Page 1

Configuration and Use Manual

MMI-20020944, Rev AC

April 2016

Micro Motion® Compact Density Meters (CDM)

Configuration and Use Manual

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136 666 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Contents

Part I Getting Started

Chapter 1 Before you begin ............................................................................................................3

1.1 About this manual ....................................................................................................................... 3

1.2 Model codes and device types ..................................................................................................... 3

1.3 Communications tools and protocols .......................................................................................... 4

1.4 Additional documentation and resources .................................................................................... 5

Chapter 2 Quick start .....................................................................................................................7

2.1 Power up the transmitter .............................................................................................................7

2.2 Check meter status ......................................................................................................................7

2.3 Make a startup connection to the transmitter ..............................................................................8

2.4 Zero the meter ............................................................................................................................ 9

2.4.1 Zero the meter using the display ...................................................................................9

2.4.2 Zero the meter using ProLink III .................................................................................. 10

2.4.3 Zero the meter using the Field Communicator ............................................................11

Part II Configuration and commissioning

Chapter 3 Introduction to configuration and commissioning ....................................................... 15

3.1 Default values ............................................................................................................................15

3.1.1 CDM default values .....................................................................................................15

3.2 Enable access to the off-line menu of the display ....................................................................... 16

3.3 Disable HART security ................................................................................................................17

3.4 Set the HART lock ...................................................................................................................... 19

3.5 Restore the factory configuration .............................................................................................. 19

Chapter 4 Configure process measurement ..................................................................................21

4.1 Verify the calibration factors ......................................................................................................21

4.1.1 Calibration factors ...................................................................................................... 22

4.2 Configure line density measurement ........................................................................................ 23

4.2.1 Configure Density Measurement Unit ................................................................................23

4.2.2 Configure Density Damping ........................................................................................... 25

4.2.3 Configure Density Cutoff ................................................................................................ 26

4.2.4 Configure two-phase flow parameters ........................................................................26

4.3 Configure temperature measurement .......................................................................................28

4.3.1 Configure Temperature Measurement Unit ........................................................................ 28

4.3.2 Configure Temperature Damping .....................................................................................29

4.3.3 Configure Temperature Input .......................................................................................... 30

4.4 Configure the pressure input ..................................................................................................... 33

4.4.1 Configure the pressure input using ProLink III ............................................................. 33

4.4.2 Configure the pressure input using the Field Communicator .......................................35

4.4.3 Options for Pressure Measurement Unit ........................................................................... 36

4.5 Set up the API referral application ..............................................................................................37

Configuration and Use Manual i

Page 4

Contents

4.5.1 Set up the API referral application using ProLink III ...................................................... 37

4.5.2 Set up the API referral application using the Field Communicator ............................... 42

4.6 Set up concentration measurement .......................................................................................... 50

4.6.1 Preparing to set up concentration measurement ........................................................50

4.6.2 Set up concentration measurement using ProLink III ...................................................51

4.6.3 Set up concentration measurement using the Field Communicator ............................58

4.6.4 Using equations to calculate specific gravity, °Baumé, °Brix, °Plato, and °Twaddell ......63

4.6.5 Matrix switching ......................................................................................................... 64

4.7 Set up flow monitoring ..............................................................................................................66

4.7.1 Configure velocity measurement ................................................................................66

4.7.2 Configure volume flow rate measurement ..................................................................68

4.7.3 Configure Flow Direction ................................................................................................70

4.7.4 Configure Flow Damping ................................................................................................74

Chapter 5 Configure device options and preferences ....................................................................75

5.1 Configure the transmitter display .............................................................................................. 75

5.1.1 Configure the language used for the display ............................................................... 75

5.1.2 Configure the process variables and diagnostic variables shown on the display ...........76

5.1.3 Configure the number of decimal places (precision) shown on the display ..................76

5.1.4 Configure the refresh rate of data shown on the display ..............................................77

5.1.5 Enable or disable automatic scrolling through the display variables ............................ 77

5.2 Enable or disable the Acknowledge All Alerts display command ......................................................78

5.3 Configure security for the display menus .................................................................................. 79

5.4 Configure alert handling ............................................................................................................80

5.4.1 Configure Fault Timeout .................................................................................................80

5.4.2 Configure Alert Severity ................................................................................................. 81

5.5 Configure informational parameters ......................................................................................... 83

Chapter 6 Integrate the meter with the control system ................................................................85

6.1 Configure Channel B ..................................................................................................................85

6.2 Configure the mA output .......................................................................................................... 86

6.2.1 Configure mA Output Process Variable ............................................................................. 86

6.2.2 Configure Lower Range Value (LRV) and Upper Range Value (URV) ....................................88

6.2.3 Configure Added Damping ............................................................................................. 89

6.2.4 Configure mA Output Fault Action and mA Output Fault Level ...............................................91

6.3 Configure the discrete output ................................................................................................... 92

6.3.1 Configure Discrete Output Source ....................................................................................92

6.3.2 Configure Discrete Output Polarity ................................................................................... 93

6.3.3 Configure Discrete Output Fault Action ............................................................................. 94

6.4 Configure an enhanced event ....................................................................................................95

6.5 Configure HART/Bell 202 communications ............................................................................... 96

6.5.1 Configure basic HART parameters ...............................................................................96

6.5.2 Configure HART variables (PV, SV, TV, QV) ..................................................................97

6.5.3 Configure burst communications ............................................................................... 99

6.6 Configure Modbus communications ........................................................................................103

6.7 Configure Digital Communications Fault Action ............................................................................... 105

6.7.1 Options for Digital Communications Fault Action ...............................................................105

Chapter 7 Complete the configuration ....................................................................................... 107

7.1 Test or tune the system using sensor simulation ......................................................................107

7.2 Back up transmitter configuration ........................................................................................... 107

7.3 Enable HART security ...............................................................................................................108

ii Micro Motion® Compact Density Meters (CDM)

Page 5

Contents

Part III Operations, maintenance, and troubleshooting

Chapter 8 Transmitter operation ................................................................................................113

8.1 Record the process variables ................................................................................................... 113

8.2 View process variables and diagnostic variables ...................................................................... 113

8.2.1 View process variables using the display ................................................................... 114

8.2.2 View process variables and other data using ProLink III ............................................. 114

8.2.3 View process variables using the Field Communicator .............................................. 115

8.3 View and acknowledge status alerts ........................................................................................ 115

8.3.1 View and acknowledge alerts using the display ........................................................ 115

8.3.2 View and acknowledge alerts using ProLink III ...........................................................117

8.3.3 View alerts using the Field Communicator ................................................................ 118

8.3.4 Alert data in transmitter memory ............................................................................. 118

Chapter 9 Measurement support ............................................................................................... 121

9.1 Perform the inline calibration check procedure ....................................................................... 121

9.1.1 Perform the inline calibration check using ProLink III .................................................122

9.1.2 Perform the inline calibration check using the Field Communicator ..........................123

9.2 Perform the Known Density Verification procedure .................................................................123

9.2.1 Perform the Known Density Verification procedure using the display ....................... 124

9.2.2 Perform the Known Density Verification procedure using ProLink III ......................... 125

9.2.3 Perform the Known Density Verification procedure using the

Field Communicator ................................................................................................. 125

9.3 Adjust density measurement with Density Offset or Density Meter Factor ....................................... 126

9.4 Perform density offset calibration ............................................................................................127

9.4.1 Perform density offset calibration using the display .................................................. 128

9.4.2 Perform density offset calibration using ProLink III ....................................................129

9.4.3 Perform density offset calibration using the Field Communicator ............................. 129

9.5 Adjust temperature measurement with Temperature Offset ........................................................130

9.6 Adjust concentration measurement with Trim Offset .................................................................131

9.7 Adjust concentration measurement with Trim Slope and Trim Offset ........................................... 132

9.8 Set up user-defined calculations .............................................................................................. 134

9.8.1 Equations used in user-defined calculations ..............................................................136

9.8.2 Measurement units used in user-defined calculations ............................................... 136

9.9 Diagnostic density ...................................................................................................................137

9.9.1 Enable diagnostic input density ................................................................................ 138

9.9.2 Enable calculated diagnostic density .........................................................................138

Chapter 10 Troubleshooting ........................................................................................................ 139

10.1 Quick guide to troubleshooting ...............................................................................................139

10.2 Check power supply wiring ......................................................................................................140

10.3 Check grounding .....................................................................................................................141

10.4 Perform loop tests ...................................................................................................................142

10.4.1 Perform loop tests using the display ......................................................................... 142

10.4.2 Perform loop tests using ProLink III ........................................................................... 143

10.4.3 Perform loop tests using the Field Communicator .................................................... 144

10.5 Status LED states ..................................................................................................................... 146

10.6 Status alerts, causes, and recommendations ........................................................................... 147

10.7 Density measurement problems ............................................................................................. 153

10.8 Temperature measurement problems .....................................................................................154

10.8.1 Thermal insulation ....................................................................................................155

Configuration and Use Manual iii

Page 6

Contents

10.9 API referral problems ...............................................................................................................155

10.10 Concentration measurement problems ...................................................................................156

10.11 Velocity measurement problems ............................................................................................156

10.12 Milliamp output problems ....................................................................................................... 158

10.13 Discrete output problems ........................................................................................................160

10.14 Time Period Signal (TPS) output problems ...............................................................................160

10.15 Using sensor simulation for troubleshooting ........................................................................... 161

10.16 Trim mA outputs ..................................................................................................................... 161

10.16.1 Trim mA outputs using ProLink III ..............................................................................161

10.16.2 Trim mA outputs using the Field Communicator .......................................................162

10.17 Check HART communications ................................................................................................. 162

10.18 Check Lower Range Value and Upper Range Value ......................................................................... 164

10.19 Check mA Output Fault Action ...................................................................................................... 164

10.20 Check for radio frequency interference (RFI) ............................................................................165

10.21 Check Flow Direction .................................................................................................................. 165

10.22 Check the cutoffs .................................................................................................................... 165

10.23 Check for two-phase flow (slug flow) .......................................................................................166

10.24 Check the drive gain ................................................................................................................ 166

10.24.1 Excessive or erratic drive gain ....................................................................................167

10.24.2 Collect drive gain data .............................................................................................. 168

10.25 Check the pickoff voltage ........................................................................................................ 168

10.25.1 Collect pickoff voltage data ...................................................................................... 169

10.26 Check for internal electrical problems ..................................................................................... 169

10.27 Locate a device using the HART 7 Squawk feature ................................................................... 170

Appendices and reference

Appendix A Calibration certificate ................................................................................................ 171

A.1 Sample calibration certificates ................................................................................................ 171

Appendix B Using the transmitter display ..................................................................................... 175

B.1 Components of the transmitter interface ................................................................................ 175

B.2 Use the optical switches .......................................................................................................... 175

B.3 Access and use the display menu system .................................................................................176

B.3.1 Enter a floating-point value using the display ............................................................177

B.4 Display codes for process variables ..........................................................................................180

B.5 Codes and abbreviations used in display menus ...................................................................... 180

Appendix C Using ProLink III with the transmitter .........................................................................193

C.1 Basic information about ProLink III ...........................................................................................193

C.2 Connect with ProLink III ........................................................................................................... 194

C.2.1 Connection types supported by ProLink III ................................................................ 194

C.2.2 Connect with ProLink III over Modbus/RS-485 ...........................................................195

C.2.3 Connect with ProLink III over HART/Bell 202 ............................................................. 198

Appendix D Using the Field Communicator with the transmitter ................................................... 207

D.1 Basic information about the Field Communicator ....................................................................207

D.2 Connect with the Field Communicator .................................................................................... 208

Appendix E Concentration measurement matrices, derived variables, and process variables ........ 211

E.1 Standard matrices for the concentration measurement application ........................................ 211

E.2 Concentration measurement matrices available by order ........................................................212

E.3 Derived variables and calculated process variables .................................................................. 214

iv Micro Motion® Compact Density Meters (CDM)

Page 7

Contents

Appendix F MID applications ........................................................................................................ 217

F.1 Certification ............................................................................................................................ 217

F.2 MID flow computer and power supply requirements ............................................................... 218

F.3 Flow computer density calculations ........................................................................................218

F.4 TPS and external input connections to the flow computer ....................................................... 220

F.5 MID support ............................................................................................................................ 220

F.6 Read revision and checksum data ............................................................................................221

F.7 Secure the meter .....................................................................................................................221

F.8 Switch to unsecured mode ...................................................................................................... 224

Configuration and Use Manual v

Page 8

Contents

vi Micro Motion® Compact Density Meters (CDM)

Page 9

Part I

Getting Started

Chapters covered in this part:

• Before you begin

• Quick start

Getting Started

Configuration and Use Manual 1

Page 10

Getting Started

2 Micro Motion® Compact Density Meters (CDM)

Page 11

1 Before you begin

Topics covered in this chapter:

• About this manual

• Model codes and device types

• Communications tools and protocols

• Additional documentation and resources

1.1 About this manual

This manual provides information to help you configure, commission, use, maintain, and

troubleshoot the Micro Motion Compact Density Meter (CDM).

The following versions of the CDM are documented in this manual:

• Compact Density Meter with Analog Outputs

• Compact Density Meter with Analog Output and Discrete Output

• Compact Density Meter with Time Period Signal Output

Before you begin

For the Compact Density Meter with FOUNDATION™ Fieldbus, see Micro Motion® Compact

Density Meters with FOUNDATION™ Fieldbus: Configuration and Use Manual.

Important

This manual assumes that the following conditions apply:

• The meter has been installed correctly and completely, according to the instructions in the

installation manual.

• The installation complies with all applicable safety requirements.

• The user is trained in all government and corporate safety standards.

1.2 Model codes and device types

Your device can be identified by the model code on the device tag.

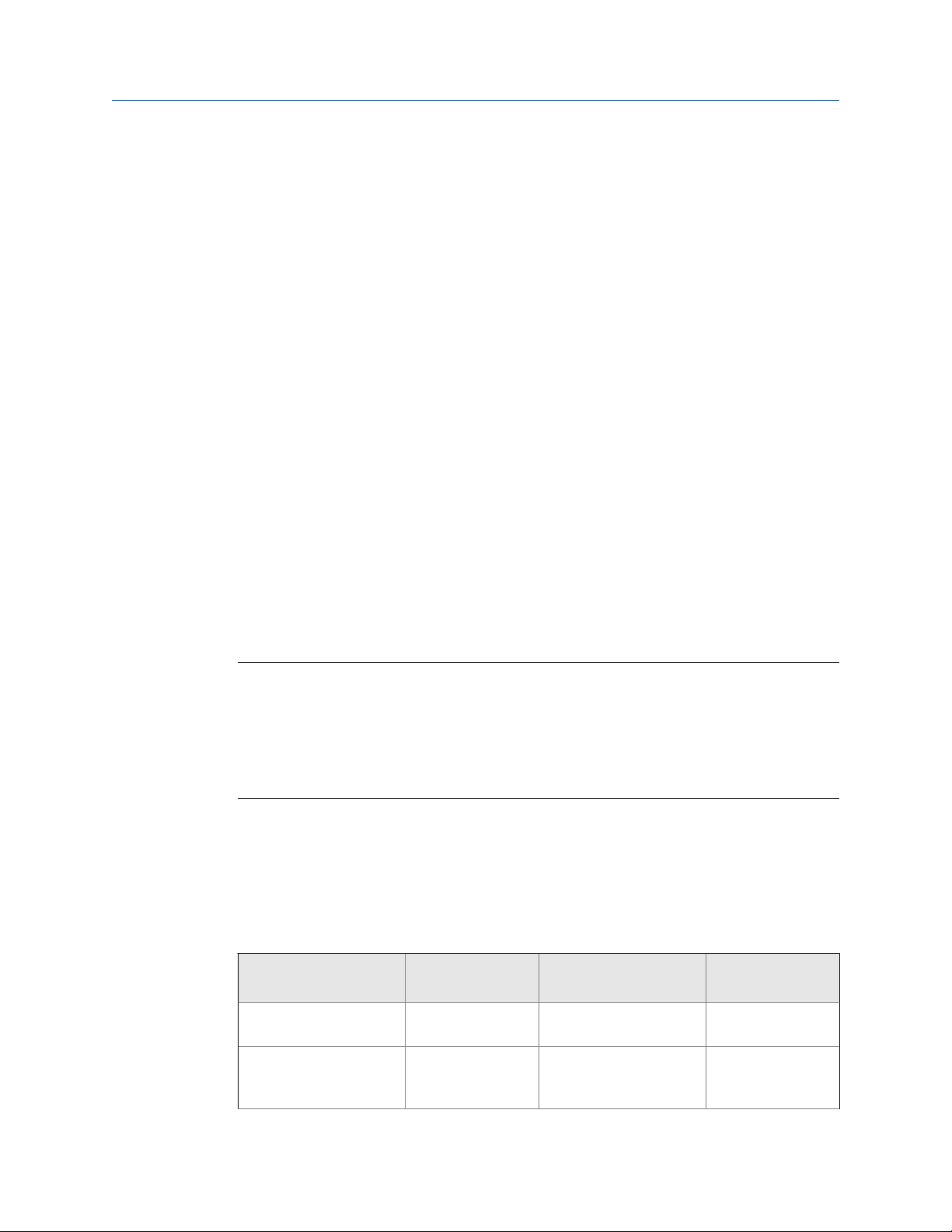

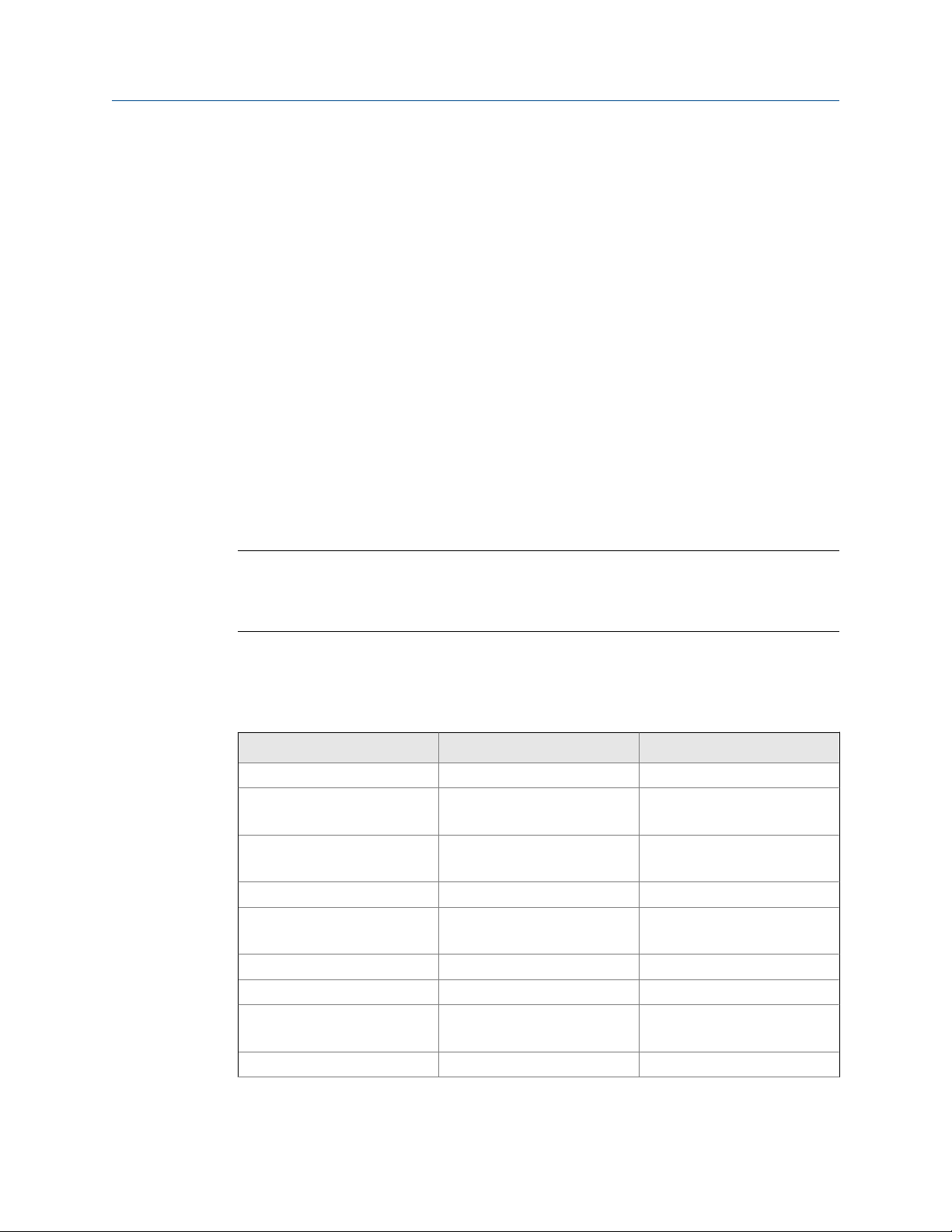

Model codes and device typesTable 1-1:

Model code Device nickname I/O

CDM100M****C CDM mA • Two mA outputs

• RS-485 terminals

CDM100M****D CDM DO • One mA output

• One discrete output

• RS-485 terminals

Electronics mounting

Integral

Integral

Configuration and Use Manual 3

Page 12

Before you begin

Model codes and device types (continued)Table 1-1:

Model code Device nickname I/O

CDM100M****B CDM TPS • One mA output

• One Time Period Sig-

nal output

• RS-485 terminals

CDM100M****A CDM FF • FOUNDATION™ field-

bus

Restriction

The CDM mA, CDM DO, and CDM FF support a complete set of application and configuration

options. The CDM TPS supports a subset of configuration options. Refer to the product data sheet for

details.

1.3 Communications tools and protocols

Electronics mounting

Integral

4-wire remote

transmitter

You can use several different communications tools and protocols to interface with the

device. You may use different tools in different locations or for different tasks.

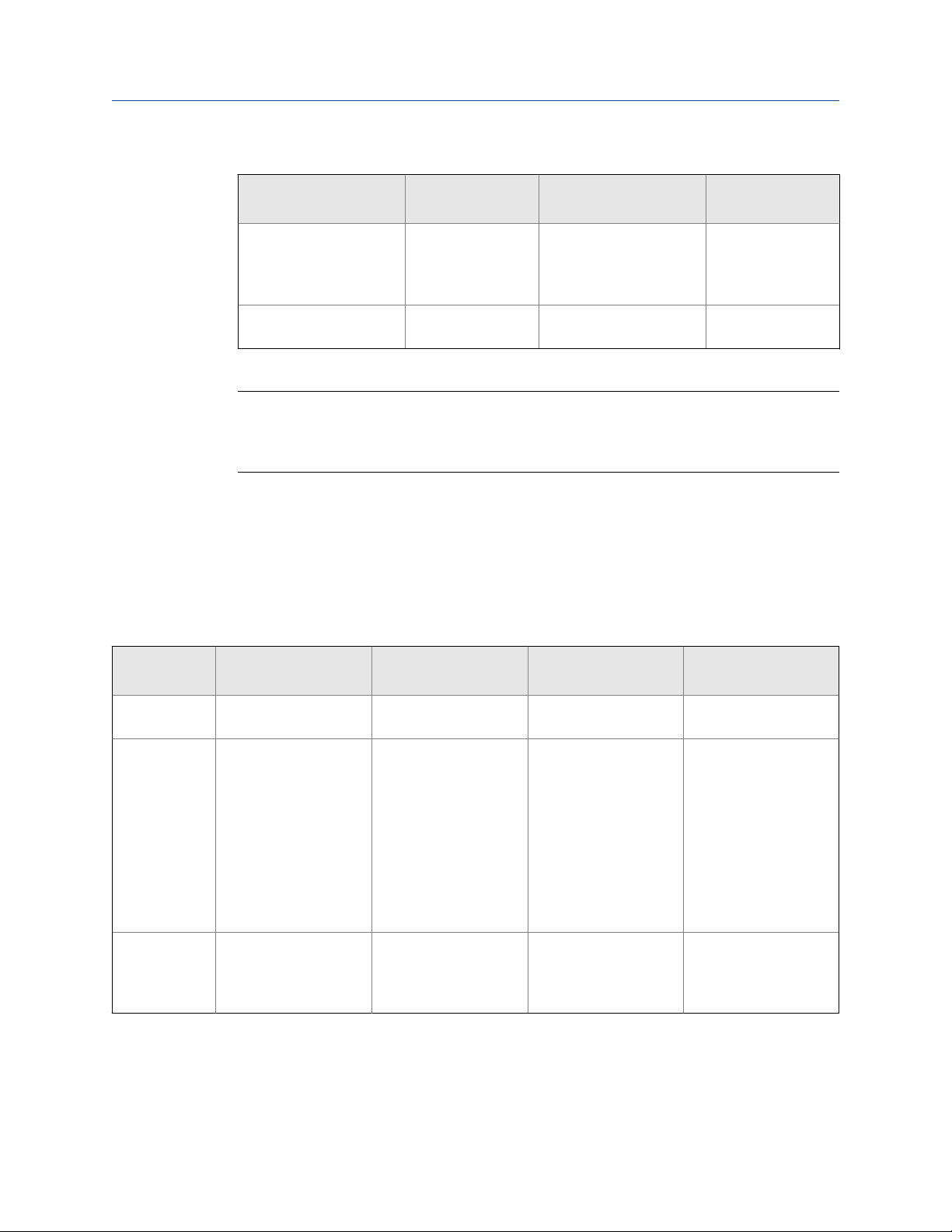

Communications tools, protocols, and related informationTable 1-2:

Communications tool Supported protocols Scope In this manual For more information

Display Not applicable Basic configuration and

commissioning

ProLink III • Modbus/RS-485

• HART/Bell 202

• Service port

Field Communicator

• HART/Bell 202 Complete configuration

Complete configuration

and commissioning

and commissioning

Complete user information. See Appendix B.

Basic user information.

See Appendix C.

Basic user information.

See Appendix D.

Not applicable

User manual

• Installed with soft-

ware

• On Micro Motion

user documentation

CD

• On Micro Motion

web site

(www.micromo‐

tion.com)

User manual on

Micro Motion web site

(www.micromo‐

tion.com )

4 Micro Motion® Compact Density Meters (CDM)

Page 13

Tip

You may be able to use other communications tools from Emerson Process Management, such as

AMS Suite: Intelligent Device Manager, or the Smart Wireless THUM™ Adapter. Use of AMS or the

Smart Wireless THUM Adapter is not discussed in this manual. For more information on the Smart

Wireless THUM Adapter, refer to the documentation available at www.micromotion.com.

1.4 Additional documentation and resources

Micro Motion provides additional documentation to support the installation and operation

of the device.

Additional documentation and resourcesTable 1-3:

Topic Document

Device installation Micro Motion Compact Density Meters (CDM): Installation Manual

Product data sheet Micro Motion Compact Density Meters: Product Data Sheet

Before you begin

All documentation resources are available on the Micro Motion web site at

www.micromotion.com or on the Micro Motion user documentation DVD.

Configuration and Use Manual 5

Page 14

Before you begin

6 Micro Motion® Compact Density Meters (CDM)

Page 15

2 Quick start

Topics covered in this chapter:

• Power up the transmitter

• Check meter status

• Make a startup connection to the transmitter

• Zero the meter

2.1 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for

process measurement.

1. Ensure that all transmitter and sensor covers and seals are closed.

Quick start

WARNING!

To prevent ignition of flammable or combustible atmospheres, ensure that all covers

and seals are tightly closed. For hazardous area installations, applying power while

housing covers are removed or loose can cause an explosion.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period,

Alert 009 is active. The diagnostic routines should complete in approximately

30 seconds.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics

can take up to 10 minutes to reach thermal equilibrium. Therefore, if this is the initial

startup, or if power has been off long enough to allow components to reach ambient

temperature, allow the electronics to warm up for approximately 10 minutes before

relying on process measurements. During this warm-up period, you may observe minor

measurement instability or inaccuracy.

2.2 Check meter status

Check the meter for any error conditions that require user action or that affect

measurement accuracy.

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and

checks for error conditions. During the power-up sequence, Alert A009 is active.

This alert should clear automatically when the power-up sequence is complete.

Configuration and Use Manual 7

Page 16

Quick start

2. Check the status LED on the transmitter.

Transmitter status reported by status LEDTable 2-1:

LED state Description Recommendation

Green No alerts are active. Continue with configuration or process meas-

urement.

Yellow One or more low-severity alerts are active. A low-severity alert condition does not affect

measurement accuracy or output behavior.

You can continue with configuration or process measurement. If you choose, you can identify and resolve the alert condition.

Flashing yellow Calibration in progress, or Known Density Veri-

fication in progress.

Red One or more high-severity alerts are active. A high-severity alert condition affects meas-

The measurement can fluctuate during the

calibration process or change as a result of the

calibration process. The alert will clear when

the calibration is complete. Check the calibration results before continuing.

urement accuracy and output behavior. Resolve the alert condition before continuing.

• View and acknowledge status alerts (Section 8.3)

• Status alerts, causes, and recommendations (Section 10.6)

2.3 Make a startup connection to the transmitter

For all configuration tools except the display, you must have an active connection to the

transmitter to configure the transmitter.

Identify the connection type to use, and follow the instructions for that connection type in

the appropriate appendix. Use the default communications parameters shown in the

appendix.

Communications tool Connection type to use Instructions

ProLink III Modbus/RS-485

HART/Bell 202

Field Communicator HART/Bell 202 Appendix D

Postrequisites

(Optional) Change the communications parameters to site-specific values.

Appendix C

• To change the communications parameters using ProLink III, choose Device Tools >

Configuration > Communications.

8 Micro Motion® Compact Density Meters (CDM)

Page 17

• To change the communications parameters using the Field Communicator, choose

Configure > Manual Setup > HART > Communications.

Important

If you are changing communications parameters for the connection type that you are using, you will

lose the connection when you write the parameters to the transmitter. Reconnect using the new

parameters.

2.4 Zero the meter

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's

output when there is no flow through the sensor tubes.

Note

Do not zero the meter if a high-severity alert is active. Correct the problem, then zero the meter. You

may zero the meter if a low-severity alert is active.

In most cases, the default value (0) is adequate for flow indication. Do not zero the meter unless the

velocity switch is being triggered incorrectly and you need to apply an offset to the velocity

measurement.

Quick start

• Zero the meter using the display (Section 2.4.1)

• Zero the meter using ProLink III (Section 2.4.2)

• Zero the meter using the Field Communicator (Section 2.4.3)

2.4.1 Zero the meter using the display

Restriction

You cannot change the Zero Time setting from the display. The current setting of Zero Time will be

applied to the zero procedure. The default value is 20 seconds. If you need to change Zero Time, you

must make a connection to the transmitter from a communications tool such as ProLink III.

Procedure

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Start the zero process.

a. Navigate to the Zero menu: OFFLINE MAINT > OFFLINE CALIB > VEL ZERO.

Configuration and Use Manual 9

Page 18

Quick start

b. Scroll to CAL VEL/ZERO and activate Select, then select CAL/YES?.

The status LED changes to flashing yellow while the zero is in progress.

3. Read the zero result on the display.

The display reports CAL PASS if the zero was successful, or CAL FAIL if it was not.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

• Ensure that there is no flow through the sensor, then retry.

• Remove or reduce sources of electromechanical noise, then retry.

• Set Zero Time to a lower value, then retry.

• If the zero continues to fail, contact Micro Motion.

• If you want to return the meter to operation using a previous zero value, choose OFFLINE

MAINT > CAL > RESTORE VEL/ZERO.

2.4.2 Zero the meter using ProLink III

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Choose Device Tools > Calibration > Zero Velocity.

3. Modify Zero Time, if desired.

Zero Time controls the amount of time the transmitter takes to determine its zeroflow reference point. The default Zero Time is 20 seconds. For most applications, the

default Zero Time is appropriate.

4. Click Calibrate Zero.

The Calibration in Progress message is displayed. When the calibration is

complete:

• If the zero procedure was successful, a Calibration Success message and a

new zero value are displayed.

• If the zero procedure failed, a Calibration Failed message is displayed.

Postrequisites

Restore normal flow through the sensor by opening the valves.

10 Micro Motion® Compact Density Meters (CDM)

Page 19

Need help? If the zero fails:

• Remove or reduce sources of electromechanical noise, then retry.

• If the zero continues to fail, contact Micro Motion.

• If you want to return the meter to operation using a previous zero value, choose Device Tools >

Calibration > Zero Velocity > Restore Prior Zero. Restore Prior Zero is available only while the Zero

Velocity window is open. If you close the Zero Velocity window, you will no longer be able to

restore the prior zero.

2.4.3 Zero the meter using the Field Communicator

1. Prepare the meter:

a. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available.

b. Verify that the sensor is blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

c. Verify that the process fluid is not flashing or condensing, and that it does not

contain particles that can settle out.

d. Remove or reduce sources of electromechanical noise if appropriate.

2. Choose Service Tools > Maintenance > Calibration > Zero Calibration.

3. Modify Zero Time, if desired.

Quick start

Zero Time controls the amount of time the transmitter takes to determine its zeroflow reference point. The default Zero Time is 20 seconds. For most applications, the

default Zero Time is appropriate.

4. Press Perform Auto Zero to start the zero, and wait while the zero calibration is

performed.

5. When the zero is complete, data from the zero calibration is displayed.

• Press OK to accept the data and store the values.

• Press ABORT to discard the data and return to the previous zero values.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

• Ensure that there is no flow through the sensor, then retry.

• Remove or reduce sources of electromechanical noise, then retry.

• Set Zero Time to a lower value, then retry.

• If the zero continues to fail, contact Micro Motion.

Configuration and Use Manual 11

Page 20

Quick start

12 Micro Motion® Compact Density Meters (CDM)

Page 21

Configuration and commissioning

Part II

Configuration and commissioning

Chapters covered in this part:

• Introduction to configuration and commissioning

• Configure process measurement

• Configure device options and preferences

• Integrate the meter with the control system

• Complete the configuration

Configuration and Use Manual 13

Page 22

Configuration and commissioning

14 Micro Motion® Compact Density Meters (CDM)

Page 23

Introduction to configuration and commissioning

3 Introduction to configuration and

commissioning

Topics covered in this chapter:

• Default values

• Enable access to the off‐line menu of the display

• Disable HART security

• Set the HART lock

• Restore the factory configuration

3.1 Default values

Default values for your meter are configured at the factory.

Important

Default values are based on your purchase order options. Therefore, the default values described in

the following tables may not be the factory default values configured for your system. For absolute

accuracy, refer to the configuration sheet that was shipped with your meter.

3.1.1 CDM default values

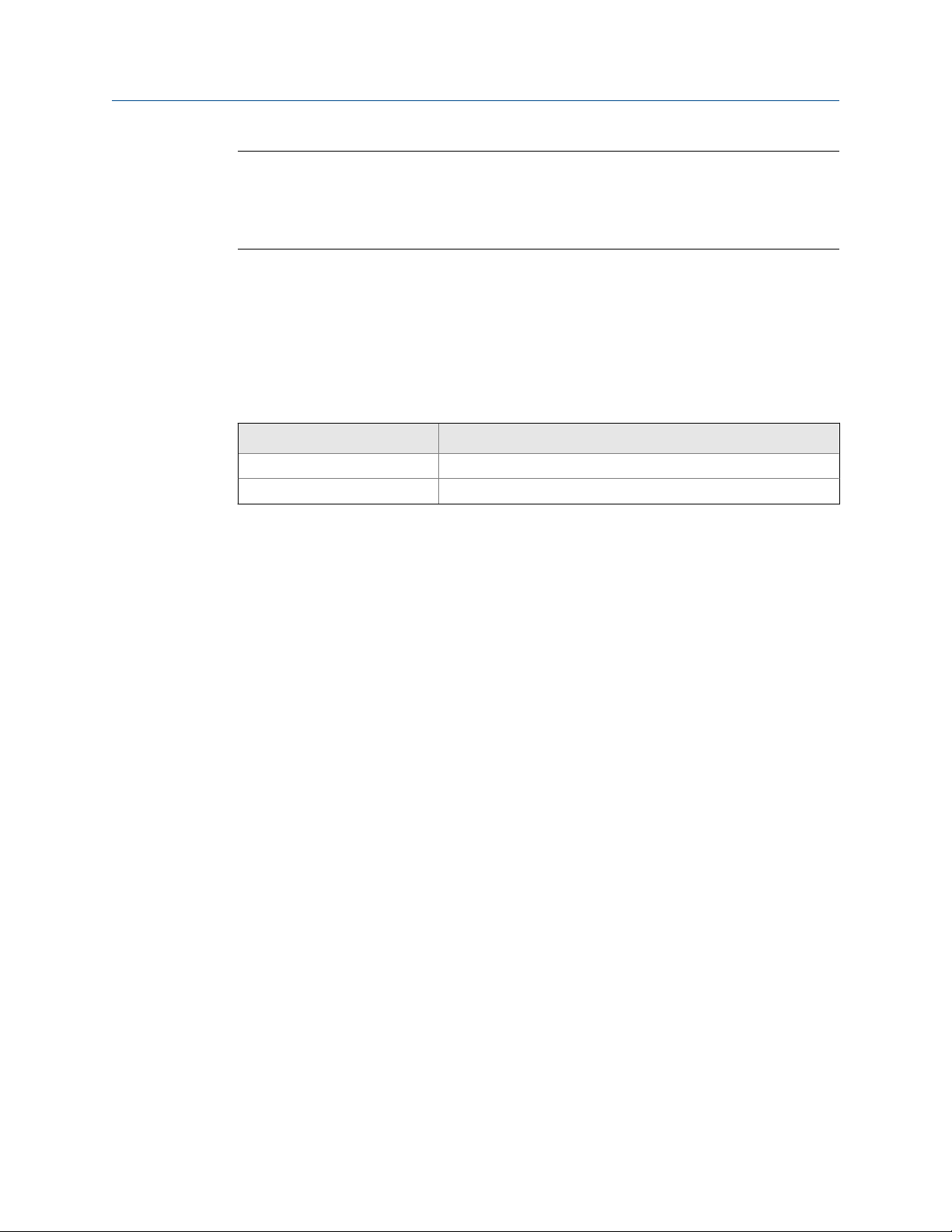

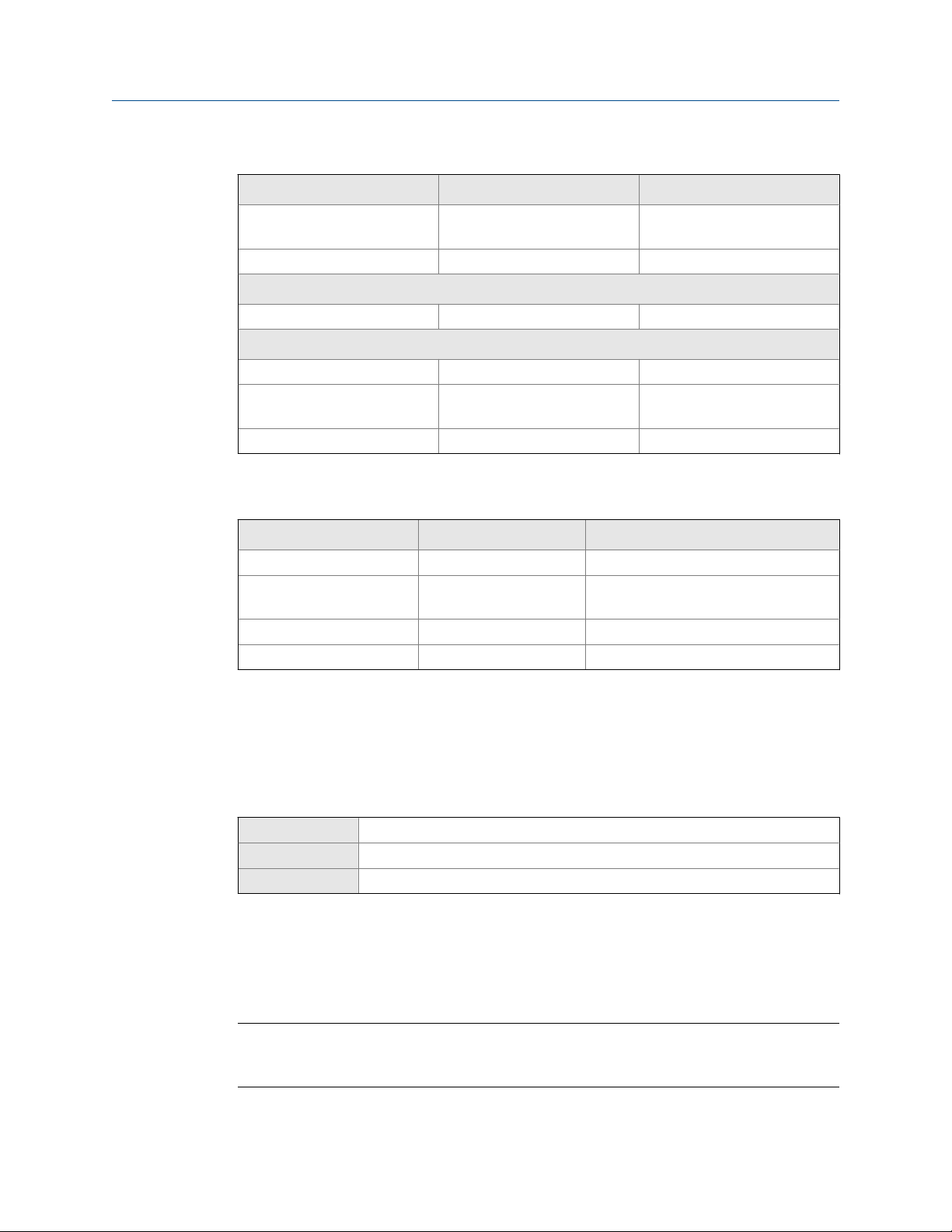

CDM default mA scaling valuesTable 3-1:

Variable Default 4 mA Default 20 mA

Line density 0.500 g/cm3 1.500 g/cm3

Line temperature -50°C

Tube-case temperature differential

Drive gain 0.000 % 100.000 %

External temperature -50.000°C

External pressure 0.000 PSIg 1450.377 PSIg

Case temperature -50°C 200°C

Sensor time period 5000 us

Velocity -10 m/s 10 m/s

-58°F

0°C

32°F

-58.00000°F

0 us

200.000°C

392°F

10°C

50°F

200.000°C

392.0000°F

10000 us

5000 us

Configuration and Use Manual 15

Page 24

Introduction to configuration and commissioning

CDM default mA scaling values (continued)Table 3-1:

Variable Default 4 mA Default 20 mA

User-defined calculation output

Volume flow rate -0.2 l/s 0.2 l/s

API Referral option enabled

Referred density (API) 500 kg/m3 1500 kg/m3c

Concentration Measurement option enabled

Concentration 0 % 100 %

Referred density (concentration)

Specific gravity 0.5 SGU 1.5 SGU

CDM default variablesTable 3-2:

Default variable Output option A Output options B and C

Primary Variable (PV), mA1 Sample Temperature Density

Secondary Variable (SV),

mA2

Tertiary Variable (TV) Velocity Velocity

Quaternary Variable (QV) Case Temp Case Temp

0 100

0.5 g/cm3 1.5 g/cm3

Sensor Time Period Sample Temperature

3.2 Enable access to the off-line menu of the display

Display Not available

ProLink III Device Tools > Configuration > Transmitter Display > Display Security

Field Communicator Configure > Manual Setup > Display > Display Menus > Offline Menu

Overview

By default, access to the off-line menu of the display is enabled. If it is disabled, you must

enable it if you want to use the display to configure the transmitter.

Restriction

You cannot use the display to enable access to the off-line menu. You must make a connection from

another tool.

16 Micro Motion® Compact Density Meters (CDM)

Page 25

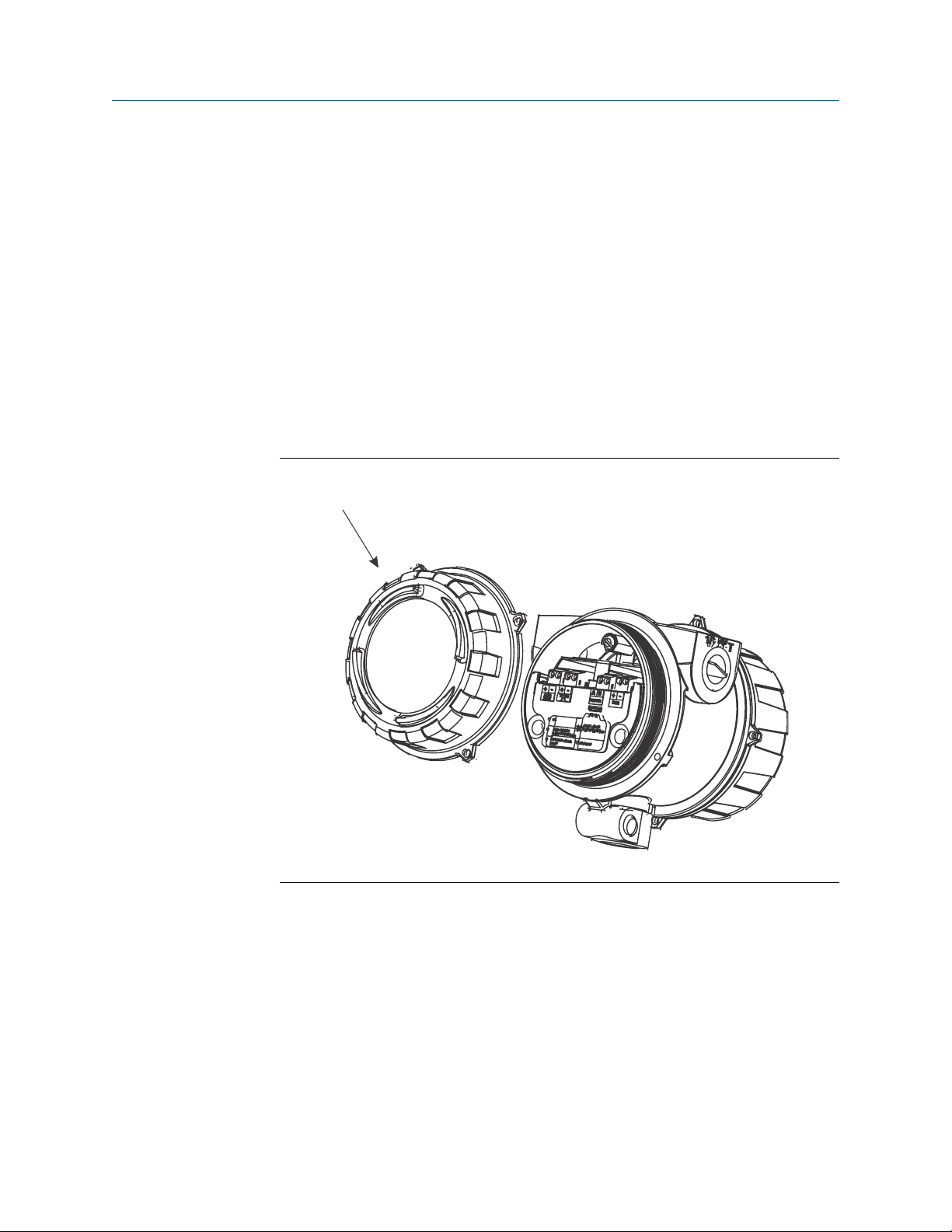

3.3 Disable HART security

A

If you plan to use HART protocol to configure the device, HART security must be disabled.

HART security is disabled by default, so you may not need to do this.

Prerequisites

• Strap wrench

• 3 mm hex key

Procedure

1. Power down the meter.

2. Using the strap wrench, loosen the grub screws and remove the transmitter end-

cap.

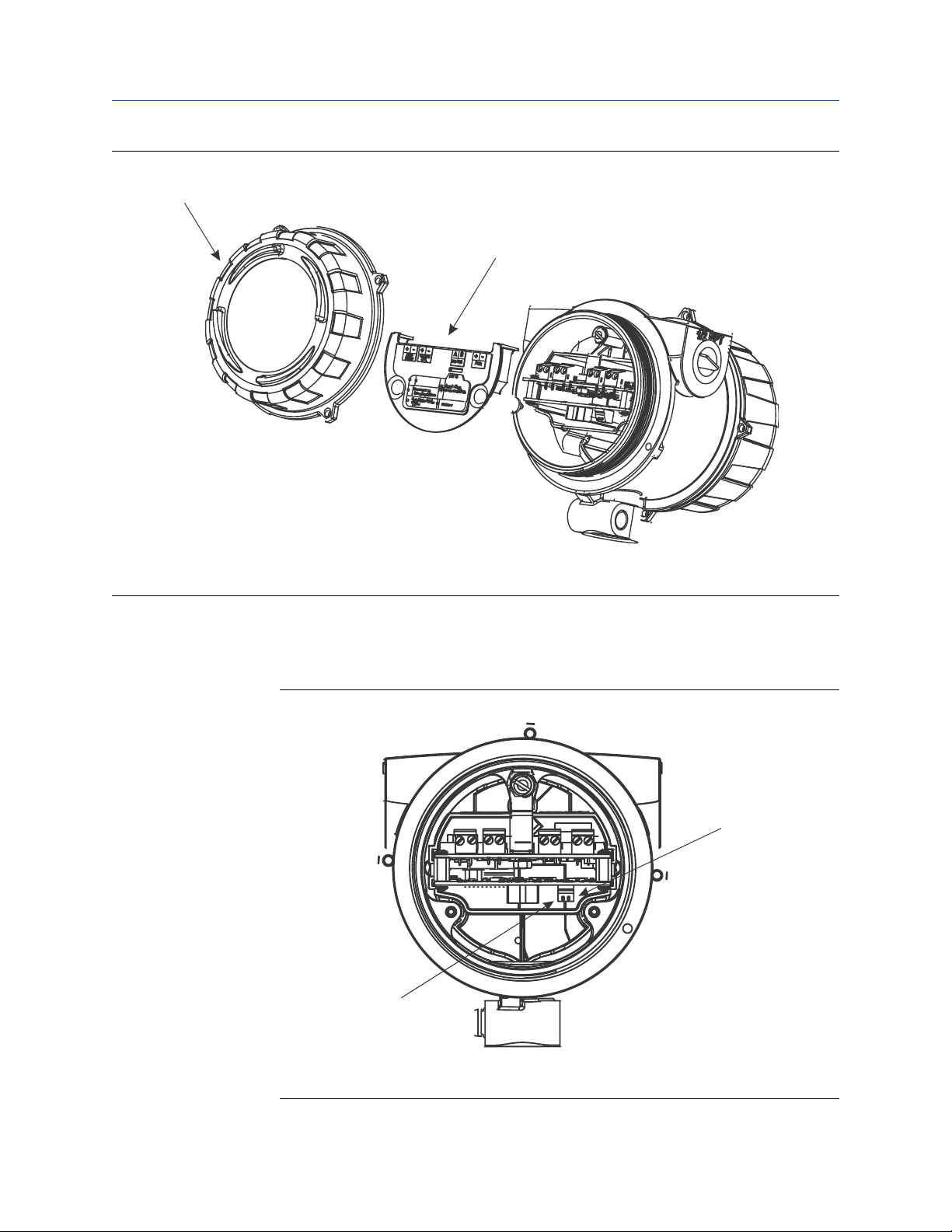

Transmitter with end-cap removedFigure 3-1:

Introduction to configuration and commissioning

A. Transmitter end‐cap

3. Using the hex key, remove the safety spacer.

Configuration and Use Manual 17

Page 26

A

B

A

B

Introduction to configuration and commissioning

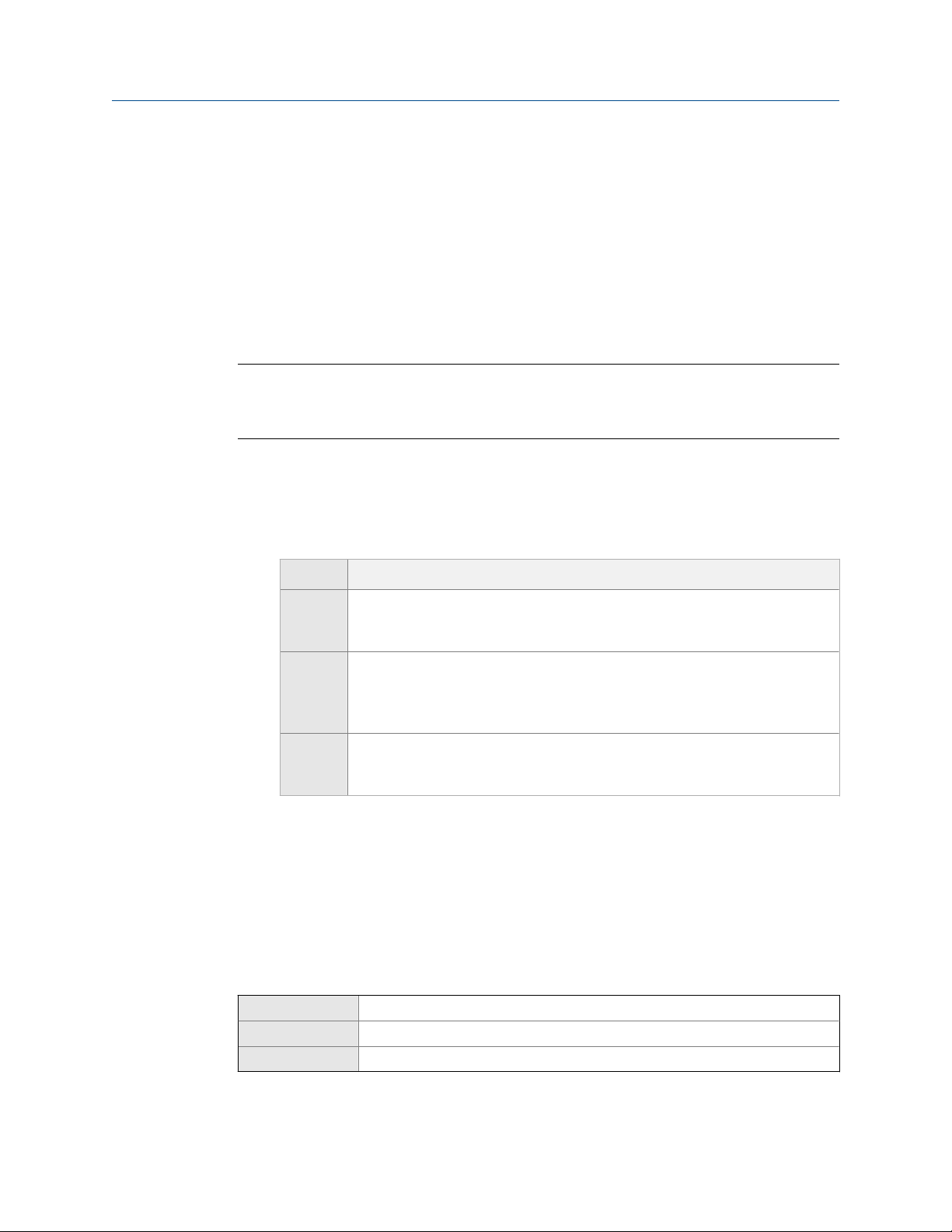

Transmitter with end-cap and safety spacer removedFigure 3-2:

A. Transmitter end‐cap

B. Safety spacer

4. Move the HART security switch to the OFF position (up).

The HART security switch is the switch on the left.

HART security switchFigure 3-3:

A. HART security switch

B. Unused

18 Micro Motion® Compact Density Meters (CDM)

Page 27

5. Replace the safety spacer and end-cap.

6. Power up the meter.

3.4 Set the HART lock

If you plan to use a HART connection to configure the device, you can lock out all other

HART masters. If you do this, other HART masters will be able to read data from the device

but will not be able to write data to the device.

Restrictions

• This feature is available only when you are using the Field Communicator or AMS.

• This feature is available only with a HART 7 host.

Procedure

1. Choose Configure > Manual Setup > Security > Lock/Unlock Device.

2. If you are locking the meter, set Lock Option as desired.

Introduction to configuration and commissioning

Option Description

Permanent Only the current HART master can make changes to the device. The device will

remain locked until manually unlocked by a HART master. The HART master can

also change Lock Option to Temporary.

Temporary Only the current HART master can make changes to the device. The device will

remain locked until manually unlocked by a HART master, or a power-cycle or

device reset is performed. The HART master can also change Lock Option to Perma-

nent.

Lock All No HART masters are allowed to make changes to the configuration. Before

changing Lock Option to Permanent or Temporary, the device must be unlocked. Any

HART master can be used to unlock the device.

Postrequisites

To avoid future confusion or difficulties, ensure that the device is unlocked after you have

completed your tasks.

3.5 Restore the factory configuration

Display Not available

ProLink III Device Tools > Configuration Transfer > Restore Factory Configuration

Field Communicator Service Tools > Maintenance > Reset/Restore > Restore Factory Configuration

Configuration and Use Manual 19

Page 28

Introduction to configuration and commissioning

Overview

Restoring the factory configuration returns the transmitter to a known operational

configuration. This may be useful if you experience problems during configuration.

Tip

Restoring the factory configuration is not a common action. You may want to contact Micro Motion

to see if there is a preferred method to resolve any issues.

20 Micro Motion® Compact Density Meters (CDM)

Page 29

Configure process measurement

4 Configure process measurement

Topics covered in this chapter:

• Verify the calibration factors

• Configure line density measurement

• Configure temperature measurement

• Configure the pressure input

• Set up the API referral application

• Set up concentration measurement

• Set up flow monitoring

4.1 Verify the calibration factors

Display Not available

ProLink III Device Tools > Calibration Data

Field Communicator Configure > Manual Setup > Calibration Factors

Overview

The calibration factors are used to adjust measurement for the unique traits of the sensor.

Your device was calibrated at the factory. However, you should verify that the calibration

factors that are configured in your device match the factory values.

Prerequisites

You will need the factory values for the calibration factors. These are provided in two

locations:

• The calibration certificate shipped with your meter

• The label inside the transmitter's end-cap

Important

If the transmitter is not the original component, do not use the values from the transmitter label.

Procedure

1. View the calibration factors that are stored in the device.

2. Compare them to the factory values.

• If the values match, no action is required.

• If the values do not match, contact Micro Motion customer service.

Configuration and Use Manual 21

Page 30

Configure process measurement

Related information

Sample calibration certificates

4.1.1 Calibration factors

The original calibration factors are obtained from factory calibration, and are unique to

each device. They are used to adjust measurements for the specific physical properties of

the device.

Contents of the calibration certificate

The calibration certificate contains several sets of factors:

Density calibration

coefficients

Temperature

compensation coefficients

Pressure compensation

coefficients

Flow compensation

coefficient

The calibration certificate also provides the results of the Known Density Verification

procedure that was performed at the factory.

For each calibration performed at the factory, the calibration certificate contains the data

used to calculate the calibration coefficients.

CDM format and legacy format (A factors and K factors)

The calibration factors are provided on three calibration certificates:

• The first certificate provides the calibration factors in the CDM format, An, in SI units.

These are obtained from factory calibration of your device.

• The second certificate provides the calibration factors in the legacy format, Kn, in SI

units. These factors represent the current calibration factors converted to the

format used by the 7835 and 7845 meters.

• The third certificate provides the calibration factors in the legacy format, Kn, in

imperial units. These factors represent the current calibration factors converted to

the format used by the 7835 and 7845 meters, and then converted to imperial units.

Define the relationship between density and the response

of your sensor

Adjust density measurement for the effect of temperature

on sensor response

Adjust density measurement for the effect of pressure on

sensor response

Adjusts density measurement for the effect of flow on

sensor response

If you have existing programs that use the K factors, update your programs with the new K

values in the appropriate units. In all other situations, use the A-format calibration factors.

Related information

Sample calibration certificates

22 Micro Motion® Compact Density Meters (CDM)

Page 31

Configure process measurement

4.2 Configure line density measurement

The density measurement parameters control how density is measured and reported.

• Configure Density Measurement Unit (Section 4.2.1)

• Configure Density Damping (Section 4.2.2)

• Configure Density Cutoff (Section 4.2.3)

• Configure two‐phase flow parameters (Section 4.2.4)

4.2.1 Configure Density Measurement Unit

Display OFF-LINE MAINT > OFF-LINE CONFG > UNITS > DENS

ProLink III Device Tools > Configuration > Process Measurement > Line Density > Density Unit

Field Communicator Configure > Manual Setup > Measurements > Density > Density Unit

Overview

Density Measurement Unit controls the measurement units that will be used in density

calculations and reporting.

Restriction

If the API referral application is enabled, you cannot change the density measurement unit here. The

density measurement unit is controlled by the API table selection.

Procedure

Set Density Measurement Unit to the option you want to use.

The default setting for Density Measurement Unit is g/cm3 (grams per cubic centimeter).

Related information

Set up the API referral application

Options for Density Measurement Unit

The transmitter provides a standard set of measurement units for Density Measurement Unit.

Different communications tools may use different labels.

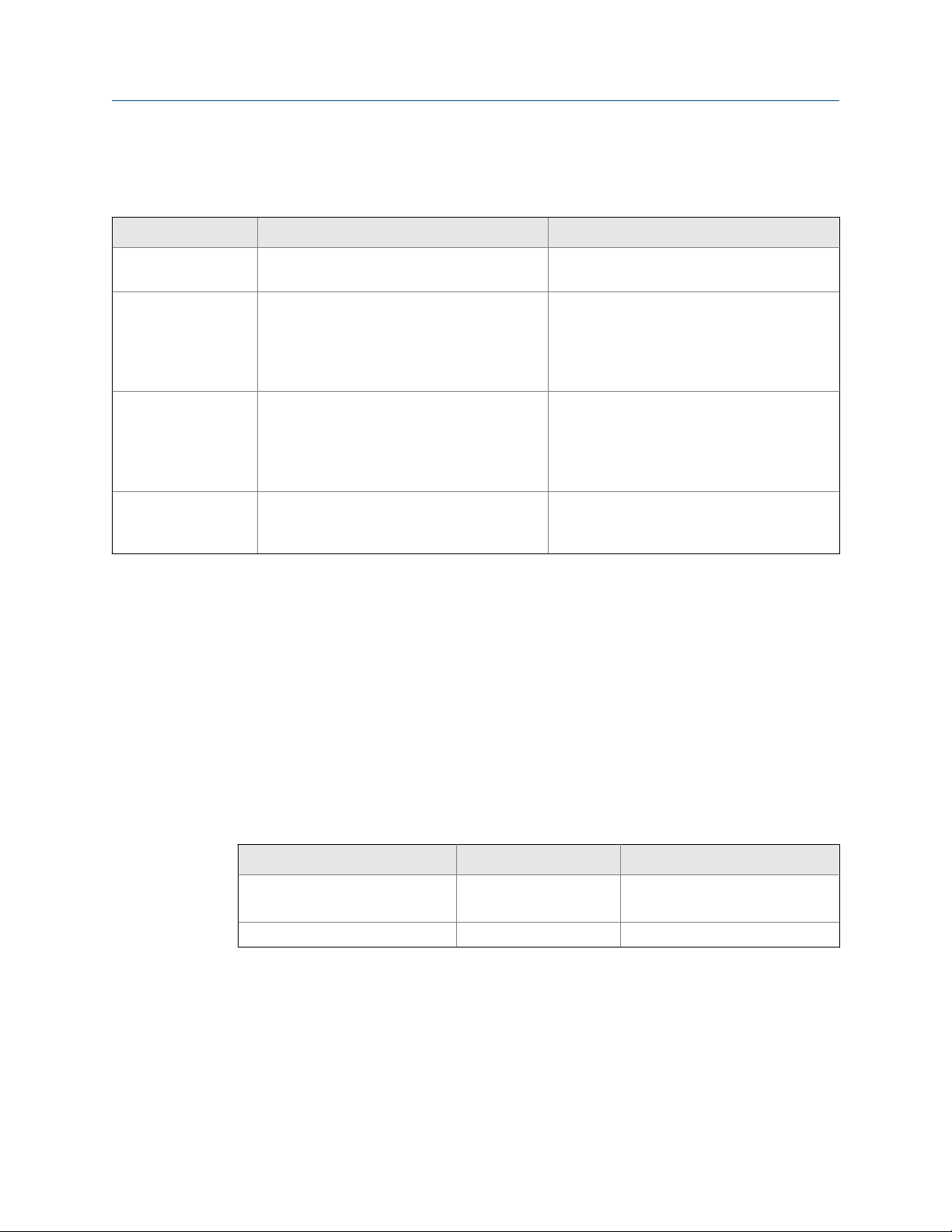

Options for Density Measurement UnitTable 4-1:

Label

Unit description

Specific gravity SGU SGU SGU

Grams per cubic centimeter G/CM3 g/cm3 g/Cucm

Grams per liter G/L g/l g/L

Configuration and Use Manual 23

Display (standard) ProLink III Field Communicator

Page 32

Configure process measurement

Options for Density Measurement Unit (continued)Table 4-1:

Label

Unit description

Grams per milliliter G/mL g/ml g/mL

Kilograms per liter KG/L kg/l kg/L

Kilograms per cubic meter KG/M3 kg/m3 kg/Cum

Pounds per U.S. gallon LB/GAL lbs/Usgal lb/gal

Pounds per cubic foot LB/CUF lbs/ft3 lb/Cuft

Pounds per cubic inch LB/CUI lbs/in3 lb/CuIn

Short ton per cubic yard ST/CUY sT/yd3 STon/Cuyd

Degrees API D API degAPI degAPI

Special unit SPECL special Spcl

Display (standard) ProLink III Field Communicator

Define a special measurement unit for density

Display Not available

ProLink III Device Tools > Configuration > Process Measurement > Line Density > Special Units

Field Communicator Configure > Manual Setup > Measurements > Special Units

Overview

A special measurement unit is a user-defined unit of measure that allows you to report

process data in a unit that is not available in the transmitter. A special measurement unit is

calculated from an existing measurement unit using a conversion factor.

Procedure

1. Specify Density Special Unit Base.

Density Special Unit Base is the existing density unit that the special unit will be based

on.

2. Calculate Density Special Unit Conversion Factor as follows:

a. x base units = y special units

b. Density Special Unit Conversion Factor = x÷y

3. Enter Density Special Unit Conversion Factor.

The original density value is divided by this conversion factor.

4. Set User-Defined Label to the name you want to use for the density unit.

The special measurement unit is stored in the transmitter. You can configure the

transmitter to use the special measurement unit at any time.

24 Micro Motion® Compact Density Meters (CDM)

Page 33

Example: Defining a special measurement unit for density

You want to measure density in ounces per cubic inch.

1. Set Density Special Unit Base to g/cm3.

2. Calculate Density Special Unit Conversion Factor:

a. 1 g/cm3 = 0.578 oz/in3

b. 1÷0.578 = 1.73

3. Set Density Special Unit Conversion Factor to 1.73.

4. Set User-Defined Label to oz/in3.

4.2.2 Configure Density Damping

Display Not available

ProLink III Device Tools > Configuration > Process Measurement > Line Density > Density Damping

Field Communicator Configure > Manual Setup > Measurements > Density > Density Damping

Configure process measurement

Overview

Density Damping controls the amount of damping that will be applied to the line density

value.

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes

in the process variable. At the end of the interval, the internal value will reflect 63% of the

change in the actual measured value.

Tip

Density damping affects all process variables that are calculated from line density.

Procedure

Set Density Damping to the value you want to use.

The default value is 1.6 seconds. The range is 0 to 60 seconds.

Interaction between Density Damping and Added Damping

When the mA output is configured to report density, both Density Damping and Added

Damping are applied to the reported density value.

Density Damping controls the rate of change in the value of the process variable in

transmitter memory. Added Damping controls the rate of change reported via the mA

output.

Configuration and Use Manual 25

Page 34

Configure process measurement

If mA Output Process Variable is set to Density, and both Density Damping and Added Damping are

set to non-zero values, density damping is applied first, and the added damping

calculation is applied to the result of the first calculation. This value is reported over the

mA output.

Related information

Interaction between mA Output Damping and process variable damping

4.2.3 Configure Density Cutoff

Display Not available

ProLink III Device Tools > Configuration > Process Measurement > Line Density > Density Cutoff Low

Field Communicator Configure > Manual Setup > Measurements > Density > Density Cutoff

Overview

Density Cutoff Low specifies the lowest density value that will be reported as measured. All

density values below this cutoff will be reported as 0.

Procedure

Set Density Cutoff Low to the value you want to use.

The default value is 0.2 g/cm³. The range is 0.0 g/cm³ to 0.5 g/cm³.

4.2.4 Configure two-phase flow parameters

Display Not available

ProLink III Device Tools > Configuration > Process Measurement > Line Density

Field Communicator Configure > Manual Setup > Measurements > Density

Overview

The two-phase flow parameters control how the transmitter detects and reports twophase flow (gas in a liquid process or liquid in a gas process).

Note

Two-phase flow is sometimes referred to as slug flow.

Procedure

1. Set Two-Phase Flow Low Limit to the lowest density value that is considered normal in

your process.

Values below this will cause the transmitter to post Alert A105 (Two-Phase Flow).

26 Micro Motion® Compact Density Meters (CDM)

Page 35

Configure process measurement

Tip

Gas entrainment can cause your process density to drop temporarily. To reduce the

occurrence of two-phase flow alerts that are not significant to your process, set Two-Phase Flow

Low Limit slightly below your expected lowest process density.

You must enter Two-Phase Flow Low Limit in g/cm³, even if you configured another unit

for density measurement.

The default value for Two-Phase Flow Low Limit is 0.0 g/cm³. The range is 0.0 to

3.0 g/cm³.

2. Set Two-Phase Flow High Limit to the highest density value that is considered normal in

your process.

Values above this will cause the transmitter to post Alert A105 (Two-Phase Flow).

Tip

To reduce the occurrence of two-phase flow alerts that are not significant to your process, set

Two-Phase Flow High Limit slightly above your expected highest process density.

You must enter Two-Phase Flow High Limit in g/cm³, even if you configured another

unit for density measurement.

The default value for Two-Phase Flow High Limit is 3.0 g/cm³. The range is 0.0 to

3.0 g/cm³.

3. Set Two-Phase Flow Timeout to the number of seconds that the transmitter will wait for

a two-phase flow condition to clear before posting the alert.

The default value for Two-Phase Flow Timeout is 0.0 seconds, meaning that the alert

will be posted immediately. The range is 0.0 to 60.0 seconds.

Detecting and reporting two-phase flow

Two-phase flow (gas in a liquid process or liquid in a gas process) can cause a variety of

process control issues. By configuring the two-phase flow parameters appropriately for

your application, you can detect process conditions that require correction.

Tip

To decrease the occurrence of two-phase flow alerts, lower Two-Phase Flow Low Limit or raise Two-Phase

Flow High Limit.

A two-phase flow condition occurs whenever the measured density goes below Two-Phase

Flow Low Limit or above Two-Phase Flow High Limit. If this occurs:

• A two-phase flow alert is posted to the active alert log.

• Line density is held at its last pre‐alert value for the number of seconds configured in

Two-Phase Flow Timeout.

If the two-phase flow condition clears before Two-Phase Flow Timeout expires:

Configuration and Use Manual 27

Page 36

Configure process measurement

• Line density reverts to actual process density.

• The two-phase flow alert is deactivated, but remains in the active alert log until it is

acknowledged.

If the two-phase flow condition does not clear before Two-Phase Flow Timeout expires, line

density reverts to actual process density, but the two-phase flow alert remains active.

If Two-Phase Flow Timeout is set to 0.0 seconds, two-phase flow will cause a two-phase flow

alert but will have no effect on how the meter measures or reports line density.

4.3 Configure temperature measurement

The temperature measurement parameters control how temperature data from the

sensor is reported.

• Configure Temperature Measurement Unit (Section 4.3.1)

• Configure Temperature Damping (Section 4.3.2)

• Configure Temperature Input (Section 4.3.3)

4.3.1 Configure Temperature Measurement Unit

Display OFF-LINE MAINT > OFF-LINE CONFG > UNITS > TEMP

ProLink III Device Tools > Configuration > Process Measurement > Line Temperature > Temperature Unit

Field Communicator Configure > Manual Setup > Measurements > Temperature > Temperature Unit

Overview

Temperature Measurement Unit specifies the unit that will be used for temperature

measurement.

Restriction

If the API referral application is enabled, the API table selection automatically sets the temperature

measurement unit. Configure the API referral application first, then change the temperature

measurement unit if desired.

Procedure

Set Temperature Measurement Unit to the option you want to use.

The default setting is Degrees Celsius.

Related information

Set up the API referral application

28 Micro Motion® Compact Density Meters (CDM)

Page 37

Options for Temperature Measurement Unit

The transmitter provides a standard set of units for Temperature Measurement Unit. Different

communications tools may use different labels for the units.

Options for Temperature Measurement UnitTable 4-2:

Unit description

Degrees Celsius °C °C degC

Degrees Fahrenheit °F °F degF

Degrees Rankine °R °R degR

Kelvin °K °K Kelvin

Display ProLink III

4.3.2 Configure Temperature Damping

Configure process measurement

Label

Field Communicator

Display Not available

ProLink III Device Tools > Configuration > Process Measurement > Line Temperature > Temperature Damping

Field Communicator Configure > Manual Setup > Measurements > Temperature > Temp Damping

Overview

Temperature Damping controls the amount of damping that will be applied to the line

temperature value, when the on-board temperature data is used (RTD).

Damping is used to smooth out small, rapid fluctuations in process measurement. Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes

in the process variable. At the end of the interval, the internal value will reflect 63% of the

change in the actual measured value.

Tip

Temperature Damping affects all process variables, compensations, and corrections that use

temperature data from the sensor.

Procedure

Enter the value you want to use for Temperature Damping.

• Default: 4.8 seconds

Tips

• A high damping value makes the process variable appear smoother because the reported value

changes slowly.

Configuration and Use Manual 29

Page 38

Configure process measurement

• A low damping value makes the process variable appear more erratic because the reported value

changes more quickly.

• Whenever the damping value is non-zero, the reported measurement will lag the actual

measurement because the reported value is being averaged over time.

• In general, lower damping values are preferable because there is less chance of data loss, and less

lag time between the actual measurement and the reported value.

The value you enter is automatically rounded down to the nearest valid value.

4.3.3 Configure Temperature Input

Temperature data from the on-board temperature sensor (RTD) is always available.

Optionally, you can set up an external temperature device and use external temperature

data.

Tip

Use an external device only if it is more accurate than the internal RTD.

Important

Line temperature data is used in several different measurements and calculations. It is possible to

use the internal RTD temperature in some areas and an external temperature in others. The

transmitter stores the internal RTD temperature and the external temperature separately. However,

the transmitter stores only one alternate temperature value, which may be either an external

temperature or the configured fixed value. Accordingly, if you set up polling for temperature in one

area, and digital communications in another, and configure a fixed temperature value in a third, the

fixed value will be overwritten by polling and digital communications, and polling and digital

communications will overwrite each other.

Prerequisites

If you plan to poll an external device, the primary mA output (Channel A) must be wired to

support HART communications.

• Configure Temperature Input using ProLink III

• Configure Temperature Input using the Field Communicator

Configure Temperature Input using ProLink III

ProLink III Device Tools > Configuration > Process Measurement > Line Temperature > Line Temperature Source

Procedure

Choose the method to be used to supply temperature data, and perform the required

setup.

30 Micro Motion® Compact Density Meters (CDM)

Page 39

Option Description Setup

Internal RTD temperature data

Polling The meter polls an external de-

Digital communications

Temperature data from the onboard temperature sensor

(RTD) is used.

vice for temperature data. This

data will be available in addition to the internal RTD temperature data.

A host writes temperature data

to the meter at appropriate intervals. This data will be available in addition to the internal

RTD temperature data.

a. Set Line Temperature Source to Internal RTD.

b. Click Apply.

a. Set Line Temperature Source to Poll for External Value.

b. Set Polling Slot to an available slot.

c. Set Polling Control to Poll as Primary or Poll as Secondary.

Option Description

Poll as Primary No other HART masters will be on the

Poll as Secondary Other HART masters will be on the net-

d. Set External Device Tag to the HART tag of the temperature

device.

e. Click Apply.

a. Set Line Temperature Source to Fixed Value or Digital Communica-

tions.

b. Click Apply.

c. Perform the necessary host programming and communica-

tions setup to write temperature data to the meter at appro-

priate intervals.

Configure process measurement

network. The Field Communicator is not

a HART master.

work. The Field Communicator is not a

HART master.

Postrequisites

If you are using external temperature data, verify the external temperature value displayed

in the Inputs group on the ProLink III main window.

Need help? If the value is not correct:

• For polling:

- Verify the wiring between the meter and the external device.

- Verify the HART tag of the external device.

• For digital communications:

- Verify that the host has access to the required data.

- Verify that the host is writing to the correct register in memory, using the correct data

type.

Configure Temperature Input using the Field Communicator

Choose the method to be used to supply temperature data, and perform the required

setup.

Configuration and Use Manual 31

Page 40

Configure process measurement

Method Description Setup

Internal RTD temperature data

Polling The meter polls an external de-

Temperature data from the onboard temperature sensor

(RTD) is used.

vice for temperature data. This

data will be available in addition to the internal RTD temperature data.

a. Choose Configure > Manual Setup > Measurements > External Inputs

b. Set External Temperature to Disable.

a. Choose Configure > Manual Setup > Measurements > External Inputs

b. Set External Temperature to Enable.

c. Choose Configure > Manual Setup > Inputs/Outputs > External Device

d. Choose an unused polling slot.

e. Set Poll Control to Poll as Primary or Poll as Secondary.

Option Description

Poll as Primary No other HART masters will be on the

Poll as Secondary Other HART masters will be on the net-

> Temperature.

> Temperature.

Polling.

network. The Field Communicator is not

a HART master.

work. The Field Communicator is not a

HART master.

Digital communications

f. Set External Device Tag to the HART tag of the external tem-

perature device.

g. Set Polled Variable to Temperature.

A host writes temperature data

to the meter at appropriate intervals. This data will be available in addition to the internal

RTD temperature data.

a. Choose Configure > Manual Setup > Measurements > External Inputs

> Temperature.

b. Set External Temperature to Enable.

c. Perform the necessary host programming and communica-

tions setup to write temperature data to the meter at appro-

priate intervals.

Postrequisites

Choose Service Tools > Variables > External Variables and verify the value for External

Temperature.

Need help? If the value is not correct:

• Ensure that the external device and the meter are using the same measurement unit.

• For polling:

- Verify the wiring between the meter and the external device.

- Verify the HART tag of the external device.

• For digital communications:

- Verify that the host has access to the required data.

- Verify that the host is writing to the correct register in memory, using the correct data

type.

• If necessary, apply an offset.

32 Micro Motion® Compact Density Meters (CDM)

Page 41

4.4 Configure the pressure input

Pressure data is required to calculate base density from line density.

• The meter does not measure pressure, so you must provide an external pressure

input.

• You must use absolute pressure.

• Pressure data is required for several different measurements.

• There are several different methods to obtain pressure data.

Tip

A fixed pressure value is not recommended as it can produce inaccurate process data.

Prerequisites

If you plan to poll an external device, the primary mA output (Channel A) must be wired to

support HART communications.

• Configure the pressure input using ProLink III (Section 4.4.1)

• Configure the pressure input using the Field Communicator (Section 4.4.2)

Configure process measurement

4.4.1 Configure the pressure input using ProLink III

1. Choose Device Tools > Configuration > Process Measurement > Line Pressure.

2. Set Pressure Type to match the pressure measurement from the external pressure

device.

Option Description

Absolute The external pressure device reports absolute pressure.

Gauge The external pressure device reports gauge pressure.

Restriction

If Line Pressure Source is set to Fixed, you cannot configure Pressure Type. You must enter the

pressure value in the required form. To set Pressure Type, you may need to change the setting

of Line Pressure Source.

The meter requires gauge pressure. If you select Absolute, the device will convert the

input pressure value to the equivalent gauge pressure.

3. Set Pressure Unit to the unit used by the external pressure device.

Restriction

If the API referral application is enabled, the API table selection automatically sets the

pressure measurement unit. Configure the API referral application first, then change the

pressure measurement unit if necessary.

Configuration and Use Manual 33

Page 42

Configure process measurement

4. Choose the method used to supply pressure data and perform the required setup.

Option Description Setup

Polling The meter polls an external de-

vice for pressure data.

Digital communications

A host writes pressure data to

the meter at appropriate intervals.

a. Set Pressure Source to Poll for External Value.

b. Set Polling Slot to an available slot.

c. Set Polling Control to Poll as Primary or Poll as Secondary.

Option Description

Poll as Primary No other HART masters will be on the

Poll as Secondary Other HART masters will be on the net-

d. Set External Device Tag to the HART tag of the temperature

a. Set Pressure Source to Fixed Value or Digital Communications.

b. Perform the necessary host programming and communica-

network. The Field Communicator is not

a HART master.

work. The Field Communicator is not a

HART master.

device.

tions setup to write pressure data to the meter at appropriate intervals.

Postrequisites

The current pressure value is displayed in the External Pressure field. Verify that the value is

correct.

Need help? If the value is not correct:

• Ensure that the external device and the meter are using the same measurement unit.

• For polling:

- Verify the wiring between the meter and the external device.

- Verify the HART tag of the external device.

• For digital communications:

- Verify that the host has access to the required data.

- Verify that the host is writing to the correct register in memory, using the correct data

type.

• If necessary, apply an offset.

Note

Do not use the offset in conjunction with the fixed pressure value. Enter the adjusted value.

Related information

Set up the API referral application

34 Micro Motion® Compact Density Meters (CDM)

Page 43

4.4.2 Configure the pressure input using the Field Communicator

1. Choose Configure > Manual Setup > Measurements > External Inputs > Pressure.

2. Set Pressure Input to Enable.

3. Set Pressure Type to match the pressure measurement from the external pressure

device.

Option Description

Absolute The external pressure device reports absolute pressure.

Gauge The external pressure device reports gauge pressure.

Restriction

If Line Pressure Source is set to Fixed, you cannot configure Pressure Type. You must enter the

pressure value in the required form. To set Pressure Type, you may need to change the setting

of Line Pressure Source.

Configure process measurement

The meter requires gauge pressure. If you select Absolute, the device will convert the

input pressure value to the equivalent gauge pressure.

4. Set Pressure Unit to the unit used by the external pressure device.

Restriction

If the API referral application is enabled, the API table selection automatically sets the

pressure measurement unit. Configure the API referral application first, then change the

pressure measurement unit if necessary.

5. Set up the pressure input.

a. Choose Configure > Manual Setup > Inputs/Outputs > External Device Polling.

b. Choose an unused polling slot.

c. Set Polling Control to Poll as Primary or Poll as Secondary.

Option Description

Poll as Primary No other HART masters will be on the network. The

Field Communicator is not a HART master.

Poll as Secondary Other HART masters will be on the network. The

Field Communicator is not a HART master.

d. Set External Device Tag to the HART tag of the external pressure device.

e. Set Polled Variable to Pressure.

Postrequisites