Page 1

TURBOFAN

Instruction manual and

installation guide

Micron Sprayers Limited

Bromyard Industrial Estate

Bromyard, Herefordshire

HR7 4HS, UK

Tel: +44 (0) 1885 482397

Fax:+44 (0) 1885 483043

E-mail: micron@micron.co.uk

URL: http://www.micron.co.uk

Page 2

DRAFT

CONTENTS

SECTION PAGE NUMBER

1.0 INTRODUCTION 2

2.0 SPECIFICATION

3.0 TEN KEY POINTS FOR USERS

4.0 INSTALLATION

4.1 Mounting of Sprayheads 5

4.2 Hydraulic System 7

4.3 Spray liquid 15

4.4 Testing 17

3

4

5

5.0 OPERATION 17

5.1 Daily Inspection 17

5.2 Calibration Procedure 17

5.3 Position of Sprayheads 17

5.4 Sequence of Operation 18

5.5 After Use 18

6.0 HEALTH AND SAFETY 18

7.0 CALIBRATION AND ADJUSTMENT

7.1 Application Rate 19

19

8.0 MAINTENANCE 23

8.1 Routine Maintenance 23

8.2 Dismantling of Sprayhead 23

9.0 PARTS LIST AND DIAGRAM 25

1

Page 3

DRAFT

1.0 INTRODUCTION

The Micron TURBOFAN Sprayhead has been developed from over 30 years experience

in the design and use of rotary atomisers. Originally developed for agricultural aircraft,

these atomisers are now used for aerial and ground applications in more than 75 countries. This unique background, combined with continuous research and development, has

enabled Micron to produce a truly versatile and reliable sprayhead for almost every agricultural spraying requirement.

The Micron TURBOFAN sprayhead uses a rotary atomiser, mounted in a protective cowl

and driven by a compact hydraulic motor. The atomiser uses a stack of toothed discs to

break the spray liquid into precise oversized droplets. This unique approach ensures that

all of the spray volume is concentrated into a narrow range of droplet sizes.

The atomiser also incorporates an axial fan which produces a turbulent, swirling airstream from the sprayhead. This carries spray to the target, disturbs foliage and ensures

good penetration to give an even coverage in dense crops.

The Micron TURBOFAN Sprayhead operates over a wide range of liquid flow rates,

enabling the same unit to be used for ultra low, low and higher volume application. The

atomiser is designed to handle all types of liquid formulations from specialised ULV

products to high concentrations of emulsifiable concentrates and solids in suspension.

The Micron TURBOFAN Sprayhead is ideally suited to most spraying tasks, whether in

fields, bushes, orchards or vines. Whatever the application, the combination of controlled droplet size, wide range of application rates and air assistance will enable the user

to achieve improved spray coverage and control with a minimum wastage of chemical,

thus ensuring the best possible biological results at a minimum cost.

Should field service be necessary, the simple design of the sprayhead enables it to be dismantled and cleaned in minutes.

TURBOFAN sprayheads require a hydraulic oil supply to operate. This can often be provided by the tractor or vehicle’s own hydraulic system. Alternatively, it may be necessary to install an auxiliary hydraulic system with its own reservoir and power driven hydraulic pump.

Because of their versatility, TURBOFAN Sprayheads can be installed on a wide range of

sprayers. These may be specially built or may be conversions of existing machines.

Through its own experience and that of its customers, Micron can advise Original Equipment Manufacturers (OEMs) on the design and construction of most types of sprayers.

2

Page 4

DRAFT

2.0 SPECIFICATION

Length (max. front to back): 35 cm (complete with mounting bracket)

Diameter: 45 cm

Weight: 6.4 Kg plus mounting bracket 1.7 Kg

Liquid flow rate: 0.25 – 2.0 l/min

Spray droplet size: 100 – 120 microns VMD

Hydraulic oil flow: 8 l/min per sprayhead.

Hydraulic pressure: 124 Bar pressure drop across each motor (approx.)

Fan/atomiser speed 4000 rpm

Hydraulic motor supply port: 3/8 BSP (F)

Hydraulic motor return port: 3/8 BSP (F)

Hydraulic motor drain port: 1/8 BSP (F)

Airflow @ 0.4 m (16 in): 98 m³/min/head (3460 ft³/min)

Air velocity @ 0.4 m (16in): 18 m/sec (40.2 mph)

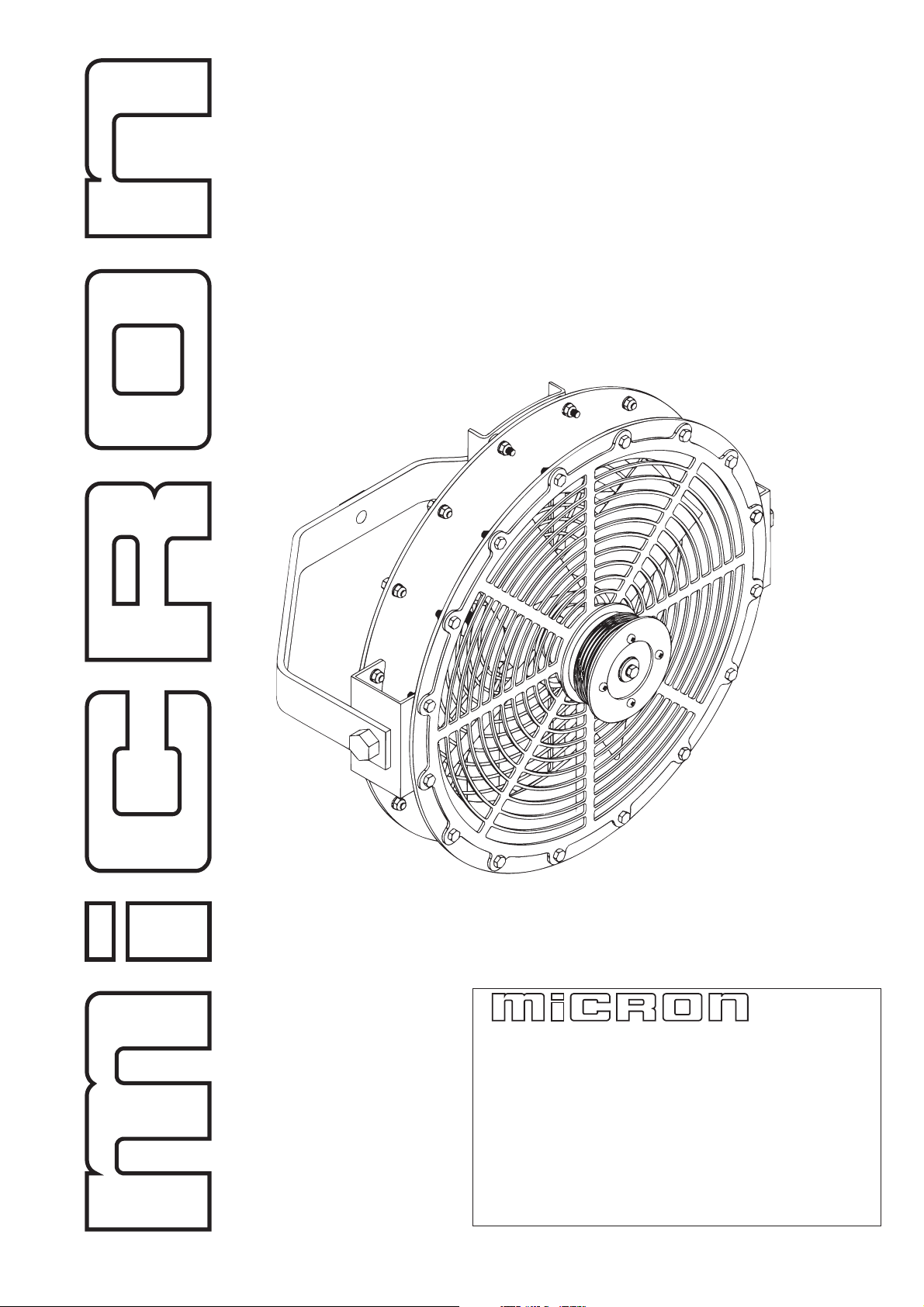

AXIAL FAN

ATOMISER

SAFETY GUAR DS

MO UNTING BRACKET

HYDR AULIC MOTO R

Figure 1. Turbofan spray head

3

Page 5

DRAFT

3.0 TEN KEY POINTS FOR USERS

The following list of ten points is intended to assist users in the efficient use of Turbofan

sprayheads. It is hoped that this section will encourage users to read the entire handbook

and follow its recommendations.

1. Check that all atomisers rotate freely. The only friction should be drag from the hydraulic motor. If binding or roughness is felt, remove the unit as described in Section

8.2 (‘Maintenance, Dismantling of Sprayhead and Atomiser’ ) and inspect the bearing, motor, etc.

2. Check that each atomiser securing screw (Page 25, Item no 7, Micron part no 5983) is

secure.

3. Check that the atomiser discs are free of damage, blockage by dried chemical or any

condition which could cause them to run out of balance.

4. Check that the fan blades are not damaged or out of balance.

5. Ensure that the hydraulic system is filled with oil, is correctly adjusted and that all

atomisers are rotating at the correct speed.

6. Check that the correct flow restrictor orifices are fitted.

7. Ensure that all atomisers are correctly positioned on the boom or support structure

and that they are the correct distance from the target being sprayed.

8. Inspect the entire sprayer for damaged or twisted hoses and ensure that there are no

leaks in the hydraulic or chemical systems.

9. Whilst spraying, verify the accuracy of the calibration of the sprayer by checking the

volume of chemical used against the area sprayed.

10. After use, always flush out the entire system with clean water or a suitable solvent.

Never leave chemical residues in the sprayheads, tank or pipework. Wash off the

outer surfaces of sprayheads, booms, etc with a pressure washer or similar to avoid

build up of pesticide residues.

4

Page 6

DRAFT

4.0 INSTALLATION

The design of a sprayer incorporating Turbofan Sprayheads will vary according to the

crop to be sprayed, the type of sprayer being used and the available hydraulic power.

This section gives general advice and design data but is not intended to provide specific

instructions for building every type of sprayer. Original Equipment Manufacturers

(OEMs) should contact Micron if they require any further information for a particular

application.

4.1 Mounting of Sprayheads

The configuration of a sprayer and mounting of sprayheads will depend upon the type

and planting of the crop to be sprayed. Some examples of typical configurations are

shown in Figures 2, 3 and 4.

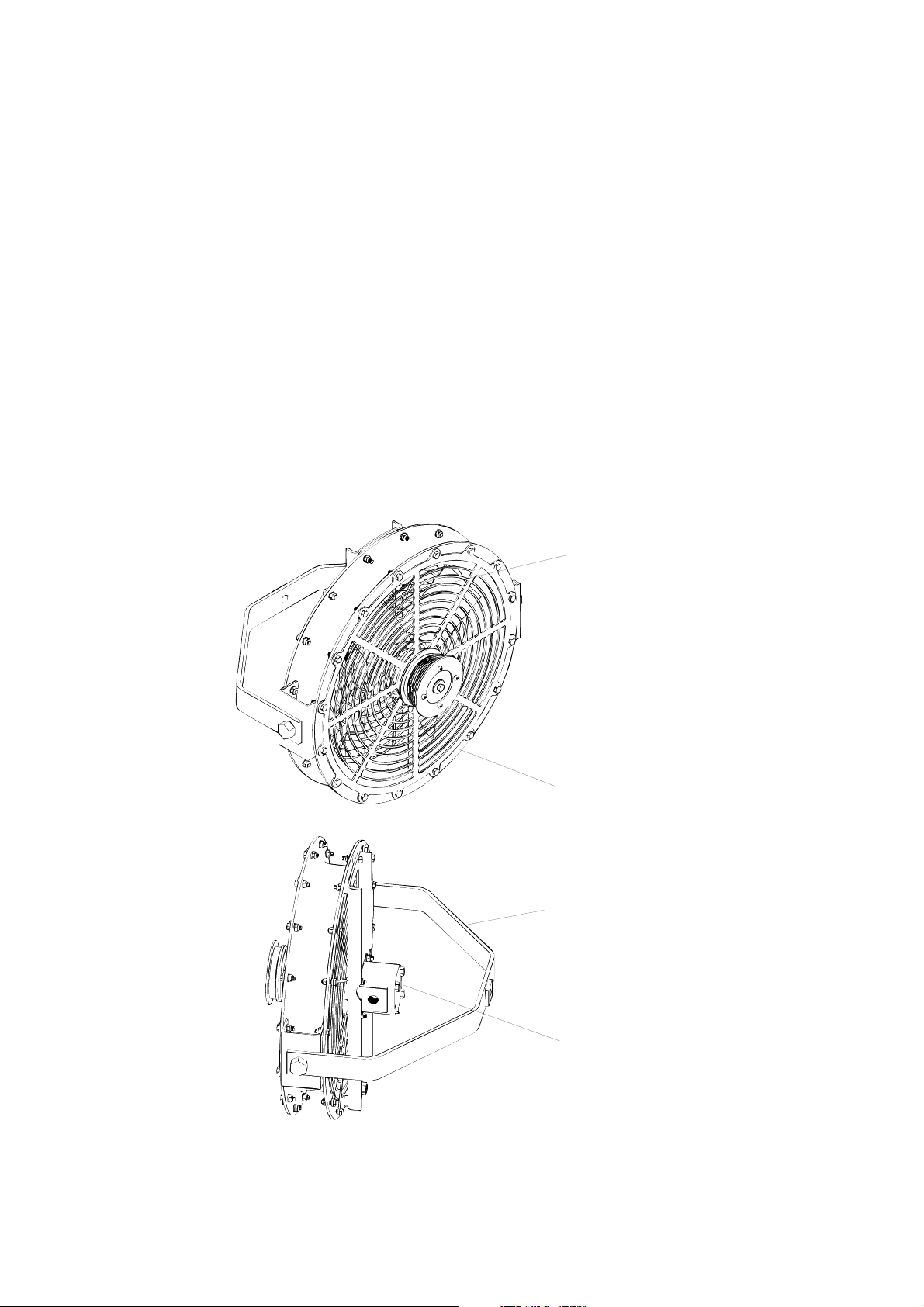

Figure 2. Typical sprayhead configuration for ground crops

Figure 3. Typical sprayhead configuration for grape harvester mounting (4 rows)

5

Page 7

DRAFT

Figure 4. Typical sprayhead configuration for tree, bush and vine crops

4.1.1 Distance from Crop

Each sprayhead must be positioned sufficiently far from the crop to allow the airflow

from the fan to disperse the spray droplets over a wide band and to prevent local overapplication of foliage close to the atomiser. However, the distance should not be so great

that the airflow becomes dissipated or that the spray droplets could be prone to drift in a

wind. In general, a distance of 0.5 m (20 inches) to the outer face of the crop is preferred

in vines. This distance can be increased to 0.75 m (30 inches) if required.

4.1.2 Spacing of Sprayheads

Sprayheads must either be mounted sufficiently close together to produce an even swath

without ‘striping’ or should be positioned so as to spray specific rows of crops where the

rows are planted far apart and the space between does not require treatment.

For broadacre crops, closely planted vegetables etc, the sprayheads should be mounted on

a horizontal boom. Sprayheads should be not more than 1.2 m (4 feet) apart to ensure an

even swath.

For field crops planted in widely spread rows or beds and for low bush crops, a

horizontal boom can also be used. However, the sprayheads should be positioned either

above or between rows or bushes. Where the row spacing varies it may be necessary to

allow for adjustment of the position of sprayheads on the boom.

For trees, tall vines, soft fruit etc, the sprayheads will normally be mounted on a vertical

frame attached to the sprayer. One sprayhead will cover a vertical distance of 1 m (3 feet

6 inches). The number of sprayheads required will depend upon the height of the bush or

tree being sprayed and the density of the foliage. In general, dense foliage will attenuate

the airflow from a sprayhead more quickly and hence more units will be required to

ensure effective penetration and coverage.

6

Page 8

DRAFT

4.1.3 Angle of Sprayheads

Sprayheads should normally be angled so as to maximise the width of the band of spray

deposited and to allow the turbulent airstream to disturb foliage in order to achieve

maximum penetration and under-leaf coverage.

Sprayheads mounted on horizontal booms should face backwards with the axis of the

atomiser at an angle of 30 – 45 degrees to the vertical for fungicide and insecticide

application. However, they should face downwards at 0 – 10 degrees to the vertical for

herbicide or liquid fertilizer application.

Sprayheads used to spray sideways on tree or bush crops should face outwards from 0 –

45 degrees backwards to the direction of travel and should also be angled upwards or

downwards according to the foliage to be sprayed.

IMPORTANT: Sprayheads must never be positioned so that spray droplets can be

blown towards the driver or operator of the sprayer. Ensure that all spray is blown

clear of the sprayer structure to eliminate contamination and run-off.

4.2 Hydraulic System

Hydraulic power for Turbofan Sprayheads can be provided either from the tractor

hydraulic system or from an hydraulic pump driven by the power take-off (PTO) if there

is not sufficient capacity from the tractor.

The following notes are intended as a guide to the design of the hydraulic system and the

choice of components. When building a system it is vital that all components should

be selected so as to have a safe working pressure well in excess of the operating

pressure, taking into account the harsh environment of an agricultural operation.

4.2.1 Hydraulic Configuration

• It is recommended that Turbofan Sprayheads are normally connected in parallel

• Drain lines must be fitted to all motors.

It is possible to connect Turbofan Sprayheads in series but the numbers of motors in each

series chain should be limited to two. It is important to note that the pressure drop across

series pairs of motors is approximately 200 bar which is higher than most tractor

hydraulic systems can provide. Drain lines must also be fitted to all

motors connected in

series.

7

Page 9

DRAFT

4.2.2 Parallel Connection

The hydraulic motors of the Turbofan are normally connected in parallel.

To calculate the hydraulic flow required for a specific number of heads :-

• each head runs at 4000 rpm

• the oil flow required per motor is 4000 x 2ml/rev = 8 1/min

• add 10% for pump and other hydraulic losses = 8.8 l/min

eg For 6 heads hydraulic flow required = 8.8 x 6 = 52.8 l/min

Alternatively if you know the maximum hydraulic flow available from the tractor or PTO

pump, etc for the Turbofans then :

Maximum number of heads which can be installed = Maximum hydraulic flow available

8.8

eg If flow available = 72 l/min

then maximum number of heads (in parallel) = 72

= 8.18 = 8 heads

8.8

The pressure drop required per Turbofan Sprayhead is 100 bar (1500 psi) therefore the

maximum pressure required by the total hydraulic system for parallel running = 100 bar

(1500 psi).

4.2.3 Series Connection

The preferred method of running Turbofan Sprayheads is in parallel. However, if more

sprayheads are needed than can be connected in parallel, then series connection can be

used, subject to the following:

• A maximum of two motors must be used in each series chain.

• A hydraulic system with a relief valve setting of 200 bar (or above) is necessary for

series running (i.e. pressure drop of Turbofan unit x 2 = 100 bar x 2 = 200 bar).

• It should be noted that most tractor hydraulic systems operate below this figure and

are therefore unsuitable for running Turbofans in series (i.e. typical tractor hydraulic

systems operate in the range 140 – 180 bar).

It must also be noted that if the hydraulic system is running at 200 bar (or above) then all

of the components in the circuit must be capable of withstanding these pressures.

8

Page 10

DRAFT

To calculate the hydraulic flow required for a specific number of Turbofan Sprayheads

running in series pairs:

• Each head and each chain runs at 8.0 l/min

• Allow 10% for pump and other hydraulic losses. Therefore flow per chain (ie 2 x

Turbofan) = 8.8 l/min

• Therefore for 6 heads (3 chains of 2) the flow required = 8.8 x 6 = 26.4 l/min

2

Alternatively if you know the maximum hydraulic flow available (and the system

pressure is 200 bar or above) then :

Maximum number of heads which can be fitted = 2 x maximum hydraulic flow available

with 2 motors in series in each chain 8.8

e.g. If flow available = 72 l/min

then maximum number of heads in series (two per chain) = 2 x 72 = 16.4 = 16 heads

8.8

4.2.4 Hydraulic Oil Flow

If a Power Take Off (PTO) driven hydraulic pump is used, the pump should be chosen to

provide the calculated maximum oil flow plus losses and no more. If a larger pump were

to be used, any unused oil would have to be by-passed and would generate heat.

The specified output of the pump must match the calculated oil requirement (see sample

calculations in Sections 4.2.2 and 4.2.3)

When calculating pump output, ensure that the actual operating speed of the tractor is

taken into account. Many pumps are specified at 540 rpm nominal PTO speed. Most

tractors are driven at an engine speed corresponding to a lower PTO speed. For example,

if running at 500 rpm a pump rated at 100 l/min at 540 rpm will actually produce:

100 l/min x 500 rpm (actual)

= 92.6 l/min

540 rpm (nominal)

4.2.5 Hydraulic Pressure and Hose Size Selection

When designing a system and selecting a pump, the additional pressure drop across all

hoses and fittings must be taken into account. The working pressure of all components

must be adequate for worst-case conditions, including start-up pressure surges.

All hoses, pipes and fittings must be chosen to give an acceptably low pressure drop at

the maximum operating flow rate. The procedure to select the sizes of the pressure and

return lines is as follows:

a) On all pressure lines – calculate flow through each section, then use the design table

(Table 1) to select the appropriate diameters so that the total pressure drop along any

route from the pump to a sprayhead does not exceed 3.0 bar (45 psi).

9

Page 11

DRAFT

TABLE 1 – Pressure drop along hydraulic hoses

0

1

Table shows pressure drop in

pounds per square inch per 10

feet (3.04m) of hose without

fittings. Oil viscocity 20 centistrokes

-4 -4 -5 -6 -6 -8 -8 -10 -10 -12 -12 -16 -16 -20 -20 -24 -24

0.19 0.25 0.25 0.31 0.38 0.41 0.50 0.50 0.63 0.63 0.75 0.88 1.00 1.13 1.25 1.38 1.5

4.82 6.3 6.3 7.9 9.7 10.4 12.7 12.7 16.0 16.0 19.1 22.4 25.4 28.7 31.8 35.1 38.

L/M UG/M

HOSE SIZE

HOSE I/D (IN)

HOSE I/D (mm)

OIL FLOW

0.9 0..25 10 3.1 3.1

1.9 0.50 19 6.0 6.0 2.7

3.8 1.00 40 12.0 12.0 5..5 2.4

7.6 2.00 95 24.0 24.0 10.0. 4.8 3.5

11.3 3.00 185 46.0 46.0 17.0 7.0 5.0 2.2 2.2

15.1 4.00 78.0 78.0 29.0 12.0 8.0 3.0 3.0 1.2 1.2

18.9 5.00 120 120 44.0 10.0 12.0 4.5 4.5 1.6 1.6 0.7

30.2 8.00 95.0 39.0 26.0 10.0 10.0 3.6 3.6 1.4 0.6

37.8 10.00 59.0 40.0 15.0 15.0 5.7 5.7 2.0 1.0 0.6

45.4 12.00 80.0 52.0 20.0 20.0 7.2 7.2 2.6 1.5 0.8 0.4

56.7 15.00 75.0 30.0 30.0 10.0 10.0 4.2 2.2 1.2 0.6 0.4

68.0 18.00 107 40.0 40.0 15.0 15.0 6.3 3.0 1.5 0.7 0.6 0.4

75.6 20.00 49.0 49.0 19.0 19.0 8.0 3.4 2.0 1.1 0.7 0.5 0.3

94.5 25.00 72.0 72.0 26.0 26.0 11.0 5.5 3.0 1.6 1.0 0.6 0.4

113 30.00 34.0 34.0 14.0 7.0 3.6 2.2 1.3 0.8 0.5

132 35.00 47.0 47.0 19.0 9.5 5.0 2.8 1.7 1.1 0.7

151 40.00 25.0 12.0 6.5 3.4 2.2 1.4 0.9

189 50.00 36.0 17.0 9.0 5.3 3.3 2.0 1.3

10

Page 12

DRAFT

O

b) On all return lines – assume that valves, fittings, etc can cause up to 10 psi (0.7 bar)

back-pressure. Refer to Table 1 to select hose sizes which give a maximum additional pressure drop of 10 psi (0.7 bar) on any route from a sprayhead to the reservoir.

c) Motor drain lines MUST be returned back to the oil reservoir in an open unrestricted

flow and MUST NOT have more than 75 psi (3.0 bar) total back pressure as the hydraulic motor shaft seal may rupture. To check the back pressure place a low pressure gauge in the case drain line on the motor furthest from the oil reservoir and with

the unit running read the pressure. If the pressure is above 75 psi (3.0 bar) the motor

drain line must be replaced with a larger diameter line.

4.2.6 Hoses, Fittings and Motor Connections

All pressure lines must be flexible hydraulic hose or steel hydraulic tube of the appropriate pressure rating.

Any type of hose fitting can be used, but the standard 37 degree JIC flare type is recommended wherever possible. Large radius hose elbows should be used to minimise pressure drops.

High pressure hose should preferably be terminated with swage type fittings. However,

if re-usable types are selected, they should never be re-used more than three times.

IMPORTANT: Never use galvanised water pipe or fittings in any part of an hydraulic

system.

Micron recommend connecting the hydraulic motors of sprayheads in parallel. If connected in series a maximum of two motors in each series chain should be used.

The supply and return connections MUST NOT be reversed as the fan will run in the opposite direction with little or no airflow.

T

U

O

L

I

O

N

I

L

I

M

O

T

O

R

L

D

I

N

R

E

A

I

N

Figure 5. Hydraulic motor connections

DRAIN LINES MUST BE FITTED. TOTAL BACK PRESSURE OF COMBINED

DRAIN LINES MUST NEVER EXCEED 3 BAR OR MOTOR SEAL FAILURE

WILL RESULT.

11

Page 13

DRAFT

4.2.7 System Protection

Any self-contained hydraulic system MUST be protected by a relief valve from the pressure side of the pump to the reservoir. This should be of the self re-setting type.

• For parallel running this must be set to 120 bar (1800 PSI) minimum.

• For series chains (two motors maximum) this must be set to 220 bar (3300 PSI) mini-

mum.

It is especially important to check that all other components and hoses are suitably specified for safe working at these higher pressures.

4.2.8 Pressure Surge Prevention

When stopping the sprayheads, it is important that neither the pressure nor return lines

are suddenly closed. The inertia of the atomisers can continue to drive the motors as

pumps and produce a high back-pressure in the system. The simplest method of stopping

the sprayheads is to by-pass all oil from the pump to the reservoir, leaving the ends of the

chains of sprayheads open. If this is not practical, a non-return valve may be fitted to allow oil to re-circulate as the motors decelerate. This option is shown in Figs 6 and 7.

4.2.9 Speed Regulation

The speed of all sprayheads may be regulated by means of either a pressure compensated

flow control valve or a by-pass valve between the pressure line from the pump and the

reservoir. Possible options are shown in Figs 6 and 7. The valve must be of an adequate

size to handle 70% of the maximum pump output without excessive back-pressure or

overheating.

4.2.10 Hydraulic Oil

Only specially formulated hydraulic oils should be used with Turbofan Sprayheads. Engine lubricating oils must never be used. Shell Tellus 32 or equivalent hydraulic oil is

recommended for most conditions but Shell Tellus 37 or equivalent should be used in

tropical climates.

4.2.11 Oil Reservoir

The oil reservoir of a self-contained system must contain sufficient hydraulic oil to prevent overheating. As a rough rule, allow two litres of oil for every one litre per minute

displacement of the pump. Under tropical conditions it may be necessary to increase this

by 50%.

The return line to the reservoir must be taken to a point below the oil level to prevent

foaming. The inlet and outlet lines to the reservoir must be as far apart as possible and

not directly in line with each other. A baffle should be placed between the inlet and outlet sides of the reservoir. The reservoir should have an air space above the oil of at least

30% of the total oil volume, or 15 cm (6 inches), whichever is greater.

4.2.12 Cooling

Overheating of the system should not be a problem if the provisions of 4.2.11 above are

followed. However, if additional cooling is required, it may be necessary to return oil to

the reservoir via a heat exchanger. Ensure that this does not cause a significant backpressure. The use of metal (as opposed to flexible) hydraulic lines wherever possible in

the system will also help to cool the oil.

12

Page 14

PRESSURE GAUGE

ON/OFFVALVE

FLOW

DRAFT

CONTROL

VALVE

CHECK

PRESSURE SIDE FILTER

FILLER/BREATHER

PUMP

SUCTION

VALVE

RELIEF

STRAINER

IN PA RALLEL

OIL

RESERVOIR

SPRAY HEADS CONNECTED

RETURN FILTER

Figure 6. Typical self-contained hydraulic system

13

Page 15

PRESSURE LINE FR OM TR ACTOR

PRESSURE SIDE

RETURN

LINE

FIL TER

DRAFT

FIL TER

PRESSURE GA UGE

FLOW

CONTROL

CHECK

VALVE

OPEN CENTRE SYSTEM

PRESSURE LINE FROM TR ACTOR

RETURN

LINE

FIL T ER

Note: Return line may have

to be taken to oil filler

point of tractor

(see tractor manual

for details)

PRESSURE SIDE

FIL TER

PRESSURE GAUG E

NEEDLE

VALVE

CHECK

VALVE

CLOSED CENTRE SYSTEM

Figure 7. Typical systems connected to tractor hydraulics

14

Page 16

DRAFT

4.2.13 Filter

All hydraulic systems MUST be filtered. For sprayers using the tractor’s hydraulic system, a return line filter with a 25 micron replaceable cartridge and a full-flow by-pass relief valve should be fitted in the return line to the tractor.

A pressure side filter MUST also be fitted in order to protect the gear motors and shaft

seals. A 10 micron filter should be used located between the tractor remote hydraulic

coupling (supply) and the first component in the sprayhead hydraulic circuit.

Self-contained systems should preferably be fitted with a 125 micron suction strainer between the oil reservoir and the hydraulic pump. A 25 micron replaceable cartridge filter

with a full-flow by-pass relief valve must always be fitted in the return to the reservoir.

Ensure that the filters are of adequate size to maintain oil flow even when partially

blocked. The return filter should be fitted with a pressure gauge to monitor the condition

of the filter by checking the back-pressure.

A pressure side filter should also be fitted to self-contained systems. See Fig 6 .

4.3 Spray Liquid

The flow of spray liquid to each Turbofan Sprayhead must be regulated to give the

correct total output from the sprayer and consequently the required application rate on the

crop.

Chemical flow can be regulated by either a fixed or a variable restrictor unit in the

feedpipe to each sprayhead.

Fixed restrictors or variable restrictors are available from Micron Sprayers as optional

extras.

The MICRON fixed restrictor uses an orifice plate fitted in a housing which can be

installed into the inlet connection of the sprayhead (Page 25, Item No. 29 , Micron Part

No. 6197).

See Section 7 (’CALIBRATION AND ADJUSTMENT’) for full details of the fixed

restrictor calibration procedure.

Unlike hydraulic nozzles, Micron Turbofan Sprayheads do not require a high pressure to

operate. Droplet size is unaffected by system pressure. The pressure should, therefore,

be selected to give the correct liquid flow through the restrictor (see Calibration section).

If an existing sprayer is to be converted, the original spray pump can often be retained. If

this pump is a high pressure type or if it has excess capacity, it may be necessary to fit an

adjustable pressure regulator in the feed to the sprayheads. If a pressure regulator is

already fitted but cannot be adjusted to a sufficiently low pressure, it will be necessary to

fit a second low pressure regulator to the output of the main regulator. This allows the

first regulator to by-pass the majority of the surplus flow to the tank and provide a

stabilised input to the second regulator.

15

Page 17

DRAFT

If a new sprayer is being designed or an original pump is to be replaced, it is suggested

that a diaphragm or centrifugal type is chosen. This should be able to provide a pressure

of about 1 – 3 bar (15 – 45 psi) and should be capable of delivering the maximum flow

rate of the sprayer plus the flow required for tank agitation (if a mechanical agitator is not

used). An output of 60 l/min is satisfactory for most low volume sprayers without

mechanical agitation.

A chemical on/off valve must be fitted in the main feed to the sprayheads. This may be

mechanically or solenoid operated. A multi-position valve can be used to select different

groups of sprayheads if required.

A filter must be incorporated in the chemical supply to the sprayheads. This should have

an 0.5 mm (50 mesh/inch) or finer mesh filter. The filter may be installed either in the

suction or pressure line of the pump but the filter must always be before the flow

restrictors and should preferably be before the pressure regulator. Fig 8 shows the

recommended chemical feed configuration for a typical sprayer.

CHEMICAL

TANK

SUCTION STRAIN ER

RETURN LINE TO AGITA T OR

SPRAY HEADS

PRESSURE

GAUGE

CHEMICAL PUMP

ON/OFF AND

PRESSURE

CONTROL

VALVE

FLOW

RESTRICTORS

Figure 8. Typical configuration of chemical feed to heads

16

Page 18

DRAFT

4.4 Testing

Any new sprayer must be tested to ensure the following:

1. That the sprayheads all rotate at the correct speed.

2. That the chemical flow from each sprayhead is equal and that the flow can be

adjusted over the full range required.

3. That the sprayheads are correctly positioned to give the required coverage without

any tendency to ‘striping’. No spray droplets should be blown towards the operator

or onto the structure of the sprayer.

Full details of the procedures to achieve the above are given in the Section 5,

(‘OPERATION’) and Section 7 (‘CALIBRATION’) sections of this handbook.

5.0 OPERATION

As with all sprayers, optimum results will only be obtained from a machine fitted with

Turbofan Sprayheads if it is correctly calibrated, operated and maintained.

It is important that every operator who uses Micron sprayheads is completely familiar

with their calibration and use. The following sections emphasise points of particular

importance.

5.1 Daily inspection

All parts of the sprayer should be checked at least once a day. A complete check list for

the sprayheads is included in the Maintenance section of this Handbook. However,

particular attention must be paid to the condition of the atomiser discs, chemical

feedpipes and restrictors and all hydraulic hoses and fittings. All atomisers must run

smoothly without vibration.

5.2 Calibration Procedure

Before use, the sprayer must be calibrated for application rate. Full details are given in

the Section 7 (‘CALIBRATION’). It is important to note that the graphs and tables are

based on performance with water and are intended only as a guide. Actual performance

will vary according to the type and formulation of chemical being used. It is therefore

vital that the calibration of the system is checked whenever a new chemical is used.

5.3 Position of Sprayheads

The position and angle of sprayheads must be checked and adjusted as necessary before

use. When sprayheads are mounted on a boom, the boom height must be adjusted to suit

the crop being sprayed. See Section 4.1 (‘Mounting of Sprayheads’) for details of

recommended positions and angles of sprayheads.

When a sprayer is used for the first time on a new crop, the coverage of spray droplets on

the foliage should be checked to ensure that the sprayheads are correctly positioned.

The coverage can sometimes be assessed visually if the colour of the active material

leaves a clearly defined droplet (as with some fungicides). However, it is preferable to

place water sensitive papers in the foliage and to check the coverage by the droplet

density on the papers. Alternatively, a fluorescent dye can be added to the spray mixture

17

Page 19

DRAFT

and the coverage assessed viewing the droplets with an ultra-violet lamp in the dark.

5.4 Sequence of Operation

It is important that all sprayheads are rotating at their correct speed before the chemical

supply is turned on. Similarly, the chemical supply must be shut off before the

sprayheads are stopped. This ensures that a stream of chemical does not run out of the

atomisers and that the correct size of droplet is always produced.

When starting the rotation of sprayheads, the speed of the PTO or other hydraulic pump

drive should be reduced to a minimum and then increased to the normal level once the

units are running.

It is not normally necessary to stop the sprayheads every time the chemical flow is turned

off. However, the sprayheads must always be stopped before folding spray booms or if

there is the risk of accidental contact with foliage when turning at the end of a row.

5.5 After Use

The entire sprayer must be emptied and flushed out with clean water or a suitable solvent

after use. This eliminates the possibility of dried chemical residues blocking valves,

restrictors or atomiser discs. This precaution is particularly important when using

wetable powders as these will tend to sediment in the tank and pipework, causing serious

blockages when the sprayer is next used.

The atomisers should be rotating during the flushing process to distribute the chemical

and flushing liquid into the crop as spray droplets. This also ensures the most efficient

cleaning of the atomiser discs.

6.0 HEALTH AND SAFETY

Any sprayer using Turbofan Sprayheads must be used by a qualified operator in

accordance with the recommendations and statutory requirements for the use of sprayers

and the product being sprayed.

These requirements will be set out in the applicable local legislation and in the label of

the product being used.

In the United Kingdom, the precautions and regulations concerning the use of pesticides

and sprayers are defined in the Code of Practice for the Use of Pesticides on Farms and

Holdings (published by HMSO for the Ministry of Agriculture, Fisheries and Food and

the Health and Safety Commission).

The use of pesticides and sprayers are subject to legislation or codes of practice in most

other countries. It is the responsibility of the user to ensure that these are read,

understood and complied with.

18

Page 20

DRAFT

The following recommendations are for guidance only and do not exclude any statutory

requirements:

1. Always wear adequate protective clothing, eye protection and respiratory protection

when mixing, transferring or spraying pesticides. The minimum level of protection

will be stated on the chemical label or in the Code of Practices in most countries.

2. Protective clothing, respirators etc must be removed as soon as exposure to pesticides

has ceased. All items must be washed or disposed of safely according to the

manufacturers’ recommendations.

3. Ensure that the sprayer is correctly calibrated for the chemical, application technique

and crop or pest being sprayed.

4. Take note of the speed and direction of the wind. Ensure that spray droplets do not

drift on adjacent crops, another person’s land or an inhabited area. Do not drive the

sprayer upwind so that spray could be blown back towards the operator.

5. Never walk into a sprayed area until it is safe to do so according to the chemical

manufacturer’s recommendations.

6. All traces of chemical must be washed from the operator’s skin immediately after

spraying and before eating, drinking or smoking.

7. Remove all traces of chemical from the tank, pipework and sprayheads as well as

from external surfaces of the sprayer.

8. All residues of chemical from the sprayer, pesticide containers or mixing vessels, etc

must be disposed of safely by an approved means. Do not contaminate an off-target

area or allow pesticides to reach streams, wells or groundwater.

9. Dispose of empty chemical containers safely by an approved means. Do not keep

containers for re-use for other purposes.

7.0 CALIBRATION AND ADJUSTMENT

As with any sprayer, a machine fitted with Turbofan Sprayheads must be calibrated

before use.

The following sections describe the calibration of a typical sprayer using Turbofan

Sprayheads. The procedure may differ slightly for some specialised sprayers.

7.1 Application Rate

The output rate of chemical from the sprayer will be determined by the required

application rate (in litres/hectare) and the area sprayed per minute (in hectares/minute).

The flow of chemical from each sprayhead is usually controlled by an interchangeable

fixed restrictor orifice in the feed to the atomiser and by the spray chemical pressure.

Spray chemical pressure is controlled by the pressure regulator or by-pass valve in the

feed from the chemical pump.

19

Page 21

DRAFT

The following steps describe the calibration procedure in detail:

1. Establish the average forward speed of the sprayer. The most accurate means of

assessing the speed is to drive the sprayer in the actual crop. The speed can than be

calculated from the time to cover a measured distance.

2. Establish the width of the swath of spray on the target. In row and broadacre crops

this will be proportional to the boom width. In orchard, vineyard and soft fruit

spraying this can be determined by the row spacing and the number of rows sprayed

at a time.

3. Calculate the area treated by the sprayer per minute. As an example, Fig 9 shows the

sprayer being operated over a field crop.

If the sprayer is being driven at S km/hr this corresponds to 1000 x S metres/hour:

Distance travelled = 1000 x S metres/minute

60

If the width of the swath is W metres, then the area treated per minute is:

Area treated = 1000 x S x W metres 2 /minute

60

DISTANCE TRAVELLED

IN ONE MINUTE

SWATH WIDTH

W METRES

Figure 9. Coverage of sprayer

SPEED S KM/HR

20

Page 22

DRAFT

This is converted to hectares by dividing by 10,000:

Area treated = 1000 x S x W = S x W ha/minute

60 x 10,000 600

This gives the standard formula for calculating the coverage of a sprayer:

Area/min = swath width (m) x speed (km/hr) ha/min

600

Example:

Speed : 8km/hour

Swath width: 12 m

Therefore:

Area treated = S x W = 8 x 12 = 0.16 ha/min

600 600

Table 2 shows the coverage of the sprayer for various swath widths and spraying

speeds.

Table 2 – Coverage of sprayer in ha/min

SWATH WIDTH (metres)

SPEED

km/hr

4 6 8 10 15 20 25 30

4 0.03 0.04 0.05 0.07 0.10 0.13 0.17 0.20

6 0.04 0.06 0.08 0.10 0.15 0.20 0.25 0.30

8 0.05 0.08 0.11 0.13 0.20 0.27 0.33 0.40

10 0.07 0.10 0.13 0.17 0.25 0.33 0.42 0.50

12 0.08 0.12 0.16 0.20 0.30 0.40 0.50 0.60

14 0.09 0.14 0.19 0.23 0.35 0.47 0.58 0.70

4. Calculate the required output from the sprayer in litres/minute to give the correct

application rate for the chemical being used.

The output rate of chemical is given by the area sprayed (in hectares) per minute

multiplied by the required application rate in litres per hectare.

Example:

Coverage: 0.16 ha/min

Application rate: 100 l/ha

Output = 0.16 x 100 = 16 l/min

21

Page 23

DRAFT

5. Calculate the output of each sprayhead by dividing the total output of the sprayer by

the number of sprayheads.

Example:

Output: 16 l/min from sprayer

No of sprayheads: 8

Output/sprayhead = 16/8 = 2 l/min

6. Sel ect the correct fixed restrictor orifice to give the required flow rate per sprayhead

at the normal working pressure of the sprayer (typically about 2 bar or 30 psi). Table

3 gives the typical flow rates for fixed restrictor orifices. These figures are based on

measurements with water. Actual flow rates may differ according to the viscosity of

the chemical being used.

Table 3. Approximate flow rates for fixed restrictor orifices

RESTRICTOR No. FLOW RATE (litres/minute)

10 0.30 0.42 0.51

48 0.62 0.87 1.07

55 0.81 1.14 1.40

86 2.05 2.90 3.55

1 Bar (15 psi) 2 Bar (30 psi) 3 Bar (45 psi)

7. Fit the appropriate orifice in the fixed restrictor of each sprayhead.

8. Place a container under each sprayhead.

9. Ensure that the chemical on/off valve is closed.

10. Fill the tank of the sprayer with at least 50 litres of the chemical to be used or a liquid

of similar properties.

11. Start the chemical pump of the sprayer but do not run the hydraulic system.

12. Open the chemical valve until all air is purged from the hoses and sprayheads.

Return the chemical collected in the containers to the tank of the sprayer.

13. Place the containers back under the sprayheads and open the chemical on/off valve

again and collect chemical for a measured time of one or two minutes. Use a

measuring cylinder or calibrated container to measure the output and calculate the

flow rate in litres per minute per sprayhead.

14. Check that the flow from each sprayhead is the same and compare the total measured

output rate from all the sprayheads with the calculated rate from step (4).

15. If the actual output is slightly too high or too low, it may be possible to adjust it by

varying the spray chemical pressure.

16. If this adjustment is insufficient, the restrictor orifice for each sprayhead must be

changed to a smaller size to reduce the flow or a larger size to increase the flow.

17. The flow must always be re-checked after making any adjustments to the restrictors

or chemical pressure.

22

Page 24

DRAFT

8.0 MAINTENANCE

The Turbofan Sprayhead is manufactured from high quality materials which have been

selected for maximum strength, reliability and resistance to agricultural products. In

order to ensure a long and trouble-free working life, it is important that each sprayhead

should be periodically checked, cleaned and lubricated.

8.1 Routine Maintenance

Before each spray operation:

1. Check the general condition of the system, including hydraulic and chemical

hoses and fittings; repair any leaks.

2. Check condition of the bearing and hydraulic motor of each sprayhead by rotating

the atomiser by hand. Any roughness, stiffness or sideways movement indicates

that the unit requires maintenance.

3. Check the condition of the atomiser and fan blades. These should not be

damaged and must be free of any chemical contamination. Clean if necessary and

replace any damaged parts.

4. Check that each atomiser is correctly positioned and that its chemical flow

restrictor is correctly adjusted for the work being undertaken.

5. Check that the hydraulic system is adjusted to give the correct rotational speed for

all sprayheads.

Each day after spraying:

1. Empty any remaining chemical from the spray system.

2. Flush the entire system through with clean water or a suitable solvent. This

procedure is particularly important if chemicals containing solids in suspension

have been used as powder can settle out in pipework and cause blockage.

3. It is recommended that the outside surfaces of all sprayheads and booms are

washed down with a pressure washer or similar in order to prevent build up of

spray chemicals.

4. Ensure that all atomiser discs are free of contamination. Any build-up of dried

chemical degrades the droplet spectrum from an atomiser and may cause

vibration that can severely damage the unit.

8.2 Dismantling of Sprayhead

Should a sprayhead require maintenance, it must be dismantled and serviced as described

below. Numbers in brackets between 1 – 42 refer to parts of the sprayhead as shown in

the parts diagram on page 25.

IMPORTANT: Any defective parts must be replaced with genuine Micron spares.

Use of substitute parts or attempts at local repairs will void all warranties.

23

Page 25

DRAFT

1. Disconnect all hoses and remove sprayhead from the sprayer. Plug all free ends of

hydraulic hoses on the sprayer and all ports on the hydraulic motor.

2. Remove atomiser (1) by unscrewing screw (7).

3. Remove frontplate (10) complete with distributor (15) by unscrewing twelve

screws, nuts and washers (2,8,4) and four screws, nuts and washers (6,8,4).

4. Separate feed tube (34) from straight connection (27) fitted in the distributor by

pushing down on the top of the straight connector and pulling the feed tube out of

it.

5. Lift the front plate complete with distributor free of the main body and put to one

side.

6. Remove front shaft (14) and fan (21) from the main unit by undoing four capscrews

and washers (39,3). These two parts should be only a sliding fit on the hub (12)

and can be removed easily. (If the front shaft proves difficult to remove then a very

long M6 setscrew (or piece of M6 threaded bar) can be used as a puller by screwing

into the end of the front shaft and reacting against the end of the screw (33) inside

the hub).

7. Remove two off drive pins (40) and two pairs of lock washers (41).

8. Next remove the hub (12) from the bearing by unscrewing the four grubscrews (13)

and pulling the hub off by hand, or with the aid of a universal bearing puller.

9. Remove the hydraulic motor (22) complete with bearing (23) and shaft extension

(42) by undoing four screws, nuts and washers (6,8,4).

10. The bearing (10) can be removed from the motor by the use of a brass or

aluminium drift or a universal bearing puller. The bearing should only be removed

if it requires replacement.

11. The shaft extension (42) can be removed from the motor by removing the capscrew

(33), lock washer pair (37) and plain washer (38). The shaft extension can be

removed using either a suitable brass or aluminium drift or a small universal

bearing puller. Take care to retain the key in the motor shaft for future use. The

shaft extension should only be removed if it is either to be replaced or if

maintainence is necessary on the hydraulic motor involving the removal of the

hydraulic motor main shaft.

12. The motor support bracket (31) and rear guard (36) can now be removed if

necessary by undoing all remaining M6 screws and nuts (8,6,4,2).

24

Page 26

DRAFT

TURBOFAN (BASIC) PARTS LIST (TBF/200)

PART NO. DESCRIPTION QTY

4915 SCREW, M5 X 16, S/S 4

5245 NUT, M4 NYLOC 2

5472 SCREW, M6 X 16, SET, HEX, S/S 24

5722 WASHER, M6, FLAT, S/S 36

5887 WASHER, M6 X 25 OD, PLAIN, S/S 1

5971 SCREW, M6 X 25, SET, HEX, S/S 12

5983 SCREW, M6 X 20, SET, HEX, S/S 1

5984 NUT, M6, NYLOC, S/S 36

6058 FAN COWL 1

6061 SADDLE 2

6066 FAN, 4-BLADE 1

6067 MOTOR, HYDRAULIC, C/W KEY 1

6068 BEARING NO.6006LLUA/2A 1

6077 WASHER, M16, NORDLOCK (PAIR) 2

6078 SCREW, M16 X 40, SET, HEX, S/S 2

6079 WASHER, 5M X 15OD X 1.6, S/S 1

6138 KEY FOR HYDRAULIC MOTOR 1

6182 WASHER, M6, SHAKEPROOF 5

6184 CARRIER, MOTOR 1

6185 SPACER 4

6186 SCREW, M5 X 16, CAP HEAD, S/S 1

6187 WASHER, 5M NORDLOCK (PAIR) 5

6194 GUARD, REAR 1

6206 LABEL, DRAINLINE 1

6207 LABEL, ROTATION 2

6247 SHAFT, FAN/ATOMISER 1

6248 RING, LOCKING 1

6249 SCREW, M6 X 25, SOCKET 4

6256 SCREW, M4 X 25, PANHEAD 2

6266 DISTRIBUTOR BLOCK 1

6278 DRIVE CROSS 1

6283 FRONT PLATE (2 HOLE FEED) 1

6743 FEED TUBE 8MM OD BRASS 1

6746 ADAPTER MALE STUD 8MM X 1/8” BSPT (13480—8-18 TECH HOSE) 1

6793 ADAPTER 1/4” BSP F/F 1

6794 ADAPER MALE STUD 8MM x 1/4” BSP 1

AJ6379 BODY 1/4” LFM BRASS 1

AJ6380 CAP LF BRASS 1

AJ6381 HOSE BARB 3/8” BRASS 1

MICRON ATOMISER PARTS (TBF/003)

6261A ATOMISER STACK ASSEMBLY 1

6277 WASHER, M8, FIBRE 1

6262 BOLT, BANJO (MICRON) 1

6263 FEED BODY (MICRON) 1

6267 SPACER (MICRON) 1

MICRONAIR ATOMISER PARTS (TBF/004)

6277 SEAL, BONDED 1

6279 ATOMISER GAUZE 1

6280 ATOMISER HUB 1

6281 BOLT, BANJO 1

6282 FEED BODY 1

6258 SCREW, 8-32 UNC X 100 DEGREE 3

25

Page 27

TURBOFAN PARTS DIAGRAM

AJ 6381

AJ 6379

AJ 6380

6793

6184

6794

DRAFT

5971

5722

5984

5971

6185

5722

6207

5984

5984

5722

6087

6078

6067

6249

6077

6138

6248

6194

6061

5984

6068

5722

6411

5971

6278

6079

6058

6187

5245

6186

6746

6266

6256

6743

6283

6066

6061

5984

5722

5472

5971

5722

5984

6277

6282

6281

MICRONAIR A T OMISER

6279

6280

6238

MI CRON A TOMISER

6277

6262

6263

26

6187

6261A

4915

6247

6182

5472

5887

6182

5983

Page 28

APPENDIX A

TURBOFAN HYDRAULIC MOTOR DOUBLE SEAL ARRANGEMENT

WITH "TELL-TALE" BOTTLE

A

B

E

D

Since February 2003 the hydraulic motor driving the Turbofan head has been fitted with a

double oil seal arrangement. Between the two seals there is a port connected to outside via

the flange of the motor. This port is connected to a small "tell-tale" bottle of transparent

plastic. A failure of the first seal will result in oil being passed into the bottle.

If oil is observed in either the bottle or the pipe leading to it, the machine must be stopped

and the seals (both) replaced.

This arrangement is shown in the above illustration.

KEY:

A = Hydraulic Motor Part No. 6358 B = Pipe Part No. 4993/8

C = Bottle Part No. 6574 D = Clip Part No. 6573

E = Nozzle Part No. 6575

C

NOTE: THE PURPOSE OF THE BOTTLE IS TO SHOW LEAKING OIL. DO

NOT PUT OIL IN THE BOTTLE.

Loading...

Loading...