Page 1

EFEU-A-1312

SERVICE MANUAL

MIDEA AIRCONDITIONER

FLOOR STANDING TYPE

Model:

MFE-60ARN1-RB4W

MFE-60AMN1-RB4W

Code

Factory model

Model

Power supply

2T0043800005

CE-KFR160LW/SDN1Y-E(B4)

MFE-60AMN1-RB4W

3Ph, 380-420V~, 50Hz

2T0043800026

CE-KFR160LW/SDN1Y-E(B4)-W[J]

MFE-60ARN1-RB4W

3Ph, 380-420V~, 50Hz

2T0043800036

EU-KFR150LW/SDN1Y-E(B4)-W

MFE-60ARN1-RB4W

3Ph, 380-420V~, 50Hz

Page 2

CONTENTS

1. Safety Precautions .................................................................................................................... 1

1.1 Precaution .................................................................................................................................................... 1

1.2 Installation .................................................................................................................................................... 1

1.3 Caution .......................................................................................................................................................... 1

1.4 Operational................................................................................................................................................... 2

2. Dimension .................................................................................................................................. 3

2.1 Indoor Unit ..................................................................................................................................................... 3

2.2 Outdoor Unit .................................................................................................................................................. 4

3. Refrigerant cycle diagram ........................................................................................................ 5

4. Wiring diagram .......................................................................................................................... 6

4.1 MFE-60AMN1-RB4W .................................................................................................................................. 6

4.2 MFE-60ARN1-RB4W(2T0043800026) .................................................................................................... 7

4.3 MFE-60ARN1-RB4W(2T0043800036) .................................................................................................... 8

5. Installation details ..................................................................................................................... 9

5.1 Installation place .......................................................................................................................................... 9

5.2 Installing ....................................................................................................................................................... 10

5.3 Refrigerant pipe connection ....................................................................................................................13

5.4 Drain pipe of the indoor unit ....................................................................................................................26

5.5 Wiring ............................................................................................................................................................ 27

5.6 Test run ......................................................................................................................................................... 27

6. External view and display ...................................................................................................... 28

6.1 Parts names ................................................................................................................................................28

6.2 Control panel ...............................................................................................................................................29

6.3 LED ...............................................................................................................................................................30

Page 3

7. Operation characteristics ...................................................................................................... 31

8. Electronic function ................................................................................................................. 32

8.1 Main data introduction ...............................................................................................................................32

8.2 Main Protection ...........................................................................................................................................32

8.3 Operation modes and functions ..............................................................................................................33

8.4 Other functions ............................................................................................................................................40

9. Trouble shooting ..................................................................................................................... 40

9.1 Self-diagnosis .......................................................................................................................... 40

9.2 LEDs for the indication of outdoor trouble .............................................................................. 41

9.3 Troubles and solutions ............................................................................................................ 42

Page 4

1

1. Safety Precautions

1.1 Precaution

To prevent injury to the user or other people and property damage, the following instruction

s must be followed.

Incorrect operation due to ignoring instruction will cause harm or damage.

Before service unit, be sure to read this service manual at first.

1.2 Installation

For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized servic

e center.

Do not disassemble or repair the product by yourself.

Sharp edges could cause injury, be especially careful of the case edges and the fins on th

e condenser and evaporator.

Be sure the installation area does not deteriorate with age.

Take care to ensure that power cable could not be pulled out or damaged during operatio

n.

Do not place anything on the power cable.

Do not plug or unplug the power supply plug during operation.

Do not store or use flammable gas or combustible near the product.

When flammable gas leaks, turn off the gas and open a window for ventilation before turn

the product on.

If strange sounds, or small or smoke comes from product. Turn the breaker off or disconne

ct the power supply cable as soon as possible.

When the product is soaked (flooded or submerged), contact an Authorized service center.

Be caution that water could not enter the product.

Turn the main power off when cleaning or maintaining the product.

When the product is not be used for a long time, disconnect the power supply plug or turn

off the breaker.

1.3 Caution

Always check for gas (refrigerant) leakage after installation or repair of product.

Install the drain hose to ensure that water is drained away properly.

Keep level even when installing the product.

Do not install the product where the noise or hot air from the outdoor unit could damage t

he neighborhoods.

Use two or more people to lift and transport the product.

Do not install the product where it will be exposed to sea wind (salt spray) directly.

Page 5

2

1.4 Operational

Do not expose the skin directly to cool air for long periods of time. (Do not sit in the draf

t).

Do not use the product for special purposes, such as preserving foods, works of art, etc. It

is a consumer air conditioner, not a precision refrigerant system.

Do not block the inlet or outlet of air flow.

Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

Do not touch the metal parts of the product when removing the air filter. They are very sh

arp.

Do not step on pr put anything on the product. (outdoor units)

Always insert the filter securely. Clean the filter every two weeks or more often if necessar

y.

Do not insert hands or other object through air inlet or outlet while the product is operated.

Do not drink the water drained from the product.

Use a firm stool or ladder when cleaning or maintaining the product.

Page 6

3

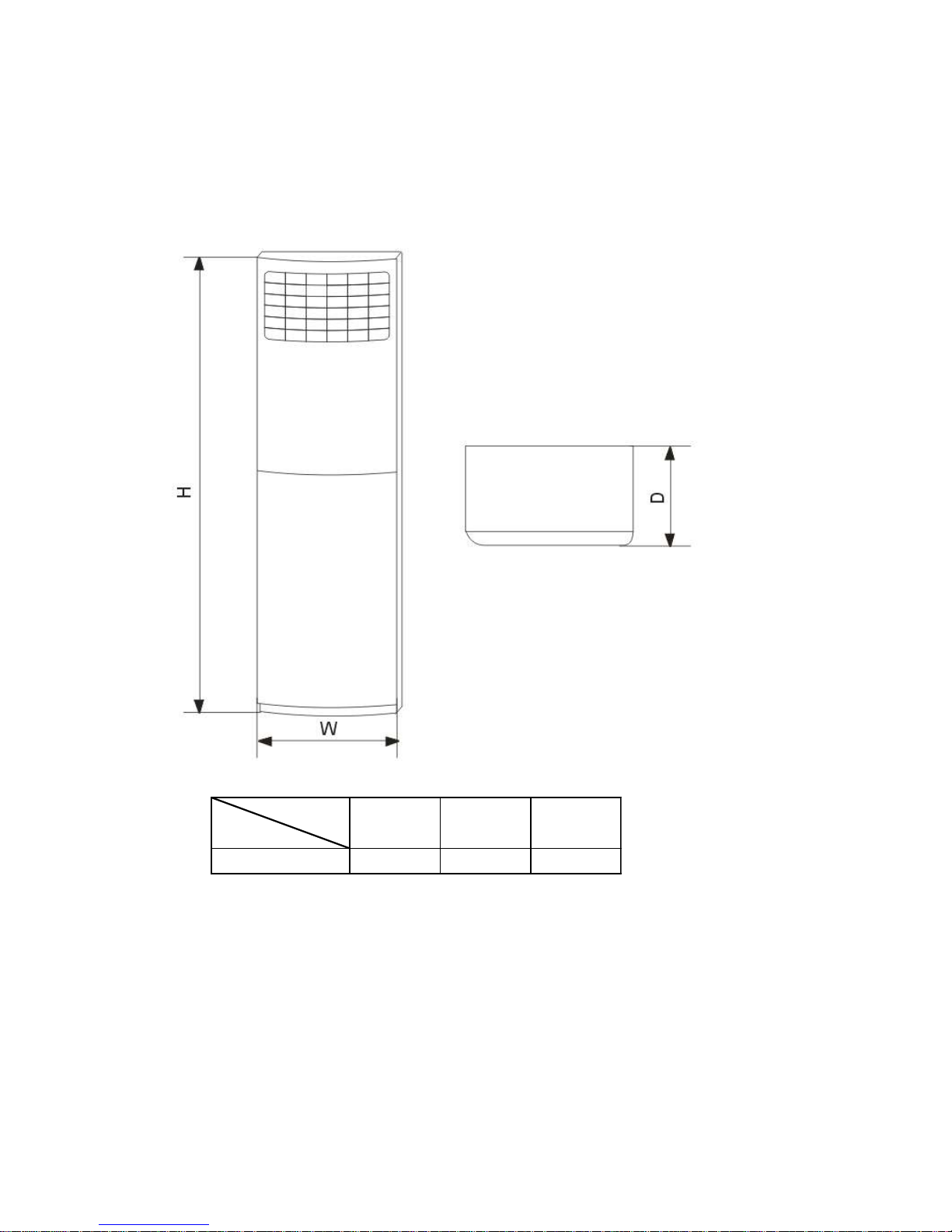

2. Dimension

2.1 Indoor Unit

Dimension

Mode

W

(mm)

D

(mm)

H

(mm)

55K 600 358 1900

Page 7

4

2.2 Outdoor Unit

Dimension

Model

W

(mm)

D

(mm)

H

(mm)

W1

(mm)

A

(mm)

B

(mm)

MOI-60H-RB4W

940

360

1245

1020

602

380

MOU-60HN1-RB4W

(2T0043800026)

900

350

1170

985

590

378

MOU-60HN1-RB4W

(2T0043800036)

938

633.5

404

448

370

392

Page 8

5

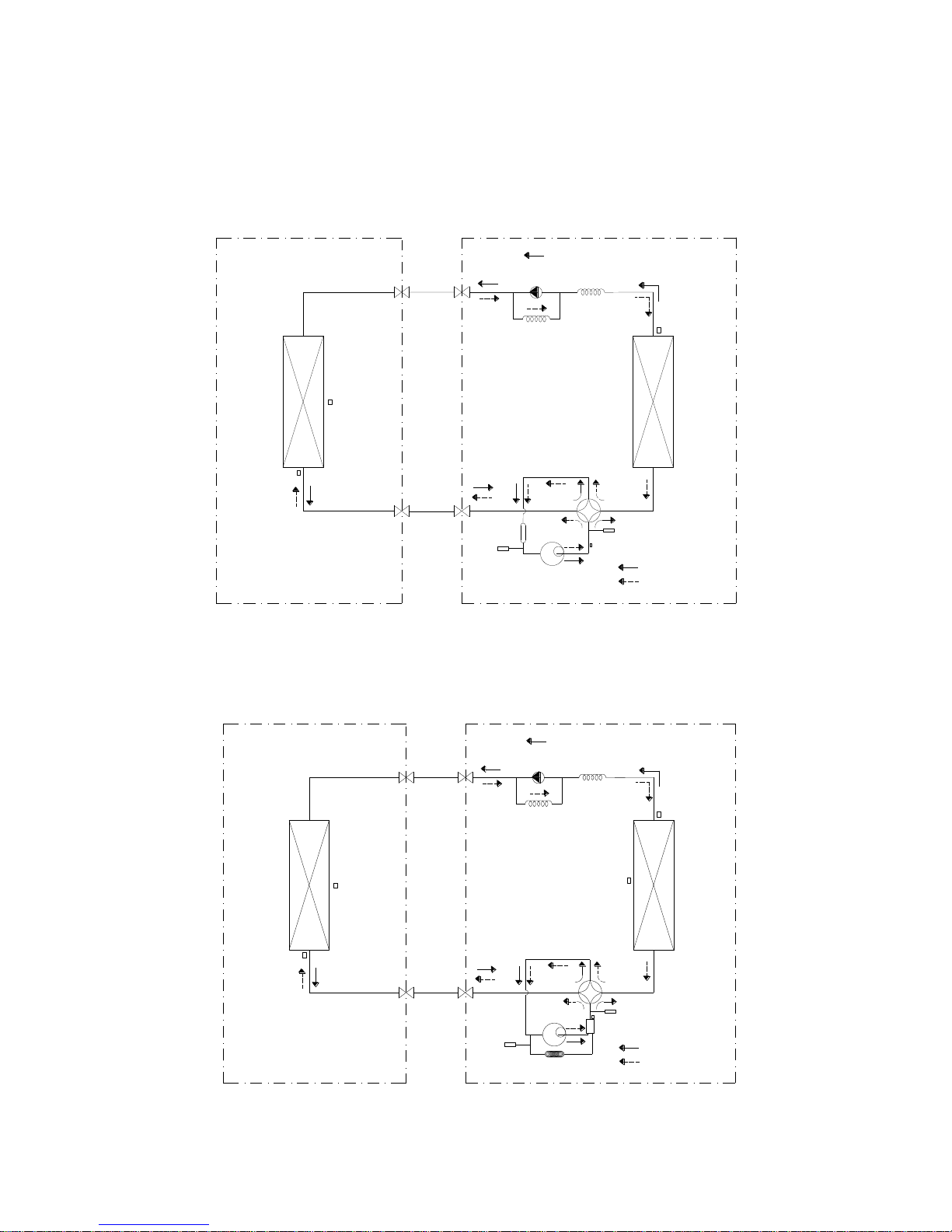

3. Refrigerant cycle diagram

MOI-60H-RB4W MOU-60HN1-RB4W(2T0043800036)

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

T3 Condenser

temp. sensor

Accumulator

T5 Discharge temp. sensor

INDOOR OUTDOOR

Low pressure

switch

High pressure switch

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

For MOI-60H-RB4W, there is no low pressure switch.

MOU-60HN1-RB4W(2T0043800026)

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

T3 Condenser

temp. sensor

T5 Discharge temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

Oil return Capillary

Oil separator

Low pressure

switch

High pressure switch

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

Page 9

6

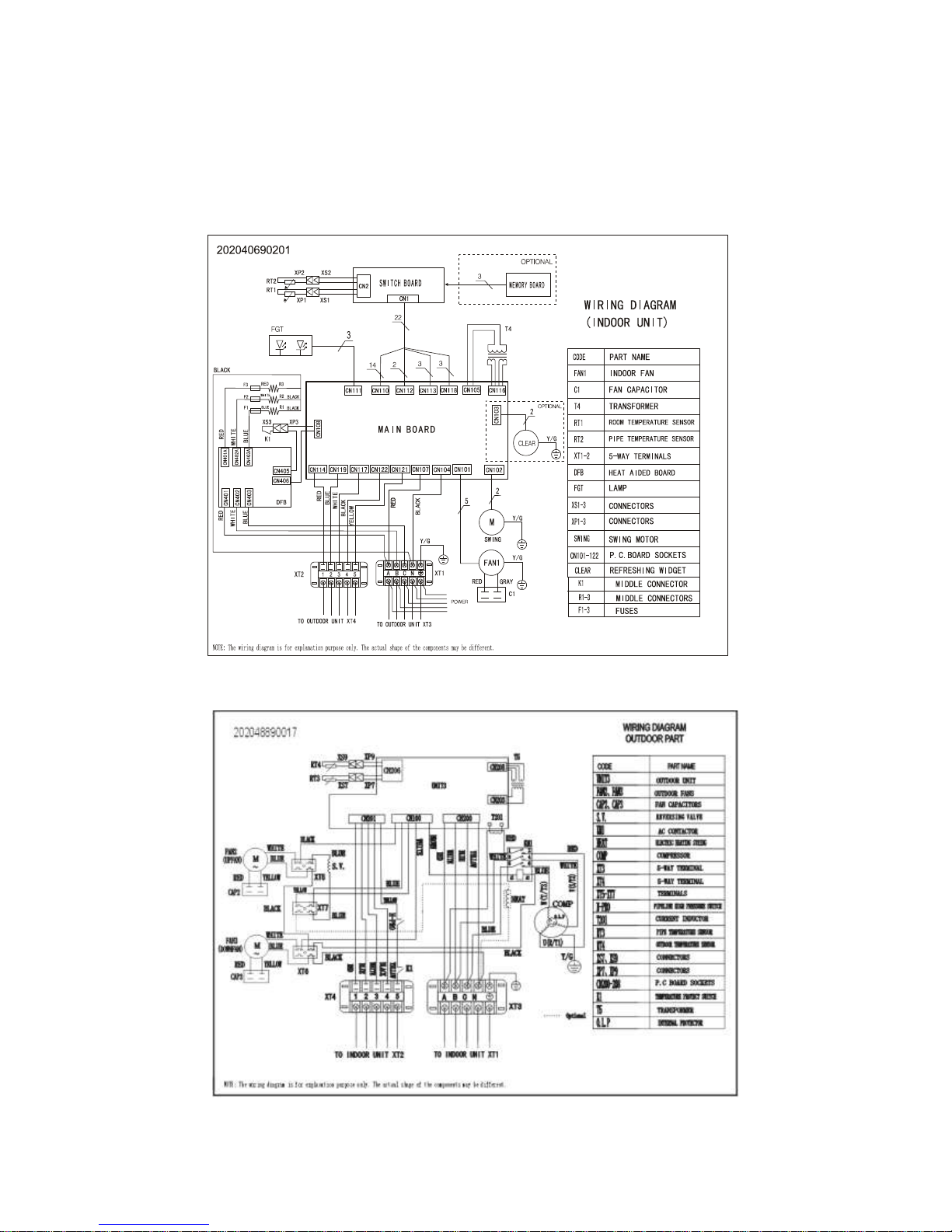

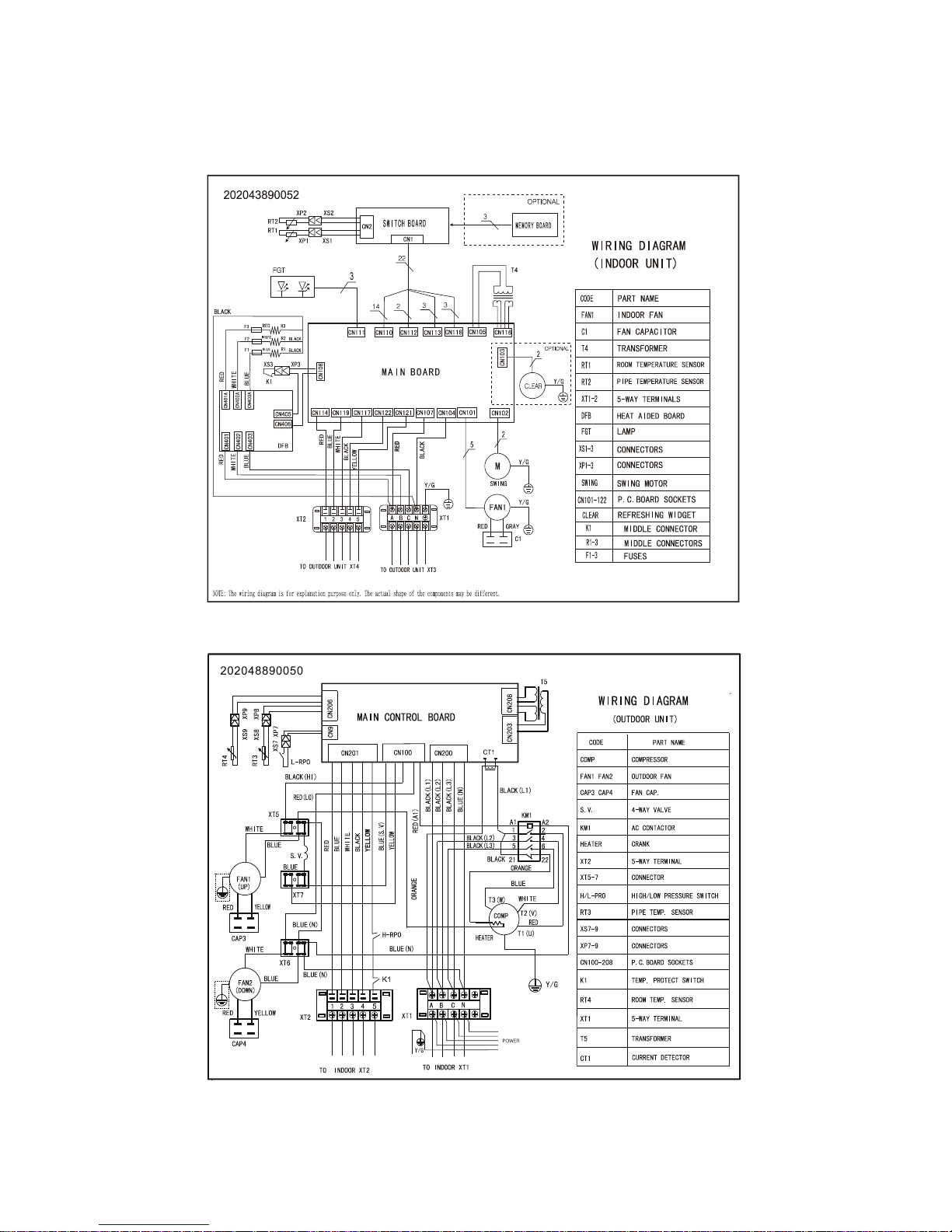

4. Wiring diagram

4.1 MFE-60AMN1-RB4W

Indoor Unit

Outdoor Unit

Page 10

7

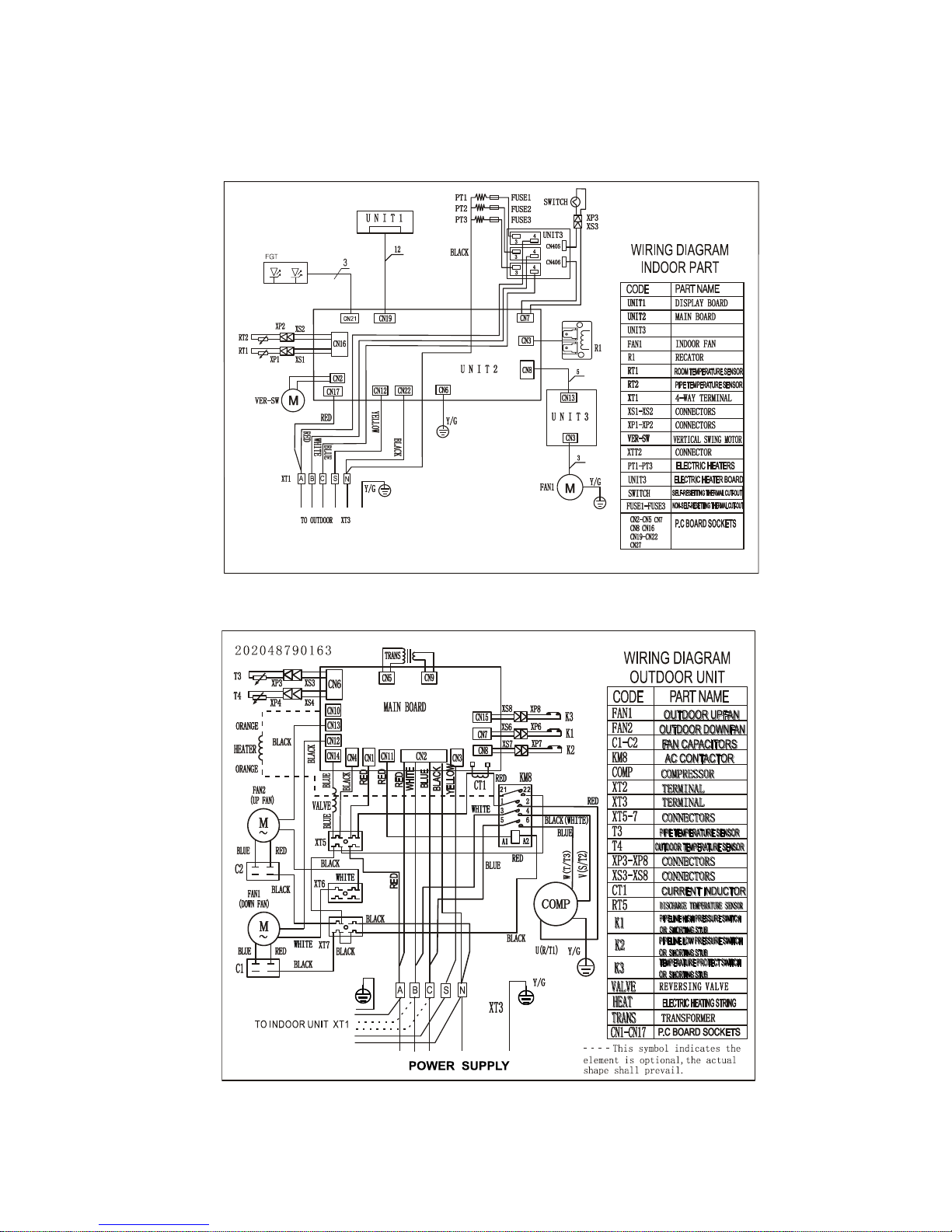

4.2 MFE-60ARN1-RB4W(2T0043800026)

Indoor Unit

Outdoor Unit

Page 11

8

4.3 MFE-60ARN1-RB4W(2T0043800036)

Indoor Unit

Outdoor Unit

Page 12

9

5. Installation details

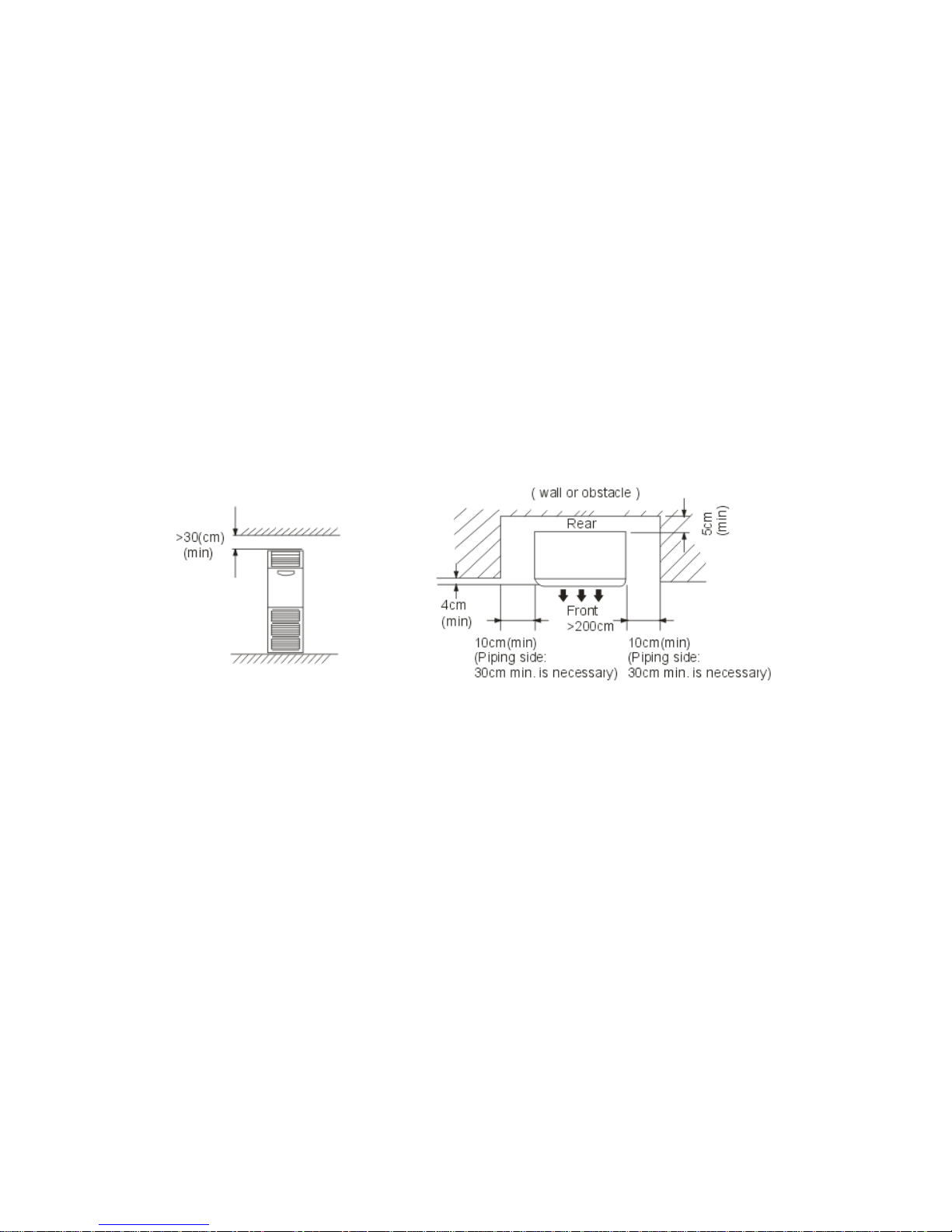

5.1 Installation place

5.1.1 Indoor Unit

a.Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles.

b.There should not be any heat source or steam near the unit.

c.There should not be any obstacles blocking the air circulation.

d.A place where air circulation in the room is good.

e.A place where drainage can be easily done.

f.Do not install the unit near the door way.

g.There should not be any direct sunlight. Otherwise, the sun will fade the plastic

cabinet and affect its appearance. If unavoidable, sunlight prevention should be taken into

consideration.

5.1.1.1 Please stand the unit in hard and flat ground;

Please reserve space for installation and maintenance.

5.1.2 Outdoor Unit

The outdoor unit should be put in a position that guarantees the minimum space for

sufficient air circulation and to allow maintenance work and the connections of electrical

and refrigerant circuit lines. It may be installed on a floor or flat roof or wall-mounted,

provided its weight is properly supported and there is no transmission of vibration to the

adjacent rooms.

5.1.2.1 Before installing the outdoor unit, you should:

a).If an awning is built over the unit to prevent direct sunlight or rain, be careful that heat

radiation from the condenser is not obstructed.

b).Select a place that is easy to connect indoor unit's pipe and electric wires.

c).Avoid a place where combustible gas may leak or stay.

d).Keep it in mind that water may drain out of the outdoor unit while in "Heat" mode.

e).Ensure the space around the back and sides and the front of the unit.

f).Take the air conditioner weight into account and select a place where noise and

vibration are minimum.

5.1.2.2 If the outdoor unit is to be installed on a roof or where no constructions are around,

you should avoid hard wind blows directly to the air outlet, because

Page 13

10

it may cause trouble for air-flow shortage.

5.1.2.3 Reserve enough space for installation, maintenance and unit-functioning.

Remove as many obstacles as possible nearby.

Caution:

Installation in the following places may cause trouble. If it is unavoidable to use in such

places,please consult with the dealer.

(1) A place full of machine oil.

(2) A saline place such as coast.

(3) Hot-spring resort.

(4) A place full of sulfide gas.

(5) A place where there are high frequency machines such as wireless installation,

welding machine, medical facility.

(6) A place of special environmental conditions.

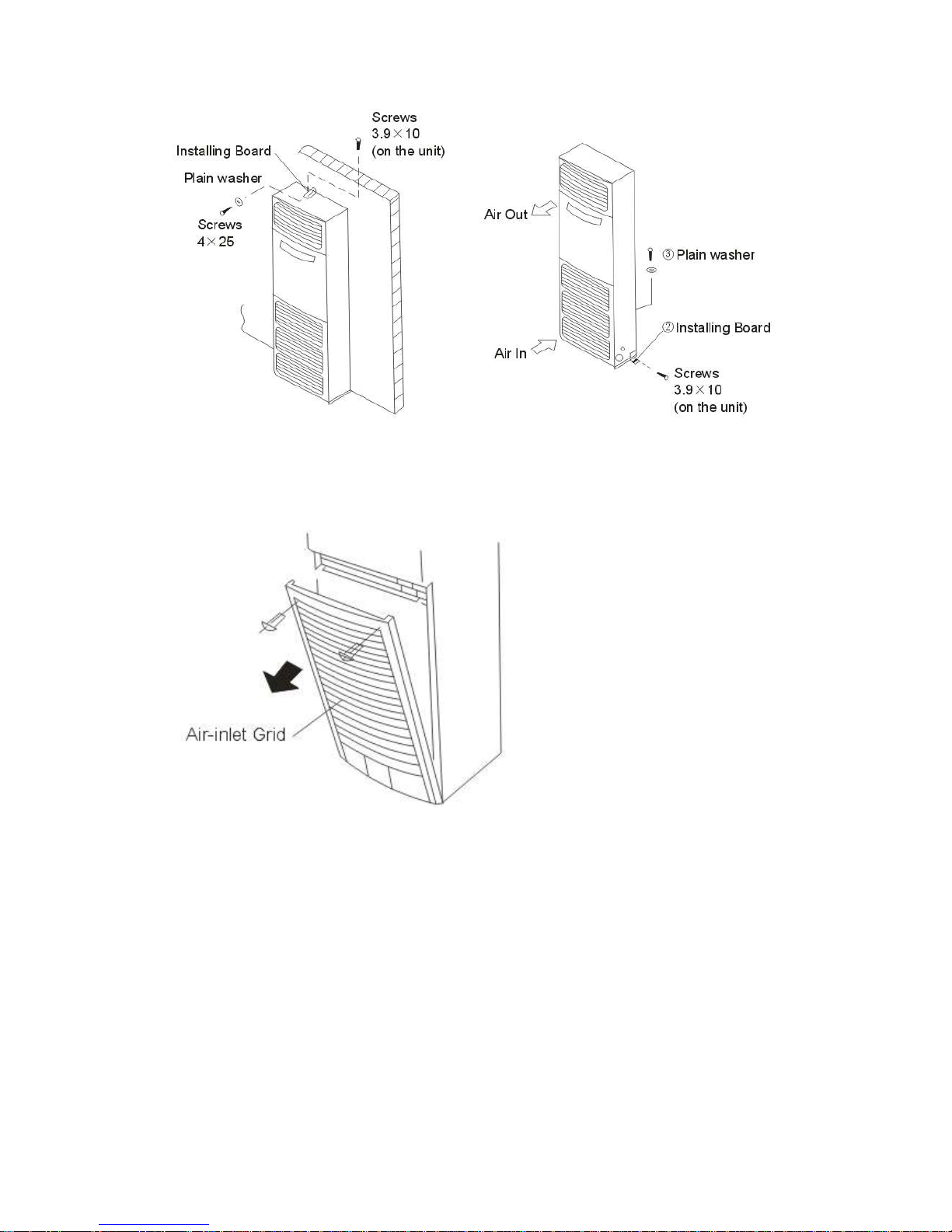

5.2 Installing

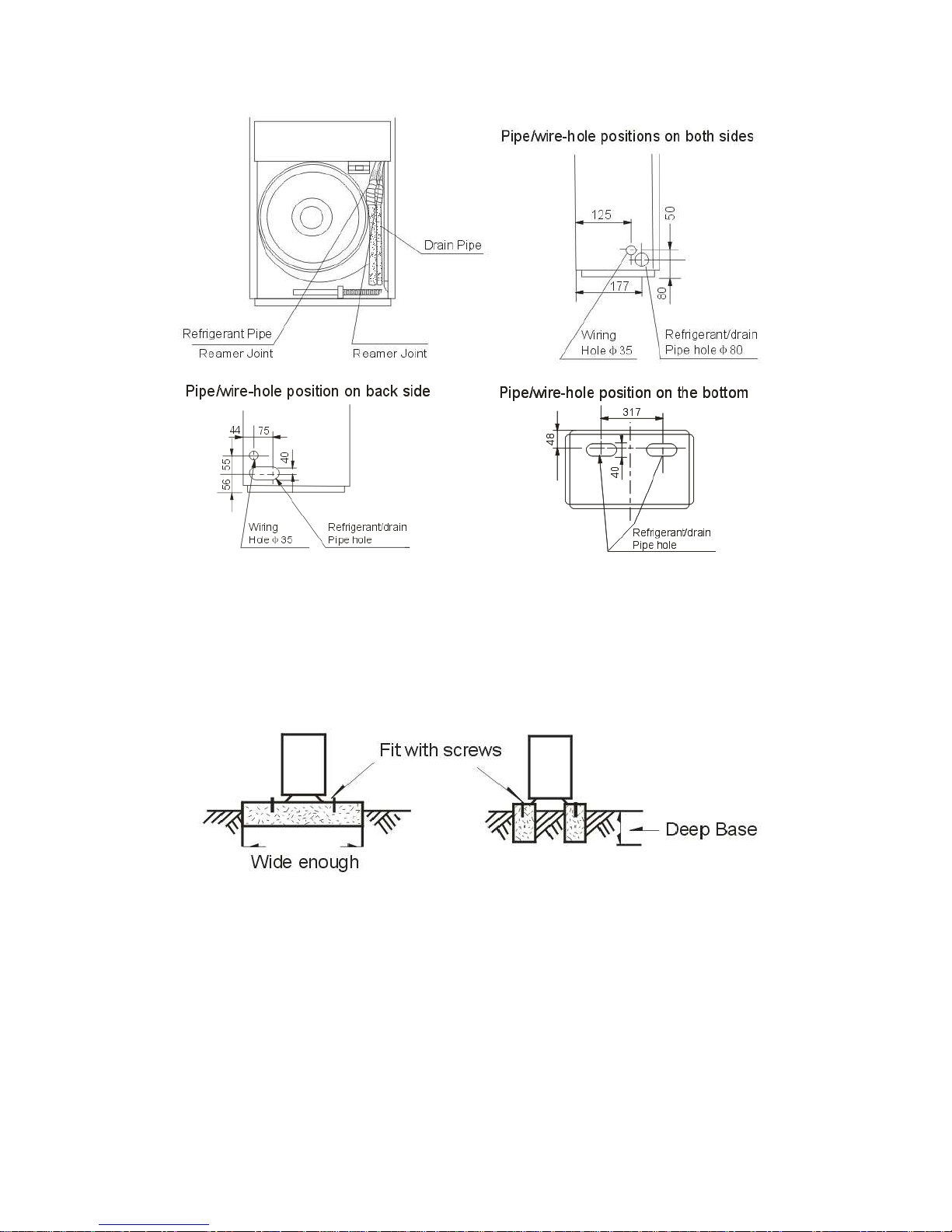

5.2.1 Indoor Unit:

1. Anti-falling;

To prevent the indoor unit from falling, you must:

a. Pay full attention to the unit because its long outer shape makes it easy to fall;

b. Firmly fix the unit to the wall or in the ground to avoid accidental falling.

Page 14

11

2. Dismounting the air-inlet grid

Please take off the air-inlet grid before connecting the pipes/wires.

Pull down the two knobs marked "PULL" on the grid, take off the two straps,

then the air-inlet grid goes free.

3. Take the Pipe Clip off before connecting the pipes and wiring; fit it when these finished.

Use accessories to connect the pipes/wires on both sides and back side.

Page 15

12

5.2.2 Outdoor Unit:

1. Ship the a/c to the installation place originally packed;

2. Be careful while hanging the unit because the center of gravity of the unit is not

centralized;

3. Do not make the angle of inclination more than 45 degrees while shipping;(Avoid

horizontal storage)

4. Be sure the electric insulation work is well done if installed on metal ceiling / wall.

5. Fix the unit feet with bolts (M10). Be sure the unit is fixed strongly enough to against

blast or earthquake.

6. Make a concrete basement to the unit by the above references.

Page 16

13

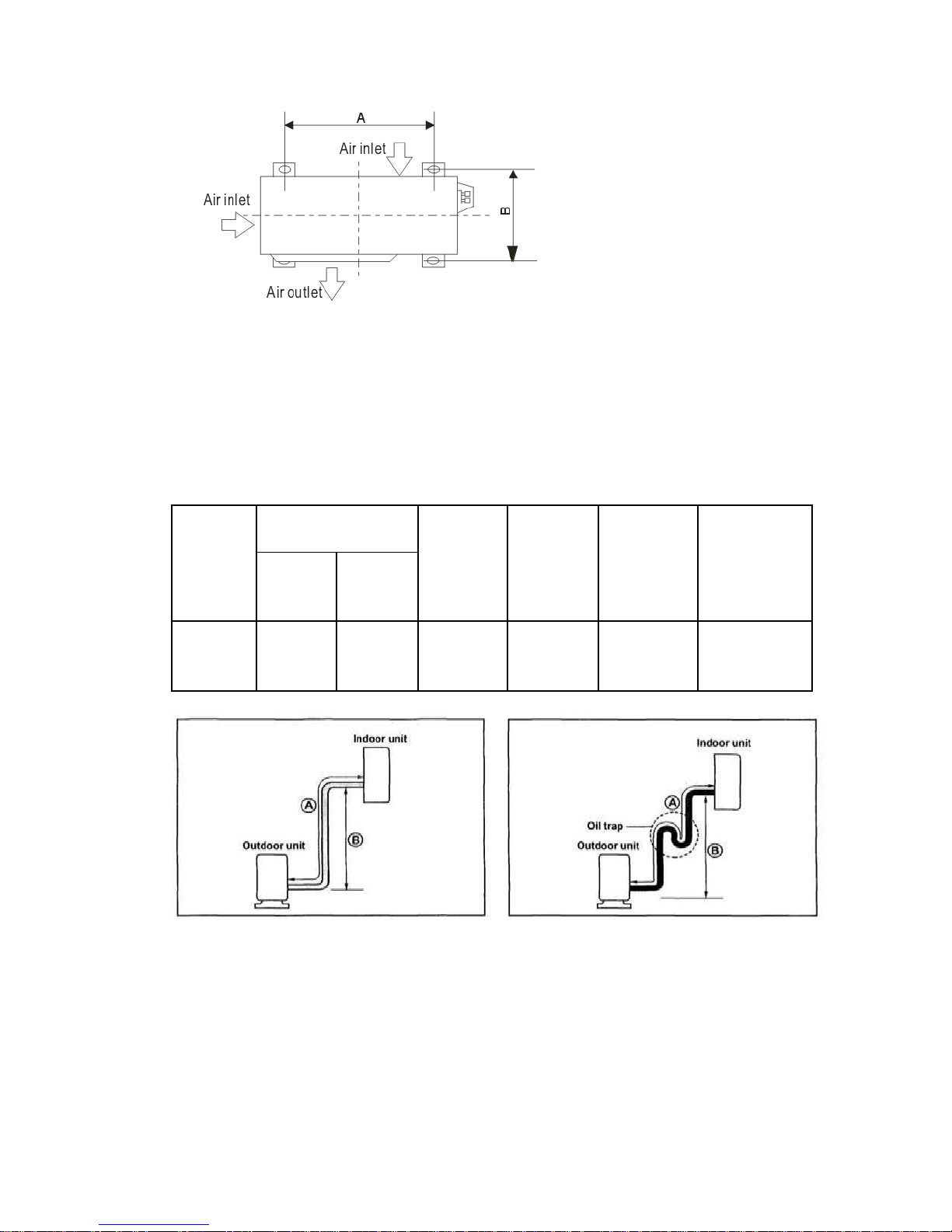

For the value of A and B, please refer to the dimension part.

5.3 Refrigerant pipe connection

5.3.1 Pipe length and the elevation

The correct refrigerant quantity filled in the 5-meter-long pipe of the outdoor unit is

marked on the Product Data Plate. If you have to use longer pipe for every meter

plus pipe, the refrigerant should be added according to the following calculation.

Capacity

Btu/h

Pipe size

Standard

length

(m)

Max.

Elevation

B (m)

Max.

Length

A (m)

Additional

refrigerant

(g/m)

Gas

Liquid

60K

3/4’’

(Ф19)

1/2’’

(Ф12.7)

5

20

30

60

Caution:

Capacity is base on standard length and maximum allowance length is base of reliability.

Oil trap should be installed per 5-7 meters.

Page 17

14

5.3.2 Piping connection

5.3.2.1 Connecting Of Refrigerant Pipe

a) Only the correctly installing of indoor and outdoor unit done, can the refrigerant

pipe be connected.

b) The cut-off valves are completely close before ex-work. Before connecting the

refrigerant pipe, be careful to check whether the valves are completely close.

c) The connecting procedure of refrigerant pipe: first, unscrew the two valves on the

outdoor unit and the pipe-jointing nut on the indoor unit(please keep them

carefully). Please connect the refrigerant pipe according to the manual, the

pipe-jointing nut should be screw tightly and no leakage. Note: you need two

wrenches to make balance.

d) When the connecting of refrigerant pipe is finished, before power on the system,

you should vacuum the indoor unit through the maintenance port on the cut-off

valves, or open the high-pressure valve, and exhaust the air through the

maintenance port on the low-pressure valve(closed). It will take about ten

seconds. Then screw tightly the maintenance port. (When supplement the

refrigerant, fill through the maintenance port of the low-pressure valves on the

outdoor unit).

e) Open all the valves completely before power on the system, or it will be sick for

low efficiency.

f) Gas leak check. Make sure no gas from connections with leak detector or soap

water.

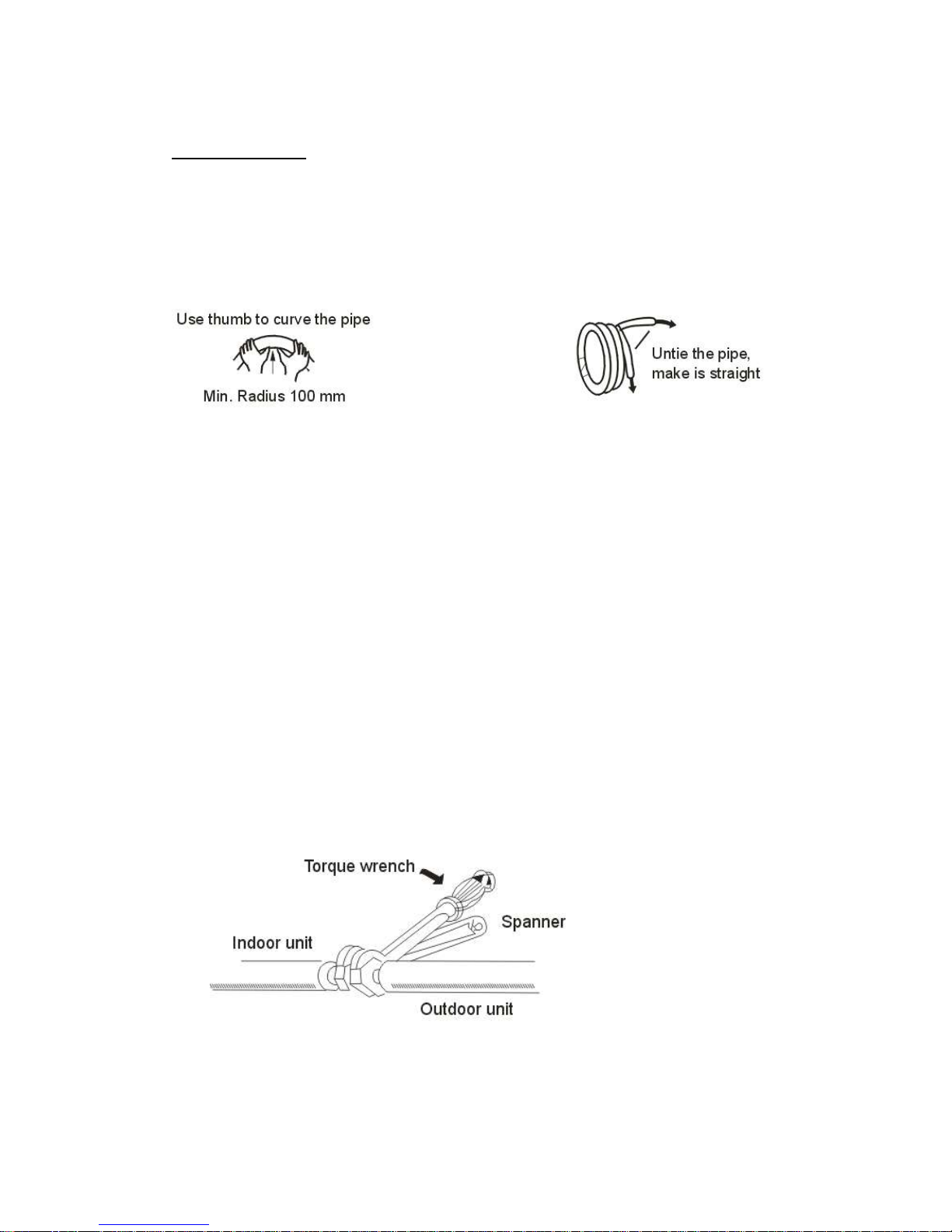

5.3.2.2 Pipe Connecting Procedures

Completely shut the cut-off valves of the outdoor unit (as ex-work status). Unscrew the

nuts on the cut-off valves and immediately connect the reamer joint (in 5 minutes). If it last

too long, dust, vapor and other obstacles may enter the pipe and cause trouble later on.

Before connecting the pipe, the air in the pipe should be removed in advance by releasing

refrigerant R-410A.

Notes for the bendable pipe

a. The bendable pipe should be used on the indoor side;

b. Bend angel may not exceed 90 degrees;

c. The bend location should be made on the center of the pipe if possible, as for bend

radius, the bigger the better;

Page 18

15

d. The bendable pipe may not be bent for more than 3 times.

Bend the thin pipe

a. While bending, expose the pipe by cutting the concave gap on the bending

heat-insulation pipe(roll it with soft band after bent).

b. To avoid pipe deformation, the radius is the bigger the better.

c. Use a pipe-bending device to make the compact bending pipe.

5.3.2.3 Using bronze pipe selling in market

Completely shut the cut-off valves of the outdoor unit (as ex-work status). After t

he refrigerant pipe has been connected with both the indoor and outdoor unit, let th

e air exhaust out from the maintenance gap on he low-pressure cut-off valves of

the outdoor unit. Screw the nuts tightly on the maintenance gap after the air has

been drained.

5.3.2.4 To make the refrigerant pipe unblocked completely

You should keep the cut-off valves of the outdoor unit completely open after you

have finished the above steps (5.3.2.2 or 5.3.2.3)

Note:

1.Before screwing the reamer nut, smear the pipe and the connecting surface with r

efrigerant oil;

2.Check and make sure there is no leakage by soap-water or leakage-checker after

connecting;

3.Be sure the connecting joint on the indoor side is insulated.

4.Use two wrenches to connecting the pipes.

Page 19

16

Outside diameter

Torque

Additional

tightening

torque

mm

inch

N.cm

N.cm

Ф12.7

1/2

4950

6030

Ф19

3/4

9720

11860

5.3.3 Installation for the first time

Air and moisture in the refrigerant system have undesirable effects as below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circuit may freeze and block capillary tubing.

● Water may lead to corrosion of parts in the refrigerant system.

Therefore, the indoor units and the pipes between indoor and outdoor units must be

leak tested and evacuated to remove gas and moisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral detergent on the indoor unit connections or

outdoor unit connections by a soft brush to check for leakage of the connecting points of

the piping. If bubbles come out, the pipes have leakage.

Page 20

17

1. Air purging with vacuum pump

1) Completely tighten the flare nuts of the indoor and outdoor units, confirm that both the

2-way and 3-way valves are set to the closed position.

2) Connect the charge hose with the push pin of handle lo to the 3-way valves gas

service port..

3) Connect the charge hose of handle hi connection to the vacuum pump.

4) Fully open the handle Lo of the manifold valve.

5) Operate the vacuum pump to evacuate.

6) Make evacuation for 30 minutes and check whether the compound meter indicates -0.1Mpa.

If

the meter does not indicate -0.1Mpa after pumping 30 minutes, it should be pumped 20 minutes

more. If the pressure can’t achieve -0.1Mpa after pumping 50 minutes, please check if there are

some leakage points.

Fully close the handle Lo valve of the manifold valve and stop the operation of the vacuum

pump. Confirm that the gauge needle does not move (approximately 5 minutes after

turning off the vacuum pump).

7) Turn the flare nut of the 3-way valves about 45° counterclockwise for 6 or 7seconds

(Indoor unit)

(Liquid side)

(Gas side)

Vacuum

pump

Vacuum

pump

Lo

Hi

Handle Hi

Two-way valve

Close

Manifold valve

Compound meter

Pressure

gauge

-0.1MPa

Handle Lo

Charge hose

Charge hose

(Outdoor unit)

Close

Three-way valve

Page 21

18

after the gas

coming out, then tighten the flare nut again. Make sure the pressure display in the

pressure indicator is a little higher than the atmosphere pressure. Then remove the

charge hose from the 3 way valve.

8) Fully open the 2 way valve and 3 way valve and securely tighten the cap of the 3 way

valve.

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

2). Connect the charge set and a charging cylinder to the service port of the 3-way

valve.

3). Air purging.

Open the valves on the charging cylinder and the charge set. Purge the air by

loosening the flare nut on the 2-way valve approximately 45’ for 3 seconds then closing

it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check the gas leakage.

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and discharge the refrigerant by loosening

Page 22

19

the flare nut on the 2-way valve approximately 45’ until the gauge indicates 0.3 to 0.5

Mpa.

6). Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way

valves to the open position.

Be sure to use a hexagonal wrench to operate the valve stems.

7). Mount the valve stems nuts and the service port cap.

Be sure to use a torque wrench to tighten the service port cap to a torque 18N·m.

Be sure to check the gas leakage.

3. Adding the refrigerant if the pipe length >5m

Procedure:

1). Connect the charge hose to the charging cylinder, open the 2-way valve and the

3-way valve.

Connect the charge hose which you disconnected from the vacuum pump to the valve at

the bottom of the cylinder. If the refrigerant is R410A, make the cylinder bottom up to

ensure the liquid charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set

to purge the air (be careful of the liquid refrigerant).

Electronic scale

Page 23

20

3) Put the charging cylinder onto the electronic scale and record the weight.

4) Operate the air conditioner at the cooling mode.

5) Open the valves (Low side) on the charge set and charge the system with liquid

refrigerant.

6).When the electronic scale displays the proper weight (refer to the table),

disconnect the charge hose from the 3-way valve’s service port immediately and turn off

the air conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service port

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas leakage.

5.3.4 Adding the refrigerant after running the system for many years

Procedure:

1). Connect the charge hose to the 3-way service port, open the 2-way valve and the

3-way valve.

Connect the charge hose to the valve at the bottom of the cylinder. If the refrigerant is

R410A, make the cylinder bottom up to ensure liquid charge.

Electronic scale

Page 24

21

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set

to purge the air (be careful of the liquid refrigerant).

3) Put the charging cylinder onto the electronic scale and record the weight.

4) Operate the air conditioner at the cooling mode.

5) Open the valves (Low side) on the charge set and charge the system with liquid

refrigerant.

6).When the electronic scale displays the proper weight (refer to the gauge and the

pressure of the low side), disconnect the charge hose from the 3-way valve’s service

port immediately and turn off the air conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service port

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas leakage.

5.3.5 Re-installation while the indoor unit need to be repaired

1. Collecting the refrigerant into the outdoor unit

Procedure

Page 25

22

1). Confirm that both the 2-way and 3-way valves are set to the opened position

Remove the valve stem caps and confirm that the valve stems are in the opened

position.

Be sure to use a hexagonal wrench to operate the valve stems.

2). Connect the charge hose with the push pin of handle lo to the 3-way valves gas

service port.

3). Air purging of the charge hose.

Open the handle Lo valve of the manifold valve slightly to purge air from the charge

hose for 5 seconds and then close it quickly.

4). Set the 2-way valve to the close position.

5). Operate the air conditioner at the cooling cycle and stop it when the gauge

indicates 0.1MPa.

6). Set the 3-way valve to the closed position immediately

Do this quickly so that the gauge ends up indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way and 3-way valve’s stem nuts.

Use a torque wrench to tighten the 3-way valves service port cap to a torque of

18N.m.

Be sure to check for gas leakage.

2. Air purging by the refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

Page 26

23

2). Connect the charge set and a charging cylinder to the service port of the 3-way

valve

Leave the valve on the charging cylinder closed.

3). Air purging.

Open the valves on the charging cylinder and the charge set. Purge the air by

loosening the flare nut on the 2-way valve approximately 45’ for 3 seconds then closing

it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check the gas leakage

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and discharge the refrigerant by loosening

the flare nut on the 2-way valve approximately 45’ until the gauge indicates 0.3 to 0.5

Mpa.

6). Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way

valves to the open position

Be sure to use a hexagonal wrench to operate the valve stems.

7). Mount the valve stems nuts and the service port cap

Be sure to use a torque wrench to tighten the service port cap to a torque 18N.m.

Be sure to check the gas leakage.

5.3.6 Re-installation while the outdoor unit need to be repaired

1. Evacuation for the whole system

Page 27

24

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the opened position.

2). Connect the vacuum pump to 3-way valve’s service port.

3). Evacuation for approximately one hour. Confirm that the compound meter

indicates -0.1Mpa.

4). Close the valve (Low side) on the charge set, turn off the vacuum pump, and

confirm that the gauge needle does not move (approximately 5 minutes after turning off

the vacuum pump).

5). Disconnect the charge hose from the vacuum pump.

Page 28

25

2. Refrigerant charging

Procedure:

1). Connect the charge hose to the charging cylinder, open the 2-way valve and the

3-way valve

Connect the charge hose which you disconnected from the vacuum pump to the valve at

the bottom of the cylinder. If the refrigerant is R410A, make the cylinder bottom up to

ensure liquid charge.

2). Purge the air from the charge hose

Open the valve at the bottom of the cylinder and press the check valve on the charge set

to purge the air (be careful of the liquid refrigerant).

3) Put the charging cylinder onto the electronic scale and record the weight.

4). Open the valves (Low side) on the charge set and charge the system with liquid

refrigerant

If the system cannot be charge with the specified amount of refrigerant, or can be

charged with a little at a time (approximately 150g each time) , operating the air

conditioner in the cooling cycle; however, one time is not sufficient, wait approximately 1

Electronic scale

Page 29

26

minute and then repeat the procedure.

5).When the electronic scale displays the proper weight, disconnect the charge hose

from the 3-way valve’s service port immediately

If the system has been charged with liquid refrigerant while operating the air conditioner,

turn off the air conditioner before disconnecting the hose.

6). Mounted the valve stem caps and the service port

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas leakage

5.4 Drain pipe of the indoor unit

1.Make sure the drain pipe is connected to the outdoor side downward;

2.The hard polyvinyl chloride(PVC)plastic pipe (external diameter 26 mm) sold is the

market is suitable for the attached soft drain pipe;

3.Please connect the Soft Drain Pipe with the Drain Pipe, then fix it with band;

4.If you have to connect the Drain Pipe indoors, to avoid condensing caused by air

intake, you must cover the pipe with heat-insulation material (polyethylene with Spe

cific Gravity of 0.03, at least 9 mm in thickness), and use Glue Band to fix it.

5.After the Drain Pipe has been connected, please check if the water drains out of

the pipe efficiently and has no leakage.

6.Refrigerant pipe and Drainpipe should be heat-insulated to avoid condensing and

water-dropping later on.

Page 30

27

5.5 Wiring

Please refer to the Wiring Diagram.

Note: The power supply of the air conditioner is different according to the models.

Please refer to the WIRING DIAGRAM pasted on the indoor and outdoor units befo

re wire connection.

5.6 Test run

1. Make sure the resistance between the socket of the electric system and the

grounded line, when detected by a 500 V million-ohmmeter, is at least 2 million ohms. If

the resistance is less than the number, please do not use the air conditioner;

2. Check again if the air conditioner is properly installed, especially for the anti-fallin

g device;

3. When accomplished all the above procedures, service people should explain and

test the air conditioner for the customer according to the "User's Manual".

Page 31

28

6. External view and display

6.1 Parts names

This unit consists of indoor unit and outdoor unit.

Note:

All the pictures in this manual are for explanation purpose only. They may be slightl

y different from the air conditioner you purchased(depend on model). The actual sh

ape shall prevail.

Air Outlet Let the conditioned air go out from it.

Control Panel (inserted) Consists of indicators and control buttons.

Air Inlet Where a filter is settled, absorbing the air in the room

and clean it.

Drain Pipe From which the condensed water is drained.

Refrigerant Pipe In which the refrigerant passes through, connects the

outdoor unit with the indoor unit.

Outdoor(condensing)Unit Consists of compressor, fan motor, heat-exchanger and

other electric parts.

Decorative LED Displays green or red lights according to running

mode.

Page 32

29

6.2 Control panel

On/Off button: Power-on and power-off the A/C(Air conditioner)

LED indicator :Lights when unit runs normally ,flashes one time per second when the unit

is waiting for orders ,flashes two times per second when the unit is sick.

Mode select button : Use this button to select among the following 5 modes :

Auto :automatically adjust the temperature (17~30℃)

Cool :normal cooling operation(17~30℃)

Heat :(for cooling and heating only)normal heating operation(17~30℃)

Dry :dehumidify the room air and keep the indoor temperature(17~30℃)

Fan :fan only ,no cooling

Temp .adjusting buttons :

warm▲:push this button to raise the setting temperature

cool▼:push this button to lower the setting temperature.

Fan Speed button :

Auto: automatically adjust the fan speed

Low: Low fan speed.

Med: Medium fan speed

High: High fan speed

Swing /fresh button :push this button to make the air-flow blow left or right and anion

producer open.

Time/clock Alter button (Short form :ALT button):use this button to alter the modes

between ‘time’ and ‘clock’.

Page 33

30

Time adjusting button:

‘Hour’: set the hour of current time

‘Minute’: set the minute of current time

Confirm/Cancel button :Push this button to confirm or cancel the timer setting

Test Running button :Push this button to make the unit run for an hour of test ,this function

is specially designed for maintenance technicians.

6.3 LED

A. Operation modes

B. Timer setting clock or trouble display

C. Timer display

D. Types of clock

E. Room temperature setting display

F. Fan speed of the indoor unit display

G. Status display

Page 34

31

7. Operation characteristics

Mode

Temperature

Cooling

operation

Heating operation

Drying

operation

Room temperature

17℃~32℃

0℃~30℃

17℃~32℃

Outdoor temperature

18℃~43℃

(-7℃~43℃:

For the models

with low

temperature

cooling system)

-7℃~24℃

18℃~ 43℃

CAUTION:

1. If air conditioner is used outside of the above conditions, certain safety protection

features may come into operation and cause the unit to function abnormally.

2. Room relative humidity less than 80%. If the air conditioner operates in excess of

this figure, the surface of the air conditioner may attract condensation. Please sets the

vertical air flow louver to its maximum angle (vertically to the floor), and set HIGH fan

mode.

3. Optimum performance will be achieved within this operating temperature.

Page 35

32

8. Electronic function

8.1 Main data introduction

Ts : Set temperature,

T1 : Room temperature

T2: Evaporator pipe temperature

T3: Condenser pipe temperature

T4: Outdoor ambient temperature

8.2 Main Protection

8.2.1 Time delay for the compressor start-up

At the beginning of energizing or after the stop of the compressor, certain time

delay will be needed to start the compressor.

When switching over between cooling/heating/dehumidifying mode, the compressor st

ops automatically.

8.2.2 Sensor protection at open circuit and breaking disconnection.

8.2.3 Phase check function

If the phase sequence is detected wrong or lack of 1 or 2 phase, the unit won’t st

art and there is error code displayed on outdoor PCB.

8.2.4 Over-current protection

When compressor is running, if the current is over twice of the rated for 3 seconds, the

compressor will stop and an error code will be displayed on the outdoor PCB. If the

current becomes normal for 3 minutes, the indoor sends signal to the outdoor, the outdoor

will display normally.

8.2.5 Outdoor protection

When outdoor protection signal is high level, outdoor unit will perform protection: the

whole machine will be shut down while the indoor unit will indicate the correspondi

ng protection signal.

The A/C will recover if outdoor protection signal is low level.

8.2.6 Air outlet of indoor unit high temperature protection

When the temperature of air outlet of indoor unit is up to 70°C, protection

signal is high level, then the unit will perform protection: electric heaters will be shu

t down at once, indoor fan speed will be high and four-way valve, compressor and

outdoor fan are shut down.

The A/C will recover if the temperature of air outlet of indoor unit is down to 55°C.

Page 36

33

8.3 Operation modes and functions

8.3.1 Manual operation

8.3.2 Heating mode

8.3.2.1 Four-way valve opens at once and anti-cold air function opens at the same time,

electric heaters starts or stops according to 8.3.2.4.

8.3.2.2 Condition for the compressor and outdoor fan action:

MFE-60ARN1-RB4W(2T0043800036)

When compressor is on, outdoor fan will follow the below rules:

Fan(below): When compressor is on, the outdoor fan runs all the time.

Fan(above):

18

T4

Off

On

16

The others modes:

When compressor is on, outdoor fan will follow the below rules:

When T4≤16℃, the two fan run at the same time.

When T4≥18℃, the below fan is on, the above fan is off.

8.3.2.3 Indoor fan action

Auto fan in heating mode

MFE-60ARN1-RB4W(2T0043800036):

Condition

Compressor and outdoor fan

Ts-T1≥1°C

On

T1-Ts>0°C

Off

Condition

Compressor and outdoor fan(High)

Ts-T1≥1°C and compressor is off

reaches up to over 4 minutes

On

T1-Ts>2°C

Off

Page 37

34

-2

T1-Ts

-3

High

Low

-5

Medium

-4

The others modes:

8.3.2.4 Electric heaters (only available to some modes)

Electric heaters only opens in heating mode

MFE-60ARN1-RB4W(2T0043800036)

The others modes:

8.3.2.5 Defrost (only available to heating mode)

MFE-60ARN1-RB4W(2T0043800036)

---Defrosting Conditions

Starting Of Defrosting Condition (meet one of the following is ok):

(1)Accumulated time when temperature of outdoor heat exchanger coil T3 is below 3°C

reaches to 40 minutes, then consecutive 3 minutes less than -5 degrees (Just for the

AC is turn on , whether or not the heating mode the temperature was detected, start

to statistical time when reach the temperature condition . Shut down or defrosting

calculate time again).

(2) Accumulated time when temperature of outdoor heat exchanger coil T3 is below 3°C

reaches to 60 minutes, then consecutive 3 minutes less than -4 degrees (Just for the

AC is turn on , whether or not the heating mode the temperature was detected, start

to statistical time when reach the temperature condition . Shut down or defrosting

Condition

Fan speed

Ts-T1≥4°C

High

2°C ≤Ts-T1 < 4°C

Med

Ts-T1 < 2°C

Low

Condition

Electric heaters

T4<5℃

On

T4>7℃

Off

Condition

Electric heaters

Ts-T1 > 6°C and indoor fan opens,T2 < 50 °C

On

T1≥Ts or indoor fan closes or T2 > 52 °C

Off

Page 38

35

calculate time again).

(3) Accumulated time when temperature of outdoor heat exchanger coil T3 is below 3°C

reaches to 80 minutes, then consecutive 3 minutes less than -2 degrees (Just for the

AC is turn on , whether or not the heating mode the temperature was detected, start

to statistical time when reach the temperature condition . Shut down or defrosting

calculate time again).

(4) Under evaporator high temperature protection, the accumulated time when outdoor

fan motor is off and compressor is on reaches up to over 90 minutes .( Shut down or

defrosting or T3 is over 15°C, calculate time again.)

--- Defrosting Action

Four-way valve, indoor fan, outdoor fan are shut down. Compressor keeps on.

--- Ending Of Defrosting Condition (meet one of the following is ok):

(1)Time of defrosting lasts 10 minutes.

(2) Temperature of outdoor coil T3 is up to 8°C and continues to 80 seconds.

(3) Temperature of outdoor coil T3 is up to 15°C.

The others modes:

---Defrosting Conditions

Starting Of Defrosting Condition:

T3< 0°C and the compressor keeps running over 45 minutes. Meanwhile T3<-3°C for

3minutes.

--- Defrosting Action

Four-way valve, indoor fan, outdoor fan are shut down. Compressor keeps on.

Page 39

36

--- Ending of defrosting condition (meet one of the following is ok):

(1)Time of defrosting lasts 10 minutes.

(2) Temperature of outdoor coil T3 is up to 20°C.

8.3.2.6 High evaporator coil temp.T2 protection:

Model

TE7

TE8

TE9

MFE-60AMN1-RB4W

60

56

54

MFE-60ARN1-RB4W

(2T0043800026)

60

56

54

MFE-60ARN1-RB4W

(2T0043800036)

62

56

50

8.3.3 Cooling mode

8.3.3.1 Conditions for the compressor and outdoor fan action

MFE-60ARN1-RB4W(2T0043800036)

When compressor is on, outdoor fan will follow the below rules:

Fan(below): When compressor is on, the outdoor fan runs all the time.

Fan(above):

33

T3

On

Off

30

Condition

Compressor and outdoor fan

T1-Ts>1°C

On

T1-Ts≤0°C

Off

Page 40

37

The others modes:

When compressor is on, outdoor fan will follow the below rules:

When T3≥33℃, the two fan run at the same time.

When T3≤30℃, the above fan is on, the below fan is off.

8.3.3.2 Action of Indoor Fan

HIGH/ MED /LOW/AUTO fan can be switched over by your comfort.

Auto fan under cooling mode.

MFE-60ARN1-RB4W(2T0043800036)

5.0

4.0

High

Low

2.0

Medium

3.0

The others modes:

8.3.3.3 Low evaporator coil temperature T2 protection

MFE-60ARN1-RB4W(2T0043800036)

AC will enter T2 protection if any of the following conditions is satisfied.

Condition 1:

T2CoolExit

T2

On

Off

T2CoolIn

Condition

Compressor and outdoor fan

T1-Ts≥1°C and compressor is off reac

hes up to over 3 minutes

On

Ts-T1>1°C

Off

Condition

Fan speed

T1-Ts≥4°C

High

2°C ≤ T1-Ts < 4°C

Med

T1-Ts < 2°C

Low

Page 41

38

When the evaporator coil temp.T2 keeps lower than T2CoolIn for 30 minutes, the

compressor and outdoor fan will shut off. When T2 is higher than T2CoolExit, the

compressor and outdoor fan will restart up.

Condition 2:

T2CoolExit

T2

On

Off

T2CoolIn-2

When the evaporator coil temp.T2 keeps lower than T2CoolIn-2 for 20 minutes, the

compressor and outdoor fan will shut off. When T2 is higher than T2CoolExit, the

compressor and outdoor fan will restart up.

Condition 3:

T2CoolExit

T2

On

Off

T2CoolIn-4

When the evaporator coil temp.T2 keeps lower than T2CoolIn-4 for 8 minutes, the

compressor and outdoor fan will shut off. When T2 is higher than T2CoolExit, the

compressor and outdoor fan will restart up.

The others modes:

When T2≤-1℃ and lasts for 4 minutes, the indoor has no capacity demand and resume

till T2≥10℃.

8.3.3.4 Condenser high temperature T3 protection

When T3≥T3CoolStop_ADD℃ for 3 seconds, the compressor will shut off. When T3<

T3CoolRts_ADD℃,the compressor will restart.

Model

T3CoolStop_ADD

T3CoolRts_ADD

MFE-60AMN1-RB4W

65

60

MFE-60ARN1-RB4W

(2T0043800026)

65

60

MFE-60ARN1-RB4W

65

48

Page 42

39

(2T0043800036)

8.3.4 Dehumidifying mode

8.3.4.1 Indoor fan speed is low.

8.3.4.2 Four-way valve is closed, the compressor and outdoor fan will operate the same

as in cooling mode.

8.3.5 Auto Mode

MFE-60ARN1-RB4W (2T0043800036):

8.3.5.1. Under auto mode, the indoor fan is set to be auto.

8.3.5.2 When entering auto mode, the heating, fan only or cooling operation will be

automatically chosen according to the room temperature T1 and the set temperature Ts.

Condition

Mode

T1-Ts>1°C

Cooling

-1°C≤ T1-Ts≤1°C

Fan

T1-Ts<-1°C

Heating(fan for cooling only type)

Indoor fan will run at auto fan of the relevant mode.

The louver operates same as in relevant mode.

If the machine switches mode between heating and cooling, the compressor will keep

stopping for 15 minutes and then choose mode according to T1-Ts.

If the setting temperature is modified, the machine will choose running function again.

The others models:

8.3.5.1. Under auto mode, the indoor fan is set to be auto.

8.3.5.2 When entering auto mode, the heating, fan only or cooling operation will be

automatically chosen according to the room temperature T1 and the set temperature Ts.

Condition

Mode

3°C ≤T1-Ts

Cooling

-3°C ≤ T1-Ts≤3°C

Fan

T1-Ts<-3°C

Heating(fan for cooling only type)

8.3.5.3. After one mode is chosen, the operation mode will be re-chosen according to the

T1 and Ts.

Condition

Mode

3°C ≤T1-Ts

Cooling

-3°C ≤ T1-Ts≤3°C

Former mode

T1-Ts<-3°C

Heating(fan for cooling only type)

8.3.6 Fan Only mode

MFE-60ARN1-RB4W (2T0043800036):

8.3.6.1 Temperature setting function is disabled, and no setting temperature is displayed.

8.3.6.2 Under this mode, four-way valve, compressor and outdoor fan are shut down.

8.3.6.3 High/Low/Auto fan can be switched over through manual control. Auto fan will be

Page 43

40

controlled in line with cooling auto fan with temperature set to be 24°C.

The others models:

8.3.6.1 Under this mode, four-way valve, compressor and outdoor fan are shut down,

indoor fan keeps on.

8.3.6.2 High/Med/Low/Auto fan can be switched over through manual control.

8.3.6.3 Under auto mode, the indoor fan is set to be Med.

8.4 Other functions

8.4.1 LCD display

Mode, Set temperature, fan speed, time, timer, etc.

8.4.2 Timer

The machine should be provided with max. Interval of 24h.

9. Trouble shooting

9.1 Self-diagnosis

MFE-60ARN1-RB4W (2T0043800036):

Codes

Contents

P4

Protection of temperature of indoor evaporator

P5

Protection of temperature of outdoor condenser

P7

Compressor discharge temperature protection

P9

Protection of anti-cold wind

P10

Low pressure protection

P11

High pressure protection

P12

Current overload protection

E1

Open- or short-circuit of T1 temperature sensor

E2

Open- or short-circuit of T2 temperature sensor

E3

Open- or short-circuit of T3 temperature sensor

E4

Open- or short-circuit of T4 temperature sensor

E5

Communication malfunction between indoor unit and outdoor unit

E10

Low pressure failure of compressor

E13

Lack of phase

E14

Default phase of compressor

E15

Indoor fan speed is out of control

EC

Refrigerant Leakage Detection

Page 44

41

The others models:

Codes

Contents

E01

The temp. sensor is open or short-circuit.

E02

Compressor is over current

E04

Outdoor unit protection

P02

Compressor is over load

P03

The temperature of evaporator coil of indoor unit is too low (when coo

ling)

P04

The temperature of evaporator coil of indoor unit is too high (when he

ating)

P05

The temperature of air outlet of indoor unit is too high (when heating)

9.2 LEDs for the indication of outdoor trouble

In normal operation, LEDs emit no light and they will flash at a frequency of 2Hz w

hen trouble occurs. Their codes are listed in the following table:

MFE-60ARN1-RB4W (2T0043800036):

Type

Contents

LED2(green)

LED3(yellow)

LED4(red)

Normal

Normal running

Light

Off

Off

Normal

Normal standby

Off

Light

Off

Trouble

Phase sequence

Off

Flash

Off

Trouble

Lack of phase

Off

Off

Flash

Trouble

Protection of low pressure

Flash

Off

Flash

Trouble

Protection of high pressure

Flash

Flash

Off

Trouble

Overload of current

Off

Flash

Light

Trouble

Communication malfunction

Off

Flash

Flash

Trouble

Open- or short-circuit of T3

temperature sensor

Off

Off

Light

Trouble

Open- or short-circuit of T4

temperature sensor

Flash

Off

Off

Trouble

Discharge temperature protection of

compressor

Light

Off

Light

Trouble

High temperature protection of condenser

Flash

Flash

Light

Trouble

Fan jump selection error

Flash

Flash

Flash

The others models:

Type

Contents

LED1

LED2

LED3

Trouble

Phase sequence or Lack of phase(A ,B)

Flash

Off

Off

Page 45

42

Trouble

Lack of phase(C)

Off

Off

Off

Trouble

Protection of low pressure

Flash

Flash

Off

Trouble

Overload of current

Off

Off

Flash

Trouble

Communication malfunction

Flash

Off

Flash

Trouble

Open- or short-circuit of T3 temperature sensor

Off

Flash

Flash

Trouble

Open- or short-circuit of T4 or T5 temperature sensor or

protection of high pressure

Off

Flash

Off

Trouble

High temperature protection of condenser

Flash

Flash

Flash

Note: When the machine stands by, LED1- LED3 flashes in low speed.

9.3 Troubles and solutions

Before calling for service, please review the following list of common problems and

solutions.

Problem

Possible Cause

Solutions

Unit Idleness

No electric power supply

Wait for power recovery

Power Switch turned off

Turn on the switch

Fuse blew

Replace the fuse

Air flow but poo

r cooling (heatin

g)

Improper temperature setting

Readjust the temp. to a lo

wer degree. See ‘OPERAT

IONS’ for details

The air -filter blocked

Clean the air- filter

Air inlet/outlet blocked

Clear the air inlet/outlet

Windows/door are open

Close windows/door

Air flow but no

cooling (heating)

The air inlet/outlet of indoor/outdoor

unit are blocked up by something

Remove the obstacles whi

ch blocks the air inlet/outl

et

Too much dust or dirt on the airfilter

Clean the air-filter

Page 46

43

9.3.1 Open or short circuit of temperature sensor

Open or short circuit of

temperature sensor

Check the connections

between temperature

sensor and PCB. Are

the connections good?

Correct the connections.No

Yes

Yes Replace indoor or outdoor PCB.

Replace the sensor

Check the resistance value

of the sensor via Appendix 1

Is it normal?

No

9.3.2 Default phase of compressor

Page 47

44

9.3.3 Phase sequence error

9.3.4 High temperature protection of condenser

High temperature protection of condenser

Check the resistance of the temp. sensor

according to Appendix 1, is it normal?

Possible reason

1. Air or other gas in the refrigerant.

2. Heat exchanger is dirty

3. Outdoor fan or fan blade is defective

4. Outdoor unit is bad ventilation

5. Refrigerant is leakage

6. Outdoor PCB is defective

Replace the sensor

No

Yes

Phase sequence error

Change the order of the wires to power supply.

Switch on the unit again.

If the problem cannot be solved, the outdoor PCB is defective

Page 48

45

9.3.5 High pressure protection

9.3.6 Low temperature protection

9.3.7 Low pressure protection

Low temperature protection

Possible reason

1: The outdoor ambient temp. is low.

2: The wires are loose to the temp. sensor.

3: The temp. sensor is defective.

4: The evaporator or the filter is dirty.

5: System has block.

Low pressure protection

Possible reason

1: The wires are loose to the pressure switch.

2: The pressure switch is defective.

3: System has refrigerant leakage.

4: The evaporator or the filter is dirty.

5: System has block.

Page 49

46

9.3.8 Overload of current

Page 50

47

9.3.9 Indoor / outdoor unit communication error

Page 51

48

Yes

Yes

Measure Vs, is it moving alternately

between positive value and negative

value?

(Vs is the voltage between S and N of

outdoor unit.)

Yes

Power off, then turn on the unit 5 seconds

later(reconnect the power wire).Is the error

still displaying after several minutes?

No

Yes

Change the outdoor main PCB.

Power on. Is the error extinguished?

Check all the wirings between indoor and

outdoor, indoor PCB and outdoor PCB

following the wiring diagram. Are all the

wirings connected correctly?

Change the indoor main PCB.

Yes

Change the outdoor main PCB.

No

Is the wiring to the outdoor PCB

connected correctly?

Power on. Is the error extinguished?

Change the indoor main PCB.

No

Is the wiring to the indoor PCB

connected correctly?

Page 52

49

9.3.10 Refrigerant Leakage Detection

Is there cool air blowing

out from indoor air outlet?

Yes

Yes

Check if T2 sensor is well

fixed. Correct the installation

or replace T2 sensor. Does

the problem remain again?

No

Is there any leakage? Especially

the connection parts, such as the

gas valve and the liquid valve.

No

Shut off the power supply and

turn it on 5 seconds later. Is it

still displaying the error code?

Replace indoor PCB.

Yes

Repair the leakage and

recharge the refrigerant.

Yes

Clear the blocking.

Yes

Is there any block i n g ? (Such as the

capillary or the welded points of the pipes.)

Page 53

50

9.3.11 Indoor fan speed has been out of control

Shut off the power supply

and turn it on 5 seconds

later. Is it still displaying

the error code?

Shut off the power supply,

rotate the fan by hand.

Does it rotate properly?

The unit operates normally.

Find out the cause and

have it solved. For

example, check

whether the fan is

blocked or the bearing

is broken?

Check the wires of fan

motor. Are all the

connections good?

No

Yes

No

Correct the connections.No

Yes

Yes

Check whether the fan

motor is normal through

index 1?

Replace the fan

motor

No

If the

malfunction is

still existing,

replace the

main PCB

Page 54

51

Index 1:

1 DC Fan Motor(control chip is in PCB)

NO. 1 2 3 4

5

Color

Orange

Grey

White

Pink

Black

Signal

Hu

Hv

Hw

Vcc

GND

Color

Red

Blue

Yellow

Signal

W V U

1) Release the UVW connector. Measure the resistance of U-V, U-W, V-W. If the

resistance is not equal to each other, the fan motor must has problems and need to be

replaced. Otherwise, go to step 2.

2) Power on and when the unit is in standby, measure the voltage of pin4-5 in feedback

signal connector. If the value is not 5V, change the PCB. Otherwise, go to step 3.

3) Rotate the fan by hand, measure the voltage of pin1-5, pin 2-5 and pin 3-5 in feedback

signal connector. If any voltage is not positive voltage fluctuation, the fan motor must

has problems and need to be replaced.

Page 55

52

9.3.12 Temperature protection of compressor discharge

Temperature protection of

compressor discharge

Check whether the

compressor discharge temp.

is more than 115°C ?

Check whether the wiring

connection is right between

compressor discharge temp.

sensor and PCB according

to wiring diagrams?

Method: Check whether the

resistance of compressor

discharge temp. sensor is

right refer to the Appendix 2

No

Yes

Yes

Trouble is solved

No

Judge: The

discharge temp.

sensor is broken

Check whether the

refrigerant is leak

Correct the wiring connection

Stop leaking and add refrigerant

Replace the compressor discharge temp. sensor

No

Yes

Replace outdoor main board

Yes

Page 56

53

Appendix Temp. Sensor Resistance Value Table (℃--K)

℃

K Ohm

℃

K Ohm

℃

K Ohm

℃

K Ohm

-20

115.266

20

12.6431

60

2.35774

100

0.62973

-19

108.146

21

12.0561

61

2.27249

101

0.61148

-18

101.517

22

11.5000

62

2.19073

102

0.59386

-17

96.3423

23

10.9731

63

2.11241

103

0.57683

-16

89.5865

24

10.4736

64

2.03732

104

0.56038

-15

84.2190

25

10.000

65

1.96532

105

0.54448

-14

79.3110

26

9.55074

66

1.89627

106

0.52912

-13

74.5360

27

9.12445

67

1.83003

107

0.51426

-12

70.1698

28

8.71983

68

1.76647

108

0.49989

-11

66.0898

29

8.33566

69

1.70547

109

0.48600

-10

62.2756

30

7.97078

70

1.64691

110

0.47256

-9

58.7079

31

7.62411

71

1.59068

111

0.45957

-8

56.3694

32

7.29464

72

1.53668

112

0.44699

-7

52.2438

33

6.98142

73

1.48481

113

0.43482

-6

49.3161

34

6.68355

74

1.43498

114

0.42304

-5

46.5725

35

6.40021

75

1.38703

115

0.41164

-4

44.0000

36

6.13059

76

1.34105

116

0.40060

-3

41.5878

37

5.87359

77

1.29078

117

0.38991

-2

39.8239

38

5.62961

78

1.25423

118

0.37956

-1

37.1988

39

5.39689

79

1.21330

119

0.36954

0

35.2024

40

5.17519

80

1.17393

120

0.35982

1

33.3269

41

4.96392

81

1.13604

121

0.35042

2

31.5635

42

4.76253

82

1.09958

122

0.3413

3

29.9058

43

4.57050

83

1.06448

123

0.33246

4

28.3459

44

4.38736

84

1.03069

124

0.32390

5

26.8778

45

4.21263

85

0.99815

125

0.31559

6

25.4954

46

4.04589

86

0.96681

126

0.30754

7

24.1932

47

3.88673

87

0.93662

127

0.29974

8

22.5662

48

3.73476

88

0.90753

128

0.29216

9

21.8094

49

3.58962

89

0.87950

129

0.28482

10

20.7184

50

3.45097

90

0.85248

130

0.27770

11

19.6891

51

3.31847

91

0.82643

131

0.27078

12

18.7177

52

3.19183

92

0.80132

132

0.26408

13

17.8005

53

3.07075

93

0.77709

133

0.25757

14

16.9341

54

2.95896

94

0.75373

134

0.25125

15

16.1156

55

2.84421

95

0.73119

135

0.24512

16

15.3418

56

2.73823

96

0.70944

136

0.23916

17

14.6181

57

2.63682

97

0.68844

137

0.23338

18

13.9180

58

2.53973

98

0.66818

138

0.22776

19

13.2631

59

2.44677

99

0.64862

139

0.22231

Page 57

54

Appendix 2

Unit: ℃---K Discharge temp. sensor table

-20

542.7

20

68.66

60

13.59

100

3.702

-19

511.9

21

65.62

61

13.11

101

3.595

-18

483

22

62.73

62

12.65

102

3.492

-17

455.9

23

59.98

63

12.21

103

3.392

-16

430.5

24

57.37

64

11.79

104

3.296

-15

406.7

25

54.89

65

11.38

105

3.203

-14

384.3

26

52.53

66

10.99

106

3.113

-13

363.3

27

50.28

67

10.61

107

3.025

-12

343.6

28

48.14

68

10.25

108

2.941

-11

325.1

29

46.11

69

9.902

109

2.86

-10

307.7

30

44.17

70

9.569

110

2.781

-9

291.3

31

42.33

71

9.248

111

2.704

-8

275.9

32

40.57

72

8.94

112

2.63

-7

261.4

33

38.89

73

8.643

113

2.559

-6

247.8

34

37.3

74

8.358

114

2.489

-5

234.9

35

35.78

75

8.084

115

2.422

-4

222.8

36

34.32

76

7.82

116

2.357

-3

211.4

37

32.94

77

7.566

117

2.294

-2

200.7

38

31.62

78

7.321

118

2.233

-1

190.5

39

30.36

79

7.086

119

2.174

0

180.9

40

29.15

80

6.859

120

2.117

1

171.9

41

28

81

6.641

121

2.061

2

163.3

42

26.9

82

6.43

122

2.007

3

155.2

43

25.86

83

6.228

123

1.955

4

147.6

44

24.85

84

6.033

124

1.905

5

140.4

45

23.89

85

5.844

125

1.856

6

133.5

46

22.89

86

5.663

126

1.808

7

127.1

47

22.1

87

5.488

127

1.762 8 121

48

21.26

88

5.32

128

1.717

9

115.2

49

20.46

89

5.157

129

1.674

10

109.8

50

19.69

90 5 130

1.632

11

104.6

51

18.96

91

4.849

12

99.69

52

18.26

92

4.703

13

95.05

53

17.58

93

4.562

14

90.66

54

16.94

94

4.426

15

86.49

55

16.32

95

4.294

B(25/50)=3950K

16

82.54

56

15.73

96

4.167

17

78.79

57

15.16

97

4.045

R(90℃)=5KΩ±3%

18

75.24

58

14.62

98

3.927

19

71.86

59

14.09

99

3.812

Loading...

Loading...