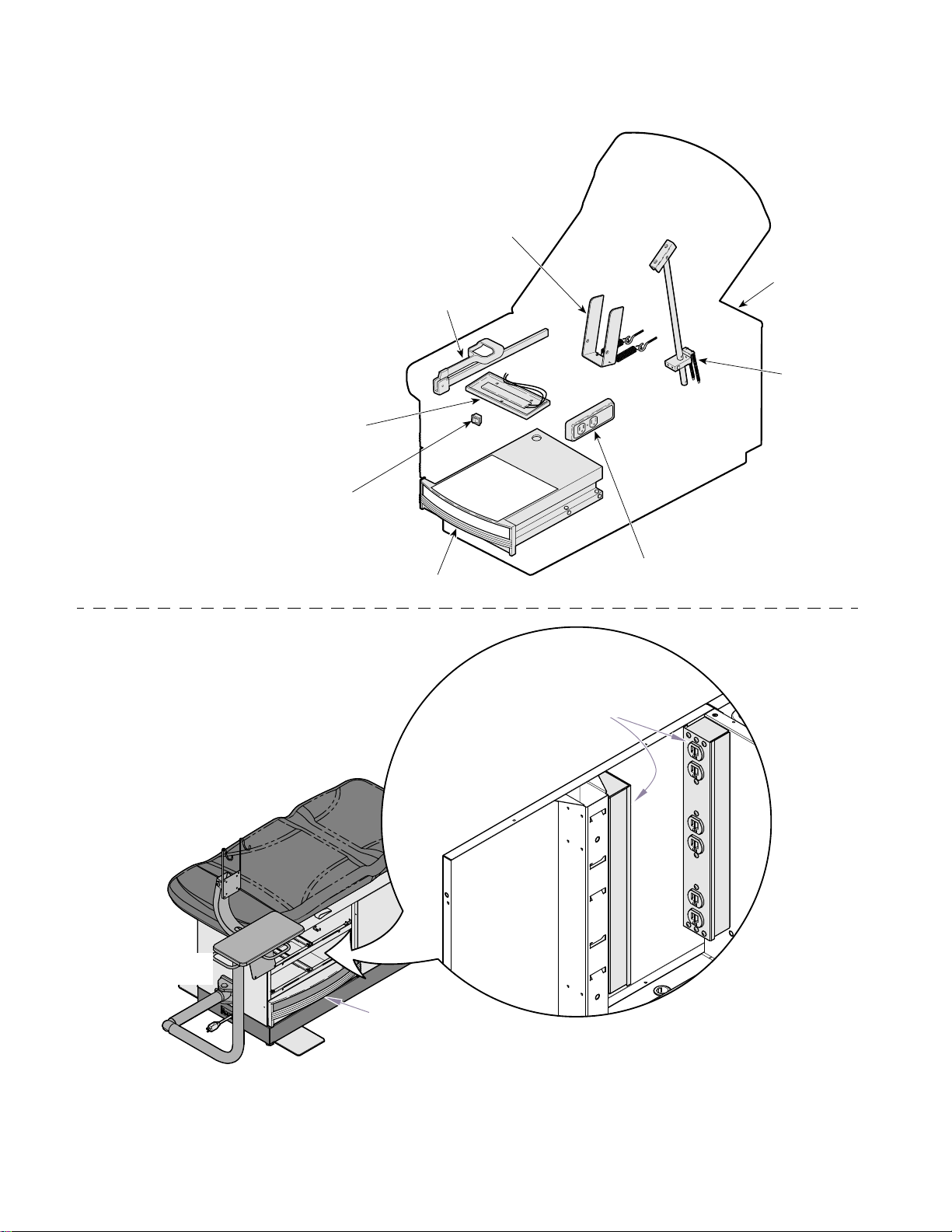

It has a magnetic drawer front on the side at the headend of the table. When removed, a storage area for a

PC or other electronic monitor equipment is accessible.

The monitor arm, provides support for a PC keyboard,

flat screen monitor or other similar equipment.

Two power strips, each containing six outlets, are

located on the head-end, inside the table frame, behind

the drawers. Two Isolation Transformers are located

beneath the base cover, below the drawers, on the

head-end of the table.

The 304-017 also contains the back lock and lift assemblies, stirrups, and step assembly same as the other

304 models.

It does not

exterior electrical receptacle.

contain a drawer heater and on/off switch, or

Model 304-001 thru -004 & -007 thru -014

Theory of Operation (120 VAC Units)

(See Section 5 for wiring diagram / electrical schematic)

Line voltage (120 VAC) is supplied thru the power cord

to electrical receptacles located on the side of the table.

As long as the power cord is plugged into a supply outlet, 120 VAC power will be present at the receptacles.

Models 304-018 thru -021

Has pelvic tilt options but no receptacles nor drawer

heaters.

Model 304-005, 006, -015, -016

Theory of Operation (220 VAC Units)

(See Section 5 for wiring diagram / electrical schematic)

Line voltage (220 VAC) is supplied thru the power cord

to the AC inlet located on the base of the table. From

the AC inlet, voltage is supplied to the receptacle

located on the side of the table. As long as the power

cord is plugged into a supply outlet, 220 VAC power will

be present at the receptacle.

Optional Heater Plate:

Some units are equipped with an optional heater plate

for drawer warming. When the operator turns the heater

ON / OFF switch to ON, closing the circuit, power

is supplied to the heater plate, heating the unit. This

provides heat in the top, foot end drawer to warm instruments.

Model 304-017

Theory of Operation (120 VAC Unit)

(See Section 5 for wiring diagram / electrical schematic)

Line voltage (120 VAC) is supplied thru the power cord

and four fuses to the two isolation transformers. The

transformers have 120 VAC input and output and are

used to maintain a level voltage

two power strips.

Each power strip, located on the head-end behind the

drawers, has six outlets to supply 120 VAC to accessories. The maximum load on each power strip cannot

exceed 5 amps.

(120 VAC) supply to the

© Midmark Corporation 1997 SF-1532 Page 1-1 Printed in U.S.A.

Rev. 5/05

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

* Not Provided on Models

304-017 thru -021

Heater

On/Off

Switch

Drawer

Heater

Plate

*

Lift

Assembly

Circuit Breakers

304-018 thru -021

Stirrup

Back Lock

Assembly

*

Head

End

Monitor

Arm

304-017

Assembly

Magnetic

Drawer

Front

Step

Power

Strips (2)

Exterior

Electrical

Receptacle

MA661202i

*

MA356102i

© Midmark Corporation 1997 SF-1532 Page 1-2 Printed in U.S.A.

Rev.1/05

Figure 1-1. Major Components

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

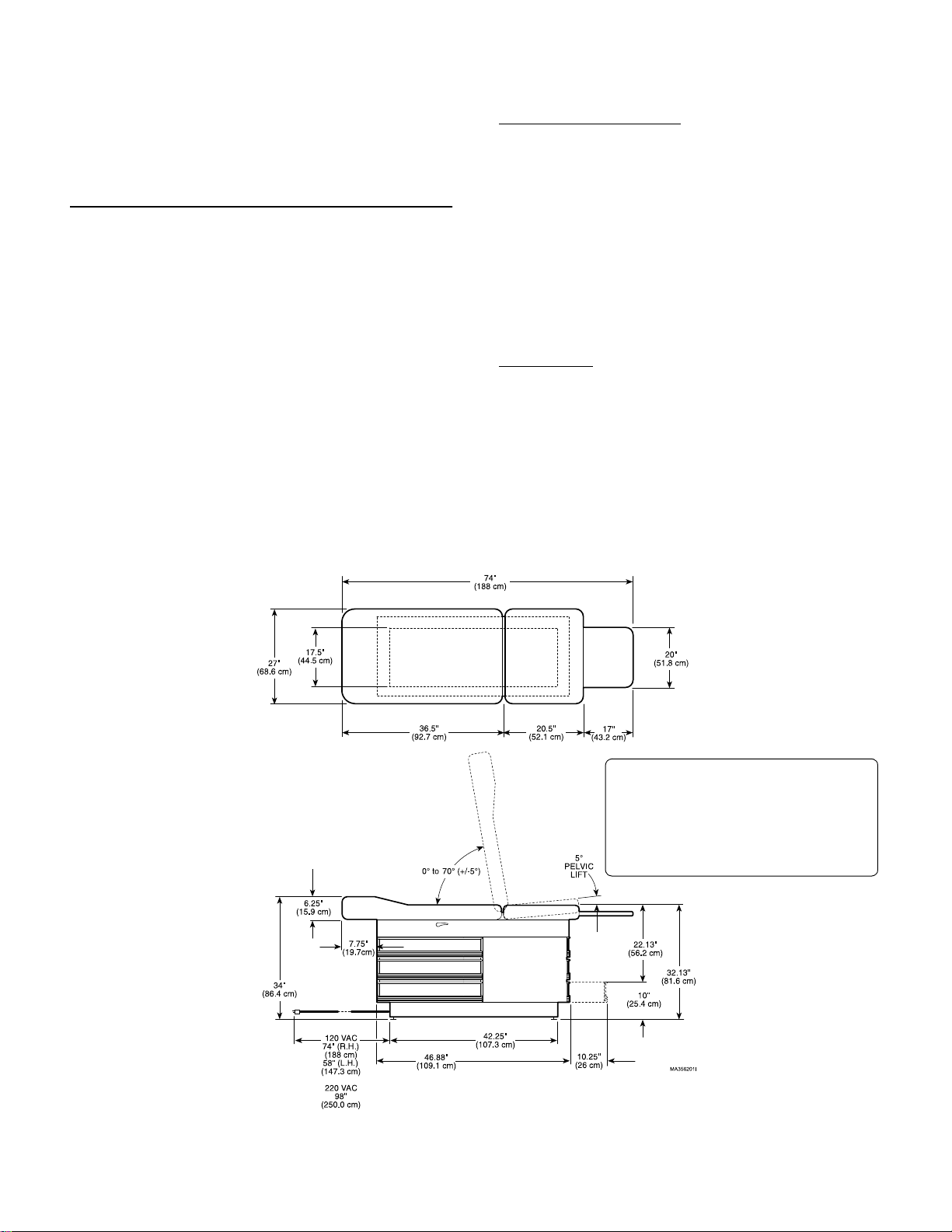

1.2 Specifications

Table 1-2. Specifications

Description Data

Weight of a Unit (304-001 thru -004 & -007 thru -014,

& -018 thru -021):

Without Shipping Carton ................. 250 lbs (113.4 kg)

With Shipping Carton ......................... 300 lbs (136 kg)

Weight of a Unit (304-017):

Without Shipping Carton ................. 400 lbs (181.4 kg)

With Shipping Carton ...................... 450 lbs (204.1 kg)

Shipping Carton: ...60.5 in. "L" x 30 in. "W" x 42 in. "H"

(153.7 cm x 76.2 cm x 106.7 cm)

Dimensions (See Figures 1-2 & 1-3).

Weight Capacity (Maximum) ............ 325 lbs. (147.4 kg)

Electrical Requirements:

304(-001, -002, -007, -008,................... 110-120 VAC,

60 HZ, 6.0 amp, single phase

304(-003, -004, -009, -010)................... 110-120 VAC,

60 HZ, 6.5 amp, single phase

304(-005, -006, -0 15, -016)................... 220- 240 VAC,

50/60 HZ, 5 amp, single phase

304(-017) .............................................. 110-120 VAC,

60 HZ, 12.0 amp, single phase

Fuse Rating:

304(-005, -006, -015, -016)............ 6.3 amp, 250 VAC

5 x 20mm “Slo-Blo”

304 (-017) (F1, F2, F3, F4) ............ 6.3 amp, 250 VAC

5 x 20mm “Slo-Blo”

© Midmark Corporation 1997 SF-1532 Page 1-3 Printed in U.S.A.

Rev. 1/05

Figure 1-2.Dimensions

304-001 thru -010

304-015 thru -016

304-017

304-018 thru -021

*

*(See Fig. 1-3 for Monitor Arm)

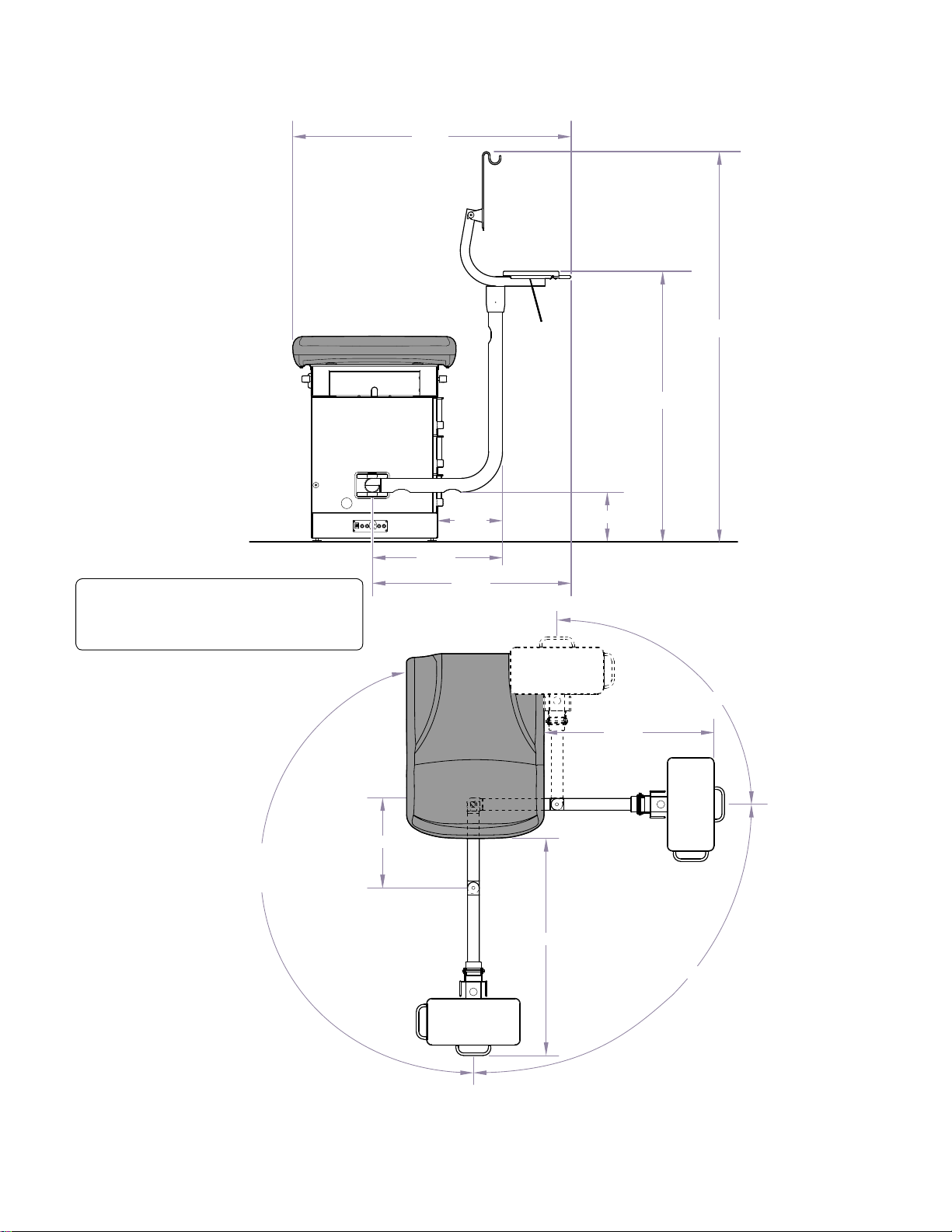

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

61"

62-3/4"

55-1/4"

Head End

304-017 Monitor Arm Assembly

For Table Dimensions

refer to Figure 1-2.

Same Arm Swing

as shown on

Opposite Side

19-1/2"

27-1/2"

37-1/4"

49-1/4"

Head End

43"

7-1/2"

37-1/2"

9"x18"

90

o

90

o

© Midmark Corporation 1997 SF-1532 Page 1-4 Printed in U.S.A.

Rev. 1/05

30 lbs.

Max. Load

Figure 1-3. Dimensions

MA662201i

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

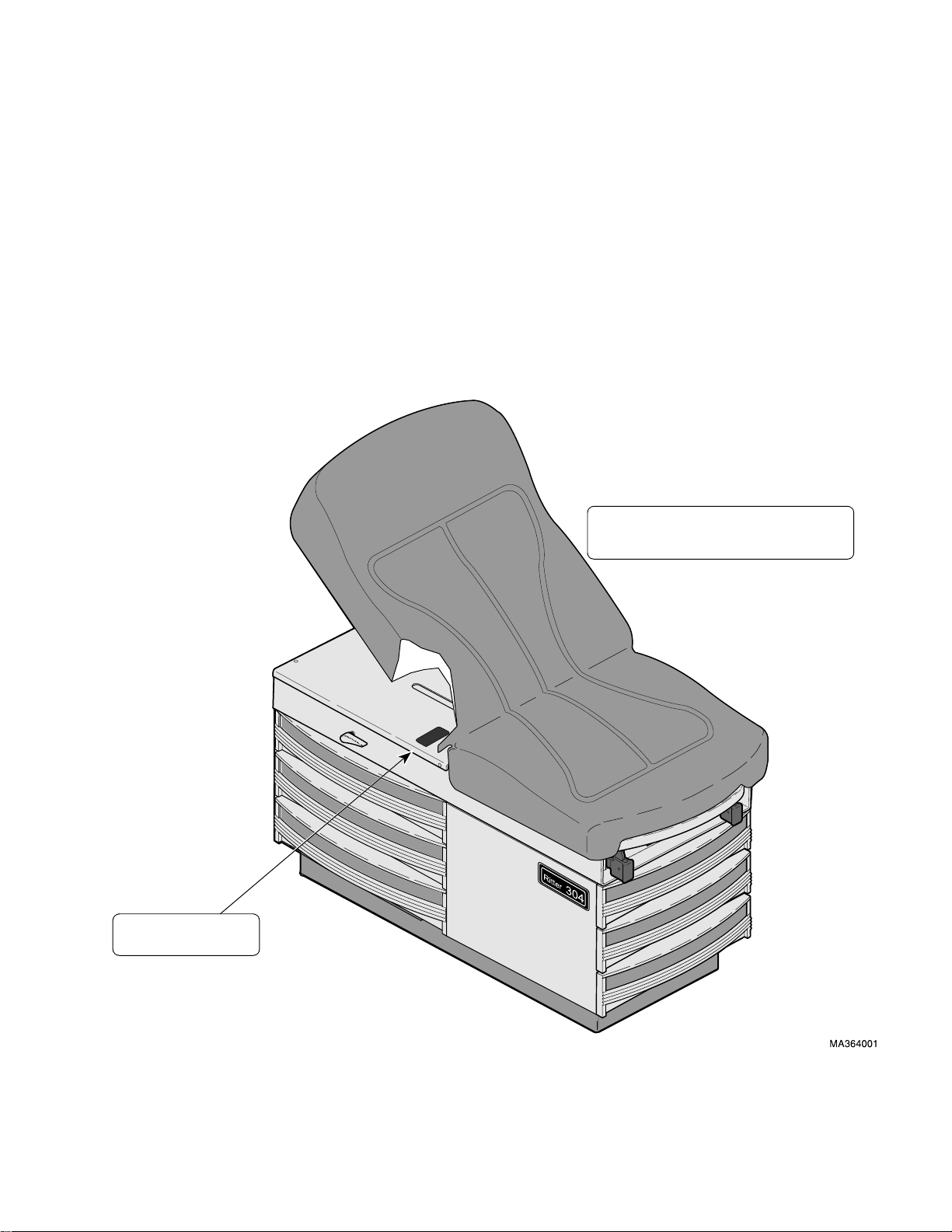

1.3 Parts Replacement Ordering

If a replacement part is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-4 to determine the location

of the model number and serial number of the

table and record this data.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the

parts, descriptions of the parts, and quantities

of parts needed and record this data (Refer to

para 6.1)

NOTE

Ask the Purchasing Department of the company that

owns the table for this information. Otherwise, this

information may be obtained from the dealer that

sold the table.

(3) Determine the installation date of the table and

record this data.Call Midmark with the recorded

information and ask for the Medical Products

Technical Services Department. See back

cover of this manual for the phone number or

use the Fax Order Form (See page 7-2 for Fax

Order Form).

Model & Serial Numbers are

required when ordering parts.

MODEL NUMBER

SERIAL NUMBER

© Midmark Corporation 1997 SF-1532 Page 1-5 Printed in U.S.A.

Rev. 1/05

Figure 1-4. Model Number / Serial Number Location

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

1.4 Special Tools

the table, how to obtain the special tools, and the purpose of each special tool.

Table 1-3 lists all of the special tools needed to repair

Table 1-3. Special Tool List

Description of Special Tool

Multimeter Commercially Available Any Type Used to perform continuity and voltage checks.

Pop Rivet Gun Commercially Available For installation of 1/8 in.

Torque Wrench Commercially Available Any Type Used to tighten nuts or screws to specified values.

Manufacturer’s

Name / Address / Phone

Manufacturer’s

Part Number

pop rivets.

Purpose of Special Tool

For installation of drawer slides and mullions.

© Midmark Corporation 1997 SF-1532 Page 1-6 Printed in U.S.A.

Rev. 1/05

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLESHOOTING

SECTION II

2.1 Operational Test (See Figure 2-1)

In order to effectively diagnose a malfunction of the

table, it may be necessary to perform an operational

test as follows:

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

examination table. Failure to do so could result

in personal injury.

NOTE

The Operational Test, for the most part, only

describes what should happen when the table is

operated. If the table does something other than

described, a problem has been discovered. Refer to

the Troubleshooting Guide to determine the cause of

the problem and its correction.

(1) Plug the table power cord into a grounded, non-

isolated, correctly polarized outlet, that has the

proper voltage for the table.

(2) Using a multimeter, check for proper voltage at

the table’s electrical receptacle (1).

(5) Lift up on the head board assembly (4) stopping

at several positions.

Observe.

raise smoothly. The back support rod and lock

assembly should hold the head board firmly at

all positions without slipping. The head board

should be able to be raised to 80°

The head board assembly (4) should

.

NOTE

The head board assembly should hold firmly with a

200 lb. (90.7 kg) load applied to the head end of the

table.

(6) Apply pressure to the head board assembly (4)

to check for drifting. Then press down on one

of the back lock handles (5) while pressing

down on the head board assembly and lower

the head board all the way down.

Observe.

drift when pressure is applied to head board

assembly. The back lock rod assembly should

retract smoothly without binding when back lock

handles are depressed. The head board

assembly should be able to be lowered to a horizontal position.

The back lock assembly should not

Observe. For 304 (-001 thru -004 &

-007 thru -014):

present at the receptacle.

-015, -016):

at the receptacle.

(3) If the unit has the optional heater, turn the

heater ON / OFF switch (2) to ON.

Observe.

should illuminate and the heater plate should

begin to warm the top drawer at the foot end of

the table (9).

Turn the heater ON / OFF switch (2) to OFF.

(4) Pull footrest assembly (3) out all the way.

Observe.

easily. The footrest assembly should hit stops

at the end of its travel, preventing accidental

removal

.

There should be 120 VAC

For 304 (-005, -006,

There should be 220 VAC present

The heater ON / OFF switch (2)

The footrest assembly should extend

(7) On units with the optional pelvic tilt, lift up on

the seat section (6) slightly.

Observe.

matically raise up into its locked position, supporting the seat section in the pelvic lift position

(+5° above horizontal).

To lower the seat section (6) to standard position, raise up slightly on seat section; then

grasp the pelvic lift bar (7) and rotate it downward while lowering the seat section.

(8) Extend the stirrups (8); then lift up on the end of

each stirrup and move them laterally. Let the

stirrups lock into each of the four positions.

While applying downward pressure, attempt to

move each stirrup to the left and to the right.

.

The pelvic lift bar (7) should auto-

© Midmark Corporation 1997 SF-1532

Rev. 12/98

Page 2-1

Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

7

6

4

8

2

3

10

Figure 2-1. Operational Test

Observe.

easily and move freely from left to right when

raised. The stirrups should lock into each of the

four positions and should not move laterally as

long as downward pressure is applied.

(9) Check operation of each drawer (9).

The stirrups (8) should slide out

5

1

9

(10) Check operation of step (10).

Observe.

The step should drop into locked position when

it is fully extended and should not pull out of the

table.

The step (10) should pull out easily.

MA380600

Observe.

All drawer rollers should move freely in the

drawer tracks.

© Midmark Corporation 1997 SF-1532

The drawers should slide out easily.

Rev. 12/98

Page 2-2

Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

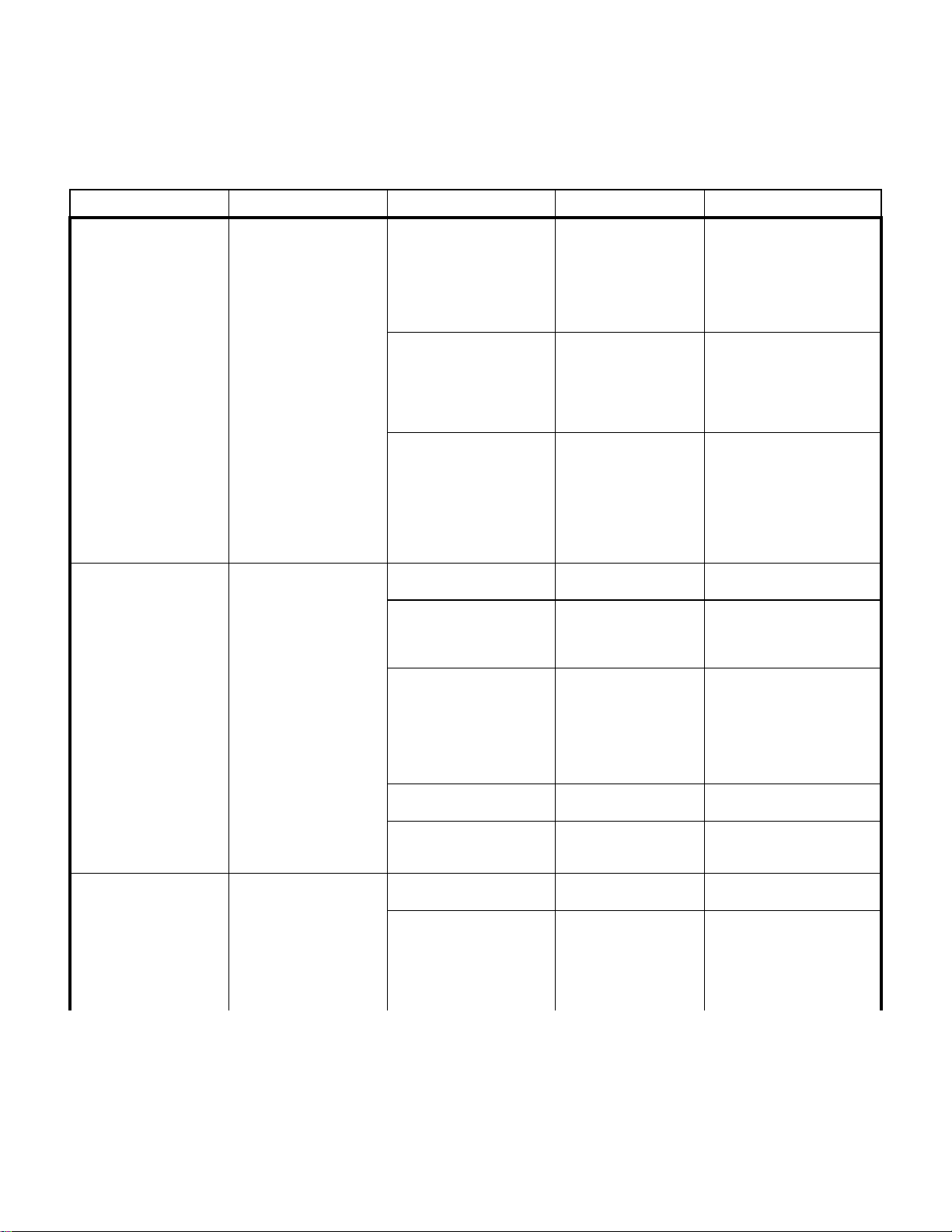

2.2 Troubleshooting Procedures

Table 2-1 is a Troubleshooting Guide which is used to

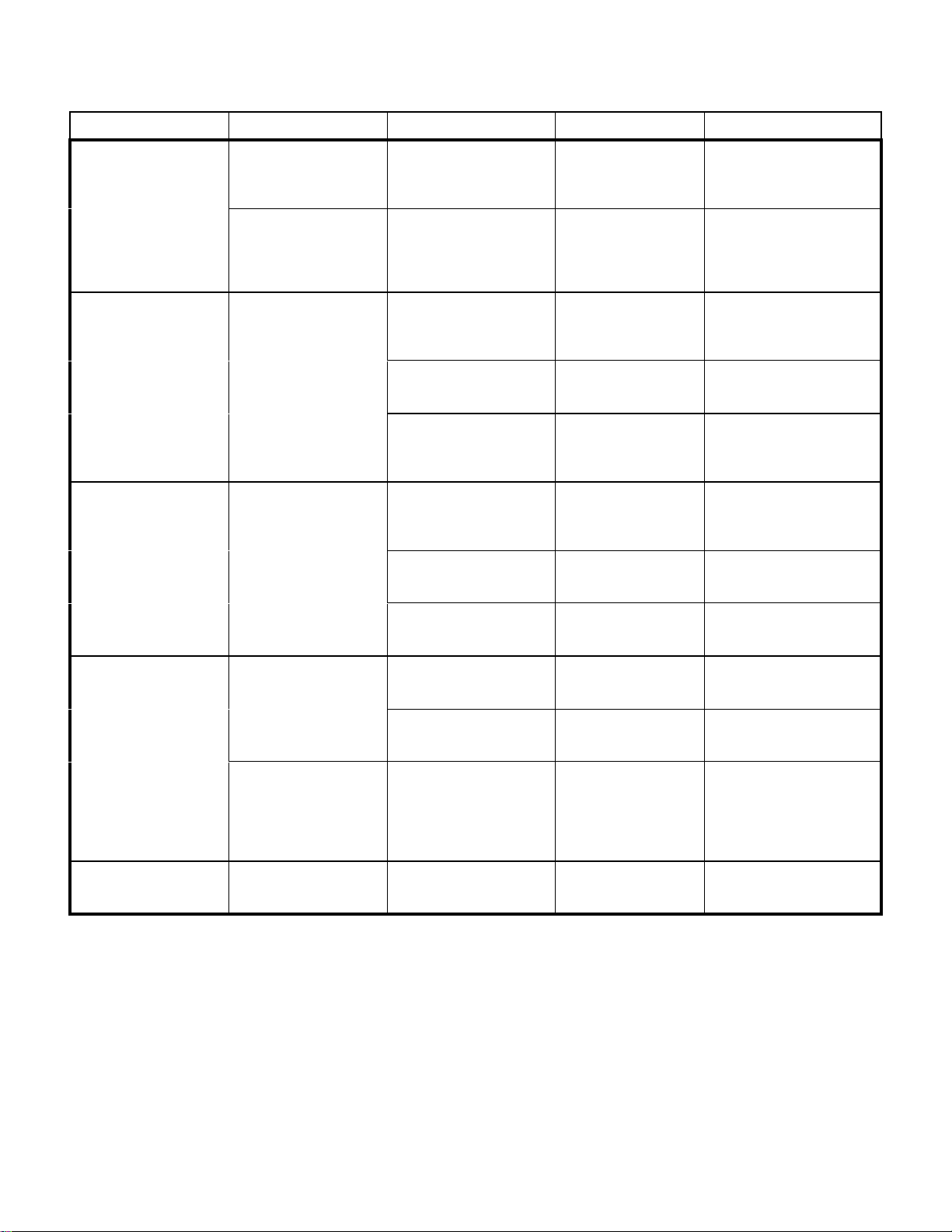

Problem Symptom Probable Cause Check Correction

Drawer warmer is not

working. Power is present

at the supply outlet.

(Not an option on 304-017)

Electrical receptacle is not

working.

(Not an option on 304-017)

Electrical receptacle or

optional drawer warmer not

working.

(Not an option on 304-017)

Heater plate assembly

does not warm up when

heater ON / OFF switch is

turned ON.

Table power cord is

plugged into wall outlet and

power is present, but there

is still no power at electrical receptacle.

No power is available at

electrical receptacle and

heater ON / OFF switch

does not illuminate when

pressed.

Heater ON / OFF switch is

malfunctioning.

Heater plate assembly is

malfunctioning

Wire connections are loose. Check all wiring connec-

Circuit Breaker(s) tripped.

(Models 304-018 thru -021)

Electrical receptacle is malfunctioning.

Wire connections are loose. Check all wiring connec-

Line fuse(s) blown (applies

to 220 VAC units only).

AC inlet is malfunctioning

(applies to 220 VAC units

only).

Power cord is not plugged

into facility wall outlet.

Facility circuit breaker providing power to table is

tripped / blown.

determine the cause of the malfunction.

When heater ON / OFF

switch is turned to ON,

heater switch should illuminate (this indicates that

there is power present at

output terminals of

switch).

Replace suspect heater

plate assembly with

known working heater

plate assembly or check

for continuity thru heater

plate assembly wires.

tions from power heater

ON / OFF switch to

heater plate assembly.

Perform continuity check

on wires. Use multimeter

to check for proper voltage levels.

Check if Circuit

Breaker(s) is tripped.

Replace suspect electrical receptacle with

known working receptacle.

tions from power cord to

electrical receptacle.

Perform continuity check

on wires. Use multimeter

to check for proper voltage levels.

Perform continuity check

on fuses.

Replace suspect AC inlet

with known working AC

inlet.

Check to see if power

cord is plugged in.

Check to see if facility circuit breaker is tripped /

blown. One way of

checking this is to plug a

lamp into wall outlet that

table was plugged into.

If heater ON / OFF switch

does not illuminate when

turned ON, replace heater

switch. Refer to para 4.8.

Replace heater plate assembly. Refer to para 4.9.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections. Refer to para

5.1.

Reset Circuit Breaker(s)

Replace electrical receptacle.

120 VAC Units: Refer to para

4.11. 220 VAC Units: Refer

to para 4.12.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections. Refer to para

5.1.

Replace fuse(s). Refer to para

4.13.

Replace AC inlet. Refer to

para 4.14.

Plug power cord into facility

wall outlet.

If circuit breaker is tripped,

determine what caused circuit

breaker to trip, correct the

problem, and then reset /

replace circuit breaker.

© Midmark Corporation 1997 SF-1532 Page 2-3 Printed in U.S.A.

Rev. 9/04

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

Electrical receptacle or

optional drawer warmer not

working. -Continued

Head Board Assembly

does not operate correctly.

Step assembly does not

function correctly.

No power is available at

electrical receptacle and

heater ON / OFF switch

does not illuminate when

pressed. -Continued

Head Board will not stay in

position, drifts down.

Headboard will not stay in

position, drifts down

(continued).

Head Board will not

descend when back lock

handle(s) are depressed.

Head Board descends rapidly when back lock handles are depressed.

Head Board descends rapidly when back lock handles are depressed

(continued).

Step assembly difficult to

pull out.

TESTING AND TROUBLESHOOTING

Wire connections are loose. Check all wiring connec-

Line fuse(s) blown (applies

to 220 VAC units only).

AC inlet is malfunctioning

(applies to 220 VAC units

only).

Springs on back lock assembly have broken or come

loose.

The hole in the back lock

assembly for the back support rod has worn or elongated.

The back support rod has

worn excessively and will not

hold in he back lock assembly.

Back lock springs are disconnected or broken.

Back support rod out of

alignment causing the rod to

bind in the back lock assembly.

Set screws that secure the

back lock assembly to the

back lock rod are loose or

missing.

Set screw(s) are loose in the

back lock handle(s) prevent

handles from rotating back

lock rod and back lock

assembly.

Lift spring(s) are broken or

disconnected from the lift

lever or the eye bolt(s).

Lift spring(s) tension out of

adjustment.

Lift support rod for the lift

lever is disconnected.

Nylon stem bumpers worn or

missing. Lack of lubrication.

tions from power cord to

electrical receptacle and

heater ON / OFF switch.

Perform continuity check

on wires. Use multimeter

to check for proper voltage levels.

Perform continuity check

on fuses.

Replace suspect AC

inlet with known working

AC inlet.

Check condition of the

back lock springs.

Check the condition of

the back lock assembly

for excessive wear.

Check for excessive wear

on the back support rod.

Inspect the back lock

springs.

Check the alignment of

the back support rod and

insure the screws are

tight on the back support

plate or bracket.

Check the set screws to

insure they are in place

and tightened to the back

lock rod.

Check the set screws to

insure they are in place

and tightened to the back

lock rod.

Check the condition of

the lift spring(s).

Check the position of the

wing nuts to insure they

are on the eye bolts sufficiently.

Check the condition of

the lift support rod to

insure it is in place.

Check the condition of

the nylon stem bumpers.

SECTION II

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections. Refer to para

5.1.

Replace fuse(s). Refer to para

4.13).

Replace AC inlet. Refer to

para 4.14.

Replace the springs on the

back lock assembly. Refer to

para 4.6.

Replace the back lock assembly. Refer to para 4.6.

Replace the back support

rod. Refer to para 4.6.

Connect and / or replace the

back lock springs. Refer to

para 4.6.

Re-align the back support rod

plate or bracket and tighten

the mounting screws. Refer to

para 4.6.

Install and / or tighten the set

screws in the back lock

assembly. Refer to para 4.6.

Install and / or tighten the set

screws in the back lock handles. Refer to para 4.6.

Reconnect or replace the lift

springs. Refer to para 4.7.

Adjust the spring tension on

the lift springs. Refer to para

4.7.

Repair or replace the lift support rod. Refer to para 4.7.

Replace and lubricate the

nylon stem bumpers. Refer to

para 4.5.

© Midmark Corporation 1997 SF-1532

Rev. 12/98

Page 2-4

Printed in U.S.A.

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

Step assembly does not

function correctly.

-Continued

Step assembly pulls completely out of table when

fully extended.

TESTING AND TROUBLESHOOTING

Step stop missing or out of

alignment.

Check the condition of

the step stop.

SECTION II

Repair or replace the step

stop. Refer to para 4.5.

Drawer(s) do not function

correctly.

Pelvic tilt does not function

correctly.

Footrest assembly does

not function correctly.

Stirrups do not work correctly.

Step will not lock into position when fully extended.

Drawer(s) difficult to slide

in and out of the table.

Pelvic tilt lift bar does not

spring to “Up” position

when the seat section is

lifted.

Footrest does not extend

or retract smoothly.

Footrest pulls all the way

out when fully extended.

Stirrups do not lock into

one of four lateral positions.

Lock tabs on bottom rails of

step weldment are not bent

down far enough.

Drawer(s) not located properly in the cabinet slides.

Drawer and / or cabinet slide

is damaged.

Ball bearings in cabinet

slides dry of lubricant or contaminated with foreign

debris.

Pivot points on pelvic lift bar

dry of lubricant and / or dirty.

Springs on the pelvic tilt bar

are broken.

Push nuts that retain pelvic

lift bar on tabs of upper weldment rubbing on bar.

The nylo tape in the footrest

cabinet guides is missing or

dry of lubricant.

The footrest weldment is

bent or damaged.

The “stop” tabs at the back

of the footrest weldment are

not bent down correctly.

Stirrups dirty and lacking

lubricant.

Check if lock tabs on bottom rails of step weldment are bent down.

Check to insure the

drawer slide is located

properly in the cabinet

slide.

Check the condition of

the slides on the

drawer(s) and cabinet.

Check the ball bearings

and cabinet slides.

Check the condition of

the pivot points on the

pelvic lift bar.

Check the condition of

the springs on the pelvic

tilt bar.

Check the position of the

push nuts in relation to

the pelvic lift bar.

Check the condition of

the nylo tape.

Inspect the footrest weldment to insure it is

straight.

Inspect the footrest weldment to insure the tabs

are bent down and that

the rubber bumpers are

in place on the footrest

cabinet guides.

Inspect the stirrup

assemblies for dirt and

lack of lubricant.

Bend the lock tabs down

approximately 1/8 inch (0.32

cm) from the bottom of the

step weldment rails. Refer to

para 4.5.

Insert the drawer slide properly in the cabinet slide.

Replace the cabinet slide(s)

and / or drawer assemblies.

Clean, lubricate or replace the

cabinet slide(s).

Clean and lubricate the pivot

points on the pelvic lift bar.

Replace the springs on the

pelvic tilt bar.

Repair or replace the push

nuts.

Lubricate and / or replace the

nylon tape in the cabinet

guides. Refer to para 4.4.

Replace the footrest weldment. Refer to para 4.4.

Repair or replace the footrest. Refer to para 4.4.

Clean and lubricate the stirrup assemblies.

© Midmark Corporation 1997 SF-1532

Rev. 12/98

Page 2-5

Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

© Midmark Corporation 1997 SF-1532

Rev. 12/98

Page 2-6

Printed in U.S.A.

SCHEDULED MAINTENANCE

Return To Table Of Contents

SECTION III

SCHEDULED MAINTENANCE

SECTION III

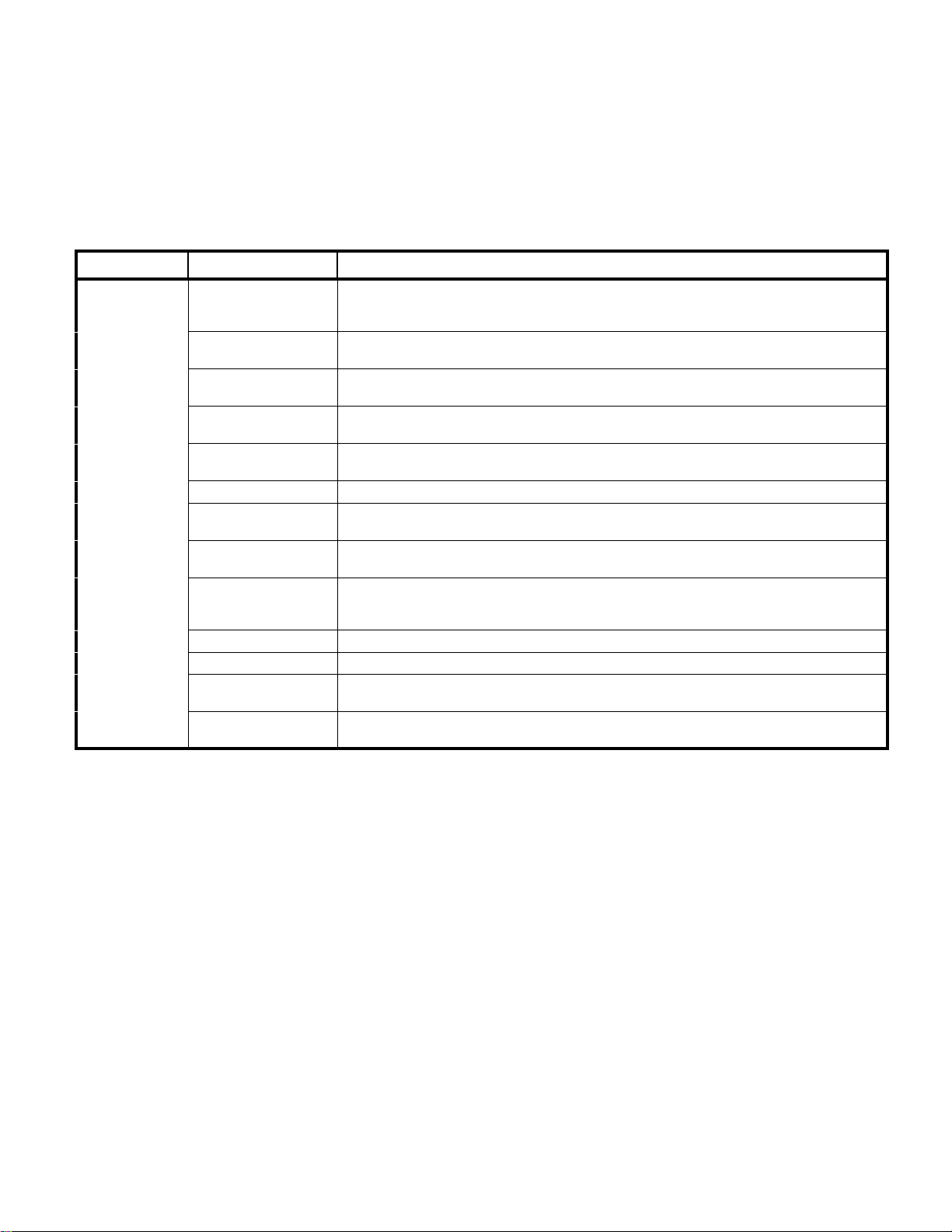

3.1 Scheduled Maintenance

periodically on the 304 Examination Table. These

inspections and services should be performed as often

Table 3-1 is a Scheduled Maintenance Chart which lists

as indicated in the chart.

the inspections and services that should be performed

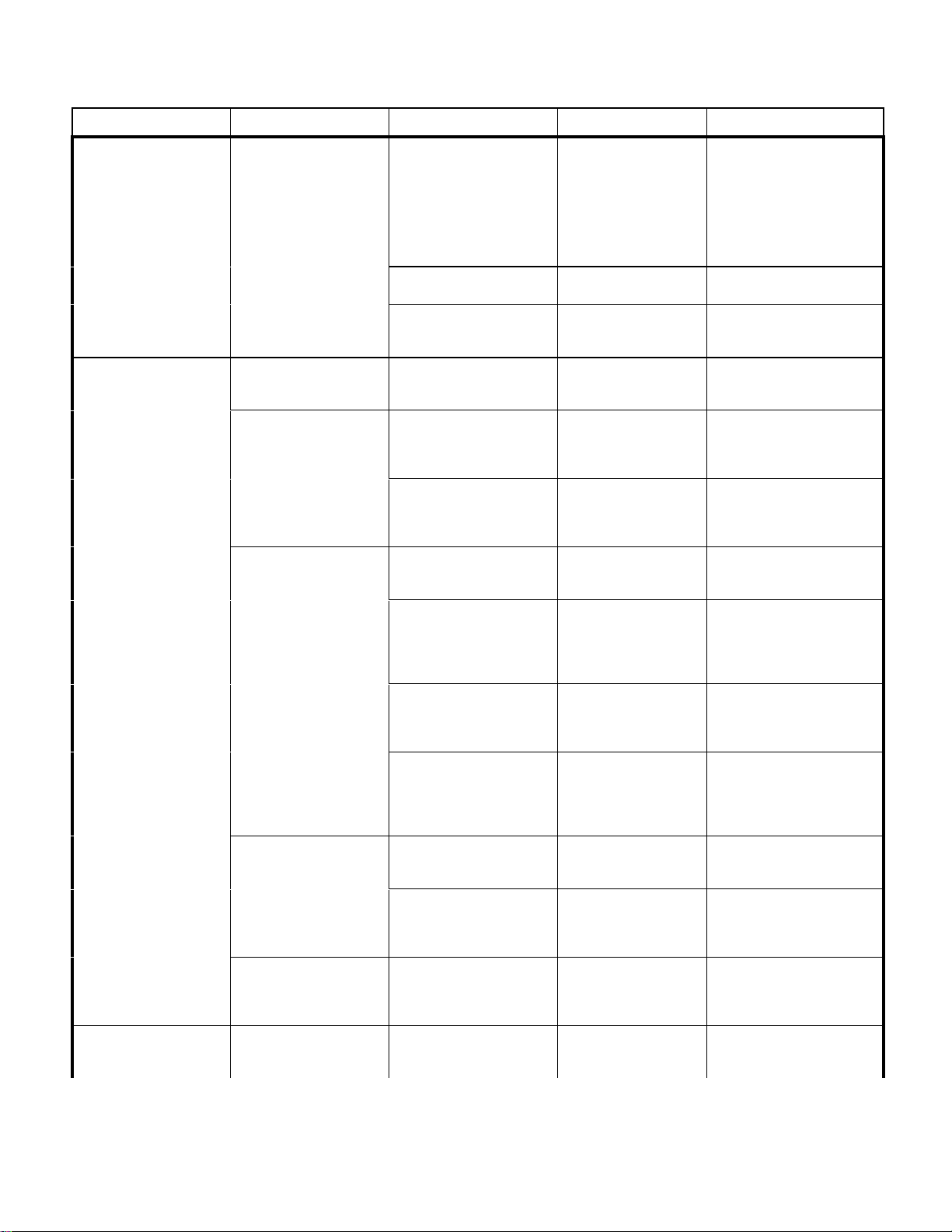

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of table for obvious damage such as: cracks in components, missing com-

Fasteners / hardware Check table for missing or loose fasteners / hardware. Replace any missing hardware and tighten

Warning and instructional

decals

Pivot points / moving

parts / accessories

Step Assembly Check step assembly to insure that it slides in and out easily. Insure that the step assembly locks in

Footrest extension Check that footrest extension can be easily extended and is not damaged. Refer to para 4.3.

Stirrup assemblies Check that stirrup assemblies lock into one of four different positions. Check for wear. Replace

Electrical receptacle Check that the electrical receptacle are functioning properly. Replace receptacle as necessary.

Drawer Heater (Optional) Where applicable, check to insure the drawer heater is heating sufficiently to warm the top drawer

Pelvic Tilt (Optional) Check that the spring loaded pelvic tilt is operating properly. Replace springs if necessary.

Upholstery Check all upholstery for rips, tears, or excessive wear. Replace cushions as necessary.

Accessories Check that all accessories have all of their components and that they function properly. If neces-

Operational Test Perform an Operational Test to determine if the table is operating within its specifications (Refer to

ponents, dents in components, or any other visible damage which would cause the table to be

unsafe to operate or would compromise its performance. Repair table as necessary.

any loose hardware as necessary.

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based lubricant.

place when extended. Refer to para 4.4.

worn components as necessary. Refer to para 4.14.

Refer to para 4.9.

and that the heater ON / OFF switch indicator light illuminates when the switch is in the ON position. If necessary, replace the heater switch or heater plate. Refer to para 4.7 or 4.8.

sary, repair or replace the accessory.

para 2.1). Replace or adjust any malfunctioning components.

© Midmark Corporation 1997 SF-1532

Page 3-1

Printed in U.S.A.

SECTION III

Return To Table Of Contents

SCHEDULED MAINTENANCE

© Midmark Corporation 1997 SF-1532

Page 3-2

Printed in U.S.A.

MAINTENANCE / SERVICE

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE INSTRUCTIONS

SECTION IV

4.1 Introduction

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

examination table. Failure to do so could result

in personal injury.

NOTE

Perform an operational test on the examination table

after the repair is completed to confirm the repair was

properly made and that all malfunctions were

repaired.

4.2 Styled Upholstery

A. Removal

WARNING

Always disconnect electrical power to

the unit before removing any of the

unit's covers/shrouds or making any repairs to

prevent the possibility of electrical shock. Failure

to comply could result in personal injury.

(5) Remove the upholstered top assembly (6).

(6) Extend the footrest and remove the upholstered

footrest pad (7).

B. Installation

CAUTION

Use care when installing the upholstered

top assembly as it weighs approximately

32 lbs. (14.5 kg). Failure to use proper lifting techniques or assistance could result in personal injury.

(1) Lay the new upholstery assembly (6, Figure

4-1) in position on the back plate assembly (5)

and upper wrap assembly (8).

(2) Secure the head section (C) to the back plate

assembly (5) with four screws (4).

(3) Secure the seat section (A) to the top hinge (3)

with two screws (2).

(4) For tables without Pelvic Tilt, install the two

screws (1) that secure the seat section (A) to

the upper wrap cross member (B).

(1) Unplug the table power cord from the wall out-

let.

(2) For tables without Pelvic Tilt, remove the two

screws (1, Figure 4-1) that secure the seat section (A) to the upper wrap cross member (B).

(3) Remove the two screws (2) that secure the

upholstered seat section (A) to the top

hinge (3).

(4) Elevate and support the head section (C) and

remove the four screws (4) that secure the

upholstered head section (C) to the back plate

assembly (5).

CAUTION

Use care when removing the upholstered

top assembly as it weighs approximately

32 lbs. (14.5 kg). Failure to use proper lifting techniques or assistance could result in personal injury.

(5) Raise and lower the head section (C) several

times to insure it operates smoothly and locks

in position without drifting. If necessary, refer to

Testing and Troubleshooting, para 2.1.

(6) Install the upholstered footrest pad (7).

(7) Plug the table power cord into a wall outlet.

© Midmark Corporation 1997 SF-1532 Page 4-1 Printed in U.S.A.

Rev. 7/04

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

A

7

C

6

4

5

8

2

B

4

Figure 4-1. Styled Upholstery

4.3 Soft Touch Upholstery

A. Removal

WARNING

Always disconnect electrical power to

the unit before removing any of the

unit's covers/shrouds or making any repairs to

prevent the possibility of electrical shock. Failure

to comply could result in personal injury.

(1) Unplug the table power cord from the wall

outlet.

3

1

MA376600

(3) Elevate and support the head section (C) and

remove the two screws (2) securing the rod

support bracket (3) to the head section (C).

(4) Lay the head section (C) forward and remove

four screws (4) securing the upholstered top

assembly (5) to upper wrap (6).

CAUTION

Use care when removing the upholstered

top assembly as it weighs approximately

32 lbs. (14.5 kg). Failure to use proper lifting techniques or assistance could result in personal injury.

(2) For tables without Pelvic Tilt, remove the two

screws (1, Figure 4-2) that secure the seat section (A) to the upper wrap cross member (B).

© Midmark Corporation 1997 SF-1532 Page 4-2 Printed in U.S.A.

Rev. 7/04

(5) Remove the upholstered top assembly (5).

(6) Extend the footrest shelf (7) and remove the

upholstered footrest pad (8).

A

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE

C

5

3

2

4

8

7

Figure 4-2. Soft Touch Upholstery

B. Installation

CAUTION

Use care when installing the upholstered

top assembly as it weighs approximately

32 lbs. (14.5 kg). Failure to use proper lifting techniques or assistance could result in personal injury.

(1) Lay the new upholstery assembly (5,

Figure 4-2) in position on the upper wrap

assembly (6) and secure with four screws (4).

B

6

1

MA485200

(2) Lay the head section (C) backward slightly and

secure to rod support bracket (3) with two

screws (2).

(3) For tables without Pelvic Tilt, install the two

screws (1) that secure the seat section (A) to

the upper wrap cross member (B).

(4) Raise and lower the head section (C) several

times to insure it operates smoothly and locks

in position without drifting. If necessary, refer to

Testing and Troubleshooting, para 2.1.

© Midmark Corporation 1997 SF-1532 Page 4-3 Printed in U.S.A.

Rev. 7/04

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(5) Install the upholstered footrest pad (8) on foot

rest shelf (7).

(6) Plug the table power cord into a wall outlet

4.4 Footrest Extension

A. Removal

(1) Unplug table power cord from the wall outlet.

(2) Pull out the on the footrest (1, Figure 4-3) until it

is fully extended.

(3) Remove the upholstered footrest pad (2) and

treatment pan (3).

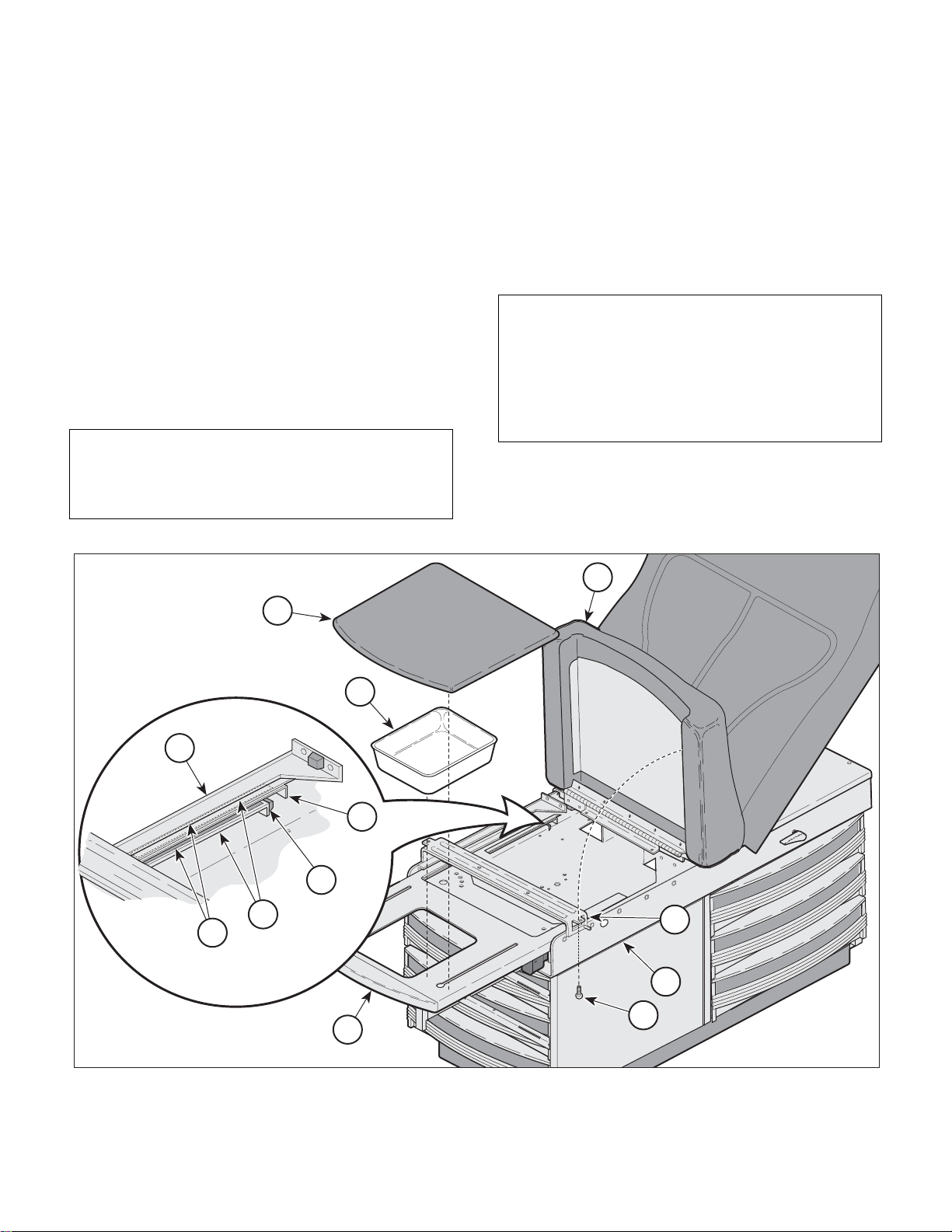

NOTE

For tables without Pelvic Tilt, remove the two screws

(4) that secure the seat section (5) to the upper wrap

cross member (A).

(4) Raise the seat section (5) and using pliers or

equivalent, bend up the two metal tabs (6) on

the back of the footrest weldment (1) until they

are horizontal.

(5) Pull the footrest weldment (1) out of the upper

wrap weldment (7).

B. Installation

NOTE

Before installing the footrest weldment, inspect the

footrest runners (B, Figure 4-3) to insure the nylon

tape glides (8) are in place at the side and top of

each runner. Also inspect the rubber bumpers (9),

located at the back of the footrest runners to insure

they are intact.

(1) Inspect the nylon tape glides (8, Figure 4-3) and

rubber bumpers (9) and replace if necessary.

Place a light coating of lubricant on the glides.

5

2

3

7

6

9

B

A

8

7

4

1

© Midmark Corporation 1997 SF-1532 Page 4-4 Printed in U.S.A.

Rev. 7/04

MA364300

Figure 4-3. Footrest Extension

(2) Insert the footrest weldment (1) into the runners

A

A

Return To Table Of Contents

(B) of the upper wrap weldment (7) and bend

the two metal tabs (6) on the footrest weldment

downward until vertical.

(3) Install the treatment pan (3) and upholstered

footrest pad (2).

(4) Plug the table power cord into wall outlet.

4.5 Step Assembly

A. Removal

WARNING

Always disconnect electrical power to

the unit before removing any of the

unit's covers/shrouds or making any repairs to

prevent the possibility of electrical shock. Failure

to comply could result in personal injury.

(1) Unplug the table power cord from the wall out-

let.

SECTION IV

MAINTENANCE / SERVICE

1

1

5

5

6

6

7

7

3

3

4

4

8

8

2

2

9

9

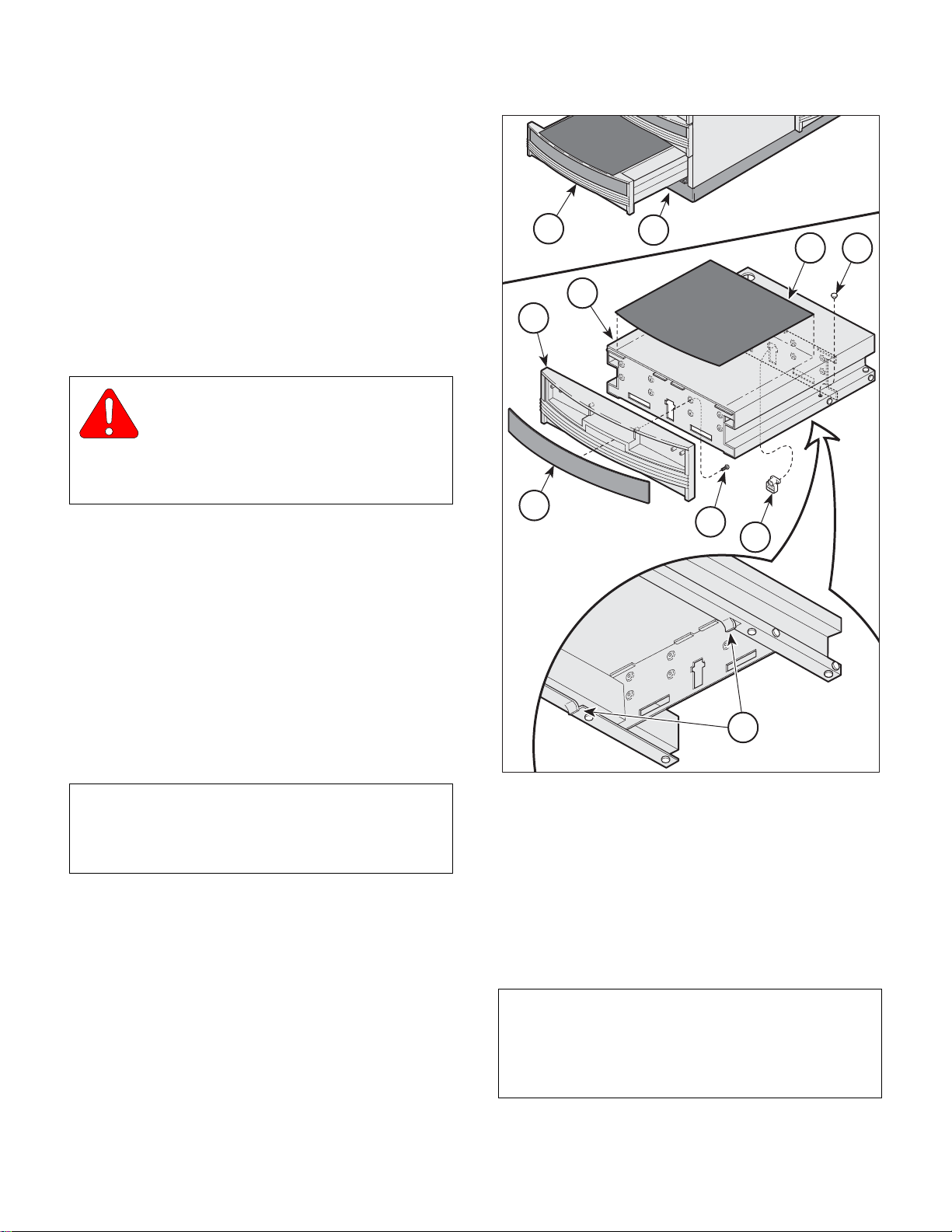

(2) Pull out on the step assembly (1, Figure 4-4)

until it is fully extended.

(3) While lightly pulling the step assembly outward,

reach beneath it and push the step stop (2)

upward until it clears the base weldment (3);

then remove the step assembly from the

cabinet.

B. Drawer Front Replacement

NOTE

Should it be necessary to replace the plastic step

front on the step assembly, the step covering must

also be replaced as it is adhered to the step front.

(1) Remove the step covering (4, Figure 4-4) from

the step assembly (5).

(2) Reaching up through the opening at the bottom

of the drawer front (6), push out on the insert

panel (7) and remove it.

(3) Remove the eight screws (8) that secure the

drawer front (6) to the step weldment (5) and

remove the drawer front.

MA356500

Figure 4-4. Step Assembly

(4) Clean the surface of the step weldment (5), to

which the step covering (4) will be attached,

with alcohol or a similar cleanser to insure the

adhesive back will bond to the surface of the

step weldment.

(5) Install the drawer front (6) to the step weld-

ment (5) and secure with eight screws (8).

NOTE

Before removing the protective cover from the adhesive backing of the step., lay the cover in place and

make some light location marks to insure the step

cover is installed uniformly on the step weldment.

Rev. 7/04

© Midmark Corporation 1997 SF-1532 Page 4-5 Printed in U.S.A.

Loading...

Loading...