Page 1

ICN OPC Server User’s Guide

ABB Inc.

Page 2

The Company

ABB Inc.

ABB Inc. is an established world force in the design and manufacture of instrumentation

for industrial process control, flow measurement, gas and liquid analysis and

environmental applications.

As a part of ABB, a world leader in process automation technology, we offer customers

application expertise, service and support worldwide.

We are committed to teamwork, high quality manufacturing, advanced technology and

unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100

years experience, combined with a continuous program of innovative design and

development to incorporate the latest technology.

The NAMAS Calibration Laboratory No. 0255(B) is just one of the ten flow calibration

plants operated by the Company, and is indicative of ABB Inc.'s dedication to quality and

accuracy.

BS EN ISO 9001

ISO 9001

EN 29001 (ISO 9001)

St Neots -

Certificate No. Q5907

Stonehouse -

Certificate No. FM 21106

Rochester, USA -

Certificate No. AQ-8618

Lenno, Italy -

Certificate No. 90/90A

Stonehouse -

Certificate No. 0255

Use of Instructions

Warning. An instruction that draws attention to the risk of

injury or death.

∆

Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

!

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process system

performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for any

other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of ABB Inc..

Note. Clarification of an instruction or additional

information.

Information. Further reference for more detailed

information or technical details.

i

Licensing, Trademarks and Copyrights

MODCELL, MOD 30 and MOD 30ML are trademarks of ASEA Brown Boveri, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning Labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given or injury or death could result.

4. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

Page 3

1

Introduction

1.1 Introduction

ICN OPC Server is an Industrial IT enabled software product. It is an OPC Foundation

compliant server application (serial communications device interface) that allows

hardware devices to communicate with OPC Clients such as ABB Operate IT Products

and other software manufacturer's HSI packages like ICONICS’ Genesis32, Intellution's

FIX Dynamics and similar packages from Wonderware, CI Technologies and others. For

client software packages that are not OPC compliant, the server also supports dynamic

data entry (DDE) type links. ViZapp, Visual Application Designer, is also an OPC Client

that can use this OPC server to communicate with the devices it configures. The OPC

server handles the reading and writing of the device data. See Overview of OPC based

configuration for steps involved in configuring the client and server.

This OPC server supports MODCELL and MOD 30ML Controllers and MOD30

Instruments such as Controller, Recorder, Math Unit and Sequence and Logic Unit (SLU)

using the ICN (Instrument Communication Network) communication protocol.

The server is used to build the tag database that contains information about the tags such

as tag name, address, device (instrument) from which they are coming and communication

port settings. Any OPC Client application, such as OPC based HMI Software, can plug

and play with this and present the data to the user.

An OPC Client is included in the ABB ICN OPC Server. This monitor client is useful for

viewing live data and determining if configured tags are receiving correct data from the

hardware.

1.2 Definitions

1.2.1 ICN Protocol

ICN (Instrument Communication Network) is a master-less token passing protocol. It is

used for Peer-to-peer communication between the members on the ICN. It can also be

used for communication to host devices such as Computer and LCP (Local Control Panel).

The maximum number of devices on the ICN is 16. Each device should have a unique

address in the range of 0 – F Hex (0 – 15). Each device on the network is assured access to

the token every 250 ms. The device can receive or transmit messages or data when it has

the token.

1 - 1

Page 4

ICN OPC Server Guide

Introduction

1.2.2 Mini-link and Mini-link External

Mini-link Internal (1731 and 1732N) or Mini-link External (1733N) is used for connecting

the ICN to a host computer. It is also considered to be a member on the ICN. The Minilink Internal is plugged into an ISA slot of the Personal Computer where as Mini-link

External is connected to a serial port of the Personal Computer. Boh types of Mini-links

can connect up to 2 ICNs. The Mini-link External has 2 serial ports (9 pin and 25 pin) for

connection to computers.

1.2.3 Built-in OPC Client

An OPC Client application is built-in with the ICN OPC Server for monitoring and

testing your Server’s configuration. It is this part of the OPC application that collects

data received by the OPC Server and presents to the user. The data presented by the

OPC Client is live.

OPC Client is useful for testing the communication between the devices and the OPC

Server. It can also be used for testing other 3rd party OPC applications connected to the

server.

1 - 2

Page 5

2

Installation

2.1 Objectives

This chapter explains the installation procedure for the ICN OPC Server.

2.2 System requirements:

For running the ICN OPC Server, you need the following computer configuration and

software installed:

• Pentium 300 MHz or faster processor with 64 MB RAM.

• At least 100 MB of available hard disk space.

• CD ROM Drive (at least 4 speed, higher speed recommended)

• A SVGA monitor or better.

• Windows 2000 or Windows XP or Microsoft Windows NT 4.0. Service Release

4.0 or higher with Service Pack 5 or higher or Microsoft Windows 98 Second

Edition or Microsoft Windows 95 B Release with DCOM

• A mouse or other compatible pointing device.

2 - 1

Page 6

ICN OPC Server Guide

Installation

2.3 Instructions:

The following procedure explains how to install ICN OPC Server on your computer. Start

your Microsoft Windows operating system.

Windows 95 needs DCOM (Distributed COM) for running the ICN OPC Server. The

ICN OPC Server setup will detect if DCOM was already installed on your computer. If

DCOM was not present, it will install it.

This is an issue with only Windows 95. If DCOM was already present in your Windows

95 system and is of a lower version, ICN OPC Server setup will update it.

Note also that DCOM is also installed as part of Internet Explorer 5.0 or higher and some

other programs.

ICN OPC Server also requires a software component called the OPC Data Access

Components.

The above programs are installed by ICN OPC Server in the background during the Setup

and do not require any user inputs.

Close all applications that are running in your computer currently before starting the

ICN OPC Server setup. If a previous installation of the software exists, you will be

prompted to choose an option from the list: Modify, Repair and Remove.

2.3.1 ICN OPC Server Setup

1. Insert the ICN OPC Server CD into the CD-ROM drive.

In most computers where auto run is enabled, the setup will start automatically as soon as

you put the ICN OPC Server CD in the drive and close the drive. If auto run is not enabled

in your computer you will need to run it manually.

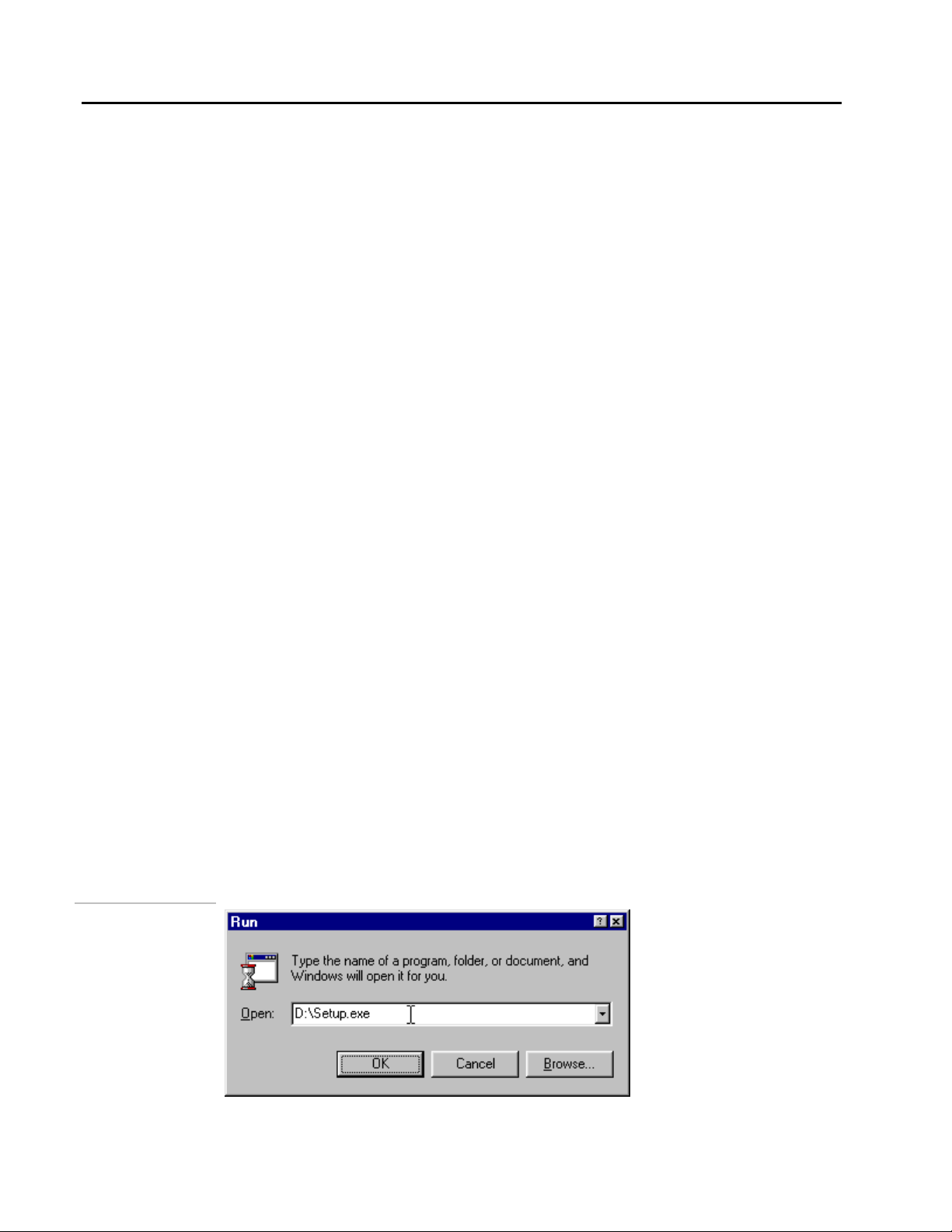

To run the setup manually, select Run from the Start Menu of Windows. The Run dialog

box will appear as shown below:

Figure 2 .1.

Run dialog box

2 - 2

Page 7

Type D:\SETUP.EXE or E:\SETUP.EXE, (CD DriveLetter:\Setup.exe depending on

2. The ICN OPC Server Setup introductory screen displays briefly while installation is

Figure 2 .2.

ICN OPC Server

Setup

the letter you use for the CD-ROM drive) and click on OK or press

initiating.

ICN OPC Server Guide

Installation

ENTER.

3. The following message will be displayed if you are installing the ICN OPC Server under

Windows 95.

Figure 2 .3.

ICN OPC Server

Setup

The features that are not supported under Windows 95 and 98 are:

• Visual properties such as color and texture of the blocks in the function block

diagram.

• Memory management – limitation on the number of documents you can have in a

project or workspace. This is due to the limitations in the operating system.

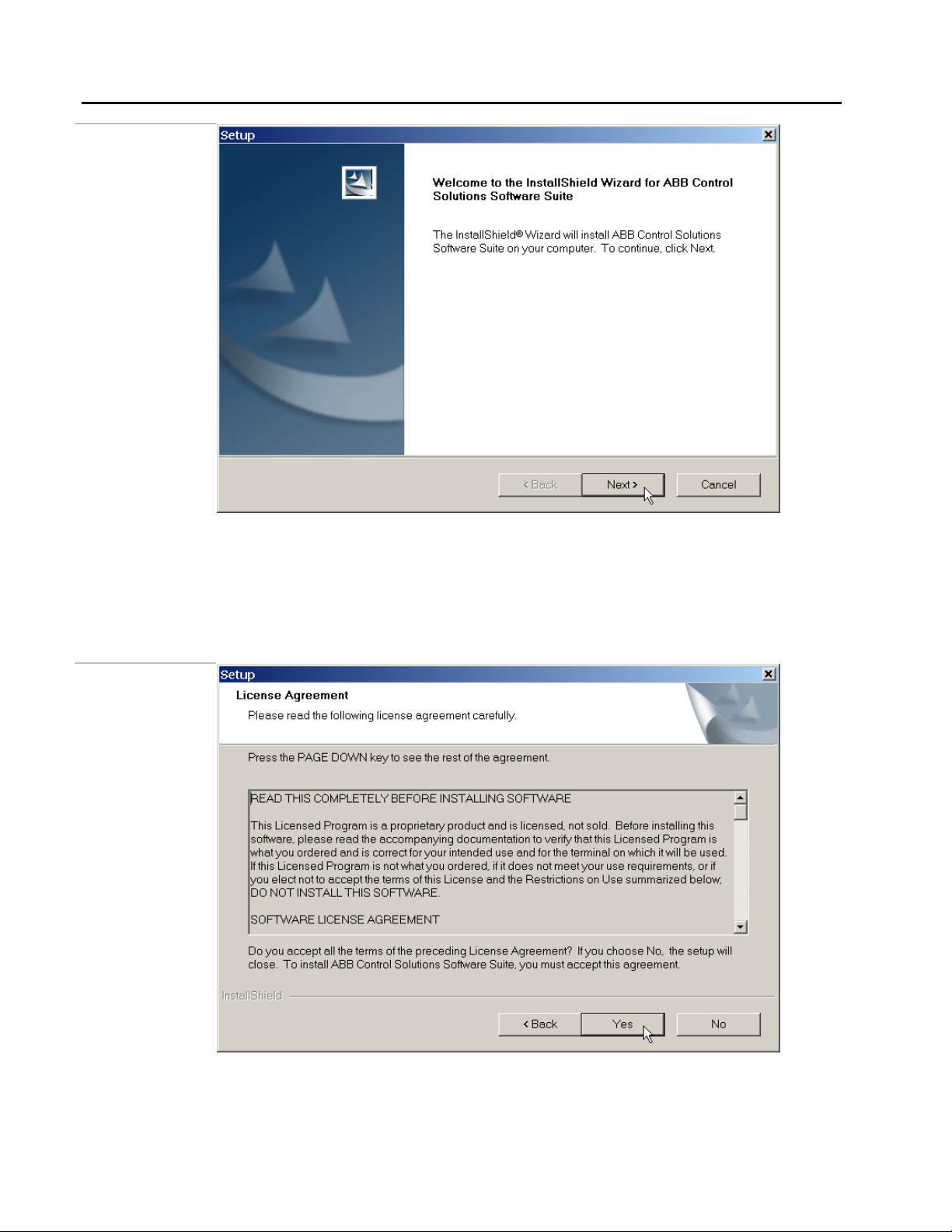

The setup will display the Welcome dialog box as shown below. Click on Next to

continue.

2 - 3

Page 8

ICN OPC Server Guide

Installation

Figure 2 .4.

ICN OPC Server

Setup -Welcome

4. ABB Software License Agreement will be displayed next and will display the legal

information about using the ICN OPC Server Software. Click on Yes if you accept the

agreement. Clicking on No will terminate the Setup. Refer to the next figure.

ABB Software License Agreement is a legal document. Read it carefully before

clicking on Yes.

Figure 2 .5.

ICN OPC Server

Setup –ABB license

Agreement

2 - 4

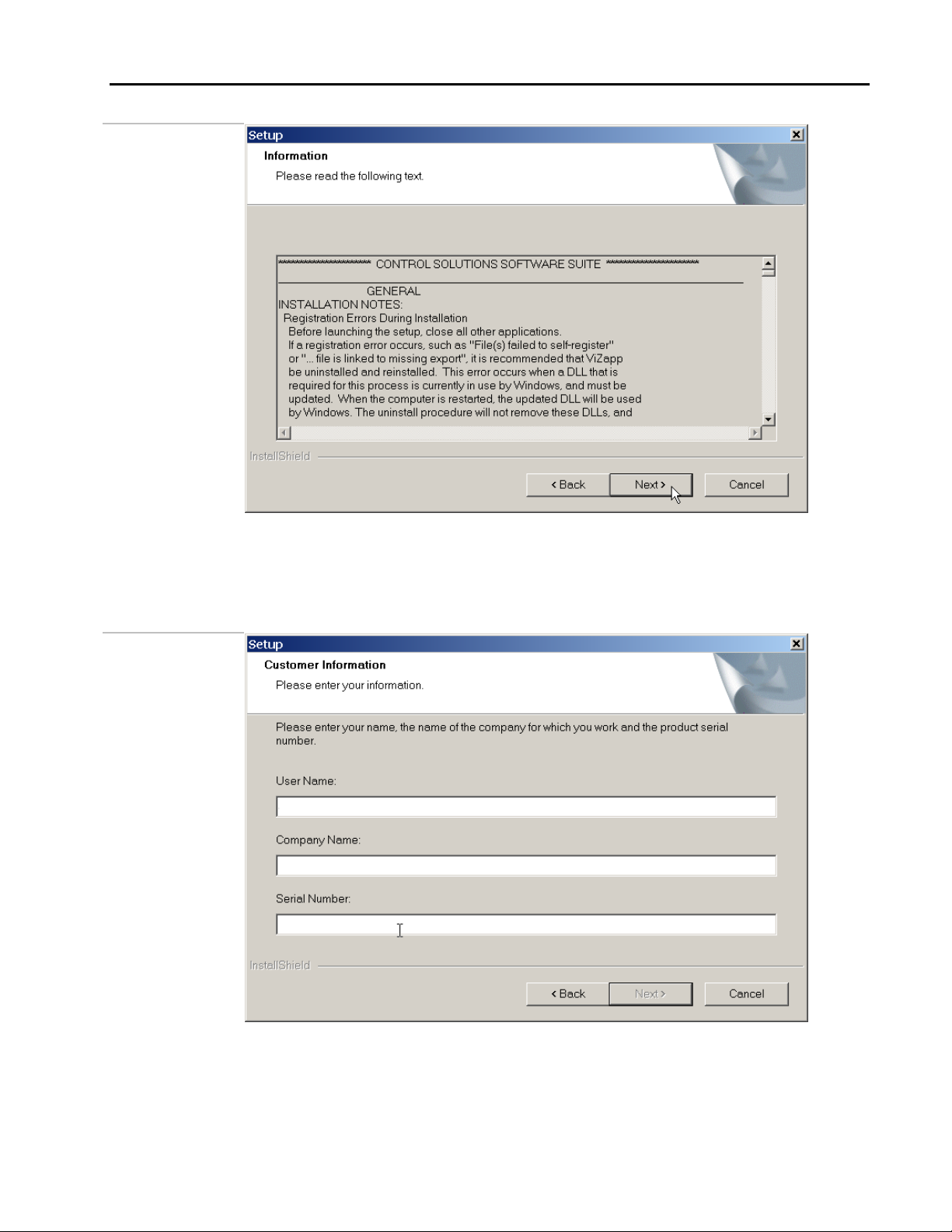

An Information dialog box will be displayed next as shown in the next figure:

Page 9

Figure 2 .6.

ICN OPC Server

Setup –Information

ICN OPC Server Guide

Installation

5. Enter User Information: The User Information dialog box will be displayed next as

Figure 2 .7.

ICN OPC Server

Setup –Destination

Location

shown below. Type your name, company name and the serial number. This serial number

can be found on the CD case or the ICN OPC Server package you received. Click on Next

to continue.

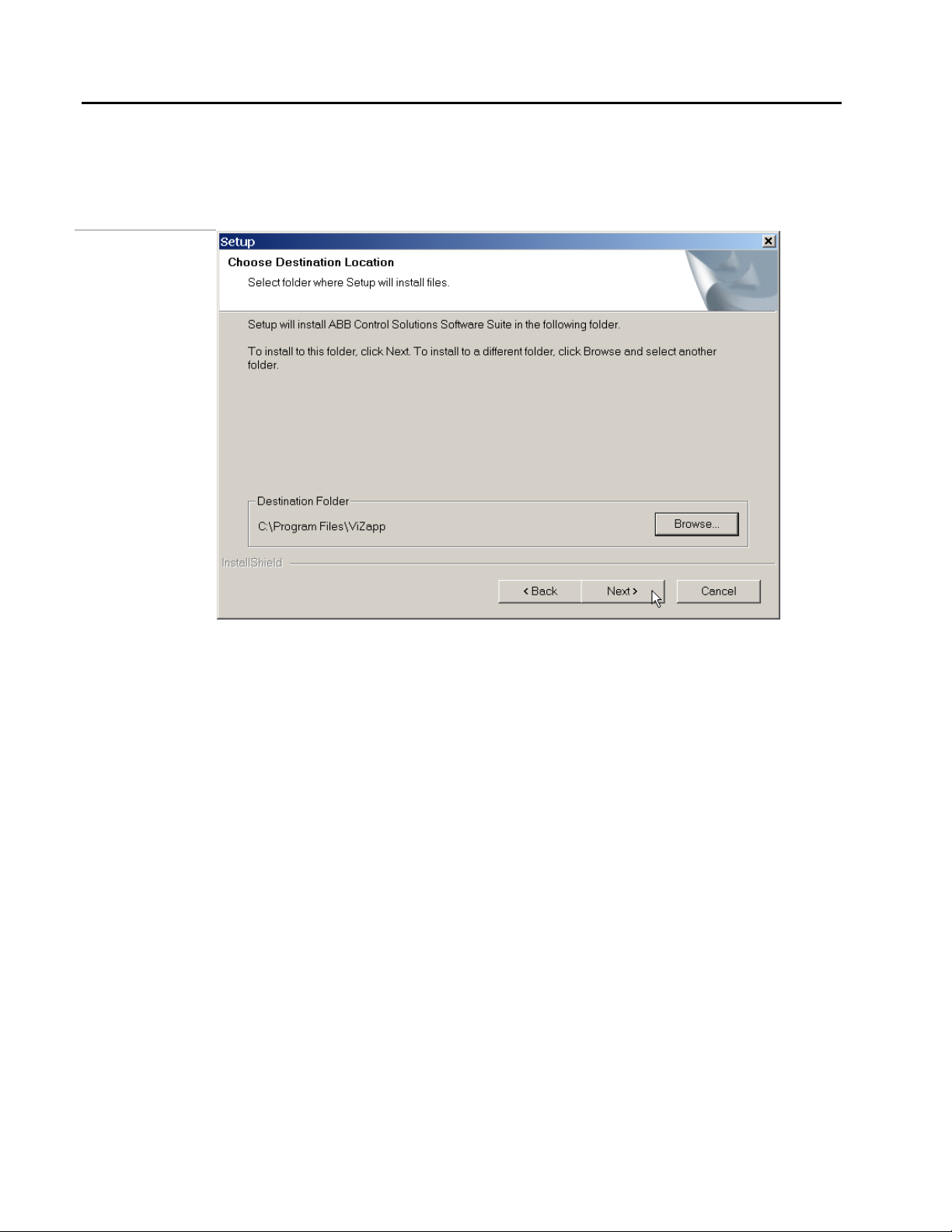

6. The Choose Destination Location dialog box will be displayed next as shown in the next

figure. We will choose the default location for the setup. Click on Next to continue.

2 - 5

Page 10

ICN OPC Server Guide

Installation

If you want to install ICN OPC Server onto a different folder, click on the Browse

button to open the Choose Folder dialog box and then browse to the desired folder or

create a new folder by typing its name in the Path field.

• Click on OK to continue.

Figure 2 .8.

ICN OPC Server

Setup –Choose

Destination

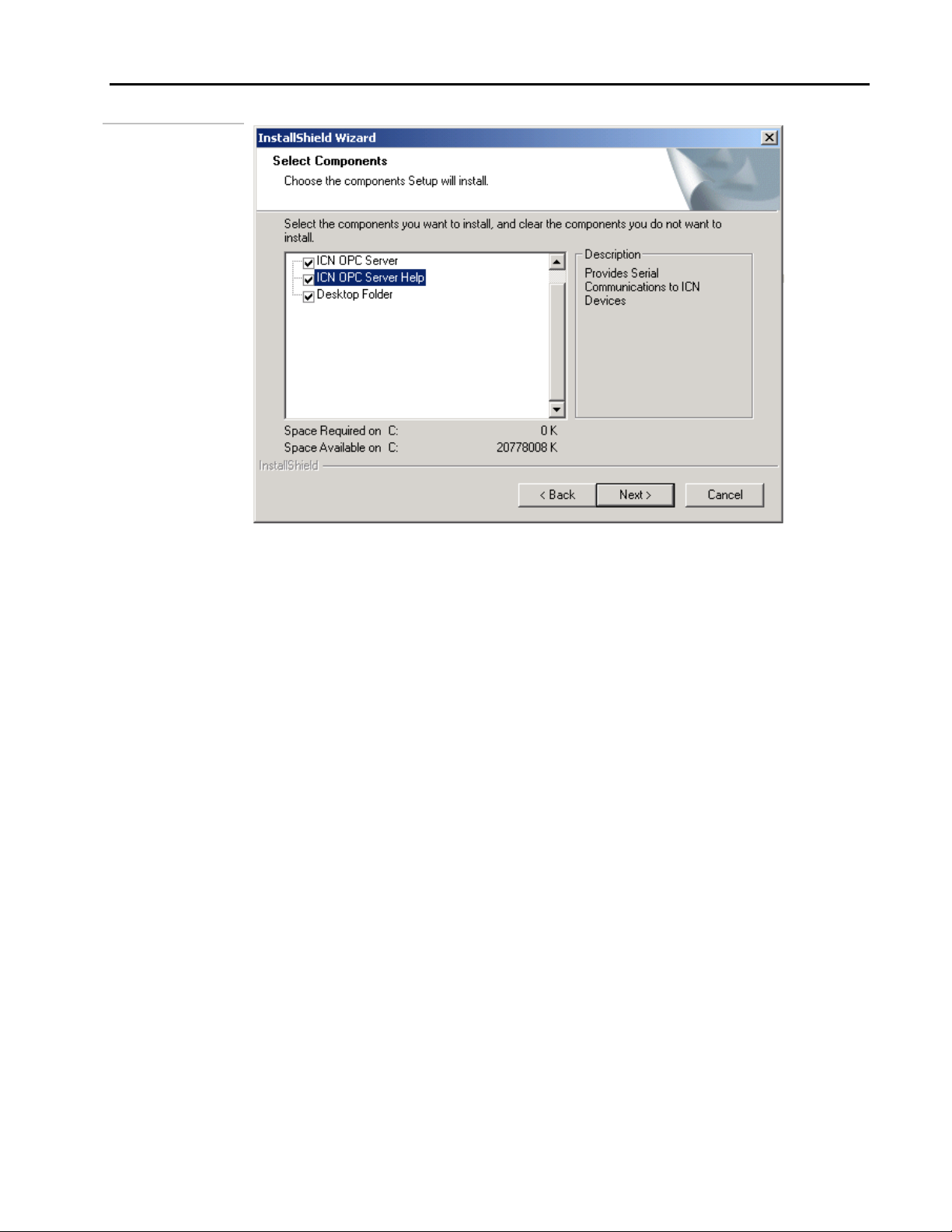

7. Select Components for installation: The ICN OPC Server Software package consists of

the main software and a few options. You can choose the options at the time of setup. By

default, all available options are selected, except for On-line Documentation.

These options will be displayed as check boxes on the dialog box. See the next figure for

example.

This dialog box also shows the space required on the hard disk to install the selected

options and the total free space on the disk. Accept the defaults and then click on Next to

continue.

2 - 6

Page 11

Figure 2 .9.

ICN OPC Server

Setup –Select

Components

ICN OPC Server Guide

Installation

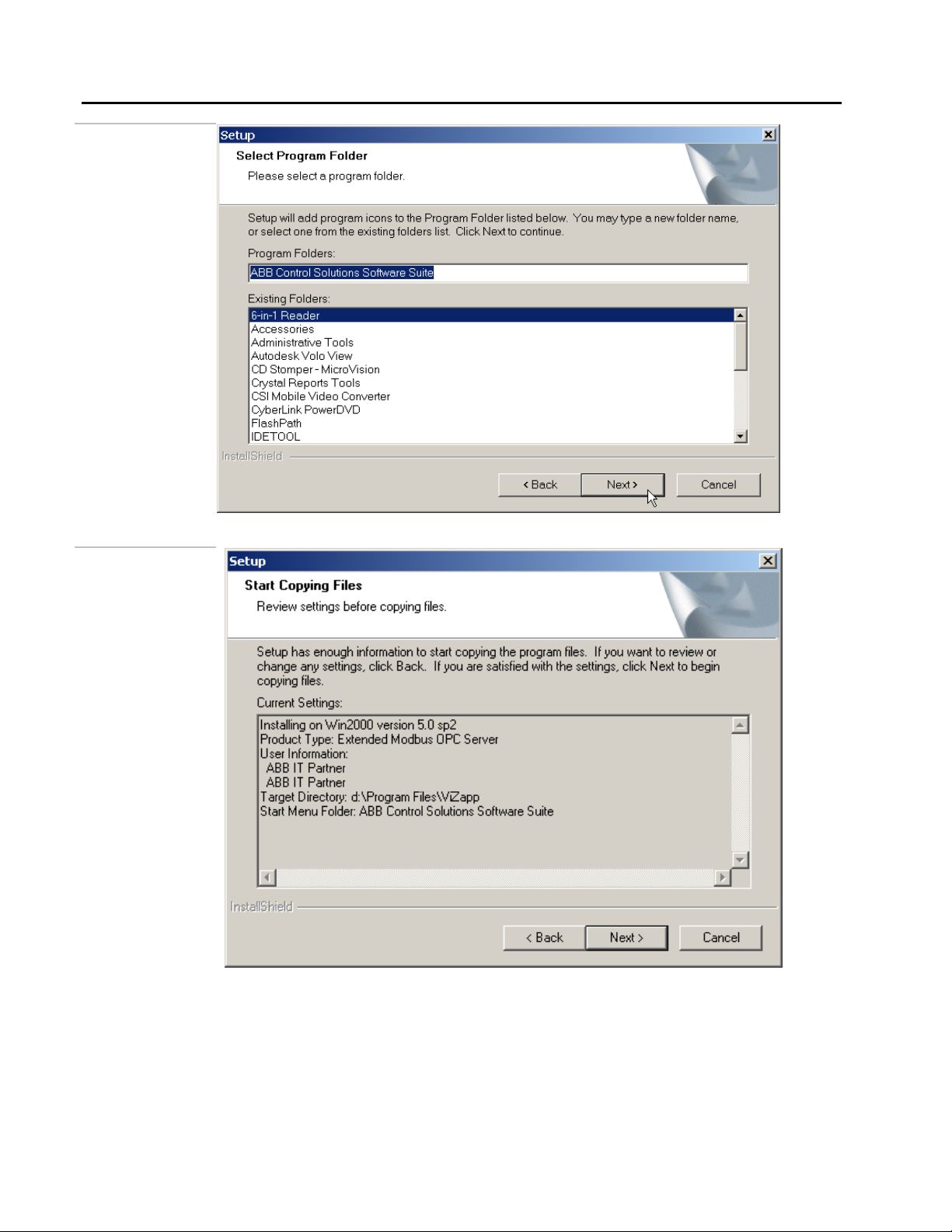

8. Choose the Program Folder: The ICN OPC Server setup will also create a program

folder and will create program shortcuts inside that folder. You can use these shortcuts to

start the programs. The default program folder that will be automatically created will be:

ABB Control Solutions Software Suite.

If you want to create a new program folder you can type its name in the Program

Folders field on this dialog box. If you want to use one of the existing program

folders, you can choose it from the Existing Folders list box on this dialog box by

clicking on it.

2 - 7

Page 12

ICN OPC Server Guide

Installation

Figure 2 .10.

ICN OPC Server

Setup –Select

Components

Figure 2 .11.

ICN OPC Server

Setup –Program

Folder

• Click on Next to continue.

2 - 8

9. The ICN OPC Server Setup will display the Start Copying Files dialog box next as

shown in the figure above. This dialog box will display the settings you have selected.

Click on Next to continue.

Page 13

Figure 2 .12.

ICN OPC Server

Setup

10. The setup will start now and will display a progress bar as shown above. After the Setup

copied all the required files, the following Information box will be displayed.

The ICN OPC Server CD contains all the technical documentation in Adobe PDF

format. If your system does not have Adobe Acrobat Reader installed already, you can

install it from the CD after the ICN OPC Server Setup completes.

Figure 2 .13.

ICN OPC Server

Setup

ICN OPC Server Guide

Installation

11. ICN OPC Server Setup will register all the software components with the Windows

Figure 2 .14.

ICN OPC Server

Setup –HardLock

Driver

12. After the files are registered, the setup will be complete and a dialog box as shown in the

registry and a message box as shown below will be displayed.

next figure will be displayed.

2 - 9

Page 14

ICN OPC Server Guide

Installation

Figure 2 .15.

ICN OPC Server

Setup –Setup

Complete

• Click on Finish to complete the installation.

• If the setup had to overwrite any DLLs that were open in the system at the time of

Setup, then you will need to restart the computer for the changes to be effective.

You can opt to restart your computer at a later time.

2 - 10

Page 15

3

Application Tutorial

3.1 Objectives

In this lab, we will configure an ICN OPC Server database and add a device to it. We will

use this database to download the PIDLAB Strategy from the previous lab to the MOD

30ML instrument.

We will also populate the OPC database with tags using the Modcell Interface File (.MIF)

created in the previous lab and monitor the data by reading them from the instrument

using the built-in OPC Client of the ICN OPC Server.

After completing this lab you should be able to:

• Configure a ICN OPC database

• Download the Instrument document (strategy)

• View the signals using the built-in OPC Client

3 - 1

Page 16

ICN OPC Server

Application Tutorial

3.2 Instructions

3.2.1 Part 1

1. Launch the ICN OPC Server: From the Windows Start menu, select Programs-ABB

Control Solutions Software Suite - ICN OPC Server.

• The OPC Server will launch as shown in the next figure.

• A blank tag database Untitled is opened by default.

We will add a device to this database. We will save this database later.

Figure 3 .1.

ABB ICN OPC

Server

3 - 2

2. Add a hardware device to the database: Click on the New ICN Device button on the

toolbar or select Add-New ICN Device from the menu bar at the top. This will open the

ICN Device Properties dialog box as shown in the figure below:

• We will configure the properties of the MOD 30ML device we are adding in this

dialog box.

Page 17

Figure 3 .2.

Add new ICN

Device

ICN OPC Server

Application Tutorial

• Type the name MOD30ML in the Name field (the name is user-configurable and

can be anything!).

• Select the Type as MOD30ML Controller from the drop down menu.

• Select the serial communication port of the computer to which the MOD 30ML is

connected, in the Port field. Click on the down arrow in this field to show the dropdown menu and then select the port. (COM1 for example).

• Type the ICN Number in the ICN Number field.

• Type the instrument’s address in the Instrument Address field. This is the

instrument’s ICN address on the ICN specified in the ICN Number field above.

• Leave the Timeout in the default value of 1000 ms.

Timeout value in ms is the time for which the OPC server tries to re-establish

communication with the device in the case of a communication failure.

• Click on OK on this dialog box. The Modcell Interface File dialog will appear

next as shown in the figure below:

3 - 3

Page 18

ICN OPC Server

Application Tutorial

Figure 3 .3.

Modcell Interface

File

Figure 3 .4.

Port Properties

• Click on the button next to the File Name field. A file selection dialog box as

shown below will appear next. Browse for the folder that has the .MIF file from

this dialog box and then select it. This is the file you generated while compiling

your database.

• Click on the Open button on this dialog box. This will attach the tags that are in

the .MIF file (tags that are configured in the CL - Configured List block) to the

device we just added.

If you do not have a MIF file to specify, you can click on the Cancel button on the

Modcell Interface File dialog box above. You can add the MIF file later if needed, by

selecting the device and then right-clicking on it and then selecting Import Modcell

Interface from the menu that appears.

3. Configure the serial port for the communication: Click on the Edit – Ports from the

menu bar. The Port Properties dialog box will be displayed as shown below:

3 - 4

Page 19

Figure 3 .5.

Port Properties

ICN OPC Server

Application Tutorial

• Select the COMM port from the drop-down menu in the Port field and then enable

it by checking the box next to the Enable field.

Figure 3 .6.

ABB ICN OPC

Server database

• Choose the Baud Rate, Parity, Flow Control, Data bits and Stop bits from this

dialog box. Make sure these entries match the settings of the instrument.

• Click on OK to complete the Port configuration.

• Click on OK. The added device will be displayed in the Device Tree on the left

frame as shown in the next figure:

4. Save the database: The OPC tag database can be save as a file with an extension .ICNS

• Select File – Save from the menu bar. Refer to the following figure.

• The Save As dialog box will be displayed next as shown below:

• Choose the same folder where you have saved the instrument database for saving

this file and then type a name for the OPC tag database file in the File name field.

3 - 5

Page 20

ICN OPC Server

Application Tutorial

Figure 3 .7.

File – Save As

• Click on the Save button to save the file. The Title bar of the OPC Server will

redisplay with the saved file name.

• You can now either close the ICN OPC Server application by selecting File – Exit

from the menu bar at the top or minimize it.

3 - 6

Page 21

3.2.2 Part 2 – Downloading database from ViZapp

5. Run the Vizapp Application and open your workspace document. Open your instrument

document on the right frame. Select Instrument – Download from the menu bar at the

top.

• The Communication Setup dialog box will be displayed as shown below:

Figure 3 .8.

Communication

Setup

ICN OPC Server

Application Tutorial

• Click on the Browse button next to the Server name field to browse the OPC

Servers registered in the system.

• The Select OPC Server dialog box will be displayed as shown in the next figure:

• Look at the Available Servers box at the bottom. The ABB ICN (item

ABB.ICN.DataAccess) Server should be listed there.

The VizApp Setup installs the ICN OPC Server and registers it to the Windows

registry. If you have other OPC Servers registered in the system, you will see them

also in the Available Servers list.

3 - 7

Page 22

ICN OPC Server

Application Tutorial

Figure 3 .9.

Select OPC Server

Figure 3 .10.

Communication

Setup

• Click on ABB.ICN.DataAccess item to select it. It should now be displayed in the

Server Name field. Click on OK.

• The Communication Setup dialog box will redisplay with ABB.ICN.DataAccess

in the Server Name field as shown below:

3 - 8

Page 23

Figure 3 .11.

Select Device

ICN OPC Server

Application Tutorial

6. Select the Device: Click on the Browse button next to the Device Name field.

• The Select Device dialog box will display as shown below next. You will also

notice the ICN OPC Server application started automatically with the OPC

database file you last saved.

• This Select Device dialog box will show the name of the device you added to the

OPC Database in Part A of this lab. Select the device and then click on OK.

The devices in the Select Device list are populated from the last saved/opened ICN

OPC Server database file

• The Communication dialog box will redisplay as shown below with the name of

the device in the Device Name field.

7. Populate OPC Server tag database with attributes selected in the Modcell Interface File

(.MIF file):

• Refer to the following display.

• Check the box Populate ViZapp and Server Tag lists by clicking on it and then

select the Modcell Interface File (.MIF) from the Available MIF Files list at he

bottom.

By doing this you can populate the OPC Server tag database with tags that will be

automatically created from the attributes defined in the MIF file (attributes added to

your Configured List blocks in the strategy). This will save a tremendous amount of

engineering time as you do not have to create each tag manually.

This will also create a list of Tags in the VizApp Configurator automatically. These

tags can be used to add graphic objects to your instrument documents and display

documents.

3 - 9

Page 24

ICN OPC Server

Application Tutorial

Figure 3 .12.

Communication

Setup

Figure 3 .13.

Downloading

Figure 3 .14.

Download

• Click on OK on this dialog box. The Download Status Indicator will display as

shown below if the communication with the instrument was established. If there

was no communication, you will get error message boxes.

• After successful download, the following message box saying “Download

completed without error” will be displayed. Click on OK.

3 - 10

• The OPC Server application will also be closed automatically if it was started by

VizApp for downloading.

Page 25

3.2.3 Part 3 – ABB ICN OPC Client

8. Launch the ICN OPC Server Application if it was not running already. It will be launched

with your last saved database (for example boiler.icns) as shown below:

Figure 3 .15.

OPC Server

database with tags

ICN OPC Server

Application Tutorial

Figure 3 .16.

OPC Live Data

• Do you notice that the OPC database is populated with tags from the MIF file

automatically? Also notice that the tags are shown with alias names.

9. View Live data by starting the built-in OPC client application:

• Select View - Monitor from the menu bar at the top. This will start the built-in

OPC client and show live data from the instrument in the Value column of the

OPC Server application. Refer to the figure above.

• The live data is read-only as this OPC client application and is mainly used for

testing the function of the OPC Server and the communication between the

hardware devices and the OPC Server tag database. It does not allow writing of the

same.

3 - 11

Page 26

ICN OPC Server

Application Tutorial

3 - 12

Page 27

4

Operation and Reference

4.1 ICN OPC Server

4.1.1 OPC Tag Database

The database is typically made up of the following:

Devices: These are hardware devices (MOD30 / MODCELL / MOD 30ML) connected to

the OPC Server.

Groups: Tags/Signals can be grouped together into groups. Groups follow a device that

means that you can make groups of tags from a device. In the ICN OPC

database, the grouping will be based on the grouping in the CL block in the

instrument database database.

Each block in the database will be one group and will have the selected attributes of that

block. For example, if you have a block named FIC-100, the group will be called FIC-100

and the signals like PVI, SP, OP etc, will be tags belonging to that group.

Blocks inside a compound will be grouped into a bigger group with name as the

compound name.

Grouping is only for the user’s convenience. If aliases are configured in the CL block for

tags, then the tags will be attached to the devices directly (at the root level).

Tags: Tags define the properties of signals such as address of the signal, group and

device it belongs to, data type and scaling. Examples of tags are PVI, SP, and

OP etc, of a PID block.

4 - 1

Page 28

ICN OPC Server

Operation and Reference

Figure 4 .1.

OPC Server Tag

database

Having a .MIF file is very handy. Connecting the MIF file to a device in the OPC tag

database will create the groups and signals automatically. This will save a tremendous

amount of time compared to creating them manually.

4.1.2 ICN Device Properties

Configure the properties of the MOD30 or MODCELL or MOD 30ML device in this

dialog.

Figure 4 .2.

ICN Device Properties

4 - 2

Name: Type a name for the device – you can type any name in the Name field.

Port: Select the serial communication port of the computer to which the device is

connected to in the Port field. Click on the down arrow in this field to show the dropdown menu and then select the port (For example, COM1).

Page 29

ICN OPC Server

Operation and Reference

Timeout: Timeout value in ms is the time for which the OPC server tries to reestablish

communication with the device in the case of a communication failure. The default value

of 1000 ms should not need to be changed.

Address: Type the instrument’s ICN address in the address field.

Interface File: MIF file - Choose the Modcell Interface file for this device: To choose a

.MIF file,

1. Click on the button next to the MIF File field on this dialog box. This will display a

list of Modcell Interface files available.

2. Choose your working directory in this dialog box and then select your MIF file inside

that directory by clicking on it. The selected file will be displayed in the File Name

field at he bottom.

3. Click on Open to accept the MIF file. The dialog box will display the Version of the

MIF file, its Time Stamp (time at which the file was created or last), Instrument ID,

Number lines in the MIF file and most importantly, the Number Elements (number of

items or tags from the device)

4. Click on OK to complete the device configuration.

Note: This field will be automatically filled in by ViZapp, if the "Populate ViZapp and

OPC Server tag lists" box is checked when downloading.

4 - 3

Page 30

ICN OPC Server

Operation and Reference

Figure 4 .3.

ViZapp

Communication

Setup

Simulate I/O: The OPC Server does not access the device in Simulate mode. When

checked, no communication takes place and I/O values are generated randomly.

4.1.3 Serial Port Configuration

Configure the serial port for the communication: Menu item Edit – Ports displays the

communication port settings as shown below:

Figure 4 .4.

Port Properties

4 - 4

Page 31

ICN OPC Server

Operation and Reference

• Select the COMM port from the drop-down menu in the Port field and then enable

it by checking the box next to the Enable field.

• Choose the Baud Rate, Parity, Flow Control, Data bits and Stop bits from this

dialog box. Make sure these entries match the settings of the instrument.

• Click on OK to complete the Port configuration.

• The ICN Device Properties dialog box will redisplay with the port number. Leave

other fields on this dialog box at their default values.

• Click on OK. The added device will be displayed in the Device Tree on the left

frame as shown in the next figure:

4 - 5

Page 32

ICN OPC Server

Operation and Reference

4.1.4 Tag Data

The ICN Tag Data property sheet shows the following configured data:

Figure 4 .5.

Tag properties

Name – Tag Name

Description – Description of the tag

Block – MOD30 Block if the Device is a MOD30 instrument such as MOD 30 Controller,

Math Unit, Recorder or SLU

Data Point – MOD30 pneumonic

Scaling – Custom Scaling for the tag if any. See the Scaling section for details.

4 - 6

Page 33

4.1.5 Saving the OPC Server Tag database:

The OPC tag database can be save as a file with an extension. ICNS.

• Menu item File – Save will save the OPC Tag database.

• The Save As dialog box will be displayed next as shown below:

• Choose the same folder where you have saved the instrument database for saving

this file and then type a name for the OPC tag database file in the File name field.

Figure 4 .6.

File – Save As

ICN OPC Server

Operation and Reference

• Click on the Save button to save the file. The Title bar of the OPC Server will

redisplay with the saved file name.

4.1.6 ABB ICN OPC Client

Menu item View – Monitor activates the built-in OPC Client application:

Figure 4 .7.

OPC Live Data

4 - 7

Page 34

ICN OPC Server

Operation and Reference

• Live data values from the instrument will be displayed in the Value column of the

OPC Server application.

• The live data is read-only as this OPC client application and is mainly used for

testing the function of the OPC Server and the communication between the

hardware devices and the OPC Server tag database. It does not allow writing of the

same.

4.1.7 Scaling

Use this menu to define the conversion of raw data into engineering units and define that

as a New Style. You may also delete any styles no longer needed.

To add a new style:

1. Select an existing style to base the new one on if available.

2. In the new style menu enter a unique name and check the initialize from box if it is to

be based on the previously selected style or leave it unchecked to use the default style

scaling data.

3. Enter the following data as appropriate.

Units

Raw Minimum value

Raw Maximum value

Scaled Units Minimum value

Scaled Units Minimum value

Conversion selection

Linear

Square Root

4 - 8

Page 35

4.2 Dynamic Data Entry (DDE) Type Links

The ICN OPC Server supports DDE (Dynamic Data Exchange) for serving data to DDE

Client applications such as Microsoft Excel.

The typical reference for DDE connections is:

Program|Topic!Point

The character between Program and Topic is called a Pipe, the dashed vertical line

character on the keyboard. An exclamation point is used between the Topic and Point.

Refer your application's documentation for using DDE. The following example is for

Microsoft Excel:

=icnopc|’mod30ml’!LICOP

ICN OPC Server

Operation and Reference

In this example, icnopc is the executable filename of the OPC Server, mod30ml the name

that was given to the device in the server configuration, and LICOP is the name given to

the tag.

Excel automatically enclosed mod30ml in quotes. The rule is that if a Topic or Name

contains spaces or special characters, it must be enclosed in quotes.

After entering the valid reference, Excel asks to start the application if it is not already

running.

The #REF! Error value occurs when a cell reference is not valid. In this example, this will

occur if the icnopc application is not found, or if the device name or point name is wrong.

4 - 9

Page 36

ICN OPC Server

Operation and Reference

4 - 10

Page 37

PRODUCTS AND SERVICING

A Comprehensive Instrumentation Range

Sensors, transmitters and related instruments for flow,

temperature, pressure, level and other process variables

Flowmeters

electromagnetic, ultrasonic, turbine, differential pressure,

Wedge, rotary shunt, coriolis, vortex.

Differential Pressure transmitters

Smart, electronic and pneumatic.

Temperature

sensors and transmitters, fiber optic systems.

Pressure transmitters

Level

sensors and controllers.

Tank gauging systems

Cable-length measuring systems

Indicators, recorders, controllers and process

management systems

Recorders

circular and strip-chart types - single and multi-point - for

temperature, pressure, flow and many other process

measurements.

Controllers

digital display, electronic. Discrete single-loop and multi-loop

controllers which can be linked to a common display station,

process computer or personal computer.

Liquid and gas monitors and analyzers for on-line and

laboratory applications

Sensors

pH, redox, selective ion, conductivity and dissolved oxygen.

Monitors and Analyzers

for water quality monitoring in environmental and power

generation and general industrial applications.

Packaged analytical instrumentation laboratories

Gas analyzers

Zirconia, paramagnetic, infrared, thermal conductivity.

Servicing

ABB Inc. provides a comprehensive after sales

service via a Worldwide Service Organization.

Contact one of the following offices for details on

your nearest Service and Repair Center.

United Kingdom

London

ABB Instrumentation Limited

Tel: (1480) 470781

FAX: (1480) 470787

United States of America

ABB Inc.

125 E. County Line Rd

Warminster, PA 18974-4995

Tel: (215) 674-6000

Fax: (215) 273-7183

140 Mushroom Blvd

Rochester, NY 14623-3204

Tel: (585) 292-6050

Fax: (585) 273-6969

Italy

Lenno (Como)

ABB Kent-Taylor SpA

Tel: (0344) 58111

Fax: (0344) 56278

Page 38

The Company’s policy is one of continuous product

improvement and the right is reserved to modify

specifications contained herein without notice.

©2002 ABB Inc.

IB-OPC-ICN, Issue 1 11/02

ABB Instrumentation Ltd. ABB Inc. ABB Kent-Taylor SpA

St. Neots Cambs. Warminster, PA USA 22016 Lenno

England, PE19 3EU Rochester, NY USA Como, Italy

Tel: (01480) 475321 Tel: (215) 674 6000 / (585) 292-6050 Tel: (0344) 58111

Fax: (01480) 217948 Fax:(215) 674 7183 / (585) 273-6969 Fax: (0344) 56278

Loading...

Loading...