Page 1

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

1

Midea R410A

Direct Heating Commercial Heat Pump

50Hz

Technical Manual

Applicable Model:

RSJ-420/SZN1-H

RSJ-800/SZN1-H

Midea reserves the right to discontinue, or change specification or designs at any time without notices and

without incurring obligations.

Page 2

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

2

Content

Part. 1 General information ............................ 3

Part. 2 Performance ........................................ 5

Part. 3 Installation ......................................... 26

Part. 4 Controller ........................................... 62

Page 3

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

3

Part. 1 General information

1. Model Names of Units ........................................................... 4

2. External Appearance ............................................................. 4

3. Nomenclature ....................................................................... 4

Page 4

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

4

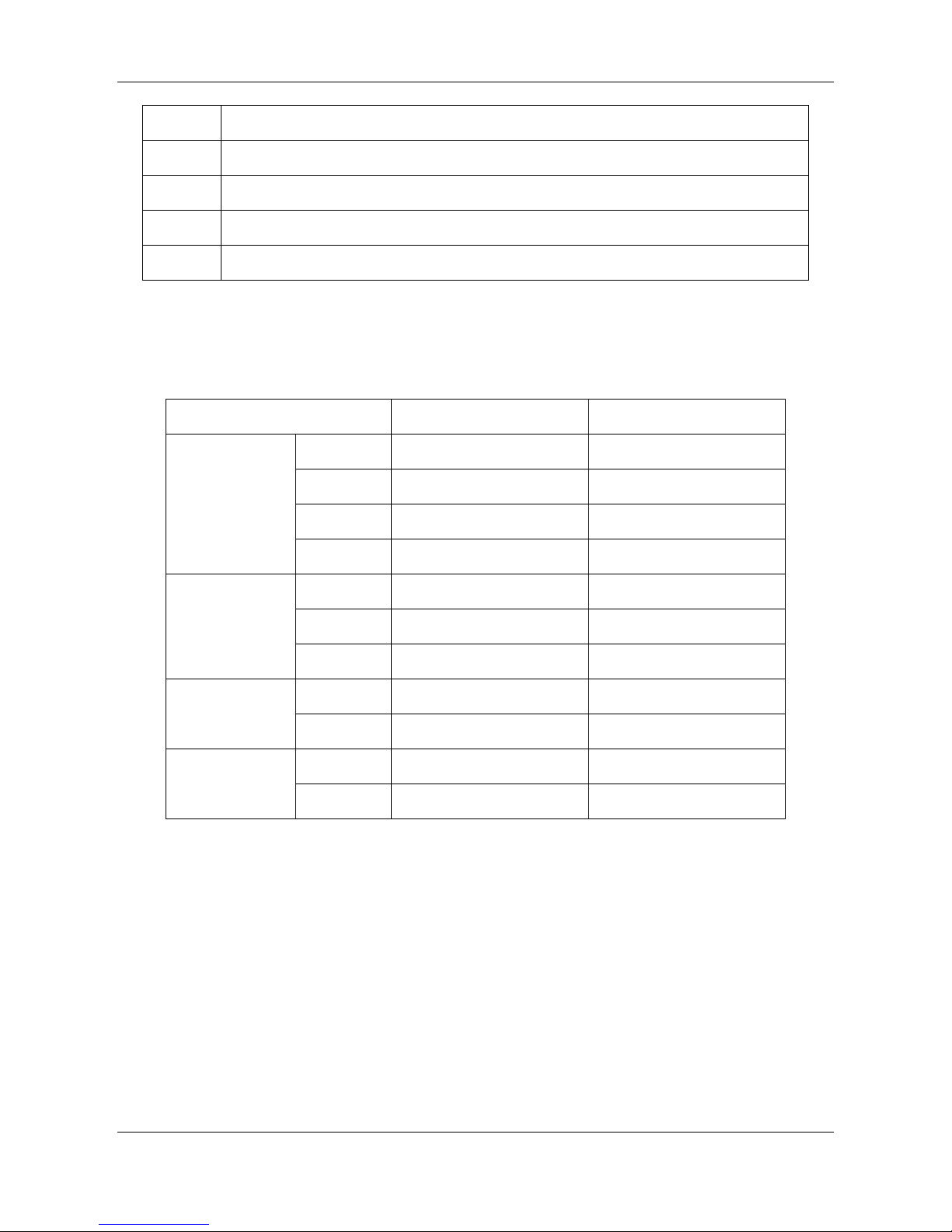

1. Model Names of Units

Model

Power supply

Direct-heating Type

RSJ-420/SZN1-H

380-415V~, 3Ph, 50Hz

RSJ-800/SZN1-H

380-415V~, 3Ph, 50Hz

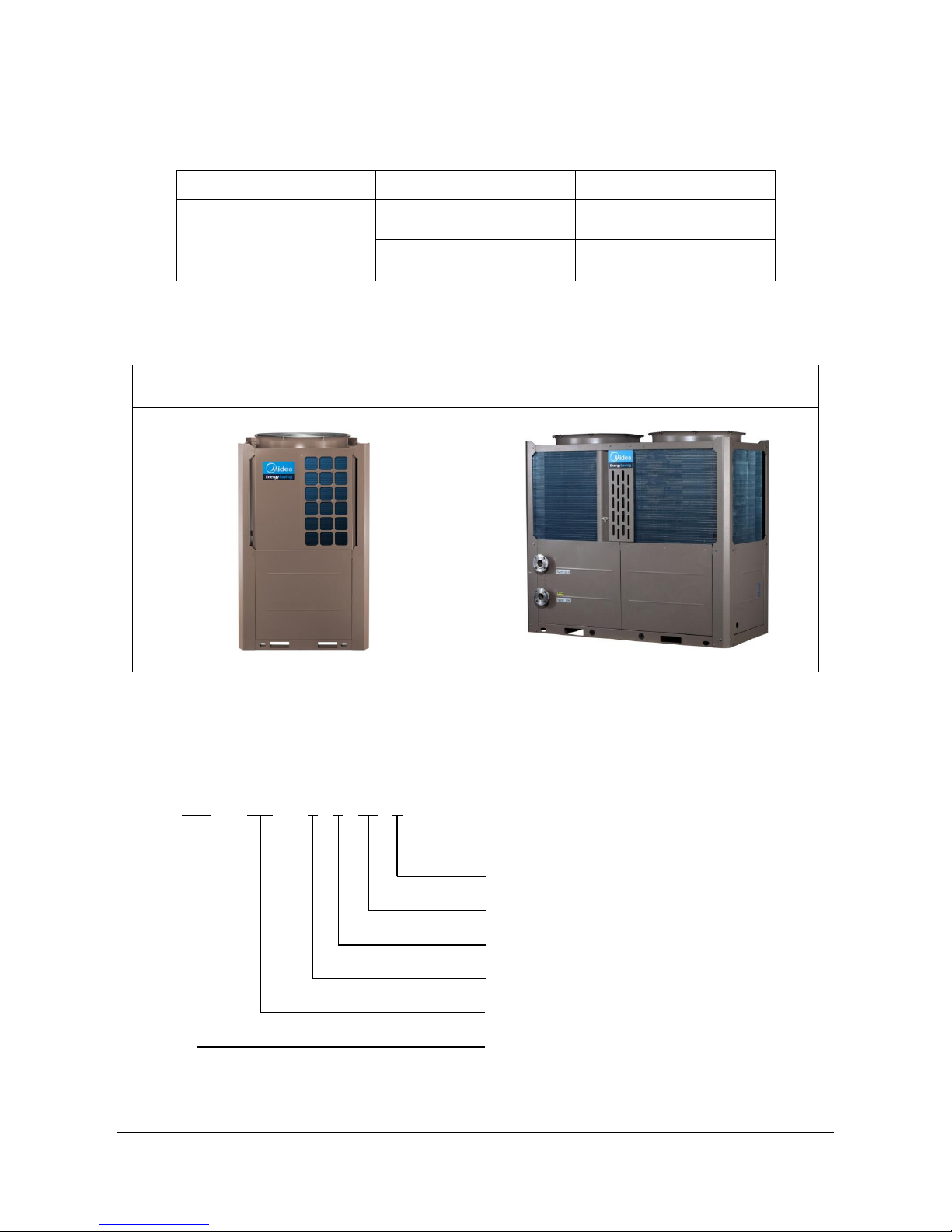

2. External Appearance

RSJ-420/PZN1-H

RSJ-800/PZN1-H

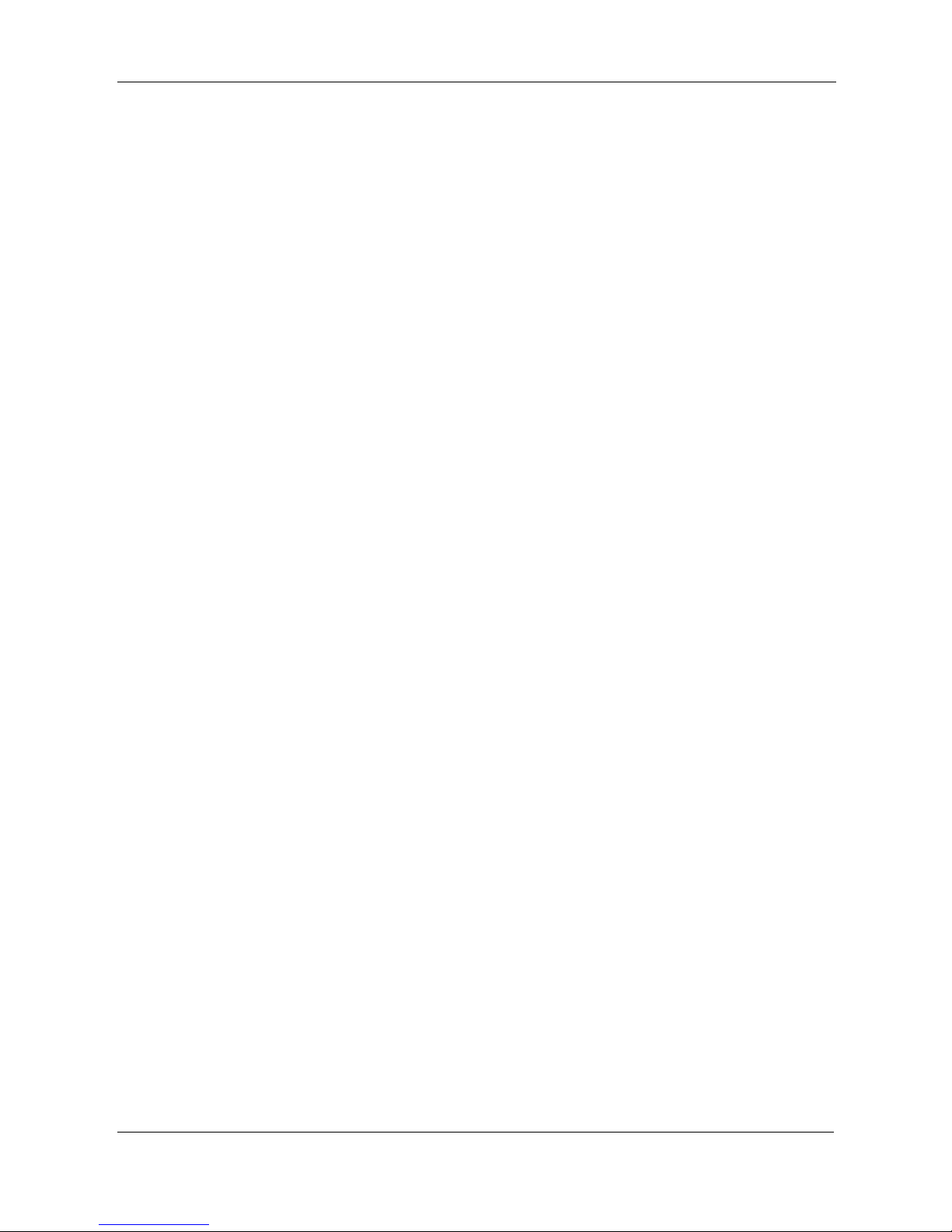

3. Nomenclature

RSJ - 420 / S Z N1 - H

H type

Refrigerant type - N1: R410A

Direct-heating type & Pressure water tank

Power supply: 380-415V 3Ph 50Hz

Nominal heating capacity (420×100W)

Midea heat pump water heater

Page 5

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

5

Part. 2 Performance

1. Features .............................................................................. 6

2. Specifications ...................................................................... 7

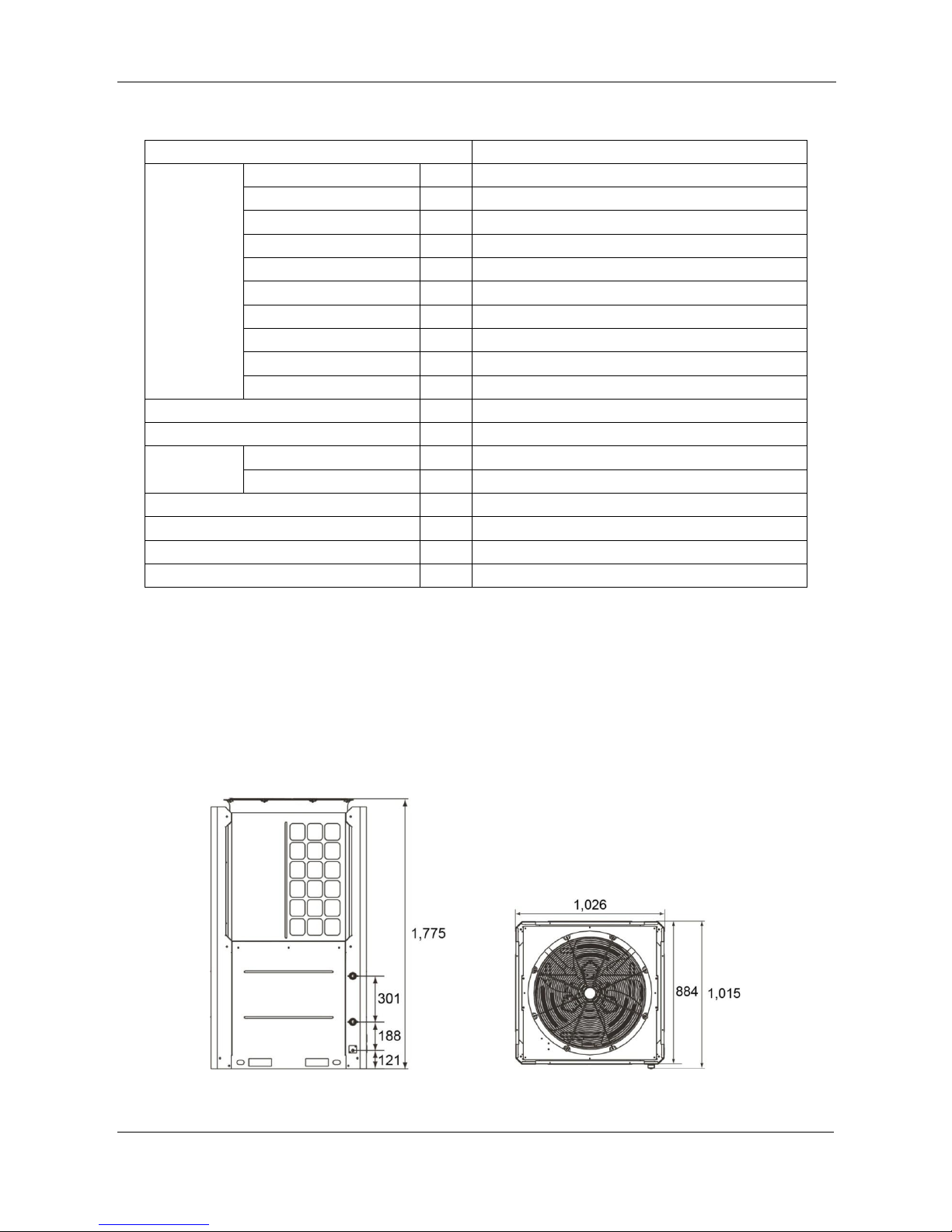

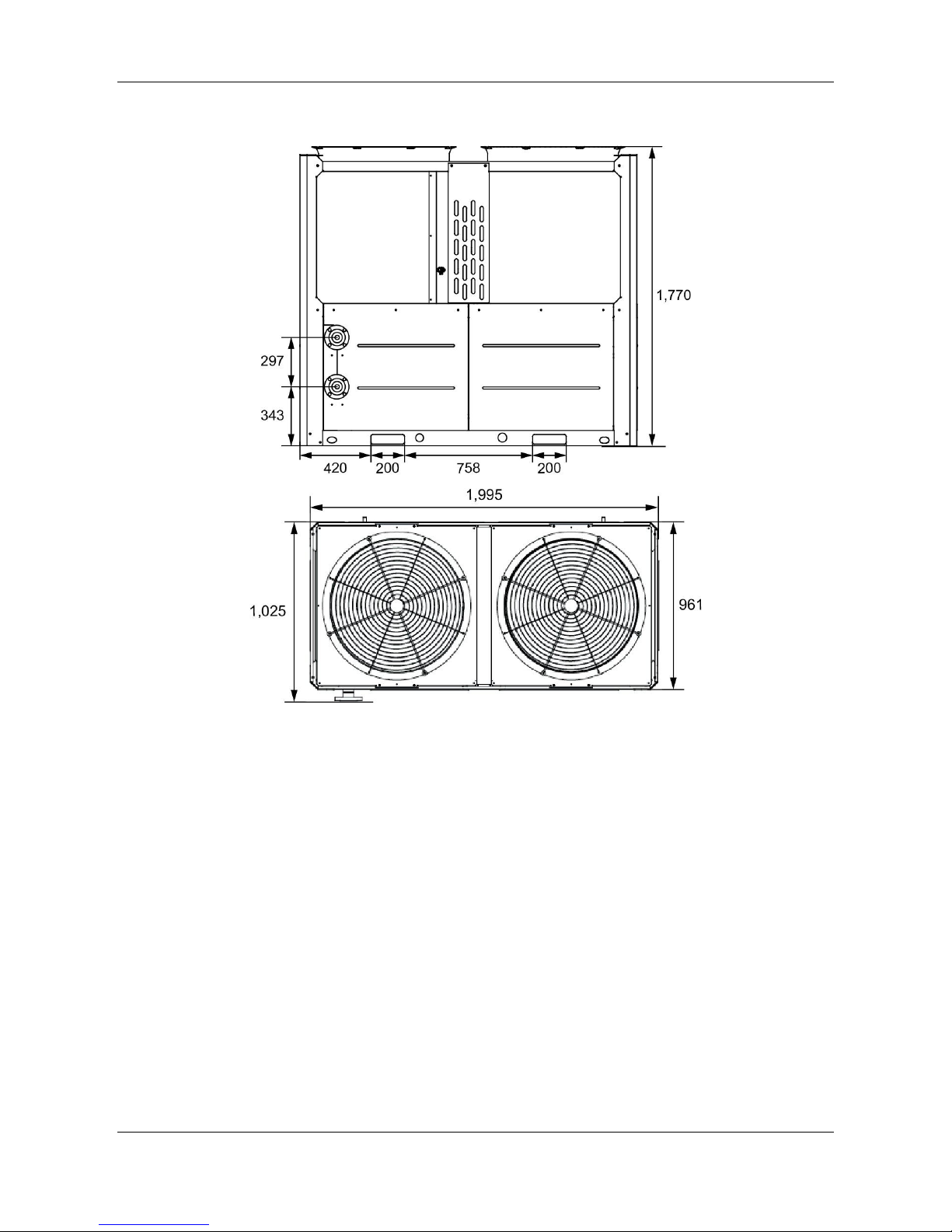

3. Dimensions (Unit: mm) ........................................................ 9

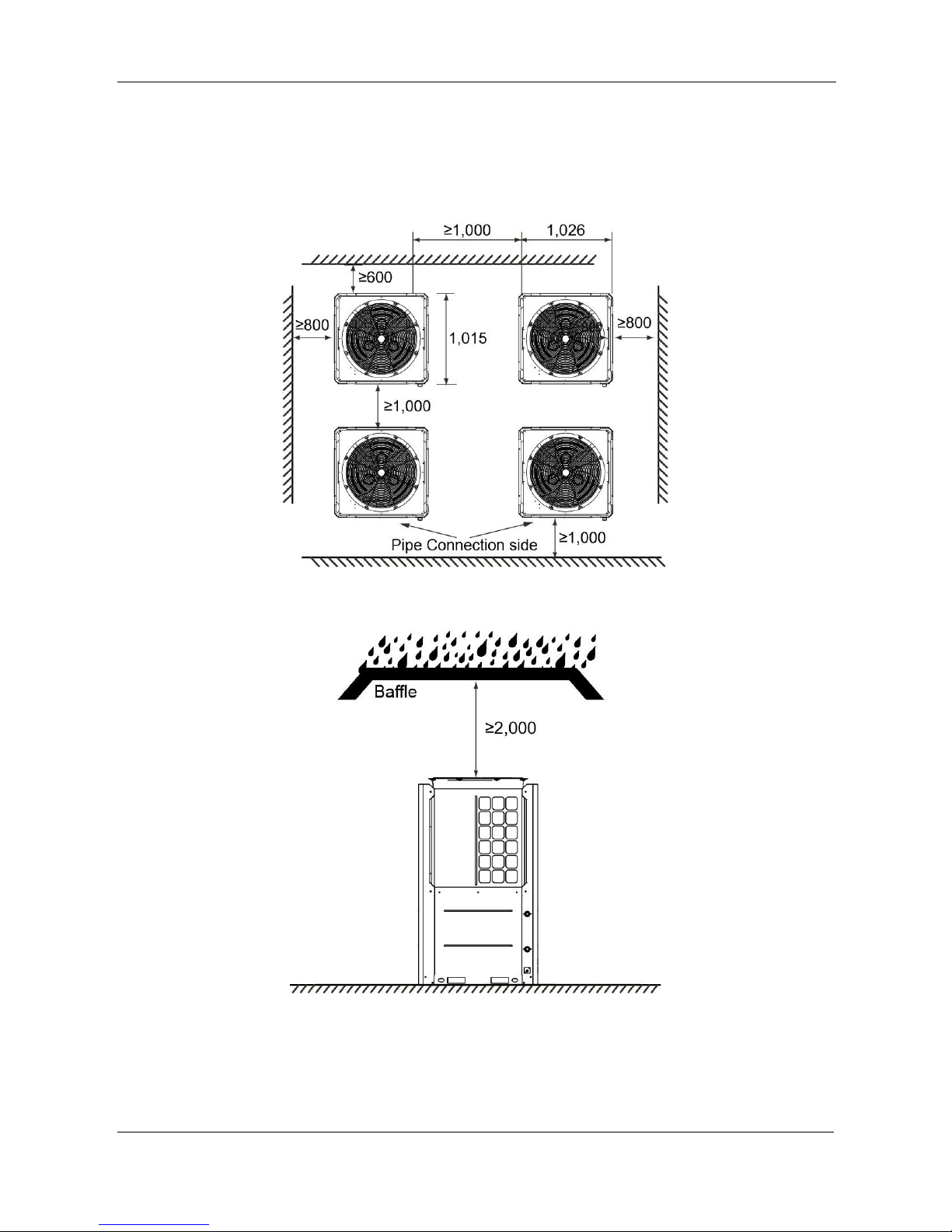

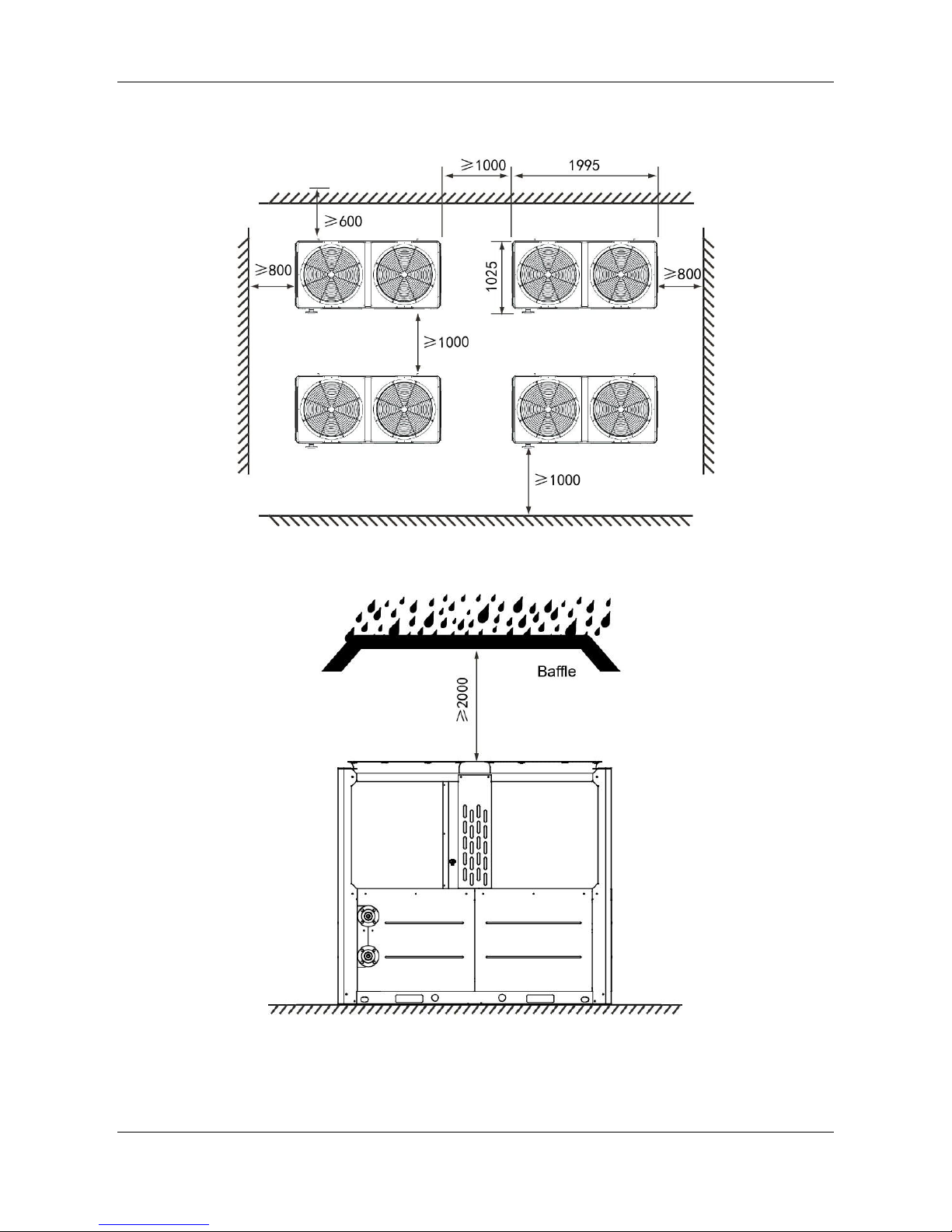

4. Service Space (Unit: mm) .................................................. 11

5. Refrigerant circuit .............................................................. 13

6. Wiring Diagrams ................................................................ 15

7. Electric Characteristics ...................................................... 22

8. Capacity Table ................................................................... 23

9. Accessories ....................................................................... 25

Page 6

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

6

1. Features

High capacity of hot water producing,

High efficient, COP is up to 4.04 (39kW) and 4.00 (80kW).

Unit applies refrigerant heating technology to increase the total energy absorb.

Refrigerant E-heater design can ensure that hot water can be produced stably during defrosting

period.

Multi protection: High and low pressure protection, over-load current protection, anti-freezing

function, etc.

Multi-temperature sensors always monitor the unit operating status.

Max. 4 units can be connected in parallel (39kW); Max. 2 units can be connected in parallel

(80kW).

User-friendly wired controller as standard, real-time clock function, power-off memory function.

Page 7

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

7

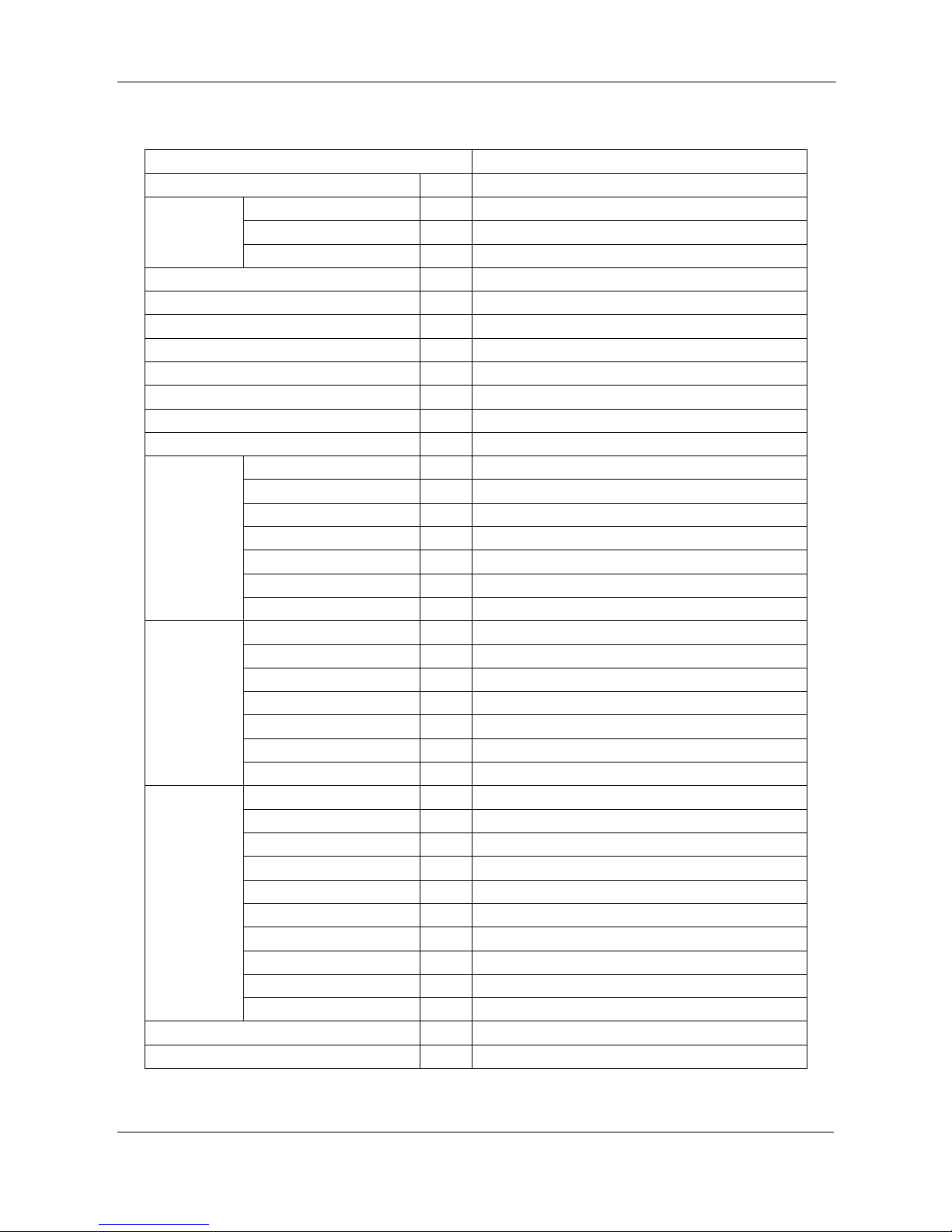

2. Specifications

Model

RSJ-420/SZN1-H

Power supply \ 380-415V~, 3Ph, 50Hz

Water heating

Capacity

kW

39.0

Input

kW

9.65

COP

W/W

4.04

Running ambient temperature

\

-15 ºC ~46 ºC

Outlet water temperature

\

Default 56ºC, 40 ºC~60 ºC

Rated input

kW

14.5

Rated current

A

24.0

Noise level

dB(A)

66

Refrigerant type

\

R410A

Quantity

\

4.5kg

Refrigerant control

\

EXV

Fan

Type

\

Axial fan

Motor model

\

YDK550-6E

Motor brand \ Yongan/Dayang/Welling/Matchwell

Quantity

\ 1 Motor input

W

810/680

Capacitor

25μF/450V

Speed (Hi/lo)

r/min

850/750

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7

No. of rows

\ 2 Fin spacing

mm

1.5

Tube pitch(a)×row pitch(b)

mm

21×13.37

Length× height

mm

2,827×798

Number of circuits

\

19

Compressor

Model

\

ZP120KCE-TFD-522

Type

\

Scroll

Brand

\

Copeland

Quantity

\ 1 Capacity

kW

29.2

Input

W

9,200

Rated current (RLA) A 20

Locked rotor Amp.(LRA) A 118

Thermal protector \ Internal

Refrigerant oil

ml

3,253

Controller \ KJR-51/BMKE-A (Wired controller)

Air flow

m3/h

≥12,000

Page 8

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

8

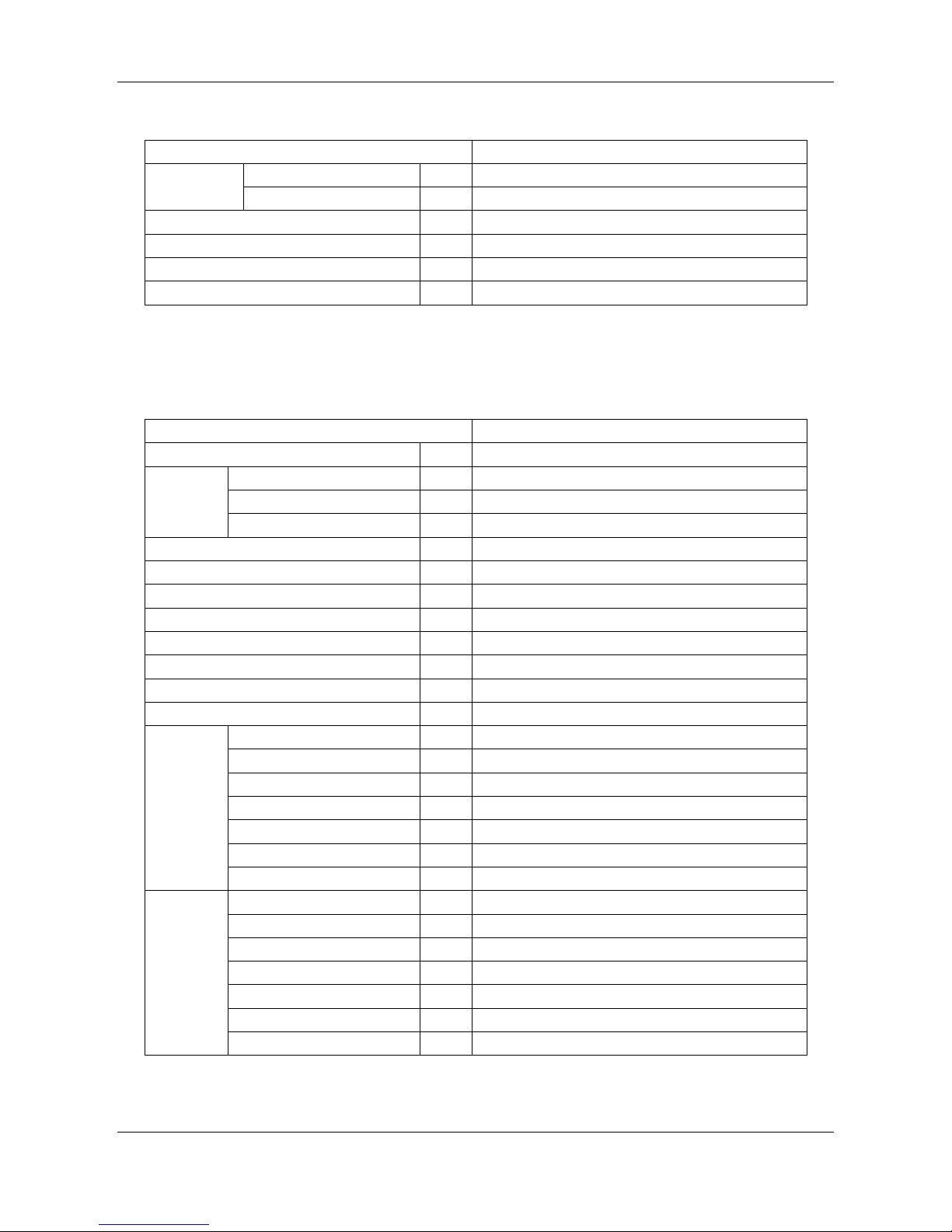

Continues

Model

RSJ-420/SZN1-H

Water pipe

Inlet pipe

mm

DN32

Outlet pipe

mm

DN32

Hot water yield

m3/h

0.85

Dimension (W×H×D)

mm

1,015×1,775×1,026

Packing (W×H×D)

mm

1,070×1,900×1,030

Net/Gross weight

kg

323/343

Notes:

The heating capacity is tested under a standard ambient with temperature of outdoor 20 ºC (DB)/15 ºC (WB),

inlet water temperature of the unit is 15 ºC , outlet water temperature is 55 ºC .

Model

RSJ-800/SZN1-H

Power supply \ 380-415V~, 3Ph, 50Hz

Water

heating

Capacity

kW

80.0

Input

kW

20.00

COP

W/W

4.00

Running ambient temperature

\

-15 ºC ~46 ºC

Outlet water temperature

\

Default 56ºC, 40 ºC~60 ºC

Rated input

kW

26.0

Rated current

A

34.0

Noise level

dB(A)

68

Refrigerant type

\

R410A

Quantity

\

4.4kg×2

Refrigerant control

\

EXV

Fan

Type

\

Axial fan

Motor model

\

YDK550-6E

Motor brand \ Yongan/Dayang/Welling/Matchwell

Quantity

\

2

Motor input

W

810/680

Capacitor

25μF/450V

Speed (Hi/lo)

r/min

850/750

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7

No. of rows

\ 2 Fin spacing

mm

1.5

Tube pitch(a)×row pitch(b)

mm

21×13.37

Length× height

mm

(2,827×798)+(2,827×798)

Number of circuits

\

20+20

Page 9

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

9

Continues

Model

RSJ-800/SZN1-H

Compressor

Model

\

SH120A4ALC

Type

\

Scroll

Brand

\

Danfoss

Quantity

\ 2 Capacity

kW

29.95

Input

W

9,462

Rated current (RLA) A 20.7

Locked rotor Amp.(LRA) A 142

Thermal protector \ Internal

Refrigerant oil

ml

3,300

Controller \ KJR-51/BMKE-A (Wired controller)

Air flow

m3/h

≥25,000

Water pipe

Inlet pipe

mm

DN50

Outlet pipe

mm

DN50

Hot water yield

m3/h

1.72

Dimension (W×H×D)

mm

1,015×1,775×1,026

Packing (W×H×D)

mm

1,070×1,900×1,030

Net/Gross weight

kg

599/627

Notes:

The heating capacity is tested under a standard ambient with temperature of outdoor 20 ºC (DB)/15 ºC (WB),

inlet water temperature of the unit is 15 ºC , outlet water temperature is 55 ºC .

3. Dimensions (Unit: mm)

RSJ-420/SZN1-H

Top view

Page 10

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

10

RSJ-800/SZN1-H

Top view

Page 11

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

11

4. Service Space (Unit: mm)

RSJ-420/SZN1-H

Page 12

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

12

RSJ-800/SZN1-H

Page 13

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

13

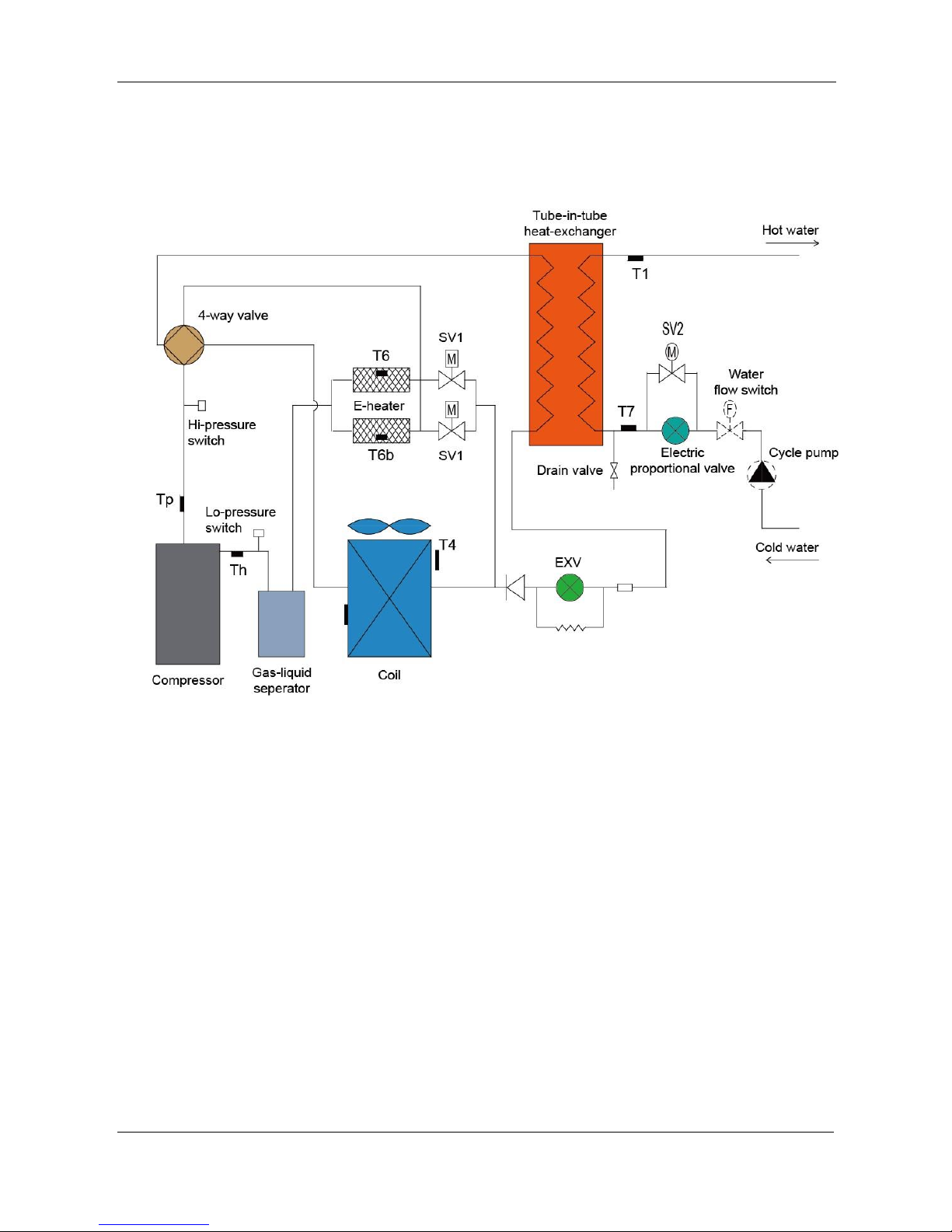

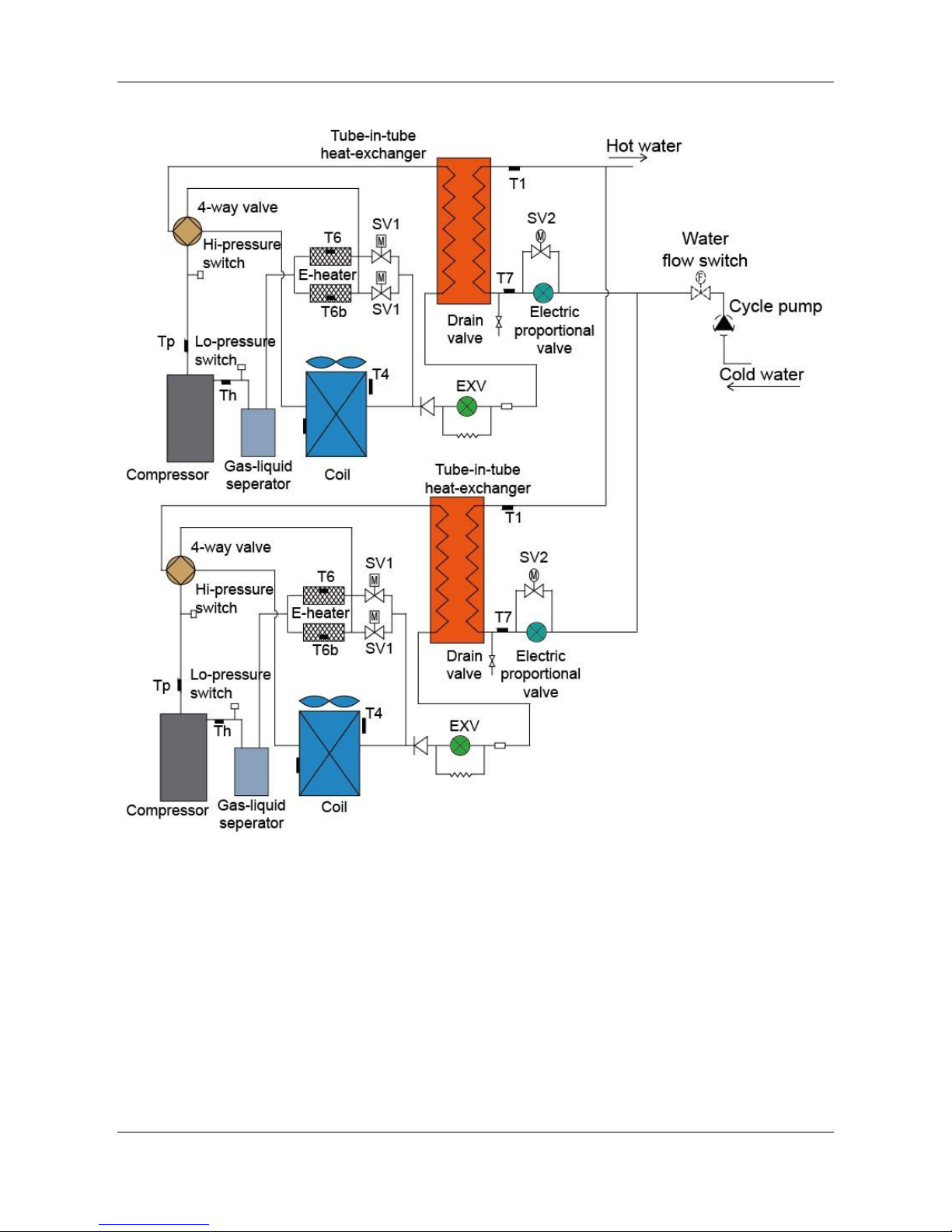

5. Refrigerant circuit

RSJ-420/SZN1-H

Page 14

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

14

RSJ-800/SZN1-H

Page 15

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

15

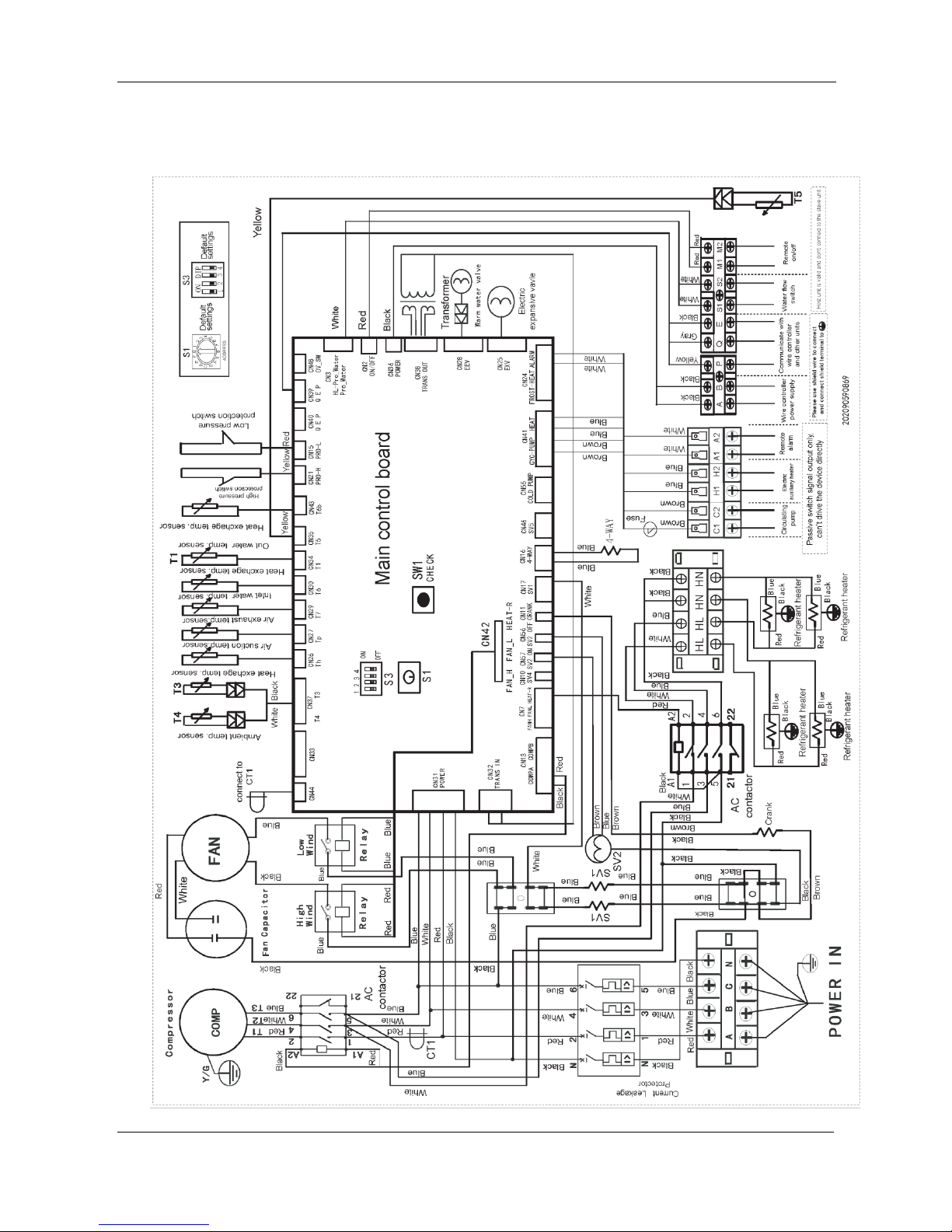

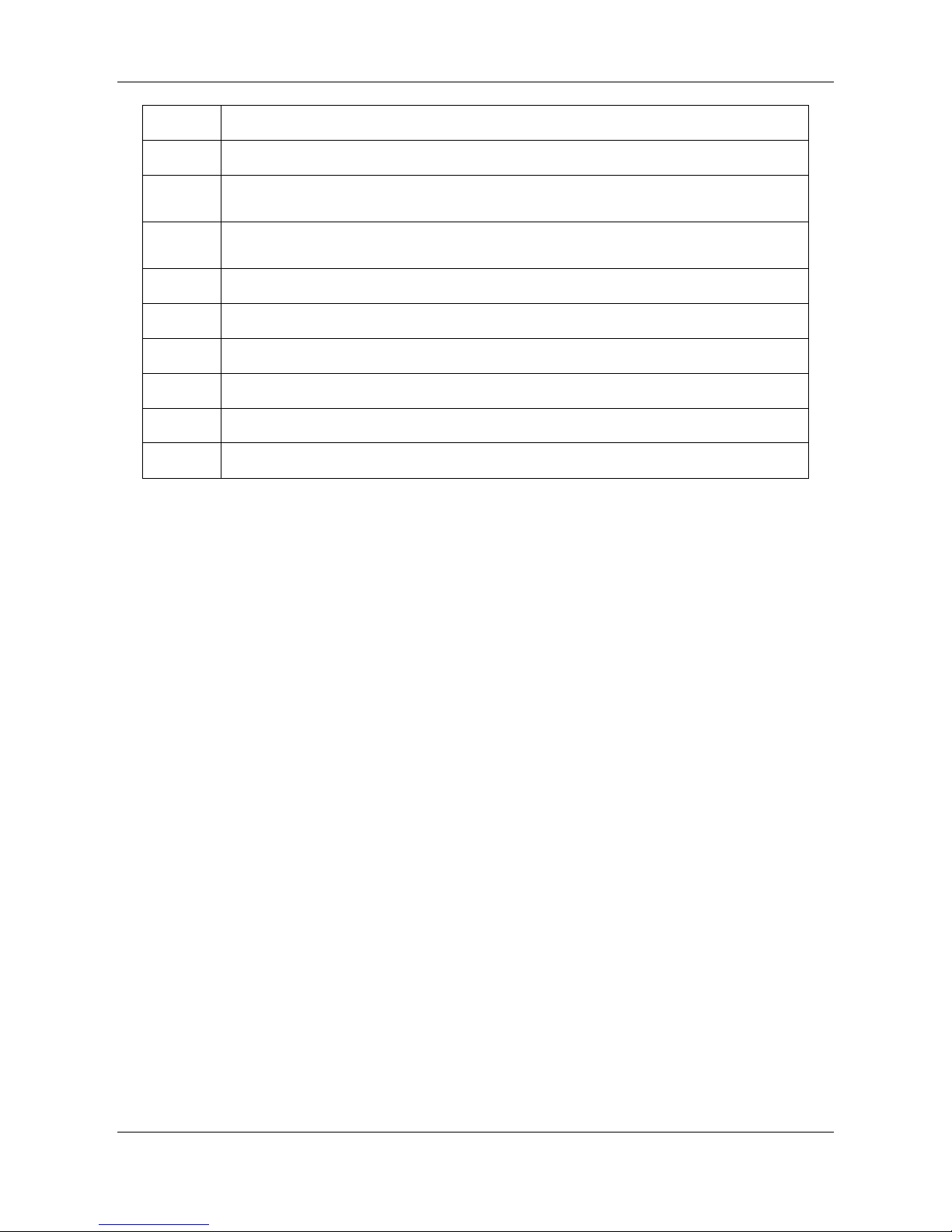

6. Wiring Diagrams

RSJ-420/SZN1-H

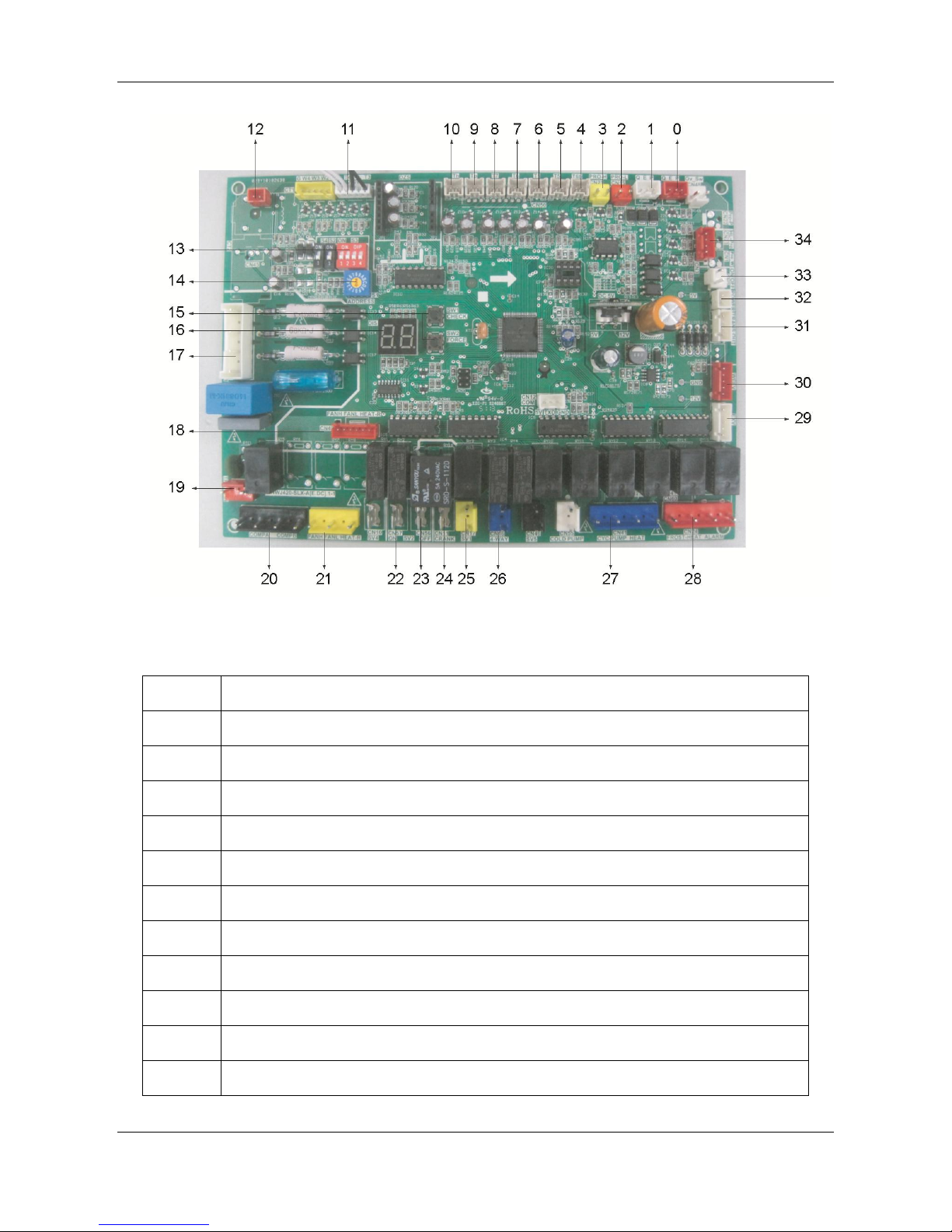

Page 16

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

16

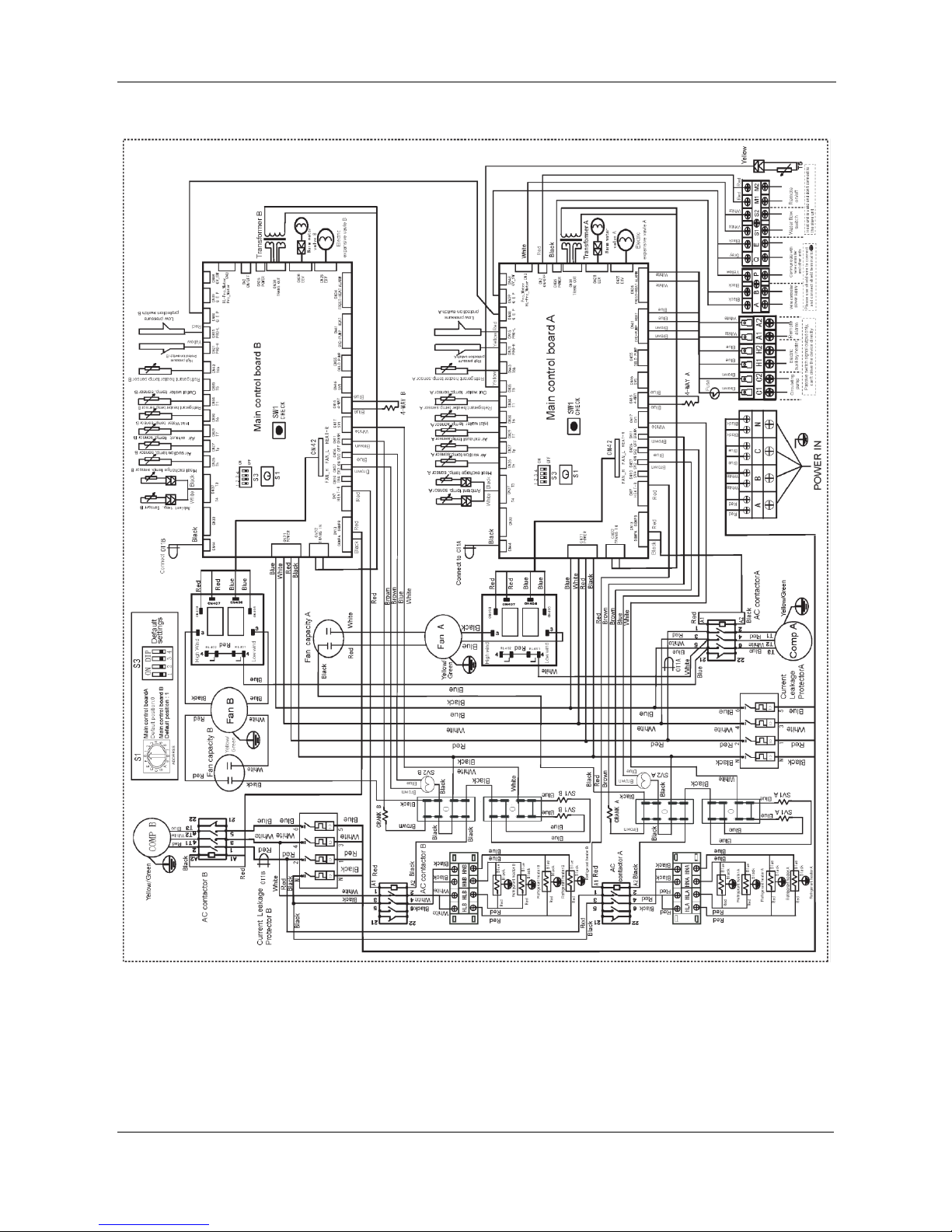

Item

Detail

0

Communication port for other unit

1

Communication port for wired controller

2

System low pressure protection connector

3

System high pressure protection connector

4

E-heater Temp. Sensor of refrigerant connector

5

Water tank (pook) Temp. sensor connector, only the host is valid, the slave is invalid

6

Water outlet Temp. sensor connector

7

E-heater pipe Temp. sensor connector of refrigerant

8

Water inlet Temp. sensor connector

9

Discharge Temp. sensor connector

10

Suction sensor connector

Page 17

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

17

11

T3: Evaporator Temp. sensor connector

T4: Outdoor ambient Temp. sensor connector

12

Detection port for compressor current

13

S3-1: Remote ON/OFF functional status (OFF: inactive (default); ON: active)

S3-2: Defrost periodical choice (OFF: default time by program; ON: 28 minutes)

S3-3,4: Auxiliary heater choice (OFF: indicates 0, ON indicates 1, the factory default

is 00)

14

Address dial code

0~3 separately stands for address 0~3, means 0~3 set units. When

dial the dial switch to 4 or more, then it will invalid.

Each module of water heat pump has the electric control function. Set the host unit

through the address dial code on electric control board. Stipulate the unit with

address dial code 0# as the host unit. Only after setting the host unit , the function of

direct communication with wired controller and other function can be activated.

15

Left side: CHECK, spot check button, for checking the operating state of unit.

Right side: FORCE, constraint button, special function for constraint exit.

16

Digital screen.

17

3-phase, 4-wire system power input. Lack of phase or wrong phase only is detected

on the initial stage of power on without detection during operation.

18

High and low fan speed.

19

Tranformer input, 220V AC current.

20

Control port for compressor.

21

Refrigerant E-heater control port.

22

Electric ball valve on.

23

Electric ball valve off.

24

Control port for crankcase E-heating belt.

Page 18

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

18

25

One-way solenoid control port.

26

4-way valve control power.

27

Left side: Circulating water pump control; right side: E-heater control. Only supply

ON/OFF signal, not supply power signal.

28

Right side: Remote alarm signal output. Only supply non-source ON/OFF signal, not

supply power signal.

29

EXV connector.

30

Electric proportional valve connector.

31

Transformer output connector.

32

Power connector for wired controller.

33

Remote control port.

34

Water flow switch connector.

Page 19

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

19

RSJ-800/SZN1-H

Page 20

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

20

Item

Detail

0

Communication port for other unit

1

Communication port for wired controller

2

System low pressure protection connector

3

System high pressure protection connector

4

E-heater Temp. Sensor of refrigerant connector

5

Water tank (pook) Temp. sensor connector, only the host is valid, the slave is invalid.

6

Water outlet Temp. sensor connector

7

E-heater pipe Temp. sensor connector of refrigerant

8

Water inlet Temp. sensor connector

9

Discharge Temp. sensor connector

10

Suction sensor connector

11

T3: Evaporator Temp. sensor connector

T4: Outdoor ambient Temp. sensor connector

12

Detection port for compressor current

13

S3-1: Remote ON/OFF functional status (OFF: inactive (default); ON: active)

S3-2: Defrost periodical choice (OFF: default time by program; ON: 28 minutes)

S3-3,4: Auxiliary heater choice (OFF: indicates 0, ON indicates 1, the factory default

is 00)

Page 21

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

21

14

Address dial code

0~1 separately stands for address 0~1, means 0~1 set units. When

dial the dial switch to 2 or more, then it will invalid.

Each module of water heat pump has the electric control function. Set the host unit

through the address dial code on electric control board. Stipulate the unit with

address dial code 0# as the host unit. Only after setting the host unit , the function of

direct communication with wired controller and other function can be activated.

15

Left side: CHECK, spot check button, for checking the operating state of unit.

Right side: FORCE, constraint button, special function for constraint exit.

16

Digital screen.

17

3-phase, 4-wire system power input. Lack of phase or wrong phase only is detected

on the initial stage of power on without detection during operation.

18

High and low fan speed.

19

Tranformer input, 220V AC current.

20

Control port for compressor.

21

Refrigerant E-heater control port.

22

Electric ball valve on.

23

Electric ball valve off.

24

Control port for crankcase E-heating belt.

25

One-way solenoid control port.

26

4-way valve control power.

27

Left side: Circulating water pump control; right side: E-heater control. Only supply

ON/OFF signal, not supply power signal.

28

Right side: Remote alarm signal output. Only supply non-source ON/OFF signal, not

supply power signal.

29

EXV connector.

Page 22

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

22

30

Electric proportional valve connector.

31

Transformer output connector.

32

Power connector for wired controller.

33

Remote control port.

34

Water flow switch connector.

Notes: RSJ-800/SZN1-H has two same PCB boards. Here only explains one PCB board.

7. Electric Characteristics

Model

RSJ-420/SZN1-H

RSJ-800/SZN1-H

Outdoor unit

Hz

50

50

Voltage

380~415V, 3Ph

380~415V, 3Ph

Min.

342V

342V

Max.

456V

456V

Power supply

MCA

21

26

TOCA

30

60

MFA

30

60

Compressor

MSC

118

142

RLA

16.6

20.7

OFM

kW

0.8

0.8

FLA

3.7

3.7

Note:

MCA: Min. Current Amps. (A) MFA: Max. Fuse Amps. (A)

TOCA: Total Over-current Amps. (A) MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A) OFM: Outdoor Fan Motor

kW: Fan Motor Rated Output (kW) FLA: Full Load Amps. (A)

Page 23

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

23

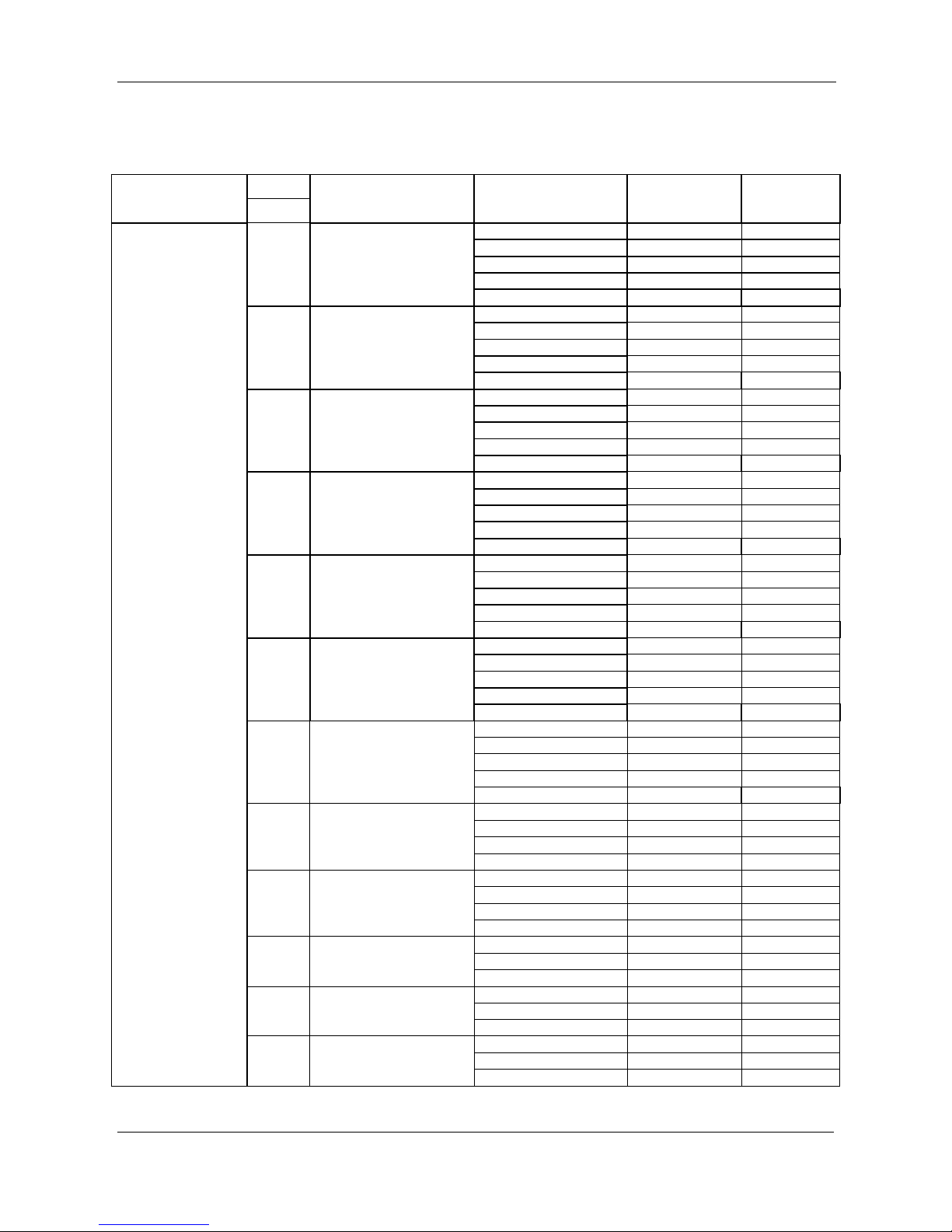

8. Capacity Table

RSJ-420/SZN1-H

Mode

OT(℃)

Inlet water Temp. (℃)

Outlet water Temp.

(℃)

Capacity(kW)

COP

DB

RSJ-420/SZN1-H

43

29

60

52.46

5.03

40

29

45

55.14

5.89

60

52.67

5.19

35

29

45

51.13

5.36

30

15

45

46.31

5.32

25

15

45

42.62

4.86

55

44.28

4.34

20

15

55

39.76

4.01

15

9

55

37.54

3.90

7

9

40

32.23

4.65

2

9

0

9

-7

9

-15

9

Page 24

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

24

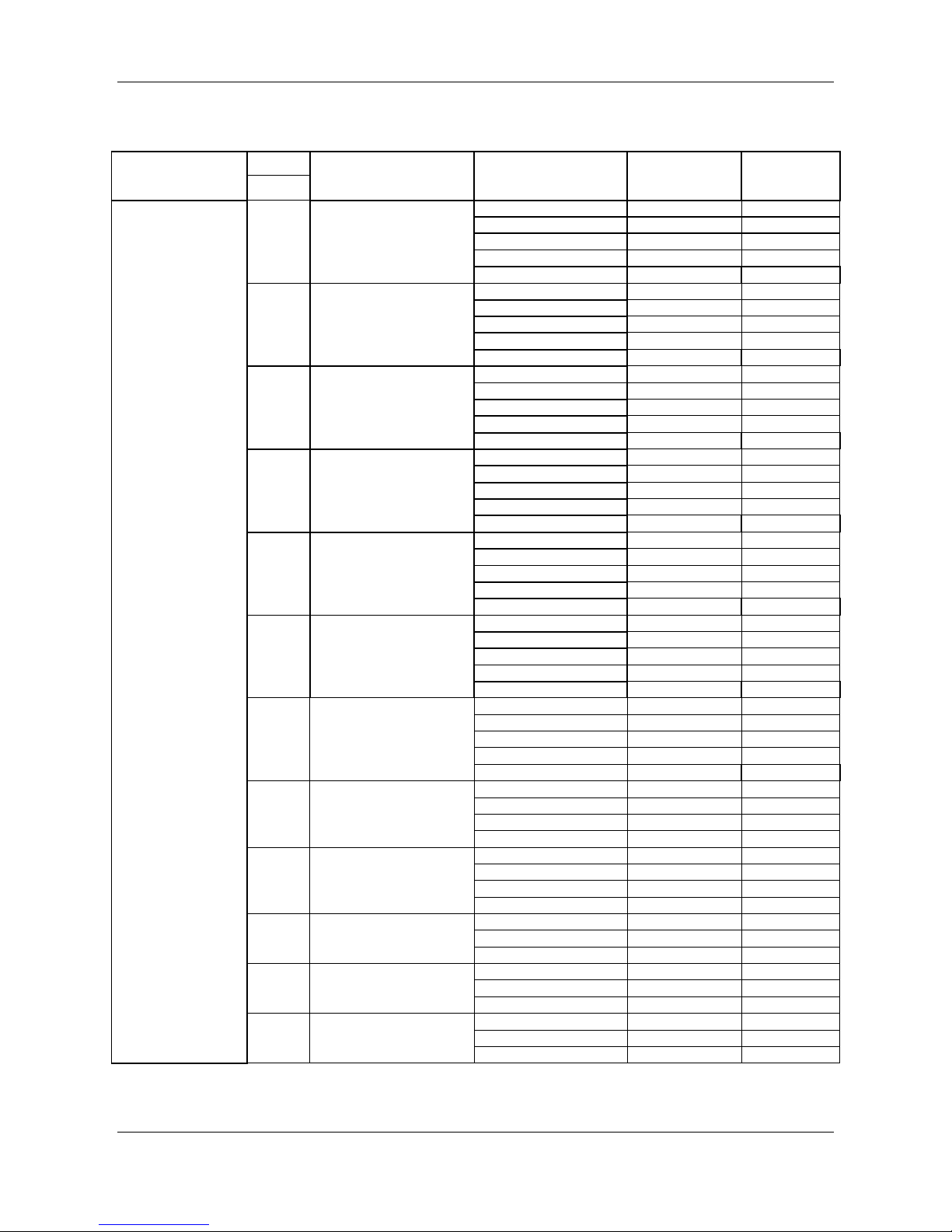

RSJ-800/SZN1-H

Note: OT – Outdoor Temperature (DB);

Mode

OT(℃)

Inlet water Temp. (℃)

Outlet water Temp.

(℃)

Capacity(kW)

COP

DB

RSJ-800/SZN1-H

43

29

60

99.08

4.44

40

29

60

97.95

4.35

35

29

45

94.75

5.06

30

15

45

88.62

5.00

25

15

45

83.64

4.64

55

83.70

4.15

20

15

55

81.05

4.04

15

9

55

75.04

3.84

7

9

40

65.25

4.04

2

9

0

9

-7

9

-15

9

Page 25

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

25

9. Accessories

Name

Qty.

Purpose

Installation & operation manual

1

Water tank temperature sensor

1

For water tank temperature inspection.

Wired controller

1

Control the unit and display unit status.

Wire harness matched with wired controller

1

Connect the master unit with wired controller.

Y-shaped filter

1

Only for RSJ-420/SZN1-H

Page 26

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

26

Part. 3 Installation

1. Safety information ............................................................... 27

2. Unit Installation ................................................................... 28

3. Trial run ............................................................................... 44

4. Fault analysis and solutions ................................................ 46

5. Maintenance ....................................................................... 59

Page 27

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

27

1. Safety information

To prevent injury to the user or other people and property damage, the following instructions must be

followed. Incorrect operation due to ignoring of instructions may cause harm or damage.

The unit must be earthed effectively. The earthing pole of socket must be grounded well, make

sure that power supply socket and plug are dry enough and connected tightly.

How to check the power supply socket and plug are qualified? Turn on power supply and keep

the unit running for a half hour, then turn off power supply and plug out, check whether the

socket and plug is hot or not.

Do not remove, cover or deface any permanent instructions, labels, or the data labels from either

the outside of the unit or inside of unit panels.

Ask qualified person to perform the installation of this unit in accordance with local national

regulations and this manual. Improper installation may result in water leakage, electric shock or

fire.

Ask qualified person for relocating, repairing and maintaining the unit. Improper installation may

result in water leakage, electric shock or fire.

Electric connection work should obey the instructions of local power company, local electric

utility and this manual.

Never use the wire and fuse with wrong rated current, otherwise unit may break down and cause

fire furthermore.

Do not insert fingers, rods or other objects into the air inlet or outlet. When the fan is rotating at

high speed, it will cause injury.

Never use a flammable spray such as hair spray, lacquer paint near the unit. It may cause a fire.

This appliance is not intended for use by person (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for their

safety. Children should be supervised to ensure that they do not play with the appliance.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or

Page 28

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

28

similarly qualified person.

Do not dispose this product as unsorted municipal waste. Collection of such waste separately for

special treatment is necessary. Do not dispose of electrical appliances as unsorted municipal

waste, use separate collection facilities. Contact your local government for information regarding

the collection systems available. If electrical appliances are disposed of in landfills or dumps,

hazardous substances can leak into the ground water and get into the food chain, damaging

people’s health and well-being.

Before cleaning, be sure to stop the operation and turn the breaker off or pull out the power plug.

Otherwise, an electric shock and injury may be caused.

Water temperature over 50°C can cause severe burns instantly or death from scalds. Children,

disabled and elderly are at highest risk of being scalded. Feel water before bathing or showering

valves are recommended.

Do not operate the unit with a wet hand. An electric shock may be caused.

The installation height of power supply should be over 1.8m, if there is any water spattered,

separate the power supply from water.

A one-way valve must be installed on the water inlet side, which is available from accessories.

Arrange the drain pipe to ensure smooth draining. Improper drainage work may cause wetting of

the building, furniture, etc.

Do not touch the inner parts of the controller. Do not remove the front panel. Some parts inside

are dangerous to touch, otherwise a machine malfunction may be caused.

Do not turn off the power supply. System will stop or restart heating automatically. A continuous

power supply for water heating is necessary, except service and maintenance.

2. Unit Installation

Except for accessories supplied by factory, the water flow switch should be supplied by site. The

cut-off value of switch should be more than V (V=0.1m3/h × Amount of units). The water flow switch is

used to detect the circulating water flow volume.

A single unit must be installed a set of water flow switch and wired controller, several units parallel

connected can choose one or more sets of above accessories as required.

Page 29

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

29

2.1 Unit outlook

RSJ-420/SZN1-H

RSJ-800/SZN1-H

2.2 Carrying of unit

Handling rope should at least can bear 3 times of the unit weight, and must go through the

handling holes shown in following pictures, and make sure there is enough strength to add a

Page 30

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

30

pad between the rop and unit in order to protect the unit.

Distance between the hood and air outlet mesh shoule be more than 1 meter, and ensure

that the hood has enough strength as well as reliability in handling process.

Unit gradient (α) should be less than 3º. Handle with care, do not collide and drag drastically.

DO NOT stand in handling operating radius.

The distance between the air outlet mesh of unit and lift hook should be more than 1 meter.

RSJ-420/SZN1-H

RSJ-800/SZN1-H

2.3 Unit installation caution

The unit can be installed on the ground or on the suitable roof, but enough ventilation

volume should be ensured in both cases.

The unit should not be installed where noise and vibration are required to a certain extent.

Page 31

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

31

The installed unit should be sheltered from direct sunlight as much as possible, and be far

away from boiler flues and ambient air which may erode condenser coils and copper tube

parts of the unit, such as the places that full of dust and oil fume.

Safety measures of isolation should be taken, such as rail guards. These measures will

avoid artificial damages and accidental damages.

The height of the installation foundation for the unit should not be less than 100mm, and

floor drains are required in installation sites, to ensure smooth drainage and remove any

seeper.

In case of installation on the ground, the steel base of the unit should be located on the

concrete foundation, and the concrete plinth should extend below frozen soil layer. The

foundation of the unit should not be connected to the foundation of the building, to avoid

affecting the people due to transfer of noise and vibration. The base of the unit is provided

with installation holes, which can be used to connect the unit and the foundation firmly.

In case of installation on the roof, the roof must possess enough strength to sustain weight

of the unit and maintenance personnel. The unit can be supported on concrete foundations

or channel steel frames similar to those used in the unit installation on the ground. The

load-bearing channel steel must be in alignment with the installation holes of the unit

damper, and the channel steel should posses enough width for installing the damper.

Consult the building contractor, the archietectural designer or other specialists about the

cased with special installation requirements.

The unit can be installed on the ground or ont the suitable roof, but it should follows the

relative standards or laws to all lightnin-proof measures for the whole water heating system.

2.4 distance of unit ground screws (Unit: mm)

RSJ-420/SZN1-H

Page 32

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

32

RSJ-800/SZN1-H

2.5 Unit installation space

Ensure enough space for installation and maintenance.

RSJ-420/SZN1-H

(Unit: mm)

RSJ-800/SZN1-H

(Unit: mm)

Page 33

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

33

Ensure there is enough air flow to supply the heat exchanger, Take influence of down draft

caused by tall building around the unit to air discharge into condenser when installing.

If install the unit at a place where ventilation is drastic, such as exposed roofs, short wall or

louvers can be applied in case of turbulence disturbs air inlet. If short walls are applied, it

should be shorter than the unit. Distance between short walls or louvers to unit should either

satisfy requirements of unit installation minimum intervals.

If the unit runs in winter, and the location has accumulated snow, the unit should stand

higher than snow in order to let airflow ge through heat exchanger fluently.

The unit circulating air volume is at least 12,000m3/h. If the unit is installed in the basement,

ensure air around the unit and outdoor air can circulate without obstruction.

RSJ-420/SZN1-H

(Unit: mm)

RSJ-800/SZN1-H

(Unit: mm)

Page 34

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

34

2.6 Water pipeline system

Water pipe joint specifications of single unit.

Water inlet pipe joint

Water outlet pipe joint

RSJ-420/SZN1-H

DN32

DN32

RSJ-800/SZN1-H

DN50

DN50

Water pipeline system design and construction must meet the national water and heating

pipeline design requirements and relative standards.

All the pipes are recommended to use PPR pipe, and the PPR pipe specificatons refers to

up table.

It must prevent dust and other sundries enter into the pipeline system during the pipeline

installation and connection.

The water flow switch which is used to detect the circulating water flow volume should be

prepaired in site. The cut-off value of water flow switch is not less than (0.1m3/h×amount of

units).

Only after unit is fixed, the water pipes can be installed.

Use thermal insulation material to wrap the inlet water pipe, outlet water pipe and circulative

water pipes.

The pipe diameter of main water pipes:

RSJ-420/SZN1-H

Amount of units connected in parallel

Water inlet pipe joint

Water outlet pipe joint

1

DN32

DN32

2

DN50

DN50

3

DN65

DN65

4

DN80

DN80

RSJ-800/SZN1-H

Amount of units connected in parallel

Water inlet pipe joint

Water outlet pipe joint

1

DN50

DN50

2

DN80

DN80

Page 35

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

35

Connection diagrammatic drawing of water pipe system

Icon specifications:

Stop valve

Motor operated valve

Flexible rubber joint (soft-connect)

Water pump

Water using end

Water supply controller

Solenoid valve

Pressure reducing valve

Reflux valve

Auto air-exhaust valve

Pressure gage

E-heater

Y-shape filter

Water flow switch

RSJ-420/SZN1-H

Single unit drawing:

Page 36

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

36

Double units drawing:

RSJ-800/SZN1-H

Single unit drawing:

Page 37

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

37

Double units drawing:

2.7 Water tank installation

The water tank temperature sensor (T5) can not be placed in the water or on the water pipe

directly. The water tank must be set a temperature pipe where the temperature sensor (T5)

is installed.

The water tank must have some safty devices to protect it such as temperature cut off

switch, pressure and temperature relief vale, etc.

Make sure E-heater is covered with water all the time.

Page 38

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

38

Water cycle pump selection:

RSJ-420/SZN1-H

Circulative heating rated water flow

7 m3/h

Water resistance of circulative rated water flow

160 kPa

RSJ-800/SZN1-H

Circulative heating rated water flow

14 m3/h

Water resistance of circulative rated water flow

160 kPa

The hot water circulative pump must use hot water pump; the temperature resistance of the

circulative water pump cannot lower than 80°C.

Rated head of circulative pump:

ΣOn-way resistance + ΣLocal resistance + Unit resistance

Rated flow of circulative pump:

Rated flow of a single circulation heating unit × Circulating unit quantity

2.8 E-heater capacity selection

As the requirement, the auxiliary electric heater can be selected. The host unit provides the

passive control signals of the auxiliary heater.

The installation location of the auxiliary heater must strictly comply with the installation

schematatic diagram.

Rated heating capacity of total unit × 10%~30%.

E-heater can apply the pipe-type or water tank E-heater. After installation, it must through

dialing codes to choose the relative E-heating mode, otherwise it will damage the unit or

Page 39

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

39

E-heater.

The selection of auxiliary heater is only for reconmendation, and the selection of auxiliary

heater can be selected according to the actual conditions.

Make sure E-heater is covered with water all the time.

2.9 Electric connection of the unit

Only use the electric components specified by product manufacture.

Electronic installation must comply with the native regulations. Independent power supply

should be applied. Power supply should satisfy electrical specifications that the unit

requires.

The unit must be ground wiring reliably.

Set leakage protective devices according to the requirements of national technical standard

about electric equipment.

Power supply wire and signal wire should be arranged properly without interruption to each

other, do not contact with connecting pipes and valves as well.

When strong electricity and weak electricity are in parallel, please put the cable into each

other’s circuit and leave a proper space.

No power supply wire is provided, please refer to the requirements in national standards or

factory.

In following table, power supply wire and connection length is the situation when voltage

drop range is within 2%, if wire continuous length exceeds the ones listed in the table,

please choose wires with a right diameters according to relative regulation.

When finishing wiring, power on when there is no mistakes after a careful inspections.

RSJ-420/SZN1-H

Power supply

380-415V, 3Ph, 50Hz

Min. wire size

(metal pipe & synthetic resin pipe wire)

Wire size (˂30m)

10# (UL1015)

Ground wire

10# (UL1015)

Manual switch

Capacity

63 A

Fuse

50 A

Leakage protector

30mA 0.1sec below

Page 40

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

40

RSJ-800/SZN1-H

Power supply

380-415V, 3Ph, 50Hz

Min. wire size

(metal pipe & synthetic resin pipe wire)

Wire size (˂30m)

25mm2

Ground wire

25mm2

Manual switch

Capacity

125A

Fuse

100A

Leakage protector

30mA 0.1sec below

Specifications of controlling wire

Item

Size (UL1015)

Remarks

E-heater controlling wire

18#

2-core

Circulating water pump controlling wire

18#

2-core

Remote alarm control wire

18#

2-core

Communication cable (shield)

22#

3-core

Wired controller power supply wire

22#

2-core

Targe flow switch

22#

2-core

Wiring diagram of water heater power

Single unit:

Page 41

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

41

Multi-units:

RSJ-420/SZN1-H

RSJ-800/SZN1-H

Page 42

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

42

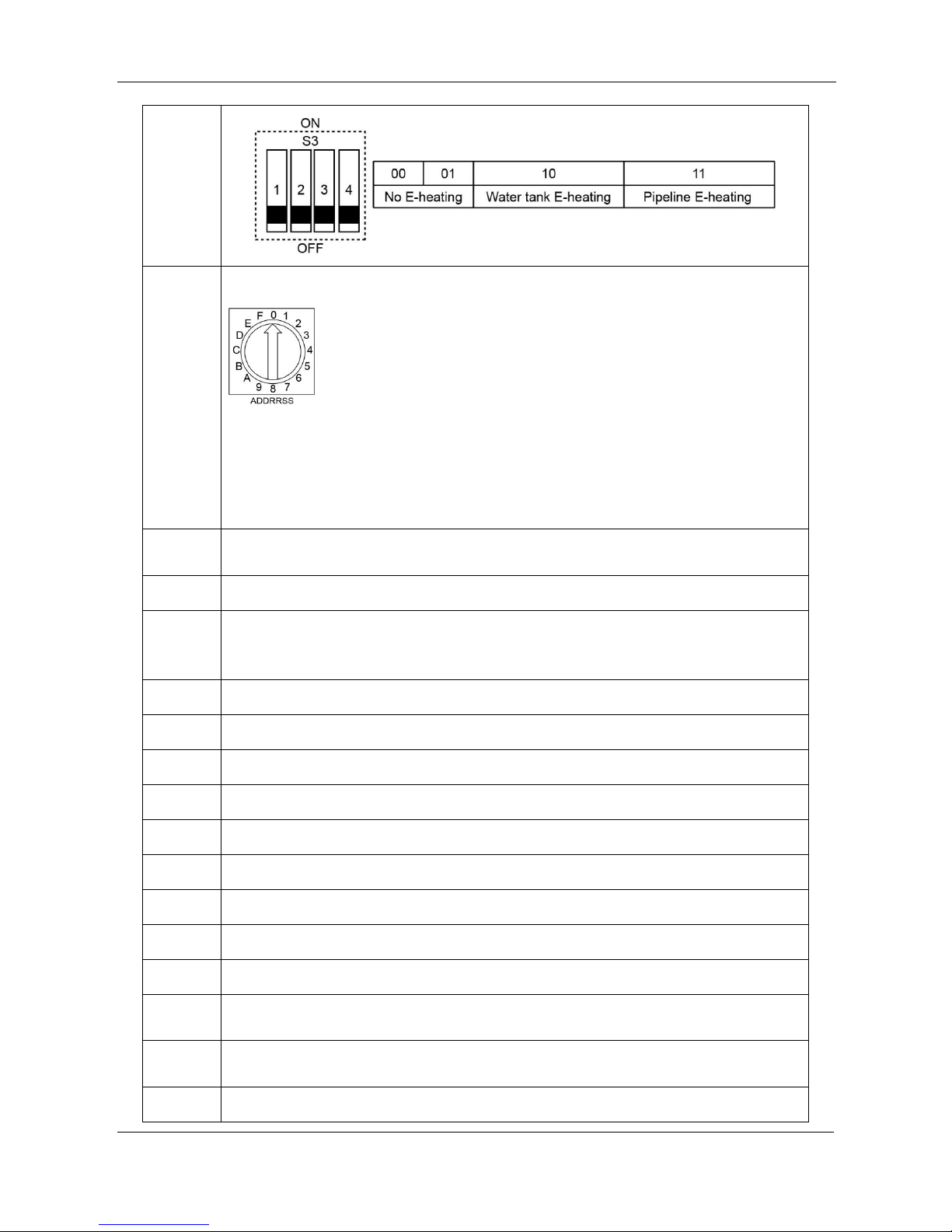

Electric wiring figure

Electric control schematic diagram of the unit (Only for reference)

Page 43

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

43

When power supply wire of the wired controller is less than 20m, wiring can be applied as

the location shown as imaginary lines, when it it exeeds 20m, the power adapter is

necessery.

Pay attention to the power phase sequence, if wrong connection of the phase sequence,

the compressor will not operate, and digital screen of the water heater electrical control

board will display error code. Change the phase sequence, and powering again until the

digital screen does not display error and compressor starts normally.

The water flow switch, water pump, ON/OFF singal and E-heater are only connected with

the host unit, which are not 220V control signal. So do not directly drive loading.

When the host unit has any one error of E1, E2 or E8, all the water heaters stop operation.

When the main unit has E4 error, the host unit and wired controller alarm the error, the slave

units do not display error, then all the unit can not normally heat water, and go into backup

mode.

When the host unit has other errors (except E1, E2, E8), then only stop the host unit, other

units will not be affected. When the slave unit has error, only stop the operation of the error

unit, other units will not be affected.

When the main or slave unit has protecton, only stop that unit, other units will not be

affected.

Page 44

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

44

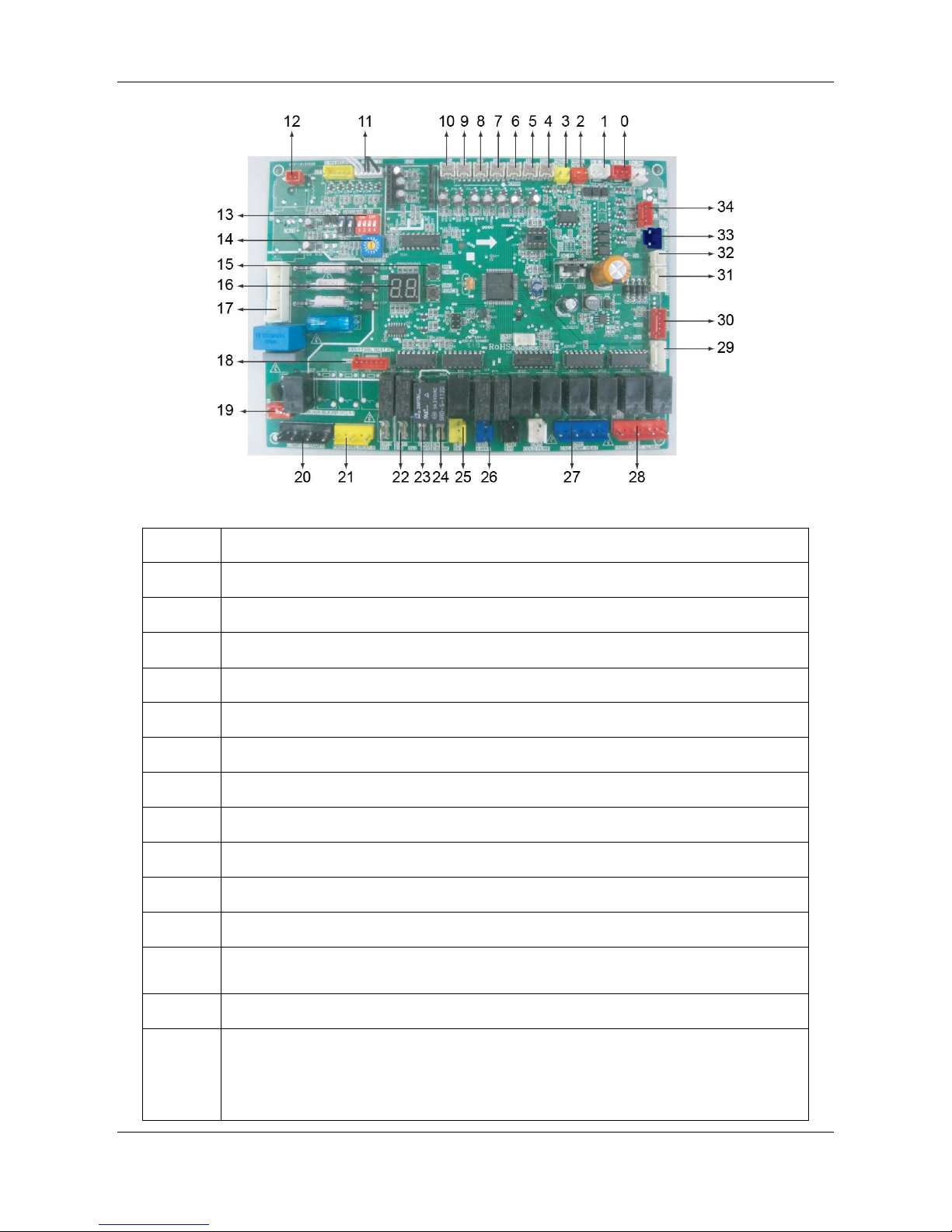

Dial code specification

S3-1: Remote ON/OFF functional status (OFF: inactive (default); ON: active).

S3-2: Defrost periodical choice (OFF: default time by program; ON: 28 minutes).

S3-3,4: Auxiliary heater choice (OFF: indicates 0, ON indicates 1, the factory default is 00).

Address dial code

0~3 separately stands for address 0~3, means 0~3 set units. When dial the

dial switch to 4 or more for the unit RSJ-420/SZN1-H, and when dial the dial switch to 2 or

more for the unit RSJ-800/SZN1-H, then it will invalid.

Each module of water heat pump has the electric control function. Set the host unit through

the address dial code on electric control board. Stipulate the unit with address dial code 0#

as the host unit. Only after setting the host unit , the function of direct communication with

wired controller and other function can be activated.

3. Trial run

When use the wired controller to operate the water heater, please check as the following list:

No.

Item

Remark

1

Whether the unit is installed firmly.

2

Whether the air inlet and outlet of the unit has obstacle.

3

Whether the dial codes of each unit has dial to the correct position.

4

Whether check the leakage of the water system.

5

Whether the water system is clean.

Page 45

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

45

6

Whether the filter is clean.

7

Whether the water drain is smoothly.

8

Whether complete the heat insulation of the water pipe.

9

Whether vacuum the pipeline of water side.

10

Whether all the valves in the water side pipeline are under correct status.

11

Whether the water flow switch work well.

12

Whether the grounding correctly.

13

Whether the power voltage meets the requirements of the unit.

14

Whether the leakage protector can work effectively.

When use the wired controller to operate the water heater, please check as the following listed:

No.

Item

Remark

1

Whether all the buttons of wired controller are normal.

2 Whether the input voltage of the unit meet the requirements of the unit.

3 Whether the electronic lock has been unlocked.

4 Whether the water outlet temperature is normal.

5 Whether there is any abnormal vibration and noise during operation.

Notes:

The unit also has one function; it can easily to make the unit enter other modes.

Enter ‘Debugging replenishing’ method: Long press ‘CHECK’ button for 3~20s within 1 minute after

power on, then the digital screen will display ‘0’ and be flashed with 2Hz frequency, means enter to

the function selection state. Short check, the digital screen will successively display each

corresponding number:

No. 4: Capacity testing mode I;

No. 5: Drain water mode;

No. 6: Force cycle pump operating;

No. 8: Force defrosting;

No.10: Capacity testing mode II.

After 5s, the digital pipe will flash with 1Hz frequency; means has already entered the debugging

replenishing function.

Page 46

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

46

4. Fault analysis and solutions

Not distribute to malfunction

Phenomena

Cause

White aerosol or globule is given out.

Or make sound of ‘hiss’ every now

and then.

When the unit is defrosting, the sound of the 4-way valve

being shifted. Air supply motor stop automatically to defrost.

At the beginning and the end of the defrost process, sound

is given out in motor valve occur.

During the process or just after have stopped, sound likes

water flow occurs, which will be amplified at the first 2~3

minutes, this is caused by process of refrigerant current or

water discharge at dehumidifying operation.

Slight ‘hiss’ is caused by heat exchanger as temperature

changes. The sound gives out, because of heat expands

and cold contracts of heat exchanger.

During the beginning or just after have stopped, sound likes

clock occur, which is caused by electric expanding valve

operation.

Water outlet temperature fluctuation.

Because of different water inlet pressure, under special

working condition that may show up water outlet

temperature fluctuation, which is a normal phenomenon,

and will not affect the actual use; appropriately adjust the

water pressure can improve this phenomenon.

Water outlet temperature cannot reach

the setting temperature.

Under low temperature condition, for the purpose of

protecting the unit, the water outlet temperature may not

reach the higher setting temperature, which is a normal

phenomenon.

The terminal circulating water

temperature lower than the setting

temperature

For purpose of protecting the unit, the terminal circulating

water temperature cannot reach 60ºC, which is a

phenomenon, and will not affect the actual use.

Re-start after the unit stop, after 3

minutes then can be operated.

Compressor delay protection. It is a normal phenomenon.

The fan operates low speed or only

operates one fan.

When the ambient temperature is high, for protecting the

unit then the fan will shift to low speed or only operate one

fan.

Heat exchanger defrosting.

If operated in winter, for the heat exchanger surface

temperature is lower than the ambient one, and the heat

exchanger surface temperature is lower than 0ºC, the

surface will be frosted, which will affect the heat exchanging

effect, so the unit should be periodically defrosting.

The fan cannot operate.

During defrosting, the fan will not be operated.

Page 47

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

47

Need to check again

Phenomena

Cause

Stop operation or drive up

automatically

Detect the timer whether be given wrong operation.

Detect anti-freezing mode is opened.

No operation

Whether the power is cut.

Whether the manual power supply switch is off.

Whether the fuse is broken.

Whether the protection device works. (Operation lamp is

lightened.)

Whether it is the time set. (Operation lamp is lightened.)

Compressor is unable to drive

Possible reason

Detect and settle measure

1. Power errors.

Connected with wrong phase sequence.

2. Wire connection is loosening.

Check and fasten again.

3. Relay or fuse errors.

Check and repair.

4. Compressor errors.

Change the compressor.

Fan has loud noise

Possible reason

Detect and settle measure

1. Fixing screw of the fan is loosening.

Re-fasten the fixing screw of the fan.

2. Fan blade touched the cover shell

or screen

Check and adjust.

3. The fan operated unsteadily.

Change the fan.

Abnormal noise given out from compressor

Possible reason

Detect and settle measure

1. Liquid refrigerant flows into

compressor and produces liquid

strikes.

Check the EXV, and whether the temperature sensor

loosen and repair.

Page 48

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

48

2. Damages of the compressor inner

components.

Change the compressor.

Water pump not operated or abnormal operated

Possible reason

Detect and settle measure

1. Power errors.

Check and repair.

2. Relay error.

Change the relay.

3. There is gas in the water pipe.

Drain off the gas.

Compressor ON and OFF frequently

Possible reason

Detect and settle measure

1. Bad circulation of water system.

Blocked the water system or has air in the water system.

Check the water pump, valves, pipeline, and clean the

water filter or drain off the air.

2. Low load.

Adjust the load or add stored energy device.

Compressor operated with no heating

Possible reason

Detect and settle measure

1. Refrigerant leakage.

Check, repair and replenish the refrigerant.

2. Compressor error.

Change the compressor.

No obvious heating effect of the unit

Possible reason

Detect and settle measure

1. Bad thermal insulation of water

system.

Enlarge the thermal insulation of the system.

2. Bad heat exchanging of evaporator.

Check the air inlet and outlet whether are normal and clean

the evaporator.

3. Lack of refrigerant.

Check whether has refrigerant leakage.

4. The water side heat exchanger has

blocked.

Clean or change the heat exchanger.

In case the unit runs under abnormal condition, failure protection code will display on both digital tube

on PCB board and wired controller. The indicator on the wired controller will flash with 5Hz. The

display codes are shown in the following table:

Page 49

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

49

No.

Error

code

Reason

1

E1

Power phase sequence error.

2

E2

Communication error of host unit and wired controller, main unit and slave unit.

3

E3

Error of water outlet temperature sensor (T1).

4

E4

Error of water temperature sensor in the water tank (only host unit displays) (T5).

5

E5

Error of air heat-exchanger temperature sensor (T3).

6

E6

Error of outdoor ambient temperature sensor (T4)

7

E7

Error of E-heater pipe temperature sensor (T6, reserved).

8

E8

Error of circulating water flow detector (Only host unit displays).

9

E9

Error of suction temperature sensor (Th).

10

Ed

Error of water inlet temperature sensor (T7).

11

EA

Error of discharge temperature sensor (Tp).

12

EE

Error of EEprom

13

P0

System low pressure protection

14

P1

System high pressure protection

15

P2

Compressor current of system is overload (Protection)

16

P4

Protection for discharge Hi-temperature (Tp≥115ºC)

17

P7

Host unit is not matched with wired controller, host unit will display P7, and wired

controller will display E2.

18

P8

Water outlet Hi-temperature protection. (≥68ºC, and keep 2 minutes)

19

C1

Compressor current is less than 2A during operation.

20

db

Anti-freezing function

21

d8

ON/OFF signal is ON close status.

22

Hb

Address conflict error.

Continuous come out any error for 4 times within 2 hours, then the unit will stop running. At the

same time, it will be counted as once. After 1 hour, the unit will be automatically running again.

If the stop frequency reaches 5 times, the protection code will be displayed and the unit should

be repowered on again.

When the unit satisfies the unit stopping conditions, the counting of stop frequency will be

Page 50

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

50

cleaned. By the way, also it will be cleaned when the unit has not any protection in 10 hours.

Otherwise, if switch off the unit by wired controller, the counting of stop frequency will not be

cleaned.

The latest 3 protections or error code through spot check. Through the spot check button on

PCB board to observe the operating status of unit. Convenient for maintaining by engineering

technicians. Press check button once, it will first display check sequence number (No. and dot),

then on second later display the parameter.

Normal display contents:

1. Under standby and no error and protection situation, the main unit will display T5, the

slave unit will display the address of this unit.

2. Under the main unit with T5 situation, display T5 temperature; if without T5 or T5 error,

the unit will display error; the slave unit will display the T1 temperature.

Detail spot check display contents as following:

No.

Display

Specification

1

Water outlet temperature

T1 temperature value

2

Coil temperature

T3 temperature value

3

Ambient temperature

T4 temperature value

4

Water tank temperature

T5 temperature value

5

Refrigerant heating pipe temperature

T6 temperature value

6

Refrigerant heating pipe temperature

T6b temperature value

7

Water inlet temperature

T7 temperature value

8

Discharge temperature

Tp temperature value

9

Suction temperature

Th temperature value

10

Water outlet setting temperature

Ts temperature value

11

Operating temperature of circulating

heating water

Tr temperature value

12

Compressor A current

IA current valve

13

Compressor B current

IB current valve (this unit display --)

14

EXV opening

EXV opening

15

Warm water valve opening

Warm water valve opening

Page 51

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

51

16

Water level height

Host unit: 0~4; 0˂S4, S4≤1˂S3, S3≤2˂S2,

S2≤3˂S1, 4≥S1. Slave: --.

17

Operating mode

Standby, stop: 0; Directly heat type: 1;

Circulation type: 2; Defrosting: dF;

Anti-freezing: db; Remote ON/OFF signal

closure: d8.

18

Fan speed

F0: No fan; F1: Low; F2: Medium; F3: High.

19

Model code

Direct and circulate heating for closed tank with

50Hz model: 3A01.

20

Protection frequency

XY: X for stop frequency because of 4

protections within 2 hours. Y for protection

frequency within 2 hours.

21

Protection, error

Display the last third protection, error code.

22

Protection, error

Display the last second protection, error code.

23

Protection error

Display the last protection, error code.

24

The number of slave units

Host unit display XY, slaves displays --; X for

amount of total units, Y for amount of operating

units

25

Program version

26

nd

End

E1: Power phase sequence error

Page 52

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

52

E2: Communication error of host unit and wired controller, main unit and slave unit.

E8: Error of circulating water flow detector (Only host unit displays).

Page 53

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

53

E3: Error of water outlet temperature sensor (T1).

E4: Error of water temperature sensor in the water tank (only host unit displays) (T5).

E5: Error of air heat-exchanger temperature sensor (T3).

E6: Error of outdoor ambient temperature sensor (T4)

E7: Error of E-heater pipe temperature sensor (T6, reserved).

E9: Error of suction temperature sensor (Th).

Ed: Error of water inlet temperature sensor (T7).

EA: Error of discharge temperature sensor (Tp).

EE: Error of EEprom

Page 54

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

54

P0: System low pressure protection

Page 55

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

55

P1: System high pressure protection

Page 56

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

56

P2: Compressor current of system is overload

Notes: the value of Io is 30A.

Page 57

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

57

P4: Protection for discharge Hi-temperature (Tp≥115ºC)

Page 58

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

58

P7: Host unit is not matched with wired controller, host unit will display P7, and wired controller

will display E2. (Power supply of wired controller is 10VAC, if the power supply is not stable,

the code of protection or error will also be displayed.)

P8: Water outlet Hi-temperature protection. (≥68ºC, and keep 2 minutes)

Page 59

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

59

C1: Compressor current is less than 2A during operation

5. Maintenance

All the safety protection devices in the unit will be set before leaving the factory, the user can not

adjust or remove them, in case to damage the unit.

First switch on the unit or switch off the power for a long-term stop (More than 1 day) and then

re-power on, it should prior to connect to the supply from the compressor operation.

Please do not place other obstacles on the unit, it should keep dry and clean and well ventilated

around the unit. When the heat exchanger has dust, it should be immediately cleaned, in case to

affect the unit capacity or cause the unit stops for the protection.

Periodically clean the filter in the water system, for avoiding blocking and damage the unit or

cause unit protection, and it should ofter check the water replenishing system devices whether

are normal.

When the ambient temperature is below zero, it is forbidden to cut off the power, otherwise, the

anti-freezing function will ineffective.

For long-time not use the unit, drain off the water in the unit and pipeline system, and open the

water plug on the water tank to drain off the water, incase the unit been frozen.

Please do not frequentyly on and off the unit, please do not manual cut-off the manual adjust

valve during the unit is operating.

Page 60

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

60

Often check the working situation of each part in the unit, and check the inner pipe connectors of

the unit and whether the high and low pressure detecition ports of the refrigerant has oil dirty, to

make sure the unit has no refrigerant leakage.

Switch check for the electricity leakage protector.

The leakage flow protector of electric control box operates a period (Generally a month), should

be in the closed power on state to press the test button, check the leakage flow protector is

normal or not (each time press the button, the leakage flow protector should be broken off once),

if it is not normal and check the cause of the accident when be found, allowing once power on,

and then, if no operation, it should find out the reason of the fault, and if necessary, do the

movement characteristic test; if it is confirmed by the check for the leakage flow protector itself

fails, it should be timely replacement or repaired.

After running for a long time, the heat transfer surface of water side heat exchanger will deposit

calcium carbonate or other minerals, when these substances on the heat transfer surface scale

is large, then can affect the heat transfer performance and lead to increased power consumption,

high air exhaust pressure (or suction pressure is too low). It can use the organic acids such as

formic acid, citric acid, acetic acid detergent for cleaning. Do not use detergents containing

fluoride chlorate, due to the material of the water side heat exchanger is stainless steel or copper,

which is easily to be corrosive and cause refrigerant leakage.

Clean the water side heat exchanger should be conducted by professionals.

After using cleaning agent, use the clean water to clean the water pipe and heat exchanger, in

case of the waterproof system will be corrosive or has cleaning scale after adsorption.

Under using the clean agents, it should accord to the dirt deposition to adjust the detergent

concentration, cleaning time and temperature.

It needs to neutralize the waste liquid after cleaning; the waste liquid processing should contact

the relative company.

The cleanser have corrosion effect for the eyes, skin, nasalmucosa etc., so the protection device

must be used in the cleaning process (such as protective glasses, protective gloves, protective

mask, protective shoes, etc.) in order to prevent the inhalation or contact with the cleaner.

Page 61

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

61

PH value

Total hardness

Electrical conductivity

Sulphate ion

6.5-8.0

˂50ppm

˂200μs/cm (25ºC)

˂50ppm

Silicon

Iron content

Sulfide ion

Chloride ion

˂30ppm

˂0.3ppm

None

˂50ppm

Ammonia ion

Sodium ion

Calcium ion

\

None

None

˂50ppm

\

Page 62

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

62

Part. 4 Controller

1. Wired Controller (Standard) ................................................ 63

Page 63

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

63

1. Wired Controller (Standard)

1.1 Wired controller specifications

Model

KJR-51/BMKE-A

Input Voltage

10.0V

Operating environment temperature

-10ºC~+43ºC

Operating RH

RH 40%~RH 90%

Performance Features

1. Touch key operation.

2. LCD displays operation parameters.

3. Multiple timers.

4. Real-time clock (battery life: 5~8 years).

1.2 Introduction of function buttons on the wired controller

The wired controller, KJR-51/BMKE-A, is universal controller, and some functions as reserved

are not available for this unit.

1. Operation icon ( ): Indicate unit ON and OFF status; the icon displays when the unit is on

and does not display when the unit is off.

2. Mode area: Indicate the main unit operating mode;

Page 64

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

64

3. Setting temperature: 3 statuses can be displayed - .

4. Timing ON/OFF indication ( ): Indicate the timing information.

5. Function icon:

: Display when water heater system connects to Modbus network;

: Displays when other heat source is provided to the system.

: Displays when water heater maintenance is needed. Press and hold ‘AUXILIARY’

key for 3 seconds to cancel the icon and timing will restart until next maintenance.

: Displays when cycle heating function is on.

: Displays when electric auxiliary heating function is on.

: Displays when check function is on.

: Displays when ambient temperature is below 2ºC which means the main unit

need anti-freezing action.

: Displays when no key operation for 2 minutes and all keys are locked. Press and

hold ‘OK’ key for 3 seconds to unlock.

: Displays when error or protection occurs and means the unit need maintenance

by professionals.

6. Online quantity indication: Under normal status display the quantity of units connected to

the wired controller; under check status display the device serial number.

7. Water level indication: Under normal status displays water level; under water level setting

status displays setting value.

8. Clock: Under normal status displays clock; under timing setting displays the setting timing.

9. Water temperature: Under normal status display water temperature; under water

Page 65

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

65

temperature setting status displays the setting value; under cycle heating water temperature

setting status displays the setting value; under check status displays check parameter.

10. ON/OFF key ( ): Turn on and turn off functions.

11. Right and left key ( and ): Press these keys to check setting water temperature,

setting cycle heating water temperature and setting water level under main page; press right

key to shift to the next step setting under timing setting status. Press these keys to turn over

the unit parameter information under check status.

12. OK key: Press this key to confirm settings. Press and hold this key for 3 seconds to unlock

under locking status.

13. Setting key: Setting water temperature, timing and mode, etc. Press and hold this key for 3

seconds to enter check status.

14. Add and Reduce key (▲ and ▼): Move up or move down values of temperature, timing,

water level, etc. Turn over #0~#15 units under check status.

15. Cancel key: Press this key to cancel parameter setting under setting status; press and hold

this key for 3 seconds to cancel timing when timing is valid.

16. Auxiliary key: Power on the cycle heating function, electric auxiliary heating function or

water pump function.

1.3 Operation instruction

1.3.1 Turn on and turn off the main unit

Press the ON/OFF key ( ) to control on and off status of the main unit.

Under off status, press the ON/OFF key ( ) to run the main unit, at that time the LCD

of wired controller will display the operation icon ( ). The main unit will running as the

current setting of the wired controller.

Under on status, press the ON/OFF key ( ) to turn off the main unit and the operation

icon ( ) on the LCD will disappear.

Page 66

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

66

1.3.2 Setting operating modes and parameters

Press SET key to enter the operation mode and parameters setting. The setting

contents will change as the following order each time the key is pressed.

The setting options in the dotted line frame are not general setting. The wired controller

automatically judges the needed setting according to the model of main unit.

Setting water temperature

Press the ▲ or ▼ button to adjust the water temperature after the controller is

powered on. Or press SET key once when ‘SET WATER TEMP’ is displayed on

the LCD and then press the ▲ or ▼ button to adjust water temperature.

To check water temperature setting, press or key under the main page (the

page displayed after the controller is powered on).

Page 67

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

67

Timing setting

3 timing periods can be set on the wired controller; Timer 1, Timer 2, Timer 3.

These 3 timers can control the main unit to be turned on and off 3 times at most

during a day.

Press SET key under man page twice to enter timing setting. Then the LCD will

display as the following:

At this time the hour of the clock will flash, which means the current setting is the

hour of Timer 1 on, press the ▲ or ▼ to adjust, press key when finished, and

then the minute of the clock will flash, which means the current setting is the

minute of Timer 1 on, press the ▲ or ▼ to adjust, press key when finished, the

LCD will display as the following:

At this time the hour of the clock will flash, which means the current setting is the

hour of Timer 1 off, press the ▲ or ▼ to adjust, press key when finished, and

then the minute of the clock will flash, which means the current setting is the

minute of Time 1 off, press the ▲ or ▼ to adjust, press key when finished, the

LCD will display as the following:

Page 68

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

68

At this time the hour of the clock will flash, it means the current setting is the hour

of the Timer 2 on. And the follow setting method will be the same as the Timer 1.

Similarly, the setting of Timing 3 is the same as this method. After setting is

finished, press OK key or wait for 7 seconds to confirm the setting, and the LCD

will display the effective timing information, as the following display:

Example of timing setting:

During any period of timing setting to press OK key, the timing periods which have

been set will be effective (only if the on and off of one timing period have been set,

the setting is effective).

Page 69

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

69

Check timing information: to check the timing which has been set, press or

key under main page, the on and off time of Timer 1, Timer 2 and Timer 3 will be

displayed in turns.

Cancel timing: press and hold CANCEL key for 3 seconds, then all the effective

timing periods will be cancelled.

To avoid timing error, each period of timing should not be crossed, e.g.:

Set the cycle heating water temperature (Reserved)

Continuous press SET key 3 times to enter cycle heating water temperature

setting. The LCD will display ‘SET CYCLE WATER TEMP.’ and temperature value

will flash.

Press the ▲ or ▼ key to adjust the temperature value, press OK key or wait for 7

seconds to confirm. During setting process pressing CANCEL key to exit without

saving.

Check cycle water temperature value setting: press or key under main

page to check the value.

Set clock

Press the SET key 4 times to enter clock setting. The hour of the clock will flash, which

means the current setting is the hour of the clock, press the ▲ or ▼ key to adjust, press

Page 70

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

70

key when finished, and then the minute of the clock will flash, it means the current

setting is the minute of the clock, press the ▲ or ▼ key to adjust, press OK key when

finished or wait for 7 seconds to confirm. During the setting process press the CANCEL

key to exit without saving.

Setting the clock should be correct, otherwise cannot get the correct timing on and

timing off.

Set water level (Reserved)

Press the SET key 5 times to enter the water level setting. Press the ▲ or ▼ key to

adjust the water level. Press OK key when finished or wait for 7 seconds to confirm.

During the setting process, press the CANCEL key to exit without saving. The setting

value is 50%, 75% or 100%. Press the or key to check the water level which has

been set under main page.

1.3.3 Auxiliary operation

Cycle heating (Reserved)

Cycle heating function makes the direct heating water heater to run the cycle heating

function.

Page 71

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

71

Operation method: press AUXILIARY key twice to enter this function. The icon

will flash, press OK key to confirm. The ’CYCLE’ icon will be on if the cycle heating

running requirement is fulfilled and will be off if not fulfilled.

Water pump (reserved for future use.)

This function is used to run the main water pump in the device installing and

debugging.

Operation method: Press AUXILIARY key 3 times to enter this function. The icon

will flash and then press OK key to confirm. The ‘PUMP’ icon will be on if the pump

running requirement is fulfilled and will be off not fulfilled.

Cancel auxiliary

To stop the auxiliary function, press the AUXILIARY key again, and then press

CANCEL key when the corresponding icon is flashing. Then the auxiliary function will

be cancelled.

1.3.4 Check

Check function allows the user to check all the operating parameters, error and

Page 72

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

72

protection information of the main unit.

Enter method: press and hold SET key for 3 seconds to enter check interface, as the

figure display:

Press the ▲ or ▼ key to adjust the main unit serial number and check 16 unit’s status

information from #0~#15. Press or to adjust the check sequence number of one

unit and check all the status information of this unit.

Check content:

Water outlet temperature T1→2, Outdoor pipe temperature T3→3, Outdoor ambient

temperature T4→4, Air exhausting temperature→

Compressor A current→6, Compressor B current→7, EXV opening→8, EXV opening

Last one error or protection→10, last second error or protection→

Last third error or protection→12, Outdoor unit model→13, Wired controller setting

value→1, Water outlet temperature T1……

Page 73

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

73

1.3.5 Error handling

When the unit has error or protection, the icon will flash. Press and hold SET key for 3

seconds to enter check status and then press the ▲ or ▼ key to check the unit of

#0~#15. If the ‘ERROR’ icon is on, it means the corresponding unit has error or

protection at that time. The last 3 error or protection codes of the unit can be checked.

The error icon will disappear if the error or protection is cleared.

For the error code, refers to trouble shooting part.

1.4 Installation of wired controller

1.4.1 Caution

Stated below are important safety issues that must be obeyed.

Confirm there is no abnormal phenomena during test operation after complete, then hand

the manual to the user.

Reinstallation must be performed by professional.

Do not install the unit in a place vulnerable to leakage of flammable gases. Once flammable

gases are leaked and left around the wired controller, fire any occur.

The wiring should adapt to the wired controller current. Otherwise, electric leakage or

heating may occur and result in fire.

The specified cables shall be applied in the wiring. No external force may be applied to the

terminal. Otherwise, wire cut and heating may occur and result in fire.

Circuit of wired controller is low voltage circuit. Never connect it with a standard 220V or

380V circuit or put it into a same wiring tube with the circuit.

The shield cable must be connected stable to the ground, or transmission may fail.

Do not attempt to extend the shield cable by cutting, if it is necessary, use terminal

connection block to connect.

Do not place the wired controller near the lamps, to avoid the signal of the controller to be

disturbed.

Page 74

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

74

Do not install the unit in a place with much oil, steam, sulfide gas. Otherwise, the product

may deform and fail.

1.4.2 Preparation before installation:

Check whether the following assemblies are complete:

Name

Qty.

Remarks

Wired controller

1

Cross round head wood mounting screw

3

M4×20, for mounting on the wall.

Cross round head mounting screw

2

M4×25, for mounting on the electric

switch box.

Installation manual

1

Owner’s manual

1

Plastic expansion pipe

3

For mounting on the wall.

Plastic screw bar

2

For fixing on the 86 electrician box.

Prepare the following assemblies on the site:

Name

Qty.

Remarks

Wiring tube (insulating sleeve and

tightening screw)

1

Embeded into wall.

Electrician box

1

Embeded into wall.

1.4.3 Dimensions

Page 75

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

75

1.4.4 Wire connection

There are two methods to connection between wired controller and main unit.

1.4.5 Back cover installation

Use straight head screwdriver to insert into the buckling position in the bottom of wired

controller, and spin the screwdriver to take down the back cover. Pay attention to

spinning direction, otherwise will damage the back cover.

Page 76

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

76

Use three M4×20 screws to directly install the back cover on the wall.

Use two M4×25 screws to install the back cover on the 86 electrician box, and use one

M4×20 screw for fixing on the wall.

Adjust the length of two plastic screw bars in the accessory to be standard length from

the electrical box screw bar to the wall. Make sure when install the screw bar to the

electrical box screw bar, make it as flat as the wall.

Use cross head screws to fix the wired controller bottom cover in the electric control

box through the screw bar. Make sure the wired controller bottom cover is on the same

level after installation, and then install the wired controller back to the bottom cover.

Page 77

Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual MCAC-HTSM-201506

77

Over fasten the screw will lead to deformation of back cover.

1.4.6 Wire outlet

Avoid the water enter into the wired controller, use trap and putty to seal the connectors of

wires during wiring installation.

Method 1:

Method 2:

Method 3:

Page 78

MCAC-HTSM-201506 Midea R410A Direct Heating Commercial Heat Pump 50Hz Technical Manual

78

1.4.7 Front cover installation

After adjusting the front cover and then buckle the front cover. It should avoid to

clamping the communication switching wire during installation.

Correct install the back cover and firmly buckle the front cover and back cover,

otherwise will make the front cover drop off.

Loading...

Loading...