Micro Motion NET OIL COMPUTER SOFTWARE AND NOC SYSTEM CONFIGURATION AND USE MANUAL Manuals & Guides

Page 1

Instruction Manual

P/N 20006444, Rev. A

Ma

y 2007

Micro Motion®

Net Oil Computer Software

and NOC System

Configuration and Use Manual

Page 2

©2007, Micro Motion, Inc. All rights reserved. ELITE and ProLink are registered trademarks, and MVD and MVD Direct Connect

are trademarks of Micro Motion, Inc., Boulder, Colorado. Micro Motion is a registered trade name of Micro Motion, Inc., Boulder,

Colorado. The Micro Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. All other trademarks

are property of their respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 About the Net Oil Computer Software and the NOC system . . . . . . . . . . . . . . . . . . . 1

1.3.1 NOC system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.2 Communication tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Documentation resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Using and maintaining the NOC system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 NOC System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Internal structure of the Net Oil Computer Software . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Sensor input to the Net Oil Computer Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 Mapping NOC Meters to MMI sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.2 Water leg measurement versus liquid leg measurement. . . . . . . . . . . . . 10

2.5 Operation modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Required well data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Water cut determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Temperature correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9 Pressure correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.10 Pressure compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11 Transient bubble remediation (TBR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11.1 Correct Density option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12 Using NOC data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.13 Using the Recalculation feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.14 Using event and alarm data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.15 Planning the configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Setting Up the ROC809 Platform. . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Configuring the ROC809 platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Verifying the Net Oil Computer Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Verifying the startup configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuration and Use Manual i

Page 4

Contents

Chapter 4 Net Oil Computer Software Displays . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 NOC Station display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.1 NOC Station display – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.2 NOC Station display – Units panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.3 NOC Station display – Totals panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.4 NOC Station display – Averages panel . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.5 NOC Station display – Well Selection panel . . . . . . . . . . . . . . . . . . . . . . 31

4.2.6 NOC Station display – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 MMI Interface display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.1 MMI Interface display – Comm Setup panel . . . . . . . . . . . . . . . . . . . . . . 33

4.3.2 MMI Interface display – Registers panel . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.3 MMI Interface display – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.4 MMI Interface display – Pressure Compensation panel . . . . . . . . . . . . . 36

4.4 NOC Meter display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.1 NOC Meter display – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.2 NOC Meter display – Inputs panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.3 NOC Meter display – TBR panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.4 NOC Meter display – Instant Values panel . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.5 NOC Meter display – Totals panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.6 NOC Meter display – Averages panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.7 NOC Meter display – Alarms panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4.8 NOC Meter display – Density Determination panel . . . . . . . . . . . . . . . . . 48

4.5 Well Data display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.1 Well Data display – Configuration panel . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.2 Well Data display – History panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.6 NOC Recalc display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.1 NOC Recalc display – General panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.2 NOC Recalc display – Totals panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.3 NOC Recalc display – Averages panel . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.6.4 NOC Recalc display – Recalculable Tests panel. . . . . . . . . . . . . . . . . . . 58

Chapter 5 Configuring the NOC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.2 General procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.3 Configuring the NOC Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4 Configuring the wells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.5 Configuring the MMI Interface(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.6 Configuring an NOC Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 6 Special Topics in Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2 Setting up gas measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3 Configuring water cut measurement using water cut probes (WCPs) . . . . . . . . . . . 69

Chapter 7 Density Determination Routines. . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.2 About the density determination routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.3 Preparing for density determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.4 Density determination for oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.5 Density determination for water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ii Micro Motion® Net Oil Computer Software and NOC System

Page 5

Contents

Chapter 8 Using the NOC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2 Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2.1 Changing operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2.2 Managing well tags when changing modes . . . . . . . . . . . . . . . . . . . . . . . 76

8.3 Using Continuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3.1 Starting Continuous mode measurement . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3.2 Using Force End of Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.3.3 Changing parameters during Continuous mode measurement . . . . . . . . 77

8.3.4 Viewing Continuous mode current data . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3.5 Viewing Continuous mode contract period data . . . . . . . . . . . . . . . . . . . 78

8.4 Performing a well test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.4.1 Pausing or stopping a well test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.4.2 Changing parameters during a well test . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.4.3 Viewing current well test data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.4.4 Viewing stored well tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.5 Viewing flow and status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.6 Viewing gas data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.7 Using the Recalculation feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.7.1 For well tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.7.2 For contract periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 9 History and Modbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 History on the ROC809 platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3 Modbus interface on the ROC809 platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.3.1 Predefined Modbus register ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 10 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.2 Connecting from ROCLINK 800 to the ROC809 platform . . . . . . . . . . . . . . . . . . . . . 97

10.3 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.3.1 Status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.4 Checking process variables and test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.5 Checking slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.6 Checking the characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.7 Checking the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.8 Diagnosing wiring problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.8.1 Checking the power supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.8.2 Checking the sensor-to-ROC809 wiring . . . . . . . . . . . . . . . . . . . . . . . . 103

10.8.3 Checking grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.9 Checking the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.9.1 Evaluating the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.9.2 Drive gain problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.9.3 Low pickoff voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.10 Checking the core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.10.1 Checking the core processor LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.10.2 Core processor resistance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.11 Checking sensor coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuration and Use Manual iii

Page 6

Contents

Appendix A User-Defined Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.1 About this appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.2 NOC Station parameters (UDP 67). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.3 NOC Meter parameters (UDP 68). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.4 Well Data parameters (UDP 69) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

A.5 NOC Recalculation parameters (UDP 70) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

A.6 MMI Interface parameters (UDP 71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

iv Micro Motion® Net Oil Computer Software and NOC System

Page 7

Chapter 1

Before You Begin

1.1 Overview

This chapter provides an orientation to the Micro Motion

manual, including configuration, use, and troubleshooting.

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

1.3 About the Net Oil Computer Software and the NOC system

The Net Oil Computer Software is one component in a net oil measurement system (NOC system)

The Net Oil Computer Software is a user program designed to run on the ROC809 Remote Operations

Controller from Remote Automation Solutions. The Net Oil Computer Software performs net oil

measurements and calculations and provides a variety of real-time, average, summary, and historical

net oil data, using functionality provided by the ROC809 platform.

®

Net Oil Computer Software and this

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

1.3.1 NOC system components

The NOC system includes the following components:

• ROC809 platform

• Net Oil Computer Software

• One to four Micro Motion sensors

- Up to three Micro Motion sensors may be used for NOC measurement

- One Micro Motion sensor may be used for gas measurement (optional)

Optional components include:

• Water cut probe(s)

• Pressure sensor, temperature sensor, level sensor, conventional (orifice plate or turbine) gas

meter

See the manual entitled Micro Motion Net Oil Computer Software and NOC System: Installation

Manual for illustrations of several different NOC systems.

Configuration and Use Manual 1

Page 8

Before You Begin

1.3.2 Communication tools

During installation, two software programs were installed on the PC for use as communication tools:

•ProLink

®

II – used to configure the core processor, and also used for some maintenance and

troubleshooting functions

• ROCLINK

™

800 from Micro Motion – used to configure the ROC809 controller and the Net

Oil Computer Software, and typically also used to operate the NOC system. ROCLINK 800

from MMI is also used for most maintenance and troubleshooting functions

Note: A standard version of ROCLINK 800 is available from Remote Automation Solutions. This

software can be used for all ROC809 functions. However, Micro Motion recommends using the

version of ROCLINK 800 supplied with the Net Oil Computer Software. Throughout this manual, the

term “ROCLINK 800” refers to ROCLINK 800 from Micro Motion. Information specific to the

ROC809 platform is provided in the standard ROCLINK 800 manual from Remote Automation

Solutions: ROCLINK 800 Configuration Software: User Manual

If desired, a customer-written Modbus or ROC Plus program may be used to communicate with the

ROC809 platform and the Net Oil Computer Software.

1.4 Documentation resources

This manual covers only topics that are specific to the Net Oil Computer Software and the

NOC system. General configuration, administration, and troubleshooting of the ROC809 platform is

provided in the manual entitled ROCLINK 800 Configuration Software: User Manual.

Table 1-1 lists other documentation resources for required or useful information.

.

Tabl e 1-1 Documentation resources

Topic Document Location

Net Oil Computer Software and

NOC system installation

ROC809 platform configuration and

administration

ProLink II installation and use ProLink II Software for Micro Motion

Point (TLP) system

Writing host programs using ROC Plus

protocol

Using the Modbus host user program Modbus Host User Program Manual Remote Automation Solutions

Micro Motion Net Oil Computer Software

and NOC System: Installation Manual

ROCLINK 800 Configuration Software:

User Manual

Transmitters: Installation and Use

Manual

ROC Plus Protocol: Specification

Manual

Shipped with Net Oil Computer

Software

Shipped with Net Oil Computer

Software

ProLink II CD

Installed with product

Micro Motion web site

Remote Automation Solutions

web site

web site

2 Micro Motion® Net Oil Computer Software and NOC System

Page 9

Before You Begin

1.5 Configuration overview

To configure the NOC system:

1. Review the information about system and configuration options in Chapter 2, and collect the

information required for your NOC system.

2. Prepare the ROC809 platform as described in Chapter 3.

3. Referring to Chapter 4 for detailed parameter definitions, configure the Net Oil Computer

Software as described in Chapter 5.

4. If your NOC system includes gas measurement, configure gas measurement as described in

Chapter 6.

5. If your NOC system uses water cut probes, configure water cut measurement as described in

Chapter 6.

6. If required for well configuration, perform density determination as described in Chapter 7.

To write a Modbus or ROC Plus program to communicate with the Net Oil Computer Software, see

the information in Chapter 9 and Appendix A.

1.6 Using and maintaining the NOC system

To use the NOC system:

1. Review the information about system and configuration options in Chapter 2.

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

2. Follow the instructions in Chapter 8.

To perform maintenance and troubleshooting tasks, see Chapter 10.

Configuration and Use Manual 3

Page 10

Before You Begin

1.7 Customer service

The best source for customer service on your NOC system is the overall system supplier. Please

contact your system supplier first to ensure the fastest resolution. To contact Micro Motion for direct

support on the flowmeter components, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at

International.MMISupport@EmersonProcess.com.

4 Micro Motion® Net Oil Computer Software and NOC System

Page 11

Chapter 2

NOC System Overview

2.1 Overview

This chapter discusses various topics that should be reviewed and considered before beginning

configuration of the Net Oil Computer Software and the NOC system. Topics include:

• Terminology – see Section 2.2

• Internal structure of the Net Oil Computer Software – see Section 2.3

• Sensor input to the Net Oil Computer Software – see Section 2.4

• Operation mode – see Section 2.5

• Required well data – see Section 2.6

• Water cut determination – see Section 2.7

• Temperature correction – see Section 2.8

• Pressure correction – see Section 2.9

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

• Pressure compensation – see Section 2.10

• Transient bubble remediation (TBR) – see Section 2.11

• Using data from the NOC system – see Section 2.12

• Using the Recalculation feature – see Section 2.13

• Using event and alarm data – see Section 2.14

This chapter also includes a list of questions that should be answered before beginning configuration.

See Section 2.15.

2.2 Terminology

The terminology used in the NOC system and the NOC documentation is defined in Table 2-1.

Tabl e 2-1 NOC system terminology

Term Also called Definition

ROC809 platform The ROC809 remote operations controller with all I/O and communications

modules

NOC system The ROC809 platform with the Net Oil Computer Software, and all sensors

Configuration and Use Manual 5

Page 12

NOC System Overview

Tabl e 2-1 NOC system terminology continued

Term Also called Definition

Production fluid The process fluid as produced initially from the well. Contains oil, gas, free water,

Three-phase

separator

Two-phase

separator

Oil leg The oil layer of a three-phase separator, or the process stream from that layer

Water leg The water layer of a three-phase separator, or the process stream from that layer

Gas leg The gas layer of a separator, or the process stream from that layer

Liquid leg Oil leg

Transition The point at which a substance changes from one phase or flow regime to

Interface The boundary between two layers in a separator

Rag layer Slang term for the interface between the oil leg and the water leg

Oil The general term applying to oil in any form

Live oil Fluid that is predominantly oil at process pressure and unspecified temperature

Dead oil Weathered oil Live oil that has been exposed to atmospheric pressure for sufficient time to

Wet oil Oil that contains water, either in a mixture or as free water, or both, at unspecified

Dry oil Oil that has been treated so that only very small quantities of water and other

Net oil Dry oil by volume, corrected to reference temperature and pressure

Liquid Oil/water mixture

Total water Produced water All water in the production fluid; the sum of free water and mixture water

Free water The water produced with oil that settles out quickly in a three-phase separator;

Mixture water The water dispersed in the liquid

Uncorrected Field measurements at process temperature and pressure

Corrected,

correction

Process

temperature

Process pressure The pressure at process conditions

Reference

temperature

Reference

pressure

Compensation Modification of density and mass measurements as required to compensate for

Oil/water leg

Emulsion

Base temperature The temperature to which field measurements are corrected

Base pressure The pressure to which field measurements are corrected

mixture water, and possibly various solids (e.g., sand).

A separator that separates the production fluid into three distinct streams: gas,

oil, and water

A separator that separates the production fluid into two distinct streams: gas and

liquid (oil/water mixture)

The liquid layer of a two-phase separator, or the process stream from that layer

another

allow the light ends to evaporate

temperature and pressure

extraneous materials remain in it. This is the oil that is considered to be pure oil

in net oil measurements.

The production fluid after gas has been removed, or the process stream from the

liquid leg of a two-phase separator. Contains oil and water.

the water in the water leg of a three-phase separator; the fluid stream that is

considered to be pure water in net oil measurements

Field measurements converted to the equivalent values at reference temperature

and pressure. If a pressure value is not available, only temperature correction is

applied.

The temperature of the process fluid at process conditions

the effect of pressure on the sensor flow tubes

6 Micro Motion® Net Oil Computer Software and NOC System

Page 13

NOC System Overview

Tabl e 2-1 NOC system terminology continued

Term Also called Definition

Water cut Percentage of water in the liquid, usually measured by volume

Density-based

water cut

Water cut probe Any of a variety of technologies that produces a direct measurement of water cut

Applied water cut The water cut value used in NOC measurements: either the density-based water

Oil density at

reference

Water density at

reference

Water cut value derived from measured density values

cut or the water cut probe value is used

The density of dry oil corrected to reference temperature and 1 ATM pressure

The density of water corrected to reference temperature and 1 ATM pressure

2.3 Internal structure of the Net Oil Computer Software

The Net Oil Computer Software is a ROC809 user program. It was loaded onto the ROC809 platform

during installation (see the manual entitled Micro Motion Net Oil Computer Software and NOC

System: Installation Manual). The Net Oil Computer Software has the following structure:

• NOC Station display – Station configuration and data, and gas measurement configuration and

data (optional). The NOC system performs NOC measurement for one station.

• Well Data display – Well configuration and history for each well.

• MMI Interface display – Sensor configuration and process data for Micro Motion sensors.

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

• NOC Meter display – NOC measurement configuration and real-time calculated data. Each

NOC measurement sensor is configured and monitored separately.

• NOC Recalc display – Recalculation functions for the ten most recent contract periods

(Continuous mode) or for the ten most recent well tests performed within the ten most recent

contract periods (Well Test mode)

2.4 Sensor input to the Net Oil Computer Software

Figures 2-1 and 2-2 illustrate two possible implementations of the Net Oil Computer Software,

supporting two different sensor input options:

• In Figure 2-1, two MMI sensors are installed on the oil leg, one MMI sensor is installed on the

water leg, and one MMI sensor is installed on the gas leg.

• In Figure 2-2, one MMI sensor is installed on the oil leg, one MMI sensor is installed on the

water leg, and a conventional meter is installed on the gas leg.

Note: These figures illustrate all sensor types, but do not illustrate all possible combinations.

Configuration and Use Manual 7

Page 14

NOC System Overview

NOC Station

NOC Meter #1 NOC Meter #2

NOC Meter #3

MMI sensor

(Oil leg)

MMI sensor

(Oil leg)

MMI sensor

(Water leg)

ROC809 gas

station

NOC Meter

data roll-up

Net Oil Computer Software

MM #1

MM #2 MM #3

MMI sensor

(Gas leg)

Sensor data

MM #4

NOC Gas Station Processed gas data

ROC809 Platform

Raw gas data

Sensor dataSensor data

Sensor data

As shown in these figures:

• The NOC Station, NOC Meters, MMI Interface, and Gas Station are structures in the Net Oil

Computer Software.

• Each MMI sensor has a corresponding MMI Interface.

• Each MMI sensor used for NOC measurement has a corresponding NOC Meter.

• All NOC Meter data is rolled up to the NOC Station.

• Gas data is handled separately from oil data. Raw gas data is input to a gas station which is

defined on the ROC809 platform using standard ROCLINK methods. The ROC809 gas station

applies AGA (or other) calculations to the gas data, and the results are input to the NOC Gas

Station in the Net Oil Computer Software. The Net Oil Computer Software reports the gas data

but does not perform any additional processing.

- If an MMI sensor is used for gas measurement, MMI Interface #4 is used to accept input

- If a conventional meter is used for gas measurement, an analog input is used to accept

Figure 2-1 Conceptual view #1

from the sensor and route data to the ROC809 gas station (see Figure 2-1).

input from the meter and route data to the ROC809 gas station (see Figure 2-2).

8 Micro Motion® Net Oil Computer Software and NOC System

Page 15

NOC System Overview

NOC Station

NOC Meter #1 NOC Meter #2

MMI sensor

(Oil leg)

MMI sensor

(Water leg)

NOC Meter

data roll-up

Net Oil Computer Software

MM #1

MM #2

Conventional

meter

(Gas leg)

ROC809 gas

station

NOC Gas Station

Processed

gas data

ROC809 Platform

Sensor data

Sensor data

Raw gas data

via analog input

Figure 2-2 Conceptual view #2

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

2.4.1 Mapping NOC Meters to MMI sensors

Figure 2-3 illustrates the standard method for mapping NOC Meters to MMI sensors. You may be

using one, two, or three NOC Meters.

As shown in Figure 2-3:

• A Modbus device address is assigned to each MMI sensor. This address resides in the sensor’s

core processor. Typically, this configuration step is performed at the factory, and device

addresses 1, 2, and 3 are assigned. If the device addresses are not preconfigured:

- The default Modbus address for a core processor is 1.

- If you need to change the default address, use ProLink II to connect directly to the core

• All MMI sensors communicate with the ROC809 and the Net Oil Computer Software through

processor.

the RS-485 sensor communications module, which is typically installed in ROC809 COM 4

(also called COMM3 or DNOC).

• An MMI Interface must be configured for each MMI sensor. The MMI Interface must identify:

- The comm port where the RS-485 sensor communications module is installed

- The Modbus device address of the Micro Motion sensor to use

• The NOC Meters are automatically mapped to the corresponding MMI Interfaces:

- NOC Meter #1 → MM #1

- NOC Meter #2 → MM #2

- NOC Meter #3 → MM #3

Configuration and Use Manual 9

Page 16

NOC System Overview

ROC809 Platform

MMI Sensor

Device Address 1

MMI Sensor

Device Address 2

MMI Sensor

Device Address 3

NOC Meter display

RS-485 Sensor Communications Module

COM 4 or DNOC (COMM 3 in Slot 1)

Sensor wiring through I.S. barriers

NOC Meter #1

· Device Address: 1

· Port: COMM 3

NOC Meter #2

· Device Address: 2

· Port: COMM 3

NOC Meter #3

· Device Address: 3

· Port: COMM 3

MMI Interface display

MM #1

· COM Port: COM 4, TAG

· Device Address: 1

MM #2

· COM Port: COM 4, TAG

· Device Address: 2

MM #3

· COM Port: COM 4, TAG

· Device Address: 3

Net Oil Computer Software

Figure 2-3 Mapping NOC Meters to MMI sensors

2.4.2 Water leg measurement versus liquid leg measurement

The default NOC Meter configuration assumes that the NOC Meter is associated with an MMI sensor

installed on the liquid or oil leg. In this configuration:

To use a NOC Meter on the water leg, set the Free Water Setpoint to 0. As a result:

• The process fluid is assumed to be a mixture of oil and water.

• The “applied” water cut value is determined according to water cut configuration (see

Section 2.7), and this value is applied to process fluid measurements.

• The applied water cut value is compared to the configured Free Water Setpoint (see

Section 4.2.1) to determine how instant values, totals, and averages are updated:

- When the applied water cut is equal to or below the Free Water Setpoint, the process fluid

is treated as a combination of oil and water. Values for free water are not updated from this

stream. Values for mixture water and total water will be updated.

- When the applied water cut is above the Free Water Setpoint, the process fluid is treated as

water. Only values for free water and total water are updated from this stream. Values for

mixture water are not updated.

• The process fluid is assumed to be water.

• No water cut options and calculations are applied.

• Only free water and total water values will be updated from this stream.

10 Micro Motion® Net Oil Computer Software and NOC System

Page 17

NOC System Overview

One well to

test separator

Test separator

Other wells to

production separator

From production

wells

To production separator

MMI sensor(s)

ROC809 with

Net Oil Computer Software

Liquid leg

To production separator

MMI sensor(s)

ROC809 with

Net Oil Computer Software

Wellhead separator

From single well Liquid leg

2.5 Operation modes

The NOC system operates in either Well Test mode or Continuous mode:

• In Well Test mode, well tests can be performed on up to 50 wells. A manifold system is used to

ensure that output from a single well is routed through the test separator and the NOC system.

See Figure 2-4.

• In Continuous mode, one well is measured continuously. See Figure 2-5.

After initial configuration, you can change the operation mode. However, changing modes affects

current measurement, data collection, and tags. Before changing modes, see Sections 8.2.1 and 8.2.2.

Figure 2-4 Well Test mode

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Figure 2-5 Continuous mode

2.6 Required well data

If you will use the density-based water cut, the following information is required for each well that

will be tested or measured by the NOC system:

• Density of dry oil from this well, at reference temperature and 1 ATM pressure

• Density of the water from this well, at reference temperature and 1 ATM pressure

• Purge time (Well Test mode only)

Configuration and Use Manual 11

Page 18

NOC System Overview

If the density values are not known, you can perform an in-line density determination for oil, water, or

both (see Chapter 7), or you can enter default values at initial configuration and recalculate

measurement data at a later time when well-specific density values are known (see Section 8.7).

If you will use only water cut probes for water cut data, these density values are not required.

2.7 Water cut determination

You must configure water cut options for each NOC Meter that is measuring oil (i.e., each MMI

sensor installed on the liquid leg). Do not configure water cut options for a NOC Meter that is

measuring free water (i.e., the MMI sensor installed on the water leg).

There are two methods available for water cut determination:

• Density-based – The NOC equations are applied to derive water cut from measured density

values.

• Water cut probe (WCP) – One or two water cut probes are used to measure the process stream

directly. For example, you might use a capacitance probe at the low end and a microwave

probe at the high end. Typically, the NOC system software receives data from these probes via

an analog input.

If no water cut probe is installed, you must use the density-based water cut value. If one or two water

cut probes are installed, you may:

• Ignore the WCP values for all NOC measurements

• Use the WCP values for all NOC measurements

• Define specific water cut ranges (a high end and/or a low end). Then:

- If the water cut value falls within a specified range, the value from the associated WCP is

used for NOC measurements.

- If the water cut falls outside defined ranges, the density-based water cut value is used.

In all cases, the water cut value used in NOC measurements is called the “applied” value.

2.8 Temperature correction

Temperature correction refers to the conversion of the observed process temperature to the equivalent

value at reference temperature.

The Net Oil Computer Software automatically applies temperature correction to NOC data. To

perform temperature correction, the Net Oil Computer Software requires a value for the current

process temperature. This value can be sourced from:

• The RTD built into the Micro Motion sensor

•An external RTD

You must configure the temperature input separately for each NOC Meter in the system.

2.9 Pressure correction

Pressure correction refers to the conversion of the observed process pressure to the equivalent value at

reference pressure.

Note: Do not confuse pressure correction with pressure compensation. See Section 2.10 for a

definition of pressure compensation.

12 Micro Motion® Net Oil Computer Software and NOC System

Page 19

NOC System Overview

Pressure correction will be automatically applied to NOC data if pressure data from an external

pressure device is input to the Net Oil Computer Software. You must configure the pressure input

separately for each NOC Meter in the system.

2.10 Pressure compensation

Pressure compensation refers to the modification of raw mass or density measurements as required to

compensate for the effect of pressure on the sensor’s flow tubes.

Note: Do not confuse pressure compensation with pressure correction. See Section 2.9 for a definition

of pressure correction.

Pressure compensation for mass or density is implemented in the Net Oil Computer Software, in the

MMI Interface and NOC Meter displays.

Note: To avoid applying pressure compensation twice to one set of data, ensure that the pressure

compensation factors in the core processor are set to 0 (see the manual entitled Micro Motion Net Oil

Computer Software and NOC System: Installation Manual).

Typically, pressure compensation should be implemented for all Micro Motion sensors in the

NOC system. To implement pressure compensation, the following sensor-specific information is

required:

• Compensation coefficient for mass flow – the percent change in the flow rate per psi

• Compensation coefficient for density – the change in fluid density, in g/cm

These values are provided in the product data sheet for your sensor. Use the pressure effect values

calculated in PSI.

Note: Do not reverse the sign. Unlike other Micro Motion products, the Net Oil Computer Software

reverses the sign in its internal calculations.

Note: Not all sensors require pressure compensation. See the sensor’s product data sheet.

2.11 Transient bubble remediation (TBR)

Because density is used to calculate water cut, which is used to calculate net oil, transient bubbles

have a negative effect on NOC measurement accuracy. Figure 2-6 shows the effect of transient

bubbles on density.

3

/psi

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Configuration and Use Manual 13

Page 20

NOC System Overview

Drive gain (%)

Density (measured)

Drive gain (actual)

Figure 2-6 Effect of transient bubbles on density

TBR is used to handle occasional gas bubbles or slugs in the process fluid. A transient bubble

condition is defined in terms of the sensor’s drive gain: if the drive gain exceeds the configured

threshold for more than three seconds, the configured TBR actions are performed. The transient

bubble interval persists until drive gain is below the configured threshold for three seconds.

The Net Oil Computer Software can perform several different actions if transient bubbles are

detected:

• Substituting a retrieved density value for the measured density value in NOC calculations (the

Correct Density option). This option is described in Section 2.11.1.

• Logging an alarm

• Energizing a discrete output

• All of the above

2.11.1 Correct Density option

The Correct Density option directs the Net Oil Computer Software to retrieve the measured density

value from an earlier point in the process. The earlier point is identified by the Lookback Period (see

Figure 2-7). The density values from a three-second period around this point are averaged, and this

retrieved density average is then used in NOC calculations. Figure 2-8 shows how the Correct Density

action affects the density measurement.

Note: If the Lookback Period happens to fall into a previous transient bubble interval, the Net Oil

Computer Software automatically extends the lookback interval as required to retrieve an averaged

value from measured density values rather than substituted density values.

14 Micro Motion® Net Oil Computer Software and NOC System

Page 21

NOC System Overview

Density (measured)

Drive gain (actual)

Drive gain setpoint

Lookback Period

(seconds)

Density values

(retrieved and averaged)

Density

(used in NOC calculations)

Drive gain (actual)

Averaged retrieved

density value

Drive gain setpoint

Figure 2-7 Correct Density option

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Figure 2-8 Correct Density effect on density measurement

2.12 Using NOC data

NOC data is stored in the internal history database:

• In Well Test mode, the database can store data for 50 wells, six tests per well. As additional

well tests are performed, older tests are overwritten.

• In Continuous mode, data for a single well is stored. In the default configuration, data for the

35 most recent contract periods (typically, days) may be stored. Older data is stored in

summary form, and the detailed data is overwritten.

Micro Motion recommends accessing NOC data through the Net Oil Computer Software instead of

the ROCLINK 800 history interface. Be sure that you view all required data before it is overwritten.

See Chapter 8 for information.

Configuration and Use Manual 15

Page 22

NOC System Overview

Note: The organization of NOC data in history is designed to support NOC calculations rather than

user access. Although you can view data, it is not easy to interpret.

For archival purposes, history data can be retrieved through the ROCLINK 800 history interface.

Information on the default history configuration and on accessing history data is provided in the

manual entitled ROCLINK 800 Configuration Software: User Manual.

2.13 Using the Recalculation feature

The Recalculation feature is used to convert existing NOC data to:

• Different measurement units

• A different time base

• A different reference temperature

• A different oil density at reference temperature

• A different water density at reference temperature

The Recalculation feature uses the periodic (15-minute) history records. Accordingly:

• You cannot perform recalculation for well tests or contract periods for which no periodic

record was written. If the well test or contract period was shorter than 15 minutes, it cannot be

recalculated.

• Periodic records are kept in history for ten days. After this time, they are deleted. Be sure to

perform all required recalculations while the periodic records are still available.

When a well test or contract period is recalculated, new NOC data can be saved to history if desired.

The original NOC data is not overwritten. NOC data produced by recalculation is shown along with

the original data on the Well History panel (see Figure 4-21).

Only one set of recalculated data is saved. If you recalculate the same well test or contract period

more than once, the most recent recalculated data overwrites the previous recalculated data.

For ease in comparison, the recalculated data is saved to history in the units used for the original data.

However, all changes resulting from new values for oil density at reference temperature and water

density at reference temperature are preserved.

2.14 Using event and alarm data

The 240 most recent events and 240 most recent alarms are stored in an internal database. Several

methods are available for using event and alarm data:

• Contents of the databases can be viewed, printed, saved to a file, or exported for use in an

external program.

• A host system can connect to the ROC809 platform and retrieve the data.

Information on accessing event and alarm data is provided in the manual entitled ROCLINK 800

Configuration Software: User Manual. Be sure that you retrieve all required data before it is

overwritten.

16 Micro Motion® Net Oil Computer Software and NOC System

Page 23

NOC System Overview

2.15 Planning the configuration

This section contains a set of questions that you should answer before beginning basic configuration

of the Net Oil Computer Software and the NOC system.

Note: These questions are specific to implementation of the NOC system. They do not address basic

system configuration (e.g., configuring the system clock, security, communications, etc.).

• Will this system be used for well testing or for continuous measurement?

• If it will be used for well testing, what wells will be tested?

• For all wells that will be measured:

- What is the oil density at reference temperature? If not known, will you perform a density

determination?

- What is the water density at reference temperature? If not known, will you perform a

density determination?

- (Well Test mode only) What is the well’s purge time?

• How many MMI (Coriolis) sensors will be used for NOC measurement on the liquid leg?

• Is an MMI sensor installed on the water leg?

• Does the system include gas measurement? If so, is an MMI sensor or a conventional meter

used?

• What are the Modbus device addresses of the MMI sensors?

• What measurement units will be used for NOC measurement?

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

• Will TBR be configured? If yes, for each MMI sensor, what drive gain will be used as a TBR

threshold?

• What method will be used for water cut determination? If you will use a water cut probe, what

is its effective range?

• Will pressure compensation be configured?

• What inputs will be configured on this system? Possible inputs include:

- External temperature sensor (RTD input)

- Water cut probe (analog input)

- Pressure sensor (analog input)

- Level sensor (analog input)

- External alarm indication (discrete input)

• What outputs will be configured on this system? Possible outputs include:

- Valve control (analog output)

- Pump or device control (discrete output or discrete output relay)

- Alarm indication (discrete output or discrete output relay)

- TBR implementation (discrete output or discrete output relay)

- Frequency or pulse output simulation (discrete output or discrete output relay)

Configuration and Use Manual 17

Page 24

18 Micro Motion® Net Oil Computer Software and NOC System

Page 25

Chapter 3

Setting Up the ROC809 Platform

3.1 About this chapter

This chapter describes the procedures required to set up the ROC809 platform before you begin

configuring the Net Oil computer software. Topics include:

• Configuring the ROC809 platform – see Section 3.2

• Verifying the Net Oil Computer Software – see Section 3.3

• Verifying the startup configuration file – see Section 3.4

3.2 Configuring the ROC809 platform

Configuration of the ROC809 platform includes all configuration that is external to the Net Oil

Computer Software. This includes items such as:

• Basic configuration

-ROC clock

- Configuring security for ROCLINK 800

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

- Configuring security for the ROC809 platform

- Defining devices and groups

- Configuring device information

- Configuring display options

- Configuring ROC809 comm ports

- Configuring ROCLINK 800 communications parameters

- Configuring I/O

- Calibrating analog and RTD inputs

• Advanced configuration

- Configuring FSTs

- Configuring PID control loops

For information on configuring the ROC809 platform, see the manual entitled ROCLINK 800

Configuration Software: User Manual. When configuring the ROC809 platform, follow

recommended practices such as saving the configuration file to flash memory during configuration,

and saving to both flash memory and a file after configuration is complete.

Note: You may want to return to specific configuration tasks after the NOC system is configured. For

example, you may want to modify I/O configuration or add an FST.

Configuration and Use Manual 19

Page 26

Setting Up the ROC809 Platform

3.3 Verifying the Net Oil Computer Software

To verify that the Net Oil Computer Software is installed and running:

1. Start ROCLINK 800.

2. Connect to the ROC809.

3. Click

Utilities > User Program Administrator. The window shown in Figure 3-1 is displayed.

4. The Net Oil Computer Software should be displayed in the list. Highlight the Net Oil

Computer Software. If its status is shown as

change to

5. Click

Running.

Close.

If you do not see the Net Oil Computer Software, load the software as described in the manual

entitled Micro Motion Net Oil Computer Software and NOC System: Installation Manual.

Figure 3-1 User Program Administrator window

Loaded, click the Start button. The status will

3.4 Verifying the startup configuration file

NOC system configuration must begin with one of the two startup configuration files shipped with the

Net Oil Computer Software. During installation, the selected file was downloaded to the ROC809. To

verify:

1. Start ROCLINK 800.

2. Connect to the ROC809.

3. Click

20 Micro Motion® Net Oil Computer Software and NOC System

Device > Comm Ports.

Page 27

Setting Up the ROC809 Platform

4. Open the list of comm ports, and check the name of the fourth port.

• If it is named DNOC, a startup configuration file was loaded. Both startup configuration

files use this port and rename it for user convenience.

• If it is named COMM3, a startup configuration file was not loaded. Download the

appropriate startup configuration file, as described in the manual entitled Micro Motion

Net Oil Computer Software and NOC System: Installation Manual.

5. Click

Close.

Figure 3-2 Verifying the startup configuration file

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Configuration and Use Manual 21

Page 28

22 Micro Motion® Net Oil Computer Software and NOC System

Page 29

Chapter 4

Net Oil Computer Software Displays

4.1 About this chapter

This chapter is designed to be used for reference. It describes all of the displays and panels that are

available for the Net Oil Computer Software via ROCLINK 800, including:

• NOC Station display – see Section 4.2

• MMI Interface display – see Section 4.3

• NOC Meter display – see Section 4.4

• Well Data display – see Section 4.5

• NOC Recalc display – see Section 4.6

For information on using these displays and panels to configure the Net Oil Computer Software, see

Chapter 5. For information on using these displays and panels for NOC measurement or recalculation,

see Chapter 8.

For a detailed listing of the user-defined points in the Net Oil Computer Software, see Appendix A.

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

4.2 NOC Station display

The NOC Station display includes six panels:

• General – see Section 4.2.1

• Units – see Section 4.2.2

• Totals – see Section 4.2.3

• Averages – see Section 4.2.4

• Well Selection – see Section 4.2.5

• Alarms – see Section 4.2.6

4.2.1 NOC Station display – General panel

There are two versions of the NOC Station General panel: the version displayed depends on the

configured Operation Mode. See Figures 4-1 and 4-2 and Table 4-1.

Operation Mode can be configured from any point in the NOC Station display, using the dropdown

list at the top of the display. For more information about Operation Mode, see Section 2.5 and

Section 8.2.

Configuration and Use Manual 23

Page 30

Net Oil Computer Software Displays

Figure 4-1 NOC Station display – General panel, Well Test mode

Figure 4-2 NOC Station display – General panel, Continuous mode

24 Micro Motion® Net Oil Computer Software and NOC System

Page 31

Net Oil Computer Software Displays

Tabl e 4-1 NOC Station parameters – General panel

Parameter Description Comments

Point Tag Name of this NOC Station This name is not the same as the

Station Tag defined in the

ROCLINK 800 Meter menu (used

for gas measurement).

Assoc Gas Station Specifies the point from which gas flow data will be read

(the ROC809 gas station)

Current Gas Flow Displays the current gas flow rate Only if gas measurement is

Contract Hour (Operation Mode = Continuous) Specifies the hour, in a

24-hour period, at which values are totaled for a single day’s

production, totals are reset, and data is logged to the Daily

History database

Force End Of Day (Operation Mode = Continuous) Used to perform

Well Selected (Operation Mode = Well Test) Displays the tag of the

Test Start Time (Operation Mode = Well Test) Displays the start time of the

Well Configuration

Oil Density at

Reference Temp

Water Density at

Reference Temp

Configured Well Densities at Process Temperature and Pressure

Water Density Displays the water density configured for the selected well,

Oil Density Displays the configured live oil density for the selected well,

Instant Values All instant values are rolled up from the NOC Meters.

Liquid Density Displays the current measured density of the process

Temperature Displays the current measured temperature of the process

Liquid Mass Flow Displays the current mass flow rate for the process stream

Uncorrected

Liquid Vol Flow

Uncorrected

Reverse Liquid

Vol F low

Corrected Liquid

Volu me F low

Water Cut –

Density-Based

Water Cut – From

Probe

Applied Water

Cut

contract-hour actions manually

currently selected well

current test

Displays the oil density at reference temperature for the

selected well

Displays the water density at reference temperature for the

selected well

converted to process temperature and pressure

converted to process temperature and pressure

stream

stream

Displays the current volume flow rate, forward flow only, for

the process stream, uncorrected for temperature or

pressure

Displays the current volume flow rate, reverse flow only, for

the process stream, uncorrected for temperature or

pressure

Displays the current volume flow rate, forward flow only, for

the process stream, corrected for temperature and pressure

Displays the current water cut derived from density values

by the Net Oil Computer Software

Displays the current water cut as measured by the relevant

water cut probe (high end or low end)

Displays the water cut currently being used for NOC

measurement

Required only for systems that

include a gas measurement meter

configured

Default: 0 (midnight)

Range: 0 to 23 (11 p.m.)

See Section 8.3

If no test is in progress, displays

the start time of the most recent

test

Read only; value configured on

Well Data display, Configuration

panel (see Section 4.5.1)

Read only; value configured on

Well Data display, Configuration

panel (see Section 4.5.1)

See Section 2.7

See Section 2.7

See Section 2.7

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Configuration and Use Manual 25

Page 32

Net Oil Computer Software Displays

4.2.2 NOC Station display – Units panel

The NOC Station Units panel is used to select the units that will be used in NOC calculations and

measurement, and to specify the reference temperature. See Figure 4-3 and Table 4-2.

Figure 4-3 NOC Station display – Units panel

Tabl e 4-2 NOC Station parameters – Units panel

Parameter Description Comments

Mass The mass unit to be used in NOC calculations

Pressure The pressure unit to be used in NOC calculations

Liquid Volume The liquid volume unit to be used in NOC calculations

Gas Volume The gas volume unit to be used in NOC calculations

Density The density unit to be used in NOC calculations

Reference

Temperature

Temperature The temperature unit to be used in NOC calculations

Time Base The time unit to be used in NOC calculations

The reference temperature to which oil density and water

density will be corrected during NOC calculations

If you change the reference

temperature, update the Oil

Density at Ref and Water Density

at Ref values for all wells. See

Table 4-16.

26 Micro Motion® Net Oil Computer Software and NOC System

Page 33

Net Oil Computer Software Displays

4.2.3 NOC Station display – Totals panel

The NOC Station Totals panel displays current NOC totals, rolled up from the NOC Meters. See

Figure 4-4 and Table 4-3. In this panel, values are totaled for the current period:

• In Continuous mode, the current period runs from the most recent contract hour to the present

moment.

• In Well Test mode, the current period runs from the beginning of the well test to the present

moment.

Figure 4-4 NOC Station display – Totals panel

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Configuration and Use Manual 27

Page 34

Net Oil Computer Software Displays

Tabl e 4-3 NOC Station parameters – Totals panel

Parameter Description Comments

Time

Current Test The duration of the current test If more than one NOC Meter is

Pause Time The duration of all pauses during the current test

TBR Time The total number of hours, minutes, and seconds that the

NOC system has detected a transient bubble condition.

TMR Time Not implemented in current version. Will be used to track Transient Mist

Purge Time (Operation Mode = Well Test) The total number of hours,

minutes, and seconds that the NOC system has spent in

purge state

Mass Totals All mass totals are rolled up from the NOC Meters.

Forward Mass The total mass, forward flow only, measured by the

NOC system in the current period

Reverse Mass The total mass, reverse flow only, measured by the

NOC system in the current period

used, all meters start, stop, and

pause at the same time. The

individual meter values are not

totaled. For example, if three

meters are used in a test that lasts

one hour, this field will report one

hour rather than three hours.

Summed across NOC Meters.

• If TBR is disabled, this field

shows zeros.

• If TBR is enabled, this field

shows total TBR time,

independent of the configured

TBR action.

Remediation

Displayed only if Operation Mode

is set to Well Test

28 Micro Motion® Net Oil Computer Software and NOC System

Page 35

Net Oil Computer Software Displays

Tabl e 4-3 NOC Station parameters – Totals panel continued

Parameter Description Comments

Volume Totals All volume totals are rolled up from the NOC Meters

Gas The amount of gas measured by the NOC system in the

current period

Uncorrected Oil The amount of oil, uncorrected for temperature or pressure,

measured by the NOC system in the current period

Uncorrected Total

Water

Uncorrected Free

Water

Uncorrected

Liquid

Uncorrected

Reverse Liquid

Corrected Oil The amount of oil, corrected for temperature and pressure,

Corrected Total

Water

Corrected Free

Water

Corrected Liquid The amount of all liquid, corrected for temperature and

The amount of total water, uncorrected for temperature or

pressure, measured by the NOC system in the current

period

The amount of free water, uncorrected for temperature or

pressure, measured by the NOC system in the current

period

The amount of liquid, forward flow only, uncorrected for

temperature or pressure, measured by the NOC system in

the current period

The amount of liquid, reverse flow only, uncorrected for

temperature or pressure, measured by the NOC system in

the current period

measured by the NOC system in the current period

The amount of total water, corrected for temperature and

pressure, measured by the NOC system in the current

period

The amount of free water, corrected for temperature and

pressure, measured by the NOC system in the current

period

pressure, measured by the NOC system in the current

period

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

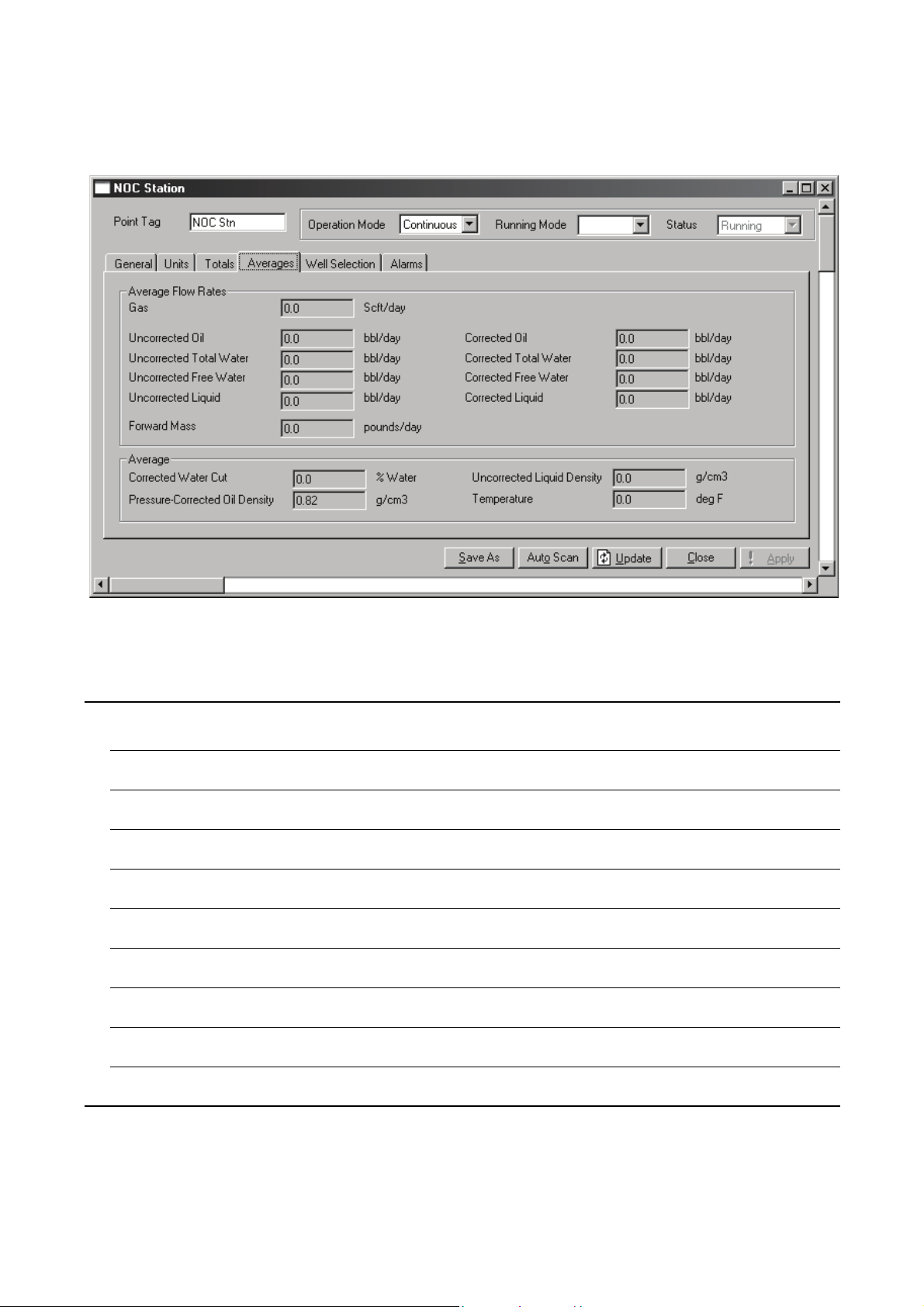

4.2.4 NOC Station display – Averages panel

The NOC Station Averages panel displays current NOC averages, rolled up from the NOC Meters.

See Figure 4-5 and Table 4-4. In this panel, values are averaged for the current period:

• In Continuous mode, the current period runs from the most recent contract hour to the present

moment.

• In Well Test mode, the current period runs from the beginning of the well test to the present

moment.

Configuration and Use Manual 29

Page 36

Net Oil Computer Software Displays

Figure 4-5 NOC Station display – Averages panel

Tabl e 4-4 NOC Station parameters – Averages panel

Parameter Description Comments

Average Flow Rates All average values in this section are rolled up from the NOC Meters and flow-weighted.

Gas Average gas volume flow rate for the current period

Uncorrected Oil The average flow rate of oil for the current period,

uncorrected for temperature or pressure

Uncorrected Total

Water

Uncorrected Free

Water

Uncorrected

Liquid

Forward Mass The average mass flow rate, forward flow only, for the

Corrected Oil The average flow rate of oil for the current period, corrected

Corrected Total

Water

Corrected Free

Water

Corrected Liquid The average flow rate of the liquid for the current period,

The average flow rate of total water for the current period,

uncorrected for temperature or pressure

The average flow rate of free water for the current period,

uncorrected for temperature or pressure

The average flow rate of the liquid for the current period,

uncorrected for temperature or pressure

current period

for temperature and pressure

The average flow rate of total water for the current period,

corrected for temperature and pressure

The average flow rate of free water for the current period,

corrected for temperature and pressure

corrected for temperature and pressure

30 Micro Motion® Net Oil Computer Software and NOC System

Page 37

Net Oil Computer Software Displays

Tabl e 4-4 NOC Station parameters – Averages panel continued

Parameter Description Comments

Average All average values in this section are rolled up from the NOC Meters and flow-weighted.

Corrected Water

Cut

PressureCorrected Oil

Density

Uncorrected

Liquid Density

Temperature The average temperature of the liquid for the current period

The average water cut applied during the current period,

corrected for temperature and pressure

The average oil density for the current period, corrected for

temperature and pressure

The average density of the liquid for the current period

4.2.5 NOC Station display – Well Selection panel

The Well Selection panel (see Figure 4-6) is used only in Well Test mode. It displays the well number

and well tag for all fifty wells that can be part of the NOC system. To select a well for testing:

1. Click its radio button.

2. Click

Apply.

Figure 4-6 NOC Station display – Well Selection panel, Well Test mode

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Configuration and Use Manual 31

Page 38

Net Oil Computer Software Displays

4.2.6 NOC Station display – Alarms panel

The NOC Station Alarms panel (see Figure 4-7) displays active alarms for the NOC Meters, in the

following alarm categories:

• No Flow alarms, as defined by the Low Flow Cutoff value configured on the NOC Meter

Inputs panel (see Section 4.4.2)

• Low Flow and High Flow alarms, as defined in the Alarms fields on the NOC Meter Alarms

panel (see Section 4.4.7)

• Coriolis alarms – alarms posted by the Micro Motion sensor associated with the NOC Meter

• No Comm alarms – the NOC Meter is not communicating with the sensor

Note: Alarm conditions are indicated for all operational states: Continuous mode and Well Test mode

with a well test running, paused, or inactive.

Note: The indicators on this panel do not distinguish between a continuous alarm condition and

several short alarm conditions.

Figure 4-7 NOC Station display – Alarms panel

4.3 MMI Interface display

The MMI Interface display includes four panels:

• Comm Setup – see Section 4.3.1

• Registers – see Section 4.3.2

• Alarms – see Section 4.3.3

• Configuration – see Section 4.3.4

32 Micro Motion® Net Oil Computer Software and NOC System

Page 39

Net Oil Computer Software Displays

4.3.1 MMI Interface display – Comm Setup panel

The MMI Interface Comm Setup panel is used to specify the core processor from which the

MMI Interface will receive data. See Figure 4-8 and Table 4-5.

Figure 4-8 MMI Interface display – Comm Setup panel

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Tabl e 4-5 MMI Interface parameters – Comm Setup panel

Parameter Description Comments

Point Number The number of the currently selected Micro Motion sensor.

Use the dropdown list to select a different sensor.

Point Tag The name of the currently selected Micro Motion sensor

Scanning • Enabled: The Net Oil Computer Software is polling the

Micro Motion sensor for current data.

• Disabled: The Net Oil Computer Software is not polling

the Micro Motion sensor for current data.

Status • Communicating: The connection between the ROC809

Comm Setup

Comm Port for

Device Address

Modbus Address The Modbus address of the core processor on this

and the Micro Motion sensor is active.

• Not Communicating: The connection between the

ROC809 and the Micro Motion sensor is not active.

The ID of the ROC809 comm port that is used to connect to

Micro Motion sensors. This must be the port of the RS-485

module used for sensor communications.

Micro Motion sensor

Read-only

In standard installations, this

module is installed in Slot 1

(COMM 3, or DNOC), so the

following TLP is used:

(DNOC 4, TAG) (95, 3, 0)

Defaults: 1–4

COM 4, TAG

Configuration and Use Manual 33

Page 40

Net Oil Computer Software Displays

Tabl e 4-5 MMI Interface parameters – Comm Setup panel continued

Parameter Description Comments

Communication Statistics

Good Responses Displays the number of good responses from this

Micro Motion sensor during the current period

Bad Responses Displays the number of bad responses from this

Micro Motion sensor during the current period

Last Poll Duration Displays the duration of the last polling interval (the number

of seconds between polls)

4.3.2 MMI Interface display – Registers panel

The MMI Interface Registers panel displays current data from the core processor. See Figure 4-9 and

Table 4-6. All values displayed on this panel are read-only.

Figure 4-9 MMI Interface display – Registers panel

Tabl e 4-6 MMI Interface parameters – Registers panel

Parameter Description Comments

Mass Flow Mass flow rate as retrieved from sensor

Density Process density value as retrieved from sensor

Temperature Process temperature as retrieved from sensor

Vol Flow Rate Volume flow rate as retrieved from sensor

Mass Total Mass total as measured by core processor Total since last reset of totalizer in

core processor

Volume Total Volume total as measured by core processor Total since last reset of totalizer in

core processor

34 Micro Motion® Net Oil Computer Software and NOC System

Page 41

Net Oil Computer Software Displays

Tabl e 4-6 MMI Interface parameters – Registers panel continued

Parameter Description Comments

Mass Inventory Mass inventory as measured by core processor Total since last reset of inventory

Volume Inventory Volume inventory as measured by core processor Total since last reset of inventory

Left Pickoff Voltage at sensor’s left pickoff

Right Pickoff Voltage at sensor’s right pickoff

Coriolis Drive Gain A measure of the sensor’s ability to vibrate freely Used in troubleshooting and

Pressure Compensated Values

Mass Flow Rate Mass flow rate from the sensor, compensated for pressure Pressure compensation must be

Density Process density from the sensor, compensated for pressure Pressure compensation must be

in core processor

in core processor

transient bubble remediation

enabled. See Section 5.5

enabled. See Section 5.5

.

.

4.3.3 MMI Interface display – Alarms panel

The MMI Interface Alarms panel (see Figure 4-10) displays all currently active alarms reported by the

Micro Motion sensor associated with this MMI Interface.

NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin NOC System Overview NOC DisplaysROC809 SetupBefore You Begin

Note: This is not a list of all active alarms. For more information on alarms, see the manual entitled

ROCLINK 800 Configuration Software: User Manual.

Figure 4-10 MMI Interface display – Alarms panel

Configuration and Use Manual 35

Page 42

Net Oil Computer Software Displays

4.3.4 MMI Interface display – Pressure Compensation panel

The MMI Interface Pressure Compensation panel is used to configure pressure compensation for mass

or density values from the associated sensor. See Figure 4-11 and Table 4-7.

Figure 4-11 MMI Interface display – Pressure Compensation panel

Tabl e 4-7 MMI Interface parameters – Pressure Compensation panel

Parameter Description Comments

Density

Compensate

Density for

Pressure

Compensation

Coefficient

Mass

Compensate

Mass for

Pressure

Compensation

Coefficient

• Enabled: Pressure compensation will be applied to

density values before NOC calculations are performed

• Disabled: Pressure compensation will not be applied to

density values before NOC calculations are performed

Specifies the factor to be used for pressure compensation

of density data

• Enabled: Pressure compensation will be applied to mass

values before NOC calculations are performed

• Disabled: Pressure compensation will not be applied to

mass values before NOC calculations are performed

Specifies the factor to be used for pressure compensation

of mass data

See Sections 2.10

See Section 2.10

See Sections 2.10

See Section 2.10