Page 1

Product Data Sheet

PS-00400, Rev V

March 2019

Micro Motion® Series 1000 and Series 2000

Transmitters with MVD™ Technology

Micro Motion Series 1000 and Series 2000 transmitters with MVD technology deliver powerful features that make managing your

process easier.

Advanced architecture with flexible installation options

■

Integral or remote mounting provides maximum flexibility

■

Cost-effective 4-wire interface reduces installation costs

■

Remote field mount models available with stainless steel housing for harsher environments

■

DIN rail option reduces complexity and increases versatility

Wide variety of I/O and application capabilities to fit your needs

■

High-speed DSP for accuracy under the toughest conditions—entrained gas, high noise, high turndown,

and more

■

Concentration and net flow measurement eliminate the need for additional instruments

■

Approved for custody transfer and certified for SIL2 and SIL3, which provides measurement confidence

and reliability

■

WirelessHART® option allows you to gain access to additional diagnostics and process information

without added wiring costs

Page 2

Series 1000 and 2000 Transmitters

March 2019

Micro Motion® Series 1000 and Series 2000 transmitters

Series 1000 and 2000 transmitters allow for the precise fit and integration for your Micro Motion Coriolis Flow and Density meters.

Powerful adaptability to your installation needs combined with ultimate flexibility in output connections provides the proper fit for

your application.

MVD technology makes your meter work smarter

■

Front end signal processing gives faster response time and dramatically reduces signal noise

■

Provides reduced wiring costs through use of standard 4 wire instrument cable

■

On-board signal processing results in the cleanest, most accurate signal delivered, even with tough measurement conditions

such as entrained gas

Smart Meter Verification: advanced diagnostics for your entire system

■

A comprehensive test that can be run locally or from the control room to provide confidence in your meter functionality and

performance

■

Verifies that your meter performs as well as the day it was installed, giving you assurance in less than 90 seconds

■

A basic version of Smart Meter Verification is included with new enhanced core processors that provides simple pass/fail results,

and simple diagnostics that run without interrupting your processes

■

A licensed version includes enhanced capabilities, such as viewing previous results and generating comprehensive reports

Mounting and Installation flexibility to fit your exact needs

■

Form factors include rugged field mounts with a full suite of hazardous area approvals or DIN rail packages for cost effective

control room cabinets

■

Local User Interfaces provide detailed operator feedback and accessibility

■

Connection to new or existing Micro Motion sensors easily achieved through flexible configurations

Connection and Interface adaptability for seamless integration

■

Broad combinations of analog and frequency outputs allow for you to get signals where you need them

■

Digital outputs bring a wealth of information to your control room, with offerings for Smart WirelessHART, HART™, Modbus,

FOUNDATION™ fieldbus and PROFIBUS-PA

■

Direct plug and play operation with the Micro Motion Ethernet/IP Module for fast, efficient communications

2 www.emerson.com

Page 3

March 2019

Overview

Series 1000 and 2000 Transmitters

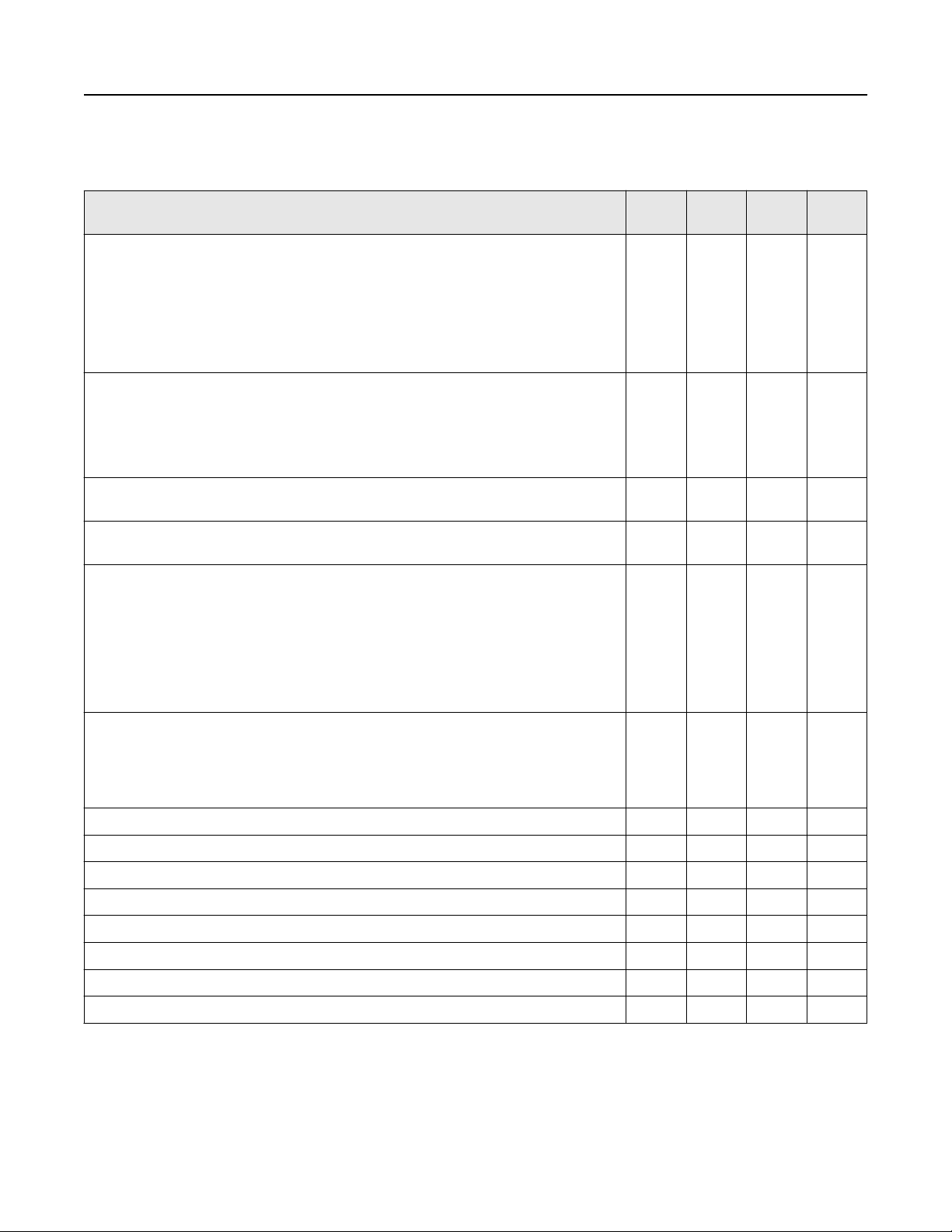

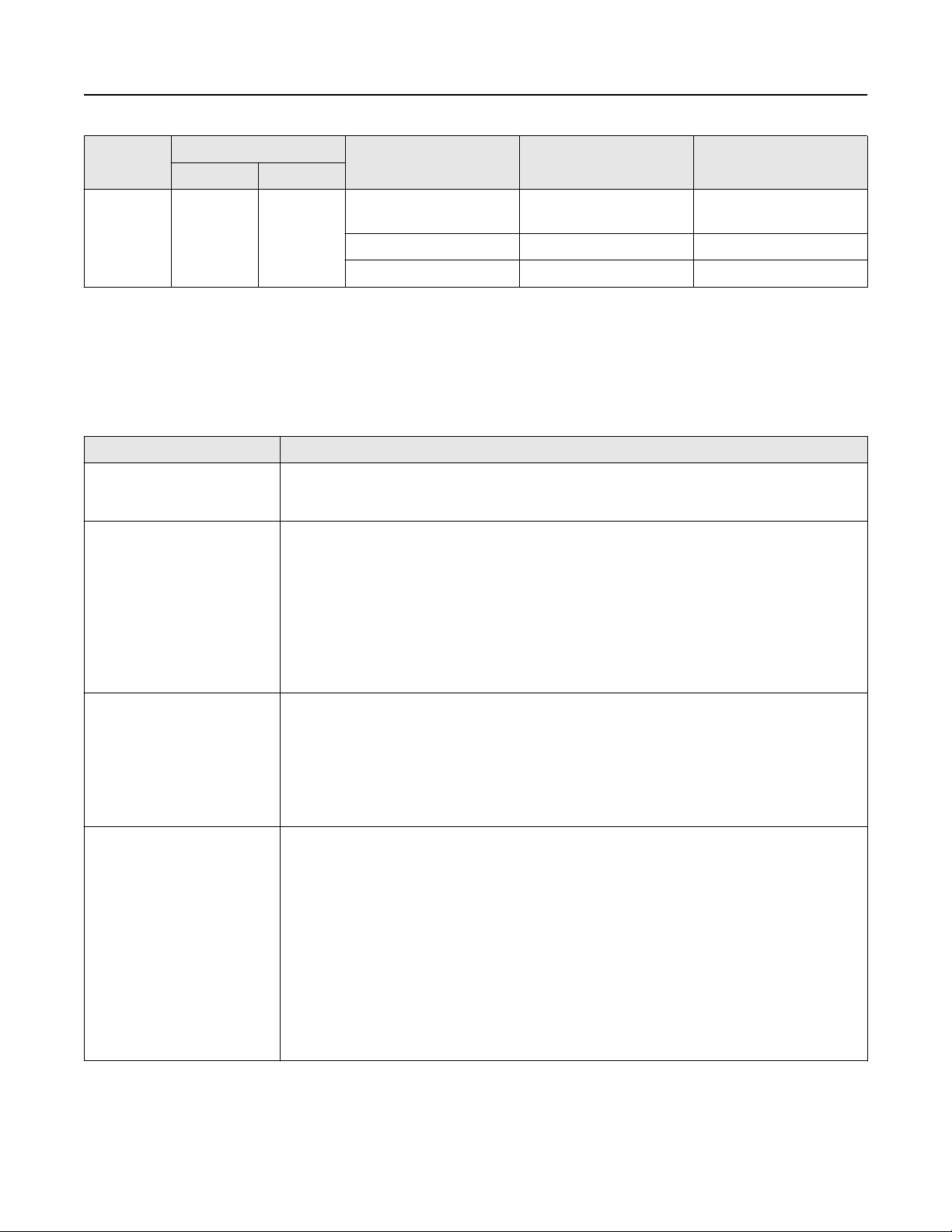

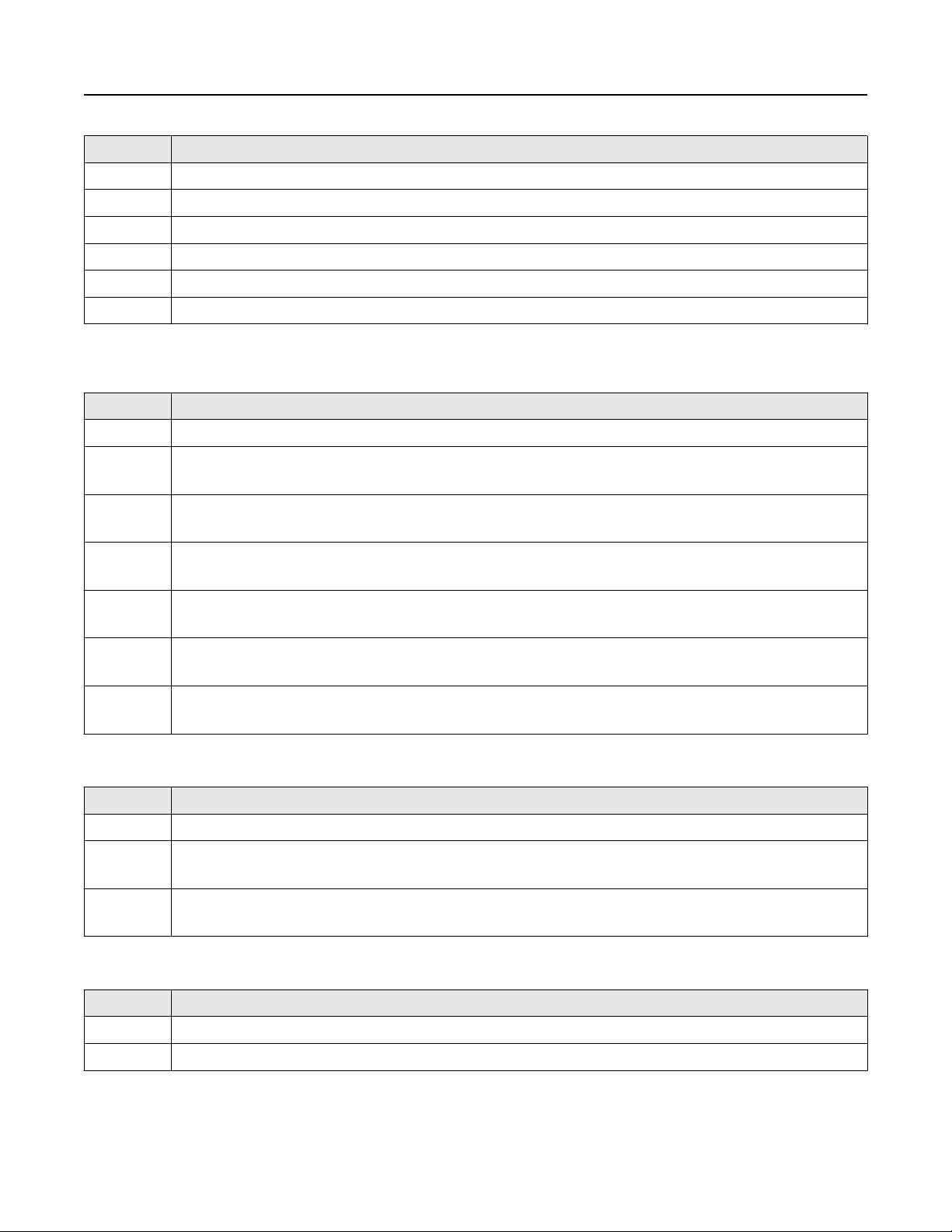

Feature Model

2700

For applications requiring simultaneous monitoring of multiple flow variables

■

Selected combinations of outputs including milliamp, frequency, and discrete I/O

■

Modbus, HART, WirelessHART, FOUNDATION fieldbus, and PROFIBUS-PA digital

communications

■

Simultaneously outputs multiple variables, including: mass flow rate, volume flow

rate, gas standard volume flow rate, density, temperature, and drive gain

For applications requiring only mass flow or volume flow measurement

■

Milliamp and a frequency/pulse output

■

HART or Modbus digital communications

■

Outputs one of: mass flow rate, volume flow rate, or gas standard volume flow rate

Compact, integral mounting to sensor with 360 degrees of rotation, or field mount

option to a 4-wire or 9-wire Micro Motion sensor.

Compact, small-footprint, remote-mount transmitter using 1.38 in (35 mm) DIN rail,

with connection to either a 4-wire or 9-wire Micro Motion sensor

Class I, Division 1/Zone 1 local operator interface:

■

Standard display supports English, French, Spanish, and German languages

■

Chinese-language display supports English and Chinese languages

■

View process variables, handle alarms, control totalizers, meter configuration, and

more

■

Interface functions can be customized and password protected

(1)

(2)

● ●

● ●

● ●

Model

2500

Model

1700

● ●

● ●

Model

1500

SIS certification:

■

Available on the milliamp output with output option codes A or D

■

One meter can be used in SIL 2 applications, and SIL 3 levels can be achieved if

redundant meters are used

Compatible with a Smart Wireless THUM Adapter for WirelessHART capability

Available with Smart Meter Verification ● ● ● ●

Available with filling and dosing application for filling, dosing, and bottling processes.

Fuel consumption application ● ●

Production Volume Reconciliation (PVR) ● ● ● ●

Piecewise Linearization (PWL) ● ● ● ●

Transient Bubble Remediation (TBR) ● ● ● ●

Transient Mist Remediation (TMR) ● ● ● ●

Models 1700M/P and 2700M/P (stainless steel housing) are only available as remote mount.

(1)

This display is available for purchase in China only, on Model 1700 and 2700 transmitters with analog outputs. This display is certified for ATEX /

(2)

NEPSI / IECEx Zone 1 use only. For detailed information regarding the approvals options available, see “Hazardous area classifications”.

For more information on the Smart Wireless THUM Adapter, see the product data sheet available at www.emerson.com.

(3)

For more information on the Model 1500 transmitter with the filling and dosing application, see the product data sheet available at

(4)

www.emerson.com.

(3)

(4)

● ●

● ● ● ●

●

www.emerson.com 3

Page 4

Series 1000 and 2000 Transmitters

March 2019

Applications

Application are custom designed programs and software available to offer additional functionality and performance to

transmitters. These applications are available through options in the transmitter model code, see the ordering information section

for details.

Smart Meter Verification (SMV)

■

Provides a quick, complete assessment of a Coriolis meter, determining whether the meter has been affected by erosion,

corrosion, or other influences affecting meter calibration.

■

No secondary references are required to perform this operation, and the meter can continue normal process measurement

while the test is in progress.

■

A basic version of Smart Meter Verification is included with new enhanced core processors that provides simple pass/fail results,

and simple diagnostics that run without interrupting your processes.

Discrete batch control

■

Simple batch control based on totalizer values

■

For transmitters with analog or intrinsically safe outputs, the Frequency Output can be configured as a Discrete Output.

■

For transmitters with configurable I/O, a channel can be configured as a Discrete Output.

Weights & Measures custody transfer

■

Physical and software security

■

Security-alarm posting

■

Mass or volume totalizer that can be configured by the user

■

Compliant with MID 2014/32/EU Annex MI-005

■

Certified by NTEP and OIML

Concentration measurement

Provides concentration measurement based on either industry-specific or liquid-specific units and relationships. Standard

measurement options include:

■

Industry-specific:

— °Brix

— °Plato

— °Balling

— °Baumé at SG60/60

— Specific gravity

■

Liquid-specific:

— %HFCS

— Concentration derived from reference density

— Concentration derived from specific gravity

Additionally, the application can be customized for site-specific concentration measurement (such as %HNO3 , %NaOH).

Petroleum measurement

Adds the following calculations to the standard software:

■

Calculates base density (corrected API Gravity) and Ctl (the correction for the effect of temperature on a liquid)

■

Calculates gross volume at standard temperature

4 www.emerson.com

Page 5

March 2019

■

Calculates flow-weighted average temperature and flow-weighted average observed gravity (flowing density)

Series 1000 and 2000 Transmitters

Fuel consumption

■

Automatically calculates the fluid consumption between two Coriolis flow sensors, typically for recirculating fuel consumption

loops

■

Eliminates the need to program an external calculation system and minimizes common inaccuracies related to time lag,

sampling issues and cumulative errors

■

Uses a proprietary algorithm that adapts to the unique calibration of each pair of Coriolis flow sensors

Production Volume Reconciliation (PVR)

■

Provides oil and water volumes through density-based calculations for both line and reference conditions

■

Detects bubble entrainment or flashing in the sensor, and can correct volumes accordingly

■

Best for undersized three-phase separators that frequently have intermittent gas or water contamination in the oil leg

■

Offers a simple, low-cost solution for net oil and net water measurement for two-phase separators

Transient Bubble Remediation (TBR)

■

Used with single-component liquid streams that may experience intermittent low levels of gas entrainment, that is, gas

carryunder

■

Enables accurate measurement of a single fluid during periods of entrained gas by providing a substitute density value based on

the immediately preceding process density (standard configuration)

■

Tracks total time of aerated flow to assist in diagnosing process issues that may cause aeration

Transient Mist Remediation (TMR)

■

Used with gas streams that may experience intermittent low levels of liquid entrainment, i.e., liquid carry-over

■

Allows gas measurement to continue during periods of entrained liquid (mist) by providing a substitute flow rate value based

on the immediately preceding process flow rate

■

Returns to reporting the measured flow rate when the mist interval is over, increased or decreased by a maximum of 10%, until

flow totals are appropriately adjusted for the unmeasured flow

■

Provides an indication of the amount of time that liquid was present in the stream — identifying process improvements to

reduce gas stream contamination

Piecewise Linearization (PWL) for enhanced gas applications

■

Provides gas calibration enhancement capability for industry-leading gas measurement performance

■

Designed specifically for midstream natural gas fiscal metering applications

Third-party gas calibration services are not included.

www.emerson.com 5

Page 6

Series 1000 and 2000 Transmitters

March 2019

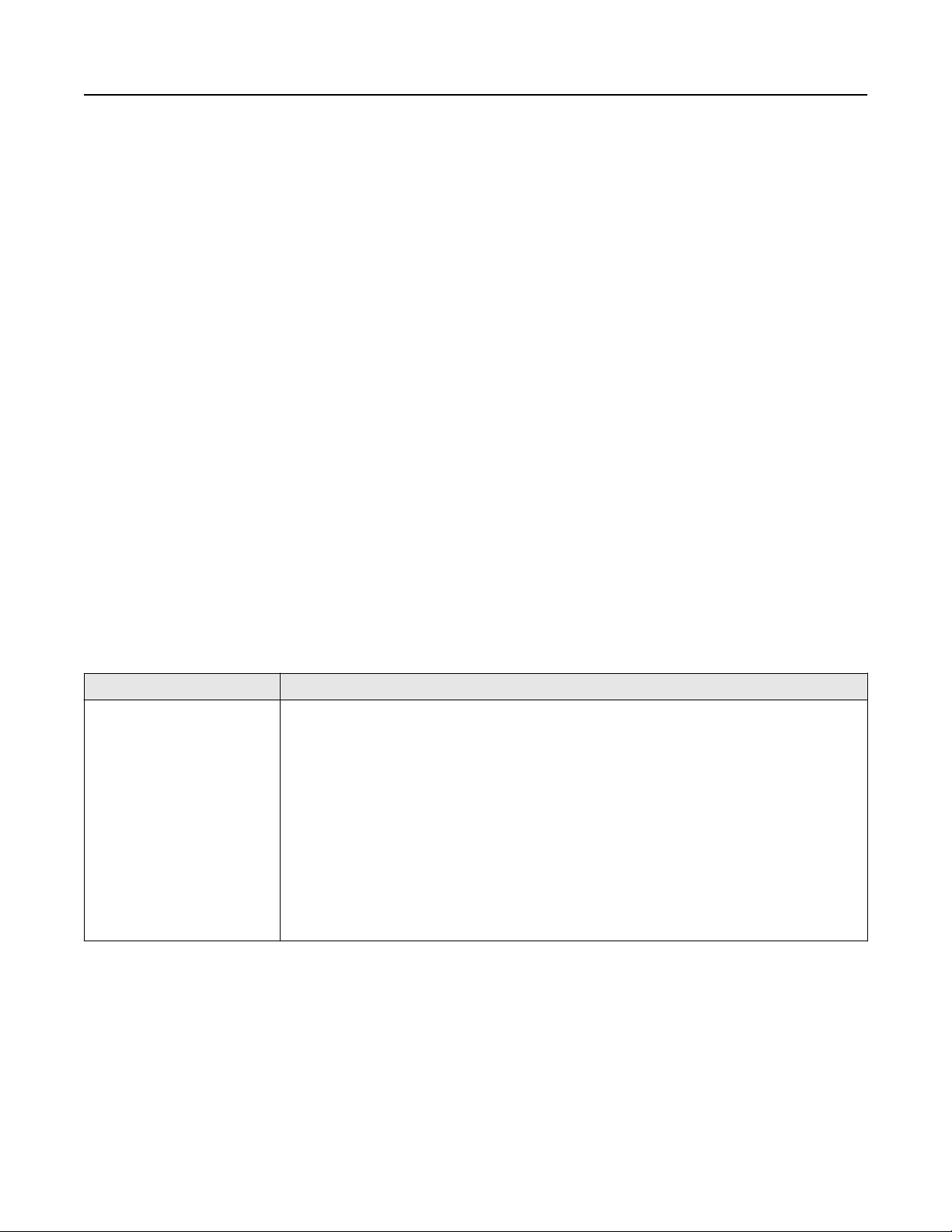

Electrical connections

Model 1500 and Model 2500 transmitters

Connection type Description

Input/Output

Power The transmitter has two pairs of terminals for the power connection:

Service port One pair of terminals supports Modbus/RS-485 signal or service port mode. On device power-up, user

Note

Each screw terminal connection accepts one or two solid conductors, 14 AWG (2.08 mm²) to 12 AWG (3.31 mm²) or one or two

stranded conductors, 22 AWG (0.326 mm²) to 14 AWG (2.08 mm²). Each plug type connector accepts one stranded or solid

conductor, 24 AWG (0.205 mm²) to 12 AWG (3.31 mm²).

■

Three pairs of wiring terminals for transmitter outputs

■

One pair of terminals for digital communications (Modbus/RS-485)

■

Either pair accepts DC power

■

The remaining pair can be used for making a jumper connection to a second transmitter

has 10 seconds to connect in service port mode. After 10 seconds, the terminals default to Modbus/

RS-485 mode.

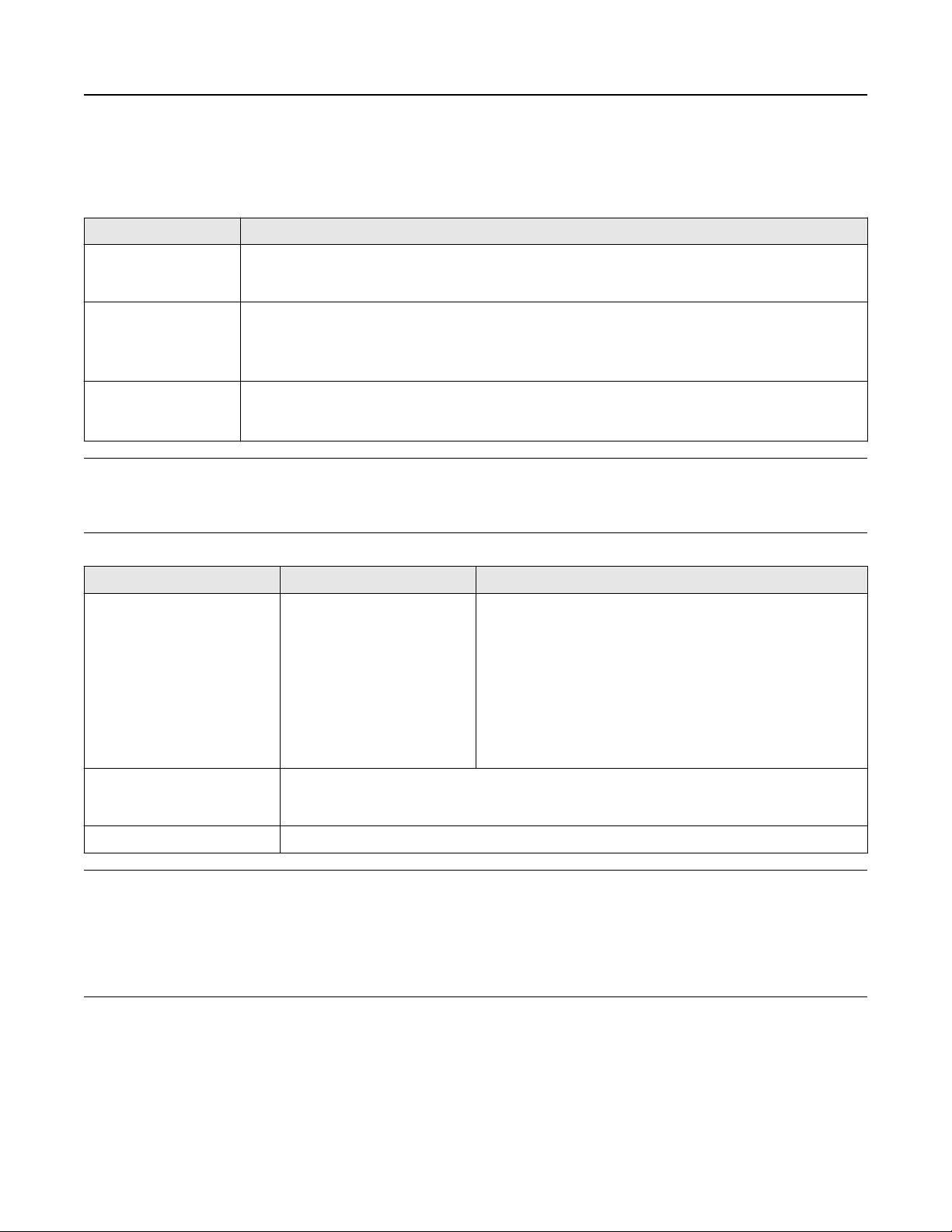

Table 1: Model 1700 and Model 2700 transmitters

Connection type Model 1700 Model 2700

Input/Output

Power

Service port Two clips for temporary connection to the service port

Note

■

Each screw terminal connection accepts one or two solid conductors, 14 AWG (2.08 mm²) to 12 AWG (3.31 mm²) or one or two

stranded conductors, 22 AWG (0.326 mm²) to 14 AWG (2.08 mm²). Each plug type connector accepts one stranded or solid

conductor, 24 AWG (0.205 mm²) to 12 AWG (3.31 mm²).

■

For Model 1700/2700 transmitters with an integral core processor (mounting code C), the 4-wire connection between the

transmitter and core processor is not normally accessed.

■

Intrinsically safe version:

Two pairs of wiring

terminals for transmitter

outputs

■

Non-intrinsically safe

analog outputs (output

option A): Three pairs of

wiring terminals for

transmitter outputs

■

One pair of wiring terminals accepts AC or DC power

■

One internal ground lug for power-supply ground wiring

Three pairs of wiring terminals for transmitter I/O and

communications

6 www.emerson.com

Page 7

March 2019

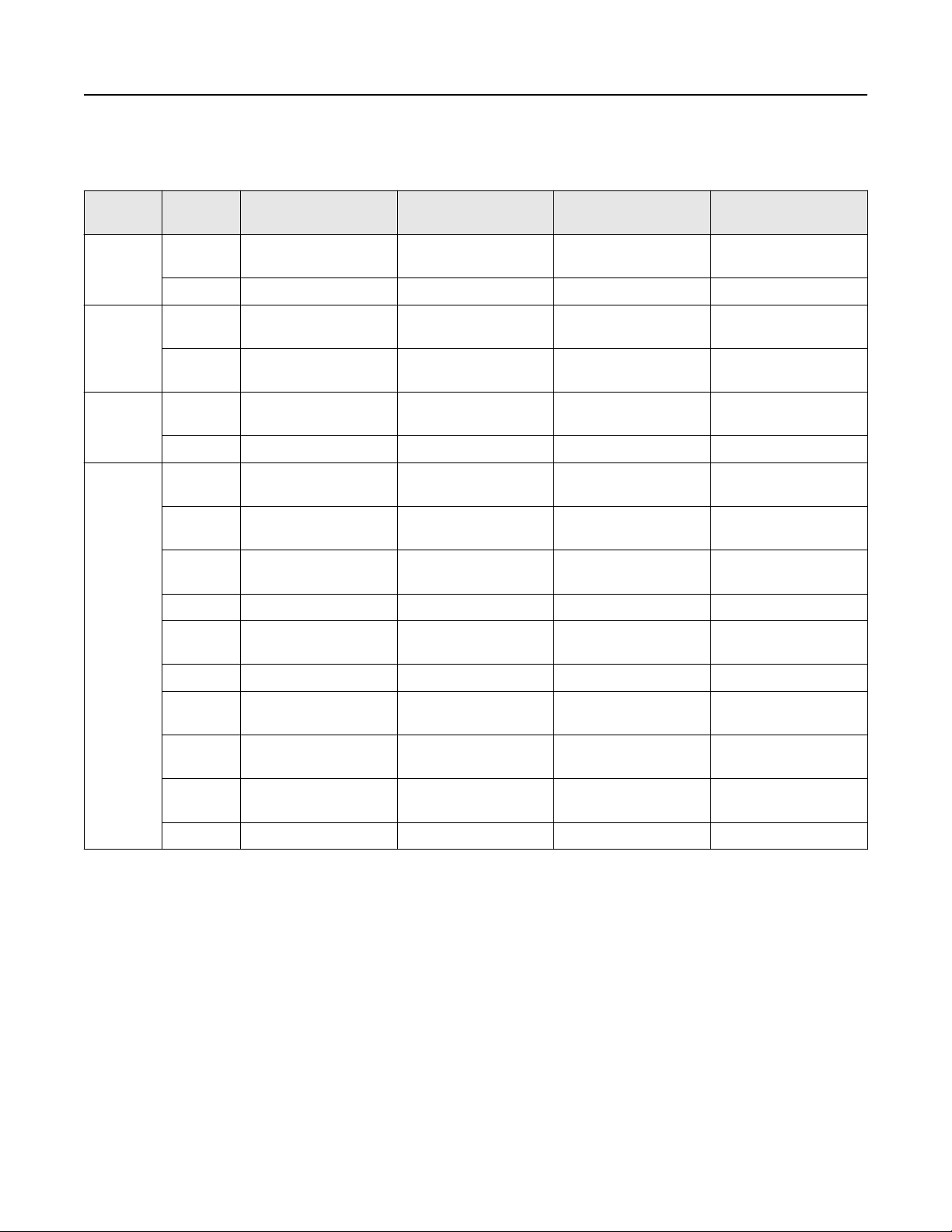

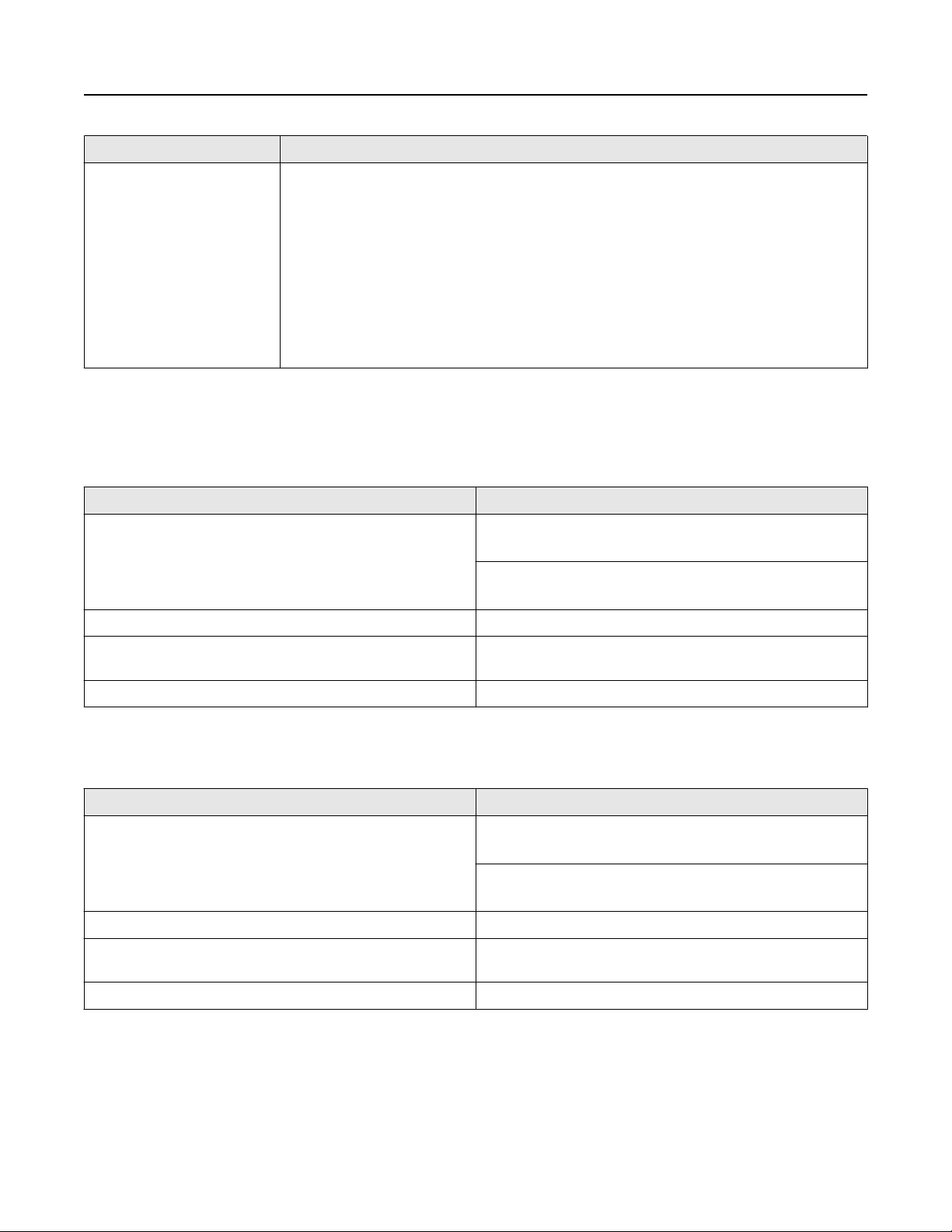

Output summary

Series 1000 and 2000 Transmitters

Model Output

code

1500 A mA w/ Bell 202 HART unused FO/DO RS-485 HART and

(1)

C

2500 B mA w/ Bell 202 HART configurable to mA, FO,

C mA w/ Bell 202 HART configurable to mA, FO,

1700 A mA w/ Bell 202 HART FO/DO RS485 HART and

D mA w/ Bell 202 HART FO/DO unused N/A

2700 A mA w/ Bell 202 HART FO/DO RS485 HART and

B mA w/ Bell 202 HART configurable to mA, FO,

C mA w/ Bell 202 HART configurable to mA, FO,

D mA w/ Bell 202 HART FO/DO mA N/A

E FOUNDATION Fieldbus

Channel A Channel B Channel C Channel D

Modbus

mA DO DO/DI RS-485Modbus

(FISCO)

configurable to FO, DO,

or DO (default mA)

or DO (custom)

or DO (default mA)

or DO (custom)

unused unused N/A

or DI (default FO)

configurable to FO, DO,

or DI (custom)

Modbus

Modbus

configurable to FO, DO,

or DI (default FO)

configurable to FO, DO,

or DI (custom)

RS-485 HART and

Modbus

RS-485 HART and

Modbus

N/A

N/A

N/A

N/A

G Profibus PA unused unused N/A

N FOUNDATION Fieldbus

(FNICO)

(2)

2

(2)

3

(2)

4

Requires filling and dosing software package.

(1)

Output codes 2, 3, and 4 include a Model 2700 transmitter housing with extra conduit connection for 775 THUM mounting capability.

(2)

Legend

FO = Frequency/pulse Output, scalable to 10,000 Hz

DO = Discrete Output

DI = Discrete Input

mA w/ Bell 202 HART FO/DO RS485 HART and

mA w/ Bell 202 HART configurable to mA, FO,

mA w/ Bell 202 HART FO mA N/A

unused unused N/A

N/A

Modbus

or DO (custom)

configurable to FO, DO,

or DI (custom)

N/A

www.emerson.com 7

Page 8

Series 1000 and 2000 Transmitters

March 2019

Input/output signal detail

All codes

Inputs for all codes

■

With mounting codes R, M, and B: One 4-wire sensor signal input connection, intrinsically safe

■

With mounting codes C and P (9-wire remote transmitter): One 9-wire sensor signal input connection, intrinsically safe

Output code A or 2

These codes are for non-intrinsically safe mA Output (with HART and Modbus) for Model 1500, Model 1700, and Model 2700

transmitters.

One active 4–20 mA Output:

■

Not intrinsically safe

■

Isolated to ±50 VDC from all other outputs and earth ground

■

Maximum load limit: 820 ohms

■

Model 1500 and Model 1700 can report mass flow or volume flow

■

Model 2700 can report mass flow, volume flow, density, temperature, or drive gain

■

Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (February 2003)

One active Frequency/pulse Output:

■

Not intrinsically safe

■

Can report mass flow or volume flow, which can be used to indicate flow rate or total

■

For Model 1500 and Model 1700, Frequency Output reports the same flow variable as the mA Output

■

For Model 2700, Frequency Output is independent of mA Output

■

Scalable to 10,000 Hz

■

For Model 1500 and 2500, output voltage is +15 VDC ±3% with a 2.2 kohm internal pull-up resistor

■

For Model 1700 and Model 2700, output voltage is +24 VDC ±3% with a 2.2 kohm internal pull-up resistor

■

Output is linear with flow rate to 12,500 Hz

■

Configurable polarity: active high or active low

■

Model 1700 Discrete Output: Can be configured as a Discrete Output to report flow direction and flow switch

■

Model 2700 Discrete Output: Can be configured as a Discrete Output to report five discrete events, flow direction, flow switch,

calibration in progress, or fault.

■

On Model 1700 and Model 2700 transmitters, this can also be configured as a Discrete Output

Output codes B, C, and 3

These codes are for non-intrinsically safe configurable output Model 2500 and and Model 2700 transmitters. The transmitter has a

total of 3 configurable inputs/outputs. Refer to the data below for the ways that these 3 inputs/outputs can be configured.

One or two active 4–20 mA Outputs:

■

Not intrinsically safe

■

Isolated to ±50 VDC from all other outputs and earth ground

■

Maximum load limit of mA1: 820 ohms; of mA2: 420 ohms

■

Can report mass flow, volume flow, density, temperature, or drive gain

■

Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (February 2003)

8 www.emerson.com

Page 9

March 2019

One or two active or passive frequency/pulse outputs:

■

Not intrinsically safe

■

Can report mass flow or volume flow, which can be used to indicate flow rate or total

■

If configured as a dual pulse output, the channels are electrically isolated but not independent (see custody transfer note

below)

■

Scalable to 10,000 Hz

■

If active, output voltage is +15 VDC ±3% with a 2.2 kohm internal pull-up resistor

■

If passive, output voltage is 30 VDC maximum, 24 VDC typical, sinking up to 500 mA at 30 VDC.

■

Output is linear with flow rate to 12,500 Hz

One or two active or passive Discrete Outputs:

■

Not intrinsically safe

■

Can report five discrete events, flow switch, forward/reverse flow, calibration in progress, or fault

■

If active, output voltage is +15 VDC ±3% with a 2.2 kohm internal pull-up resistor

■

If passive, output voltage is 30 VDC maximum, 24 VDC typical, sinking up to 500 mA at 30 VDC

One Discrete Input:

■

Can be configured for active or passive power

■

Not intrinsically safe

■

Active power +15 VDC, 7 mA maximum source current

■

Passive power +3–30 VDC maximum

■

Can start/stop totals and inventories, reset all totals, reset mass total, reset volume total, start sensor zero, or initiate multiple

actions

For custody transfer using double-pulse Frequency Output, the transmitter can be configured for two Frequency Outputs. The

second output can be phase-shifted –90, 0, 90, or 180 degrees from the first output, or the dual-pulse output can be set to

quadrature mode.

Series 1000 and 2000 Transmitters

Output codes E and G

These codes are for intrinsically safe FOUNDATION fieldbus and PROFIBUS-PA Model 2700 transmitters.

One FOUNDATION fieldbus H1 or PROFIBUS-PA output:

■

FOUNDATION fieldbus and PROFIBUS-PA wiring is intrinsically safe with an intrinsically safe power supply

■

The transmitter fieldbus circuit is passive, and draws power from the fieldbus segment. Current draw from the fieldbus segment

is 13 mA

■

Manchester-encoded digital signal conforms to IEC 61158-2

■

Entity parameters:

— Ui = 30 VDC

— Ii = 300 mA

— Pi = 1,3 W

— Ci = negligable

— Li = negligable

Output code N

These codes are for non-incendive FOUNDATION Fieldbus transmitters.

One FOUNDATION fieldbus H1 output:

www.emerson.com 9

Page 10

0

100

200

300

400

500

600

700

800

900

1000

12 14 16 18 20 22 24 26 28 30

A

B

C

Series 1000 and 2000 Transmitters

■

FOUNDATION fieldbus wiring is non-incendive

■

The transmitter fieldbus circuit is passive, and draws power from the fieldbus segment. Current draw from the fieldbus segment

March 2019

is 13 mA

■

Manchester-encoded digital signal conforms to IEC 61158-2

■

Entity parameters:

— Ui = 30 VDC

— Ii = 300 mA

— Pi = 1,3 W

— Ci = negligable

— Li = negligable

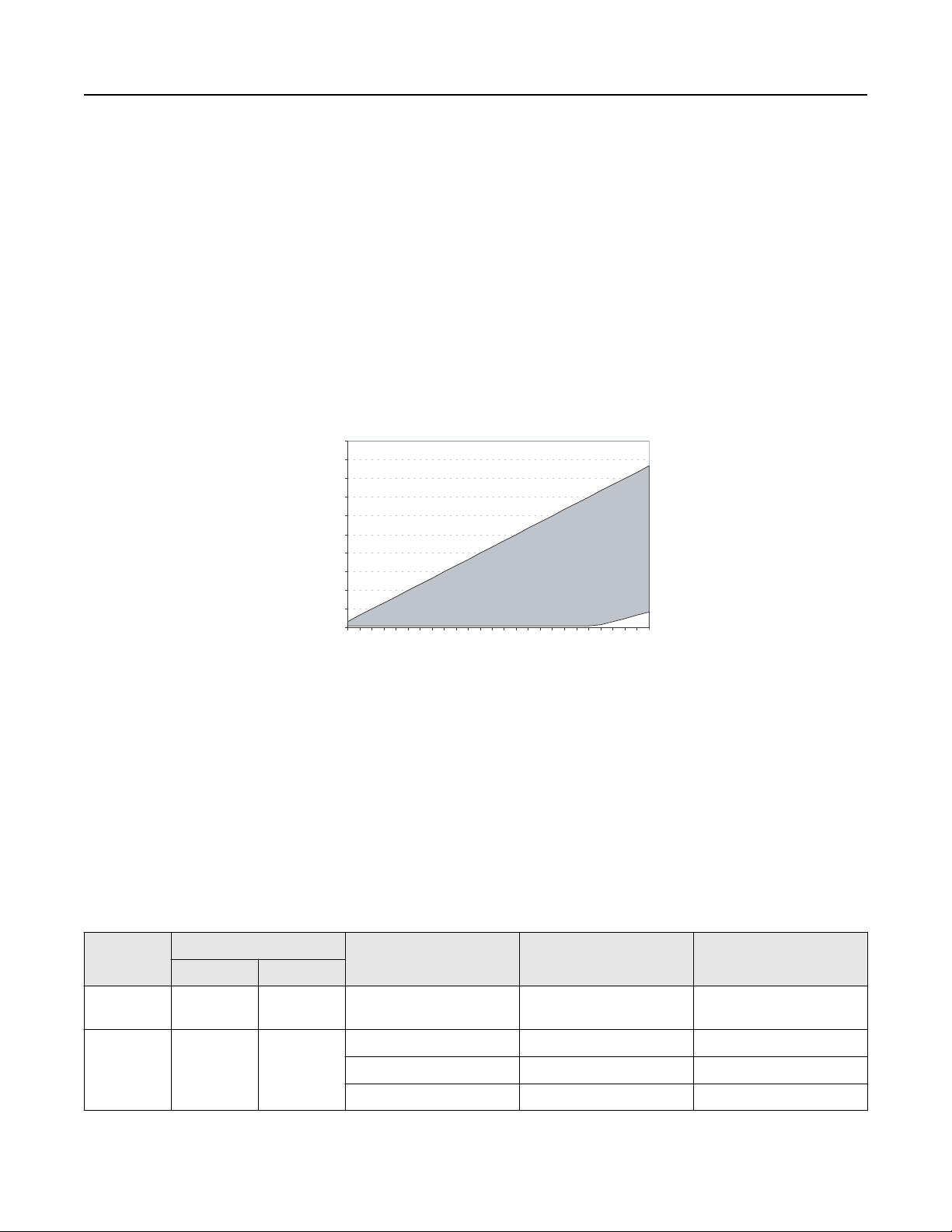

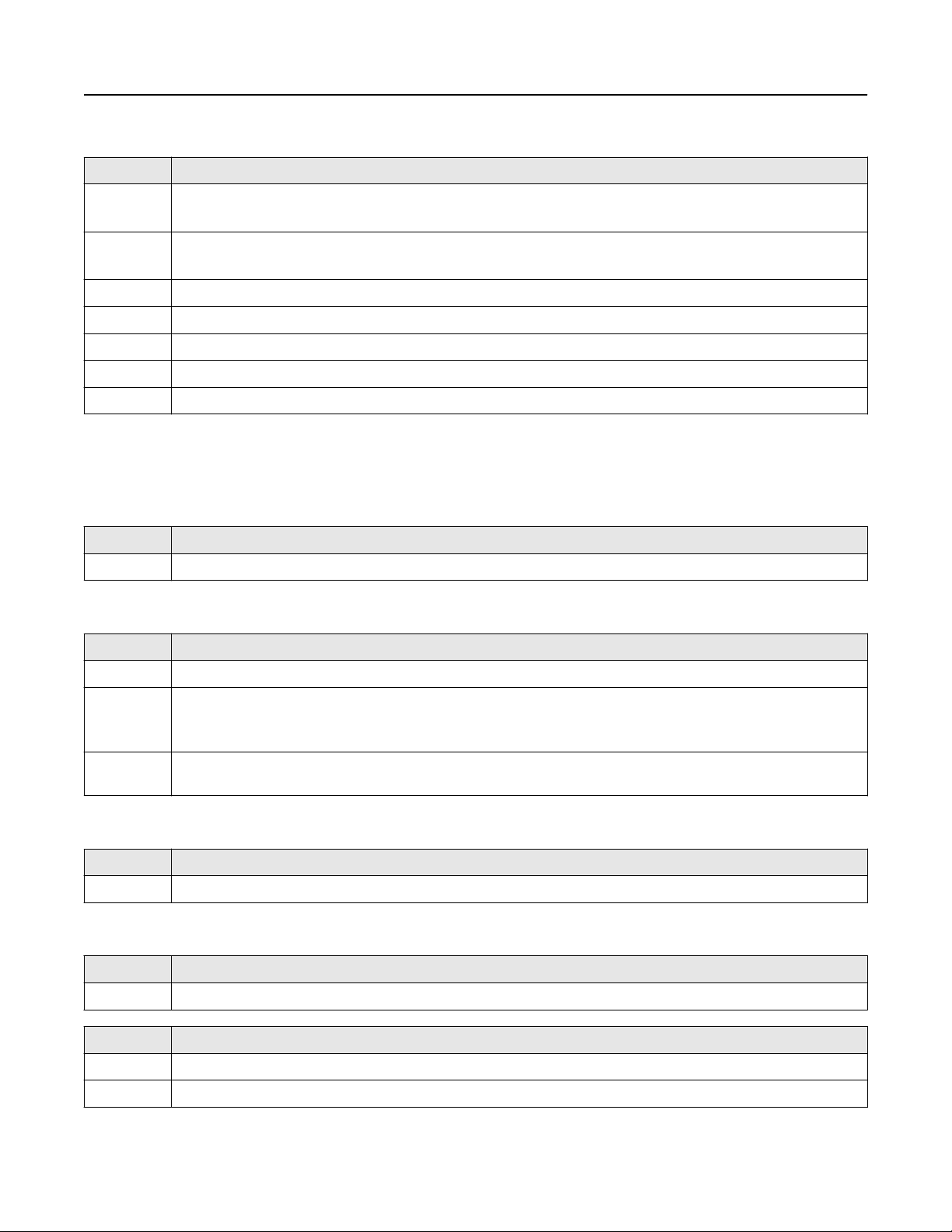

Output codes D and 4

These codes are for intrinsically safe Model 1700 and Model 2700 transmitters.

One intrinsically safe passive 4–20mA Output (two with Model 2700):

■

Maximum input voltage: 30 VDC, 1 watt maximum

■

Maximum load limit: see chart below

■

Model 1700 can report mass flow or volume flow; Model 2700 can report mass flow, volume flow, density, temperature, or

drive gain

■

Entity parameters:

— Ui = 30 VDC

— Ii = 300 mA

— Pi = 1 W

— Ci = 0.0005 µF

— Li = Less than 0.05 mH

■

Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (February 2003)

mAOutputLoadResistanceValue

R

= (V

max

* If communicating with HART, a minimum or 250 ohms and 17.75 V supply is needed.

supply

− 12)/0.023*

A. External resistor (ohms)

B. Operating region

C. Supply voltage (volts)

One intrinsically safe frequency/pulse output or configurable frequency/pulse/Discrete Output:

10 www.emerson.com

Page 11

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

5 7 9 11 13 15 17 19 21 23 25 27 29

A

B

C

March 2019 Series 1000 and 2000 Transmitters

■

Maximum input voltage: 30 VDC, 0.75 watt maximum

■

Maximum load limit: see chart below

■

Can report mass flow or volume flow, which can be used to indicate flow rate or total

■

For Model 1700, Frequency Output reports the same flow variable as the mA Output

■

For Model 2700, Frequency Output is independent of the mA Output

■

Scalable to 10,000 Hz

■

Entity parameters: Ui = 30 VDC, Ii = 100 mA, Pi = 0.75 W, Ci = 0.0005 µF, Li = Less than 0.05 mH

■

Output is linear with flow rate to 12,500 Hz

FrequencyOutputLoadResistanceValue

R

* Absolute minimum = 100 ohms for V

supply

max

*R

min

< 25.6 volts

= (V

= (V

supply

supply

− 4)/0.003

− 25)/0.006

A. External resistor (ohms)

B. Operating region

C. Supply voltage (volts)

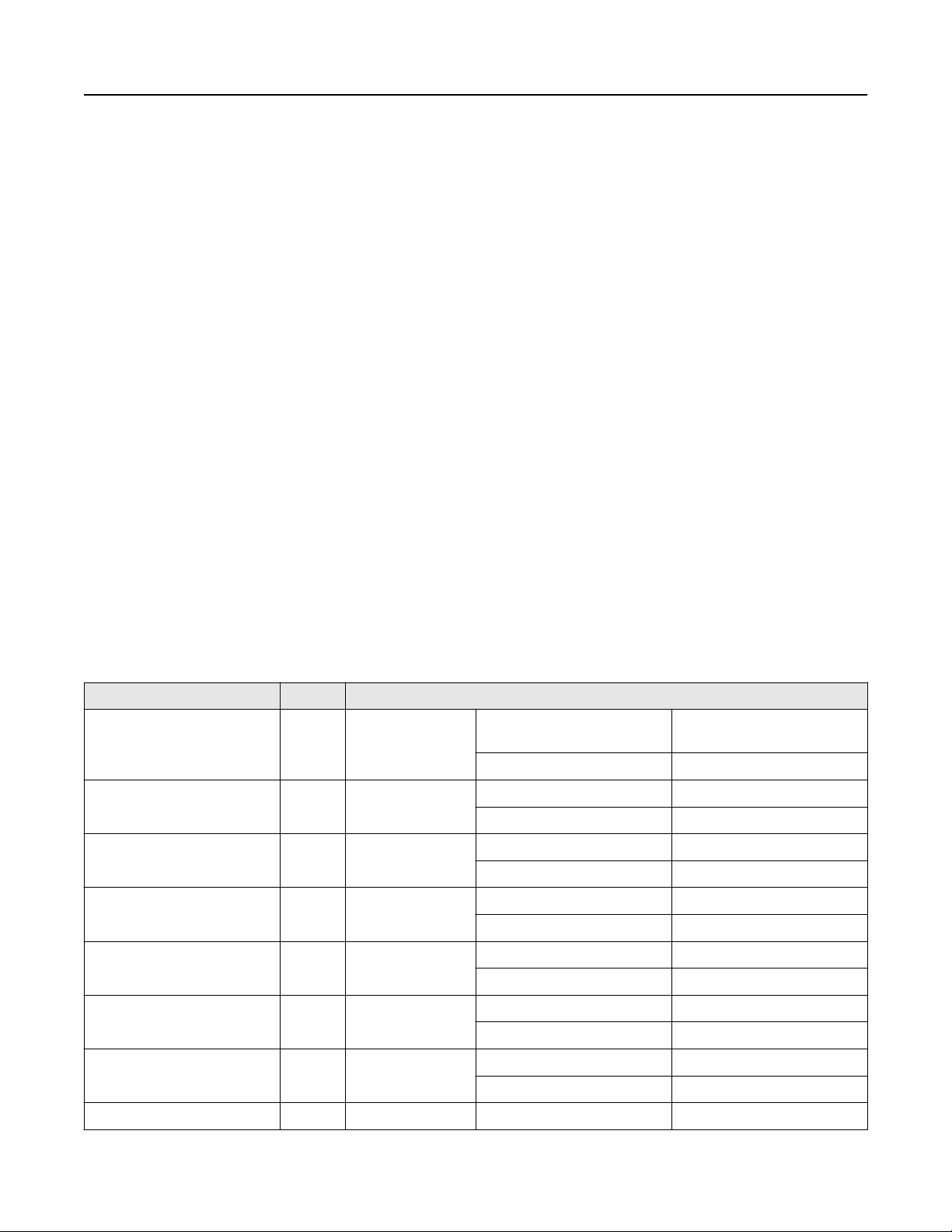

Series 2000 transmitters with configurable I/O functionality

The Series 2000 transmitter with configurable inputs and outputs is designed to increase transmitter flexibility and reduce the

number of transmitter variations required in inventory. The table below shows the various configuration options that can be

produced with the configurable I/O output option.

Channel assignments for Series 2000 transmitters with configurable I/O (output option codes B, C, and 3)

■

When output code B is selected, the transmitter ships with channels assigned to default values.

■

When output codes C or 3 are selected, the transmitter is custom configured prior to shipment. Output code 3 is only available

with Model 2700 transmitters.

Channel

A 1 & 2 21 & 22 mA Output with Bell 202/

B 3 & 4 23 & 24 mA Output (default) Density Active

www.emerson.com 11

Terminals Configuration options Default variable

Model 2700 Model 2500

Power

assignment

Mass flow Active

HART (only)

Discrete Output

(1)

Mass flow Active or passive

(2)

Discrete Output Fwd/rev flow Active or passive

Page 12

Series 1000 and 2000 Transmitters March 2019

Channel Terminals Configuration options Default variable

Model 2700 Model 2500

C 5 & 6 31 & 32 Discrete Output

(default)

Discrete Output Flow switch Active or passive

Discrete Input None Active or passive

If channels B and C are both configured as a Frequency Output (dual pulse), both outputs are generated from the same signal. The outputs are

(1)

electrically isolated but not independent.

The user must supply power when a channel is set to passive power.

(2)

(1)

assignment

Mass flow Active or passive

Power

Digital communications

Output type Outputs and descriptions

All

HART/RS-485, Modbus/RS-485

■

One service port can be used for temporary connection only

■

Uses RS-485 Modbus signal, 38.4 kilobaud, one stop bit, no parity

■

Models/output codes:

— All models with output code A, except when ordered with display code 8

— Model 2500 with output codes B and C

— Model 2700 with output code 2

■

One RS-485 output can be used for direct connection to a HART or Modbus host system;

accepts data rates between 1200 baud and 38.4 kilobaud

■

HART revision 7 as default, selectable to HART revision 5

HART/Bell 202

FOUNDATION fieldbus

■

Models/output codes: Model 1500 with output code A, Models 1700 and 2500 with output

codes A, B, C, and D. Model 2700 with output codes A, B, C, D, 2, 3, and 4

■

HART Bell 202 signal is superimposed on the primary milliamp output, and is available for

host system interface. Frequency 1.2 and 2.2 kHz, Amplitude: to 1.0 mA, 1200 baud,

Requires 250 to 600 ohms load resistance

■

HART revision 7 as default, selectable to HART revision 5

■

Models/output codes:

— Model 2700 with output code E

— Model 2700 with output code N

■

Transmitters are registered with the Fieldbus Foundation, and conform to the FOUNDATION

fieldbus H1 protocol specification. Transmitters with output code E are FISCO certified.

Transmitters with output code N are FNICO certified

■

FISCO:

— Field device in compliance with EN/IEC 60079-11:2012 Annex G

— Ui = 30 V, Ii = 380 mA, Pi = 5.32 W, Ci = 0.0005 µF, Li = Less than 0.05 mH

■

Non intrinsically safe FF output

12 www.emerson.com

Page 13

March 2019

Output type Outputs and descriptions

PROFIBUS-PA

■

Model 2700 with output code G

■

Transmitters are registered with the Profibus Organization, and fulfill the requirements of the

PROFIBUS-PA Profile for Process Control Devices. Compatible for configuration with

Siemens® Simatic® PDM

■

FISCO:

— Field device in compliance with EN/IEC 60079-11:2012 Annex G

— Ui = 30 V, Ii = 380 mA, Pi = 5.32 W, Ci = 0.0005 µF, Li = Less than 0.05 mH

Series 1000 and 2000 Transmitters

Model 2700 transmitter with FOUNDATION fieldbus

Fieldbus software functionality

The Model 2700 FOUNDATION fieldbus software is designed to permit remote testing and configuration of the transmitter using the

DeltaV™ Fieldbus Configuration Tool, or other FOUNDATION fieldbus compliant hosts. The Coriolis sensor signal is channelled through

the flowmeter to the control room and the FOUNDATION fieldbus configuration device.

Transducer blocks

Transducer blocks hold data from the Coriolis sensor, including process variables, configuration, calibration, and diagnostics.

The Model 2700 transmitter with FOUNDATION fieldbus provides up to seven transducer blocks:

■

Measurement - For process variables

■

Calibration - For calibration information

■

Diagnostic- For diagnosing problems and running diagnostic tests (including the Smart Meter Verification procedure, if the

transmitter is paired with an enhanced core processor)

■

Device Information - For data such as sensor type

■

Local Display - For configuring the transmitter display

■

API - For petroleum measurement calculations using API MPMS Chapter 11.1

■

Concentration measurement

■

For complex density and concentration calculations (e.g.,%HFCS, SG60/60)

Resource block

The resource block contains physical device information, including available memory, manufacturer identification, type of device,

and features.

Analog input function blocks

The Analog Input (AI) function block processes the measurement from the Coriolis sensor and makes it available to other function

blocks. It also allows filtering, alarm handling, and engineering unit changes. Each of the four Model 2700 AI blocks can be assigned

to one of 19 available variables.

Analog output block

The AO function block assigns an output value to a field device through a specified channel. The block supports mode control,

signal status calculation, and simulation. The AO block can report either pressure from an external pressure source or temperature

from an external temperature source.

www.emerson.com 13

Page 14

Series 1000 and 2000 Transmitters March 2019

Discrete Input block

One permanent Discrete Input (DI) function block can be assigned to any of the discrete input variable channels in the transducer

block. The DI block channels are: forward/reverse indication, zero in progress, fault condition indication, and meter verification

failure.

Discrete Output block

One permanent Discrete Output (DO) function block can be assigned to any of the Discrete Output variable channels in the

transducer block. The DO block channels are: start sensor zero, reset mass total, reset volume total, reset API reference (standard)

volume total, reset all process totals, reset concentration measurement reference volume total, reset concentration measurement

net mass total, reset concentration measurement net volume total, start/stop all totals, increment concentration measurement

curve, reset gas standard volume total, and start meter verification in continuous measurement mode.

Proportional integral derivative block

The optional proportional integral derivative (PID) function block combines all the necessary logic to perform proportional/

integral/derivative control. The block supports mode control, signal scaling and limiting, feed forward control, override tracking,

alarm limit detection, and signal status propagation.

Integrator block

The integrator block provides functionality for the transmitter totalizers. Any process total can be selected and reset.

Diagnostics and service

Model 2700 transmitters automatically perform continuous self diagnostics. Using the Diagnostic transducer block, the user can

perform on-line testing of the transmitter and sensor. Diagnostics are event driven and do not require polling for access.

PlantWeb® Field Diagnostic is supported. The diagnostic information is based on NAMUR NE 107 standard.

Power supply

Model

Model 1700 and Model 2700

Description

■

Self switching AC/DC input, automatically recognizes supply voltage

■

Complies with low voltage directive 2014/35/EU per EN 61010-1 (IEC 61010-1) with

amendment 2; Installation (Overvoltage) Category II, Pollution Degree 2

■

AC power: 85 to 265 VAC, 50/60 Hz, 6 watts typical, 11 watts maximum

■

DC power:

— 18 to 100 VDC, 6 watts typical, 11 watts maximum

— Minimum 22 VDC with 1,000 ft (305 m) of 18 AWG (0.823 mm²) power-supply cable

— At startup, transmitter power source must provide a minimum of 1.5 amperes of short-

term current at a minimum of 18 volts at the transmitter’s power input terminals

■

Fuse: IEC 127-1.25 non-serviceable fuse, slow blow

14 www.emerson.com

Page 15

March 2019 Series 1000 and 2000 Transmitters

Model Description

Model 1500 and Model 2500

■

Transmitter power supply meets Installation (Overvoltage) Category II, Pollution Degree 2

requirements

■

DC power:

Minimum 19.2 to 28.8 VDC, 6.3 watts

—

— At startup, transmitter power source must provide a minimum of 1.0 amperes of short-

term current per transmitter

— Length and conductor diameter of the power cable must be sized to provide 19.2 VDC

minimum at the power terminals, at a load current of 330 mA

■

Fuse: IEC 1.6A non-serviceable fuse, slow blow

Environmental limits

Model 1500 and Model 2500

Type Value

Ambient temperature limits

(1)

Operating:

-40 °F (-40.0 °C) to 131 °F (55.0 °C)

Storage:

-40 °F (-40.0 °C) to 185 °F (85.0 °C)

Humidity limits 5 to 95% relative humidity, non-condensing at 140 °F (60.0 °C)

Vibration limits Meets IEC 60068.2.6, endurance sweep, 5 to 2000 Hz, 50

sweep cycles at 1.0 g

Housing rating None

If the temperature is above 131 °F (55.0 °C), and you are mounting multiple transmitters, the transmitters must be at least 0.33 in (8.4 mm)

(1)

apart.

Model 1700 and Model 2700

Type Value

Ambient temperature limits

Humidity limits 5 to 95% relative humidity, non-condensing at 140 °F (60.0 °C)

Vibration limits

Housing rating NEMA 4X (IP66/67/69(K))

Display responsiveness decreases, and display may become difficult to read below -4 °F (-20.0 °C). Above 131 °F (55.0 °C), some darkening of

(1)

display might occur.

The protection is IP69K-based NEN-ISO 20653:2013 and IP69 when using standard IEC/EN 60529.

(2)

(1)

Operating:

-40 °F (-40.0 °C) to 140 °F (60.0 °C)

Storage:

-40 °F (-40.0 °C) to 140 °F (60.0 °C)

Meets IEC 60068-2-6,endurance sweep, 5 to 2000 Hz

up to 1.0 g

(2)

www.emerson.com 15

Page 16

Series 1000 and 2000 Transmitters March 2019

Environmental effects

EMI effects

■

Complies with EMC directive 2014/30/EU per EN 61326 Industrial

■

Complies with NAMUR NE-21 (May 2012). With the exception of voltage dip when powered by 24 VDC on 1700/2700

transmitters

Ambient temperature effect

■

On analog outputs: ±0.005% of span per °C change from temperature at which the outputs were trimmed

Hazardous area classifications

Model 1700 and Model 2700

UL, CSA, and CSA-US

■

Ambient temperature is limited to -40 °F (-40.0 °C) to 140 °F (60.0 °C) for UL and CSA compliance.

■

Class I, Div. 1, Groups C and D. Class II, Div. 1, Groups E, F, and G explosion proof (when installed with approved conduit seals).

Otherwise, Class I, Div. 2, Groups A, B, C, and D.

■

Provides nonincendive sensor outputs for use in Class I, Div. 2, Groups A, B, C, and D; or intrinsically safe sensor outputs for use

in Class I, Div. 1, Groups C and D or Class II, Div. 1, Groups E, F, and G.

IECEx

■

Ambient temperature is limited to -40 °F (-40.0 °C) to 131 °F (55.0 °C) for IECEx compliance. Transmitters with output codes A,

B, C, D, E, G, and N are rated for increased safety or flameproof with approved cable glands.

Output option

Analog outputs A Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display or Chinese-

Configurable I/O B or C Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display

FOUNDATION fieldbus (nonintrinsically safe)

Intrinsically safe D Flameproof Ex d [ia Ga] [ib] IIB+H2 T5 Gb Standard display

FOUNDATION fieldbus (IS), or

PROFIBUS-PA

Intrinsically safe D Increased Safety Ex de [ia Ga] [ib] IIB+H2 T5 Gb Standard display

FOUNDATION fieldbus (IS), or

PROFIBUS-PA

I.S. with WirelessHART 4 Increased safety

(1)

Code Approval

language display

Ex d [ib] IIC T5 Gb No display or IIC display

Ex d [ib] IIC T5 Gb No display or IIC display

N Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display

Ex d [ib] IIC T5 Gb No display or IIC display

Ex d [ia Ga] [ib] IIC T5 Gb No display or IIC display

E or G Flameproof Ex d [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex d [ia Ga] [ib] IIC T5 Gb No display or IIC display

Ex de [ia Ga] [ib] IIC T5 Gb No display or IIC display

E or G Increased Safety Ex de [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex de [ia Ga] [ib] IIC T5 Gb No display or IIC display

(2)

Ex de [ia Ga] [ib] IIB+H2 T4 Gb Standard display

16 www.emerson.com

Page 17

March 2019 Series 1000 and 2000 Transmitters

Output option Code Approval

Ex de [ia Ga] [ib] IIC T4 Gb No display or IIC display

Non-I.S. with WirelessHART 2 or 3 non-Sparking Ex nA de [ib Gb] IIB+H2 T4 Gc Standard display

Ex nA de [ib Gb] IIC T4 Gc No display or IIC display

Output codes E and G are FISCO field devices in compliance with IEC 60079-11:2012.

(1)

Models 1700M, 1700P, 2700M, and 2700P (stainless steel housing) are limited to flameproof (Exd) rating.

(2)

ATEX

Ambient temperature is limited to below 140 °F (60.0 °C) for ATEX compliance. Transmitters with output codes A, B, C, D, E, G, and

N are rated for increased safety or flameproof with approved cable glands.

Output option Code Approval

Analog outputs A

II 2G II 2D Ex tb IIIC T65 °C Db IP66/IP67

Increased safety

(1)

Ex de [ib] IIB+H2 T5 Gb Standard display or Chinese-

language display

Ex de [ib] IIC T5 Gb No display or IIC display

Configurable I/O B or C

FOUNDATION fieldbus (non-

N

intrinsically safe)

Intrinsically safe D

Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display or Chinese-

language display

Ex d [ib] IIC T5 Gb No display or IIC display

II 2G II 2D Ex tb IIIC T65 °C Db IP66/IP67

Increased safety

(2)

Ex de [ib] IIB+H2 T5 Gb Standard display

Ex de [ib] IIC T5 Gb No display or IIC display

Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display

Ex d [ib] IIC T5 Gb No display or IIC display

II 2G II 2D Ex tb IIIC T65 °C Db IP66/IP67

Increased safety

(2)

Ex de [ib] IIB+H2 T5 Gb Standard display

Ex de [ib] IIC T5 Gb No display or IIC display

Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display

Ex d [ib] IIC T5 Gb No display or IIC display

II (1) 2G II 2D Ex tb IIIC T65 °C Db IP66/IP67

Increased safety

(2)

Ex de [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex de [ia Ga] [ib] IIC T5 Gb No display or IIC display

Flameproof Ex d [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex d [ia Ga] [ib] IIC T5 Gb No display or IIC display

www.emerson.com 17

Page 18

Series 1000 and 2000 Transmitters March 2019

Output option Code Approval

FOUNDATION fieldbus (IS), or

PROFIBUS-PA

(2)

E or G

II (1) 2G II 2D Ex tb IIIC T65 °C Db IP66/IP67

Increased safety

(2)

Ex de [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex de [ia Ga] [ib] IIC T5 Gb No display or IIC display

Flameproof Ex d [ia Ga] [ib] IIB+H2 T5 Gb Standard display

Ex d [ia Ga] [ib] IIC T5 Gb No display or IIC display

I.S. with WirelessHART 4

II (1) 2G

Increased safety

(2)

Ex de [ia Ga] [ib] IIB+H2 T4 Gb Standard display

Ex de [ia Ga] [ib] IIC T4 Gb No display or IIC display

Non-I.S. with WirelessHART 2 or 3

II (2) 3G

non-Sparking Ex nA de [ib Gb] IIB+H2 T4 Gc Standard display

Ex nA de [ib Gb] IIC T4 Gc No display or IIC display

Models 1700M, 1700P, 2700M, and 2700P (stainless steel housing) are limited to flameproof (Exd) rating.

(1)

Output codes E and G are FISCO field devices in compliance with EN/IEC 60079-11:2012 Annex G.

(2)

NEPSI

Output option

Analog outputs A Increased safety

Configurable I/O B or C Increased safety

Intrinsically safe D Increased safety

FOUNDATION

fieldbus (IS), or PROFIBUS-

(1)

PA

Code Approval

Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display or Chinese-

Flameproof Ex d [ib] IIB+H2 T5 Gb Standard display

Flameproof Ex d [ia/ib] IIB+H2 T5 Gb Standard display

E or G Increased safety

Flameproof Ex d [ia/ib] IIB+H2 T5 Gb Standard display

(1)

Ex de [ib] IIB+H2 T5 Gb Standard display or Chinese-

language display

Ex de [ib] IIC T5 Gb No display or IIC display

language display

Ex d [ib] IIC T5 Gb No display or IIC display

(1)

Ex de [ib] IIB+H2 T5 Gb Standard display

Ex de [ib] IIC T5 Gb No display or IIC display

Ex d [ib] IIC T5 Gb No display or IIC display

(1)

Ex de [ia/ib] IIB+H2 T5 Gb Standard display

Ex de [ia/ib] IIC T5 Gb No display or IIC display

Ex d [ia/ib] IIC T5 Gb no display or IIC display

(1)

Ex de [ia/ib] IIB+H2 T5 Gb Standard display

Ex de [ia/ib] IIC T5 Gb No display or IIC display

18 www.emerson.com

Page 19

March 2019 Series 1000 and 2000 Transmitters

Output option Code Approval

Ex d [ia/ib] IIC T5 Gb No display or IIC display

Output codes E and G are FISCO field devices in compliance with EN/IEC 60079-11:2012 Annex G.

(1)

Model 1500 and 2500

CSA and CSA-US

■

Transmitter (when installed in a suitable enclosure): Class I, Div. 2, Groups A, B, C, and D.

■

Sensor, including wiring to sensor: Class I, Div. 1, Groups C and D or Class II, Div. 1, Groups E, F, and G.

ATEX

Ambient temperature

Operating conditions: Environmental

Limited to -40 °F (-40.0 °C) to 131 °F (55.0 °C) for ATEX

compliance

II (2) 3G [EEx ib] IIB/IIC

Marine approval classifications

Marine approval

Det Norske Veritas- Germanischer Lloyd (Models 1500 and 2500 only) Norway-Germany

American Bureau of Shipping (all models) USA

Country

Physical specifications

Model 1700 and Model 2700

Specification

Housing

Value

■

Polyurethane-painted cast aluminum or CF3M stainless steel; NEMA 4X (IP66)

www.emerson.com 19

Page 20

Series 1000 and 2000 Transmitters March 2019

Specification Value

(1)

Weight

Terminal compartments

■

Painted aluminum, 4-wire remote:

■

with display: 8 lb (4 kg)

■

without display: 7 lb (3 kg)

■

Painted aluminum, 9-wire remote:

■

With display: 14 lb (6 kg)

■

Without display: 13 lb (6 kg)

■

Stainless steel:

■

With display: 21 lb (10 kg)

■

Without display: 20 lb (9 kg)

■

Option with Smart Wireless THUM Adapter: Add 0.65 lb (0.295 kg) to transmitter weight

■

Output terminals are physically separated from the power and service-port terminals.

Cable gland entrances

Mounting

Maximum cable lengths

between sensor and

transmitter

(2)

■

½ in–14 NPT or M20 × 1.5 female conduit ports for outputs and power supply

■

¾ in–14 NPT female conduit port for sensor/core processor cable

■

Painted aluminum transmitters with WirelessHART, and all stainless steel transmitters, have

one additional ½ in–14 NPT conduit opening

■

Integral or remote mounting options (stainless steel versions are always remote mounted)

■

May be remotely connected to any 4-wire or 9-wire Micro Motion sensor

■

Remote-mount transmitters:

■

Painted aluminum versions include a 304L stainless steel mounting bracket; hardware for

installing the transmitter on the mounting bracket is included

■

Stainless steel versions include a 316 stainless steel mounting bracket and hardware

■

Transmitter can be rotated on the sensor or the mounting bracket, 360 degrees, in 90degree increments.

Cable type Wire gauge Maximum length

■

Micro Motion 9-wire Not applicable 60 ft (18 m)

■

Micro Motion 4-wire Not applicable 1,000 ft (305 m)

■

User-supplied 4-wire

power wires (VDC)

22 AWG (0.326 mm²) 300 ft (91 m)

20 AWG (0.518 mm²) 500 ft (152 m)

18 AWG (0.823 mm²) 1,000 ft (305 m)

■

User-supplied 4-wire signal

22 AWG (0.326 mm²) or larger 1,000 ft (305 m)

wires (RS-485)

20 www.emerson.com

Page 21

March 2019 Series 1000 and 2000 Transmitters

Specification Value

Standard interface/display

■

Segmented 2-line display with LCD screen with optical controls and flowmeter-status LED is

standard; suitable for hazardous area installation

■

Available in both backlit and non-backlit versions

■

Depending on purchase option, transmitter housing cover has non-glass or non-glare

tempered glass lens

■

To facilitate various mounting orientations, the display can be rotated on transmitter, 360

degrees, in 90-degree increments

■

LCD line 1 lists the process variable; LCD line 2 lists engineering unit of measure

■

Display supports English, French, German, and Spanish languages

■

Display controls feature optical switches that are operated through the glass with a red LED

for visual feedback to confirm when a button is pressed

■

Chinese-language interface/

(3)

display

Six-line graphical display optimized for Chinese-language support. Has LCD screen with

optical controls and flowmeter-status LED; suitable for hazardous area installation

■

Available in both backlit and non-backlit versions

■

Transmitter housing cover has non-glare tempered-glass lens

■

To facilitate various mounting orientations, the display can be rotated on transmitter, 360

degrees, in 90-degree increments

■

Display shows the process variable name, value, and units of measure

■

Display supports English and Chinese languages

■

Display controls feature three optical switches that are operated through the lens with a red

LED for visual feedback to confirm when a button is pressed.

■

Pressing specific optical switch combinations can access the display menu, change the

language display, lock/unlock display access, and return to the process variables view

Display functions

(4)

■

Operational: View process variables; start, stop, and reset totalizers; view and acknowledge

alarms.

■

Off-line: Zero flowmeter, Smart Meter Verification, simulate outputs, change measurement

units, configure outputs, and set RS-485 communications options.

■

Status LED: Three-color LED status light on display panel indicates flowmeter condition at a

glance.

For transmitters integrally mounted to a sensor, you may need to add the weight of the transmitter to the sensor. Refer to the sensor product

(1)

data sheet.

Where 4-wire cable is required, use only Micro Motion 4-wire cable. Depending on the specific model number ordered, 10 ft (3.05 m) of cable (4-

(2)

wire or 9-wire) may be included (see ordering information for details). For longer cable lengths, contact customer support.

This option is available for purchase in China only.

(3)

Applies to all display options.

(4)

Model 1500/2500

Weight

0.52 lb (0.2 kg)

www.emerson.com 21

Page 22

Series 1000 and 2000 Transmitters March 2019

Mounting

Maximum cable lengths

between sensor and

transmitter

Status LED Three-color status LED on face of transmitter indicates flowmeter condition at a glance, using a

Zero button A zero button on the face of the transmitter can be used to start the transmitter zero procedure

(1)

■

Mounted on 1.4 in (36 mm) rail

■

Rail must be grounded

■

May be remotely connected to any Micro Motion sensor

■

Requires standard 4-wire twisted, shielded signal cable, up to 1,000 ft (305 m) in length,

between the sensor and the transmitter - if the core processor is remotely mounted from the

sensor, the maximum length of the 9-wire signal cable between the sensor and the remote

core processor is 60 ft (18 m).

Cable type Wire gauge Maximum length

■

Micro Motion 9-wire Not applicable 60 ft (18 m)

■

Micro MOtion 4-wire Not applicable 1,000 ft (305 m)

■

User-supplied 4-wire

power wires (VDC)

■

User-supplied 4-wire signal

wires (RS-485)

solid green, yellow, or red light. Zero in progress is indicated by a flashing yellow light

22 AWG (0.326 mm²) 300 ft (91 m)

20 AWG (0.518 mm²) 500 ft (152 m)

18 AWG (0.823 mm²) 1,000 ft (305 m)

22 AWG (0.326 mm²) or larger 1,000 ft (305 m)

Where 4-wire cable is required, use only Micro Motion 4-wire cable.

(1)

22 www.emerson.com

Page 23

6 13/16

(174)

3 15/16

(99)

2 7/16

(62)

Ø4 11/16

(119)

4 13/16

(119)

4 1/2

(114)

2 11/16

(69)

1 7/8

(47)

A

B

D

2 1/4

(57)

9 5/16

(237)

C

8 7/16

(214)

4 5/16

(110)

1 3/4

(45)

1

(25)

2 1/4

(57)

3 11/16

(93)

2 13/16

(71)

2 13/16

(71)

4 3/4

(120)

March 2019

Series 1000 and 2000 Transmitters

Model 1700/2700 4-wire remote-mount transmitter with display – painted aluminum housing

½ in -14 NPT or M20 x 1.5

A. 3 x

B. Wall mount

C. To centerline of 2 in (51 mm) pipe (pipe mount)

D. To conduit opening

Note

Dimensions are in inches (mm).

www.emerson.com 23

Page 24

3 11/16

(93)

2 13/16

(71)

2 13/16

(71)

4 1/2

(114)

5 13/16

(148)

2 15/16

(74)

13/16

(21)

2 11/16 (69)

1 7/8 (47)

1

(25)

2 1/4

(57)

4 5/16

(110)

7/7/16

(188)

8 5/16

(211)

A

B

2 7/16

(62)

Ø4 1/16

(104)

4 7/16

(113)

4 1/2

(114)

2 1/4

(57)

4 3/4

(120)

C

1 3/4

(45)

Series 1000 and 2000 Transmitters

March 2019

Model 1700/2700 4-wire remote-mount transmitter without display – painted aluminum housing

A. To center line of 2 in (51 mm) pipe (pipe mount)

B. Wall mount

C. To conduit opening

Note

■

Dimensions are in inches (mm).

■

For integrally-mounted transmitter and sensor dimensions, see the sensor product data sheet.

24 www.emerson.com

Page 25

A

B

9 5/8

(244)

5 7/16

(139)

2 13/16

(71)

2 13/16

(71)

6 13/16

(174)

3 15/16

(99)

2 11/16

(69)

3 13/16

(97)

2 5/8

(66)

2 13/16

(72)

3/4”-14 NPT

13/16

(21)

3 1/16

(78)

4 9/16

(116)

8 11/16

(220)

2 7/16

(62)

Ø4 11/16

(119)

6 5/16

(160)

6 3/16

(158)

3

(76)

5 11/16

(144)

March 2019

Series 1000 and 2000 Transmitters

Model 1700/2700 9-wire remote-mount transmitter and core processor assembly with display – painted aluminum housing

A. 2 x 1/2 in-14 NPT or M20 x 1.5

B. To center line of 2 in (51 mm) pipe (pipe mount)

Note

■

Dimensions are in inches (mm).

■

For integrally-mounted transmitter and sensor dimensions, refer to the sensor product data sheet.

www.emerson.com 25

Page 26

5 7/16

(139)

2 13/16

(71)

2 13/16

(71)

4 1/2

(114)

5 13/16

(148)

2 15/16

(74)

13/16

(21)

2 11/16 (69)

3 13/16 (97)

2 13/16

(72)

4 9/16

(116)

2 5/8

(66)

3 1/16

(78)

7 11/16

(195)

8 5/8

(219)

3/4”-14 NPT

B

A

2 7/16

(62)

Ø4 1/16

(104)

6 1/16

(154)

6 3/16

(158)

3

(76)

5 11/16

(144)

Series 1000 and 2000 Transmitters

Model 1700/2700 9-wire remote-mount transmitter and core processor assembly without display – painted aluminum housing

March 2019

A. To centerline of 2 in (51 mm) pipe (pipe mount)

B. Wall mount

Note

■

Dimensions are in inches (mm).

■

For integrally-mounted transmitter and sensor dimensions, refer to the sensor product data sheet.

26 www.emerson.com

Page 27

March 2019

Series 1000 and 2000 Transmitters

Model 1700/2700 4-wire and 9-wire remote mount transmitter – stainless steel housing

Note

Dimensions are in inches (mm).

www.emerson.com 27

Page 28

Ø4 3/8

(111)

5 11/16

(144)

A

B

C

2 1/2

(64)

2 3/8

(61)

1 11/16

(43)

3/4”-14 NPT

3 5/16

(84)

2 1/4

(57)

5 7/16

(139)

2 13/16

(71)

2 13/16

(71)

4 1/2

(114)

4 x Ø3/8

(10)

6 3/16

(158)

Series 1000 and 2000 Transmitters

Remote (standard) core processor

March 2019

A. 5.5 in (140 mm) pipe mount: To center line of 2 in (51 mm) pipe

B. 4.57 in (116 mm) wall mount

C. ½ in-14 NPT or M20 x 1.5

Note

Dimensions are in inches (mm).

28 www.emerson.com

Page 29

March 2019

Remote enhanced core processor

Series 1000 and 2000 Transmitters

A. To centerline of 2 in (51 mm) pipe

B. 5.5 in (140 mm) pipe mount

C. 4.57 in (116 mm) wall mount

D. 1/2 in14 NPT or M20 x 1.5

Note

Dimensions are in inches (mm).

Model 2700 transmitter with Smart Wireless THUM™ Adapter

Output options 2 and 3 (all approval codes) and output option 4 (approval codes E and Z only)

The Model 2700 transmitter with the WirelessHART option provides an additional conduit opening at the top of the transmitter to

install the Smart Wireless THUM Adapter. The THUM Adapter comes integrally mounted to the transmitter for output options 2 and

3 (all approval codes) and output option 4 (approval codes E and Z).

www.emerson.com 29

Page 30

Ø 2.000

(51)

9.601

(244)

11.222

(285)

A B

Series 1000 and 2000 Transmitters

March 2019

A. Remote-mount transmitter with integral-mount THUM Adapter

B. Remote-mount transmitter/core processor assembly with integral-mount THUM Adapter

Note

Dimensions are in inches (mm).

Model 2700 transmitter with Smart Wireless THUM™ Adapter Output option 4 (approval code A)

The Model 2700 transmitter with WirelessHART output option 4 (approval code A) requires using poured conduit seals or a

stopping box between the transmitter and Smart Wireless THUM Adapter. The THUM Adapter is not pre-installed for approval code

A.

30 www.emerson.com

Page 31

A

C D

Ø 2.000

(51)

5.149

(131)

B

6.607

(168)

4.986

(127)

March 2019

Series 1000 and 2000 Transmitters

A. Smart Wireless THUM Adapter

B. 1/2-14 NPT male

C. Remote-mount transmitter with additional conduit opening for installation of the THUM Adapter

D. Remote-mount transmitter/core processor assembly with additional conduit opening for installation of the THUM Adapter

Note

Dimensions are in inches (mm).

www.emerson.com 31

Page 32

4.41

(112)

3.67

(93)

3.90

(99)

1.78

(45)

1.39

(35)

A

Series 1000 and 2000 Transmitters March 2019

Model 1500/2500

A. For mounting on a 1.39 in (35 mm) rail

Note

Dimensions are in inches (mm).

Ordering information

Model 1500

Base model

Model

1500 Micro Motion Coriolis MVD 1500 single variable flow transmitter

32 www.emerson.com

Product description

Page 33

March 2019 Series 1000 and 2000 Transmitters

Mounting

Code Mounting options for Model 1500

D 4-wire remote 1.39 in (35 mm) DIN rail transmitter

E 4-wire remote 1.39 in (35 mm) DIN rail transmitter with 9-wire remote enhanced core processor; includes 10 ft

(3 m) each 9-wire shielded FEP and 4-wire shielded PVC cable;

Available with approval codes M, C, A, B or P only

B 4-wire remote 1.39 in (35 mm) DIN rail transmitter with 9-wire remote core processor; includes 10 ft (3 m) 9-wire

shielded FEP cable

Power

Code Power options for Model 1500

3 19.2 to 28.8 VDC

Conduit connection

Code Conduit connection options for Model 1500 — with mounting code D

A None

Code Conduit connection options for Model 1500 — with mounting code B or E

B 1/2-in NPT remote core processor – no gland

E M20 remote core processor – no gland

F Remote core processor – brass/nickel cable gland

Not available with approval code S, T, or J

G Remote core processor – stainless steel cable gland

Not available with approval code S, T, or J

K JIS B0202 1/2G – no gland

Only available with approval code M, T, or S

L Japan - brass nickel cable gland

Only available with approval code M, T, or S

M Japan - stainless cable gland

Only available with approval code M, T, or S

Output

Code

A One mA, one frequency, RS-485

C One mA, two DO, RS-485

Output options for Model 1500

Not available with software option 1 code B

Only available with software 1 code B

www.emerson.com 33

Page 34

Series 1000 and 2000 Transmitters March 2019

Terminal

Code Terminal options for Model 1500

B Screw terminals

Approval

Code Approval options for Model 1500

M Micro Motion Standard (no approval, with CE/EAC mark)

C CSA (Canada only)

A CSA (US and Canada)

B ATEX - Safe area with IS sensor outputs

P NEPSI – Safe area

Only available with language code M (Chinese)

T TIIS - IIC sensor (not available for quotes outside of Japan)

Available for quote only.

S TIIS - IIB sensor (not available for quotes outside of Japan)

Available for quote only.

J Hardware ready for TIIS approval (EPM Japan only)

Approval Code J is only available with Conduit Connections Option E; Available for order only

G Country Specific Approval - Requires a selection from the Approvals section of the “Add on Options”

Language

Code

A Danish CE requirements document; English installation and configuration manuals

D Dutch CE requirements document; English installation and configuration manuals

E English installation manual; English configuration manual

F French installation manual; French configuration manual

G German installation manual; German configuration manual

H Finnish CE requirements document; English installation and configuration manuals

I Italian installation manual; English configuration manual

J Japanese installation manual; Japanese configuration manual

M Chinese installation manual; Chinese configuration manual

N Norwegian CE requirements document; English installation and configuration manuals

O Polish installation manual; English configuration manual

P Portuguese installation manual; English configuration manual

Language options for Model 1500

S Spanish installation manual; Spanish configuration manual

W Swedish CE requirements document; English installation and configuration manuals

(1)

C

(1)

B

Czech CE requirements document, English installation and configuration manuals

Hungarian CE requirements document; English installation and configuration manuals

34 www.emerson.com

Page 35

March 2019 Series 1000 and 2000 Transmitters

Code Language options for Model 1500

(1)

K

(1)

T

(1)

U

(1)

L

(1)

V

(1)

Y

Not available with approval code J, T, or S.

(1)

Slovak CE requirements document; English installation and configuration manuals

Estonian CE requirements document; English installation and configuration manuals

Greek CE requirements document; English installation and configuration manuals

Latvian CE requirements document; English installation and configuration manuals

Lithuanian CE requirements document; English installation and configuration manuals

Slovenian CE requirements document; English installation and configuration manuals

Software 1

Code Software options 1 for Model 1500

Z Flow variable (standard)

B Filling and dosing application

Not available with Output code A.

J Production Volume Reconciliation

Available with software option 2 codes Z and C only

K Transient Mist Remediation

Available with software option 2 codes Z and C only

L Transient Bubble Remediation

Available with software option 2 codes Z and C only

R Piece-wise linearization for gas

Available with software option 2 codes Z and C only

X ETO software option 1

Requires “X” Factory option code

Software 2

Code

Z No software options 2

C Smart Meter Verification

X ETO software option 2

Software options 2 for Model 1500

Not available with Mounting Option B; Smart Meter Verification is not available with all sensors.

Requires “X” Factory option code

Factory

Code

Factory options for Model 1500

Z Standard product

X ETO product

www.emerson.com 35

Page 36

Series 1000 and 2000 Transmitters March 2019

Add on Options

Code Add on options for Model 1500

Country specific approval (select one from the following if approval code G is selected):

R4 EAC Safe Area Only with IS Sensor Outputs - Hazardous Area Approval

B4 INMETRO Safe Area Only with IS Sensor Outputs - Hazardous Area Approval

Model 1700

Base model

Model Product description

1700 Micro Motion Coriolis MVD Model 1700 single variable flow transmitter

Mounting

Code Mounting options for Model 1700

R 4-wire remote mount transmitter (polyurethane-painted aluminum housing) includes10 ft (3 m) 4-wire shielded

PVC cable)

I Integral mount transmitter (polyurethane-painted aluminum housing)

E 4-wire remote mount transmitter with 9-wire remote enhanced core processor; includes 10 ft (3 m) each of 4-wire

shielded PVC cable and 9-wire shielded FEP cable

Not available with conduit connection code C or D; Not available with approval option codes S or T with conduit

connections L or M

B 4-wire remote mount transmitter with 9-wire remote core processor; includes 10 ft (3 m) each of 4-wire shielded

PVC cable and 9-wire shielded FEP cable

Not available with conduit connection code C or D

C 9-wire remote transmitter with integral core processor (polyurethane-painted aluminum housing) includes 10 ft

(3 m) CFEPS cable

M 4-wire remote mount transmitter with stainless steel housing; includes 10 ft (3 m) 4-wire shielded PVC cable;

Not available with Approval codes U, Z, P, K, T, S, J or G with country-specific approval codes R1 or B1.

P 9-wire remote mount transmitter with stainless steel housing and integral core processor; includes 10 ft (3 m)

CFEPS cable

Not available with Approval codes U, Z, P, K, T, S, J or G with country-specific approval codes R1 or B1.

Power

Code

1 18 to 100 VDC or 85 to 265 VAC; self switching

Power options for Model 1700

Display

Code

1 Dual line display for CSA, UL, and IIB + H2 ATEX, IECEx and NEPSI ratings

Display options for Model 1700

Not available with mounting code M or P

36 www.emerson.com

Page 37

March 2019 Series 1000 and 2000 Transmitters

Code Display options for Model 1700

2 Backlit dual line display for CSA, UL, and IIB + H2 ATEX, IECEx and NEPSI ratings

3 No display

Not available with approval codes J, T, or S

5 Backlit dual line display for IIC ATEX, IECEx, and NEPSI rating

Only available with approval codes Z, F, P, K, I or G with country specific approval R1, B1, R2, B2

7 Non-glass backlit dual line display for General Purpose (no approvals)

Only available with approval code M; Not available with either mounting code M or P

8 Display optimized for Chinese-language support; China only

Available with Mounting Option codes R, I, C, or B; Output code A; Conduit Connections codes B, C, D, E, F or G;

Approval codes M, Z, F, P, K , I or G with country specific approval codes R1, B1, R2, or B2; Language codes E or M;

Software 2 Options Z or C; Factory Option Z.

Output

Code Output options for Model 1700

A Analog outputs: one mA; one frequency; RS-485

D Intrinsically safe analog outputs: one mA, one frequency

Not available with approval code T, S, or J

Conduit connection

Code

B 1/2-in NPT – no gland

C 1/2-in NPT with brass nickel cable gland (not approved for Class 1 Division 1 installations)

D 1/2-in NPT with stainless-steel cable gland (not approved for Class 1 Division 1 installations)

E M20 – no gland

F M20 with brass nickel cable gland (not approved for Class 1 Division 1 installations)

G M20 with stainless steel cable gland (not approved for Class 1 Division 1 installations)

K JIS B0202 1/2G – no gland;

L Japan - brass nickel cable gland;

Conduit connection options for Model 1700

Not available with approval code T, S, or J

Not available with approval code T, S, or J; Not available with mounting codes B, E, M, or P

Not available with approval code T, S, or J; Not available with mounting code B or E.

Not available with approval code T or S

Not available with mounting code M or P

Only available with approval code M; Not available with mounting code M or P

Only available with approval code M, T, or S; Not available with mounting code M or P

M Japan - stainless-steel cable gland;

Only available with approval code M, T, or S; Not available with mounting code M or P

www.emerson.com 37

Page 38

Series 1000 and 2000 Transmitters March 2019

Approval

Code Approval options for Model 1700

M Micro Motion Standard (no approval, with CE/EAC mark)

U UL

Only available with conduit connection code B or E

C CSA (Canada only)

A CSA (US and Canada)

Z ATEX – Equipment Category 2 (Zone 1 – Increased safety terminal compartment)

F ATEX – Equipment Category 2 (Zone 1 – Flameproof terminal compartment)

P NEPSI – Equipment Category 2 (Zone 1– Flameproof terminal compartment)

Only available with language code M (Chinese)

K NEPSI – Equipment Category 2 (Zone 1 – Increased safety terminal compartment)

Only available with language code M (Chinese)

I IECEx Equipment Category 2 (Zone 1 – Flameproof terminal compartment)

T TIIS - IIC sensor (not available for quotes outside of Japan)

Available for quote only

S TIIS - IIB sensor (not available for quotes outside of Japan)

Available for quote only

J Hardware ready for TIIS approval (EPM Japan only)

Approval code J is only available with Conduit Connections Option E; Available for order only

G Country Specific Approval - Requires a selection from the Approvals section of the Add on Option

Language

Code

A Danish CE requirements document; English installation and configuration manuals

D Dutch CE requirements document; English installation and configuration manuals

E English installation manual; English configuration manual

F French installation manual; French configuration manual

G German installation manual; German configuration manual

H Finnish CE requirements document; English installation and configuration manuals

I Italian installation manual; English configuration manual

J Japanese installation manual; Japanese configuration manual

M Chinese installation manual; Chinese configuration manual

N Norwegian CE requirements document; English installation and configuration manuals

Language options for Model 1700

O Polish installation manual; English configuration manual

P Portuguese installation manual; English configuration manual

S Spanish installation manual; Spanish configuration manual

W Swedish CE requirements document; English installation and configuration manuals

38 www.emerson.com

Page 39

March 2019 Series 1000 and 2000 Transmitters

Code Language options for Model 1700

C Czech CE requirements: English installation and configuration manuals

B Hungarian CE requirements document; English installation and configuration manuals

K Slovak CE requirements document; English installation and configuration manuals

T Estonian CE requirements document; English installation and configuration manuals

U Greek CE requirements document; English installation and configuration manuals

L Latvian CE requirements document; English installation and configuration manuals

V Lithuanian CE requirements document; English installation and configuration manuals

Y Slovenian CE requirements document; English installation and configuration manuals

Software 1

Code Software options 1 for Model 1700

Z Flow variable (standard)

J Production volume reconciliation

Available with software option 2 Z and C only

K Transient mist remediation

Available with software option 2 Z and C only

L Transient bubble remediation

Available with software option 2 Z and C only

R Piece-wise linearization for gas

Available with software option 2 Z and C only

Software 2

Code

Z No software options 2

C Smart Meter Verification

S Safety certification of 4–20 mA Output per IEC 61508

V Safety Certification per IEC 61508 with Smart Meter Verification

Software options 2 for Model 1700

Not available with Mounting Option I, B, C, or P; Smart Meter Verification is not available with all sensors.

Only available with output code A or D

Not available with Mounting Option I, B, C, or P; Smart Meter Verification is not available with all sensors. Only

available with output code A or D

Factory

Code

Z Standard product

X ETO product

Factory options for Model 1700

www.emerson.com 39

Page 40

Series 1000 and 2000 Transmitters March 2019

Add on Options

Code Add on options for Model 1700

CL Hardware for cover lockout

Hardware only; does not include Weights & Measures software

PK 2 in (51 mm) pipe mount U-bolt kit for electronics

Not available with Mounting Option I

Country specific approval (select one from the following if approval code G is selected)

R1 EAC Zone 2 - Hazardous Area Approval - Increased safety terminal compartment (Exe)

R2 EAC Zone 1 - Hazardous Area Approval - Flameproof terminal compartment

B1 INMETRO Zone 1 - Hazardous Area Approval - Increased safety terminal compartment

B2 INMETRO Zone 1 - Hazardous Area Approval - Flameproof terminal compartment

Model 2500

Base model

Model Product description

2500 Micro Motion Coriolis MVD 2500 multivariable flow and density transmitter

Mounting

Code

D 4-wire remote 1.4 in (36 mm) DIN rail transmitter

E 4-wire 1.4 in (36 mm) DIN rail transmitter with 9-wire remote enhanced core processor; includes 10 ft (3 m) each 9-

B 4-wire remote 1.4 in (36 mm) DIN rail transmitter with 9-wire remote core processor; includes 10 ft (3 m) 9-wire

Mounting options for Model 2500

wire shielded FEP and 4-wire shielded PVC cable

Available with approval options M, C, A, B or P only

shielded FEP cable

Power

Code

3 19.2 to 28.8 VDC

Power options for Model 2500

Conduit connection

Code

Conduit connection options for Model 2500 — with mounting code D

A None

Code Conduit connection options for Model 2500 — with mounting code B or E

B 1/2-in NPT remote core processor – no gland

E M20 remote core processor – no gland

40 www.emerson.com

Page 41

March 2019 Series 1000 and 2000 Transmitters

Code Conduit connection options for Model 2500 — with mounting code B or E

F Remote core processor – brass/nickel cable gland

Not available with approval code S, T, or J

G Remote core processor – stainless steel cable gland

Not available with approval code S, T, or J

K JIS B0202 1/2G – no gland;

Only available with approval code M, T, or S

L Japan - brass nickel cable gland;

Only available with approval code M, T, or S

M Japan - stainless cable gland;

Only available with approval code M, T, or S

Output

Code Output options for Model 2500

B One mA, two configurable I/O channels, RS-485 – default configuration of two mA, one FO

C One mA, two configurable I/O channels, RS-485 – custom configuration

Terminal

Code

B Screw terminals

Terminal options for Model 2500

Approval

Code

M Micro Motion Standard (no approval, with CE/EAC mark)

C CSA (Canada only)

A CSA (US and Canada)

B ATEX - Safe area with IS sensor outputs

P NEPSI – Safe area

T TIIS - IIC sensor (not available for quotes outside of Japan)

S TIIS - IIB sensor (not available for quotes outside of Japan)

J Hardware ready for TIIS approval (EPM Japan only)

Approval options for Model 2500

Only available with language code M (Chinese)

Available for quote only

Available for quote only

Approval code J is only available with Conduit Connections Option E; Available for order only.

G Country Specific Approval - Requires a selection from the Approvals section of the Add on Options

www.emerson.com 41

Page 42

Series 1000 and 2000 Transmitters March 2019

Language

Code Language options for Model 2500

A Danish CE requirements document; English installation and configuration manuals

D Dutch CE requirements document; English installation and configuration manuals

E English installation manual; English configuration manual

F French installation manual; French configuration manual

G German installation manual; German configuration manual

H Finnish CE requirements document; English installation and configuration manuals

I Italian installation manual; English configuration manual

J Japanese installation manual; Japanese configuration manual

M Chinese installation manual; Chinese configuration manual

N Norwegian CE requirements document; English installation and configuration manuals

O Polish installation manual; English configuration manual

P Portuguese installation manual; English configuration manual

S Spanish installation manual; Spanish configuration manual

W Swedish CE requirements document; English installation and configuration manuals

(1)

C

(1)

B

(1)

K

(1)

T

(1)

U

(1)