Page 1

Installation Manual

P/N 3300991, Rev. C

November 2003

Micro Motion

Series 3000

Installation Manual

®

Micro Motion

TM

Page 2

Page 3

Micro Motion

®

Series 3000

Installation Manual

For online technical support, refer to the EXPERT2™ tool at

www.expert2.com. To speak to a customer service

representative, call the support center nearest you:

• In U.S.A., phone 1-800-522-MASS (1-800-522-6277)

• In Canada and Latin America, phone (303) 530-8400

• In Asia, phone (65) 6770-8155

• In the U.K., phone 0800 - 966 180 (toll-free)

• Outside the U.K., phone +31 (0) 318 495 670

©2003, Micro Motion, Inc. All rights reserved. Micro Motion is a registered trademark

of Micro Motion, Inc. The Micro Motion and Emerson logos are trademarks of

Emerson Electric Co. All other trademarks are property of their respective owners.

Page 4

Page 5

Contents

1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 European installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Installing the Model 3300 or 3500 in a Panel . . . 3

2.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Procedure for mounting in a panel . . . . . . . . . . . . . . . . . . 3

3 Installing the Model 3300 or 3500

in a Subrack. . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . 15

3.3 Procedure for mounting in subrack . . . . . . . . . . . . . . . . 15

4 Installing the Model 3350 or 3700 . . . . . . . . . . 23

4.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Hazardous area classifications . . . . . . . . . . . . . . . . . . . 23

4.3 Procedure for field mounting . . . . . . . . . . . . . . . . . . . . . 23

5 Connecting the Transmitter to a Sensor . . . . . . 33

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3 Cable and conduit preparation. . . . . . . . . . . . . . . . . . . . 34

5.4 Wiring connections to sensor. . . . . . . . . . . . . . . . . . . . . 37

5.5 Wiring connections to transmitter. . . . . . . . . . . . . . . . . . 37

6 Installing Relays. . . . . . . . . . . . . . . . . . . . . . 43

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2 Specifications for user-supplied relays. . . . . . . . . . . . . . 43

6.3 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . 43

6.4 Replacing relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Software configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.6 Installing factory-supplied relays . . . . . . . . . . . . . . . . . . 45

6.7 Installing user-supplied relays . . . . . . . . . . . . . . . . . . . . 50

6.8 Discrete output configuration . . . . . . . . . . . . . . . . . . . . . 53

Series 3000 Installation Manual i

Page 6

Contents continued

7 Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.1 Startup and display test . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2 Configuration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.3 Sensor zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.4 Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.5 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.6 Repair and substitution of components . . . . . . . . . . . . . 66

8.7 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix A Specifications . . . . . . . . . . . . . . . . . . 67

Model 3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Model 3350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Model 3500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Model 3700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Model 3100 accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix B Optional Housing Dimensions . . . . . . . 85

Appendix C Labels . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix D Return Policy . . . . . . . . . . . . . . . . . . 93

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

ii Series 3000 Installation Manual

Page 7

1 Before You Begin

1.1 About this manual This instruction manual explains how to install the Micro Motion

3000 Applications Platform.

Chapters • Chapter 2 explains how to mount the Model 3300 application

peripheral or Model 3500 transmitter in a panel.

• Chapter 3 explains how to mount the Model 3300 application

peripheral or Model 3500 transmitter in a 19-inch (486,2 mm)

subrack.

• Chapter 4 explains how to mount the Model 3350 application

peripheral or Model 3700 transmitter.

• Chapter 5 explains how to connect the Model 3500 or 3700

transmitter to a Micro Motion

• Chapter 6 explains how to connect internally or externally powered

relays to the discrete outputs.

• Chapter 7 explains how to set up the applications platform to send a

ticket to a printer.

• Chapter 8 explains startup procedures.

®

flow and density sensor.

Appendixes • Appendix A lists specifications.

• Appendix B provides dimensions for NEMA housing options.

• Appendix C shows labels on the applications platform.

• Appendix D is the return goods policy.

®

Series

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

1.1 Safety Safety messages are provided throughout this manual to protect

personnel and equipment. Read each safety message carefully before

proceeding to the next step.

WARNING

Improper installation in a hazardous area can cause

an explosion.

For information about hazardous applications, refer to

Micro Motion ATEX, UL, or CSA installation instructions,

shipped with the applications platform or available from

the Micro Motion web site.

CAUTION

Improper installation could cause measurement error

or flowmeter failure.

Follow all instructions to ensure applications platform will

operate correctly.

Series 3000 Installation Manual 1

Page 8

Before You Begin continued

1.2 European installations This Micro Motion product complies with all applicable European

directives when properly installed in accordance with the instructions in

this manual. Refer to the EC declaration of conformity for directives that

apply to this product.

The EC declaration of conformity, with all applicable European

directives, and the complete ATEX Installation Drawings and Instructions

are available on the internet at www.micromotion.com/atex or through

your local Micro Motion support center.

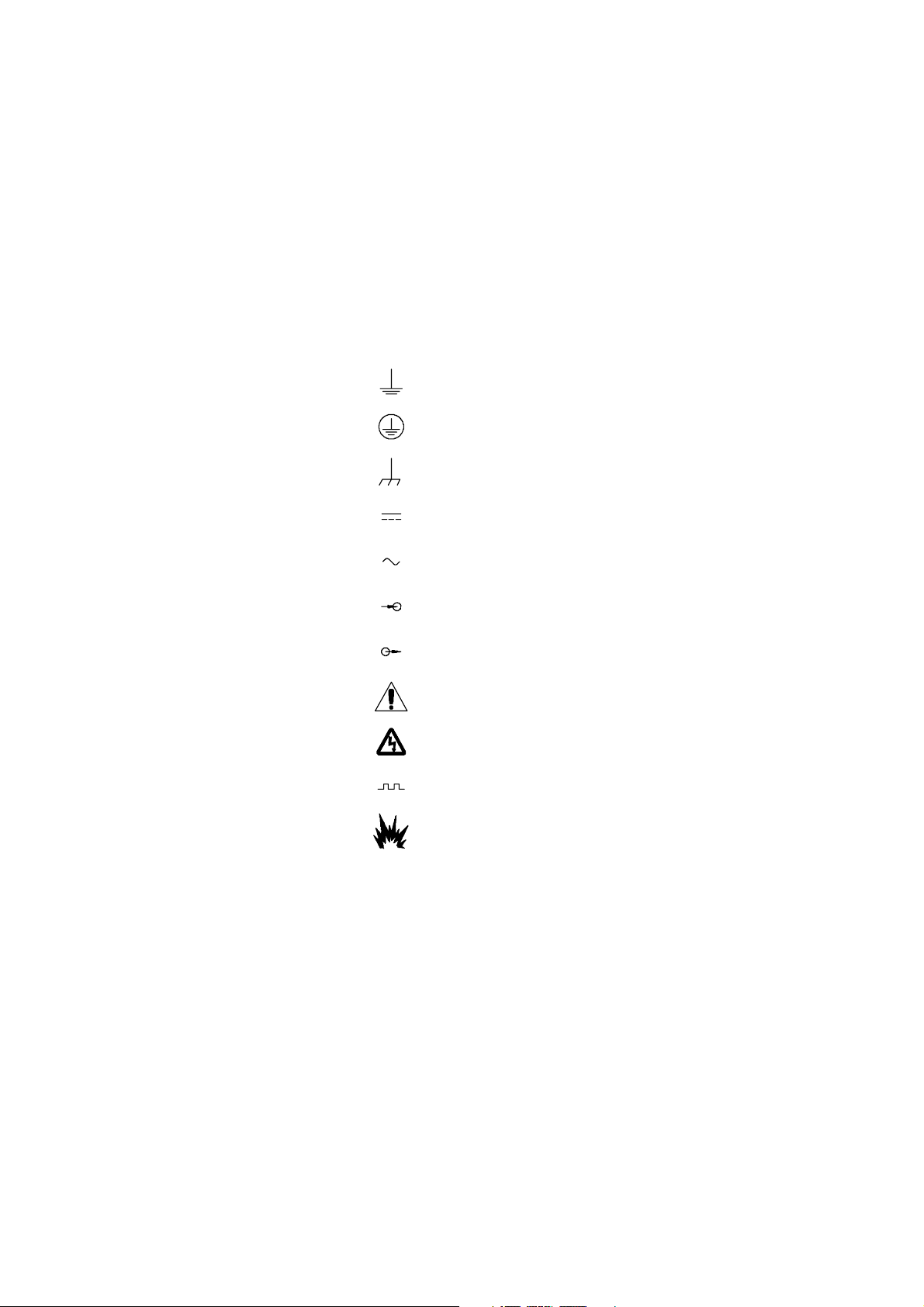

1.2 Symbols Below is a list of symbols pertaining to the manual and the product:

Earth (ground) terminal

Protective conductor terminal

Frame or chassis terminal

Direct current

Alternating current

Input

Output

Alert

Warning, risk of electric shock

Pulse wave

Explosion hazard

2 Series 3000 Installation Manual

Page 9

2 Installing the Model 3300

or 3500 in a Panel

2.1 About this chapter This chapter explains how to mount the Model 3300 application

peripheral or Model 3500 transmitter through a panel cutout.

2.2 Hazardous area installations

2.3 Procedure for mounting in a panel

If you are installing the applications platform or the core processor in a

hazardous area, ensure that your equipment and installation meet the

hazardous area requirements. For more information about hazardous

area classifications, see Appendix A. See Figure 2-4 or Figure 2-5 for

location of the approvals tag on your applications platform.

If you are installing the Model 3300 application peripheral, see the

following section.

Model 3300 installation

The Model 3300 may be installed outdoors, if it is installed in a panel

providing a degree of ingress protection IP 65 according to EN 50529

(IEC 529). The Model 3300 is suitable for installation in Zone 2,

complying with ATEX Directive (94/9/EC) for group II category 3G,

according to CENELEC standard prEN 50021:1998 and marked as EEx

nVL IIC T4.

The procedure for mounting the applications platform in a panel includes

the following steps:

1. Choosing an appropriate location

2. Installing the applications platform in the panel

3. Installing power-supply wiring

4. Installing input and output wiring using the I/O cable or the

screw-type wiring connector

5. If the applications platform is a Model 3500, connecting the Model

3500 to a sensor. To perform Step 5, see Chapter 5.

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

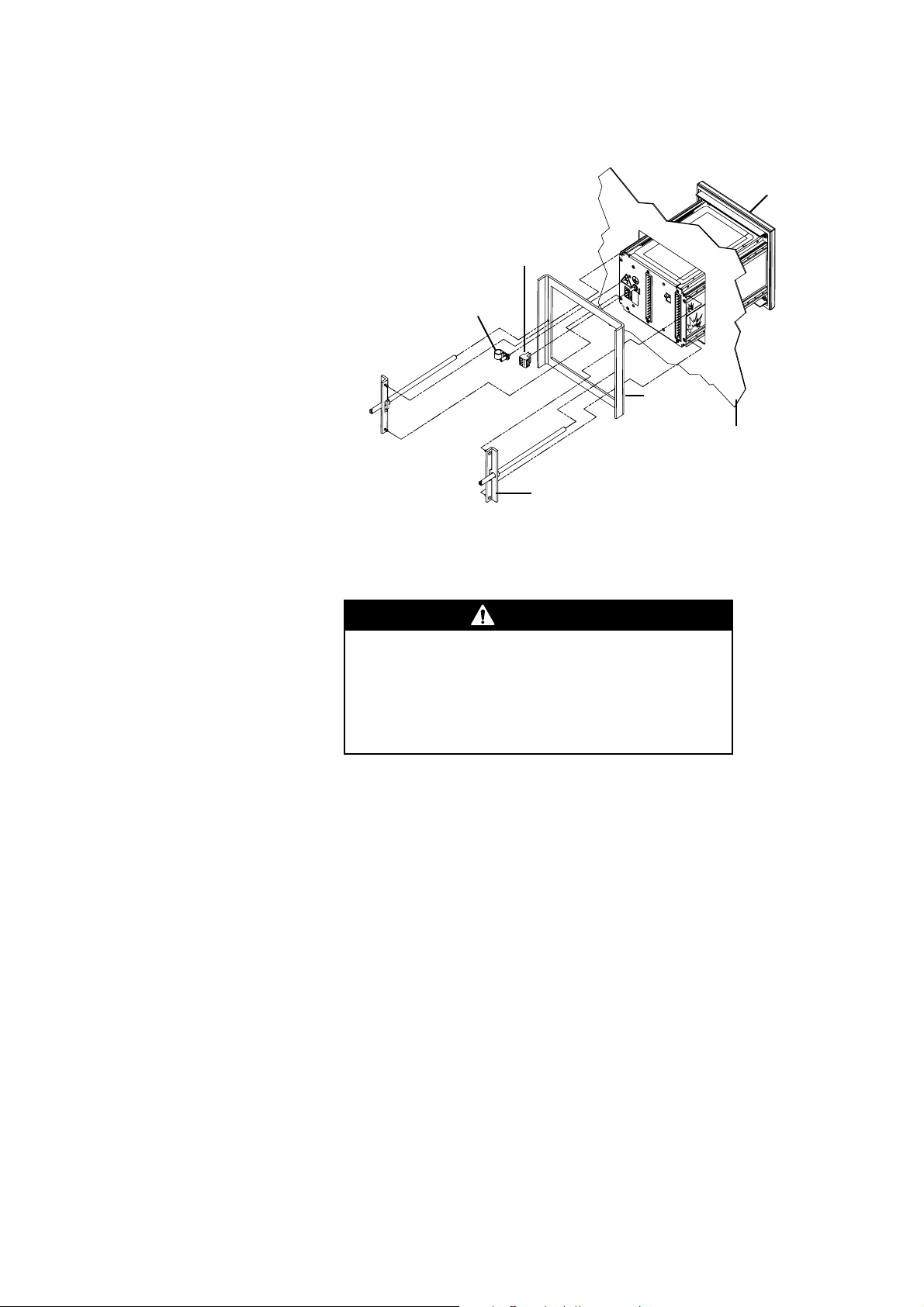

Installation kit for panel mounting

Series 3000 Installation Manual 3

For mounting in a panel, the installation kit includes a bezel, frame, two

mounting brackets with screws, a power-supply wiring connector, and a

retaining clip assembly for power-supply wiring. See Figure 2-1.

• The applications platform fits through a 5 7/16-inch (138 mm) square

cutout in a panel that is 5/64 inch (2 mm) to 1/2 inch (13 mm) thick.

• The panel cutout is the same size as the cutout for a Micro Motion

DRT, FMS-3, DMS, NFC, or NOC peripheral device.

• The bezel provides a NEMA 4X (IP65) watertight seal between the

panel cutout and the applications platform housing.

• The bezel is larger than the bezel on a Micro Motion DRT, FMS-3,

DMS, NFC, or NOC peripheral device.

Page 10

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-1. Panel-mount installation kit

Retaining-clip

power-supply wiring

Bezel

Power-supply

wiring connector

assembly for

Fram e

Panel thickness:

• 5/64 inch (2 mm) minimum

• 1/2 inch (13 mm) maximum

2 x Mounting bracket with screw

Step 1 Choose an appropriate location

WARNING

Improper installation in a hazardous area could cause

an explosion.

Install the applications platform in an area that is

compatible with the rating on the approvals tag. See

Figure 2-4 and Figure 2-5.

• Install the applications platform where ambient temperature remains

between –4 and 140 °F (–20 and 60 °C).

• Maximum length of cable from a Micro Motion

3500 is 1000 feet (300 meters).

• Maximum length of wiring from the frequency input for a Micro

Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters).

• If the applications platform has I/O cables, illustrated in Figure 2-2,

see Figure 2-4 for dimensions.

• If the applications platform has screw-type wiring connectors,

illustrated in Figure 2-3, see Figure 2-5 for dimensions.

®

sensor to the Model

4 Series 3000 Installation Manual

Page 11

Installing the Model 3300 or 3500 in a Panel continued

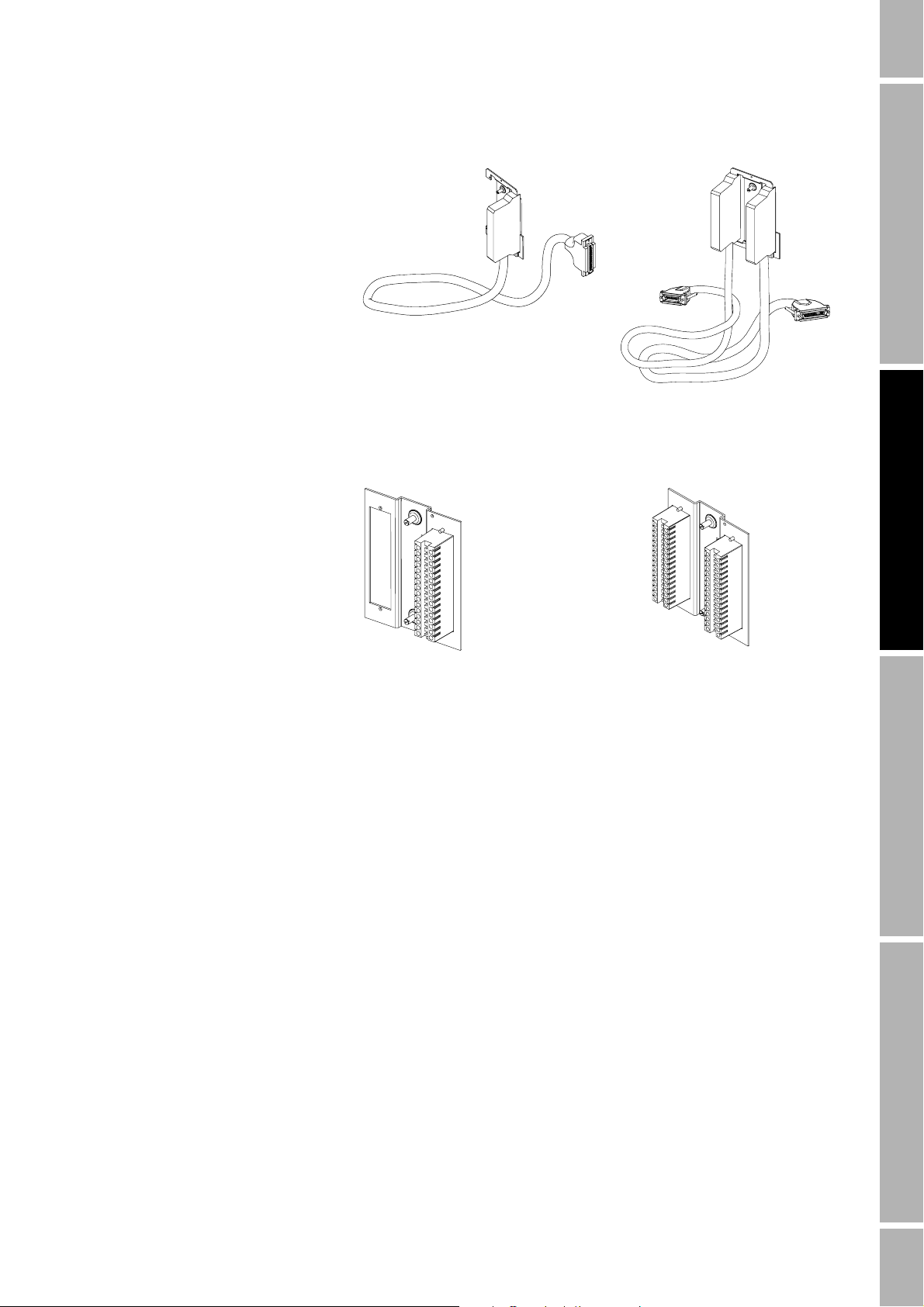

Figure 2-2. I/O cables

Model 3300 Model 3500

Figure 2-3. Screw-type wiring connectors

Model 3300 Model 3500

Series 3000 Installation Manual 5

Installation: Field-MountInstallation: Rack-MountInstallation: Panel-MountBefore You Begin

Page 12

Installing the Model 3300 or 3500 in a Panel continued

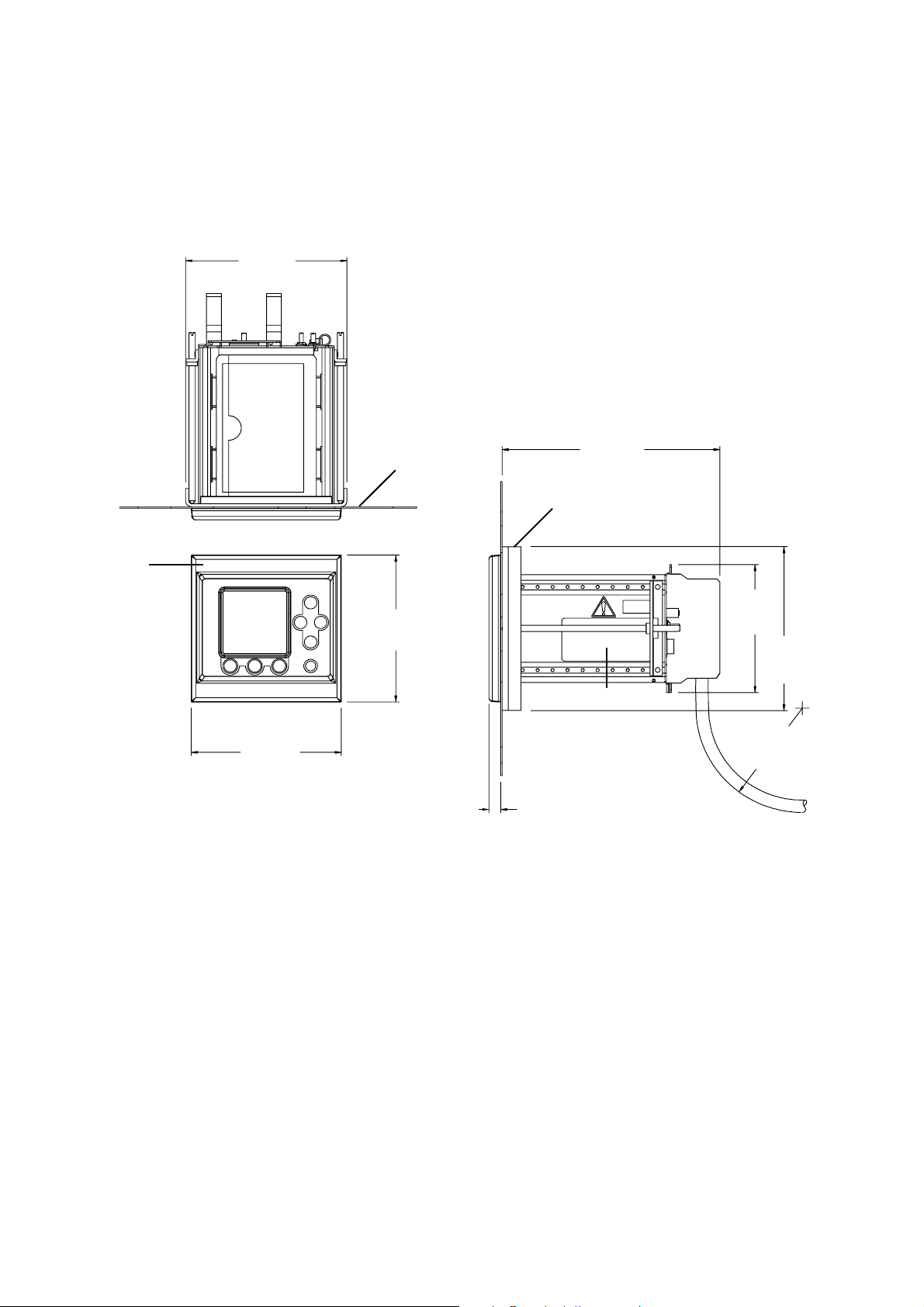

Figure 2-4. Panel-mount dimensions with I/O cables

6 1/2

(165)

Panel

8 3/4

(222)

Fram e

Bezel

6

(152)

6

(152)

5 5/16

(135)

6 11/16

(170)

Approvals tag

Minimum 4 1/4"

(108 mm)

bend radius

1/2

(12)

6 Series 3000 Installation Manual

Page 13

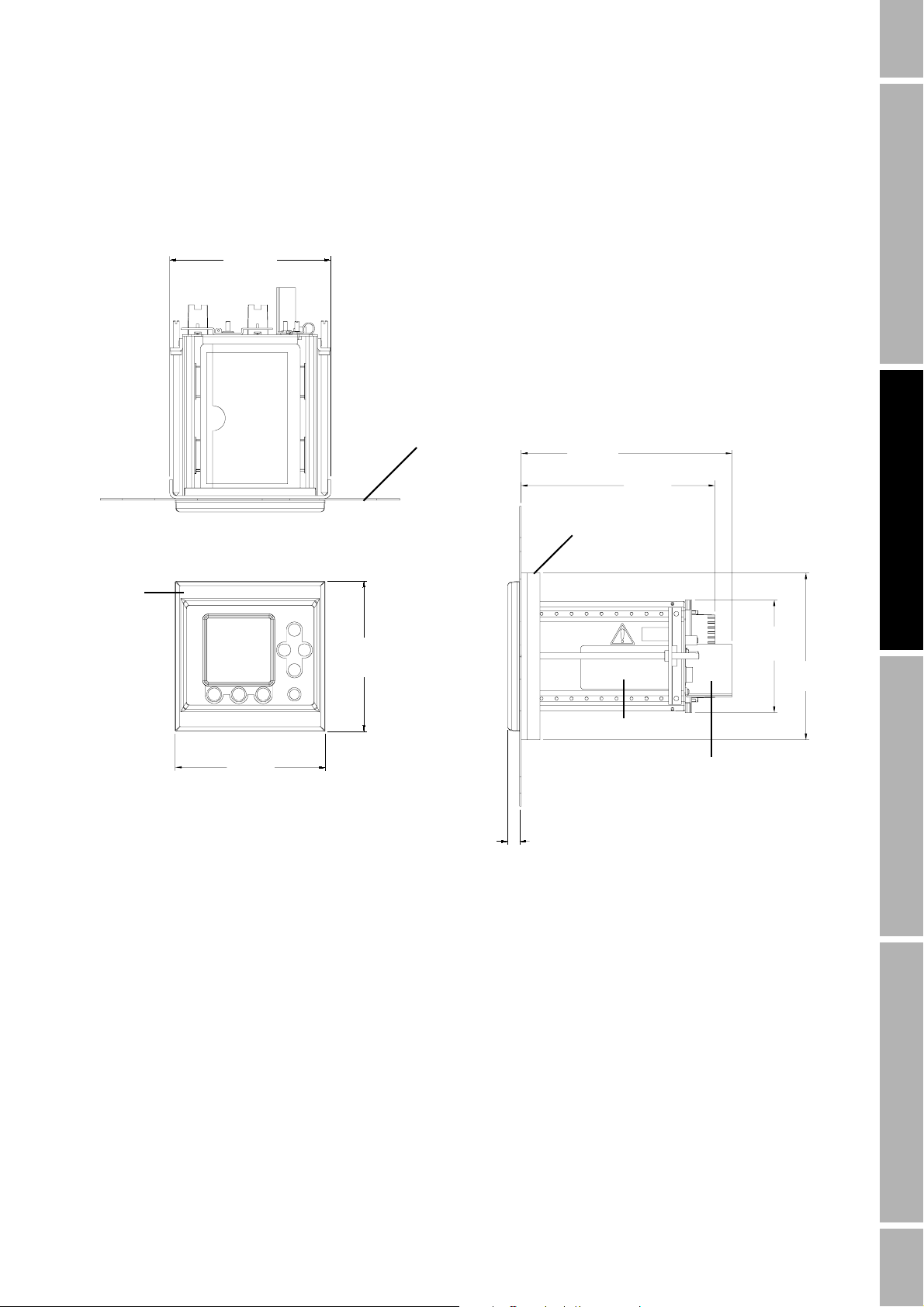

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-5. Panel-mount dimensions with screw-type connectors

6 1/2

(165)

Bezel

6

(152)

6

(152)

Panel

8 7/16

(214)

7 7/8

(200)

Frame

4 1/2

(114)

6 11/16

(170)

Approvals tag

Intrinsic safety barrier

Model 3500 only

1/2

(12)

Series 3000 Installation Manual 7

Installation: Field-MountInstallation: Rack-MountInstallation: Panel-MountBefore You Begin

Page 14

Installing the Model 3300 or 3500 in a Panel continued

Step 2 Install the applications platform in the panel

Refer to Figure 2-6 and follow these steps:

a. Insert the applications platform through the cutout.

b. Slide the frame over the housing.

c. Insert the posts on the brackets into the rails on the housing.

d. Tighten the screws evenly to 10 to 14 inch-pounds (1,13 to 1,38 Nm)

to ensure a watertight seal between the gasket and the panel.

Figure 2-6. Steps for installation in panel

2. Slide frame

over housing

1. Insert applications platform

through cutout in panel

3. Insert brackets into

upper and lower rails

8 Series 3000 Installation Manual

4. Tighten screws to 10 to 14

in-lb (1,13 to 1,38 Nm)

Page 15

Installing the Model 3300 or 3500 in a Panel continued

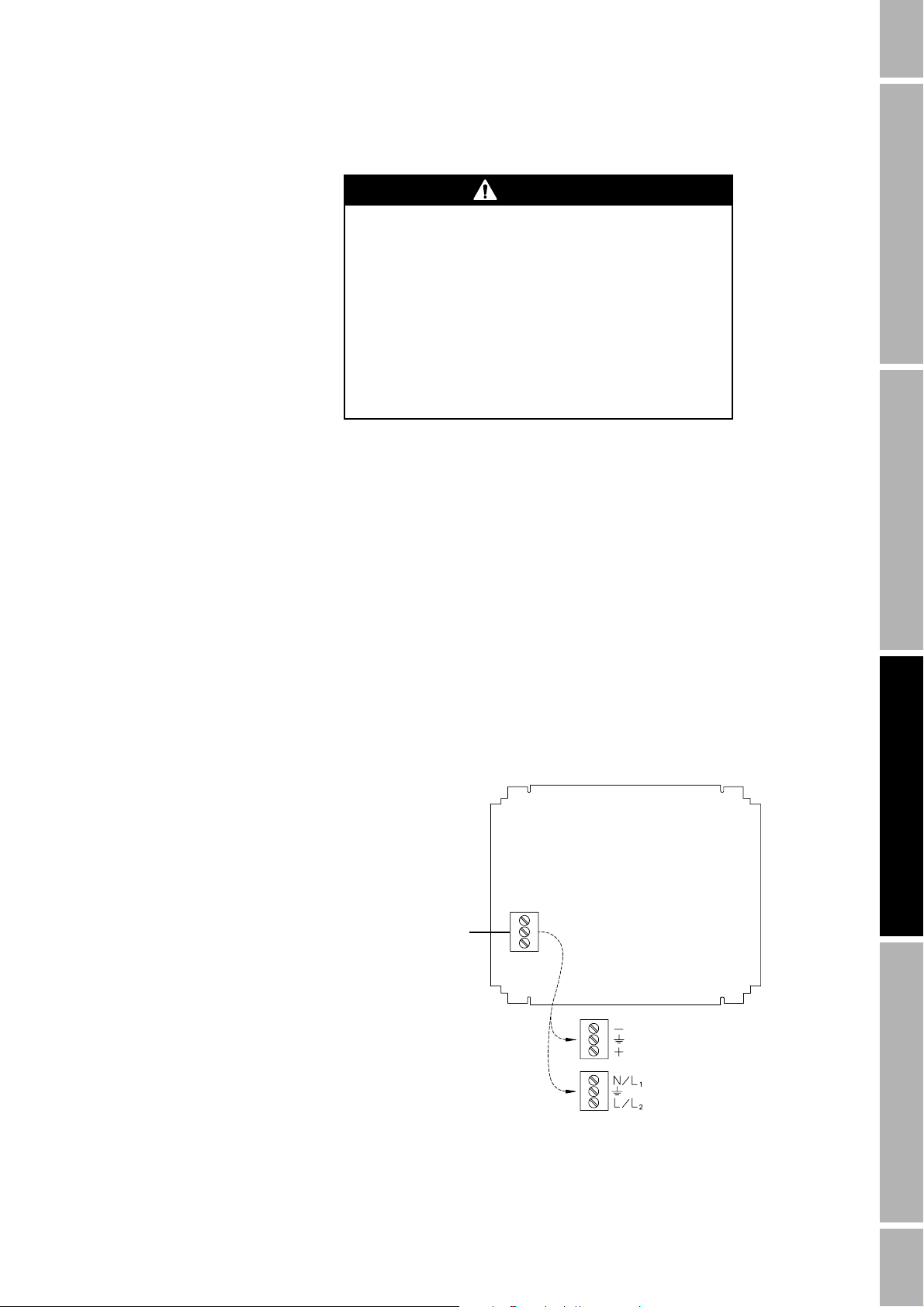

Step 3 Install power-supply wiring

Improper wiring installation can cause device failure

or measurement error.

• To avoid device failure or measurement error, do not

install power-supply wiring in the same cable tray or

conduit as input/output wiring.

• Shut off power supply before installing the applications

platform.

• Make sure power-supply voltage matches voltage that is

indicated on power-supply wiring terminals. See

Figure 2-8.

To install power-supply wiring, follow these steps:

a. Plug in the power-supply wiring connector. See Figure 2-7.

b. Connect 18 to 14 AWG (0,75 to 2,5 mm

wiring connector. See Figure 2-8.

• Connect the ground wire to the ground lug for the power supply.

Connect the power-supply ground directly to earth ground.

• Keep all ground leads as short as possible.

• Ground wiring must have less than 1 ohm impedance.

c. Connect wires to the power-supply wiring terminals.

• If the applications platform has a DC power supply, the upper

terminal is negative (–), the lower terminal is positive (+).

• If the applications platform has an AC power supply, the upper

terminal is neutral (N or L1), the lower terminal is line (L or L2).

d. Slide the retaining clip over the wiring, then tighten the screw to hold

the clip in place. See Figure 2-7.

e. A switch may be installed in the power-supply line. For compliance

with low-voltage directive 73/23/EEC, a switch in close proximity to

the applications platform is required.

CAUTION

2

) wiring to the power-supply

Series 3000 Installation Manual 9

Installation: Field-MountInstallation: Rack-MountInstallation: Panel-MountBefore You Begin

Page 16

Installing the Model 3300 or 3500 in a Panel continued

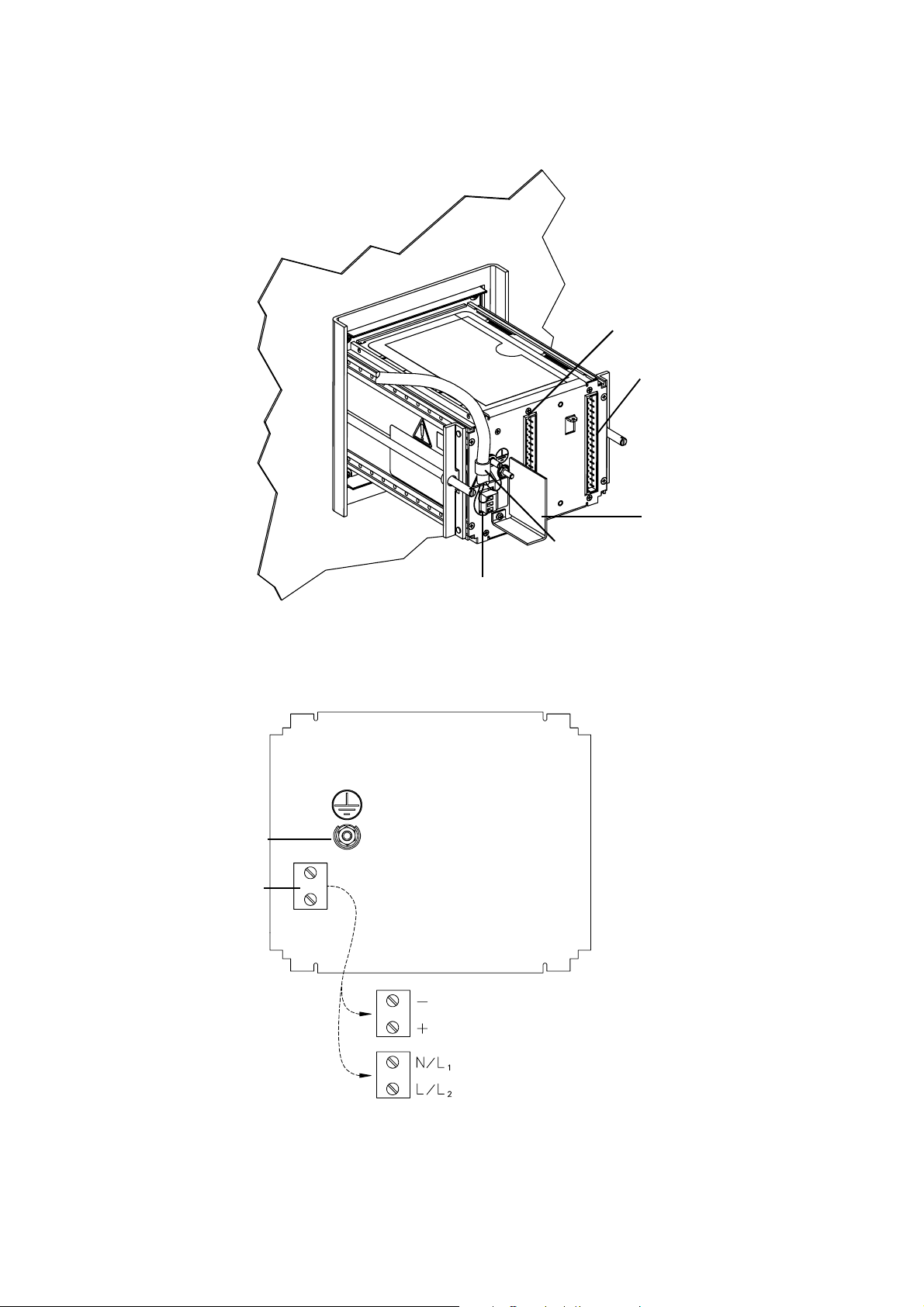

Figure 2-7. Wiring connectors and terminals on panel-mount platform

Retaining clip and

screw

Power-supply wiring connector

Sensor wiring

terminal strip

Model 3500 only

Input/output wiring

terminal strip

Intrinsic safety barrier

Model 3500 only

Figure 2-8. Power-supply wiring terminals on panel-mount platform

Ground lug for

power supply

Power-supply

wiring terminals

DC power-supply

terminal designations

AC power-supply

terminal designations

• Connect power-supply ground

directly to earth ground

• Keep all ground leads as short

as possible

• Ground wiring must have less

than 1 ohm impedance

10 Series 3000 Installation Manual

Page 17

Installing the Model 3300 or 3500 in a Panel continued

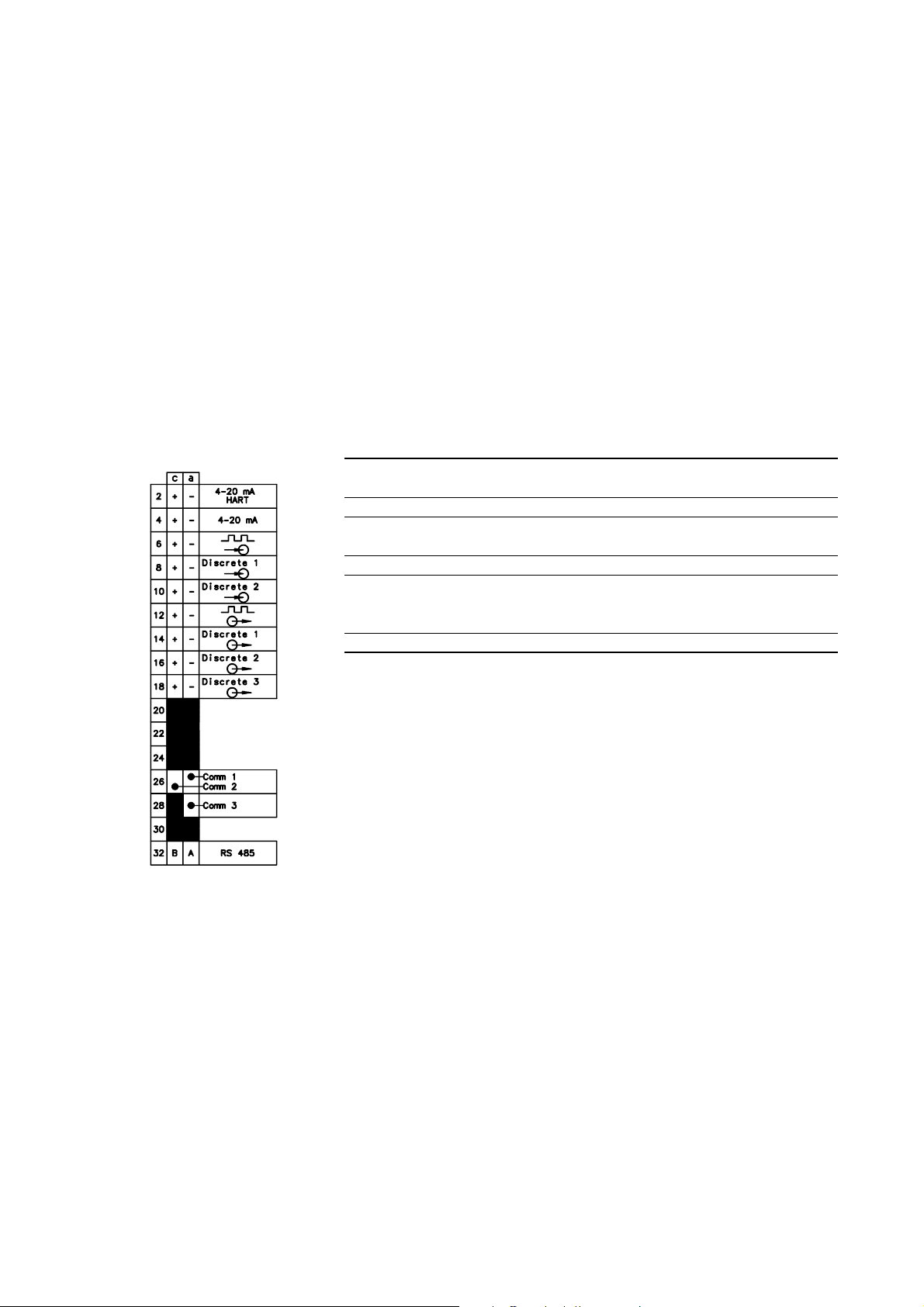

Step 4 Install input and output wiring

Installation of input and output wiring depends on the type of wiring

connector that is installed.

If the platform has screw-type connectors

a. Plug the bracketed wiring connectors onto the terminal strips on the

back panel of the applications platform.

b. Tighten the captive screws to secure the bracket to the back panel.

c. Connect input and output wiring to the appropriate terminals in the

input/output wiring connector, which is the far right connector.

• Install twisted-pair shielded wiring.

2

• Wire size is 24 to 16 AWG (0,25 to 1,5 mm

).

• Ground the shields at the field device.

• Clip the shields at the end that connects to the applications

platform.

A card that is inserted into the sleeve on the top panel lists input/output

wiring terminal designations.

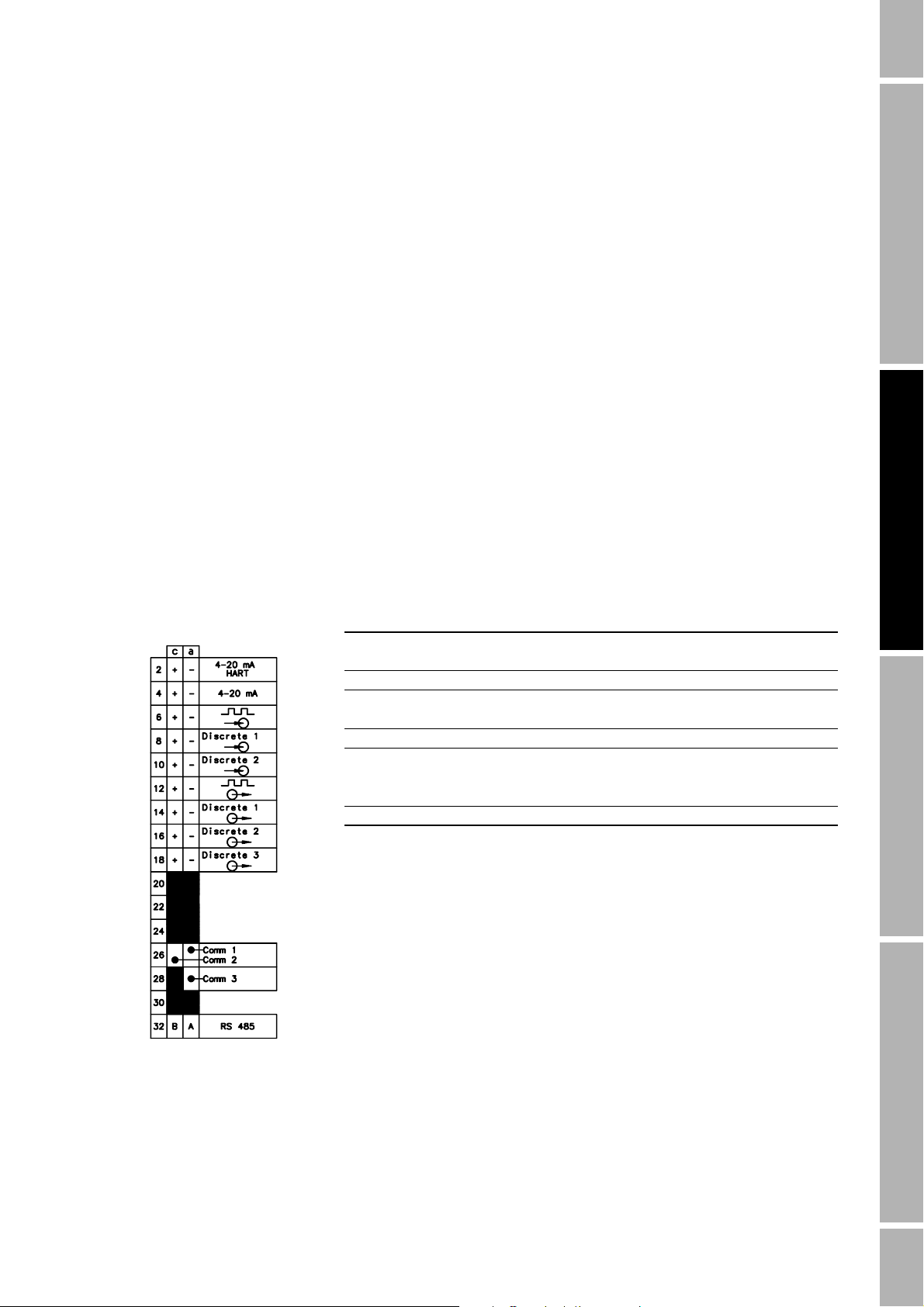

•See Tabl e 2 -1 and the accompanying figure.

• Input and output assignments depend on the application. For more

information, see the Series 3000 Detailed Setup Manual.

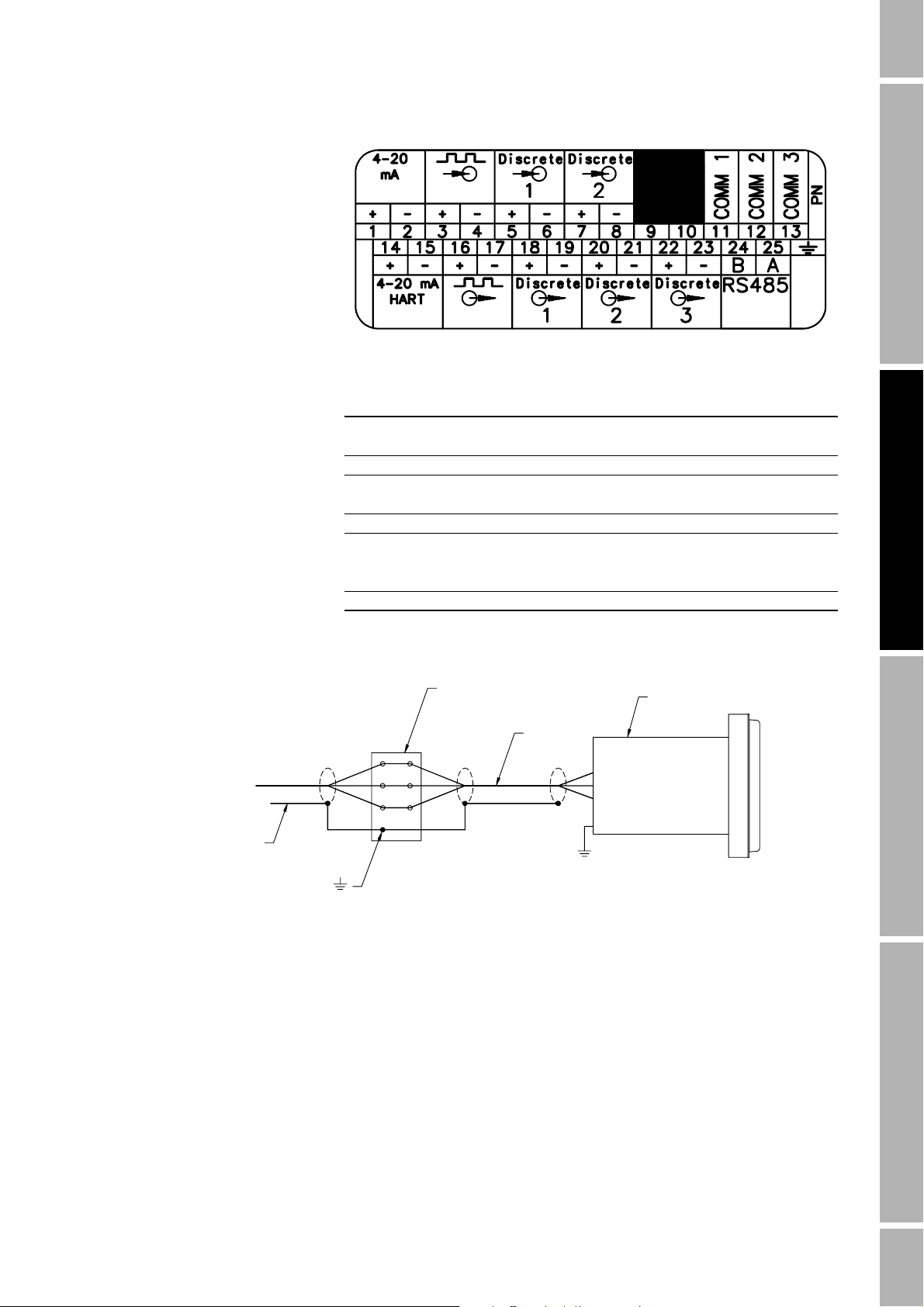

Table 2-1. Input/output wiring terminals on screw-type connector

Terminal number Designation

c 2+ a 2 – Primary 4-20 mA output

c 4 + a 4 – Secondary 4-20 mA output

c 6 + a 6 – Frequency input

c 8 + a 8 – Discrete input 1

c 10 + a 10 – Discrete input 2

c 12 + a 12 – Frequency output

c 14 + a 14 – Discrete output 1

c 16 + a 16 – Discrete output 2

c 18 + a 18 – Discrete output 3

c 32 (B line) a 32 (A line) RS-485 output

Series 3000 Installation Manual 11

Installation: Field-MountInstallation: Rack-MountInstallation: Panel-MountBefore You Begin

Page 18

Installing the Model 3300 or 3500 in a Panel continued

If the platform has I/O cables

a. Plug the bracketed wiring connectors onto the terminal strips on the

back panel of the applications platform. Tighten the captive screws to

secure the bracket to the back panel.

b. Attach the supplied I/O terminal block to a DIN rail. The terminal

block accommodates various rail types. See Figure 2-9.

c. Plug the I/O cable connector onto the terminal block. Tighten the

captive screws to secure the connector to the terminal block.

d. Connect input and output wiring to the appropriate terminals on the

terminal block.

• Install twisted-pair shielded wiring.

• Wire size is 24 to 16 AWG (0,25 to 1,5 mm

• A label that is attached to the terminal block shows terminal

designations for input/output wiring. See Ta ble 2 -2.

• Input and output assignments depend on the application. For

more information, see the Series 3000 Detailed Setup Manual.

e. The terminal block ground is available for continuation of user cable

shielding to I/O cable shielding.

• The cable connector does not connect the I/O cable shielding to

the chassis ground.

•See Figure 2-10.

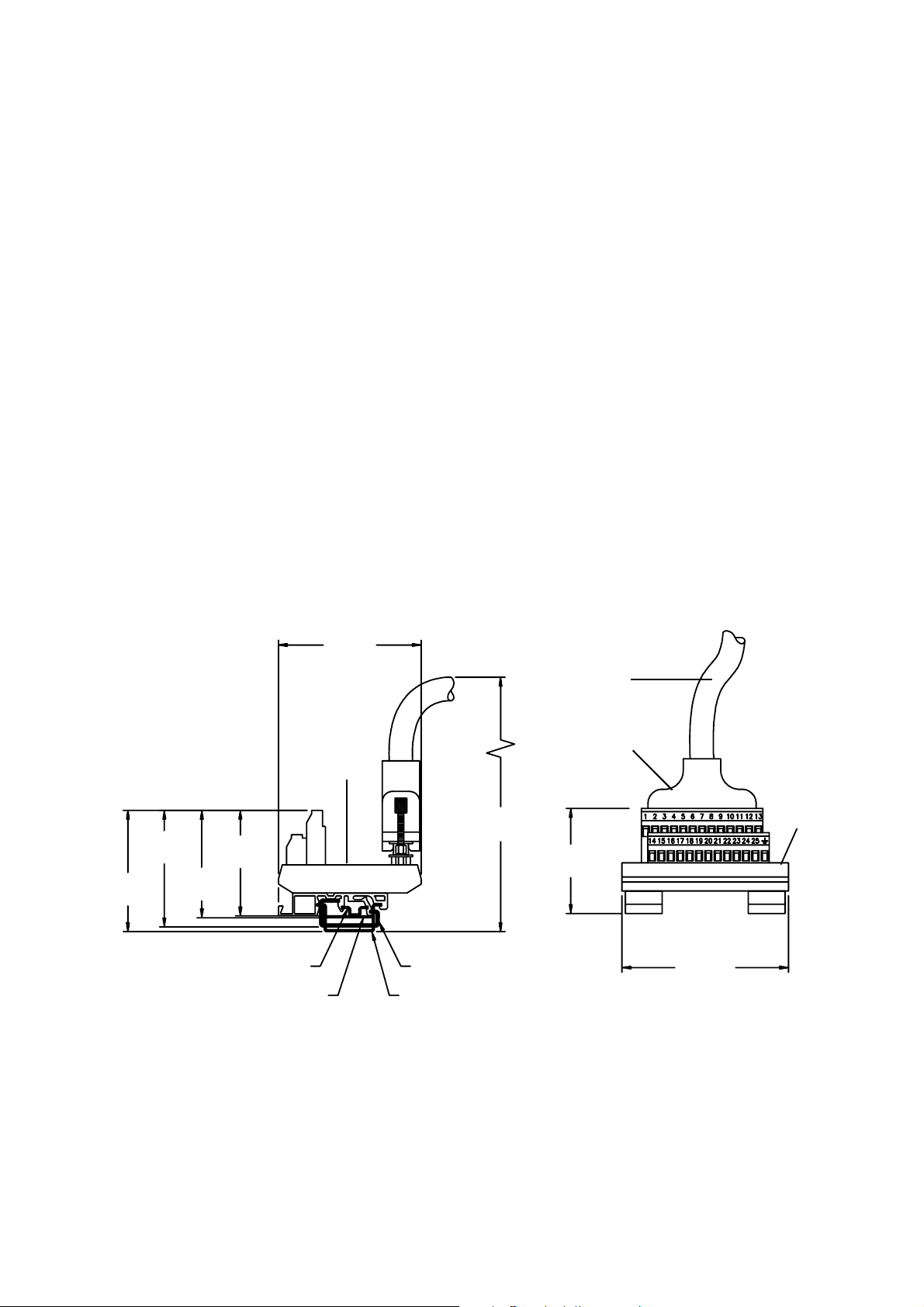

Figure 2-9. Installing input/output terminal block on DIN rail

2

).

2 37/64

(66)

3 3/64

(77)

Label is

mounted

here

2 31/64

(63)

DIN rail type TS 35 x 7.5 DIN rail type TS 35 x 15

2 1/4

(57)

2 19/64

(59)

DIN rail type TS 15 Din rail type TS 32

9

(229)

I/O cable

Connector

Terminal

block

2 15/64

(57)

3 17/32

(90)

12 Series 3000 Installation Manual

Page 19

Installing the Model 3300 or 3500 in a Panel continued

Table 2-2. Input/output wiring terminals on terminal block

Terminal number Designation

1 + 2 – Secondary 4-20 mA output

14 + 15 – Primary 4-20 mA output

3 + 4 – Frequency input

5 + 6 – Discrete input 1

7 + 8 – Discrete input 2

16 + 17 – Frequency output

18 + 19 – Discrete output 1

20 + 21 – Discrete output 2

22 + 23 – Discrete output 3

24 (B line) 25 (A line) RS-485 output

Figure 2-10.Shield wiring for I/O cable to field device

Te r mi n a l b l oc k

Ground shields at

field device only

Terminal marked

Do not ground at this point

Step 5 Connect the Model 3500 to the sensor

To connect the Model 3500 transmitter to a Micro Motion® sensor, see

Chapter 5.

Applications platform

I/O cable

Chassis

ground

Installation: Field-MountInstallation: Rack-MountInstallation: Panel-MountBefore You Begin

Series 3000 Installation Manual 13

Page 20

14 Series 3000 Installation Manual

Page 21

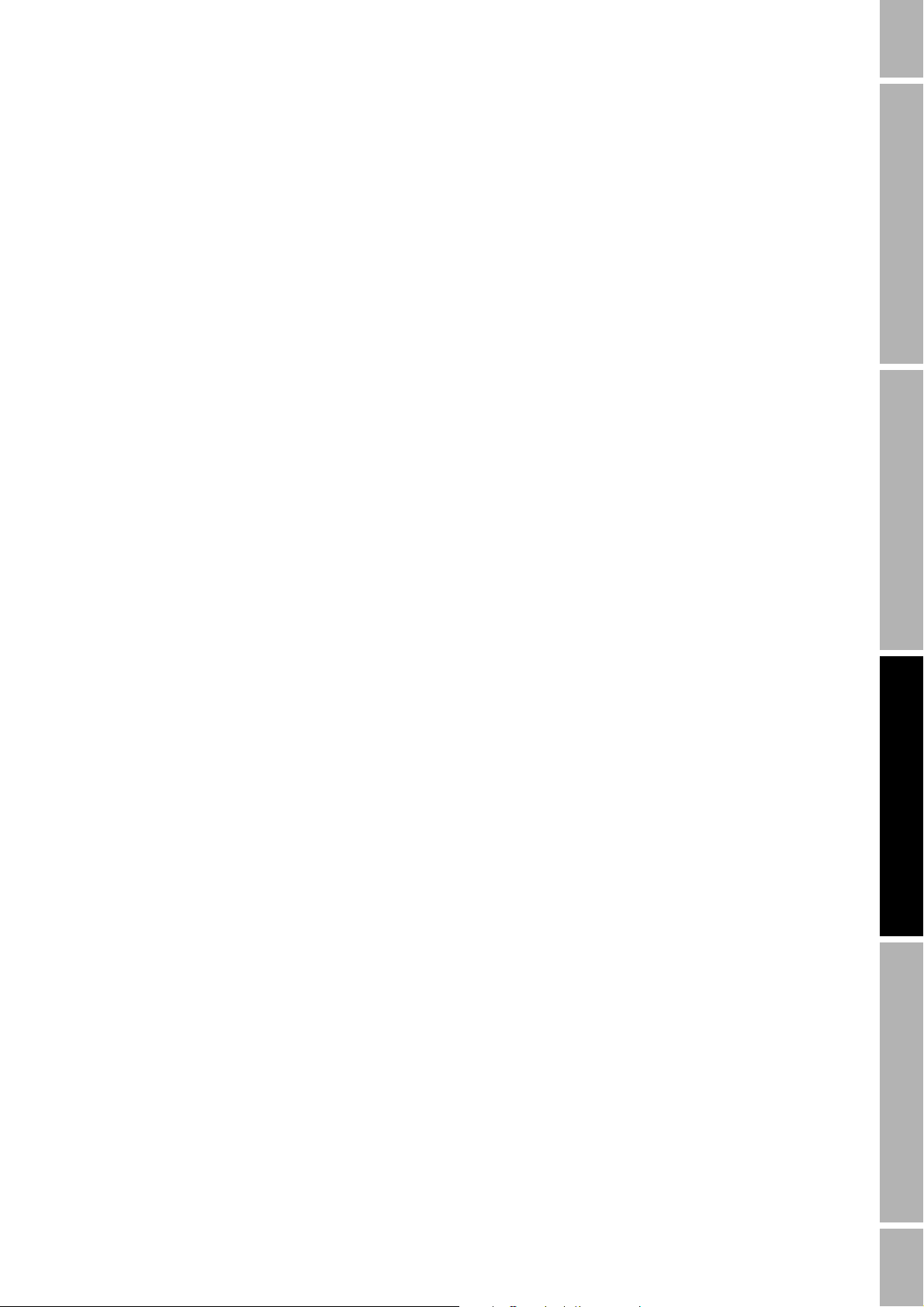

3 Installing the Model 3300

or 3500 in a Subrack

3.1 About this chapter This chapter explains how to mount the Model 3300 application

peripheral or Model 3500 transmitter in a 19-inch (486,2 mm) subrack.

3.2 Hazardous area installations

3.3 Procedure for mounting in subrack

If you are installing the applications platform or the core processor in a

hazardous area, ensure that your equipment and installation meet the

hazardous area requirements. For more information about hazardous

area classifications, see Appendix A. See Figure 3-1 for location of the

approvals tag on your applications platform. If you are installing the

Model 3300 application peripheral, see below.

Model 3300 installation

The Model 3300 should be installed in a rack providing a degree of

ingress protection IP 4X according to EN 50529 (IEC 529). The Model

3300 is suitable for installation in Zone 2, complying with ATEX Directive

(94/9/EC) for group II category 3G, according to CENELEC standard

prEN 50021:1998 and marked as EEx nVL IIC T4.

The procedure for mounting the applications platform in a subrack

includes the following steps:

1. Choosing an appropriate location for the installation

2. Installing guide rails and wiring connectors

3. Installing the applications platform in the subrack

4. Connecting power-supply wiring

5. Connecting input/output wiring

6. If the applications platform is a Model 3500, connecting the Model

3500 to a sensor. To perform Step 6, see Chapter 5.

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Installation kit for rack mounting

Series 3000 Installation Manual 15

Model 3300 installation kit

For mounting in a subrack, the Model 3300 installation kit includes the

following parts (see Figure 3-3):

• One DIN standard 41612, Type D connector for input/output wiring,

with solder tails or screw terminals

• One plug-in connector for power-supply wiring

• Four slotted cheese-head machine screws, size M2.5x8, for securing

wiring connectors to the subrack

Model 3500 installation kit

For mounting in a subrack, the Model 3500 installation kit includes the

following parts (see Figure 3-3):

• One DIN standard 41612, Type D connector for input/output wiring,

with solder tails or screw terminals

• One DIN standard 41612, keyed Type D connector for sensor wiring,

with solder tails or screw terminals

• One plug-in connector for power-supply wiring

• Six slotted cheese-head machine screws, size M2.5x8, for securing

wiring connectors to the subrack

Page 22

Installing the Model 3300 or 3500 in a Subrack continued

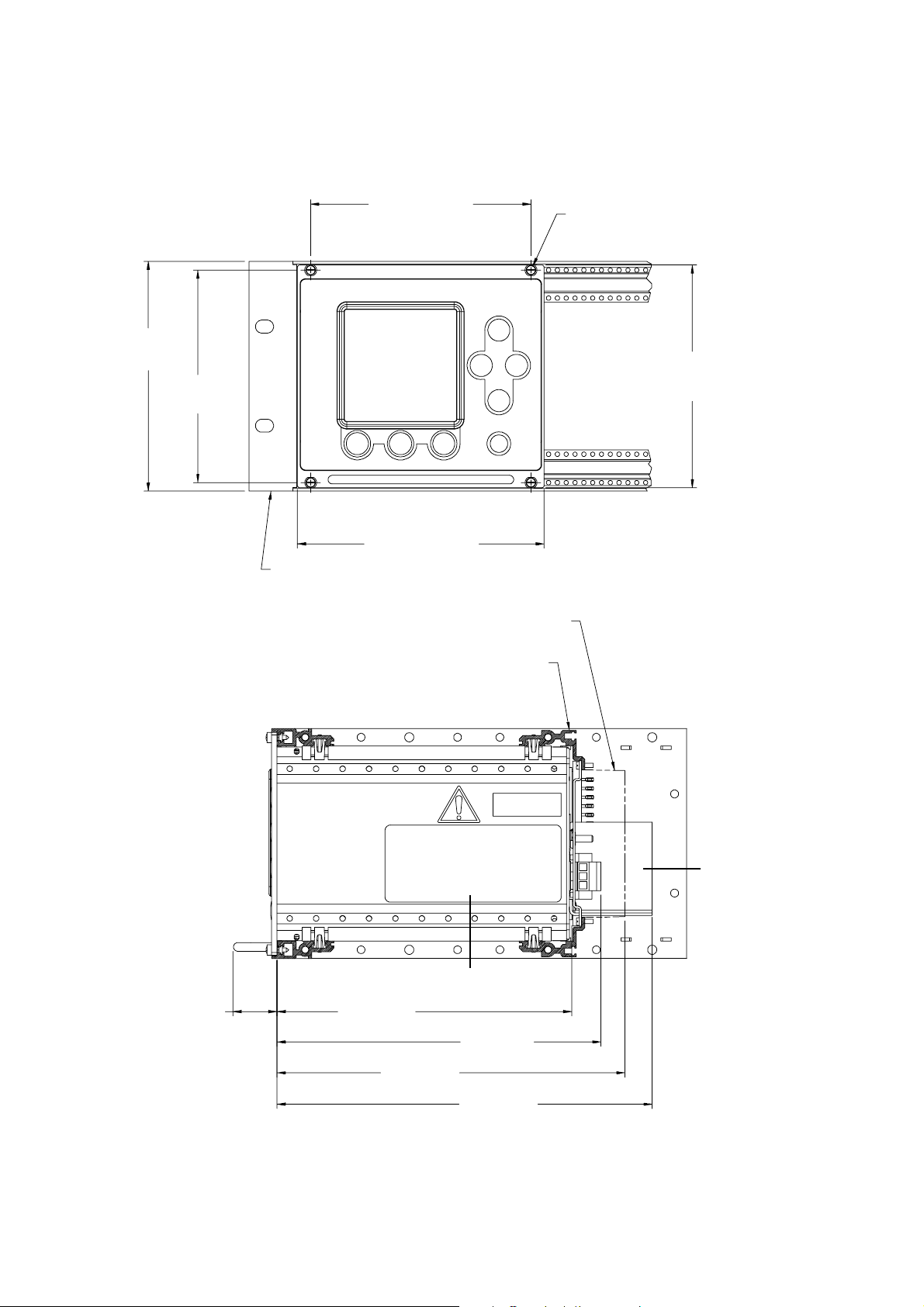

Figure 3-1. Dimensions for mounting in subrack

25 HP (25 TE)

3 U

(3 HE)

4 13/16

(122,5)

5.6

(142,2)

28 HP (28 TE)

19-inch (486,2 mm) subrack conforms to DIN 41494, Part 5, and IEC 297-3

Not included with applications platform

1 U = 1 HE = 1.750 inches (44,45 mm)

1 HP = 1 TE = 0.200 inch (5,08 mm)

4 x M2.5x11

5 1/16

(128,52)

1

(25,4)

Optional screw terminal

Rear rail for mounting connectors

that conform to DIN 41612 and IEC 603-2

Not included with applications platform

Intrinsic safety barrier

Model 3500 only

Approvals tag

6 11/16

(169,93)

7 11/32

(186,7)

7 29/32

(200,6)

8 33/64

(216,23)

16 Series 3000 Installation Manual

Page 23

Installing the Model 3300 or 3500 in a Subrack continued

Step 1 Locate and orient the applications platform

Improper installation in a hazardous area could cause

an explosion.

Install the applications platform in an area that is

compatible with the rating on the approvals tag. See

Figure 3-1.

WARNING

Dimensions

The applications platform conforms to DIN standard 41494, Part 5

(IEC 297-3) for 19-inch (486,2 mm) racks.

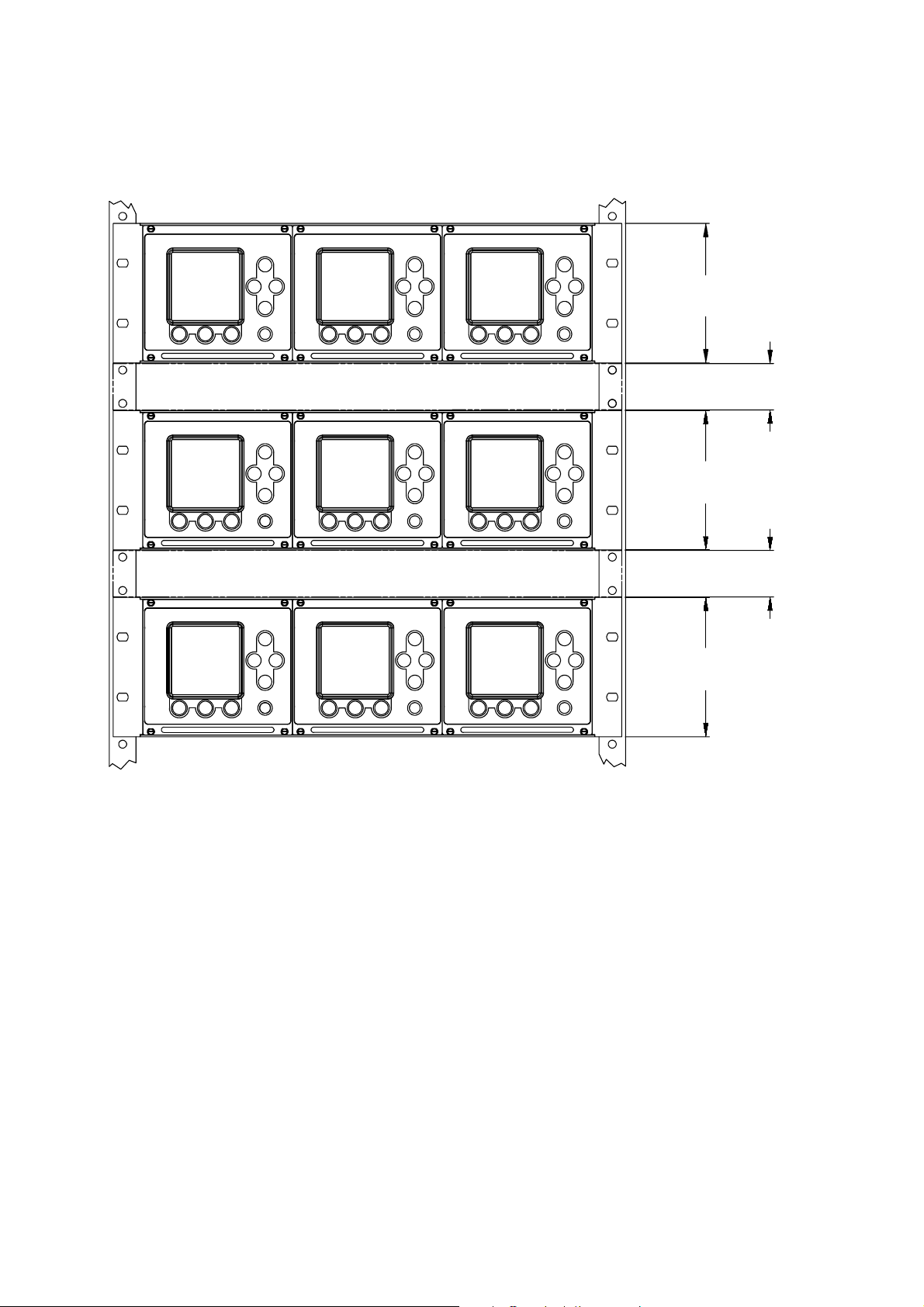

• Up to three applications platform enclosures fit into one subrack. See

Figure 3-2.

• Height is 128 mm (3 U or 3 HE).

• Width is 142 mm (28 HP or 28 TE).

• Depth is 160 mm.

Location guidelines • Locate the applications platform where ambient temperature remains

between –4 and 140 °F (–20 and 60 °C).

• Maximum length of cable from a Micro Motion

3500 is 1000 feet (300 meters).

• Maximum length of wiring from the frequency input for a Micro

Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters).

• To ensure proper ventilation if multiple application platforms are

installed, provide at least 1 U (1 HE) of vertical space between

subracks, as shown in Figure 3-2.

®

sensor to the Model

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Series 3000 Installation Manual 17

Page 24

Installing the Model 3300 or 3500 in a Subrack continued

Figure 3-2. Space requirements for proper ventilation

1 U = 1 HE = 1.750 inches (44,45 mm)

3 U (3 HE)

1 U (1 HE)

3 U (3 HE)

3 U (3 HE)

1 U (1 HE)

18 Series 3000 Installation Manual

Page 25

Installing the Model 3300 or 3500 in a Subrack continued

Step 2 Install guide rails and wiring connectors

Guide rails

Positions of guide rails and wiring connectors are indicated in

Figure 3-3. Centers of guide rails should be 27 HP (27 TE) apart, for

example, at 1 HP (TE) and 28 HP (TE).

Wiring connectors • Use the supplied M2.5x8 screws to install the wiring connectors onto

the back of the subrack.

• Install screws and connectors from the front of the subrack.

Model 3300 wiring connectors

The Model 3300 comes with a solder tail or screw-type connector for

input/output wiring and a plug-in connector for power-supply wiring.

Model 3500 wiring connectors

The Model 3500 comes with a solder tail or screw-type connector for

input/output wiring, a keyed solder tail or screw-type connector for

sensor wiring, and a plug-in connector for power-supply wiring.

Using the centers of the guide rails as reference points and referring to

Figure 3-3, install the wiring connectors in the following positions on the

back of the subrack:

• Install the input/output wiring connector at 4 HP (4 TE) from the

neighboring unit or from the edge of the subrack.

• If the applications platform is a Model 3500, install the keyed sensor

wiring connector at 16 HP (16 TE) from the neighboring unit or from

the edge of the subrack.

• Install the power-supply wiring connector at 25 HP (25 TE) from the

neighboring unit or from the edge of the subrack.

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Series 3000 Installation Manual 19

Page 26

Installing the Model 3300 or 3500 in a Subrack continued

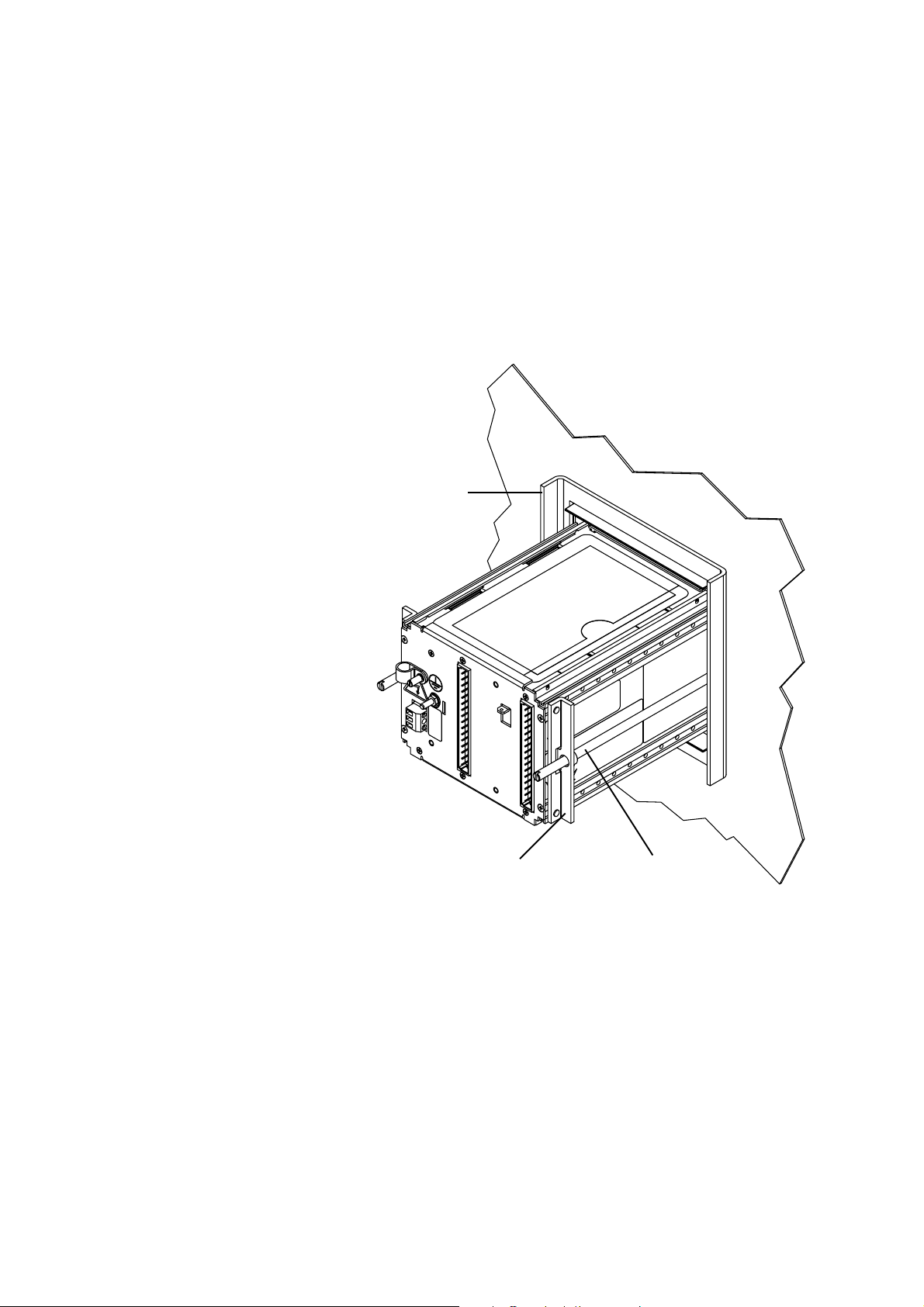

Step 3 Install the applications platform in the subrack

After installing guide rails and wiring connectors as instructed in Step 2,

follow these steps to install the applications platform in the subrack:

a. Align the applications platform with the guide rails.

b. Slide the applications platform into the subrack. Make sure the pins

on the back panel make contact with the wiring connectors.

c. Tighten the supplied captive screws to secure the front panel of the

applications platform to the guide rails.

Figure 3-3. Positions of guide rails and wiring connectors

Guide rail centers should be 27 HP (27 TE) apart;

for example, 1 HP (1 TE) and 28 HP (28 TE)

Install screws and connectors from front of subrack

• Model 3300 has four M2.5x8 screws and two connectors

• Model 3500 has six M2.5x8 screws and three connectors

Front

Back

Keys on sensor

wiring connector

Model 3500 only

M2.5x8

Power-supply wiring connector is

25 HP (25 TE) from neighboring

unit or from edge of subrack

Model 3500 only

Keyed sensor wiring connector is

16 HP (16 TE) from neighboring unit

or from edge of subrack

Input/output wiring connector is 4 HP (4 TE) from

neighboring unit or from edge of subrack

20 Series 3000 Installation Manual

Page 27

Installing the Model 3300 or 3500 in a Subrack continued

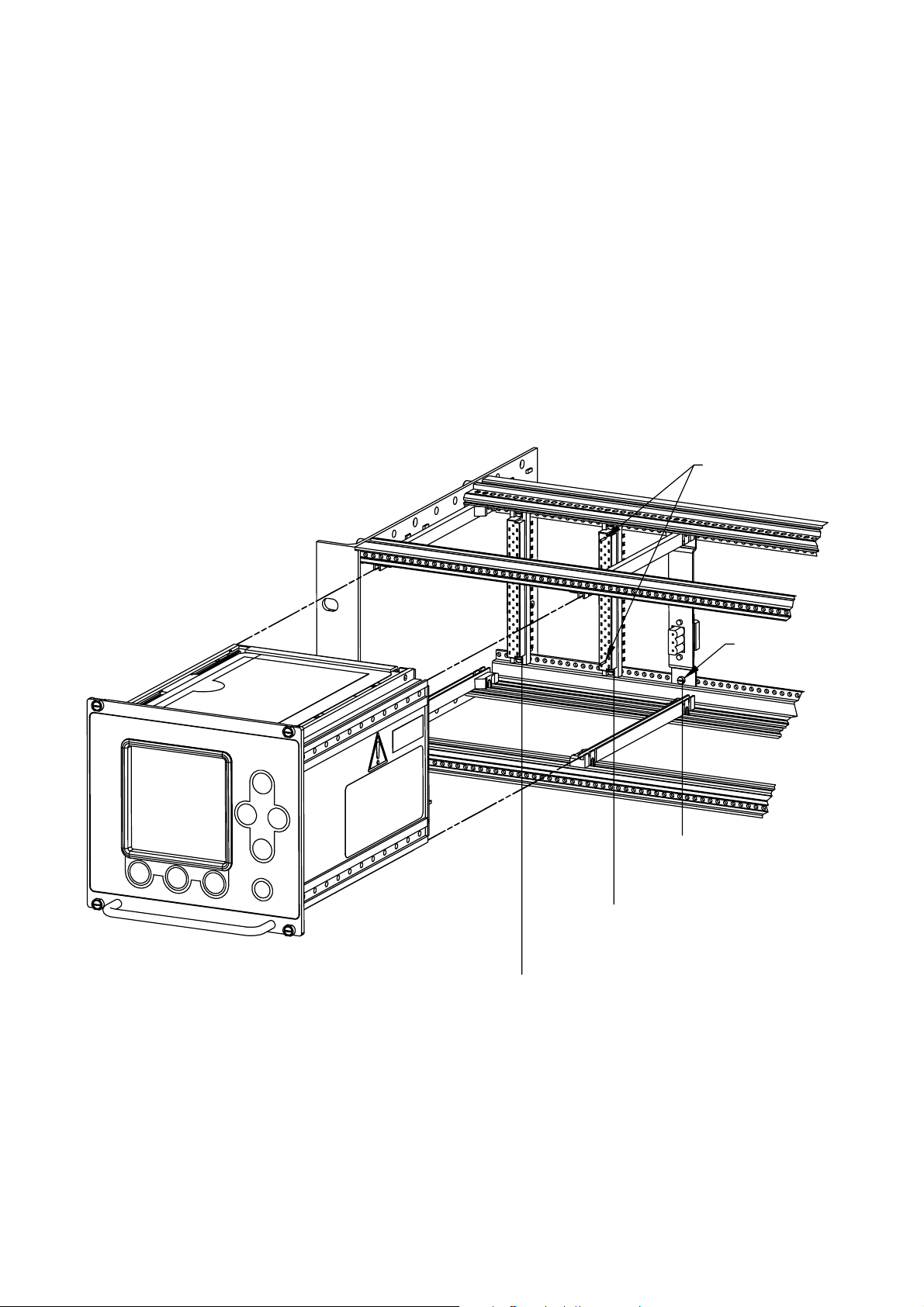

Step 4 Connect power-supply wiring

Improper wiring installation can cause device failure

or measurement error.

• To avoid device failure or measurement error, do not

install power-supply wiring in the same cable tray or

conduit as input/output wiring.

• Shut off power supply before installing the applications

platform.

• Make sure power-supply voltage matches voltage that is

indicated on power-supply wiring terminals. See

Figure 3-4.

CAUTION

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Referring to Figure 3-4, follow these steps to connect 18 to 14 AWG

2

(0,75 to 2,5 mm

) wiring to the power-supply wiring connector.

a. Connect the ground wire to the middle terminal.

b. Connect the power-supply ground directly to earth ground.

• Keep all ground leads as short as possible.

• Ground wiring must have less than 1 ohm impedance.

c. Connect wires to the upper and lower terminals.

• If the applications platform has a DC power supply, the upper

terminal is negative (–), the lower terminal is positive (+).

• If the applications platform has an AC power supply, the upper

terminal is neutral (N or L1), the lower terminal is line (L or L2).

d. A switch may be installed in the power-supply line. For compliance

with low-voltage directive 73/23/EEC, a switch in close proximity to

the subrack is required.

Figure 3-4. Power-supply wiring terminals on rack-mount platform

Power-supply

wiring terminals

Terminal designations

for DC power

Terminal designations

for AC power

Series 3000 Installation Manual 21

Page 28

Installing the Model 3300 or 3500 in a Subrack continued

Step 5 Connect input and output wiring

Connect input and output wiring to the appropriate terminals on the

input/output wiring connector, which is the far right connector.

• Install twisted-pair shielded wiring, 24 to 16 AWG (0,25 to 1,5 mm

• Ground the shields at the field device.

• Clip the shields at the end that connects to the applications platform.

A card that is inserted into the sleeve on the top panel lists input/output

wiring terminal designations.

•See Tabl e 3 -1 and the accompanying figure.

• Input and output assignments depend on the application. For more

information, see the Series 3000 Detailed Setup Manual.

Table 3-1. Input/output wiring terminals on rack-mount platform

Terminal number Designation

c 2+ a 2 – Primary 4-20 mA output

c 4 + a 4 – Secondary 4-20 mA output

c 6 + a 6 – Frequency input

c 8 + a 8 – Discrete input 1

c 10 + a 10 – Discrete input 2

c 12 + a 12 – Frequency output

c 14 + a 14 – Discrete output 1

c 16 + a 16 – Discrete output 2

c 18 + a 18 – Discrete output 3

c 32 (B line) a 32 (A line) RS-485 output

2

).

Step 6 Connect the Model 3500 to the sensor

To connect the Model 3500 transmitter to a Micro Motion® sensor, see

Chapter 5.

22 Series 3000 Installation Manual

Page 29

4 Installing the

Model 3350 or 3700

4.1 About this chapter This chapter explains how to install the Model 3350 application

peripheral or Model 3700 transmitter. The Model 3350 or 3700 can be

installed on an instrument pole or a flat surface.

4.2 Hazardous area classifications

If you are installing the applications platform or the core processor in a

hazardous area, ensure that your equipment and installation meet the

hazardous area requirements. For more information about hazardous

area classifications, see Appendix A. See Figure 4-2 for location of the

approvals tag on your applications platform.

WARNING

Explosion Hazard.

Do not open wiring compartments when an explosive

gas atmosphere is present.

Figure 4-4 identifies the compartments.

WARNING

Using a dry cloth to clean the display cover can cause

static discharge, which could result in an explosion in

an explosive atmosphere.

To prevent an explosion, use a clean, damp cloth to clean

the display cover in an explosive atmosphere.

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

4.3 Procedure for field mounting

Installation kit for field

The procedure for field mounting includes the following steps:

1. Choosing an appropriate location for the installation

2. Orienting the display cover for optimal viewing

3. Mounting the applications platform on an instrument pole or flat

surface

4. Connecting power-supply wiring

5. Connecting input/output wiring

6. If the applications platform is a Model 3700, connecting the Model

3700 to a sensor. To perform Step 6, see Chapter 5.

The field-mount installation kit includes the parts shown in Figure 4-1.

mounting

Series 3000 Installation Manual 23

Page 30

Installing the Model 3350 or 3700 continued

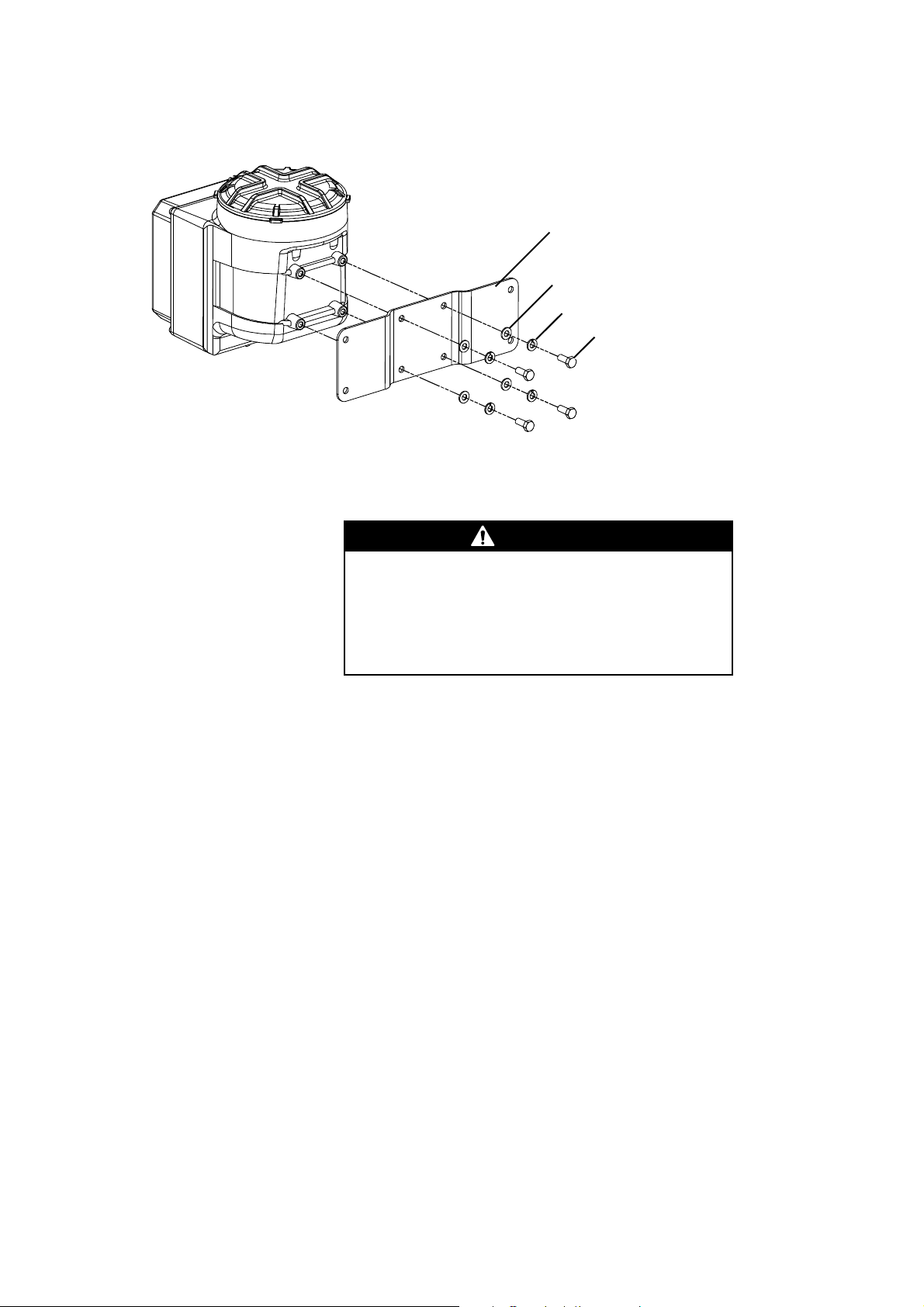

Figure 4-1. Parts in field-mount installation kit

Step 1 Locate and orient the applications platform

Mounting bracket

4 x Flat washer

4 x Lock washer

4 x M8x16

Using a 13 mm hex wrench,

install to 12 ft-lb (16 Nm)

WARNING

Improper installation in a hazardous area could cause

an explosion.

Install the applications platform in an area that is

compatible with the rating on the approvals tag. See

Figure 4-2.

Proximity to other devices

• Maximum length of cable from a Micro Motion® sensor to the Model

3700 is 1000 feet (300 meters).

• Maximum length of wiring from the frequency input for a Micro

Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters).

Visibility of tags To ensure personal and system safety, all tags attached to the housing

must remain visible. Clean them as often as necessary. Replace tags

that are damaged, missing, or worn.

Temperature, humidity, and vibration

Install the applications platform according to specified limits:

• Ambient temperature: –4 to 140°F (–20 to 60°C)

• Humidity: SAMA PMC 31.3, Section 5.2, Environmental

NEMA 4X (IP65)

• Vibration: Per IEC 68-2-6 at 1.0 g, 15 to 2000 Hz, 50 sweep cycles

Orientation Orient the applications platform so wiring compartments and conduit

openings are easily accessible. Conduit openings can be on the right,

left, bottom, or top of the housing, regardless of the positions of the

display cover or wiring compartments. See Figure 4-2 and Figure 4-3.

• To orient the applications platform on the mounting bracket, use the

four supplied mounting bolt assemblies.

• Install the bolt assemblies to 12 ft-lb (16 Nm) of torque.

24 Series 3000 Installation Manual

Page 31

Installing the Model 3350 or 3700 continued

Figure 4-2. Approvals tag and wiring terminals

Mounting bracket can

be rotated 90°

If CENELEC approval is required:

• Remove thread protectors from

conduit openings

• Install factory-supplied cable

glands or user-supplied EExe

cable entry devices in conduit

openings that are in use

• Install EExe plugs in conduit

openings that are not in use

• Mounting with conduit openings on left

• For other possible orientations, see

Figure 4-3

Approvals tag

Intrinsically safe wiring

terminals

(blue terminal block)

Non-intrinsically safe

wiring terminals

(gray terminal block)

Display cover can be

rotated 90 ° or 180°

(see Step 2)

Figure 4-3. Typical orientations

Mounting with conduit openings on right Mounting with conduit openings

Mounting bracket

can be rotated 90 °

pointing downward

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Lockout device

Platform approved for ATEX Zone 1

Conduit openings for

non-intrinsically safe wiring

Conduit openings for

intrinsically safe wiring

Mounting bracket

can be rotated 90°

The circuit board compartment has a lockout device, shown in

Figure 4-4. The lockout device must be loosened and rotated before the

compartment cover can be opened.

If the applications platform carries a ATEX Zone 1 approval, wiring

terminals are rated as shown in Figure 4-4.

• Remove thread protectors from conduit openings.

• Install factory-supplied cable glands or user-supplied EExe cable

entry devices in conduit openings that are in use.

• Install EExe plugs in conduit openings that are not in use.

The wiring compartments are rated EEx e. They must remain closed

when power is on.

• The wiring terminals on the blue terminal block are rated EEx i

(intrinsically safe).

• The wiring terminals on the gray terminal block are rated EEx e

(increased safety).

Series 3000 Installation Manual 25

Page 32

Installing the Model 3350 or 3700 continued

Figure 4-4. Wiring terminals and lockout device

Circuit board

compartment

Rated EEx d

Lockout device

Loosen and rotate before opening

circuit board compar tment

Intrinsically safe

wiring terminals

(blue terminal block)

Rated EEx i

Wiring compartment

Should remain closed

while power is on

Label for intrinsically safe

wiring terminals

Increased safety

wiring terminals

(gray terminal block)

Rated EEx e

Power-supply ground

Label for increased safety wiring

terminals (See Figure 4-8)

26 Series 3000 Installation Manual

Page 33

Installing the Model 3350 or 3700 continued

Figure 4-5. Model 3350 or 3700 dimensions

4 x 5/16-inch

(9 mm)

diameter

2 13/16

(71)

Mounting bracket

can be rotated 90 °

12

(305)

11

(279)

9 3/16

(234)

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

4

(102)

Display cover can be

rotated 90° or 180°

6 1/8

(158)

3 5/8

(92)

6

(152)

5 1/16-inch (129 mm)

clearance for removal

of circuit boards

Approvals tag

11 5/16

(288)

8 11/16

(221)

15 1/2

(394)

Series 3000 Installation Manual 27

Page 34

Installing the Model 3350 or 3700 continued

Step 2 Orient the display cover

a. Use a flat-head screwdriver to loosen the captive screws that secure

b. Use a flat-head screwdriver to loosen the captive screws that secure

the display cover to the housing.

the back cover to the display cover. Take note of which screw

attaches the ground wire to the back cover.

c. Pull up on the pressure relief valve while removing the back cover.

d. Rotate the display cover to any desired position.

e. Without touching the circuit board, tuck the wiring out of the way of

the circuit board to prevent the wiring from crimping, then reinstall the

back cover.

28 Series 3000 Installation Manual

Page 35

Installing the Model 3350 or 3700 continued

f. Pull up on the pressure relief valve while pressing the back cover into

g. Tuck the wiring out of the way of the connectors to prevent the wiring

place. Be sure to attach the ground wire to the back cover using the

correct screw. Attaching the ground wire to the wrong screw may

result in crimping of the ground wire.

from crimping, then reinstall the display cover.

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Guidelines for flat-surface mounting

Guidelines for pole mounting

Step 3 Mount the Model 3350 or 3700

• Use four 5/16-inch (M8) lag bolts (not included), suitable for the

environment.

• Do not secure bolts to separate beams, girders, wall studs, etc.,

which can move independently.

• For more information, see Figure 4-6.

• Use two 5/16-inch U bolts for 2-inch pipe, and four 5/16-inch nuts

(not included), suitable for the environment.

• For more information, see Figure 4-7.

Figure 4-6. Mounting to a wall or other surface

4 x 5/16-inch (M8) bolt (user-supplied)

• Mount all 4 bolts to the same surface

• If mounting surface is not flat, use

washers to shim the bracket

Series 3000 Installation Manual 29

Page 36

Installing the Model 3350 or 3700 continued

Figure 4-7. Mounting to an instrument pole

Step 4 Connect power-supply wiring

4 x 5/16-inch nut

(user-supplied)

2 x 5/16-inch U bolt for

2-inch pipe (user-supplied)

CAUTION

Improper wiring installation can cause device failure

or measurement error.

• To avoid device failure or measurement error, do not

install power-supply wiring in the same cable tray or

conduit as input/output wiring.

• Shut off power supply before installing the applications

platform.

• Make sure power-supply voltage matches voltage that is

indicated on power-supply wiring terminals. See

Figure 4-8.

Follow these steps to connect 18 to 12 AWG (0,75 to 4,0 mm2) wiring to

the power-supply wiring terminals.

a. Using a flat-head screwdriver, loosen the captive screws that secure

the display cover to the housing.

b. Connect the ground wire to green screw.

c. Connect the green screw directly to earth ground.

• Keep all ground leads as short as possible.

• Ground wiring must have less than 1 ohm impedance.

d. Connect wires to terminals 9 and 10 on the gray terminal strip. See

Figure 4-8.

• If the Model 3700 has a DC power supply, terminal 9 is

positive (+), terminal 10 is negative (–).

• If the Model 3700 has an AC power supply, terminal 9 is line (L or

L2), terminal 10 is neutral (N or L1).

e. A switch may be installed in the power-supply line. For compliance

with low-voltage directive 73/23/EEC, a switch in close proximity to

the applications platform is required.

30 Series 3000 Installation Manual

Page 37

Installing the Model 3350 or 3700 continued

Figure 4-8. Field-mount input/output wiring terminals

DC power supplyAC power supply

Installation: Panel-Mount Installation: Field-MountInstallation: Rack-MountBefore You Begin

Terminal 9: line (L or L2)

Terminal 10: neutral (N or L1)

Terminal 9: positive

Terminal 10: negative

Step 5 Connect input and output wiring

Follow these steps to connect twisted-pair, shielded wiring, 22 to

16 AWG (0,34 to 1,5 mm

a. Using a flat-head screwdriver, loosen the captive screws that secure

the display cover to the housing.

b. Connect input/output wiring to the gray terminal strip.

• Ground the shields at the field device.

• Clip the shields at the end that connects to the applications

platform.

• If more than two wires must be connected to a single terminal, use

a butt splice or spade lug to connect the wires.

A label that is attached to the back of the display cover shows terminal

designations for input/output wiring.

•See Figure 4-8 and Table 4-1.

• Input and output assignments depend on the application. For more

information, see the Series 3000 Detailed Setup Manual.

2

), to the input/output wiring terminals.

Series 3000 Installation Manual 31

Page 38

Installing the Model 3350 or 3700 continued

Table 4-1. Field-mount input/output wiring terminals

Terminal number Designation

1 – 2 + Primary 4-20 mA output

3 – 4 + Secondary 4-20 mA output

5 – 6 + Frequency input

5 – 7 + Discrete input 1

5 – 8 + Discrete input 2

11 (B line) 12 (A line) RS-485 output

20 – 16 + Discrete output 3

20 – 17 + Discrete output 2

20 – 18 + Discrete output 1

20 – 19 + Frequency output

Step 6 Connect the Model 3700 to the sensor

To connect the Model 3700 transmitter to a Micro Motion® sensor, see

Chapter 5.

32 Series 3000 Installation Manual

Page 39

5 Connecting the

Transmitter to a Sensor

5.1 About this chapter This chapter explains how to connect the Model 3500 or 3700

®

transmitter to a Micro Motion ELITE

DL, or Model DT sensor. For other sensors, see the sensor installation

manual.

• Use Micro Motion 9-wire cable to connect the transmitter to the

sensor.

• Total length of cable from sensor to transmitter must not exceed

1000 feet (300 meters).

, T-Series, BASIS®, Model D, Model

WARNING

Failure to maintain intrinsic safety could result in an

explosion.

To keep sensor wiring intrinsically safe:

• Keep intrinsically safe sensor wiring separated from

power-supply and output wiring.

• Do not install power cable in the same conduit or cable

tray as flowmeter cable.

• Use this document with Micro Motion ATEX, UL, or CSA

installation instructions that are shipped with the sensor.

Installation: Relays StartupPrinter SetupSensor Wiring

CAUTION

Improper installation of cable, cable gland, or conduit

could cause inaccurate measurements or flowmeter

failure.

To ensure 360° termination of shielding for flowmeter

wiring, install the factory-supplied cable gland or

user-supplied sealed metallic conduit to the conduit

opening on the sensor junction box.

Series 3000 Installation Manual 33

Page 40

Connecting the Transmitter to a Sensor continued

5.2 Cable types Micro Motion supplies 9-wire jacketed, shielded, or armored cable.

• Jacketed cable is CE-compliant when it is installed inside

user-supplied sealed metallic conduit that provides 360 ° termination

shielding and continuous coverage for the enclosed cable.

• Shielded and armored cable are CE-compliant when the cable is

installed with the factory-supplied cable glands.

• Shielded and armored cable are acceptable for cable tray

installation.

®

• Each cable type is available with a PVC or Teflon

FEP jacket. For

temperature ranges of cable jacket materials, see Tabl e 5-1 .

• Use shielded or armored cable with Micro Motion T-Series sensors.

CAUTION

Failure to use shielded or armored cable with Micro

Motion T-Series sensors could cause inaccurate

measurements.

Install Micro Motion shielded or armored cable with Micro

Motion T-Series sensors.

5.3 Cable and conduit preparation

Guidelines for cable gland 1. Prepare cable ends and assemble the supplied cable gland

Guidelines for conduit If sealed metallic conduit is installed, it must provide 360 ° termination

Prepare cable and conduit according to the cable preparation

instructions that are shipped with the sensor.

according to the instructions that are enclosed with the cable

preparation kit.

2. Connect the ¾-inch NPT male cable gland to the ¾-inch NPT female

conduit opening on the sensor junction box.

shielding for the enclosed flowmeter cable.

1. Install a drip leg in conduit to prevent liquids from entering the

junction box.

2. Connect the sealed end of the conduit to the ¾-inch NPT female

conduit opening on the sensor junction box.

34 Series 3000 Installation Manual

Page 41

Connecting the Transmitter to a Sensor continued

Figure 5-1. Jacketed cable

Jacket

material

PVC .415 (10) 3 1/8 (80) 6 1/4 (159)

Teflon FEP .340 (9) 2 5/8 (67) 5 1/8 (131)

Figure 5-2. Shielded cable

Jacket

Drain wire (4)

Filler (5)

Minimum bend radii

Outside diameter Static (no load) Dynamic load

inches (mm) inches (mm) inches (mm)

Outer jacket

Installation: Relays StartupPrinter SetupSensor Wiring

Tin-plated copper

braided shield

Foil shield

Inner

jacket

Filler

(5)

Note for Figure 5-2

Drain wire (4)

You must install shielded or armored cable with Micro Motion T-Series

sensors.

Minimum bend radii

Jacket

material

PVC .560 (14) 4 1/4 (108) 8 1/2 (216)

Teflon FEP .425 (11) 3 1/4 (83) 6 3/8 (162)

Outside diameter Static (no load) Dynamic load

inches (mm) inches (mm) inches (mm)

Series 3000 Installation Manual 35

Page 42

Connecting the Transmitter to a Sensor continued

Figure 5-3. Armored cable

Filler

(5)

Note for Figure 5-3

You must install shielded or armored cable with Micro Motion T-Series

sensors.

Jacket

material

PVC .560 (14) 4 1/4 (108) 8 1/2 (216)

Teflon FEP .425 (11) 3 1/4 (83) 6 3/8 (162)

Outer jacket

Stainless steel

braided shield

Foil shield

Inner

jacket

Drain wire (4)

Minimum bend radii

Outside diameter Static (no load) Dynamic load

inches (mm) inches (mm) inches (mm)

Table 5-1. Temperature ranges for cable jacket material

Cable jacket material

PVC –40 °F (–40°C) 221 °F (105°C)

Teflon FEP –76°F (–60°C) 302°F (150 °C)

Low operating

temperature limit

High operating

temperature limit

Table 5-2. Requirements for CE Mark in Europe,

recommendations for elsewhere

Installation requirements

Conduit is used X

Conduit is not used X

Conduit is not used and

mechanical protection is required X

Micro Motion T-Series sensor is

being installed

Jacketed

cable

Shielded

cable

XX

Armored

cable

36 Series 3000 Installation Manual

Page 43

Connecting the Transmitter to a Sensor continued

5.4 Wiring connections to sensor

1. Insert the ends of the individual wires into the terminals inside the

sensor junction box. No bare wires should remain exposed.

2. Match the wire colors of the cable with the wire colors at the sensor

wiring terminal as described in Table 5 -3.

3. If possible, position the junction box so the conduit entrance points

downward to prevent moisture from entering.

CAUTION

Failure to seal sensor junction box or transmitter

housing could cause a short circuit, which would

result in measurement error or flowmeter failure.

To avoid risk of condensation or excessive moisture

entering the junction box or transmitter housing:

• Seal all conduit openings.

• Install drip legs in cable or conduit.

• Fully tighten sensor junction box and transmitter housing

covers.

Table 5-3. Sensor terminal designations

Terminal

number

1

2

3

4

5

6

7

8

9

Wire

color Function

Brown

Red

Orange

Ye l l o w

Green

Blue

Violet

Gray

White

Drive +

Drive –

Temperature –

Temperature lead length compensator

Left pickoff +

Right pickoff +

Temperature +

Right pickoff –

Left pickoff –

Installation: Relays StartupPrinter SetupSensor Wiring

5.5 Wiring connections to transmitter

Screw-type or solder-tail connectors

The procedure for connecting sensor wiring to the transmitter depends

on the type of wiring connections.

Connect the ends of the individual wires to the appropriate terminals. No

bare wires should remain exposed.

• Match the wire colors of the cable with the wire colors at the sensor

wiring terminals. To connect to a Micro Motion ELITE, T-Series,

BASIS, Model D, or Model DL sensor, see Table 5 - 4, Figure 5-5,

and Figure 5-6.

• To connect to a Model DT sensor, see Tabl e 5 -4, Figure 5-7, and

Figure 5-8.

I/O cables 1. Attach the supplied terminal block to a DIN rail. The terminal block

accommodates various rail types. See Figure 5-4.

2. Plug the sensor I/O cable connector onto the terminal block. Tighten

the captive screws to secure the connector to the terminal block.

3. Connect the ends of the individual wires of the sensor cable to the

appropriate terminals on the terminal block. No bare wires should

remain exposed.

Series 3000 Installation Manual 37

Page 44

Connecting the Transmitter to a Sensor continued

4. Match the wire colors of the cable with the wire colors at the sensor

wiring terminals.

• To connect to a Micro Motion ELITE, T-Series, BASIS, Model D, or

Model DL sensor, see Table 5 - 4 and Figure 5-5.

• To connect to a Model DT sensor, see Tabl e 5 -4 and Figure 5-7.

The I/O cables do not have CENELEC approval.

Table 5-4. Transmitter terminals for sensor cable

Transmitter terminal numbers

Model 3500

with I/O cable

4

10

7

3

5

9

6

8

1

2

*Combined drain wires from brown/red, green/white, and gray/blue pairs and yellow/orange/violet triplet.

Model 3500 with

screw-type or

solder-tail terminals Model 3700

c 4

a 4

c 6

a 6

c 8

a 8

c 10

a 10

c 12

a 12

13

14

15

16

17

18

19

20

12

11

Wire

color Function

Yellow

Black*

Violet

Orange

Green

White

Blue

Gray

Brown

Red

Temperature lead length compensator

Drain wires

Temperature +

Temperature –

Left pickoff +

Left pickoff –

Right pickoff +

Right pickoff –

Drive +

Drive –

Figure 5-4. Installing sensor wiring terminal block on DIN rail

2 11/16

(68)

2 9/16

(66)

2 1/2

(63)

2 5/16

2 1/4

(57)

(58)

3 1/16

(77)

9

(229)

TS 15 TS 32

TS 35 x 7.5 TS 35 x 15

38 Series 3000 Installation Manual

Page 45

Connecting the Transmitter to a Sensor continued

Figure 5-5. Cable connections: Model 3500 to ELITE®, T-Series, BASIS®, Model D, or Model DL sensor

green

gray

blue

orange

violet

yellow

ELITE sensor with

rectangular

terminal block

Use shielded or armored cable with

Micro Motion T-Series sensors.

Sensor end Transmitter end

white

green

red

brown

violet

yellow

orange

white

brown

ELITE or T-Series

sensor with radial

terminal block

blue

gray

red

BASIS, D or DL sensor

terminal block

black (drain wires

from all wire sets)

brown

red

orange

yellow

green

blue

violet

gray

white

Installation: Relays StartupPrinter SetupSensor Wiring

Clip drain wire back

Clip drain wire back

Clip drain wire back

Clip drain wire back

Connect outer braid

of shielded or

armored cable here

brown

red

green

white

blue

gray

orange

violet

yellow

white

black (drains)

Sensor

cable

brown

red

orange

yellow

green

blue

violet

gray

yellow

violet

green

blue

brown

brown

red

green

white

blue

gray

orange

violet

yellow

black (drains)

orange

white

gray

red

Model 3500

with I/O cable

Series 3000 Installation Manual 39

Model 3500 with

screw-type or solder-tail

wiring connectors

Page 46

Connecting the Transmitter to a Sensor continued

Figure 5-6. Cable connections: Model 3700 to ELITE®, T-Series, BASIS®, Model D, or Model DL sensor

green

gray

blue

orange

violet

yellow

ELITE sensor with

rectangular

terminal block

Use shielded or armored cable with

Micro Motion T-Series sensors.

Sensor end Transmitter end

white

green

red

brown

violet

yellow

orange

white

brown

ELITE or T-Series

sensor with radial

terminal block

blue

gray

red

BASIS, D or DL sensor

terminal block

black (drain wires

from all wire sets)

brown

red

orange

yellow

green

blue

violet

gray

white

brown

Clip drain wire back

green

white

Clip drain wire back

Clip drain wire back

orange

violet

yellow

Clip drain wire back

red

blue

gray

Sensor

cable

brown

red

green

white

blue

gray

orange

violet

yellow

red

brown

yellow

black (drains)

violet

orange

green

white

blue

gray

Model 3700 wiring terminals

(blue terminal block)

40 Series 3000 Installation Manual

Page 47

Connecting the Transmitter to a Sensor continued

Figure 5-7. Cable connections: Model 3500 to Model DT sensor

Sensor end Transmitter end

brown

Clip drain wire back

green

white

Clip drain wire back

Clip drain wire back

orange

violet

yellow

Clip drain wire back

red

blue

gray

Model DT

sensor

Metallic cable

junction box

brown

red

orange

yellow

green

blue

violet

gray

white

Earth ground

• Install metal conduit or flexible braided shield over leads

• For braided shield, ensure 360° contact at junction box;

bond shield at sensor

black (drain wires

from all wire sets)

brown

red

green

Sensor

cable

white

blue

gray

orange

violet

yellow

Installation: Relays StartupPrinter SetupSensor Wiring

black (drains)

orange

white

gray

red

white

black (drains)

brown

red

orange

yellow

violet

green

blue

brown

yellow

green

blue

Connect outer braid

of shielded or

armored cable here

violet

gray

Model 3500

with I/O cable

Model 3500 with

screw-type or solder-tail

wiring connectors

Series 3000 Installation Manual 41

Page 48

Connecting the Transmitter to a Sensor continued

Figure 5-8. Cable connections: Model 3700 to Model DT sensor

Sensor end Transmitter end

brown

Clip drain wire back

green

white

Clip drain wire back

gray

Clip drain wire back

orange

violet

yellow

Clip drain wire back

red

blue

Model DT

sensor

Metallic cable

junction box

brown

red

orange

yellow

green

blue

violet

gray

white

Earth ground

• Install metal conduit or flexible braided shield over leads

• For braided shield, ensure 360° contact at junction box;

bond shield at sensor

black (drain wires

from all wire sets)

brown

red

green

Sensor

cable

white

blue

gray

orange

violet

yellow

red

brown

yellow

black (drains)

violet

orange

green

white

blue

gray

Model 3700 wiring terminals

(blue terminal block)

42 Series 3000 Installation Manual

Page 49

6 Installing Relays

6.1 About this chapter This chapter explains how to install relays for the Series 3000

applications platform.

• To install optional solid-state relays supplied by Micro Motion

Section 6.6. Factory-supplied relays are internally powered.

• To install user-supplied relays, see Section 6.7. User-supplied relays

can be internally or externally powered.

After relays have been installed, discrete outputs must be configured for

operation with an internal or external power source. See Section 6.8.

®

, see

6.2 Specifications for user-supplied relays

6.3 Hazardous area installations

Model 3100 relays ATEX

If user-supplied relays are internally powered, they must be solid-state

relays that are compatible with the Series 3000 discrete outputs.

If user-supplied relays are externally powered, they may be mechanical

relays that are compatible with the Series 3000 discrete outputs.

Three discrete outputs are configurable for the application.

• Power: Internal or external, software selectable

• Voltage: 24 VDC nominal

• Current: Sourcing at 5.6 mA when V

Sinking up to 500 mA at 30 VDC supply maximum

If you are installing the relay or relay module in a hazardous area, review

the information in this section.

Model 3100 relay modules are suitable for installation in Zone 2,

complying with ATEX Directive (94/9/EC) for Group II, Category 3G,

according to CENELEC standard prEN 50021:1998 and marked as:

• EEx n V II T4

• KEMA 97 ATEX 4940 X

• Ambient temperature –20 to +60 °C (–4 to +140 °F)

= 3 VDC

out

Installation: Relays StartupPrinter SetupSensor Wiring

To comply with hazardous area requirements:

• Model 3100 relay modules must be mounted into a suitable and

classified enclosure that provides ingress protection of at least IP4X

according to EN 60529, taking into account the environmental

conditions into which the equipment will be installed and clause 6 of

prEN50021:1998.

• Cable entries for the enclosure shall comply with clause 7.2.6 of

prEN50021:1998.

• The external metal parts of the relay module (heat sinks) must be

connected to the potential equalizing system within the hazardous

area.

Series 3000 Installation Manual 43

Page 50

Installing Relays continued

UL and CSA

Model 3100 relay modules are suitable for installation in Class I, Division

2, Groups A, B, C, and D.

For CSA compliance, the relay module must be installed in a suitable

enclosure where the final combination is subject to acceptance by the

Canadian Standards Association (CSA).

User-supplied relays User-supplied relays to be used for Zone 2 applications must be certified

as Category 3 equipment.

6.4 Replacing relays You may not replace a defective relay separately. If an individual relay is

defective, you must replace the entire relay module.

This requirement applies to both the Model 3100 and to user-supplied

relays, and to both hazardous and non-hazardous areas.

6.5 Software configuration Relays connect to discrete outputs from the applications platform.

• Discrete outputs can operate from an internal or external power

source.

• For more information about configuring discrete outputs, see

Section 6.8.

CAUTION

Improper configuration of the software can cause

relays to be activated.

Before startup, make sure discrete output power source is

configured as "internal" if relays are energized by this unit;

or configured as "external" if relays are energized by an

external power source.

Use the Series 3000 software to select an internal or external power

source for the discrete outputs that are connected to the relays.

• If relays are internally powered, select an internal power source for

the discrete outputs. (Internal power source is the default.)

• If relays are externally powered, select an external power source for

the discrete outputs.

44 Series 3000 Installation Manual

Page 51

Installing Relays continued

6.6 Installing factory-supplied relays

To install factory-supplied (internally powered) solid-state relays, follow

these steps:

1. Mount the relay terminal block to a DIN rail. See Figure 6-1.

2. Connect wiring from the applications platform to the relay terminal

block. See Figure 6-2, Figure 6-3, and Figure 6-4.

3. Connect wiring from the relay terminal block to the devices the relays

will control. See Figure 6-5 and Figure 6-6.

WARNING

Shock Hazard.

Improper installation of wiring, or installation with power

supply on, can cause electric shock or property damage.

For personal and system safety:

• Shut off power before installing wiring.

• Make sure the installation meets or exceeds local code

requirements.

• Install relays and wiring in accordance with the

illustrations in these instructions.

• Install relays and wiring where ambient temperature

remains between –4 and 140°F (–20 and 60°C).

WARNING

Explosion Hazard.

Improper installation of relays can cause ignition of

explosive atmospheres.

For personal and system safety:

• Ensure relay contact ratings are:

0.04 to 5 amps at 24 to 280 Volts AC (RMS) or

0.02 to 5 amps at 0 to 70 Volts DC.

• Ensure correct polarity of diode and power source.

StartupPrinter SetupInstallation: RelaysSensor Wiring

Series 3000 Installation Manual 45

Page 52

Installing Relays continued

Step 1 Mount relay terminal block

Mount the supplied relay terminal block to a DIN rail. The terminal block

accommodates various standard rail types. See Figure 6-1.

Figure 6-1. Relay terminal block dimensions

2

2 1/32

(52)

(50)

3 3/64

(77)

2 7/32

(56)

2 21/64

(59)

TS 15

TS 35 x 7.5

TS 32

TS 35 x 15

8

(203)

46 Series 3000 Installation Manual

Page 53

Installing Relays continued

Step 2 Connect wiring to relays

• Wire size is 24 to 16 AWG (0,25 to 1,5 mm2) for the Model 3300 or

3500; 22 to 16 AWG (0,34 to 1,5 mm

• One relay, two relays, or all three relays may be connected.

• For a Model 3300 or 3500 with screw-type or solder-tail connectors,

see Figure 6-2.

• For a Model 3300 or 3500 with I/O cables, see Figure 6-3.

• For a Model 3350 or 3700, See Figure 6-4.

Figure 6-2. Relay wiring: Screw-type or solder-tail connector

Wire size is 24 to 16 AWG (0,25 to 1,5 mm

Relay 3 Relay 1

Relay 2

2

) for the Model 3350 or 3700.

2

)

Figure 6-3. Relay wiring: I/O cable

Relay 3 Relay 1Relay 2

Model 3300/3500 input/output

wiring terminals

(far right terminal block)

Wire size is 24 to 16 AWG (0,25 to 1,5 mm2)

StartupPrinter SetupInstallation: RelaysSensor Wiring

Model 3300 or 3500 input/output

wiring terminals (terminal block

attached to DIN rail)

Series 3000 Installation Manual 47

Page 54

Installing Relays continued

Figure 6-4. Relay wiring: Model 3350 or 3700

Relay 3 Relay 2 Relay 1

Step 3 Connect wiring to control devices

Model 3350 or 3700

input/output wiring

terminals

Wire size is 22 to 16 AWG (0,34 to 1,5 mm

Gray

terminal

block

2

)

• If the relay loads have an AC power supply, see Figure 6-5. AC

output terminals do not have polarity.

• If the relay loads have a DC power supply, see Figure 6-6.

DC output terminals have polarity.

48 Series 3000 Installation Manual

Page 55

Installing Relays continued

Figure 6-5. Wiring to control devices, AC power

24 to 280 VAC

(no polarity)

One relay, two relays,

or all three relays may

be connected

Relay 1

Relay 2

Relay 3

Figure 6-6. Wiring to control devices, DC power

Primary control valve or

other control device

Secondary control valve

or other control device

Pump or other

control device

12 to 30 VDC

One relay, two relays,

or all three relays may

be connected

Primary control valve or

Relay 1

Relay 2

Relay 3

Series 3000 Installation Manual 49

other control device

Secondary control valve

or other control device

Pump or other

control device

StartupPrinter SetupInstallation: RelaysSensor Wiring

Page 56

Installing Relays continued

6.7 Installing user-supplied relays

To install user-supplied relays, follow these steps:

1. Connect wiring from the applications platform to the relays.

2. Connect wiring from the relays to the devices the relays will control.

• User-supplied relays may be internally or externally powered.

• User-supplied AC solid-state relays are internally powered, and

should be a zero-crossing type requiring less than 5.6 mA current

to energize the relays. (The relay will switch the output on or off

when the output voltage reaches 0 V.)

WARNING

Shock Hazard.

Improper installation of wiring, or installation with power

supply on, can cause electric shock or property damage.

For personal and system safety:

• Shut off power before installing wiring.

• Make sure the installation meets or exceeds local code

requirements.

• Install relays and wiring in accordance with the

illustrations in these instructions.

• Install relays and wiring where ambient temperature

remains between –4 and 140°F (–20 and 60°C).

WARNING

Explosion Hazard.

Improper installation of relays can cause ignition of

explosive atmospheres.

For personal and system safety, use the following input

ratings for user-supplied relays:

• If the applications platform serves as the power source,

voltage is 24 VDC nominal; current is 5.6 mA when

output voltage = 3 VDC.

• If the current requirements are higher than 5.6 mA,

configure the applications platform to sink current up to a

maximum of 500 mA at 30 VDC supply maximum, and

use an external power source appropriate for the relays.

For information about configuring the power source for

user-supplied relays, see Section 6.8.

Step 1 Connect wiring to relays

• Wire size is 24 to 16 AWG (0,25 to 1,5 mm2) for the Model 3300 or

3500; 22 to 16 AWG (0,34 to 1,5 mm

• One relay, two relays, or all three relays may be connected.

• For a Model 3300 or 3500 with screw-type or solder-tail connectors,

see Figure 6-7.

• For a Model 3300 or 3500 with I/O cables, see Figure 6-8.

• For a Model 3350 or 3700 see Figure 6-9.

2

) for the Model 3350 or 3700.

50 Series 3000 Installation Manual

Page 57

Installing Relays continued

Figure 6-7. Wiring for user-supplied relays to screw-type or solder-tail connector

input/output wiring terminals

Wire size is 24 to 16 AWG

Model 3300 or 3500

(far right terminal block)

2

(0,25 to ,5 mm

)

500 mA

maximum

500 mA

maximum

500 mA

maximum

External

power

supply

12 to 30 VDC

• Minimum capacity 1.5 A

• Maximum coil load is 500 mA

per relay

User-supplied relays

Figure 6-8. Wiring for user-supplied relays to I/O cable

Model 3300

or 3500

input/output

wiring terminals

(terminal block

attached to

DIN rail)

maximum

500 mA

maximum

500 mA

maximum

500 mA

12 to 30 VDC

External

power

supply

Wire size is 24 to 16 AWG

(0,25 to 1,5 mm

• Minimum capacity

1.5 A

• Maximum coil load is

500 mA per relay

2

)

User-supplied

relays

StartupPrinter SetupInstallation: RelaysSensor Wiring

Series 3000 Installation Manual 51

Page 58

Installing Relays continued

Figure 6-9. Wiring for user-supplied relays to Model 3350 or 3700

500 mA

maximum

500 mA

Model 3350 or 3700

input/output

wiring terminals

(gray terminal block)

maximum

500 mA

maximum

User-supplied relays

Wire size is 22 to 16 AWG (0,34 to 1,5 mm

Step 2 Connect wiring to control devices

To connect wiring from the relay wiring terminal block to the devices the

relays will control, see Figure 6-10.

• The installation depends on the functions the relays will perform.

• Figure 6-10 illustrates a typical wiring installation for a 2-stage batch

application.

Figure 6-10.Typical wiring diagram, 2-stage batch application

To connect relays to applications platform,

see Figure 6-7, Figure 6-8, or Figure 6-9

External

power

supply

2

)

Maximum 12 to 30 VDC

• Minimum capacity 1.5 A

• Maximum coil load is

500 mA per relay

Primary control valve

or other control device

Secondary control

User-supplied relays

52 Series 3000 Installation Manual

valve or other

control device

Pump or other

control device

Page 59

Installing Relays continued

6.8 Discrete output configuration

The applications platform will not operate properly unless configuration

tasks are performed in the proper sequence.

CAUTION

Failure to perform configuration tasks in the proper

sequence could result in an incomplete or flawed

configuration, causing measurement error.

To avoid measurement error, perform configuration tasks

in the following sequence:

1. Configure system parameters

2. Configure inputs

3. Configure application parameters

4. Configure measurement parameters

5. Configure outputs

6. Configure digital communications

To configure the discrete outputs, follow these steps:

1. Configure system parameters. (See the Series 3000 Detailed Setup

Manual.)

2. Configure inputs. (See the Series 3000 Detailed Setup Manual.)

3. Configure application parameters. (See the Series 3000 Detailed

Setup Manual.)

4. Configure measurement parameters. (See the Series 3000 Detailed

Setup Manual.)

5. Configure outputs.

a. Configure Discrete Output 1, Discrete Output 2, and Discrete

Output 3 to operate from the appropriate power source. See

Table 6 - 1.

b. Assign functions to outputs. (See the Series 3000 Detailed Setup

Manual.)

6. Configure digital communications. (See the Series 3000 Detailed

Setup Manual.)