Page 1

Page 2

Page 3

54321

-

6

C1

103

CON1

温度传感器

EC1

47U/16V

2.7V/DO35

P0.3

R43

2K

R62

1K

P0.5

P1.0

3

2

1

IC1

Vss4SDA

A2

A1

A0

24C02

R15

R16

4.7k(%)

4.7k

R14

123

100k

TR7

8550

+5V

+5V

R46

R44

20K

20K

P4.1

RN2

P1.1/BUZ

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P4.0

SWD

R592KR60

1

2

3

4

5

6

7

SWC

2K

IC3

IC/ULN2003

IN1

IN2

IN3

IN4

IN5

IN6

IN7

TR8

8550

R38

RESET

1K

R37

10K

C14

C13

104

104

RN10K*7

P0.4

P4.5

P4.4

R47

R45

2K

R49

2K

2K

VSS8VDD

+5V

R63

10K

TR8

R60

10K

8050

C24

104

Title

R61

3K3

Number RevisionSize

B

Date: 26-Mar-2008 Sheet of

File: C:\PROG RAM FILES\DESIGN EXPLORER 99 SE\EXAMPLES\

SCL

WP

Vcc

P4.2

SWB

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

C17

104

R48

20K

R61

2K

1N4007

D11

+5V

5

6

7

+5V C2

8

R50

20K

P4.3

SWA

R62

2K

16

15

14

13

12

11

10

9

R17

10K

104/25V

+12

R18

10K

P0.1

P0.0

D

+12

R58

3k

BUZ1

RLY1

N

+12

J

C

LAMP

RLY2

N

+12

J

FAN

RLY3

CONVECTION

J

J

J

DOOR1

RLY4

GRILL

RLY5

MICRO

+12

B

A

Drawn By:

微波炉电脑板ACXEEMP-02

+5V

P2.0

TR1

8550

D

TR2

8550

R1

4.7K

TR3

8550

R2

4.7K

TR4

8550

R3

4.7K

TR5

8550

R4

4.7K

TR6

8550

R5

4.7K

R6

4.7K

P2.1

P2.2

P2.3

+5V

P2.4

P2.5

P2.6

P3.2

P3.1

P3.0

P4.6

P4.5

P4.4

P4.3

P2.7

P2.6

P2.5

44

43

42

41

40

39

38

37

36

35

34

C3

471C4471C5471C6471

EC2

47U/16V

+5V

s17/txd/p3.2

s16/rxd/p3.1

s15/p3.0

s14/p4.6

s13/p4.5

s12/p4.4

s11/p4.3

s10/p2.7

s9/p2.6

s8/p2.5

s7/p2.4

C7

104/50V

P3.3

P3.4

P3.5

2

1

3

s18/int0/p3.3

tout/int1/p3.4

S3F9488-QFP

C8

C10

471

471

C9

20P

CSA1

4MHz

P3.6

4

6

5

Vss

Vdd

tack/int2/p3.5

tacap/int3/p3.6

44-QFP

R34

7

8

Xin

Xouot

33

C20

104

P2.3

P2.2

P2.1

P2.0

P4.2

P4.1

P4.0

P1.7

+5V

R55

R54

10K

10K

R52

1K

P0.6

P0.7

C22

C21

R53

1K

471

471

P3.0

P3.6

EC4

Z3

R41

1K

R42

390/1/4W

P3.1

C16

471

Q1

8050/TO92

220UF/16V

P3.4

P3.5

1

DIG1 DIG2 DIG3 DIG4

P3.3

2

9

10

34512678

+5V

CON-WRITE1

6PIN

CON2

3.96MM*7

L

6

5

4

3

2

1

7

6

5

4

3

2

1

RN1

RN20K*7

FAN

LAMP

N

L

P3.6

P3.5

test

resetb

TRAN1

+5V

D1

4148

R26

220

R39

2K

D2

1N4007

220

D3

1N4007

1N4007

R29

R28

R27

R30

220

220

220

C15

103

D5

1N4007

D4

470UF/25V

C

B

P3.2

14

LED1

11 13

R31

R32

R33

220

220

220

P2.7

P2.4

P2.5

P2.6

P2.3

P2.2

P2.1

P2.0

Z2

R40

4.7V

2K

EC3

C18

104

5.6V/DO35

1N4007

D6

N

A

PT6329A

1N4007

1N4007

D9

D8

1N4007

D7

470UF/25V

+12

EC5

C19

R51

104

5K1(1/4W)

R7

2K

R8

2K

R9

2K

R10

2K

R11

2K

R12

2K

R13

2K

C11

471

1M

P0.0

P0.1

TEST

10

9

11

test

XTin/p0.0

XTout/p0.1

p0.2/resetb

p0.3/adc8

p0.4/com7/adc7

p0.5/com6/adc6

p0.6/com5/adc5

p0.7/com4/adc4

p1.0/adc3/tbpwm

p1.1/adc2/buz

p1.2/adc1

p1.3/adc0

p1.4/com323p1.5/com224p1.6/com125p1.7/com026p4.0/s027p4.1/s128p4.2/s229p2.0/s330p2.1/s431p2.2/s532p2.3/s6

P1.6

P1.5

P1.4

B1 SW_CONDER

C12

20P

AVref

SW1

SW2

SW3

SW4

SW5

SW6

SW7

+5V

R35

1K

R36

1.2k

Z1

IC2

12

RESET

13

P0.3

P0.4

14

15

P0.5

16

P0.6

17

P0.7

18

19

P1.0

20

P1.1/BUZ

21

P1.2

22

P1.3P2.4

P4.6

C23

104

1 2 3 4 56

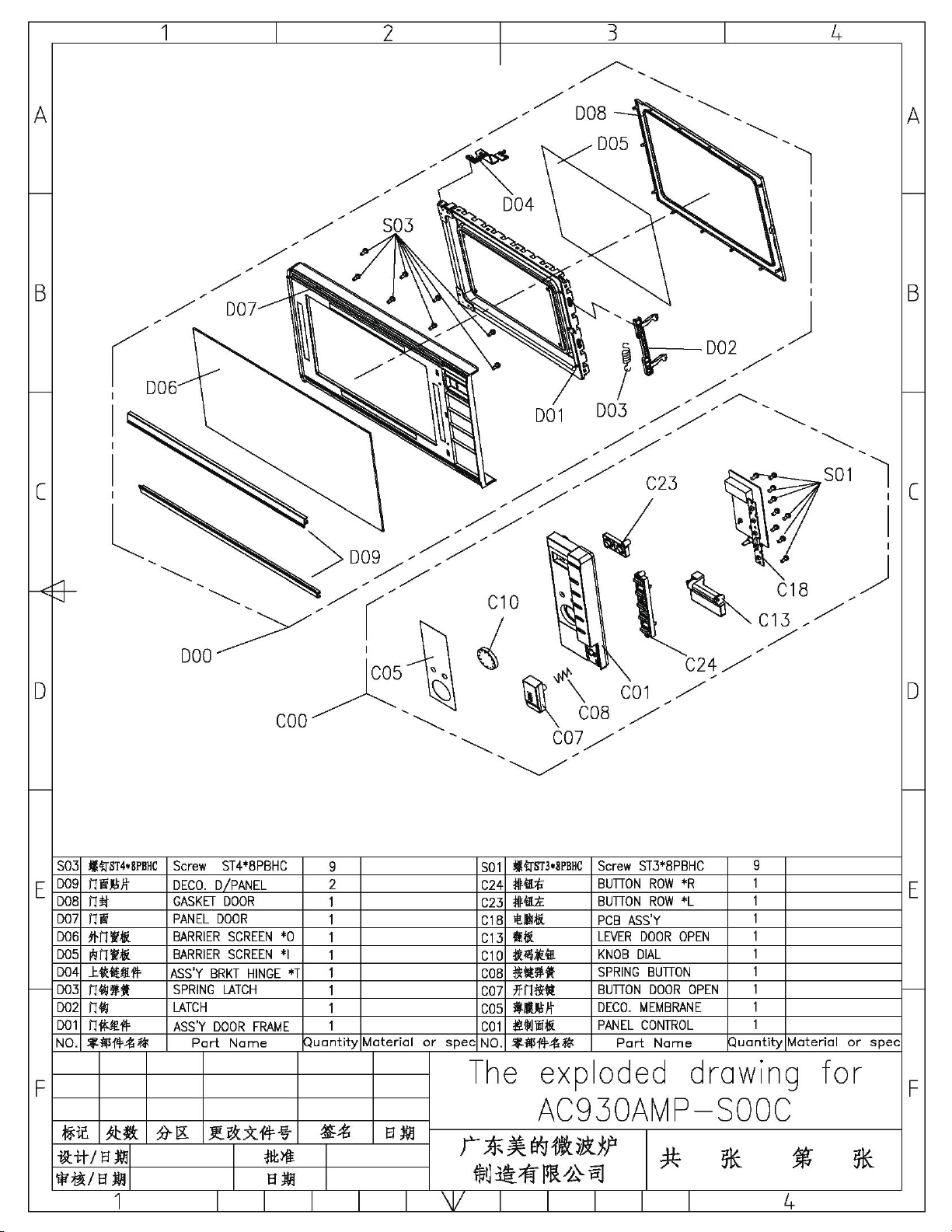

Page 4

MICROWAVE OVEN

MODEL:

AC930AMP-S00C

(900W 220 V 50Hz)

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,READTHE SAFETY PRECAUTIONS IN THIS

MANUAL

Page 5

SAFETY PRECAUTIONS

This device is to be serviced only by properly qualified service personnel.

Consult the service manual for proper service procedures to assure continued safety operation and for precautions to

be taken to avoid possible exposure to excessive microwave energy.

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

A) Do not operate or allow the oven to be operated with the door open.

B) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary; (1) interlock operation, (2) pr oper door closing, (3)

seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and

latches, (5) evidence of dropping or abuse.

C) Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, wave guide or transmission line, and cavity for proper a lignment,

integrity, and connections.

D) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generatio n

and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual

before the oven is released to the owner.

E) A microwave leakage check should be performed on each oven prior to release to the owner.

CAUTION

MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM THE MICROWAVE GENERATOR

OR OTHER PARTS CONDUCTING MICROWAVE ENERGY.

Page 6

TABLE OF CONTENTS

(page)

SAFETY PRECAUTIONS---------------------------------------------------------Inside front cover

CAUTIONS------------------------------------------------------------------------------------------------1-1

THE HEATING PRINCIPLE OF MICROWAVE--------------------------------------------------2-1

INSTALLATIONS----------------------------------------------------------------------------------------3-1

OPERATING INSTRUCTIONS----------------------------------------------------------------------4-1

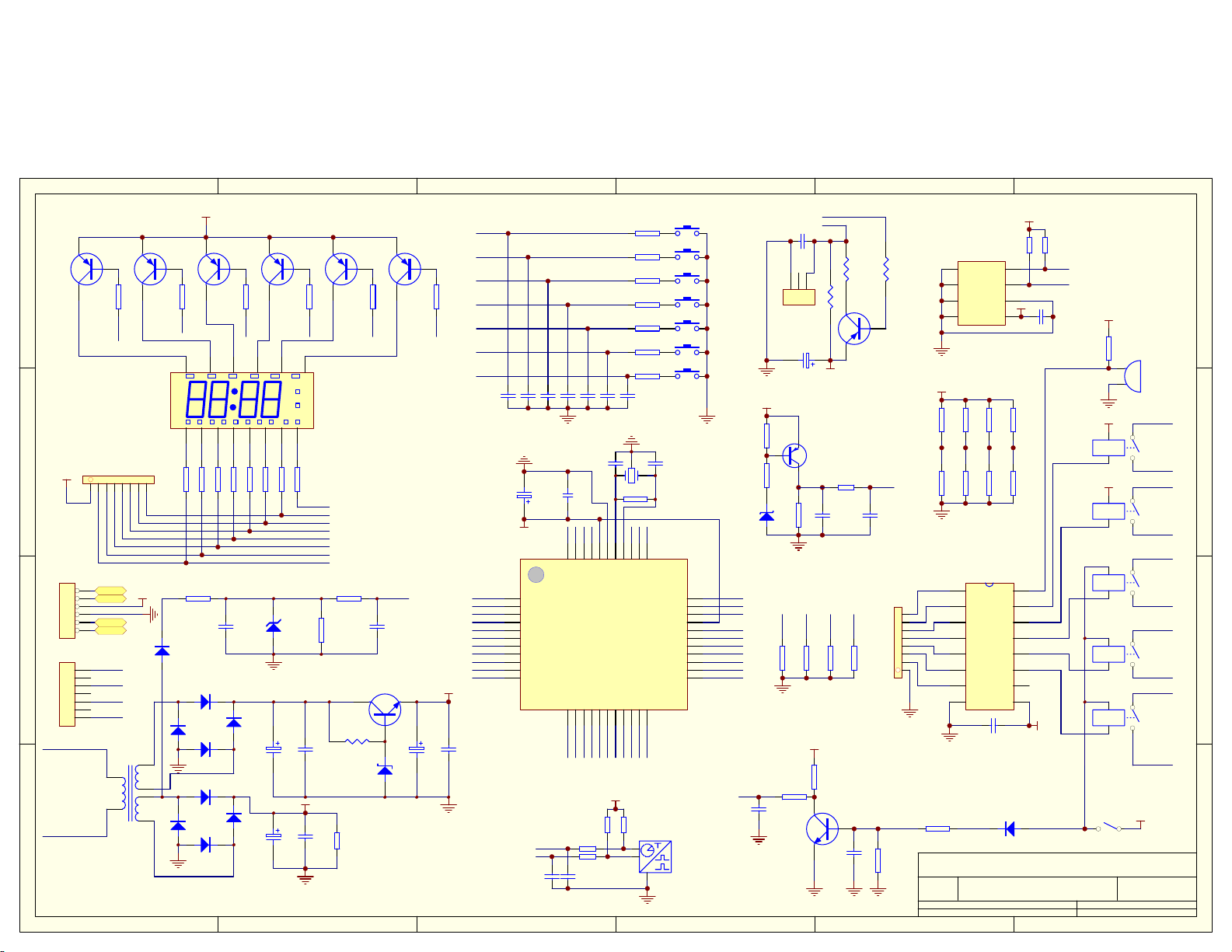

SCHEMATIC DIAGRAM--------------------------------------------------------------------------4-1

CIRCUIT DESCRIPTION-------------------------------------------------------------------------4-2

SERVICE INFORMATION-----------------------------------------------------------------------------5-1

TOOLS AND MEASURING INSTRUMENTS------------------------------------------------5-1

MICROWAVE LEAKAGE TEST----------------------------------------------------------------5-2

MEASUREMENT OF MICROWAVE POWER OUTPUT---------------------------------5-3

TROUBLE SHOOTING PROCEDURES------------------------------------------------------5-4

COMMON BREAKDOWN AND MEANS OF REPAIRING-------------------------------5-8

I M PORTANT TH I N GS TO DO PRIOR T O C RITICAL PA R T S E RVIC I N G-------------------------5-9

SAFETY CHECKS AND TESTS AFTER SERVING--------------------------------------5-10

EXPLODED VIEW---------------------------------------------------------------------------------------6-1

REPLACEMENT PARTS LIST-----------------------------------------------------------------------6-1

Page 7

CAUTIONS

Unlike other appliances, the microwave oven

is

high-voltage and high-current equipment.

Though it is free from danger in ordinary use,

extreme care should be taken during repair.

• DO NOT operate on a 2-wire extension cord during

repair and use.

• NEVER TOUCH any oven components or wiring during

operation.

• BEFORE TOUCHING any parts of the oven, always

remove the power plug from the outlet.

• For about 30 seconds after the oven stops, an electric

charge remains in the high voltage capacitor. When

replacing or checking, you must discharge the high

voltage capacitor by shorting across the two terminals

with an insulated screwdriver.

• Remove your watches whenever working close to or

replacing the Magnetron.

• DO NOT touch any parts of the control panel circuit. A

resulting static electric discharge may damage this

P.C.B.

• NEVER operate the oven with no load.

• NEVER injure the door seal and front plate of the oven

cavity.

• NEVER put iron tools on the magnetron.

• NEVER put anything into the latch hole and the

interlock switches area.`

1-1

MICROWAVE RADIATION

Personnel should not be exposed to the

microwave energy which may radiate from the

magnetron or other microwave generating

device if it is improperly used or connection.

All input and output microwave connections,

waveguide, flange and gasket must be secure

never operate the device without a microwave

energy absorbing load attached.

Never look into an open waveguide or antenna

while the device is energized.

• Proper operation of the microwave oven

requires that

the magnetron be assembled to the waveguide

and

cavity. Never operate the magnetron unless it is

properly installed.

• Be sure that the magnetron gasket is

properly

installed around the dome of the tube

whenever

installing the magnetron.

THE OVEN IS TO BE SERVICED

ONLY

BY PROPERLY QUALIFIED SERVICE

PERSONNEL.

Page 8

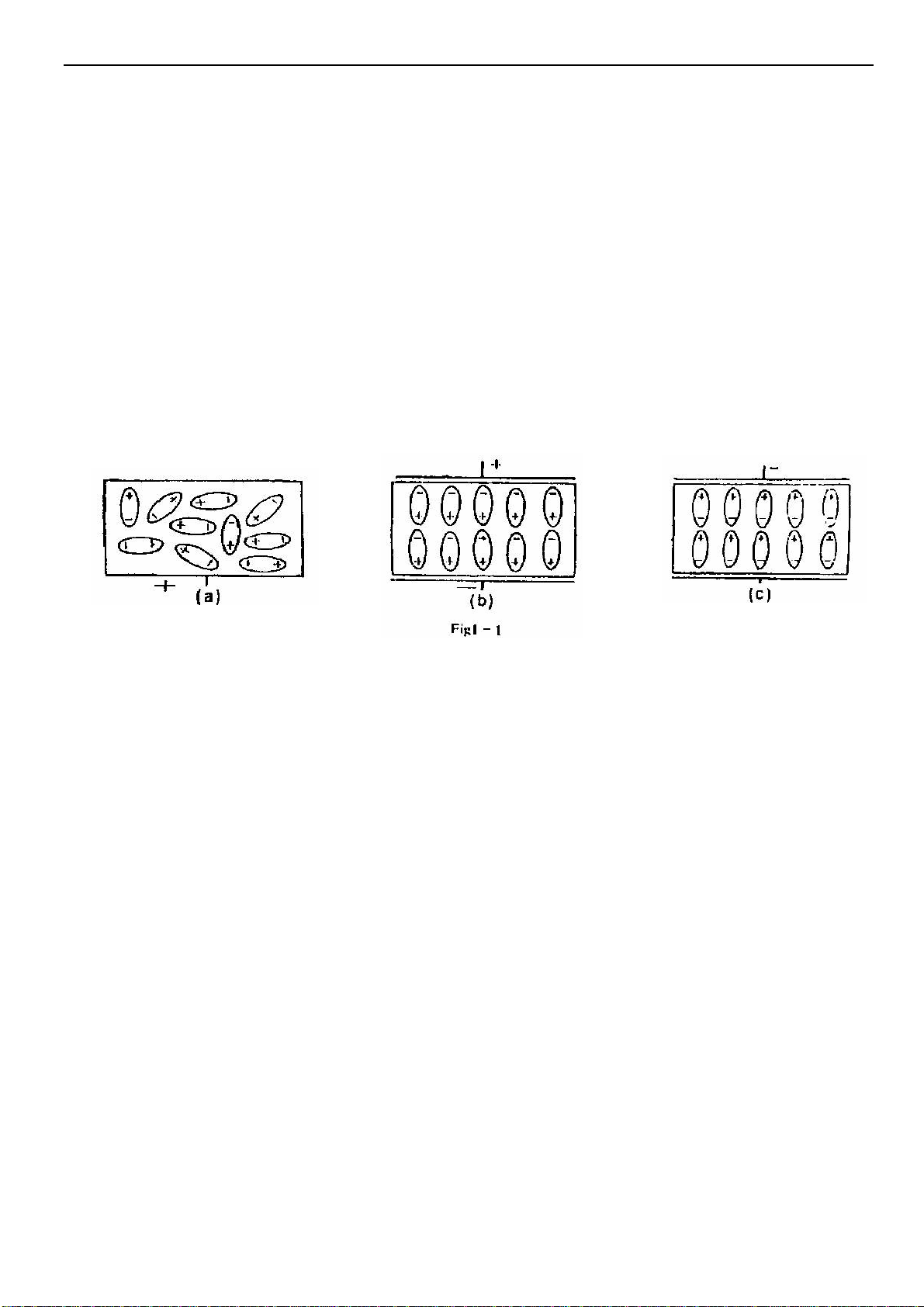

THE HEATING PRINCIPLE OF MICROWAVE

Microwave is one kind of radio wave whose wave length is very short, frequency is very high. Therefore, it is called ultrahigh

frequency electromagnetic wave. Microwave can heat food mainl y result in the mutual affect of the food in the microwave field and

microwave field itself.

Under the affect of microwave field, the thermal effect mechanism produced from the mutual affect of the microwave and the food

includes two aspects: One is Dielectric loss of polar molecule, the other is conductive loss of ion.

Usually, food is constitute of organism (plant and animal).The organism is formed by all kinds of polar water molecule, polar

protein molecule, and all sorts of salt ion. The center of gravity of the positive and negative charge in the molecule is not c oincide.

In normal condition, the molecule is in irregular order due to its thermal action, thus the food do not appear polarity (FIG.11a).Under the action of outer electric field, the positive end of the polar molecule tre nd to the negative electric field, the negative

end of polar molecule trend to the positive electric field, and somewhat arrange in order through the direction of the electric

field(FIG.1-1c).This phenomenon usually be called “TORQUE POLARITY”. When the outer electric field apply for the opposite

polarity, the polar molecule then arrange an opposite direction order accordingly (FIG.1-1b).If the direction of the outer electric field

changed repeatedly, the polar molecule would repeatedly sway accordingly. During the swaying, it understands that the polar

molecule would produce heat due to somewhat similar friction among them.

When the electric field is applied for ultrahigh frequent microwave field from the outside, its direction would chang e tens billion

times per second, so do the molecule. This kind of molecule swaying producing similar frictional heat from the interference and

block of the action strength among the molecule, and changed to microscopic microwave heating. Microwave heating not only

concerned the nature of the matter itself, but also closely connected with the electric field strength and frequency. When the

frequency is low, the molecule swaying rate and the acute degree of the mutual friction among the molecule is low, and would

produce much heat. When the frequency is too high, as the swing of the polar molecule is with rotating inertia, it made the swing

do not in line with the changing rhythm of the electric field because of the friction drag, thus, actually lowed the polar molecule

swaying speed. The friction dragging degree is concerning a bout the ma gneto electric wave frequenc y, polar molecule shape, and

the matter’s sticky degree. To different matter’s molecule, there are different special frequency zone. Those ado absorb microwave

energy from these zone are most capable to turn microwave energy to heat energy.

Apart from the above said action, there is another action which is electric ion under t he action of microwave field, act fiercely

accompanied with the acceleration of electric field. The positive ion transfer to the negative polarity of the field while the negative

ion do opposite. Accompanying with the changing electric field, the electric ion changing according ly. During the transferring, heat

produced with the crash among the ion. This kind of action take the main effect to those microwave heating of high salt molecule.

No matter it is the polar molecule swaying or the ion transferring, they both are turning the microwave energy which the heatin g

matter got from the microwave field to hear energy. From the analysis of theory, we can draw such a conclusion that the power

which a unit of volume matter absorbed from the microwave field as the following formula:

Pa=K·E· F·Er·tgδ

Pa Stands for the power the heated matter absorbed from the microwave field.

K Stands for a constant

E Stand for microwave field strength

F Stands for the microwave frequency.

Er Stands for relative dielectric constant of the heated matter.

tgδStands for loss angle tangent of the heated matter

2-1

Page 9

INSTALLATIONS

BEFORE YOU BEGIN, READ THE FOLLOWING INSTRUCTIONS COMPLETELY

INSTALLING

1. Empty the microwave oven and clean inside it with

a soft, damp cloth. Check for damage such as

misaligned door, damage around the door or dents

inside the cavity or on the exterior.

2. Put the oven on a counter, table, or shelf that is

strong enough to hold the oven and the food and

utensils you put in it. (The control panel side of the

oven is the heavy side. Use care when handling.)

3. Do not block the vent and the air intake openings.

Blocking vent or air intake openings can cause

damage to the oven and poor cooking results.

Make sure the microwave oven legs are in place to

ensure proper air flow.

4. The oven should not be installed in any area where

heat and steam are generated, because they may

damage the electronic or mechanical parts of the

unit.

Do not install the oven next to a conventional

surface unit or above a conventional wall oven.

5. Use microwave oven in an ambient temperature

less than 104°F(40°C).

6. Place the microwave oven on a sturdy and flat

surface at least 10 cm(4 inches) from the wall.

7. Place the microwave oven as far away as possible

from TV, RADIO, COMPUTER, etc., to prevent

interference.

EARTHING INSTRUCTIONS

This microwave oven is designed to be used in a fully

earthed condition.

It is imperative, therefore, to make sure it is properly

earthed before servicing

WARNING-

THIS APPLIANCE

MUST BE EARTHED

IMPORTANT

The wires in this mains lead are colored in

accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colors of the wires in the mains lead of this

appliance may not correspond with the colored

markings identifying the terminals in your plug,

proceed as follows.

The wire which is colored green-and-yellow must be

connected to the terminal in the plug which is marked

with the letter E or by the earth symbol (

colored green or green-and-yellow.

The wire which is colored blue must be connected to

the terminal in the plug which is marked with the letter

N or colored black.

The wire which is colored brown must be connected

to the terminal in the plug which is marked with the

letter L or colored red.

) or

3-1

Page 10

AC930AMP-S00C

Page 11

CIRCUIT DESCRIPTION

As the door is closed, the contact of MONITOR

SWITCH opens. This switch creates the short circuit to

blow fuse during operation under abnormal condition.

(ie, should the contacts of primary and secondary

switch fail to open the circuit)

• The latches are secured by latch board. The oven light

turns on while the oven is in operation.

WHEN MICROWAVE POWER LEVEL

AND COOKING TIME SET

• The contacts of the timer switch changes to ON

position when the timer knob is rotated.

(While power control knob is set )

• The contacts of primary and secondary switch close

the circuit.

• Input Volts AC. is applied to the high voltage

transformer through V.P.C.

• 3.2 volts AC is generated from the filament winding of

the high voltage transformer. This 3.2 volts is applied

to the magnetron to heat the magnetron filament

through two noise-preventing choke coils.

A high voltage of approximately 2100 volts AC is

generated in the secondary of the high voltage

transformer which is increased by the action of the

diode and charging of the high voltage capacitor.

The negative DC voltage is then applied to the filament

of the magnetron

WHEN THE DOOR IS OPENED DURING

COOKING

• Both primary switch and secondary switch open to cut

off the primary winding voltage to the high voltage

transformer to stop microwave oscillation.

• Timer, turntable and fan motor stop.

• As the door is opened, if the contact of primary switch

fail to open, the fuse opens due to the large current

surge caused by the monitor switch activation which in

turn stops magnetron,oscillation.

• Turntable rotates.

• The fan motor rotates and cools the magnetron by

blowing the air (coming from the intake holes on the

baseplate) over the magnetron.

• The air is also directed into the oven to exhaust the

vapor in the oven through the upper plate.

• Timer starts rotating.

4-2

Page 12

SERVICE INFORMATION

TOOLS AND MEASURING INSTRUMENTS

NECESSARY TOOLS

Tools normally used for TV servicing are sufficient.

Standard tools are listed below.

• Diagonal pliers

• Long nose pliers

• Phillips screwdriver

• Flat blade screwdriver

• Wrench (size 5mm)

• Nutdriver (size 5mm)

• Adjustable wrench

• Soldering iron

• Solder

• Vinyl insulation tape

• Polishing cloth

MICROWAVE LEAKAGE TEST

CAUTIONS

• Be sure to check microwave leakage prior to

servicing the oven if the oven is operative prior to

servicing.

• The service personnel should inform the

manufacture importer, or assembler of any certified

oven unit found to have a microwave emission

2

level in excess of 5 mW/cm

unit found to have excessive emission levels at no cost

to the owner and should ascertain the cause of the

excessive leakage. The service personnel should

instruct the owner not to use the unit until the oven has

been brought into compliance.

• If the oven operates with the door open, the service

personnel should:

- Tell the user not to operate the oven.

- Contact the manufacturer.

• The service personnel should check all surface and

vent openings for microwave leakage.

• Check for microwave leakage after every servicing. The

power density of the microwave radiation leakage

emitted by the microwave oven should not exceed

2

5 mW/cm

to assure safety for operating personnel from radiation

leakage.

. Always start measuring of an unknown field

and should repair any

5-1

NECESSARY MEASURING

INSTRUMENTS

• TESTER(VOLTS-DC, AC., Ohmmeter)

• Microwave survey meter

- Holaday HI-1710(A)

- Narda 8100

8200

• Inch scale

• 600 cc non conductive material beaker (glass or

plastic), inside diameter: approx. 8.5 cm(3

• Cylindrical and made of borosilicate glass vessel.

max. thickness: 3 mm

outside diameter: approx. 190mm

height: approx. 90mm

• Glass thermometer: 100°C or 212°F (1 deg scale)

1/2 in.)

MEASURING MICROWAVE ENERGY

LEAKAGE

• Pour 275±15 cc of 20±5°C(68±9°F) water in a

beaker

which is graduated to 600 cc, and place the beaker

on the center of the turntable.

• Set the energy leakage monitor to 2,450 MHz and

use it following the manufacturer's recommended

test procedure to assure correct result.

• When measuring the leakage, always use the 2-

inch (5 cm) spacer supplied with the probe.

• Operate the oven at its maximum output.

• Measure the microwave radiation using and

electromagnetic radiation monitor by holding the

probe perpendicular to the surface being measured

Move probe along shaded area

Probe scanning speed: Less than 2.5 cm/sec

Page 13

MEASUREMENT WITH OUTER CASE

REMOVED

• When you replace the magnetron, measure for

microwave energy leakage before the outer case is

installed and after all necessary components are

replaced or adjusted.

Special care should be taken in measuring the

following parts.

- Around the magnetron

- The waveguide

WARNING : AVOID CONTACTING ANY

(Magnetron, H.V. Transformer,

H.V. Capacitor, H.V. Cable Ass’y,

H.V. Fuse)

HIGH VOLTAGE PARTS

MEASUREMENT WITH A FULLY

ASSEMBLED OVEN

• After all components, including the outer case, are fully

assembled, measure for microwave energy leakage

around the door viewing window, the exhaust opening,

and air inlet openings.

• Microwave energy leakage must not exceed the values

prescribed below.

NOTE: Leakage with the outer case removed less than

2

3 mW/cm

oven (Before the latch switch (primary) is

interrupted) with the door in a slightly opened

position-less than 1 mW/cm

. Leakage for a fully assembled

2

NOTES WHEN MEASURING

• Do not exceed meter full scale deflection.

• The test probe must be removed no faster than

1 inch/sec (2.5 cm/sec) along the shaded area,

otherwise a false reading may result.

• The test probe must be held with the grip portion of

the

handle.

A false reading may result if the operator's hand is

between the handle and the probe.

• When testing near a corner of the door, keep the

probe

perpendicular to the surface making sure the probe

horizontally along the oven surface, this may possibly

cause probe damage.

RECORD KEEPING AND NOTIFICATION

AFTER MEASUREMENT

• After adjustment and repair of any microwave energy

interruption or microwave energy blocking device,

record the measured values for future reference. Also

enter the information on the service invoice.

• The microwave energy leakage should not be more

2

than 1.0 mW/cm

good condition, functioning properly and genuine

replacement parts which are listed in this manual have

been used.

• At least once a year, have the electromagnetic energy

leakage monitor checked for calibration by its

. after determining that all parts are in

5-2

Page 14

MEASUREMENT OF MICROWAVE POWER OUTPUT

• Microwave power output measurement is made with

the microwave oven supplied at its rated voltage and

operated at its maximum microwave power setting with

a load of (1000±5) g of potable water.

• The water is contained in a cylindrical borosilicate glass

vessel having a maximum material thickness of 3 mm

and an outside diameter of approximately 190mm.

• The oven and the empty vessel are at ambient

temperature prior to the start of the test.

• The initial temperature (T1) of the water is (10±2)°C It

is measured immediately before the water is added to

the vessel. After addition of the water to the vessel,

the load is immediately placed on the center of the

turntable which is in the lowest position and the

microwave power switched on.

• The time T for the temperature of the water to rise by a

value . T of (10±2)°K is measured, where T is the time

in seconds and .T is the temperature rise. The initial

and final water temperatures are selected so that the

maximum difference between the final water

temperature and the ambient temperature is 2°K.

• The microwave power output P in watts is

calculated

approximately from the following formula :

P=4187 x (△T)/T

is measured while the microwave generator is

operating at full power. Magnetron filament heat-up

time is not included. (about 3 sec)

• The water is stirred to equalize temperature

throughout

the vessel, prior to measuring the final water

temperature.

• Stirring devices and measuring instruments are

selected in order to minimize addition or removal of

heat.

5-3

Page 15

TROUBLE SHOOTING PROCEDURES

Before overhauling a microwave oven, you should judge the breakdown and the cause correctly, then you can repair it with

corresponding ways. The overhauling must be proceed in order, any hasty conclusion is not recommendable, otherwise

overworking would be done when repair. The microwave oven may occur compound breakdown due to all kinds of different

reasons, thus, when overhaul, they all should be taken into consideration. Special attention must be given to the microwave

leakage and the electric insulation when examine because they may do harmful to the repairing staff.

Ⅰ.MEANS OF THE BREAKDOWN EXAMINING

How to examine a microwave oven with breakdown? A better means which demonstrated in practical operating are through

inspecting and listening. On the basis of large amounts of perceptual knowledge, you can judge and analysis the breakdown

quickly and correctly.

1. Inspection.

Inspect whether the oven shape is disordered and where is the disordered position, if any. It is normal if the outer case

disordered a little, but abnormal if the oven, the door disordered, the door hook broken, the door crooked, or there are too

much looseness between the door and the oven after the door is closed.

2. Listening.

Listening to the voice of the oven operating and the noise of the fan after it conducted. Minor “wen wen” noise, cycling “kala”

noise and “shishi” noise should be consider as normal. But it is abnormal if the following noise occurred:

(1) Sound “wenwen” noise.

(2) Long time “shishi” noise.

(3) Strike voice like “pipa pipa”.

Ⅱ.SPOT EXAMINING STEPS OF THE MICROWAVE OVEN.

1. Examine the microwave insulating res istance.

Measure the insulating resistance with a multi meter or a mega ohmmeter. The value should not less than 2 mega ohm.

Otherwise, part examination should be taken at once. Such as checking whether the motor, the thermal cutout, the

transformer or the capacitor are electricity leaking.

2. Examination of the resistance value of the micro wave oven.

Close the door, set the time (the oven is at operating condition but the power plug haven’t been pl ugged in), measure the t wo

feet(L-N)of the power plug with Rx1 grade of a multimeter, the resistance value should be about 22 ohm.

If open circuit occurred, then you must check whether the 10 A fuse is broken、the primary winding of the transformer is open

circuit、the thermal cutout is open circuit or not, you must check whether the interlock device is put through or all the plugs

are connected well. If short circuit occurred, you should check whether the primar y winding of the power transformer is shortcircuited or part short-circuited.

3. Examination of microwave leakage

Measure the microwave leakage with a microwave leakage Measure. Place a graduat e of 275ml water at the middle of the

glass tray of the oven (FIG.5-1). Close the door, power set high, time set to 3 minutes, press the starting button to operate the

oven. After rectified the microwave leakage measure, measure around the door crack, those hole position of the window and

the air vent at four sides of the oven with the probe of the measure. When meas ure, the moving speed of the probe shoul d

not exceed 2.5cm per second, and the measuring direction should be the same with the outing direction of the microwave

leakage (FIG.5-2).

When measuring, the ultimate value of microwave leakage of all the measured position should not exceed 1.0 mili watt/cm

or should be considered as abnormal.

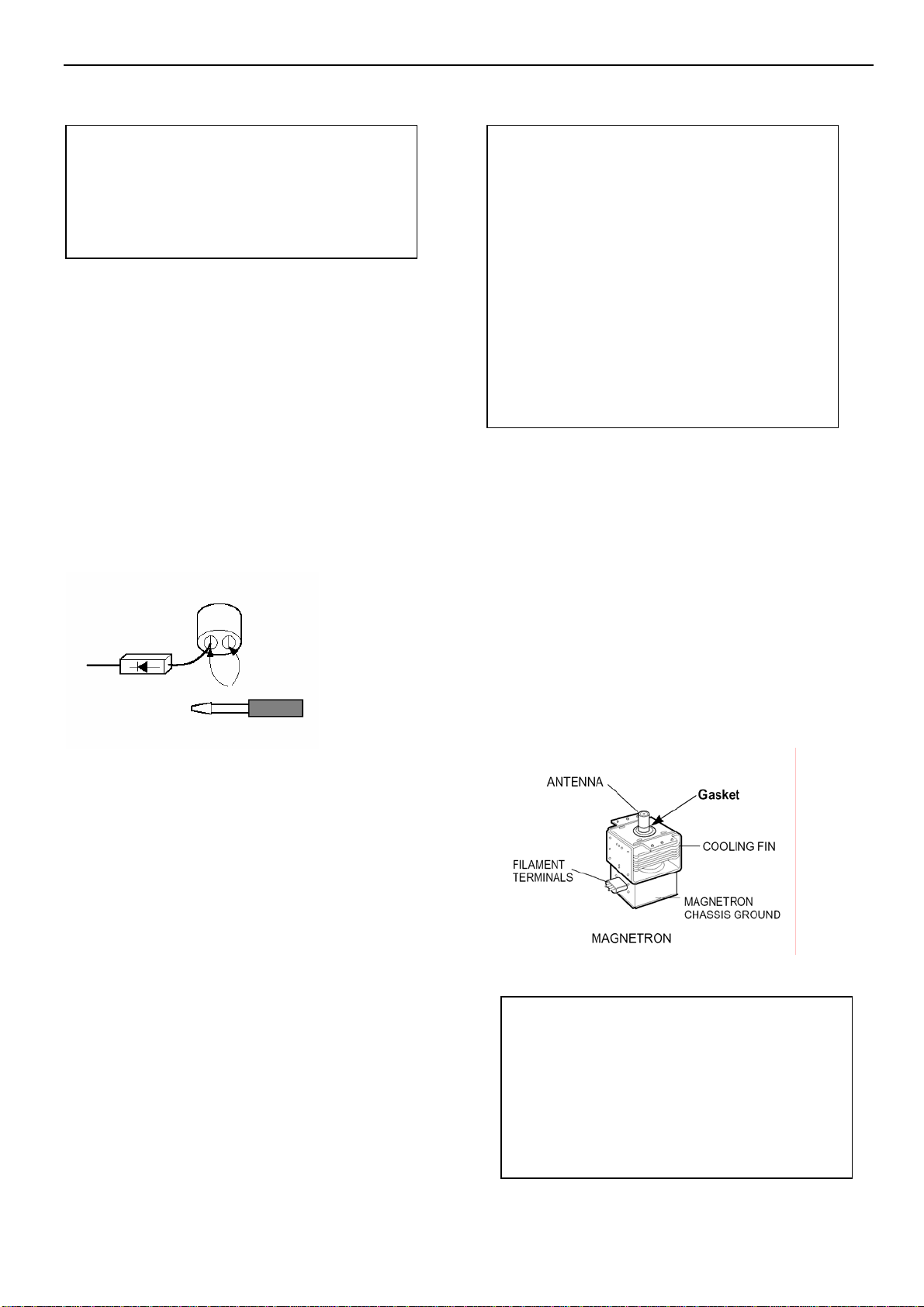

FIG.5-1

275ml

Glass tray

FIG.5-2

5-4

2

,

Page 16

4. Examine when the oven at operatin g, but the food can’t be heated

Pull out the power plug, take off the outer case, discharge the capacitor, measure the resistance value of the primary winding and

the secondary winding of the transformer with a multi meter (FIG.5-3 and FIG.5-4). The resistance value of the primary winding

should be about 2.2 ohm, the secondary winding should be about 130 ohm, other wise, it indicates the transformer has broken,

and should be replaced by a new one.

If the transformer is normal, then the high voltage capacitor should be checked. Pull out the connecting plug of the capacitor,

and measure it with Rx1 grade of a multi meter, the two rod of the multi meter connect the two polarity of the capacitor. When

they just connected, the reading of the multi meter should be zero, then enlarge to nine mega ohm slo wly. Change the rod to

different polarity, the reading repeat from zero to 9 mega ohm (FIG.5-5),it means the capacitor is normal. If the indicator of the

multi meter can’t point out from zero to 9 mega ohm, it indicates the high voltage capacitor has broken, and should be

replaced by a new one.

If it is normal between the two pole of the capacitor, then the insulation between the capacitor pole and the cabinet (FIG.5-6)

should be checked.

If the resistance value between the capacitor pole and the cabinet is “∞”,the capacitor is normal. Then check the earth of the

magnetron’s two filament to see whether they are short-circuited (FIG.5-7).If they are short-circuited and the filament strikes

the shell of the magnetron, it indicates the magnetron has broken, and should be replaced by a new, same model one.

If there is no problem with the magnetron, check the high voltage diode then. Measure the diode with Rx10k grade of a multi

meter, the “-” rod end of the multi meter connect the cathode of diode, the “+ “ rod end of the multi meter connect the anode of

the diode(FIG.5-8).The multi meter reading should be about 150 thousand ohm. Then change the rod to different

electrode(FIG.5-9), the reading should be “∞”.If the reading is very small, and near to short circuit, it indicates the high

voltage diode has been punctured, and should be replaced by a new one.

If high voltage diode is also normal, then test the pilot switch(FIG.5-10). Pull out the two plugs of the switch, Measure it with

the Rx1 grade of a multi meter, the two rod connect the plug of the switch, the resistance value should be “∞”.Then press

down the pilot switch with a screwdriver, if the reading of the multi meter pointed to zero, it indicates the pilot switch has

broken, and should replace it with a new, same model one.

FIG5-5

FIG.5-7

FIG5-6

FIG.5-8

5-5

Page 17

Ⅲ.REPAIRING METHOD OF SEVERAL BREAKDOWN

1. Repair when there occurred large amounts microwave leakage. T here are man y factors, which may cau se micro wave leaking .

Following mentioned may be the main cause of microwave leakage:

(1) The door deformed, the hinge loosed or damaged that caused the door can not close tightly.

(2) The door pressing cover or the embed piece damaged or come off.

(3) Obvious damage or uneven of the oven.

(4) There are filth between the door and the oven.

(5) The door and the oven are serious loosed after the door closed.

(6) The crack of the door shielding net cover.

Before repairing, check whether the above listed point are existed, if not, you can start the microwave oven. Place a

graduate of about 275ml water at the middle of the glass tray, close the door, time set at 3 minutes, power at high,

makes the oven operating in normal. Rectify the microwave leakage measure, measure the amount of the microwave

leakage around the oven with its probe. If there are places which the leakage exceed the standard requirement, then

repair them accordingly. If the leakage amount exceed 1.0 mW/cm

take down the outer case, adjust the screws of the hinge to less the gap bet ween the door and the ove n. Then measur e

again, the leakage amount should less than 1.0 mW/cm

some allowance.

If the leakage occurred at the right door crack, adjust the screws that fix the interlock holder and the hook . If the leakag e

is on the larger side at the right-above of the oven, then adjust the upper screw. Loosen out the screw, push the door

close to the oven to hook the door hook with the plastic parts, then tighten the screw again . If the leakage is larger at

the right-below, then adjust the lower screw. Loosen the screw, push the door close to the oven to hook the door hook

with the switch holder tightly, then tighten the screw again, and open and close the door repeatedly to check whether the

door can operate flexibly, whether the hook and the switch are in their normal position. If it is not in position, then adjust

the door hook and the switch holder the loose between the door and the oven, then measure the leakage with

microwave leakage measure again.

If there still exist microwave leakage, measure near the magnetron with the pr obe of the micro wave leakage m easure. If

the leakage is larger, the oven should be turned off and check whether the 2 or 4 screws which fix the magnetron have

been loosed, if loosed, twist them tightly with socket wrench. If the screws are fixedly, then the magnetron should be

take down to check the copper filament weaved washer of the magnetron has been placed well or whether the wave

guide housing coupling has been oxidized or have lacquer on it. If do have, scrape the oxi dized layer or the lacquer off,

when fix the magnetron, the copper filament weaved washer must be placed well, the screws must be twist tightly. Then

turn on the oven and measure again until it complies with t he requirement. If the microwave leakage is larger at those

hole position of the window board, the oven should be tur ned off to inspect whether there are crack among them. If

several holes formed a crack, it would enlarge the microwave leakage. If that is the case, it indicates the door has

broken, and should be replaced with a new door.

FIG.5-9

2

at the left door crack, then pull out the power plug,

2

. Generally, it should be controlled below 0.8 mill watt/cm2 with

5-6

FIG5.10

Page 18

2. Means of repair when the oven can heat, but the turntable glass can’t move

Firstly, check whether the turntable holder is placed correctly. If it is correct, then pull out the power plug and take down the

turntable combination, measure the resistance value of the turntable motor with Rx1k grade of a multi meter If it is opencircuited, it indicates the turntable motor has broken, and should be replaced by a ne w, same model one. If the resistance

value is between 15-22k,it indicates the turntable motor is normal, then check the connecting shaft weave. If the plastic that

the shaft insert in has broken, a new shaft weave should replace it.

3. Repair when the oven can heat, but the lamp is not on.

Pull out the power plug, take down the outer case and discharge the capacitor.

Pull out the two terminal plugs of the lamp, measure the two plugs of the lamp with the Rx100 grade of a multi meter. If it is

open-circuited, it indicates the lamp has broken, and should be replaced by a same model one.

4. Means of repair when the oven stop working after several minutes operating

The phenomenon indicated the thermal cutout is playing its protective role, and you should check whether the fan is working

in normal. Turn off the oven, pull out the power plug, take down the outer case, discharge the capacitor, then turn the fan with

hand to see whether it is moving flexibly. If not, it indicates that the oil bearing of the fan motor has run off the oil, and should

take down the fan combination to repair the motor. Loosen the two screws which fix the bearing out the shaft and the bearing,

and rinse them with kerosene (ATTENTION: The bearing can only be wiped with a silk which moistened with kerosene rather

than be washed in the kerosene because there are felt on it. If the felt are soaked with kerosene, then the engi ne oil can not

be sucked up.).After the bearing being cleaned, the felt should be refueled full y with engine oil(for when the oven is operating,

the engine oil empty into the oil bearing slowl y).Fix the bearing cover with two screws, turn the fan around till it can move

flexibly. Than install them to the oven, and plug in the two terminal plugs.

If the fan can move flexibly, then the winding of the fan motor should be examined. Meas ure the winding with R x100 grade of

a multi meter, if it is open-circuited, it indicates the winding of the fan motor has broken, and should be replaced by a new,

same model one.

5-7

Page 19

MOTOR TEST PROCEDURE

COMPONENTS TEST PROCEDURE RESULTS

Fan Motor

(Wire leads removed)

Turntable Motor

(Wire leads removed)

Measure the resistance.

(Ohm-meter scale:R×100)

Measure the resistance.

(Ohm-meter scale:R×1000)

Normal:Approx. 47Ω

Abnormal:∞ or Several Ω

Normal:Approx. 3.2kΩ

Abnormal:

∞ or Several Ω

NOTE:

z A MICROWAVE LEAKGE TEST MUST ALWAYS BE PERFORMED WHEN THE UNIT IS

SERVICED FOR ANY REASON.

z MAKE SURE THE WIRE LEADS ARE IN THE CORRECT POSITION.

z WHEN REMOVING THE WIRE LEADS FROM THE PARTS,BE SURE TO GRASP THE

CONNECTOR ,NOT THE WIRES.

5-8

Page 20

COMMON BREAKDOWN AND MEANS OF REPAIRING

PHENOMENON CAUSE REPAIRING MEANS

1.When starting the

oven, the lamp is not on,

the turntable tray can’t

rotate and the food can’t

be heated

2.When starting the

oven, the lamp is on, the

turntable rotating, the fan

cycling but the food can’t

be heated.

3.The food can be

heated, but the lamp is

not on.

4.The food can be

heated but the turntable

tray is not rotating.

5.The oven can heat

within 2-3 minutes, but

can not heat from the

fourth minutes.

6.When starting the

oven, it can’t heat, and

with “wenwen” noise

7.The oven can heat,but

with sound “shishi” noise

8.Large amount of

microwave leakage

9.The door can’t open 1. After long time using, the wear and the rust-

10.The door release

button fall off

11.Electricity leaking The earthing insulation resistances of all the

1. fuse broken

2. The primary and secondary winding of the

transformer are short-circuited.

3. The earthing or the polarity of the capacitor is

punctured.

4. The pilot switch can’t cut off.

5. The interlock switch hasn’t closed.

6. The power plug and the socket are not in good

connection.

7. The door hook broken.

1. The primary and secondary winding, the

filament of the transformer are open-circuited.

2. The magnetron filament is open-circuited, the

magnetic steel of the magnetron broken or the

magnetron is air leaking.

3. Time and power distributor broken..

4. The plugs of the magnetron of the capacitor

loosed.

1. The lamp broken.

2. The plug fall off.

1. The turntable motor broken

2. The plug fall off

3. Connecting shaft weave broken

1. The winding of the fan motor in open-circuited.

2. The fan falls off

3. The plug of the fan motor falls off

4. The turntable shaft is griped with the motor

bearing.

5. The cooling vent blocked

The high voltage diode was punctured Change a new diode

The iron core of the transformer loosed Change a new transformer

1. The door deformed

2. The door metal net cracked

3. The gap of the door crack is too large

4. The welding point of the oven fall off

5. The screws which fix the magnetron loosed

6. The wave guide connection oxidized

7. The magnetron copper filament washer is too

thin cause the wave guide opening not in good

earth.

eaten enlarged the gap of the door shaft and

the shaft hole, thus cause the door crooked.

2. The door hook broken

Wore aged after long time operating Overhaul it or renew it

motors or the transformer are less than 2 mega

ohm.

1. Change a new fuse.

2. Change a new

transformer.

3. Change a new capacitor.

4. Change a new pilot

switch.

5. Change a new interlock

switch.

6. Adjust the connection or

replace it by a new one.

7. Change a new book.

1. Change a new

transformer.

2. Change the magnetron.

3. Change the time power

distributor or the microswitch.

4. Fix them.

1. Change a new lamp

2. Insert the plug again

1. Change the turntable

motor

2. Insert the plug securely

3. Change the weave

1. Change the fan motor

2. Change the fan

3. Insert the plug

4. Overhauling them

5. Repairing it

1. Mend the door

2. Change the door

3. Adjust the gap

4. Change the oven

5. Tighten the screws

6. Scrape the oxidized and

tighten the screws

7. Thick the copper filament

washer

1. Adjust the hinge to rectify

the position of the door.

2. Change the hook

Test where is the leaking

place, then repair it or

change those damaged

components.

5-9

Page 21

IMPORTANT THINGS TO DO PRIOR TO CRITICAL PART

The following instructions are CRITICAL to the owner’s safety. Be sure to follow all the instructions. Contact the

manufacturer of distributor if you have any question.

1.1 If the oven is operative prior to servicing a Microwave Leakage Test (Microwave Emission Check) should be

performed prior to servicing the oven.

1.2 in the event that any microwave oven found to have microwave emission level in excess of 1 mW/cm

following procedures should be followed:

a. Inform the distributor, importer, or manufacture the finding. Record it in the logbooks well.

b. Repair the unit at no cost to the owner.

c. Investigate the oven and ascertain the cause of the excessive leakage.

d. Hold the oven in your facility and instruct the owner not to use the unit until the oven has been brought into

compliance.

1.3 In the event that the oven operates with the door open. The following procedures should be followed:

a. Tell the user not to operate the oven.

b. Hold the oven in your facility until it is investigated and repaired.

c. Contact the manufacturer immediately.

2. Interlock Assembly Replacement and Adjustment

2.1 If you suspect defective primary, secondary or monitor interlock switches, use your ohmmeter(digital or analog

type the check the electrical continuity.

2.2 Make sure the power cord is pulled out and the high-voltage capacitor is discharged before the electrical

continuity check.

2.3 Set the ohmmeter to “Low Resistance” range and connect both leads (alligator clips) to the switch terminals.

2.4 Open the door and notice the meter reading. The primary or secondary interlock s witch should sho w an “infinite”

resistance when the door is open. Replace it when it is defective. T he monitor interlock should show a “zero or

near zero” resistance when the door is open. When the door is closed, the readings will be opposite.

2.5 If the oven has been received inoperative due to the failure of the monitored safety(primary and/or secondary)

interlock(s),you should replace all of the monitored safety interlock switched and the moni tor switch.

3. Door and Hinge Replacement and Adjustment

3.1 Pull the power cord from the outlet. Check the door for warped or dama ged areas. Check the hing es for broken

or worn areas. Check other areas such as cracked from glass, broken door latched, worn/cracked viewing

screen and etc.

3.2 After determining the door assembly should be replaced, check the parts list for the correct part number. All oven

door components must be ordered directly from the manufacturer or its authorized distributor.

4. Magnetron Replacement

4.1 Check for the presence of the wire mesh gasket before installation.

4.2 Conduct a Microwave Leakage Test at the magnetron area prior to installing the top cover.

SERVICING

5-10

2

.The

Page 22

SAFETY CHECKS AND TESTS AFTER SERVING

Constructional Checks

If mechanical or electrical(electronic) parts have been replaced be sure to follow the following steps.

1.1 Check for correct wiring, adequate mechanical decrements of parts, and firm connectors.

1.2 Check for adequate grounding.

1.3 Check the following items before turning the oven ON.

1) Proper door closing, seal/choke surfaces, and hinges.

2) No outer case damage.

3) Proper interlock and monitor operations.

Insulation Resistance Test

If the low voltage power supply has been repaired, use a 500 V Mega ohmmeter to measure the resistance between the

primary(Line and Neutral)of the power plug and oper ator accessible metal parts. The resistance should be no less than 2 Mega

Ohms. Repair the oven again when necessary.

5-11

Page 23

AC930AMP-S00C

Page 24

AC930AMP-S00C

Loading...

Loading...