Page 1

OPERATOR’S MANUAL

Data Visualization Software

53PW6000

Release 4.0

Micro-PWC™ SYSTEM

PN26004 Rev. 0

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most ost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

∆ Warning. An instruction that draws

attention to the risk of injury or death.

❢ Caution. an instruction that draws

attention to the risk of the product,

process, or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, re sult in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipmen t. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

✎Note. Clarification of an instruction

or additional information.

i Information. Further reference for

more detailed information or

technical details.

Licensing, Trademarks and Copyrights

Micro-DCI and MicroLink are trademarks of MicroMod Automation, Inc.

Microsoft is a registered trademark, and Windows is a trademark of Microsoft Corporation

© 2005 MicroMod Automation, Inc. (September 2005)

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted.

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions

of high pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and

source codes, is copyrighted by MicroMod Automation, Inc.,

and is owned by MicroMod Automation or its suppliers.

Page 3

Micro-PWC OPERATOR’S MANUAL

TABLE OF CONTENTS

1.0 - Introduction..........................................................................1

1.1 Intended Audience.........................................................................................1

1.2 Functional Description ..................................................................................1

1.2.1 User Interface...................................................................................1

1.2.2 Micro-PWC Management Features..................................................2

1.2.3 Hierarchical Displays........................................................................2

1.2.4 Graphic Displays ..............................................................................2

1.2.5 Logging.............................................................................................2

1.2.6 Trends..............................................................................................2

1.2.7 Process Alarms ................................................................................2

1.2.8 Events ..............................................................................................3

1.2.9 Message Review..............................................................................3

1.2.10 Micro-PWC Utilities ........................................................................3

1.2.11 Printer Review ................................................................................3

1.3 Document Conventions.................................................................................3

1.4 Reference Documents...................................................................................4

1.5 Glossary of Terms and Abbreviations............................................................4

2.0 - User Interface.......................................................................7

2.1 Introduction....................................................................................................7

2.2 Micro-PWC Appearance................................................................................7

2.3 Input Devices.................................................................................................7

2.3.1 Pointing Devices...............................................................................7

2.3.2 Keyboard..........................................................................................8

2.4 Micro-PWC Display .....................................................................................10

2.4.1 System Window..............................................................................10

2.4.2 System Window Components ........................................................ 11

2.4.3 Menu Functions..............................................................................11

2.4.3.1 Micro-PWC Parameters...............................................11

2.4.3.2 Security Parameters.....................................................12

2.4.3.3 Network Parameters ....................................................12

2.4.4 Mini-Alarm Window ........................................................................12

2.4.5 Operator Window ...........................................................................14

2.4.5.1 Operator Window Components....................................15

2.4.6 Operator Window Operations.........................................................16

2.4.6.1 Open an Operator Window ..........................................16

2.4.6.2 Page Up/Page Down Operator Window Commands..16

2.4.6.3 Display Back/Display Forward .....................................16

2.4.6.4 Acknowledge................................................................17

2.4.6.5 Close............................................................................17

2.4.6.6 Resize an Operator Window........................................17

Contents i

Page 4

Micro-PWC OPERATOR’S MANUAL

2.4.7 Show Users and Screen Contents.................................................18

2.4.8 Arrange Windows Function............................................................18

2.5 Summary - Window Types, Components, and Operations..........................19

3.0 - Micro-PWC Features.......................................................... 21

3.1 Introduction................................. ... ... .... ... ... ... .... ... .......................................21

3.2 Getting Started...................................................... ... ... .... ... ..........................21

3.2.1 System Default State......................................................................21

3.2.2 Logging In.......................................................................................22

3.2.3 Logging Out....................................................................................23

3.2.4 Show Users Option ........................................................................23

3.2.5 Changing Your Password...............................................................24

3.2.6 Exiting the Micro-PWC System ......................................................25

3.3 System Features ........... ... .... .......................................... ... ... ... ... .... ... ... ... ....25

3.3.1 Security ..........................................................................................26

3.3.2 Message Configuration ..................................................................26

3.3.2.1 Message Text. ... .... ... ... ... .... ... ... ... .... ... ... ... ....................27

3.3.2.2 Message Priority ......................... .... ... ... ... ... .... ... ... ... ....27

3.3.2.3 Message Destination Area...........................................27

3.3.2.4 Send the Operator Message........................................28

3.3.3 Message Routing ...........................................................................28

3.3.3.1 Message Color Definition.............................................28

3.3.3.2 Message Indentation Definition....................................29

3.3.3.3 Message Class: Process Alarm Messages..................29

3.3.3.4 Message Class: System Event Messages...................29

3.3.3.5 Message Class: Operator Messages...........................30

3.3.3.6 Message Class: Operating Errors................................30

3.3.3.7 Message Class: Operator Actions ...............................30

3.3.3.8 Message Filter Parameters..........................................30

3.4 System Status Display............. ... ... ... .... ... ... ... .... ... .......................................31

3.4.1 General Information for All Node Types.........................................32

3.4.1.1 Node Name.................... .... ... ... ... .... ... ... ... ... .... ... ... ... ....32

3.4.1.2 Info Menu.............................................................. ... ....33

3.4.2 Information for Specific Node Types...............................................34

3.4.2.1 Console-Type Notes: Micro-PWC............ ... .... ... ... ... ....34

3.4.2.2 Micro-DCI Communications Node ...............................34

3.4.2.3 The Utilities Menu ........................................................34

3.4.2.4 Printer Queue Control..................................................35

3.4.2.5 Printer Queue Information .................................... .......36

3.4.2.6 Console Group Information..........................................37

ii Contents

4.0 - Hierarchical Process Displays ......................................... 39

4.1 Overview........................ .......................................... ... .................................39

4.2 The Summary Display.................................................................................40

Page 5

Micro-PWC OPERATOR’S MANUAL

4.2.1 Accessing the Summary Display....................................................40

4.2.2 Using the Summary Display...........................................................41

4.3 The Group Display.......................................................................................43

4.3.1 Accessing the Group Display .........................................................43

4.3.2 Group Display.................................................................................43

4.3.2.1 Group Legends ............................................................44

4.3.2.2 Point Tagnames...........................................................44

4.3.2.3 Status Area...................................................................45

4.3.2.4 Process Display Area...................................................45

4.4 Process Control Functions ..........................................................................46

4.4.1 Dynamic Faceplates.......................................................................46

4.5 Control Faceplates ......................................................................................47

4.6 The Point Display ........................................................................................48

4.6.1 Accessing the Point Display...........................................................48

4.6.2 Point Display Appearance..............................................................48

4.6.2.1 Tagname......................................................................49

4.6.2.2 Legend.........................................................................49

4.6.2.3 Status Area...................................................................49

4.6.2.4 Param Pushbutton .......................................................49

4.6.2.5 Info Pushbutton...........................................................50

4.6.2.6 Process Display Area...................................................50

5.0 - Logs ....................................................................................51

5.1 Introduction..................................................................................................51

5.1.1 Accessing Log Print.................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .52

5.2 Event Logs...................................................................................................53

5.2.1 Print Event Logs.............................................................................53

5.3 Spreadsheet Logs........................................................................................54

5.3.1 Print Spreadsheet Logs..................................................................54

5.3.2 Clearing the Recovery Log Notify Window.............................. ... ... .54

6.0 - T rend Displays ...................................................................55

6.1 Trend Display Format..................................................................................59

6.1.1 Trend Graph...................................................................................59

6.1.2 Time Base and Size of Display Window.........................................59

6.1.3 Trend Readout Arrow.....................................................................59

6.1.4 Time at Arrow Button and Arrows...................................................60

6.1.5 Trace On/Off Button .......................................................................60

6.1.6 Display Option Button.................... ... .... ... ... ... ... .... ... ... ... .... ... ..........61

6.1.7 Trace Scale Button.........................................................................61

6.1.8 Trace Tag and Atom .......................................................................61

6.1.9 Value at Arrow................................................................................61

6.1.9.1 Value Precision Indicator..............................................61

6.1.10 Database Select Button................................................................62

Contents iii

Page 6

Micro-PWC OPERATOR’S MANUAL

6.1.11 Info Button ....................................................................................62

6.1.12 Compression Button and Arrows..................................................62

6.1.12.1 Trend Compression Speed Factors...........................65

6.1.13 Zoom/Unzoom Button ....... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....65

6.1.14 Reset Button.................................................................... ... ... ... ....66

6.1.15 Pause/Resume Button ...... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....66

6.1.16 Segment Button and Arrows ........................................................66

7.0 - Using Graphic Displays .................................................... 69

7.1 Introduction................................. ... ... .... ... ... ... .... ... .......................................69

7.1.1 Accessing Graphic Displays...........................................................70

7.2 Control Through Graphics...........................................................................71

7.3 Display Vectoring........................ ... ... .... ... ... ... .... ... ... ... .... .............................72

7.4 Error Indication........................................... ... .... ... ... ... .................................73

7.5 Alarm Acknowledgment..................................... ... ... ... .... ... ... ... ... .... ... ... ... ....74

7.6 The Zoom Menu Item..................................................................................74

7.6.1 The Pan Operations: Up, Down, Left, Right, Center ......................75

7.6.2 The Zoom Operations: In, Out, Fit, Pick.........................................75

7.6.3 Zoom and Pan Operations in Pop-up Graphic Windows................76

7.6.4 Resizing the Zoomed/Panned Operator Window. ... ... ....... ... ... ... ....76

8.0 - Process Alarms.................................................................. 77

8.1 Introduction................................. ... ... .... ... ... ... .... ... .......................................77

8.2 Mini-Alarm Window Title Bar................................................ ... ... .... ... ... ... ....77

8.2.1 Alarm Indicator...............................................................................77

8.3 Process Alarms in the Mini-Alarm Window..................................................78

8.3.1 Process Alarm Priorities.................................................................78

8.3.2 Audible Alarm Format.....................................................................78

8.3.3 Acknowledging Alarms in the Mini-Alarm Window.........................78

8.3.4 Filtering Alarms in the Mini-Alarm Window.....................................79

8.4 Process Alarm Review ............ ... ... ... .... ... ............................................. ... ....80

8.4.1 Accessing the Alarm Review Display.............................................80

8.4.2 Alarm Review Display Acknowledgment........................................80

8.4.2.1 Display Vectoring from the Alarm Review Display.......81

8.4.3 Filtering Alarms ..............................................................................82

8.4.3.1 Message Class: Process Alarm Messages..................83

8.4.3.2 Message Class: Priority ...............................................83

8.4.3.3 Message Class: Area ..................................................83

8.4.3.4 Clearing and Setting Alarm Review Message Types...84

8.4.4 Sort Alarms in the Alarm Review....................................................84

8.4.5 Freeze Alarm Review Display........................................................84

8.4.6 Search Alarm Review Display........................................................85

8.5 ADP Panel Operation.............................................. ... .... ... ... ... ... .... ... ... ... ....85

8.5.1 The Soft ADP Panel Window .........................................................86

iv Contents

Page 7

Micro-PWC OPERATOR’S MANUAL

9.0 - Events .................................................................................87

9.1 Introduction..................................................................................................87

9.2 System Events in the Mini-Alarm Window............................... ... .... ... ... ... ... .87

9.2.1 Audible Alarm Format for Event Messages....................................87

9.2.2 Acknowledging Event Messages in the Mini-Alarm Window..........87

9.2.3 System Event Format.....................................................................87

9.3 System Event Review.................... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... .............8 8

9.3.1 Accessing the Event Review Display .............................................88

9.3.2 Event Review Display Acknowledgment ........................................88

9.3.3 Filtering Event Messages...............................................................89

9.3.3.1 Message Class: System Event Messages...................90

9.3.3.2 Clearing and Setting Event Review Message Types...90

9.3.4 Sort Events in the Event Review Display ......................................90

9.3.5 Freeze Event Review Display ........................................................91

9.4 Event Historian............................................................................................92

9.4.1 Accessing the Event Historian........................................................92

9.4.2 Scrolling the Event Historian ..........................................................92

9.4.3 Pause/Resume the Event Historian ...............................................93

9.4.4 Filtering Messages in the Event Historian......................................93

9.4.4.1 Filtering Messages by Time.........................................94

9.4.4.2 Filtering Messages by Class and Type........................95

9.4.5 Print Event Historian File................................................................97

10.0 - Message Review ..............................................................99

10.1 Introduction................................................................................................99

10.2 Messages in the Mini-Alarm Window ........................................... ... ... ... ... .99

10.2.1 Audible Alarm Format for Operator Messages.............................99

10.2.2 Acknowledging Messages in the Mini-Alarm Window..................99

10.2.3 Operator Message Format...........................................................99

10.3 Message Review .....................................................................................100

10.3.1 Accessing the Message Review Display....................................100

10.3.2 Message Review Display Acknowledgment...............................100

10.3.3 Filtering Messages.....................................................................101

10.3.3.1 Message Class: Operator Messages.......................102

10.3.3.2 Message Class: Priority ......... ... ... .... ... ... ... .... ... ... ... ..103

10.3.3.3 Message Class: Area....... ... ... ... ... .... ... ... ... .... ... ... ... ..103

10.3.3.4 Clearing and Setting Message Review

Message Types..................................................103

10.3.4 Sort Messages in the Message Review Display ........................103

10.3.5 Freeze Message Review Display...............................................104

11.0 - Utilities ............................................................................105

11.1 Introduction..............................................................................................105

11.1.1 Notes on QIC Tape Drive Use ....................................................105

Contents v

Page 8

Micro-PWC OPERATOR’S MANUAL

11.1.2 Notes on DAT Tape Drive Use....................................................106

11.2 Backup and Restore................................................................................107

11.2.1 The Backup Utility.............. .... .......................................... ... ... ... ..107

11.2.1.1 Backing Up Information Distributed to

Console Group Members ..................................108

11.2.1.2 Backup Options........................................................109

11.2.1.3 Backing Up User Model Data...................................109

11.2.2 Performing the Backup............................................................... 110

11.2.2.1 Select a Backup Device Type................................... 110

11.2.2.2 Select a Backup ....................................................... 110

11.2.2.3 View the Contents of a Tape .................................... 110

11.2.2.4 Compress the Backed Up Data.................................111

11.2.2.5 Add a Comment about the Backup ...........................111

11.2.2.6 Backup Status...........................................................111

11.2.2.7 Cancel a Backup................................................. ... .. 112

11.2.2.8 Completing the Backup Operation ........................... 112

11.2.3 The Restore Utility...................................................................... 112

11.2.3.1 List Tape Button........................................................114

11.2.3.2 List Disk Button ................... ..................................... 114

11.2.3.3 Restore File Button................................................... 115

11.2.4 ADP Backup and Restore........................................................... 115

11.3 Database Maintenance............................................................................ 116

11.3.1 Historical Manual Entry............................................................... 116

11.3.1.1 Viewing an Historical Database Value...................... 117

11.3.1.2 Changing an Historical Database Value................... 118

11.3.1.3 Adding an Historical Database Value.......................118

11.3.1.4 Deleting an Historical Database Value.....................118

11.3.2 Database Maintenance Windows............................................... 118

11.3.2.1 Archival Database Maintenance...............................119

11.3.2.2 Archival Block Database Maintenance.....................121

11.4 Archival Utilities .......................................................................................122

11.4.1 Archive Historical Data ...............................................................122

11.4.2 Archive Historical Block Data......................................................124

11.4.3 Restore Archival Data.................................................................125

11.4.3.1 Restore Operation Window.................................... ..125

11.4.4 Restore Archival Block Data.......................................................126

11.4.5 List Archival Block Data..............................................................127

11.5 Alarm Groups...........................................................................................128

11.6 CRT Print.................................................................................................128

11.6.1 Selecting the Image Type...........................................................128

11.6.2 Invert Image................................................................................128

11.6.3 Stretch, Auto Fit and Scale Options............................................128

11.6.4 Printing the Image ......................................................................129

vi Contents

Page 9

Micro-PWC OPERATOR’S MANUAL

11.7 Other Applications ...................................................................................129

11.8 Release All Configuration Locks.. ... .... ... ... .......................................... ... ..130

11.9 System Help ............................................................................................131

11.10 User Help................... ... ... .... ... .......................................... ... ... ...............131

11.10.1 Edit User Help Information .......................................................131

11.10.2 Clear User Help Information.....................................................132

11.10.3 Import User Help Information ...................................................132

11.10.3.1 The File Filter Text Entry Box and List Boxes.........132

11.10.3.2 The Directories List Box .........................................133

11.10.3.3 The Selected File Text Entry Box...........................133

11.10.3.4 The Filter Button................................ ... ... .... ...........133

11.11 Quick Keys.............................................................................................134

11.11.1 Accessing the Quick Keys Feature...........................................134

11.11.2 Configuring Quick Keys ............................................................135

11.11.2.1 Configuring Quick Keys 33 through 64.............. ... ..136

11.11.2.2 Clearing Quick Key Assignments ...........................136

11.11.2.3 Exiting Quick Keys...... .... ... ... ... ... .... ... ... ... .... ...........136

11.11.3 Summary - Quick Keys........................................ ... ... .... ... ... ... ..137

11.12 CRT Context Keys.................................................. ... .... ... ... ... .... ... ... .....138

11.12.1 Preparing the Context...............................................................138

11.12.2 Initial Display Layout - Login Context Key................................138

11.12.3 Accessing CRT Context Keys...................................................138

11.12.4 Configuring CRT Context Keys.................................................139

11.12.5 Clearing CRT Context Keys......................................................139

11.12.6 Exiting CRT Context Keys........................................................139

11.12.7 Summary - CRT Context Keys .................................................140

11.13 Console Group Synchronization............................................................141

11.13.1 Console Group Synchronization Overview...............................141

11.13.2 Selecting a Console Node to Synchronize With.......................143

11.13.3 Selecting Configuration Data for Synchronization....................145

11.13.3.1 String File Considerations......................................147

11.13.3.2 Substituting Node Names During Synchronization 147

11.13.3.3 Replacing Node Name Prefixes Unconditionally....147

11.13.3.4 Replacing Multiple Node Name Prefixes................148

11.13.4 Performing the Synchronization ...............................................149

11.14 Time Adjustment.................. ... ... ... .... ... ... ... .... ... ... ... ... .... ........................150

11.14.1 Using the Time Adjustment Utility.............................................150

11.14.2 Adjusting the Time More than 5 Minutes..................................151

12.0 - Printer Review................................................................153

12.1 Introduction..............................................................................................153

12.1.1 Accessing the Printer Review Display........................................153

12.2 Using Printer Review...............................................................................155

Contents vii

Page 10

Micro-PWC OPERATOR’S MANUAL

12.2.1 Scrolling the Printer Review Display ..........................................155

12.2.2 Pause/Resume the Printer Review Display................................155

12.2.3 T ime Selection............................... .......................................... ..156

12.2.4 Printing Messages......................................................................156

List of Figures

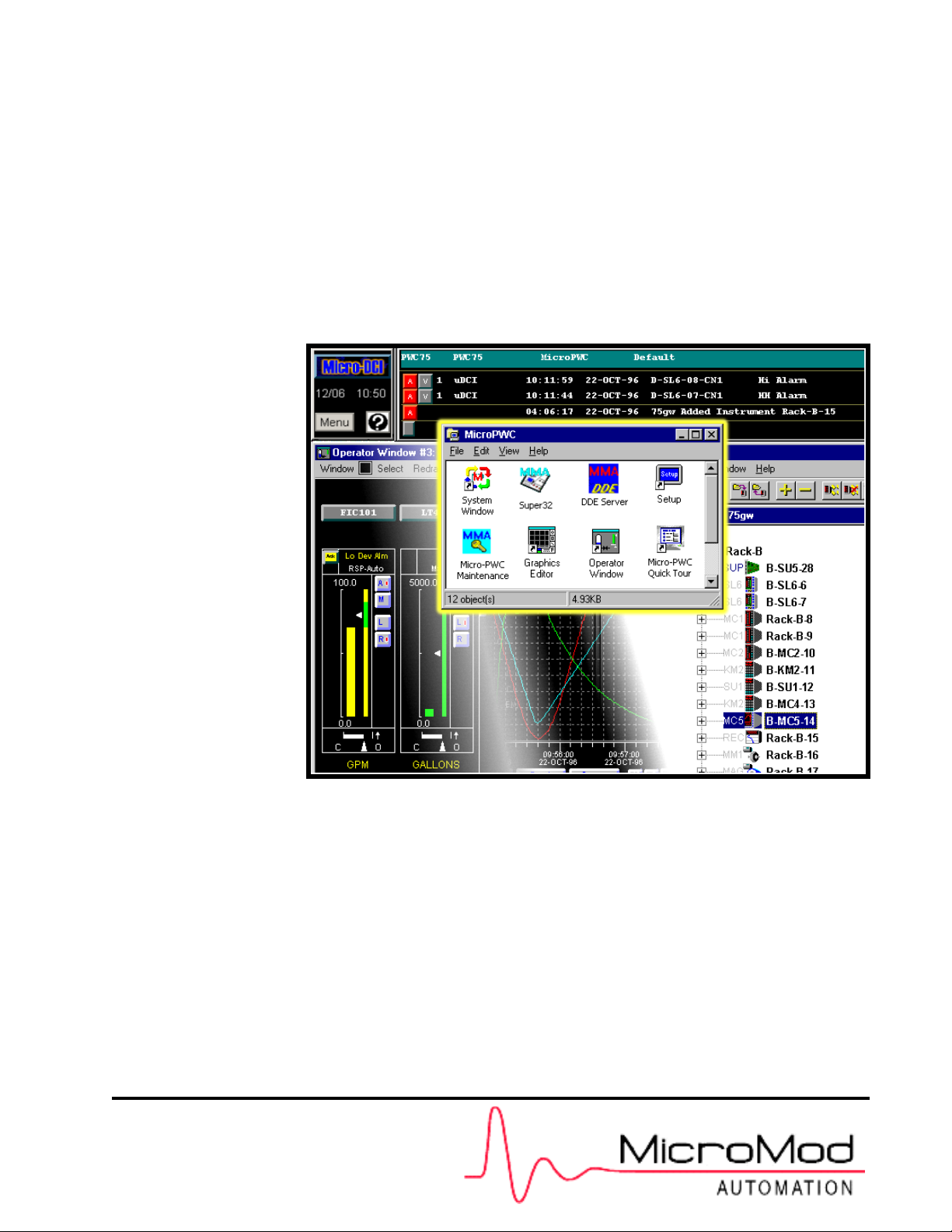

Figure 2-1. Micro-PWC System Default Window ..............................................10

Figure 2-2. System Window ................................................ ... ... ... ... .... ............. 11

Figure 2-3. Micro-DCI Logo Pushbutton ...........................................................11

Figure 2-4. Mini-Alarm Window .............................. ... ... ... .... ... ... ... ... .... ... ... ... ....13

Figure 2-5. Show Users Window .. ... ... ... .......................................... .... ... ... ... ....18

Figure 3-1. User Login Window ................................................................. ... ....22

Figure 3-2. Change Password Window ............................................................24

Figure 3-3. Message Configuration Window ....................................................27

Figure 3-4. Area Selection Window ..................................................................27

Figure 3-5. System Status Display ...................................................................31

Figure 3-6. SSD Object for a Micro-PWC .........................................................31

Figure 3-7. SSD Object for a Micro-PWC Client ...............................................32

Figure 3-8. Network Info Window Example ......................................................33

Figure 3-9. Services Window Example ......................... ... .... ... ... ... ... .... ... ... ... ....34

Figure 3-10. Device Status Window .................................................................35

Figure 3-11. Printer Queue Control Window .....................................................36

Figure 3-12. Console Groups Display ..............................................................38

Figure 4-1. Operator Window Select Menu ...................................................... 39

Figure 4-2. Summary Index Entry Window ...................................... ................. 40

Figure 4-3. Select Summary Window ...............................................................40

Figure 4-4. Summary Display Example . .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....41

Figure 4-5. Group Information Window ............................................................42

Figure 4-6. Group Selection Window ................................................................43

Figure 4-7. Group Display Configured for Four Points .....................................44

Figure 4-8. Tagname and Point Status Areas from a 6 Point Group Display ....45

Figure 4-9. Value Entry Window ............................................................. ... ... ....46

Figure 4-10. Enter Tagname Pop-up Window .................................................. 48

Figure 4-11. ANI Module Point Display .............................................................49

Figure 5-1. Log Print Window ....... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... .............52

Figure 5-2. Print Log Window (Event Logs) ......................................................53

Figure 5-3. Print Log Window (Spreadsheet Logs) ...........................................54

Figure 6-1. Selecting the Trend Option .............................................................56

Figure 6-2. Trend Index Entry Window ................................... ... ... ... .... ... ... ... ....56

Figure 6-3. Select Trend Window .....................................................................57

viii Contents

Page 11

Micro-PWC OPERATOR’S MANUAL

Figure 6-4. Trend Display Example ..................................................................58

Figure 6-5. Time Entry Window ........................................................................60

Figure 6-6. Compression Value Entry Window ................................................. 63

Figure 6-7. Original Waveform ..........................................................................64

Figure 6-8. Compressed Waveform - 6:1 Compression ...................................64

Figure 6-9. Compressed Waveform - 7:1 Compression ...................................64

Figure 6-10. Compressed Waveform - 5:1 Compression ................................. 64

Figure 6-11. Segment Number Entry Window ..................................................67

Figure 7-1. Typical Graphic Display ..................................................................69

Figure 7-2. Select Graphic Pop-up Window .....................................................70

Figure 7-3. Graphic Display with Control Pushbutton Labelled “M” ..................71

Figure 7-4. Control Window .......................... ... ... .... ... ... ... ... .... ... ... ... .... ... ..........71

Figure 7-5. Display Vector Pushbuttons ....................................................... ... .72

Figure 7-6. Error Indicator ..... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ....................73

Figure 7-7. Zoom/Pan Window ..................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... .......74

Figure 8-1. Alarm Review Window ...................................................................80

Figure 8-2. Number Entry Keypad ....................................................................81

Figure 8-3. Alarm Review Filter Window ..........................................................82

Figure 8-4. Alarm Review Sort Window ............................................................84

Figure 8-5. Display Frozen Window ................................................ .... ... ... ... ... .85

Figure 8-6. ADP Button Face ...........................................................................85

Figure 8-7. ADP Panel .................. ... ... ... .... ... ... ... .... ... .......................................86

Figure 9-1. Event Review Window ...................................................................88

Figure 9-2. Event Review Filter Window ..........................................................89

Figure 9-3. Event Review Sort Window ............................................................90

Figure 9-4. Event Historian Display ..................................................................92

Figure 9-5. Event Historian Filter Window ........................................................94

Figure 9-6. Time Selection Window ..................................................................94

Figure 9-7. Print Event Log Window ............................. ... ... .... ... ... ... .... ... ... ... ... .97

Figure 9-8. Printer Selection Window ...............................................................98

Figure 10-1. Message Review Window ..........................................................100

Figure 10-2. Number Entry Keypad ................................................................101

Figure 10-3. Message Review Filter Window ................................................. 102

Figure 10-4. Message Review Sort Window ..................................................104

Figure 11-1. Backup Window ..........................................................................107

Figure 11-2. Backup File Selection Window ...................................................108

Figure 11-3. Find Window ...............................................................................108

Figure 11-4. Configuration Data from Backup/Restore .............................. ..... 109

Figure 11-5. Backup Operation Window .........................................................110

Figure 11-6. List Tape Window ....................................................................... 111

Figure 11-7. Backup Status Window ............................................................... 111

Figure 11 -8. Restore Operation Window ........................................................ 112

Figure 11-9. File Restore Confirmation Box .................................................... 113

Contents ix

Page 12

Micro-PWC OPERATOR’S MANUAL

Figure 11-10. Restore Window ............................... ... ... ... .... ... ... ... ... .... ... ... ... .. 113

Figure 11-11. Restore File Selection Window .................................................114

Figure 11-12. Disk File Selection Window ...................................................... 114

Figure 11-13. Manual Data Entry Window ......................................................116

Figure 11-14. Historical Tags Window .................... ... ... .................................. 117

Figure 11 -15. Archival Database Maintenance Window ................................. 119

Figure 11-16. Historical Database Archive Window ........................................122

Figure 11-17. Database Archive Parameters Window ............... ... ... .... ... ... ... ..123

Figure 11-18. Backup Operation Window .......................................................123

Figure 11-19. Historical Block Archive Window .............................................. 124

Figure 11-20. Historical Block Archive Child Window .....................................124

Figure 11-21. Archival Database Restore Window .......................... ............... 125

Figure 11-22. Restore Operation Window ......................................................125

Figure 11-23. Archive Restore Confirmation Window .....................................126

Figure 11-24. Archival Block Database Restore Window ...............................126

Figure 11-25. Block List Window ....................................................................127

Figure 11-26. CRT Print Setup Window ..........................................................128

Figure 11-27. Configuration in Progress Warning Window .............................130

Figure 11-28. Configuration Lock Information Window ...................................130

Figure 11-29. Help Button ................... ............................................................131

Figure 11-30. Display Information Window ...................... ............................... 131

Figure 11-31. Import File Window ...................................................................132

Figure 11-32. Default Quick Keys Keypad Display .................................... ..... 134

Figure 11-33. Quick Key Label Assignment Window ........... ... ... ... ... .... ... ... ... ..135

Figure 11-34. Quick Key Pop-Up with Text String Assignments .....................135

Figure 11-35. Quick Key Window ...................................................................136

Figure 11-36. CRT Context Keys Keypad .......................................................138

Figure 11-37. CRT Context Key Assignment Window ....................................139

Figure 11-38. Console Groups Display Window .............................................142

Figure 11 -39. Console Group Synchronization Window .................................143

Figure 1 1-40. Console Node Selection Window ............................................. 144

Figure 11-41. Console Group Synchronization Selection Window .................144

Figure 11-42. onfiguration Item Selection Window .........................................145

Figure 11-43. Find Window .................... .... ... ... .......................................... ... ..146

Figure 11-44. System Configuration Data Window .........................................146

Figure 11-45. Time Adjustment Window .........................................................150

Figure 12-1. Printer Selection Window ...........................................................153

Figure 12-2. Printer Review Display Example ................................................ 154

Figure 12-3. Time Selection Window ..............................................................156

Figure 12-5. Device Reprint Banner Example ................................................ 157

Figure 12-4. Select Time Window ...................................................................157

x Contents

Page 13

Micro-PWC OPERATOR’S MANUAL

List of Tables

Table 1-1. Reference Documents ....................................................................... 4

Table 1-2. Glossary........................ ... ... ... .... ... ... ... .......................................... ... .. 4

Table 2-1. Function Key Operation..................................................................... 8

Table 3-1. Access Levels.................................................................................. 26

Table 4-1. Group Status Conditions.................................................................. 41

Table 4-2. Recommended Point and Format Combinations............................. 46

Table 9-1. Event Historian Time Entries ........................................................... 95

Table 12-1. Time Entry.................................................................................... 156

Contents xi

Page 14

Micro-PWC OPERATOR’S MANUAL

xii Contents

Page 15

Micro-PWC OPERATOR’S MANUAL

1.0 Introduction

The Micro-PWC is an operator’s console for use with Micro-DCI instruments. This manual describes the

operations required to use a configured Micro-PWC. It is designed to accomplish the following objectives:

• provide instructions on how to perform operational tasks on the Micro-PWC

• provide suggestions and examples for op er a tor ac tiv itie s

• provide additional information as necessary

1.1 Intended Audience

This manual is intended for use by personnel engaged in operating Micro-DCI equipment.

1.2 Functional Description

Micro-DCI provides the capability to divide process functions among many system components to provide

operating flexibility , system reliability, reduced system costs and ease of implementation. Distribution combined with redundancy also allows system control and operating functions to be divided among system

elements to increase reliability and flexibility, and to reduce risk.

Micro-PWCs can be organized into console groups with a maximum of 10 console-type server nodes in

each group. Many types of data and configuration information are distributed automatically to all server

nodes in the same console group.

Automation of most processes requires more than control at the unit operations level. The system must

also include an inherent ability to provide process management functions such as graphical presentation of

plant process conditions as well as reporting functions. The Micro-PWC and Micro-DCI process control

instruments form the basic building bl ocks of the Micr o-DCI Distributed Control System. Th e Micro-PWC is

the human/machine interface to this system, providing the Process Operator, Process Engineer, Instrument Engineer and Maintenance personnel with global access to all process and system parameters

required by each to perform their respective tasks.

The 53PW6000 (Micro-PWC) on a Pentium-based Personal Computer hardware platform provides the

user interface in a Windows NT environment. Using interactive process graphics and hierarchical displays, the Process Operator can monitor and control all analog loop s and discrete devices interfaced to the

network, as well as sequential batch operations.

The Micro-PWC provides the Engineer with an interface through which to configure and change Graphic

and Hierarchical Displays, database I/O, Micro-DCI process contr ol functions and sequences, Log (repor t)

formats, and security features (including access levels for opera ting personnel). Most cha nges are immediate, on-line and distributed to all Micro- PWCs within the same co nsole group, requiring no com pilation time

before downloading and therefore no interruption of the process.

The Micro-PWC provides Maintenance Personnel with the capability to globally monitor the operating status of any system component on the network, and to diagnose component failures.

1.2.1 User Interface

The Micro-PWC provides the Process Operator, Engineer, and Maintenance Technician with a windowbased interface to both the process and the Micro-PWC itself. The user interface is described in detail in

Section 2.

Introduction 1

Page 16

Micro-PWC OPERATOR’S MANUAL

1.2.2 Micro-PWC Management Features

The Micro-PWC contains many items which aid in managing use of the system. These include:

• User Logins

• Security Features

• Messages

• Message Routing

• System Status Display

These items are described in Section 3.

1.2.3 Hierarchical Displays

Hierarchical displays are a set of pre-configured, console group-wide, graphical representations emulating

traditional instrument displays. A three-tiered hierarchy of displays exists to provide the user with inform ation about the process. This hierarchy consists of Summary, Group, and Point displays, which are available

on all console nodes in the same console group.

A summary display provides an overview of 24 groups, arranged in six rows of four blocks. There are

1,000 summary displays available.

A group display provides an operation overview of four, six, or eight points simult aneously. All process control actions and alarm acknowledgment for po ints within a group can be performed from the group display

on a point-by-point basis.

A point display provides the most detailed information and operation functions about a single point in the

hierarchical display system. From this level the operator can perform regulatory changes. Hierarchical displays are described in Section 4.

1.2.4 Graphic Displays

Up to 10,000 group wide graphic displays can be configured on the Micro-PWC. A graphic display configured on any Micro-PWC is distributed (when saved or installed) to all Micro-PWCs on the same network.

The operator may control a process by using control pushbuttons located on graphic displays. The display

vector pushbutton allows the user to move quickly and easily to other graphics or displays of other types.

Graphic displays, control through graphics, and display vectoring are discussed in Section 7.

1.2.5 Logging

Logs are used to collect and format data for use in repo rts and spreadsheet calculations. The two types of

logs available on the Micro-PWC include event lo gs and spreadsheet logs. Logs are available group wide.

Logs are covered in Section 5.

1.2.6 Trends

Trend traces display the values of one to eight points in an analog trend format similar to tha t presented b y

a conventional strip chart recorder. Three types of trend recording are provided on the Micro-PWC, including current trending, historical trending and archival trending. Trend displays are available group wide.

Trends are covered in Section 6.

1.2.7 Process Alarms

A process alarm is generated when a pro cess variable is in a n abnormal condition . Process alarms are displayed in the top two lines of the Mini-Alarm Window, in the Alarm Review display, and are accompanied

2 Introduction

Page 17

Micro-PWC OPERATOR’S MANUAL

by audible alarms. The optional annunciator display panel (ADP) and the other process alarms are covered in Section 8.

1.2.8 Events

System events occur when a problem or change-of-state is detected with the control system, as opposed

to abnormal conditions, problems, or changes-of-state associated with the process which is being monitored. System event messages are displayed in the third lin e of the Mini-Alar m Window, the Event Review

display, and the Event Historian. System events are covered in Section 9.

1.2.9 Message Review

Operator messages are used to provide the operator with information and instructions for performing

actions, and can be generated from any Micro-PWC. Operator messages are displayed in the fou rth line of

the Mini-Alarm Window and in the Message Review display, and ca n be accomp anied by an aud ible alarm.

Message review is covered in Section 10.

1.2.10 Micro-PWC Utilities

A number of useful maintenance and information management functions are provided as Micro-PWC utilities. Utilities covered in this manual include:

•CRT Print

• Release All Configuration Locks

• System Help

• User Help

• Quick Keys

• CRT Context Keys

These utilities are covered in Section 11.

1.2.11 Printer Review

Messages which have been sent to a printer or to a file ca n be d i splayed using th e Printer Review display.

Printer review is covered in Section 12.

1.3 Document Conventions

This document uses standard text conventions to represent keys, display items and user data inputs:

Display item Any item displayed on a screen appears as italic text. Example: Running

User data input

Bold Identifies any part of a command line that is not optional or variable and

must be entered exactly as shown.

Italic Identifies a variable parameter entered in a command line.

[ ] Brackets indicate an optional parameter; text within the bracke ts follows the

previously described conventions. For example:

CUP [port] [baud] [file_name.CSP]

Introduction 3

Page 18

Micro-PWC OPERATOR’S MANUAL

Special Keys Identifies a specific key that is not alphabetic, numeric or punctuation.

Examples:

Press ENTER.

Press ESC V M. (Press and release each key in sequence.)

Press CTRL-ALT-SHIFT-DEL. (Press all keys in sequence without releasing any one key

until you have pressed them all.)

File name Indicates a file or directory name. Example:

file1.exe

c:\new

Revision variable A ? indicates a value that may change depending on the version of an item.

Example:

Part number: 1234567?0

Part number: 1234567??

1.4 Reference Documents

This manual provides information only for the operation of the Micro-PWC. Table 1-1 lists additional documents that relate to the operation of the available control systems.

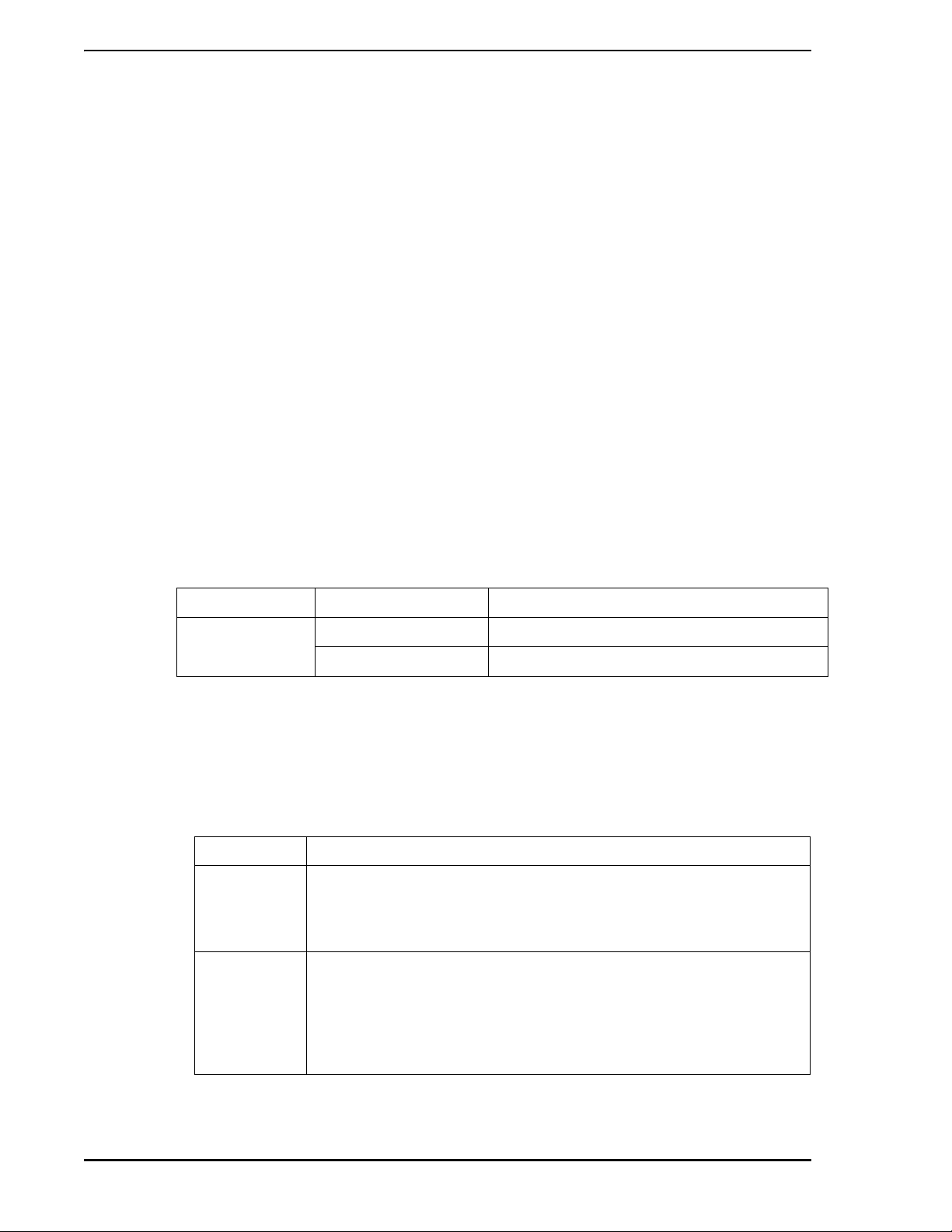

Table 1-1. Reference Documents

System Number Document Title

General PN26005 Micro-PWC Configuration

PN26001 Micro-PWC Introduction an d In stallation

1.5 Glossary of Terms and Abbreviations

This glossary provides definition for terms used in the Micro-PWC Operator’s Manual. Where alternate

usage is defined in the glossary, the first listed term is considered the preferred usage.

Table 1-2. Glossary

Term Definition

Atom A single data element in the global database. Atoms can exist in various

forms, including (but not limited to) a single bit (e.g., Auto/Manual), a

floating point number , a t agname or a multi-chara cter legend; there is no

predefined limit to the size of an atom.

4 Introduction

Mini-Alarm

Window

The Mini-Alarm Window is located to the right of the System Window on

the Micro-PWC screen. It automatically appears upon system startup

and is visible at all times. The Mini-Alarm Window provides a title bar, an

alarm display area, an event display area, Alarm Acknowle dge buttons

to acknowledge alarms and events, a Filter button, and a More Alarms

indicator.

Page 19

Micro-PWC OPERATOR’S MANUAL

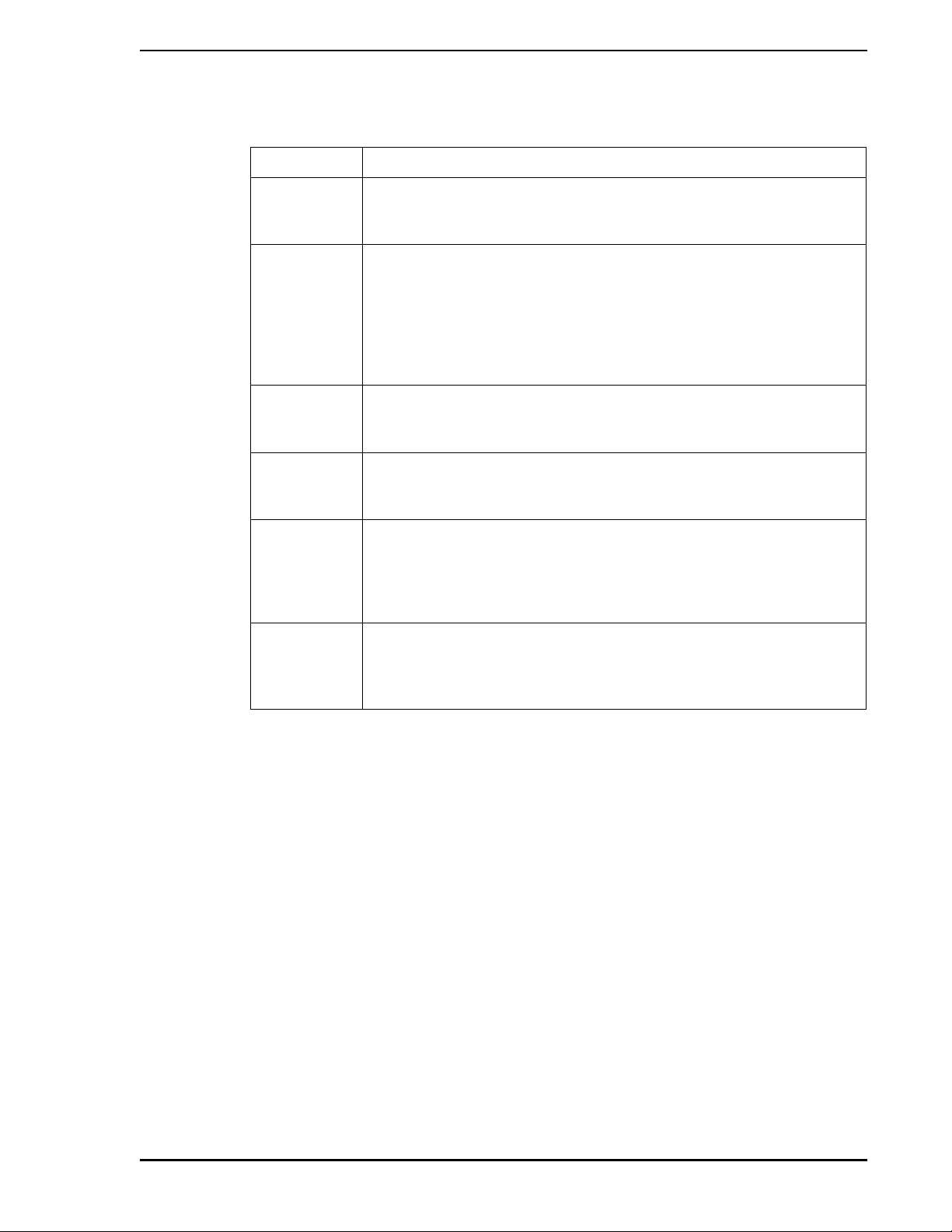

Table 1-2. Glossary (Continued)

Term Definition

Node A point of interconnection to a network. On the process control network

operator and process control stations connections are considered

nodes, and on the Ethernet all Micro-PWCs and servers are nodes.

Operator

Window

Process Area A functional partition of the process. A tag is assigned to and often

Quick Key A menu option available from the Micro-PWC Operator Window menu

Software

license

System Window

Located on the Micro-PWC screen below the System Window and MiniAlarm Window, the Oper ator Window provides the operator interface to

the process, and displays program outpu t fro m Ope ra to r Win dow

applications such as Hierarchical Displays, Trends, Graphics, Alarm

Review, etc. The Operator Window is composed of a title bar , a menu

bar, and a display area. Up to four Operator Windows may be present

simultaneously on a Micro-PWC.

located in a particular process area. Micro-PWC functions can be

assigned by area.

bar, which, when selected, provides the user with the ability to vector

directly to one of 64 possible displays.

A software license conveys to the purchaser the right to use a defined

software product. Local software products are licensed for a specific

platform, while global application product s are licensed for network-wide

usage. Software licenses are enforced with PICs and with a software

licensing manager program.

A small window located at the top left corner of the Micro- PWC screen. It

appears automatically upon system startup and is visible at all times.

The System Window provides a date/time indicator and a Menu button

for access to other system features and utilities.

Introduction 5

Page 20

Micro-PWC OPERATOR’S MANUAL

6 Introduction

Page 21

Micro-PWC OPERATOR’S MANUAL

2.0 User Interface

2.1 Introduction

The Micro-PWC user interface provides:

• Window management

• One System Window

• One Mini-Alarm Window

• Up to four Operator Windows

The function and use of these user interface elements are explained in this section.

2.2 Micro-PWC Appearance

Visually, the graphical user interface is presented in a window based format. Multiple windows can be

opened simultaneously, allowing the user to view up to four different process displays at once.

The window format provides a three-dimensional (3D) appearance to such screen objects as buttons,

scroll bars and window frames. A pointing device, such as a mouse or track ball (refer to Section 2.3,

Input Devices), is used to select objects on the screen.

2.3 Input Devices

Operation of Micro-PWC functions is most conveniently accomplished by the use of a pointing device,

such as a mouse or track ball. Although it is possible to access all displays and all menu bar choices via

the keyboard, a pointing device is required to access the object-oriented graphical functions such as pushbuttons, toggle buttons, radio buttons and so on. (Section 2. 4, Micro -PWC Disp lay provides a detailed discussion of these items.)

✎ NOTE While it is possible to perform all process operation functions at the

PC using only a pointing device, a keyboard is required for some

configuration activities.

2.3.1 Pointing Devices

The pointer cursor (also known as the mouse cursor) is a small, mobile image on the screen, which is controlled by a pointing device such as a mouse or track ball. In this manual, the term pointer refers to the

pointer cursor, while the term mouse refers to the pointing device.

User Interface 7

Page 22

Micro-PWC OPERATOR’S MANUAL

2.3.2 Keyboard

The IBM A T comp atible 101-ke y keyboard provides the function keys (F1 through F12) and ALT-function key

combinations. They are used to perform the functions listed in Table 2-1 Where an A

nation is specified, press and hold A

LT simultaneously with the specified function key.

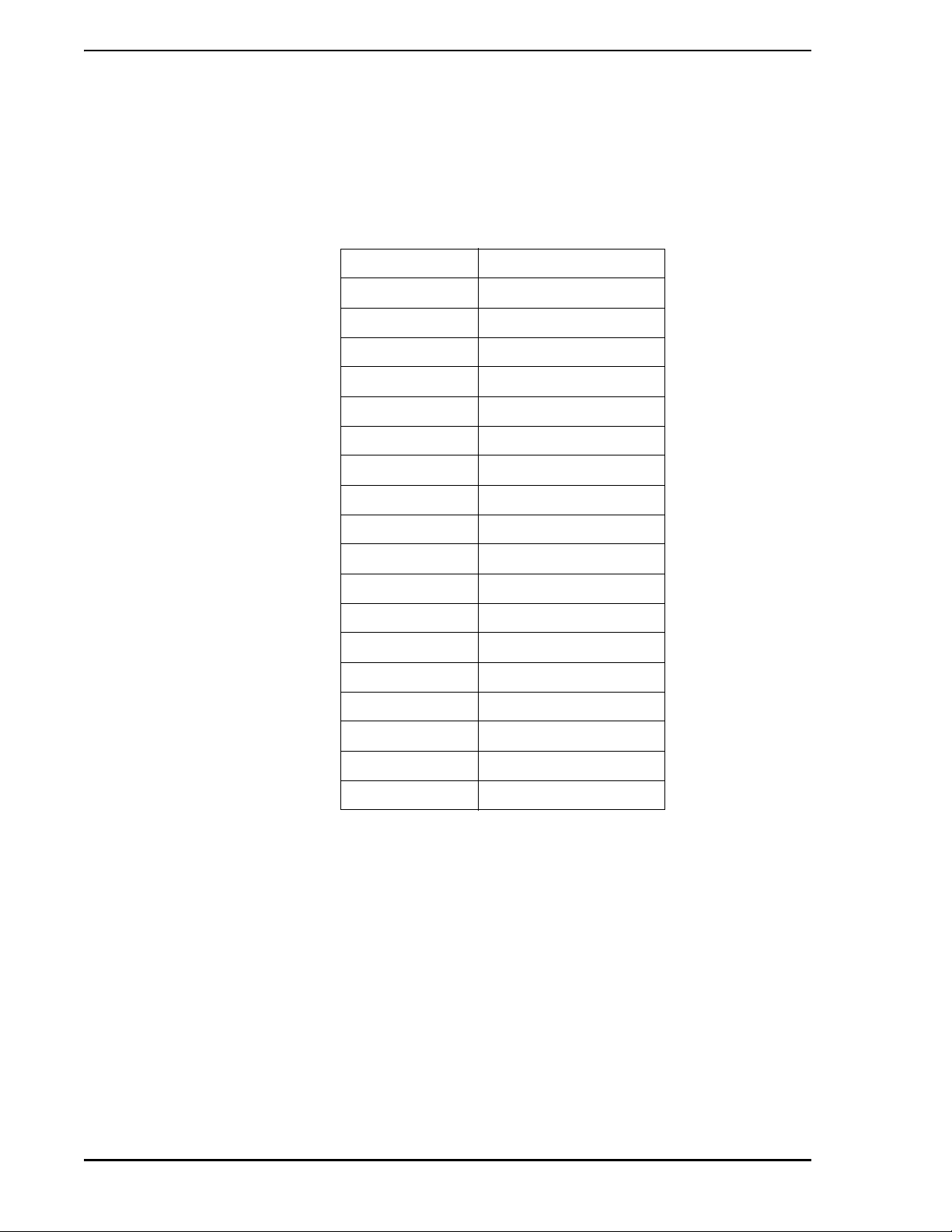

Table 2-1. Function Key Operation

Key Function

F1 Graphic

ALT-F1 Network status display

F2 Summary

F3 Group

F4 Point display

F5 Quick keys

F6 Trend

LT-function key combi-

F7 Alarm review

ALT-F7 Print log

F8 Event review

ALT-F8 Arrange windows

F9 Display forward

ALT-F9 Alarm ack

F10 Display backward

ALT-F10 Window acknowledge

F11 Not used

ALT-F11 Silence

F12 Help

F1 G

RAPHIC Displays the graphic selection box. Enter the number of the graphic (one to

10,000), then click OK (or press R

ETURN) to display a specific graphic. To view

an index list of all graphics which have been defined, click List located at the

bottom of the graphic selection box.

F2 S

UMMARY Displays the summary selection box. Enter the number of the summary (one

to 1,000) to be displayed, then click OK. To view an index list of all summaries

which have been defined, click List located at the bottom of the summary

selection box.

After viewing a point or group display called up via the hierarchy (i.e., the user

first called up a summary, then a group from that summary, then a point from

that group), recall the last summary displayed by pressing F2. This is the only

instance in which the system will automatically vector to the last summary

display shown.

8 User Interface

Page 23

Micro-PWC OPERATOR’S MANUAL

F3 G

ROUP Displays the group selection box. Enter the summary number (one to 1,000)

and group number (one to 24) for the group to be displayed (separated by a

period [.]), then click OK. To view an index list of all groups which have been

defined, click List located at the bottom of the group selection box.

After viewing a point display called up via the hierarchy (i.e., first a group was

called up, then a point from that group), the last group displayed can be

recalled by pressing F3. This is the only instance in which the system will

automatically vector to the last group display shown.

F4 P

OINT Displays the point box. Enter the tagname of the point to be displayed (up to

16 alphanumeric characters), then click OK.

F5 Q

UICK Calls up the Quick Key keypad for the Operator Window which has keyboard

focus.

F6 T

REND Calls up the trend selection box. Enter the number of the trend (one to 512) to

be displayed, then click OK. To view an index list of all trends which have been

defined, click List located at the bottom of the trend selection box.

F7 A

LARM REVIEW Shows the Alarm Review display, a list of all active process alarms captur ed

on the system. The order in which process alarms are listed on the Alarm

Review display is the same as that used in the Mini-Alarm Window. The configurer can elect to display either the newest or oldest high priority alarm, and

this can depend on whether or not unacknowledged alarms exist.

If more than one page of process alarms exists, use the scroll bar or P

and P

AGE DOWN to view the additional alarms.

AGE UP

F8 E

VENT REVIEW Shows the Event Review display, a list of all active process alarms and system

events captured on the system.

If more than one page of system alarms exists, use the scroll bar or P

and P

AGE DOWN to view the additional alarms.

F9 D

ISPLAY

F

ORWARD

Use F9 and F10 to move forward and backward between the last 10 displays

which have appeared in the window with keyboard focus, regardless of display type. These keys correspond to the Display Forward and Display Back

functions available from the window option on the menu bar of each Operator

Window.

Changing displays by any means other than Display Forward and Display

Back will affect the list which keeps track of the last 10 displays viewed. For

example, if the user is on display n (where n is greater than one and less than

10) and selects another display by any means other than Dis pla y Fo rward or

Display Back, then displays n+1 through 10 will be discarded, and the new

display will be placed at the end of the list (i.e., it becomes display n +1).

✎ NOTE Use F9 display forward and F10 display back function keys to move

through displays of different types, which h ave already appeared on

the screen; these keys should not be confused with P

P

AGE DOWN, which are used to move through different pages of one

AGE UP and

display type.

ISPLAY BACK See Display Forward.

F10 D

AGE UP

F12 H

ELP Calls up context sensitive help displays.

User Interface 9

Page 24

Micro-PWC OPERATOR’S MANUAL

A

LT-F7 PRINT LOG Displays the log print window. This window provides access to lists of

summary logs, event logs and spreadsheet logs, and also provides access to

the printing mechanism for the logs which appear in these lists.

A

LT-F8 ARRANGE

W

INDOWS

A

LT-F9 ALARM ACK Acknowledges the alarm in the top line of the Mini-Alarm Win dow and silences

Returns all windows to their original size and location, and moves the pointer

to the upper left hand corner of the screen.

the audible alarm.

A

LT-F10 WINDOW

A

CK

Acknowledges all alarms associated with the page on display. This button is

functional only on Point and Group displays, Alarm and Event Review

displays, and on Graphic displays. Use of this button is equivalent to clicking

the Acknowledge item on the menu bar of an Operator Window.

A

LT-F11 SILENCE Silences the audible alarm. Does not perform alarm acknowledgment.

2.4 Micro-PWC Display

The Micro-PWC provides a window-based user interface to the process. Windows contain displays which

can be accessed by the user via the input devices available on the system. The standard input devices are

the keyboard and the mouse.

Three key types of windows which appear on the Micro-PWC are the System, Mini-Alarm, and Operator

Windows. One System Window, one Mini-alarm Window, and up to four Oper ator Windo ws can a ppear on

the display. Each of these window types has a different purpose and appearance.

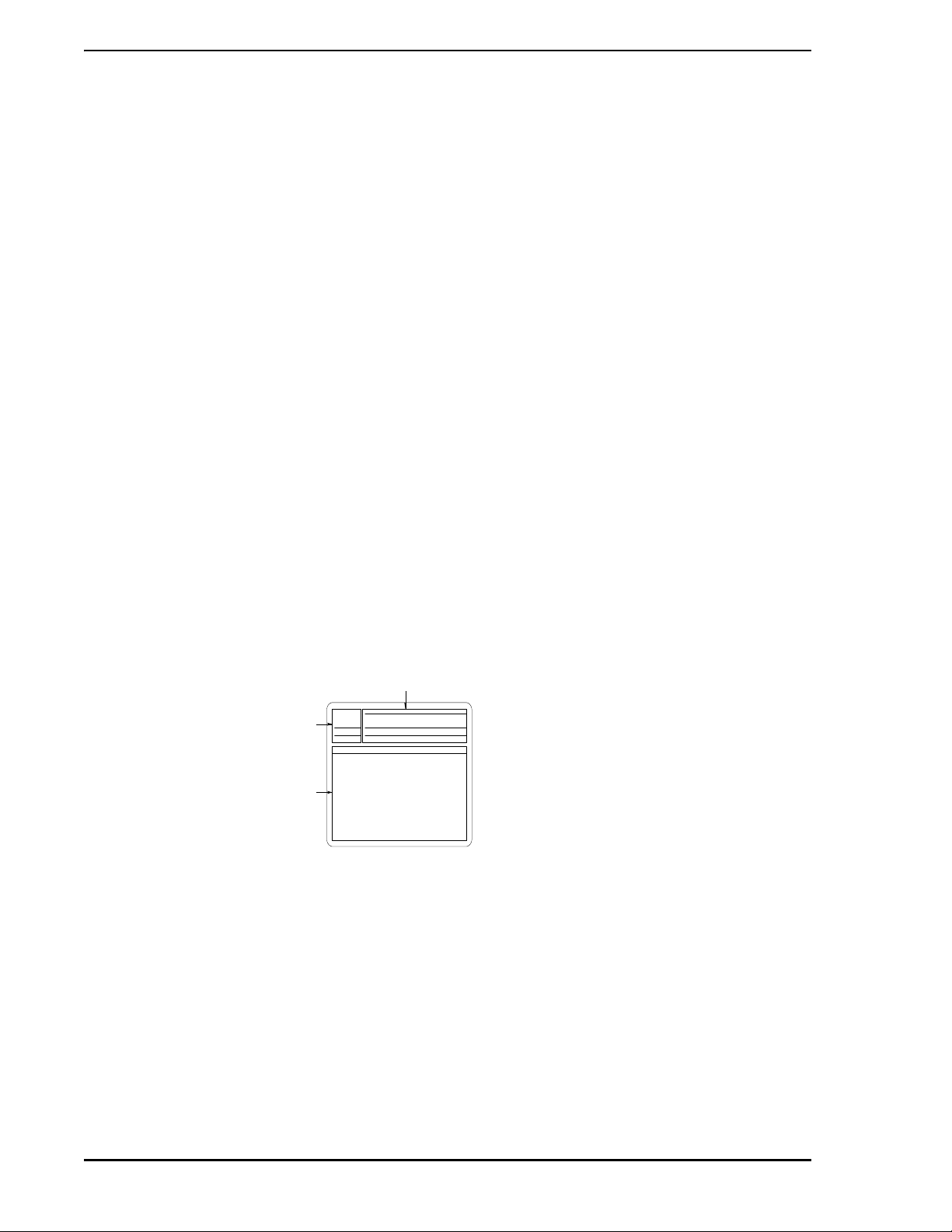

The Micro-PWC default display consists of the System Window , the Mini- Alarm Window, and one Operator

Window, as shown in Figure 2-1. This default window configuration is used at system startup. If no other

default window configuration has been configured, it is also used when an operator logs out.

MINI-ALARM

WINDOW

SYSTEM

WINDOW

OPERATOR

WINDOW

T02738A

Figure 2-1. Micro-PWC System Default Window

2.4.1 System Window

The System Window (Figure 2-2) is a small window located in the top left corner of screen, immediately to

the left of the Mini-Alarm Window. The System Window appears automatically upon system startup and is

visible at all times, unless it is intentionally covered by the operator or is temporarily covered by a pop-up

10 User Interface

Page 25

Micro-PWC OPERATOR’S MANUAL

window. The System Window cannot be moved, closed, or resized. Normal window operations such as

opening an Operator Window or maximizing a window will not cover or overlap the System Window.

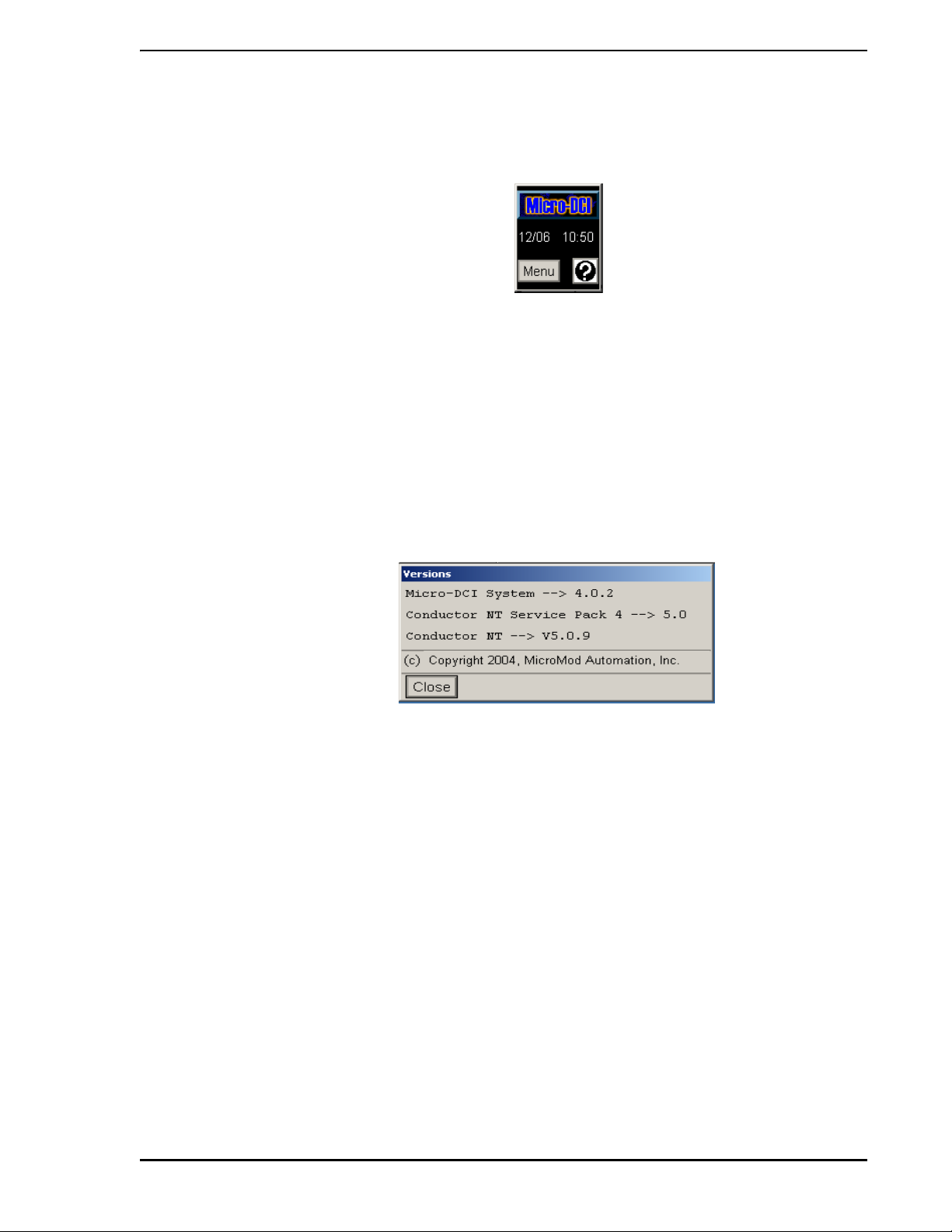

Figure 2-2. System Window

2.4.2 System Window Components

The System Window is composed of three main parts:

• Micro-DCI logo pushbutton

• Date and time indicator

• Menu pushbutton and Help icon

The Micro-DCI logo pushbutton identifies the system as a member of the Micr o-DCI p roduct line ; pre ssing

the button causes the Micro-PWC software version number to be displayed (Figure 2-3).

Figure 2-3. Micro-DCI Logo Pushbutton

The date and time indicator continuously displays the date and time.

The Menu pushbutton provides access to the System Window menu functions.

2.4.3 Menu Functions

The Menu button on the System Window provides access to configuration of Micro-PWC parameters,

security parameters, and network parameters.

2.4.3.1 Micro-PWC Parameters

The following Micro-PWC setup parameters are available for user configuration from the System Window:

• System name (title bar in Mini-Alarm Window)

• PC network name

• Alarm presentation on top line of Mini-Alarm Window

• Priority color assignments

User Interface 11

Page 26

Micro-PWC OPERATOR’S MANUAL

2.4.3.2 Security Parameters

The following security parameters are configurable for each user logged into Micro-PWC:

• Password

• Operator access level

• Area access

• Priority access

• Node access

• Initial displays

• 64 Quick Keys per login name (single window display)

• 16 CRT context keys per login name (multi-window display)

• Message filtering

The following security parameters are configurable for a Micro-PWC with no user logged in (default security):

• Operator access level

• Area access

• Priority access

• Node access

• Initial displays

• 64 Quick Key assignments

• 16 CRT context key assignments

• Message filtering

2.4.3.3 Network Parameters

The following network parameters allow for configuration of parameters that are global to the network:

• Alarm setup

• Alarm vectors

• Area names

• Event bit names

• Printer assignment

• Message routing

• Network device assignments

• Operator Window parameters

✎ NOTE If a client is being run, the event bit configuration can be run only

from the node where the data base resides. This node should be a

server node.

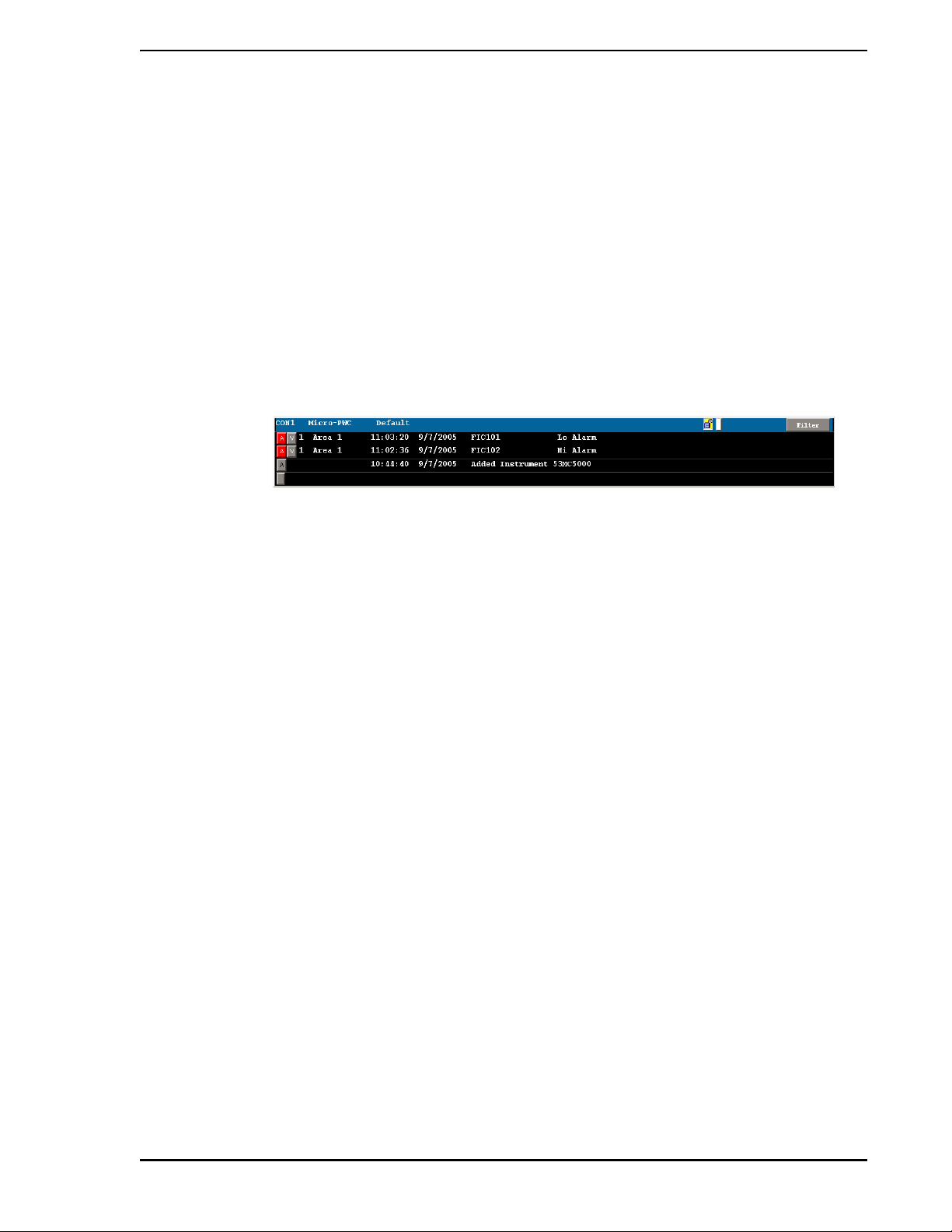

2.4.4 Mini-Alarm Window

The Mini-Alarm Window appears to the right of the System Window on the scr een (Figure 2-4). Like the

System Window, the Mini-Alarm Window appears automatically upon system start up and is visible at all

times, unless it is intentionally covered by the operator or is temporarily covered by a pop-up window.

12 User Interface

Page 27

Micro-PWC OPERATOR’S MANUAL

The Mini-Alarm Window appears on all screens and cannot be maximized, minimized, closed or resized.

Two alarm lines, one event line, and one operator message line are displayed.

The Mini-Alarm Window (Figure 2-4) is composed of the following parts:

• Title bar

• Process alarm display area

• System event display area

• Operator message display area

• Alarm Acknowledge buttons to acknowledge alarms, events and messages

•a Vector button on each process alarm line (lines 1 and 2), used to call up a predetermined

display associated with the point which is in alarm.

•a Filter button and More Alarms (+ALARMS) indicator.

Figure 2-4. Mini-Alarm Window

The title bar identifies the window by Micro-PWC name. The nam e of the current host node is displa yed to

the right of the Micro-PWC address. If the system (i.e., Micro-PWC1) communicating with the Micro-PWC

is the primary node assigned to the Micro-PWC1 (refer to the Micro-PWC Configuration Guide), it will be

displayed in normal video. If the host node is a backup node, the host node name will be displayed in

reverse video. The title bar also contains a string which can be configured to provide further information,

such as plant name and location. The login name of the user currently logged in on the Micro-PWC

appears on the title bar, followed by the +ALARMS indicator (if more alarms exist), a Silence button, and

the Filter button. The Silence button contains a horn icon on the button face, and is visible only when audi-

ble alarms exist.

The process alarm display area has a black background, on which up to two process alarms appear. The

data contained in each line of the process alarm display area is displayed in a number of fields; the width of

each field is configurable. The fields are:

•Priority

•Area

•Time

•Date

•Tag

•Status

•Alarm tag

• Legend

The system event display area appears below the process alarm display ar ea. Event messages r eport th e

occurrence of system events (as opposed to process events) such as database loading and serve r status

(e.g., Server is Offline). One event message is displayed in this area.

The operator message display area appears below the system event display. Operator messages are sent

to all operators in an area of the plant to provide information. This feature provides the users with online

User Interface 13

Page 28

Micro-PWC OPERATOR’S MANUAL

communication between areas which are distant from o ne ano ther. Refer to Sectio n 3 .3, System Fe atures

for details on use of the operator message feature.

An Alarm Acknowledge button is located at the left side of each alarm line. This button is displayed in the

priority color of the alarm, and contains the letter A until the associated alarm is acknowledged. If the associated alarm has been acknowledged, the button is displayed in the priority color of the alarm, but is othe rwise blank. Individual alarms can be acknowledged by clicking this button.

A Vector button is located immediately to the right of the Alarm Acknowledge button. This button contains the letter V. If alarm vectoring (see Section 8.4.2.1, Display Vectoring from the Alarm Review Display)

has been configured for the point named in that alarm line, the display assigned via alarm vectoring will

appear in the Operator Window which has the lowest number. If no display has been assigned via alarm

vectoring, the point display for the point in alarm will be used. If no Operator Window is open when the

Vector button is clicked, no display appears. To cause the display to appear in an Operator Window other

than the one with the lowest number, drag and drop the Vector button inside the frame of the window

where the resulting display will be contained. If the user attempts to place the display in a window other

than an Operator Window (e.g., a pop-up window), the Micro-PWC will emit a beep to indicate an error,

and no further action will be taken. If the contents of the alarm line change during the drag operation, the

alarm vectoring configuration in effect when the Vector button was selected will remain in effect until the

operation is completed.

The +ALARMS indicator is located immediately to the right of the title bar. This indicator appears when

more process alarms exist than can be shown in the alarm display area (i.e., when there are more tha n two

process alarms).

The Filter button is located to the right of the title bar, beyond the +ALARMS indicator. Clicking on th is button causes the Mini-Alarm Filtering window to appear. This window contains options which can be used to

filter process alarms by Priority and Area. If all alarms will be d isplayed the la bel on this button reads Filter;

if some alarms will not be displayed due to filtering configured for the user’s login, the label reads Filtered.

The Mini-Alarm Filtering window also provides a toggle button with which to enable or disable audible

alarms. This toggle button always present when audible alarms have been enabled for the local MicroPWC via the Device Type Assignment window described in the Micro-PWC Configuration Guide.

✎ NOTE The message filtering configured for a user’s login takes

precedence over filtering configured at any other level. If access to

a particular Message Type is filtered out at the login level, it cannot

be turned on using Filter on the Mini-Alarm or using the filter o ptions

which appear on the menu bars of the Alarm Review, Event

Review, Message Review, or Event Historian displays. All

messages which are accessible to the us er can be fur th er filter ed

using these items. If the user elects to filter the contents of a display

using a Filter option from a window menu bar or the Mini-Alarm

Window Filter, the menu bar item will change to L-FILTERED, to

indicate that filtering is local (L) to the window.

2.4.5 Operator Window

The Operator Window provides the operator interface to the process, and can display output contained in

process displays. These process displays include:

• Hierarchical displays (including Summary, Group and Point displays)

• Trend displays

•Graphics

• System Status Display (SSD)

• Process Alarm Review

14 User Interface

Page 29

Micro-PWC OPERATOR’S MANUAL

• System Event Review

• Printer Review

• Event Historian

• Message Review

By default, one Operator Window automatically appears at system startup (when the Default account logs

in) or when a new user logs in, if no default CRT contexts (describ ed in Section 11.12, CRT Context Keys)

have been defined for these accounts. Under these conditions, additional Operator Windows will not automatically appear, but can be opened by the user.

It is possible to have up to four Operator Windows open simultaneously on a Micro-PWC. Section 2.4.6,

Operator Window Operations, provides further information on the default arrangement of Operator Win-

dows. A user’s login account can be configured to automatically open up to four Operator Windows each

time that user logs in. The Operator Window can be maximized, closed and resized.