Midea EL-KF36GW/N2Y-A(B), EL-KFR20GW/N2Y-A(B), EL-KFR36GW/N2Y-A(B), EL-KF50GW/N2Y-A(B), EL-KFR50GW/N2Y-A(B) Service Manual

...Page 1

0

Website: www.mideaaircon.com

Service manual

CAUTION

- BEFORE SERVICING THE UNIT, READ THE SAFETY

- PRECAUTIONS IN THIS MANUAL.

- ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODELS:

EL-KF20GW/N2Y-A(B) EL-KFR20GW/N2Y-A(B) EL-KF26GW/N2Y-A(B) EL-KFR26GW/N2Y-A(B)

EL-KF36GW/N2Y-A(B) EL-KFR36GW/N2Y-A(B) EL-KF50GW/N2Y-A(B) EL-KFR50GW/N2Y-A(B)

EL-KF61GW/N2Y-A(B) EL-KFR61GW/N2Y-A(B) EL-KF70GW/N2Y-A(B) EL-KFR70GW/N2Y-A(B)

EL-KFR20GW/N1Y-A(B) EL-KFR26GW/N1Y-A(B) EL-KFR36GW/N1Y-A(B)

EL-KF20GW/Y-A(B) EL-KFR20GW/Y-A(B) EL-KF26GW/Y-A(B) EL-KFR26GW/Y-A(B)

EL-KF32GW/Y-A(B) EL-KFR32GW/Y-A(B) EL-KF36GW/Y-A(B) EL-KFR36GW/Y-A(B)

EL-KF50GW/Y-A(B) EL-KFR50GW/Y-A(B) EL-KF61GW/Y-A(B) EL-KFR61GW/Y-A(B)

EL-KF70GW/Y-A(B) EL-KFR70GW/Y-A(B) EL-KF90GW/Y-A(B) EL-KFR90GW/Y-A(B)

EL-KF90GW/SY-A(B) EL-KFR90GW/SY-A(B) AU-KF61GW/Y-A(B) AU-KFR61GW/Y-A(B)

AU-KF70GW/Y-A(B) AU-KFR70GW/Y-A(B) AU-KF85GW/Y-A(B) AU-KFR85GW/Y-A(B)

EL1-KF20GW/Y-A(B) EL1-KFR20GW/Y-A(B) EL1-KF26GW/Y-A(B) EL1-KFR26GW/Y-A(B)

EL1-KF32GW/Y-A(B) EL1-KFR32GW/Y-A(B) EL1-KF20GW/N2Y-A(B) EL1-KFR20GW/N2Y-A(B)

EL1-KF26GW/N2Y-A(B) EL1-KFR26GW/N2Y-A(B) EL1-KF35GW/N2Y-A(B) EL1-KFR35GW/N2Y-A(B)

EL-KT3F53GW/Y-T2 EL-KT3F53GW/Y-T1 EL-KT3FR53GW/Y-T1

EL-KT3F70GW/Y-T2 EL-KT3F70GW/Y-T1 EL-KT3FR70GW/Y-T1

SEL-KF20GW/Y-A(B) SEL-KFR20GW/Y-A(B) SEL-KF26GW/Y-A(B) SEL-KFR26GW/Y-A(B)

SEL-KF32GW/Y-A(B) SEL-KFR32GW/Y-A(B) SEL-KF53GW/Y-A(B) SEL-KFR53GW/Y-A(B)

SEL-KF61GW/Y-A(B) SEL-KFR61GW/Y-A(B) SEL-KF70GW/Y-A(B) SEL-KFR70GW/Y-A(B)

SEL1-KF26GW/Y-A(B) SEL1-KFR26GW/Y-A(B) SEL1-KF36GW/Y-A(B) SEL1-KFR36GW/Y-A(B)

Page 2

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

1

CONTENTS

1. PREFACE

1.1 SAFETY PRECAUTIONS........................................................................................................................1

1.2 INSULATION RESISTANCE TEST.........................................................................................................1

1.3 FEATURES...............................................................................................................................................2

1.4 CONTROL LOCATIONS.................................................. ...........................................................................2

1.5 OUTSIDE DIMENSIONS............................................................................................................................3

2. INSTALLATION

2.1 TOOLS NEEDED FOR INSTALLATION....................................................................................................5

2.2 ITEMS REQUIRED FOR INSTALLING THE UNIT........................................ ............................................5

2.3 INSTALLATION OF INDOOR UNIT AND OUTDOOR UNIT .....................................................................6

2.4 FLARING WORK AND CONNECTION OF PIPING........................................................ ...........................8

2.5 CONNECTING THE CABLE BETWEEN INDOOR UNIT AND OUTDOOR UNIT……………..................12

2.6 CHECKING THE DRAINAGE AND FORMING THE PIPING .................................................... ... ....... .... .14

2.7 AIR PURGING............................................. ............................................... ...............................................15

2.8 TEST RUNNING ................................................. ...................... ...................... ..........................................17

3. TROUBLE SHOOTING GUIDE

3.1 Refrigeration Cycle Diagram......................................... ............................................................................19

3.2 TROUBLE SHOOTING GUIDE..................................................................................................................20

4. WIRING DIAGRAM

4.1 Wiring diagram for indoor units……..........................................................................................................26

4.2 Wiring diagram for outdoor units...............................................................................................................32

5. EXPLODED VIEWS…………………………………………...........................................................................40

6 SPECIFICATIONS........................................................................................................................................40

7 SPARE PARTS LIST……………………………………………………..………….……………………………..40

8 MODEL CHECK LIST……………………………………………………………………………………………….40

1. PREFACE

This SERVICE MANUAL provides various servicing information, including the mechanical and electrical parts,

etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the POWER SWITCH to OFF and unplug the power cord.

2. Inspect the service cord for damage or wear.

If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

3. After servicing the unit, make an insulation resistance test to protect the customer from being exposed to

shock hazards.

1.2 INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper lead between the two (2) live pins.

2. The grounding conductor (yellow/green) is to be open.

3. Measure the resistance value with an ohm meter between the jumped lead and each exposed metallic part

on the equipment at all the positions (except OFF) of the ROTARY SWITCH or POWER SWITCH.

4. The value should be over 1MΩ.

Page 3

2

1.3 FEATURES

Error self diagnosis function.

Anti-icing function at cooling mode.

Anti-cold air function at heating mode.

Auto-defrosting and heating recovering function

at heating mode.

Outdoor unit overload current protection.

Temperature protection of the outdoor

compressor top.

Restart protection for the compressor.

24 hours on/off mode time setting.

Protection against over-load or too-low current

input through alternating current.

1.4 CONTROL LOCATIONS

For reverse cycle models:

T

I

M

E

R

P

O

W

E

R

A

U

T

O

℃

D

E

F

R

O

S

T

For cooling only models:

T

I

M

E

R

P

O

W

E

R

A

U

T

O

℃

AUTO

COOL

DRY

FAN

HIGH

MED

LOW

TEMP

MODE ON/OFF

FAN

SWING ECONOM Y

TIME R

RESET

LOCK

R

CANCEL

DIGITAL DISPLAY

HEAT

LED lamp:

POWER

AUTO

TIMER

DEFROST

Remote controller:

LCD display

Mode button: Select the operation mode, AUTO,

COOL, DRY, HEAT (Reverse cycle

models only) and FAN.

Fan speed button: Select the Fan speed, AUTO,

LOW, MED, HIGH.

ON/OFF button: Press this button to operation

the unit, again to stop.

Temperature setting up button: Press this

button to increase temperature

setting or adjust the TIMER in a

clockwise direction.

Temperature setting down button: Press this

button to decrease temperature

setting or adjust the TIMER in a

counter-clockwise direction.

Swing button: Press this button to activate the

auto swing, again to stop.

Economy button: Push this button to set the

economical operation mode.

Timer button: Press this button to set TIMER

ON and/or TIMER OFF.

Cancel button: Press this button to cancel

TIMER ON and TIMER OFF.

Lock button: Press this button to lock all button

except this button.

Reset button: Press this button to reset all

settings to original.

Digital display button: Press this button to

activate/eliminate the digital

temperature display on the indoor

unit.

Page 4

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

3

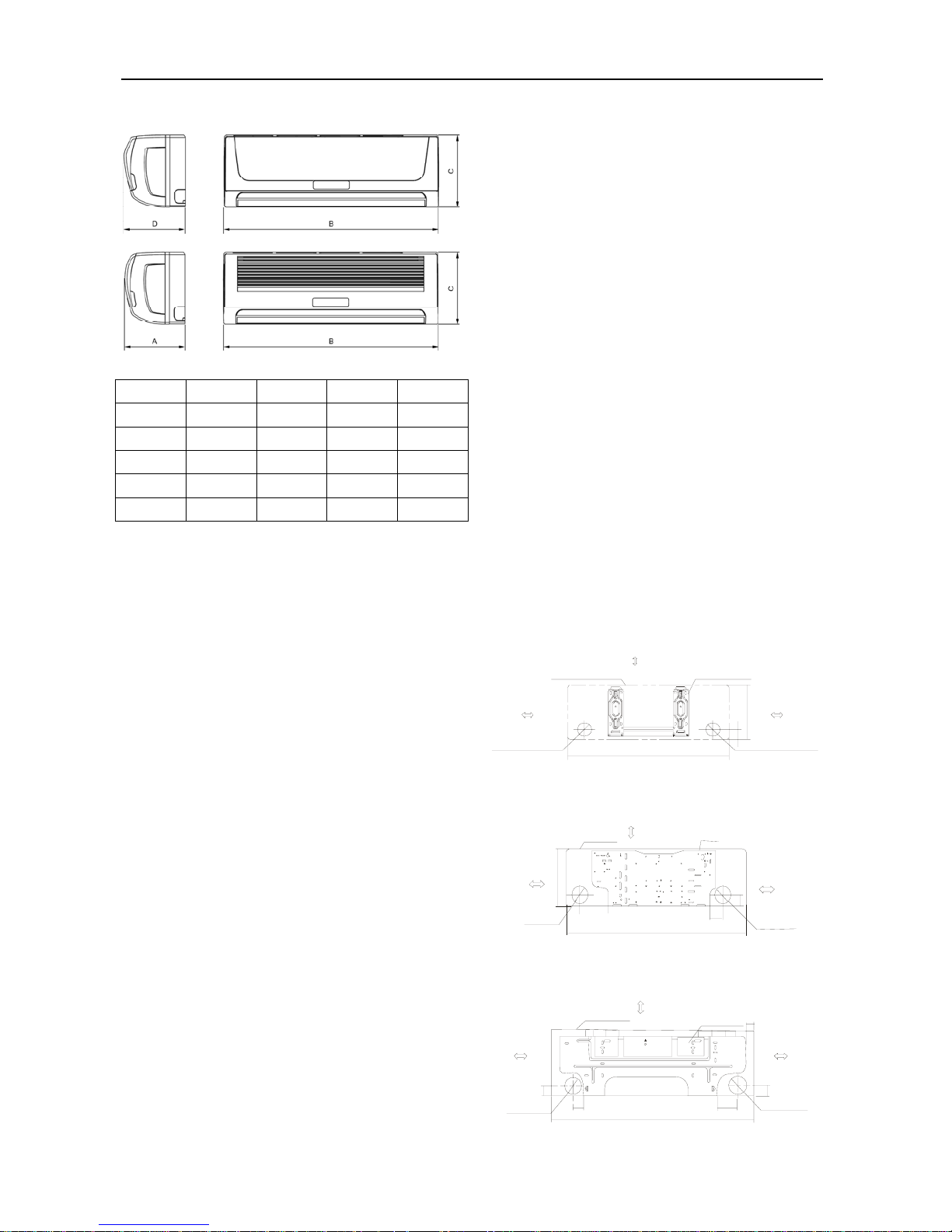

1.5 OUTSIDE DIMENSIONS

1.5.1 Indoor units:

A: width (mm) B: Depth (mm) C: Height (mm)

Unit A(mm) B(mm) C(mm) D(mm)

Size A 210 750 250 214

Size B 213 815 282 217

Size C 228 1000 298 232

Size D 240 1080 330 245

Size E 230 1250 325 230

Model list:

Size A indoor units:

Size B indoor units:

Size C indoor units:

Size D indoor units:

EL-KF61GW/N2Y-A(B) EL-KFR61GW/N2Y-A(B)

EL-KF70GW/N2Y-A(B) EL-KFR70GW/N2Y-A(B)

EL-KF61GW/Y-A(B) EL-KFR61GW/Y-A(B)

EL-KF70GW/Y-A(B) EL-KFR70GW/Y-A(B)

AU-KF61GW/Y-A(B) AU-KFR61GW/Y-A(B)

AU-KF70GW/Y-A(B) AU-KFR70GW/Y-A(B)

EL-KT3F70GW/Y-T2

EL-KT3F70GW/Y-T1 EL-KT3FR70GW/Y-T1

SEL-KF61GW/Y-A(B) SEL-KFR61GW/Y-A(B)

SEL-KF70GW/Y-A(B) SEL-KFR70GW/Y-A(B)

Size E indoor units:

1.5.2 Installation plate

For Size A indoor unit:

750

45

250

Right refrigerant

pipe hole D65

Inst all ation plate

Indoor unit outline

Left refrigerant

pipe ho le D65

150mm or more to ceiling

120mm or more

to wall

120mm or m ore

to wal l

For Size B indoor unit:

Indoor unit outline

120mm or more

to wal l

120mm or more

to wal l

Left refrigerant

pipe hole D65

Right refriger ant

pipe hole D 65

Installation plate

280

815

150mm or more to ceiling

50

50

For Size C indoor unit:

50

1000

49

90

55

50

Rig h t pi pe

hole D 65

120mm or more

to the wa ll

Indoor unit outl ine

Installation plate

150mm or more to the c e i l i n g

Left pipe

hole D65

120mm or more

to the wall

EL-KF20GW/N2Y-A(B) EL-KFR20GW/N2Y-A(B)

EL-KF26GW/N2Y-A(B) EL-KFR26GW/N2Y-A(B)

EL-KFR20GW/N1Y-A(B) EL-KFR26GW/N1Y-A(B)

EL-KF20GW/Y-A(B) EL-KFR20GW/Y-A(B)

EL-KF26GW/Y-A(B) EL-KFR26GW/Y-A(B)

EL-KF32GW/Y-A(B) EL-KFR32GW/Y-A(B)

EL1-KF20GW/Y-A(B) EL1-KFR20GW/Y-A(B)

EL1-KF26GW/Y-A(B) EL1-KFR26GW/Y-A(B)

EL1-KF32GW/Y-A(B) EL1-KFR32GW/Y-A(B)

EL1-KF20GW/N2Y-A(B) EL1-KFR20GW/N2Y-A(B)

EL1-KF26GW/N2Y-A(B) EL1-KFR26GW/N2Y-A(B)

SEL-KF20GW/Y-A(B) SEL-KFR20GW/Y-A(B)

SEL-KF26GW/Y-A(B) SEL-KFR26GW/Y-A(B)

SEL-KF32GW/Y-A(B) SEL-KFR32GW/Y-A(B)

SEL1-KF26GW/Y-A(B) SEL1-KFR26GW/Y-A(B)

EL-KF36GW/N2Y-A(B) EL-KFR36GW/N2Y-A(B)

EL-KFR36GW/N1Y-A(B)

EL-KF36GW/Y-A(B) EL-KFR36GW/Y-A(B)

EL1-KF35GW/N2Y-A(B) EL1-KFR35GW/N2Y-A(B)

SEL1-KF36GW/Y-A(B) SEL1-KFR36GW/Y-A(B)

EL-KF50GW/N2Y-A(B) EL-KFR50GW/N2Y-A(B)

EL-KF50GW/Y-A(B) EL-KFR50GW/Y-A(B)

EL-KT3F53GW/Y-T2

EL-KT3F53GW/Y-T1 EL-KT3FR53GW/Y-T1

SEL-KF53GW/Y-A(B) SEL-KFR53GW/Y-A(B)

EL-KF90GW/Y-A(B) EL-KFR90GW/Y-A(B)

EL-KF90GW/SY-A(B) EL-KFR90GW/SY-A(B)

AU-KF85GW/Y-A(B) AU-KFR85GW/Y-A(B)

Page 5

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

4

For Size D indoor unit:

150 or more to the ceiling

Hooked Part

Indoor Unit Outline

Hooked Part

Left Pipe

hol e D95

120mm or more to

the wall

432

58

465

465

115

50

Rig h t pi pe

hole D95

5850

115

Hooked Part

432

1080

120mm o r more to

the wall

108

22

For Size E indoor unit:

150mm or mo re to the ceiling

1250

815

257

178

Ho oke d Par t

Hooker Part

120mm or more

to the wa ll

120mm or more

to the wa ll

325

55

55

55

58

Left pipe

hole D95

R

i

g

h

t

p

i

p

e

h

o

l

e

D

9

5

I

n

d

o

o

r

u

n

i

t

o

u

t

l

i

n

e

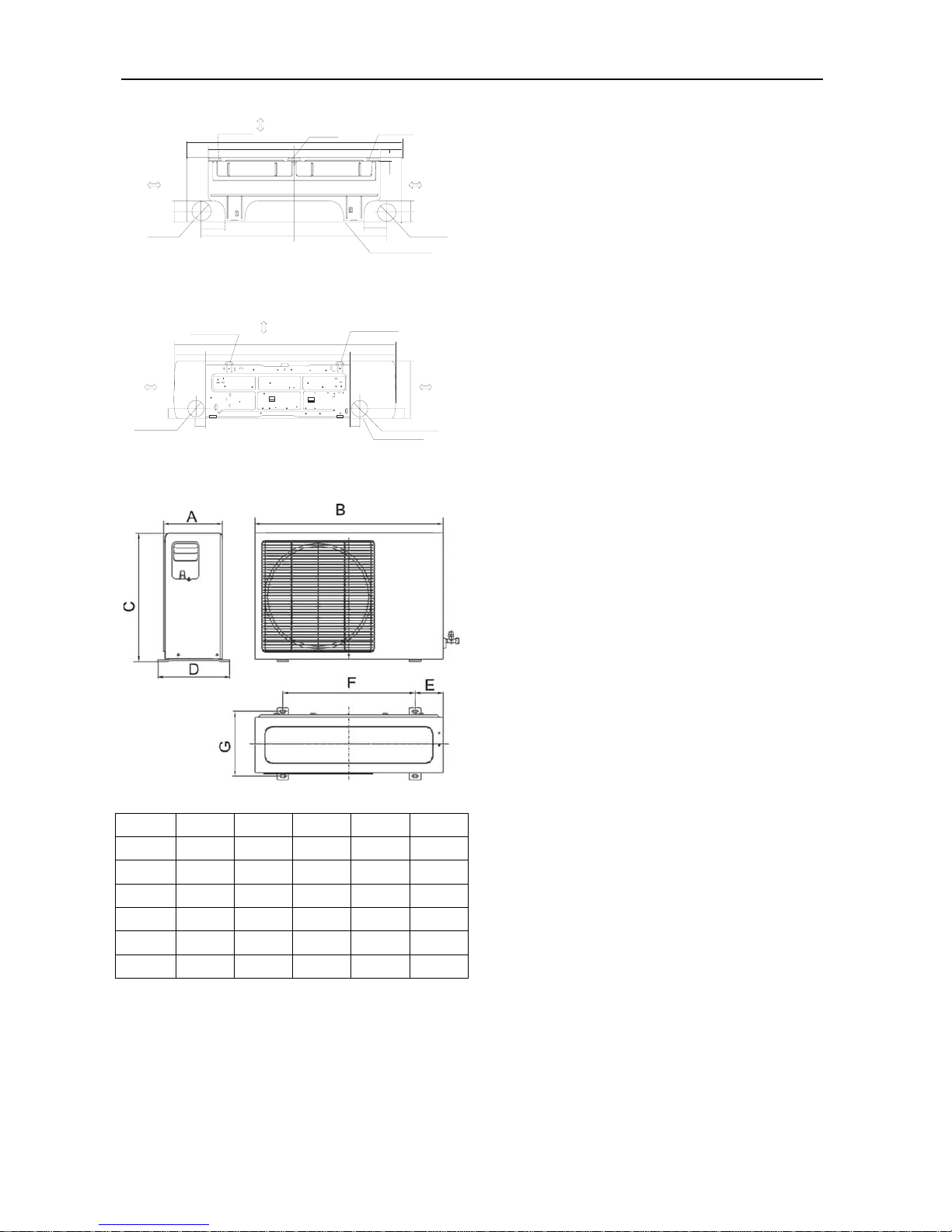

1.5.3 Outdoor units:

A: Depth (mm) B: Width (mm) C: Height (mm)

Unit Size F Size G Size H Size I Size J

A(mm) 235 250 285 335 330

B(mm) 700 780 760 845 895

C(mm) 535 540 590 695 860

D(mm) 275 298 315 360 355

E(mm) 120 114.5 110 140 141.3

F(mm) 458 549 530 560 589.6

Size F outdoor units:

EL-KF20GW/N2Y-A(B) EL-KFR20GW/N2Y-A(B)

EL-KF26GW/N2Y-A(B) EL-KFR26GW/N2Y-A(B)

EL-KFR20GW/N1Y-A(B)

EL-KF20GW/Y-A(B) EL-KFR20GW/Y-A(B)

EL-KF26GW/Y-A(B) EL-KFR26GW/Y-A(B)

EL1-KF20GW/Y-A(B) EL1-KFR20GW/Y-A(B)

EL1-KF26GW/Y-A(B) EL1-KFR26GW/Y-A(B)

EL1-KF20GW/N2Y-A(B) EL1-KFR20GW/N2Y-A(B)

EL1-KF26GW/N2Y-A(B) EL1-KFR26GW/N2Y-A(B)

SEL-KF20GW/Y-A(B) SEL-KFR20GW/Y-A(B)

SEL-KF26GW/Y-A(B) SEL-KFR26GW/Y-A(B)

Size G outdoor units:

EL-KFR26GW/N1Y-A(B) EL-KFR36GW/N1Y-A(B)

EL-KF32GW/Y-A(B) EL-KFR32GW/Y-A(B)

EL-KF36GW/Y-A(B) EL-KFR36GW/Y-A(B)

EL1-KF32GW/Y-A(B) EL1-KFR32GW/Y-A(B)

EL1-KF35GW/N2Y-A(B) EL1-KFR35GW/N2Y-A(B)

SEL-KF32GW/Y-A(B) SEL-KFR32GW/Y-A(B)

SEL1-KF26GW/Y-A(B) SEL1-KFR26GW/Y-A(B)

Size H outdoor units:

EL-KF36GW/N2Y-A(B) EL-KFR36GW/N2Y-A(B)

SEL1-KF36GW/Y-A(B) SEL1-KFR36GW/Y-A(B)

Size I outdoor units:

EL-KF50GW/N2Y-A(B) EL-KFR50GW/N2Y-A(B)

EL-KF61GW/N2Y-A(B) EL-KFR61GW/N2Y-A(B)

EL-KF70GW/N2Y-A(B) EL-KFR70GW/N2Y-A(B)

EL-KF50GW/Y-A(B) EL-KFR50GW/Y-A(B)

EL-KF61GW/Y-A(B) EL-KFR61GW/Y-A(B)

EL-KF70GW/Y-A(B) EL-KFR70GW/Y-A(B)

AU-KF61GW/Y-A(B) AU-KFR61GW/Y-A(B)

AU-KF70GW/Y-A(B) AU-KFR70GW/Y-A(B)

EL-KT3F53GW/Y-T2

EL-KT3F53GW/Y-T1 EL-KT3FR53GW/Y-T1

EL-KT3F70GW/Y-T1 EL-KT3FR70GW/Y-T1

SEL-KF53GW/Y-A(B) SEL-KFR53GW/Y-A(B)

SEL-KF61GW/Y-A(B) SEL-KFR61GW/Y-A(B)

SEL-KF70GW/Y-A(B) SEL-KFR70GW/Y-A(B)

Size J outdoor units:

EL-KF90GW/Y-A(B) EL-KFR90GW/Y-A(B)

EL-KF90GW/SY-A(B) EL-KFR90GW/SY-A(B)

AU-KF85GW/Y-A(B) AU-KFR85GW/Y-A(B)

EL-KT3F70GW/Y-T2

Page 6

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

5

2 INSTALLATION

2.1 TOOLS NEEDED FOR INSTALLATION

Level gauge

Screwdriver

Electric drill

Hole core drill ( φ85mm or φ115mm depending

on Model)

Flaring tool set

Specified torque wrenches: 1.8kgm, 4.2kgm,

5.5kgm, 6.6kgm (Vary depending on model

No.)

Spanner (half union)

A glass of water

Hexagonal wrench (4mm)

Gas-leak detector

Vacuum pump

Gauge manifold

User’s manual

Thermometer

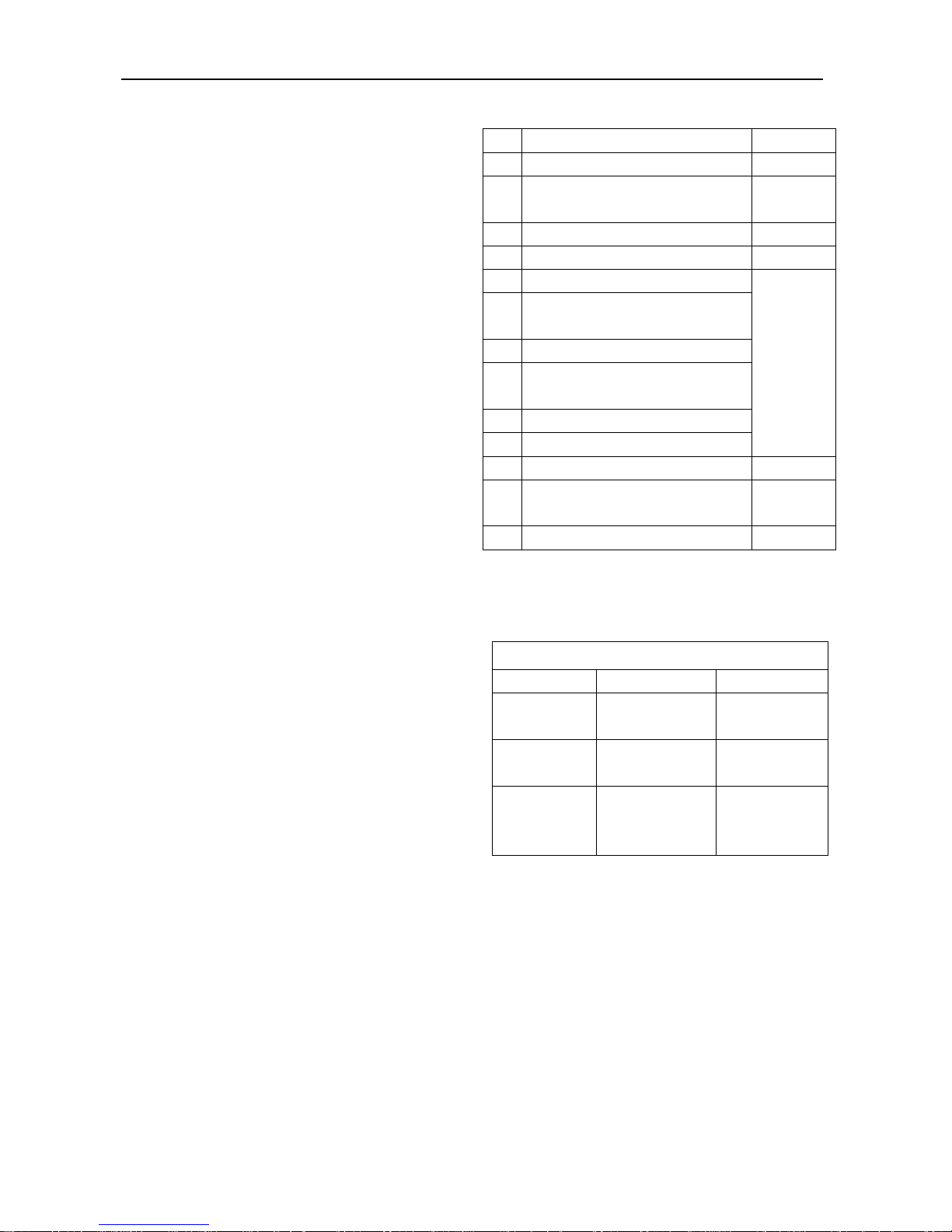

2.2 ITEMS REQUIRED FOR INSTALLING THE

UNIT

No. Name of Accessories Quantity

1 Installation Plate 1

2 Self-tapping Screw ST3.9x25

(Type “A”)

8

3 Plastic Expansion Sheath 8

4 Drain Joint 1

5 Wrapping Tape

6 Connection Pipe Assembly

(Detail in below table)

7 Connecting Cable

8 Additional Drain Pipe (Outer

Diameter15.5mm)

9 Insulation Materials

10 Cable Tie (5~10)

Parts

purchased

separately

11 Remote Control Holder 1

12 Self-tapping Screw ST2.9x10

(Type “B”)

2

13 Remote Control 1

Note: Excluding the parts that are provided with

the unit detailed above all other parts must be

purchased separately.

Connection Pipe Assembly

model Liquid side pipe Gas side pipe

7,000Btu/h

9,000Btu/h

6.35mm

1/4”

9.53mm

3/8”

12,000Btu/h

18,000Btu/h

6.35mm

1/4”

12.7mm

1/2”

21,000Btu/h

24,000Btu/h

30,000Btu/h

9.53mm

3/8”

16mm

5/8”

NOTE: For pipes used on R410A system, the

wall thickness of the pipes should be

no less than 0.7mm. Otherwise, the

pipes may be broken when using.

Page 7

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

6

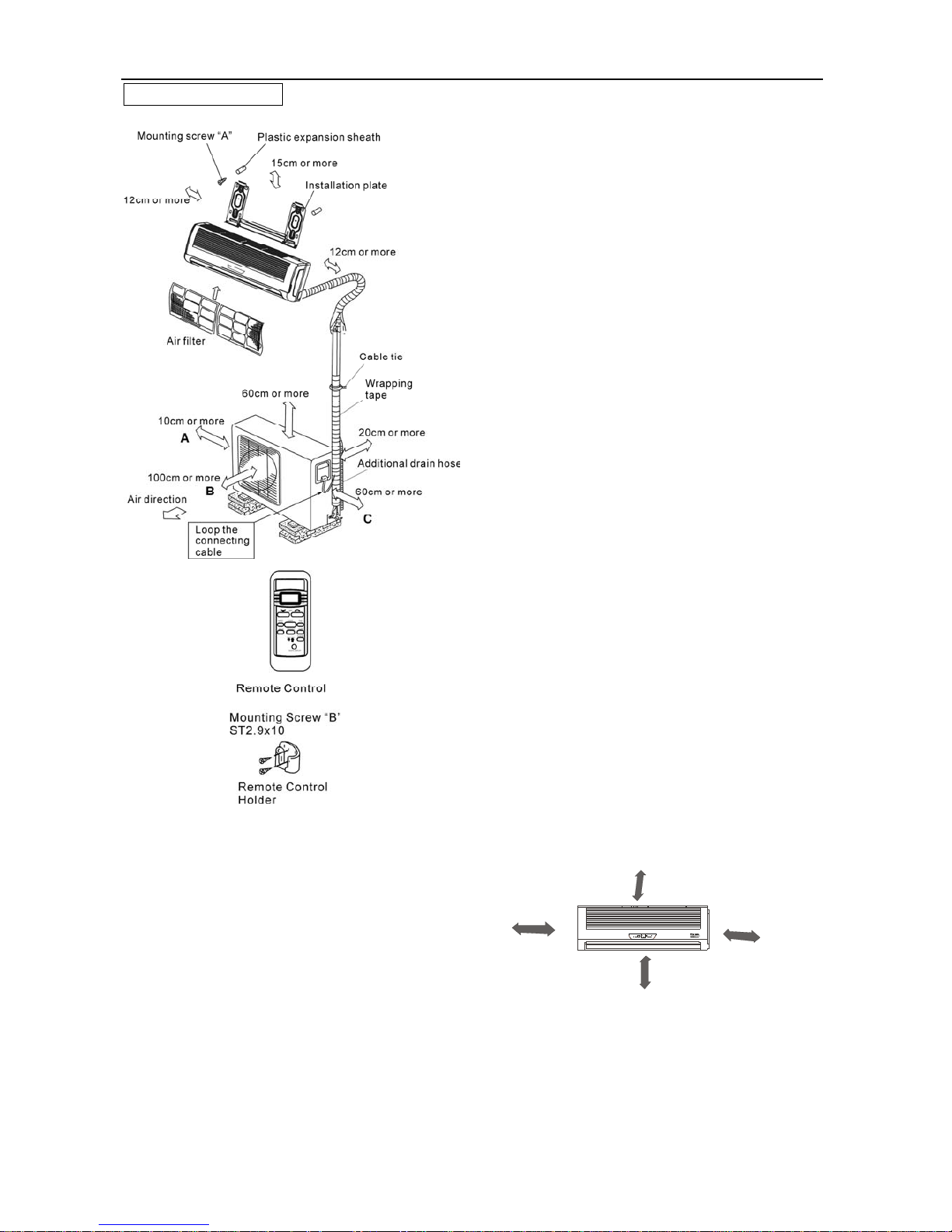

Typical installation

CAUTIONS:

1. Ensure that the space around the left and

right of the indoor unit is more than 12cm.

2. The indoor unit should be installed allowing a

minimum clearance of 15cm from the ceiling.

3. Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

4. For optimum performance the Indoor Unit

should be installed on the wall in areas where

the height from the floor to the ceiling is not

more than 2.3 meters.

5. A minimum pipe run of 3 meters is required to

minimize vibration & excessive noise.

6. The indoor unit should be installed on the wall

at a height of 1.7 meters or more from the

floor but less than 2.3 meters from the floor.

7. Directions A, B and C should be free from

obstructions.

2.3 INSTALLATION OF INDOOR UNIT AND

OUTDOOR

2.3.1 Indoor unit

● Do not expose the indoor unit to heat or

steam.

● Select a place where there are no obstacles in

front or around the unit.

● Make sure that condensation drainage can be

conveniently routed away.

● Do not install near a doorway.

● Ensure that the space on the left and right of

the unit is more than 12cm.

● Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

● For optimum performance the indoor unit

should be installed on the wall in areas where the

height from the floor to the ceiling is not more than

2.3 meters.

● A minimum pipe run of 3 meters is required to

minimize vibration & excessive noise.

● The indoor unit should be installed on the wall

at a height of 1.7 meters or more from the floor but

less than 2.3 meters from the floor.

● The indoor unit should be installed allowing a

minimum clearance of 15cm from the ceiling.

● Any variations in pipe length will/may require

adjustment to refrigerant charge (Refer to item

2.3.3).

M

o

r

e

t

h

a

n

1

.

7

m

L

e

s

s

t

h

a

n

2

.

3

m

Mo

r

e

t

h

a

n

1

5

c

m

More than 12cm

More than 12cm

2.3.2 Outdoor unit

● If an awning is built over the outdoor unit to

prevent direct sunlight or rain exposure, make

sure that heat radiation from the condenser is not

restricted.

Page 8

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

7

● Ensure that the clearance around the back of

the unit is more than 20cm and left side is more

than 10cm.

● The front of the unit should have more than

100cm of clearance and the connection side (right

side) should have more than 60cm of clearance.

● Do not place animals and plants in the path of

the air inlet or outlet.

● Take the air conditioner weight into account

and select a place where noise and vibration will

not be an issue.

● Select a place so that the warm air and noise

from the air conditioner do not disturb neighbors.

Mo

r

e

t

h

a

n

2

0

c

m

Mo

r

e

t

h

a

n

6

0

c

m

Mo

r

e

t

h

a

n

1

0

c

m

M

o

r

e

t

h

an

1

0

0

c

m

Rooftop installation:

● If the outdoor unit is installed on a roof

structure, be sure to level the unit.

● Ensure the roof structure and anchoring

method are adequate for the unit location.

● Consult local codes regarding to rooftop

mounting.

● If the outdoor unit is installed on roof

structures or external walls, this may result in

excessive noise and vibration, and may also be

classed as a non serviceable installation.

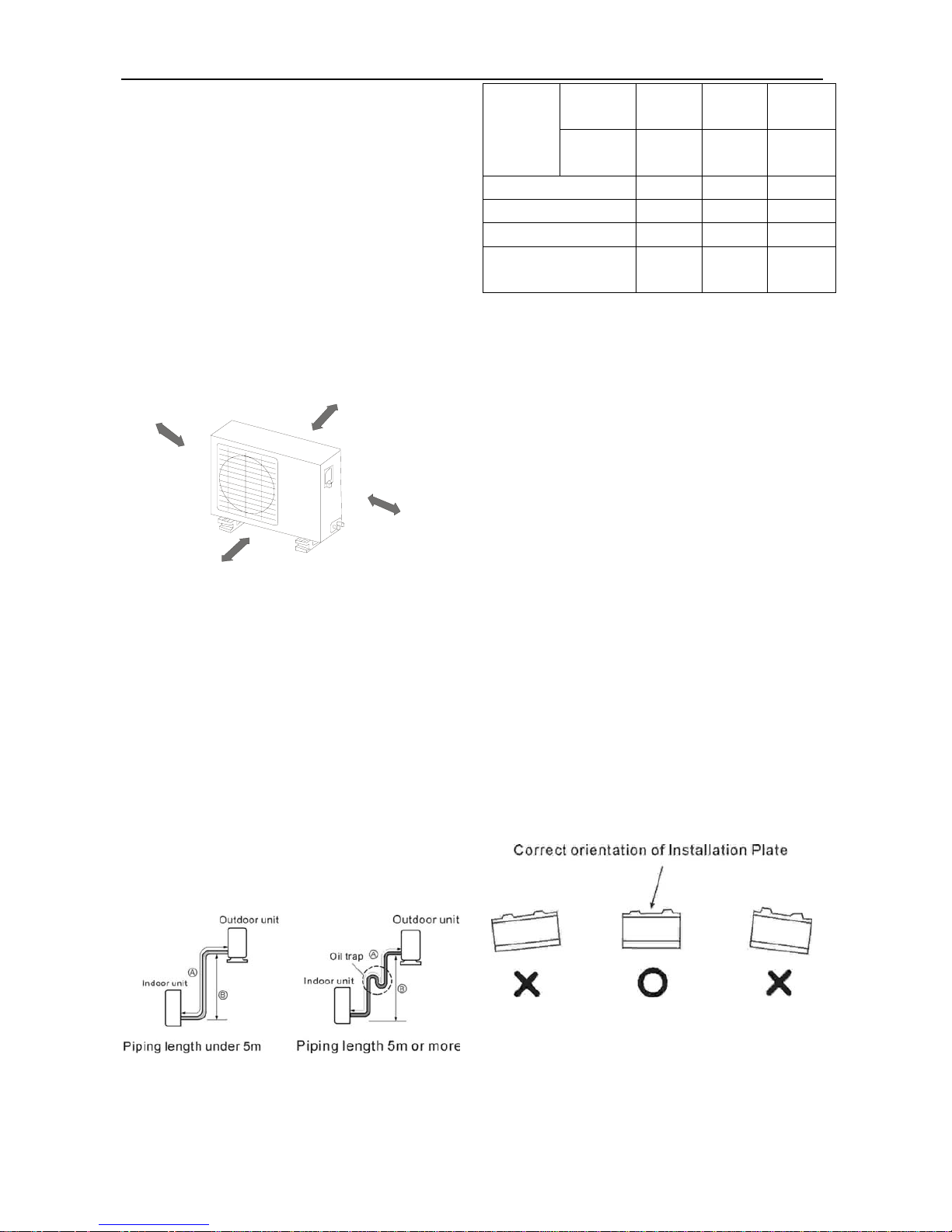

2.3.3 Piping length and elevation

GAS

3/8”

9.53mm

1/2”

12.7mm

5/8”

16.0mm

Piping

LIQUID

1/4”

6.35mm

1/4”

6.35mm

3/8”

9.53mm

Standa rd Length(m) 5 5 5

Max. Elevation B (m) 5 5 5

Max. Length A (m) 10 10 10

Additional

Refrigerant (g/m)

30 30 65

Cautions:

● Capacity is based on standard length and

maximum allowance length is on the basis of

reliability.

● Oil trap should be installed every 5~7 meters.

● When the connecting pipe is longer than 5

meters, Additional refrigerant should be added

into the unit according to the above table through

the service port on the “LO” valve on outdoor unit.

2.3.4 Fitting the installation plate

Fit the Installation Plate and drill holes in the wall

according to the wall structure and corresponding

mounting points on the installation plate.

1. Fit the installation plate horizontally on

structural parts of the wall with spaces around the

installation plate (Detailed on page 3 as

applicable).

2. If the wall is made of brick, concrete or the like,

drill eight (8) 5mm diameter holes in the wall.

Insert Plastic Expansion Sheath for appropriate

mounting screws.

3. Fit the installation plate on the wall with eight (8)

type “A” screws.

2.3.5 Drill a hole in the wall

1. Determine hole positions according to the

diagram detailed on page 3 as applicable. Drill

one (1) hole (φ85mm for those models need

φ65mm pipe hole or φ115mm for models need

φ95mm pipe hole) slanting slightly to outdoor

Page 9

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

8

side.

2. Always use wall hole

conduit when drilling

metal grid, metal plate

or the like.

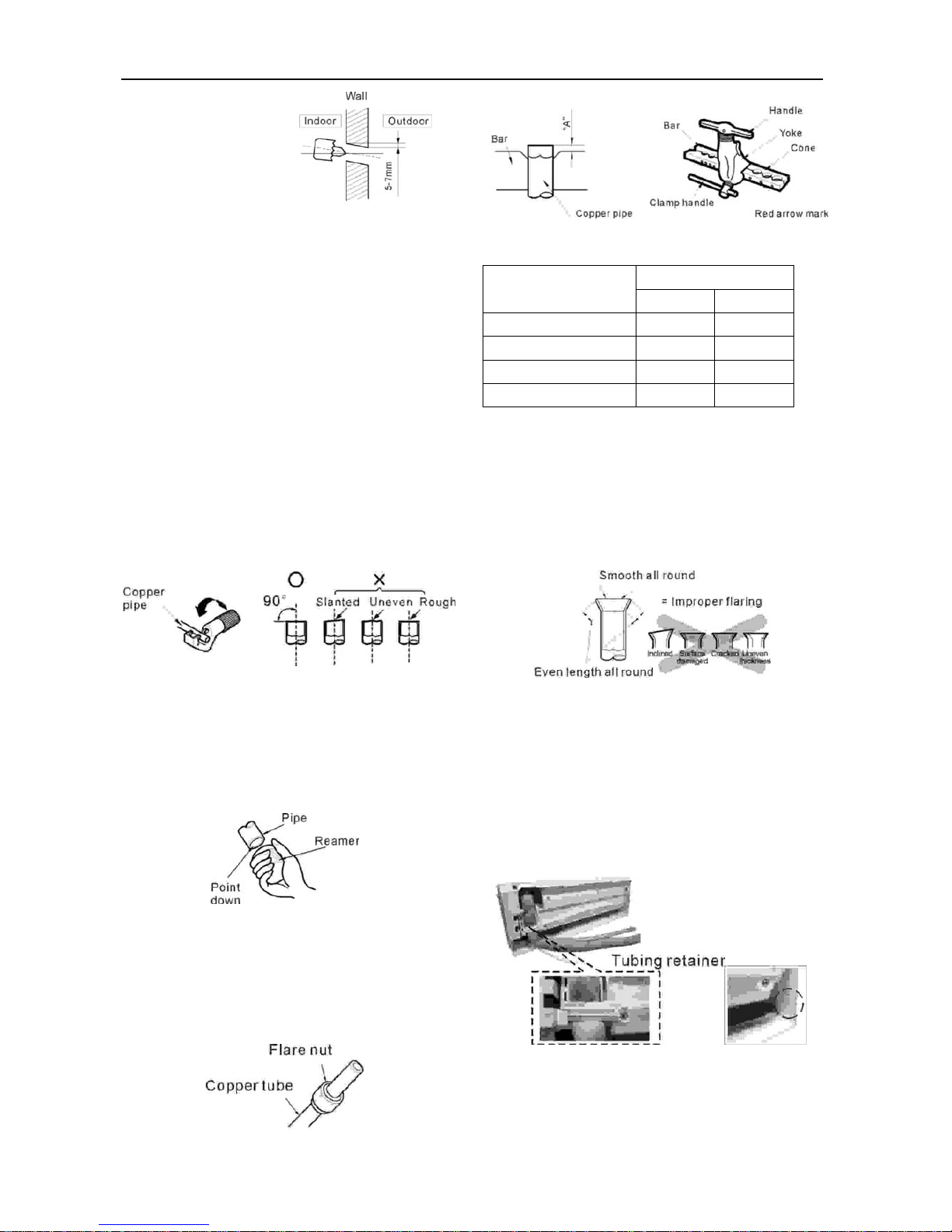

2.4 FLARING WORK AND CONNECTION OF

PIPING

The main cause for gas leakage is due to defects

in flaring work. Carry out correct flaring work using

the following procedure.

2.4.1 Flaring work

2.4.1.1 Cut the pipes and the cable.

● Use the piping kit accessory (if applicable) or

the pipes purchased locally.

● Measure the distance between the indoor and

the outdoor unit.

● Cut the pipes a little longer than measured

distance.

● Cut the cable 1.5m longer than the pipe

length.

2.4.1.2 Burrs removal

● Completely remove all burrs from the cut cross

section of pipe/tube.

● Place the end of the copper tube/pipe in a

downward direction as you remove burrs in order

to avoid dropping burrs into the tubing.

2.4.1.3 Putting flare nut on

● Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube having

completed burr removal.

(Note: It is not possible to put them on after flaring

work.)

2.4.1.4 Flaring work

● Carry out flaring work using flaring tool as

shown below.

“A” (mm)

Out diameter

Max. Min.

1/4” (6.35mm) 1.3 0.7

3/8” (9.53mm) 1.6 1.0

1/2” (12.7mm) 1.8 1.0

5/8” (16.0mm) 2.4 1.8

Hold copper pipe firmly in a die according to the

dimension shown in the table above.

2.4.1.5 Check

● Compare the flared work with the adjacent

diagram.

● If flare is found to be defective, cut off the

flared section and do flaring work again.

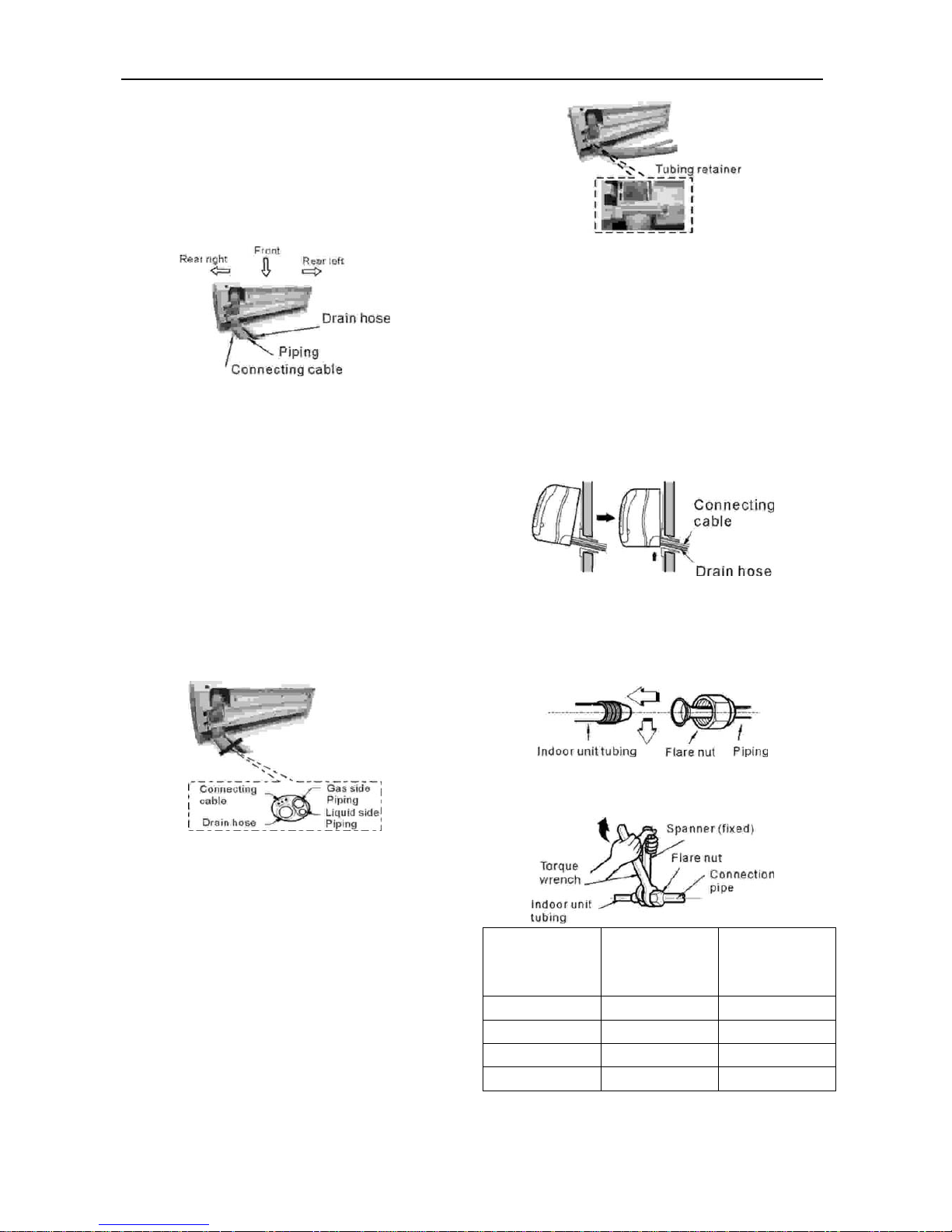

2.4.2 Connection of pipes - Indoor

● Prepare the indoor unit’s piping an d drain hose

for installation through the wall.

● Remove the tubing retainer (see illustration

right) and pull the tubing and drain hose away

from chassis (If required). For some models thi s is

not needed.

Replace the tubing retainer in its original position.

CAUTION

When installing the indoor unit, be sure to remove

the relevant sections where required (see

Page 10

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

9

adjacent diagram for example). This will allow

piping and cable routing to be completed without

damaging the unit.

2.4.2.1 For rear right piping

Note: When viewed from the front of the indoor

unit.

2.4.2.1.1 Route the indoor tubing and the drain

hose in the direction of rear right.

2.4.2.1.2 Insert the connecting cable into the

indoor unit from the outdoor unit through the

piping hole.

● Do not connect the cable to the indoor unit.

● Make a small loop with the cable for easy

connection later.

2.4.2.1.3 Tape the tubing, drain hose and the

connecting cable. Be sure that the drain hose is

located at the lowest side of the bundle. Locating

at the upper side can cause drain pan to overflow

inside the unit.

Note: If the drain hose is routed inside the room,

insulate the hose with an insulation material so

that dripping from "sweating" (condensation) will

not damage furniture or floors.

*Foamed polyethylene or equivalent is

recommended.

2.4.2.1.4 Insert the piping, drain hose and the

connecting cable into the piping hole.

2.4.2.1.5 Set the piping and the drain hose to the

back of the chassis with the tubing holder.

● Set the tubing retainer into position and tighten

screw.

2.4.2.1.6 Locating the indoor unit

● Hook the indoor unit onto the upper portion of

the installation plate (Engage the hooks of the

installation plate into the openings at the rear

top of the indoor unit). Ensure that the hooks are

properly seated on the installation plate by moving

the indoor unit left and right.

● Press the lower left and right sides of the unit

against the installation plate until the hooks

engage into their slots (clicking sound).

2.4.2.1.7 Connecting the piping to the indoor unit

and the drain hose to drain pipe.

● Align the centre of the piping and sufficiently

tighten the flare nut by hand.

● Tighten the flare nut with a wrench, in

accordance with the following table.

Outside

Diameter

Tightening

Torque

(Kg.m)

Additional

Tightening

Torque (Kg.m)

1/4” (6.35mm) 1.6 2.0

3/8” (9.53mm) 3.0 3.5

1/2” (12.7mm) 5.0 5.5

5/8” (16.0mm) 7.5 8.5

● When extending the drain hose of the indoor

unit, install the drain pipe extension as shown in

Page 11

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

10

adjacent diagram.

2.4.2.1.8 Wrap the insulation material around the

connecting portion.

● Overlap the connection pipe heat insulation

and the indoor unit pipe heat insulation material.

Bind them together with vinyl tape so that there is

no gap.

● Wrap the area which accommodates the rear

piping housing section with vinyl tape.

● Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping housing

section.

2.4.2.2 For rear left piping

Note: When viewed from the front of the indoor

unit.

2.4.2.2.1 Route the indoor tubing and the drain

hose to the required piping hole position in the

direction of left.

2.4.2.2.2 Insert the connecting cable into the

indoor unit from the outdoor unit through the

piping hole.

● Do not connect the cable to the indoor unit.

● Make a small loop with the cable for easy

connection later.

2.4.2.2.3 Tape the drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper

side can cause drain pan to overflow inside the

unit.

Note: If the drain hose is routed inside the room,

insulate the hose with an insulation material so

that dripping from "sweating" (condensation) will

not damage furniture or floors.

*Foamed polyethylene or equivalent is

recommended.

2.4.2.2.4 Insert the piping, drain hose and the

connecting cable into the piping hole.

2.4.2.2.5 Indoor unit installation

● Hang the indoor unit from the hooks at the top

of the installation plate.

● Insert a spacer between the indoor unit and

the installation plate to separate the bottom of the

indoor unit from the wall.

2.4.2.2.6 Connecting the piping to the indoor unit

and the drain hose to drain pipe.

● Align the centre of the piping and sufficiently

tighten the flare nut by hand.

Page 12

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

11

● Tighten the flare nut with a wrench, in

accordance with the following table.

Outside

Diameter

Tightening

Torque

(Kg.m)

Additional

Tightening

Torque (Kg.m)

1/4” (6.35mm) 1.6 2.0

3/8” (9.53mm) 3.0 3.5

1/2” (12.7mm) 5.0 5.5

5/8” (16.0mm) 7.5 8.5

● When extending the drain hose of the indoor

unit, install the drain pipe extension as shown in

adjacent diagram.

2.4.2.2.7 Wrap the insulation material around the

piping connections.

● Overlap the connection pipe heat insulation

and the indoor unit pipe heat insulation

material. Bind them together with vinyl tape

so that there is no gap.

● Wrap the area which accommodates the rear

piping housing section with vinyl tape.

● Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping

housing section.

2.4.2.2.8 Set the piping and the drain hose to the

back of the chassis with the tubing holder.

● Set the tubing retainer into position and

tighten screw.

2.4.2.2.9 Reroute the piping and the drain hose

across the back of the chassis, for rear left side

external passage.

Piping for passage

th r ough piping hole

2.4.2.2.10 Locating the indoor unit

● Remove the spacer.

● Hook the indoor unit onto the upper portion of

the installation plate.

(Engage the two hooks of the installation plate

into the openings at the rear top of the indoor unit.)

● Ensure that the hooks are properly seated on

the installation plate by moving the indoor unit left

and right.

● Press the lower left and right sides of the unit

against the installation plate until the hooks

engage into their slots (clicking sound).

2.4.3 Connection of pipes - outdoor

2.4.3.1 Align the centre of the piping and

Page 13

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

12

sufficiently tighten the flare nut by hand.

2.4.3.2 Finally, tighten the flare nut with torque

wrench until the wrench clicks.

● Tighten the flare nut with a wrench, in

accordance with the following table.

Outside

Diameter

Tightening

Torque

(Kg.m)

Additional

Tightening

Torque (Kg.m)

1/4” (6.35mm) 1.6 2.0

3/8” (9.53mm) 3.0 3.5

1/2” (12.7mm) 5.0 5.5

5/8” (16.0mm) 7.5 8.5

2.5 CONNECTING THE CABLE BETWEEN

INDOOR UNIT AND OUTDOOR UNIT

Max. current

(A)

Circuit Breaker /

Fuse Rating (A)

Wire Size

(mm

2

)

<=8 10 >=1.0

>8 & <=12.5 16 >=1.5

>12.5 & <=16 20 >=2.5

>16 & <=25 32 >=4.0

>25 & <=32 40 >=6.0

Max. current (A): Detail in SPECIFICATIONS list.

Note: To be used as a guide only.

2.5.1 Connect the cable to the indoor unit

● Connect the cable to the indoor unit by

connecting the wires to the terminals on the

control box individually according to the outdoor

unit connection. (Refer to Wiring diagram.)

(Ensure that the color of the wires of the outdoor

unit and the terminal number are the same as

CAUTION

Ensure that all electrical work complies with

relevant Standards and Supply Authority

Service Rules.

An individual branch Circuit Breaker/Fuse must

be used with this Air Conditioner. See the

table following for electrical requirements.

Notes:

● Power Source and Power Cord

specifications must comply with requirements

following.

● Circuit Breaker or Fuse specified in this

manual must be installed in the power supply

circuit.

● For your safety and protection, this unit is

earthed through the power cord plug when

plugged into a matching wall receptacle.

● Do not connect two power cords together to

supply power to the air conditioner.

● Do not extend the power cable conductors

by cutting.

● Power supply should be in the range of

90%~110% of rated voltage.

● Refer to the attached Electrical Connection

Diagram located on the panel of the outdoor

unit to connect the wire.

Page 14

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

13

those of the indoor unit.)

1. Lift the front panel up and remove the

window cover from the indoor unit by

loosening the screw.

2. Connect wires to the Indoor Unit terminals

from the Outdoor Unit as identified by their

colors.

3. Secure the cable with the cord clamp.

4. Wrap wires (conductors) that were not

connected with insulating tape so that they do

not touch any electrical or metal parts.

Notes:

Wrong wire connection may cause some

electrical parts to malfunction.

The length of the power supply cord should

be at least 1.8m measured from the power

supply cord entry of the cabinet to the middle

of the live pin of the plug.

2.5.2 Connect the cable to the outdoor unit

2.5.2.1 Remove the control cover from the unit by

loosening the screw. Connect the wires to the

terminals on the control board individually.

2.5.2.2 Secure the cable onto the control board

with the cord clamp.

2.5.2.3 Re-fix the control cover to the original

position with the screw.

2.5.2.4 Use a recognized circuit breaker (Refer to

table on page 11.) between the power source and

the unit. An isolation device to adequately

disconnect all supply lines must be fitted.

CAUTIONS:

After confirming the above conditions, prepare the

wiring as follows:

1) Never fail to have an individual powe r circuit

specifically for the air conditioner. As for the

method of wiring, be guided by the circuit

diagram posted on the inside of control cover.

2) The screws which fasten the wiring in the

casing of electrical fittings may come loose

from vibrations to which the unit is subjected

during the course of transportation. Check

them and make sure that they are all tightly

fastened. If they are loose, it could cause

burn-out of the wires.

3) Specification of power source.

4) Confirm that electrical capacity of the

installation is sufficient.

5) Ensure that the starting voltage is maintained

at more than 90 percent of the rated voltage

marked on the name plate.

6) Confirm that the cable thickness is as

specified in the power source specification.

Particularly note the relation between cable

length and thickness. (Refer to page 11.)

7) Always install a Residual Current Device

(RCD) in wet or moist area.

8) The following may be caused by voltage drop.

Vibration of a contactor, which will damage

the contact point, fuse blowing, disturbance of

the normal function of the overload.

9) The means for disconnection from a power

supply shall be incorporated in the fixed

wiring and have an air gap contact separation

of at least 3mm in each active (phase)

conductor.

If a power plug is not to be used, provide a Circuit

Breaker/Fuse between power source and the unit

as shown in adjacent diagram.

Page 15

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

14

2.6 CHECKING THE DRAINAGE AND

FORMING THE PIPE

2.6.1 Checking the drainage

2.6.1.1 To remove the front panel from the indoor

unit.

● Pull the lower left and right sides of the grille

toward you and lift it up.

2.6.1.2 To check the drainage.

● Pour a glass of water on the evaporator.

● Ensure the water flows through the drain hose

of the indoor unit without any leakage and goes

out the drain exit.

2.6.1.3 Drain piping

● The drain hose should point downward for

easy drain flow.

● Do not make drain piping similar to diagrams

shown below.

2.6.2 Form the piping

2.6.2.1 Form the piping by wrapping the

connecting portion of the indoor unit with

insulation material and secure it with narrow vinyl

tape and wide vinyl tape.

● If you want to connect an additional drain hose,

the end of the drain outlet should be routed above

the ground. Secure the drain hose appropriately.

2.6.2.2 In cases where the outdoor unit is installed

below the indoor unit perform the following.

● Tape the piping, drain hose and connecting

cable from down to up.

● Secure the tapped piping along the exterior

wall using saddle or equivalent.

2.6.2.3 In cases where the outdoor unit is installed

above the indoor unit perform the following.

Tape the piping and connecting cable from down

to up.

Secure the taped piping along the exterior wall.

Form a trap to prevent water entering the room.

Fix the piping onto the wall by saddle or

equivalent.

Page 16

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

15

2.7 AIR PURGING

2.7.1 Air purging

Air and moisture remaining in the refrigerant

system have undesirable effects as indicated

below.

● Pressure in the system rises.

● Operating current rises.

● Cooling (or heating if applicable) efficiency

drops.

● Moisture in the refrigerant circuit may freeze

and block capillary tubing.

● Water may lead to corrosion of parts in the

refrigeration system.

Therefore, the indoor unit and tubing between the

indoor and outdoor unit must be leak tested and

evacuated to remove any non-condensable

substance and moisture from the system.

2.7.2 Air purging with vacuum pump

2.7.2.1 Preparation

● Check that each tube (both liquid and gas side

tubes) between the indoor and outdoor units have

been properly connected and all wiring for the test

run has been completed. Remove the service

valve caps from both the gas and the liquid side

on the outdoor unit. Note that both the liquid and

the gas side service valves on the outdoor unit are

kept closed at this stage.

2.7.2.2 Leak test

● Connect the manifold set (with pressure

gauges) and dry nitrogen gas cylinder to this

service port with charge hoses.

● Pressurizes the system to no more than 1MPa

(Approx. 145psi) with dry nitrogen gas and close

the cylinder valve when the gauge reading

reaches 1MPa (Approx. 145psi). Next, test for

leaks with liquid soap.

Lo Hi

Indoor unit

Outdoor unit

Ma nifold set

Pressure

gauge

Charge hose

Nitrogen g as

cyli nder (in vertical

standing position)

● Do a leak test of all joints of the tubing (both

indoor and outdoor) and both gas and liquid side

service valves. Bubbles indicate a leak. Be sure to

wipe off the soap with a clean cloth.

● After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening the

charge hose connector at the nitrogen

cylinder. When the system pressure is

reduced to normal, disconnect the hose from

the cylinder.

Gas leak check

1. Apply a soap water or a liquid neutral detergent

CAUTION

To avoid nitrogen entering the refrigerant

system in a liquid state, the top of the cylinder

must be higher than its bottom then you

pressurise the system. Usually, the cylinder is

used in a vertical standing position.

CAUTION

Be sure to use a manifold set for air purging. If it

is not available, use a stop valve for this

purpose. The "Hi" knob of the manifold valve

must always be kept closed.

Page 17

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

16

on the indoor unit connection or outdoor unit

connections using a soft brush to check for

leakage of the connecting points of the piping.

2. If bubbles come out, the pipes have leakage.

Note:

A: Lo stop valve

B: Hi stop valve

C and D: connections to the indoor unit.

2.7.2.3 Evacuation

● Connect the charge hose end described in the

preceding steps to the vacuum pump to evacuate

the tubing and indoor unit. Confirm the "LO" knob

of the manifold set is open. Then run the vacuum

pump. The operation time for evacuation varies

with tubing length and capacity of the pump. The

following table is a guide for evacuation times.

Times are dependent on tubing length and pump

capacity.

Pipe Length (L)

Air Purge

Method

Timer required

(min)

<5m

Use Vacuum

Pump

25

5~10m

Use Vacuum

Pump

30

● When the desired vacuum is reached, close

the "LO" knob of the manifold set and stop the

vacuum pump.

Indoor unit

Outdoor unit

Manifold set

Pressure

gauge

Vacu um pu mp

Open

Close

2.7.2.4 Finishing the job

● With a service valve wrench, turn the valve

stem of liquid side valve counter-clockwise to fully

open the valve.

● Turn the valve stem of gas side valve

counter-clockwise to fully open the valve.

● Loosen the charge hose connected to the gas

side service port slightly to release the pressure,

then remove the hose.

● Replace the valve cap on the gas side service

port and fasten the cap securely.

● This process is very important to prevent

leakage from the system.

● Replace the valve caps at both gas and liquid

side service valves and fasten them tightly.

● This completes air purging with a vacuum

pump. The air conditioner is now ready to test run.

Page 18

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

17

2.8 TEST RUNNING

1. Check that all tubing and wiring have been

properly connected.

2. Check that the gas and liquid side service

valves are fully open.

2.8.1 Settlement of outdoor unit

● Anchor the outdoor unit with a bolt and nut

(φ10mm) tightly and horizontally on a concrete or

rigid mount.

● When installing on a wall, roof or rooftop,

anchor the mounting base securely.

● In the case when the vibration of the unit is

conveyed to the connecting pipes, secure the unit

with an anti-vibration mount.

2.8.2 Prepare remote control

Notes:

● There are two methods to test the unit using

either the remote control or using the switch on

the indoor unit.

● It is recommended that you test the unit using

the switch on the indoor unit.

To use the remote control for test running, operate

as per the following instruction.

To use the switch on the indoor unit for test

running, skip the following instructions and move

to item “2.8.3”.

Prepare remote control

The remote control uses two alkaline dry cell

batteries (2 X AAA 1.5Volt).

(1) Slide the cover of the battery compartment (on

the rear of the remote control) off.

(2) Insert new batteries, making sure that the (+)

and (-) of battery are installed correctly.

(3) Slide the battery compartment cover back on.

NOTES:

● Always use 2 x AAA (1.5Volt) batteries. Do not

use rechargeable batteries.

● Remove the batteries from the remote control

if the system is not going to be used for a long

period.

2.8.3 Operating the unit with the switch on the

indoor unit

1. Open and lift the front panel up to angle until it

remains fixed with a clicking sound.

2. Press the AUTO/COOL button twice (For Size

A and Size B indoor units) or COOL button once

(For Size C indoor units) or Manual button twice

(For Size D and Size E indoor units), the unit will

work on test mode for cooling (Refer to page 3).

Note:

Cooling test mode running can only continue for

30 minutes. After this time it will automatically

change into AUTO mode with setting temperature

at 24

o

C.

If using the Remote Control for test running, set it

in COOL mode (Refer to User Manual). The unit

will not change into AUTO mode automatically. If

the ambient temperature is too low, the unit

cannot perform test running on COOL mode.

2.8.4 Evaluation of performance

Operate unit for 15~20 minutes, then check the

system refrigerant charge:

1. Measure the pressure of the gas side service

valve.

2. Measure the temperature of the intake and

discharge of air.

Page 19

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

18

3. Ensure the difference between the intake

temperature and the discharge is more than 8

o

C.

4. For reference: the gas side pressure of

optimum condition is as detailed (Cooling).

Outside ambient

TEMP.

The pressure of the

gas side service valve

35oC(95oF)

4~5kg/cm

2

(400~490KPa)

NOTE:

If the actual pressure is higher than shown, the

system is most likely overcharged, and charge

should be reduced.

If the actual pressure is lower than shown, the

system is most likely undercharged, and charge

should be added.

The air conditioner is now ready for use.

PUMP DOWN

This is performed when the unit is to be relocated

or the refrigerant circuit is serviced.

Pump Down means collecting all refrigerant in the

outdoor unit without loss of refrigerant gas.

CAUTION:

Be sure to perform Pump Down procedure with

the unit in cooling mode.

Pump Down Procedure

1. Connect a low-pressure gauge manifold hose

to the charge port on the gas side service valve.

2. Open the gas side service valve halfway and

purge the air from the manifold hose using the

refrigerant gas.

3. Close the liquid side service valve (all the way

in).

4. Turn on the unit's operating switch and start the

cooling operation.

5. When the low-pressure gauge reading

becomes 1 to 0.5kg/cm

2

(100~50kPa), fully close

the gas side valve stem and then quickly turn off

the unit.

At this time Pump Down has been completed and

all refrigerant gas will have been collected in the

outdoor unit.

Page 20

19

3 TROUBLESHOOTING GUIDE

3.1 REFRIGERATION CYCLE DIAGRAM

For Reverse Cycle Type

For Cooling Only Type

Page 21

20

3.2 TROUBLESHOOTING GUIDE

In general, possible trouble is classified in three kinds. One is called Starting Failure which is caused

from an electrical defect, another is ineffective Air Con ditioning caused by a defect in the refrigeration circuit

and improper application, and the other is called the Structure Damage.

ROOM AIRCONDITIONER VOLT AGE LIMITS:

MODELS NAMEPLATE RATING MINIMUM MAXIMUM

FOR SINGLE-PHASE

POWER MODELS

220~240V 196V 253V

FOR THREE-PHASE

POWER MODELS

Phase voltage 380~420V

Single phase 220~240V

338V

196V

445V

253V

ROOM AIRCONDITIONER TEMPERATURE OPERATION LIMITS:

Cooling operation

Outdoor unit air temp.℃ DB

45

40

35

30

25

20

Indoor air temp. ℃ DB 10 15 20 25 30 35 40

Note: The chart is the result from the continuous operation under constant air temperature conditions.

However, excludes the initial pull-down stage.

Heating operation

Indoor air temp. ℃ DB

30

25

20

15

10

Outdoor unit air temp.℃ DB -5 5 15 25

Note : The chart is the result from the continuous operation under const ant air temperature conditions.

However, excludes the initial pull-down stage.

DRY COOLING

Page 22

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

21

The following tables will help to find where error happened (LED on indoor unit):

For models adopting electrical function (part I) (cooling only models):

Failure phenomenon

Operation

lamp

Timer

lamp

Indoor fan speed has been out of control for

over 1 minute

☆

X

Indoor room temp. or evaporator sensor is

open circuit or short circuit

☆

On

Over current protection of the compressor

occurs 4 times

X

☆

EEPROM error On

☆

No over-zero signal

☆ ☆

For models adopting electrical function (part I) (reverse cycle models):

Failure phenomenon

Operation

lamp

Timer

lamp

Defrosting

lamp

Over current protection of the compressor

occurs 4 times

☆

X

☆

Indoor fan speed has been out of control for

over 1 minute

X

☆ ☆

No over-zero signal

☆ ☆ ☆

Temp. sensor on indoor evaporator is open

circuit or short circuit

X X

☆

Indoor room temp. sensor is open circuit or

short circuit

X

☆

X

EEPROM error On

☆

X

For models adopting electrical function (part II):

Failure phenomenon

Operation

lamp

Timer

lamp

Defrosting

lamp

Auto lamp

Over current protection of the compressor

occurs 4 times

☆ ☆ ☆ ☆

Indoor room temp. sensor is open circuit or

short circuit

X

☆

X X

Temp. sensor on indoor evaporator is open

circuit or short circuit

☆

X X X

Temp. sensor on outdoor condenser is open

circuit or short circuit (without for cooling only

models)

X X

☆

X

Outdoor unit protects(outd oor temp sensor,

phase order etc)

X X

☆ ☆

EEPROM error

☆ ☆

X X

Indoor unit communication err X X X

☆

r Extinguish ☆ Flash at 5Hz

Page 23

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

22

Cu rrent pr ot ec ti on

(LED in dicates)

Check the indoor

air filter.

Does outdoor heat exchanger fros ted?

No

It is norma l under

that ambi ent temp .

Check the

dra i nage

system of

outdoor unit.

Yes

Does indoor heatexchanger frosted?

Yes

Check speed

of in door

motor.

Yes

No

Does the outdoor

temp over 48 C ?

o

Check the outdoor

condenser.

Does it occur in

Cool mode?

Check speed

of outdoor

motor.

Yes

Check the overcurre nt protect or of

compressor.

No

Replace the

main PCB board.

Replace the

compressor.

Recycle the

refrigerant

and rech ar ge.

No

Does the indoor

temp low than 10 C?

o

Yes

No

Check the solenoid

coil of reverse valve.

Check the overcurre nt protect or of

compressor.

Replace the

main PCB board.

Recyc le the refrigerant and rec harge.

Replace the reverse

valve.

Ch ec k the po s i tion

and wiri ng of temp

sensor (all of the m).

If wrong, t he unit will

result in current

protection, not temp.

Check the soft

starter mould.

Check the soft

start er mould.

The unit does not

operate

Does the power LED

light after turning

the switch on?

Check the electrical

source.

No

Check the power

supplie r.

Does the voltage

between input

terminates o f

transformer is

corre ct?

Does the voltage

between outp ut

terminates o f

transformer is

corre ct?

Does the power

tran sfer to the

disp lay board ?

Replace the main

PCB board.

Yes

Yes

No

Check wiring.

Replace the

transformer.

No

No

Do th e LED lam ps

indicat es ERR?

Ye s

Perform

the rela te d

inst ructions.

Yes

No

Is there beep from

the unit when using

remoter?

Check th e soft

starter

Check the battery

of the r emoter.

No

Che ck the displ ay

board .

Replace the

disp lay board .

Yes

No

Replace the

display board .

Yes

Ye s

Does the uni t run in

Forced Cool mode?

Page 24

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

23

Abnormal n oise

from the indoor unit

Does it happen in

Fan Only mode?

Yes No

Does it happ en with

auto swing?

Check the

swing motor.

Yes

Check the

swing louver.

Check the fan

motor.

No

Check the cross flow

fan.

Replace the b ear.

Does i t just happen

in the beginning of

cooling or heating

mode?

It is because

of the heat

rub between

plas tics parts.

It is normal.

Yes

Check the input

and output pi pe .

No

Recyc le the ref rigerant and rec har ge.

Abnor mal noise

from the outdoo r

unit

Does it happen in

Cool mode?

Yes

Do the fan blade rub

with the shroud?

Chec k t he

motor.

Yes

Chec k t he

fan blade.

Chec k the fixing nut s

of outdoor unit.

No

Che ck the

motor

supporter.

Check the capillary.

Check the

compressor.

No

Recycle the refrig erant and recharge.

PROBLEM CAUSE REMEDY

Power failure Check the power cord.

Wiring failure Check the wiring. Replace the terminates or wires if failure.

Transformer failure Check the input and the output on transformer. Replace if failure.

Not operating

Indoor PCB failure Replace after checked failure.

Cross flow fan failure Replace the fan if cracked, out of balance, or partially missing.

Loose screws Tighten them.

Worn bearings Replace after checke d failure.

Indoor abnormal

noise.

Motor failure

Replace the motor if knocking sounds continue when running or loose,

or the motor hums or noise appears to be internal while running.

Fan blade failure Replace the fan blade if cracked, out of balance, or partially missing.

Loose screws Tighten them.

Motor failure

Replace the motor if knocking sounds continue when running or loose,

or the motor hums or noise appears to be internal while running.

Compressor failure Replace the compressor if sounds coming from inner of the compressor.

Outdoor

abnormal noise.

Copper tubing

Remove the cabinet and carefully rearrange tubing not to contact

cabinet, compressor.

Display board or

indoor PCB failure Replace the di splay board. If it is still false, replace the PCB.

Battery failure

Check the voltage of battery. Replace batteries if the voltage is lower

than 2.3V.

Remote control

failure.

Remote control failure

Normally, the remote control is not easy to damage. If the above two

methods are not effectual, replace the remote control.

Page 25

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

24

PROBLEM CAUSE REMEDY

Outdoor transformer

failure

Replace if failure.

Indoor PCB failure Replace the PCB if the photon coupling on indoor PCB is failure.

Insufficient

cooling or

heating.

Indoor PCB failure Replace after checked failure.

Lack of refrigerant

Check leakage. Recycle the refrigerant. Correct and recharge if there is

any leakage in the refrigerant system.

Soft starter module

failure

Check the module and the capacitor connected to the module. Replace

if failure.

Overcurrent protector

failure

Check the resistance of compressor overcurrent protector. Replace if

failure.

Compressor

protection

Outdoor PCB failure Replace after checked failure.

Temperature sensor

failure

Replace after checked failure.

Connector failure or

loose

Repair or replace the sensor.

Open or short

circuit of outdoor

temperature

sensor

Outdoor PCB failure Replace after checked failure.

Temperature sensor

failure

Replace after checked failure.

Connector failure or

loose

Repair or replace the sensor.

Room temp or

evap temp

sensor open or

short circuit

Indoor PCB failure Replace after checked failure.

Soft starter module

failure

Check the module and the capacitor connected to the module. Replace

if failure.

Over load or too

low voltage

protection

Power failure Wait if checked the power voltage is really too low.

Wiring failure Correct if indoor fan motor wiring is loose.

Indoor fan motor

failure

Check the input of fan motor. Replace if failure.

Fan speed

beyond control

Indoor PCB failure Replace after checked failure.

Zero-crossing

error

Indoor PCB failure Replace after checked failure.

LED failure Replace the display if checked failure.

No display on

indoor unit.

Remote control shut

the display

Push the button to turn the display on.

No power Check the voltage. Call an electrician if not within the limit.

Wiring Check the terminals. Repair and correct if loose.

Temperature setting Check and adjust the temperature setting.

Mode setting Check and adjust the mode setting.

Soft starter module

failure

Check the module and the capacitor connected to the module. Replace

if failure.

Reverse valve

solenoid coil

Check the reverse valve solenoid coil. Replace the coil if short, open or

damaged.

No cooling or

heating.

Reverse valve

If the reverse valve is blocked, the heating mode will not perform.

Replace the reverse valve after checking the reason.

Page 26

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

25

PROBLEM CAUSE REMEDY

Air filter Clean or replace if restricted.

Unit undersized

Determine if the unit is properly sized for the area to be cooled or

heated.

Condenser and

Evaporator

Clean or replace if restricted.

Room structure

Take proper measures to make the door and windows sealed well if gap

is found.

Air flow

Clean or remove if any barrier is found to block the inlet/outlet wind flow

of the unit.

Sunlight Add a awning if the outdoor unit is exposed to the sunl ight.

Outdoor fan motor

Check the fan capacitor on outdoor power control board and replace the

board if not within +/-10% of manufacturer's rating. Replace the motor if

the speed is not within +/-10% of manufacturer's rating but not because

of the capacitor.

indoor fan motor

For electrical function 2.3 models. Check the fan capacitor in indoor

electric box (for some models, the capacitor is on main PCB.) and

replace the capacitor (or main PCB) if not within +/-10% of

manufacturer's rating.

Replace the motor if the speed is not within +/-10% of manufacturer's

rating but not because of the capacitor.

Less refrigerant

Check the tubes for reasons of leakage. Recycle the refrigerant, correct

the leakage points and recharge.

Capillary tube

Regulate the flow if capillary tube is blocked. Make the evaporating

temperature appropriate if the evaporator is frosted.

Compressor

The inlet and outlet valve of the compressor is damaged, making the low

pressure connected with the high pressure. The refrigerating system is

difficult to produce high pressure and low pressure. Replace the

compressor after checking for the reason.

Insufficient

cooling or

heating.

Heat sources Reduce if over loaded.

Water drainage failure Check the drainage pipe and repair if failure.

The indoor unit is

incorrect installed

Correct the installation if not correct.

Drainage pipe

blocked

Correct it.

Water drops from

indoor unit

The humidity in room

is too high

It's normal if the humidity in the room is over 85%.

Wiring failure Check wiring. Correct if wrong wiring or loosen.

Wire EMC

Check wiring. Correct if the commucication wire is not shielded wire or

twisted with other wires.

Zero-crossing

error

Outdoor PCB failure Replace if the LED is not on.

Page 27

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

26

4 WIRING DIAGRAM

4.1 WIRING DIAGRAM FOR INDOOR UNITS

4.1.1 For models:

EL-KF20GW/N2Y-A(B) EL-KF26GW/N2Y-A(B)

EL-KF20GW/Y-A(B) EL-KF26GW/Y-A(B) EL-KF32GW/Y-A(B)

EL1-KF20GW/Y-A(B) EL1-KF26GW/Y-A(B) EL1-KF32GW/Y-A(B)

EL1-KF20GW/N2Y-A(B) EL1-KF26GW/N2Y-A(B)

12

34

5

12345

212121

21

351

351

321

321

31

13

1

3

DISPLAY BOARD

CN 6 CN 4 CN12 CN2

CN 3

CN 11

RE D

BL UE

BL AC K

CN 1

TR AN SFOR MER

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

RO OM T EM P ER AT UR E

SENSOR

PIPE TEMPERATURE

SENSOR

JX1

INDOOR UNIT

TO OUTDOOR UNI T

Y/ G

1 2 (N) 3 4

BR OW N

Y/ G

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

4.1.2 For models:

EL-KFR20GW/N2Y-A(B) EL-KFR26GW/N2Y-A(B) EL-KFR36GW/N2Y-A(B)

EL-KFR20GW/Y-A(B) EL-KFR26GW/Y-A(B) EL-KFR32GW/Y-A(B) EL-KFR36GW/Y-A(B)

EL-KFR20GW/N1Y-A(B) EL-KFR26GW/N1Y-A(B) EL-KFR36GW/N1Y-A(B)

EL1-KFR20GW/Y-A(B) EL1-KFR26GW/Y-A(B) EL1-KFR32GW/Y-A(B) EL1-KFR20GW/N2Y-A(B)

EL1-KFR26GW/N2Y-A(B) EL1-KFR35GW/N2Y-A(B) SEL1-KFR26GW/Y-A(B) SEL1-KFR36GW/Y-A(B)

12

34

5

1

2345

21

2

1

21

2

1

351

35

1

321

321

31

13

13

DIS PL A Y B OARD

CN 6

CN4CN12CN2

CN 3

CN 11

RE D

BL UE

BL AC K

CN13_

CN 1

TR AN SFOR ME R

CN 5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

ROO M TEMPERATURE

SENSOR

PIPE TEMPERATURE

SENSOR

JX 1

IN DO OR UNI T

TO O UT DOOR U NIT

Y/ G

1

2(N)

34

2

1

BR OW N

Y

E

L

L

O

W

B

L

U

E

Y/ G

C

O

M

P

R

E

S

S

O

R

R

E

L

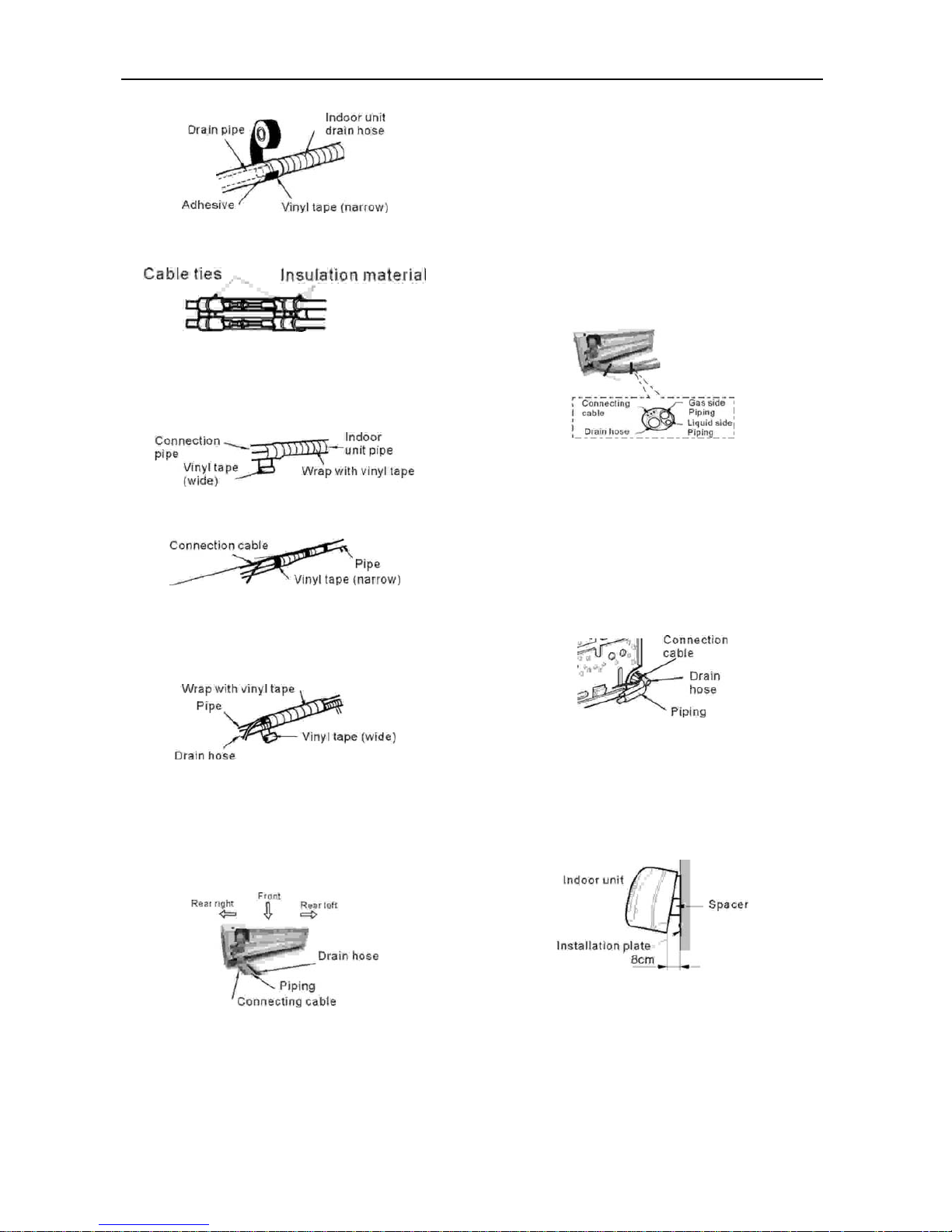

A

Y

C

N

1

5

8 7 6 5 4 3 21

CN13_

Page 28

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

27

4.1.3 For models:

EL-KF36GW/N2Y-A(B) EL-KF36GW/Y-A(B) SEL1-KF36GW/Y-A EL1-KF35GW/N2Y-A(B)

12

34

5

1

2345

21

2

1

21

2

1

351

35

1

32

1

321

31

13

13

DISPLAY BOARD

CN 6 CN 4

CN 12

CN 2

CN3

CN 11

RED

BL UE

BL AC K

CN1

TRANSFORMER

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

PIPE TEMPERATURE

SENSOR

JX 1

IN DO OR U NI T

TO O UT DO OR U NI T

Y/ G

12(N)3 4

BR OW N

Y/ G

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

4.1.4 For models:

EL-KF50GW/N2Y-A(B) EL-KF50GW/Y-A(B) EL-KT3F53GW/Y-T1 EL-KT3F53GW/Y-T2

2

1

21

2

1

21

351

35

1

321

321

31

13

13

DISPLAY BOARD

CN 6

CN4

CN12

CN2 CN 3

CN11

RED

BLUE

BLACK

CN1

TR AN SF OR ME R

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

P IPE TEMPERA TURE

SENSOR

JX1

INDOO R UNIT

TO OUTD OOR UNIT

Y/G

1

2(N)

34

BR OW N

Y/G

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

1

2

34

5

12 345

LOUVER MOTOR 2

LOUVE R MOTOR 1

Page 29

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

28

4.1.5 For models:

EL-KFR50GW/N2Y-A(B) EL-KFR50GW/Y-A EL-KT3FR53GW/Y-T1

212121

21

35

1

35

1

321

321

31

13

13

DISPLAY BOARD

CN6

CN4

CN12

CN2

CN3

CN11

RED

BLUE

BLACK

CN13_

CN1

T RAN SF OR ME R

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

PI PE TEMPERATURE

SENSOR

JX1

IND OOR UNIT

TO OUTDOOR UNIT

Y/G

1

2(N )

34

2

1

BROWN

Y

E

L

L

O

W

B

L

U

E

Y/G

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

CN13_

12

34

5

12 345

LO UV ER M OTOR 2

LOU VE R M OTOR 1

4.1.6 For models:

EL-KF61GW/N2Y-A(B) EL-KFR61GW/N2Y-A(B) EL-KF70GW/N2Y-A(B) EL-KFR70GW/N2Y-A(B)

EL-KF61GW/Y-A(B) EL-KFR61GW/Y-A(B) EL-KF70GW/Y-A(B) EL-KFR70GW/Y-A(B)

AU-KF61GW/Y-A(B) AU-KFR61GW/Y-A(B) AU-KF70GW/Y-A(B) AU-KFR70GW/Y-A(B)

SEL-KF61GW/Y-A(B) SEL-KFR61GW/Y-A(B) SEL-KF70GW/Y-A(B) SEL-KFR70GW/Y-A(B)

EL-KT3F70GW/Y-T1 EL-KT3FR70GW/Y-T1 EL-KT3F70GW/Y-T2

CN2

CN5

CN11

CN1

CN9

CN3

M

~

SWING SWING

UNIT2

CN7

CN8

CN

6

Y/G

RED

Y/G

WHITE

BLUE

FUSE 3.15A/250V

FAN1

TRANS1

CAP1

XT1

RT2

RT1

TO OUTDOOR UNIT

UNIT1

1

2(N)

S

WIRING DIAGRAM

(INDOOR UNIT)

CO DE

UN IT 1

UN IT 2

FA N1

CA P1

SW IN G

TR AN S1

RT 1

RT 2

XT 1

CN 1- CN 11

XP 2, XS 2

PART NAME

MAIN CONTROL PCB

DISPLAY PCB

INDOOR FAN

FAN CAPACITOR

SWING MOTOR

TRANSFORMER

ROOM TEMPERATURE SENSOR

PIPE TEMPERATURE SENSOR

5-WAY TERMINAL

PCB SOCKETS

CONNECTORS

XS2

XP2

Page 30

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

29

4.1.7 For models:

EL-KF90GW/Y-A(B) EL-KFR90GW/Y-A(B) EL-KF90GW/SY-A(B) EL-KFR90GW/SY-A(B)

AU-KF85GW/Y-A(B) AU-KF85GW/Y-A(B)

CN5

CN4

CN3

CN11

CN1

CN9

M

~

SWI NG SWING

UNIT2

CN7

CN8

C

N

6

Y/G

BROWN

BROWN

Y/G

WHITE

BLUE

BLACK

FUSE 3.15A/250V

FAN1

TRANS 1

XT1

RT2

RT1

XS2

XP2

TO O UTDO OR U NIT

UNIT1

1

2(N)

S

WIRING DIAGRAM

(INDOOR UNIT)

CODE

UNIT1

UNIT2

FAN1

SWING

TRANS1

RT1

RT2

XT1

CN1-CN11

XP2,XS2

P ART N AM E

MA IN CONT RO L PCB

DI SP LAY P CB

IN DO OR FA N

SW IN G MOT OR

TR AN SFORM ER

RO OM TEMP ER ATURE S ENSOR

PI PE TEMP ER ATURE S ENSOR

5- WA Y TER MI NAL

PC B SOCKE TS

CO NN ECTOR S

P1

P2

P3

4.1.8 For models:

SEL-KF20GW/Y-A SEL-KF26GW/Y-A SEL-KF32GW/Y-A

12

34

5

12 345

212121

21

351

351

321

32

1

31

13

1

3

DISPLAY BOARD

CN6

CN4 CN1 2

CN2 CN3

CN11

BLACK

CN1

TRANSFORMER

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

P IPE TEM PE RATURE

SEN SO R

JX 1

INDO OR UNI T

TO O UT DOOR U NIT

Y/G

1

2(N)

34

WHI TE

GRE EN

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 2 1

RED

B

L

A

C

K

Page 31

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

30

4.1.9 For models:

SEL-KFR20GW/Y-A(B) SEL-KFR26GW/Y-A(B) SEL-KFR32GW/Y-A(B)

12

34

5

12345

2

1

21

2

1

21

35

1

351

32 1

32 1

31

13

13

DISPLAY BOARD

CN 6

CN4 CN12 CN2

CN3

CN11

WHI T E

C N13_

CN1

TRANSFOR ME R

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

P IP E T EM P ER AT U RE

S EN S OR

JX1

INDOO R U NIT

TO OUTDOOR UNI T

Y/ G

12(N)3 4

2

1

Y

E

L

L

O

W

B

L

U

E

GREE N

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

CN15

8 7 6 5 4 3 21

CN 13 _

BL AC K

RED

BLACK

4.1.10 For models:

SEL-KF53GW/Y-A(B)

21

2

1

21

2

1

351

351

321

321

31

13

13

DISPLAY BOARD

CN 6

CN4

CN 1 2

CN2

CN 3

CN 1 1

RED

WHITE

BLAC K

CN 1

TR ANSFORME R

CN 5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

PIPE TE MPERA TURE

SE NSOR

JX1

INDOOR UNIT

TO OUTDOOR UNIT

Y/G

1

2(N )

34

BLAC K

GREEN

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

12

34

5

123

4

5

LO UVER MOTOR 2

LOUVER MOTOR 1

Page 32

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

31

4.1.1 1 For models:

SEL-KFR53GW/Y-A(B)

212121

21

351

3

5

1

32

1

32

1

31

13

13

DISPLAY BOARD

CN6

CN4

CN12

CN2

CN3

CN11

RED

WHITE

BLACK

C N13_

CN1

TRA NS FO RM ER

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

PIP E TEM PERAT URE

SEN SOR

JX1

INDOOR UNIT

TO OUTDOOR UNIT

Y/G

1

2(N)

34

2

1

BLA CK

Y

E

L

L

O

W

B

L

U

E

GREEN

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

CN13_

12

34

5

1

2345

LO UVER MOTOR 2

LOUVER MO TOR 1

4.1.12 For models:

SEL1-KF26GW/Y-A(B)

12

34

5

1

2345

2

1

2

1

2

1

2

1

35

1

35

1

321

321

31

13

13

DISPLAY BOARD

CN 6 CN4 CN12 CN2

CN 3

CN 11

RE D

BLUE

BL ACK

CN 1

TRANSFORMER

CN5

P

O

W

E

R

S

U

P

P

L

Y

I

N

D

O

O

R

M

O

T

O

R

S

T

E

P

M

O

T

O

R

ROOM TEMPERATURE

SENSOR

PIPE TEMPERATURE

SENSOR

JX 1

IN DO OR U NI T

TO O UT DO OR UNI T

Y/ G

12(N) 3 4

BR O WN

Y/ G

C

O

M

P

R

E

S

S

O

R

R

E

L

A

Y

C

N

1

5

8 7 6 5 4 3 21

Page 33

GD Midea Refrigerant Equipment Co. Ltd Service manual for Electrolux split Series

32

4.2 WIRING DIAGRAM FOR OUTDOOR UNITS

4.2.1 For models:

EL-KF20GW/N2Y-A(B) EL-KF26GW/N2Y-A(B) EL-KF36GW/N2Y-A(B)