Micron Industries Low Voltage General Purpose Transformers General Product Line Information

Low Voltage General Purpose Transformers

UL Listed, CSA Certified

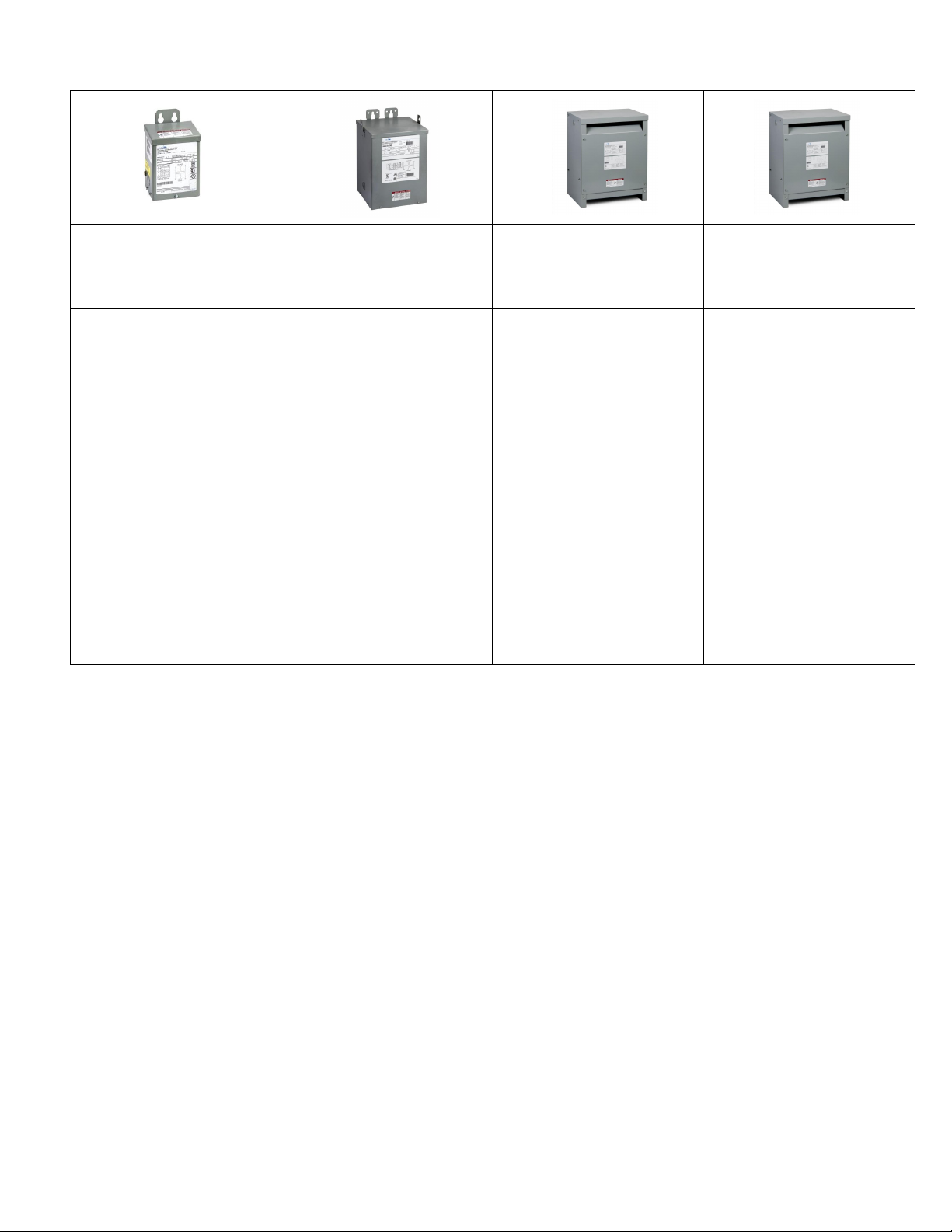

Single Phase

Type 1-E

Encapsulated

UL Listed

Three Phase

Type 3-E

Encapsulated

UL listed

Single Phase

Type 1-V

Ventilated

UL Listed

Three Phase

Type 3-V

Ventilated

Type 1-E general purpose

transformers are single

phase, resin encapsulated

designs suitable for indoor

or outdoor applications. It's

totally enclosed, nonventilated enclosure make

it ideally suited for use in

areas that contain dust,

moisture, or corrosive

fumes. Available in ratings

through 25 KVA type 1-E

transformers can be

mounted in any position for

indoor installations and in

upright positions only for

outdoor installations.

Type 3-E resin

encapsulated, 3-phase

transformers are available

in ratings of 3-75 KVA. Its

totally enclosed nonventilated enclosure makes

the 3-E ideally suited for

outdoor as well as indoor

locations. Type 3-E

transformers utilize the

185°C insulation system

with 115°C rise. 3-E

transformers 3-15 KVA are

T-T connected.

1-V general purpose

transformers are single

phase ventilated units

designed primarily for

indoor locations (also for

outdoor , 600 volt class

with the addition of

weathershields). The 1-V

utilizes a 220°C insulation

system with 150°C rise and

is available in ratings of 15167 KVA.

1-V products are compliant

to DOE 2016.

The 3-phase 3-V ventilated

dry-type is available in

ratings of 15-750 KVA. Its

220°C insulation system

(150°C rise) is selfextinguishing. 3-V

enclosures are designed for

indoor locations (or

outdoor, 600 volt class with

addition of

weathershields).

3-V products are compliant

to DOE 2016.

Mounting

Units installed outdoors must be mounted in upright position.

Efficiency

The Micron series of ventilated, three-phase, 600 volt class general purpose distribution transformers meet the DOE

2016 efficiency requirements and federal energy efficiency laws. New distribution transformers installed in the United

States are required to meet these energy efficiency requirements as of January 2016.

Winding Terminations

Primary and secondary windings are terminated in the wiring compartment. Encapsulated units have copper leads or

stabs brought out for connections. Micron recommends external cables be rated 90°C (sized at 75°C ampacity) for

encapsulated designs.

Series-Multiple Windings

Series-multiple windings consist of 2 similar coils in each winding which can be connected in series or parallel

(multiple). Transformers with series-multiple windings are designated with an "X" or"/" between the voltage ratings.

such as primary voltage of "120/240" or "240 X 480". If the series-multiple winding is designated by an "X" the winding

can be connected only for a series or parallel. With the"/" designation, a mid-point also becomes available in addition

to the series or parallel connection. As an example, a 120 X 240 winding can be connected for either 120 (parallel) or

240 (series), but a 120/240 winding can be connected for 120 (parallel), or 240 (series), or 240 with a 120 mid-point.

2

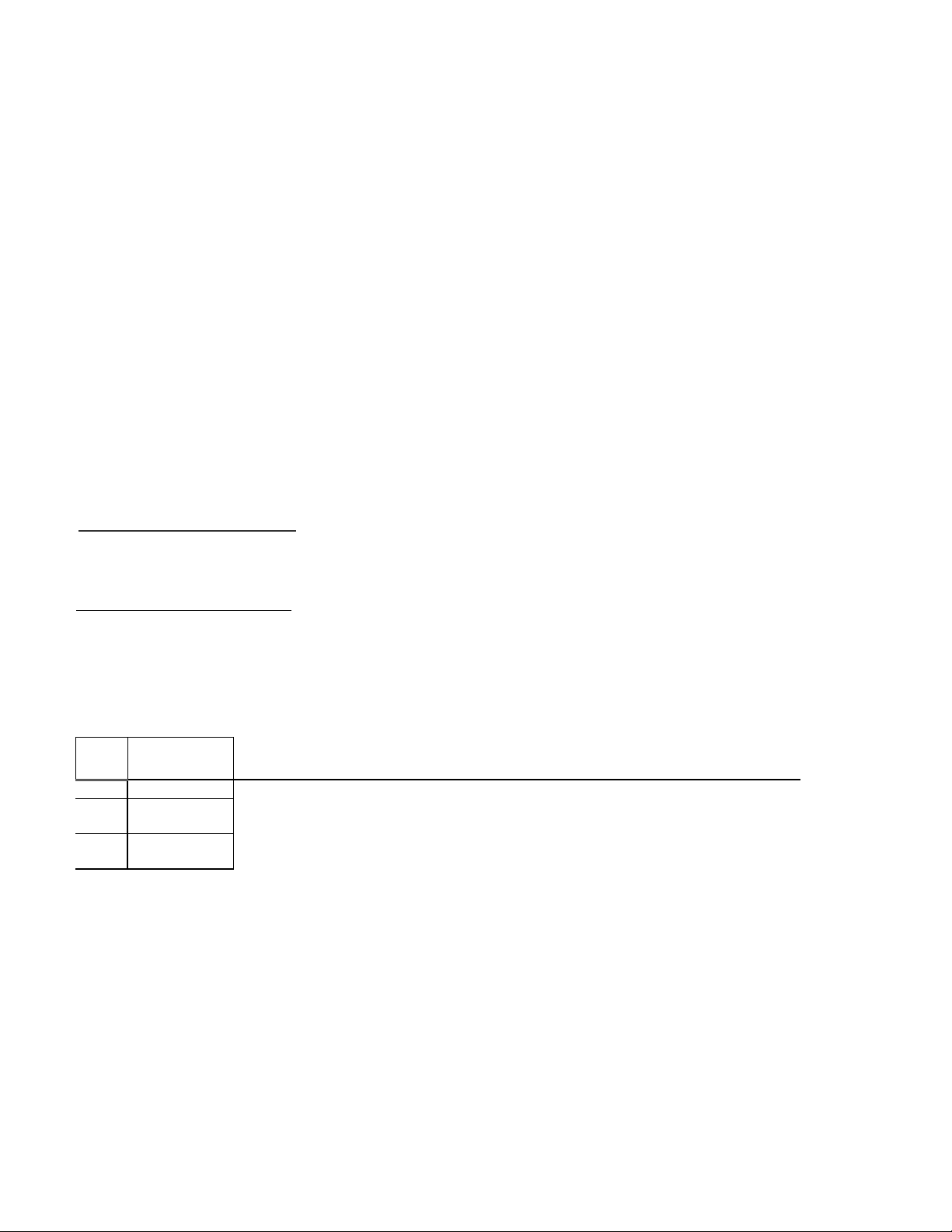

Ambient

+

Winding

Rise

+

Hot

Spot

=

Temp.

Class

The design life of transformers having different insulation systems is the same – the

lower temperature systems are designed for the same life as the higher temperature

systems.

40°C

55°C

10°C

105°C

40°C

80°C

30°C

150°C

40°C

115°C

30°C

185°C

KVA

NEMA Average₁

Sound Level in dB

All Micron 600 volt class dry-type distribution transformers are designed to meet

NEMA ST-20 levels as listed.

0-9

40

10-50

45

51-150

50

151-300

55

301-500

60

General Information

Industry Standards

All Micron dry-type distribution and control transformers are built and tested in accordance with applicable NEMA,

ANSI and IEEE standards. All 600 volt class transformers are UL listed unless otherwise noted.

Seismic Qualified

The Micron family of dry-type distribution transformers is seismically tested, seismically qualified, and exceeds

requirements of the Uniform Building Code (UBC) and California Code Title 24.

Frequency

Micron standard dry-type distribution transformers are designed for 60 Hz operation. Transformers required for other

frequencies must be specifically designed.

Overload Capability

Short term overload is designed into transformers as required by ANSI. Basically, dry-type distribution transformers

will deliver 200% nameplate load for one-half hour; 150% load for one-hour; and 125% load for four-hours without

being damaged provided that a constant 50% load precedes and follows the overload. See ANSI C57 .96-01.250 for

additional limitations.

Continuous overload capacity is not deliberately designed into a transformer because the design objective is to be

within the allowed winding temperature rise with nameplate loading.

Insulation System & Temperature Rise

Industry standards classify insulation systems and rise as shown below:

Insulation System Classification

Sound Levels

₁. Applies to general purpose transformers only.

3

Loading...

Loading...