Page 1

Installation Manual

MMI-20031632, Rev AA

August 2016

Micro Motion® 2-Wire Time Period Signal (TPS)

Compact Density Meter (CDM)

2-Wire TPS CDM Installation Supplement

Page 2

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product. The EC declaration of

conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available on

the internet at www.micromotion.com or through your local Micro Motion support center.

For information about the Pressure Equipment Directive, go to www.micromotion.com/documentation.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the transmitter

configuration manual. Product data sheets and manuals are available from the Micro Motion web site at

www.micromotion.com/documentation.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.micromotion.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

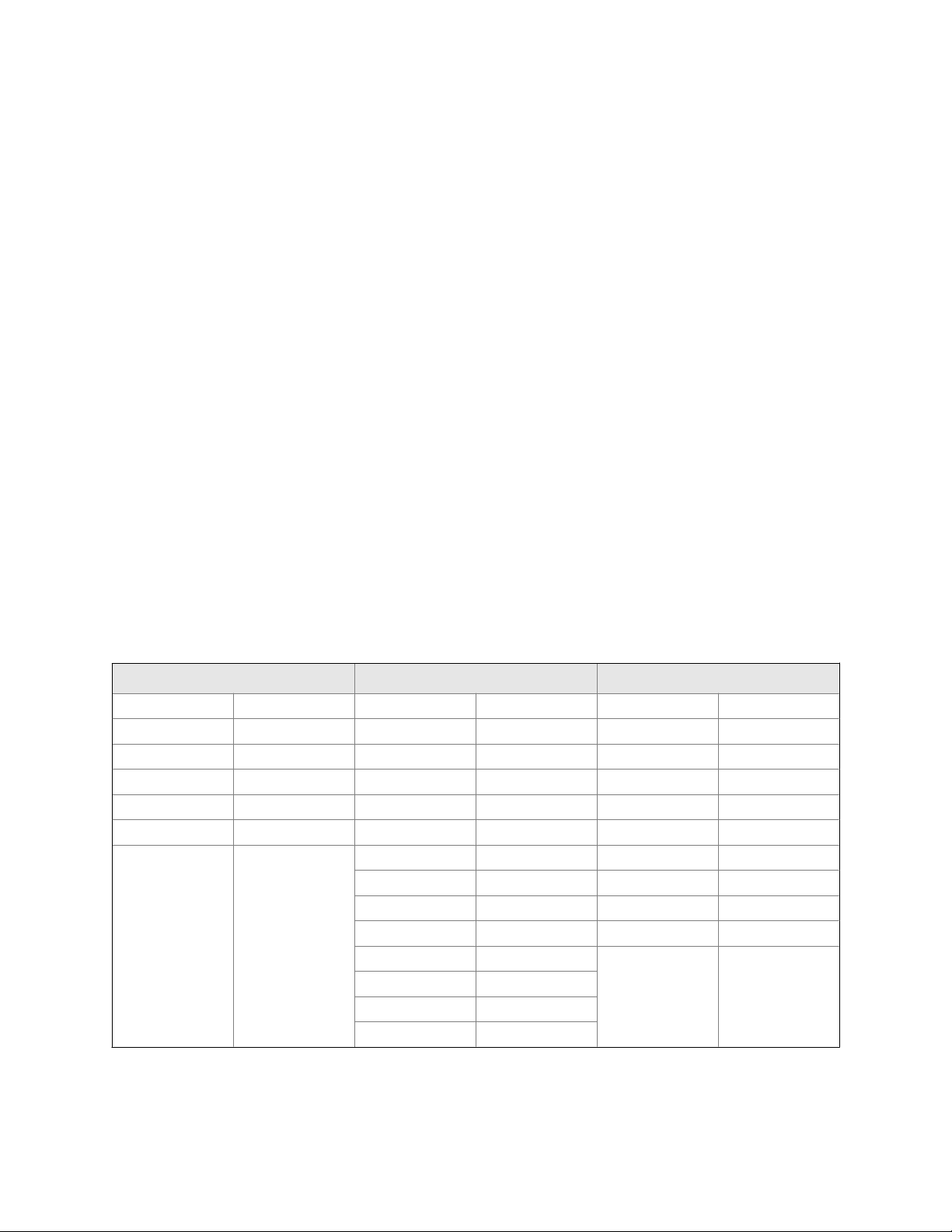

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136 666 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Contents

Chapter 1 Planning ........................................................................................................................ 1

1.1 2-wire installations .......................................................................................................................1

1.2 Installation checklist .................................................................................................................... 1

1.3 Best practices .............................................................................................................................. 2

1.4 Pressure drop in the meter ...........................................................................................................3

1.5 Recommended flow rates ............................................................................................................4

1.6 Power requirements .................................................................................................................... 5

1.7 Perform a pre-installation meter check ........................................................................................ 7

Chapter 2 Mounting .......................................................................................................................9

2.1 Mount the meter ......................................................................................................................... 9

2.2 Rotate the electronics on the meter (optional) .......................................................................... 10

Chapter 3 Wiring ......................................................................................................................... 12

3.1 Terminals and wiring requirements ............................................................................................12

3.2 Hazardous area output wiring ....................................................................................................13

3.3 Wire to galvanic isolators ...........................................................................................................19

Chapter 4 Grounding ....................................................................................................................21

Chapter 5 Verifying ...................................................................................................................... 22

Appendices and reference

Appendix A Sample calibration certificate .......................................................................................23

Installation Manual i

Page 4

Contents

ii Micro Motion Compact Density Meter

Page 5

1 Planning

Topics covered in this chapter:

2-wire installations

•

Installation checklist

•

Best practices

•

Pressure drop in the meter

•

Recommended flow rates

•

Power requirements

•

Perform a pre-installation meter check

•

1.1 2-wire installations

The 2-wire Time Period Signal (TPS) is a configuration option available on the Compact

Density Meter (CDM).

Planning

1.2

This option provides:

• A TPS output superimposed on the same pair of wires used to power the meter

• An optional 4-wire connection to the internal RTD

Restriction

The 2-wire TPS device does not support:

• Internal calculations of density

• Internal calculations of process variables, such as velocity indication, case temperature

measurement, or integral health diagnostics

• The display option available on the CDM

For more information on the availability of these features and functionality, refer to the full CDM

installation and configuration manuals.

Installation checklist

□

Make sure that the hazardous area specified on the approval tag is suitable for the

environment in which the meter will be installed.

□

Verify that the local ambient and process temperatures are within meter limits.

□

For optimal performance, install the meter in the preferred orientation.

The meter will work in any orientation as long as the vibrating tubes remain full of

the process fluid. However, you should validate the meter performance prior to

operation if you have installed it in a non-preferred orientation.

Installation Manual 1

Page 6

Planning

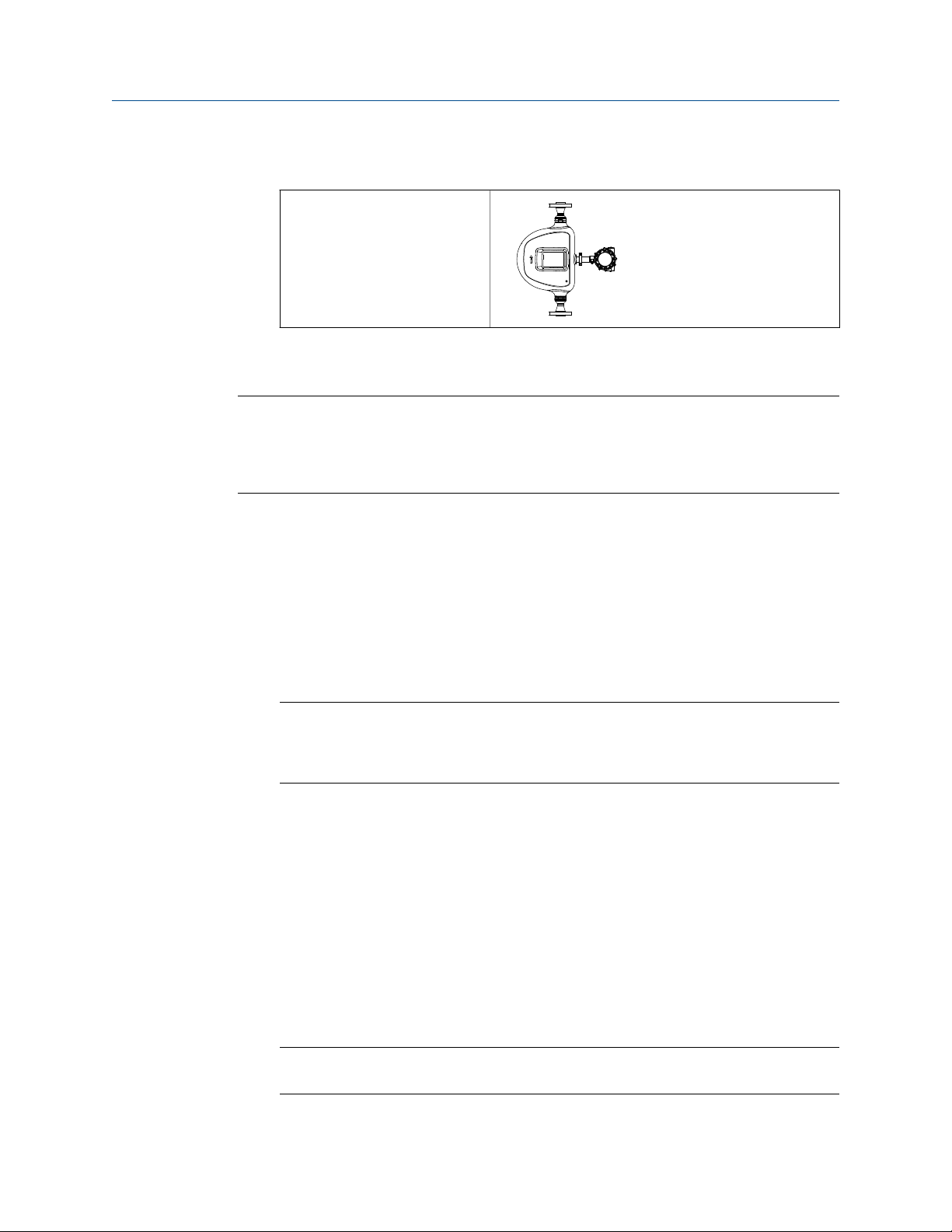

Preferred meter orientation — vertical, flowing upTable 1-1:

Liquids and slurries

□

Confirm the CDM output wiring requirements.

Tip

Micro Motion provides safety barriers for wiring the CDM in a hazardous environment. For the 2-wire

TPS CDM electronics, the spare part model codes BARRIER7787+ and BARRIER7764+ provide the

barriers needed for an intrinsically-safe installation. For ordering information, contact

flow.support@emerson.com.

1.3 Best practices

The following information can help you get the most from your meter.

• Handle the meter with care. Follow local practices for lifting or moving the meter.

• Install the meter in the preferred orientation in a vertical pipeline with liquids and

slurries flowing upward.

Important

If you do not install the meter in the preferred orientation, you may need to apply a field

offset to ensure optimal performance. Refer to your organizational standards for sampling

and reference measurement to determine what the offset may be.

• Do not apply a compression force greater than 200 lbs (90.7 kg) when installing the

meter.

• Thermally insulate the meter and the inlet and bypass-loop pipeline to maintain

stable temperatures.

• There are no pipe run requirements for Micro Motion meters. Straight runs of pipe

upstream or downstream are unnecessary.

• Keep the meter tubes full of process fluid.

• For halting flow through the meter with a single valve, install the valve downstream

from the meter.

• Minimize bending and torsional stress on the meter.

Important

Do not use the meter to align misaligned piping as this can invalidate the meter calibration.

2 Micro Motion Compact Density Meter

Page 7

• The meter does not require external supports. The flanges will support the meter in

any orientation.

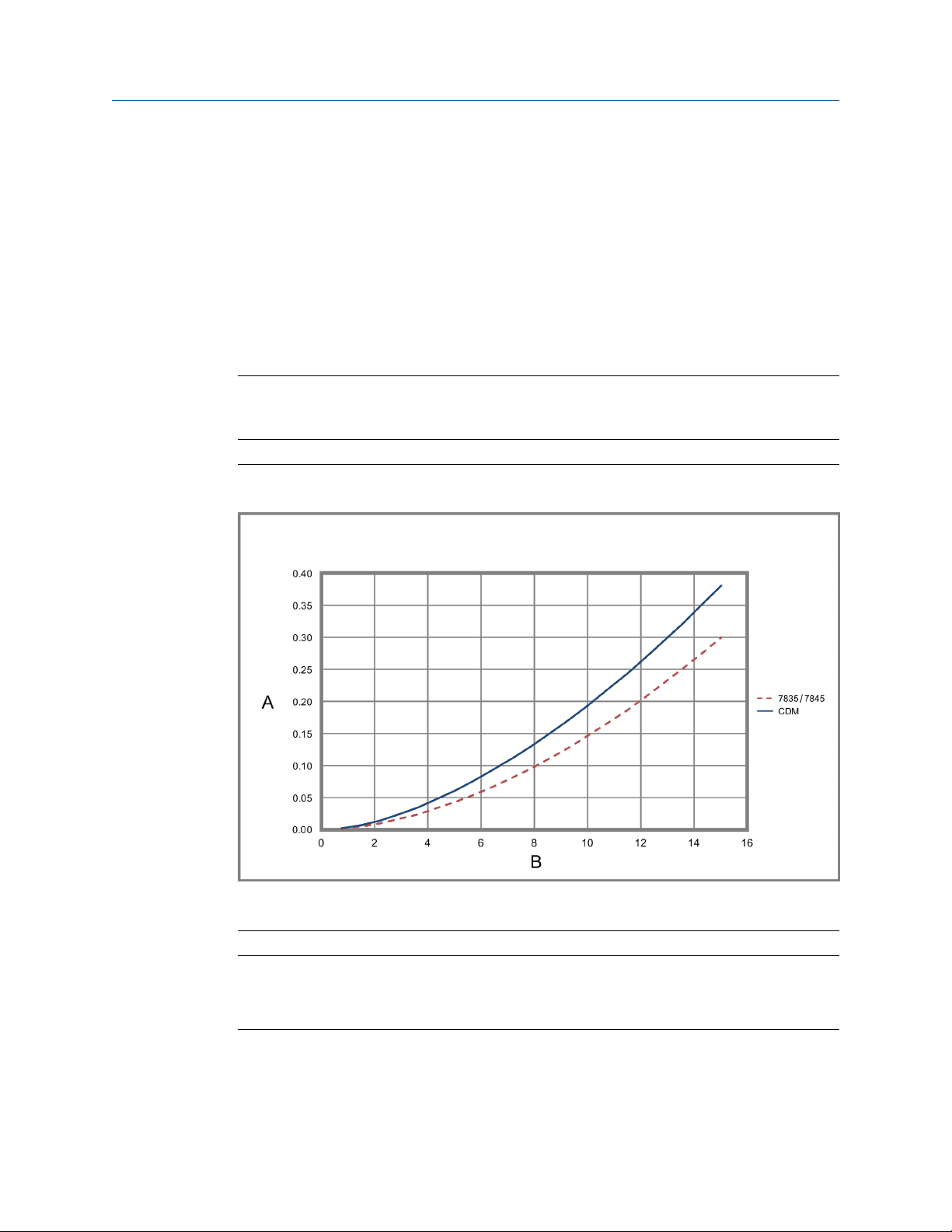

1.4 Pressure drop in the meter

The pressure drop in the meter depends on the process conditions. The following figures

illustrate the pressure drop for the meter at varying fluid density and viscosity. In addition,

these charts show how the meter compares to the Micro Motion 7835/7845 liquid density

meters.

Important

For the most accurate pressure drop calculations using your process variables, use the Micro Motion

product selector available at www.micromotion.com.

Sample pressure drop calculations (fluid viscosity equals 2 cP)Figure 1-1:

Planning

A. Pressure drop (bar)

B. Flow rate (m3/hr)

Note

• Density = 800 kg/m

• Viscosity = 2 cP

3

Installation Manual 3

Page 8

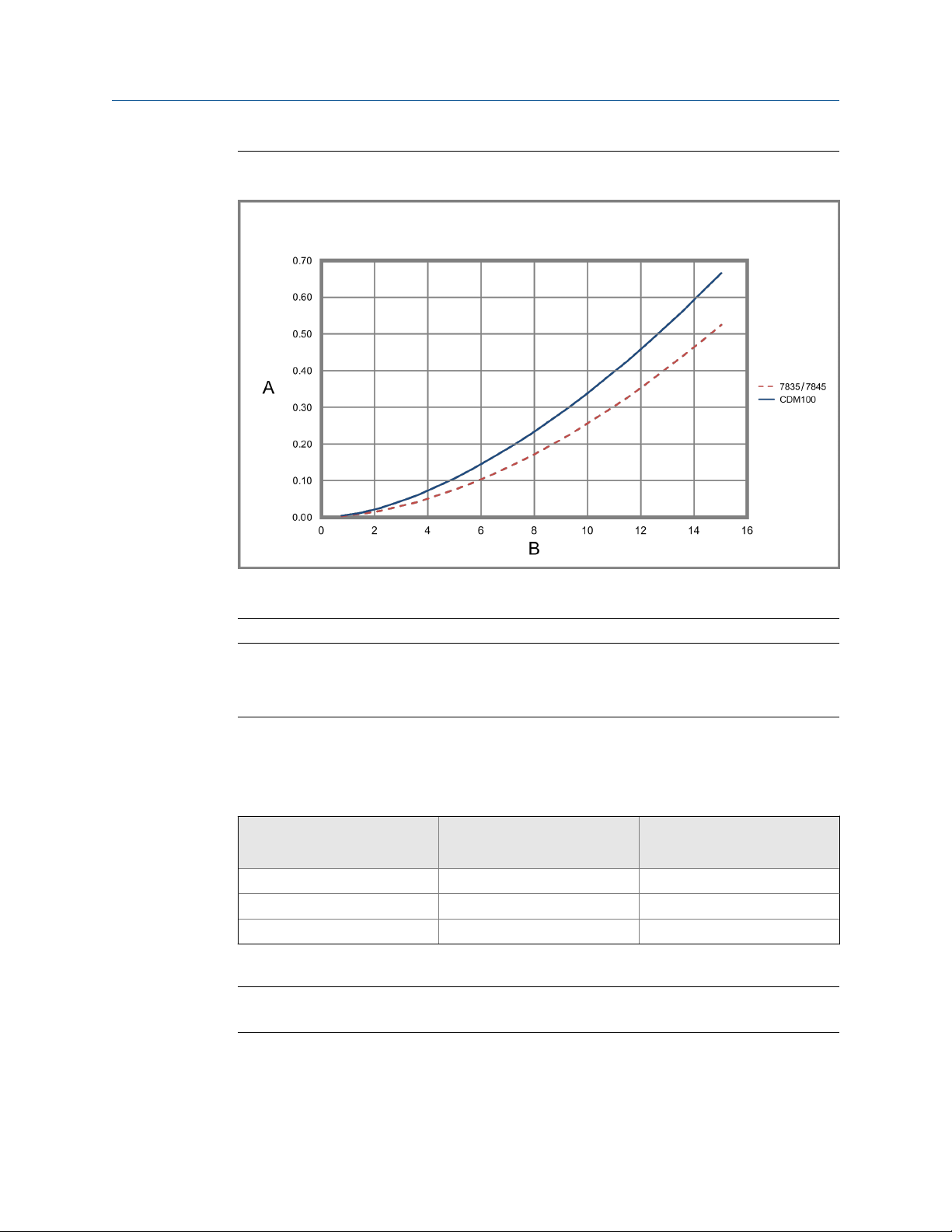

Planning

Sample pressure drop calculations (fluid viscosity equals 10 cP)Figure 1-2:

1.5

A. Pressure drop (bar)

B. Flow rate (m3/hr)

Note

• Density = 800 kg/m

• Viscosity = 10 cP

3

Recommended flow rates

Typical flow

recommendations Flow rate Velocity

Minimum 3 gpm (700 L/hr) 1.5 ft/sec (0.5 m/sec)

Normal 11 gpm (2,500 L/hr) 5 ft/sec (1.5 m/sec)

Maximum 75 gpm (17,000 L/hr) 30 ft/sec (9 m/sec)

Note

For fluids that contain abrasive particles, velocity should be below 10 ft/s (3 m/s).

4 Micro Motion Compact Density Meter

Page 9

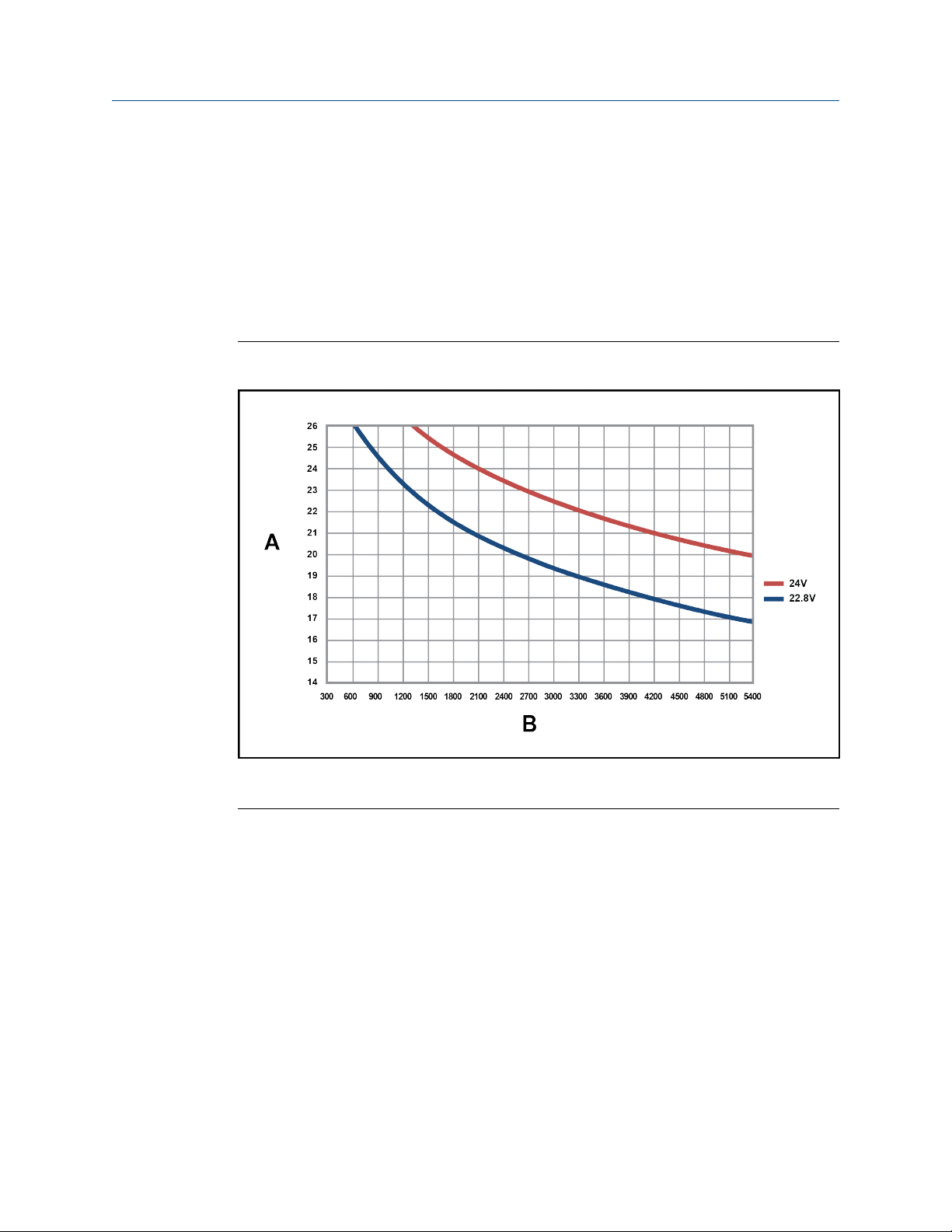

1.6 Power requirements

The following DC power requirements are needed to operate the meter:

• 24 VDC, 0.25 W typical with 300 Ω barrier, 0.3 W maximum with 300 Ω barrier

• Minimum recommended voltage: 22.8 VDC with 1000 ft of 22 AWG (300 m of 0.25

mm2) power-supply cable with 300 Ω barrier

Power cable recommendations for intrinsically-safe meters

Minimum wire gauge with 300 Ω barrierFigure 1-3:

Planning

A. AWG

B. Distance of installation in feet

Installation Manual 5

Page 10

Planning

Minimum wire area with 300 Ω barrierFigure 1-4:

A. Minimum wire area (mm2)

B. Distance of installation in meters

6 Micro Motion Compact Density Meter

Page 11

Planning

Limits of series resistance versus supply voltageFigure 1-5:

1.7

A. Series resistance (Ω)

B. Supply voltage (V)

C. 300 Ω barrier resistance

D. Normal operating point

E. Maximum resistance for correct operation

F. Minimum resistance for 5 volt TPS

G. The 2-wire CDM fully operates anywhere in the shaded area

Perform a pre-installation meter check

Micro Motion recommends that you check the meter prior to installation. This check

confirms that the meter was not damaged during shipment.

1. Remove the meter from the box.

CAUTION!

Handle the meter with care. Follow all corporate, local, and national safety regulations

for lifting and moving the meter.

2. Visually inspect the meter for any physical damage.

If you notice any physical damage to the meter, immediately contact Micro Motion

Customer Support at flow.support@emerson.com.

3. Connect and power up the meter.

To access the PWR terminals, remove the back transmitter housing cover.

4. Verify that the meter is empty, clean, and dry.

Installation Manual 7

Page 12

Planning

5. Allow the Time Period Signal (TPS) to stabilize to +/- 100ns before recording the

value.

6. Once stabilized, measure the TPS output and temperature of the meter from the

internal RTD.

7. Verify that the measured TPS value matches the Verification Time Period (on Air) @

20C (68F) value shown on the calibration certificate to within the limits in the

following table.

Air check limit at 68 °F

Meter type

CDM100M +/- 2 µs -570 (ns/°C) * (T-20 °C)

CDM100P +/- 2 µs -445 (ns/°C) * (T- 20 °C)

(20 °C) Added temperature effect

8 Micro Motion Compact Density Meter

Page 13

2 Mounting

Topics covered in this chapter:

Mount the meter

•

Rotate the electronics on the meter (optional)

•

2.1 Mount the meter

Use your common practices to minimize torque and bending load on process connections.

Tip

To reduce the risk of condensation or excessive moisture, the transmitter conduit opening should

not point upward (if possible). The conduit opening of the transmitter can be rotated freely to

facilitate wiring.

Mounting

CAUTION!

Do not lift the meter by the electronics. Lifting the meter by the electronics can damage the

device.

Installation Manual 9

Page 14

Mounting

Mounting the sensorFigure 2-1:

Notes

• Do not use the meter to support the piping.

• The meter does not require external supports. The flanges will support the meter in any orientation.

• All pipework joints and couplings must be airtight to minimize the presence of gas bubbles in the

fluid.

2.2

10 Micro Motion Compact Density Meter

Rotate the electronics on the meter (optional)

You can rotate the transmitter on the meter up to 90°.

1. Using a 4 mm hex key, loosen the cap screw that holds the transmitter in place.

Page 15

Component to secure transmitter in placeFigure 2-2:

A

A. M5 socket-head cap screw

2. Rotate the transmitter clockwise to the desired orientation up to 90°.

3. Secure the cap screw in place and tighten to 60 lb·in (6.8 N·m).

Mounting

Installation Manual 11

Page 16

Wiring

3 Wiring

Topics covered in this chapter:

Terminals and wiring requirements

•

Hazardous area output wiring

•

Wire to galvanic isolators

•

3.1 Terminals and wiring requirements

Three pairs of wiring terminals are available for transmitter outputs. One terminal is

designated for the 24 VDC Power and Time Period Signal (TPS). The other two terminals

are for the internal RTD connection.

The screw connectors for each output terminal accept a maximum wire size of 14 AWG

(2.5 mm2).

Important

Output wiring requirements depend on whether the meter will be installed in a safe area or a

hazardous area. It is your responsibility to verify that this installation meets all corporate, local, and

national safety requirements and electrical codes.

12 Micro Motion Compact Density Meter

Page 17

Wiring

Output wiring terminalsFigure 3-1:

3.2

A. RTD connector block

B. Chassis ground (external)

C. Chassis ground (internal)

D. Power/TPS connector block

Hazardous area output wiring

Micro Motion provides safety barrier installation kits for wiring the meter in a hazardous

environment. These kits provide the appropriate barriers depending on the outputs

available and approvals required.

Information provided about wiring the safety barriers is intended as an overview. You

should wire the meter according to the standards that are applicable at your site.

Installation Manual 13

Page 18

Wiring

CAUTION!

• Meter installation and wiring should be performed by suitably trained personnel only in

accordance with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

3.2.1 Hazardous area entity parameters

DANGER!

• Hazardous voltage can cause severe injury or death. To reduce the risk of hazardous

voltage, shut off power before wiring the meter.

• Improper wiring in a hazardous environment can cause an explosion. Install the meter

only in an area that complies with the hazardous classification tag on the meter.

Input entity parameters

Power in/signal output terminals 1, 2Table 3-1:

Parameter

Maximum input voltage Ui 28 V

Maximum input current li 93 mA

Maximum input power Pi 0.65 W

Maximum internal capacitance Ci 0 nF

Maximum internal inductance Li 0 mH

RTD terminals 5, 6, 7 and 8Table 3-2:

Parameter

Maximum input voltage Ui 12 V

Maximum input current li 36 mA

Maximum input power Pi 0.432 W

Maximum internal capacitance Ci 0 nF

Maximum internal inductance Li 0 mH

The voltage, current, and power values are the total available to all four RTD connections.

The total inductance (La) and capacitance (Ca) allowable for the electronics plus the cable

connecting it to the Zener barriers must be equal or less than the specified values for the

hazardous are classification. Refer to the hazardous area approvals documentation

shipped with the meter.

14 Micro Motion Compact Density Meter

Page 19

Wiring

Hazardous area

capacitance

The capacitance (Ci) of the meter is 0.0 µF. There is no extra

capacitance when calculating the maximum capacitance allowable for

the connecting cable. Therefore, the cable capacitance may be less or

equal to the maximum permitted capacitance (Ca) specified by the

safety barrier: (Ccable ≤ Ca)

Hazardous

area

inductance

The inductance (Li) of the meter is 0.0 µH. There is no extra inductance

when calculating the maximum inductance allowable for the

connecting cable. Therefore, the cable inductance may be less or equal

to the maximum permitted inductance (La) specified by the safety

barrier: (Lcable ≤ La)

3.2.2 Wire all intrinsically-safe installations using Zener safety barriers

Micro Motion provides safety barriers for wiring the meter in a hazardous area. Contact

your local sales representative or Micro Motion Customer Support at

flow.support@emerson.com for more information on ordering the appropriate barriers.

CAUTION!

• Install the meter installation and wiring only if you are suitably trained in accordance

with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

• Wire the i.s. barrier earth directly to its own earth bar as described in the safety

instructions. If you do not have a good i.s. earth — for example, if you are installing the

meter in a dry area, then use galvanic isolators instead of Zener safety barriers. Order

galvanic isolators from an external supplier since Micro Motion does not sell them.

The barriers are used for connecting all of the available meter outputs. Use the following

barriers with the designated output.

Output(s)

Power and TPS MTL 7787+ BARRIER7787

RTD MTL 7764+ (two) BARRIER7764

Barrier Model code for ordering

Procedure

Using the 2-wire wiring diagrams, wire the barriers to the appropriate output terminal and

pins.

Installation Manual 15

Page 20

Wiring

2-wire wiring diagrams

CAUTION!

• To meet the EC Directive for Electromagnetic Compatibility (EMC), use a suitable

instrumentation cable to connect the meter. The instrumentation cable should have

individual screens, foil or braid over each twisted pair, and an overall screen to cover all

cores. Where permissible, connect the overall screen to earth at both ends (360° bonded

at both ends). Connect the inner individual screens at only the controller end.

• Use metal cable glands where the cables enter the meter amplifier box. Fit unused cable

ports with metal blanking plugs.

Minimum 2-wire barrier connectionFigure 3-2:

A. Power / TPS out

B. IS barrier earth bar

C. IS ground

D. TPS signal +

E. TPS signal –

16 Micro Motion Compact Density Meter

Page 21

2-wire barrier connection with flow computer / signal converterFigure 3-3:

The following figure describes a 2-wire barrier connection that is powered through a flow computer /

signal converter.

A. Power / TPS out

B. IS barrier earth bar

C. IS ground

D. Flow computer / signal converter

E. Power +

F. TPS signal +

G. Power –

H. TPS signal –

Wiring

Installation Manual 17

Page 22

Wiring

2-wire barrier connection plus RTD barrier connectionFigure 3-4:

A. Power / TPS out

B. IS barrier earth bar

C. RTD

D. Flow computer / signal converter

E. Power +

F. TPS signal +

G. Power –

H. TPS signal –

I. RTD supply +

J. RTD signal +

K. RTD signal –

L. RTD supply –

18 Micro Motion Compact Density Meter

Page 23

M. IS ground

Note

If required, use two separate screened cables via two separate cable glands, one for the power and

one for the RTD. However, Micro Motion recommends that you use a single cable to facilitate a good

seal through a single cable entry gland.

3.3 Wire to galvanic isolators

In hazardous area installations where there is no proper I.S. ground available, such as dry

locations, Micro Motion recommends that you use galvanic isolators instead of Zener

barriers. Galvanic isolators convert the signal differently from Zenier barriers when passing

the signal across an isolation gap.

Prerequisites

• Galvanic isolators (MTL5532 and MTL5575)

Wiring

Note

Micro Motion does not sell galvanic isolators. Obtain the isolators from an external supplier.

• A Zener diode

The MTL5532 pulse isolator has a trigger level connected to the power + pin that is

not connected to the power – pin. Therefore, a Zener diode ensures a reliable

switching point.

• A pull-up resistor

The resistor is required because the output is passive.

• A 20 V to 35 V supply on the safe area side.

The MTL5575 is used specifically for the 4-wire RTD, and converts the RTD voltage and

current into a 4-20mA loop signal on the safe area side. The isolator requires 20 V to 35 V

DC energization from the safe area side that also supplies the active output of the 4-20 mA

loop.

Procedure

Using the 2-wire galvanic isolator wiring diagram, wire the isolators to the appropriate

output terminal and pins.

Installation Manual 19

Page 24

Wiring

2-wire galvanic isolator connectionsFigure 3-5:

A. Hazardous area

B. Safe area

C. Flow computer / signal converter

D. Power +

E. Power –

F. TPS signal +

G. TPS signal –

H. Analog i/p +

I. Analog i/p –

J. Analog pwr +

K. Analog pwr –

Note

Connect the screens to the chassis if no better earth is available.

Isolator trip level switch setting

12 V 6.2 V

6 V 13 V

3 V 16 V

Zener voltage

20 Micro Motion Compact Density Meter

Page 25

4 Grounding

The meter must be grounded according to the standards that are applicable at the site.

The customer is responsible for knowing and complying with all applicable standards.

Prerequisites

Micro Motion suggests the following guides for grounding practices:

• In Europe, EN 60079-14 is applicable to most installations, in particular Sections

12.2.2.3 and 12.2.2.4.

• In the U.S.A. and Canada, ISA 12.06.01 Part 1 provides examples with associated

applications and requirements.

• For IECEx installations, IEC 60079-14 is applicable.

If no external standards are applicable, follow these guidelines to ground the meter:

• Use copper wire, 18 AWG (0.75 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

Grounding

CAUTION!

Ground the meter to earth, or follow ground network requirements for the facility. Improper

grounding can cause measurement error.

Procedure

Check the joints in the pipeline.

- If the joints in the pipeline are ground-bonded, the sensor is automatically grounded

and no further action is necessary (unless required by local code).

- If the joints in the pipeline are not grounded, connect a ground wire to the grounding

screw located on the sensor electronics.

Installation Manual 21

Page 26

Verifying

5 Verifying

Use the following procedure after installation to verify that your meter is working

correctly.

1. Check for a series resistance of approximately 300 Ω either as a load resistor or the

Zener barrier.

2. Measure the current consumption and the supply voltage at the meter terminals.

3. Verify that the measured values match the values in the following table.

Power supply voltage (safe

area)

22.8 VDC 18.4 ± 0.5 VDC 13.6 mA ± 0.7 mA

24.0 VDC 20.0 ± 0.5 VDC 12.4 mA ± 0.7 mA

28.0 VDC 24.9 ± 0.5 VDC 9.8 mA ± 0.7 mA

CDM terminal voltage (hazardous area) Supply current

22 Micro Motion Compact Density Meter

Page 27

Appendix A

Sample calibration certificate

Your meter was shipped with a calibration certificate. The calibration certificate describes

the calibrations and configurations that were performed or applied at the factory.

Sample calibration certificate: 2-wire TPS CDMFigure A-1:

Sample calibration certificate

Installation Manual 23

Page 28

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.micromotion.com

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

*MMI-20031632*

MMI-20031632

Rev AA

2016

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

©

2016 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Process

Management family of companies. All other marks are property of

their respective owners.

Loading...

Loading...