PRO Series Live Audio Systems

Owner’s Manual

Midas Klark Teknik Limited,

Klark Industrial Park,

Walter Nash Road,

Kidderminster.

Worcestershire.

DY11 7HJ.

England.

Tel: +44 1562 741515

Fax: +44 1562 745371

Email: info@midasklarkteknik.com

Website: www.midasconsoles.com

PRO Series Live Audio Systems — Owner’s Manual

DOC02-PROSERIES Issue A — September 2010

In line with the company’s policy of continual improvement, specifications and function may be

subject to change without notice. This Owner’s Manual was correct at the time of writing. E&OE.

© Red Chip Company Ltd.

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol within an equilateral triangle is

intended to alert the user to the presence of uninsulated “dangerous voltage”

within the product's enclosure that may be of sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instructions

in the literature accompanying the product.

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings.

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with a dry cloth.

7 Do not block any of the ventilation

openings. Install in accordance with the

manufacturer’s instructions.

8 Do not install near any heat sources such

as radiators, heat registers, stoves, or

other apparatus (including amplifiers) that

produce heat.

9 Do not defeat the safety purpose of the

polarized or grounding-type plug. A

polarized plug has two blades with one

wider than the other. A grounding type

plug has two blades and a third grounding

prong. The wide blade or the third prong

are provided for your safety. If the

provided plug does not fit into your outlet,

consult an electrician for replacement of

the obsolete outlet.

10 Protect the power cord from being walked

on or pinched particularly at plugs,

convenience receptacles and the point

where they exit from the apparatus.

11 Only use attachments/accessories

specified by the manufacturer.

12 Use only with the cart, stand,

tripod, bracket, or table

specified by the

manufacturer, or sold with

the apparatus. When a cart

is used, use caution when moving the

cart/apparatus combination to avoid injury

from tip-over.

13 Unplug this apparatus during lightning

storms or when unused for long periods of

time.

14 Refer all servicing to qualified personnel.

Servicing is required when the apparatus

has been damaged in any way, such as

power-supply cord or plug is damaged,

liquid has been spilled or objects have

fallen into the apparatus, the apparatus

has been exposed to rain or moisture,

does not operate normally, or has been

dropped.

15 Use the mains plug to disconnect the

apparatus from the mains.

16 Warning: To reduce the risk of fire or

electric shock, do not expose this

apparatus to rain or moisture.

17 Warning: Do not expose this

equipment to dripping or splashing

and ensure that no objects filled with

liquids, such as vases, are placed on

the equipment.

18 Warning: The mains plug of the power

supply cord shall remain readily

operable.

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

Le symbole représentant un éclair fléché dans un triangle équilatéral a pour but

d'alerter l'utilisateur de la présence d'une "tension dangereuse" non isolée à

l'intérieur du boîtier, pouvant être d'une force suffisante pour constituer un risque

d'électrocution.

Le point d'exclamation dans un triangle équilatéral a pour but d'alerter

l'utilisateur de la présence d'instructions importantes concernant le

fonctionnement et la maintenance, dans la documentation qui accompagne

l'appareil.

1 Veuillez lire ces instructions.

2 Conservez ces instructions.

3 Respectez toutes les consignes de

sécurité.

4 Suivez scrupuleusement toutes les

instructions.

5 N'utilisez pas cet appareil près d'un point

d'eau.

6 Utilisez uniquement un chiffon sec pour le

nettoyer.

7 N'obstruez aucune des ouïes de

ventilation. Installez-le en respectant les

instructions du fabricant.

8 Ne l'installez pas près de sources de

chaleur tels que radiateurs, panneaux

chauffants, étuves, ou autres appareils

produisant de la chaleur (dont les

amplificateurs).

9 Ne pas utiliser d'adaptateur pour

supprimer la prise de terre des prises à

trois fiches. Si la prise fournie ne peut pas

être branchée dans la prise électrique,

adressez-vous à un électricen qui

remplacera la prise obsolète.

10 Protégez le cordon secteur afin que l'on ne

marche pas dessus et qu'il ne soit pas

pincé, surtout au niveau des prises, ou à

l'endroit où il sort de l'appareil.

11 Utilisez exclusivement des fixations et des

accessoires recommandés par le fabricant.

12 Utilisez l'appareil uniquement

avec le chariot, le trépied, le

support ou la table spécifiés

par le fabricant, ou vendus

avec l'appareil. Si un chariot

est utilisé, prenez toutes les précautions

nécessaires lorsque vous devez déplacer

l'ensemble (chariot et appareil) afin qu'ils

ne se renversent pas.

13 Débranchez l'appareil en période d'orage

ou s'il doit rester inutilisé pendant

longtemps.

14 Confiez toutes les réparations et

interventions à un personnel qualifié. Une

intervention est nécessaire si l'appareil a

été endommagé d'une façon ou d'une

autre, si son cordon ou sa prise secteur

ont été endommagés, si du liquide a été

renversé ou si des objets sont tombés à

l'intérieur, ou encore si l'appareil a été

exposé à la pluie ou à l'humidité, s'il ne

fonctionne pas normalement, ou s'il est

tombé.

15 Débrancher l'appareil du réseau électrique

par la prise de secteur.

16 Avertissement : afin de réduire le

risque d'incendie ou de choc

électrique, ne pas exposer cet

appareil à la pluie ou à de l'humidité.

17 Avertissement : n'exposez pas cet

équipement aux éclaboussures et

veillez à ce qu'aucun récipient rempli

de liquide, verre ou vase, ne soit posé

dessus.

18 Avertissement : la prise secteur doit

toujours rester directement

accessible.

PRO6 EC-Declaration of Conformity

Midas

DOC04-PRO3ECDOC Rev. A

EC-Declaration of Conformity

The undersigned, representing the following manufacturer

Manufacturer: Address:

Midas Klark Teknik Ltd. Klark Industrial Park, Walter Nash Road,

Kidderminster. Worcestershire. DY11 7HJ.

hereby declares that the following product

Product Type Number Product Description Nominal Voltage(s) Current Freq.

PRO3 Control Centre

115V AC

230V AC

2.9A

1.5A

50/60Hz

is in conformity with the regulations of the following marked EC-directives and bears the

-mark accordingly

reference number title

2004/108/EC EMC Directive (EMC)

2006/95/EC Low-Voltage Directive (LVD)

The conformity of the product with EC Directives for use in environment E4 is provided by compliance with

the following standards:

Standards/date:

Applied Electrical Safety test standards:

reference number title

EN 60065:2002

Audio, video and similar electronic apparatus. Safety requirements.

Applied EMC emission test standards:

ref. no. title

EN 55103-1:1996

Class A

EN 55103-1 Annex A: Radiated

magnetic disturbance, 50Hz-50kHz

CISPR 22: Radiated disturbance,

30-1000MHz

CISPR 22: Conducted disturbance,

ac & signal ports

CISPR 16: Discontinuous

disturbance

EN 61000-3-2:2000 Mains

harmonics

EN 61000-3-3:1995 Mains voltage

flicker

Applied EMC immunity test standards:

ref. no. title

EN 61000-4-2:1995 Electrostatic

discharge

EN 55103-2:1996

Class A

EN 61000-4-3:1996: Radiated RF

disturbance, 80-1000MHz

EN 55103-2 Annex A: Magnetic LF

disturbance, 50Hz–10kHz

EN 61000-4-4:1995: Fast transient

bursts, ac & signal ports

EN 61000-4-5:1995: Surge, ac port

EN 61000-4-6:1996: Conducted RF

field, ac & signal ports

EN 61000-4-11:1994: Mains voltage

dips and interruptions

Place, date: Kidderminster, UK

18th August 2010

General Manager AVP, Product Development

Printed name: John Oakley Printed name: Alex Cooper

PRO6 EC-Declaration of Conformity

Midas

DOC04-PRO6ECDOC Rev. B

EC-Declaration of Conformity

The undersigned, representing the following manufacturer

Manufacturer: Address:

Midas Klark Teknik Ltd. Klark Industrial Park, Walter Nash Road,

Kidderminster. Worcestershire. DY11 7HJ.

hereby declares that the following product

Product Type Number Product Description Nominal Voltage(s) Current Freq.

PRO6 Control Centre

115V AC

230V AC

2.9A

1.5A

50/60Hz

is in conformity with the regulations of the following marked EC-directives and bears the

-mark accordingly

reference number title

2004/108/EC EMC Directive (EMC)

2006/95/EC Low-Voltage Directive (LVD)

The conformity of the product with EC Directives for use in environment E4 is provided by compliance with

the following standards:

Standards/date:

Applied Electrical Safety test standards:

reference number title

EN 60065:2002

Audio, video and similar electronic apparatus. Safety requirements.

Applied EMC emission test standards:

ref. no. title

EN 55103-1:1996

Class A

EN 55103-1 Annex A: Radiated

magnetic disturbance, 50Hz-50kHz

CISPR 22: Radiated disturbance,

30-1000MHz

CISPR 22: Conducted disturbance,

ac & signal ports

CISPR 16: Discontinuous

disturbance

EN 61000-3-2:2000 Mains

harmonics

EN 61000-3-3:1995 Mains voltage

flicker

Applied EMC immunity test standards:

ref. no. title

EN 61000-4-2:1995 Electrostatic

discharge

EN 55103-2:1996

Class A

EN 61000-4-3:1996: Radiated RF

disturbance, 80-1000MHz

EN 55103-2 Annex A: Magnetic LF

disturbance, 50Hz–10kHz

EN 61000-4-4:1995: Fast transient

bursts, ac & signal ports

EN 61000-4-5:1995: Surge, ac port

EN 61000-4-6:1996: Conducted RF

field, ac & signal ports

EN 61000-4-11:1994: Mains voltage

dips and interruptions

Place, date: Kidderminster, UK

14th June 2010

General Manager AVP, Product Development

Printed name: John Oakley Printed name: Alex Cooper

PRO9 EC-Declaration of Conformity

Midas

DOC04-PRO9ECDOC Rev. A

EC-Declaration of Conformity

The undersigned, representing the following manufacturer

Manufacturer: Address:

Midas Klark Teknik Ltd. Klark Industrial Park, Walter Nash Road,

Kidderminster. Worcestershire. DY11 7HJ.

hereby declares that the following product

Product Type Number Product Description Nominal Voltage(s) Current Freq.

PRO9 Control Centre

115V AC

230V AC

2.9A

1.5A

50/60Hz

is in conformity with the regulations of the following marked EC-directives and bears the

-mark accordingly

reference number title

2004/108/EC EMC Directive (EMC)

2006/95/EC Low-Voltage Directive (LVD)

The conformity of the product with EC Directives for use in environment E4 is provided by compliance with

the following standards:

Standards/date:

Applied Electrical Safety test standards:

reference number title

EN 60065:2002

Audio, video and similar electronic apparatus. Safety requirements.

Applied EMC emission test standards:

ref. no. title

EN 55103-1:1996

Class A

EN 55103-1 Annex A: Radiated

magnetic disturbance, 50Hz-50kHz

CISPR 22: Radiated disturbance,

30-1000MHz

CISPR 22: Conducted disturbance,

ac & signal ports

CISPR 16: Discontinuous

disturbance

EN 61000-3-2:2000 Mains

harmonics

EN 61000-3-3:1995 Mains voltage

flicker

Applied EMC immunity test standards:

ref. no. title

EN 61000-4-2:1995 Electrostatic

discharge

EN 55103-2:1996

Class A

EN 61000-4-3:1996: Radiated RF

disturbance, 80-1000MHz

EN 55103-2 Annex A: Magnetic LF

disturbance, 50Hz–10kHz

EN 61000-4-4:1995: Fast transient

bursts, ac & signal ports

EN 61000-4-5:1995: Surge, ac port

EN 61000-4-6:1996: Conducted RF

field, ac & signal ports

EN 61000-4-11:1994: Mains voltage

dips and interruptions

Place, date: Kidderminster, UK

18th August 2010

General Manager AVP, Product Development

Printed name: John Oakley Printed name: Alex Cooper

Licences

The following are the license agreements applicable to the Midas Digital Equipment.

End-User Licence Agreement for Midas™ and Klark Teknik™ Software

IMPORTANT - Please read this document carefully before using this Midas™ or

Klark Teknik™ Product. This is an agreement governing your use of software or

other machine instructions already installed on this Midas™ or Klark Teknik™

Product, as well as other software that we provide for installation on this Product.

The Midas™ or Klark Teknik™ Product will not operate in accordance with its

documentation without this software.

THIS AGREEMENT ("AGREEMENT" OR "LICENCE") STATES THE TERMS AND CONDITIONS UPON WHICH

MIDAS KLARK TEKNIK LIMITED ("COMPANY") OFFERS TO LICENSE THE INSTALLED FIRMWARE,

SOFTWARE AND/OR PROGRAMS ("the SOFTWARE") WITH THE MIDAS™ OR KLARK TEKNIK™ CONSOLE

OR SIGNAL PROCESSING PRODUCT ("PRODUCT") IN WHICH IT HAS BEEN INSTALLED BY, OR FOR

WHICH IT IS PROVIDED BY, THE COMPANY. BY USING THIS PRODUCT YOU WILL BE AGREEING TO

BECOME BOUND BY THE TERMS OF THIS LICENCE. IF YOU DO NOT AGREE TO THE TERMS OF THIS

LICENCE, DO NOT USE THIS PRODUCT AND PROMPTLY RETURN THE PRODUCT TO THE PLACE WHERE

YOU OBTAINED IT FOR A FULL REFUND. You agree to notify any persons whom you permit to operate

this Product of the terms of this Licence, and to require them to comply with these terms.

The Software is licensed, not sold, to you for use only under the terms of this Licence, and the

Company reserves all rights not expressly granted to you. The Company retains ownership of all copies

of the Software itself, and all proprietary parts of it, including those stored on or in the Product.

1. Licence: Subject to the terms and conditions of this agreement, the Company grants you, and

other persons you permit to operate the Product, a personal, limited, non-exclusive,

non-transferable licence to use the Software only on the single Product unit in which it has been

installed.

2. Restrictions: (a) The Software, and the accompanying written materials, are copyrighted and

contain trade secrets and other proprietary matter, including confidential information relating to

the specifications and performance characteristics of this Product. Save for such elements as

may be licensed to the Company, as described in paragraph 5, all rights to copyrights, trade

marks and trade secrets in the Software, or any modifications to it, are owned by the Company.

Unauthorised use or copying of the Company's proprietary Software, or any portion thereof, or

copying of those written materials, is prohibited. (b) You may not create, market, distribute, or

transfer copies of the Company's proprietary Software, or any part of it, to others, or duplicate,

rent, lease or loan that Software, or any part of it, except that you may transfer that Software

installed in this Product in conjunction with the sale, transfer, loan, rent or lease of this Product,

and subject at all times to this Licence. YOU MAY NOT REVERSE ENGINEER, DECOMPILE,

DISASSEMBLE, EXTRACT OR SEPARAT E OUT, MODIFY, ADAPT, PORT, OR TRANSLATE THE

SOFTWARE, DERIVE THE SOURCE CODE OF THE SOFTWARE OR CREATE DERIVATIVE WORKS

BASED ON THE SOFTWARE OR ANY ACCOMPANYING WRITTEN MA TERIALS, save as is allowed by

licences pertaining to component parts of the Software which are licensed by third parties, as

described under paragraph 5, or otherwise by law. (c) In the event you violate any term of this

Licence, all rights granted herein will automatically and immediately terminate and you must stop

using the Software and destroy any copies of the Software.

3. Limited Warranty: Subject to your installation of any Software updates issued by the Compan y

as described herein, and the condition below, the Company warrants that the Software will

operate in compliance with the Software's material specifications and documentation for a period

of 90 days from your purchase of this Product. The Software is provided "as is" and the Company

does not warrant that the operation of the Software will meet your requirements or operate free

from error. To the greatest extent permissible by law, the Company DISCLAIMS ALL

WARRANTIES AND CONDITIONS, EITHER EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, NON-INFRINGEMENT OF THIRD

PARTY RIGHTS OR CAPABILITY OF CORRECTLY PROCESSING PROVIDING AND/OR RECEIVING

DATE INFORMATION. You understand that the Company may update or revise the Software but

in so doing incurs no obligation to furnish such updates to you. However , the Company may in its

discretion make updates available from time to time upon such terms and conditions as it shall

determine. It is a condition of the above warranty that you install any such Software updates, as

may be issued from time to time by the Company for the Software, in accordance with the

Company's instructions, and if you do not do so such warranty will cease to apply. You may view

current Software updates at http://www.klarkteknik.com and http://www.midasconsoles.com.

4. Limited Liability: THE ENTIRE RISK ARISING OUT OF YOUR USE OR PERFORMANCE OF THE

SOFTWARE REMAINS WITH YOU. THE LIABILITY OF THE COMPANY FOR ANY CLAIMS ARISING

OUT OF THIS LICENCE AND/OR BASED UPON THE SOFTWARE, REGARDLESS OF THE FORM OF

ACTION, AND INCLUDING WORK STOPPAGE, PRODUCT FAILURE OF MALFUNCTION OR ANY

OTHER COMMERCIAL LOSS OR DAMAGE, SHALL NOT EXCEED THE COST OF THE LICENCE FEE

FOR THE SOFTWARE OR THE COST OF THIS PRODUCT. SUBJECT TO THE PROVISIONS OF

APPLICABLE LAW, IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY LOSS OF DATA, LOST

OPPORTUNITY OR PROFITS, COST OF COVER OR SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR

INDIRECT DAMAGES, EVEN IF YOU ADVISE THE COMPANY OF THE POSSIBILITY OF SUCH

DAMAGES. THIS IS A FUNDAMENTAL TERM OF THIS AGREEMENT AND YOU ACKNOWLEDGE

THAT THE AMOUNT YOU PAID FOR THE SOFTWARE AND/OR THE PRODUCT REFLECTS THIS

ALLOCATION OF RISK. NOTHING IN THIS PARAGRAPH PURPORTS TO EXCLUDE OR LIMIT THE

COMPANY'S LIABILITY FOR DEATH OR PERSONAL INJURY CAUSED BY NEGLIGENCE OR ANY

OTHER LIABILITY WHICH CANNOT BE EXCLUDED OR LIMITED BY LAW.

5. Other Third-Party Computer Programs: As referred to herein, the term "Software" refers

only to proprietary Midas™ or Klark Teknik™ software, owned by the Company, that has been

provided to you for installation on, or already installed in, a Product. In addition to the Softw are,

you may have also been provided, at no additional charge, with a version of the widely-available

GNU Linux Operating System, which is a modular operating system made up of hundreds of

individual software components, each of which was written, and the copyright and other rights in

which are owned individually, by various parties (collectively, "the GNU Linux Programs"). Each

component has its own applicable end user li cence agreement, and many of these agreements

permit you to copy, modify, and redistribute the applicable software, but you must review the

on-line documentation that shares a directory or otherwise accompanies each of the GNU Linux

Programs provided to you for the specific terms and conditions. Nothing in this Licence limits

your rights under, or grants you rights that supersede, the terms of any other applicable end user

licence agreement. If you wish to receive a computer-readable copy of the source code for any

of the GNU Linux Programs that have been provided with your Midas™ or Klark Teknik™ Product,

send a cheque or money order (no cash accepted), your address and [£10.00] to cover the cost

of optical media, postage and handling, to:

Midas Klark Teknik Limited

ATTN: Linux Programs CD for Midas™/Klark Teknik™

Walter Nash Road,

Kidderminster.

Worcestershire.

DY11 7HJ.

England.

In your request, indicate your Product's name and model number, serial number and

version/release information. In your request, also indicate the relevant Software version/release

information. This offer, made pursuant to the GNU Linux Programs' end user licence agreements,

may expire according to the terms of those agreements, in which case your cheque will be

returned to you or destroyed at our option. Please note that the GNU Linux Programs that may

be available to you under this offer consists of the GNU Linux Operating System components only

and none of the proprietary application software developed by Midas or Klark Teknik is included.

Other updated Linux distributions containing application software are widely available from a

variety of Internet sources, and are often available at minimal or no cost.

6. Termination: This Licence will terminate immediately if you violate any of the Licence terms.

Upon termination you must discontinue use of the Software, and either destroy, erase or return

to Company all copies of the Software in your possession, custody or control, including those in

or on the Product.

7. General: This Licence constitutes the entire agreement between you and the Company with

respect to this Software and, save in the case of fraud, supersedes any other communication

(including advertising). Company reserves all rights not expressly granted to y ou in this licence.

If any provision of this Licence is held unenforceable, that provision shall be enforced to the

maximum extent permissible so as to give effect the intent of this Licence, and the remainder of

this Licence shall continue in full force and effect. This Licence shall be governed by English law

and the Courts of England and Wales will have exclusive jurisdiction to hear and decide any

dispute concerning it or its formation. No breach by you of any provision of this Licence shall be

waived or discharged except with the express written consent of the Company and no failure or

delay by the Company to exercise any of its rights under this Licence shall operate as a waiver

thereof and no single or partial exercise of any such right shall prevent any other or further

exercise of that or any other right. You acknowledge that the Company could be irreparably

damaged if the terms of this Licence were not specifically enforced, and agree that the Company

may seek appropriate equitable remedies with respect to breaches of this Licence, including

injunctive relief, in addition to such other remedies as the Company may otherwise have

available to it under applicable laws.

GNU General Public License (GPL)

For details of the Third Party Software License Attribution, Copyright and Terms and Conditions and

Notices, and the GNU LESSER GENERAL PUBLIC LICENSE, see the Midas Digital Equipment GNU

General Public License (GPL) Booklet part number DOC04-GPL issue A.

xvii

Precautions

Before installing, setting up or operating this equipment make sure you have read and

fully understand all of this section and the “IMPORTANT SAFETY INSTRUCTIONS” at the

front of this document.

This equipment is supplied by a mains voltage that can cause electric shock injury!

The following must be observed in order to maintain safety and electromagnetic compatibility (EMC)

performance.

Safety warnings

Signal 0V is connected internally to the

chassis.

To completely isolate this equipment from

the AC mains, while observing full safety

precautions (see “Power”), switch off the

isolator switch (above the mains power

sockets on rear of control centre) and then

switch off the mains at the three mains

outlets. Unplug the three mains leads from

the rear of the control centre.

To avoid electrical shock do not remove

covers.

General precautions

In the event of ground loop problems,

disconnect the signal screen at one end of the

connecting cables. Note that this can only be

done when the equipment is used within a

balanced system.

Do not remove, hide or deface any warnings or

cautions.

Power

The power supplies contain LETHAL VOLTAGES

greatly in excess of the mains voltage and its

rails can produce extremely large currents that

could burn out equipment and wiring if shorted.

distributed so as to meet local safety

regulations.

A Volex locking type plug is fitted on each

supplied mains cable, which plugs into a mains

IEC connector on the equipment. When fitted

properly the Volex plug locks into place,

preventing it from working loose, or being

inadvertently knocked loose or pulled out. To fit

a Volex plug, insert it into the mains IEC

connector and push it in until it locks in place.

Then, check to make sure it is locked in place.

To remove it, release its locking device and then

pull it out. When fitting or removing a Volex

plug, always hold the plug itself and never use

the cable, as this may damage it.

During operation of the control centre, a

minimum of two of its three mains inlets must

be connected and supplying power.

When removing the equipment’s electric plugs

from the outlets, always hold the plug itself and

not the cable. Pulling out the plug by the cable

can damage it.

Never insert or remove an electric plug with wet

hands.

Do not connect/disconnect a mains power

connector to/from the control centre while

power is being applied to it. Switch the power

off first.

Before switching the control centre on or off,

make sure that all monitor loudspeaker power

amplifiers are turned off or muted.

The internal power supplies are of the switch

mode type that automatically sense the

incoming mains voltage and will work where the

nominal voltage is in the range 100VAC to

240VAC.

Each mains inlet is to be sourced from its own

separate wall-mounted mains outlet socket.

Otherwise, their mains sources must be suitably

PRO Series Live Audio Systems

Owner’s Manual

xviii Precautions

Handling the equipment

Completely isolate the equipment electrically

and disconnect all cables from the equipment

before moving it.

When lifting or moving the equipment, always

take its size and weight into consideration. Use

suitable lifting equipment or transporting gear,

or sufficient additional personnel.

Do not insert your fingers or hands in any gaps

or openings on the equipment, for example,

vents.

Do not press or rub on the sensitive surface of

the GUI screens.

If the glass of the GUI screen is broken, liquid

crystals shouldn’t leak through the break due to

the surface tension of the thin layer and the

type of construction of the LCD panel. However,

in the unlikely event that you do make contact

with this substance, wash it out with soap.

Installation

Before installing the equipment:

• Make sure the equipment is correctly

connected to the protective earth conductor

of the mains voltage supply of the system

installation through the mains leads.

• Power to the equipment must be via a fused

spur(s).

• Power plugs must be inserted in socket

outlets provided with protective earth

contacts. The electrical supply at the socket

outlets must provide appropriate

over-current protection.

• Both the mains supply and the quality of

earthing must be adequate for the

equipment.

• Before connecting up the equipment, check

that the mains power supply voltage rating

corresponds with the local mains power

supply . The rating of the mains power supply

voltage is printed on the equipment.

Location

Ideally a cool area is preferred, away from

power distribution equipment or other potential

sources of interference.

Do not install the equipment in places of poor

ventilation.

Do not install this equipment in a location

subjected to excessive heat, dust or mechanical

vibration. Allow for adequate ventilation around

the equipment, making sure that its fans and

vents are not obstructed. Whenever possible,

keep the equipment out of direct sunlight.

Do not place the equipment in an unstable

condition where it might accidentally fall over.

Make sure that the mains voltage and fuse

rating information of the equipment will be

visible after installation.

Audio connections

To ensure the correct and reliable operation of

your equipment, only high quality, balanced,

screened, twisted pair audio cable should be

used.

XLR connector shells should be of metal

construction so that they provide a screen when

connected to the control centre and, where

appropriate, they should have Pin 1 connected

to the cable screen.

Electrostatic discharge

(ESD) precautions

Observe full electrostatic discharge

(ESD) — also known as “anti-static”

— precautions when carrying out

procedures in this manual that are

accompanied by the ESD Susceptibility Symbol

(shown above). This caution symbol shows you

that ESD damage may be caused to items

unless proper ESD precautions are taken, which

include the following practices:

• Keep the work area free from plastic, vinyl or

styrofoam.

• Wear an anti-static wrist strap.

• Discharge personal static before handling

devices.

• Ground the work surface.

• Avoid touching ESD-sensitive devices.

Radio frequency

interference—Class A

device

This equipment has been tested and found to

comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference when

the equipment is operated in a commercial

environment. This equipment generates, uses,

and can radiate radio frequency energy and, if

PRO Series Live Audio Systems

Owner’s Manual

Precautions xix

not installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area

is likely to cause harmful interference in which

case the user will be required to correct the

interference at his own expense.

Electric fields

Caution:

In accordance with Part 15 of the FCC

Rules & Regulations, “… changes or

modifications not expressly approved by

the party responsible for compliance could

void the user's authority to operate the

equipment.”

Should this product be used in an

electromagnetic field that is amplitude

modulated by an audio frequency signal (20Hz

to 20kHz), the signal to noise ratio may be

degraded. Degradation of up to 60dB at a

frequency corresponding to the modulation

signal may be experienced under extreme

conditions (3V/m, 90% modulation).

Safety equipment

Never remove, for example, covers, housings or

any other safety guards. Do not operate the

equipment or any of its parts if safety guards

are ineffective or their effectiveness has been

reduced.

Optional equipment

Unless advised otherwise, optional equipment

must only be installed by service personnel and

in accordance with the appropriate assembly

and usage regulations.

Special accessories

To comply with part 15 of the FCC Rules, any

special accessories (that is, items that cannot be

readily obtained from multiple retail outlets)

supplied with this equipment must be used with

this equipment; do not use any alternatives as

they may not fulfil the RF requirement.

PRO Series Live Audio Systems

Owner’s Manual

xx Precautions

PRO Series Live Audio Systems

Owner’s Manual

xxi

Recommandations

Avant l'installation, la mise au point ou l'exploitation de cet équipement, veiller à lire

attentivement et à comprendre l'intégralité de ce chapitre et la partie "CONSIGNES DE

SÉCURITÉ IMPORTANTES" au début de ce manuel.

Cet équipement est alimenté par une tension de secteur pouvant provoquer des blessures par choc

électrique !

Les points suivants doivent être observés afin de maintenir la sécurité et une compatibilité

électromagnétique (CEM) correcte.

Avertissements de sécurité

Une tension 0V de signal est raccordée en

interne au châssis.

Afin de déconnecter complètement cet

appareil du secteur CA, tout en observant

les précautions de sécurité (voir

“Puissance”), couper le sectionneur (audessus des prises secteur sur le panneau

arrière du centre de contrôle), puis couper

le secteur aux trois socles de secteur.

Isoler l'appareil en débranchant les trois

câbles de secteur du panneau arrière du

centre de contrôle.

Afin d'éviter un choc électrique, ne pas

retirer les couvercles.

Recommandations

générales

En cas de problème de boucle de terre,

débrancher le blindage de signal à une

extrémité des câbles de raccordement. Il

convient de noter que cela n'est faisable que si

l'équipement est utilisé dans un système

équilibré.

Ne pas retirer, cacher ni dégrader les

avertissements ou les mises en garde.

Puissance

Les alimentations électriques contiennent des

TENSIONS LÉTALES largement supérieures à la

tension de secteur et les barres peuvent

produire des courants extrêmement élev és

capables de griller l'équipement et le câblage en

cas de court-circuit.

Les alimentations électriques internes sont des

alimentations à découpage détectant

automatiquement la tension de secteur d'entrée

et fonctionnant lorsque la tension nominale se

trouve dans la plage de 100 VCA à 240 VCA.

Chaque prise de secteur doit être raccordée à

son propre socle mural séparé. Sans quoi, les

alimentations de secteur doivent être

correctement distribuées conformément aux

réglementations locales de sécurité.

Chaque câble d'alimentation fourni est équipé

d'une fiche Volex verrouillable qui se branche

dans une prise connecteur CEI sur l'appareil.

Lorsqu'elle est montée correctement la fiche

Volex se verrouille dans son logement,

l'empêchant de se desserrer ou d'être

déconnectée par inadvertance. Pour brancher

une fiche Volex, l'insérer dans la prise

connecteur secteur CEI et la pousser jusqu'à ce

qu'elle se verrouille dans son logement. Penser

ensuite à vérifier qu'elle soit correctement

verrouillée. Pour l'enlever, libérer son dispositif

de verrouillage pour ensuite la tirer. Lors de la

connection ou déconnection d'une fiche Volex,

toujours saisir la fiche elle-même et ne jamais

utiliser le câble, car cela pourrait l'endommager.

Pendant le fonctionnement du centre du contrôle

un minimum de deux de ses trois entrées

secteur doivent être connectés et alimentation.

Pour débrancher les cordons d'alimentation de

l'équipement des prises murales, tenir toujours

la prise et non le câble. Tirer la prise par le câble

peut l'endommager.

Ne jamais brancher ni débrancher une prise

électrique avec des mains humides.

Ne jamais brancher/débrancher un connecteur

de secteur au/du centre de contrôle s'il est sous

tension. Mettre d'abord hors tension.

Avant de metre le centre de contrôle ou se

désactiver, assurez-vous que tous les

amplificateurs de haut-parleur de surveiller

l'alimentation sont désactivées ou coupé.

PRO Series Live Audio Systems

Owner’s Manual

xxii Recommandations

Manipulation de

l'équipement

Isoler électriquement et totalement l'appareil et

débrancher tous ses câbles avant de le déplacer.

En soulevant ou en déplaçant l'appareil, tenir

toujours compte de sa taille et de son poids.

Utiliser un dispoitif de levage adapté ou un

matériel de transport, ou encore suffisamment

de personnel supplémentaire.

Ne pas introduire les doigts ni les mains dans les

fentes ni les ouvertures de l'appareil, telles que

les ouïes de ventilation.

Ne pas appuyer ou de frotter sur la surface

sensible des ecrans GUI.

Si le verre de l’écran GUI est cassé, les crystaux

liquids ne doit pas s’infiltrer dans la rupture en

raison de la tension superificielle de la couche

mince et le type de construction de l’écran LCD.

Toutefois, dans le cas improbable où vous ne

prendre contact avec cette substance, le laver

avec du savon.

Installation

Avant d'installer l'équipement :

• Vérifier qu'il est correctement raccordé au

conducteur de terre de protection de

l'alimentation de tension de secteur du

système par les câbles de secteur.

• L'équipement doit être alimenté par

l'intermédiaire de(s) dérivation(s) avec

fusible.

• Les prises doivent être branchées sur des

prises femelles dotées de contacts de terre

de protection. L'alimentation électrique aux

prises femelles doit assurer une protection

adéquate contre la surintensité.

• L'alimentation de secteur et la qualité de la

mise à la terre doivent être d'un niveau

convenant à l'appareil.

• Avant de brancher l'équipement, vérifier que

la tension nominale de l'alimentation de

secteur correspond à l'alimentation de

secteur locale. La valeur nominale de la

tension d'alimentation de secteur est

imprimée sur l'équipement.

Ne pas installer l'équipement dans des endroits

mal aérés.

Ne pas installer cet équipement dans un local

exposé à la chaleur, à la poussière ou à des

vibrations mécaniques excessives. Prévoir une

ventilation adéquate autour de l'appareil, en

s'assurant que les ventilateurs et les ouïes ne

sont pas obstrués. Dans la mesure du possible,

le garder à l'écart de la lumière directe du soleil.

Ne pas placer l'appareil sur un support instable

d'où il pourrait tomber par accident.

S'assurer que les informations relatives à la

tension de secteur et au calibre des fusibles de

l'équipement sont visibles après l'installation.

Connexions audio

Afin d'assurer le fonctionnement correct et fiable

de l'équipement, utiliser uniquement un câble

audio à paire torsadée, blindé, équilibré, de

première qualité.

Les boîtiers de connecteurs XLR doivent être en

métal de façon à former un blindage lors du

raccordement au centre de commande et, le cas

échéant, la Fiche 1 devrait être raccordée au

blindage du câble.

Electrostatic discharge

(ESD) precautions

Observe full electrostatic discharge

(ESD) — also known as “anti-static”

— precautions when carrying out

procedures in this manual that are

accompanied by the ESD Susceptibility Symbol

(shown above). This caution symbol shows you

that ESD damage may be caused to items

unless proper ESD precautions are taken, which

include the following practices:

• Keep the work area free from plastic, vinyl or

styrofoam.

• Wear an anti-static wrist strap.

• Discharge personal static before handling

devices.

• Ground the work surface.

• Avoid touching ESD-sensitive devices.

Lieu d'installation

L'idéal est de disposer d'une zone fraîche, à

l'écart de tout équipement de distribution

électrique ou d'autres sources potentielles

d'interférences.

PRO Series Live Audio Systems

Owner’s Manual

Recommandations xxiii

Interférences

radioélectriques - Dispositif

de Classe A

Cet équipement a été testé et est conforme aux

limites d'un produit numérique de Classe A, en

application de la Partie 15 des Règles de la FCC.

Ces limites sont destinées à assurer une

protection raisonnable contre les interférences

néfastes lorsque l'équipement fonctionne dans

un environnement commercial. Cet équipement

génère, utilise et peut rayonner de l'énergie de

fréquence radio et, s'il n'est pas installé et utilisé

conformément au manuel d'exploitation, il peut

causer des interférences dommageables aux

communications radio. L'utilisation de cet

équipement dans une zone résidentielle est

susceptible de provoquer des interférences

néfastes, dans quel cas l'utilisateur se devra de

corriger les interférences à ses propres frais.

Champs électriques

Attention :

Conformément à la Partie 15 des Règles et

Réglementations de la FCC, "… tout

changement ou toute modification non

expressément approuvé(e) par la partie

responsable de la conformité pourrait

annuler l'autorisation accordée à

l'utilisateur d'utiliser cet appareil. "

Dans le cas où ce produit est utilisé dans un

champ électromagnétique dont l'amplitude est

modulée par un signal audiofréquence (20 Hz à

20 kHz), le rapport signal-bruit peut être

détérioré. Une détérioration atteignant 60 dB à

une fréquence correspondant au signal de

modulation peut se produire dans des conditions

extrêmes (modulation 90%, 3 V/m).

Équipement de sécurité

Ne jamais retirer les couvercles, les boîtiers ni

autres caches de sécurité. Ne pas faire

fonctionner l'appareil ni aucun de ses

composants si les protecteurs de sécurité ne

sont pas en mesure de remplir leur fonction ou

si leur efficacité a été réduite.

Équipement en option

Sauf indication contraire, tout équipement en

option doit être installé uniquement par le

personnel d'entretien et conformément aux

réglementations appropriées de montage et

d'usage.

Accessoires spéciaux

Aux fins de la conformité à la Partie 15 des

Règles de la FCC, tous les accessoires spéciaux

fournis avec cet équipement (à savoir les

articles que l'on ne peut se procurer facilement

auprès des chaînes de détaillants), doivent être

utilisés avec cet équipement ; ne pas utiliser de

composants de remplacement car ils pourraient

ne pas respecter l'exigence de RF.

PRO Series Live Audio Systems

Owner’s Manual

xxiv Recommandations

PRO Series Live Audio Systems

Owner’s Manual

xxv

Contents

Cover page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Information page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES. . . . . . . . . . . . . . . . . . . . . vi

PRO6 EC-Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

PRO6 EC-Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

PRO9 EC-Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Licences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Recommandations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Overview

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GUI diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

PRO Series user documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PRO Series host software version . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warranty and registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 PRO Series Live Audio Systems . . . . . . . . . . . . . . . . . .7

Introducing the PRO3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Introducing the PRO6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Introducing the PRO9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Key features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PRO Series Live Audio Systems

Owner’s Manual

xxvi Contents

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FOH and MON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

System buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Mix matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Processing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Input channel processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Mix channel processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Output channel processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Effects processing and GEQs . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Audio physical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Surround capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Reliability (redundancy) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Control software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

System card expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Console linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Integration of third party hardware/software . . . . . . . . . . . . . . . . . . .24

Chapter 3 About The Control Centre . . . . . . . . . . . . . . . . . . . . . 27

Overview of the control centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Bay and GUI layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Control surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Front and rear panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . .31

External interfaces and peripheral devices . . . . . . . . . . . . . . . . . . . . .32

Mix buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Processing elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Getting Started

Chapter 4 Setting Up The System . . . . . . . . . . . . . . . . . . . . . . . 37

Initial set-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Unpacking the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Making up a rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Outboard equipment rack requirements . . . . . . . . . . . . . . . . . . . . .37

Wiring instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Powering the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Switching the control centre on/off . . . . . . . . . . . . . . . . . . . . . . . . . .43

Setting up the ID of the unit(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Basic Operation Of The PRO Series

Chapter 5 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Principles of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Using the 4-channel input bay as area B . . . . . . . . . . . . . . . . . . . .47

PRO Series Live Audio Systems

Owner’s Manual

Contents xxvii

Operating the top output fast strips from the master bay . . . . . . . . 48

Controlling the mix buses in flip mode . . . . . . . . . . . . . . . . . . . . . 48

Hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Saving your work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Saving a show versus storing a scene . . . . . . . . . . . . . . . . . . . . . . 49

Shutting down the control centre properly . . . . . . . . . . . . . . . . . . 49

Chapter 6 Working With The Control Centre . . . . . . . . . . . . . . .51

About the PRO Series controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

About channel operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

About GUI operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Click . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Drag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Common GUI screen elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Parameter values displayed on touch . . . . . . . . . . . . . . . . . . . . . . . . 54

Operating the GUI screen controls . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Using drop-down lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Spin buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

About windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using the GUI menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Text editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 7 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

An introduction to navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Navigating the input channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Navigating the mix buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Navigating the output channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Navigation via the GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Fault finding a problem channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 8 Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Terms used in PRO Series patching . . . . . . . . . . . . . . . . . . . . . . . . . . 71

About the Patching screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

What the Patching screen symbols mean . . . . . . . . . . . . . . . . . . . 74

About the tabs in the From and To sections . . . . . . . . . . . . . . . . . . 75

Navigating to the Patching screen . . . . . . . . . . . . . . . . . . . . . . . . 85

About the devices on the stage and FOH I/O tabs . . . . . . . . . . . . . 85

Patching tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Standard tooltip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

List tooltip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

About the patching procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Configuring the devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

About the configuration window . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Device configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Configuring the snake type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Setting up the I/O rack devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Device set-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

How to patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Working with patch connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Single patching (SINGLE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Sequence patching (SEQ.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

PRO Series Live Audio Systems

Owner’s Manual

xxviii Contents

Automatic patching (AUTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Clearing all current patching . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Chapter 9 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Setting a mic amplifier’s input gain . . . . . . . . . . . . . . . . . . . . . . . . . .99

Setting the high and low pass filters . . . . . . . . . . . . . . . . . . . . . . . .100

Input equalisation (E zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Input dynamics processing (D zone) . . . . . . . . . . . . . . . . . . . . . . . .102

Output processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Using VCA/POP groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Configuring VCA/POP groups . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Setting up a mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Mix bus routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Using fader flip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Setting up the effects rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Simple routing to master stereo outputs . . . . . . . . . . . . . . . . . . . . .111

Scene and show management (automation) . . . . . . . . . . . . . . . . . . .112

Managing the shows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Managing the scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Additional control — managing events . . . . . . . . . . . . . . . . . . . . .116

Show editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Configuring the inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . .118

Using copy and paste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Copy and paste rules and restrictions . . . . . . . . . . . . . . . . . . . . .119

User library (presets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Surround panning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Two-man operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Saving your show files to a USB memory stick . . . . . . . . . . . . . . . . .123

External AES50 synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Security (locking mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Advanced Operation And Features

Chapter 10 Stereo Linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Changing the linking options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Linking the master channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Chapter 11 Panning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Stereo panning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

SIS™ (LCR) mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

SIS image control knob fully clockwise (LCR) . . . . . . . . . . . . . . . .132

SIS image control knob fully anti-clockwise (stereo) . . . . . . . . . . .132

SIS image control knob centred (equal power) . . . . . . . . . . . . . . .132

Surround panning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

About the controls in surround mode . . . . . . . . . . . . . . . . . . . . . .134

Speaker placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

PRO Series Live Audio Systems

Owner’s Manual

Contents xxix

Chapter 12 Soloing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Using solo A/B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Solo hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Solo in place (SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Chapter 13 Muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Chapter 14 Monitors And Communications . . . . . . . . . . . . . . . .143

Monitors (A and B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Delay (GUI only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Solo system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

solo in place switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

C/O switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Monitor output (a and b) sections . . . . . . . . . . . . . . . . . . . . . . . 147

source (a and b) sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

solo (a and b) sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

solo mode section (GUI only) . . . . . . . . . . . . . . . . . . . . . . . . . . 149

solo system section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Signal generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Talk osc/routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Internal talk groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Talk mic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Internal talk mic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

External talkback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Chapter 15 Graphic Equaliser (GEQ) . . . . . . . . . . . . . . . . . . . . .157

Overview of the GEQs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

About the Graphic EQs screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

About the GEQ window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

GEQ front panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Configuring the number of GEQs (and effects) . . . . . . . . . . . . . . . . . 161

Copying settings between GEQs . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Chapter 16 Internal Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Overview of the internal effects . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Rack unit number allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

About the effect window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Working with the effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Effect configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Effect programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Delay effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Virtual DN780 Reverb effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Flanger effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Phaser effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Pitch Shifter effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

SQ1 Dynamics effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3-Band Compressor effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

PRO Series Live Audio Systems

Owner’s Manual

xxx Contents

Chapter 17 Control Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

VCA and POP groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

VCA fast strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

POP groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Working with VCA/POP groups . . . . . . . . . . . . . . . . . . . . . . . . . .179

Auto-mute (mute) groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Talk groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

About the control group screens . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Management section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Programming the groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Configuring the groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Chapter 18 Copy And Paste . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Channels versus scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Chapter 19 Assignable Controls (I Zone) . . . . . . . . . . . . . . . . . 187

About the I zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Controlling a rotary control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

About the Assignable Controls window . . . . . . . . . . . . . . . . . . . .188

Using the I zone to control an internal effect/GEQ . . . . . . . . . . . . . . .190

About the assignable controls panel on the GUI . . . . . . . . . . . . . .190

Rack and unit control navigation . . . . . . . . . . . . . . . . . . . . . . . . .191

Controlling an internal effect via the I zone . . . . . . . . . . . . . . . . . . .193

Controlling a GEQ via the I zone . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Chapter 20 Scenes And Shows (Automation) . . . . . . . . . . . . . . 197

About automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

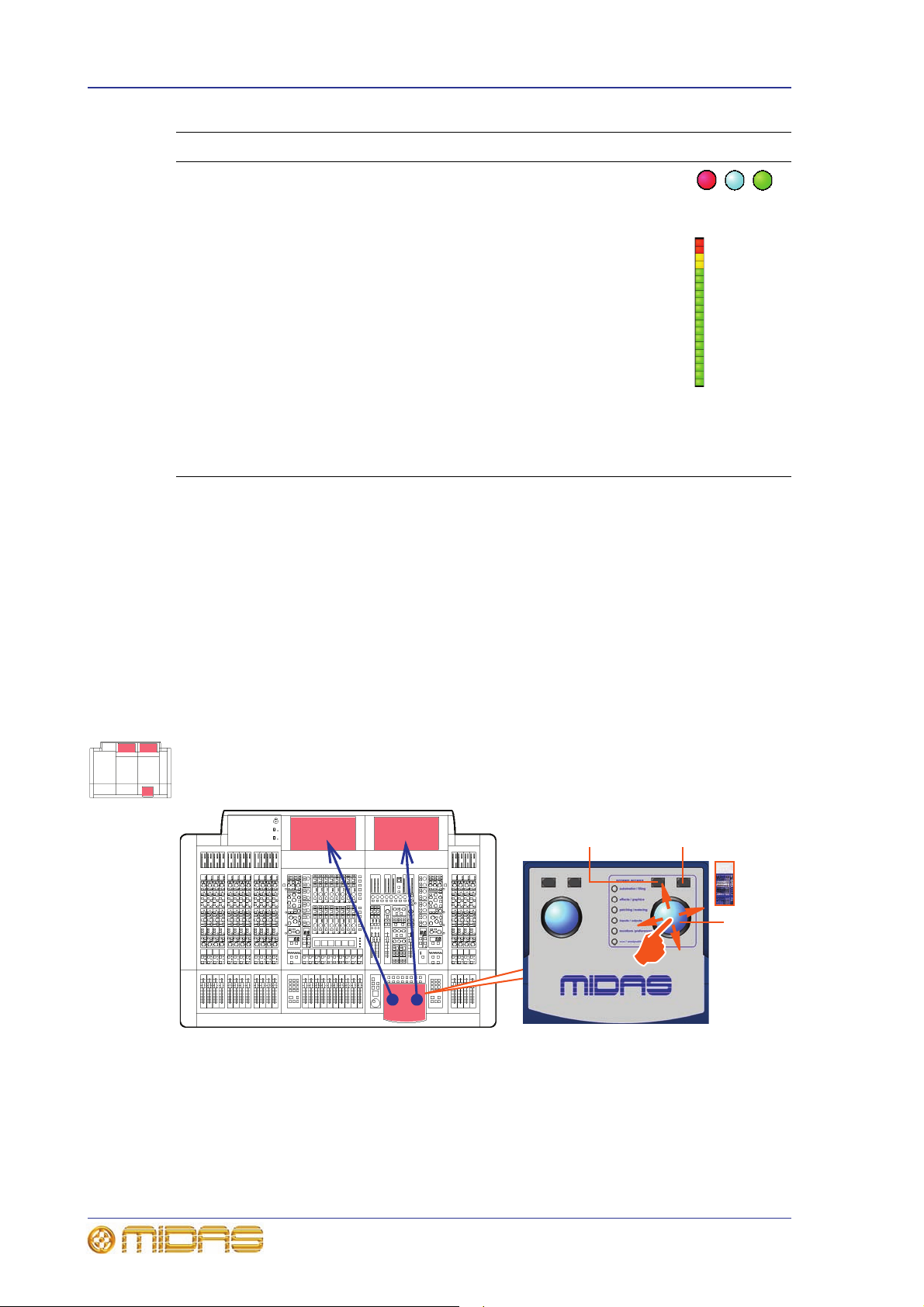

Automation controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

next LCD button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Automation screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Using the right-click menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Scene contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Point scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Numbering and navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Global scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Initial snapshot scene (scene 0) . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Scene cue list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Configuring the scene cue list view . . . . . . . . . . . . . . . . . . . . . . .205

Editing scene properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Adding a new scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Copying and deleting scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Changing the order of the scenes . . . . . . . . . . . . . . . . . . . . . . . . . .207

Overriding store scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Using patching in automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Using zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Show files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Managing show files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Managing show files on the Files screen . . . . . . . . . . . . . . . . . . . .210

Rehearsals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

Safes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

PRO Series Live Audio Systems

Owner’s Manual

Contents xxxi

Chapter 21 Scope (Automation). . . . . . . . . . . . . . . . . . . . . . . . .213

About scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

About the Recall Scope screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Selecting scope parameter sections . . . . . . . . . . . . . . . . . . . . . . . . 215

Selecting bus parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Saving scope parameters in a scene . . . . . . . . . . . . . . . . . . . . . . . . 219

Using store scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Chapter 22 Events (Automation) . . . . . . . . . . . . . . . . . . . . . . . .221

About events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

MIDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Crossfades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Global scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Connecting up the MIDI/GPIO equipment . . . . . . . . . . . . . . . . . . 222

About the Edit Event window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Programming events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Chapter 23 Crossfades (Automation). . . . . . . . . . . . . . . . . . . . .227

About the crossfade Edit Event window . . . . . . . . . . . . . . . . . . . . . . 227

About the crossfade parameters . . . . . . . . . . . . . . . . . . . . . . . . 228

Crossfade set up section in the Edit Event window . . . . . . . . . . . . 229

How a crossfade operates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Crossfade groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Global events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Manually controlling a crossfade . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Chapter 24 User Libraries (Presets). . . . . . . . . . . . . . . . . . . . . .235

About the Preset Manager screen . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Managing user libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Deleting presets from a user library . . . . . . . . . . . . . . . . . . . . . . . . 237

Chapter 25 File Management . . . . . . . . . . . . . . . . . . . . . . . . . . .239

About the Files screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

About the Master Controller File Synchronisation window . . . . . . . . . 241

Chapter 26 Using Other Devices With The PRO Series. . . . . . . .243

Using multiple digital consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Synchronising the consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Sharing DL431 Mic Splitter A and B inputs . . . . . . . . . . . . . . . . . 244

Using an external USB mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Using an external USB keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Using an external monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Chapter 27 Changing The User Settings. . . . . . . . . . . . . . . . . . .247

Setting the meter preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Configuring a virtual soundcheck . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Restoring the PRO Series defaults . . . . . . . . . . . . . . . . . . . . . . . . . 248

Checking the PRO Series build information . . . . . . . . . . . . . . . . . . . 248

Setting the configuration preferences . . . . . . . . . . . . . . . . . . . . . . . 249

Changing the user interface preferences . . . . . . . . . . . . . . . . . . . . . 250

PRO Series Live Audio Systems

Owner’s Manual

xxxii Contents

Changing the signal processing preferences . . . . . . . . . . . . . . . . . . .250

Configuring the channels, groups and internal units . . . . . . . . . . . . .251

Changing the default input/output names . . . . . . . . . . . . . . . . . . . .251

Adjusting PRO Series illumination . . . . . . . . . . . . . . . . . . . . . . . . . .251

Setting the time and date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Chapter 28 Delay Compensation (Latency) . . . . . . . . . . . . . . . . 253

Insert compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

GEQ compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

GUI Delay Compensation options . . . . . . . . . . . . . . . . . . . . . . . . . .254

Monitor Mode (Align with Masters) . . . . . . . . . . . . . . . . . . . . . . . . .256

Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

Master to matrix post-processing option . . . . . . . . . . . . . . . . . . . . .257

Solo bus delay compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

Typical configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

FOH mix setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

FOH mix low latency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Monitor mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

Monitor mix (low latency) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

Description

Chapter 29 Panel Connections. . . . . . . . . . . . . . . . . . . . . . . . . . 265

Front panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Rear panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

Mains power and ventilation section . . . . . . . . . . . . . . . . . . . . . .266

External connections and communications (centre left) section . . .267

Audio, networking and synchronisation section . . . . . . . . . . . . . . .273

I/O section (far right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .276

Chapter 30 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Input channel routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

Input channel areas of the control surface . . . . . . . . . . . . . . . . . . . .278

Input fast strips, channel strips and mix buses . . . . . . . . . . . . . . . . .279

Inputs on the GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

GUI input fast strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

GUI channel strips (inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

Input metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

Channel configuration controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Input channel ID (GUI only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

Input channel source select (GUI only) . . . . . . . . . . . . . . . . . . . .284

Input channel delay (GUI only) . . . . . . . . . . . . . . . . . . . . . . . . . .284

Stereo linking (GUI only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

Safes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

Mic amp input gain (preliminary input processing) . . . . . . . . . . . . . .286

Using gain swap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

Processing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

Direct output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

Dynamics (D zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .290

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .290

Compressor graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .292