Page 1

MODBUS™ RTU Communications Guide

for use with

MODCELL, MOD 30ML and Commander Products

Page 2

Page 3

MODBUS RTU

CONTENTS

CONTENTS

Page

OVERVIEW ......................................................................................................................................................... 1

HARDWARE REQUIREMENTS.......................................................................................................................... 2

SERIAL INTERFACE CONSIDERATIONS .................................................................................................... 2

CABLE REQUIREMENTS .............................................................................................................................. 2

COMMUNICATIONS MODE........................................................................................................................... 2

RS-232 INTERFACE....................................................................................................................................... 3

RS-422 INTERFACE....................................................................................................................................... 3

RS-485 INTERFACE....................................................................................................................................... 3

BIAS RESISTORS................................................................................................................ ..........................3

TERMINATION RESISTORS ......................................................................................................................... 3

SOFTWARE BASICS.......................................................................................................................................... 5

MASTER/SLAVE RELATIONSHIP................................................................................................................. 5

MESSAGE RESPONSE TIMES ..................................................................................................................... 5

INSTRUMENT RESPONSE TIMES TO HOST COMMANDS........................................................................ 5

SOFTWARE DRIVERS................................................................................................................................... 6

MODBUS WITH MODCELL MLP AND MOD30ML.............................................................................................7

STANDARD PROTOCOL...............................................................................................................................7

EXTENDED PROTOCOL............................................................................................................................... 7

MOD 30ML COMMUNICATION CHANNELS................................................................................................. 7

USING ML AND CL BLOCKS:............................................................................................................................. 8

DIRECTING DATA WITH ML AND CL BLOCKS............................................................................................ 8

BLOCK CONNECTIONS................................................................................................................................ 9

USING MODBUS MODULES:........................................................................................................................... 10

MODULE LOCATION................................................................................................................................... 10

THE RS-485’S TERM (MASTER/SLAVE) SWITCH..................................................................................... 10

THE COM DEFAULTS SWITCH .................................................................................................................. 10

THE HIGH AND LOW SWITCHES............................................................................................................... 10

MODBUS MASTER........................................................................................................................................... 12

MASTER REQUIREMENTS......................................................................................................................... 12

DATA CONVERSION ................................................................................................................................... 12

SCALER BLOCK........................................................................................................................................... 12

INPUT CONVERT BLOCK ........................................................................................................................... 13

OUTPUT CONVERT BLOCK ....................................................................................................................... 13

MODBUS WITH COMMANDER SERIES INSTRUMENTS .............................................................................. 14

SCALING ANALOG VALUES....................................................................................................................... 14

COMMUNICATIONS CONFIGURATION..................................................................................................... 14

CONNECTION WITHIN THE NETWORK .................................................................................................... 14

HOST CONFIGURATION EXAMPLES............................................................................................................. 15

MODBUS WITH FIX AND COMMANDER 150............................................................................................. 15

MODBUS WITH FIX AND COMMANDER 300............................................................................................. 16

MODBUS WITH INTOUCH AND COMMANDER 300.................................................................................. 17

MODCELL MLP WITH TCP QUICKPANEL.................................................................................................. 18

PLC & Protocols........................................................................................................................................ 18

Tags .......................................................................................................................................................... 18

Addressing ................................................................................................................................................ 18

Scaling....................................................................................................................................................... 19

MOD30ML AND MODCELL MLP REFERENCE TABLES................................................................................ 20

WIRE CONNECTIONS...................................................................................................................................... 22

MODBUS MODULE TROUBLESHOOTING WITH MOD30ML AND MODCELL MLP..................................... 23

GLOSSARY....................................................................................................................................................... 25

i

Page 4

MODBUS RTU

CONTENTS

TABLES

Page

Table 1. Cable Requirements .............................................................................................................................2

Table 2. Instrument Response Times.................................................................................................................5

Table 3. Software Drivers....................................................................................................................................6

Table 4. MOD30ML and Modcell MLP Port Numbers.......................................................................................10

Table 5. Integer Conversion - Signed to Unsigned...........................................................................................12

Table 6. MODBUS with FIX and Commander 150............................................................................................15

Table 7. MODBUS with FIX and Commander 300............................................................................................16

Table 8. MODBUS with InTouch and Commander 300....................................................................................17

Table 9. Wiring for RS-485 Full Duplex.............................................................................................................18

Table 10. TCP QuickPanel Addressing.............................................................................................................18

Table 11. MOD30ML and Modcell Multiloop Processor to Host Device or PC Sample Configuration Entries .20

Table 12. MODBUS Reference Information for MOD30 ML and Modcell Communications.............................21

Table 13. Wire Connections for RS-232 Devices..............................................................................................22

Table 14. Wire Connections for RS-485 (4 or 5-Wire) Devices ........................................................................22

Table 15. Wire Connections for RS-485 (2 or 3-Wire) Devices ........................................................................22

FIGURES

Page

Figure 1. RS-485 Biasing and Termination.........................................................................................................4

Figure 2. Extended and Standard MODBUS Lists..............................................................................................8

Figure 3. Block Connections...............................................................................................................................9

Figure 4. Module Switches................................................................................................................................11

ii

Page 5

MODBUS RTU

COMUNICATIONS GUIDE

OVERVIEW

MODBUS RTU is a non-proprietary serial communications protocol that is widely used in the process control

industry. The protocol was developed by Modicon for PLC communications and later released for public use.

This protocol is available in all major Human Machine Interface (HMI) software packages and terminals. Many

of the major controller and PLC manufacturers also offer MODBUS protocol as a standard or optional protocol

in their instrumentation.

The hardware over which MODBUS RTU communications are performed is not defined by the protocol.

MODBUS RTU is supported on RS-232, RS-422, RS-485, Ethernet and other electrical standards.

It should be noted that MODBUS RTU, MODBUS ASCII and MODBUS Plus are unique communication

formats, and are not compatible with each other. This document will discuss MODBUS RTU only.

1

Page 6

MODBUS RTU

COMUNICATIONS GUIDE

HARDWARE REQUIREMENTS

SERIAL INTERFACE CONSIDERATIONS

The Modbus protocol communicates with the instrumentation by means of an industry standard serial

interface. This interface may be RS-232, RS-422 or RS-485. Some systems may also support the protocol

over other busses or networks, such as Ethernet.

An RS-232 interface allows only two devices to be connected together. RS-422 supports 1 driver and up to 10

receivers on a single network. For bi-directional communications, special tri-state circuitry is provided on the

drivers of some instrumentation, allowing 10 driver/receiver pairs. RS-485 supports up to 32 driver/receiver

pairs. With special hardware, the RS-422 and RS-485 limits can be expanded to allow as many as 248

devices on a single network. Each device on a network must have a unique address, which may be softconfigured or set with switches. Address zero is reserved for broadcast messages from the host to all slaves.

All devices on a network must also be configured with the same parameters, such as baud rate and parity.

In designing the communication architecture, one should consider communications performance when

deciding how many devices to connect to a host port. Generally, nearly twice the performance can be

achieved by splitting the devices from one port, onto two ports.

CABLE REQUIREMENTS

The type of wire to use is usually specified by the hardware manufacturer and will vary with required length.

Wire with twisted pairs and an overall shield is used most often. The shield is tied to earth ground or chassis,

and typically at one end only. The shield is not to be used as a signal common or ground. The table below

lists typical cable recommendations.

Table 1. Cable Requirements

RS-232

Up to 15m (50ft) virtually any standard shielded twisted pair with drain

(Beldon 9502 or equivalent)

RS-422 and RS-485

Up to 6m (20ft) virtually any standard shielded or twisted pair

Up to 300m (1000ft) 24 AWG twisted pair with overall foil shield with drain wire

(Beldon 9841 for 2-wire and 9502 for 4-wire or equiv.)

Up to 1200m (4000ft) 24 AWG twisted pair with foil shield and drain wire on each pair

(Beldon 9841 for 2-wire and 9729 for 4-wire or equiv.)

COMMUNICATIONS MODE

Communications can take place in full or half-duplex mode. The communications hardware must be able to

support whatever mode the software is using. Half-duplex hardware shares the same lines for transmit and

receive, whereas, full-duplex hardware has dedicated transmit and receive lines. MODBUS protocol uses

half-duplex communications, regardless of the hardware. Full-duplex hardware is more widely supported by

software drivers and devices, than half-duplex.

2

Page 7

MODBUS RTU

COMUNICATIONS GUIDE

RS-232 INTERFACE

An RS-232 interface is rated for distances up to 15 meters (50 feet). At least three wires are required for an

RS-232 interface. Wires are required for Transmit, Receive and Signal Ground. Some devices support

additional wires for communication handshaking. RS-232 hardware is a full-duplex configuration, having

separate Transmit and Receive lines.

RS-422 INTERFACE

An RS-422 interface requires at least four wires. Two wires each are used for Transmit and Receive. A fifth

wire is usually required for Signal Ground, when connecting non-isolated devices together. Handshaking lines

may also be supported by some hardware. This interface is full-duplex, allowing use of the same software

drivers as for RS-232. The differential drivers allow for distances up to 1200 meters (4000 feet). The

receivers of an RS-422 device are always enabled. For multi-drop operation, drivers must capable of tri-state

operation.

RS-485 INTERFACE

An RS-485 interface requires at least two wires. In a two-wire configuration, the same pair of wires is used for

Transmit and Receive. The two-wire configuration utilizes half-duplex communications. A four-wire

configuration functions much like an RS-422 system, except the Transmit driver circuits are always taken offline or tri-stated, when not in use. This tri-state feature reduces the load on the network, allowing more

devices, without the need of special hardware. A fifth wire is usually required for Signal Ground, when

connecting non-isolated devices together. Additional wires for handshaking may also be supported by some

hardware. This interface also uses differential drivers, supporting distances up to 1200 meters (4000 feet).

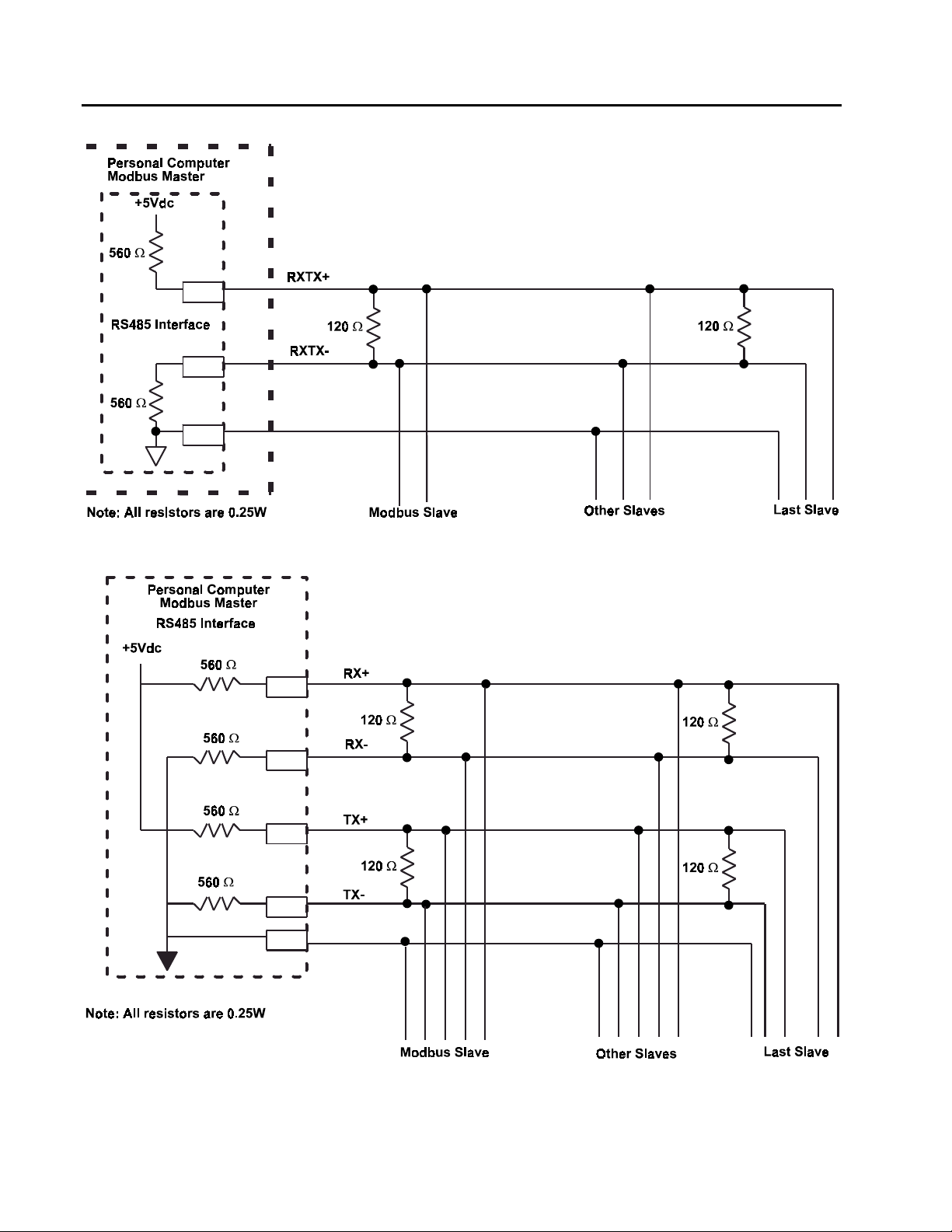

BIAS RESISTORS

RS-422 and RS-485 networks often require bias, or pull-up and pull-down resistors. These resistors are used

to stabilize the network. By definition, in a MODBUS RTU network, it is the responsibility of the Master to

provide this function. Functionally, any device on the network may provide the bias stabilization. Biasing may

also be installed external to the devices, with the appropriate resistors and power supply. If the Master is not

the device providing this function, careful consideration must be given to the consequences of that device

failing. If the Master is providing this function, and it fails, there would be no communications anyway. In

some systems, bias resistors may be installed on two slaves, offering redundant biasing. This feature is

available with MOD30ML and Modcell MLP modules (TERM switch). Some systems may function without

these stabilizing resistors, but may be more susceptible to communication errors. Though the pull-up and pulldown resistors are the same, the value of these resistors varies from device to device. The actual

recommended resistance may be calculated, and varies with the number of devices on the bus. Commander

series instruments use 1.8KΩ, while MOD30ML and Modcell use 560Ω. The pull-up resistor is connected

from the positive communication line to +5Vdc. The pull-down resistor is connected from the negative

communication line to the power supply common.

TERMINATION RESISTORS

Termination resistors are often used to reduce reflections on the network. This problem occurs most with long

wires and high baud rates. Due to variations in wire and equipment, whether or not to use these terminators is

usually determined by system testing. The general rule is to add them only if needed. The resistors are

typically 120Ω, and installed across the Transmit and Receive wire pairs. Normally, one resistor is installed at

each end of each pair of wires. For two-wire installations, one resistor would be installed at each end. If bias

stabilization resistors are not installed, use of these terminations will probably drown the signal, preventing

communications.

3

Page 8

MODBUS RTU

COMUNICATIONS GUIDE

2-Wire Configuration

4-Wire Configuration

Figure 1. RS-485 Biasing and Termination

4

Page 9

MODBUS RTU

COMUNICATIONS GUIDE

SOFTWARE BASICS

MASTER/SLAVE RELATIONSHIP

A MODBUS RTU system consists of a Master and one or more Slave devices. Multiple Masters are not

permitted on the same network. The Master is responsible for initiating all communications, therefore, no

peer-to-peer capability is supported. With some hardware, it is possible to dynamically switch the device

between Master and Slave modes. This capability allows multiple Masters, though not simultaneously. With

special hardware, such as Phoenix Digital’s MPE Plus, having multiple Masters is possible, though it limits the

communications to the basic “Standard” MODBUS commands. Using the MPE Plus will block extended

MODBUS communications, including the Application Builder.

MESSAGE RESPONSE TIMES

The MODBUS RTU protocol relies on precise timing for reliable communications. The message structure is

such that a 3.5 character or greater pause will be interpreted as the end of a message. The actual time

varies with the baud rate. Conversely, most devices require a defined minimum amount of time between

messages. Another factor to consider is that each device has its own response time. This response time can

be anywhere from a few milliseconds to a few hundred milliseconds. The Host must be configured to allow

adequate time for the slowest device to respond.

INSTRUMENT RESPONSE TIMES TO HOST COMMANDS

These times represent the maximum time from when the instrument receives a request from the master, to

when it begins to send the response.

Table 2. Instrument Response Times

Device Max Response Time Device Max Response Time

C100 250 mSec C1900 250 mSec

C150 250 mSec Modcell MLP 60 mSec *

C200 250 mSec 2050R 100 mSec

C300 180 mSec MOD30ML 60 mSec *

C310 160 mSec MR250 125 mSec

C500 125 mSec PR100 90 mSec

* NOTE: The response times for Modcell MLP and MOD30ML are for read

messages. Write messages may take longer. These instruments have a

configurable Write Message Timeout parameter.

5

Page 10

MODBUS RTU

COMUNICATIONS GUIDE

SOFTWARE DRIVERS

Table 3. Software Drivers

Driver Description Use With

1719S Standard MODBUS Driver PC-30 and GFW

1733S Extended MODBUS Driver PC-30 and GFW

2010S EMP 16-bit Standard and Extended MODBUS Driver FIX 5.x for Windows 3.x

2011S EMP 32-bit Standard and Extended MODBUS Driver FIX 6.x for Windows 95 and NT

I/O Server Standard MODBUS GFW

DDE Server Standard MODBUS Wonderware InTouch

OPC Server Standard and Extended MODBUS GFW32, FIX Dynamics and

other OPC Clients

MODCELL Enhanced Standard MODBUS Citect

MODBUS Standard MODBUS Citect and others

6

Page 11

MODBUS RTU

COMUNICATIONS GUIDE

MODBUS WITH MODCELL MLP AND MOD30ML

STANDARD PROTOCOL

“Standard” MODBUS supports single-register, 16-bit integer values. Modcell and MOD30ML floating-point

data may be converted to this format with ML blocks. For maximum resolution, specify an actual engineeringunit range in the ML block. If the engineering range is greater than 65535, a scaled range must be selected.

Some standard MODBUS drivers may be capable of reading floating-point data, using a 32-bit two-register

format.

The standard MODBUS driver (MB1) for Fix DMACS does not support the floating point format from Modcell

MLP and MOD30ML.

The standard MODBUS driver for PC-30 and GFW supports Modcell MLP and MOD30ML floating point

signals. A MODBUS I/O Server is also available for GFW, supporting floating-point.

EXTENDED PROTOCOL

Modcell and MOD30ML devices support an extended protocol, in addition to standard MODBUS RTU as a

subset. If the Master is capable of utilizing the extended features, additional data types, diagnostics and event

information may be obtained. The extended protocol also supports the Status Page in the Application Builder

and very fast uploads and downloads. Note that the 2-wire RS-485 module does not support these features.

The Extended MODBUS protocol implemented in Modcell and MOD30ML utilizes a user-defined MODBUS

command, and custom drivers are required in the host to support it. Custom drivers supporting this Extended

MODBUS protocol are available for PC-30, Genesis for Windows and FIX DMACS. The PC-30/GFW driver

supports only Extended MODBUS. The FIX drivers also support standard MODBUS devices, even on the

same network as Extended MODBUS devices.

When using Extended MODBUS, special interface files are created when compiling the instrument database.

These files provide automatic configuration of host poll records, significantly reducing engineering time. A MIF

file is used for FIX software. PC-30 and GFW use a TIF file. With Extended MODBUS, user-friendly alias

names are given to points in the Configured List. In the host software, these alias names are used instead of

register addresses.

MOD 30ML COMMUNICATION CHANNELS

The built-in communication channel on a MOD30ML can be used with front or rear connection, but not

simultaneously. The front connection is RS-232 only, and the rear connection can be either RS-232 or RS-

485. Connecting wires to the rear terminations may prevent communications through the front port, even if the

rear terminations are not being used. Installing a communication module in slots S9-10 or S10 will disable the

built-in channel. A second communication channel can be added by installing a module in slots S7-8 or S8.

7

Page 12

MODBUS RTU

COMUNICATIONS GUIDE

USING ML AND CL BLOCKS:

DIRECTING DATA WITH ML AND CL BLOCKS

CL blocks can be connected to MSC blocks, and are usually used for discrete points. A CL block is required

for multi-register “standard” MO DBUS functions, such as those needed for floating point s ignals. If a floating

point value is placed into an ML block, it is conver ted to a 16- bit integer v alue to be s ent to the host. If floating

point values are placed into a CL, they can be connected to a multi-register input of the MSC block using two

registers, or 32 bits. The data format is per ANSI / IEEE Std 754-1985 for Binary Floating-Point Arithmetic.

This is the format used by Motorola.

* NOTE: Solid connection lines represent the most commonly used connections.

Figure 2. Extended and Standard MODBUS Lists

8

Page 13

BLOCK CONNECTIONS

MODBUS RTU

COMUNICATIONS GUIDE

(Up to 99 Inputs per Block)

Figure 3. Block Connections

9

Page 14

MODBUS RTU

COMUNICATIONS GUIDE

USING MODBUS MODULES:

MODULE LOCATION

The sockets in which the module is installed determines its Port number

Table 4. MOD30ML and Modcell MLP Port Numbers

Port Number MOD30ML Modcell MLP

1 Built-In, Slots 9-10 or 10 Slots 31-32 or 32

2 Slots 7-8 or 8 Slots 29, 28-28, 30 or 29-30

3 not available Slots 25-26, 26, 26-27, 27, 27-28 or 28

THE RS-485’S TERM (MASTER/SLAVE) SWITCH

• The master is responsible for stabilizing the bus

• In the YES position the module provides this master function by pulling the comm+ line high and

the comm- line low, each through 560Ω resistors

• Some PC cards have these resistors built in, generally only on the receiver. This works fine in 4-

wire mode if the transmitter does not tri-state, or in 2-wire mode. 4- wire mode, with a tri-stating

transceiver, may require a module to have its switch in the master position, even if its not acting

as the master.

THE COM DEFAULTS SWITCH

• If the MOD30 ML or Modcell MLP configuration is unknown, setting this switch to th eYES position

will allow communications with the unit at 9600 baud, no parity, 8 data bits and 1 stop bit. After

downloading the desired parameters, remove power, COM DEFAULTS switch to NO and power

up.

THE HIGH AND LOW SWITCHES

• Set the MODBUS Address

• The High switch sets the first hexadecimal digit of the address, and the Low switch sets the

second. For example, a switch setting of 13 hex represents a decimal address of 19.

The 2-wire RS-485 module has no switches. It mus t be configured by the Application Builder softwar e, to

change the factory defaults. The factory defaults are 9600 baud, no parity, 8 data bits, one stop bit and a

MODBUS address of one. Do not connect an unconfigured module to a network if there is another device on

the network with address one.

10

Page 15

MODBUS RTU

COMUNICATIONS GUIDE

COMM

RS232

CAT. NO.

2033NZ10000A

COMM

RS485

T

E

R

M

YES

NO

COMM

DEFAULTS

COMM

DEFAULTS

YES

NO

YES

NO

HIGH LOW

CAT. NO.

2034NZ10000A

HIGH LOW

* NOTE: Address is indicated with the flat side of the switch

Figure 4. Module Switches

11

Page 16

MODBUS RTU

COMUNICATIONS GUIDE

MODBUS MASTER

MASTER REQUIREMENTS

MODBUS Master communication requires a few special configuration items.

1. MSC Block - Each MSC block that will be used for MODBUS Master communications must have the Port

Functionality set to Master.

2. EX Block for Port Configuration - Each MODBUS Master port requires a specially configured Expression

block to define its parameters.

3. EX Block for Communications - Expression blocks are configured to send and receive the actual

communication messages. The first 10 inputs are dedicated to configuration and status. The remaining

inputs may be used to read or write data. Each block is configured to execute a specific type of MODBUS

function. The only relevant factor that limits the number of these blocks is performance.

DATA CONVERSION

Analog data in a newer Commander instruments and the 2050R is stored as a 16-bit signed integer value.

Integer values in the Modcell MLP and MOD30ML are unsigned. The dec imal point position is also read as a

separate value. When reading or writing analog values between these instruments, expression blocks are

used to convert from one integer type to the other. The table below indic ates the r elations hip between the two

number formats.

Table 5. Integer Conversion - Signed to Unsigned

Signed 16-Bit Number Unsigned 16-Bit Number

00

32767 32767

-32768 32768

-1 65535

SCALER BLOCK

One expression block is requir ed for each slave instrument, for decimal point scaling. The expres sion is as

follows:

if DecPt == 0 then 1.0 else

if DecPt == 1 then 10.0 else

if DecPt == 2 then 100.0 else 1000.0

DecPt is a COUNT input which is read from the slave instrument.

The block’s Result is a FLOATING-POINT scaler.

12

Page 17

MODBUS RTU

COMUNICATIONS GUIDE

INPUT CONVERT BLOCK

One expression block is required for each analog value read from the slave instrument, for data type

conversion. The expression is as follows:

if Input > 32767 then (Input - 65536.0) / Scaler

else Input / Scaler

Input is a COUNT value which is read from the slave instrument.

Scaler is the FLOATING-POINT result of the Scaler block.

OUTPUT CONVERT BLOCK

One expression block is required for each analog value written to the slave instrument, for data type

conversion. The expression is as follows:

if (Output * Scaler) > 32767.0 then 32767 else

if (Output * Scaler) < -32768.0 then 32768 else

if Output >= 0 then Output * Scaler else

65536.0 + (Output * Scaler)

Output is the FLOATING-POINT number to be converted to a COUNT, and send to the slave instrument.

Scaler is the FLOATING-POINT result of the Scaler block.

13

Page 18

MODBUS RTU

COMUNICATIONS GUIDE

MODBUS WITH COMMANDER SERIES INSTRUMENTS

SCALING ANALOG VALUES

The first Commander instruments to support MO DBUS handled scaling of analog values in a different way

than later instruments. The C200, C300, C1900 and PR100 use a 12-bit register with a raw range of 0 to

4095. The host must scale the value to obtain the desired engineering unit value.

Newer models, such as the C100, C150, C250, C500 and PR250, place an engineering unit value into one or

two 16-bit registers. If two registers are used, the data type is considered a long integer. Values are

represented as positive or negative integers without a decimal point. If a decimal point is used in the

instrument, additional scaling must be performed at the host.

COMMUNICATIONS CONFIGURATION

The Commander must be configured from the face of the instrument via the Serial Data Communications

page. If this page is not accessible, the communications option may not be installed. Some Commanders use

a security switch to acces s the c onfigur ation mode. The par ameters on this menu gr oup mus t be set to match

host or Modbus Master device. The 3 Line type refers to 2-wire (half-duplex) with a common, wher e 5 Line is

4-wire (full-duplex) with a common. The number of Star t and Data bits are fixed at 1, 8 respectively. The

number of Stop Bits is not configurable and can be set to 1 or 2 at the host. Par ity can be set to none, odd or

even and must match the Host setting. The Ident or Addr entry configures the Modbus Slave address.

CONNECTION WITHIN THE NETWORK

One additional subject that must be addressed, is the electrical stabilization and elec trical connection of the

RS-485 network. By definition, the Modbus Master devic e is to supply the pull-up and pull-down resistors to

stabilize the network. If the interface device does not have that capability, you may select the "Linked In"

jumper setting on the Commander. If the stabilizing is performed at the Commander, and the Commander

fails or is removed from the network, all communic ations may be stopped. Depending on the length of your

cable, you may also need termination resistors, which may be ins talled ex ternally for 3-wir e or by a jumper for

5-wire configurations.

14

Page 19

MODBUS RTU

COMUNICATIONS GUIDE

HOST CONFIGURATION EXAMPLES

MODBUS WITH FIX AND COMMANDER 150

Either the MB1 or EMP driver may be used, though EMP is recommended. The MODBUS guide uses 1 and

2-digit numbers for addresses. Note that the actual addressing requires a 5-digit number. For digital

addresses, use 000xx format, where xx represents the coil address from the instruction book. For analog

addresses, use 400xx format, where xx represents the register address from the instruction book.

Table 6. MODBUS with FIX and Commander 150

Poll Record Configuration

Hardware MODBUS

Addressing Type 5-Digit

Bit Base 0-15

Data Types Unsigned - Positive Analog Ranges (up to 9999)

Signed - Analog Ranges (between -999 and +9999)

Long - Analog Double Register Values (between -9999 and 99999)

Database Configuration

Data Type Database Block Address Range Notes

Digital Input DI 000xx

Digital Output DO 000xx

Digital I/O DR 000xx select output enable

Analog Input AI 400xx LIN Signal Conditioning

Analog Output AO 400xx LIN Signal Conditioning

Analog I/O AR 400xx LIN Signal Conditioning

NOTES:

1. Each line of the poll record can have no more than 8 analog or 16 digital addresses.

2. It is acceptable to “read through” undefined addresses.

3. Use a calculation block to scale for proper decimal point position.

15

Page 20

MODBUS RTU

COMUNICATIONS GUIDE

MODBUS WITH FIX AND COMMANDER 300

Either the MB1 or EMP driver may be used, though EMP is recommended. The MODBUS guide uses 3-digit

numbers for addresses. Note that the actual addressing requires a 5-digit number. For digital addresses, use

00xxx format, where xxx represents the coil address from the instruction book. For analog addresses, use

40xxx format, where xxx represents the register address from the instruction book.

Table 7. MODBUS with FIX and Commander 300

Poll Record Configuration

Hardware MODBUS

Addressing Type 5-Digit

Bit Base 0-15

Data Type Unsigned - Positive Analog Ranges (0 to 4095)

Signed - Analog Ranges that go Negative (-2048 to +2047)

Database Configuration

Data Type Database Block Address Range Notes

Digital Input DI 00xxx

Digital Output DO 00xxx

Digital I/O DR 00xxx select output enable

Analog Input AI 40xxx 12BN (positive) or LZ12 (live zero)

Signal Conditioning

Analog Output AO 40xxx 12BN (positive) or LZ12 (live zero)

Signal Conditioning

Analog I/O AR 40xxx 12BN (positive) or LZ12 (live zero)

Signal Conditioning

NOTES:

1. Ensure that each line of the poll record contains no more than 8 analogs or 16 digital addresses.

2. It is acceptable to “read through” undefined addresses.

16

Page 21

MODBUS RTU

COMUNICATIONS GUIDE

MODBUS WITH INTOUCH AND COMMANDER 300

Below are configuration entries that have been tested with the InTouch Modbus DDE Server and C300.

Table 8. MODBUS with InTouch and Commander 300

Hardware 584/984 PLC

String Variable Style Full Length

Register Type Binary

Block I/O Sizes

Coil Read - 16 Register Read - 8

Coil Write* - 8 Register Write - 8

* NOTE: The Commander supports only Single-Coil writes (Function Code 05), so

Block I/O does not apply. InTouch allows a minimum setting of 8.

In the InTouch Display Configuration Window;

1. Select the desired Value Display Wizard to place a display field into the window

2. Double-click on the display field to configure it

3. Assign a Tagname

4. Check the Allow Input box if you wish to write values from the PC to the Commander

5. Define the Tagname

6. Select DDE Real for analog values

7. Set the Min and Max EU values to match the Commander Display Range

8. Set the Min and Max Raw values to the Response/Entry range specified in the Modbus guide

9. Select DDE Access Name as defined in the I/O Server

10. Specify the Item as a 5-digit Modbus address (i.e. 40051 for Process Variable 1)

11. Coil addresses in the Commander range from 00011 to 00181

12. Register addresses in the Commander range from 40011 to 40230

17

Page 22

MODBUS RTU

COMUNICATIONS GUIDE

MODCELL MLP WITH TCP QUICKPANEL

Table 9. Wiring for RS-485 Full Duplex

QuickPanel jr. Modcell MLP

TXA 11 ————— 29-1 Rx+

TXB 15 ————— 29-2 RxRXA 10 ————— 30-1 Tx+

RXB 16 ————— 30-2 Tx-

Frame Ground 1 — Shield

RTS 4 ——

CTS 5 ——

CTSB 18 ——

DTRB 19 ——

CTSA 21 ——

DTRA 22 ——

PLC & Protocols

SIO/CN1 PLC Modicon Modbus is used when QuickPanel is Master to MLP

Modicon Modbus Slave is used when QuickPanel is slave to MLP

Port Electrical Format: RS-422/485 Full duplex

Baud rate, Data bits, Parity and Stop Bits to match the MLP configuration

Handshake: None

Protocol PLC ID: Modbus address of the MLP

Tags

Analog points are read from the MLP as an integer value (16-bit).

MLP floating-point numbers are not supported by this interface.

Addressing

Registers are referenced as a type and offset. Below are examples for Input Registers and Output (Holding)

Registers.

Table 10. TCP QuickPanel Addressing

ML to MSC SROIN1 Modbus Address QuickPanel Tag

Entry 1 30001 IR001

Entry 2 30002 IR002

ML to MSC SRWIN1

Entry 1 40001 OR001

Entry 2 40002 OR002

If connecting more than one slave to the QuickPanel, append an underscore and Modbus address to the tag.

Example:

QuickPanel is configured to access PLC ID 1

For MLP at address 2, with the same registers as above, the tags would be IR001_2, IR002_2,

OR001_2 and OR002_2.

18

Page 23

MODBUS RTU

COMUNICATIONS GUIDE

Scaling

In ML Block, specify actual range for variable, if the number of significant digits is 5 or less. For ranges with

more than 7 significant digits, such as 500,000 or 750.000, change the units to allow smaller numbers. For

example, instead of 0 to 500,000 CFH, use 0 to 500 KCFH. Also note that the scale factor is for use only with

mSec time values. The field is enabled for sources that can support the data type. If your source data is not

mSec time, do not change the scale factor from default.

In QuickDesigner, leave Input Low at 0 and High at 65535. The Scale Low and High values should match

what is in the Modbus List, unless a decimal is required. If digits to the right of the decimal are needed,

multiply the range value by 10 for one place, 100 for two and etc.. For example, if two places are desired to

the right of the decimal point with a range of 0 to 10, specify a Scale High of 1000. In display Data Format,

specify 2 decimal places.

19

Page 24

MODBUS RTU

COMMUNICATIONS GUIDE

MOD30ML AND MODCELL MLP REFERENCE TABLES

Table 11. MOD30ML and Modcell Multiloop Processor to Host Device or PC Sample Configuration Entries

MOD30ML or Modcell Multiloop Processor Host Device or PC

Signal Source List

Engineering

Data

Type Low High CL ML Number Low High Factor Connection Address Type Low High Low High Note

Floating

Point

Floating

Point

Floating

Point

Floating

Point

mSec

Time

mSec

Time

mSec

Time

mSec

Time

mSec

Time

mSec

Time

Discrete 0 1 X 8 SRWIN2 40108 WORD 0 65535 0 1 Bit 1 of

Discrete 0 1 X 9 SRWIN2 40109 WORD 0 65535 0 1 Bit 1 of

Discrete 0 1 X 1 DRWIN1 00001 BIT 0 1 0 1 Bit 1 of 1

Discrete 0 1 X 2 DRWIN1 00002 BIT 0 1 0 1 Bit 1 of 1

Floating

Point

Floating

Point

Floating

Point

Floating

Point

Range Type Entry

0 100 X 1 0 100 SRWIN1 40001 WORD 0 65535 0 100

-10 10 X 2 -10 10 SRWIN1 40002 WORD 0 65535 -10 10

-14 0 X 3 -14 0 SRWIN1 40003 WORD 0 65535 -14 0

0 80000 X 1 0 8000 SRWIN2 40101 WORD 0 65535 0 8000 10x mult

0 4294967295 X 2 0 65535 1 SRWIN2 40102 WORD 0 65535 0 65535 1 mSec /

0 4294967295 X 3 0 65535 10 SRWIN2 40103 WORD 0 65535 0 65535 10 mSec

0 4294967295 X 4 0 65535 100 SRWIN2 40104 WORD 0 65535 0 65535 100

0 4294967295 X 5 0 65535 1000 SRWIN2 40105 WORD 0 65535 0 65535 1 Sec /

0 4294967295 X 6 0 65535 10000 SRWIN2 40106 WORD 0 65535 0 65535 10 Sec /

0 4294967295 X 7 0 65535 100000 SRWIN2 40107 WORD 0 65535 0 65535 100 Sec

0 100 X 1 MRWIN1 41001 FLOAT 0 100 0 100

-10 10 X 2 MRWIN1 41003 FLOAT -10 10 -10 10

-14 0 X 3 MRWIN1 41005 FLOAT -14 0 -14 0

0 80000 X 1 MRWIN2 41101 FLOAT 0 80000 0 80000

Modbus List

Range Scale MSC Modbus Data

Device

Range

Engineering

Range

req’d

count

/ count

mSec /

count

count

count

/ count

16

16

20

* NOTE: When connections are made from a source that has a variable data type,

the Range and Scale Factor fields may be enabled when they do not

apply. In this case, leave the default Range of 0 to 65535 and Scale

Factor of 1.

Page 25

MODBUS RTU

COMMUNICATIONS GUIDE

Table 12. MODBUS Reference Information for MOD30 ML and Modcell Communications

Code Function Action Data Types Max Points per

Command

01 Read Coil Status Read one or more

consecutive points

02 Read Input Status Read one or more

consecutive points

03 Read Holding

Registers

04 Read Input

Registers

05 Force Single Coil Write one point Discrete 1 00001-00499 CL DRWIN1-5

06 Preset Single

Register

08 Loopback Test Return of Query (00) For Diagnostic Use Only N/A N/A N/A N/A

15 Force Multiple

Coils

16 Preset Multiple

Registers

65 Extended Modbus Read and/or Write any

Read one or more

consecutive registers

Read one or more

consecutive registers

Write one register All except ASCII and HEX -

Write one or more

consecutive points

Write one or more

consecutive registers

Data Type

Discrete 99 00001-00499 CL DRWIN1-5

Discrete 99 10001-10499 CL DROIN1-5

All except ASCII and HEX One Register per Point

Any - Uses as many

Registers as req'd for Data

All except ASCII and HEX One Register per Point

Any - Uses as many

Registers as req'd for Data

One Register per Point

Any - Uses as many

Registers as req'd for Data

Discrete 16 00001-00499 CL DRWIN1-5

All except ASCII and HEX One Register per Point

Any - Uses as many

Registers as req'd for Data

Any - Data in buffer, rather

than Coils or Registers

32 40001-40499 ML SRWIN1-5

125 41001-45999 CL MRWIN1-5

32 30001-30499 ML SROIN1-5

125 31001-35999 CL MROIN1-5

1 40001-40499 ML SRWIN1-5

1 41001-45999 CL MRWIN1-5

16 40001-40499 ML SRWIN1-5

16 41001-45999 CL MRWIN1-5

Note 6 n/a CL FGLISTIN

Address

Range

From To

NOTES:

1. Placing discrete points into Holding or Input Registers uses an entire 16 bit register for one point. This

may be more efficient when only a small amount of discrete data is required, along with analog data. If a

significant number of discrete points are required, communications and memory efficiency would be

improved by placing them into the Coil or Input Status area. Another possibility would be to pack 16

discrete points into a count and store it in an Input or Holding Register. This would be dependent on the

host device's ability to accept the packed data format.

2. Date, Floating Point and mSec Time are converted to 16 bit integers when tied to an ML register.

3. It is recommended that no more than the number of points supported per command be put into each Slave

ML block. This will prevent the Master device from accessing more than the allowed number of points in a

single command. The instrument will not return any data if the maximum number of registers is exceeded

or an invalid register is included. Some HMI packages, such as Fix DMACS, allow poll records to be

broken into groups to avoid this problem.

4. When using Extended Modbus, group control loop data together in CL blocks for greatest efficiency.

5. Some peripheral equipment that is designed for Modbus communications may not support Extended

Modbus (function code 65).

6. The instrument's foreground can hold up to 2400 bytes of data. The number of points that can be handled

per command depends on the host software. Connecting the CL block to BGLISTIN may provide

increased performance with some host configurations. This is the case when using Database Caching

with PC-30 or Genesis for Windows. Without Database Caching enabled, a connection to FGLISTIN is

recommended.

7. Each Modbus List block can contain up to 99 points, and each type of connection provides inputs for five

lists. This is also true for Configured List blocks for Standard Modbus. When using Extended Modbus,

Configured List blocks may be nested, allowing more than 99 points to be connected to FGLISTIN or

BGLISTIN.

21

Page 26

MODBUS RTU

COMMUNICATIONS GUIDE

PC Serial Port MOD30ML Mod RS-232 MOD30ML Modcell

25-Pin 9-Pin Port 1 Port 2 cell Port 1 Port 2

2 3 3 9 13 Hi-1 Tx

3 2 2 8 12 Hi-2 Rx

7 5 1 10 14 Lo-2 Gnd

Table 14. Wire Connections for RS-485 (4 or 5-Wire) Devices

B&B Quatech OPTO-22 MOD30ML Mod RS-485 MOD30ML Modcell

3PXOCC2A

3PXCC2A DS-300 or AC 34 BI 9&10 7&8 MLP Master Slave BI 9&10 7&8 MLP 2050R

DSP-225 AC 24 AT Port 1 Port 2 cell

2 2 4 3 9 13 Hi-1 Tx+

3 7 5 2 8 12 Hi-2 Tx9 4 8 5 11 15 Lo-1 Rx+

1 8 9 4 10 14 Lo-2 Rx5331 Gnd⇔Gnd 1 29

WIRE CONNECTIONS

Table 13. Wire Connections for RS-232 Devices

BI 9&10 7&8 MLP Master Slave BI 9&10 7&8 MLP

⇒

Rx 2 8 12 Hi-2

⇐

Tx 3 9 13 Hi-1

⇔

Gnd 1 10 14 Lo-2

(4 or 5-Wire)

⇒

⇒

⇐

⇐

Rx+ 5 11 15 Lo-1 35

Rx- 4 10 14 Lo-2 34

Tx+ 3 9 13 Hi-1 33

Tx- 2 8 12 Hi-2 32

Port 1 Port 2

B&B Quatech OPTO-22 RS-485 Commander

3PXOCC2A

3PXCC2A DS-300 or AC 34 Master Slave MR250 C1900 C150 C200 C300 C310 C500 PR100

DSP-225 AC 24 AT

224Tx+⇒Rx+ 7 7 22 7 9 21 34 3

375Tx-⇒Rx- 8 6 23 6 102235 2

948Rx+⇐Tx+ 3 4 20 4 111832 5

189Rx-⇐Tx- 2 5 21 5 121933 6

533Gnd⇔Gnd 12 8 24 Gnd 8 20 36 8

(4 or 5-Wire)

C100

Table 15. Wire Connections for RS-485 (2 or 3-Wire) Devices

B&B Quatech OPTO-22 MOD30ML Mod RS-485 MOD30ML Modcell

3PXOCC2A

3PXCC2A DS-300 or AC 34 BI 9&10 7&8 MLP Master Slave BI 9&10 7&8 MLP 2050R

B&B Quatech OPTO-22 RS-485 Commander

3PXOCC2A

3PXCC2A DS-300 or AC 34 Master Slave MR250 C1900 C150 C200 C300 C310 C500 PR100

DSP-225 AC 24 AT Port 1 Port 2 cell

2&9 2&4 4-8 3&5 9&11 13&15 Hi&Lo-1 RxTx+

3&1 7&8 5-9 2&4 8&10 12&14 Hi&Lo-2 RxTx-

5331 Gnd⇔Gnd 1 29

DSP-225 AC 24 AT

2&9 2&4 4-8 RxTx+

3&1 7&8 5-9 RxTx-

533Gnd⇔Gnd 12 8 24 7 36

(2 or 3-Wire)

⇔

RxTx+ 3&7 4 22 4 34

⇔

RxTx- 2&8 5 23 5 35

(2 or 3-Wire)

⇔

RxTx+ 3&5 9 13 -1 33&35

⇔

RxTx- 2&4 8 12 -2 32&34

C100

Port 1 Port 2

* NOTES: 1. MOD30ML and Modcell do not support MODBUS Master

communications with a 2-wire RS-485 module.

2. On Modcell MLP and MOD30ML, 4-wire modules are recommended for

all applications, even for 2-wire installations.

22

∆

WARNING Incorrect wiring can damage communication hardware.

Page 27

MODBUS RTU

COMMUNICATIONS GUIDE

MODBUS MODULE TROUBLESHOOTING

WITH MOD30ML AND MODCELL MLP

* NOTE: The extended Modbus communications required for diagnostics and

downloading is supported by the 2033N and 2034N modules only. On

Modcell, the Identity module firmware must be at least version 4 Logic,

version 3 Regulatory, Batch, or Advanced.

1. Remove power from the instrument.

2. Note the switch settings on the Modbus module. Two rotary switches are used to select the address. The

address is indicated in hexadecimal, by the flat side of the spindle, with A through F representing 10

through 15.

3. Set the COMM DEFAULTS switch to YES. This will force the module to communicate at 9600 baud, 8

data bits, 1 stop bit and no parity, regardless of the database configuration. Note that these default

parameters will be in effect whenever the default database is being executed.

4. If using an RS-485 module, set the TERM switch to NO. This switch provides pull-up and pull-down

resistors to stabilize the network. This function is defined by the Modbus specification as the responsibility

of the master node, which is the PC in this case. In some cases, it may be necessary to enable this

termination, if the PC interface is unable to stabilize the network.

5. Apply power to the equipment.

6. Start the Application Builder software and select the serial port configuration button. Select the serial port

that is connected to the instrument and confirm the port settings. The standard Base Addresses are 3F8,

2F8, 3E8 and 2E8 for Com1 through Com4 respectively. If unsure of the address, check the hardware

manual for configuration information. Set the Baud Rate to 9600, Data Bits to 8, Parity to None and Stop

Bits to 1.

7. Enter the Status display and select the communications setup button. Set the communications type to

Extended Modbus. Set the Modbus Address to match the module setting and select the com port to be

used. Select OK to close the dialog box. The ICN and Instrument number settings have no effect.

8. Click on the Status line at the bottom of the screen and enter R VERSION. This command will return the

version of the instrument. If the instrument responds, confirm that the reported version agrees with the

type of instrument that is being tested.

9. If unable to establish communications, disconnect power and remove all analog and communications

modules, except for the Modbus module being used. If still unable to communicate, replace the Modbus

module. If all previous procedures fail, replace the instrument.

23

Page 28

MODBUS RTU

COMMUNICATIONS GUIDE

24

Page 29

MODBUS RTU

COMMUNICATIONS GUIDE

GLOSSARY

The following terms are defined as they relate to this document. The definitions given here may not be the

same throughout the industry.

Alias A meaningful short-hand name given to a data point

Baud Serial communication data transmission rate

Bit A binary digit, representing a one or zero

Bus An electrical circuit over which data is transmitted

Byte A whole number value represented by eight bits (0 to 255)

CL block Configured List block

Chassis or Chassis Ground A connection to an electrically conductive housing or frame of a device. It

may or may not be connected to Earth Ground.

Common The voltage reference point of a circuit. It may or may not be connected to

earth ground, though it is generally assumed to be at zero volts, unless

otherwise indicated. In floating circuits, the common is sometimes at a

relatively high potential. This term is sometimes used interchangeably with

the term “Ground”.

CRC Cyclic Redundancy Check. Complex error checking on a message block.

CTS ClearToSend hardware handshaking signal. Used with RequestToSend.

Earth or Earth Ground Global zero voltage reference point. Physical connection is made to the

earth through a grounding rod, water pipe or other reliable connection.

Ground Voltage reference point of a circuit. It may or may not be connected to

earth ground, though it is generally assumed to be at zero volts.

Sometimes used interchangeably with the term “Common”.

Handshaking A method of data flow control for serial communications

Hexadecimal or HEX A number system using a decimal 16 as its base. A single digit number in

HEX ranges from 0 to 15, represented by 0 to 9 and A to F.

HMI Human-Machine Interface (formerly MMI)

Live Zero Indicates that a numeric range contains both positive and negative

numbers

Loopback A test used for checking functionality of a serial port, utilizing a test plug

that connects send, receive and handshaking signals

Long Integer Analog value consisting of two consecutive 16-bit registers

ML block MODBUS List block

MLP MultiLoop Processor (Modcell 2000 Series Controller)

MSC block MODBUS Serial Communications block

Parity Simple method of data error checking performed at the byte level. May be

user-specified as Odd, Even or None with most equipment and software.

25

Page 30

MODBUS RTU

COMMUNICATIONS GUIDE

PC Personal Computer

Receive Incoming communication signal. (Rx)

RTS RequestToSend hardware handshaking signal. Used with ClearToSend.

Rx See Receive

RxA Usually the negative Receive line. May vary with manufacturer. Also see

Receive

RxB Usually the positive Receive line. May vary with manufacturer. Also see

Receive

Signed Integer Whole number value represented by 16 bits (-32768 to 32767)

Transmit Outgoing communication signal. (Tx)

Tri-State The ability of a communications transmitter to turn its circuitry off, reducing

the load on the network

Tx see Transmit

TxA Usually the negative Transmit line. May vary with manufacturer. Also see

Transmit

TxB Usually the positive Transmit line. May vary with manufacturer. Also see

Transmit

Unsigned Integer Positive whole number value represented by 16 bits (0 to 65535)

Word A group of 16 bits

Xon/Xoff Software implementation of data flow control

26

Page 31

Page 32

The Company’s policy is one of continuous product improvement and the right

is reserved to modify the information contained herein without notice, or to

make engineering refinements that may not be reflected in this bulletin.

Micromod Automation assumes no responsibility for errors that may appear in

this manual.

© 2004 MicroMod Automation, Inc. Printed in USA

IB-MODBUS-RTU, Issue 2 04/2005

MicroMod Automation, Inc.

75 Town Center Drive

Rochester, NY USA 14623

Tel. 585-321-9200

Fax 585-321-9291

Loading...

Loading...