Page 1

Command Series Migration to MOD 30ML™

Tutorial and Reference Guide for

Command Series Migration to MOD 30ML

Training

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed

information or technical details.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, Inc. and is owned by

MicroMod Automation or its suppliers.

Page 3

Command Series Migration to MOD 30ML

CONTENTS

CONTENTS

Page

BOOK 1

SECTION 1 – FUNCTIONCODES - INTRODUCTION

HOW TO USE THIS BOOK .................................................................................................. 1-1

ENVIRONMENT BLOCKS.................................................................................................... 1-2

I/O AND COMMUNICATION BLOCKS................................................................................. 1-5

FUNCTION BLOCKS............................................................................................................ 1-5

FUNCTION BLOCK EXECUTION ORDER .......................................................................... 1-9

COMPOUNDS ...................................................................................................................... 1-11

LOOP COMPOUNDS ........................................................................................................... 1-15

THE CONFIGURATON PROCESS...................................................................................... 1-18

PROCEDURE FOR ADDING THE DISPLAY TAG TO DISPLAY INTERFACE BLOCK ..... 1-19

PID CONFIGURATION REFERENCE ................................................................................. 1-22

SECTION 2 – GALLERY TUTORIAL

FOREWARD ......................................................................................................................... 2-1

OBJECTIVES........................................................................................................................ 2-1

INSTRUCTIONS – CREATING A NEW WORKSPACE, PROJECT AND DOCUMENT ..... 2-2

CONFIGURING SCAN GROUPS AND LOOP COMPOUNDS............................................ 2-10

ADDING COMPOUNDS FROM THE GALLERY.................................................................. 2-17

ADDING I/O .......................................................................................................................... 2-20

MAKING CONNECTIONS .................................................................................................... 2-24

CHANGING ENGINEERING RANGES AND ALARM TRIP VALUES ................................. 2-30

CONFIGURING DISPLAY TAG FOR DISPLAY................................................................... 2-34

SETTING UP COMMUNICATIONS WITH MODBUS........................................................... 2-41

COMPILING DATABASE...................................................................................................... 2-43

i

Page 4

Command Series Migration to MOD 30ML

CONTENTS

BOOK 2 – FUNCTION CODE GALLERY COMPOUNDS REFERENCE

SECTION 1 – PRE-CONFIGURED CONTROL STRATEGIES

1 PRE-CONFIGURED SIGLE LOOP PID CONTROL ............................................................. P1-1

2. PRE-CONFIGURED DUAL LOOP PID CONTROL .............................................................. P2-1

3 PRE-CONFIGURED SIGLE LOOP PID WITH REMOTE SP ............................................... P3-1

4 PRE-CONFIGURED DUAL LOOP PID WITH REMOTE SP ................................................ P4-1

5 PRE-CONFIGURED CASCADE CONTROL ........................................................................ P5-1

6 PRE-CONFIGURED PID RATIO WITH REMOTE SP .......................................................... P6-1

SECTION 2 – FUNCTION CODE COMPOUNDS

1 FUNCTION CODE 1 – FUNCTION GENERATOR............................................................... 1-1

2 FUNCTION CODE 2 – MANUAL SET CONSTANT ............................................................. 2-1

3 FUNCTION CODE 3 – LEAD / LAG...................................................................................... 3-1

4 FUNCTION CODE 6 – HIGH / LOW LIMITER...................................................................... 6-1

5 FUNCTION CODE 7 – SQUARE ROOT............................................................................... 7-1

6 FUNCTION CODE 8 – RATE LIMITER................................................................................. 8-1

7 FUNCTION CODE 9 – ANALOG TRANSFER...................................................................... 9-1

8 FUNCTION CODE 10 – HIGH SELECT ............................................................................... 10-1

9 FUNCTION CODE 11 – LOW SELECT ................................................................................ 11-1

10 FUNCTION CODE 12 – HIGH /LOW COMPARE................................................................. 12-1

11 FUNCTION CODE 14 – SUMMER ....................................................................................... 14-1

12 FUNCTION CODE 15 – SUMMER (2 INPUTS).................................................................... 15-1

13 FUNCTION CODE 16 – MULTIPLY...................................................................................... 16-1

14 FUNCTION CODE 17 – DIVIDE ........................................................................................... 17-1

15 FUNCTION CODE 20 – INDICATOR STATION................................................................... 20-1

16 FUNCTION CODES 25 AND 41 – ANALOG/DIGITAL INPUT ............................................. 25-1

17 FUNCTION CODE 28 – ANALOG/DIGITAL OUTPUT ......................................................... 28-1

18 FUNCTION CODE 33 – NOT................................................................................................ 33-1

19 FUNCTION CODE 34 – MEMORY (R/S FLIP FLOP)........................................................... 34-1

ii

Page 5

Command Series Migration to MOD 30ML

CONTENTS

20 FUNCTION CODE 35 – TIMER............................................................................................ 35-1

21 FUNCTION CODE 36 – QUALIFIED OR ............................................................................. 36-1

22 FUNCTION CODE 37 – AND (2 INPUT) .............................................................................. 37-1

23 FUNCTION CODE 38 – AND (4 INPUT) .............................................................................. 38-1

24 FUNCTION CODE 39 – OR (2 INPUT) ................................................................................ 39-1

25 FUNCTION CODE 40 – OR (4 INPUT) ................................................................................ 40-1

26 FUNCTION CODE 51 – MANUAL SET CONSTANT........................................................... 51-1

27 FUNCTION CODE 59 – DIGITAL TRANSFER .................................................................... 59-1

28 FUNCTION CODE 156 – PID WITH LOCAL SP .................................................................. 156-1

29 FUNCTION CODE 156 – PID WITH CASCADE .................................................................. 156c-1

30 FUNCTION CODE 156 – PID WITH REMOTE SP .............................................................. 156r-1

31 FUNCTION CODE 156 – PID RATIO WITH REMOTE SP .................................................. 156rr-1

32 FUNCTION CODE 156 – AUTO BIAS STATION ................................................................. 156ab-1

33 FUNCTION CODE 165 – MOVING AVERAGE.................................................................... 165-1

SECTION 3 – FUNCTION CODE COMPOUNDS - EXTRAS

1 EXTRAS – REJECT TO MANUAL........................................................................................ R-1

iii

Page 6

Command Series Migration to MOD 30ML

CONTENTS

iv

Page 7

BOOK 1

SECTION 1

FUNCTION CODES –

INTRODUCTION

Page 8

Page 9

HOW TO USE THIS BOOK

This book is meant for users of Bailey SLC, CLC controllers who are migrating to the

new generation MicroMod MOD 30ML controllers. Though both Bailey controllers and

MicroMod controllers are microprocessor based programmable controllers, the

configuration and the programming approach to them is different. This book should help a

Bailey user to understand the MOD 30ML controller with minimum time spent in learning

the new technology.

How to use this book:

The ViZapp Software contains Compound Galleries. A compound is a grouping of

function blocks configured and connected together for a specific control application. A

compound gallery is a library of commonly used compounds. Most of the commonly used

Bailey function codes have been translated to MOD 30ML compounds and stored in the

default gallery. This is included in ViZapp software versions 3 and above. The default

gallery contains multiple sections (tabs) for compounds:

Function Codes – Introduction

• General Compounds

• Bailey Function Codes

• Bailey Templates that contain pre-configured Control strategies

• Bailey Extras

This library can also be downloaded from the MicroMod Support website at

http://www.micromodautomation.com

The best way to use this book is to understand the MOD 30ML instrument database by

reading this chapter and then by going through the tutorial in the next chapter. Complete

the hands-on lab on configuring the MOD 30ML controller in the next chapter using the

ViZapp Software. After you have completed the lab, you will understand the mechanics of

configuring the MOD 30ML controller using ViZapp and the subtle difference in the

configuration process between Bailey tools and the ViZapp Software. You will also get

used to the new terminology and how easier and more powerful the MOD 30ML/Modcell

function blocks can be.

The subsequent chapters are reference material for the compounds.

For a complete training on MOD 30ML, use the ViZapp training manual IB-VIZAPP-TUT

with the 3

rd

chapter (PID Loop Lab) replaced by the tutorial in the next chapter. This

tutorial is written in such a manner that you could jump to chapter 4 in the ViZapp

Training manual (IB-VIZAPP-TUT) after completing the tutorial.

Look for updates to the Bailey FC Gallery file at out support website. For technical

support and questions, contact 585 292 9200 or visit the website at

http://www.micromodautomation.com

1 - 1

Page 10

Command Series Migration to MOD 30ML

Function Codes – Introduction

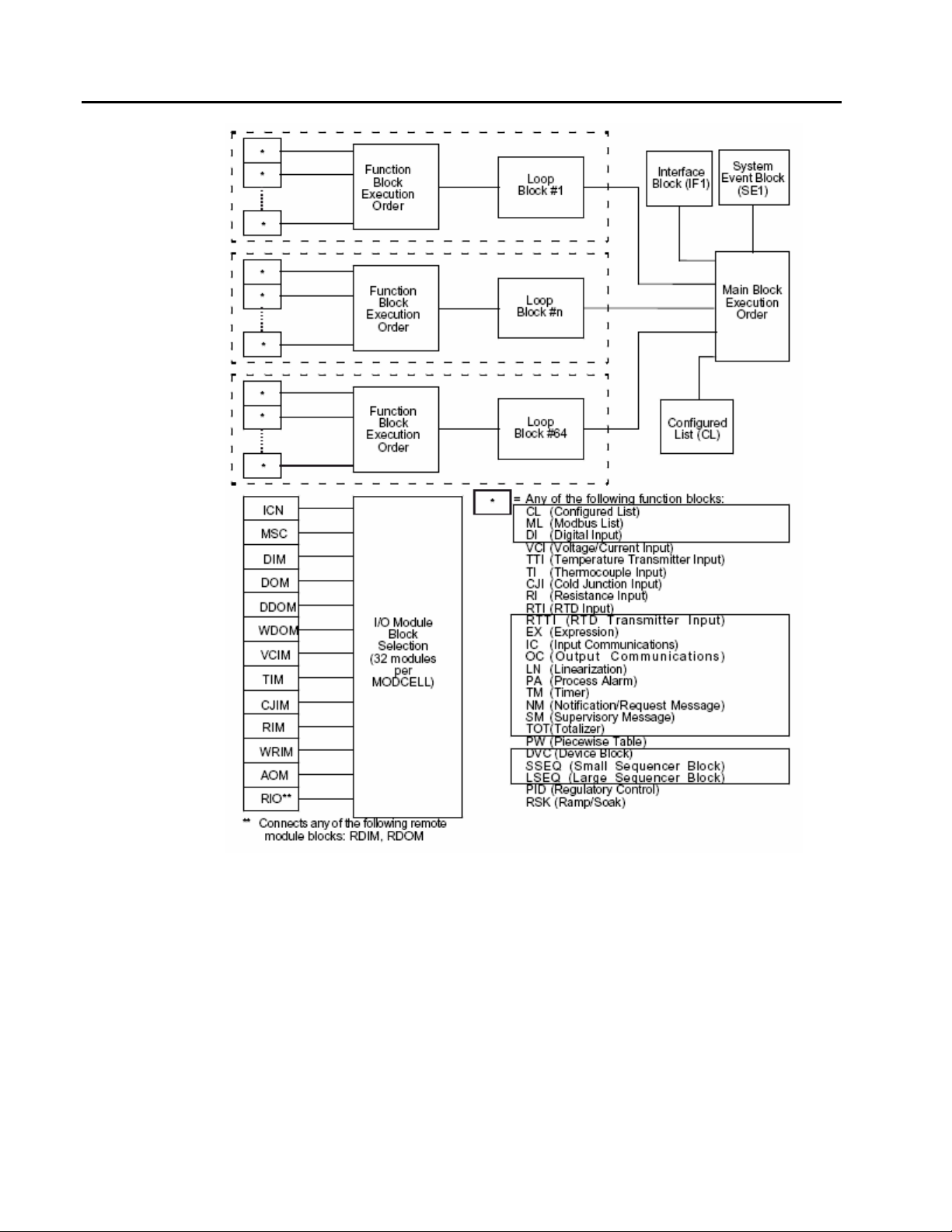

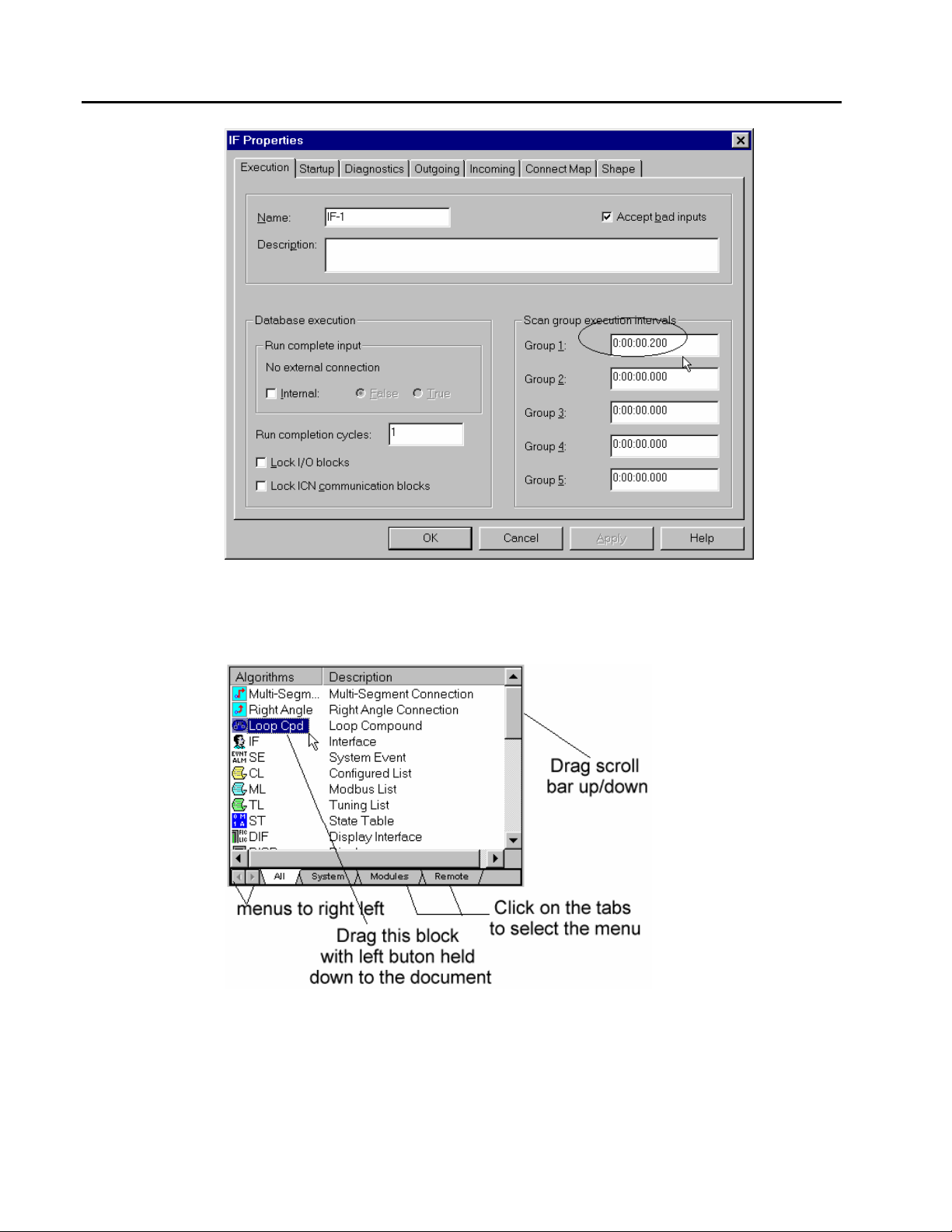

The user database is configurable and writable to make the instrument perform a variety of

executable functions. The basic logical element of the database is a function block.

Function blocks are grouped to form multiple process loops. Loops in turn are grouped

into sets that are scanned (executed) at the same rate. Up to five different scan rates can be

configured through the interface block. The instrument operates at a fixed base rate (50

milliseconds) and each of the five groups can be configured at any multiple of the base

rate up to the maximum time value (about 1193 hours). I/O module blocks define the

physical interface to the database and serve as data handling blocks between the process

and the function blocks.

The MOD 30ML has a wide variety of function blocks with which you can configure any

complex control strategy. There are 4 types of configuration blocks in the MOD 30ML /

Modcell database. They are:

1. Environment Blocks

2. I/O Module blocks

3. Function Blocks

4. System Blocks

Environment Blocks:

The environment blocks support general instrument operation and do not directly perform

the user defined control functions. These blocks always exist as part of any configuration.

Some of the functions that are executed by these blocks are similar to that of the Station

type blocks in the CLC/SLC world.

The default database contains the following 4 blocks. (In the case of Modcell, the default

database contains only 2 blocks namely the IF and SE).

Interface block (IF):

The interface block contains the overall instrument related information and functionality.

Up to five scan intervals can be specified in this block. The function blocks in the database

can be grouped in to loop compounds and each loop compound can be assigned a scan rate

from this group of five scan rates. The function blocks will be executed at the assigned

rate in the instrument RUN state.

This block also has configurable parameters for start-up options such as running on I/O

mismatch and start-up types such as warm and cold starts. This block also has parameters

that are used for enabling or disabling certain diagnostics.

System Event Block (SE): The system event block supports general instrument operation.

This block defines diagnostic and system event acknowledgement and reporting

capabilities. System events occur in the instrument, are reported by database blocks, and

can be stored into the system event queue. The different types of system events are:

Informational only, Process Alarms, Notification/Request Messages, Diagnostics and

Acknowledge Only Diagnostics.

1 - 2

The system event queue stores a configurable number of time stamped event codes for the

diagnostic points and events reported by the database blocks. These codes are translated

into messages for operator display or logging by the interface software.

Page 11

Command Series Migration to MOD 30ML

Function Codes – Introduction

Display Interface Block(DIF):

This block is used in MOD 30ML only. This block has configurable parameters for the

following:

• Define an instrument device tag

• Faceplate access and entry constraints (tune and configure passwords, access and entry

timeouts)

• Customize alarm/diagnostic presentation (flash/beep on/off and rates)

• Power up display

• Order in which user displays are selected by the tag key and/or

• Input for remote selection of user display

State Table Block (ST):

This block is used in MOD 30ML only. The State Table block is used by the Display

(DISP) and Process Alarm Display (PAD) blocks. The block consists of a set of tables,

each identified by a unique name. Each table contains a list of values and associated

mnemonic strings which are displayed for the corresponding value on the instrument

faceplate.

The MOD 30ML/Modcell database architecture is shown in the next figure:

1 - 3

Page 12

Command Series Migration to MOD 30ML

Function Codes – Introduction

Figure 1 .1.

Instrument

Database

Architecture

1 - 4

Page 13

Command Series Migration to MOD 30ML

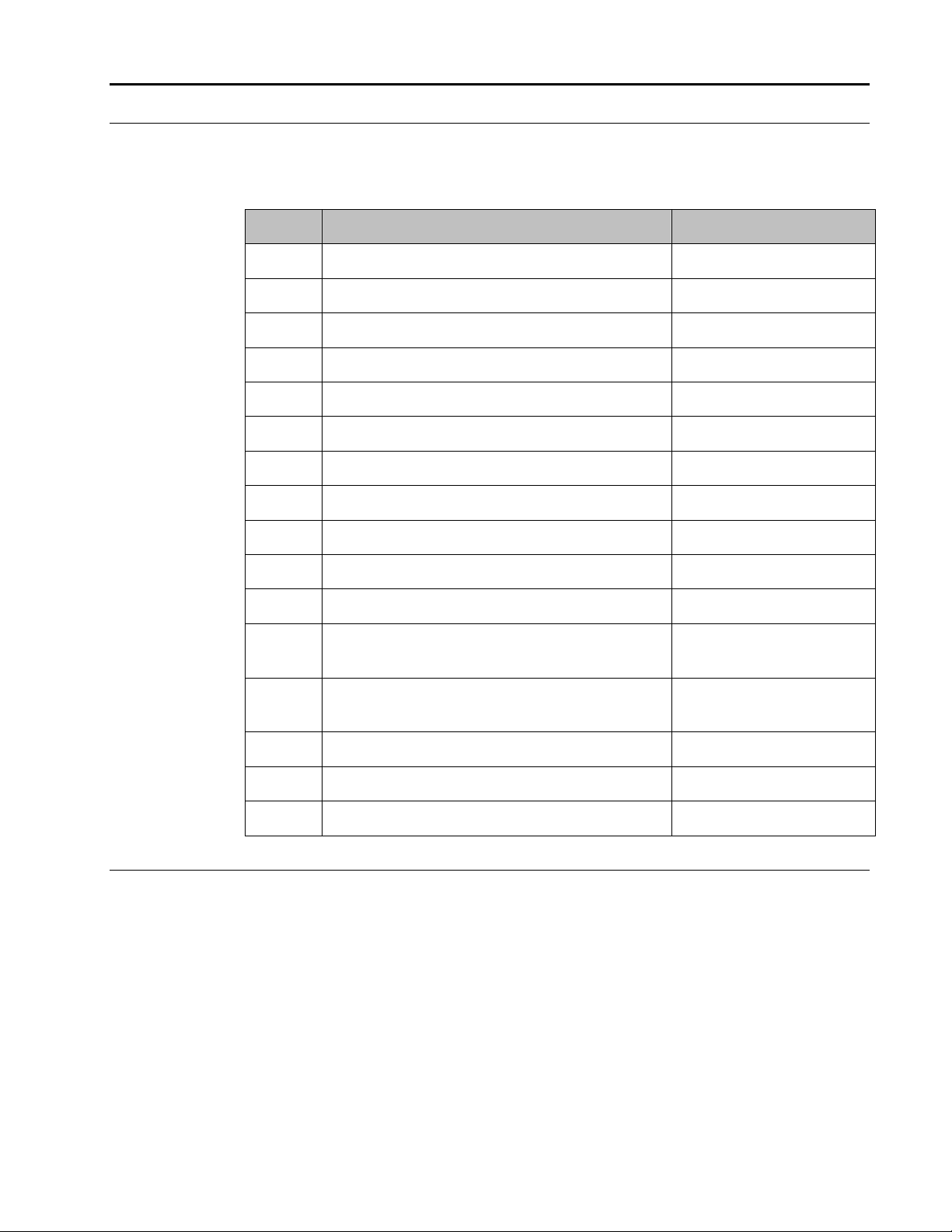

I/O AND COMMUNICATION MODULE BLOCKS:

These blocks specify the physical I/O complement of the instrument. The following I/O

module blocks are available:

Type Function Availability

AIN Built-in universal analog input MOD 30ML

AOUT Built-in analog output MOD 30ML

VCIM Voltage or current input MOD 30ML and Modcell

TIM Thermocouple input MOD 30ML and Modcell

RIM 2 wire RTD / Resistance Input MOD 30ML and Modcell

WRIM 3 wire RTD / Resistance input MOD 30ML and Modcell

DIM Discrete input MOD 30ML and Modcell

Function Codes – Introduction

DOM Discrete output MOD 30ML and Modcell

DDOM Double Relay output MOD 30ML and Modcell

WDOM Form-C relay output MOD 30ML and Modcell

AOM Analog Output MOD 30ML and Modcell

ICN Instrument Communication Network (Peer-to-

MSC Modcell Serial Communication (RS232, Rs485

RIO Remote digital interface module MOD 30ML and Modcell

RDIM Remote digital input (extended digital inputs) MOD 30ML and Modcell

RDOM Remote digital output (extended digital outputs) MOD 30ML and Modcell

FUNCTION BLOCKS

There are three types of function blocks.

Process input function blocks configure input signal conditioning, engineering unit

conversion and linearization for inputs.

MOD 30ML and Modcell

peer)

MOD 30ML and Modcell

Modbus)

Algorithm function blocks define the user configured control functions on the

instrument.

Communication function blocks handle transfer of data between groups, as well as

transfer of data to the communication interfaces.

These are shown in the next table:

1 - 5

Page 14

Command Series Migration to MOD 30ML

Function Codes – Introduction

Type Description Availability

Input Function Blocks or signal conditioning blocks:

VCI Voltage or current MOD 30ML and Modcell

TI Thermocouple input MOD 30ML and Modcell

RTI RTD input MOD 30ML and Modcell

TTI Thermocouple transmitter input MOD 30ML and Modcell

RTTI RTD Transmitter input MOD 30ML and Modcell

RI Resistance input MOD 30ML and Modcell

DI Digital input MOD 30ML and Modcell

Communication function blocks

ML Modbus List block MOD 30ML and Modcell

CL Configured list block (for both ICN and Modbus) MOD 30ML and Modcell

System function blocks:

TL Tuning List Only MOD 30ML

DISP Display block (one required for each display) Only MOD 30ML

LP Loop Block (one required for each loop

MOD 30ML and Modcell

compound)

Algorithm blocks

PID PID Control with Setpoint, A/M switching and

MOD 30ML and Modcell

tracking etc.

EX Expression block (multi-purpose configurable

MOD 30ML and Modcell

block for arithmetic, continuous and discrete

logic)

IC Input Communication (for incoming peer-to-peer

MOD 30ML and Modcell

communication)

OC Output Communication (for outgoing peer-to-

MOD 30ML and Modcell

peer communication)

1 - 6

LN Linearization MOD 30ML and Modcell

PW Piecewise and inverse piecewise table MOD 30ML and Modcell

PA Process Alarm MOD 30ML and Modcell

PAD Process Alarm Display Only MOD 30ML

Page 15

Command Series Migration to MOD 30ML

Function Codes – Introduction

NM Notification Message MOD 30ML and Modcell

SM Supervisory Message MOD 30ML and Modcell

RSK Ramp – Soak Profile block MOD 30ML and Modcell

TOT Totalizer MOD 30ML and Modcell

TM Timer block MOD 30ML and Modcell

SEQ Sequencer MOD 30ML and Modcell

1 - 7

Page 16

Command Series Migration to MOD 30ML

Function Codes – Introduction

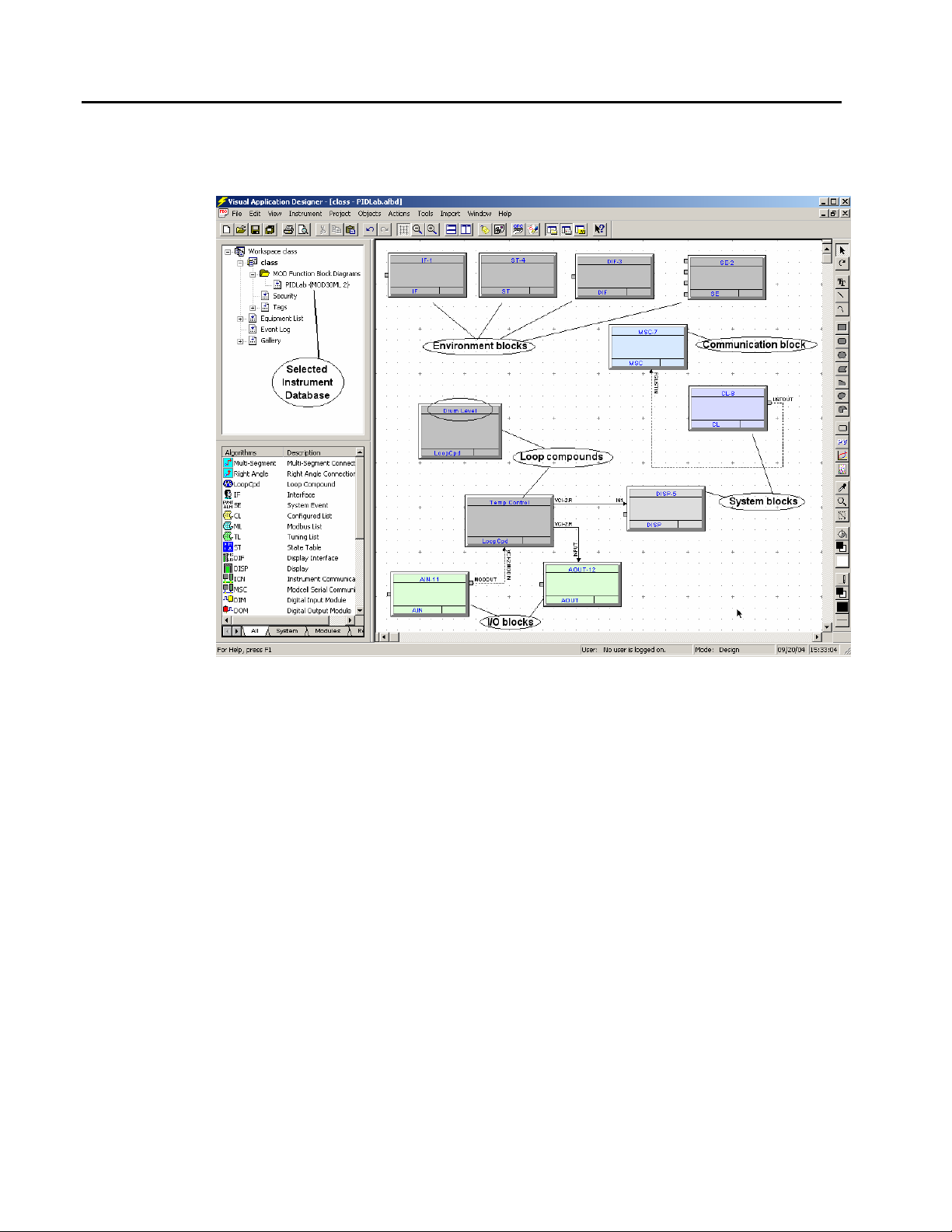

A typical instrument database as function block diagram configured in ViZapp is shown in

the next figure: A typical instrument database has the environment blocks, I/O blocks,

communication blocks, and loop compounds.

Figure 1 .2.

Instrument

database

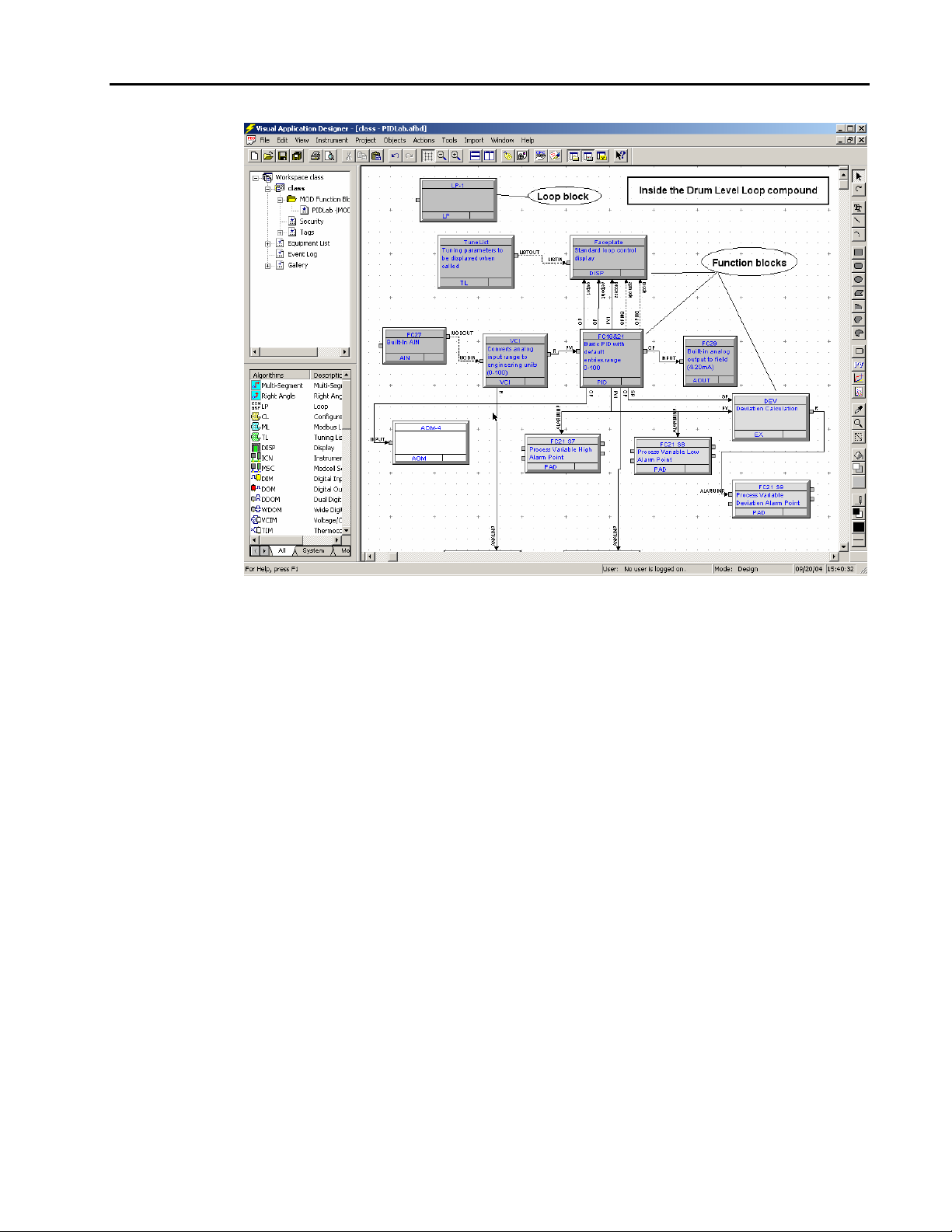

Algorithm function blocks are configured inside a loop compound to implement control

strategies. Each loop compound has a loop block (LP) by default.

The next figure shows function blocks inside a loop compound:

1 - 8

Page 17

Figure 1 .3.

Function blocks

inside a loop

compound

Command Series Migration to MOD 30ML

Function Codes – Introduction

1 - 9

Page 18

Command Series Migration to MOD 30ML

Function Codes – Introduction

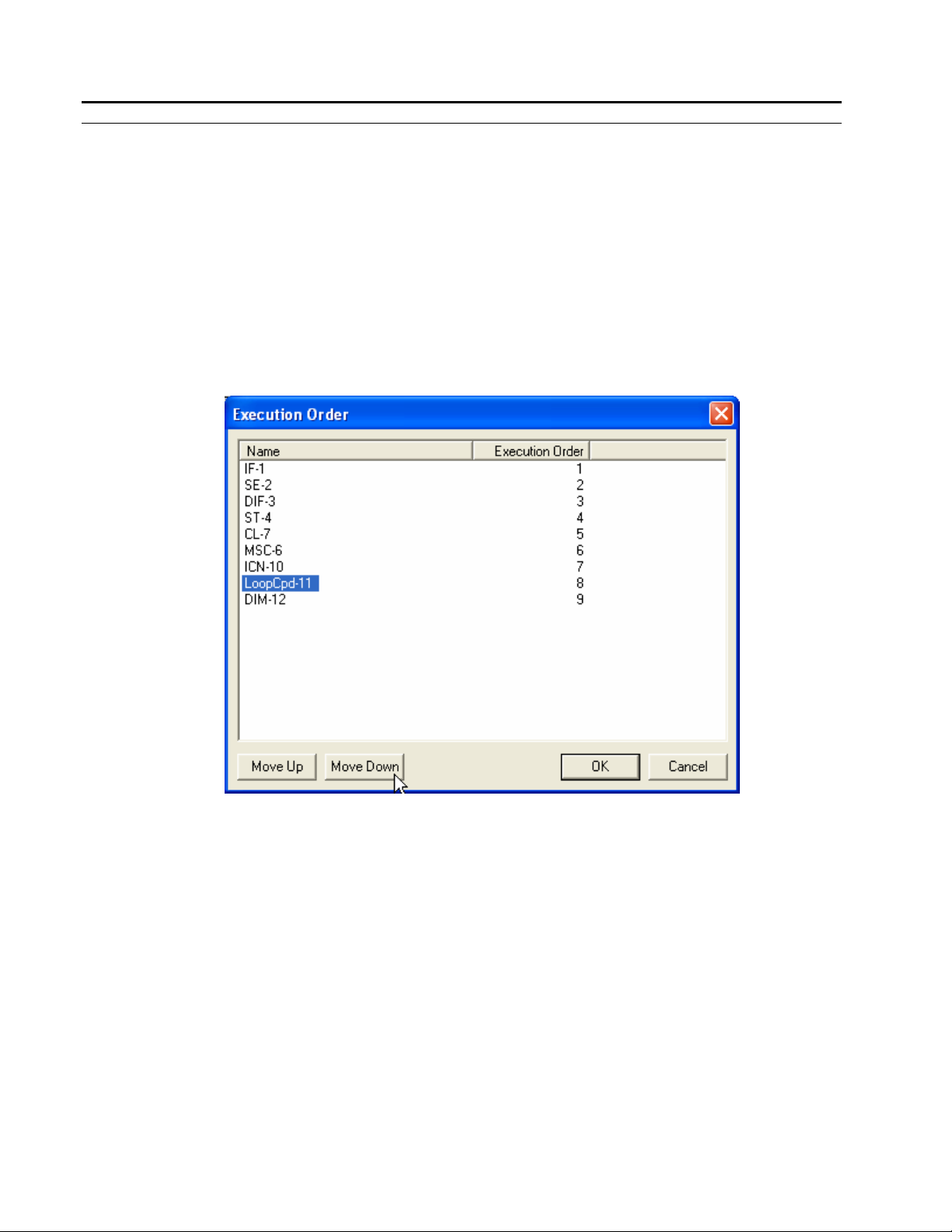

FUNCTION BLOCK EXECUTION ORDER:

The order in which the blocks in the database are executed is known as the Function Block

execution order. The execution order is set at the top level where the loop compounds are

added to the database. The default execution order for the loop compounds is the order in

which they are placed in the database. The default execution order for the blocks inside the

loop compound is the order in which they are placed inside the loop compound.

The execution order of the loop compounds and the function blocks can be changed by the

user during the configuration process.

To view and change the execution order of function blocks in a database, select Objects –

Set Execution Order – List Mode from the menu bar in ViZapp. See the following

figure:

Figure 1 .4.

Function blocks

Execution Order

1 - 10

Page 19

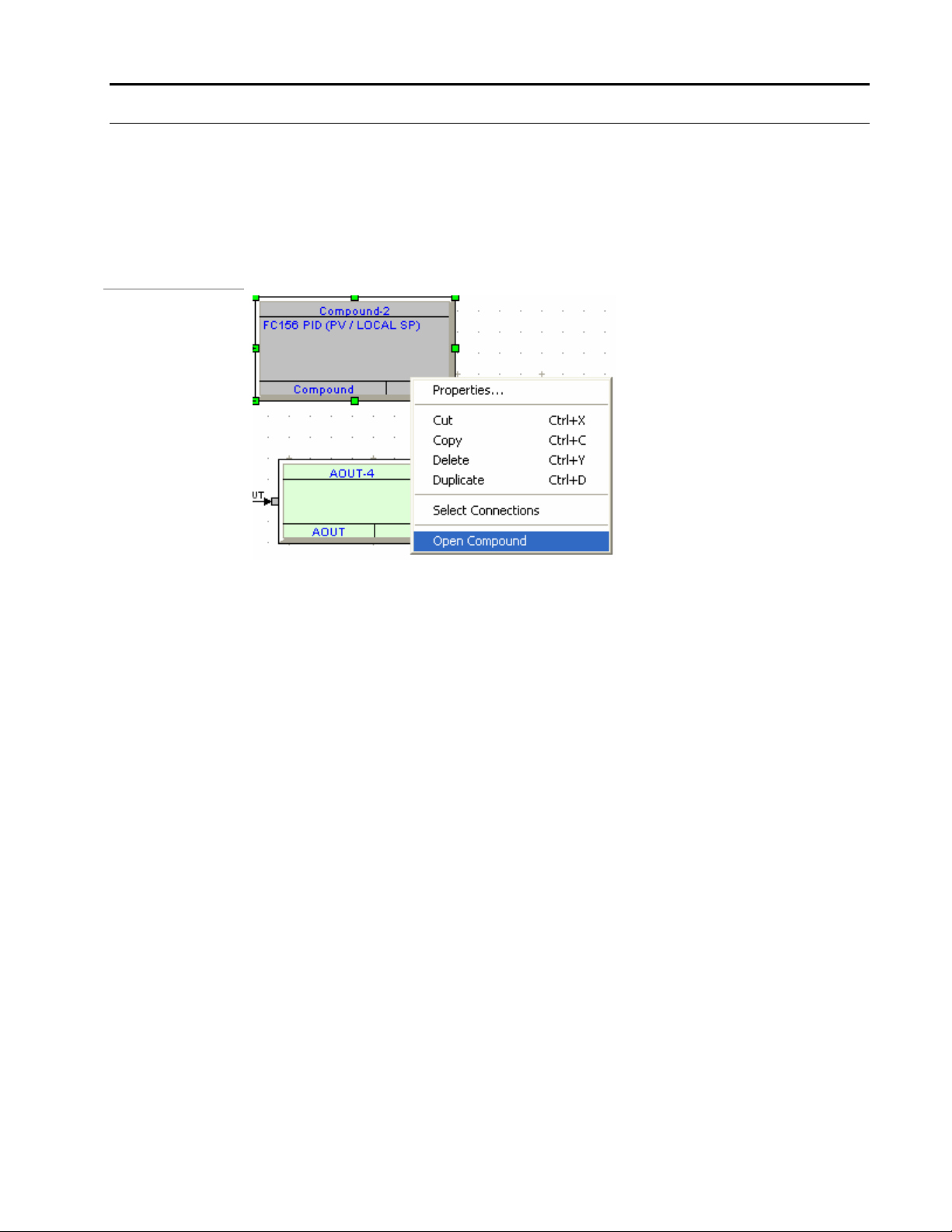

COMPOUNDS:

Function blocks in a database can be compounded (grouped) into a single group. This may

be done to functionally or visually organize the blocks in a database. Compounds can be

created at the top level or inside loop compounds. To compound a set of function blocks,

first select them and then select Objects – Compound from the ViZapp menu bar. When a

compound is made it creates a sub-level in the function block diagram and places the

blocks inside that level.

Figure 1 .5.

Open Compound

Command Series Migration to MOD 30ML

Function Codes – Introduction

The compound looks like a function block. See the above figure. To view the blocks,

select the compound and then right-click on the mouse to show a context sensitive menu

as shown in the above figure and then select Open – Compound.

If there were connections existing between the blocks that were compounded and other

blocks in the database, these connections are translated into jump objects inside the

compound.

1 - 11

Page 20

Command Series Migration to MOD 30ML

Function Codes – Introduction

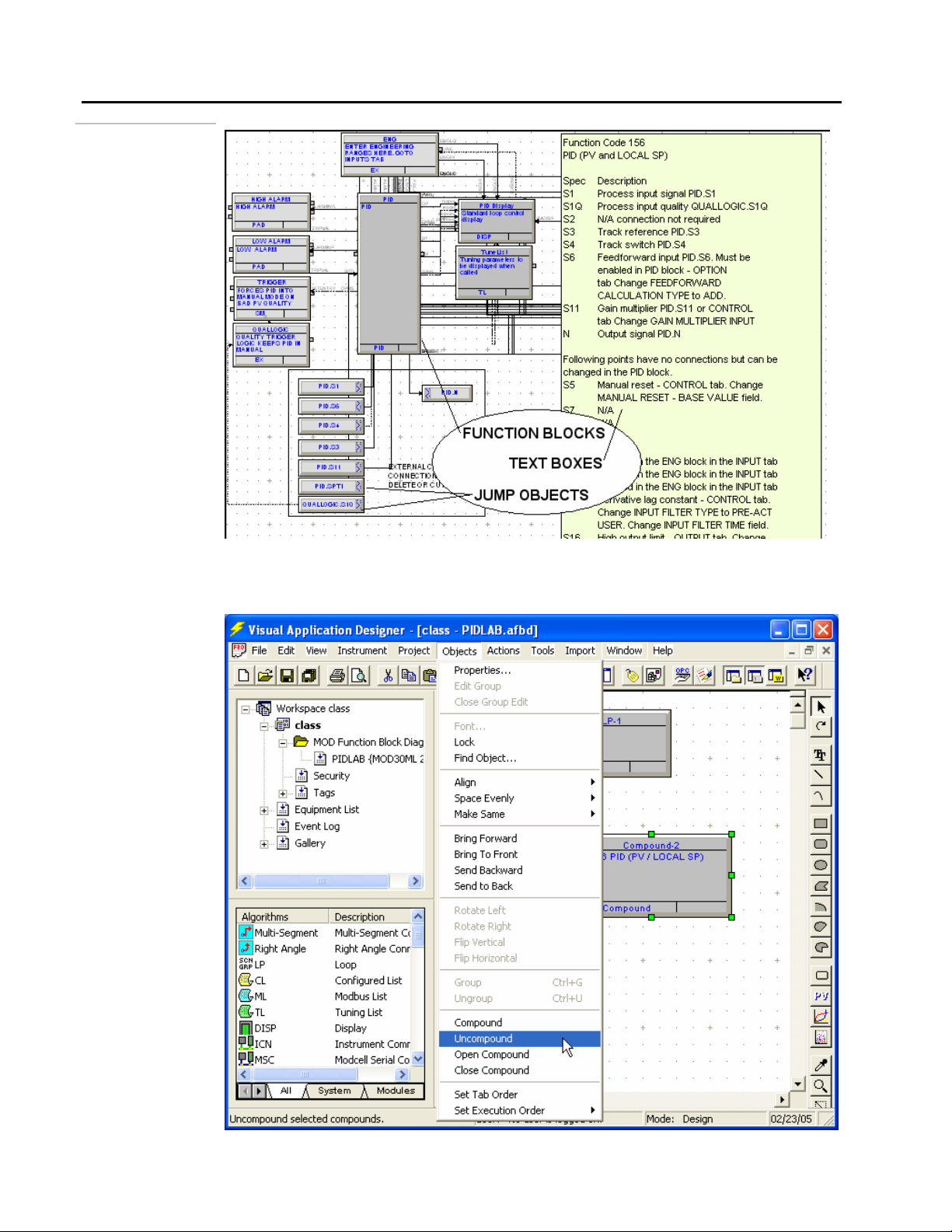

Figure 1 .6.

Inside a Compound

• You can ungroup a compound by un-compounding it. Select the compound by clicking on

Figure 1 .7.

Bailey FC Gallery

it and then select Objects from the menu bar and then select UnCompound from the

drop-down menu as shown in the next figure.

1 - 12

Page 21

Command Series Migration to MOD 30ML

Function Codes – Introduction

• This will un-group the function blocks and place them where the grouped compound was.

When you uncompound a compound, the function blocks come out selected. You can

move all of them to a desired location by dragging them with the left mouse button

pressed.

a The advantage of uncompounding is that you can place the function blocks at the same

level as other function blocks you might already have at that level thereby making the

connections easier.

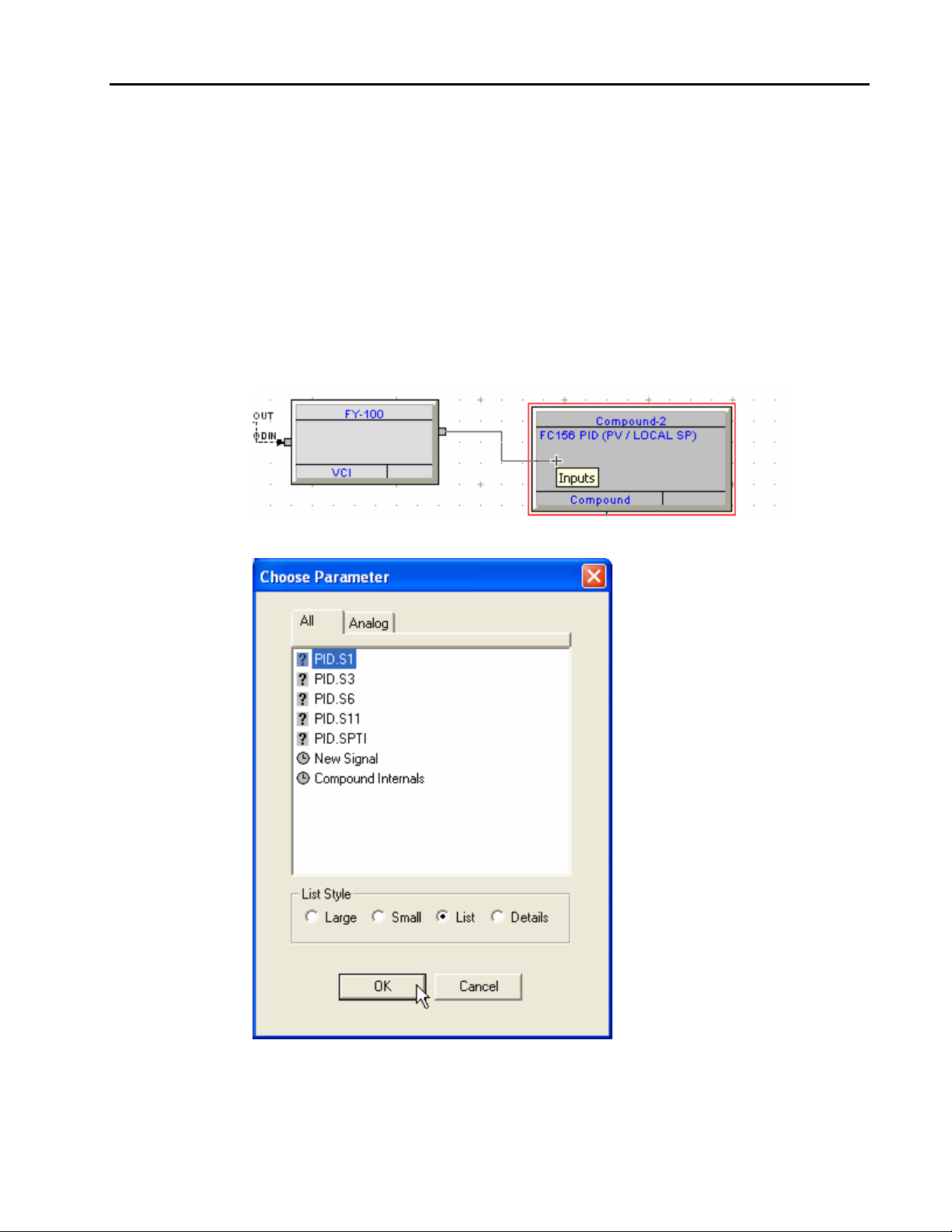

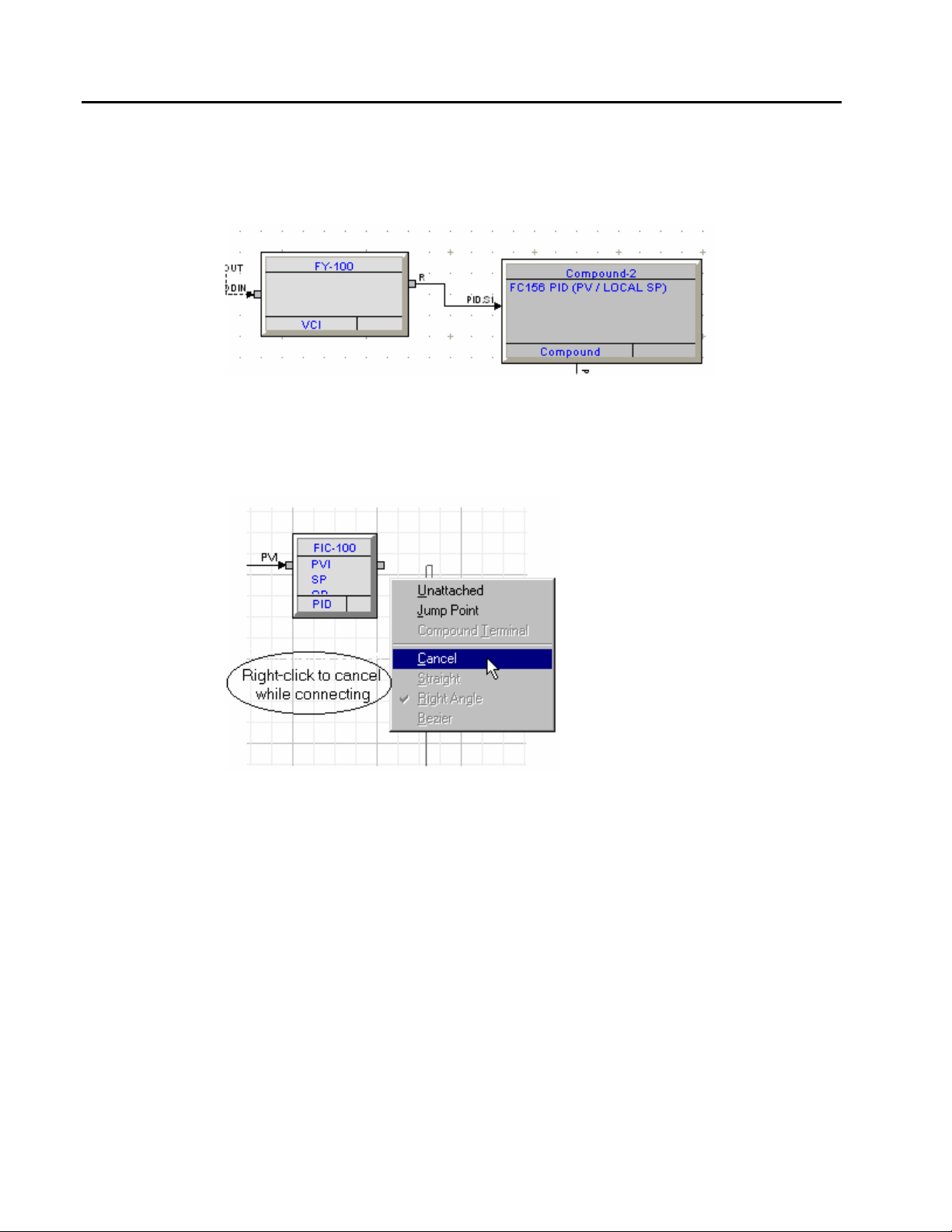

To connect to a compound from outside of it:

• Select the connector and select the attribute to connect from the desired block.

• Drag the line to the compound and click on it. See the figure below:

Figure 1 .8.

Right Angle

connection

• The Choose Parameter menu will be displayed as shown in the next figure:

Figure 1 .9.

Choose Parameter

• Select the desired jump object (if it was already present, for example PID.S1 in the above

figure) from the list and then click on OK.

1 - 13

Page 22

Command Series Migration to MOD 30ML

Function Codes – Introduction

• You can also double-click on the Compound Internals and then select from the displayed

list of function blocks inside and then select the block and then the attribute to connect to.

• This will complete the connection for the process variable input. The connection will look

like in the next figure:

Figure 1 .10.

If you made a mistake while connecting, or if you do not know where to connect, you can

always cancel it or get out of the connection mode by clicking on the right mouse button

to show a menu as shown below:

• Select Cancel from this menu to cancel the connection.

Figure 1 .11.

Cancel Connection

1 - 14

Page 23

LOOP COMPOUNDS

Loop compound is a special compound that contains a loop block. Loop compounds are

placed at the top level of a function block diagram (where the IF, DIF, SE and ST blocks

are located). All the function blocks other than Input, Output, Modules, Communication

and System blocks have to be configured inside a loop compound.

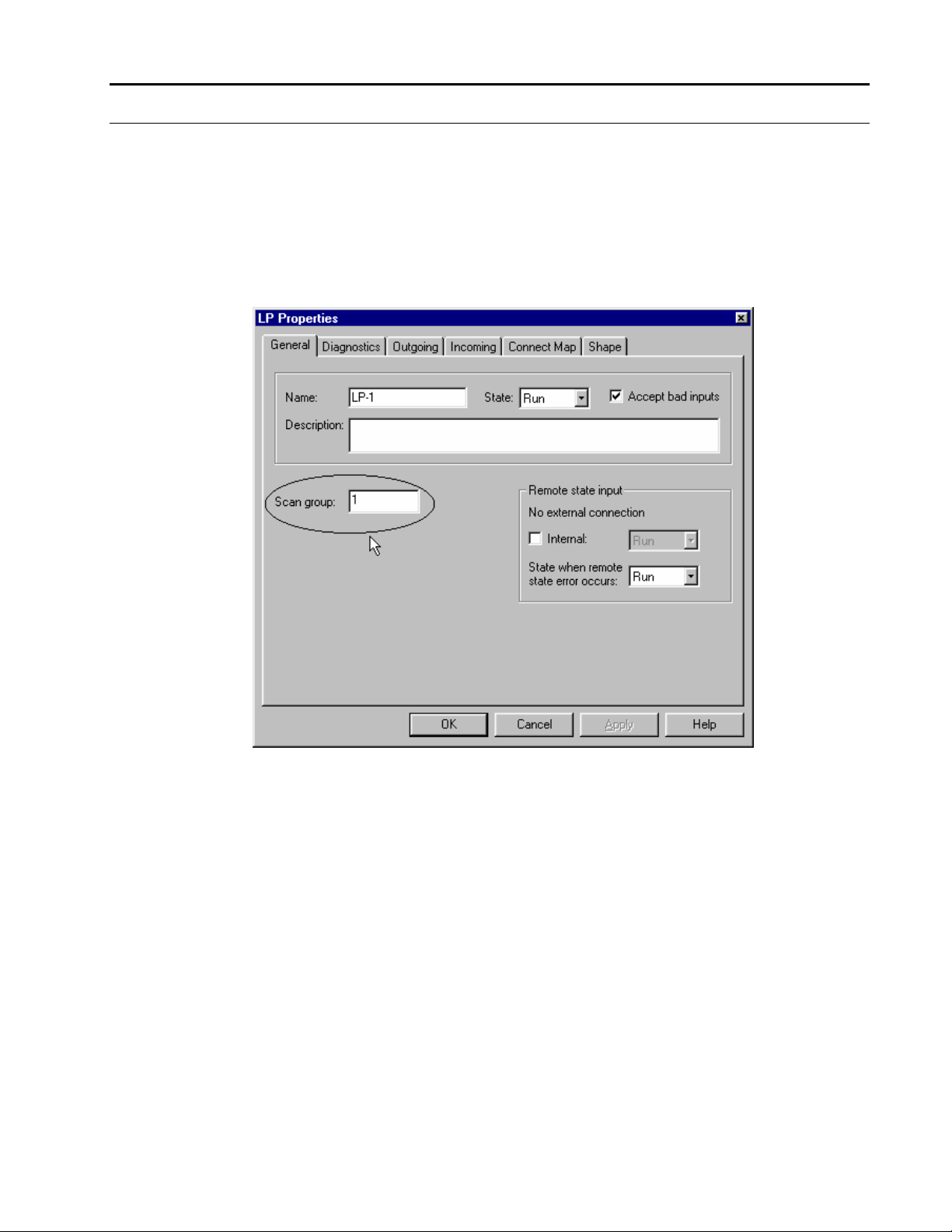

The loop block that is present inside the loop compound specifies the scan group at which

the blocks inside the loop compound get executed. See the next figure:

Figure 1 .12.

Cancel Connection

Command Series Migration to MOD 30ML

Function Codes – Introduction

The scan groups are configured in the Interface Block at the top level. There could be as

many as 5 different scan groups. The scan time is in multiples of 50 ms and can be as low

as 50 ms.

The next figure shows the Interface (IF) block configuration:

1 - 15

Page 24

Command Series Migration to MOD 30ML

Function Codes – Introduction

Figure 1 .13.

Cancel Connection

Figure 1 .14.

Algorithms menu

To add a loop compound: Select the Loop Cpd (Loop compound) block from the

Algorithms window add it to the document. Do this by first locating the block in the menu

by selecting the All submenu at the bottom and then by dragging the scroll bar on the right

up/down. See the next figure:

1 - 16

• Drag the Loop Cpd block (Loop Compound) from the Algorithms menu on the left frame

to the right frame. Click on the Loop Cpd block with your left mouse button and then

drag it to the instrument document. Click on the mouse button to place the Loop

compound block with the other existing blocks (IF, SE, DIF and ST) on the right frame.

• Opening and closing of loop compound is exactly same as that of the compound explained

in the previous section.

Page 25

Command Series Migration to MOD 30ML

Function Codes – Introduction

• Loop compounds also have jump objects when connections are made from or to the

outside of the compound.

• Refer to the previous section (COMPOUNDS) for more information.

1 - 17

Page 26

Command Series Migration to MOD 30ML

Function Codes – Introduction

THE CONFIGURATION PROCESS

The steps involved configuring a MOD 30ML or Modcell controller are listed below:

1. Create a Workspace document in ViZapp

2. Create a Project document in ViZapp

3. Add a new instrument database for each controller to the project document.

4. Configure the instrument database in ViZapp.

5. Save and compile the instrument database

6. Configure the OPC Server (XModbus or ICN depending on which communication

protocol is used for connecting the controllers to the computer running ViZapp and

the OPC Server).

7. Add a device in the OPC Server for each controller that needs to be configured.

Communication settings for the device and the comm. Port should match that of the

instrument.

8. Download the compiled database from ViZapp using the OPC Server to the desired

instrument.

These steps are further explained in the next chapter and in the ViZapp training manual.

1 - 18

Page 27

Command Series Migration to MOD 30ML

Function Codes – Introduction

Procedure for adding the Display Tag to the Display Interface Block

Each display configured in the MOD 30ML has a unique display tag.

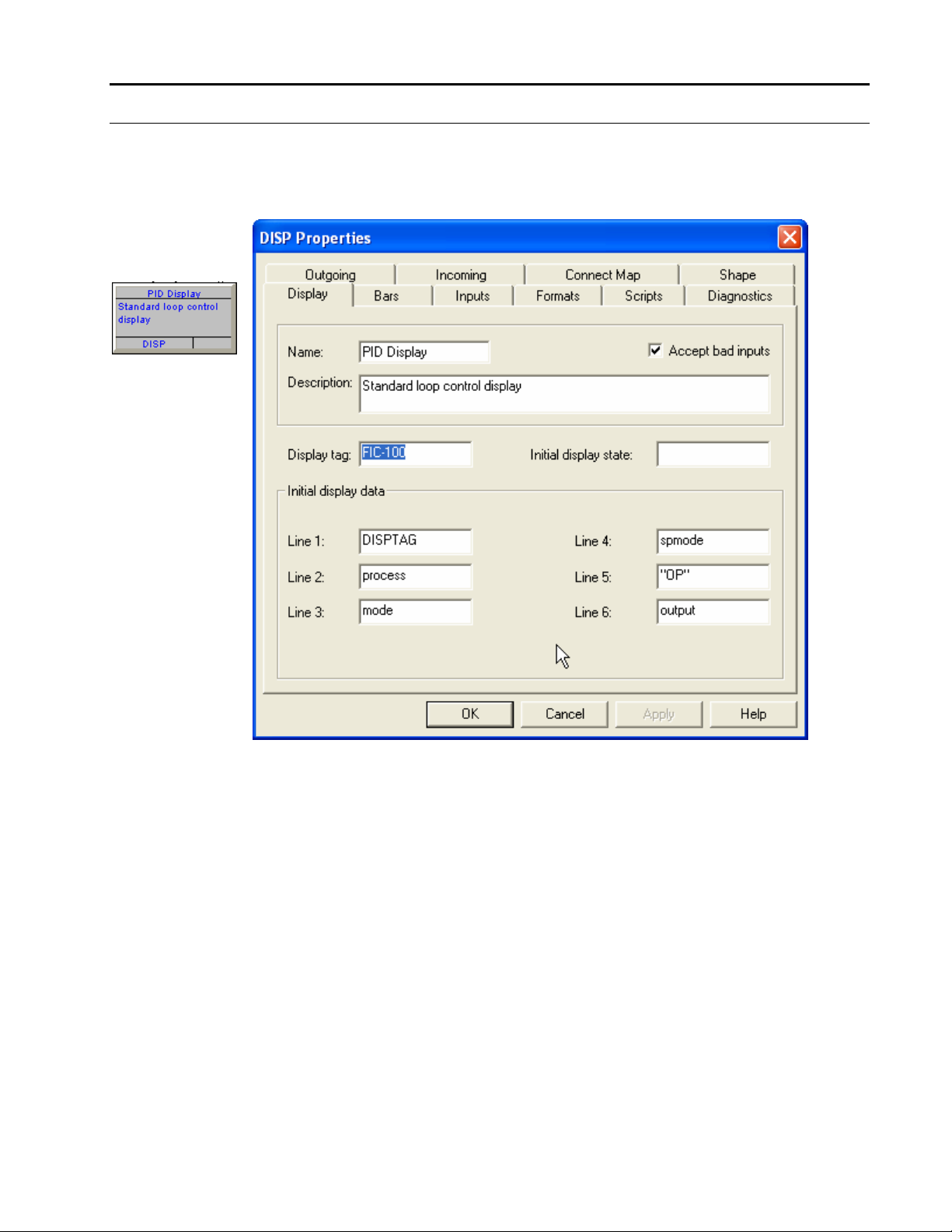

• Open the display block by double-clicking on it. See the next figure:

Figure 1 .15.

PID Display

• As an example, the default display tag name configured in this compound is FIC-100.

During runtime, you can scroll through the displays in this list by pressing the Tag button

on the instrument.

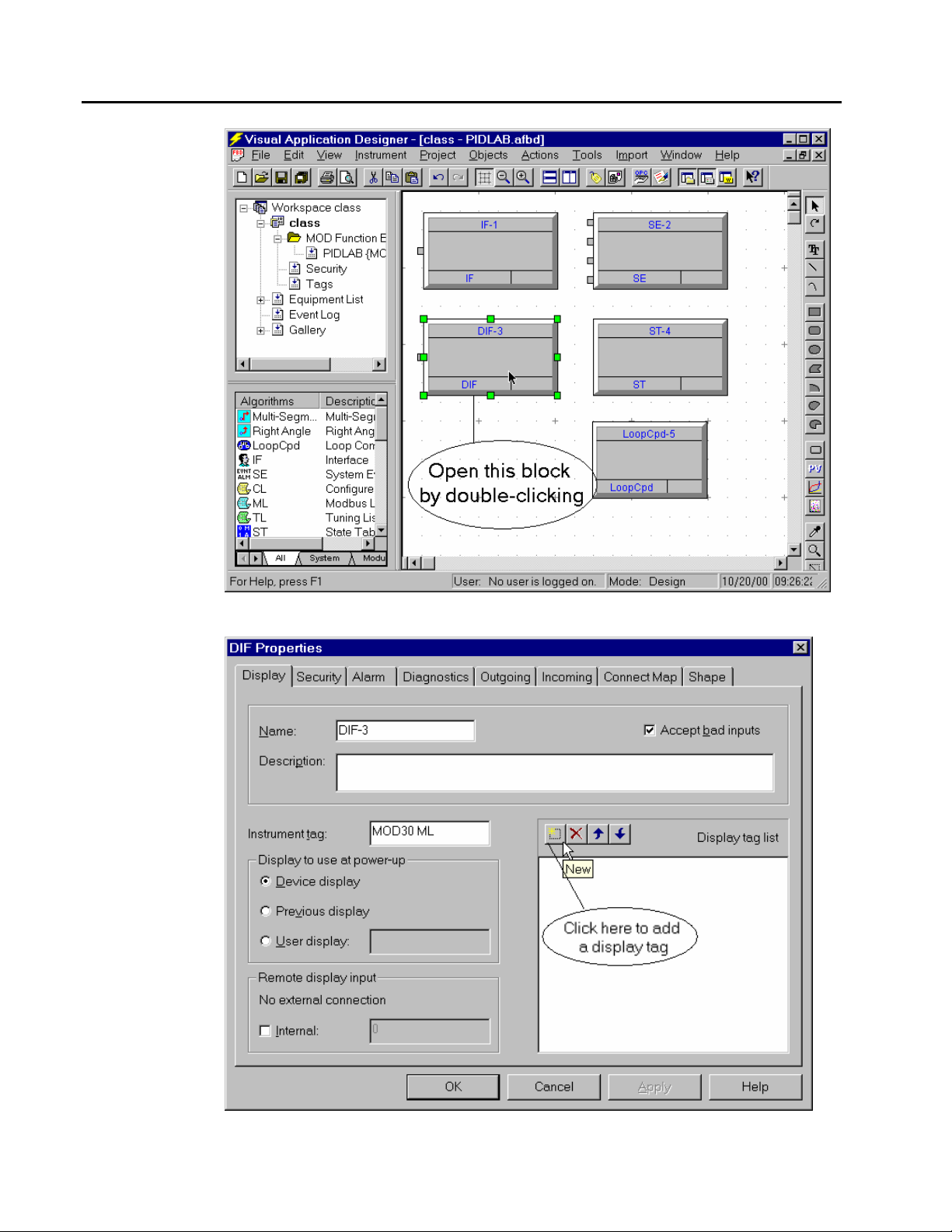

Close the compound and the loop compound and go to the top level of the function block

diagram where the IF, DIF, ST, SE blocks and the loop compounds are located. See figure

below.

Start by opening the DIF (Display Interface) block as shown in the figure below:

1 - 19

Page 28

Command Series Migration to MOD 30ML

Function Codes – Introduction

Figure 1 .16.

DIF block

Figure 1 .17.

DIF block

Click on the New button on this block as shown in figure below:

1 - 20

Page 29

Command Series Migration to MOD 30ML

Function Codes – Introduction

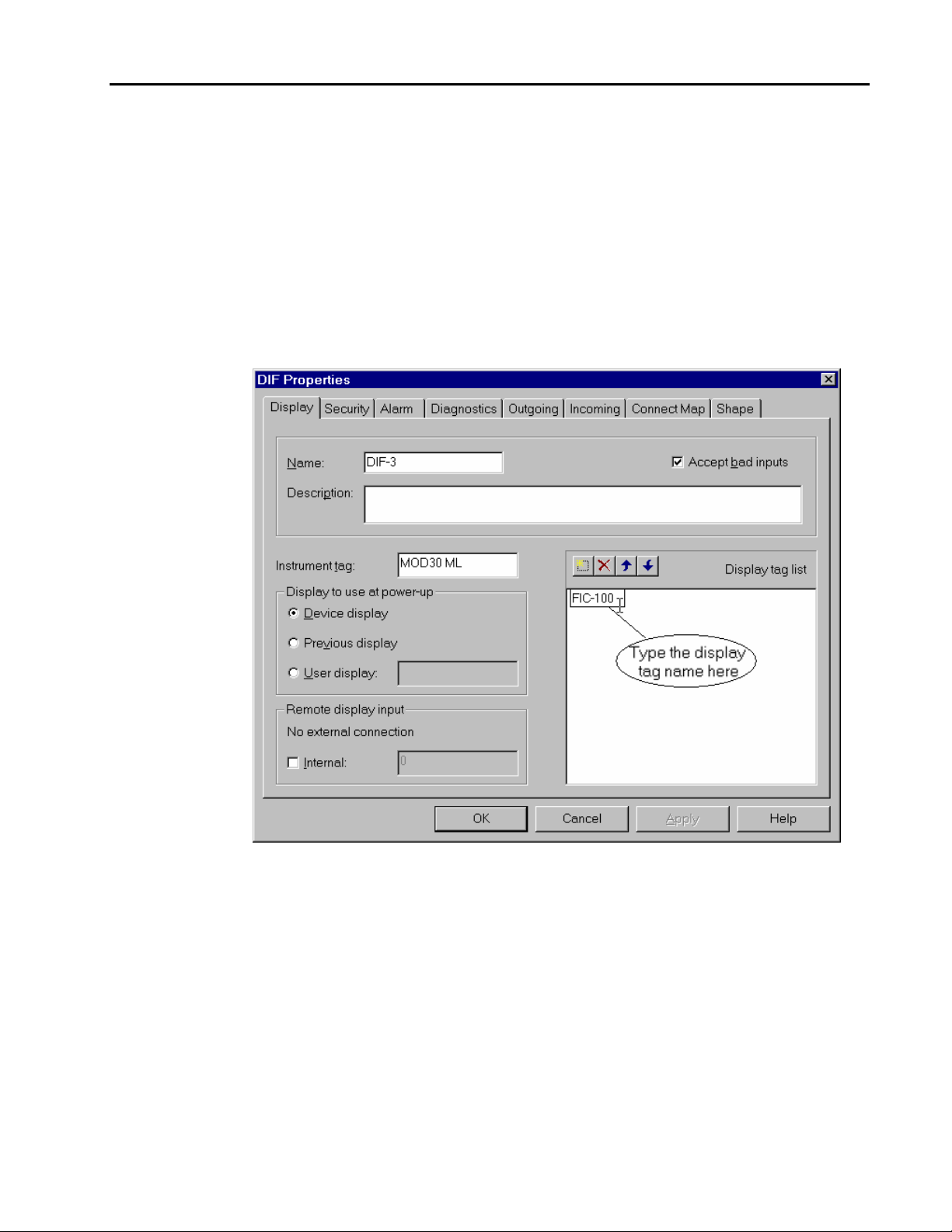

A text edit box will appear in the area below and you will see a text edit cursor blinking.

Type the name of your display tag (FIC-100 for example).

a If you had more than one display blocks in your configuration, you will need to add

their display tags in the DIF block as explained in the above step. The order in which

the display tags appear in this list is the order in which the displays will scroll when

you press the Tag button on the instrument. The display block gets executed by the

instrument when it is loaded on the face of the instrument. If you did not add the

display tag of a display block to this list, that display will not appear on the instrument

when you press the Tag button.

Figure 1 .18.

DIF block

The Instrument tag field displays a unique tag name for the instrument. An instrument can

have multiple displays each with its own tag name. The instrument tag is useful in

identifying the instrument.

• Click on the OK button when you are done.

1 - 21

Page 30

Command Series Migration to MOD 30ML

Function Codes – Introduction

PID CONFIGURATION REFERENCE

The PID block in the MOD 30ML/Modcell is versatile and extremely powerful. We will

focus only on the parameters that we would typically use in a CLC or SLC controller.

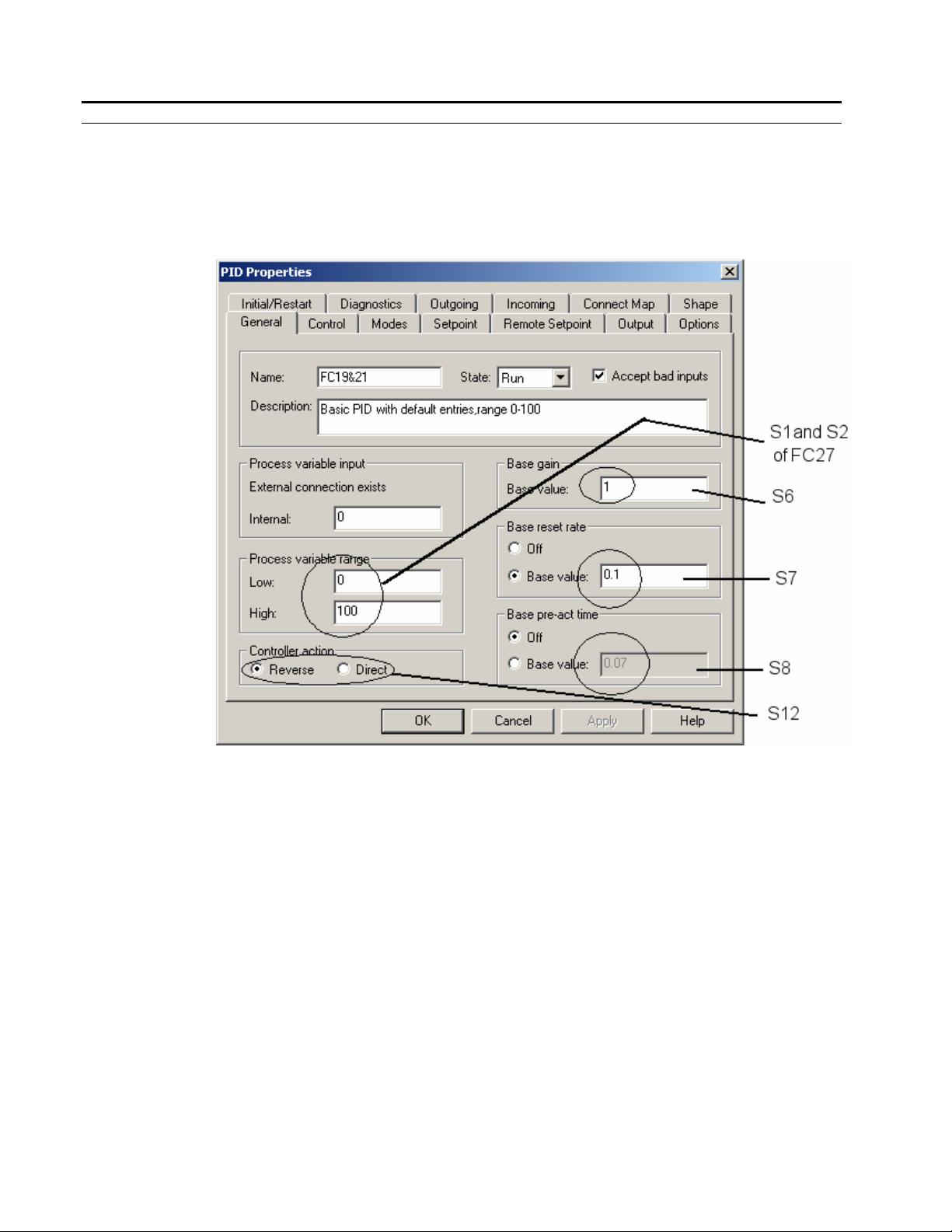

• Open the PID block by double-clicking on it. The General tab will be displayed by

default as shown below:

Figure 1 .19.

Bailey FC Gallery

1 - 22

• Change the values as desired for the parameters as shown in the figure above.

• Click on the Control tab of the PID block. This tab contains configurable parameters that

are associated with the control algorithm used in the MOD 30ML/Modcell. See the

following figure:

Page 31

Figure 1 .20.

PID Control Tab

Command Series Migration to MOD 30ML

Function Codes – Introduction

• Select the Algorithm Type and change it to ESEO. This stands for a PID algorithm that

does the Proportional action on the Error, uses a Standard Integral action and Derivative

action on the Error and the Manual Reset is set to Off.

You can click on the Help button on the dialog box for context sensitive help and

explanation

Algorithm type (mnemonic - CATYPE) specifies the types of control actions for the

controller. The valid actions and their values are described below:

Gain (column 1):

O 0 Off. Gain response is turned off.

P 1 On Process. Gain response value is determined by process input signal.

E 2 On Error. Gain response value is determined by error signal.

Reset (column 2):

O 0 Off. Reset response is turned off.

S 4 Standard. Reset response is turned on and is operating with Standard Algorithm.

It can be used with externally generated adaptive gain or reset and/or external

feedback. Manual reset must be turned off.

1 - 23

Page 32

Command Series Migration to MOD 30ML

Function Codes – Introduction

M 8 MICRO-SCAN. Reset response is turned on and is operating with MICROSCAN algorithm. It can be used with either externally generated adaptive gain or

reset, but not with external feedback. Manual reset must be turned off.

The Standard Algorithm and Microscan Algorithm have different antireset windup

characteristics that affect how they approach limits. Otherwise, the two algorithms

integrate the same. Standard is necessary on applications requiring external feedback

and where better management of blips is required.

Microscan comes out of a limit one reset time constant ahead of the setpoint/process

crossover and is required on applications needing good startup characteristics without

overshooting and on applications with large setpoint changes which also require an

approach to the new setpoint without overshooting.

Pre-Act (column 3):

O 0 Off. Pre-Act response is turned off.

P 16 On Process. Pre-Act response value is determined by process signal.

E 32 On Error. Pre-Act response value is determined by error signal.

Manual Reset (column 4):

O 0 Off. Manual reset response is turned off.

E 64 Enabled. Manual reset response is turned on (only if reset response is turned

off).

1 - 24

Page 33

The valid actions for CATYPE are:

EOOO Gain on error, Reset off, Pre-Act off, manual reset off.

OSOO Gain off, standard Reset, Pre-Act off, manual reset off

PSOO Gain on process, standard Reset, Pre-Act off, manual reset off.

ESOO Gain on error, standard Reset, Pre-Act off, manual reset off.

OMOO Gain off, MICRO-SCAN Reset, Pre-Act off, manual reset off.

PMOO Gain on process, MICRO-SCAN Reset, Pre-Act off, manual reset off.

EMOO Gain on error, MICRO-SCAN Reset, Pre-Act off, manual reset off.

EOPO Gain on error, Reset off, Pre-Act on process, manual reset off

PSPO Gain on process, standard Reset, Pre-Act on process, manual reset off

Command Series Migration to MOD 30ML

Function Codes – Introduction

ESPO Gain on error, standard Reset, Pre-Act on process, manual reset off

PMPO Gain on process, MICRO-SCAN Reset, Pre-Act on process, manual reset off

EMPO Gain on error, MICRO-SCAN Reset, Pre-Act on process, manual reset off.

EOEO Gain on error, Reset off, Pre-Act on error, manual reset off

ESEO Gain on error, standard Reset, Pre-Act on error, manual reset off

EMEO Gain on error, MICRO-SCAN Reset, Pre-Act on error, manual reset off

EOOE Gain on error, Reset off, Pre-Act off, manual reset enabled

EOPE Gain on error, Reset off, Pre-Act on process, manual reset enabled

EOEE Gain on error, Reset off, Pre-Act on error, manual reset enabled.

1 - 25

Page 34

Command Series Migration to MOD 30ML

Function Codes – Introduction

• Click on the Setpoint tab to select the Setpoint configuration options. See the next figure:

• Change the Setpoint limits to desired values. Setpoint values to the PID algorithm are

limited to these numbers.

• Setpoint modes limited is used to apply limits to the setpoint when it is in a certain mode.

The limits can be applied to: None, Local, Remote, Track or their combinations. See the

next figure:

Figure 1 .21.

PID Setpoint Tab

1 - 26

Page 35

Figure 1 .22.

PID Setpoint Tab

Command Series Migration to MOD 30ML

Function Codes – Introduction

• Click on the Output tab to select the output configuration options. See the next figure:

• Change the output limits and range to desired values: Click on the Output tab of the PID

block. See the next figure:

• The output limits are applied to the active output when the proper output modes limited

condition is met. Output values from the PID algorithm are limited to these numbers.

• The output modes limited count value is used to limit the output modes to those selected.

The limits can be applied to: Auto, Manual&Auto, Auto&Track, Manual&Auto&Track.

• The output range high and low values represents the top and bottom of the output range.

The output range values are used to denormalize the output units.

Output Modes in MOD 30ML:

The PID output mode can be Manual or Auto or Track. When the output is in Manual

mode, the user can change the output from the faceplate. When the output is in Auto

mode, the PID block calculates the output.

When the output is in Track mode the output tracks the signal connected to the OPTI

(Output Track Input) attribute of the PID block. An external signal can be connected to the

OPTI attribute of the PID block or it can be an internal value in the PID block that can be

manually changed by the user from the faceplate. The output can be switched to Track

mode by the TCI (Track Command Input) attribute of the PID block. The data type of the

TCI is discrete and can be connected to switch the output mode to track (1 – track Enable,

0 – track Disable). An external signal can be connected to the TCI attribute of the PID

1 - 27

Page 36

Command Series Migration to MOD 30ML

Function Codes – Introduction

block or it can be an internal value in the PID block that can be manually changed by the

user from the faceplate.

This is in contrast to the SCL/CLC PID where the Track (S3 – Track Reference Signal) of

the PID block is enabled with the help of TS (S4 – track switch signal) for anti reset

windup during a Manual to Auto transfer. In the case of MOD 30ML/Modcell PID, this is

taken care automatically during the Manual/Auto transfer since the MOD 30ML/Modcell

PID block has the PID and M/A in one.

See the following figure where the Options tab of the PID block is shown:

Figure 1 .23.

PID Options Tab

1 - 28

• We have made some changes to the default configuration of the PID block. Click on OK

to accept the changes and close the PID block.

Page 37

BOOK 1

SECTION 2

GALLERY TUTORIAL

Page 38

Page 39

FOREWORD

OBJECTIVES

Function Codes – Gallery Tutorial

The ViZapp (Visual Application Designer) software has a library of function block

compounds that represent the function codes of the Bailey SLC Controller. These

compounds are created with the MOD 30ML/MODCELL function blocks. Each of the

compounds in the gallery is pre-configured to offer SLC functionality with in the MOD

30ML controller. This will make the migration from SLC to MOD 30ML, a much easier

process and reduce engineering time.

This tutorial will walk you through the configuration of MOD 30ML to perform SLC

functionality. We will use a pre-configured compound from ViZapp’s SLC Function code

gallery to configure the MOD 30ML.

After completing this lab you should know how to:

• Be familiar with the ViZapp Software

• Know how to create new workspace, project and instrument documents

• Know how to configure a MOD 30ML database using ViZapp Configurator for a simple

PID Control loop.

• Be able to setup communications for communicating to the MOD 30ML/MODCELL

instrument from the PC.

• Be able to build a PID loop faceplate display for displaying and changing process and

operator parameters.

• Know how to compile and download the database to the instrument

2- 1

Page 40

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

INSTRUCTIONS – CREATING A NEW WORKSPACE, PROJECT AND

DOCUMENT

1. Launch ViZapp: Select Programs from the Windows Start menu. Select ViZapp from the

menu. The ViZapp configurator will launch as shown in the next figure. As you will

notice, the configurator will be blank with no workspace loaded on the screen.

Figure 2 .1.

ViZapp

Configurator

Figure 2 .2.

File-New

Note that the configurator screen has two frames (left and right).

2. We will create a new Workspace and a new project in this step. Click on the File menu

on the menu bar at the top. Select New from the drop-down menu as shown in the next

figure:

• This will open the New dialog box as shown in the next figure. There are 2 tabs (sections)

in this dialog box and it displays the Project tab as default. Click on the Workspace tab.

2 - 2

Page 41

Figure 2 .3.

New Workspace

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .4.

Browse

• By default, the workspace file is created in the Project folder that is located inside the

folder where the ViZapp software is installed. For example:

C:\Program Files\ViZApp\Project.

• We will change the location for the purpose of this lab. Click on the little button next to

the Location field. This will open the Browser for Folder dialog as shown in the next

figure:

• Select the desired drive (C or D or other) from this dialog by double-clicking on it. The

next figure shows the selection of the C drive for example. See next figure:

2 - 3

Page 42

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• The New dialog box will redisplay

Figure 2 .5.

New Workspace

Figure 2 .6.

New Workspace

• Type a name for your workspace in the name field. For the purpose of this lab, we will

type CLASS as the name. See the next figure. Click on OK. The ViZapp Configurator

will redisplay with the workspace that is created as shown in the next figure:

2 - 4

Page 43

Figure 2 .7.

New Project

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Notice that the workspace Class is added to the project tree. We will create a new project

next. Click on the workspace name Class in the project tree to select it and then right-click

on it. A context menu will be displayed as shown in the next figure:

• Select New Project from this menu. The New dialog box will be redisplayed as shown in

the next figure:

• We will type the name Class for the project for the purpose of this lab. Notice that the

name of the location for this project changes to C:\Class. It creates a folder under the C:

drive (or any other drive you choose) automatically.

Figure 2 .8.

New Project

All project files and the instrument and display documents will be saved in this folder.

This makes project portability easier.

• The configurator will redisplay with a new workspace and a project as shown below:

2 - 5

Page 44

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .9.

Class Workspace

• The left frame shows the project tree. The Workspace is at the root of this tree and

contains the Project, and other components such as Event Log and Components.

• The newly created workspace is given the same name as that of the project. The project

sub-tree or branch contains the components Security and Tags.

3. With what we have above, we have only created an environment to configure instrument

database and display files. Next we will create an instrument database. We will hereafter

call it the instrument document.

• Click on the New Document button on the tool bar or Select File-New form the menu bar

to display the New dialog box again as shown below:

2 - 6

Page 45

Figure 2 .10.

New Document

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• The New dialog box shows the Document tab now. Select the type MOD Function Block

diagram by clicking on it and then type the name PIDLab for the document in the Name

field.

• This document will be created in the project folder \class automatically and will be added

to your Class project by default. See figure above.

4. When you create a new project, a file with the project name and file extension .APRJ will

be created. This file is called project file in the ViZapp installation directory.

The instrument document is basically the controller database or the configuration file. It is

also known as the MOD Function block diagram. This file has an extension .AFBD and is

saved in the project folder. The workspace we created is saved as a file with extension

.AWSP (Class.awsp) and a file with same name and .FEQP extension (Class.feqp) in the

root folder where the project folder is located.

IF you move your workspace and project to a different location/ drive, move the project

folder and the two files for the workspace (.AWSP and .FEQP), maintaining their relative

location.

• Click on OK. This will display the Choose Instrument Version dialog box as shown in

the next figure: This dialog box will display the different instrument ID module versions

(MODCELL and MOD 30ML).

2 - 7

Page 46

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .11.

Choose

Instrument

Version

• Select MOD 30ML 2 from this list as our instrument version by clicking on it and then

click on the Close button.

• The Configurator will redisplay as shown below. The instrument database will be opened

Figure 2 .12.

Default Instrument

Database

on the right frame and the environment blocks (IF, SE, ST and DIF) for the MOD 30ML

database will be loaded.

Notice that the newly created document PIDLab is shown in the project tree attached to

the Project Class.

2 - 8

The algorithm blocks belonging to the instrument version selected will be shown as a

menu on the left frame.

Page 47

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Each instrument will have its own database. The databases of the instruments will be

added to the corresponding project. This is done for convenience and the grouping is done

based on functionality or geography or logic.

For example, for a process area like a boiler house that has 2 boilers, there can be 2

projects called Boiler1 and Boiler2. Each project will have databases of the controllers that

control the boiler.

The following figure shows a workspace called Plant1 and 2 projects namely Boiler1 and

Boiler2.

Figure 2 .13.

Default Instrument

Database

2 - 9

Page 48

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

CONFIGURING SCAN GROUPS AND LOOP COMPOUNDS

5. Let us first configure a scan group:

There could be as many as five scan groups in an instrument database. The control loops

(database blocks connected together) are grouped into Loop Compounds. The Loop

Compounds can be assigned to any of these scan groups. All the blocks and compounds in

a particular scan group will be executed at the same scan rate configured for the group.

This way you can have many loops in the database and they can be executed at different

rates depending on their priority and speed of the process they are controlling.

• Notice that all the four blocks on the screen are selected. Reset the screen by deselecting

them by clicking on a blank space.

• Double-click on the IF (Interface) block. The Interface block will open as shown in the

next figure: The block is displayed in a visual notebook format, with tabbed “pages”

containing the parameters for configuration. The Execution tab (page) of this block will be

displayed by default.

Figure 2 .14.

Interface Block

6. We will now configure a typical PID control loop in this tutorial.

2 - 10

Application1: Typical PID control in the Loop Command Controller CLC03/04:

The following diagram shows a typical single loop control with local Setpoint and uses the

following function codes:

Analog Input AI – Function Code 27

PID control – Function Code 19

Page 49

Figure 2 .15.

Typical Loop

Configuration in

CLC 03/04

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

M/A Station – Function Code 21

Analog output AO – Function Code 29

In the case of SLC or CLC, the display faceplate operator interface functionality is

automatic and does not need any user configuration. The operator interface provides

display of the process variable, Setpoint, control output, control mode and tuning

parameters and access to change parameters such as Setpoint, control output, mode and

tuning parameters.

The MOD 30ML requires configuration for each function. There is a function block for

each function. You will need to add the required function blocks to the instrument

database. For example, if you need operator interface for the PID control you need to add

a DISP (display) block and for tuning you need to add the TL (tuning list) function block.

To perform a simple PID control loop that involves a 4-20 mA input, PID and a 4-20 mA

output in MOD 30ML, you need the following function blocks:

AIN (built-in analog input) block – There are 2 AIN blocks available. This block reads the

analog input and has some basic linearization capabilities.

VCI (Voltage or current input function) block – This block is capable of signal

conditioning, engineering unit range conversion and linearization.

PID block – This block generates the Setpoint, deviation, performs PID control and

Setpoint and output selection etc.

AOUT (built-in current output) block – There are 2 AOUT blocks available. This block is

capable of converting the PID output to 4-20 mA

DISP (display) block – This block provides the operator interface for the control

TL (tuning list) block – to configure the tuning parameters and provide operator interface

for them.

The PID block in the MOD 30ML combines PID control and M/A station. This is in

contrast to the SLC/CLC database where you would need both PID function code and an

M/A function code.

7. Add a loop compound. We will configure our control loop within this loop compound.

2 - 11

Page 50

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Select the Loop Cpd (Loop compound) block from the Algorithms window add it to the

document. Do this by first locating the block in the menu by selecting the All submenu at

the bottom and then by dragging the scroll bar on the right up/down. See the next figure:

Figure 2 .16.

Algorithms menu

Figure 2 .17.

Loop Compound

Properties

• Drag the Loop Cpd block (Loop Compound) from the Algorithms menu on the left frame

to the right frame. Click on the Loop Cpd block with your left mouse button and then

drag it to the instrument document. Click on the mouse button to place the Loop

compound block with the other existing blocks (IF, SE, DIF and ST) on the right frame.

8. Configure a name and description for the Loop Compound: Click once on this block with

your right mouse button. A menu as shown in the next figure will appear.

2 - 12

• Select Properties from the menu. The Algorithm Properties of the Loop Cpd block will be

displayed next as shown in the next figure.

• Type “Control” in the Name field.

Page 51

Figure 2 .18.

Loop Compound

Properties

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Type a description "This compound is for the Flow Control Loop"

• Click on OK to close the Properties.

9. Open the loop compound:

• Right-Click on the Control compound (Loop compound you just named) again and select

Open compound at the bottom of this menu.

2 - 13

Page 52

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .19.

Open Compound

• The loop compound will open as shown below and will have a Loop block (LP) by

default.

2 - 14

Page 53

Figure 2 .20.

Inside the Loop

Compound

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

A loop compound is a compound or group that contains a loop block. You configure other

blocks and compounds inside the loop compound. The compound can be added to one of

the five scan groups defined in the Interface block. All the blocks inside the compound

will be executed at that scan rate.

10. Open the Loop block (LP-1) by double-clicking on it. The block will open as shown in the

next figure. We will not change anything in this block. Just notice that scan group this

compound belongs to defaults to Scan Group 1. (200 ms– refer to step 4 - Interface block).

2 - 15

Page 54

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .21.

Loop Block

• Close the Loop block by clicking on the OK button.

2 - 16

Page 55

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

ADDING COMPOUND FROM THE GALLERY

11. We will now use a compound from the Bailey Function Code section of the gallery to

configure this control loop.

Compound Gallery: Pre-configured control loops and applications are stored in the

Gallery in the Vizapp Software. The gallery is basically a library of preconfigured

function blocks that are also connected for performing control and calculation tasks. The

software is shipped with a default gallery that includes most of the commonly used loops

and functions in the MOD 30ML. The user can also create configuration of frequently

used control applications and store them in this default gallery. The default gallery is

contained in the file Defaultgallery.fgal.

• To display the gallery, select Project from the menu bar again and then select Gallery-

Component Gallery from the drop-down menu as shown in the next figure:

Figure 2 .22.

Gallery Menu

• The gallery will be displayed as shown in the next figure:

2 - 17

Page 56

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .23.

Bailey FC Gallery

• The compounds in this gallery have been given names. Some of the names FC# where # is

the Bailey function code number. There is a compound named FC156 PID (PV / LOCAL

SP) in the gallery. This compound can be used to configure the MOD 30ML for the CLC

Single loop control functionality. Select this compound from the list by clicking on it.

Verify the description of this compound in the description field at the bottom of the

Component Gallery dialog as shown in the above figure.

• Click on the Export button on the dialog.

2 - 18

Page 57

Figure 2 .24.

Bailey FC Gallery

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• The exported compound will be placed inside the loop compound with in the instrument

document as shown in the figure above.

• The function blocks that make this compound are located inside this new compound. It is

basically a grouped set of function blocks.

• Click on an empty area of the database to unselect the compound.

For a detailed reference of this compound FC156 PID (PV / LOCAL SP), refer to the

chapter Function Code 156 PID with Local SP in the reference section of this manual.

2 - 19

Page 58

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

ADDING I/O

12. The loaded compound has all the function blocks for doing the PID control but does not

have inputs and outputs required for the PID. We will use the built-in analog input and

output of the MOD 30ML.

• The MOD 30ML has 2 built-in inputs and outputs and you can choose the first or second.

If you have already used up both the built-in inputs and outputs, you can add a module for

the additional input. The configuration will require one of the following blocks (VCIM,

TIM, RIM, WRIM) depending on the type of input.

• Add the following blocks to the database:

• AIN – Built-in Analog input

• VCI – Voltage or Current input function block

• AOUT – Built-in Current output block

You can either select the specific category at the bottom of the Algorithms menu first and

then the blocks or you can select the category All to pick any block.

Figure 2 .25.

Algorithm blocks in

the Loop

Compound

After you placed the above blocks in the database, the right frame on your configurator

screen should look something like the next figure.

2 - 20

13. Resize and move these blocks to fit them on the database workspace.

• Select a block by clicking on it. The selected block will have handles around it. See figure

below:

• Move the block with the left mouse button pressed on it and by moving the mouse.

Page 59

Figure 2 .26.

Move, Resize and

Configure

Figure 2 .27.

AIN Block

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Resize the block by dragging one of the handles (corner or side)

14. Configure these blocks:

• Configure the Analog Input block.

• Double-click on the AIN block to open its Properties menu as shown below:

• Type FT-100 as the name.

• Select Current as the Input type from the drop-down menu.

• Type the Input number as 2 and Description as shown in the above figure. This is the

built-in input 2 of the MOD 30ML. Note that changing the input type changes the Input

Low and High signal ranges automatically. This can also be manually changed.

• Click on OK when done.

2 - 21

Page 60

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• The next function block VCI, is a signal conditioning block. This block is used for

converting the analog input range (voltage or current) to engineering units. The default

configuration of this block is as shown in the next figure:

Figure 2 .28.

VCI Properties

• Type the name and description for this block as shown above. Move the cursor to the

Linearization Type field and click on the down arrow. Select Modifies Square Root as the

type from the drop-down menu. This will compensate for errors at very low flow

measurements.

• Change the Range to 0 to 200 and Quality limits also to 0 to 200. The measured signal (4-

20mA or 1-5V) will be interpreted as 0 to 200 flow units.

• We will not change anything else in this menu. Click on the OK button to complete the

configuration of this block.

Configure the AOUT block: Open the built-in analog output (AOUT) block.

• Configure the built-in output number (1 or 2).

• Configure the Action for this output (direct or reverse). Direct action specifies 4-20 mA

output for 0 – 100% output range. Reverse action specifies 4-20 mA for 100 – 0% output

range.

• Refer to the next figure:

2 - 22

Page 61

Figure 2 .29.

PID Options Tab

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Click on OK to accept the changes and close the block.

2 - 23

Page 62

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

MAKING CONNECTIONS

15. The next step is to connect the blocks together.

• Click on the Multi-Segment connection item on the Algorithms menu to enable

connection mode. See figure below:

Figure 2 .30.

Algorithm Connection

• Move to the workspace on the right and click on the AIN block’s (FT-100 – source

Figure 2 .31.

Connecting blocks

• Move the cursor to the VCI block’s (destination block FY-100) input now. Moving the

Figure 2 .32.

Connecting blocks

block) output connection point as shown in the next figure. Notice that moving the cursor

over the output of a block, shows a fly-by box. This box shows the name of the output (for

example, in this case MODOUT).

cursor will draw a line.

2 - 24

• You will get a fly-by box that will say MODIN when you move over the input.

• Click on the input of the VCI block. See the figure above.

Page 63

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .33.

Connecting blocks

• The connection will now be complete. The connection line will have the source name and

destination name displayed right on it as shown in the above figure.

The input connection points are on the left side of the blocks and the output connection

points are on the right hand side.

There might be more than one input or output for each block. All the inputs or outputs

need not be shown as connections attached to the block. To see all the inputs or outputs of

a block, you need to click right on the block in the connection mode.

As an example, the figure below shows the possible inputs of the PID block (destinations

for inputs into this block).

Figure 2 .34.

Choose parameter

for connecting

16. Connect the corrected flow as the process variable:

• Let us take Right angle connector this time. The right angle connector will connect the

blocks by horizontal and vertical lines instead of making a point to point straight

connection.

• Select the right angle connector from the Algorithms menu as shown below:

2 - 25

Page 64

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .35.

Right Angle

connection

• Click on the output point of the FY-100 block. This point is the result of the FY-100 input

function block. The fly-by box will say R when you click on the output.

• Drag the line to the FC156 PID (PV/LOCAL SP) compound and click on it. See the

figure below:

Figure 2 .36.

Right Angle

connection

• The Choose Parameter menu will be displayed as shown in the next figure:

2 - 26

Page 65

Figure 2 .37.

Choose Parameter

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Select PID.S1 from the list and then click on OK. This will complete the connection for

the process variable input. The connection will look like in the next figure:

Figure 2 .38.

If you made a mistake while connecting, or if you do not know where to connect, you

can always cancel it or get out of the connection mode by clicking on the right mouse

button to show a menu as shown below:

• Select Cancel from this menu to cancel the connection.

2 - 27

Page 66

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .39.

Cancel Connection

17. Connect the PID output from the compound to the analog output:

• Select the connector and then click on the FC156 PID (PV/LOCAL SP) compound and

click on it. The Choose Parameter menu will be displayed as shown below: Select PID.N

from the menu and click on OK.

Figure 2 .40.

Choose Parameter

2 - 28

• Drag the connection line to left of the AOUT block and connect to the Input point. The

connected blocks and the compound will look like in the next figure:

Page 67

Figure 2 .41.

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

2 - 29

Page 68

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

CHANGING ENGINEERING RANGES AND ALARM TRIP VALUES

18. The FC156 PID (PV/LOCAL SP) has default values for the process variable range (0

to100). We need to change this to 0 – 200 to match the input range defined in step 14.

• Open the compound by first selecting it and then by clicking on the right mouse button. A

context sensitive menu will appear as shown in the next figure:

Figure 2 .42.

Open Compound

Figure 2 .43.

Inside the FC 150

PID (PV/LOCAL

SP) Compound

• Click on the Open Compound item from this menu. This will open the compound and

display the function blocks inside. See the next figure:

2 - 30

• Select the function block ENG (Expression block). This function block is where you

would set the engineering ranges, alarm setpoints and initial PID settings. Double-click on

it to open it.

Page 69

Figure 2 .44.

ENG block

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Select the Inputs tab of this block. Double-click on the number for the input ENGHI

(Engineering High). See the above figure.

• Change the value of Internal data to 200. Click on OK.

• Double-click on the ALMHI input and change the High Alarm Trip-value to 175 as shown

I the next figure:

2 - 31

Page 70

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .45.

ENG block

• Repeat the above process to configure the Low process alarm by changing the ALMLO

input of the ENG block.

• Click on OK and then OK on the ENG block configuration.

2 - 32

Page 71

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

If you press the ALARM key on the faceplate when the alarm is active, the instrument will

display the custom alarm display as shown in the next figure:

Figure 2 .46.

Faceplate

displaying a

process alarm

2 - 33

Page 72

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

CONFIGURING DISPLAY TAG FOR THE PID DISPLAY

19. Each display configured in the MOD 30ML has a unique display tag. The FC156 PID

(PV/LOCAL SP) has a pre-configured display.

• Open the display block PID Display by double-clicking on it. See the next figure:

Figure 2 .47.

PID Display

2 - 34

• The default display tag name configured in this compound is PID-101. Change it to FIC-

100. See the next figure:

Page 73

Figure 2 .48.

PID Display

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Click on OK to close the block.

2 - 35

Page 74

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

20. Close the compound:

• First click on a blank area of the function block diagram to de-select any block or

connection selected.

Figure 2 .49.

Close Compound

Figure 2 .50.

Close Compound

• Click on the right mouse button to show the context sensitive menu as shown in the figure

above.

• Select Close Compound from the menu.

• You should be back in the level where the loop compound, Loop blocks are located. See

the next figure:

2 - 36

Page 75

21. Add the Display Tag to the Display Interface Block: The next step is to add the display

• Start by opening the DIF (Display Interface) block as shown in the figure below:

Figure 2 .51.

Closing Compound

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

tag of the display block we configured in the previous steps to the display list in the

display interface block. During runtime, you can scroll through the displays in this list by

pressing the Tag button on the instrument.

• Click on the New button on this block as shown in figure below:

2 - 37

Page 76

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .52.

Closing Compound

• A text edit box will appear in the area below and you will see a text edit cursor blinking.

• Type the name of your display tag (FIC-100). Refer to the next figure.

a If you had more than one display blocks in your configuration, you will need to add

their display tags in the DIF block as explained in the above step. The order in which

the display tags appear in this list is the order in which the displays will scroll when

you press the Tag button on the instrument. The display block gets executed by the

instrument when it is loaded on the face of the instrument. If you did not add the

display tag of a display block to this list, that display will not appear on the instrument

when you press the Tag button.

2 - 38

Page 77

Figure 2 .53.

Closing Compound

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• Refer back to the figure 1-37 for the display block set up.

The Instrument tag field displays a unique tag name for the instrument. An instrument can

have multiple displays each with its own tag name. The instrument tag is useful in

identifying the instrument.

• Click on the OK button when you are done.

2 - 39

Page 78

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

SAVING DOCUMENTS

22. Save your Document.

Figure 2 .54.

File Menu

• It is essential to save your document at frequent intervals.

• Refer to the above figure. The highlighted item is the instrument document. Click on the

Save button on the toolbar at the top to save the document. You can also save a document

by selecting File-Save from the menu bar. This saves the instrument document.

• File – Save All on the menu bar will save the document, the project file and the workspace

file.

Note that Save only saves the currently opened document. If you made changes in other

documents and wish to save, you may select Save-All instead.

2 - 40

Page 79

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

SETTING UP COMMUNICATIONS WITH MODBUS

23. We need to setup communications for communicating with the MOD 30ML instrument so

that we can download the database to the instrument. We will use the built-in RS-232 port

of the instrument to download to the instrument via Modbus.

The instrument supports up to 2 communication ports. These ports can be used for

Modbus or ICN (Instrument Communication Network, a proprietary peer-to-peer

communication network). The built-in communication port can be used for either ICN or

Modbus.

The built-in communication port jumper is located on the main board of the instrument as

shown in the next figure. The possible positions are: RS232 (Modbus), RS 485 (Modbus)

and ICN.

Figure 2 .55.

Built-in

Communications

jumper

Figure 2 .56.

Jumper locations

for built-in comm.

port

Built-in Circuit Modular Circuit

RS-232 RS-485 ICN Jumper Removed

2 - 41

Page 80

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

The connections for the port are available in the terminals in the back. In the case of an

instrument that is not NEMA4, the RS 232 port is also available in the front at the bottom

of the faceplate.

• Add a MSC block (Modcell serial communications) to the workspace by dragging it from

Algorithms menu. Double-click on it to configure. The properties menu of the MSC block

will display as shown below:

Figure 2 .57.

MSC

Communication

block

• Type a name and description for this block.

• Select RS-232 (built-in) from the drop-down menu in the Type field.

• Leave all other entries in their default values and click on OK to save the configuration of

this block.

2 - 42

Page 81

Command Series Migration to MOD 30ML

COMPILING THE DATABASE

It is necessary to compile the database without errors before downloading to the

instrument.

Only compiled databases can be downloaded to the instrument.

24. Select Instrument-Compile from the menu bar.

Figure 2 .58.

Instrument Compile

Function Codes – Gallery Tutorial

Figure 2 .59.

Compile Setup

• The Compile Setup dialog box as shown below will appear. Click on OK (Do not reassign

block occurrence numbers).

• The Interface File Options dialog box will be displayed as shown next. The interface files

are needed for integrating an HMI system with the controller and requires configuration of

a CL (Configured List) block in this database. It is beyond the scope of this lab and we do

not need to create an interface file.

• Click on the Cancel button on this dialog box.

2 - 43

Page 82

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

Figure 2 .60.

Interface File

Options for Modbus

• If the database has errors, it will not be compiled successfully. A list of errors will be

displayed on the screen in a sub-window along with other information such as the number

of errors, warnings and info messages as shown below:

2 - 44

Page 83

Figure 2 .61.

Information Window

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

• You can double-click on an error to open the block that has a configuration problem. If the

database has no errors, there is a message saying that the Compile was completed without

error.

• Also look for messages on database size and current consumption of the instrument.

• You can close this info sub-window by right-clicking on the window and then clicking on

the resulting Hide Window button or by selecting View-Information from the menu bar

at the top.

Refer to chapter 4 in the ViZapp Training manual (IB-VIZAPP-TUT) after

completing the tutorial for setting up the OPC Server and downloading the

database to the MOD 30ML Controller.

2 - 45

Page 84

Command Series Migration to MOD 30ML

Function Codes – Gallery Tutorial

2 - 46

Page 85

BOOK 2

REFERENCE

SECTION 1

PRE-CONFIGURED CONTROL

STRATEGIES

Page 86

Page 87

Pre-configured Single Loop PID Control

GENERAL DESCRIPTION

UTILIZATION

The advanced PID controller function code implements a proportional integral derivative

controller.

This control strategy has a loop compounds (SINGLE LOOP CONTROL) with PID

loops with local setpoint, I/O and other function blocks.

The loop compound has the function code compound FC156 – PID internally. This is

PID with Local SP and uses a PID block, PAD (Process Alarm Display) blocks and a

variety of other blocks to perform a full-pledged PID with PV and Local Setpoint. The

PID is advanced with feed-forward control, bump-less transfers and other features.

Load the loop compound at the top level (where the IF, DIF, SE and ST blocks are

located) of the function block diagram.

Figure P1.1.

PID with Local SP