Page 1

MOD 30ML™ Multiloop Controller Installation

Replacement for MOD 30 Instruments

Product Description, Installation and Wiring for

1800R Model A with MOD 30 Termination Assembly

and Associated Hardware

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed

information or technical details.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned by

MicroMod Automation or its suppliers.

Page 3

MOD 30ML Replacement for MOD 30 Instruments

CONTENTS

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

CONTENTS

Page

SECTION 1 -PRODUCT DESCRIPTION

1.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 The Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 EXPLANATION OF CATALOG NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 BASIC HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 1800R With MOD 30 Termination Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 1800P MOD 30ML Identity Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.3 2010P Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 I/O MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.1 2001A Voltage Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.2 2006A Nonisolated Digital Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.3 2007A Nonisolated Digital Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.4 2030N ICN Communication Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2 - PREREPLACEMENT CONSIDERATIONS

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 COMMUNICATIONS AND I/O SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.2 I/O Signal Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.3 I/O Signal Specification Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 MATH UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 3 - REPLACEMENT PROCEDURE

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 UNPACKING THE REPLACEMENT INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . 19

3.3 INSTALLING MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 SETTING UP COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 REMOVING OLD MOD 30 INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6 INSTALLING NEW MOD 30ML REPLACEMENT INSTRUMENT . . . . . . . . . . . . . 24

3.6.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.6.2 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

APPENDIX A - PLANNING FORMS

i

Page 4

MOD 30ML Replacement for MOD 30 Instruments

CONTENTS

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

ILLUSTRATIONS

Page

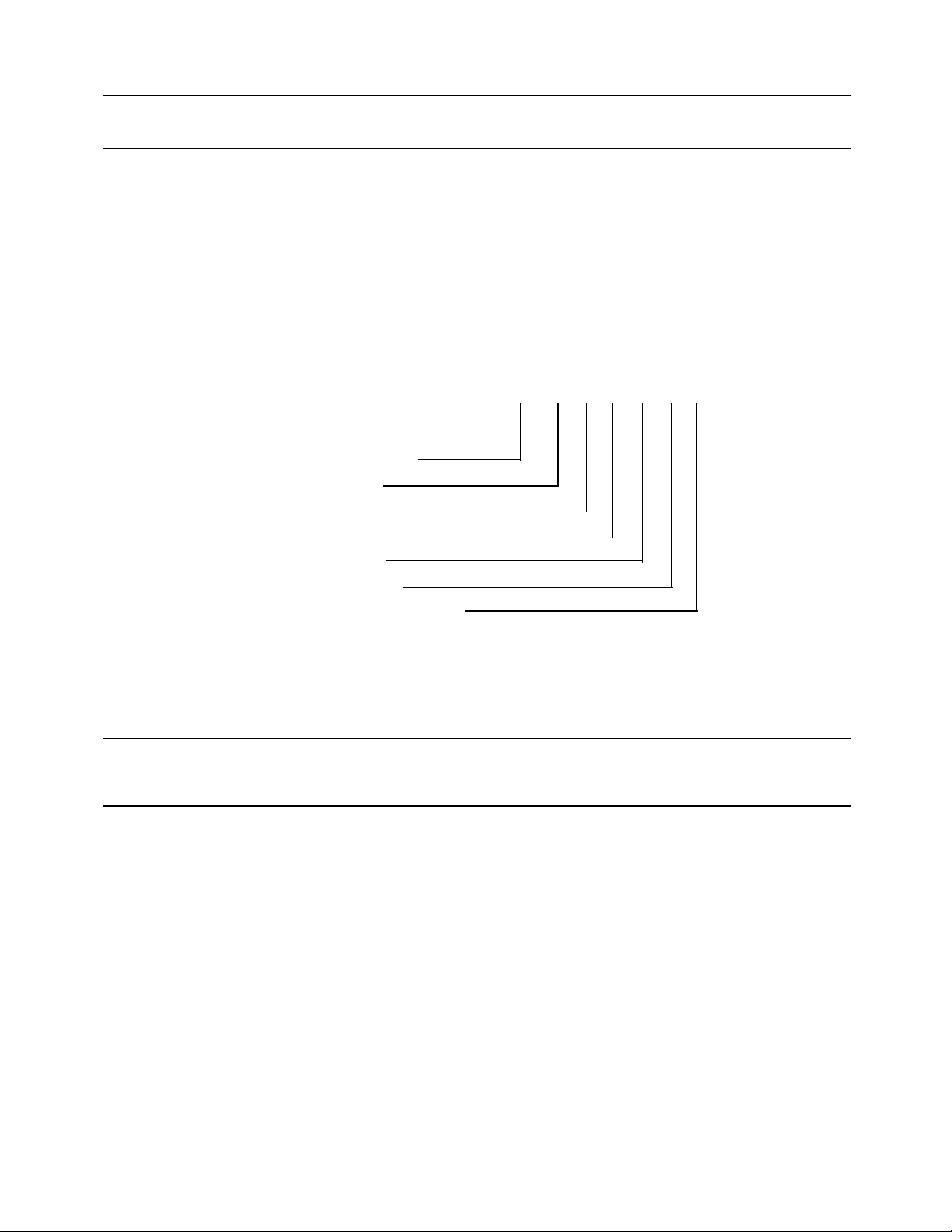

1-1 Location of Controller Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

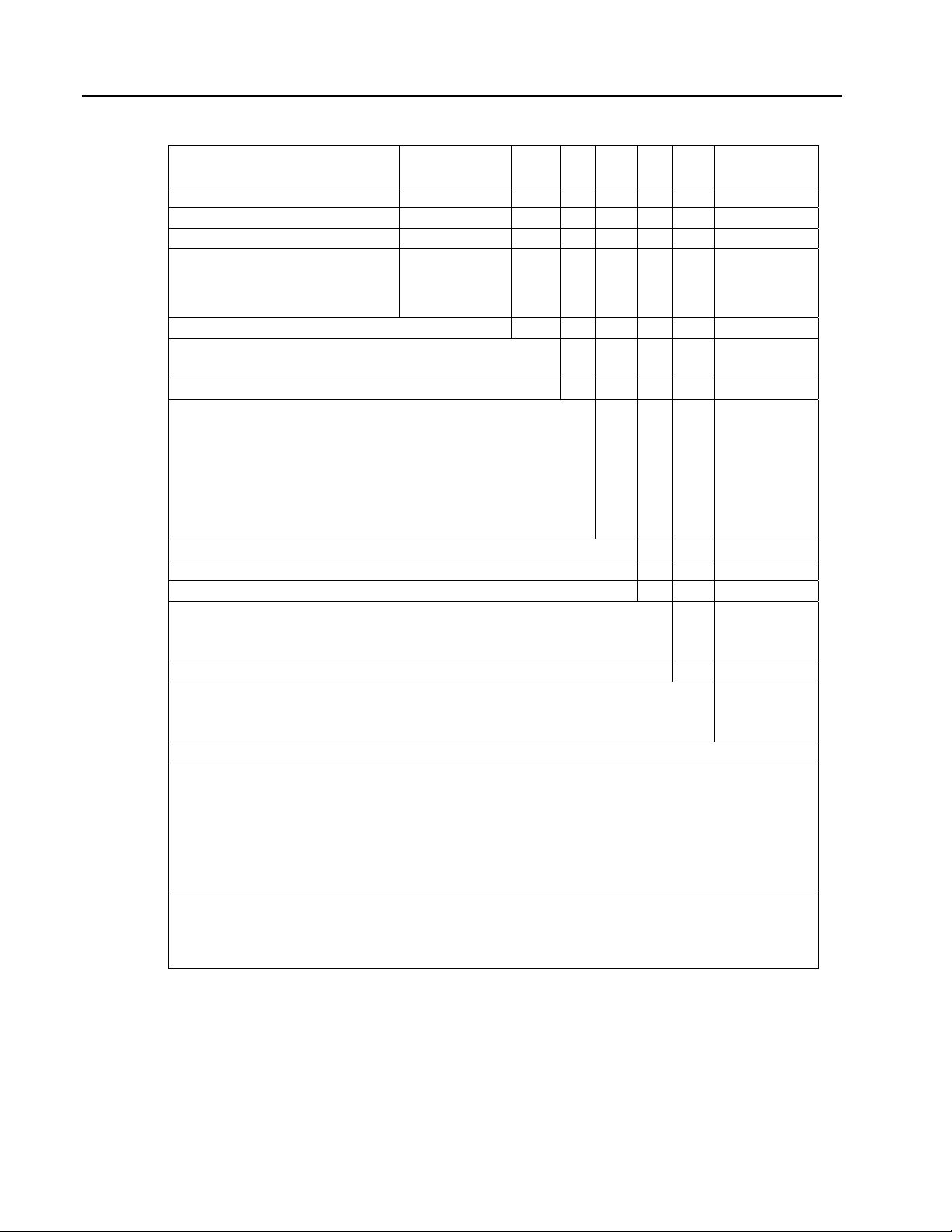

2-1 Example of an I/O Module Plan for a Controller Replacement . . . . . . . . . . . . . . . . 15

2-2 Example of an I/O Module Plan for a Math Unit Replacement . . . . . . . . . . . . . . . . 17

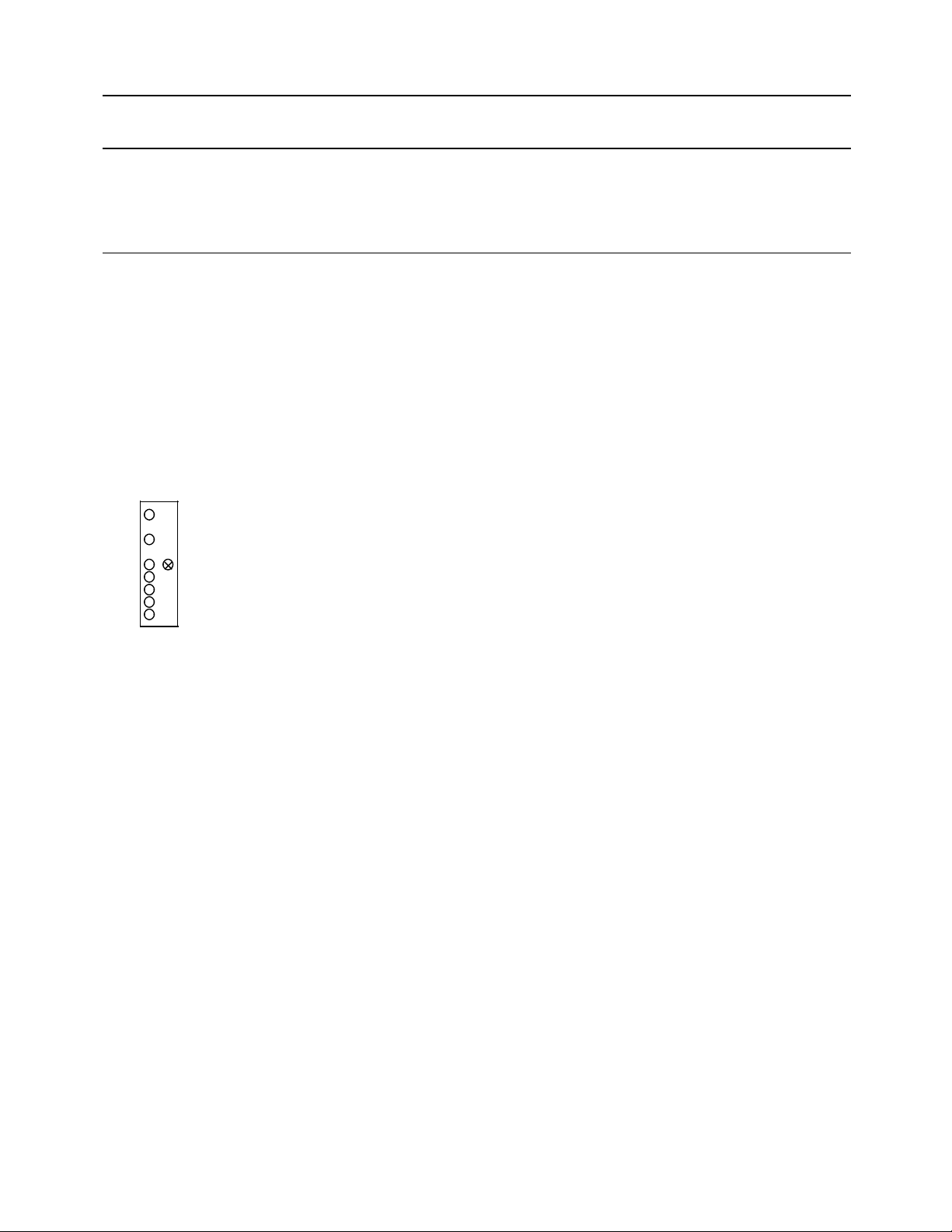

3-1 Communication Jumper locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-2 Removing Mod 30 Instrument Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-3 Location of Static Drain Clip on Replacement Instrument . . . . . . . . . . . . . . . . . . . 23

3-4 Cable Connector Locations in Back Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-5 Identification of Negative Terminals for Analog Input Numbers 3, 4, 5, 6, and Power 26

TABLES

Table Page

2-3 I/O Signals Assigned to Dedicated Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 I/O Signals which Share a Module Location - No ICN Module Installed . . . . . . . . . 13

2-3 I/O Signals which Share a Module Location - ICN Module Installed . . . . . . . . . . . . 13

ii

Page 5

1.1 OVERVIEW

1.1.1 The Product

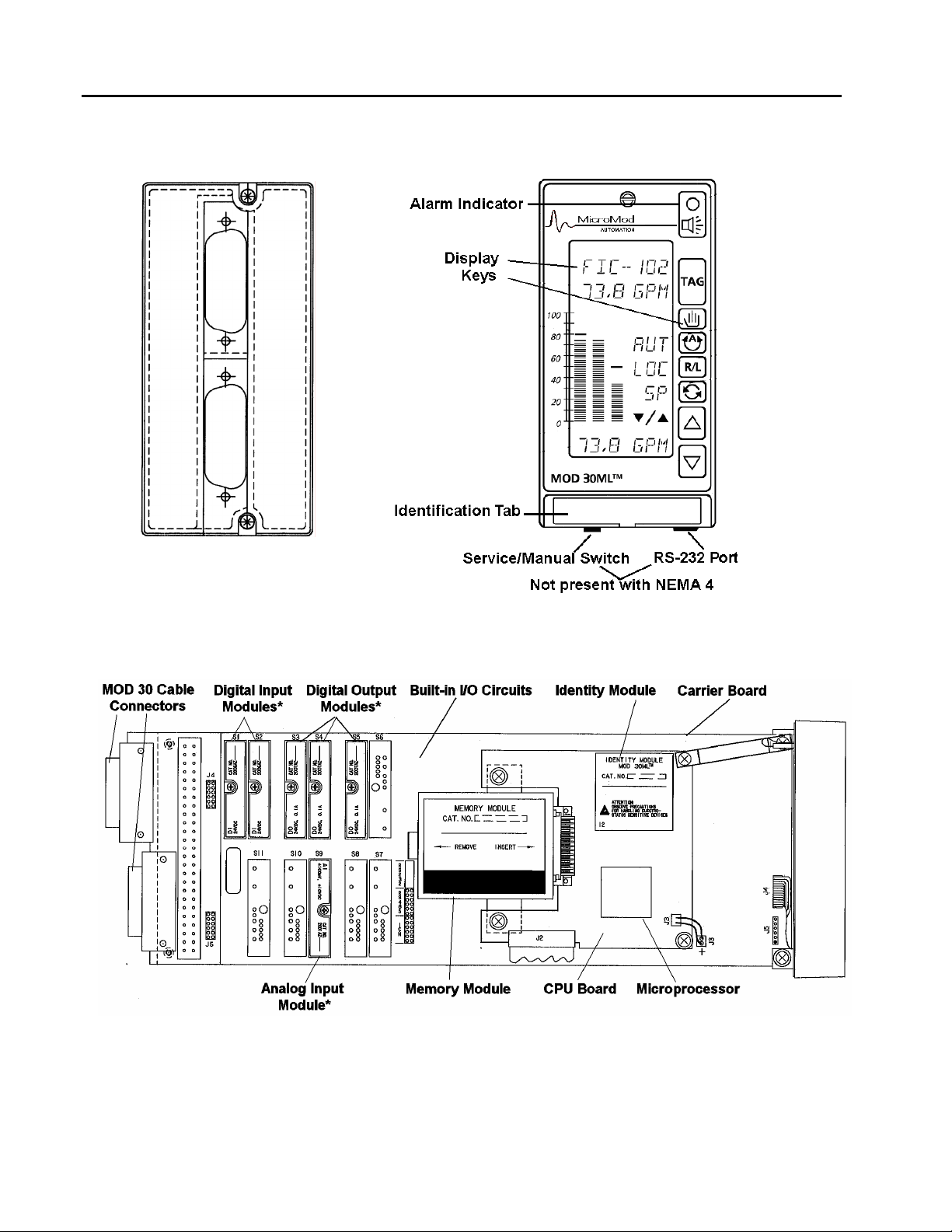

The MOD 30ML Replacement Instrument, Figure 1-1, can be used to replace an installed

MOD 30 instrument, or to expand an existing MOD 30 installation. The replacement is a

microprocessor based instrument which can be configured to perform all the PID,

mathematical, sequencing, and logic functions available in MOD 30 instruments. The front

panel display presents process variable, set-point, output, and other operational data in a

format similar to the MOD 30 instrument displays.

Features of the MOD 30ML replacement instrument are as follows:

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

SECTION 1

PRODUCT DESCRIPTION

• Can be installed in existing MOD 30 bezels or panel cutouts.

• Accepts Mod 30 plug-in cable connections.

• Can match all MOD 30 controller and indicator I/O configurations and many math unit

configurations with a combination of built-in I/O circuits and plug-in I/O modules.

• Communicates on the ICN.

• Front panel data base configuration capability.

• Provides extended data base configuration capability using Application Builder software

running on a personal computer and communicating via the ICN.

• An RS-232 port in the front panel permits easy connection of a portable computer for

data base configuration.

• An optional plug-in memory module provides the same data base backup and data

base transfer function as the MOD 30 memory module.

1

Page 6

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

Back of Housing

Front Panel

• These modules are factory

installed when ordering

option package 2.

2

Figure 1-1. Location of Controller Components

Page 7

1.1.2 Related Documents

Instructions on the operation and setup activities performed at the front panel of the

replacement instrument are found in the following document:

• IB-1800R-OPR Operation/Setup, MOD 30ML

Reference information on the data base structure and configuration parameters for the

replacement instrument can be found in the following documents:

• IB-1800R-APP Data Base Reference for MOD 30ML Functions

• IB-23G600 Data Base Reference for System, Logic, I/O and Communication Functions

• IB-23G601 Data Base Reference for Advanced Control Functions

• IB-23G602 Data Base Reference for Algorithms, Sequencers, and Table Functions

• IB-23H141 User’s Guide for Application Builder Software

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

Reference information on ICN/Link communications

following documents.

• IB-23A160 ICN Planning

• IB-23C001 ICN Communication Link Instruction Book for 1720N

• IB-23C003 ICN Mini Link Board Instruction Book for 1731N, 1732N

• IB-23C004 ICN Mini Link External Instruction Book for 1733N, 1732N

The following set of books is supplied as a bound set with the Application Builder Software

for the MOD 30ML:

• 98280-418 MOD 30ML Multiloop Controller User’s Guide

(includes binder, tabs, IB-1800R-INS, IB-1800R-OPR, IB-1800R-APP,

IB-23G600, IB-23G601, IB-23G602 and IB-23A160)

for this instrument can be found in the

3

Page 8

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

1.2 EXPLANATION OF CATALOG NUMBERS

The products described in this book have catalog numbers that help identify specific

features. In addition, some products are assigned a serial number which can be used to

track manufacturing data. The general format of the catalog number is described in this

section. Specific product descriptions are provided in the following sections.

The catalog number stamped on the product data plate contains a series of single and

multiple-character codes. These codes provide specific information concerning various

electrical and/or structural options. Certain code combinations are not allowed, and

options and combinations are subject to change. An example of a typical catalog number

is as follows:

Sample Catalog No. 1800R Z 10 0 2 0 A

Base Number

Unused

Electrical Code

Power

Options

Unused

Model/Design Level

1.3 BASIC HARDWARE

1.3.1 1800R With MOD 30 Termination Assembly.

The 1800R with MOD 30 termination assembly, Figure 1-1, is designed specifically for

replacement of installed MOD 30 instruments, or expansion of existing MOD 30

installations. The replacement instrument mounts in a MOD 30 bezel or panel cutout

using a mounting scheme that is essentially identical to that of the MOD 30 instruments.

Two cable connectors which accept the MOD 30 instrument cables are provided at the

back of the replacement instrument.

4

Page 9

The MOD 30 complement of analog and digital inputs and outputs are supported by a

combination of built-in and modular I/O in the replacement instrument. The built-in circuits

reside on the carrier board and provide two analog inputs and two analog outputs. The

modular I/O circuits are contained in plug-in I/O modules; they provide digital inputs, digital

outputs, and additional analog inputs. The carrier board provides the connection locations for

eleven I/O modules. Thus, a total of 15 I/O points (4 built-in and 11 modular) are available in

the replacement instrument. The modular I/O provides flexibility to vary the mix of digital

inputs, digital outputs, and analog inputs to fit specific replacement requirements. The

parameters of each replacement I/O point can be configured to match the parameters of the

corresponding MOD 30 point. A form of the replacement instrument is available with factory

installed I/O modules. The I/O complement of this form matches the full I/O complement of

the MOD 30 controller and controller XL..

Built-in ICN communications circuitry is provided on the carrier board. When required, the

replacement instrument can communicate on the ICN in the same manner as any MOD 30

instrument. When using a Communications Link to provide data to a personal computer, a

link firmware upgrade may be required to handle some new mnemonics from the

replacement instrument.

The built-in communications circuit can be used to support the RS-232 port in the front panel

instead of the ICN. This provides direct communication with a personal computer for data

base configuration. In this case, ICN communication can be provided by installing a 2030N

ICN Communications Module.

The replacement instrument CPU is based on the 16MHZ 68302 microprocessor. An identity

module (1800P) provides the functionality that gives the instrument the capability to execute

a user-configured database. The CPU supports 64K bytes of nonvolatile RAM for database

storage, and a time-of-day clock with battery support. A high speed communications channel

is used between the CPU and both the built-in I/O and any I/O modules installed on the

instrument. The CPU board provides for connection of a plug-in memory module.

1.3.2 1800P MOD 30ML IDENTITY MODULE

The identity module, Figure 1-1, gives the instrument a specific level of process and

communications functionality. The 1800P module is factory installed and provides the

capability to execute a user-configured database which consists of built-in and modular I/O

handling capabilities, PID functionality, and a collection of other control related functions.

which are available in MOD 30 instruments. These functions reside in a group of basic data

base elements called function blocks.

1.3.3 2010P MEMORY MODULE

The optional memory module plugs directly into the CPU board, Figure 1-1, and provides a

mechanism for porting a database from one replacement instrument to another. An

instrument with this option can upload from or download to this module. The memory module

has a write protect setting to prevent accidental erasures. When a memory module is

installed in an instrument with the write protection off, the operating software keeps the

module up-to-date with all real time changes in the instrument. Enhanced security is thereby

provided through this backup database copy. Data retention is more than 10 years with

instrument un-powered.

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

5

Page 10

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

Catalog Number Description for 1800R MOD 30 Retropak

MOD30 RETROPAK

Base Controller 1800RZ

Approvals

General Purpose 10

CE (European Community

destinations only) 12

Power Supply

24V dc 0

I/O Options - see Note 1

Standard I/O only (two universal 1

analog inputs, two current outputs)

Pre-installed I/O modules 2

(one additional analog input, 2 digital

inputs, 3 digital outputs)

Standard I/O only, NEMA 4, conformal coating 5

Not Used 0

Design Model

General Purpose, FM/CSA approval A

European Approval (CE Certification - B

for European Community destinations)

Programming / Special Features - see Note 2

None S T D

Configured to customer's MOD 30 specifications M 3 0

ACCESSORIES

ICN Termination Assembly (1 per ICN network) 2030FZ00001A

Portable Memory Module (optional) 2010PZ10000A

Upgrade to Version 2 Identity Module 1800PZ10102C

Housing & termination assembly only 1800FZ00002A

(no instrument) - MOD 30 conversion

Output Holder / Manual Loader (see S-MOD-1750N)

Configuration Software Visual Application

Designer - Refer to P-CS-MOD-Vizapp

Note 1: Pre-installed modules match MOD 30 1701R I/O. Other I/O combinations may be ordered by using

Standard I/O option and selecting additional modules from P-MOD-MODULES

____ __ __ __ __ __- __ __ __

0-6 07-08 09 10 11 12 13 14 15

1750NZ10001A

6

Note 2: Customer must provide existing database files and documentation. Excludes 1710R/1711R Sequence

and Logic Unit.

Page 11

1.4 I/O MODULES

The descriptions included in this section give a brief overview of the functions and

features of the I/O modules which can be used in a replacement instrument..

1.4.1 2001A Voltage Input Module

The voltage input module provides dual ranges of ±10V dc and ±100 mV dc. The 10V

dc range can be selected and scaled for 1 to 5 V dc by configuration to match the input of

MOD 30 instruments. Input to the module is scaled and then applied to an integrating

analog to digital converter. Line cycle integration can be performed at integrals of either 50

or 60 Hz line frequencies to reject any line frequency noise. Transformer isolation from

the +5 volt supply is used to derive all the internal voltages to run the isolated front end.

Optical isolation is used to transfer the information from the A/D converter serially to the

microprocessor. The microprocessor takes the raw A/D voltage, compares it to the

reference, and then presents it to the host as requested over the serial communications

bus. This module uses the Voltage/Current Input Module (VCIM) Block for configuration of

input parameters. The default configuration of this block provides the 1 to 5 V dc input

range.

VCIM

1

2

6

7

3

4

5

Catalog Number Description for 2001A

BASE NUMBER 2001A Voltage Input Module

UNUSED Z Unused Character

ELECTRICAL CODE 10 General Purpose, Kent-Taylor standard

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

INPUT RANGE 10 ±100 mV or ±10 Vdc

ISOLATION 1 Isolated

MODEL A Design Level

Sample Number 2001AZ10101A

7

Page 12

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

1.4.2 2006A Nonisolated Digital Input Module

The Nonisolated Digital Input Module accepts switch contact closures without external

power requirements. It is functionally equivalent to a digital input circuit in a MOD 30

instrument. This module uses the Digital Input Module (DIM) Block for configuration of

input parameters.

DIM

1

2

3

4

5

Catalog Number Description for 2006A

BASE NUMBER 2006A Nonisolated Digital Input Module

UNUSED Z Unused Character

ELECTRICAL CODE 10 General Purpose, Kent-Taylor standard

INPUT RANGE 10 2.2 V to 24 VDC

UNUSED 0 Unused Character

MODEL A Design Level

Sample Number 2006AZ10100A

1.4.3 2007A Nonisolated Digital Output Module

The Nonisolated Digital Output Module is primarily intended for instrument-to-instrument

signaling. The module interfaces 24-volt on/off signals with no isolation or works as an

open collector switch that also supports 5V TTL. This module uses the Digital Output

Module (DOM) Block for configuration of output parameters.

DOM

1

2

3

4

5

Catalog Number Description for 2007A

BASE NUMBER 2007A Nonisolated Digital Output Module

UNUSED Z Unused Character

ELECTRICAL CODE 10 General Purpose, Kent-Taylor standard

OUTPUT RANGE 10 24 V, 50 mA TTL

UNUSED 0 Unused Character

MODEL A Design Level

Sample Number 2007AZ10100A

8

Page 13

1.4.4 2030N ICN Communication Module

The ICN Communication module provides Instrument Communication Network (ICN)

communications capability for the instrument when the built-in communications circuit is

used to support the RS-232 communications port on the instrument front panel. The ICN

is a proprietary network that allows peer-to-peer communications between the

replacement instrument and MOD 30 Instruments. It also uses a communication link to a

computer running the Application Builder, or PC-30 Series Software or other operator

interface software. The ICN Baud rate is 31,250 bits per second. The Model B ICN

requires an external ICN terminator such as the 2030F ICN Terminator.

ICN

Catalog Number Description for 2030N

13

1

BASE NUMBER 2030N ICN Communication Module

14

2

6

8

7

9

3

10

11

4

12

5

UNUSED Z Unused Character

15

ELECTRICAL CODE 10 General Purpose, Kent-Taylor standard

16

17

UNUSED 000 Unused Character

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

MODEL A Design Level (includes termination relay)

B Design Level (removes termination relay)

Sample Number 2030NZ10000B

9

Page 14

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

10

Page 15

2.1 GENERAL

This section provides information for planning the replacement of installed MOD 30

instruments using the MOD 30ML Replacement Instrument. The principal factors to be

considered when making a replacement are as follows:

• The replacement applies to the instruments only. Most MOD 30 associated equipment

• A single MOD 30ML instrument (Catalog No. 1800R) is used to replace any MOD 30

• Two forms of the replacement instrument are available:

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

SECTION 2

REPLACEMENT CONSIDERATIONS

such as termination panels, field input boards, power supplies, etc. are required for

operation of the replacement instrument.

Controller, Controller XL, Indicator, Math Unit or Sequence and Logic Unit.

- Catalog No. 1800RZ_ _ _1_A is supplied without I/O modules. The user must

specify the modules required for the specific application, and install the modules

as part of the replacement procedure.

- Catalog No. 1800RZ_ _ _2_A is supplied with factory installed I/O modules to

fully match the I/O complement of the 1700R and 1701R controllers.

• The maximum possible I/O count for a MOD 30 instrument using both cables (i.e., a

1700N Math Unit) is 22 points. The maximum possible I/O count for the MOD 30ML is

15 points of which 11 points are provided by plug-in I/O modules. The modular nature

of these 11 points provides I/O flexibility to cover many replacement requirements.

• Some I/O module locations in the MOD 30ML can accept either an analog or digital

signal. When these locations are used for digital inputs, the corresponding analog input

negative terminal must be grounded to the power supply negative at the termination

panel (specific connection instructions are provided in Section 3).

• The output holder used with the MOD 30 controllers is not supported by the

replacement instrument.

• The replacement instrument is an indicating device; it cannot replace the MOD 30

recorder.

• If it is necessary to obtain both ICN communication and RS-232 communication for

data base configuration via the port in the front panel, a 2030N ICN module must be

installed.

• After completing installation of a replacement instrument, its data base must be

configured to match the functional requirements of the application. Configuration

information is provided in other documents; see Section 1.1.2.

11

Page 16

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

2.2 COMMUNICATIONS AND I/O SIGNALS

2.2.1 COMMUNICATIONS

A built-in communications circuit supports either the RS-232 port in the front panel or

communication over the ICN. If the built-in circuit is used for the RS-232 port, an ICN

module must be installed to support ICN communication. The communication options

are selected by positioning two jumpers. Specific instructions for locating the jumpers

are provided in Section 3.4.

Selection of the jumper positions is based on one of the following requirements:

•

Both ICN and RS-232 communication is required

provide modular ICN communication, and RS-232 communication via the built-in

circuit. A 2030N ICN Communications module must be installed in module

locations S7 and S8 to support the ICN. Note that use of this module reduces the

number of I/O signals which can be accepted as shown in Tables 2-2 and 2-3.

- The jumpers are located to

•

Only ICN communication is required

communication via the built-in circuit. Installation of an ICN module is not required.

The RS-232 port is not active.

•

Only RS-232 communication is required

232 communication via the built-in circuit. Installation of an ICN module is not

required because the ICN is not being used.

2.2.2 I/O Signal Availability

The I/O points available in the replacement instrument are distributed between built-in and

modular circuits as follows:

• Built-in circuits provide 4 points; 2 analog inputs, 2 analog outputs.

• I/O Modules provide the following points:

- 3 module locations are dedicated to digital input numbers 1, 2, and 3.

- 4 module locations are dedicated to digital output numbers 1, 2, 3, and 4.

- When the built-in communications circuit is used for the ICN, 4 module locations

can be used for analog inputs, digital inputs or digital outputs on a shared basis.

- When a communications module is used for the ICN, 2 module locations can be

used for analog inputs, digital inputs or digital outputs on a shared basis.

- The jumpers are located to provide ICN

- The jumpers are located to provide RS-

12

The MOD 30 I/O signals which are assigned to a specific I/O module or built-in circuit are

identified in Table 2-1. The signals which share assignment to an I/O module location with

1 or 2 other signals are as identified in Tables 2-2 and 2-3. The user must select one

shared signal for each module depending on the requirements of the application. As

shown in Table 2-3, the modules available to accept shared signals is reduced when an

ICN module is used.

Page 17

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

Table 2-1. I/O Signals Assigned to Dedicated Locations

Signal Location

Digital Input No. 1 Module Location S1

Digital Input No. 2 Module Location S2

Digital Input No. 3 Module Location S11

Digital Output No. 1 Module Location S3

Digital Output No. 2 Module Location S4

Digital Output No. 3 Module Location S5

Digital Output No. 4 Module Location S6

Analog Input No. 1 Built-in Volt Input No. 1

Analog Input No. 2 Built-in Volt Input No. 2

Analog Output No. 1 Built-in milliamp Output No. 1

Analog Output No. 2 Built-in milliamp Output No. 2

Table 2-2. I/O Signals Which Share a Module Location - No ICN Module Installed

Communications

//////// No. 5 No. 7 ////// Location S7

//////// No. 6 No. 6 No. 7 Location S8

//////// No. 3 No. 5 No. 6 Location S9

//////// No. 4 No. 4 No. 5 Location S10

Built-in ICN //////// //////// //////// ////////

Analog

Input

Digital

Input

Digital

Output

I/O Module

Location

Table 2-3. I/O Signals Which Share a Module Location - ICN Module Installed

Communications Analog

Input

ICN Module //////// //////// //////// Locations S7&S8

//////// No. 3 No. 5 No. 6 Location S9

//////// No. 4 No. 4 No. 5 Location S10

RS-232 Port //////// //////// //////// ////////

Digital

Input

Digital

Output

I/O Module

Location

13

Page 18

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

2.2.3 I/O Signal Specification Differences

In general the specifications for the replacement instrument are compatible with the MOD

30 instrument specifications. The following differences should be noted:

Specification MOD 30 Replacement

Current Requirements

Controller 0.55A max 0.63A max

Indicator 0.50A max 0.63A max

Math Unit 0.58A max 0.63A max

Digital input

High Level (Logic 1) 4.0V dc min 2.2V dc min

Low Level (Logic 0) 1.5V dc max 0.65V dc max

current load 3mA 2.5mA max

Digital Output

Voltage 30V dc max 24V dc max

Current 50mA max 100mA dc max

2.3 CONTROLLERS

The MOD 30 Controller and Controller XL require a single interconnecting cable to carry

power, ICN communication, and I/O signals between the instrument and the termination

panel. The replacement instrument uses this same cable. The full complement of 10 I/O

points and one communications point can be accommodated by the replacement

instrument. The controller I/O signals are as follows:

• 3 Analog Inputs

• 2 Analog Outputs

• 2 Digital Inputs

• 3 Digital Outputs

If the full I/O complement is required, the replacement instrument with factory installed I/O

modules (Catalog No. 1800RZ_ _ _2_A) should be used. The locations of the factory

installed modules, their catalog numbers, and I/O signals are shown on the planning form,

Figure 2-1. This form of the instrument simplifies the replacement procedure because the

user does not need to plan for and specify the required modules, and install the modules

when making the replacement.

If the full I/O complement is not required, the required I/O modules must be selected and

installed when making the replacement. Use the controller I/O module planning form to

record the selected modules and their locations. An example of the form filled in for a

controller having one digital input and 2 digital outputs is shown in Figure 2-1. Note that an

ICN communications module is specified so that both ICN and RS-232 communication are

supported (see Section 2.2.1). See Appendix A for a blank copy of the planning form.

14

Page 19

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

I/O MODULE PLANNING FORM FOR MOD 30 CONTROLLER

MOD 30ML Replacement for Controller No. FIC-102

Signal

Digital Input No. 1 S1 2006A

Digital Input No. 2 S2 2006A

Digital Output No. 1 S3 2007A

Digital Output No. 2 S4 2007A

Digital Output No. 3 S5 2007A

Analog Input No. 3 S9 2001A

Analog Input No. 1 & 2 Built-in

Analog Output No. 1 & 2 Built-in

Built-in Communication Built-in

ICN Module S7 & S8 2030N

I/O Module

Location

I/O Module

Catalog

No.

Module

Package*

(option 2)

////////// //////////

////////// //////////

//////////

No Module

Package

(check if

used)

X

X

X

X

RS-232

X

* Factory installed package.

Note: Locations S6, S10 and S11 are not used for a controller.

Figure 2-1 Example of an I/O Planning Form for a Controller Replacement

15

Page 20

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

2.4 INDICATOR

The MOD 30 indicator requires a single interconnecting cable to carry power and I/O

signals between the instrument and the termination panel. The replacement instrument

uses this same cable. The full complement of 5 I/O points can be accommodated by the

replacement instrument. The I/O signals are as follows:

• 3 Analog Inputs

• 3 Digital Outputs (Model B only)

The replacement instrument accepts analog inputs No. 1 and No. 2 via built-in input

circuits 1 and 2 as indicated in Table 2-1. An analog input module (Catalog No. 2001A)

must be installed in location S4 to provide the third analog input. Digital output modules

(2007A) must be installed in locations S3, S4 and S5 to provide digital outputs No. 1,

No. 2, and No. 3.

Since the MOD 30 Indicator does not communicate over the ICN, the replacement

instrument must be configured via the RS-232 port in the front panel (see Section 2.2.1).

2.5 MATH UNIT

The MOD 30 math unit requires two interconnecting cables to carry power, ICN

communication, and I/O signals between the instrument and the termination panel. The

replacement instrument uses both of these cables. The full I/O complement for the math

unit is as follows:

• 6 Analog Inputs

• 2 Analog Outputs

• 7 Digital Inputs

• 7 Digital Outputs

The 22 I/O points available in a math unit are not fully covered by the replacement

instrument which can accommodate only 15 I/O points. The combination of built-in and

modular I/O in the replacement instrument does accommodate many math unit I/O

combinations. For example, a possible arrangement using all 15 available points can

provide an I/O combination as follows:

• 4 Analog Inputs

• 2 Analog Outputs

• 5 Digital Inputs

• 4 Digital Outputs

16

In this example, 2 analog inputs and 2 analog outputs are accommodated by the built-in

I/O circuits. The remaining 11 points are handled by the modular I/O.

Use the Math Unit I/O planning form to record the required modules and their locations for

a specific application. An example of the form filled in to document the above example is

shown in Figure 2-2. Note that the built-in circuit is specified for the ICN so that all module

locations are available for I/O signals (see Section 2.2.1). See Appendix A for a blank

copy of the planning form.

Page 21

MOD 30ML Replacement for MOD 30 Instruments

PRODUCT DESCRIPTION

I/O MODULE PLANNING FORM FOR MOD 30 MATH UNIT

MOD 30ML Replacement for Controller No. FIC-101

Signal

Digital Input No. 1 S1 2006A

Digital Input No. 2 S2 2006A

Digital Input No. 11 S2 2006A

Digital Output No. 1 S3 2007A

Digital Output No. 2 S4 2007A

Digital Output No. 3 S5 2007A

Digital Output No. 4 S6 2007A

Analog Input No. 1 & 2 Built-in Volt Input ////////// //////////

Analog Output No. 1 & 2 Built-in mA Output ////////// //////////

Built-in Communication Built-in

ICN Module S7 & S8 2030N

I/O Module

Location

I/O Module

Catalog No.

Module Package*

(option 2)

//////////

No Module

Package (check if

used)

X

X

X

X

X

X

X

ICN

Communication

X No. 3* No. 7 /////

Using Builtin Circuit

Using ICN

Module

* Factory

installed

package

( ) Analog

Input

X No. 4 No. 6 No. 7

No. 5 X No. 5 No. 6

No. 6 X No. 4 No. 5

No. 3* No. 5 No. 6

No. 4 No. 4 No. 5

( ) Digital

Input

( ) Digital

Output

Module

Location

S7

S8

S9

S10

S9

S10

I/O Module

Catalog No.

2001A

2001A

2006A

2006A

Figure 2-2 Example of an I/O Planning Form for a Math Unit Replacement

17

Page 22

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT CONSIDERATIONS

18

Page 23

3.1 GENERAL

Read these instructions thoroughly before starting this procedure. Installation personnel

should be qualified technicians.

The replacement procedure involves:

• Unpacking the replacement instrument (Section 3.2)

• Installing I/O modules and optional memory module if used (Section 3.3)

• Setting up communications (Section 3.4)

• Removing the old MOD 30 instrument(Section 3.5)

• Installing the new replacement instrument (Section 3.6)

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

SECTION 3

REPLACEMENT PROCEDURE

3.1.1 Display

The display is protected by an overlay that can be removed after installation. The face of the

display, while made of scratch-resistant plastic, can be abraded by harsh materials such as paper

towels and industrial wipes. Lens cleaning tissues and soft cloths are suitable for cleaning displays.

3.1.2 Storage

The ambient temperature for any equipment kept in storage must be between –40 and+75°C (–40

and 167

°F)

3.2 UNPACKING THE REPLACEMENT INSTRUMENT

Unpack and visually inspect the instrument housing, instrument, and associated modules

for any damage. Save packing materials for any reshipment, or to support any claim of

shipment damage. All damage claims are made against the carrier and are the

responsibility of the customer.

Included in the shipping container is a bag containing the following items:

• Mounting brackets and retaining screws

• Static drain clip

• Cable connector mounting screws

• Information package

Instructions for assembly of the mounting bracket, static drain clip, and cable connector

mounting screws are provided in Section 3.6.1. The information package includes a card

containing several copies of a writeable instrument identification tag. Write required data

on the tag and insert it under the translucent strip at the bottom of the front panel after the

replacement instrument is installed.

19

Page 24

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

3.3 INSTALLING MODULES

The I/O modules mount on the carrier board, and the optional memory module mounts on

the processor board as shown in Figure 1-1. The I/O modules must be installed before

placing the controller into operation.

Each I/O module must be installed in a location which receives or transmits the

appropriate MOD 30 signal. The following procedure is based on the assumption that the

number of modules, the module types, and the location of each module has been

determined as described in Section 2.

* NOTE:

Install the modules as follows:

1. Loosen the 2 retaining screws in the front panel, Figure 1-1, and pull the

instrument out of its housing.

! CAUTION

If a MOD 30 controller is being replaced by the MOD 30ML Replacement

Instrument with factory installed I/O (Catalog No. 1800R Z___2_A), this

procedure is not required. Proceed to Section 3.4.

Support the instrument from the front and bottom or from the insulator

plate whenever the instrument is outside its housing. Do not allow the full

weight of the circuit boards to be suspended unsupported from the front

panel as this may overstress the brackets at that end.

2. Place the instrument on a flat surface with the front panel overhanging the

edge of the surface so that the black insulator plate is firmly supported. This

positioning assures that the instrument is not damaged by the force applied

when inserting I/O modules.

3. Plug each I/O module into its required location on the carrier board and

tighten the retaining screw.

4. If the optional memory module is being used, it can be plugged into the

location provided on the CPU board.

5. If ICN or RS-232 communication is to be used, go to Section 3.4, otherwise

continue with Step 6.

6. Insert the instrument into its housing and tighten the screws to draw the front

panel tight against the housing.

3.4 SETTING UP COMMUNICATIONS

Use this procedure to make the required communications available. See Section 2.2.1 for

detailed information about communication options.

1. If the instrument is in its housing, loosen the 2 retaining screws in the front panel,

Figure 1-1, and pull the instrument out of the housing.

2. If a 2030N ICN Communications module is required, install the module in locations S7

and S8 using the procedure described in Section 3.3

20

Page 25

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

3. Position the communication jumpers, Figure3-1, as follows:

• If an ICN Module is installed, place the jumpers as shown for ICN and RS-232.

• If the ICN is to use the built-in communication circuit (no ICN module), place the

jumpers as shown for ICN ONLY.

• If the ICN is not being used, place the jumpers as shown for RS-232 ONLY.

4. Insert the instrument into its housing and tighten the screws to draw the front panel tight

against the housing.

Communication Jumper Locations

ICN & RS-232 ICN Only RS-232 Only

21

Page 26

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

3.5 REMOVING OLD MOD 30 INSTRUMENT

The replacement instrument uses the cables in the existing installation. If there is a MOD

30 instrument installed in the location planned for the replacement, remove the MOD 30

instrument and its housing as follows:

1. Be sure the process is in a safe condition before removing the instrument.

2. Pull the MOD 30 instrument out of its housing.

3. Remove the back cover, Figure 3-2, from the housing.

4. Disconnect the drain wire from the static drain clip. If the drain wire is

connected to other MOD 30 instruments which are to remain installed, the

wire must remain in place to connect each of these instruments together and

to ground.

5. Remove the cable mounting screws to disconnect the cable(s) from the back

cover.

6. Loosen the retaining screws and remove mounting brackets from the top and

bottom of the housing.

7. From the front of the panel, remove the housing.

22

Page 27

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

Figure 3-2. Removing MOD 30 Instrument Housing

Figure 3-3. Location of Static Drain Clip On Replacement Instrument

23

Page 28

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

3.6 INSTALLING NEW MOD 30ML REPLACEMENT INSTRUMENT

After removing a MOD 30 instrument, the replacement instrument can be installed

in the same panel or bezel opening and connected to the existing MOD 30 cables

using the following procedures.

3.6.1 Mounting

1. If the replacement instrument is not in its housing, insert the instrument and

2

. From the front of the panel, insert the instrument into the panel or bezel

3. From the back of the panel, insert mounting brackets into the slots in the

4. Tighten retaining screws to hold instrument in place. Use torque of 5 inch-

5

. Remove the back cover from the mounted instrument and install the static

tighten the screws to draw the front panel tight against the housing. It is

recommended that the housing be mounted with the instrument installed.

This improves the housing rigidity and helps prevent the possibility of

distortion when the mounting screws are tightened.

opening.

top and bottom of the housing

pounds (0.6 Nm), or turn each screw 1-1/2 turns after contact is made with

the back of the panel.

drain clip on the back of the housing (the clip is supplied with the

instrument). Locate the clip near the upper right corner as shown in Figure

3-3. This location aligns the clip with a recess in the back cover allowing

the cover to seat properly against the back of the housing with the clip

installed.

.

24

6

. Connect the MOD 30 J1 cable to the J1 location in the back cover, Figure

3-4. The cable is attached to the cover using two mounting screws as

shown in Figure 3-2 (cable mounting screws are supplied with the

instrument). Two cables are used when a math unit is replaced; connect

the second cable to location J2

7. Mount the back cover with attached cable on the instrument housing. The

cable connectors must mate with the connectors on the instrument circuit

.

board

8. Connect the existing drain wire to the static drain clip on the back of the

replacement instrument. The drain wire must connect the replacement

instrument to all other instruments and to ground.

.

Page 29

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

J1

J2

Figure 3-4. Cable Connector Locations In Back Cover

3.6.2 Electrical Connections

The required power, ICN communication, and I/O signal connections to the replacement

instrument are made via the cables which are installed as part of the mounting procedure.

! CAUTION

The negative analog and power terminals are identified in Figure 3-5. The required

connections are as follows:

• To use module location S7 for a digital signal, ground Analog Input 5 negative.

• To use module location S8 for a digital signal, ground Analog Input 6 negative.

• To use module location S9 for a digital signal, ground Analog Input 3 negative.

• To use module location S10 for a digital signal, ground Analog Input 4 negative.

* NOTE:

If I/O module location S7, S8, S9, or S10 is used for a digital input or

output, the negative terminal of the alternate analog signal which can use

the location must be grounded to the negative power supply terminal at

the termination panel, and the positive terminal of the analog signal must

be open circuited.

Before putting the instrument into operation, it must be configured using either

the front panel keys or the 2006S Application Builder software. See Section

1.1.2 for related documents.

25

Page 30

MOD 30ML Replacement for MOD 30 Instruments

REPLACEMENT PROCEDURE

Power

Analog

Input No. 3

Analog

Input No. 4

Analog

Input No. 5

Analog

Input No. 6

1720F Termination Panel Section

Connected to J1 on Instrument

1720F Termination Panel Section

Connected to J2 on Instrument

Figure 3-5. Identification of Negative Terminals for Analog Input Numbers 3, 4, 5, 6, and Power

26

Page 31

A.1 GENERAL

The forms included in this appendix may be copied as necessary to record the I/O module

layout for MOD 30ML replacement instruments used to replace MOD 30 controllers and

math units.

MOD 30ML Replacement for MOD 30 Instruments

APPENDIX A

APPENDIX A

PLANNING FORMS

27

Page 32

MOD 30ML Replacement for MOD 30 Instruments

APPENDIX A

I/O MODULE PLANNING FORM FOR MOD 30 CONTROLLER

MOD 30ML Replacement for Controller No.

Signal

Digital Input No. 1 S1 2006A

Digital Input No. 2 S2 2006A

Digital Output No. 1 S3 2007A

Digital Output No. 2 S4 2007A

Digital Output No. 3 S5 2007A

Analog Input No. 3 S9 2001A

Analog Input No. 1 & 2 Built-in

Analog Output No. 1 & 2 Built-in

Built-in Communication Built-in

ICN Module S7 & S8 2030N

I/O Module

Location

I/O Module

Catalog

No.

Module

Package*

(option 2)

////////// //////////

////////// //////////

//////////

No Module

Package

(check if

used)

* Factory installed package.

Note: Locations S6, S10 and S11 are not used for a controller.

28

Page 33

MOD 30ML Replacement for MOD 30 Instruments

I/O MODULE PLANNING FORM FOR MOD 30 MATH UNIT

MOD 30ML Replacement for Controller No.

APPENDIX A

Signal

Digital Input No. 1 S1 2006A

Digital Input No. 2 S2 2006A

Digital Input No. 11 S2 2006A

Digital Output No. 1 S3 2007A

Digital Output No. 2 S4 2007A

Digital Output No. 3 S5 2007A

Digital Output No. 4 S6 2007A

Analog Input No. 1 & 2 Built-in Volt Input ////////// //////////

Analog Output No. 1 & 2 Built-in mA Output ////////// //////////

Built-in Communication Built-in

ICN Module S7 & S8 2030N

I/O Module

Location

I/O Module

Catalog No.

Module Package*

(option 2)

//////////

No Module

Package (check if

used)

Communication

No. 3* No. 7 /////

Using Builtin Circuit

Using ICN

Module

* Factory

installed

package

( ) Analog

Input

No. 4 No. 6 No. 7

No. 5 No. 5 No. 6

No. 6 No. 4 No. 5

No. 3* No. 5 No. 6

No. 4 No. 4 No. 5

( ) Digital

Input

( ) Digital

Output

Module

Location

S7

S8

S9

S10

S9

S10

I/O Module

Catalog No.

29

Page 34

MOD 30ML Replacement for MOD 30 Instruments

APPENDIX A

30

Page 35

Page 36

The Company’s policy is one of continuous product improvement and the right

is reserved to modify the information contained herein without notice, or to

make engineering refinements that may not be reflected in this bulletin.

Micromod Automation assumes no responsibility for errors that may appear in

this manual.

© 2004 MicroMod Automation, Inc. Printed in USA

IB-1800R-M30, Issue 2 12/2004

MicroMod Automation, Inc.

75 Town Centre Drive

Rochester, NY USA 14623

Tel. 585-321 9200

Fax 585-321 9291

Loading...

Loading...