Page 1

Universal

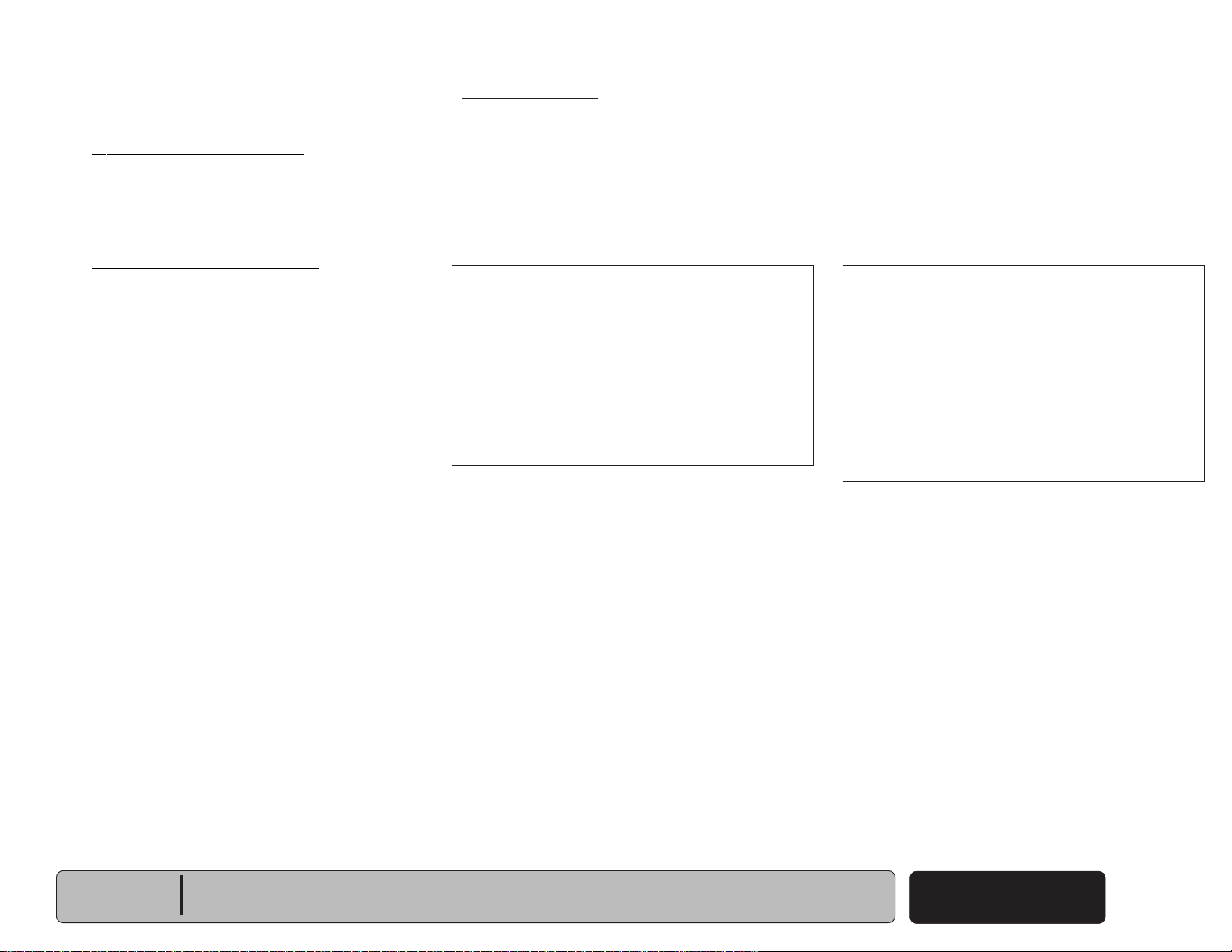

Style B

Procedures Chair

Model Numbers:

230

630

75

-001 thru -004

-001 thru -009

-019 thru -021

Service and

Parts Manual

Some Models NO LONGER IN PRODUCTION

Some service parts may not be available for this product!

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1838 Part No. 004-0409-00 Rev. AA6 (3/11/19)

630 shown

Page 2

GENERAL INFORMATION

Back

Symbols ....................................iii

Ordering Parts .......................... iii

Model / Serial Number

Location .................................. iii

Weights, Dimensions,

Electrical Specifications ....... iv

Model Identification /

Compliance Charts:

230 & 75 (-019) .........................

630 & 75 (-020 / -021) ...............

General Information

Scheduled Maintenance .......... vii

OPERATION &

TROUBLESHOOTING

Error Codes

Power To The Chair:

Models w/ Standard Base .............

Models w/ Rotational Base ...........

Base Up / Down ........................ A-8

Section A

Back Up / Down ........................ A-18

Tilt Up / Down ........................... A-28

Foot Up / Down......................... A-38

Crash Avoidance System ........A-48

Position Programming ............ A-52

"Home" Function ..................... A-56

Quick Chair™

Chair Receptacles .................... A-66

Upholstery Heater System ...... A-68

Rotational Base

Brake System ......................... A-72

(Refer to page B-40)

Function........... A-62

v

vi

A-2

A-4

COMPONENT

TESTING & REPAIR

Isolation Transformer /

Chair Receptacles.................. B-29

Main System Transformer ....... B-30

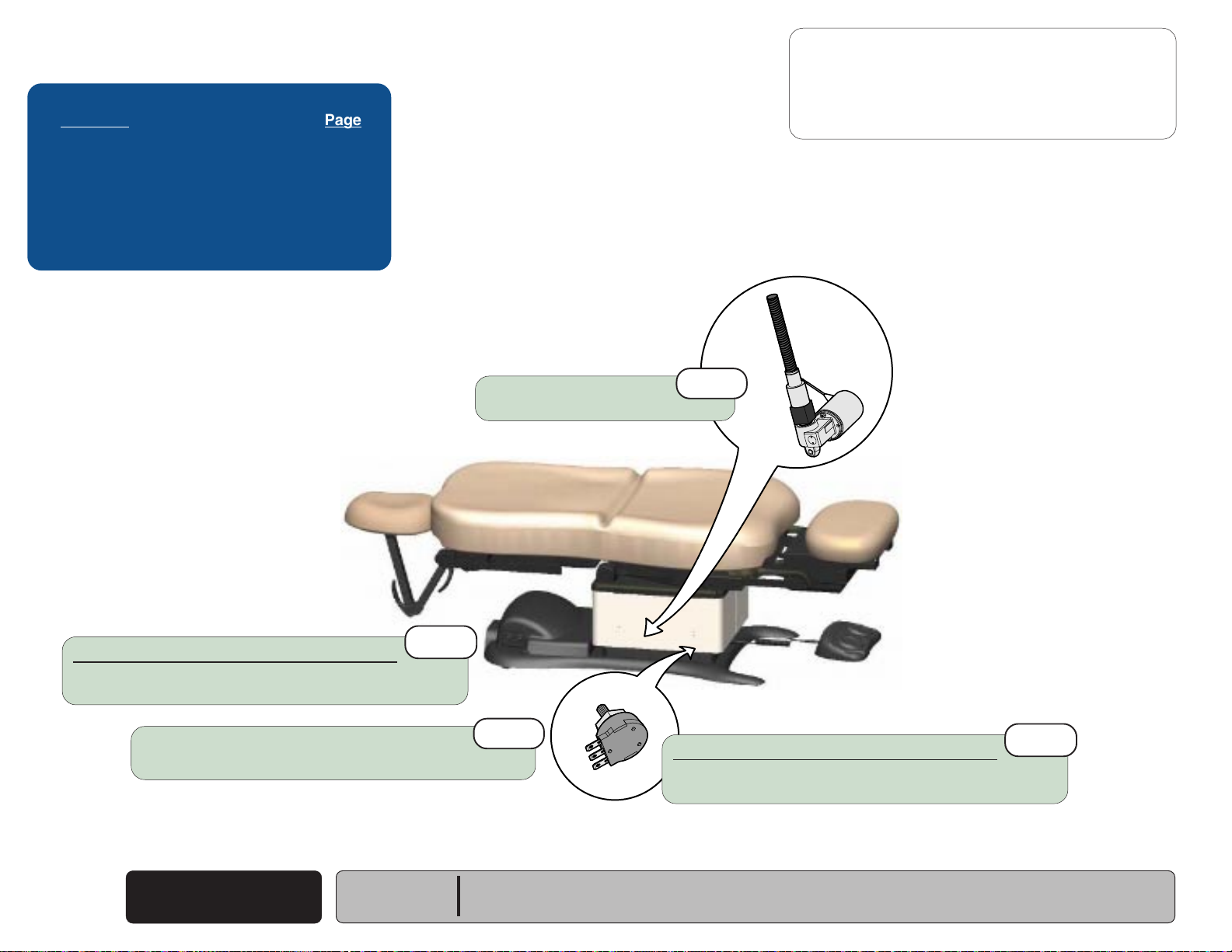

Position Sensors...................... B-32

Section B

Main PC Board

Upholstery Heater System ......B-45

Headrest Mechanism ............... B-50

Rotational Base

Brake System ......................... B-51

- continued

(Error Codes) .......

ACCESS PROCEDURES

Removing & Installing:

PC Board Cover:

Models w/ Standard Base ........

Models w/ Rotational Base ......

Base Shrouds:

Raising (w/bungee cord) ..........

Section C

Removing / Installing................

Upholstery ........................... C-6

Back Section Covers .......... C-7

Seat Section Covers ........... C-8

Foot Section Covers:

Midmark Models ......................

Ritter Models .........................

Junction Board Cover....... C-11

WIRING DIAGRAMS

230 ..........................................D-1

630 ..........................................D-1

75 ........................................... D-1

B-40

C-2

C-3

C-4

C-5

C-9

C-10

COMPONENT

Section D

TESTING & REPAIR

Primary Fuses .......................... B-2

Limit Switches .......................... B-3

Hand / Foot Controls ............... B-6

Table Of Contents

Base Actuator........................... B-11

Back Actuator........................... B-17

Section B

Tilt Actuator .............................. B-21

Foot Actuator ........................... B-25

Gas Springs .............................. B-28

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

Section E

EXPLODED VIEWS / PARTS LISTS

230 .........................................E-2

630 .........................................E-3

75:

Section E

*

Indicates multiple pages due to a serial number break for the parts illustration

(-019) .......................................

(-020 / -021) .............................

E-2

E-3

Rev. 10/5/18

Page 3

Symbols

Go To Table Of Contents

Next

Back

General Information

Ordering Parts

WARNING

Indicates a potentially hazardous situation which

could result in serious injury if not avoided.

Caution

Indicates a potentially hazardous situation

which could result in injury if not avoided.

Equipment Alert

Indicates a potentially hazardous situation which

could result in equipment damage if not avoided.

Note

Amplifies a procedure, practice, or condition.

In Section A, test the components in the order indicated.

(ex.

1st

then,

These symbols are used throughout this manual to represent the

operational status of chair functions and components.

Refer to Section B for component testing procedures.

2nd

)

The following information is required when ordering parts:

• Serial number & model number

• Part number for desired part.

[Refer to Exploded Views / Parts Lists section]

Non-warranty parts orders may be faxed to Midmark using

the Fax Order Form in the back of this manual.

For warranty parts orders, call Midmark's Technical Service

Department with the required information.

Hours: 8:00 am until 5:00 pm EST [Monday - Friday]

Phone: 1-(800)-Midmark

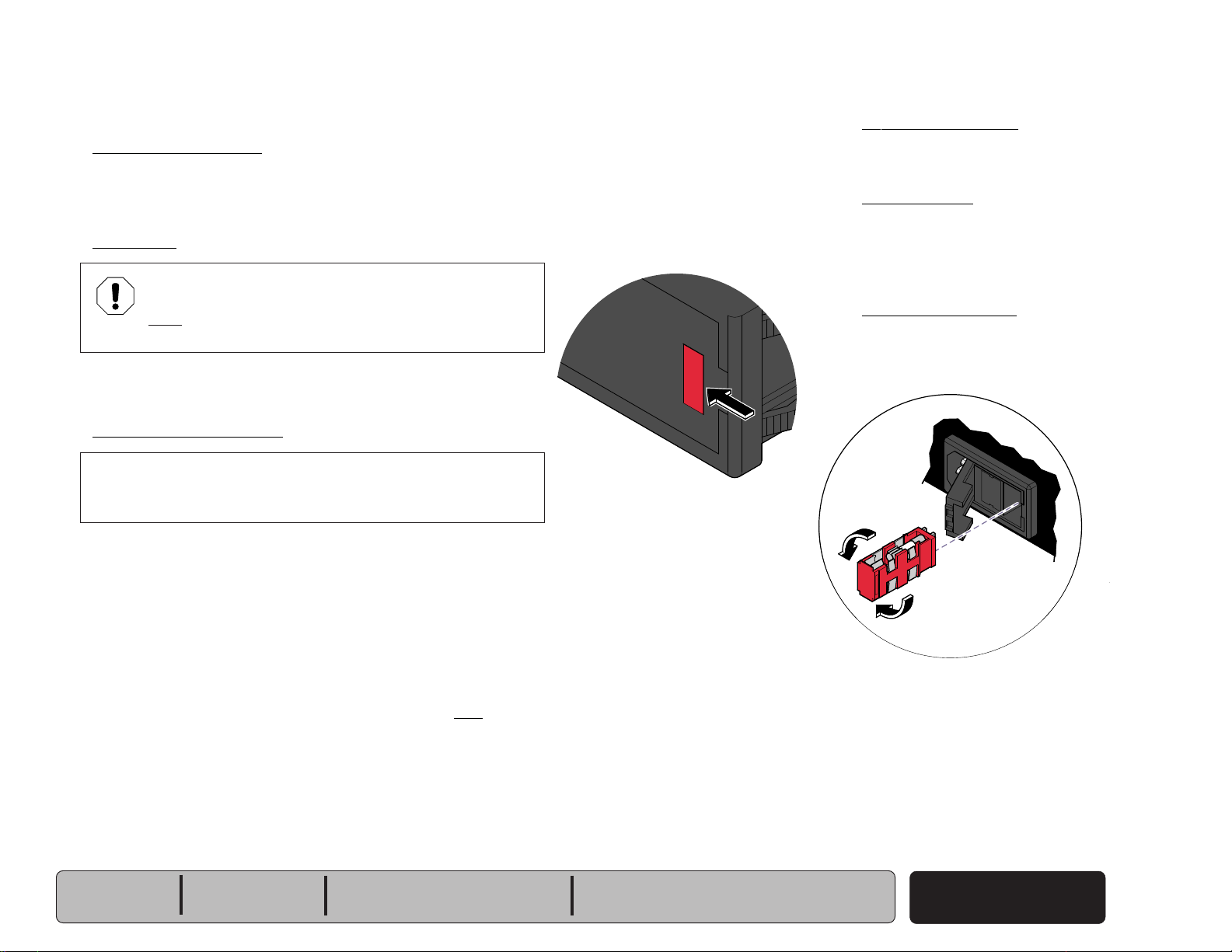

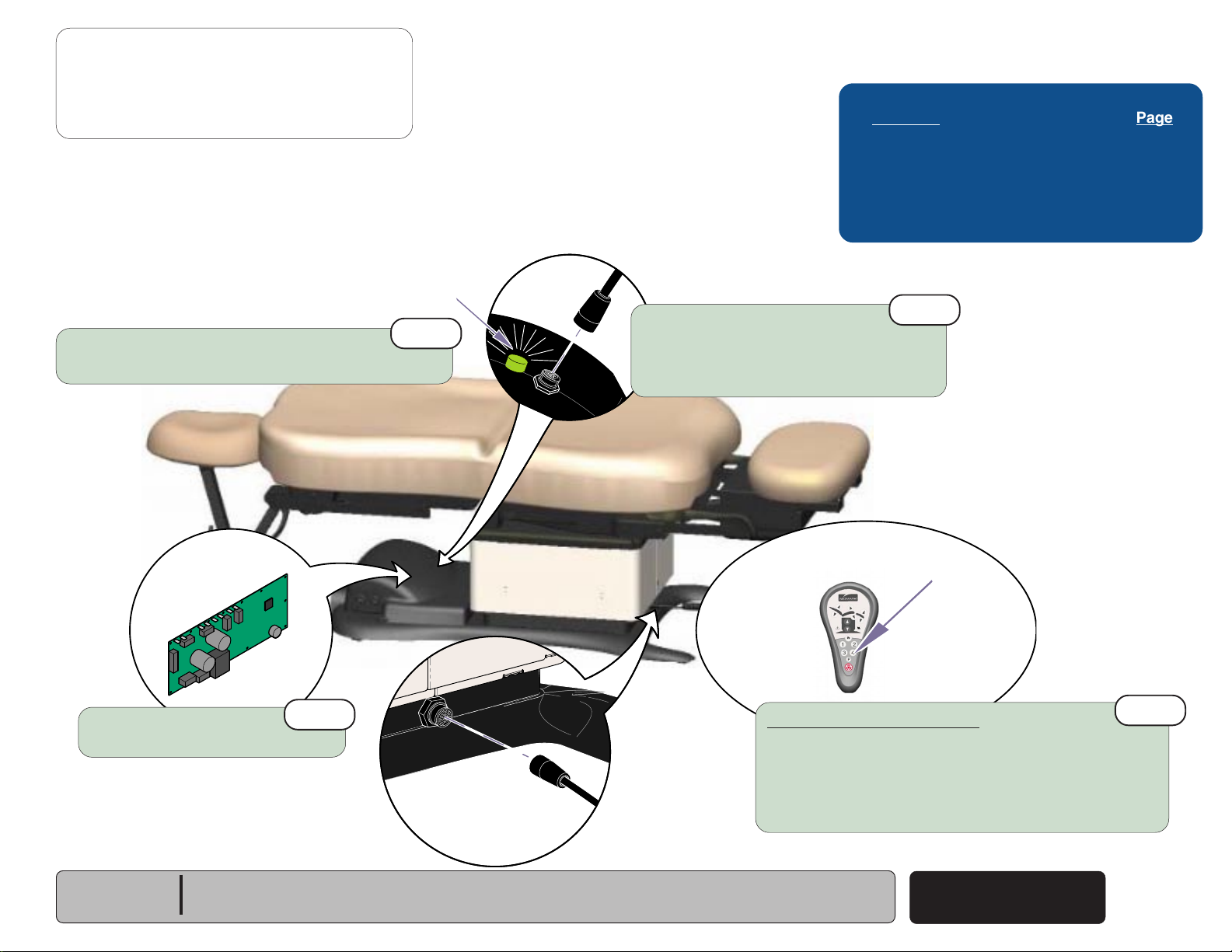

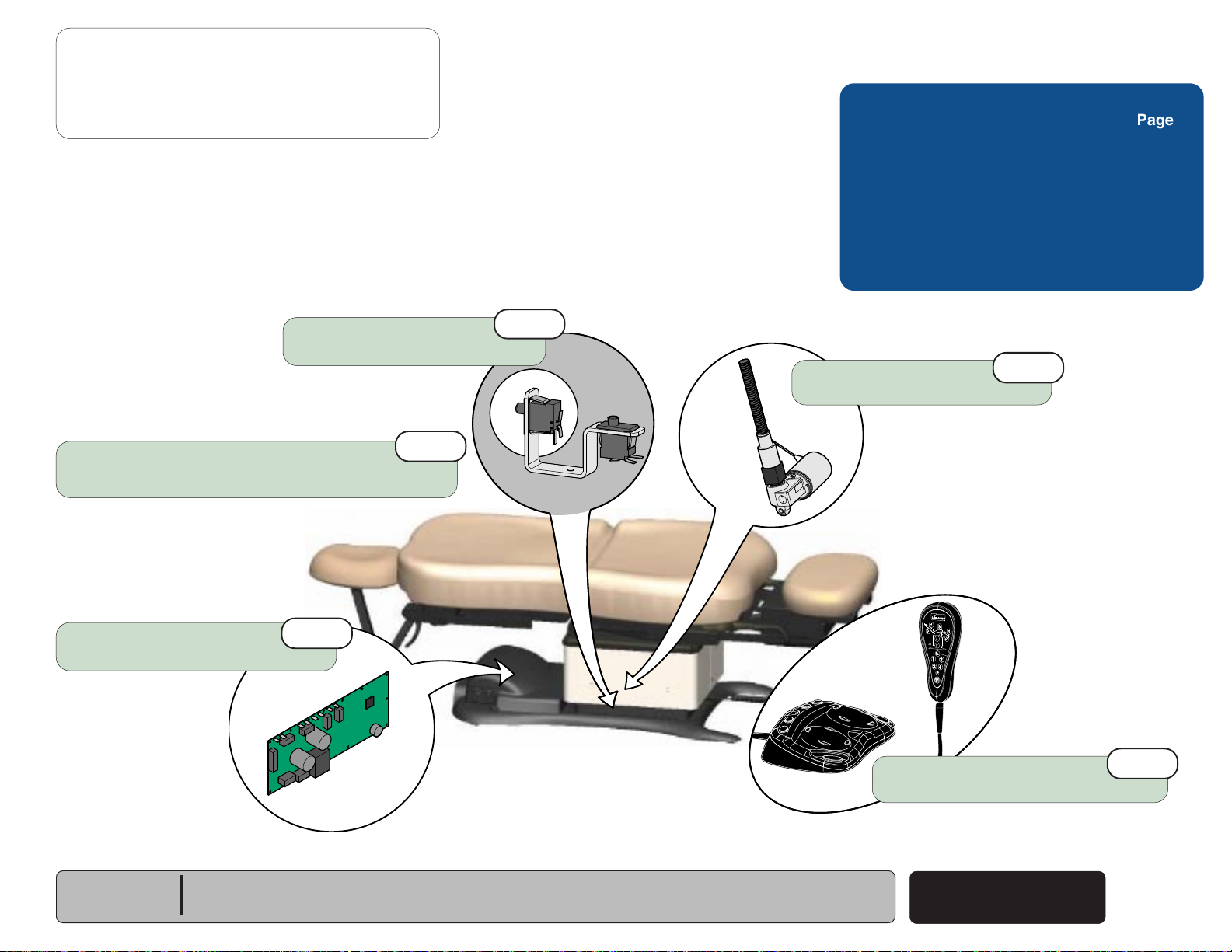

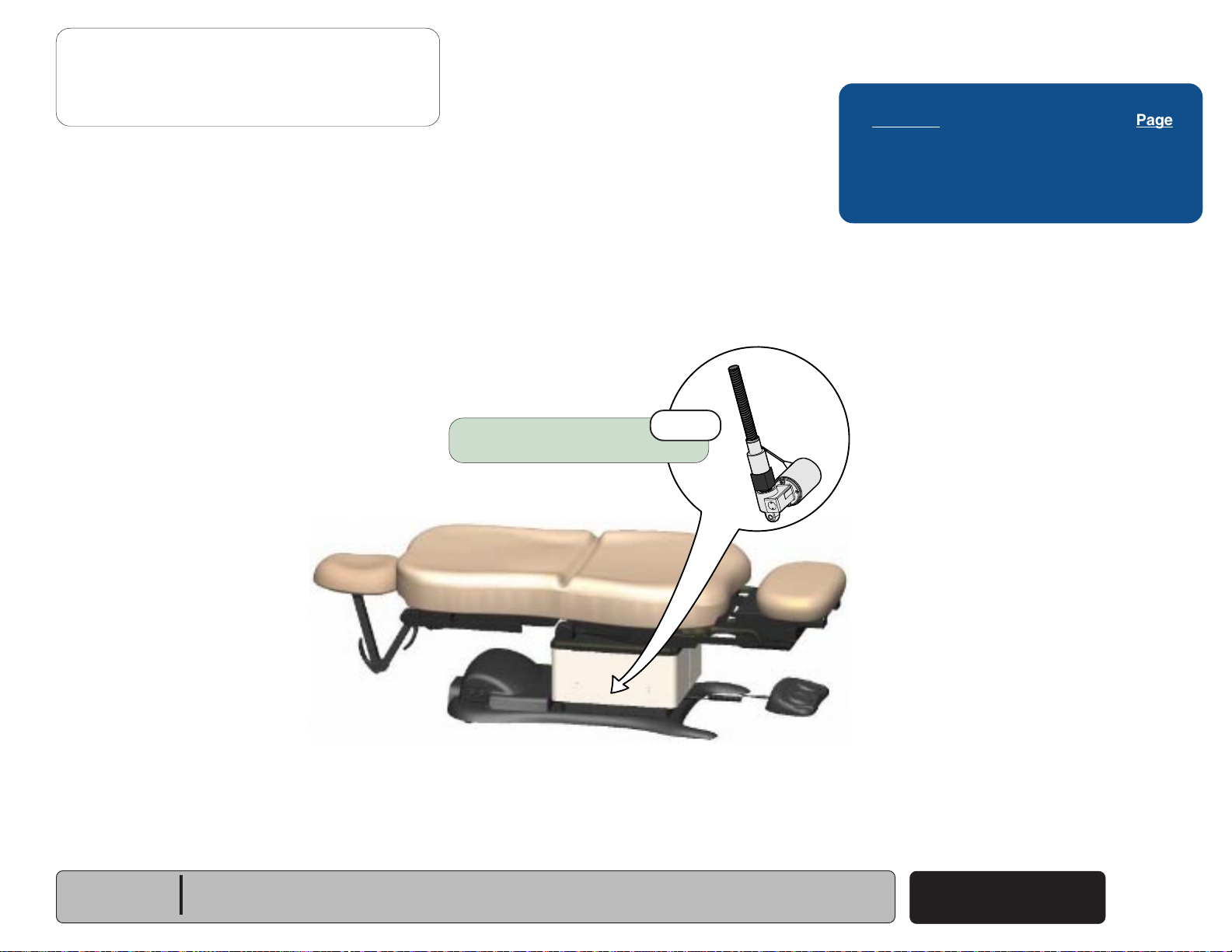

Model / Serial Number Location

Indicates the function / component is working properly.

No action required.

Indicates the function / component is working,

but a problem exists.

Indicates the function / component is not working at all.

General Information

Model 630-000 thru -009 is shown.

Location is the same for

230 & 75 models.

© Midmark Corporation 2005 SF-1838

MA643201i

iii

Rev. (10/5/18)

Page 4

General Information

MA643601i

i

Go To Table Of Contents

Next

Back

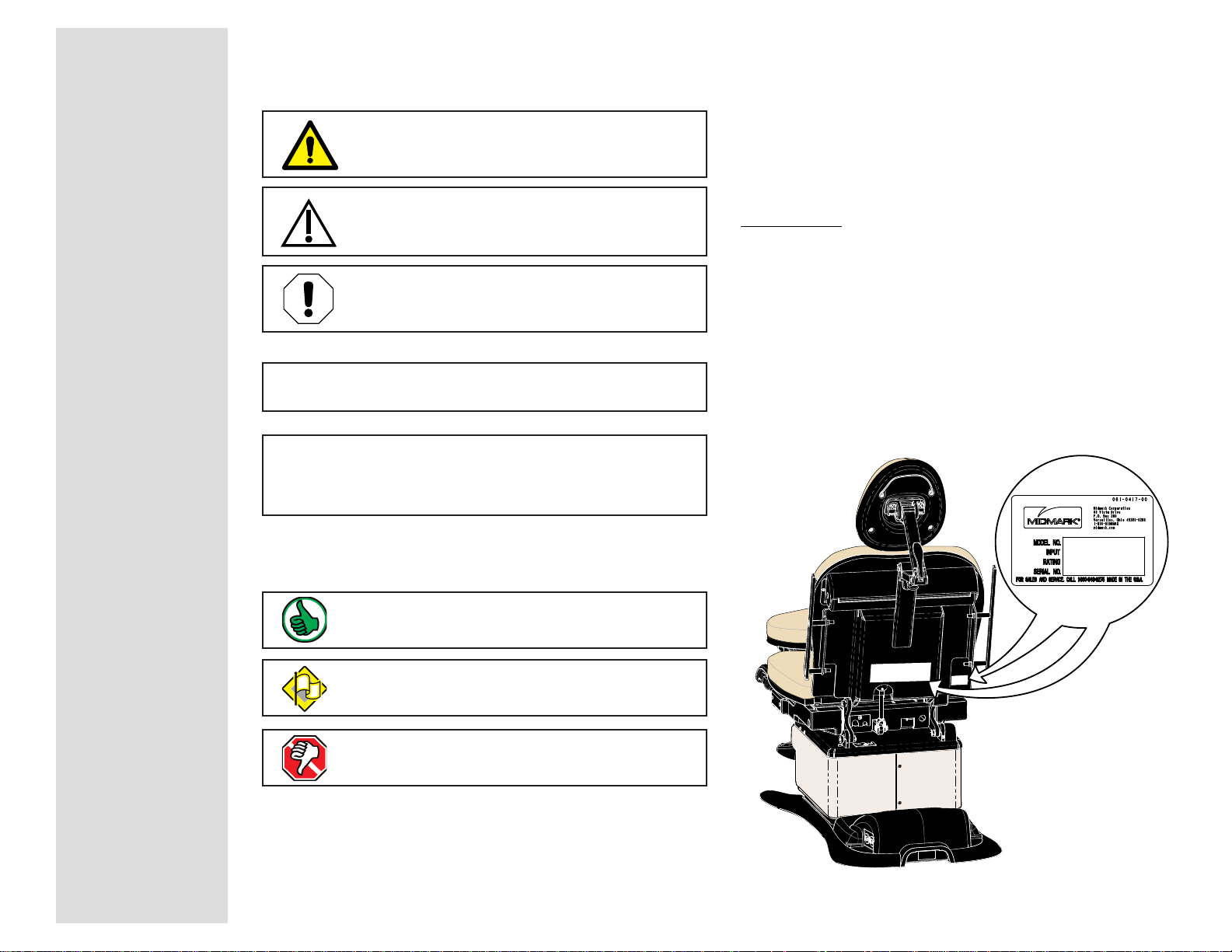

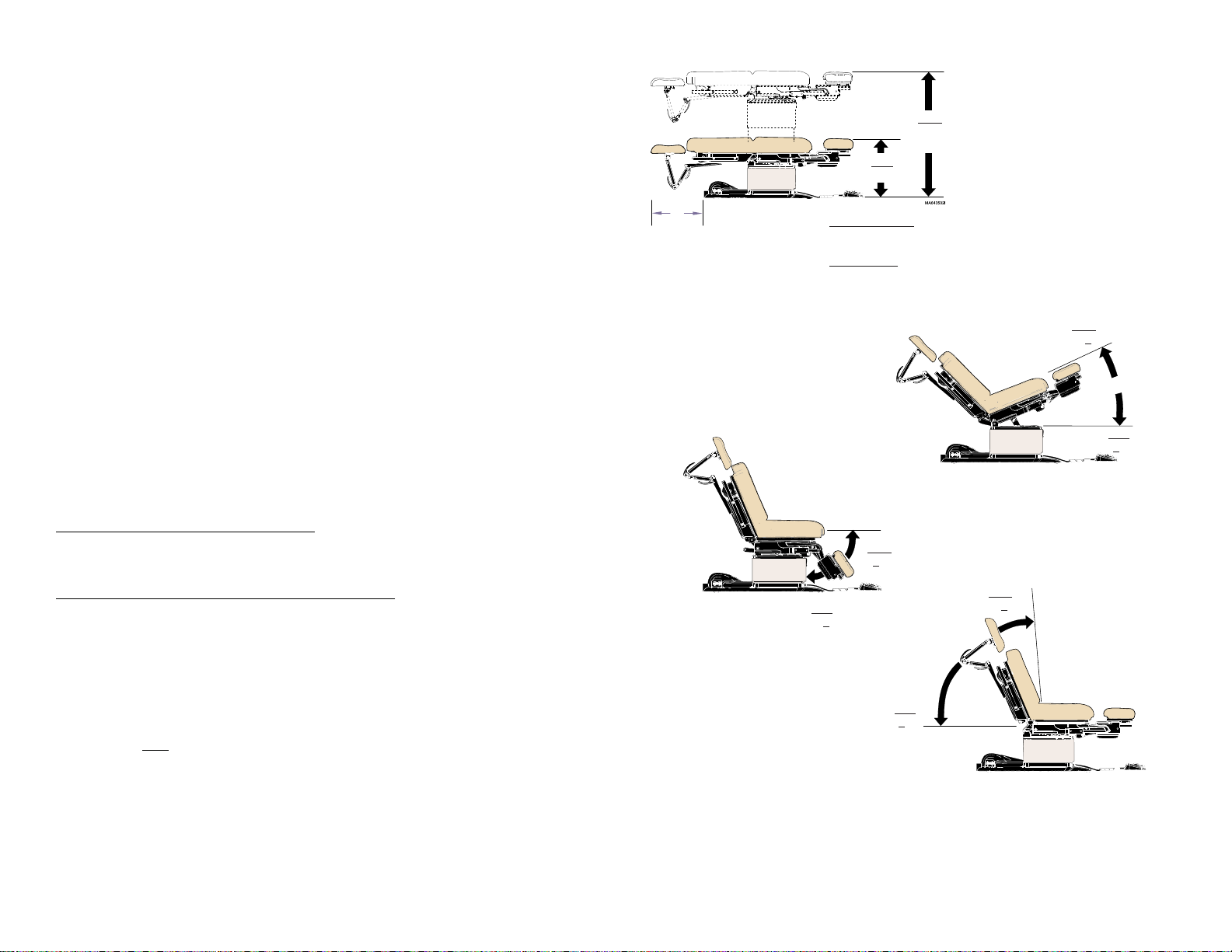

Weights, Dimensions, Electrical Specifications

Patient Weight (Maximum) .................................450 lbs (204.1 kgs)

Paper Roll (maximum size): ..............................18 in. long x 3.5 in. diameter

(45.7 x 8.9 cm)

Range of Motion &

Dimensions .......................................................[See illustration]

Weight of Chair:

230 / 630 / 75 (w/standard base) ....................... 455 lbs (206.4 kg)

w/packaging & skid ........................................... 510 lbs (231.3 kg)

230 / 630 / 75 (w/rotational base) ......................540 lbs (244.9 kg)

w/packaging & skid ........................................... 600 lbs (271.1 kg)

Power Cord: ........................................................ 8 ft. (243.8 cm) long

Electrical Requirements: ................................... [See Compliance Charts]

19 in.

(48.2 cm)

Min.

* see below

* Midmark models

w/ standard base:

w/rotational base:

Ritter models

w/standard base:

w/rotational base:

Max.

Standard base:

Rotational base:

19 in. (48.2 cm)

22.5 in. (57.1 cm)

22.5 in. (57 cm)

26 in. (66 cm)

40 in. (101.6 cm)

43.5 in. (110.5 cm)

Max.

30° +2°

Foot / Hand Control Voltage: .............................10 VAC, SELV (Safety Extra Low Voltage)

Duplex Receptacle (optional)

maximum load: ................................................. 115 VAC, 3A, 50/60 Hz

Fuses:

Main Power

(located at power cord inlet)

:

F1 & F2 .................................................................6.3A, 250V, Type-T, 5 x 20 mm

High-Breaking Current

Upholstery Heater

(located on uph. heater PC board)

:

F1 & F2 .................................................................1/2 A, 250V, Type-T, 1-1/4" x 1/4"

Duty Cycle

(motor run time)

: ............................... Intermittent Operation

[30 seconds ON / 5 minutes off]

Classifications: ...................................................Class 1, Type B Applied Part

Protection against ingress of fluids: ............... Ordinary Equipment

Foot Control only: ................................................

IPX1

Regulatory Compliance: ....................................[See Compliance Charts]

Chair Speeds (by function):

Base / Back / Tilt

Foot

(630) .............................................................

Foot

(230) .............................................................

(all models) ..............................

15 - 25 seconds

less than 15 seconds

less than 20 seconds

Min.

89° +1°

Max.

0° +0.5°

MA643801

0° +0.5°

Min.

0° +0.5°

MA643701i

Max.

85° +3°

Min.

iv

© Midmark Corporation 2005 SF-1838

Equipment not suitable for use in the presence of a flammable anesthetic mixture with air, or with oxygen, or nitrous oxide.

Rev. 10/5/18

Page 5

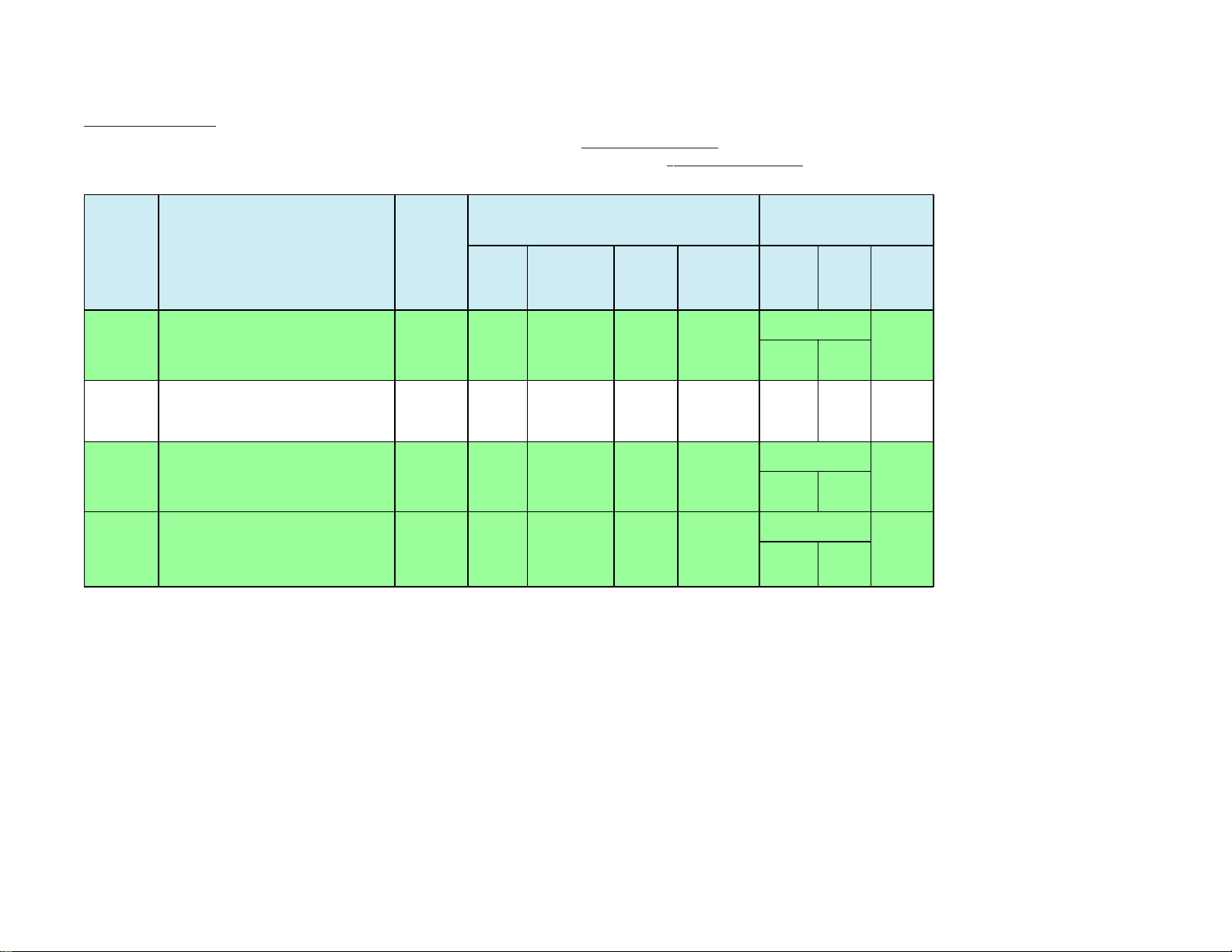

Model Identification / Compliance Chart - 230 & 75 (-019)

Go To Table Of Contents

Next

Back

Fire Code Ratings

All standard upholstery sets comply with: California Bureau of Home Furnishing Technical Bulletin 117

Optional upholstery sets are available that comply with:California Bureau of Home Furnishing Technical Bulletin 133.

General Information

Model Description

230-001

230-002

230-003

75-019

(230-004)

Ritter Universal Proc. Chair

(Non-Programmable)

Ritter Universal Proc. Chair

(Non-Programmable)

w/ Receptacle

Ritter Universal Proc. Chair

(Non-Programmable)

w/ rotational base

Ritter Universal Proc. Chair

(Non-Programmable)

Serial

Number

Prefix

V

V

V

V

Complies To: Electrical Ratings:

UL

60601-1

CAN/CSA

22.2,

#601.1-M90

IEC

60601-1

EN

60601-1-2

(EMC)

x x x x

xx xx

x x x x

x x x x

VAC

+/-10%

Configurable

115

230

Amps

3.5

Cycles

(Hz)

50 / 60

7

115 10 50 / 60

Configurable

115

230

Configurable

115

230

7.5

3.8

3.5

50 / 60

50 / 60

7

© Midmark Corporation 2005 SF-1838

Rev. (10/5/18)

v

Page 6

General Information

Go To Table Of Contents

Next

Back

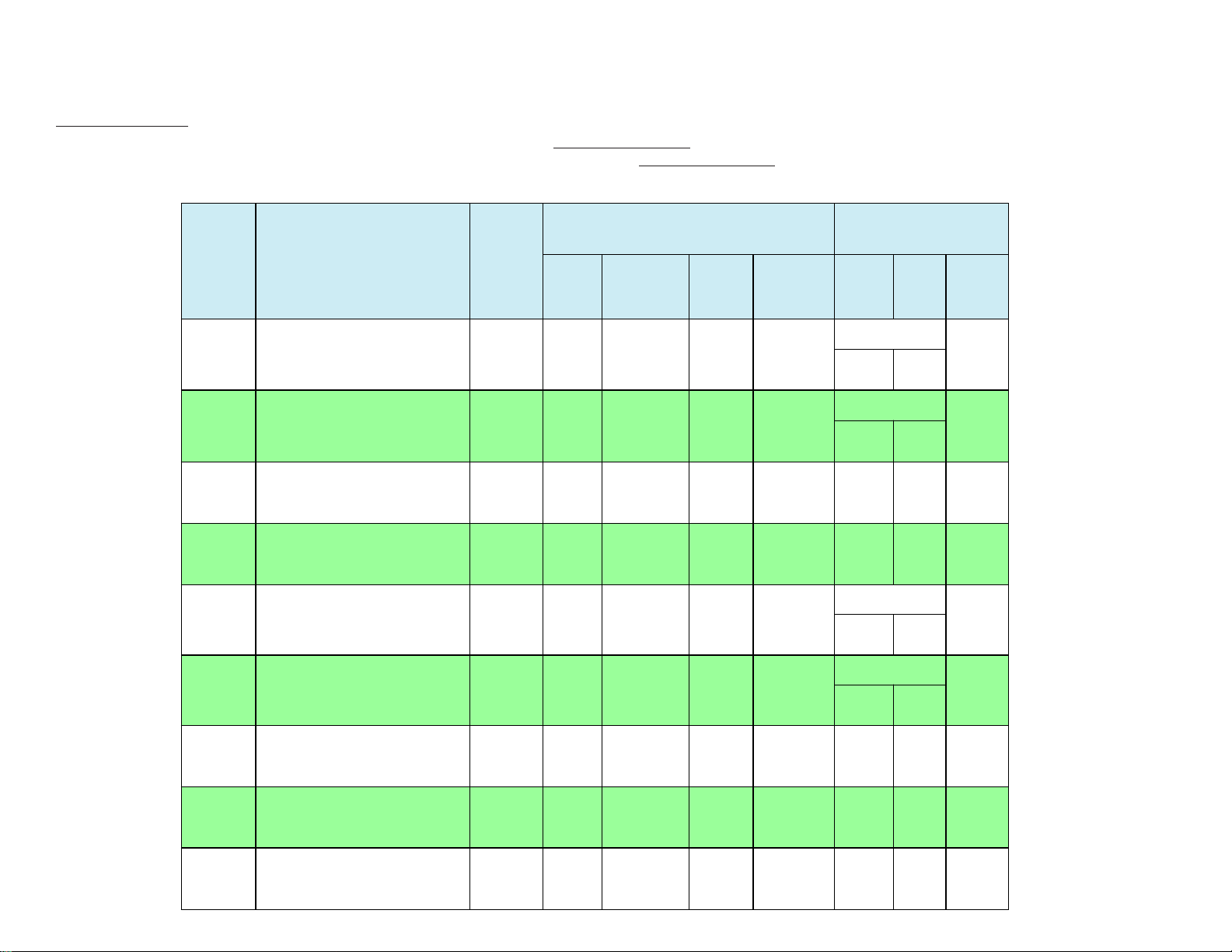

Model Identification / Compliance Chart - 630 & 75 (-020 / -021)

Fire Code Ratings

All standard upholstery sets comply with: California Bureau of Home Furnishing Technical Bulletin 117

Optional upholstery sets are available that comply with:California Bureau of Home Furnishing Technical Bulletin 133.

Model Description

630-001

630-002

630-003

630-004

630-005

630-006

Midmark Universal Proc. Chair

(Non-Programmable)

Midmark Universal Proc. Chair

(Programmable)

Midmark Universal Proc. Chair

(Non-Programmable)

w/ Receptacle

Midmark Universal Proc. Chair

(Programmable)

w/ Receptacle

Midmark Universal Proc. Chair

(Non-Programmable)

w/ Rotational Base

Midmark Universal Proc. Chair

(Prog.) w/ Rotational Base

Serial

Number

Prefix

V

V

V

V

V

V

Complies To: Electrical Ratings:

UL

60601-1

CAN/CSA

22.2,

#601.1-M90

IEC

60601-1

EN

60601-1-2

(EMC)

xx xx

x x x x

xx xx

x x x x

xx xx

x x x x

VAC

+/-10%

Configurable

115

230

Configurable

115

230

Amps

3.5

3.5

Cycles

(Hz)

50 / 60

7

50 / 60

7

115 10 50 / 60

115 10 50 / 60

Configurable

115

230

Configurable

115

230

7.5

3.8

7.5

3.8

50 / 60

50 / 60

vi

© Midmark Corporation 2005 SF-1838

630-007

75-020

(630-008)

75-021

(630-009)

Midmark Universal Proc. Chair

(Programmable)

w/ Heated Upholstery

Midmark Universal Proc. Chair

(Non-Programmable)

w/ Receptacle

Midmark Universal Proc. Chair

(Programmable)

w/ Receptacle , no foot control

Rev. (10/5/18)

V

V

V

xx xx

x x x x

xx xx

115 7 50 / 60

115 10 50 / 60

115 10 50 / 60

Page 7

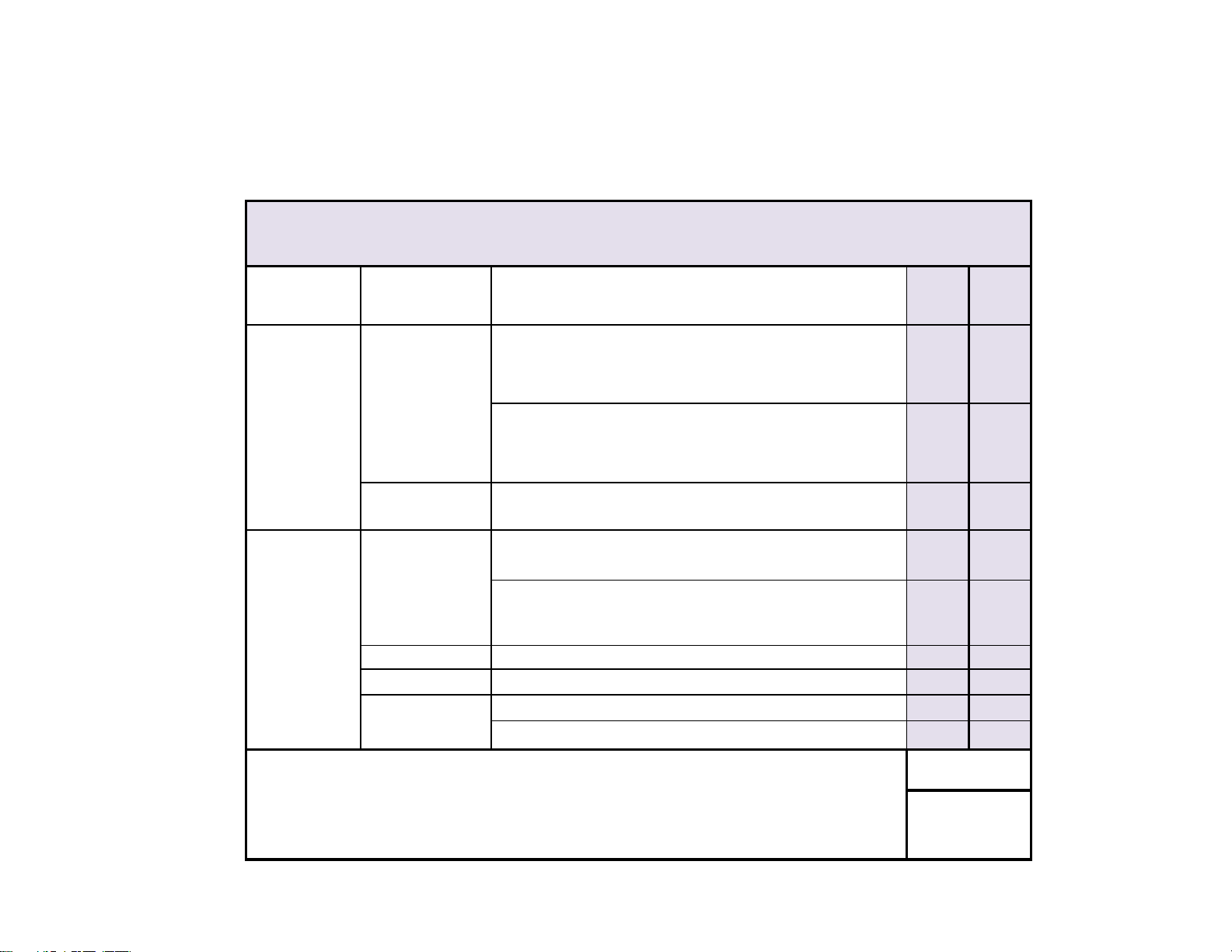

General Information

Interval

Inspection or

Service

Service, Adjust , Repair

and / or Replace as Required

(Refer to appropriate S&P or Quick Reference Guide)

230 630

Clean upholstery with diluted bleach solution 10:1

(water:bleach)

XX

Wipe painted metal & plastic surfaces with a clean soft cloth

and mild cleaner.

XX

Obvious Damage

Visually inspect components for damage that could cause

problems during operation or unsafe operation.

XX

Check all mechanical functions using the foot control. Repeat

using the hand control when present.

XX

Chair shrouds should move smoothly & quietly when base is

raised & lowered. (NOTE: There are plastic glides on the

shroud tabs. Missing glides may result in noisy operation.)

XX

Labels / Decals Replace any missing or illegible labels.

XX

Hardware All fasteners must be present and fastened securely.

XX

Inspect power cord and all wiring for damage.

XX

Be sure all electrical connections are tight.

XX

Date of Service: _____/____/____

Location:

Service

Technician:

Model:

Serial Number:

Scheduled Maintenance

Universal Procedures Chair

Weekly

Cleaning

Semi-Annually

Electrical System

Mechanical

Operation

Go To Table Of Contents

Next

Back

© Midmark Corporation 2005 SF-1838

Rev. (10/5/18)

vii

Page 8

General Information

Back

Go To Table Of Contents

viii

© Midmark Corporation 2005 SF-1838

Page 9

Operation & Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Click on the Go To Page button and

enter the desired page number. (Note:

Letters are case sensitve. ex. A-2)

Operation &

Troubleshooting

Function / System Page

Power To The Chair:

models w/Standard Base ..................

models w/Rotational Base .................

Base Up / Down ................................... A-8

Back Up / Down .................................... A-18

Tilt Up/Down ......................................... A-28

Foot Up/Down ...................................... A-38

Crash Avoidance System ..................... A-48

Position Programming .......................... A-52

"Home" Function ................................... A-56

Quick Chair Function ............................ A-62

Chair Receptacles ................................. A-66

Upholstery Heater System .................... A-68

Rotational Base Brake System ............. A-72

A-2

A-4

Section A

Models:

Serial Numbers:

© Midmark Corporation 2005 SF-1838

A-1

Page 10

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

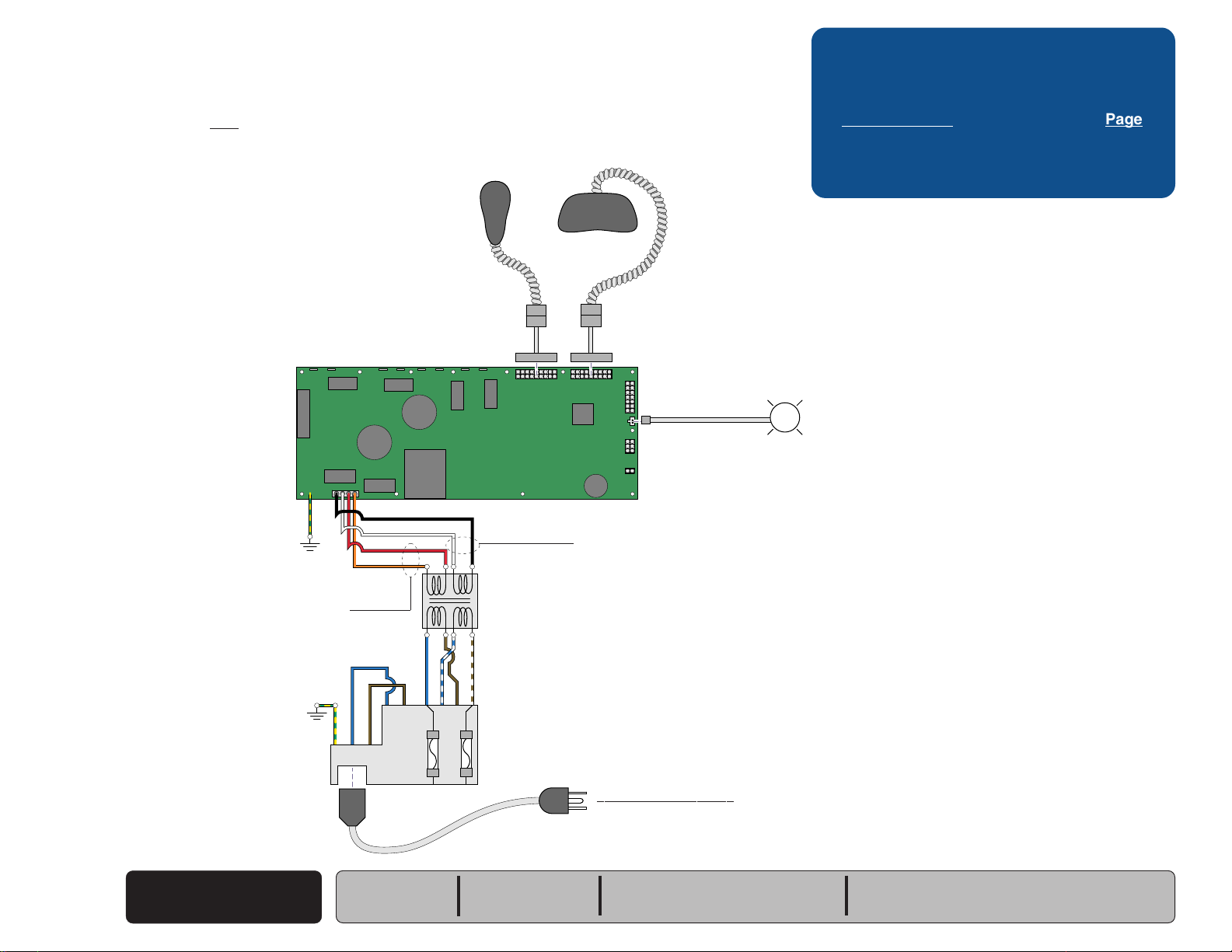

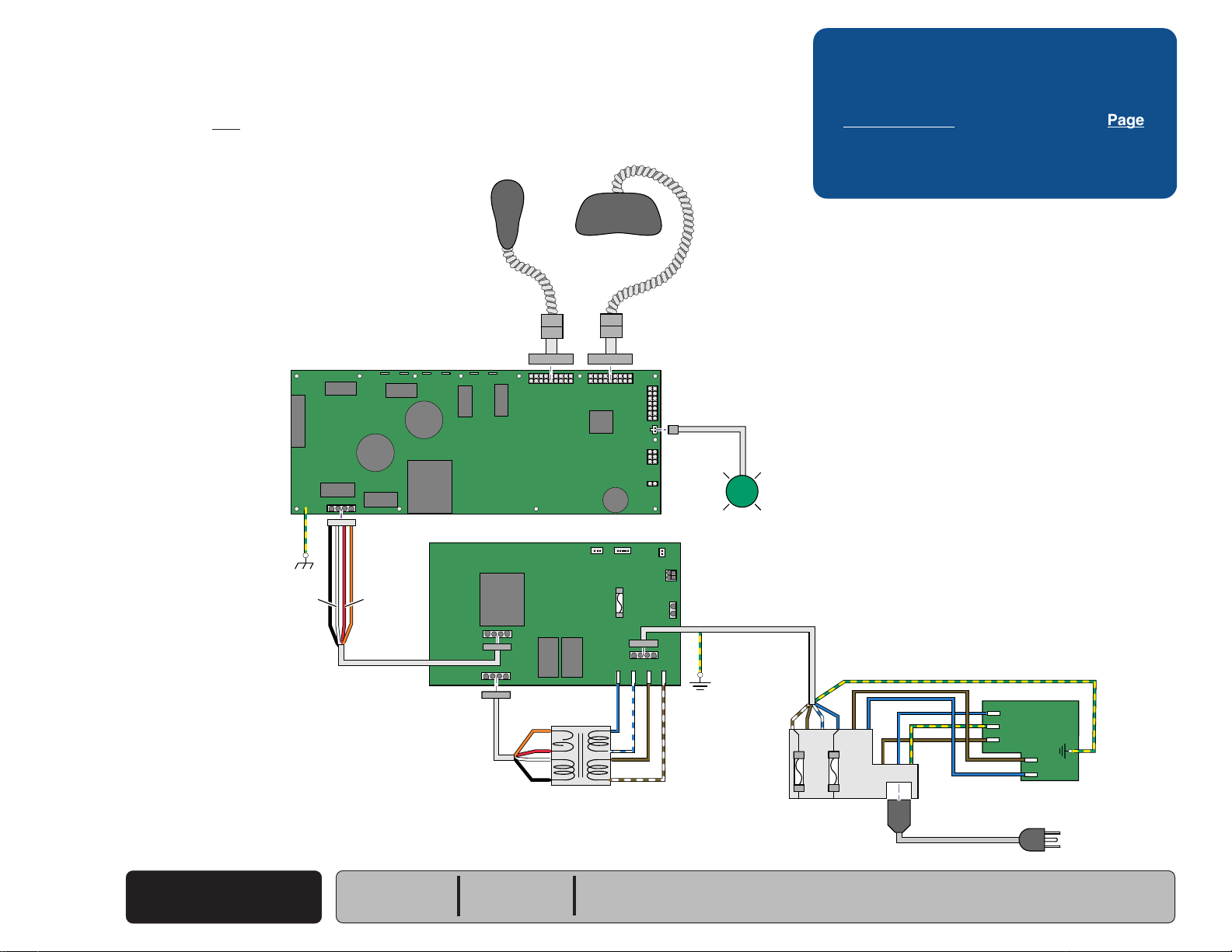

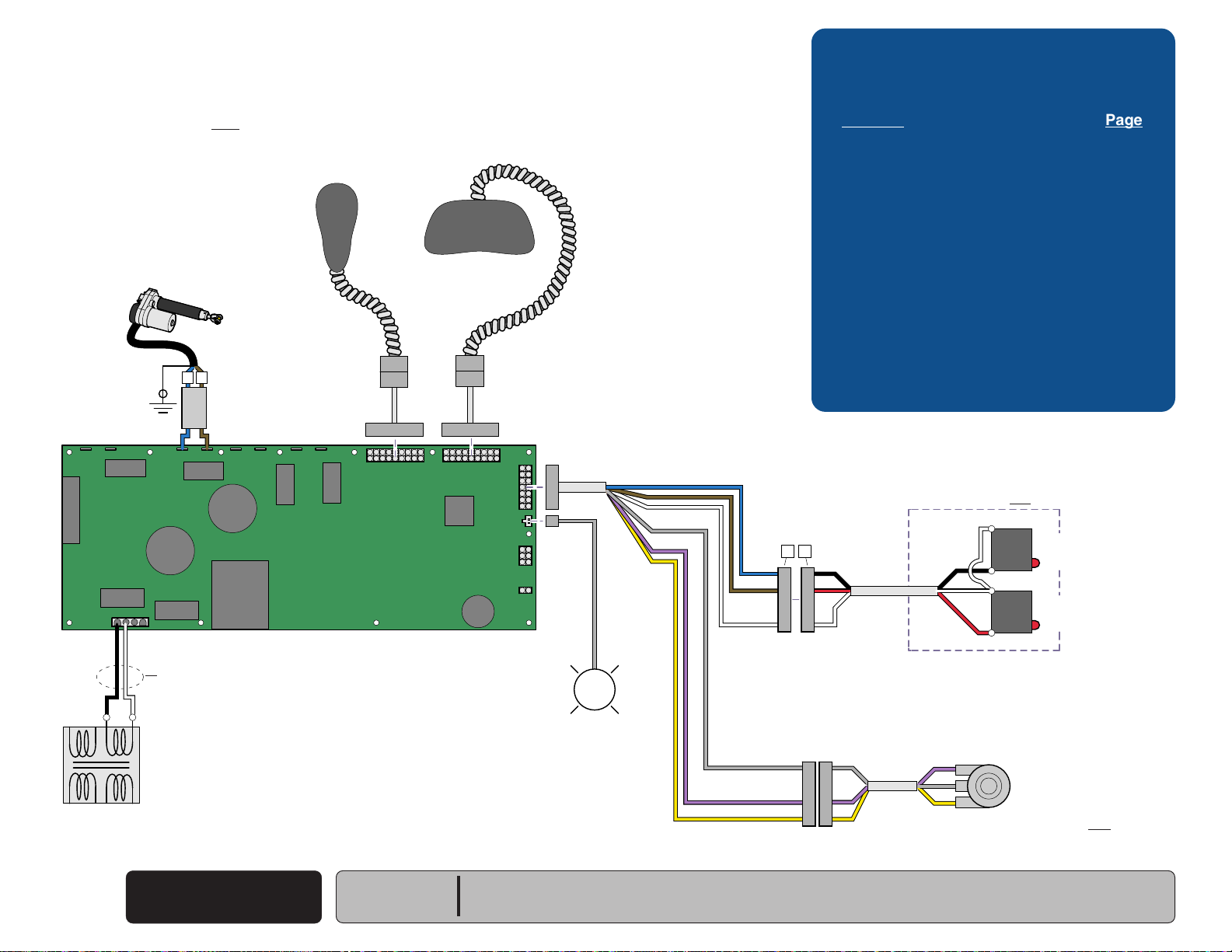

Power To The Chair

This illustration shows only the components that affect ALL CHAIR FUNCTIONS.

Refer to the following page for a detailed description of the power supply to the chair.

(models w/ Standard Base)

Hand

Control

P9 P10

Foot

Control

Troubleshooting

[No Power / No Functions Will Operate]

Power Light is: Page

OFF

..................................................... A-6

ON .......................................................

8-10 VAC8-10 VAC

A-7

J2

J1

J15

GN / YL

[Red & orange wires supply 34-37 VAC to power

circuitry for the Tilt & Foot actuators, hand/foot controls,

power light, all limit switches, and position sensors]

GN / YL

J4J3

BK

WH

RD

OR

J8J7J6J5

Main PC

Board

J10J9

MA646300i

J11

J12

J13

J14

P12

P11

L

Power

Light

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

If Power Light is OFF, there is no power to PC Board.

If Power Light is ON, proper voltage is present at PC Board.

Main System

Transformer

BL

BR

N

BL

BR

BR / WH

BL / WH

A

B

C

D

G

H

Power

F1

L

F2

Inlet

Facility Supply Voltage

Power To The Chair

A-2

© Midmark Corporation 2005 SF-1838

(Standard Base)

Rev. 10/5/18

Models:

Serial Numbers:

230

(-001/-002/-004)

all

630

(-001 thru -004) & (-007 thru -009)

all

75

(-019 thru -021)

all

Page 11

Operation & Troubleshooting

115V

MA646200i

230V

115V

Go To Table Of Contents

Next

Back

Power To The Chair

Facility Supply Voltage

With the chair's power cord properly connected, facility supply

voltage

inlet.

Power Inlet

(115 or 230 VAC)

(models w/ Standard Base)

is supplied thru the cord to the power

EQUIPMENT ALERT

The voltage setting displayed in the power inlet window

must match facility supply voltage

(115 or 230 VAC)

.

[Remove fuse holder and rotate 180° to change voltage setting].

Current flows thru two fuses in the power inlet, to the main system

transformer.

Main System Transformer

NOTE

This transformer is protected from overload by a thermal cutout

feature. This will automatically reset when the transformer cools.

Line voltage

transformer. The transformer reduces the voltage and current

flows to the main PC board thru two separate windings

(115 or 230 VAC)

is supplied to the main system

(four wires)

Power Indicator Light

When voltage is applied to the PC board, the

power light is illuminated.

Main PC Board

Circuitry on the PC board provides the required

voltage to power all of the chair's components:

hand/foot controls, actuators, limit switches, and

position sensors.

Hand / Foot Controls

Circuitry on the main PC board supplies 8-10

VAC to the hand / foot control connection ports.

.

[The black & white wires supply 48-54 VAC to power circuitry for

the Base & Back actuators only].

[The red & orange wires supply 34-37 VAC to power circuitry for

the Tilt & Foot actuators, hand/foot controls, power light, all limit

switches, and position sensors (on Midmark models only)].

Models:

Serial Numbers:

230

(-001/-002/-004)

all

630

(-001 thru -004) & (-007 thru -009)

all

75

(-019 thru -021)

all

Power To The Chair

(Standard Base)

© Midmark Corporation 2005 SF-1838

Rev. 10/5/18

A-3

Page 12

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

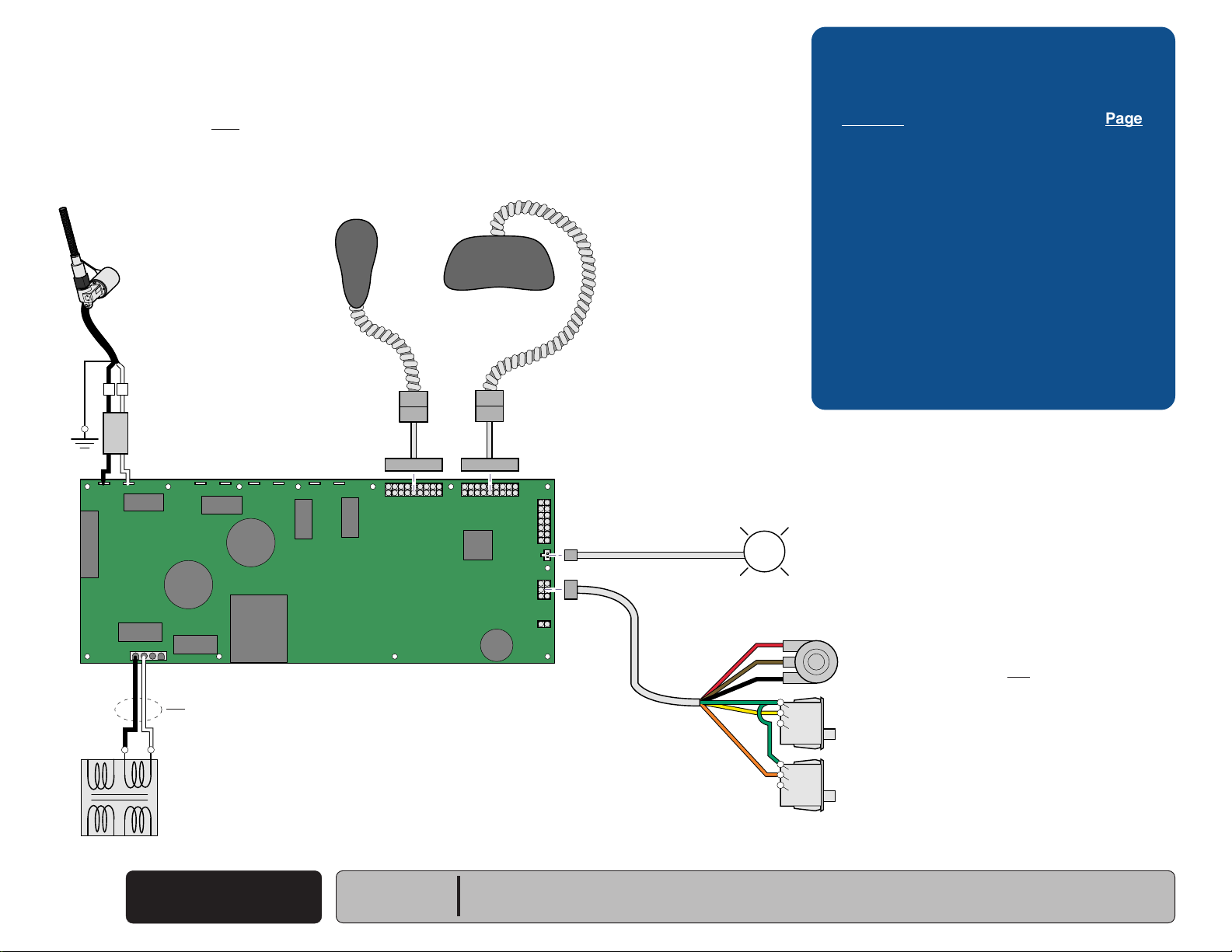

Power To The Chair

This illustration shows only the components that affect ALL CHAIR FUNCTIONS.

Refer to the following page for a detailed description of the power supply to the chair.

(models w/ Rotational Base)

Hand

Control

Foot

Control

Troubleshooting

[No Power / No Functions Will Operate]

Power Light is: Page

OFF

..................................................... A-6

ON .......................................................

A-7

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

[Red & orange wires supply 34-37 VAC

to power circuitry for the Tilt & Foot actuators,

hand/foot controls, power light, all limit switches,

and position sensors]

J1

J15

GN / YL

WH

BK

8-10 VAC

P9 P10

J2

J4J3

J8J7J6J5

J10J9

Main PC

Board

8-10 VAC

J11

J12

J13

J14

P12

If Power Light is OFF, there is no power to PC Board.

If Power Light is ON, proper voltage is present at PC Board.

Power

Light

OR

RD

Rotational

Base

PC Board

J10

J9

OR

RD

WH

BK

Main System

Transformer

J3

J7

BL

BR

BR/WH

J6

J5

BL/WH

J12

J2

GN / YL

J4

C

A

B

Power Inlet

GN / YL

BR

D

G

GN / YL

H

BR

L

N

BL

BL

J4

EMI Filter

J6

PC Board

J5

J1

J2

J3

Facility Supply Voltage

MA709900i

Power To The Chair

A-4

© Midmark Corporation 2005 SF-1838

(Rotational Base)

Rev. 10/5/18

Models:

Serial Numbers:

230

(-003)

all

630

(-005 & -006)

all

Page 13

Operation & Troubleshooting

115V

Go To Table Of Contents

Next

Back

Power To The Chair

Facility Supply Voltage

With the chair's power cord properly connected, facility supply

voltage

inlet.

Power Inlet / EMI Filter Board

(115 or 230 VAC)

(models w/ Rotational Base)

is supplied thru the cord to the power

EQUIPMENT ALERT

The voltage setting displayed in the power inlet window

must match facility supply voltage

(115 or 230 VAC)

.

[Remove fuse holder and rotate 180° to change voltage setting].

Current flows from the power inlet thru the EMI filter board,

then back thru the power inlet fuses to the rotational base

PC board.

115V

230V

MA646200i

Rotational Base PC Board

Current flows thru the rotational base PC board to the main system

transformer. The transformer reduces the voltage and current flows

back to the rotational base PC board.

Circuitry on the rotational base PC board provides the required

voltage to power the rotational base brake system.

The reduced voltage is supplied to the main PC board thru the

rotational base PC board.

Main System Transformer

NOTE

This transformer is protected from overload by a

thermal cutout feature. This will automatically reset

when the transformer cools.

Line voltage

main system transformer thru the rotational base

PC board. The transformer reduces the voltage

and current flows back to the rotational base

PC board, then to the main PC board thru two

separate windings

[The black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators only].

[The red & orange wires supply 34-37 VAC to

power circuitry for the Tilt & Foot actuators, hand/

foot controls, power light, all limit switches, and

position sensors (on Midmark models only)].

Power Indicator Light

When voltage is applied to the PC board, the power

light is illuminated.

Main PC Board

Circuitry on the PC board provides the required

voltage to power all of the chair's components:

hand/foot controls, actuators, limit switches, and

position sensors.

Hand / Foot Controls

Circuitry on the main PC board supplies 8-10 VAC

to the hand / foot control connection ports.

(115 or 230 VAC)

(four wires)

is supplied to the

.

Models:

Serial Numbers:

230

(-003)

all

630

(-005 & -006)

all

Power To The Chair

(Rotational Base)

© Midmark Corporation 2005 SF-1838

Rev. 10/5/18

A-5

Page 14

Operation & Troubleshooting

115V

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Primary Fuses ...................................... B-2

Main System Transformer .................... B-30

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Voltage setting

Must match facility supply voltage (115 / 230 V).

2nd

Power to the Chair

Problem: No functions will operate - and

Power Light: OFF

- continued

Power light is OFF.

1st

3rd

4th

Primary Fuses

Refer to: Section B - Primary Fuses

Faclity Supply Voltage

Check power cord connections.

Check facility circuit breaker.

Main System Transformer

Check all wire connections between power inlet

& main PC board. If connections are OK, test transformer.

Refer to: Section B - Main System Transformer

Models w/Rotational Base only:

If there is no power to the main system transformer...

Rotational Base PC Board / EMI Filter Board

Check all wire connections between rotational base PC board &

the transformer. If connections are OK, perform EMI Filter Board Test.

Refer to: Section B - Rotational Base Brake System

Main PC Board

If the transformer is OK, replace the main PC board.

Refer to: Section B - Main PC Board

MA645500i

5th

A-6

© Midmark Corporation 2005 SF-1838

Power To The Chair

Rev. 10/5/18

Models:

Serial Numbers:

ALL

Page 15

Power to the Chair

Go To Table Of Contents

Next

Back

Go To Page:

Problem: No functions will operate - and

Power light is ON.

Loose / Damaged Wire Connections

(between connection ports & PC board)

- continued

Power Light: ON

3rd

Operation & Troubleshooting

Refer To: Page

Hand & Foot Controls ............................ B-6

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

1st

Hand / Foot Controls

Check cords for damage / proper connection.

Check both connection ports on chair.

Refer to: Section B - Hand & Foot Controls

Check for error code(s)

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

ALL

6th

MA645401i

Position "4" Button

Programmable Models only:

Press "4" button on hand control for

five seconds, then try functions again...

If chair functions operate, go to Section B,

Main PC Board (Control Lockout Feature)

If chair functions still will not move, go to next check.

Power To The Chair

© Midmark Corporation 2005 SF-1838

2nd

Rev. 10/5/18

A-7

Page 16

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Base UP / DOWN Function

This illustration shows only the components that affect the Base UP / DOWN function.

Refer to the following page for a detailed description of Base UP / DOWN operation.

Hand

Base

BK

BK

Actuator

WH

WH

Control

Foot

Control

Troubleshooting

[Base Up / Down Function]

Problem Page

No Base UP or DOWN

No Base UP (DOWN - OK)

No Base DOWN (UP - OK)

All other chair functions - OK

No Base Down / Back Down / Tilt Up .............

Base Drifts Down .................................

Noisy Operation ...................................

Moves Slowly / Will Not Lift Patient ......

Up and/or Down Function

Moves Briefly, Then Stops ...............

Headrest Collides w/Floor....................

........................ A-10

.................. A-11

.......................... A-12

A-48

A-13

A-14

A-15

A-16

A-48

Choke

WH

BK

J2

J1

J15

BK

WH

A-8

© Midmark Corporation 2005 SF-1838

P9 P10

J4J3

J8J7J6J5

Main PC

Board

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

Main System

Transformer

Base Up / Down

Note: On models w/ rotational base, the Main System

Transformer connections are supplied thru the

Rotational Base PC Board (not shown).

Models:

Serial Numbers:

Rev. 10/5/18

J10J9

J11

J12

J13

J14

MA646400i

ALL

P12

P13

Only the wires that affect the Base Function are shown.

If Power Light is ON, proper voltage is present at PC Board.

L

If Power Light is OFF, refer to Page A-2 for troubleshooting.

Power

Light

RD

OR

YL

BN

BK

GN

GN

1

2

3

COM

NC

NO

COM

NC

NO

Base

Sensor

(Midmark models only)

Base Up

Limit Switch

Base Down

Limit Switch

Page 17

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Base UP / DOWN Function

Is There Power To The Chair?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Chair' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Base Up Operation

When the Base Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the base

actuator motor.

The actuator motor runs and raises the chair.

NOTE

The PC board continuously monitors the Base

Up limit switch and the Base position sensor*.

If the Base Up limit switch is tripped (open),

the Base Up function will not operate.

If the Base position sensor* detects that the

chair has reached its upper limit, the Base Up

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Base Up limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Position Sensor* malfunction.

5. Overcurrent protection tripped.

6. Software time-out limit is reached

(approx. 25 seconds)

.

Base Down Operation

When the Base Down function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 40 VDC to the base

actuator motor.

The actuator motor runs and lowers the chair.

NOTE

The PC board continuously monitors the Base

Down limit switch and the Base position sensor.

If the Base Down limit switch is tripped (open),

the Base Down function will not operate.

If the Base position sensor* detects that the chair

is in a potential "crash position", or that the base

has reached its lower limit, the Base Down

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Base Down limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Crash Avoidance System* activated.

5. Position Sensor* malfunction.

6. Overcurrent protection tripped.

7. Software time-out limit is reached

(approx. 25 seconds)

.

Models:

Serial Numbers:

ALL

* Midmark models only.

[This feature is not available on Ritter models]

Base Up / Down

Base Up / Down

© Midmark Corporation 2005 SF-1838

Rev. 10/5/18

A-9

Page 18

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-4

Hand & Foot Controls ........................... B-6

Base Actuator ....................................... B-11

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers .......... E-1

Base Up / Down Function

Problem: No Base Up or Base Down

- continued

Loose / Damaged Wire Connections

(Base Actuator, Base Up/Down Limit Switches, hand/foot control ports,

black & white wires between main system transformer & PC board)

Main PC Board

Refer to: Section B - Main PC Board

4th

1st

MA646801i

Base Actuator

Refer to: Section B - Base Actuator

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

3rd

2nd

A-10

© Midmark Corporation 2005 SF-1838

Base Up / Down

Rev. 4/24/13

Models:

Serial Numbers:

ALL

Page 19

Base Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: No Base Up.

Base Down - OK.

Loose / Damaged Wire Connections

(Hand/Foot Control & Base Up Limit Switch)

- continued

Base Up Limit Switch

Refer to: Section B - Limit Switches

1st

2nd

Operation & Troubleshooting

Refer To: Page

Limit Switches ...................................... B-3

Hand & Foot Controls ............................ B-6

Base Actuator ....................................... B-11

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Actuator

Refer to: Section B - Base Actuator

4th

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

ALL

5th

MA646901i

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Base Up / Down

© Midmark Corporation 2005 SF-1838

A-11

Page 20

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-3

Hand & Foot Controls............................ B-6

Base Actuator ....................................... B-11

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Down Limit Switch

Refer to: Section B - Limit Switches

2nd

Base Up / Down Function

Problem: No Base Down.

Base Up - OK.

[All other chair functions - OK]

- continued

Loose Wire Connections

(Hand/Foot Control & Base Down Limit Switch)

Main PC Board

Refer to: Section B - Main PC Board

5th

1st

MA647001i

Base Actuator

Refer to: Section B - Base Actuator

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

4th

3rd

A-12

© Midmark Corporation 2005 SF-1838

Base Up / Down

Rev. 10/5/18

Models:

Serial Numbers:

ALL

Page 21

Base Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Base drifts down.

- continued

Operation & Troubleshooting

Refer To: Page

Base Actuator ....................................... B-11

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Actuator

Refer to: Section B - Base Actuator

1st

MA647101i

Models:

Serial Numbers:

ALL

Base Up / Down

© Midmark Corporation 2005 SF-1838

A-13

Page 22

Operation & Troubleshooting

MA647201i

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Base Actuator ....................................... B-11

Gas Springs.......................................... B-28

Base Shroud Removal.......................... C-5

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Clean / lubricate base actuator threads.

Recommended lubricant: Lithium grease

Base Up / Down Function

Problem: Noisy operation. (Grinding, squeaking, etc)

2nd

- continued

Wipe guide bars with a clean, dry cloth.

NEVER lubricate base slides / scissor mechanism.

Refer to: Section C - Base Shoud Removal

3rd

Guide Bars

Base Actuator

Refer to: Section B - Base Actuator

Pivot Joints

4th

Clean / lubricate gas spring pivot joints

Recommended lubricant: Lithium grease

1st

A-14

© Midmark Corporation 2005 SF-1838

Base Up / Down

Models:

Serial Numbers:

Refer to: Section B - Gas Springs

ALL

Page 23

Base Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Moves slowly - and/or

Will not lift patient.

- continued

Operation & Troubleshooting

Refer To: Page

General Information

Base Actuator ....................................... B-11

Gas Springs.......................................... B-28

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

(Specifications).....

ii

Base Actuator

Refer to: Section B - Base Actuator

2nd

Low voltage to chair

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............230 +10% VAC

4th

450

lbs.

MA647301i

3rd

Gas Springs

Refer to: Section B - Gas Springs

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General InformationSection

1st

Models:

Serial Numbers:

ALL

Base Up / Down

© Midmark Corporation 2005 SF-1838

Rev. 10/5/18

A-15

Page 24

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Base Actuator ....................................... B-11

Position Sensors .................................. B-32

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Up / Down Function

Problem: Base Up and/or Base Down

moves briefly, then stops ("beeps").

- continued

Models 630 (all) & 75 (-020 /-021) only:

Calibrate PC Board

Refer to: Section B - Main PC Board

Loose / Damaged Wire Connections

(Base Position Sensor, Hand/Foot Controls)

1st

Base Actuator

Refer to: Section B - Base Actuator

2nd

Models 630 (all) & 75 (-020 /-021) only:

Base Position Sensor

Refer to: Section B - Position Sensors

4th

MA647401i

3rd

A-16

© Midmark Corporation 2005 SF-1838

Base Up / Down

Models:

Serial Numbers:

ALL

Page 25

This page intentionally blank.

Go To Table Of Contents

Next

Back

Operation & Troubleshooting

Models:

Serial Numbers:

Base Up / Down

© Midmark Corporation 2005 SF-1838

A-17

Page 26

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Back UP / DOWN Function

This illustration shows only the components that affect the Back UP / DOWN function.

Refer to the following page for a detailed description of Back UP / DOWN operation.

Hand

Control

Back

Actuator

Foot

Control

Troubleshooting

[Back Up / Down Function]

Problem Page

No Back UP or DOWN

No Back UP (DOWN - OK)

No Back DOWN (UP - OK)

All other chair functions - OK

No Back Down / Base Down / Tilt Up .............

Back Drifts Down .................................

Noisy Operation ...................................

Moves Slowly ......................................

Up / Down Function

Moves Briefly, then Stops ..................

Headrest Collides w/Floor....................

........................ A-20

.................. A-21

.......................... A-22

A-48

A-23

A-24

A-25

A-26

A-48

Choke

J1

BL

J2

BR

J4J3

J8J7J6J5

Main PC

Board

J15

BK

WH

[Black & white wires supply 48-54 VAC

to power the Base & Back actuators]

Main System

Transformer

Note: On models w/ rotational base, the Main System

Transformer connections are supplied thru the

Rotational Base PC Board (not shown).

If Power Light is ON, proper voltage is present at PC Board.

If Power Light is OFF, refer to Page A-2 for troubleshooting.

P9 P10

J10J9

J11

J12

J13

J14

MA646500i

P12

P11

Power

Light

L

Only the wires that affect the Back Function are shown.

These limit switches are not serviceable.

Part of Back Actuator

COM

WH

BK

RD

VI

GY

YL

NC

WH

COM

NC

1

2

3

(Midmark models only)

YL

BL

3 3

BK

4

4

3

BR

WH

GY

VI

3

RD

2

2

1

1

WH

GY

4

4

3

3

VI

2

2

YL

1

1

Back Up

Limit Switch

Back Down

Limit Switch

Back

Position

Sensor

A-18

© Midmark Corporation 2005 SF-1838

Back Up / Down

Rev. 10/5/18

Models:

Serial Numbers:

ALL

Page 27

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Back UP / DOWN Function

Is There Power To The Chair?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Chair' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Back Up Operation

When the Back Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the back

actuator motor.

The actuator motor runs and raises the back

section.

NOTE

The PC board continuously monitors the Back

Up limit switch

and the Back position sensor*.

If the Back Up limit switch is tripped (open),

the Back Up function will not operate.

If the Back position sensor detects that the back

section has reached its upper limit, the Back Up

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Back Up limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Position Sensor* malfunction.

5. Overcurrent protection tripped.

6. Software time-out limit is reached

(approx. 30 seconds)

(mounted inside the actuator)

.

Back Down Operation

Troubleshooting

When the Back Down function is activated,

[Crash Protection System]

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

Problem Page

supplies approximately 44 VDC to the back

Headrest Mechanism

actuator motor.

Collides w/Floor .................................

The actuator motor runs and lowers the back

section.

Chair NOT in "Crash Position:

Base Down, Back Down, & Tilt Up

NOTE

Functions Will Not Move ...................

The PC board continuously monitors the Back

Down limit switch

and the Back position sensor*.

If the Back Down limit switch is tripped (open),

the Back Down function will not operate.

If the Back position sensor detects that the chair

is in a potential "crash position", or that the back

section has reached its lower limit, the Back Down

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Back Down limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Crash Avoidance System* activated.

5. Position Sensor* malfunction.

6. Overcurrent protection tripped.

7. Software time-out limit is reached

(approx. 30 seconds)

(mounted inside the actuator)

.

A-x

A-x

Models:

Serial Numbers:

ALL

* Midmark models only.

[This feature is not available on Ritter models]

Back Up / Down

© Midmark Corporation 2005 SF-1838

Rev. 10/5/18

A-19

Page 28

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Hand & Foot Controls ............................ B-6

Back Actuator ....................................... B-17

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Back Up / Down Function

Problem: No Back Up or Back Down.

1st

Loose / Damaged Wire Connections

(Back Actuator, Back Up/Down Limit Switches, hand/foot control ports,

black & white wires between main system transformer & PC board)

- continued

A-20

© Midmark Corporation 2005 SF-1838

Back Up / Down

Back Actuator

Refer to: Section B - Back Actuator

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

ALL

4th

MA647701i

3rd

2nd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Page 29

Back Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: No Back Up.

Back Down - OK.

- continued

Operation & Troubleshooting

Refer To: Page

Hand & Foot Controls ............................ B-6

Back Actuator ....................................... B-17

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Loose / Damaged Wire Connections

(Hand/Foot Control & Back Up Limit Switch)

Back Actuator

Refer to: Section B - Back Actuator

1st

Main PC Board

Refer to: Section B - Main PC Board

4th

3rd

MA647701i

2nd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Models:

Serial Numbers:

ALL

Back Up / Down

© Midmark Corporation 2005 SF-1838

A-21

Page 30

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-4

Hand & Foot Controls ........................... B-6

Back Actuator ....................................... B-17

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers .......... E-1

Back Up / Down Function

Problem: No Back Down.

Back Up - OK.

[All other chair functions - OK]

Loose / Damaged Wire Connections

(Hand/Foot Control & Back Down Limit Switch)

1st

- continued

A-22

© Midmark Corporation 2005 SF-1838

Back Up / Down

Back Actuator

Refer to: Section B - Back Actuator

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

Rev. 10/5/18

ALL

4th

MA647701i

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

2nd

Page 31

Back Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Back drifts down.

- continued

Operation & Troubleshooting

Refer To: Page

Back Actuator ....................................... B-17

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Back Actuator

Refer to: Section B - Back Actuator

1st

Models:

Serial Numbers:

ALL

MA647801i

Back Up / Down

© Midmark Corporation 2005 SF-1838

A-23

Page 32

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Back Actuator ....................................... B-17

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Back Up / Down Function

Problem: Noisy operation.

(Grinding, squeaking, etc)

- continued

Back Actuator

Refer to: Section B - Back Actuator

1st

MA647801i

A-24

© Midmark Corporation 2005 SF-1838

Back Up / Down

Models:

Serial Numbers:

ALL

Page 33

Back Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Moves slowly - and/or

Will not lift patient.

- continued

Operation & Troubleshooting

Refer To: Page

General Information

Back Actuator ....................................... B-17

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General Information Section

(Specifications).....

1st

ii

Back Actuator

Refer to: Section B - Back Actuator

Low voltage to chair

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............ 230 +10% VAC

Models:

Serial Numbers:

ALL

3rd

2nd

MA647901i

450

lbs.

Back Up / Down

© Midmark Corporation 2005 SF-1838

A-25

Rev. 10/5/18

Page 34

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Back Actuator ...................................... B-17

Position Sensors .................................. B-32

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Back Actuator

Refer to: Section B - Back Actuator

4th

Back Up / Down Function

Problem: Back Up and/or Back Down

moves briefly, then stops ("beeps").

Models 630 (all) & 75 (-020 /-021) only:

Back Position Sensor

Refer to: Section B - Position Sensors

- continued

3rd

Models 630 (all) & 75 (-020 /-021) only:

Calibrate PC Board

Refer to: Section B - Main PC Board

A-26

© Midmark Corporation 2005 SF-1838

Back Up / Down

1st

Models:

Serial Numbers:

MA648001i

Loose / Damaged Wire Connections

(Back Position Sensor, Hand/Foot Controls)

ALL

2nd

Page 35

This page intentionally blank.

Go To Table Of Contents

Next

Back

Operation & Troubleshooting

Models:

Serial Numbers:

Back Up / Down

© Midmark Corporation 2005 SF-1838

A-27

Page 36

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Tilt UP / DOWN Function

This illustration shows only the components that affect the Tilt UP / DOWN function.

Refer to the following page for a detailed description of Tilt UP / DOWN operation.

Hand

Control

Foot

Control

J10J9

J11

J12

J13

J14

MA648100i

P11

P12

Power

J1

J15

J2

Tilt

Actuator

BL

P9 P10

BR

J4J3

J8J7J6J5

Main PC

Board

If Power Light is ON, proper voltage is present at PC Board.

If Power Light is OFF, refer to Page A-2 for troubleshooting.

Only the wires that affect the

Tilt Function are shown.

L

Light

BK

RD

WH

YL / WH

VI

YL

Troubleshooting

[Tilt Up / Down Function]

Problem Page

No Tilt UP or DOWN

No Tilt DOWN (UP - OK)

No Tilt UP (DOWN - OK)

All other chair functions - OK

No Tilt Up / Base Down / Back Down .............

Seat Drifts Down .................................

Noisy Operation ...................................

Moves Slowly ......................................

Up / Down Function

Moves Briefly, Then Stops ...............

Headrest Collides w/Floor .................... A-48

These limit switches are not serviceable.

Part of Tilt Actuator

5 5

BK

4

4

3

3

RD

2

2

1

1

WH

4

4

WH

3

[Connected to Foot Limit Switch Harness]

2

1

3

4

WH

[Connected to Back Limit Switch Harness]

3

2

1

4

4

BR

3

3

2

2

1

1

1 1

VI

YL

BK

RD

............................ A-30

..................... A-31

.......................... A-32

COM

Tilt Up

Limit Switch

NC

COM

Tilt Down

Limit Switch

NC

Tilt

Position

Sensor

(Midmark models only)

VI

BR

YL

WH

WH

3

2

1

A-48

A-33

A-34

A-35

A-36

A-28

© Midmark Corporation 2005 SF-1838

Tilt Up / Down

Rev.10/5/18

Models:

Serial Numbers:

ALL

Page 37

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Tilt UP / DOWN Function

Is There Power To The Chair?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Chair' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Tilt Up Operation

When the Tilt Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the tilt

actuator motor.

The actuator motor runs and reclines the seat

section.

NOTE

The PC board continuously monitors the Tilt

Up limit switch

and the Tilt position sensor*.

If the Tilt Up limit switch is tripped (open),

the Tilt Up function will not operate.

If the Tilt position sensor detects that the chair

is in a potential "crash position", or that the seat

section has reached its upper limit, the Tilt Up

function will not operate.

(mounted inside the actuator)

Tilt Down Operation

When the Tilt Down function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the tilt

actuator motor.

The actuator motor runs and brings the seat

section back to a flat position.

NOTE

The PC board continuously monitors the Tilt

Down limit switch

and the Tilt position sensor*.

If the Tilt Down limit switch is tripped (open),

the Tilt Down function will not operate.

If the Tilt position sensor detects that the

seat section has reached its lower limit, the

Tilt Down function will not operate.

(mounted inside the actuator)

Models:

Serial Numbers:

ALL

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Tilt Up limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Crash Avoidance System* activated.

5. Position Sensor* malfunction.

6. Overcurrent protection tripped.

7. Software time-out limit is reached.

(approx. 30 seconds)

* Midmark models only.

[This feature is not available on Ritter models]

.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Tilt Down limit switch is tripped.

3. Emergency Stop button* is pressed.

4. Position Sensor* malfunction.

5. Overcurrent protection tripped.

6. Software time-out limit is reached

(approx. 30 seconds)

Tilt Up / Down

© Midmark Corporation 2005 SF-1838

.

Rev.10/5/18

A-29

Page 38

Operation & Troubleshooting

MA648201i

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-4

Hand & Foot Controls ........................... B-6

Tilt Actuator .......................................... B-21

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Tilt Up / Down Function

Problem: No Tilt Up or Tilt Down.

- continued

Loose / Damaged Wire Connections

(Tilt Actuator, Tilt Up/Down Limit Switches,

& hand/foot control ports)

Main PC Board

Refer to: Section B - Main PC Board

1st

4th

Tilt Actuator

Refer to: Section B - Tilt Actuator

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

2nd

A-30

© Midmark Corporation 2005 SF-1838

Tilt Up / Down

Rev. 4/24/13

Models:

Serial Numbers:

ALL

Page 39

MA648201i

Tilt Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: No Tilt Down.

Tilt Up - OK.

- continued

Operation & Troubleshooting

Refer To: Page

Hand & Foot Controls ............................ B-6

Tilt Actuator .......................................... B-21

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Loose / Damaged Wire Connections

(Tilt Down Limit Switch, & hand/foot control ports)

Main PC Board

Refer to: Section B - Main PC Board

1st

Tilt Actuator

Refer to: Section B - Tilt Actuator

4th

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

2nd

Models:

Serial Numbers:

ALL

Tilt Up / Down

© Midmark Corporation 2005 SF-1838

A-31

Page 40

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Hand & Foot Controls............................ B-6

Tilt Actuator .......................................... B-21

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Tilt Up / Down Function

Problem: No Tilt Up.

Tilt Down - OK.

[All other chair functions - OK]

- continued

Loose / Damaged Wire Connections

(Tilt Up Limit Switch, & hand/foot control ports)

1st

Main PC Board

Refer to: Section B - Main PC Board

4th

Tilt Actuator

Refer to: Section B - Tilt Actuator

MA648201i

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

2nd

A-32

© Midmark Corporation 2005 SF-1838

Tilt Up / Down

Rev.10/5/18

Models:

Serial Numbers:

ALL

Page 41

Tilt Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Seat drifts down.

- continued

Operation & Troubleshooting

Refer To: Page

Tilt Actuator .......................................... B-21

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Tilt Actuator

Refer to: Section B - Tilt Actuator

MA647601i

1st

Models:

Serial Numbers:

ALL

Tilt Up / Down

© Midmark Corporation 2005 SF-1838

A-33

Page 42

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Tilt Actuator .......................................... B-21

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Tilt Up / Down Function

Problem: Noisy operation.

(Grinding, squeaking, etc)

- continued

Tilt Actuator

Refer to: Section B - Tilt Actuator

MA647601i

1st

A-34

© Midmark Corporation 2005 SF-1838

Tilt Up / Down

Models:

Serial Numbers:

ALL

Page 43

Tilt Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Moves slowly - and/or

Will not lift patient.

Tilt Actuator

Refer to: Section B - Tilt Actuator

- continued

3rd

Operation & Troubleshooting

Refer To: Page

General Information

Tilt Actuator .......................................... B-21

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

(Specifications).....

1st

ii

Models:

Serial Numbers:

2nd

Low voltage to chair

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............230 +10% VAC

ALL

MA648301i

450

lbs.

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General Information Section

Tilt Up / Down

© Midmark Corporation 2005 SF-1838

Rev.10/5/18

1st

A-35

Page 44

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Tilt Actuator .......................................... B-21

Position Sensors .................................. B-32

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

3rd

Models 630 (all) & 75 (-020 /-021) only:

Tilt Position Sensor

Refer to: Section B - Position Sensors

Tilt Up / Down Function

Problem: Tilt Up and/or Tilt Down

moves briefly, then stops ("beeps").

Tilt Actuator

Refer to: Section B - Tilt Actuator

4th

- continued

Models 630 (all) & 75 (-020 /-021) only:

Calibrate PC Board

Refer to: Section B - Main PC Board

A-36

© Midmark Corporation 2005 SF-1838

Tilt Up / Down

1st

Models:

Serial Numbers:

MA648401i

Loose / Damaged Wire Connections

(Tilt Position Sensor, Hand/Foot Controls)

ALL

2nd

Page 45

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

This page intentionally blank.

Models:

Serial Numbers:

Tilt Up / Down

© Midmark Corporation 2005 SF-1838

A-37

Page 46

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Foot UP / DOWN Function

This illustration shows only the components that affect the Foot UP / DOWN function.

Refer to the following page for a detailed description of Foot UP / DOWN operation.

Hand

Control

Foot

Actuator

Foot

Control

Only the wires that affect the

Foot Function are shown.

Troubleshooting

[Foot Up / Down Function]

Problem Page

No Foot UP or DOWN

No Foot UP (DOWN - OK)

No Foot DOWN (UP - OK)...................

Foot Drifts Down ..................................

Noisy Operation ...................................

Moves Slowly ......................................

Up / Down Function

Moves Briefly, Then Stops ...............

......................... A-40

................... A-41

A-42

A-43

A-44

A-45

A-46

J1

J15

J2

BL

BR

J4J3

If Power Light is ON, proper voltage is present at PC Board.

If Power Light is OFF, refer to Page A-2 for troubleshooting.

J8J7J6J5

P9 P10

Main PC

Board

J10J9

J11

J12

J13

J14

MA648700i

P12

P11

Power

Light

GN

OR

GN / WH

VI

VI

YL

WH

RD

WH

NC

NO

COM

COM

NC

NO

COM

NC

NO

Foot

Position

Sensor

BK / WH

WH

5

4

3

[Connected to Tilt Limit Switch Harness]

2

1

WH

4 4

YL

VI

GN

BK

3

2

1

4

4

RD

3

3

BK

2

2

1

1

WH

4

3

WH

YL

[Connected to Back Limit Switch Harness]

WH

2

1

Programmable models only

4

4

GN

3

3

VI

2

2

1

1

2 2

4

3

2

1

1

YL

[Connected to Tilt / Back Position Sensor Harness]

Pan

Limit Switch

Foot Up

Limit Switch

Foot Down

Limit Switch

A-38

© Midmark Corporation 2005 SF-1838

Foot Up / Down

Rev. 7/20/18

Models:

Serial Numbers:

ALL

Page 47

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Foot UP / DOWN Function

Is There Power To The Chair?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Chair' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Foot Up Operation

When the Foot Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the foot

actuator motor.

The actuator motor runs and raises the foot

section.

NOTE

The PC board continuously monitors the Foot

Up Limit Switch, the Pan Limit Switch, and

the Foot position sensor*.

If the Foot Up Limit Switch is tripped (open),

the Foot Up function will not operate.

When the treatment pan (located under the

seat section) is pulled out, the Pan Limit

Switch opens. If the Pan Limit Switch is open,

the Foot Up function will not operate.

If the Foot position sensor* detects that the

foot section has reached its upper limit, the

Foot Up function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Foot Up limit switch is tripped.

3. Pan Limit Switch opens.

(Treatment pan is pulled out)

3. Emergency Stop button** is pressed.

4. Position Sensor malfunction*.

5. Overcurrent protection tripped.

6. Software time-out limit is reached.

(approx. 20 seconds)

.

Foot Down Operation

When the Foot Down function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the foot

actuator motor.

The actuator motor runs and lowers the foot

section.

NOTE

The PC board continuously monitors the Foot

Down limit switch and the Foot position sensor*.

If the Foot Down limit switch is tripped (open),

the Foot Down function will not operate.

If the Foot position sensor detects that the foot

section has reached its lower limit, the Foot Down

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Foot Down limit switch is tripped.

3. Emergency Stop button** is pressed.

5. Position Sensor malfunction*.

6. Overcurrent protection tripped.

7. Software time-out limit is reached

(approx. 20 seconds)

* Programmable models only.

** Midmark models only.

[This feature is not available on Ritter models]

.

Models:

Serial Numbers:

ALL

Foot Up / Down

© Midmark Corporation 2005 SF-1838

Rev.10/5/18

A-39

Page 48

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-4

Hand & Foot Controls ........................... B-6

Foot Actuator ........................................ B-25

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Foot Up / Down Function

Problem: No Foot Up or Foot Down.

- continued

Loose / Damaged Wire Connections

(Hand/Foot Control, Foot Actuator,

& Foot Up/Down Limit Switches)

Main PC Board

Refer to: Section B - Main PC Board

1st

4th

MA648801i

Foot Actuator

Refer to: Section B - Foot Actuator

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

3rd

2nd

A-40

© Midmark Corporation 2005 SF-1838

Foot Up / Down

Rev. 4/24/13

Models:

Serial Numbers:

ALL

Page 49

Foot Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: No Foot Up.

Foot Down - OK.

Pan Limit Switch

Push Treatment Pan all the way in, then try again.

Still no movement? Check Pan Limit Switch

Loose / Damaged Wire Connections

(Hand/Foot Control, Foot Up & Pan Limit Switches)

- continued

2nd

1st

Pan Limit Switch

(later models)

Operation & Troubleshooting

Refer To: Page

Limit Switches ...................................... B-3

Hand & Foot Controls ............................ B-6

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Pan Limit Switch

(older models)

Foot UP Limit Switch

(Ritter models)

Foot Up Limit Switch

Refer to: Section B - Limit Switches

3rd

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

5th

ALL

Foot UP Limit Switch

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Foot Up / Down

© Midmark Corporation 2005 SF-1838

4th

MA648903i

(Midmark models)

A-41

Rev. 1/05

Page 50

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Limit Switches ...................................... B-3

Hand & Foot Controls............................ B-6

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

1st

Loose / Damaged Wire Connections

(Hand/Foot Control, Foot Down Limit Switch)

Ritter Models

Foot Up / Down Function

Problem: No Foot Down.

Foot Up - OK.

Foot Down Limit Switch

Refer to: Section B - Limit Switches

2nd

- continued

A-42

© Midmark Corporation 2005 SF-1838

Foot Up / Down

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

4th

ALL

MA649001i

Midmark Models

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

3rd

Page 51

Foot Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Foot drifts down.

- continued

Operation & Troubleshooting

Refer To: Page

Foot Actuator ........................................ B-25

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Foot Actuator

Refer to: Section B - Foot Actuator

MA649101i

1st

Models:

Serial Numbers:

ALL

Foot Up / Down

© Midmark Corporation 2005 SF-1838

A-43

Page 52

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Foot Actuator ........................................ B-25

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Foot Up / Down Function

Problem: Noisy operation.

(Grinding, squeaking, etc)

- continued

Foot Actuator

Refer to: Section B - Foot Actuator

MA649101i

1st

A-44

© Midmark Corporation 2005 SF-1838

Foot Up / Down

Models:

Serial Numbers:

ALL

Page 53

Foot Up / Down Function

Go To Table Of Contents

Next

Back

Go To Page:

Problem: Moves slowly - and/or

Will not lift patient.

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General Information Section

- continued

1st

450

Operation & Troubleshooting

Refer To: Page

General Information

Foot Actuator ........................................ B-25

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

(Specifications).....

ii

Low voltage to chair

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............ 230 +10% VAC

Models:

Serial Numbers:

ALL

2nd

lbs.

MA649201i

Foot Actuator

Refer to: Section B - Foot Actuator

Foot Up / Down

© Midmark Corporation 2005 SF-1838

3rd

Rev.10/5/18

A-45

Page 54

Operation & Troubleshooting

MA649301i

Go To Table Of Contents

Next

Back

Go To Page:

Refer To: Page

Foot Actuator ........................................ B-25

Position Sensors .................................. B-32

Main PC Board ..................................... B-40

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Programmable models only:

Foot Position Sensor

Refer to: Section B - Position Sensors

3rd

Foot Up / Down Function

Problem: Foot Up and/or Foot Down

moves briefly, then stops ("beeps").

- continued

Programmable models only:

Calibrate PC Board

Refer to: Section B - Main PC Board

1st

Loose / Damaged Wire Connections

(Foot Position Sensor, Hand/Foot Controls,

Foot limit switches, Foot actuator)

2nd

Foot Actuator

Refer to: Section B - Foot Actuator

4th

A-46

© Midmark Corporation 2005 SF-1838

Foot Up / Down

Models:

Serial Numbers:

ALL