Page 1

Product Data Sheet

PS-001446, Rev. F

ProLink® III Software

A Configuration and Service Tool for Micro Motion® and

Rosemount Flow

®

Devices

March 2016

World-class configuration, service, and

troubleshooting tool

Supports all Micro Motion flow, density, and

viscosity meters.

Supports Rosemount 8600D, 8732E, 8712E,

8712H, and 8800D

Management and simulation of configuration

files

Intuitive display of process variables and

diagnostics

Enhanced data logging functionality, both on-

demand or time-based

Graphical process variable trending views

Support for multiple devices and protocols

Supports HART, Modbus RS-485, USB-A to USB-A

wired communications from PC to Model 5700

devices, and Modbus/TCP communications

Simultaneously connect to multiple devices

Process variable comparison tool for evaluating

multiple devices simultaneously

Page 2

ProLink® III Configuration and Service Tool

March 2016

ProLink® III configuration and service software

About ProLink® III

ProLink® III delivers all the power and flexibility you need to configure and manage Micro Motion® and Rosemount Flow devices and

analyze process data. ProLink III provides an easy-to-use interface that allows you to have your meter up and running quickly no

matter how complex your configuration or diagnostic needs are.

ProLink III provides an intuitive, dashboard-like interface where you can simultaneously access all the information you may need to

assess your meter’s health. You can easily see your process variables and alert conditions from a single screen. You can also view

detailed information about the raw signals being processed by a device; such as drive gain, time period, and pickoff values. This kind

of information can be extremely helpful when troubleshooting device behavior and can minimize expensive downtime.

ProLink III also provides configuration capabilities that allow you to save and upload configuration information from one device to

another. Or, you can use the offline configuration tool to configure a device prior to making a physical connection. With features

like these, you can more efficiently manage the set up and commissioning of your Micro Motion or Rosemount Flow device.

Advantages

Intuitive interface for clear, concise data portrayal

Improved connectivity through HART, Modbus and

Modbus/TCP support

Task-oriented interface design that streamlines work

practices

Online process variable trending tool can highlight process

control opportunities

Capability to diagnose meters remotely using Modbus/TCP

connection

Simultaneously view process data from more than one

meter

Offline configuration reduces connection time to meters in

hazardous areas

Device simulation that allows you to understand a meter’s

capabilities and functionality

Easily view calibration and configuration data in a printable

report that allows you to quickly reference a device’s setup

Guided connection tool with a drag-and-drop interface that

allows you to easily configure your device connection

2 www.micromotion.com

Page 3

March 2016

ProLink

®

III Configuration and Service Tool

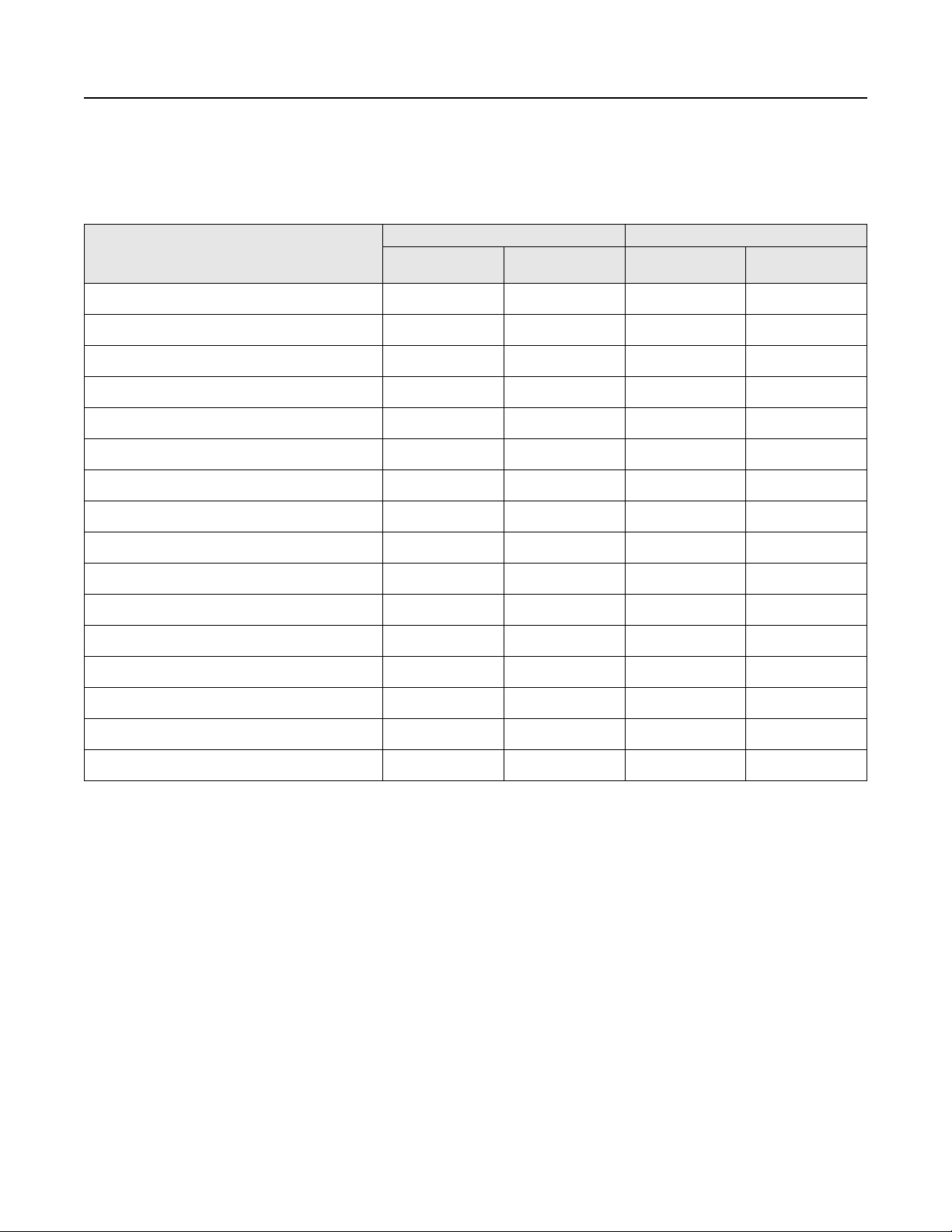

ProLink III versions – Basic or Professional

You have two options for purchasing ProLink III: as a Basic edition or a Professional edition for either Micro Motion or Rosemount

Flow. Following are the features available in each edition of ProLink III.

Micro Motion Basic and Professional features per edition

Basic Professional

Feature

Full transmitter configuration

Coriolis

Transmitters

✓✓✓✓

Density/Viscosity

Meters

Coriolis

Transmitters

Density/Viscosity

Meters

Alert notifications

Alert resolution guide

Diagnostics/inputs/outputs display

Smart Meter Verification launch

Load and save device configurations

Known Density Verification launch

Known Density Verification reports

Smart Meter Verification reports

Process variable trending (one or more devices)

Offline configuration management

Device simulation

Data logging

Multidevice comparison tool

Guided process support tools

Modbus/TCP

✓✓✓✓

✓✓✓✓

✓✓✓✓

✓✓

✓✓✓✓

✓✓

✓✓

✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

www.micromotion.com 3

Page 4

ProLink® III Configuration and Service Tool

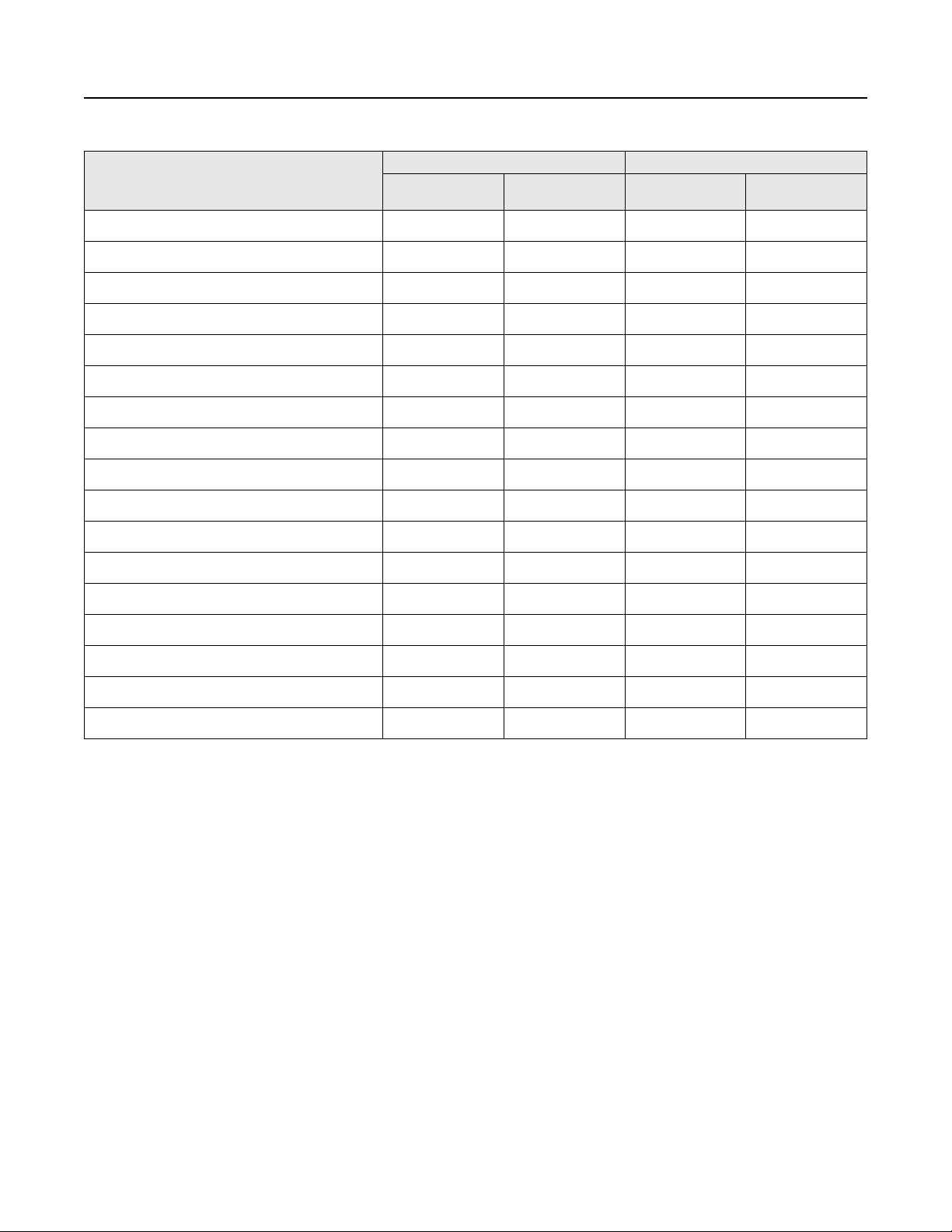

Rosemount Flow Basic and Professional features per edition

Basic Professional

Feature

Full transmitter configuration

Magmeter

transmitters

✓✓✓✓

Vortex

transmitters

Magmeter

transmitters

March 2016

Vortex

transmitters

Alert notifications

Alert resolution guide

Diagnostics/inputs/outputs display

Smart Meter Verification launch

Load and save device configurations

Known Density Verification launch

Known Density Verification reports

Smart Meter Verification reports

Process variable trending (one or more devices)

Offline configuration management

Device simulation

Data logging

Multidevice comparison tool

Guided process support tools

Modbus/TCP

✓✓✓✓

✓✓✓✓

✓✓✓✓

✓✓

✓✓✓✓

✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

Filter visualization tool

✓

4 www.micromotion.com

Page 5

March 2016

At a glance, you can see your key process

variables and diagnostics data – allowing

you to better manage your system

performance.

Connect to and navigate

between multiple devices

simultaneously.

Simulate a device

or create an offline

configuration.

Monitor meter performance by

charting process trends and

logging system data.

Easy access to active alerts, and receive

immediate support in understanding how to

respond to the issues.

ProLink

®

III Configuration and Service Tool

ProLink III – A clear window into your process

ProLink III offers a clear, reliable view of your key process

information from one main display screen. ProLink III can help

you to manage your system process variables more efficiently –

saving you time when investigating process problems – and

reducing the need for physically viewing the local device

displays. Regardless of how you have configured your device

outputs, ProLink III displays all the process variable information

that the device has available, including totalizer and inventory

data.

Easily configure your device from a single access point

With ProLink III, you can quickly navigate to the settings you

need because all configuration information is accessible from a

single access point. ProLink III communicates configuration

changes to the device, which allows you to evaluate the effect of

your changes and pick the right settings for your process.

Additionally, you can save and load configurations to/from a file

on your computer, allowing convenient set up of one or

multiple devices. This same feature also allows you to choose

the data transferred between devices, and provides a

convenient method for backing up your device configuration.

www.micromotion.com 5

Page 6

ProLink® III Configuration and Service Tool

Use the alert view to quickly and efficiently

manage alert conditions. You can easily

understand the priority of the alerts and receive

immediate support in knowing how to locate and

respond to the problem’s source.

Easy access to alerts for viewing and acknowledgment

Alert conditions are displayed by ProLink III on the main screen

when you first connect to a device. This first view into the

process makes alert handling and troubleshooting a fast and

efficient process. Alert information is separated by severity so

that you can quickly understand and prioritize remedial actions.

In addition, you have one-click access to alert information to

help you quickly locate and respond to the source of the

problem.

March 2016

6 www.micromotion.com

Page 7

March 2016

When connected to

multiple devices, you

can easily navigate

between the different

transmitters by

selecting or clicking on

the desired transmitter

tab. The highlighted tab

shows the active device.

Use trending and data logging to track and

monitor what is happening in your process.

Use the multi-device

comparison tool to view and

compare the process

variables, status and

configuration of the

connected devices.

ProLink

®

III Configuration and Service Tool

Simultaneously connect to multiple devices

You can simultaneously connect to multiple devices in your

process. This feature allows you to more easily view your system

performance and troubleshoot process conditions across more

than one device. Additionally, ProLink III provides a multidevice

comparison tool that allows you to view the outputs of each

connected device from one main screen – making meter

monitoring more efficient and less cumbersome than having to

connect to each device separately. A common application of

this feature is verifying the performance of a test meter against

a known reference meter under the same process conditions.

Monitor system performance with trending and data logging

The trending and data logging features in ProLink III help you to

chart and graph selected process, diagnostic, and output

variables. This look into time can help you understand what is

really going on in the process so you can determine techniques

for improving the productivity and quality of the process. You

can save the data recorded by the data logging tool and view it

in an external program (such as a spreadsheet application) to

chart your data for further analysis. Or, the trending tool in

ProLink III allows you to instantaneously view graphed key

process variables for one or more devices.

www.micromotion.com 7

Page 8

ProLink® III Configuration and Service Tool

Choose to create an

offline configuration

and you can open an

existing configuration

file or create a new

configuration file to

more efficiently manage

the set up of one or

more devices.

Creating an offline configuration

Device simulation

allows you to simulate

a connection to one or

multiple devices. This

feature provides a

convenient way for you

to navigate the ProLink

III interface and

understand the key

features available.

Simulating a device

March 2016

Offline configuration tool to facilitate transmitter setup

With offline configuration, you can create or edit a device

configuration file without the need for a physical connection to

your device. This feature allows efficient management of

configurations before loading them to a connected device.

Device simulation for a quick view into meter capabilities

With device simulation, you can simulate any Emerson Flow

device (Coriolis, Magnetic, Vortex, Density and Viscosity

meters) to allow you to view and navigate the ProLink III

interface without a true physical connection. This feature

provides a convenient way to understand the software features

and know how to navigate the interface when making a device

connection.

8 www.micromotion.com

Page 9

March 2016

ProLink

®

III Configuration and Service Tool

Support for advanced applications

If the device has advanced functionality such as Smart Meter

Verification, concentration measurement, API referral or

petroleum measurement, discrete batching, or filling & dosing

software installed, you can configure these options with

ProLink III. The appropriate menus and menu options are

automatically populated by ProLink III if the measurements and

options are supported by the device.

Supported devices

Supported Micro Motion and Rosemount Flow devices

Model 1700 and Model 2700

Model 2400S

Model 2200S

MVD Direct Connect

Model 1500 and Model 2500

9739 MVD

Model 5700

8600D

8712E

8712H

8732E

8800D

Series 3000 (MVD)

Model FMT

LF-Series

Compact Density Meter (CDM)

Gas Density Meter (GDM)

Specific Gravity Meter (SGM)

Fork Density Meter (FDM)

Fork Viscosity Meter (FVM)

Heavy Fuel Viscosity Meter (HFVM)

™

ProLink III installation kits

ProLink III can communicate serial data from your computer to

the device’s RS-485 or HART terminals. To help you make this

connection, you can purchase a ProLink III installation kit that

contains the appropriate converter or adapter for your

connection. Micro Motion and Rosemount Flow recommend

certain converters and adapters, which have been packaged

into purchasable kits that can accompany ProLink III. Refer to

the ordering information for more information.

Communication protocols

Protocol Physical layer

HART Bell 202

RS-485

Modbus RS-485

Universal Serial Bus (USB)

Modbus/TCP Ethernet

System requirements

Supported operating systems

For either 32-bit (x86) or 64-bit (x64) processor:

Windows 10

Windows 8

Windows 7

Windows Vista (with Service Pack 1 or later)

Windows XP (with Service Pack 3 or later)

Hardware requirements

Processor

RAM

Disk space

Video

Pentium

1GHz minimum, 2 GHz or higher

recommended

1 GB minimum, or 2 GB or higher

recommended

1 GB for 32-bit (x86) Windows

2 GB for 64-bit (x64) Windows

24-bit color graphics or higher

1024 x 768 display minimum,

1280 x 800 or higher widescreen

format preferred

®

4 or higher

www.micromotion.com 9

Page 10

ProLink® III Configuration and Service Tool

Ordering information

Model Product description

PLK ProLink software

Code ProLink version

(1)

2

3 ProLink III software – Professional version

(1)

4

9 ProLink III software – Basic version

Code License

U Single user license (one copy of ProLink III on a single computer)

Code Language

EEnglish

FFrench

GGerman

M Chinese

SSpanish

RRussian

PPortuguese

Code Converter

A None. Available with all ProLink III upgrade codes.

(2)

V

(2)

M

(2)

D

(2)

E

(2)

F

(2)

G

(2)

H

(2)

J

(2)

K

(2)

L

Typical model number: PLK 9 U E A

(1) Requires completed Declaration of Ownership from prior version of ProLink, available as software upgrade only.

(2) Available only with ProLink III upgrade codes 3 and 9.

Upgrade from ProLink II to ProLink III Professional version

Upgrade from ProLink III Basic to ProLink III Professional

RS-232 to Bell 202 HART converter with integral cables

RS-232 to RS-485 Modbus/HART converter with tester and cables

Both RS-232 to Bell 202 HART converter and RS-232 to RS-485 Modbus/HART converter (options V and M)

USB to Bell 202 HART converter with integral cables

USB to RS-485 converter with integral cables

USB to Bell 202 HART converter with integral cables and USB to RS-485 Modbus/HART converter and integral cables

(options E and F)

USB cable Type A (both ends) for 5700 transmitter

USB cable Type A (both ends) for 5700 transmitter and USB to Bell 202 Hart converter with integral cables (options H

and E)

USB cable Type A (both ends) for 5700 transmitter and USB to RS485 converter with integral cables (options H and F)

USB cable Type A (both ends) for 5700 transmitter and USB to Bell 202 Hart converter with integral cables, and USB to

RS485 converter with integral cables (options H, E and F)

March 2016

10 www.micromotion.com

Page 11

March 2016

ProLink

®

III Configuration and Service Tool

www.micromotion.com 11

Page 12

ProLink® III Configuration and Service Tool

7070 Winchester Circle

Boulder,

Colorado USA 80301

www.MicroMotion.com

www.Rosemount.com

I: +1 800 522 6277

T: +1 (303) 527 5200

F: +1 (303) 530 8459

Mexico

Argentina

Brazil

Venezuela

T: 52 55 5809 5300

T: 54 11 4837 7000

T: 55 15 3413 8000

T: 58 26 1300 8100

Emerson Process Management

Americas

Central & Eastern Europe

Dubai

Abu Dhabi

France

Germany

Italy

The Netherlands

Belgium

Spain

U.K.

Russia/CIS

T: +41 41 7686 111

T: +971 4 811 8100

T: +971 2 697 2000

T: 0800 917 901

T: 0800 182 5347

T: 8008 77334

T: +31 -&*'),,,,

T: +32 2 716 77 11

T: +34 913 586 000

T: 0870 240 1978

T: +7 495 981 9811

Emerson Process Management

Europe/Middle East

Australia

China

India

Japan

South Korea

Singapore

T: (61) 3 9721 0200

T: (86) 21 2892 9000

T: (91) 22 6662 0566

T: (81) 3 5769 6803

T: (82) 2 3438 4600

T: (65) 6 777 8211

Emerson Process Management

Asia Pacific

© 201, Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct Connect marks are

marks of one of the Emerson Process Management family of companies. All other marks are property of their respective owners.

PS-001446 Rev. F

Product Data Sheet

March 2016

Loading...

Loading...