Page 1

MCAC-UTSM-2009-03 Contents

Contents i

Part 1 General Information ........................................................................ 1

Part 2 Indoor Units ...................................................................................... 5

Part 3 Outdoor Units ................................................................................. 17

Part 4 Installation ...................................................................................... 36

Part 5 Control ............................................................................................ 56

※The specifications, designs, and information in this book are subject to change without notice for

product improvement.

Page 2

Page 3

MCAC-UTSM-2009-03 General Information

General Information 1

Part 1

General Information

1. Model Names of Indoor/Outdoor Units ....................... 2

2. External Appearance ..................................................... 2

2.1 Indoor Units .................................................................................. 2

2.2 Outdoor Units ............................................................................... 2

3. Nomenclature ................................................................ 3

4. Features ......................................................................... 4

Page 4

Model Names of Indoor/Outdoor Units MCAC-UTSM-2009-03

2 General Information

1. Model Names of Indoor/Outdoor Units

1.1 Indoor Units

Model name Dimension (mm) Net/Gross weight (kg) Power supply

MFA-12HRN1

Width: 700

Height: 600

Depth: 210

15/20 220~240V-1ph-50Hz

MFA-18HRN1

Width: 700

Height: 600

Depth: 210

15/20 220~240V-1ph-50Hz

MFA-12HRN1-Q

Width: 700

Height: 600

Depth: 210

20/25 220~240V-1ph-50Hz

1.2 Outdoor Units

Model name Dimension (mm) Net/Gross weight (kg) Power supply

MON-12HN1

Width: 780

Height: 547

Depth: 250

34/38 220~240V-1ph-50Hz

MON-18HN1

Width: 842

Height: 695

Depth: 324

52/56 220~240V-1ph-50Hz

MON-12HN1-Q

Width: 780

Height: 547

Depth: 250

35/39 220~240V-1ph-50Hz

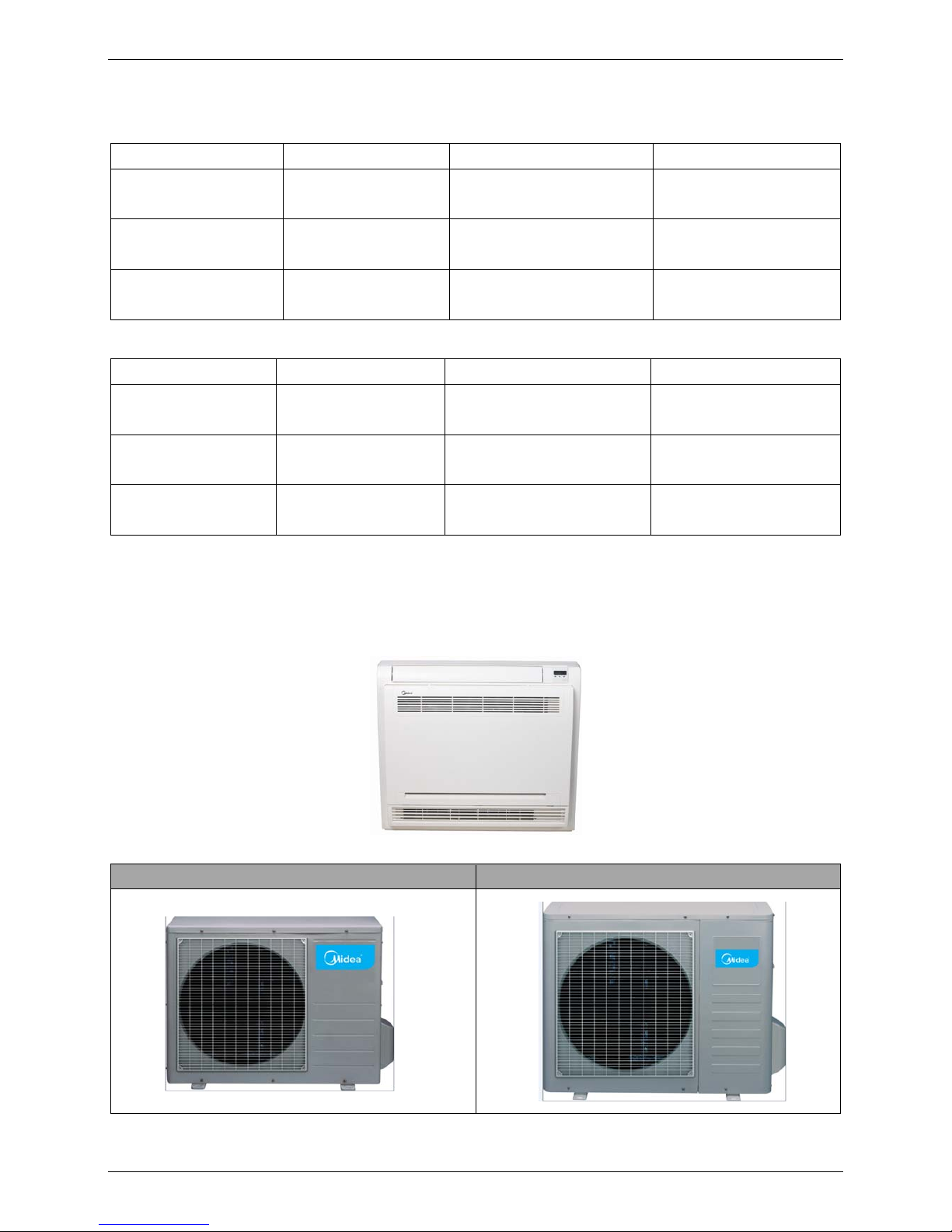

2. External Appearance

2.1 Indoor Units

MFA-12HRN1/MFA-18HRN1/MF A -12HRN1-Q

2.2 Outdoor Units

12,000Btu/h 18,000Btu/h

Page 5

MCAC-UTSM-2009-03 Nomenclature

General Information 3

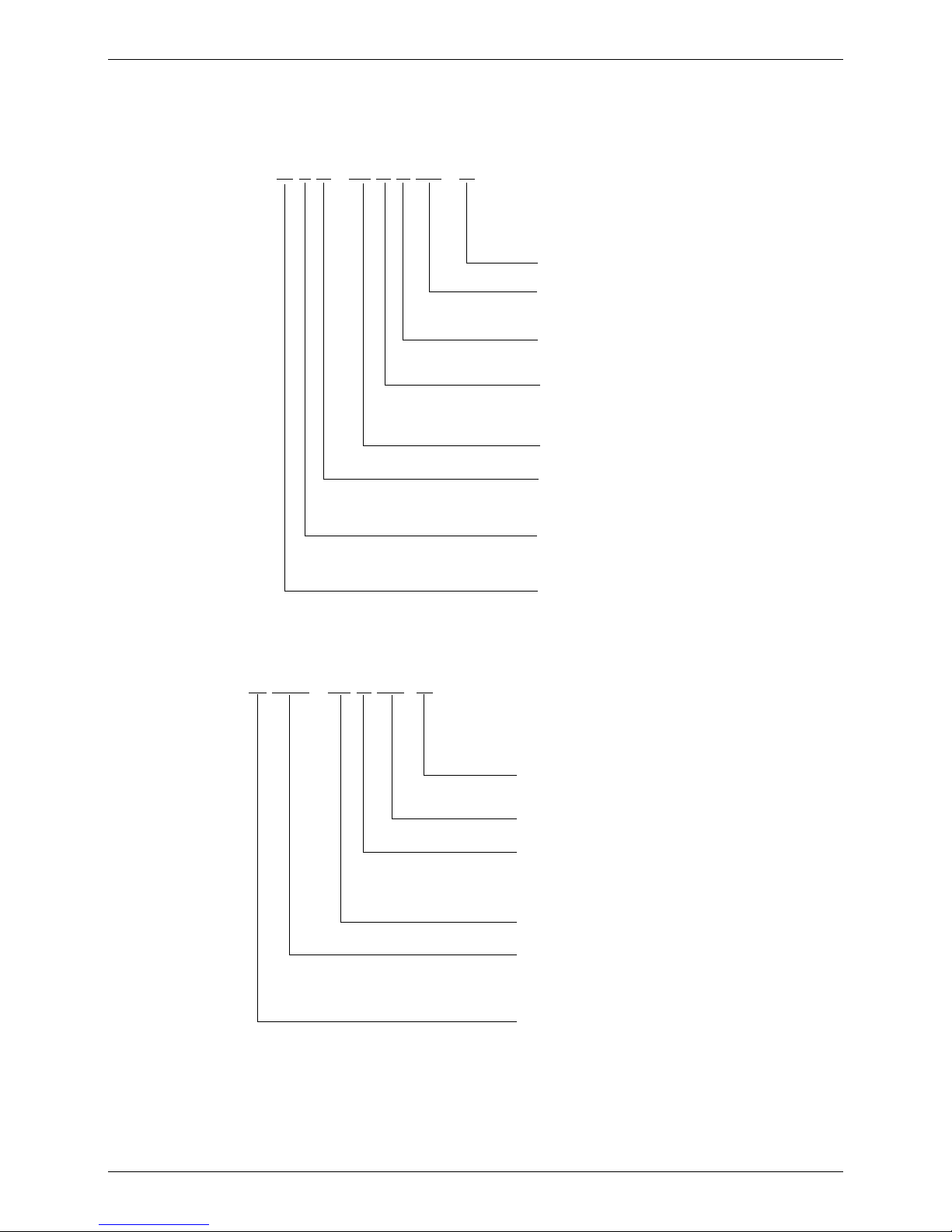

3. Nomenclature

3.1 Indoor Unit

M F A - 12 H R N1 - Q

Q: Quickly Coupling

Refrigerant Type

N1 : R410A

Control Mode

R: Remote Control

Function Code

C: Cooling Only

H: Cooling & Heating

Capacity (×1000Btu/h)

Product Series

A: 1st Designed

Product Category

F: Console Type

Midea

3.2 Outdoor Unit

M O N - 12 H N1- Q

Q: Quickly Coupling

Refrigerant

N1: R410A

Function Code

C: Cooling Only

H: Cooling & Heating

Capacity (×1000Btu/h)

Non-universal Outdoor Unit

O: Outdoor unit

N: Non-universal

Midea

Page 6

Features MCAC-UTSM-2009-03

4 General Information

4. Features

1. Achieves set temperature more quickly

——air supplying from top and bottom or from top only

——air inlet from four directions

2. Compact unit body, space saving

——this unit body is very thin and harmonious with room. It is beautiful, elegant and space saving.

——light weight and compact.

3. Flexible installation

——can be used for floor standing or lower wall applications

4. High efficiency filter

——built in Formaldehyde nemesis filter

——active-carbon and biological anti-virus filter is optional.

5. Comfort

——flexible air blow: vertical auto swing and wide angle louvers ensure that warm air reaches the furthest

corners of the room and increase the air flow coverage

——Low noise operation

——Low starting power and precise room temperature adjustment

6. Powerful mode can be selected for rapid cooling or heating.

7. Easy cleaning grille and maintenance

Page 7

MCAC-UTSM-2009-03 Indoor Units

Indoor Units 5

Part 2

Indoor Units

1. Specifications ................................................................ 6

2. Dimensions .................................................................... 7

3. Service Space ................................................................ 7

4. Wiring Diagrams ............................................................ 8

5. Air Velocity and Temperature Distributions ............... 9

6. Capacity Tables ........................................................... 10

7. Electric Characteristics .............................................. 13

8. Sound Levels ............................................................... 13

9. Exploded View ............................................................. 14

10. Accessories ............................................................... 16

Page 8

Specifications MCAC-UTSM-2009-03

6 Indoor Units

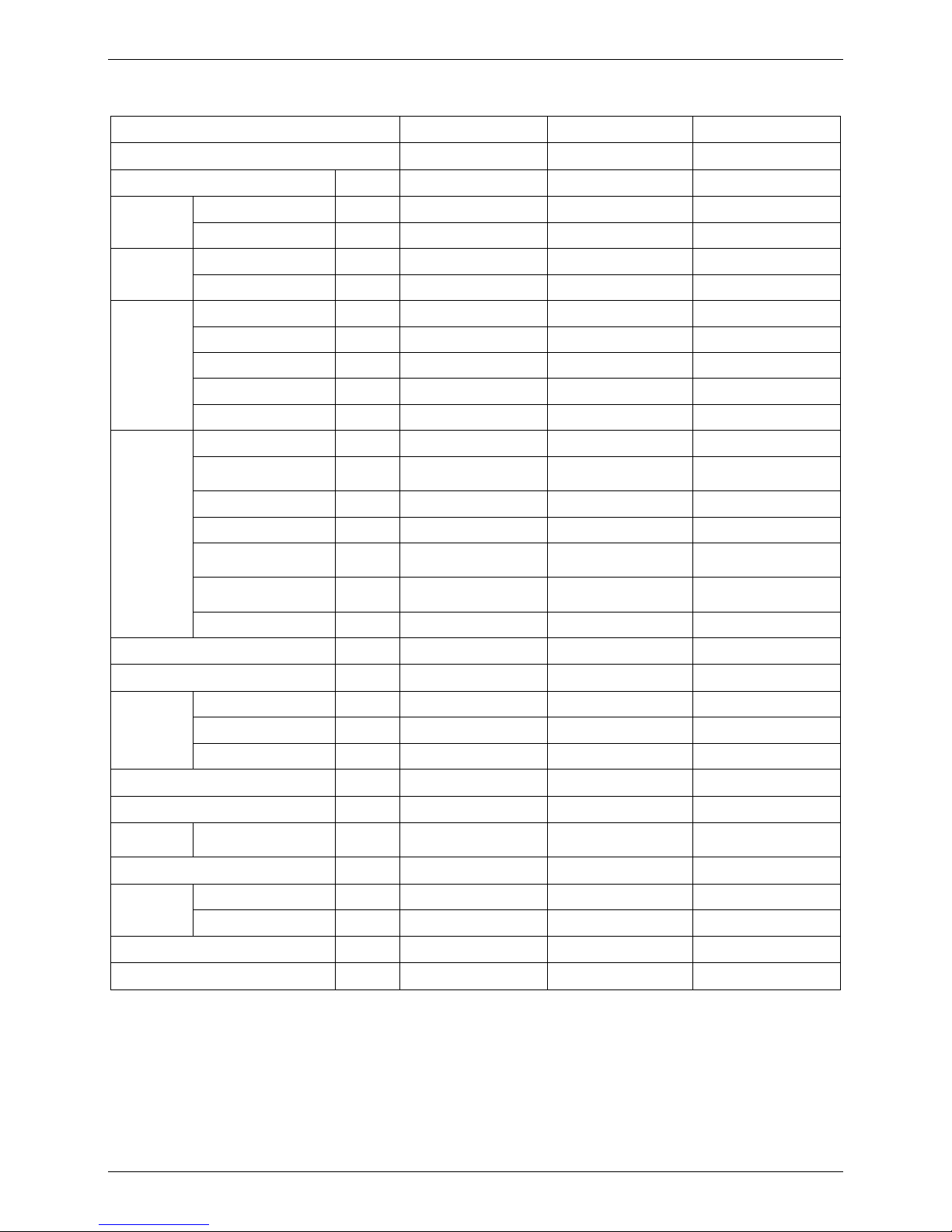

1. Specifications

Model MFA-12HRN1 MFA-18HRN1 MFA-12HRN1-Q

Code 220044000090 220044100280 220044000100

Power supply V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50

Cooling

Capacity Btu/h 12000 18000 12000

Input W 1096 1650 1101

Heating

Capacity Btu/h 13380 19600 13300

Input W 1122 1715 1117

Indoor fan

motor

Model RD-280-20-8A RD-280-20-8A RD-280-20-8A

Type DC MOTOR DC MOTOR DC MOTOR

Input W 24.5/19.5/16.8/13/10.5 38/33.5/24.5/15.2 24.5/19.5/16.8/13/10.5

Capacitor uF / / /

Speed(Hi/Mi/Lo) r/min 680/610/560/460/420 890/840/780/680/530 680/610/560/460/420

Indoor coil

Number of rows 2 2 2

Tube pitch(a)×row

pitch(b)

mm 21×13.37 21×13.37 21×13.37

Fin spacing mm 1.3 1.3 1.3

Fin type (code) Hydrophilic aluminum Hydrophilic aluminum Hydrophilic aluminum

Tube outside dia. and

type

mm

Ф7 Inner grooved

copper tube

Ф7 Inner grooved

copper tube

Ф7 Inner grooved

copper tube

Coil length× height ×

width

mm 512×378×26.74 512×378×26.74 512×378×26.74

Number of circuits 2 2 2

Indoor air flow(Hi/Mi/Lo) m3/h 550/490/460/380/350 740/700/640/560/440 550/490/460/380/350

Indoor noise level (sound pressure) dB(A) 35/33/31/27/23 38/35/33/31/29 35/33/31/27/23

Indoor unit

Dimension (W×H×D) mm 700×600×210 700×600×210 700×600×210

Packing (W×H×D) mm 810×710×305 810×710×305 810×710×365

Net/Gross weight kg 15/20 15/20 20/25

Refrigerant type R410A R410A R410A

Design pressure MPa 4.2/2.0 4.2/2.0 4.2/2.0

Refrigerant

piping

Liquid side/ Gas side mm φ6.4/φ12.7 φ6.4/φ12.7 φ6.4/φ12.7

Drainage water pipe diameter mm φ16 φ16 φ16

Connection

wiring

Power wiring mm

2

3×1.5 3×2.5 3×1.5

Signal wiring mm2 4×1.5 4×2.5 4×1.5

Controller R51D/E(standard) R51D/E(standard) R51D/E(standard)

Operation temperature ℃ 17~30 17~30 17~30

Page 9

MCAC-UTSM-2009-03 Dimensions

Indoor Units 7

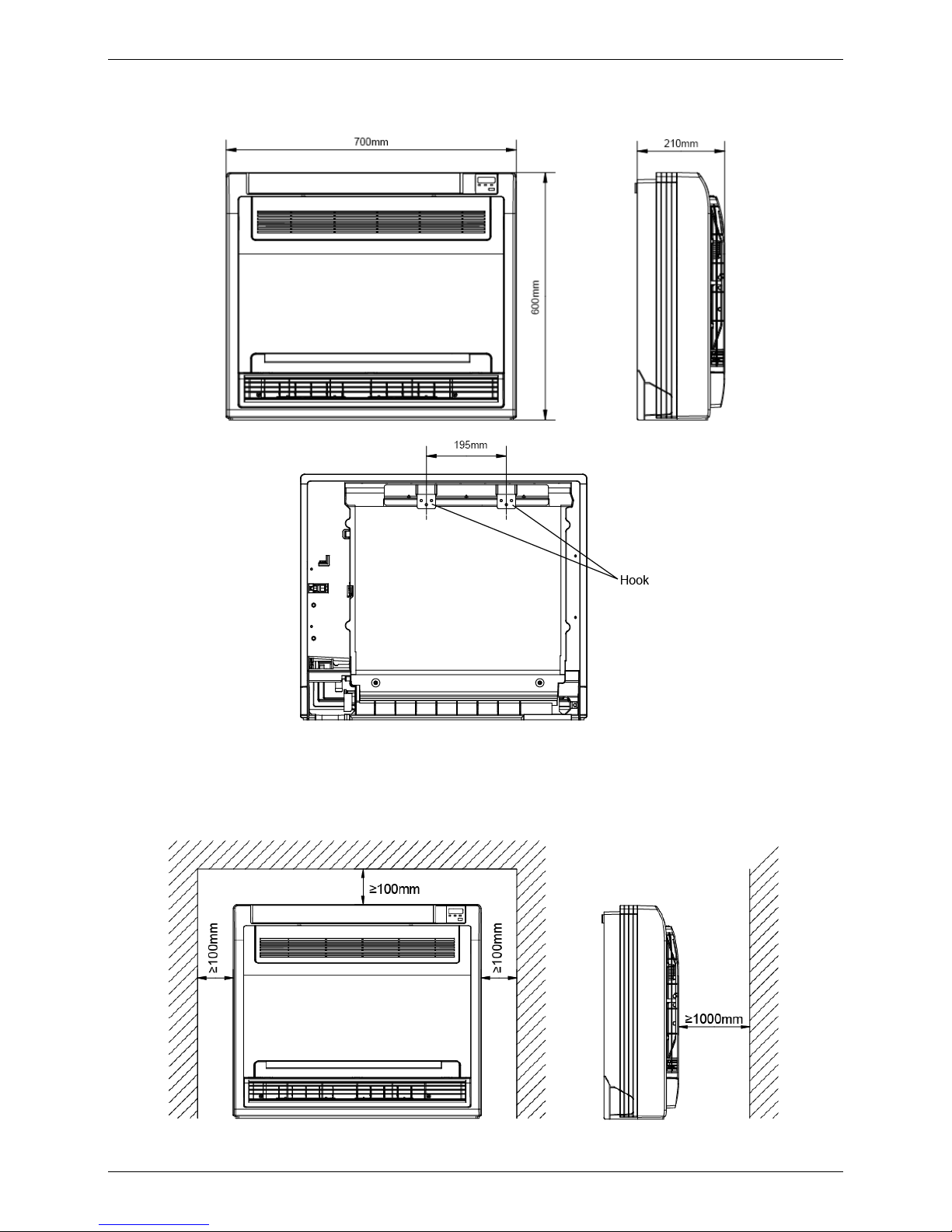

2. Dimensions

3. Service Space

Page 10

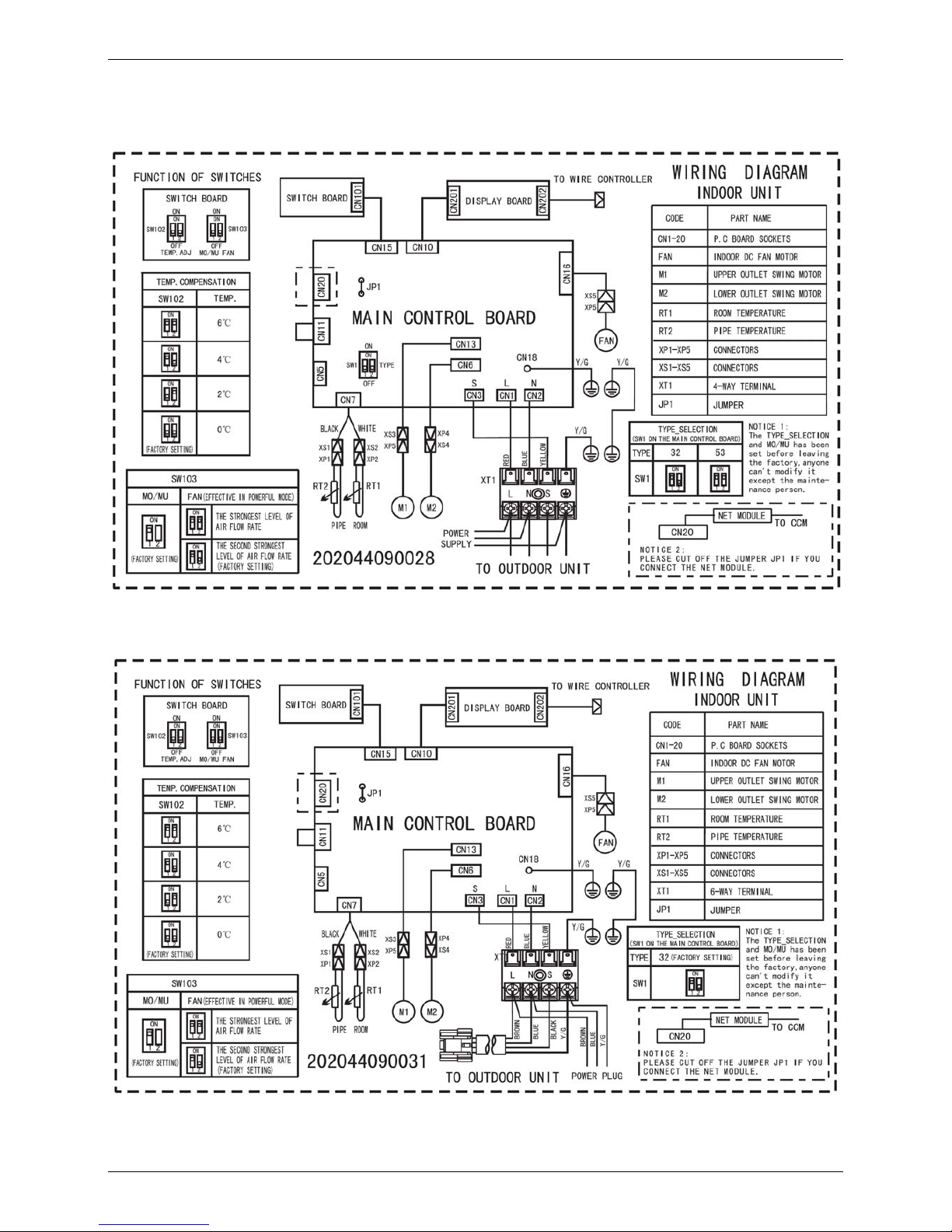

Wiring Diagrams MCAC-UTSM-2009-03

8 Indoor Units

4. Wiring Diagrams

4.1 MFA-12HRN1 MFA-18HRN1

4.2 MFA-12HRN1-Q

Page 11

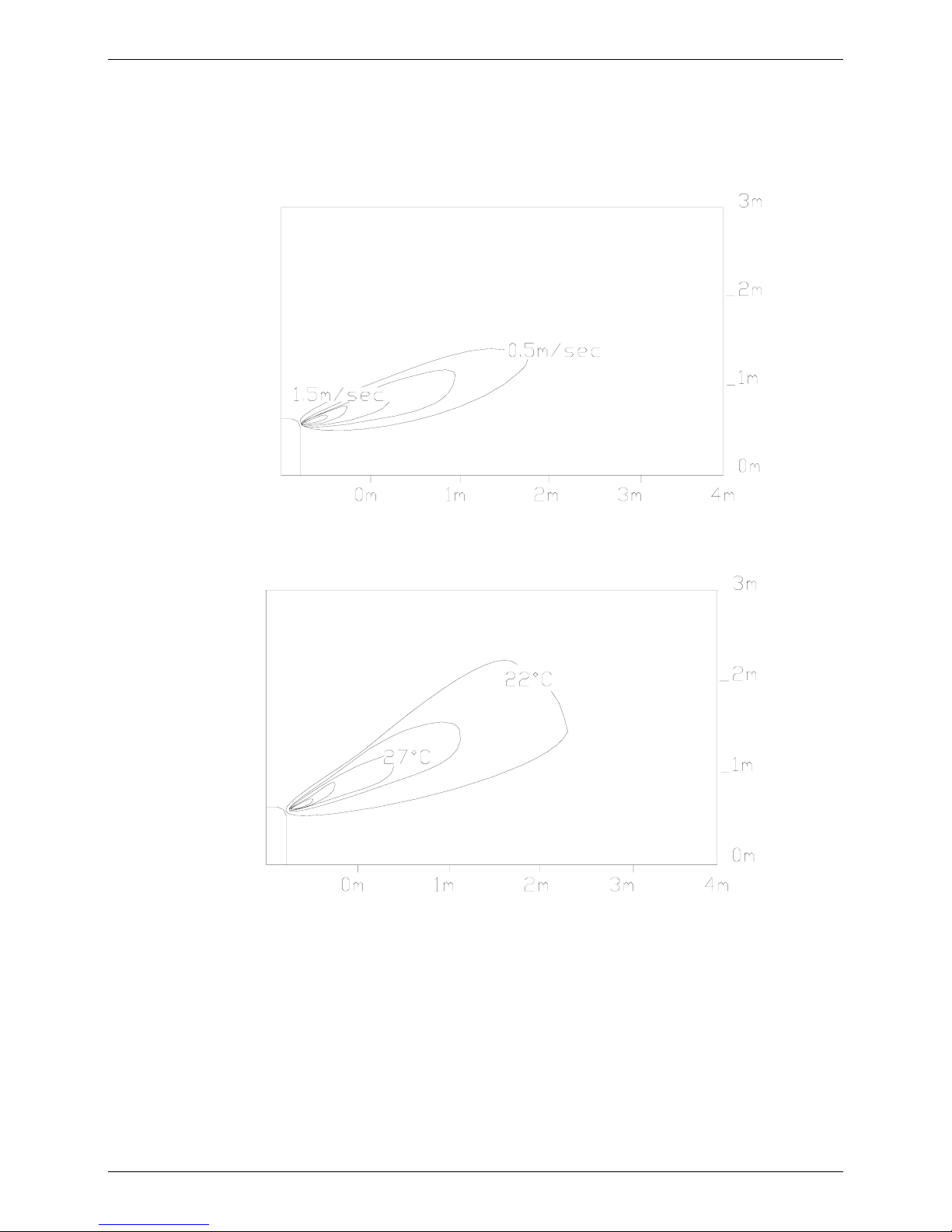

MCAC-UTSM-2009-03 Air Velocity and Temperature Distributions

Indoor Units 9

5. Air Velocity and Temperature Distributions

Discharge angle 60

Airflow velocity

Temperature

Page 12

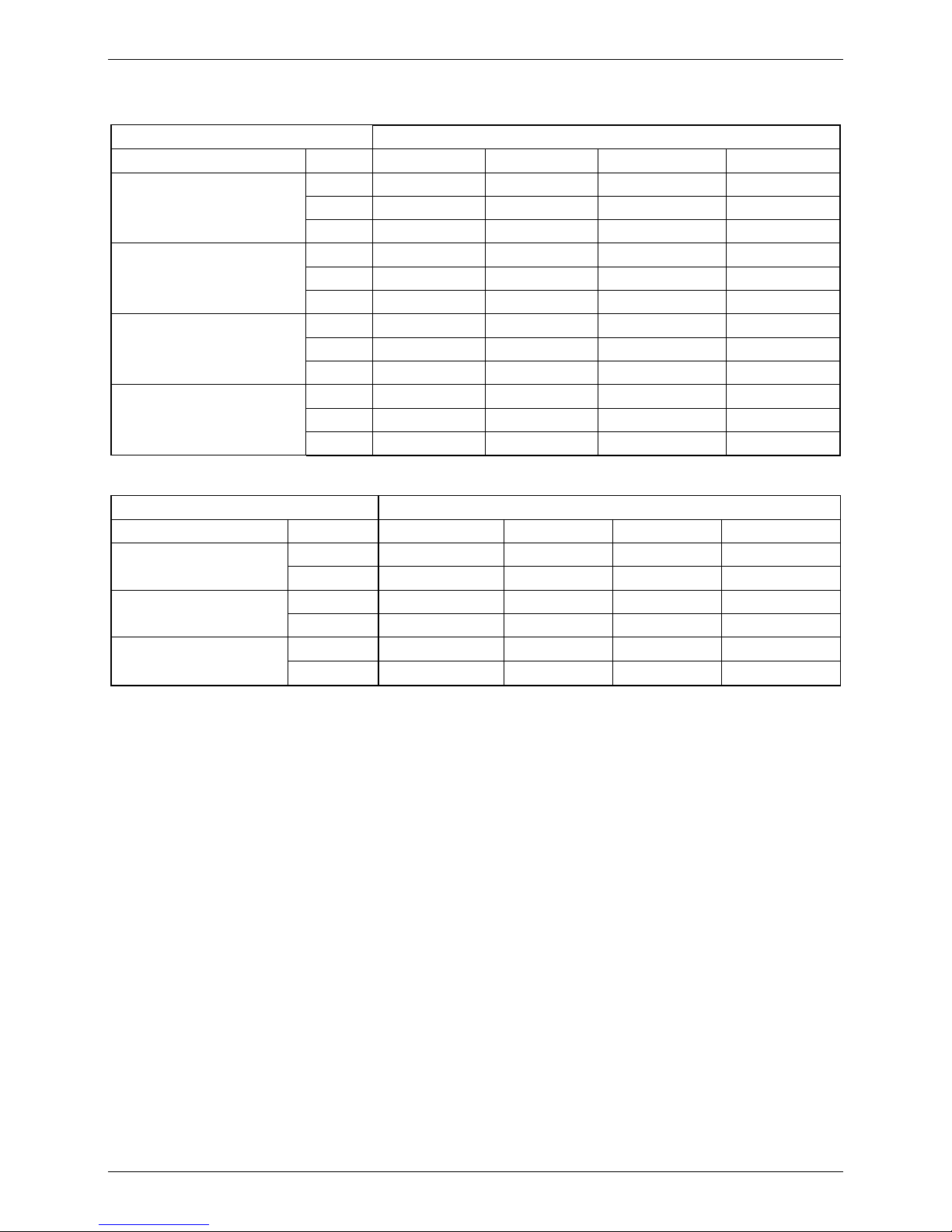

Capacity Tables MCAC-UTSM-2009-03

10 Indoor Units

6. Capacity Tables

6.1 MFA-12HRN1

Cooling capacity

Cooling Outdoor conditions (DB)

Indoor Conditions (kW) 21ºC 28ºC 35ºC 43ºC

21/15ºC DB/WB

TC 3.30 3.14 2.98 2.85

SC 2.44 2.41 2.38 2.39

Input 0.91 0.99 1.03 1.06

24/17ºC DB/WB

TC 3.39 3.23 3.07 2.88

SC 2.54 2.52 2.49 2.42

Input 0.96 1.03 1.07 1.13

27/19ºC DB/WB

TC 3.46 3.30 3.22 2.98

SC 2.56 2.54 2.50 2.44

Input 0.99 1.04 1.096 1.15

32/23ºC DB/WB

TC 3.52 3.39 3.33 3.07

SC 2.99 2.95 2.93 2.86

Input 1.03 1.07 1.15 1.19

Heating capacity

Heating Outdoor conditions

Indoor Conditions (DB) (kW) 24/18ºC DB/WB 7/6ºC DB/WB 2/1ºC DB/WB -5/-6ºC DB/WB

15ºC

TC 4.58 3.95 3.03 2.75

Input 1.21 1.04 0.90 0.84

20ºC

TC 4.44 3.92 2.85 2.68

Input 1.32 1.122 0.99 0.91

27ºC

TC 4.15 3.31 2.68 2.60

Input 1.40 1.21 1.07 0.99

Page 13

MCAC-UTSM-2009-03 Capacity Tables

Indoor Units 11

6.2 MFA-18HRN1

Cooling capacity

Cooling Outdoor conditions (DB)

Indoor Conditions (kW) 21ºC 28ºC 35ºC 43ºC

21/15ºC DB/WB

TC 5.46 5.19 4.93 4.72

SC 4.04 4.00 3.94 3.96

Input 1.32 1.43 1.50 1.55

24/17ºC DB/WB

TC 5.62 5.35 5.09 4.77

SC 4.21 4.18 4.12 4.01

Input 1.40 1.50 1.56 1.64

27/19ºC DB/WB

TC 5.72 5.46 5.30 4.93

SC 4.24 4.20 4.13 4.04

Input 1.43 1.51 1.65 1.67

32/23ºC DB/WB

TC 5.83 5.62 5.51 5.09

SC 4.96 4.89 4.85 4.73

Input 1.50 1.56 1.67 1.74

Heating capacity

Heating Outdoor conditions

Indoor Conditions (DB) (kW) 24/18ºC DB/WB 7/6ºC DB/WB 2/1ºC DB/WB -5/-6ºC DB/WB

15ºC

TC 7.80 6.30 5.16 4.68

Input 1.85 1.59 1.37 1.29

20ºC

TC 7.56 5.74 4.86 4.56

Input 2.02 1.715 1.51 1.39

27ºC

TC 7.08 5.64 4.56 4.44

Input 2.14 1.85 1.63 1.51

Page 14

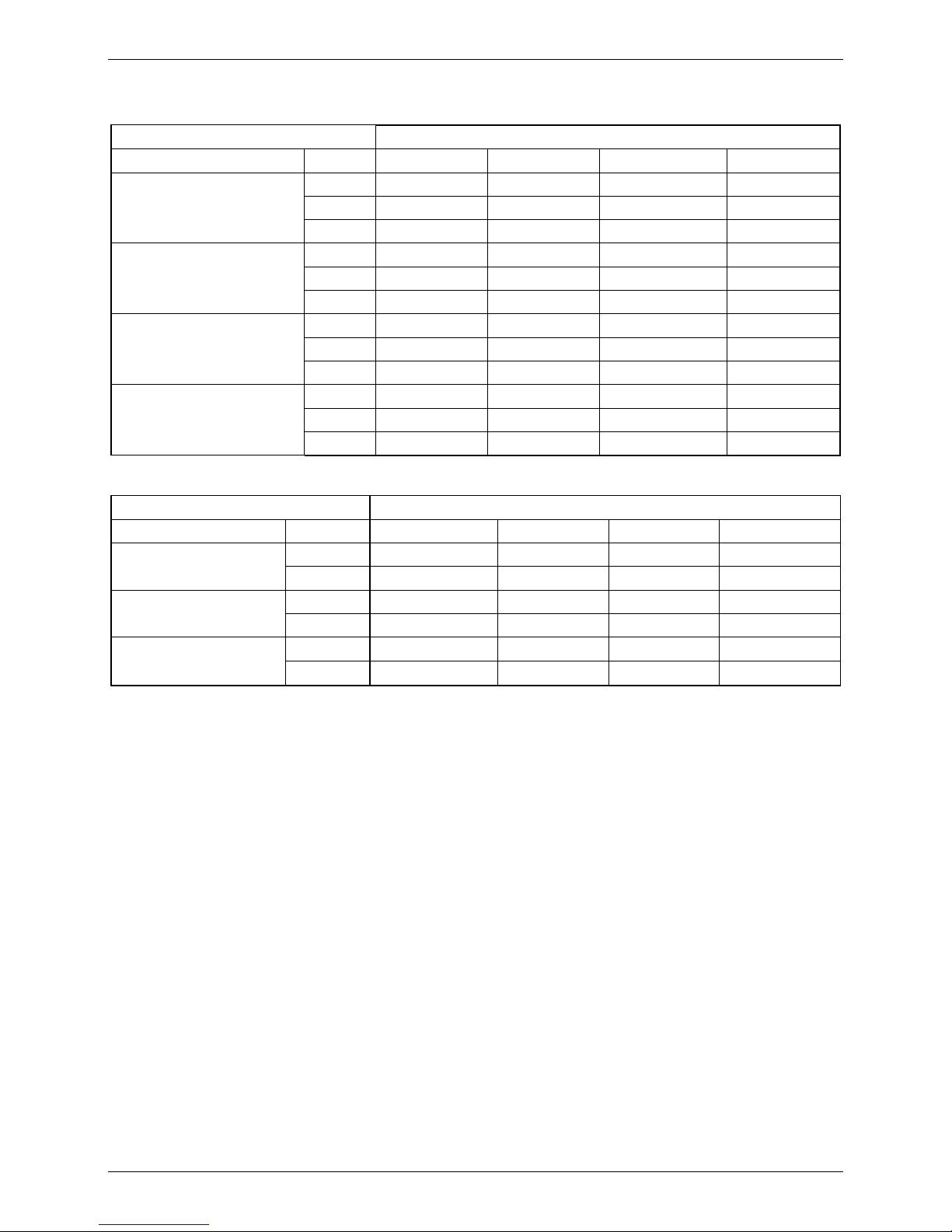

Capacity Tables MCAC-UTSM-2009-03

12 Indoor Units

6.3 MFA-12HRN1-Q

Cooling capacity

Cooling Outdoor conditions (DB)

Indoor Conditions (kW) 21ºC 28ºC 35ºC 43ºC

21/15ºC DB/WB

TC 3.30 3.14 2.98 2.85

SC 2.44 2.41 2.38 2.39

Input 0.91 0.99 1.03 1.07

24/17ºC DB/WB

TC 3.39 3.23 3.07 2.88

SC 2.54 2.52 2.49 2.42

Input 0.97 1.03 1.08 1.13

27/19ºC DB/WB

TC 3.46 3.30 3.21 2.98

SC 2.56 2.54 2.50 2.44

Input 0.99 1.05 1.101 1.16

32/23ºC DB/WB

TC 3.52 3.39 3.33 3.07

SC 2.99 2.95 2.93 2.86

Input 1.03 1.08 1.16 1.20

Heating capacity

Heating Outdoor conditions

Indoor Conditions (DB) (kW) 24/18ºC DB/WB 7/6ºC DB/WB 2/1ºC DB/WB -5/-6ºC DB/WB

15ºC

TC 4.58 3.70 3.03 2.75

Input 1.21 1.04 0.89 0.84

20ºC

TC 4.44 3.68 2.85 2.68

Input 1.32 1.117 0.98 0.90

27ºC

TC 4.15 3.31 2.68 2.60

Input 1.40 1.21 1.06 0.98

Remark:

TC: Total capacity; kW

SC: Sensible heat capacity; kW

Input: Input power; kW

Page 15

MCAC-UTSM-2009-03 Electric Characteristics

Indoor Units 13

7. Electric Characteristics

Model

Indoor Units Power Supply Indoor Fan Motor

Hz Voltage Min. Max. MCA MFA kW FLA

MFA-12HRN1(-Q) 50 220-240V 198V 254V 0.1 15 0.02 0.08

MFA-18HRN1 50 220-240V 198V 254V 0.156 20 0.02 0.125

Remark:

MCA: Min. Current Amps. (A)

MFA: Max. Fuse Amps. (A)

KW: Fan Motor Rated Output (kW)

FLA: Full Load Amps. (A)

8. Sound Levels

Model

Noise level dB(A)

Highest Higher H M L

MFA-12HRN1/ MFA-12HRN1-Q 35 33 31 27 23

MFA-18HRN1 38 35 33 31 29

Page 16

Exploded View MCAC-UTSM-2009-03

14 Indoor Units

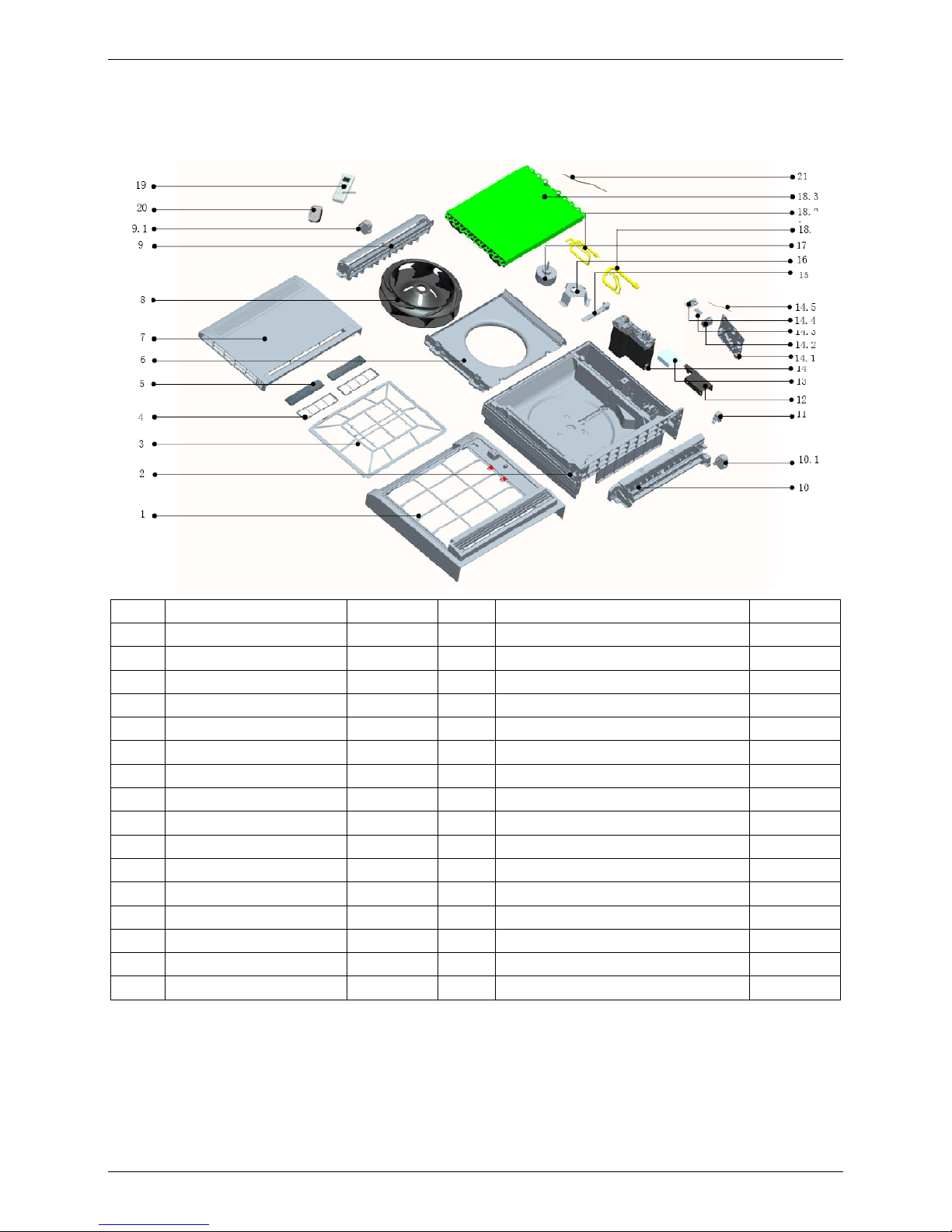

9. Exploded View

9.1 MFA-12HRN1 MFA-18HRN1

No. Part Name Quantity No. Part Name Quantity

1 Panel frame ass'y 1 14.1 Main control board ass'y 1

2 Base ass'y 1 14.2 Wire joint 1

3 Filter 1 14.3 Dial-up board ass'y 1

4 Air fresh net 2 14.4 Display board ass'y 1

5 Formaldehyde-killer 2 14.5 Room temp sensor ass'y 1

6 Air guide ring ass'y 1 15 Wire clamp 1

7 Panel ass'y 1 16 Motor bracket 1

8 Centrifugal fan 1 17 Dc motor 1

9 Air outlet frame ass'y 1 18 Evaporator ass'y 1

9.1 Stepper motor 1 18.1 Output pipe ass'y 1

10 Drainage pan ass'y 1 18.2 Input pipe ass'y 1

10.1 Stepper motor 1 18.3 Evaporator 1

11 Pipe clamp 1 19 Remote controller 1

12 E-Part box cover 1 20 Remote controller holder ass'y 1

13 Insulation washer 1 21 Temp.sensor ass'y 1

14 E-part box ass'y 1

18

Page 17

MCAC-UTSM-2009-03 Exploded View

Indoor Units 15

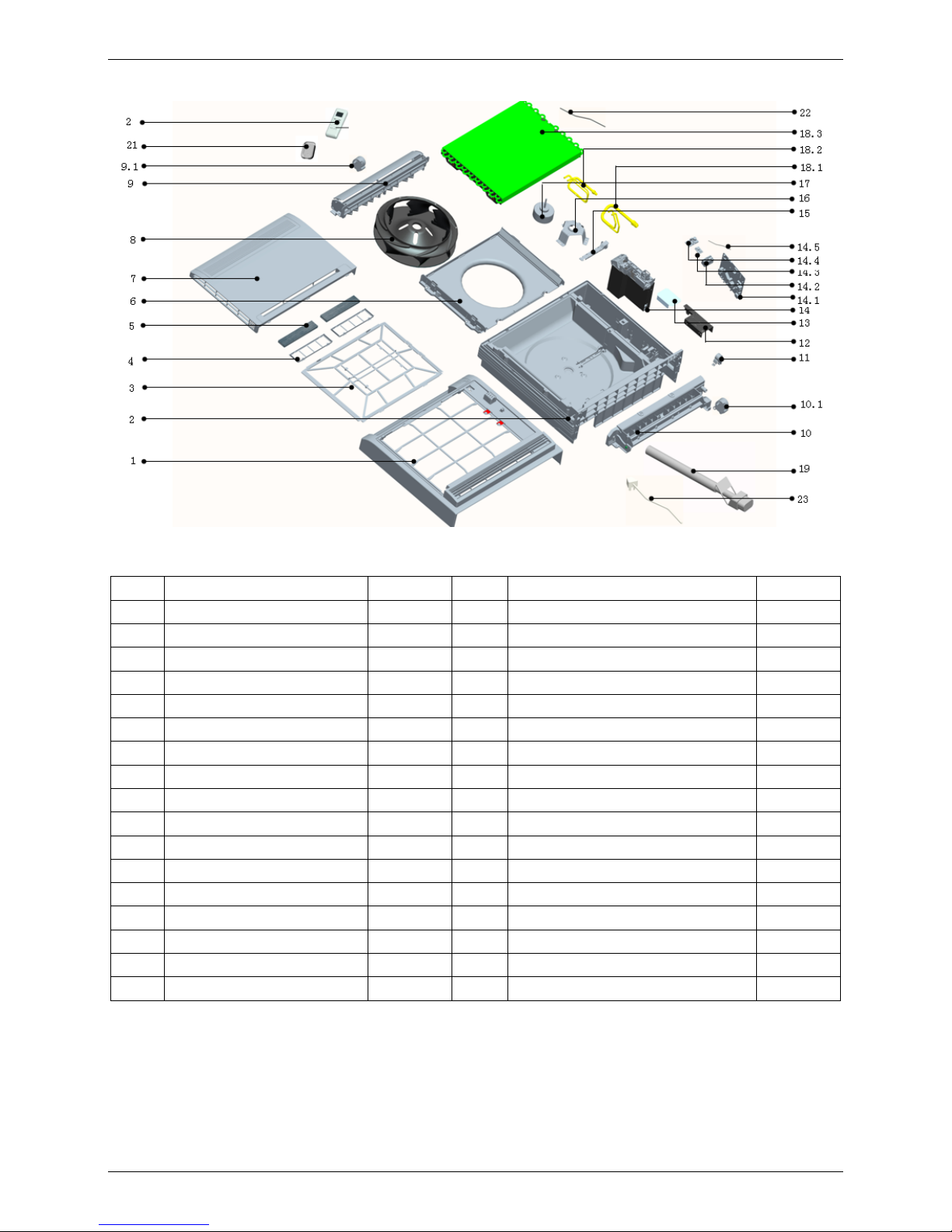

9.2 MFA-12HRN1-Q

No. Part Name Quantity No. Part Name Quantity

1 Panel frame ass'y 1 14.2 Wire joint 1

2 Base ass'y 1 14.3 Dial-up board ass'y 1

3 Filter 1 14.4 Display board ass'y 1

4 Air fresh net 2 14.5 Room temp. sensor ass'y 1

5 Formaldehyde-killer 2 15 Wire clamp 1

6 Air guide ring ass'y 1 16 Motor bracket 1

7 Panel ass'y 1 17 Dc motor 1

8 Centrifugal fan 1 18 Evaporator ass'y 1

9 Air outlet frame ass'y 1 18.1 Output pipe ass'y 1

9.1 Stepper motor 1 18.2 Input pipe ass'y 1

10 Drainage pan ass'y 1 18.3 Evaporator 1

10.1 Stepper motor 1 19 Connection tube ass'y 1

11 Pipe clamp 1 20 Remote controller 1

12 E-Part box cover 1 21 Remote controller holder ass'y 1

13 Insulation washer 1 22 Temp. sensor ass'y 1

14 E-part box ass'y 1 23 Power supply wire 1

14.1 Main control board ass'y 1

Page 18

Accessories MCAC-UTSM-2009-03

16 Indoor Units

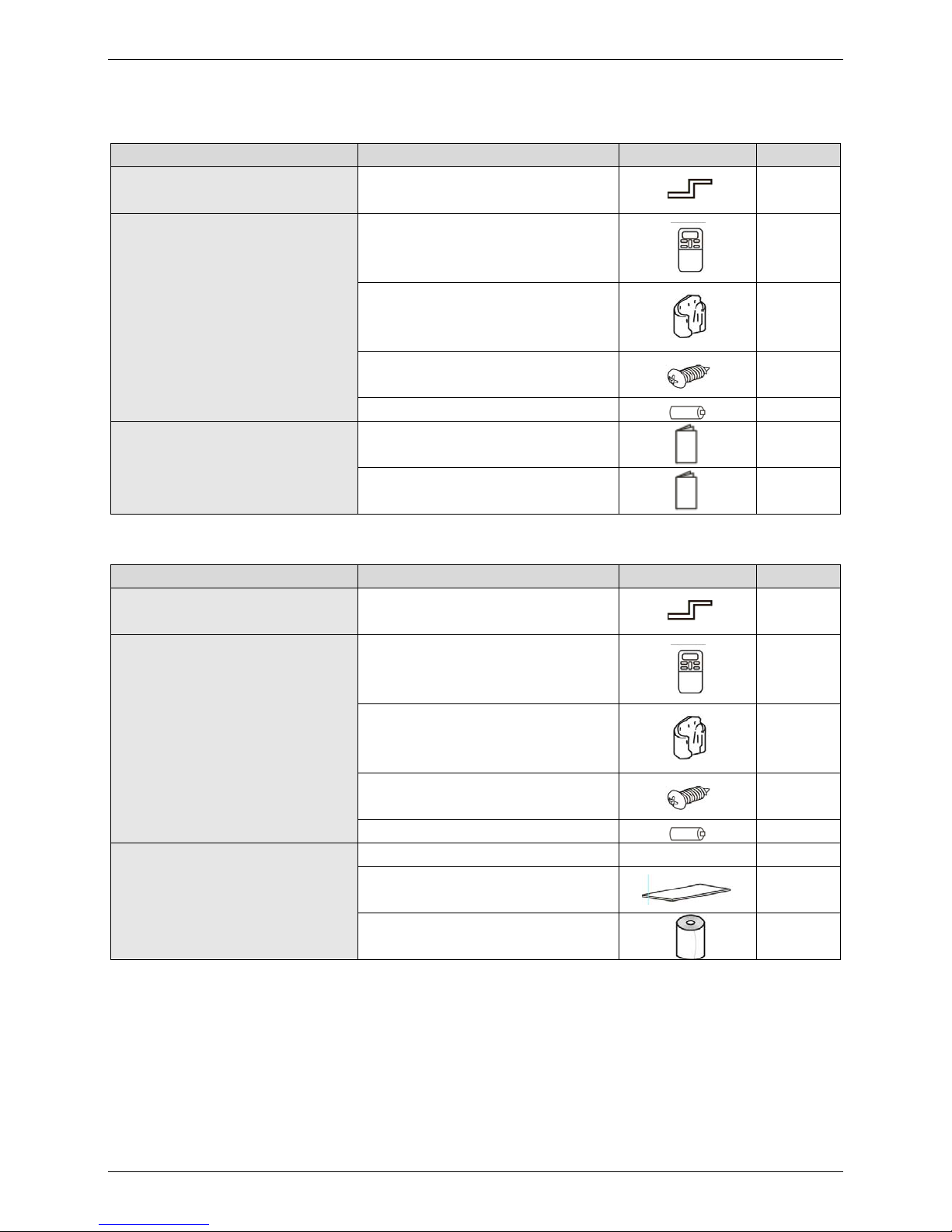

10. Accessories

10.1 MFA-12HRN1/ MFA-18HRN1

Name Shape Quantity

Installation fittings

Hook

2

Remote controller & Its Frame

Remote controller

1

Frame

1

Mounting screw(ST2.9×10-C-H)

2

Alkaline dry batteries (AM4)

2

Others

Installation manual

1

Owner's manual

1

10.2 MFA-12HRN1-Q

Name Shape Quantity

Installation fittings

Hook

2

Remote controller & Its Frame

Remote controller

1

Frame

1

Mounting screw(ST2.9×10-C-H)

2

Alkaline dry batteries (AM4)

2

Others

Installation & Owner's manual / 1

Holding sponge

2

Wrapping tape

1

Page 19

MCAC-UTSM-2009-03 Outdoor Units

Outdoor Units 17

Part 3

Outdoor Units

1. Specifications .............................................................. 18

2. Dimensions .................................................................. 19

3. Service Space .............................................................. 20

4. Piping Diagrams .......................................................... 20

5. Wiring Diagrams .......................................................... 21

6. Electric Characteristics .............................................. 24

7. Operation Limits .......................................................... 24

8. Sound Levels ............................................................... 25

9. Exploded View ............................................................. 26

10. Troubleshooting ........................................................ 29

Page 20

Specifications MCAC-UTSM-2009-03

18 Outdoor Units

1. Specifications

Model MON-12HN1 MON-18HN1 MON-12HN1-Q

Code 220075100200 220075200460 220075100210

Power supply V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50

Max. input consumption W 1500 2000 1500

Max. input current A 7.5 12 7.5

Starting current A 29.9 31.8 29.9

Compressor

Model PA140X2C-4FT PA200X2CS-4KU1 PA140X2C-4FT

Type Rotary Rotary Rotary

Brand Midea-TOSHIBA Midea-TOSHIBA Midea-TOSHIBA

Supplier Midea-TOSHIBA Midea-TOSHIBA Midea-TOSHIBA

Capacity Btu/h 11566.68 16787.04 11566.68

Input W 1150 1670 1150

Rated current (RLA) A 5.3 7.81 5.3

Locked rotor Amp (LRA) A 29.9 31.8 29.9

Thermal protector Internal Internal Internal

Capacitor μF 35μF/440-450V 50μF/440-450V 35μF/440-450V

Refrigerant oil ml

ESTEL OIL VG74,

480

ESTER OIL VG74,

750

ESTEL OIL VG74,

480

Outdoor fan

motor

Model YDK24-6F YDK53-6K YDK24-6F

Type AC MOTOR AC MOTOR AC MOTOR

Brand WELLING WELLING WELLING

Input W 58 130 58

Capacitor μF 2.5μF/450V 2.5μF/450V 2.5μF/450V

Speed r/min 800 750 800

Outdoor coil

Number of rows 2 2 2

Tube pitch(a) × row

pitch(b)

mm 21×13.37 22×19.05 21×13.37

Fin spacing mm 1.5 1.6 1.5

Fin type

Hydrophilic

aluminum

Hydrophilic

aluminum

Hydrophilic

aluminum

Tube outside dia. and type mm

Ф7 Inner grooved

copper tube

Ф7.94 Inner grooved

copper tube

Ф7 Inner grooved

copper tube

Coil length × height × width mm 628×504×26.74 630×660×38.1 628×504×26.74

Number of circuits 2 2 2

Outdoor air flow m3/h 1985 2770 1985

Outdoor noise level (sound pressure) dB(A) 52.8 55.5 52.6

Outdoor unit

Dimension(W×H×D) mm 780×547×250 842×695×324 780×547×250

Packing (W×H×D) mm 910×575×335 975×770×405 910×575×335

Net/Gross weight kg 34/38 52/56 35/39

Refrigerant

Type R410A R410A R410A

Charged volume g 1120 1300 1120

Design pressure MPa 4.2/2.0 4.2/2.0 4.2/2.0

Refrigerant

piping

Liquid side/ Gas side mm φ6.4/φ12.7 φ6.4/φ12.7 φ6.4/φ12.7

Max. pipe length m 15 20 —

Max. difference in level m 5 10 —

Ambient temp. ℃

cooling: 21~43;

heating: -5~24

cooling: 21~43;

heating: -5~24

cooling: 21~43;

heating: -5~24

Page 21

MCAC-UTSM-2009-03 Dimensions

Outdoor Units 19

2. Dimensions

2.1 MON-12HN1 MON-12HN1-Q

2.2 MON-18HN1

Page 22

Service Space MCAC-UTSM-2009-03

20 Outdoor Units

3. Service Space

4. Piping Diagrams

T1

T2

Indoor units

Outdoor unit

stop valve

room temp. sensor

evaporator temp. sensor

4-way valve

compressor

condenser temp. sensor

stop valve

one way valve

filter

T3

Throttle capiliary

Page 23

MCAC-UTSM-2009-03 Wiring Diagrams

Outdoor Units 21

5. Wiring Diagrams

5.1 MON-12HN1

Page 24

Wiring Diagrams MCAC-UTSM-2009-03

22 Outdoor Units

5.2 MON-18HN1

Page 25

MCAC-UTSM-2009-03 Wiring Diagrams

Outdoor Units 23

5.3 MON-12HN1-Q

Page 26

Electric Characteristics MCAC-UTSM-2009-03

24 Outdoor Units

6. Electric Characteristics

Model

Outdoor Unit Power Supply Compressor OFM

Hz Voltage Min. Max. MCA TOCA MFA MSC RLA KW FLA

MON-12HN1 50 220~240V 198V 254V 6.6 13 15 29.9 5.3 0.024 0.275

MON-18HN1 50 220~240V 198V 254V 9.8 18 20 31.8 7.81 0.053 0.592

MON-12HN1-Q 50 220~240V 198V 254V 6.6 13 15 29.9 5.3 0.024 0.275

Remark:

MCA: Min. Current Amps. (A)

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A)

OFM: Outdoor Fan Motor.

FLA: Full Load Amps. (A)

KW: Rated Motor Output (W)

7. Operation Limits

Operation mode Outdoor temperature ( )℃ Room temperature ( )℃

Cooling operation 21~43 17~30

Heating operation -5~24 17~30

10 15 25 30 3520

15

20

25

30

35

40

45

Indoor temperature(℃ WB)

Outdoor temperature(℃ DB)

STD

Cooling

10 15 25 30 3520

-10

-5

0

5

10

15

20

Indoor temperature(℃ DB)

Outdoor temperature(℃ WB)

STD

Heating

25

Page 27

MCAC-UTSM-2009-03 Sound Levels

Outdoor Units 25

8. Sound Levels

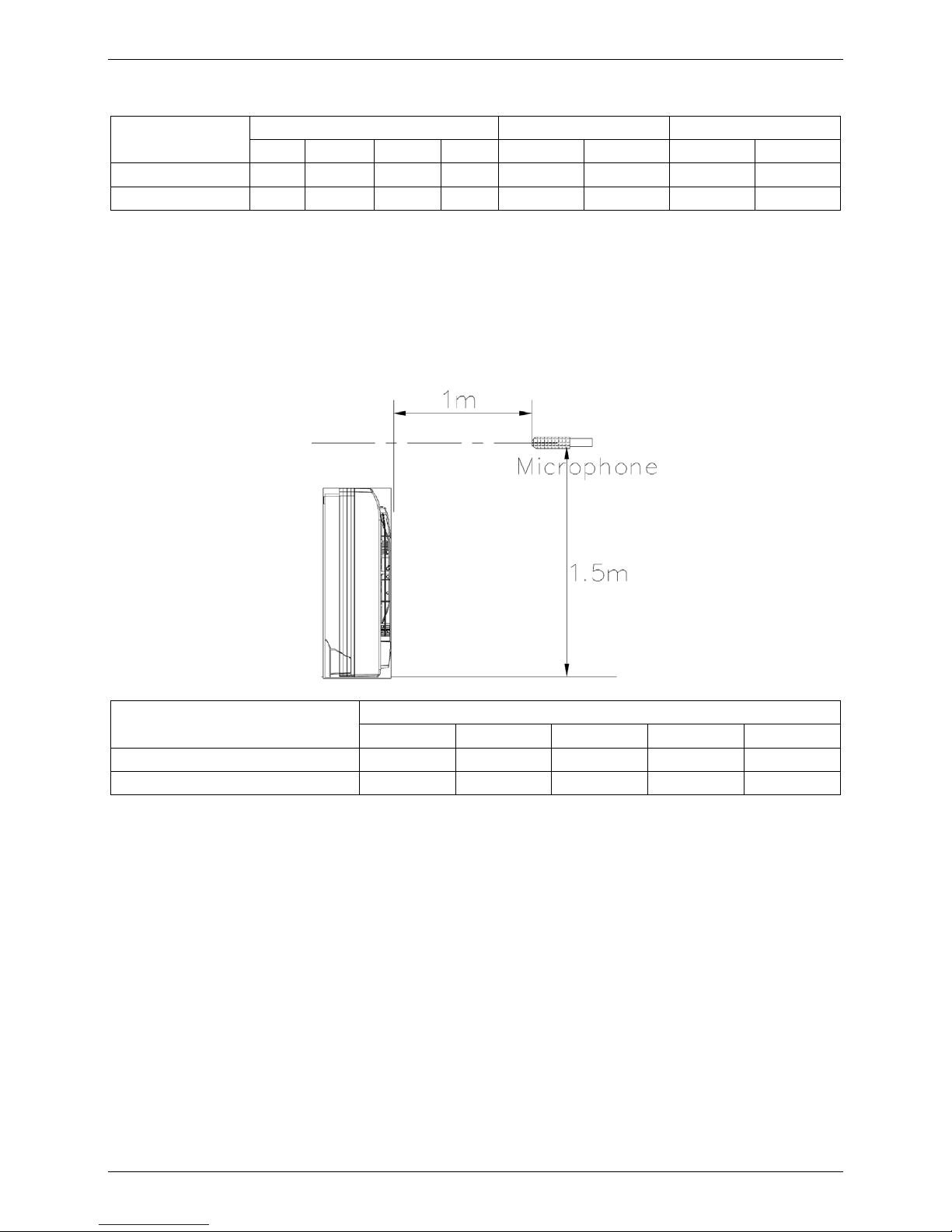

Microphone

Outdoor Unit

H

1.0m

Note: H= 0.5 × height of outdoor unit

Model Noise level dB(A)

MON-12HN1 52.8

MON-18HN1 55.5

MON-12HN1-Q 52.6

Page 28

Exploded View MCAC-UTSM-2009-03

26 Outdoor Units

9. Exploded View

9.1 MON-12HN1

No. Part Name Quantity No. Part Name Quantity

1 Fan motor 1 9 High pressure valve ass'y 1

2 Motor bracket ass'y 1 9.1 High pressure valve 1

3 Rear net 1 9.2 Strainer 1

4 Condenser ass'y 1 9.3 One way valve 1

4.1 Condenser 1 10 Base ass'y 1

4.2 Condenser output pipe 1 11 Grille 1

4.3 Condenser connecting pipe ass'y 1 12 Front panel 1

4.4 Condenser inlet pipe ass'y 1 13 Compressor 1

5 E-part box ass'y 1 14 Net clamp 6

5.1 Wire joint,4p 1 15 Right clapboard 1

5.2 Transformer 1 16 Partition board ass'y 1

5.3 Compressor capacitor 1 17 Left supporter 1

5.4 Motor capacitor 1 18 Small handle 1

5.5 Relay 1 19 Top cover 1

5.6 E-Part box 1 20 Axial flow fan 1

5.7 Main control board ass'y 1 21 Drain hose 1

6 4-way valve ass'y 1 22 Copper nut 1

6.1 4-way valve 1 23 Copper nut 1

6.2 Solenoid 1 24 Sphere pad 1

6.3 Low pressure valve 1 25 Sphere pad 1

7 Big handle 1 26 Temp. sensor ass'y 1

8 Valve plate 1

Page 29

MCAC-UTSM-2009-03 Exploded View

Outdoor Units 27

9.2 MON-18HN1

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 18 Grille 1

2 Foam 1 19 Small handle 1

3 Motor bracket ass'y 1 20 E-part box ass'y 1

4 Rear net frame 1 20.1 Wire joint, 4p 1

5 Fan motor 1 20.2 Compressor capacitor 1

6 Axial flow fan 1 20.3 Electric installation board 1

7 Compressor 1 20.4 Motor capacitor 1

8 Partition board ass'y 1 20.5 Main control board ass'y 1

9 Drainage cover 1 20.6 Transformer 1

10 Valve plate 1 20.7 Relay 1

11 Base ass'y 1 21 Drain hose 1

12 High pressure valve ass'y 1 22 Net clamp 8

12.1 Strainer 1 23 Temp. sensor ass'y 1

12.2 One way valve 1 24 Condenser ass'y 1

12.3 High pressure valve 1 24.1 Fluted pipe ass'y 1

13 4-way valve ass'y 1 24.2 Input pipe ass'y 1

13.1 Solenoid 1 24.3 Condenser ass'y 1

13.2 Low pressure valve 1 25 Rear net 1

13.3 4-way valve 1 26 Left holder 1

13.4 Muffler 1 27 Copper nut 1

14 Big handle 1 28 Copper nut 1

15 Rear right clapboard ass'y 1 29 Sphere pad 1

16 Front right clapboard ass'y 1 30 Sphere pad 1

17 Front panel 1

Page 30

Exploded View MCAC-UTSM-2009-03

28 Outdoor Units

9.3 MON-12HN1-Q

No. Part Name Quantity No. Part Name Quantity

1 Fan motor 1 7 Big handle 1

2 Motor bracket ass'y 1 8 Drainage cover 1

3 Rear net 1 9 Valve plate 1

4 Condenser ass'y 1 10 High pressure valve ass'y 1

4.1 Condenser 1 10.1 One way valve 1

4.2 Condenser output pipe 1 10.2 Filter ass'y 1

4.3 Condenser connecting pipe ass'y 1 11 Base ass'y 1

4.4 Condenser inlet pipe ass'y 1 12 Grille 1

5 E-part box ass'y 1 13 Front panel 1

5.1 Connect wiring 1 14 Compressor 1

5.2 Transformer 1 15 Net clamp 6

5.3 Compressor capacitor 1 16 Right clapboard 1

5.4 Motor capacitor 1 17 Partition board ass'y 1

5.5 Relay 1 18 Left supporter 1

5.6 E-Part box 1 19 Small handle 1

5.7 Main control board ass'y 1 20 Top cover 1

6 4-way valve ass'y 1 21 Axial flow fan 1

6.1 4-way valve 1 22 Drain hose 1

6.2 Solenoid 1 23 R410A

6.3 Pipe joint 1 24 Temp. sensor ass'y 1

6.4 Coupling ass'y 1

Page 31

MCAC-UTSM-2009-03 Troubleshooting

Outdoor Units 29

10. Troubleshooting

10.1 Indoor Unit Malfunction

Indoor unit display panel

No. Running lamp Timer lamp Defrosting lamp Malfunction

1 ☆ × × Room temp. sensor checking channel is abnormal

2 × × ☆ Evaporator temp. sensor checking channel is abnormal

3 ☆ ☆ ☆ Condenser temp. sensor checking channel is abnormal

4 × ☆ × In-outdoor unit communication malfunction

5 ☆ ● ☆ DC Fan malfunction

6 ☆ ☆ ● EEPROM malfunction

(× Extinguish, Flash at 5Hz, ☆ ● Light)

1. Running lamp flash at 5Hz

Judge: Room temp. sensor checking channel is abnormal

Validate: Check whether the resistance of the room

temp. sensor is correct according to Annex 1

Yes

Replace the room temp. sensor

Replace the indoor main board

No

Running lamp flash at 5Hz

Page 32

Troubleshooting MCAC-UTSM-2009-03

30 Outdoor Units

2. Defrosting lamp flash at 5Hz

3. Running lamp, Timer lamp, Defrosting lamp all flash at 5Hz

Judge: Evaporator temp. sensor checking channel is abnormal

Validate: Check whether the resistance of the evaporator

temp. sensor is correct according to Annex 1

Yes

Replace the evaporator temp. sensor

Replace the indoor main board

No

Judge: Condenser temp. sensor checking channel is abnormal

Validate: Check whether the resistance of the condenser

temp. sensor is correct according to Annex 1

Yes

Replace the condenser temp. sensor

Replace the PCB

No

Defrosting lamp flash at 5Hz

Running lamp, Timer lamp, Defrosting lamp all flash at 5Hz

Page 33

MCAC-UTSM-2009-03 Troubleshooting

Outdoor Units 31

4. Timer lamp flash at 5Hz

In-outdoor unit communication malfunction

Judge 1: Check whether the wiring of communication line is break off

Yes

Connect the wiring well

Judge 2: Check whether the wiring of L, N and S is wrong

No

Connect the wiring of L, N and S rightly

Replace the PCB

Yes

No

Timer flash at 5Hz

Page 34

Troubleshooting MCAC-UTSM-2009-03

32 Outdoor Units

5. Running lamp and Defrosting lamp flash at 5Hz, the Timer lamp light

6. Running lamp and Timer lamp flash at 5Hz, the Defrosting lamp light

DC fan malfunction

Judge 1: Check whether the wiring of DC fan is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the DC fan is failure

Running lamp and Defrosting lamp flash at 5Hz, the Timer lamp light

EEPROM malfunction

Judge 1: Check whether the EEPROM is inserted well

No

Insert the EEPROM well

Yes

Running lamp and Timer lamp flash at 5Hz, the Defrosting lamp light

Replace the indoor main board

No

Replace the DC fan

Yes

Replace outdoor main board

Judge 2: Check whether the EEPROM is ok

No

Replace the EEPROM

Yes

Page 35

MCAC-UTSM-2009-03 Troubleshooting

Outdoor Units 33

10.2 Outdoor Unit Malfunction

No. LED1 LED2 LED3 Malfunction

1 ☆ × ☆ In-outdoor unit communication malfunction

2 × ☆ ☆ T3 condenser pipe temp. sensor malfunction

× Extinguish, Flash ☆

1. LED1 and LED3 flash

LED1 and LED3 flash

In-outdoor unit communication malfunction

Judge 1: Check whether the wiring of communication line is break off

Yes

Connect the wiring well

Judge 2: Check whether the wiring of L, N and S is wrong

No

Connect the wiring of L, N and S rightly

Replace the PCB

Yes

No

Page 36

Troubleshooting MCAC-UTSM-2009-03

34 Outdoor Units

2. LED2 and LED3 flash

T3 condenser pipe temp. sensor malfunction

Check whether the temp. sensor is connected well

No

Connect it well

LED2 and LED3 flash

Check whether the resistance of the temp. sensor is correct

accordin

g

to Annex 1

Yes

Replace the temp. sensor

Replace the PCB

No

Yes

Page 37

MCAC-UTSM-2009-03 Troubleshooting

Outdoor Units 35

Appendix Indoor Temp. and Pipe Temp. Sensor Resistance Value Table (℃--K)

℃

K Ohm

℃

K Ohm

℃

K Ohm

℃

K Ohm

-20

115.266

20

12.6431

60

2.35774

100

0.62973

-19

108.146

21

12.0561

61

2.27249

101

0.61148

-18

101.517

22

11.5000

62

2.19073

102

0.59386

-17

96.3423

23

10.9731

63

2.11241

103

0.57683

-16

89.5865

24

10.4736

64

2.03732

104

0.56038

-15

84.2190

25

10.000

65

1.96532

105

0.54448

-14

79.3110

26

9.55074

66

1.89627

106

0.52912

-13

74.5360

27

9.12445

67

1.83003

107

0.51426

-12

70.1698

28

8.71983

68

1.76647

108

0.49989

-11

66.0898

29

8.33566

69

1.70547

109

0.48600

-10

62.2756

30

7.97078

70

1.64691

110

0.47256

-9

58.7079

31

7.62411

71

1.59068

111

0.45957

-8

56.3694

32

7.29464

72

1.53668

112

0.44699

-7

52.2438

33

6.98142

73

1.48481

113

0.43482

-6

49.3161

34

6.68355

74

1.43498

114

0.42304

-5

46.5725

35

6.40021

75

1.38703

115

0.41164

-4

44.0000

36

6.13059

76

1.34105

116

0.40060

-3

41.5878

37

5.87359

77

1.29078

117

0.38991

-2

39.8239

38

5.62961

78

1.25423

118

0.37956

-1

37.1988

39

5.39689

79

1.21330

119

0.36954

0

35.2024

40

5.17519

80

1.17393

120

0.35982

1

33.3269

41

4.96392

81

1.13604

121

0.35042

2

31.5635

42

4.76253

82

1.09958

122

0.3413

3

29.9058

43

4.57050

83

1.06448

123

0.33246

4

28.3459

44

4.38736

84

1.03069

124

0.32390

5

26.8778

45

4.21263

85

0.99815

125

0.31559

6

25.4954

46

4.04589

86

0.96681

126

0.30754

7

24.1932

47

3.88673

87

0.93662

127

0.29974

8

22.5662

48

3.73476

88

0.90753

128

0.29216

9

21.8094

49

3.58962

89

0.87950

129

0.28482

10

20.7184

50

3.45097

90

0.85248

130

0.27770

11

19.6891

51

3.31847

91

0.82643

131

0.27078

12

18.7177

52

3.19183

92

0.80132

132

0.26408

13

17.8005

53

3.07075

93

0.77709

133

0.25757

14

16.9341

54

2.95896

94

0.75373

134

0.25125

15

16.1156

55

2.84421

95

0.73119

135

0.24512

16

15.3418

56

2.73823

96

0.70944

136

0.23916

17

14.6181

57

2.63682

97

0.68844

137

0.23338

18

13.9180

58

2.53973

98

0.66818

138

0.22776

19

13.2631

59

2.44677

99

0.64862

139

0.22231

Page 38

Installation MCAC-UTSM-2009-03

36 Installation

Part 4

Installation

1. Installation Place ......................................................... 37

2. Installation of Indoor Unit ........................................... 38

3. Installation of outdoor unit ......................................... 40

4. Installation of the Connecting Pipe ........................... 41

5. Connect the Drain Pipe ............................................... 48

6. Wiring ........................................................................... 50

7. Test Operation ............................................................. 55

Page 39

MCAC-UTSM-2009-03 Installation Place

Installation 37

1. Installation Place

1.1 The indoor Unit

5. There is enough room for installation and maintenance.

6. The air outlet and the air inlet are not impeded, and the influence of external air is the least.

7. The air flow can reach throughout the room.

8. The connecting pipe and drainpipe could be extracted out easily.

9. There is no direct radiation from heaters

1.2 The Outdoor Unit

1. There is enough space for installation and maintenance.

2. The air outlet and the air inlet are not impeded, and can not be reached by strong wind.

3. The place is dry and ventilative.

4. The support is flat and horizontal and can stand the weight of the outdoor unit. And no additional noise

or vibration.

5. Your neighborhood will not feel uncomfortable with the noise or expelled air.

6. There is no leakage of combustible gas.

7. It is easy to install the connecting pipe or cables.

Caution:

Don’t install the air conditioner in the following locations:

a. There exists petrolatum.

b. There is salty air surrounding (near the coast).

c. There is caustic gas (the sulfide, for example) existing in the air (near a hot spring).

d. The Volt vibrates violently (in the factories).

e. In buses or cabinets.

f. In kitchen where it is full of oil gas.

g. There is strong electromagnetic wave existing.

h. There are inflammable materials or gas.

i. There is acid or alkaline liquid evaporating.

j. Other special conditions

1.3 Notes before Installation

1. Select the correct carry-in path.

2. Move this unit as originally packaged as possible.

3. If the air conditioner is installed on a metal part of the building, it must be electrically insulated according

to the relevant standards to electrical appliances.

Page 40

Installation of Indoor Unit MCAC-UTSM-2009-03

38 Installation

2. Installation of Indoor Unit

2.1 Service Space

The indoor unit should be installed in a location that meets the following requirements:

There is enough room for installation and maintenance. (Refer to the following figure )

The outlet and the inlet are not impeded, and the influence of external air is the least.

The air flow can reach throughout the room.

The connecting pipe and drainpipe could be extracted out easily.

There is no direct radiation from heaters.

Caution: Keep indoor unit, outdoor unit, power supply wiring and transmission wiring at least 1 meter away

from televisions and radios. This is to prevent image interference and noise in those electrical appliances.

(Noise may be generated depending on the conditions under which the electric wave is generated, even if

1 meter is kept.)

Page 41

MCAC-UTSM-2009-03 Installation of Indoor Unit

Installation 39

2.2 Installation the main body

z Fix the hook with tapping screw onto the wall

z Hang the indoor unit on the hook.

(The bottom of body can touch with floor or suspended, but the body must install vertically.)

Page 42

Installation of outdoor unit MCAC-UTSM-2009-03

40 Installation

3. Installation of outdoor unit

3.1 Necessary space for Installation and Maintenance

If possible, please remove the obstacles nearby to prevent the performance from being impeded by too little

of air circulation. The minimum distance between the outdoor unit and obstacles described in the installation

chart doesn’t mean that the same is applicable to the situation of an airtight room. Leave open two of the

three directions (M, N, P).

3.2 Moving and Installing

1. Since the gravity center of the unit is not at its physical center, so please be careful when lifting it with a sling.

2. Never hold the inlet of the outdoor unit to prevent it from deforming.

3. Do not touch the fan with hands or other objects.

4. Do not lean it more than 45°, and do not lay it sidelong.

5. Make concrete foundation according to the specifications of the outdoor units.

6. Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of earthquake or strong wind.

Page 43

MCAC-UTSM-2009-03 Installation of the Connecting Pipe

Installation 41

4. Installation of the Connecting Pipe

Caution:

For your safety, always wear safety eye wear and work gloves when connecting the pipes.

4.1 MFA-12HRN1-Q (Quick connecter)

Remove the water tray before performing the connection.

Page 44

Installation of the Connecting Pipe MCAC-UTSM-2009-03

42 Installation

To connect the couplings:

Step 1: Ensure that the handle on the male coupling is in a reclined position away from the mating male

coupling.

Step 2: Retract the “Release Sleeve” on female coupling, insert the male coupling located on the indoor unit

into the female coupling.

Step 3:

Release the “Release Sleeve” to the lock the male coupling into places.

Step 4: Fold the male coupling handle towards the female coupling half and push until the handle seals

behind the “Release Sleeve” and flat against the entire coupling assembly.

Frost proof processing

For prevent that the connect pipe produce frost to drip, you need to inhibit the holding sponge on the connect

pipe of inside door, and then bundle it by wrapping tape.

Page 45

MCAC-UTSM-2009-03 Installation of the Connecting Pipe

Installation 43

4.2 MFA-12HRN1and MFA-18HRN1

Check whether the height drop between the indoor unit and outdoor unit, the length of refrigerant pipe, and

the number of the bends meet the following requirements:

Capacity(Btu/h) 12000 18000

The max. height drop 5m 10m

The length of refrigerant pipe Less than 15m Less than 20m

The number of bends Less than 5 Less than 8

4.2.1 The Procedure of Connecting Pipes

Caution:

z All field piping must be provided by a licensed refrigeration technician and must comply with the

relevant local and national codes.

z Do not let air, dust, or other impurities fall in the pipe system during the time of installation.

z The connecting pipe should not be installed until the indoor and outdoor units have been fixed already.

z Keep the connecting pipe dry, and do not let moisture in during installation.

z Execute heat insulation work completely on both sides of the gas piping and the liquid piping. Otherwise,

this can sometimes result in water leakage.

1. Drill a hole in the wall (suitable just for the size of the wall conduit), then set on the fittings such as

the wall conduit and its cover.

2. Bind the connecting pipe and the cables together tightly with binding tapes.

3. Pass the bound connecting pipe through the wall conduct from outside. Be careful of the pipe

allocation to do on damage to the tubing.

4. Connect the pipes.

5. Expel the air with a vacuum pump. Refer to "How to expel the air with a vacuum pump" for details.

6. Open the stop valves of the outdoor unit to make the refrigerant pipe connecting the indoor unit with

the outdoor unit in fluent flow.

7. Check the leakage. Check all the joints with the leak detector or soap water.

8. Cover the joints of the connecting pipe with the soundproof / insulating sheath (fittings), and bind it

well with the tapes to prevent leakage.

Caution:

Be sure to with insulating materials cover all the exposed parts of the flare pipe joints and refrigerant

pipe on the liquid-side and the gas-side. Ensure that there is no gap between them.

Incomplete insulation may cause water condensation.

Page 46

Installation of the Connecting Pipe MCAC-UTSM-2009-03

44 Installation

How to take indoor unit apart to connect the pipes

1. Open the front panel

Slide the two stoppers on the left and right sides until they click.

2. Remove the front panel

Remove the string.

Allowing the front panel to fall forward will enable you to remove it.

Page 47

MCAC-UTSM-2009-03 Installation of the Connecting Pipe

Installation 45

3. Remove the face plate

Remove the four screws.

Opening bottom of face plate for a angle that is 30 degree, then the top of face plate will be take up.

How to take outdoor unit apart to connect the pipes

Remove the water tray

How to connect the pipes

1. Flaring:

Cut a pipe with a pipe cutter.

Page 48

Installation of the Connecting Pipe MCAC-UTSM-2009-03

46 Installation

Insert a flare nut into a pipe and flare the pipe.

Refer to the following table for the dimension of flare nut spaces.

Pipe gauge Tightening torque

Flare dimension (A)

Flare shape

Min Max

Φ6.4

15

~16N.m

(153

~163kgf.cm)

8.3 8.7

Φ9.5

25

~26N.m

(255

~265 kgf.cm)

12.0 12.4

Φ12.7

35

~36 N.m

(357

~367 kgf.cm)

15.4 15.8

Φ15.9

45

~47 N.m

(459

~480 kgf.cm)

18.6 19.0

Φ19.1

65

~67 N.m

(663

~684 kgf.cm)

22.9 23.3

2. Connect the indoor unit at first, then the outdoor unit.

z Bend the tubing in proper way. Do not harm to them.

z The bending angle should not exceed 90°.

z Bending position is preferably in the middle of the bendable pipe. The larger the bending radius the

better it is.

z Do not bend the pipe more than three times.

z When connecting the flare nut, coat the flare both inside and outside with either oil or ester oil and

initially tighten by hand 3 or 4 turns before tighting firmly.

z Be sure to use both spanner and torque wrench together when connecting or disconnecting pipes to the unit.

Caution:

z Too large torque will harm the bell mouthing and too small will cause leakage.

z After the connecting work is finished, be sure to check that there is no gas leak.

Page 49

MCAC-UTSM-2009-03 Installation of the Connecting Pipe

Installation 47

How to expel the air with a vacuum pump

Stop valve operation introduction

1. Opening stop valve

1) Remove the cap and turn the valve counter clock-wise with the hexagon wrench.

2) Turn it until the shaft stops. Do not apply excessive force to the stop valve. Doing so may break the

valve body, as the valve is not a backseat type. Always use the special tool.

3) Make sure to tighten the cap securely.

2. Closing stop valve

1) Remove the cap and turn the valve clockwise with the hexagon wrench.

2) Securely tighten the valve until the shaft contacts the main body seal.

Make sure to tighten the cap securely.

For the tightening torque, refer to the table below.

Tightening torque N.M (Turn clockwise to close)

Stop Valve size Shaft (valve body) Cap (Valve lid) Maintenance nut

φ6.4

5.4~6.6

Hexagonal

wrench 4 mm

13.5~16.5

11.5

~13.9

φ9.5

φ12.7 8.1~9.9 18~22

φ15.9 13.5~16.5

Hexagonal

wrench 6mm

23~27

φ22.2

27~33

Hexagonal

wrench 10 mm

36~44

φ25.4

Caution:

z Always use a charge hose for service port connection.

z After tightening the cap, check that no refrigerant leaks are present

Using the vacuum pump

1) Loosen and remove the maintenance nuts of stop valves A and B, and connect the charge hose of the

manifold valve to the service port of stop valve A. (Be sure that stop valves A and B are both closed)

2) Connect the joint of the charge hose with the vacuum pump.

3) Open the Lo-lever of the manifold value completely.

4) Turn on the vacuum pump. At the beginning of pumping, loosen the maintenance nut of stop valve B a

little to check whether the air comes in (the sound of the pump changes, and the indicator of compound

meter turns below zero). Then fasten the maintenance nut.

5) When the pumping has finished, close the Lo-lever of the manifold valve completely and turn off the

vacuum pump. Make pumping for 15 minutes or more and check that the compound meter indicates

-76cmHg (-1×10

5

Pa)

6) Loosen and remove the cap of stop valves A and B to open stop valve A and B completely, then fasten

the cap.

7) Disassemble the charge hose from the service port of stop valve A, and fasten the nut.

Page 50

Connect the Drain Pipe MCAC-UTSM-2009-03

48 Installation

4.2.2 Additional Refrigerant Charge

Caution:

z Refrigerant cannot be charged until field wiring has been completed.

z Refrigerant may only be charged after performing the leak test and the vacuum pumping.

z When charging a system, care shall be taken that its maximum permissible charge is never exceeded,

in view of the danger of liquid hammer.

z Charging with an unsuitable substance may cause explosions and accidents, so always ensure that the

appropriate refrigerant is charged.

z Refrigerant containers shall be opened slowly.

z Always use protective gloves and protect your eyes when charging refrigerant.

The outdoor unit is factory charged with refrigerant. Calculate the added refrigerant according to the

diameter and the length of the liquid side pipe of the outdoor unit/indoor unit connection.

R(g) D(mm)

L(m)

Φ6.4 Φ9.5

Less than 5m (One-way) — —

Added refrigerant when over 5m (One-way) 11g/m×(L-5) 30g/m×(L-5)

R(g): Additional refrigerant to be charged

L(m): The length of the refrigerant pipe(one-way)

D(mm): Liquid side piping diameter

5. Connect the Drain Pipe

5.1 Install the drainpipe of the indoor unit

The outlet has PTI screw bread, Please use sealing materials and pipe sheath(fitting) when connecting PVC

pipes.

Caution:

1) The drain pipe of indoor unit must be heat insulated, or it will condense dew, as well as the connections

of the indoor unit.

2) Hard PVC binder must be used for pipe connection, and make sure there is no leakage.

3) With the connection part to the indoor unit, please be noted not to impose pressure on the side of indoor

unit pipes.

4) When the declivity of the drain pipe downwards is over 1/100, there should not be any winding.

5) The total length of the drain pipe when pulled out traversely shall not exceed 20m, when the pipe is over

long, a prop stand must be installed to prevent winding.

6) Refer to the figures on the right for the installation of the pipes.

Page 51

MCAC-UTSM-2009-03 Connect the Drain Pipe

Installation 49

5.2 Drainage test

1) Check whether the drainpipe is unhindered.

2) New built house should have this test done before paving the ceiling.

5.3 Install the drain joint of the outdoor unit

Fit the seal into the drain elbow, then insert the drain elbow into the base pan hole of outdoor unit, rotate

90°to securely assemble them. Connect the drain elbow with an extension drain hose (Locally purchased),

in case of the condensate draining off the outdoor unit during the heating mode. (Refer to below chart)

Page 52

Wiring MCAC-UTSM-2009-03

50 Installation

6. Wiring

6.1 MFA-12HRN1-Q (Quick connecter)

Attention:

Make sure the power supply has been cut off when inserting or pulling out the plug connecters.

1) The connection cables of indoor and outdoor units have been connected to the terminals on the control

board.

2) Remove the control cover from the outdoor unit by loosening the screw.

3) Hold the indoor plug connector and insert the mating plug connector located on the outdoor unit until it

fixed with a clicking sound. Secure the cable onto the control board with the cord clamp.

4) Connect the ground wire (yellow &green) reliably with sheet-metal by screws.

5) The electrical connection has finished now.

Connect the wire

Number ① ②

Area of the connecting wiring(mm2 ) 4×1.5 3×1.5

Page 53

MCAC-UTSM-2009-03 Wiring

Installation 51

6.2 MFA-12HRN1 and MFA-18HRN1

Caution:

1) The appliance shall be installed in accordance with national wiring regulations.

2) The air conditioner should use separate power supply with rated voltage.

3) The external power supply to the air conditioner should have ground wiring, which is linked to the

ground wiring of the indoor and outdoor unit.

4) The wiring work should be done by qualified persons according to circuit drawing.

5) An all-pole disconnection device which has at least 3mm separation distance in all pole and a residual

current device (RCD) with the rating of above 10mA shall be incorporated in the fixed wiring according

to the national rule.

6) Be sure to locate the power wiring and the signal wring well to avoid cross-disturbance.

7) Do not turn on the power until you have checked carefully after wiring.

Remark per EMC Directive 89/336/EEC

For to prevent flicker impressions during the start of the compressor (technical process), following

installation conditions do apply.

1. The power connection for the air conditioner has to be done at the main power distribution. The

distribution has to be of a low impedance, normally the required impedance reaches at a 32 A fusing

point.

2. No other equipment has to be connected with this power line.

3. For detailed installation acceptance please refer to your power supplier, if restrictions do apply for

products like washing machines, air conditioners or electrical ovens.

6.2.1 Connect the cable

1. The installation bearer of sensing device rotated to another side, and then takes off cover of electrical box.

Page 54

Wiring MCAC-UTSM-2009-03

52 Installation

2. Dissemble the bolts from the cover. (If there isn't a cover on the outdoor unit, disassemble the bolts from

the maintenance board, and pull it in the direction of the arrow to remove the protection board.)

3. Connect the connective cables to the terminals as identified with their respective matched numbers on

the terminal block of indoor and outdoor units.

4. Re-install the indoor unit and outdoor unit.

6.2.2 The Specification of Power

Type 12000Btu/h 18000Btu/h

Power

Phase 1-phase 1-phase

Frequency and Voltage 220-240V, 50Hz 220-240V, 50Hz

Circuit Breaker/ Fuse (A) 20/16 20/16

Indoor Unit Power Wiring (mm2) 3×1.5 3×2.5

Indoor/Outdoor Connecting Wiring (mm2)

Ground Wiring 1.5 2.5

Outdoor Unit Power Wiring

Strong Electric Signal 4×1.5 4×2.5

Weak Electric Signal

Page 55

MCAC-UTSM-2009-03 Wiring

Installation 53

6.2.3 Wiring figure

Page 56

Wiring MCAC-UTSM-2009-03

54 Installation

Note:

All the pictures in this manual are for explanation purpose only. They may be slightly different from the air

conditioner you purchased (depend on model).The actual shape shall prevail.

Page 57

MCAC-UTSM-2009-03 Test Operation

Installation 55

7. Test Operation

1. The test operation must be carried out after the entire installation has been completed.

2. Please confirm the following points before the test operation:

z The indoor unit and outdoor unit are installed properly.

z Tubing and wiring are correctly completed.

z The refrigerant pipe system is leakage-checked.

z The drainage is unimpeded.

z The heating insulation works well.

z The ground wiring is connected correctly.

z The length of the tubing and the added stow capacity of the refrigerant have been recorded.

z The power voltage fits the rated voltage of the air conditioner.

z There is no obstacle at the outlet and inlet of the outdoor and indoor units.

z The gas-side and liquid-side stop valves are both opened.

z The air conditioner is pre-heated by turning on the power.

3. According to the user's requirement, install the remote controller frame where the remote controller's

signal can reach the indoor unit smoothly.

4. Test operation

Set the air conditioner under the mode of "COOLING" with the remote controller, and check the following

points. If there is any malfunction, please resolve it according to the chapter "Troubleshooting" in the

"Owner's Manual".

1) The indoor unit

a. Whether the switch on the remote controller works well.

b. Whether the buttons on the remote controller works 10.well.

c. Whether the air flow louver moves normally.

d. Whether the room temperature is adjusted well.

e. Whether the indicator lights normally.

f. Whether the temporary buttons works well.

g. Whether the drainage is normal.

h. Whether there is vibration or abnormal noise during operation.

I. Whether the air conditioner heats well in the case of the HEATING/COOLING type.

2) The outdoor unit

a. Whether there is vibration or abnormal noise during operation.

b. Whether the generated wind, noise, or condensed of by the air conditioner have influenced your

neighborhood.

c. Whether any of the refrigerant is leaked.

Caution:

A protection feature prevents the air conditioner from being activated for approximately 3 minutes when it is

restarted immediately after shut off.

Page 58

Control MCAC-UTSM-2009-03

56 Control

Part 5

Control

1. Wireless remote controller R51D/E ........................... 57

Page 59

MCAC-UTSM-2009-03 Wireless remote controller R51D/E

Control 57

1. Wireless remote controller R51D/E

1.1 Remote Controller Specifications

Model

Environment

Reaching Distance

Signal Range

Lowest Voltage of CPU

Emitting Signal

Rated Voltage

R51D/E R51D/CE,

-5 C 60 C

。。

8m (when using 3.0 voltage,

it Gets 11m)

3.0V(Alkaline dry batteries L R03 2)

2.0V

×

1.2 Introduction of Function Buttons on the Remote Controller

1

2

4

6

7

3

8

9

10

11

12

13

SET T EM PERATURE C )(

O

AUTO

COOL

DRY

HEAT

FAN

HIGH

MED

LOW

TE M P .

MODE

ON/ OFF

FAN S PEE D

SWING

ECON OMIC

TI MER ON

RE S ET

LOCK

TI MER OFF

AIR DIRECTION

POWE RFU L

5

1. TEMP Button

: Press the button to decrease the indoor temperature setting.

2. TEMP Button

: Press the button to increase the indoor temperature setting.

3. ON/OFF Button: Push this button to start the unit operation. Push the button again to stop the unit

operation.

4. MODE Select Button: Each time you push the button, a mode is selected in a sequence that goes from

AUTO、COOL、DRY、HEAT and FAN, as the following figure indicates:

5. SWING Button: Push this button, the louver would swing up and down automatically. Push again to stop it.

6. RESET Button: When the RESET button is pushed, all of the current settings are cancelled and the

control will return to the initial settings.(Use a φ1mm little round stick to push the button )

7. AIR DIRECTION Button: Push this button, the louver can be fixed at a desired angle. The louver swing

(upward or downward) to a certain angle for each press. When the louvers swing at an angle which

would affect the cooling and heating efficiency of the air conditioner, it would automatically change the

swing direction (upward or downward).

8. FAN SPEED Button: This button is used for setting Fan Speed in the sequence that goes from AUTO,

LOW , MED to HIGH, then back to Auto.

Page 60

Wireless remote controller R51D/E MCAC-UTSM-2009-03

58 Control

9. TIMER ON Button: Press this button to preset the time ON (start to operate). Each press will increase

the time ON setting in 30minutes increments. When the setting time displays 10:00, each press will

increase the time ON setting in 60 minutes increments. To cancel the time ON program, simply adjust

the time ON to 0:00.

10. ECONOMIC RUNNING Button: Press this button to go into the energy-Saving operation mode. Press

the button again to cancel.

11. TIMER OFF Button: Press this button to preset the time OFF (turn off the operation). Each press will

increase the time OFF setting in 30 minutes increments. When the setting time displays 10:00, each

press will increase the time OFF setting in 60 minutes increments. To cancel the time OFF program,

simply adjust the time OFF to 0:00

12. LOCK Button: Push this button to lock in all the current settings. To release settings, push again. (Use

a φ1mm little round stick to push this button)

13. POWERFUL Button: Press this button on cooling/heating mode to go into powerful cooling (heating

operation. Press again to cancel it.

Note: The unit will automatically revert back to the previous operational mode after continuously operating

under the powerful cooling mode.

1.3 Names and Functions of indicators on Remote Controller

1

2

4

6

7

5

4

3

Display Pan el

TIME R ON/ OFF

1. DIGITAL DISPLAY area: This area will show the temperature and, if in the TIMER mode, will show the

ON and OFF settings of the TIMER. It will automatically revert back to show the temperature after

5 seconds. Under "FAN" operation mode, nothing is shown in this area.

2. TRANSMISSION Indicator: This indicator flashes once when remote controller transmits signals to the

indoor unit.

3. ON/OFF Indicator: This symbol appears when the unit is turned on by the remote controller, and

disappears when the unit is turned off.

4. OPERATION MODE Indicator: Shows the current operation modes--"AUTO", "COOL", "DRY", "HEAT"

and "FAN".HEAT only available for heat pump model.

5. FAN SPEED Indicator: Press the FAN SPEED button to select the desired fan speed setting

(Auto-Low-Med-High). You selection will be displayed in the LCD window except the Auto fan speed.

6. LOCK Indicator: This symbol appears when press the LOCK button, and disappears when presses it

again.

7. TIMER ON/OFF Display: This display area shows the settings of TIMER. That is, if only the starting time

of operation is set, it will display the TIMER ON. If only the turning off time of operation is set, it will

display the TIMER OFF. If both operations are set, it will show TIMER ON/ OFF which indicates you

have chosen to set both the starting time and off time.

Loading...

Loading...