Page 1

Model:

MFJ-24ARN1-QB8

MFJ-48ARN1-RB6

Floor Standing Type Air Conditioner

Page 2

Content

CONTENT

1

Safety Precautions .......................................................................................... 1

1.1 Precaution .................................................................................................................... 1

1.2 Installation ................................................................................................................... 1

1.3 Caution ......................................................................................................................... 1

1.4 Operational .................................................................................................................. 1

3

Out Dimensions ............................................................................................... 3

3.1 Indoor Unit ................................................................................................................... 3

3.2 Outdoor Unit ................................................................................................................. 4

4

External view and display ............................................................................... 5

4.1 External view ................................................................................................................ 5

4.2 Display panel ............................................................................................................... 6

5

Refrigerant cycle diagram .............................................................................. 7

5.1 Cooling only .................................................................................................................. 7

5.2 Heat pump mode ......................................................................................................... 7

6

PCB drawing & wiring diagram ...................................................................... 8

6.1 MFJ-24ARN1-QB8 ........................................................................................................ 8

6.2 MFJ-48ARN1-RB6 ........................................................................................................ 9

7

Installation detail ........................................................................................... 10

7.1 Installation place ....................................................................................................... 10

7.2 Installing ..................................................................................................................... 11

7.3 Refrigerant pipe connecting .....................................................................................13

7.4 Drain Pipe of The Indoor Unit ...................................................................................15

7.5 Wiring .........................................................................................................................15

7.6 Test operation ............................................................................................................ 16

8

Electronic function ........................................................................................ 17

8.1 Performance Index .................................................................................................... 17

8.2 Main data Introduction.............................................................................................. 17

8.3 Operation Modes and Functions .............................................................................. 17

8.4 Other Functions .........................................................................................................19

9

Characteristic of temperature sensor ......................................................... 20

10 Trouble shooting ........................................................................................... 21

10.1 Protective Function .................................................................................................... 21

10.2 Self-diagnosis ............................................................................................................ 21

10.3 Troubles and Solutions ............................................................................................. 22

Page 3

Safety Precautions

1

1 Safety Precautions

1.1 Precaution

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

Incorrect operation due to ignoring instruction will cause harm or damage.

Before service unit, be sure to read this service manual at first.

1.2 Installation

For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized service

center.

Do not disassemble or repair the product by yourself.

Sharp edges could cause injury, be especially careful of the case edges and the fins on the

condenser and evaporator.

Be sure the installation area does not deteriorate with age.

Take care to ensure that power cable could not be pulled out or damaged during operation.

Do not place anything on the power cable.

Do not plug or unplug the power supply plug during operation.

Do not store or use flammable gas or combustible near the product.

When flammable gas leaks, turn off the gas and open a window for ventilation before turn the

product on.

If strange sounds, or small or smoke comes from product. Turn the breaker off or disconnect the

power supply cable as soon as possible.

When the product is soaked (flooded or submerged), contact an Authorized service center.

Be caution that water could not enter the product.

Turn the main power off when cleaning or maintaining the product.

When the product is not be used for a long time, disconnect the power supply plug or turn off the

breaker.

1.3 Caution

Always check for gas (refrigerant) leakage after installation or repair of product.

Install the drain hose to ensure that water is drained away properly.

Keep level even when installing the product.

Do not install the product where the noise or hot air from the outdoor unit could damage the

neighborhoods.

Use two or more people to lift and transport the product.

Do not install the product where it will be exposed to sea wind (salt spray) directly.

1.4 Operational

Do not expose the skin directly to cool air for long periods of time. (Do not sit in the draft).

Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a

consumer air conditioner, not a precision refrigerant system.

Do not block the inlet or outlet of air flow.

Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

Page 4

Safety Precautions

2

Do not touch the metal parts of the product when removing the air filter. They are very sharp.

Do not step on pr put anything on the product. (outdoor units)

Always insert the filter securely. Clean the filter every two weeks or more often if necessary.

Do not insert hands or other object through air inlet or outlet while the product is operated.

Do not drink the water drained from the product.

Use a firm stool or ladder when cleaning or maintaining the product.

Replace the all batteries in the remote control with new ones of the same type. Do not mix old

and mew batteries or different types of batteries.

Do not recharge or disassemble the batteries. Do not dispose of batteries in a fire.

If the liquid from the batteries gets onto your skin or clothes, wash it well with clean water. Do not

use the remote of the batteries have leaked.

Page 5

Outer Dimensions

3

2 Out Dimensions

2.1 Indoor Unit

Dimension

Mode

Width

(mm)

Height

(mm)

Depth

(mm)

24K 500 1700 290

48K 540 1825 410

Page 6

Outer Dimensions

4

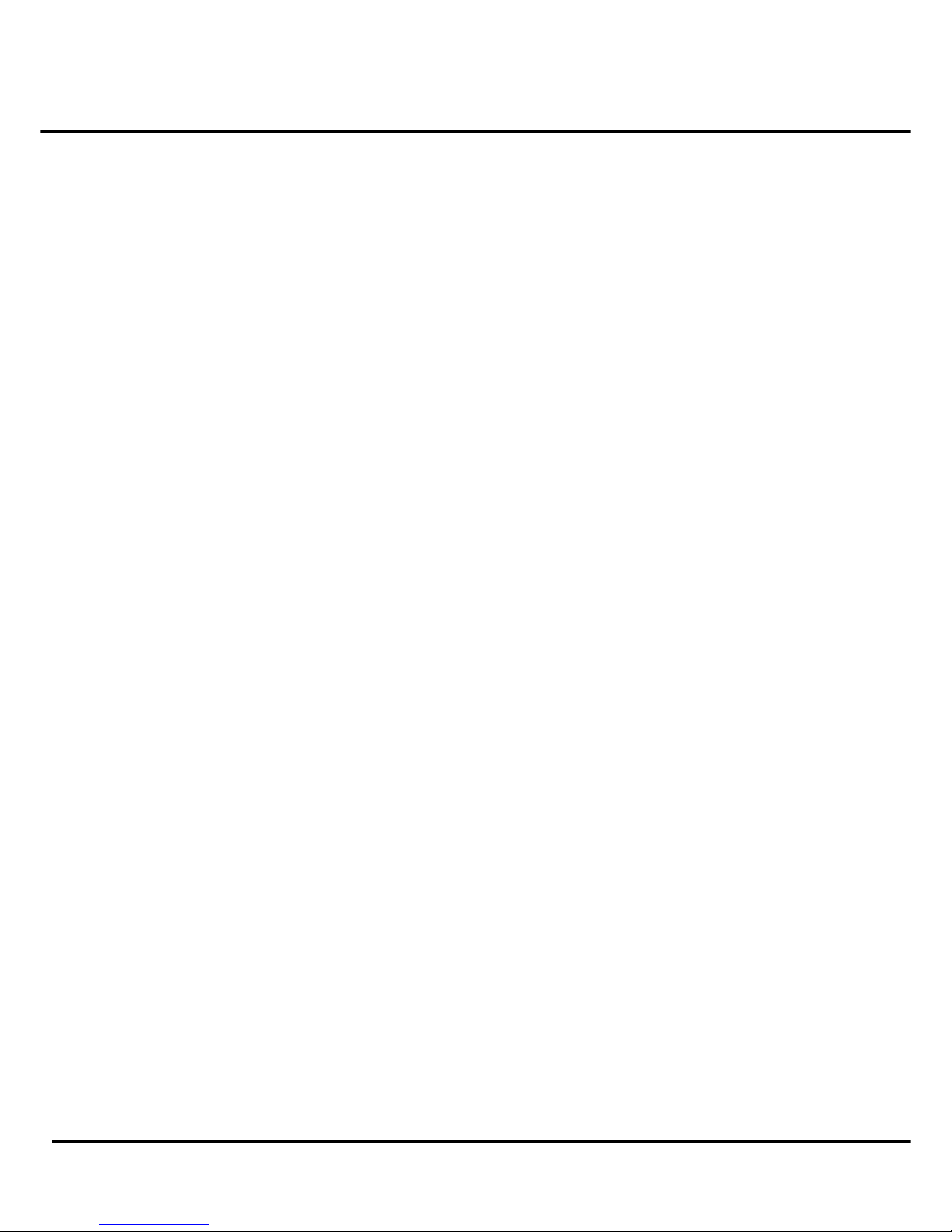

2.2 Outdoor Unit

Dimension

Mode

W idth

(mm)

Height

(mm)

Depth

(mm)

A

(mm)

B

(mm)

24K

840

695

335

560

335

Dimension

Mode

W idth

(mm)

Height

(mm)

Depth

(mm)

A

(mm)

B

(mm)

48K

940

1245

360

602

380

Page 7

External view and display

5

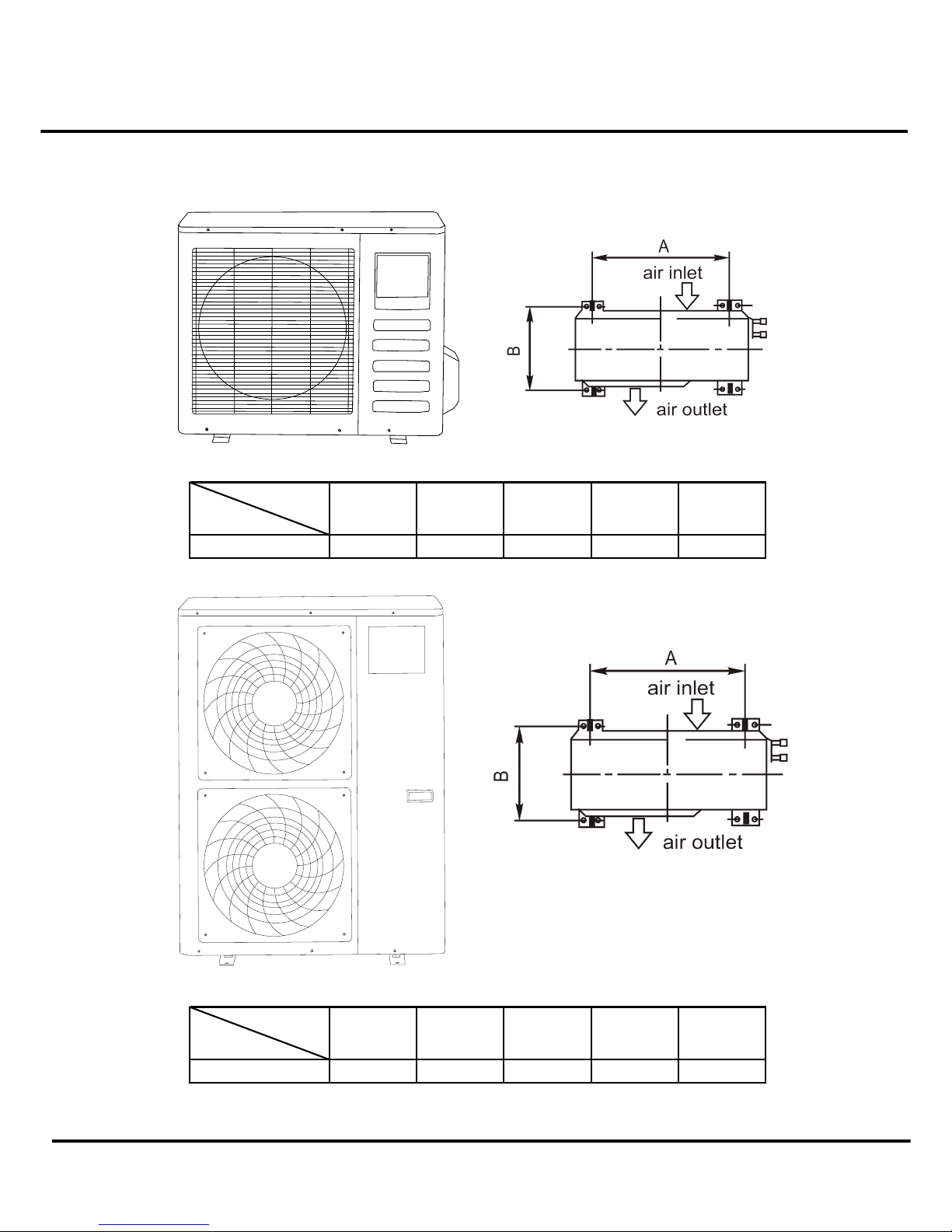

3 External view and display

3.1 External view

1

2

3

4

5

6

7

8

11

10

9

Ou tdoor unit

1

Air outle t

2

Operation panel

3

Hori zo ntal airf lo w co nt ro l l ouve r

4

Vertical ai rflo w co ntr ol louve r

5

Remote con troller holder( on so me mod els)

6

Air inl et(2 sides )

7

Drain pi pe , vent pip e

8

Co nn ectio n cabl e

9

Co nn ectio n pipe

10

Refrigerant pipe po rt

11

Air outlet

In door un i t

Note: All the pictures in this manual are for explanation purpose only. They may be slightly

different from the air conditioner you purchased(depend on model). The actual shape shall prevail.

Page 8

External view and display

6

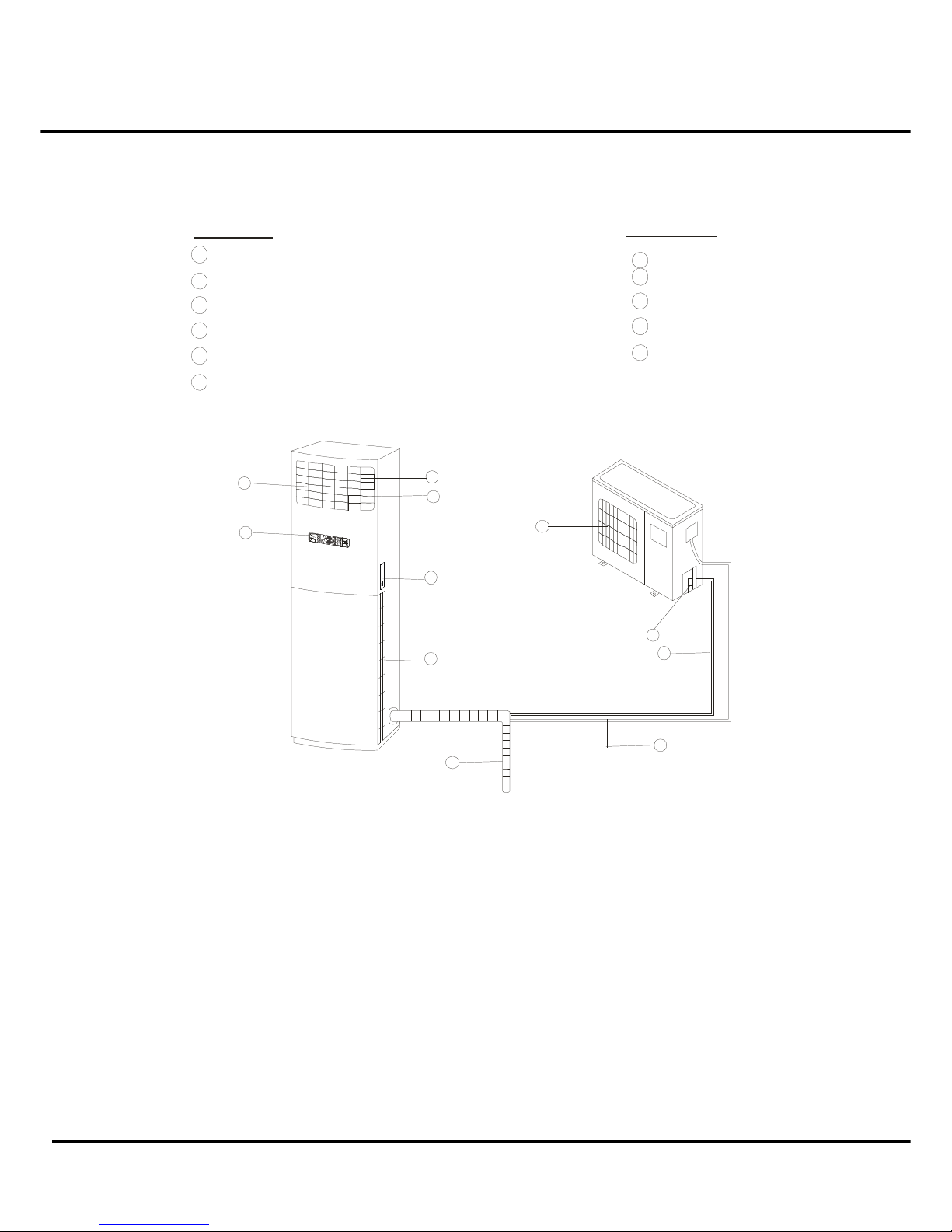

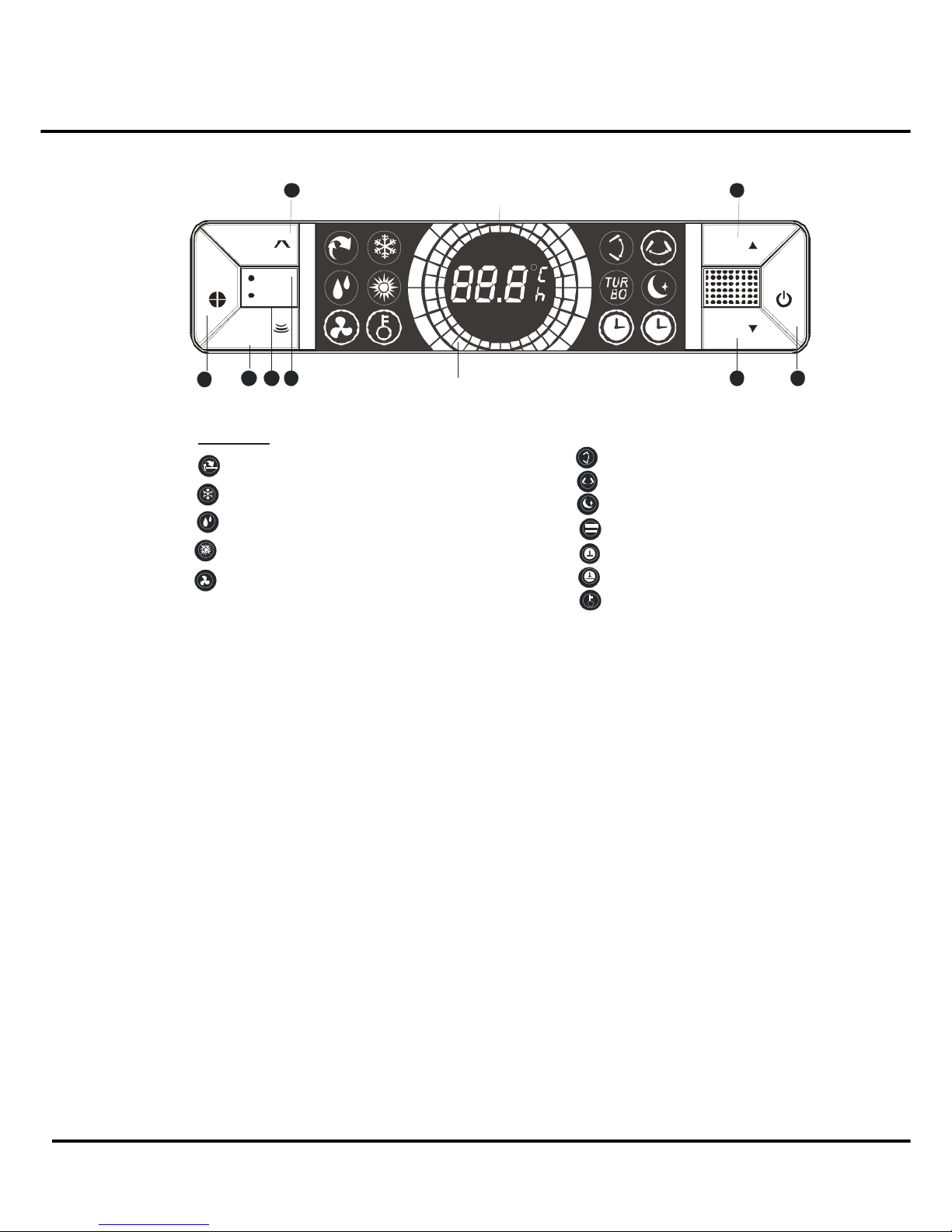

3.2 Display panel

au to

T2

T3

T4

T1

OFF

ON

AUX IL IARY

FU NCT ION

M ODE

FA N

S PEED

A DJU ST

M ODE

A DJU ST

LOCK

TE ST

RUN NING

ON /OF F

1

2 3 4 5 6

57

In di c ators

Auto op eration display

Co ol ing op er at ion d i sp l ay

Dry op era tio n display

Heating operati on di sp lay

Fa n op era tion di s play

Vert ical ai r f low di spl ay

Hor i zontal airflo w disp lay

Slee p opera ti on display

Turbo ope rat io n displa y

On t imer op eration display

Of f timer operati on dis play

Loc k oper a tion di s pl ay

Fa n spe ed

operat io n display

Room Te mp/Set Temp

/Set Tim er displa y

Page 9

Refrigerant cycle diagram

7

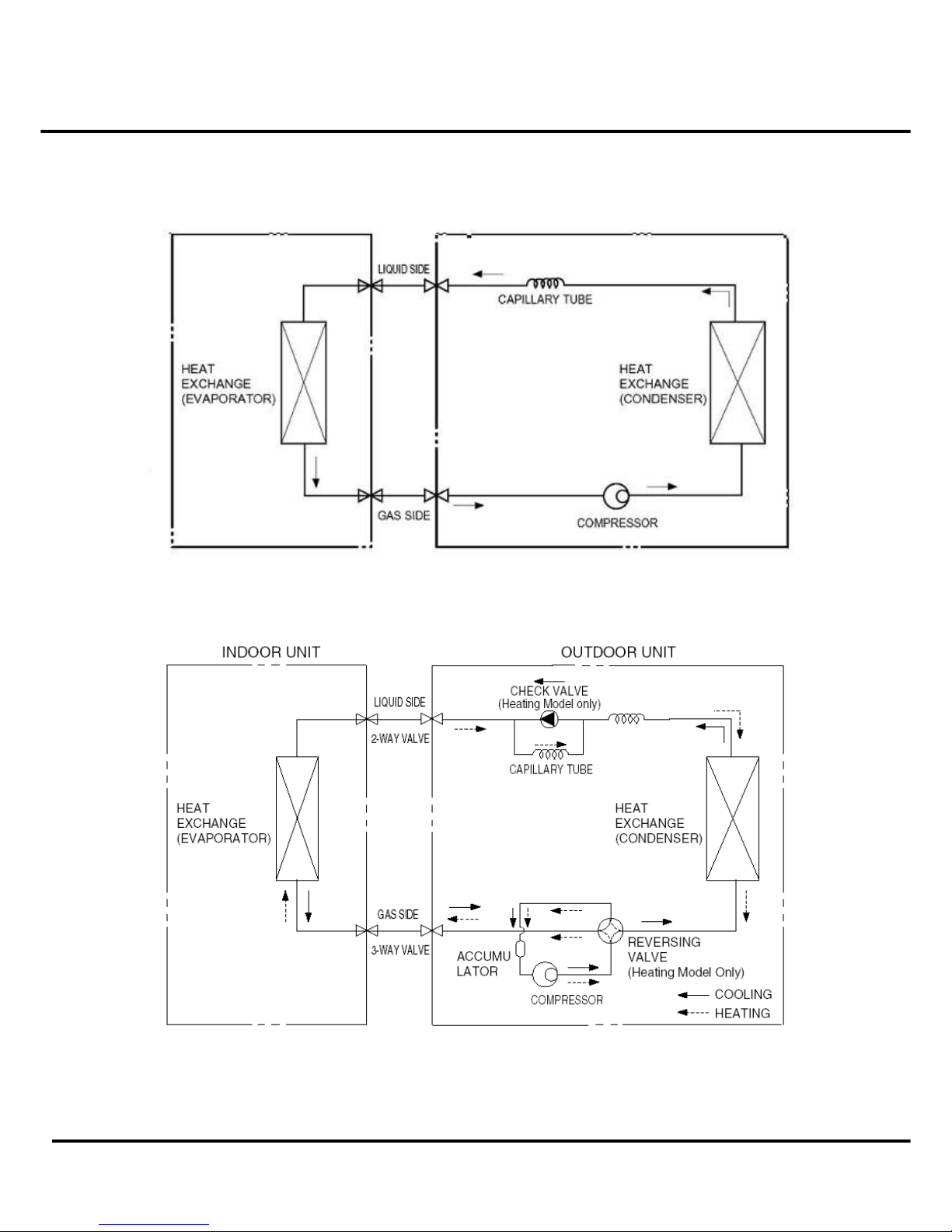

4 Refrigerant cycle diagram

4.1 Cooling only

4.2 Heat pump mode

Page 10

PCB drawing & Wiring diagram

8

5 PCB drawing & wiring diagram

5.1 MFJ-24ARN1-QB8

Indoor unit

Outdoor unit

Page 11

PCB drawing & Wiring diagram

9

5.2 MFJ-48ARN1-RB6

Indoor unit

Outdoor unit

Page 12

Installation detail

10

6 Installation detail

6.1 Installation place

6.1.1 Indoor Unit

A place which provides the spaces around the indoor unit as required above in the diagram.

A place where is no obstacle near the inlet and outlet area.

A place which can bear the weight of the indoor unit.

A place which allows the air filter to be removed downward.

A place where the reception range is not exposed to direct sunlight.

In the center of the room where possible.

6.1.1.1 Please stand the unit in hard and flat ground;

Please reserve space for installation and maintenance.

6.1.1.2 Please check the elevation difference between the indoor unit and the

outdoor unit, the length of the refrigerant pipe, and the curved places (bend) of

the pipe are no more than the following numbers:Elevation difference: no more

than 10 M (if the elevation difference between indoor and outdoor unit is more

than 10 meters, it is recommended that the outdoor unit be placed above

the indoor unit.)

Pipe length: no more than 20 M

Bends: no more than 5 places

6.1.2 Outdoor Unit

6.1.2.1 Before installing the outdoor unit, you should:

Select a place where no direct sunlight or other heat-radioactivity may reach. A sunshade is

needed if it is unavoidable.

Select a place that is easy to connect indoor unit's pipe and electric wires.

Avoid a place where combustible gas may leak or stay.

Keep it in mind that water may drain out of the outdoor unit while in "Heat" mode.

Page 13

Installation detail

11

6.1.2.2 If the outdoor unit is to be installed on a roof or where no constructions are

around, you should avoid hard wind blows directly to the air outlet, because it

may cause trouble for air-flow shortage.

6.1.2.3 Reserve enough space for installation, maintenance and unit-functioning.

Remove as many obstacles as possible nearby.

6.2 Installing

6.2.1 To prevent the indoor unit from falling, you must:

Pay full attention to the unit because its long outer shape makes it easy to fall;

Safety Lock

Screws

3.9 25

×

M8 Screws

Screws

3.9 25

×

Air Outlet

Air Inlet

Screw hole

(on the unit

)

2

Firmly fix the unit to the wall and in the ground to avoid accidental falling.

6.2.2 Dismounting the air-inlet grid

Please take off the air-inlet grid before connecting the pipes/wires.

Pull down the two knobs on the grid, take off the two screws, then the air-inlet grid goes free.

Page 14

Installation detail

12

6.2.3 Take the Pipe Clip off before connecting the pipes and wiring; fit it when these

finished.

Use accessories 4 and 9 to connect the pipes/wires on both sides and back side.

Drain Pipe

Reamer Joint

Pipe/wire-hole positions on both sides

Wiring

Hole 35

φ

Refrigerant/drain

Pipe hole 80

φ

Reamer Joint

Refrigerant Pipe

Pipe/wire-hole position on the bottom

Wiring

Hole 35

φ

Refrigerant/drain

Pipe hole

Refrigerant/drain

Pipe hole

6.2.4 Ship the a/c to the installation place originally packed;

Be careful while hanging the unit because the center of gravity of the unit is not centralized;

Do not make the angle of inclination more than 45 degrees while shipping;(Avoid horizontal

storage)

Be sure the electric insulation work is well done if installed on metal ceiling / wall.

Fix the unit feet with bolts (M10/M8). Be sure the unit is fixed strongly enough to against blast or

earthquake.

Page 15

Installation detail

13

Make a concrete basement to the unit by the above references.

6.3 Refrigerant pipe connecting

6.3.1 Pipe length and the elevation

The correct refrigerant quantity filled in the 5-meter-long pipe of the outdoor unit is marked on

the Product Data Plate. If you have to use longer pipe for every meter plus pipe, the refrigerant

should be added according to the following calculation.

Standard

length

Max. Max. A dditional

(m) E lev ation Elev ation refrigerant

Btu/h GAS LIQUID B (m) A (m) (g/m)

24K

5/8’’ (φ16)

1/4’’ (φ9.53)

51020

65

48K

3/4’’ (φ19)

1/2’’ (φ12.7)

51530

90

Pipe sizeC apacity

6.3.2 Piping connection

6.3.2.1 Connecting Of Refrigerant Pipe

a.

Only the correctly installing of indoor and outdoor unit done, can the refrigerant pipe be connected.

b.

The cut-off valves are completely close before ex-work. Before connecting the refrigerant pipe, be

careful to check whether the valves are completely close.

c.

The connecting procedure of refrigerant pipe: first, unscrew the two valves on the outdoor unit and

the pipe-jointing nut on the indoor unit(please keep them care fully). Please connect the refrigerant

pipe according to the manual, the pipe-jointing nut should be screw tightly and no leakage. Note:

you need two wrenches to make balance.

d.

When the connecting of refrigerant pipe is finished, before power on the system, you should

Page 16

Installation detail

14

vacuum the indoor unit through the maintenance port on the cut-off valves, or open the

high-pressure valve, and exhaust the air through the maintenance port on the low-pressure

valve(closed). It will take about ten seconds. Then screw tightly the maintenance port. (When

supplement the refrigerant, fill through the maintenance port of the low-pressure valves on the

outdoor unit ).

e.

Open all the valves completely before power on the system, or it will be sick for low efficiency.

f.

Gas leak check. Make sure no gas from connections with leak detector or soap water.

6.3.2.2 Using bronze pipe selling in market

Completely shut the cut-off valves of the outdoor unit (as ex-work status). After the refrigerant

pipe has been connected with both the indoor and outdoor unit, let the air exhaust out from the

maintenance gap on he low-pressure cut-off valves of the outdoor unit. Screw the nuts tightly

on the maintenance gap after the air has been drained.

6.3.2.3 To make the refrigerant pipe unblocked completely

you should keep the cut-off valves of the outdoor unit completely open after you have finished

the above steps (step1) or step 2))

Note: Before screwing the reamer nut, smear the pipe and the connecting surface with

refrigerant oil; Check and make sure there is no leakage by soap-water or leakage-checker after

connecting;

Be sure the connecting joint on the indoor side is insulated.

Use two wrenches to connecting the pipes.

Tubing size Torque

9.52 3270~3990N.cm(333~407kgf.cm)

12.7 4950~6030N.cm(504~616kgf.cm)

16 6180~7540N.cm(630~770kgf.cm)

19 9720~11860N.cm(990~12106kgf.cm)

6.3.3 Air Purging

When Using the Vacuum Pump

(For method of using a manifold valve, refer to its operation manual.)

a.

Completely tighten the flare nuts, A, B, C, D, connect the manifold valve charge hose to a

charge port of the low-pressure valve on the gas pipe side.

b. Connect the charge hose connection to the vacuum pump.

c. Fully open the handle Lo of the manifold valve.

d. Operate the vacuum pump to evacuate. After starting evacuation, slightly loose the flare nut of

the Lo valve on the gas pipe side and check that the air is entering.(Operation noise of the

vacuum pump changes and a compound meter indicates 0 instead of minus)

e. After the evacuation is complete, fully close the handle Lo of the manifold valve and stop the

operation of the vacuum pump. Make evacuation for 15 minutes or more and check that the

compound meter indicates -76cmHg (-10x106Pa).

Page 17

Installation detail

15

f. Turn the stem of the packed valve B about 45 counterclockwise for 6~7 seconds after the gas

coming out, then tighten the flare nut again. Make sure the pressure display in the pressure

indicator is a little higher than the atmosphere pressure.

g. Remove the charge hose from the low pressure charge hose.

h. Fully open the packed valve stems B and A.

i. Securely tighten the cap of the packed valve.

6.4 Drain Pipe of The Indoor Unit

Make sure the drainpipe is connected to the outdoor side downward;

The hard polyvinyl chloride(PVC)plastic pipe (external diameter 26 mm) sold is the market is

suitable for the attached soft drain pipe;

Please connect the Soft Drain Pipe with the Drain Pipe, then fix it with band;

If you have to connect the Drain Pipe indoors, to avoid condensing caused by air intake, you

must cover the pipe with heat-insulation material (polyethylene with Specific Gravity of 0.03, at least

9 mm in thickness), and use Glue Band to fix it.

After the Drain Pipe has been connected, please check if the water drains out of the pipe

efficiently and has no leakage.

Refrigerant pipe and Drainpipe should be heat-insulated to avoid condensing and

water-dropping later on.

6.5 Wiring

Please refer to the Wiring Diagram.

Page 18

Installation detail

16

(Wiring size: 2.5mm )

≥

2

(Wiring size: 2.5mm )

≥

2

Note: Some models is equipped with a cord having a plug, So a wall outlet shall be properly

installed.

6.6 Test operation

Perform test operation after completing gas leak and electrical safety check. The test operation

time should last more than 30 minutes.

1). Open the panel and lift the panel up to angle which remains fixed. Do not lift the panel any

further when it stops with a "click"sound.

2). Press the manual switch button twice until the operation indicator lights, the unit will operate on

Manual Cool mode.

3). Check if all the functions work well while testing the air conditioner. Especially check whether

the drainage of indoor unit is smooth or not.

4). Press the manual switch button again till the operation indicator turns dark after finishing the

test operation and the unit stops operation.

Page 19

Electronic function

17

7 Electronic function

7.1 Performance Index

No. Item Index

1 Applicable Voltage Range 185-253V, 342-418V

2 A/C Frequency 50Hz

3 Working environment temperature -7°C- +45°C

7.2 Main data Introduction

Ts : Set temperature,

T1 : Room temperature

T2: Evaporator pipe temperature

7.3 Operation Modes and Functions

7.3.1 Manual Operation

7.3.2 Heating Mode

7.3.2.1 Four-way valve opens at once, while defrosting process closes.

7.3.2.2 Condition for the compressor action: (Ts=set temperature, T1=room

temperature)

7.3.2.3 Indoor Fan Action

Anytime remote switchover for fan speed among high/low/auto, anti-cold air function takes

priority.

Auto fan in heating mode

Anti-cold air:

Switchover between fan speed and fine tune can be set according to temperature of evaporator

pipe (T2).

Condition Compressor and outdoor fan

Room temperature up T1-Ts=0°C Off

T1-Ts>-1°C On

Room temperature down T1-Ts<-1°C On

T1-Ts=0°C Off

Condition Fan speed

Room temperature up T1-Ts>-1°C Low

T1-Ts<-1°C Hi.

Room temperature down T1-Ts<-2°C Hi.

-2°C <T1-Ts <-1°C Low

Condition Fan speed

Room temperature up T2<25°C Off

25°C <T2<32°C Low

T2>32°C Set fan speed

Room temperature down T2>22°C Set fan speed

20°C <T2<22°C Low

Page 20

Electronic function

18

7.3.3 Defrost (only available to heating mode)

7.3.3.1 Defrosting Conditions

Starting Of Defrosting Condition (meet one of the following is ok):

(1)Accumulated compressor operating time when temperature of outdoor heat exchanger coil

T3 is below -2°C reaches up to over 46 minutes.(When T3 is over 20°C, calculate time again.)

(2) Under evaporator high temperature protection, the accumulated time when outdoor fan

motor is off and compressor is on reaches up to over 90 minutes .(When T3 is over 20°C, calculate

time again.)

High temperature defrosting condition:

Under high temperature protection of evaporator, the time when outdoor fan is shut down but

compressor is not has been accumulated for up to 90 minutes.

7.3.3.2 Defrosting Action

Four-way valve, indoor fan, outdoor fan are shut down. Compressor keeps on.

7.3.3.3 Ending Of Defrosting Condition (meet one of the following is ok):

(1)Time of defrosting lasts 10 minutes.

(2)Temperature of outdoor coil T3 is up to 20°C.

7.3.4 Cooling Mode

7.3.4.1 Four-way valve is closed.

If four-way valve is open before the machine enters cooling mode, then four-way valve will be

closed at the first time, the compressor starts under the cooling mode.

7.3.4.2 Conditions for the compressor and outdoor fan action (Ts = set temperature)

7.3.4.3 Action of Indoor Fan

HIGH/LOW/AUTO fan can be switched over by your comfort.

Auto fan under cooling mode.

7.3.5 Dehumidifying Mode

7.3.5.1 Indoor fan speed is low.

7.3.5.2 If certain protective condition is met, operation will be carried out.

T2<20°C Off

Condition Compressor and outdoor fan

Room temperature up T1-Ts=0°C Off

T1-Ts>1°C On

Room temperature down T1-Ts>0°C On

T1-Ts=0°C Off

Condition Fan speed

Room temperature up T1-Ts>2°C Hi.

1°C < T1-Ts <2°C Low

Room temperature down T1-Ts>1°C Hi.

T1-Ts <1°C Low

Page 21

Electronic function

19

7.3.6 Auto Mode

7.3.6.1 Under auto mode, the indoor fan is set to be auto.

7.3.6.2 When entering auto mode, the heating, fan only or cooling operation will be

automatically chosen according to the room temperature T1 and the set

temperature Ts.

Condition Mode

T1-Ts>1°C Cooling

-1°C< T1-Ts<1°C Fan

T1-Ts<-1°C Heating(fan for cooling only type)

7.3.6.3 After one mode is chosen, if the condition lasts for 15 minutes, meanwhile the

compressor doesn't start up within consecutive 15 minutes, the operation mode

will be re-chosen according to the T1and Ts.

7.3.6.4 If certain condition is met, then the corresponding protective function will be

executed.

7.3.7 Fan Only Mode

7.3.7.1 Under this mode, four-way valve, compressor and outdoor fan are shut down.

7.3.7.2 High/Low/Auto fan can be switched over through manual control. Auto fan will

be controlled in line with cooling auto fan with temperature set to be 24C.

7.4 Other Functions

7.4.1 LCD display

Mode, Set temp.,fan speed, time, timer, protection etc.

7.4.2 Timer

The machine should be provided with max. Interval of 24h and min. resolution ratio of 15

minutes.

Page 22

Characteristic of temperature sensor

20

8 Characteristic of temperature sensor

Temp.℃Resistance KΩ Temp.℃Resistance KΩ Temp.℃Resistance KΩ

-10 62.2756 17 14.6181 44 4.3874

-9 58.7079 18 13.918 45 4.2126

-8 56.3694 19 13.2631 46 4.0459

-7 52.2438 20 12.6431 47 3.8867

-6 49.3161 21 12.0561 48 3.7348

-5 46.5725 22 11.5 49 3.5896

-4 44 23 10.9731 50 3.451

-3 41.5878 24 10.4736 51 3.3185

-2 39.8239 25 10 52 3.1918

-1 37.1988 26 9.5507 53 3.0707

0 35.2024 27 9.1245 54 2.959

1 33.3269 28 8.7198 55 2.8442

2 31.5635 29 8.3357 56 2.7382

3 29.9058 30 7.9708 57 2.6368

4 28.3459 31 7.6241 58 2.5397

5 26.8778 32 7.2946 59 2.4468

6 25.4954 33 6.9814 60 2.3577

7 24.1932 34 6.6835 61 2.2725

8 22.5662 35 6.4002 62 2.1907

9 21.8094 36 6.1306 63 2.1124

10 20.7184 37 5.8736 64 2.0373

11 19.6891 38 5.6296 65 1.9653

12 18.7177 39 5.3969 66 1.8963

13 17.8005 40 5.1752 67 1.83

14 16.9341 41 4.9639 68 1.7665

15 16.1156 42 4.7625 69 1.7055

16 15.3418 43 4.5705 70 1.6469

Page 23

Exploded view & spare-part

21

9 Trouble shooting

9.1 Protective Function

9.1.1 3-minute delay for the compressor start-up

At the beginning of energizing or after the stop of the compressor, 3-minute delay will be needed

to start the compressor.

When switching over between cooling/heating mode, the compressor stops automatically.

9.1.2 Evaporator protection against high temperature

9.1.2.1 Only available under heating mode.

9.1.2.2 The operation principle is as follows: (T2 = evaporator temperature)

Condition Outdoor fan Compressor

T2>56°C Off On

T2>62°C Off Off

T2<62°C On Off

T2<50°C On On

Note: During protection, the indoor fan continues operating at a set speed, while the anti-cold air

function of heating and the compressor will be 3 minute delayed to shut down for protection.

9.1.3 Evaporator Protection against low temperature

9.1.3.1 Only available under cooling and dehumidifying status.

9.1.3.2 Protection principle:

Condition Outdoor fan Compressor

T2<2°C(last 3 minute) Off Off

T2>8°C On On

9.1.3.3 The restart of the compressor shall execute the delay protection.

9.1.4 Condenser high temperature protection

9.1.4.1 Only available to cooling and dehumidifying mode.

9.1.4.2 Action condition

Condition Outdoor fan Compressor

Condenser temp.>62°C Off Off

Condenser temp.<48°C On On

9.1.4.3 Delay protection should be performed when the compressor restarts.

9.1.5 Outdoor protection

When outdoor protection signal is high level, outdoor unit will perform protection: the whole

machine will be shut down while the indoor unit will indicate the corresponding protection signal.

The A/C will recover if outdoor errors are eliminated after the outdoor protection occurs.

9.2 Self-diagnosis

Codes Contents

P4 Protection of temperature of indoor evaporator

P5 Protection of temperature of outdoor condenser

P9 Protection of defrosting or anti-cold wind

E1 Open-circuit and short-circuit of temperature sensors T1

E2 Temp. sensor T2 on indoor evaporator is open circuit or short circuit

Page 24

Exploded view & spare-part

22

E3 The condenser temperature sensor T3 is open or short

E6 Protection of outdoor unit

9.2.1 LEDs for the indication of outdoor trouble

In normal operation, LEDs emit no light and they will flash at a frequency of 5 Hz when trouble

occurs. Their codes are listed in the following table:

LED1 LED2 LED3 Contents

Off Off On Ok

On Off On Phase sequence error

Off On On Overload of current

On On On Lack of phase

9.3 Troubles and Solutions

Before calling for service, please review the following list of common problems and solutions.

If any of the following conditions occur, check your unit and resolve corresponding problems referring

to given remediation. If the trouble can't be settled contact our dealer.

Trouble Cause Solutions

Unit does not start Power failure. Wait for the comeback of power

Power switch is open. Switch on the power

Fuse of power switch may have blown. Replace the fuse

Batteries remote controller are exhausted. Replace the batteries

The time is not start-up time you have set. Wait or cancel the time set.

Air flowing normally

with low

cooling(heating)

effect

Temperature is not set correctly. Set the temperature properly.

Door or window is open. Close door and window.

Air filter is blocked with dust or dirtiness. Clean the air filter.

Inlet/outlet of indoor/outdoor units are

blocked.

Clear all blockages.

Inlet/outlet of indoor/outdoor units are

blocked.

Clear the blockage, then restart

your operation.

Be in 3 minutes protection of compressor Wait

Page 25

Exploded view & spare-part

23

Number Display code Problem What to do

1 E1 E2 E3 E4 Temperature Sensor is off or short-circuit. Contact service people

2 E6 Outdoor unit protection Contact service people

3 E8 Electrostatic dust collection Contact service people

4

P4

The temperature of the evaporator of indoor

unit is too low or high (For the protection

feature, the compressor turns off

automatically)

Turn off the unit, clean the air

filter, then restart the unit. If this

operation does not work, please

contact service people.

5

P5

The temperature of condenser of the

outdoor unit is too high (For the protection

feature, the compressor turns off

automatically)

Turn off the unit, check if there is

any obstacle in the air-inlet,

otherwise call the service people.

6 P9 Defrosting protection or warm-air

controlling is off

The unit will auto restart after

finishing the defrosting or the

temperature of the Heat

Exchanger of indoor unit raise.

Page 26

Exploded view & spare-part

24

Specification

Model

ModelModel

Model

MFJ-24ARN1-QB8 MFJ-48ARN1-RB6

Factory Code

Factory CodeFactory Code

Factory Code

2T004330T031 2T004370T020

Electrical Data

Electrical DataElectrical Data

Electrical Data

Power supply Ph-V-Hz

1φ,220-240V,50HZ 3φ,380-420V,50HZ

Capacity

Cooling/Heating

Btu/h

24000/27000+7200 46000/49000+12000

Power consumption

Cooling/Heating

W

2500/2450+2100 5200/5100+3500

Rated current Coo

ling/Heating

A

12/11.5+9.6 8.6/8.5+5.6

EER

Cooling/Heating

Btu/w.h

9.5/10.9 8.9/10.2

System data

System dataSystem data

System data

Refrigerant type g

R410A/2000 R410A/4500

Design pressure MPa

4.2 4.2

Air flow m3/h

1100 1750

Noise level

Indoor dB(A)

48 50

Outdoor dB(A)

60 62

Dimension&Weight

Dimension&WeightDimension&Weight

Dimension&Weight

Indoor

Dimension (W*H*D)

mm

500x1700x290 540x1825x410

Packing (W*H*D) mm

615x1805x415 655x1935x555

Net/Gross weight

Kg

41.5/58.5 58/75

Outdoor

Dimension (W*H*D)

mm

840x695x335 940x1245x360

Packing (W*H*D) mm

965x755x395 1018x1380x435

Net/Gross weight

Kg

60/63 104/115

Refrigerant piping

Refrigerant pipingRefrigerant piping

Refrigerant piping

Liquid side/ Gas side mm

Ф9.53/Ф16 Ф12.7/Ф19

Max. refrigerant pipe length m

20 30

Max. difference in level m

10 15

Applicable ambient

Applicable ambientApplicable ambient

Applicable ambient

Ambient temp

℃

-7-45 -7-45

Application area m2

40-56 80-112

Compressor

CompressorCompressor

Compressor

Compressor

Model

PA290X3CS-4MU1 C-SBN373H8D

Type

Rotary Scroll

Brand

GMCC Sanyo

Capacity Btu/h

24490 48109

Input W

2430 4750

Rated current(RLA) A

11.4 8.22

Locked rotor Amp(LRA)

A

61 66

Thermal protector

UP14SE5145 internal

Capacitor uF

50 No

Refrigerant oil ml

950 1700

Fan Motor

Fan MotorFan Motor

Fan Motor

Indoor Model

YDK75-8 YDK120-8T

Page 27

Exploded view & spare-part

25

Brand

Welling Welling

Input W

164 300

Capacitor uF

5UF/450V 6.5UF/450V

Speed(high/low) r/min

575/540/440 600/550/480

Outdoor

Model

YDK100-6D YDK65-6F/YDK65-6

Brand

Welling Welling

Input W

170 156/148

Capacitor uF

5UF/450V 3.5UF/450V

Speed r/min

900 800

Loading...

Loading...