Middleby PS636G Service Manual

PS636 Series

Gas

Domestic & Std Export

ENGLISH

P/N 66639

December 2014 Rev. E

PS636 Series Gas Ovens

Model:

• PS636G Gas

Combinations:

• Single Oven

• Double Oven (Two-Stack)

• Triple Oven (Three-Stack)

OWNER'S OPERATING AND

INSTALLATION MANUAL

for domestic and standard export ovens

©2014 Middleby Marshall Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)741-4406

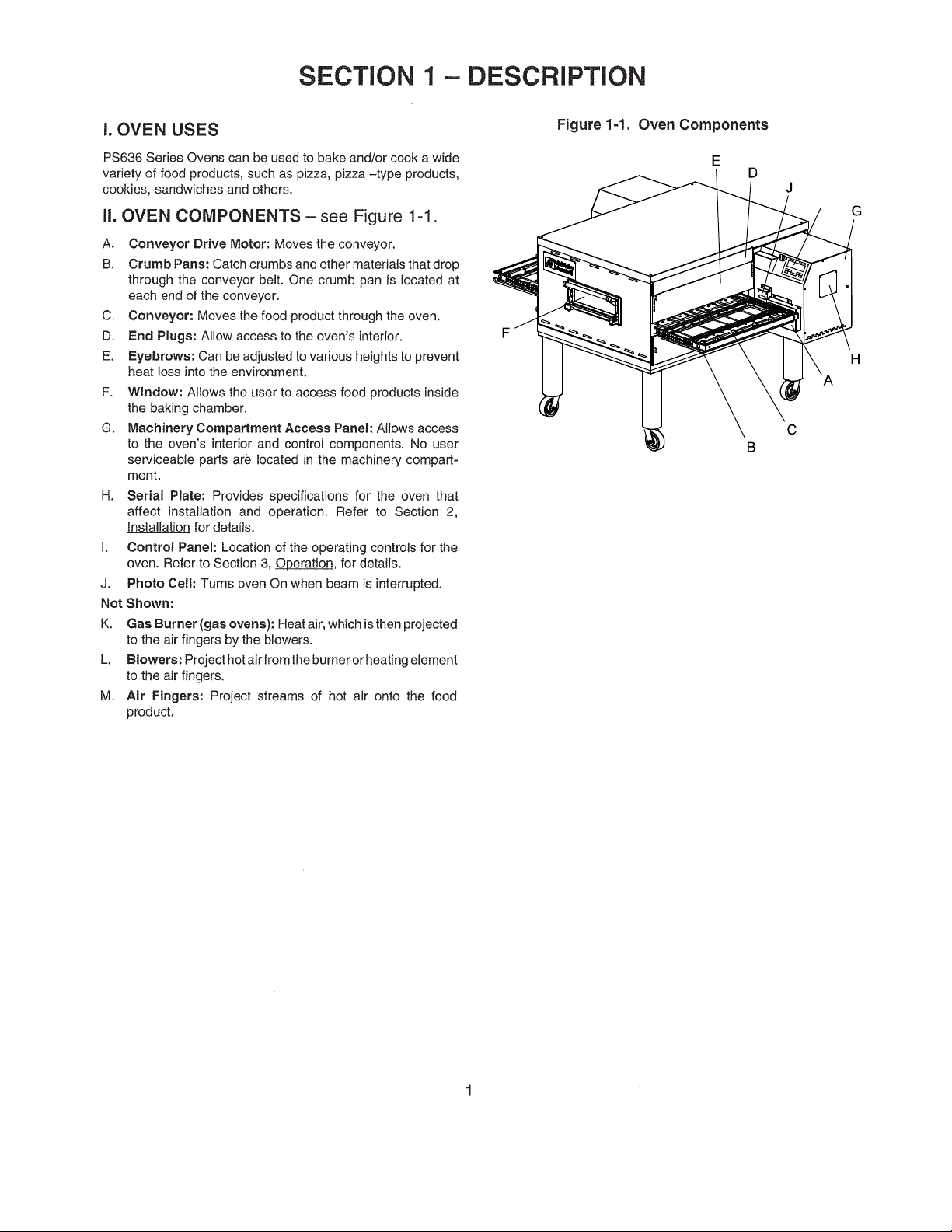

I. OVEN SPECIFICATIONS

Table 1-1 Dimensions Single Oven Double Oven Triple Oven

Overall Height 44″ (1118mm) 62-3/8” (1635mm) 69-3/4″ (1171mm)

Overall Depth 44-1/2″ (1130mm) 44-1/2” (1130mm) 44-1/2” (1130mm)

Overall Length (w/o exit trays) 65-3/4″ (1670mm) 65-3/4″ (1670mm) 65-3/4″ (1670mm)

Conveyor Width – belt width is 24″ 25-1/2″ (648mm) 25-1/2″ (648mm) 25-1/2″ (648mm)

or 2 x 11” (279mm) or 2 x 11” (279mm) or 2 x 11” (279mm)

Recommended Minimum Clearances

Rear of Oven to Wall 0″ (0mm) 0″ (0mm) 0″ (0mm)

Control end of conveyor to Wall 2″ (50.8mm) 2″ (50.8mm) 2″ (50.8mm)

Non-control end of conveyor to Wall) 2″ (50.8mm) 2″ (50.8mm) 2″ (50.8mm)

Table 1-2: General Specications PS636 GAS 24″ Belt

Weight 734 lbs. (333kg)

Rated Heat Input 75,000 BTU (18,892kcal, 22 kW/hr)

Maximum Operation Temperature 600°F / 315°C

Air Blowers Four Blowers at 3400 RPM (max)

Warmup Time 15 min.

Table 1-3: Electrical specications for PS363G gas ovens

Main Blower Control Circuit Phase Freq Current Poles Wires

Voltage Voltage Draw

208-240VAC 208-240VAC 1Ph 50/60Hz 4-3 Amp 2 Pole 3 Wire (2 hot, 1 gd)

Table 1-4: Gas orice and pressure specications for PS636G gas ovens

Gas Main Orice I.D. Supply (Inlet) Orice (Manifold) Bypass

Type PS745G Pressure Pressure Pressure

Natural 0.094 (2.375120mm) 8-12″ W.C. (19.9 - 29.9mbar) 3.5″ W.C. (8.7mbar) 0.3-0.35″ W.C. (0.8-0.9 mbar)

Propane 0.057″ (1.45mm) 11-14″ W.C. (27.4 - 34.9mbar) 10.0″ W.C. (24.9mbar) 0.9-1.0″ W.C. (2.2-2.5 mbar)

IMPORTANT – Additional electrical information is provided on the oven’s serial plate, and on the wiring diagram inside the

machinery compartment.

GAS ORIFICE AND PRESSURE SPECIFICATIONS (PER OVEN CAVITY) - CE OVENS

AT,BG,CR

CZ,DK,EE

FI,GR,HR FI,CR,GR BG,CY,CR BE,CY,CZ

HU,IS,IE IE,HR,LU CZ,DK,EE EE,FR

IT,LV,LT NL,PL,SK SW,CH FI,GR,HR GR,IE,IT

NO,PT,RO SI,ES,CH AT,DK LV,LT,LU PL LT,LU,LV

SK,SI,ES DE TR,GB,CY CY,CZ NO,FI MT,NL,NO AT,DE PT,RO,SK

Main SE,CH,TR LU BE CZ,DE,MT DE,MT NI,CR SK,SI,SE HU,SK ES,CH Orice Rated

Gas Orice GB NL PL FR SK SK FR TR CH GB,PL (Manifold) Heat

Type dia.

I2H

I

2L

I2E

I

2E+

I

3P

I

I

3P

3B/P

I

3B/P

I

3B/P

I3+ Pressure Input

G20 .0935″ 20 -- 20 20 -- -- -- -- -- -- 3.5” w.c. 22kW

Natural (2.375 mm) mbar mbar mbar 8.7mbar

G25 .0935″ -- 25 -- -- -- -- -- -- -- 3.5” w.c. 22kW

Natural (2.375 mm) mbar -- 8.7mbar .

G30 .057″ -- -- -- -- -- -- 28-30/50 30 37/50 28-30 10.0” w.c. 24.6kW

Butane (1.45 mm) mbar mbar mbar mbar 24.9mbar

G31 .057″ -- -- -- -- 37 50 30 37/50 37 10.0” w.c. 22kW

Propane (1.45 mm) mbar mbar -- mbar mbar mbar 24.9mbar

NOTE

Wiring Diagrams are contained in Section 5 of this Manual

and are also located inside the oven at the

bottom of the Control Panel.

Additional electrical information is provided on the oven's serial plate.

This Manual Must Be Kept For Future Reference

2

SECTION 2 – INSTALLATION

WARNING – After any conversions, readjustments, or service work on the oven:

• Perform a gas leak test. • Test for proper combustion and gas supply.

• Test for correct air supply, particularly to the • Check that the ventilation system is in operation.

burner blower.

WARNING - Keep the appliance area free and clear of combustibles.

WARNING – The oven must be installed on an even (level) non-ammable ooring and any adjacent

walls must be non-ammable. Recommended minimum clearances are specied in the Description

section of this manual.

WARNING – Do not obstruct the ow of combustion and ventilation air to and from your oven. There

must be no obstructions around or underneath the oven. Constructional changes to the area where

the oven is installed shall not affect the air supply to the oven.

CAUTION: To reduce the risk of re, the appliance is to be mounted on oors of noncombustible construction

with noncombustible ooring and surface nish and with no combustible material against the underside thereof, or on noncombustible slabs or arches having no combustible material against the underside thereof, such

construction shall in all cases extend not less than 12 inches (304mm) beyond the equipment on all sides.

CAUTION: For additional installation information, contact your local Authorized Service Agent.

NOTE – There must be adequate clearance between the oven and combustible construction. Clearance must

also be provided for servicing and for proper operation.

NOTE – An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE: All aspects of the oven installation, including placement, utility connections, and ventilation require-

ments, must conform with any applicable local, national, or international codes. These codes supersede the

requirements and guidelines provided in this manual.

NOTE: In the USA, the oven installation must conform to local codes. In the absence of local codes, gas oven

installations must conform with the National Fuel Gas Code, ANSI Z223.1. Gas and electric ovens, when

installed, must be electrically grounded in accordance with local codes, or in the absence of local codes, with

the National Electrical Code (NEC), or ANSI/NFPA70.

NOTE: In Canada, the oven installation must conform with local codes. In the absence of local codes, gas

oven installations must conform with the Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane

Gas Installation Code, CAN/CGA-B149.2, as applicable. Gas and electric ovens, when installed, must be

electrically grounded in accordance with local codes, or in the absence of local codes, with the Canadian

Electrical Code

CSA C22.2.

NOTE: In Australia, the oven installation must conform with local codes. In the absence of local codes, gas

oven installations must conform with the requirements of AS5601/AG601, Gas, Electricity, and any other

relevant statutory regulations.

3

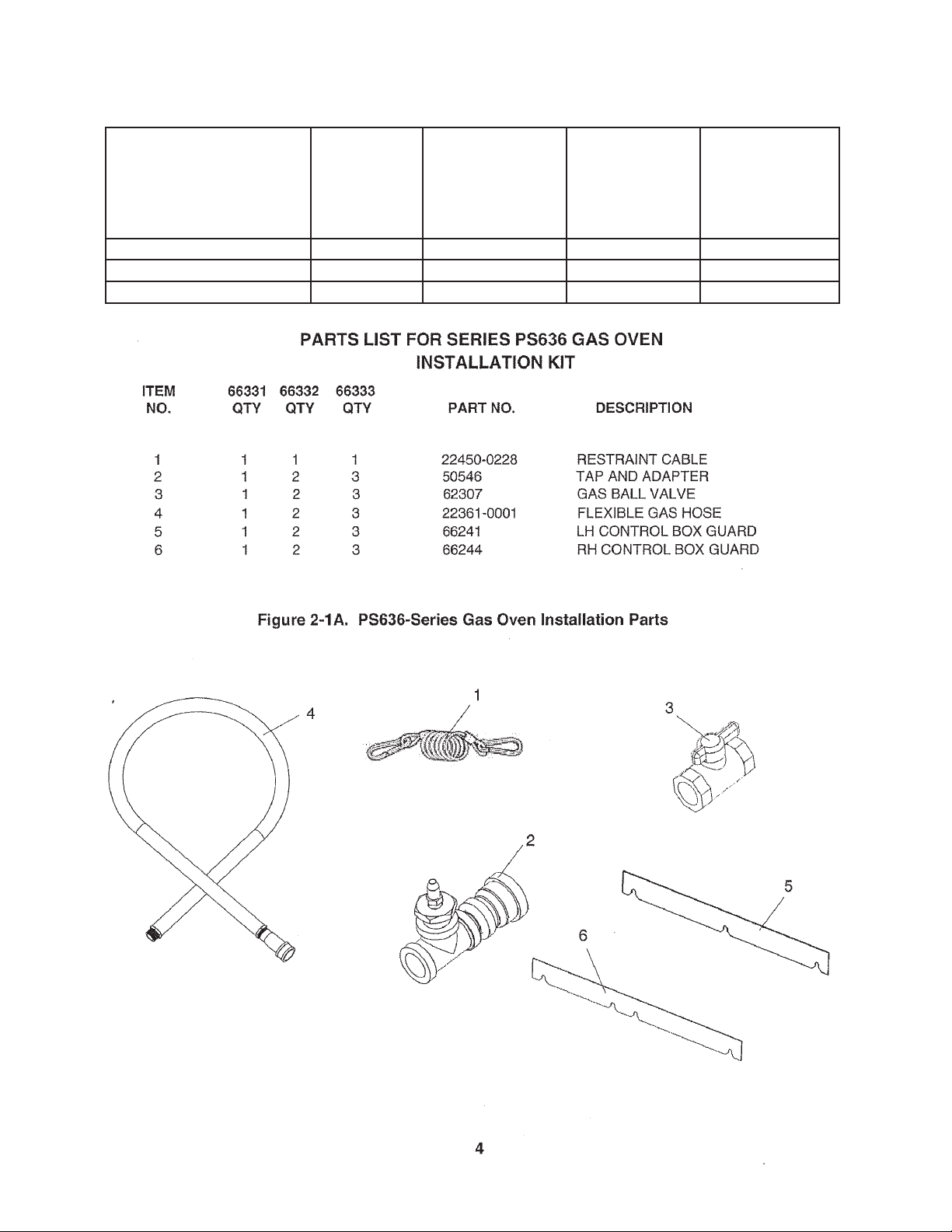

PS636 24” OVEN INSTALLATION

REQUIRED KITS AND EQUIPMENT

PS636

Gas Oven

Type Of Installation

PS636 Single Gas Oven 66331 1

PS636 Double Gas Oven 66332 1

PS636 Triple Gas Oven 66333 1

Installation

Kit

PS636

Single Oven

Option Base w/

15” Legs,

Casters & Top

Kit

P/N 66129

PS636

Double Oven

Option Base w/

15” Legs,

Casters & Top

Kit

P/N 66027

PS636

Triple Oven

Option Base w/

15” Legs,

Casters & Top

P/N 6xxxx

Kit

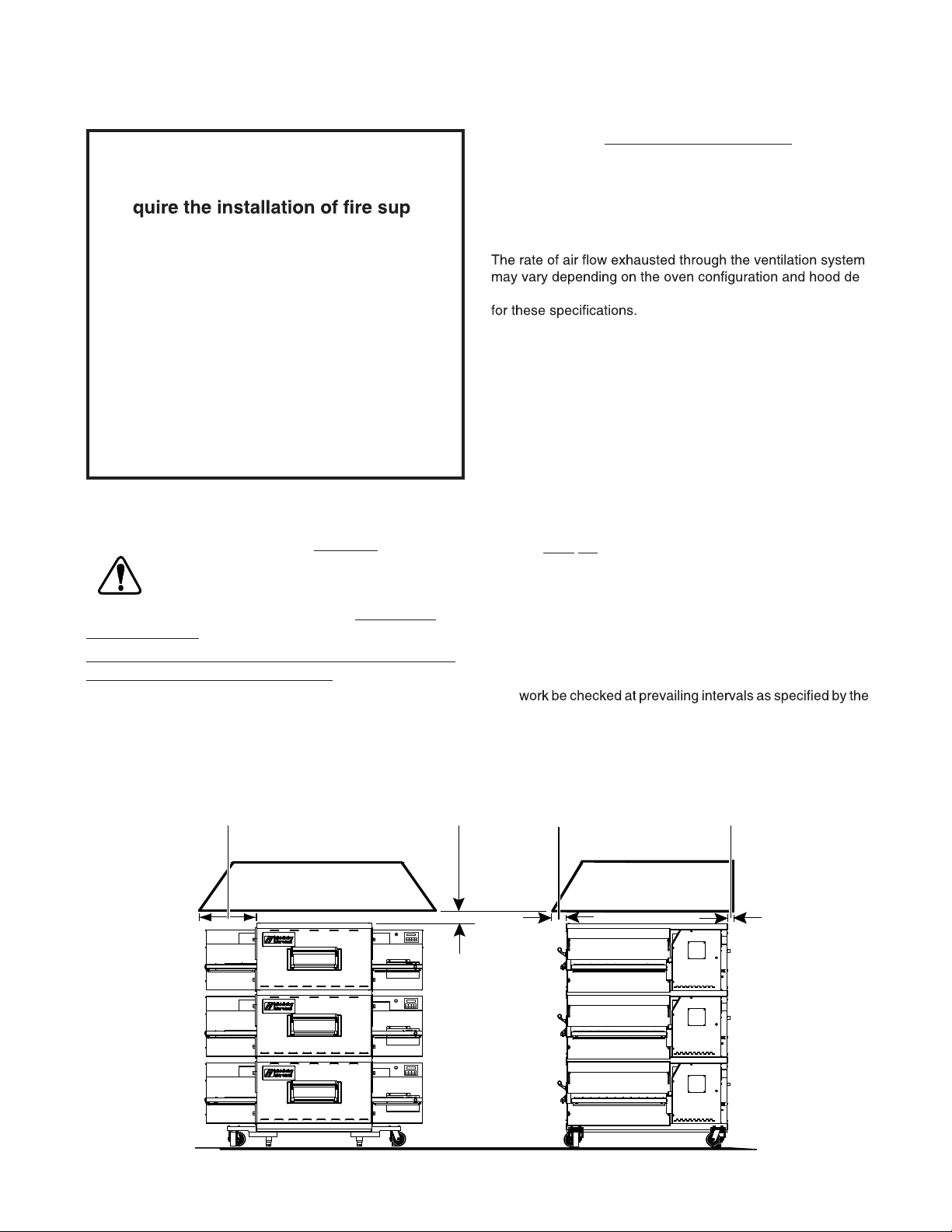

III. VENTILATION SYSTEM

IMPORTANT

Where national or local codes re-

pression equipment or other

supplementary equipment, DO NOT

mount the

equipment directly to the oven.

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN

FIGURE 2-5 ARE RECOMMENDATIONS ONLY.

LOCAL, NATIONAL AND INTERNATIONAL CODES MUST

BE FOLLOWED WHEN INSTALLING THE

VENTILATION SYSTEM. ANY APPLICABLE CODES

-

SUPERSEDE THE RECOMMENDATIONS SHOWN IN

THIS MANUAL. IN AUSTRALIA COMPLIANCE TO REGULATIONS AS5601/AG601 IS MANDATORY.

-

sign. Consult the hood manufacturer or ventilation engineer

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

• VOID AGENCY CERTIFICATIONS

• RESTRICT SERVICE ACCESS

• LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

A. Requirements

CAUTION: Gas oven installations REQUIRE a mechani-

cally driven ventilation system with electrical

exhaust air sensing control.

A mechanically driven ventilation system is STRONGLY

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE RESPONSIBILITY OF THE OWNER.

Figure 2-5. Ventilation System

6″ (152mm)

minimum

(Typical - both

ends of oven)

2″ (51mm)

minimum

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause

heat- related problems to the oven components as if there

were no ventilation at all. The best method of supplying

return air is through the heating, ventilation and air conditioning (HVAC) system. Through the HVAC system, the air can

be temperature-controlled for summer and winter. Return air

can also be brought in directly from outside the building, but

detrimental effects can result from extreme seasonal hot and

cold temperatures from the outdoors.

NOTE: Return air from the mechanically driven system

must not blow at the opening of the baking chamber.

Poor oven baking performance will result.

C. Other ventilation concerns

• Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

• Inadequate ventilation can inhibit oven performance.

• It is recommended that the ventilation system and duct

hood manufacturer and/or HVAC engineer or specialist.

2″ (51mm)

minimum

3″ (76mm)

minimum

5

Loading...

Loading...