Page 1

ALTUS

™

Net Oil Computer Manual

May 2000

Page 2

Page 3

ALTUS

™

Net Oil Computer Manual

For technical assistance, phone the Micro Motion Customer

Service Department:

• In the U.S.A., phone 1-800-522-6277, 24 hours

• Outside the U.S.A., phone 303-530-8400, 24 hours

• In Europe, phone +31 (0) 318 549 443

• In Asia, phone (65) 770-8155

Copyright ©1998, Micro Motion, Inc. A l l rig h ts res erved.

Micro Motion, ELITE, and BASIS are registered trademarks, and ALTUS is a

trademark of Micro Mo tion, Inc., Boulder, Colorado. Hastelloy is a registered

trademark of Haynes International, Inc., Kokomo Indiana. Inconel is a re gi st er ed

trademark of Inco Alloys International, Inc., Huntington, West Virginia. Teflon is a

registered trademar k of E.I. DuPont de Nemours Co., Inc., Wilmington, Delaware.

Page 4

Page 5

Contents

1 Before You Begin

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Application software described in this manual. . . . . . . 1

1.3 Introduction to the ALTUS

Replacing an older NOC and transmitter. . . . . . . . . . . 1

Water cut determination . . . . . . . . . . . . . . . . . . . . . . . 1

NOC capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Installation Considerations

2.1 Piping arrangement and ancillary equipment . . . . . . . 3

2.2 Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sensor orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Avoiding inaccurate flow counts . . . . . . . . . . . . . . . . . 6

2.3 Flow direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Using the Person-Process Interface

3.1 Person-Process Interface . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Security button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Function buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Cursor control buttons . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

™

NOC . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

1

3

9

ALTUS™ Net Oil Computer Manu al

4 Configuration

4.1 Recording the configuration. . . . . . . . . . . . . . . . . . . . . 15

4.2 Configuration sequence. . . . . . . . . . . . . . . . . . . . . . . . 15

Step 1 Configure well performance measurements . . . . . . . . 15

Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Units of measurement . . . . . . . . . . . . . . . . . . . . . . . . . 16

Well data-densities . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Compensations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Step 2 Configure system data. . . . . . . . . . . . . . . . . . . . . . . . . 24

Step 3 Configure inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Flow variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Density inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sensor calibration data . . . . . . . . . . . . . . . . . . . . . . . . 28

Sensor information . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Step 4 Configure outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Discrete outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Milliamp outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Pulse output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

i

Page 6

Contents

continued

5 Using the View Menu

5.1 Accessing the view menu . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Well performance measurements . . . . . . . . . . . . . . . . 44

Continuous mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Well test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3 Process totalizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4 Inventory totalizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5 Active alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.6 LCD options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.7 Diagnostic monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.8 Applications list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.9 Power outage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 Continuous Mode

6.1 Continuous mode configuration . . . . . . . . . . . . . . . . . . 49

6.2 Startup and display test . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Process monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.4 Accessing continuous mode . . . . . . . . . . . . . . . . . . . . 49

6.5 Viewing production measurements . . . . . . . . . . . . . . . 50

6.6 Quick view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.7 Pause and resume. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.8 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

49

7 Well Test Mode

7.1 Well test mode configuration . . . . . . . . . . . . . . . . . . . . 55

7.2 Startup and display test . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3 Process monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4 Accessing well test mode. . . . . . . . . . . . . . . . . . . . . . . 55

7.5 Conducting a well test . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.6 Stopping and continuing a well test . . . . . . . . . . . . . . . 58

7.7 Viewing performance measurements . . . . . . . . . . . . . 60

7.8 Viewing performance measurements for the

current test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.9 Viewing previous well tests . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55

ii

ALTUS™ Net Oil Computer Manu al

Page 7

Contents

continued

8 Maintenance

8.1 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Responding to alarms . . . . . . . . . . . . . . . . . . . . . . . . 67

NOC alarm messages . . . . . . . . . . . . . . . . . . . . . . . . 68

Transmitter alarm messages. . . . . . . . . . . . . . . . . . . 68

Alarms that do not generate fault outputs . . . . . . . . . 69

Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Critical status fault alarms . . . . . . . . . . . . . . . . . . . . . 74

Transmitter failure fault alarms . . . . . . . . . . . . . . . . . 74

Fault alarms requiring troubleshooting . . . . . . . . . . . 75

Active alarm log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.2 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3 Setting outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Setting discrete outputs. . . . . . . . . . . . . . . . . . . . . . . 79

Setting milliamp outputs . . . . . . . . . . . . . . . . . . . . . . 79

Setting the frequency output . . . . . . . . . . . . . . . . . . . 80

8.4 Density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Density unit for calibration. . . . . . . . . . . . . . . . . . . . . 80

Duplicating the factory calibration . . . . . . . . . . . . . . . 81

Duplicating a previous calibration . . . . . . . . . . . . . . . 82

Two-point density calibration. . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Laboratory Determination of Dry Oil and

67

Produced Water Densities

9.1 Reasons for using live oil density . . . . . . . . . . . . . . . 87

9.2 Laboratory density measurement . . . . . . . . . . . . . . . 87

Taking a sample from the flow line . . . . . . . . . . . . . . 88

Processing sample and measuring densities . . . . . . 91

. . . . . . . . . . . . . . . . .

10In-Line Determination of Live Oil and

Produced Water Densities

10.1 Reasons for using live oil density . . . . . . . . . . . . . . . 93

10.2 In-line density determination . . . . . . . . . . . . . . . . . . . 93

Density determination procedures. . . . . . . . . . . . . . . 93

Measuring and saving the water density . . . . . . . . . . 94

Manually entering the water density . . . . . . . . . . . . . 99

Measuring and saving the oil density . . . . . . . . . . . . 103

Entering the water cut . . . . . . . . . . . . . . . . . . . . . . . . 104

11Sensitivity Analysis

11.1 Error factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.2 Individual sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.3 Overall uncertainty. . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

87

93

107

ALTUS™ Net Oil Computer Manu al

iii

Page 8

Contents

continued

12Software Diagrams

12.1 View menu in well test mode . . . . . . . . . . . . . . . . . . 111

12.2 View menu in continuous mode. . . . . . . . . . . . . . . . 112

12.3 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . 113

12.4 Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendixes

Appendix A ALTUS™ NOC Software Configuration

Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Appendix B Return Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

111

123

iv

ALTUS™ Net Oil Computer Manu al

Page 9

Contents

continued

Figures

Figure 1-1 Water cut calculation. . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 2-1 Typical installation, Micro Motion

NOC with 3-phase separator . . . . . . . . . . . . . . . 4

Figure 2-2 Typical installation, Micro Motion

NOC with 2-phase separator . . . . . . . . . . . . . . . 4

Figure 2-3 Sensor in horizontal pipe run,

tubes downward . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-4 Sensor in vertical pipe run. . . . . . . . . . . . . . . . . . . . 5

Figure 3-1 Person-Process Interface . . . . . . . . . . . . . . . . . . . . 9

Figure 3-2 Pressing security button, security disabled. . . . . . . 10

Figure 3-3 Pressing security button, security enabled . . . . . . . 10

Figure 3-4 Function buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3-5 Cursor control buttons. . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4-1 Effect of transient bubbles on density . . . . . . . . . . . 22

Figure 4-2 Holding at last measured density . . . . . . . . . . . . . . 22

Figure 4-3 Correction of density readings . . . . . . . . . . . . . . . . 22

Figure 4-4 Flow calibration values on sensor serial

number tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 4-5 D1 and D2 on sensor serial number tag . . . . . . . . . 30

Figure 4-6 K1 and K2 on sensor serial number tag . . . . . . . . . 31

Figure 4-7 K1 and K2 values from comments section . . . . . . . 32

Figure 4-8 K1 and K2 values from second page . . . . . . . . . . . 32

Figure 4-9 FD and dens temp coeff on sensor serial

number tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5-1 Using buttons in the view menu . . . . . . . . . . . . . . . 43

Figure 6-1 Process monitor mode . . . . . . . . . . . . . . . . . . . . . . 49

Figure 7-1 Process monitor mode . . . . . . . . . . . . . . . . . . . . . . 55

Figure 8-1 Model 3500 sensor wiring terminals . . . . . . . . . . . . 76

Figure 8-2 Model 3700 sensor wiring terminals . . . . . . . . . . . . 76

Figure 9-1 Sample port for laboratory density

measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 9-2 Laboratory sampling procedure using

water-filled cylinder . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 9-3 Laboratory sampling procedure using

empty cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 9-4 Laboratory density measurement system,

low pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 9-5 Laboratory density measurement system,

high pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 10-1 Stratification with no flow. . . . . . . . . . . . . . . . . . . . . 96

Figure 10-2 Diameter and length of cylindrical vessel . . . . . . . . 97

Figure 10-3 Taking a water sample from the separator . . . . . . . 101

Figure 10-4 Using a hygrometer to measure water density . . . . 101

Figure 10-5 Taking an oil sample . . . . . . . . . . . . . . . . . . . . . . . . 103

®

sensor and

®

sensor and

ALTUS™ Net Oil Computer Manu al

v

Page 10

Contents

continued

Tables

Table 4-1 Densities and deviations for continuous mode . . . . 18

Table 4-2 Well data for well test mode. . . . . . . . . . . . . . . . . . . 21

Table 4-3 Transient bubble remediation parameters. . . . . . . . 23

Table 4-4 System parameters . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 4-5 Flow variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 4-6 Density inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 4-7 Temperature inputs . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 4-8 Flow calibration values . . . . . . . . . . . . . . . . . . . . . . 29

Table 4-9 D1 and D2 density values . . . . . . . . . . . . . . . . . . . . 30

Table 4-10 K1 and K2 tube period values . . . . . . . . . . . . . . . . . 31

Table 4-11 FD and dens temp coeff values. . . . . . . . . . . . . . . . 33

Table 4-12 Nominal FD values for sensors . . . . . . . . . . . . . . . . 34

Table 4-13 Temperature calibration values . . . . . . . . . . . . . . . . 35

Table 4-14 Sensor information variables. . . . . . . . . . . . . . . . . . 35

Table 4-15 Discrete output 1 power sources. . . . . . . . . . . . . . . 36

Table 4-16 Discrete output assignment variables . . . . . . . . . . . 36

Table 4-17 Fault conditions and settings for

milliamp outputs . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 4-18 Process variables for milliamp outputs . . . . . . . . . . 38

Table 4-19 Calibration span variables . . . . . . . . . . . . . . . . . . . . 39

Table 4-20 Pulse output variables . . . . . . . . . . . . . . . . . . . . . . . 40

Table 6-1 Continuous production measurements . . . . . . . . . . 51

Table 7-1 Performance measurements for

current well test . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 7-2 Performance measurements for

previous well tests. . . . . . . . . . . . . . . . . . . . . . . . 65

Table 8-1 Using NOC alarms. . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 8-2 Using slug flow alarms. . . . . . . . . . . . . . . . . . . . . . . 69

Table 8-3 Using output saturation alarms . . . . . . . . . . . . . . . . 70

Table 8-4 Using totalizer alarms . . . . . . . . . . . . . . . . . . . . . . . 70

Table 8-5 Using calibration and trim alarms . . . . . . . . . . . . . . 71

Table 8-6 Using conditional status alarms. . . . . . . . . . . . . . . . 72

Table 8-7 Fault output levels . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 8-8 Configurations for fault outputs . . . . . . . . . . . . . . . . 73

Table 8-9 Using critical status fault alarms . . . . . . . . . . . . . . . 74

Table 8-10 Using transmitter failure fault alarms. . . . . . . . . . . . 74

Table 8-11 Troubleshooting excessive drive gain . . . . . . . . . . . 75

Table 8-12 Nominal resistance ranges for

flowmeter circuits. . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 8-13 Troubleshooting sensor error fault alarms. . . . . . . . 77

Table 8-14 Density of air in grams per cubic centimeter . . . . . . 84

Table 8-15 Maximum flow rates for high-density

calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 8-16 Density of water. . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 9-1 Laboratory equipment for determining live oil

and produced water densities . . . . . . . . . . . . . . 87

Table 10-1 Approximate capacity of cylindrical vessels. . . . . . 97

Table 10-2 Approximate capacity of spherical ends . . . . . . . . 97

Table 11-1 Uncertainty factors for percent water cut and

percent net oil . . . . . . . . . . . . . . . . . . . . . . . . . . 107

vi

ALTUS™ Net Oil Computer Manu al

Page 11

1 Before You Begin

Water cut

D

eDo

–

DwD

o

–

-------------------- -=

1.1 About this manual

1.2 Application software

described in this manual

1.3 Introduction to the ALTUS™

NOC

Replacing an older NOC

and transmitter

This manual explains how to configure, operate, and maintain the

ALTUS

™

Net Oil Computer (NOC). This manual does not explain

installation or wiring. For information about installation and wiring, see

ALTUS Installation Manual

the

.

This manual pertains to software menus that enable operation,

configuration, and maintenance of the NOC.

• The ALTUS applications platform has software functions that do not

pertain to the NOC.

• For information about software functions that are not described in

this manual, refer to the installation and detailed setup manuals for

the applications platform.

The ALTUS NOC works with a Micro Motion® sensor to produce realtime measurements of water cut, net oil volume flow, and net water

volume flow. The NOC measures full-stream mass flow and volumetric

flow at rates from a few barrels to more than 100,000 barrels per day.

If an AL TUS NOC is installed as a replacement for an older Micro Motion

Net Oil Computer and RFT9739 or RFT9712 transmitter, power-supply

and output wiring does not need to be replaced. Because transmitter

software is included with the ALTUS NOC, a transmitter is not required.

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

Water cut determination

ALTUS™ Net Oil Computer Manu al

The NOC calculates water cut from the following equation:

Where

:

D

= Emulsion density

e

D

= Oil density

o

D

= Water density

w

Figure 1-1

, page 2, shows how water cut is calculated by the NOC. The

operator enters the oil and water densities at the reference temperature

(60°F in

temperature (100°F in

Figure 1-1

). The Micro Motion sensor measures the fluid

Figure 1-1

). The NOC extrapolates the densities

to the operating temperature, using an API equation for oil and a

Chevron Research equation for produced water. The water cut equation

is solved at operating temperature, then referenced back to 60°F. Using

water cut, mass flow rate, and net oil and water densities, the NOC

calculates net oil, net water, and gross flow at reference temperature.

1

Page 12

continued

Before You Begin

Figure 1-1. Water cut calculation

1.05

1.00

0.95

0.90

0.85

0.80

Density (g/cc)

0.75

0.70

Produced water density enter ed in NOC

Crude oil density ent er ed i n N O C

60° 90°

NOC capabilities

Produced water density

D

–

Water cut

100°

Temperature (°F)

eDo

-------------------- -=

DwD

–

o

120° 150°

Crude oil density

The NOC can operate in continuous mode or well test mode:

• In continuous mode, the NOC can continuously monitor a well,

separator, or pipeline.

• In well test mode, the NOC can perform a well test on any of up to 48

different wells. Well performance data for the test that is in progress

or for previous tests can be viewed during the test.

The NOC nonvolatile memory archives data acquired during the last

three well tests. The NOC resumes testing if a power failure or shutoff

interrupts the test that is in progress. The last three power outages are

recorded with power-on and power-off time/date stamps.

The NOC has three discrete outputs, two milliamp outputs, and a pulse

output:

• Discrete output 1 can be an alarm for transient bubble remediation.

• Discrete output 2 indicates net oil. It produces 10 output pulses per

barrel or 10 output pulses per cubic meter of net oil.

• Discrete output 3 indicates net water. It produces 10 output pulses

per barrel or 10 output pulses per cubic meter of net water.

• Milliamp output 1 can indicate any measured variable.

• Milliamp output 2 can indicate any measured variable.

• The pulse output can represent a flow variable.

The NOC can remediate density readings to compensate for the

presence of transient bubbles in the sensor. If erratic density resulting

from transient bubbles causes sensor drive gain to exceed the

programmed value, the NOC can be programmed to respond in one of

three ways:

• The NOC can hold the density value that was measured at a

specified time before transient bubbles were detected.

• The NOC can produce an alarm indicating the presence of transient

bubbles. The alarm can be assigned to discrete output 1.

• The NOC can stop the well test that is in progress.

2

ALTUS™ Net Oil Computer Manu al

Page 13

2 Installation Considerations

2.1 Piping arrangement and

ancillary equipment

Figure 2-1

when a 3-phase test separator is used.

Figure 2-2

when a 2-phase test separator is used.

Adhere to the following general guidelines:

• Design and size the test separator to ensure complete separation of

the entrained gas from the liquid phase.

• Size the Coriolis sensor so that at maximum liquid flow, pressure

drop is less than 3 psi.

• Install the sensor as far below the test separator as possible.

Install the sensor upstream from the dump valve

•

• Balance any sensor pressure drop with hydrostatic head, measured

from the lowest level in the separator down to the sensor inlet. Rule

of thumb: pressure drop should be about 0.4 psi per foot.

• If the liquid temperature is significantly different from the ambient

temperature, thermally insulate or heat trace the sensor and

upstream pipe to minimize paraffin coating and transient temperature

at the start of dumping periods.

• Install a meter proving loop, if required.

• Install a static mixer and sampling port for calibration and verification

purposes. Locate the static mixer and sampling port downstream

from the sensor and the proving loop connections.

• Make sure the dump valve is capable of regulating back pressure

and controlling the liquid flow rate.

, page 4, shows a typical installation of a sensor and an NOC

, page 4, shows a typical installation of a sensor and an NOC

.

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

3

Page 14

continued

Installation Considerations

Figure 2-1. Typical installation, Micro Motion® sensor and NOC with 3-phase separator

Figure 2-2. Typical installation, Micro Motion

®

sensor and NOC with 2-phase separator

4

ALTUS™ Net Oil Computer Manu al

Page 15

Installation Considerations

continued

2.2 Sensor installation

Sensor orientation

Install the sensor according to the appropriate sensor instruction

manual.

If possible, mount the sensor with its flow tubes downward in a

horizontal pipe run, as shown in

Figure 2-3

.

If necessary to prevent sand or other solid particles from accumulating

in the flow tubes, or to accommodate existing vertical piping, mount the

sensor in a vertical pipe run, as shown in

Figure 2-4

. The oil/water

interface should flow upward through the pipeline.

Figure 2-3. Sensor in horizontal pipe run, tubes downward

Flow direction

Using the Person-Process

Interface

Figure 2-4. Sensor in vertical pipe run

Flow direction

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

5

Page 16

Installation Considerations

PgPpP

m

+

>

Avoiding inaccurate flow

counts

continued

CAUTION

Settling of the oil/water interface in a sensor can

cause the flowmeter to indicate flow when there is no

flow.

• To avoid inaccurate flow counts, program a low flow

cutoff. To program a low flow cutoff, see page 25.

• Settling of the oil/water interface is more likely to occur if

the sensor is mounted in a vertical pipe run than if the

sensor is mounted in a horizontal pipe run.

Because the crude oil in the separator is at an equilibrium condition, any

pressure reduction can cause the solution gas (i.e., the light end

components) to break out from the saturated crude oil.

Even a seemingly small amount of free gas in the liquid phase can result

in substantial measurement errors in water cut and net oil. (See pages

107-109 to estimate the effect of free gas).

The amount of gas that is produced varies, and depends on the

properties of the crude oil and the operating conditions.

To prevent formation of solution gas in the flowmeter, the following

criterio n shou ld be followed:

Where:

Pg= Static head pressure of liquid, measured from liquid level at

separator to sensor inlet

P

= Frictional pressure loss of flow line, from test separator to

p

sensor inlet

P

= Pressure drop across sensor

m

Detailed pressure drop calculations are strongly recommended during

design and installation of the piping system.

6

ALTUS™ Net Oil Computer Manu al

Page 17

Installation Considerations

continued

The following general guidelines are suggested:

• To maximize the static head gain (P

), install the sensor as far below

g

the test separator as possible.

• Note that 1 psi (6.9 kPa) of static head gain results from 28 inches of

water column.

• To minimize the frictional head loss (P

), install the sensor as near as

p

possible to the test separator, and use larger-diameter connecting

pipes. Minimize use of piping elements such as tees, elbows, and

reducing unions.

• Install sampling ports, static mixer , proving connections, dump valve ,

back pressure regulator, or other flow-restricting devices downstream

from the sensor. A full-port valve should be considered if a cutoff

valve must be installed between the separator and the sensor.

• Whenever possible, frictional pressure loss should be less than 3 psi

(20.7 kPa) at the maximum anticipated flow rate.

• To minimize pressure drop across the sensor (P

), install a larger

m

sensor. Pressure drop across the sensor should be less than 3 psi

(20.7 kPa) at the maximum anticipated flow rate.

• In some environments, extremely tight emulsion occurs. Extremely

tight emulsion can make removal of entrained gas difficult, even with

a large separator. Using a suitable demulsifier chemical to break

down the emulsion is a possible method of alleviating this problem.

Using the Person-Process

Interface

2.3 Flow direction

If the sensor is installed directly at the wellhead, (i.e., if a test separator

is not used), the line pressure at the sensor should be maintained above

the crude oil bubble point pressure.

The sensor measures accurately regardless of flow direction. The arrow

on the sensor housing indicates normal forward flow direction. Refe r to

ALTUS Detailed Setup Manual

the

for directions about setting the NOC

to indicate forward flow, reverse flow, or forward and reverse flow.

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

7

Page 18

8

ALTUS™ Net Oil Computer Manu al

Page 19

3 Using the Person-Process

Interface

3.1 Person-Process Interface

Figure 3-1. Person-Process Interface

Volume Flow

Backlit

display

Volume Total

NEXT PRINT VIEW

Figure 3-1

• Configure the NOC

• Monitor and control the application

• Perform maintenance and diagnostic tasks

DEVICE 1

shows the Person-Process Interface. Use the interface to:

4,352.33

bpd

56,485.88

bbl

Using the Person-Process

Interface

Cursor control

buttons

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

Function buttons

ALTUS™ Net Oil Computer Manu al

Security button

9

Page 20

Using the Person-Process Interface

continued

3.2 Security button

The security button is in the lower right of the interface, marked by an

icon of a padlock.

• If security is disabled, press the security button to access the main

menu. See

• If security has been enabled, you will be prompted to enter a

password. See

• To enable security, see the

You can use the security button to return to the main menu or password

entry screen. Press the security button once to return to:

• The main menu, shown in

• The password entry screen, shown in

enabled

At the main menu or password entry screen, press EXIT to return to the

operation screen.

Figure 3-2

Figure 3-2. Pressing security button, security disabled

DEVICE 1

Volume Flow

4,532.33

bpd

Mass Total

56,485.88

bbl

NEXT PRINT VIEW

.

Figure 3-3

.

ALTUS Detailed Setup Manual

Figure 3-2

DEVICE 1

Configuration

Maintenance

Security

Language

SEL HELP EXIT

, if security is disabled

Figure 3-3

, if security is

.

Figure 3-3. Pressing security button, security enabled

DEVICE 1

Volume Flow

4,532.33

bpd

Mass Total

56,485.88

bbl

NEXT PRINT VIEW

10

Enter Password

SEL HELP EXIT

ALTUS™ Net Oil Computer Manu al

Page 21

Using the Person-Process Interface

continued

3.3 Function buttons

Figure 3-4. Function buttons

The pushbuttons below the display are the function buttons. The action

each button performs appears on the display just above the button.

Figure 3-4

reviews the functions that are assigned to each button.

DEVICE 1

Configuration

Maintenance

Security

SEL HELP EXIT

Using the Person-Process

Interface

START • Start well test

• Start averaging oil or water densities

STOP • Stop well test

• S t op averaging oil or water densities

CLEAR Clear all displayed values

RESET Reset total

PAUSE • Pause counting of all displayed totals

• Pause performance measurements

RESUME • R esume counting of all displ ayed totals

• R esume production meas ur em ents

SEL Select the highlighted option

CHG Make a change to the highlighted option

SAVE Save a change

ENTER Enter a password

YES Proceed with action

OK Proceed with action

NEXT • Scroll to next screen

• At the last screen, scroll to the first screen

• Test the next well in the sequence

RETURN Retu rn to well test screen

PGDN Page down to next help screen

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

VIEW Access the view menu

ACK Acknowledge an alarm message

EXIT Return to the previous screen

NO Cancel action

HELP Show a help screen

RESET Reset total

START Start a new well test

VIEW View performance meas urements for a

well that is being tested

PRINT Send a ticket to a printer

PGUP Page up to previous help screen

ALTUS™ Net Oil Computer Manu al

11

Page 22

Using the Person-Process Interface

continued

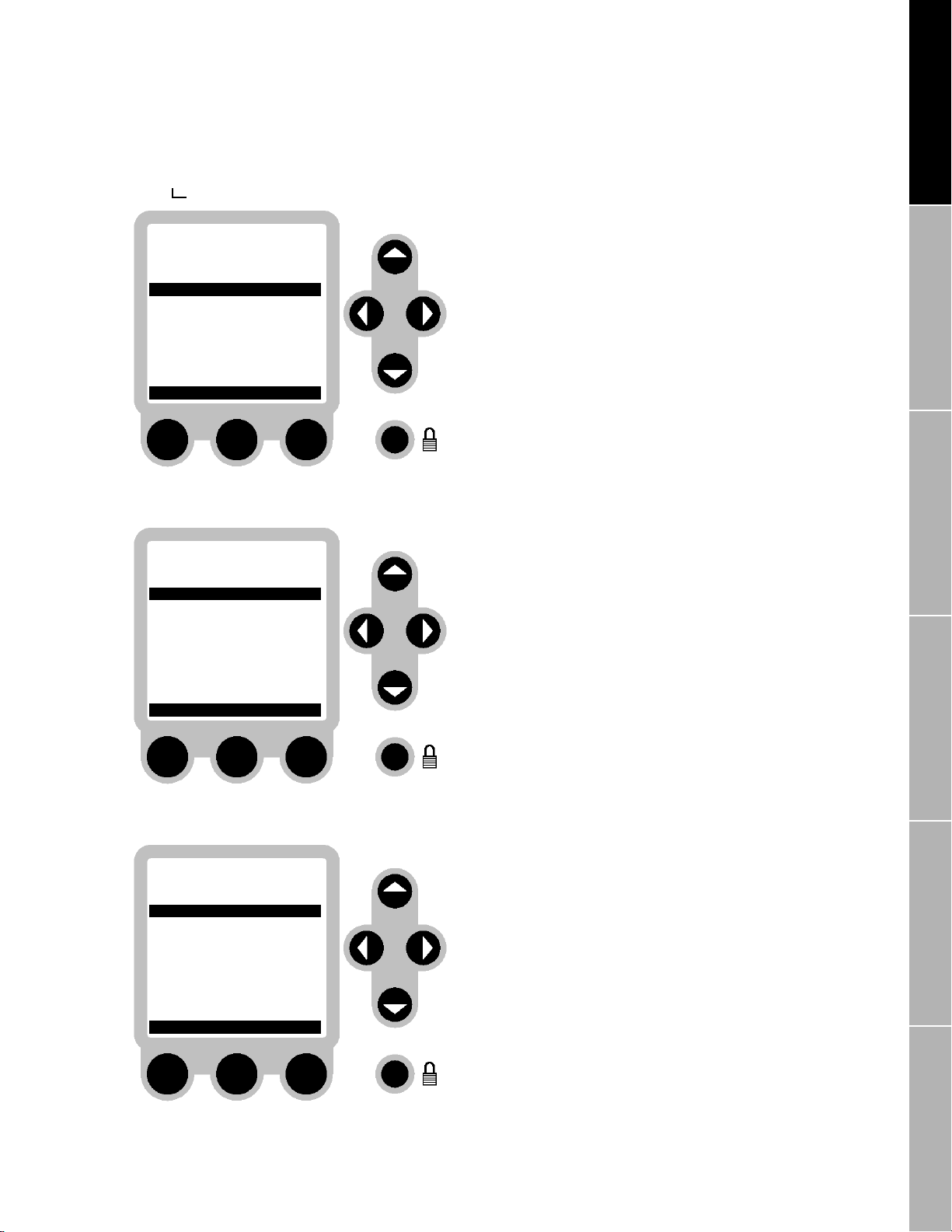

3.4 Cursor control buttons

Actions performed by the function buttons apply to the item at the cursor.

Figure 3-5

, page 13, shows a typical configuration sequence involving

both a menu item and a variable edit item. Pressing HELP produces a

screen that has help for the item at the cursor.

Menus

Each menu includes a list of items.

• The cursor is a reverse-video highlight bar.

• Use the up or down arrow buttons to locate the cursor at the menu

item you want to select or change.

• After locating the cursor at the desired menu item, press CHG or the

right cursor button to select the item.

Items

After a menu item has been selected, the cursor enables you to enter or

change the selected item:

• The cursor is an underscore character, which is located under a

character.

• If the item has a value of Yes or No, all arrows toggle between the

two choices. Otherwise, press the up and down arrow buttons to

increase or decrease the value of the character at the cursor.

• If the item has more than one digit or character (like the oil density in

the example), press the left and right arrow buttons to move the

cursor to the next or previous character.

• When the value is correct, press SAVE.

• If y ou wish to cancel the change, press EXIT. The interface returns to

the previous screen without saving the changes.

12

ALTUS™ Net Oil Computer Manu al

Page 23

Using the Person-Process Interface

Figure 3-5. Cursor control buttons

continued

Menu

Indicates items

available to scroll

Cursor is a

highlight bar

Item

Cursor is an

underscore

Well Data-Densities

Oil Density

Water Density

Oil Deviation

Water Deviation

CHG HELP EXIT

Well Data-Densities

Oil Density

Water Density

Oil Deviation

Water Deviation

SAVE EXIT

0.9000 g/cc

1.1000 g/cc

0.0005 g/cc

0.0005 g/cc

0.9000

g/cc

1.1000 g/cc

0.0005 g/cc

0.0005 g/cc

EXIT

↓

Move cursor to left or toggle YES/NO

↓

Move cursor up/Scroll up

SELECT

Move cursor down/Scroll down

Increase value at cursor

or toggle YES/NO

Move cursor to right

or toggle YES/NO

Decrease value at cursor

or toggle YES/NO

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

13

Page 24

14

ALTUS™ Net Oil Computer Manu al

Page 25

4 Configuration

4.1 Recording the

configuration

4.2 Configuration sequence

While you are configuring the NOC, record configuration parameters in

the NOC configuration record (

Failure to perform configuration tasks in the proper sequence could

result in an incomplete or flawed configuration. Perform configuration

tasks in the following sequence:

1. Configure well performance measurements.

2. Configure system data.

3. Configure inputs.

4. Configure outputs.

Appendix A

).

CAUTION

Selecting configuration will interrupt measurement

and control functions. All outputs will go to their

configured fault settings.

Set control devices for manual operation before accessing

configuration menus.

Step 1

Configure well performance measurements

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

Well performance measurements include the following parameters:

• Mode of operation

• Units of measurement

• Well data – densities

• Compensations

15

Page 26

Configuration

Mode of operation

Configuration

Well performance meas

continued

Mode of operation

CAUTION

Changing the mode of operation will erase all

stored test data.

Mode of Operation

Continuous Mode

Well Test Mode

SAVE EXIT

Units of measurement

To avoid erasing test data, d o not chan ge the mo de of

operation during a well test.

To set the mode of operation:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Well Performance Meas.

d. Select Mode of Operation.

e. Select Continuous Mode or Well Test mode, then

press SAVE.

The units of measurement menu allows you to select

a reference temperature for measuring net oil and net

water.

To select a unit of temperature, see page 27.

To select a unit of volume flow, see page 25.

CAUTION

Changing reference temperature changes the

indicated standard volumes and reference

densities.

If the reference temperature is changed, change oil

and water reference density values.

16

ALTUS™ Net Oil Computer Manu al

Page 27

Configuration

Configuration

Well performance meas

Units of Measurement

60 degF

15 degC

20 degC

continued

Units of measurement

To select the reference temperature:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Well Performance Meas.

d. Select Units of Measurement.

e. Select the desired refer ence temperature, then

press SAVE.

The reference temperature that is currently being

used is always the one that is highlighted.

SAVE EXIT

Well data-densities

Configuration

Well performance meas

Well data-densities

Well Data-Densities

Oil Density

0.9000 g/cc

Water Density

1.1000 g/cc

Oil Deviation

0.0005 g/cc

Water Deviation

0.0005 g/cc

CHG HELP EXIT

Using the Person-Process

Interface

Continuous mode

To enter oil and water densities and deviations for

continuous mode:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Well Performance Meas.

d. Select Well Data-Densities.

↓

e. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-1

in

, page 18.

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

17

Page 28

Configuration

continued

Oil and water densities, deviations, and duration

averages are described in the chapter that explains

density determination (pages 93-104

).

Well Data-Densities

Oil Deviation

0.0005 g/cc

Water Deviation

0.0005 g/cc

Oil Duration Ave

Water Duration Ave

CHG HELP EXIT

↑

5 sec

5 sec

Table 4-1. Densities and deviations for continuous mode

Variable Default Description

Oil density 0.9000 g/cc • I f oil density at reference temperature is known, enter the densi ty value

Water density 1.1000 g/cc • If water density at reference temperature is known , e nt e r the density value

Oil deviation 0.0005 g/cc • E nter the maximum oil density deviation that wi ll be allowed du ring density

Water deviation 0.0005 g/cc • Enter the maximum water density deviation that will be allowed during density

Oil density ave 5 sec Enter the amount of time during which oil density will be averaged during density

Water density ave 5 sec Enter the amount of time during which water density will be averaged during

• If oil density at reference tempe rature is unk nown, perform a density

determina tio n (see pages 93-104)

• If water density at reference temperature is unknown, perform a density

determina tio n (see pages 93-104)

determina tio n (see pages 93-104)

• I f t he dif ference bet wee n t wo co nsecutive density readings i s grea te r t han the

programmed deviation, the densit y average is restarted. The averaging is

completed when the deviation is not exceeded during the averaging period

determina tio n (see pages 93-104)

• I f t he dif ference bet wee n t wo co nsecutive density readings i s grea te r t han the

programmed deviation, the densit y average is restarted. The averaging is

completed when the deviation is not exceeded during the averaging period

determina tio n (see pages 93-104)

density determ i nation (see pages 93 -104)

18

ALTUS™ Net Oil Computer Manu al

Page 29

Configuration

Configuration

Well performance meas

Well Data-Densities

Wells 1 to 12

Wells 13 to 24

Wells 25 to 36

Wells 37 to 48

continued

Well data-densities

Well test mode

To enter well names, oil and water densities,

deviations, and purge times for well test mode:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Well Performance Meas.

d. Select Well Data-Densities.

e. Select the menu item for the number of the well

that will be configured, then press CHG.

CHG HELP EXIT

Wells 1 to 12

01: Tinsley 22-14b

02: N Cowden 24-17a

03: R Dutton 36-13c

04: B Olsen 23-15d

05: 13-24-44-5E6

06: 08-11-23-6E2

07: 18-44-04-3W5

08: 12-28-36-6W7

SAVE EXIT

Using the Person-Process

Interface

f. Select the well that will be configured, then press

SAVE.

↓

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

19

Page 30

Configuration

Well Name:

Oil Density

Water Density

Purge Time

CHG HELP EXIT

continued

Well #1

Tinsley 22-14b

0.8000 g/cc

1.0000 g/cc

30 minutes

g. To enter a well name:

• Begin entering characters at the far left

position

• Enter up to 18 alphanumeric characters,

↓

including spaces

h. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-2

in

.

Oil and water densities, deviations, and duration

averages are described in the chapter that explains

density determination (pages 93-104

).

Well #1

Oil Deviation

0.0005 g/cc

Water Deviation

0.0005 g/cc

Oil Duration Ave

5 sec

Water Duration Ave

5 sec

CHG HELP EXIT

↑

20

ALTUS™ Net Oil Computer Manu al

Page 31

continued

Configuration

Table 4-2. Well data for well test mode

Variable Default Description

Well name Not applicable

(none)

Oil density 0.8000 g/cc • I f oil density at reference temperature is known, enter the densi ty value

Water density 1.0000 g/cc • If water density at reference temperature is known , e nt e r the density value

Purge time 30 minutes Enter t he time during which, prior to a well test, measurements will not be recorded

Oil deviation 0.0005 g/cc • E nter the maximum oil density deviation that wi ll be allowed during density

Water deviation 0.0005 g/cc • Enter the maximum water density deviation that will be allowed during density

Oil density ave 5 sec Enter the amount of time during which oil density will be averaged during density

Water density ave 5 sec Enter the amount of time during which water density will be averaged during density

Beginning at the far left position , en te r up to 18 alphanumeri c ch aracters, including

spaces, that will serve as the name for the selected well

• I f oil density at reference temperature is unknown, perform a density

determina tio n (see pages 93-104)

• I f water density at reference temperature is unknown, perform a density

determina tio n (see pages 93-104)

until separator conte nt s f ro m the previous tes t have been purg ed

determina tio n (see pages 93-104)

• I f t he dif ference bet wee n t wo co nsecutive density readings i s grea te r t han the

programmed deviation, the densit y average is restarted. Th e averaging is

completed when the deviation is not exceeded during the averaging period

determina tio n (see pages 93-104)

• I f t he dif ference bet wee n t wo co nsecutive density readings i s grea te r t han the

programmed deviation, the densit y average is restarted. Th e averaging is

completed when the deviation is not exceeded during the averaging period

determina tio n (see pages 93-104)

determina tio n (see pages 93-104)

Using the Person-Process

Interface

Compensations

The compensations menu allows you to configure the

NOC to perform transient bubble remediation.

Transient bubble remediation (TBR) corrects density

and water cut read ings during brief period s when gas

bubbles are passing through the sensor.

Figure 4-1

•

, page 22, illustrates the effect of

transient bubbles on measured density.

Figure 4-2

•

, page 22, illustrates how the NOC

holds the measured density at the time period

before transient bubbles were detected, if hold

last value is selected as the action taken.

Figure 4-3

•

, page 22, illustrates how transient

bubble remediation corrects density readings.

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

21

Page 32

continued

Configuration

Figure 4-1. Effect of transient bubbles on density

15.00 V

10.00 V

5.00 V

Drive gain (volts)

0.00 V

Figure 4-2. Holding at last measured density

15.00 V

10.00 V

5.00 V

Drive gain (volts)

0.00 V

Programmed drive gain

level (see

Table 4-3

)

Programmed

time period

Table 4-3

(see

1.0 g/cc

Density (g/c c)

0.9 g/cc

Drive gain (volts)

0.8 g/cc

Time

1.0 g/cc

Density (g/c c)

0.9 g/cc

Drive gain (volts)

0.8 g/cc

Time

)

Figure 4-3. Correction of density readings

15.00 V

10.00 V

5.00 V

Drive gain (volts)

0.00 V

Programmed drive gain

level (see

22

Table 4-3

)

1.0 g/cc

Density (g/c c)

0.9 g/cc

Drive gain (volts)

0.8 g/cc

Time

ALTUS™ Net Oil Computer Manu al

Page 33

continued

Configuration

Transient Bubble Remd

Drive Gain Level

Action Taken

Time Period

Configuration

Well performance meas

Hold Last Value

Compensations

Transient bubble remd

5.4 V

15 seconds

To set parameters for transient bubble remediation:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Well Performance Meas.

d. Select Compensations.

e. Select Transient Bubble Remd.

f. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-3

in

.

CHG HELP EXIT

Table 4-3. Transient bubble remediation parameters

Variable Default Definition

Drive gain level 14.5 volts • Enter a value of 0.5 to 14.5 volts

Action taken Hold last value • Hold last value:

Time period 15 seconds If hold last value is selected as the action t aken, enter the amount of time before

• T he ent er ed value is the voltage above which the NOC will indicate transient bubbles

• To determine the appropria te value, view the average and maximum values in the

view production measureme nt s m enu ( see 50-51), the view current test me nu (se e

pages 61-62), or the view well tests me nu (se e pages 63-65)

• Entering a value of 14.5 will disable transient bubble remediation

-

The NOC will hold the measured density at the time period before transient bubb le s

were detected

-

Transient bubbles can be indicated by discrete output 1 (see page 36)

-

This option requires configuration of a time period (s ee below)

• Stop well test:

-

The NOC will stop the well test if transient bubbles are detected

-

Transient bubbles can be indicated by discrete output 1 (see page 36)

• A larm only: Transient bubbles will be indicated by discrete output 1 (se e pa ge 36)

transient bubbles were detected that w ill be used to derive a density re ading

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

23

Page 34

Configuration

continued

Step 2

Configure system data

To configure system data:

Configuration

System

a. Press the security button on the display face.

b. Select Configuration.

c. Select System.

d. Use the function buttons and the cursor control

System

Tag

Time

Date

Master Reset

SEL HELP EXIT

buttons to configure the parameters that are listed

Table 4-4

in

.

Table 4-4. System parameters

Variable Default Description

Ta g Device 1 Enter up to 8 digits and/or characters that identify this NOC, well, or separator

Time Current time Enter a value of 0 to 23 for hours, a value of 00 to 59 for minutes, and a value of 00

Date Cur rent date Enter 4 digits for the year, a character code for the month, and 2 digits for the day

to 59 for seconds

24

ALTUS™ Net Oil Computer Manu al

Page 35

Configuration

continued

Flow variables

Configuration

Inputs

Coriolis

Config process var

Flow variables

Flow Variables

Flow Damping

0.8 sec

Meter Direction

Forward

Mass Units

g/s

Mass Low Flow Cutoff

0.00000 g/s

CHG HELP EXIT

Step 3

Configure inputs

To confi gur e flow variables:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Inputs.

d. Select Coriolis.

e. Select Config Process Var.

f. Select Flow Variables.

g. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-5

↓

in

.

Using the Person-Process

Interface

Table 4-5. Flow variables

Variable Default Description

Flow damping 0.8 sec • The selected value is the time req ui re d for flow outputs and di s pl ays to

achieve 63% of their new value in response to a step change at the input

• D amping filters out nois e or th e ef fects of rapid changes in the flow rate

without affecting measurem e n t acc uracy

Meter direction Forward • S el ect the direction in whi ch process fluid will flow thr ough the sensor

relative to the flow direction arrow on th e sensor

• T he sensor can measure forward or backward flow

Mass units g/s • Sel ect the desired unit of mass flow

• Mass flow outputs and displays will indicate flow in the selected unit

Mass low flow cutoff 0.00000 g/s • Enter the mass flow rate below which mass flow outputs and displays will

indicate zero flow

• T he recommended flow cut of f is 0.02% of the flow rate that is repre sented

by the milliamp output at 20 mA. For example, if an output of 20 mA

represents 100 lb/min, the flow cutoff should 0.02 lb/min

• To set the calibration span for milliamp outputs, see page 39

Volume units l/s • S elect the desired unit of volume flow

• Volume flow outputs and displays will indicate flow in the selected unit

V olume low flow cutoff 0.0000 0 l/s • Enter the volume flow rate belo w which v olu me flo w outputs and d ispla ys wil l

indicate zero flow

• T he recommended flow cut of f is 0.02% of the flow rate that is repre sented

by the milliamp output at 20 mA. For example, if an output of 20 mA

represents 100 l/min, t he f low cutof f sho ul d 0. 02 l/min

• To set the calibration span for milliamp outputs, see page 39

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

25

Page 36

Configuration

continued

Density inputs

Configuration

Inputs

Coriolis

Config process var

Density

Density

Density Units

Density Damping

1.7 sec

Slug Low Limit

0.000000 g/cc

Slug High Limit

5.000000 g/cc

CHG HELP EXIT

Table 4-6. Density inputs

g/cc

To configure density inputs:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Inputs.

d. Select Coriolis.

e. Select Config Process Var.

f. Select Density.

g. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-6

↓

in

.

Variable Default Description

Density units g/cc • Select the desired unit of density

Density damping 1.7 sec • The selected value is the time required for density outputs and displays to

Slug low limit 0.000000 g/ cc • E nter the desired low limit, in g/cc, for the fluid density. The recommended slug

Slug high limit 5.000000 g/cc • Enter the desire d hi gh limit, in g/cc, for the fluid density. The recommended slug

Slug time 1.0 sec • Enter the number of seconds for which flow outputs will hold their last measured

• D ensity outputs and displays will indicate density in the selected un it

achieve 63% of their new value in response to a step change at the input

• D am ping filters out noise or the effects of rapid cha nges in density without

affecting measurement accurac y

low limit is 0.8 x the lowest density to be measured

• T he ent er ed value is the density below which a slug flow alarm will be generated

• T he ent er ed value should be lower than the density that will cau se drive gain to

indicate the presenc e of tran sient bubbles in the sensor (see pages 21 -23)

• For more information about slug flow, see page 69

high limit is 1.4 g/cc

• T he ent er ed value is the density above which a slug flow alar m will be ge nerat ed

• The entered value should be higher than the density that will cause drive gain to

indicate the presenc e of tran sient bubbles in the sensor (see pages 21 -23)

• For more information about slug flow, see page 69

flow r ate w hile d ens ity i s ou tside the r an ge sp ecif ied b y the s lug l ow limit and s lu g

high limit

• If transient bubble remediation has been implemented, set slug time to 0.0 sec. If

a value of 0.0 is entered, flow outputs will go to th e l evel that indicates zero flow

as soon as slug flow is detected

• T he maximum slug time is 300 seconds

• For more information about slug time, see page 69

26

ALTUS™ Net Oil Computer Manu al

Page 37

Configuration

continued

Temperature

Configuration

Inputs

Coriolis

Config process var

Temperature

Temperature

Temperature Units

degC

Temp. Damping

3.5 sec

CHG HELP EXIT

Table 4-7. Temperature inputs

To confi gure temperature inputs:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Inputs.

d. Select Coriolis.

e. Select Config Process Var.

f. Select Temperature.

g. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-7

in

.

Using the Person-Process

Interface

Variable Default Description

Temperature units degC • Select degrees Celsius, Fahrenheit, Rankine, or Kelvin

• Temperature outputs and displays will indicate temperature in the selected unit

Temperature damping 3.5 sec • The selected value is the time required for temperature outputs and displays to

achieve 63% of their new value in response to a step change at the input

• D am ping filters out noise or the effects of rapid cha nges in temperature without

affecting measurement accurac y

• I f de nsi t y de te rmination will be per form ed, set temperature damping at 1.0 sec.

To perform a density determinatio n, see pages 93-104

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

27

Page 38

Configuration

continued

Sensor calibration data

Configuration

Inputs

Coriolis

Sensor cal data

Sensor Cal Data

Flow Factor

1.00000

Flocal Temp Coef

5.130

D1

0.000000

D2

1.000000

CHG HELP EXIT

Sensor calibration data describe the sensor’s

sensitivity to flow, density, and temperature.

To configure sensor calibration data:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Inputs.

d. Select Coriolis.

↓

e. Select Sensor Cal Data.

f. Use the function buttons and the cursor control

buttons to configure sensor calibration data.

• Sensor cal data should be entered from the

sensor serial number tag or factory calibration

certificate.

• Tags and certificates vary in appearance,

depending on the sensor model number and

manufacturing date.

Flow calibration values

include the flow factor and

the flow calibration temperature coefficient. To

configure flow calibration values, see page 29.

Density calibration values

include D1 and D2

density values, K1 and K2 tube periods, the flowing

density correction factor, and the density calibration

temperature coefficient. T o configure density

calibration values, see pages 30-34.

Temperature calibration values

include the

temperature slope and the temperature offset. To

configure temperature calibration values, see

page 35.

28

ALTUS™ Net Oil Computer Manu al

Page 39

continued

Configuration

Flow calibration values

Flow calibration values include the flow factor and the flow calibration

temperature coefficient. To configure flow calibration values, see

Table 4-8

and

Figure 4-4

.

Table 4-8. Flow calibration values

Variable Default Description

Flow factor 1.00000 g/sec • Enter the first 5 di gi ts of th e flow cal factor (see

Flowcal temp coef 5. 130 • Enter the last 3 digits of th e f low cal factor (see

• T he ent er ed value is the flow rate, in g/sec, that generates 1

between velocity signals from the sensor

• T he ent er ed value represents the percent change in the measured flow rate per

100°C change in tempe ratur e

Figure 4-4

Figure 4-4

)

sec of time shift

µ

)

Figure 4-4. Flow calibration values on sensor serial number tag

Flow factor

on

newer

tag

Flow factor

19.0005.13

Flocal temp coef

on

newer

tag

Flocal temp coef

19.0005.13

on

older

on

tag

19.0005.13

older

tag

19.0005.13

Using the Person-Process

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

29

Page 40

continued

Configuration

Density calibration values

Density calibration values include D1 and D2 density values, K1 and K2

tube periods, the flowing density correction factor (FD), and the density

calibration temperature coefficient (dens temp coeff).

• To configure D1 and D2, see

• To configure K1 and K2, see

Table 4-9

Table 4-10

• To configure FD and the dens temp coeff, see

Figure 4-9

, page 33.

and

and

Figure 4-5

Figure 4-6

Table 4-11

Table 4-9. D1 and D2 density values

Variable Default Description

D1 0.000000 g/cc • If the se ns or tag shows a D1 value, enter the D1 value (see

D2 1.000000 g/cc • If the se ns or tag shows a D2 value, enter the D2 value (see

• I f the sensor tag does not show a D1 value, enter the Dens A or D1 value from

the calibration certificate

• The entered value is the density of the low-density calibration fluid (Micro Motion

uses air)

• I f the sensor tag does not show a D2 value, enter the Dens B or D2 value from

the calibration certificate

• The entered value is the density of the high-density calibration fluid (Micro Motion

uses water)

, below.

, page 31.

Figure 4-5

Figure 4-5

and

)

)

Figure 4-5. D1 and D2 on sensor serial number tag

D1

newer

on

tag

0.0010

D2

on

newer

0.9980

tag

30

ALTUS™ Net Oil Computer Manu al

Page 41

continued

Configuration

Table 4-10. K1 and K2 tube period values

Note

If K1 and K2 values are being entered from a factory calibration certificate:

• D O N OT enter values from the CO M MENTS section on the firs t pa ge ( see

• D O ent er values listed on the second page (see

Variable Default Description

K1 5000.000 • If the sensor tag shows a K1 value, enter the K1 value (see

• I f the sensor tag does not show a K1 value, enter the first 5 di gits of the den si ty

calibration factor (see

• T he ent er ed value represents the sensor flow tube period in

adjusted to 0°C

K2 50000.000 • If the sensor tag shows a K2 value, enter th e K2 value (see

• I f the sensor tag does not show a K2 value, enter the second 5 digits of the density

calibration factor (see

• T he ent er ed value represents the sensor flow tube period in

adjusted to 0°C

Figure 4-8

, page 32)

Figure 4-6

Figure 4-6

Figure 4-7

, older tag)

, older tag)

, page 32)

Figure 4-6

sec associated with D1,

µ

Figure 4-6

, newer tag)

, newer tag)

µsec associated with D2,

Using the Person-Process

Figure 4-6. K1 and K2 on sensor serial number tag

K1

newer

on

tag

12500142864.44

12502.000

K2

newer

on

tag

12500142864.44

14282.000

K1

K2

on

on

older

older

Interface

tag

12500142864.44

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

tag

12500142864.44

ALTUS™ Net Oil Computer Manu al

31

Page 42

continued

Configuration

Figure 4-7. K1 and K2 values from comments section

not

Do

use these

K1 and K2 values

Figure 4-8. K1 and K2 values from second page

These K1

and K2

values can

be used

32

ALTUS™ Net Oil Computer Manu al

Page 43

continued

Configuration

Table 4-11. FD and dens temp coeff values

Variable Default Description

FD 0.000 • If the se ns or tag shows an FD value, enter the FD value (see

Dens temp coeff 4.440000 • If the se nsor tag shows a TC value, enter the TC value (see

• I f the sensor tag does not show an FD value, enter the ap pr opriate FD value from

Table 4-12

• The entered value adjusts density calculations for the effect of high flow rates on

measured dens i ty

• If the sensor tag does not show a TC value, enter the last 3 digits of the density

calibration factor (see

• T he ent er ed value represents the percent change in the measured density per 100°C

change in temperature

, page 34

Figure 4-9

, older tag)

Figure 4-9. FD and dens temp coeff on sensor serial number tag

FD

newer

on

tag

Figure 4-9

Figure 4-9

)

, newer tag)

Using the Person-Process

Interface

Dens temp coeff

4.44000

newer

on

tag

12500142864.44

310

Dens temp coeff

on

older

tag

12500142864.44

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

33

Page 44

continued

Configuration

Table 4-12. Nominal FD values for sensors

Nominal

ELITE

®

CMF010 standard pressure 316L stainless steel 140

CMF010 standard pressure Inconel

®

686 220

Sensor model Flow tube material

FD value

CMF010 high pressur e Inconel 686 760

CMF025 standard pressure 316L stainless steel or Hastelloy

®

C-22 450

CMF050 standard pressure 316L stainless steel or Hastelloy C-22 430

CMF100 standard pressure 316L stainless steel or Hastelloy C-22 230

CMF200 standard pressure 316L stainless steel or Hastelloy C-22 320

CMF300 standard pressure 316L stainless steel or Hastelloy C-22 280

®

BASIS

F025S 316L stainless steel 0

F050S 316L stainless steel 0

F100S 316L stainless steel 0

F200S 316L stainless steel 350

Model D DS006 standard pressure 316L stainless steel or Hastelloy C-22 450

DS012 stand ard pressure 316L stainless steel 900

DS012 standard pressure Hastelloy C-22 490

DS025 stand ard pressure 316L stainless steel 110

DS025 standard pressure Hastelloy C-22 330

DS040 stand ard pressure 316L stainless steel 220

DS040 standard pressure Hastelloy C-22 610

DS065 stand ard pressure 316L stainless steel 310

DS100 standard pressure 316L stainless steel or Hastelloy C-22 520

DS150 standard pressure 316L stainless steel or Hastelloy C-22 480

DS150 standard pressure 316L stainless steel with Tefzel

®

lining 640

DS300 standard pressure 316L stainless steel or Hastelloy C-22 200

DS300 standard pressure 316L stainless steel with Tefzel lining 260

DS600 standard pressure 316L stainless steel 50

Model DH DH006 high pressure 316L stainless steel 0

DH012 high pressure 316L stainless steel 0

DH025 high pressure 316L stainless steel 0

DH038 high pressure 316L stainless steel 0

DS100 high pressure 316L stainless steel 0

DH150 high pressure 316L stainless steel 0

DH300 high pressure 316L stainless steel 0

Model DL DL065 316L stainless steel 210

DL100 316L stainless steel 670

DL200 316L stainless steel 150

Model DT DT065 Hastelloy C-22 550

DT100 Hastelloy C-22 380

DT150 Hastelloy C-22 130

34

ALTUS™ Net Oil Computer Manu al

Page 45

continued

Configuration

Temperature calibration values

Temperature calibration values include the

temperature slope and the temperature offset. To

configure temperature calibration values, see

Table 4-13

.

Table 4-13. Temperature calibration values

Variable Default Description

Temperature slope 1.000000 • Enter the temperature sl ope value provided by Micro Motion, or pe rfor m a

Temperature offset 0.000000 • Ente r th e t em perature offset value provided by Micro Mo tion, or perform a

temperature calibration

• To perform a temperature calibration, see the

temperature calibration

• To perform a temperature calibration, see the

ALTUS Detailed Setup Manual

ALTUS Detailed Setup Manual

Using the Person-Process

Sensor information

Configuration

Inputs

Coriolis

Sensor information

Sensor information includes variables that serve as

references without affecting calibration parameters,

totalizers, or outputs.

To configure sensor information:

a. Press the security button on the display face.

b. Select Configuration.

Sensor Information

↓

Sensor Model No.

CMF025

Sensor Serial No.

000000

Sensor Material

304 SS

Sensor End Connection

ANSI 150

CHG HELP EXIT

c. Select Inputs.

d. Select Coriolis.

e. Select Sensor Information.

f. Use the function buttons and the cursor control

buttons to configure the parameters that are listed

Table 4-14

in

.

Table 4-14. Sensor information variables

Variable Default Description

Sensor model no. Uninitialized Enter a description of the sensor model, such as "CMF30 0"

Sensor serial no. 000000 Enter the serial number that is on the sensor serial number ta g

Sensor material 304 SS Select the appropriate sensor flow tube material (304 SS, 316L SS, Hastelloy C,

Sensor end connection ANSI 150 Select the appropriate flange, union fitting, sanitary fitting, or wafer fitting

Sensor liner None Select the appropriate liner mater i al for the sensor flow tubes (Tefzel or none)

Inconel, or Tantalum)

Interface

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

35

Page 46

Configuration

continued

Discrete outputs

Configuration

Outputs

Discrete outputs

Discrete output 1

Discrete output 2

Discrete output 3

Discrete Output 1

Power Source

Internal

Assignment

None

CHG HELP EXIT

Step 4

Configure outputs

To configure discrete outputs:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Outputs.

d. Select Discrete Outputs.

e. Select Discrete Output 1, Discrete Output 2, or

Discrete Output 3.

f. Use the function buttons and the cursor control

buttons to configure the power source and

assignment for the selected discrete output.

Power source

Discrete outputs can be connected to factorysupplied or user-supplied relays.

• To select the appropriate power source for

discrete output 1, see

Table 4-15

, below.

• The power source for discrete output 2 and

discrete output 3 cannot be configured.

• For relay specifications and installation

instructions, see the

ALTUS Installation Manual

Assignment

Discrete output 1 can be inactive or can indicate

transient bubble remediation. See

Table 4-16

.

• Discrete output 2 represents net oil.

• Discrete output 3 represents net water.

.

Table 4-15. Discrete output 1 power sources

Note

For relay specifications and installation instructions, see the

Relay type

Factory-supplied relays Internal Select internal power

User-supplied relays Internal • Select internal power if relays are internally powered

Default

Power source

• S el ect external power if relays are externall y powere d

ALTUS Installation Manual

Table 4-16. Discrete output assignment variables

Discrete output Variable

Discrete output 1 Transient bubble

remediation event

None Discrete output 1 will be inactive

Discrete output 2 Net oil Cannot be

Discrete output 3 Net water Cannot be

36

Default

None Discrete output 1 will indicate high drive gain

re-assigned

re-assigned

Description

Discrete output 2 will produce 10 output pulses per

barrel or 10 output pulses per cubic mete r of net oil

Discrete output 3 will produce 10 output pulses per

barrel or 10 output pulses per cubic mete r of net water

ALTUS™ Net Oil Computer Manu al

Page 47

Configuration

CAUTION

continued

Milliamp outputs

Configuration

Outputs

Milliamp outputs

Milliamp output 1

Fault indication

Milliamp output 2

Fault indication

Fault Indication

Condition

Downscale

Setting

3.60 mA

CHG HELP EXIT

Configuring milliamp outputs includes the following

procedures:

• Configuring fault indication

• Assigning a process variable to the output

• Configuring the calibration span

Fault indication

To configure fault indication for milliamp outputs:

a. Press the security button on the display face.

b. Select Configuration.

c. Select Outputs.

d. Select Milliamp Outputs.

e. Select Milliamp Output 1 or Milliamp Output 2.

f. Select Fault Indication.

g. Use the function buttons and the cursor control

buttons to configure the condition and setting of

fault indicators for the selected milliamp output.

Condition:

•

Milliamp outputs can produce

downscale, upscale, last measured value, or

internal zero fault indicators. See

Table 4-17

The default condition is downscale.

Setting:

•

If downscale or upscale is selected

as the fault condition, the setting determines

the amount of current that indicates a fault.

Table 4-17

See

.

Using the Person-Process

Interface

.

Using last measured value or internal zero may

hamper identification of fault outputs.

To make sure fault outputs can be identified, select

downscale or upscale.

Table 4-17. Fault conditions and settings for milliamp outputs

Note

The default condition for fault indication is downscale

Condition Description

Downscale Can be configured from 1. 0 to 3.6 m A 3.6 mA

Upscale Can be configured from 21.0 to 24.0 mA 22.0 mA

Last measured value • Holds at the mA value that represents the last measured value for the process

variable before the fault occurred

• A pp arent lack of variation in the process variable could i ndi cate a fault

Internal zero • Goes to the mA value that rep resents a value of 0.0 for the process variable

• An apparent value of 0.0 for the process variable could indicate a fault

Default

setting

Not applicable

Not applicable

Configuration Using the View Menu Continuous ModeBefore You Begin Installation Considerations

ALTUS™ Net Oil Computer Manu al

37

Page 48

Configuration

None

Frequency Input

Unc Oil Rate

Unc Water Cut

Unc Water Rate

Net Oil Rate

Water Cut

Gross Flow Rate

Net Water Rate

Ave Unc Oil Rate

SAVE EXIT

continued

Configuration

Outputs

Milliamp outputs

Process Variable

Milliamp output 1

Variable assignment

Milliamp output 2

Variable assignment

↓

Process variable