Page 1

Product Data Sheet

Micro Motion® Compact Density Meters

Peak performance precision density meter

PS-001482, Rev H

June 2018

Unparalleled real-world performance

■

Superior application performance via traceable calibrations, performed at combined pressure and

temperature conditions

■

OIML R117-1 approved for MID conformance

■

ISO/IEC accredited calibration

Superior multi-variable I/O, meter health, and application capabilities

■

Flow rate indication (velocity/volume flow) ensures sample integrity

■

Internal diagnostics for fast verification of meter health and installation

■

Application-specific factory configurations ensure fit-for-purpose operation

Installation flexibility and compatibility

■

Fluid, process and environmental effects are minimized to ensure superb measurement confidence

■

Supports multiple protocols for connection to DCS, PLC, and flow computers

■

Retrofit option available for Micro Motion 7835 and 7845 liquid density meters

■

Optional stainless steel transmitter housing for corrosion resistance in harsh environments

Page 2

Density

Referred Density

Specific Gravity

Flow rate indication (velocity)

°API

%Concentration

%Alcohol by Volume (ABV)

°Brix, °Baume, °Plato

STATUS

SCROLL

SELECT

0(7(5+($/7+

Compact Density Meter

June 2018

Micro Motion Compact Density Meters

Compact Density Meters use the Micro Motion dual curved-tube meter technology to measure density. These meters use a multivariable measurement system, designed for fiscal metering of high-value products such as crude oil, refined hydrocarbons, alcohol,

and many aggressive process liquids.

Application configurations

You can preselect an application-specific configuration for your meter from a wide range of options.

Integral transmitter

Supports Time Period Signal (TPS), 2-wire TPS, Analog (4–20 mA), HART, WirelessHART®, and Modbus RS-485 communications.

Meter diagnostics

Ensure measurement health through known density verification (KDV) and other meter and installation diagnostic capabilities.

2 www.micromotion.com

Page 3

June 2018

Compact Density Meter

Retrofit capabilities

Retrofit option has the same face-to-face dimensions as the Micro Motion 7835 and 7845 density meters.

Thermal insulation

The CDM is available with a soft, weather-proof insulating jacket that is easily fitted to all CDM versions to maintain stable

temperatures and achieve optimal performance.

Accreditation and standards

Accredited calibrations are in compliance with domestic and international standards.

www.micromotion.com 3

Page 4

Compact Density Meter

June 2018

ProLink® III software: a configuration and service tool

ProLink III software is an easy-to-use interface that allows you to view key process variables and diagnostics data for your meter. For

more information on ordering the software, contact your local sales representative or email customer support at

flow.support@emerson.com.

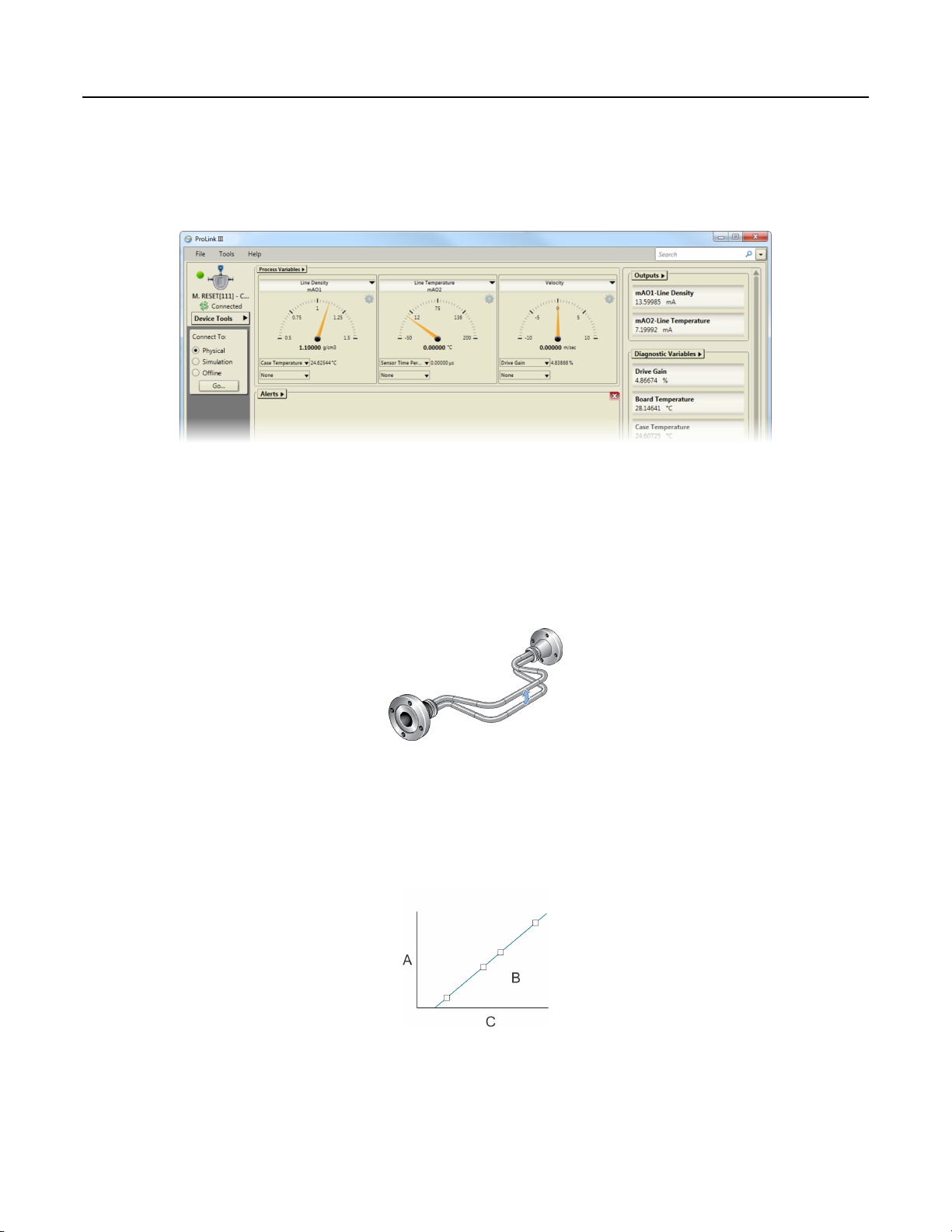

Operating principle

Tube vibration

■ Dual, parallel tubes vibrate at their natural frequency.

■ The natural frequency changes with the density of the liquid inside the tubes.

Density calibration

■ Micro Motion transmitters accurately measure time period.

■ Measured time periods are converted into density readings using meter calibration coefficients.

■ Minimum of 12 calibration points ensures optimum meter performance.

A. Density (kg/m3)

B. Time period = 1 / frequency

C. [Time period]2 (μs2)

4 www.micromotion.com

Page 5

June 2018

Compact Density Meter

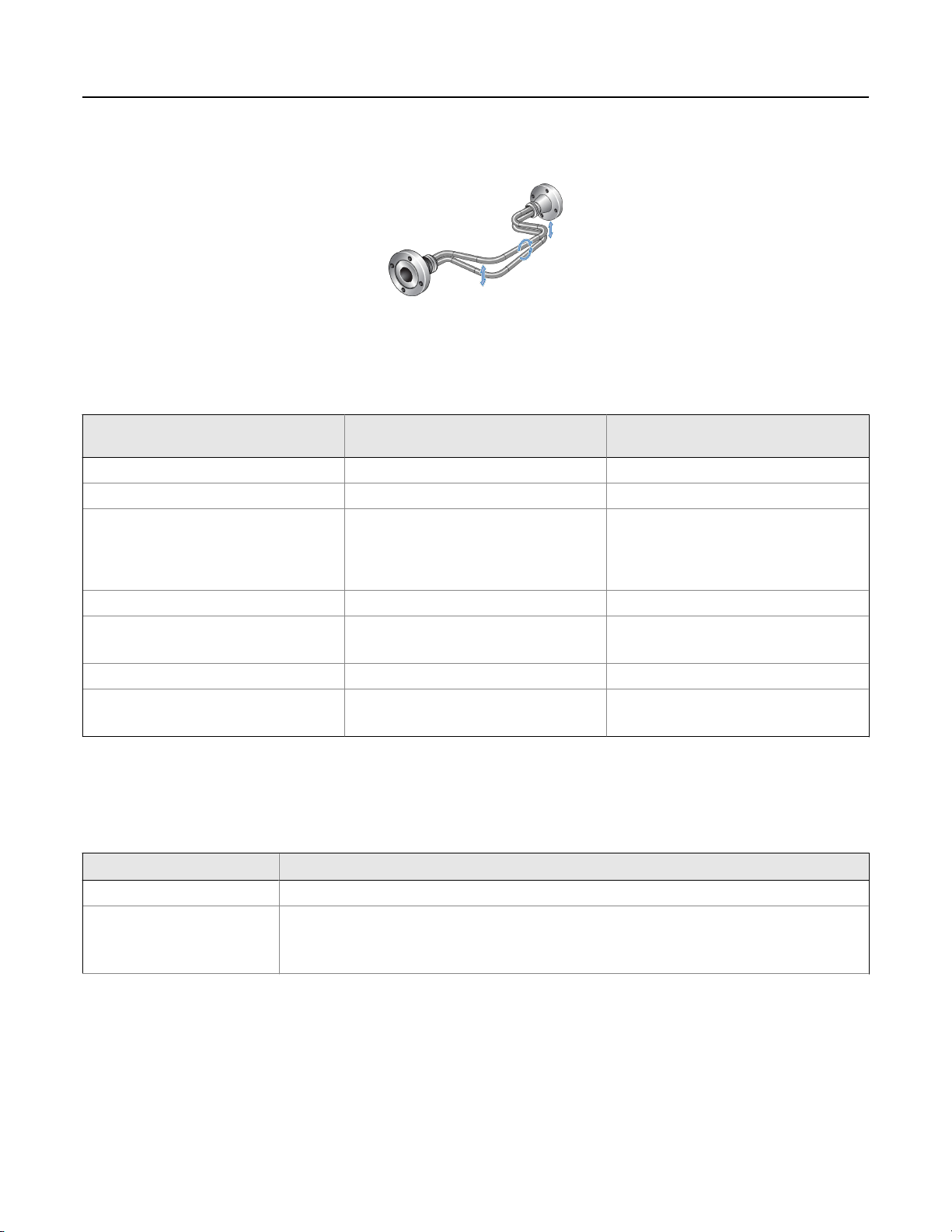

Flow rate indication (velocity/volume flow)

■ Measuring the twist in the vibrating tubes gives an indication of the liquid flow rate (velocity/volume flow).

Performance specifications

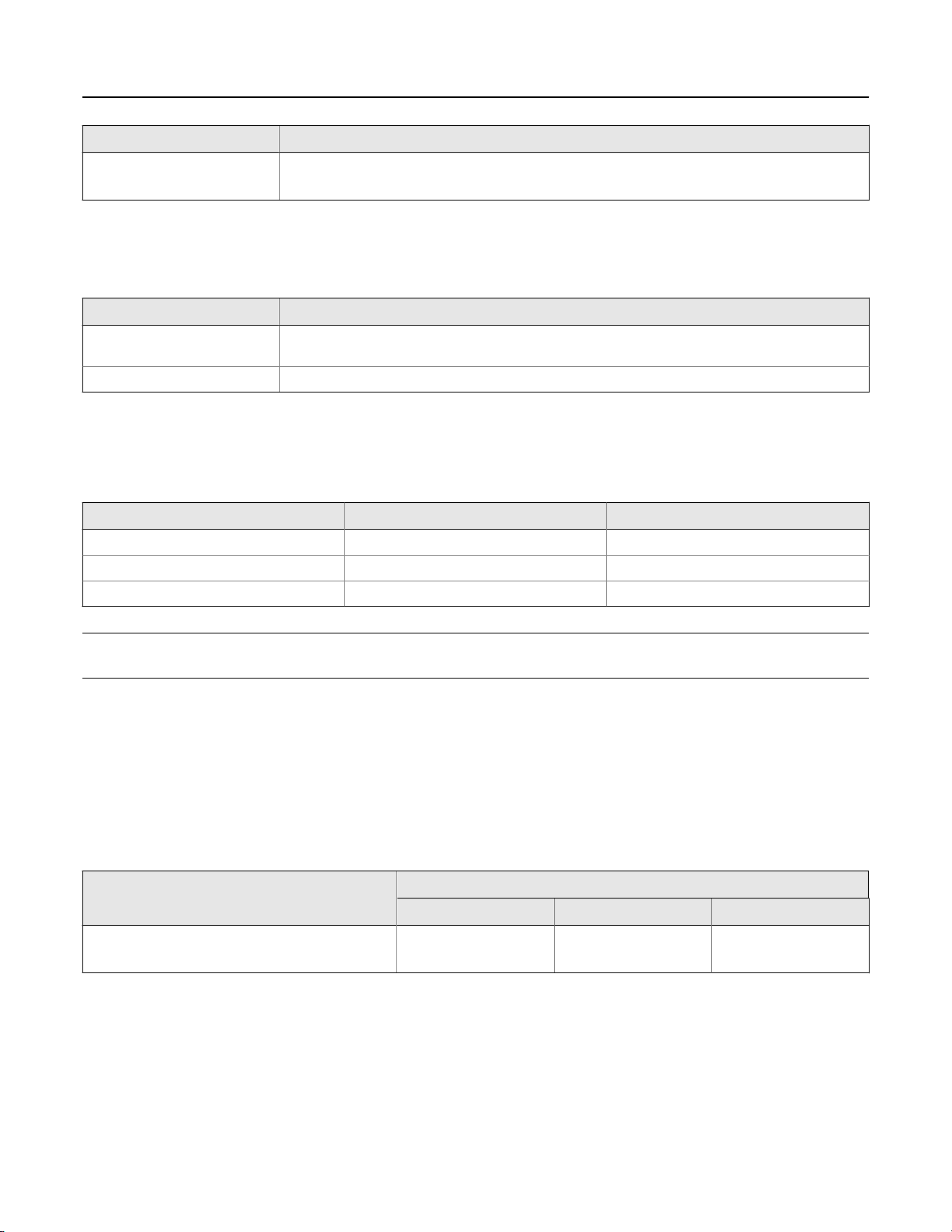

Density measurement

Specification

Accuracy (liquid) ±0.1 kg/m3 (±0.0001 g/cm3) ±0.2 kg/m3 (±0.0002 g/cm3)

Repeatability ±0.02 kg/m3 (±0.00002 g/cm3) ±0.02 kg/m3 (±0.00002 g/cm3)

Operating density range 0–3000 kg/m3 (0–3 g/cm3)

Calibration range 300–1300 kg/m3 (0.3–1.3 g/cm3) 300–1300 kg/m3 (0.3–1.3 g/cm3)

Process temperature effect (corrected)

Sensor maximum working pressure 248 bar (3600 psi) or flange limit 100 bar (1450 psi) or flange limit

Process pressure effect (corrected)

(1) Process temperature effect is the maximum measurement offset due to process fluid temperature changing away from the reference calibration

temperature of 20 °C.

(2) Process pressure effect is the maximum measurement offset due to process fluid pressure changing away from the reference calibration pressure

of 1 bar.

(2)

CDM100P (Peak performance precision

density meter)

(1)

■ ±0.005 kg/m3 per °C

■ ±0.278 kg/m3 per 100 °F

■ ±0.003 kg/m3 per bar

■ ±0.021 kg/m3 per 100 psi

CDM100M (General purpose precision

density meter)

■ TPS transmitter version:0-1000 kg/m

(0–1 g/cm3)

■ Analog/Discrete transmitter versions:

0–3000 kg/m3 (0–3 g/cm3)

■ ±0.015 kg/m3 per °C

■ ±0.834 kg/m3 per 100 °F

■ ±0.006 kg/m3 per bar

■ ±0.042 kg/m3 per 100 psi

Temperature measurement

Specification

Operating temperature range –58 °F to +400 °F (–50 °C to +204 °C)

Integral temperature sensor

Value

■ Traceable calibration

■ Technology: 100 Ω RTD

■ Accuracy: BS1904 Class, DIN 43760 Class A (±0.15 +0.002 x Temp °C)

3

www.micromotion.com 5

Page 6

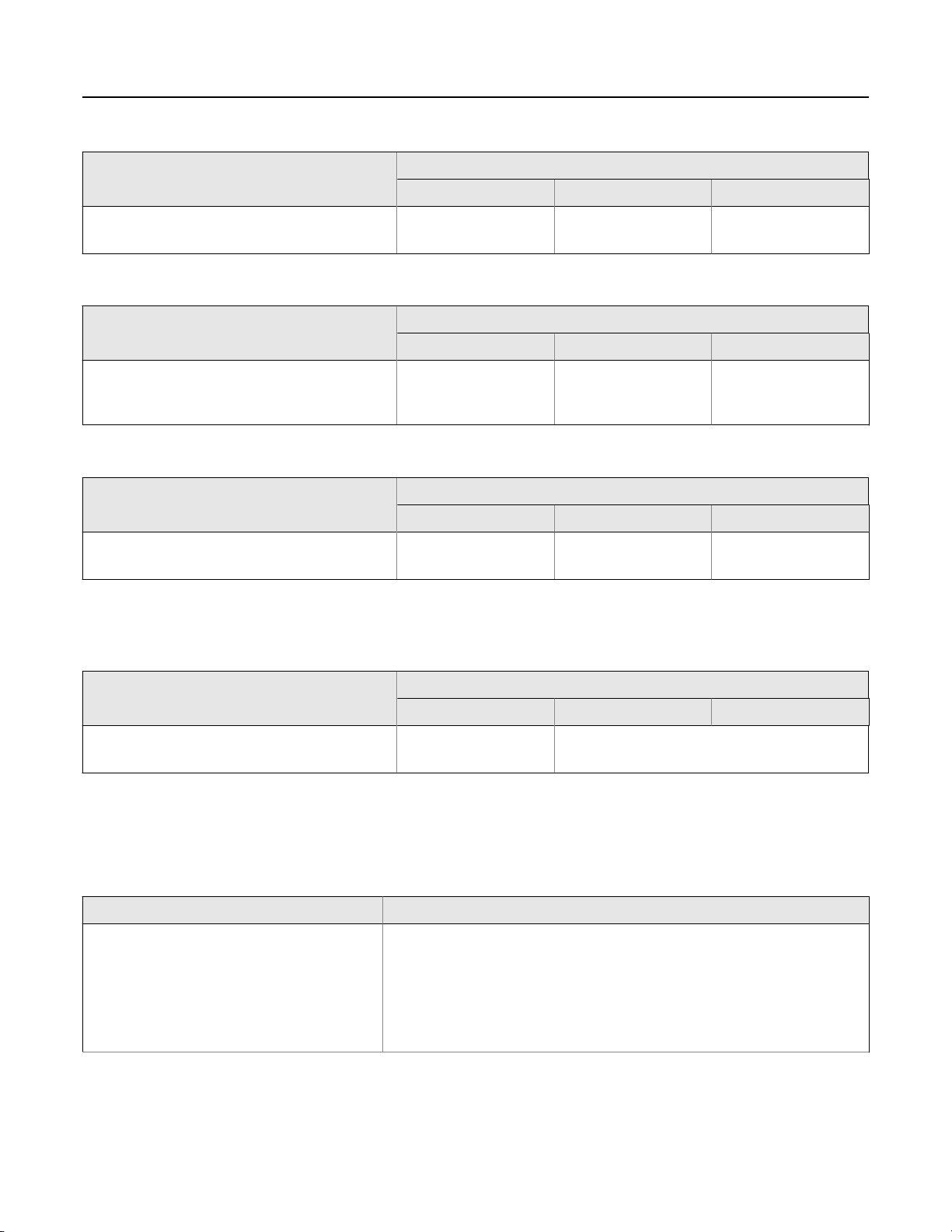

Compact Density Meter

Specification Value

Case temperature sensors

(1) Case temperature sensors are used for environmental temperature effect correction in applications where the case temperature measurement

does not need to be traceable and/or accredited. Where accreditation and measurement traceability are required, these sensors are used for

diagnostics purposes only and do not perform any correction on the density measurement.

(1)

■ Technology: 3 x 100 Ω RTD

■ Accuracy: BS1904 Class, DIN 43760 Class B (±0.30 +0.005 x Temp °C)

June 2018

Case pressure

Specification Value

Maximum case working pressure

Typical burst pressure (case) 195 bar (2824 psig)

27 bar (389 psig)

Diagnostic flow rate indication (velocity/volume flow)

Expected accuracy is within ±5% of reading.

Typical flow recommendations

Minimum 3 gpm (700 L/hr) 1.5 ft/sec (0.5 m/sec)

Normal 11 gpm (2,500 L/hr) 5 ft/sec (1.5 m/sec)

Maximum 75 gpm (17,000 L/hr) 30 ft/sec (9 m/sec)

Note

For fluids that contain abrasive particles, velocity should be below 10 ft/s (3 m/s).

Flow rate Velocity

Transmitter specifications

Available transmitter versions

For more information on the transmitter outputs and ordering codes, see the product ordering information.

Analog

Output channels

Typical application

■ General purpose measurement

■ DCS/PLC connection

A B C

4–20 mA + HART

(passive)

4–20 mA (passive) Modbus/RS-485

6 www.micromotion.com

Page 7

June 2018

Processor for remote-mount Model 2700 FOUNDATION fieldbus transmitter

Output channels

Compact Density Meter

Typical application

■ General purpose measurement

■ DCS/PLC connection

A B C

Disabled Disabled Modbus/RS-485

Discrete

Output channels

Typical application

■ General purpose measurement with output

switch

■ DCS/PLC connection

A B C

4–20 mA + HART

(passive)

Time Period Signal (TPS)

Output channels

Typical application

■ Fiscal/Custody Transfer

■ Flow computer connection

The 4-20 mA output cannot be configured to output line density.

A B C

4–20 mA + HART

(passive)

Discrete output Modbus/RS-485

Time Period Signal

(TPS)

Modbus/RS-485

2-wire TPS

Output channels

Typical application

■ Fiscal/Custody Transfer

■ Flow computer connection

For the 2-wire transmitter version, TPS is superimposed on power lines.

A B C

Disabled 4-wire 100 Ω, RTD

Local display

Design

Physical

Features

■ Segmented two-line LCD screen.

■ Can be rotated on transmitter, in 90-degree increments, for ease of viewing.

■ Suitable for hazardous area operation.

■ Optical switch controls for hazardous area configuration and display.

■ Glass lens.

■ Three-color LED indicates meter and alert status.

www.micromotion.com 7

Page 8

Compact Density Meter

Design Features

Functions

■ View process variables.

■ View and acknowledge alerts.

■ Configure mA and RS-485 outputs.

■ Supports Known Density Verification (KDV).

■ Supports multiple languages.

June 2018

Process measurement variables

Variables Value

Standard

Derived The derived output variables vary, depending on the application configuration of the meter.

■ Density

■ Time period

■ Temperature

■ Drive gain

■ External temperature input

■ External pressure input

■ Flow rate (velocity/volume flow)

■ Referred density (API Tables 53A, 53B)

■ Referred density (Concentration)

■ Specific gravity (Concentration)

■ %Alcohol by Volume (ABV)

■ Alcohol proof

■ °API

■ °Balling

■ °Baume

■ °Brix

■ °Plato

■ %Mass

■ %Solids

■ °Twaddle

■ User-defined calculation output

Note

■ For the TPS transmitter version, process measurement variables are limited to Time Period, Temperature, and Flow.

■ For the 2-wire transmitter version, process measurement variables are limited to Time Period and Temperature.

8 www.micromotion.com

Page 9

June 2018

Compact Density Meter

Additional communication options

The following communications accessories are purchased separately from the meter.

Type Description

WirelessHART WirelessHART is available via the THUM adapter

FOUNDATION fieldbus Remote-mount Model 2700 transmitter with FOUNDATION fieldbus

■ One FOUNDATION fieldbus H1 connection provided

HART® Tri-Loop Three additional 4-20 mA outputs are available via connection to a HART Tri-

Loop

Hazardous area approvals

Ambient and process temperature limits are defined by temperature graphs for each meter and electronics interface option. Refer

to the detailed approval specifications, including temperature graphs for all meter configurations, and safety instructions. See the

product page at www.emerson.com.

ATEX, CSA, and IECEx approvals

ATEX

Zone 1 Intrinsically safe With display (Analog, TPS, Discrete versions only)

■ II 2G Ex ib IIC T4...T1 Gb (–40 °C to +65 °C)

■ II 2D Ex ib IIIC T

■ IP 66/67

Without display (All transmitter versions)

■ II 2G Ex ib IIC T6...T1 Gb (–40 °C to +65 °C

■ II 2D Ex ib IIIC T

■ IP 66/67

Zone 1 Flameproof With display (Analog, TPS, Discrete versions with stainless steel transmitter housing material only)

■ II 2G Ex db [ib] IIC T6...T1 Gb (–40 °C to +65 °C)

■ II 2D Ex tb IIIC T

■ IP 66/67

Without display (All transmitter versions except 2-wire TPS)

■ II 2G Ex ib IIC T6...T1 Gb (–40 °C to +65 °C

■ II 2D Ex ib IIIC T

■ IP 66/67

(1) See the ATEX or IECEx instructions shipped with the product for the maximum surface temperature (T) for dust.

(2) Maximum ambient temperature of 2-wire TPS transmitter version is 167 °F (75 °C).

(1)

(1)

(1)

(1)

°C Db

°C Db

°C Db

°C Db

(2)

(2)

)

)

CSA

Intrinsically safe With display (Analog, TPS, Discrete versions only) or without display (all transmitter versions)

■ Class I, Division 1, Groups A, B, C & D

■ Class I, Division 2, Groups A, B, C & D

■ Class II, Division 1, Groups E, F, & G

www.micromotion.com 9

Page 10

Compact Density Meter

June 2018

CSA

Explosion proof With display (Analog, TPS, Discrete versions and stainless steel transmitter housing material only) or

without display (all transmitter versions except 2-wire TPS)

■ Class I, Division 1, Groups C & D

■ Class I, Division 2, Groups A, B, C & D

■ Class II, Division 1, Groups E, F & G

IECEx

Zone 1 Intrinsically safe With display (Analog, TPS, Discrete versions only)

■ Ex ib IIC T4...T1 Gb (–40 °C to +65 °C)

■ Ex ib IIIC T

(1)

°C Db

■ IP66/IP67

Without display (All transmitter versions)

■ Ex ib IIC T6...T1 Gb (–40 °C to +65 °C

■ Ex ib IIIC T

(1)

°C Db

(2)

)

■ IP66/IP67

Zone 1 Flameproof Without display (All transmitter versions except 2-wire TPS)

■ Ex db [ib] IIC T6...T1 Gb (–40 °C to +65 °C)

■ Ex tb IIIC T

(1)

°C Db

■ IP66/IP67

With display (Analog, TPS, Discrete versions and stainless steel transmitter housing material only)

■ Ex db [ib] IIC T6...T1 Gb (–40 °C to +65 °C)

■ Ex tb IIIC T

(1)

°C Db

■ IP66/IP67

(1) See the ATEX or IECEx instructions shipped with the product for the maximum surface temperature (T) for dust.

(2) Maximum ambient temperature of 2-wire TPS transmitter version is 167 °F (75 °C).

Required barriers and isolators for hazardous area installations

When installing the meter in a hazardous area, safety barriers and galvanic isolators must be installed between the meter and the

signal processing equipment. Micro Motion provides the required barriers and isolators for purchase according to the transmitter

output type.

Safety barrier/galvanic isolator kits ordering informationTable 1:

Model code Description Barrier/Isolator Output Notes

BARRIERSETAA Barrier set, including barriers for all in-

trinsically safe transmitter versions (CH B:

mA, TPS, or DO)

ISOLATORSETBB Isolator set, including isolators for intrins-

ically safe Analog version (CH B: mA)

10 www.micromotion.com

MTL7728P+ mA + HART

MTL7728P+ mA / TPS / DO

MTL7761AC RS-485

MTL7728P+ Power

MTL5541 mA + HART RS-485 barrier is

MTL5541 mA

not isolated

MTL7761AC RS-485

MTL5523 Power

Page 11

June 2018

Compact Density Meter

Safety barrier/galvanic isolator kits ordering information (continued)Table 1:

Model code Description Barrier/Isolator Output Notes

ISOLATORSETCC Isolator set, including isolators for intrins-

ically safe Time Period Signal (TPS)/

Discrete versions (CH B: TPS or DO)

BARRIER7787 Barrier for 2-wire meter, TPS/Power out-

put

BARRIER7764 Barrier set for 2-wire meter, 4-wire RTD

output

MTL5541 mA + HART RS-485 barrier is

MTL5532 TPS/DO

MTL7761AC RS-485

MTL5523 Power

MTL7787+ TPS/Power Quantity (1)

MTL7764+ RTD Quantity (2)

not isolated

Environmental specifications

Type

Humidity limits 5 to 95% relative humidity, non-condensing at 140 ° F (60 °C)

Ambient temperature –40 °C to +65 °C –40 °F to +149 °F

Vibration limits Meets IEC 68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cycles at 1.0 g

Ingress protection rating

Rating

■ IP66/67, NEMA4 aluminum housing

■ NEMA4X stainless steel housing

Thermal insulation options

For optimal performance, thermally insulate the meter and the inlet and bypass-loop pipeline to maintain stable temperatures.

Micro Motion offers a soft, weather-proof insulating jacket that is easily fitted to all CDM versions.

Model code

INSJKTCMFS075 Insulation Jacket for:

STMKTCMFS075 Steam Heat Kit with Insulation Jacket for:

Description

CMFS075, CMFS100 or CMFS150 CASE CODE M or N

and

CDM100 CASE CODE M or C

CMFS075, CMFS100 or CMFS150 CASE CODE M or N

and

CDM100 CASE CODE M or C

www.micromotion.com 11

Page 12

Compact Density Meter

Power requirements

Following are the DC power requirements to operate the meter:

Meter type Description

Explosion-proof/flameproof

meters

Intrinsically safe meters

(1) For power requirements specific to the 2-wire TPS transmitter version, refer to the 2-Wire TPS CDM Installation Supplement.

■ 24 VDC, 0.65 W typical, 1.1 W maximum

■ Minimum recommended voltage: 21.6 VDC with 1000 ft of 24 AWG (300 m of 0.20 mm2)

power-supply cable

■ At startup, power source must provide a minimum of 0.5 A of short-term current at a minimum of 19.6 V at the power input terminals

■ 24 VDC, 0.7 W typical with 250 Ω barrier, 0.96 W maximum with 250 Ω barrier

■ Minimum recommended voltage: 22.8 VDC with 1000 ft of 22 AWG (300 m of 0.25 mm2)

power-supply cable

Physical specifications

Materials of construction

June 2018

(1)

Wetted parts

Process connections 316L stainless steel

Measurement tubes

Non–wetted parts

Sensor housing 316L stainless steel

Transmitter housing Polyurethane-painted aluminum or 316L stainless steel

■ Nickel alloy C-22 (or UNS 06022) — CDM100P option

■ 316L stainless steel — CDM100M option

Weight

Meter weights assume ANSI CL600 weld-neck, raised-face flanges, and integral transmitter electronics. Meters with other options

may have weights that differ slightly from those listed.

Meter type

Compact density meter (standard option)

Compact density meter (7835/7845 retrofit model with spools)

Weight with aluminum housing Weight with stainless steel housing

Approximately 28 lbs (13 kg) Approximately 34 lbs (16 kg)

Approximately 31 lbs (14 kg) Approximately 37 lbs (17 kg)

Dimensions

These dimensional drawings are intended to provide a basic guideline for sizing and planning. Complete and detailed dimensional

drawings can be found through the product drawings link in our online store at www.micromotion.com/onlinestore.

Depending on the flange connection, the face-to-face dimension may vary for the CDM standard option.

12 www.micromotion.com

Page 13

June 2018

Compact Density Meter

Compact density meter dimensions – standard option

A. Dim. A — see table below

B. Nominal flow direction — the meter can be configured for normal (forward), reversed, or bi-directional flow

C. 2x 1/2-14 NPT female electronic interface

Note

Drawing dimensions are in inches.

Flange fitting type

1-inch, CL900, ASME B16.5, F316/316L, Weld neck flange 26.9 (683)

1-inch, CL900, ASME B16.5, F316/316L, Weld neck flange, RTJ face 26.9 (683)

1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange 24.5 (623)

1-inch, CL300, ASME B16.5, F316/316L, Weld neck flange 24.0 (610)

1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, RTJ face 24.8 (627)

1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, Raised face 63-125, Raised face finish 24.8 (627)

1-inch, CL150, ASME B16.5, F316/316L, Weld neck flange 23.5 (597)

DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type B1 22.5 (573)

DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type D 22.5 (573)

DN25, PN100, EN 1092-1, F316/316L, Weld neck flange, Type B2 23.9 (608)

Dim. A [± 0.125 in (3 mm)]

www.micromotion.com 13

Page 14

Compact Density Meter

Compact density meter dimensions – 7835/45 retrofit option

June 2018

A. Dim. A — face to face is up to 40.4 inches (1026 mm) ± 0.125 in (3 mm)

B. Nominal flow direction — the meter can be configured for normal (forward), reversed, or bi-directional flow

C. 2x 1/2-14 NPT female electronic interface

Note

Drawing dimensions are in inches.

Ordering information

Peak performance precision density meter (CDM100P)

Model

CDM100P Micro Motion Compact Density Meter, 1-inch (25mm) nickel alloy manifold and measurement tubes with

Code Process connection

A18 1-inch, CL900/1500, ASME B16.5, F316/316L, Weld neck flange

A25 1-inch, CL900/1500, ASME B16.5, F316/316L, Weld neck flange, RTJ Face

330 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange

329 1-inch, CL300, ASME B16.5, F316/316L, Weld neck flange

A24 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, RTJ Face

A21 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, Raised face 63-125, Raised face finish

179 DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type B1

311 DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type D

180 DN25, PN100, EN 1092-1, F316/316L, Weld neck flange, Type B2

Description

stainless steel fittings

14 www.micromotion.com

Page 15

June 2018

Code Process connection

(1)

999

(1) Requires factory option X.

Code Case option

M 316L stainless steel case

K 316L stainless steel case with purge fittings (one 1/2-inch NPT female)

(1)

C

(1)

D

(1) Available only with process connection codes 329, 330, and A18.

ETO process connection

7835/45 retrofit model with standard 316L stainless steel sensor case

7835/45 retrofit model with purge fittings (1/2-inch NPT) 316L stainless steel sensor case

Compact Density Meter

Code

(1)(2)

A

Transmitter output option

Integral processor for remote mount Model 2700 FOUNDATION™ fieldbus transmitter (Channels A and B

inactive)

B Integral transmitter, Channel B = Time Period Signal, Channel A = mA + HART, Channel C = RS485 Modbus

(3)

C

Integral transmitter, Channel B = mA output, Channel A = mA + HART, Channel C = RS485 Modbus

D Integral transmitter, Channel B = Discrete output, Channel A = mA + HART, Channel C = RS485 Modbus

F Integral electronics, 2-wire time period signal output, superimposed on power (no internal calculations)

(1) Requires remote-mount Model 2700 transmitter with mounting option H, 4-wire connection option (power and communications).

(2) With transmitter output options code A, all signal outputs on the integrally mounted transmitter are disabled, except for the Modbus/RS-485

communications which is used for communication to the Model 2700 transmitter.

(3) For the TPS version, the 4-20mA output cannot be configured to output line density.

Code

Display option

A No display

(1)

B

(1) For transmitter housing option code Z, available with only approvals codes M, Z, B, E and 2.

Code

Two-line display (non-backlit)

Approvals

For all transmitter output options

M Safe area - no hazardous area approval

Z ATEX – Intrinsically safe (zone 1)

B CSA (US and Canada) – Intrinsically safe Class 1 Div. 1 Groups B, C, D

E IECEx – Intrinsically safe (zone 1)

2 CSA (US and Canada) Class 1 Div. 2

For transmitter output options B, C, and D

A CSA (US and Canada) – Explosion-proof Class 1 Div. 1 Groups C, D (US and Canada)

F ATEX – Zone 1 flameproof

I IECEx – Zone 1 flameproof

G Country-specific approval. Requires an R1 or R2 selection from the Special tests and certificates, tests, calibra-

tions and services (optional) table.

Also see Required barriers and isolators for hazardous area installations.

www.micromotion.com 15

Page 16

Compact Density Meter

June 2018

Code Application configuration

(1)

Available with all Transmitter output options

00 No Application configuration

95 Process temperature (4 mA = 0 °C, 20 mA = 200 °C)

(2)

XX

ETO analog output configuration (customer data required)

Available with transmitter output options B only

96 Process temperature (4 mA = –50 °C, 20 mA = 200 °C)

97 Process temperature (4 mA = –50 °C, 20 mA = 150 °C)

98 Process temperature (4 mA = 0 °C, 20 mA = 100 °C)

Available with transmitter output options C and D only

11 Degrees API (4 mA = 0°, 20 mA = 100°) (Process temperature = 0 °C to 60 °C)

12 Line Density (4 mA = 500 kg/m3, 20 mA = 1500 kg/m3) (Process temperature = -40 °C to +140 °C)

13 Referred Density to API tables (metric) (4 mA = 500 kg/m3, 20 mA = 1500 kg/m3) (Process temperature =

-40 °C to +140 °C)

21 % Alcohol (4 mA = 0%, 20 mA = 20%) (Process temperature = 0 °C to 40 °C)

22 % Alcohol (4 mA = 50%, 20 mA = 100%) (Process temperature = 40 °C to 70 °C)

23 % Alcohol (4 mA = 80%, 20 mA = 100%) (Process temperature = 50 °C to 90 °C)

24 Alcohol proof (4 mA = 100, 20 mA = 200) (Process temperature = 50 °C to 70 °C)

25 Alcohol proof (4 mA = 160, 20 mA = 200) (Process temperature = 50 °C to 90 °C)

26 % Methanol concentration (4 mA = 35%, 20mA = 60%) (Process temperature = 0 °C to 40 °C)

27 % Ethylene Glycol concentration (4 mA = 10%, 20 mA = 50%) (Process temperature = -20 °C to 40 °C)

31 Brix (sucrose) (4 mA = 0°, 20 mA = 40°) (Process temperature = 0 °C to 100 °C)

32 Brix (sucrose) (4 mA = 30°, 20 mA = 80°) (Process temperature = 0 °C to 100 °C)

41 Balling (4 mA = 0°, 20 mA = 20°) (Process temperature = 0 °C to 100 °C)

51 % NaOH Concentration (4mA = 0%, 20 mA = 20%) (Process temperature = 0 °C to 50 °C)

52 % H2SO4 Concentration (4 mA = 0%, 20 mA = 10%) (Process temperature = 0 °C to 38 °C)

53 % H2SO4 Concentration (4 mA = 75%, 20 mA = 94%) (Process temperature = 24 °C to 38 °C)

64 % HFCS - 42 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0 °C to 100 °C)

65 % HFCS - 55 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0 °C to 100 °C)

66 % HFCS – 90 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0° to 100 °C)

71 Plato (4 mA = 0°, 20 mA = 30°) (Process temperature = 0 °C to 100 °C)

(1) When the transmitter output options code is B, C, or D, the chosen application configuration code low and high limits are also programmed as the

channel A mA output 4mA and 20mA points.

(2) Requires factory option X.

Code

Language (manual and software)

Transmitter display language English

E English installation manual and English configuration manual

I Italian installation manual and English configuration manual

M Chinese installation manual and English configuration manual

R Russian installation manual and English configuration manual

16 www.micromotion.com

Page 17

June 2018

Compact Density Meter

Code Language (manual and software)

Transmitter display language French

F French installation manual and English configuration manual

Transmitter display language German

G German installation manual and English configuration manual

Transmitter display language Spanish

S Spanish installation manual and English configuration manual

Code Sensor calibration options

A Standard ±0.1kg/m3 (±0.0001g/cc) density accuracy

(1)

M

(1) MID (OIML R117) calibration option not available with transmitter output option code A. MID evaluated component (OIML R117) - Requires

installation with an approved power supply. See the CDM100 Measuring Instruments Directive Supplement for more information.

MID evaluated component (OIML R117) - Requires installation with an approved power supply

Code

Transmitter housing option

Z Integral, aluminum alloy

B Integral, stainless steel

Code Conduit connections

Z Standard 1/2-inch NPT fittings (no adapters)

B M20 stainless steel adapters

Code Factory options

Z Standard product

X ETO product

Code Special tests and certificates, tests, calibrations, and certificates (all are optional)

(1)

Material Quality Examination Tests and Certificates (select any from this group)

MC Material Inspection Certificate 3.1 (Supplier Lot Traceability per EN 10204)

NC NACE Certificate 2.1 (MR0175 and MR0103)

Pressure testing (select any from this group)

HT Hydrostatic Test Certificate 3.1

Radiographic examination (select only one from this group)

RT X-Ray Package 3.1 (Process connection only; Radiographic Examination Certificate with digital image; Weld

map; Radiographic Inspection NDE Qualification)

Dye penetrant examination (select only one from this group)

D1 Dye Penetrant Test Package 3.1 (Process connection only; Liquid Dye Penetration NDE Qualification)

D2 Dye Penetrant Test Package 3.1 (Case only; Liquid Dye Penetration NDE Qualification)

Weld examination

WP Weld Procedure Package (Weld Map, Weld Procedure Specification, Weld Procedure Qualification Record,

Welder Performance Qualification)

www.micromotion.com 17

Page 18

Compact Density Meter

June 2018

Code Special tests and certificates, tests, calibrations, and certificates (all are optional)

(1)

Positive material testing (select only one from this group)

PM Positive Material Test Certificate 3.1 (without carbon content)

Sensor completion options (select any from this group)

WG Witness General

SP Special Packaging

Instrument tagging

TG Instrument Tagging – customer information required (max. 24 characters)

Country-specific approvals (select only one when Approvals option G is selected)

(2) (3)

R1

(2) (3)

R2

(1) Multiple test or certificate options can be selected.

(2) Available only with approval G

(3) Not available with Transmitter Output Options code F or Transmitter Housing Option B

EAC Zone 1 - Hazardous area approval - intrinsically safe

EAC Zone 1 - Hazardous area approval - flameproof terminal compartment

General purpose precision density meter (CDM100M)

Model

CDM100M Micro Motion Compact Density Meter, 1-inch (25 mm), 316L stainless steel manifold and measurement

Description

tubes

Code Process connection

330 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange

329 1-inch, CL300, ASME B16.5, F316/316L, Weld neck flange

A24 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, RTJ Face

A21 1-inch, CL600, ASME B16.5, F316/316L, Weld neck flange, Raised face 63-125, Raised face finish

179 DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type B1

311 DN25, PN40, EN 1092-1, F316/316L, Weld neck flange, Type D

180 DN25, PN100, EN 1092-1, F316/316L, Weld neck flange, Type B2

328 1-inch, CL150, ASME B16.5, F316/316L, Weld neck flange

(1)

999

(1) Requires factory option X.

Code

ETO process connection

Case options

M 316L stainless steel case

K 316L stainless steel case with purge fittings (one 1/2-inch NPT female)

(1)

C

7845 retrofit model with standard 316L stainless steel sensor case

18 www.micromotion.com

Page 19

June 2018

Compact Density Meter

Code Case options

(1)

D

(1) Available only with process connection codes 329 and 330.

7835/45 retrofit model with purge fittings (1/2-inch NPT) 316L stainless steel sensor case

Code Transmitter output option

(1)(2)

A

Integral processor for remote mount Model 2700 FOUNDATION™ fieldbus transmitter (Channels A and B

inactive)

B Integral transmitter, Channel B = Time Period Signal, Channel A = mA + HART, Channel C = RS485 Modbus

(3)

C

Integral transmitter, Channel B = mA output, Channel A = mA + HART, Channel C = RS485 Modbus

D Integral transmitter, Channel B = Discrete output, Channel A = mA + HART, Channel C = RS485 Modbus

F Integral electronics, 2-wire time period signal output, superimposed on power (no internal calculations)

(1) Requires remote-mount Model 2700 transmitter with mounting option H - 4 wire connection option (power and communications).

(2) With transmitter output options code A, all signal outputs on the integrally mounted transmitter are disabled except for the Modbus/RS-485

communications which is used for communication to the Model 2700 transmitter.

(3) For the TPS version, the 4-20mA output cannot be configured to output line density.

Code

Display option

A No display

(1)

B

(1) For transmitter housing option code Z, available only with approvals codes M, Z, B, E and 2.

Code

Two-line display (non-backlit)

Approvals

Available with all transmitter output options

M Safe area - no hazardous area approval

Z ATEX – Intrinsically safe (zone 1)

B CSA (US and Canada) – Intrinsically safe Class 1 Div. 1 Groups B, C, and D

E IECEx – Intrinsically safe (zone 1)

2 CSA (US and Canada) Class 1 Div. 2

Available with transmitter output option codes B, C, and D

A CSA (US and Canada) – Explosion-proof Class 1 Div. 1 Groups C and D (US and Canada)

F ATEX – Zone 1 flameproof

I IECEx – Zone 1 flameproof

G Country-specific approval. Requires an R1 or R2 selection from the Special tests and certificates, tests, calibra-

tions and services (optional) table.

Also see Required barriers and isolators for hazardous area installations.

Code

Application configuration

(1)

Available with all transmitter output options

00 No application configuration

95 Process temperature (4 mA = 0 °C, 20 mA = 200 °C)

(2)

XX

ETO analog output configuration (customer data required)

Available with transmitter output option code B only

96 Process temperature (4 mA = –50 °C, 20 mA = 200 °C)

www.micromotion.com 19

Page 20

Compact Density Meter

June 2018

Code Application configuration

(1)

97 Process temperature (4 mA = –50 °C, 20 mA = 150 °C)

98 Process temperature (4 mA = 0 °C, 20 mA = 100 °C)

Available with transmitter output option codes C and D only

11 Degrees API (4 mA = 0°, 20 mA = 100°) (Process temperature = 0 °C to 60 °C)

12 Line Density (4 mA = 500kg/m3, 20 mA = 1500 kg/m3) (Process temperature = -40 °C to +140 °C)

13 Referred Density to API tables (metric) (4 mA = 500 kg/m3, 20mA = 1500 kg/m3)(Process temperature =

-40 °C to +140 °C)

21 % Alcohol (4 mA = 0%, 20 mA = 20%) (Process temperature = 0 °C to 40 °C)

22 % Alcohol (4 mA = 50%, 20 mA = 100%) (Process temperature = 40 °C to 70 °C)

23 % Alcohol (4 mA = 80%, 20 mA = 100%) (Process temperature = 50 °C to 90 °C)

24 Alcohol proof (4 mA = 100, 20 mA = 200) (Process temperature = 50 °C to 70 °C)

25 Alcohol proof (4 mA = 160, 20 mA = 200) (Process temperature = 50 °C to 90 °C)

26 % Methanol concentration (4 mA = 35%, 20 mA = 60%) (Process temperature = 0 °C to 40 °C)

27 % Ethylene Glycol concentration (4 mA = 10%, 20 mA = 50%) (Process temperature = -20 °C to 40 °C)

31 Brix (sucrose) (4 mA = 0°, 20 mA = 40°) (Process temperature = 0 °C to 100 °C)

32 Brix (sucrose) (4 mA = 30°, 20 mA = 80°) (Process temperature = 0 °C to 100 °C)

41 Balling (4 mA = 0°, 20 mA = 20°) (Process temperature = 0 °C to 100 °C)

51 % NaOH Concentration (4 mA = 0%, 20 mA = 20%) (Process temperature = 0 °C to 50 °C)

52 % H2SO4 Concentration (4 mA = 0%, 20 mA = 10%) (Process temperature = 0 °C to 38 °C)

53 % H2SO4 Concentration (4 mA = 75%, 20 mA = 94%) (Process temperature = 24 °C to 38 °C)

54 % HNO3 Concentration (4 mA = 0%, 20 mA = 40%) (Process temperature = 10 °C to 50 °C)

55 % KOH Concentration (4 mA = 0%, 20 mA = 40%) (Process temperature = 0 °C to 90 °C)

64 % HFCS - 42 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0 °C to 100 °C)

65 % HFCS - 55 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0 °C to 100 °C)

66 % HFCS - 90 (4 mA = 0%, 20 mA = 50%) (Process temperature = 0 °C to 100 °C)

71 Plato (4 mA = 0°, 20 mA = 30°) (Process temperature = 0 °C to 100 °C)

(1) When the transmitter output options code is B, C or D, the chosen application configuration code low and high limits are also programmed as the

channel A mA output 4 mA and 20 mA points.

(2) Requires factory option X.

Code

Language (manual and software)

Transmitter display language English

E English installation manual and English configuration manual

I Italian installation manual and English configuration manual

M Chinese installation manual and English configuration manual

R Russian installation manual and English configuration manual

Transmitter display language French

F French installation manual and English configuration manual

Transmitter display language German

G German installation manual and English configuration manual

20 www.micromotion.com

Page 21

June 2018

Compact Density Meter

Code Language (manual and software)

Transmitter display language Spanish

S Spanish installation manual and English configuration manual

Code Sensor calibration options

A Standard ±0.2 kg/m3 (±0.0002g/cc) density accuracy

(1)

M

(1) MID (OIML R117) calibration option is not available with transmitter output options code A. Requires installation with an approved power supply.

See the CDM100 Measuring Instruments Directive Supplement for more information.

MID evaluated component (OIML R117) - Requires installation with an approved power supply

Code Transmitter housing option

Z Integral, aluminum alloy

B Integral, stainless steel

Code Conduit connections

Z Standard 1/2-inch NPT fittings (no adapters)

B M20 stainless steel adapters included

Code Factory options

Z Standard product

X ETO product

Code Special tests and certificates, tests, calibrations, and services (all optional)

(1)

Material quality examination tests and certificates (select any from this group)

MC Material Inspection Certificate 3.1 (Supplier Lot Traceability per EN 10204)

NC NACE Certificate 2.1 (MR0175 and MR0103)

Pressure testing (select any from this group)

HT Hydrostatic Test Certificate 3.1

Radiographic examination (select only one from this group)

RT X-Ray Package 3.1 (Process connection only; Radiographic Examination Certificate with digital image; Weld

map; Radiographic Inspection NDE Qualification)

Dye penetrant examination (select only one from this group)

D1 Dye Penetrant Test Package 3.1 (Process connection only; Liquid Dye Penetration NDE Qualification)

D2 Dye Penetrant Test Package 3.1 (Case only; Liquid Dye Penetration NDE Qualification)

Weld examination

WP Weld Procedure Package (Weld Map, Weld Procedure Specification, Weld Procedure Qualification Record,

Welder Performance Qualification)

Positive material testing (select only one from this group)

PM Positive Material Test Certificate 3.1 (without carbon content)

PC Positive Material Test Certificate 3.1 (including carbon content)

Sensor completion options (select any from this group)

www.micromotion.com 21

Page 22

Compact Density Meter

June 2018

Code Special tests and certificates, tests, calibrations, and services (all optional)

WG Witness General

SP Special Packaging

Instrument tagging

TG Instrument Tagging – customer information required (max. 24 characters)

Country-specific approvals (select only one when Approvals option G is selected)

(2)(3)

R1

(2)(3)

R2

(1) Multiple add-ons may be selected.

(2) Available only with approval G

(3) Not available with Transmitter Output Options code F or Transmitter Housing Option B

EAC Zone 1 - Hazardous area approval - intrinsically safe

EAC Zone 1 - Hazardous area approval - flameproof terminal compartment

(1)

22 www.micromotion.com

Page 23

June 2018

Compact Density Meter

www.micromotion.com 23

Page 24

Compact Density Meter

PS-001482, Rev H

Product Data Sheet

June 2018

Emerson Automation Solutions

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado USA 80301

T: +1 800-522-6277

T: +1 303-527-5200

F: +1 303-530-8459

Mexico: 52 55 5809 5300

Argentina: 54 11 4837 7000

Brazil: 55 15 3413 8147

Chile: 56 2 2928 4800

©

2018 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE,

ProLink, MVD and MVD Direct Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of their respective owners.

Emerson Automation Solutions

Central Europe: +41 41 7686 111

Eastern Europe: +41 41 7686 111

Dubai: +971 4 811 8100

Abu Dhabi: +971 2 697 2000

France: 0800 917 901

Germany: +49 (0) 2173 3348 0

Italy: 8008 77334

The Netherlands: +31 (0) 70 413 6666

Belgium: +32 2 716 77 11

Spain: +34 913 586 000

U.K.: 0870 240 1978

Russian/CIS: +7 495 981 9811

Emerson Automation Solutions

Australia: (61) 3 9721 0200

China: (86) 21 2892 9000

India: (91) 22 6662 0566

Japan: (81) 3 5769 6803

South Korea: (82) 31 8034 0000

Singapore: (65) 6 363 7766

Loading...

Loading...