Page 1

MDV 2

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

nd

Generation ALL IN ONE Type

Heat Pump Water Heater

Technical Manual

Applicable Models:

RSJ-35/300RDN3-B

1

Page 2

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

MDV reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations.

2

Page 3

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Contents

Part 1 General Information ........................................................................5

1. Measurements....................................................................................................... 6

2. External Appearance............................................................................................ 6

3. Nomenclature........................................................................................................ 7

4. Features................................................................................................................. 8

Part 2 Outdoor Units.................................................................................10

1. Specifications......................................................................................................11

2. Operation range.................................................................................................. 17

3. Capacity&COP table........................................................................................... 17

4. Dimensions .........................................................................................................17

5. Service Space ..................................................................................................... 18

6. Wiring Diagrams................................................................................................. 18

7. Piping Diagrams ................................................................................................. 20

8. Duct connection.................................................................................................. 17

9. Exploded View .................................................................................................... 22

Part 3 Installation......................................................................................25

1. Precautions......................................................................................................... 26

2. Installation information...................................................................................... 27

3. Unit Appearance and Composition................................................................... 28

4. Accessories......................................................................................................... 29

5. Inspecting and Handling the Unit ...................................................................... 29

6. Electric Wiring..................................................................................................... 29

Part 4 Trial Operation ...............................................................................31

1. Confirmation before the trial operation............................................................ 32

2. OPERATING INSTRUCTION............................................................................... 32

3. PCB explanation................................................................................................. 51

4. Maintenance........................................................................................................ 51

5. Malfunctions and Resolutions........................................................................... 53

3

Page 4

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Part 1

General Information

1. Measurements...................................................................6

2. External Appearance........................................................6

3. Nomenclature....................................................................7

4. Features.............................................................................8

5

Page 5

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

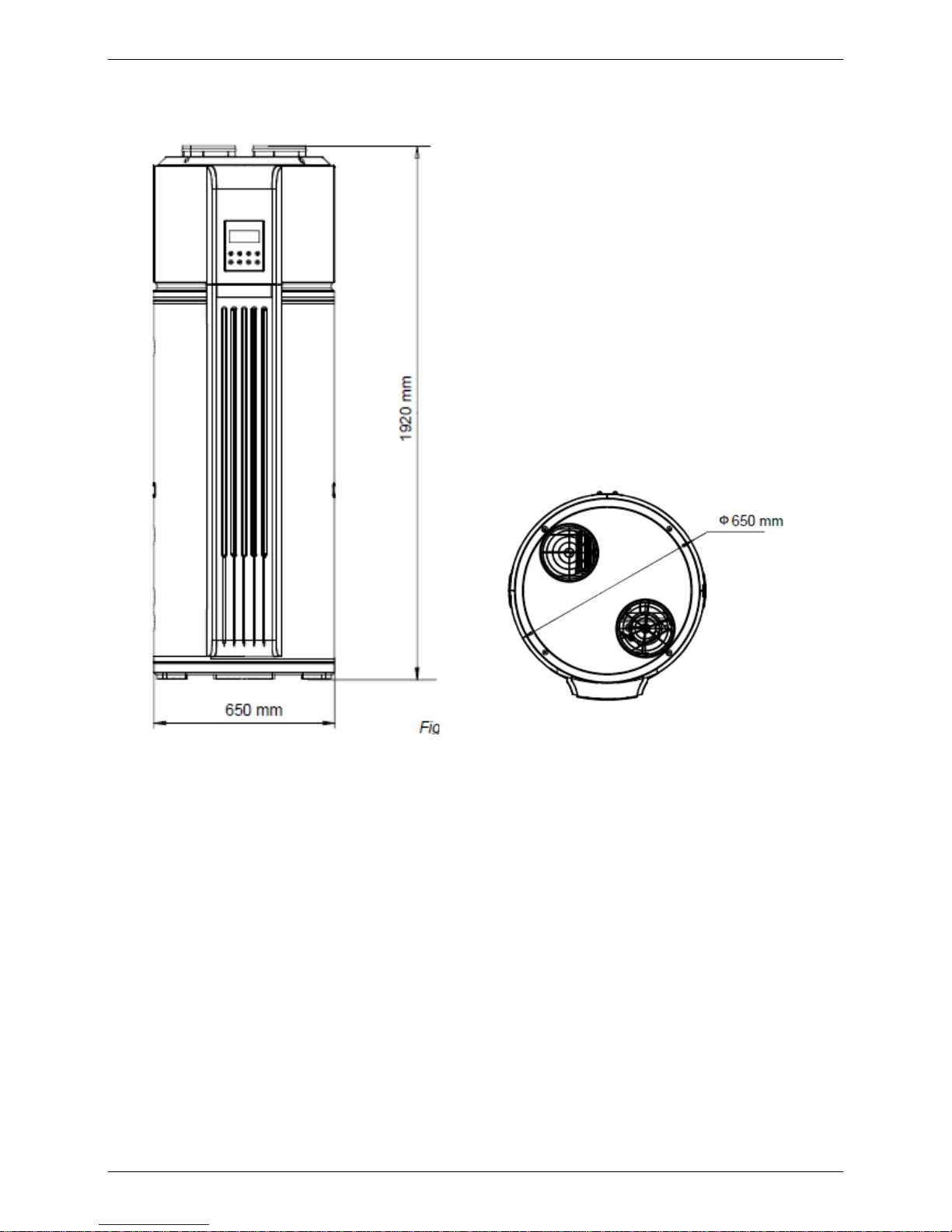

1. Measurements

Model

Dimension

(mm: OD x H)

Net weight / Gross weight

(kg)

Power Supply

RSJ-35/300RDN3-B Φ650×1920

113 /129 220~240V-1ph-50Hz

2. External Appearance

RSJ-35/300RDN3-B

6

Page 6

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

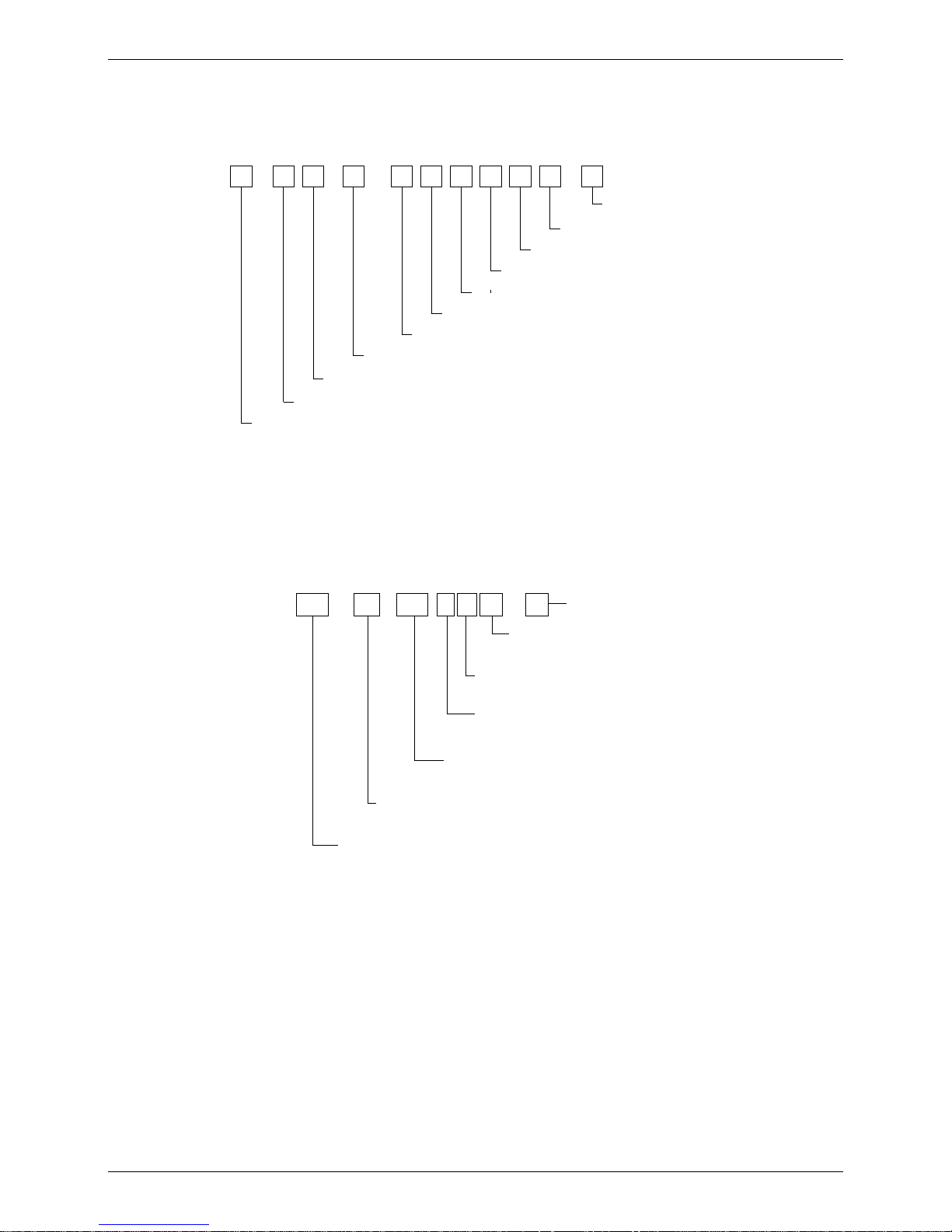

3. Nomenclature

Household Water Heating Unit

1

23

-

/

-5

Rated hot water output, unit: 100 W

6

7

8

Power supply specification code

Heating mode code

Water tank volume, unit: L

9

Other functions code

10 11

12

-

Water supply pump lift code

Refrigerant code

Design code

Installation type code

Water heating unit code

Export model code

For example:

-

B

Design code

300

Refrigerant code

Other functional code

N3

D

-

/

Water heating unit code

Rated hot water output, unit: 100 W

Water tank volume.unit:L

Heating mode code

R

35RSJ

7

Page 7

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

4. Features

4.1 Safety

a. Complete isolation between water and electricity. No

electric shock problem, more safety.

b. No fuel tubes and storage, no potential danger from oil

leakage, fire, explosion etc.

c. No cross contamination potential, the condenser coil

wrapped around the stainless steel inner tank

4.2 Max. outlet water Temperature: 60℃.

The system is adopted innovative heating methods: combined the Electric heating and Heat Pump heating

properly, made the water be heated stably and quickly.

4.3 Flexible installation achieved by long air intake/outlet duct with pressure

4.4 Built-in heat exchanger inside tank for integrating multiple energy, such as solar

energy.

8

Page 8

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

4.5 Automatic Control:

Automatic start-up and shutdown, automatic defrosting by revising refrigerant cycle. Save you much extra

operation.

4.6 High Efficiency and Energy Saving.

The unit adopts heat pump principle, which absorbs heat from outdoor air and produce heat water, thermal

efficiency can be approximately 3.6 (under the condition A15/12 W15/45)

4.7 All-the-weather Running.

Within the temperature range from -30 to 43℃, it will not be affected by night, cloudy sky,

rain even snow whether.

9

Page 9

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Part 2

Outdoor Units

1. Specifications..................................................................11

2. Operation range..............................................................17

3. Capacity & COP table .....................................................17

4. Dimensions......................................................................17

5. Service Space..................................................................18

6. Wiring Diagrams .............................................................18

7. Piping Diagrams..............................................................20

8. Duct connection..............................................................17

9. Exploded View.................................................................22

10

Page 10

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

1. Specifications

Model RSJ-35/300RDN3-B

Running Models

Economy Hybrid E-heater

Running Ambient temp. ℃ -7~43 -30~43 -30~43

Power supply ph-V-Hz 220~240V-1ph-50Hz

Storage size Ltr 300

Capacity KW 3.00 3.00 3.00

Input KW 0.83 0.83 3.00

Cop W/W 3.60 3.60 1.00

Rated current A 3.00 3.00 3.00

Testing Condition

Economy: A15/12 W15/45, setting Economy Mode;

Hybrid: A15/12 W15/45, setting Hybird Mode;

E-heater: A15/12 W15/45, setting E-heater Mode;

Max. Input KW 1.50 4.30 3.00

Max. Current A 6.50 18.7 13

Water

Heating

Nonimal

Testing Condition

Economy: A 43 W60, setting Economy Mode;

Hybrid: A 10 W60, setting Hybird Mode;

E-heater: A15 W60, setting E-heater Mode;

Max. Input KW 4.3

Max. current A 18.7

Starting current A 49.0

Model RB233GRDC

Type Rotary

Brand Guangzhou Mitsubishi electric

Supplier Guangzhou Mitsubishi electric

Capacity Btu/h 9500

Input W 850

Rated current(RLA) A 4.1

Locked rotor Amp(LRA) A 30

Thermal protector ℃ 115

Capacitor uF 30

Crankcase W 25

Compressor

Refrigerant oil ml 440 (HAB (NEO 32 or similar))

Model YDK30-6R

Type AC Motor

Brand Welling

Insulation class B

Safety class IPX4

Input W 68

Rated current A 0.3

Capacitor uF 2.5

outdoor fan

motor

Speed(hi/lo) r/min 620/530/465

material ASG20

Type Centrifugal type

Pressure pa 30

Diameter mm 271

outdoor fan

Height mm 130

Number of rows 3

Tube pitch(a)x row pitch(b) mm 22*19.05

Fin spacing mm 1.5

Fin type Arc hydrophile seam punching fin

Tube outer dia.and type mm Ф8.0 innergroove tube

Coil length x height 482*352

outdoor coil

Number of circuits 4

Outdoor air flow (Hi/mid/lo) m3/h 414/355/312

Noise level dB(A) 46.6

11

Page 11

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Running Operation

Auto/Manual start up, Energy-saving, standard, Enhanced

heating type heating water

Protection Method

High-pressure protection, Over-load protection,

Temp protection, Electric leakage protection

Dimension (D*H) mm Φ650×1920

Packing (W*H*D) mm 745*2030*775

Outdoor unit

Net/Gross weight kg 113/129

Refrigerant type/Quantity Kg R134a/1.2

Design pressure

(Operating pressure Refrigerant)

MPa 3.0/1.2

Tank pressure Mpa 0.15/0.7

Tank Foaming Material/Depth(mm) polyurethane/55mm

Ambient temp ℃ -30~43

Diameter, water inlet pipe mm DN20

Diameter, water outlet pipe mm DN20

Diameter, drainage pipe mm DN20

Diameter, PT valve joint mm DN20

PT valce Brand Watts (active condition 99℃ or 1.0Mpa )

Rated pressure MPa 1.2

Max. Operation pressure MPa 0.7

Water outlet Temp ℃ (default) 55℃, 38℃~60℃

water

pipeline

Heat exchanger Copper tube wrapped around outside of tank

Diameter, water inlet pipe

mm

DN20

Diameter, water outlet pipe mm DN20

Heat exchanger Surface heat exchanger; Stailess steel SUS316L

heat exchanger tupe Dim.*Length mm Φ22*10000

heat exchanger area m2 0.7

Solar heat

exchanger

pipeline

Max.pressure MPa 0.7

Power wiring

mm2

4

Connection

wiring

Signal wiring

mm2

0.75

Fresh Air Diameter

mm

190.0

static pressure

Pa

30.0

Fresh air

Max Length

m

10.0

Hot Water Yield m3/h 0.075 0.075 0.064

Electric Heater kW 3.0

Remark:

1. The test conditions: outdoor temp. 15/12℃(DB/WB), inlet water temp. 15℃, outlet water temp. 45℃.

2. The operation range:-30℃-48℃, heat pump operation range: -7℃-43℃

3. The specification may be changed for product improvement, please refer to the nameplate.

12

Page 12

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

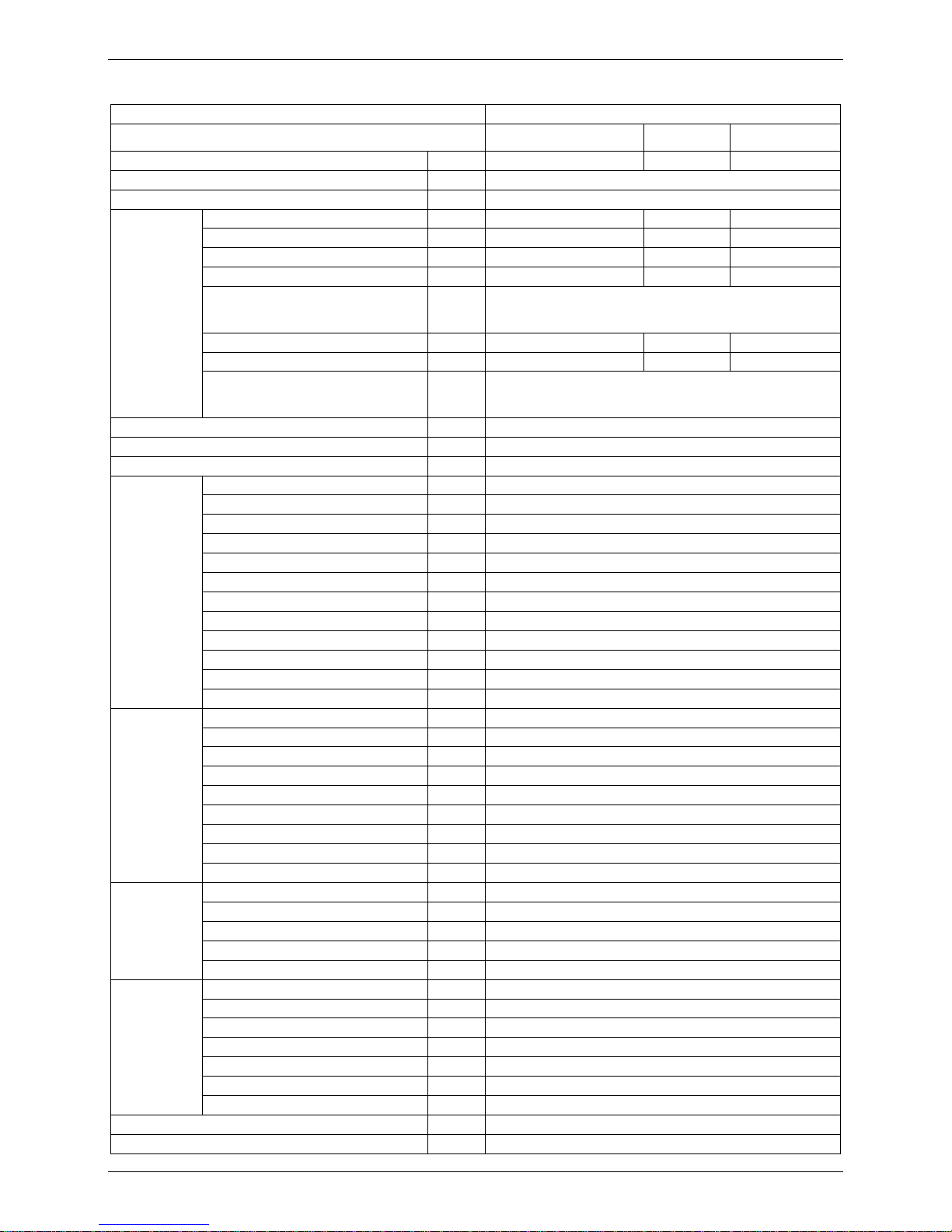

2. Operation range

Mode explanation: there are 3 operation MODE: ECONOMY, HYBRID and E-HEATER

ECONOMY MODE: Water firstly is heated by compressor, if can’t get target temp when ambient temp. too low or too high

(limitation figure is shown above), element will start as a secondary heat resource.

Hybrid mode: In case of massive hot water consumption, compressor & element will start at the same time.

E-HEATER MODE: Water is only heated by element;

13

Page 13

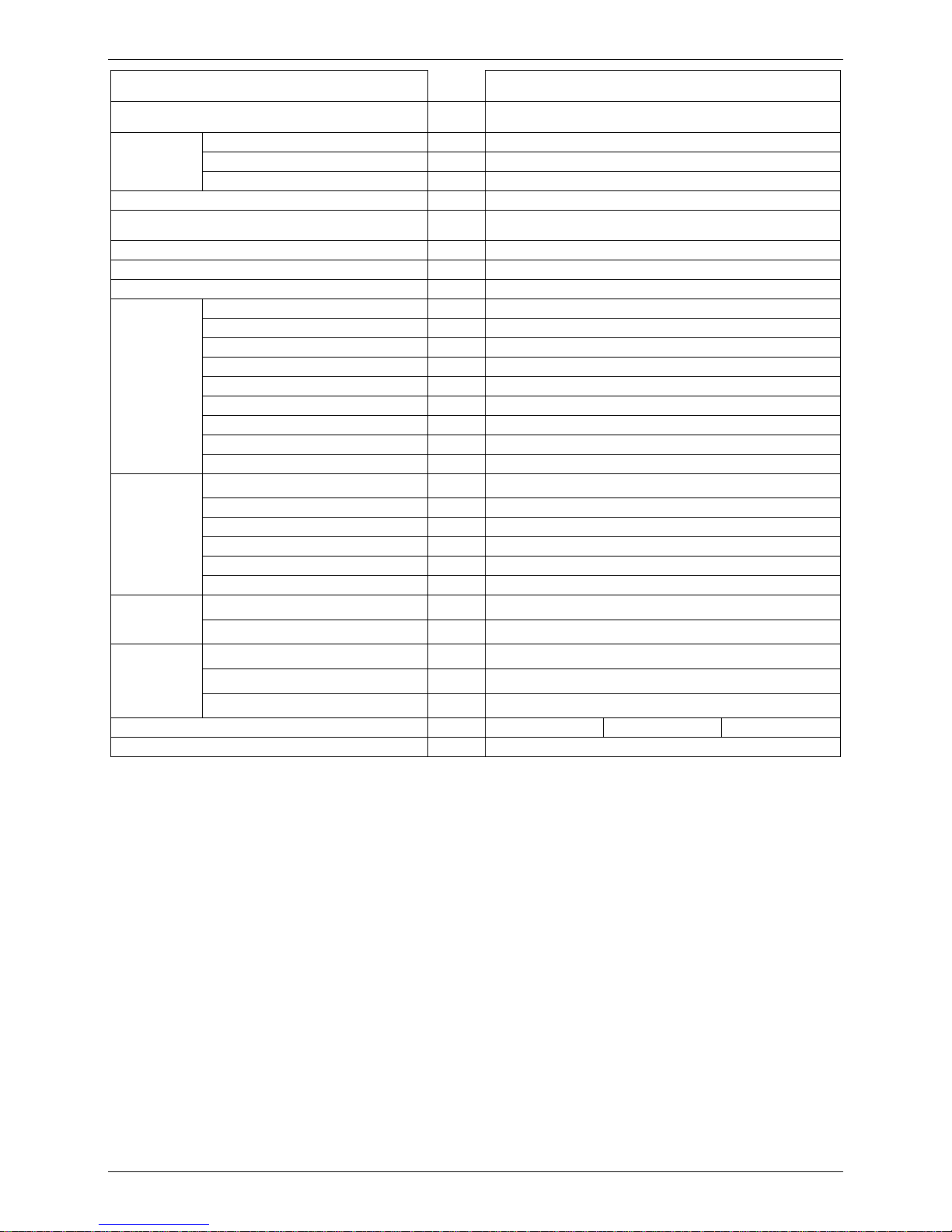

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

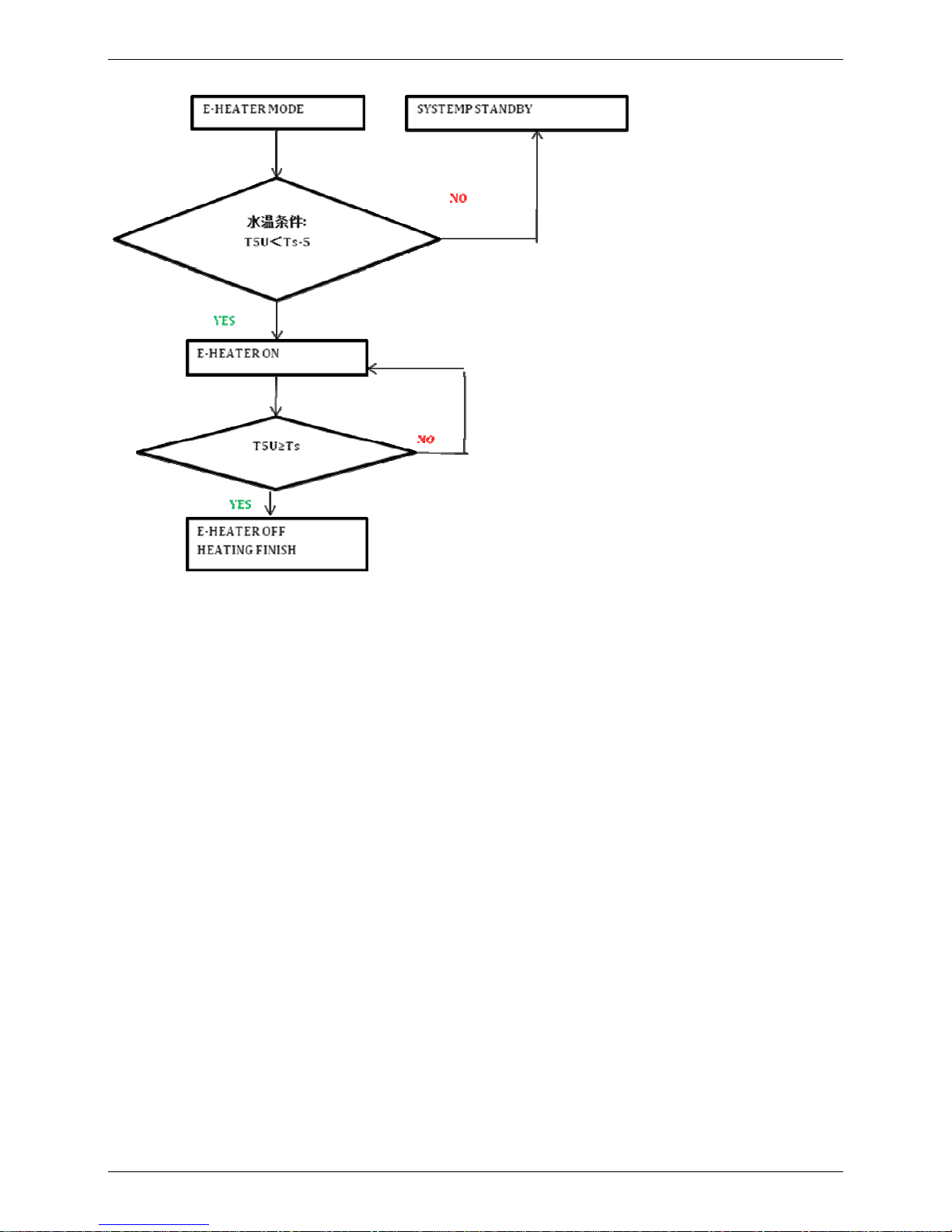

ECONOMY MODE:

Hybrid mode:

14

Page 14

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

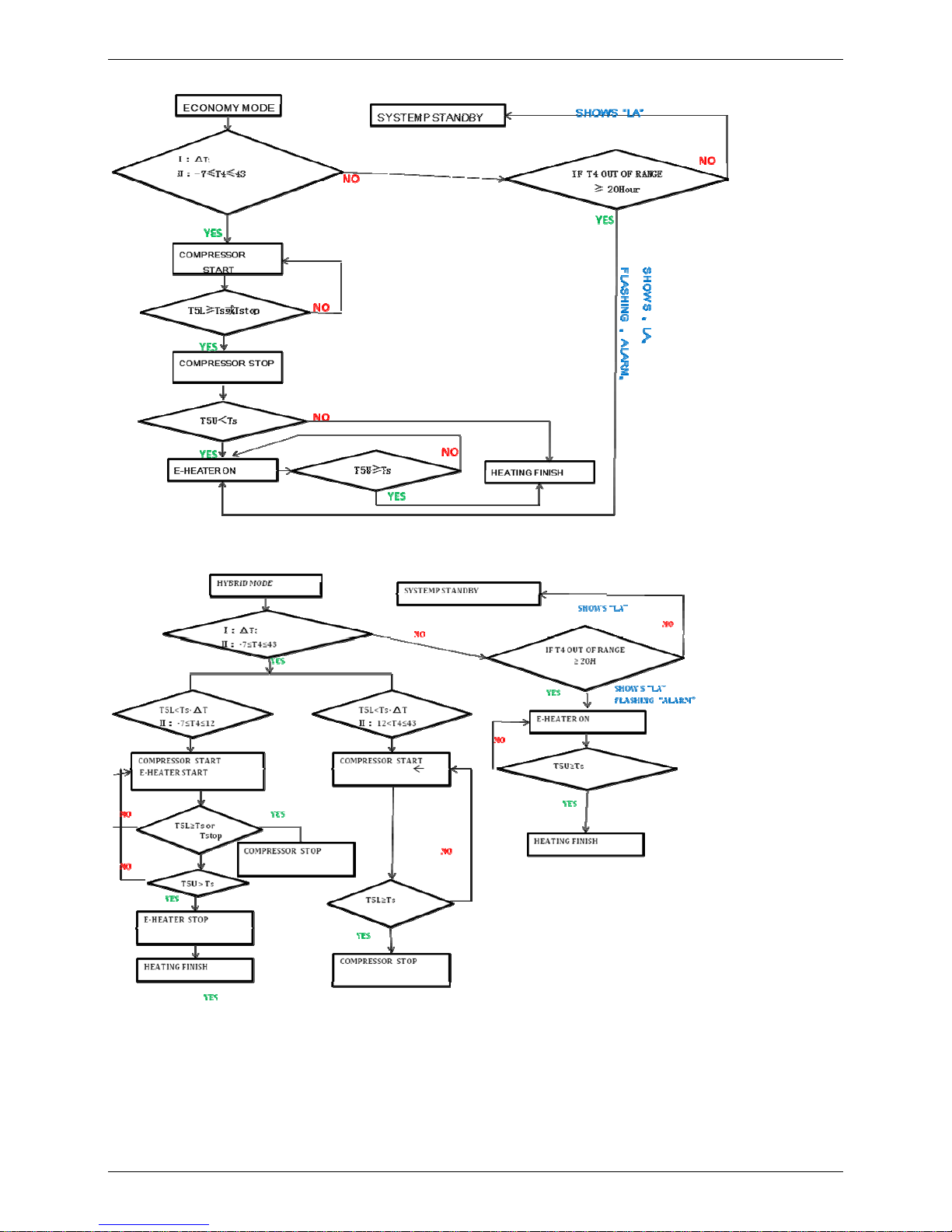

E-HEATER MODE:

15

Page 15

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

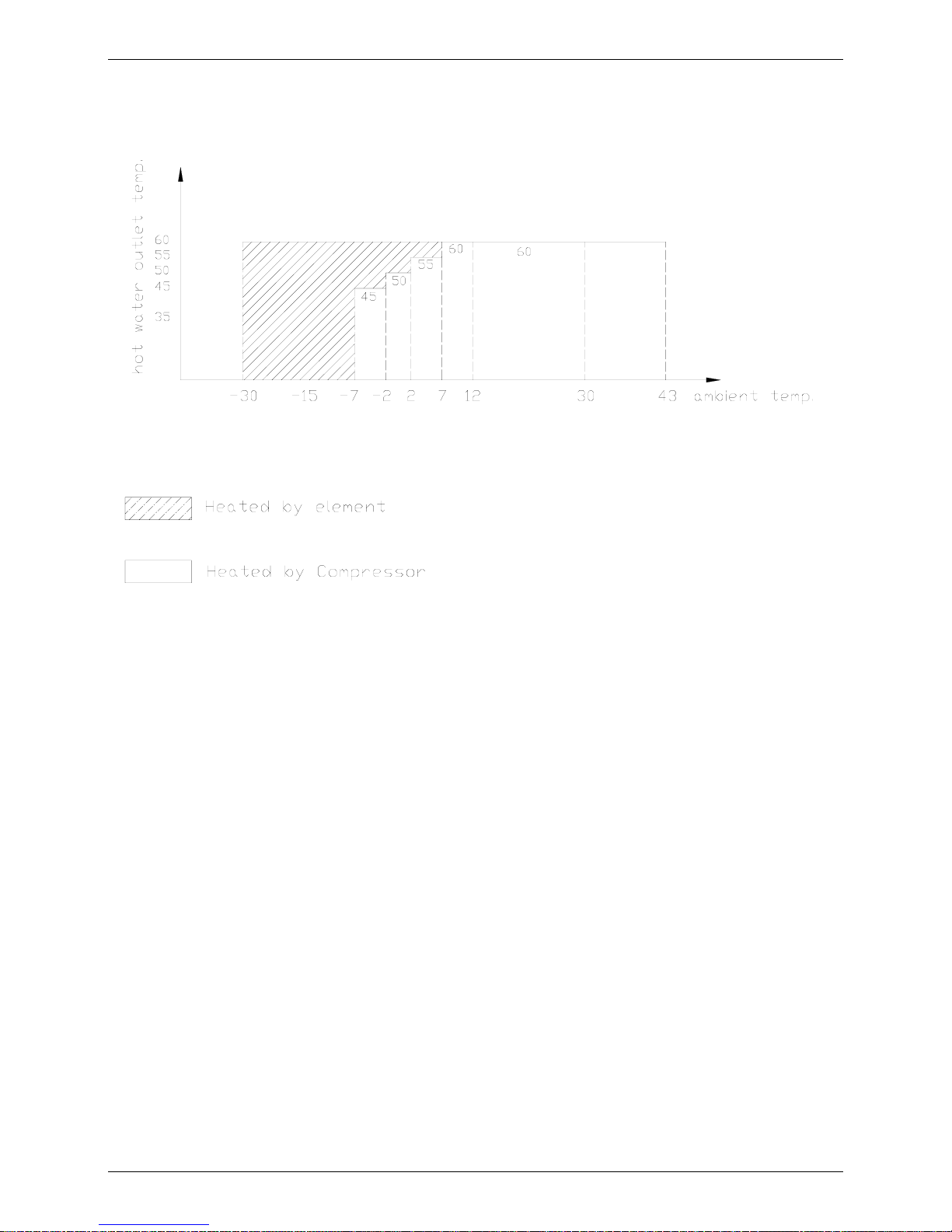

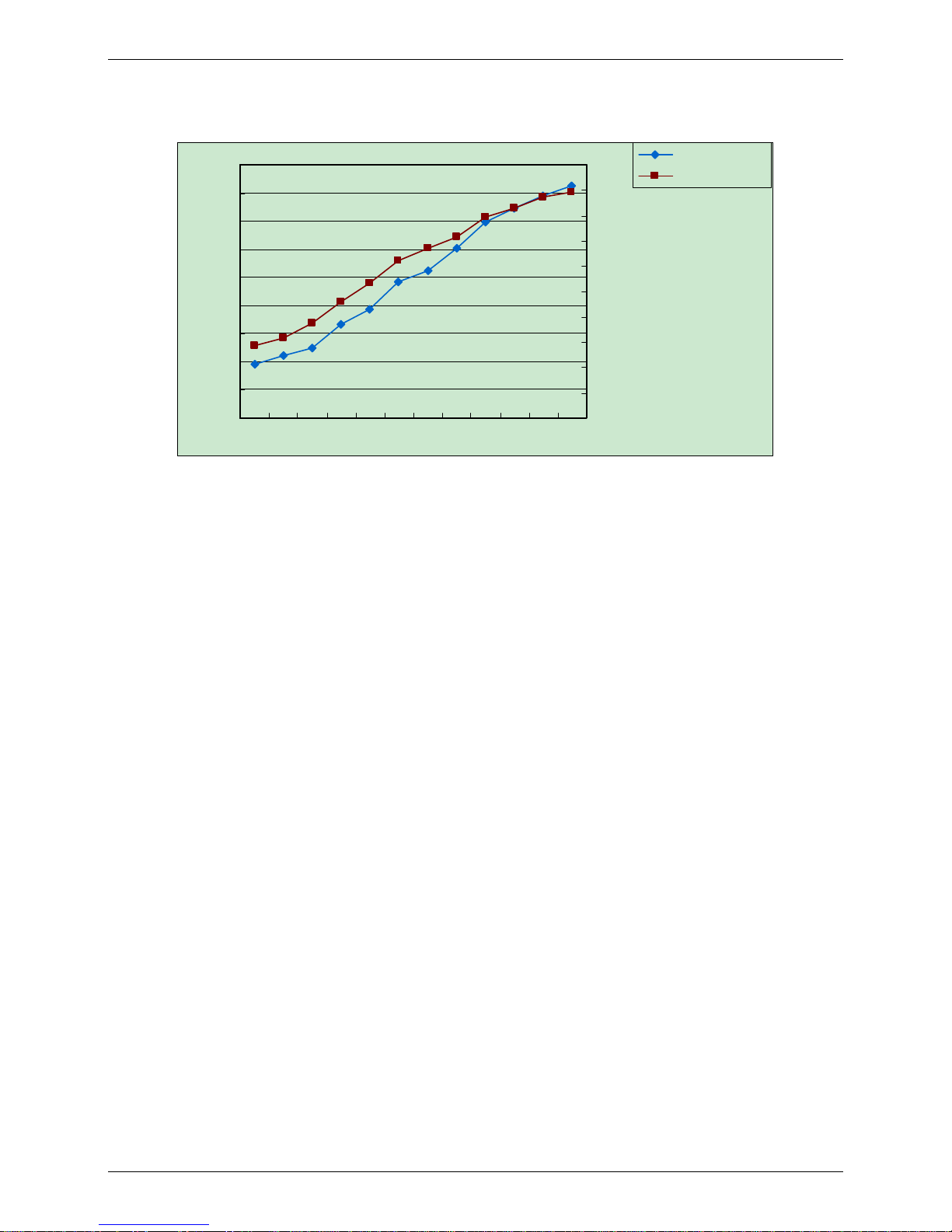

3.

Capacity & COP table

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

-7 -2 2 7 10 15 20 25 30 35 40 43

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

Capa. (W)

COP (W/W)

Ambient temp(℃)

Remark:

Water inlet temp. 15℃, Water outlet temp. 45℃

16

Page 16

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

4. Dimensions

17

Page 17

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

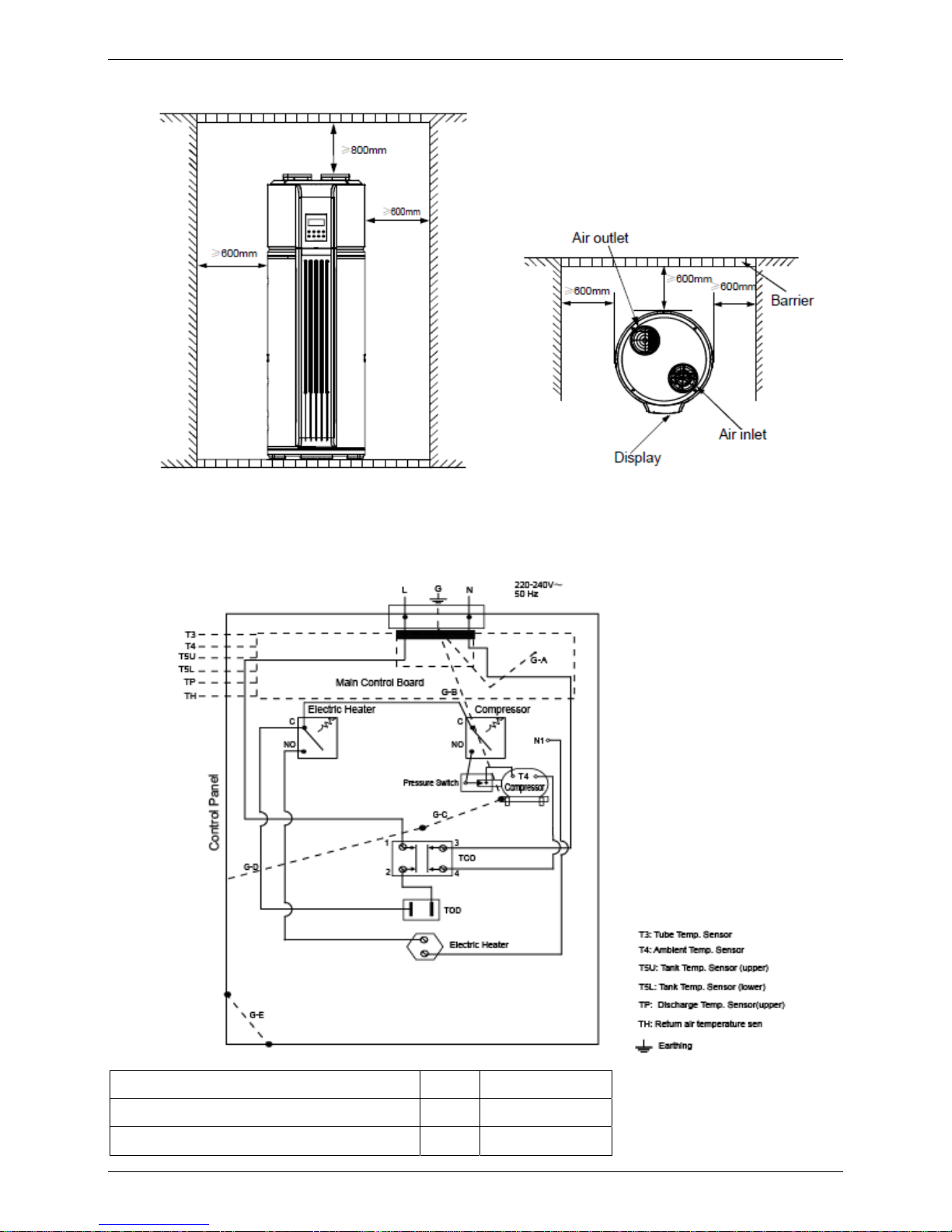

5. Service Space

6. Wiring Diagrams

manometer (High Pressure Switch)

1 202301800820

Discharge temp sensor ass'y (Tp)

1 202301300130

room temp sensor ass'y (T4)

1 202301300196

18

Page 18

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Temp.sensor ass'y (T3)

1 202301300437

Temperature sensor (Th)

1 202301300303

senor ass'y, for the pipe (T5L)

1 202301300485

senor ass'y, for the pipe (T5Up)

1 202301300486

Relay of Elment & Compressor

2 202300800003

TCO(turn off temp. 85±3°C,manually recovery)

1 202301610028

TOD Auto Recovery, turn off temp.78±3°C,Recovery

temp 68±3°C。

1 202301600046

19

Page 19

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

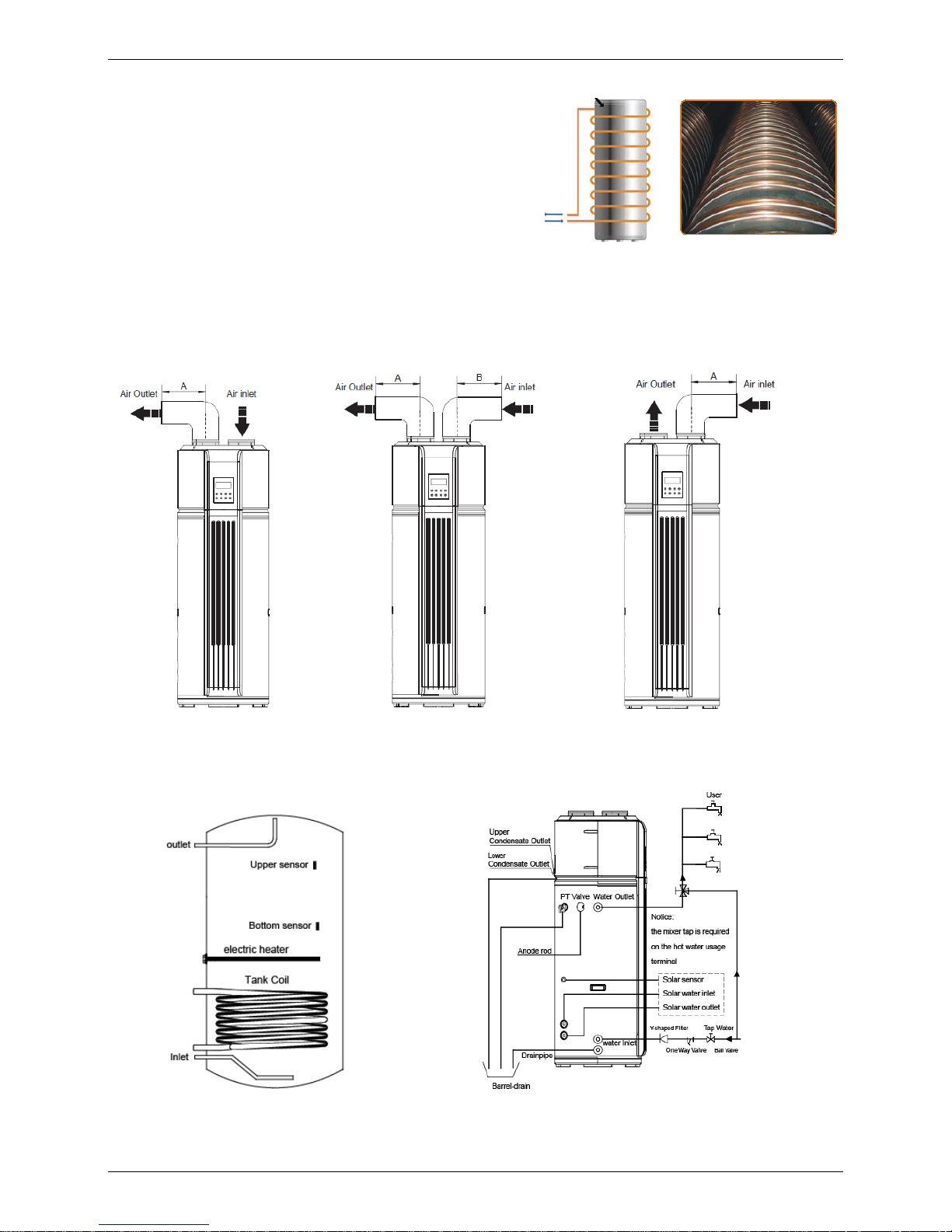

7. Piping Diagrams

20

Page 20

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

8. Duct connection

A: Air inlet & outlet without canvas B: Only air outlet with canvas, A≤10m

When there is stable heat source in room in winter

C: Air inlet & outlet with canvas, A+B≤10m D: Only air inlet with canvas A≤10m

Charge fresh air from ambient in summer

21

Page 21

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

9. Exploded View

22

Page 22

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

No. Part Name

Quantity

No. Part Name

1

airout ring

2 18

decorating board

2

air filter

1 19

cover, upper heating element

3

filter

2 20

Deck magnet

4

plastic hourse

1 21

Magnet clip

5

top

1 22

Magnet cover

6

magnesium stick plug

1 23

four-way valve

7

cover, wire-connceting box

1 23.1

Pipe joint

8

asynchronism motor

1 23.2

manometer (High Pressure Switch)

9

Display board

1 23.3

4-way valve

10

Display board ass'y

1 23.4

Solenoid

11

centrifugal fan

1 24

Electronic Expansion Valve ass'y

12

cover, display

1 24.1

EEV solenoid

13

electric control box

1 24.2

Solenoid valve winding

14

forming

1 24.3

Electronic Expansion Valve

14.1

forming plug

1 24.4

Solenoid valve

14.2

Froth plug

2 25

compressor

14.3

TCO(turn off temp. 85±3°C,

manually recovery)

1 26

Discharge temp sensor ass'y (Tp)

14.4

magnesium stick

1 27

room temp sensor ass'y (T4)

14.5

TOD Auto Recovery, turn off

temp.78±3°C,Recovery temp 68

±3°C。

1 28

Temp.sensor ass'y (T3)

14.6

Stator of temp. sensor

1 29

Temperature sensor (Th)

14.7

heating element

1 30

senor ass'y, for the pipe (T5L)

14.8

Sealed ring

1 31

senor ass'y, for the pipe (T5Up)

14.9

Seal Stopper

4 32

Compressor electric heater

14.10

Drain stop up

1 33

evaperator ass'y

14.11

lower cover, for the tank

1 33.1

evaperator

14.12

PT velve loop

7 33.2

evaperator output pipe ass'y

14.13

handle for the tank

2 33.3

evaperator input pipe ass'y

14.14

PT valve

1 34

wire connecting box

15

magnetic holder

1 34.1

holder

23

Page 23

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

16

electric control board ass'y

1 34.2

Wire joint, 3p

16.1

electric control board

jointing

1 35

front snail shell

16.2

Compressor capacitor

1 36

compressor connector

16.3

main control board ass'y

1 37

Platen

16.4

transformer for power supply

1 38

back snail shell

16.5

Motor capacitor

1 39

Drainage bend

16.6

Wire joint

4 40

upper plastic house

16.7

Relay of Elment & Compressor

2 41

filter

17

holder for electric control

board ass'y

1

24

Page 24

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Part 3

Installation

1. Precautions .....................................................................26

2. Installation information..................................................27

3. Unit Appearance and Composition...............................28

4. Accessories.....................................................................29

5. Inspecting and Handling the Unit..................................29

6. Electric Wiring.................................................................29

25

Page 25

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

1. Precautions

To prevent injury to the user or other people and property damage, the following instructions must be

followed. Incorrect operation due to ignoring of instructions may cause harm or damage.

The safety precautions listed here are divided into two categories. In either case, important safety

instructions are listed to which close attention must be paid.

WARNING

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage to the equipment.

WARNING

■ The water heating unit must be earthed effectively.

■ A creepage breaker must be installed near the power supply.

■ Ask your supplier for installation of the air source heat pump water heating units. Incomplete installation

performed by yourself may result in water leakage, electric shock, or fire.

■ Ask your supplier for the repair and maintenance. Incomplete repair and maintenance may result in

water leakage, electric shock or fire.

■ In order to avoid electric shock, fire or injury, if any abnormality is detected, such as smell of fire, turn off

the power supply and call your supplier for instructions.

■ Never replace a fuse with that of wrong rated current or other wires when a fuse blows out. Use of

wrong wire or copper wire may cause the unit to break down or a fire.

■ Do not insert fingers, rods or other objects into the air inlet or outlet. When the fan is rotating at high

speed, it will cause injury.

■ Never use a flammable spray such as hair spray, lacquer paint near the unit. It may cause a fire.

■ Never touch the air outlet or the horizontal blades while the swing flap is in operation. Fingers may

become caught or the unit may break down.

■ Never put any objects into the air inlet or outlet. Objects touching the fan of high speed can be

dangerous.

■ Do not dispose this product as unsorted municipal waste. Collection of such waste separately for

special treatment is necessary.

■ The appliance shall be installed in accordance with national wiring regulations.

CAUTION

■ The ground pole of socket must be grounded, and the rated current should be more than 10A. Make

sure that socket and attaching plug are dry always and have a good connection.

Method: Turn on power supply, run the unit for half a hour, then turn it off and check if the attaching plug

is hard. If it’s hard (more than 50℃), please change it with a new and eligible one, or it may result in an

electric shock or fire.

■ Do not use the air-source water heater for other purposes.

■ Before cleaning, be sure to stop the operation and turn the breaker off or pull out the power cord.

Otherwise, an electric shock and injury may be caused.

■ In order to avoid injury, do not remove the fan guard on the outdoor unit.

■ Do not operate the air-source water heater with a wet hand. An electric shock may be caused.

■ In the place and the wall where water may be spattered, the installation height must be more than 1.8m.

■ At the water inlet, the One Way valve must be installed.

26

Page 26

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

■ It’s normal if some water drips from the hole of PT valve in operation. But, if the water is in a great

amount, call your supplier for instructions.

■ After a long use, check the unit stand and fittings. If damaged, the unit may fall and result in injury.

■ Arrange the drain hose to ensure smooth drainpipe. Incomplete drainpipe may cause wetting of the

building, furniture etc.

■ Never touch the internal parts of the controller.

■ Do not remove the front panel. Some parts inside are dangerous to touch, and a machine malfunction

may be caused.

■ Never expose babies, plants or animals directly to the air flow. Adverse influence to babies, animals and

plants may be resulted.

2. Installation information

■ Enough space is installation and maintenance shall be preserved.

■ The air inlet and outlet should be free from obstacles and strong wind.

■ The bearing surface should be flat, able to bear weight of the unit and suitable for installing the unit

horizontally without increasing noise or vibration.

■ The operation noise and air flow expelled shall not affect neighbors.

■ No flammable gas is leaked nearby.

■ It is convenient for piping and wiring.

CAUTION

■ Installing the equipment in any of the following places may lead to malfunction of the equipment (if it is

inevitable, consult the supplier):

1) The site contains mineral oils such as cutting lubricant.

2) Seaside where the air contains much salt.

3) Hot spring area where corrosive gases exist, e.g., sulfide gas.

4) Factories where the power voltage fluctuates seriously.

5) Inside a car or cabin.

6) Place like kitchen where oil permeates.

7) Place where strong electromagnetic waves exist.

8) Place where flammable gases or materials exist.

9) Place where acid or alkali gases evaporate.

10) Other special environments.

■ Precautions before installation

1) Decide the correct way of conveying the equipment.

2) Try to transport this equipment with the original package.

3) If the unit has to be installed on a metal part of the building, electric insulation must be installed, and the

installation must meet the relevant technical standards for electric devices.

■ Installation space

Before installing the unit, reserve the space of maintenance .

WARNING

■ Ask your supplier to install the air source heat pump water heating units. Incomplete installation

performed by yourself may result in a water leakage, electric shock, or fire.

■ The place without direct sunlight and other heat supplies. If there’s no way to avoid these, please install

a covering.

27

Page 27

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

■ The unit must be securely fixed, or else, noise and shaking will be resulted.

■ Make sure that there’s no remora around the unit.

■ In the place where there is strong wind like seashore, fix the unit in the location protected from the wind.

■ Carry the unit onto the site

1) In order to avoid scratch or deformation of the unit surface, apply guard boards to the contacting

surface.

2) No contact of fingers and other things with the vanes.

3) Don’t incline the unit more than 45° in moving, and keep it vertical when installing.

■ Install the unit.

1) The circulating air for every unit should be more than 700m3/h.

2) Make sure there is enough Installation space.

3) Outline dimensional drawing

3. Unit Appearance and Composition

28

Page 28

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

4. Accessories

Check whether the following assemblies are complete.

Name Quantity Note Purpose

Installation& Operation Manual 1 —— Installation and Operation instruction

Y-sharp Filter 1 —— Inlet water filter

Drain Pipe for Condensate water 2 —— For condensed water discharge use

One Way Valve 1 —— To prevent water from flowing back

Wired Controller (optional) —— —— To control and monitor the unit status

5. Inspecting and Handling the Unit

After delivery, the package should be checked and any damage should be reported immediately to the

carrier claims agent.

When handling the unit, take into account the following:

1.

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

2. Choose before hand the path along which the unit is to be brought in.

3. Move this unit with original package.

4. When lifting the unit , always use protectors to prevent belt damage and pay attention to the balance of

the unit’s gravity.

6. Electric Wiring

6.1 Attention

● The water heater should powered separately and the power voltage should be in line with rated voltage..

● The power supply circuit of the water heater should be earthed, the power cord should be connected

with the external earthing line in reliable state and all the external earthing cables are effective.

● The construction of the wiring should be carried out by professionals in accordance with the circuit diagram.

● Set up leakage protection devices in accordance with the requirements of the relevant national

technical standards.

● The power cord and the signal line should be laid neatly without cross-interfere and should not contact

with the connecting pipe and the valves.

● The unit is not equipped with power cord. Please refer to the prescribed power specification for

selecting the power cord and cross-connection between two lines are not allowed.

● Check whether all the connections are correct before powering the unit.

6.2 Power specification

4

29

Page 29

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

6.3 Power Supply Wiring .

A. Power Supply Schematic Diagram

Earthing

Water Heating Unit

Manual Switch

Power

supply

Creepage Breaker

Warming:

Although there is a leakage protector in the electric control box of the unit, for the security reason, it is

required that a leakage protection equipped cable and Earthing should be applied for the unit according to

the requirement on the above diagram.

B. Cable Diameter Selection

The power supply wiring refers to the wiring to the main line (a) of junction box and the wiring (b) to the

power supply equipment. Please select the cable diameter according to the following methods

1) Diameter of the main line (a):

Get from the power supply specification table according to the sum of horsepower of the unit.

2) Diameter of the wiring from the junction box to the power supply equipment:

When the water heaters are less than 5 sets, the diameter the wiring from the junction box to the power

supply equipment should be the same as the main line (a); when the water heaters are more than 6 sets, the

power supply equipment should have two sets of electric control box and the diameter should be get from

the power supply specification table according to the sum of horsepower of the units connected by the

electric control box.

30

Page 30

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Part 4

Trial Operation

1. Confirmation Before the Trial Operation....................327

2. Operating Instruction .....................................................32

3. PCB explanation .............................................................51

4. Maintenance....................................................................51

5. Malfunctions and Resolutions.......................................53

31

Page 31

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

1. Confirmation Before the Trial Operation

1.1 All the installation is complete.

1.2 Water heater is installed correctly.

1.3 The pipelines and wiring are correct.

1.4 The accessories are installed correctly.

1.5 The drainage is smooth.

1.6 The thermal insulation is sound.

1.7 The earthing wire is connected correctly.

1.8 The power voltage is consistent with the rated voltage of the heater.

1.9 No obstacle at the air inlet and outlet of the unit.

1.10 The leakage protector can work effectively.

2. Operating Instruction

2.1 Instruction

2.1.1 Before using this unit, please follow the steps below.

Water Affusion: If the unit is used for the first time or used again after emptying the tank, please make sure

that the tank is full of water before turning on the power. Method: see figure 2.1.1

Hot water outlet

Close

Water out

When water flows out from the water

outlet, the tank is full.

Turn o

ff the hot

water outlet valve and water a

ffusion

is finished.

Hot water outlet

Cool water inlet

Open

Open the cool water inlet and

hot water outlet

Open

Water Affusion

NOTE:

1. The Ball Valve at water inlet should be open when the unit is in operation.

2. Operation without water in water tank may result in damage of auxiliary e-heater. Due to such damage, the supplier is not

responsible for the quality issue.

3. Over 50℃ may result in serious burn or so caused death. Special care should be paid to the children, the disabled and

the old in case of water burn.

32

Page 32

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.1.2 After powered on, the display lights up. Users can operate the unit through the buttons under the

display for different modes. Emptying: If the unit needs cleaning, moving etc, the tank should be

emptied. Method: See Figure 2.1.2

Close

Open

Drainpipe

Open

Cool water inlet

Hot water outlet

Close the cool water inlet, open the hot

drainpipe.

water outlet and open the nut of

After emptying, please close the nut

of drainpipe

Close

Drainpipe

Emptying

NOTE: The outlet water temp. may be very high when emptying, beware of your body for burns.

2.2 Operation

2.2.1 Control Panel Explanation

Display

Operation

HYBRID MODE

OUTLET TEMP

ECONOMY MODE

HIGH TEMP

FILL WA TER

ALARM

LOCK

TIME OFF

TIME ON

TIMER

CONFLICT

TEMP-SET

E-HEATER MODE

33

Page 33

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.2.2 Display Explanation

TEMP-SET

16

15

14

13 12 11 10 9

8

7

6

5

4321

HYBRID MODE

OUTLET TEMP

ECONOMY MODE

HIGH TEMP

FILL WATER

ALARM

LOCK

TIME OFF

TIME ON

TIMER

CONFLICT

E-HEATER MODE

Number Explanation Number Explanation

1

HIGH TEMP indicator. When the setting temp.

exceeds 50℃, it lights up to remind you that the

outlet temp. is too high for direct spray.

9

OUTLET TEMP indicator. It displays water temp.

of the upper part of the tank, which can be used.

It always lights.

2

FILL WATER indicator. When the power supply is

turned on, it lights up to remind you to re-affuse

water.

10

TIMER CONFLICT indicator. When the temp

you set through Wired Controller conflicts with

that through User Interface, it lights up.

3

ALARM indicator: It will flashing at the malfunction

or protection time.

11

TIME OFF indicator: It will light up when timing

off mode is set, blanks when screen

protection.et, blanks when screen protection.

4

TEMP-SET indicator: Show the setting

temperature and blank when screen protection.

Codes are show at the

malfunction or protection time

12

TIME ON indicator: It will light up when timing

on mode is set, blanks when screen

protection.et, blanks when screen protection.

5

LOCK indicator. When the UI is locked, it always

lights.

13

CLOCK indicator. It displays present time, it will

blanks when screen protection

6

Water temp. indicator. When the actual water

temp. exceeds 60℃, it lights up.

14

E-HEATER MODE indicator. When user sets the

E-heating Mode, it lights up.

7

Water temp. indicator. When the actual water

temp.exceeds 50℃, it lights up.

15

HYBRID MODE indicator. When user sets the

Hybrid Mode, it lights up.

8

Water temp. indicator. When the actual water

temp. exceeds 40℃ it lights up.

16

ECONOMY MODE indicator. When user set the

Economy Mode, it lights up.

2.2.3 Operation

OFF timer

used to set the

DOWN ke

y,

used to abate

time or temp.

UP key,

used to add

time or temp.

MODE ke

y,

used to set

di

fferent modes

CANCE

L key,

used to canel

timer and lock

CLOCK ke

y,

used to set

time.

ON\OFF ke

y,

used to turn the

unit on or o

ff

34

Page 34

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.2.4 Operation Instruction

2.2.4.1 Preparation before running the unit.

a) When you run the unit for the first time, all the indicators on the UI will light for 3 second, and the

buzzer will “didi” ring twice at the same time, and then, display the fiducially web page. After no

operation for 1 minute, all indicators will go out automatically except Water fill indicator flashing and

Clock indicator lighting. Buzzer will “di” ring when you press it.

b) When the tank is full, please press the ON\OFF key, the Water fill indicator will stop flashing and

you can continue to function other settings. When all settings finished, please press the ON\OFF

key again and the Water fill indicator will go out. And then run the unit.

c) When the unit is running, if there is no operation or malfunction for 20s, the backlight of the display

will go out automatically except Clock indicator and Water fill indicator. If there no operation for

1min, the unit will lock automatically, but the lock indirator would be right all time.

2.2.4.2 Lock and Unlock

In order to prevent wrong operation, a special lock function has been designed. If there is no operation for

1min, the unit will be locked automatically, and display the lock sign (Lock indicator lights up).When the unit

is locked, no keys can be operated.

Press the CANCEL key 3s, the unit will

be unlocked, the LOCK sign disappears

and all keys can be operated normally

2.2.4.3 Clock Setting

The clock is for a 24-hour system and the initial time is 00:00. To make a better use of this unit, it is

recommended to set the time for accurate local time. Every time powered off, the clock will be reset to the

initial time 00:00.Method for time set

35

Page 35

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Stop operation for about 10s, flashing will

stop and clock set is successful.

Press the “UP” and “

DOWN

” key, you can

adjust the hour.

Press the CLOCK key again, the minute

digit stops flashing while the hour digit

starts.

Press the “UP” and “

DOWN

” key, you can

adjust the minute.

Press the CLOCK key, the minute digit of

the clock on the display starts flashing

slowly.

36

Page 36

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.2.4.4 Mode Selection

a) The unit is enhanced with three operation modes, Economy Mode, Hybrid Mode and E-heater

Mode.

b) Economy Mode: The unit heats water only by compressor drive according to heat-pump principle.

Used when the ambient temp. is high.

c) Hybrid Mode: The unit heats water not only by compressor drive but also by electric heater. Used

when the ambient temp. is low or large amount of hot water is needed.

d) E-heater Mode: The unit heats water only by electric heater. Used when the ambient temp. is very

low.

e) By default, the unit operates in Hybrid Mode.

Change:

Press the

MODE

key, operation mode will

be

shifted

among the three modes in a

cycle, meanwhile the corresponding

indicator on the display will light up.

2.2.4.5 Temperature Setting

Temp displayed is the water temp. in the upper part of the tank. Default is 55℃and the setting range is

38~60℃.

Method for set.

Press the"UP" and "DOWN" key, you

can increase and decrease the water

temp setting.

High Temp

When the setting temp is higher than 50

℃

the Temp Operation Hign indicator will light

37

Page 37

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.2.4.6 TIMER

User can set up a running start time and a stop time on a specifically by the timer function. The least

numbers of timer is ten minutes.Time on: User can set up a start time by this. The unit will auto run one time

between the set time and 24:00 on the same day.

Method for set.

and TIMER ON set is finished

Stop operation for about 10s, flashing stops

Press the “UP” and “

DOWN

” key, you can

adjust the hour.

Press the TIMER ON key again, the minute

Press the “UP” and “

DOWN

” key, you can

adjust the minute.

, the minute digit

of the clock on the display starts flashing

slowly.

Press the TIMER ON key

CANCEL:

In the unlocked status, press CANCEL

key 1s and the TIMER ON function will

be canceled.

2.2.4.7 TIMER ON and TIMER OFF: Users can set up a running start time and a stop time. When the start

time is earlier than the stop time, the unit will run between the set time. When the start time is later than

the stop time, the unit will run between the start time today and the stop time next day.

38

Page 38

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Method for set.

Stop operation for about 10s, flashing

stops and TIMER ON +TIMER OFF

setting are finished.

Press the UP and DOWN key,you can

adjust the hour setting.

Press the TIMER OFF key again, the

minute digit stops flashing and hour

digit starts to flash.

Press the UP and DOWN key,you can

adjust the hour setting.

Press the TIMER OFF key , the minute

digit on the display start to flash slowly.

Press the UP and DOWN key,you can

adjust the hour setting.

Press the TIMER ON key again, the

minute digit stops flashing and hour

digit starts to flash.

Press the UP and DOWN key,you can

adjust the minute setting.

Press the TIMER ON key, the minute

digit of the clock on the display starts

flashing slowly

39

Page 39

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

CANCEL:

In the unlocked status, press the

CANCEL key for 1s, the TIMER ON

and TIMER OFF fuction will be

canceled.

NOTE:

1) TIMER ON and TIMER OFF can not be set to the same time. If they are the same, the stop time will delay 10 minutes

automatically.

For example,Time on and Time off set to 1:00 at the same time,then the stop time will adjust to 1:10

automatically.

2) TIMER OFF function can not be used alone. The key can be used only after stetted the on time.

2.2.4.8 Power On and Power Off

Press Power On/Power Off button after all the above have finished and the system will run as the setting.

And simply press the same button to stop it.

2.2.4.9 Operation status

The LA code from the screen of set Temp. will appear and remind user when ambience temp. not meet the

opetation condition of heat pump unit(beyond -7~43℃),User can sw-itch the economy mode to E-heating

mode in sure of enogh volume of hot water if need, The unit will return operation pre-status automatically in

no any opetation when the ambie-nce temp. meet the operation condition of heat pump mode and the error

LA will be disappeat at the same time,the screen display nomally.

2.2.4.10 Error Shooting

If some errors happen, the buzzer will buzz 3 times every other minute and the error indicator will glitter fast.

Press CANCEL for several seconds to stop the buzzer but the light will keep glittering.

40

Page 40

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

ALARM

The light will flash with Alarm

Press CANCEL key to stop the buzzer.

The system will display the error code and the water tempera-ture alternatively on the display in error.

The water temperature and error

code will display alternatively

OUTLET T

41

Page 41

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

When error happens, though the system could be used in some circumstances, it could not reach the

expected efficiency. Please contact your supplier for help. Error Code Explanation (See table below table)

Display Malfunction Description Display Malfunction Description

E0 Error of sensor T5U P1

System high pressure protection

≥3.0MPa active;

≤2.4Mpa inactive

E1 Error of sensor T5L P2

High discharge temp. protection

Tp>115℃,Protection active

Tp<90℃,Protection inactive

E2

Tank and Wired Controller communication

error

P3

Open compressor circuit protection

(PCB current_induction_circuit check there

is no current (I<1A)

E4

(T3) Condenser output pipe temperature

sensor error

P4

Compressor overloaded protection (10 secs after

compressor startup, Current checking starts , If it

is over 10A lasting for 2sec or over 12A, the

compressor will be stopped and protected.)

On hybrid mode, when T4<12℃,as well as hot

water is consumed too fast, compressor &

element will start at the same time, under this

condition, if current I>32A, system consider it as

current overload protection, shows P4 Or P9

E5

(T4) Outdoor ambient temperature sensor

error

P8

When there is no current on element circuit,

consider it as element open circuit

protection, shows P8, when system OFF,

protection inactive

E6 (Tp) Comp. discharge Sensor error P9

When there is more than 16A current on

Element circuit, Element overload current

protection active, inactive when system OFF

E7

Heat Pump system error

If any of P3/P4/P2/P1 continuously appear

3 times within single heating cycle, system

will consider it as “Heat Pump system

error”

LA

When the ambient temp is out of Heat Pump

running zone [-7~43℃],Heat Pump will stop ,then

LA protection code will appear, and ALARM

indicator flashes if the condition maintain more

than 20hr, Need to switch to Enhanced heating

Mode.

E8

Electric leakage error

If PCB current_induction_circuit check the

current difference between L,N >14mA,

system consider it as” electric leakage

error”

E9 (Th) Comp. suction Sensor error

42

Page 42

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.3 Running and Operating

2.3.1 Trial Running

1) Before running, please check the following items first:

2) Correct installation of the system;

3) Correct connection of pipeline and wiring;

4) Leakage of the refrigerant pipeline tested;

5) Efficient drainpipe;

6) Complete insulation protection;

7) Correct earthing;

8) Correct power supply;

9) No obstacle outside the air inlet and outlet;

10) No air in the water pipeline and all valve opened;

11) Effective electric leakage protector;

12) Sufficient inlet water pressure(≥0.15MPa)

43

Page 43

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

2.4 Refrigerant figure

2.4.1 System Piping figure

T

3

T

4

T

p

4

-

way valve

Tup

EEV

T5L

T

h

Water outle

t

Secondary heat

source inle

t

Seconde heat

source outlet

Water inlet

Element

Dryer

High pressure switc

h

Evaparator

Condenser

compressor

Compressor: Mitshubishi RB233GRDC, R134a;Element: located in the mid of tank, 3000W/230VAC;

TCO (Temp. Switch): when water Temp. >80, switch OFF, when water Temp. <60, switch ON;

High Pressure Switch: switch OFF when 3.0MPa; switch ON when 2.4MPa;Fan: Centrifugal type,

220V—240V/50Hz,3 Speeds; EEV: Sanhua Φ1.3 EEV; 4-Way Valve: Hualu STF-02BN2

Compressor crankcase belt heater: DJRD-390A-1300-25W; Wire controller(Optional):KJR-90B

manometer (High Pressure Switch)

1 202301800820

Discharge temp sensor ass'y (Tp)

1 202301300130

room temp sensor ass'y (T4)

1 202301300196

Temp.sensor ass'y (T3)

1 202301300437

Temperature sensor (Th)

1 202301300303

senor ass'y, for the pipe (T5L)

1 202301300485

senor ass'y, for the pipe (T5Up)

1 202301300486

Relay of Elment & Compressor

2 202300800003

TCO(turn off temp. 85±3°C,manually recovery)

1 202301610028

TOD Auto Recovery, turn off temp.78±3°C,Recovery

temp 68±3°C。

1 202301600046

2.4.2 System I/O figure

44

Page 44

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

PCB

Evaporator Temp. T3

Ambient Temp. T

4

Discharge Temp. T

p

Suction Temp. T

h

Upper tank Temp. T5

U

Lower tank Temp. T5

U

Electric control box temp.(preserved)

High pressure protectio

n

Remote On/Off signal input(preserved)

Middle tank temp.(preserved

)

Wire

controlle

r

Display

Panel

Comp.

4-way valve

Fan motor (3 speed)

Comp. heate

r

EEV

Element

Element(preserved

)

Electric control box fan (preserved

)

Remote On/Off signal output(preserved

)

2.4.3 Fan motor speed control

Fan motor speed has 3 levers, High, Middle, Low speed;

Fan motor will start with high speed 30s in advance of the start of compressor;

After staring, Fan motor speed will be regulated by Tp ( Compressor discharge temperature) with

following logic

100

105

Tp

95

Stop Fan

Degrade Fan Speed

Maintain Current Fan Speed

Fan motor will stop 30s behind of the stop of compressor

2.4.4 Defrosting during Water-heating

Conditions to activate defrosting cycle

When T3 ≤0℃, Comp. is continually running for 40min

45

Page 45

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

(If Comp. restart frequently, which can only run within 10 min. for each start cycle, system will count

accumulated running time, when accumulated running time reaches 40min, defrosting cycle will activate 2

min. after Compressor’s next start

Conditions to inactivate defrosting cycle (when achieve any one of following conditions)

1. Defrosting time reaches 10 min;

2. T3≥15℃;

Main components’ movement when defrosting

4-way valve

Comp.

fan

EEV

Previous opeing degre

e

Previous opening degree

Max. defrosting time 10 Min

EEV stay 480P opening degree when defrosting, 4min after defrosting EEV start regulating

2.4.5 Ambient Temperature

a) The system’s operation temperature is within -30~43℃ and below are the operation temperature for

each mode.

b) Economy Mode: -7~43℃

c) Hybrid Mode: -30~43℃

d) E-heater Mode: -30~43℃

2.4.6 Self-Protection Detection

a) When the self-protection happens, the system will be stopped and start self-check, and restart when the

protection resolved;

b) When the self-protection happens, the buzzer will buzz in every other minute, the Warning indicator

glitter and the display indicate the error code and water temperature alternatively. Press CANCEL

button for 3sec to stop the alarm. All stop when he protection is resolved and error code disappears on

the display.

c) In the following circumstances, self-protection starts:

Air inlet or outlet is obstacles;

The heat exchanger is covered with too much dust;

Incorrect power supply (exceeding the range of 220±10%)

NOTE: When self-protection happens, cut the power supply manually and restart after the error resolved.

2.4.7 Water Temperature Display

a) The temperature on the display is the water temperature in upper part of water tank (over 1/4) which you

will use, but not that of all the water.

46

Page 46

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

47

b) The 6 indicators beside the water temperature on the display are the lower part water temperature.

When the temperature is 15℃ lower than the set temperature, the blue one will light up; when 10℃

lower, the blue and yellow ones light up; when 5℃ lower, the blue, yellow and red ones light up and

when all light up, the water temperature has reached the set point.

c) In water using, the temperature of the lower part may decrease while the upper part still keeps a high

one, and the system will start heating the lower part. And it is normal.

7 Error Shooting

a) When common error happens, the system enters Standby Mode and could still work, but not so efficient

as normal. Please contact the technician.

b) When serious error happens, the system will be unable to carry on. Please contact the technician.

c) When error happens, the buzzer will buzz in every other minute, the Warning light glitter and the display

indicate the error code and water temperature alternatively. Press CANCEL button for 3sec to stop the

alarm.

2.4.8 Restart after Long Stop

When the system is started after a long time (trial running included), it is normal if the outlet water is unclean.

Keep the tap on and it will be clean soon.

Page 47

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

3. PCB explanation

48

2.5 PCB I/O Ports description

Crank Heater

4-way valve

L、N

Transformer

Input

Transformer

Output

Wire Controller

Power Supply

Output

Panel

Display

output

Panel Display

Button input

Wire controller

Communication

T4 : Ambient

Temp. Sensor

T3: Evaporator

output Temp.

Senso

r

T5_U: Upper tank

water Temp. senor

T5_L: Lower tank

water Temp. senor

Tp: Comp

discharge Temp.

senor

Th: Comp Suction

Temp. senor

Preserved

Remote On/OFF input from Solar

pre-warming system

low electrical level signal means ON

High electrical level signal means

OFF

Remote On/Off Response

High electrical level signal

means HPWH ON

Low electrical level signal

means HP OFF

High-Pressure

switch

EEV

Fan

SW2 Factory setting

for Auto-restart &

element model

selection

SW3 Factory setting

for Element On/Off

Page 48

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

49

Wiring explanation

MCAC-R

Page 49

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

3.2 SW2/SW3 SETTING

3.3 Self-checking function

How to get in self-checking function?

Press 2 buttons together: “Cancel” + “Clock”

No

.

Hour

Low

bit

Min.

High

bit

Min.

Low

bit

Ts

High

bit

Ts

Low

bit

Tank

Te mp .

Low

Tank

Te mp .

High

Explanation

50

Page 50

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

bit bit

0

Temp. valve T5L

1

Te m p . v a l ve T 5 U

2

Te m p . va l v e T4

3

Te m p . va l v e T3

4

Te m p . va l v e Tp

5

Te m p . va l v e Th

6 X X Current valve

XX: COPM; Upper Element;

Lower Element

7

Opening

degree

EEV opening degree, 8 times to real value

8 X

Running mode::

Economy, Hybird,

E-heater, Close

9

X

Fan speed:

stop, High, Mid,

Low

10

X

Model:

domestic type; oversea type

11

X X Previous 1

st

error or protection code

12

X X Previous 2

nd t

error or protection code

13

X X Previous 3

rd

error or protection code

14 Y M M D D Software version, record by date

4 Maintenance

4.1 Maintenance

3.1.1 Check the connection between power supply plug and socket and ground wiring regularly;

3.1.2 In some cold area (below 0℃), if the system will be stopped for a long time, all the water should be

released in case of freezing of inner tank and damage of e-heater.

3.1.3 It is recommended to clean the inner tank and e-heater regularly to keep an efficient performance.

51

Page 51

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

3.1.4 Check the sacrificial anode every half year and change it if it has been used out. For more details,

please contact the supplier or the after-sale service.

3.1.5 It is recommended to set a lower temperature to decrease the heat release, prevent scale and save

energy if the outlet water is sufficient.

3.1.6 Clean the air filter every month in case of any affect on the heating performance.

3.1.7 Before shutting the system down for a long time, please: Shut down the power supply; Release all the

water in water tank and the pipeline and close all the valves; Check the inner components regularly.

4.2 Non-error Malfunction

3.2.1 3-min Protection With the power supplied, an immediate restart after the shutting down will have to

wait 3 min as to protect the compressor.

3.2.2 If self-protection happens and the system stops, check :

When the power indicator lights up, if the system is forced to run while startup requirement has not been met;

If the air outlet or inlet is jammed or strong wind blows to air outlet.

3.2.3 Defrosting

When it is humid and cold, the condenser may defrost and the water-heating capacity decrease. And the

system will stop heating water and start defrosting and then restart water-heating

3.2.4 During defrosting, the compressor keeps running but reverse to defrosting cycle while fan motor stops;

3.2.5 The defrosting time varies from 3min to 10min according to the ambient temperature and the frost.

4.3 Temperature Display

3.3.1 When the system stops, a decrease of the temperature is normal as heat released. When it decreases

to some point, the system will restart automatically;

3.3.2 During water-heating, the displayed water temperature might still decrease or not increase for a period

of time because of the heat exchange of the water. When the whole tank of water has reached the set

temperature, the system will stop automatically.

52

Page 52

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

5 Malfunctions and Resolutions

Malfunction Cause Resolutions

Outlet water

is cold.

The display

is dark.

Bad connection of power supply

plug and socket;

Outlet water is set an a low

temperature;

Outlet water temperature

controller is damaged;

Circuit board of indicating

indicator is damaged;

Reconnect the plug;

Set outlet water an a

higher temperature;

Contact the technician.

No hot

water from

the outlet.

Tap water has been cut away;

Water pressure is too low;

Inlet valve has been closed.

It’ll return to normal

after water supplied;

Use it when the

pressure is higher;

Open the inlet water

valve.

Water

leakage

The joints on the pipeline are not

sealed well.

Check and reseal all

the joints.

If the unit occurs any malfunction or error, please shut down the system, turn off the power supply, and

consult your service persons for help.

53

Page 53

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Appendix 1 Temp.—Resistance Table of TP Sensor

54

Page 54

2nd Generation ALL IN ONE Type Heat Pump Water Heater Technical Manual

Appendix 2 Temp.—Resistance Table of T3/T4/Tp/T5Up/T5L Sensor

55

Loading...

Loading...