Page 1

INSTALLATION & SETUP GUIDE

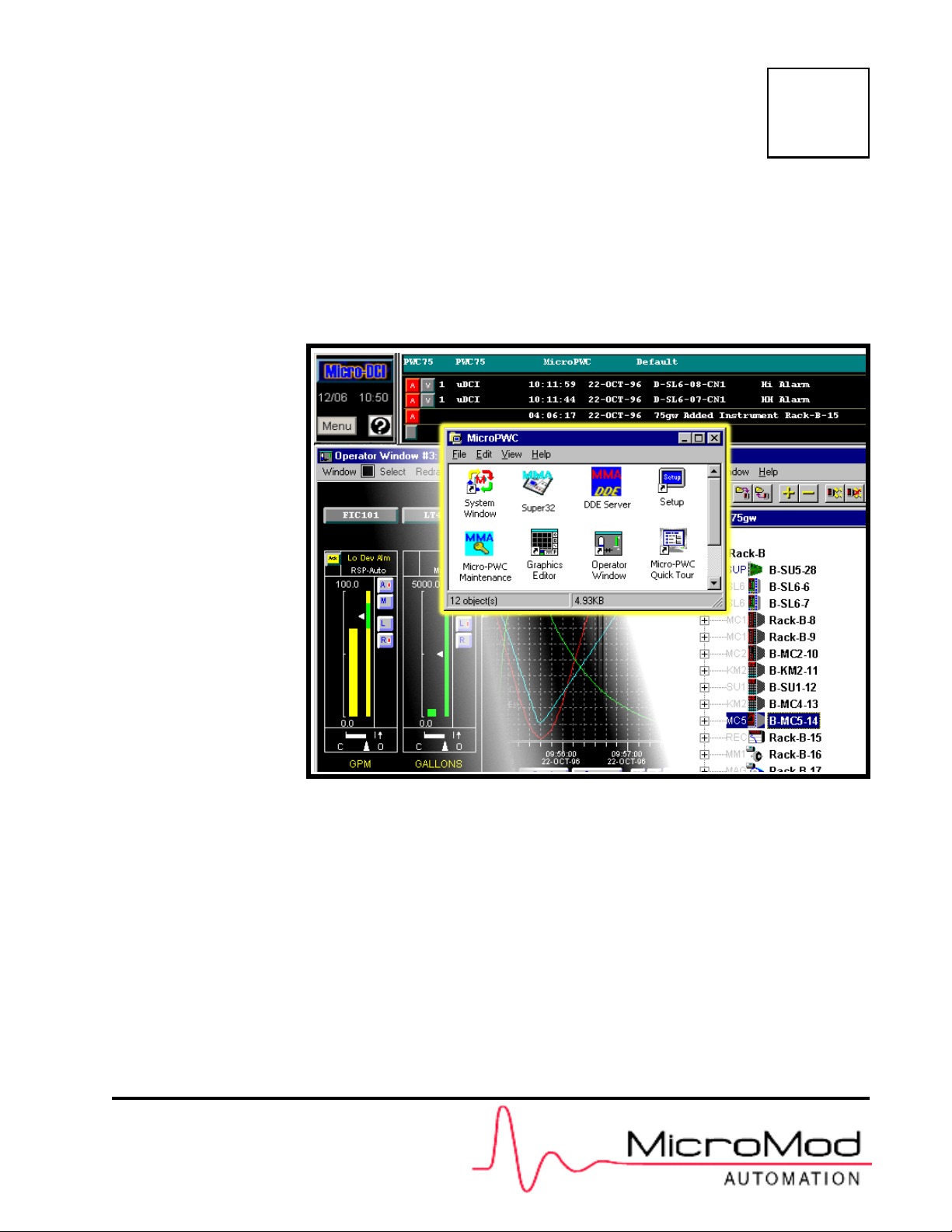

Data Visualization Software

53PW6000

Micro-PWC® SYSTEM

PN26001 Rev. 1

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

∆ Warning. An instruction that draws

attention to the risk of injury or death.

❢ Caution. an instruction that draws

attention to the risk of the product,

process, or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

✎ Note. Clarification of an instruction

or additional information.

i Information. Further reference for

more detailed information or

technical details.

Licensing, Trademarks and Copyrights

MOD 30 and Micro-PWC are trademarks, and MOD 30ML and Micro-DCI are registered trademarks of MicroMod Automation, Inc.

All other trademaks are the property of their respective owners.

© 2005 MicroMod Automation, Inc. (September 2005)

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted.

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with

the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and

source codes, is copyrighted by MicroMod Automation, Inc.,

and is owned by MicroMod Automation or its suppliers.

Page 3

Micro-PWC™ Installation & Setup Guide

Table of Contents

1.0 - INTRODUCTION

1.1 Overview........................................................................................................1

1.2 Intended User................................................................................................2

1.3 Functional Description...................................................................................2

1.3.1 User Interface...................................................................................2

1.3.2 Micro-PWC Management Features..................................................2

1.3.3 Hierarchical Displays........................................................................2

1.3.4 Graphic Configuration ......................................................................3

1.3.5 Historical Database ..........................................................................3

1.3.6 Logging.............................................................................................3

1.3.7 Trending...........................................................................................3

1.3.8 System Status Display......................................................................3

1.3.9 Instrument Configuration..................................................................3

1.3.10 Micro-PWC System Utilities ...........................................................3

1.3.11 Historical Block Data Collection.......................................... ... ... ... ...4

1.3.12 Process Alarms..............................................................................4

1.3.13 Events ............................................................................................4

1.3.14 Message Review............................................................................4

1.3.15 Alarm Groups and External Alarm Annunciation............................4

1.3.16 Printer Review................................................................................4

1.3.17 The @aGlance/IT Application Server interface..............................4

1.4 How to Use This Manual ...............................................................................5

1.5 Glossary of Terms and Abbreviations............................................................5

1.6 Reference Documents...................................................................................9

1.7 Notation Conventions....................................................................................9

2.0 - REQUIREMENTS

2.1 Hardware Requirements.............................................................................. 11

2.1.1 Minimum Hardware Requirements................................................. 11

2.2 Software Requirements...............................................................................11

2.2.1 Requirements.................................................................................11

2.2.1.1 Requirements for Optional Software Packages........... 11

2.3 Micro-DCI Instrument Compatibility.............................................................12

3.0 - INSTALLATION

3.1 Setting Up the Base PC........................ ... ... ... .... ... ... ... ... .... ... ... ... .................13

3.2 Verifying/Installing the Windows Workstation Software...............................13

3.2.1 Verifying Windows Version.............................................................14

3.3 Determine I/O Address for Supervisor Board..............................................15

3.3.1 Windows 2000 Professional...........................................................15

3.3.2 Windows XP Professional ..............................................................16

Contents i

Page 4

Micro-PWC™ Installation & Setup Guide

3.4 Hardware Installation..................................................................................17

3.4.1 Supervisor Board Installation .........................................................17

3.4.1.1 Mechanical Specification................................. ... ... ... ....17

3.4.1.2 Electrical Specification....................... ... ... ... .... ... ... ... ....17

3.4.1.3 Environmental Specification..... ... .... ... ... ... ....... ... ... ... ....17

3.4.1.4 Jumper Settings.......................... .... ... ... ... ... .... ... ..........17

3.4.1.5 Inserting the Supervisor Board ....................................18

3.4.2 Installing the Ethernet Board(s)......................................................19

3.4.3 Installing the Ethernet Drivers and Related Software.....................19

3.4.4 TCP/IP Verification/Installation.......................................................19

3.4.5 Installing the Hardware Key ...........................................................22

3.4.6 Connecting Micro-DCI Instruments to the Base PC.......................22

3.4.6.1 Connecting to a Single 53MC5000 Controller..............23

3.4.6.2 Connecting a COM Port to a Datalink................... ... ....23

3.4.6.3 Connecting the Micro-PWC System to the Datalink Network23

3.4.6.4 Connecting the Micro-PWC System to the Microlink Network24

3.4.7 Verifying System Configuration......................................................28

3.4.7.1 Verifying Version, Processor Type and Memory Amount28

3.4.7.2 Verify Display Configuration........ .... ... ... ... ... .... ... ... ... ....29

3.4.7.3 Verify Configuration of Printer Spool Options...............29

3.4.7.4 Verify Configuration of Tasking Option.........................30

3.4.7.5 Verify Configuration of Desktop Options............ ... ... ....30

3.4.7.6 Verify Taskbar Options... .... ... ... ... .... ... ... ... ... .... ... ... ... ....31

3.4.7.7 Verify Power Management Options .............................31

3.5 Installing the Micro-PWC Software..............................................................31

3.5.1 Micro-PWC Mode Installation..................................... ... .... ... ... ... ....32

3.5.1.1 Pre-Setup Procedure ............................... ... .... ... ... ... ....32

3.5.1.2 Beginning Micro-DCI Master Setup for Full Micro-PWC Operation

.............................................................................32

3.5.1.3 Beginning Micro-PWC Installation................................32

3.5.1.4 Micro-PWC Setup ................................. ... ... .... ... ... ... ....33

3.5.1.5 The SETUP Window....................................................33

3.5.1.6 Copying Micro-PWC Files.................. ... ... ... .... ... ... ... ....33

3.5.1.7 Installation Options............................................. ... ... ....34

3.5.1.8 Installing Micro-PWC License Keys.............................34

3.5.1.9 Choosing Location for the Micro-DCI Portion of Micro-PWC

System.................................................................34

3.5.1.10 New Program Group/Program Folder........................35

3.5.1.11 Adding Micro-DCI Networks.......................................35

3.5.2 Micro-PWC Client Installation Mode...............................................36

3.5.2.1 Pre-Setup Procedure ............................... ... .... ... ... ... ....36

3.5.2.2 Beginning Micro-DCI Master Setup .............................36

3.5.2.3 Beginning Micro-PWC Installation................................36

ii Contents

Page 5

Micro-PWC™ Installation & Setup Guide

3.5.2.4 Micro-PWC Setup ........................................................36

3.5.2.5 The SETUP Window....................................................37

3.5.2.6 Copying Micro-PWC Files............................................37

3.5.2.7 Installation Options.......................................................37

3.5.2.8 Installing Micro-PWC Client License Key . ... .... ... ... ... ... .38

3.5.2.9 Select a Program Folder..............................................38

3.5.3 Microsoft Excel Installation Requirements......................................38

3.5.3.1 Add-in Functions for Microsoft Excel............................39

3.5.3.2 Printing Microsoft Excel Spreadsheets.........................39

4.0 - START-UP and OPERATION

4.1 Micro-PWC Startup......................................................................................41

4.1.1 Startup Options...............................................................................41

4.1.2 Micro-PWC Program Group.... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .41

4.1.3 Licensing During Initial Startup.......................................................43

4.1.4 Micro-PWC Network Service Startup .............................................43

4.2 Stopping the Micro-PWC Software..............................................................44

4.2.1 Closing the Micro-PWC System Windows .....................................44

4.2.2 Stopping the Micro-PWC System Network Service........................44

4.3 The Capuser Account..................................................................................45

4.4 Re-installing the Micro-PWC Software ........................................................46

4.5 Removing a Micro-PWC Installation............................................................46

4.6 Network Time, Time Zones, and Time Adjustment......................................47

4.6.1 Verifying Consistent Network GMT

.................................................................................................47

4.6.2 Time Settings..................................................................................47

4.6.2.1 Changing the Time Zone Setting .................................47

4.6.2.2 Daylight Saving Time...................................................48

4.6.3 Time Adjustment.............................................................................48

4.7 Naming Conventions...................................................................................49

4.7.1 TAGs ..............................................................................................49

4.7.1.1 Types of TAGs..............................................................49

4.7.1.2 Special Considerations in Using TAGnames................49

4.7.2 ATOMS...........................................................................................50

4.7.2.1 Types of ATOMnames..................................................50

4.8 Other Considerations...................................................................................50

5.0 - TROUBLE-SHOOTING

5.1 General Recommendations.........................................................................51

5.2 Diagnostic Messages ..................................................................................52

5.2.1 Windows Messages .......................................................................52

5.2.2 Micro-PWC System Diagnostic Output ..........................................52

5.3 Technical Support........................................................................................52

Contents iii

Page 6

Micro-PWC™ Installation & Setup Guide

6.0 - MAINTENANCE

6.1 The Basic Menu.................................... ... ... ... .... ... ... ... .... .............................53

6.1.1 The Display Log File Menu Item.....................................................53

6.1.2 The Set System Language Menu Item...........................................54

6.1.3 Exit .................................................................................................54

6.2 The String Files Menu .................................................................................54

6.2.1 Modify a Language String File........................................................54

6.2.2 Save Changes to a Language String File.......................................55

6.2.3 Create a Language Directory.........................................................55

6.2.4 Verify a Language Directory...........................................................55

6.2.5 Update a Language Directory ........................................................55

6.2.6 Delete a Language Directory..........................................................56

6.3 The License Administration Menu ...............................................................57

6.3.1 Accessing the License Administration Utilities ...............................57

6.3.1.1 Add a Licensed Feature...............................................57

6.3.1.2 Modify Licensing of an Existing Feature ......................57

6.3.1.3 Delete a Licensed Feature...........................................57

6.3.1.4 Save Licensing Data for Licensed Features ................57

6.3.2 Show Machine/Host ID...................................................................58

7.0 - SUPPORT SERVICES

7.1 Software Maintenance Agreement..............................................................59

7.2 Training.......................... ....................................... ... ... .... ... ... ... ....................59

7.3 Replacement Parts.. ... ... ... .... ... ... ... ... .... .......................................... ... ... ... ....59

7.4 Technical Documentation .................................. ... ... ....................................62

8.0 - THE @aGlance/IT SERVER INTERFACE

8.1 Overview........................ ....................................... ... ... .... ... ... .......................63

8.1.1 General Information About @aGlance/IT.......................................63

8.1.2 The @aGlance/IT API for Micro-DCI..............................................63

8.1.3 Micro-DCI @aGlance/IT Server Requirements - Micro-PWC Version64

8.2 THE @aGlance/IT Server Operation...........................................................65

8.2.1 Configuring the @aGlance/IT Server Internal Interface.................65

8.2.1.1 Registering Server Nodes.................. ... ... ... .... ... ... ... ....65

8.2.2 Starting a Server and Server Names..............................................66

8.2.2.1 Starting a Server with Non-Default Options .................66

8.3 Security for the @aGlance/IT Server...........................................................68

8.3.1 Security for Access to the @aGlance/IT Server for Micro-DCI ......68

8.3.2 Security for Micro-DCI Database Access.......................................68

8.4 Supported @aGlance/IT Client Applications...............................................68

iv Contents

Page 7

Micro-PWC™ Installation & Setup Guide

List of Figures

Figure 3-1. I/O Address List on Windows, Windows 2000 Professional ...........15

Figure 3-2. I/O Address List on Windows XP Professional ....... ... ... .... ... ...... ... .16

Figure 3-3. Jumper Settings, Supervisor Board ...............................................18

Figure 3-4. My Network Places Icon and Menu ................................................20

Figure 3-5. Configuring the IP Address, Steps 2 and 3 ....................................20

Figure 3-6. Internet Protocol (TCP/IP) Properties ............................................21

Figure 3-7. Hardware Key for Use with Micr o- PWC Syst em Software

(Parallel Port Version) ...................................................................22

Figure 3-8. Connecting the Computer’s COM Port to the Datalink ...................25

Figure 3-9. 53SU6000Datalink SUPERVISOR Card to

Datalink Interconnection Diagram (ID-53-1610) .............................26

Figure 3-10. 53SU6000 Microlink SUPERVISOR Card to Microlink

Interconnection Diagram (ID-53-1597) ..........................................27

Figure 4-1. Micro-PWC Program Group ...........................................................41

Figure 4-2. Time Adjustment Window ..................................................... ... ... ... .48

List of Tables

Table 3-1. License Type and Operational Mode Interaction............................. 32

Table 5-1. Micro-PWC Installation and Setup Problems and

Recommendations........................................................................... 51

Table 7-1. Interconnection Terminal Boards (ITB)...... ... ... ... .... ... ... ... ................ 60

Table 7-2. Supervisor Cards............................................................................. 60

Table 7-3. Firmware Upgrade Kits.....................................................................60

Table 7-4. Cable Assemblies 61

Table 8-1. Options for Use When Starting a Server 66

Contents v

Page 8

Micro-PWC™ Installation & Setup Guide

vi Contents

Page 9

READ FIRST

Micro-PWC™ Installation & Setup Guide

∆ WARNING

INSTRUCTION MANUALS

Do not install, maintain, or operate this equipment without

reading, understanding and following the proper MicroMod

Automation Inc. instructions and manuals, otherwise injury or

damage may result.

Read these instructions before starting installation;

save these instructions for future reference.

Contacting MicroMod Automation Inc.

Should assistance be required with any MicroMod Automation Inc. product, use the follo wing contact

information.

Telephone:

MicroMod Automation Inc., Rochester NY:

Phone: 1 (585) 321-9200

Fax: 1 (585) 321-9291

MicroMod Automation Inc., Southampton, PA:

Phone: 1 (215) 355-4377

Fax: 1 (215) 355-4378

E-Mail:

support@micmod.com

Read First vii

Page 10

Micro-PWC™ Installation & Setup Guide

viii Read First

Page 11

Micro-PWC™ Installation & Setup Guide

1.0 INTRODUCTION

The Micro-PWC™ system is a software product designed to run on an Intel Pentium®-based Personal

®

Computer running the Microsoft

system. This product provides a process control operator interface for the following Micro-DCI

ments.

Windows® 2000 Professional or Windows® XP Professional operating

®

instru-

53MC5000 Process Control Station

53SL6000 Single Loop Controller

50XM2000 Magnetic Flowmeter

53MC4000 Four Loop Controller

53MC2000 Single Loop Controller

50KM2000 Chameleon

53MC1000 Single Loop Controller

The heart of this product is a suite of applications that provide easy to use, state -of-the-art displays and

tools to a plant operator . All o f the applications combine a rich se t of default st arting point s with the cap ability to completely customize the applications to meet any operational need.

The Pentium processor is the minimum level processor for acceptable performance. Hardware from several vendors has been qualified and is supported for use with the Micro-PWC system softwa re. The list of

hardware requirements and approved ven dors is contained in Section 2.1, Hardware Requirements, in this

Guide. In addition to the computer, related har dware component s are available for use with the Micro-PWC

system. Several styles of keyboards are available along with a variety of cursor control devices. Interface

cards for Micro-DCI Datalink and Microlink networks are available to provide high performance interfaces

to the Micro-DCI instrument line.

1.1 Overview

Micro-DCI is a distributed process control and information management system which provides the capability to divide process functions among many system components to provide operating flexibility, system

reliability, reduced system costs and ease of implementation. Distribution combined with redundancy also

allows system control and operating functions to be divided among system elements to increase reliability

and flexibility and to reduce risk.

Automation of most processes requires more than control at the unit operations level. The system must

also include an inherent ability to provide process management functions such as scheduling and graphical presentation of plant process conditions as well as reporting functions. The Micro-PWC system is a

human/machine interface to this system, providing the Process Operator, Process Engineer, Instrument

Engineer and Maintenance personnel with global access to all process and system p arameters required by

each to perform their respective tasks.

The Micro-PWC system provides the Process Operator with a window to the process. Using interactive

process graphics and hierarchical displays, the Proce ss Oper ator can mon itor and contr ol all analo g loop s

and discrete devices interfaced to the network, as well as sequential batch operations.

The Micro-PWC system provides the Engineer with an interface through which to configure and change

Graphic and Hierarchical Displays, database I/O, instrument process control functions and sequences,

Log (report) formats, and security fe atures (including access levels for operating personnel). Most changes

Introduction 1

Page 12

Micro-PWC™ Installation & Setup Guide

are immediate, on-line and network-wide, requiring no compilation time before downloading and therefore

no interruption of the process.

The Micro-PWC system provides Maintenance Personnel with the capability to globally monitor the operating status of any system component on the network, and to diagn ose component failures from any MicroPWC system.

1.2 Intended User

The Micro-PWC Installation and Setup Guide is intended for use by personnel engaged in the installation

of the hardware and software components of the Micro-PWC system (PWC).

It is the job of the Micro-PWC system to communicate with the various Micr o- DCI instrumen ts that may be

connected. It is necessary to have some degree of familiarity with the configuration and operation of the

attached instruments in order to understand the function of the Micro-PWC system.

1.3 Functional Description

1.3.1 User Interface

The Micro-PWC system provides the Process Operator, Engineer and Maintenance Technician with a window-based interface to both the process and the Micro-PWC system itself. The window environment on

the Micro-PWC system is based on the Windows operating system from Microsoft.

1.3.2 Micro-PWC Management Features

The Micro-PWC system allows the user to configure many items which aid in managing use of the system.

These include:

• Security Features

• User Logins

• Network Parameters

• Archival Groups

• Messages

• Message Routing

• Network Device Assignment

See the Micro-PWC Configuration Guide for further information on these items.

1.3.3 Hierarchical Displays

Hierarchical displays are a set of preconfigured, network-wide graphical representations emulating traditional instrument displays. A three tiered hierarchy of displays exists to provide the user with infor mation

about the process. This hierarchy consists of Summa ry, Group and Point displays.

A Summary Display provides an overview of 24 groups, arranged in 6 rows of 4 blocks. Ther e ar e 10 0 0

Summary Displays available.

A Group Display provides an operation overview of 4, 6 or 8 points simultaneously. All process control

actions and alarm acknowledgment for points within a group can be performed from the Group Display on

a point-by-point basis.

2 Introduction

Page 13

Micro-PWC™ Installation & Setup Guide

A Point Display provides the most detailed information and operation functions about a single instrument

function block in the Hierarchical Display system. From this level the operator can perform regulatory

changes. Hierarchical Display configuration is discussed in the Micro-PWC Configuration Guide.

1.3.4 Graphic Configuration

Up to 10,000 network-wide graphic displays can be configured using the Micro-PWC system. Because

they are network-wide, a graphic display can be configured on any Micro-PWC system; a copy of the file

containing the graphic is then distributed to all Micro-PWC systems on the network whenever a graphic is

saved or installed. Graphic Configuration is discussed in the Micro-PWC Configuration Guide.

1.3.5 Historical Database

The Historical Database provides the means to collect data from the instruments and store it for use by

various other applications on the Micro-PWC system, such as Logging, Trending and Data Archiving. Historical Data collection is an option on the Micro-PWC system. Configuration of Historical Database data

collection is discussed in the Micro-PWC Configuration Guide.

1.3.6 Logging

Logs are used to collect and format data for use in reports and spreadsheet calculations. The three types

of logs available on the Micro-PWC system include Summary Logs, Event Logs and Spreadsheet Logs.

Spreadsheet logs are an optional feature, configured via Microsoft Excel on the Micro-PWC system. Logs

are available network-wide. Log configuration is discussed in the Micro-PWC Configuration Guide.

1.3.7 Trending

Trending functions display the values of from 1 to 8 points in an analog trend format similar to that presented by a conventional strip chart recorder. Three types of trend recording are provided on the MicroPWC system, including Current Trending, Historical Trending and Archival Trending. Trend displays are

network-wide. Trend configuration is discussed in the Micro-PWC Configuration Guide.

1.3.8 System Status Display

The System Status Display provides an overview of the nodes connected to the Micro-DCI console network. The System Status display also provides access to instrument configuration, which is discussed in

Chapter 10 of the Micro-PWC Configuration Guide. The System Status Display is described in the

Micro-PWC Configuration Guide.

1.3.9 Instrument Configuration

The Micro-PWC system can be used to configure the various Micro-DCI instruments, and can also be used

to updump or download the instrument database, as well as F-tran program files. The mechanics of using

the Micro-PWC system to perform these functions and other services such as file management and database structure verification are provided in the Micro-PWC Configuration Guide.

1.3.10 Micro-PWC System Utilities

A number of useful maintenance and information management functions are provided as Utilities.

Utilities available on the Micro-PWC system include: Backup/Restore, Database Maintenance utilities,

Alarm Groups, Release All Configuration Locks, Other Applications, (Micro-PWC) System Help, User

Help, Quick Keys, CRT Context Keys, and CRT Print.

Utilities of use to personnel involved in configuration activities are discussed in the Micro-PWC Configura-

tion Guide. Utilities of use to the process operator are discussed in the Micro-PWC Operator's Manual.

Introduction 3

Page 14

Micro-PWC™ Installation & Setup Guide

(Some utilities which are of use to both the configurer and the operator [e.g., CRT Print, System Help, User

Help, and so on] are discussed in both manuals.)

1.3.1 1 Historical Block Data Collection

The optional Historical Block Database is designed for the efficient collection of data from a large number

of instrument tag.atoms. Like the data collected in the Historical Database, the Historical Block data is

stored for use by other applications, such as Logging, Trending and Data Archiving. Conf iguration of this

item is discussed in the Micro-PWC Configuration Guide.

1.3.12 Process Alarms

A Process Alarm is generated when a process variable is in an abnormal condition. Process Alarms are

displayed in the top two lines of the Mini-Alarm window and in the Alarm Review display, and are accomp anied by audible alarms. Process Alarms are discussed in the Micro-PWC Operator's Manual.

1.3.13 Events

System Events occur when a problem or change of state is detected within the system, as opposed to

abnormal conditions, problems, or changes of state associated with the process which is being monitored.

System Event messages are displayed in the third line of the Mini-Alarm window, the Event Review display, and the Event Historian. Events are discussed in the Micro-PWC Operator's Manual.

1.3.14 Message Review

Operator Messages are used to provide the operator with information and instr uctions for performing

actions, and can be generated from both the instrument and from the Micro-PWC system. Operator Messages are displayed in the fourth line of the Mini-Alarm window and in the Me ssage Review display, and

can be accompanied by an audible alarm. Message Review is discussed in the Micro-PWC Operator's

Manual.

1.3.15 Alarm Groups and External Alarm Annunciation

An Alarm Group is a list of tagname.atoms, each with an associated value, which are downloaded to the

instrument database; this action is triggered by the occurrence of alarm messages which pass through a

user-configurable filter. This feature can be used to trigger external alarm annunciators when the downloaded values are used to change the value of the Discrete Output (DO) modules in the instrument database. See your system administrator for information on use of this feature at your site.

1.3.16 Printer Review

Messages which have been sent to a printer or to a file can be displayed using the Printer Review display.

Printer Review is discussed in the Micro-PWC Operator's Manual.

1.3.17 The @aGlance/IT Application Server interface

The @aGlance/IT server interface is an optional utility which provides a live data link between a node and

a variety of software applications resident on other distributed control systems, supervisory control systems, personal computers, and so on.

There are two aspects to @aGlance/IT Server configuration: external interface configuration and internal

interface configuration. The @aGlance/IT external interface configuration is used to identify tagnames and

attributes (atoms) in the Global Database, and is described in the Micro-PWC Configuration Guide.

4 Introduction

Page 15

Micro-PWC™ Installation & Setup Guide

The @aGlance/IT internal interface configuration is used to identify the nodes on which @aGlance/IT servers will run. Details on requirements for and configuration of the internal interface for this utility on the

Micro-PWC system are provided in this document, the Micro-PWC Installation and Setup Guide.

1.4 How to Use This Manual

The Micro-PWC Installation and Setup Guide is designed to provide the user with the information necessary to install those hardware and software components of the Micro-PWC system supplied by MicroMod

Automation, Inc.

Section 1.0, INTRODUCTION, describes provides an introduction and overview of the Micro-PWC system.

It also includes a brief glossary, and a list of associated documents.

Section 2.0, REQUIREMENTS, describes the minimum and recommended hardware r equire ment s for the

Micro-PWC system.

Section 3.0, INSTALLATION, describes hardware and software installation procedures.

Section 4.0, START-UP and OPERATION, describes Micro-PWC system operating procedures.

Section 5.0, TROUBLE-SHOOTING, describes trouble-shooting techniques.

Section 6.0, MAINTENANCE, describes the Maintenance Menu subsystem.

Section 7.0, SUPPORT SERVICES, describes support services.

Section 8.0, THE @aGlance/IT SERVER INTERF ACE, describes configuration of the @aGlance/IT Serv er

Interface.

1.5 Glossary of Terms and Abbreviations

This Glossary provides definition for terms used in the Micro-PWC Installation and Setup Guide. Where

alternate usage is defined in the Glossary, the first listed term is considered the preferred usage.

Active Window. The active window is the window with keyboard focus, which receives all keyboard input,

regardless of pointer location. What is typed appears in the active window. If there is no active window,

what is typed is lost. There can be only one active window at a time on a Micro-PWC system monitor.

Area. A functional partition of the Process. Each Micro-DCI network can be assigned to an Area. MicroPWC system functions can then be assigned by Area.

Atom. A single data element in the global database. Atoms can exist in various forms, including (but not

limited to) a single bit (e.g., Auto/Manual), a floating point number, a tagname or a multi- character legend;

there is no pre-defined limit to the size of an atom. See also Module.

Banner. A header page which precedes a printout, which contains identifying information. This is especially useful when the user initiating the printout is not in the immediate vicinity of the printer.

Button. A graphical object in a window that has a three dimensional appearance and acts as a pushbutton. When the user selects or "presses" the button (mouse cursor is placed on button and mouse button is

pressed), its three dimensional appearance inverts, giving the illusion that the button has been pressed.

When the user releases the button, the button appearance returns to normal.

Cancel Button. A pushbutton in some windows which closes the window without implementing any

changes.

Cascading Menu. A submenu which provides selections that amplify the parent selection on a pull-down

or pop-up menu.

Introduction 5

Page 16

Micro-PWC™ Installation & Setup Guide

Check Button. A type of graphic control button used to select settings which are not mutually exclusive.

The visual cue to indicate selection is that a selected button is filled in or checked.

Child Window. A sub-window opened from a parent window. Easily recognized examples are pop-up

menus and help screens. Also known as a pop-up window.

Click. The act of pressing and releasing a mouse button without moving the pointer. The term comes from

the fact that pressing and releasing the mouse buttons produces a clicking sound.

Close Button. The Close button is used to close a window when there are no changes and no data to

save.

Combo Box. See Drop-down Combo Box.

Control Key. The keyboard key labelled CONTROL or <C

TRL> and used as a modifier key.

CRT (Cathode Ray Tube). The Micro-PWC system monitor. The terms CRT and terminal are sometimes

used interchangeably in the documentation.

Cursor. A graphical image, usually an I-beam, arrow, or rectangle, that shows the location where text will

appear on the screen when keys on the keyboard are typed, or where a selection will be made when using

the Select mouse button or <E

NTER> key on the Micro-PWC system Keyboard.

Database. A set of information that resides in a n ode on the network. Several data bases may reside at a

node. See also Global Data Base.

Data Dictionary. A table containing all the rules required to access and configure a data base. The Data

Dictionary resides in the node with the data base.

Dialog Box. A secondary window which is displayed as a result of a user action and contains graphical

controls such as toggle buttons, radio buttons or other pushbuttons.

Digital I/O. Input/output data which is encoded in a digital format (as in ser ial or parallel bytes or words).

See also Discrete I/O.

Discrete I/O. Used to designate two state process input/output types. See also Digital I/O.

Drag. A type of interaction in which the mouse Select button is pressed and held. The mouse is then

moved so that the pointer is "dragged" to the desired location on the screen; the Select button is then

released to complete the action.

Drop-down Combo Box. A drop-down combo box consists of a text entry box and drop-down pushbut-

ton; clicking on the pushbutton provides access to a drop-down list box of selections.

Entry Box. An area used for text entry. An entry box is typically part of a dialog box.

Full Travel Keyboard. A keyboard with separate and distinct keys; each key is capable of complete and

independent travel.

GDBA (Global Data Base Access). See Global DBA.

Global Data Base. The set of all data bases which are accessible by the Micro-PWC product. A foreign

data base joins the Micro-PWC Global Data Base through the mechanisms of Global DBA.

Global DBA (Global Data Base Access, alternate usage is GDBA). The convention for providing access

to data base atoms.

GMS (Graphical Modeling System). A application program licensed from SL Corporation. GMS is used

to create graphical displays on the Micro-PWC system. Each Micro-PWC system incorporates an R T (run time) license to utilize GMS models.

Highlight. An item selected from the list in a list box will be highlighted by a background color different

from the rest of the list box. To highlight an item, position the pointer on that item and click the left mouse

button.

6 Introduction

Page 17

Micro-PWC™ Installation & Setup Guide

ISO (International Standardization Organization). A worldwide federation of national member bodies

providing guidelines for the development of standards.

Icon. An icon is a representation (in miniature), on the monitor screen, of a larger entity, such as a window.

To iconify a window (change it from full size to a small visual representation), the user presses an iconify

button located in the upper right corner of the window's frame. The procedure is rever sible.

Keyboard Focus. The Micro-PWC system uses the "explicit" or "click-to-type" model of keyboar d focus ;

that is, the user must position the pointer (also known as the "mouse cursor") somewhere on the window

which is to receive input from the keyboard (or other input device), and press the lef t mouse butto n once to

select the window. The color of the title bar of the selected window will then change, and that window will

become the active window. The active window receives all keyboard and mouse input.

License. See Software License.

List Box. A list box is an area within a window which provides the user with a scrollable list of options from

which to choose.

Lower. To move a window to the bottom of the window stack in the work area.

Maximize. To enlarge a window to its largest allowable size.

Menu Bar. An area located below the title bar on an Operator Window, which provides the user with sev-

eral options, including Exit, Select and Help.

Menu Pushbutton. A pushbutton on the System Window, which causes a pull-down menu to appear.

Message Box. Message box is the generic name for any dialog box that provides information, gives the

current state of a work in progress, asks a question, issues a warning, or draws attention to an error.

Micro-PWC system. The Micro-PWC system is a Windows-based system which provides the process

control operator with an interface to the distributed control system.

Mini-Alarm Window. The Mini-Alarm Window is located to the right of the System Window on the Micro-

PWC monitor screen. The Mini-Alarm Window automatically appears upon system start-up and is visible at

all times. The Mini-Alarm Window provides a title bar, an alarm display area, an event display area, Alarm

Acknowledge buttons to acknowledge alarms and events, and a Filter button and More Alarms indicator.

Modal Pop-up Window . A pop-up window which require s input from the user. Until the user responds and

closes the modal pop-up window, the parent window will reject any user input.

Model. When used in the graphical context of GMS, a model is an object or group of objects. Models can

be used as objects in other models.

Modifier Key. A key which, when pressed in conjunction with another key, changes the meaning of the

other key. <C

TRL>, <ALT>, and <SHIFT> are modifier keys.

Module. An atom or group of atoms which are combined into a data base structure.

Mouse. A small device with three buttons on top, connected by a cable to the PC on which the Micro-

PWC system software resides. When moved on the surface of a desk or table, the mouse allows the user

to point to locations on the monitor screen and to issue commands by pressin g buttons. The user point s to

a screen location by controlling the position of an image on the screen known as a pointer or mouse cur-

sor. By positioning the pointer on an item and pressing the app ropriate mouse button, the user can select

the desired option. The left mouse button is used for most operations on the Micro-PWC system.

Mouse Button. One of the buttons on the mouse.

Mouse Cursor. (See Pointer.)

Node. A node is a unit or system on the Micro-PWC system Ethernet.

Object. When used in the graphical context of GMS, an entity such as a circle, rectangle, or text field.

Introduction 7

Page 18

Micro-PWC™ Installation & Setup Guide

Operator Window. Located on the Micro-PWC system monitor screen below the System window and

Mini-Alarm window, the Operator Window provides the operator interface to the process, and displays program output from Operator Window applications such as hierarchical displays, trends, graphics, alarm

review, etc. The Operator Window is composed of a title bar, a menu bar, and a display area. Up to four

Operator windows may be present simultaneously on a Micro-PWC system display terminal.

Option Menu. A list of items selectable via associated check or toggle buttons.

Parent Window. The top level window placed on the screen when a new application is started. When a

parent window is closed (removed from display), all child windows are also closed. The Micro- PWC system

keyboard (alphanumeric keys, mouse, etc.) is focused on one parent window, with the color of the parent

window border indicating the focus.

PEM. Process Event Message.

Pointer. A small, mobile image on the monitor screen, controlled by the mouse, which allows the user to

point to specific locations on the monitor screen. The user positions the pointer by moving the mo use on a

desk or tabletop. Also known as the mouse cursor.

Pop-up Menu. A menu which provides no visual clue to its presence, but simply "pops up" when a particular action is performed.

Pop-up Window. A sub-window opened from a parent window. Easily recognized examples are pop-up

menus and help screens. See also Modal Pop-up Window and Child Window.

Pull-down Menu. A menu that is "pulled down" from a window's menu bar.

Pushbutton. A pushbutton is an area of the screen surrounded by a border shadow. When the pushbutton

is selected, the shadow moves to give the illusion that the pushbutton has been pressed in. When the

pushbutton is unselected, the shadow moves to give the appearance that the pushbutton has been

released. Pushbuttons can contain text, numbers, colors or symbols such as directional arrows. For example, the company logo appears on a button in the System Window.

Quick Key . A menu item a ccessed via the SELECT item on the Operator Wind ow menu bar, which, when

pressed, provides the user with the ability to vector directly to one of 64 possible displays.

Radio Button. A graphic control button that simulates the buttons found on an actual car radio. Each button represents a mutually exclusive selection. Radio buttons are typically used to set states or modes.

Redraw Button. A selection on the Operator Window menu bar which allows the user to redraw the

screen on demand.

Resize Handles. The function of resize handles is to resize a window and the display it contains. The

resize handles form a frame which consists of eight separate pieces: the top, bottom, two sides and the

four corners of the frame.

Screen. The monitor screen of a Micro-PWC system monitor.

Scroll Bar. A scroll bar is a feature which allows the user to view data that is too large to be viewed in its

entirety in the associated work area. (The work area typically contains data such as a list or block of text.)

A scroll bar consists of two arrows pointing in opposite directions at each end of a small rectangle. The

rectangle is called the scroll region. A smaller rectangle called the slider is located within the scroll region.

Scroll bars can be located both horizontally and vertically. Horizontal scroll bars are located at the bottom

edge of a work area; vertical scroll bars appear at the right edge.

Scroll Region. The rectangular portion of a Scroll Bar that contains the two arrows and the slider. See

Scroll Bar.

SL-GMS (SL Corporation Graphical Modeling System). See GMS.

Slider. See Scroll Bar.

8 Introduction

Page 19

Micro-PWC™ Installation & Setup Guide

Software License. A software license conve ys to th e purchaser the right to use a defined software prod-

uct. Software licenses are enforced with a Software Licensing Manager program.

Stippling. The technique of displaying items in a lighter shade (typically gray) to denote some special

characteristic. This method is employed in the Micro-PWC system to display items which reside on a particular menu, but which are not currently available to the user (typically, because of access level considerations).

System Window. A small window located at the top left corner of the Micro-PWC system monitor display.

It appears automatically upon system start-up, an d is visible at all times (unless deliberately covered by the

user). The System Window provides a date/time indicator and a menu button for access to other system

features and utilities.

Title Bar. An area located at the top of a window, which provides information to identify the window.

Touchscreen. A monitor with a screen that is sensitive to touch, allowing selections to be made without

the use of a keyboard, mouse or trackball.

Trackball. A ball, movable about its center, that is used to position the pointer on the monitor screen.

(Synonymous with control ball.)

Window. A rectangular section of the screen, which has a background color and a border. Windows may

also incorporate scroll bars, title bars, an d other hig her-level u ser interface comp onent s. See also System

Window, Mini-Alarm Window, Operator Window, Parent Window, and Child Window.

1.6 Reference Documents

•The Micro-PWC Configuration Guide, which provides information for the person configuring

the Micro-PWC system.

•The Micro-PWC Operator's Manual, which provides information for the operator of a

configured Micro-PWC system.

1.7 Notation Conventions

Window titles, menu items, and labels on tabs are shown in italic type.

The labels on keys and pushbuttons are shown in bold type.

Text that the user types in, computer responses, and example text are shown in constant width type.

The term pushbutton refers to video buttons with a three-dimensional appearance; selecting such buttons

via the cursor positioning device (mouse or trackball) or keyboard causes them to appear "pushed in".

Many of the windows which appear on the Micro-PWC system contain buttons labelled Ok, Cancel and

Close. The Ok button is used to save data and close the window in which it app ears. The Cancel button is

used when data is not to be saved, and the current window closed. The Close button is used when there is

no data to be saved, and the current window is to be closed (except in the case of dialog pop-up windows,

which are closed using an Ok button).

Introduction 9

Page 20

Micro-PWC™ Installation & Setup Guide

10 Introduction

Page 21

Micro-PWC™ Installation & Setup Guide

2.0 REQUIREMENTS

2.1 Hardware Requirements

2.1.1 Minimum Hardware Requirements

The following minimum hardware requirements must be met to successfully load and run the Micro-PWC

system software. These include:

• A personal computer (PC) that meets the minimum requirements for running the Windows

operating system. (See Section 2.2, Software Requ irements.)

• 512 MB of memory.

• A 4 GB disk drive.

• A CD-ROM drive. (The Micro-PWC system software is distributed on CD-ROM.)

• A video board and monitor which support 256 colors (8 bit mode) at 1024 x 768 pixel

resolution. A video board and monitor which suppor t 65 K colo rs (1 6 bit mode ) ar e

recommended.

• A single Ethernet communication channel.

• A parallel port or USB port for printing and hardware key installation.

• A DAT tape drive is required on Micro-PWC systems on which large backup and restore

operations will be performed.

• A full size ISA bus slot is required for each installed Supervisor card.

2.2 Software Requirements

The software versions required for the Micro-PWC system are discussed in this sub-section, as well as

requirements for compatibility between the Micro-PWC system and other Micro-DCI products.

2.2.1 Requirements

The following software versions are required for the Micro-PWC system, Release 4.0:

• Windows 2000 Professional or Windows XP Professional

• 53MC5000 Firmware, Rev. 5

• 53SL6000 Firmware, Rev. 1

2.2.1.1 Requirements for Optional Software Packages

Optional software packages supported on the Micro-PWC system require the following software versions:

• Microsoft EXCEL

• @aGlance/IT, Version 3.2 (or later)

• Loopmaster, Version 4.0

• Micro-Tools, Version 4.0

Requirements 11

Page 22

Micro-PWC™ Installation & Setup Guide

2.3 Micro-DCI Instrument Compatibility

In order to use Release 4.0 of the 53SU6000 Micro-DCI Com munication Se rvices system so f twa re, th e following changes or upgrades must be made to any Micro-DCI instruments to be used with the new software:

• Supervisor cards require an upgrade to REV5 of the firmware

• 53MC5000 units with firmware levels of REV0 through REV4 generate pre-acknowled ged

alarms. REV5 firmware is available that enables ala rm s to be ack no wle dg e d by the op er at or.

• 53SL6000 units with REV0 firmware generate pre-acknowledged alarms. REV1 firmware is

available that enables alarms to be acknowledged by the operator.

• The following control modules can only be used in Hierarchical Displays by connecting them to

CON modules on the Supervisor Card:

53MC1000

53MC2000

53MC4000

50KM2000

12 Requirements

Page 23

Micro-PWC™ Installation & Setup Guide

3.0 INSTALLATION

Micro-PWC is composed of several hardware and software components integrated into a base personal

computer (PC). This section provides information on installing these hardware and software components.

Some of the instructions for this installation will be included with the hardware or software components and

are not addressed in this Installation and Setup Guide. The installation order of these component s is significant, and should be done in the following sequence:

1. Set up the base PC. (See Section 3.1.)

2. Ve rify that the base PC is running the Windows 2000 Professional W orkstation or Windows XP

Professional Workstation operating system.

3. Determine the available I/O addresses that can be used when installing a supervisor board.

(See Section 3.3.)

4. Install the optional Micro-DCI network interface board. This can be either a Datalink

Supervisor board, Microlink Supervisor board, or Redundant Microlink Supervisor board pair.

These Supervisor boards enable multiple instruments to be networked together and

connected to this base PC. (See Section 3.4.1.)

5. Install the Ethernet network interface board. This board enables the base PC to connect to an

Ethernet network. (See Section 3.4.2.)

6. Install the drivers and any related software for the Ethernet network interface board(s). A

diskette containing drivers for each of the network interface board(s) will come with the

network board(s). These drivers will enable the base PC to recognize which network board(s)

have been installed. (See Section 3.4.3.)

7. Verify that the TCP/IP network protocols have been installed on the base PC. If TCP/IP has

not been installed on this PC, install it. (See Section 3.4.4.)

8. Install the Micro-PWC system hardware key. (See Section 3.4.5.)

9. Connect the Micro-DCI instruments to the base PC. (See Section 3.4.6.)

10. Verify that the pr oper Windows operatin g system software h as been properly configur ed to run

the Micro-PWC system. (See Section 3.4.7.)

11. Install the Micro-PWC system software. (See Section 3.5.)

3.1 Setting Up the Base PC

Connect all peripheral hardware units to the base PC, including the monitor, keyboard, mouse, and CDROM unit. Connect the base PC and all peripheral units to a power source. See the instructions that are

included with the PC for setting up these components.

Section 2.1 lists all of the Micro-PWC system hardware requirements. Verify that all of the hardware com-

ponents of the base PC meet or exceed these hardware requirements. You can refer to the base PC's documentation to verify these hardware requirements.

3.2 Verifying/Installing the Windows Workstation Software

The Micro-PWC system requires that the base PC is running Windows 2000 Professional Workstation or

Windows XP Professional Workstation software.

This section provides the procedure for che cking which operating system is running on your base PC.

Installation 13

Page 24

Micro-PWC™ Installation & Setup Guide

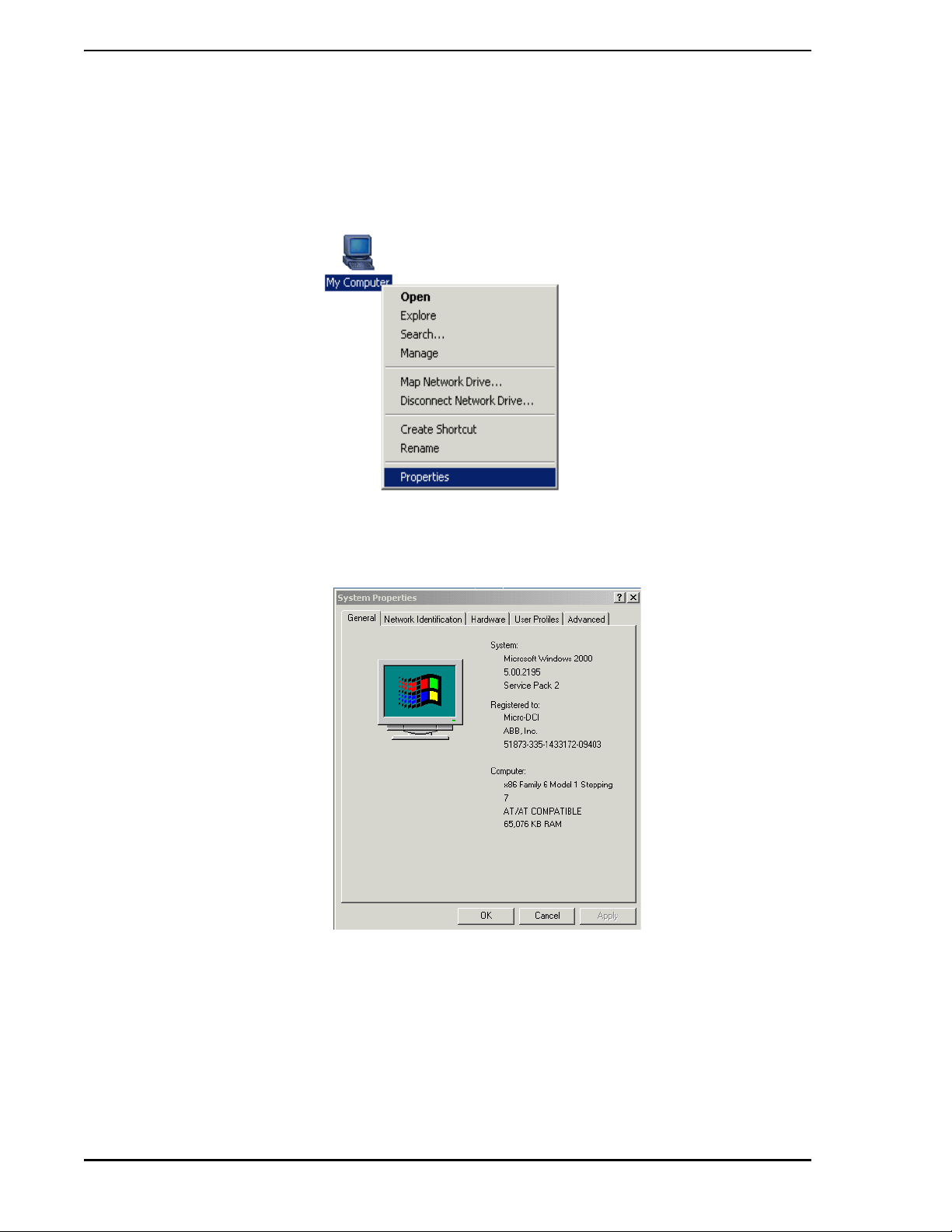

3.2.1 Verifying Windows Version

Follow these steps to determine which version of Windows is running on the PC:

• Locate the icon labeled My Computer on the Windows Desktop. With the mouse, right-click

on this icon. The drop-down menu should appear as shown below.

• From the drop-down menu, select the Properties item. The System Properties window will

appear as shown in the following figure:

• If the General tab is not selected, select it. The operating system version appears as shown in

the above figure. Verify that Windows Windows 2000 Professional Workstation or Windows

XP Professional Workstation software is installed.

14 Installation

Page 25

Micro-PWC™ Installation & Setup Guide

3.3 Determine I/O Address for Supervisor Board

Part of the Micro-PWC system installation procedure includes determining which I/O addresses have

already been assigned to other devices and function s and what I/O addre sses are ava ilable. Th is information will be necessary for installing a Supervisor Board. When installing a Supervisor Board, the I/O

address on this card must be set before it is installed. For this reason, you need to know what I/O

addresses are available when you are installing this board. Valid Supervisor Board I/O addresses are:

0x280, 0x290, 0x300, 0x310, 0x380, 0x390 and 0x3A0.

3.3.1 Windows 2000 Professional

1. Right-click on the My Computer icon on the Windows desktop. The following drop-down

menu will appear:

2. Select Manage > System Tools > System Information > Hardware Resour ces.

3. From the Computer Management dialog that appears, click I/O. The first set of four digits in

the Address column, as shown below, contains the physical I/O addresses that have already

been assigned to another function.

4. Find an unused I/O address for each Supervisor Board in the system. Valid Supervisor Board

I/O addresses are: 0x280, 0x290, 0x300, 0x310, 0x380, 0x390 and 0x3A0.

Figure 3-1. I/O Address List on Windows, Windows 2000 Professional

Installation 15

Page 26

Micro-PWC™ Installation & Setup Guide

3.3.2 Windows XP Professional

1. Locate the My Computer icon and right-click on it.

2. Select Manage > System Tools > Device Manager.

3. On the Device Manager window menu bar, select View > Resources by type.

4. Click on the Input/Output (IO) option. The I/O addresses for the PC will be listed. The first set

of four digits in the Address column contains the physical I/O addresses that have already

been assigned to another function.

Figure 3-2. I/O Address List on Windows XP Professional

5. Find an unused I/O address for each Supervisor Board in the system. Valid Supervisor Board

I/O addresses are: 0x280, 0x290, 0x300, 0x310, 0x380, 0x390 and 0x3A0.

16 Installation

Page 27

Micro-PWC™ Installation & Setup Guide

3.4 Hardware Installation

3.4.1 Supervisor Board Installation

The Supervisor board for the ISA bus is an optional Micro-DCI network communication printed circuit

board. The Supervisor board provides the software products running on PC with the ability to communicate with the Micro-DCI Networks. (If your Micro-PWC system is not equipped with Supervisor boards, you

may skip to Section 3.4.2.)

✎ NOTE One full-size ISA bus slot must be available for each Supervisor

board installed in the personal computer on which the Micro-PWC

system software will be used. An additional half-size ISA bus slot is

required immediately to the right of each Microlink Supervisor board

for which a redundant network connection is required.

3.4.1.1 Mechanical Specification

The Supervisor board is a rectangular board measuring 12.3 inches by 3.9 inches.

3.4.1.2 Electrical Specification

Power Requirements:

Component Requirement

Volt age 5 V dc =/- 5%

Current 1.5 Amps

3.4.1.3 Environmental Specification

Temperature: 0 to +60 degrees C (board only)

The temperature specification of the personal computer is a function of other product component tempera-

ture specifications (if lower) and internal temperature gradients.

3.4.1.4 Jumper Settings

The Supervisor board has three jumpers (J3, J4 and J5) that set the I/O- Port address fo r the board. Th ese

are set at the factory for I/O address 300H. Figure 3-3 shows the jumper settings that provide alternate

addressing if required, possibly for multiple board installations. Using the boa rd 's jumper s, se lect a uniq ue

I/O address for each Supervisor Board in the system based on the results of activities performed for

Section 3.3, Determine I/O Address for Supervisor Board.

To change the I/O address set by these three jumpers, remove the plastic "shorting block" from the two

undesired jumper pins and slide it over the pins th at create the desired I/O address for this supervisor

board. You can change the settings on one, two, or all three jumpers.

Installation 17

Page 28

Micro-PWC™ Installation & Setup Guide

Figure 3-3. Jumper Settings, Supervisor Board

J3 J4 J5 Base Address

AB AB AB 300H

AB AB BC 310H

AB BC AB 380H

AB BC BC 390H

BC AB AB 3A0H

BC AB BC 280H

BC BC AB 290H

3.4.1.5 Inserting the Supervisor Board

This sub-section details the steps needed to insert the Supervisor board in the expansion slot of the personal computer on which the Micro-PWC system software will be installed.

✎ NOTE The internal configuration of personal computers can vary between

models and between manufacturers. If you have questions about

the internal layout of your PC, or difficulty in following the steps

below, refer to the documentation that came with your computer.

∆ WARNING

The Supervisor board will be installed in a computer which

operates with possibly lethal voltages. Before removing the

computer cover, observe the precautions shown in

Step 1

below, to provide personal protection and prevent damage to

the systems components.

18 Installation

Page 29

Micro-PWC™ Installation & Setup Guide

1. Prepare to install the Supervisor boa rd as follows.

a. Turn off the computer and unplug the unit from its power source.

b. Disconnect all cables that are connected to the main system unit.

c. Remove any jewelry fr om you r ha nd s an d wr is ts.

d. Use only insulated or non-conductive tools.

2. Remove the computer's cover.

3. Choose an expansion slot. This can be any ISA slot that can accommodate a full length ISA

board.

4. Remove the expansion slot's backplate by removing the screw found at the top of the

backplate. Retain this screw for use in a later step.

5. Install the Supervisor board into the expansion slot. Do not touch the gold fingers on the

connector edge when handling the Supervisor board. Make sure that the board is firmly seated

in the connector slot.

6. Secure the Supervisor board to the computer chassis, using the scr ew retained in step 4. The

attachment is made at the top of the expansion slot.

7. Make sure that no components on the motherboard (e.g., heat sinks) interfere with the

Supervisor board when it is fully inserted in the motherboard card slot.

8. Replace the computer's cover.

9. Reconnect all devices and cables.

10. Turn the computer power on.

Testing the correctness of the Supervisor board installation can be performed af ter the Supervisor driver

and related software are installed. Supervisor software installation is discussed in Section 3.2, Verifying/

Installing the Windows Workstation Software.

3.4.2 Installing the Ethernet Board(s)

Before installing the Micro-PWC system software , one or mo re Ether ne t ne twork in terface boar ds must be

installed. These Ethernet network boards enable the base PC to be wired to an Ethernet network.

To install the Ethernet network board(s), see the installation instructions that are provided with each

Ethernet network board.

3.4.3 Installing the Ethernet Drivers and Related Software

Once the Ethernet network interface board(s) are installed, the drivers and related software for these

board(s) must be installed. The drivers enable the base PC to recognize that the Ethernet network

board(s) have been installed.

To install the drivers and related software for the Ethernet network board(s), see the installation instructions provided with the software for the network board(s) . See your Ethernet networ k administra tor for the

correct address for these Ethernet network board(s).

3.4.4 TCP/IP Verification/Installation

The Micro-PWC system requires the TCP/IP network interface software to be installed on the base PC.

TCP/IP software enables the base PC to communicate with other PCs over a network.

To check to see if the TCP/IP software has already been installed on the base PC, and to install the TCP/

IP software, if necessary , follow the step s below. The figures illustrating this procedure were captured on a

Micro-PWC with a Windows 2000 Professional operating system installed. The procedure is equally valid

Installation 19

Page 30

Micro-PWC™ Installation & Setup Guide

on a Micro-PWC with Windows XP Professional installed, despite slight differences in the appearance of

the windows.

1. Right-click on the My Network Places desktop icon and select the Properties menu item from

the drop-down menu that appears (Figure 3-4).

Figure 3-4. My Network Places Icon and Menu

2. In the resulting window, select Local Area Connection (see Figure 3-5).

3. Select Internet Protocol (TCP/IP) (see Figure 3-5).

20 Installation

Figure 3-5. Configuring the IP Address, Steps 2 and 3

Page 31

Micro-PWC™ Installation & Setup Guide

4. Click on the Properties button on the Local Area Connection Properties window (Figure 3-5).

The Internet Protocol (TCP/IP) Properties window is displayed (Figure 3-6).

Figure 3-6. Internet Protocol (TCP/IP) Properties

5. When installing the TCP/IP Protocols, configure the IP address and subnet mask as follows:

a. IP Address: If this PC is connected to a network, you must obtain the IP add ress from your

network administrator. If this PC is not connected to a network, it will not matter what IP

address is entered, as long as it is a number between 1 and 255.

b. Subnet Mask: Enter 255.0.0.0 as the subnet mask.

Installation 21

Page 32

Micro-PWC™ Installation & Setup Guide

3.4.5 Installing the Hardware Key

The Micro-PWC system software is licensed by MicroMod Automation Inc. The license is protected by a

hardware key . Th e hardware key is available in two versions: choose one for u se on a parallel por t, or on a

USB port. The parallel port version of the hardware key is shown in Figure 3-7.

The hardware key does not functionally compromise the port it resides on. When installed, the hardware

key provides a female connector allowing a parallel device to be attached to it. If a device (for example, a

printer) is already connected to the port, remove the cable connector from the port, connect the hardware

key to the port, and reconnect the cable to the hardware key. Signals to and from the attached device will

be passed through the hardware key. The hardware key must be installed for the Micro-PWC system software to run.

Figure 3-7. Hardware Key for Use with Micro-PWC System Software (Parallel Port Version)

Installation of Micro-PWC system software and licenses (Section 4.1.3) can proceed if the hardware key is

not attached; however, no Micro-PWC system windows can be opened. In this case, Micro-PWC™

Network Service Startup (Section 4.1.4) will not occur; instead, a pop-up window will be displayed which

states:

Can't read hardware key.

Key must be attached to port.

If the wrong hardware key is attached to the port, a pop-up window will display the following message:

No valid Micro-PWC software license found.

If problems reading the hardware key persist, test the operation of the port. This can be done by attaching

a printer to the port and attempting to print to it.

3.4.6 Connecting Micro-DCI Instruments to the Base PC

The connection necessary for this communication can be made in one of several ways:

• The computer's COM port can be connected directly to the mini-DIN configuration port on the

front of the controller as described in Section 3.4.6.1.

• A COM port on the computer can be connected to a Datalink network using a special Interface

Terminal Board (ITB) that converts the RS-232 signals used by the computer's COM port to

the RS-485 signals used by the Datalink instruments. This scheme is described in Sub-

Section 3.4.6.2.

• If the computer contains Datalink SUPERVISOR cards, each card can be connected to a

22 Installation

Page 33

Micro-PWC™ Installation & Setup Guide

Datalink network.

• If the computer contains Microlink SUPERVISOR cards, each card can be connected to a

Microlink peer-to-peer network. If each standard Microlink SUPER VISOR card is p aired with a

Redundant Microlink SUPERVISOR card, the computer can communicate with one or two

redundant Microlink networks.

3.4.6.1 Connecting to a Single 53MC5 00 0 Con trolle r

To connect a COM port on the compute r to a single 53MC5000 all you need are:

• an available COM port on the computer

• a cable to connect the COM port with the mini-DIN configuration port on the front of the

controller (behind the flip-down door below the display).

An appropriate cable is P/N 698B184U01. Six feet (1.8 m) in length, the cable has a DIN

connector on one end and a 9-pin connector on the other.

If your COM port requires a 25-pin connector, use one of these two options:

• buy an adapter locally to use the 9-pin cable

• order cable P/N 698B183U01; it has a 25-pin connector instead of a 9-pin

3.4.6.2 Connecting a COM Port to a Datalink

A COM port on the computer can be connected to a Datalink network using a special Interface Terminal

Board (ITB) (P/N 686B720U01) that converts the RS-232 signals used by the computer's COM port to the

RS-485 signals used by the Datalink instruments.

This connection scheme is illustrated in Figure 3-8. Note that this drawing shows how to connect the special RS-232/RS-485 ITB to the first 53MC5000 on the Datalink (both standard rear terminal block and

optional cord set rear connection are shown). For details concerning the rest of the Datalink (which is

essentially a "daisy chain" of instruments), its termination, and suitable wire, consult the installation section

of the 53MC5000 instruction bulletin.Note that Figure 3-8 shows a cable used to connect the ITB with a

53MC5000 having the cord set option. This cable is available in many lengths; the part numbers are

shown in Table 7-4.

3.4.6.3 Connecting the Micro-PWC System to the Datalink Network

Once a Datalink SUPERVISOR card is installed in the computer, connect the computer to the Datalink

network.

If your controllers have standard rear terminal connections, making this connection requires only one

cable. This cable has a 10-pin connector with a grounding lug on one end and five bare wires on the other.

Cables may be ordered using the part numbers shown in Table 2 in Figure 3-9.

Making this connection if your controllers are equipped for optional rear cord sets requires:

• A cable from Table 2 in Figure 3-9.

• The Communications ITB 686B622U01.

• A modular cable 677B943Uxx; this cable has a modular telephone connector on each end.

(See Table 1 in Figure 3-9 for part numbers and available cable lengths.)

To make the connection:

1. Plug the 10-pin connector on the cable to the port at the top of the SUPERVISOR card.

2. Connect the grounding lug on the connector end of the cable to the same ground as the

datalink instruments' power common.

Installation 23

Page 34

Micro-PWC™ Installation & Setup Guide

3. The bare wire end of the 677B907 cable can be connected to the st andard rear terminal

connector on the first instrument on the Datalink as shown in Figure 3-9.

If your controllers use optional cord sets, connect the bare wire end of the 677B907 cable to the terminals

on the communication ITB. Remove the resistors on the ITB as shown in Figure 3-9, then connect a

677B943 modular cable to J2 on the ITB and to J10 on the first instrument in the Datalink, as shown in

Figure 3-9.

3.4.6.4 Connecting the Micro-PWC System to the Microlink Network

Once a Microlink SUPERVISOR card is installed in the computer on which you will run the 53PW6000 software, connect the computer to the Microlink network. Making this connection requires:

• one modular cable to connect the Microlink SUPERVISOR card to the Communications ITB.

Cable 677B943Uxx can be ordered in several lengths as shown in Table 1 in Figure 3-10.

• one communications ITB (Interconnection Terminal Board) P/N 686B622U01.

• one modular cable is required to connect the Communication ITB to the fir st instrument on th e

Microlink network. Cable 677B943Uxx can be ordered in several lengths as shown in Table 1

in Figure 3.5 .

To make the connection:

1. Plug one end of the 2.5 ft (.76 m) modular cable into the port at the to p of the M ic rolink

SUPERVISOR card.

2. Plug the other end of the same modular cable into J3 on the Commun ications ITB. Le ave the

resistors on the ITB. The purpose of this ITB is to serve as a termination for the network.

3. Plug one end of the modular cable (P/N 677B943) in J1 on the ITB.

4. Plug the other end of this modular cable into J6 o n the fir st co ntro ller on the Microlink network.

If you are using a Redundant Microlink, continue with the following steps.

5. Plug the second 2.5 ft (.76 m) modular cable p rovided with the Redundant Microlink option into

the connector on the Redundant Microlink Supervisor card.

6. Plug the other end of the same modular cable into J3 on the second Communication ITB

provided. Leave the resistors on this ITB, also.

7. Plug one end of the second modular cable (P/N 677B943) in J1 on the second ITB.

8. Plug the other end of this modular cable into J8 of the first controller on the Microlink network.

24 Installation

Page 35

Micro-PWC™ Installation & Setup Guide

Figure 3-8. Connecting the Computer’s COM Port to the Datalink

Installation 25

Page 36

Micro-PWC™ Installation & Setup Guide

26 Installation

Figure 3-9. 53SU6000Datalink SUPERVISOR Card to

Datalink Interconnection Diagram (ID-53-1610)

Page 37

Micro-PWC™ Installation & Setup Guide

Figure 3-10. 53SU6000 Microlink SUPERVISOR Card to Microlink

Interconnection Diagram (ID-53-1597)

Installation 27

Page 38

Micro-PWC™ Installation & Setup Guide

3.4.7 Verifying System Configuration

The Micro-PWC system is a powerful system and has specific system requirements. Before installing the

Micro-PWC system, proper configuration of the base PC and the Ethernet network must be verified.

3.4.7.1 Verifying Version, Processor Type and Memory Amount

3.4.7.1.1 Windows 2000 Professional

Right-click on the My Computer icon on the Windows 2000 desktop and select Properties from the dropdown menu:

Select System Summary from the Computer Management dialog that displays.

28 Installation

Page 39

Micro-PWC™ Installation & Setup Guide

3.4.7.2 Verify Display Configuration

To determine the number of colors and resolution configuration on your Windows-based PC, navigate to

the Control Panel and click on Display.