Midmark 255, 255-021, 255-022, 255-026, 255-025 User Manual

...

Style P

255

LED Procedure Light

For Models:

Ceiling: 255 (-021 to -024)

Mobile 255 (-025 / -027)

Wall: 255 (-026)

User’s Guide

003-2848-99 Rev AA4 (1/9/19)

TP202 20-42-FO-00014 Rev A1 C2169

User’s Guide

English

Español

Français

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 2

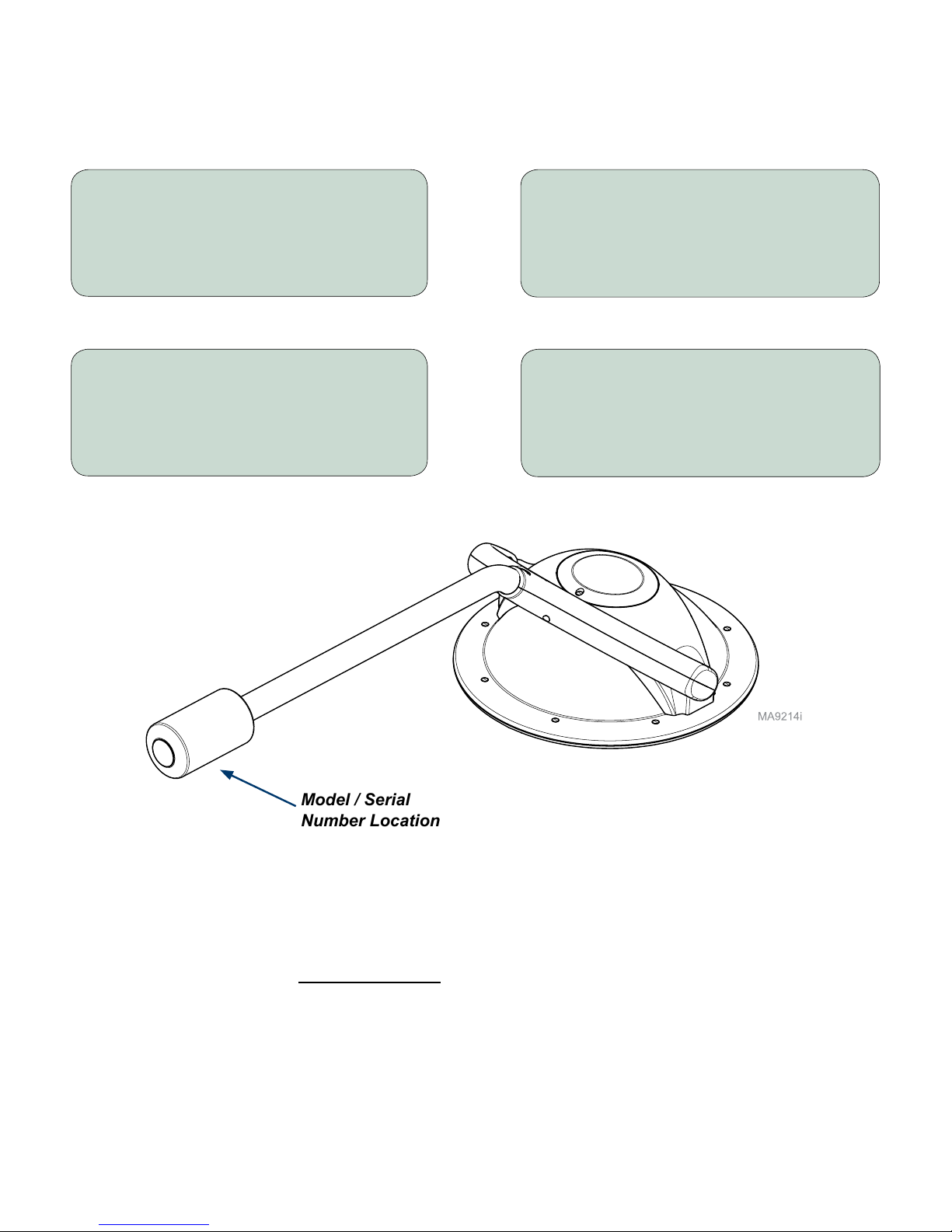

Model / Serial Number:

Date of Purchase:

Midmark Authorized Service

Company:

Dealer :

Product Information

Model / Serial

Number Location

Basic Cross Tube/

Lighthead shown

Product Registration

To register your product, go to www.midmark.com.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 3

Table of Contents

Important Information

Safety Symbols ......................................................................................................................4

Intended Use ..........................................................................................................................5

Electromagnetic Interference ...............................................................................................5

Disposal of Equipment ..........................................................................................................5

Transportation / Storage Conditions ...................................................................................5

Operation

Power & Adjustment Switches .............................................................................................6

Positioning the Lighthead .....................................................................................................7

Maintenance

Preventative Maintenance....................................................................................................8

Cleaning & Disinfecting .............................................................................................. 9

Sterilizing the Handle .......................................................................................................... 11

Replacing the Fuses:

Ceiling Mounted Lights .....................................................................................................12

Wall Mounted Lights ..........................................................................................................13

Mobile Lights .....................................................................................................................14

Ball Pivot Tension Adjustment ...........................................................................................15

Cross Tube Counterbalance Adjustment .................................................................. 16

Specications

Specications Chart ............................................................................................................17

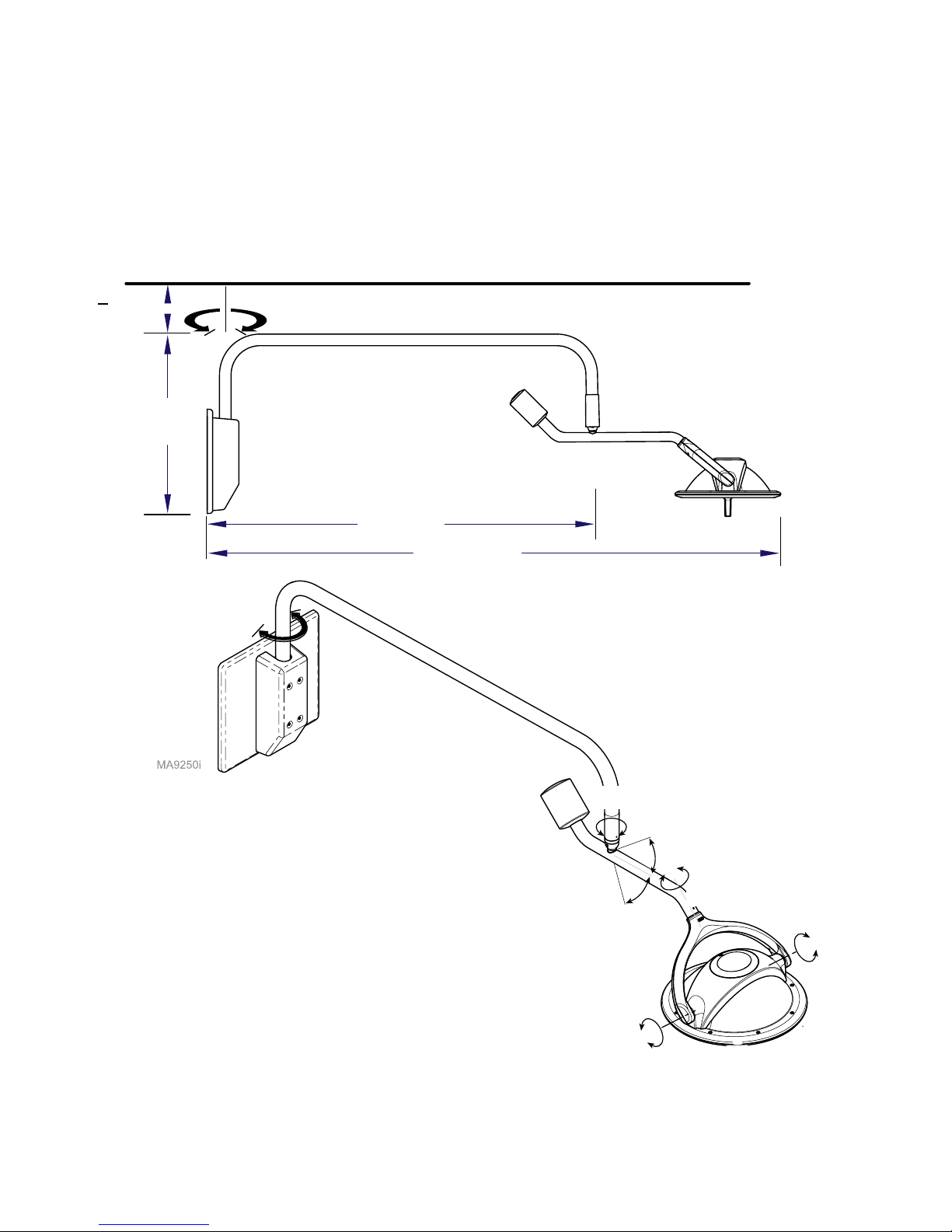

Dimensions / Range of Motion:

Ceiling Mounted Lights .....................................................................................................20

Wall Mounted Lights ..........................................................................................................21

Mobile Lights .....................................................................................................................22

Model Identication / Compliance

Model Identication / Compliance Chart ..........................................................................23

Warranty Information

Limited Warranty .................................................................................................................25

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 4

Proper Shipping

Orientation

Fragile

Keep Dry

Fuse Rating Specication

Protective Earth Ground

Type B, Applied Part

Refer to instruction manual/booklet

Maximum stacking height

(Refer to “n” number on

package.

Transportation Orientation

Atmospheric Pressure

Relative Humidity

100 F

38 C

23 F

-5 C

Transportation & Storage

Temperature

Important Information - Safety Symbols

WARNING

Indicates a potentially hazardous situation which could result in serious injury.

Caution

Indicates a potentially hazardous situation which may result in minor or moderate injury. It

may also be used to alert against unsafe practices

Equipment Alert

Indicates a situation which could result in equipment damage.

Note

Amplifies a procedure, practice, or condition.

Symbol Glossary

These symbols may appear on your equipment and/or in the manuals.

Manufacturer

Serial Number

Catalogue Number

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 5

Intended Use

This product is intended to be used in medical environments where illumination is required for medical use

during external examinations and procedures.

Electromagnetic Interference

This product is designed and built to minimize electromagnetic interference with other devices. However, if

interference is noticed between another device and this product:

• Remove interfering device from room

• Plug light into isolated circuit

• Increase separation between light and interfering device

• Contact Midmark if interference persists

Authorized EU Representative

Countries in the EU should direct all questions, incidents, and complaints to Midmark’s Authorized EU

representative listed below:

Newmed Srl.

Via Lenin 79/A

Quattro Castella (RE), 42020, Italy

Phone: +39.0522.875.166

Fax: +39.0522.243.096

Disposal of Equipment

At the end of product life, the light, accessories, and other consumable goods may become contaminated

from normal use. Consult local codes and ordinances for proper disposal of equipment, accessories and

other consumable goods.

Transportation / Storage Conditions

Ambient Temperature Range: ....................................................................-30°C (-22°F) to 60°C (140°F)

Relative Humidity...................................................................................................................10% to 90%

Atmospheric Pressure ...........................................................500 hPa (15 in.Hg) to 1060 hPa (31 in.Hg)

Operation Conditions

Ambient Temperature Range: ....................................................................10°C (50°F) to +40°C (104°F)

Relative Humidity...................................................................................................................30% to 75%

Atmospheric Pressure ...........................................................700 hPa (20 in.Hg) to 1060 hPa (31 in.Hg)

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 6

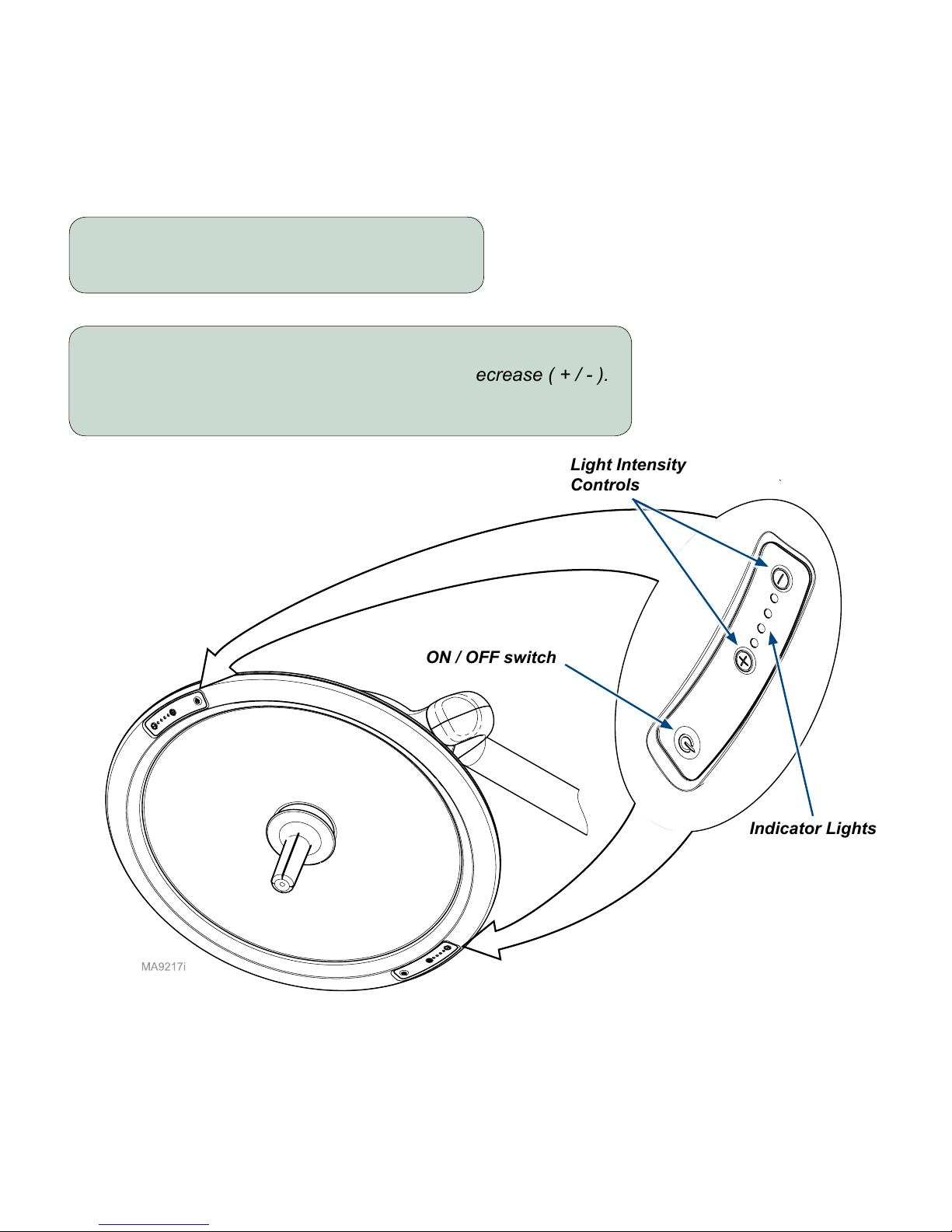

Operation

Power and Adjustment Switches

To turn the light ON / OFF...

Press the power button ( ).

O

I

ON / OFF switch

Light Intensity

Controls

To adjust the light...

Press the light intensity controls to increase / decrease ( + / - ).

Note: Indicator lights show current settings.

Indicator Lights

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 7

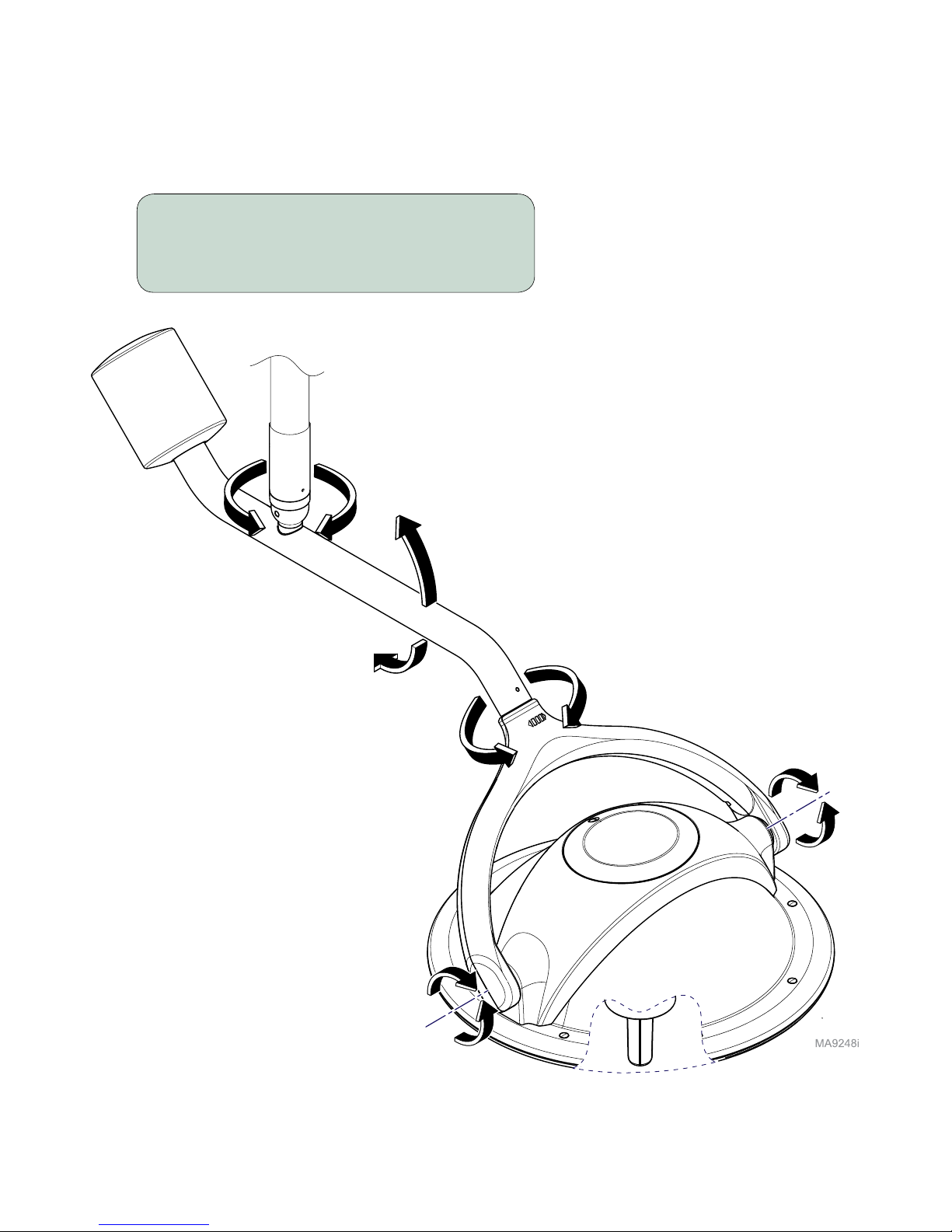

Positioning the Lighthead

To position the lighthead...

Grasp the sterilizable handle, then rotate

the arm / lighthead to desired position.

Ceiling / Wall model shown

Mobile model is similar.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 8

Maintenance

Calling for Service

If service is required, contact your authorized Midmark dealer.

To contact Midmark directly:

1-800-MIDMARK (1-800-643-6275)

8:00 am until 5:00 p.m. Monday - Friday (EST)

www.midmark.com

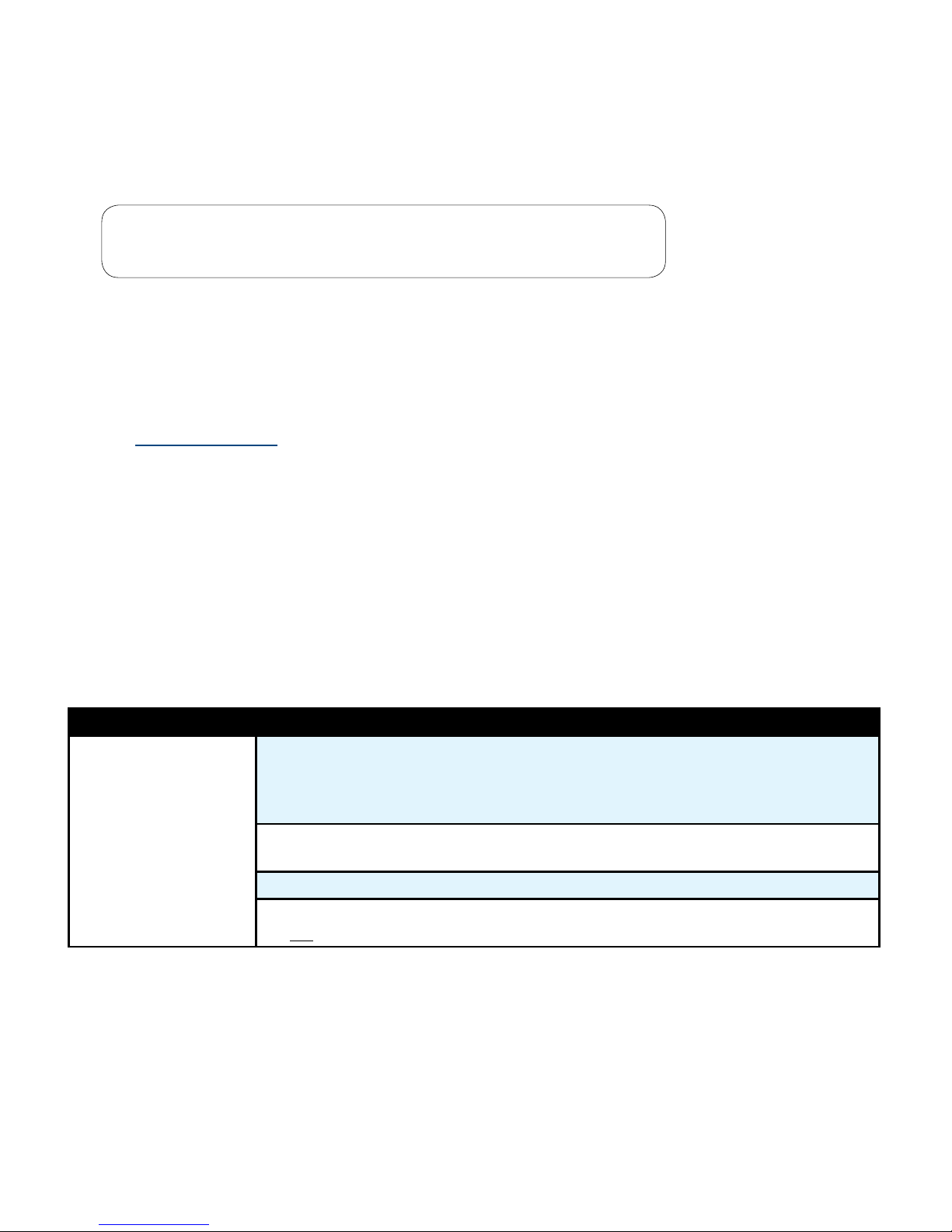

Preventative Maintenance

Periodically inspect the following areas:

• Power cord(s) should be free of cuts or other visible damage.

• All fasteners should be in place and tightened securely.

• All mechanical functions should operate properly.

Have an authorized service technician inspect your equipment every six months.

Frequency Activity

Semi-annually Inspect rotation of lighthead / arms at all pivot points.

Arms should move freely, without noise. Arms should not drift when released.

Check for excessive rotation. (This would indicate internal stops may be broken).

Use the Range of Motion section in this manual as a reference.

Turn light ON. Rotate lighthead / arms at all pivot points.

Light should not icker or ash at any time.

Inspect the faceplate and inside of the lighthead for signs of damage.

Inspect lighthead for excessive dust or dirt buildup inside lighthead.

Do not attempt to clean interior - contact an authorized service technician.

Note

Model / serial number information is required when calling for service.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 9

Maintenance

Cleaning & Disinfecting

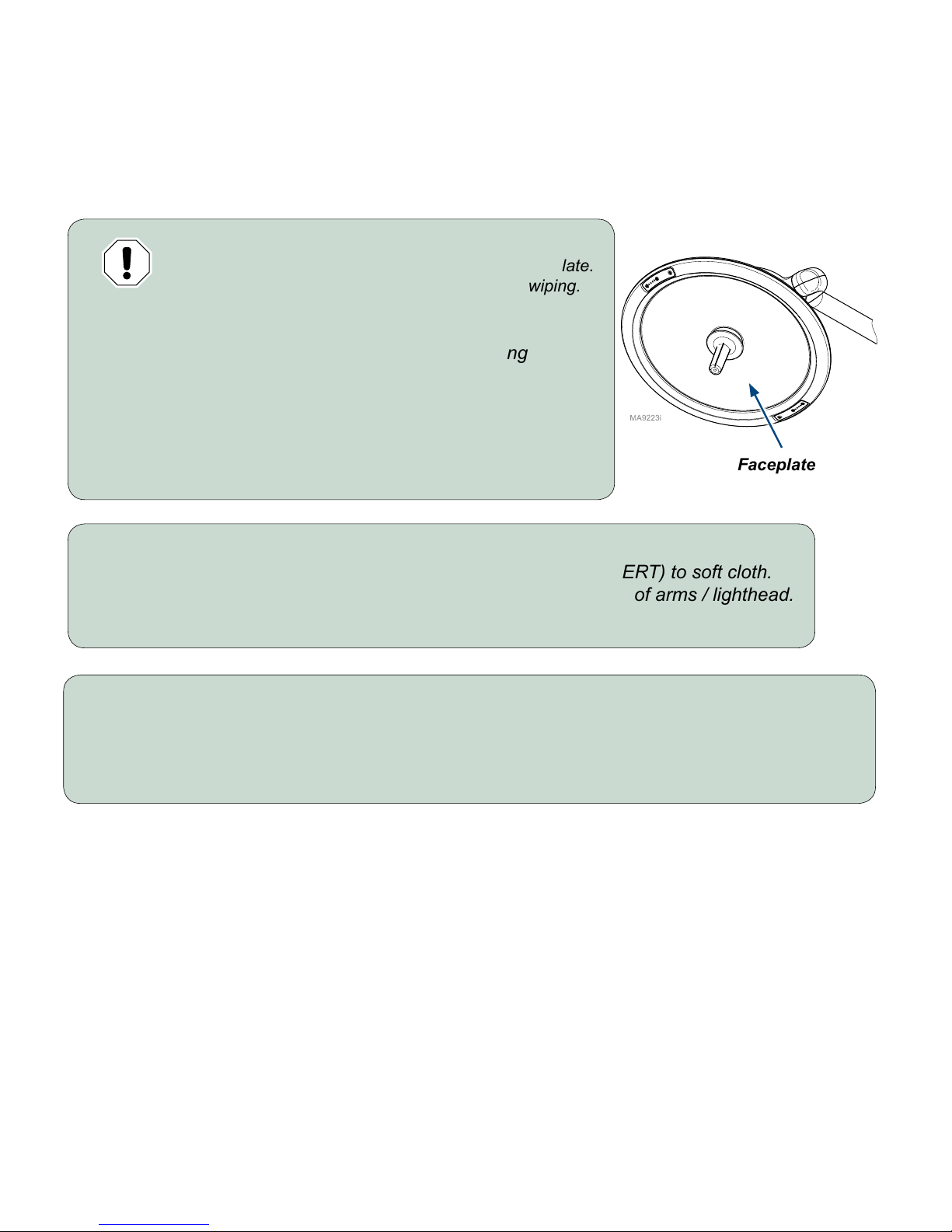

Equipment Alert

Use only quaternary disinfectants on light. Staining, pitting, discoloration, or softening could

occur if phenolic, iodophor, or glutaraldehyde-based solution is used on plastic surfaces of

the lighthead. Also, using alcohol or aerosol spray cleaners / disinfectants containing substantial amounts

of alcohol in the formula may damage the lens.

WARNING

• Always disconnect power before cleaning / disinfecting.

• Prevent fluids from leaking into interior or onto electrical contacts.

• Clean EXTERNAL SURFACES ONLY (arm assemblies / lighthead).

• Do NOT attempt to clean / disinfect internal surfaces. Contact an authorized service technician.

Equipment Alert

Follow current National Guidelines for Disinfection & Sterilization in Healthcare Facilities.

Caution

The light and surrounding components may be HOT! Allow the light to cool for at least

five minutes before contacting surfaces. Never operate the light with faceplate removed.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 10

Painted Metal / Plastic Surfaces

Clean the painted metal and plastic surfaces weekly using a clean soft cloth, and mild cleaner.

To disinfect external surfaces...

A) Apply appropriate disinfecting solution (see EQUIPMENT ALERT) to soft cloth.

B) Wring excess solution from cloth, then wipe external surfaces of arms / lighthead.

C) Do not rinse or dry. Allow solution to air dry.

Equipment Alert

Do not use alcohol or abrasive compounds on faceplate.

Wring excess water / solution from cloth before wiping.

To clean external surfaces...

A) Clean faceplate with an antistatic acrylic cleaning

solution using a soft, clean, cloth.

B) Wipe external surfaces of arms / lighthead with a

mild detergent and water solution.

C) Rinse all surfaces with a soft cloth and clean water.

D) Wipe all surfaces dry.

Faceplate

To clean faceplate...

Use an antistatic acrylic cleaning solution (ex: Brillianize) or an LCD screen cleaner (ex: Klear Screen).

The solution should be free of ammonia, carbon tetrachloride, and acetone. After softly blowing away

free debris and dust, apply the cleaning product with a non-abrasive, lint-free cloth or microber cloth.

Cleaning & Disinfecting (continued)

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 11

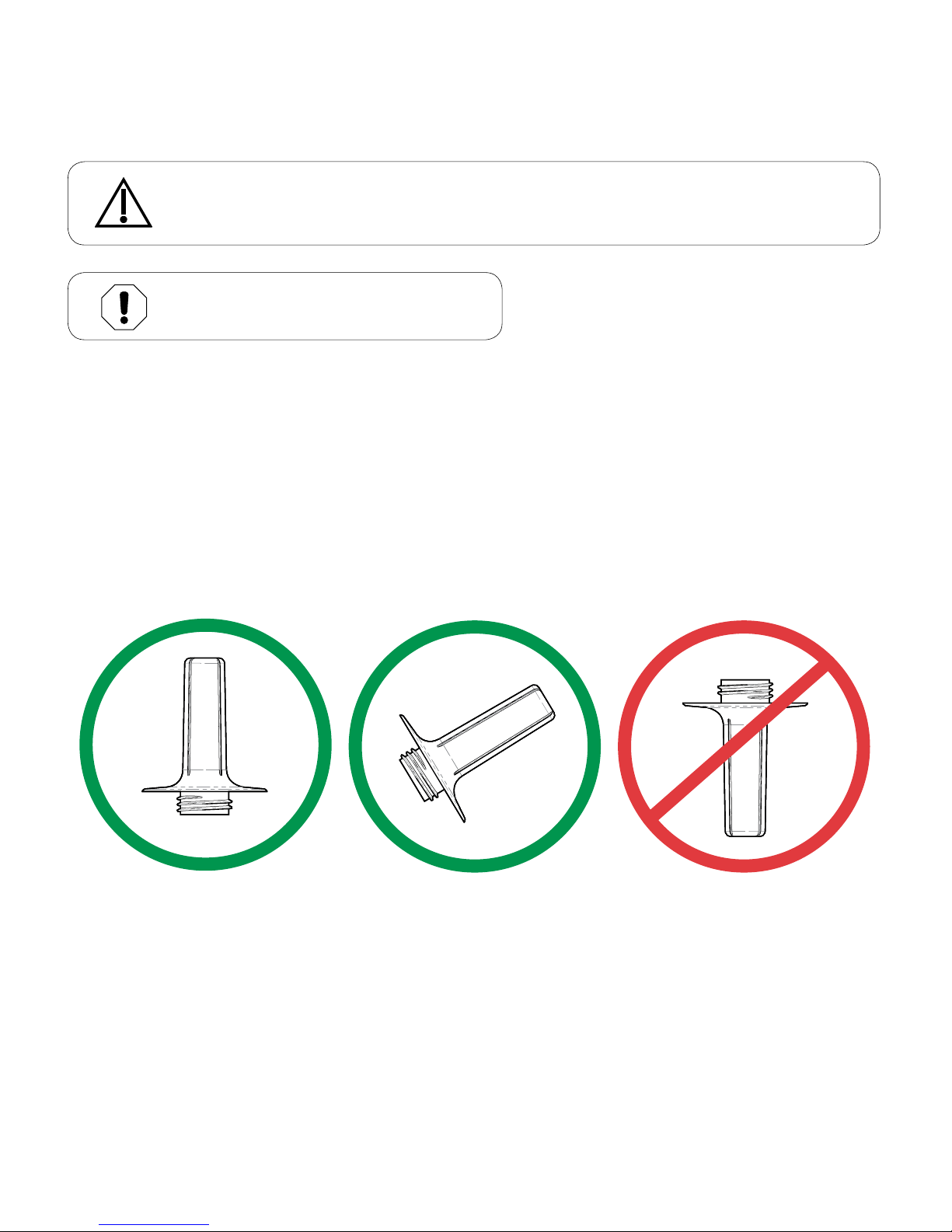

Sterilizing the Handle

To sterilize, process the handle in a dynamic air removal steam sterilizer (sterilizer that uses pressure

pulses and / or vacuum purges to remove air from the chamber) at a temperature of 270° F (132° C) for four

minutes minimum. If using a Midmark M9 or M11 sterilizer, use the “POUCHES” cycle. It is recommended

that the handle be pouched or wrapped for sterilization to maintain its sterility until placed on the light. When

pouching or wrapping the handle, use only sterilizer pouches or wraps that have been cleared by the FDA

and labeled for use with the steam sterilization cycle parameters (e.g. temperature and exposure time) of the

sterilization cycle being used. Place the handle on the sterilizer tray so steam can enter the opening and air

and any steam condensate can drain from the handle (see illustration below).

Equipment Alert

Use only steam sterilization on the handle.

MA8156i

Caution

The handle is not sterile when shipped. If your application requires the handle to be sterile,

it must be sterilized before use, or covered with a sterile protective barrier.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 12

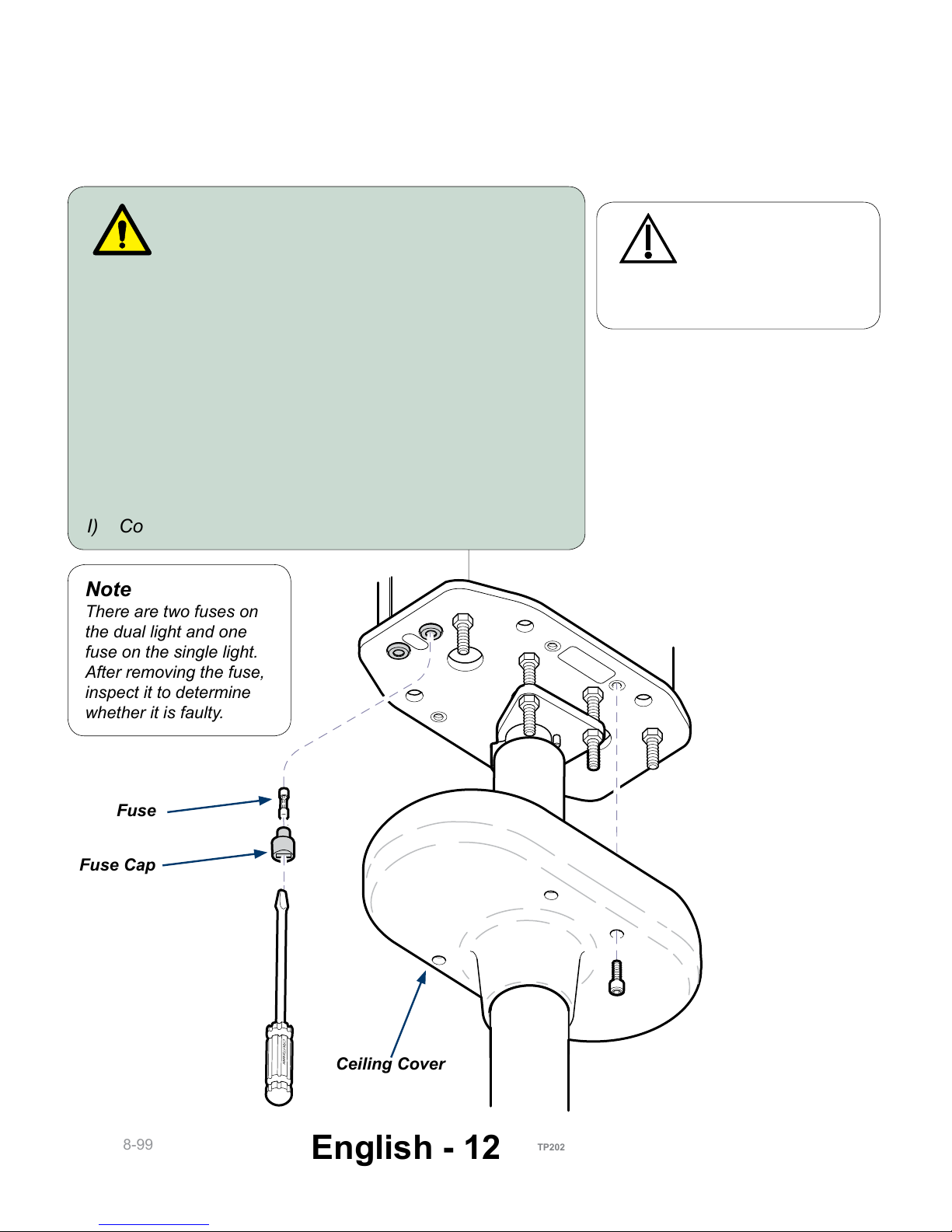

Replacing the Fuses

Ceiling Mounted Lights

CRAFTSMAN

Note

There are two fuses on

the dual light and one

fuse on the single light.

After removing the fuse,

inspect it to determine

whether it is faulty.

Caution

To completely isolate

the light from electrical

mains supply, the circuit breaker

must be turned off.

Warning

Always disconnect power before replacing fuses.

To install fuses...

A) Turn light OFF ( ).

B) Disconnect power from light.

C) Remove four screws, then lower ceiling cover.

D) Using a flat-bladed screwdriver, rotate fuse cap

counter-clockwise 1/4 turn, while pushing upward.

E) Pull fuse out of fuse cap. See Note.

F) Insert new fuse into fuse cap.

G) Using a flat-bladed screwdriver, rotate fuse cap

clockwise 1/4 turn, while pushing into fuse socket.

H) Install ceiling cover.

I) Connect power and verify operation.

O

I

Fuse Cap

Fuse

Ceiling Cover

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 13

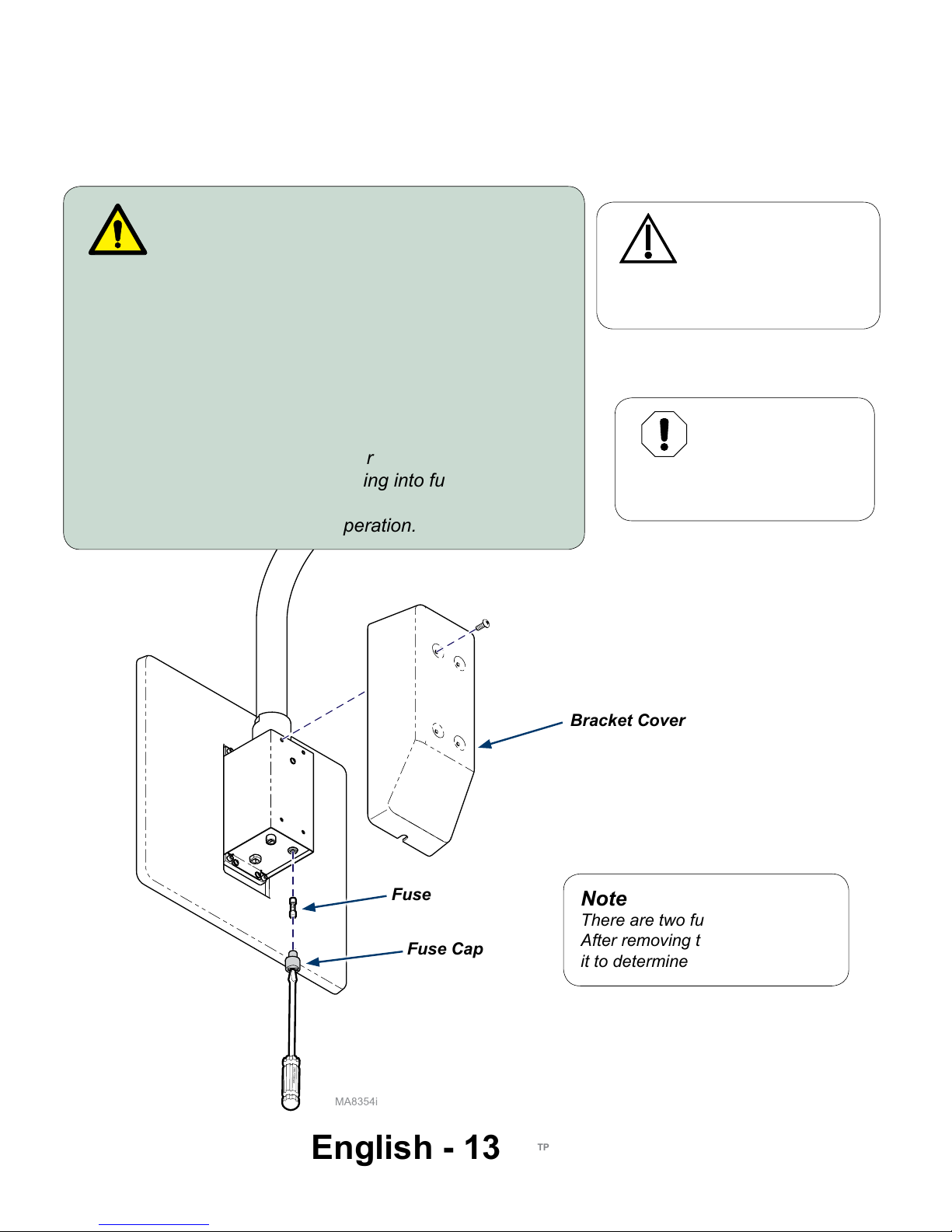

Replacing the Fuses - continued

Wall Mounted Lights

Note

There are two fuses on this light.

After removing the fuse, inspect

it to determine whether it is faulty.

CRAFTSMA

N

Fuse Cap

Fuse

Bracket Cover

Warning

Always disconnect power before replacing fuses.

To install light...

A) Turn light OFF ( ).

B) Disconnect power from light.

C) Remove bracket cover.

D) Using a flat-bladed screwdriver, rotate fuse cap

counter-clockwise 1/4 turn, while pushing upward.

E) Pull fuse out of fuse cap.

F) Insert fuse into fuse cap.

G) Using a flat-bladed screwdriver, rotate fuse cap

clockwise 1/4 turn, while pushing into fuse socket.

H) Install bracket cover.

I) Connect power and verify operation.

O

I

Caution

To completely isolate

the light from electrical

mains supply, power cord must be

unplugged.

Equipment

Alert

Do not block the

electrical outlet where light

connects into.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 14

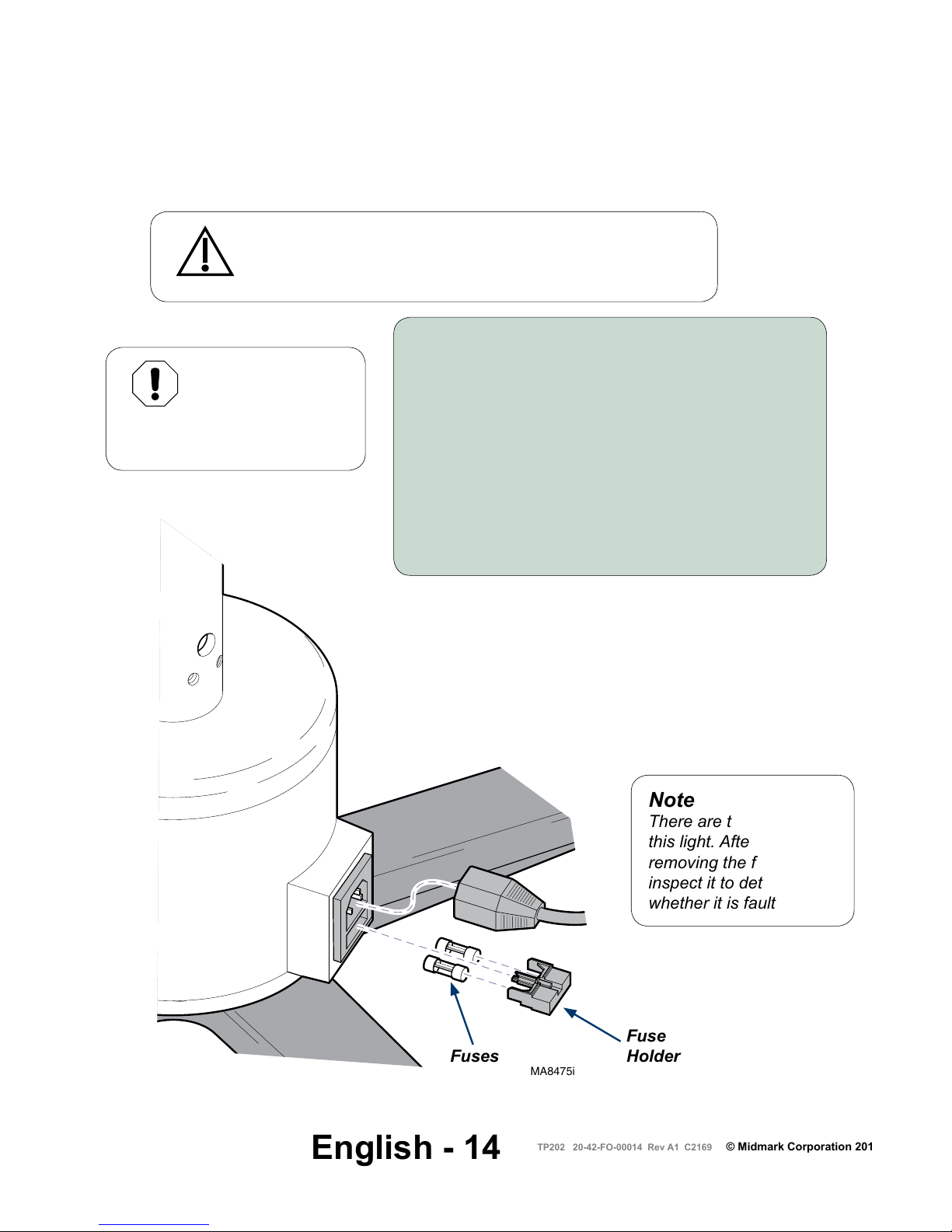

Replacing the Fuses - continued

Mobile Lights

MA8475i

To replace fuses...

A) Turn light OFF ( ).

B) Disconnect power from light.

C) Using a flat-bladed screwdriver, push in on

locking tab, then pull fuse drawer out.

D) Pull fuses out of fuse drawer to inspect.

E) Insert fuses into fuse drawer.

F) Insert fuse drawer into AC inlet.

(Push in until you hear a clicking sound).

G) Connect power and verify operation.

O

I

Caution

To completely isolate the light from electrical mains supply,

power cord must be unplugged.

Note

There are two fuses on

this light. After

removing the fuse,

inspect it to determine

whether it is faulty.

Equipment

Alert

Do not block the

electrical outlet where light

connects into.

Fuses

Fuse

Holder

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 15

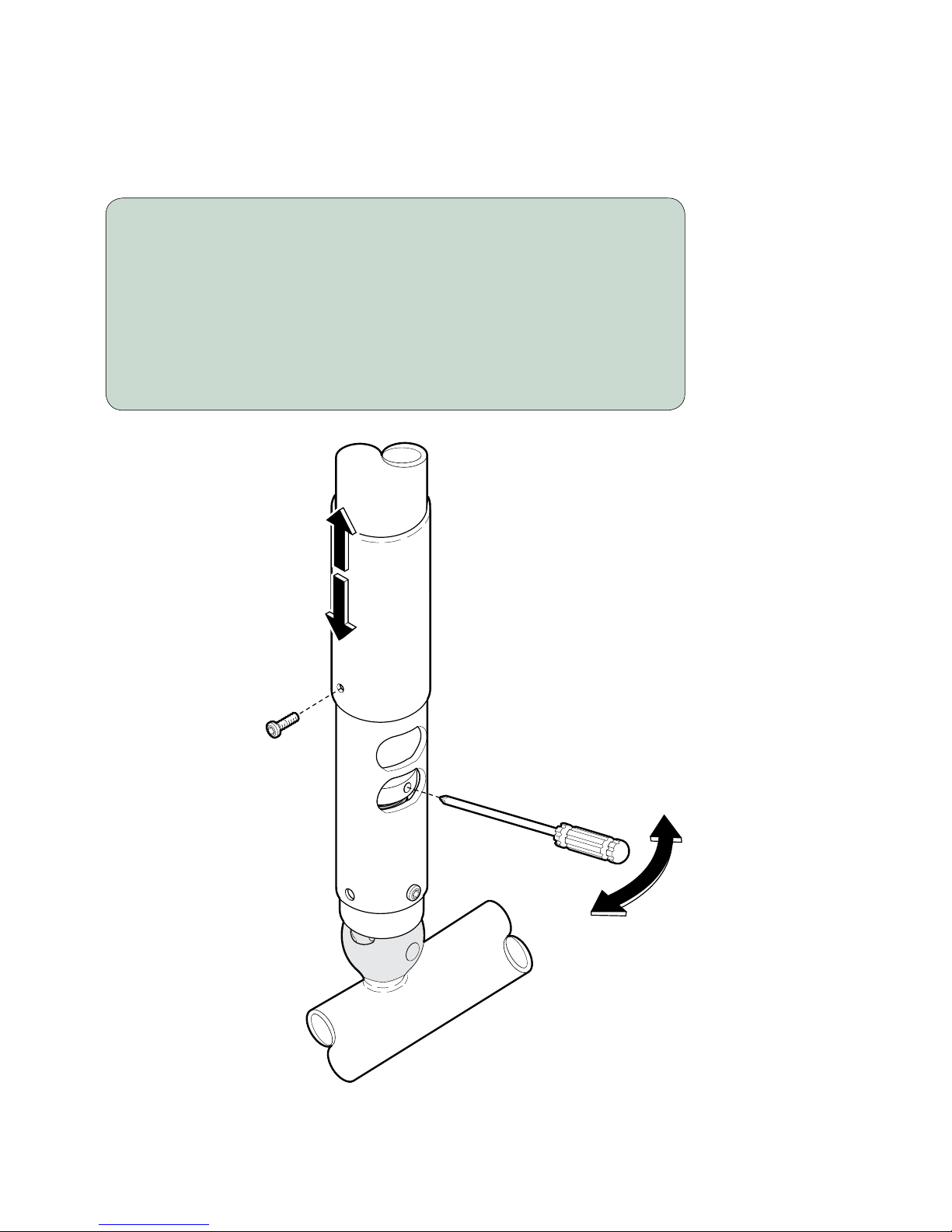

Ball Pivot Tension Adjustment

To adjust ball pivot tension...

A) Remove screw, then slide sleeve up to expose opening.

B) Insert screwdriver into adjustment hole.

C) Move the screwdriver LEFT / RIGHT to adjust tension setting

(LEFT: decreases tension / RIGHT: increases tension)

D) Remove screwdriver, and check for desired tension.

Repeat Step C until desired tension is achieved.

E) Slide sleeve down, then install screw.

MA8355i

CRAFTSM

AN

Increase

Decrease

Ceiling / Wall model shown.

Mobile model is similar

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 16

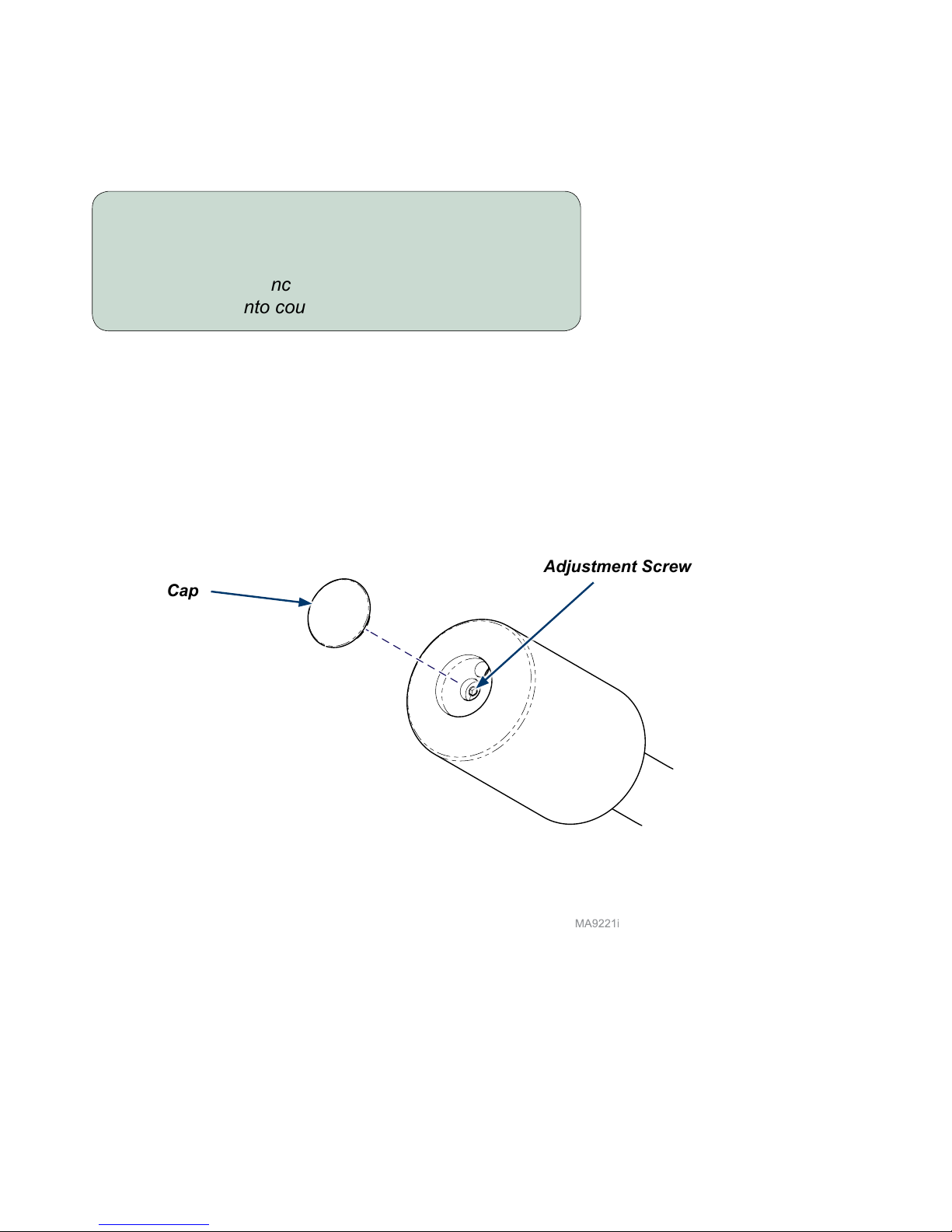

Cross Tube Counterbalance Adjustment

To adjust cross tube counterbalance...

A) Remove cap from counterbalance.

B) Loosen / tighten the adjustment screw until the

cross tube balances in horizontal position.

C) Install cap onto counterbalance.

Cap

Adjustment Screw

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 17

Specications

Specications

Illumination @ 1 m (39 in): 7500 fc (80,729 lux)

Dim Setting Central Illuminance

Setting 1 (highest) 7500 fc (80,729 lux)

Setting 2 6200 fc (66,736 lux)

Setting 3 4400 fc (47,361 lux)

Setting 4 (lowest) 3400 fc (36,597 lux)

LED Light Life: >30,000 hours @ Ec≥70

Color Temperature: 4,400K (±300)

Color Rendering Index (CRI): 98

Total Irradiance: 300 w/m

2

Lighthead Field Diameter: 7.5 in. (19 cm)

D50 / D10 ratio: 0.5

Electrical Requirements:

115 VAC models 115 VAC, 50/60 Hz, 0.7 A, single phase

230 VAC models 230 VAC, 50/60 Hz, 0.5 A, single phase

Fuse Rating:

115 VAC models 1.6A, 250 VAC, 5mm x 20mm,

Type T, Slo-Blo, Time Lag, High Breaking Capacity

(HBC)

230 VAC models 1.6A, 250 VAC, 5mm x 20mm,

Type T, Slo-Blo, Time Lag, High Breaking Capacity

(HBC)

Range of Motion / Height: Refer to Dimension / Range of Motion section

Power Cord (Mobile Models only): 120 in. (3 m) long, Hospital Grade grounding plug

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 18

Specications - continued

Specications - continued

Classications: FDA Class 1, Type B, continuous operation (refer to

Model Identication / Compliance Chart)

Certications:

All Models Listed by TUV

Weight:

Mobile Models 65.8 lbs (29.8 kg)

Wall Mounted Model 85 lbs (38.6 kg)

Ceiling Mounted Models:

single light (8 ft. ceiling) 64 lbs (29.1 kg)

single light (9 ft. ceiling) 65 lbs (29.5 kg)

double light (8 ft. ceiling) 116 lbs (52.7 kg)

double light (9 ft. ceiling) 118 lbs (53.6 kg)

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 19

WARNING

Equipment is not suitable for use in the presence of a flammable anesthetic

mixture.

Clarification: Equipment is suitable for use in the presence of oxygen, air, or nitrous oxide.

WARNING

Do not modify this equipment without authorization of the manufacturer.

Caution

To completely isolate the light from electrical mains supply:

For lights provided with a power cord, the power cord must be unplugged.

For lights wired directly to mains supply, the wiring must be connected to an appropriately sized

circuit breaker and the circuit breaker must be turned off.

WARNING

No modification of this equipment is allowed.

WARNING

Use of this equipment adjacent to or stacked with other equipment should be avoided

because it could result in improper operation. If such use is necessary, this equipment

and the other equipment should be observed to verify that they are operating normally.

WARNING

Use of accessories, transducers and cables other than those specified or provided

by the manufacturer of this equipment could result in increased electromagnetic

emmisions or decreased electromagnetic immunity of this equipment and result in improper

operation.

WARNING

Portable RF communications equipment (including peripherals such as antenna cables

and external antennas) should be used no closer than 12 inches (30 cm) to any part of

the Procedure Light, including cables specified by the manufacturer. Otherwise, degradation of

the performance of this equipment could result.

Warnings

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 20

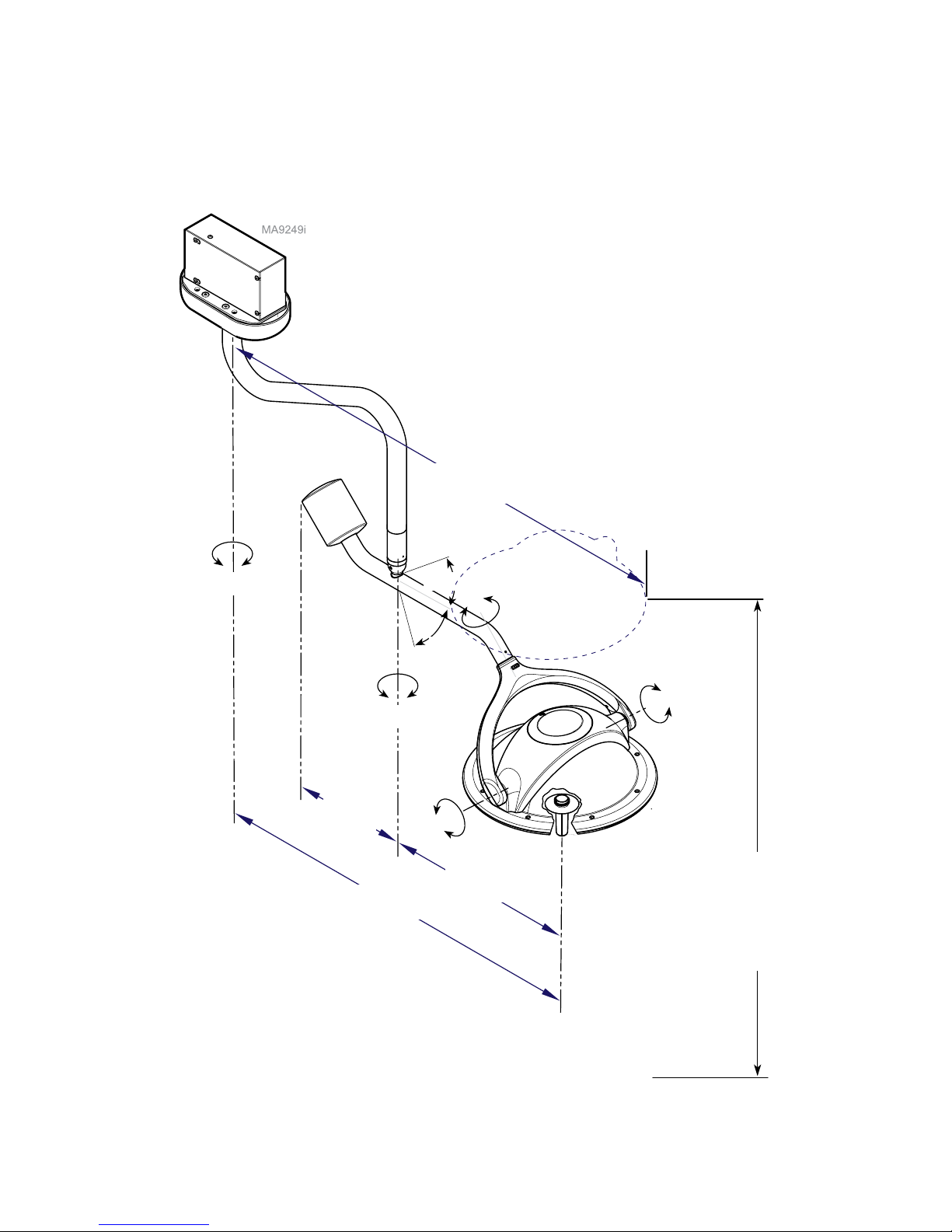

Dimensions / Range of Motion

Ceiling Lights

41

o

41

o

180

o

22.3 in

(56.7 cm)

180

o

46.3 in

(117.7 cm)

13.6 in

(34.6

cm)

56 in

(142.2 cm)

580

o

580

o

300

o

Height of lighthead adjustable from 53 in.

(135 cm) to 78 in. (198 cm) above oor.

Based on 8’ models with 8’ ceiling

and 9’ models with 9’ ceiling

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 21

Dimensions / Range of Motion - continued

Wall Mounted Lights

63.5 in

(161.3 cm)

99 in

(251.5 cm)

31 in

(81 cm)

580

o

41

o

41

o

180

o

180

o

300

o

170

o

> 3 in.

(7.6 cm)

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 22

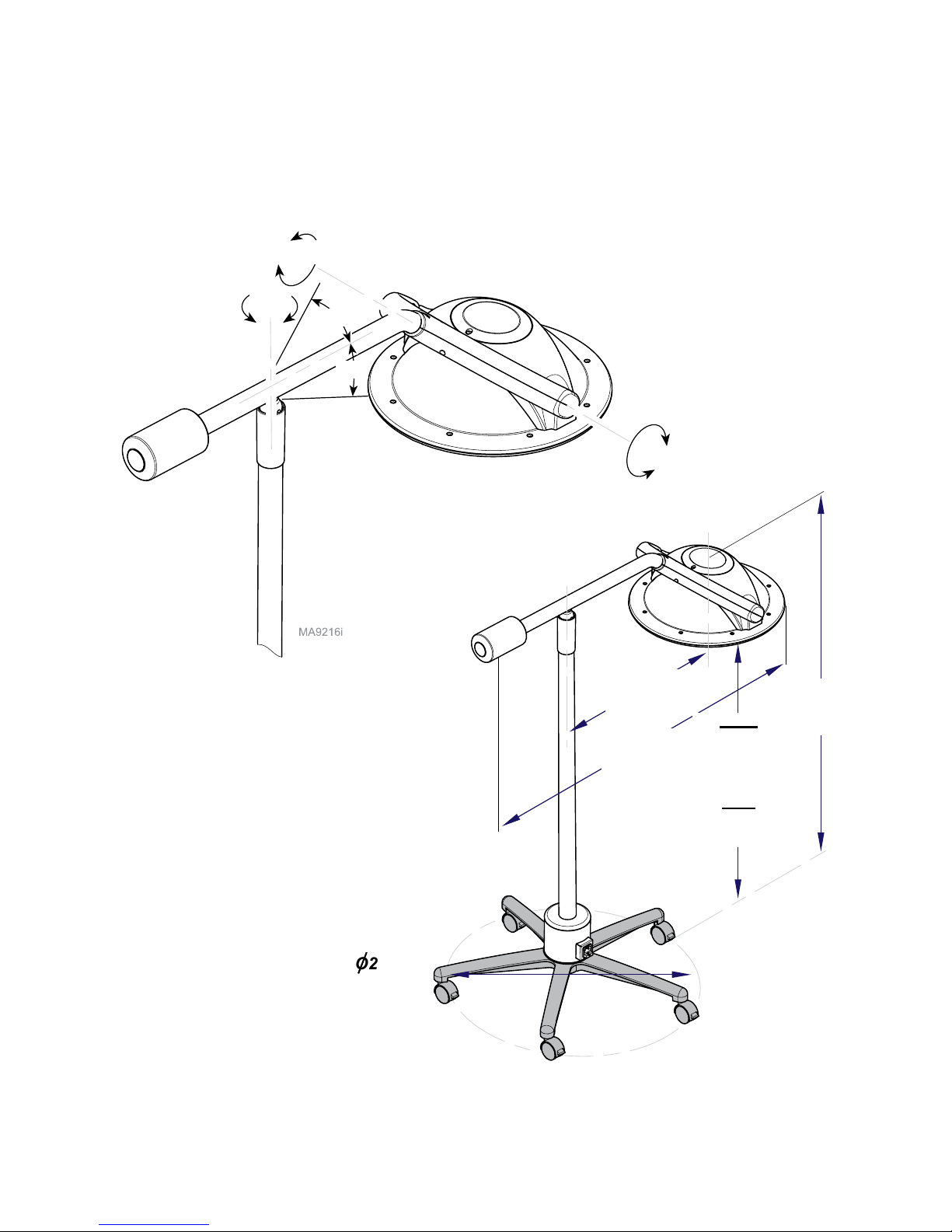

Dimensions / Range of Motion - continued

Mobile Lights

41

o

300

o

540

o

41

o

180

o

O28 in

(71.1 cm)

25.3 in

(64.3 cm)

47 in

(119.4 cm)

68 in

(172.7

cm)

Max.

88 in

(223.5 cm)

Min.

52 in

(132.1 cm)

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 23

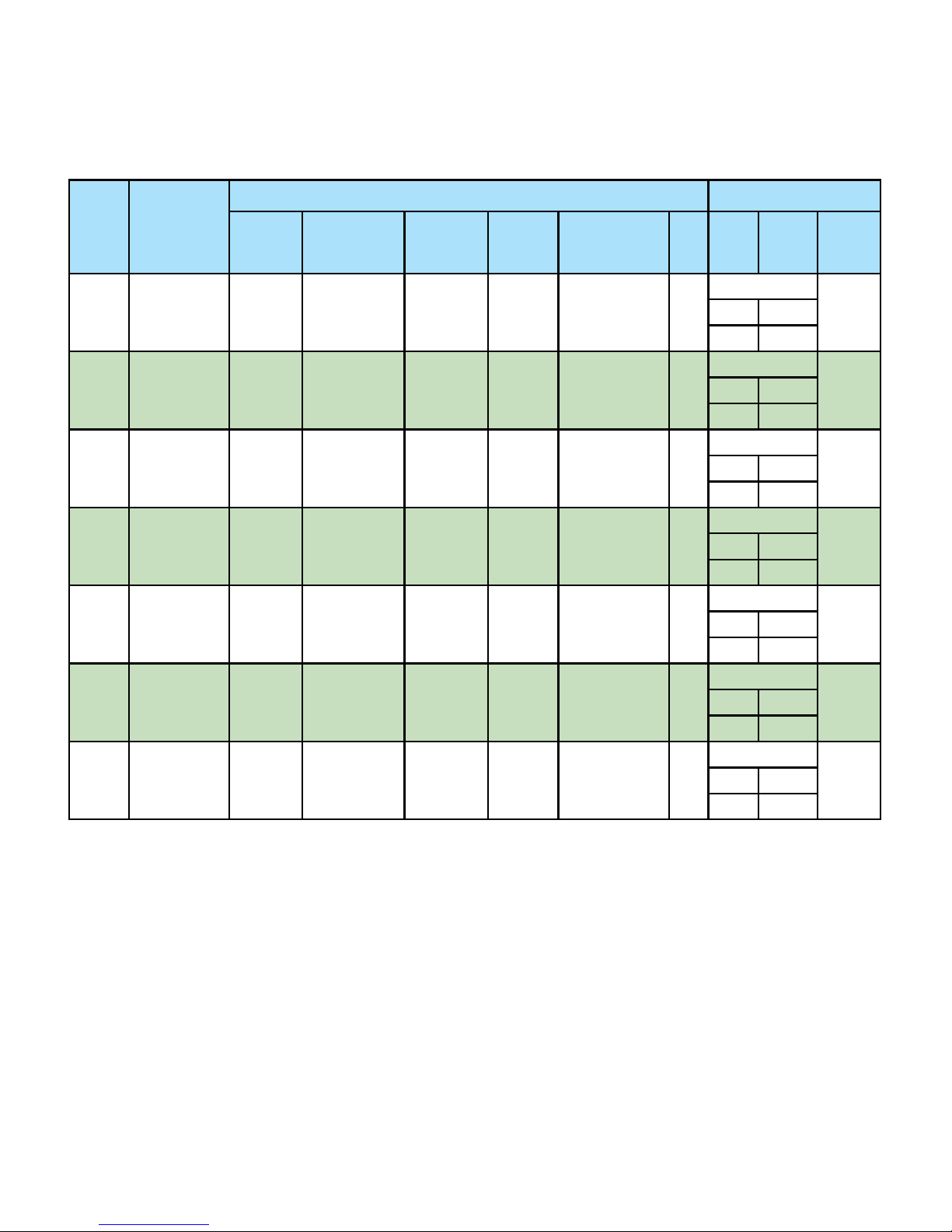

Model Identication / Compliance Chart

Model Description

Complies To: Electrical Ratings:

ES

60601-1

CAN / CSA

C22.2

#60601-1

60601-1-2

(EMC)

IEC

60601-1

60601-2-41

(Luminaires)

CE

VAC

+/-

10%

Amps

Cycles

(Hz)

255-

021

8’ single

light, ceiling,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

022

9’ single

light, ceiling,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

023

8’ double

light, ceiling,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

024

9’ double

light, ceiling,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

025

Mobile light,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

026

Wall Mount

light,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

255-

027

Mobile Light

w/o cord,

Midmark

• • • • • •

Congurable

50 / 60115 0.7

230 0.5

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 24

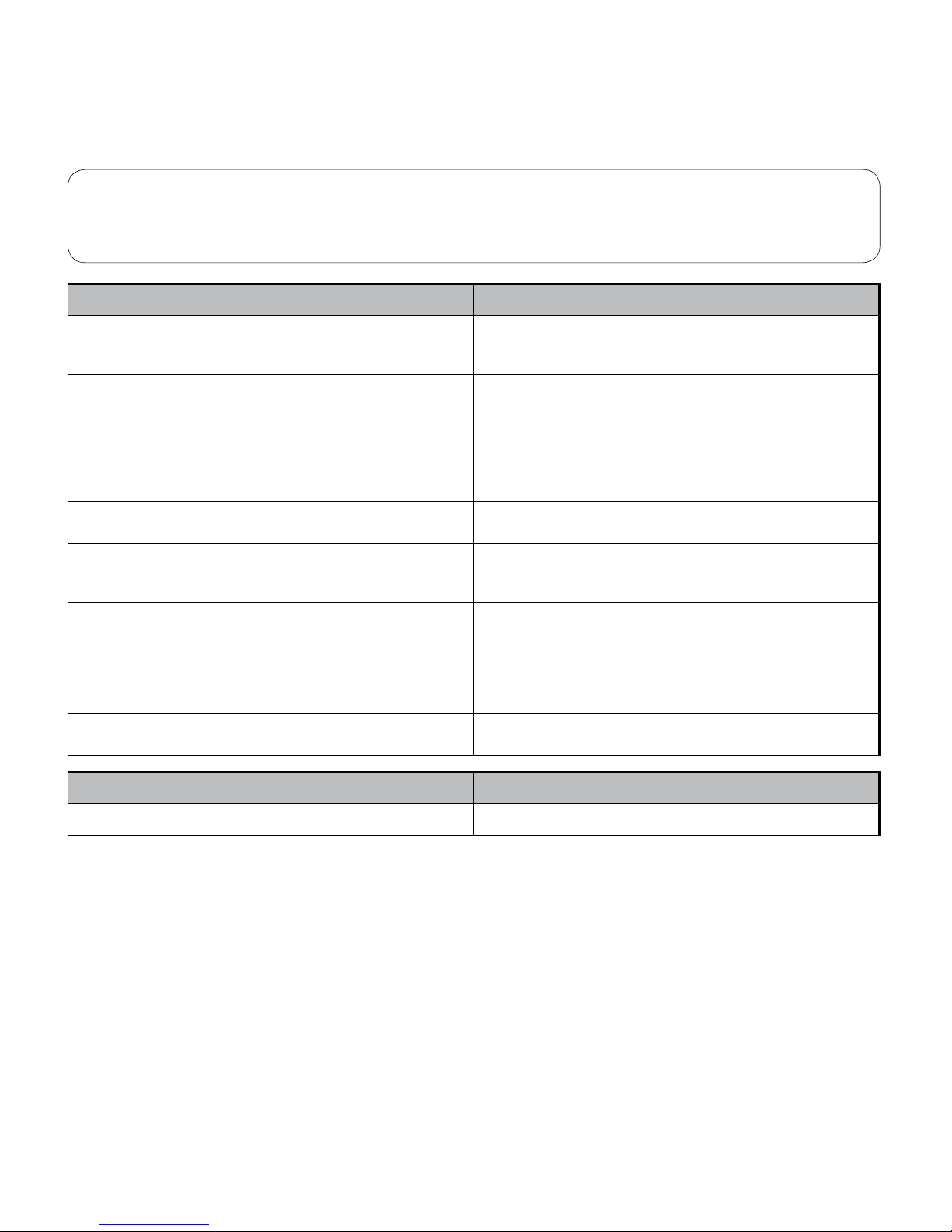

Immunity Test Immunity Test Level

Electrostatic Discharge (ESD)

IEC 61000-4-2

± 8 kV Contact, ±8 kV Air – Limited movement of patient

and practitioner during procedure minimizes need to

reposition light

Radiated RF EM Fields

IEC 61000-4-3

3V/m

80MHz-2.7 GHz 80% AM at 1kHz

Rated Power Frequency Magnetic Fields

IEC 61000-4-8

30 A/m

Electrical Fast Transients

IEC 61000-4-4

±2 kV at 100kHz repetition frequency

Surges

IEC 61000-4-5

Line to Line: ±1 kV

Line to Ground: ±2 kV

Conducted RF

IEC 61000-4-6

3V: 0.15MHz -80MHz

6V in ISM Bands between 0.15MHz - 80MHz

80% AM at 1kHz

Voltage Dips

IEC 61000-4-11

0 % UT; 0,5 cycle

At 0°, 45°, 90°, 135°, 180°, 225°, 270° and 315°

0 % UT; 1 cycle

and

70 % UT; 25/30 cycles

Single phase: at 0°

Voltage Interruptions

IEC 61000-4-11

0 % UT; 250/300 cycle

Note

The emissions characteristics of this equipment make it suitable for use in industrial areas and

hospitals. The procedure light is not intended to be used in a residential environment.

Emissions Test Emissions Test Level

Conducted and Radiated RF Emissions CISPR 11 Group 1 Class A

EMC - Manufacturer’s Declaration and Guidance

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 25

Midmark Limited Warranty - Dental Products

SCOPE OF WARRANTY

Midmark Corporation (“ Midmark”) warrants to the original retail purchaser that it will at Midmark’s option repair

or replace components of the dental products manufactured by Midmark (except for components not warranted

under “Exclusions”) that are defective in material or workmanship under normal use and service. Midmark’s

obligation under this limited warranty is limited to the repair or replacement of the applicable components. This

limited warranty shall only apply to defects that are reported to Midmark within the applicable warranty period

and which, upon examination by Midmark, prove to be defective. This warranty extends only to the rst retail

purchaser of a product and is not transferable or assignable. Replacement components or products may be

used and/or refurbished components or products, provided they are of like quality and specications as new

components or products.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original user, shall be as follows:

Eective March 1, 2018 these applicable warranty periods are measured from the date of invoice to the

original user, shall be as follows:

1. OPERATORY PRODUCTS

a. Five (5) years for all products (except for the items in (b) through (e)).

b. Two (2) years for upholstery (chairs and stools).

c. “KINK-VALVE” module carries a ten (10) year warranty.

d. The original light bulb on a new light carries a one (1) year warranty.

e. Accessories not manufactured by Midmark are excluded including but not limited to Bien Air handpiece

systems, Dentsply Cavitron scaler, Satelec scaler and curing light, and Sopro cameras.

2. ORAL SURGERY PRODUCTS are warranted for a period of one (1) year.

3. STERILIZER PRODUCTS are warranted for a period of one (1) year.

4. ULTRASONIC CLEANER PRODUCTS are warranted for a period of two (2) years.

5. AIR AND VACUUM PRODUCTS

a. PowerAir® oil-less compressors – Five (5) years or 3,500 hours of use, whichever occurs rst. b.

PowerVac® and PowerVac® G dry vacuums – Five (5) years or 10,000 hours of use, whichever

occurs rst (except that the vacuum pump warranty term is ten (10) years or 20,000 hours of use,

whichever occurs rst).

c. Classic Series® wet-ring vacuums – Five (5) years or 10,000 hours of use, whichever occurs rst.

d. PowerMax surgical suction – Two (2) years.

e. Hg5 Series Amalgam Separator - One (1) year. (f) Midmark manufactured accessories - One (1) year.

6. SYNTHESIS™ DENTAL CASEWORK AND ARTIZAN® EXPRESSIONS PRODUCT

a. Five (5) years for all products and components including door and drawer fronts, casters and

slides, except for the items in (b), (c) and (d).

b. Three (3) years for electrical components such as task lights/LED lights, cords, controls and

accessories.

c. Two (2) years for sliding track monitor mount and components and upholstery. (d) One (1) year for

countertops and resin, including accessories.

© Midmark Corporation 2016

003-2848-99

TP202 20-42-FO-00014 Rev A1 C2169

English - 26

7. IMAGING PRODUCTS are warranted for a period of two (2) years except for the ClearVision CR reader

which is warranted for a period of one (1) year.

8. MIDMARK Replacement Parts and Accessories carry a ninety (90) day warranty

EXCLUSIONS

This warranty does not cover and Midmark shall not be liable for the following;

1. defects, damage or other conditions caused, in whole or in part, by misuse, abuse, negligence,

alteration, accident, freight damage, negligent storage, tampering or failure to seek and obtain repair

or replacement in a timely manner;

2. products which are not installed, used, and properly cleaned and maintained as required or

recommended in the Midmark “Installation” and/or “Installation/Operation Manual” for the applicable

product, including the specied structural and operational environment conditions and electrical

power requirements;

3. products considered to be of a consumable or sterile nature;

4. accessories or parts not manufactured by Midmark;

5. charges by anyone for adjustments, repairs, replacement parts, installation or other work performed

upon or in connection with such products which are not expressly authorized in writing in advance

by Midmark

6. costs and expenses of routine maintenance and cleaning;

7. representations and warranties made by any person or entity other than Midmark;

8. matching of color, grain or texture except to commercially acceptable standards;

9. changes in color caused by natural or articial light;

10. custom manufactured products;

11. alterations or modications to the product by any person or entity other than Midmark; and

12. Products that would otherwise by covered under Sections 1 and 2 of this limited warranty, but are

acquired: (i) from a person or entity that is not Midmark or one of its authorized dealers; or (ii) from a

Midmark dealer that is not authorized to sell the product at issue in the geographic territory where the

purchaser is located, or is not authorized to sell the product at issue within the medical, animal

health or dental market, as the case may be, in which purchaser intends to use the product.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER

MIDMARK’S ONLY OBLIGATION UNDER THIS LIMITED WARRANTY IS THE REPAIR OR

REPLACEMENT OF DEFECTIVE PARTS. MIDMARK SHALL NOT BE LIABLE FOR AND HEREBY

DISCLAIMS ANY DIRECT, SPECIAL, INDIRECT, INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL

DAMAGES OR DELAYS, INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR LOSS OF PROFITS OR

INCOME, LOSS OF USE, DOWNTIME, COVER AND EMPLOYEE OR INDEPENDENT CONTRACTOR

WAGES, PAYMENTS AND BENEFITS.

WARRANTY DISCLAIMER

THIS LIMITED WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.MIDMARK MAKES NO IMPLIED WARRANTIES OF ANY KIND

INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS.

STATUE OF LIMITATIONS

No action my be brought against Midmark for breach of this limited warranty, or implied warranty, if any, or

for any other claim arising out of or relating to the products, more than ninety (90) days following expiration

of the limited warranty period.

Loading...

Loading...