Page 1

A

LIN DOC #:

1562

LX1562/1563

S ECOND-GENERATION POWER FACTOR CONTROLLER

THE INFINITE POWER OF INNOVATION

DESCRIPTION KEY FEATURES

The LX1562 is a second-generation

family of power factor correction

controllers using a discontinuous mode

of operation. They are optimized for

electronic ballast applications. Many

improvements have been made over

the original SG3561A controller

introduced by Silicon General Semiconductor in 1992.

New features include the addition of

an internal start-up circuit eliminating

bulky external components while

allowing independent boost converter

operation. Addition of internal current

sense blanking eliminating the need for

an external R/C filter network. Internal

clamping of the error amplifier and

multiplier outputs improves turn on

overshoot characteristics and current

limiting. Special circuitry has also been

added to prevent no load runaway

conditions. And finally, output drive

clamps limiting power MOSFET gate

drive independent of supply voltage

greatly enhance the products practical

application.

Although the IC design has been

optimized for electronic ballast applications, it can also be used for power

factor correction in lower power (typ <

300W) AC-DC converters. One unique

feature of the device is encompassed

by the addition of internal logic

circuitry to detect zero crossing of the

inductor current thus maintaining the

discontinuous current mode of operation. This feature prevents large

current gaps from appearing thereby

minimizing distortion and enhancing

power factor correction.

PRODUCT HIGHLIGHT

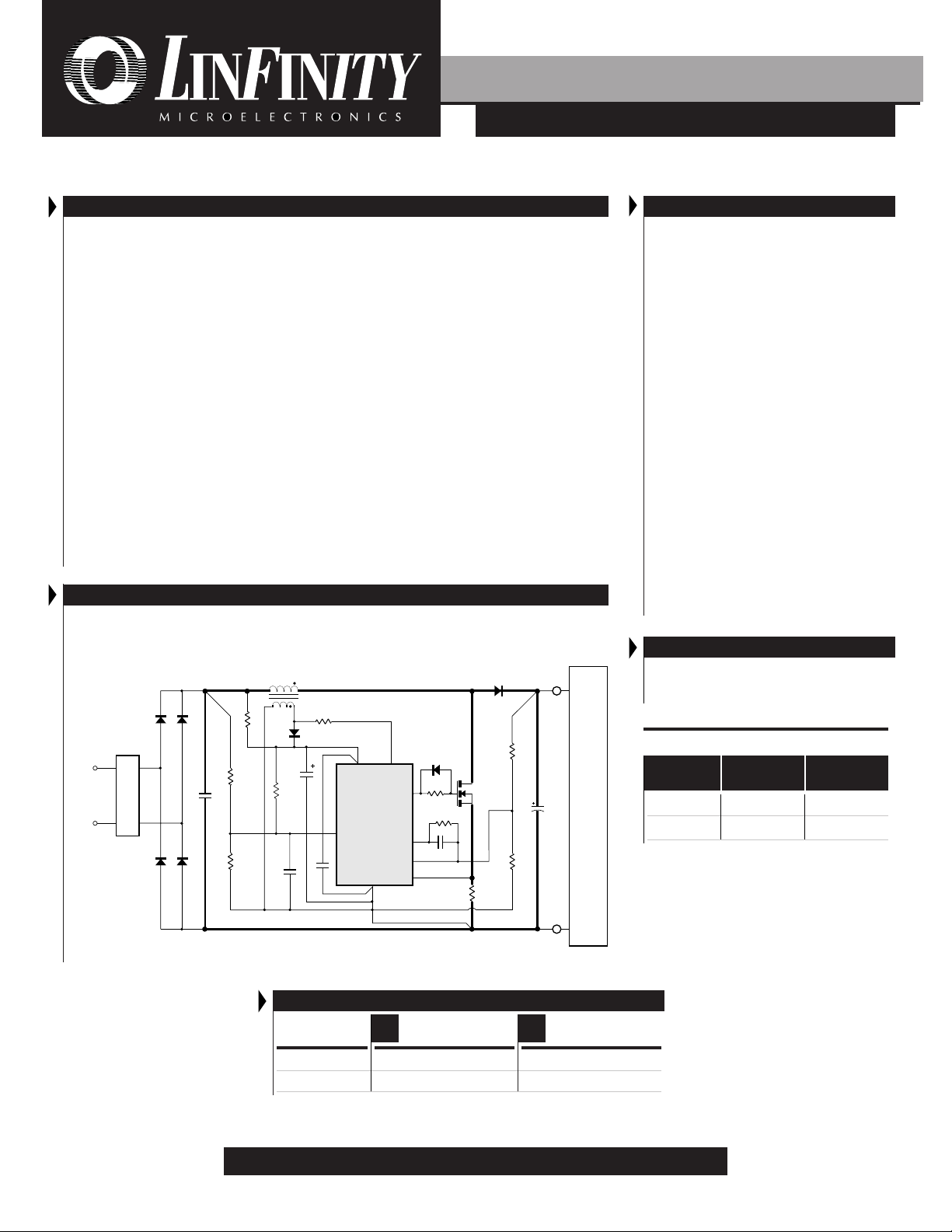

TYPICAL APPLICATION OF THE LX1562 IN AN 80W

F

LUORESCENT LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL

450µH

61T #22AWG

L1

AC-

C+

120V

AC

D1 D3

EMI FILTER

D2

1N4004

1N4004

1N4004

1N4004

100k

½W

R3

2.2M

R1

1%

1µF

C1

250V

D4

29k

R2

1%

C4

.01µF

7T

D5

22µF

R10

4.7M

1N4935

C2

C3

R4

22k

0.1µF

3

VINI

MULT

IN

8

DET

COMP

LX1562

GND

6

5

OUT

INV

C.S.

1N4148

7

2

1

4

D6

47

Ω

R5

R9 620k

C5

0.1µF

1/4W

P RODUCTION DATA SHEET

■■

■ INTERNAL START-UP CIRCUIT

■■

■■

■ INTERNAL CURRENT SENSE BLANKING

■■

■■

■ IMPROVED MICROPOWER START-UP

■■

CURRENT (300µA max.)

■■

■ CLAMPED E.A. OUTPUT FOR LOWER

■■

TURN-ON OVERSHOOT

■■

■ MULTIPLIER CLAMP LIMITS MAXIMUM

■■

INPUT CURRENT

■■

■ INTERNAL OVERVOLTAGE PROTECTION

■■

REPLACES BUILT-IN C.S. OFFSET

■■

■ PWM OUTPUT CLAMP LIMITS MOSFET

■■

GATE DRIVE VOLTAGE

■■

■ INCREASED UVLO HYSTERESIS REDUCES

■■

START-UP TIMING (LX1562 only)

■ LOW OPERATING CURRENT CONSUMPTION

■ INTERNAL 1.5% REFERENCE

■ TOTEM POLE OUTPUT STAGE

■ AUTOMATIC CURRENT LIMITING OF BOOST

STAGE

■ DISCONTINUOUS MODE OF OPERATION

WITH NO CURRENT GAPS

■ NO SLOPE COMPENSATION REQUIRED

APPLICATIONS

V

BOOST

MR854

230V

D7

1M

Ω

R7

1%

Q1

1RF730

11k

1%

3x

R6

1.3

Ω

C6

100µF

400V

R8

FLOURESCENT LAMP BALLAST

■■

■ ELECTRONIC BALLAST

■■

■ SWITCHING POWER SUPPLIES

A VAILABLE OPTIONS PER PART #

Part # Start-Up Hysteresis

LX1562 13.1V 5.2V

LX1563 9.8V 2.1V

Voltage Voltage

Note: Thick trace on schematic shows high-frequency, high-current path in circuit.

Lead lengths must be minimized to avoid high-frequency noise problems.

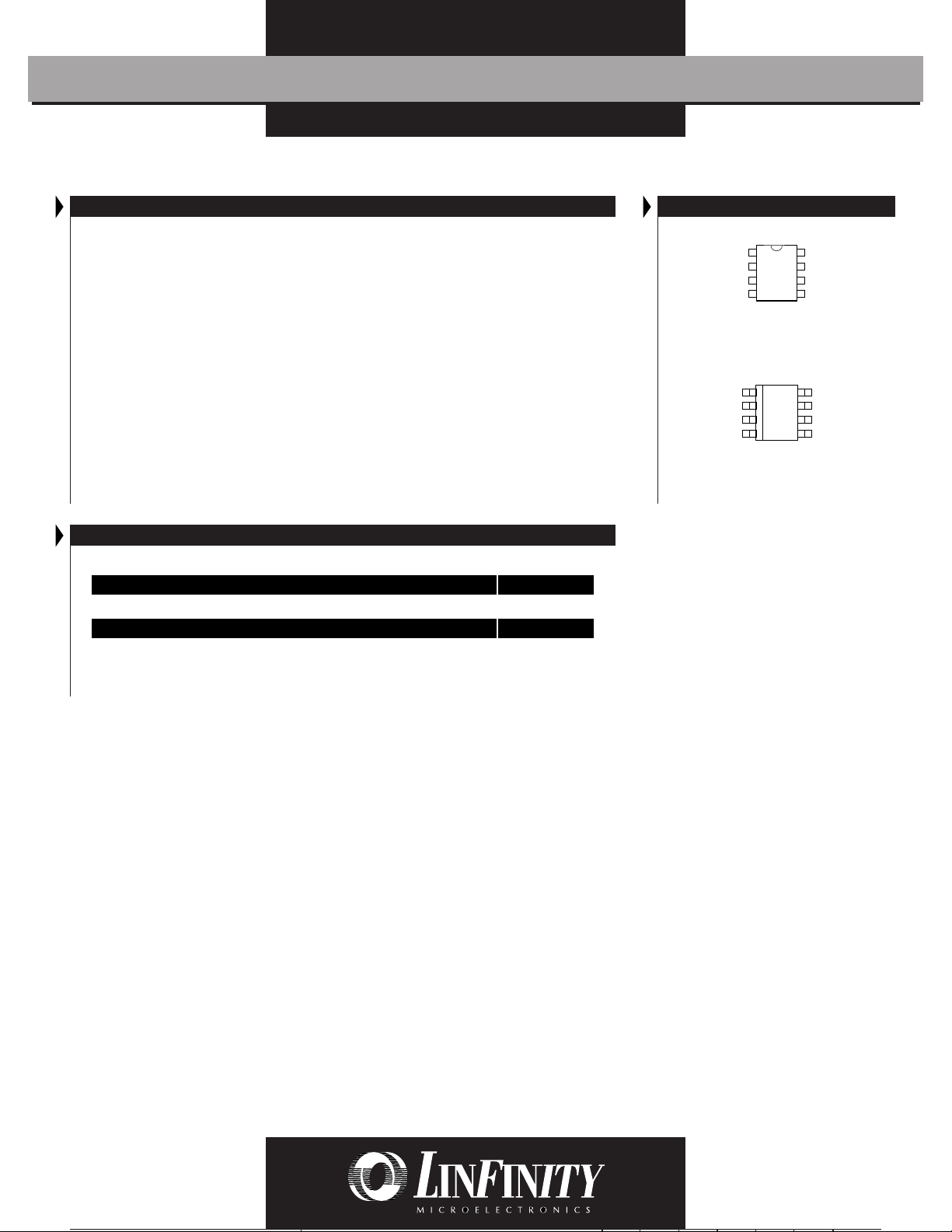

PACKAGE ORDER INFORMATION

T

(°C)

A

0 to 100 LX1562IM LX1562IDM

Plastic DIP

M

8-pin

Plastic SOIC

DM

8-pin

0 to 100 LX1563IM LX1563IDM

Note: All surface-mount packages are available in Tape & Reel.

Append the letter "T" to part number. (i.e. LX1562IDMT)

FOR FURTHER INFORMATION CALL (714) 898-8121

Copyright © 1996

Rev. 1.3 12/96

11861 WESTERN AVENUE, GARDEN GROVE, CA. 92841

1

Page 2

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

ABSOLUTE MAXIMUM RATINGS (Note 1)

Supply Voltage (VIN) ...................................................................................... -0.3V to 28V

Peak Driver Output Current (Note 3) ................................................................. ±500mA

Driver Output Clamping Diodes

V

> VCC or VO < -0.3V ........................................................................................ ±10mA

O

Detector Clamping Diodes

> 6V or V

V

DET

Error Amp, Multiplier, and Comparator Input Voltages ................................ -0.3V to 6V

< 0.9V ..................................................................................... ±10mA

DET

Detector Input Voltage (Note 2) ....................................................................... -0.3 to 6V

Operating Junction Temperature

Plastic (M and DM Packages) ............................................................................... 150°C

Storage Temperature Range ...................................................................... -65°C to 150°C

Lead Temperature (Soldering, 10 Seconds) ............................................................ 300°C

Note 1. Values beyond which damage may occur. All voltages are specified with respect to

ground, and all currents are positive into the specified terminal.

Note 2. With no limiting resistor.

Note 3. Current duty cycle is chosen such that T

is below 150°C.

J

THERMAL DATA

M PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

θθ

θ

θθ

JA

DM PACKAGE:

D

θθ

θ

θθ

x θ

JA

).

JA

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

Junction Temperature Calculation: TJ = TA + (P

numbers are guidelines for the thermal performance of the device/pc-board system.

The θ

JA

All of the above assume no ambient airflow

95°C/W

165°C/W

PACKAGE PIN OUTS

E.A. INV.

E.A. OUT

MULT. INPUT

E.A. INV.

E.A. OUT

MULT. INPUT

C.S.

1 8

27

36

45

C.S.

M PACKAGE

(Top View)

1 8

27

36

45

DM PACKAGE

(Top View)

V

OUT

GROUND

I

IN

DET

V

IN

OUT

GROUND

I

DET

2

Copyright © 1996

Rev. 1.3 12/96

Page 3

PRODUCT DATABOOK 1996/1997

LX1562/1563

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

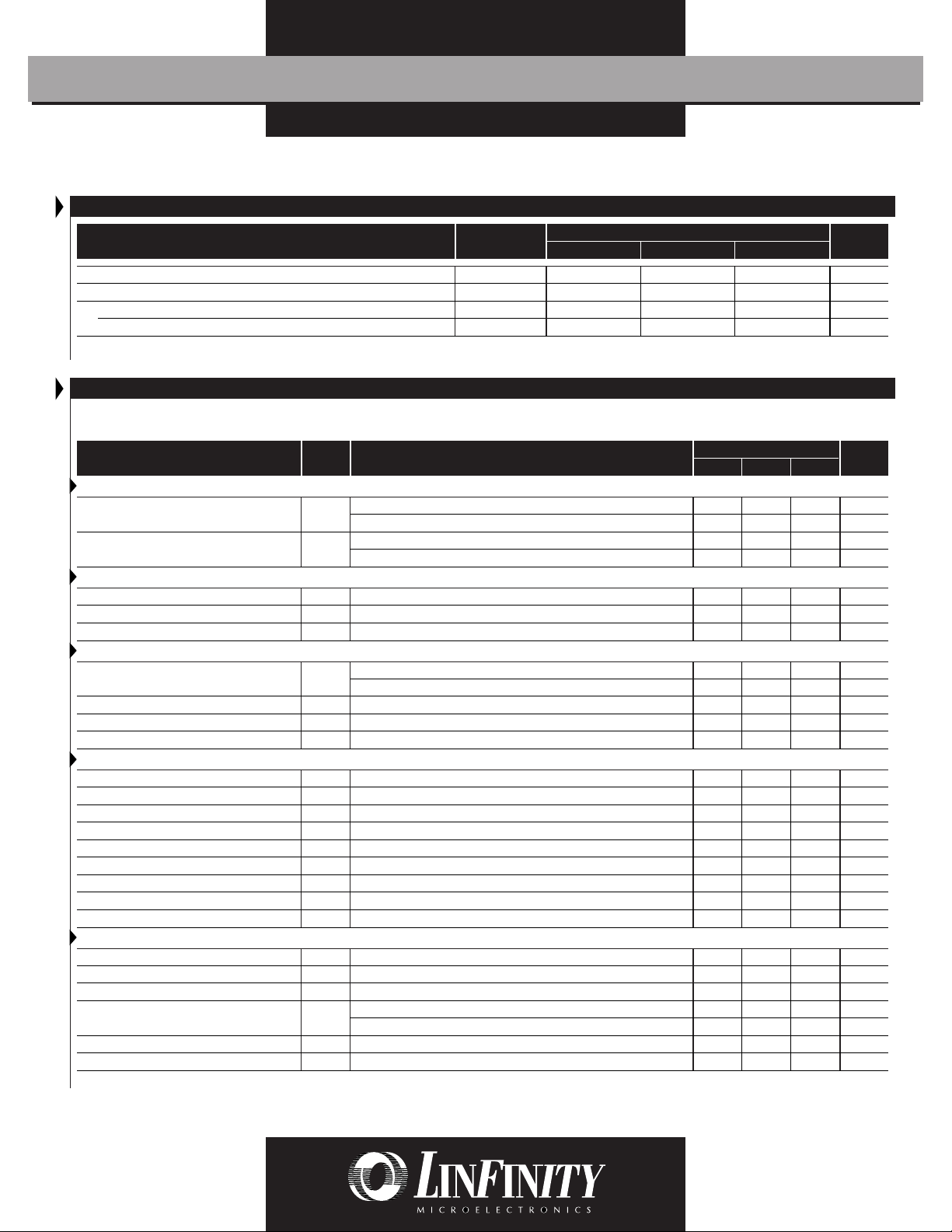

RECOMMENDED OPERATING CONDITIONS (Note 4)

Parameter

Symbol

Supply Voltage Range

Peak Driver Output Current

Operating Ambient Temperature Range:

LX1562/1563

Note 4. Range over which the device is functional.

ELECTRICAL CHARACTERISTICS

(Unless otherwise specified, these specifications apply over the operating ambient temperatures for the LX1562/1563 with 0°C ≤ TA ≤ 100°C; V

testing techniques are used which maintains junction and case temperatures equal to the ambient temperature.)

Parameter

Symbol

Test Conditions

Under-Voltage Lockout Section

Start Threshold Voltage V

UV Lockout Hysteresis ∆V

ST

H

LX1562 Only

LX1563 Only

LX1562 Only

LX1563 Only

Supply Current Section

Start-Up Supply Current I

Operating Supply Current I

Dynamic Operating Supply Current I

VIN < V

ST

Q

OP

TH

VIN = 12V, Output Not Switching

VIN = 12V, 50kHz, CGS = 1000pF

Reference Section (Note 5)

Initial Accuracy (Note 8) VRI

Line Regulation ∆V

Load Regulation ∆V

Temperature Stability ∆V

= 0mA, TA = 25°C

REF

= 0mA

I

REF

12V < VIN < 25V

I

0 < I

L

T

< 2mA

REF

Error Amplifier Section

Input Bias Current I

Large Signal Open Loop Voltage Gain A

Slew Rate S

Power Supply Rejection Ratio (Note 5) PSRR 11 to 25V

Output Source Current I

Output Sink Current I

Output Voltage Range (Note 7) E.A.

Unity Gain Bandwidth f

Phase Margin φ

B

(Note 5)

VOL

VOH = 3V

SR

VOL = 2V

SK

No Load on E.A. Output

O

B

B

Multiplier Section

Mult. Input Voltage Range V

M2 Input Voltage Range V

Mult. Input Bias Current (M1) I

Multiplier Gain (Note 5 & 6) K V

Multiplier Gain Temperature Stability ∆K

Maximum Multiplier Output Voltage V

M1

M2

MB

∆V

T

CLMPVM1

= 1V, ∆V

M1

M1

= 2V, V

EA0

= 0.5V to 1.5V, V

PIN1

= 2.7V to 3.3V

= V

EA0

= 0V

REF

+ 1V

(Electrical Characteristics continue next page.)

Recommended Operating Conditions

Min. Typ. Max.

11 25 V

±200 mA

0 100 °C

LX1562I/1563I

Min. Typ. Max.

12 13.1 14 V

9.2 9.8 10.6 V

4 5.2 6 V

1.7 2.1 2.5 V

2.465 2.50 2.535 V

2.44 2.56 V

-500 50 500 nA

60 80 dB

60 80 dB

-2 -4.5 mA

3 4.5 mA

1.2 3.8 V

02V

V

REF

0.55 0.68 0.8 V/V

0.55 0.61 0.75 V/V

1.1 1.24 1.45 V

Units

=12V. Low duty cycle pulse

IN

Units

200 300 µA

58mA

610mA

0.1 mV

1.3 mV

20 m V

0.63 V/µsec

1.7 MHz

49 °

V

+ 1 V

-0.24 µA

-0.2 %/°C

REF

2

2

Copyright © 1996

Rev. 1.3 12/96

3

Page 4

PRODUCT DATABOOK 1996/1997

LX1562/1563

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

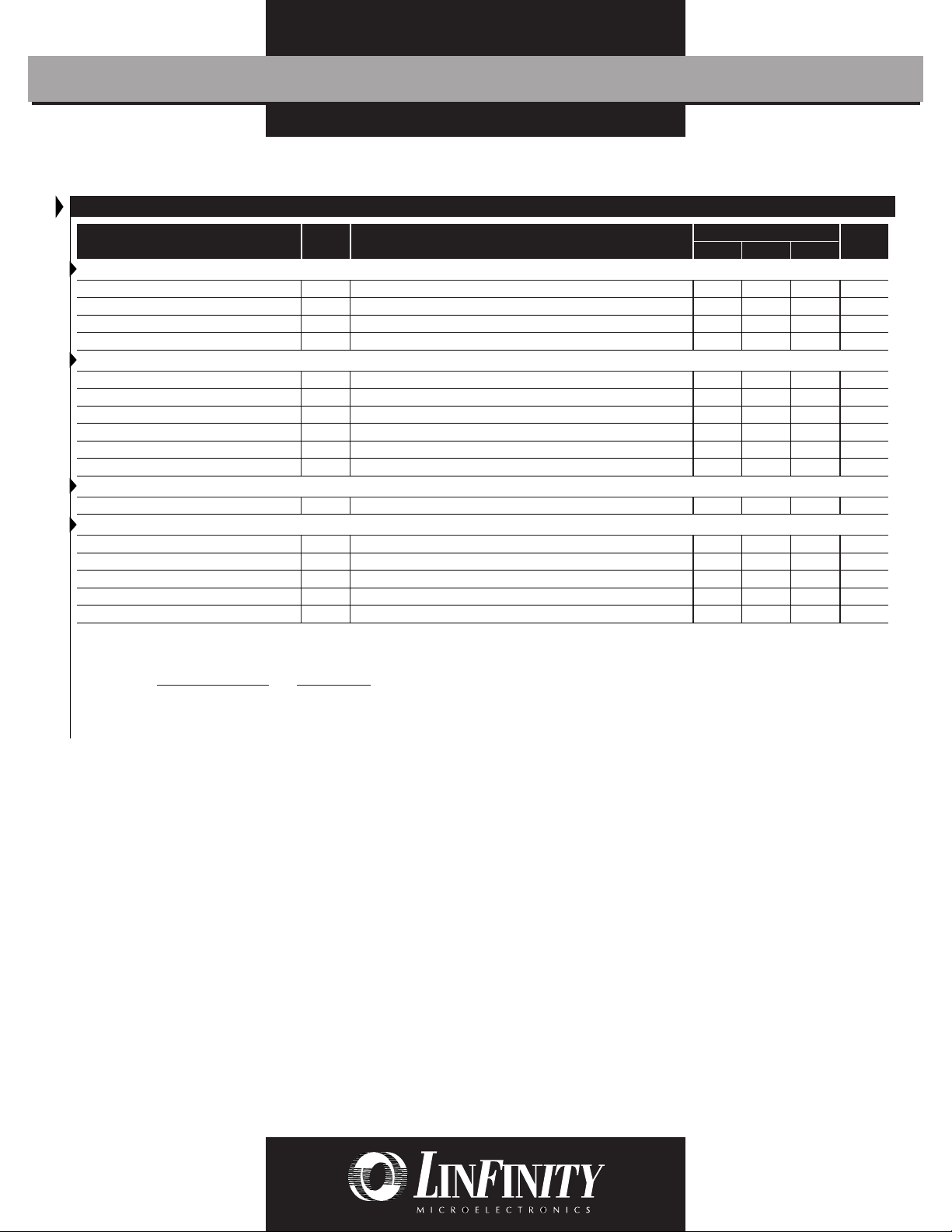

ELECTRICAL CHARACTERISTICS (Con't.)

Parameter

Symbol

Test Conditions

Current Sense Comparator Section

Input Bias Current I

Current Sense Delay to Output t

C.S. Blanking Time t

C.S. Input Offset Voltage V

0V ≤ VCS ≤ 1.7V

CSB

E.A.

d

BLK

OFFVEA0

= 3.7V, VCS = 0 to 1.2V, VM1 = 1V

OUT

= 2.2V, VM1 = 0V, I

DETC

= 0V

Detect Section

Input Voltage Threshold - High V

Hysteresis H

Input LO Clamp Voltage V

Input HI Clamp Voltage V

Input Current I

Input HI/LO Clamp Diode Current I

HI

D

DLIDET

DZIDET

1V ≤ V

DB

DMXVDET

= 100µA

= 3mA

≤ 6V

DET

< 0.9V, V

DET

> 6V

Restart Timer Section

Restart Time t

RST

Output Driver Section

Output High Voltage V

Output Low Voltage V

Output Rise Time t

Output Fall Time tfCL = 1000pF

Maximum Output Voltage V

Notes: 5. Because the reference is not brought out externally, these specifications are tested at probe only, and cannot be tested on the packaged part.

They are guaranteed by design, and shown for illustrative purposes only.

∆V

6. K = ≈

(∆V

) x (V

M1

C.S.

- V

)

EA0

REF

(V

M1

7. This parameter, although guaranteed, is not tested in production.

8. Initial accuracy includes input offset voltage of error amplifier.

= -10mA, VIN = 12V

PRHIL

= 10mA, VIN = 12V

PRLIL

CL = 1000pF

R

DRMXVIN

∆V

C.S.

) (∆V

)

EA0

= 20V

LX1562I/1563I

Min. Typ. Max.

-1 -0.3 1 µA

280 500 ns

0.4 0.9 1.2 µs

-20 3 20 mV

1.6 1.72 1.9 V

180 240 300 mV

0.4 0.62 0.85 V

7.0 7.8 8.6 V

-1 -0.2 1 µA

300 µsec

8.5 9 V

0.8 1 V

130 200 ns

50 120 ns

13 13.8 15 V

Units

±3 mA

4

Copyright © 1996

Rev. 1.3 12/96

Page 5

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

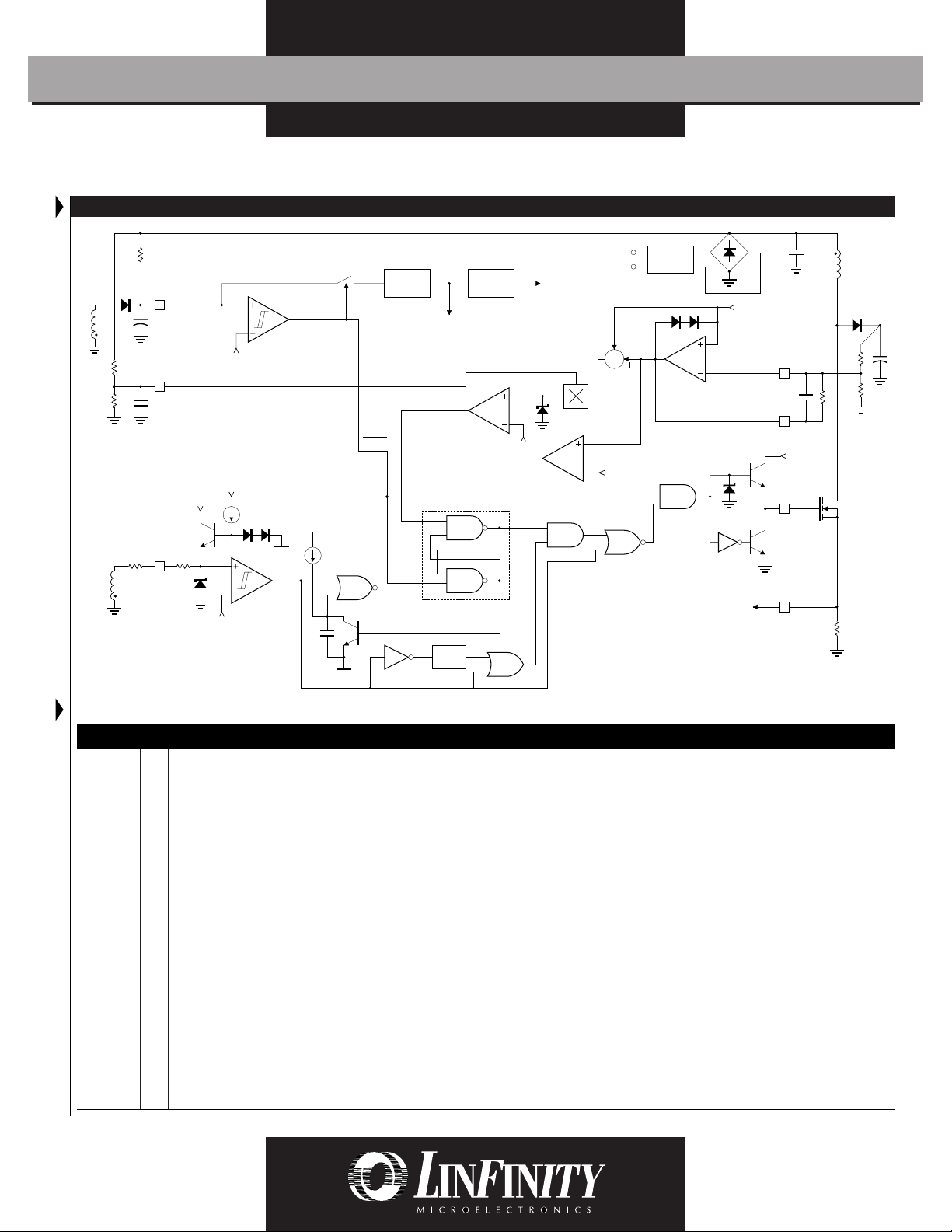

BLOCK DIAGRAM / PIN DESCRIPTIONS

LX1562/1563

E.A. INV.

1

2

E.A. OUT

V

OUT

7

C.S.

4

C1

L1

D1

IN

AC

Internal

V

IN

8

L1

300

13.1V (1562)

9.8V (1563)

Ω

1.72V

MULT

IN

3

I

DET

5

L1

5.2V (1562)

2.1V (1563)

V

REF

V

TIMER

Bias

6.8V To All

Internal Circuitry

UVLO

R

S

1µs

Delay

LATCH

2.5V

REF

Q

1.24V

C.S.

Q

M1

V

REF

Input

M2

1.8V

EMI

Filter

V

C.S.

REF

FUNCTIONAL DESCRIPTION

Pin # Description

V

GND 6

INV 1

E.A. OUT 2

MULT IN 3

C.S. 4

I

DET

OUT 7

8

IN

Input supply voltage.

Input supply voltage return. Must always be the lowest potential of all the pins.

Inverting input of the Error Amplifier. The output of the Boost converter should be resistively divided to 2.5V and

connected to this pin.

The output of the Error Amplifier. A feedback compensation network is placed between this pin and the INV pin.

Input to the multiplier stage. The full-wave rectified AC is divided to less than 2V and is connected to this pin.

Input to the PWM comparator. Current is sensed in the Boost stage MOSFET by a resistor in the source lead, and is

fed to this pin. An internal blanking circuit eliminates the RC low pass filter that otherwise is required to eliminate leading

edge spike.

5

A current driven logic input with internal clamp.

A second winding on the Boost inductor senses the flyback voltage associated with the zero crossing of the inductor

current and feeds it to the I

PWM output pin. A totem-pole output stage specially designed for direct driving the MOSFET.

pin through a limiting resistor. Low on this pin causes VO (pin 7) to go high.

DET

Copyright © 1996

Rev. 1.3 12/96

5

Page 6

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

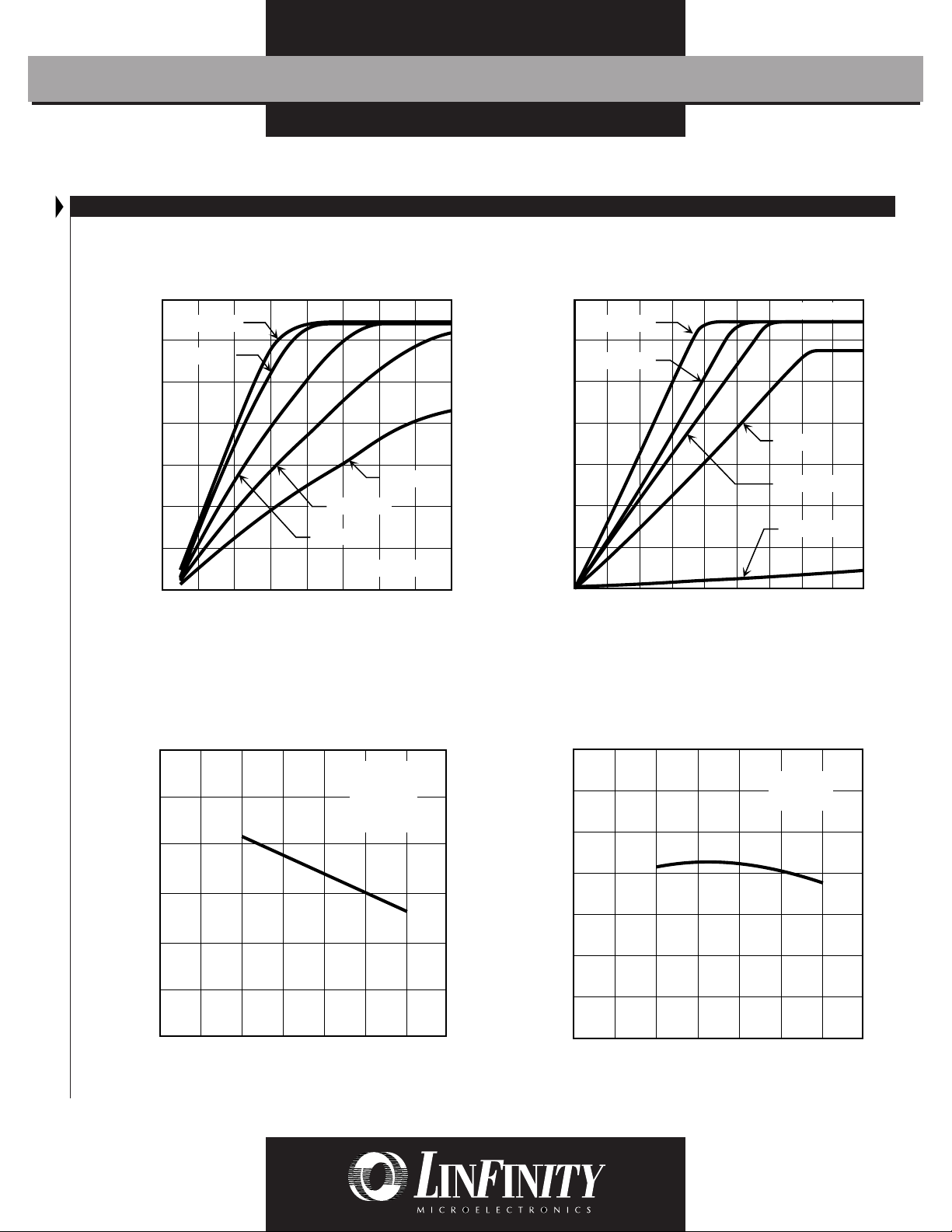

GRAPH / CURVE INDEX

Characteristic Curves

FIGURE #

1. E.A. OUTPUT VOLTAGE vs. C.S. THRESHOLD

2. MULTIPLIER INPUT VOLTAGE vs. C.S. THRESHOLD

=1V, V

3. MULTIPLIER GAIN (V

4. REFERENCE VOLTAGE (Including Offset) vs. TEMPERATURE

5. E.A. INPUT BIAS CURRENT vs. TEMPERATURE

6. E.A. SINK CURRENT @2V vs. TEMPERATURE

7. START-UP SUPPLY CURRENT vs. TEMPERATURE (LX1563)

8. START-UP SUPPLY CURRENT vs. TEMPERATURE (LX1562)

9. START-UP THRESHOLD vs. TEMPERATURE (LX1562)

10. START-UP THRESHOLD vs. TEMPERATURE (LX1563)

11. UV LOCKOUT HYSTERESIS vs. TEMPERATURE (LX1562)

12. UV LOCKOUT HYSTERESIS vs. TEMPERATURE (LX1563)

THRESHOLD HIGH vs. TEMPERATURE

13. I

DET

14. I

INPUT HYSTERESIS vs. TEMPERATURE

DET

15. RUN-AWAY COMPARATOR THRESHOLD vs. TEMPERATURE

16. C.S. DELAY TO OUTPUT vs. TEMPERATURE

17. C.S. BLANKING TIME vs. TEMPERATURE

18. RESTART TIME vs. TEMPERATURE

19. FALL TIME vs. TEMPERATURE

20. RISE TIME vs. TEMPERATURE

21. SUPPLY CURRENT vs. SUPPLY VOLTAGE (LX1562)

22. SUPPLY CURRENT vs. SUPPLY VOLTAGE (LX1563)

22a. MAXIMUM MULTIPLIER OUTPUT VOLTAGE vs. TEMPERATURE

M1

=3.5V) vs. TEMPERATURE

EA0

FIGURE INDEX

IC Description

FIGURE #

23. INDUCT CURRENT

24. TYPICAL APPLICATION OF START-UP CIRCUITRY

25. START-UP CAPACITOR VOLTAGE

26. VOLTAGE REFERENCE vs. TEMPERATURE

27. THE AMPLIFIER CONFIGURED AS AN INTEGRATOR FOR LOOP

COMPENSATION

28. MULTIPLIER SECTION

29. CURRENT SENSE SECTION

30. START-UP TIMER

Application Information

FIGURE #

31. TYPICAL APPLICATION OF THE LX1562 IN AN 80W FLUORESCENT

LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL

32. NORMALIZED OPERATING FREQUENCY vs. OFF-TIME DUTY CYCLE

33. INDUCT CURRENT

34. LOAD TRANSIENT RESPONSE CIRCUIT

35. FLYBACK VOLTAGE ACROSS I

WINDING

DET

Typical Applications

FIGURE #

36. TYPICAL APPLICATION OF THE LX1562 IN AN 80W FLUORESCENT

LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL - 120V

37. TYPICAL APPLICATION OF THE LX1562 IN AN 80W FLUORESCENT

LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL - 220V

38. TYPICAL APPLICATION OF THE LX1562 IN AN 80W FLUORESCENT

LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL - 277V

6

Copyright © 1996

Rev. 1.3 12/96

Page 7

PRODUCT DATABOOK 1996/1997

2.47

2.45

(TA) Ambient Temperature - (°C)

2.52

(V

R

) Reference Voltage - (V)

2.48

-50

-25 0

25

50 75 100 125

VCC = 12V

C

L

= 1nF

2.46

2.49

2.50

2.51

)

4

)

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

CHARACTERISTIC CURVES

LX1562/1563

FIGURE 1. — E.A. OUTPUT VOLTAGE vs. C.S. THRESHOLD

1.4

VM1 = 3V

1.2

VM1 = 2.5V

1.0

0.8

0.6

C.S. Threshold - (V)

0.4

0.2

VM1 = 1.5V

VM1 = 2V

VM1 = 1V

TA = 25°C

0

2.6

2.4 2.8

3.233.43.6

3.8

E.A. Output Voltage - (V

FIGURE 3. — MULTIPLIER GAIN (V

vs. TEMPERATURE

=1V, V

M1

EA0

=3.5V)

FIGURE 2. —

1.4

1.2

1.0

0.8

0.6

0.4

C.S. Threshold Voltage - (V)

0.2

0

MULTIPLIER INPUT VOLTAGE vs. C.S. THRESHOLD

V

= 4V

EA0

V

= 3.5V

EA0

0.4

00.8

1.61.2 2 2.4

TA = 25°C

V

= 3V

EA0

V

= 3.25V

EA0

V

EA0

Multiplier Input Voltage - (V

FIGURE 4. — REFERENCE VOLTAGE (Including Offset)

vs. TEMPERATURE

= 2.5V

3.2

3.62.8

0.80

0.75

0.70

0.65

0.60

(K) Multiplier Gain - (1/V)

0.55

0.50

-50

Copyright © 1996

Rev. 1.3 12/96

-25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

VCC = 12V

= 1nF

C

L

V

= 3.5V

EA0

V

= 1V

M1

7

Page 8

LX1562/1563

100.0

0.0

(TA) Ambient Temperature - (°C)

350.0

(I

ST

) Start-up Supply Current - (µA)

150.0

-50

-25 0

25

50 75 100 125

VIN < V

TH

CL = 1nF

50.0

200.0

250.0

300.0

LX1562

4.0

3.0

(TA) Ambient Temperature - (°C)

6.0

(I

SK

) E.A. Sink Current @2V - (mA)

4.5

-50

-25 0

25

50 75 100 125

VCC = 12V

C

L

= 1nF

V

EA0

= 2V

3.5

5.0

5.5

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

CHARACTERISTIC CURVES

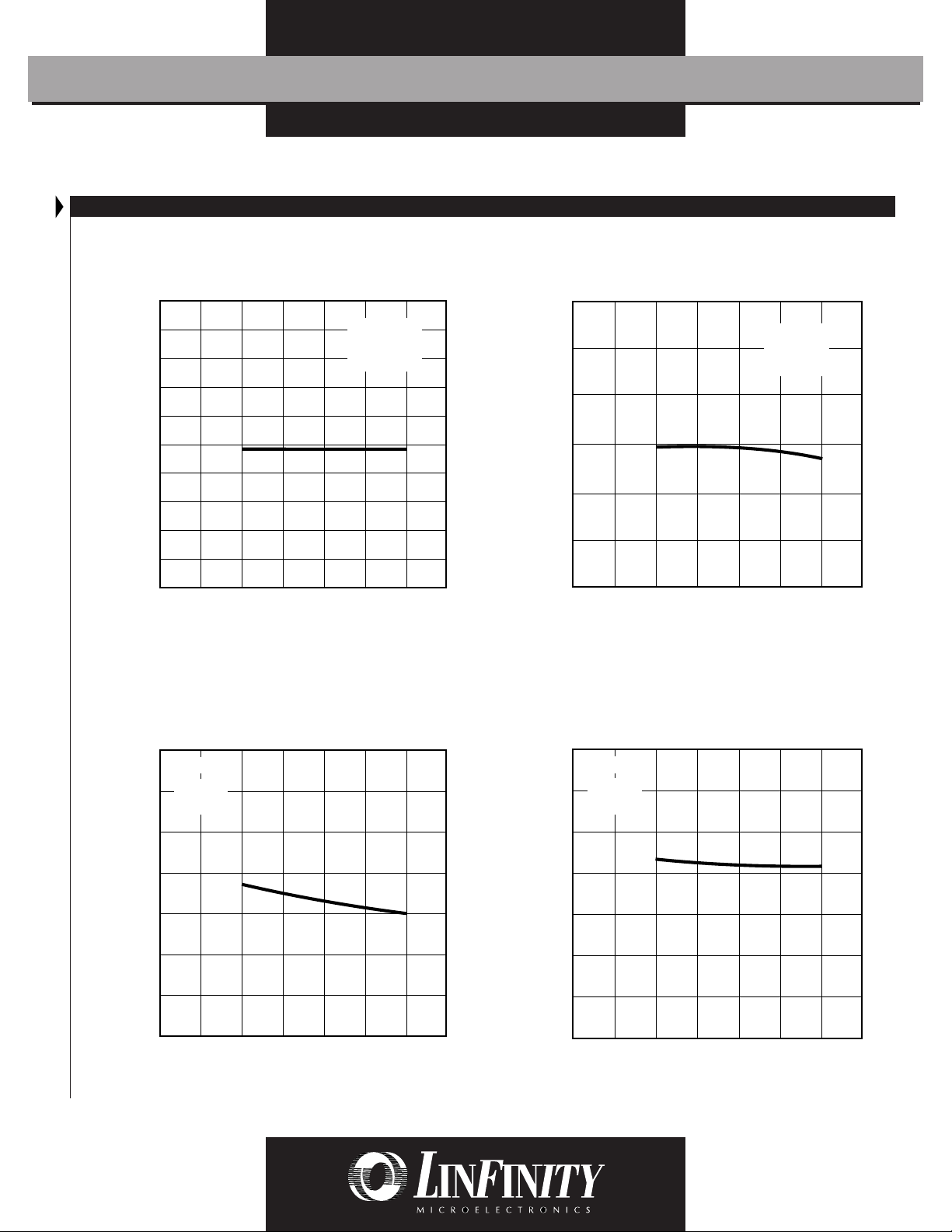

FIGURE 5. — E.A. INPUT BIAS CURRENT vs. TEMPERATURE

0.5

0.4

0.3

0.2

0.1

0.0

-0.1

-0.2

) E.A. Input Bias Current - (µA)

-0.3

B

(I

-0.4

-0.5

-50

-25 0

25

VCC = 12V

C

= 1nF

L

E.A.- = 2.5V

50 75 100 125

FIGURE 6. —

E.A. SINK CURRENT @2V vs. TEMPERATURE

(TA) Ambient Temperature - (°C)

FIGURE 7. — START-UP SUPPLY CURRENT vs. TEMPERATURE FIGURE 8. — START-UP SUPPLY CURRENT vs. TEMPERATURE

350.0

LX1563

0.0

-50

VIN < V

CL = 1nF

-25 0

(TA) Ambient Temperature - (°C)

300.0

250.0

200.0

150.0

8

100.0

) Start-up Supply Current - (µA)

ST

50.0

(I

TH

25

50 75 100 125

Copyright © 1996

Rev. 1.3 12/96

Page 9

PRODUCT DATABOOK 1996/1997

9.60

9.40

(TA) Ambient Temperature - (°C)

(V

ST

) Start-up Threshold

-50 -25 0

25

50 75 100 125

9.50

LX1563

9.70

9.80

9.90

10.00

10.10

10.20

VCC = 0V to 16V

C

L

= 1nF

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

CHARACTERISTIC CURVES

LX1562/1563

FIGURE 9. — START-UP THRESHOLD vs. TEMPERATURE

14.0

FIGURE 10. —

START-UP THRESHOLD vs. TEMPERATURE

LX1562

13.5

13.0

12.5

12.0

) Start-up Threshold - (V)

ST

(V

11.5

11.0

-50

-25 0

25

VCC = 0V to 16V

= 1nF

C

L

50 75 100 125

(TA) Ambient Temperature - (°C)

FIGURE 11. — UV LOCKOUT HYSTERESIS vs. TEMPERATURE FIGURE 12. — UV LOCKOUT HYSTERESIS vs. TEMPERATURE

Copyright © 1996

Rev. 1.3 12/96

) UV Lockout Hysteresis - (V)

H

V

∆

(

6.0

5.5

5.0

4.5

4.0

3.5

3.0

-50

LX1562

-25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

2.50

2.40

2.30

2.20

2.10

2.00

1.90

1.80

) UV Lockout Hysteresis - (V)

H

1.70

V

∆

(

1.60

1.50

LX1563

-50 -25 0

25

(TA) Ambient Temperature - (°C)

50 75 100 125

9

Page 10

LX1562/1563

250

150

(TA) Ambient Temperature - (°C)

500

(t

d

) C.S. Delay to Output - (ns)

300

-50

-25 0

25

50 75 100 125

VCC = 12V, CL = 1nF

V

M1

= 1V, V

EA0

= 3.7V

V

CS

= 0V to 1.2V

200

350

400

450

100

0

(TA) Ambient Temperature - (°C)

(H

D

) I

DET

Input Hysteresis - (mV)

-50 -25 0

25

50 75 100 125

50

150

200

250

300

350

400

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

CHARACTERISTIC CURVES

FIGURE 13. — I

1.90

1.85

1.80

1.75

1.70

Threshold High - (V)

1.65

DET

) I

1.60

HI

THRESHOLD HIGH vs. TEMPERATURE

DET

(V

1.55

1.50

-50 -25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

FIGURE 15. — RUN-AWAY COMPARATOR THRESHOLD

vs. TEMPERATURE

FIGURE 14. —

I

INPUT HYSTERESIS vs. TEMPERATURE

DET

FIGURE 16. — C.S. DELAY TO OUTPUT vs. TEMPERATURE

2.8

2.6

2.4

2.2

10

2.0

1.8

1.6

Run-Away Comp. Threshold

1.4

1.2

-50 -25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

Copyright © 1996

Rev. 1.3 12/96

Page 11

PRODUCT DATABOOK 1996/1997

80

40

(TA) Ambient Temperature - (°C)

(t

R

) Rise Time - (ns)

-50 -25 0

25

50 75 100 125

60

100

120

140

160

180

200

VCC = 12V

C

L

= 2200pF

200

0

(TA) Ambient Temperature - (°C)

600

(t

RST

) Restart Time - (µs)

300

-50

-25 0

25

50 75 100 125

VCC = 12V

C.S. = Pulse

100

400

500

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

CHARACTERISTIC CURVES

LX1562/1563

FIGURE 17. — C.S. BLANKING TIME vs. TEMPERATURE

1000

900

800

700

600

500

) C.S. Blanking Time - (ns)

BLK

(t

400

300

-50

-25 0

25

50 75 100 125

FIGURE 18. —

RESTART TIME vs. TEMPERATURE

(TA) Ambient Temperature - (°C)

FIGURE 19. — FALL TIME vs. TEMPERATURE FIGURE 20. — RISE TIME vs. TEMPERATURE

Copyright © 1996

Rev. 1.3 12/96

) Fall Time - (ns)

F

(t

90

80

70

60

50

40

30

20

-50

VCC = 12V, CL = 2200pF

-25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

11

Page 12

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

CHARACTERISTIC CURVES

FIGURE 21. — SUPPLY CURRENT vs. SUPPLY VOLTAGE

14

LX1562

12

10

8

6

4

) Supply Current - (mA)

CC

(I

2

0

01020

30

TA = 25°C

= 0V

V

CS

V

= 0V

M1

V

= V

PIN2

PIN1

40 50 60

(VCC) Supply Voltage - (V)

FIGURE 22a. — MAXIMUM MULTIPLIER OUTPUT vs. TEMPERATURE

FIGURE 22. —

14

SUPPLY CURRENT vs. SUPPLY VOLTAGE

LX1563

12

10

8

6

4

) Supply Current - (mA)

CC

(I

2

0

01020

(VCC) Supply Voltage - (V)

30

TA = 25°C

= 0V

V

CS

V

= 0V

M1

V

= V

PIN2

PIN1

40 50 60

12

1.45

VCC = 12V, CL = 1nF

1.40

1.35

1.30

1.25

1.20

1.15

1.10

) Maximum Mult. Output Voltage - (V)

1.05

CLMP

(V

1.00

= 0V, VM1 = 2V, VCS = 0-2V

V

PIN1

-50

-25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

Copyright © 1996

Rev. 1.3 12/96

Page 13

PRODUCT DATABOOK 1996/1997

Rectified

AC Line

GND

LX1562

GND

V

O

V

IN

IST < 300µA

I

1

> 300µA

C1

R1

R

S

D1

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

FUNCTIONAL DESCRIPTION

LX1562/1563

The operation of the IC is best described by referring to the

block-diagram. The output of the multiplier stage generates a

voltage proportional to the product of the rectified AC line and

the output of the error amplifier. This voltage serves as the

reference for the inductor peak current that is sensed by the

resistor in series with the external power MOSFET. When the

sense voltage exceeds this threshold, C.S. comparator trips and

resets the latch as well as turning the power MOSFET off.

The energy stored during switch on-time is now transferred

and stored in the output capacitor, causing the inductor current

Inductor Peak

Current Envelope

Average

AC Input Current

FIGURE 23 — INDUCTOR CURRENT

TONT

UNDERVOLTAGE LOCK OUT

The LX1562/63 undervoltage lock-out is designed to maintain

an ultra low quiescent current of less than 300µA, while guaranteeing the IC is fully functional before the output stage is

activated. Comparing this to the SG3561A device, a 40% reduction in start-up current is achieved, resulting in 40% less power

dissipation in the start-up resistor. This is especially important

in electronic ballast applications that are designed to operate in

harsh environments, with convection cooling as the only means

of heat dissipation.

Figure 24 shows an efficient supply voltage using the ultra

low start-up current of the LX1562 in conjunction with a bootstrap winding off of the power transformer. Circuit operation

is as follows:

The start-up capacitor (C1) is charged by current through

resistor (R1) minus the start-up current drawn by the IC. This

resistor is typically chosen to provide 2X the maximum start-up

current at low line to guarantee start-up under the worst case

condition. Once the capacitor voltage reaches the start-up

threshold, the IC turns on, starting the switching cycle. The

operation of the IC demands an increase in operating current

which results in discharging the capacitor. During the discharge

cycle, the flyback voltage of the auxiliary winding is rectified

and filtered via rectifier (D1) and charges the capacitor above

the minimum operating voltage of the device and takes over as

the supply voltage. The start-up capacitor and auxiliary winding must be selected such that it satisfies worst case IC conditions. Figure 25 shows start-up time and voltage of capacitor C1.

to ramp down. When current reaches zero level (inductor runs

out of energy) , boost diode (D1) stops conducting and the

residual inductor energy and the drain to source capacitance of

the power MOSFET create an LC tank circuit which causes drain

voltage to resonate at this frequency. The resonating voltage is

detected by the secondary winding (Idet winding) of the inductor. When this voltage swings negative “I detect” pin senses

it and activates the blanking circuit , sets the latch, and turns

power MOSFET on, repeating the cycle. This operation continues for the entire cycle of the AC rectified input resulting in an

inductor current as shown in Figure 23. The high frequency

I

L

content of this current is then filtered by the input capacitor

(C1) resulting in a sine wave input current in phase with the

AC line voltage.

Output voltage regulation is accomplished when the error

amplifier compares this voltage to an internal 2.5V reference

and generates an error voltage. This voltage then controls the

amplitude of the multiplier output adjusting the peak inductor

current proportional to the load and line variations, maintain-

OFF

ing a well regulated voltage.

IC DESCRIPTION

Table 1 shows the start-up voltage and hysteresis for LX1562

and LX1563. The LX1562 is used for stand alone pre-regulator

applications while LX1563 is ideal for applications where supply voltage is derived elsewhere and requires less than 14V

start-up.

FIGURE 24 — TYPICAL APPLICATION OF START-UP CIRCUITRY

T ABLE 1

Part # Start-Up Hysteresis

Voltage Voltage

LX1562 13.1V 5.2V

LX1563 9.8V 2.1V

Copyright © 1996

Rev. 1.3 12/96

13

Page 14

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

IC DESCRIPTION

VOLTAGE REFERENCE (continued)

V

C1

V

START

V

HYST

RT & CT TIME CONSTANT

FIGURE 25 — START-UP CAPACITOR VOLTAGE

C1

DISCHARGE

DISCHARGE

TIME

BOOTSTRAP

WINDING

VOLTAGE REFERENCE

The voltage reference is a low drift bandgap design which provides a stable +2.5V output with maximum of ±1.5% initial accuracy. This voltage is internally tied to the non-inverting input of the amplifier and is not available for external connection. The initial accuracy of the reference includes error amplifier input offset voltage. Figure 26 shows typical variation of

the reference voltage vs. temperature.

2.52

2.51

2.50

VCC = 12V

= 1nF

C

L

ERROR AMPLIFIER

The error amplifier is an internally compensated op-amp with

access to the inverting input and the output pin. The noninverting input is internally connected to the voltage reference

and is not available for external connection. The amplifier is

designed for an open loop gain of 80dB, along with a typical

bandwidth of 1.7MHz and 49 degrees of phase margin. The

boost output voltage of the power factor pre-regulator is divided down and monitored by the inverting input. Input bias

current (0.5µA max) can cause an output voltage error that is

equal to the product of the input bias current and the value of

the upper divider resistor. The amplifier's output is available

for external loop compensation. Typically, the loop bandwidth

is set below 10Hz in order to reject the low frequency ripple

associated with 2X the line frequency. For example, if the

t

error amplifier is configured as an integrator with 1.2Hz bandwidth, it will have 40dB ripple rejection at 120Hz frequency.

This means that if the output of the error amp is allowed to

have 100mV of ripple, the boost converter must be limited to

less than 10V of ripple on its output.

To prevent boost output run away condition that may occur

during removal of the output load, a separate comparator monitors the E.A. output voltage and compares it to an internal 1.8V

reference. When load is removed, E.A. output swings lower

than 1.8V, trips the comparator and turns output driver off till

the inverting input voltage drops below 2.5V. At this point, the

E.A. output swings positive, turns the output driver back on

and repeats the cycle until the load is returned to normal condition.

To reduce output overshoot during line and load transients,

the E.A. output is clamped to two diode drops above the reference voltage. This prohibits the amplifier from being saturated, allowing it to recover faster thus minimizing the boost

voltage overshoot.

2.49

2.48

2.47

) Reference Voltage - (V)

R

(V

2.46

2.45

-50

-25 0

25

50 75 100 125

(TA) Ambient Temperature - (°C)

FIGURE 26 — REFERENCE VOLTAGE (Including Offset) vs. TEMPERATURE

14

V

R10

O

R9

I

9

1

Bias

V

C4

REF

1.8V

From I

BW =

I9 >> I

2

Logic

DET

1

π

R9 C4

2

BIAS

2f

f = Line Freq.

FIGURE 27 — THE AMPLIFIER CONFIGURED AS AN INTEGRATOR

FOR LOOP COMPENSATION

OUTPUT

7

DRIVE

Copyright © 1996

Rev. 1.3 12/96

Page 15

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

IC DESCRIPTION

MULTIPLIER

The LX1562/63 features a one quadrant multiplier stage having

two inputs. One (VM2) is internally driven by a DC voltage

which is the difference of E.A. output and V

is connected to an external resistor divider monitoring the rectified AC line. The output of the multiplier which is a function

of both inputs, controls inductor peak current during each cycle

of operation. This allows the inductor peak current to follow

the AC line thus forcing the average input current to be sinusoidal.

The multiplier is in the linear region if the V

to less than 2V and the E.A. output is kept below 3.5V under all

line and load conditions. The output is internally clamped to

1.24V typically to limit the MOSFET peak current during turn on

or under excessive load conditions. The equation below describes the relationship between multiplier output voltage and

the its inputs.

V

= K * V

M0

M1

*

(V

EA0

- V

REF

)

where: K = Multiplier gain (typ. 0.65)

V

= Voltage at pin3 (0 to 2V)

M1

V

= Error amp output voltage (2.5 to 3.5V)

EA0

= Multiplier output voltage

V

M0

E.A.

OUTPUT

2

V

EA

Σ

V

INV.

INPUT

AC

R1

R2

1

V

REF

2.5V

V

3

M1

FIGURE 28 — MULTIPLIER SECTION

CURRENT SENSE COMPARATOR

Current sense comparator is configured as a PNP input differential stage with one input internally tied to the multiplier output and the other available for current sensing. Current is converted to voltage using an external sense resistor in series with

the external power MOSFET. When sense voltage exceeds the

threshold set by the multiplier output, the current sense comparator terminates the gate drive to the MOSFET and resets the

PWM latch. The latch insures that the output remains in a low

state after the switch current falls back to zero. The LX1562/63

features a leading edge blanking circuit that eliminates the need

. The other (VM1),

REF

input is limited

M1

MULT.

OUTPUT

V

V

M2

M0

C.S.

INPUT

4

LX1562/1563

for an external RC filter otherwise required for proper operation of the circuit. This function is described in detail under

“current detect logic” section.

The current sense comparator voltage is limited by an internal 1.24V (typ.) voltage clamp of the multiplier output. Therefore maximum switch current is typically given by:

I

= 1.24V / R

PK (MAX)

Maximum switch peak current happens at full load and minimum line conditions.

TO

PIN 7

3

R

S

V

M0

5

FIGURE 29 — CURRENT SENSE SECTION

CURRENT DETECT LOGIC

The function of “current detect logic” is to sense the operating

state of the boost inductor and to enable the output driver

accordingly. To achieve this, the downward slope of the inductor current is indirectly detected by monitoring the voltage

across a separate winding and connecting it to the detector

input “I

level, the voltage across the winding reverses polarity and

changes the “I

state (See Figure 30). When comparator changes state, it sets

” pin. Once the inductor current reaches ground

DET

” input and the comparator output to the low

DET

the latch and turns on the output driver for a period of 1µs

(typ.) regardless of any changes in the latch output (Q) within

this period. This ensures that if the C.S. comparator changes

state due to any turn-on spike, the driver output remains on

and does not turn off prematurely.

However if the spike lasts longer than 1µs, the output driver

turns off and the MOSFET stops conducting. This type of digital current sense blanking which is not amplitude dependent

has higher noise immunity than the commonly used external

RC filtering, allowing for more flexibility in board layout.

Since inductor voltage swings both positive and negative,

internal voltage clamping is provided to protect the IC. The

S

Logic

Circuit

R

1µsec

Blank

7

Copyright © 1996

Rev. 1.3 12/96

15

Page 16

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

IC DESCRIPTION

CURRENT DETECT LOGIC (continued)

upper 7.8V clamp prevents input overvoltage breakdown dur-

switch off time, while during the on time the lower 0.7V

ing

clamp prevents substrate injection. An internal current limit

resistor protects the lower clamp transistor in case the “I

is accidently shorted to ground.

DET

” pin

START-UP TIMER

A start-up timer circuit eliminates the need for an external oscillator when used in stand alone applications. The timer, as

shown in Figure 30, provides a means to automatically start the

pre converter if the latch output Q comes up in a wrong (HI)

state. The timer capacitor ramps up and resets the latch to a

low state, turning the output driver on.

V

REF

I

DEF

300

Ω

5

L1

V

1.72V

TIMER

C.S.

C.S. Latch

OUTPUT DRIVER STAGE

The LX1562/63 output driver is designed for direct driving of

an external power MOSFET. It is a totem pole stage with

±500mA peak current capability. This typically results in a

130ns rise and fall times into a 1000pF capacitive load. Additionally the output is held low during the undervoltage condition to ensure that the MOSFET remains in the off state until

supply voltage reaches the start-up threshold.

Internal voltage clamping ensures that output driver is always lower than 13.8V (typ.) when supply voltage variation

exceeds more than rated V

nal MOSFET. This eliminates an external zener diode and extra

threshold (typ 20V) of the exter-

GS

power dissipation associated with it that otherwise is required

for reliable circuit operation.

HI

C.S.

V

M0

S

1µs

Delay

R

Q

Q

L1

OUT

7

C.S.

4

16

FIGURE 30 — START-UP TIMER & CURRENT DETECT LOGIC CIRCUITRY

Copyright © 1996

Rev. 1.3 12/96

Page 17

PRODUCT DATABOOK 1996/1997

A

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

APPLICATION INFORMATION

TYPICAL APPLICATION

The application circuit shown in Figure 31 uses the LX1562 as the

controller to implement a boost type power factor regulator. The

I.C. controls the regulator, such that the inductor current is always

operating in a discontinuous conduction mode with no current

gaps. This mode of operation has several advantages over the

fixed frequency discontinuous conduction mode: 1) The switching frequency adjusts itself to the AC line envelope, causing a

sinusoidal current draw, 2) Since there is no current gap between

the switching cycles, the inductor voltage does not oscillate,

causing less radiated noise, 3) The lower peak inductor current

causes less power dissipation in the power MOSFET.

LX1562/1563

A set of formulas have been derived specifically for this mode,

and are used throughout the design procedure. An example with

the following specifications for the boost converter is given as:

Input Voltage Range - 100 to 130V RMS

Output Power - 80W

Efficiency - 95% at full load

Power Factor - > 0.99 at full load

Total Harmonic Distortion - < 10% at full load

followed by a step by step design procedure which walks through

component selection.

AC-

C+

120V

AC

450µH

61T #22AWG

L1

100k

D1 D3

1N4004

1N4004

EMI FILTER

D2

C1

D4

1N4004

1N4004

Note: Thick trace on schematic shows high-frequency, high-current path in circuit.

FIGURE 31 — TYPICAL APPLICATION OF THE LX1562 IN AN 80W FLUORESCENT LAMP

½W

2.2M

R1

1%

1µF

250V

29k

R2

1%

Lead lengths must be minimized to avoid high-frequency noise problems.

7T

R3

D5

R10

4.7M

C4

.01µF

BALLAST WITH ACTIVE POWER FACTOR CONTROL

C2

22µF

R4

22k

1N4935

C3

0.1µF

8

V

IN

MULT

IN

3

LX1562

GND

6

I

DET

OUT

COMP

INV

C.S.

1N4148

47

7

R5

R9 620k

2

1

4

D6

5

Ω

C5

0.1µF

1/4W

3x

MR854

1M

Q1

1RF730

R6

1.3

Ω

D7

1%

11k

1%

V

BOOST

230V

Ω

R7

C6

100µF

400V

R8

FLOURESCENT LAMP BALLAST

OUTPUT VOLTAGE REQUIREMENT

Since the converter is a boost type topology, it requires the output

voltage to always be higher than the input voltage. It is

recommended to select this voltage at least 15% higher than the

maximum input voltage in order to: A) Avoid the inductor

saturation during line transience, and B) To keep the operating

frequency above the audible range at high line.

Figure 32 (next page) shows that when boost voltage is

selected near the maximum AC line, the increase in off-time could

reduce the operating frequency below the audible frequency and

cause inductor humming. In fact, Figure 32 (next page) shows

Copyright © 1996

Rev. 1.3 12/96

that for ±13% (100V to 130V) change in the line voltage the

optimum range of the operating frequency is when off-time duty

cycle (D') is between 0.57 and 0.75. This means that the boost

voltage needs to be 245V when selecting D' = 0.75 at maximum

AC line.

In this example, D' is chosen to be 0.8, to slightly reduce the

voltage rating of the back end DC to AC fluorescent lamp inverter.

This sets the boost voltage at:

130

√2

= = 230V

V

O

*

0.8

17

Page 18

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

APPLICATION INFORMATION

OUTPUT VOLTAGE REQUIREMENT (continued)

0.2

fn = (1 - D') D'²

0.15

0.1

2 V

D' =

0.05

f = f

) Normalized Operating Frequency

n

(f

0.3

0.4 0.5

AC

V

O

η

VO²

n

4 LP

O

0.6

0.7 0.8 0.9 1.0

(D') Off Time Duty Cycle

FIGURE 32 — NORMALIZED OPERATING FREQUENCY vs.

OFF-TIME DUTY CYCLE

INDUCTOR PEAK CURRENT

It can be shown by referring to Figure 33 that the inductor peak

current is always twice the average input current.

Inductor Peak

Current Envelope

Average

AC Input Current

FIGURE 33 — INDUCTOR CURRENT

I

= AVE [ IL (t) ]

IN(t)

Σ

(IL) (T)

1

I

IN

I

INpeak

I

LP

==

T

= IP =

2

I

LP

2

= Inductor peak current at peak input voltage.

I

L

2

I

L

TONT

OFF

Maximum peak input current can be calculated using:

2P

O

=

I

P

ηV

P

where: η≡Converter efficiency

V

≡ Peak AC input voltage

P

assuming: η = 95%, P

2 x 80

= = 1.2A

I

P

(.95)(141)

I

= 2 * 1.2 = 2.4A

LP/min AC

= 80W, V

O

= 100√2 = 141

Pmin

INDUCTOR DESIGN

The inductor value is calculated assuming a 50KHz operating

frequency at the nominal AC voltage using the following equation:

VO - V

P

O

O

230 - 120√2

230

2

P

4 * 80

V

≡ Output DC voltage

O

≡ Peak AC input voltage

V

P

T ≡ Switching period

≡ Output Power

P

O

(120√2)

*

2

η T V

= where: η≡Efficiency

L

1

L1 = = 448µH

V

4 P

.95 ( ) 20 * 10-6

choose T = 20µsec (50kHz)

Figure 32 shows that at nominal AC line (D' = 0.74) the normalized

frequency is 0.142 and dropping to 0.13 at maximum line

condition. This translates to a 10% drop in operating frequency

which is still well above the audible range.

Once the inductance is known, we can either use the area

product method (AP) or the K

for selecting proper core size. In this example, we apply the K

(based on copper losses method),

g

approach using the following steps:

Step 1: Calculate K

=( )

K

g

where: L

g

Ω

P

CU

1

Ω≡1.724

using

2

L1I

LP

2

B

≡ Required inductance

-8

10

m

*

B ≡ Maximum flux density

≡ Maximum peak inductor current

I

LP

P

≡ Maximum copper dissipation

CU

Assume: P

1.724 * 10

= = 3.21 * 10

K

g

1.6

= 1.6W (2% of total output)

CU

-8

450 * 10

-6

0.15

* (2.4)

2

2

-12 m5

g

18

Copyright © 1996

Rev. 1.3 12/96

Page 19

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

APPLICATION INFORMATION

LX1562/1563

INDUCTOR DESIGN (continued)

Step 2: Choose a core with higher Kg than the one calculated in

Step 1.

Kg/core = k

AW A

l

2

E

W

where: k ≡ Winding coefficient (typ. k=0.4)

A

≡ Bobbin window area

W

≡ Effective core area

A

E

l

≡ Mean length per turn

W

K

factor for TDK PQ2625:

g

= 47.7mm

A

W

AE= 118mm

2

2

lW= 56.2mm

56.2

2

-12 m5

(47.7) (118)

= 0.4 (mm)5 = 4.7 * 10

K

g

Step 3: Determine number of turns.

L I

N =

N = = 61 turns

A

LP

B A

E

450 * 10-6 * 2.4

0.15 * 118 * 10

A

W

= k = 0.4 = 0.31mm

WIRE

N

-6

47.7

61

= 480mil

2

2

choose #22 AWG with r = 0.0165Ω/feet resistance.

R

= N * lw * r

W

R

= 0.185Ω

W

Step 4: Calculate air gap.

µO N2 A

4π

*

L

10

E

-7

(61)

*

450 * 10

2

118*10

*

-6

-6

=

l

g

l

= = 0.122cm = 48 mil

q

CURRENT SENSE RESISTOR

Current sense resistor, R6 is selected using the minimum multiplier output clamp voltage and the maximum inductor peak

current such that:

V

CLAMP(MIN)

R6 = = = 0.45Ω

I

L (MAX)

1.1

2.4

Power dissipation is approximated by:

1

≈ I

P

R

6

1

P

≈ (2.4)

R

6

2

(1 - D'

2 (MAX)

2

(1 - 0.61) = 0.374

), where D'

MIN

MIN

= 1 -

√2 V

V

AC(MIN)

BOOST

Select THREE 1.3Ω , ¼W carbon comp resistors in parallel.

MULTIPLIER COMPONENT SELECTION

Calculate R1 & R2 resistor values such that under low line AC input

the multiplier output is lower than the minimum clamp voltage.

R2

R1 + R2

√2 V

*

AC (MIN)

* K * (V

EA0 (MAX)

- V

REF

) < V

CLAMP (MIN)

where: K ≡ Mult. Gain

V

≡ Maximum error amp output where

EA)(MAX)

multiplier is still in linear range.

This voltage is ≈ 3.5V.

For K = 0.65 & V

R1

> 83

R2

CLAMP (MIN)

= 1.1V, the ratio of R1/R2 is:

Assuming R1 is selected to be:

* R1 = 2.2M (1%)

2.2M

R2 = = 26.4k (1%) select R

83

= 26.7k (1%)

2

* For high input applications such as 277V, R1 must be divided

into two resistors in series to meet the maximum rated voltage of

the resistors.

To improve THD further (typ. 2-3%), a high value resistor can

be connected from the supply voltage to this pin to allow an

increase in the switch on-time at the zero crossing by adding an

effective offset at the multiplier output.

ERROR AMPLIFIER COMPONENT SELECTION

Boost voltage is programmed with R7 & R8 resistor dividers using

the following equation:

R7

R8

V

BOOST

= -1,

V

REF

assuming that the product of R7 and the E.A. input bias current

does not cause significant error in the output voltage setting.

ΩΩ

Assuming R7 = 1M

two resistors may be added in series to meet the voltage

requirement of the resistor.)

∆V

(106) (0.5 * 10-6) = 0.5V, which is < 0.25% of the

ERROR

(for output voltage of higher than 250V,

Ω

ΩΩ

output voltage.

Calculating R8:

V

BOOST

V

REF

R7

- 1

R8 = = 11k (1%)

Worst case output tolerance is the total of ±3.75% which is the sum

of ±1.5% (Ref), ±2% (resistor dividers), and ±0.25% (E.A. input

bias current).

Copyright © 1996

Rev. 1.3 12/96

19

Page 20

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

APPLICATION INFORMATION

ERROR AMPLIFIER COMPONENT SELECTION (continued)

Capacitor C5 is primarily selected to reject the output ripple

associated with twice the line frequency. For a 40dB ripple

rejection:

C5 ≥ where f

C5 ≥ = 0.062µF, Select C5 = 0.1µF

100

2π f

R7

l

2π

120*2.2*10

*

100

= 2x line frequency

l

6

Resistor R9 can be used to improve load transient response at the

cost of loosing 1 or 2% of load regulation. The value of this resistor

should be much greater than R8:

R9 = 620k

One way of achieving desired load transient response without

resorting to a complex mathematical model of the converter, is to

dynamically switch the output load and empirically find the

compensation network. The value of resistor R9 is selected using

the method shown in Figure 34.

V

BOOST

Min.

R

L

10Hz

50% D.C.

FIGURE 34 — LOAD TRANSIENT RESPONSE CIRCUIT

I

COMPONENT SELECTION

DETECT

Load

Figure 35 shows voltage envelope generated by flyback voltage

across I

Select turns ratio n such that,

n =

n = = 0.11

I

selected to be 7T.

winding:

DET

5V

- √2 V

V

BOOST

5V

230 - √2

winding turns are

DET

*

130

AC (MAX)

(V

- VAC)

n

BOOST

V

n

AC

FIGURE 35 — FLYBACK VOLTAGE

ACROSS I

WINDING

DET

and R4 resistor:

n * V

BOOST

< R4 < 500k

-3

3 * 10

0.11 * 230

3 * 10

< R4 < 500k, or 8.4k < R4 < 500k

-3

Select R4 = 22k

SUPPLY VOLTAGE

Resistor R3 must be selected such that it ensures converter startup at low line and is rated for high line power dissipation.

√2 V

R3 < where: I

R3 < = 466kΩ

R3 > 4 V

AC (MIN)

I

ST (MAX)

√2

100

*

0.3 * 10

-3

(to keep power dissipation below 0.5W)

AC (MAX)

≡ Maximum start-up

ST

V

ST

T

ST(MAX)

current

≡ Start-up voltage

≡ Maximum start-up

time at AC power-on

R3 > 68k , select R3 = 120k.

Start-up time of converter is given by:

V

T

ST (MAX)

≈ C2

√2 V

AC (MIN)

R3

ST

- I

ST

for our application this will be 25ms/µF.

The start-up capacitor is selected such that capacitor discharge

time is always longer than the time it takes for the bootstrap

voltage to reach above the minimum start-up threshold of the IC.

I

* ∆t

C3 < where: I

OP

∆V

MIN

≡ Maximum dynamic

OP

supply current of the IC

∆t ≡ Rise time of the

bootstrap voltage

≡ Minimum hysteresis

∆V

MIN

10 * 10-3 * 10 * 10

C3 < = 29µF

4

-3

(4V for 1562,

voltage

1.7V for 1563)

Select C3 = 33µF.

Start-up time is approximately 0.8 seconds.

The auxiliary winding turns are selected such that it provides 15V

of operating voltage.

V

N

≈ N

S

S

* = 61 * = 4T

P

V

O

However, in this example I

which eliminates the need for a third winding. This is possible

V

S

V

O

winding is used to power the IC

DETECT

since the internal clamping of the output drive limits the gate

drive voltage to 14V (typ.) if the supply voltage exceeds this limit.

20

Copyright © 1996

Rev. 1.3 12/96

Page 21

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

APPLICATION INFORMATION

POWER MOSFET SELECTION

The voltage rating of MOSFET and rectifier must be higher than

the maximum value of the output voltage.

≥ 1.2 V

V

DS

O MAX

The RMS current can be approximated by multiplying the RMS

current at the peak of the line by 0.7.

I

= 0.7 I

RMS

D = 0.39 at V

I

= (0.7)(2.4)(√.39/3) = 0.61A

I

RMS

R

P

√D/3 D ≡ On-time duty cycle

LP

= 2.4A

LP

≤

DS

≡ allowable power I

DC

AC

P

DC

2

I

RMS

dissipation.

1

≤ = 1.6Ω

R

DS

0.61

IRF730 with R

requirements.

DS

= 1

INPUT RECTIFIER AND CAPACITOR SELECTION

The current through each diode is a half-wave rectified sine wave.

The maximum current happens at minimum line with a peak

value of 1.2A.

I

I

PEAK

= = = 0.38A

AVE

π

choose 1N4004 with 1A rating.

= (I

P

DISS

= TA + P

T

J

T

= 80 + (.344)(65) = 102°C

J

) (VF) = 0.38 x 0.9 = 0.344W

AVE

x θ

D

JA

= 100V

ΩΩ

Ω and V

ΩΩ

1.2

π

V

≥ 282V

DS

RMS

= 400V meets the above

DS

assuming θ

lead length.

= 65°C/W for 1/8"

JA

I

LP

D

/triangle = I

√D/3

LP

LX1562/1563

Assuming ϕ is the percentage of allowable input current ripple,

C1 can be calculated using the following equations:

2 P

R

EFF

C1 ≥ f

if ϕ = 3%

R

EFF

C1 ≥ = 0.9µF

choose 1µF, 250V capacitor.

OUTPUT CAPACITOR SELECTION

There are mainly two criteria for selecting the output capacitor:

A large enough capacitance to maintain a low ripple voltage, and

a low ESR value in order to prevent high power dissipation due

to RMS currents.

The output capacitance can be approximated from the following

equation:

C6 ≥ where: I

I

DC

assuming 5% peak to peak ripple,

C6 ≥ = 81µF

choose C6 = 100µF.

O

=

2

η I

P

1

ϕ 2π R

EFF fSW

2 x 80

= = 117Ω

(.95)(1.2)

2

1

(.03)(2π)(117)(50000)

I

DC

2π f

∆V

LINE

80

= = 0.348A

230

0.348

2π (60) (11.5)

≡ Switching frequency

SW

of inductor current

at peak input voltage.

≡ DC output current

DC

DV ≡ Output ripple

Copyright © 1996

Rev. 1.3 12/96

21

Page 22

LX1562/1563

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

TYPICAL APPLICATIONS

120V

450µH

L1

61T

#22AWG

D7

V

BOOST

R3

D3

D1

AC+

AC-

120V

AC

R1

C1

R2

D2 D4

Note: Thick trace on schematic shows high-frequency, high-current path in circuit. Lead lengths

must be minimized to avoid high-frequency noise problems.

FIGURE 36 — TYPICAL APPLICATION OF THE LX1562 IN AN 80W

FLUORESCENT LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL.

Electrical

Specification

Ref. Component Manuf.

120VAC Input — 230VDC / 80W Output

7T

D5

C4

#26AWG

R4

C2

R10

3

C3

IC LX1562 Linfinity

L1 PQ2625/H7C1 Core TDK

Q1 IRF730, 400V, 1Ω rds I.R.

D1-D4 IN4004 1A, 400V Motorola

D5 1N4935 1A Motorola

D6 1N4148

(improves Q1 power dissipation)

Motorola

D7 MR854, 3A, 400V Motorola

R1 2.2MΩ , ±1%

R2 26.7kΩ, ±1%

R3 100kΩ, ½W

R4 22kΩ

R5 47Ω

R6 1.5Ω, Carbon type (3X)

R7 1MΩ, 1%

R8 11kΩ, 1%

R9 620kΩ

(improves load transient response)

R10 4.7MΩ

A complete evaluation board is available from Linfinity Microelectronics Inc.

MULT

IN

8

V

IN

5

I

DET

D6

R7

R5

OUT

COMP

LX1562

INV

GND

C.S.

6

7

R9

2

C5

1

4

Q1

C6

R8

R6

Ref. Component Manuf.

C1 QXF2E105KRPT

1µF/250V - Plastic Film (high freq.) Nichicon

C2 22µF/35V - Electrolytic

C3 0.1µF/50V - Ceramic

C4 0.01µF/50V - Ceramic

C5 0.1µF/50V - Ceramic

C6 LGQ2G101MHS A/Z* Nichicon

100µF/400V - Electrolytic

* A = 25mm diam.

Z = 22mm diam.

FLOURESCENT LAMP BALLAST

22

Copyright © 1996

Rev. 1.3 12/96

Page 23

A

C+

AC-

220V

AC

D1

D3

D2 D4

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

TYPICAL APPLICATIONS

220V

L1

1.2mH

C1

R3

80T

7T

4T

R1

R2

C4

R10

C2

#24AWG

#26AWG

#26AWG

D5

3

C3

MULT

IN

V

R4

8

IN

GND

6

5

I

DET

OUT

COMP

LX1562

INV

C.S.

D6

7

2

1

4

R5

R9

C5

Q1

R6

LX1562/1563

D7

R7

R8

V

BOOST

C6

FLOURESCENT LAMP BALLAST

Note: Thick trace on schematic shows high-frequency, high-current path in circuit. Lead lengths

must be minimized to avoid high-frequency noise problems.

FIGURE 37 — TYPICAL APPLICATION OF THE LX1562 IN AN 80W

FLUORESCENT LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL.

Electrical

Specification

Ref. Component Manuf.

IC LX1562 Linfinity

L1 PQ2625/H7C1 Core TDK

Q1 IRF830, 500V, 1.5Ω rds I.R.

D1-D4 IN4007 1A, 1000V Motorola

D5 1N4935 1A Motorola

D6 1N4148

D7 MR856, 3A, 600V Motorola

R1 2.2MΩ , ±1%

R2 12kΩ, ±1%

R3 220kΩ, ½W

R4 22kΩ

220VAC Input — 400VDC / 80W Output

Ref. Component Manuf.

C1 QXF2J224KRPT

0.22µF/630V - Plastic Film Nichicon

C2 22µF/35V - Electrolytic

C3 0.1µF/50V - Ceramic

C4 0.01µF/50V - Ceramic

(improves Q1 power dissipation)

Motorola

C5 0.1µF/50V - Ceramic

C6* LGQ2W680MHS A/Z* Nichicon

68µF/450V - Electrolytic

* A = 25mm diam.

Z = 22mm diam.

R5 47Ω

R6 1.8Ω, Carbon type (2X)

R7 1MΩ, 1%

R8 6.19kΩ, 1%

R9 620kΩ

(improves load transient response)

R10 2.7MΩ

A complete evaluation board is available from Linfinity Microelectronics Inc.

Copyright © 1996

Rev. 1.3 12/96

23

Page 24

LX1562/1563

V

IN

I

DET

OUT

COMP

INV

C.S.

GND

MULT

LX1562

Q1

V

BOOST

FLOURESCENT LAMP BALLAST

IN

5

8

7

2

1

4

6

3

277V

AC

R4

R3

R1

C1

R2

C4

D5

C2

R5

C5

R7

A

C6

A

D7

R8

R9

R6

D6

AC+

AC-

D1

L1

2.2mH

15T

D3

D2 D4

C3

#24AWG

#26AWG

80T

#26AWG

3T

R10

R7

B

C6

B

PRODUCT DATABOOK 1996/1997

S ECOND-GENERATION POWER FACTOR CONTROLLER

RODUCTION DATA SHEET

P

TYPICAL APPLICATIONS

277V

24

Note: Thick trace on schematic shows high-frequency, high-current path in circuit. Lead lengths

must be minimized to avoid high-frequency noise problems.

FIGURE 38 — TYPICAL APPLICATION OF THE LX1562 IN AN 80W

FLUORESCENT LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL.

Electrical

Specification

Ref. Component Manuf.

IC LX1562 Linfinity

L1 PQ2625/H7C1 Core TDK

Q1 IRF830, 500V, 1.5Ω rds I.R.

D1-D4 IN4007 1A, 1000V Motorola

D5 1N4935 1A Motorola

D6 1N4148

277VAC Input — 480VDC / 80W Output

(improves Q1 power dissipation)

Motorola

D7 MR856, 3A, 600V Motorola

R1 2.2MΩ , ±1%

R2 10kΩ, ±1%

R3 390kΩ, ½W

R4 22kΩ

R5 47Ω

R6 2.2Ω, Carbon type (2X)

R7 499kΩ, 1% (2X)

R8 5.23kΩ, 1%

R9 620kΩ

R10 2.2MΩ

(improves load transient response)

A complete evaluation board is available from Linfinity Microelectronics Inc.

Ref. Component Manuf.

C1 QXF2J224KRPT

C2 22µF/35V - Electrolytic

C3 0.1µF/50V - Ceramic

C4 0.01µF/50V - Ceramic

C5 0.22µF/50V - Ceramic

C6 UVZ2F470MEH (2X) Nichicon

0.22µF/630V - Plastic Film Nichicon

47µF/315V - Electrolytic

Copyright © 1996

Rev. 1.3 12/96

Page 25

PRODUCT DATABOOK 1996/1997

A

S ECOND-GENERATION POWER FACTOR CONTROLLER

P RODUCTION DATA SHEET

TYPICAL APPLICATIONS

LX1562/1563

C+

90-265V

AC

AC-

#24AWG

#26AWG

#26AWG

D5

90V - 265V

R4

8

V

IN

5

I

DET

D6

D1

D3

R3

R1

62T

7T

L1

450µH

3T

C2

R5

C1

OUT

7

R9

MULT

IN

3

R2

D2 D4

Note: Thick trace on schematic shows high-frequency, high-current path in circuit. Lead lengths

must be minimized to avoid high-frequency noise problems.

C4

C3

LX1562

GND

6

COMP

INV

C.S.

2

C5

1

4

Q1

R6

D7

R7

R8

V

BOOST

C6

FLOURESCENT LAMP BALLAST

FIGURE 39 — TYPICAL APPLICATION OF THE LX1562 IN AN 80W

FLUORESCENT LAMP BALLAST WITH ACTIVE POWER FACTOR CONTROL.

Electrical

Specification

Ref. Component Manuf.

IC LX1562 Linfinity

L1 PQ2625/H7C1 Core TDK

Q1 IRF840, 500V, 1Ω rds I.R.

D1-D4 IN4007 1A, 1000V Motorola

D5 1N4935 1A Motorola

D6 1N4148

D7 MR856, 3A, 600V Motorola

R1 2.2MΩ , ±1%

R2 16.3kΩ, ±1%

R3 130kΩ, ½W

R4 22kΩ

90-265VAC Input — 400VDC / 80W Output

Ref. Component Manuf.

C1 QXF2J224KRPT

0.47µF/630V - Plastic Film Nichicon

C2 22µF/35V - Electrolytic

C3 0.1µF/50V - Ceramic

C4 0.01µF/50V - Ceramic

(improves Q1 power dissipation)

Motorola

C5 0.33µF/50V - Ceramic

C6* LGQ2W680MHS A/Z* Nichicon

68µF/450V - Electrolytic

* A = 25mm diam.

Z = 22mm diam.

R5 47Ω

R6 1Ω, Carbon type (4X)

R7 1MΩ, 1%

R8 6.19kΩ, 1%

R9 620kΩ

(improves load transient response)

A complete evaluation board is available from Linfinity Microelectronics Inc.

Copyright © 1996

Rev. 1.3 12/96

25

Loading...

Loading...