Page 1

Service Manual

Microwave Oven

Model: KOC-1C0K5S

S/M No. :

Jul. 2013

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

Page 2

1

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs if necessary: (1) Interlock operation, (2) Proper door closing, (3)

Seal and sealing surfaces (arcing, wear, and other damage), (4) Damage to or loosening of hinges and

latches (5) Evidence of dropping or abuse.

(c) Before turning on power to the microwave oven for any service test or inspection within the microwave

generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper

alignment, integrity, and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door seal and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures described

in this manual before the oven is released to the owner.

TABLE OF CONTENTS

1. SAFETY AND PRECAUTIONS ...................................................................................................................................2

2. SPECIFICATION ..........................................................................................................................................................3

3. INSTALLATION ...........................................................................................................................................................4

4. CONTROL PANEL ......................................................................................................................................................5

5. DISPLAY WINDOW .....................................................................................................................................................6

6. ACCESSORIES ...........................................................................................................................................................7

7. INTERLOCK MECHANISM AND ADJUSTMENT ......................................................................................................8

8. WIRING PROCEDURE ................................................................................................................................................9

9. WIRING DIAGRAM ....................................................................................................................................................10

10. ELECTRICAL PARTS LIST ....................................................................................................................................11

11. DISASSEMBLY AND ASSEMBLY ..........................................................................................................................12

12. COMPONENT TEST PROCEDURE .......................................................................................................................25

13. TROUBLE SHOOTING GUIDE ...............................................................................................................................28

14. PRINTED CIRCUIT BOARD ...................................................................................................................................34

Page 3

2

1. SAFETY AND PRECAUTIONS

1. FOR SAFE OPERATION

Damage that allows the microwave energy (that cooks or heats the food) to escape will result in poor cooking and may

cause serious bodily injury to the operator.

IF ANY OF THE FOLLOWING CONDITIONS EXIST, OPERATOR MUST NOT USE THE APPLIANCE. (Only a trained

service personnel should make repairs.)

1) A broken door hinge.

2) A broken door viewing screen.

3) A broken front panel, oven cavity.

4) A loosened door lock.

5) A broken door lock.

The door gasket plate and oven cavity surface should be kept clean.

No grease, soil or spatter should be allowed to build up on these surfaces or inside the oven.

DO NOT ATTEMPT TO OPERATE THIS APPLIANCE WITH THE DOOR OPEN.

The microwave oven has concealed switches to make sure the power is turned off when the door is opened.

Do not attempt to defeat them.

DO NOT ATTEMPT TO SERVICE THIS APPLIANCE UNTIL YOU HAVE READ THIS SERVICE MANUAL.

2. FOR SAFE SERVICE PROCEDURES.

1. If the oven is operative prior to servicing, a microwave emission check should be performed prior to servicing the

oven.

2. If any certified oven unit is found to servicing, a microwave emission check should be performed prior to servicing the

oven.

(a) inform the manufacturer, importer or assembler,

(b) repair the unit at no cost to the owner,

(c) attempt to ascertain the cause of the excessive leakage,

(d) tell the owner of the unit not to use the unit until the oven has been brought into compliance.

3. If the oven operates with the door open, the service person should tell the user not to operate the oven and contact

the manufacturer immediately.

IMPORTANT

The wire in this mains lead coloured in accordance with the following code.

Green-and-yellow : Earth

Blue : Neutral

Brown : Live

As the colours of the wires in the mains lead of this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

The wire which is coloured green-and-yellow must be connected to the terminal in the plug which is marked with the

letter ‘E’ or by earth symbol or green-and-yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the letter ‘N’ or coloured

black.

The wire which is coloured brown must be connected to the terminal which is marked with the letter ‘L’ or coloured

red.

NOTE : This oven is designed for counter-top use only.

Page 4

3

2. SPECIFICATIONS

MODEL KOC-1C0K5S

POWER SUPPLY 230V~50Hz, SINGLE PHASE WITH earthing

MICROWAVE 1450W

POWER GRILL 1250W

CONSUMPTION CONVECTION 2650W

COMBINATION 2750W, MAX 2900W

MICROWAVE ENERGY OUTPUT 800W (IEC705)

MICROWAVE FREQUENCY 2450MHz

OUTSIDE DIMENSIONS (W X H X D) 524X375X477mm(20.63X14.76X18.78in)

CAVITY DIMENSIONS (W X H X D) 400x233x365mm(15.75x9.17x14.37in)

NET WEIGHT Approx. 25kg(55.06 lbs)

FUNCTION SELECTIONS MICROWAVE/ GRILL/ CONVECTION/ COMBINATION

POWER SELECTIONS 10 LEVELS

CAVITY VOLUME 1.3 Cu.Ft (34ὀ)

* Specifications are subject to change without notice.

Page 5

4

3. INSTALLATION

1. Steady, flat location

This microwave oven should be set on a steady, flat surface.

This microwave oven is designed for counter top use only.

2. Leave space behind and side

All air vents should be kept a clearance. If all vents are covered during operation, the oven may overheat and, eventually,

cause failure.

3. Away from Radio and TV sets

Poor television reception and radio interference may result if the oven is located close to a TV, Radio, antenna or feeder

and so on.

Position the oven as far from them as possible.

4. Away from heating appliances and water taps

Keep the oven away from hot air, steam or splash when choosing a place to position it, or the insulation might be

adversely affected and breakdowns occur.

5. Power supply

• Check your local power source. This microwave oven requires a current of approximately 15 amperes, 230V, 50Hz.

• Power supply cord is about 1.5 meters long.

• The voltage used must be the same as specified on this oven. Using a higher voltage may result in a fire or other

accident causing oven damage. Using low voltage will cause slow cooking. We are not responsible for damage

resulting from use of this oven with a voltage of ampere fuse other than those specified.

• This appliance is supplied with cable of special type, which, if damaged, must be repaired with cable of same type.

• Such a cable can be purchased from DAEWOO and must be installed by a Qualified Person.

6. Examine the oven after unpacking for any damage such as:

A misaligned door, broken door or a dent in cavity.

If any of the above are visible, DO NOT INSTALL, and notify dealer immediately.

7. Do not operate the oven if it is colder than room temperature.

(This may occur during delivery in cold weather.) Allow the oven to become room temperature before operating.

This appliance must be earthed. In the event of an electrical short circuit, earthing reduces the risk of the electric shock by

providing an escape wire for the electric current. This appliance is equipped with a cord having a earthing wire with a

earthing plug. The plug must be plugged into an outlet that is properly installed and earthed.

EARTHING INSTRUCTIONS

WARNING

Improper use of the earthing plug can result in a risk of electric shock.

Consult a qualified electrician of serviceman if the earthing instructions are not completely understood, or if doubt

exists as to whether the appliance is properly earthed, and either:

If it is necessary to use an extension cord, use only a 3-wire extension cord that has a 3-blade earthing plug, and a

3-slot receptacle that will accept the plug on the appliance.

The marked rating of the extension cord should be equal to or greater than the electrical rating of the appliance, or

Do not use an extension cord.

Page 6

5

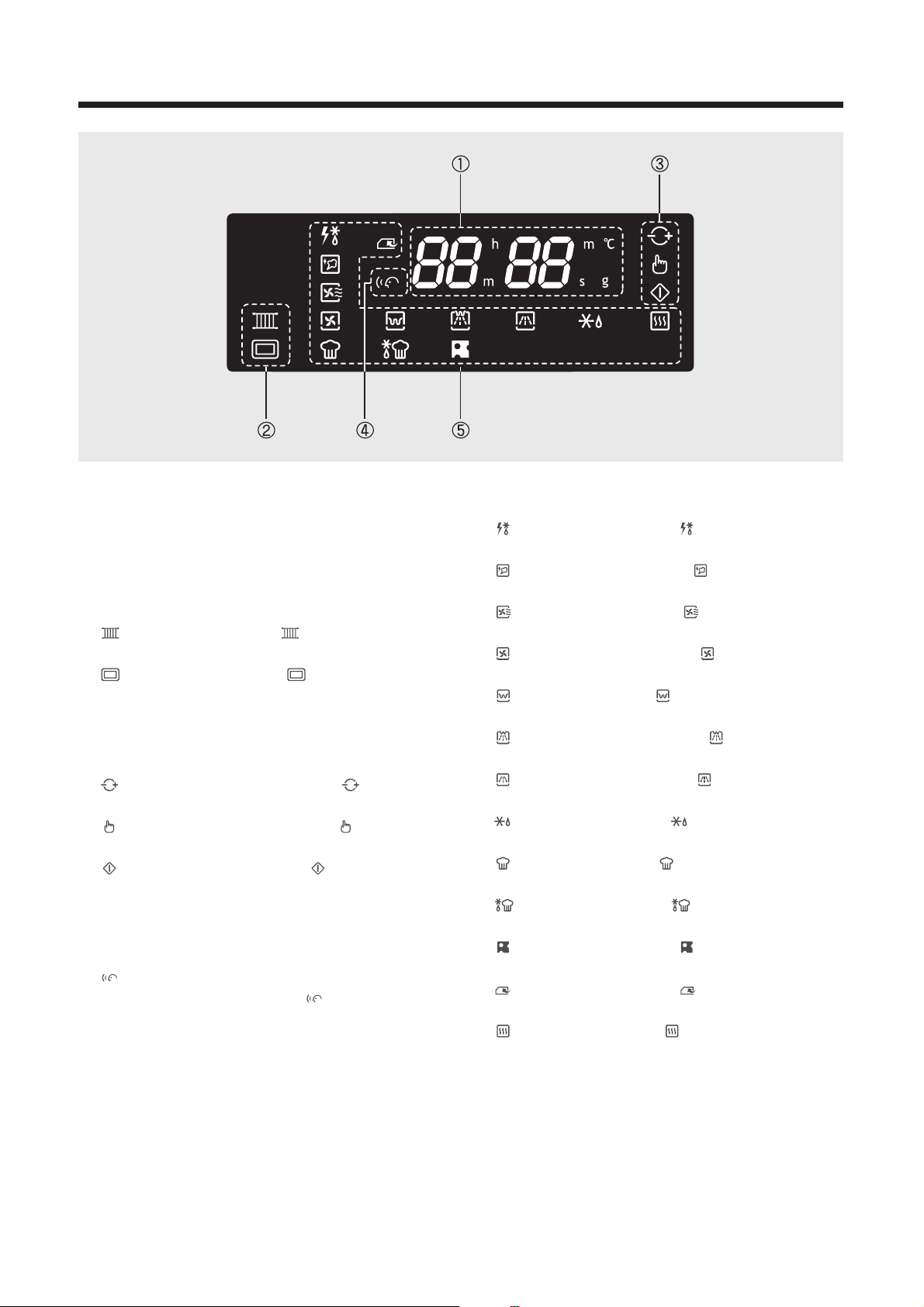

4. CONTROL PANEL

1 Display

The display shows you some information such as

cooking time, menu, quantity and temperature and so

on.

2 Quick defrost( ) Button

You can defrost a 500 grams of food quickly and

easily.

3 Steam cleaning() Button

This function helps you to clean the inside of oven.

4 Deodorization( ) Button

The oven has a special function to blow off smells in

the oven.

5 Menu Dial Knob :

You can choose a cooking menu by turning the Menu

Dial knob.

6 Control Dial Knob () :

You can enter cooking time, quantity, weight, and

temperature by turning the Control Dial knob.

7 Selection() Button: You can confirm the contents

you entered by pressing the Selection button.

8 Start/Speedy Cook () Button:

- You can start cooking immediately by pressing the

Start button after entering cooking information such

as cooking time, power level and so on.

- You can start the Microwave cook at power level 10

quickly by pressing the Start button.

You can add 30 seconds to the cooking time up to 5

minutes each time the Start button is pressed.

9 Stop/Clear() Button:

It is used for stopping the oven operation or clearing

the display.

Page 7

6

5. DISPLAY WINDOW

1 Display window

The display shows you some cooking information such

as cooking time, clock, temperature, quantity and so on.

2 Icons of cookware

: It means a Grill rack. If lights in the display ,

use a grill rack for cooking.

: It means a Metal tray. If lights in the display ,

use a metal tray for cooking.

3 Icons of operation guide

: It means the Control dial knob. If blinks, turn

the control dial knob.

: It means the Selection button. If blinks, press

the selection button.

: It means the Start button. If blinks, press the

start/speedy cook button.

4 Icons of voice guide function

: It means the Voice guide function. If the voice

guide function is activated, turns on in the

display. (OPTIONAL)

(Refer to “Setting the volume level” on the page 9.)

5 Icons of cooking menu

: It means Quick defrost. lights in the display

during Quick defrosting.

: It means Steam cleaning. lights in the display

during Steam cleaning.

: It means Deodorization. lights in the display

during Deodorization.

: It means Convection cook. lights in the display

during Convection cooking.

: It means Grill cook. lights in the display during

Grill cooking.

: It means Combination cook. lights in the

display during Combination cooking.

: It means Microwave cook. lights in the display

during Microwave cooking.

: It means Auto defrost. lights in the display

during Auto defrosting.

: It means Auto cook. lights in the display during

Auto cook.

: It means Instant cook. lights in the display

during Instant cook.

: It means Fermentation. lights in the display

during Fermentation.

: It means Memory cook. lights in the display

during Memory cook.

: It means Preheating. lights in the display

during preheating in Convection cooking.

Page 8

7

6. ACCESSORIES

This oven is equipped with several accessories. They can be used in various ways to facilitate cooking.

1 Metal Tray - Put food or proper cookware on the metal tray.

2 Grill Rack - Put the grill rack on the metal tray.

It should be always used with the metal tray for

cooking.

■ HOW TO USE THE ACCESSORIES OF COOKING

■ Metal Tray

NOTE : Metal Tray is attached to the left cushion.

• Microwave cooking

• Auto defrosting

• Quick defrosting

• Fermentation

• Memory cooking

• Convection cooking

• Auto cook menu: 3, 5

• Instant cook menu: 1, 5

1

2

Page 9

8

7. INTERLOCK MECHANISM AND ADJUSTMENT

CONDITION : DOOR OPEN

RED/RED

RED/RED

BLACK/BLUE

WHITE/BLUE

WHITE

BLUE

YELLOW

BLUE

LEFT RIGHT

CONDITION : DOOR CLOSE

LEFT RIGHT

INTERLOCK

MONITOR

SWITCH

DOM

SWITCH

HOOK

PRIMARY

INTERLOCK

SWITCH

Page 10

9

1 MW RELAY Black & White, Black & White Control M/W

2 HALOGEN HEATER RELAY White & Red, Black Control halogen heater(Side heater)

3 TOP HEATER RELAY White & Black, Black Control heater top

4 CONVECTION RELAY Blue, Blue Control heater back

5 SLOW ACTING RELAY Blue, Blue

6 D.O.M CONNECTOR Blue, Green(Middle), Blue

7 SUB RELAY

8 THERMISTER CONNECTOR White, White Temperature sensor

LOCATION

PART NAME WIRING COLOR FUNCTION

8. WIRING PROCEDURE

MAIN PCB

NO. 1 : Red

NO. 3 : White

NO. 5 : Black

NO. 7 : Blue

NO. 9 : Grey

Prevent the current of oven from rising rapidly in

Microwave Mode

D.O.M(DOOR OPEN MONITOR) helps the

MICOM checking the Interlocking system of DOOR

NO. 1 & 3 : Supply power to PCB

NO. 5 : Convection motor

NO. 7 : Blower-Motor

NO. 9 : Lamp

8 7 6

5

1

2

3

4

Page 11

10

9. WIRING DIAGRAM

CAPACITOR

H.V.

FUSE

H.V.

MAGNETRON

H.V. DIODE

THERMISTOR

TRANSFORMER

HIGH VOLTAGE

RD

SWITCH

NC.

COM.

MONITOR

INTERLOCK

RD

BL

SWITCH

NO.

PRIMARY

INTERLOCK

COM.

THERMAL

STEAM HEATER

BL

THERMAL CUT-OUT

CONVECTION HEATER

CUT-OUT

RD

BK

RD

RD

BL

BL

THERMAL

CUT-OUT

TOP HEATER

RD

BK

CM

FM

OL

BL

TOP HEATER

CONVECTION HEATER

BL

WH

BL

D.O.M. SWITCH

WH

STEAM HEATER

GY

SWITCH

SECONDARY

WH

BK

INTERLOCK

WH

PTC

BK

BL

BK

BL

GY

RD

RD

BL

CONVECTION

FAN

LAMP

WH

CONTROL P.W.B. ASS'Y

SLOW ACTING

RELAY

RELAY

HEATER

STEAM

POWER

RELAY

HEATER

TOP

RELAY

HEATER

CONVECTION

RELAY

FAN

RELAY

RELAY

RELAY

T/MOTOR

BL:BLUE

GY:GRAY

GN:GREEN

WH:WHITE

YW:YELLOW

BK:BLACK

RD:RED

OL:OVEN LAMP

NOTE :

BR:BROWN

FM:FAN MOTOR

CM:Convection motor

RD

L

FUSE

L

LINE FILTER ASS'Y

BR

L

ONLY

SINGLE PHASE

POWER SUPPLY :

BL

RD

WH

WH

GN

N

N

GE

N

L.V. TRANSFORMER

DOOR : CLOSED

COOK : OFF

[CONDITION]

Page 12

11

1 3518302301 CAPACITOR HV 2100VAC 1.10UF #187 80MM 1

2 3518400800 DIODE HV ESJC13-12BX (CL01-12) 1

3 3513601710 LAMP BL 240V 25W T25 CC7A H187 99% 1

4 3512784230 HARNESS MAIN KOC-1C0K5S 1

5 3512783910 HARNESS CONVECTION AS KOC-1C0KKS 1

6 3518701900 FUSE H.V 5kV 0.8A T.H.V. 060T 1

74415A17352 SW MICRO SZM-V16-FA-63 2

84415A66600 SW MICRO SZM-V16-FA-62 1

9 3512808510 HEATER 230V 1200W 1

10 3518125200 TRANS HV R1S58D 1

11 3518606880 NOISE-FILTER DWLF-M27-4 1

12 35113A5Q0T CORD POWER AS 3X1.5 80X80 120-RTML 1.6M 1

13 3518003710 MAGNETRON 2M218HFL 6CF 1

14 3518904000 THERMOSTAT OFF:120 ON:105 V #187 BRAKET 1

15 3518903200 THERMOSTAT OFF:145 ON:135 V #187 BRAKET 1

16 3963513950 MOTOR SHADED POLE 230V 50HZ OEM-10DWC2-T08 1

17 3512808000 HEATER 230V 1400W / 220V 1280W KAWAI 1

18 3963320200 MOTOR BLOWER 220V 60HZ OEB-2505B1 1

NO PART CODE PART NAME SPECIFICATION Q’TY REMARK

Page 13

12

11. DISASSEMBLY AND ASSEMBLY

- Cautions to be observed when trouble shooting.

Unlike many other appliances, the microwave oven is high-voltage, high-current equipment. It is completely safe

during normal operation. However, carelessness in servicing the oven can result in an electric shock or possible

danger from a short circuit. You are asked to observe the following precautions carefully.

1. Always remove the power plug from the outlet before servicing.

2. Use an insulated screwdriver and wear rubber gloves when servicing the high voltage side.

3. Discharge the high voltage capacitor before touching any oven components or wiring.

(1) Check the grounding.

Do not operate on a two-wire extension cord.

The microwave oven is designed to be used while grounded.

It is imperative, therefore, to make sure it is grounded

properly before beginning repair work.

(2) Warning about the electric charge in the high voltage capacitor.

For about 30 seconds after the operation has stopped, electric

charge remains in the high voltage capacitor.

When replacing or checking parts, short between oven chassis

and the negative high terminal of the high voltage capacitor by

using a properly insulated screwdriver to discharge.

4. When the 15A fuse is blown out due to the operation of the monitor

switch; replace primary interlock switch, secondary interlock switch

and interlock monitor switch.

5. After repair or replacement of parts, make sure that the screws are

properly tightened, and all electrical connections are tightened.

6. Do not operate without cabinet.

CAUTION : Service personnel should remove their watches whenever working close to or replacing the magnetron.

WARNING : When servicing the appliance, take care when touching or replacing high potential parts because of

electrical shock or exposing microwave. These parts are as follows - HV Transformer, Magnetron,

HV Capacitor, HV Diode.

Page 14

13

12. DISASSEMBLY AND ASSEMBLY

1. To remove cabinet

1) Remove four screws on cabinet back.

2) Push the cabinet backward.

2. To remove door ASS'Y

1) Remove each two screws (total 4EA) on left and right

sides.

2) Remove spring hinges in both sides.

* It is easy to remove the bottom of spring firstly and to

set the top of spring firstly.

3) Remove HINGE TOP *R and HINGE TOP *L.

* HINGE TOP must be connected to the inside of DOOR.

4) Reverse the above steps for reassembly.

3. To remove C-Panel ASS'Y

1) Remove the screws.

2) Slide the C-PANEL in the direction of left and pull out

forward.

3) Reverse the above steps for reassembly.

SPRING HINGE

Page 15

14

4. EXPLODED VIEW AND PARTS LIST OF DOOR ASS'Y.

A01 3512603830 HANDLE DOOR *O ABS SPRAY KOC-1C0KQS 1

A02 3515309510 SUPPROTER HANDLE PO T1.6 1

A03 3512603910 HANDLE DOOR *I ABS 1

A04 3517010740 BARRIER-SCREEN *O TEMP GLASS T3.2 BLACK 1

A05 3512210320 FRAME DOOR

PC+ABS HR-5007A SPRAY KOC-1C0KQS

1

A06 3513304620 INSULATOR GLASS T2.0 TEMPERED 1

A07 3513003100 HOLDER INNER GLASS *R PBT 1

A08 3511728810 DOOR PAINTING AS KOC-1C0KQS 1

A09 3512902020 HINGE HOOK SWRM3 2

A10 3513102110 HOOK POM 2

A11 3512303000 GASKET DOOR PBT 1

A12 3512902000 HINGE UNDER *L AS KOC-1C0KQS 1

A13 3512902010 HINGE UNDER *R AS KOC-1C0KQS 1

A14 3515103600 SPRING HOOK PW1 2

A15 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 3

A16 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 4

A17 3513003100 HOLDER INNER GLASS *R PBT 1

A18 7122401211 SCREW TAPPING T2S TRS 4X12 MFZN 2

A19 7121401211 SCREW TAPPING T2S PAN 4X12 MFZN 2

A20 7121400612 SCREW TAPPING T2S PAN 4X7 MFZN 3

NO. PART CODE PART NAME DESCRIPTION Q'TY REMARK

DOOR AS : 3511728890

Page 16

15

5. EXPLODED VIEW AND PARTS LIST OF CONTROL PANEL.

B01 3511620100 DECORATOR C-PANEL SAN T1.5 BLACK 1

B02 3516725930 CONTROL-PANEL

PC+ABS HR-5007A SPRAY KOC-1C0KPSA8

1

B03 3516913020 BUTTON FUNCTION-A ABS COATING 2

B04 3516913010 DECORATOR KNOB ABS COATING 2

B05 3513411530 KNOB VOLUME ABS SPRAY KOC-1C0KQS 2

B06 3514333150 PCB MAIN AS KOC-1C0K5SV0 1

B07 3514333220 PCB SUB1 AS KOC-1C0K5S (GLOBAL) 1

B08 3514333300 PCB SUB2 AS KOC-1C0KQS 1

B10 7621301011 SCREW TAPPING T2S PAN 3X10 PW MFZN 9

B11 7122401211 SCREW TAPPING T2S TRS 4X12 MFZN 7

NO. PART CODE PART NAME DESCRIPTION Q'TY REMARK

CONTROL-PANEL AS : PKCPSWALB0

B01 B02 B03 B04 B05 B06 B07 B08

B11

Page 17

16

6. To remove high voltage capacitor

1) Remove a screw which secure the grounding ring

terminal of the H.V.diode and capacitor holder.

2) Remove the H.V.capacitor from the capacitor holder.

3) Remove the H.V.diode from the H.V.Capacitor.

4) Reverse the above steps for reassembly.

1) Connect two terminals(1) from H.V. transformer to

magnetron using the all-in-one connector.

2) Connect the connector, which connected two wires(2)

from H.V. transformer, to H.V. capacitor .

3) Connect H.V. diode(3) to H.V. capacitor in same

location with terminal 2

4) The one direction of 4 connect to secondary terminal of

H.V. transformer and another connect to H.V

capacitor(except of terminal 2, 3)

NOTE: Connecting procedure of magnetron, H.V.

transformer, H.V, diode, H.V. fuse, H.V.

capacitor.

Capacitor Holder

H.V.Capacitor

H.V.Diode

Page 18

17

7. TO REMOVE MAGNETRON

1) Remove a screw which secure the magnetron.

2) Remove the magnetron.

3) Reverse the above steps for reassembly.

NOTE: Never install the magnetron without the metallic gasket plate which is packed with each magnetron to

prevent microwave leakage. Whenever repair work is carried out on magnetron, check the microwave

leakage. It shall not exceed 4mW/cm2 for a fully assembled oven with door normally closed.

g

Metallic

gasket

plate

Cooling fin

Filament

terminal

Magnetron

antenna

<MAGNETRON>

Wave guide Magnetron antenna

Metallic

asket plate

Page 19

18

9. TO REMOVE H.V.TRANSFORMER

1) Remove four screws holding the H.V.transformer.

2) Remove the H.V.transformer.

3) Reverse the above steps for reassembly.

8. TO REMOVE BLOWER MOTOR

1) Remove a screw which secure the cover motor blower.

2) Remove a screw which secure the blower motor.

3) Remove the cover motor blower.

4) Remove the wire which connecting the blower motor

5) Push a latch of blower motor and draw backward

6) Reverse the above steps for reassembly.

LATCH

COVER MOTOR BLOWER

BLOWER MOTOR

Page 20

19

10. TO REMOVE TOP HEATER

1) Remove a nut which secure the top heater.

2) Pull out the heater.

11. TO REMOVE HALOGEN HEATER (OPTIONAL)

(SIDE HEATER)

1) Remove a screw in insulator heater top.

2) Remove the wire which connecting the halogen heater.

3) Remove a screw on cover of halogen heater.

4) Remove a bracket of halogen heater.

5) Remove a halogen heater.

6) Reverse the above steps for reassembly.

Halogen heater cover

Halogen heater

braket

Page 21

20

12. TO REMOVE NOISE FILTER

1) Remove a screw which secure the noise filter.

2) Remove a screw which earth to wire from noise filter.

3) Remove a noise filter from the bracket noise filter.

13. TO REMOVE SPEAKER (OPTIONAL)

1) Remove a screw which secure the base plate and

speaker holder

2) Remove speaker holder and speaker

Page 22

21

15. EXPLODE VIEW AND PARTS LIST OF BACK HEATER ASSEMBLY

C01 7S628W40X1 NUT HEX NUT FLANGE M4X0.7P MFZN 1

C02 3511800700 FAN CONVECTION SA1D T0.5 1

C03 3512808000 HEATER 230V 1400W KAWAI 1

C04 3512806000 HEATER REFLECTOR SA1D T0.5 1

C05 3511409800 COVER HEATER *B SA1D-80 T0.5 1

C06 3513303400 INSULATOR HEATER *B SBHG-1 T0.5 1

C07 7113400814 SCREW TAPPING T1 BIN 4X8 MFNI 6

C08 3963513950 MOTOR SHADED POLE 230V 50HZ ,OEM-10DWC2-T08 1

C09 7121400611 SCREW TAPPING T2S PAN 4X6 MFZN 1

C10 3518903200 THERMOSTAT OFF:145 ON:135 V #187 1

C11 7601400811 SCREW MACHINE PAN 4X8 PW MFZN 2

C12 3512783940 HARNESS CONVECTION AS KOC-1C4K5SC1 1

C13 3513002300 HOLDER HEATER SUS304 T0.5 3

C14 7113400814 SCREW TAPPING T1 BIN 4X8 MFNI 3

C15 7400104011 WASHER PLAIN PW-1-4 MFZN 1

NO. PART CODE PART NAME DESCRIPTION Q'TY REMARK

C01 C02 C03 C04 C05 C06 C07 C08

C14 C12 C10 C09C11C13C15

Page 23

22

16. TOTAL ASSEMBLY AND PARTS LIST

F02 F03 F05 F06 F07 F08 F09 F10 F11 F12 F13

F01

F55

F78

F59

F60

F56

F54

F53

F57

F58

F61

F62

F63

F41

F77

F50

F44

F43

B00

A00

F42

F69

F71

F35

F51

F49

F52

F68

F70

F37

F36

F40

F38

F39

F27F28F29F30F31F32

F14

F15

F16

F17F18F20F21F22F23F25

Page 24

23

A00 3511728890 DOOR AS KOC-1C0K5S BK 1

B00 PKCPSWALB0 CONTROL-PANEL AS KOC-1C0K5S 1

F02 3510611600 BRACKET NOISE FILTER PP 1

F03 3518606880 NOISE FILTER DWLF-M27-4 250V 15A 1

F05 3513001900 HOLDER HV CAPACITOR SECC T0.5 1

F06 3518303901 CAPACITOR HV 2100VAC 1.1UF #187+3 1

F07 3518701900 FUSE HV 5KV 0.8A T.H.V.060T 1

F08 3518125200 TRANS HV R1S58D 1

F09 3513005300 HOLDER LAMP STS T0.4 1

F10 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 2

F11 35113A5Q0T CORD POWER AS 3X1.5 80X80 120-RTML 1.6M 1

F12 3517505210 PROTECTOR HEAT STS T0.6 1

F13 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 2

F14 3510810920 CABINET AS KOC-1C0KQS 1

F15 3511415000 COVER *B SBHG T0.8 1

F16 3512808410 HEATER *B AS KOC-1C0K5S 1

F17 3963320200 MOTOR BLOWER 220V~240V 60Hz OEM-2505B1 1

F18 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 2

F20 3511415200 COVER MOTOR BLOWER PP(TB-53) 1

F21 7121400611 SCREW TAPPING T2S PAN 4X6 MFZN 1

F22 3518003710 MAGNETRON 2M218HFL 6CF 1

F24 3512784230 HARNESS MAIN KOC-1C0K5S 1

F27 3510613030 BRACKET ROLLER *R AS KOC-1C0KQS 1

F28 3516003700 SCREW SPECIAL TTS HEX 4X8 FLG MFZN 4

F29 3510313410 BASE SBHG T0.7 1

F30 7122401211 SCREW TAPPING T2 TRS 4X12 MFZN 1

F31 3512101400 FOOT DASF-310 2

F32 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 9

F35 7272400811 SCREW TAPTIE TT3 TRS 4X8 MFZN 4

F36 3515103500 SPRING HINGE PW1 2

F37 3510611900 HINGE TOP *R PO T2.6 1

F38 3513821210 LOCK *R PBT EE-2306F(V0) 1

F39 4415A17352 SW MICRO VP-533-OF SPNO #187 200G 1

4415A66600 SW MICRO SZM-V16-FA-62 1

F40 3514801900 SENSER TEMPERATURE PTM-K312-D10 1

F42 3512808510 HEATER GRILL 230V 1200W 1

F43 7113400810 SCREW TAPPING T1 BIN 4X8 STS430 MFZN 4

F44 3511408320 COVER WAVE GUIDE MICA T1.0 1

F49 3513821220 LOCK *L PBT EE-2306F(V0) 1

NO. PART CODE PART NAME DESCRIPTION Q'TY REMARK

Page 25

24

F50 4415A17352 SW MICRO SZM-V16-FA-63 1

F51 3513703700 LEVER LOCK POM 1

F52 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 6

F53 3513304610 INSULATOR HEATER *T SBHG T0.8 1

F54 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 5

F55 3518400800 DIODE HV AS DIODE HV AS 1

F56 7122400811 SCREW TAPPING T2S TRS 4X8 MFZN 1

F57 3513601710 LAMP BL 240V 25W T25 CC7A H187 99% 1

F58 3511407810 COVER LAMP T/GLASS T2.0 1

F59 7122400811 SCREW TAPPING HVR-1X-3AB 12KV #187 1

F60 7S312X40A1 SCREW SPECIAL T1 TRS 4X10 SE MFZN 3

F61 3512529710 GUIDE WIND SECC T0.4 1

F62 7121400611 SCREW TAPPING T2S PAN 4X6 MFZN 1

F63 3518904000 THERMOSTAT OFF:120 ON:105 V #187 1

F68 7122401211 SCREW TAPPING T2S TRS 4X12 MFZN 2

F69 3510611910 HINGE TOP *L PO T2.6 1

F70 7113400810 SCREW TAPPING T1 BIN 4X8 STS430 MFZN 1

F71 3510613020 BRACKET ROLLER *L AS KOC-1C0KQS 1

F77 3517212100 TRAY METAL AS KOC-1C0KQS 1

F78 3517212400 TRAY RACK AS KOC-1C0KQS 1

NO. PART CODE PART NAME DESCRIPTION Q'TY REMARK

Page 26

25

12. COMPONENT TEST PROCEDURE

• High voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle.

• It is neither necessary nor advisable to attempt measurement of the high voltage.

• Before touching any oven components or wiring, always unplug the oven from its power source and discharge the

capacitor.

• To measure resistance of each component, refer to figures.

1. High voltage transformer

1) Remove connections from the transformer terminals and check continuity.

2) Normal readings should be as follows :

1 Secondary winding ... Approx. 130Ω ~ 160Ω

2 Filament winding ... Approx. 0.2Ω ~ 0.4Ω

3 Primary winding ... Approx. 1.3Ω ~ 2.1Ω

2. High voltage capacitor

1) Check continuity of capacitor with meter on the highest OHM scale.

2) A normal capacitor will show continuity for a short time, and then indicate 10MΩ once

the capacitor charged.

3) A shorted capacitor will show continuous continuity.

4) An open capacitor will show constant 10MΩ ..

5) Resistance between each terminal and chassis should be infinite.

4. Magnetron

For complete magnetron diagnosis, refer to "Measurement of the Microwave Power

Output." Continuity checks can only indicate and open filament or a shorted magnetron.

To diagnose for an open filament or a shorted magnetron,

1) Isolate magnetron from the circuit by disconnecting the leads.

2) A continuity check across magnetron filament terminals should indicate 0.1Ω or less.

3) A continuity check between each filament terminal and magnetron case should read

open.

5. Fuse

If the fuse in the primary and monitor switch circuit is blown when the door is opened, check the primary and monitor switch

before replacing the blown fuse. In case the fuse is blown by an improper switch operation, replace the defective switch

and fuse at the same time. Replace just the fuse if the switches operate normally.

3

2

1

Measuring point

Measuring

point

Page 27

26

5. BLOWER MOTOR AND CONVECTION MOTOR

1) Remove a connector from the motor.

2) Measure resistance between two terminals like as following figure.

3) Reading of blower motor is 60Ω and convection motor is 270Ω .

4) It is normal to stop convection motor smoothly, when door is open during convection mode.

=> You can see the motion of convection motor,

6. HEATER (TOP HEATER, REAR HEATER, HALOGEN HEATER)

1) Remove a connector from the heater

2) Measure resistance between two terminals like as following figure.

3) Normal readings of top heater, rear heater and halogen heater are 36Ω , 36Ω , 23Ω .

4) The oven should be cooled enough to measure resistance of the heater.

7. NOISE FILTER

1) Remove a connector from the noise filter.

2) Check each continuity of N-N and L-L terminal like as following figure.

3) It should be normal to keep continuous continuity.

L-L

N-N

BLOWER MOTOR CONVECTION MOTOR

TOP HEATER REAR HEATER HALOGEN HEATER

Measuring

point

Measuring

point

Measuring

point

Measuring

point

Measuring

point

Page 28

27

11. THERMOSTAT (Anti-superheating device)

Thermostat shut off power supply through opening connection of terminals,

when product arrive in particular temperature by superheating.

Measuring

point

8. POWER CODE

1) Remove a connector from the power code.

2) Check each continuity of N-N and L-L terminal like as following figure.

3) It should be normal to keep continuous continuity.

L-L

N-N

9. INTERLOCK SWITCH

There are three terminals in interlock switch : COM, NO, NC.

1) NC and COM terminals are connected by ordinary condition.

2) NO and COM terminals are connected by pushing a button terminal.

It is the same to two terminal interlock switch and Confirm the connection of

terminals by pushing button terminal to check continuity of interlock switch.

BUTTON

NC

NO

COM

10. THERMESTER (Temperature sensor)

Thermester is a variable resistance by temperature. Normal resistance

should be 200~300Ω in ambient(room) temperature.

Measuring

point

Page 29

28

13. TROUBLE SHOOTING GUIDE

1. Check points

Yes

No

CHECK

Check continuity of main fuse No continuity Replace main fuse

RESULT CAUSE AND REMEDY

Yes

replace the control panel and

check the power

Display shows

The problem was caused by

the control panel

Yes

Check continuity of power code,

noise filter

Power code :

Check continuity

of N-N and L-L

terminals.

Noise filter :

Check continuity

of N-N and L-L

terminals.

Replace the components

which are no continuity

No

Following the procedure below to check if the oven is defective or not.

1) Check grounding before checking trouble

2) Be careful of the high voltage circuit.

3) Discharge the high voltage capacitor.

4) When checking the continuity of the switches, fuse or high voltage tranformer, check continuity with the AC plug

removed. To do otherwise may result in a false reading or damage to your meter or harmful to your body

TROUBLE 1) Despite plugging the cord into the outlet , but the display doesn't show.

NOTE : When electric parts are checked, be sure the power cord is not inserted the wall outlet.

Check wire harness, wiring and connection of the terminals and power cord before check the parts

listed below.

Page 30

29

2. Check points after repair

- After repair or replacement of parts, operate the oven in M/W mode.

There will be occur following problems.

2-1) Display doesn't show again, after opening and closing the door

CHECK

Check the continuity between

the primary interlock switch and

the monitor switch

find the trouble in

switch

1) Replace switch

2) Replace main fuse

RESULT CAUSE AND REMEDY

CHECK

Check the connecting location of

H.V. transformer, H.V. diode and

H.V. capacitor

False connection

1) Modify connection

2) Replace main fuse

RESULT CAUSE AND REMEDY

Right connection

1) Replace H.V. transformer

2) Replace main fuse

2-2) There is no problem during opening and closing the door, but display doesn't show as soon

as the oven operate in Microwave mode

Page 31

30

1. Check points

CHECK RESULT CAUSE AND REMEDY

Trouble2) Although display shows, No microwave oscillation or the oven does not start cooking

2. Check points after repair

- After repair or replacement of parts, operate the oven in Microwave mode.

- Operate M/W mode using a cup of water about 300ml and check the water grow warm.

- You need to reconfirm the above guidances in trouble again.

Yes

No

Check contact of door hook to

primary interlock switch, monitor

switch and DOM switch

Fault contacts

Modify location of door and

door hook or replace door

assembly

Yes Check

Check continuity of monitor

switch and DOM switch

No continuity

Replace switch which

causes a problem

No

No

No

No

No

Yes

Check insertion of DOM terminal

to PCB

No

insertion

Replace

high voltage fuse

Yes

Check continuity of high voltage

fuse

No

continuity

Replace

high voltage fuse

Yes

Check the resistance of H.V.

transformer

Resistance of

H.V. transformer

is higher or lower

than the standard

Replace H.V. transformer

Yes

Check continuity of M/W RELAY

No

continuity

Replace Control Assembly

Yes

Check the problems of

magnetron

Resistance of

magnetron is lower

than the standard

or Insulation is

defected

Replace magnetron

Page 32

31

1. Check points

CHECK RESULT CAUSE AND REMEDY

TROUBLE3) Although display shows, oven cooking is not operated

(Including operating problems of start button)

2. Check points after repair

- After repair or replacement of parts, operate the oven in convection 200°C during 10 minutes

- Check the cavity grow warm

- You need to reconfirm the above guidances in trouble again.

Yes

No

Check contact of door hook to

primary interlock switch, monitor

switch and DOM switch

Fault contacts

Modify location of door and

door hook or replace door

assembly

Yes

Check continuity of monitor

switch and DOM switch

No continuity

Replace switch which cause

a problem

No

Yes

Check insertion of DOM terminal

to PCB

No

insertion

Insert DOM terminal to PCB

No

Yes

Check resistance of top heater,

back heater and halogen heater

Resistance of

heater is lower or

higher than the

standard

Replace heater which

causes a problem

No

Yes

Check continuity of all the heater

relay

No continuity Replace Control Assembly

No

Yes

Check resistance and rotation of

convection fan motor and blower

motor

Resistance of

convection fan

motor and blower

motor are lower or

higher than the

standard, so that

rotation does not

stop smoothly

Replace motor which causes

a problem

Page 33

32

Trouble4) When "ERROR2" or "ERROR3" come on display

When does happen these ERRORs ?

Error3 happen that the temperature sensor (thermister) dosen't connect to P.C.B

connector

Error2 happens if the temperature of cavity is very high

After the oven is cooled enough, operate again

If Display show "Err2" again, following the below procedure

DISPLAY

CAUSE

REMEDY

CONDITION CHECK

Check continuity of thermistor

(resistance of thermistor)

Defective

thermistor

RESULT

0Ω or infinite

Replace

“ERROR 2 &

ERROR 3”

come on

display

Check continuity of heater

(convection, upper, lower)

Defective touch

control circuit

Replace

Approx

200k~300kΩ

(room

temperature)

Defective

heater

No

continuty

continuity

Replace

Page 34

33

CONDITION CHECK

Check each button for

continuity of the button

Malfunction of sub

pcb assembly

RESULT

Normal

CAUSE REMEDY

Replace sub

pcb assembly

Display does

not show

programming

at all, even if

keyboard is

touched.

TROUBLE 5) The following visual conditions indicate a probable defective touch control Circuit or button

P.C.B. assembly

1. Incomplete segments.

1) segment missing

2) partial segments missing

3) digit flickering other than normal fluorescent slight flickering

2. A distinct change in the brightness of one or more numbers exists in the display

3. One or more digits in the display are not on when they should be.

4. Display does not count down or up with time cooking or clock operation.

5. Oven is programmable and cooks normally but no display shows.

6. Display obviously jumps in time while counting down.

7. Display counts down noticeably too fast while cooking.

8. Display does not show the time of day when clear button is touched.

9.Oven lamp and turn table motor do not stop although cooking is finished.

Page 35

34

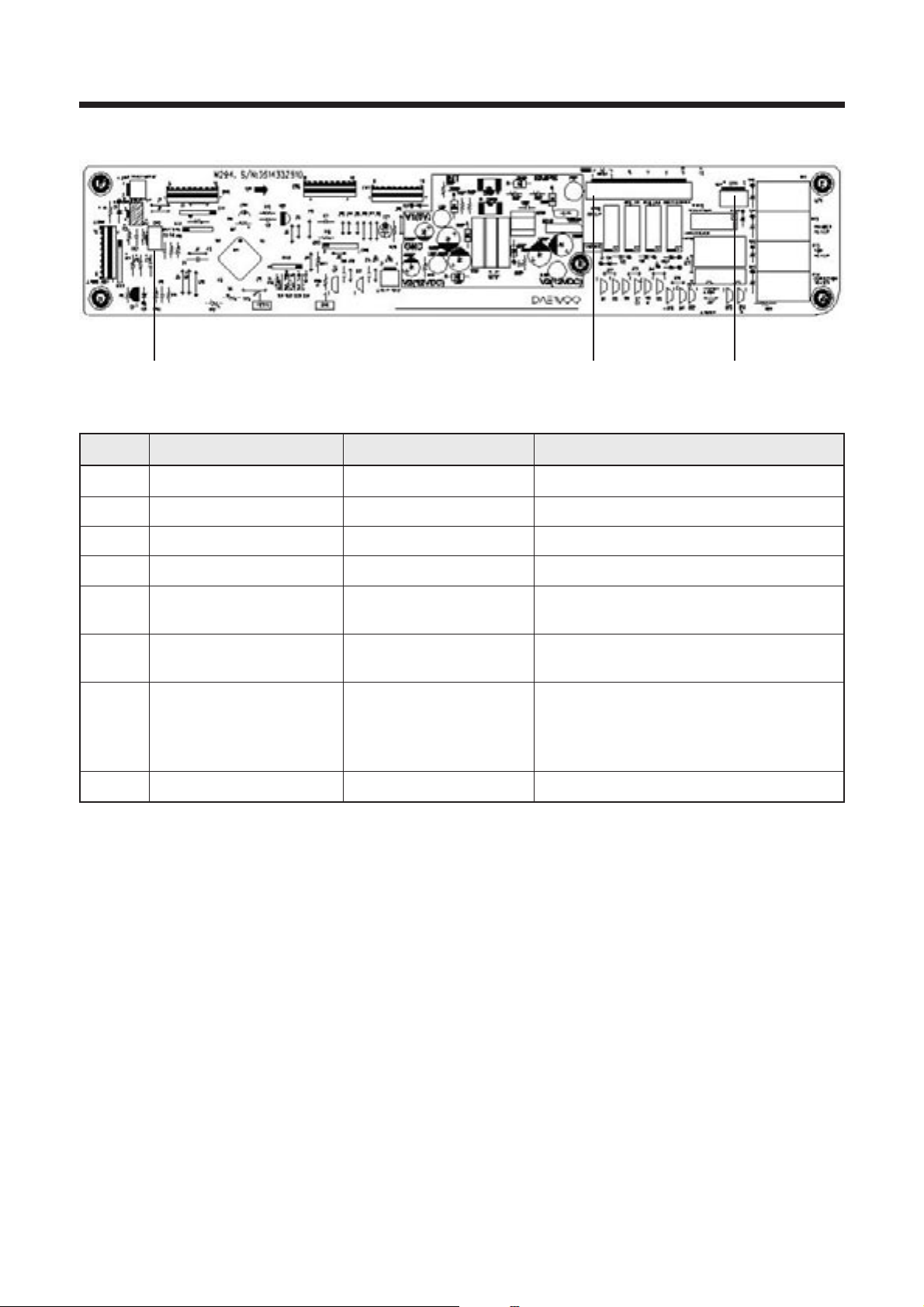

14. PRINTED CIRCUIT BOARD

1 MW R ELAY Control M/W

2 HALOGEN HEATER RELAY Control halogen heater (side heater)

3 TOP HEATER RELAY Control top heater

4 CONVECTION RELAY Control back heater

5 SLOW ACTING RELAY Prevent the transient current (while)operating M/W

6 DOM Let a micon decide Open and close of door

7 SUB R ELAY

8 THERMISTER Temperature sensor

LOCATION PART NAME FUNCTION

MAIN PCB

NO. 1 & 3 : Supply power to PCB

NO. 5 : Convection motor

NO. 7 : Blower-Motor

NO. 9 : Lamp

8 7 6

5

1

2

3

4

Page 36

35

PCB PATTERN DIAGRAM

12V

5V

GND

Page 37

S/M NO. :

DAEWOO ELECTRONICS CORP.

1-2, Jeo-dong 1(il)-ga, Jung-gu, Seoul, Korea

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

PRINTED DATE: Jul. 2013

Page 38

vviissiioonn@

@

ccrreeaattiivveeLL@@iinnccNN

Էړ ܞĸ ࣃۉʷ

VѨݖ ێΟӂ˱ T ࠚ

ABOUT THIS MANUAL

ABOUT THIS MANUAL

ɽʁێŢڙ ɮ

m@o@d@e@l kocMQcPkUs@HsOmI

܂րRPQSNPWNQU

memo@@߭ SW

ِߏ

vision

ɽ ʁ

іОր

telZ WSPMPVVP@faxZ WSPMSWXX

QSNPWNQUMݖL@ݖ˒L@SL@VL@QPL@QQL@QTL@QUL@RPL@RQL@RRL

RSL@RT@ր܄@֭Ŕ QS

Loading...

Loading...