Midea M2OC-14HRDN1-Q, M3OC1-21HRDN1-Q, M2OC-18HRDN1, M2OC1-18HRDN1-Q, M3OC-27HRDN1 Technical & Service Manual

...Page 1

ODMI-A-1202

GD Midea Refrigeration Equipment Co.,Ltd

MULTI SPLIT TYPE, HEAT PUMP AIR CONDITIONERS

Technical service manual

R410A Multi DC inverter

220~240V-1Ph-50Hz

Outdoor units Models

M2OC-14HRDN1

M2OC-14HRDN1-Q

M2OC-18HRDN1

M2OC1-18HRDN1-Q

M3OC1-21HRDN1-Q

M3OC-27HRDN1

M3OC1-27HRDN1-Q

M4OC-24HRDN1-Q

M4OC1-27HRDN1-Q

M4OC-27HRDN1

M4OC-36HRDN1-Q

M5OA-36HRDN1-Q

Page 2

CONTENTS

1. General information of Outdoor Units ................................... 3

2. Features .................................................................................. 4

3. Dimensions ............................................................................. 5

4. Wiring Diagram ....................................................................... 6

5. Refrigeration Cycle Diagram ................................................ 11

6. Indoor units combination ..................................................... 13

7. Electronic control function .................................................. 15

8. Troubleshooting ................................................................... 24

Page 3

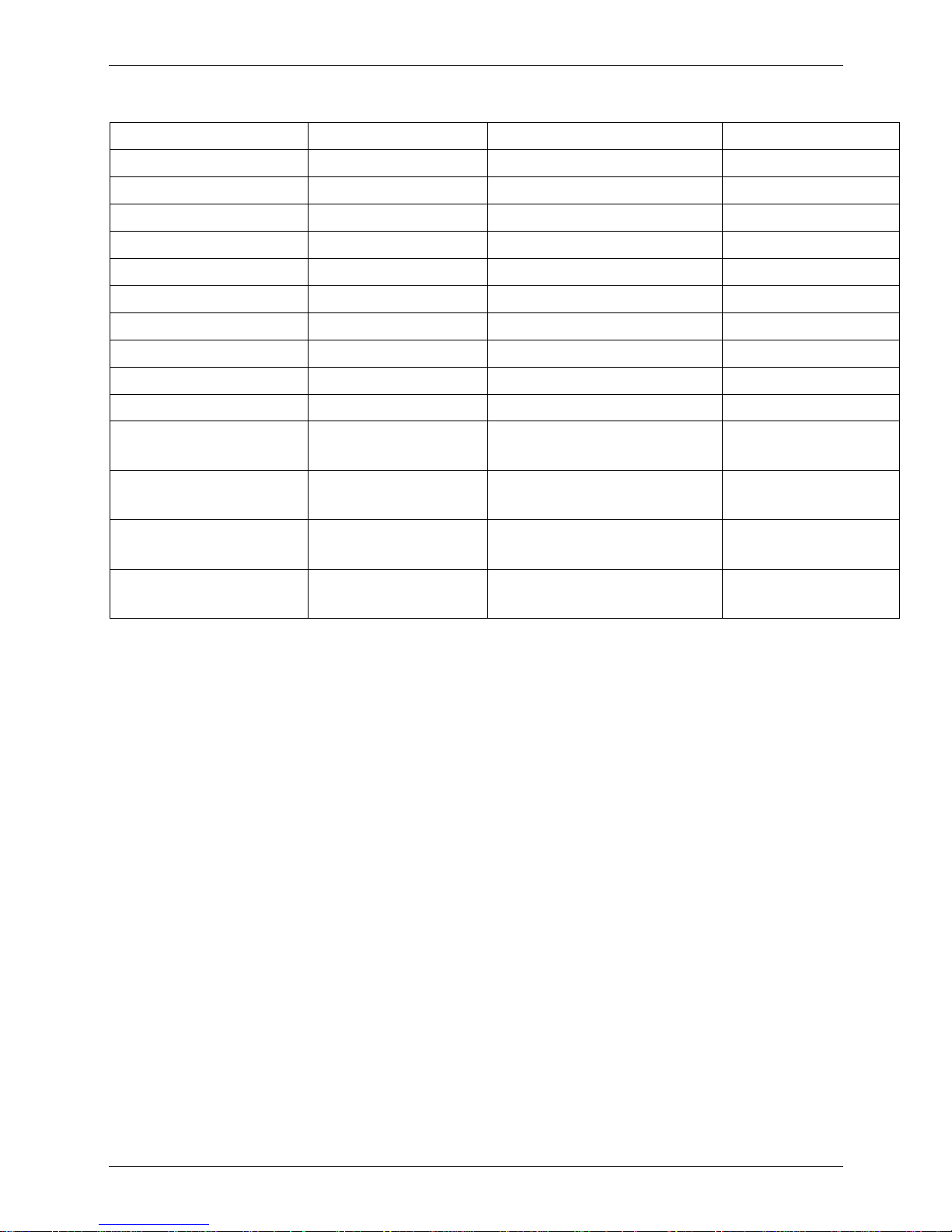

1. General information of Outdoor Units

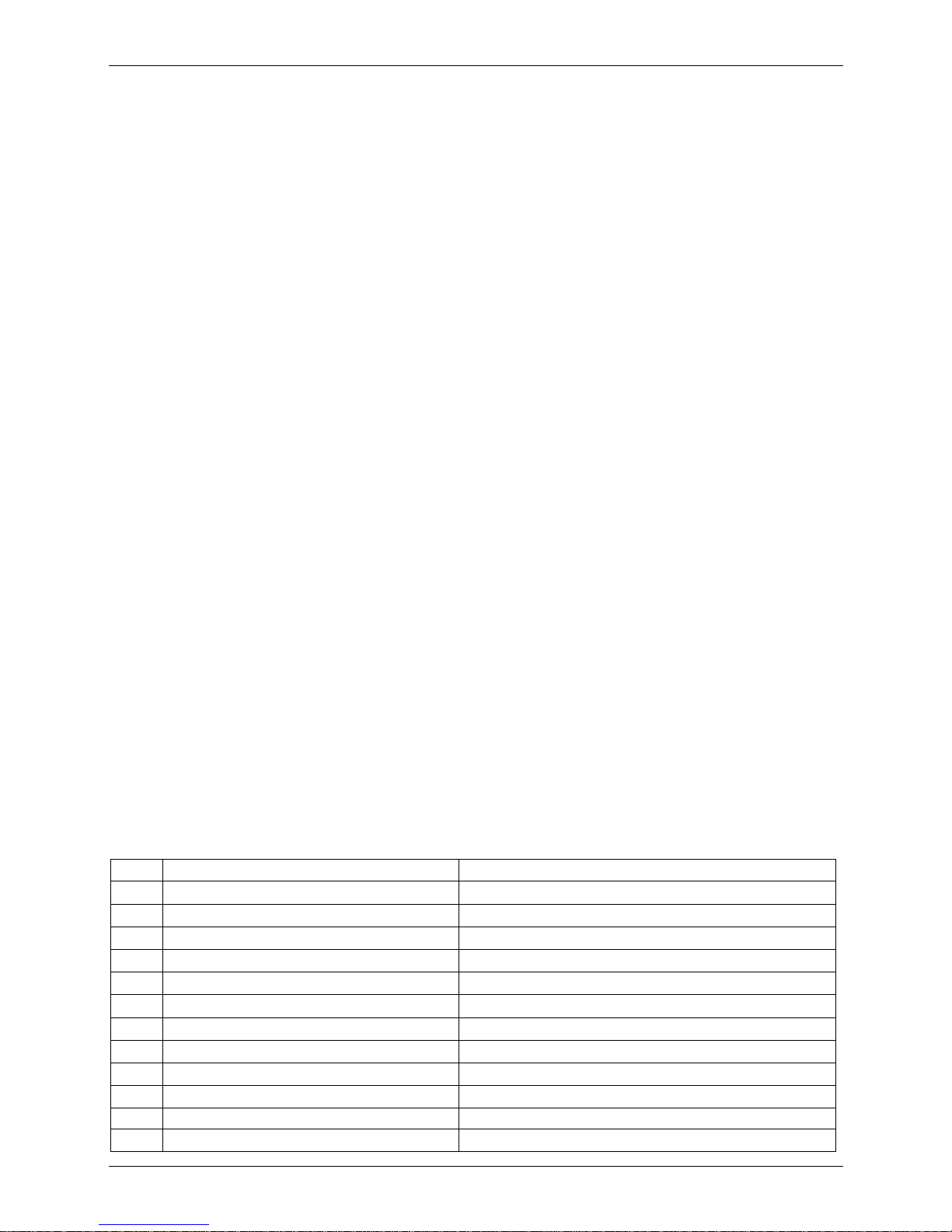

Model name Dimension (mm) Net/Gross weight (kg) Compressor

M2OC-14HRDN1 760*590*285 39/41 DA108X1C-20FZ3

M2OC-14HRDN1-Q 760*590*285 39/41 DA108X1C-20FZ3

M2OC-18HRDN1 845*700*320 57.5/61.5 C-6RVN93H0N

M2OC1-18HRDN1-Q 845*700*320 53.5/57 DA130S1C-20FZ

M3OC1-21HRDN1-Q 845*700*320 55/60 DA130S1C-20FZ

M3OC-27HRDN1 845*700*320 59/62 C-6RZ146H1A

M3OC1-27HRDN1-Q 845*700*320 57/60.5 DA150S1C-20FZ

M4OC-24HRDN1-Q 845*700*320 56/60 DA150S1C-20FZ

M4OC-27HRDN1 900*860*315 73/78 TNB220FLHMC-L

M4OC1-27HRDN1-Q 900*860*315 73/78 DA250S2C-30MT

M4OC-36HRDN1-Q

(220057200010)

990*965*345 86/90 TNB306FPGM

M4OC-36HRDN1-Q

(220057200011)

990*965*345 86/90 TNB306FPGMC-L

M5OA-36HRDN1-Q

(220057100360)

990*965*345 86.5/91 TNB306FPGM

M5OA-36HRDN1-Q

(220057100361)

990*965*345 86.5/91 TNB306FPGMC-L

Page 4

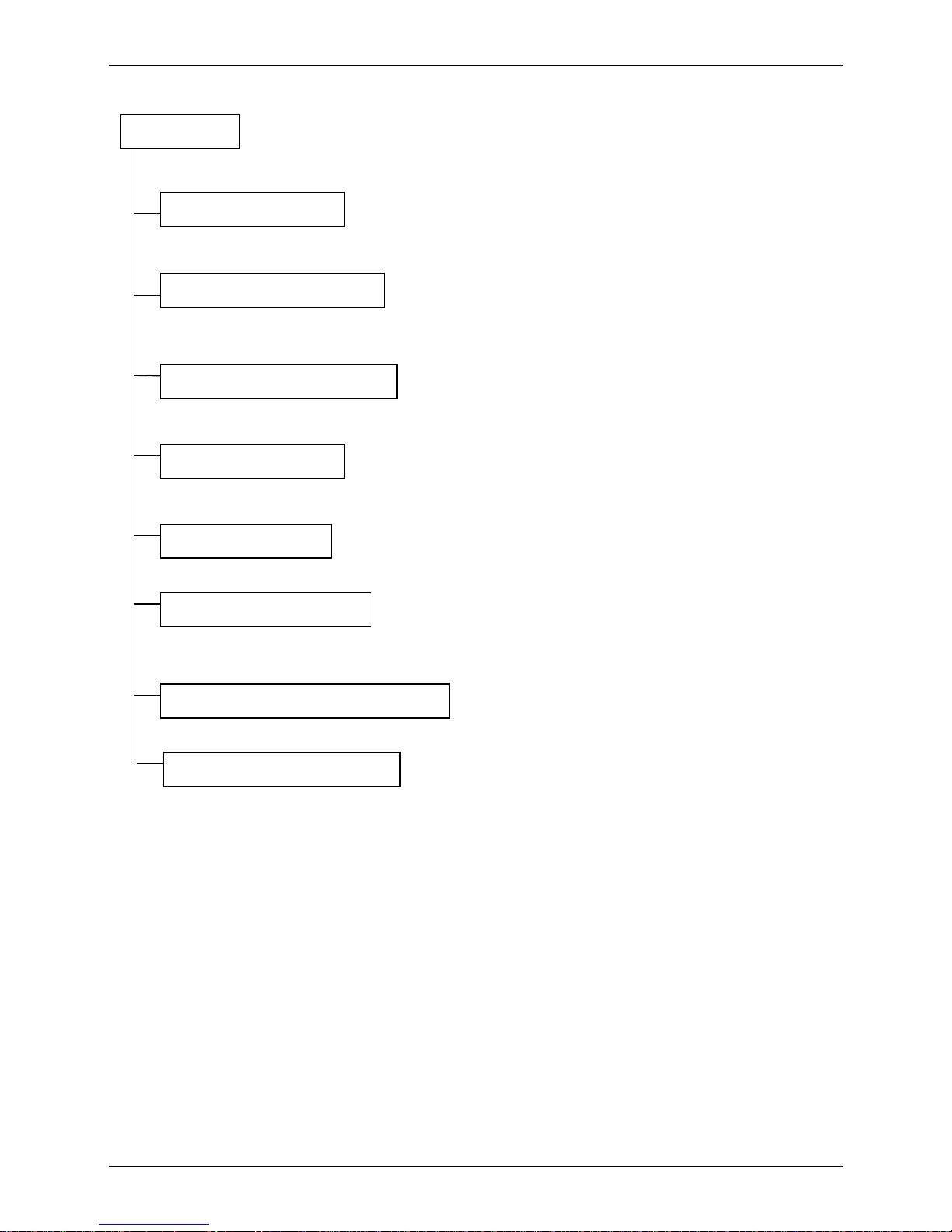

2. Features

The hydrophilic fin can improve the heating efficiency at operation mode.

It is only operated in the heating operation mode ex

cept defrosting operation.

It protects the valves and prevents water from dripping.

Outdoor unit

Power relay control

Hydrophilic aluminum fin

Anti-rust cabinet

Valve protection cover

4 way valve control

Low noise air flow system

Discharge pipe temperature protection

Compressor crankcase heater

Page 5

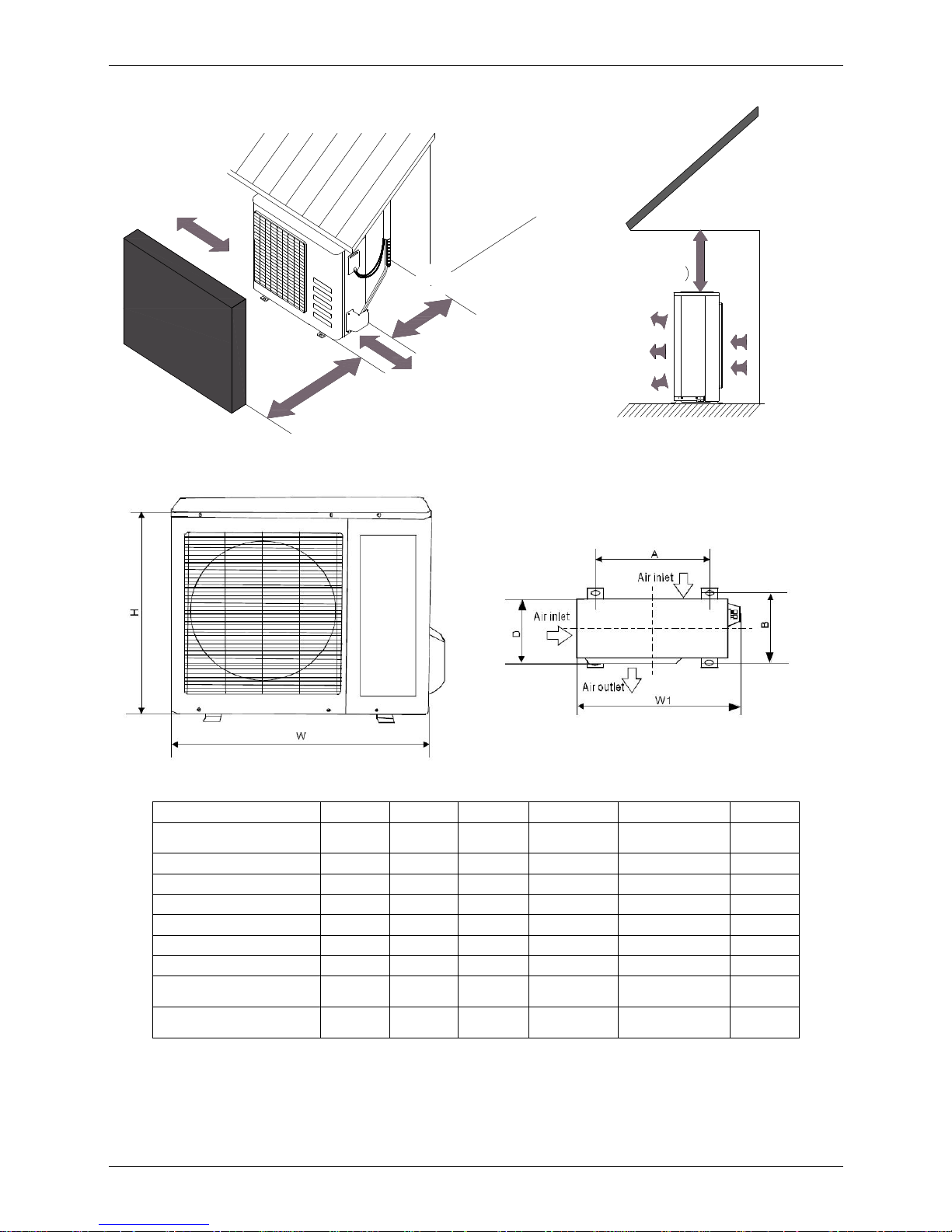

3. Dimensions

More than 30cm

More than 60cm

More than 70cm

More than 30cm

More than 60cm

(Service space

Fence or

obstacles

MODEL W D H W1 A B

M2OC-14HRDN1-Q

M2OC-14HRDN1

760 285 590 823 530 290

M2OC-18HRDN1 845 320 700 908 560 335

M2OC1-18HRDN1-Q 845 320 700 908 560 335

M3OC1-21HRDN1-Q 845 320 700 908 560 335

M3OC-27HRDN1 845 320 700 908 560 335

M3OC1-27HRDN1-Q 845 320 700 908 560 335

M4OC-24HRDN1-Q

845 320 700 908 560 335

M4OC-27HRDN1

M4OC1-27HRDN1-Q

900 315 860 980 590 333

M4OC-36HRDN1-Q

M5OA-36HRDN1-Q

990 345 965 1075 624 366

Page 6

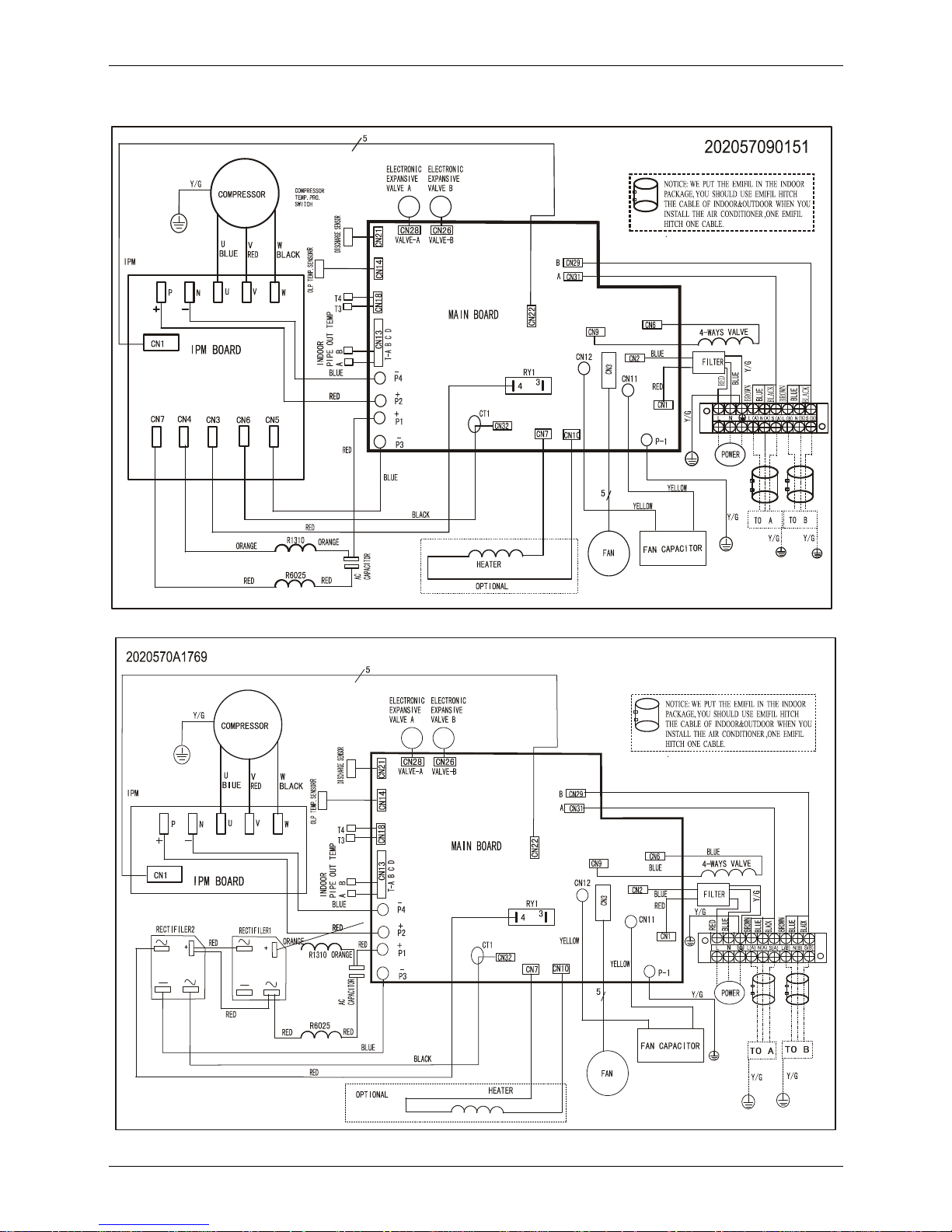

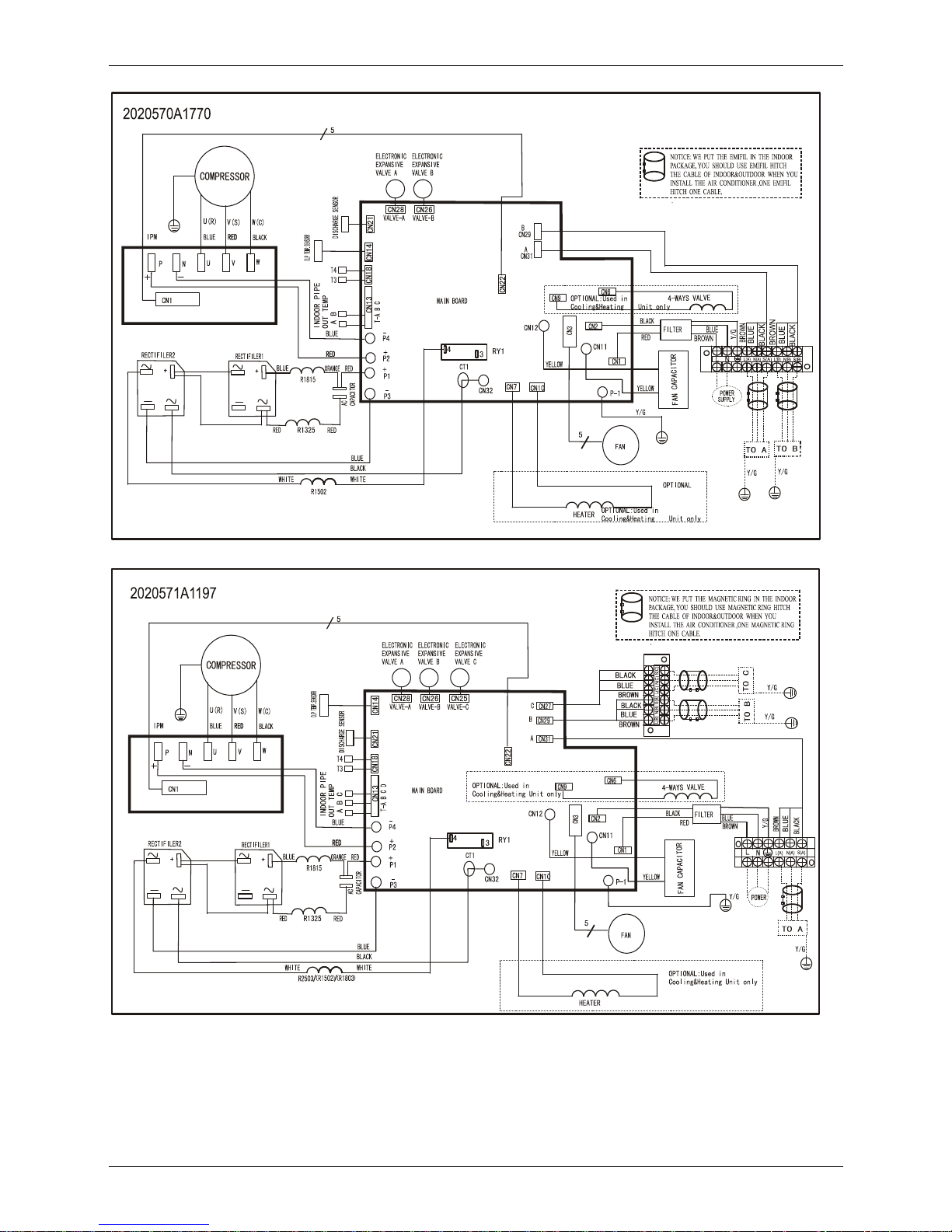

4. Wiring Diagram

4.1 M2OC-14HRDN1-Q

4.2 M2OC-14HRDN1

Page 7

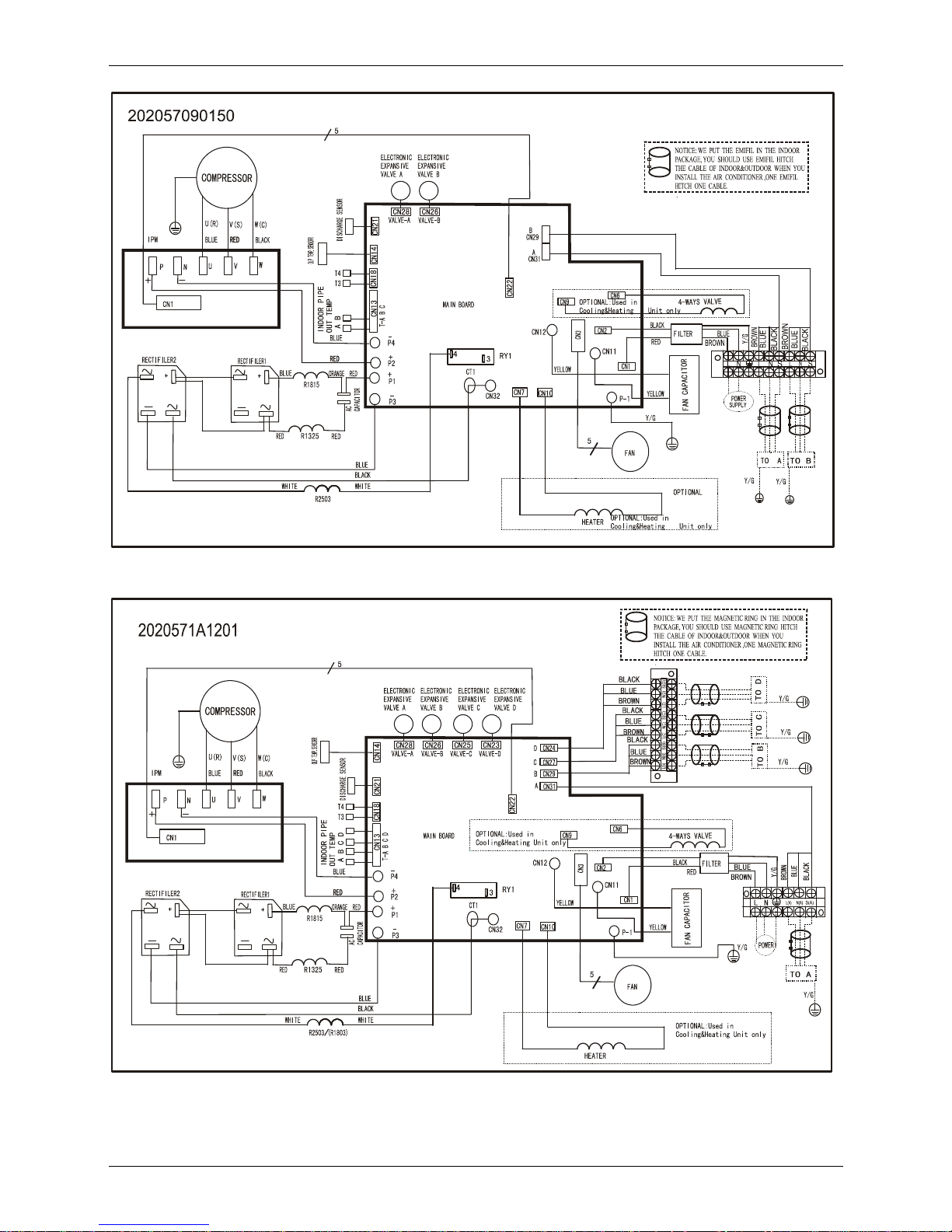

4.3 M2OC1-18HRDN1-Q

4.4 M3OC1-21HRDN1-Q M3OC1-27HRDN1-Q M3OC-27HRDN1

Page 8

4.5 M2OC-18HRDN1

4.6 M4OC-24HRDN1-Q

Page 9

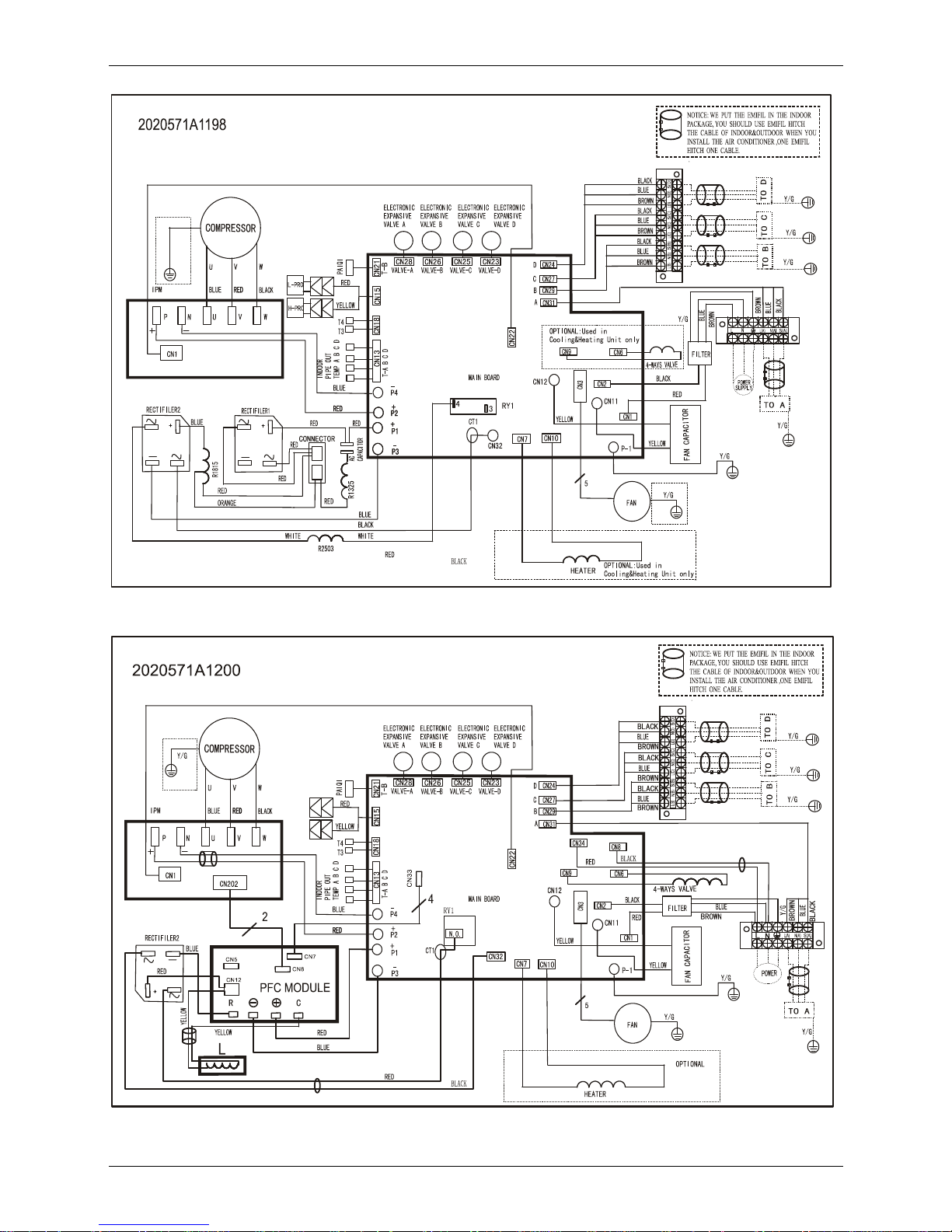

4.7 M4OC1-27HRDN1-Q、M4OC-27HRDN1

4.8 M4OC-36HRDN1-Q

Page 10

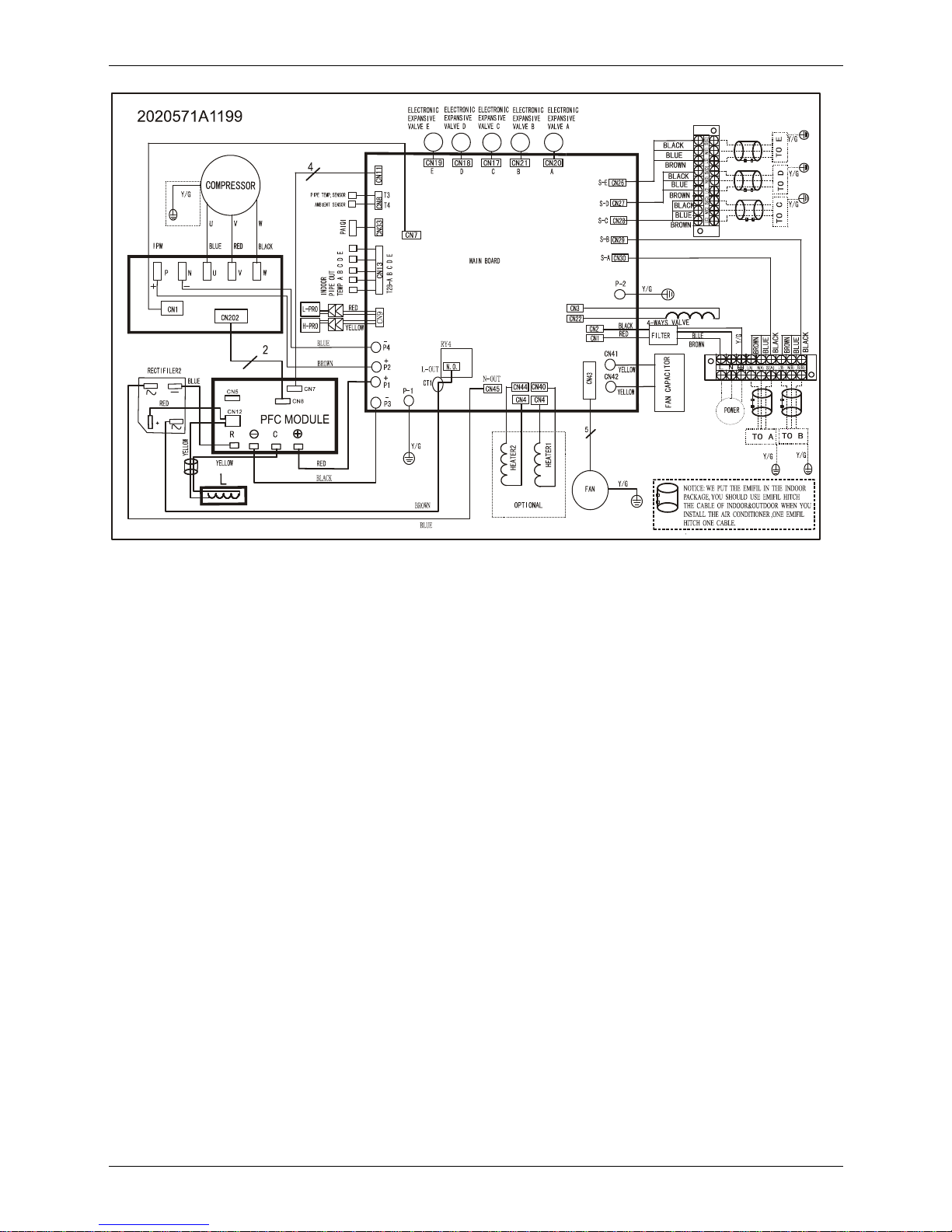

4.9 M5OA-36HRDN1-Q

Page 11

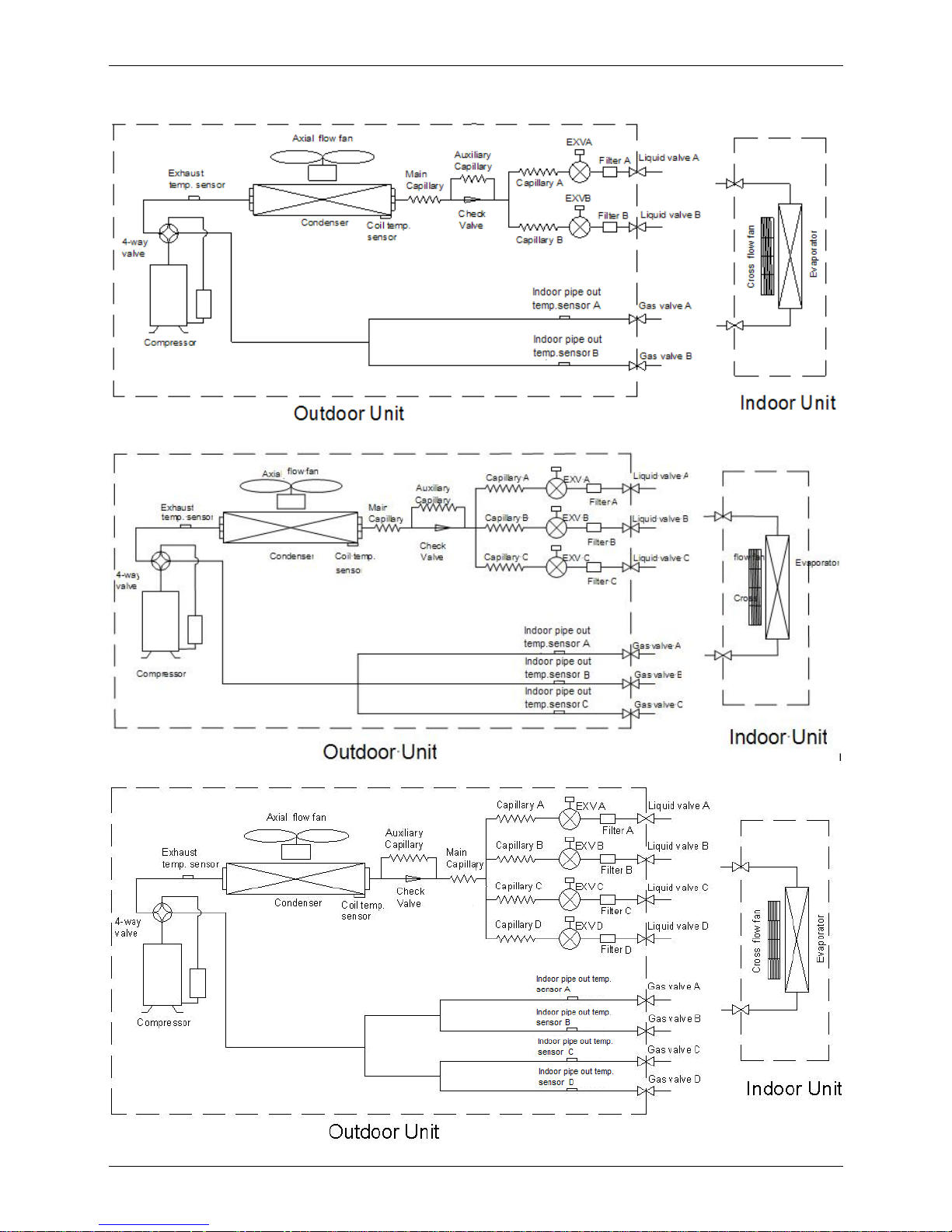

5. Refrigeration Cycle Diagram

5.1 Refrigeration circuit drawing of inverter binary type

4.2 Refrigeration circuit drawing of inverter trinary type

5.3 Refrigeration circuit drawing of inverter quadplex type

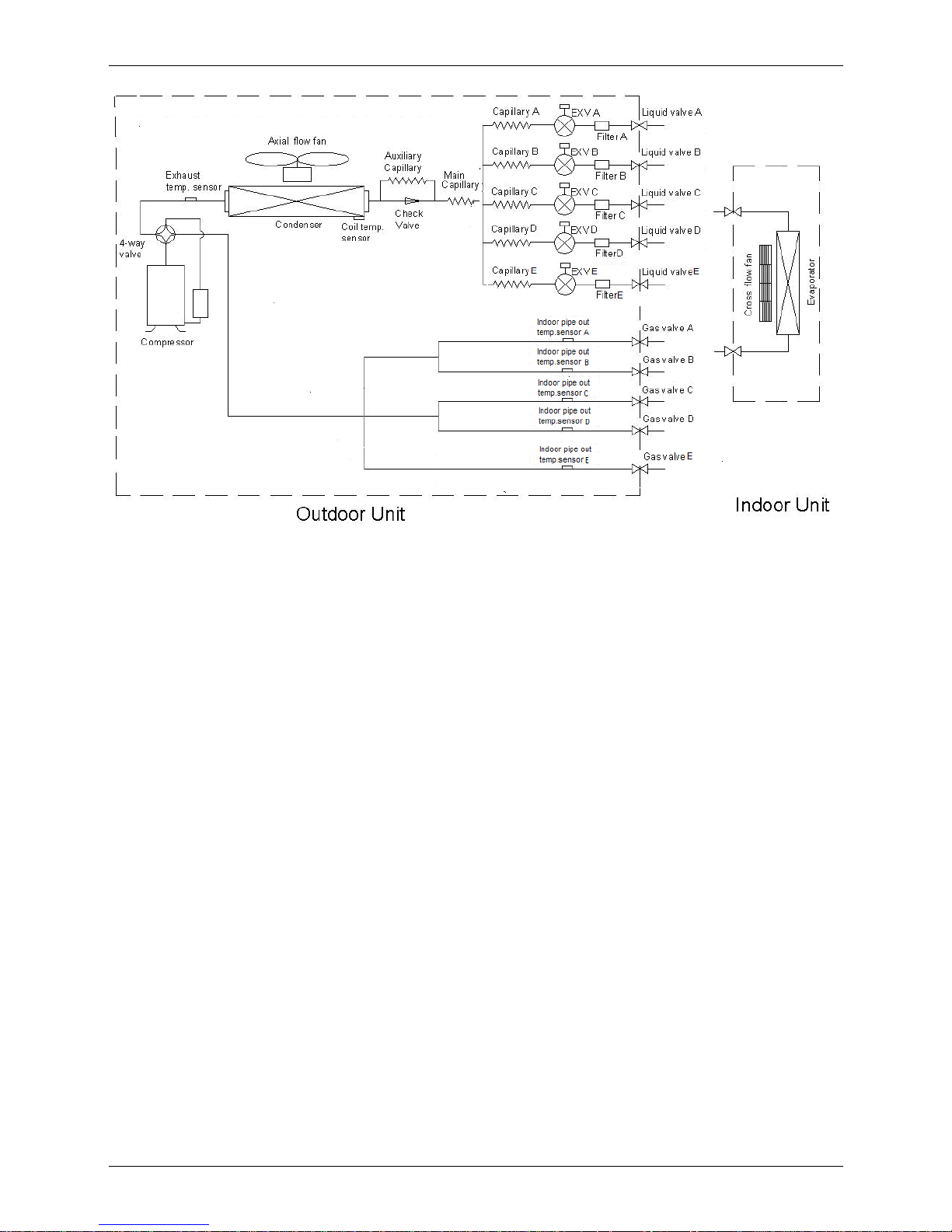

Page 12

5.4 Refrigeration circuit drawing of inverter quintuple type

Page 13

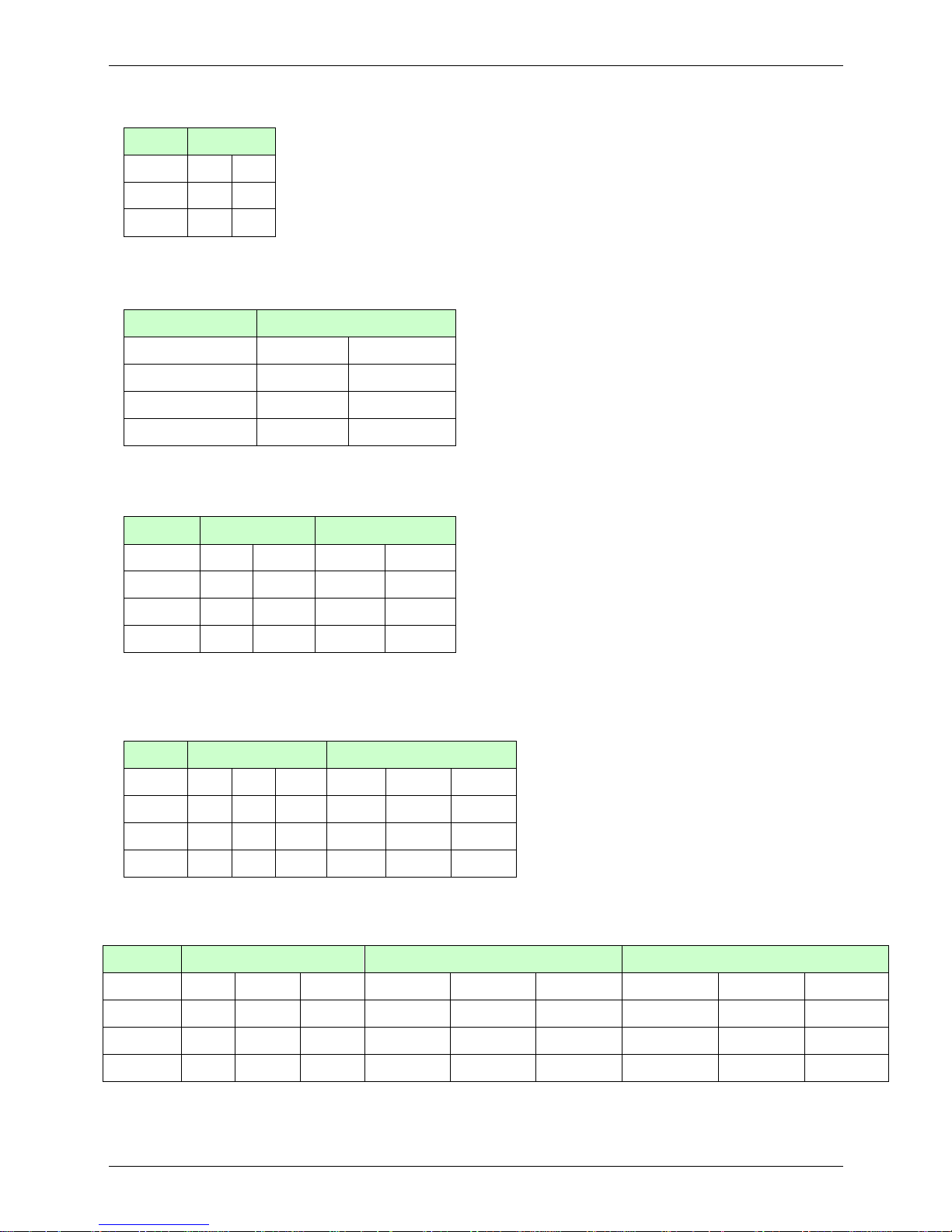

6. Indoor units combination

6.1 Indoor unit combination for M2OC-14HRDN1-Q、M2OC-14HRDN1

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12

Note: There should be no more than one cassette or duct or console or ceiling & floor unit.

6.2 Indoor unit combination for M2OC1-18HRDN1-Q、M2OC-18HRDN1

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12 12+12

18 7+18

Note: The 18k indoor unit should only be wall mounted unit.

6.3 Indoor unit combination for M3OC1-21HRDN1-Q

One unit Two unit Three unit

7 7+7 9+9 7+7+7 7+9+12

9 7+9 9+12 7+7+9 9+9+9

12 7+12 9+18 7+7+12 9+9+12

18 7+18 12+12 7+9+9

Note: There should be no more than one cassette or duct or console or ceiling & floor unit. And the 18k indoor unit

should only be wall mounted unit.

6.4 Indoor unit combination for M3OC1-27HRDN1-Q、M3OC-27HRDN1

One unit

Two unit Three unit

7 7+7 9+9 12+12 7+7+7 7+9+9 9+9+9

9 7+9 9+12 12+18 7+7+9 7+9+12 9+9+12

12 7+12 9+18 7+7+12 7+12+12 9+12+12

18 7+18 7+7+18

Note: The 18k indoor unit should only be wall mounted unit.

6.5 Indoor unit combination for M4OC-24HRDN1-Q

One unit Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+9+9 9+9+9 7+7+7+7 7+7+9+9 9+9+9+9

9 7+9 9+12 12+18 7+7+9 7+9+12 9+9+12 7+7+7+9 7+7+9+12 9+9+9+12

12 7+12 9+18 7+7+12 7+12+12 9+12+12 7+7+7+12 7+9+9+9

18 7+18 7+7+18 7+9+9+12

Note: The 18k indoor unit should only be wall mounted unit.

Page 14

6.6 Indoor unit combination for M4OC1-27HRDN1-Q、M4OC-27HRDN1

One unit Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+9+12 9+9+9 7+7+7+7 7+7+9+9 7+9+9+12

9 7+9 9+12 12+18 7+7+9 7+9+18 9+9+12 7+7+7+9 7+7+9+12 7+9+12+12

12 7+12 9+18 18+18 7+7+12 7+12+12 9+9+18 7+7+7+12 7+7+12+12 9+9+9+9

18 7+18 7+7+18 7+12+18 9+12+12 7+7+7+18 7+9+9+9 9+9+9+12

7+9+9 12+12+12 9+12+18

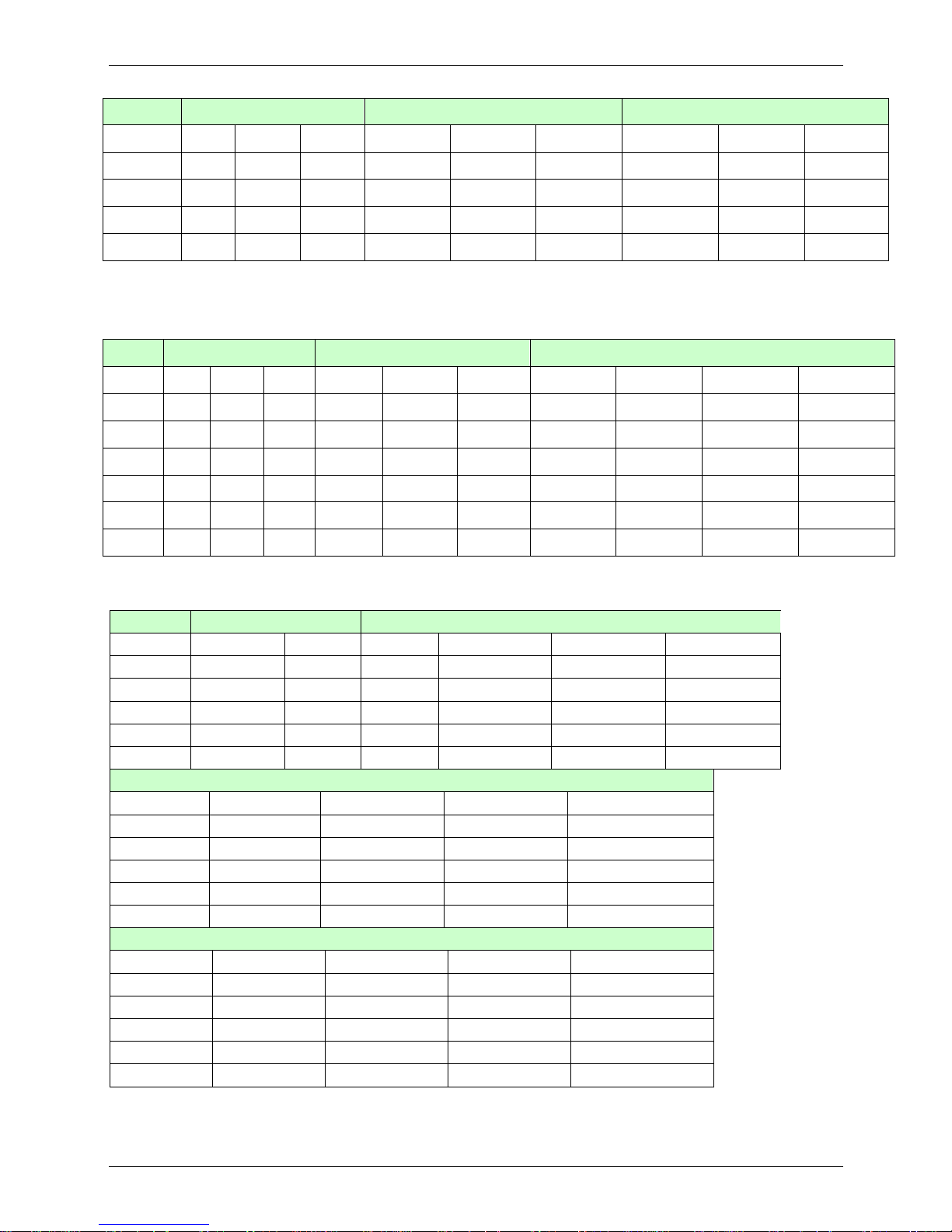

6.7 Indoor unit combination for M4OC-36HRDN1-Q

6.8 Indoor unit combination for M5OA-36HRDN1-Q

One Unit Two Unit Three Unit

7 7+7 9+12 7+7+7 7+9+18 9+9+18 12+18+18

9 7+9 9+18 7+7+9 7+12+12 9+12+12 18+18+18

12 7+12 12+12 7+7+12 7+12+18 9+12+18

18 7+18 12+18 7+7+18 7+18+18 9+18+18

9+9 18+18 7+9+9 9+9+9 12+12+12

7+9+12 9+9+12 12+12+18

Four Unit

7+7+7+7 7+7+9+18 7+9+9+18 7+12+18+18 9+9+18+18

7+7+7+9 7+7+12+12 7+9+12+12 9+9+9+9 9+12+12+12

7+7+7+12 7+7+12+18 7+9+12+18 9+9+9+12 9+12+12+18

7+7+7+18 7+7+18+18 7+9+18+18 9+9+9+18 12+12+12+12

7+7+9+9 7+9+9+9 7+12+12+12 9+9+12+12 12+12+12+18

7+7+9+12 7+9+9+12 7+12+12+18 9+9+12+18

Five Unit

7+7+7+7+7 7+7+7+9+18 7+7+9+12+18 7+9+9+12+18 9+9+9+12+12

7+7+7+7+9 7+7+7+12+18 7+7+12+12+18 7+9+12+12+12 9+9+9+12+18

7+7+7+7+12 7+7+7+18+18 7+9+9+9+9 7+9+12+12+18 9+9+12+12+12

7+7+7+7+18 7+7+9+9+9 7+9+9+9+12 9+9+9+9+9 9+12+12+12+12

7+7+7+9+9 7+7+9+9+12 7+9+9+9+18 9+9+9+9+12 12+12+12+12+12

7+7+7+9+12 7+7+9+9+18 7+9+9+12+12 9+9+9+9+18

One unit

Two unit Three unit Four unit

7 7+7 9+9 12+12 7+7+7 7+12+12 9+12+18 7+7+7+7 7+7+12+12 7+9+12+18 9+9+12+12

9 7+9 9+12 12+18 7+7+9 7+12+18 9+18+18 7+7+7+9 7+7+12+18 7+9+18+18 9+9+12+18

12 7+12 9+18 18+18 7+7+12 7+18+18 12+12+12 7+7+7+12 7+7+18+18 7+12+12+12 9+12+12+12

18 7+18

7+7+18 9+9+9 12+12+18 7+7+7+18 7+9+9+9 7+12+12+18 9+12+12+18

7+9+9 9+9+12 12+18+18 7+7+9+9 7+9+9+12 9+9+9+9 12+12+12+12

7+9+12 9+9+18 7+7+9+12 7+9+9+18 9+9+9+12 12+12+12+18

7+9+18 9+12+12

7+7+9+18 7+9+12+12 9+9+9+18

Page 15

7. Electronic control function

7.1 Abbreviation

T1: Indoor ambient temperature

T2: Coil temperature of indoor heat exchanger middle.

T2B: Coil temperature of indoor heat exchanger outlet.

T3: Coil temperature of outdoor heat exchanger

T4: Outdoor ambient temperature

T5: Compressor discharge temperature

Ts: Setting temp.

7.2 Electric Control working environment.

7.2.1 Input voltage: 190~264V.

7.2.2 Input power frequency:50Hz.

7.2.3 Indoor fan normal working amp. is less than 1A.

7.2.4 Outdoor fan. Normal working amp. is less than 1.5A.

7.2.5 Four-way valve normal working amp. is less than 1A.

7.2.6 Swing motor: DC12V.

7.3 Outdoor unit’s digital display tube

There is a digital display tube in outdoor PCB.

Digital display tube display function

In standby , the LED displays “- -”

In compressor operation, the LED display the running frequency,

In defrosting mode, The LED displays “dF” or alternative displays between running frequency and

“dF”(each displays 2s)

In compressor pre-heating, The LED displays “- -”

In protection or malfunction, the LED displays error code or protection code.

7.4 Outdoor unit point check function

There is a check switch in outdoor PCB.

Push the switch SW1 to check the states of unit when the unit is running. The digital display tube will display

the follow procedure when push SW1 each time.

For units except M5OA-36HRDN1-Q model:

Display Remark

1

Indoor unit capacity demand code

2

Outdoor unit running mode code Off:0, Cooling:1, Heating:2

3

Amendatory capacity demand code

4

Outdoor unit fan motor state Off:0, Low speed:1, High speed:2

5

Evaporator outlet temp. for 1# indoor unit Actual data

6

Evaporator outlet temp. for 2# indoor unit Actual data

7

Evaporator outlet temp. for 3# indoor unit Actual data

8

Evaporator outlet temp. for 4# indoor unit Actual data

9

Condenser pipe temp. Actual data

10

Ambient temp. Actual data

11

Compressor discharge temp. Actual data

12

Inverter current Actual data

Page 16

13

EXV open angle for 1# indoor unit Actual data/8

14

EXV open angle for 2# indoor unit Actual data/8

15

EXV open angle for 3# indoor unit Actual data/8

16

EXV open angle for 4# indoor unit Actual data/8

17

Power supply of outdoor unit AD data

18 Indoor unit number The indoor unit can communicate with outdoor unit well.

19 The last error or protection code 00 means no malfunction

20

frequency value Actual data

21 Ambient temp. of 1# indoor unit Actual data

22 Condenser pipe temp. of 1# indoor unit Actual data

23

Ambient temp. of 2# indoor unit Actual data

24 Condenser pipe temp. of 2# indoor unit Actual data

25 Ambient temp. of 3# indoor unit Actual data

26

Condenser pipe temp. of 3# indoor unit Actual data

27 Ambient temp. of 4# indoor unit Actual data

28 Condenser pipe temp. of 4# indoor unit Actual data

29

―― Check point over

For M5OA-36HRDN1-Q model:

Display Remark

1

No. of indoor units in good connection Actual data

2

Outdoor unit running mode code Off:0, Cooling:2, Heating:3, Forced cooling:4

3

A indoor unit capacity

The capacity unit is horse power. If the indoor unit is not

connected, the digital display tube will show: “――”

4

B indoor unit capacity

5

C indoor unit capacity

6

D indoor unit capacity

7

E indoor unit capacity

8

A Indoor unit capacity demand code

9

B Indoor unit capacity demand code

10

C Indoor unit capacity demand code

11

D Indoor unit capacity demand code

12

E Indoor unit capacity demand code

13

Total indoor units amendatory capacity

demand code

14

The frequency corresponding to the total

indoor units amendatory capacity demand

15

The frequency after the frequency limit

16

The frequency sending to compressor control

chip

17

A indoor unit evaporator outlet temp.(T2BA)

If the temp. is lower than -9 degree, the digital display tube will

show “-9”.If the temp. is higher than 70 degree, the digital display

tube will show “70”. If the indoor unit is not connected, the digital

display tube will show: “――”

18

B indoor unit evaporator outlet temp.(T2BB)

19

C indoor unit evaporator outlet temp.(T2BC)

20

D indoor unit evaporator outlet temp.(T2BD)

21

E indoor unit evaporator outlet temp.(T2BE)

22

A indoor unit room temp.(T1A)

23

B indoor unit room temp.(T1B)

24

C indoor unit room temp.(T1C)

25

D indoor unit room temp.(T1D)

26

E indoor unit room temp.(T1E)

Page 17

27

A indoor unit evaporator outlet temp.(T2BA)

If the temp. is lower than -9 degree, the digital display tube will

show “-9”.If the temp. is higher than 70 degree, the digital display

tube will show “70”. If the indoor unit is not connected, the digital

display tube will show: “――”

28

B indoor unit evaporator outlet temp.(T2BB)

29

C indoor unit evaporator outlet temp.(T2BC)

30

D indoor unit evaporator outlet temp.(T2BD)

31

E indoor unit evaporator outlet temp.(T2BE)

32

Condenser pipe temp.(T3)

33

Outdoor ambient temp.(T4)

34

Compressor discharge temp.(Tp) The display value is between 30~120 degree. If the temp. is lower

than 30 degree, the digital display tube will show “30”.If the temp.

is higher than 99 degree, the digital display tube will show single

digit and tens digit. For example, the digital display tube show

“0.5”,it means the compressor discharge temp. is 105 degree.)

35

AD value of current

The display value is hex number.

36

AD value of voltage

37

EXV open angle for A indoor unit

Actual data/4.

If the value is higher than 99, the digital display tube will show

single digit and tens digit.

For example ,the digital display tube show “2.0”,it means the EXV

open angle is 120×4=480p.)

38

EXV open angle for B indoor unit

39

EXV open angle for C indoor unit

40

EXV open angle for D indoor unit

41

EXV open angle for E indoor unit

42

Frequency limit symbol

Bit7 0

The display

value is hex

number. For

example, the

digital display

tube show

2A,then Bit5=1,

Bit3=1, Bit1=1.

It means

frequency limit

caused by

T4,T3 and

current.

Bit6 0

Bit5

Frequency limit caused by T4.

Bit4

Frequency limit caused by T2.

Bit3

Frequency limit caused by T3.

Bit2

Frequency limit caused by Tp.

Bit1

Frequency limit caused by current

Bit0

Frequency limit caused by voltage

43

Average value of T2 (Sum T2 value of all indoor units)/(indoor units number)

44

Outdoor unit fan motor state Off:0, High speed:1, Med speed:2, Low speed:3

45

The last error or protection code 00 means no malfunction

7.4.1 Frequency of compressor:

Display Frequency of compressor (Hz)

30 30

-- Stand by

60 60

7.4.2 Running mode:

Display Corresponding mode

0 Off

1 Cooling mode

2 Heating mode

Page 18

7.4.3 Capacity demand:

Cooling mode

Capacity 2000-2

500

2000-2

500

3000-3

800

4500-5

000

5000-5

500

5500-6

100

6100-7

000

7000-7

500

7500-8

000

>7500

Correspondi

ng Code

1 2 3 4 5 6 7 8 9 >=10

Heating mode

Capacity 2000-2

500

2000-2

500

3000-3

800

4500-5

000

5500-6

100

6100-7

000

6100-7

000

7000-7

500

7500-8

000

>8000

Correspondin

g Code

1 2 3 4 5 6 7 8 9-10 >=11

Note:

The capacity is just for reference.

Page 19

7.4.4Number of indoor unit

Display Number of indoor unit

1 1

2 2

3 3

7.4.5 Outdoor ambient temp:

Display Corresponding temp.

Display

Corresponding

temp.

Display

Corresponding

temp.

15 -7.5 50 10 80 25

16 -7 51 10.5 81 25.5

17 -6.5 52 11 82 26

18 -6 53 11.5 83 26.5

19 -5.5 53 11.5 84 27

20 -5 54 12 85 27.5

21 -4.5 55 12.5 86 28

22 -4 56 13 87 28.5

23 -3.5 57 13.5 88 29

24 -3 58 14 89 29.5

26 -2 59 14.5 90 30

27 -1.5 60 15 91 30.5

28 -1 61 15.5 92 31

29 -0.5 62 16 93 31.5

30 0 63 16.5 93 31.5

31 0.5 63 16.5 94 32

32 1 64 17 95 32.5

33 1.5 65 17.5 96 33

34 2 65 17.5 97 33.5

35 2.5 66 18 98 34

36 3 67 18.5 99 34.5

37 3.5 68 19 10. 35~40

38 4 69 19.5 11. 40~45

39 4.5 70 20 12. 45~50

40 5 71 20.5 13. 50~55

41 5.5 72 21 14. 55~60

42 6 73 21.5 15. 60~65

43 6.5 74 22 16. 65~70

44 7 75 22.5

45 7.5 75 22.5

46 8 76 23

47 8.5 77 23.5

48 9 78 24

49 9.5 79 24.5

Page 20

7.4.6 Opening degree of electronic expansion valve:

Opening degree equals the display data times 8

7.5 Protection

7.5.1 Three minutes delay at restart for compressor.

7.5.2 Temperature protection of compressor discharge.

When the compressor discharge temp. is getting higher, the running frequency will be limited as below

rules:

----If 102℃<T5<115 , decrease the freq℃ uency to the lower level every 2 minutes till to F1.

---If T5>115℃ for 10 seconds, the compressor will stop and restart till T5<90℃.

7.5.3 Under voltage protection

VOLLIMT1

VOLTAGE

No limit

VOLLIMT2

VOLLIMT3

Off

VOLFRE2

VOLFRE1

VOLREL1

VOLREL2

VOLREL3

Mode VOLLIMT1(V) VOLLIMT2(V) VOLLIMT3(V) VOLREL1(V) VOLREL2(V) VOLREL3(V) VOLFRE1(Hz) VOLFRE2(Hz)

M2OC-14HRDN1 220 200 80 250 210 100 62 54

M2OC-14HRDN1-Q 220 200 80 250 210 100 62 54

M2OC-18HRDN1 230 200 80 260 210 100 62 54

M2OC1-18HRDN1-Q

230 200 120 260 210 135 62 54

M3OC1-21HRDN1-Q

245 220 80 265 240 100 78 45

M3OC-27HRDN1 245 220 80 265 240 100 78 45

M3OC1-27HRDN1-Q

245 220 120 265 240 135 78 45

M4OC-24HRDN1-Q 245 220 120 265 240 135 78 45

M4OC-27HRDN1 221 210 80 260 225 100 62 54

M4OC1-27HRDN1-Q

221 210 80 260 225 100 53 44

M4OC-36HRDN1-Q 200 185 80 210 195 100 54 42

For M5OA-36HRDN1-Q,

VO LT_RST1_A DD

VO LTAGE

No limit

VO LT_LTM1_ADD

VOLT_RS T2_ADD

VO LT_LT M2_ADD

VO LT_LT M_FR EQ 1_ADD

VO LT_LT M_F R EQ 2 _ADD

Page 21

VOLT_RST1_ADD=210V, VOLT_LIM1_ADD=200V, VOLT_RST2_ADD=195V, VOLT_LIM2_ADD=185V.

VOLT_LIM_FREQ1_ADD=54Hz, VOLT_LIM_FREQ2_ADD=42Hz.

7.5.4 Compressor current limit protection

If the compressor current exceeds the current limit value for 10 seconds, the compressor frequency will be

limited as below table.

For models except M5OA-36HRDN1-Q.

Cooling mode:

Current frequency(Hz) Current limit value(A) Frequency limit

COOL_F10 ICOOLLMT6 Decrease the frequency to COOL_F4 and

run at COOL_F4 for 3 minutes.

After that, the frequency will be adjusted

according to the capacity demand and rise

to the upper level every 3 minutes

(When the frequency>COOL_F4 via

capacity demand).

COOL_F9 ICOOLLMT5

COOL_F8 ICOOLLMT4

COOL_F7 ICOOLLMT3

COOL_F6 ICOOLLMT2

COOL_F5 ICOOLLMT1

If the current frequency is lower than COOL_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>ICOOL, the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

Heating mode:

Current frequency(Hz) Current limit value(A) Frequency limit

HEAT_F12 IHEATLMT8 Decrease the frequency to HEAT_F4 and

run at HEAT_F4 for 3 minutes.

After that, the frequency will be adjusted

according to the capacity demand and rise

to the upper level every 3 minutes

(When the frequency>Heat_F4 via capacity

demand).

HEAT_F11 IHEATLMT7

HEAT_F10 IHEATLMT6

HEAT_F9 IHEATLMT5

HEAT_F8 IHEATLMT4

HEAT_F7 IHEATLMT3

HEAT_F6 IHEATLMT2

HEAT_F5 IHEATLMT1

If the current frequency is lower than HEAT_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>IHEAT, the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

For M5OA-36HRDN1-Q model:

Cooling mode:

Current frequency

(Hz)

Current limit value(A)

Frequency limit

COOL_F16 ICOOLLMT12 Decrease the frequency to COOL_F4 and run at

COOL_F4 for 3 minutes.

After that, the frequency will be adjusted according to

the capacity demand and rise to the upper level every

3 minutes

(When the frequency>COOL_F4 via capacity

demand).

COOL_F15 ICOOLLMT11

COOL_F14 ICOOLLMT10

COOL_F13 ICOOLLMT9

COOL_F12 ICOOLLMT8

COOL_F11 ICOOLLMT7

COOL_F10 ICOOLLMT6

Page 22

COOL_F9 ICOOLLMT5

COOL_F8 ICOOLLMT4

COOL_F7 ICOOLLMT3

COOL_F6 ICOOLLMT2

COOL_F5 ICOOLLMT1

If the current frequency is lower than COOL_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>ICOOL, the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

Heating mode:

Current frequency

(Hz)

Current limit value(A)

Frequency limit

HEAT_F16 IHEATLMT12 Decrease the frequency to HEAT_F4 and run at

HEAT_F4 for 3 minutes.

After that, the frequency will be adjusted according to

the capacity demand and rise to the upper level every

3 minutes

(When the frequency>Heat_F4 via capacity

demand).

HEAT_F15 IHEATLMT11

HEAT_F14 IHEATLMT10

HEAT_F13 IHEATLMT9

HEAT_F12 IHEATLMT8

HEAT_F11 IHEATLMT7

HEAT_F10 IHEATLMT6

HEAT_F9 IHEATLMT5

HEAT_F8 IHEATLMT4

HEAT_F7 IHEATLMT3

HEAT_F6 IHEATLMT2

HEAT_F5 IHEATLMT1

If the current frequency is lower than HEAT_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>IHEAT, the AC will display the failure for 30 seconds

and stop. The AC will restart 3 minutes later.

6.5.5 Indoor / outdoor units communication protection

If the indoor units can not receive the feedback signal from the outdoor units for 2 minutes, the AC will stop

and display the failure.

7.5.6 High condenser coil temp. protection.

When T3>65 for ℃ 3 seconds, the compressor will stop while the indoor fan and outdoor fan will continue.

When T3<52 , the protection will release℃ and the compressor will restart after 3 minutes.

7.5.7 Outdoor unit anti-freezing protection

When T2B<0 for 250 seconds℃ , the indoor unit capacity demand will be zero and resume to normal when

T2B>10 .℃

7.5.8 Oil return

Running rules:

Page 23

1. If the compressor frequency keeps lower than RECOILINFRE for Te minutes, the AC will rise the

frequency to RECOILFRE for Tf seconds and then resume to former frequency. For M4OC-36HRDN1-Q,

RECOILINFRE=45Hz, RECOILFRE=48Hz,Te=120,Tf=180; For M5OA-36HRDN1-Q, RECOILINFRE=45Hz,

RECOILFRE=48Hz, Te=90,Tf=100; For other models, RECOILINFRE=50Hz, RECOILFRE=62Hz,

Te=120,Tf=180.

2. During the Tf seconds, the EXV and indoor units keep the current running mode(except

M5OA-36HRDN1-Q model), the frequency will not be limited by the compressor discharge temp. and the

current. For M5OA-36HRDN1-Q model, the EXV will keep 300p while the indoor units will keep the current

running mode.

3. If the outdoor ambient is higher than 15℃ during the oil return, the AC quit oil return.

7.5.9 Compressor preheating functions

----Preheating permitting condition:

If T4(outdoor ambient temperature)<3 and the machine connects to powe℃ r supply no longer than 5

seconds or if T4<3 and compressor has stopped for over 3 hours, the compressor heating cable will ℃

work.

----Preheating mode:

A weak current flow through the coil of compressor from the wiring terminal of compressor, then the

compressor is heated without operation.

----Preheating release condition:

If T4≧5 or ℃ the compressor starts running, preheating function will stop.

7.5.10 Compressor crankcase heater

When T4<3℃ and the compressor is not running, the crankcase heater will be active.

When T4≧5℃ or the compressor starts up, the crankcase heater will stop work.(For M5OA-36HRDN1-Q,T4

≧8℃)

Page 24

8. Troubleshooting

8.1 Indoor unit error code explanation:

Glory series

NO.

MALFUNCTION DEF TIMER AUTO RUN

1 Indoor EEPROM malfunction

O O O O

2 Indoor / outdoor units communication error

★ ★ ★ ★

3

Zero-crossing signal error O O

★ ★

4 Indoor fan speed has been out of control

O O

★ ★

5

Open circuit or short circuit of outdoor temperature sensor

X O X

★

6

Open circuit or short circuit of T1 or T2 temperature sensor

O O O

★

8 IPM module protection or IGBT over-strong current protection

X X O

★

9

Over voltage or too low voltage protection X O O

★

10

Temperature protection of compressor top O X X

★

11

Inverter compressor drive protection O X

★ ★

12

Mode conflict X O

★ ★

★Flash(at 0.5Hz, Mode conflict at 0.25Hz) O light X(off)

9V series+VERTU series+9A series+Corona series+ R series+Y series+ X series

Display LED STATUS

E0

Indoor EEPROM malfunction

E1 Indoor/ outdoor units communication error

E2 Zero-crossing signal error

E3 Indoor fan speed has been out of control

E5 Open circuit or short circuit of outdoor temperature sensor

E6 Open circuit or short circuit of T1 or T2 temperature sensor

P0 IPM module protection or IGBT over-strong current protection

P1 Over voltage or too low voltage protection

P2 Temperature protection of compressor top

P4 Inverter compressor drive protection

P5 Mode conflict

NEOLA series +PREMIER series +OASIS series:

Display

Operation lamp flash times

Timer lamp

Failure

E0 1 X Indoor EEPROM malfunction

E1 2 X Indoor / outdoor units communication error

E2 3 X Zero-crossing signal error

E3 4 X Indoor fan speed has been out of control

E4

5 X Open or short circuit of T1 temperature sensor

E5

6 X Open or short circuit of T2 temperature sensor

F1

2 O Open or short circuit of T4 temperature sensor

Page 25

F2

3 O Open or short circuit of T3 temperature sensor

F3 4 O Open or short circuit of T5 temperature sensor

F4 5 O Outdoor EEPROM malfunction

F6 7 O Open or short circuit of T2B temperature sensor

P0

1 ☆

IPM module protection or IGBT over-strong current

protection

P1 2

☆

Over voltage or too low voltage protection

P2 3

☆

Temperature protection of compressor top

P4 5

☆

Inverter compressor drive protection

P5 6

☆

Mode conflict

O (light) X (off) ☆ (flash)

Cassette series:

Operation Timer De-frost Alarm LED STATUS

★

X X X Open or short circuit of T1 temperature sensor

X X

★

X Open or short circuit of T2 temperature sensor

X

★

X X Indoor / outdoor units communication error

X X X

★

Full-water malfunction

★ ★

X X Indoor EEPROM malfunction

★

X X

IPM module protection

★

X X Open or short circuit of T3 or T4 temperature sensor

★

X

Outdoor voltage protection

★ ★ ★ ★

Temperature protection of compressor top

★

X

Mode conflict

★

X Inverter compressor drive protection

★ flash, light, X extinguished.

Ceiling &Floor series:

Operation Timer De-frost Alarm LED STATUS

★

X X X Open or short circuit of T1 temperature sensor

X X

★

X Open or short circuit of T2 temperature sensor

X

★

X X Indoor / outdoor units communication error

X X X

★

Full-water malfunction

★ ★

X X Indoor EEPROM malfunction

★

X X

IPM module protection

★

X X Open or short circuit of T3 or T4 temperature sensor

★

X

Outdoor voltage protection

★

X

X Temperature protection of compressor top

★

X

Mode conflict

★ flash, light, X extinguished.

Page 26

A5 Duct series:

Operation Timer De-frost Alarm

LED STATUS

DISPLAY DIGITAL TUBE

★

X X X Open or short circuit of T1 temperature sensor

E0

X X

★

X Open or short circuit of T2 temperature sensor

E1

X

★

X X Indoor / outdoor units communication error

E2

X X X

★

Full-water malfunction

E3

★ ★

X X Indoor EEPROM malfunction

E4

★

X X

IPM module protection

E5

★

X X

Open or short circuit of T3 or T4 temperature

sensor

E6

★

X

Outdoor voltage protection

P0

★ ★ ★ ★

Temperature protection of compressor top P3

★

◎ X X Inverter compressor drive protection P4

★

X

X Mode conflict P5

★ flash at 5Hz, light, X extinguished ◎flash at 0.5Hz

Console series:

Operation Timer De-frost LED STATUS

★

X X Open or short circuit of T1 temperature sensor

X X

★

Open or short circuit of T2 temperature sensor

X

★

X Indoor / outdoor units communication error

★ ★

X Indoor EEPROM malfunction

★

X

★

IPM module protection

★ ★ ★

Open or short circuit of T3 or T4 temperature sensor

★

X Top temperature protection of compressor

★

◎ X Inverter compressor drive protection

★

X

Mode conflict

★

★

Indoor fan speed has been out of control

★ flash at 5Hz, light, X extinguished

Page 27

Outdoor unit error code explanation:

For units(except M5OA-36HRDN1-Q model)

Display LED STATUS

E0 Outdoor EEPROM malfunction

E1 No A Indoor unit coil outlet temp. sensor or connector of sensor is defective

E2 No B Indoor unit coil outlet temp. sensor or connector of sensor is defective

E3 No C Indoor unit coil outlet temp. sensor or connector of sensor is defective

E6 No D Indoor unit coil outlet temp. sensor or connector of sensor is defective

E4 Open or short circuit of outdoor unit temperature sensor

E5 Compressor voltage protection

E7 Communication malfunction between IPM board and outdoor main board

P0

Temperature protection of compressor discharge or compressor top.

For M4OC-27HRDN1, M4OC1-27HRDN1-Q,M4OC-36HRDN1-Q,it only means Temperature

protection of compressor discharge

P1 High pressure protection(only for M4OC1-27HRDN1-Q, M4OC-27HRDN1-Q,M4OC-36HRDN1-Q)

P2 Low pressure protection(only for M4OC1-27HRDN1-Q, M4OC-27HRDN1-Q,M4OC-36HRDN1-Q)

P3 Current protection of compressor

P4 IPM module protection

P6 High temperature protection of condenser

P7 Inverter compressor drive protection

Page 28

For M5OA-36HRDN1-Q model

Display LED STATUS

E0 Outdoor EEPROM malfunction

E2 Indoor / outdoor units communication error

E3 Communication malfunction between IPM board and outdoor main board

E4 Open or short circuit of outdoor unit temperature sensor

E5 Compressor voltage protection

E6 PFC module protection

F1 No A Indoor unit coil outlet temp. sensor or connector of sensor is defective

F2 No B Indoor unit coil outlet temp. sensor or connector of sensor is defective

F3 No C Indoor unit coil outlet temp. sensor or connector of sensor is defective

F4 No D Indoor unit coil outlet temp. sensor or connector of sensor is defective

F5 No E Indoor unit coil outlet temp. sensor or connector of sensor is defective

P1 High pressure protection

P2 Low pressure protection

P3 Current protection of compressor

P4 Temperature protection of compressor discharge

P5 High temperature protection of condenser

P6 IPM module protection

Page 29

8.3Trouble shooting

8.3.1 For the indoor unit

8.3.1.1 Indoor EEPROM malfunction

Page 30

8.3.1.2 Indoor / outdoor units communication error

No

No fist time

Yes

Yes

No

Reconnect the wiring

Check wiring on the outdoor

and indoor t er

minal follow

the wiring

diagram. Is all

connecting correctly?

Turn on all indoor unit

by remote controller.

Is

all indoor unit display

Measure Vs, is i

t moving

alternately between positive

value and negative value?

(Vs is the voltage between

Turn off the all indoor

units. Is IPM power LED

lamp On? Refer PIC 3

Is PFC power LED lamp

off? Refer PIC 3.

No

Yes

Start: Power off , then Power on the A/C by the

Breaker. (reconnect the power wire). Is E1

extinguish?

change

IPM

No

No

Yes

Yes

Is indoor units number

correct? C

heck on the

outdoor check poi

nt (18). (2

for dual zone, 3 for tri

zone, 4

for qua zone). Refer PIC 5.

Is Main board

“ "

lamp on?

Reconnect the wiring

No

A:

Is all the wiring

between t

erminal

and Indoor PCB

change

PFC

No

Yes

No

change the

Indoor PCB

Yes

Power on by remote

controller, Is the E1

extinguish after 3

minutes?

E1 error problem solved. The unit

operation normally.

Is the Reactor

connection.

Reconnect the wiring

Change Outdoor Main

PCB

No

No

Yes

Change

outdoor unit PCB

assembly(include wiring) totally

No second time

A

Yes

Yes

Page 31

Pic 1: Measure the voltage of L2 to S (Vs), is

it moving alternately between positive value

and negative value?

PIC 2, Check the wiring.

PFC (qua-zone only)

PIC 3:IPM

(For dual/tri/qua

-

zone)

Power on

Self-Check OK

Operati

Off is OK

PIC 5: check piont buttom,

pess 18 times for check how many indoor units are

connected.

Page 32

8.3.1.3 Zero-crossing signal error

8.3.1.4 Indoor fan speed has been out of control

Shut off the power supply

and turn it on 1 minute

later. Is it still displaying

the error code?

S h u t o ff t he p o w e r

su p ply, rotate the cross

fan by hand. Does it

rotate properly?

The unit operates normally.

Disassembly the

connection between

fan and motor, check if

the bearing is normal?

Replace the bearing.

Check the wires of

fan motor. Are all the

connections good?

No

Yes

No No

Replace indoor fan motor.

Yes

Correct the connections.No

No

Yes

Yes

Check the resistance value of

indoor fan motor, is it normal?

Replace indoor PCB.

Yes

Page 33

8.3.1.5 Open or short circuit of temperature sensor.

8.3.1.6 Full-water malfunction

Full-water malfunction

Check whether the water-level switch is inserted well

Check whether the water-level switch is broken

Check PCB board or replace the indoor main PCB

Replace the water-level switch

Yes

No

Check whether the water pump is normal

Yes

Insert the water-level switch well

No

Yes

Replace the water pump

No

Page 34

8.3.2 For the outdoor unit

8.3.2 1 Outdoor EEPROM malfunction

Outdoor EEPROM malfunction

Yes

No

Insert the EEPROM well

Replace the outdoor main board

If the EEPROM chip is welded on

PCB, replace the PCB directly.

Otherwise, check whether the

EEPROM chip plugged in PCB

well?

Page 35

8.3.2.2 Voltage protection of compressor

Check the power supply

No

Check the voltage of outdoor unit power supply, whether the voltage

between L(1) and N is about 220VAC

No

Replace the power board, then check whether the system can run

normally

Yes

Yes

Trouble is solved

No

Check whether the voltage of IPM board P and N is 280-400VDC

Replace bridge rectifiers, then check whether the

system can run normally

Trouble is solved

Replace IPM board

No

Yes

No

No

Replace outdoor main board

Voltage protection of compressor

Page 36

8.3.2.3 Communication malfunction between IPM board and outdoor main board

No

Check whether the IPM board has error display

Replace IPM board

Yes

Insert the connecting wiring between the IPM module and the main

board well over again

Trouble is solved

Yes

No

Replace the IPM board

No

Trouble is solved

Yes

No

Replace outdoor PCB

Replace the electric control box

Trouble is solved

Yes

The problem is not

resolved.

Page 37

8.3.2.4 Temperature protection of compressor discharge

Discharge temperature protection of compressor

Check whether the compressor discharge temp. is more than 115°C ?

No

Check whether the wiring connection is right

between compressor discharge temp. sensor and

PCB according to wiring diagrams

Yes

Method: Check whether the resistance of compressor discharge

temp. sensor is right refer to the Appendix 2

No

Correct the wiring connection

Yes

Replace outdoor main board

Judge: The discharge temp. sensor is broken

No

Replace the compressor

discharge temp. sensor

Check whether the refrigerant is leak

Stop leaking and add refrigerant

Yes

Yes

Page 38

8.3.2.5 Temperature protection of compressor top

Judge 2: Whether

refrigerant circulation volume is

normal?

Whether

abnormality is the same after gas charging?

Check refrigerant system (such as clogging of capillary etc.)

Temperature protection of compressor top

Judge 1: Whether

compressor operates?

Yes

No

Whether

the

connection

is

good?

Method:

Charge refrigerant

Yes

Whether

protector is

normal?

No

No

Reconnect and

retest.

No

Replace the protector.

No

Check the outdoor

main PCB. Is there

Yes

Replace the outdoor

main PCB

Yes

Page 39

8.3.2.6 High pressure protection(For M4OC1-27HRDN1-Q, M4OC-27HRDN1-Q,M4OC-36HRDN1-Q,

M5OA-36HRDN1-Q)

High pressure protection

Judge 1: Whether the wiring between the high pressure switch and main

control board is connected well or correctly

Judge 2: Whether the high pressure switch is broken

Yes

No

Connect it well

Method: Short connect the high pressure switch socket, check

whether the system can run normally

Yes

Replace high pressure switch

No

Check whether the refrigerant system is ok

Replace outdoor main board

No

Judge 3: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

No

Judge 4: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 5: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 6: Check whether the refrigerant pipe is blocked

Yes

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

Page 40

8.3.2.7 Low pressure protection (For M4OC1-27HRDN1-Q, M4OC-27HRDN1-Q,M4OC-36HRDN1-Q,

M5OA-36HRDN1-Q)

Low pressure protection

Judge 1: The wiring between the low pressure switch and main control

board is connected well or correctly

Judge 2: Whether the low pressure switch is broken

Connect it well

Method: Short connect the low pressure switch socket, check

whether the system can run normally

Check whether the refrigerant system is ok

Yes

No

Judge 3: Check whether the outdoor ambient temperature is too low

Yes

Stop the unit

No

Judge 4: The refrigerant of the system is leakage

Yes

Method: Connect the pressure gauge to the gauge joint of the system,

check whether the pressure is lower than 0.14MPa

Leak hunting: Charge nitrogen or refrigerant to

the system, if the leakage is serious, there will

be distinct gas leakage “cici” sound; if the

leakage is slight, use the suds (mixture of water

and abluent is also ok if it can make bubble) or

electronic leak detector.

Judge 5: The refrigerant pipe is blocked

Yes

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

No

Replace outdoor main board

No

No

Yes

Replace low pressure switch

Page 41

8.3.2.8 Current protection of compressor

Current protection of compressor

Judge 1: Check whether the input current of the power supply wire is more

than 8.5A (For 18-21K, it is 15A..For 27K(1x3) , it is 15A .For 27K(1x4), it is

Check whether the refrigerant system is ok

Yes

Judge 2: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

Replace outdoor main board

No

No

Judge 3: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 4: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 5: The refrigerant pipe is blocked

Yes

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

Replace the electric control box

Trouble is solved

Yes

The problem is not

resolved.

Page 42

8.3.2.9 IPM module protection

IPM module protection

Check whether the voltage range of P-N on

IPM module is normal? DC277-356V for

14-27KBtu/h; DC277-410V for 36KBtu/h

No

Check whether the input power supply

is correct? 220-240V, 1N, 50Hz

No

Regulate it to correct,

then check whether the

system can work

normally?

Yes

Check whether the power

supply line is connected

correctly and tightly

No

Connect it correctly and

tightly, check ok or not?

No

Yes

Check whether the lines in

E-part box are connected tightly

No

Connect it tightly,

check ok or not?

No

Yes

Check whether the single-phase bridge is

normal? Use the multimeter to measure the

resistance between each two terminals, check

whether there is the condition that value of

resistance is 0

Yes

Replace the

single-phase bridge

No

No

Check whether the connecting line

of every reactor is normal? If the

line is broken, the resistance of the

two ports is ∞(models except for

M5OA-36HRDN1-Q);Check

whether the PFC module

broken(for M5OA-36HRDN1-Q)

Yes

Replace the

connecting line or

reactor or replace

the PFC module

Yes

Check whether the connecting line

between main board and the IPM

module is connected tightly

Yes

Check whether the connecting

line of the compressor is

connected correctly or tightly

Yes

Replace the IPM module, check

whether the system can work

normally?

No

Replace the main board, check

whether the system can work

normally?

Yes

Trouble is solved

Replace the compressor, check

whether the system can work

normally?

Connect it tightly,

check ok or not?

No

No

Yes

Trouble is solved

No

No

Yes

Trouble is solved

Connect it well,

check ok or not?

Page 43

8.3.2.10 High temperature protection of condenser

When outdoor pipe temp. is more than 65°C, the unit will stop, and unit runs again when outdoor pipe

temp. less than 52°C.

Check whether the condenser temperature is more than 65°C

Check whether the resistance of condenser temp.

sensor is correct refer to the Appendix 1

Replace outdoor main board

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

High temperature protection of condenser

No

Yes

No

Replace the temperature sensor

Yes

Judge1: The outdoor temp. is too high

No

Judge 2: Check whether the heat exchanger is dirty

No

Judge 3: The refrigerant pipe is blocked

Clean the heat exchanger

Yes

Yes

Yes

Stop the unit

No

Page 44

8.3.2.11 PFC module protection

8.3.2.12 Inverter compressor drive protection

The trouble shooting is same with one of IPM module protection

PFC module protection

Check whether the connecting line between main

board and the PFC module is connected tightly

No

Connect it tightly, check normal or not

Yes

Check whether the voltage between P

and N of IPM module is 380-390VDC

No

Yes

Replace the outdoor main board

No

Replace the PFC module

Check whether the inductance of PFC module is

Replace the inductance

Page 45

Appendix 1 Temperature Sensor Resistance Value Table (℃--K)

℃

K Ohm

℃

K Ohm

℃

K Ohm

℃

K Ohm

-20 115.266 20 12.6431 60 2.35774 100 0.62973

-19 108.146 21 12.0561 61 2.27249 101 0.61148

-18 101.517 22 11.5000 62 2.19073 102 0.59386

-17 96.3423 23 10.9731 63 2.11241 103 0.57683

-16 89.5865 24 10.4736 64 2.03732 104 0.56038

-15 84.2190 25 10.000 65 1.96532 105 0.54448

-14 79.3110 26 9.55074 66 1.89627 106 0.52912

-13 74.5360 27 9.12445 67 1.83003 107 0.51426

-12 70.1698 28 8.71983 68 1.76647 108 0.49989

-11 66.0898 29 8.33566 69 1.70547 109 0.48600

-10 62.2756 30 7.97078 70 1.64691 110 0.47256

-9 58.7079 31 7.62411 71 1.59068 111 0.45957

-8 56.3694 32 7.29464 72 1.53668 112 0.44699

-7 52.2438 33 6.98142 73 1.48481 113 0.43482

-6 49.3161 34 6.68355 74 1.43498 114 0.42304

-5 46.5725 35 6.40021 75 1.38703 115 0.41164

-4 44.0000 36 6.13059 76 1.34105 116 0.40060

-3 41.5878 37 5.87359 77 1.29078 117 0.38991

-2 39.8239 38 5.62961 78 1.25423 118 0.37956

-1 37.1988 39 5.39689 79 1.21330 119 0.36954

0 35.2024 40 5.17519 80 1.17393 120 0.35982

1 33.3269 41 4.96392 81 1.13604 121 0.35042

2 31.5635 42 4.76253 82 1.09958 122 0.3413

3 29.9058 43 4.57050 83 1.06448 123 0.33246

4 28.3459 44 4.38736 84 1.03069 124 0.32390

5 26.8778 45 4.21263 85 0.99815 125 0.31559

6 25.4954 46 4.04589 86 0.96681 126 0.30754

7 24.1932 47 3.88673 87 0.93662 127 0.29974

8 22.5662 48 3.73476 88 0.90753 128 0.29216

9 21.8094 49 3.58962 89 0.87950 129 0.28482

10 20.7184 50 3.45097 90 0.85248 130 0.27770

11 19.6891 51 3.31847 91 0.82643 131 0.27078

12 18.7177 52 3.19183 92 0.80132 132 0.26408

13 17.8005 53 3.07075 93 0.77709 133 0.25757

14 16.9341 54 2.95896 94 0.75373 134 0.25125

15 16.1156 55 2.84421 95 0.73119 135 0.24512

16 15.3418 56 2.73823 96 0.70944 136 0.23916

17 14.6181 57 2.63682 97 0.68844 137 0.23338

18 13.9180 58 2.53973 98 0.66818 138 0.22776

19 13.2631 59 2.44677 99 0.64862 139 0.22231

Page 46

Appendix 2

Unit: ℃---K Discharge temp. sensor table

-20 542.7 20 68.66 60 13.59 100 3.702

-19 511.9 21 65.62 61 13.11 101 3.595

-18 483 22 62.73 62 12.65 102 3.492

-17 455.9 23 59.98 63 12.21 103 3.392

-16 430.5 24 57.37 64 11.79 104 3.296

-15 406.7 25 54.89 65 11.38 105 3.203

-14 384.3 26 52.53 66 10.99 106 3.113

-13 363.3 27 50.28 67 10.61 107 3.025

-12 343.6 28 48.14 68 10.25 108 2.941

-11 325.1 29 46.11 69 9.902 109 2.86

-10 307.7 30 44.17 70 9.569 110 2.781

-9 291.3 31 42.33 71 9.248 111 2.704

-8 275.9 32 40.57 72 8.94 112 2.63

-7 261.4 33 38.89 73 8.643 113 2.559

-6 247.8 34 37.3 74 8.358 114 2.489

-5 234.9 35 35.78 75 8.084 115 2.422

-4 222.8 36 34.32 76 7.82 116 2.357

-3 211.4 37 32.94 77 7.566 117 2.294

-2 200.7 38 31.62 78 7.321 118 2.233

-1 190.5 39 30.36 79 7.086 119 2.174

0 180.9 40 29.15 80 6.859 120 2.117

1 171.9 41 28 81 6.641 121 2.061

2 163.3 42 26.9 82 6.43 122 2.007

3 155.2 43 25.86 83 6.228 123 1.955

4 147.6 44 24.85 84 6.033 124 1.905

5 140.4 45 23.89 85 5.844 125 1.856

6 133.5 46 22.89 86 5.663 126 1.808

7 127.1 47 22.1 87 5.488 127 1.762

8 121 48 21.26 88 5.32 128 1.717

9 115.2 49 20.46 89 5.157 129 1.674

10 109.8 50 19.69 90 5 130 1.632

11 104.6 51 18.96 91 4.849

12 99.69 52 18.26 92 4.703

13 95.05 53 17.58 93 4.562

14 90.66 54 16.94 94 4.426

15 86.49 55 16.32 95 4.294 B(25/50)=3950K

16 82.54 56 15.73 96 4.167

17 78.79 57 15.16 97 4.045 R(90℃)=5KΩ±3%

18 75.24 58 14.62 98 3.927

19 71.86 59 14.09 99 3.812

Page 47

Appendix 3

1. Reference voltage data:

a) Rectifier : Input :220-230V(AC), output :310V(DC)

b) Inverter module: U,V, W 3ph.

Result

U-V 60-150V(AC)

U-W 60-150V(AC)

V-W 60-150V(AC)

P-N DC 310V

2. Check the Diode Bridge component ( In wiring diagram, rectifier)

Remark: If this part is abnormal, the LED will not light.

Multi-meter Result

Forward Resistance Backward Resistance

+ _

Infinite Infinite

~

+

~1.7M ohm Infinite

~ - ~

~1.7M ohm Infinite

~

~ +

- ~

Loading...

Loading...