Page 1

Micro-DCI Single-Loop Controller

53SL5100B

Instruction Manual

Page 2

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

MicroMod Automation & Controls, Inc.

The Company

MicroMod Automation & Controls is dedicated to improving customer efficiency by providing the most cost-effective, application-specific

process solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design

and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional information.

! Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process system

performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for any

other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation & Controls, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation & Controls, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

SAFETY ADVICE CONCERNING THE USE OF THE EQUIPMENT DESCRIBED IN THIS MANUAL MAY BE OBTAINED FROM THE

COMPANY ADDRESS ON THE BACK COVER, TOGETHER WITH SERVICING AND SPARES INFORMATION.

i Information. Further reference for more detailed information

or technical details.

Page 3

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

INTRODUCTION ......................................................................................................................................... 1

1

1.1 PRODUCT OVERVIEW .............................................................................................................................. 1

1.2 SPECIFICATIONS ..................................................................................................................................... 2

2 INSTALLATION........................................................................................................................................... 5

2.1 INSPECTION ............................................................................................................................................ 5

2.2 LOCATION............................................................................................................................................... 5

2.3 MOUNTING.............................................................................................................................................. 5

2.3.1 General.......................................................................................................................................... 5

2.3.2 Mounting Procedure ...................................................................................................................... 6

2.4 POWER & SIGNAL WIRING ....................................................................................................................... 9

2.4.1 Power Wiring ............................................................................................................................... 12

2.4.2 Field Signal Wiring ...................................................................................................................... 12

2.4.3 Datalink Communication ............................................................................................................. 13

2.5 FACTORY SET CALIBRATION .................................................................................................................. 13

2.6 GROUNDING ......................................................................................................................................... 13

3 FRONT PANEL ......................................................................................................................................... 15

3.1 DISPLAY ............................................................................................................................................... 15

3.2 FRONT PANEL PUSHBUTTONS................................................................................................................ 19

3.3 DISPLAYING A DATAPOINT ..................................................................................................................... 21

3.4 ALTERING A DATAPOINT ........................................................................................................................ 22

3.5 DEFAULTING THE DATABASE.................................................................................................................. 23

3.6 RESPONDING TO THE PROMPT: KEY?.................................................................................................... 25

4 CONFIGURATION PARAMETERS .......................................................................................................... 27

4.1 DATAPOINT TYPES ................................................................................................................................27

4.2 FACTORY STANDARD CALIBRATION........................................................................................................ 27

4.3 CONFIGURING THE DATABASE MODULES................................................................................................ 28

5 SINGLE LOOP (PID) CONTROLLER....................................................................................................... 37

5.1 OPERATION OVERVIEW ......................................................................................................................... 37

5.2 SINGLE LOOP CONTROLLER FRONT PANEL PUSHBUTTONS ..................................................................... 40

5.3 SINGLE LOOP CONTROLLER PARAMETER SELECTIONS............................................................................ 42

5.3.1 Abbreviated Configuration Tables............................................................................................... 43

6 ANALOG BACKUP CONTROLLER......................................................................................................... 45

6.1 ANALOG BACKUP CONTROLLER OPERATION OVERVIEW.......................................................................... 45

6.2 ANALOG BACKUP CONTROLLER FRONT PANEL PUSHBUTTONS ................................................................ 47

6.3 ANALOG BACKUP CONTROLLER PARAMETER SELECTIONS ...................................................................... 49

6.4 ABBREVIATED CONFIGURATION TABLES ................................................................................................. 50

7 RATIO (PID) CONTROLLER .................................................................................................................... 53

7.1 RATIO (PID) CONTROLLER OPERATION OVERVIEW................................................................................. 53

7.2 RATIO (PID) CONTROLLER FRONT PANEL PUSHBUTTONS ....................................................................... 55

7.3 RATIO CONTROLLER PARAMETER SELECTIONS....................................................................................... 57

7.4 ABBREVIATED CONFIGURATION TABLES ................................................................................................. 58

8 AUTOMATIC/MANUAL STATION............................................................................................................ 61

8.1 AUTOMATIC/MANUAL STATION OPERATION OVERVIEW............................................................................ 61

8.2 AUTOMATIC/MANUAL STATION FRONT PANEL PUSHBUTTONS.................................................................. 63

8.3 AUTOMATIC/MANUAL STATION PARAMETER SELECTIONS ........................................................................ 65

9 PARAMETER DISPLAY ........................................................................................................................... 67

9.1 PARAMETER DISPLAY CONFIGURATION SETTINGS................................................................................... 69

Page 4

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

INSTRUMENT TUNING ......................................................................................................................... 71

10

10.1 PROPORTIONAL ACTION (PB)................................................................................................................. 71

10.2 INTEGRAL ACTION (TR)..........................................................................................................................71

10.3 DERIVATIVE ACTION (TD) ......................................................................................................................71

10.4 INSTRUMENT TUNING ............................................................................................................................. 72

11 EASY-TUNE ........................................................................................................................................... 75

11.1 GENERAL CONSIDERATIONS................................................................................................................... 75

11.2 INITIATING THE EASY-TUNE SEQUENCE ............................................................................................... 75

11.3 EASY-TUNE PARAMETERS .................................................................................................................. 76

11.4 EASY-TUNE SEQUENCE STATUS ......................................................................................................... 77

11.5 MODIFICATIONS TO TUNING CRITERIA ..................................................................................................... 79

11.6 ABORTING THE EASY-TUNE SEQUENCE ...............................................................................................81

11.7 EASY-TUNE SEQUENCE COMPLETION.................................................................................................. 81

12 MAINTENANCE ..................................................................................................................................... 83

12.1 SERVICE APPROACH.............................................................................................................................. 83

12.2 PARTS REPLACEMENT ...........................................................................................................................83

12.3 CALIBRATION......................................................................................................................................... 84

12.4 ERROR AND HARDWARE MALFUNCTION MESSAGES ................................................................................ 84

12.5 RESETTING THE INSTRUMENT................................................................................................................. 84

12.6 PARTS LIST ........................................................................................................................................... 86

APPENDIX A: DISCRETE CONTACT OUTPUT CCO’S .................................................................................90

APPENDIX B : COMMUNICATIONS ...............................................................................................................94

APPENDIX C: DATABASE ............................................................................................................................101

Page 5

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

IMPORTANT NOTICE

All software, including design, appearances, algorithms and source code is copyrighted by MicroMod

Automation & Controls, Inc. and is owned by MicroMod or its suppliers.

Page 6

Page 7

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

1 INTRODUCTION

1.1 Product Overview

The 53SL5100 Controller is capable of functioning as any one of four selectable application-specific

instruments. The instrument application is selected with the front panel push buttons by entering the

appropriate number (1 through 4 respectively) into a designated database location. The four instrument

selections are:

1. Single Loop (PID) Controller - a PID controller that fulfills the requirements of a majority of process

applications. It is used with other devices in a standard feedback control loop to automatically control

a process variable (PV) at a predetermined setpoint (SP). The proportional, integral, and derivative

(PID) terms can be activated as needed.

2. Analog Backup Controller - for operations requiring computer backup. It is used where a remote

computer is normally controlling the final element directly. In this configuration, the controller acts as a

control signal selector and as an automatic backup to the computer. The controller continually adjusts

its output to match the feedback signal from the final element so that transfer to on-line operation is

bumpless.

3. Ratio (PID) Controller - for applications where one variable must automatically be maintained in

definite proportion to another variable. The PID algorithm is executed to maintain a controlled line at a

predetermined proportion to the uncontrolled or wild line.

4. Automatic/Manual Station - for installations requiring a single station automatic/manual selector. In

Auto, the Auto input is passed directly through the station to the output. In Manual, the station acts as

a manual loader for direct operator control of the process.

Each of the four instrument selections has its own unique display of process attributes (e.g., process variable,

output, etc.) as well as a supplemental parameter display that is invoked by pressing a front panel push

button. The parameter display provides quick access to view and/or alter three values such as % Proportional

Band, Reset (integral action), and Rate (derivative action). The instrument is configured at the factory to

display these three values, but the parameter display selections can be altered.

1

Page 8

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

1.2 Specifications

Item Specification(s)

Power

Range (as specified in model number) 22 - 26 V dc

Power Consumption (ac/dc operation) 36 VA maximum

Internal Power Supply:

Available Power Output for Transmitters

Output Ripple 200 mV p-p maximum

Analog Input (ANI0, ANI1) Signals (all analog in-puts are referenced to signal common)

Quantity 4 (ANI0, ANI1)

Signal Range 0 -5 V dc or 1 -5 V dc (0 -20 mA and 4 -20 mA dc respectively).

Input Impedance 1 megohm minimum for voltage inputs; value of ranging resistor for

Measurement Accuracy ± 0.1% of span

Contact Input CCI0 Signal (referenced to power common)

Quantity 1 (CCI0)

Type discrete input

Permitted Contact Resistance 100 ohm maximum

Open/Close Contact Duration for open recognition: 0.05 seconds minimum

Contact Recognition Level Closed

Contact Recognition Level Open 4 V dc to 24 V dc

Analog Output (ANO0) Signal (referenced to power common)

Quantity 1 (ANO0)

Signal Range 0 -20 mA dc (4 -20 mA dc typically)

Load Range 0 - 750 ohms

Accuracy ± 0.2% of span

Switch Output (CCO0) Signal (referenced to power common)

Quantity 1 (CCO0)

Type

Configuration solid state equivalent of a single pole single throw, normally open or

Voltage 30 V dc maximum

Current 50 mA dc maximum

Datalink Communication

Sampling and Update Attributes

Program Scan Rate 0.05 seconds

Analog Input Signal Sampling Rate 0.05 seconds

Contact Input Signal Sampling Rate 0.05 seconds

Display Update 0.10 seconds

Output Signal Update 0.05 seconds

Control Ranges

Proportional Band 2 - 1000% and OFF

Integral 0.02 -200 minutes/repeat or Manual Reset from 0-100%

Derivative 0.01 - 8 minutes and OFF

108 - 132 V rms

216 - 264 V rms

50/60 Hz

25 V dc ± 1 V dc @ 80 mA maximum, short circuit protected.

NOTE: The rear terminal board has the appropriate resistors for

ANI0 and ANI1.

current signals.

for closed recognition: 0.05 seconds minimum

1 V dc maximum

solid state switch output

normally closed contacts referenced to common.

RS485, four wire, asynchronous; baud rates 300 to 28,800

2

Page 9

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Item Specification(s)

Environmental Characteristics

Controlled Environment Enclosed temperature controlled location (Class A and B per ISA-

Ambient Temperature Limits 4 -52°C (40 - 125°F)

Relative Humidity Limits 10 - 90% maximum

Temperature Effects on Accuracy ± 0.28% per 28°C (50°F) change from reference temperature 25°C

Transient Immunity (all circuits) ANSI C37.90a - 1974/IEEE Std 472-974: Ring Wave: 1.5 MHz, 3 kV,

EMI Susceptibility SAMA PMC 33.1-1978: Class 3-abc: no effect at 30 V/m, at 27, 146,

Enclosure Classification/Environment Panel Mounted Equipment: No enclosure rating. Designed to be

Shock 0.5g

Vibration SAMA PMC 31.1-1978; point-to-point constant displacement 0.05 in.

Drop and Topple SAMA PMC 31.1-1978; Tilt 30 degrees from horizontal and fall freely

Safety Classification General Purpose: Complies with ANSI/ISA S82.01-1988, Safety

Physical Characteristics

Material of Construction:

Case Steel, black enamel

Circuit Boards Glass epoxy

Bezel ULTEM 1000 (Polyethermide Resin) Flammability-UL94 5V

Dimensions 2.844W x 5.656H x 12.906L (inches) 73W x 144H x 329L (mm)

Flush Panel Mounting 0.125 inch - 1 inch thickness (3.2 mm - 25.4 mm)

Electrical Connections Screw type terminal block at rear of casework

Weight 5 lbs (2.3 kg)

Front Panel Display 96 x 48 dot addressable

Front Panel Push Buttons 10 membrane type switches

S71.01 1985)

(77°F)

60 pulses/s for 2.0 s

and 446 MHz

installed in a user provided panel or enclosure.

Rated for installation in a Pollution Degree 2 location per U.L. 5081989/Controlled Environment per CSA C22.2 No. 142-M1987. An

indoor, temperature controlled location (Control Room or Shop Floor)

where normally, only non-conductive pollution occurs; however,

temporary conductivity caused by condensation may be expected.

Location in environments more severe than those stated requires

supplementary protection

(1.27 mm), 5 -14 Hz: 0.5 g, 14 - 200 Hz.

to a hard surface, all sides, front and back.

Standard for Electrical and Electronic Test Measuring, Controlling and

Related Equipment; General Requirements and S82.03-1988 Safety

Standard for Electrical and Electronic Test, Measuring, Controlling and

Related Equipment; Electrical and Electronic Process Measurement

and Control Equipment.

FM Approved: Nonincendive for Class 1, Division 2, Groups A, B, C, &

D, Temperature Code T3C 160 ° C.

3

Page 10

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

4

Page 11

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

2 INSTALLATION

2.1 Inspection

A list of all items in the shipment is attached to the shipping container. Inspect the equipment upon arrival for

damage that may have occurred during shipment. All damage claims should be reported to the responsible

shipping agent before installation is attempted. If damage is such that faulty operation is likely to result, the

MicroMod Customer Service Department should be notified.

Inspect the packing material before discarding it as a precaution to prevent loosing mounting hardware or

special instructions that may have been included with the shipment. Normal care in the handling and

installation of this equipment will contribute toward its satisfactory performance.

2.2 Location

The 53SL5100 is supplied with an enclosure designed specifically for indoor mounting. The installation site

selected should be dry, well lighted, and vibration free. The ambient temperature should be stable and

maintained within the specified minimum and maximum temperature limits listed in the Section 1,

specifications of this Instruction Bulletin.

The instrument can be supplied for use with a 24 V dc supply or 120, 220 and 240 V ac line service.

Instrument power requirements are given on the instrument data tag.

2.3 Mounting

2.3.1 General

It is normally not necessary to open the instrument case during installation. If the instrument must be removed

from the case, refer to Section 5 for details. Incorrect procedures may damage the instrument.

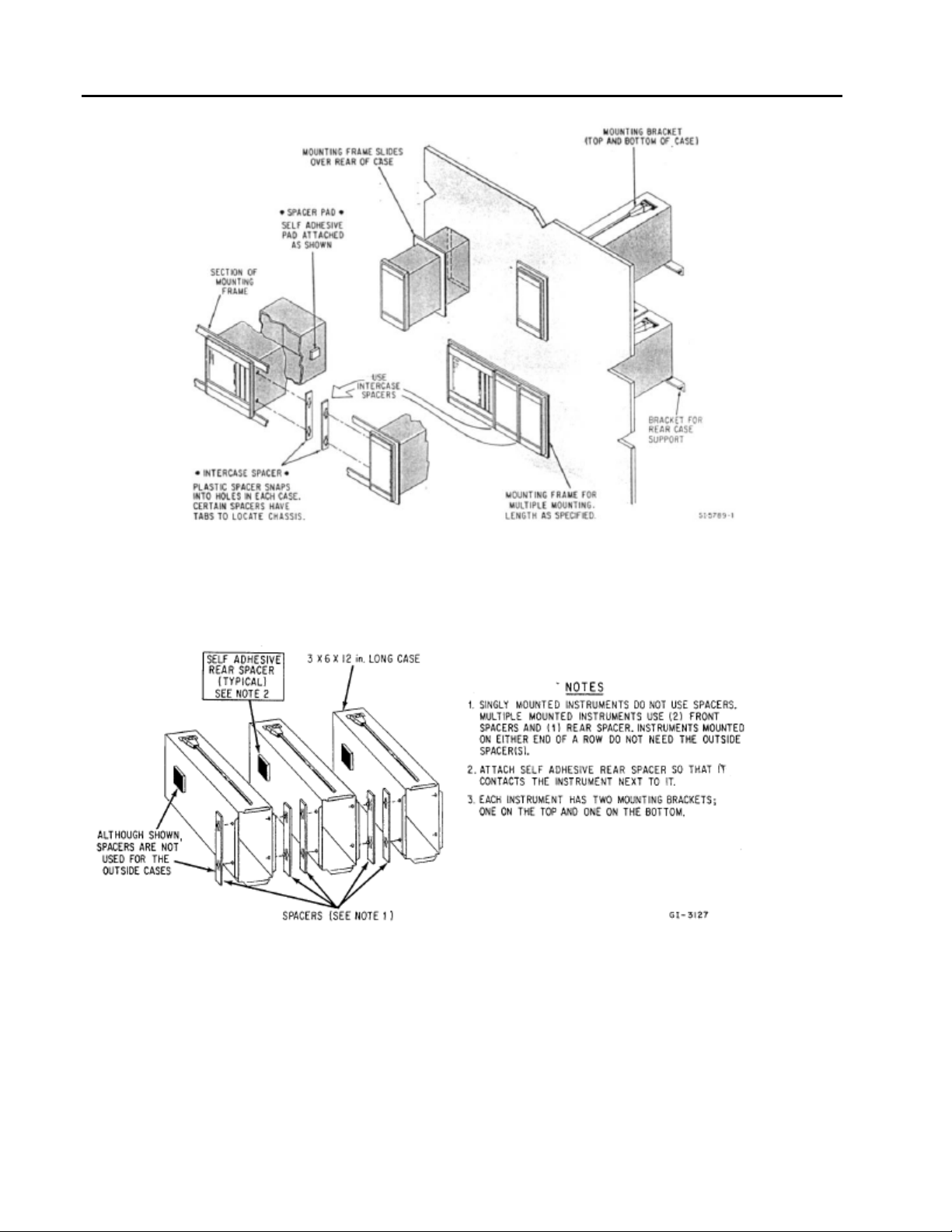

The instrument can be flush panel mounted, either as a single unit or side by side. Appropriate mounting

hardware is supplied. Outline dimensions and panel cut-out requirements for case mounting are shown in

Figure 2-1.

The dimensions given for spacing between instruments were selected on the basis of 1/8" thick panel

strength. Panel strength must be considered when multiple case mounting is required. As the panel cut-out

becomes longer it may be necessary to install supporting members. Because the panel area between

instrument rows becomes weaker as the cut-out becomes longer to the point where the panel offers very little

support. It is recommended that the 9 inch minimum center line dimension between horizontally mounted

rows be increased as the number of units increases, or that the panel strip be stiffened.

The rear of the instrument case must be supported to prevent panel distortion. Mount an angle iron or similar

member along the bottom of the cases as indicated in Figure 2-2. If the panel is to be moved the instrument

cases must be tied down to prevent damage.

If multiple mounted instruments are installed in a panel that tilts back, it may be necessary to support the

instruments so the panel does not sag. The downward weight should be supported by additional panel

supports and/or by increasing panel thickness.

5

Page 12

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

2.3.2 Mounting Procedure

For single and multiple case mounting the instruments are furnished with a trim collar (mounting frame).

Figure 2-2 illustrates the installation and use of the trim collar (mounting frame). Trim collars (mounting

frames) are available in various sizes and are supplied to conform with the particular panel cut-out.

NOTE: Mounting brackets and trim collars (mounting frames) are packaged separately. Check the

shipment carefully to prevent loss of mounting hardware.

To install single or multiple mounted instruments in a prepared panel cut-out, proceed as follows:

1. Remove the through-case shipping bolt.

2. Slip the trim collar (mounting frame) over the rear of the case and slide it forward to the front of the

case.

3. Slide the instrument case through the panel opening.

a. Single mounting case - support the weight of the case and attach the top and bottom

mounting brackets. Tighten the bracket screws.

b. Multiple mounted cases - spacer bars and self-adhesive pads must be used between the

cases, as shown in Figure 2-3. Start the installation from the right (when facing the panel),

installing the spacers as each case is added. Also, as each case is positioned in place, install

and tighten the top and bottom mounting brackets. Each case must be tight against the

previous case.

NOTE: Spacers are not required on the outside of the right and left cases.

6

Page 13

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

NOTES:

1. DIMENSIONS ARE IN INCHES. DIMENSIONS IN BRACKETS (

) ARE IN MILLIMIETERS.

2. DIMENSIONS GUARANTEED ON CERTIFIED PRINTS ONLY.

3. CASE MOUNTING HARDWARE SUPPLIED UNLESS

OTHERWISE SPECIFIED.

4. THIS DRAWING IS THIRD-ANGLE PROJECTION AS SHOWN

5. UNLESS OTHERWISE INDICATED ALL TOLERANCES ARE ±

1/16 (1.6)

Figure 2.1 Outline Dimensions & Panel Cut-out Requirements

7

Page 14

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Figure 2-2. Single or Multiple Panel Mounting

Figure 2-3. Intercase Spacing

8

Page 15

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

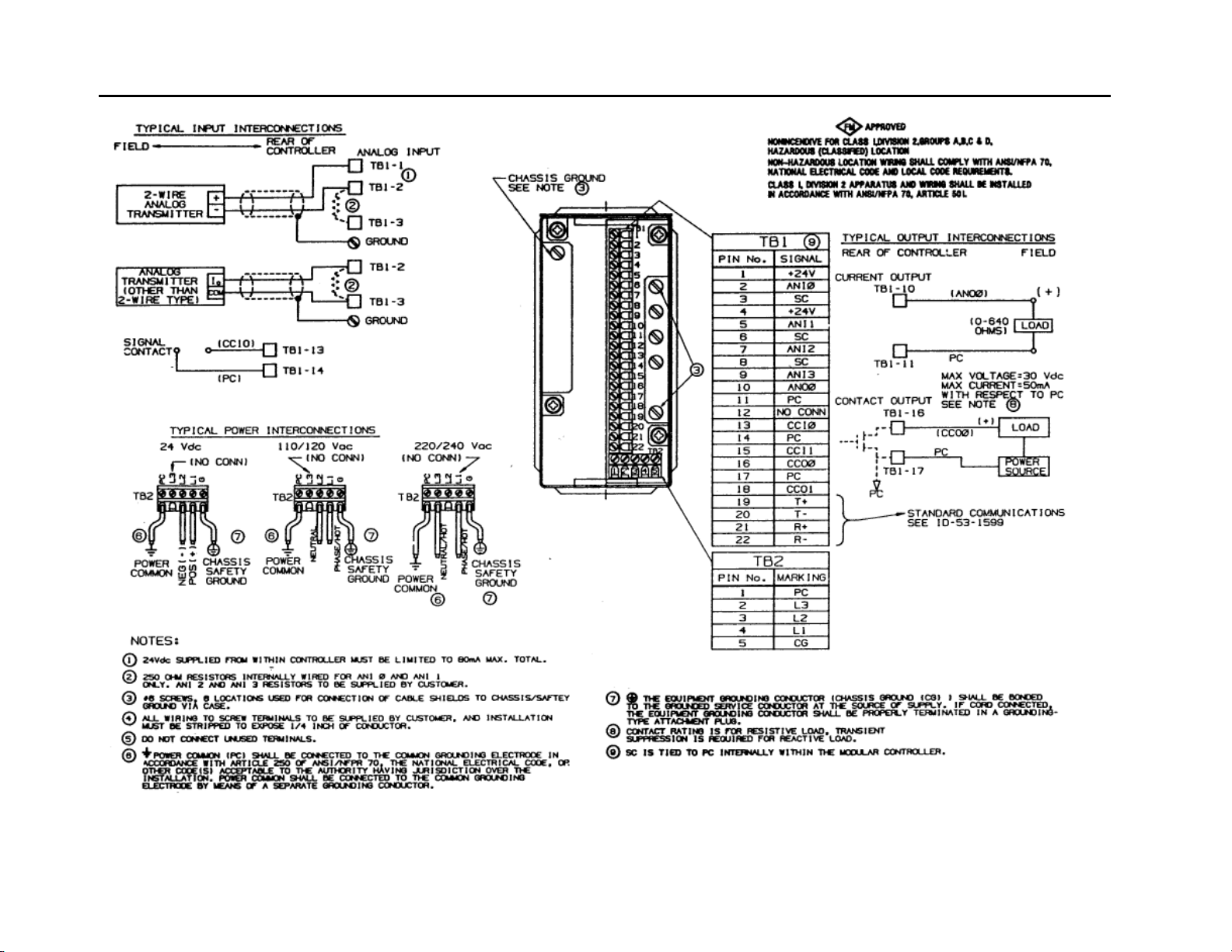

2.4 Power & Signal Wiring

PREPARATORY: The 53SL5100 can be configured for one to four analog inputs (ANI0-3), one analog output

(ANO0), two control contact inputs (CCI0 and 1), two control contact outputs (CCO0 and 1) and Datalink

network interconnectivity. Therefore, prior to making electrical connections, the particular instrument

configuration should be determined with all assigned inputs and outputs identified to assure proper signal

routing.

Provisions for electrical interconnections are located at the rear of the instrument case. Under ideal conditions

shielded cable may not be required. In noisy locations all system input, output and power wiring should be

enclosed in electrical conduit. System interconnection cables (except for power cables) should be fabricated

from 2-wire shielded signal cable. Signal transmission distance should not exceed the limit specified for the

particular transmitter (refer to applicable technical literature provided for the respective device). Polarity must

be observed when connecting the remote transmitters to the instrument.

The instrument has a vertically mounted terminal strip (TB1) for signal interconnections and a horizontally

mounted terminal strip (TB2) for power wiring. Both terminal strips are located at the rear terminal board of

the instrument case.

SNAP-OUT TERMINAL CONNECTORS

Both terminal strips, TB1 and TB2, have removable plug-in connectors. The upper connector for TB1 has

screw lugs 1 through 12 and the lower connector has screw lugs 13 through 22. All of the screw lugs are on a

single connector for TB2. To remove a signal connector, grasp it securely on both sides with the thumb and

forefinger, rock it gently from top to bottom (not side to side) and pull it straight out. To remove the power

connector, grasp the sides firmly with the thumb and forefinger, rock it gently from side to side and pull

straight out.

NOTE: The screw lugs on the back of the instrument are designed for 12 – 24 AWG wire. It is

important that the wire be stripped to expose 1/2 inch of conductor before installation.

WARNING! Instruments that are powered from an ac line service constitute a potential

electric shock hazard to the user. Make certain that these system ac power lines are

disconnected from the operating branch circuit before attempting electrical interconnections.

9

Page 16

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

10

Figure 2-4. Controller Rear Power and Signal Terminal Boards

Page 17

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

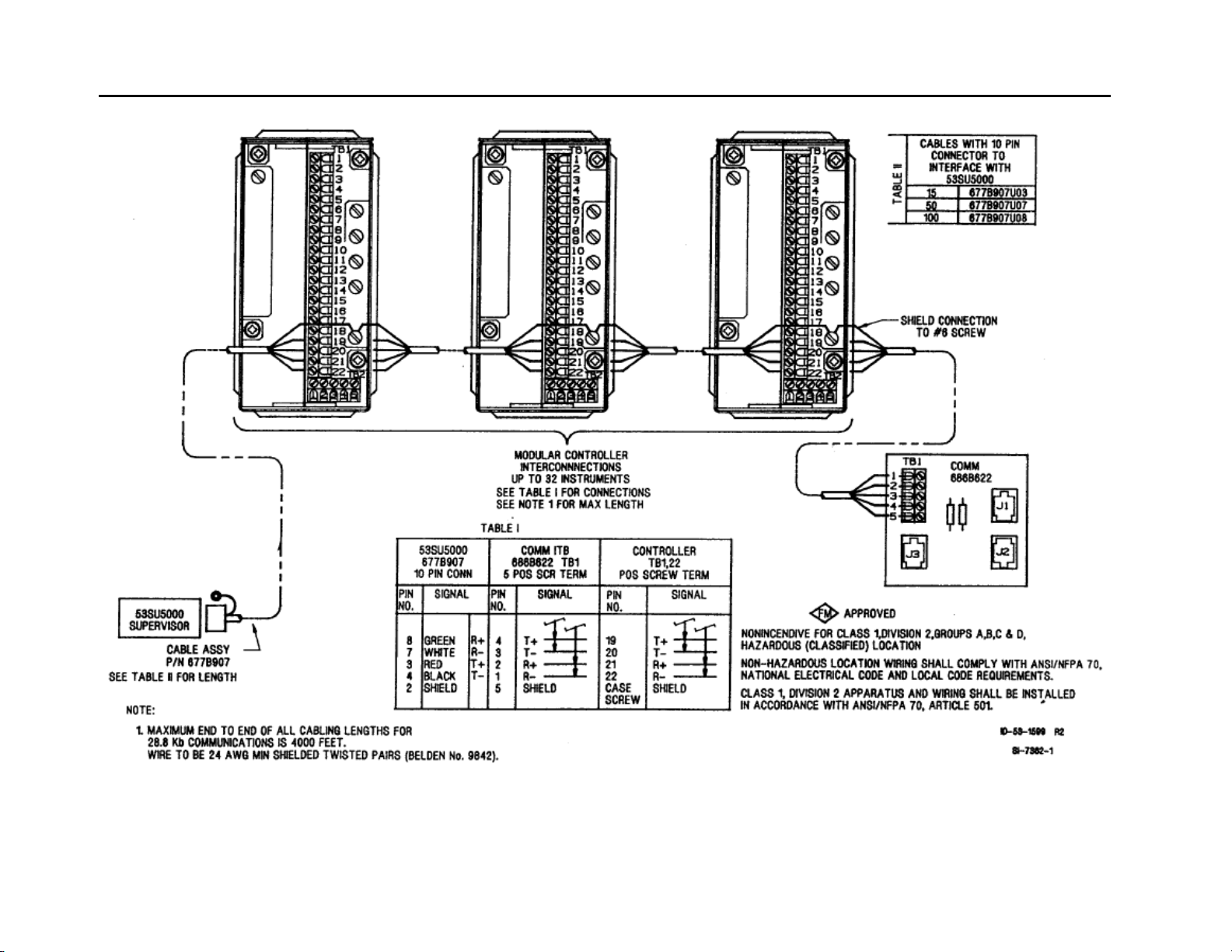

Figure 2-5. Datalink Installation Diagram

11

Page 18

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

2.4.1 Power Wiring

Refer to the instrument model number to verify the power input requirements:

53SL511…. – AC Power

53SL512…. – DC Power

2.4.1.1 DC Power

Reference Figure 2-4 and connect the remote 24 V dc power supply to the instrument as follows:

1.

Connect (+) input line, via remote SPST switch, to terminal L1.

2. Connect (-) input line to the system bus bar. The bus bar should be connected to a good earth ground

(#8 AWG wire is recommended). Individual wires should be run from the controller Power Common

(PC ) and Signal Common (SC ) terminals to the bus bar. The chassis should be grounded by

connecting terminal G to earth ground.

NOTE: Use of a common bus bar is recommended to minimize potential

voltage differences that may occur as the result of ground current loops, e.g.,

potential difference between separate signal grounds, power grounds, etc.

2.4.1.2 AC Power

Reference Figure 2-4 and connect the specified line service (110-120, 220-240 V ac, 50 or 60 Hz) to the

trument as follows:

ins

1. Connect the phase or hot line L, via a remote power disconnect switch or circuit breaker, to terminal

L1.

2. Connect the neutral line N to terminal L2 for 110-120 V ac. Connect the neutral line N to terminal L3

for 220-240 V ac.

3. Connect Power Common to a good earth ground (#12 AWG wire is recommended). The instrument

case should be grounded by connecting terminal G to earth ground at the source of supply

(green/green-yellow ground).

All supply connections include surge protection rated at 275 V ac normal mode.

NOTE: To minimize possible interference, ac power wiring should be routed away from signal

wiring.

2.4.2 Field Signal Wiring

2.4.2.1 Current/Voltage Input to AIN0 and AIN1

When the input signal is from a 4-20 mA current transmitter, a precision 250 ohms (+/-0.1%) resistor is

required. (The resistor tolerance is critical, as the resistor is used to accurately convert the current signal from

the transmitter, which is typically 4-20 mA, to a specified analog input voltage of 1 to 5 V dc). The back of the

rear terminal board has the appropriate resistors (R1 and R2, respectively) for ANI0 and ANI1.

2.4.2.2 Contact Input to CCI0

Separate contact input signals to CCI0 and CCI1 can be used for alarm inputs. One side of each

remote contact must be connected to power common as illustrated in Figure 2-4. Minimum opened

or closed recognition time for a remote contact must be 0.05 seconds.

2.4.2.3 Current Output from ANO0

A current output signal is available for re-transmission of one of the input signals ANI0 through

ANI3. Observe the proper polarity when connecting the output to another instrument.

2.4.2.4 Contact Output CCO0

Discrete contact output CCO0 is identified in Figure 2-4. Each discrete output is a solid state switch with a

rating of 30 V dc, 50 mA maximum. A CCO is referenced to power common. When this contact is connected

to an inductive load, an external arc suppression network is required for contact protection.

12

Page 19

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

2.4.3 Datalink Communication

Datalink is an interrogator/responder serial interface capable of supporting 32 instruments on a single

network. It uses an RS485 physical interface. The Datalink wiring diagram for this instrument is provided as

Figure 2-5. Complete coverage of the Datalink is provided in Instruction Bulletin 53SU5000.

2.5 Factory Set Calibration

Each unit contains individual factory set entries that calibrate the four analog inputs (ANI0 through ANI3) and

analog output (ANO0). There is a calibration sheet supplied with each instrument that should be retained for

future reference when the installation is completed. Reference Section 5.3 for additional information.

2.6 Grounding

Installations are expected to have access to an independent, high quality, noise-free point of earth reference.

The system should be connected by a dedicated, low resistance (less than one ohm) lead wire directly to the

installation’s point of earth reference. This ground reference is referred to as the Instrumentation Ground. If

an instrumentation ground reference does not exist in the installation, an earth ground electrode should be

established with an independent grounding rod or ground grid mesh.

13

Page 20

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

14

Page 21

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

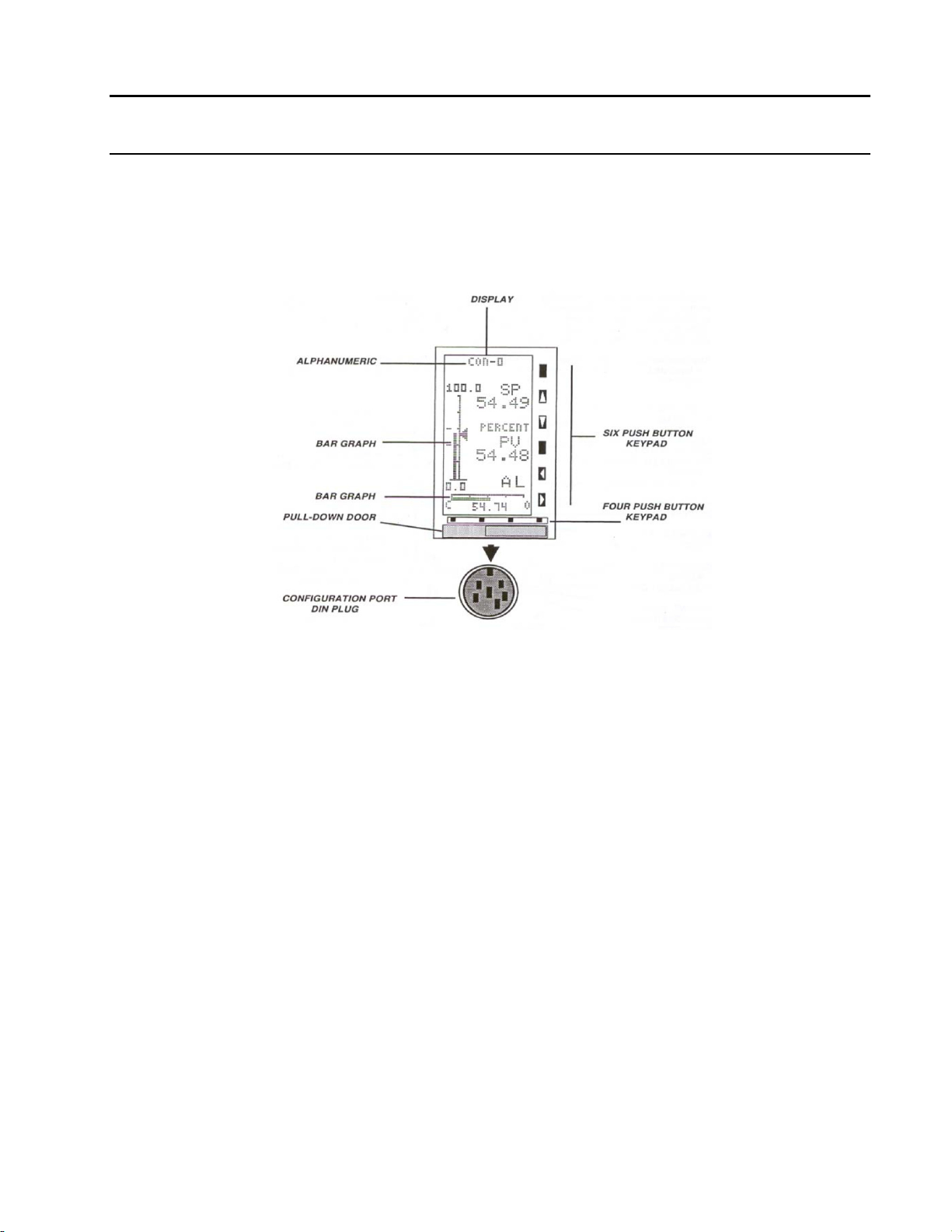

3 FRONT PANEL

The front panel of the instrument contains the display and all push buttons used to change display

presentations and parameters. The front panel has a gas discharge 96 X 48 dot matrix display, a six

pushbutton vertical keypad, and a four pushbutton horizontal keypad. It also has a configuration port DIN

plug, which is concealed behind the identification tag pull-down door. To open this door, press on the lower

front edge. Front panel display information is presented as bar graphs with associated alphanumerics or as

alphanumeric only. (See Figure 3-1.)

Figure 3-1. Front Panel

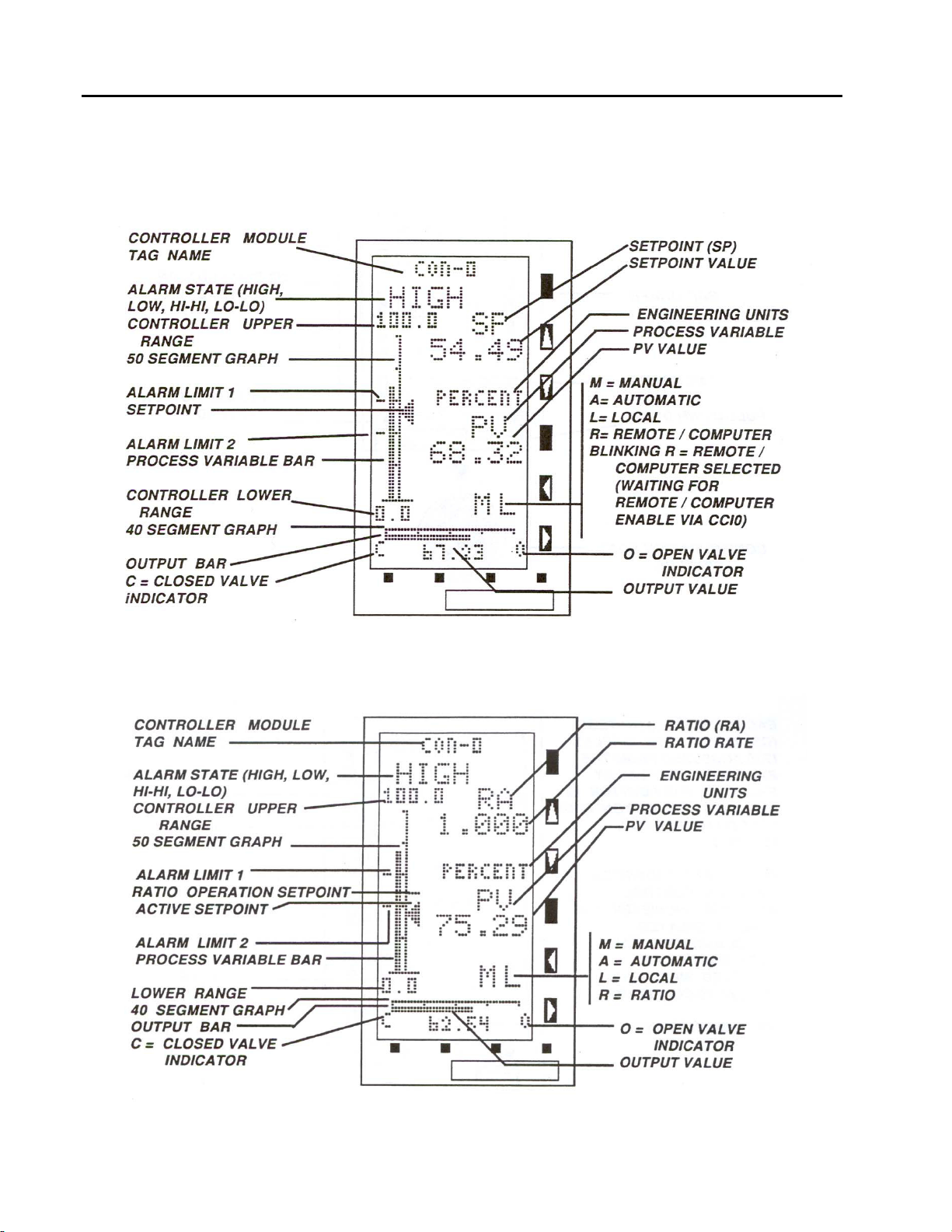

3.1 Display

The bar graph display is a visual indication of the process events monitored and subsequently altered either

by the instrument or other device. This instrument provides three unique bar graph displays and one

alphanumeric parameter display. Bar graph response dynamics as well as the alphanumerics on all of the

display types are selected when the instrument is configured.

There are four configurable operating modes, called control strategies (CS1-4). The control strategies are:

CS1, Single Loop PID Controller

CS2, Analog Backup Controller

CS3, Ratio Controller

CS4, Automatic/Manual Station

Two of the control strategies, CS1 and CS2, have identical bar graph presentations; that is why there are

three, rather than four, unique bar graph types. Each control strategy (CS1 - CS4) also has a pushbutton

selectable parameter display. Although the contents of the parameter display are selectable configuration

items, the display format is identical for each of the four control strategies.

Any display type can have a portion of its contents overlaid with an ALARM indicator. If the instrument is

manually set to engineering mode, the display can be overlaid with the CONFIGURATION or DISPLAY data

entry line. Alarm indicators warn of variation changes that exceed tolerance limits; the process may require

immediate attention. The engineering mode (EMODE) overlay provides a single entry line for data display and

alteration.

15

Page 22

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

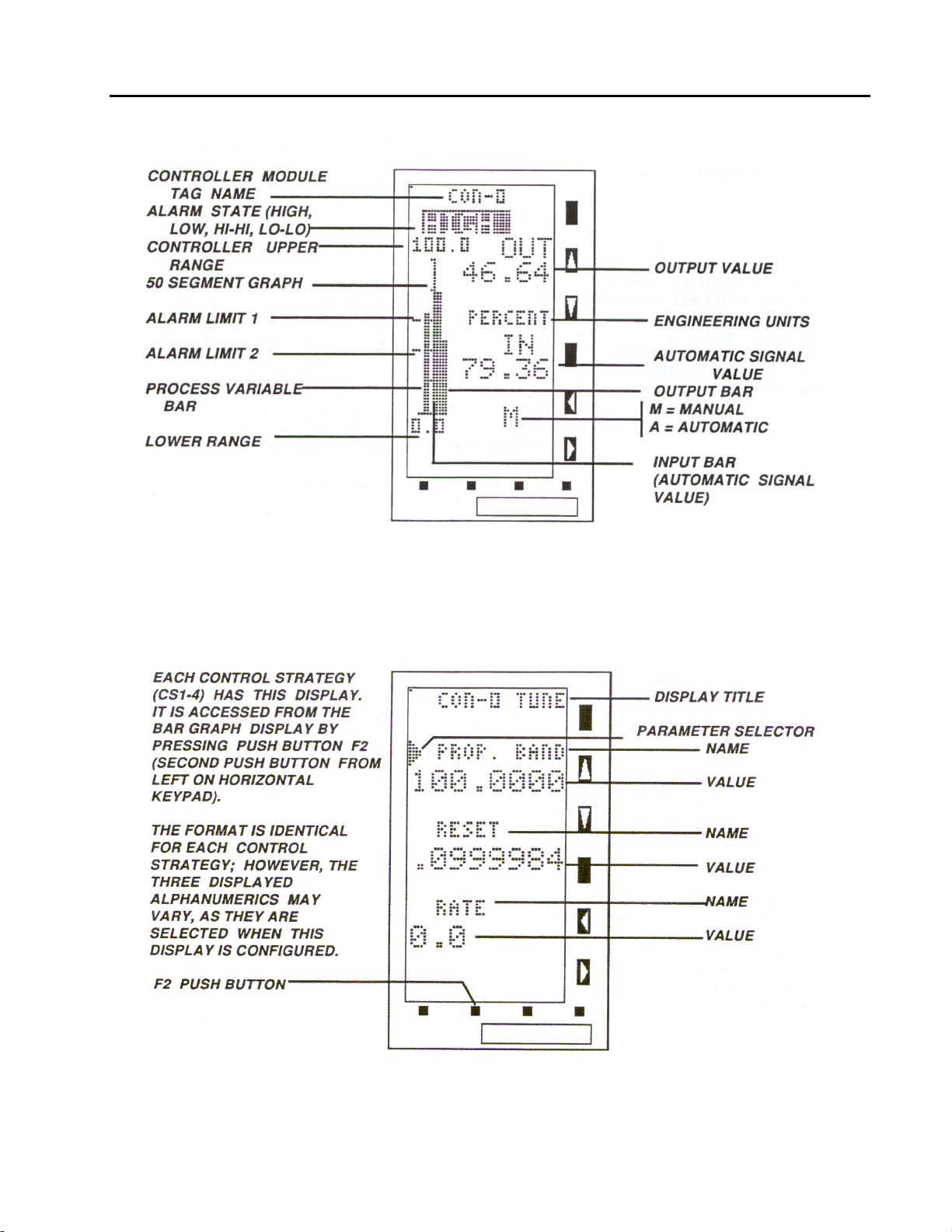

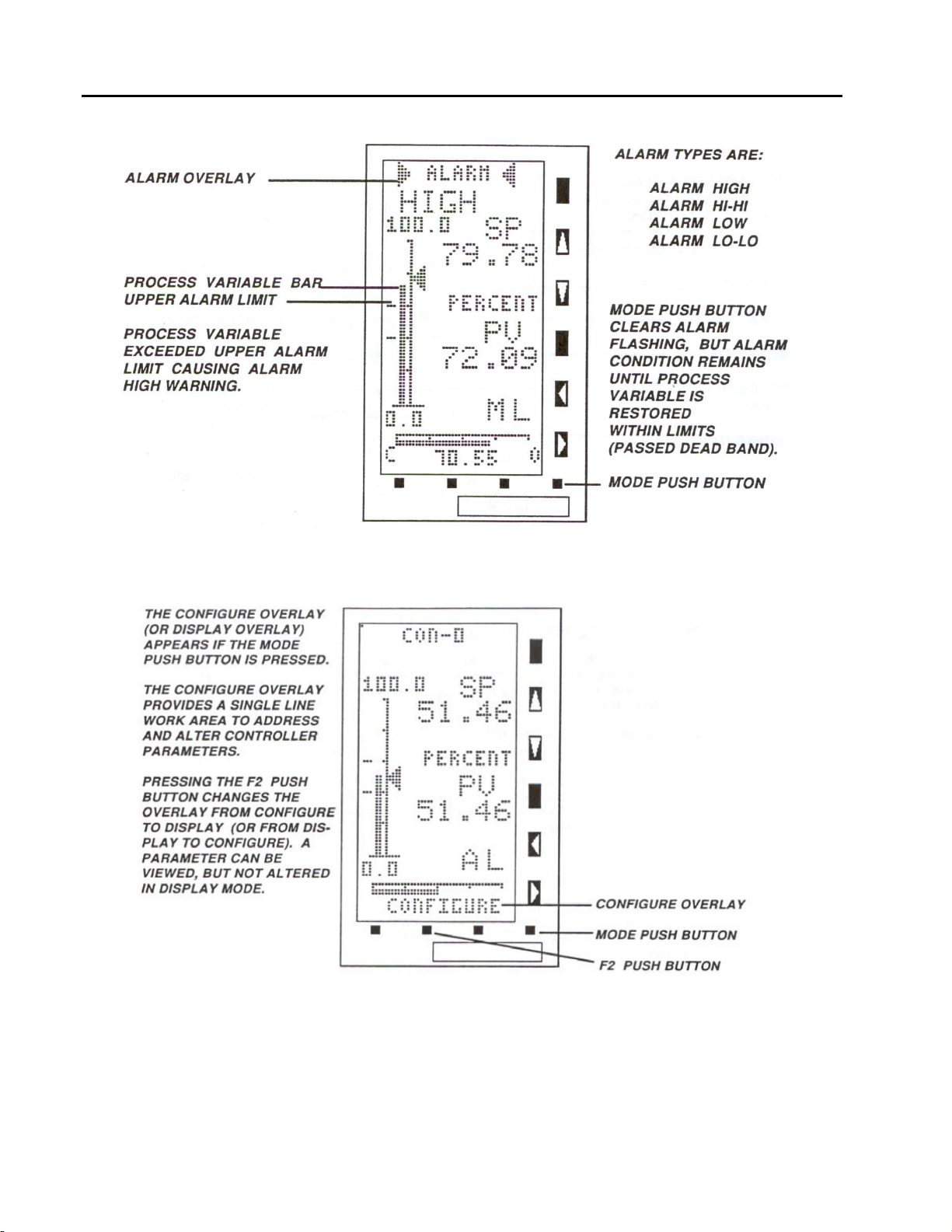

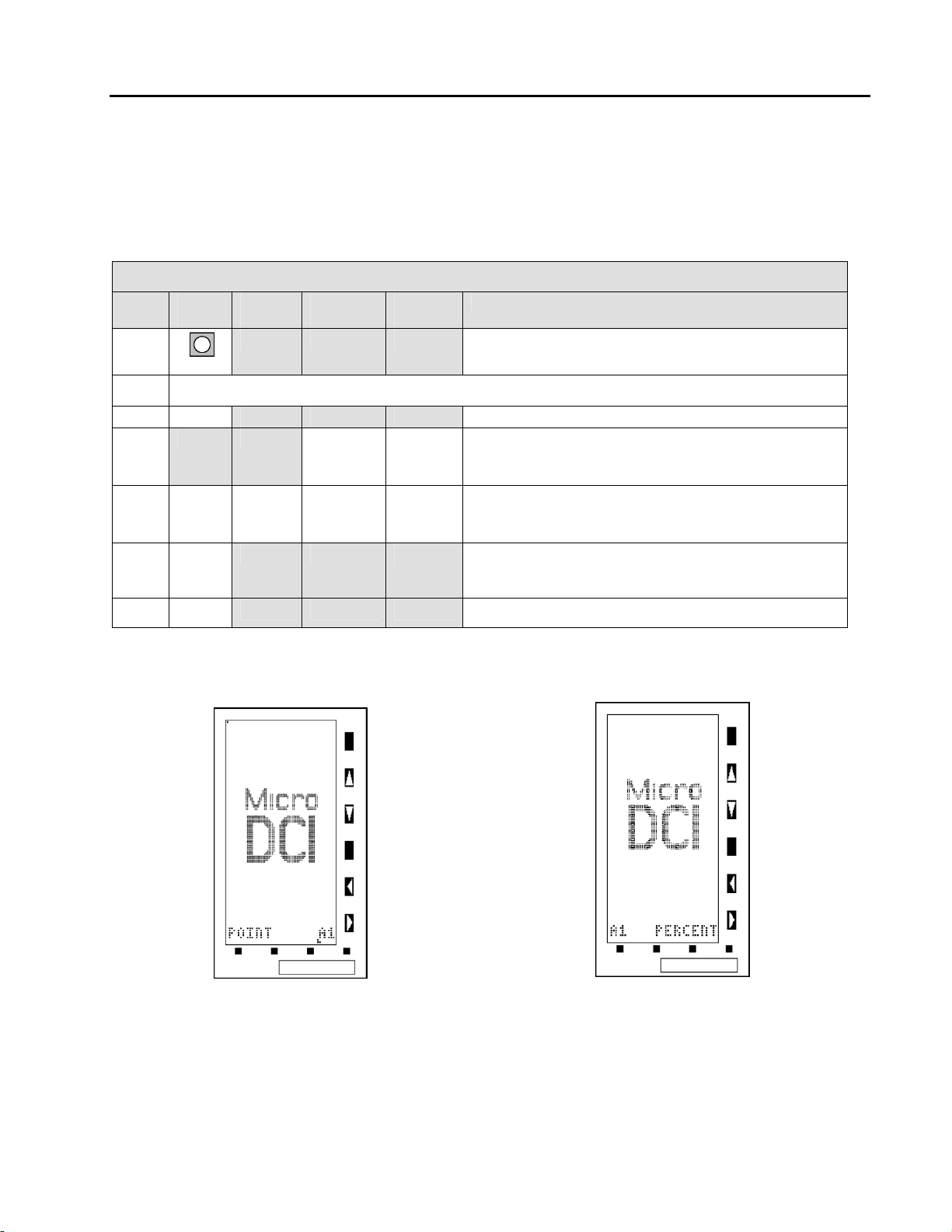

The three bar graph display types for CS1-4 and the parameter display, with appropriate call outs, are

illustrated in Figure 3-2 through Figure 3-5. Figure 3-6 and Figure 3-7 illustrate displays with alarm and

configuration overlays.

Figure 3-2. CS1, Single Loop PID Controller or CS2, Analog Backup Controller

16

Figure 3-3. CS-3, Ratio Controller

Page 23

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Figure 3-4. CS4, Automatic/Manual Station

Figure 3-5. CS1 - CS4 Parameter Display

17

Page 24

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Figure 3-6. Alarm Overlay

18

Figure 3-7. Configure Overlay

Page 25

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

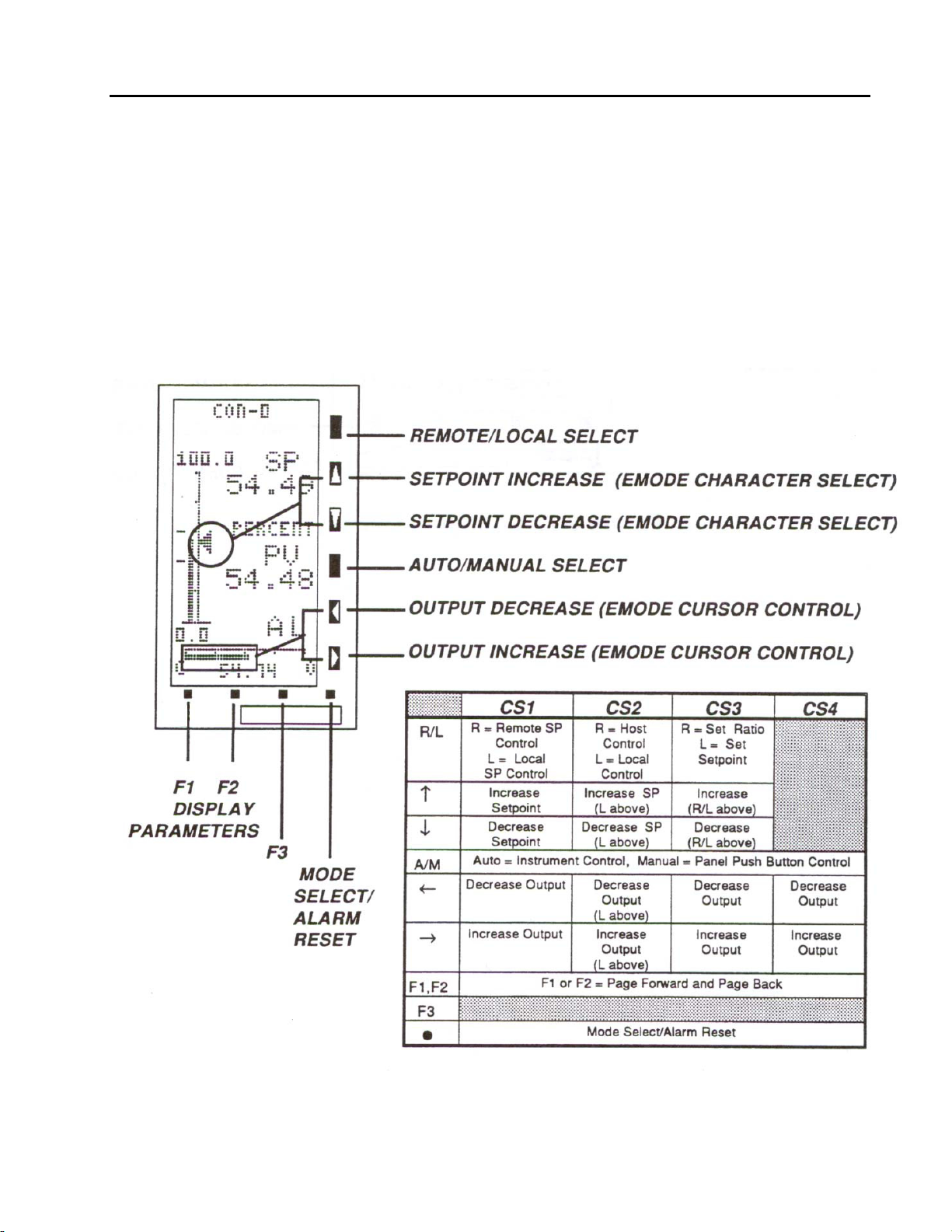

3.2 Front Panel Pushbuttons

The front panel pushbuttons are used to vary the display presentation, to select instrument operator or

engineering modes, and to select local or remote setpoint levels. In engineering mode, (EMODE) they are

also used to display and/or alter database parameters which are presented as single line datapoints in the

configuration overlay.

Pushbutton operator mode functions differ slightly with each control strategy implemented; however, the

engineering mode pushbutton functions are identical for all four control strategies. General pushbutton

functions are illustrated in Figure 3-8 below and defined in Table 3-1 on the facing page. The summary table

in Figure 3-8 shows the functional differences of the push buttons by control strategy. These differences are

included as part of the push button descriptions provided in each individual control strategy section of the

book.

Figure 3-8. Front Panel Pushbuttons

19

Page 26

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Pushbutton Title Operator Mode Engineering Mode

Used to select between Remote setpoint control

and Local setpoint control. When in Remote, an

R appears in the lower right of the display. When

in Local, anLappears in the lower right of the

display.

The setpoint indicator increases (rises) when this

pushbutton is pressed and held. Release the

pushbutton when the desired setpoint level is

reached. This pushbutton is for Local operation

only.

The setpoint indicator decreases (falls) when this

push button is pressed and held. Release the

pushbutton when the desired setpoint level is

reached. This pushbutton is for Local operation

only.

This pushbutton is the Auto/ Manual mode

toggle. When toggled to Auto, an A appears

before the R or L (for Remote or Local), in the

lower middle right of the display. When toggled to

Manual, an M appears before the R or L (for

Remote or Local), in the lower right of the

display. Auto indicates the process is under

instrument control. Manual indicates the process

is controlled by the instrument panel pushbuttons

(e.g., output increase and decrease.

The output indicator decreases when this

pushbutton is pressed and held. Release the

pushbutton when the desired output level is

reached. This pushbutton is for Manual operation

only.

The output indicator increases when this

pushbutton is pressed and held. Release the

push button when the desired output level is

reached. This push button is for Manual

operation only.

These two push buttons have similar functions,

but work in reverse of one another. They are the

bar graph - Param display toggles. The two

display types interchange and alternately appear

each time either one of these two pushbuttons is

pressed.

Not used

This pushbutton clears the flashing ALARM message, but the alarm indication remains until the

process variable is restored within tolerable limits past dead band. It is also used to toggle between

Operator and Engineering modes. If no ALARM message is present, pressing this pushbutton will

toggle the instrument between Operator mode and Engineering mode.

Not used

For configure or a display function, the character

set displays one character at a time in ascending

alphanumeric order when this pushbutton is

pressed and held. Release the push button when

the desired character, number, or symbol

appears.

For configure or a display function, the character

set displays one character at a time in descending

alphanumeric order when this pushbutton is

pressed and held. Release the pushbutton when

the desired character, number, or symbol

appears.

Not used

For configure or display functions, the cursor shifts

one position to the left each time this button is

pressed. When pressed and held, characters

continue to shift left one position at a time.

Maximum character length is 10 characters (9

character shifts).

For configure or display functions, the cursor shifts

one position to the right each time this button is

pressed. When pressed and held, characters

continue to shift right one position at a time.

Maximum character length is 10 characters (9

character shifts).

Pushbutton F2 is used to select the configure or

display functions in EMODE. Pressing F2 in

EMODE alternately selects one function or the

other.

In the configuration function, pressing this

pushbutton causes the addressed datapoint to be

altered with the character string that was entered

with the EMODE Cursor Control and Character

Select pushbuttons. In display function, pressing

this pushbutton causes the addressed datapoint to

display its contents.

F1, F2

F3

Remote/

Local

Select

Setpoint

Increase

(EMODE

Character

Select)

Setpoint

Decrease

(EMODE

Character

Select)

Auto/Manual

Select

Output

Decrease

(EMODE

Cursor

Control)

Output

Increase

(EMODE

Cursor

Control)

Page Forward

and Page

Back

(EMODE

ENTER key)

Mode

Select/Alarm

Reset

20

Page 27

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

3.3 Displaying a Datapoint

The following procedure illustrates how to enter Engineering Mode (EMODE) and use the display function to

access the contents of datapoint A001 (A1). The displayed contents will be PERCENT. Figure 3-9 and Figure

3-10 are supporting illustrations for the display procedure which is described in Table 3-2. It should be noted

that EMODE has a 20 second timeout if it is accessed and its functions (e.g., configure or display) are not

used.

Table 3-2. Procedures to Display a Datapoint

Step Press

Once

1

MODE

2

3

F3

4

Shift

Result

Press to

Locate

If CONFIGURE appears instead of DISPLAY, press F2.

Target

Char.

A

Result

Puts instrument in engineering mode.

Displays entry line: POINT .

Puts A on entry line: POINT .A.

5

6

7

NOTE:

F3

MODE

Δ = space.

.AΔ

1

Shifts A and puts 1 on entry line: POINT .A1.

Enters address to display datapoint contents.

The address and the contents are displayed as

follows: A1 PERCENT.

Returns instrument to operator mode.

Figure 3-9. POINT.A1 Figure 3-10. A1 PERCENT

21

Page 28

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

3.4 Altering a Datapoint

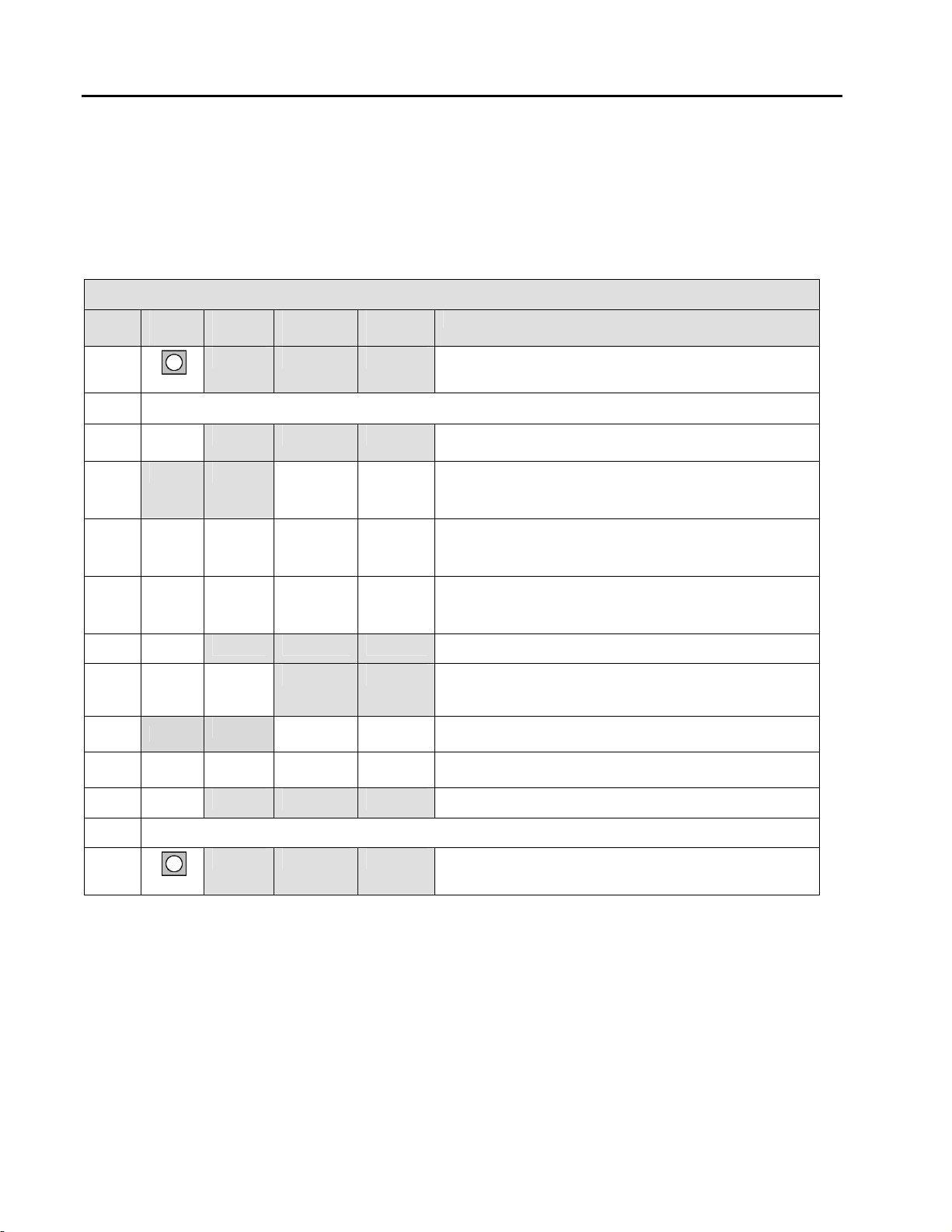

The following procedure illustrates how to enter EMODE and use the configuration function to alter the

contents of datapoint B000 (B0) with a 97. Entering a 97 in B00 invokes the display test which strobes the

display matrix dots on and off at 5 second intervals (approximate). When off, a perimeter of dots still remains

lit. Figures 3-11 and 3-12 are display test illustrations that support the procedure provided in Table 3-3. It

should be noted that EMODE has a 20 second timeout if it is accessed and its functions (e.g., configure or

display) are not used.

Table 3-3. Procedures to Display a Datapoint

Step Press

Once

1

MODE

2

3

F3

4

Shift

Result

Press to

Locate

If CONFIGURE appears instead of DISPLAY, press F2.

Target

Char.

B

Result

Puts instrument in engineering mode.

Displays entry line: POINT .

(If the prompt KEY? appears, see Table 3-5.)

Puts B on entry line: POINT .B.

5

6

7

8

9

F3

Hold

.BΔ

0

Shifts B and puts 0 on entry line: POINT .B0.

.B0Δ

0

Shifts B0 and puts 0 on entry line: POINT .B00.

.

locator

9

Displays contents of B00 (0).

B00 contents shifted right; only locator point

remains on the entry line: B00 .

Puts 9 on entry line: B00 .9.

10

11

12

13

NOTE:

22

F3

MODE

Δ = space.

.9Δ

To stop test, change B00 contents from 97 to 00 (Instrument Suspend State).

7

Shifts 9 and puts 7 on entry line: B00 .97.

Enters 97 in B00 to start the display test.

Returns instrument to operator mode.

Page 29

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Figure 3-11. Checkerboard Pattern Figure 3-12. Permiter Dots Illuminated

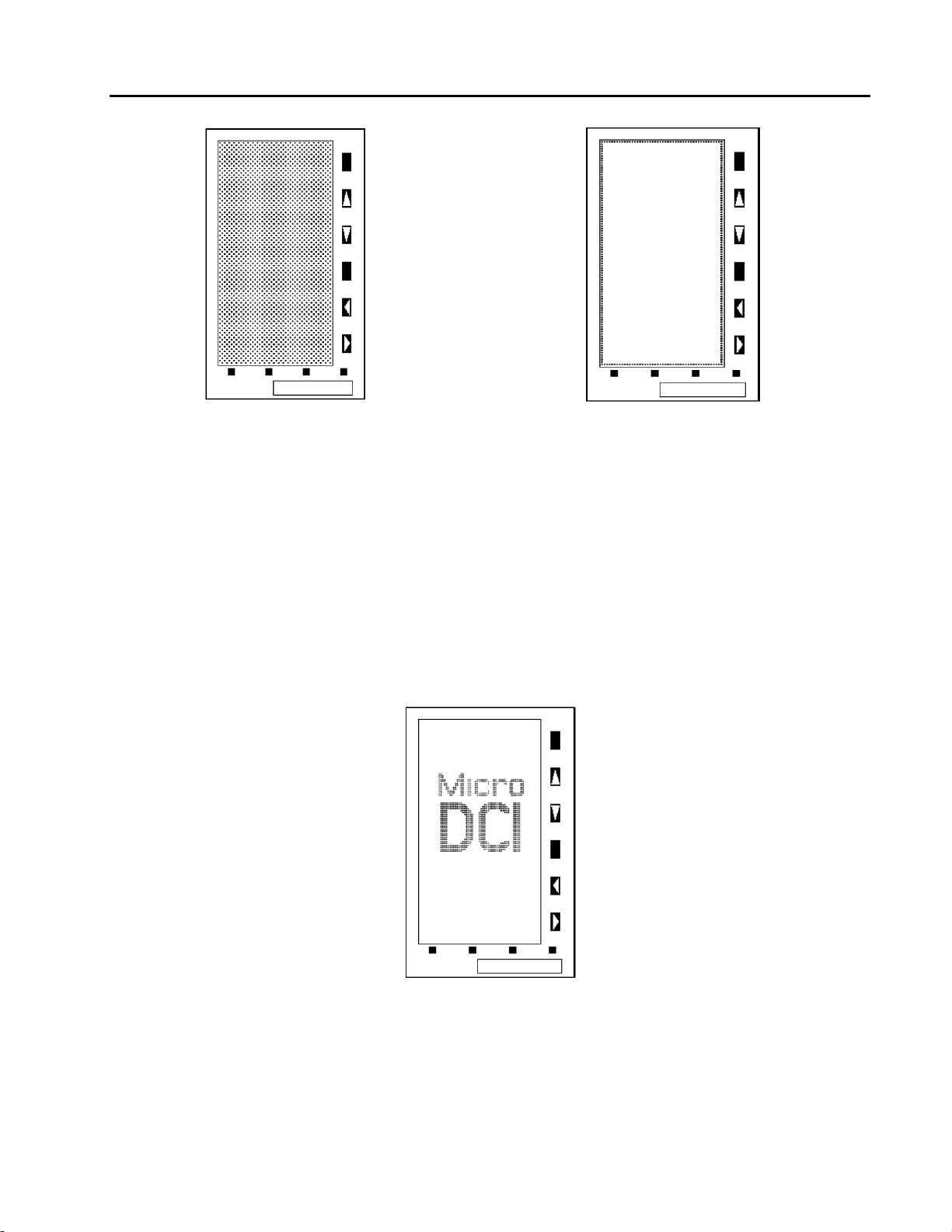

3.5 Defaulting the Database

Defaulting the database sets all non-instrument-specific datapoint parameters to predetermined values, then

suspends the instrument which is indicated by the logo presented on the display. When instrument operation

is suspended, instrument algorithmic control ceases.

The procedure to default the database is presented in Table 3-4 and the display logo is illustrated in Figure 3-

13. Entering a 98 in datapoint B00 defaults the database. If it is desired to suspend instrument operation

without defaulting the database, enter a 00 in lieu of a 98 into B00. The defaulted database values are

provided in the configuration tables of Section 4 and the database tables in Appendix C, Database, under the

column headed Default. Those parameter values that are left unaltered when the database is defaulted are

identified with gray-tone shading in the Default column of the tables. It should be noted that EMODE has a 20

second timeout if it is accessed and its functions (e.g., configure or display) are not used.

Figure 3-13. Display Logo

23

Page 30

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

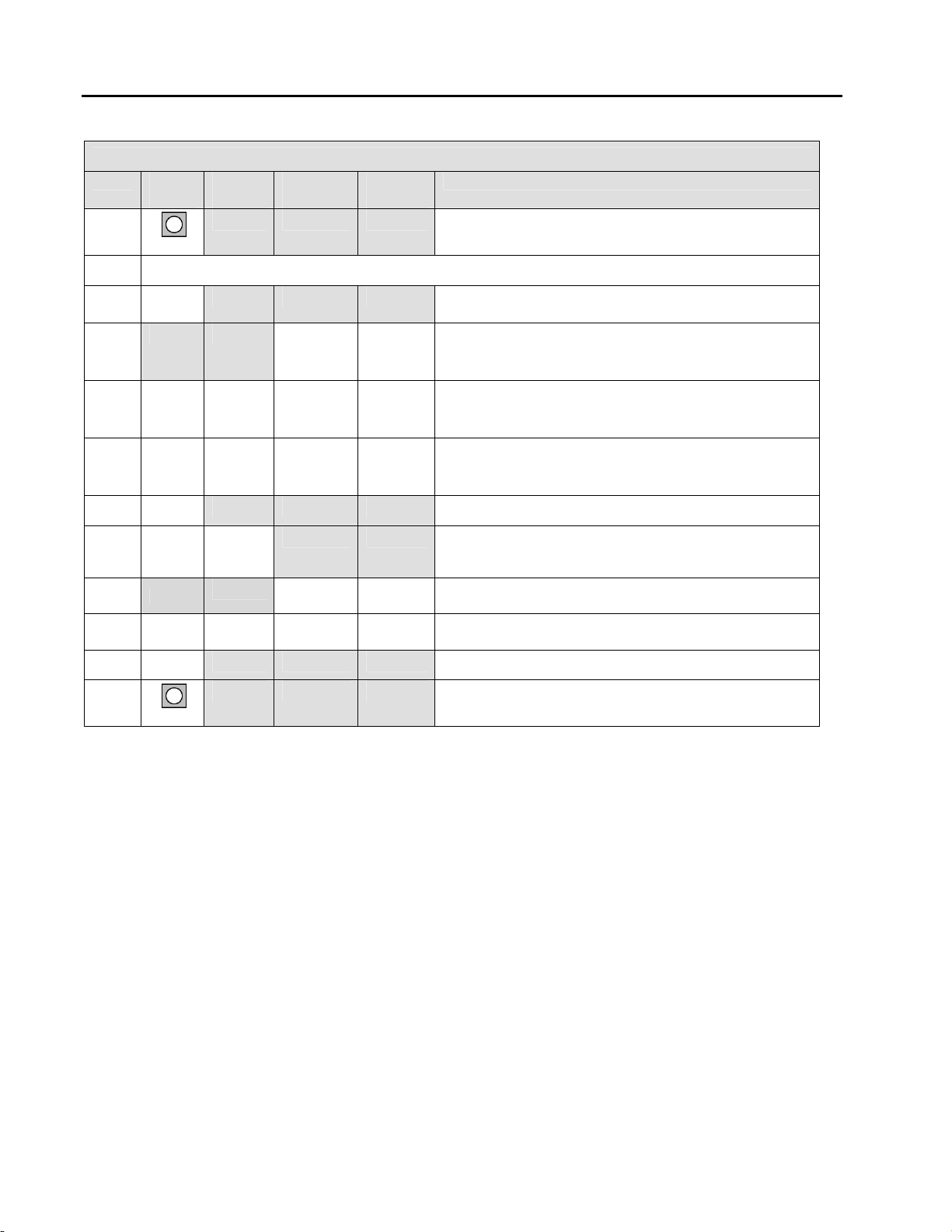

Table 3-4. Defaulting the Database

Step Press

Once

1

MODE

2

3

F3

4

Shift

Result

Press to

Locate

If DISPLAY appears instead of CONFIGURE press F2.

Target

Char.

B

5

6

7

8

9

F3

Hold

.BΔ

0

.B0Δ

0

.

locator

9

Result

Puts instrument in engineering mode.

Displays entry line: POINT .

(If the prompt KEY? appears, see Table 3-5.)

Puts B on entry line: POINT .B.

Shifts B and puts 0 on entry line: POINT .B0.

Shifts B0 and puts 0 on entry line: POINT .B00.

Displays contents of B00 (0).

B00 contents shifted right; only locator point

remains on the entry line: B00 .

Puts 9 on entry line: B00 .9.

10

11

12

NOTE:

F3

MODE

Δ = space.

.9Δ

8

Shifts 9 and puts 7 on entry line: B00 .98.

Enters 97 in B00 to default the database.

Returns instrument to operator mode.

24

Page 31

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

3.6 Responding to the Prompt: KEY?

When the password prompt KEY? appears, it indicates a password was set in the MicroTools software. The

password can not be set via the front panel push buttons.

A password key is a maximum of 10 numeric characters (numbers 0-9 only). It does not impede display

functions in engineering mode but must be unlocked to perform configuration functions. A password key is

NOT SET FOR NEW INSTRUMENTS from the factory; therefore, if it is set, it must have been done locally.

The password must first be obtained from the originator before the procedure in Table 3-1 can be used to

access the engineering mode configuration function capabilities.

Table 3-5. Entering a Key Password

Step Press

Once

1

Shift

Result

Press to

Locate

Target

Char.

Result

Puts instrument in engineering mode.

2

3

F3

4

If DISPLAY appears instead of CONFIGURE, press F2.

Displays password query: KEY?

2

Puts first password number on entry line: KEY? .N.

5

.2Δ

6

7 Repeat step 6 until all of the password characters are entered.

.22Δ

2

2

8

F3

NOTE: Δ indicates Space. N = any numeric value 0-9.

Shifts 2 and puts second password number on entry

line: KEY? .NN.

Shifts 22 and puts third password number on entry

line: KEY? .NNN.

Enters the password key and displays the entry line:

POINT . The engineering mode configuration

function is now accessible for use.

25

Page 32

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

26

Page 33

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

4 CONFIGURATION PARAMETERS

The configuration parameters provide the latitude to define the instrument’s personality attributes, so that

while still functioning within its designed specifications, it can perform application requirements with greater

refinement. Typical configuration parameters are the instrument’s indicator zero point and span, the display

tag names, engineering units of the displayed process value, and alarm limits, etc. IT IS NOT NECESSARY

TO DEFINE ALL OF THE CONFIGURATION PARAMETERS, as commonly used preset values may not have

to be altered and certain parameter selections eliminate others.

Although all resident in a memory database as datapoints, the configuration parameters are clustered into

modular groups that may have specific hardware identities (e.g., the ANI, ANO, CCI, and CCO circuits

illustrated in Figures 4-1 through 4-4), or may represent software controlled functions that are not specific to

any one hardware element.

4.1 Datapoint Types

A parameter can be any one of five data types. Each data type represents a specific data format:

integers, alphanumeric text strings, etc. A database module containing multiple parameters can

have a mix of data types. The data types are defined in Table 4-1 as follows:

Table 4-1. Datapoint Types

Type Byte

Size

L 1 Bit Represents a single binary bit that can have the value of 0 or 1.

B 1 Represents a positive integer with values from 0 to 255.

C 3 Represents a real analog (floating point) value that has a resolution of one part in 32,768 (15 bits)

H 5 Represents a high precision analog (floating point) value that has a resolution of one part in 2

A 10 Represents a text string that can be 10 characters long.

F 5 Represents text strings that can be 5 characters long.

4.2 Factory Standard Calibration

The instrument is shipped from the factory configured as summarized in Table 4-2.

Table 4-2. Factory Standard Calibration

Datapoint Value Attribute

B000 1

C106 100

C107 0

C108 0

B335 1

C256 100

L416 0

L106 1

L115 0

Displays

2. Parameter 1 Display

Format

and a dynamic range of ± 10

billion (31 bits) and a dynamic range of ± 10

This value indicates Single Loop PID Controller operation.

Proportional Band = 100%.

No Reset (TR) action.

No Derivative (TD) action.

No Alarms.

ANI0 Engineering Span Input (Process Variable [PV] Input) = 0% - 100%.

ANI0 Input Voltage Range is 1 -5 V.

Reverse Switch is set so that the instrument output decreases as PV increases.

Remote Setpoint Disabled indicates the setpoint value established in Local mode

remains in effect when the instrument is placed in Remote mode.

1. As configured: Display of Single Loop Controller, Analog Back-up Controller,

Ratio Controller, or Automatic Manual Station

38 .

38 .

27

Page 34

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

If the state of the database is unknown, the instrument can be returned to the factory standard configuration

with two datapoint entries:

1. Set B00 to 98 to default the database.

2. Set B00 to 1 to start functioning as a Single Loop Controller.

If the unit is to be operated online, it must be installed as described in Section 2, Installation. ANI0 (PV Input)

and ANO0 (Output) must be connected, and the unit must have power applied.

4.3 Configuring the Database Modules

The datapoints in the database modules must be changed to reflect required alterations in the factory

standard configuration or when the instrument is re-configured. There are generally four datapoint parameter

types contained in the eight database modules. The parameter types affect Datalink communications, display

indications, input-output signals, and alarm conditions. The eight database modules are described in Table 4-

2. Although it is not an absolute criterion, it is assumed the modules will be configured in the table Item order;

however, if the instrument is to be connected to a Datalink network, item 7, Communication Module, should

be configured first. By configuring the Communication Module first, the instrument can function on the

Datalink and the remaining datapoint values can be entered via the Datalink interrogator (master). Reference

the applicable instruction bulletin IB 53SU5000 for the procedure.

Table 4-2 is also a pointer to the descriptions of the database modules; the descriptions are presented

as Tables 4-3 through 4-10. (The gray tone shading in the default cell of a datapoint indicates the datapoint

contents are left unchanged after default. See Section 5.5 for the default procedure.)

Table 4-3. Database Modules

Item Title Purpose See

Table

1 Analog Input Module This module is used to configure the voltage input

characteristics (e.g., input voltage range) and how the input

signal is interpreted (linear or square root representation).

2

Analog Output Module

3 Contact Input Module This module allows the action of the CCIs to be reversed

4 Contact Output

Module

5 Controller

Module

6 Parameter

Display Module

7 Communication

Module

8 System Module This module is used to set the instrument tag name and the

The primary purpose of this module is to set the 0 - 20 mA

output signal relative to the displayed percent output.

(normally a closed contact = 1, but can be change to = 0).

This module allows the action of a CCOs to be reversed

(normally a closed contact = 1, but can be changed to = 0).

The primary purpose of this module is to set the instrument’s

responsiveness, Alarm Limits t & 2, Alarm Dead Band, and

the range limits (e.g., 0 - 100, -20 - 80, etc.).

This module provides quick pushbutton display access to

any

three selected datapoints for viewing or modifying (e.g.,

Alarm Limits 1 & 2 and Alarm Dead Band) without the

necessity of entering Engineering mode and addressing the

datapoints.

This module is used to configure the Datalink port

parameters (e.g., baud rate, parity selection, etc.).

display brightness.

4-10

4-11

4-4

4-5

4-6

4-7

4-8

4-9

28

Page 35

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-4. Analog Input (ANI) Module

Purpose: This module is used to configure input voltage characteristics (e.g., input voltage range), and how the

input signals are interpreted (linear or square root representation).

Title Symbol

Analog

Input

(Display

Only)

ANI H000 H001 0

ANI0

Datapi

nt

ANI1

Datapoint

Default Attributes

This is the value in engineering units of the

measured input after all signal conditioning has

been applied.

Engineering

Span

Engineering

Zero

Digital Filter

Index

0 - 5 V Input NOBIAS L416 L417 0

Square Root

Signal

Calibrate

Zero

Calibrate

Span

SPAN C256 C257 100

ZERO

DFILT B269 B270 3

SQRT L440 L441 0

CIZ B263 B264

CIS C296 C297

C276

C277 0 This is the lower range value.

This determines the upper range the analog

input represents in engineering units. The

upper range value equals Engineering Zero

plus Engineering Span.

This controls a first order filter that is applied

to the input signal. The time constant is

entered as an index value as follows:

0 -No Smoothing (no effect)

1 -0.05 s

2 - 0.1 s

3 - 0.3 s

4 - 0.7 s

5 - 1.5 s

Setting this parameter to 1 indicates the input

range is from 0 -5 volts (0 -20 mA). 0

indicates the input range is from 1 -5 volts (4 20 mA).

When a 0, it indicates the analog input signal

should be interpreted linearly.

When 1, it indicates the analog input signal

should be interpreted as a square root

representation of the value. When square root is

selected, input signals less than 1% (10% input

range) forces the input to its zero value.

This is the calibration zero adjustment. This

parameter is factory set and should not need

adjustment under normal operation.

See Section 5.3 for adjustment.

This is the calibration span adjustment. This

parameter is factory set and should not

need adjustment under normal operation.

See Section 5.3 for adjustment.

6 - 3.1 s

7 - 6.3 s

8 -12.7 s

9 -25.5 s

10 -51.1 s

11 - 102 s

12 - 205 s

13 - 410 s

14 - 819 s

15 -1638 s

Tag Name AITAG A224 A225

Engineering

Units

AIEU A298 A299

ANI-0

ANI-1

PERCENT

(ALL)

An assignable 10 character name for the analog

input (ANI-0, ANI-1, ANI-2, ANI-3).

Assignable for units of measure the ANI

represents (e.g., GPM for gallons/minute).

29

Page 36

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Figure 4-1. ANI0-3 Figure 4-2. ANO0

NOTE: These figures are graphical representations of the signal conditioning that occurs on the

instrument main board. They are provided for reference purposes only.

Table 4-5. Analog Output (ANO) Module

Purpose: The primary purpose of this module is to set the 0 - 20 mA output signal relative to the

displayed percent and to select the analog input signal (ANI0-3) that is to be routed to the analog

output (ANO0).

Title Symbol ANO0

Datapoint

Analog Output

(Display Only)

0 -20 mA

Output

Calibrate Zero COZ0 B267

Calibrate

Span

Tag Name AOTAG0 A244 ANO0 The assignable 10 character name for ANO0.

ANO0 C000 0 The value in this datapoint represents the

OZBASE0 L472 0

COS0 C300

Default Attribute

percent of output to be generated by hardware

(e.g., 100% output = 20 mA).

When a 0, the percentage output generates a 4

-20 mA signal. When set to 1 , the percentage

output generates a 0 -20 mA signal.

These parameters are factory set and should

not need adjustment under normal operation.

See Section 5.3 for adjustment.

Table 4-6. Contact Input Module (CCI)

Purpose: This module allows the action of the CCI to be reversed (normally a closed contact = 1, but can be

changed to = 0).

Datapoint

Title Symbol

Contact

Input

(Display

Only)

Contact

Input

Invert

Tag

Name

30

CCI0 L000 0

IINV0 L264 0 0 As shown above, it reverses the action of the CCI datapoint.

CITAG A262 CCI0 It is an assignable 10 character name for the contact control input.

Default Attribute

When open, a 4 -24 V dc input signal = 0 when IINV = 0.

When open, a 4 -24 V dc input signal = 1 when IINV = 1.

When closed, a < 1 V dc input signal = 1 when IINV = 0.

When closed, a < 1 V dc input signal = 0 when IINV = 1.

Page 37

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-7. Contact Output Module (CCO)

Purpose: This module allows the action of the CCO to be reversed (normally a closed contact = 1, but can be

changed to = 0).

Title Symbol Data-point Default Attribute

Contact

Output

(Display

Only)

Contact

Output

Invert

Tag

Name

CCO L024 0

OINV L288 0

COTAG0

COTAG1

A280

A281

CCO-0

CCO-1

If CCO = 0 and OINV = 0, then it is open.

If CCO = 0 and OINV = 1, then it is closed.

If CCO = 1 and OINV = 0, then it is closed.

If CCO = 1 and OINV = 1, then it is open.

As shown above, it reverses the action of the

CCO datapoint.

An assignable 10 character name for the

contact control output.

Figure 4-3. CCI0 Figure 4-4. CCO0

NOTES:

WD = Watchdog

These figures are graphical representations of the signal conditioning that occurs on the

instrument main board. They are provided for reference purposes only.

31

Page 38

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-8. Control Module

Purpose: The primary purpose of this module is to set the instrument’s responsiveness, Alarm Limits 1 &

2, Alarm Dead Band, and the range limits (e.g., 0 - 100, -20 - 80, etc.).

Note:

Title Symbol

Control Alarm

Mode

B335 PV PL1

0 >60 60 HIGH Alarm Llimit 1 is set for 60: PV > 60 = HIGH alarm

0 <40 40 LOW Alarm Limit 2 is set for 40: PV < 40 = LOW alarm

2 >60 60 HIGH Alarm Limit 1 is set for 60: PV > 60 = HIGH alarm

2 <40 40 N/A Alarm Limit 2 is set for 40: PV < 40 = no alarm

3 >60 60 N/A Alarm Limit 1 is set for 60: PV > 60 = no alarm

3 <40 40 LOW Low Alarm Limit 2 is set for 40: PV < 40 = LOW alarm

4 >60 60 HIGH Alarm Limit 1 is set for 60: PV > 60 = HIGH alarm

4 <70 70 HI- HI Alarm Limit 2 is set for 70: PV > 70 = HI-HI alarm

5 >40 40 LOW Alarm Limit 1 is set for 40: PV < 40 = LOW alarm

5 <30 30 LO-LO Alarm Limit 2 is set for 30: PV < 30 = LO-LO alarm

6 >50 10

6 <30 -10

■= applicable to the Control Strategy (CS) as shown in column three.

AIX

(C103)

CS

■

1 | 2 | 3 | 4

■

PL2

(C104)

Alarm Setpoint Notes

DEV

LO-

DEV

CON-0

Datapoint

B335 1

Alarm Examples:

HI-

40 Alarm Limit 1 is set for 40: PV < 40 = HI-DEV alarm

40 Alarm Limit 2 is set for 30: PV < 30 = LO-DEV alarm

Default Attribute

This parameter defines the Alarm Active (PA1

& PA2) interpretation of the two Alarm Limits

(PL1 & PL2). It is entered into the datapoint as

an index value (0-6 ) as follows:

0 PA1n: high when PV> PL1

PA2n: low when PV< PL2

1 None

2 PA1n: high when PV> PL1

PA2n: not affected

3 PA1n: not affected

PA2n: low when PV< PL1

4 PA1n: high when PV> PL1

PA2n: hi-hi when PV> PL2

5 PA1n: low when PV< PL1

PA2n: lo-lo when PV< PL2

6 PA1: Hi-Dev when Dev > PL1

PA2: Lo-Dev when Dev < PL2

32

Page 39

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-8. Control Module (continued)

Purpose: The primary purpose of this module is to set the instrument’s Alarm Index mode, Alarm

Limits 1 & 2, and Alarm Dead Band.

CS

Title Symbol

■

1 | 2 | 3 | 4

Control Action RSW

Reverse Valve RSV

Manual

Fallback

Disable

Alarm Limit 1 PL1

Alarm Limit 2 PL2

Alarm

Dead

Band

Proportional

Band

Reset Time TR

Rate Time TD

Manual Reset MR

Controller

Span

Controller

Lower Range

Control Tag

Name

Engineering

Units

MFD

ADB

PB

■

■

■

■

■

■

■

■

■

■

■

■

■

■

NOTE: CS1 = Single Loop (PID) Controller, CS2 = Analog Backup Controller, CS3 = Ratio

Controller, and CS4 = Automatic/Manual Station.

CON-0

Datapoint

106 0

L109 0

L120 0

C103 100

C104 0

C105 2

C106 100

C107 0

C108 0

C111 50

C115 1100

C116 0

A000

A001 Percent The default is PERCENT, but is assignable as units

Default Attribute

When set to a 0, the controller output increases as

the process value increases.

When set to a 1, the controller output decreases as

the process value increases.

This parameter provides information for the control

display to indicate which direction the control output

must go to close the final control element. A 1

indicates that 20 mA closes the valve. A 0 indicates

that 20 mA opens the valve.

Under normal operation, whenever the controller is

powered up, the Auto/Manual Selector is forced to

the Manual position. When this datapoint is set to a

1, the selector will not be forced to the Manual

position at power up but will remain in the last

position before power was removed.

These parameters are the points in engineering

units at which the alarms are triggered.

This parameter sets the activation/deactivation gap

for the alarm. This value in engineering units

defines an area of hysteresis at the alarm point.

This parameter is the percent of error required to

move the output full scale for proportional action. It

modifies the controller response in standard PID

terms.

This parameter represents the number of minutes

per repeat of integral action. It modifies the

controller response in standard PID terms.

This parameter value represents the minutes that

proportional action is advanced (derivative action).

This parameter determines the position of the valve

(output) when the instrument is in Automatic mode

and the error is zero. (It is only in effect when TR =

0.)

These two parameters set the upper and lower

values on the controller display. They permit the

control action to be defined over a range

independent of the process variable input range.

They also determine the speed at which the

setpoint changes when the up or down arrow

pushbuttons are pressed (CS1 through CS3). For

CS4, they determine only the displayable range, as

the setpoint pushbuttons are not used.

An assignable 10 character name that appears with

CS1-4 displays.

of measure the Process Variable represents.

33

Page 40

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-9. Parameter Display Module

Purpose: This module provides quick pushbutton display access to any three selected datapoints (e.g.,

Alarm Limits 1 & 2 and Alarm Dead Band) without the necessity of entering Engineering mode and

addressing the datapoints.

Title Symbol PAR1 Default Attribute

Title

Point 1 Name

Point 2 Name

Point 3 Name

Point 1 Designator

Point 2 Designator

Point 3

Modify Disable

PTAG A014

PNA A015

PNB A016 RESET

PNC A017 RATE

PDA F087

PDB F088

PDC F089 C108

PMD L313 0

CON-0

TUNE

PROP.

BAND

C106

value

C107

value

This is an assignable in character name that appears

with the parameter display.

This is an assignable 10 character name for the Point

1 Designator.

This is an assignable 10 character name for the Point

2 Designator.

An assignable 10 character name for the Point 3

Designator

A database datapoint whose contents will be

displayed under the Point 1 Name (e.g., C103 to

display the Alarm Limit 1 setting).

A database datapoint whose contents will be

displayed under the Point 2 Name (e.g., C104 to

display the Alarm Limit 2 setting).

A database datapoint whose contents will be

displayed under the Point 3 Name (e.g., C105 to

display the Alarm Dead Band).

When this value is 1, the datapoints in this module can

not be altered with the pushbuttons. The values of

these datapoints are only for display purposes. When

this value is 0, the datapoints in this module can be

altered by the operator with the pushbuttons when this

module is displayed.

34

Page 41

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-10. Communication Module

Purpose: This module is used to configure the Datalink port parameters (e.g., baud rate, parity selection,

etc.).

Title Symbol Datapoint Default Attribute

It identifies the address of this instrument on the

Instrument

Address

Baud Rate BR B02 253

No Parity CP L2561 0

No Byte

Stuffing

Datalink

Disable

IA B01 0

CB L2581 0

DLD L257 0

Datalink network. Each unit connected to the Datalink

network must have its own unique address. Valid

addresses are from 0 -31.

This datapoint value designates the baud rate (data

transfer rate) of the Datalink network. The baud rate

must be the same for all of the instruments connected to

the same Datalink network. Datapoint values and their

corresponding baud rates are as follows:

Value Baud Rate Value Baud Rate

255 28800 9 28800

254 14400 8 14400

N/A N/A 7 19200

253 9600 6 9600

250 4800 5 4800

244 2400 4 2400

232 1200 3 1200

208 600 2 600

160 300 1 300

N/A N/A 0 110

This datapoint indicates if parity generation and

checking should be turned on or off. It is set to 0 for

even parity serial byte protocol. It is set to 1 for no parity

protocol.

When set to a 1, this datapoint disables the standard

communication protocol feature which inserts a 00

(NUL) byte after every 7EH (SOH) that is not the

beginning of a message. (This permits user written

communications software to determine the number of

bytes to expect in a response message.) It must be set

to 0 when using the Micro-DCI communications

software or equipment.

When set to 0 , it permits full Datalink communication

capabilities. When set to 1, it disables Datalink

communication capabilities.

35

Page 42

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 4-11. System Module

Purpose: This module is used to set the instrument tag name and the display brightness.

System

Title Symbol

Function Index FIX B00 0

Display

Brightness

Index

EASY-TUNE

Enable

BRIGHT B012 4

ETE B08 0

Module

Datapoint

Default Attribute

The operational algorithm of the unit is selected

by the value of this parameter:

0 = Suspend mode. No control algorithm

execution. The logo is displayed.

1 = CS1, Single Loop PID Controller operation

2 = CS2, Analog Backup Controller operation.

3 = CS3, Ratio Controller operation.

4 = CS4, Automatic/Manual Station operation.

97 = Display Test. The entire display alternately

flashes on and off. When off, a border around

the display perimeter remains lit.

98 = Defaults database then sets FIX to 0.

This parameter controls the display screen

intensity. A value of 0 is the brightest and a

value of 7 is the dimmest intensity. Normal

viewing setting is 4.

When set to a 1, the EASY-TUNE algorithm is

implemented. This parameter is left at 0 for

normal instrument operation. (See Section 11 for

Unit Tag Name TAG A08 SL5100

EASY-TUNE.)

An assignable 10 character name for the system

module (SL5100).

36

Page 43

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

5 SINGLE LOOP (PID) CONTROLLER

5.1 Operation Overview

In a standard feedback control loop, the Single Loop (PID) Controller functions as the primary processing unit.

When the process is altered due to disturbances (e.g., flow rate changes), the controller gauges this change

from the process variable (PV) feedback signal sent to it by a process measurement instrument (e.g., flow

meter) in the loop.

The controller compares the feedback signal to the setpoint level and calculates the required error correction,

which is applied as an output signal to the final control element (e.g., valve) in the loop. The final control

element responds to alter the process (manipulated variable) toward a predetermined operational setpoint

(SP), which can be set locally at the controller front panel or remotely from another instrument. If the process

variable exceeds tolerable limits of change, the controller activates a signal to an alarm. These events are

illustrated in Figure 5-1.

Figure 5-1. Standard Feedback Control Loop

Process variable feedback input (Analog Input) received from the process measurement instrument is

typically 1-5 V dc, 4-20 mA dc. The Single Loop Controller zero and span inputs for this signal are calibrated

by the factory and should not be altered. The controller is defaulted to display the process variable input as a

percentage value determined by input signal amplitude; however, it can be configured to display direct units

of measurement (e.g., gallons per minute [GPM]).

The setpoint value is received from another device (e.g. Single Loop Controller, PC, host computer, etc.), or

is manually entered at the controller front panel.

NOTE: To minimize sudden process changes, adjust the local setpoint value to the

original remote setpoint value before switching back to remote setpoint control

(Remote).

37

Page 44

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

It is the difference between the setpoint (SP) and received process variable (PV), augmented by the action of

the tuning constants Proportional Band, Reset Time, and Rate Time, that determines the required output to

the final element to restore the process. The output signal (Analog Output) to the final element is 4-20 mA dc.

This signal is also factory calibrated for zero and span, and should not be altered. On the controller display,

the output signal value correlates to the desired control element operation (e.g., an output of 100% equals a

20 mA signal amplitude, which causes a valve to be fully opened or closed, depending on the reverse valve

setting in the Single Loop Controller).

Single Loop Controller output response characteristics to the process changes are determined by

Proportional, Integral, and Derivative parameters (also called PID constants). The controller PID constants, as

well as other controller functions (e.g., reverse valve), can be defined with configuration datapoint parameter

entries. The PID general response characteristics are defined in Section 10, Instrument Tuning.

As illustrated in Figure 5-2, Single Loop Controller Block Diagram, when a 1 is loaded into System Module

datapoint B00 to initiate CS1, the signal designators are as follows:

1. ANI0 = Process Variable Input

2. ANI1 = Remote Setpoint Input

3. ANO0 = Controller Output

4. CCI0 = Enable Remote Setpoint

5. CCO0 = Process Alarm

38

Page 45

53SL5100B Single-Loop Controller

Figure 5-2. Single Loop Controller Block Diagram

INSTRUCTION MANUAL

39

Page 46

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

5.2 Single Loop Controller Front Panel Pushbuttons

The front panel pushbuttons for the Single Loop Controller are illustrated in Figure 5-3 and defined in Table 5-

1. The pushbutton functions for the Single Loop Controller are identical to those provided in Section 3.

40

Figure 5-3. Single Loop Controller Pushbuttons

Page 47

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

Table 5-1. Controller Pushbuttons

Pushbutton Title Operator Mode Engineering Mode

Used to select between Remote setpoint control