Page 1

®

Go To Table Of Contents

Style B

Barrier-Free

Examination Table

Model Numbers:

222

223

622

623

-001 thru -017

-001 thru -016

-001 thru -008

-001 thru -010

Service and

Parts Manual

SF-1822 Part No. 004-0363-00 Rev. F (12/18/12)

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

Page 2

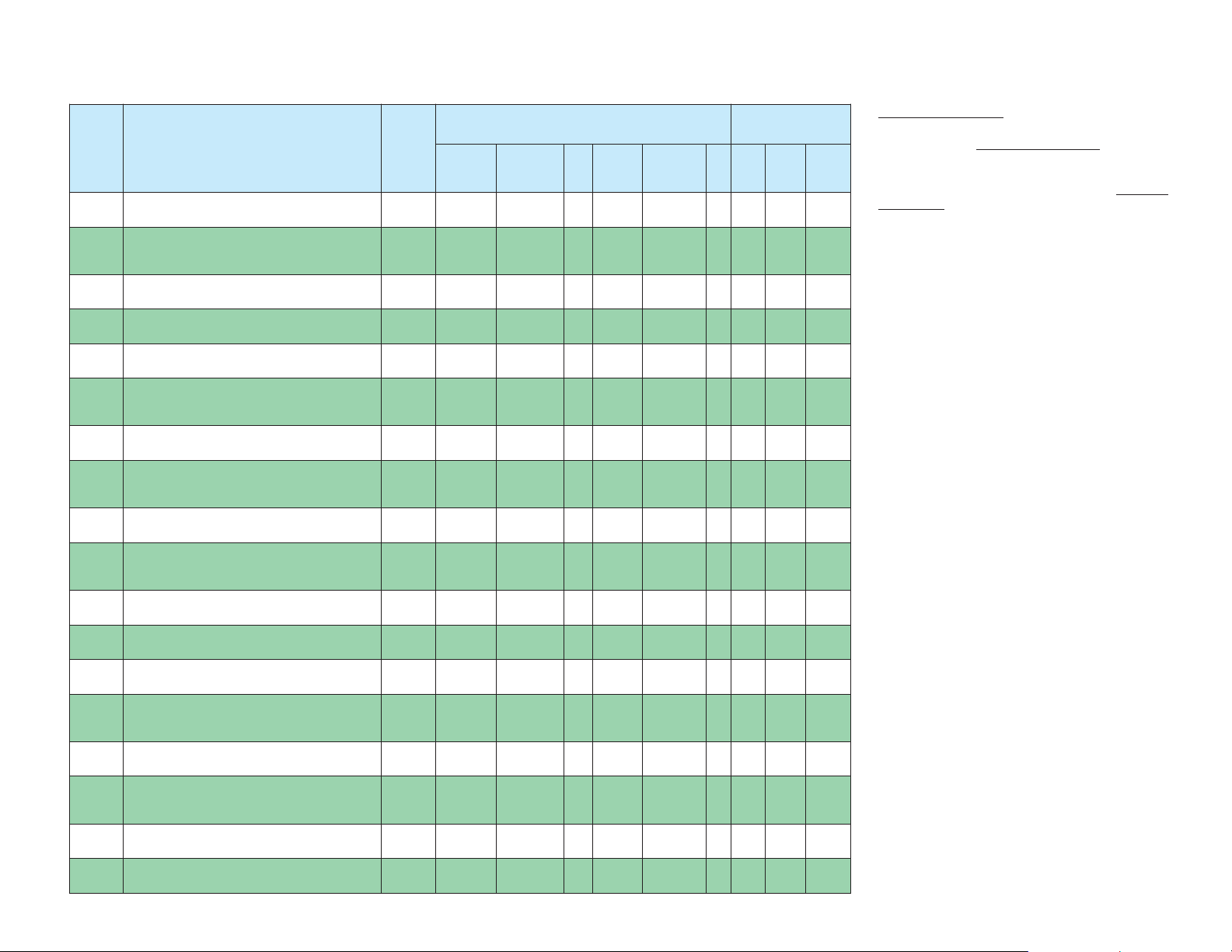

GENERAL INFORMATION

Symbols ....................................iii

Ordering Parts ......................... iii

Serial Number Location .......... iii

Specifications ........................... iv

Range of Motion ............................ iv

Model Identification /

Compliance Charts:

222 ................................................

223 ................................................

622 / 623 .......................................

General Information

Scheduled Maintenance ............ viii

Warranty Information................. ix

OPERATION &

TROUBLESHOOTING

Attention!

If table has no power, refer to Base Up / Down

Function to troubleshoot

Section A

Base Up / Down Function........ A-2

Back Up / Down Function:

Manual (222 / 622) ........................

Power (223 / 623) ..........................

Optional Features

Drawer Heater System ............. A-23

Table Receptacle ...................... A-27

Auto Return Function .............. A-29

Upholstery Heater System ...... A-32

(No Up or Down)

v

vi

vii

.

A-11

A-14

ACCESS PROCEDURES

Table Shrouds

Removal/Installation ......... C-2

Raising / Lowering

Table Manually .................. C-5

Upholstery Removal/Installation:

Ritter models.......................

Section C

Midmark models .................

Chair Arm / Brace

Removal ............................. C-8

Top Cover

Removal / Installation ....... C-9

Back Limit Switch Access . C-9

WIRING DIAGRAMS

222 ........................................ D-1

223 ........................................ D-1

622 ........................................ D-1

623 ........................................ D-1

C-6*

C-7*

Section D

EXPLODED VIEWS / PARTS LISTS

222 .........................................E-2

223 .........................................E-3

622 .........................................E-4

623 .........................................E-5

Section E

COMPONENT

TESTING & REPLACEMENT

Fuses......................................... B-2

Limit Switches .......................... B-4

Foot Control ............................. B-6

Base / Back Actuator ............... B-11

Section B

Back Release Mechanism ....... B-17

Main PC Board ......................... B-19

Table Of Contents

Drawer Heater System ............ B-23

Upholstery Heater System ...... B-29

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

* Indicates multiple pages due to model / serial number break(s)

Rev. 7/09

Page 3

General Information

Go To Table Of Contents

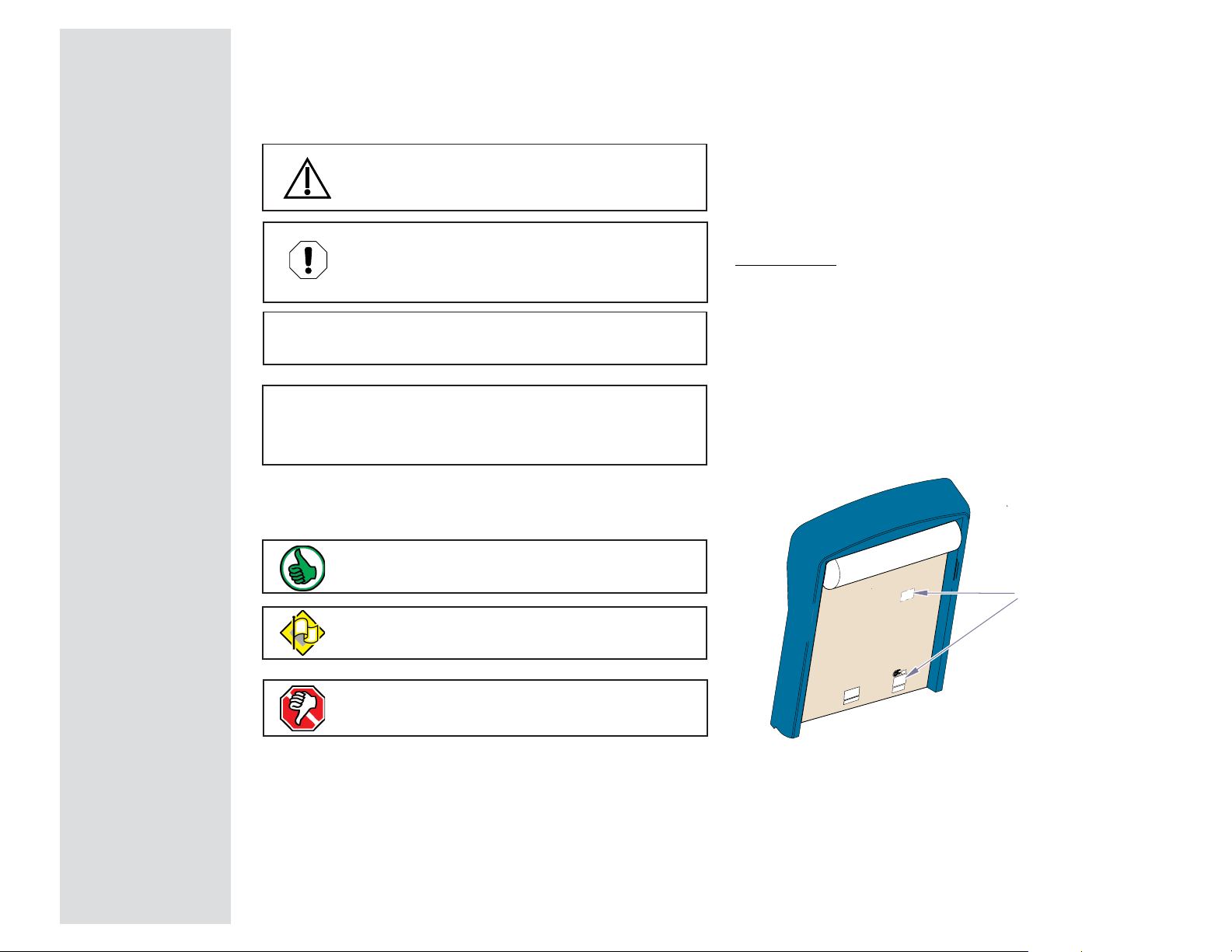

Symbols

Caution

Indicates a potentially hazardous situation

which could result in injury if not avoided.

Equipment Alert

Indicates a potentially hazardous situation

which could result in equipment damage

if not avoided.

Note

Amplifies a procedure, practice, or condition.

In Section A, test the components in the order indicated.

(ex.

1st

then,

These symbols are used throughout this manual to represent the

operational status of table functions and components.

Refer to Section B for component testing procedures.

2nd

)

Ordering Parts

The following information is required when ordering parts:

• Serial number & model number

• Part number for desired part.

[Refer to Exploded Views / Parts Lists section]

Non-warranty part orders may be faxed to Midmark using

the Fax Order Form in the back of this manual.

For warranty part orders, call Midmark's Technical Service

Department with the required information.

Hours: 8:00 am until 5:00 pm EST [Monday - Friday]

Phone: 1-(800)-Midmark

Serial Number Location

General Information

Indicates the function / component is working properly.

No action required.

Indicates the function / component is working,

but a problem exists.

Indicates the function / component is not working at all.

MA731100i

Serial / Model

Number Label

(exact location may vary)

© Midmark Corporation 2003 SF-1838

iii

Rev. 8/24/12

Page 4

General Information

Go To Table Of Contents

Specifications

Patient Weight (maximum) ................................400 lbs (181.4 kgs)

Paper Roll (maximum size): ..............................21 in. long x 3.5 in. diameter

(53.3 x 8.9 cm)

Export models ....................................................19.7 in. long x 4.7 in. diameter

(50 cm x 12 cm)

Range of Motion .................................................

Dimensions .........................................................

See illustration on this page

See illustration on next page

Max.

37 +0.5 in.

(94 +1.3 cm)

Weight of Table:

[230 VAC models only: 230 V transformer adds 14.5 lbs (6.5 kg)]

w/ upholstery .....................................................325 lbs (147.4 kg)

w/packaging & skid

Weight of Upholstery:

w/packaging

Power Cord(s)

Electrical Rating: ................................................

Foot Control Voltage: ......................................... 14 VAC, SELV (Safety Extra Low Voltage)

Duplex Receptacle

maximum load: .................................................

Fuses: ..................................................................Refer to:

Duty Cycle

:

Actuator motor run time

(Domestic: 30 seconds ON / 5 minutes OFF)

(Export: 25 seconds ON / 7 minutes OFF)

Receptacle / Drawer Heater / Uph. Htr

Classifications: ...................................................Class I, Type B Applied Part,

Ordinary Equipment, Intermittent Operation

(Domestic: 30 seconds ON / 5 minutes OFF)

(Export: 25 seconds ON / 7 minutes OFF)

(no upholstery) .................

(shipped separately) .................

[115V models have two cords]

: ...................................... Intermittent Operation

: ......8 ft. (243.8 cm) long

: .............. Continuous Operation

375 lbs (192.7 kg)

40 lbs (18.1 kg)

See Compliance Charts

115 VAC, 5A

Section E - Fuses

623 only

Home Height

20 +0.5 in.

(50.8 +1.3 cm)

0° (horizontal) to

+80° +5°

Min.

18 +0.5 in.

(45.7 +1.3 cm)

Pelvic Tilt

(optional)

Max: 7° +2°

Min: 1.5°

Protection against ingress of fluids: ................ IPX0

Regulatory Compliance: ....................................

Table Speeds

Base ...................................................................... 14 - 26 seconds

Back

(models w/power back) ...............................

iv

© Midmark Corporation 2003 SF-1838

(by function):

Rev. 12/18/12

See Regulatory Compliance Charts

15 - 20 seconds

[Foot Control only: IPX1]

MA599801i

Page 5

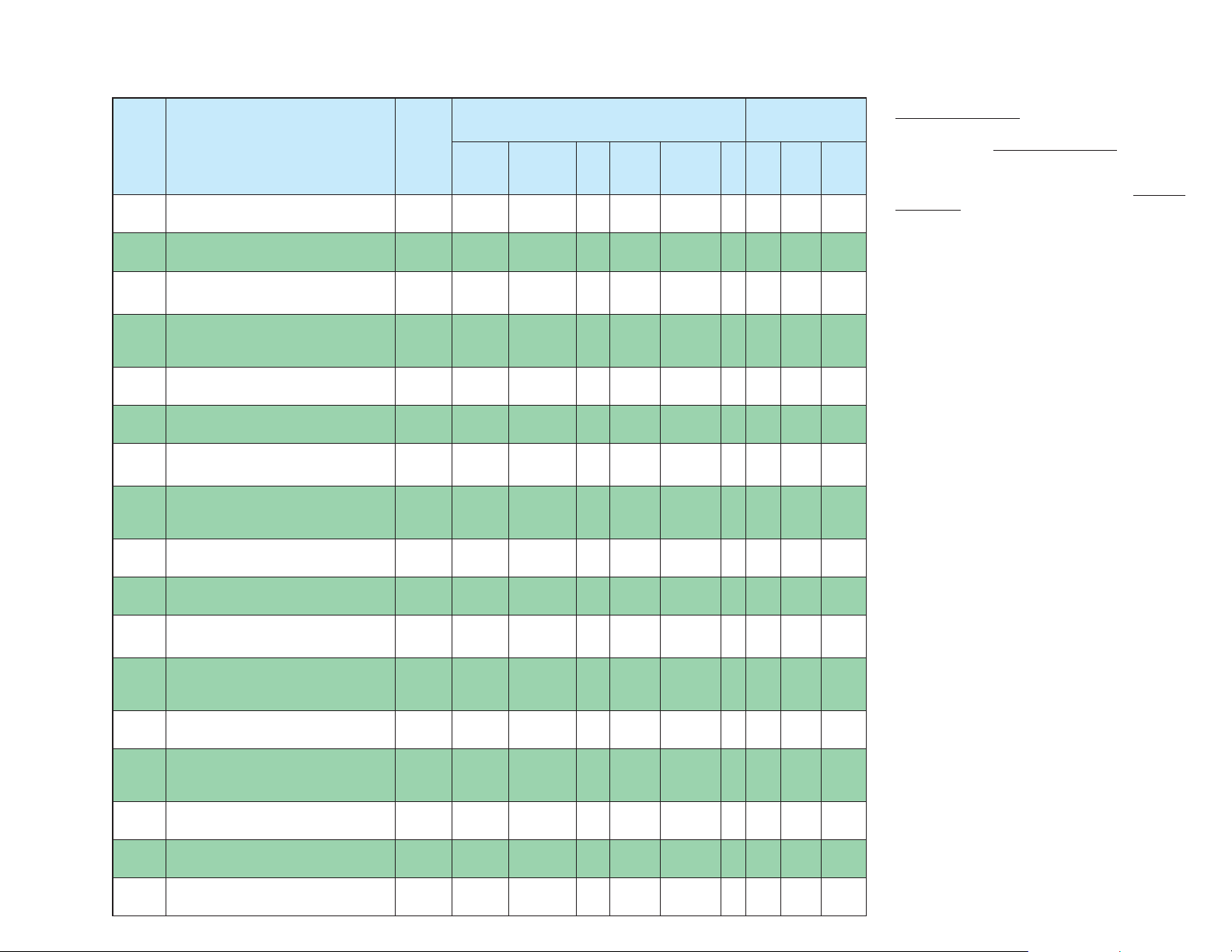

Model Identification / Compliance Chart - 222

Go To Table Of Contents

General Information

ledoM noitpircseD

100-222elbaTcisaBrettiR

200-222 elbaTcisaBrettiR

300-222elbaTcisaBrettiR

400-222 elbaTcisaBrettiR

500-222elbaTcisaBrettiR

600-222 elbaTcisaBrettiR

700-222elbaTcisaBrettiR

800-222 elbaTcisaBrettiR

900-222elbaTtropxEcisaBrettiR

010-222 elbaTtropxEcisaBrettiR

110-222)adanaC(elbaTcisaBrettiR

laireS

rebmuN

LU

xiferP

)poTdradnatS(

)poTdradnatS(elcatpeceR/w

)poTdradnatS(tliTcivleP,retaeHrewarD/w

tliTcivleP,elcatpeceR/w

)poTdradnatS(,retaeHrewarD

)poTsselmaeS(

)poTsselmaeS(,elcatpeceR/w

)poTsselmaeS(tliTcivleP,retaeHrewarD/w

tliTcivleP,elcatpeceR/w

)poTsselmaeS(,retaeHrewarD

)poTsselmaeS(tliTcivleP/w

)poTsselmaeS(retaeHrewarD,tliTcivleP/w

)poTdradnatS(elcatpeceR/w

V,GRXX XXX

V,HR

V,JRXX XXX

V,KR X X X

V,GRXX XXX

V,HR

V,JRXX XXX

V,KR X X X

V,LRXXX

V,MR

VX XX

1-10606

ASC/NAC

,2.22

09M-1.106#

:oTseilpmoC :sgnitaRlacirtcelE

LU

NE

445

X X

X X

1-10606

X X

NE

2-1-10606

)CME(

EC

X

X

X

CAV

-/+

spmA

%01

5115.506/05

511 5.01 06/05

5116 06/05

511 11 06/05

5115.506/05

511 5.01 06/05

5116 06/05

511 11 06/05

03257.206/05

032 3 06/05

5115.0106/05

Fire Code Ratings:

All upholstery complies with California Bureau of

Home Furnishing Technical Bulletin 117.

selcyC

Optional upholstery is available that complies

)zH(

with California Bureau of Home Furnishing Technical

Bulletin 133.

210-222 )adanaC(elbaTcisaBrettiR

310-222)adanaC(elbaTcisaBrettiR

410-222

510-222elbaTcisaBrettiR

610-222

710-222

X

511 11 06/05

5115.0106/05

511 11 06/05

5115.0106/05

511 11 06/05

03257.206/05

)poTdradnatS(

retaeHrewarD,tliTcivleP,elcatpeceR/w

)poTsselmaeS(elcatpeceR/w

elbaTcisaBrettiR)adanaC(

retaeHrewarD,tliTcivleP,elcatpeceR/w

)poTsselmaeS(

elcatpeceR/w

elbaTcisaBrettiR

retaeHrewarD,tliTcivleP,elcatpeceR/w

tropxE-elbaTcisaBrettiR

tliTcivleP/w

V X X X

VX XX

V X X X

VX X XXX

V X X X X X

V

XX XX

v

© Midmark Corporation 2003 SF-1838

Page 6

General Information

Go To Table Of Contents

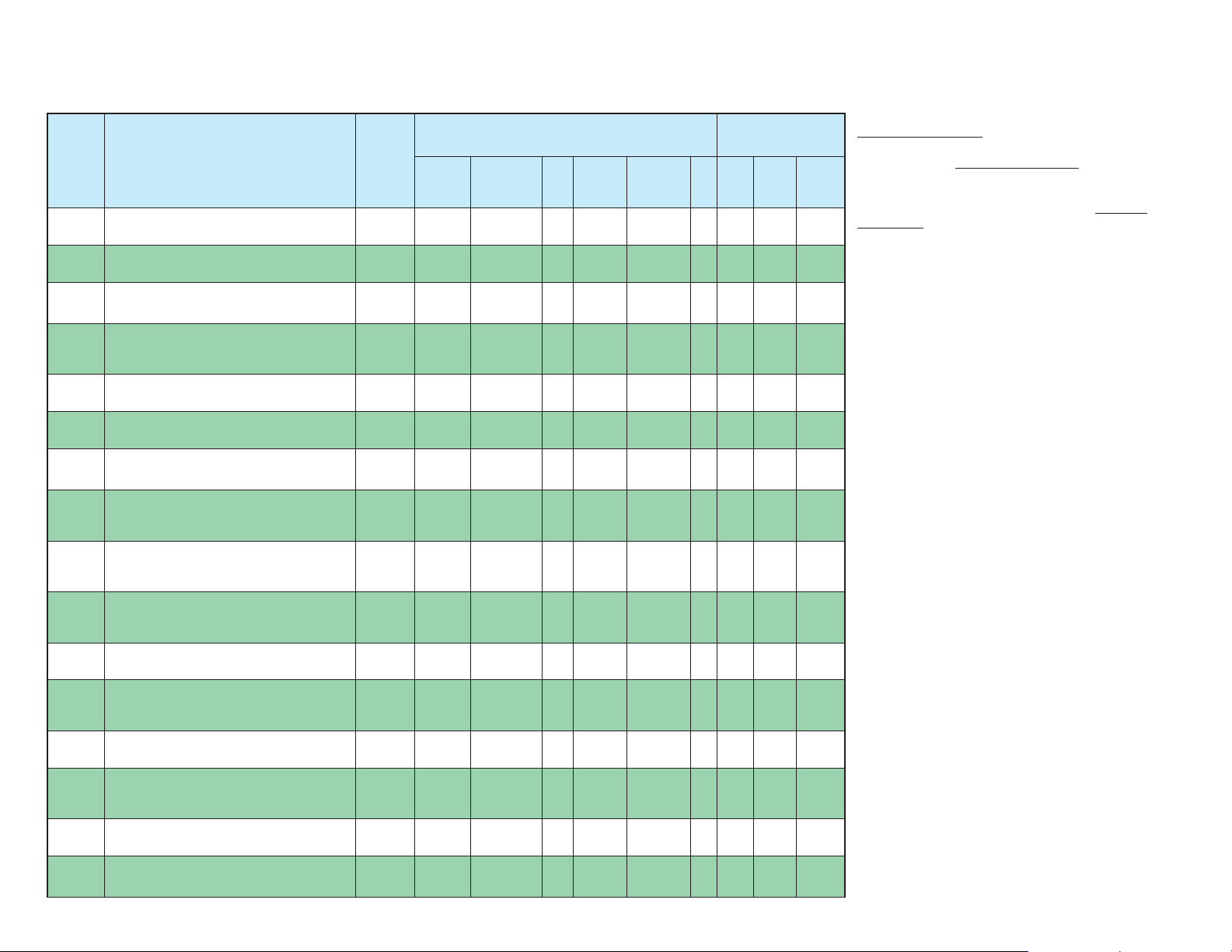

Model Identification / Compliance Chart - 223

ledoM noitpircseD

100-322

200-322

300-322

400-322

500-322

600-322

700-322

800-322

900-322

010-322

110-322

210-322

310-322

410-322

510-322

610-322

)poTdradnatS(

)poTsselmaeS(

elbaTtropxE

elbaTtropxE

elcatpeceR/w

laireS

rebmuN

LU

xiferP

elbaTkcaBrewoPrettiR

elbaTkcaBrewoPrettiR

)poTdradnatS(elcatpeceR/w

elbaTkcaBrewoPrettiR

)poTdradnatS(tliTcivleP,retaeHrewarD/w

elbaTkcaBrewoPrettiR

tliTcivleP,elcatpeceR/w

)poTdradnatS(,retaeHrewarD

elbaTkcaBrewoPrettiR

elbaTkcaBrewoPrettiR

)poTsselmaeS(elcatpeceR/w

elbaTkcaBrewoPrettiR

)poTsselmaeS(tliTcivleP,retaeHrewarD/w

elbaTkcaBrewoPrettiR

tliTcivleP,elcatpeceR/w

)poTsselmaeS(,retaeHrewarD

kcaBrewoPrettiR

)poTsselmaeS(tliTcivleP/w

kcaBrewoPrettiR

)poTsselmaeS(retaeHrewarD,tliTcivleP/w

elbaTkcaBrewoPrettiR)adanaC(

)poTdradnatS(elcatpeceR/w

elbaTkcaBrewoPrettiR)adanaC(

tliTcivleP,elcatpeceR/w

)poTdradnatS(,retaeHrewarD

elbaTkcaBrewoPrettiR)adanaC(

)poTsselmaeS(elcatpeceR/w

elbaTkcaBrewoPrettiR)adanaC(

tliTcivleP,elcatpeceR/w

)poTsselmaeS(,retaeHrewarD

elbaTkcaBrewoPrettiR

elbaTkcaBrewoPrettiR

retaeHrewarD,tliTcivleP,elcatpeceR/w

V,CSXX XXX

V,DS X

V,ESXX XXX

V,FS X

V,CSXX XXX

V,DS X

V,ESXX XXX

V,FS X

V,GSXXX

V,HS X X X

VX

V X

VX

V X

VX X X XX

V

1-10606

X X X X

ASC/NAC

,2.22

09M-1.106#

:oTseilpmoC :sgnitaRlacirtcelE

LU

NE

445

1-10606

NE

2-1-10606

)CME(

X

X

X

X

X

X

X

X

EC

X

X

X

X

X

X

X

X

X

CAV

-/+

%01

spmA

5117 06/05

511 21 06/05

5115.706/05

511 5.21 06/05

5117 06/05

511 21 06/05

5115.706/05

511 5.21 06/05

03257.306/05

032 4 06/05

5112106/05

511 5.21 06/05

5112106/05

511 5.21 06/05

5112106/05

511 5.21 06/05

Fire Code Ratings:

All upholstery complies with California Bureau of

Home Furnishing Technical Bulletin 117.

selcyC

)zH(

Optional upholstery is available that complies

with California Bureau of Home Furnishing Technical

Bulletin 133.

vi

© Midmark Corporation 2003 SF-1838

Page 7

Model Identification / Compliance Chart - 622 / 623

Go To Table Of Contents

General Information

ledoM noitpircseD

100-226

200-226

300-226

400-226

500-226

600-226

700-226

800-226

100-326

200-326

300-326

400-326

500-326

600-326

700-326

800-326

900-326

010-326

elcatpeceR/w

tliTcivleP/w

elcatpeceR/w

elcatpeceR/w

elcatpeceR/w

tliTcivleP/w

elcatpeceR/w

elcatpeceR/w

tliTcivleP/w

laireS

rebmuN

xiferP

elbaTkcaBlaunaMkramdiM

elbaTkcaBlaunaMkramdiM

,tliTcivleP,retaeHrewarD,elcatpeceR/w

yretslohpUdetaeH&

elbaTkcaBlaunaMkramdiM

elbaTkcaBlaunaMkramdiM

yretslohpUdetaeH&,tliTcivleP,retaeHrewarD/w

elbaTkcaBlaunaMkramdiM)adanaC(

elbaTkcaBlaunaMkramdiM)adanaC(

,tliTcivleP,retaeHrewarD,elcatpeceR/w

yretslohpUdetaeH&

elbaTkcaBlaunaMkramdiM

elbaTkcaBlaunaMkramdiM

,tliTcivleP,retaeHrewarD,elcatpeceR/w

yretslohpUdetaeH&

elbaTkcaBrewoPkramdiM

elbaTkcaBrewoPkramdiM

tliTcivleP,elcatpeceR/w

yretslohpUdetaeH&,retaeHrewarD

elbaTkcaBrewoPkramdiM

elbaTkcaBrewoPkramdiM

yretslohpUdetaeH&,retaeHrewarD,tliTcivleP/w

elbaTkcaBrewoPkramdiM)adanaC(

elbaTkcaBrewoPrettiR)adanaC(

tliTcivleP,elcatpeceR/w

yretslohpUdetaeH,retaeHrewarD

elbaTkcaBrewoPkramdiM

elbaTkcaBrewoPkramdiM

tliTcivleP,elcatpeceR/w

yretslohpUdetaeH&,retaeHrewarD

elbaTkcaBrewoPkramdiMtropxE-

elbaTkcaBrewoPkramdiMtropxE-

yretslohpUdetaeH&,retaeHrewarD,tliTcivleP/w

V,JSXXX

V,KS X

V,NSXX XXX

V,PS

VX XX

V

VX X XXX

V

V,LSXXX

V,MS X

V,RS

V,SS

VX

V X

VX X XXX

V

VX X XXX

V

LU

1-10606

X X X X

X X X X X

XX

X X

X X X X X

X X X X X

ASC/NAC

,2.22

09M-1.106#

X X

:oTseilpmoC :sgnitaRlacirtcelE

LU

NE

445

1-10606

NE

2-1-10606

EC

)CME(

X

X

X

X

X

X

XX

X X

X

X

X

X

CAV

-/+

spmA

%01

5115.0106/05

511 5.11 06/05

03257.206/05

032 52.3 06/05

5115.0106/05

511 5.11 06/05

5115.0106/05

511 5.11 06/05

5115.2106/05

511 5.31 06/05

03257.306/05

032 52.4 06/05

5115.2106/05

511 5.31 06/05

5115.2106/05

511 5.31 06/05

03257.306/05

032 52.4 06/05

All upholstery complies with California Bureau of

Home Furnishing Technical Bulletin 117.

selcyC

Optional upholstery is available that complies

)zH(

with California Bureau of Home Furnishing Technical

Bulletin 133.

Fire Code Ratings:

© Midmark Corporation 2003 SF-1838

vii

Page 8

General Information

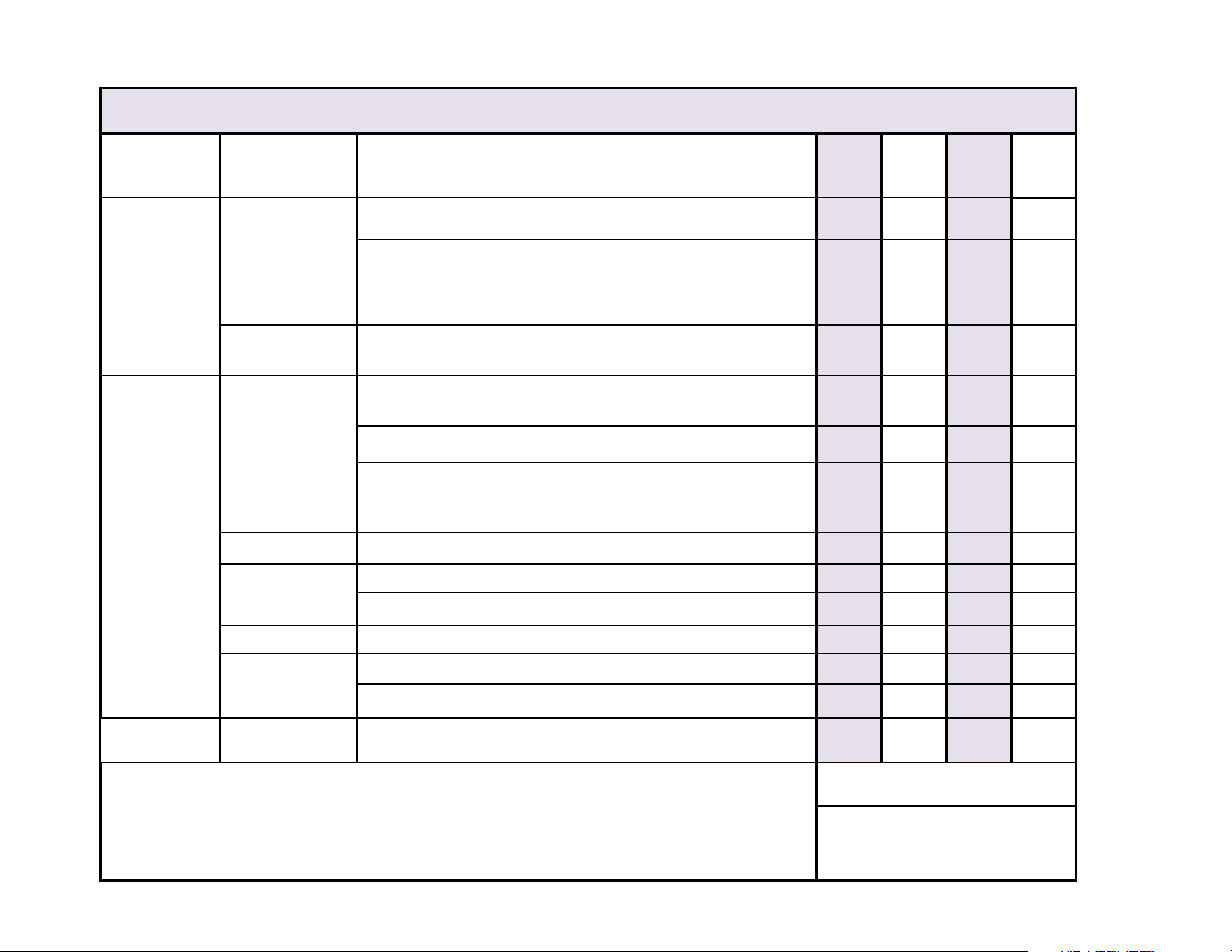

Interval

Inspection or

Service

Service, Adjust , Repair

and / or Replace as Required

(Refer to appropriate S&P or Quick Reference Guide)

222 223 622 623

Clean upholstery with diluted bleach solution.

10:1 (water:bleach)

X X X X

Wipe painted metal & plastic surfaces with a clean soft cloth and

mild cleaner. (NOTE: Periodic application of common furniture

wax will ease cleaning, and maintain the luster of the surfaces).

X X X X

Obvious Damage

Visually inspect components for damage that could cause

problems during operation or unsafe operation.

X X X X

Check all mechanical functions using the foot control. Repeat

using the hand control when present.

X X X X

Check manual back releaase mechanism for proper operation.

X X X X

Table shrouds should move smoothly & quietly when base is

raised & lowered. (NOTE: There are plastic glides on the shroud

tabs. Missing glides may result in noisy operation.)

X X X X

Labels / Decals Replace any missing or illegible labels.

X X X X

Lubricate back hinge with light machine oil.

X X X X

Lubricate footrest slide with household furniture wax.

X X X X

Hardware All fasteners must be present and fastened securely.

X X X X

Inspect power cord and all wiring for damage.

X X X X

Be sure all electrical connections are tight.

X X X X

Stirrups

Check that stirrups extend easily, and lock securely into each

lateral position.

X X X X

Date of Service: _____/____/____

Location:

Service

Technician:

Serial Number:

Mechanical

Operation

Semi-Annually

Lubricate

Scheduled Maintenance / Barrier-Free® Examination Table

Weekly

Cleaning

Electrical System

Model:

Go To Table Of Contents

viii

© Midmark Corporation 2003 SF-1838

Rev. 10/24/12

Page 9

Warranty Information

Go To Table Of Contents

General Information

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original purchaser its new Alternate Care

products and components (except for components not warranted under “Exclusions”)

manufactured by Midmark to be free from defects in material and workmanship under normal use

and service. Midmark’s obligation under this warranty is limited to the repair or replacement, at

Midmark’s option, of the parts or the products the defects of which are reported to Midmark

within the applicable warranty period and which, upon examination by Midmark, prove to be

defective.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original user, shall be

one (1) year for all warranted products and components.

EXCLUSIONS

This warranty does not cover and Midmark shall not be liable for the following: (1) repairs and

replacements because of misuse, abuse, negligence, alteration, accident, freight damage, or

tampering; (2) products which are not installed, used, and properly cleaned as required in the

Midmark “Installation” and or “Installation / Operation Manual for this applicable product. (3)

products considered to be of a consumable nature; (4) accessories or parts not manufactured

by Midmark; (5) charges by anyone for adjustments, repairs, replacement parts, installation, or

other work performed upon or in connection with such products which is not expressly

authorized in writing in advance by Midmark.

EXCLUSIVE REMEDY

Midmark’s only obligation under this warranty is the repair or replacement of defective parts.

Midmark shall not be liable for any direct, special, indirect, incidental, exemplary, or

consequential damages or delay, including, but not limited to, damages for loss of profits or loss

of use.

NO AUTHORIZATION

No person or firm is authorized to create for Midmark any other obligation or liability in

connection with the products.

Additional Information

Failure to follow the guidelines listed below will void the

warranty and/or render the table unsafe for use.

• If a malfunction is detected, do not use the table until

necessary repairs are made.

• Do not attempt to disassemble table, replace

components, or perform adjustments unless you are

a Midmark authorized service technician.

• Do not use another manufacturer's parts to replace

malfunctioning components. Use only Midmark

replacement parts

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED WARRANTIES OF

ANY KIND INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACE

MENT OF DEFECTIVE PARTS.

SF-1487 REV. A1

© Midmark Corporation 2003 SF-1838

ix

Page 10

Troubleshooting

Go To Table Of Contents

Click on the Go To Page button and enter the desired

page number. (Note: Letters are case sensitve. ex. A-2)

Go To Page:

Troubleshooting

Table Function Page

Base Up / Down ................................... A-2

Back Up / Down .................................... A-11

Drawer Heater ....................................... A-23

Table Receptacle .................................. A-27

Auto Return .......................................... A-29

Upholstery Heater System.................... A-32

Section A

Models:

Serial Numbers:

© Midmark Corporation 2003 SF-1838

A-1

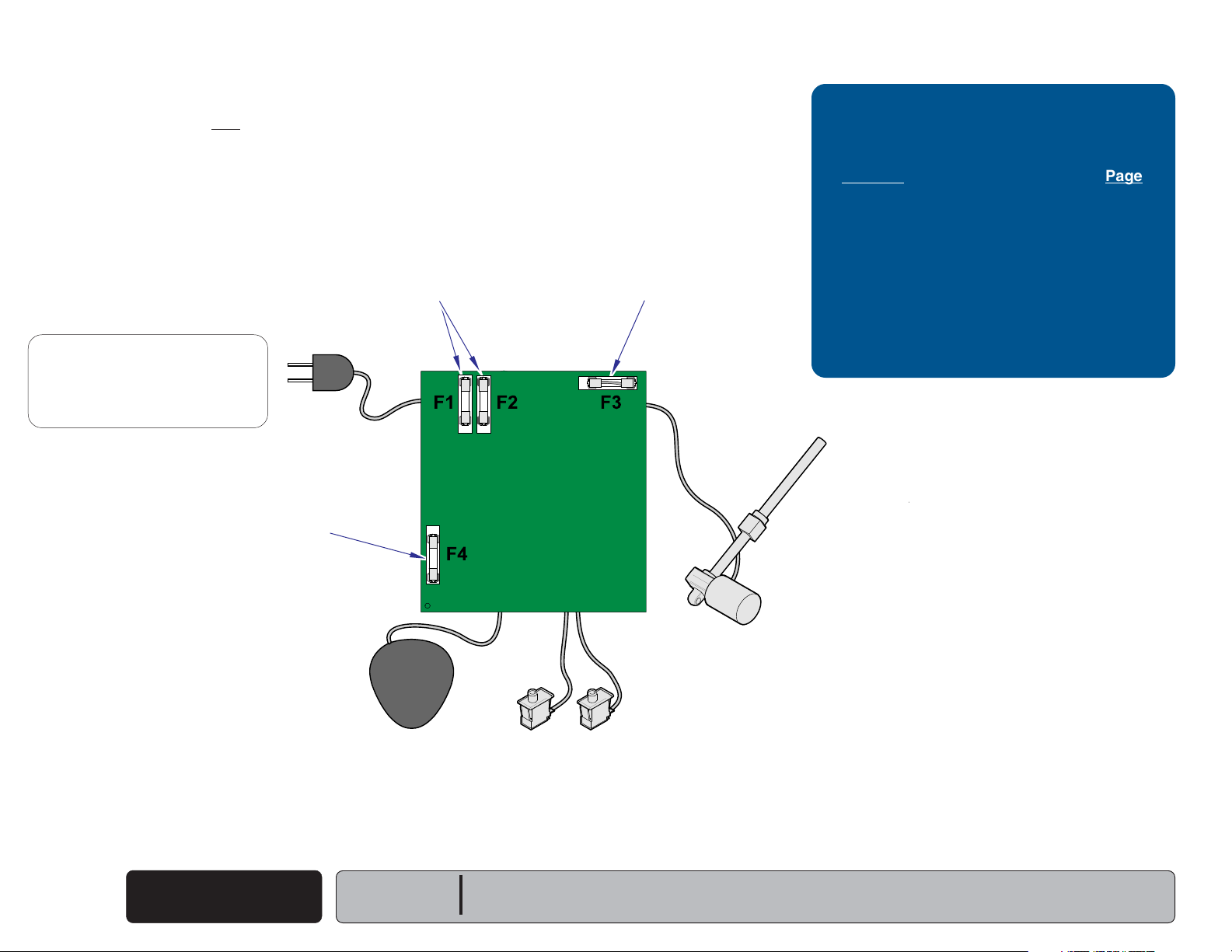

Page 11

Troubleshooting

Go To Table Of Contents

Go To Page:

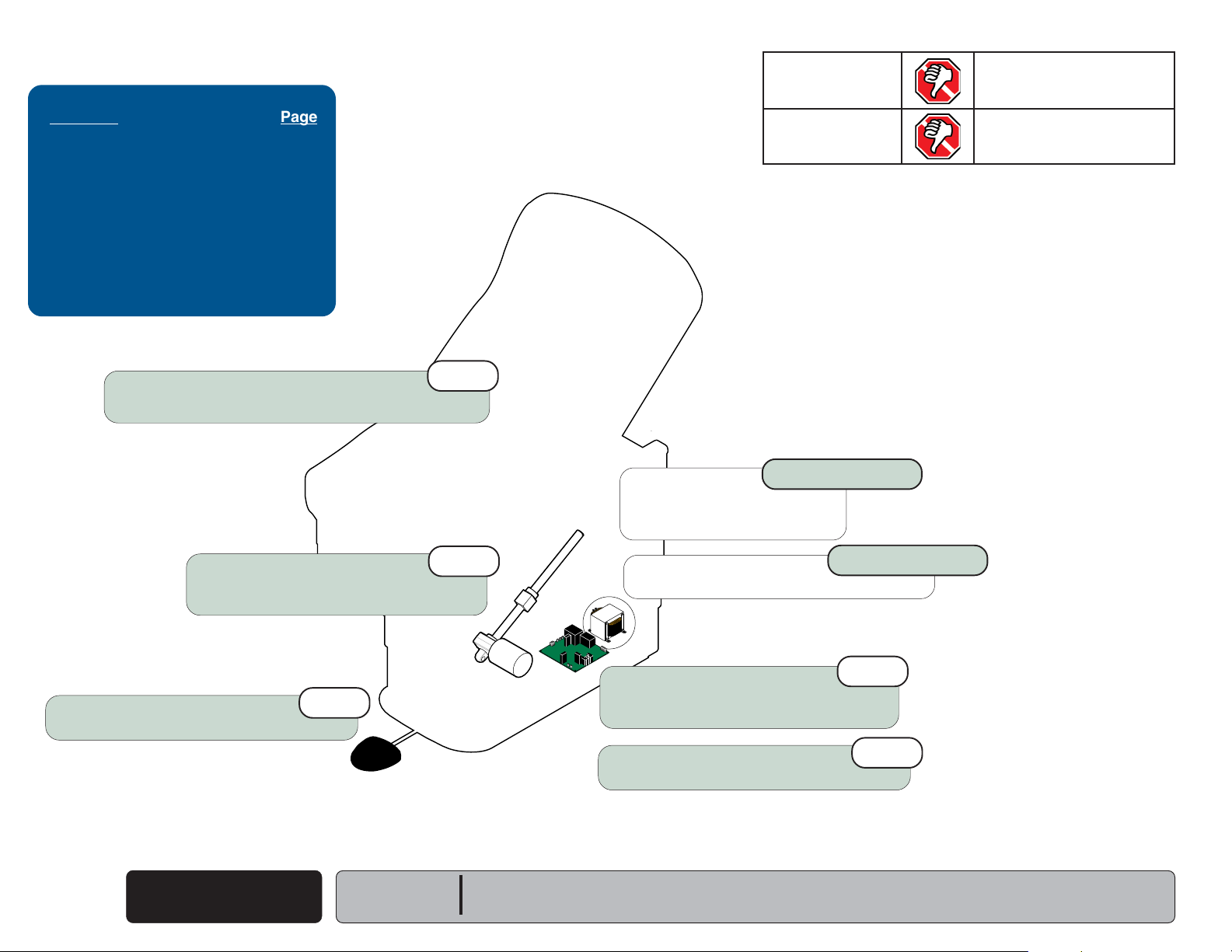

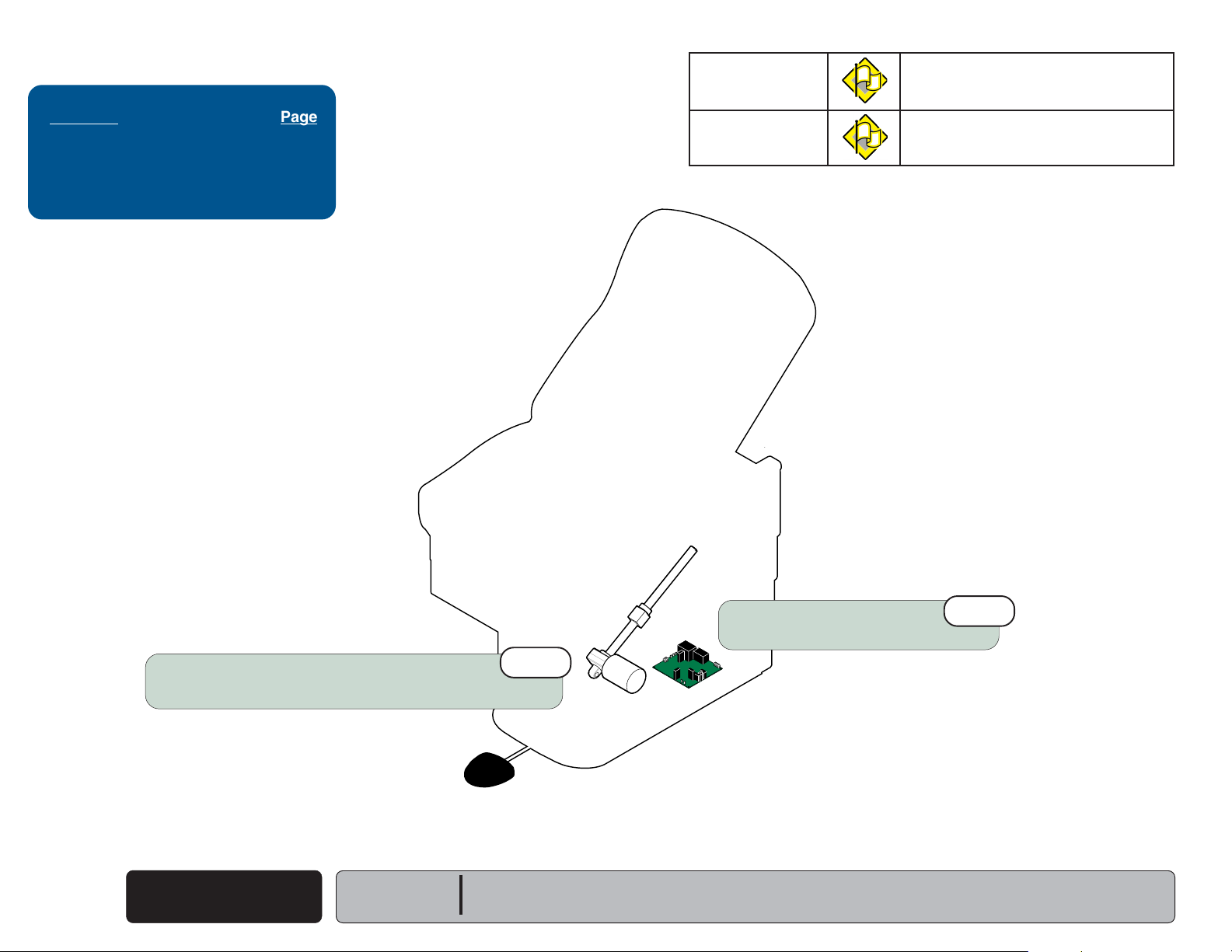

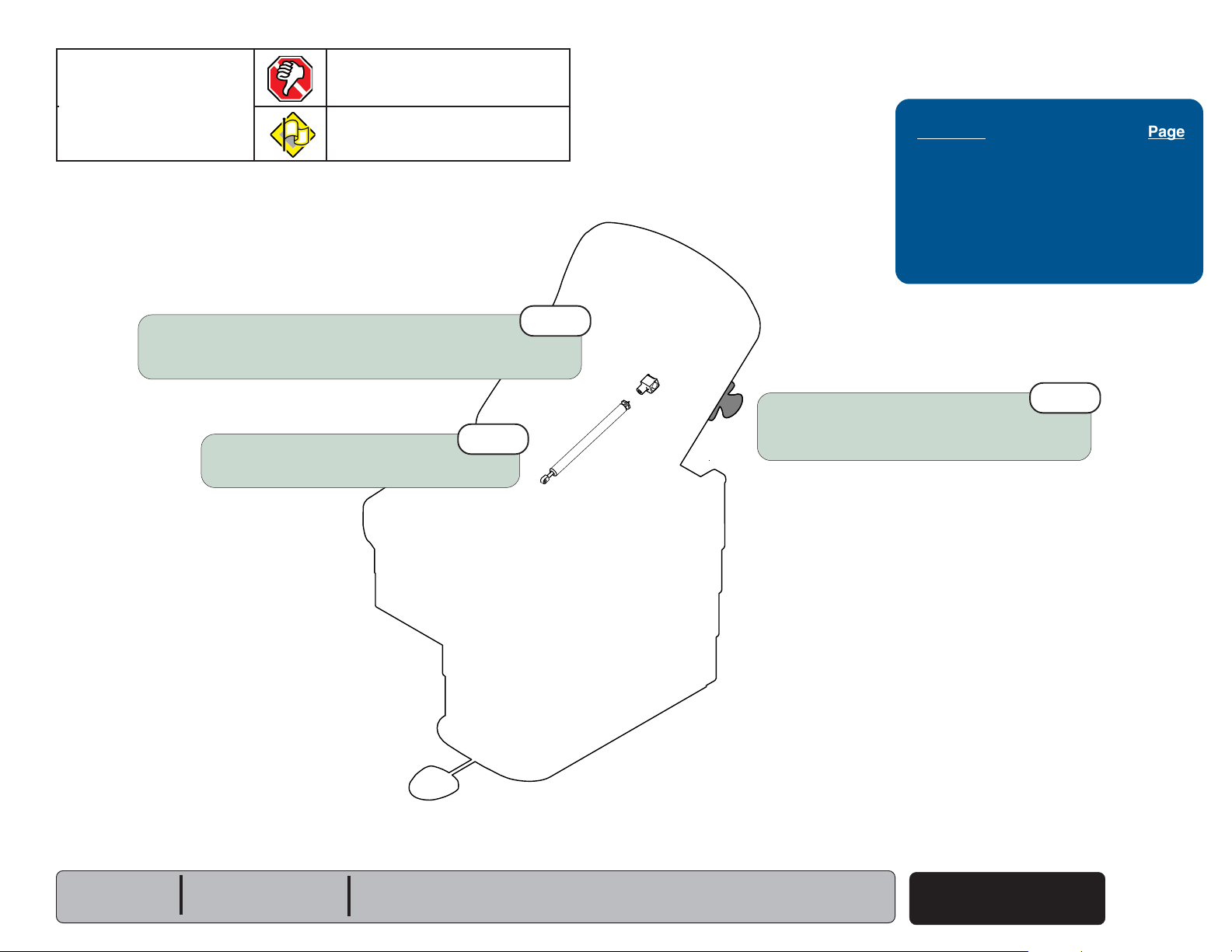

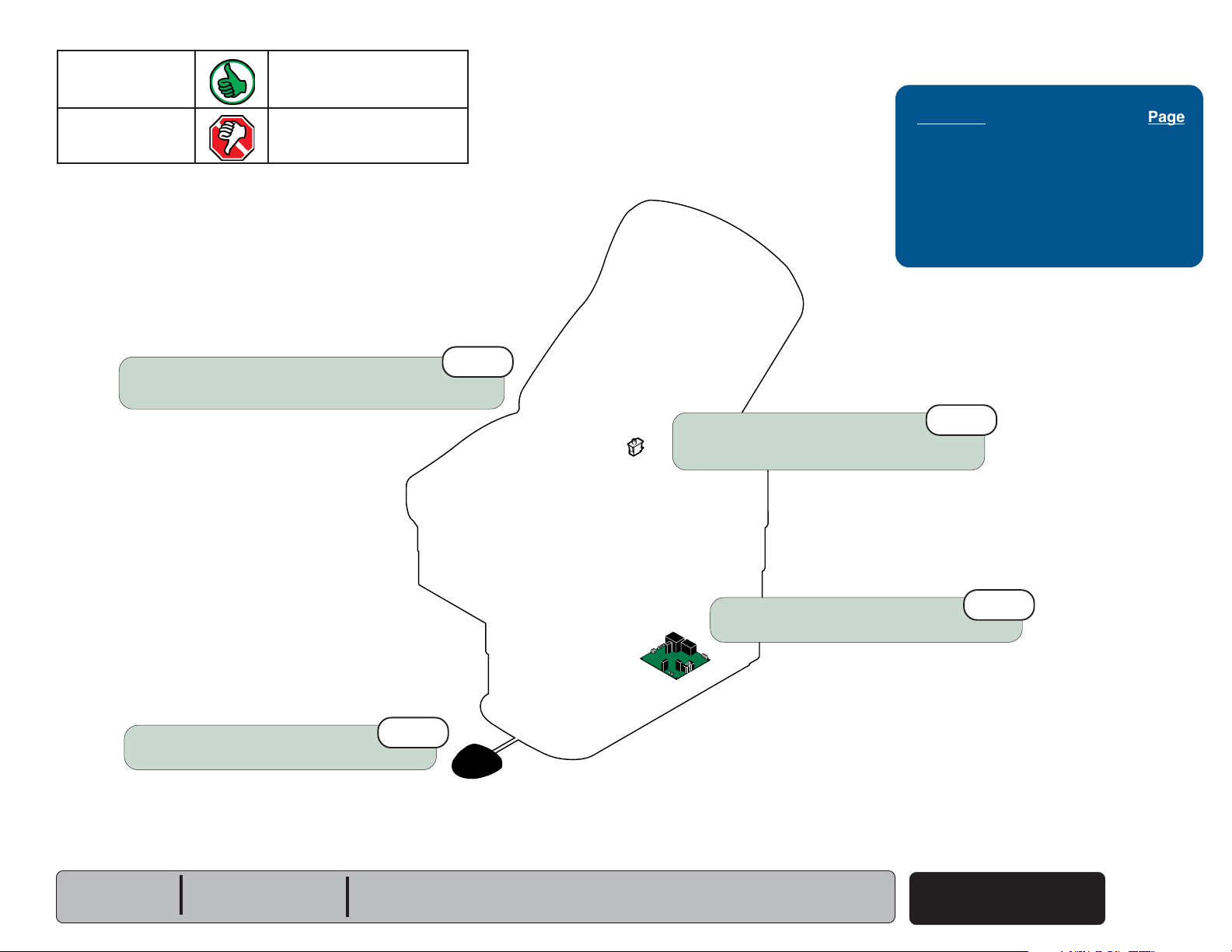

Base UP / DOWN Function

This illustration shows only the components that affect the Base UP / DOWN function.

Refer to the following page for a detailed description of current flow during this function.

Primary Fuses

NOTE:

Line voltage (230 VAC) is supplied thru

two fuses

inlet)

line voltage to 115 VAC before it

reaches the PC Board.

230 VAC models only

(located by the power cord

to a transformer that reduces the

[All Functions]

115 VAC

[Base Up & Down Functions]

Base Motor Fuse

Troubleshooting

[Base Up / Down Function]

Problem Page

No UP or DOWN Functions

No UP Function (DOWN - OK)

No DOWN Function (UP - OK)

Base Drifts Down .................................

Moves Wrong Direction .......................

Noisy Operation ...................................

Moves Slowly ....................................

................ A-4

............ A-5

............ A-6

A-7

A-8

A-9

A-10

A-2

© Midmark Corporation 2003 SF-1838

Transformer Fuse

[All Functions]

Foot Control

Base Up / Down

Main PC Board

14 VAC

Base Up Limit Switch

[Base Up will not operate if switch is tripped]

Models:

Serial Numbers:

All

All

48 VDC

MA627300i

Base Actuator

Base Down Limit Switch

[Base Down will not operate if switch is tripped]

Page 12

Troubleshooting

Go To Table Of Contents

Base UP / DOWN Function

NOTE

On 230 VAC models, line voltage

supplied thru two fuses

to a transformer that reduces the line voltage

to 115 VAC before it gets to the PC board.

Power To Foot Control

115 VAC is supplied thru the two primary fuses

(F1 & F2)

[F4 fuse protects the transformer]

The transformer reduces the line voltage and

supplies 14 VAC to the foot control.

to the transformer on the PC board.

(located by IEC inlet)

(230 VAC)

.

is

Base Up Operation

NOTE

If the Base Up limit switch is tripped (open),

the Base Up function will not operate.

When the Base Up function is activated,

current

switch

on the PC Board energizes the base relay.

[F3 fuse protects the base motor]

(14 VAC)

(N.O)

flows thru the Up function foot

, then back to the PC board. Circuitry

.

NOTE

The Base Up/Down relay has four contacts:

(2) Normally Open: Base Up function

(2) Normally Closed: Base Down function

When the base relay is energized,

the (2) Normally Open contacts of the relay

close. When these contacts close, current

(

48 VDC)

When current flows to the actuator thru the

Normally Open contacts of the relay, the actuator

motor runs and raises the table.

Actuator Motor runs until:

1. Foot control pedal is released.

2. Base Up limit switch is tripped.

3. 26 second software time limit is reached.

4. Fuse(s) opens (blows).

flows to the actuator motor.

[Primary, Base Motor, Transformer fuse]

Base Down Operation

NOTE

If the Base Down limit switch is tripped (open),

the Base Down function will not operate.

When the Base Down function is activated,

current

switch

(14 VAC)

(N.O.)

flows thru the Down function foot

, then back to the PC Board.

NOTE

The Base Up/Down relay has four contacts:

(2) Normally Open: Base Up function

(2) Normally Closed: Base Down function

When this voltage is applied, current

to the actuator motor thru the (2) Normally Closed

contacts of the Base Up/Down relay.

[The relay does not energize].

When voltage flows to the actuator thru the Normally

Closed contacts of the relay, the actuator motor runs

andlowers the table.

Actuator Motor runs until:

1. Foot control pedal is released.

2. Base Down limit switch is tripped.

3. 26 second software time limit is reached.

4. Fuse(s) opens (blows).

[Primary, Base Motor, Transformer fuse]

(48 VDC)

flows

Models:

Serial Numbers:

All

All

Equipment Alert

If an overload condition* is detected the PC board will "beep" and all power functions will be

disabled. Release the function button, remove load, then retry function.

*(weight limit exceeded, mechanical binding, etc),

Base Up / Down

© Midmark Corporation 2003 SF-1838

Rev. 8/24/12

A-3

Page 13

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Fuses ........................................... B-2

Limit Switches.............................. B-4

Foot Control ................................. B-6

Base / Back Actuator ................... B-11

Base Relay Test .......................... B-20

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

Loose Wire Connections

(esp. Foot Control & Base Up/Down Limit Switches)

1st

noitcnuFsutatSmelborP

Base Up No movement

Base Down No movement

Perform

Refer to: Section B - Foot Control

Footswitch Test

A-4

© Midmark Corporation 2003 SF-1838

Base Actuator

To isolate the malfunction,

Refer to: Section B - Base / Back Actuator

3rd

Base Up / Down

Rev. 2/08

Serial Numbers:

4th

Models:

MA626600i

All

All

230 V models only

230 VAC

Transformer Fuses (2)

Refer to: Section B - Fuses

230 VAC Transformer

Main PC Board Fuse(s):

[Test fuses: F1, F2, F3, & F4]

Refer to: Section B - Fuses

Perform

Refer to: Section B - Main PC Board

Base Relay Test

230 V models only

2nd

5th

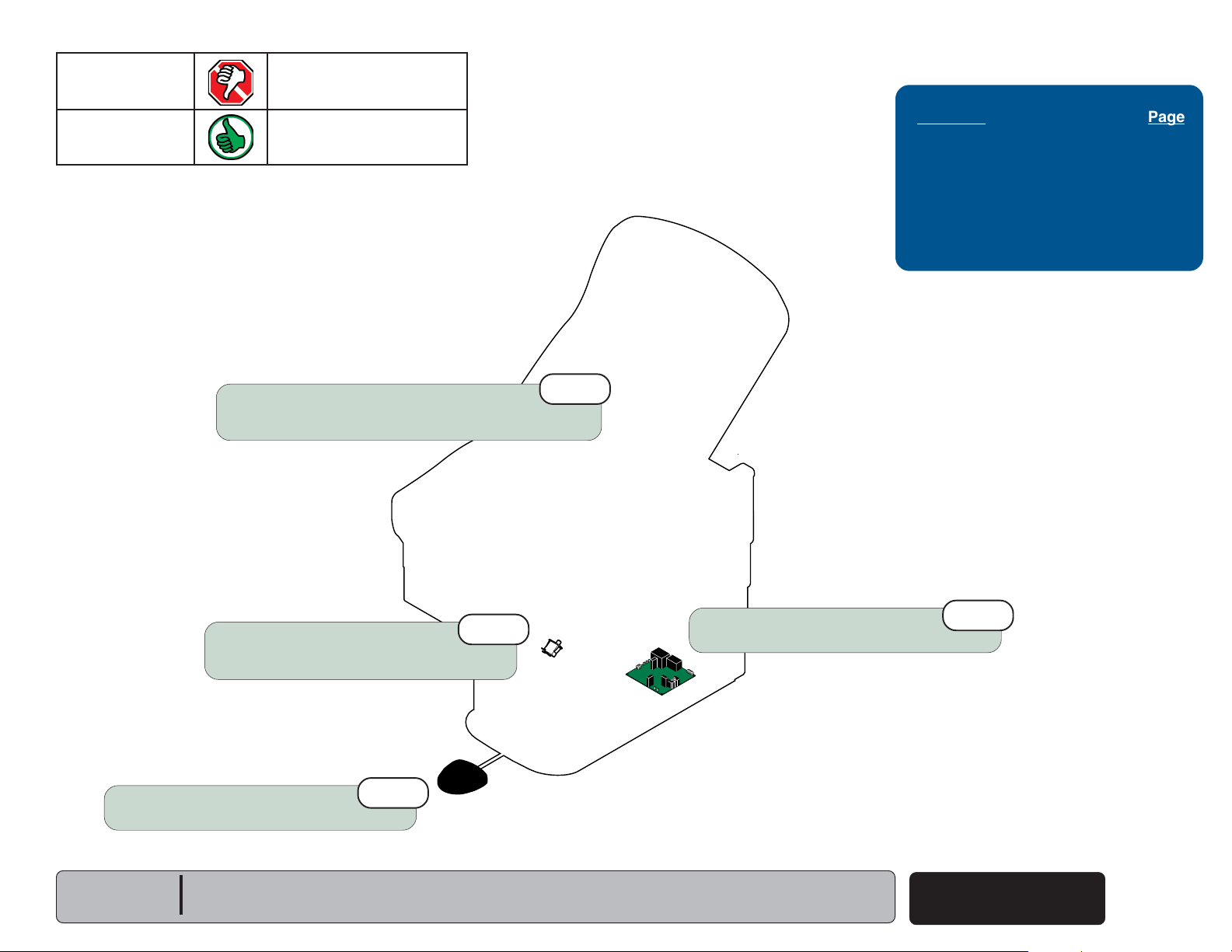

Page 14

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Base Up No movement

Base Down OK

Loose Wire Connections

(esp. Foot Control & Base Up/Down Limit Switches)

1st

Troubleshooting

Refer To: Page

Limit Switches.............................. B-4

Footswitch Test ........................... B-6

Base Relay Test .......................... B-20

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

Perform

Refer to: Section B - Foot Control

Models:

Serial Numbers:

Base Up Limit Switch

Perform

Refer to: Section B - Limit Switches

Footswitch Test

Limit Switch Test.

3rd

All

All

2nd

MA626800i

Perform

Refer to: Section B - Main PC Board

Base Relay Test

© Midmark Corporation 2003 SF-1838

4th

Base Up / Down

Rev. 2/08

A-5

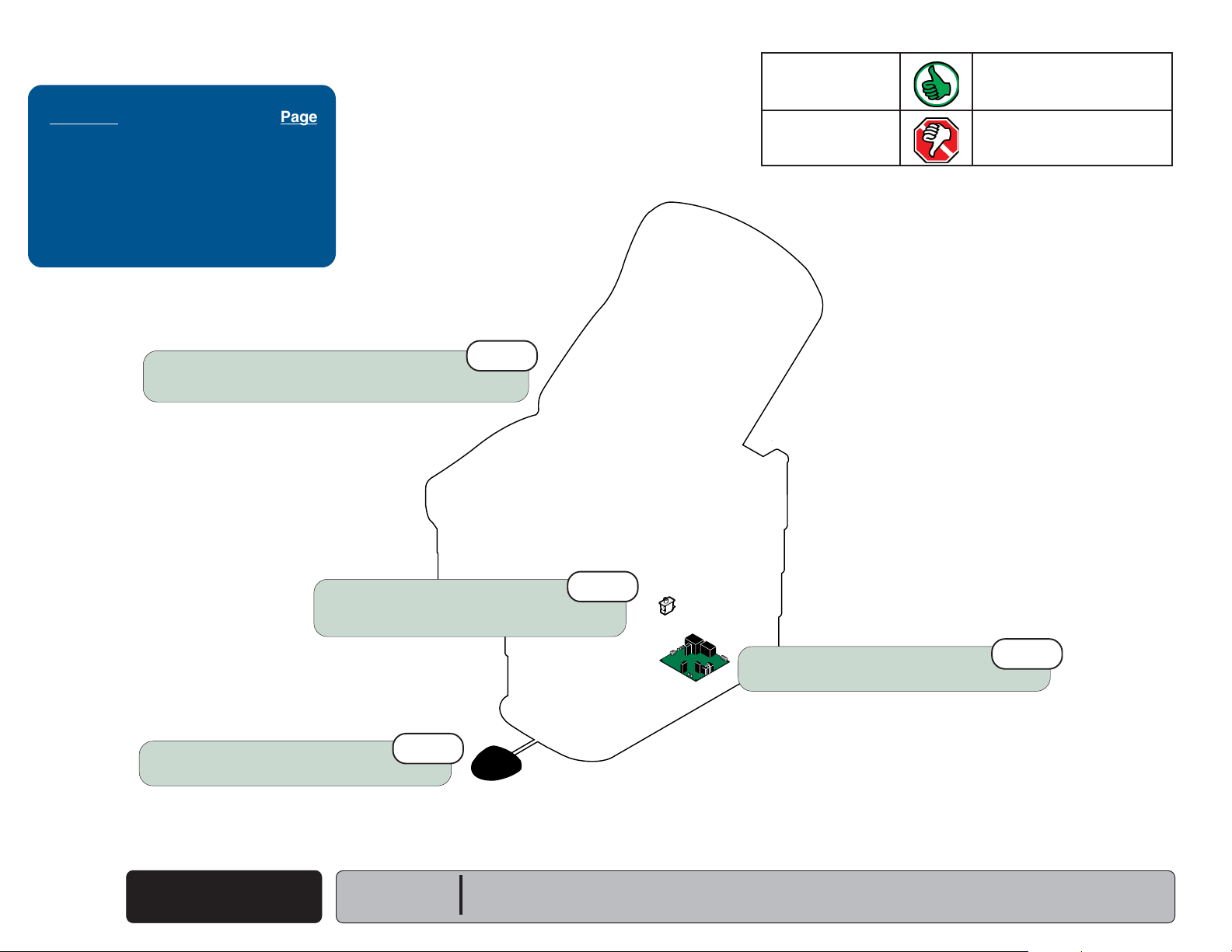

Page 15

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Limit Switches.............................. B-4

Foot Control ................................. B-6

Base Relay Test .......................... B-20

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

Loose Wire Connections

(esp. Foot Control & Base Down Limit Switches)

1st

noitcnuFsutatSmelborP

Base Up OK

Base Down No movement

Perform

Refer to: Section B - Foot Control

A-6

© Midmark Corporation 2003 SF-1838

Footswitch Test

Base Up / Down

Base Down Limit Switch

Perform

Refer to: Section B - Limit Switches

Rev. 2/08

Limit Switch Test.

3rd

Models:

Serial Numbers:

All

All

2nd

MA626700i

Perform

Refer to: Section B - Main PC Board

Base Relay Test

4th

Page 16

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Base Up Table drifts down.

Base Down Table drifts down.

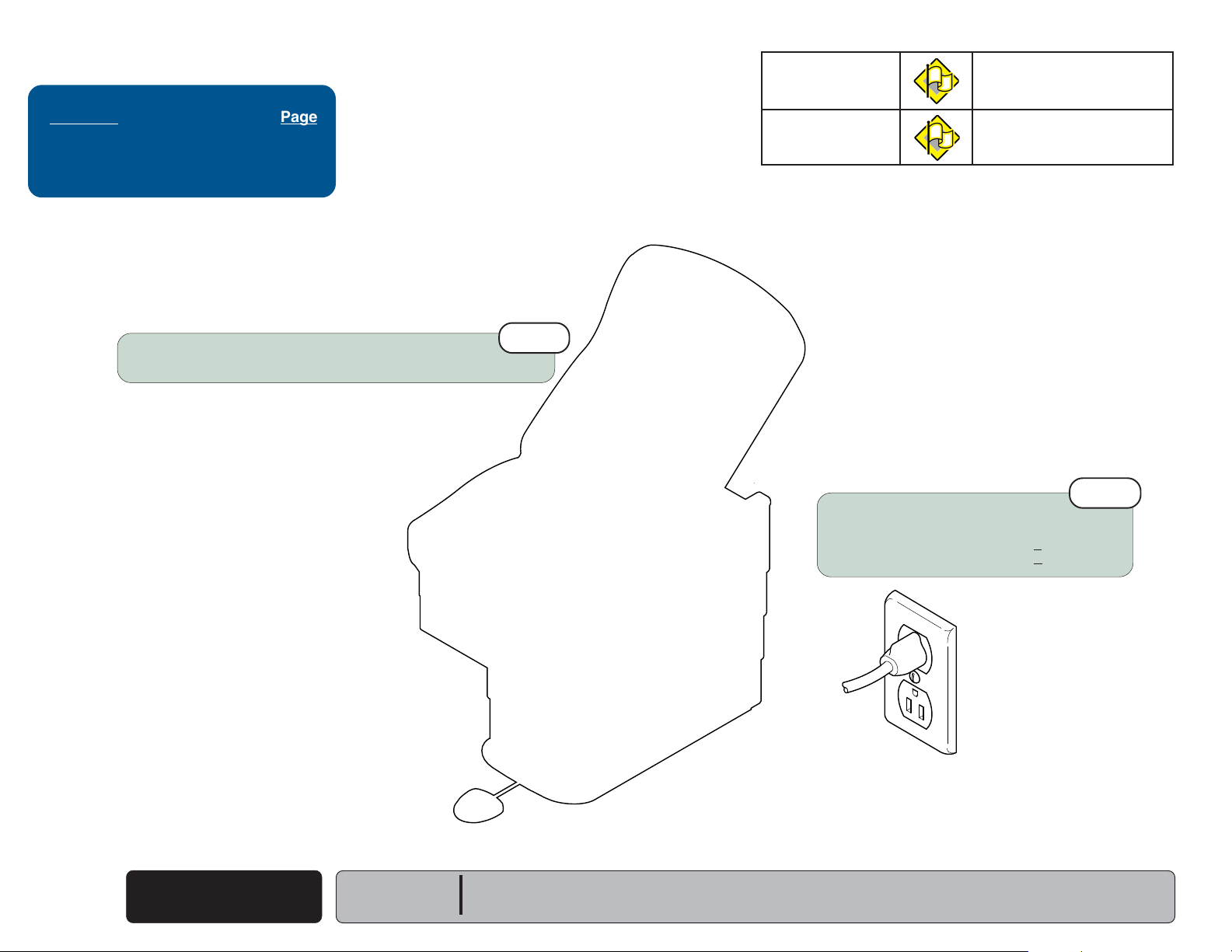

Run table up, then unplug power cord.

If drifting stops, perform

If drifting continues, check Base Actuator.

Footswitch Test

.

1st

Troubleshooting

Refer To: Page

Foot Control ................................. B-6

Base / Back Actuator ................... B-11

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

Models:

Serial Numbers:

Perform

Refer to: Section B - Foot Control

Footswitch Test

All

All

MA626900i

Base Actuator

To isolate the malfunction,

Refer to: Section B - Base / Back Actuator

© Midmark Corporation 2003 SF-1838

Base Up / Down

A-7

Page 17

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Main PC Board Replacement ....... B-22

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

noitcnuFsutatSmelborP

Base Up Press Base UP pedal,

table moves DOWN.

Base Down Press Base DOWN pedal,

table moves UP.

A-8

© Midmark Corporation 2003 SF-1838

Wire connections

(Check Foot Control & Base Actuator motor connections)

Base Up / Down

(reversed?)

Models:

Serial Numbers:

1st

All

All

MA627000i

Replace Main PC Board

Refer to: Section B - Main PC Board

2nd

Page 18

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Base Up Noisy / grinding / squeaking

Base Down Noisy / grinding / squeaking

Troubleshooting

Refer To: Page

Base Actuator Replacement .........B-11

Table Shroud Removal ..................C-2

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

Clean and lubricate base actuator threads.

Recommended lubricant: Lithium grease

If necessary, refer to:

Section C - Table Shroud Removal

1st

Remove any debris from base slides.

Do not lubricate base slides.

If necessary, refer to:

Models:

Serial Numbers:

2nd

Section C - Table Shroud Removal

All

All

MA627100i

3rd

Replace Base Actuator

Refer to: Section B - Base / Back Actuator

© Midmark Corporation 2003 SF-1838

Base Up / Down

A-9

Page 19

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Did patient exceed 400 lb. weight limit?

Inform staff that max. patient weight is 400 lbs.

1st

noitcnuFsutatSmelborP

Base Up Moves slowly

Base Down Moves slowly

A-10

© Midmark Corporation 2003 SF-1838

Base Up / Down

Models:

Serial Numbers:

All

All

MA627200i

Low voltage to table

Required voltage:

115 VAC models ............... 115

230 VAC models .............. 230

2nd

+10% VAC

+10% VAC

Page 20

MA630300i

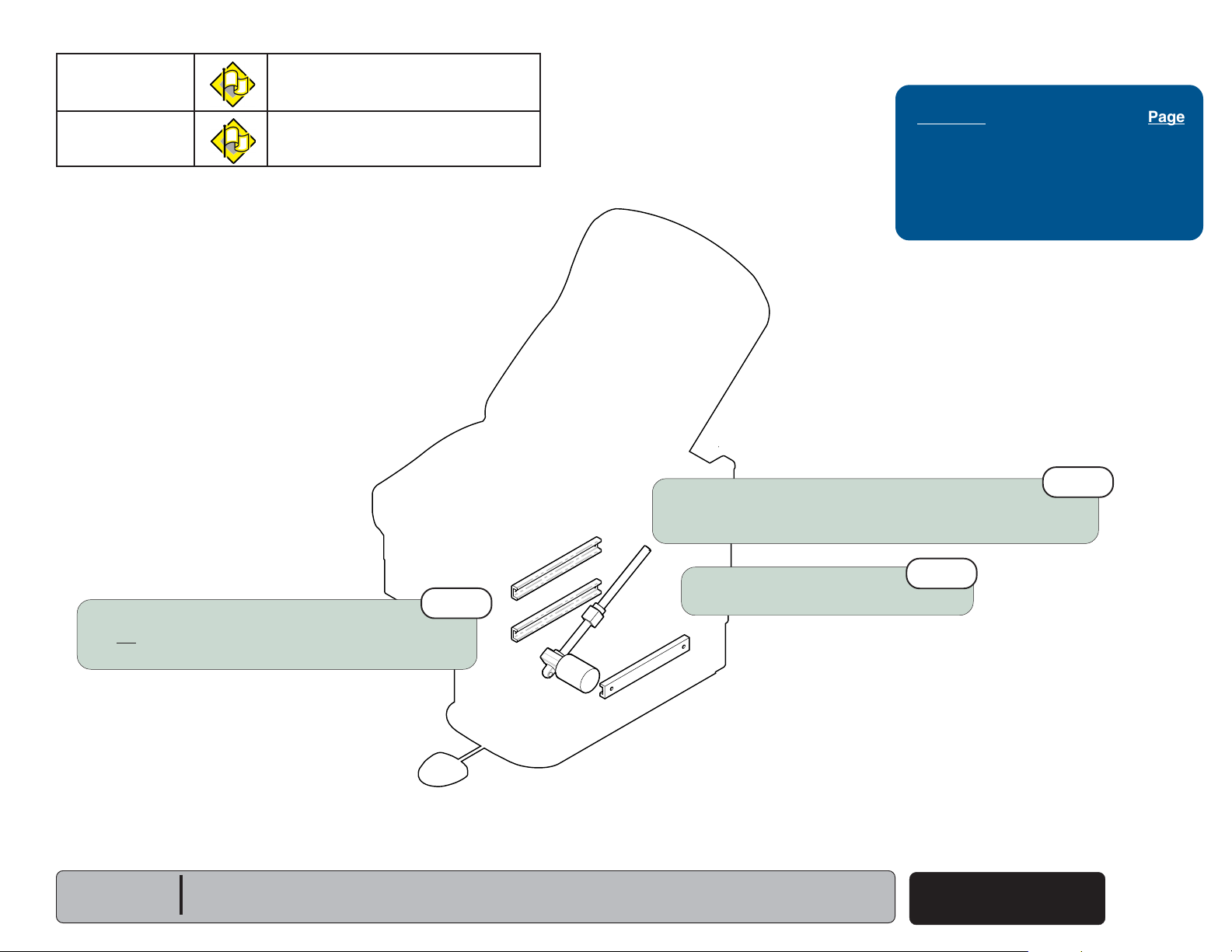

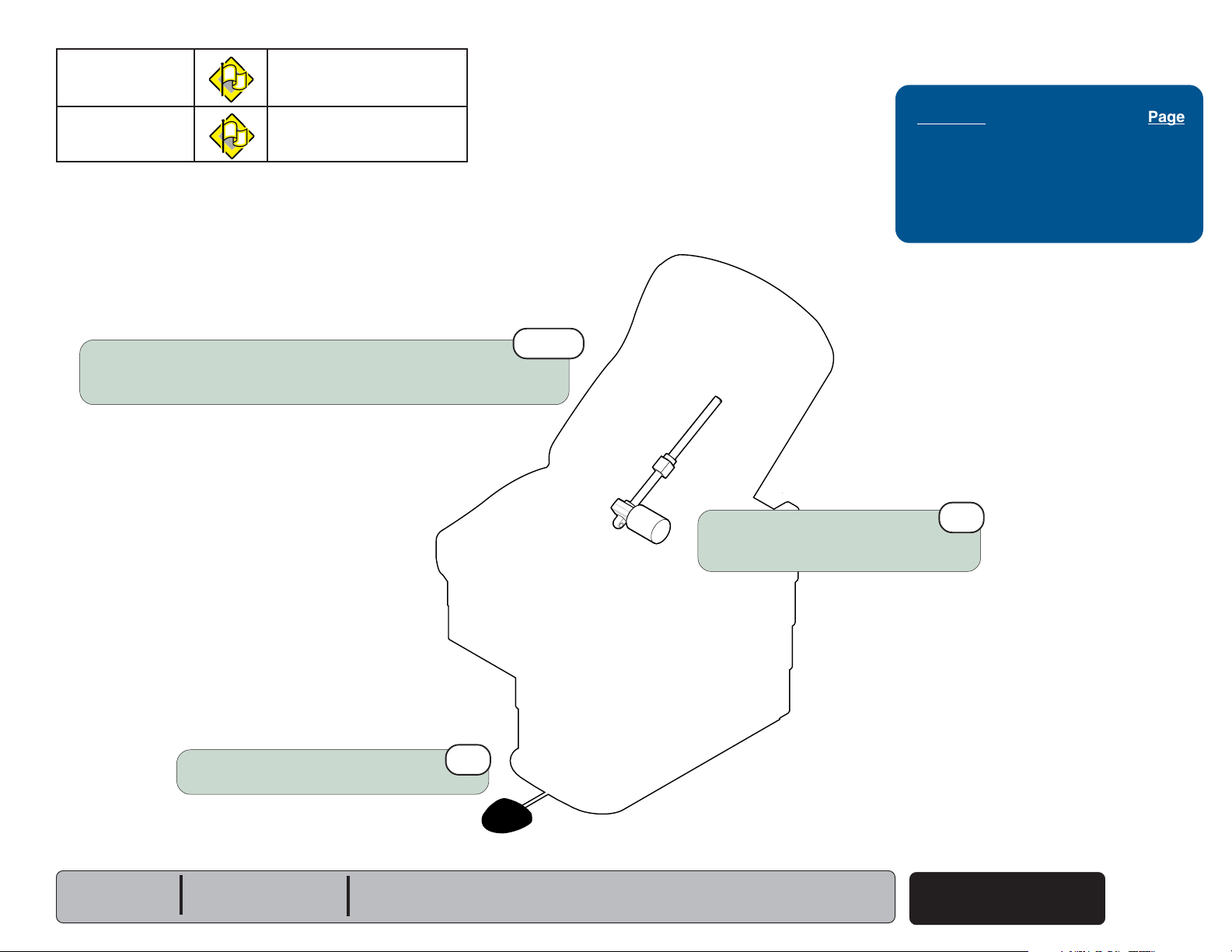

Back UP / DOWN Function (Manual)

Go To Table Of Contents

Go To Page:

This illustration shows only the components that affect the Back UP / DOWN function.

Cam

Troubleshooting

Troubleshooting

[Back Up / Down Function (Manual)]

Problem Page

Back Drifts Up or Down .....................

No Movement ....................................

Difficult To Position ............................

A-12

A-13

A-13

Back Up / Down Operation

When either back release handle is squeezed,

linkage causes the cam to rotate. When the cam

compresses the pin on the top of the gas

cylinder, the pressure inside the cylinder is

released and the back section can be positioned

Up or Down.

Back Release

Handle

(Manual)

Gas Cylinder

Models:

Serial Numbers:

222 (all)

All

622 (all)

All

Back Up / Down

Manual

© Midmark Corporation 2003 SF-1838

A-11

Page 21

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Back Release Handle

Adjustment ............................. B-17

Gas Cylinder

Replacement & Adjustment.... B-18

Exploded Views / Part Numbers .. E-1

Gas cylinder screwed in too far.

Perform Gas Cylinder Adjustment

Refer to: Section B - Back Release Mechanism

1st

noitcnuFsutatSmelborP

Back Up/Down Back section drifts

2nd

Perform

Handle Adjustment

Refer to: Section B - Back Release Mechanism

Replace Gas Cylinder

Refer to: Section B - Back Release Mechanism

Back Release

3rd

A-12

© Midmark Corporation 2003 SF-1838

Back Up / Down

Manual

Models:

Serial Numbers:

222 (all)

All

MA630400i

622 (all)

All

Page 22

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Back Up/Down No movement

Troubleshooting

Difficult to position

Gas cylinder not screwed in far enough.

Perform Gas Cylinder Adjustment

Refer to: Section B - Back Release Mechanism

3rd

Replace Gas Cylinder

Refer to: Section B - Back Release Mechanism

1st

Refer To: Page

Back Release Handle

Adjustment ............................. B-17

Gas Cylinder

Replacement & Adjustment.... B-18

Exploded Views / Part Numbers .. E-1

2nd

Perform

Handle Adjustment

Refer to: Section B - Back Release Mechanism

Back Release

Models:

Serial Numbers:

222 (all)

All

622 (all)

All

MA630400i

Back Up / Down

Manual

© Midmark Corporation 2003 SF-1838

A-13

Page 23

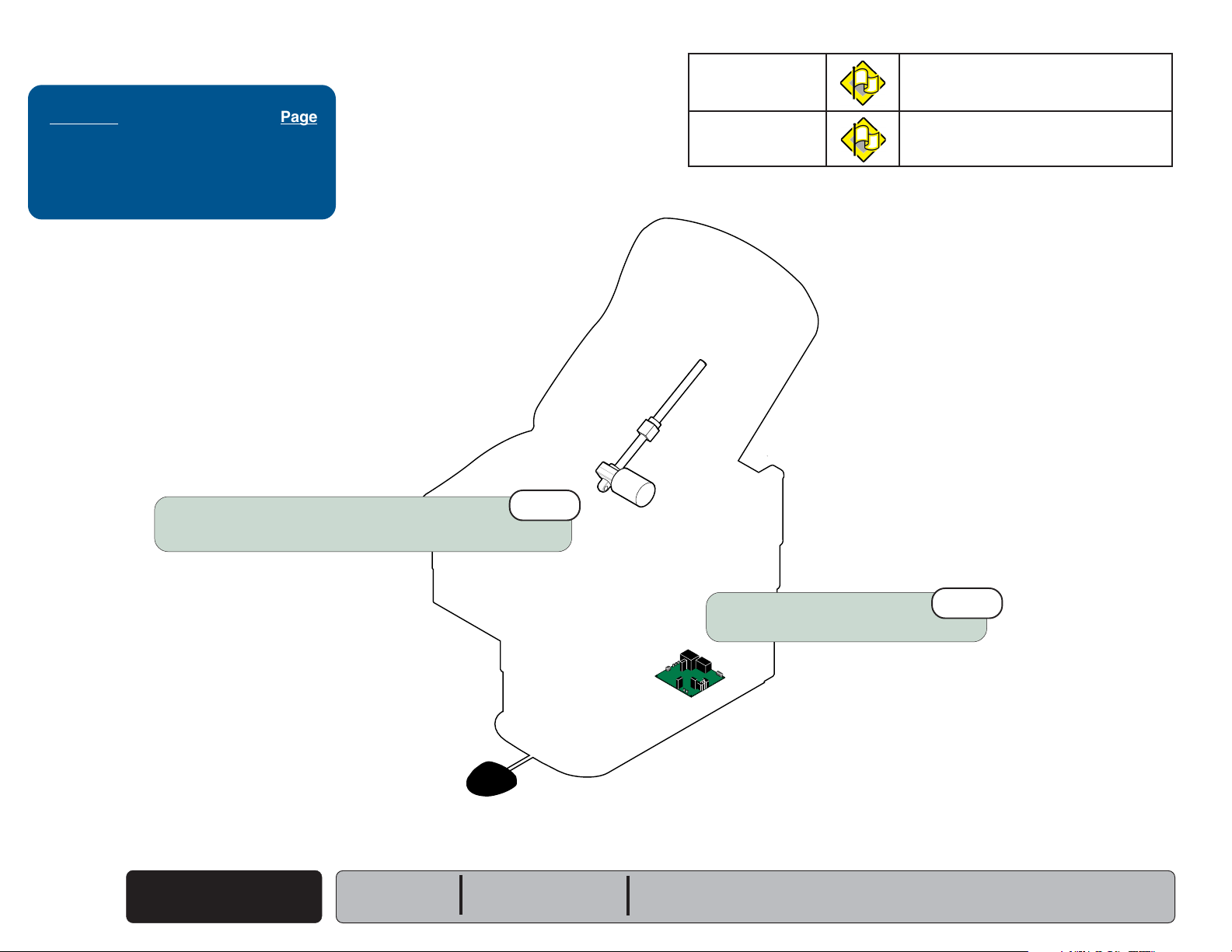

Troubleshooting

Go To Table Of Contents

Go To Page:

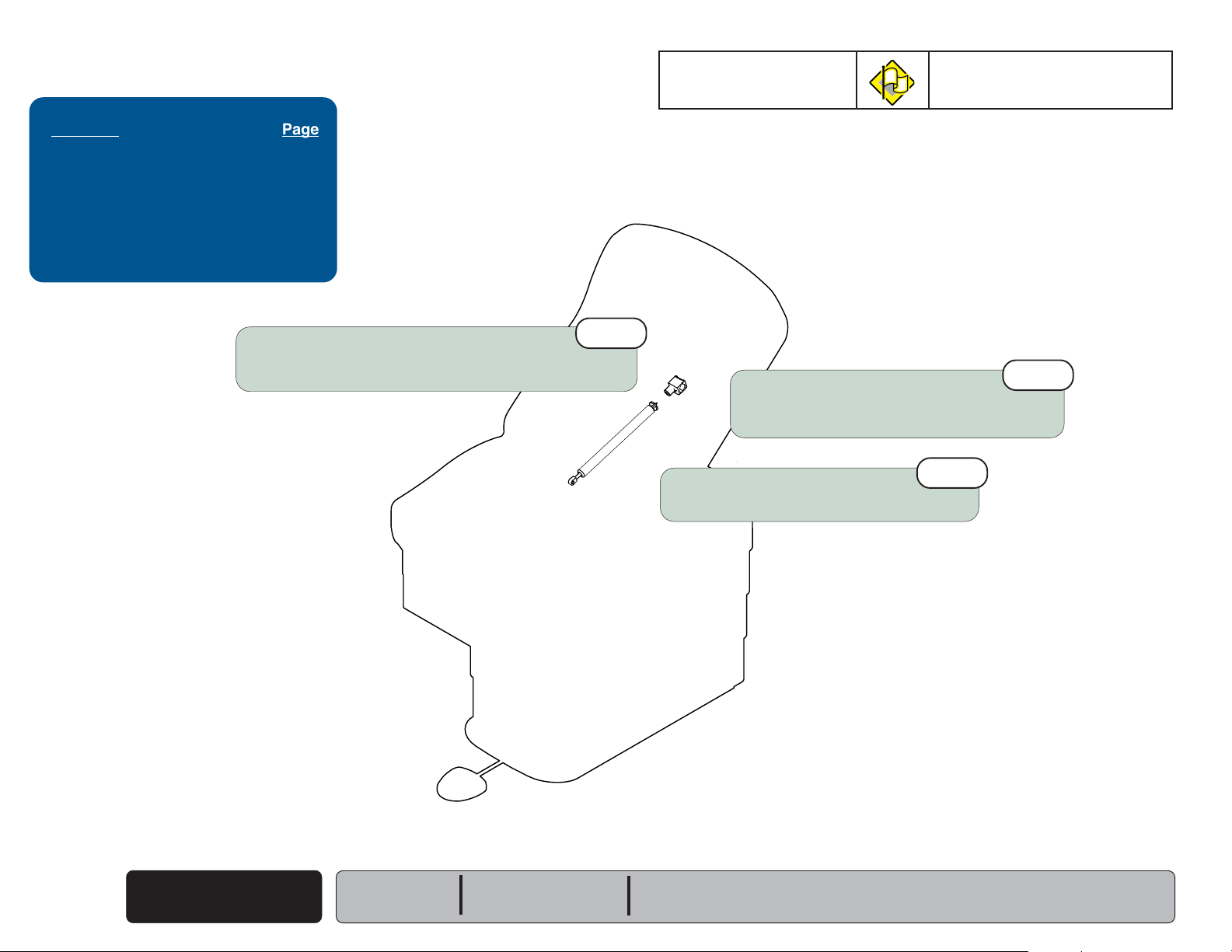

Back UP / DOWN Function (Power)

This illustration shows only the components that affect the Back UP / DOWN function.

Refer to the following page for a detailed description of current flow during this function.

Primary Fuses

[All Functions]

NOTE:

Line voltage (230 VAC) is supplied thru

two fuses

inlet)

line voltage to 115 VAC before it

reaches the PC Board.

230 VAC models only

(located by the power cord

to a transformer that reduces the

115 VAC

[Back Up / Down Functions]

Back Motor Fuse

Troubleshooting

[Back Up / Down Function (Power)]

Problem Page

No UP or DOWN Functions

No DOWN Function (UP - OK)

No UP Function (DOWN - OK)

Back Drifts Down .................................

Moves Wrong Direction .......................

Noisy Operation ...................................

Moves Slowly ......................................

................ A-16

............ A-17

............ A-18

A-19

A-20

A-21

A-22

A-14

© Midmark Corporation 2003 SF-1838

Transformer Fuse

[All Functions]

Back Up / Down

Power

14 VAC

Foot Control

Back Up Limit Switch

[Back Up will not operate if switch is tripped]

Models:

Serial Numbers:

Main PC Board

223 (all)

All

48 VDC

Back Actuator

Back Down Limit Switch

[Back Down will not operate if switch is tripped]

MA630200i

623 (all)

All

Page 24

Troubleshooting

Go To Table Of Contents

Back UP / DOWN Function

(Power)

NOTE

On 230 VAC models, line voltage

supplied thru two fuses

to a transformer that reduces the line voltage

to 115 VAC before it gets to the PC board.

Power To Foot Control

115 VAC is supplied thru the two primary fuses

(F1 & F2)

[F4 fuse protects the transformer]

The transformer reduces the line voltage and

supplies 14 VAC to the foot control.

to the transformer on the PC board.

(located by IEC inlet)

(230 VAC)

.

is

Back Up Operation

NOTE

If the Back Up limit switch is tripped (open),

the Back Up function will not operate.

When the Back Up function is activated,

current

switch

on the PC Board energizes the back relay.

[F5 fuse protects the back motor]

(14 VAC)

(N.O)

flows thru the Up function foot

, then back to the PC board. Circuitry

.

NOTE

The Back Up/Down relay has four contacts:

(2) Normally Open: Back Up function

(2) Normally Closed: Back Down function

When the back relay is energized,

the (2) Normally Open contacts of the relay

close. When these contacts close, current

(

48 VDC)

When current flows to the actuator thru the

Normally Open contacts of the relay, the actuator

motor runs and raises the back section.

Actuator Motor runs until:

1. Foot control pedal is released.

2. Back Up limit switch is tripped.

3. 26 second software time limit is reached.

4. Fuse(s) opens (blows).

flows to the actuator motor.

[Primary, Back Motor, Transformer fuse]

Back Down Operation

NOTE

If the Back Down limit switch is tripped (open),

the Back Down function will not operate.

When the Back Down function is activated,

current

switch

(14 VAC)

(N.O.)

flows thru the Down function foot

, then back to the PC Board.

NOTE

The Back Up/Down relay has four contacts:

(2) Normally Open: Back Up function

(2) Normally Closed: Back Down function

When this voltage is applied, current

to the actuator motor thru the (2) Normally Closed

contacts of the Back Up/Down relay.

[The relay does not energize].

When voltage flows to the actuator thru the Normally

Closed contacts of the relay, the actuator motor runs

and lowers the back section.

Actuator Motor runs until:

1. Foot control pedal is released.

2. Back Down limit switch is tripped.

3. 26 second software time limit is reached.

4. Fuse(s) opens (blows).

[Primary, Back Motor, Transformer fuse]

(48 VDC)

flows

Models:

Serial Numbers:

223 (all)

All

623 (all)

All

Equipment Alert

If an overload condition* is detected the PC board will "beep" and all power functions will be

disabled. Release the function button, remove load, then retry function.

*(weight limit exceeded, mechanical binding, etc),

Back Up / Down

Power

© Midmark Corporation 2003 SF-1838

Rev. 8/24/12

A-15

Page 25

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Fuses ........................................... B-2

Limit Switches.............................. B-4

Foot Control ................................. B-6

Base / Back Actuator ................... B-11

Back Relay Test .......................... B-21

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

noitcnuFsutatSmelborP

Back Up No movement

Back Down No movement

Loose Wire Connections

(esp. Foot Control & Back Up/Down Limit Switches)

Main PC Board Fuse(s):

[Test fuses: F1, F2, F4, & F5]

Refer to: Section B - Fuses

Perform

Refer to: Section B - Main PC Board

Perform

Refer to: Section B - Foot Control

Footswitch Test

Back Relay Test

3rd

1st

5th

2nd

MA630100i

Back Actuator

To isolate the malfunction,

Refer to: Section B - Base / Back Actuator

230 V models only

230 VAC

Transformer Fuses (2)

Refer to: Section B - Fuses

230 VAC Transformer

4th

230 V models only

A-16

© Midmark Corporation 2003 SF-1838

Back Up / Down

Power

Rev. 5/07

Models:

Serial Numbers:

223 (all)

All

623 (all)

All

Page 26

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Back Up OK

Back Down No movement

Loose Wire Connections

(esp. Foot Control & Back Down Limit Switches)

1st

Troubleshooting

Refer To: Page

Limit Switches.............................. B-4

Foot Control ................................. B-6

Back Relay Test ......................... B-18

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Perform

Refer to: Section B - Foot Control

Footswitch Test

3rd

MA629200i

Back Down Limit Switch

Perform

Refer to: Section B - Limit Switches

Limit Switch Test.

Perform

Refer to: Section B - Main PC Board

Back Relay Test

2nd

4th

Models:

Serial Numbers:

223 (all)

All

623 (all)

All

Back Up / Down

Power

© Midmark Corporation 2003 SF-1838

A-17

Page 27

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Limit Switches.............................. B-4

Foot Control ................................. B-6

Back Relay Test ......................... B-18

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Loose Wire Connections

(esp. Foot Control & Back Up Limit Switches)

1st

noitcnuFsutatSmelborP

Back Up No movement

Back Down OK

Back Up Limit Switch

Perform

Refer to: Section B - Limit Switches

Limit Switch Test.

2nd

A-18

© Midmark Corporation 2003 SF-1838

Perform

Refer to: Section B - Foot Control

Back Up / Down

Power

Footswitch Test

Serial Numbers:

3rd

Models:

223 (all)

All

MA629100i

623 (all)

All

Perform

Refer to: Section B - Main PC Board

Back Relay Test

4th

Page 28

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Back Up Back drifts down.

Back Down Back drifts down.

Run back section up, then unplug power cord.

If drifting stops, perform

If drifting continues, check Back Actuator.

Footswitch Test

.

1st

Troubleshooting

Refer To: Page

Foot Control ................................. B-6

Base / Back Actuator .................. B-11

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Models:

Serial Numbers:

Perform

Refer to: Section B - Foot Control

Footswitch Test

223 (all)

All

623 (all)

All

MA629300i

Back Actuator

To isolate the malfunction,

Refer to: Section B - Base / Back Actuator

Back Up / Down

© Midmark Corporation 2003 SF-1838

Power

A-19

Page 29

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Main PC Board Replacement ....... B-22

Wiring Diagrams ............................ D-1

Exploded Views / Part Numbers ....E-1

noitcnuFsutatSmelborP

Back Up Press Back UP pedal,

back section moves DOWN.

Back Down Press Back DOWN pedal,

back section moves UP.

A-20

© Midmark Corporation 2003 SF-1838

Wire connections

(Check Foot Control & Base Actuator motor connections)

Back Up / Down

Power

(reversed?)

Models:

Serial Numbers:

1st

223 (all)

All

MA629400i

Replace Main PC Board

Refer to: Section B - Main PC Board

623 (all)

All

2nd

Page 30

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Back Up Noisy / grinding / squeaking

Back Down Noisy / grinding / squeaking

Troubleshooting

Refer To: Page

Back Actuator Replacement ....... B-15

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Clean and lubricate back actuator threads.

Recommended lubricant: Lithium grease

[NOTE: Unscrew the shaft cover to access actuator threads.

]

1st

Models:

Serial Numbers:

223 (all)

All

623 (all)

All

MA629500i

3rd

Replace Back Actuator

Refer to: Section B - Base / Back Actuator

Back Up / Down

Power

© Midmark Corporation 2003 SF-1838

A-21

Page 31

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Did patient exceed 400 lb. weight limit?

Inform staff that max. patient weight is 400 lbs.

1st

noitcnuFsutatSmelborP

Back Up Moves slowly

Back Down Moves slowly

2nd

Low voltage to table

Required voltage:

115 VAC models ............... 115

230 VAC models .............. 230

+10% VAC

+10% VAC

A-22

© Midmark Corporation 2003 SF-1838

Back Up / Down

Power

Models:

Serial Numbers:

223 (all)

All

MA627200i

623 (all)

All

Page 32

Drawer Heater System (optional)

Go To Table Of Contents

Go To Page:

This illustration shows only the components that affect the drawer heater system.

A detailed description of current flow during this function also appears below.

Drawer Heater Operation

115 VAC is supplied directly to the Drawer Heater

switch thru two fuses on the Distribution Board.

[Voltage bypasses the Main PC Board].

When the drawer heater switch is turned ON,

current flows to the heater plate. When the heater

plate is energized, it warms the contents of the

drawer.

NOTE:

Line voltage (230 VAC) is supplied thru

two fuses

a transformer that reduces the line

voltage to 115 VAC before it reaches

the Distribution Board.

230 VAC models only

(located by the IEC inlet)

to

115 VAC

Troubleshooting

Troubleshooting

[Drawer Heater System]

Problem Page

Drawer Heater Does Not Warm Up:

Switch Does Not Illuminate

Switch Illuminates...........................

Drawer Heater Works Properly:

Switch Does Not Illuminate.............

Distribution Board Fuses

[Drawer Heater only]

............ A-24

A-25

A-26

Models:

Serial Numbers:

Heater Plate

222

(-003 /-004 /-007 /-008 /-010 /-016)

All

(-003 /-004 /-007 /-008 /-010 /-016)

223

All

115 VAC

622

(-002 /-004 /-006-008)

All

115 VAC

Heater Switch

MA629000i

623

(-002 /-004 /-008 / -010)

All

Drawer Heater System

A-23

© Midmark Corporation 2003 SF-1838

Page 33

Troubleshooting

Go To Table Of Contents

Go To Page:

noitcnuFsutatSmelborP

Drawer Heater Does not heat up.

Refer To: Page

Fuses ........................................... B-2

Drawer Heater System ............... B-23

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Loose Wire Connections

(between heater switch and power cord)

1st

Heater Switch Does

2nd

Distribution Board Fuses

Refer to: Section B - Fuses

not illuminate

Drawer Heater System

A-24

© Midmark Corporation 2003 SF-1838

3rd

Perform

Heater Switch Test

Refer to: Section B - Drawer Heater System

Drawer

Models:

Serial Numbers:

MA628800i

222

(-003 /-004 /-007 /-008 /-010 /-016)

All

(-003 /-004 /-007 /-008 /-010 /-016)

223

All

(-002 /-004 /-006-008)

622

All

(-002 /-004 /-008 / -010)

623

All

Page 34

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Drawer Heater Does not heat up.

Heater Switch OK

Loose Wire Connections

(between heater switch and heater plate)

(Illuminates)

1st

Troubleshooting

Refer To: Page

Fuses ........................................... B-2

Drawer Heater System ............... B-23

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Models:

Serial Numbers:

(-003 /-004 /-007 /-008 /-010 /-016)

222

All

Perform

Heater Plate Test

Refer to: Section B - Drawer Heater System

223

(-003 /-004 /-007 /-008 /-010 /-016)

All

Drawer

MA628900i

622

(-002 /-004 /-006-008)

All

2nd

(-002 /-004 /-008 / -010)

623

All

Drawer Heater System

A-25

© Midmark Corporation 2003 SF-1838

Page 35

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Drawer Heater System ............... B-23

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

noitcnuFsutatSmelborP

Drawer Heater OK

Heater Switch Does

not illuminate

Replace Drawer Heater Switch

Refer to: Section B - Drawer Heater System

Drawer Heater System

A-26

© Midmark Corporation 2003 SF-1838

2nd

Models:

Serial Numbers:

MA628800i

222

(-003 /-004 /-007 /-008 /-010 /-016)

All

(-003 /-004 /-007 /-008 /-010 /-016)

223

All

(-002 /-004 /-006-008)

622

All

(-002 /-004 /-008 / -010)

623

All

Page 36

Table Receptacle (optional)

Go To Table Of Contents

Go To Page:

This illustration shows only the components that affect the table receptacle.

A detailed description of current flow also appears below.

Table Receptacle

115 VAC is supplied directly to the table

receptacle thru the circuit breaker(s)*.

[Voltage bypasses the Main PC Board].

NOTE:

There is a connection point for the receptacle

wiring harness at the distribution board.

Current does not flow thru the distribution board fuses.

Models w/drawer heater only

Toggle style

(Tripped = no power)

Push-Button style

(Tripped = no power)

Troubleshooting

Troubleshooting

[Table Receptacle]

Problem Page

No Power At Receptacle ...................

A-28

Circuit Breakers (2)

222/223

(-015 & -016)

622/623

(-007 & -008)

5

A

M

P

5

A

M

P

(Reset = power)

(Reset = power)

Circuit Breaker (1)*

(*Canadian models do not have a circuit breaker)

222/223

(-002 /-004 /-006 /-008)

(-011 thru -014)

622/623

(-001 /-002 /-005 /-006)

MA603405i

Models:

Serial Numbers:

Models:

Serial Numbers:

(-002 /-004 /-006 /-008)

222

(-011 thru -016)

All

(-002 /-004 /-006 /-008)

223

(-011 thru -016)

All

622

(-001 /-002)

(-005 thru -008)

All

623

(-001 /-002)

(-005 thru -008)

All

Table Receptacle

© Midmark Corporation 2003 SF-1838

Rev. 4/06

A-27

Page 37

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Is circuit breaker tripped?

[Lift seat section to access circuit breaker(s) - press to reset]

Toggle style

(Tripped = no power)

(Reset = power)

1st

noitcnuFsutatSmelborP

Table Receptacle No power.

All other functions OK

5

A

M

P

5

A

M

P

A-28

© Midmark Corporation 2003 SF-1838

Table Receptacle

Replace receptacle

Models:

Serial Numbers:

Models:

Serial Numbers:

(-002 /-004 /-006 /-008)

3rd

222

(-011 thru -016)

All

Loose wire connections

(between table receptacle and power cord)

MA630601i

223

(-002 /-004 /-006 /-008)

(-011 thru -016)

All

622

(-001 /-002)

(-005 thru -008)

All

2nd

623

(-001 /-002)

(-005 thru -008)

All

Page 38

Auto Return Function

Go To Table Of Contents

Go To Page:

This illustration shows only the components that affect the Auto Return function.

Refer to the following page for a detailed description of current flow during this function.

Primary Fuses

[All Functions]

115 VAC

Base Motor Fuse

[Base Up & Down Functions]

48 VDC

Troubleshooting

Troubleshooting

[Auto Return Function]

Problem Page

Auto Return Function Does Not Work /

Base Down Function:

Malfunctioning ..................................

Works Properly...............................

A-2

A-31

Transformer Fuse

[All Functions]

Auto Return

Stop Switch

Models:

Serial Numbers:

Auto Return

Start Switch

623

14 VAC

(all)

All

Foot

Control

MA627800i

Auto Return

Limit Switches

[Auto Return function will not operate

if any of these limit switches are tripped]

Base Down

Limit Switch

Base Actuator

Auto Return

Function

© Midmark Corporation 2003 SF-1838

A-29

Page 39

Troubleshooting

Go To Table Of Contents

Auto Return Function

Power To Foot Control

115 VAC is supplied thru the two primary fuses

(F1 & F2)

[F4 fuse protects the transformer]

The transformer reduces the line voltage and

supplies 14 VAC to the foot control.

to the transformer on the PC board.

.

Auto Return Operation

NOTE

If either of the Auto Return limit switches or

the Base Down limit switch are tripped (open),

the Auto Return function will not operate.

When the Auto Return Switch is depressed

(closed), current

switch, to the PC Board.

(14 VAC)

flows thru the

NOTE

The Base Up / Down relay, located on the PC

Board, has four contacts (DPDT):

(2) Normally Open: Base Up function

(2) Normally Closed: Base Down function

Auto Return

A-30

© Midmark Corporation 2003 SF-1838

Function

When this voltage is applied, current

to the actuator motor thru the (2) Normally Closed

contacts of the Base Up / Down relay.

[The relay does not energize].

When voltage flows to the actuator thru the Normally

Closed contacts of the relay, the actuator motor runs

lowering the table.

Actuator Motor runs until:

1. Stop button is depressed.

2. Auto Return limit switch(es) is tripped.

3. 18 second software time limit is reached.

4. Base Down limit switch is tripped.

5. Fuse(s) opens (blows).

Models:

Serial Numbers:

(48 VDC)

[Primary, Base Motor, Transformer fuse]

623

(all)

All

flows

Page 40

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Auto Return No movement

Base Down OK

Loose Wire Connections

(esp. Foot Control, Auto Return Limit Switches)

1st

Troubleshooting

Refer To: Page

Limit Switches.............................. B-4

Foot Control ................................. B-6

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Perform

Test Auto Return Start & Stop switches

Refer to: Section B - Foot Control

Models:

Serial Numbers:

Footswitch Test

623

(all)

All

3rd

MA630701i

Auto Return Limit Switches

Perform

Refer to: Section B - Limit Switches

Limit Switch Test.

© Midmark Corporation 2003 SF-1838

2nd

Auto Return

Function

A-31

Page 41

Troubleshooting

Go To Table Of Contents

Go To Page:

Upholstery Heater System (optional)

This illustration shows only the components that affect the Upholstery Heater System.

A detailed description of current flow during this function also appears below.

Upholstery Heater Operation

115 VAC is supplied thru the IEC inlet

to the Distribution PC board and then to

the Upholstery Heater PC board at J2 & J3.

Fuses F1 and F2 protect the circuit.

Circuitry on PC board converts 115 VAC to 12 VAC.

Troubleshooting

[Upholstery Heater System]

Problem Page

Heater Does Not Warm Up:

Switch Does Not Illuminate

Switch Illuminates ............................

Heater Works Properly:

Switch Does Not Illuminate ..............

............. A-33

A-34

A-35

Depressing and releasing the momentary

On/ Off Switch supplies approximately

12 VAC to the Upholstery Heater.

A timer on the PC board

On/ Off Switch is depressed)

activated for an 8 hour period unless the Switch

is depressed Off.

(Temperature knob not present on later models)

The upholstery heater temperature can be

regulated by the operator. Turning the

temperature knob will increase or decrease the

voltage to the heater. The temperature can be

varied to a maximum of 105O F (41O C).

A thermostat, located in Back Heating Pad,

opens at 131O F (55OC) +/- 10% removing

power from both Back and Seat heating

elements.

Upholstery Heater runs until:

1. Stop button is depressed.

2. 8 hour time limit is reached.

3. Fuse(s) on Upholstery Heater PCB

opens (blows).

(initiated when the

keeps the heater

Back

Upholstery

Heater

12 VAC

On/Off

Switch

Temperature

Control Knob

(Early models only)

Seat

12 VAC

Upholstery

Heater PCB

Upholstery

Heater

PCB

Fuses

F1

F2

Distribution

Board

115 VAC

Upholstery Heater

A-32

© Midmark Corporation 2003 SF-1838

Rev. 2/11

Models:

Serial Numbers:

(-002 /-004 /-006-008)

622

All

MA629600i

623

(-002 /-004 /-008 / -010)

All

Page 42

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Upholstery Heater Does not heat up.

Heater Switch Does

Loose Wire Connections

Distribution Board to Upholstery PCB,

Upholstery PCB to Heater Switch.

not illuminate

1st

Upholstery PCB Fuse(s)

Test Uph. PC Board fuses.

Refer to: Section B - Fuses

Troubleshooting

Refer To: Page

Fuses ........................................... B-2

Uph. Heater PC Board Test ........ B-29

Uph. Heater Switch Test ............. B-33

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

2nd

Perform

Refer to: Section B - Upholstery Heater System

Models:

Serial Numbers:

Uph. Heater Switch Test

(-002 /-004 /-006-008)

622

(-002 /-004 /-008 / -010)

All

3rd

623

All

Perform

Refer to: Section B - Upholstery Heater System

MA629900i

Uph. Heater PC Board Test

4th

Upholstery Heater

© Midmark Corporation 2003 SF-1838

A-33

Page 43

Troubleshooting

Go To Table Of Contents

Go To Page:

Refer To: Page

Fuses ........................................... B-2

Uph. Heater PC Board Test ........ B-29

Uph. Heater Test ........................ B-32

Uph. Heater Switch Test ............. B-33

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

3rd

Perform

Refer to: Section B - Upholstery Heater System

Uph. Heater Test

noitcnuFsutatSmelborP

Upholstery Heater Does not heat up.

Heater Switch Illuminates.

Perform

Refer to: Section B - Upholstery Heater System

Upholstery Heater

A-34

© Midmark Corporation 2003 SF-1838

Uph. Heater Switch Test

Perform

Refer to: Section B - Upholstery Heater System

Uph. Heater PC Board Test

Serial Numbers:

2nd

Models:

4th

622

(-002 /-004 /-006-008)

All

MA629900i

(-002 /-004 /-008 / -010)

623

All

Loose Wire Connections

Upholstery PCB to heater,

Back and Seat heater connection.

Upholstery PCB to heater switch.

1st

Page 44

noitcnuFsutatSmelborP

Go To Table Of Contents

Go To Page:

Upholstery Heater OK

Heater Switch Does not illuminate

Troubleshooting

Refer To: Page

Upholstery Heater Switch

Replacement .......................... B-25

Wiring Diagrams .......................... D-1

Exploded Views / Part Numbers .. E-1

Replace Uph. Heater Switch

Refer to: Section B - Upholstery Heater System

Models:

Serial Numbers:

622

(-002 /-004 /-006-008)

All

1st

(-002 /-004 /-008 / -010)

623

All

MA629900i

Upholstery Heater

A-35

© Midmark Corporation 2003 SF-1838

Page 45

Troubleshooting

Go To Table Of Contents

A-36

© Midmark Corporation 2003 SF-1838

Models:

Serial Numbers:

Page 46

Component Testing & Repair

Go To Table Of Contents

Click on the Go To Page button and enter the desired

page number. (Note: Letters are case sensitve. ex. B-2)

Go To Page:

Component

Testing & Repair

Components Page

Fuses ............................................... B-2

Limit Switches ...................................... B-4

Foot / Hand Control .............................. B-6

Base Actuator ....................................... B-11

Back Actuator

Back Release Mechanism

Main PC Board ..................................... B-19

Drawer Heater System ......................... B-23

Upholstery Heater System .................... B-29

(power) ..........................

(manual) .....

B-11

B-17

Section B

Models:

Serial Numbers:

© Midmark Corporation 2003 SF-1838

B-1

Page 47

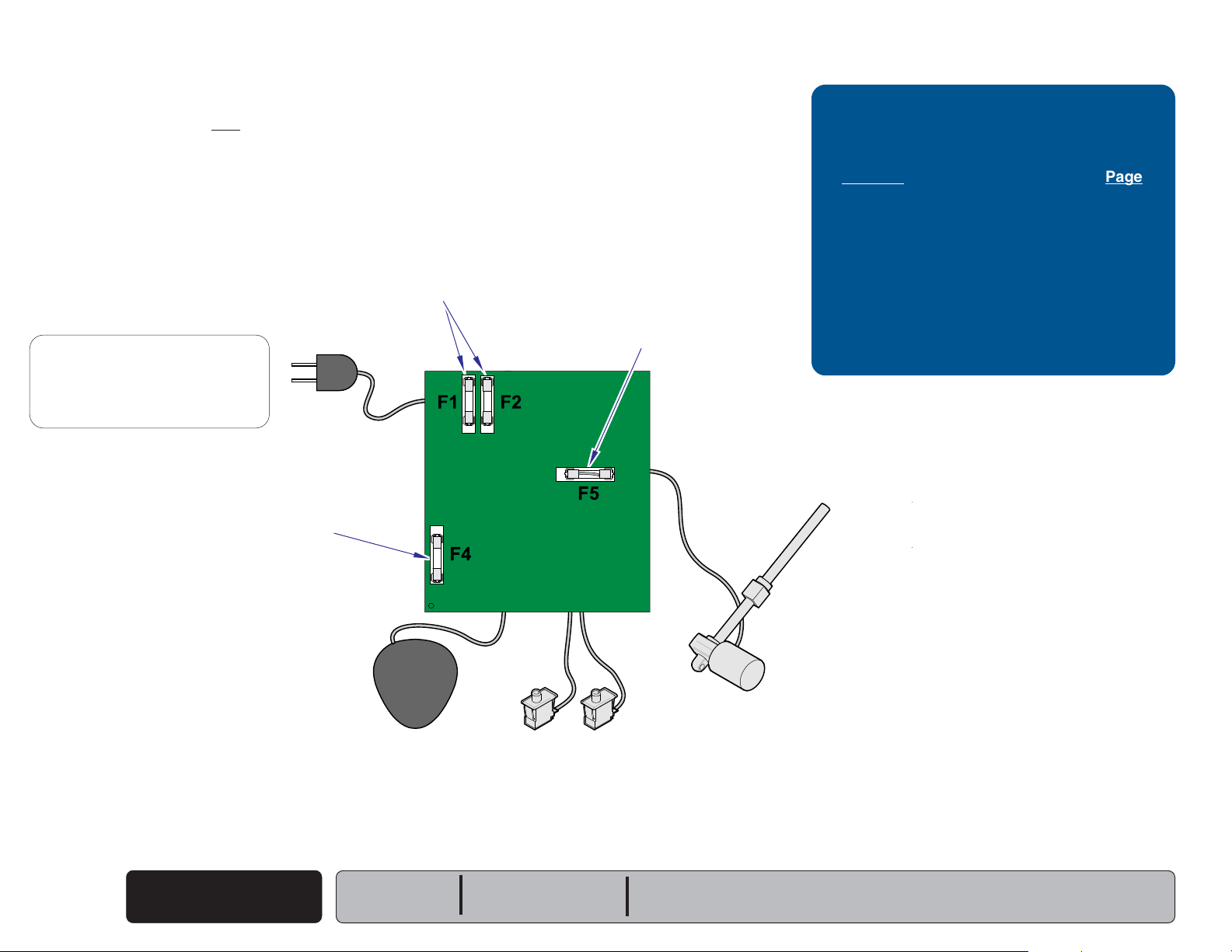

Component Testing & Repair

Go To Table Of Contents

Go To Page:

Fuses

Location

Distribution Board

(Early models w/drawer heater)

Fuses Page

Location ............................................... B-2

Fuse Test ............................................. B-3

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Fuse Ratings & Part Numbers .............. E-24

Upholstery Heater PC Board

B-2

© Midmark Corporation 2003 SF-1838

Fuses

Distribution Board

(Later models w/drawer heater)

Models:

Serial Numbers:

Power Cord Inlet

(230V & Canadian models only)

Main PC Board

MA627400i

All

All

Page 48

Component Testing & Repair

Go To Table Of Contents

Fuses

Fuse Test

- continued

Fuse Test

Step 1: Set meter to 200

Ω.Ω.

Ω.

Ω.Ω.

Fuse Test

Step 2: Place meter probes

on each end of fuse.

Models:

Serial Numbers:

All

All

gndaeRreteMsutatSnoitcAderiuqeR

OL

Any

resistance Fuse is good.

reading

© Midmark Corporation 2003 SF-1838

Replace fuse.

Fuses

B-3

Page 49

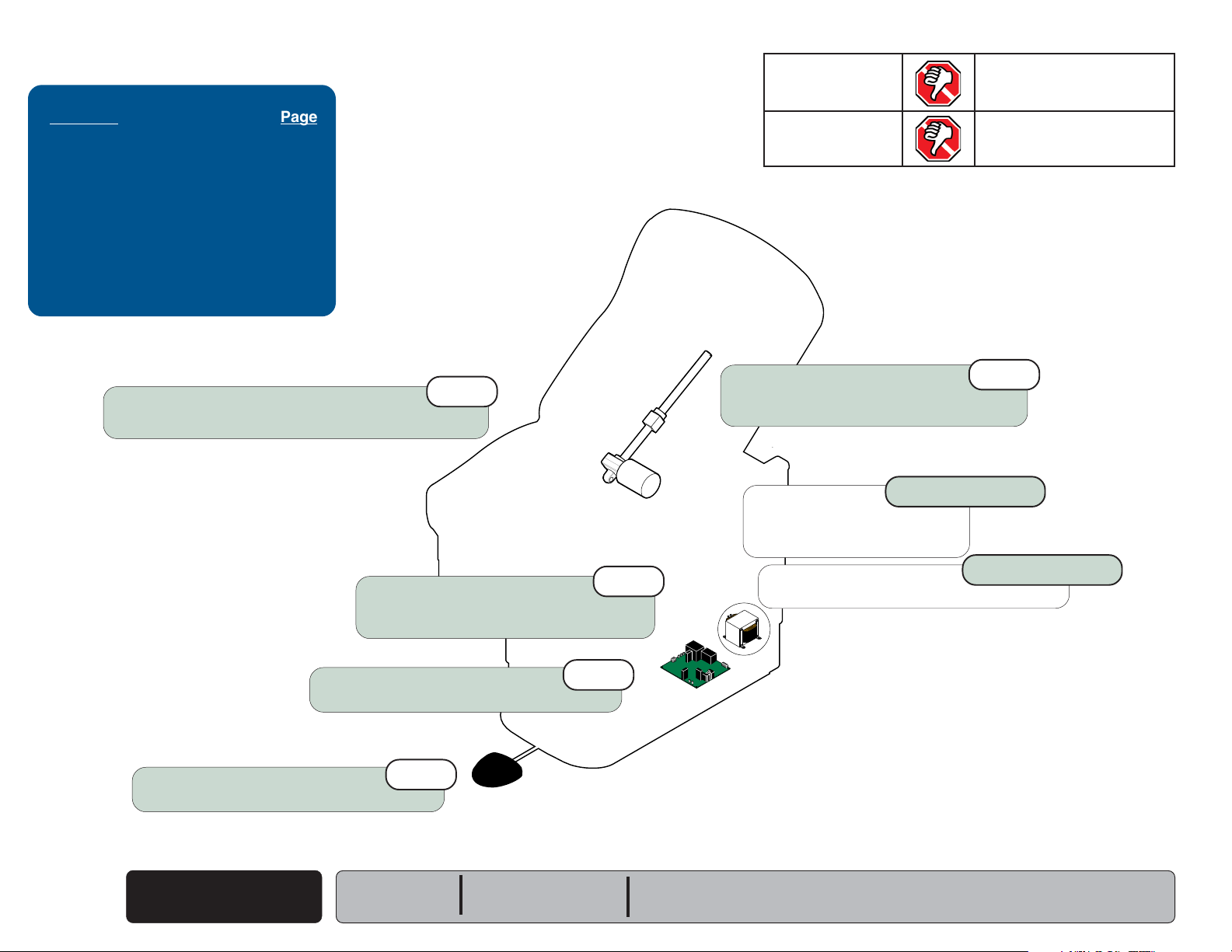

Component Testing & Repair

Go To Table Of Contents

Go To Page:

Limit Switches

Location

Limit Switches Page

Location ............................................... B-4

Limit Switch Test .................................. B-5

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Part Number

(all) ....................

015-1055-00

Attention!

All limit switches are the same.

They can be "traded" to troubleshoot.

Base Down Limit Switch

Affected Functions: Base DOWN

Auto Return (623 only)

623 only

Auto Return Limit Switches (2)

Affected Function: Auto Return

Back Up Limit Switch

Affected Function: Back UP

MA627600i

Base Up Limit Switch

Affected Function: Base UP

Back Down Limit Switch

Affected Function: Back DOWN

223 / 623 only

223 / 623 only

B-4

© Midmark Corporation 2003 SF-1838

Limit Switches

Models:

Serial Numbers:

All

All

Page 50

Component Testing & Repair

Go To Table Of Contents

Limit Switches

- continued

Limit Switch Test

Attention!

All limit switches are the same.

They can be "traded" to troubleshoot.

Limit Switch Test

Step 1: Remove limit switch.

Disconnect wires.

MA627700i

Limit SwitchTest

Step 2: Set meter to 200

Limit Switch Test

Step 3: Place meter probes on

Note: Check switch 'tripped' and 'untripped'.

Ω.Ω.

Ω.

Ω.Ω.

COM and NC

terminals.

With switch 'tripped'...

Models:

Serial Numbers:

gndaeRreteMsutatSnoitcAderiuqeR

OL

less than or = to Replace switch

5 ohms

Switch is good.

Perform next check.

All

All

With switch 'untripped'...

gndaeRreteMsutatSnoitcAderiuqeR

OL

Any

resistance Switch is good.

reading Perform next check.

Replace switch

Limit Switches

© Midmark Corporation 2003 SF-1838

B-5

Page 51

Component Testing & Repair

Go To Table Of Contents

Go To Page:

Foot / Hand Control

Foot Switch Test - 222 / 622

Foot SwitchTest

Step 1: Remove foot control switch.

Note: Refer to Foot Switch Replacement 222 / 622.

Foot Switch Test

Step 2: Set meter to

Ω.Ω.

Ω.

Ω.Ω.

Foot Switch Test

Step 3: Place meter probes on

COM and NO

terminals.

Foot / Hand Control Page

Foot Switch Test

Foot / Hand Control Test

Foot Switch Replacement:

222 / 622 ...........................................

223 / 623 (old style foot control) ........

Switch Membrane Replacement:

223 / 623 (new style foot control).......

623 Hand Control ..............................

Wiring Diagrams ................................... D-1

Exploded View / Part Numbers:

Foot Contol - 222 / 622 ......................

Foot Control - 223 .............................

Foot Control - 623 .............................

Hand Control - 623 ............................

* multiple pages due to model / serial # break

- 222 / 622 .................

- 223 / 623 ....

B-6

B-7

B-8

B-9

B-10

B-10

E-26

E-27*

E-28*

E-29

With switch 'tripped'...

less than or = to Switch is good.

5 ohms Perform next check.

OL

Foot / Hand Control

B-6

© Midmark Corporation 2003 SF-1838

gndaeRreteMsutatSnoitcAderiuqeR

Replace switch

Models:

Serial Numbers:

222 (all)

All

Note: Check switch

'tripped' and 'untripped'.

With switch 'untripped'...

Any

reading

OL

622 (all)

gndaeRreteMsutatSnoitcAderiuqeR

resistance Replace switch.

Switch is good.

Perform next check.

All

Page 52

Component Testing & Repair

Go To Table Of Contents

Foot / Hand Control

Foot / Hand Control Test

- continued

- 223 / 623

Foot / Hand Control Test

Step 1: Disconect wire harness from J8* on main PC board

* Note: Model 623 only: If the foot or hand control to be tested

is plugged into the inlet at the head end of the table,

disconnect harness from J7 on main PC board.

J8

Foot / Hand Control Test

Step 2: Set meter to

Ω.Ω.

Ω.

Ω.Ω.

..

.

..

With switch 'untripped'...

gndaeRreteMsutatSnoitcAderiuqeR

Any

resistance Replace switch /

reading switch membrane.

Switch is good.

Perform next check.

(Base Down)

Red

(com.)

Black

OL

With switch 'tripped'...

gndaeRreteMsutatSnoitcAderiuqeR

Foot / Hand Control Test

Step 3: Place one meter probe on black wire

(common)

Place other meter probe on the wire that

corresponds to the switch to be tested:

Switch Wire Color

Base Up .......... white

Base Down ...... red

Back Up ........... green

Back Down ...... orange

Auto Return ..... blue

Stop ................. brown

Models:

Serial Numbers:

of foot / hand control harness.

223 (all)

All

623 (all)

All

Probe position to test:

Base Down switch

MA727300i

less than or = to Switch is good.

5 ohms Perform next check.

OL

Foot / Hand Control

© Midmark Corporation 2003 SF-1838

Replace switch /

switch membrane.

B-7

Page 53

Component Testing & Repair

Go To Table Of Contents

Foot / Hand Control

- continued

Foot Switch Replacement - 222 / 622

Removal

Step 1: Remove cover.

Installation

Step 2: Install cover

.

Removal

Step 2: Remove switch.

Disconnect wires.

Foot / Hand Control

B-8

© Midmark Corporation 2003 SF-1838

Models:

Serial Numbers:

222 (all)

All

MA628300i

622 (all)

All

Installation

Step 1: Install switch.

Connect wires.

Note: Be sure insulating

material is in place.

Page 54

Component Testing & Repair

Go To Table Of Contents

Foot / Hand Control

- continued

Foot Switch Replacement - 223 / 623*

* Old-style Foot Control

Installation

Step 3: Connect coil cord & pedal switch

wire harness to PC board.

Removal

Step 3: Disconnect coil cord & pedal

switch wire harness from PC board.

Installation

Step 2: Insert switch wires into connector

Connect wire harness to PC board.

Removal

Step 4: Disconnect proper wire harness from PC board.

Press tabs, then disconnect faulty switch wires.

Tab

.

Removal

Step 1: Disconnect coil cord from table.

Remove strain relief clamp.

Installation

Step 5: Install strain relief clamp.

Connect coil cord to table.

Models:

Serial Numbers:

Removal

Step 2: Remove four screws.

Installation

Step 4: Install top section.

223 (-001 thru -014)

SC1000 thru present SD1000 thru present

SE1000 thru present SF1000 thru present

V2200 thru V3302

Separate top section.

623 (-001 thru -006)

SL1000 thru present SM1000 thru present

V2200 thru V3302

Installation

Step 1: Install switch

Removal

Step 5: Remove faulty switch.

Foot / Hand Control

© Midmark Corporation 2003 SF-1838

.

B-9

Page 55

Component Testing & Repair

Go To Table Of Contents

Foot / Hand Control

- continued

Switch Membrane Replacement - 223 / 623*

* New-style Foot Control

Installation

Step 1: Install touch pad onto switch panel.

Removal

Step 3: Peel touch pad off of switch panel.

Installation

Step 2: Insert control cord thru hole in base.

Connect to membrane connector.

Note: Slide strain relief block (on cord) into slot on base.

Hand Control - 623 only

Removal

Step 1: Remove base plate.

Installation

Step 3: Install base plate.

Foot / Hand Control

B-10

© Midmark Corporation 2003 SF-1838

Removal

Step 2: Disconnect control cord

MA727600i

Models:

Serial Numbers:

from membrane connector.

223 (all)

V3303 thru present

623 (all)

V3303 thru present

Page 56

Base / Back Actuator

Go To Table Of Contents

Go To Page:

This illustration shows the three seviceable components of the actuator.

Use the table below to isolate the malfunctioning part.

melborPnoitcAderiuqeR

Motor runs, but makes grinding noise. Clean Ball Screw threads.

Replace Ball Screw Assy.

Motor runs, but table does not move. Inspect / replace

Motor Coupler.

-or

Component Testing & Repair

Base / Back Actuator Page

Actuator Motor Test ............................. B-12

Replacement:

Base Actuator ...................................

Back Actuator (223 / 623) ..................

Wiring Diagrams ................................... D-1

Exploded View / Part Numbers:

Back Actuator (223 / 623) ..................

Base Actuator....................................

B-13

B-15

E-12

E-21

Motor does not run. Perform

Actuator Motor Test

Actuator Motor

Ball Screw Assembly

MA628200i

Motor Coupler

Models:

Serial Numbers:

All

All

Base / Back Actuator

© Midmark Corporation 2003 SF-1838

B-11

Page 57

Component Testing & Repair

Go To Table Of Contents

Base / Back Actuator

Actuator Motor Test

Actuator Motor Test

Step 2: Set meter to 200

- continued

Caution

Unplug power cord before

removing PC Board cover.

Actuator Motor Test

Step 1: Disconnect actuator wires from PC Board.

[Base Actuator: J2 & J3]

[Back Actuator: J4 & J5

Note: Refer to next page to access PC Board.

(223 / 623 only)

]

Base / Back Actuator

B-12

© Midmark Corporation 2003 SF-1838

Rev. 7/10/12

Models:

Serial Numbers:

Actuator Motor Test

Step 3: Place meter probes on actuator wires.

gndaeRreteMsutatSnoitcAderiuqeR

2- 3

0

All

All

Motor is good.

Perform next check.

Replace motor.