Page 1

Commercial Air Conditioners

Service

Manual

Page 2

Aqua Tempo Super II

CONTENTS

CONTENTS

Part 1 General Information ............................................................................ 3

Part 2 Component Layout and Refrigerant Circuits ..................................... 5

Part 3 Control ............................................................................................... 15

Part 4 Diagnosis and Troubleshooting ......................................................... 33

201709 1

Page 3

Aqua Tempo Super II

Midea Aqua Tempo Super II

Manual

2 201709

Page 4

Aqua Tempo Super II

Part 1

- General Information

Part 1

General Information

1 Unit Capacities and External Appearance ................................................... 4

2 Water outlet temperature range ................................................................ 4

201709 3

Page 5

M-Thermal Mono

Midea Aqua Tempo Super II Service Manual

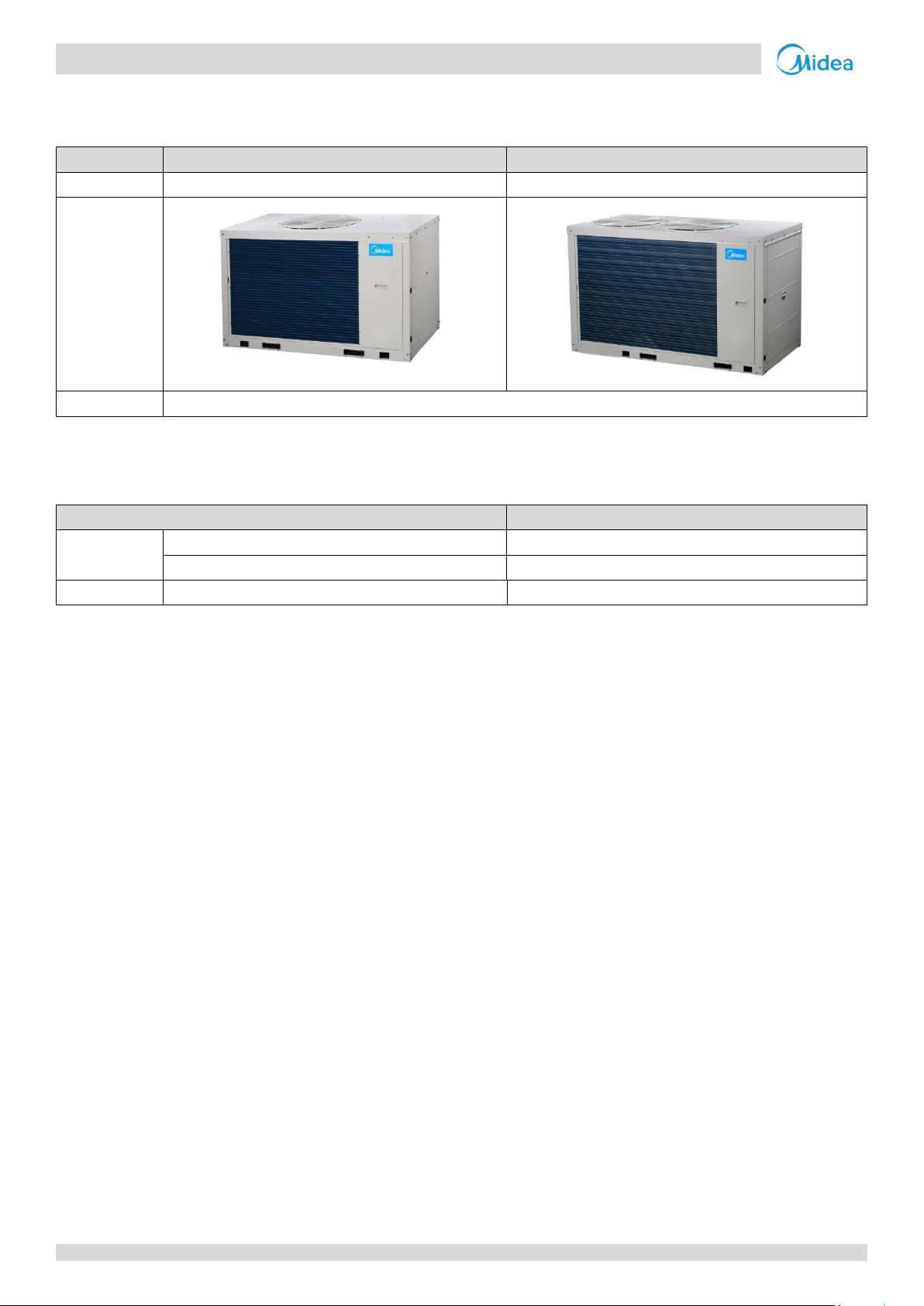

Table 1-2.1: Aqua Tempo Super II unit capacity range and unit appearances

Capacity

30kW

60kW

Model

MC-SU30-RN1L

MC-SU30-RN1L

Appearance

Power supply

380-415V/3Ph/50Hz

Table 1-2.1: Aqua Tempo Super II unit water outlet temperature range

Mode

Range

Cooling

Normal

5-20°C

Low water outlet

0-20°C

Heating

Normal

25-55°C

Note:

1. Use dial switch S5_1 on the main PCB to select the water outlet temperature range.

1 Unit Capacities and External Appearance

2 Water outlet temperature range

4 201709

Page 6

Aqua Tempo Super II

Refrigerant Ci rcuits

Part 2

Component Layout and

Refrigerant Circuits

1 Layout of Functional Components ........................................................... 6

2 Piping Diagrams ..................................................................................... 10

3 Refrigerant Flow Diagrams ..................................................................... 13

Part 2 - Component Layout and

201709 5

Page 7

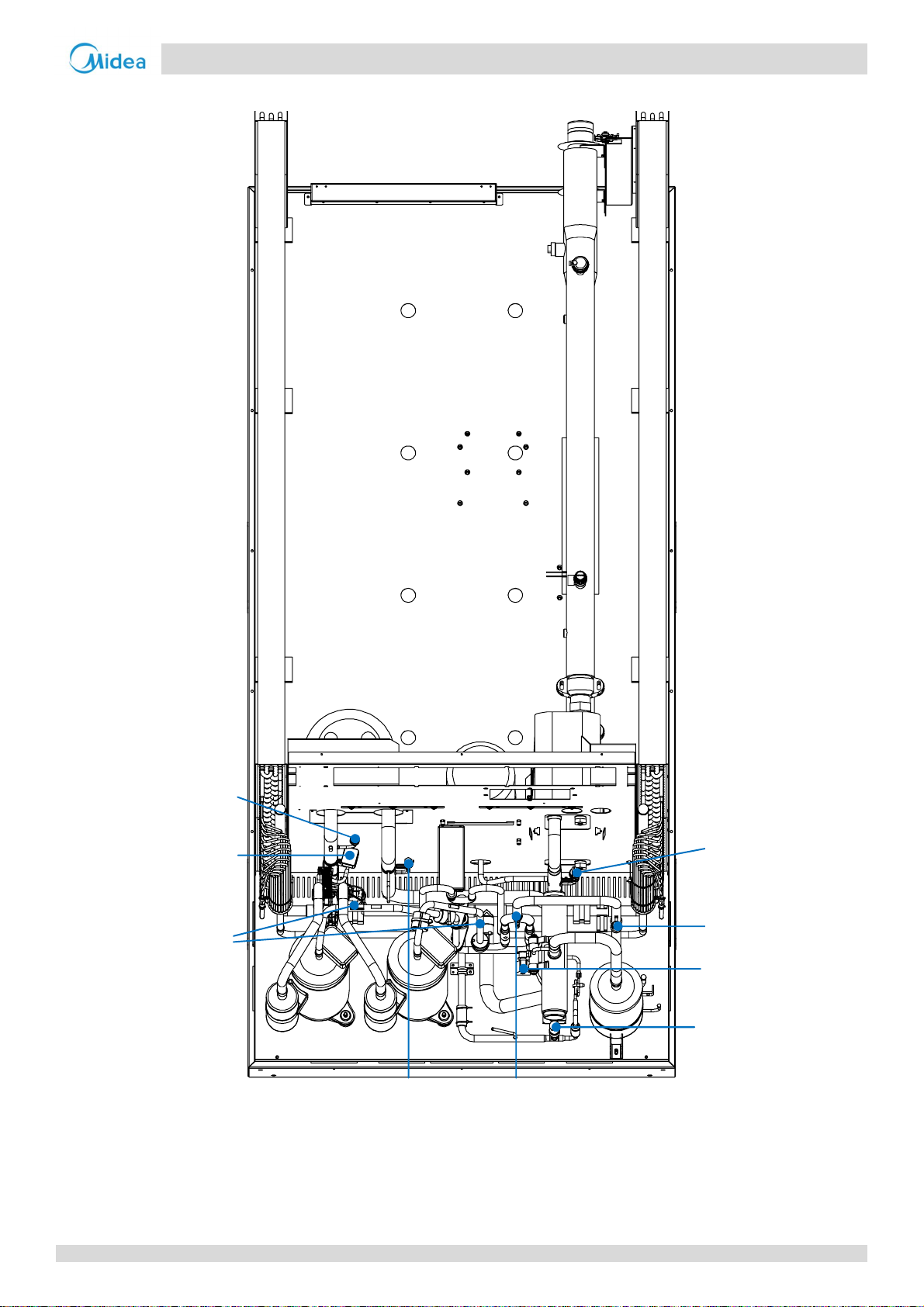

Aqua Tempo Super II

Midea

Aqua Tempo S uper II

Service Manual

Safety

valve

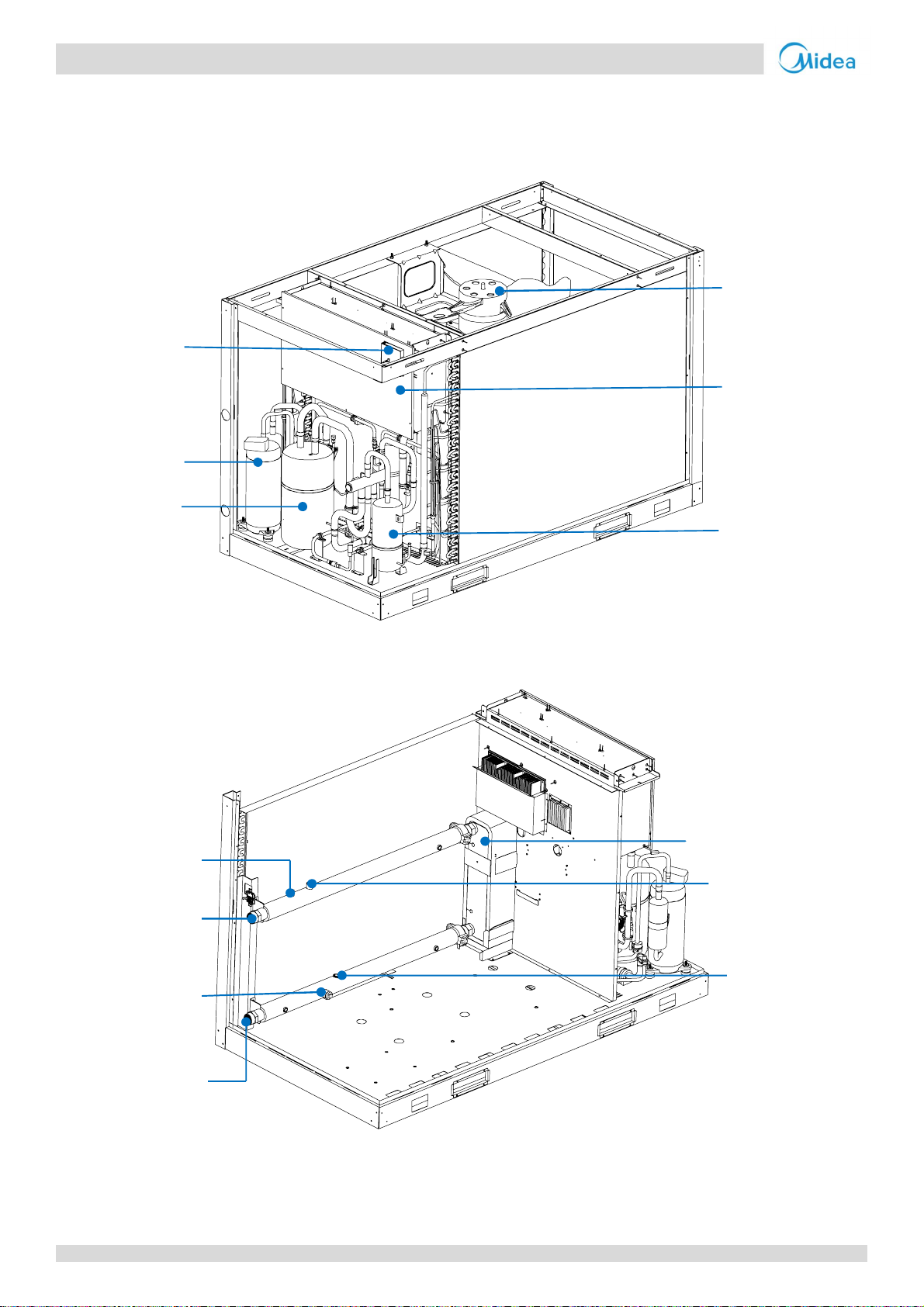

1 Layout of Functional Components

MC-SU30-RN1L

Figure 2-1.1: MC-SU30-RN1L front view

Wired

controller

DC inverter

compressor

Fan motor

Electric

control box

Accumulator

Figure 2-1.2: MC-SU30-RN1L rear view

Manual air

purge valve

Water inlet pipe

Oil separator

Water side heat exchanger

Manual water

drain valve

Water outlet

pipe

6 201612

Water flow switch

Page 8

Refrigerant Ci rcuits

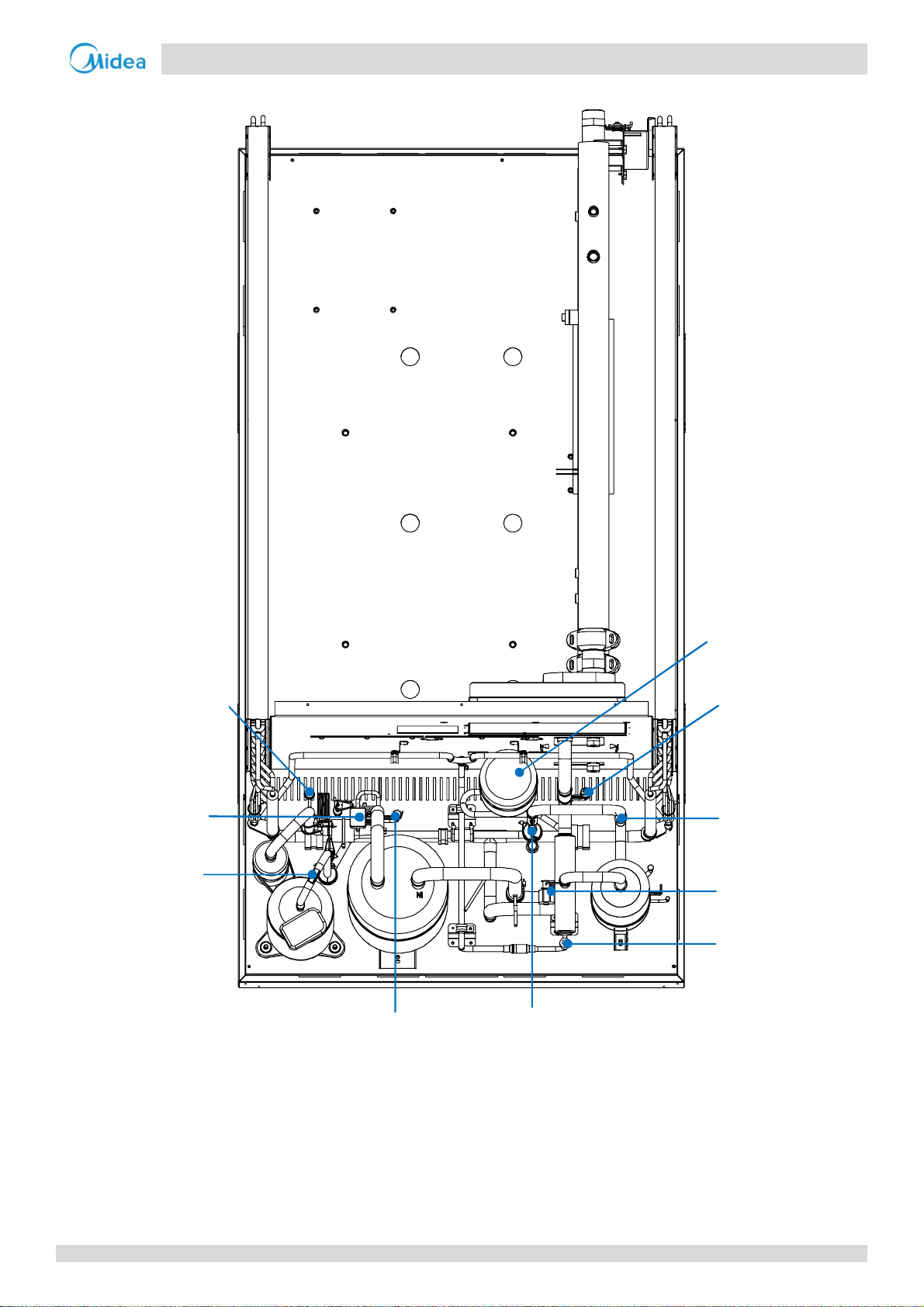

Figure 2-1.3: MC-SU30-RN1L top view

expansion valve

Aqua Tempo Super II

Part 2 - Component Layout and

Low pressure

switch

Solenoid valve

SV4

Discharge

temperature

switch

Low pressure

gauge point

Accumulator

High pressure

sensor

High pressure

switch

Four-way valve

Electronic

High pressure

gauge point

201709 7

Page 9

Aqua Tempo Super II

Midea

Aqua Tempo S uper II

Service Manual

control box

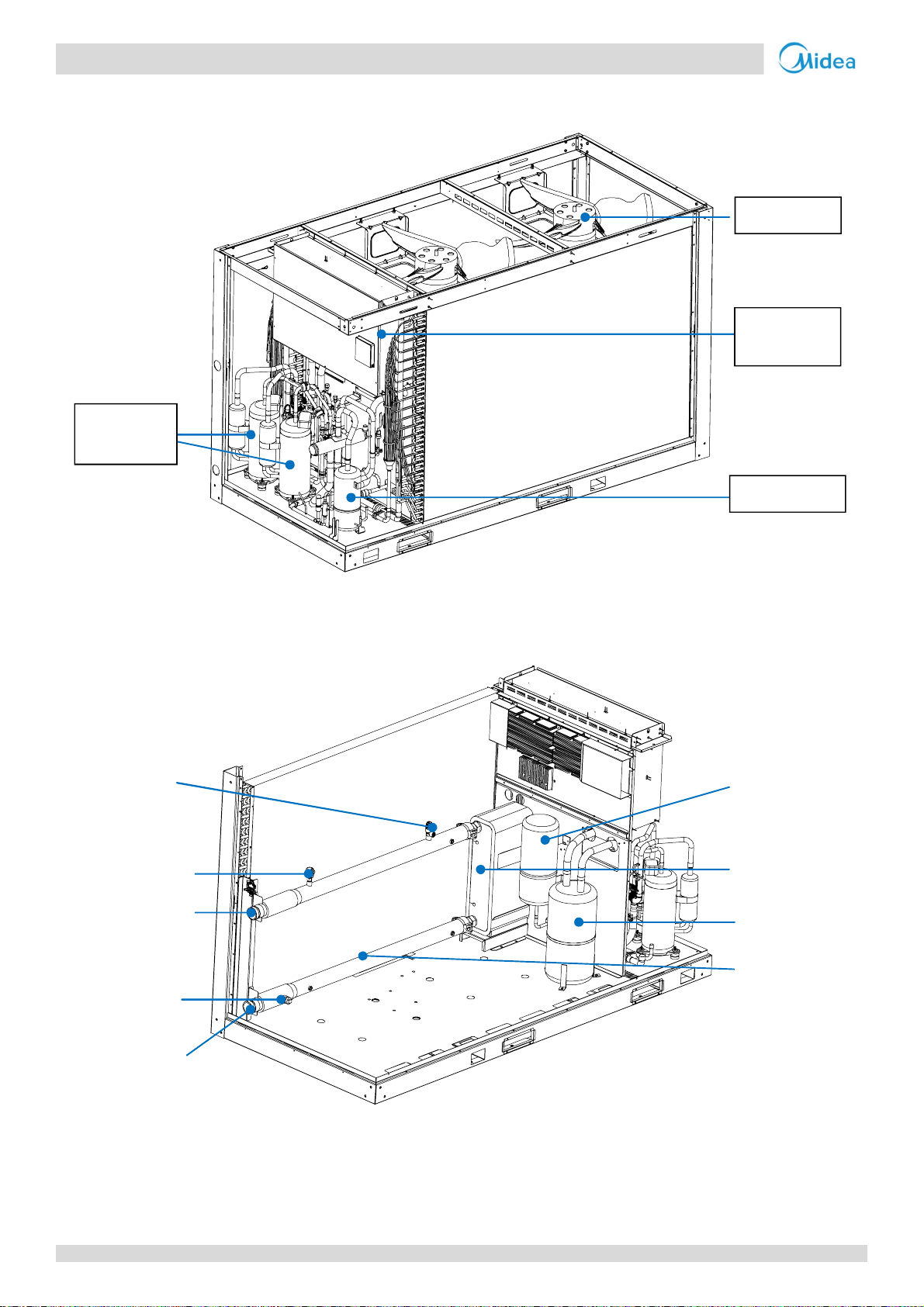

MC-SU60-RN1L

Figure 2-1.4: MC-SU60-RN1L front view

DC inverter

compressor

Fan motor

Electric

Oil separator

Figure 2-1.5: MC-SU60-RN1L rear view

Safety valve

Air purge valve

Water inlet pipe

Manual water

drain valve

Water outlet

pipe

Accumulator

Water side

heat exchanger

Accumulator

Water flow

switch

8 201612

Page 10

Refrigerant Ci rcuits

Figure 2-1.6: MC-SU60-RN1L top view

expansion valve

Aqua Tempo Super II

Part 2 - Component Layout and

Low pressure

switch

High pressure

Solenoid

valve SV4

Discharge

temperature

switch

Low pressure

gauge point

High pressure

gauge point

sensor

High pressure

switch

Four-way valve

Electronic

201709 9

Page 11

Aqua Tempo Super II

Midea

Aqua Tempo S uper II

Service Manual

6

2 Piping Diagrams

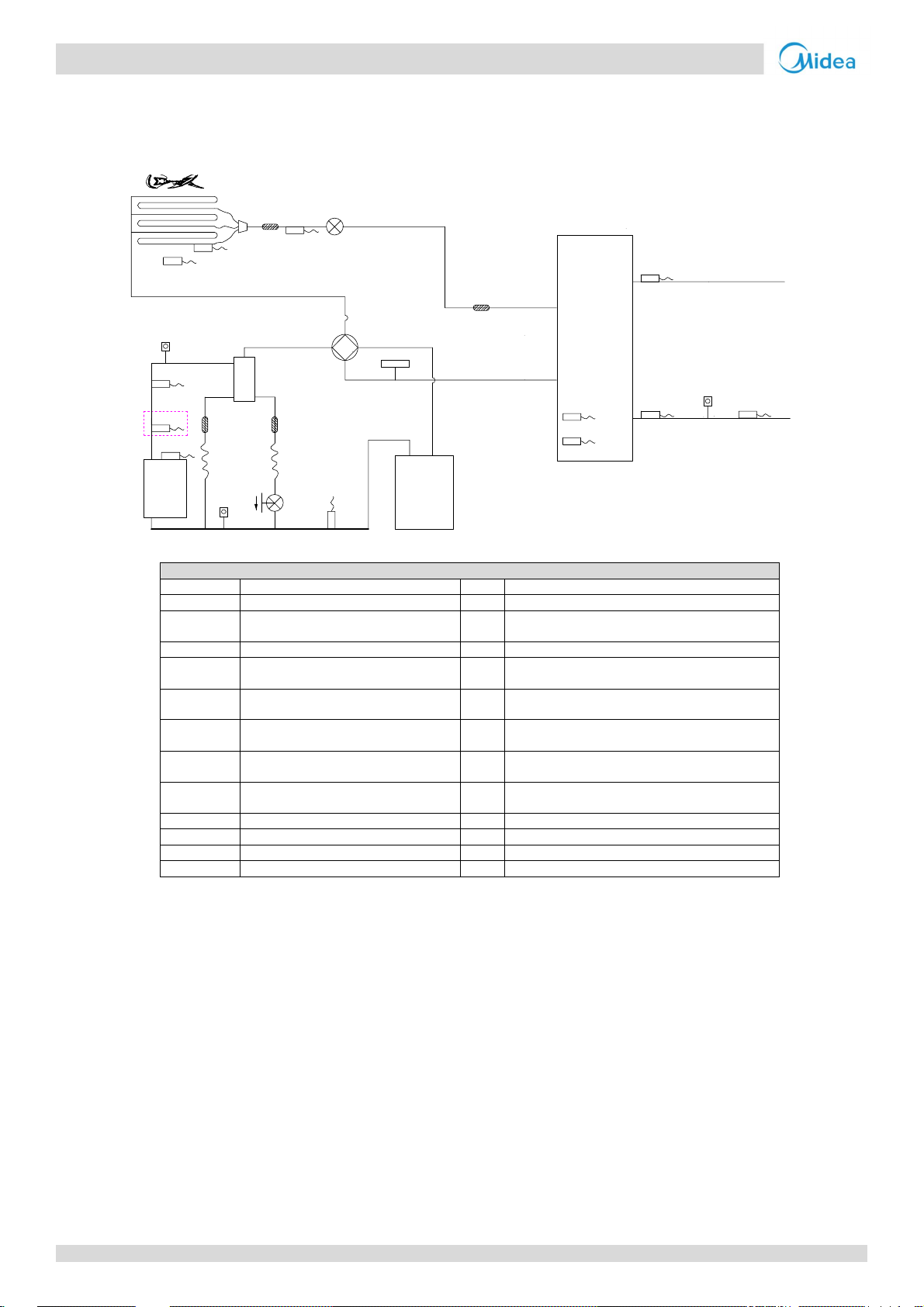

MC-SU30-RN1L

Figure 2- 2.1: MC-SU30-RN1L pipi ng diagram

Tz/7

T3

T4

EXV

11

Twi

4

ST1

9

7

3

TP2

TP1

1

Legend

10 Water flow switch Tw Combined water outlet temperature sensor

11 Filter Th Air suction temperature sensor

EXV Electronic expansion valve SV4 Oil return solenoid valve

ST1 4-way valve

5

Taf2 Tw

Taf1

2

1 Compressor Tp1 Discharge temperature sensor 1

2 Low pressure switch Tp2 Discharge temperature sensor 2

3 Discharge temperature control switch T3 Air side heat exchanger refrigerant outlet

4 High pressu re switch T4 Outdoor ambient temperature sensor

5 Oil separator TZ/7 Air side heat exchanger refrigerant total outlet

6 Air side heat excha nger Taf1 Water side heat exchanger anti-freezing

7 Pressure sensor Taf2 Water side heat exchanger anti-freezing

8 Accumulator Twi Water side heat exchanger water inlet temperature

9 Water side heat exchanger Two Water side heat exchanger water outlet

Th

SV4

8

temperature sensor

temperature sensor

temperature sensor 1

temperature sensor 2

sensor

temperature sensor

Two

10

10 201612

Page 12

Refrigerant Ci rcuits

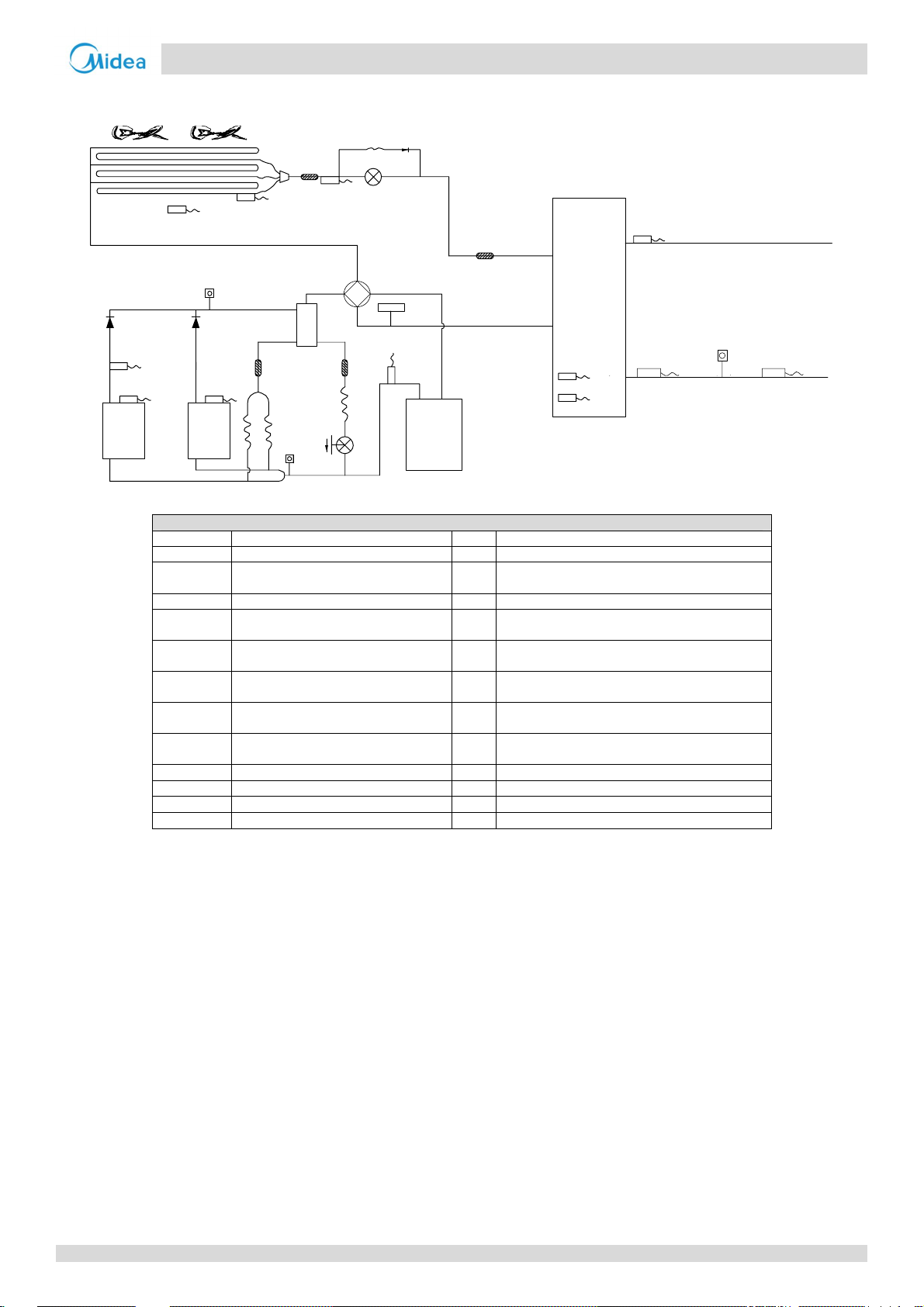

MC-SU60-RN1L

6

Figure 2- 2.2: MC-SU60-RN1L pipi ng diagram

T3

T4

Capillary

Tz

EXV

11

Aqua Tempo Super II

Twi

3

Tp1

1.1

4

ST1

Taf2

Taf1

9

Two

5

Tp2

1.2

SV4

Legend

1 Compressor Tp1 Discharge temperature sensor 1

2 Low pressure switch Tp2 Discharge temperature sensor 2

3 Discharge temperature control switch T3 Air side heat exchanger refrigerant outlet

4 High pressure switch T4 Outdoor ambient temperature sensor

5 Oil separator TZ/7 Air side heat exchanger refrigerant total outlet

6 Ai r side heat exchanger Taf1 Water side heat exchanger anti-freezing

7 Pressure sensor Taf2 Water side heat exchanger anti-freezing

8 Accumulator Twi Water side heat exchanger water inlet temperature

9 Water side heat exchanger Two Water side heat exchanger water outlet

10 Water flow switch Tw Combined water outlet temperature sensor

11 Filter Th Air suction temperature sensor

EXV Electronic expansion valve SV4 Oil return solenoid valve

ST1 4-way valve

7

Th

8

temperature sensor

temperature sensor

temperature sensor 1

temperature sensor 2

sensor

temperature sensor

10

Tw

Part 2 - Component Layout and

201709 11

Page 13

Aqua Tempo Super II

Midea

Aqua Tempo S uper II

Service Manual

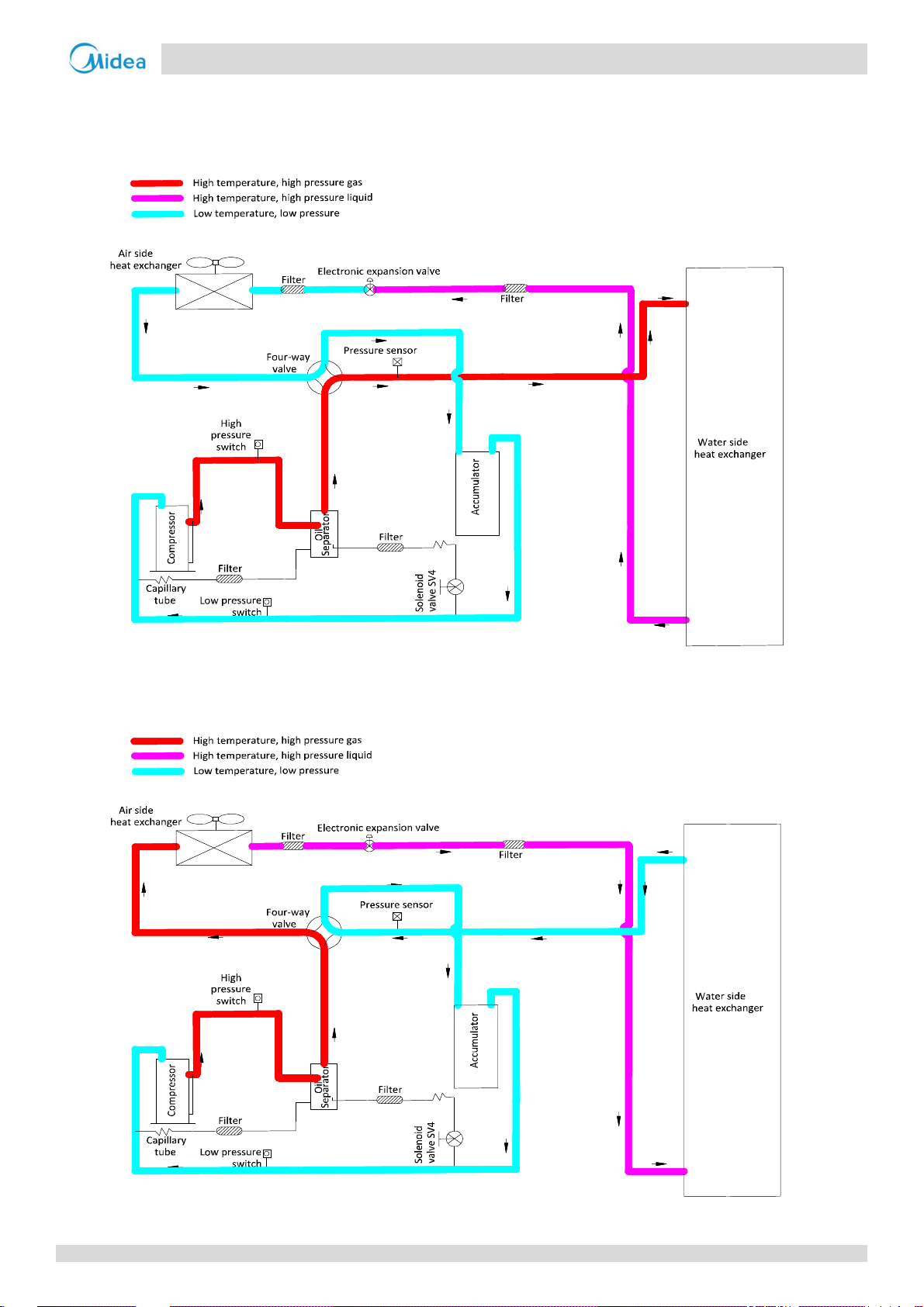

Key components:

1. Compressor

Maintains pressure differential between high and low pressure sides of the refrigerant system.

2. Fan

Ventilates the air side heat exchanger.

3. Oil separato r:

Separates oil from gas refrigerant pumped out of the compressor and quickly returns it to the compressor. Separation

efficiency is up to 99%.

4. Accumulator:

Stores liquid refrigerant and oil to protect the compressor from liquid hammering.

5. Electronic expansion valve (EXV):

Controls refrigerant flow and reduces refrigerant pressure.

6. Four-way valve:

Controls refrigerant flow direction. Closed in cooling mode and open in heating mode. When closed, the air side heat

exchanger functions as a condenser and water side heat exchanger functions as an evaporator; when open, the air

side heat exchanger functions as an evaporator and water side heat exchanger function as a condenser.

7. High and low pressure switches:

Regulate refrigerant system pressure. When the refrigerant system pressure rises above the upper limit or falls below

the lower limit, the high or low pressure switches turn off, stopping the compressor.

8. Discharge temperature switch:

Protects the compressor from abnormally high temperatures and transient spikes in temperature.

9. Air purge valve:

Automatically removes air from the water circuit.

10.Safety valve

Prevents excessive water pressure by opening at 43.5psi (3bar) and discharging water from the water circuit.

11.Water flow switch:

Detects water flow rate to protect the compressor and wat er pump in the event of insu fficient water flow.

12.Water pump:

Circulates water in the water circuit.

13.Pressure se n so r

Measures refrigerant system pressure.

14.Crankcase heater

Prevents refrigerant from mixing with compressor oil when the compressors are stopped.

15.Water side heat exchanger e lectric heater

Protects the water side heat exchanger from ice formation.

16.Water flow switch electric heater:

Provides additional heating when heating capacity provided by the heat pump is insufficient due to low ambient

temperatures, it also protects external water pipes from freezing.

17.Solenoid valve SV4

Returns oil to the compressor. It opens after 17 minut es of com pressor operation, closes after 3 minut es, t hen opens

again for 3 minutes at 17 minute increments.

12 201612

Page 14

Refrigerant Ci rcuits

3 Refrigerant Flow Diagrams

Heating operation

Figure 2-3.1: Refrigerant flow during heating operation

Aqua Tempo Super II

Part 2 - Component Layout and

Cooling and defrosting operation

Figure 2-3.2: Refrigerant flow during cooling and defrosting o perations

201709 13

Page 15

Aqua Tempo Super II

Midea

Aqua Tempo S uper II

Service Manual

14 201612

Page 16

Aqua Tempo Super II

Part 3

- Control

Part 3

Control

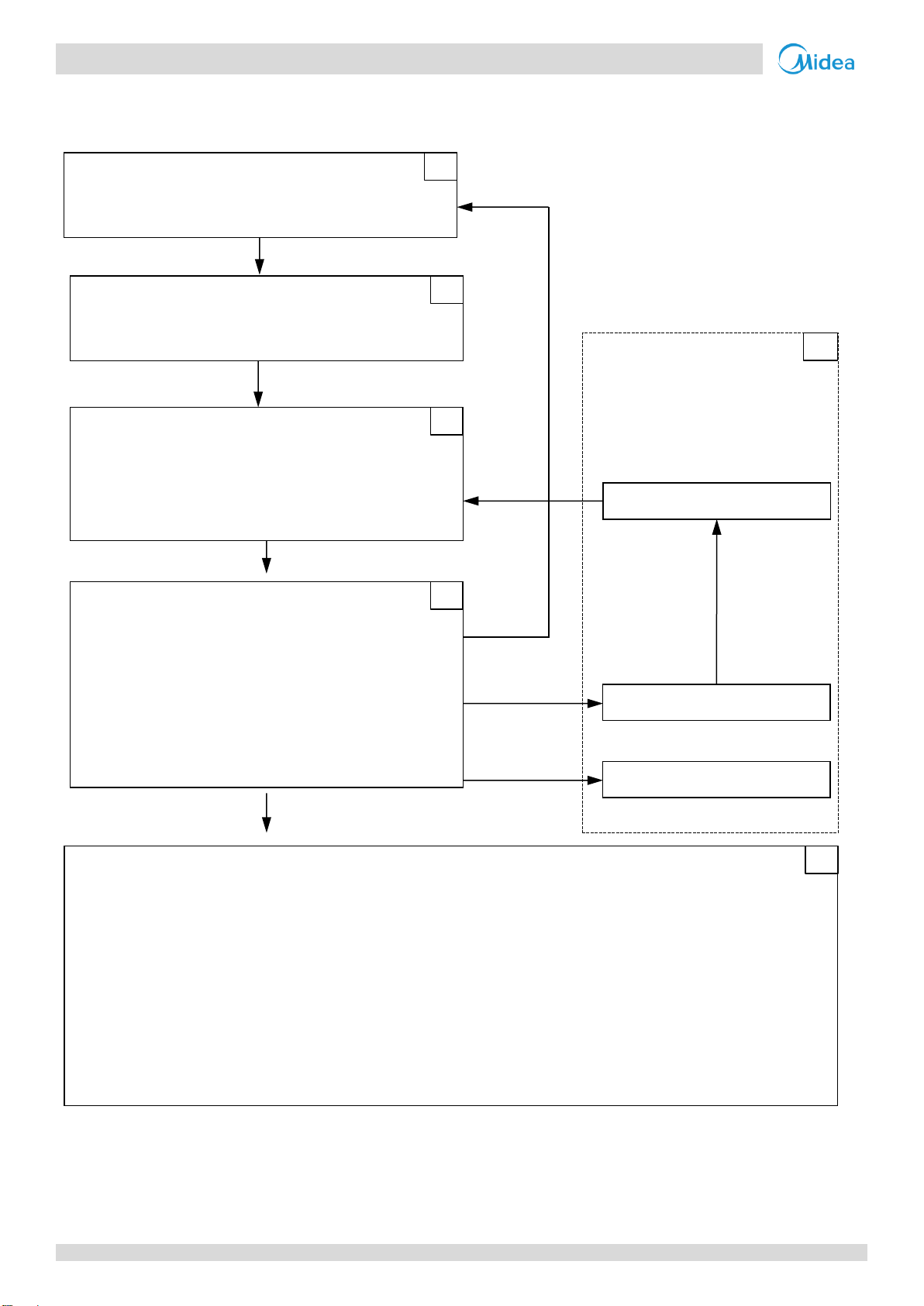

1 General Control Scheme Flowchart ..................................................... 16

2 Stop Operation .................................................................................... 17

3 Standby Control .................................................................................. 17

4 Startup Control .................................................................................... 18

5 Normal Operation Control ................................................................... 20

6 Protection Control ............................................................................... 23

7 Special Control .................................................................................... 29

8 Role of Temperature Sensors in Control Functions ............................... 31

201709 15

Page 17

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

S5_4 on main

PCB set to ON

Conditions met

for defrosting

Thermo on

Special control

Outdoor unit duty cycling

Additional control

Defrosting operation

7

Stop operation

System stops

2

Standby control

Water pump control

3

Startup control

Startup control for cooling operation

4

Thermo on

Normal operation control

Outdoor fan control

5

Protection control

Water side heat exchanger temperature difference protection control

6

1 General Control Scheme Flowchart

Sections 3-2 to 3-7 on the following pages detail when each of the controls in the flowchart below is activated.

Abnormal shutdown

Crankcase heater control

Compressor startup delay control

Compressor startup program

Startup control for heating operation

Component control during normal operation

Compressor output control

Compressor step control

Water pump select control

Four-way valve control

Electronic expansion valve control

High pressure protection control

Low pressure protection control

Discharge temperature protection control

Compressor and inverter module protection control

Voltage protection control

DC fan motor protection control

Water side heat exchanger anti-freeze protection control

Air side heat exchanger high temperature protection control

Note:

1. Numbers in the top right-hand corners of boxes indicate the relevant section of text on the following pages.

16 201709

Page 18

Aqua Tempo Super II

Part 3

- Control

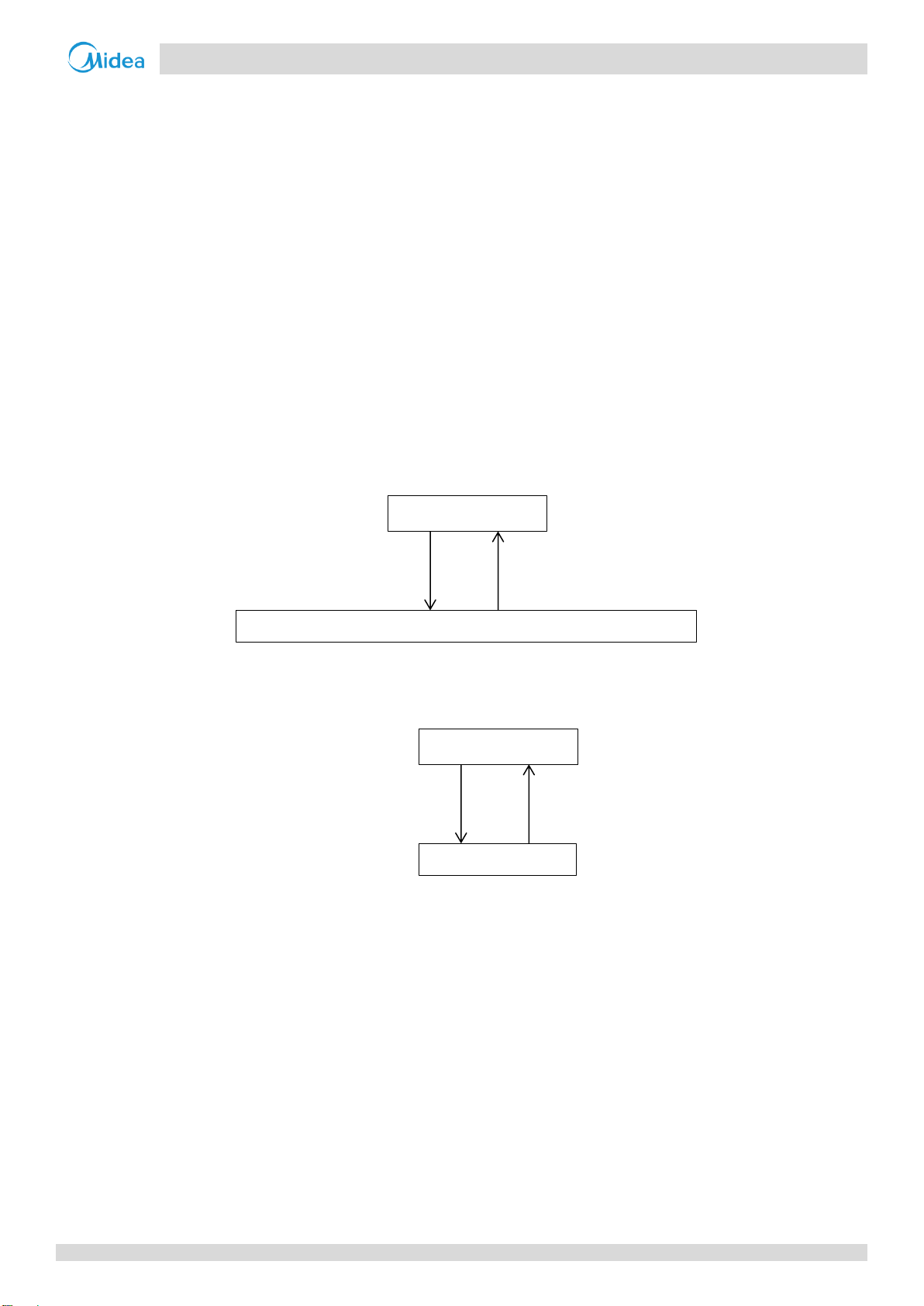

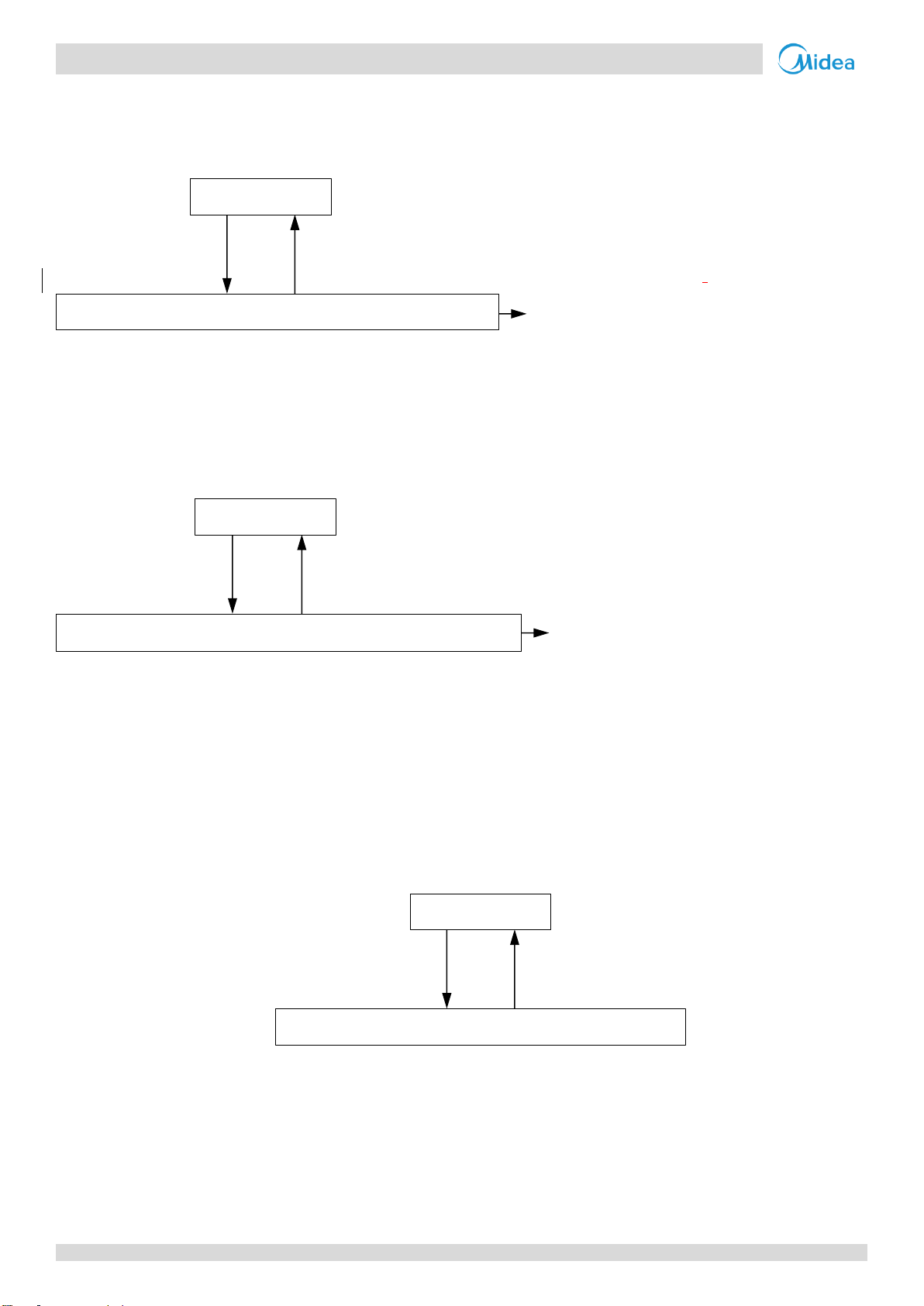

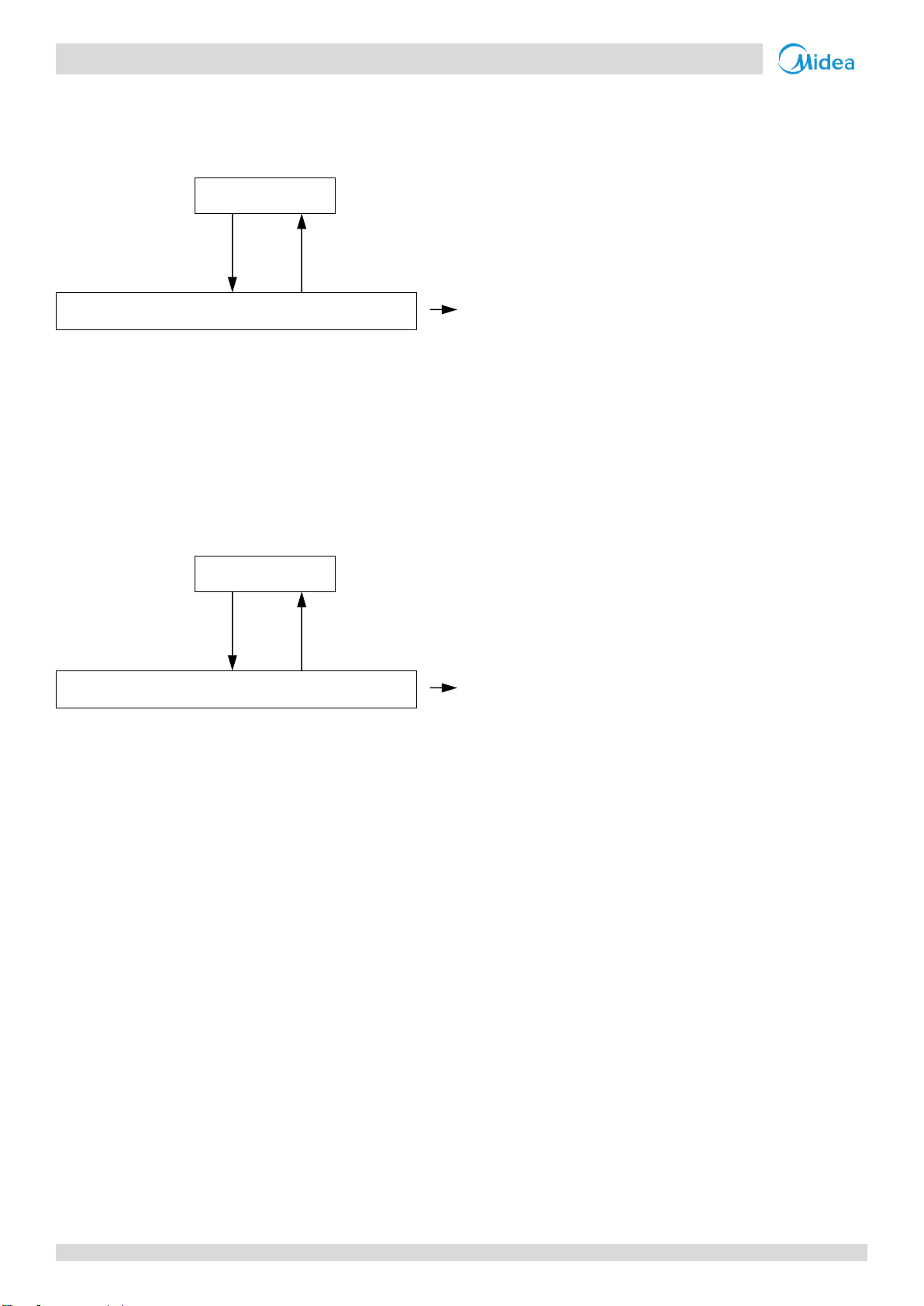

Figure 3-3.1: Crankcase heater controlled according to outdoor ambient temperature

Figure 3-3.2: Crankcase heater controlled according to discharge temperature

Notes:

1. Tp1: discharge temperature sensor 1, Tp2: discharge temperature sensor 2.

Ambient temperature < 35 oC

Ambient temperature > 40 oC

Crankcase heater off

Crankcase heater is controlled according to discharge temperature

Max (Tp1, Tp2) < 40 oC

Max (Tp1, Tp2) > 50 oC

Crankcase heater off

Crankcase heater on

2 Stop Operation

The stop operation occurs for one of the following reasons:

1. Abnormal shutdown: in order to protect the compressors, if an abnormal state occurs the system makes a 'stop with

thermo off’ operation and an error code is displayed on the outdoor unit’s PCB digital displays and on the user

interface.

2. The system stops when the set temperature has been reached.

3 Standby Control

3.1 Crankcase Heater Control

The crankcase heater is used to prevent refrigerant from mixing with compressor oil when the compressors are stopped.

The crankcase heater is controlled according to the outdoor ambient temperature and discharge temperature. When the

outdoor ambient temperature is above 40°C, the crankcase heater is off; when the outdoor ambient temperature is below

35°C, the crankcase heater is controlled according to discharge temperature. Refer to Figures 3-3.1 and 3-3.2.

3.2 Water Pump Control

When the outdoor unit is in standby, the circulator pumps run continuously。

201709 17

Page 19

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

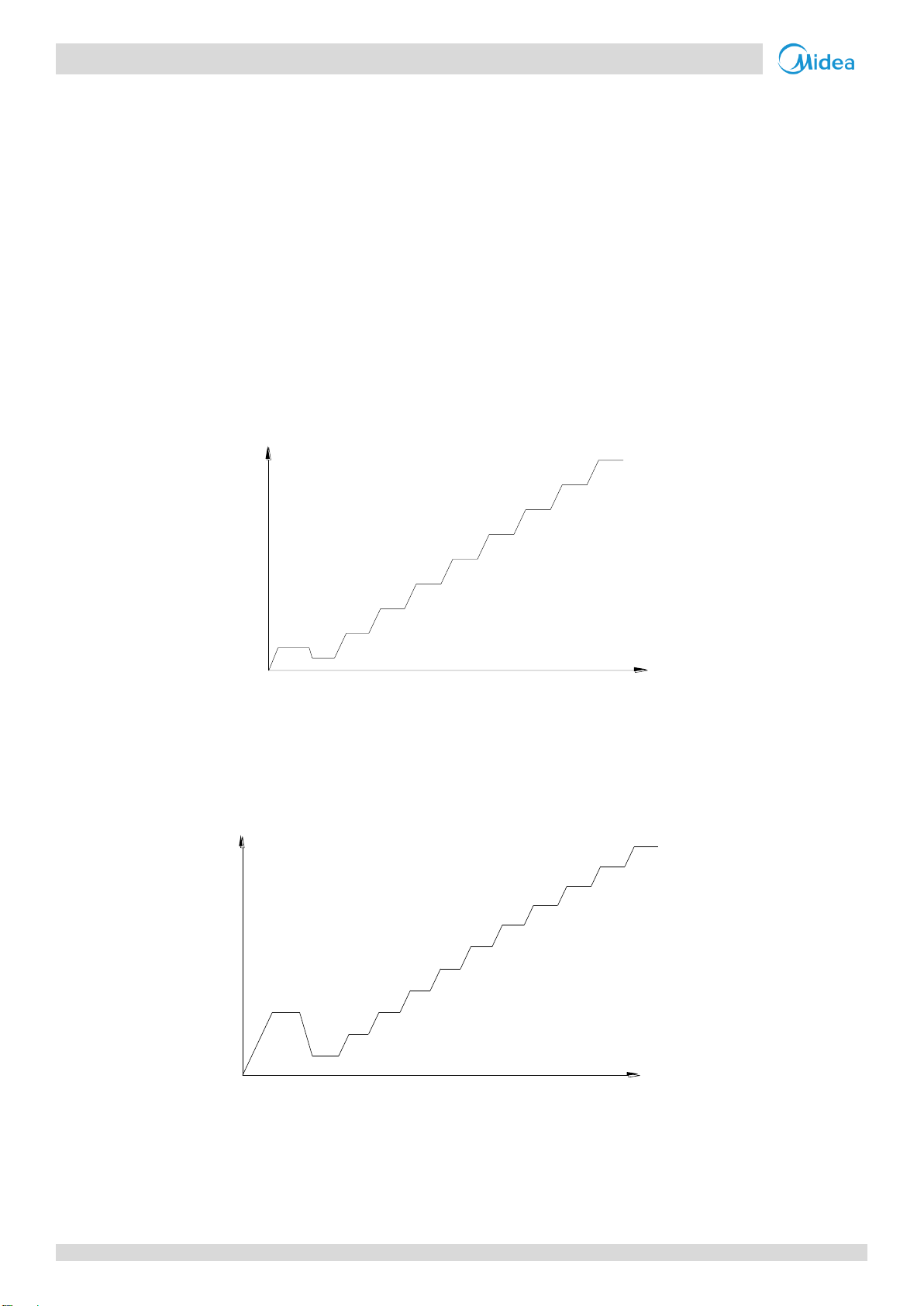

Figure 3-4.1: Compressor startup program1 when ambient temperature is above 10°C

Notes:

1. Once the first, 60-second stage of the program is complete, the program proceeds to the subsequent stages in a

step-by-step fashion and exits when the target rotation speed has been reached.

Figure 3-4.2: Compressor startup program1 when ambient temperature is at or below 10°C

Notes:

1. Once the first, 90-second stage of the program is complete, the program proceeds to the subsequent stages in a

step-by-step fashion and exits when the target rotation speed has been reached.

42rps

60S

56rps

34rps

66rps

76rps

80rps

90rps

90S

90S

90S

90S

180S

60S

180S

100rps

Target rotation speed

Compressor

rotation speed (rps)

Time (s)

105rps

300S

42rps

90S

28rps

120S

34rps

60S

42rps

90S

56rps

60S

76rps

60S

66rps

60S

80rps

90S

90rps

180S

100rps

180S

Target rotation speed

Compressor

rotation speed (rps)

Time (s)

105rps

300S

4 Startup Control

4.1 Compressor Startup Delay Control

In initial startup control and restart control (except in defrosting operation), compressor startup is delayed such that a

minimum 7 minutes has elapsed since the compressor stopped, in order to prevent frequency compressor on/off and to

equalize the pressure within the refrigerant system.

4.2 Compressor Startup Program

In initial startup control and in re-start control, compressor startup is controlled according to outdoor ambient

temperature and discharge temperature. Compressor startup follows one of two startup programs until the target rotation

speed is reached. Refer to Figures 3-4.1, 3-4.2.

18 201709

Page 20

Aqua Tempo Super II

Part 3

- Control

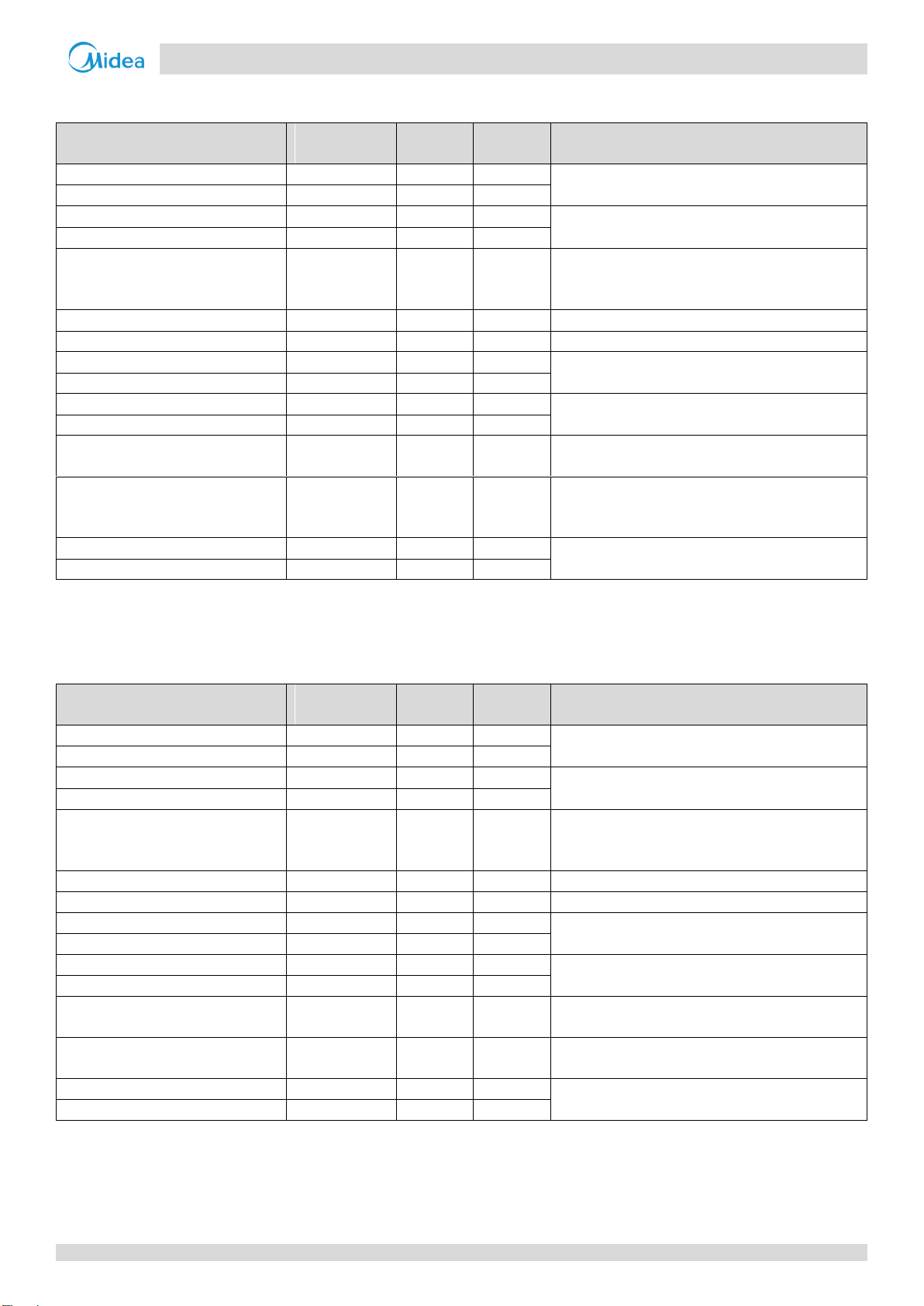

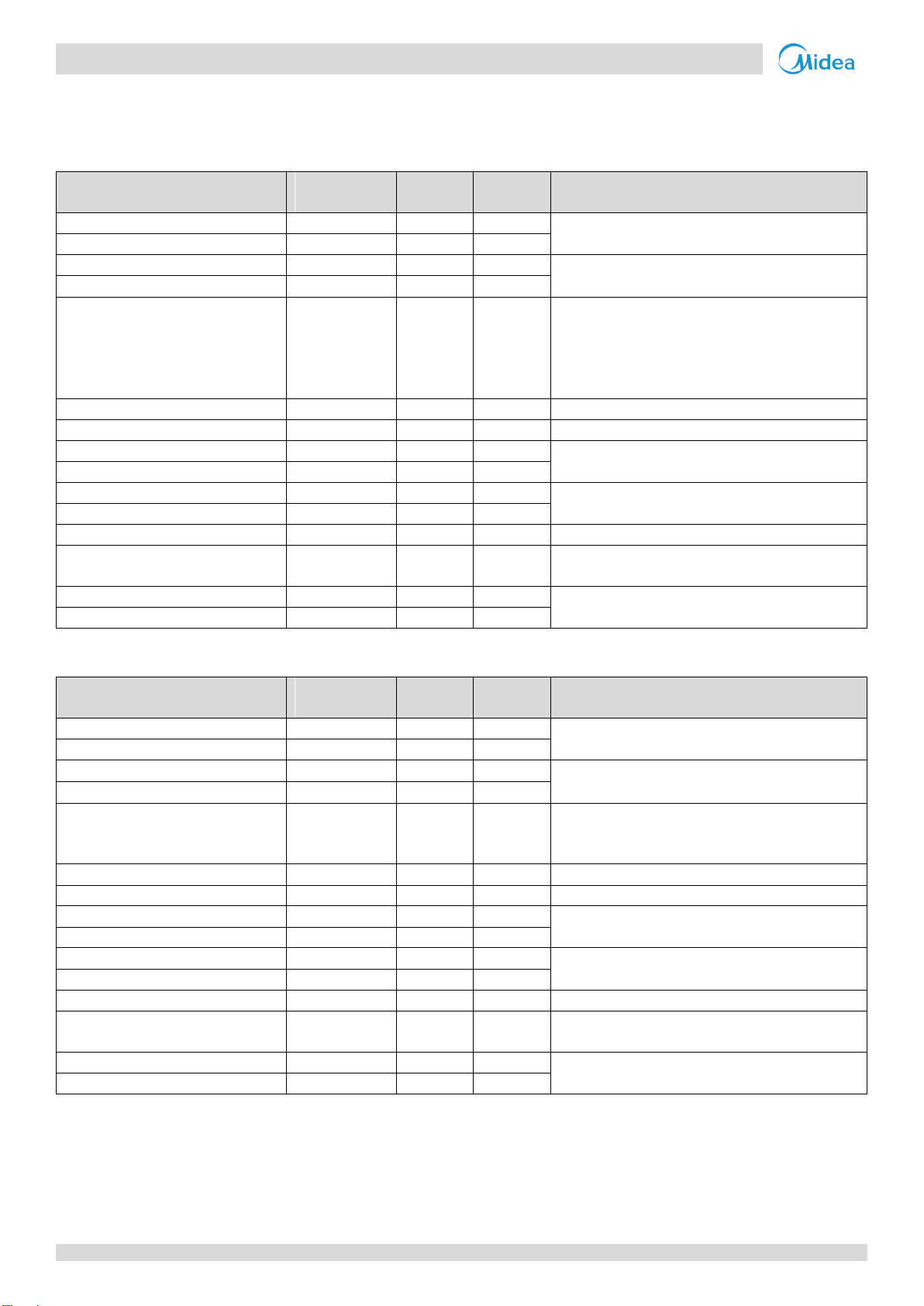

Component

Wiring diagram

label

30kW

60kW

Control functions and states

Inverter compressor A

COMP A

●

●

Compressor startup program selected according to

ambient temperature and discharge temperature1

Inverter compressor B

COMP B

●

DC fan motor A

FAN A

●

●

Controlled according to ambient temperature

DC fan motor B

FAN B

●

Electronic expansion valve

EXV 1

●

●

Position (steps) from 0 (fully closed) to 480 (fully

open), controlled according to outdoor ambient

temperature, unit capacity.

Four-way valve

STF1

●

●

On after the compressor startup for 10s

Solenoid valve (oil balance)

SV4_1

●

●

Closed for 200s, open for 600s, then closed

Water pump1

PUPM1

●

●

On

Water pump2

PUPM2

●

●

Water side heat exchanger heater 1

EVA-HEAT 1

●

●

According to water side heat exchanger

anti-freezing temperature (Taf)

Water side heat exchanger heater 2

EVA-HEAT 2

●

Water flow switch heater

W-HEAT1

●

●

Controlled according to ambient temperature, water

inlet temperature and water outlet temperature

Electric auxiliary heater

E-HEAT_L/

E-HEAT_N

●

●

Controlled according to ambient temperature and

total water outlet temperature after the compressor

is on

Crank case heater 1

HEAT1

●

●

Controlled according to ambient temperature and

discharge temperature

Crank case heater 2

HEAT2

●

Notes:

1. Refer to Figure 3-4.1, Figure 3-4.2 and in Part 3, 4.2 “Compressor Startup Program”.

Component

Wiring diagram

label

30kW

60kW

Control functions and states

Inverter compressor A

COMP A

●

●

Compressor startup program selected according to

ambient temperature and discharge temperature1

Inverter compressor B

COMP B

●

DC fan motor A

FAN A

●

Controlled according to air side heat exchanger

refrigerant total outlet temperature (Tz/7)

DC fan motor B

FAN B

●

Electronic expansion valve

EXV 1

●

●

Position (steps) from 0 (fully closed) to 480 (fully

open), controlled according to outdoor ambient

temperature, outdoor unit initial frequency

Four-way valve

STF1

●

●

Off

Solenoid valve (oil balance)

SV4_1

●

●

Closed for 200s, open for 600s, then closed

Water pump1

PUPM1

●

●

On

Water pump2

PUPM2

Water side heat exchanger heater 1

EVA-HEAT 1

●

●

According to water side heat exchanger

anti-freezing temperature (Taf)

Water side heat exchanger heater 2

EVA-HEAT 2

●

Water flow switch heater

W-HEAT1

●

●

Controlled according to ambient temperature, water

inlet temperature and water outlet temperature

Electric auxiliary heat

E-HEAT_L/

E-HEAT_N

●

●

Off

Crank case heater 1

Heat 1

●

●

Controlled according to ambient temperature and

discharge temperature

Crank case heater 2

Heat 2

●

Notes:

1. Refer to Figure 3-4.1, Figure 3-4.2 and in Part 3, 4.2 “Compressor Startup Program”.

4.3 Startup Control for Heating Operation

Table 3-4.1: Component control during startup in heating mode

4.4 Startup Control for Cooling Operation

Table 3-4.2: Component control during startup in cooling mode

201709 19

Page 21

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

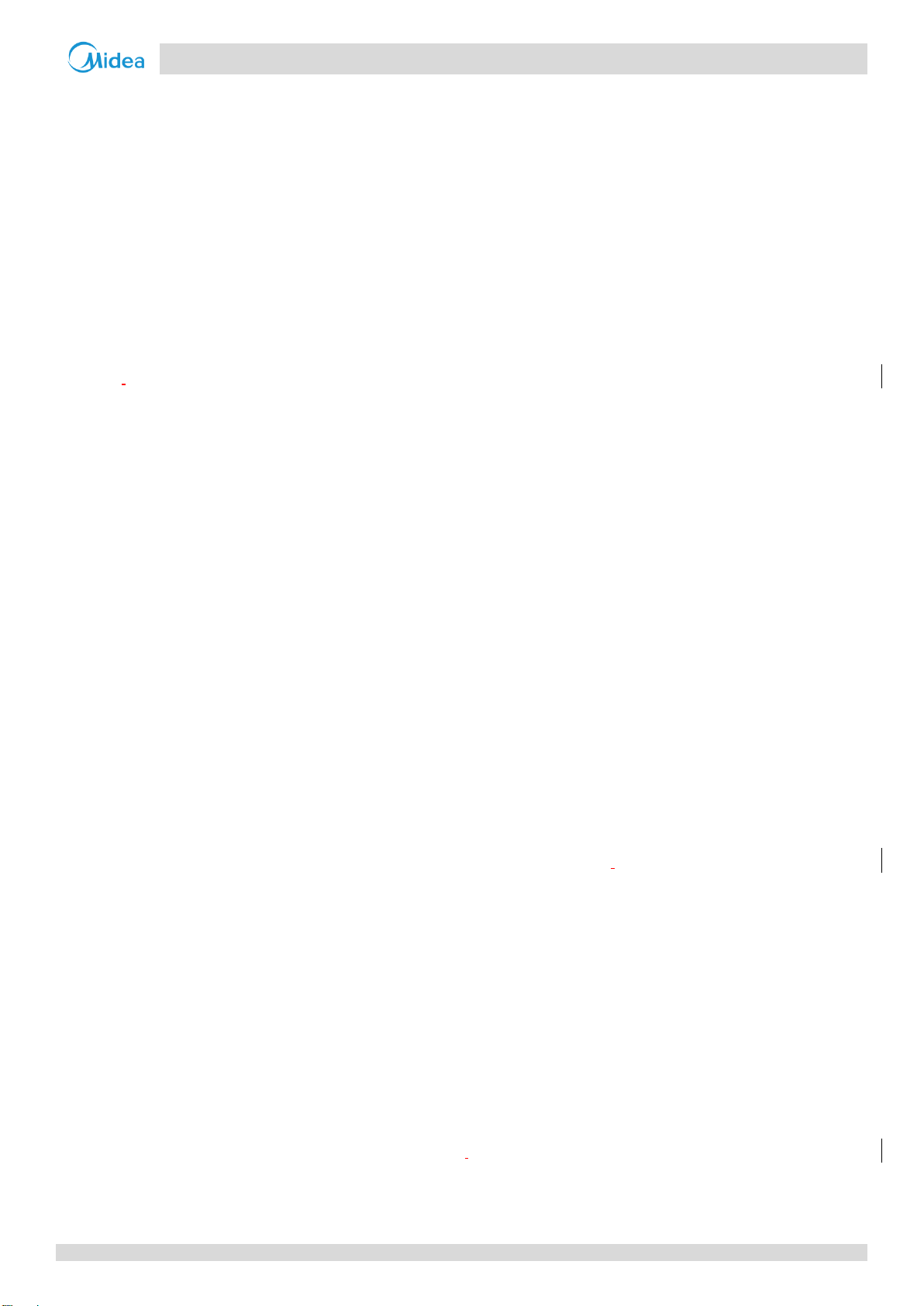

Component

Wiring diagram

label

30kW

60kW

Control functions and states

Inverter compressor A

COMP A

●

●

Controlled according to load requirement

Inverter compressor B

COMP B

●

DC fan motor A

FAN A

●

●

Controlled according to air side heat exchanger pipe

temperature and discharge pressure

DC fan motor B

FAN B

●

Electronic expansion valve

EXV 1

●

●

Position (steps) from 0 (fully closed) to 480 (fully

open), controlled according to discharge superheat

and compressor frequency, and use suction

temperature, air side heater exchanger temperature,

discharge temperature to modify the control.

Four-way valve

STF1

●

●

On

Solenoid valve (oil balance)

SV4_1

●

●

Open regularly

Water pump1

PUPM1

●

●

On

Water pump2

PUPM2

●

●

Water side heat exchanger heater 1

EVA-HEAT 1

●

●

Off

Water side heat exchanger heater 2

EVA-HEAT 1

●

Water flow switch heater

W-HEAT1

●

●

Off

Electric auxiliary heater

E-HEAT_L/

E-HEAT_N

●

●

Controlled according to ambient temperature

Crank case heater 1

HEAT1

●

●

Off

Crank case heater 2

HEAT2

●

Component

Wiring diagram

label

30kW

60kW

Control functions and states

Inverter compressor A

COMP A

●

●

Controlled according to load requirement

Inverter compressor B

COMP B

●

DC fan motor A

FAN A

●

●

Controlled according to air side heat exchanger

refrigerant total outlet temperature (Tz/7)

DC fan motor B

FAN B

●

Electronic expansion valve

EXV 1

●

●

Position (steps) from 0 (fully closed) to 480 (fully

open), controlled according to suction superheat,

water inlet temperature and compressor frequency.

Four-way valve

STF1

●

●

Off

Solenoid valve (oil balance)

SV4_1

●

●

Open regularly

Water pump1

PUPM1

●

●

On

Water pump2

PUPM2

●

●

Water side heat exchanger heater 1

EVA-HEAT 1

●

●

According to water side heat exchanger

anti-freezing temperature (Taf)

Water side heat exchanger heater 2

EVA-HEAT 2

●

Water flow switch heater

W-HEAT1

●

●

Off

Electric auxiliary heater

E-HEAT_L/

E-HEAT_N

●

●

Off

Crank case heater 1

HEAT1

●

●

Off

Crank case heater 2

HEAT2

●

5 Normal Operation Control

5.1 Component Control during Normal Operation

Table 3-5.1: Component control during heating operation

Table 3-5.2: Component control during cooling operation

20 201709

Page 22

Aqua Tempo Super II

Part 3

- Control

5.2 Compressor Output Control

The compressor rotation speed is controlled according to the load requirement. Before compressor startup, the outdoor

unit determines the compressor target speed according to outdoor ambient temperature, discharge temperature and then

runs the appropriate compressor startup program. Refer to Part 3, 4.2 “Compressor Startup Program”. Once the startup

program is complete, the compressor runs at the target rotation speed.

The compressor speed is controlled according to two parts in normal operation:

In cooling mode: In a single system, the compressor speed is controlled according to the water outlet temperature and

water outlet setting temperature. In a combination system, the compressor of master unit is controlled according total

water outlet temperature and water outlet setting temperature, the compressor of the slave unit is controlled according to

water inlet and water outlet temperature. Both in a single system and combination system, the compressor speed is

limited by the inverter module temperature (Tf), ambient temperature, discharge temperature and air side heat exchanger

refrigerant total outlet temperature (Tz/7).

In heating mode: In a single system, the compressor speed is controlled according to the water outlet temperature and

water outlet setting temperature. In a combination system, all compressors are controlled according to the total water

outlet temperature and the water outlet setting temperature. Both in a single system and combination system, the

compressor speed is limited by inverter module temperature (Tf), ambient temperature, discharge temperature, discharge

pressure.

5.3 Compressor Step Control

The running speed of six-pole compressors in rotations per second (rps) is one third of the frequency (in Hz) of the

electrical input to the compressor motor. The frequency of the electrical input to the compressor motors can be altered at

a rate of 1Hz in two seconds.

5.4 Water pump select control

When the dial switch S5_3 on the main PCB is switched ON, the system runs “one small pump per unit” mode, when S5_3

is switched OFF, the system run “one large pump controlled by master unit” mode.

One pump control: only the master unit output pump signal, no pump signal output on the slave units.

Multiple pump control: output pump signal on all units.

S5_3 in one system must be switched to the same position or not error code FP will be displayed.

5.5 Four-way Valve Control

The four-way valve is used to change the direction of refrigerant flow through the water side heat exchanger in order to

switch between cooling and heating operations. Refer to Figures 2-3.1 and 2-3.2 in Part 2, 3 “Refrigerant Flow Diagrams”.

During heating operation, the four-way valve is on; during cooling and defrosting operation, the four-way valve is off.

5.6 Electronic Expansion Valve Control

The position of the electronic expansion valve (EXV) is controlled in steps from 0 (fully closed) to 480 (fully open).

At power-on:

The EXV first closes fully, then moves to the standby position (352 (steps)). After 30seconds the EXV moves to an

initial running position, which is determined according to the operating mode and outdoor ambient temperature.

When the unit operate in cooling mode, after 60 seconds, the EXV is controlled according to suction superheat, water

inlet temperature and compressor frequency.

When the unit operates in heating mode, after a further 60 seconds, the EXV is controlled according to discharge

201709 21

Page 23

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

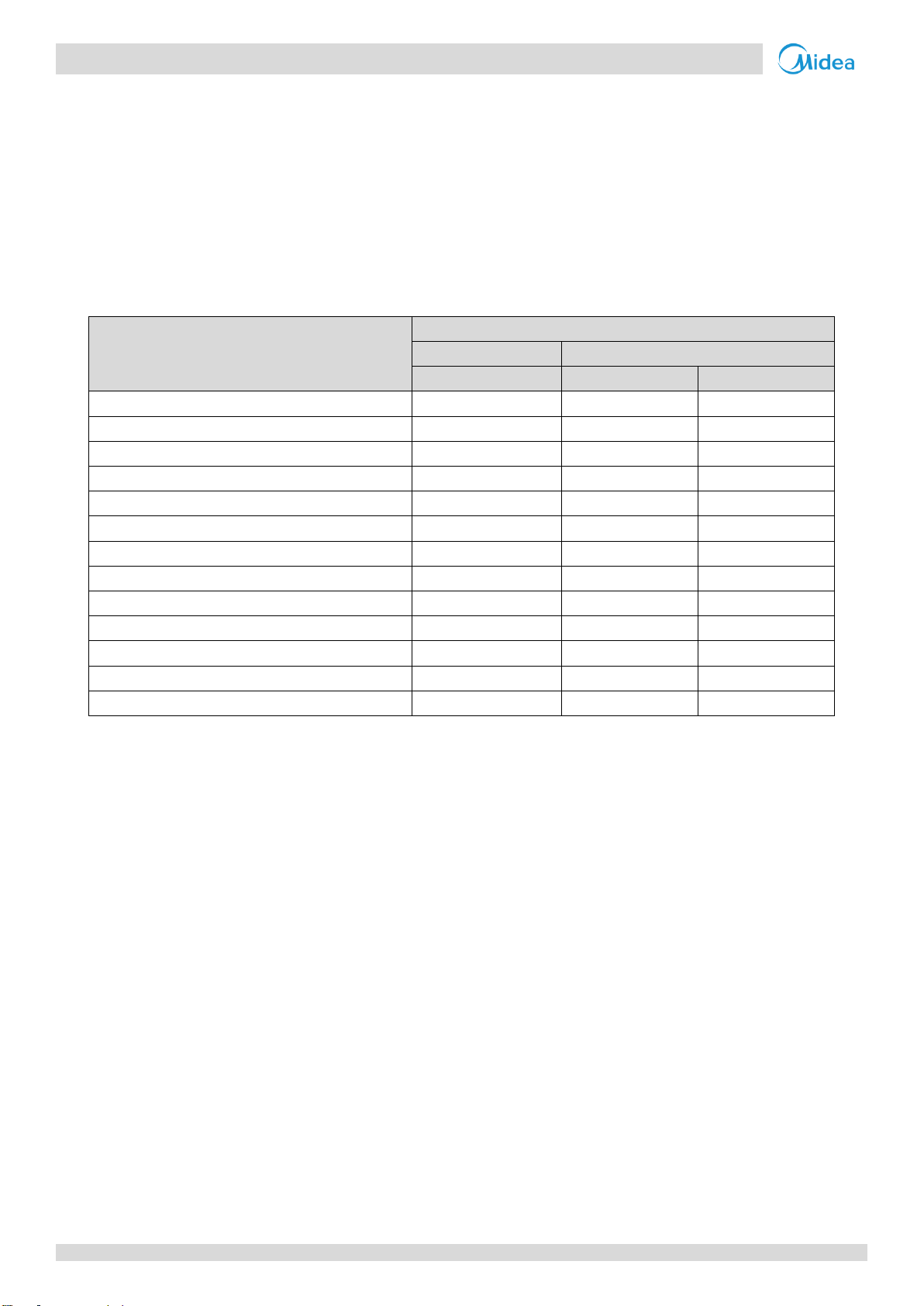

Table 3-5.3: Outdoor fan speed steps

Fan speed index

Fan speed (rpm)

30kW

60kW

FAN A

FAN A

FAN B 0 0 0 0 1 150

150

0 2 200

200

0 3 250

250

0 4 300

300

250 5 360

360

300 6 430

430

360 7 480

530

460

8 (super silent mode)

530

650

580 9 650

760

680

10(silent mode)

710

850

800

11

800

900

850

12(standard ESP mode)

820

950

900

Abbreviations:

ESP: External static pressure

superheat and compressor frequency, and uses the suction temperature, air side heater exchanger temperature,

discharge temperature to modify the control.

When the outdoor unit is in standby:

The EXV is at position 352 (steps).

When the outdoor unit stops:

The EXV first closes fully, then moves to the standby position (352 (steps)).

5.7 Outdoor Fan Control

The speed of the outdoor unit fan(s) is adjusted in steps, as shown in Table 3-5.3.

22 201709

Page 24

Aqua Tempo Super II

Part 3

- Control

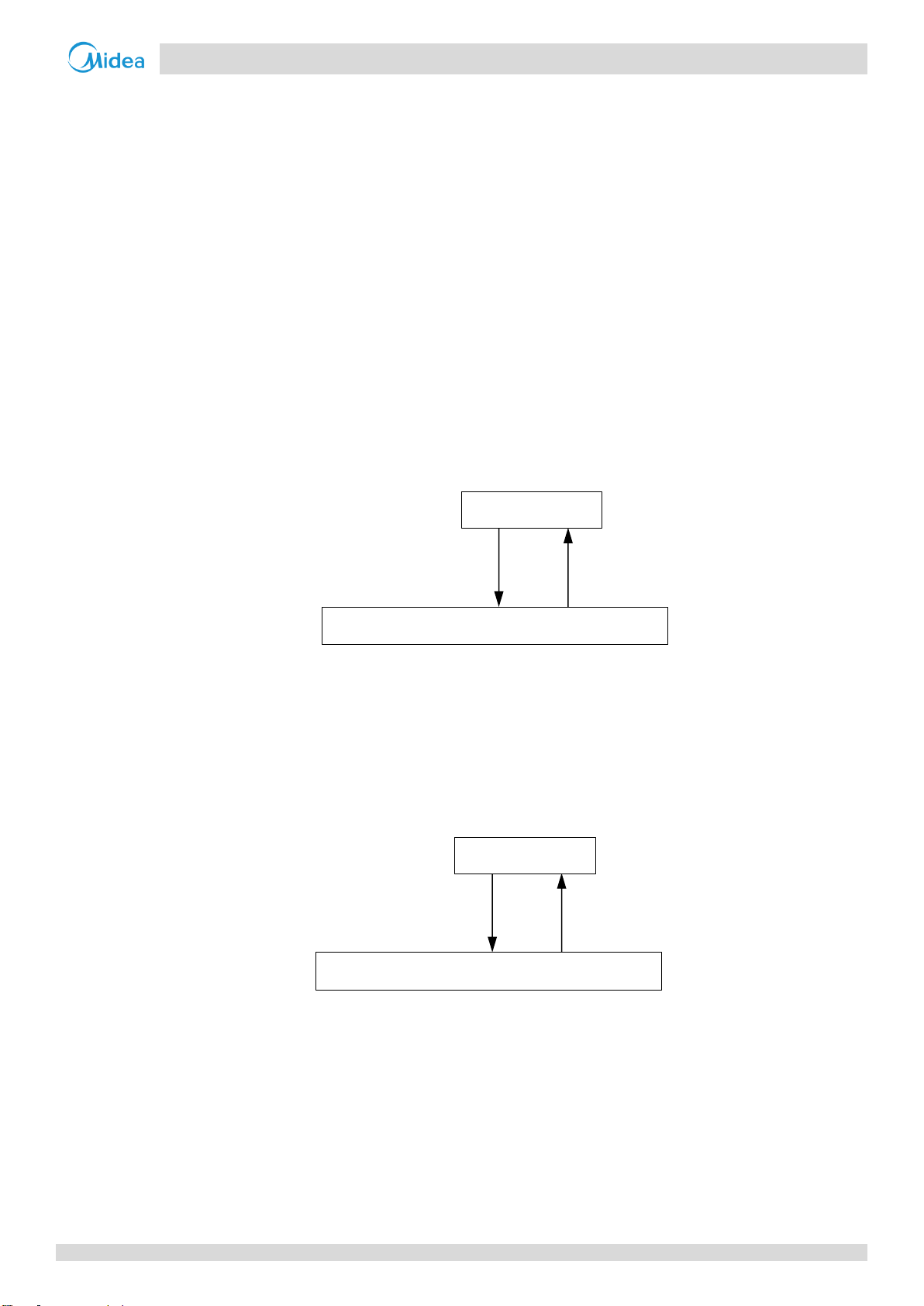

Figure 3-6.1: High pressure protection control

Notes:

1. P

c

: Discharge pressure

Figure 3-6.2: Low pressure protection control

Notes:

1. P

e

: Suction pressure

Figure 3-6.3: High discharge temperature protection control

When P1 protection occurs 5 times

in 120 minutes, ta manual system

restart is required before the system

can resume operation.

Pc > 4.4MPa

Pc < 3.2MPa

Normal operation

Low pressure protection, error code P0 is displayed

When P0 protection occurs 5 times

in 120 minutes, a manual system

restart is required before the system

can resume operation.

Pe < 0.14MPa

Pe > 0.3MPa

Normal operation

Low pressure protection, error code P1 is displayed

Discharge temperature > 110°C

Discharge temperature < 100°C

Normal operation

High discharge temperature protection, error code P0 is

When P0 protection occurs 5 times

in 120 minutes, ta manual system

restart is required before the system

can resume operation.

6 Protection Control

6.1 High Pressure Protection Control

This control protects the refrigerant system from abnormally high pressure and protects the compressor from transient

spikes in pressure.

When the discharge pressure rises above 4.4MPa the system displays P0 protection and all units stop running. When the

discharge pressure drops below 3.2MPa, the compressor enters re-start control.

6.2 Low Pressure Protection Control

This control protects the refrigerant system from abnormally low pressure and protects the compressor from transient

drops in pressure.

When the suction pressure drops below 0.14MPa the system displays P0 protection and all the units stop running. When

the suction pressure rises above 0.3MPa, the compressor enters re-start control.

6.3 Discharge Temperature Protection Control

This control protects the compressor from abnormally high temperatures and transient spikes in temperature.

When the discharge temperature rises above 110°C the system displays P0 protection and all the units stop running. When

the discharge temperature drops below 100°C , the compressor enters re-start control.

201709 23

Page 25

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

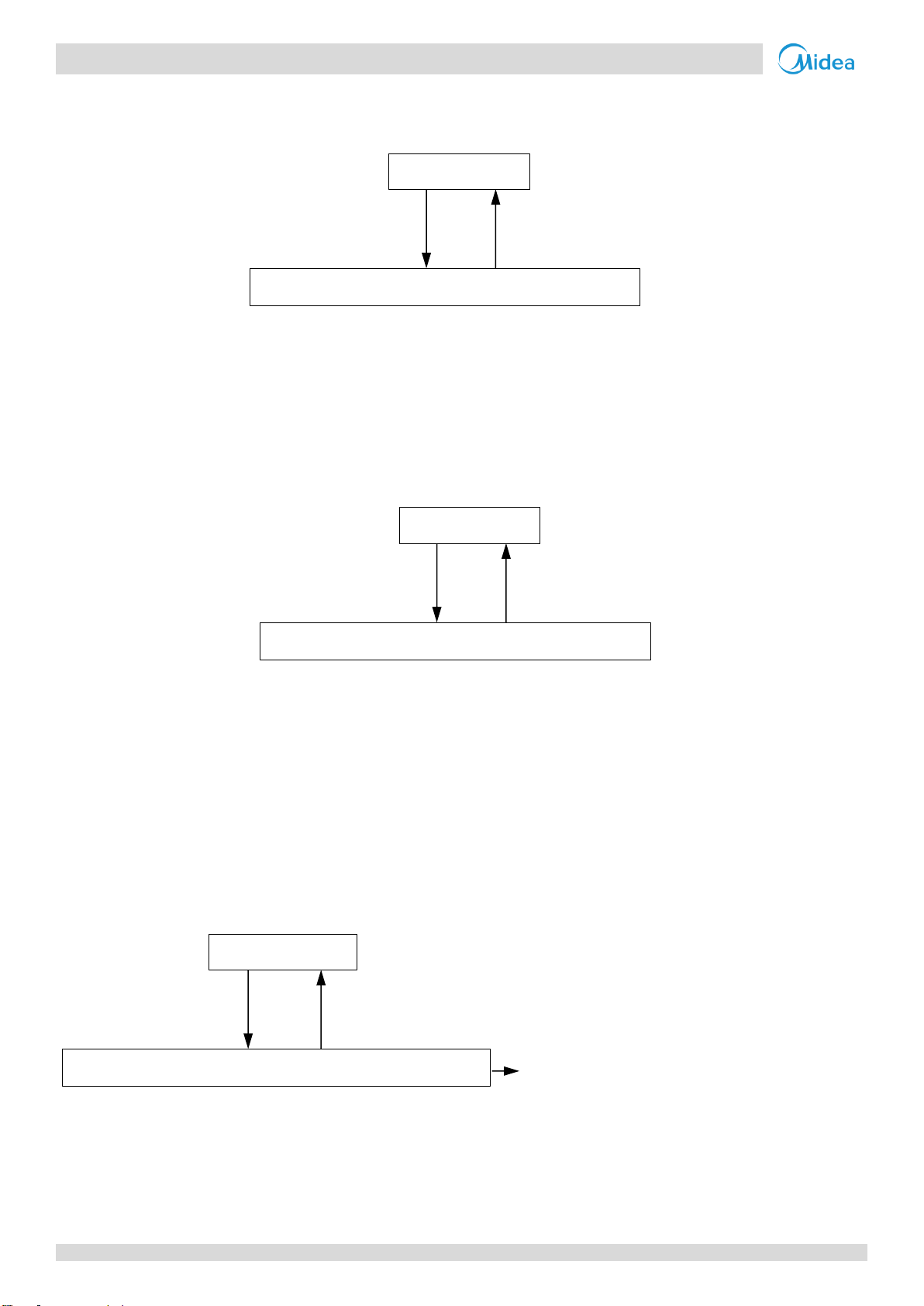

Figure 3-6.4: Compressor current protection control

Notes:

1. P4 is the protection for the power supply phase B, P5 is the protection for the power supply phase C.

Figure 3-6.5: Inverter module temperature protection control

Notes:

1. Tf1:Heat sink temperature 1; Tf2:Heat sink temperature 2

Figure 3-6.6: Compressor voltage protection control

Current > 25A

Current < 25A

Normal operation

Compressor current protection, error code P4 or P5 is displayed

Tf1 or Tf2 > 82°C

Tf1 and Tf2 < 60°C

Normal operation

Inverter module temperature protection, error code PL is displayed

Voltage ≥ 260V

or Voltage < 165V

180V ≤ Voltage < 250V

Normal operation

Compressor voltage protection, error code H1 is displayed

When P4 or P5 protection occurs 5

times in 120 minutes, ta manual

system restart is required before the

system can resume operation.

C7 is displayed when PL error occurs

3 times in 100 minutes, a manual

system restart is required before the

system can resume operation.

6.4 Compressor and Inverter Module Protection Control

This control protects the compressors from abnormally high currents and protects the inverter modules from abnormally

high temperatures. It is performed for each compressor and inverter module.

When the compressor current rises above25A, the system displays P4 or P5 protection and all the units stop running.

When the compressor current drops below 25A, the compressor enters re-start control.

When the Tf1 or Tf2 temperature rises above 82°C , the system displays PL protection and all the units stop running. When

the Tf1 and Tf2 temperature drops below 60°C, the compressor enters re-start control.

6.5 Voltage Protection Control

This control protects the units from abnormally high or abnormally low voltages.

When the phase voltage of AC power supply is at or above 260V for more than 30 seconds, the system displays H1

protection and all the units stop running. When the phase voltage drops below 250V for more than 30 seconds, the units

restart once the compressor re-start delay has elapsed. When the phase voltage is below 165V for more than 30 seconds,

the system displays H1 protection and all the units stop running. When the AC voltage rises to at or above 180V for more

than 30 seconds, the refrigerant system restarts once the compressor re-start delay has elapsed.

24 201709

Page 26

Aqua Tempo Super II

Part 3

- Control

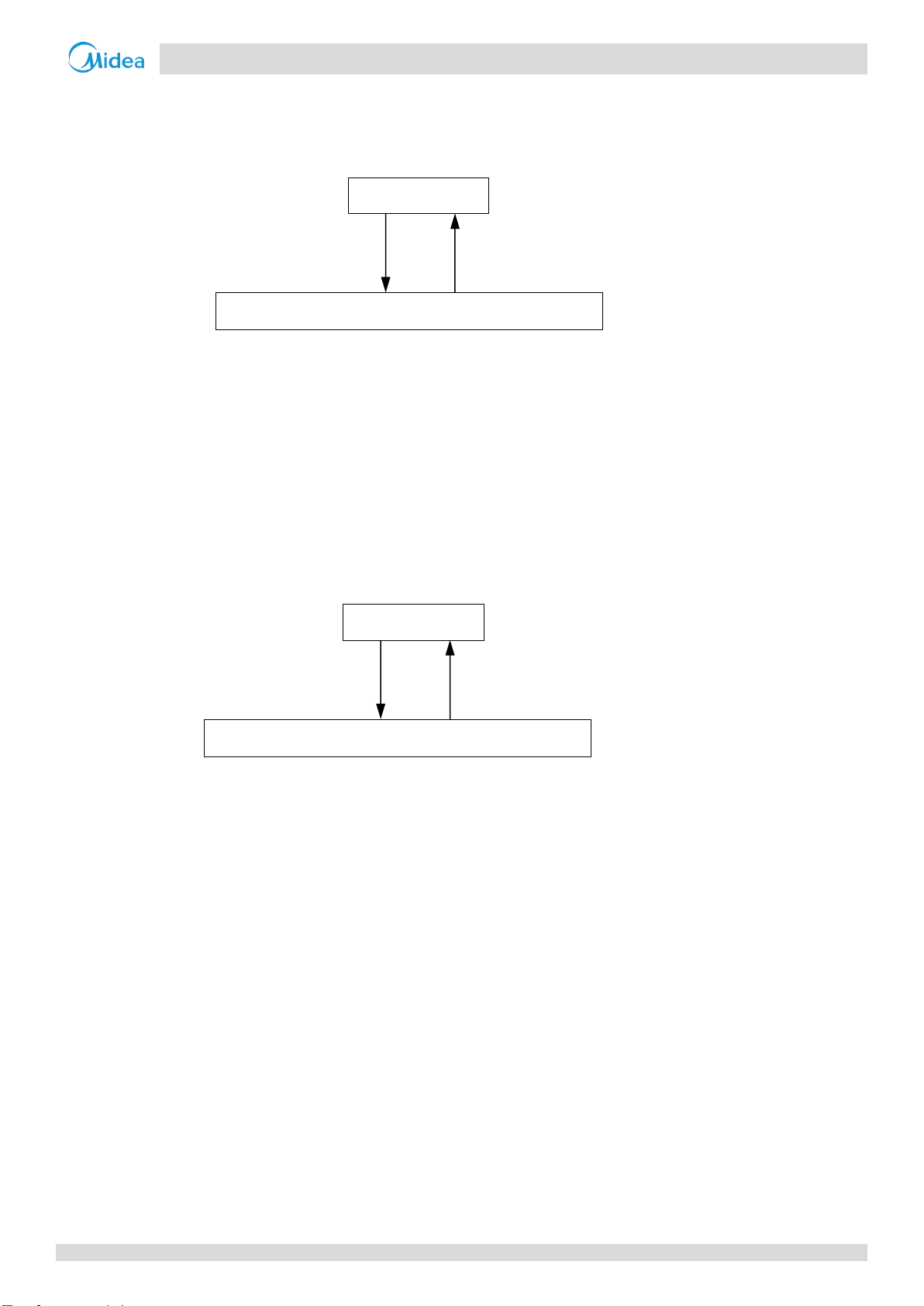

Figure 3-6.7: Anti-freeze protection control in normal cooling mode

Note:

1. Taf include Taf1 and Taf2.

Figure 3-6.8: Anti-freeze protection control in low water outlet cooling mode

Note:

1. Taf include Taf1 and Taf2.

Min(Tw/Two/Twi/Taf1) ≤ 4°C

Tw > 15°C

Normal operation

Anti-freeze protection, error code Pb is displayed

Min(Tw/Two/Twi/Taf1) ≤ 0°C

Tw > 15°C

Normal operation

Anti-freeze protection, error code Pb is displayed

6.6 DC Fan Motor Protection Control

This control protects the DC fan motors from abnormal power supply. DC fan motor protection occurs when the fan

module does not receive any feedback from the fan motor.

When DC fan motor protection control occurs the system displays the PU error code and the unit stops running. When PU

protection occurs 2 times in 120 minutes, the FF error is displayed. When an FF error occurs, a manual system restart is

required before the system can resume operation.

6.7 Water Side Heat Exchanger Anti-freeze Protection Control

This control protects the water side heat exchanger from ice formation. The water side heat exchanger electric heater is

controlled according to water side heat exchanger anti-freezing temperature (Taf), water inlet temperature (Twi), water

outlet temperature (Two) and total water outlet temperature (Tw).

When water side heat exchanger anti-freeze protection occurs the system displays error code Pb and all the units stop

running.

In standby or normal cooling mode, either water side heat exchanger anti-freezing temperature (Taf), water inlet

temperature (Twi), water outlet temperature (Two) or total water outlet temperature (Tw) is below 4°C, the unit will run

heating mode , until the total water outlet temperature is above 15°C, and restart the normal operation.

In low water outlet cooling mode, either water side heat exchanger anti-freezing temperature (Taf), water inlet

temperature (Twi), water outlet temperature (Two) or total water outlet temperature (Tw) is below 0°C, the unit will run

heating mode , until the total water outlet temperature is above 15°C, and restart the normal operation.

201709 25

Page 27

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 3-6.9: Air side heat exchanger high temperature protection control 1

Note:

1. T3: Air side heat exchanger refrigerant outlet temperature

Figure 3-6.10: Air side heat exchanger temperature protection control 2

Note:

1. Tz/7: Air side heat exchanger refrigerant total outlet temperature

Figure 3-6.11: Water side heat exchanger temperature difference protection control

Notes:

1. Twi: Water side heat exchanger inlet temperature

2. Two: Water side heat exchanger outlet temperature

T3 > 65°C

T3 < 60°C

Normal operation

High temperature protection, error code P7 is displayed

Tz/7 ≥ 62°C

Tz/7 < 62°C

Normal operation

High temperature protection, error code P7 is displayed

∣Twi-Two∣≥ 12°C

∣Twi-Two∣< 6°C

Normal operation

Temperature difference protection, error code P9 is displayed

When P9 protection occurs 3 times

in 60 minutes, a manual system

restart is required before the system

can resume operation.

6.8 Air Side Heat Exchanger High Temperature Protection Control

This control protects the air side heat exchanger from high temperature.

When the air side heat exchanger refrigerant outlet temperature (T3) rises above 65°C , the system displays P7 protection

and all the units stop running. When the air side heat exchanger refrigerant outlet temperature (T3) drops below 60°C, the

compressor enters re-start control.

When the air side heat exchanger refrigerant total outlet temperature (Tz/7) temperature rises at or above 62°C , the

system displays P7 protection and the unit stops running. When the air side heat exchanger refrigerant total outlet

temperature (Tz/7) temperature drops below 62°C, the compressor enters re-start control.

6.9 Water Side Heat Exchanger Temperature Difference Protection Control

This control protects the water side heat exchanger from ice formation.

When the temperature difference rises at or above 12°C , the system displays P9 protection and all the units stop running.

When the Temperature difference drops below 6°C, the compressor enters re-start control.

26 201709

Page 28

Aqua Tempo Super II

Part 3

- Control

Figure 3-6.12: Water side heat exchanger low temperature protection control in normal cooling mode

Notes:

1. Taf1: Water side heat exchanger anti-freezing temperature1

2. Taf2: Water side heat exchanger anti-freezing temperature2

Figure 3-6.13: Water side heat exchanger low temperature protection control in low water outlet mode

Min (Taf1 or Taf2) ≤ 3°C

Min (Taf1 and Taf2) >10°C

Normal operation

Low temperature protection, error code PE is

Min (Taf1 or Taf2) ≤ 0°C

Min (Taf1 and Taf2) > 5°C

Normal operation

Low temperature protection, error code PE is displayed

6.10 Water Side Heat Exchanger Low Temperature Protection Control

This control protects the water side heat exchanger from ice formation.

When water side heat exchanger anti-freezing temperature1 (Taf1) or water side heat exchanger anti-freezing

temperature2 (Taf2) is at or below 3°C for more than 3 seconds, the system displays PE protection and the corresponding

unit stop running. When water side heat exchanger anti-freezing temperature1 (Taf1) and Water side heat exchanger

anti-freezing temperature2 (Taf2) rise to 10°C or higher, the compressor enters re-start control. Use the user interface to

clear the error.

When water side heat exchanger anti-freezing temperature1 (Taf1) or water side heat exchanger anti-freezing

temperature2 (Taf2) is at or below 0°C for more than 3 seconds, the system displays PE protection and orders the

corresponding units to stop running. When water side heat exchanger anti-freezing temperature1 (Taf1) and Water side

heat exchanger anti-freezing temperature2 (Taf2) rise to 5°C or higher, the compressor enters re-start control. Use the user

interface to clear the error.

201709 27

Page 29

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 3-6.14: Water side heat exchanger low pressure protection control in normal cooling mode

Note:

1. Pe: Suction pressure

Figure 3-6.15: Water side heat exchanger low pressure protection control in low water outlet cooling mode

Note:

1. Pe: Suction pressure

Pe < 0.6Mpa

Pe ˃ 0.6Mpa

Normal operation

Low pressure protection, error code PC is

Pe < 0.4Mpa

Pe ˃ 0.4Mpa

Normal operation

Low pressure protection, error code PC is

When system displays PC protection

and a manual system restart is

required before the system can

resume operation.

When system displays PC protection

and a manual system restart is

required before the system can

resume operation.

6.11 Water Side Heat Exchanger Low Pressure Protection Control

This control protects the water side heat exchanger from ice formation.

In normal cooling mode, when the suction pressure drops below 0.6Mpa, the system displays PE protection and all the

units stop running. When the suction pressure is above 0.6Mpa or higher, the compressor enters re-start control. It will not

display the PC error when the suction pressure drops below 0.6Mpa for the first time until the suction pressure drops

below 0.6Mpa for the second time in 30 minutes.

In low water outlet cooling mode, when the suction pressure drops below 0.4Mpa, the system displays PE protection and

all the units stop running. When the suction pressure is above 0.4Mpa or higher, the compressor enters re-start control. It

will not display the PC error when the suction pressure drops below 0.4Mpa for the first time until the suction pressure

drops below 0.4Mpa for the second time in 30 minutes.

28 201709

Page 30

Aqua Tempo Super II

Part 3

- Control

Startup control

Normal operation

After defrosting operation or on

restart following compressor stop

after set temperature s reached

Normal operation

Outdoor unit

duty cycling

Priority

1

Priority

2

……

Priority

16

Master

Slave 1

Slave 15

Outdoor unit

duty cycling

Priority

16

Priority

15

Priority

1

Master

Slave 1

Slave 15

……

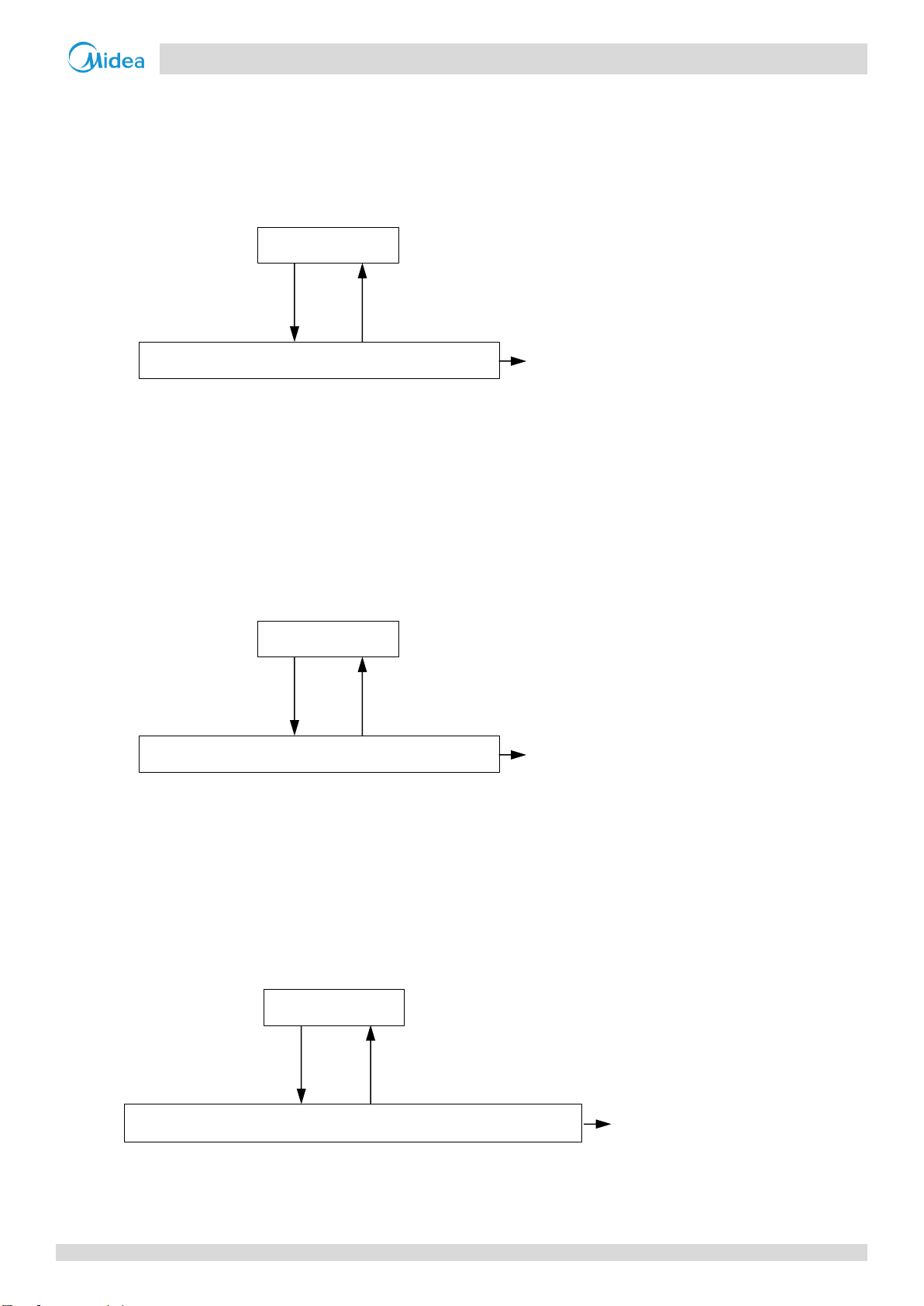

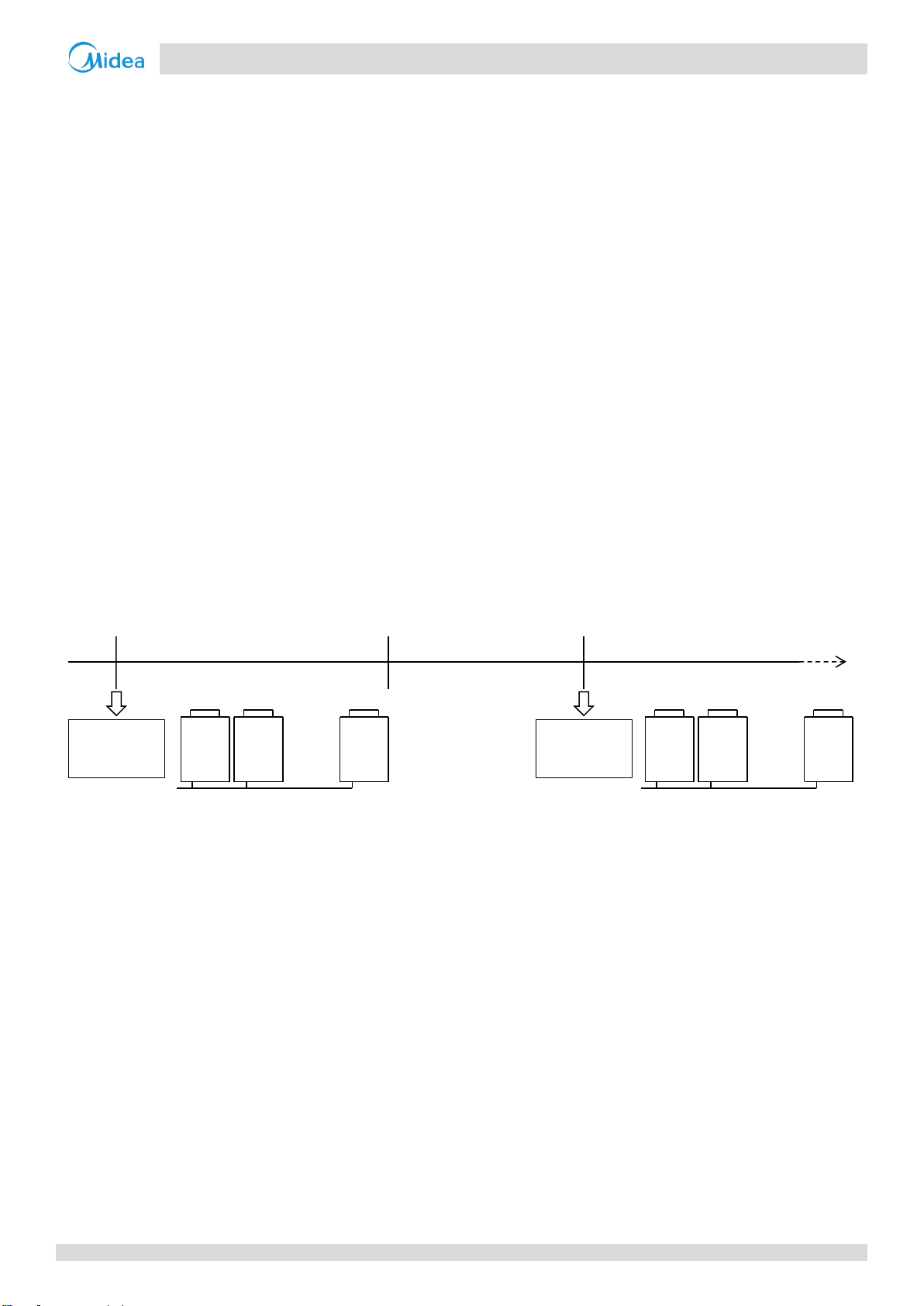

7 Special Control

7.1 Outdoor Unit Duty Cycling

In systems with multiple outdoor units, outdoor unit duty cycling is used to balance the compressor running time.

Outdoor unit duty cycling occurs whenever all the outdoor units stop running (either because the leaving water set

temperature has been reached or because a master unit error has occurred):

When the outdoor units are powered on for the first time, if there is a load requirement, the units turn on, starting

with the master unit. As the leaving water temperature approaches its set temperature, units shut down in succession,

starting with the unit with the highest address. Once the set temperature has been reached, the master unit shuts

down.

The next time a load requirement exists (or, following a master unit error), the units turn on, starting with the unit

with the highest address. As the leaving water temperature approaches its set temperature, units shut down in

succession, starting with the unit with the lowest address (the master unit). Once the set temperature has been

reached, the unit with the highest address shuts down.

Figure 3-7.1 shows an example of duty cycling in a system with 16 outdoor units.

Figure 3-7.1: Duty cycling in a system with 16 outdoor units

1

Notes:

1. The address settings on the outdoor unit main PCBs for master unit and slave unit do not change.

7.2 Defrosting Operation

In order to recover heating capacity, the defrosting operation is conducted when the outdoor unit air side heat exchanger

is performing as a condenser. The defrosting operation is controlled according to outdoor ambient temperature, air side

heat exchanger refrigerant outlet temperature and the compressor running time.

The defrosting operation ceases when any one of the following three conditions occurs:

Defrosting operation duration reaches 10 minutes.

The air side heat exchanger refrigerant outlet temperature reaches the target temperature.

The water outlet temperature is at or below 5°C .

201709 29

Page 31

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Component

Wiring diagram

label

30kW

60kW

Control functions and states

Inverter compressor A

COMP A

●

●

Runs at defrosting operation rotation speed

Inverter compressor B

COMP B

●

DC fan motor A

FAN A

●

●

Off

DC fan motor B

FAN B

●

Electronic expansion valve

EXV 1

●

●

Full open

Four-way valve

STF1

●

●

Off

Solenoid valve (oil balance)

SV4_1

●

●

Open regularly

Water pump1

PUPM1

●

●

ON

Water pump2

PUPM2

●

●

Water side heat exchanger heater 1

EVA-HEAT 1

●

●

Off

Water side heat exchanger heater 2

EVA-HEAT 2

●

Water flow switch heater

W-HEAT1

●

●

Off

Electric auxiliary heat

E-HEAT_L

●

●

According to ambient temperature

Crank case heater 1

HEAT1

●

●

Off

Crank case heater 2

HEAT2

●

Table 3-7.1: Component control during defrosting operation

7.3 Additional control

When dial switch S5_4 on main PCB is switched ON, additional control is valid, connect a controller or not is permissible.

When dial switch S5_4 is switched OFF, additional control is invalid. This function is only valid on the master unit.

When dial switch S5_4 is switched ON and disconnect a wired controller:

The system ON/OFF state is controlled by the ON/OFF port (CN44 on the main PCB). Connecting this port, system on,

disconnecting this port, system off.

The mode of the system is controlled by the Cool/Heat port (CN44 on the main PCB). Connecting this port, system

running heating mode, disconnecting this port, system running cooling mode.

The default water outlet temperature setting in heating mode is 45°C and in cooling mode is 7°C . The default

hysteresis temperature setting is 2°C .

The network icon on the wired controlled flashes, frequency and “rctc” alternate display on main PCB .

When dial switch S5_4 is switched ON and connect a wired controller, the water outlet temperature and hysteresis

temperature can be set by the wired controller.

30 201709

Page 32

Aqua Tempo Super II

Part 3

- Control

Number

Sensor name1

Sensor

code

Mode

Control functions

1

Discharge pipe temperature sensor 1/ Discharge pipe

temperature sensor 2

Tp1/Tp2

Heating

Crankcase heater control

1

Electronic expansion valve control

2

Compressor output control

3

Discharge temperature protection

control4

Cooling

Crankcase heater control

1

Compressor output control

3

Discharge temperature protection

control4

2

Outdoor ambient temperature sensor

T4

Heating

Crankcase heater control

1

Electric auxiliary heater control

Water flow switch heater control

Compressor output control

3

Electronic expansion valve control

2

Outdoor fan control

5

Cooling

Crankcase heater control

1

Compressor output control

3

Defrosting operation control

6

Electronic expansion valve control

2

Outdoor fan control

5

3

Air side heat exchanger refrigerant outlet temperature

sensor

T3

Heating

Outdoor fan control

5

Electronic expansion valve control

2

Cooling

Defrosting operation control

6

Air side heat exchanger high

temperature protection control7

4

Total cooling outlet temperature sensor

TZ/7

Heating

None

Cooling

Outdoor fan control

5

Compressor output control

3

Air side heat exchanger high

temperature protection control7

5

Water side heat exchanger anti-freezing temperature

sensor1/Water side heat exchanger anti-freezing

temperature sensor 2

Taf1/

Taf2

Heating

None

Cooling

Water side heat exchanger heater

control

Water side heat exchanger anti-freeze

protection control8

Water side heat exchanger low

temperature protection control9

6

Suction pipe temperature sensor

Th

Heating

Electronic expansion valve control

2

Cooling

Electronic expansion valve control

2

7

Water inlet temperature sensor

Twi

Heating

Water flow switch heater control

Cooling

Electronic expansion valve control

2

Compressor output control

3

Water flow switch heater control

Water side heat exchanger anti-freeze

protection control8

Water side heat exchanger

temperature difference protection

control10

8

Water outlet temperature sensor

Two

Heating

Compressor output control

3

Water flow switch heater control

Cooling

Compressor output control

3

Defrosting operation control

6

Water flow switch heater control

Water side heat exchanger anti-freeze

protection control8

Water side heat exchanger

temperature difference protection

control10

8 Role of Temperature Sensors in Control Functions

Table 3-8.1: Names and functions of the temperature sensors

201709 31

Page 33

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

9

Total water outlet temperature sensor

Tw

Heating

Compressor output control

3

Electric auxiliary heater control

Cooling

Compressor output control

3

Water side heat exchanger anti-freeze

protection control8

10

Inverter module temperature sensor 1/ Inverter module

temperature sensor 2

Tf1/Tf2

Heating

Compressor output control

3

Inverter module temperature

protection11

Cooling

Compressor output control

3

Outdoor fan control

5

Inverter module temperature

protection11

Notes:

1. Refer to part 3, 3.1 “Crankcase Heater Control".

2. Refer to part 3, 5.6 “Electronic Expansion Valve Control".

3. Refer to part 3, 5.2 “Compressor Output Control".

4. Refer to part 3, 6.3 “Discharge Temperature Protection Control".

5. Refer to part 3, 5.7 “Outdoor Fan Control".

6. Refer to part 3, 7.2 “Defrosting Operation".

7. Refer to part 3, 6.8 “Air Side Heat Exchanger High Temperature Protection Control".

8. Refer to part 3, 6.7 “Water Side Heat Exchanger Anti-freeze Protection Control ".

9. Refer to part 3, 6.10 “Water Side Heat Exchanger Low Temperature Protection Control ".

10. Refer to part 3, 6.9 “Water Side Heat Exchanger Temperature Difference Protection Control ".

11. Refer to part 3, 6.4 “Compressor and Inverter Module Protection Control "

12. All sensor names in his service manual referring to refrigerant flow is named according refrigerant flow during cooling operation refer to

part2,3 ”Refrigerant Flow Diagram ”.

32 201709

Page 34

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Part 4

Diagnosis and

Troubleshooting

1 Outdoor Unit Electric Control Box Layout ............................................. 34

2 Outdoor Unit PCBs ............................................................................... 36

3 Error Code Table .................................................................................. 47

4 Troubleshooting .................................................................................. 49

5 Appendix to Part 5 ............................................................................... 95

201709 33

Page 35

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 4-1.1: Electric control box front view- top layer

Main control board

Wired controller

Power supply terminal

3-way terminal

Figure 4-1.2: Electric control box front view-bottom layer

AC indicator A

AC filter board

Reactor

Inverter module

AC indicator B

Fan module

Three-phase bridge rectifier

1 Outdoor Unit Electric Control Box Layout

MC-SU30-RN1L

34 201709

Page 36

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Figure 4-1.3: Electric control box front view-top layer

AC filter board A

Main control board

Wired controller

3-way terminal

Figure 4-1.4: Electric control box side view-bottom layer

Inverter module A

Three-phase bridge

rectifier B

Inverter module B

Reactor A

AC indicator A

Three-phase

bridge

rectifier A

Reactor B

Power supply

terminal

Fan module B

AC filter board B

AC indicator B

Fan module A

MC-SU60-RN1L

201709 35

Page 37

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 4-2.1: Outdoor unit main PCB

1 2 3 4 5 6 7 8 9

36

35

34

33

32

31

30

10

11

12

13

14

15

16

29 28 27 26 25 24 23 22 21 20 19 18 17

30

2 Outdoor Unit PCBs

2.1 Types

Aqua Tempo Super II units have four PCBs – main control board, three phase AC filter board, DC fan inverter module board

and compressor inverter module board.

In addition to the four PCBs, MC-SU30-RN1L model each has one board while MC-SU30-RN1L model have one main control

board and the other boards each has two boards.

The locations of each PCB in the outdoor unit electric control boxes are shown in Figures 4-1.1 to 4-1.4 in Part 4, 1

“Outdoor Unit Electric Control Box Layout”.

2.2 Main PCB

Note:

1. Label descriptions are given in Table 4-2.1

36 201709

Page 38

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Table 4-2.1:Outdoor unit main PCB

Label in

Figure

4-2.1

Code

Content

Voltage

1

CN1

Pump 1 connection

0-220V AC(varying)

2

CN30

Power sequence detection connection

380V 3 S5

DIP switches

- 4 CN72

Power supply to user interface

9V DC 5 ENC1

Unit capacity dial switch

- 6 ENC3

Address dial switch

- 7 DSP1

Digital display

- 8 FUS1

Fuse

220V AC

9

CN43

Power input

220V AC

10

CN12_1,

CN12_2

Solenoid valve(SV4) drive ports

0-220V AC(varying)

11

IC25

Main control chip

-

12

CN64

Debug port

5V DC

13

CN16

Four-way valve drive port

0-220V AC(varying)

14

CN5,

CN5_1

Water side heat exchanger heater connections

0-220V AC(varying)

15

CN4,

CN4_1

Water flow switch heater connection

0-220V AC(varying)

16

CN3

CN3_1

Compressor crankcase heater connections

0-220V AC(varying)

17

CN49

Reserved communication port

2.5-2.7V DC

18

CN52

CN53

Fan inverter module communication ports

2.5-2.7V DC

19

CN50

CN51

Compressor inverter module communication ports

2.5-2.7V DC

20

CN55

EXV drive port

12V DC

21

CN60

CN71

Wired controller communication ports

2.5-2.7 DC

22

CN24

Outdoor ambient temperature sensor and air side heat exchanger refrigerant

outlet temperature sensor connections

0-5V DC (varying)

23

CN69

Water side heat exchanger anti-freezing temperature sensor 1, air side heat

exchanger refrigerant total outlet temperature sensor, discharge temperature

sensor 2 and discharge temperature sensor 1 connections

0-5V DC (varying)

24

CN31

Air suction temperature sensor, water side heat exchanger anti-freezing

temperature sensor 2, water side heat exchanger water outlet temperature

sensor, water side heat exchanger water inlet temperature sensor and combined

water outlet temperature sensor connections

0-5V DC (varying)

25

CN40

Pressure sensor connection

0-5V DC (varying)

26

CN41

CN42

Inverter module temperature sensor 1 and Inverter module temperature sensor 2

connections

0-5V DC (varying)

27

CN62

AC indicator A and AC indicator B connections

0-5V DC (varying)

28

CN65

Low pressure switch connection

0 or 5V DC (varying)

29

CN47

High pressure switch and discharge temperature switch (es) connections

0 or 5V DC (varying)

30

CN58

CN59

AC filter board communication ports

12V DC

201709 37

Page 39

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

31

CN44

Water flow switch, additional control and Cool/heat connections

0 or 12V DC

32

IC10

EEPROM - 33

CN21

Remote alarm connection

On/off signal

34

CN19_N

Electric auxiliary heater N line connection

On/off signal

35

CN19_L

Electric auxiliary heater N line connection

On/off signal

36

CN2

Pump 2 connection

On/off signal

Table 4-2.2: Main PCB switch settings

Switch

Description

ON

OFF

Default factory

setting

S5

S5-1

Water outlet temperature1

Low

Normal

OFF

S5-2

ON/OFF function

Activated

Deactivated

OFF

S5-3

Water pump

One large pump

controlled by

master unit

One small

pump per

unit

OFF

S5-4

Reserved

- - OFF

ENC2

ENC2

0: MC-SU30-RN1L

- - 0

3: MC-SU60-RN1L

- - 3

ENC1

ENC1

0: master unit

1,2,3…F: slave units

-

-

0

-

-

Table 4-2.3: Function of buttons SW1 to SW4

Button

Function

SW3

Up

SW4

Down

SW5

Menu

SW5

Ok

Table 4-2.4: SW4 system check

Number

Parameters displayed on digital display

Remarks

0

Operating status

Standby: ODU address (DSP1 display) + number

of on-line units (DSP2 display)

On: display frequency

Defrosting: dF and operating frequency flash

alternately at 1s intervals frequency

OFF

ON

1 2 3 4

SW3

SW6

SW4

SW5

Main PCB field setting 2.2.1

Note:

1. Low water outlet temperature range: 0⁰C to 20⁰C; normal water outlet temperature range: 5⁰C to 20⁰C.

Function of buttons SW3 to SW6 2.2.2

SW2 system check button 2.2.3

Before pressing SW3 or SW4, allow the system to operate steadily for more than an hour. On pressing SW4, the parameters

listed in Table 4-2.4 will be displayed in sequence.

38 201709

Page 40

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Anti-freezing protection: Pb and operating

frequency flash alternately at 1s intervals

1

Outdoor unit address

Actual value = value displayed

2

Outdoor unit capacity

0:30KW; 3:60KW

3

Number of outdoor units (main unit display)

Actual value = value displayed

4

Unit capacity corrected for ambient temperature

Actual value = value displayed

5

Operating mode

8: Off; 0: Standby; 1: Cooling; 2: Heating

6

Fan A speed index

Refer to Note1

7

Fan B speed index

Refer to Note1

8

Air side heat exchanger refrigerant outlet temperature (sensor T3)

Actual value = value displayed

9

Outdoor ambient temperature (sensor T4)

Actual value = value displayed

10

Reserved

-

11

Water side heat exchanger anti-freezing temperature1 (sensor Taf1)

Actual value = value displayed

12

Water side heat exchanger anti-freezing temperature2 (sensor Taf2)

Actual value = value displayed

13

Total water outlet temperature(Tw)

Actual value = value displayed

14

Water inlet temperature(Twi, displays to decimal places)

Actual value = value displayed

15

Water outlet temperature(Two)

Actual value = value displayed

16

Air side heat exchanger refrigerant total outlet temperature (Tz/7)

Actual value = value displayed

17

Reserved

-

18

Compressor discharge temperature 1 (sensor Tp1)

Actual value = value displayed

19

Compressor discharge temperature 2 (sensor Tp2)

Actual value = value displayed

20

Compressor module temperature(Tf1)

Actual value = value displayed

21

Compressor module temperature(Tf2)

Actual value = value displayed

22

Air discharge superheat degree

Actual value = value displayed

23

Power supply phase B current

Actual value = value displayed

24

Power supply phase C current

Actual value = value displayed

25

Reserved

-

26

EXV 1 position

Steps=value displayed*4

27

Reserved

-

28

Compressor discharge pressure(in heating mode)

Actual value = value displayed

29

Compressor suction pressure (displays to decimal places in cooling mode)

Actual value = value displayed

30

Air suction superheat degree

Actual value = value displayed

31

Air suction temperature (Th)

Actual value = value displayed

32

Silent selection

Refer to Note2

33

Static pressure selection

0

34

Reserved

-

35

Reserved

-

36

Most recent error or protection code

“--”is displayed if no error or protection events

have occurred since start-up

37

Limit frequency number

0: no limits;

1: ambient temperature(T4) limit frequency;

2: voltage limit frequency;

3: air discharge limit frequency;

4: low voltage ratio;

5: instant limit frequency;

6: current limit frequency;

7: voltage limit frequency;

201709 39

Page 41

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

8: pressure ratio and capacity demand

adjusting;

9: cooling low pressure limit frequency)

38

Defrosting process status

The first digit: T4 selection solution;

The second digit: scheme's range;

The third and fourth digits : defrosting time

39

EEPROM mismatch indicator:

1 : failure;

0 : no failure

40

Defrosting scheme

Actual value = value displayed

41

Initial frequency

Actual value = value displayed

42

Tc(+30)/Te(+25)

Actual value = value displayed

43

Online units statistic

Actual value = value displayed

44

Program version

Actual value = value displayed

45

---

-

Notes:

1. The fan speed index is related to the fan speed in rpm as described in Table 3-5.3 in Part 3, 5.6 “Outdoor Fan Control”.

2. Silent mode:

0: night silent mode; 1: silent mode; 2: super silent mode; 3: no silent mode.

40 201709

Page 42

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Table 4-2.5: Digital display output in different operating states

Outdoor unit state

Parameters displayed on DSP1

Parameters displayed on DSP2

Standby

0

1

Normal

operation

For single

compressor units

None

Running speed of compressor

For dual

compressor units

Running speed of compressor A in

rotations per second

Running speed of compressor B in

rotations per second

Error or protection

-- or placeholder

Error or protection code

System check

Refer to Table 4-2.4

Refer to Table 4-2.4

DSP1

DSP2

Digital display output 2.2.4

201709 41

Page 43

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 4-2.2: Compressor inverter module PCB

1

17

16

15

14

2

3

4

5

6

13 12 11 10 9 8 7

Notes:

1. Label descriptions are given in Table 4-2.6.

2.3 Compressor Inverter Module Board

42 201709

Page 44

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Table 4-2.6: Compressor inverter module PCB

Label in

Figure

4-2.2

Code

Content

Voltage

1

SW1

Inverter module address switch

- 2 IC14

EEPROM

-

3

CN9

CN10

Inverter module communication port

2.5-2.7V DC

4

W

Compressor connections

V

UV

= V

Uw

= VVW

0-380V AC

5 V 6 U 7

N

IPM module input port N

VPN= 540V DC

8

P

IPM module input port P

9

N2

IPM module protection port N2

V

P2N2

= 540V DC

10

P2

IPM module protection port P2

11

CN15

Power supply inverter module board

310V DC

12

N1

IPM module power supply port N1

V

P1N1

=540V DC

13

P1

IPM module power supply port P1

14

CN3

Three-phase bridge rectifier positive port

540V DC relative

to N

15

CN11

Three-phase bridge rectifier control port

15V DC

16

CN1

Reactor port

540V DC relative

to N

17

CN4

Capacity positive port

540V DC relative

to N

Table 4-2.7: Compressor inverter module PCB switch settings

Switch

Description

SW1

000: MC-SU30-RN1L compressor inverter module address setting

000: MC-SU60-RN1L compressor A inverter module address setting

001: MC-SU60-RN1L compressor B inverter module address setting

OFF

ON

1 2 3

Compressor Inverter Module PCB field setting 2.3.1

201709 43

Page 45

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Figure 4-2.3: Fan module PCB

1 2

7

6

5 4 3

Table 4-2.8: Fan module PCB

Label in

Figure

4-2.3

Code

Content

Voltage

1

CN2

EEPROGRAM

-

2

CN1

CN4

Communication port for inverter module

2.5-2.7 DC

3

P

Power supply for inverter module

V

PN

= 310V DC

4

CN3

Power supply for the fan motor

V

UV

= V

Uw

= VVW

0-310V AC

5

N

Power supply for inverter module

V

PN

= 310V DC

6

U3

IPM - 7

SW1

Address for the inverter module

-

Table 4-2.9: Fan module PCB switch settings

Switch

Description

SW1

SW1-1

SW1-2

00: MC-SU30-RN1L fan module address setting

00: MC-SU60-RN1L fan module A address setting

01: MC-SU60-RN1L fan module B address setting

SW1-3

SW1-4

Reserved

OFF

ON

1 2 3 4

2.4 Fan Module Board

Fan Module PCB field setting 2.4.1

44 201709

Page 46

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Figure 4-2.4: AC filter board1

12

11

10

9

8

1

2

3

4

5

6

5

6

7

Notes:

1. Label descriptions are given in Table 4-2.10.

2.5 AC Filter Board

201709 45

Page 47

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

Table 4-2.10: MHC-V10(12, 14, 16)W/D2N1 outdoor unit main PCB for

refrigerant system

Label in

Figure

4-2.4

Code

Content

Voltage

1

CN39

N1

V

L1N1=VL2N1=VL3N1

=220V

V

CN38

L1 3 CN37

L2 4 CN36

L3

5

CN1

CN2

Power supply for compressor inverter module

310V DC

6

CN3

CN4

Power supply for fan inverter module

310V DC

7

CN6

AC filter board communication port

12 DC

8

CN40

L3’

V

L1’N1’=VL2’N1’=VL3’N1’

=220V

9

CN41

L2’

10

CN42

L1’

11

CN43

N1’

12

GND

GND

-

46 201709

Page 48

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

Error

code

Content

Remarks

1E0

Main PCB EEPROM mismatch

Displayed on main PCB and user interface

2E0

Inverter module A EEPROM mismatch

Displayed on main PCB and user interface

3E0

Inverter module B EEPROM mismatch

Displayed on main PCB and user interface

E1

Power phase sequence error

Displayed on main PCB and user interface

E2

Communication error between main PCB and wired

controller

Displayed on main PCB and user interface

E3

Total water outlet temperature sensor (Tw) error

(displayed on master unit only)

Displayed on main PCB and user interface

E4

Outlet water temperature sensor (Two) error

Displayed on main PCB and user interface

E5

Air-side heat exchanger temperature sensor (T3) error

Displayed on main PCB and user interface

E7

Outdoor ambient temperature sensor (T4) error

Displayed on main PCB and user interface

E9

Water flow failure

Displayed on main PCB and user interface

1Eb

Water-side heat exchanger anti-freezing temperature

sensor1 (Taf1) error

Displayed on main PCB and user interface

1Eb

Water-side heat exchanger anti-freezing temperature

sensor2 (Taf2) error

Displayed on main PCB and user interface

EC

Number of units detected by wired controller has

decreased

Displayed on main PCB and user interface

1Ed

Compressor discharge temperature sensor1 (Tp1) error

Displayed on main PCB and user interface

2Ed

Compressor discharge temperature sensor2 (Tp2) error

Displayed on main PCB and user interface

EF

Inlet water temperature sensor (Twi) error

Displayed on main PCB and user interface

EH

System self-check error

Displayed on main PCB and user interface

EP

Compressor discharge temperature sensor error

Displayed on main PCB and user interface

EU

Total cooling outlet temperature sensor (Tz/7) error

Displayed on main PCB and user interface

P0

Compressor discharge temperature protection

Displayed on main PCB and user interface

P1

Compressor suction temperature protection

Displayed on main PCB and user interface

P4

Power supply phase B Current protection

Displayed on main PCB and user interface

P5

Power supply phase C Current protection

Displayed on main PCB and user interface

1P6

System A inverter module protection

Displayed on main PCB and user interface

2P6

System A inverter module protection

Displayed on main PCB and user interface

P7

Condenser tube and Total cooling outlet high

temperature protection

Displayed on main PCB and user interface

P9

Water-side heat exchanger inlet/outlet temperature

difference protection

Displayed on main PCB and user interface

PA

Inlet water high temperature in cooling mode

Displayed on main PCB and user interface

Pb

System anti-freezing protection

Displayed on main PCB and user interface

PC

Evaporator pressure low in cooling mode

Displayed on main PCB and user interface

PE

Low-temperature protection of evaporator (manual

recovery)

Displayed on main PCB and user interface

PL

Module high temperature protection

Displayed on main PCB and user interface

1PU

DC fan 1 module protection

Displayed on main PCB and user interface

2PU

DC fan 2 module protection

Displayed on main PCB and user interface

3 Error Code Table

201709 47

Page 49

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

1H0

System A IPM module Communication error

Displayed on main PCB and user interface

2H0

System B IPM module Communication error

Displayed on main PCB and user interface

H1

Under/Over voltage protection

Displayed on main PCB and user interface

1H6

System 1 DC bus voltage error

Displayed on main PCB and user interface

2H6

System 2 DC bus voltage error

Displayed on main PCB and user interface

Fb

Pressure sensor error

Displayed on main PCB and user interface

Fd

Air suction temperature(Th) protection error

Displayed on main PCB and user interface

1FF

DC fan 1 error

Displayed on main PCB and user interface

2FF

DC fan 2 error

Displayed on main PCB and user interface

FP

DIP inconsistency of multiple water pumps(Power

failure recovery required)

Displayed on main PCB and user interface

L0

Inverter module protection

-

L1

DC bus low voltage protection

-

L2

DC bus high voltage protection

-

L4

MCE error

-

L5

Zero speed protection

-

L7

Phase sequence error

-

L8

Compressor frequency variation greater than 15Hz

within one second protection

-

L9

Actual compressor frequency differs from target

frequency by more than 15Hz protection

-

dF

Defrosting indicator

Displayed on main PCB and user interface

48 201709

Page 50

Aqua Tempo Super II

Part

4 - Diagnosis and Troubleshooting

All electrical work must be carried out by competent and suitably qualified, certified and

accredited professionals and in accordance with all applicable legislation (all national, local and other laws,

Power-off the outdoor units before connecting or disconnecting any connections or wiring, otherwise electric

shock (which can cause physical injury or death) may occur or damage to components may occur.

Warning

4 Troubleshooting

4.1 Warning

standards, codes, rules, regulations and other legislation that apply in a given situation).

201709 49

Page 51

Aqua Tempo Super II

Midea Aqua Tempo Super II

Service Manual

E0

Main PCB or IPM inverter module

EEPROM1 is not connected properly

Yes

Ensure the EEPROM is connected

properly

No

EEPROM damaged

Yes

Replace the EEPROM

No

Replace refrigerant system Main PCB or

IPM inverter module

4.2 E0 Troubleshooting

Digital display output 4.2.1

Description 4.2.2

1E0 indicates main PCB EEPROM error.

2E0 indicates IPM inverter module (compressor A) EEPROM error.

3E0 indicates IPM inverter module (compressor B) EEPROM error.

All units stop running.

Error code is displayed on main PCB and user interface...d user interface.

Possible causes 4.2.3

Main PCB or IPM inverter module EEPROM is not connected properly.

Main PCB or IPM inverter module damaged.

EEPROM damaged.

Procedure 4.2.4

Notes:

1. Main PCB EEPROM is designated IC10 on the main PCBs (labeled 32 in Figure 4-2.1 in Part 4, 2.2 “Main PCB”).

2. Compressor inverter module PCB EEPROM is designated IC14 on compressor inverter module PCB (labeled 2 in Figure 4-2.2 in Part 4, 2.3 “Compressor