Midea M3OC1-21HRDN1-Q, M2OC-14HRDN1-Q, M3OC-27HRDN1, M3OC1-27HRDN1-Q, M4OC-24HRDN1-Q Technical & Service Manual

...Page 1

ODMI-1103-A

GD Midea Refrigeration Equipment Co.,Ltd

MULTI SPLIT TYPE, HEAT PUMP AIR CONDITIONERS

Technical service manual

R410A Multi DC inverter

220~240V-1Ph-50Hz

Outdoor units Models

M2OC-14HRDN1

M2OC-14HRDN1-Q

M2OC-18HRDN1

M2OC1-18HRDN1-Q

M3OC1-21HRDN1-Q

M3OC-27HRDN1

M3OC1-27HRDN1-Q

M4OC-24HRDN1-Q

M4OC1-27HRDN1-Q

M4OC-27HRDN1

M4OC-36HRDN1-Q

M5OA-36HRDN1-Q

Page 2

ODMI-1103-A

CONTENTS

1. General information of Outdoor Units ................................... 3

2. Features .................................................................................. 4

3. Dimensions ............................................................................. 5

4. Wiring Diagram ....................................................................... 6

5. Refrigeration Cycle Diagram ................................................ 10

6. Indoor units combination ..................................................... 12

7. Electronic control function .................................................. 14

8. Troubleshooting ................................................................... 23

Page 3

ODMI-1103-A

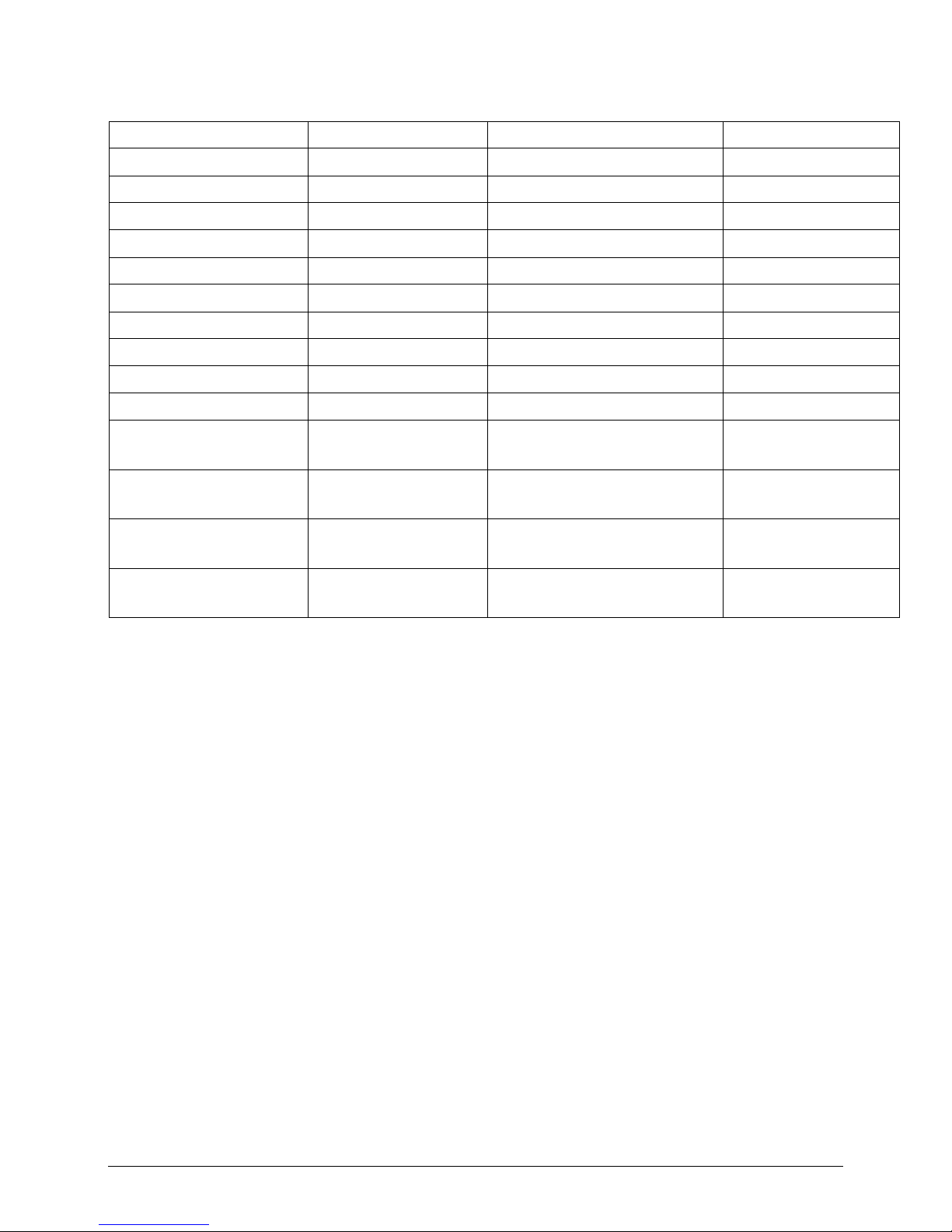

1. General information of Outdoor Units

Model name Dimension (mm) Net/Gross weight (kg) Compressor

M2OC-14HRDN1 760*590*285 39/41 DA108X1C-20FZ3

M2OC-14HRDN1-Q 760*590*285 39/41 DA108X1C-20FZ3

M2OC-18HRDN1 845*700*320 57.5/61.5 C-6RVN93H0N

M2OC1-18HRDN1-Q 845*700*320 53.5/57 DA130S1C-20FZ

M3OC1-21HRDN1-Q 845*700*320 55/60 DA130S1C-20FZ

M3OC-27HRDN1 845*700*320 59/62 C-6RZ146H1A

M3OC1-27HRDN1-Q 845*700*320 57/60.5 DA150S1C-20FZ

M4OC-24HRDN1-Q 845*700*320 56/60 DA150S1C-20FZ

M4OC-27HRDN1 900*860*315 73/78 TNB220FLHMC-L

M4OC1-27HRDN1-Q 900*860*315 73/78 DA250S2C-30MT

M4OC-36HRDN1-Q

(220057200010)

990*965*345 86/90 TNB306FPGM

M4OC-36HRDN1-Q

(220057200011)

990*965*345 86/90 TNB306FPGMC-L

M5OA-36HRDN1-Q

(220057100360)

990*965*345 86.5/91 TNB306FPGM

M5OA-36HRDN1-Q

(220057100361)

990*965*345 86.5/91 TNB306FPGMC-L

Page 4

ODMI-1103-A

2. Features

The hydrophilic fin can improve the heating efficiency at operation mode.

It is only operated in the heating operation mode except defrosting operation.

It protects the valves and prevents water from dripping.

Outdoor unit

Power relay control

Hydrophilic aluminum fin

Anti-rust cabinet

Valve protection cover

4 way valve control

Low noise air flow system

Discharge pipe temperature protection

Compressor crankcase heater

Page 5

ODMI-1103-A

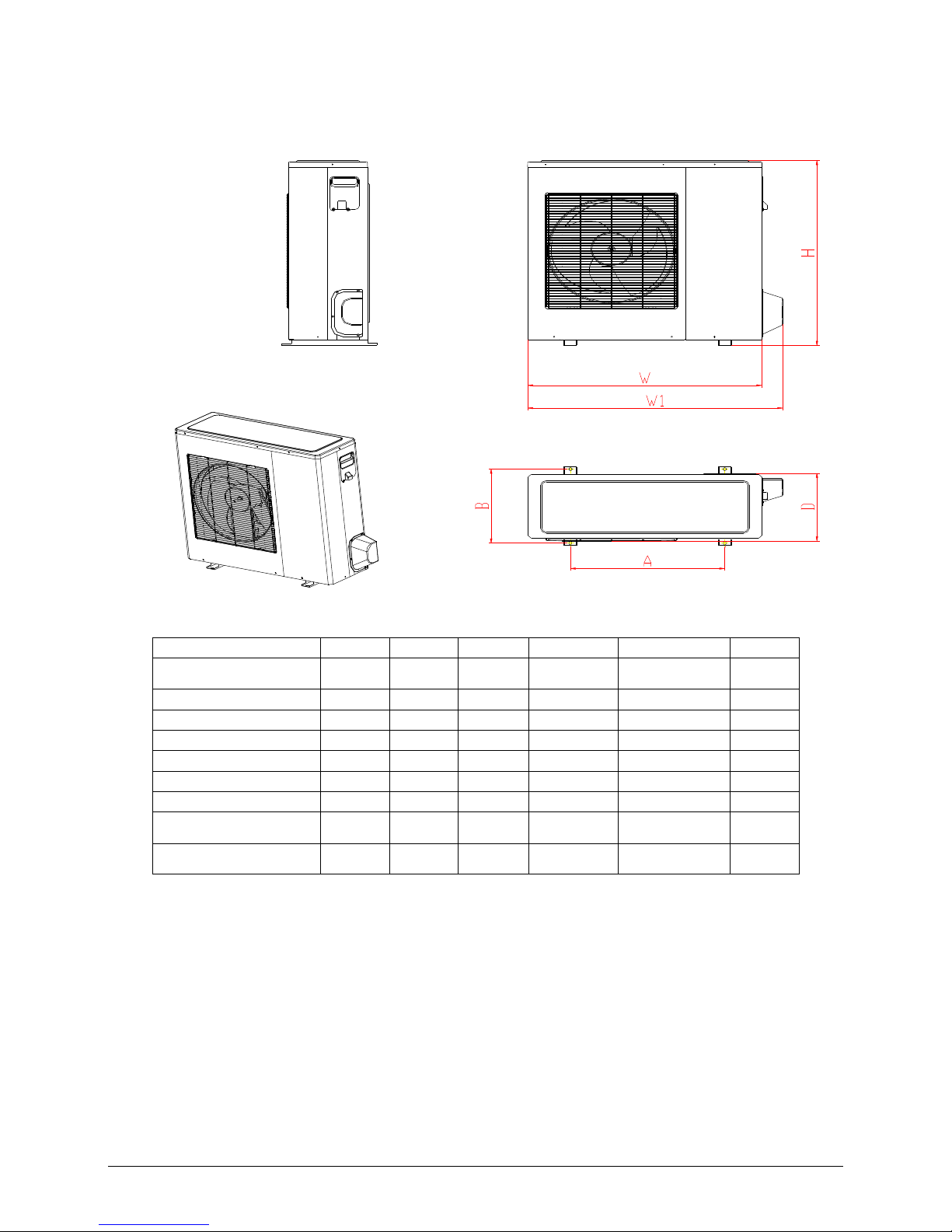

3. Dimensions

MODEL W D H W1 A B

M2OC-14HRDN1-Q

M2OC-14HRDN1

760 285 590 823 530 290

M2OC-18HRDN1 845 320 700 908 560 335

M2OC1-18HRDN1-Q 845 320 700 908 560 335

M3OC1-21HRDN1-Q 845 320 700 908 560 335

M3OC-27HRDN1 845 320 700 908 560 335

M3OC1-27HRDN1-Q 845 320 700 908 560 335

M4OC-24HRDN1-Q

845 320 700 908 560 335

M4OC-27HRDN1

M4OC1-27HRDN1-Q

900 315 860 980 590 333

M4OC-36HRDN1-Q

M5OA-36HRDN1-Q

990 345 965 1075 624 366

Page 6

ODMI-1103-A

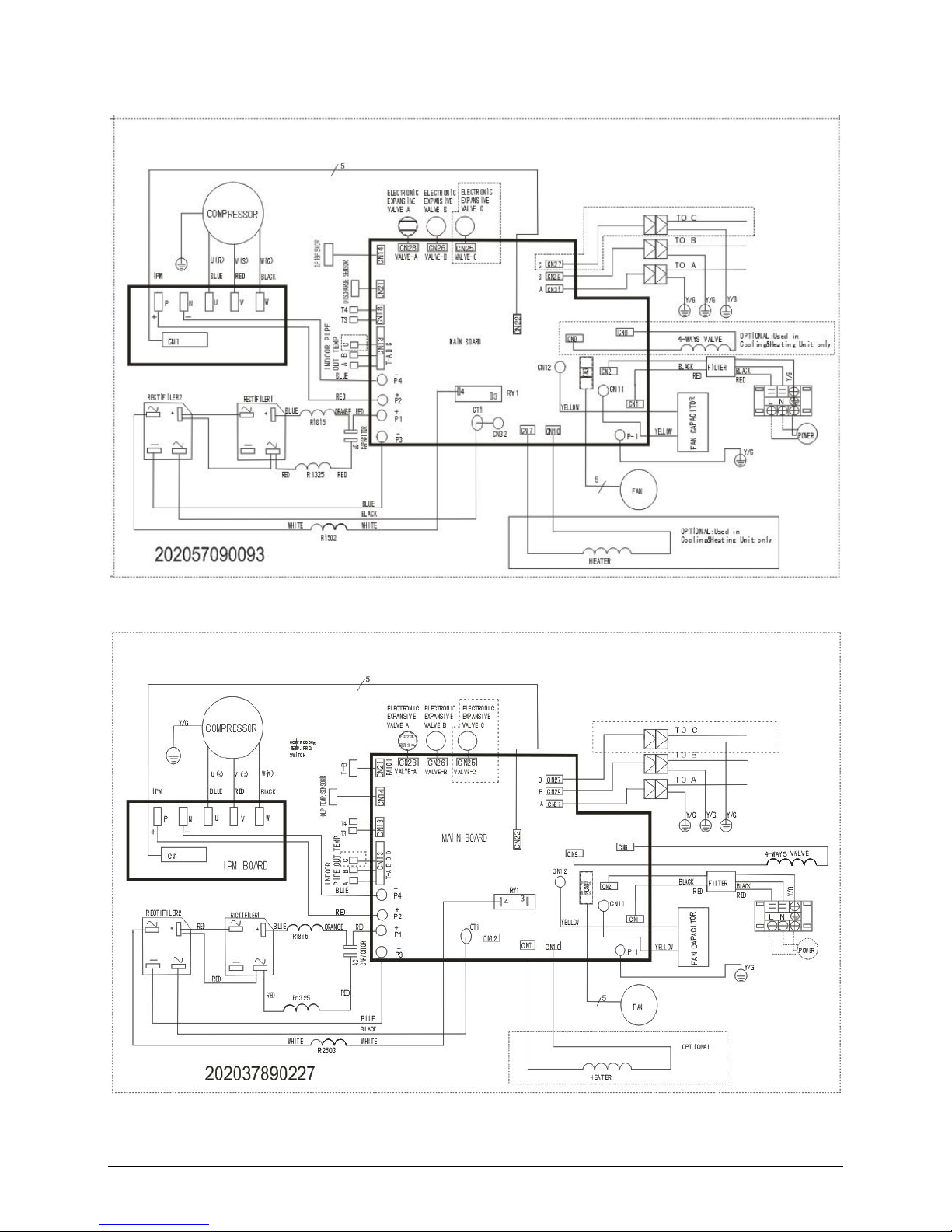

4. Wiring Diagram

4.1 M2OC-14HRDN1-Q

4.2 M2OC-14HRDN1

Page 7

ODMI-1103-A

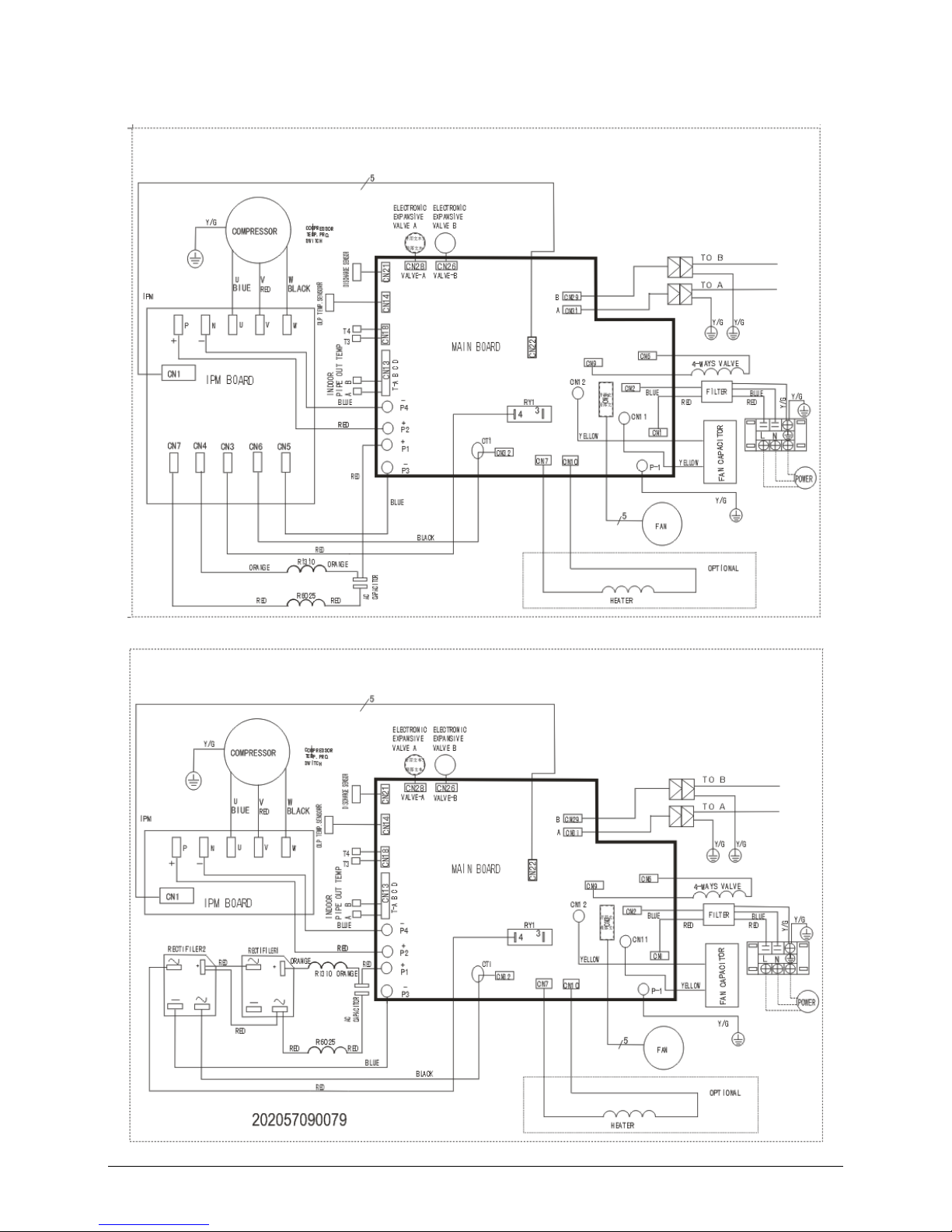

4.3 M2OC1-18HRDN1-Q 、M3OC1-21HRDN1-Q

4.4 M2OC-18HRDN1、M3OC-27HRDN1

Page 8

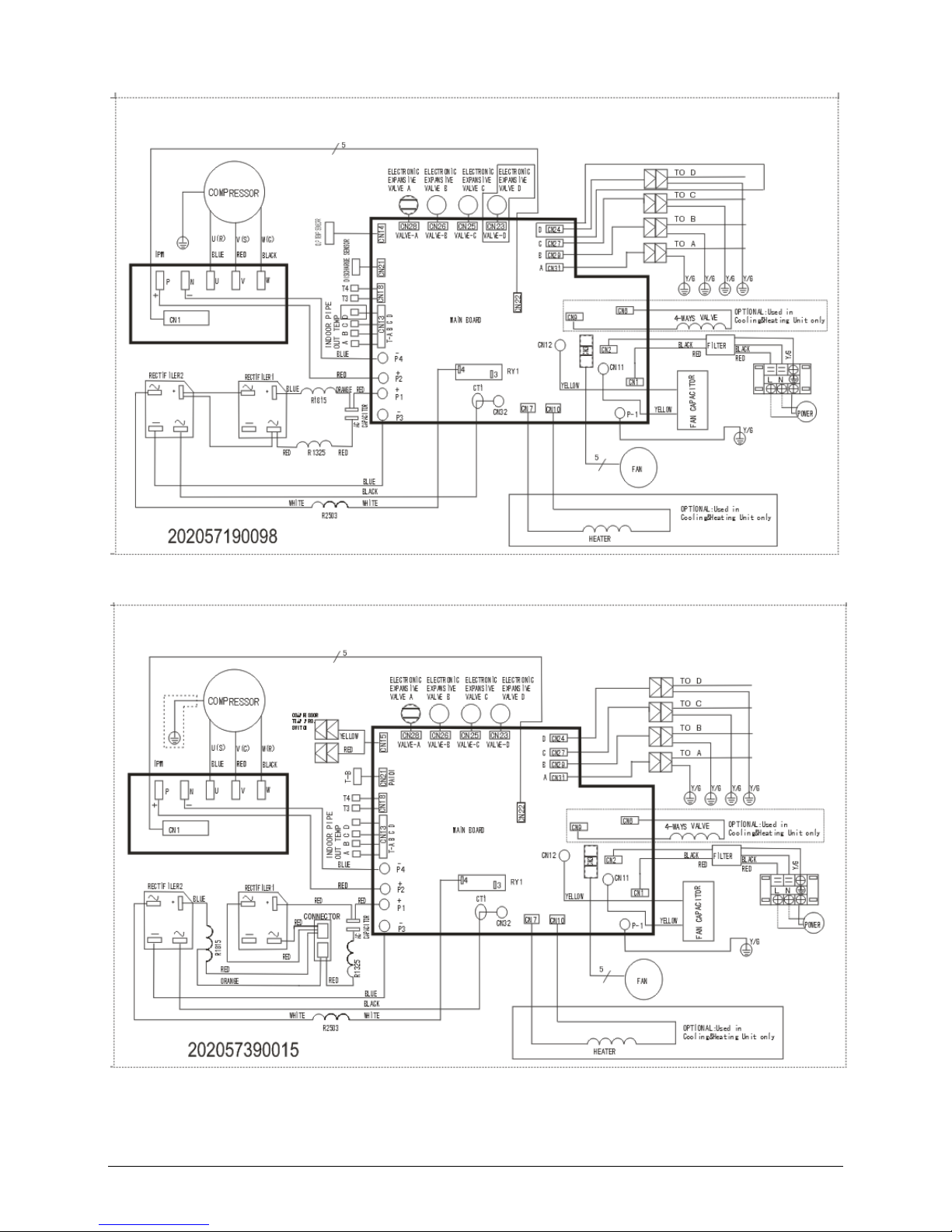

ODMI-1103-A

4.5 M3OC1-27HRDN1-Q、M4OC-24HRDN1-Q

4.6 M4OC1-27HRDN1-Q、M4OC-27HRDN1

Page 9

ODMI-1103-A

4.7 M4OC-36HRDN1

4.8 M5OA-36HRDN1-Q

Page 10

ODMI-1103-A

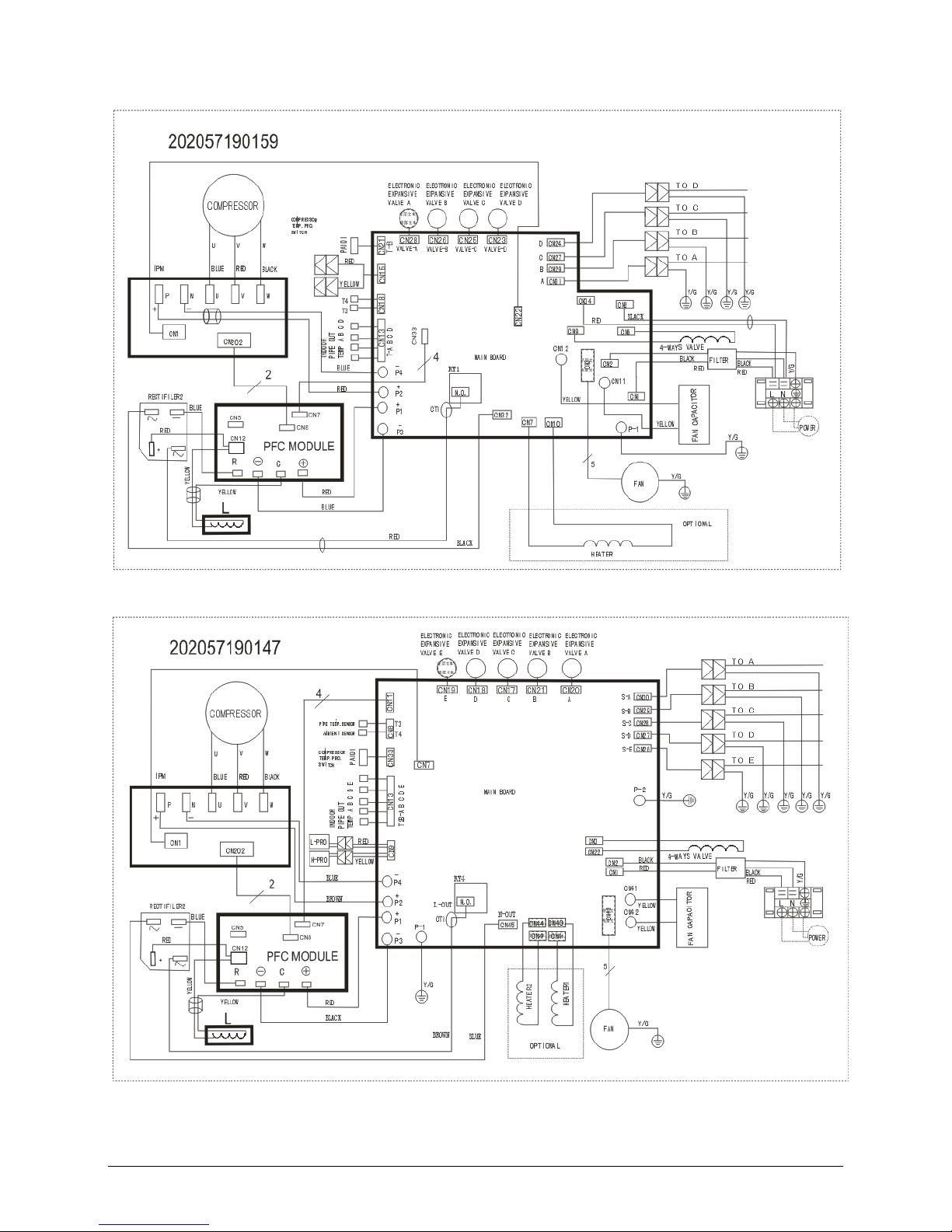

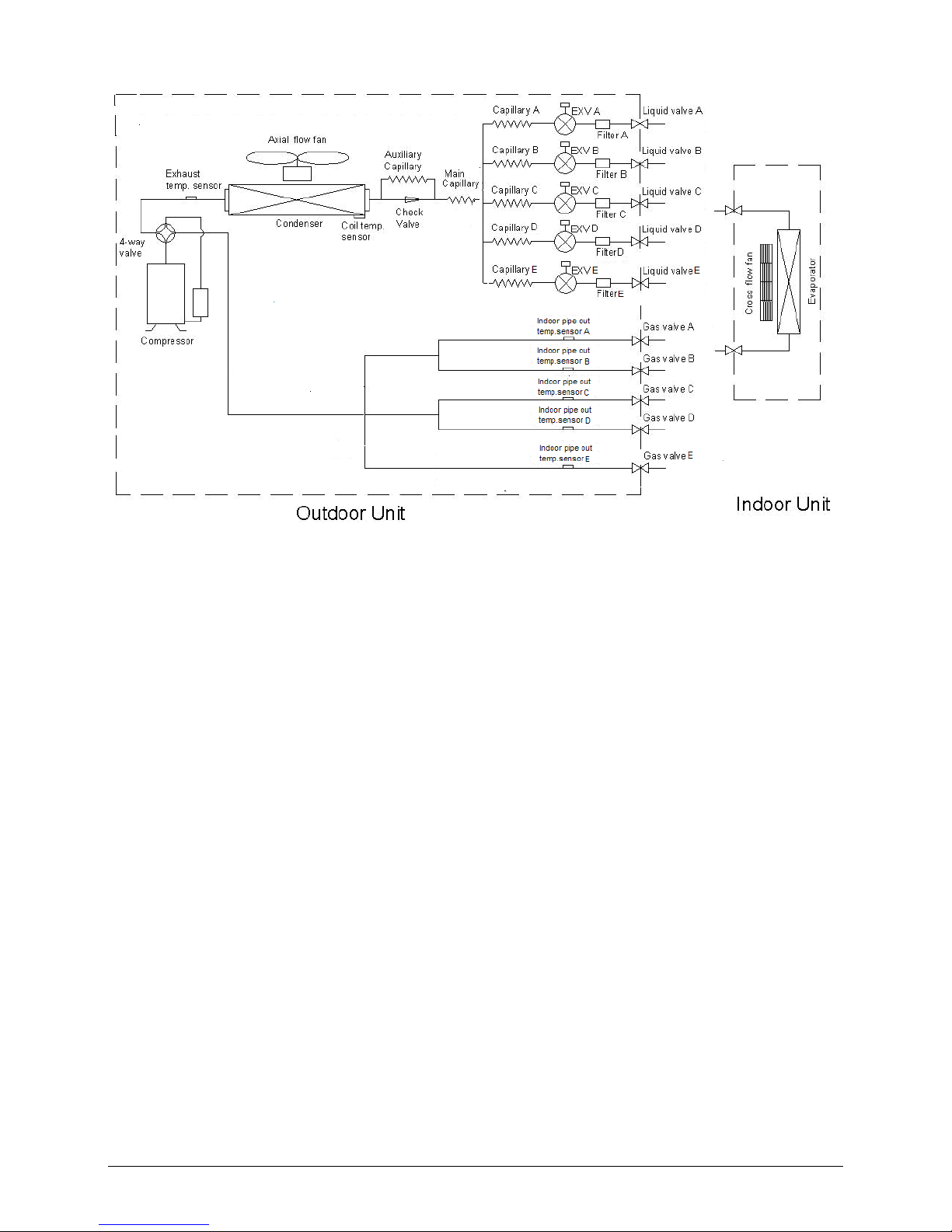

5. Refrigeration Cycle Diagram

5.1 Refrigeration circuit drawing of inverter binary type

4.2 Refrigeration circuit drawing of inverter trinary type

5.3 Refrigeration circuit drawing of inverter quadplex type

Page 11

ODMI-1103-A

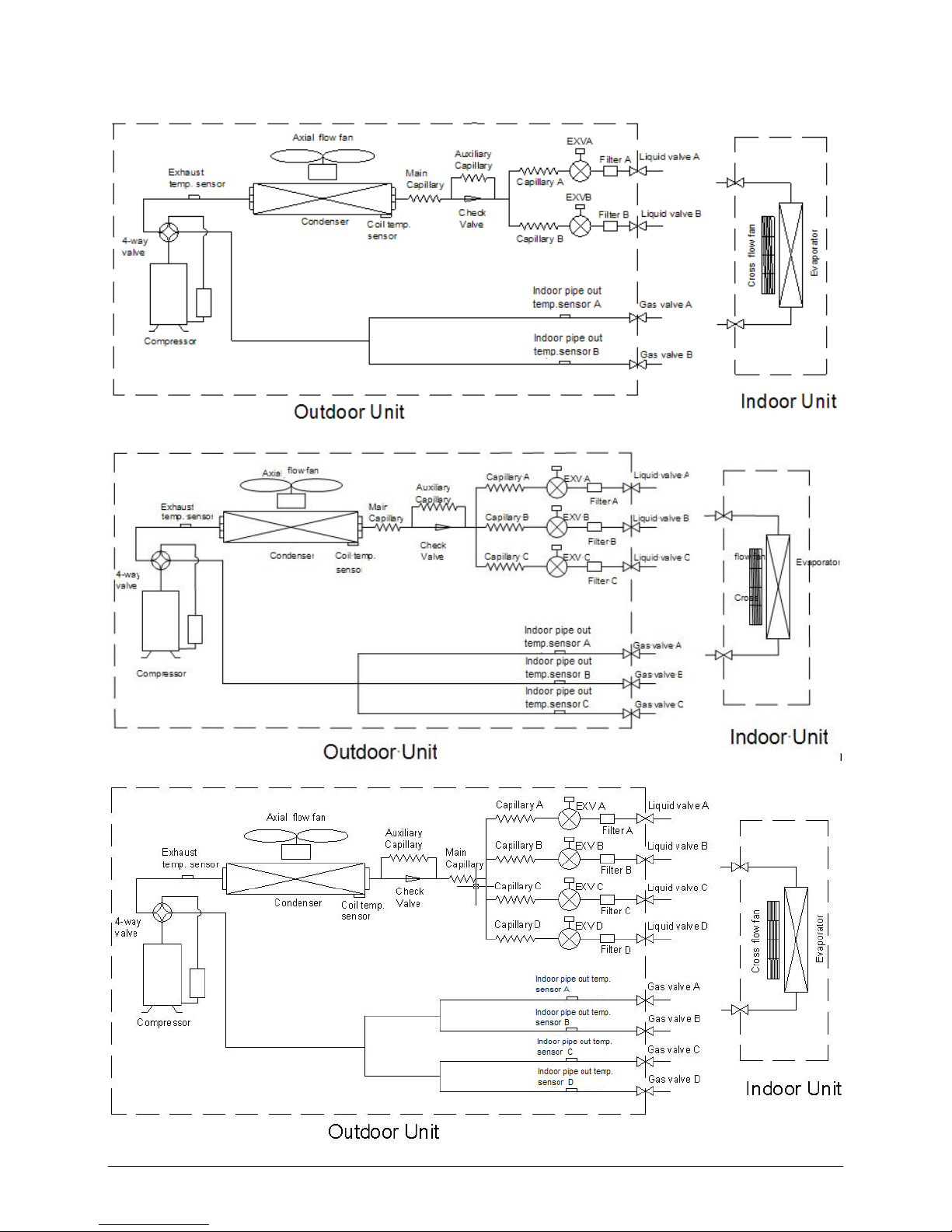

5.4 Refrigeration circuit drawing of inverter quintuple type

Page 12

ODMI-1103-A

6. Indoor units combination

6.1 Indoor unit combination for M2OC-14HRDN1-Q、M2OC-14HRDN1

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12

Note: There should be no more than one cassette or duct or console or ceiling & floor unit.

6.2 Indoor unit combination for M2OC1-18HRDN1-Q、M2OC-18HRDN1

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12 12+12

18 7+18

Note: The 18k indoor unit should only be wall mounted unit.

6.3 Indoor unit combination for M3OC1-21HRDN1-Q

One unit Two unit Three unit

7 7+7 9+9 7+7+7 7+9+12

9 7+9 9+12 7+7+9 9+9+9

12 7+12 9+18 7+7+12 9+9+12

18 7+18 12+12 7+9+9

Note: There should be no more than one cassette or duct or console or ceiling & floor unit. And the 18k indoor unit

should only be wall mounted unit.

6.4 Indoor unit combination for M3OC1-27HRDN1-Q、M3OC-27HRDN1

One unit

Two unit Three unit

7 7+7 9+9 12+12 7+7+7 7+9+9 9+9+9

9 7+9 9+12 12+18 7+7+9 7+9+12 9+9+12

12 7+12 9+18 7+7+12 7+12+12 9+12+12

18 7+18 7+7+18

Note: The 18k indoor unit should only be wall mounted unit.

6.5 Indoor unit combination for M4OC-24HRDN1-Q

One unit Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+9+9 9+9+9 7+7+7+7 7+7+9+9 9+9+9+9

9 7+9 9+12 12+18 7+7+9 7+9+12 9+9+12 7+7+7+9 7+7+9+12 9+9+9+12

12 7+12 9+18 7+7+12 7+12+12 9+12+12 7+7+7+12 7+9+9+9

18 7+18 7+7+18 7+9+9+12

Note: The 18k indoor unit should only be wall mounted unit.

Page 13

ODMI-1103-A

6.6 Indoor unit combination for M4OC1-27HRDN1-Q、M4OC-27HRDN1

One unit Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+9+12 9+9+9 7+7+7+7 7+7+9+9 7+9+9+12

9 7+9 9+12 12+18 7+7+9 7+9+18 9+9+12 7+7+7+9 7+7+9+12 7+9+12+12

12 7+12 9+18 18+18 7+7+12 7+12+12 9+9+18 7+7+7+12 7+7+12+12 9+9+9+9

18 7+18 7+7+18 7+12+18 9+12+12 7+7+7+18 7+9+9+9 9+9+9+12

7+9+9 12+12+12 9+12+18

6.7 Indoor unit combination for M4OC-36HRDN1-Q

6.8 Indoor unit combination for M5OA-36HRDN1-Q

One Unit Two Unit Three Unit

7 7+7 9+12 7+7+7 7+9+18 9+9+18 12+18+18

9 7+9 9+18 7+7+9 7+12+12 9+12+12 18+18+18

12 7+12 12+12 7+7+12 7+12+18 9+12+18

18 7+18 12+18 7+7+18 7+18+18 9+18+18

9+9 18+18 7+9+9 9+9+9 12+12+12

7+9+12 9+9+12 12+12+18

Four Unit

7+7+7+7 7+7+9+18 7+9+9+18 7+12+18+18 9+9+18+18

7+7+7+9 7+7+12+12 7+9+12+12 9+9+9+9 9+12+12+12

7+7+7+12 7+7+12+18 7+9+12+18 9+9+9+12 9+12+12+18

7+7+7+18 7+7+18+18 7+9+18+18 9+9+9+18 12+12+12+12

7+7+9+9 7+9+9+9 7+12+12+12 9+9+12+12 12+12+12+18

7+7+9+12 7+9+9+12 7+12+12+18 9+9+12+18

Five Unit

7+7+7+7+7 7+7+7+9+18 7+7+9+12+18 7+9+9+12+18 9+9+9+12+12

7+7+7+7+9 7+7+7+12+18 7+7+12+12+18 7+9+12+12+12 9+9+9+12+18

7+7+7+7+12 7+7+7+18+18 7+9+9+9+9 7+9+12+12+18 9+9+12+12+12

7+7+7+7+18 7+7+9+9+9 7+9+9+9+12 9+9+9+9+9 9+12+12+12+12

7+7+7+9+9 7+7+9+9+12 7+9+9+9+18 9+9+9+9+12 12+12+12+12+12

7+7+7+9+12 7+7+9+9+18 7+9+9+12+12 9+9+9+9+18

One unit

Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+12+12 9+12+18 7+7+7+7 7+7+12+12 7+9+12+18 9+9+12+12

9 7+9 9+12 12+18 7+7+9 7+12+18 9+18+18 7+7+7+9 7+7+12+18 7+9+18+18 9+9+12+18

12 7+12 9+18 18+18 7+7+12 7+18+18 12+12+12 7+7+7+12 7+7+18+18 7+12+12+12 9+12+12+12

18 7+18

7+7+18

9+9+9 12+12+18 7+7+7+18 7+9+9+9 7+12+12+18 9+12+12+18

7+9+9 9+9+12 12+18+18 7+7+9+9 7+9+9+12 9+9+9+9 12+12+12+12

7+9+12 9+9+18 7+7+9+12 7+9+9+18 9+9+9+12 12+12+12+18

7+9+18 9+12+12

7+7+9+18 7+9+12+12 9+9+9+18

Page 14

ODMI-1103-A

7. Electronic control function

7.1 Abbreviation

T1: Indoor ambient temperature

T2: Coil temperature of indoor heat exchanger middle.

T2B: Coil temperature of indoor heat exchanger outlet.

T3: Coil temperature of outdoor heat exchanger

T4: Outdoor ambient temperature

T5: Compressor discharge temperature

Ts: Setting temp.

7.2 Electric Control working environment.

7.2.1 Input voltage: 190~264V.

7.2.2 Input power frequency:50Hz.

7.2.3 Indoor fan normal working amp. is less than 1A.

7.2.4 Outdoor fan. Normal working amp. is less than 1.5A.

7.2.5 Four-way valve normal working amp. is less than 1A.

7.2.6 Swing motor: DC12V.

7.3 Outdoor unit¡s digital display tube

There is a digital display tube in outdoor PCB.

Digital display tube display function

In standby , the LED displays ¡- -¡

In compressor operation, the LED display the running frequency,

In defrosting mode, The LED displays ¡dF¡ or alternative displays between running frequency and

¡dF¡(each displays 2s)

In compressor pre-heating, The LED displays ¡- -¡

In protection or malfunction, the LED displays error code or protection code.

7.4 Outdoor unit point check function

There is a check switch in outdoor PCB.

Push the switch SW1 to check the states of unit when the unit is running. The digital display tube will display

the follow procedure when push SW1 each time.

For units except M5OA-36HRDN1-Q model:

Display Remark

1

Indoor unit capacity demand code

2

Outdoor unit running mode code Off:0, Cooling:1, Heating:2

3

Amendatory capacity demand code

4

Outdoor unit fan motor state Off:0, Low speed:1, High speed:2

5

Evaporator outlet temp. for 1# indoor unit Actual data

6

Evaporator outlet temp. for 2# indoor unit Actual data

7

Evaporator outlet temp. for 3# indoor unit Actual data

8

Evaporator outlet temp. for 4# indoor unit Actual data

9

Condenser pipe temp. Actual data

10

Ambient temp. Actual data

11

Compressor discharge temp. Actual data

12

Inverter current Actual data

Page 15

ODMI-1103-A

13

EXV open angle for 1# indoor unit Actual data/8

14

EXV open angle for 2# indoor unit Actual data/8

15

EXV open angle for 3# indoor unit Actual data/8

16

EXV open angle for 4# indoor unit Actual data/8

17

Power supply of outdoor unit AD data

18 Indoor unit number The indoor unit can communicate with outdoor unit well.

19 The last error or protection code 00 means no malfunction

20

frequency value Actual data

21 Ambient temp. of 1# indoor unit Actual data

22 Condenser pipe temp. of 1# indoor unit Actual data

23

Ambient temp. of 2# indoor unit Actual data

24 Condenser pipe temp. of 2# indoor unit Actual data

25 Ambient temp. of 3# indoor unit Actual data

26

Condenser pipe temp. of 3# indoor unit Actual data

27 Ambient temp. of 4# indoor unit Actual data

28 Condenser pipe temp. of 4# indoor unit Actual data

29

―― Check point over

For M5OA-36HRDN1-Q model:

Display Remark

1

No.of indoor units in good connection Actual data

2

Outdoor unit running mode code Off:0, Cooling:2, Heating:3, Forced cooling:4

3

A indoor unit capacity

The capacity unit is horse power.If the indoor unit is not

connected,the digital display tube will show: “――”

4

B indoor unit capacity

5

C indoor unit capacity

6

D indoor unit capacity

7

E indoor unit capacity

8

A Indoor unit capacity demand code

9

B Indoor unit capacity demand code

10

C Indoor unit capacity demand code

11

D Indoor unit capacity demand code

12

E Indoor unit capacity demand code

13

Total indoor units amendatory capacity

demand code

14

The frequency corresponding to the total

indoor units amendatory capacity demand

15

The frequency after the frequency limit

16

The frequency sending to compressor contol

chip

17

A indoor unit evaporator outlet temp.(T2BA)

If the temp.is lower than -9 degree, the digital display tube will

show ¡-9¡.If the temp.is higher than 70 degree,the digital display

tube will show ¡70¡. If the indoor unit is not connected,the digital

display tube will show: “――”

18

B indoor unit evaporator outlet temp.(T2BB)

19

C indoor unit evaporator outlet temp.(T2BC)

20

D indoor unit evaporator outlet temp.(T2BD)

21

E indoor unit evaporator outlet temp.(T2BE)

22

A indoor unit room temp.(T1A)

23

B indoor unit room temp.(T1B)

24

C indoor unit room temp.(T1C)

25

D indoor unit room temp.(T1D)

26

E indoor unit room temp.(T1E)

Page 16

ODMI-1103-A

27

A indoor unit evaporator outlet temp.(T2BA)

If the temp.is lower than -9 degree, the digital display tube will

show ¡-9¡.If the temp.is higher than 70 degree,the digital display

tube will show ¡70¡. If the indoor unit is not connected,the digital

display tube will show: “――”

28

B indoor unit evaporator outlet temp.(T2BB)

29

C indoor unit evaporator outlet temp.(T2BC)

30

D indoor unit evaporator outlet temp.(T2BD)

31

E indoor unit evaporator outlet temp.(T2BE)

32

Condenser pipe temp.(T3)

33

Outdoor ambient temp.(T4)

34

Compressor discharge temp.(Tp) The display value is between 30~120 degree.If the temp.is lower

than 30 degree,the digital display tube will show ¡30¡.If the

temp.is higher than 99 degree, the digital display tube will show

single digit and tens digit.For example,the digital display tube

show ¡0.5¡,it means the compressor discharge temp.is 105

degree.)

35

AD value of current

The display value is hex number.

36

AD value of voltage

37

EXV open angle for A indoor unit

Actual data/4.

If the value is higher than 99, the digital display tube will show

single digit and tens digit.

For example,the digital display tube show ¡2.0¡,it means the EXV

open angle is 120¡ 4=480p.)

38

EXV open angle for B indoor unit

39

EXV open angle for C indoor unit

40

EXV open angle for D indoor unit

41

EXV open angle for E indoor unit

42

Frequency limit symbol

Bit7 0

The display

value is hex

number.For

example,the

digital display

tube show

2A,then Bit5=1,

Bit3=1, Bit1=1.

It means

frequency limit

caused by

T4,T3 and

current.

Bit6 0

Bit5

Frequency limit caused by T4.

Bit4

Frequency limit caused by T2.

Bit3

Frequency limit caused by T3.

Bit2

Frequency limit caused by Tp.

Bit1

Frequency limit caused by current

Bit0

Frequency limit caused by voltage

43

Average value of T2 (Sum T2 value of all indoor units)/(indoor units number)

44

Outdoor unit fan motor state Off:0, High speed:1, Med speed:2, Low speed:3

45

The last error or protection code 00 means no malfunction

7.4.1 Frequency of compressor:

Display Frequency of compressor (Hz)

30 30

-- Stand by

60 60

7.4.2 Running mode:

Display Corresponding mode

0 Off

1 Cooling mode

2 Heating mode

Page 17

ODMI-1103-A

7.4.3 Capacity demand:

Cooling mode

Capacity 2000-2

500

2000-2

500

3000-3

800

4500-5

000

5000-5

500

5500-6

100

6100-7

000

7000-7

500

7500-8

000

>7500

Correspondi

ng Code

1 2 3 4 5 6 7 8 9 >=10

Heating mode

Capacity 2000-2

500

2000-2

500

3000-3

800

4500-5

000

5500-6

100

6100-7

000

6100-7

000

7000-7

500

7500-8

000

>8000

Correspondin

g Code

1 2 3 4 5 6 7 8 9-10 >=11

Note:

The capacity is just for reference.

Page 18

ODMI-1103-A

7.4.4Number of indoor unit

Display Number of indoor unit

1 1

2 2

3 3

7.4.5 Outdoor ambient temp:

Display Corresponding temp.

Display

Corresponding

temp.

Display

Corresponding

temp.

15 -7.5 50 10 80 25

16 -7 51 10.5 81 25.5

17 -6.5 52 11 82 26

18 -6 53 11.5 83 26.5

19 -5.5 53 11.5 84 27

20 -5 54 12 85 27.5

21 -4.5 55 12.5 86 28

22 -4 56 13 87 28.5

23 -3.5 57 13.5 88 29

24 -3 58 14 89 29.5

26 -2 59 14.5 90 30

27 -1.5 60 15 91 30.5

28 -1 61 15.5 92 31

29 -0.5 62 16 93 31.5

30 0 63 16.5 93 31.5

31 0.5 63 16.5 94 32

32 1 64 17 95 32.5

33 1.5 65 17.5 96 33

34 2 65 17.5 97 33.5

35 2.5 66 18 98 34

36 3 67 18.5 99 34.5

37 3.5 68 19 10. 35~40

38 4 69 19.5 11. 40~45

39 4.5 70 20 12. 45~50

40 5 71 20.5 13. 50~55

41 5.5 72 21 14. 55~60

42 6 73 21.5 15. 60~65

43 6.5 74 22 16. 65~70

44 7 75 22.5

45 7.5 75 22.5

46 8 76 23

47 8.5 77 23.5

48 9 78 24

49 9.5 79 24.5

Page 19

ODMI-1103-A

7.4.6 Opening degree of electronic expansion valve:

Opening degree equals the display data times 8

7.5 Protection

7.5.1 Three minutes delay at restart for compressor.

7.5.2 Temperature protection of compressor discharge.

When the compressor discharge temp. is getting higher, the running frequency will be limited as below

rules:

----If 102℃<T5<115 , decrease the freq℃ uency to the lower level every 2 minutes till to F1.

---If T5>115℃ for 10 seconds, the compressor will stop and restart till T5<90℃.

7.5.3 Under voltage protection

VOLLIMT1

VOLTAGE

No limit

VOLLIMT2

VOLLIMT3

Off

VOLFRE2

VOLFRE1

VOLREL1

VOLREL2

VOLREL3

Mode VOLLIMT1(V) VOLLIMT2(V) VOLLIMT3(V) VOLREL1(V) VOLREL2(V) VOLREL3(V) VOLFRE1(Hz) VOLFRE2(Hz)

M2OC-14HRDN1 220 200 80 250 210 100 62 54

M2OC-14HRDN1-Q 220 200 80 250 210 100 62 54

M2OC-18HRDN1 230 200 80 260 210 100 62 54

M2OC1-18HRDN1-Q

230 200 120 260 210 135 62 54

M3OC1-21HRDN1-Q

245 220 80 265 240 100 78 45

M3OC-27HRDN1 245 220 80 265 240 100 78 45

M3OC1-27HRDN1-Q

245 220 120 265 240 135 78 45

M4OC-24HRDN1-Q 245 220 120 265 240 135 78 45

M4OC-27HRDN1 221 210 80 260 225 100 62 54

M4OC1-27HRDN1-Q

221 210 80 260 225 100 53 44

M4OC-36HRDN1-Q 200 185 80 210 195 100 54 42

For M5OA-36HRDN1-Q,

VOLT_RST1_ADD

VOLTAGE

No limit

VOLT_LTM1_ADD

VOLT_RST2_ADD

VOLT_LTM2_ADD

VOLT_LTM_FREQ1_ADD

VOLT_LTM_FREQ2_ADD

Page 20

ODMI-1103-A

VOLT_RST1_ADD=210V, VOLT_LIM1_ADD=200V, VOLT_RST2_ADD=195V, VOLT_LIM2_ADD=185V.

VOLT_LIM_FREQ1_ADD=54Hz, VOLT_LIM_FREQ2_ADD=42Hz.

7.5.4 Compressor current limit protection

If the compressor current exceeds the current limit value for 10 seconds, the compressor frequency will be

limited as below table.

For models except M5OA-36HRDN1-Q.

Cooling mode:

Current frequency(Hz) Current limit value(A) Frequency limit

COOL_F10 ICOOLLMT6 Decrease the frequecny to COOL_F4 and

run at COOL_F4 for 3 minutes.

After that,the frequency will be adjusted

according to the capacity demand and rise

to the upper level every 3 minutes

(When the frequency>COOL_F4 via

capacity demand).

COOL_F9 ICOOLLMT5

COOL_F8 ICOOLLMT4

COOL_F7 ICOOLLMT3

COOL_F6 ICOOLLMT2

COOL_F5 ICOOLLMT1

If the current frequency is lower than COOL_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>ICOOL,the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

Heating mode:

Current frequency(Hz) Current limit value(A) Frequency limit

HEAT_F12 IHEATLMT8 Decrease the frequecny to HEAT_F4 and

run at HEAT_F4 for 3 minutes.

After that,the frequency will be adjusted

according to the capacity demand and rise

to the upper level every 3 minutes

(When the frequency>Heat_F4 via capacity

demand).

HEAT_F11 IHEATLMT7

HEAT_F10 IHEATLMT6

HEAT_F9 IHEATLMT5

HEAT_F8 IHEATLMT4

HEAT_F7 IHEATLMT3

HEAT_F6 IHEATLMT2

HEAT_F5 IHEATLMT1

If the current frequency is lower than HEAT_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>IHEAT,the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

For M5OA-36HRDN1-Q model:

Cooling mode:

Current frequency

(Hz)

Current limit value(A)

Frequency limit

COOL_F16 ICOOLLMT12 Decrease the frequecny to COOL_F4 and run at

COOL_F4 for 3 minutes.

After that,the frequency will be adjusted according to

the capacity demand and rise to the upper level every

3 minutes

(When the frequency>COOL_F4 via capacity

demand).

COOL_F15 ICOOLLMT11

COOL_F14 ICOOLLMT10

COOL_F13 ICOOLLMT9

COOL_F12 ICOOLLMT8

COOL_F11 ICOOLLMT7

COOL_F10 ICOOLLMT6

Page 21

ODMI-1103-A

COOL_F9 ICOOLLMT5

COOL_F8 ICOOLLMT4

COOL_F7 ICOOLLMT3

COOL_F6 ICOOLLMT2

COOL_F5 ICOOLLMT1

If the current frequency is lower than COOL_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>ICOOL,the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

Heating mode:

Current frequency

(Hz)

Current limit value(A)

Frequency limit

HEAT_F16 IHEATLMT12 Decrease the frequecny to HEAT_F4 and run at

HEAT_F4 for 3 minutes.

After that,the frequency will be adjusted according to

the capacity demand and rise to the upper level every

3 minutes

(When the frequency>Heat_F4 via capacity

demand).

HEAT_F15 IHEATLMT11

HEAT_F14 IHEATLMT10

HEAT_F13 IHEATLMT9

HEAT_F12 IHEATLMT8

HEAT_F11 IHEATLMT7

HEAT_F10 IHEATLMT6

HEAT_F9 IHEATLMT5

HEAT_F8 IHEATLMT4

HEAT_F7 IHEATLMT3

HEAT_F6 IHEATLMT2

HEAT_F5 IHEATLMT1

If the current frequency is lower than HEAT_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>IHEAT,the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

6.5.5 Indoor / outdoor units communication protection

If the indoor units can not receive the feedback signal from the outdoor units for 2 minutes,the AC will stop

and display the failure.

7.5.6 High condenser coil temp. protection.

When T3>65 for ℃ 3 seconds, the compressor will stop while the indoor fan and outdoor fan will continue.

When T3<52 , the protection will release℃ and the compressor will restart after 3 minutes.

7.5.7 Outdoor unit anti-freezing protection

When T2B<0 for 250 seconds℃ ,the indoor unit capacity demand will be zero and resume to normal when

T2B>10 .℃

7.5.8 Oil return

Running rules:

Page 22

ODMI-1103-A

1. If the compressor frequency keeps lower than RECOILINFRE for Te minutes,the AC will rise the

frequency to RECOILFRE for Tf seconds and then resume to former frequency.For M4OC-36HRDN1-Q,

RECOILINFRE=45Hz, RECOILFRE=48Hz,Te=120,Tf=180; For M5OA-36HRDN1-Q, RECOILINFRE=45Hz,

RECOILFRE=48Hz, Te=90,Tf=100; For other models, RECOILINFRE=50Hz, RECOILFRE=62Hz,

Te=120,Tf=180.

2. During the Tf seconds, the EXV and indoor units keep the current running mode(except

M5OA-36HRDN1-Q model), the frequency will not be limited by the compressor discharge temp.and the

current.For M5OA-36HRDN1-Q model,the EXV will keep 300p while the indoor units will keep the current

running mode.

3. If the outdoor ambient is higher than 15℃ during the oil return,the AC quit oil return.

7.5.9 Compressor preheating functions

----Preheating permitting condition:

If T4(outdoor ambient temperature)<3 and the machine connects to power suppl℃ y no longer than 5

seconds or if T4<3 and compressor has stopped for over 3 hours, the compressor heating cable will ℃

work.

----Preheating mode:

A weak current flow through the coil of compressor from the wiring terminal of compressor, then the

compressor is heated without operation.

----Preheating release condition:

If T4≧5 or ℃ the compressor starts running, preheating function will stop.

7.5.10 Compressor crankcase heater

When T4<3℃ and the compressor is not running,the crankcase heater will be active.

When T4≧5℃ or the compressor starts up,the crankcase heater will stop work.(For M5OA-36HRDN1-Q,T4

≧8℃)

Page 23

ODMI-1103-A

8. Troubleshooting

8.1 Indoor unit error code explanation:

R series(except model MSR1I-07HRDN1-Q&MSR1I-09HRDN1-Q)+X series+Y series:

Display

MALFUNCTION

E0 EEPROM parameter error

E1 Indoor / outdoor units communication protection

E2 Zero-crossing signal error

E3 Fan speed out of control

E5 Open or short circuit of outdoor temperature sensor

E6 Open or short circuit of room or evaporator temperature sensor

P0 IGBT over-strong current protection

P1 Over voltage or too under voltage protection

P2 Temperature protection of compressor top.

P4 Inverter compressor drive error

9V series+VERTU series

NO.

MALFUNCTION DEF TIMER AUTO RUN

DISPLAY

DIGITAL TUBE

1 EEPROM error

O O O O E0

2 Indoor / outdoor units communication protection

☆ ☆ ☆ ☆ E1

3 Zero-crossing signal error

O O

☆ ☆

E2

4 Indoor fan speed out of control O O

☆ ☆ E3

5

Outdoor unit temp. sensor or connector of temp. sensor is

defective

X O X

☆

E5

6

Open or short circuit of room or evaporator temperature

O O O

☆

E6

7 Outdoor fan speed out of control O O

☆ ☆ E7

8 IBM malfunction or IGBT over-strong current protection X X O ☆

P0

9

Over voltage or too under voltage protection X O O

☆

P1

10

Temperature protection of compressor top. O

X X

☆

P2

11 Compressor position protection

O X ☆ ☆ P4

12 Inverter module protection

X O ☆ ☆ P5

☆ Flash(at 0.5Hz, P5 at 0.25Hz) O light X(off)

9A series+R series(Only for model MSR1I-07HRDN1-Q&MSR1I-09HRDN1-Q)

NO.

MALFUNCTION DEF TIMER AUTO RUN

DISPLAY

DIGITAL TUBE

1 EEPROM error

O O O O E0

2 Indoor / outdoor units communication protection

☆ ☆ ☆ ☆ E1

3 Zero-crossing signal error

O O

☆ ☆

E2

4 Indoor fan speed out of control O O

☆ ☆ E3

5

Outdoor unit temp. sensor or connector of temp. sensor is

defective

X O X ☆

E5

6

Open or short circuit of room or evaporator temperature

O O O

☆

E6

7 Outdoor fan speed out of control

☆

O

☆ ☆ E7

8 IBM malfunction or IGBT over-strong current protection X X O ☆

P0

9

Over voltage or too under voltage protection X O O

☆

P1

10

Temperature protection of compressor top. O X X

☆

P2

11 Compressor position protection

O X ☆ ☆ P4

12 Inverter module protection

X O ☆ ☆ P5

☆ Flash(at 0.5Hz, P5 at 0.25Hz) O light X(off)

Page 24

ODMI-1103-A

Cassette/Ceiling&Floor series:

Operation Timer De-frost Alarm LED STATUS

X X X Indoor room temp. sensor open or short-circuit

X X ★ X Indoor pipe temp. sensor open or short-circuit

X

X X Indoor and outdoor communication error

X X X ★ Water level alarm

X X EEPROM error

X X

Inverter module protection

X X Outdoor sensor open or short circuit

X

Outdoor voltage protection

X

X Compressor top temp. protection

X

Mode conflict

X

Outdoor current protection

flash, light, X extinguished.

A5 Duct:

Operation Timer De-frost Alarm LED STATUS

DISPLAY

DIGITAL

TUBE

★ X X X

Indoor room temp. sensor open or

short-circuit

E0

X X ★ X

Indoor pipe temp. sensor open or

short-circuit

E1

X ★ X X

Indoor and outdoor communication

error

E2

X X X ★ Water level alarm

E3

★ ★ X X EEPROM error

E4

★ X X

Inverter module protection

E5

★

X X Outdoor sensor open or short circuit

E6

★ ● ★

X Outdoor fan speed out of control

E7

★

X

Outdoor voltage protection

P0

★ ★ ★ ★ Compressor top temp. protection

P3

★ ◎

X X Compressor position. protection

P4

★ X

X Mode conflict

P5

flash at 5Hz, light, X extinguished ◎flash at 0.5Hz

Page 25

ODMI-1103-A

8.2 Outdoor unit error code explanation:

For units(except M5OA-36HRDN1-Q model)

Display LED STATUS

E0 EEPROM error

E1 No A Indoor unit coil outlet temp. sensor or connector of sensor is defective

E2 No B Indoor unit coil outlet temp. sensor or connector of sensor is defective

E3 No C Indoor unit coil outlet temp. sensor or connector of sensor is defective

E6 No D Indoor unit coil outlet temp. sensor or connector of sensor is defective

E4 Outdoor unit temp. sensor or connector of temp. sensor is defective

E5 Compressor voltage protection

E7 Communication malfunction between outdoor main chip and compressor control chip

P0

Temperature protection of compressor discharge or compressor top.

For M4OC-36HRDN1-Q,it only means compressor discharge temp.protection.

P1 High pressure protection(only for M4OC1-27HRDN1-Q, M4OC-36HRDN1-Q)

P2 Low pressure protection(only for M4OC1-27HRDN1-Q, M4OC-36HRDN1-Q)

P3 Compressor current protection

P4 Inverter module protection

P6 Condenser high-temperature protection

Page 26

ODMI-1103-A

For M5OA-36HRDN1-Q model

Display LED STATUS

E0 EEPROM error

E2 Communication malfunction between outdoor unit and indoor units

E3 Communication malfunction between outdoor main chip and compressor control chip.

E4 Outdoor unit temp. sensor or connector of temp. sensor is defective

E5 Compressor voltage protection

E6 PFC module protection

F1 No A Indoor unit coil outlet temp. sensor or connector of sensor is defective

F2 No B Indoor unit coil outlet temp. sensor or connector of sensor is defective

F3 No C Indoor unit coil outlet temp. sensor or connector of sensor is defective

F4 No D Indoor unit coil outlet temp. sensor or connector of sensor is defective

F5 No E Indoor unit coil outlet temp. sensor or connector of sensor is defective

P0 Compressor top. temperature protection

P1 High pressure protection

P2 Low pressure protection

P3 Compressor current protection

P4 Compressor discharge high-temperature protection

P5 Condenser high-temperature protection

P6 Inverter module protection

Page 27

ODMI-1103-A

8.3Trouble shooting

8.3.1 EEPROM parameter error diagnosis and solution

8.3.2 Indoor / outdoor units communication protection(Only for M5OA-36HRDN1-Q model)

Shut off the power supply and turn on it 5s later

The problem comes out again

Is the EEPROM chip plugged in PCB well?

No

Correct the connection

Replace the

PCB

Disconnect the power supply, after 1

minute, connect the power supply , turn on

the unit with remote controller

Does the unit work

normally ?

Check the wiring between

indoor and outdoor unit. Is

the connection of L, N, S

and GND good?

Is the GND connection on

outdoor PCB good?

No

No

Reconnect and retest

Is the LED4(red) on

outdoor PCB bright and

LED1(yellow) blinking?

Replace outdoor e-box.

Yes

Yes

The power supply for

outdoor PCB is fail. Check

the wiring on outdoor PCB

comparing with wiring plate.

Is the connection good?

No

Correct the connection

.

Yes

No

Replace indoor PCB

and repower on. Is

the failure cleared?

No

Page 28

ODMI-1103-A

8.3.3 Zero-crossing signal error

8.3.4 Fan speed out of control diagnosis

Is the indoor fan motor connector and

connection good?

The unit does not work normally

Turn off the unit, rotate the indoor

fan.Does it rotate freely?

No

Disassemble the connection

between fan and motor, check if the

bearing is normal. If not, change the

bearing.If yes, follow the below step.

Replace the indoor fan motor

Yes

Replace the indoor PCB

No

Yes

Check the voltage of motor power

input .Is it in range of AC90-160V?

Yes

Shut off the power supply and turn on it 5s later

Is power supply and

connection of

connectors good?

Indoor PCB is defective.

Replace the indoor PCB.

Be sure the power supply

is good and correct the

connection

No

Yes

Page 29

ODMI-1103-A

8.3.5 Open or short circuit of temperature sensor diagnosis and solution.

8.3.6 Compressor voltage protection

Yes

Replace outdoor PCB

Yes

Check the connections between

the sensors and the PCB. Are the

connections good?

Replace the sensor and check if

the errors happen again?

Check the voltage of power supply, if the voltage is about 220V, turn off the power

supply to indoor unit and turn it on again after 1 minute

Does the trouble occur again?

Check the voltage of P,N port in IPM board.

If it is not higher than 310V, follow the below step.

Replace the IPM board

Yes

No

Page 30

ODMI-1103-A

8.3.7 Communication malfunction between outdoor main chip and compressor control chip.

Check whether the IPM board has error display

Replace the IPM board

Replace the electric control box

No

No

Yes

Replace the outdoor PCB

No

Page 31

ODMI-1103-A

8.3.8 Temperature protection of compressor discharge or compressor top.

Yes

Does

compressor

operate?

Is the

connection

good?

Is refrigerant

circulation

volume

normal?

No

No

Charge

refrigerant

Is abnormality

the same after

gas charging?

No

Check refrigerant system

(such as clogging of

capillary, etc)

Reconnect and retest.

No

Yes

Is protector

normal?

Replace the protector.

No

Yes

Check the

outdoor main

PCB. Is there

some problem?

Replace the outdoor

PCB.

Yes

Page 32

ODMI-1103-A

8.3.9 Compressor current protection

Check the resistance of compressor, is it

normal?

Turn one indoor unit only, Does the compressor start

after 3 minutes?

Does the trouble occur again after compressor

running some time?

No

Yes

No

The compressor is defective

Check the refrigerant circulation volume and pressure

No

The compressor is defective

Yes

If refrigerant circulation volume and pressure is OK, change the outdoor main PCB.

Page 33

ODMI-1103-A

8.3.10 Inverter module protection

8.3.11 Condenser high-temperature protection

When outdoor pipe temp. is more than 65¡C, the unit will stop, and unit runs again when outdoor pipe

temp. less than 52¡C.

Is the outdoor pipe temp. more than 65¡C ?

Is the outdoor pipe temp sensor right according to the annex 1

Replace the outdoor main board

No

Yes

Replace the outdoor pipe temp sensor

No

Replace inverter compressor

Repair connector

If the problem comes to again, check wingding resistance of inverter compressor, is it right?

Replace the IPM board

Are the U,V,W connected to compressor and inverter module right?

Yes

No

No

Page 34

ODMI-1103-A

8.3.12 PFC module protection

No

No

Yes

Check whether the power

supply of bridge rectifiers

output port is 325VDC

Replace bridge rectifiers

Does the unit work

normally ?

No

Check whether the

power supply of bridge

rectifiers input port is

normal.

Replace the

outdoor PCB

Yes

Replace the PFC inductance

Check whether the

voltage between P and

N port in IPM is 380V.

No

Replace outdoor e-box.

Yes

Check whether the

wiring between PCB

and PFC module is

normal.

Yes

No

Check the voltage of power supply, if the voltage

is about 220V, turn off the power supply and

turn it on again after 1 minute

Yes

Check whether

the PFC

inductance is

normal.

Replace PFC

Page 35

ODMI-1103-A

Annex 1

Characteristic of temp. sensor

Temp.℃ Resistance KΩ

Temp.℃ Resistance KΩ

Temp.℃ Resistance KΩ

-10 62.2756 17 14.6181 44 4.3874

-9 58.7079 18 13.918 45 4.2126

-8 56.3694 19 13.2631 46 4.0459

-7 52.2438 20 12.6431 47 3.8867

-6 49.3161 21 12.0561 48 3.7348

-5 46.5725 22 11.5 49 3.5896

-4 44 23 10.9731 50 3.451

-3 41.5878 24 10.4736 51 3.3185

-2 39.8239 25 10 52 3.1918

-1 37.1988 26 9.5507 53 3.0707

0 35.2024 27 9.1245 54 2.959

1 33.3269 28 8.7198 55 2.8442

2 31.5635 29 8.3357 56 2.7382

3 29.9058 30 7.9708 57 2.6368

4 28.3459 31 7.6241 58 2.5397

5 26.8778 32 7.2946 59 2.4468

6 25.4954 33 6.9814 60 2.3577

7 24.1932 34 6.6835 61 2.2725

8 22.5662 35 6.4002 62 2.1907

9 21.8094 36 6.1306 63 2.1124

10 20.7184 37 5.8736 64 2.0373

11 19.6891 38 5.6296 65 1.9653

12 18.7177 39 5.3969 66 1.8963

13 17.8005 40 5.1752 67 1.830

14 16.9341 41 4.9639 68 1.7665

15 16.1156 42 4.7625 69 1.7055

16 15.3418 43 4.5705 70 1.6469

Page 36

ODMI-1103-A

Annex 2

1. Reference voltage data:

a) Rectifier : Input :220-230V(AC), output :310V(DC)

b) Inverter module: U,V, W 3ph.

Result

U-V 60-150V(AC)

U-W 60-150V(AC)

V-W 60-150V(AC)

P-N DC

310V

c) Photo-couple PC817, PC851: Control side <+5V, AC side :< 24V(AC)

d) S terminal and N: changeable from 0-24V

2. Check the Diode Bridge component ( In wiring diagram, rectifier)

Remark: If this part is abnormal, the LED will not light.

Multi-meter Result

Forward Resistance Backward Resistance

+ _

Infinite Infinite

~

+

~500 ohm Infinite

~ - ~

~500 ohm Infinite

~

~ +

- ~

Loading...

Loading...