Page 1

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

1

Midea High-temperature Direct-heating

Heat Pump Water Heater

Technical Manual

Applicable Models:

RSJ-100/N1-540V-D

RSJ-200/SN1-540V-D

RSJ-380/SN1-820-D

Midea reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations.

Page 2

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

2

Contents

Part 1 General Information ....................................................................... 3

1. Measurements....................................................................................................... 4

2. External Appearance ............................................................................................ 4

3. Nomenclature ........................................................................................................ 5

4. Features ................................................................................................................. 6

Part 2 Outdoor Units ................................................................................. 7

1. Specifications ....................................................................................................... 8

2. Capacity tables ................................................................................................... 10

3. Dimensions ......................................................................................................... 13

4. Service Space ..................................................................................................... 14

5. Wiring Diagrams ................................................................................................. 15

6. Piping Diagrams ................................................................................................. 20

Part 3 Installation .................................................................................... 21

1. Precautions ......................................................................................................... 22

2. Installation information ...................................................................................... 23

3. Accessories ......................................................................................................... 24

4. Inspecting and Handling the Unit ...................................................................... 24

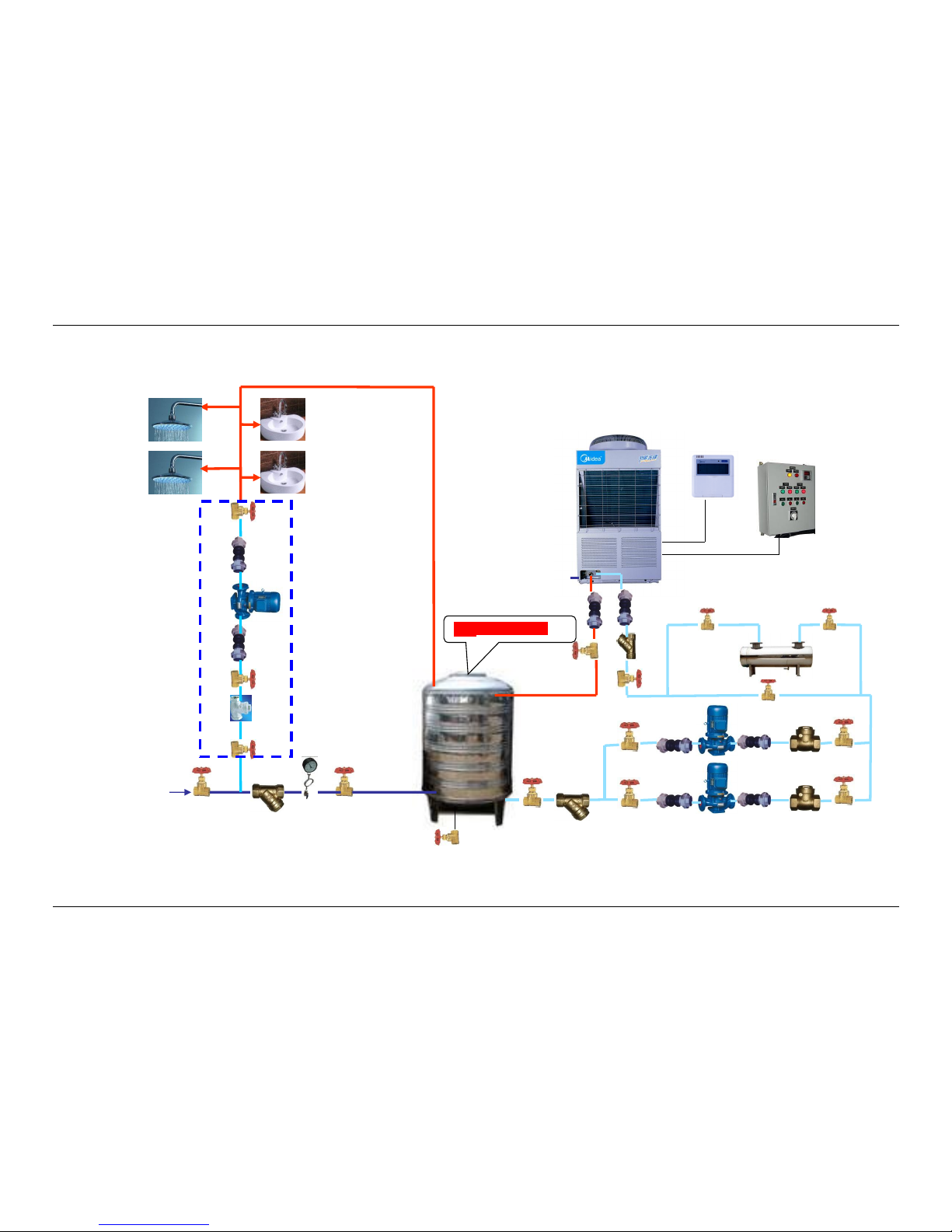

5. Connection Diagram ........................................................................................... 25

6. Operation Instruction ......................................................................................... 27

7. Installation Instruction ....................................................................................... 28

8.Electric Wiring ...................................................................................................... 31

Part 4 Trial Operation ................................ ................................ .............. 34

1. Confirmation before the trial operation ............................................................ 35

2. Water Pump Air Extraction ................................................................................. 35

3. Wired Controller and Operation ........................................................................ 36

4. Water tank cleaning ............................................................................................ 43

5. Schematic Diagram of the Unit System ............................................................ 43

6. Error Code Cause Analysis and the Solutions ................................................. 44

7. Main control board spot check .......................................................................... 46

8. Failure without Code .......................................................................................... 46

9. Troubleshoot of abnormal phenomena ............................................................ 47

Page 3

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

3

Part 1

General Information

1. Measurements ....................................................................................... 4

2. External Appearance ................................................................ ............. 4

3. Nomenclature ........................................................................................ 5

4. Features ................................................................................................. 6

Page 4

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

4

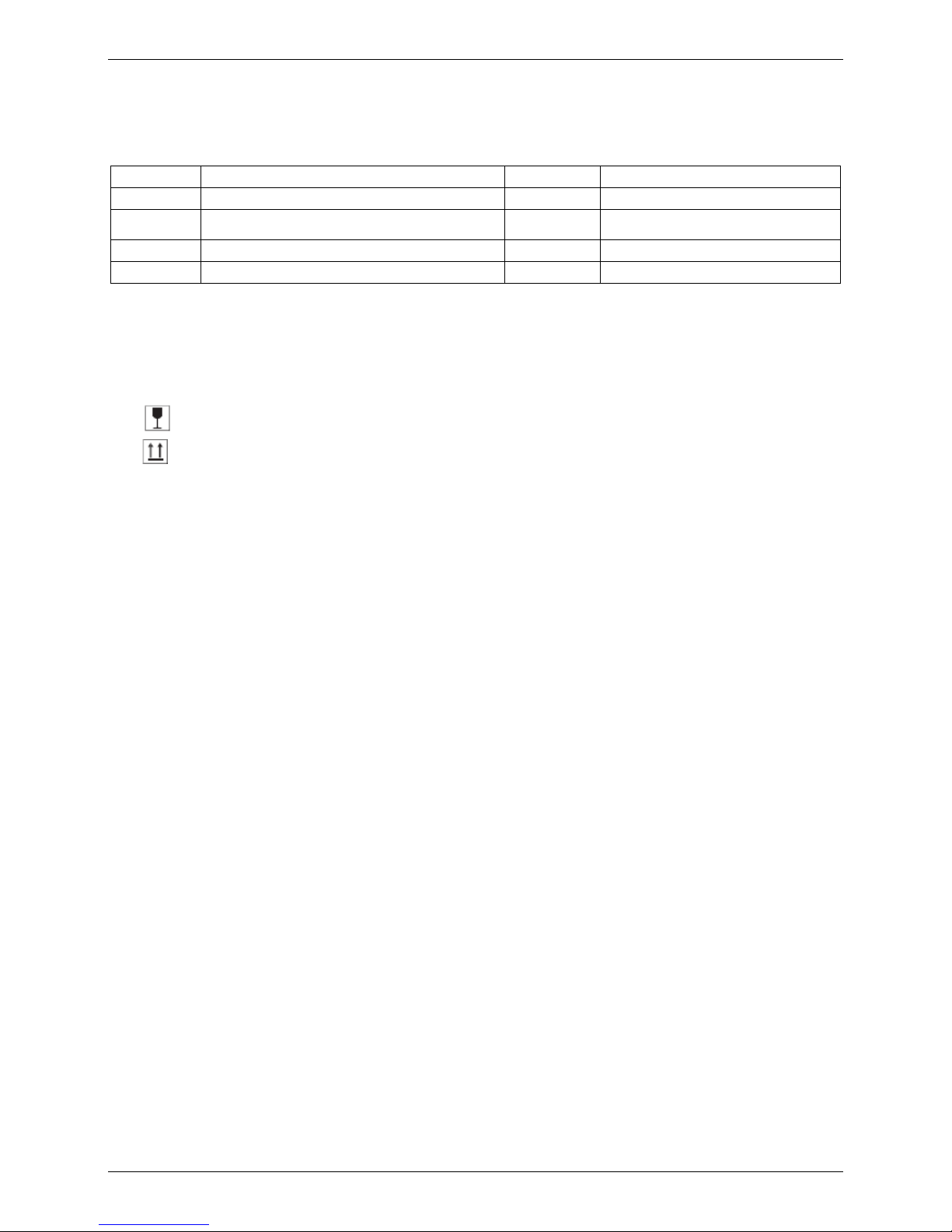

1. Measurements

Model

Dimension (mm)

Net/ Gross Weight

Power Supply

RSJ-100/N1-540V-D

Width: 750

Height: 1100

Depth: 750

121/129

220~240V-1ph-50Hz

RSJ-200/SN1-540V-D

Width: 750

Height: 1100

Depth: 750

145/152

340~420V-3ph-50Hz

RSJ-380/SN1-820-D

Width: 992

Height:1750

Depth:893

290/297

340~420V-3ph-50Hz

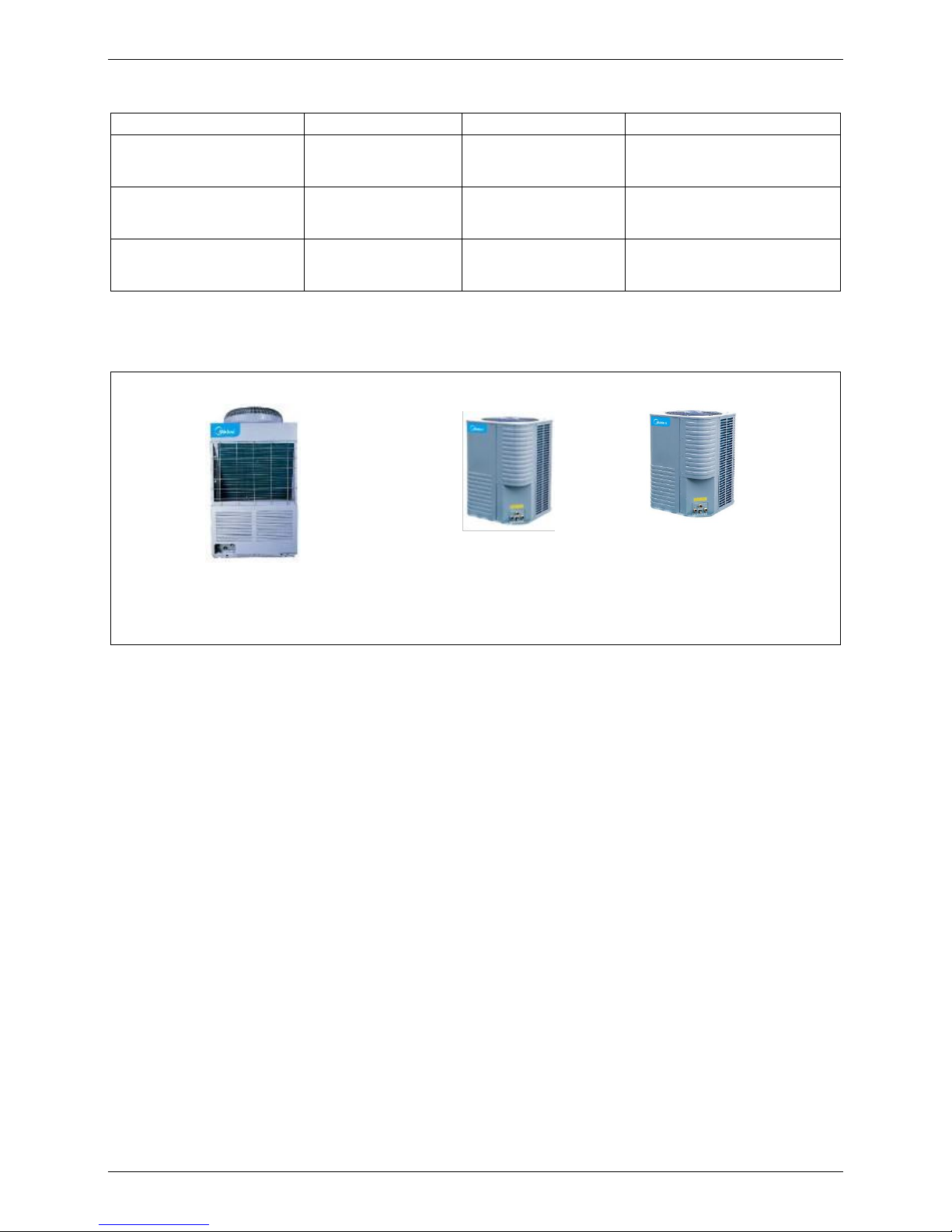

2. External Appearance

RSJ-380/SN1-820-D

RSJ-200/SN1-540V-D

RSJ-100/N1-540V-D

Page 5

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

5

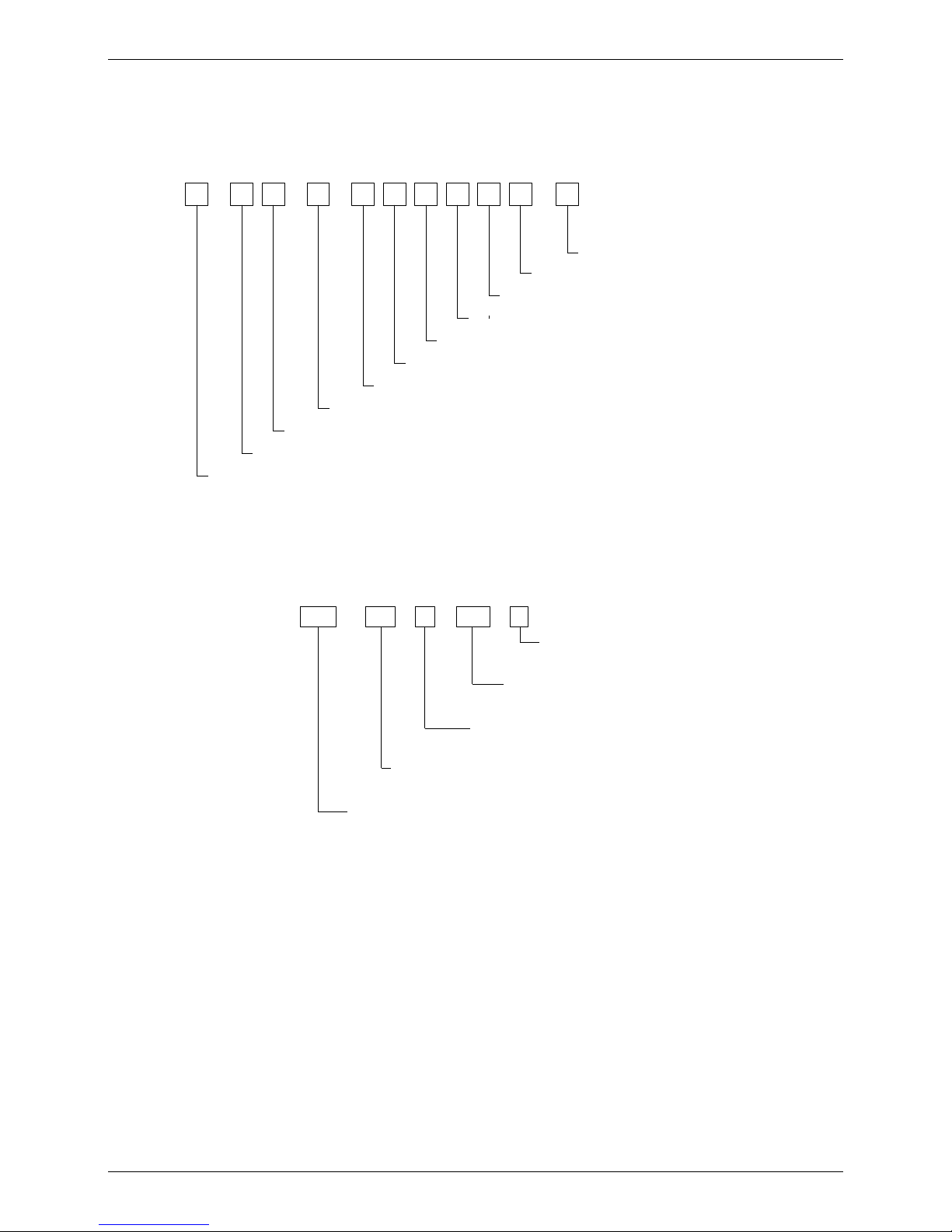

3. Nomenclature

Commercial Water Heating Unit

1

2 3

4 5

6

7

8

-

Installation type code

Water heating unit code

Export model code

/

-

9 10

Power supply specification code

Heating mode code

Rated hot water output, unit: 100 W

Water tank volume, unit: L

Other functions code

Water supply pump lift code

Refrigerant code

11

-

Design code

For example:

S

820

RSJ

-

B

- -

/

380

Configuration code

Power supply specification cod

Water heating unit code

Rated hot water output, unit: 100 W

Refrigerant code

Page 6

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

6

4. Features

4.1 Safety

a. Complete isolation between water and electricity. No electric shock problem, more safety.

b. No fuel tubes and storage, no potential danger from oil leakage, fire, explosion etc.

4.2 Easy operation

The system can be controlled simply through the wired controller.

4.3 Automatic control:

Automatic start-up and shutdown, automatic defrosting. Save you much extra operation.

4.4 Rapid speed to produce hot water.

4.5 High efficiency and energy saving.

The unit adopts heat pump principle, which absorbs heat from outdoor air and produce heat water, thermal

efficiency can be approximately 4.9.

4.6 All-the-weather running.

Within the temperature range from -15℃ to 43℃, it will not be affected by night, overcast sky, rain and

snow.

4.7 Modular design, maximum connection 16sets basic unit

Page 7

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

7

Part 2

Outdoor Units

1. Specifications ........................................................................................ 8

2. Capacity tables .................................................................................... 10

3. Dimensions .......................................................................................... 13

4. Service Space ...................................................................................... 14

5. Wiring Diagrams .................................................................................. 15

6. Piping Diagrams .................................................................................. 20

Page 8

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

8

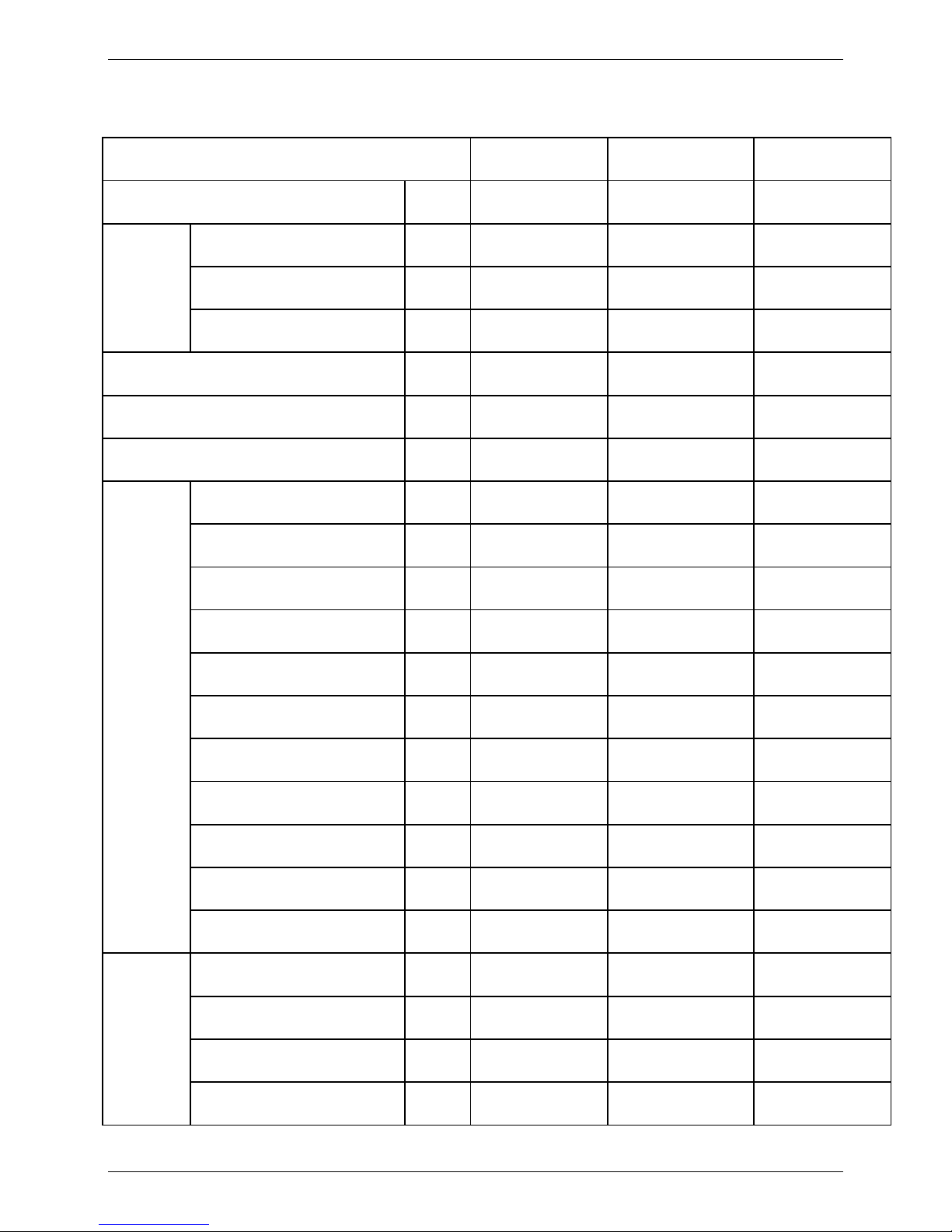

1. Specifications

HPWH SPECIFICATION

Model

RSJ-100/N1-540V-D

RSJ-200/SN1-540V-D

RSJ-380/SN1-820-D

Power supply

Ph-V-Hz

1-220-50

3-380-50

3-380-50

Water

Heating

Capacity

kW

11.2

20.4

43

Input

kW

2.85

5.2

10.5

Rated current

A

13.8

9.5

15.9

Max. input consumption

kW

3.97

7.5

15.26

Max. input current

A

18.2

13

26.7

starting current

A

98

74

74

Compressor

Model

ZP36KSE-PFZ-522

ZP67KCE-TFD-522

ZP67KCE-TFD-420

Type

SCROLL

SCROLL

SCROLL

Brand

COPELAND

COPELAND

COPELAND

Supplier

EMERSON

EMERSON

EMERSON

Capacity

kW

8.8

16.2

16.2

Input

kW

2.94

5.2

5.2

Rated current(RLA)

A

13.6

9.1

9.1

Locked rotor Amp(LRA)

A

98

74

74

Thermal protector

℃

145

135

135

Capacitor

uF

80μF/440V

/

/

Refrigerant oil

POE

POE

POE

outdoor fan

motor

Model

YDK140-6N

YDK220-6R

YDK550-6E

Brand

welling

Changzhouyongan

Changzhouyongan

Input

W

230×1

360

810/680

Capacitor

uF

12

12

25

Page 9

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

9

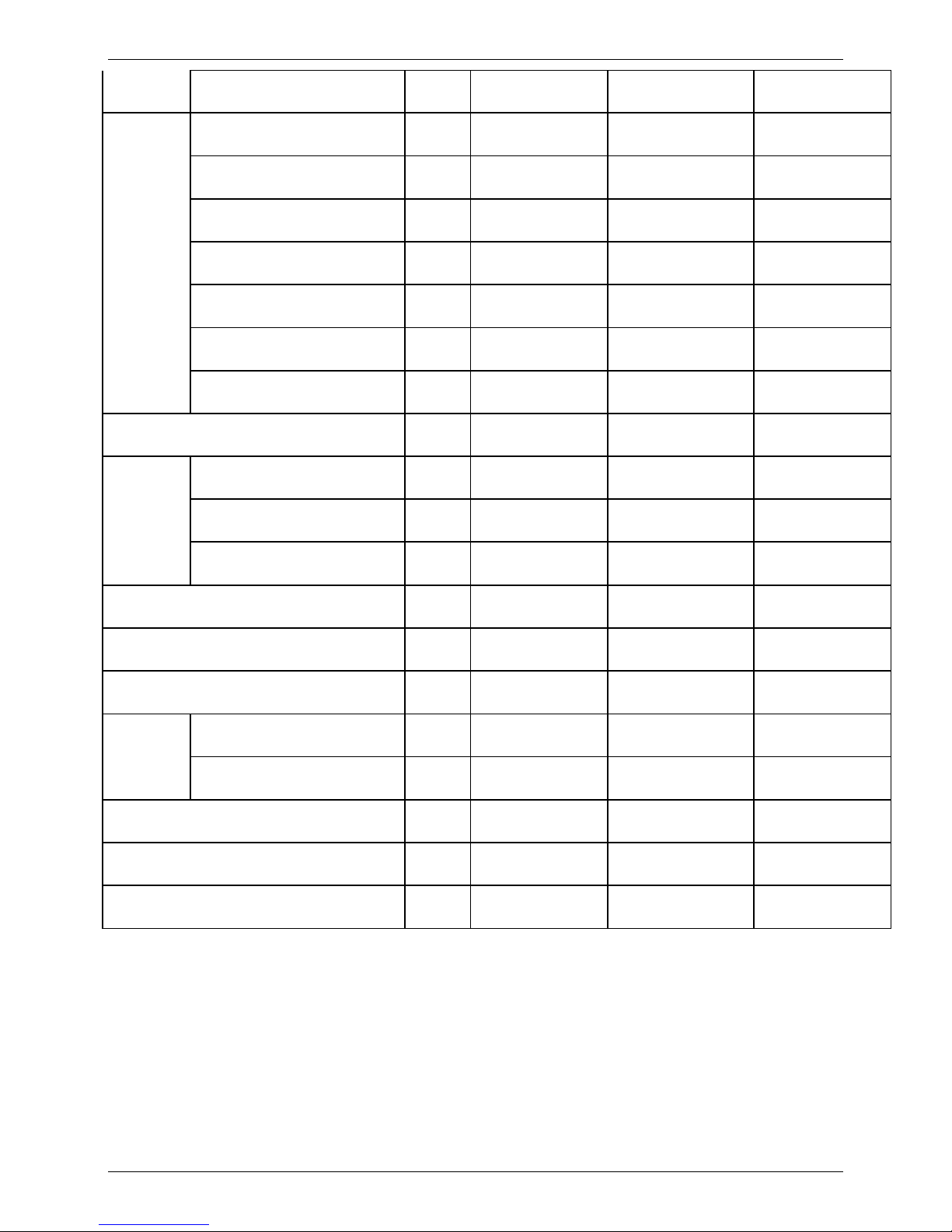

Speed(hi/lo)

r/min

735 / 530

905/730

850/750

outdoor coil

a. Number of rows

1 2

2×2

b. Tube pitch(a)x row pitch(b)

mm

25.4X0

25.4X22

25.4X22

c. Fin spacing

mm

1.8

1.8

1.8

c. Fin type

Hydrophilic

aluminum

Hydrophilic

aluminum

Hydrophilic

aluminum

d. Tube outer diameter and type

mm

Ф9.52 inner groove

tube

Ф9.52 inner groove

tube

Ф9.52 inner groove

tube

e. Coil length x height x width

mm

1378×1016×22

1378×1016×44

855×969×22*2

G .Number of circuits

8 18

12*2

Outdoor noise level

dB(A)

61

61

62

Outdoor

unit

Dimension (W×H×D)

mm

750×1100×750

750×1100×750

992×1750×893

Packing (W×H×D)

mm

770×1160×770

770×1160×770

1075×1920×920

Net/Gross weight

kg

121 / 129

145 / 152

290 / 297

Refrigerant type/Quantity

Kg

R410a 1.5

R410a 2.8

R410a 5.7

Design pressure

MPa

4.4/2.6

4.4/2.6

4.4/2.6

Ambient temp

℃

(-15~43)

(-15~43)

(-15~43)

water pipe

Diameter, water inlet pipe

mm

DN25

DN25

DN25

Diameter, water outlet pipe

mm

DN25

DN25

DN25

Hot Water Yield

m3/h

0.25

0.52

1.0

Wire controller

KJR-51/BMKE-A

KJR-51/BMKE-A

KJR-51/BMKE-A

Out water Temp

℃

(default)56℃,

40℃~60℃

(default)56℃,

40℃~60℃

(default)56℃,

40℃~60℃

1. The test conditions: outdoor temp. 20/15℃(DB/WB), inlet water temp. 15℃, outlet water temp. 55℃.

2. The operation range:-15℃~43℃.

3. The specification may be changed for product improvement, please refer to the nameplate.

Page 10

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

10

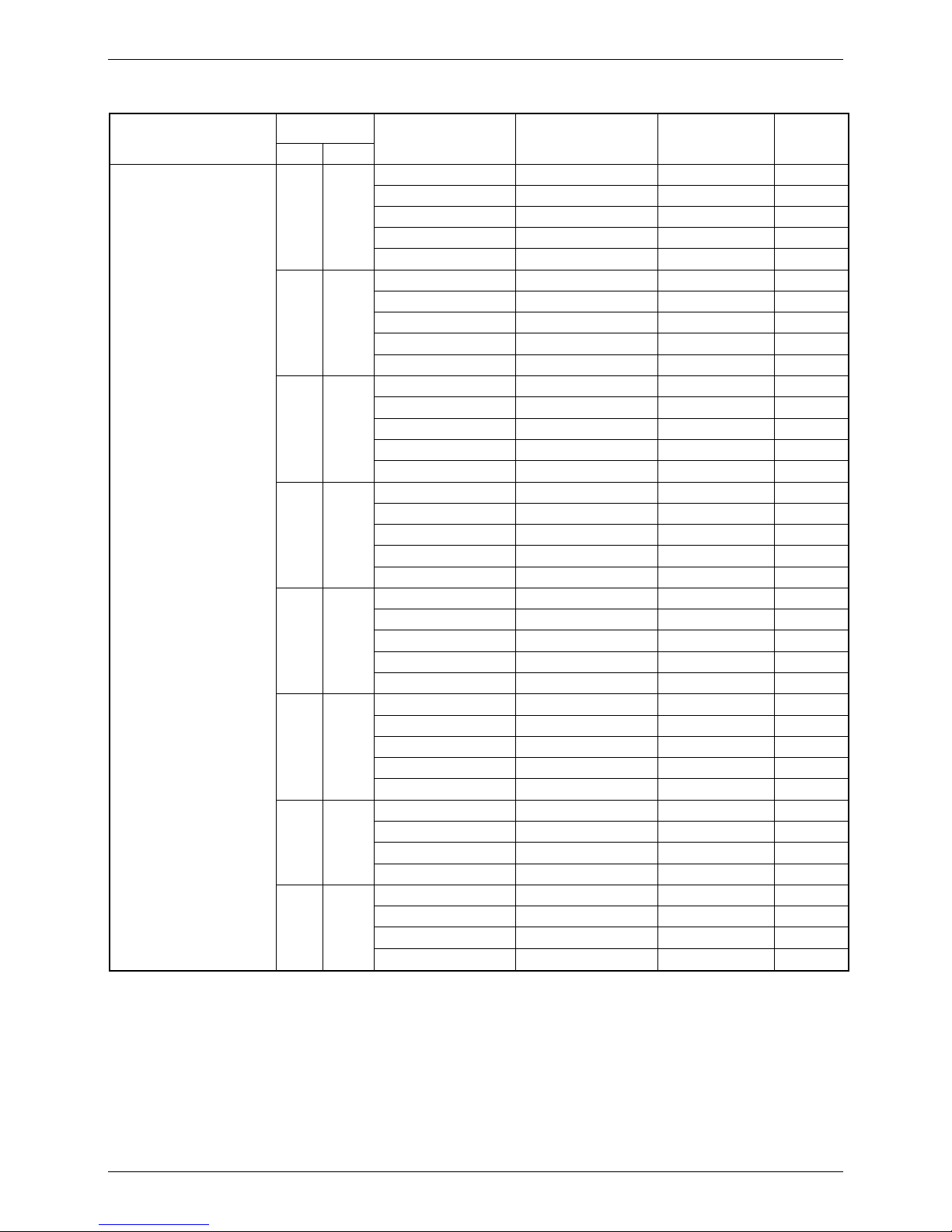

2. Capacity tables

Note: OT – Outdoor Temperature (DB);

Mode

OT(℃)

Inlet water

temperature (℃)

Outlet water

temperature(℃)

Capacity(kW)

COP

DB

WB

RSJ-100/N1-540V-D

20

15

15

40

11.37

4.56

15

45

11.48

4.36

15

50

11.47

4.09

15

55

11.41

3.82

15

60

11.30

3.53

15

12

9

40

10.50

4.23

9

45

10.88

4.29

9

50

10.89

4.03

9

55

10.81

3.76

9

60

10.67

3.48

10

8

9

40

9.67

3.84

9

45

9.63

3.43

9

50

10.05

3.60

9

55

9.96

3.45

9

60

9.22

3.04

5

4

9

40

8.91

3.46

9

45

9.06

3.39

9

50

9.16

3.24

9

55

9.22

3.13

9

60

8.85

2.90

0

–

9

40

7.69

3.14

9

45

7.69

2.99

9

50

6.62

2.51

9

55

6.53

2.34

9

60

6.51

2.20

-5

–

9

40

6.68

2.86

9

45

6.64

2.67

9

50

6.67

2.49

9

55

6.15

2.22

9

60

5.59

1.86

-10

–

9

40

5.40

2.34

9

45

5.18

2.06

9

50

5.05

1.91

9

55

4.95

1.78

-15

–

9

40

4.22

1.84

9

45

4.21

1.73

9

50

4.19

1.62

9

55

3.06

1.20

Page 11

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

11

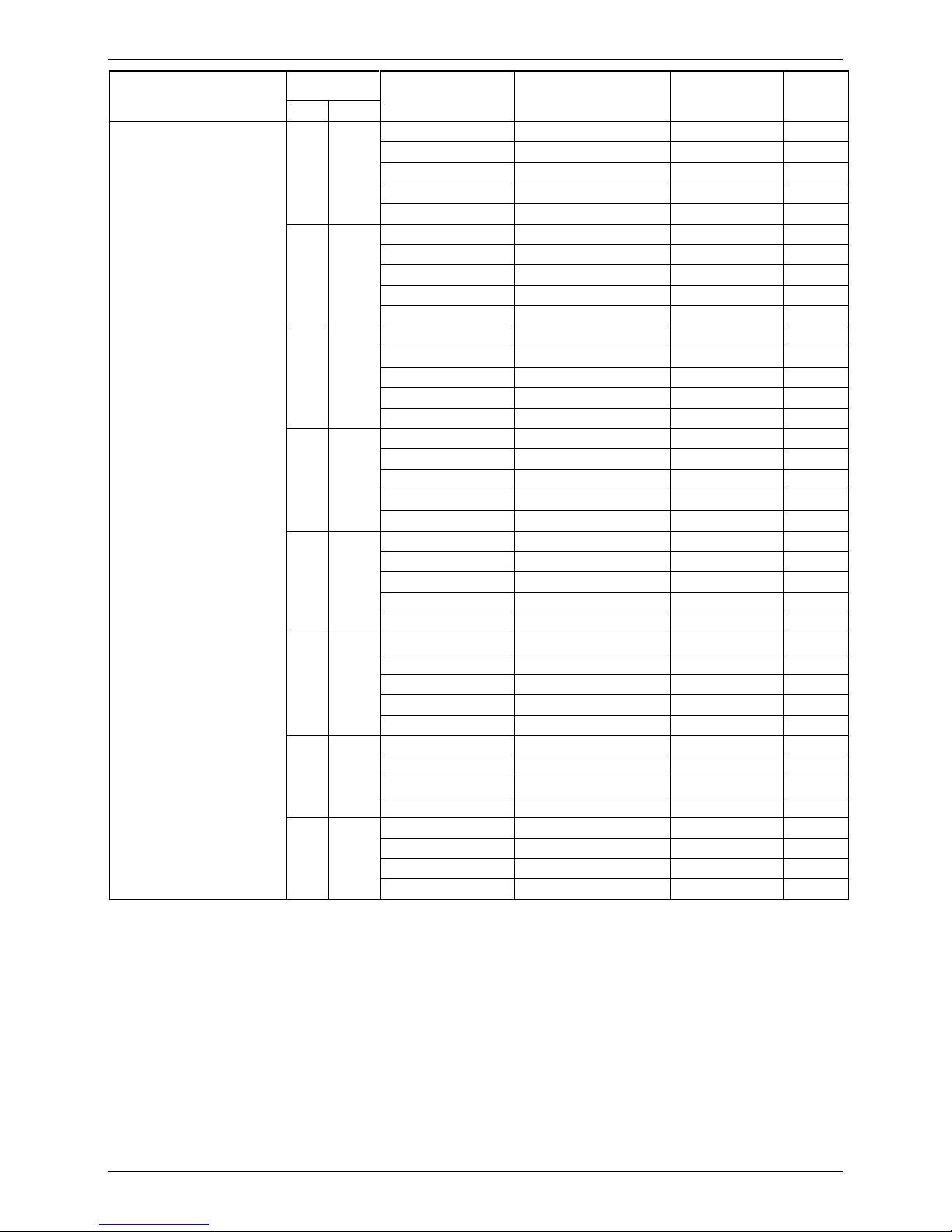

Mode

OT(℃)

Inlet water

temperature (℃)

Outlet water

temperature(℃)

Capacity(kW)

COP

DB

WB

RSJ-200/SN1-540V-D

20

15

15

40

20.88

4.75

15

45

21.00

4.48

15

50

20.99

4.20

15

55

21.85

4.00

15

60

20.05

3.76

15

12

9

39

19.62

4.45

9

45

19.90

4.28

9

50

19.89

4.02

9

55

19.54

3.90

9

60

18.96

3.60

10

8

9

41

17.56

3.85

9

45

17.47

3.91

9

50

18.09

3.75

9

55

17.97

3.57

9

60

17.34

3.32

5

4

9

40

16.21

3.80

9

45

16.63

3.66

9

50

16.51

3.42

9

55

16.20

3.31

9

60

15.98

3.14

0

–

9

41

14.42

3.27

9

45

14.67

3.17

9

50

13.98

2.99

9

55

13.83

2.73

9

57

13.47

2.58

-5

–

9

40

13.14

3.14

9

45

13.10

2.97

9

50

12.75

2.73

9

55

11.04

2.42

9

57

10.42

2.24

-10

–

9

40

10.48

2.67

9

45

10.08

2.41

9

50

9.69

2.18

9

53

9.10

2.04

-15

–

9

40

8.72

2.29

9

45

8.57

2.09

9

50

8.59

1.96

9

53

7.99

1.72

Page 12

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

12

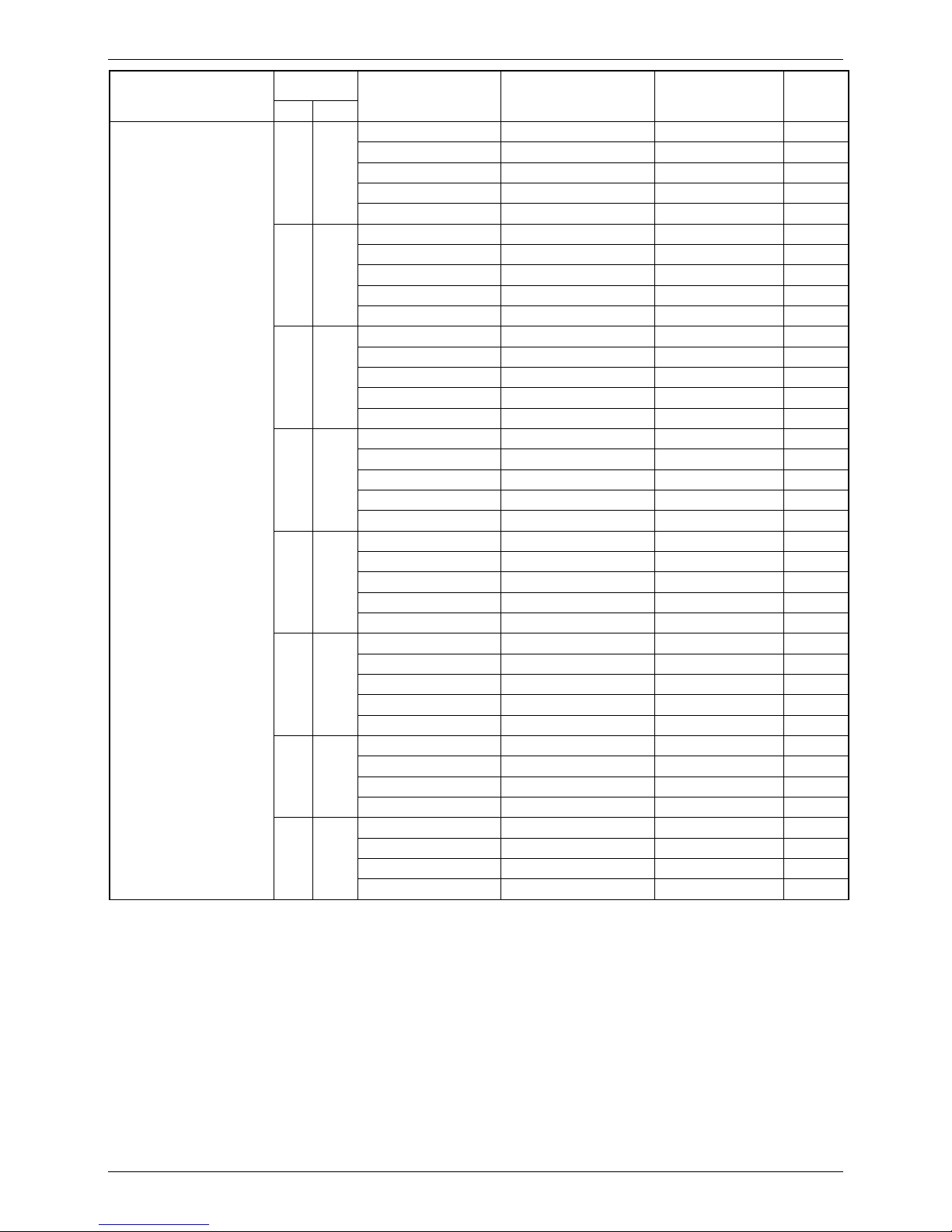

Mode

OT(℃)

Inlet water

temperature (℃)

Outlet water

temperature(℃)

Capacity(kW)

COP

DB

WB

RSJ-380/SN1-820-D

20

15

15

40

43.00

5.07

15

45

42.88

4.70

15

50

42.41

4.35

15

55

42.21

4.12

15

60

40.72

3.79

15

12

9

40

40.32

4.90

9

45

40.04

4.53

9

50

39.56

4.19

9

55

38.46

3.96

9

60

37.04

3.61

10

8

9

40

36.48

4.48

9

45

35.84

4.07

9

50

34.89

3.69

9

55

33.67

3.36

9

60

32.15

3.08

5

4

9

40

31.71

3.89

9

45

30.58

3.48

9

50

30.04

3.19

9

55

29.21

2.97

9

60

28.01

2.71

0

–

9

40

25.51

3.16

9

45

25.43

2.95

9

50

24.94

2.74

9

55

24.89

2.55

9

60

23.99

2.39

-5

–

9

40

21.77

2.75

9

45

20.92

2.47

9

50

20.79

2.33

9

55

20.12

2.20

9

60

19.71

2.05

-10

–

9

40

18.51

2.38

9

45

18.10

2.19

9

50

17.37

1.99

9

53

16.55

1.84

-15

–

9

40

14.81

1.95

9

45

14.41

1.80

9

50

14.02

1.66

9

53

13.23

1.35

Page 13

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

13

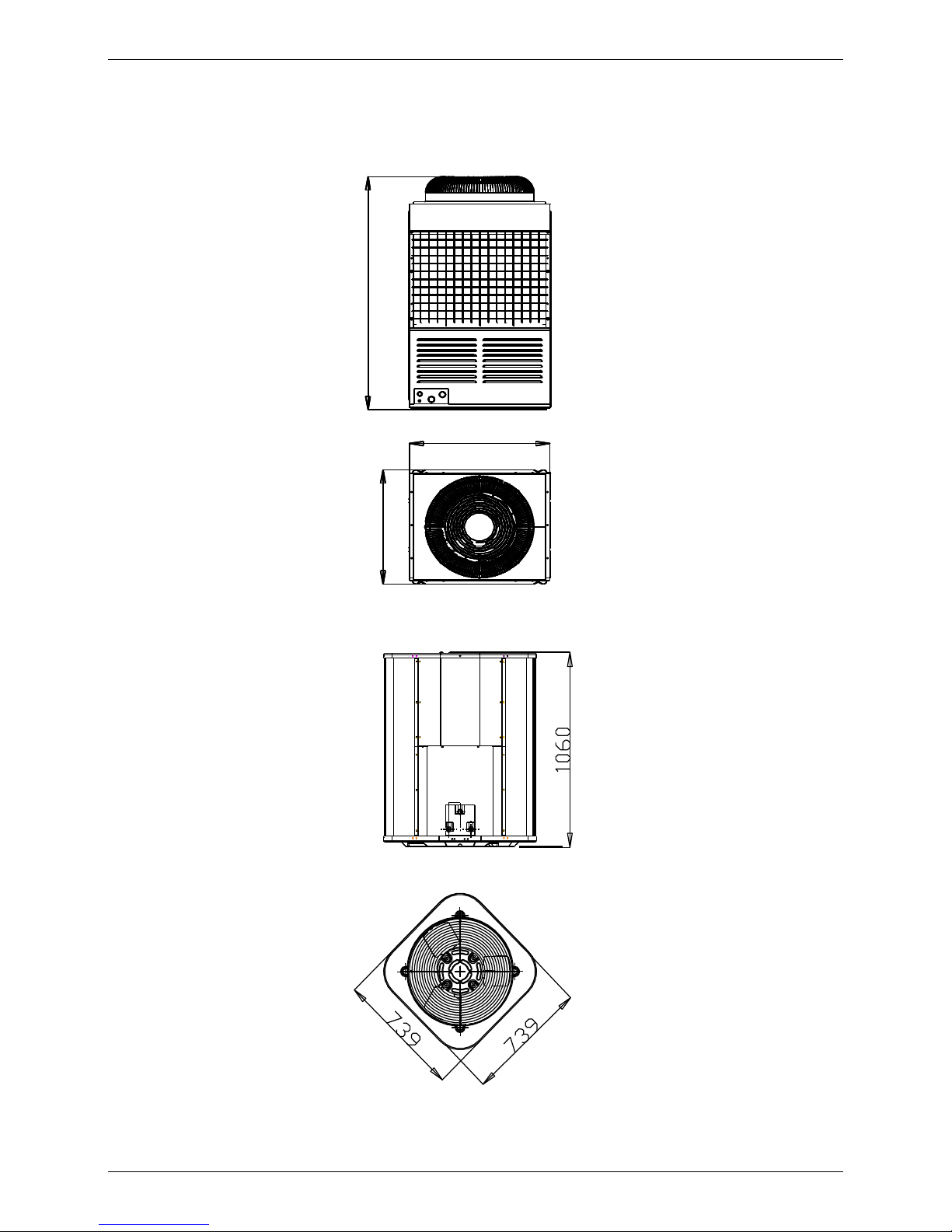

3. Dimensions

RSJ-380/SN1-820-D

RSJ-100/N1-540V-D RSJ-200/SN1-540V-D

998

865

1765

998

865

1765

998

865

1765

Page 14

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

14

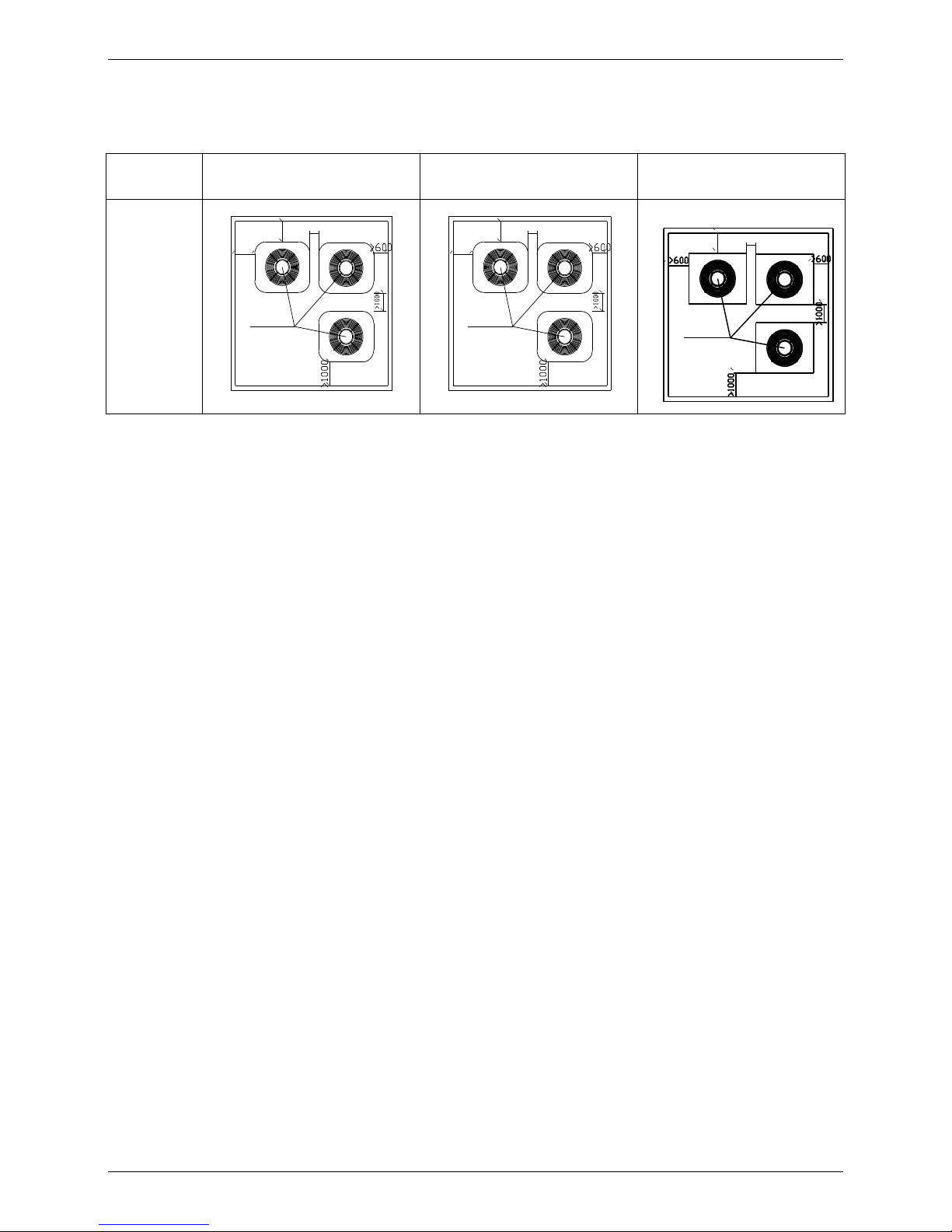

4. Service Space

Make sure that enough space for maintenance and air inlet is left when installing (as

diagrams below)

Model

RSJ-100/N1-540V-D

RSJ-200/SN1-540V-D

RSJ-380/SN1-820-D

Maintenance

space

>600

>1000

>400

Heat pump water heating unit

>600

>1000

>400

Heat pump water heating unit

>600

>400

Heat pump water heating unit

Note: The air outlet of the unit at the top cannot be blocked. If there are obstacles above it, keep the unit at least 2000 mm

away from them.

Page 15

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

15

5. Wiring Diagrams

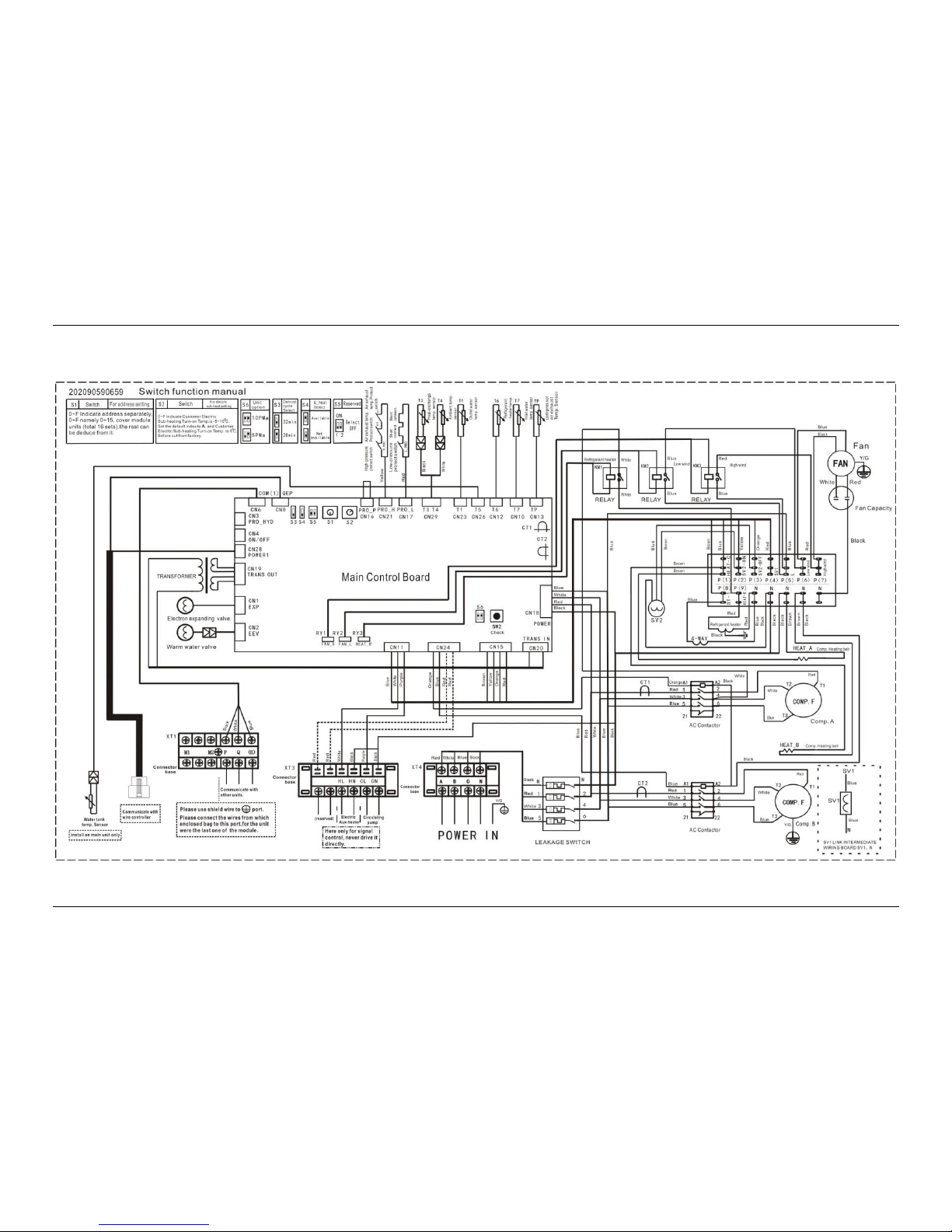

Internal wiring schematic diagram of RSJ-380/SN1-820-D

Page 16

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

16

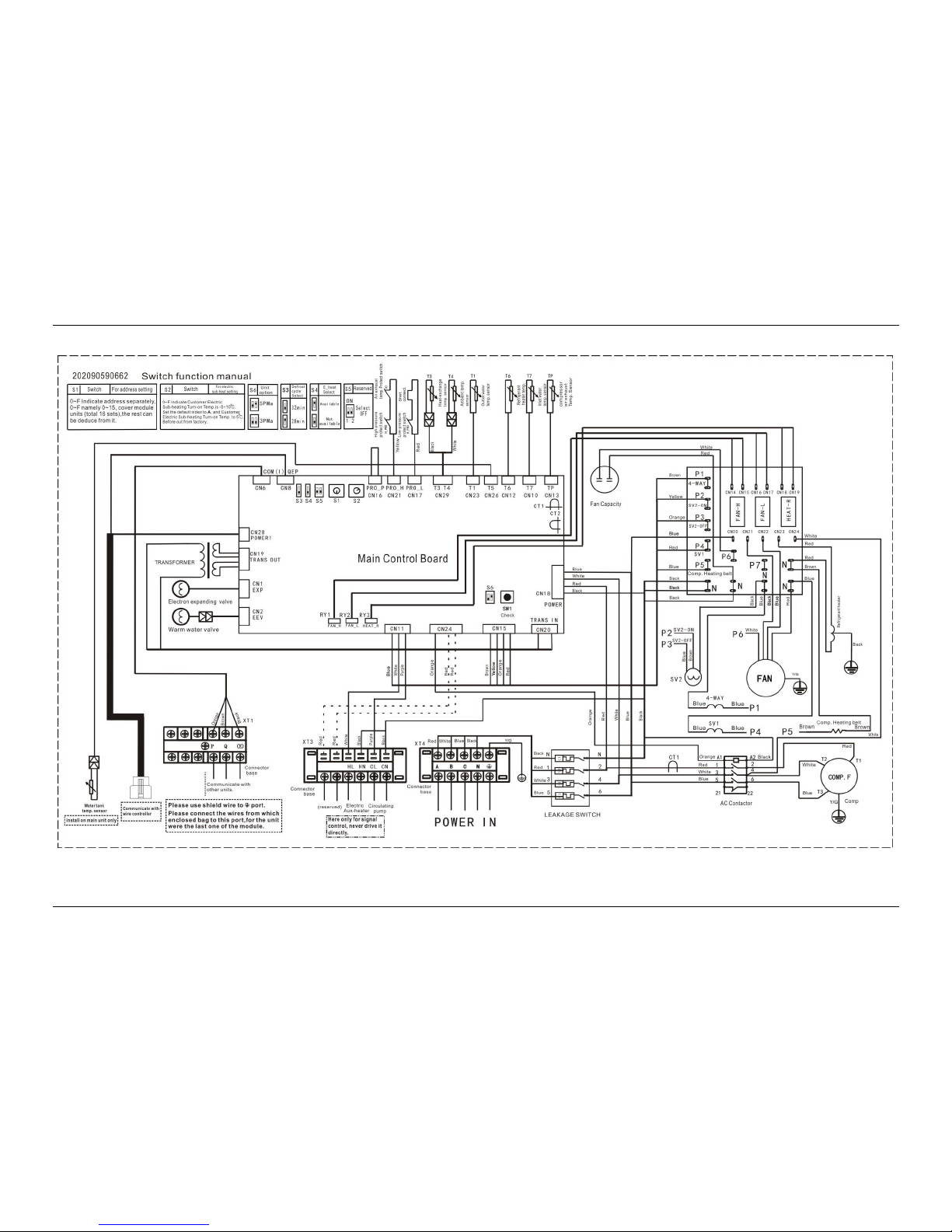

Internal wiring schematic diagram of RSJ-200/SN1-540V-D

Page 17

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

17

Internal wiring schematic diagram of RSJ-100/N1-540V-D

Page 18

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

18

Main Control Board Interface

Page 19

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

19

Ports explanation

No.

Port explanation

No.

Port explanation

1

Low-Pressure Protection Short Connection

2

Digital Tube

3

Defrosting Cycle Select

4

E-Heater Select

5

Reserved

6

Address Setting Dip

7

Electric-Heating Temperature Setting Dip

8

Heat-Exchanger Temp. Sensor And Ambient

Temp. Sensor

9

Outlet Water Temperature Sensor

10

Water Tank Temperature Sensor

11

Refrigerant Heater Temperature Sensor

12

Inlet Water Temperature Sensor

13

Compressor Air Exhaust Temperature

Sensor

14

1# Compressor Current Transformer

15

2# Compressor Current Transformer

16

Power Interface

17

Fuse(5A)

18

Transformer Input Port

19

Controlling Wire (Defrosting Valve, By-Pass

Solenoid Valve, Circulating Water Pump And

Crankcase Heating Zone)

20

Inspection Button

21

Model Selection Dip

22

Alarm Controlling Wire

23

Main Chip

24

E-Heater And Circulating Pump Controlling

Wire

25

Refrigerant Electric Heating Stick Controlling

Wire

26

Fan Low Wind Controlling Wire

27

Fan High Wind Controlling Wire

28

Warm Water Valve Port

29

Transformer Output Port

30

Electric Expanding Valve Controlling Wire

31

Protection Of HYD

32

Power 1

33

Alarm Controlling Wire

34

PQE Communication Port

35

PQE Communication Port (To Wire

Controller)

36

The Exhaust Temperature Protection Port

37

High-Pressure Protection Port

Page 20

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

20

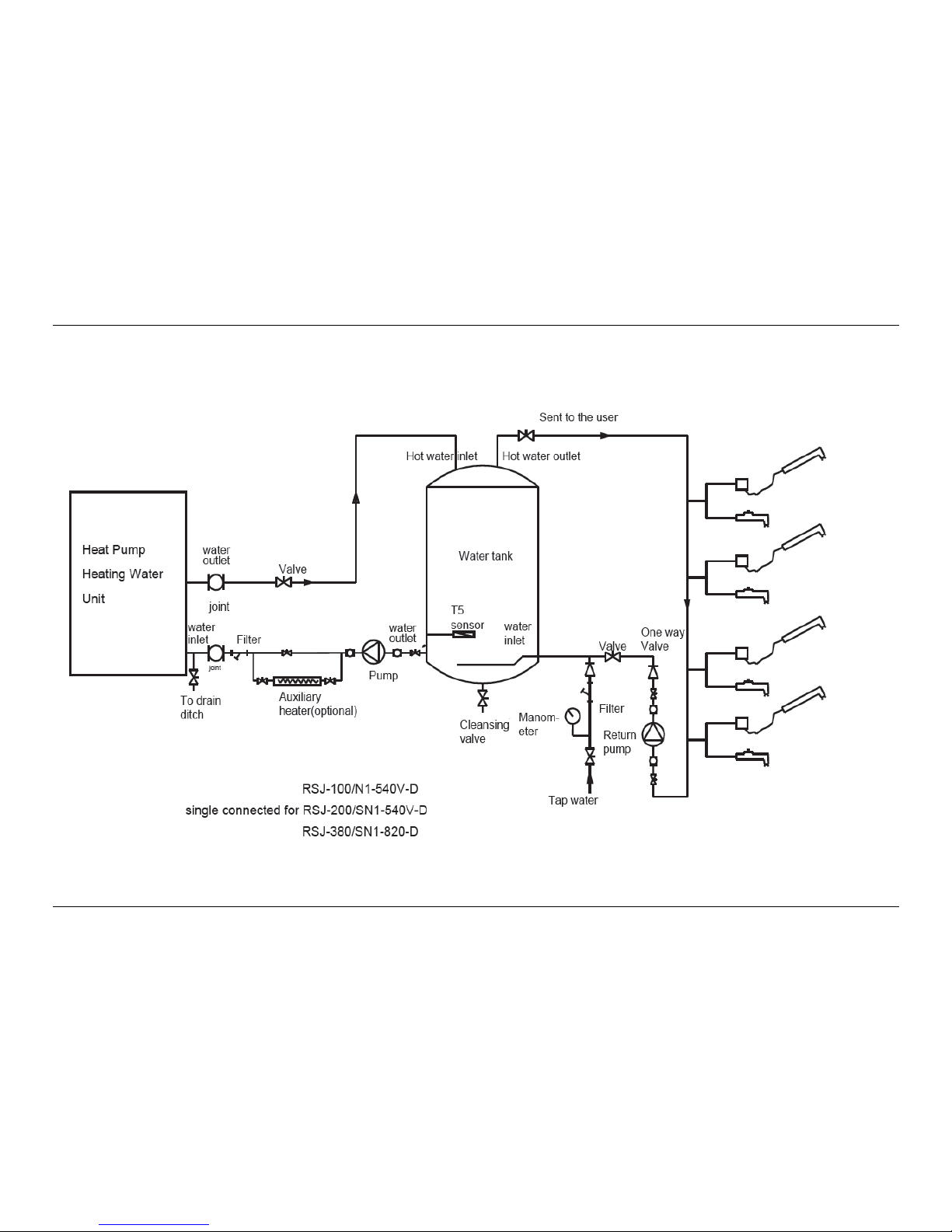

Tap water

Pressure-bearing

To the user

Used for pipe

network water

returning

6. Piping Diagrams

RSJ-100/N1-540V-D RSJ-200/SN1-540V-D RSJ-380/SN1-820V-D

Page 21

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

21

Part 3

Installation

1. Precautions ................................................................................................. 22

2. Installation information .............................................................................. 23

3. Accessories ................................................................................................. 24

4. Inspecting and Handling the Unit .............................................................. 24

5. Connection Diagram ................................................................................... 25

6. Operation Instruction .................................................................................. 27

7. Installation Instruction ................................................................................ 28

8.Electric Wiring .............................................................................................. 31

Page 22

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

22

1. Precautions

■ To prevent injury to the user or other people and property damage, the following instructions must be

followed. Incorrect operation due to ignoring of instructions may cause harm or damage.

■ The safety precautions listed here are divided into two categories. In either case, important safety

information is listed which must be read carefully.

WARNING

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage to the equipment.

WARNING

■ The water heating unit must be earthed effectively.

■ A Leakage breaker must be installed near the power supply.

■ Ask your supplier for installation of the air source heat pump water heating units. Incomplete installation

performed by yourself may result in water leakage, electric shock, or fire.

■ Ask your supplier for the repair and maintenance. Incomplete repair and maintenance may result in

water leakage, electric shock or fire.

■ In order to avoid electric shock, fire or injury, if any abnormality is detected, such as smell of fire, turn off

the power supply and call your supplier for instructions.

■ Never replace a fuse with that of wrong rated current or other wires when a fuse blows out.

Use of wrong wire or copper wire may cause the unit to break down or a fire.

■ Do not insert fingers, rods or other objects into the air inlet or outlet. When the fan is rotating at high

speed, it will cause injury.

■ Never use a flammable spray such as hair spray, lacquer paint near the unit. It may cause a fire.

■ Never touch the air outlet or the horizontal blades while the swing flap is in operation. Fingers may

become caught or the unit may break down.

■ Never put any objects into the air inlet or outlet. Objects touching the fan of high speed can be

dangerous.

■ Do not dispose this product as unsorted municipal waste. Collection of such waste separately for

special treatment is necessary.

■ The appliance shall be installed in accordance with national wiring regulations.

CAUTION

■ Do not use the air source water heater for other purposes.

■ Before cleaning, be sure to stop the operation, turn the breaker off or pull out the supply cord.

Otherwise, an electric shock and injury may result.

■ Be sure the water heating unit is grounded.

In order to avoid electric shock, make sure that the unit is grounded.

■ In order to avoid injury, do not remove the fan guard of the outdoor unit.

■ Do not operate the air source water heater with a wet hand. An electric shock may happen.

■ Do not touch the heat exchanger fins. These fins are sharp and could result in cutting injuries.

■ Do not place items which might be damaged by moisture under the indoor unit.

Condensation may form if the humidity is above 80%, the drain outlet is blocked or the filter is polluted.

■ After a long use, check the unit stand and fitting for damage. If damaged, the unit may fall and result in

injury.

■ To avoid oxygen deficiency, ventilate the room sufficiently if equipment with burner is used together with

the air conditioner.

■ Arrange the drain hose to ensure smooth drainage. Incomplete drainage may cause wetting of the

building, furniture etc.

Page 23

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

23

■ Never touch the internal parts of the controller. Do not remove the front panel. Some parts inside are

dangerous to touch, and a machine trouble may happen.

■ Never expose little children, plants or animals directly to the air flow. Adverse influence to little children,

animals and plants may result.

■ The appliances connected to the water mains

the maximum inlet water pressure is 0.7Mpa

the minimum inlet water pressure is 0.2Mpa

maximum water temperatures is 55℃ and minimum water temperatures is 48℃.

■ That the appliance shall be installed in accordance with national wiring regulations.

■ The means for disconnection from a power supply shall be incorporated in the fixed wiring and have an

air gap contact separation of at lease 3mm in each (phase) conductor.

2. Installation information

■ Enough space is installation and maintenance shall be preserved.

■ The air inlet and outlet should be free from obstacles and strong wind.

■ The bearing surface should be flat, able to bear weight of the unit and suitable for installing the unit

horizontally without increasing noise or vibration.

■ The operation noise and air flow expelled shall not affect neighbors.

■ No flammable gas is leaked nearby.

■ It is convenient for piping and wiring.

CAUTION

■ Installing the equipment in any of the following places may lead to malfunction of the equipment (if it is

inevitable, consult the supplier):

1) The site contains mineral oils such as cutting lubricant.

2) Seaside where the air contains much salt.

3) Hot spring area where corrosive gases exist, e.g., sulfide gas.

4) Factories where the power voltage fluctuates seriously.

5) Inside a car or cabin.

6) Place like kitchen where oil permeates.

7) Place where strong electromagnetic waves exist.

8) Place where flammable gases or materials exist.

9) Place where acid or alkali gases evaporate.

10) Other special environments.

■ Precautions before installation

1) Decide the correct way of conveying the equipment.

2) Try to transport this equipment with the original package.

3) If the unit has to be installed on a metal part of the building, electric insulation must be installed,

and the installation must meet the relevant technical standards for electric devices.

■ Installation space

Before installing the unit, reserve the space of maintenance shown in the following figure.

Page 24

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

24

3. Accessories

Please check whether the following fittings are of full scope. If there are some spare fittings, please restore

them carefully.

NO.

Name

Quantity

Application

1

Installation and Operation Manual

1

——

2

Wire controller module

1

Status of the control unit and

display unit

3

Water tank temperature sensor

1

Water tank temperature check

4

Y type filter

1

Inlet water filter

4. Inspecting and Handling the Unit

After delivery, the package should be checked and any damage should be reported immediately to the

carrier claims agent.

When handling the unit, take into account the following:

1. Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

2. Choose before hand the path along which the unit is to be brought in.

3. Move this unit with original package.

4. When lifting the unit, always use protectors to prevent belt damage and pay attention to the balance of

the unit’s gravity.

Page 25

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

25

5. Connection Diagram

5.1 Single Unit Connection Diagram

Page 26

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

26

5.2 Multiple Unit Connection Diagram

Page 27

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

27

6. Operation Instruction

1. This type of heat pump is designed to connect with a pressure-bearing tank. While installing, please

refer to the recommended connection diagram in the owner’s manual. If it is needed to be connected

with an open tank, the water level controlling and the water cycling heating controlling should be realized

in projecting. It is relatively a bit complex. In this condition, we suggest to adopt the C series of the

commercial direct-heating type.

2. Water heating: The water output temperature range is 40℃~60℃ (default 56℃). When the water

temperature(T5) in the tank is 2℃ (or even more) lower than the stopped temperature of the heat pump(T

stop), the unit will star working automatically until the water temperature(T5) reaches up to (or even higher

than) the stopped temperature(T stop). The temperature of hot water outlet can achieve the setting

temperature only by an once-through circulation.

3. Hot water supply: There is no need to use an additional hot water pump to boost the hot water to the end

users since the storage tank is a pressurized type. If the pressure of the tap water is not stable, an

one-way valve is suggested to be located near the cold water inlet of the tank.

4. Pipe network return (not essentially for the hot water supplying system): When the return temperature

controller detects that the water temperature in the pipe is lower than the lower limit of the return temperature

(set at 40 ℃ ~ 45 ℃), the return controlling solenoid valve will open. Then, the hot water returning pump will

open. The hot water will enter the pipeline and the cold water will return back to the water tank. When the

temperature controller detects that the water temperature is higher than the upper limit of the return water

temperature (set at 45 ℃ ~ 50 ℃), the return solenoid valve and the hot water supplying pump will close by

order. Then, the pipe network returning will stop. (This manner can only be realized in the project and the

main unit of the heat pump cannot control it. This is only one of the pipe network return manner and other

manners can be selected according to different projects.)

Page 28

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

28

7. Installation Instruction

7.1. Y-type filter must be installed in the inlet pipeline

A brass DN25 mode Y-type filter in 80 meshes is equipped with each finished unit of the

RSJ-380/SN1-820-D, RSJ-200/SN1-540V-D and RSJ-100/N1-540V-D model. The filter is required to be

installed in the water inlet pipeline at the place closed to the water tank, otherwise, the filter and

high-precision temperature valve inside the unit might be blocked out by dirt.

7.2. The selection of lift and flow of the circulating pump

The circulating pump requires for large flow and the rated flow should be more than 6 m3/h for

RSJ-380/SN1-820-D, 4 m3/h for RSJ-200/SN1-540V-D and 2 m3/h for RSJ-100/N1-540V-D. The lift of

the pump is sampled according to the hydraulic calculation.

7.3. The fall between the main unit and the hot water tank

The lift of the circulating pump should be corresponded to the fall between the main unit

and the hot water tank. If it is not big enough, some protecting code may appear while

running and the unit will stop.

7.4. Installation Water Tank

7.4.1 The hole site of the tank

Remark:

1. The diameter of the cycle water inlet and outlet should be in accordance with the charts of the water pipe

selection.

2. The diameter of blind pip for the location of the water temperature sensor may be about Φ8~Φ10.

3. The diameter of the tap water inlet and the hot water outlet should be determined by the maximum

hourly hot water flow of all the end water users.

Page 29

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

29

7.4.2 Installation of the Temp. Sensor

Water Pipe Selection 7.5

RSJ-380/SN1-820-D

Unit number

Main water inlet pipeline

Main water outlet pipeline

1 set

DN25

DN25

2 sets parallel

connection

DN50

DN50

3 sets parallel

connection

DN65

DN65

4~5 sets parallel

connection

DN80

DN80

6~8 sets parallel

connection

DN100

DN100

9~12 sets parallel

connection

DN125

DN125

13~14 sets parallel

connection

DN125

DN125

15~16 sets parallel

connection

DN150

DN150

RSJ-200/SN1-540V-D

Unit number

Main water inlet pipeline

Main water outlet pipeline

1 set

DN25

DN25

2 sets parallel

connection

DN32

DN32

3 sets parallel

connection

DN50

DN50

4~5 sets parallel

connection

DN50

DN50

6~7 sets parallel

connection

DN65

DN65

8 sets parallel

connection

DN65

DN65

9~12 sets parallel

connection

DN65

DN65

13~14 sets parallel

connection

DN80

DN80

15~16 sets parallel

connection

DN80

DN80

8 blind copper pipe or

stainless steel pipe

Water tank temperature sensor

Heat conduction silica gel filling

Port airproof

water outlet

Connect 0# main unit

Page 30

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

30

RSJ-100/N1-540V-D

Unit number

Main water inlet pipeline

Main water outlet pipeline

1 set

DN25

DN25

2 sets parallel connection

DN25

DN25

3 sets parallel connection

DN32

DN32

4~5 sets parallel connection

DN32

DN32

6~7 sets parallel connection

DN50

DN50

8~12 sets parallel connection

DN50

DN50

13~14 sets parallel

connection

DN65

DN65

15~16 sets parallel

connection

DN65

DN65

7.6. Installation pipe-hot --Heat Preservation

Formation: a. Antisepsis layer; b. Glide layer; c. Adiabatic layer:

d. Waterproof layer; e. Outer safeguard layer.

Pipe Antisepsis Formation: a. Antisepsis layer:

b. Waterproof layer; c. Outer safeguard layer.

Antisepsis layer: red lead paint

Adiabatic layer: mineral wool, rubber plastic sponge、foaming polyurethane etc

Outer safeguard layer:

Outdoor, aluminum foil sheet+0.3mm galvanized steel sheet;

Indoor, aluminum foil sheet.

Thickness of Adiabatic

layer≥30mm

Pipe

Waterproof &

Antisepsis layer

Adiabatic

layer

Page 31

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

31

8.Electric Wiring

1. Attention

● The water heater should powered separately and the power voltage should be in line with rated

voltage..

● The power supply circuit of the water heater should be earthed, the power cord should be connected

with the external earthed line in reliable state and all the external earthed cables are effective.

● The construction of the wiring should be carried out by professionals in accordance with the circuit

diagram.

● Set up leakage protection devices in accordance with the requirements of the relevant national

technical standards.

● The power cord and the signal line should be laid neatly without cross-interfere and should not contact

with the connecting pipe and the valves.

● The unit is not equipped with power cord. Please refer to the prescribed power specification for

selecting the power cord and cross-connection between two lines are not allowed.

● Check whether all the connections are correct before powering the unit.

2. Electric Control Box Wiring Diagram

G A B C N

~380V

Wire controller

Circulating pump

Electric-heate

Page 32

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

32

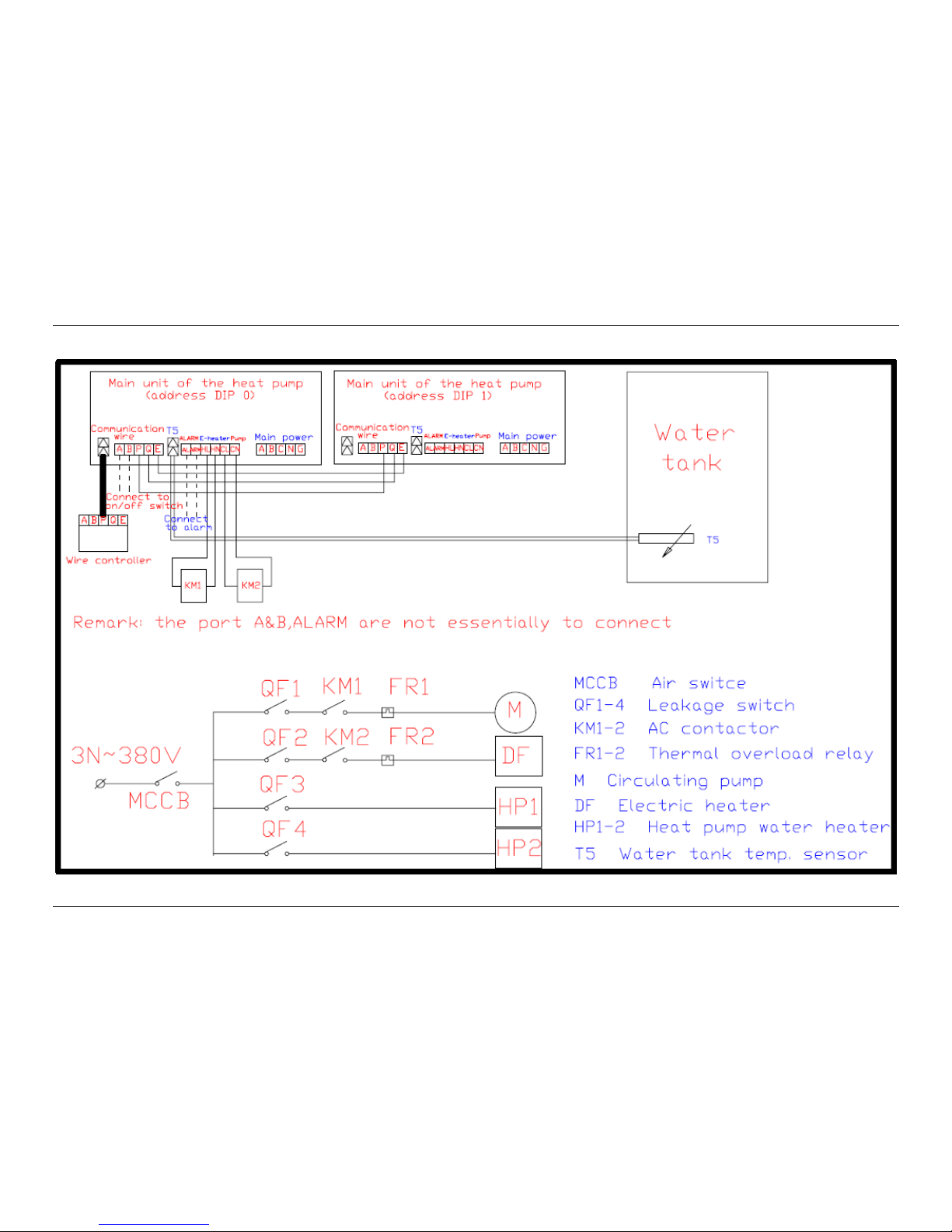

3. Electric Control Schematic Diagram of Parallel Connection of Two Units

Page 33

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

33

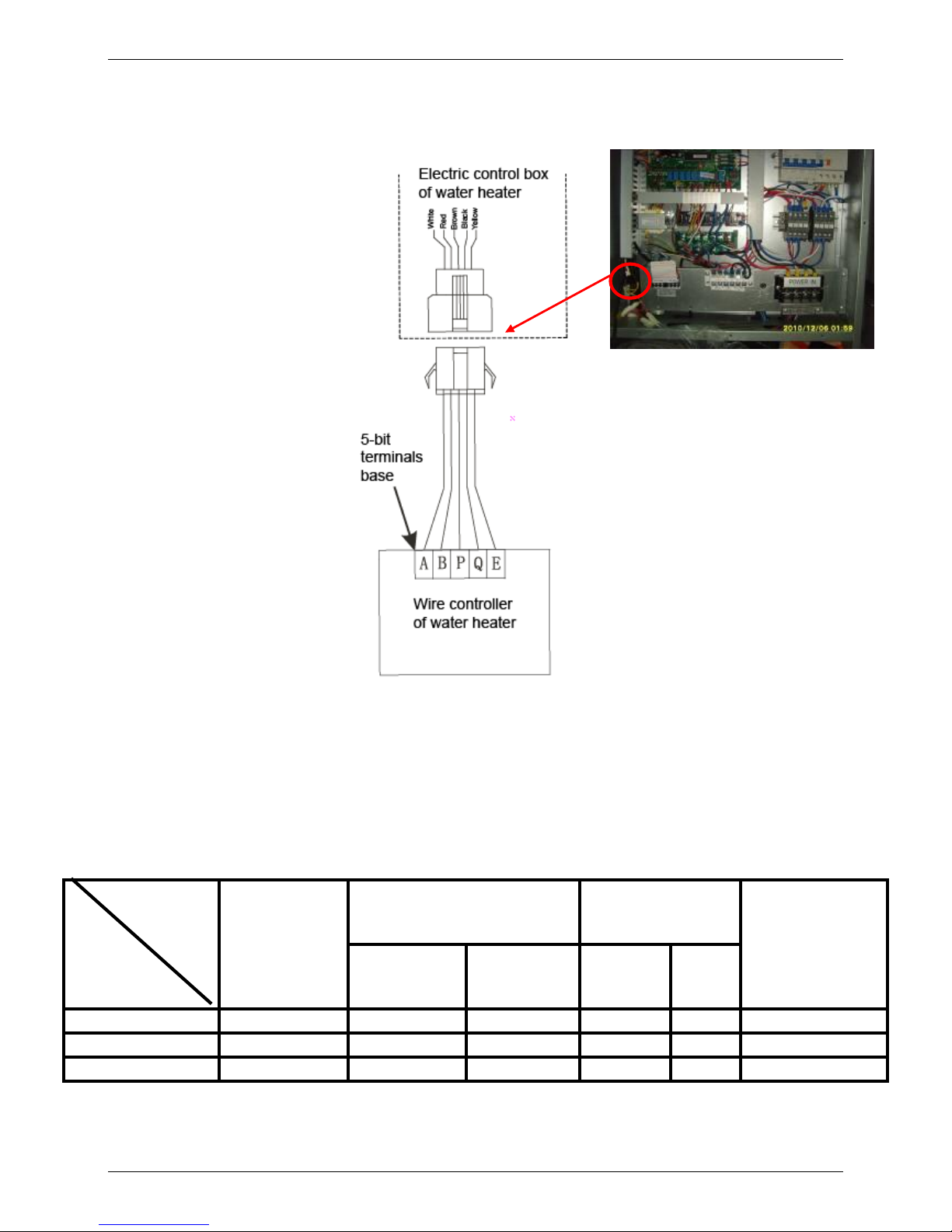

4. Connection of the wire controller

Please connect by 5-bit shielded wire in accessory bag (a 10m end-to-end wire), which length depends on

the specific situation to lengthen, but couldn’t exceed than 40 m. If a longer one you need, please consult the

factory and the dealer.

5. Power specification

Power

MIN. Cord Diameter(m ㎡)

Manual Switch (A)

Leakage Protector

Phase Wire

(Length≤30m)

Ground Wire

Capacity

Fuse

RSJ-100/N1-540V-D

220V-1PH-50Hz

6

4

50

30

30mA<0.1 sec

RSJ-200/SN1-540V-D

380V-3PH-50Hz

6

4

50

30

30mA<0.1 sec

RSJ-380/SN1-820-D

380V-3PH-50Hz

10

5

60

50

30mA<0.1 sec

Note: The wire diameter and the continuous length in the table are for the condition that the voltage drop range is within 2%.

When the continuous length of the wire exceeds the value in the table, please select proper wire diameter according to

relevant rules.

Model

Items

Page 34

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

34

Part 4

Trial Operation

1. Confirmation before the trial operation ..................................................... 35

2. Water Pump Air Extraction ......................................................................... 35

3. Wired Controller and Operation ................................................................. 36

4. Water tank cleaning .................................................................................... 43

5. Schematic Diagram of the Unit System ..................................................... 43

6. Error Code Cause Analysis and the Solutions ......................................... 44

7. Main control board spot check .................................................................. 46

8. Failure without Code................................................................................... 46

9. Troubleshoot of abnormal phenomena ..................................................... 47

Page 35

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

35

1. Confirmation before the trial operation

1.1 All the installation is complete.

1.2 Water heater is installed correctly.

1.3 The pipelines and wiring are correct.

1.4 The accessories are installed correctly.

1.5 The drainage is smooth.

1.6 The thermal insulation is sound.

1.7 The earthing wire is connected correctly.

1.8 The power voltage is consistent with the rated voltage of the heater.

1.9 No obstacle at the air inlet and outlet of the unit.

1.10 The leakage protector can work effectively.

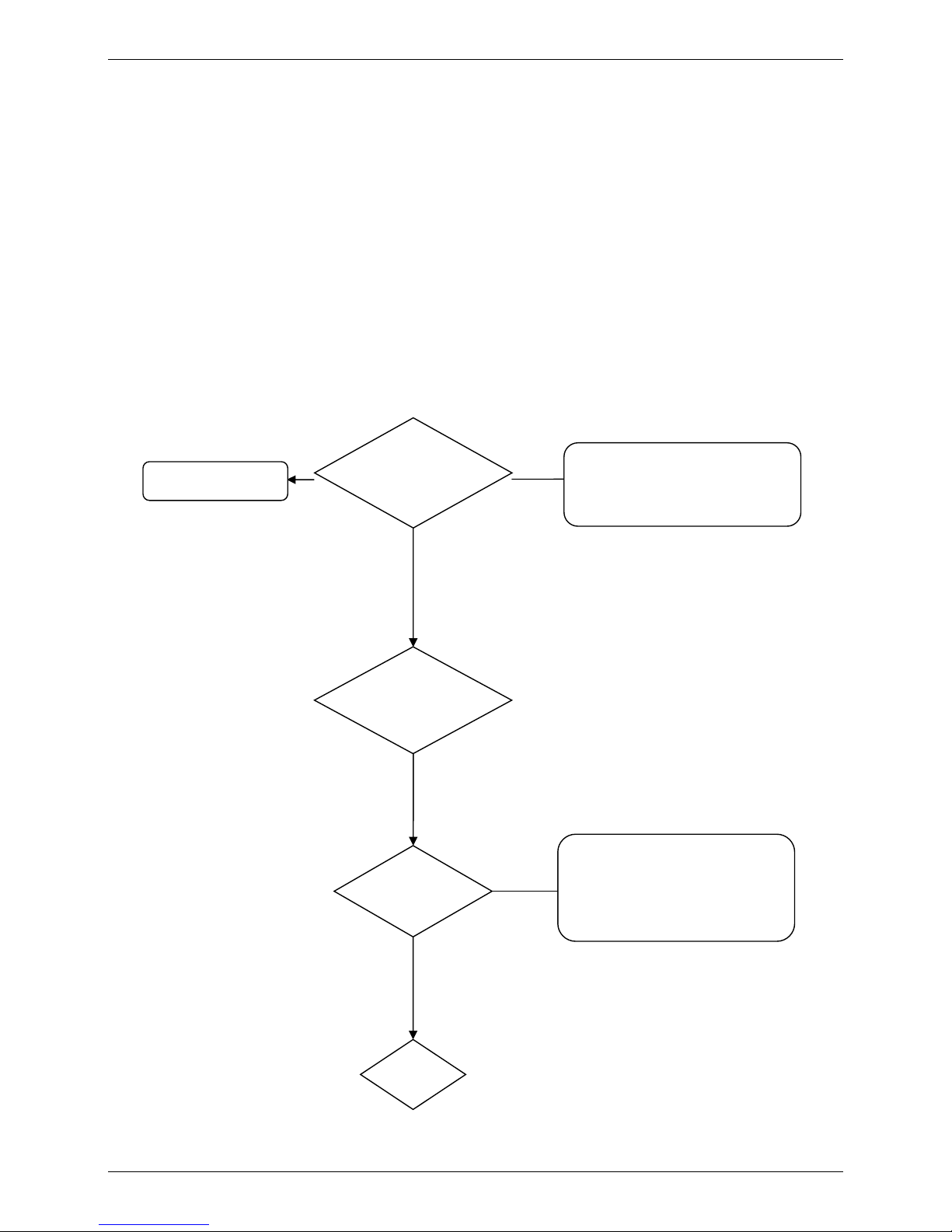

2. Water Pump Air Extraction

Exchange water pump

power line

Open the

valves on the

Y

Pipeline

air

Hit the AD conductor of the circulating

pump to inhale manually and the water

pump runs. The water is inhaled into the

pipeline and flow through the unit then

return to the tank at last. The air in the

pipe line will be discharged from the air

Y

End

Hit the AD conductor of the circulating

pump to inhale manually and release the

contactor after the pump idling. Observe

whether the running direction of the pump

impeller is correct。

Idling the water

pump for

direction

N

Page 36

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

36

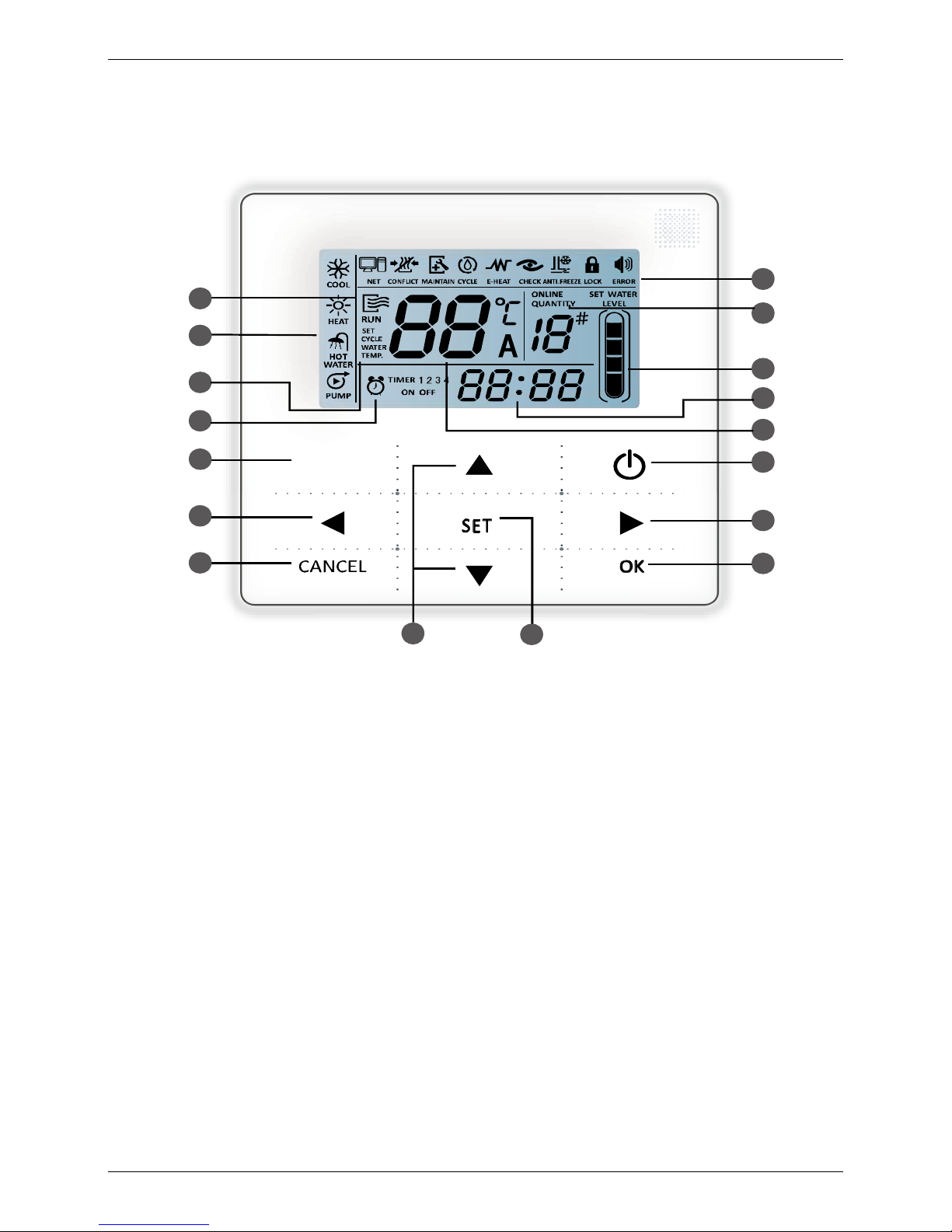

3. Wired Controller and Operation

Technical data and characteristic

1. Input voltage 10V AC

2. Operation ambient temperature of wired controller: -10℃~43℃

3. Operation relative humidity of wired controller: 40%~90%

4. Touch key operation and LED displays operation parameters

5. Multiple timer and real-time clock (battery life: 5~8 years).

14

13

3

1

2

4

16

11

15

5

6

7

8

9

10

11

12

(Press for 3sec to

cancel timer)

(Press for 3sec to

unlock)

AUXILIARY

1. Operation icon

2. Mode area

3. Setting temperature

4. Timing on/off

5. Function icon

6. On-line units quantity indication

7. Water level indication

8. Clock

9. Water temperature

10. On/Off key

11. Left/Right key

12. Confirm key

13. Set key

14. Add and reduce key

15. Cancel key

16. Auxiliary key

Page 37

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

37

Icon description

1. Operation icon : Indication of unit ON or OFF status

2. Mode area: Indicate the main unit operation mode.

3. Setting temperature: Three statuses about water temperature, setting water temperature and

setting cycle water temperature can be displayed.

4. Timing On/OFF indication : Indicate the timing information. Three timers can be set on

the wire controller: Timer 1, Timer 2, and Timer 3. These three timers can control the main unit to turn

ON and OFF three times at most during one day.

5. Function icon:

1) : Display when water heater system connects to Modbus network;

2) : Display when other heat source is provided to the system;

3) : Display when water heater maintenance is needed. You can press and hold “AUXILIARY”

key for 3 seconds to cancel the icon and timing will restart until next maintenance;

4) : Display when cycle heating function is operational;

5) : Display when electric auxiliary heating function is operational;

6) : Display when check function is operational;

7) : Display when ambient temperature is below 2℃ which means the main unit need

anti-freezing action;

8) : Display when no key operation for 2 minutes and all keys are locked.

You can press and hold “OK” key for 3 seconds to unlock;

9) : Display when error or protection occurs and means the unit need maintenance by

professionals.

6. On-line unit qty. indication: Under normal status display the quantity of units connected to the wire

controller; under check status display the device serial number;

7. Water level indication: Under normal status displays water level; under water level setting status

displays setting value;

8. Clock: Under normal status displays clock; under timing setting displays the setting timing;

9. Water temperature: Under normal status display water temperature; under water temperature

setting status displays the setting value; under cycle heating water temperature setting status

display the setting value; under check status displays check parameter;

10. ON/OFF key: Turn on and turn off functions;

11. Right and Left key: Press these keys to check setting water temperature, setting cycle heating

water temperature and setting water level under main page; Press right key to shift to the next step

setting under timing setting status; Press these keys to turn over the unit parameter information

under check status;

Page 38

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

38

12. OK key: Press this key to confirm settings. Press and hold this key for 3 seconds to unlock under

locking status;

13. Setting key: Setting water temperature, timing and mode etc.; Press and hold this key for 3

seconds to enter check status;

14. Add and Reduce key: Move up or move down values of temperature, timing, water level etc.; Turn

over #0~#15 units under check status;

15. Cancel key: Press this key to cancel parameter setting under setting status; Press and hold this key

for 3 seconds to cancel timing when timing is valid;

16. Auxiliary key: Power on the cycle heating function, electric auxiliary heating function or water pump

function.

Operation instruction

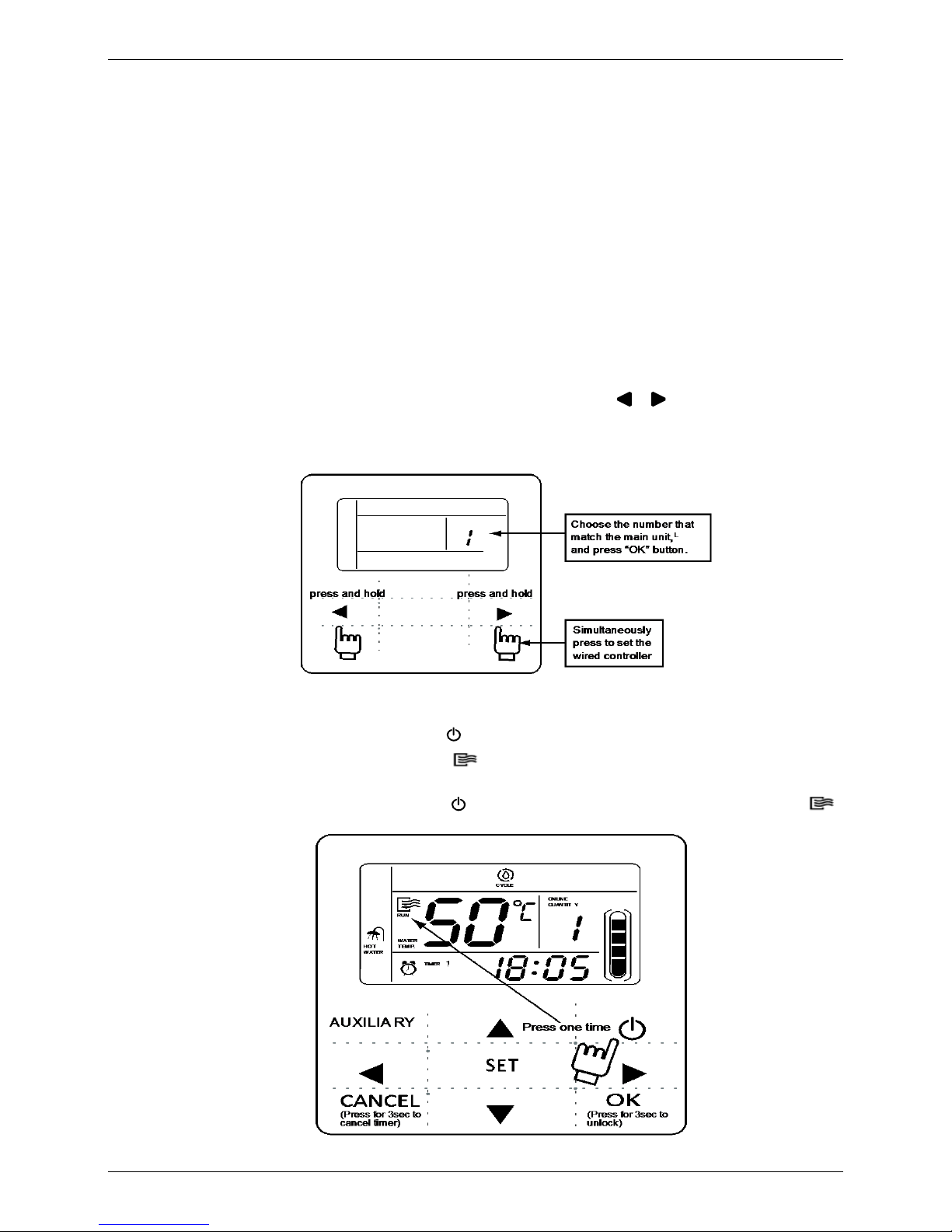

1. Setting wired controller

This controller needs setting before applying to certain HPWH models.

Setting method: When the controller is “OFF” , press and hold “ ” “ ” two buttons, waiting for

one number (1 to 5) displayed on the screen, press “▲ ”or “▼ ” button and select the number “1”

which match with the main unit, then press “OK” button to confirm.

2. Turn on and turn off the main unit

1) Press the On/Off key to control on and off status of the main unit.

2) Under off status, press the On/Off key “ ” to run the main unit, at the same time the LCD of wired

controller will display the operation icon “ ”. The main unit will running as the current setting of

the wired controller.

3) Under on status, press the On/Off key “ ” to turn off the main unit and the operation icon “ ”

on the LCD will disappear.

Page 39

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

39

3. Setting water temperature

You can press the“▲”or“▼”directly to adjust the water temperature after the controller powered

on. Or press“SET”key once when“SET WATER TEMP”is displayed on the LCD and then press

“▲”or“▼”to adjust water temperature.

Water temperature setting check: To check the water temperature setting value, press the

“ ” or “ ” key under the main page (the page displayed after the controller powered on).

4. Timing setting

Press “SET” key under main page twice to enter timing setting. Then the LCD will display as the

following:

At this time the hour of the clock will flash, which means the current setting is the hour of Timer 1,

please press the “▲” or “▼” to adjust and “ ” key to confirm when finished; and then the minute of the

clock will flash, which means the current setting is the minute of Timer 1, press the “▲” or “▼” to adjust

and “ ” key to confirm when finished, the LCD will display as the following:

The setting of Timer 2 and Timer 3 are the same method as this.

1

TIMER

ON

1

TIMER

OFF

Page 40

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

40

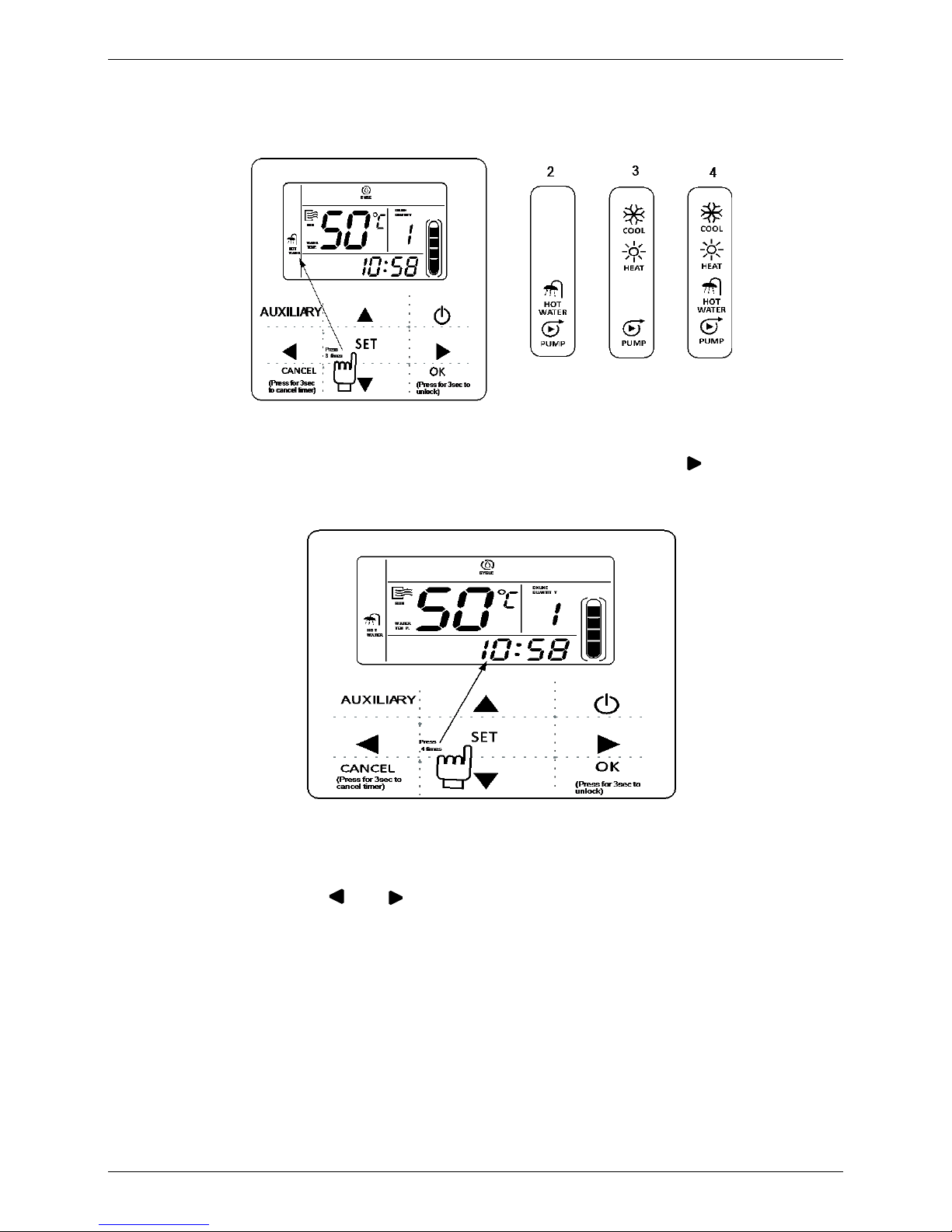

5. Setting working mode

Pressing “SET” key three times to enter the working mode setting page, then pressing the“▲” or “▼”

key to adjust , after selecting your need mode you can press “OK” key or wait seven seconds to

confirm; During setting process you can press “CANCEL” key to exit without saving. The controller

will show different working mode when it is applied to different main unit respectively.

6. Setting clock

Press the “SET” key 4 times to enter clock setting. The hour of the clock will flash, which means the

current setting is the hour of the clock, press the “▲” or “▼” to adjust, press “ ” key when finished,

and then the minute of the clock will flash, it means the current setting is the minute of the clock,

press the “▲” or “▼” to adjust, press “OK” key when finished or wait for 7 seconds to confirm. During

the setting process you can press the “CANCEL” key to exit without saving.

7. Setting water level

You can press the “SET” key 5 times to enter the water level setting, then press “▲” or “▼” to adjust

the water level, at last press “ OK ”key when finished or wait for 7 seconds to confirm. During the

setting process press the “CANCEL” key to exit without saving. The setting value is 50%, 75%

or100%. You can press “ ” or “ ” key under main page to check the water level which has been

set.

Page 41

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

41

8. Auxiliary operation

1) Electric auxiliary heating

This function allows running the electric auxiliary heating of main unit manually.

Operation method: press “AUXILIARY” key once to enter this function“ ” icon will flash, and then

press “OK” key to confirm.

2) Cycle heating

Cycle heating function makes the direct heating water heater to run the cycle heating function.

Operation method: Press “AUXILIARY” key twice to enter this function “ ” icon will flash, press

“OK” key to confirm.

Page 42

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

42

3) Water pump (reserved for future use.)

This function is used to run the main water pump in the device installing and debugging.

Operation method: when the wire controller is set to be 1, press “AUXILIARY” key 3 times to enter

this function. “ ” icon will flash and then press “OK” key to confirm.

4) Cancel auxiliary: To stop the auxiliary function, press the “AUXILIARY” key again, and then press

“CANCEL” key when the corresponding icon is flashing. Then the auxiliary function will be

cancelled.

PUMP

Page 43

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

43

4. Water tank cleaning

To guarantee the water quality, the water tank should be washed and the initially produced hot water should

be drained away from the effluent at the bottom of the water tank.

5. Schematic Diagram of the Unit System

1. Directing water heating (thick line part)

2. De-frosting (thick line part)

Water tank

PTE

Heat exchanging

Compressor

Water tank

Heat exchanging

PTE

Compressor

Page 44

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

44

6. Error Code Cause Analysis and the Solutions

Code

Code explanation

Cause analysis

Solution

E1

Power phase

sequence failure

Reverse-connection of the unit three-phase

supply line

Exchange the two supply lines after

power off.

One phase or two phases are not connected

well

Connect the supply line well after

power off.

E2

Communication

failure

Communication failure between the main unit

and the wire controller.

Correct connection between the main

unit and the A, B, P, Q and E lines of

the wire controller.

Communication failure between the main unit

and the wire controller, slave unit failure

P, Q and E lines correct connection

between the slave unit and the main

unit, no connection of the A and B lines.

Electromagnetic interference because

communication line is not the shielded line

Replace the communication line with

the shielded line.

E3

Outlet water

temperature sensor

failure

The water port between the sensor and the

main board is loose

Insert the port well.

Sensor damage

Replace the sensor.

E4

Water temperature

sensor in the water

tank failure (the unit

can also be start up,

but only for the

directly-heating type)

The T5 port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

E5

Condenser

temperature sensor

failure

The T3 port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

E6

Outdoor ambient

temperature sensor

failure

The T4 port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

E7

Electric-heating pipe

temperature sensor

failure

( RSJ-380/SN1-820D)

The T6 port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

Ec

Water inlet temp.

sensor error(T7

temp.)

The T7 port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

Eb

Exhaust temp.

sensor error(TP

temp.)

The Tp port between the sensor and the main

board is loose

Insert the port well.

Sensor damage

Replace the sensor.

P0

System low pressure

protection

Outdoor fan is not open

Check the motor of the fan.

The evaporator is dirty

Clean the evaporator

Leakage of refrigerant

Check the leaking place, mend by

welding, drawing out the air and add

refrigerant again.

P1

System high

pressure protection

Circulating

mode

Deficient circulating water

pump flow use

RSJ-380/SN1-820-D flow should be ≥

6 m3/h;

RSJ-200/SN1-540V-D flow should be

≥ 4 m

3

/h;

RSJ-100/N1-540V-D flow should be ≥

2 m3/h.

Circulation pipeline filter is dirty

and blocked

Clean the filter.

The water pump doesn’t work

Check the water pump

Warm water valve fault

Check the operation of the warm water

valve.

Bad bypass solenoid valve

operation and lack of water

flow PTE

Check the bypass solenoid valve.

Warm water valve

Check the operation of the warm water

valve.

Page 45

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

45

De-frosting

mode

De-frosting solenoid

valve is not open

Check the de-frosting solenoid valve.

The four-way directional valve

cannot change the direction

Check the four-way directional valve.

P2

Current protection for

system 2

Compressor current protection before system

high pressure protection

The same as the system high

pressure protection.

P3

Current protection for

system 1

Compressor current protection before system

high pressure protection

The same as the system high

pressure protection.

P8

Protection for

excessive high outlet

water temperature

Deficient water flow, the outlet water

temperature is higher than 70℃ and maintain

for one minute

The same as the system high

pressure protection.

Pb

Anti-freezing

protection

Prevent PTE cracking by freezing in the winter

Normal protection, no need for treatment.

P4

Manual mode setting is invalid.

When there is any failure or protection, the red indicator of the wire controller will twinkling and the wire controller and the

digital pipe of the main unit control panel will display the code. The code of the slave unit should be checked and transferred to

the corresponding address on the wire controller and then be found by page down and page up.

Page 46

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

46

7. Main control board spot check

Sequence

System operation parameters

Remarks

1st

Normal display Water out temperature

Value of T1

2nd

Pipe temperature

Value of T3

3rd

Ambient temperature

Value of T4

4th

Water tank temperature

Value of T5 (Just for main unit)

5th

Electric heating tube temperature

Value of T6

6th

Compressor discharge temperature

Value of Tp

7th

Setting water temperature

Value of Ts

8th

Circulate heat starting temperature

Value of Tr

9th

Current of compressor A

Value of IA

10th

Current of compressor B

Value of IB

11th

Opening of electric expansion valve

Value of electric expansion valve opening / 8

12th

Opening of electric water flow valve

Value of electric water flow valve opening / 32

13th

Operate mode

0: Stand by 1: Direct heating mode 2:Circulate

heating mode

14th

Fan speed

0: OFF 1: Low 2:Middle 3:High

15th

Elevation of water surface

0:Lower than S4 1: Between S4 and S3

2:Between S3 and S2 3:Between S2 and S1

4:Higher than S1

16th

The last error code or protection code

Display the latest error code or protection code.

If there is no code, display “--”

8. Failure without Code

Failure description

Cause analysis

Solution

The leakage switch is

switched off, which resulted

in the impossible of

switching in.

The input of the leakage switch is not equal to

the output.

1. Check whether the neutral line is connected

through the output end of leakage switch. The

neutral line is not allowed to couple in the unit

bypassing the leakage switch.

Connect the neutral line out from the

output end of the leakage switch.

2. The live line and neutral line in the same

power use equipment are coupled in different

output end of the leakage switch.

2. Connect the live line and neutral line in

the same power use equipment out from

the same output end of leakage switch.

Wire controller screen is

kept on initializing, and the

display of the water level

changes between the zero

grade and the fourth grade

continually.

1. Both the main unit and the slave unit of the A

and B power lines of wire controller are connected

1. Dismantle the A and B power lines of

the slave unit.

2. The address codes of the main unit and the

slave unit are set improperly (or no adjustment

is carried out, each unit is set to 0 before

delivering, and the default is the main unit).

2. The S1 on the panel of the main unit is

set to 0, and the DIP switches on the

panel of the slave units are set to 1, 2,

3…

Page 47

MCAC-RTSM-2013-12 Midea High-temperature Direct-heating Heat Pump Water Heater Technical Manual

47

9. Troubleshoot of abnormal phenomena

Not distribute to

malfunction

Phenomena

Cause

White aerosol or

globule is give out.

Make sound of “hiss”

every now and then.

Air supply motor stop automatically to defrost.

At the beginning and the end of the defrost process, sound is give out in

motor valve occur.

During the process or just after have stopped, sound like water flow occur,

which will be amplified at the first 2~3 minutes, this is caused by process

of refrigerant current or water discharge at dehumidifying operation.

Slight ”hiss” is caused by heat exchanger as temperature changes. The

sound give out because of heat expands and cold contracts of heat

exchanger.

During the beginning or just after have stopped, sound like clock occur,

which is caused by electric expanding valve operation.

Please check

that again

Stop operation or drive up

automatically

Detect the timer whether be given wrong operation.

Detect anti-freezing mode is opened.

No operate

Whether the power is cut.

Whether the manual power supply switch is off.

Whether fuse is broken.

Whether the protection device works.(Operation lamp is lightened.)

Whether it is the time set.(Operation lamp is lightened.)

Inefficient heating

Whether the inlet and outlet of boiler units is blocked.

Loading...

Loading...