Micro Motion Configuration and Use Manual: Micro Motion LNG-Series Meters Configuration and Use Manual Manuals & Guides

Page 1

Micro Motion® LNG Series Meters

Configuration and Use Manual

MMI-20032809, Rev AA

February 2017

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136 666 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Contents

Part I Getting Started

Chapter 1 Before you begin ............................................................................................................3

1.1 About this manual ....................................................................................................................... 3

1.2 Meter model codes ......................................................................................................................3

1.3 Communications tools and protocols .......................................................................................... 4

1.4 Additional documentation .......................................................................................................... 4

Chapter 2 Quick start .....................................................................................................................7

2.1 Power up the meter .....................................................................................................................7

2.2 Check meter status ......................................................................................................................7

2.3 Make a startup connection to the transmitter ..............................................................................8

2.4 Characterize the flowmeter (if required) ......................................................................................8

2.4.1 Sensor tags ................................................................................................................... 9

2.4.2 Density calibration parameters (D1, D2, K1, K2, FD, TC) .................................................. 9

2.5 Verify mass flow measurement ....................................................................................................9

2.6 Verify the zero ............................................................................................................................. 9

2.6.1 Verify the zero using ProLink III ...................................................................................10

2.6.2 Terminology used with zero verification and zero calibration ......................................11

Part II Configuration and commissioning

Chapter 3 Introduction to configuration and commissioning ....................................................... 15

3.1 Default values and ranges ..........................................................................................................15

3.2 Disable write-protection on the transmitter configuration ........................................................ 15

3.3 Restore the factory configuration .............................................................................................. 15

Chapter 4 Configure process measurement ..................................................................................17

4.1 Configure mass flow measurement ........................................................................................... 17

4.1.1 Configure Mass Flow Measurement Unit ...........................................................................17

4.1.2 Configure Flow Damping ...............................................................................................19

4.1.3 Configure Mass Flow Cutoff ...........................................................................................20

4.2 Configure volume flow measurement for liquid applications ..................................................... 21

4.2.1 Configure Volume Flow Type for liquid applications ........................................................21

4.2.2 Configure Volume Flow Measurement Unit for liquid applications ......................................21

4.2.3 Configure Volume Flow Cutoff ........................................................................................24

4.3 Configure gas standard volume (GSV) flow measurement .........................................................24

4.3.1 Configure Volume Flow Type for gas applications ........................................................... 25

4.3.2 Configure Standard Gas Density .....................................................................................25

4.3.3 Configure Gas Standard Volume Flow Measurement Unit .................................................... 26

4.3.4 Configure Gas Standard Volume Flow Cutoff .....................................................................28

4.4 Configure flow direction ........................................................................................................... 28

4.4.1 Options for Flow Direction .............................................................................................29

4.5 Configure density measurement .............................................................................................. 30

4.5.1 Configure Density Measurement Unit ...............................................................................30

Configuration and Use Manual i

Page 4

Contents

4.5.2 Configure two-phase flow parameters ........................................................................31

4.5.3 Configure density damping ........................................................................................33

4.5.4 Configure Density Cutoff ............................................................................................... 34

4.6 Configure temperature measurement .......................................................................................34

4.6.1 Configure Temperature Measurement Unit ........................................................................34

4.6.2 Configure Temperature Damping .................................................................................... 35

Chapter 5 Configure device options and preferences ....................................................................37

5.1 Configure response time parameters ........................................................................................ 37

5.1.1 Configure Calculation Speed (Response Time) .................................................................. 37

5.2 Configure alert handling ............................................................................................................38

5.2.1 Configure Fault Timeout ................................................................................................38

5.2.2 Configure Status Alert Severity .......................................................................................38

5.3 Configure informational parameters ......................................................................................... 40

5.3.1 Configure the sensor index ......................................................................................... 40

5.3.2 Configure the RTD cable length .................................................................................. 41

5.3.3 Configure Sensor Serial Number .....................................................................................41

5.3.4 Configure Sensor Material ............................................................................................. 41

5.3.5 Configure Sensor Liner Material ......................................................................................42

5.3.6 Configure Sensor Flange Type ....................................................................................... 42

5.3.7 Configure Descriptor .................................................................................................... 43

5.3.8 Configure Message ......................................................................................................43

5.3.9 Configure Date ............................................................................................................43

Chapter 6 Integrate the meter with the control system ................................................................45

6.1 Configure events ....................................................................................................................... 45

6.1.1 Configure an enhanced event ..................................................................................... 45

6.2 Configure digital communications ............................................................................................ 46

6.2.1 Configure Modbus/RS-485 communications .............................................................. 47

6.2.2 Configure RS-485 terminals ........................................................................................ 48

6.2.3 Configure Digital Communications Fault Action .................................................................. 49

Chapter 7 Complete the configuration ......................................................................................... 51

7.1 Back up transmitter configuration ............................................................................................. 51

7.2 Enable write-protection on the transmitter configuration ......................................................... 51

Part III Operations, maintenance, and troubleshooting

Chapter 8 Transmitter operation ................................................................................................. 55

8.1 Custody transfer ........................................................................................................................55

8.2 Record the process variables ..................................................................................................... 55

8.3 View process variables ...............................................................................................................56

8.3.1 View process variables and other data using ProLink III ...............................................56

8.4 View transmitter status using the status LED ............................................................................. 56

8.5 View and acknowledge status alerts .......................................................................................... 57

8.5.1 View and acknowledge alerts using ProLink III ............................................................57

8.5.2 Alert data in transmitter memory ............................................................................... 58

8.6 Read totalizer and inventory values ........................................................................................... 59

8.7 Start and stop totalizers and inventories ....................................................................................59

8.8 Reset totalizers ..........................................................................................................................60

8.9 Reset inventories .......................................................................................................................60

ii Micro Motion® LNG Series Meters

Page 5

Contents

Chapter 9 Measurement support ................................................................................................. 61

9.1 Options for measurement support ............................................................................................ 61

9.2 Zero the meter .......................................................................................................................... 61

9.2.1 Zero the meter using ProLink III ..................................................................................61

9.2.2 Record the zeros .........................................................................................................63

9.3 Validate the meter .....................................................................................................................63

9.3.1 Alternate method for calculating the meter factor for volume flow .............................65

9.4 Perform a (standard) D1 and D2 density calibration ...................................................................65

9.4.1 Perform a D1 and D2 density calibration using ProLink III ........................................... 66

Chapter 10 Troubleshooting .......................................................................................................... 69

10.1 Status LED states ....................................................................................................................... 69

10.2 Status alerts, causes, and recommendations ............................................................................. 70

10.3 Flow measurement problems ................................................................................................... 75

10.4 Density measurement problems ............................................................................................... 77

10.5 Temperature measurement problems .......................................................................................78

10.6 Check power supply wiring ........................................................................................................78

10.7 Check grounding .......................................................................................................................79

10.8 Check for radio frequency interference (RFI) ..............................................................................79

10.9 Check for two-phase flow (slug flow) ......................................................................................... 80

10.10 Check the drive gain .................................................................................................................. 80

10.10.1 Collect drive gain data ................................................................................................ 81

10.11 Check the pickoff voltage .......................................................................................................... 81

10.11.1 Collect pickoff voltage data ........................................................................................ 82

10.12 Check for internal electrical problems ....................................................................................... 82

10.12.1 Check the sensor coils .................................................................................................83

Appendices and reference

Appendix A Using ProLink III with the transmitter ...........................................................................85

A.1 Connect with ProLink III ............................................................................................................ 85

A.1.1 Connection types supported by ProLink III ..................................................................85

A.1.2 Connect with ProLink III to the service port ................................................................. 85

A.1.3 Connect with ProLink III to the RS-485 port ................................................................. 86

Appendix B Default values and ranges ............................................................................................ 89

B.1 Default values and ranges ..........................................................................................................89

Configuration and Use Manual iii

Page 6

Contents

iv Micro Motion® LNG Series Meters

Page 7

Part I

Getting Started

Chapters covered in this part:

Before you begin

•

Quick start

•

Getting Started

Configuration and Use Manual 1

Page 8

Getting Started

2 Micro Motion® LNG Series Meters

Page 9

1 Before you begin

Topics covered in this chapter:

About this manual

•

Meter model codes

•

Communications tools and protocols

•

Additional documentation

•

1.1 About this manual

This manual provides information to help you configure, commission, use, maintain, and

troubleshoot the Micro Motion LNG Series meter.

Important

This manual assumes that the following conditions apply:

• The meter has been installed correctly and completely according to the instructions in the

installation manual

• The installation complies with all applicable safety requirements

• The user is trained in applicable safety standards

Before you begin

1.2

Meter model codes

Your device can be identified by the model code on the device tag.

The transmitter model number has the following form:

LNGM10S***N(P/Z)(D/I/N)***********

Model codes and device typesTable 1-1:

Model code Description I/O and communications

N Standard case • One dedicated service port/

P LNGS06S and LNGM10S

are paired

D With a dual core processor

Z Standalone sensor

I With enhanced core pro-

cessor for direct host connection with IS barrier

Modbus

• One dedicated RS-485 port/

Modbus

Configuration and Use Manual 3

Page 10

Before you begin

Model codes and device types (continued)Table 1-1:

Model code Description I/O and communications

N Spare sensor without elec-

tronics

1.3 Communications tools and protocols

You can use these communications tools and protocols to interface with the transmitter.

Communications tools, protocols, and related informationTable 1-2:

Communications tool Supported protocols Scope In this manual For more information

ProLink III • Modbus/RS-485

• Service port

Modbus host • Service port

• Modbus/RS-485

Complete configuration

and commissioning

Complete configuration

and commissioning

Basic user information.

See Appendix A.

None.

User manual

• Installed with soft-

ware

• Micro Motion user

documentation CD

• www.micromo‐

tion.com

Modbus Interface Tool

(MIT) — available at

www.micromotion.com

1.4 Additional documentation

Micro Motion provides additional documentation to support the installation and operation

of the meter.

Additional documentation and resourcesTable 1-3:

Topic Document

Transmitter installation

Product Data Sheet

Hazardous area installation

4 Micro Motion® LNG Series Meters

Micro Motion Liquified Natural Gas Dispenser Installation Manual

Micro Motion LNG Series Meters Product Data Sheet (PDS)

See the approval documentation shipped with the transmitter, or

download the appropriate documentation from the Micro Motion web

site at www.micromotion.com.

Page 11

All documentation resources are available on the Micro Motion web site at

www.micromotion.com.cn or on the Micro Motion user documentation DVD.

Before you begin

Configuration and Use Manual 5

Page 12

Before you begin

6 Micro Motion® LNG Series Meters

Page 13

2 Quick start

Topics covered in this chapter:

Power up the meter

•

Check meter status

•

Make a startup connection to the transmitter

•

Characterize the flowmeter (if required)

•

Verify mass flow measurement

•

Verify the zero

•

2.1 Power up the meter

The meter must be powered up for all configuration and commissioning tasks, or for

process measurement.

1. Ensure that all device covers and seals are closed.

Quick start

2.2

WARNING!

To prevent ignition of flammable or combustible atmospheres, ensure that all covers

and seals are tightly closed. For hazardous area installations, applying power while

housing covers are removed or loose can cause an explosion.

2. Turn on the electrical power at the power supply.

Postrequisites

Although the sensor is ready to measure shortly after power-up, the electronics can take

up to 10 minutes to reach thermal equilibrium. Therefore, if this is the initial startup, or if

power has been off long enough to allow components to reach ambient temperature,

allow the electronics equalize for approximately 10 minutes.

Check meter status

Check the meter for any error conditions that require user action or that affect

measurement accuracy.

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and

checks for error conditions.

2. Connect to the transmitter and check for active alerts.

Configuration and Use Manual 7

Page 14

Quick start

Related information

View and acknowledge status alerts

Status alerts, causes, and recommendations

2.3 Make a startup connection to the transmitter

Identify the connection type to use, and follow the instructions for that connection type in

the appropriate appendix.

Communications tool Connection type to use Instructions

ProLink III Service Port Section A.1.2

RS-485 port Section A.1.3

2.4 Characterize the flowmeter (if required)

ProLink III Device Tools > Calibration Data

Overview

Characterizing the flowmeter adjusts your transmitter to match the unique traits of the

sensor it is paired with. The characterization parameters (also called calibration

parameters) describe the sensor’s sensitivity to flow, density, and temperature.

Depending on your sensor type, different parameters are required. Values for your sensor

are provided by Micro Motion on the sensor tag or the calibration certificate.

Tip

If your meter was ordered as a unit, it has already been characterized at the factory. However, you

should still verify the characterization parameters.

Procedure

1. Specify Sensor Type.

• LNG-Series (LNGS06S, LNGM10S)

2. Set the flow characterization parameters. Be sure to include all decimal points.

• Set Flow Cal (Flow Calibration Factor).

3. Set the density characterization parameters.

• Set D1, D2, TC, K1, K2, and FD.

8 Micro Motion® LNG Series Meters

Page 15

2.4.1 Sensor tags

Tag on sensorsFigure 2-1:

Quick start

2.4.2 Density calibration parameters (D1, D2, K1, K2, FD, TC)

Density calibration parameters are typically on the sensor tag and the calibration

certificate.

2.5

2.6

Verify mass flow measurement

Check to see that the mass flow rate reported by the transmitter is accurate. You can use

any available method.

Connect to the transmitter with ProLink III and read the value for Mass Flow Rate in the

Process Variables panel.

Postrequisites

If the reported mass flow rate is not accurate:

• Check the characterization parameters.

• Review the troubleshooting suggestions for flow measurement issues.

Verify the zero

Verifying the zero helps you determine if the stored zero value is appropriate to your

installation, or if a field zero can improve measurement accuracy.

Configuration and Use Manual 9

Page 16

Quick start

The zero verification procedure analyzes the Live Zero value under conditions of zero flow,

and compares it to the Zero Stability range for the sensor. If the average Live Zero value is

within a reasonable range, the zero value stored in the transmitter is valid. Performing a

field calibration will not improve measurement accuracy.

2.6.1 Verify the zero using ProLink III

Verifying the zero helps you determine if the stored zero value is appropriate to your

installation, or if a field zero can improve measurement accuracy.

Important

In most cases, the factory zero is more accurate than the field zero. Do not zero the meter unless one

of the following is true:

• The zero is required by site procedures.

• The stored zero value fails the zero verification procedure.

Prerequisites

ProLink III v3.5, or a later release

Important

Do not verify the zero or zero the meter if a high-severity alert is active. Correct the problem, then

verify the zero or zero the meter. You may verify the zero or zero the meter if a low-severity alert is

active.

Procedure

1. Prepare the meter:

a. Allow the meter to warm up for at least 20 minutes after applying power.

b. Run the process fluid through the sensor until the sensor temperature reaches

the normal process operating temperature.

c. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

d. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

2. Choose Device Tools > Device Calibration > Zero Verification and Calibration > Verify Zero and

wait until the procedure completes.

3. If the zero verification procedure fails:

a. Confirm that the sensor is completely blocked in, that flow has stopped, and that

the sensor is completely full of process fluid.

b. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

c. Repeat the zero verification procedure.

d. If it fails again, zero the meter.

10 Micro Motion® LNG Series Meters

Page 17

Quick start

Postrequisites

Restore normal flow through the sensor by opening the valves.

2.6.2 Terminology used with zero verification and zero

calibration

Terminology used with zero verification and zero calibrationTable 2-1:

Term Definition

Zero In general, the offset required to synchronize the left pickoff and the right pickoff under

conditions of zero flow. Unit = microseconds.

Factory Zero The zero value obtained at the factory, under laboratory conditions.

Field Zero The zero value obtained by performing a zero calibration outside the factory.

Prior Zero The zero value stored in the transmitter at the time a field zero calibration is begun. May

be the factory zero or a previous field zero.

Manual Zero The zero value stored in the transmitter, typically obtained from a zero calibration proce-

dure. It may also be configured manually. Also called “mechanical zero” or “stored zero.”

Live Zero The real-time bidirectional mass flow rate with no flow damping or mass flow cutoff ap-

plied. An adaptive damping value is applied only when the mass flow rate changes dramatically over a very short interval. Unit = configured mass flow measurement unit.

Zero Stability A laboratory-derived value used to calculate the expected accuracy for a sensor. Under

laboratory conditions at zero flow, the average flow rate is expected to fall within the

range defined by the Zero Stability value (0 ± Zero Stability). Each sensor size and model

has a unique Zero Stability value. Statistically, 95% of all data points should fall within the

range defined by the Zero Stability value.

Zero Calibration The procedure used to determine the zero value.

Zero Time The time period over which the Zero Calibration procedure is performed. Unit = seconds.

Field Verification Zero A 3-minute running average of the Live Zero value, calculated by the transmitter. Unit =

configured mass flow measurement unit.

Zero Verification A procedure used to evaluate the stored zero and determine whether or not a field zero

can improve measurement accuracy.

Configuration and Use Manual 11

Page 18

Quick start

12 Micro Motion® LNG Series Meters

Page 19

Configuration and commissioning

Part II

Configuration and commissioning

Chapters covered in this part:

Introduction to configuration and commissioning

•

Configure process measurement

•

Configure device options and preferences

•

Integrate the meter with the control system

•

Complete the configuration

•

Configuration and Use Manual 13

Page 20

Configuration and commissioning

14 Micro Motion® LNG Series Meters

Page 21

Introduction to configuration and commissioning

3 Introduction to configuration and

commissioning

Topics covered in this chapter:

Default values and ranges

•

Disable write‐protection on the transmitter configuration

•

Restore the factory configuration

•

3.1 Default values and ranges

See Default values and ranges to view the default values and ranges for the most commonly

used parameters.

3.2 Disable write-protection on the transmitter configuration

ProLink III Device Tools > Configuration > Write-Protection

Overview

If the transmitter is write-protected, the configuration is locked and you must unlock it

before you can change any configuration parameters. By default, the transmitter is not

write-protected.

Tip

Write-protecting the transmitter prevents accidental changes to configuration. It does not prevent

normal operational use. You can always disable write-protection, perform any required configuration

changes, then re-enable write-protection.

3.3

Restore the factory configuration

ProLink III Device Tools > Configuration Transfer > Restore Factory Configuration

Overview

Restoring the factory configuration returns the transmitter to a known operational

configuration. This may be useful if you experience problems during configuration.

Configuration and Use Manual 15

Page 22

Introduction to configuration and commissioning

Tip

Restoring the factory configuration is not a common action. You may want to contact Micro Motion

to see if there is a preferred method to resolve any issues.

16 Micro Motion® LNG Series Meters

Page 23

Configure process measurement

4 Configure process measurement

Topics covered in this chapter:

Configure mass flow measurement

•

Configure volume flow measurement for liquid applications

•

Configure gas standard volume (GSV) flow measurement

•

Configure flow direction

•

Configure density measurement

•

Configure temperature measurement

•

4.1 Configure mass flow measurement

The mass flow measurement parameters control how mass flow is measured and reported.

The mass flow measurement parameters include:

Mass Flow Measurement Unit

•

Flow Damping

•

Mass Flow Cutoff

•

4.1.1

Configure Mass Flow Measurement Unit

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Mass Flow Measurement Unit specifies the unit of measure that will be used for the mass flow

rate. The unit used for mass total and mass inventory is derived from this unit.

Procedure

Set Mass Flow Measurement Unit to the unit you want to use.

The default setting for Mass Flow Measurement Unit is g/sec (grams per second).

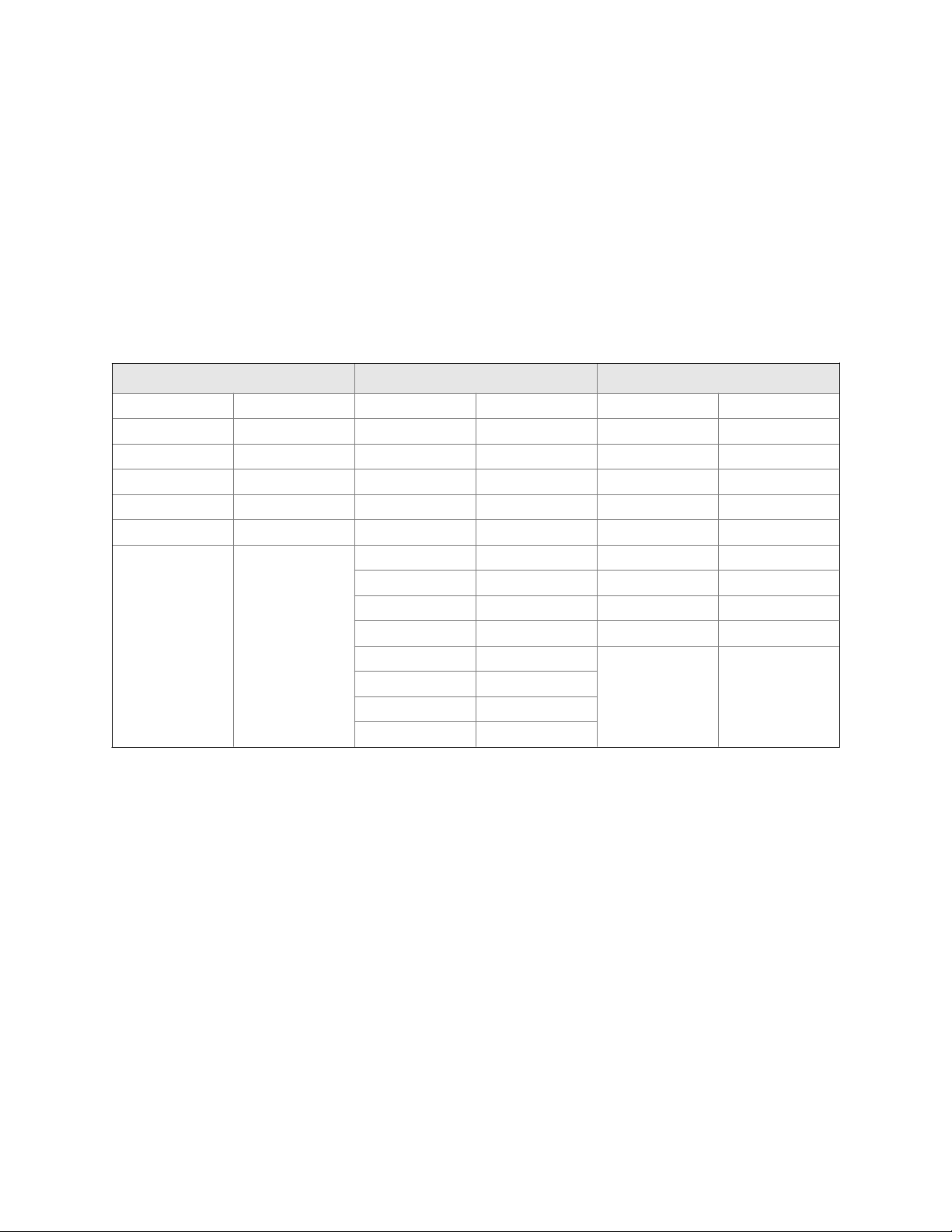

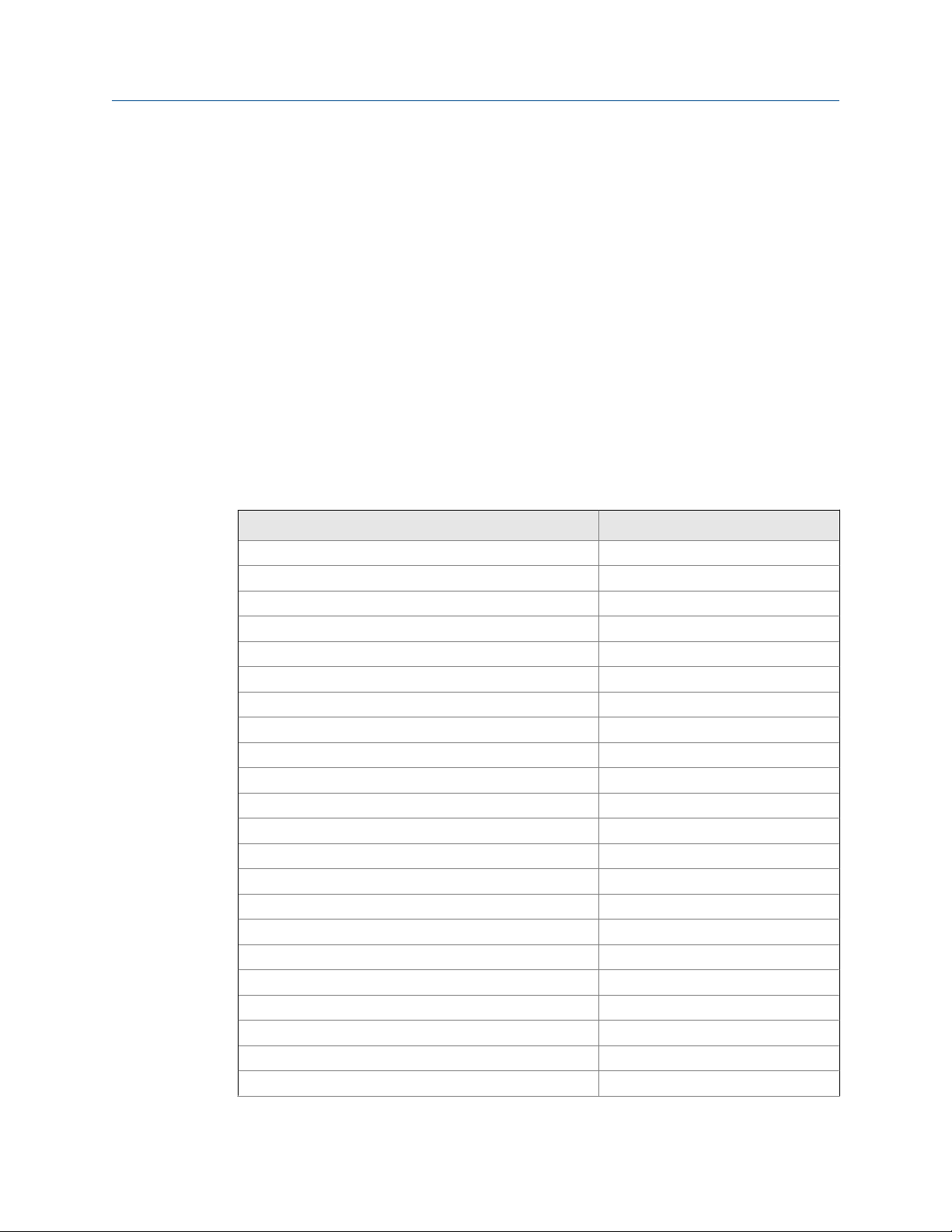

Options for Mass Flow Measurement Unit

The transmitter provides a standard set of measurement units for Mass Flow Measurement

Unit, plus one user-defined special measurement unit. Different communications tools may

use different labels for the units.

Configuration and Use Manual 17

Page 24

Configure process measurement

Unit description ProLink III label

Grams per second

Grams per minute

Grams per hour

Kilograms per second

Kilograms per minute

Kilograms per hour

Kilograms per day

Metric tons per minute

Metric tons per hour

Metric tons per day

Pounds per second

Pounds per minute

Pounds per hour

Pounds per day

Short tons (2000 pounds) per minute

Short tons (2000 pounds) per hour

Short tons (2000 pounds) per day

Long tons (2240 pounds) per hour

Long tons (2240 pounds) per day

Special unit

Options for Mass Flow Measurement Unit Table 4-1:

g/sec

g/min

g/hr

kg/sec

kg/min

kg/hr

kg/day

mTon/min

mTon/hr

mTon/day

lbs/sec

lbs/min

lbs/hr

lbs/day

sTon/min

sTon/hr

sTon/day

lTon/hr

lTon/day

special

Define a special measurement unit for mass flow

ProLink III

Overview

A special measurement unit is a user-defined unit of measure that allows you to report

process data, totalizer data, and inventory data in a unit that is not available in the

transmitter. A special measurement unit is calculated from an existing measurement unit

using a conversion factor.

Procedure

1. Specify Base Mass Unit.

Base Mass Unit is the existing mass unit that the special unit will be based on.

2. Specify Base Time Unit.

18 Micro Motion® LNG Series Meters

Device Tools > Configuration > Process Measurement > Flow > Special Units

Page 25

Configure process measurement

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Mass Flow Conversion Factor as follows:

a. x base units = y special units

b. Mass Flow Conversion Factor = x ÷ y

The original mass flow rate value is divided by this value.

4. Enter Mass Flow Conversion Factor.

5. Set Mass Flow Label to the name you want to use for the mass flow unit.

6. Set Mass Total Label to the name you want to use for the mass total and mass

inventory unit.

The special measurement unit is stored in the transmitter. You can configure the

transmitter to use the special measurement unit at any time. You must use ProLink III to

select the special measurement unit.

Example: Defining a special measurement unit for mass flow

You want to measure mass flow in ounces per second (oz/sec).

4.1.2

1. Set Base Mass Unit to Pounds (lb).

2. Set Base Time Unit to Seconds (sec).

3. Calculate Mass Flow Conversion Factor:

a. 1 lb/sec = 16 oz/sec

b. Mass Flow Conversion Factor = 1 ÷ 16 = 0.0625

4. Set Mass Flow Conversion Factor to 0.0625.

5. Set Mass Flow Label to oz/sec.

6. Set Mass Total Label to oz.

Configure Flow Damping

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes

in the process variable. At the end of the interval, the internal value will reflect 63% of the

change in the actual measured value.

Procedure

Set Flow Damping to the value you want to use.

The default value is 0.64 seconds. The range is 0 to 60 seconds.

Configuration and Use Manual 19

Page 26

Configure process measurement

Tips

• A high damping value makes the process variable appear smoother because the reported value

changes slowly.

• A low damping value makes the process variable appear more erratic because the reported value

changes more quickly.

• The combination of a high damping value and rapid, large changes in flow rate can result in

increased measurement error.

• Whenever the damping value is non-zero, the reported measurement will lag the actual

measurement because the reported value is being averaged over time.

• In general, lower damping values are preferable because there is less chance of data loss, and less

lag time between the actual measurement and the reported value.

• For gas applications, Micro Motion recommends setting Flow Damping to 2.56 or higher.

The value you enter is automatically rounded down to the nearest valid value. Valid

damping values are 0, 0.04, 0.08, 0.16, 0.32... 40.96.

Effect of Flow Damping on volume measurement

Flow Damping affects volume measurement for liquid volume data. Flow Damping also affects

volume measurement for gas standard volume data. The transmitter calculates volume

data from the damped mass flow data.

4.1.3

Configure Mass Flow Cutoff

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Mass Flow Cutoff specifies the lowest mass flow rate that will be reported as measured. All

mass flow rates below this cutoff will be reported as 0.

Procedure

Set Mass Flow Cutoff to the value you want to use.

The default value for Mass Flow Cutoff is 0.0 g/sec or a sensor-specific value set at the

factory. The recommended value is 0.5% of the nominal flow rate of the attached sensor.

See the sensor specifications. Do not leave Mass Flow Cutoff to 0.0 g/sec.

Effect of Mass Flow Cutoff on volume measurement

Mass Flow Cutoff does not affect volume measurement. Volume data is calculated from the

actual mass data rather than the reported value.

20 Micro Motion® LNG Series Meters

Page 27

Configure process measurement

4.2 Configure volume flow measurement for liquid applications

The volume flow measurement parameters control how liquid volume flow is measured

and reported.

The volume flow measurement parameters include:

Volume Flow Type

•

Volume Flow Measurement Unit

•

Volume Flow Cutoff

•

Restriction

You cannot implement both liquid volume flow and gas standard volume flow at the same time. You

must choose one or the other.

4.2.1 Configure Volume Flow Type for liquid applications

4.2.2

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Volume Flow Type controls whether liquid or gas standard volume flow measurement will be

used.

Restriction

If you are using the concentration measurement application, you must set Volume Flow Type to Liquid.

Gas standard volume measurement is incompatible with the concentration measurement

application.

Procedure

Set Volume Flow Type to Liquid.

Configure Volume Flow Measurement Unit for liquid applications

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Volume Flow Measurement Unit specifies the unit of measurement that will be displayed for the

volume flow rate. The unit used for the volume total and volume inventory is based on this

unit.

Configuration and Use Manual 21

Page 28

Configure process measurement

Prerequisites

Before you configure Volume Flow Measurement Unit, be sure that Volume Flow Type is set to

Liquid.

Procedure

Set Volume Flow Measurement Unit to the unit you want to use.

The default setting for Volume Flow Measurement Unit is l/sec (liters per second).

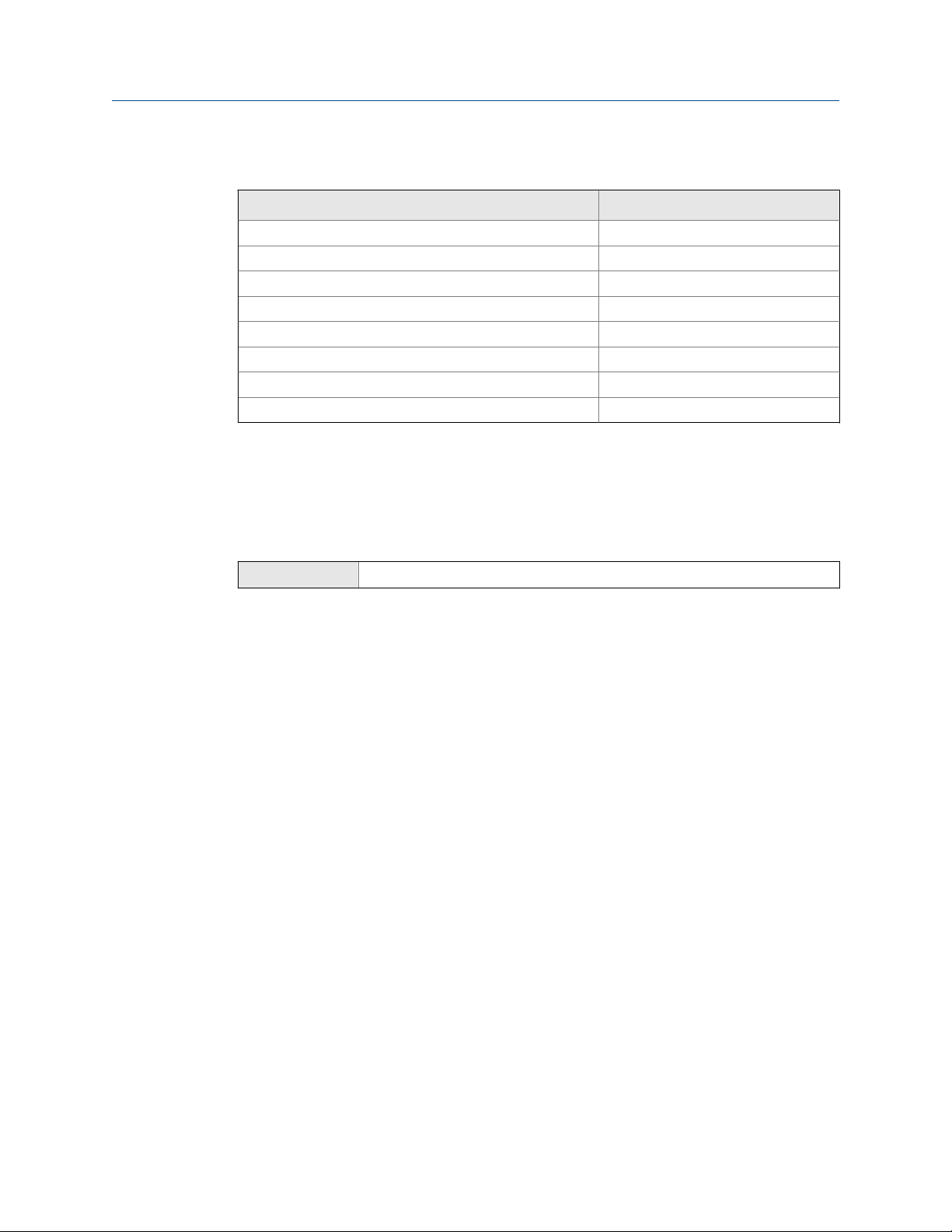

Options for Volume Flow Measurement Unit for liquid applications

The transmitter provides a standard set of measurement units for Volume Flow Measurement

Unit, plus one user-defined measurement unit. Different communications tools may use

different labels for the units.

Unit description ProLink III label

Cubic feet per second

Cubic feet per minute

Cubic feet per hour

Cubic feet per day

Cubic meters per second

Cubic meters per minute

Cubic meters per hour

Cubic meters per day

U.S. gallons per second

U.S. gallons per minute

U.S. gallons per hour

U.S. gallons per day

Million U.S. gallons per day

Liters per second

Liters per minute

Liters per hour

Million liters per day

Imperial gallons per second

Imperial gallons per minute

Imperial gallons per hour

Imperial gallons per day

Barrels per second

Options for Volume Flow Measurement Unit for liquid applicationsTable 4-2:

ft3/sec

ft3/min

ft3/hr

ft3/day

m3/sec

m3/min

m3/hr

m3/day

US gal/sec

US gal/min

US gal/hr

US gal/day

mil US gal/day

l/sec

l/min

l/hr

mil l/day

Imp gal/sec

Imp gal/min

Imp gal/hr

Imp gal/day

(1)

barrels/sec

22 Micro Motion® LNG Series Meters

Page 29

Configure process measurement

Options for Volume Flow Measurement Unit for liquid applications (continued)Table 4-2:

Unit description ProLink III label

Barrels per minute

Barrels per hour

Barrels per day

Beer barrels per second

Beer barrels per minute

Beer barrels per hour

Beer barrels per day

Special unit

(1) Unit based on oil barrels (42 U.S. gallons).

(2) Unit based on U.S. beer barrels (31 U.S. gallons).

(2)

barrels/min

barrels/hr

barrels/day

Beer barrels/sec

Beer barrels/min

Beer barrels/hr

Beer barrels/day

special

Define a special measurement unit for volume flow

ProLink III

Device Tools > Configuration > Process Measurement > Flow > Special Units

Overview

A special measurement unit is a user-defined unit of measure that allows you to report

process data, totalizer data, and inventory data in a unit that is not available in the

transmitter. A special measurement unit is calculated from an existing measurement unit

using a conversion factor.

Procedure

1. Specify Base Volume Unit.

Base Volume Unit is the existing volume unit that the special unit will be based on.

2. Specify Base Time Unit.

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Volume Flow Conversion Factor as follows:

a. x base units = y special units

b. Volume Flow Conversion Factor = x ÷ y

4. Enter Volume Flow Conversion Factor.

5. Enter Volume Flow Conversion Factor.

The original volume flow rate value is divided by this conversion factor.

6. Set Volume Flow Label to the name you want to use for the volume flow unit.

Configuration and Use Manual 23

Page 30

Configure process measurement

7. Set Volume Total Label to the name you want to use for the volume total and volume

The special measurement unit is stored in the transmitter. You can configure the

transmitter to use the special measurement unit at any time. You must use ProLink III to

select the special measurement unit.

Example: Defining a special measurement unit for volume flow

You want to measure volume flow in pints per second (pints/sec).

1. Set Base Volume Unit to Gallons (gal).

2. Set Base Time Unit to Seconds (sec).

3. Calculate the conversion factor:

4. Set Volume Flow Conversion Factor to 0.1250.

5. Set Volume Flow Label to pints/sec.

6. Set Volume Total Label to pints.

inventory unit.

a. 1 gal/sec = 8 pints/sec

b. Volume Flow Conversion Factor = 1 ÷ 8 = 0.1250

4.2.3 Configure Volume Flow Cutoff

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Volume Flow Cutoff specifies the lowest volume flow rate that will be reported as measured.

All volume flow rates below this cutoff are reported as 0.

Procedure

Set Volume Flow Cutoff to the value you want to use.

The default value for Volume Flow Cutoff is 0.0 l/sec (liters per second). The lower limit is 0.

The upper limit is the sensor’s flow calibration factor, in units of l/sec, multiplied by 0.2.

4.3

Configure gas standard volume (GSV) flow measurement

The gas standard volume (GSV) flow measurement parameters control how gas standard

volume flow is measured and reported.

The GSV flow measurement parameters include:

Volume Flow Type

•

24 Micro Motion® LNG Series Meters

Page 31

Configure process measurement

Standard Gas Density

•

Gas Standard Volume Flow Measurement Unit

•

Gas Standard Volume Flow Cutoff

•

Restriction

You cannot implement both liquid volume flow and gas standard volume flow at the same time. You

must choose one or the other.

4.3.1 Configure Volume Flow Type for gas applications

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Volume Flow Type controls whether liquid or gas standard volume flow measurement is

used.

4.3.2

Procedure

Set Volume Flow Type to Gas Standard Volume.

Configure Standard Gas Density

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

The Standard Gas Density value is used to convert the measured flow data to the standard

reference values.

Prerequisites

Ensure that Density Measurement Unit is set to the measurement unit you want to use for

Standard Gas Density.

Procedure

Set Standard Gas Density to the standard reference density of the gas you are measuring.

Note

ProLink III provides a guided method that you can use to calculate the standard density of your gas, if

you do not know it.

Configuration and Use Manual 25

Page 32

Configure process measurement

4.3.3 Configure Gas Standard Volume Flow Measurement Unit

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Gas Standard Volume Flow Measurement Unitspecifies the unit of measure that will be displayed

for the gas standard volume flow rate. The measurement unit used for the gas standard

volume total and the gas standard volume inventory is derived from this unit.

Prerequisites

Before you configure Gas Standard Volume Flow Measurement Unit, be sure that Volume Flow Type

is set to Gas Standard Volume.

Procedure

Set Gas Standard Volume Flow Measurement Unit to the unit you want to use.

The default setting for Gas Standard Volume Flow Measurement Unit is SCFM (Standard Cubic

Feet per Minute).

Tip

If the measurement unit you want to use is not available, you can define a special measurement unit.

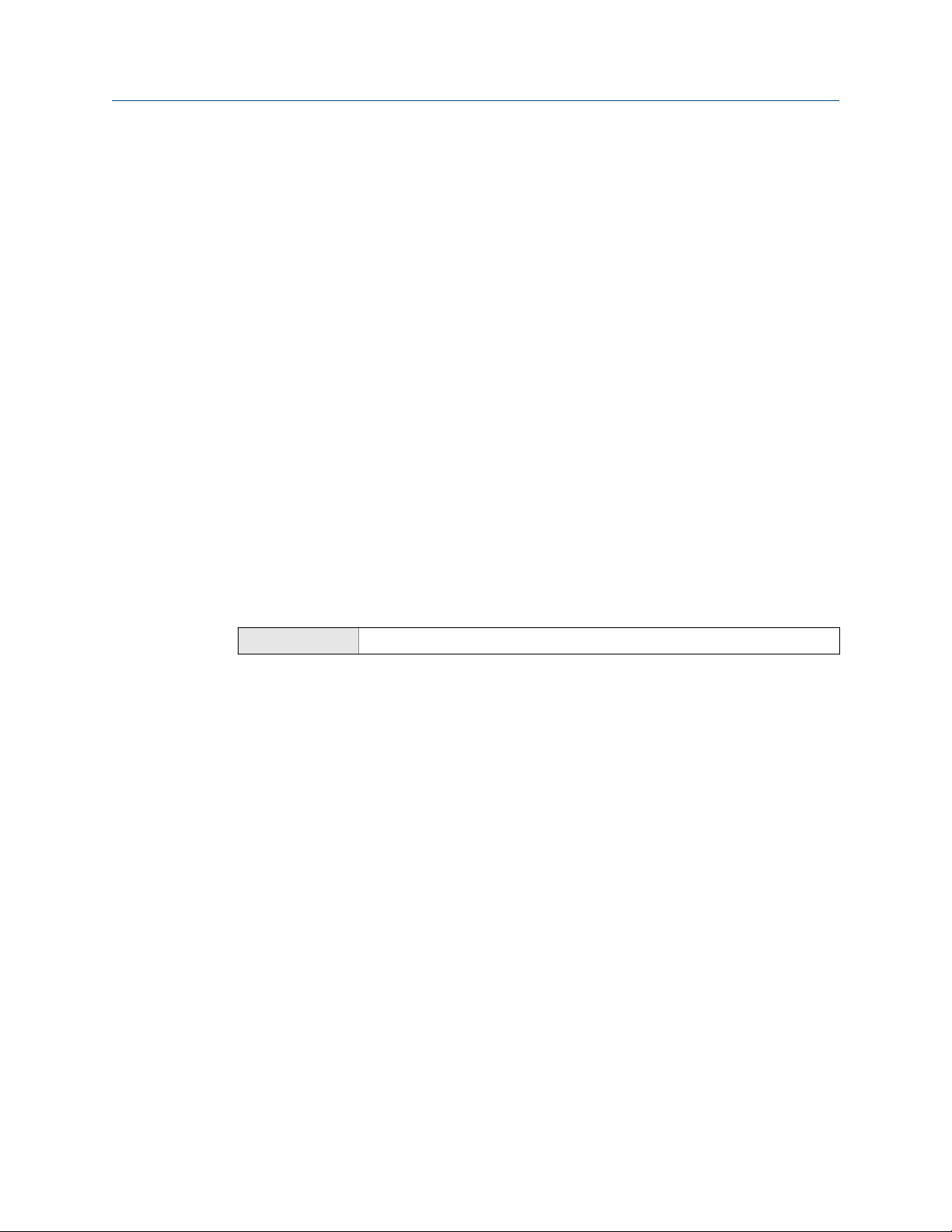

Options for Gas Standard Volume Flow Measurement Unit

The transmitter provides a standard set of measurement units for Gas Standard Volume Flow

Measurement Unit, plus one user-defined special measurement unit. Different

communications tools may use different labels for the units.

Options for

Unit description ProLink III label

Normal cubic meters per second

Normal cubic meters per minute

Normal cubic meters per hour

Normal cubic meters per day

Normal liter per second

Normal liter per minute

Normal liter per hour

Normal liter per day

Standard cubic feet per second

Standard cubic feet per minute

Gas Standard Volume Measurement Unit Table 4-3:

Nm3/sec

Nm3/sec

Nm3/hr

Nm3/day

NLPS

NLPM

NLPH

NLPD

SCFS

SCFM

26 Micro Motion® LNG Series Meters

Page 33

Configure process measurement

Options for Gas Standard Volume Measurement Unit (continued)Table 4-3:

Unit description ProLink III label

Standard cubic feet per hour

Standard cubic feet per day

Standard cubic meters per second

Standard cubic meters per minute

Standard cubic meters per hour

Standard cubic meters per day

Standard liter per second

Standard liter per minute

Standard liter per hour

Standard liter per day

Special measurement unit

SCFH

SCFD

Sm3/sec

Sm3/min

Sm3/hr

Sm3/day

SLPS

SLPM

SLPH

SLPD

special

Define a special measurement unit for gas standard volume flow

ProLink III

Overview

A special measurement unit is a user-defined unit of measure that allows you to report

process data, totalizer data, and inventory data in a unit that is not available in the

transmitter. A special measurement unit is calculated from an existing measurement unit

using a conversion factor.

Procedure

1. Specify Base Gas Standard Volume Unit.

Base Gas Standard Volume Unit is the existing gas standard volume unit that the special

unit will be based on.

2. Specify Base Time Unit.

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Gas Standard Volume Flow Conversion Factor as follows:

Device Tools > Configuration > Process Measurement > Flow > Special Units

a. x base units = y special units

b. Gas Standard Volume Flow Conversion Factor = x ÷ y

4. Enter the Gas Standard Volume Flow Conversion Factor.

The original gas standard volume flow value is divided by this conversion factor.

Configuration and Use Manual 27

Page 34

Configure process measurement

5. Set Gas Standard Volume Flow Label to the name you want to use for the gas standard

6. Set Gas Standard Volume Total Label to the name you want to use for the gas standard

The special measurement unit is stored in the transmitter. You can configure the

transmitter to use the special measurement unit at any time. You must use ProLink III to

select the special measurement unit.

Example: Defining a special measurement unit for gas standard volume flow

You want to measure gas standard volume flow in thousands of standard cubic feet per

minute.

1. Set Base Gas Standard Volume Unit to SCFM.

2. Set Base Time Unit to minutes (min).

3. Calculate the conversion factor:

volume flow unit.

volume total and gas standard volume inventory unit.

a. 1 thousands of standard cubic feet per minute = 1000 cubic feet per minute

b. Gas Standard Volume Flow Conversion Factor = 1 ÷ 1000 = 0.001

4.3.4

4. Set Gas Standard Volume Flow Conversion Factor to 0.001.

5. Set Gas Standard Volume Flow Label to KSCFM.

6. Set Gas Standard Volume Total Label to KSCF.

Configure Gas Standard Volume Flow Cutoff

ProLink III Device Tools > Configuration > Process Measurement > Flow

Overview

Gas Standard Volume Flow Cutoff specifies the lowest gas standard volume flow rate that will

reported as measured. All gas standard volume flow rates below this cutoff will be

reported as 0.

Procedure

Set Gas Standard Volume Flow Cutoff to the value you want to use.

The default value for Gas Standard Volume Flow Cutoff is 0.0. The lower limit is 0.0. There is no

upper limit.

4.4

28 Micro Motion® LNG Series Meters

Configure flow direction

ProLink III Device Tools > Configuration > Process Measurement > Flow

Page 35

Configure process measurement

Overview

Flow Direction controls how forward flow and reverse flow affect flow measurement and

reporting. You can configure two flow directions - one flow direction to map to the first

group of totals, and a second flow direction to map to the second group of totals. The

default flow directions are: Forward for the first group of totals, and Reverse for the second

group of totals.

Flow Direction is defined with respect to the flow arrow on the sensor:

• Forward flow (positive flow) moves in the direction of the flow arrow on the sensor.

• Reverse flow (negative flow) moves in the direction opposite to the flow arrow on

the sensor.

Tip

Micro Motion sensors are bidirectional. Measurement accuracy is not affected by actual flow

direction or the setting of the Flow Direction parameter.

Procedure

Set Flow Direction to the value you want to use.

4.4.1

You can configure two flow directions:

• The first flow direction is configured and applied to the first totals. The default setting is

Forward.

• The second flow direction is configured and applied to the second totals. The default

setting is Reverse.

Options for Flow Direction

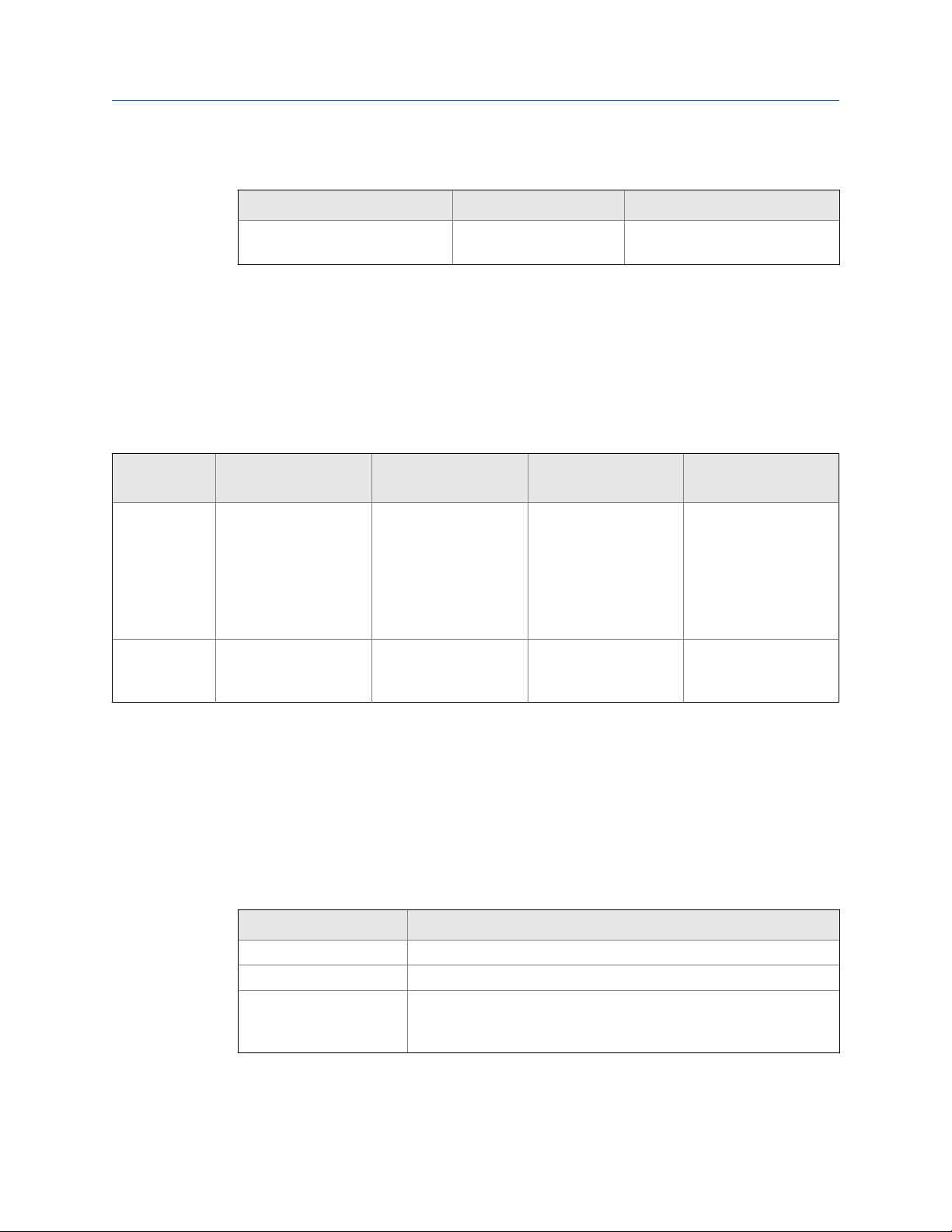

Options for Flow Direction Table 4-4:

Flow direction setting from

ProLink III Relationship to Flow Direction arrow on sensor

Forward

Reverse

Absolute Value

Bidirectional

Negate Forward

Appropriate when the Flow Direction arrow is in the same

direction as the majority of flow.

Appropriate when the Flow Direction arrow is in the same

direction as the majority of flow.

Flow Direction arrow is not relevant.

Appropriate when both forward and reverse flow are expected, and forward flow will dominate, but the amount

of reverse flow will be significant.

Appropriate when the Flow Direction arrow is in the opposite direction from the majority of flow.

Configuration and Use Manual 29

Page 36

Configure process measurement

Flow direction setting from

Negate Bidirectional

Effect of Flow Direction on flow totals

Flow Direction affects how flow totals and inventories are calculated.

Options for Flow Direction (continued)Table 4-4:

ProLink III Relationship to Flow Direction arrow on sensor

Appropriate when both forward and reverse flow are expected, and reverse flow will dominate, but the amount of

forward flow will be significant.

Table 4-5:

Effect of the Flow Direction parameter and actual flow direction on flow

totals and inventories

Actual flow direction

Flow Direction setting

Forward

Reverse

Bidirectional

Absolute Value

Negate Forward

Negate Bidirectional

Forward Zero flow Reverse

Totals increase Totals do not change Totals do not change

Totals do not change Totals do not change Totals increase

Totals increase Totals do not change Totals decrease

Totals increase Totals do not change Totals increase

Totals do not change Totals do not change Totals increase

Totals decrease Totals do not change Totals increase

4.5 Configure density measurement

The density measurement parameters control how density is measured and reported.

Density measurement (along with mass measurement) is used to determine liquid volume

flow.

4.5.1

Configure Density Measurement Unit

ProLink III Device Tools > Configuration > Process Measurement > Density

Overview

Density Measurement Unit controls the measurement units that will be used in density

calculations and reporting.

30 Micro Motion® LNG Series Meters

Page 37

Configure process measurement

Procedure

Set Density Measurement Unit to the option you want to use.

The default setting for Density Measurement Unit is g/cm3 (grams per cubic centimeter).

Options for Density Measurement Unit

The transmitter provides a standard set of measurement units for Density Measurement Unit.

Different communications tools may use different labels.

Options for Density Measurement Unit Table 4-6:

Unit description ProLink III label

Specific gravity unit (not temperature-corrected)

Grams per cubic centimeter

Grams per liter

Grams per milliliter

Kilograms per liter

Kilograms per cubic meter

Pounds per U.S. gallon

Pounds per cubic foot

Pounds per cubic inch

API gravity

Short ton per cubic yard

SGU

g/cm3

g/l

g/ml

kg/l

kg/m3

lbs/Usgal

lbs/ft3

lbs/in3

degAPI

sT/yd3

4.5.2 Configure two-phase flow parameters

ProLink III Device Tools > Configuration > Process Measurement > Density

Overview

The two-phase flow parameters control how the transmitter detects and reports twophase flow (gas in a liquid process or liquid in a gas process).

Note

Two-phase flow is sometimes referred to as slug flow.

Procedure

1. Set Two-Phase Flow Low Limit to the lowest density value that is considered normal in

your process.

Configuration and Use Manual 31

Page 38

Configure process measurement

2. Set Two-Phase Flow High Limit to the highest density value that is considered normal in

Values below this will cause the transmitter to post Alert A105 ( Slug Flow.

Tip

Gas entrainment can cause your process density to drop temporarily. To reduce the

occurrence of two-phase flow alerts that are not significant to your process, set Two-Phase Flow

Low Limit slightly below your expected lowest process density.

You must enter Two-Phase Flow Low Limit in g/cm³, even if you configured another unit

for density measurement.

your process.

Values above this will cause the transmitter to post Alert A105 ( Slug Flow.

Tip

To reduce the occurrence of two-phase flow alerts that are not significant to your process, set

Two-Phase Flow High Limit slightly above your expected highest process density.

You must enter Two-Phase Flow High Limit in g/cm³, even if you configured another

unit for density measurement.

3. Set Two-Phase Flow Timeout to the number of seconds that the transmitter will wait for

a two-phase flow condition to clear before posting the alert.

The default value for Two-Phase Flow Timeout is 0.0 seconds, meaning that the alert

will be posted immediately. The range is 0.0 to 60.0 seconds.

Detecting and reporting two-phase flow

Two-phase flow (gas in a liquid process or liquid in a gas process) can cause a variety of

process control issues. By configuring the two-phase flow parameters appropriately for

your application, you can detect process conditions that require correction.

Tip

To decrease the occurrence of two-phase flow alerts, lower Two-Phase Flow Low Limit or raise Two-Phase

Flow High Limit.

A two-phase flow condition occurs whenever the measured density goes below Two-Phase

Flow Low Limit or above Two-Phase Flow High Limit. If this occurs:

• A two-phase flow alert is posted to the active alert log.

• All outputs that are configured to represent flow rate hold their last pre‐alert value

for the number of seconds configured in Two-Phase Flow Timeout.

If the two-phase flow condition clears before Two-Phase Flow Timeout expires:

• Outputs that represent flow rate revert to reporting actual flow.

32 Micro Motion® LNG Series Meters

Page 39

• The two-phase flow alert is deactivated, but remains in the active alert log until it is

acknowledged.

If the two-phase flow condition does not clear before Two-Phase Flow Timeout expires, the

outputs that represent flow rate report a flow rate of 0.

If Two-Phase Flow Timeout is set to 0.0 seconds, the outputs that represent flow rate will

report a flow rate of 0 as soon as two-phase flow is detected.

4.5.3 Configure density damping

ProLink III Device Tools > Configuration > Process Measurement > Density

Overview

Density Damping controls the amount of damping that will be applied to the line density

value.

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes

in the process variable. At the end of the interval, the internal value will reflect 63% of the

change in the actual measured value.

Configure process measurement

Procedure

Set Density Damping to the value you want to use.

The default value is 1.28 seconds. The range is 0 to 60 seconds.

Tips

• A high damping value makes the process variable appear smoother because the reported value

changes slowly.

• A low damping value makes the process variable appear more erratic because the reported value

changes more quickly.

• Whenever the damping value is non-zero, the reported measurement will lag the actual

measurement because the reported value is being averaged over time.

• In general, lower damping values are preferable because there is less chance of data loss, and less

lag time between the actual measurement and the reported value.

The value you enter is automatically rounded down to the nearest valid value. The valid

values for Density Damping are: 0, 0.04, 0.08, 0.16, 0.32... 40.96.

Effect of density damping on volume measurement

Density Damping affects liquid volume measurement. Liquid volume values are calculated

from the damped density value rather than the measured density value. Density Damping

does not affect gas standard volume measurement.

Configuration and Use Manual 33

Page 40

Configure process measurement

4.5.4 Configure Density Cutoff

ProLink III Device Tools > Configuration > Process Measurement > Density

Overview

Density Cutoff specifies the lowest density value that will be reported as measured. All

density values below this cutoff will be reported as 0.

Procedure

Set Density Cutoff to the value you want to use.

The default value for Density Cutoff is 0.2 g/cm³. The range is 0.0 g/cm³ to 0.5 g/cm³.

Effect of Density Cutoff on volume measurement

Density Cutoff affects liquid volume measurement. If the density value goes below Density

Cutoff, the volume flow rate is reported as 0. Density Cutoff does not affect gas standard

volume measurement. Gas standard volume values are always calculated from the value

configured for Standard Gas Density.

4.6 Configure temperature measurement

The temperature measurement parameters control how temperature data from the

sensor is reported.

4.6.1

Configure Temperature Measurement Unit

ProLink III Device Tools > Configuration > Process Measurement > Temperature

Overview

Temperature Measurement Unit specifies the unit that will be used for temperature

measurement.

Procedure

Set Temperature Measurement Unit to the option you want to use.

The default setting is Degrees Celsius.

Options for Temperature Measurement Unit

The transmitter provides a standard set of units for Temperature Measurement Unit. Different

communications tools may use different labels for the units.

34 Micro Motion® LNG Series Meters

Page 41

Options for Temperature Measurement Unit Table 4-7:

Unit description ProLink III

Degrees Celsius

Degrees Fahrenheit

Degrees Rankine

Kelvin

4.6.2 Configure Temperature Damping

ProLink III Device Tools > Configuration > Temperature

Overview

Temperature Damping controls the amount of damping that will be applied to the line

temperature value, when the on-board temperature data is used (RTD).

Configure process measurement

°C

°F

°R

°K

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes

in the process variable. At the end of the interval, the internal value will reflect 63% of the

change in the actual measured value.

Tip

Temperature Damping affects all process variables, compensations, and corrections that use

temperature data from the sensor.

Procedure

Enter the value you want to use for Temperature Damping.

The default value is 4.8 seconds. The range is 0.0 to 38.4 seconds.

Tips

• A high damping value makes the process variable appear smoother because the reported value

changes slowly.

• A low damping value makes the process variable appear more erratic because the reported value

changes more quickly.

• Whenever the damping value is non-zero, the reported measurement will lag the actual

measurement because the reported value is being averaged over time.

• In general, lower damping values are preferable because there is less chance of data loss, and less

lag time between the actual measurement and the reported value.

The value you enter is automatically rounded down to the nearest valid value. Valid values

for Temperature Damping are 0, 0.6, 1.2, 2.4, 4.8, … 38.4.

Configuration and Use Manual 35

Page 42

Configure process measurement

Effect of Temperature Damping on process measurement

Temperature Damping affects all processes and algorithms that use temperature data from

the internal sensor RTD.

Temperature compensation

Temperature compensation adjusts process measurement to compensate for the effect of

temperature on the sensor tubes.

36 Micro Motion® LNG Series Meters

Page 43

Configure device options and preferences

5 Configure device options and

preferences

Topics covered in this chapter:

Configure response time parameters

•

Configure alert handling

•

Configure informational parameters

•

5.1 Configure response time parameters

You can configure the rate at which process data is polled and process variables are

calculated.

Response time parameters include:

Update Rate

•

• Calculation Speed (Response Time)

5.1.1

Configure Calculation Speed (Response Time)

ProLink III Device Tools > Configuration > Process Measurement > Response > Calculation Speed

Overview

Calculation Speed is used to apply a different algorithm to the calculation of process variables

from the raw process data. Calculation Speed = Special produces faster and “noisier” response

to changes in the process.

Tip

You can use Calculation Speed = Special with either setting of Update Rate. The parameters control

different aspects of flowmeter processing.

Procedure

Set Calculation Speed as desired.

Option

Normal

Special

Description

Transmitter calculates process variables at the standard speed.

Transmitter calculates process variables at a faster speed.

Configuration and Use Manual 37

Page 44

Configure device options and preferences

5.2 Configure alert handling

The alert handling parameters control the transmitter’s response to process and device

conditions.

• Configure Fault Timeout (Section 5.2.1)

• Configure Status Alert Severity (Section 5.2.2)

5.2.1 Configure Fault Timeout

ProLink III Device Tools > Configuration > Fault Processing

Overview

Fault Timeout controls the delay before fault actions are performed.

Restriction

Fault Timeout is applied only to the following alerts (listed by Status Alert Code): A003, A004, A005,

A008, A016, A033. For all other alerts, fault actions are performed as soon as the alert is detected.

5.2.2

Procedure

Set Fault Timeout as desired.

The default value is 0 seconds. The range is 0 to 60 seconds.

If you set Fault Timeout to 0, fault actions are performed as soon as the alert condition is

detected.

The fault timeout period begins when the transmitter detects an alert condition. During

the fault timeout period, the transmitter continues to report its last valid measurements.

If the fault timeout period expires while the alert is still active, the fault actions are

performed. If the alert condition clears before the fault timeout expires, no fault actions

are performed.

Configure Status Alert Severity

ProLink III Device Tools > Configuration > Alert Severity

Overview

Use Status Alert Severity to control the fault actions that the transmitter performs when it

detects an alert condition.

38 Micro Motion® LNG Series Meters

Page 45

Configure device options and preferences

Restrictions

• For some alerts, Status Alert Severity is not configurable.

• For some alerts, Status Alert Severity can be set only to two of the three options.

Tip

Micro Motion recommends using the default settings for Status Alert Severity unless you have a specific

requirement to change them.

Procedure

1. Select a status alert.

2. For the selected status alert, set Status Alert Severity as desired.

Option

Fault

Informational

Ignore

Description

Actions when fault is detected:

• The alert is posted to the Alert List.

• Outputs go to the configured fault action (after Fault Timeout has expired, if

applicable).

• Digital communications go to the configured fault action (after Fault Timeout

has expired, if applicable).

• The status LED (if available) changes to red or yellow (depending on alert se-

verity).

Actions when alert clears:

• Outputs return to normal behavior.

• Digital communications return to normal behavior.

• The status LED (if available) returns to green and may or may not flash.

Actions when fault is detected:

• The alert is posted to the Alert List.

• The status LED (if available) changes to red or yellow (depending on alert se-

verity).

Actions when alert clears:

• The status LED (if available) returns to green and may or may not flash.

No action

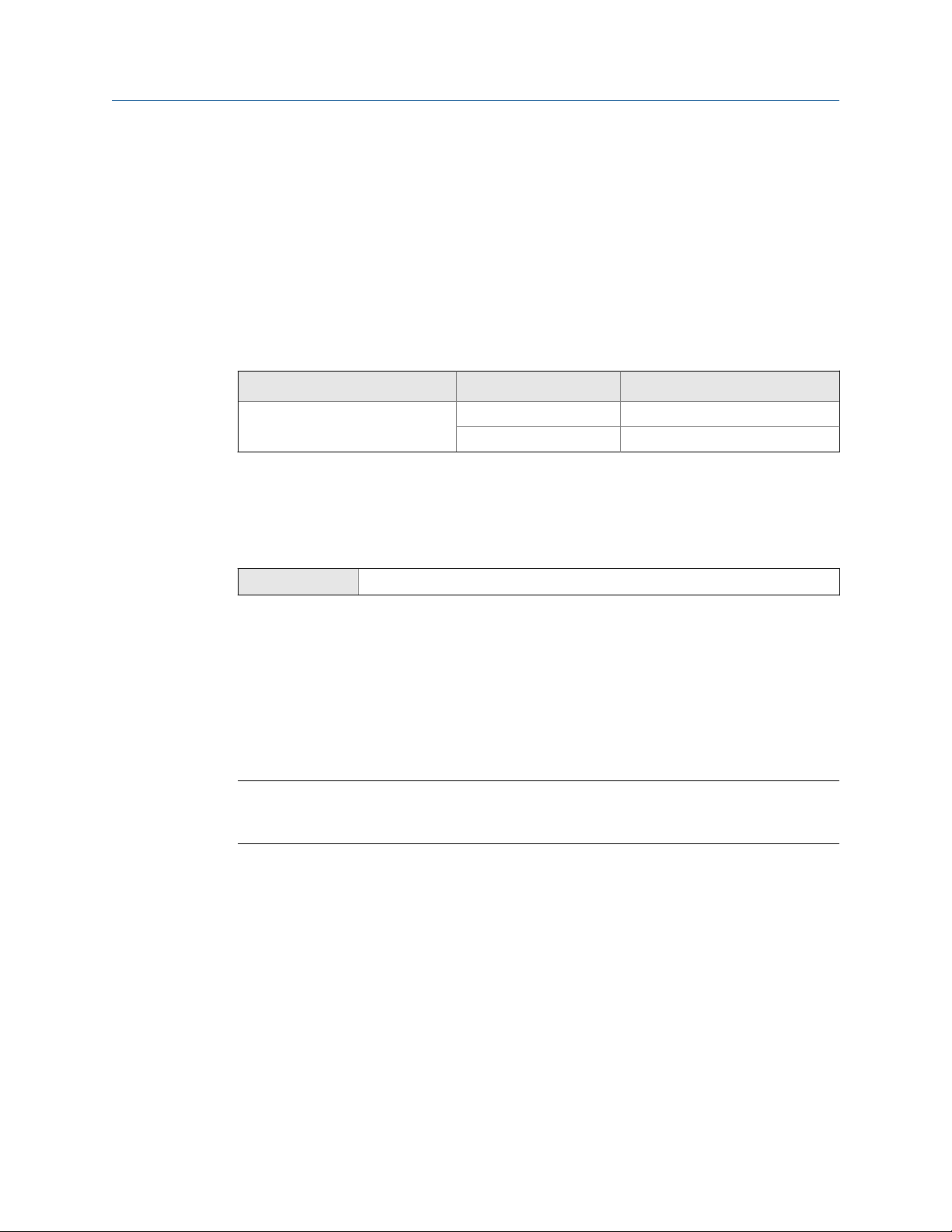

Status alerts and options for Status Alert Severity

Status alerts and

Alert code Status message Default severity Notes Configurable?

A001 EEPROM Error

A002 RAM Error

A003 No Sensor Response

A004 Temperature Overrange

Status Alert Severity Table 5-1:

Fault

Fault

Fault

Fault

No

No

Yes

No

Configuration and Use Manual 39

Page 46

Configure device options and preferences

Status alerts and Status Alert Severity (continued)Table 5-1:

Alert code Status message Default severity Notes Configurable?

A005 Mass Flow Rate Overrange

A006 Characterization Required

A008 Density Overrange

A009 Transmitter Initializing/

Warming Up

A010 Calibration Failure

A011 Zero Calibration Failed:

Low

A012 Zero Calibration Failed:

High

A013 Zero Calibration Failed:

Unstable

A014 Transmitter Failure

A016 Sensor RTD Failure

A020 No Flow Cal Value

A021 Incorrect Sensor Type (K1)

A027 Security Breach

A030 Incorrect Board Type

A033 Insufficient Right/Left Pick-

off Signal

A102 Drive Overrange

A104 Calibration in Progress

A105 Slug Flow

A107 Power Reset Occurred

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Fault

Informational

Informational

Informational

Informational

Applies only to flowmeters with the

enhanced core processor.

Can be set to either Informational or

Ignore, but cannot be set to Fault.

Normal transmitter behavior; occurs after every power cycle.

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

No

Yes

Yes

No

No

No

Yes

Yes

Yes

Yes

Yes

5.3 Configure informational parameters

The informational parameters can be used to identify or describe your meter. They are not

used in process measurement and they are not required.

5.3.1

40 Micro Motion® LNG Series Meters

Configure the sensor index

ProLink III Device Tools > Configuration > Informational Parameters > Sensor Index

Page 47

You can configure the sensor index only if the connection is through a service port. If the

connection is an RS-485 port, the sensor index is read-only, with each Modbus address

corresponding to a different sensor. In default, Modbus address 1 corresponds to sensor 1,

Modbus address 2 corresponds to sensor 2.

5.3.2 Configure the RTD cable length

ProLink III Device Tools > Configuration > Informational Parameters > Sensor > RTD1(2) Cable Length

Overview

Configure the RTD cable length if your 9-wire cable length is other than three meters.

Prerequisites

Verify that the sensor index is correct.

Procedure

Enter the cable length (unit:m) in the RTD 1(2) Cable Length field.

Configure device options and preferences

5.3.3

5.3.4

Related information

Configure the sensor index

Configure Sensor Serial Number

ProLink III Device Tools > Configuration > Informational Parameters > Sensor

Overview

Sensor Serial Number lets you store the serial number of the sensor component of your

flowmeter in transmitter memory. This parameter is not used in processing and is not

required.

Procedure

1. Obtain the sensor serial number from your sensor tag.

2. Enter the serial number in the Sensor Serial Number field.

Configure Sensor Material

ProLink III Device Tools > Configuration > Informational Parameters > Sensor

Configuration and Use Manual 41

Page 48

Configure device options and preferences

Overview

Sensor Material lets you store the type of material used for your sensor’s wetted parts in

transmitter memory. This parameter is not used in processing and is not required.

Procedure

1. Obtain the material used for your sensor’s wetted parts from the documents

shipped with your sensor, or from a code in the sensor model number.

To interpret the model number, refer to the product data sheet for your sensor.

2. Set Sensor Material to the appropriate option.

5.3.5 Configure Sensor Liner Material

ProLink III Device Tools > Configuration > Informational Parameters > Sensor

Overview

5.3.6

Sensor Liner Material lets you store the type of material used for your sensor liner in

transmitter memory. This parameter is not used in processing and is not required.

Procedure

1. Obtain your sensor’s liner material from the documents shipped with your sensor, or

from a code in the sensor model number.

To interpret the model number, refer to the product data sheet for your sensor.

2. Set Sensor Liner Material to the appropriate option.

Configure Sensor Flange Type

ProLink III Device Tools > Configuration > Informational Parameters > Sensor

Overview

Sensor Flange Type lets you store your sensor’s flange type in transmitter memory. This

parameter is not used in processing and is not required.

Procedure

1. Obtain your sensor’s flange type from the documents shipped with your sensor, or

from a code in the sensor model number.

To interpret the model number, refer to the product data sheet for your sensor.

2. Set Sensor Flange Type to the appropriate option.

42 Micro Motion® LNG Series Meters

Page 49

5.3.7 Configure Descriptor

ProLink III Device Tools > Configuration > Informational Parameters > Transmitter

Overview

Descriptor lets you store a description in transmitter memory. The description is not used in

processing and is not required.

Procedure

Enter a description for the transmitter or device

You can use up to 16 characters for the description.

5.3.8 Configure Message

Message lets you store a short message in transmitter memory. This parameter is not used

in processing and is not required.

Configure device options and preferences

5.3.9

Procedure

Enter a short message for the transmitter or device.

Your message can be up to 32 characters long.

Configure Date

ProLink III Device Tools > Configuration > Informational Parameters > Transmitter

Overview

Date lets you store a static date (not updated by the transmitter) in transmitter memory.

This parameter is not used in processing and is not required.

Procedure

Enter the date you want to use, in the form mm/dd/yyyy.

Tip

ProLink III provides a calendar tool to help you select the date.

Configuration and Use Manual 43

Page 50