Page 1

Service Manual

Single Tub Washing Machine

Htt p://g lobal .mide a.com .cn

Note:

Bef ore ser ving th e unit, pleas e read th is at fir st,

Alw ays con tact wi h your se rvice c enter i f meet pr oblem .

Page 2

1.SAFETY PRECAUTION

-2-

1. Sa fety pr ecaut ion

2. In trodu ction o f produ ct

2.1 N ame of pa rts

3.T roub le sh ooti ng

3.1 M alfuc tion an d solut ion

3.11 . Unus ual sou nd when w ashing or wa sh

wea kly (mo tor wit h sou nd)

3.1 2. Can no t wash( motor d oes not r otate )

3.1 3. Elec tric le akage

3.1 4.Unu sual so und whe n pulsa tor rot ates

3.1 5. Wate r leak age f rom th e side o f

was h tub

3.1 6.No dr ain or un smoot h drain

3.2 F ault tr ee

3.2 1. Can no t wash (m otor do es not ro tate)

3.2 3. No dra in or uns mooth d rain

4.D isman tling w ays of ma in part s

4.1 . Remov e the kno bs

4.2 . Remov e the con trol pa nel

4.3 . Remov e the was h cover

4.4 . Remov e the pul sator

4.5 . Remov e the ove rflow c over ki t

4.6 . Remov e the fra me

4.7 . Remov e the bas e

4.8 . Remov e the mot or pull ey

4.9 . Remov e the cap acito r

5.E lectr onic co mpone nts

5.1 . Self- test me thod of w ash tim er

and w ash-d rain se lecti on swit ch

5.2 . Self- test me thod of c apaci tor

5.3 . Self- test me thod of m otor

6.C ircui t diagr am

7.E xplor ed view & l ist of pa rts

TABLE OF CONTENES

Do not s pray wa ter dir ectly t o

the ma chine .

Avoid s prayi ng wate r

Do not i nstal l the mac hine in

damp o r rainy e nviro nment t o

avoi d elect ric sho ck, fir e,

mach ine fai lure, or defo rmati on.

Avoid d ampne ss

Do not d isman tle the m achin e

by you rself .

Forbi d disma ntlin g

Do not i nsert o r unplu g the plu g

with w et hand s to avoi d elect ric

shoc k.

Forbi d wet han ds

To avoid e lectr ic shoc k

resu lting f rom ele ctric l eakag e,

plea se conn ect gro undin g wire

of the p lug pro perly.

Groun ding

Do not p lace in flamm able

mate rials l ike bur ning ca ndle,

mosq uito in cense , cigar et etc.

or hea ting so urce li ke elec tric

stov e, calo rifie r etc. on t he

mach ine.

Forbi d

W

ip

e o

ff dir t

y a

n

d d

us

t o

n t

he

plu

g o

f

t

en t

o p

re

v

en

t poor

c

o

n

t

ac

t w

i

t

h p

ower s uppl

y.

+

Do not e xceed t he max. w ater

leve l to avoi d water o verfl owing

and ma chine f ailur e.

Forbi d

+

Make s ure tha t the wat er inle t

hose i s conne cted an d the tap

is ope ned bef ore was hing.

Unpl ug the pl ug from s ocket

afte r use.

Unplu g the plu g

Do not p ut hand s into th e tub

befo re it sto pping r unnin g.

Forbi d putti ng into

D

o n

ot w

as

h c

l

ot

h

e

s th

a

t are

s

tain

e

d w

it

h ke

ro

s

e

n

e

, p

etr

o

l

,

alc

o

ho

l, a

n

d o

t

h

er fl

a

mm

a

b

l

e

s

ub

s

ta

nc

e.

Forbi d

D

o not da mage th e p

o

we

r cord

and pl u

g t

o a

v

o

i

d ele

c

t

ri

c

s

hock , s h

ort c

ir

cuit o

r fi

re.

Forbi d

D

o n

ot let b ab

y c

li

mb to th e

mach in

e o

r p

l

a

y nea

r ru

n

ni

ng

t

ub t

o a

v

oi

d a

ccid

e

nt

.

Forbi d

If use w arm wat er, the wa ter

temp eratu re shou ld not

exce ed 50℃.

Forbi d

Do not r eplac e power c ord by

your self.

Forbi d

Do not l et baby s it on it or p lace

heav y thing s on it.

Forbi d

Do not p ull the c ord whe n

unpl ug the pl ug.

Do not w ash dow n-fil led coa t,

rain coat or s imila r cloth es.

waterproo f

Forbi d

Inse rt the pl ug tigh tly whe n

use.

-1-

2

3

3

4

4

4

4

4

5

5

5

6

6

7

8

8

8

8

9

9

9

10

10

10

11

11

11

11

13

13

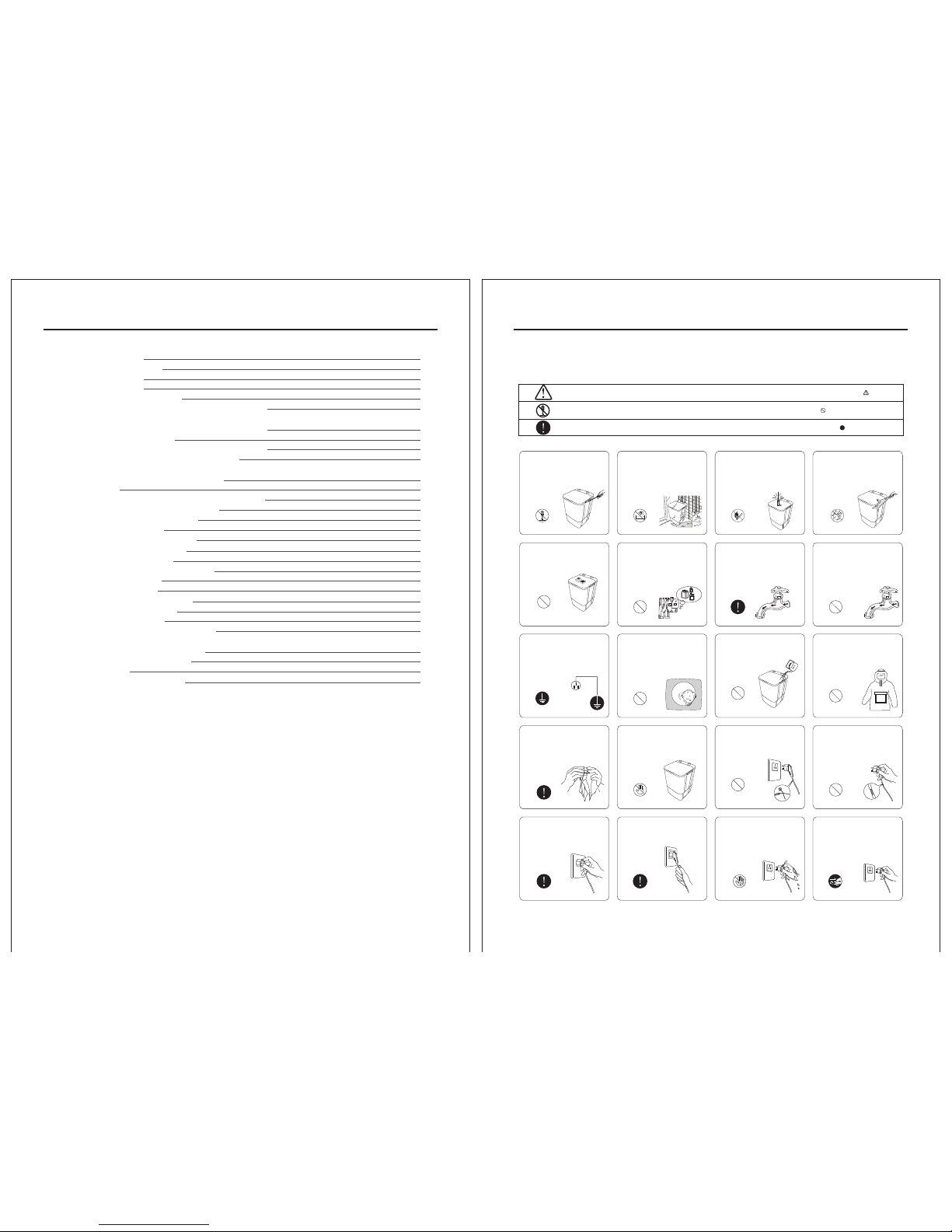

Be su re to com ply wit h the fol lowin g to prev ent dam age to bo dy and pr opert y of you an d

oth ers:

The s ign sta nds for “ pay att entio n” , and th e pictu re of spe cific i tems ne eds att entio n shows i n .

The s ign sta nds for “ forbi d”, and t he pict ure of sp ecifi c items f orbid den sho ws in .

The s ign sta nds for “ must do ”, and th e pictu re of spe cific i tems mu st be don e shows i n .

Page 3

SAFETY PRECAUTION

*T he dr awi ng ab ove is based on th e act ual w asher.

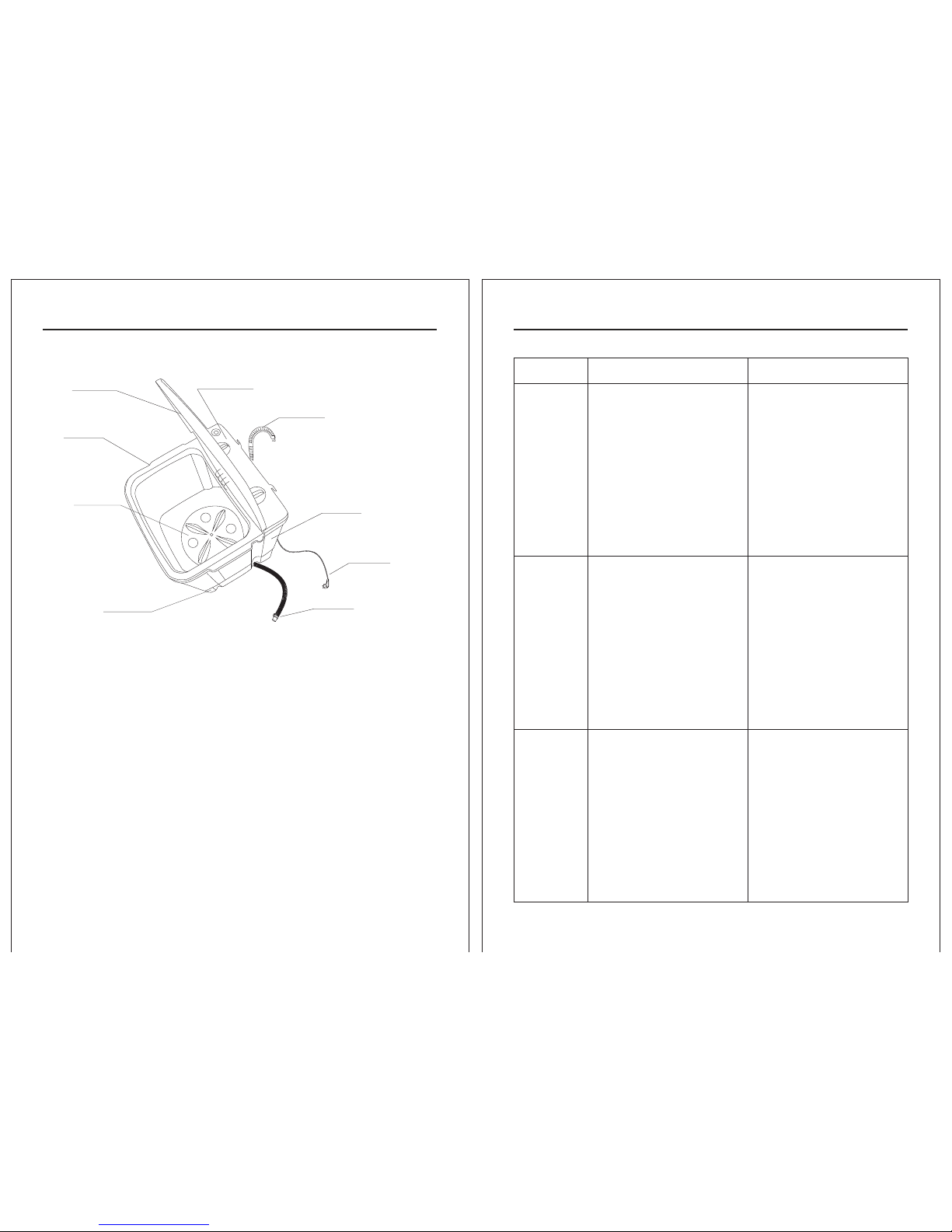

2. INTRODUCTION OF PRODUCTS

2.1 Nam e of pa rts

Sympto m

Possib le re aso n

Soluti on

1. Un usual

sou nd when

was hing or

was h weakl y

(mo tor wit h

sou nd)

a. La undry i s much mo re than r ated

was hing ca pacit y.

b. pu lsato r is tang led wit h cloth es or

blo cked by t hings l ike coi ns.

d. Pu lley br oken or p ulley s crew is

loo se .

e. Ca pacit or fail ure.

c. V-b elt loo se, bro ken or fa ll from

the s trap wh eel.

a. Re duce th e laund ry till t he

pul sator c an rota te norm ally.

b. Take o ff plu g, re move t he

pul sator a nd take o ut the

tan gled cl othes o r other t hings .

c. Re place v -belt o r reloa d the

v-b elt.

d. Re place t he pull ey or tig ht the

pul ley loc king sc rew.

e. Re place t he capa citor.

a. Po wer sup ply is cu t off or po or

con tact of p lug and s ocket .

b.

c. Wa sh tim er is i n poor c onta ct or

fau lted.

d.

e. Wa sh mot or fa ilur e.

Volt age is to o low.

Fus e is burn ed.

3. El ectri c

lea kage

a. Con ducti ve wire or alive par ts in

the mac hine co nta cts wi th me tal

cab inet.

b. Ba d earth w ire.

c. 2 po wer lin es of the p ower su pply.

d. We ak insula tion s tre ngth o f mot or

e. In sulat ion lay er of wir e harne ss is

bro ken.

a. Ch eck the p ower su pply an d

adj ust the p lug to in sure go od

con tact.

b.

c. Ch eck the w ire har ness or

rep lace th e wash ti mer.

d.

e. Re place t he wash m otor.

Do no t use the w ashin g

mac hine un til the v oltag e rise to

rat ed volt age.

Rep lace th e fuse.

a. Ch eck wir e conne cting i n the

mac hine.

b. Ch eck the e arth wi re.

c. Ex amine a nd repl ace the p ower

sup ply.

d. Re place t he moto r.

e. Ex amine t he wire h arnes s and

bin d up the br oken wi re.

2. Ca n not was h

(mo tor doe s

not r otate )

3.TROUBLE SHOOTING

3.1 Malf uct ion a nd so lution

-4--3-

Control panel

Wash cover

Pulsator

Base

Cab inet

Dra in hose

Fra me

(Fo r lower d rain on ly)

Dra in hose

(Fo r upper d rain on ly)

Pow er plug

Page 4

Sympto m

Possib le re aso n

Soluti on

3.TROUBLE SHOOTING

a. Th ere is thin gs lik e coi ns, bu tto ns

und er the pu lsato r.

b. Th e fixing sc rew be com e loos e

and t he puls ator vi brate s.

c. Ge ar in the r etard er is dam aged.

d. Ant i-loo se nuts o n the big p ulley

bec ome loo se, so th e wheel

jum ps and ma ke unus ual noi se.

e. Th e v-belt is n ot smo oth a nd

mak es nois e when ru nning o n the

pul ley.

f. Th e motor pul ley an d the b ig

pul ley is no t at a leve l.

g. No ise ins ide the w ash mot or.

a. Di smant le the pu lsato r and tak e

out t he thin gs.

b. Tig hten th e fixin g screw.

c. Re place t he reta rder.

d. Sc rew tig ht the an ti-lo ose nut s.

e. Re place t he v-be lt.

f . Adju st the mo tor pul ley to ma ke

it at t he same l evel wi th the bi g

pul ley.

g. Re place t he wash m otor.

4.U nusua l

sou nd when

pul sator

rot ates

-6--5-

a. Wa sh tub l eak s.

b. Se al ring o f the ret arder l eaks.

c. Th e overflo w hose b rak es and

wat er leak s from th e broke n place .

d. Dr ain val ve core b rakes a nd wate r

lea ks from t he valv e cover.

e. Dr ain hos e joint i s badly b ound

and w ater le aks fro m the joi nt

pla ce.

a. Re place t he wash t ub.

b. Re place t he seal r ing of th e

ret arder.

c. Re place t he over flow ho se.

d. Re place t he drai n valve c ore.

e. Di smant le drai n hose jo int and

sti ck them a gain.

5. Wa ter

lea kage fr om

the s ide of

was hing tu b

a. Wh en drai ning, t he hose i s not put

dow n and the w ater ca n not be

dra ined. (for lo wer dra in func tion

onl y)

b. Wa sh -dr ain s elec tion s witch i s

not i n “drai n”pos ition .

e. Dr ain out let is bl ocked a t the sid e

of wa sh tub.

f. Dr ain fal ls from t he swit ch.

g. Dr ain bel t is loos ened or b roken .

c. Dr ain out let is no t laid pr operl y.

(fo r upper d rain fu nctio n only)

d. Dr ain pum p failu re

( for u pper dr ain fun ction o nly).

bel t

a. Pu t down th e drain h ose and

mak e the hos e mouth t o the

sew er.

c. Th e drain hos e shou ld be p lace d

86 cm -100c m from th e botto m of

the g round .

e. Di smant le the pu lsato r and tak e

out t he bloc ks at the d rain ou tlet .

f. Co nnect t he drai n wit h the

swi tch.

g.R eplac e the dra in belt .

b. Tur n the swi tch to “d rain” p ositi on

d. Re place t he pump o r open th e

val ve cove r to clea r up the pu mp.

bel t

6. No d rain or

uns mooth d rain

Can n ot wash

Y

Y

N

N

N

Y

Y

Y

N

N

Whe ther th e power

sup ply is we ll

Che ck the po wer sup ply

Whe ther th e plug

is co ntact

Adj ust the p lug to in sure

goo d conta ct

Whe ther th e volta ge

is co rrect

Wait t he volt age to ri se

to co rrect v oltag e

Whe ther th e wash

tim er is wel l

Y

N

Rep lace th e wash ti mer

Whe ther th e fuse

is we ll

Rep lace th e fuse

Whe ther th e capac itor

is we ll

Rep lace th e capac itor

Y

N

Whe ther th e wash

mot or is wel l

Rep lace th e wash mo tor

3.TROUBLE SHOOTING

1. Ca n not was h (moto r does no t rotat e)

3.2 Faul t tre e

Page 5

-8--7-

3. No d rain or u nsmoo th drai n

Can n ot drai n

Y

Y

N

N

N

Y

Y

Y

N

N

Whe ther th e drain

hos e is put do wn

Put d own the d rain ho se

Whe ther th e washdra in sele ction s witch i s

not i n “drai n”pos ition

Whe ther th e drain

hos e is laid p roper ly

Whe ther th e drain

pum p is well

Y

N

Rep lace th e drain p ump

Whe ther th e drain

hos e at the si de of

was h tub is bl ocked

Dis mantl e the pul sator

and t ake out t he bloc ks

in th e water d rain ho se

Whe ther th e drain

bel t is on the s witch

Han g the dra in

bel t onto th e switc h

Y

N

Whe ther th e drain

bel t is well

Rep lace th e drain b elt

Turn t he swit ch to “dr ain”

pos ition

The d rain ho se shou ld be

pla ced 86c m-100 cm from

the b ottom o f the gro und

for l ower dr ain fun ction o nly

for u pper dr ain fun ction o nly

for u pper dr ain fun ction o nly

3.TROUBLE SHOOTING 4.DISMANTLING WAYS OF MAIN PARTS

1. Remov e the k nob s

a.Take out the knobs dire ctly

because knob s are in ser ted

int o the con trol pa nel.

b. If i t is diff icul t to take k nobs ou t,

a str aight s crew drive r wrappe d

with clo th can be use d for he lp.

Operation step

Picture

a.

b.

2. Remov e the c ont rol p anel

a. Take dow n the back co ver by

loo sen-i ng off th e screw s.

b. Take dow n the plastic bag by

cuttin g off the nyl on clip. Take

down all wi re nut wit h a pli er

and make all w ire clamps loose.

and then unfasten the dr ain belt

connec tor.

c. Scr ew off th e scre ws on the

con trol pa nel.

d. Th e contr ol pane l can be li fted

and r emove d.

a. b.

c.

d.

a.

3. Remov e the w ash c ove r

a

dra w out the w ash cov er with

the h elp of a sc rew-d river .

. Kee p the was h cover o pen and

Page 6

-10 --9-

4.DISMANTLING WAYS OF MAIN PARTS

Operation step

a.

4. Remov e the p uls ato r

a. the p ulsat or scre w.

b. Dr aw out th e pulsa tor wit h

han ds.

Scr ew off

Picture

b.

a.

5. Remov e the o ver flo w cover

kit

a.H old the

the n pull it o ut.

overfl ow co ver k it

a. b.

6.Remo ve th e fra me

a. Sc rew off t he scr ews of th e

fra me.

b. Th e frame c an be rem oved.

4.DISMANTLING WAYS OF MAIN PARTS

Operation step

Picture

a.

a.

9. Remov e the m oto r pul ley

a.L oosen t he nut wi th spec ial

wre nch,t hen loo sen the s crew.

10. Remo ve th e cap aci tor

a.H old fir m the cap acito r then

pul l it out.

a.

b.

8. Remov e the b ase

a. Pr ess the V-be lt at the par t near

the pull ey. Then t ake do wn th e

V-be lt by rot ating t he pull ey.

b. Spr ead one bl anket on the

floor th en lay down the wash ing

machine. Pul l out the drain hose

from the cl amp and dr aw out the

drain ho se subassem bly. Af ter

screws on the base a re

uns crewe d, the ba se asse mbly

can b e disas sembl ed.

Page 7

-12 --11-

5.ELECTRONIC COMPONENTS

Operation step

Picture

1. Self- tes t met hod o f wash

timer an d

Turn th e wash tim er to work

condi tion . Use a multime ter to

mea sure th e conne ction a nd

di scon nect ion c ond iti on o f

in put t erm ina l(b rown w ire) a nd

out put ter minal ( yello w or oran ge

wir e), and t he wash t imer sh ould

be re gular o n-off .

wash-d rai n

select ion s wit ch

Use a m ulime ter to me asure t he

sel ectio n switc h, the sw itch

sho uld be re gular o n-off .

5.ELECTRONIC COMPONENTS

2. Self- tes t met hod o f capacit or

Use an analog multimeter to measure

capacitance by connecting t he t wo

ends of capacitor with the multim eter

rod connecto r . If the pointer swi ng

to the direction of smaller

resistance ,and then turn back to

the dir ectio n of “0” slowly, it means

that the capacitor is ok . If not , it

mea ns that t he capa citor i s

fau lted.

3. Self- tes t met hod o f motor

a. To check wheth er the mo tor

in sul ati on i s da mag ed b y

wa ter le aka ge:

Use a 500 V megohmmet er to

measure whe ther the insu lation

resista nce of motor is higher than

30MΩ At th e same ti me, che ck

whe ther th e other r esist ance of

the m otor ar e norma l. If the

oth er resi stanc e are abn ormal

(an y short-circuit, open circuit

appears), the mo tor c an not be

used. Only the two items are

normal, the motor can b e used .

.

Operation step

Picture

b. Check whether the motor

resistance is normal i n the

condit ion o f no wa ter

condit ion :

Use a m ultim eter to m easur e the

res istan ce of the three leads, and

name them R1, R2, R3

.On ly the

“R1 +R2=R 3” indicates that the

motor resistance is normal.

(th e max.

one n ame R3)

c. Check t he mo tor o per ation

condit ion :

For the motor under

use, add certain 20 # machine oil on

the upper and down bearing to

eliminate the negative effect arisin g

from water leakag e.After pow ering

on the two component s, ther e

sho uld be no o bviou s noise ,

vib ratio n,or od or of the m otor.

Use power cab le with fuse to

connect the motor a nd capacito r

correctl y, and do the prepara tion

for i nsula tion.

Page 8

-14 --13 -

6.CIRCUIT DIAGRAM

Circuit diagram

Black

Brown

Fuse

Yellow

/Green

Brown

Light blue

Red

Wash motor

C1

M1

Green

Red

Yellow

Yellow Yellow

Yellow

Wash timer

7.EXPLORED VIEW & LIST OF PARTS

1 Control Panel Assembly

2 Twin-tub Assembly

3

/

4 Base Assembly

1

4

2

Circuit diagram

Abo ve Circ uit Dia gram is o nly for r efere nce, an d the sta ndard C ircui t Diagr am is

acc ordin g to the ra ting la bel of co mplet e machi ne.

Page 9

-16 --15 -

7.EXPLORED VIEW & LIST OF PARTS

1.1

/

1.2

/

1.3

/

1.4

/

1.5

/

1.6

/

1.7

/

1.8

/

1.9

/

1.1O

/

1.11

Top Frame

1.12

/

1.13

/

1.14

/

1.15

Wash Cover Kit

1.16 Wash Timer

1.17 Control Panel

1.18 /

1.19 Knob

1.17

1.15

1.11

1.19

1.5

1.16

7.EXPLORED VIEW & LIST OF PARTS

2.3.1 Overflow Cover

2.3.2 Lint Filter

2.4 Back Cover

2.5 Drain Pipe

2.6 Retarder kit

2.7 Drain Valve K it

2.8 Bottom Valve

2.9 Anti-vibration Ring

2.1O Rubber Washer

2.11 B rake Block

2.12 Twin-tub

2.13 Flas hing

2.14 P ulsator Screw Kit

2.14

2.1

2.3.1

2.3.2

2.4

2.5

2.12

2.8

2.6

2.13

2.5

2.3

Page 10

-18 --17 -

7.EXPLORED VIEW & LIST OF PARTS

4.1

V-belt

4.2

Small Pulley

4.3

Wash Motor

4.4.1

Specific Screw for Wash Motor

4.4.2

Specific Washer

4.4.3

Rubber (upper)

4.5

Rubber (lower)

4.6

Base

4.7

/

4.8

Wire

4.9

/

4.1O

/

4.11

/

4.12

/

4.13

/

4.14

/

4.1

4.2

4.3

4.4.2

4.5

4.6

4.8

4.4.1

4.4

Loading...

Loading...