Micropump GC Series Service Instructions

SERVICE INSTRUCTIONS: L23104

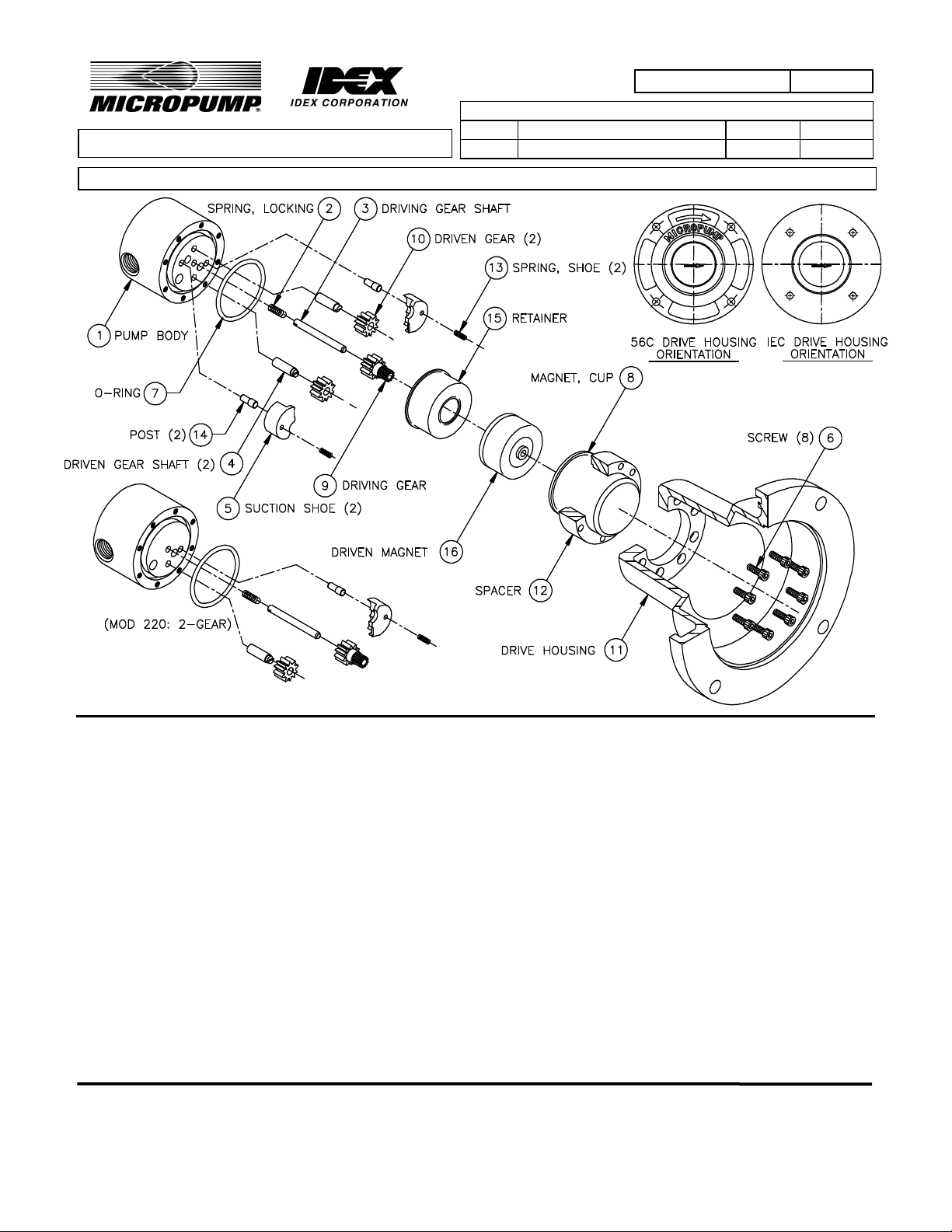

MOD: GC SERIES INDUSTRIAL MOUNTS (E, K, 3, 4, 5, & 6)

LTR. DESCRIPTION DATE BY

PART NUMBER: L23104

REVISION

A ORIGINATED FOR E14147. 12/19/03 LFK

GENERAL:

1. All service work should be performed in a clean area.

2. Care should be taken to avoid scratching any sealing surfaces or allowing metal chips to

come in contact with the driven magnet assembly.

3. An even, light coat of high vacuum silicone grease (Dow Corning or equiv.) should be applied

to all seals or O-Rings.

4. O-Rings with chamfers should always be installed with the chamfer up, away from the groove.

5. All assembly screws should be tightened evenly and in an alternating pattern.

6. Only Micropump factory authorized replacement parts should be used when servicing any

Micropump products.

SPECIFIC:

1. Engage Spring (2) half loop into Driving Gear Shaft (3) slot and rotate Spring/Shaft assembly

clockwise while pressing into Pump Body (1) as shown. Firmly seat Spring/Shaft assembly

into hole.

2. Orient Driven Gear Shaft(s) (4) to allow the step to engage with Suction Shoe(s) (5)

permitting the Suction shoe to seat flat against the Pump Body (1) face.

3. Torque assembly Screws (6) to 40 in/lbs.

4. Gears and Suction Shoe(s) should always be replaced in matched sets.

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

Howard Road, Eaton Socon, St.

MICROPUMP

A Subsidiary of Micropump, Inc.

Neots, Cambridgeshire, PE 19 8ET England, • Phone: (44) (0) 1480-356600 • Fax: (44) (0) 1480-356300

LIMITED

Loading...

Loading...