Page 1

PRO X

Live Digital Console Control Centre and Audio System

Engine with 168 Input Channels, 99 Mix Buses and 96 kHz Sample Rate

Quick Start Guide

Page 2

2 PRO X Quick Start Guide 3

Important Safety

Instructions

LEGAL DISCLAIMER

Instrucciones de

seguridad

NEGACIÓN LEGAL

GARANTÍA LIMITADA

LIMITED WARRANTY

Terminals marked with this symbol carry

electrical current of su cient magnitude

to constitute risk of electric shock.

Use only high-quality professional speaker cables with

¼" TS or twist-locking plugs pre-installed. Allother

installation or modi cation should be performed only

by quali edpersonnel.

This symbol, wherever it appears,

alertsyou to the presence of uninsulated

dangerous voltage inside the

enclosure-voltage that may be su cient to constitute a

risk ofshock.

This symbol, wherever it appears,

alertsyou to important operating and

maintenance instructions in the

accompanying literature. Please read the manual.

Caution

To reduce the risk of electric shock, donot

remove the top cover (or the rear section).

No user serviceable parts inside. Refer servicing to

quali ed personnel.

Caution

To reduce the risk of re or electric shock,

do not expose this appliance to rain and

moisture. The apparatus shall not be exposed to dripping

or splashing liquids and no objects lled with liquids,

suchas vases, shall be placed on the apparatus.

Caution

These service instructions are for use

by quali ed ser vice personnel only.

Toreduce the risk of electric shock do not perform any

servicing other than that contained in the operation

instructions. Repairs have to be performed by quali ed

servicepersonnel.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves, or other apparatus

(including ampli ers) that produce heat.

9. Do not defeat the safety purpose of the polarized

or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. Ifthe

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Use only attachments/accessories speci ed by

themanufacturer.

12. Use only with the

cart, stand, tripod, bracket,

or table speci ed by the

manufacturer, orsold with

the apparatus. When a cart

is used, use caution when

moving the cart/apparatus

combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or

when unused for long periods of time.

14. Refer all servicing to quali ed service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed

to rain or moisture, does not operate normally, or has

beendropped.

15. The apparatus shall be connected to a MAINS socket

outlet with a protective earthing connection.

16. Where the MAINS plug or an appliance coupler is

used as the disconnect device, the disconnect device shall

remain readily operable.

17. Correct disposal of this

product: This symbol indicates that

this product must not be disposed

of with household waste,

according to the WEEE Directive

(2012/19/EU) and your national

law. This product should be taken

to a collection center licensed for the recycling of waste

electrical and electronic equipment (EEE). The

mishandling of this type of waste could have a possible

negative impact on the environment and human health

due to potentially hazardous substances that are generally

associated with EEE. At the same time, your cooperation

in the correct disposal of this product will contribute to

the e cient use of natural resources. For more

information about where you can take your waste

equipment for recycling, please contact your local city

o ce, or your household waste collection service.

18. Do not install in a con ned space, such as a book

case or similar unit.

19. Do not place naked ame sources, such as lighted

candles, on the apparatus.

20. Please keep the environmental aspects of battery

disposal in mind. Batteries must be disposed-of at a

battery collection point.

21. Use this apparatus in tropical and/or

moderate climates.

MUSIC Group accepts no liability for any loss which

may be su ered by any person who relies either

wholly or in part upon any description, photograph,

or statement contained herein. Technical speci cations,

appearances and other information are subject to

change without notice. All trademarks are the property

of their respective owners. MIDAS, KLARK TEKNIK,

LAB GRUPPEN, LAKE, TANNOY, TURBOSOUND,

TC ELECTRONIC, TC HELICON, BEHRINGER, BUGERA

and DDA are trademarks or registered trademarks

of MUSIC Group IP Ltd. © MUSIC Group IP Ltd.

2017 All rights reserved.

For the applicable warranty terms and conditions

and additional information regarding MUSIC Group’s

Limited Warranty, please see complete details online at

music-group.com/warranty.

Las terminales marcadas con este símbolo

transportan corriente eléctrica de

magnitud su ciente como para constituir

un riesgo de descarga eléctrica. Utilice solo cables de

altavoz profesionales y de alta calidad con conectores

TS de 6,3 mm o de bayoneta pre jados. Cualquier otra

instalación o modi cación debe ser realizada únicamente

por un técnico cuali cado.

Este símbolo, siempre que aparece,

leadvierte de la presencia de voltaje

peligroso sin aislar dentro de la caja;

estevoltaje puede ser su ciente para constituir un riesgo

dedescarga.

Este símbolo, siempre que aparece,

leadvierte sobre instrucciones operativas

y de mantenimiento que aparecen en la

documentación adjunta. Por favor, lea el manual.

Atención

Para reducir el riesgo de descarga

eléctrica, no quite la tapa (o la parte

posterior). No hay piezas en el interior del equipo que

puedan ser reparadas por el usuario. Si es necesario,

póngase en contacto con personal cuali cado.

Atención

Para reducir el riesgo de incendio o

descarga eléctrica, no exponga este

aparato a la lluvia, humedad o alguna otra fuente que

pueda salpicar o derramar algún líquido sobre el aparato.

Nocoloque ningún tipo de recipiente para líquidos sobre

el aparato.

Atención

Las instrucciones de servicio deben

llevarlas a cabo exclusivamente personal

cuali cado. Para evitar el riesgo de una descarga eléctrica,

no realice reparaciones que no se encuentren descritas

en el manual de operaciones. Lasreparaciones deben ser

realizadas exclusivamente por personalcuali cado.

1. Lea las instrucciones.

2. Conserve estas instrucciones.

3. Preste atención a todas las advertencias.

4. Siga todas las instrucciones.

5. No use este aparato cerca del agua.

6. Limpie este aparato con un paño seco.

7. No bloquee las aberturas de ventilación. Instale el

equipo de acuerdo con las instrucciones del fabricante.

8. No instale este equipo cerca de fuentes de calor

tales como radiadores, acumuladores de calor, estufas u

otros aparatos (incluyendo ampli cadores) que puedan

producir calor.

9. No elimine o deshabilite nunca la conexión a tierra

del aparato o del cable de alimentación de corriente.

Unenchufe polarizado tiene dos polos, uno de los cuales

tiene un contacto más ancho que el otro. Una clavija con

puesta a tierra dispone de tres contactos: dos polos y la

puesta a tierra. El contacto ancho y el tercer contacto,

respectivamente, son los que garantizan una mayor

seguridad. Si el enchufe suministrado con el equipo no

concuerda con la toma de corriente, consulte con un

electricista para cambiar la toma de corriente obsoleta.

10. Coloque el cable de suministro de energía de manera

que no pueda ser pisado y que esté protegido de objetos

a lados. Asegúrese de que el cable de suministro de

energía esté protegido, especialmente en la zona de la

clavija y en el punto donde sale del aparato.

11. Use únicamente los dispositivos o accesorios

especi cados por el fabricante.

12. Use únicamente la

carretilla, plataforma,

trípode, soporte o mesa

especi cados por el

fabricante o suministrados

junto con el equipo.

Altransportar el equipo,

tenga cuidado para evitar

daños y caídas al tropezar con algún obstáculo.

13. Desenchufe el equipo durante tormentas o si no va a

utilizarlo durante un periodo largo.

14. Confíe las reparaciones únicamente a servicios

técnicos cuali cados. La unidad requiere mantenimiento

siempre que haya sufrido algún daño, si el cable de

suministro de energía o el enchufe presentaran daños,

sehubiera derramado un líquido o hubieran caído objetos

dentro del equipo, si el aparato hubiera estado expuesto

a la humedad o la lluvia, si ha dejado de funcionar de

manera normal o si ha sufrido algún golpe o caída.

15. Al conectar la unidad a la toma de corriente eléctrica

asegúrese de que la conexión disponga de una unión

atierra.

16. Si el enchufe o conector de red sirve como único

medio de desconexión, éste debe ser accesiblefácilmente.

17. Cómo debe deshacerse de

este aparato: Este símbolo indica

que este aparato no debe ser

tratado como basura orgánica,

según lo indicado en la Directiva

WEEE (2012/19/EU) y a las

normativas aplicables en su país.

En lugar de ello deberá llevarlo al punto limpio más

cercano para el reciclaje de sus elementos eléctricos/

electrónicos (EEE). Al hacer esto estará ayudando a

prevenir las posibles consecuencias negativas para el

medio ambiente y la salud que podrían ser provocadas por

una gestión inadecuada de este tipo de aparatos. Además,

el reciclaje de materiales ayudará a conservar los recursos

naturales. Para más información acerca del reciclaje de

este aparato, póngase en contacto con el Ayuntamiento

de su ciudad o con el punto limpio local.

18. No instale esta unidad en un espacio muy reducido,

tal como encastrada en una librería o similar.

19. No coloque objetos con llama, como una vela

encendida, sobre este aparato.

20. Tenga presentes todas las advertencias relativas

al reciclaje y correcta eliminación de las pilas. Las pilas

deben ser siempre eliminadas en un punto limpio y nunca

con el resto de la basura orgánica.

21. Use este aparato en rangos de temperatura

moderados y/o tropicales.

MUSIC Group no admite ningún tipo de responsabilidad

por cualquier daño o pérdida que pudiera sufrir

cualquier persona por con ar total o parcialmente en la

descripciones, fotografías o a rmaciones contenidas en

este documento. Las especi caciones técnicas, imágenes

y otras informaciones contenidas en este documento

están sujetas a modi caciones sin previo aviso. Todas las

marcas comerciales que aparecen aquí son propiedad

de sus respectivos dueños. MIDAS, KLARK TEKNIK,

LAB GRUPPEN, LAKE, TANNOY, TURBOSOUND,

TC ELECTRONIC, TC HELICON, BEHRINGER, BUGERA

y DDA son marcas comerciales o marcas registradas

de MUSIC Group IP Ltd. © MUSIC Group IP Ltd.

2017 Reservados todos los derechos.

Si quiere conocer los detalles y condiciones aplicables

de la garantía así como información adicional sobre la

Garantía limitada de MUSIC Group, consulte online toda la

información en la web music-group.com/warranty.

Page 3

4 PRO X Quick Start Guide 5

Consignes de sécurité

DÉNI LÉGAL

GARANTIE LIMITÉE

Wichtige

Sicherheitshinweise

HAFTUNGSAUSSCHLUSS

BESCHRÄNKTE GARANTIE

Les points repérés par ce symbole portent

une tension électrique su sante pour

constituer un risque d’électrocution.

Utilisez uniquement des câbles d’enceintes professionnels

de haute qualité avec ches Jack mono 6,35 mm ou ches

à verrouillages déjà installées. Touteautre installation ou

modi cation doit être e ectuée uniquement par un

personnel quali é.

Ce symbole avertit de la présence d’une

tension dangereuse et non isolée à

l’intérieur de l’appareil - elle peut

provoquer des chocs électriques.

Attention

Ce symbol signale les consignes

d’utilisation et d’entre ! Tien importantes

dans la documentation fournie. Lisez les consignes de

sécurité du manuel d’utilisation de l’appareil.

Attention

Pour éviter tout risque de choc électrique,

ne pas ouvrir le capot de l’appareil ni

démonter le panneau arrière. L’intérieur de l’appareil

ne possède aucun élément réparable par l’utilisateur.

Laissertoute réparation à un professionnel quali é.

Attention

Pour réduire les risques de feu et de choc

électrique, n’exposez pas cet appareil à la

pluie, à la moisissure, aux gouttes ou aux éclaboussures.

Ne posez pas de récipient contenant un liquide sur

l’appareil (un vase par exemple).

Attention

Ces consignes de sécurité et d’entretien

sont destinées à un personnel quali é.

Pouréviter tout risque de choc électrique, n’e ectuez

aucune réparation sur l’appareil qui ne soit décrite par le

manuel d’utilisation. Les éventuelles réparations doivent

être e ectuées uniquement par un technicien spécialisé.

1. Lisez ces consignes.

2. Conservez ces consignes.

3. Respectez tous les avertissements.

4. Respectez toutes les consignes d’utilisation.

5. N’utilisez jamais l’appareil à proximité d’un liquide.

6. Nettoyez l’appareil avec un chi on sec.

7. Veillez à ne pas empêcher la bonne ventilation de

l’appareil via ses ouïes de ventilation. Respectezles

consignes du fabricant concernant l’installation

del’appareil.

8. Ne placez pas l’appareil à proximité d’une source

de chaleur telle qu’un chau age, une cuisinière ou tout

appareil dégageant de la chaleur (y compris un ampli

depuissance).

9. Ne supprimez jamais la sécurité des prises bipolaires

ou des prises terre. Les prises bipolaires possèdent deux

contacts de largeur di érente. Leplus large est le contact

de sécurité. Les prises terre possèdent deux contacts plus

une mise à la terre servant de sécurité. Si la prise du bloc

d’alimentation ou du cordon d’ali-mentation fourni ne

correspond pas à celles de votre installation électrique,

faites appel à un électricien pour e ec tuer le changement

de prise.

10. Installez le cordon d’alimentation de telle façon

que personne ne puisse marcher dessus et qu’il soit

protégé d’arêtes coupantes. Assurez-vous que le cordon

d’alimentation est suffisamment protégé, notamment au

niveau de sa prise électrique et de l’endroit où il est relié à

l’appareil; cela est également valable pour une éventuelle

rallonge électrique.

11. Utilisez exclusivement des accessoires et des

appareils supplémentaires recommandés par lefabricant.

12. Utilisez

exclusivement des

chariots, des diables,

desprésentoirs, despieds

et des surfaces de

travail recommandés

par le fabricant ou

livrés avec le produit.

Déplacezprécautionneusement tout chariot ou diable

chargé pour éviter d’éventuelles blessures en cas dechute.

13. Débranchez l’appareil de la tension secteur en cas

d’orage ou si l’appareil reste inutilisé pendant une longue

période de temps.

14. Les travaux d’entretien de l’appareil doivent

être e ectués uniquement par du personnel qualifié.

Aucunentretien n’est nécessaire sauf si l’appareil est

endommagé de quelque façon que ce soit (dommagessur

le cordon d’alimentation ou la prise par exemple), siun

liquide ou un objet a pénétré à l’intérieur du châssis,

si l’appareil a été exposé à la pluie ou à l’humidité, s’il ne

fonctionne pas correctement ou à la suite d’une chute.

15. L’appareil doit être connecté à une prise secteur

dotée d’une protection par mise à la terre.

16. La prise électrique ou la prise IEC de tout appareil

dénué de bouton marche/arrêt doit rester accessible

enpermanence.

17. Mise au rebut appropriée de

ce produit: Ce symbole indique

qu’en accord avec la directive DEEE

(2012/19/EU) et les lois en vigueur

dans votre pays, ce produit ne doit

pas être jeté avec les déchets

ménagers. Ce produit doit être

déposé dans un point de collecte agréé pour le recyclage

des déchets d’équipements électriques et électroniques

(EEE). Une mauvaise manipulation de ce type de déchets

pourrait avoir un impact négatif sur l’environnement et la

santé à cause des substances potentiellement

dangereuses généralement associées à ces équipements.

En même temps, votre coopération dans la mise au rebut

de ce produit contribuera à l’utilisation e cace des

ressources naturelles. Pour plus d’informations sur

l’endroit où vous pouvez déposer vos déchets

d’équipements pour le recyclage, veuillez contacter votre

mairie ou votre centre local de collecte des déchets.

18. N’installez pas l’appareil dans un espace con né tel

qu’une bibliothèque ou meuble similaire.

19. Ne placez jamais d’objets en ammés, tels que des

bougies allumées, sur l’appareil.

20. Gardez à l’esprit l’impact environnemental lorsque

vous mettez des piles au rebus. Les piles usées doivent

être déposées dans un point de collecte adapté.

21. Utilisez l’appareil dans un climat tropical

et/ou modéré.

MUSIC Group ne peut être tenu pour responsable pour

toute perte pouvant être subie par toute personne

se ant en partie ou en totalité à toute description,

photographie ou a rmation contenue dans ce

document. Les caractéristiques, l’apparence et d’autres

informations peuvent faire l’objet de modi cations

sans noti cation. Toutes les marques appartiennent à

leurs propriétaires respectifs. MIDAS, KL ARK TEKNIK,

LAB GRUPPEN, LAKE, TANNOY, TURBOSOUND,

TC ELECTRONIC, TC HELICON, BEHRINGER, BUGERA

et DDA sont des marques ou marques déposées

de MUSIC Group IP Ltd. © MUSIC Group IP Ltd.

2017 Tous droits réservés.

Pour connaître les termes et conditions de garantie

applicables, ainsi que les informations supplémentaires

et détaillées sur la Garantie Limitée de MUSIC Group,

consultez le site Internet music-group.com/warranty.

Vorsicht

Die mit dem Symbol markierten

Anschlüsse führen so viel Spannung,

dassdie Gefahr eines Stromschlags besteht.

Verwenden Sie nur hochwertige, professionelle

Lautsprecherkabel mit vorinstallierten 6,35 mm

MONO-Klinkensteckern oder Lautsprecherstecker

mit Drehverriegelung. Alle anderen Installationen

oder Modi kationen sollten nur von quali ziertem

Fachpersonal ausgeführt werden.

Achtung

Um eine Gefährdung durch Stromschlag

auszuschließen, darf die Geräteabdeckung

bzw. Geräterückwand nicht abgenommen werden.

ImInnern des Geräts be nden sich keine vom Benutzer

reparierbaren Teile. Reparaturarbeiten dürfen nur von

quali zier tem Personal ausgeführt werden.

Achtung

Um eine Gefährdung durch Feuer bzw.

Stromschlag auszuschließen, darf dieses

Gerät weder Regen oder Feuchtigkeit ausgesetzt werden

noch sollten Spritzwasser oder tropfende Flüssigkeiten

in das Gerät gelangen können. Stellen Sie keine mit

Flüssigkeit gefüllten Gegenstände, wie z. B. Vasen,

aufdasGerät.

Achtung

Die Service-Hinweise sind nur durch

quali zier tes Personal zu befolgen.

Umeine Gefährdung durch Stromschlag zu vermeiden,

führen Sie bitte keinerlei Reparaturen an dem Gerät

durch, die nicht in der Bedienungsanleitung beschrieben

sind. Reparaturen sind nur von quali ziertem

Fachpersonaldurchzuführen.

1. Lesen Sie diese Hinweise.

2. Bewahren Sie diese Hinweise auf.

3. Beachten Sie alle Warnhinweise.

4. Befolgen Sie alle Bedienungshinweise.

5. Betreiben Sie das Gerät nicht in der Nähe vonWasser.

6. Reinigen Sie das Gerät mit einem trockenen Tuch.

7. Blockieren Sie nicht die Belüftungsschlitze. Beachten

Sie beim Einbau des Gerätes die Herstellerhinweise.

8. Stellen Sie das Gerät nicht in der Nähe von

Wärmequellen auf. Solche Wärmequellen sind z. B.

Heizkörper, Herde oder andere Wärme erzeugende Geräte

(auch Verstärker).

9. Entfernen Sie in keinem Fall die

Sicherheitsvorrichtung von Zweipol- oder geerdeten

Steckern. Ein Zweipolstecker hat zwei unterschiedlich

breite Steckkontakte. Ein geerdeter Stecker hat zwei

Steckkontakte und einen dritten Erdungskontakt.

Derbreitere Steckkontakt oder der zusätzliche

Erdungskontakt dient Ihrer Sicherheit. Falls das

mitgelieferte Steckerformat nicht zu Ihrer Steckdose

passt, wenden Sie sich bitte an einen Elektriker, damit die

Steckdose entsprechend ausgetauscht wird.

10. Verlegen Sie das Netzkabel so, dass es vor

Tritten und scharfen Kanten geschützt ist und nicht

beschädigt werden kann. Achten Sie bitte insbesondere

im Bereich der Stecker, Verlängerungskabel und an

der Stelle, an der das Netzkabel das Gerät verlässt,

aufausreichendenSchutz.

11. Das Gerät muss jederzeit mit intaktem Schutzleiter

an das Stromnetz angeschlossen sein.

12. Sollte der Hauptnetzstecker oder eine

Gerätesteckdose die Funktionseinheit zum Abschalten

sein, muss diese immer zugänglich sein.

13. Verwenden Sie nur Zusatzgeräte/Zubehörteile,

dielaut Hersteller geeignet sind.

14. Verwenden

Sie nur Wagen,

Standvorrichtungen,

Stative, Halter oder Tische,

die vom Hersteller benannt

oder im Lieferumfang

des Geräts enthalten

sind. Falls Sie einen

Wagen benutzen, seien Sie vorsichtig beim Bewegen

der Wagen- Gerätkombination, umVerletzungen durch

Stolpern zuvermeiden.

15. Ziehen Sie den Netzstecker bei Gewitter oder wenn

Sie das Gerät längere Zeit nicht benutzen.

16. Lassen Sie alle Wartungsarbeiten nur von

quali zier tem Service-Personal ausführen. EineWartung

ist notwendig, wenn das Gerät in irgendeiner Weise

beschädigt wurde (z. B. Beschädigung des Netzkabels oder

Steckers), Gegenstände oder Flüssigkeit in das Geräteinnere

gelangt sind, das Gerät Regen oder Feuchtigkeit ausgesetzt

wurde, das Gerät nicht ordnungsgemäß funktioniert oder

auf den Boden gefallen ist.

17. Korrekte Entsorgung dieses

Produkts: Dieses Symbol weist

darauf hin, das Produkt

entsprechend der WEEE Direktive

(2012/19/EU) und der jeweiligen

nationalen Gesetze nicht

zusammen mit Ihren

Haushaltsabfällen zu entsorgen. DiesesProdukt sollte bei

einer autorisierten Sammelstelle für Recycling elektrischer

und elektronischer Geräte (EEE) abgegeben werden.

Wegen bedenklicher Substanzen, diegenerell mit

elektrischen und elektronischen Geräten in Verbindung

stehen, könnte eine unsachgemäße Behandlung dieser

Abfallart eine negative Auswirkung auf Umwelt und

Gesundheit haben. Gleichzeitig gewährleistet Ihr Beitrag

zur richtigen Entsorgung dieses Produkts die e ektive

Nutzung natürlicher Ressourcen. Fürweitere

Informationen zur Entsorgung Ihrer Geräte bei einer

Recycling-Stelle nehmen Sie bitte Kontakt zum

zuständigen städtischen Büro, Entsorgungsamt oder zu

Ihrem Haushaltsabfallentsorgerauf.

18. Installieren Sie das Gerät nicht in einer beengten

Umgebung, zum Beispiel Bücherregal oder ähnliches.

19. Stellen Sie keine Gegenstände mit o enen

Flammen, etwa brennende Kerzen, auf das Gerät.

20. Beachten Sie bei der Entsorgung von Batterien

den Umweltschutz-Aspekt. Batterien müssen bei einer

Batterie-Sammelstelle entsorgt werden.

21. Verwenden Sie das Gerät in tropischen und/oder

gemäßigten Klimazonen.

MUSIC Group übernimmt keine Haftung für Verluste,

die Personen entstanden sind, die sich ganz oder

teilweise auf hier enthaltene Beschreibungen,

Fotos oder Aussagen verlassen haben. Technische Daten,

Erscheinungsbild und andere Informationen können

ohne vorherige Ankündigung geändert werden.

Alle Warenzeichen sind Eigentum der jeweiligen

Inhaber. MIDAS, KLARK TEKNIK, LAB GRUPPEN, LAKE,

TANNOY, TURBOSOUND, TC ELECTRONIC, TC HELICON,

BEHRINGER, BUGERA und DDA sind Warenzeichen oder

eingetragene Warenzeichen der MUSIC Group IP Ltd.

© MUSIC Group IP Ltd. 2017 Alle Rechte vorbehalten.

Die geltenden Garantiebedingungen und zusätzliche

Informationen bezüglich der von MUSIC Group

gewährten beschränkten Garantie nden Sie online unter

music-group.com/warranty.

Page 4

6 PRO X Quick Start Guide 7

Instruções de Segurança

Importantes

LEGAL RENUNCIANTE

GARANTIA LIMITADA

安全にお使いいただくために

限定保証

法的放棄

Aviso!

Terminais marcados com o símbolo

carregam corrente elétrica de magnitude

su ciente para constituir um risco de choque elétrico.

Use apenas cabos de alto-falantes de alta qualidade

com plugues TS de ¼" ou plugues com trava de torção

pré-instalados. Todas as outras instalações e modi cações

devem ser efetuadas por pessoasquali cadas.

Este símbolo, onde quer que o encontre,

alerta-o para a leitura das instruções de

manuseamento que acompanham o

equipamento. Por favor leia o manual de instruções.

Atenção

De forma a diminuir o risco de choque

eléctrico, não remover a cobertura

(ouasecção de trás). Não existem peças substituíveis por

parte do utilizador no seu interior. Para esse efeito recorrer

a um técnico quali cado.

Atenção

Para reduzir o risco de incêndios ou

choques eléctricos o aparelho não deve ser

exposto à chuva nem à humidade. Além disso, não deve

ser sujeito a salpicos, nem devem ser colocados em cima

do aparelho objectos contendo líquidos, tais como jarras.

Atenção

Estas instruções de operação devem ser

utilizadas, em exclusivo, por técnicos de

assistência quali cados. Para evitar choques eléctricos

não proceda a reparações ou intervenções, que não as

indicadas nas instruções de operação, salvo se possuir as

quali - cações necessárias. Para evitar choques eléctricos

não proceda a reparações ou intervenções, que não as

indicadas nas instruções de operação. Só o deverá fazer se

possuir as quali cações necessárias.

1. Leia estas instruções.

2. Guarde estas instruções.

3. Preste atenção a todos os avisos.

4. Siga todas as instruções.

5. Não utilize este dispositivo perto de água.

6. Limpe apenas com um pano seco.

7. Não obstrua as entradas de ventilação. Instale de

acordo com as instruções do fabricante.

8. Não instale perto de quaisquer fontes de calor

tais como radiadores, bocas de ar quente, fogões de

sala ou outros aparelhos (incluindo ampli cadores)

que produzam calor.

9. Não anule o objectivo de segurança das chas

polarizadas ou do tipo de ligação à terra. Uma cha

polarizada dispõe de duas palhetas sendo uma mais larga

do que a outra. Uma cha do tipo ligação à terra dispõe

de duas palhetas e um terceiro dente de ligação à terra.

A palheta larga ou o terceiro dente são fornecidos para

sua segurança. Se a cha fornecida não encaixar na sua

tomada, consulte um electricista para a substituição da

tomada obsoleta.

10. Proteja o cabo de alimentação de pisadelas ou

apertos, especialmente nas chas, extensões, e no local

de saída da unidade. Certi que -se de que o cabo eléctrico

está protegido. Veri que particularmente nas chas, nos

receptáculos e no ponto em que o cabo sai doaparelho.

11. O aparelho tem de estar sempre conectado à rede

eléctrica com o condutor de protecção intacto.

12. Se utilizar uma cha de rede principal ou uma

tomada de aparelhos para desligar a unidade de

funcionamento, esta deve estar sempre acessível.

13. Utilize apenas ligações/acessórios especi cados

pelofabricante.

14. Utilize apenas com

o carrinho, estrutura,

tripé, suporte, ou mesa

especi cados pelo

fabricante ou vendidos

com o dispositivo.

Quandoutilizar um

carrinho, tenha cuidado ao

mover o conjunto carrinho/dispositivo para evitar danos

provocados pela terpidação.

15. Desligue este dispositivo durante as trovoadas

ou quando não for utilizado durante longos períodos

detempo.

16. Qualquer tipo de reparação deve ser sempre

efectuado por pessoal quali cado. É necessária uma

reparação sempre que a unidade tiver sido de alguma

forma dani cada, como por exemplo: no caso do cabo

de alimentação ou cha se encontrarem dani cados;

naeventualidade de líquido ter sido derramado ou

objectos terem caído para dentro do dispositivo; no caso

da unidade ter estado exposta à chuva ou à humidade;

seesta não funcionar normalmente, ou se tiver caído.

17. Correcta eliminação deste

produto: este símbolo indica que

o produto não deve ser eliminado

juntamente com os resíduos

domésticos, segundo a Directiva

REEE (2012/19/EU) e a legislação

nacional. Este produto deverá

ser levado para um centro de recolha licenciado para a

reciclagem de resíduos de equipamentos eléctricos e

electrónicos (EEE). O tratamento incorrecto deste tipo

de resíduos pode ter um eventual impacto negativo

no ambiente e na saúde humana devido a substâncias

potencialmente perigosas que estão geralmente

associadas aos EEE. Ao mesmo tempo, a sua colaboração

para a eliminação correcta deste produto irá contribuir

para a utilização e ciente dos recursos naturais. Paramais

informação acerca dos locais onde poderá deixar o seu

equipamento usado para reciclagem, é favor contactar

os serviços municipais locais, a entidade de gestão de

resíduos ou os serviços de recolha de resíduosdomésticos.

18. Não instale em lugares con nados, tais como

estantes ou unidades similares.

19. Não coloque fontes de chama, tais como velas

acesas, sobre o aparelho.

20. Favor, obedecer os aspectos ambientais de descarte

de bateria. Baterias devem ser descartadas em um ponto

de coletas de baterias.

21. Use este aparelho em climas tropicais

e/ou moderados.

O MUSIC Group não se responsabiliza por perda alguma

que possa ser sofrida por qualquer pessoa que dependa,

seja de maneira completa ou parcial, de qualquer

descrição, fotogra a, ou declaração aqui contidas.

Dados técnicos, aparências e outras informações

estão sujeitas a modi cações sem aviso prévio.

Todas as marcas são propriedade de seus respectivos

donos. MIDAS, KLARK TEKNIK, LAB GRUPPEN, LAKE,

TANNOY, TURBOSOUND, TC ELECTRONIC, TC HELICON,

BEHRINGER, BUGERA e DDA são marcas ou marcas

registradas do MUSIC Group IP Ltd. © MUSIC Group

IP Ltd. 2017 Todos direitos reservados.

Para obter os termos de garantia aplicáveis e condições e

informações adicionais a respeito da garantia limitada do

MUSIC Group, favor veri car detalhes na íntegra através

do website music-group.com/warranty.

注意

感電の.恐れがありますので、カ

バーや その他の部品を取り外

したり、開けたりしないでください。高品

質なプロ用スピーカーケーブル(¼" T S標準

ケーブルおよびツイストロッキングプラ

グケーブル)を使用してください。

注意

火事および感電の危険を防ぐ

ため、本装置を水分や湿気の

あるところには設置しないで下さい。装置

には決して水分がかからないように注意

し、花瓶など水分を含んだものは、装置の

上には置かないようにしてください。

注意

このマークが 表 示されている

箇所には、内部に高圧電流が

生じています。手を触れると感電の恐れが

あります。

注意

取り扱いとお手入れ の方法に

ついての重要な説明が付属の

取扱説明書に記載されています。ご使用の

前に良くお読みください。

注意

1. 取扱説明書を通してご覧ください。

2. 取扱説明書を大切に保管してくだ

さい。

3. 警告に従ってください。

4. 指示に従ってください。

5. 本機を水の近くで使用しないでくだ

さい。

6. お手入れの際は常に乾燥した布巾を使

ってくだ さい 。

7. 本機は、取扱説明書の指示に従い、

適切な換気を妨げない場所に設置してく

ださい。取扱説明書に従って設置してくだ

さい。

8. 本機は、電気ヒーターや温風機器、

ストーブ、調理台やアンプといった熱源か

ら離して 設 置してください 。

9. ニ極式プラグおよびアースタイプ

(三芯)プラグの安全ピンは取り外さないで

ください 。ニ極式プラグにはピンが二本つ

いており、そのうち一本はもう一方よりも幅

が広くなっています。アースタイプの三芯プ

ラグにはニ本のピンに加えてアース用のピ

ンが一本ついています。これらの幅の広い

ピン、およびアースピンは、安全のためのも

のです。備え付けのプラグが、お使いのコン

セントの形 状と異 なる場合は、電器技師に

相談してコンセントの交換をして下さい。

10. 電源コードを踏みつけたり、挟んだり

しないようご注 意ください。電源コードや

プラグ、コンセント及び製品との 接 続には

十分にご注意ください。

11. すべての装置の接地(アース)が確保

されていることを確認して下さい。

12. 電源タップや

電源プラグは電

源遮断機として利

用されている場合

には、これが 直ぐ

に操作できるよう

手元に設置して下

さい。

13. 付属品は本機製造元が指定したもの

のみをお使いください。

14. カートスタンド、三脚、ブラケット、

テーブルなどは、本機製造元が指定したも

の、もしくは 本 機 の 付属品となるもののみ

をお使いください。カートを使用しての運

搬の際は、器具の落下による怪我に十分ご

注意ください。

15. 雷雨の場合、もしくは長 期 間ご 使用 に

ならない 場 合は 、電源プラグをコンセント

から抜いてください。

16. 故障の際は当社指定のサービス技術

者にお問い合わせください。電源コードも

しくはプラグの損 傷、液体の装置内への浸

入、装置の上に物が落下した場合、雨や湿

気に装置が晒されてしまった場合、正常に

作動しない場合、もしくは装 置を 地 面に落

下させてしまった場合など、いかなる形で

あれ装置に損傷が加わった場合は、装置

の修理・点検を受けてください。

17. 本製品に電源コード

が付属されている場合、

付属の電源コードは本製

品以外ではご使用いただ

けません。電源コードは

必ず本製品に付属された

電源コードのみご使用く

ださい。

18. ブックケースなどのような 、閉じたス

ペースには設置しないでください。

19. 本機の上に点火した蝋燭などの裸火

を置かないでください。

20. 電池廃棄の際には、環境へのご配慮

をお願いします。電池は、かならず電池回

収場所に廃棄してください。

21. 本機器は熱帯気候および/または温

帯気候下でご使用ください。

ここに含ま れ る記 述、写真、意見の全

体または一部に依拠して、いかなる人が

損害を生じさせた場合にも、MUSIC Group

は一切の賠 償 責任を負いません。技術

仕様、外観およびその他の情報は予告

なく変 更になる場 合があります。商標

はすべて、それぞれの所有者に帰属しま

す。MIDAS、KLARK TEKNIK、LAB GRUPPEN、

LAKE、TANNOY、TURBOSOUND、TC ELECTRONIC、

TC HELICON、BEHRINGER、BUGERAおよびDDA

はMUSIC Group IP Ltd.の商標または登録商

標です。© MUSIC Group IP Ltd. 2017無断転用

禁止。

適用される保証条件とMUSIC Groupの限定

保証に関する概要については、オンライン

上music-group.com/warrantyにて詳細をご確

認ください 。

Page 5

8 PRO X Quick Start Guide 9

其他的重要信息

保修条款

法律声明

ࣝధ൦ಗᄋጽቬܭЧధ

ܹᄋႄุߜڛᝐႄԁᬘǎᬎ

Ώၺࣝధ ¼ '' TSᩛତ݁

ᄋᰵַ᠐˅ˋܧ٩ጴǎధᄋ߸ᜊួ

ڪᮍႁՍಬᄋ˅ˋցᤊᛢǎ

൦ಗଣᧉ১ַаߜڛఴ

ፑᎇᄋԁᬘႄԎధᝐႄԁᬘǎ

൦ಗଣᧉ১ಋᬅᄋ᧙

ᄋΏၺԤ፦οឮǎឱ឵ధ

Угǎ

࠶

˟ᥙГᝐႄԁᬘឱӉ఼

ᮈᄧᑁ᭨ౝǎܭа෦

ధԼΚၺ፦οΏၺᄋᦋǎឱ࠳፦ο

ᮋႁՍಬᄋ˅ˋցᤊᛢǎ

࠶

˟ᥙГᅍ༣ᝐႄԁᬘឱӉ

࠳൦ܭᎷᭂິ˘ǎ

൦ܭ˸ˁԼԫ͵ຶᄪధ͵ᄋࠕ

٩˸ˁԼᎷЦʾݡᔊၬǎ

11. ឱԷΏၺԉࠓࠁᄋᬅܭ֘

ᦢǎ

12. ឱԷΏၺԉࠓ

ࠁᄋᬥ᠏ᩚ

ᄋଏᢽ౷ߖ

ʽᝉ౷౷֘ಹ

ߖǎᔫΏၺଏᢽ

ୄᤃܭឱญ

߸МᎷܭ

ᥙГଏᢽ֘

ܭϛωᏬԫǎ

13. ᥆ႄᭈᲟఱˁΏၺశܭ

ឱફѤႄ຺ତ݁ǎ

14. ధ፦οڪᮍႁՍಬᄋ፦οցᤊ

ᛢǎܭԫ૰ᭋᤊᛢ፦οΔݡႄ຺ጴ

ႄ຺ତ݁ԫ૰͵ุЛྮᗁЛܭ

аܭᥔᭂԫܭˁᑠࣣᤃͼ

ᜃگǎ

15. శܭᤍႄ຺ʸࠁధڢ

εઑǎ

16. ᔫႄ຺ତ݁٩Ч

ᏺՍ٩ၺͼளႄᜊᎷ

ε߳ܬᬥԼ

ஶΨ୳ͼ࿅ঘǎ

17. శַᤡၺ๓

ફ2000ዜʿڢӞశ

ַᤡၺ᭥མࣝජό

ʿǎ

ࠬͶڃڛ൦ឮ˻ଣ҃ᄋМᦋ

ᦋଢᤙǍڐྠܧᏬᤶᄋ૰

MUSIC Groupˁ᠈Ͷ᠋ǎస

݀

ԡஞ֘ܲᔫధటஉিˁԴᛢᤱ

ᅽǎధᄋಗڪ˟ЦՋᒮధᏩᄋ

MIDAS, KLARK TEKNIK, LAB GRUPPEN,

᠊ǎ

LAKE, TANNOY, TURBOSOUND, TC ELECTRONIC,

TC HELICON, BEHRINGER, BUGERA

֘ DDA ௨

MUSIC Group IP Ltd.ОՄᄋಗญгಗǎ

© MUSIC Group IP Ltd. 2017ྡీధǎ

ధУᮄˮᬸڅεοᄋᤡၺ൝ԤЦ߳ᄲУ

θ্ឱᄇᬇmusic-group.com/warrantyᎫቤಋ

ᄻߺᄋឡጻθ্ǎ

࠶

፦οឮ௨ፍՍಬᄋ˅ˋ፦

οցΏၺ ᄋǎ˟ᥙГᝐႄԁ

ᬘᬕΏၺឮ˻ଣ҃ᄋܲឱӉᤊᛢ

ͶЦ߳፦οǎధ፦οڪᮍႁՍಬᄋ˅

ˋցᤊᛢǎ

1. ឱ឵ᤉឮǎ

2. ឱݱؔεߜᤉឮǎ

3. ឱญధᄋᇩǎ

4. ឱᥗ߷ధᄋឮǎ

5. ឱӉڛ᭦ᤄබᄋڢஶΏၺశַǎ

6. ឱၺࣱ࣌ຎพశַǎ

7. ឱӉ܅܌ᤱ᮴Աǎ߸ᜊశַឱᥗ

ཱིԉࠓᄋឮǎ

8. ឱӉ࠳శַ߸ᜊڛམ຺ᬅᤄ

ݡජྠ༰ߖЦ߳ၸམᄋܭ

Ӌҫ٩ǎ

9. ឱӉሩᬕমତ݁ڢତ݁ᄋ߸М

ᜊᎷǎڢତ݁௨ႁˑ˕ତ܌གྷԤʸ˕

ڢ݁ǎᔫᬥ᠏ଣΚᄋତ݁ˁᤡՍ১

ᄋତឱႄࢻటʸ˕Սᤡᄋତǎ

10. ݱؔεઑႄ຺ጴΏЦˁᜃᢇ҉

ᆢࡀЦญႄ຺ତ݁ǍܴၺତԤܭ

ᤍܬǎ

Page 6

10 11PRO X Quick Start Guide

Overview

Introduction

Welcome to the PRO X Live Audio System. The PRO X is a user-friendly, state-ofthe-art, high performance digital console speci cally designed for live use.

The control centre, which forms an integral part of its Live Audio System,

was conceived by MIDAS to o er audio professionals high

-performance audio

equipment, designed to provide no-compromise sonic quality with a feature

set that o ers all essential facilities and functions. It represents the very best

of British design and engineering combined with contemporary, e cient

manufacturing methods, and will give you many years of reliable se

rvice.

So, to obtain the best results with a minimum of e ort, please read this

Quick Start Guide and, nally, enjoy your MIDAS PRO X Live Audio System!

About This Guide

This is the Quick Start Guide for the PRO X Live Audio System. Its purpose is to

quickly familiarise the user with the control centre, show how to set up the

system and then show how to carry out some basic operations on the control

centre in order to produce some au

dio. This guide is structured such that it may

also provide a useful introductory guide for training purposes.

This document is aimed at professionals, such as front of house (FOH)

and monitor (MON) engineers, who will be using this equipment in a live

performance environment. It is assume

d that the reader has prior experience of

using professional audio equipment and has, most likely, undergone training on

this system.

This guide has been designed speci cally so that mix engineers and

system technicians can go straight to the areas applicable to them, that is,

Opera

tion and Connecting And Setting Up The System. The rest of the

guide is intended for general readership.

For full details of the PRO X Live Audio System, refer to the PRO X Live

Audio System Owner’s Manual, which can be found on our website at

midasconsoles.com.

NOTE: The content of this guide does not sup

ersede any information

supplied with any other item of this PRO Series Live Audio System.

PRO X Host Software Version

Our team of software engineers is constantly working to ensure that you get the

most from the PRO X Live Audio System host software, so please ensure that you

have the latest version installed on your PRO X by visiting the downloads page on

midasconsoles.com

Warranty & Registration

MIDAS has total con dence in the quality and reliability of this product. To back

this up, this product comes with the standard MIDAS three year warranty.

Please take the time to register your product by completing and returning the

registration card or by registering on our we

bsite at midasconsoles.com.

Service & Support

The PRO Series Live Audio Systems are very hi-tech pieces of equipment.

We provide superb levels of support and service to give users con dence in

MIDAS digital products.

The PRO X Live Audio System

Introducing The PRO X

With their exemplary audio performance and road-proven rugged and reliable

construction, the MIDAS PRO Series has become the gold standard in concert

touring and installed live sound. Employing technologies developed from the

class-leading and visionary agship MIDAS XL8 cons

ole, and o ering the same

outstanding sample-synchronised and phase-coherent audio performance,

interpolated control functions and intuitive navigation, the PRO3, PRO6 and

PRO9 Live Audio Systems have become the industry’s go-to choice for live sound

reinforcement consoles.

Now the PRO Series family moves up a gear with the PRO X Liv

e Audio System

and the industry-changing NEUTRON Audio System Engine. Featuring 168

simultaneous input channels and 99 time-aligned and phase-coherent buses

with no trade-o s in channel or bus counts.

True and consistent 96 kHz sampling frequency and 40 bit oa

ting point

processing provide exemplary quality audio processing, and the oversampled

and interpolated digital signal processing algorithms, combined with the

fully interpolated and touch sensitive user controls, result in the smooth

continuous response and immediacy of working on an analogue cons

ole.

Parameter adjustment becomes fast and easy, the continuous phase shift of a

swept frequency control is heard without the quantisation e ects of the discrete

steps found in other digital consoles.

The PRO X features the rugged and road-proven KLARK TEKNIK HyperMAC and

SuperMAC (AES50-compliant) networking te

chnologies with their ultra-low and

deterministic latencies and robust error correction.

Its powerful audio networking o ers up to 288 inputs and 294 outputs at the

96 kHz sample frequency. For enhanced reliability, both the PRO X Live Audio

System and the NEUTRON Au

dio System Engine feature a HyperMAC router

with 192 bidirectional channels over dual-redundant copper or optical bre

snake connections.

The PRO X Live Audio System features dual 15" full colour daylight-viewable

TFT displays for use in all environments, both inside and outdoors.

The 10 VC

A (variable control association) and eight POPulation groups,

combined with the advanced navigation o ered by the output-centric centre

section, allows the simultaneous display of 24 mono or stereo mix buses.

All of this provides an unparalleled mix experience.

Overview

The PRO X is a very powerful and exible audio processing system that provides

a complete solution for any audio mixing and signal distribution application in a

live sound environment. Operation of the control surface is intuitive, unique and

easy. Its layout is based on familiar analogue line

s to retain that ‘analogue’ feel.

To manage the numerous channels, the control centre utilises VCA/POP groups

and colours, and additionally there are various navigational controls that aid

quick channel/bus access and selection. A daylight-viewable GUI at the to

p of the

control surface assists operation and provides extra functionality.

The live audio system is tolerant of many types of hardware or software failure.

To achieve this the system employs dual redundancy, where a key component has

an identical redundant spare that is ready to ta

ke over should it fail. Other failure

scenarios are managed by the N+1 principle, where redundant components form

an acceptable fraction of the system.

The KLARK TEKNIK DN9696 Recorder can be used with the live audio system for

live multi-track recording and ‘vir

tual’ sound check.

Applications

The PRO Series are the work horse mid- to high-end MIDAS Digital Console

Systems, akin to the industry standard Heritage 3000. Although the PRO Series

are designed for the traditional touring live sound environment, they are

also ideal for medium-sized theatres, small houses of worship installations,

and broadc

ast. So, being a truly multi-functional console in the MIDAS tradition,

the PRO Series are suitable for many applications, such as:

• • Live sound touring MON or FOH duties

• • Live sound small theatre MON or FOH duties

• • Live sound house of worship MON or FOH duties

• • Live sound broadcast mixer with basic 5.1 surround capabilities

and monitoring.

PRO X - The Next Generation

PRO Series Console

If you are already familiar with the PRO Series consoles, then you are already

well on your way to mastering the PRO X. With a few exceptions outlined here,

the functionality of the PRO X is almost identical to its PRO Series predecessors.

Because of it

s improved functionailty and increased processing power it was

necessary to make the following changes to the well-established format:

NEUTRON

The powerhouse at the centre of the PRO X system is the new NEUTRON Audio

System Engine. NEUTRON is the result of a three-year research and development

programme that has seen MIDAS engineers push beyond the envelope with their

expertise and knowledge.

Its cut

ting-edge, latest generation DSPs and high-performance FPGA,

couple with MIMD (Multiple Instruction, Multiple Data) architecture delivers

more than 100 giga ops of real-time audio processing performance. This means

that NEUTRON has the potential to provide more than 800 audio paths.

Yo

ur system remains absolutely future proof. It delivers impeccable MIDAS sonic

performance and functionality.

But it’s not just about raw, number-crunching power and high channel counts,

NEUTRON is also about nesse. Adding I/O boxes with the best converters

and custom processing algor

ithms that draw upon over 40 years of listening

experience at the top of the industry, NEUTRON takes the audio quality of those

channels to another level.

All MIDAS digital console systems have a comprehensive and automatic latency

management system and NEUTRON is no ex

ception. This system manages all

internal routing and processing latency and also includes compensation for

external analogue inserts. All audio samples are synchronised before summing,

resulting in absolute phase coherency at the outputs and completely avoiding

the ‘comb ltering’ e ec

ts of less carefully designed systems that result in

speci c frequencies cancelling out completely.

Channel Count

With 168 inputs, 96 buses and three master channels, on the PRO X what you see

is what you get. There’s no ‘smoke and mirror’ DSP sharing, the PRO X provides a

full input channel count and full bus count at 96 kHz at any time.

Mix Bay Output Fast Zone

The PRO X control surface features an entirely new output section that makes

handling the potentially huge number of buses a breeze. A page of 24 of the

possible 96 bus masters is displayed across three rows of eight, each position

easily identi ed by the sa

me kind of select switch as the channel bay.

The digital write-on name and RGB backlight colour means ‘can’t miss’ selection.

Pressing ‘to faders’ on any row drops the master fader for those buses onto the

mix bay.

All of the buses can be scrolled through, in pa

ges of 24, and when an output is

added to a POP group, it will unfold to the dedicated output section, making it

even easier to organise your work ow.

Channel & Bus Navigation Zone

At the heart of MIDAS console navigation are the VCA and POPulation groups,

which provide primary access to multiple channels (typically grouped into related

clusters by mix engineers). To access all the channels belonging to any of the VCA

or POP groups

, merely press the select switch and those channels unfold to the

control surface.

If you think of the VCA faders as if they were each containers for all the channels

they control then nding channels becomes a natural and easy task. This method

is fu

rther expanded through the provision of user customised POP (POPulation)

groups, which can contain any combination of channels that you want to access

instantly, at the press of a switch.

Additional E ects

The PROX can simultaneously process up to 24 simultaneous internal

multi-channel e ects and NEUTRON’s 40 bit oating-point audio processing

hosts a wide choice of virtual FX devices, which range from dual-mono delay

units, stereo modulation and many diverse reverb FX, multiband comp

ression,

dynamic EQ and multichannel dual-function dynamics processing.

All FX processors are custom-designed to function within the MIDAS automatic

latency compensation system. This ensures a phase-coherent sample- accurate

mix regardless of whether the FX devices are used as channel inserts or as a

send-and-return.

Delay FX can be individually con gure

d to synchronise to the PRO X’s Global

Tap-Tempo hardware button, making on-the- y changes to tempo-based

e ect parameters child’s play. Up to 36 1/3 octave KLARK TEKNIK DN370 Graphic

Equalisers (GEQs) are provided, which can be pa

tched into any output.

Page 7

12 13PRO X Quick Start Guide

About The Control Centre

Overview Of The Control Centre

The control centre has a combined control surface and GUI that provide an array

of easy-to-use controls for the precise manipulation of audio.

The control centre is of modular construction and is built on a robust MIDAS steel

frame chassis similar to those used for es

tablished MIDAS analogue products.

The frame houses three full size bays with a smaller one on the right. All of the

bays are controlled from a single processor and, collectively, provide the primary

mixing needs of the engineer.

All associated power supplie

s, computer motherboards, memory and graphics

cards are housed within the control centre, which also contains a digital audio

router box that supports local FOH (insert) I/O connectors on the rear panel.

Substantial forced air-cooling is provided by a bulkhead and large (but slow

moving) internal fa

ns. These produce very low noise, suitable for seated

areas, theatres and concert sound, and can even be turned o under the user

preferences menu.

Externally, the control centre has three main areas: control surface, GUI and

rear panel. The control surface is populated with instantly recognis

able controls

that are logically distributed in major sections. The GUI, which comprises two

screens at the top of the centre bays, enhances operation by providing visual

representations of the control surface and also gives you extra functionality.

The rear panel provides all of the cont

rol centre and network connectivity,

and houses the mains power sockets and isolator switch.

Being of modular design, the overall form and shape of the control centre is

similar to MIDAS’s agship XL8. The control surface is split into bays, each one

cont

aining a at fader tray and shallow raked control area. The centre bays also

have a third area that houses a steep-raked display screen.

Multiple hardware fault types are tolerated by the control centre without loss

of audio control due to the dual redundanc

y and N+1 methods incorporated in

the system. This is further helped by the modular nature of the bays and GUI

independence. Either of the GUI screens can be used to operate the whole control

centre, even if none of the control surface hardware is working. The unit o er

s

the facility of universal input, N+1 redundant power supplies with three latching

mains connectors.

Bay And GUI Layout

The control centre has four discrete bays that house the following control

surface controls:

• • Input bays (12-channel and 4-channel) — two input

bays provide fast access to input faders and important signal

processing controls

• • Mix bay — provides access to outputs and groups, a detailed

processing controller (all channels) and navigational controls

• • Master bay — provides access to the master output mixes,

monitor (A and B) faders, automation, comms control,

assignable e ects control, and another set of detailed processing and

navigational controls.

Two GUI display screens at the top of the central bays provide extensive screen

support (standard con guration

) and extra functionality for the channels and

buses. For example, when mixing or processing. They also facilitate the use of the

GUI menu, which gives you access to the many powerful features of the control

centre, such as patching, e ects, GEQs, diagnostics et

c.

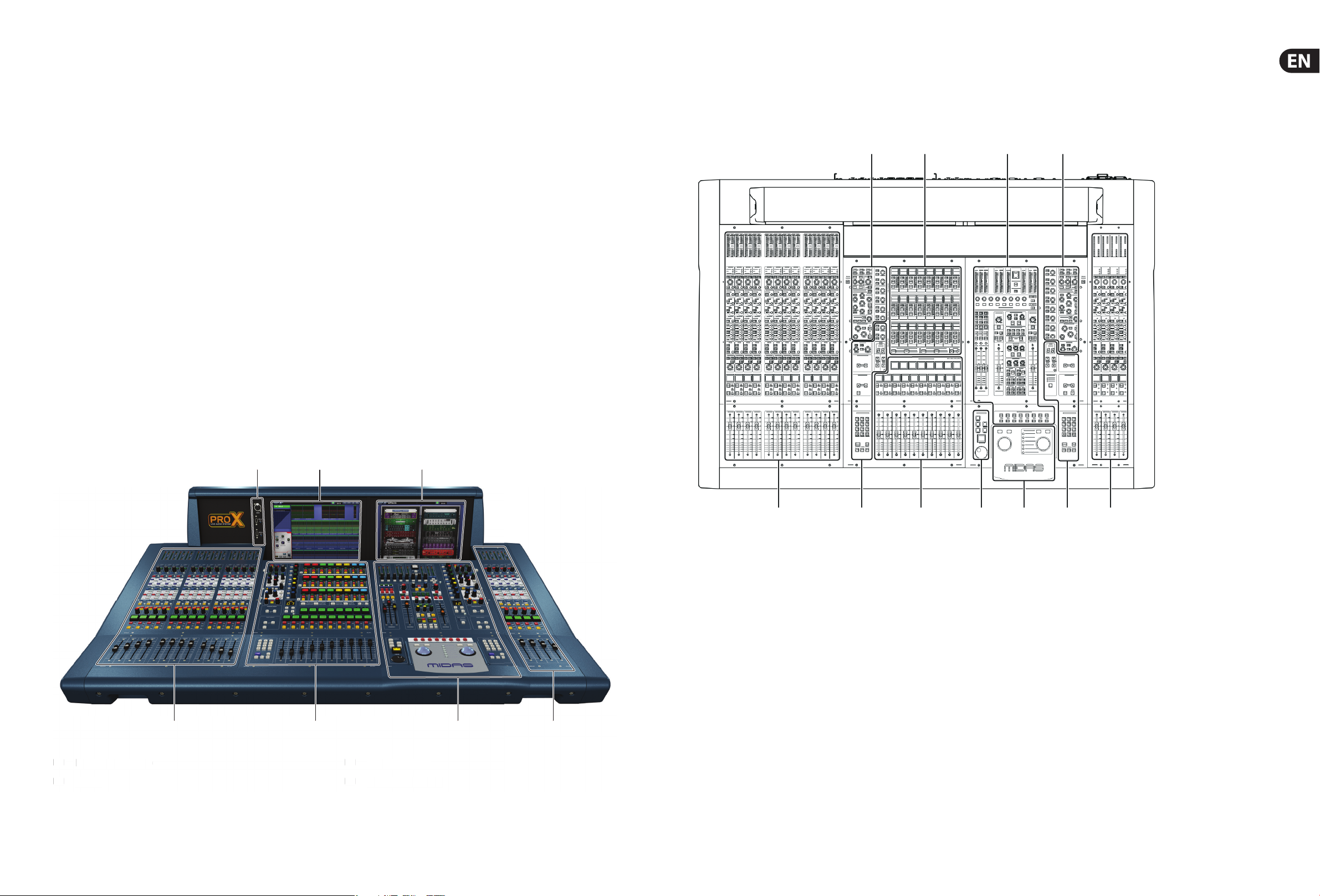

(1) Input bay (12-channel)

(2) Mix bay

(3) Master bay

(4) Input bay (4-channel)

(5) Mix bay GUI screen

(6) Master bay GUI screen

(7) Talk mic and USB connectors.

(1)

l)

(2)

n

(6)

Control Surface

The control surface is divided into areas whose function is, largely, dependent on

bay location. Each bay has assorted control elements with local feedback and/or

support from the two centrally located GUI display screens. The screens can be

controlled remotely via external VGA connections, and third pa

rty systems can

also be viewed/controlled via an integrated KVM switch on the rear panel.

A — input fast zone: 16 input fast strips across the 12-channel and 4-channel

input bays provide the operator’s ‘must have now’ controls.

B — channel strip and mixes: processing areas, such as the D-

zone (dynamic),

E-zone (EQ) and mix controls, provide a more comprehensive control by allowing

detailed adjustments to a single channel’s audio parameters.

C — channel and bus navigation zone: sections for channel and bus navigation

and selection. For details, see Navigation.

D — output fa

st zone: the new output-centric centre section, allows

the simultaneous display of 24 mono or stereo mix buses, and advanced

navigation buttons.

E — VCA and POP groups: VCA faders and POP group sections.

F — miscellaneous: master channel strips, A and B signal path monitoring,

communications, I-zone, surround monitor

ing and mute groups.

G — primary navigation zone: trackballs for mix and master bay GUI screen

control, and a screen access panel (between trackballs) for direct access to GUI

menu options.

H — automation: scene store/recall and system edit.

BD F B

Input bay (12-channe

Mix bay

(1)

(7) (5) (6)

(7) (5) (6)

(2) (3) (4)(1)

(2) (3) (4)

(5) Mix bay GUI scree

Master bay GUI screen

ACEHGCA

Page 8

14 15PRO X Quick Start Guide

During show time the screen functions that require fast access are controlled by

control knobs, pushbutton switches, faders, etc. More complex functions that do

not require this fast access are controlled by the trackballs and navigational keys.

A keyboard integral to the ight case is used for te

xt entry via the master bay GUI

screen. An external USB keyboard can be used to operate the mix bay GUI screen.

The choice of controls provided by each bay type are prioritised by access time

importance. Fast zone areas, which contain fast strips, give instant access to

speci c fu

nctions across the bay, and channel strips give greater control of the

selected fast strip.

GUI

The GUI comprises two screens that provide a pictorial representation of the

control surface layout so that its displays are easy to follow at a glance. Not only

does it re ect what is happening on the control surface, but it also provides

extra functionality vi

a a GUI menu. This menu provides access to all the screens

that you will require to set up, con gure, manage and operate the entire control

centre, all from a single drop-down list of easy to follow options.

Above: Typical Overview screen (default of the mix bay GUI screen)

Above: Typical Meters screen with no show loaded (default of the master bay GUI screen)

Channels strip

Banner

Inputs

Outputs

Channel type

select buttons

All meters

display

Inputs and automation

summary

Each GUI screen has its own default display, although either is selectable via

the GUI main menu. The Overview screen displays 12 inputs and 24 outputs,

which are selected on the surface. The Console Overview screen shows the

meters; both screens have a banner at the to

p, which is constantly displayed,

and a channel strip down the outermost side.

The channel strips have a similar function to the ones on the control surface,

but provide extra functionality. Each displays an overview of the associated

selected channel, which is divide

d into speci c sections that provide access to

processing areas.

Front And Rear Panel Connections

The control centre has connector panels on both the front and rear, and also to

the left of the mix bay GUI screen.

The connector panel to the left of the GUI has an XLR socket and two USB sockets

for connecting a talk mic and USB devices, respec

tively. For example, you can

connect a USB memory stick for show le backup and transfer, or a USB keyboard

for text editing on the GUI. The top USB socket is associated with the mix bay and

the bottom one with the master bay.

There are tw

o panels at either end of the front of the control centre, under the

armrests. Each has a keyboard and phones socket. The left and right keyboard

sockets operate the mix and master bay GUI screens, respectively. The phones

socket in the left panel is for the monitor A sec

tion and the other one is for

monitor B.

A connector panel on the rear of the control centre has three main sections

(see below). On the left are three mains power inlet and ventilation assemblies,

with a DC power switch above. The mid-section contains connections for the

au

dio, network, communications, intercoms, synchronisation, external remote

devices and peripheral devices. The section on the right is the user-con gurable

modular I/O section.

The modular I/O section can house up to three of any of the following I/O

modules in any combination: DL441 analogue input (m

ic) module; DL442

analogue output module; DL443 analogue Jack I/O module; DL444 8 analogue

mic in and 8 analogue line out module and DL452 AES/EBU input and output

module. This gives a maximum of 24 inputs and 24 output

s, if the appropriate

cards are tted.

Above: Rear view of the Control Centre.

Mains power

and ventilation

Audio, control

and networking

(conguration dependent)

I/O

Page 9

16 17PRO X Quick Start Guide

Basic Principles

Before You Start

This chapter is intended to familiarise you with the control centre by showing you

how to carry out some basic operations in order to get some audio out of it.

NOTE: As the operation of both input bays is principally the same, this

chapter will generally only show the operation of the 12

-channel input

bay. However, any di erences in operation between the 4-channel and

12-channel input bays will be shown.

Please don’t forget that, although this system is a complex, high-tech piece of

equipment, it is very easy to use.

Principles Of Operation

Control centre operation is based on the concept of colours and groups rather

than ‘layering’ or ‘paging’, which is the case with most digital consoles on the

market today.

With so many channels available it is far easier to remember them by their usercon gured individual/g

roup colour and name rather than their channel number.

The control surface is populated with instantly recognisable controls that are

logically distributed in major sections, so that all the controls you need to access

most of the time are always on the cont

rol surface, while the remainder are only

one action away. You can display all I/O meters, both on the control surface and

the GUI, to give instant monitoring feedback.

Operating Modes

You can change certain aspects of control centre operation by assigning di erent

tasks to certain areas of the control surface. This section will explain the di erent

ways in which the control surface can operate.

Normal mode

During normal operation the 12-channel input bay is operated from the mix bay

controls and GUI scree

n, while the controls and GUI screen in the master bay

operate the 4-channel input bay. Both input bays operate in unison and are,

in e ect, area A.

NOTE: The 12-channel input bay will always be area A, no matter which

operating mode you are using.

Us

ing the 4-channel input bay as area B

You can assign the 4-channel input bay as area B, thus making both the

input bays independent from each other. This facilitates two-man operation

(see Two-Man Operation).

Controlling the mix buses in ip mode

Flip provides a more global approach to mix bus level control. Normally, you can

only use the level cont

rol knobs in the channel strips to adjust the signal level of

the aux/matrix mix buses going to the aux/matrix channels. However, by using

ip you have the option of controlling them from either the pan control knobs or

the faders in the input fast strips.

In ip mode the lef

t/right arrow buttons in the upper channel select section

scroll across the input fast strips.

>> To con gure the control centre for pan or fader ip

1. At the GUI, choose home > Preferences > General.

2. Depending on which option you require, click the option button of one of the

following in the Fader ip section. When an option is selec

ted, it will contain

a red circle:

• • “Flip to Faders”

• • “Flip to Pans”.

>> To ip mixes to input pan/fader control

With an output selected on the control surface, press FLIP. The button will

illuminate to show you are in ‘ ip’ mode. The currently selected mix bus in the

input fast strips will change to AuxS1 and, on the GUI, the ba

ckground colour of

the pans and faders will change accordingly.

Also, the LCD select buttons in the input fast strips will display the current bus

mode, for example, “MONO AUX”.

Hints And Tips

• • Check what is hidden - On the control centre, unlike on an analogue

control surface, some of the settings and parameters will be hidden

from view. At various times during a mix we recommend that you

select and view unused parameters to make sure there are no hidden

surprises, for example, a rev

erb send left from a previous mix

• • Check the Meters screen - It is a good idea to frequently

monitor the Meters screen (default display of the master bay GUI),

which provides at a glance an overview of the control centre’s status

and operation. It shows all the meters and the status condition of

faders and some s

witches, such as solos and mutes. However, some

things will still remain hidden.

Saving Your Work

We recommend that you save your work regularly while carrying out the

procedures included in this guide. Not only is this good practise during normal

operation, but in this instance it may save you from losing some set-ups that

could prove useful later on. To do this

, create a new show (see To Open The

Automation Screen), and then continue reading through the remainder of this

section, following the instructions carefully. Save your work at convenient points

(see To Create A New Scene Using The Current Settings and To Save A

Show Or Create A New One From The Current Settings).

Saving a show versus storing a scene

It is important to understand the di erences between saving a show and storing

a sc

ene.

• • Storing a scene saves the current settings of the system to the show

le. Scene data is never updated unless you manually store a scene.

The show le remains unsaved in RAM.

Although the state of the control centre is copied every ve seconds, it is not

s

tored in a scene. Instead, it is placed in the NVRAM (non-volatile random access

memory) of the control centre’s memory, which is a type of RAM that doesn’t lose

its data when the power goes o . If the control centre loses power accidentally,

these set

tings are loaded so that audio parameters are identical, thus avoiding

audio level jumps. When power is lost, the show le loaded (if any) will not

subsequently be restored, and any unsaved changes to it will be lost.

• • Saving a show copies the show le onto the internal solid-state disk

of the control centre. This provides you with a ‘permanent’ copy,

provided you shut down the system properly as detailed in the

following section.

Shutting down the control centre properly

When switching o the control centre, we recommend that you use the

shu

tdown option of the GUI menu (see To Switch O The Control Centre).

By using shutdown, the cached copy of the show data, which is maintained by the

system, is automatically stored. Shutdown then uses the current show le, NVRAM

data and cache les to restore the control centre to exactly the sa

me state as at

power down; even to the point of loading the unsaved show and placing you at the

correct scene, with non-stored scene data at the control surface.

If you don’t use the Shutdown option the audio parameters are still restored,

but the show and show sta

tus (saved/unsaved) cannot be restored automatically.

You must manually reload the show, and any unsaved changes will be lost.

Working With The Control Centre

Although many controls on the control centre are similar to their equivalent

analogue-type counterparts, some have been speci cally designed for the PRO

Series, particularly those for navigation and GUI operation. As you will probably

have had experience on analogue consoles

, you will already be familiar with

most of the PRO X controls and their operation. Therefore, this chapter only deals

with the GUI controls that may be new to you.

The navigational controls, such as quick access buttons and scroll buttons, are

described in Na

vigation, and the ones speci cally for automation can be found

in Managing The Scenes.

About Channel Operation

During normal operation the task of controlling the input (12 channels), aux,

return, aux sends and matrix channels is allocated to the two bays on the left.

The two bays on the right control the input (4-channel) and master channels.

This task allocation applie

s similarly to the GUI screens. However, you can control

any channel from either GUI screen. This is done by navigating the channel to

the GUI channel strip via the GUI menu; control is also then available via the local

channel strip on the cont

rol surface.

About GUI Operation

This section explains the basic procedures you can perform at the GUI screens.

In general, you will control and operate the GUI by combining the operations

described here.

Each trackball controls the movement of a pointer on its respective GUI screen.

The left trackball operates the mix ba

y GUI screen and the right one operates the

GUI screen in the master bay. Each trackball has two buttons, which have similar

functionality to the buttons on a PC/laptop mouse. The left button is used in click

and drag operations, while the right button is generally used for ed

iting and ner

control operations.

Operating The GUI Screen Controls

This section shows you how to operate GUI screen elements, such as buttons,

control knobs, drop-down lists and sliders.

>> To switch a GUI button on/o

Click the button. If it has a status indicator, this will illuminate/extinguish to

show that it is on/o , respectively.

>> To adjust a GUI control knob or fader

Use a drag operation. Move the pointer up

/down/left/right for adjustment.

>> To select an option from a drop-down list

Click the drop-down arrow. The drop-down list will unfold to display some or all

of its contents, depending on how many items it contains.

Do one of the following:

Click the option you require

If necessary, scroll the list (see “To scroll a drop

-down list” below) to display the

option, and then click it.

>> To scroll a drop-down list

With the drop-down list displayed, do one of the following:

Drag the scroll box

Click the scroll bar. The scroll box will ‘jump’ in the direction of the click to

another position in the scroll ba

r

Click an up/down scroll arrow. The scroll box will ‘jump’ in the direction of the

scroll arrow to another scroll bar position. Clicking a scroll arrow when the scroll

box is adjacent to it has no e ect.

Using The GUI Menu

You can open the GUI menu at either GUI screen, or you can go directly a GUI

menu screen by using a screen access button.

Throughout this guide, menu/submenu option selection sequences are shown in

the following format (for example, for choosing the general preferences screen):

home > Preferences > General

>> To open the GUI menu

Clic

k home.

Page 10

18 19PRO X Quick Start Guide

>> To select a GUI menu option

Click the menu option, for example, Monitors. The background of the menu

option will change to blue when it is ready for selection.

>> To open the submenu of a GUI menu option

Move the pointer over the arrow to the right of the desired menu option.

The submenu will open automatically to the right of the ar

row.

>> To open a GUI menu screen using a screen access button

In the primary navigation zone, press a screen access button to open the

rst screen (printed to the right of the button). Press it again to open the

second screen.

Tex t Edi tin g

A keyboard is used to type in text on the GUI, for example, to con gure input

and output channel names. Editable text on the GUI is contained in text boxes,

which generally consist of a single line of limited length. Although all text editing

ca

n be done using the normal keyboard functions, the GUI can be used to assist

you, for example, by highlighting portions of text (using drag).

These two examples show you how to use the screen access buttons to open the Automation screen (single press) and the Graphic EQs screen (two presses).

These buttons take you directly to the screen you want.

>> To enter/edit text via the keyboard

At the GUI, click in the text box to place an insertion point in it. The pointer will

change to an I-beam shape.

Using the keyboard, type in the new text. If the text box already contains some

text, you can delete this rst or ed

it it, which can be done via the keyboard or by

using the cut, copy and paste options after right-clicking.

Press ENTER on the keyboard to exit the text box (or click on an empty area of

the GUI screen). The pointer’s shape will change back to an arrow.

Navigation

An Introduction To Navigation

The control centre provides you with unique navigational controls to quickly and

easily access the items, such as channels, buses, groups and processing areas,

that you will require for mixing.

Navigation is an important feature of the control centre. One of the advantages

digital consoles have ove

r analogue ones is that their channel count is not

limited by the control surface hardware. However, this means that only a certain

amount of channels can be at the control surface at any time, while the others

are ‘hidden’. So, navigation is required to access these hidden ch

annels whenever

you need them.

NOTE: The way the control centre is set to operate may alter the

function of some of the navigational controls. For more information,

see Operating Modes.

Navigation is primarily via the control surface, although the GUI may provide an

alter

native and also has some unique navigational features of its own.

Navigating The Input Channels

The input channels are grouped into ‘banks’, with each bank containing four

consecutively numbered channels.

During normal operation, four banks of input channels populate the input bays,

and these are displayed across the control surface in ascending order from

left to right.

Page 11

20 21PRO X Quick Start Guide

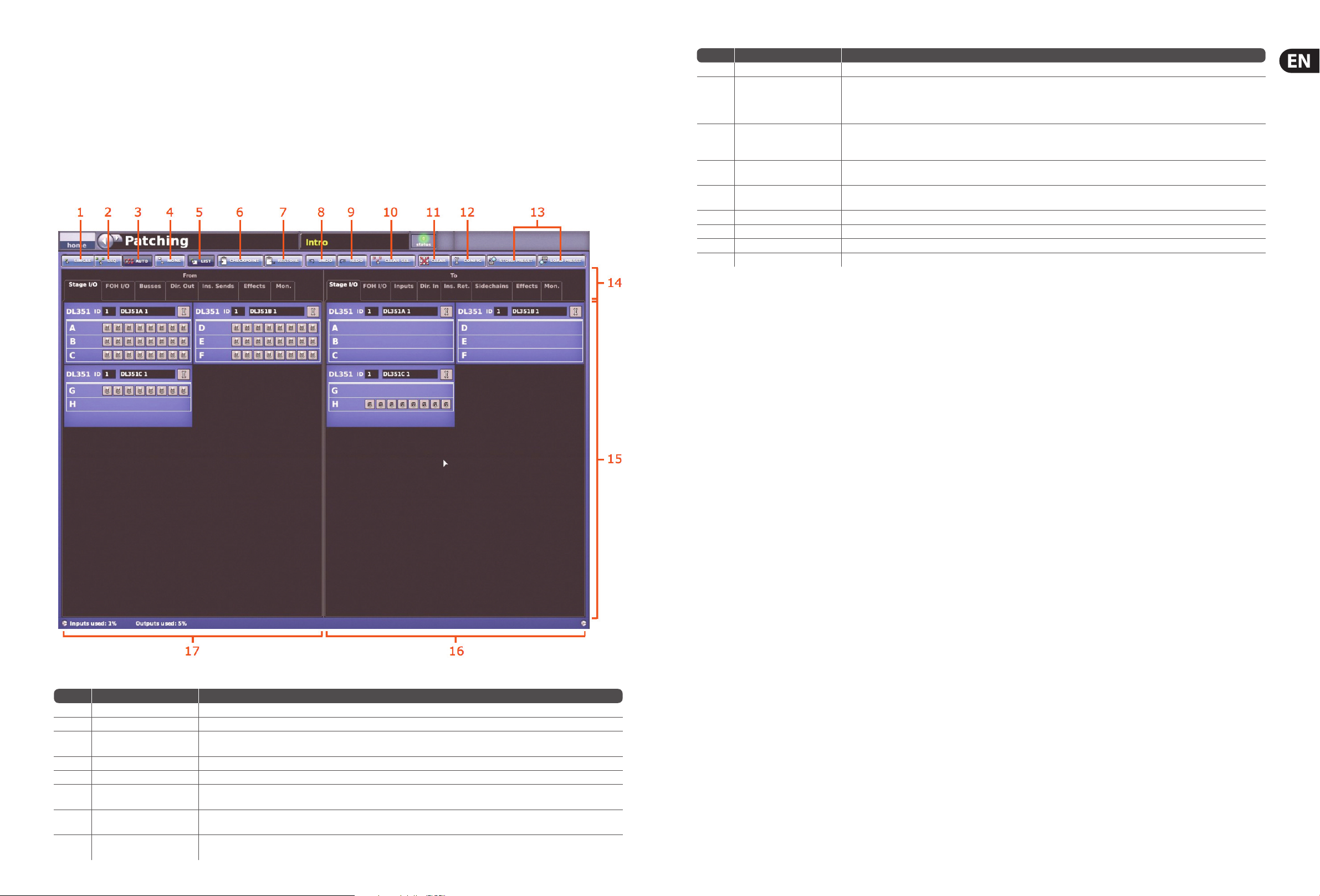

Input channel navigation controls on the PRO X.

7

9

5

6

8

1

Mix bay channel strip

Input fast

strip

3

2

4

Item Element(s) Description

1

Quick access button —

channel strip

Quickly selects the local processing area of the selected channel or channel pair, but doesn’t a ect channel selection.

Illuminates (blue) when active.

2

Quick access button — input

fast strip

Quickly selects the local input channel and assigns the local proc

essing area to the mix bay channel strip.

Illuminates (blue) when active.

3

LCD select button — input

fast strip

Selects the local input channel. Has a backlit LCD display (with user-con gurable backlight colour), which shows channel name etc.

When selected, the display ch

anges to a ‘negative’ image.

4

LCD select button — VCA/

POP group

Selects the VCA/POP group, unfolding the group members to the control surface. Has a backlit LCD display (with user-con gurable

backlight colour), which shows group name. When selected, the display ch

anges to a ‘negative’ image.

This button is also used for setting up the group (see To Assign Channels to a VCA/POP Grou p).

5

Channel select keys and

button

The INPUT button in the channel type section is used with the number keys in the lower channel select section to select a sp

eci c

channel number, assigning it to the control surface (see Fault Finding A Problem Channel).

6 ALIGN button

Navigates the currently selected input channel to the local input bay (see To Navigate The Selected Input Channel Back To

The Control Surface” ).

7 scroll by 4 / 12 buttons

These left and right scroll buttons scroll through the input channels 12 channels at a time on the lef

t 12-channel bay, and 4 at a time

on the right 4-channel bay

8 B button Assigns the 4-channel input bay as area B, which then operates with the master bay channel strip.

9 scroll by 1 buttons These left and right scroll buttons scroll through the channels one at a time. Channel selec

tion follows the scrolling.

>> To assign an input channel to the control surface

Do one of the following:

• • Scroll buttons - Scroll the desired input channel to the control

surface using the scroll by 1 / 12 buttons in the input select section.

• • VCA/POP group buttons - If the desired input channel is in a group,

press its VCA/POP group LCD select button.

You can use the GUI menu to select any VCA/POP group you want via the

home > Control Groups > VCA Groups option.

>> To select an input channel

With the desired input channel currently assigned to the input fast strips on the

cont

rol surface, do one of the following:

• • LCD select button - Press the LCD select button in the desired input

fast strip. This will assign the input channel to the local channel strip

and its input channel overview to the GUI channel strip

• • Quick access button - Press any quick access button in the desired

input fast strip. This will assign the input channel to the local channel

strip and its local processing area to the GUI channel strip.

You can use the scroll by 1 buttons in the upper channel select section to

scroll channel by channel to go to the input ch

annel you want. You can scroll all

of the input channels using this method and the desired input channel doesn’t