Middleby PS870 Parts Manual

PS870 “WOW” SERIES GAS FIRED:

SPL031107-PF-BD

March 11, 2007

A MIDDLEBY COMPANY

Parts Manual

with Wiring Diagrams

for domestic ovens

Serial # Code (Nine Digit Code)

(for units produced prior to mid-July, 2006)

First 4 digits - order of production

Fifth digit - model specific

Sixth and Seventh digit - month of production

Eighth and Ninth digit - year of production

Serial # Code (Ten Digit Code)

(for units produced after to mid-July, 2006)

First 5 digits - order of production

Sixth digit - model specific

Seventh and Eighth digit- month of production

Ninth and Tenth digit - year of production

Replaces SPL062506-PF-BD

Dated June 25, 2006

Starting Serial # 982150606

Table of Contents: Page 2

email: techsupport@middleby.com

1400 Toastmaster Drive

1-847-741-3300 fax 1-847-741- 4406

© 2006 Middleby Marshall Inc.

www.middleby.com

Elgin, IL 60120

Table of Contents

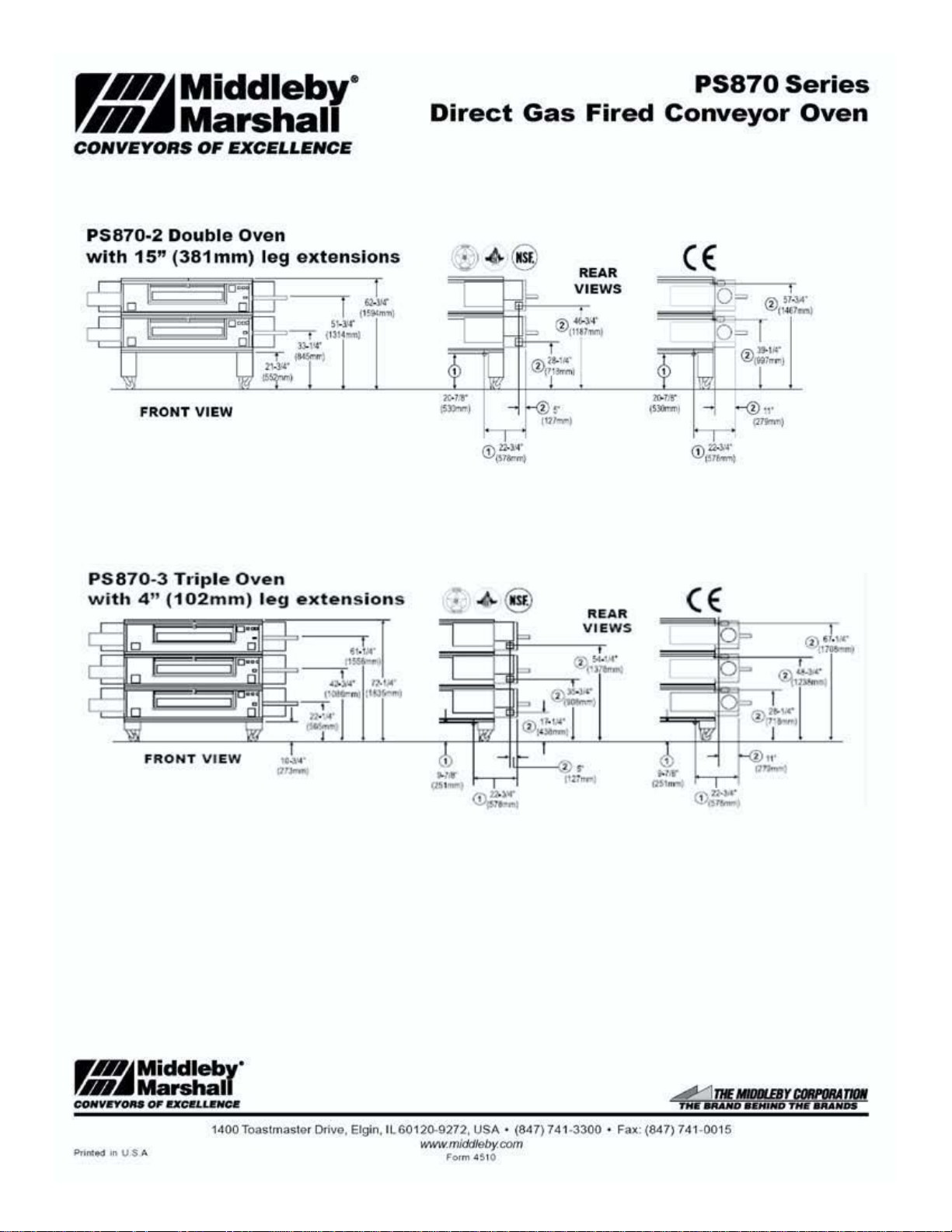

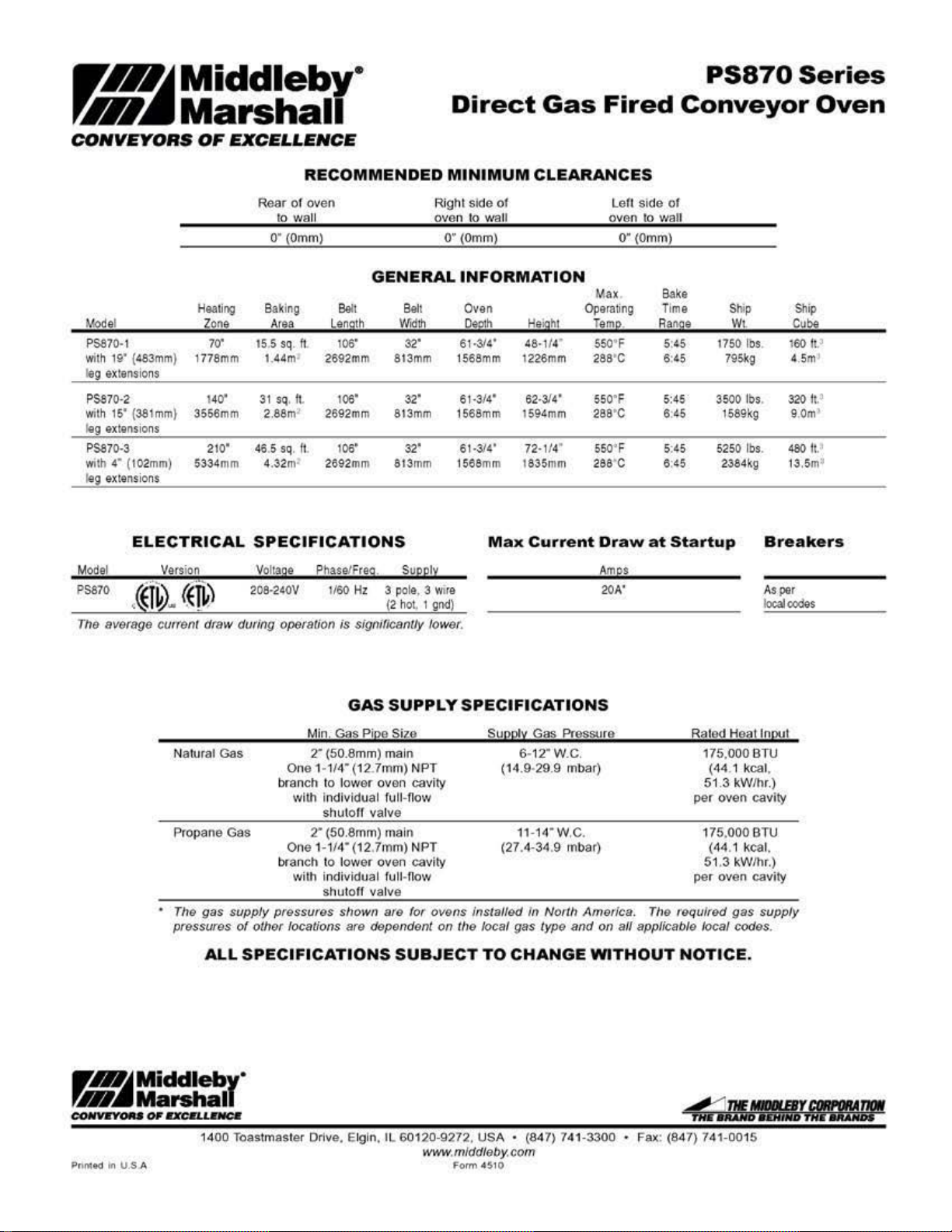

Spec Sheet ...................................................................................................................... 3

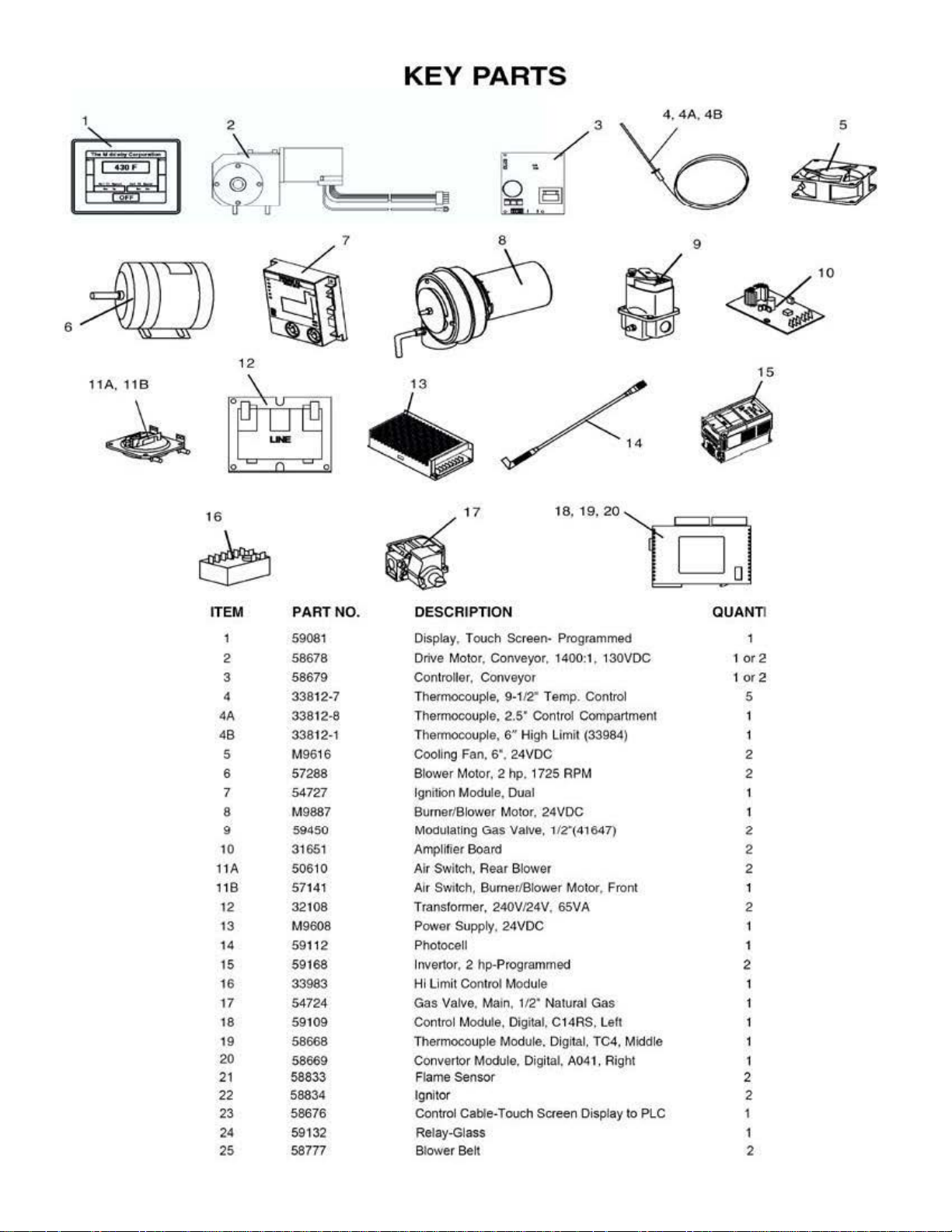

Key Parts ........................................................................................................................ 6

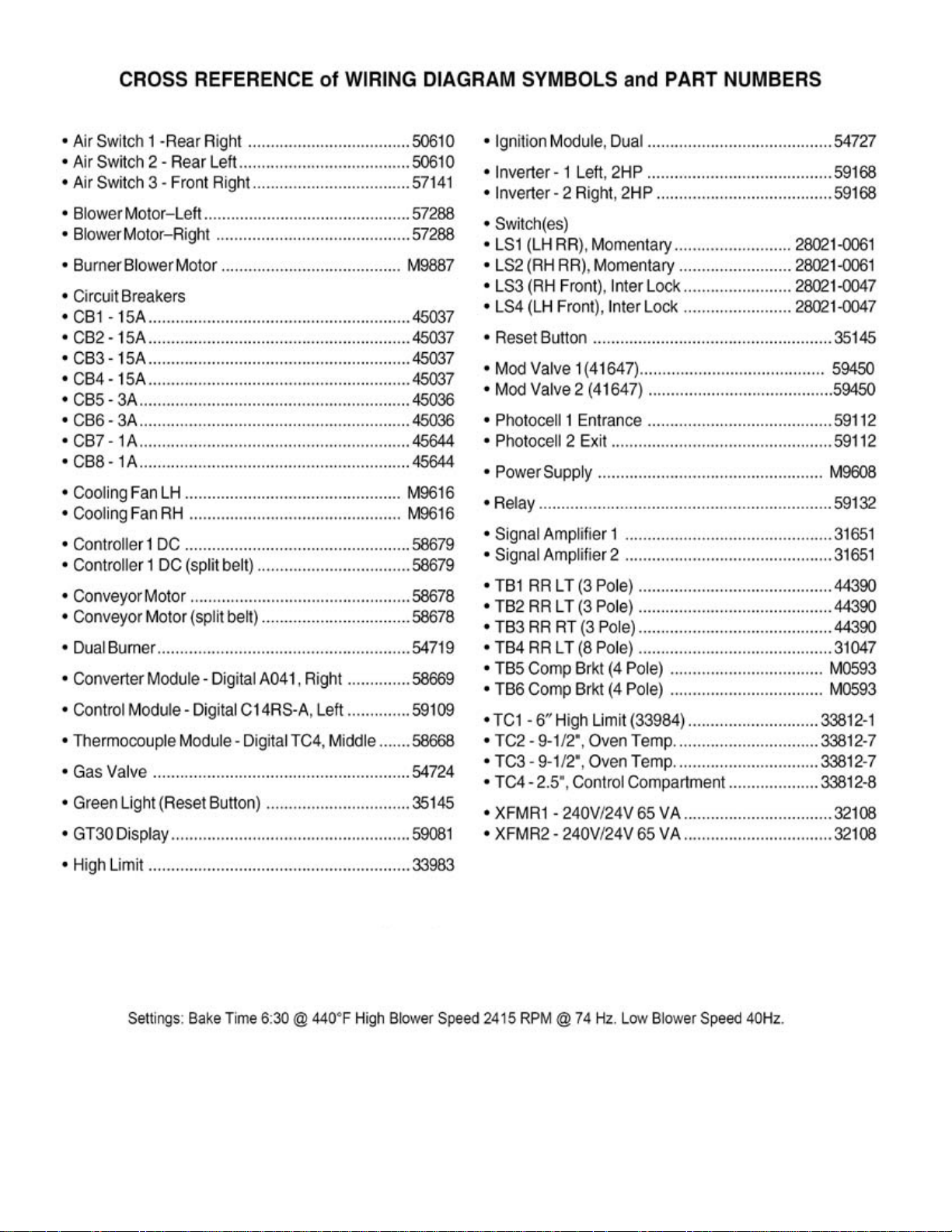

Cross Reference of Wiring Diagram Symbols and Part Number(s) .............................. 7

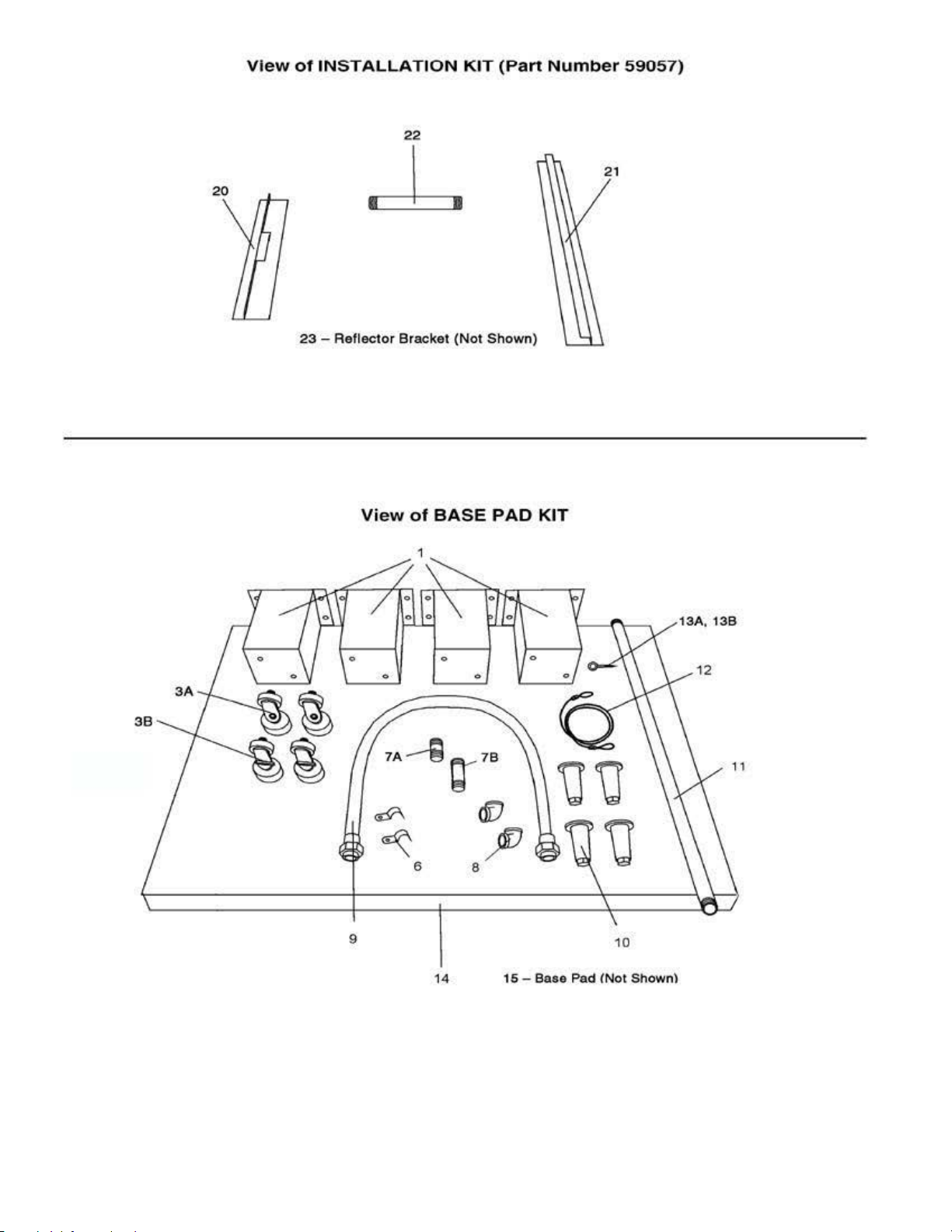

View of Installation Kit(s) and Base Kit(s) ....................................................................8

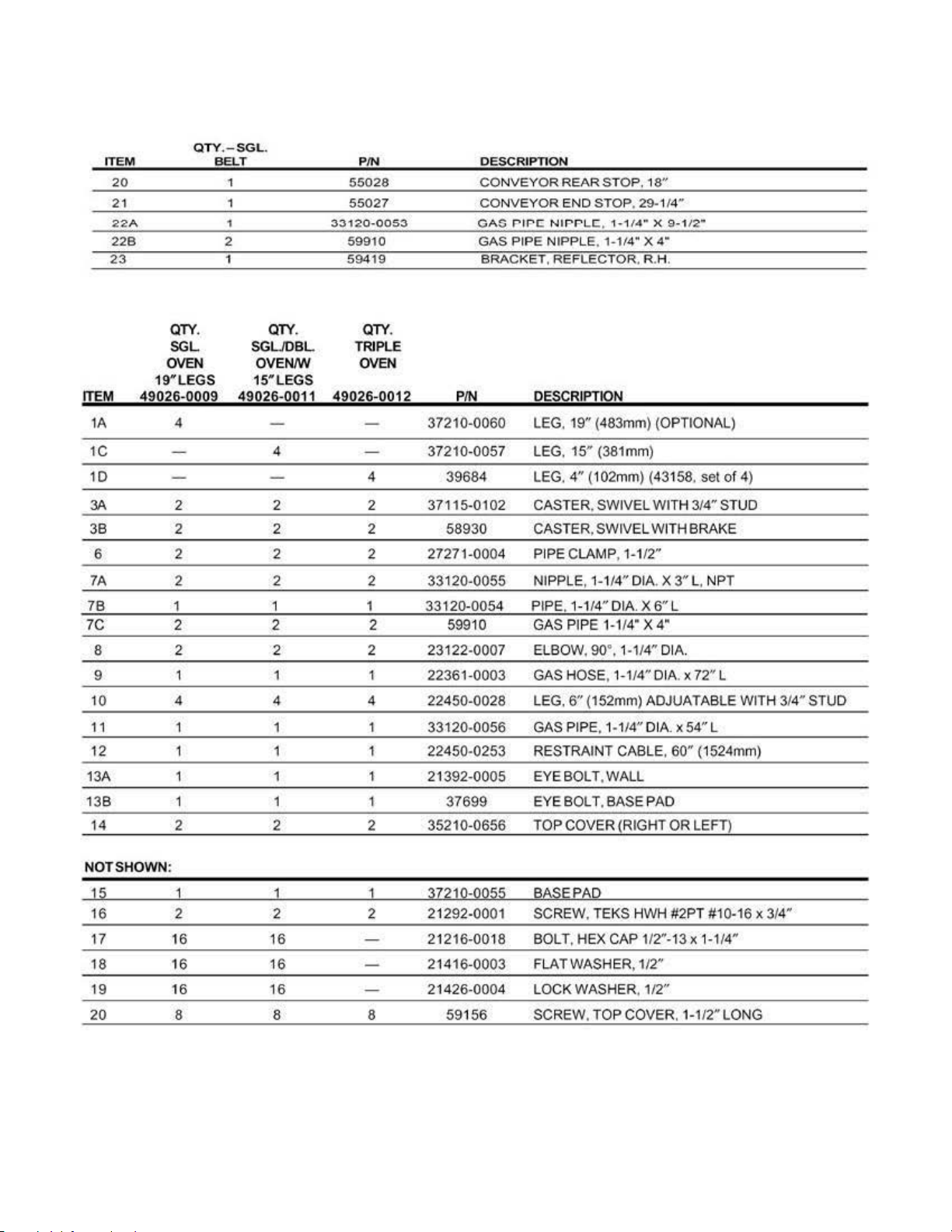

Parts for Installation Kit(s) and Base Kit(s) ................................................................... 9

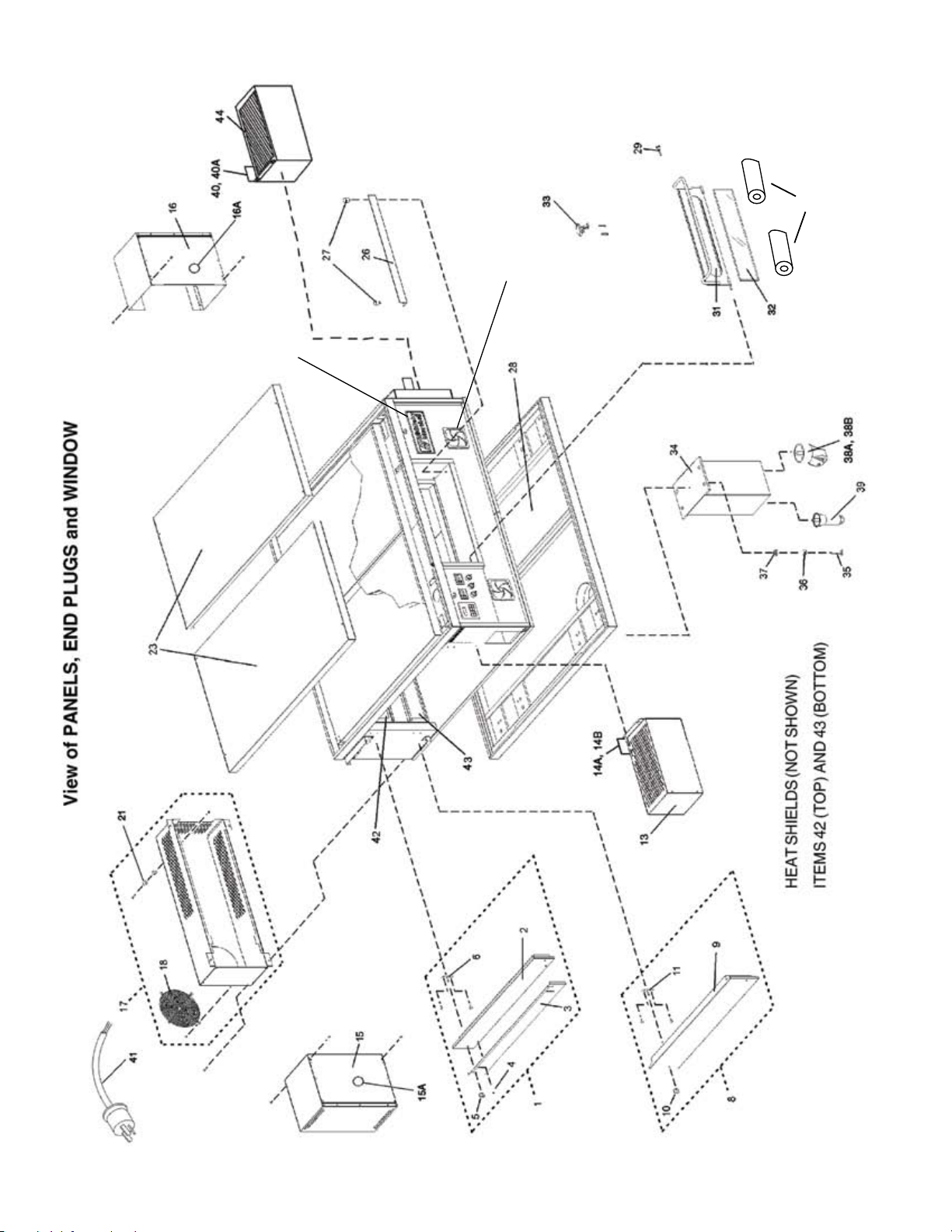

View of Oven Panels, End Plugs and Window ............................................................. 10

Parts for Oven Panels, End Plugs and Window ............................................................ 11

View of Gas Piping ....................................................................................................... 12

Parts for Gas Piping ...................................................................................................... 13

View(s) of Burner/Blower Motor Assembly ................................................................. 14

Parts for Burner/Blower Motor Assembly .................................................................... 15

View(s) of Front Control Area(s) .................................................................................. 16

Parts for Front Control Area(s) ..................................................................................... 17

View of Rear Compartment and Blowers (Conveyor Drive End Shown) .................... 18

Parts for Rear Compartment and Blowers (Conveyor Drive End Shown) ................... 19

View of “Single” Belt Conveyor ................................................................................... 20

Parts for “Single” Belt Conveyor .................................................................................. 21

View of “Split” 50/50 15” Wide Belt Conveyor ........................................................... 22

Parts for “Split” 50/50 15” Wide Belt Conveyor .......................................................... 23

View of “Split” 40/60 Belt Conveyor (12”/18”) ........................................................... 24

Parts for “Split” 40/60 Belt Conveyor (12”/18”) .......................................................... 25

Standard Finger Conguration 59730D and Part Numbers .......................................... 26

Finger Label -59730-1 ................................................................................................... 27

Thermocouple Placements L-R (Shipped Standard) 59072G ........................................ 28

Thermocouple Placements R-L (Converted to Right to Left in Field) 59073G ............ 29

Wiring Diagram, G208-240, 50/60Hz, 1 Phase 54745 Rev. I ....................................... 30

2

lriiiJ

Middleby

·

~~~Marshall

CONVEYORS

OF

EXCEI.I.ENCE

enerav

managa

;tfe~

t

system

Pnn

ctple

Middleby Marsha

faster and at a lower tempera ture than other ovens.

ented vertical columns

ll

y instead

ca

hot air remove the boundary layers

tend to insulate the product. This gives

bu

without

cook pizza

rning. All PS870WOW ovens

ll

PS

Series Conveyor ovens bake both

of

hot

air

move heat aerodynami-

of

using high temperatures. The streams

of

cool heavy air which

very

rapid baking

are

designed to

at 5:45

to 6:45 minutes belt speed.

Pa

A/A

Item

t-

of

FileNo.:

No

.:--------

_____

_

Direct Gas

PA

TENTS PENDING

•

Standard F

Impingement

return

Patented

duces

ci

70"/1778mm-long cooking chamb

32"/813mm-wide, 1 06"/2692mm-long conveyor belt

Energy Management

The

(EMS)

Touch Screen

saving mode.

gas

ency

P$870

that

eatures

PLUS I l

EMS Energ

consumption and increases cooking

features

automatically reduces

Co

ntrol can

ow

oven profile and

y Man

System

an

Energy Management System

be

agement

er

gas

consumption.

programmed in one ener

System re-

dual air

effi-

gy

cleanabthty

PS870 ovens are designed for easy cleaning. Removab

parts include: crumb pans, end panels, air fingers, and a

folding conveyo r belt assembly.

ily

Eas

Control compartment is designed

cess

Serviced

. All electrical controls

for

quick and easy ac-

are

door·mounted.

Warranty

All PS870 models have a one year parts and labor

and

ranty. Oven start-up

no additional char

Ve

ntilat i

on

For installation under a ventilation

ge (USA

demonstrati

only).

on

hood

are included

only

.

Midcllebr·

Marshal

t400

T

o•W~"ett..-

EJg1n

Ulor!oit80,20US

(847)1-41..3"300 F":u:(&47)74 1.0015

WNNn

t~<Om

3

Olive

A

war

le

-

at

WIHJ

~

CONVEY

P

with 15"

r-

S870

..

ORS

-2 Dou bl e

r-1

w

FRON

Middleby

Marshall

OF

EXCELLENCE

Ove

n

(38

1 m

m)

leg

extensio

O

il

_l

~ (1)14~

,.

,

..

_,_

T

~~

lril

T VIEW

.1

s""

•

11~

ns

1

62.,.

111

11)

Direct

l

1 h

\.It;

t

l$,..,j

""

'"

--,-1

Gas

h J

l=

p

-

~~

® ......

®] .....

VI'"""'

'"""'"'

Fired

REAR

VIEWS

lllf1m,l

PS870

Conveyor

CE

=

0=

0,

=1

I

Wll

(

S»m

""

t

""

!

-(j) .,.

~

®

-,.

Series

Oven

1

®"~

(l~J'

&t.i&•

r~~

~·

P

S870

with

~

¢::

c.:-~

·3

Trip

le

4"

(102mm)

D 0

lo

lo

'w!

FRONT

VIEW

Oven

leg

.

..

•

=

••

~

:=!.l ...... ,

\w'

Ql-

extension

-

•

»'4

4

:·;tdr-fflll

t

I

~

""'7

t

G~-4

... I..·

l59"""+

"

~~~~

tl~·

s

~.

~·""

.

I

l h

~

1

\w

I

!

nst

CE

l

l

I

tw

.....

(>)

.l.,

'

,

ur

..

-

Qi='

'

~

Ji=@

t I

-1

<>1,~

J...

r

....

~,;::....

·'·

REAR

J

l=

"'

"'

Q)

-

- I

VIEWS

(?)"~

~~

I - I

!.&,.,.,..:

'"'"·

I

'

!)~

1tU~~r

N •

Middlebr

CONVaYCHUM

Pmwifd,

Marshal

1n

V$

A.

·

UC'fi.~

1400 Too.slma•lor Drive, Elgin, ILG012G-9272, USA • (

www.rniddJOOy.

Fo

1m .4$10

4

com

847

) 741 ·

3300

• Fax: (

847

) 741·0015

IIFID~

~

CONVEYORS

Middlebr

..

Marshal

OF

EXCEI.I.ENCE

·

Direct

Gas

Fired

PS870

Series

Conveyor

Oven

M«Je

PS8

with

le

g

PS870·2

with

leg

P$870·3

With

f.eg

Mode

PS870

1'he

t

70·

t

19' (

483mm

extens1ons

15' (381mm

extensions

4"

extension$

) 1778mm 1.44m

) 3556mm 2.

(t02mm)

ELECTRICAL

l

avera

ge

Vers

current

Rear

of

to wall

0"

(Omm)

Heating

Zofle

70'

14

0'

210'

5334

Baking

Area

f5

.5 sq. h.

3t sq. II.

88m

46

.5 sq. 11.

mm 4.32m· 2692mm

SPECIFICATIONS

too

draw

Voltasa

208·240V

during

operation

RECOMMENDED

oven

GENERAL

Belt

Length

106'

2692mm

106'

2692mm

106'

PhasetFre

1160

Hz 3

is

significantly

Belt

WKI

JIJ

32'

813mm

32'

813mm

32'

8t3mm

9: Suoclv

pole

. 3

(2 hot,

1

lower.

MINIMUM

Ri

ght

side

oven

o•

of

to

wall ove-n to

(Omm)

INFORMATION

Oven

D

<>tllh

61·3/4'

1S

68mm l226mm

61

-31

4'

1568mm

61-314'

1566mm

Max

w~re

god)

CLEARANCES

Left Side

Max

Operating

HekJh1

48·fl4"

62·3/4'

1

594mm

72·1

1

83Smm

Current

14'

Tam

pz

560

'F

2ss

•c 6:

550

'f

288

'C

ss

o•F 5:

288

' C

Draw

Am.

20A'

o·

wall

(Omm)

Bake

Time

Rang

at

of

e

5:45

11.5

5:45

6:~5

45

6:

<5

Startup

Ship

Wt.

1750

795kg

3600

1589kg

5

250

2384

Ship

Cuba

160

lbs

.

.t

.5m

lbs

.

320 tt

9.0m'

lbs

.

460 II.'

kg 13.5m

Breaker

As

per

local

codes

ft.

l

.'

:,

s

Pnmtcl

In U.SA

GAS

SUPPLY

M

in.

Gas Pipe

Natural Gas

Propane G

The gas supply pressures siJOWt1 are for ovons lnstall&d In North

pressures

as

of

other focatlons are dependent on the local gas type

ALL

SPECIFICATIONS

14

00

Toastmaster Drive. Et

'2"

(50.8mm) main

One1·114" (12.7mm)

branch to l

with Individual lull-fl

s

ower

hul

2" (50.8mm) main

One 1·114" (12.7r

bran

ch

to l

with indi

ower

vidua

shuto

oven

off valve

nn>)

oven cavity

l fuii·U

ff

valve

gln

. IL 60

SiZQ

NPT

cavity

ow

NPT

ow

SUBJECT

120·9272.

SPECIFICATIONS

Supety Gas Pressure

(14.9·29.9 mbar)

(27.4-34

TO

CHANGE

www.mldd

USA • (8

leby.

Form .4$10

com

6·12" w

.c.

11-14" w.c.

.9 rnbar)

4 7) 741-3300

5

Amsr

lca.

and

on alf applicab

WITHOUT

TIJo

• Fax: (84

Rated

Hea

tln

oot

175.000 BTU

(44.1 k

cal

51.3

per

oven cavity

175.

(44.1 k

51.3 kW/hr.)

per

oven cavity

roqulr&d gas supply

le

local codes.

NOTICE

7) 741-00

.

kW

/hr.)

000BTU

cal

.

.

15

\

KEY

2

PARTS

4, 4A,

4B

5

6

1

1A,11B

~

12

~

16

~

ITEM PART NO.

1 59081

2

3 58679

4

4A

4B 33812·1

5

6 57288

7 54727

8 M9887

9

10 31651

11A

11B 57141

12 32108

13

14 59112

15 59168

16

17

18

19

20

21 58833

22

23 58676

24 59132

25

58678

33812·7

33812·8

M9616

59450

506

10

M9608

33983

54724

59109

58668

58669

56634

58777

7

13

8

9

15

6

18. 19,

DESCRIPTION

Di

splay, Touch Screen-P

Drive Motor, Conve)IOr. 1400:1, 130VDC

Cont

roller

, Conveyor

Thermooouple, 9·112" Temp. Control

Thermocouple. 2.5"

Th

ermocouple. 6" High Limil (33984)

Cooling Fan, 6". 24VDC

Blower Motor.

l

gnHion Module, Dual

ri

Biower M

Buma

Modulating

Amplifier

Air Switch.

Afr

Swttch.

Translormer. 240V/24V, 65VA

Power Supply. 24VDC

Photocell

Invertor. 2 hp-Programmed

HI

Limit Control Module

Gas

Control Module, Oigilal, C1

Thermocouple Module. Di

Convertor Module.

Flame

Ignitor

Control Cable-Touch

Relay-Glass

Blower Belt

Gas

Board

Rear

Bumer/Biower Motor.

Valve. Main,

sensor

ContrOl

2

hp

. 1725 RPM

otor

, 24VDC

Valve, 1/2"(41647)

Blower

112'

Natural Gas

Digit

al. A041. Right

Saeen

20

rogrammed

Compartment

Front

4RS.lelt

gi1al,

TC4. Middle

Display

to

PLC

QUAN

1

1

TI

or2

or2

5

2

2

2

2

2

2

1

2

1

2

2

1

1

2

6

Wiring Diagram on Page 30.

7

20

VIew

Of

INSTALLATION

23-

Ref

lector

Brac

ket

KIT

(Not

(Pan

Shown

Number

)

59057)

21

View

of

1

BASE

PAD

7A~g-7B

dfJ

)'

6

9

8

KIT

10

13

A,

138

11

14

15-

Base

Pad /Not

Shown)

8

Parts for INSTALLATION KIT (Part Number 59057)

ITEM

fTEM

1A

1C

10

3A

QTY.-SG

20

21

22A

228

23

QTY. QTY.

SGL

OVEN

19"

LEGS 15*LEGS

49026-0009 49026-0011 49026-0012

4 37210-0060 LEG.

2 2 2

L.

BELT

1

1

2

1

SGLJDBL TRIPLE

OVENfW OVEN

4 37210-

PIN

55028

55027

33120-0053

59910

59419

QTY

.

4

PIN

39684

37115-

DESCR

IPTI

ON

C0NVEYORREARSTOP.18"

CONVEYOR

GA$

PI

GAS

PIPE NIPP

BRACKET.

END

STOP. 29-1/4"

PC: NIPPL.C:, 1-11.4'" X 9-112'"

LE. 1-11

REFLECTOR

4" X 4"

DESCRIPTION

19"

{483mm) (OPTIONAL)

0057

LEG.

15"

(381mm)

LEG. 4" (102mm) (43158. set

0102

CASTER. SWIVEL WITH 3/4" STUD

. R.H.

3B 2 2 2 58930 CASTER, SWIVEL WITH BRAKE

1-112

6 2 2 2 27271-0004 PIPE CLAMP,

7A

7B

7C

8

9

10 4 4 4 22450-0028 LEG.

2 2 2 33120-0055 NIPPLE, 1-1/4" DIA. X

1 1

1 33120-

2 2 2

2 2 2 23122 -0007 ELBOW,

0054

PIPE. 1-1/4" DIA. X

59910 GAS PIPE

90

1 22361-0003 GAS HOSE,

6"

{152mm) ADJUATABLE WI

1-1

',

"

6"

/4" X 4"

1-1/4" DIA.

1-114

" OIA. x 72" L

L

3"

L, N

of

PT

4)

TH

3/4" STUD

11

1 33120-0056 GAS PIPE. 1-114"DI

12 1 22450-

13A

13B

14

2 2 2

1 1 21392-0005

1

37699

35210-0656 TOP COVER (RIGHT

NOT SHOWN:

15

16

1 1 1

2 2 2 21292-0001 SCREW, TEKS HWH #2PT #10-16 x 3/4"

17 16 16

18 16

16 21416-0003 FLAT WASHER, 1/2"

19 16 16

20

8 8 8

37210-0055 BASE

21

216-00

21426-0004 LOCK WASHER,

59156

0253

RESTRAINT CABLE,

EY

EBOLT, WALL

EYEBOLT, BASE PAD

PAD

18 BOLT, HEX CAP 112"

SCREW. TOPCOVER.1-1/2"LONG

A.

112"

x54"L

60"

OR

-13x

(1524mm)

LEFT)

1-1/4"

9

47

48 FILTER-ONLY

46

10

EARLIER MODELS REQUIRED A RIGHT TO LEFT KIT TO CONVERT TO RIGHT TO LEFT OPERATION PART #59340

NOT SHOWN ITEM 45

Loading...

Loading...