Page 1

INSTRUCTION MANUAL

Single Loop Controller

53SL6000

53SL6000 CONTROLLER

PN24991A

Rev. 1

Page 2

MicroMod Automation, Inc.

p

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most ost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

✎ Note. Clarification of an instruction or additional

information.

❢ Caution. An instruction that draws attention to the risk of

roduct, process or surroundings.

the

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed

information or technical details.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned

by MicroMod Automation or its suppliers.

Page 3

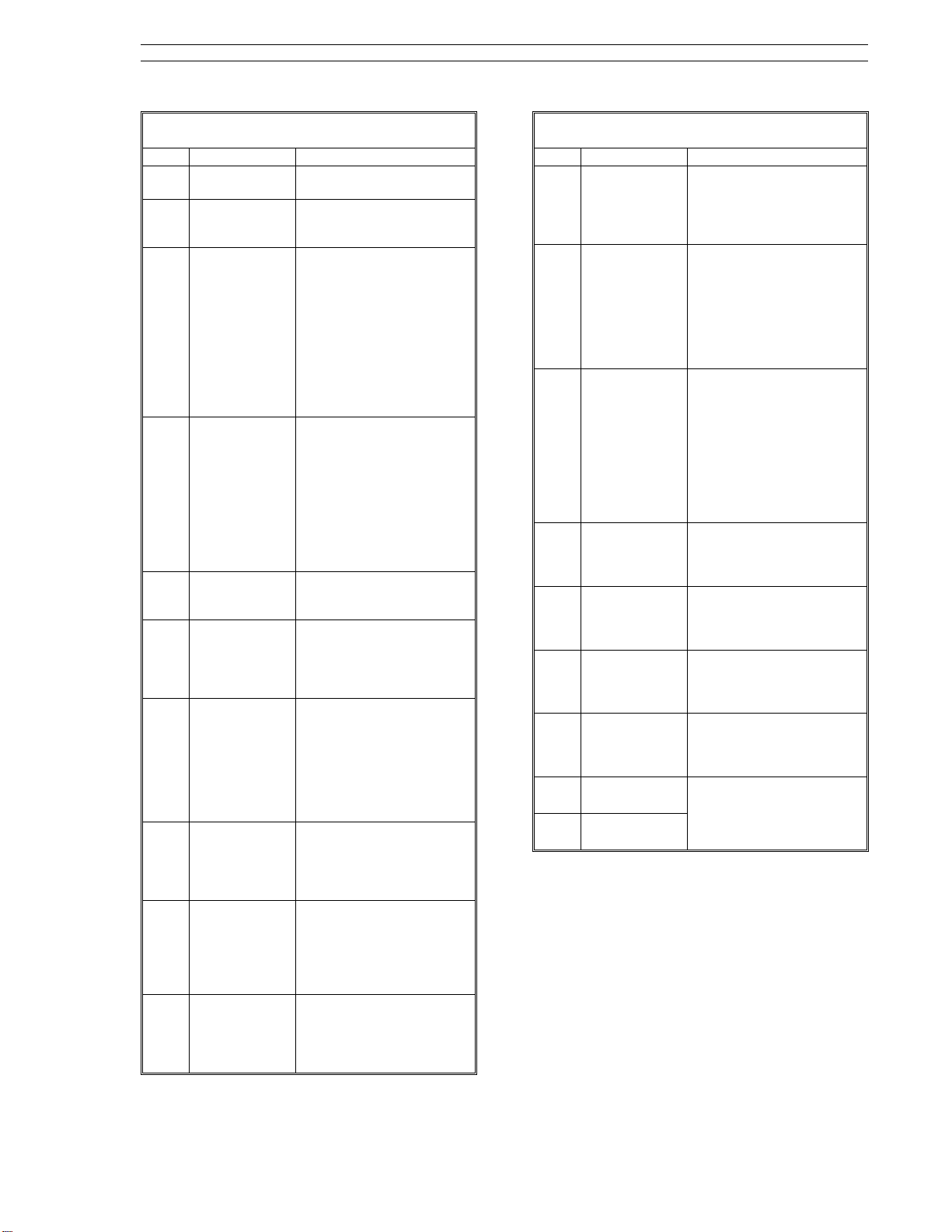

Table of Contents 53SL6000 Instruction Manual

Table of Contents

Safety Summary I

Read First II

1.0 Introduction 1-1

1.1 53SL6000 Controller Overview . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Controller Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.0 Installation and Power-Up Procedures 2-1

2.1 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Site Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.1 Single Cutout Installation (NEMA4 Compliant) . . . . . . . . . . . . . . . 2-1

2.3.2 Multiple Cutout Installation . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4.1 24 V DC Power Connections . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.1 Analog Inputs AI1 and AI2 . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.2 Discrete Outputs DO1 and DO2 . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.3 Discrete Inputs DI1 and DI2 . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.4 Analog Output AO1 . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Universal Analog Input Module . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6.1 Universal Analog Input Module Backplane Installation . . . . . . . . . . . . 2-5

2.6.2 Universal Analog Input Module Signal Wiring . . . . . . . . . . . . . . . 2-5

2.6.2.1 Thermocouple Connections and Burn-out Detection . . . . . . . . . 2-5

2.7 2DI/2DO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7.1 2DI/2DO Backplane Installation . . . . . . . . . . . . . . . . . . . . . 2-6

2.7.2 2DI/2DO Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.8 RS-232 and RS-485 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8.1 RS-232 Plug Connections . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8.2 RS-485 Plug Connections . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.9 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.9.1 Power-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.0 Display Panel 3-1

3.1 Display Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Operator Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Operator Mode Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Auxiliary Operator Access . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Operator Mode Overflow/ Underflow Indication . . . . . . . . . . . . . . . 3-4

i

Page 4

53SL6000 Instruction Manual Table of Contents

3.5 Engineer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.1 Engineer Mode Display Panel . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.2 Engineer Mode Hierarchical Structure . . . . . . . . . . . . . . . . . . 3-5

3.5.2.1 Editing a Parameter . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.2.2 Deselecting and Scrolling Backward . . . . . . . . . . . . . . 3-6

3.5.2.3 Editing a Numeric Value . . . . . . . . . . . . . . . . . . . 3-6

3.5.2.4 Editing the Tag Parameter . . . . . . . . . . . . . . . . . . 3-7

3.6 Entering a Pass-Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6.1 Configuring a Pass-Key . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.7 Offline Display Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8 Engineer Mode oPEr Selections . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.9 Display Alphanumerics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.10 Engineer Mode Summary . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4.0 Functional Overview 4-1

4.1 Simplified Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Detailed Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5.0 Inputs/Outputs (I/O) 5-1

5.1 I/O Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Universal Analog Input Module . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Universal Analog Input Module Parameter Entries . . . . . . . . . . . . . 5-2

5.4 Analog Output 1 (AO1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5 Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.6 Discrete Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.7 RS-232 and RS-485 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6.0 Signal Value Modification 6-1

6.1 Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Characterizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1. 3SEG Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.2 LSEG Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.3 PrGM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.4 DtoA Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 Math Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.1 ALG Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.2 SuMM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.3 PoLY Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.4 PoWr Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.5 LoG Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.6 LiM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.7 SEL Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.8 Gas Flow Compensation Equations . . . . . . . . . . . . . . . . . . . 6-7

6.3.8.1 Linear Gas Flow Compensation (LFLo) Equation . . . . . . . . . 6-7

6.3.8.2 Square Root Gas Flow Compensation (SFLo) Equation . . . . . . 6-7

6.4 Logic Blocks 1, 2, 3, and 4 . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

ii

Page 5

Table of Contents 53SL6000 Instruction Manual

7.0 Control Scheme Block 7-1

7.1 Control Scheme Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Control Scheme Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Control Scheme Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.4 Signal Paths for the SnGL, cASc, L.LiM, and h.LiM Control Schemes . . . . . . . . . 7-6

7.4.1 Setpoint (SP-PV) Paths for the SnGL, cASc, L.LiM, and h.LiM Control . . . . . 7-6

7.4.2 PID Paths for the SnGL, cASc, L.LiM, and h.LiM Control Schemes . . . . . . 7-6

7.4.3 OUT Paths for the SnGL, cASc, L.LiM, and h.LiM Control Schemes . . . . . . 7-6

7.5 Signal Paths for the in.Ld Control Scheme . . . . . . . . . . . . . . . . . . . . . 7-7

7.6 Control Scheme Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

7.7 Control Loop Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.8 Control Scheme Signal Connector Pin Assignments . . . . . . . . . . . . . . . . 7-28

8.0 Eight Control Strategies 8-1

8.1 Single Loop Control with Remote Setpoint . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 AI1 - Process Variable Input . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.2 AI2 - Remote Setpoint Input . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.3 DO1 - PV High Alarm Contact Out . . . . . . . . . . . . . . . . . . . . 8-2

8.1.4 DO2 - PV Low Alarm Contact Out . . . . . . . . . . . . . . . . . . . . 8-2

8.1.5 DI1 - Force Control Output Contact Input . . . . . . . . . . . . . . . . . 8-2

8.1.6 DI2 - Remote Enable Contact Input . . . . . . . . . . . . . . . . . . . 8-2

8.1.7 AO1 - Control Output . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.8 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Analog Back-Up Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2.1 AI1 - Process Variable Input . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.2 AI2 - Control Element Feedback . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.3 DO1 - Computer Output Diverter . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.4 DO2 - Backup Output Diverter . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.5 DI1 - Computer Ready . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.6 DI2 - Auto Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.7 A01 - Backup Control Output . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.8 SchM Selection and Path Connections . . . . . . . . . . . . . . . . . . 8-4

8.3 Ratio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3.1 AI1 - Controlled Variable Input . . . . . . . . . . . . . . . . . . . . . 8-5

8.3.2 AI2 - Wild Variable Input . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3.3 DO1 - Controlled Variable High Alarm Contact Out . . . . . . . . . . . . . 8-5

8.3.4 DO2 - Controlled Variable Low Alarm Contact Out . . . . . . . . . . . . . 8-5

8.3.5 DI1 - Force Control Output Contact Input . . . . . . . . . . . . . . . . . 8-6

8.3.6 DI2 - Ratio Enable Contact Input . . . . . . . . . . . . . . . . . . . . . 8-6

8.3.7 Control Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.3.8 SPM = K-SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.3.9 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.4 Auto/Manual Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.1 AI1 - Process Variable 1 Input . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.2 AI2 - Process Variable 2 Input (Auto) . . . . . . . . . . . . . . . . . . . 8-7

8.4.3 DO1 - PV1 High Alarm Contact Out . . . . . . . . . . . . . . . . . . . 8-7

8.4.4 D02 - PV1 Low Alarm Contact Out . . . . . . . . . . . . . . . . . . . . 8-8

8.4.5 DI1 Force Output Contact Input . . . . . . . . . . . . . . . . . . . . . 8-8

8.4.7 A01 - PV2 Re-Transmit (Auto) . . . . . . . . . . . . . . . . . . . . . . 8-8

8.4.8 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

iii

Page 6

53SL6000 Instruction Manual Table of Contents

8.5 Single Station Cascade Control . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.5.1 AI1 - Secondary PV Input . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.5.2 AI2 - Primary PV Input . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.5.3 DO1 - Secondary PV High Alarm Contact Out . . . . . . . . . . . . . . 8-9

8.5.4 DO2 - Secondary PV Low Alarm Contact Out . . . . . . . . . . . . . . 8-10

8.5.5 DI1 - Force Control Output Contact Input . . . . . . . . . . . . . . . . 8-10

8.5.6 DI2 - Cascade Enable Contact Input . . . . . . . . . . . . . . . . . . 8-10

8.5.7 Primary Output (the Setpoint into the Secondary Loop) . . . . . . . . . . . 8-10

8.5.8 AO1 - Control Output . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.5.9 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.6 Single Station Override Control . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.6.1 AI1 - Primary PV Input . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.6.2 AI2 - Limiting PV Input . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.6.3 DO1 - Primary PV High AlarmContact Out . . . . . . . . . . . . . . . . 8-11

8.6.4 DO2 - Primary PV Low Alarm Contact Out . . . . . . . . . . . . . . . . 8-12

8.6.5 DI1 - Force Control Output Contact Input . . . . . . . . . . . . . . . . 8-12

8.6.6 DI2 - Secondary Setpoint Enable . . . . . . . . . . . . . . . . . . . . 8-12

8.6.7 AO1 - Control Output . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.6.8 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.7 Dual Indicator with Re-Transmitted PV . . . . . . . . . . . . . . . . . . . . . 8-13

8.7.1 AI1 - PV1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.7.2 AI2 - PV2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.7.3 DO1 - PV1 High Alarm Contact Out . . . . . . . . . . . . . . . . . . . 8-13

8.7.4 DO2 - PV1 Low Alarm Contact Out . . . . . . . . . . . . . . . . . . . 8-13

8.7.5 A01 - Retransmitted PV1 or PV2 . . . . . . . . . . . . . . . . . . . . 8-13

8.7.6 SchM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.8 Proportional Speed Floating Control . . . . . . . . . . . . . . . . . . . . . . 8-14

8.8.1 Motorized Valve Connections . . . . . . . . . . . . . . . . . . . . . 8-14

8.8.2 Configuration Requirements . . . . . . . . . . . . . . . . . . . . . . 8-14

8.8.3 Speed Factor Adjusting . . . . . . . . . . . . . . . . . . . . . . . . 8-15

9.0 Commissioning 9-1

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Proportional Action (Pb) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.3 Integral Action (tr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.4 Derivative Action (td) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.5 Trial and Error Tuning Method . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.6 Proportional Cycle Tuning Method . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.7 Step Response Tuning Method (Ziegler-Nichols) . . . . . . . . . . . . . . . . . 9-2

9.8 Easy-Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.8.1 Executing Easy-Tune . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.8.2 Easy-Tune Determined Values . . . . . . . . . . . . . . . . . . . . . 9-7

9.8.3 Easy-Tune Status Responses . . . . . . . . . . . . . . . . . . . . . 9-7

9.8.3.1 out Response . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.2 dout Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.3 dPV Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.4 outX Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.5 StiM Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.6 PtiM Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.7 WtiM Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.8 KtiM Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.9 ttiM Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.10 Abrt Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

iv

Page 7

Table of Contents 53SL6000 Instruction Manual

9.8.3.11 PidL Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.12 cM Response . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.13 cASc Response . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.8.3.14 oVr Response . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Appendix A: Glossary A-1

Appendix B: Maintenance and Parts List B-1

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.3 Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.4 Controller Confidence Test Procedure . . . . . . . . . . . . . . . . . . . . . . B-3

B.4.1 Jumper Connections for the Controller Confidence Test . . . . . . . . . . . B-3

B.4.2 Starting the Controller Confidence Test via the Faceplate Push Buttons . . . . B-4

B.4.3 Starting the Controller Confidence Test via Datalink . . . . . . . . . . . . B-4

B.4.4 Controller Confidence Test Suite . . . . . . . . . . . . . . . . . . . . B-5

B.4.5 Controller Confidence Test Status . . . . . . . . . . . . . . . . . . . . B-5

B.4.6 Exiting the Controller Confidence Test via the Faceplate Push Buttons . . . . . B-5

B.4.7 Exiting the Controller Confidence Test via Datalink . . . . . . . . . . . . . B-5

B.5 Defaulting the Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

B.6 Analog Input/Output Calibration Values . . . . . . . . . . . . . . . . . . . . . . B-6

B.7 Watchdog LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Appendix C: Datalink Protocol C-1

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.2 Configuring the System Module for Datalink . . . . . . . . . . . . . . . . . . . . C-1

C.3 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.3.1 Message Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.3.2 Transaction Examples . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.4 Mnemonic-to-Datapoint Cross Reference . . . . . . . . . . . . . . . . . . . . . C-3

C.4.1 Database Starting Addresses . . . . . . . . . . . . . . . . . . . . . . C-3

C.4.2 Controller Memory Address Scheme . . . . . . . . . . . . . . . . . . . C-3

C.4.3 Database Prompt-to-Datapoint Cross Reference . . . . . . . . . . . . . . C-5

C.5 Executing Controller Self Tests via Datalink . . . . . . . . . . . . . . . . . . . . C-8

Appendix D: Prompt List D-1

Photocopy-Ready Pocket Reference Guide Last Sheet

v

Page 8

53SL6000 Instruction Manual Table of Contents

List of Tables

Table 1-1. 53SL6000 Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 2-1. Controller Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 3-1. Operator Mode Display Items . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-2. Setpoint Up/Down Push Buttons . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-3. oPEr Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Table 3-4. Operator Enable (oPr) Prompts . . . . . . . . . . . . . . . . . . . . . 3-11

Table 5-1. Analog Input Selections . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-2. Analog Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-3. Input Type Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-4. Volt/Millivolt Input Types . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-5. Thermocouple Types . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-6. RTD Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-7. Frequency/Pulse Input Types . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-8. Calibration Constants . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-9. Analog Output Selections . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-10. Analog Output Registers . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-11. Discrete Input Selections . . . . . . . . . . . . . . . . . . . . . . . 5-5

Table 5-12. Discrete Output Selections . . . . . . . . . . . . . . . . . . . . . . . 5-5

Table 5-13. System (SYS) Prompts . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 6-1. Characterizer Parameters . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Table 6-2. Math Function Block Parameters . . . . . . . . . . . . . . . . . . . . . 6-5

Table 6-3. Logic Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 6-4. Discrete Logic Block Functions . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 7-1. Control Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table 7-2. Control Scheme Parameters . . . . . . . . . . . . . . . . . . . . . . . 7-24

Table 7-3. Control Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Table 9-1. ITAE Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Table 9-2. Easy-Tune Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Table 9-3. Easy-Tune Determined Values . . . . . . . . . . . . . . . . . . . . . . 9-7

Table B-1. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table B-2. Confidence Test Suite . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-3. Factory Subtest Descriptions . . . . . . . . . . . . . . . . . . . . . . B-5

Table C-1. System (SYS) Prompts (Datalink) . . . . . . . . . . . . . . . . . . . . C-1

Table C-2. Datalink Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Table C-3. Datapoint Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Table C-4. Database Starting Addresses . . . . . . . . . . . . . . . . . . . . . . C-3

Table C-5. Datapoint Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Table C-6. Prompt-to-Datapoint Cross Reference . . . . . . . . . . . . . . . . . . . C-5

vi

Page 9

Table of Contents 53SL6000 Instruction Manual

List of Figures

Figure 1-1. 53SL6000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

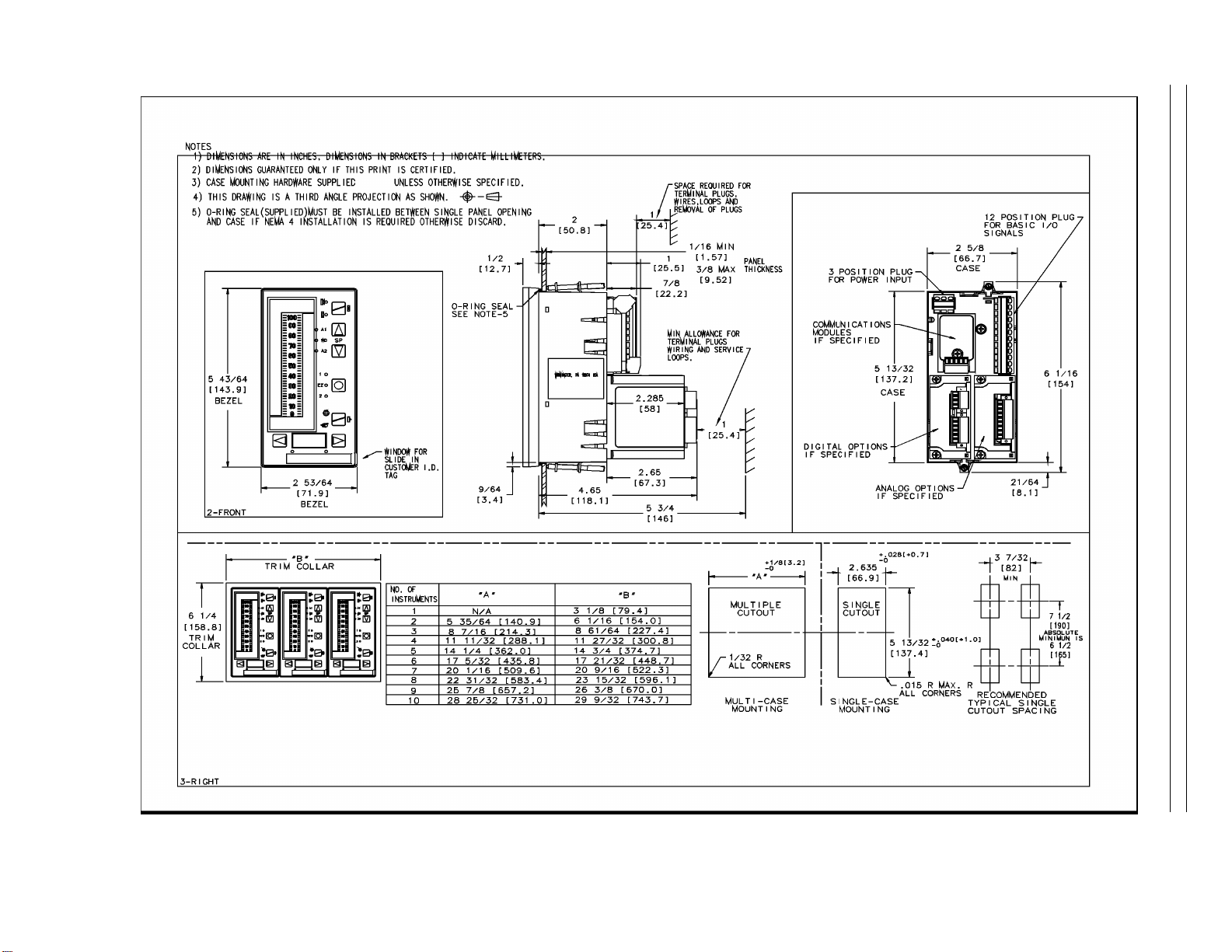

Figure 2-1. Panel Cutout and Installation . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2. Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3. 24 V DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4. AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-5. Signal Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6. Signal Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-7. Universal Analog Input Module . . . . . . . . . . . . . . . . . . . . . . 2-5

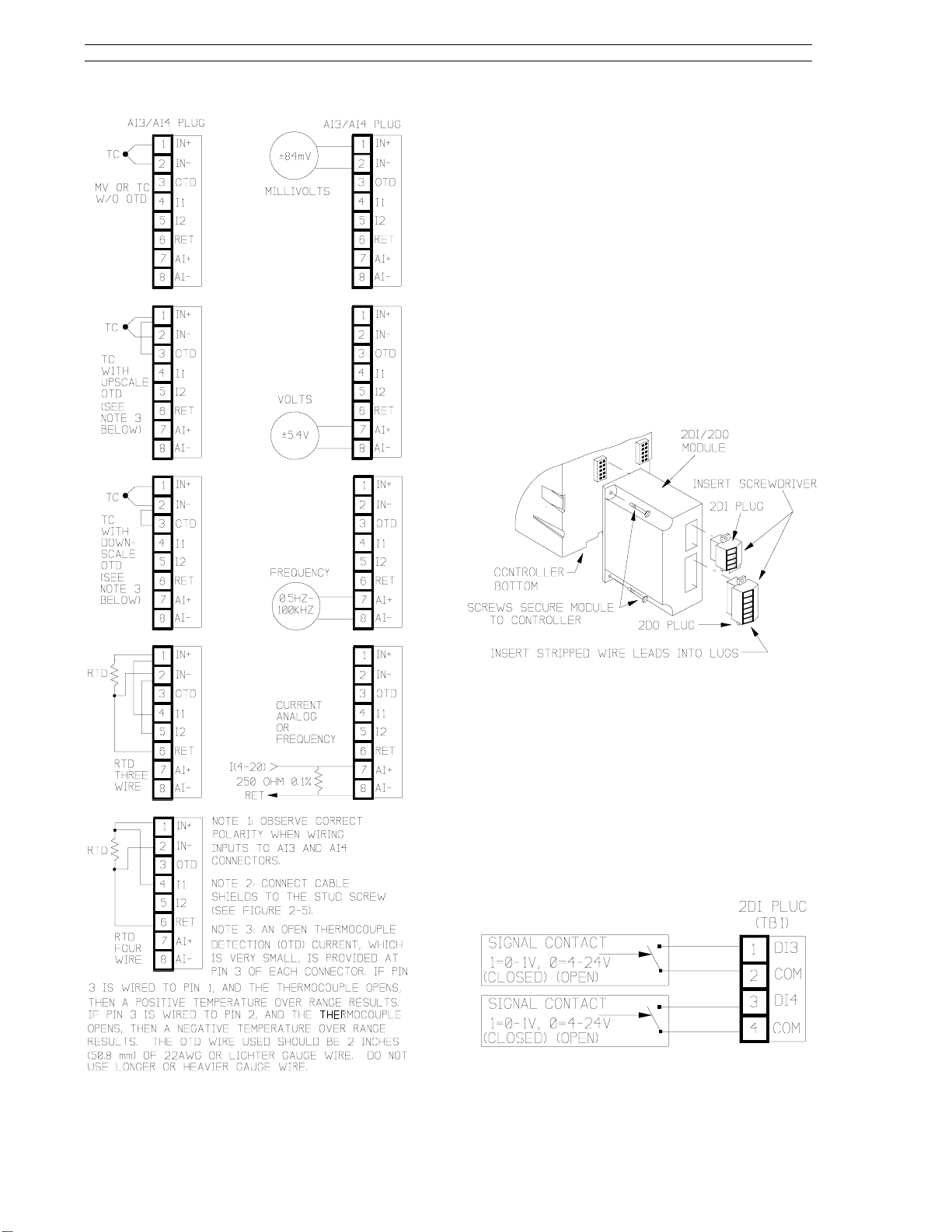

Figure 2-8. Input Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-9. 2DI/2DO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-10. 2DI Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

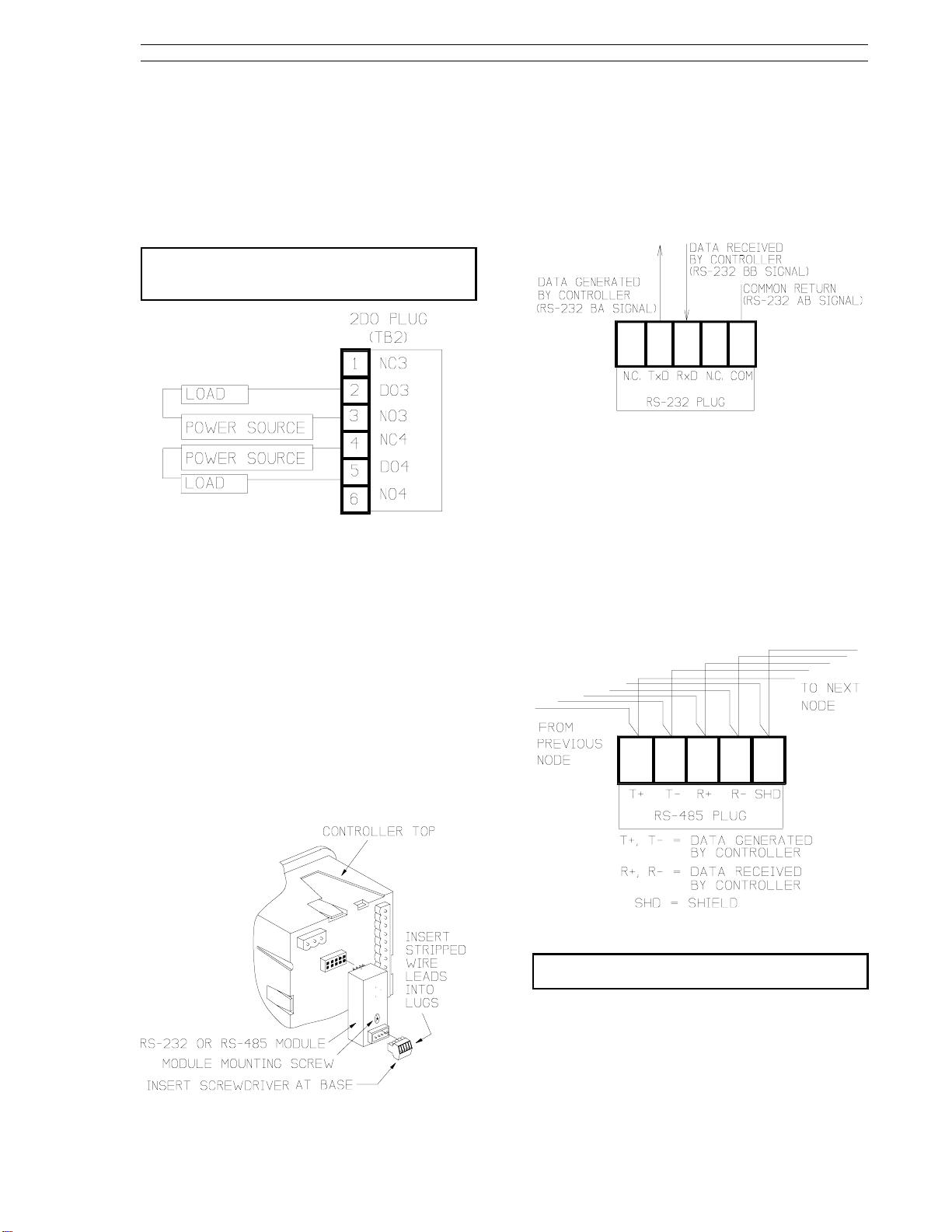

Figure 2-11. 2DO Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-12. RS-232 or RS-485 Module . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-13. RS-232 Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-14. RS-485 Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 3-1. Display Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Figure 3-3. Overflow/Underflow Indicators . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-4. Engineer Mode Display Panel . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-5. Editing a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-6. Deselecting and Scrolling Backward . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-7. Editing a Red dro Value . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-8. Moving the Red dro Decimal Point . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-9. Editing a tAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-10. KEY? Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-11. Offline Display Pattern . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-12. Display Alphanumerics . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 4-1. Simplified Controller Block Diagram . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-2. Detailed Functional Controller Block Diagram . . . . . . . . . . . . . . . . 4-5

Figure 7-1. Input Signal Designators by Control Scheme . . . . . . . . . . . . . . . . 7-2

Figure 7-2. Control Signal Logic Paths . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Figure 7-3. SnGL, cASc, L.LiM, and h.LiM Signal Paths . . . . . . . . . . . . . . . . . 7-8

Figure 7-4. Common Setpoint Logic Paths . . . . . . . . . . . . . . . . . . . . . . 7-9

Figure 7-5. Local Standard (Std) Setpoint Path . . . . . . . . . . . . . . . . . . . . 7-9

Figure 7-6. Remote Ratio Setpoint Path . . . . . . . . . . . . . . . . . . . . . . 7-10

Figure 7-7. StV Setpoint Tracking . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Figure 7-8. PVt Setpoint Tracking . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Figure 7-9. cASc Control Scheme Setpoint Path . . . . . . . . . . . . . . . . . . . 7-12

Figure 7-10. Pb, td, and tr PID Paths . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Figure 7-11. Pb, td, tr, and FF PID Paths . . . . . . . . . . . . . . . . . . . . . . 7-14

Figure 7-12. Pb, td, tr, and FF PID Paths with EXrF . . . . . . . . . . . . . . . . . 7-15

Figure 7-13. Output Tracking Path . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Figure 7-14. Auto Output Path . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Figure 7-15. Manual Output Path . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

vii

Page 10

53SL6000 Instruction Manual Table of Contents

Figure 7-16. Auto Digital Output Path . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Figure 7-17. in.Ld Control Scheme Alarmed Variable Input . . . . . . . . . . . . . . . 7-20

Figure 7-18. in.Ld Control Scheme Auto Input with Digital Output . . . . . . . . . . . . 7-21

Figure 7-19. in.Ld Control Scheme Output Tracking . . . . . . . . . . . . . . . . . . 7-22

Figure 7-20. in.Ld Control Scheme Manual Operation . . . . . . . . . . . . . . . . . 7-23

Figure 7-21. Control Schemes Signal Connector Pin Assignments . . . . . . . . . . . . 7-29

Figure 8-1. Single Loop Application . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Figure 8-2. Single Loop Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Figure 8-3. Backup Control Application . . . . . . . . . . . . . . . . . . . . . . . 8-3

Figure 8-4. Output Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Figure 8-5. Backup Control Signals . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Figure 8-6. Ratio Control Application . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Figure 8-7. Ratio Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Figure 8-8. A/M Selector Application . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Figure 8-9. A/M Selector Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Figure 8-10. Single Station Cascade Control Application . . . . . . . . . . . . . . . . 8-9

Figure 8-11. Single Station Cascade Signals . . . . . . . . . . . . . . . . . . . . 8-9

Figure 8-12. Single Station Override Control Application . . . . . . . . . . . . . . . . 8-11

Figure 8-13. Single Station Override Control Signals . . . . . . . . . . . . . . . . . 8-11

Figure 8-14. Dual Indicator Application . . . . . . . . . . . . . . . . . . . . . . . 8-13

Figure 8-15. Dual Indicator Signals . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Figure 8-16. Proportional Speed Floating Control . . . . . . . . . . . . . . . . . . . 8-14

Figure 9-1. Typical Step Response Record . . . . . . . . . . . . . . . . . . . . . 9-3

Figure 9-2. Easy-Tune Process . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Figure 9-3. Preliminary Step Response - Actual Curve . . . . . . . . . . . . . . . . 9-4

Figure 9-4. Preliminary Step Response - Approximated Curve . . . . . . . . . . . . . 9-4

Figure 9-5. Easy-Tune Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Figure B-1. Illustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . B-1

Figure B-2. Bezel and Lever Tabs . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-3. Confidence Test Connections . . . . . . . . . . . . . . . . . . . . . . B-4

Figure B-4. Watchdog LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Figure C-1. Floating Point Examples . . . . . . . . . . . . . . . . . . . . . . . . C-4

viii

Page 11

Safety Summary

GENERAL Electric Shock Hazard During Maintenance

WARNINGS

GENERAL Equipment Environment

CAUTIONS

Disconnect power or take precautions to ensure that contact with

energized parts is avoided when servicing.

Input Connector Shock Hazard

Instruments powered from an ac line source may cause input connectors to have power even though the controller is powered off.

Safety Hazard

Substitution of or modification with improper replacement components

may impair the safety of this device.

All components, whether in transportation, operation or storage must

be in a noncorrosive environment.

SPECIFIC

WARNINGS

SPECIFIC

CAUTIONS

Special Handling

This unit uses electrostatic sensitive devices.

Instruments that are powered from an ac line service

constitute a potential electric shock hazard to the user; therefore, only

qualified technicians should install the unit. Make certain that the ac

power lines are disconnected from the operating branch circuit before

attempting electrical connections. (p. 2-1)

Always remove power before attempting to install, disassemble, or

service the controller. Failure to remove power may result in serious

personal injury and/or equipment damage. (p. B-2)

Use a grounded wrist strap to prevent damage to integrated circuit

devices when handling circuit boards. (p. B-2)

53SL6000 Instruction Manual I

Page 12

53SL6000 INSTRUCTION MANUAL

READ FIRST

WARNING

INSTRUCTION MANUALS

Do not install, maintain, or operate this equipment without reading, understanding and

following the proper MicroMod Automation Inc. instructions and manuals, otherwise

injury or damage may result.

Read these instructions before starting installation;

save these instructions for future reference.

Contacting MicroMod Automation Inc.

Should assistance be required with any MicroMod Automation Inc. product, contact the following:

Telephone:

MicroMod Automation Inc., Rochester NY:

Phone: 1 (585) 321-9200

Fax: 1 (585) 321-9291

MicroMod Automation Inc., Southampton, PA:

Phone: 1 (215) 355-4377

Fax: 1 (215) 355-4378

E-Mail:

support@micmod.com

II

Page 13

Section 1. Introduction 53SL6000 Instruction Manual

1.0 Introduction

Summation

•

Setpoint Programmer

1.1 53SL6000 Controller Overview

•

The 53SL6000 controller is a functionally robust

instrument capable of performing any one of many

control strategies. Typical control strategies that

can be readily implemented are:

Single Loop Control with Remote Setpoint

•

(PID control)

Analog Back-up Control

•

Ratio Control (PID control)

•

Auto/Manual Selector

•

Single Station Cascade Control (Dual PID

•

control)

Single Station Override Control (Dual PID

•

control)

Dual Indicator with Re-Transmitted Proc-

•

ess Variable (PV)

Proportional Speed Floating Control (re-

•

quires the 2DI/2DO option module)

The complexity of learning software languages or

signal interconnection schemes is eliminated, as all

parameter entries are

a control strategy. Mnemonic prompts appear on

the display panel to solicit the necessary responses.

As listed below, a suite of control modifiers and

signal conditioners is provided to supplement every

control strategy.

prompt-driven

to configure

Every control strategy is also supported with a

standard controller I/O complement that includes

two 0/4-20 mA inputs, two digital/contact inputs,

one 0/4-20 mA output, and two contact outputs.

Also available for every control strategy is additional functionality provided by optional I/O modules that mount externally at the rear of the

controller for easy upgrade. Available option modules are as follows:

•

RS-232 Communications Module - provides

personal computer communication port connectivity (can not coexist with the RS-485 module).

•

RS-485 Communications Module - provides

datalink connectivity capabilities (can not coexist with the RS-232 module).

•

Universal Analog Input Module - provides one

or two isolated inputs that accept RTD, thermocouple, millivolt, volt, and frequency inputs.

The thermocouple and RTD inputs are automatically linearized.

•

2DI/2DO Module - provides two additional digital inputs and two digital outputs. With this

option, a time proportional or three-step output

can be applied to the 2DO relays for proportional speed floating control.

Control Modifiers:

External Reset Feedback

•

Additive Feedforward

•

External/Internal (Safety) Output Tracking

•

Output High/Low/Rate-of-Change Limiting

•

Process Variable/Internal (Safety) Set-

•

point Tracking

Setpoint High/Low/Rate-of-Change

•

Limiting

Signal Conditioners:

Twelve Linear Segment Characterizer

•

Five Third Order Segment Characterizer

•

Third Order Polynomial

•

Flow Compensation

•

Exponentiation

•

Algebraic Component Combinations

•

Logarithmic Extraction

•

Contact Duration-to-Analog

•

Power dependent transmitters are provided operating current from a 50 mA (24 V dc) transmitter

power supply located in the controller.

Tuning the 53SL6000 controller is automated with

EasyTune, the MicroMod algorithm designed to calculate the optimal PID values for precise analog control responses to process

deviations.

The 53SL6000 controller is easy to install due to its

small size. Installation depth is only 2 7/8 inches

(73 mm) without option modules and 4 21/32

inches (118.1 mm) with option modules. A 1 inch

(25.4 mm) access space is required for rear terminal plug removal and insertion.

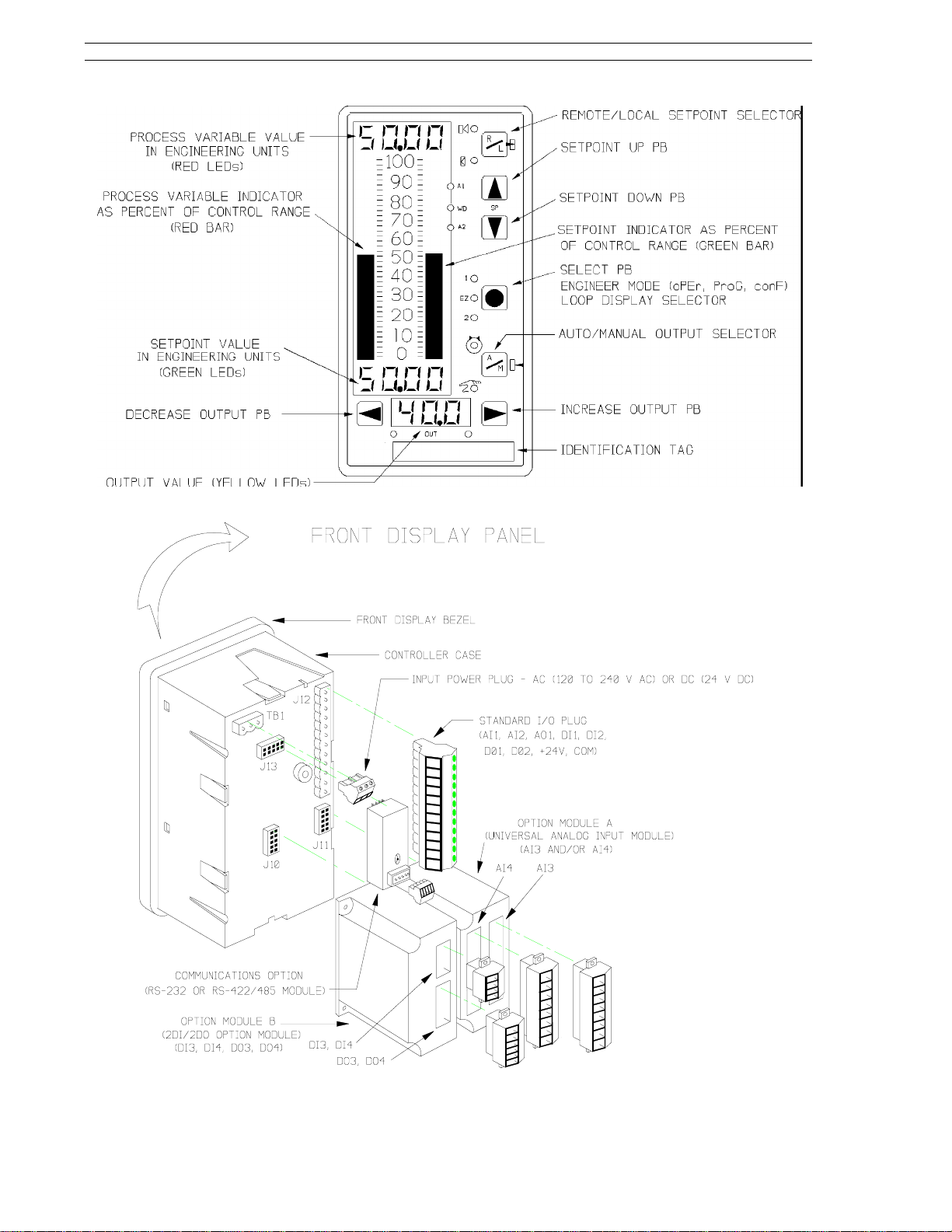

An illustration of the 53SL6000 controller that depicts the front display panel and the option modules

is provided in Figure 1-1.

1-1

Page 14

53SL6000 Instruction Manual Section 1. Introduction

1-2

Figure 1-1. 53SL6000 Controller

Page 15

Section 1. Introduction 53SL6000 Instruction Manual

1.2 Controller Model Numbers

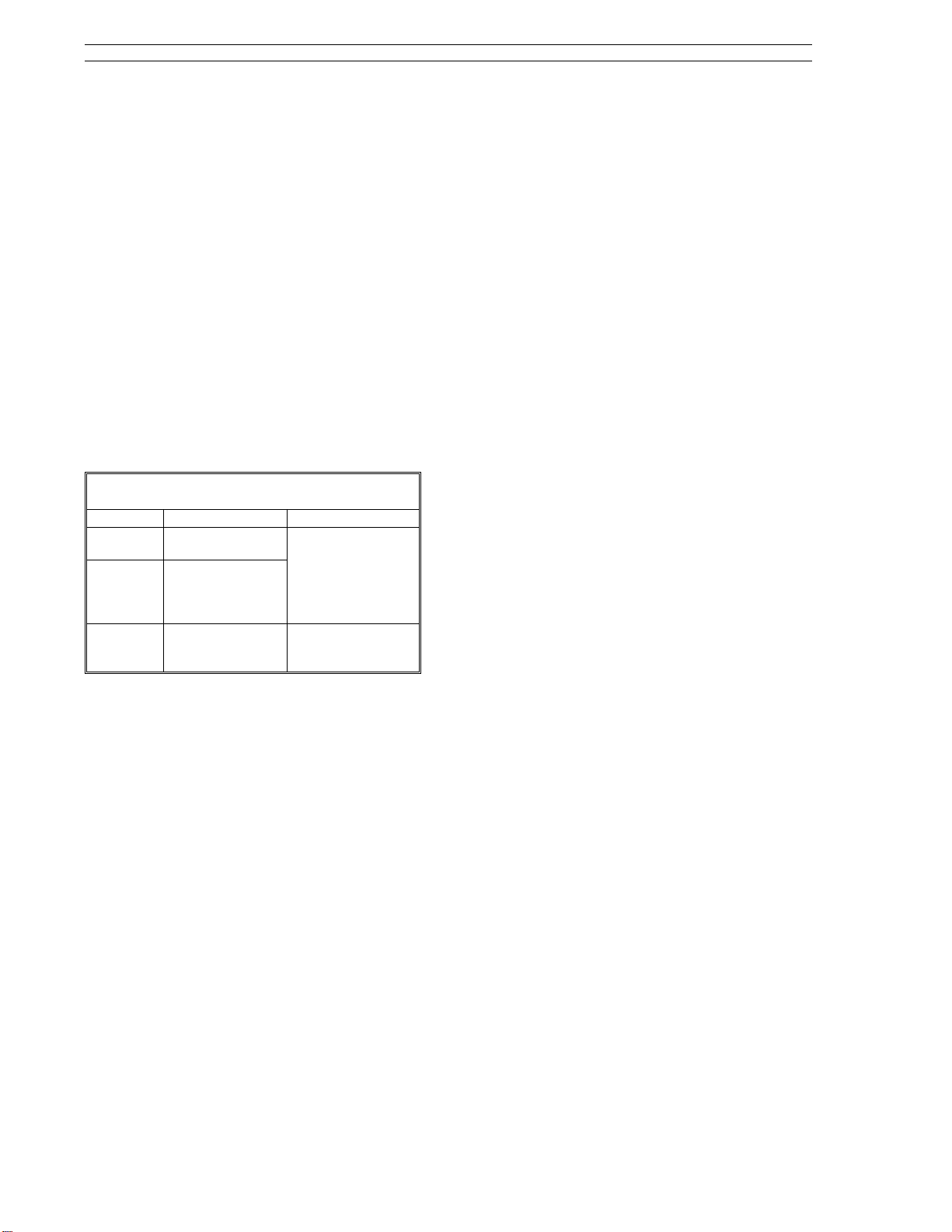

The 53SL6000 controller model numbers are described in Table 1-1.

Table 1-1. 53SL6000 Model Numbers

53 SL6

Controllers

Design Designator

(includes analog inputs

1 and 2, analog output

1, discrete inputs 1 and

2, discrete outputs 1

and 2)

Power Requirements:

120/240 V ac 0

24 V dc 1

Option Slot A Module:

None 0

Single Universal Analog Input

(analog input 3)

Dual Universal Analog Input

(analog inputs 3 and 4)

(Each universal analog input can

accept RTD, thermocouple,

millivolt, voltage, and

frequency inputs. Thermocouple inputs are linearized

by this module.)

Option Slot B Module:

None.

53

♦♦♦A♦♦

SL6

1

2

0

Physical Ch ar a cte r is tic s

Weight

Front Dimension

Overall Length

< 1.5 kg (3 lb 5 oz)

72 x 144 mm

(2 53/64 x 5 43/64 in)

With Option Modules - 130.8 mm

(5.15 in)

Without Option Modules - 85.7

mm (3 3/8 in)

Panel Insta llat ion

Panel Cutout

Installation Depth

Mounting Position

See Figure 2-1

Allow an additional 25.4 mm (1

inch) for rear plug removal and

insertion.

Flush panel mounting ± 60

Degree of Pr ote cti on

Facial

Housing

NEMA4 (IP64)

NEMA1 (IP20)

Safety Classification

CSA

FM

Approved for Class 1,

Division 2 (planned).

FM Approved for Class 1,

Division 2 (planned)

°

2 Discrete Input/2 Discrete

Output (discrete inputs 3

and 4, discrete outputs 3

and 4)

Design Level A

Communications Mode:

None

RS-485 (allows datalink connection)

RS-232 (allows connection to a

personal computer or a modem)

Enclosure:

Standard Panel Mount Case

3

0

1

2

0

1.3 Product Specifications

The 53SL6000 controller conforms to the following

specifications and complies with the following regulatory requirements:

Environmental Limits

Operating Ambient

Temperature Limits

Storage/Transport

Ambient

Temperature Limits

-5 to 50°C (23 to 122° F)

-40 to 85°C (-40 to 185° F)

Relative Humidity Limits

Humidity Limits

(operation)

Humidity Limits

(storage/transport)

Barometric

Pressure

(operation)

Barometric

Pressure

(storage/transport)

Thermal Shock

(operation)

5 to 95%

5 to 100%

82.7 to 103.4 kPa

13.8 to 103.4 kPa

±

20°C/hr ( ± 68° F /hr)

1-3

Page 16

53SL6000 Instruction Manual Section 1. Introduction

Thermal Shock

(storage/transport)

Physical Shock

(operation)

Physical Shock

(storage/transmit)

Vibration point-to-point

constant

displacement

(operation)

Vibration

(storage/transport)

Corrosion

ESD

Transient Immunity

EM Emission

EMI Susceptibility

Surge Withstand

Capability

±

66°C/hr ( ± 150.8° F /hr)

15 g 1/2 sine, 11 ms

ASTM D4169, DC1

0.76 mm, 5 to 14 Hz

0.3 g, 14 to 200 Hz

ASTM D999

B 3-100 Hz

0.5 g

ISA S71.04, airborne contaminates G3 for 10 years.

IEC 801-2 8.0 kV

IEC 801-4,

power 4 kV direct,

signal 2 kV capacitively coupled

CISPR Pub. 11 Class A

SAMA PMC 33.1 - 1978

Class 3 - abc: no effect at 30 V/m,

at 27, 146, and 446 MHz;

IEC 801-3 10 V/m

ANSI C37.90a - 1974/IEEE

Standard 472 - 1974

Ring Wave: 1.5 MHz, 3 kV,

60 pulses/second for 2.0 seconds

Power Consumption

(no options

installed

transmitter supply

not in use)

Power Consumption

(options installed

transmitter supply

in use)

Permitted Voltage

Dips

8 W

15 W

≤

20 ms

Transmitte r Su pp ly

(referenced to power common)

Voltage Range

Ripple

On-Load Current

Pulsing Short

Circuit Current

24 V to 26 V

≤

200 mVp-p

≤

50 mA (short circuit protected)

50 mA

Analog Inputs 1 and 2

(referenced to power common)

Number

Rated Signal Range

(for each input)

Control Range

Input Impedance

2, non-isolated

0/4 to 20 mA

0 to 21.5 mA

250 ohm

AC Power

Voltage Range

Frequency Range

Power Consumption

(no options

Installed,

transmitter supply

not in use)

Power Consumption

(options installed

transmitter supply

in use)

Permitted Voltage

Dips

DC Power

Voltage Range

93.5 to 276 V ac

47 to 63 Hz

8 W/14 VA

20 W/36 VA

≤

20 ms

20 to 30 V dc

Filter Time Constant

Measurement Error

Temperature Effects

50 ms

≤ ±

0.02 mA

≤ ±

0.002 mA/°C

Discrete Inputs 1 and 2

(referenced to power common)

Number

Signal Low

Voltage

Signal High

Voltage

Input Impedance

Signal Low Contact

(closed)

Signal High Contact

(open)

2 (dry contacts or power contacts

up to 24 V dc)

0 to 1 V dc

4 to 24 V dc

1000 ohm

≤

100 ohms

≥

5000 ohms

1-4

Page 17

Section 1. Introduction 53SL6000 Instruction Manual

Analog Output 1

(referenced to power common)

Number

Rated Signal Range

Control Range

No-Load Voltage

Load Range

Filter Time Constant

Output Measurement

Error

Temperature Effects

1

0/4 to 20 mA

0 to 21.5 mA

≤

24 V

0 to 750 ohms

50 ms

≤ ±

0.02 mA

≤ ±

0.002 mA/°C

Discrete Outpu ts 1 and 2

(open drain tied to power common)

Number

2

(Contact ratings are for resistive

loads; transient suppression is required for reactive loads.)

Input Ranges (cont)

RTD - 3 or 4 wire connection (see

list)

Thermocouple (see list)

High/Low Level Input Specifications

Low Level Input High Level Input

Input Connection Differential Differential

Input Range:

Input Resistance: 10 Mohm 800 Kohm

Filter - 3db Point: 4.0 Hz no filter

Filter Response

(63%): 0.025 sec N/A

Normal Mode

Rejection:

Common Mode

Rejection: 160 db 160 db

Common Mode

Operating: 250 V rms 250 V rms

Normal Mode

Maximum: 250 V rms < 25 V

Conversion Type: Volts to

Resolution (17

bits plus sign): 2.5618 uV 0.1636 mV

Analog

Measurement

Error:

±

83 mV

24 db @ 60 Hz,

22 db @ 50 Hz

frequency

±

0.1% F.S.

±

25 ppm/°C

±

5.3 V

N/A

Volts to

frequency

±

0.1% F.S.

±

25 ppm/°C

Open (off)

Closed (on)

≤

1 mA leakage

2.0 V dc maximum voltage drop,

50 mA maximum operating current,

30 V dc maximum operating voltage, and

100 mA maximum short circuit

current

Universal Analog Input Option Module

(Isolated inputs, see Common Mode Rejection in

High/Low Level Input chart on next column)

Number

Update Rate

General Input Types

Input Ranges

Single: 1 input module,

Dual: 2 input module

300 msec

Low Level - mV, RTDs,

thermocouples

High Level - voltage, current,

frequency, pulse

1 to 5 V linear

1 to 5 V square root

0 to +5 V square root

0 to ±80 mV

Frequency input 8 Hz - 100 kHz

Frequency input 2.5 Hz - 100 kHz

Frequency input 0.5 Hz - 30 kHz

Pulse input (incremental sum)

0-100 kHZ

Frequency

Measurement Error

Frequency Input

Requirement

Pulse Measurement

Error

Thermocouple

CJC Measurement

Error

RTD List

Platinum RTDs

0.01%

Pulse, Square Wave:

+5 V, 5 usec-minimum

Sine, Triangular Wave:

10 V p-p

0%

Internal CJC

±2°

C

Platinum 100 Ohm RTD

= 0.003850

α

-

200° to +850° C

(-320° to 1560° F)

Platinum 100 Ohm RTD

= 0.003926

α

-

200° to +870° C

(-320° to 1590° F)

Platinum 100 Ohm RTD

= 0.003911

α

-200° to +850° C

1-5

Page 18

53SL6000 Instruction Manual Section 1. Introduction

Copper RTDs

Nickel RTDs

Thermocouple List

J

K

T

E

N

C

R

S

(-320° to 1560° F)

Copper 10 Ohm RTD

= 0.00427

α

-

200° to +260° C

(-320° to 500° F)

Copper 53 Ohm RTD

= 0.00427

α

-50° to +150° C

(-55° to 300° F)

Copper 100 Ohm RTD

= 0.00427

α

-100° to + 260° C

(-150° to 500° F)

Nickel 100 Ohm RTD

= 0.00618

α

-60° to +180° C

(-80° to 350° F)

Nickel 120 Ohm RTD

= 0.00672

α

-80° to +273° C

(-110° to 520° F)

Fe/Cu-Ni

-200° to +1200° C

(-325° to 2190° F)

Ni-Chrom/Ni-Al

-200° to +1370° C

(-320° to 2490° F)

Cu/Cu-Ni

-250° to +400° C

(-418° to 750° F)

Ni-Chrom/Cu-Ni

-260° to +1000° C

(−

436° to 1830° F)

Ni-14%Chrom-1.4%Si/Ni-4.4%Si

-0.1%Mg

-200° to +1300° C

(-320° to 2370° F)

Tungsten-5%Rhenium/Tungsten

-26%Rhenium

0° to +2320° C

(32° to 4200° F)

Pt-13%Rhodium/Pt

0° to +1765° C

(32° to 3200° F)

Pt-10%Rhodium/Pt

0° to +1765° C

(32° to 3200° F)

B

L

U

CHE

CHS

F

G

D

PLII

Pt-30%Rhodium/Pt-6%Rhodium

+20° to +1820° C

(68° to 3300° F)

Fe/Cu-Ni

-200° to +900° C

(-320° to 1650° F)

Cu/Cu-Ni

-200° to +600° C

(-325° to 1110° F)

Ni-Chrom/Cu-Ni (Chinese E)

-50° to +800° C

(-50° to 1470° F)

Pt-10%Rhodium/Pt (Chinese S)

0° to +1600° C

(32° to 2900° F)

0° to +1400° C

(32° to 2550° F)

Tungsten/Tungsten-26%Rhenium

20° to +2320° C

(68° to 4200° F)

Tungsten-3%Rhenium/Tungsten

-25%Rhenium

0° to +2320° C

(32° to 4200° F)

Au-Pt-Palladium/Au-Pall

(Platinel II)

-100° to +1395° C

(-140° to 2540° F)

2DI/2DO Option Module

Discrete Inputs

Signal Low, Voltage

Signal High, Voltage

Input Impedance

Signal Low Contact

Signal High Contact

Discrete Outputs

Contact Load

Life Expentancy

2

0 to 1 V dc

4 to 24 V dc

1000 ohms

≤

100 ohms

≥

5000 ohms (minimum

recognition 10 ms)

2 (Form C Relays)

250 V switching voltage,

≤

5 A switching current, and

≤

1250 VA-ac,

≤

30 W at 250 V dc, and

≤

100 W at 24 V dc

switching power

20,000,000 mechanical switching

operations and 2,000,000 electri-

1-6

Page 19

Section 1. Introduction 53SL6000 Instruction Manual

cal 24 V/4 A ohmic Amp switching

operations

Spark Suppressor

Electrical Isolation

CPU Cycle Time

Input Sample Rate

Output Update Rate

Display Update Rate

Control Ranges

Proportional (P)

Integral (I)

Derivative (D)

Display

Element Type

Digital Readouts

In series 5nF/51 ohm with varistor

420 Veff in parallel

1000 V contact coil

1000 V contact-contact

1000 V between relays

50 ms

50 ms

50 ms

1000% - 2%

200 min/repeat - 0.02 min/repeat,

0 is off.

8 min - 0.01 min, 0 is off

Red, green, and yellow LEDs

8.9 mm in height

Analog Bar Graphs

LED Indicators

Keypad

two 4 digit, 7 segment digital

readouts

one 3 digit, 7 segment digital

readouts

two columns of 40 LEDs

80.7 mm in height

4.8 mm in width

0 to 100% range

2.5% bargraph

operation resolution

red PV LEDs

green SP LEDs

twelve LEDs: red, green, yellow

Seven positive tactile-feel keys

1-7

Page 20

Section 2. Installation and Power-Up Procedures 53SL6000 Instruction Manual

2.0 Installation and Power-Up Procedures

rear of the controller so that it butts against the

2.1 Inspection

Inspect the equipment upon arrival for damage that

may have occurred during shipment. If damage is

such that faulty operation is likely to result, do not

install the controller and contact the MM Automation representative if purchased direct, or contact

the appropriate supplier for repair/replacement procedures. Inspect the packing material before discarding it to prevent the loss of any additional

product literature that may have been included in

the shipment. Also inspect the controller data tag

to ensure it has the correct power requirements for

the intended application (e.g., 120/240 V ac or 24 V

dc).

display flange. This step is optional and not

required.

The applicable option modules can be installed

2.

before each controller is mounted in the panel

cutout, or after mounting. If installing the option modules now, see Figure 2-7 to install the

universal analog input module, Figure 2-9 to

install the 2DI/2DO module, and Figure 2-12

to install the RS-232 or RS-485 module.

This step can be skipped if none of these modules were ordered with the controllers.

Slide each controller through the mounting col-

3.

lar and panel cutout. Secure each controller in

place using the two mounting brackets as

shown in Figure 2-1.

2.2 Site Location

The 53SL6000 controller is designed to operate on

a plant floor where the controller faceplate might be

exposed to occassional wash-downs. See Section

1.3 for the stated environmental specifications of

the controller.

2.3 Panel Mounting

Dimensions for single and multi-controller mounting in a single panel cutout are provided in Figure

2-1.

2.3.1 Single Cutout Installation

(NEMA4 Compliant)

From the rear of the controller, slide on the

1.

rubber O-ring so that it butts against the display flange.

The applicable option modules can be installed

2.

now, before the controller is mounted in the

panel cutout, or after mounting. If installing the

option modules now, see Figure 2-7 to install

the universal analog input module, Figure 2-9

to install the 2DI/2DO module, and Figure 212 to install the RS-232 or RS-485 module.

This step can be skipped if none of these modules were ordered with the controller.

Slide the controller through the panel cutout

3.

and secure it in place using the two mounting

brackets as shown in Figure 2-1.

2.3.2 Multiple Cutout Installation

Multi-controller mounting collar part numbers are

provided in Table B-1, Parts List.

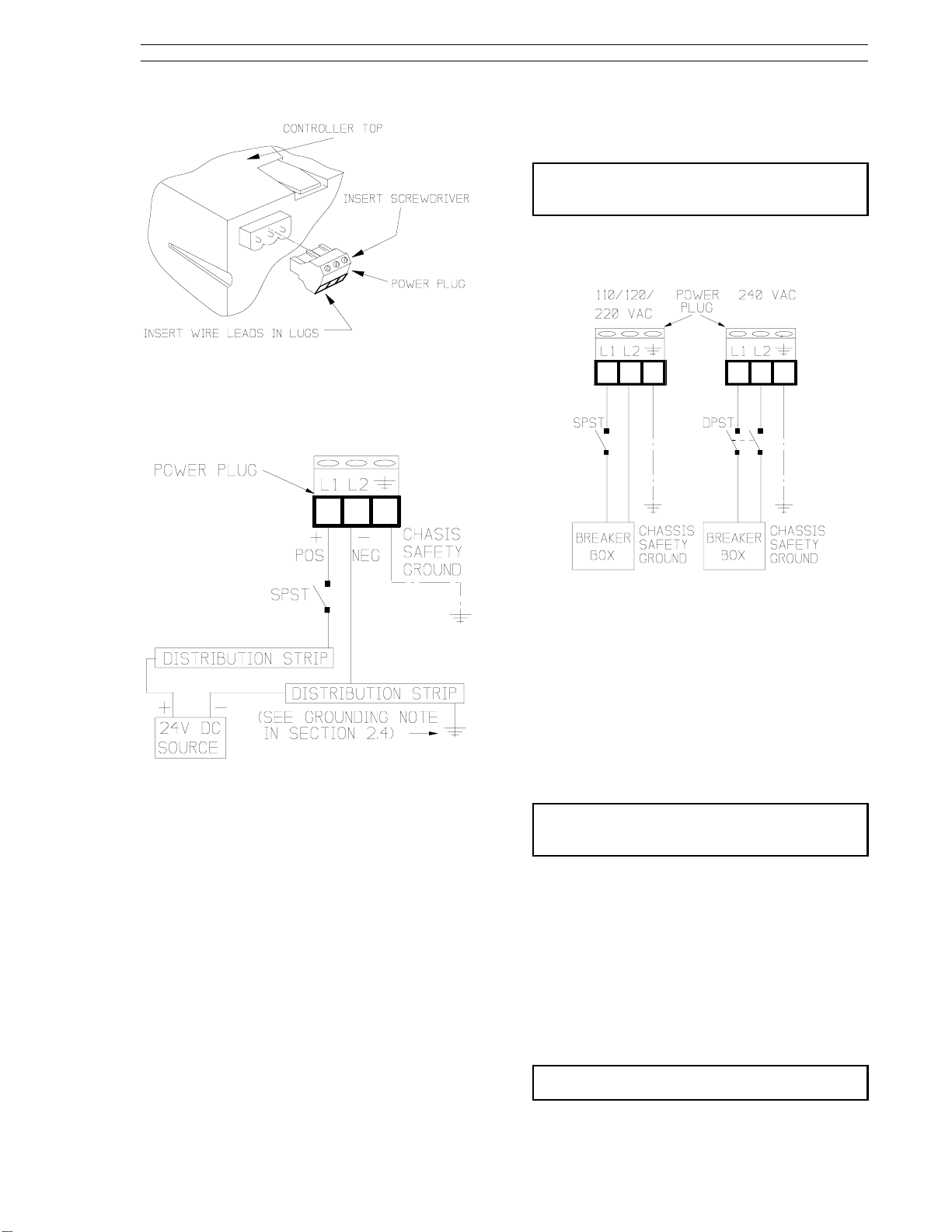

2.4 Power Connections

Figure 2-2 illustrates the power plug location on the

controller backplane. The power plug is removable

and can be pulled straight out from its backplane

connector. The plug is scalloped on one side to

ensure proper insertion after the power wires are

connected.

WARNING:

ac line service constitute a potential electric shock

hazard to the user; therefore, only qualified

technicians should install the unit. Make certain

that the ac power lines are disconnected from the

operating branch circuit before attempting

electrical connections.

NOTE:

to a high quality, noise-free point of earth

reference. Connection should be through a low

resistance (less than one ohm) lead wire directly

to the installation’s point of earth reference which

can be an independent grounding rod or ground

grid mesh that penetrates the permanent moisture

level below the frost line in accordance with Article

250 of ANSI/NFPA 70, the National Electrical

Code, or other code(s) acceptable to the authority

having jurisdiction over the installation.

NOTE:

signal wiring. Also, the power wiring should not

be routed in close proximity to signal wiring.

NOTE:

to expose 1/4 inch (6.4 mm) conductor.

Instruments that are powered from an

Installations are expected to have access

In electrically noisy locations, use shielded

Each power wire lead should be stripped

If it is desired to cushion the controller from the

1.

collar, then slide on the rubber O-ring from the

2-1

Page 21

2-2

53SL6000 Instruction Manual Section 2. Installation and Power-Up Procedures

Figure 2-1. Panel Cutout and Installation

Page 22

Section 2. Installation and Power-Up Procedures 53SL6000 Instruction Manual

Connect the chassis safety ground lug of the

3.

power plug to the ground wire.

NOTE: DO NOT APPLY POWER TO THE

CONTROLLER.

(Applying power is performed in Section 2.9.)

2.4.2 AC Power Connections

Figure 2-2. Power Plug

2.4.1 24 V DC Power Connections

Figure 2-3. 24 V DC Power Connections

Refer to Figure 2-3 to make the following connections:

Connect the positive (+) 24 V input line, via an

1.

SPST switch, to L1 of the power plug. As

shown in Figure 2-3, the positive input should

come from a distribution strip; do not daisychain the input power from one controller to

another. Leave the SPST switch in the OFF

position.

Connect the negative (-) input line to L2 of the

2.

power plug. As shown in Figure 2-3, the negative input should come from a distribution strip;

do not daisy-chain the negative input from one

controller to another. The distribution strip

should be connected to a noise free earth reference as shown in Figure 2-3.

Figure 2-4. AC Power Connections

Refer to Figure 2-4 to make the following connections:

For 110/120/220 V ac, connect the phase and

1.

neutral inputs to the power plug. For 240 V ac,

connect the two phase inputs to the power

plug.

Connect the chassis safety ground lug of the

2.

power plug to the ground wire (green, greenyellow).

NOTE: DO NOT APPLY POWER TO THE

CONTROLLER.

(Applying power is performed in Section 2.9.)

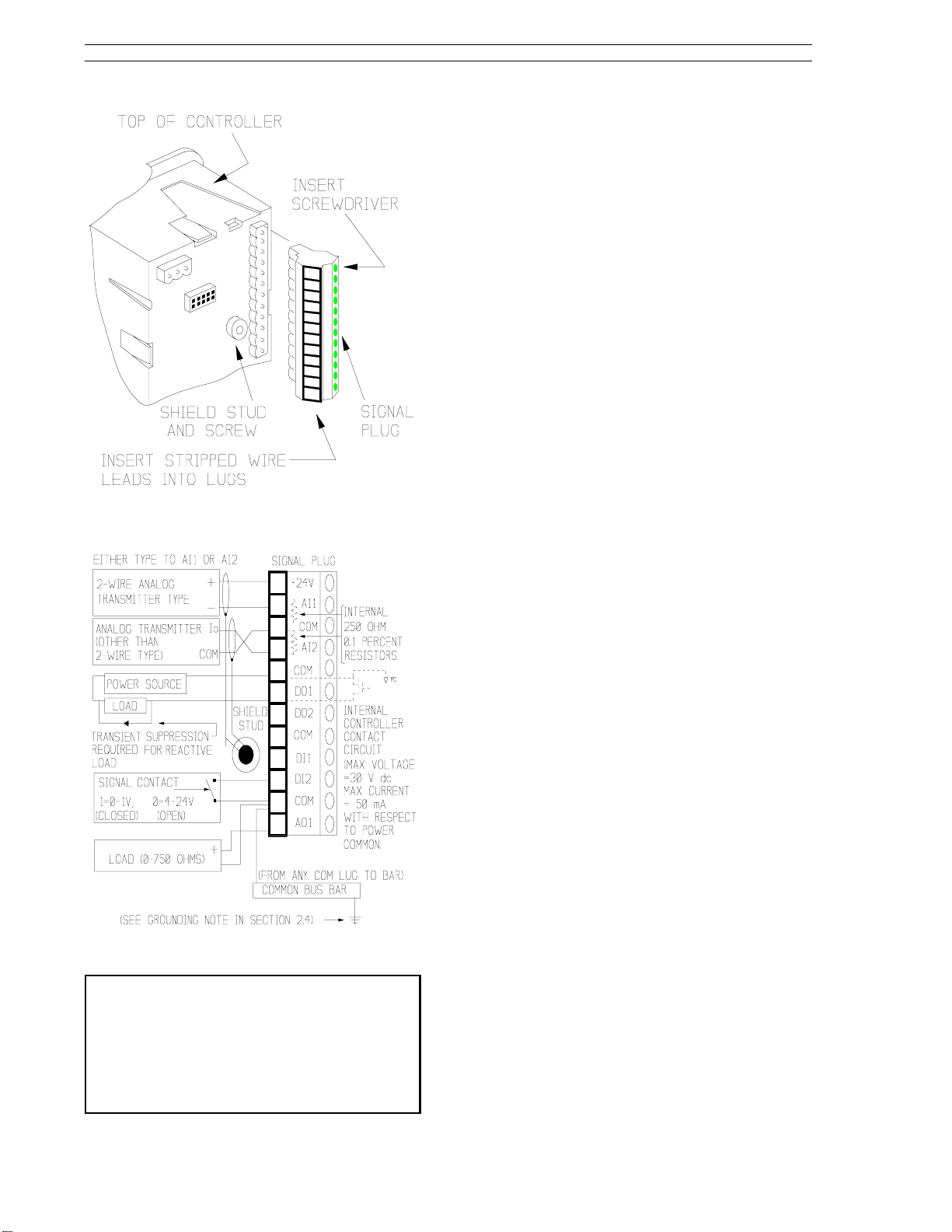

2.5 Signal Connections

Figure 2-5 illustrates the signal plug location on the

controller backplane. The signal plug is removable

and can be pulled straight out from its backplane

connector. The plug is scalloped on one side to

ensure proper insertion after the signal wires are

connected. Figure 2-6 illustrates the signal wire

connections.

Each signal wire lead should be stripped

NOTE:

to expose 1/4 inch (6.4 mm) conductor.

2-3

Page 23

53SL6000 Instruction Manual Section 2. Installation and Power-Up Procedures

2.5.1 Analog Inputs AI1 and AI2

In Figure 2-6, AI1 is connected to a transmitter that

requires power from the controller. Both, AI1

and/or AI2 can be connected to transmitters that

require controller power provided the total required

power does not exceed the specifications stated for

the transmitter supply in Section 1.3. The current

path for AI1 is from +24V to the + transmitter input,

through the transmitter element, out of the transmitter (-), to the AI1 plug connection, across the

internal 250 ohm (0.1%) voltage dropping resistor,

and down to Common.

In Figure 2-6, AI2 is connected to a transmitter type

that has its own power source and does not require

power from the controller. This transmitter type

can be connected to both AI1 and/or AI2. The

current path for AI2 is from the transmitter current

out (Io), to the AI2 plug connection, across the

internal 250 ohm (0.1%) voltage dropping resistor,

out the plug Common connection, to the transmitter

Figure 2-5. Signal Plug

Common connection.

Figure 2-6. Signal Plug Connections

NOTE 1:

be used in electrically noisy locations.

NOTE 2:

exceed the limit specified for the particular

transmitter (refer to the applicable technical

literature provided with the respective device).

NOTE 3:

connecting remote transmitters to the controller.

Shielded signal cable (two-wire) should

Signal transmission distance must not

Correct polarity must be observed when

Notice in Figure 2-6 that the signal cable shields

are connected to the backplane shield stud.

2.5.2 Discrete Outputs DO1 and DO2

Only DO1 is shown connected in Figure 2-6; connections to DO2 are identical. A discrete output

resistive load does not require transient suppression; however, reactive loads do to prevent coil

ringing or spiking from feeding back into the controller. The required diode shown as the suppression device is circuit dependent (typical: a 24V, 430

ohm, dc coil relay would require a 1N4003 diode).

2.5.3 Discrete Inputs DI1 and DI2

Only DI2 is shown connected in Figure 2-6; connections to DI1 are identical. In the figure, the

discrete input solid state circuitry is depicted as a

signal contact that opens or closes (logic states) in

response to input voltage levels (the discrete inputs

also work with dry contacts: ≤ 100 ohms is closed

and ≥ 5000 ohms is open).

2.5.4 Analog Output AO1

In Figure 2-6, the control output device is connected across the AO1 and COM lugs. Signal current passes from the AO1 connection, through the

device and back to Common. Control output device response to alter process operation is depenedent upon the analog signal amplitude.

2-4

Page 24

Section 2. Installation and Power-Up Procedures 53SL6000 Instruction Manual

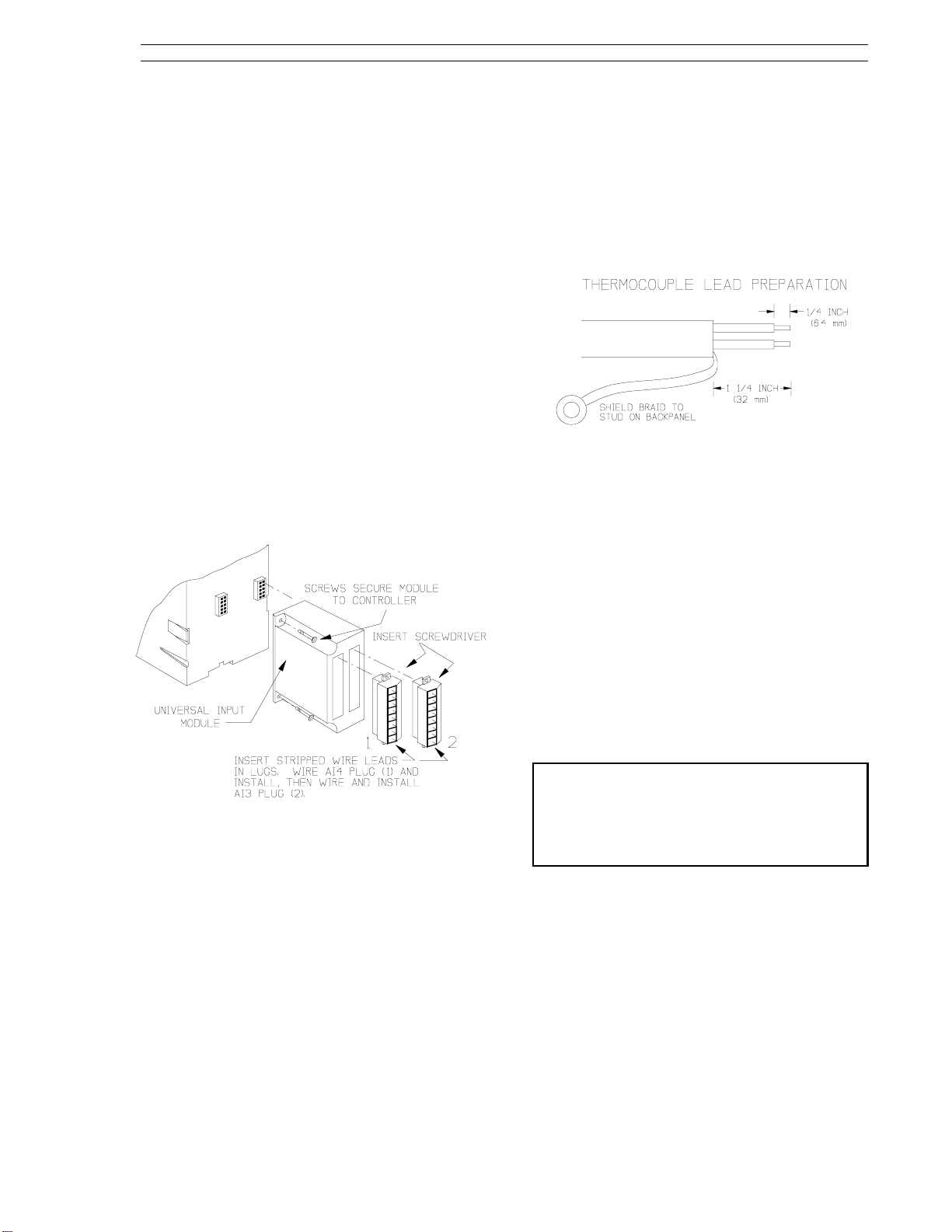

2.6 Universal Analog Input Module

This information applies to only those controllers

with an optional universal analog input module.

2.6.1 Universal Analog Input Module

Backplane Installation

Figure 2-7 illustrates the universal analog input

module location on the controller backplane. The

universal input module is socket mounted and is

secured to the backplane with two screws. Also

shown in Figure 2-7 are the signal plugs AI3 (right

plug) and AI4 (left plug) that are screw mounted to

the universal analog input module (the plug mounting screws are not illustrated). Depending on the

option ordered, one (AI3) or both (AI3 and AI4) of

these plugs will require installation and input connections. The plugs for AI3 and AI4 are identical;

therefore, care should be taken to ensure each

plug is installed in its proper location. Each plug,

however, is keyed to prevent inverted insertion into

its module connector.

2.6.2.1 Thermocouple Connections and

Burn-out Detection

To ensure proper cold junction compensation

(CJC) operation, the steps to wire a thermocouple

to the universal analog input module are as follows:

Prepare the thermocouple leads as shown in

1.

the following illustration:

For dual universal analog input modules that

2.

will have one thermocouple connected, ensure

it is installed on AI3 and that the other input is

installed on AI4.

For dual universal analog input modules that

3.

will have only one terminal plug connected, the

other terminal plug must still be installed on the

module for proper performance.

4. Thermocouple Burn-out Detection

shown in Figure 2-8, an open thermocouple

detection (OTD) current, which is very small, is

provided at pin 3 of each connector plug. If pin

3 is wired to pin 1 and the thermocouple opens,

then a positive temperature over range results.

If pin 3 is wired to pin 2 and the thermocouple

opens, then a negative temperature over range

results.

- As

Figure 2-7. Universal Analog Input Module

2.6.2 Universal Analog Input Module

Signal Wiring

As shown in Figure 2-7 (e.g., INSERT SCREWDRIVER), the signal wire lug screws are accessed

on the side of each plug.

Each analog input (AI3 and AI4) can accept only

one device input configuration as illustrated in Figure 2-8.

to another input.

Unused plug lugs can not be dedicated

NOTE: If an upscale or downscale open

thermocouple detection (OTD) wire is installed as

part of the thermocouple connection, then the wire

should be 2 inches (50.8 mm) of 22AWG wire or

lighter. Do not use longer or heavier gauge (e.g.,

14AWG) wire.

The complete assembly will reach thermal

5.

equilibrium approximately 30 minutes after the

controller is powered up (see Section 2.9, Applying Power).

2-5

Page 25

53SL6000 Instruction Manual Section 2. Installation and Power-Up Procedures

2.7 2DI/2DO Module

This information applies to only those controllers

with the optional 2DI/2DO module.

2.7.1 2DI/2DO Backplane Installation

Figure 2-9 illustrates the 2DI/2DO module location

on the controller backplane. The 2DI/2DO module

is socket mounted and is secured to the backplane

with two screws. Also shown in Figure 2-9 are the

2DI and 2DO signal plugs that are screw mounted

to the module (the plug mounting screws are not

illustrated). The two plugs are different in size;

therefore, they can not be inadvertently installed in

the wrong sockets and each plug is keyed to prevent inverted insertion into its module socket.

Figure 2-8. Input Configurations

Figure 2-9. 2DI/2DO Module

2.7.2 2DI/2DO Signal Wiring

As shown in Figure 2-9 (e.g., INSERT SCREWDRIVER), the lug adjusting screws are accessed

on the side of the plug.

Signal input connections for the 2DI four terminal

plug are illustrated in Figure 2-10. The functional

description for DI3 and DI4 is identical to that described in Section 2.5.3 for DI1 and DI2.

Figure 2-10. 2DI Plug Connections

2-6

Page 26

Section 2. Installation and Power-Up Procedures 53SL6000 Instruction Manual

Signal input connections for the 2DO six terminal

plug are illustrated in Figure 2-11. Both, DO1 and

DO2 are Form C relays. The contact load capacities are 250 V ac or 250 V dc maximum switching

voltage; 5 A switching current; 1250 VA-ac maximum, and 30 W at 250 V-DC maximum or 100 W at

24 V-DC maximum switching power.

The 2DI/2DO module provides line

NOTE:

suppression; appropriate load suppression must

be supplied by the user.

Figure 2-11. 2DO Plug Connections

2.8 RS-232 and RS-485 Modules

This information applies to only those controllers

with the optional RS-232 module or RS-485 module.

2.8.1 RS-232 Plug Connections

Signal connections to the RS-232 module plug are

illustrated in Figure 2-13. Transmitted (TxD) and

received (RxD) signals are with respect to the controller.

Figure 2-13. RS-232 Plug Connections

2.8.2 RS-485 Plug Connections

Signal connections to the RS-485 module plug are

illustrated in Figure 2-14. In the illustration, the

controller is shown wired as a drop on the datalink.

Two wires are therefore connected to each lug:

one set (T+, T-, R+, R-, SC) that comes from the

previous node and another set that is connected to

the next datalink node.

Figure 2-12 illustrates the RS-232 module or the

RS-485 module location on the controller backplane. The module is socket mounted and is secured to the backplane with a screw. Also shown in

Figure 2-12 is the module signal plug, which is

keyed to prevent inverted insertion in its socket.

As shown in Figure 2-12 (e.g., INSERT SCREWDRIVER AT BASE), the lug adjusting screws are

accessed at the bottom of the plug.

Figure 2-12. RS-232 or RS-485 Module

Figure 2-14. RS-485 Plug Connections

Cable shield should be connected to

NOTE:

ground at only one location.

2.9 Applying Power

Verify all controller connections and ensure each

connection is mechanically sound before closing

the power switch to apply controller power. The

2-7

Page 27

53SL6000 Instruction Manual Section 2. Installation and Power-Up Procedures

controller powers up in the last state it was in before power was removed.

2.9.1 Power-up Sequence

The power-up sequence is as follows:

At power-up, the controller performs a power-

1.

on self test which includes lighting all faceplate

LEDs for three seconds to show they are working.

After completing the power-on self test, status

2.

information is presented in the dros. During

status, both of the vertical bars have five

equally spaced LEDs lit.

If the power-on self test is successful, the

2a.

dros will contain option identification

codes and the firmware revision level identification for the next three seconds as described in Table 2-1.

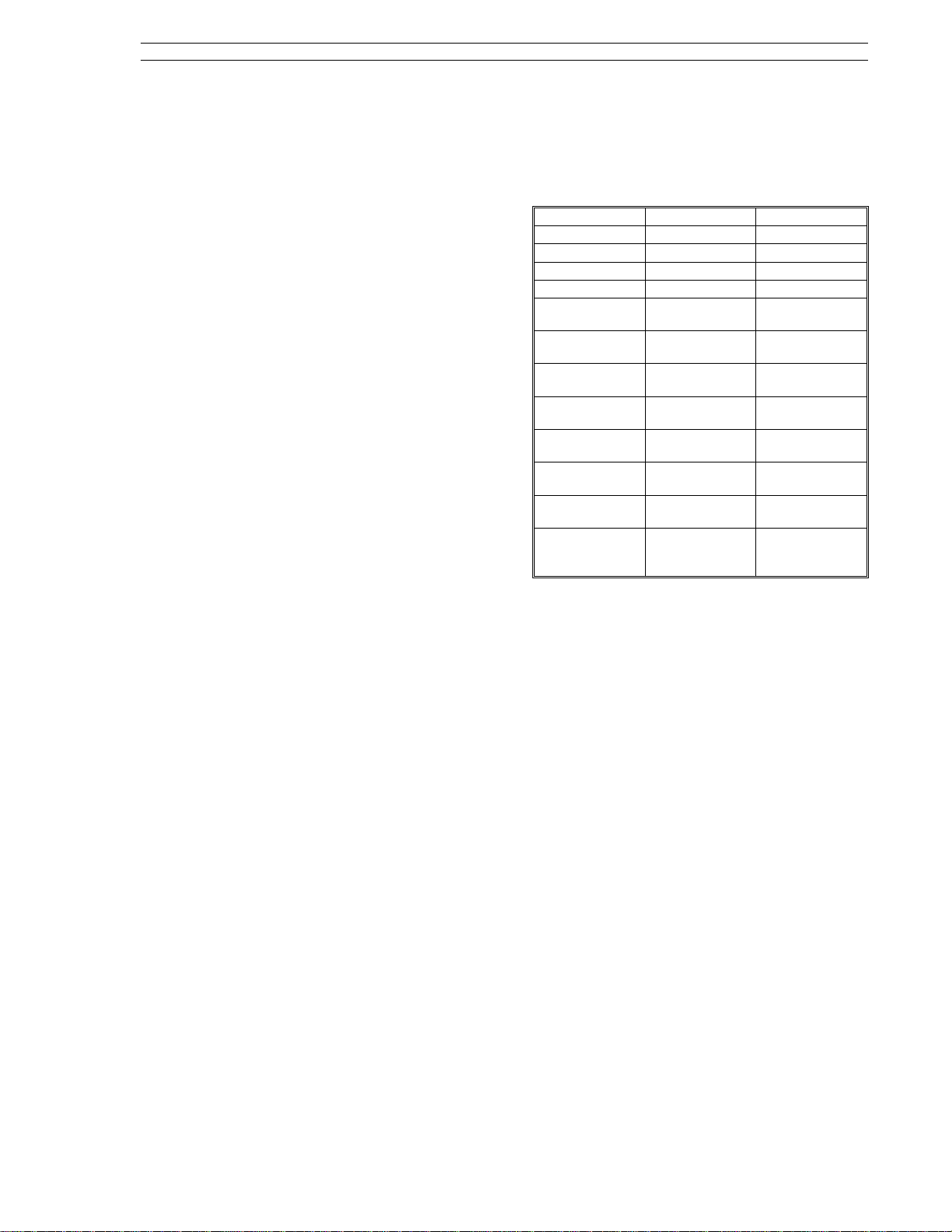

Table 2-1. Controller Status Codes

dro Attribute Status Code

Top (red) Option A status

Middle

(green)

Bottom

(yellow)

code.

Option B status

code.

Firmware revision

level identifier.

0 = no options.

192 = 2DI/2DO.

193 = Single Universal Analog Input.

194 = Dual Universal Analog Input.

Code must be cross

referenced to

revision level.

controller confidence tests when it was powereddown. Both vertical bars and all status indicator

LEDs, except the WD indicator, will be lit during the

controller confidence test execution.

If a power-on self-test database memory

2b.

error occurs, the

error appears in

nrAM

the top (red) dro and the controller halts

further operation. Return unit to for

service

After a successful power-on self test and

3.

status presentation, the controller enters operator mode, unless it was offline or executing

the controller confidence test when it was powered-down.

Offline is indicated by four equally spaced

pairs of lit LEDs in the green vertical bar.

When offline, no control is being performed

and all outputs are held at their values previous to being placed in offline mode. (For

more information about operator mode see

Section 3.2, Operator Mode; for more information about the offline state, see Section 3.7,

Offline Display Pattern.)

Reference Section B.4.6, Exiting the Controller

Confidence Test via the Faceplate Push Buttons, if

it is suspected that the controller was executing the

2-8

Page 28

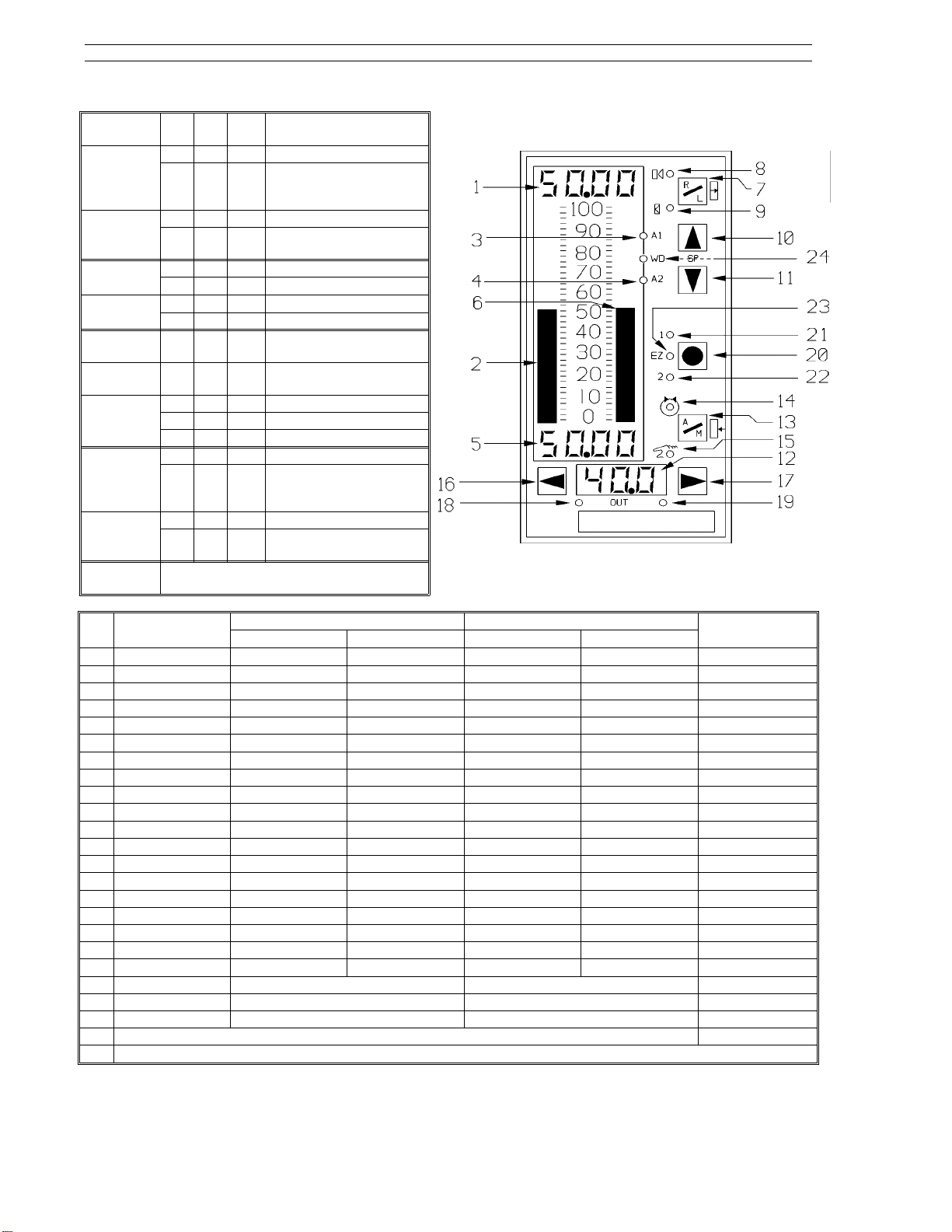

Section 3. Display Panel 53SL6000 Instruction Manual

3.0 Display Panel

3.1 Display Panel Overview

As shown in Figure 3-1, the controller display panel

contains three digital read-out (dro) fields, two vertical bar indicators, twelve function specific status

indicators, and seven push buttons (pbs). The display panel is used to alter controller settings (which

in turn affect process operation), to monitor process operation, and to configure controller functionality. (It is also used to commission the controller,

which is described in Section 9.) Process operation is altered and monitored with the controller in

operator mode; controller functionality is configured with the controller in engineer mode.

The red display area includes the left vertical

Red:

bar, upper dro, and alarm status indicators (A1,

A2). This display area is assigned to the process

variable input. The red vertical bar indicates the

process variable as a percent of control range and

the red dro is the process variable in engineering

units.

Green:

vertical bar, the dro immediately beneath it, the

remote/local pb with its two status indicators, and

the setpoint up/down pbs. This display area is usually assigned to setpoint indication and control, although the green vertical bar and dro can be used

to indicate a second process variable if the selected control scheme is an indicator. The green

vertical bar indicates the setpoint as a percent of

control range and the green dro is the value in

engineering units.

Yellow:

tom dro, the auto/manual pb with its status indicators, the output pbs, and the two multistate (MS1,

MS2) indicators. This display area is primarily assigned to output indication and control. The yellow

dro is an output value in percent of the scaled final

control element travel range.

The green display area includes the right

The yellow display area includes the bot-

Figure 3-1. Display Panel Overview

3.2 Operator Mode

The colors red, green, and yellow are used to visually partition the display panel into general operating mode functional areas as follows:

red - process variable presentation.

•

green - setpoint presentation and control.

•

yellow - output presentation and control.

•

3.2.1 Operator Mode Panel Functions

The operator mode panel functions are described

in Figure 3-2 on the next page. The figure has

three major parts: an illustration of the controller

with item number call-outs in the upper right, a

supporting chart in the upper left that defines the

Off/On/Blinking status indicator states, and a summary chart at the bottom that lists the assigned

functions of each item call-out by control scheme.

The illustration item call-outs are defined in more

detail in Table 3-1.

As shown in Figure 3-2, many of the push buttons

and status indicators have identical functions in the

different control schemes; however, the indicator/loader (in.Ld) control scheme is the most

unique.

3-1

Page 29

53SL6000 Instruction Manual Section 3. Display Panel

Item/LED Off On Blink-

8 - R X Remote/Ratio.

9 - L X Local Setpoint.

3 - A1

4 - A2

24 - Watch dog

21 - Loop 1 X Loop 1 selected (cASc,

22 - Loop 2 X Loop 2 selected (cASc,

23 - Easy Tune

14 - Auto X In Auto.

15 - Manual X In Manual.

18, 19 MS1, MS2

X No alarm.

X Normal operation.

X Not running Easy-Tune.

Alternately on/off for time proportioned

or three step output.

ing

X Remote requested, but

X Setpoint is tracking the

XAlarm active.

XOut of service.

XFailed Easy-Tune.

X Running Easy-Tune.

X Auto requested but not

X Output is tracking the

Description

not granted (Remote

Enable [RE] not true).

SP tracking signal.

L.LiM, h.LiM).

L.LiM, h.LiM).

granted - (Auto Enable

[AE] not true.)

Force Output signal.

Item SnGL

1 PV dro PV dro PV dro PV dro PV dro PV(1) dro

2 PV bar PV bar PV bar PV bar PV bar PV(1) bar

3 PV Alarm 1 status PV Alarm 1 status PV Alarm 1 status PV Alarm 1 status PV Alarm 1 status PV(1) Alarm 1

4 PV Alarm 2 status PV Alarm 2 status PV Alarm 2 status PV Alarm 2 status PV Alarm 2 status PV(1) Alarm 2

5 Setpoint* dro Setpoint* dro Setpoint dro Setpoint* dro Setpoint dro Auto/PV2 dro

6 Setpoint bar Setpoint bar Setpoint bar Setpoint bar Setpoint bar Auto/PV2 bar

7 R/L pb R/L pb N/A R/L pb N/A N/A

8 Remote LED Remote status N/A Remote status N/A N/A

9 Local LED Local status N/A Local status N/A N/A

10 SP Up pb SP Up pb SP Up pb SP Up pb SP Up pb N/A

11 SP Down pb SP Down pb SP Down pb SP Down pb SP Down pb N/A

12 Out dro Out dro Out dro Out dro Out dro Auto/PV2 Xmt dro

13 Auto/Manual pb Auto/Man. pb Auto/Man. pb Auto/Man. pb Auto/Man. pb Auto/Manual pb

14 Auto LED Auto status Auto status Auto status Auto status Auto status

15 Manual LED Manual status Manual status Manual status Manual status Manual status

16 Decrease Out pb Decr. Out pb Decr. Out pb Decr. Out pb Decr. Out pb Decrease Out pb

17 Increase Out pb Incr. Out pb Incr. Out pb Incr. Out pb Incr. Out pb Increase Out pb

18 Multistate 1 Multistate 1 N/A Multistate 1 N/A Multistate 1

19 Multistate 2 Multistate 2 N/A Multistate 2 N/A Multistate 2

20 Mode pb Mode pb, Loop 1/2 Select pb Mode pb, Loop 1/2 Select pb Mode pb

21 N/A Loop 1 select Loop 1 select N/A

22 N/A Loop 2 select Loop 2 select N/A

23 Easy-Tune status N/A

24 Watchdog condition indicator

Control

Secondary (L1) Primary (L2) Primary (Loop 1) Limiting (Loop 2)

cASc Control L.LiM/h.LiM Control in.Ld

PV(1)=PV/PV1

*Ratio based on conF-cn.1-SPM setting.

Figure 3-2. Operator Mode Display Panel Summary

3-2

Page 30

Section 3. Display Panel 53SL6000 Instruction Manual

Table 3-1. Operator Mode Display Items

Item Call-Out Description

1 PV dro It is the process variable

2 PV bar It indicates the process

3PV Alarm 1

Status

4PV Alarm 2

Status

5 Setpoint dro It is the setpoint value in

6 Setpoint bar It indicates the setpoint

7R/L

Push

Button

8Remote

Setpoint

Status

9Local

Setpoint

Status

10 Setpoint

Up

Push

Button

value in engineering units.

variable percent of control

range.

When active, it indicates

alarm 1 of the selected

alarm index limits (e.g.

high/low alarms; high, highhigh alarms; etc.) was not

within tolerable limits.

For high/low alarms, an

active Alarm 1 LED

indicates the the PV

exceeded the high

alarmed value.

When active, it indicates

alarm 2 of the selected

alarm index limits (e.g.

high/low alarms; low, lowlow alarms; etc.) was not

within tolerable limits. For

high/low alarms, an active

Alarm 2 LED indicates the

PV fell below the low

alarmed value.

engineering units or a ratio

setpoint.

percent of control range.

It also produces a striped

pattern when the