Page 1

This service manual is not available to the general users, but only applies to professional

technicians with relevant qualifications. Any incorrect maintenance may result in other

dangers!

The power and gas supply must be cut off before maintenance!

A new power cord which meets the relevant technical requirements must be used once

possible hidden malfunctions are found with the current power cord (refer to this

Manual)!

Please read carefully all safety warnings in this Manual before maintenance!

The product is prohibited from using until test is conducted as per relevant regulations

after maintenance!

This service manual applies to many models, so the specific operations please prevail in

kind!

Service Manual For Free-standing Oven

( 90X60 Gas COOKTOP and Electric oven )

Warnings

V2.0

Mar, 2014

Page 2

Contents

1. Precaution .................................................................................................................................................................. 1

1.1. Safety Precaution ................................................................................................................................................ 1

1.2. Warning ............................................................................................................................................................... 1

2. Dimension................................................................................................................................................................... 1

3. Function ...................................................................................................................................................................... 2

3.1 Flame thrower function............................................................................................................................................ 2

3.2 Oven function ........................................................................................................................................................... 2

4. Attention .................................................................................................................................................................... 3

5. Circuit diagram ........................................................................................................................................................... 4

6. Disassembly ................................................................................................................................................................ 5

6.1 Disassembly of cooktop ........................................................................................................................................ 5

6.2 Disassembly of knob .............................................................................................................................................. 6

6.3 Disassembly of drawer .......................................................................................................................................... 7

6.4 Disassembly of oven door ..................................................................................................................................... 7

6.5 Overview of inside structure ................................................................................................................................. 8

6.6 Disassembly of heating element(upper) ............................................................................................................... 9

6.7 Disassembly of heating element(bottom)........................................................................................................... 11

6.8 Disassembly of oven lamp ................................................................................................................................... 12

6.9 Disassembly of rotary motor ............................................................................................................................... 13

7. Troubleshooting ....................................................................................................................................................... 15

7.1 Gas troubleshooting ............................................................................................................................................ 15

7.2 Electronics troubleshooting ................................................................................................................................ 16

8. Maintenance and test .............................................................................................................................................. 17

8.1 Air leakage test .................................................................................................................................................... 17

8.2 Replacement of injector and adjustment of valve .............................................................................................. 18

8.3 Replacement of valve body ................................................................................................................................. 19

8.4 Replacement of gas-type fitting .......................................................................................................................... 19

Page 3

1. Precaution

1.1. Safety Precaution

1. To prevent injury to the user or other people and property damage, the following instructions must

be followed.

2. Incorrect operation due to ignoring instructions will cause harm or damage.

3. Before maintenance, please read carefully the following instructions at first.

1.2. Warning

1. The power cord shall be replaced withan insulation power line which is no less than AWG*2

+AWG10*1 and resists temperature of greater than 60℃.

2. All apparatus within a radius of 50mm from this product must resist temperature of greater than

75°C, otherwise, deformations are easily to be caused during the application process of this product.

3.When the wrapping materials are removed, keep such materials like metal sheet, packingbag, foam

and screws out of reach of children’s reach to avoid potential dangers. For example, the children

may suffocate as a result of swallowing tiny components or playing with packing bag

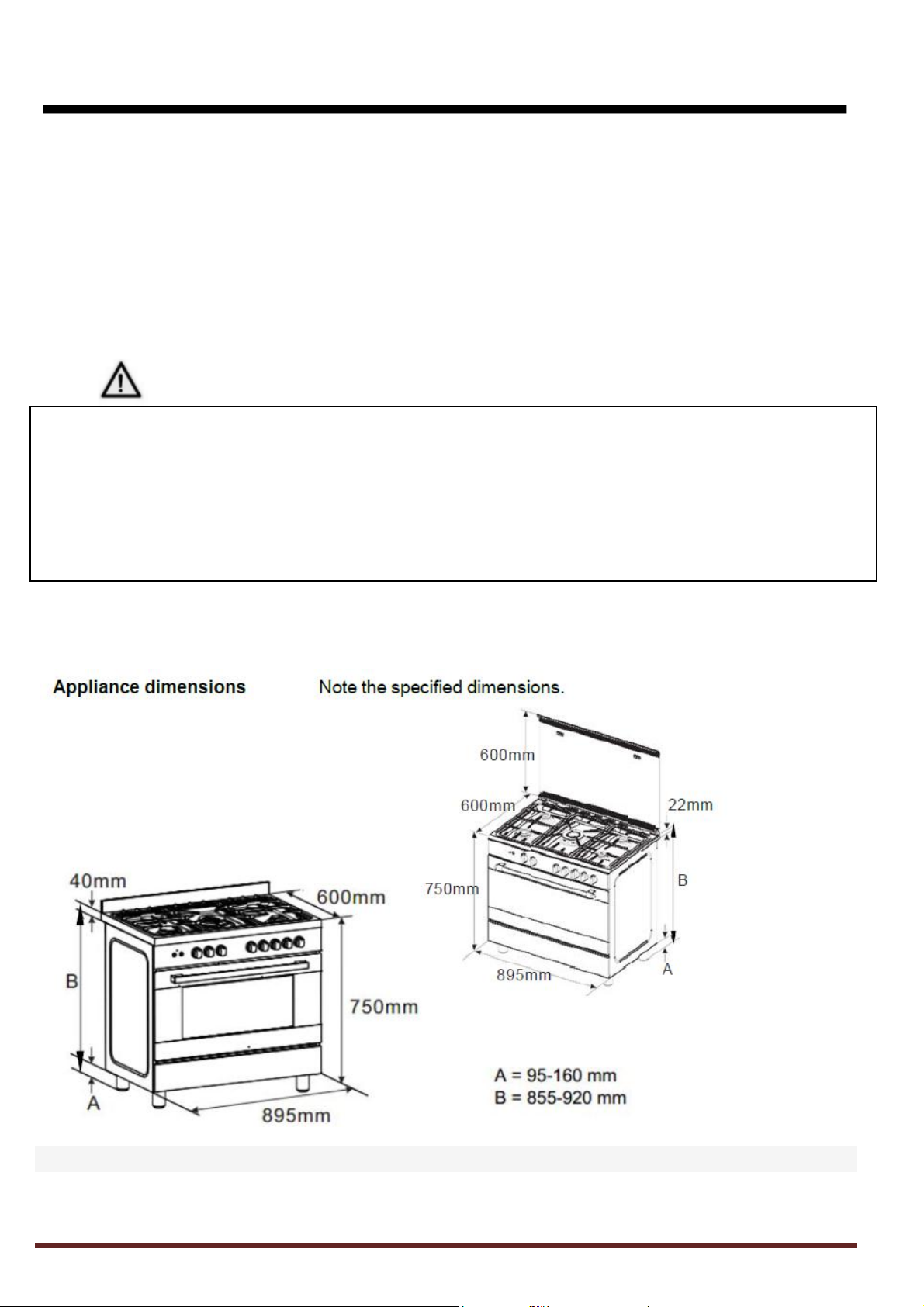

2. Dimension

Note: Dimensions for reference only.

Page1

Page 4

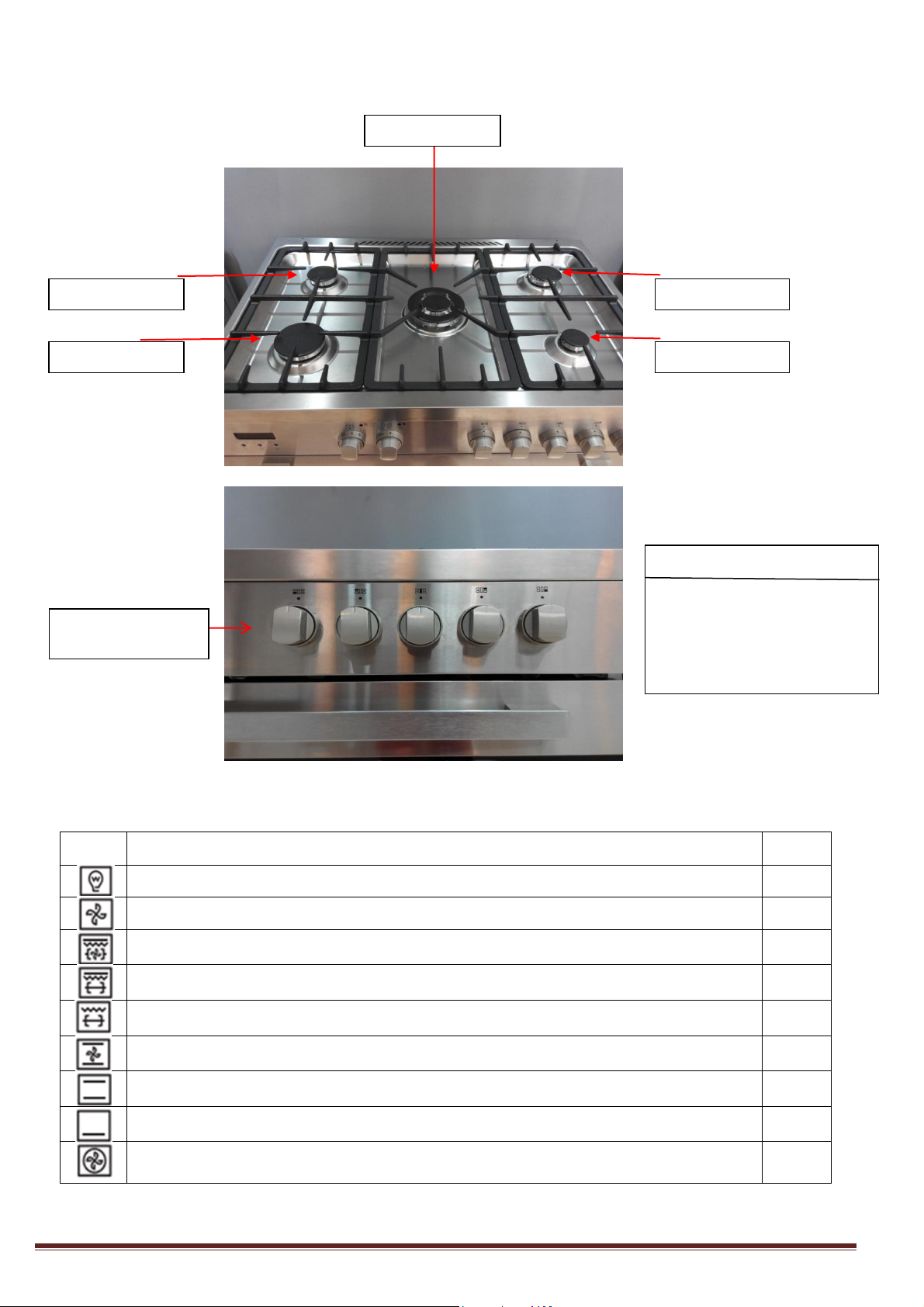

3. Function

Function

Power

lamp

96W

Fan

162W

heating element (upper)+infrared element+fan+rotary barbecue+lamp

2966W

heating element (upper)+ infrared element + rotary barbecue+lamp

2900W

infrared element + rotary barbecue+lamp

1900W

heating element (upper) + heating element (bottom)+ fan+lamp

2862W

heating element (upper) + heating element (bottom) +lamp

2796W

heating element (bottom) +lamp

1796W

Heating air+lamp

2562W

Flame thrower 1

Flame thrower 2

Flame thrower 3

Flame thrower 5

Flame thrower 4

Switch 1~5

(from left to right)

One-to-one match

Switch 1 ~Flame thrower 1

Switch 2 ~Flame thrower 2

Switch 3 ~Flame thrower 3

Switch 4 ~Flame thrower 4

Switch 5 ~Flame thrower 5

3.1 Flame thrower function

3.2 Oven function

Page2

Page 5

4. Attention

Hand holding

position when oven is

moved

The oven door shall be opened to contact the upper part and back of the oven cavity if the oven is

required to be lifted or moved. It is prohibited from using door handle directly to lift the oven(see the

following figure).

All inflammable, combustible and non-heat resistant articles shall be kept away from the surrounding of

the oven.

The ground shall be maintained flat enough for placing the oven to ensure sufficient stability of the

product.

Page3

Page 6

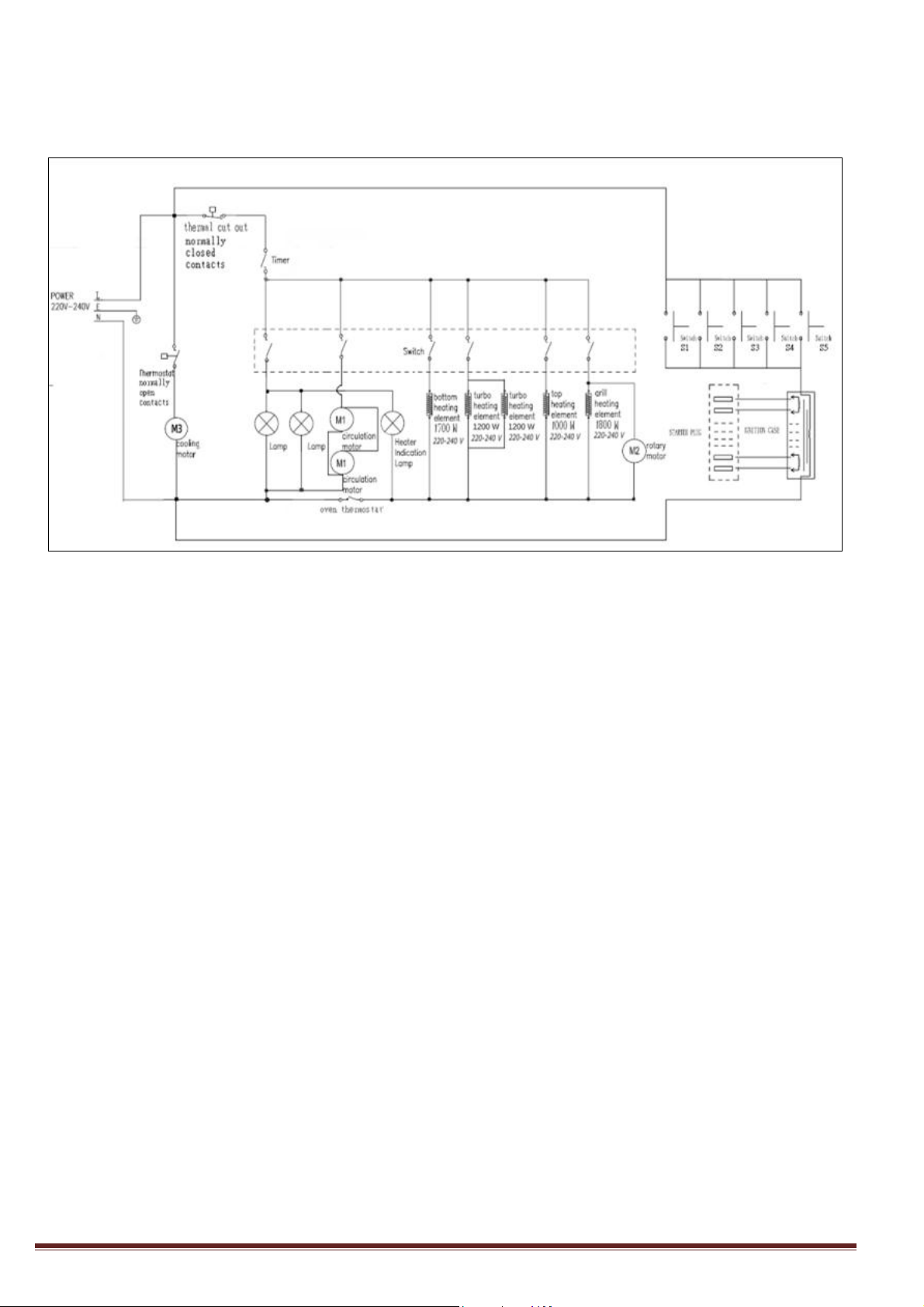

5. Circuit diagram

Circuit diagram for gas oven

Page4

Page 7

6. Disassembly

6.1 Disassembly of cooktop

Step 1: Remove the pan supports, sprayers and burner caps on the cooktop.

Step2: Remove the cook top lid

Step 3: Unscrew the screws used on the burner cup

Page5

Page 8

Step 4: Unscrew rear section.

Screw

1.PUSH UP

2.PUSH FORWARD

Step 5: Lift the rear of cook top gently and push forward to front.

6.2 Disassembly knob

Step 1: Lift the knob base and pull it out.

Page6

Page 9

6.3 Disassembly of drawer

Step 1: Open the drawer to a maximum angle.

Step 2: Remove the four screws attached to the drawer hinge with a screwdriver.

6.4 Disassembly of oven door

In reference to the instruction manual “Removing and fitting the appliance door”.

Page7

Page 10

6.5 Overview of inside structure

Valve body *5

The main gas tupe

Bottom cup*5

Flame ignitor

Rotating motor

Thermo switch 55℃

normal open

Heating element (upper)

Lamp

Terminal block

Rotating motor

Heating element

(Bottom)

Cooling motor

Picture 1.Inside structure

Page8

Page 11

Heater Terminals

screw

6.6 Disassembly the heating element(upper)

Step 1: disassembly the rear panel.

Step 2: Pull out the terminal of upper heating element.

Page9

Page 12

Step 3:Open the door, take out the Cooking grid ,Cooking grid(with cooking pan) and cooking pan.

Screw

cooking grid

cooking grid

(with cooking pan)

door

cooking pan

Step 4:Unscrew four screws, take out the heating element(upper)

Page10

Page 13

6.7 Disassembly the heating element(bottom)

screw

Screw

Step 1: Disassemble screws, open the rear panel.

Step 2: Pull out the terminal, unscrew the bracket of heating element(bottom).

Page11

Page 14

6.8 Disassembly of oven lamp

Lamp wire

Ground wire

Bulb cover

Bulb

Step 1: Disassemble the cooktop and pull out the lamp wire and ground wire.

Step 2: Remove the bulb by screwing the bulb cover off the cavity only if the bulb is required to be replaced.

Page12

Page 15

6.9 Disassembly of rotary motor

wire harness

Step 1: Disassemble the control panel.

Step 2:Ddisassemble the left side board to expose the rotary motor.

Step 3: Pull out the wire harness on the rotary motor.

Page13

Page 16

Step 4: Remove the rotary motor and loosen the fixed screws at both ends of the rotary motor support.

screw

Page14

Page 17

7. Trouble shooting

Phenomenon

Inspection method

Repair measures

(I)The burner is detected with

yellow flame.

1 Examine if the gas source of the

product is in conformity with the

application requirements;

2 Examine if the gas pressure is in

conformity with the application

requirements;

Please turn to Inspection method

(II)The burner flames out.

Examine if the gas source of the

product is in conformity with the

application requirements;

(III) The burner cannot be

ignited easily;

1 Examine if the gas source of the

product is in conformity with the

application requirements;

2 Examine if the gas pressure is in

conformity with the application

requirements;

3 Check if the ignition holes of the

burner are blocked or detected with

burrs;

4 Check if the fire-conductive leaf

overlaps with the flash hole;

Replace or adjust

(IV) No suction of flame-out

protection valve and

temperature controller valve

1 Check if the flame ignites the

thermocouple;

2 Check the joint between

thermocouple and electromagnetic

valve for any loosening and if the

connecting wire of the

thermocouple is cut off;

3 Adjust the distance between the

head of thermocouple and the

burner to 2mm to 4mm.

thermocouple

7.1 Gas trouble shooting

Page15

Page 18

Phenomenon

Cause

Solution

(I) The heating elements are

not heated.

1 The heating element is damaged.

2 Wire fault(open circuit)

3 Failure on heating element control switch

1 Replace the heating element

2 Change the wireharness

3 Change the control switch

(II) The oven lamp cannot be

light up

1.The oven lamp is damaged;

2.Wire failure

3.Failure on lamp control switch

1 Replace the oven lamp

2 Change the wireharness

3.Chnage the lamp control switch

(III) The ignition needle can

not strike fire.

1 The pulse igniter is damaged;

2 The ignition needle is damaged or ill

contacted;

3 Wire failure

4 Failure on ignition control switch

1 Replace the pulse igniter

2 Replace the ignition needle

3 Change the wire harness

4 Change the ignition control switch.

(IV) The rotary motor did not

rotate at all.

1 The rotary motor is damaged.

2 Wire failure

3 Failure on rotary control switch

1 Replace the rotary motor

2 Change the wire harness

3 Change the rotary control switch

Note!

1 Check the ground wire before the fault is detected;

2 Enough attention must be given to high voltage circuit.

7.2 Electronics troubleshooting

Page16

Page 19

8. Maintenance and test

Smear with suds-immersed

fabric each joint of the gas

pipe lines and check visually

for any air bubbles.

8.1 Air leakage test

Tool: Air leakage device, soap water

1. Professional repair procedures

a) Connect product to the air leakage device and set the test pressure at 15kPa;

b) The plug valve shall be kept closed and the gas pipelines may be tested its leakage through air leakage

device;

c) All plug valves shall be kept open, block the injector at the burner, the flame-out protection valve is kept

open and the gas pipelines may be tested their leakage through air leakage device.

The leakage must be controlled below 0.5mL/min as required in the test.

2. Simple procedures:

a) Connect the product to the gas being used;

b) Smear soap water at each joint of the product gas pipelines, the plug valve is kept closed, check visually

each joint for air bubbles;

c) Smear soap water at each joint of product gas pipelines, all plug valves shall be kept open, the injector of

the burner shall be blocked, the flameout protection device valve shall be kept open and check visually

for any air bubbles;

No air bubbles shall be detected at each joint as required in the test.

Note: Any component of the product gas pipelines shall not be disassembled or replaced only if the air

leakage is proved in conformity with relevant requirements.

Page17

Page 20

8.2 Replacement of injector and adjustment of valve

烤箱换喷嘴

调阀

Comparison list forinjectorreplacement

Change the injector

Replace the injector in the oven

Adjustable valve

Tool: Inner hexagon S7 sleeve/straight screwdriver of 2mm diameter

Steps for operation:

a) Disassembly respectively the cooktop, the injectors of upper and lower burners with sleeve.

b) Get a corresponding substitute injector(see the following table), apply thread sealant around its screw

thread and reassemble with sleeve.

c) Switch on the gas source, ignite corresponding burner and turn to small fire mode;

d) Pull out the knob, use screwdriver to enter from the small holes on the valve stem, adjust the core of

valve and observe the size of flame until moderate small flame is seen(the flame envelope is 4mm higher

than the burner); Adjust the fire of lower burner until moderate small fire is seen and no flameout as the

door is being closed.

Page18

Page 21

8.3 Replacement of valve body

Gas tube

Joint

Seal washer

Disassembly (assembly) aluminum gas tube

Disassembly (assembly) aluminum gas tube

Tool: screwdriver, open spanner

Steps for operation:

a) Disassembly the thermocouple connected to the valve body;

b) Disassembly the aluminum gas tube connected to the valve body with open spanner (see the picture);

c) Unscrew the screws on the mounting valve with screwdriver

d) Assembly a replaceable valve onto the product by following a reverse order of above mentioned

procedures and connect aluminum gas tube and thermocouple.

8.4 Replacement of gas-type fitting

Tool: open spanner

Steps for operation:

a) Disassembly the gas-type fittings from main gas tube with spanner.

b) To replace gas-type fitting ,note to lock tightly onto the main gas tube.

Page19

Loading...

Loading...