Page 1

INSTRUCTION MANUAL

MICRO-DCI

53MT6000

®

Micro-Tools

™

PN26002 Rev.1

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most ost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

∆ Warning. An instruction that draws

attention to the risk of injury or death.

❢ Caution. an instruction that draws

attention to the risk of the product,

process, or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, re sult in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipmen t. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

✎Note. Clarification of an instruction

or additional information.

i Information. Further reference for

more detailed information or

technical details.

Licensing, Trademarks and Copyrights

MOD 30 and Micro-Tools are trademarks, and Micro-DCI and MOD 30ML are registered trademarks of MicroMod Automation, Inc.

All other trademarks are the property of their respective owners.

© 2005 MicroMod Automation, Inc. (September 2005)

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted.

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions

of high pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and

source codes, is copyrighted by MicroMod Automation, Inc.,

and is owned by MicroMod Automation or its suppliers.

Page 3

53MT6000 INSTRUCTION MANUAL

TABLE OF CONTENTS

SAFETY SUMMARY.................................................................. viii

READ FIRST................................................................................ ix

1.0 - INTRODUCTION

1.1 Overview........................................................................................................1

1.2 Notation Conventions....................................................................................1

1.3 Model Number Breakdown............................................................................2

2.0 - REQUIREMENTS

2.1 Hardware Requirements................................................................................3

2.1.1 Minimum Hardware Requirements...................................................3

2.1.2 Hardware Compatibility....................................................................3

2.2 Software Requirements.................................................................................3

2.2.1 Requirements...................................................................................3

2.2.2 Requirements for Optional Software Packages................................3

3.0 - INSTALLATION

3.1 Setting Up the Base PC........................ ... ... ... .... ... ... ... ... ................................5

3.2 Verifying/Installing Windows® Workstation Software ....................................5

3.2.1 Verifying Version of Windows Workstation.......................................5

3.3 Hardware Installation....................................................................................6

3.3.1 Installing the Hardware Key .............................................................6

3.3.2 Connecting Micro-DCI Instruments to the Base PC.........................7

3.3.2.1 Connecting to a Single 53MC5000 Controller................8

3.3.2.2 Connecting a COM Port to a

DataLink Network ..................................................8

3.3.2.3 Installing MicroLink or DataLink

SUPERVISOR-PC Cards ......................................8

3.3.2.4 Connecting Micro-Tools to the DataLink Network..........9

3.3.2.5 Connecting Micro-Tools to the MicroLink Network.......10

3.4 Installing the Micro-Tools Software..............................................................14

3.4.1 Pre-Setup Procedure......................................................................14

3.4.2 Beginning Micro-DCI Master Setup................................................14

3.4.3 Beginning Micro-Tools Installation..................................................14

3.4.4 Micro-DCI Communications Services Setup ..................................14

3.4.5 Micro-DCI Communication Services Location................................15

3.4.6 Installing Data Access Objects (DAO)............................................15

3.4.7 Installing the Micro-DCI Communications Services

and Program Folder.................................................................15

3.4.8 Adding Micro-DCI Networks...........................................................16

3.4.8.1 COM: PC Serial Com Port Network Addition...............16

3.4.8.2 SUP: MicroDCI Supervisor Network Card....................16

Contents i

Page 4

53MT6000 INSTRUCTION MANUAL

3.4.9 Selecting the Target Location for the Micro-Tools System .............16

3.4.10 New Program Folder....................................................................17

3.4.11 Integrating Into Super32...............................................................17

3.4.12 Installing the Micro-Tools License Keys .......................................17

4.0 - START-UP

4.1 Micro-Tools Startup........ ... .... ... ... ... ... .......................................... .... ... ... ... ....19

5.0 - OVERVIEW OF USER INTERFACE

5.1 Starting the Micro-Tools Software......... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....21

5.2 The Micro-Tools Window .............................................................................21

5.3 Toolbars............................................................................................. ... ... ....23

5.3.1 Project Toolbar ...............................................................................23

5.3.2 Application Toolbar.........................................................................24

5.4 Status Bar.......................................................................... ... ... ....................24

5.5 Cursor and Mouse Conventions..................................................................24

5.6 Accessing On-Line Help..............................................................................25

5.7 Specifying a Default Project............................................... ... ... ....................25

6.0 - THE MICRO-TOOLS PROJECT MANAGER

6.1 Project Manager Window ........ ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....28

6.1.1 Opening the Window......................................................................28

6.1.2 The Hierarchical View ....................................................................28

6.1.2.1 Project Folder Hierarchy (Tree View)...........................28

6.1.2.2 Folder Commands ............................................. ... ... ....30

6.1.2.3 Shortcuts..................... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....30

6.2 How to Create a Project .................................................... ... ... ... .... ... ... .......31

6.3 Project Backup and Restore.......................... .... ... ... ... .... ... ... ... ....................32

6.4 Importing and Exporting Project Configuration Data...................................34

6.4.1 Importing ........................................................................................34

6.4.1.1 Importing F-TRAN Project Files...................................34

6.4.1.2 Importing Individual Control, Display and

Subroutine F-TRAN Files ....................................34

6.4.1.3 Importing the F-TRAN Image Only ..............................35

6.4.1.4 Importing the Controller’s Database ............................36

6.4.2 Exporting........................................................................................36

6.4.2.1 Exporting F-TRAN Project Files......................... ... ... ....36

6.4.2.2 Exporting the F-TRAN Image Only ....................... ... ....36

6.4.2.3 Exporting the Controller’s Database .................. ... .......36

6.5 Project Variables................... ... ... ... ... .... ... ... .......................................... ... ....37

ii Contents

7.0 - DATABASE EDITOR

7.1 Accessing the Database Editor Window......................................................39

7.2 Selecting an On-Line or Off-Line Instrument Database

to Configure......................................................................................39

Page 5

53MT6000 INSTRUCTION MANUAL

7.2.1 Specifying an Off-Line Instrument Database in a Project...............39

7.2.2 Selecting an On-Line 53MC5000 to Configure...............................40

7.3 Using the Database Editor Window.............................................................40

7.3.1 Overview ........................................................................................40

7.3.2 Selecting a Function Index.. .... .......................................................41

7.3.3 Making Changes to a Module’s Configuration................................44

7.4 Sub-Menu Descriptions...............................................................................45

7.4.1 ANI Menu .......................................................................................45

7.4.2 ANO Menu......................................................................................46

7.4.3 CCI Menu.......................................................................................47

7.4.4 CCO Menu .....................................................................................48

7.4.5 Menu ..............................................................................................49

7.4.6 Display List Configuration...............................................................53

7.4.7 CONTROL MODULE Configuration..............................................53

7.4.7.1 GENERAL Configurable Parameters...........................54

7.4.7.2 OUTPUT Configurable Parameters .............................55

7.4.7.3 SETPOINT Configurable Parameters..........................57

7.4.7.4 ALARM Configurable Parameters................................59

7.4.7.5 TUNING Configurable Parameters ..............................60

7.4.7.6 TREND Configurable Parameters................................61

7.4.7.7 STATUS Configurable Parameters ..............................62

7.4.8 PARAMETER Menu .......................................................................64

7.4.9 SDT Menu......................................................................................65

7.4.10 TOTALIZER Menu........................................................................67

7.4.11 TREND Menu ................. ... .... ... ... ... .... ... ... ... ... .... ... .......................69

7.4.12 EXTERNAL Menu ........................................................................71

7.4.13 COMMUNICATION Menu ............................................................73

7.4.14 DATA TABLES Menu... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .75

7.4.14.1 Viewing and Changing Database Points....................75

7.4.15 OPTIONS Menu ...........................................................................76

7.4.16 DDI Menu.....................................................................................77

7.4.16.1 Allen Bradley Parameter Configuration......................78

7.4.16.2 OPTO 22 Parameter Configuration............................82

7.4.16.3 Modbus Master Parameter Configuration..................8 7

7.4.16.4 Modbus Slave Parameter Configuration....................91

7.4.16.5 Siemens Parameter Configuration.............................93

7.4.16.6 Koyo Parameter Configuration...................................97

7.4.16.7 HART Parameter Configuration...............................101

7.4.16.8 Printer Parameter Configuration ..............................103

7.4.17 PASSWORDS Menu ..................................................................104

7.4.18 CALIBRATION Menu..................................................................105

Contents iii

Page 6

53MT6000 INSTRUCTION MANUAL

8.0 - F-TRAN PROGRAMMING

8.1 F-TRAN File Storage.................................................................. .... ... ... ... ..107

8.2 Specifying an F-TRAN File to Edit.............................................................107

8.3 Editing an F-TRAN File..............................................................................108

8.3.1 Free-Style Editing.........................................................................108

8.4 Compiling.......................... .... ... ... ... ... .... .......................................... ... ... .....108

8.5 Saving an F-TRAN File..............................................................................108

8.5.1 Overwriting the Opened File.........................................................108

8.5.2 Saving with a New Name.............................................................108

8.6 Assigning the Function Index ....................................................................109

8.7 Building An F-TRAN Image.......................................................................109

8.7.1 How to Initiate the Image Build..................................................... 110

9.0 - GRAPHICAL CONFIGURATION

9.1 Introduction................................. ... ... .... ... .......................................... ... ......111

9.2 The Flexible Control Strategy.....................................................................111

9.3 F-CIM....................... ... ... ... ..........................................................................111

9.4 Library and Installed Applications...............................................................111

9.5 Creating a New FCS or F-CIM Application................................................ 112

9.5.1 Starting from an Existing Application............................................ 112

9.5.2 Starting from Scratch.................................................................... 112

9.6 Softwiring Through Graphics...... ... ............................................................ 113

9.6.1 Introduction to STG...................................................................... 113

9.6.2 The Function Block Editor............................................. .... ... ... ... .. 113

9.6.3 The Application Editor....................................... ... ... ... ... .... ... ... ... .. 114

9.6.3.1 Opening the Editor................................................... .. 114

9.6.3.2 Adding Function Blocks to the Worksheet................. 114

9.6.3.3 Adding Text, Drawing Parts and Free Form

Graphics to the Worksheet................................ 114

9.6.3.4 Adding Notes ............................................................. 115

9.6.3.5 Function Block ID........................ .... ... ... ... ... .... ... ... ... .. 115

9.6.4 Component Editor ........................................................................ 115

9.6.4.1 Object Selection.................... ... ... .... ... ... ... ... .... ... ... ... .. 115

9.6.4.2 Moving Lines and Objects.......................................... 115

9.6.4.3 Zooming/Panning........................ ............................... 116

9.6.4.4 Connecting Function Blocks ...................................... 116

9.6.5 Border Editor................................................................................116

9.6.5.1 Notes Window....................... ... ... .... ... ... ... .................. 117

9.6.5.2 Netlist Window ...................... ... ... .... ... ... ... ... .... ... ... ... .. 117

9.6.5.3 Function Block Parameter Window.................... ...... .. 117

iv Contents

10.0 - THE DOCUMENTER

10.1 Overview..................................................................................................119

10.2 Creating a Report.................................................................................... 119

Page 7

53MT6000 INSTRUCTION MANUAL

10.2.1 Database.................................................................................... 119

10.2.2 FCS Program ............................................................................. 119

10.2.3 F-CIM Program........................................................................... 119

10.2.4 F-TRAN Programs......................................................................119

10.2.5 OK..............................................................................................120

10.3 Editing a Report.......................................................................................120

10.3.1 General.......................................................................................120

10.3.2 Report Templates .......................................................................120

10.3.3 Headers & Footers.....................................................................120

10.4 Previewing a Report ................................................................................120

10.5 Printing a Report......................................................................................120

11.0 - TROUBLESHOOTING

11.1 General Recommendations.....................................................................121

11.2 Diagnostic Messages...............................................................................121

11.2.1 Windows Operating System Messages......................................121

11.3 Technical Support....................................................................................121

12.0 - SUPPORT SERVICES

12.1 Software Maintenance Agreement..........................................................123

12.2 Training....................................................................................................123

12.3 Replacement Parts..................................................................................124

12.4 Technical Documentation ........................................................................125

Contents v

Page 8

53MT6000 INSTRUCTION MANUAL

LIST OF FIGURES

Figure 3-1. My Computer Icon and Menu................................... ... ... .... ... ... ... .... . 6

Figure 3-2. System Properties Window.............................................................. 6

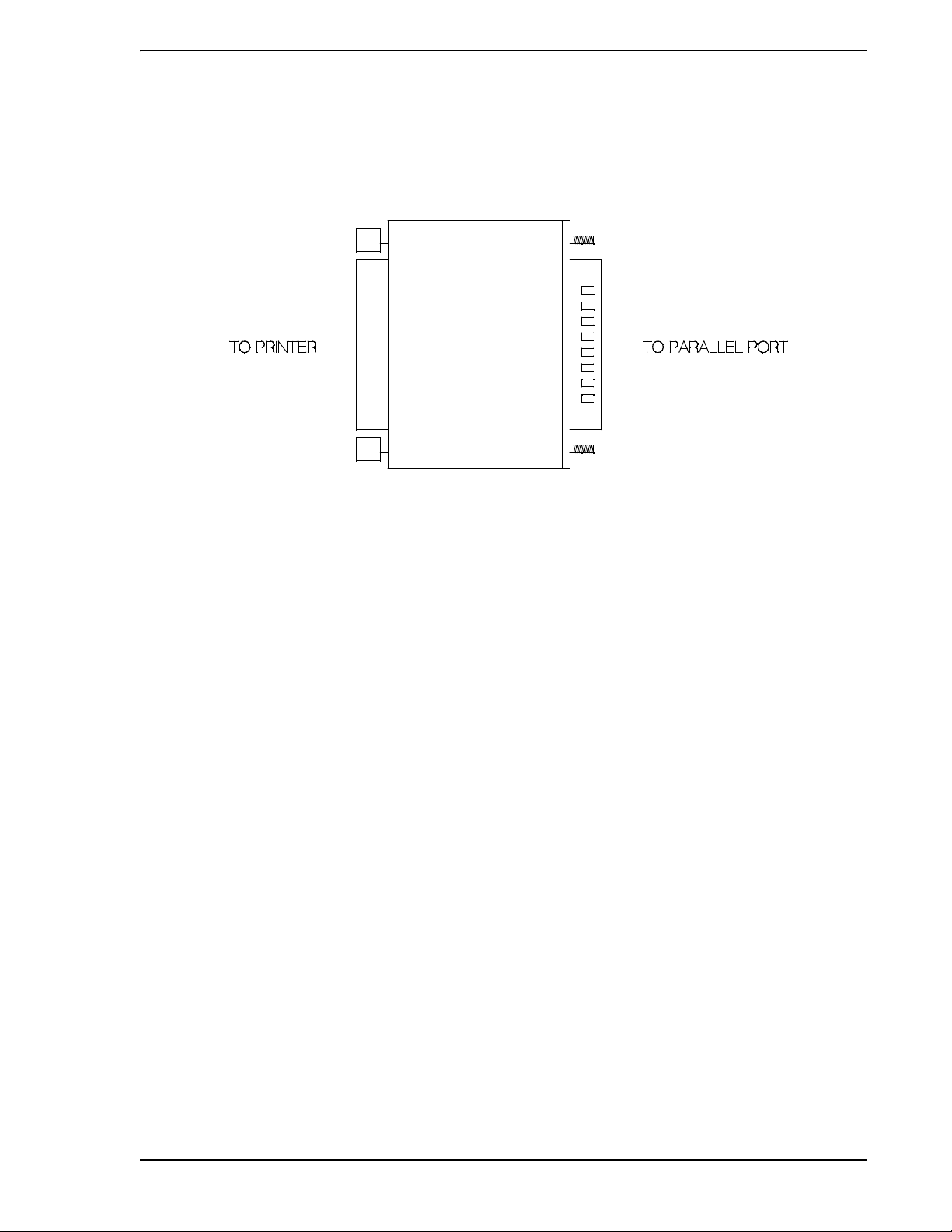

Figure 3-3. Hardware Key for Use with Micro-Tools System Software ... ... ... .... ..7

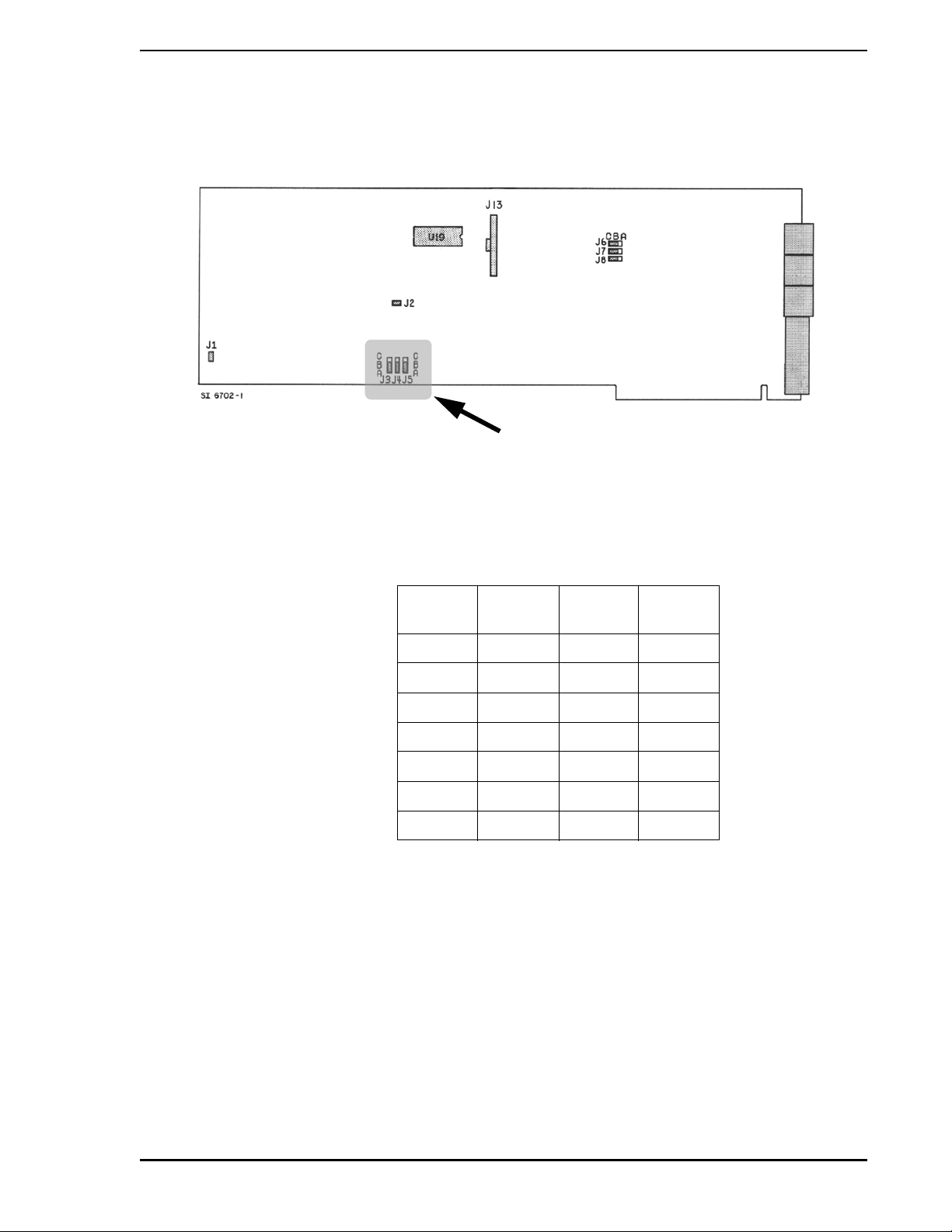

Figure 3-4. SUPERVISOR-PC Jumper Terminal Locations ...............................9

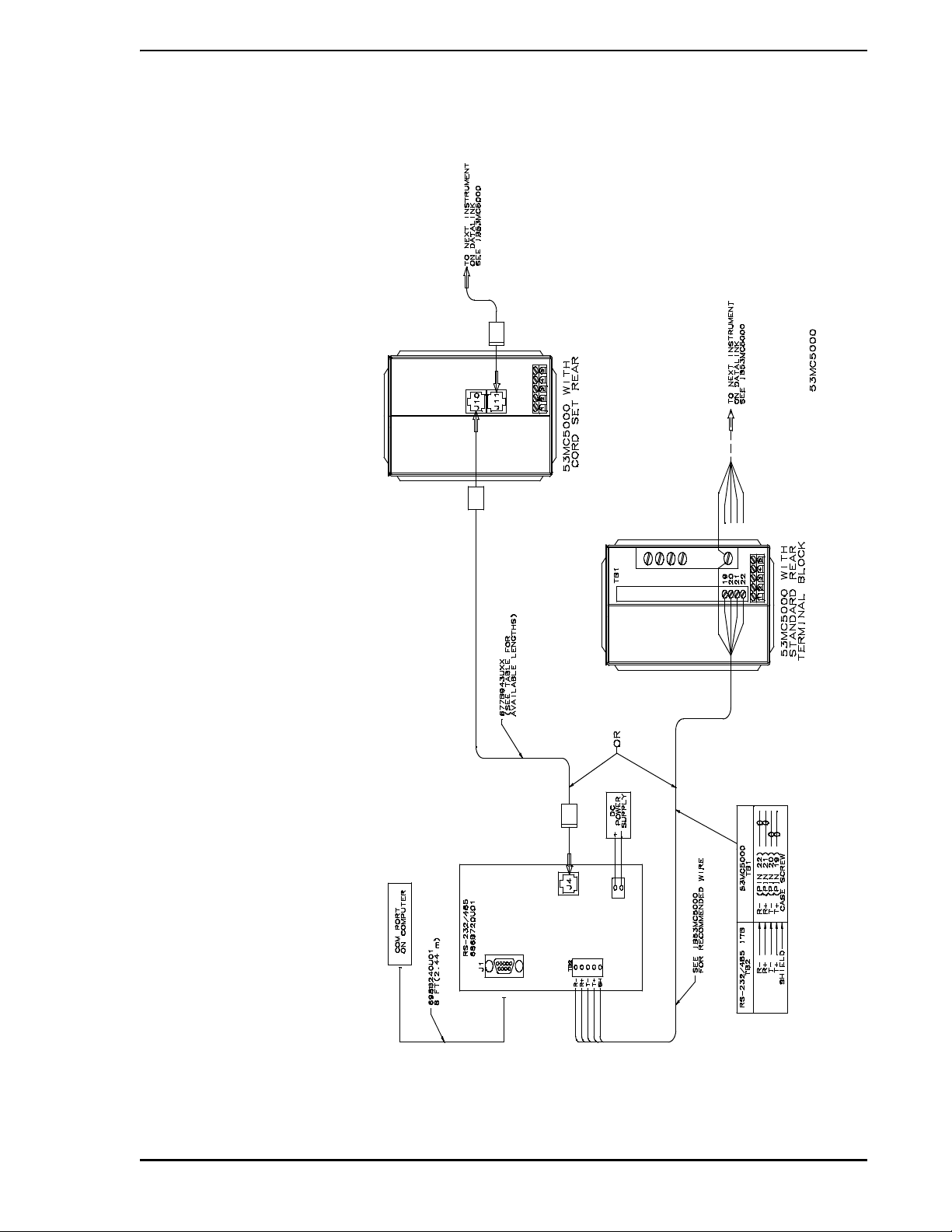

Figure 3-5. Connecting the Computer’s COM Port to the DataLink .................11

Figure 3-6. Micro-Tools DataLink SUPERVISOR Card to DataLink

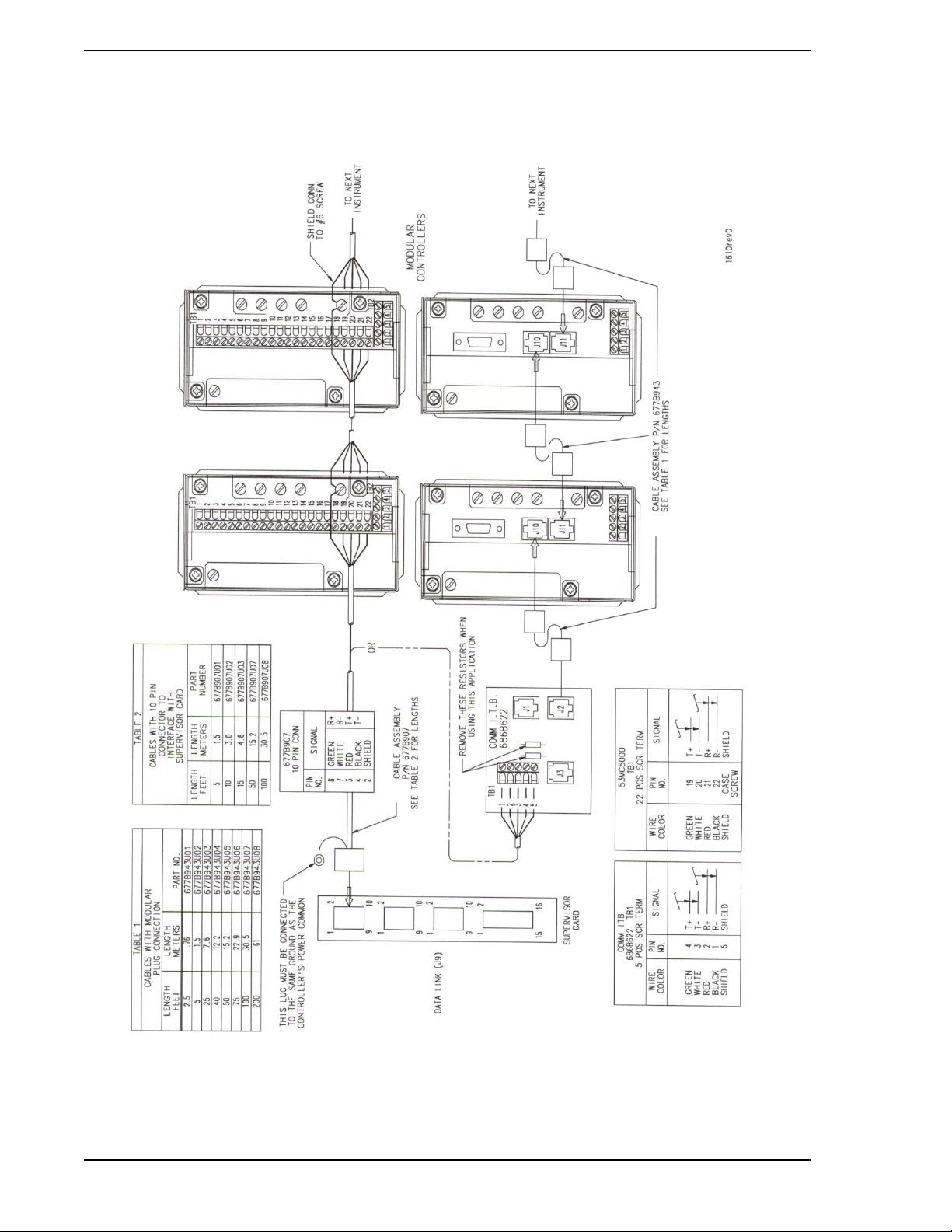

Interconnection Diagram (ID-53-1610) . ... .... ... ... ... .... ... ... ... ... .... ...... ... ....12

Figure 3-7. Micro-Tools MicroLink SUPERVISOR Card to MicroLink

Interconnection Diagram (ID-53-1597) . ... .... ... ... ... .... ... ... ... ... .... ...... ... ....13

Figure 4-1. MicroTools Windows Menu Group .................................................19

Figure 4-2. Micro-DCI Communications Services Windows Menu Group ........19

Figure 5-1. Micro-Tools Window ............................................. ... ... ... .................22

Figure 6-1. Project Manager Window ...............................................................27

Figure 6-2. Library Folder Contents ..................................................................29

Figure 6-3. Project Folder Examples .. ... .... ... ... ... .... ... ... ... .... .............................29

Figure 6-4. Create a New Project, Method 1 ....................................................31

Figure 6-5. Create a New Project, Method 2 ....................................................31

Figure 6-6. Create a New Project, Method 3 ....................................................31

Figure 6-7. Backing up the Micro-Tools Library and All Project Data ...............32

Figure 6-8. Backing Up the Library or a Single Project ... .... ... ... ... ... ....... ... ... ....32

Figure 6-9. Restoring All Project Data in a Backup File ...... ... ... ... ... .... ... ... ... ....33

Figure 6-10. Restoring Only the Library or a Single Project .............................33

Figure 6-11. Importing F-TRAN Project F iles ...................................................34

Figure 6-12. Importing Individual F-Tran Source Files .....................................34

Figure 6-13. Iimporting the F-TRAN Image Only ..............................................35

Figure 6-14. Importing the Controller’s Database .............................................36

Figure 6-15. Variable Store Assignment Window .............................................37

Figure 7-1. Database Editor Window ...................... ... ... ... .... ... ... ... ... .... ... ... ... ....41

Figure 7-2. Function Index Drop-Down Box ..................................................... 42

Figure 7-3. Example of a Submenu Window ....................................................44

Figure 7-4. ANI Parameter Configuration Window .................................... ... ....45

Figure 7-5. ANO Parameter Window ................................................................46

Figure 7-6. CCI Parameter Window .................................................................47

Figure 7-7. CCO Parameter Window ................................................................48

Figure 7-8. System Configuration Window ....................................................... 49

Figure 7-9. Configuration Window ... ... ... .... ... ... ... .... ... ... ... .... .............................53

Figure 7-10. Controller Configuration Window ....... ... ... ... .... ... ... ... ... .... ... ... ... ....53

Figure 7-11 . Output Parameter Configuration Window .....................................55

Figure 7-12. Setpoint Parameter Configuration Window ..................................57

Figure 7-13. Alarm Parameter Configuration Window ......................................59

Figure 7-14. Tuning Parameter Configuration ..................................................60

Figure 7-15. Trend Parameter Configuration Window ......................................61

vi Contents

Page 9

53MT6000 INSTRUCTION MANUAL

Figure 7-16. Status Parameter Configuration Window .....................................62

Figure 7-17. Parameter Configuration Window ................................................64

Figure 7-18. SDT Configuration Menu ............. ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .65

Figure 7-19. TOTALIZER Configuration Window .... ... ... ... ... ....... ... ... .... ... ... ... ... .67

Figure 7-20. Trend Configuration Window ................. ... ... ... .... ... ... ... .... ... ... ... ... .69

Figure 7-21. External I/O Configuration Window .............................................. 71

Figure 7-22. Communication Configuration Window ........................................73

Figure 7-23. Data Tables Display .....................................................................75

Figure 7-24. OPTIONS Configuration Window .................................................76

Figure 7-25. DDI Selection Window .................................................................77

Figure 7-26. Drop-Down Menu .........................................................................77

Figure 7-27. Allen Bradley Configuration Window ............................................78

Figure 7-28. Opto 22 Parameter Configuration Window ..................................82

Figure 7-29. Modbus Master Configuration Window ........................................87

Figure 7-30. Modbus Slave Configuration Window ..........................................91

Figure 7-31. Siemens Parameter Configuration Window ............................. ... .93

Figure 7-32. Koyo Parameter Configuration Window .......................................97

Figure 7-33. HART Parameter Configuration Window ....................................101

Figure 7-34. Printer Parameter Configuration Window ...................................103

Figure 7-35. Passwords Configuration Window .............................................104

Figure 7-36. CALIBRATION Configuration Window .......................................105

Figure 8-1. Open F-TRAN File Window ..........................................................107

Figure 8-2. F-TRAN Editor Window for a New File .........................................108

Figure 8-3. Diagram of Image File Building Process ...................................... 110

Figure 8-4. F-TRAN Image Parts List .............................................................110

Figure 9-1. Zoom/Pan Window ..................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... .....11 6

Figure 3-1. My Computer Icon and Menu ...........................................................6

Figure 3-2. System Properties Window ..............................................................6

Figure 3-3. Hardware Key for Use with Micro-Tools System Software ...............7

Figure 3-4. SUPERVISOR-PC Jumper Terminal Locations ................................9

Figure 3-5. Connecting the Computer’s COM Port to the DataLink .................11

Figure 3-6. Micro-Tools DataLink SUPERVISOR Card to DataLink

Interconnection Diagram (ID-53-1610) .................................... ... ... .12

Figure 3-7. Micro-Tools MicroLink SUPERVISOR Card to MicroLink

Interconnection Diagram (ID-53-1597) ....................................... .... 13

Figure 4-1. MicroTools Windows Menu Group .................................................19

Figure 4-2. Micro-DCI Communications Services Windows Menu Group ........19

Figure 5-1. Micro-Tools Window ................................... ... ... .... ... ... ... .... ... ... .......22

Figure 6-1. Project Manager Window ...............................................................27

Figure 6-2. Library Folder Contents ..................................................................29

Figure 6-3. Project Folder Examples ................................................................29

Figure 6-4. Create a New Project, Method 1 ....................................................31

Figure 6-5. Create a New Project, Method 2 ....................................................31

Contents vii

Page 10

53MT6000 INSTRUCTION MANUAL

Figure 6-6. Create a New Project, Method 3 ....................................................31

Figure 6-7. Backing up the Micro-Tools Library and All Project Data ...............32

Figure 6-8. Backing Up the Library or a Single Project ... .... ... ... ... ... ....... ... ... ....32

Figure 6-9. Restoring All Project Data in a Backup File ...... ... ... ... ... .... ... ... ... ....33

Figure 6-10. Restoring Only the Library or a Single Project .............................33

Figure 6-11. Importing F-TRAN Project F iles ...................................................34

Figure 6-12. Importing Individual F-Tran Source Files .....................................34

Figure 6-13. Iimporting the F-TRAN Image Only ..............................................35

Figure 6-14. Importing the Controller’s Database .............................................36

Figure 6-15. Variable Store Assignment Window .............................................37

Figure 7-1. Database Editor Window ...................... ... ... ... .... ... ... ... ... .... ... ... ... ....41

Figure 7-2. Function Index Drop-Down Box ..................................................... 42

Figure 7-3. Example of a Submenu Window ....................................................44

Figure 7-4. ANI Parameter Configuration Window .................................... ... ....45

Figure 7-5. ANO Parameter Window ................................................................46

Figure 7-6. CCI Parameter Window .................................................................47

Figure 7-7. CCO Parameter Window ................................................................48

Figure 7-8. System Configuration Window ....................................................... 49

Figure 7-9. Configuration Window ... ... ... .... ... ... ... .... ... ... ... .... .............................53

Figure 7-10. Controller Configuration Window ....... ... ... ... .... ... ... ... ... .... ... ... ... ....53

Figure 7-11 . Output Parameter Configuration Window .....................................55

Figure 7-12. Setpoint Parameter Configuration Window ..................................57

Figure 7-13. Alarm Parameter Configuration Window ......................................59

Figure 7-14. Tuning Parameter Configuration ..................................................60

Figure 7-15. Trend Parameter Configuration Window ......................................61

Figure 7-16. Status Parameter Configuration Window .....................................62

Figure 7-17. Parameter Configuration Window ................................................64

Figure 7-18. SDT Configuration Menu ..............................................................65

Figure 7-19. TOTALIZER Configuration Window .......... ... .... ... ... ... ... .... ... ... ... ....67

Figure 7-20. Trend Configuration Window .............................. ... ... ... .... ... ... ... ....69

Figure 7-21. External I/O Configuration Window ..............................................71

Figure 7-22. Communication Configuration Window . ... ... ....... ... ... ... .... ... ... ... ....73

Figure 7-23. Data Tables Display .....................................................................75

Figure 7-24. OPTIONS Configuration Window .................................................76

Figure 7-25. DDI Selection Window .................................................................77

Figure 7-26. Drop-Down Menu .........................................................................77

Figure 7-27. Allen Bradley Configuration Window ............................................78

Figure 7-28. Opto 22 Parameter Configuration Window ..................................82

Figure 7-29. Modbus Master Configuration Window ........................................87

Figure 7-30. Modbus Slave Configuration Window ..........................................91

Figure 7-31. Siemens Parameter Configuration Window .................................93

Figure 7-32. Koyo Parameter Configuration Window .......................................97

Figure 7-33. HART Parameter Configuration Window ...................................101

viii Contents

Page 11

53MT6000 INSTRUCTION MANUAL

Figure 7-34. Printer Parameter Configuration Window ...................................103

Figure 7-35. Passwords Configuration Window .............................................104

Figure 7-36. CALIBRATION Configuration Window .......................................105

Figure 8-1. Open F-TRAN File Window ..........................................................107

Figure 8-2. F-TRAN Editor Window for a New File .........................................108

Figure 8-3. Diagram of Image File Building Process ...................................... 110

Figure 8-4. F-TRAN Image Parts List .............................................................110

Figure 9-1. Zoom/Pan Window ..................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... .....11 6

LIST OF TABLES

Table 3-1. Selecting Supervisor Board Base Address With

Jumpers J3, J4, and J5 ......................................................................9

Table 5-1. Cursor Status By Cursor Shape........................................................24

Table 5-2. Cursor/Mouse Functions...................................................................25

Table 11-1. 53MT6 000 Installation and Setup Problems and

Recommendations.........................................................................121

Table 12-1. Interconnection Terminal Boards (ITB).........................................124

Table 12-2. Supervisor Cards..........................................................................124

Table 12-3. Firmware Upgrade Kits.................................................................124

Table 12-4. Cable Assemblies.........................................................................125

Contents ix

Page 12

53MT6000 INSTRUCTION MANUAL

x Contents

Page 13

53MT6000 INSTRUCTION MANUAL

SAFETY SUMMARY

∆ GENERAL

WARNINGS

∆ SPECFIC

WARNINGS

POSSIBLE PROCESS UPSETS

Maintenance must be performed only by qualified personnel

and only after securing equipment controlled by this product.

Adjusting or removing this product while it is in the system may

upset the process being controlled. Some process upsets may

cause injury or damage.

INSTRUCTION MANUALS

Do not install, maintain, or operate this equipment without

reading, understanding and following the proper MicroMod

Automation Inc. instructions and manuals, otherwise injury or

damage may result.

INSTRUCTION MANUALS

Do not install, maintain, or operate this equipment without

reading, understanding and following the proper MicroMod

Automation Inc. instructions and manuals, otherwise injury or

damage may result. (page ii)

When you use the Database Editor to specify a data point value

in an on-line controller, the chan ge to the instrument’s database

is made as soon as you click on OK in a pop-up window or

when you press the ENTER key during editing of the Data

Tables.

viii Safety Summary

If you do not want the change to affect your process

immediately, PUT THE 53MC5000 IN SUSPEND MODE

FIRST, before performing off-line configuration using the MicroTools software.

To put the instrument into Suspend mode, use the right mouse

button to click on the instrument in the Network V iew and select

SUSPEND from the menu displayed. When you are ready to

resume control of the process using the 53MC5000, use the

same menu to return the controller to operation.

While the 53MC5000 is in SUSPEND mode, its outputs remain

at the last value before the unit was placed in Suspend.

However, IF YOU CHANGE THE VALUE OF ONE OF THE

53MC5000 OUTPUTS IN THE DATABASE while the unit is in

Suspend, THE CHANGE WILL TAKE EFFECT IMMEDIATELY.

Think about the effects on your process before changing an

output! (page 7-2)

Page 14

53MT6000 INSTRUCTION MANUAL

ix Safety Summary

Page 15

53MT6000 INSTRUCTION MANUAL

READ FIRST

∆ WARNING:INSTRUCTION MANUALS

Do not install, maintain, or operate this equipment

without reading, understanding and follo wing the pro per

MicroMod Automation Inc. instructions and manuals,

otherwise injury or damage may result.

Read these instructions before starting installation;

save these instructions for future reference.

Contacting MicroMod Automation Inc.

Should assistance be required with any MicroMod Automation Inc. product, use the follo wing contact

information.

Telephone:

MicroMod Automation Inc., Rochester NY:

Phone: 1 (585) 321-9200

Fax: 1 (585) 321-9291

MicroMod Automation Inc., Southampton, PA:

Phone: 1 (215) 355-4377

Fax: 1 (215) 355-4378

E-Mail:

support@micmod.com

Read First ix

Page 16

53MT6000 INSTRUCTION MANUAL

x Read First

Page 17

53MT6000 INSTRUCTION MANUAL

1.0 INTRODUCTION

1.1 Overview

Micro-Tools™ is a Windows®-based configuration tool for the 53MC5000 family of Process Control

Statio ns. The Micro-Tools product help s reduce con troller configuration and maintenance time by providing

an easy to use view into the database and configuration of the instrument.

Key features include:

• On-line and off-line configuration of 53MC5000 Controlle r databases

• Support for both DATALINK and Micro-Link communication networks

• Provides CAD-style interface for FCS configuration

• Provides an F-TRAN Integrated Environm en t

• Provides a configuration reporter capable of printing out drawing files an d parameter data sets

on graphic-capable printers supported by the Microsoft

®

Windows®-based operating system.

1.2 Notation Conventions

Window titles, menu items, and the labels on keys and pushbuttons are shown in bold UPPER CASE type.

Text that the user types in, comp u ter responses, and example text are shown in constant width type.

The term pushbutton refers to video buttons with a three-dimensional appearance; selecting such buttons

via the cursor positioning device (mouse or trackball) or keyboard causes them to appear "pushed in".

Many of the windows which appear on the 53MT6000 system contain buttons labelled OK, CANCEL and

CLOSE. The OK button is used to save data and close the window in which it appears. The CANCEL button is used when data is not to be saved, and the current window closed. The CLOSE button is used when

there is no data to be saved, and the current window is to be closed (except in the case of dialog pop-up

windows, which are closed using an OK button).

Introduction 1

Page 18

53MT6000 INSTRUCTION MANUAL

1.3 Model Number Breakdown

Refer to the MicroMod data sheet or data t ag for the model number of the pr oduct fu rnished. T he det ails of

a specific number are as follows:

53MT 6 0 _ _A0 _

Product Identifier

Design Sequence

Design Modifier 0

Software Type

Basic Functionality, Standalone 0

Basic Functionality, Add-on 1

Full Functionality, Standalone 2

Full Functionality, Add-on 3

Full Functionality, Micro-PWC Add-on 4

Cable Type

None 0

9 Pin “D” to MC5 Front Port 1

25 Pin “D” to MC5 Front Port 2

Design Level A

Operating System Compatibility

Windows-based Workstation 0

Media Type

None 0

CD-ROM 1

2 Introduction

Page 19

53MT6000 INSTRUCTION MANUAL

2.0 REQUIREMENTS

2.1 Hardware Requirements

2.1.1 Minimum Hardware Requirements

The following minimum hardware requirements must be met to successfully load and run the

53MT6000 software. These include:

• A personal computer (PC) that meets the minimum requirements for running the Windows

operating system (see Section 2.2, Software Requirements).

®

• A 500 MB disk drive, with the ability to expand to 5 GB of disk space. This can be a SCSI or

IDE drive, but must be compatible with the Windows

Professional operating systems. 1.2 GB of disk space is recommended.

• A CD-ROM drive. (The 53MT6000 software is distributed on CD-ROM.)

• A video board and monitor which support at least 256 colo rs (8 bit mode) and 1024 x 768 pixel

resolution.

• A parallel port for printing and hardware key inst allation.

• A full size ISA bus slot is required for each installed Supervisor card.

®

2000 Professional or Windows® XP

2.1.2 Hardware Compatibility

The 53MT6000 software can be installed and run on any personal computer which meets the minimum

requirements listed in Section 2.1.1 and which can run the Windows

Professional operating system.

2000 Professional or Windows XP

2.2 Software Requirements

The software versions required for the 53 MT6000 are discussed in this sub-section, as well as requirements for compatibility between the 53MT6000 and other Micro-DCI products.

2.2.1 Requirements

The following software versions are required for the 53MT6000, Relea se 1.0:

• Windows 2000 Professional or Windows XP Professional

2.2.2 Requirements for Optional Software Packages

• Supervisor Card Firmware, Rev. 5 or higher.

Requ irements 3

Page 20

53MT6000 INSTRUCTION MANUAL

4 Requirements

Page 21

53MT6000 INSTRUCTION MANUAL

3.0 INSTALLATION

Micro-Tools is composed of several hardware and software components integrated into a base personal

computer (PC). This section provides information on installing these hardware and software components.

Some of the instructions for this installation will be included with the hardware or software components and

are not addressed in this Installation and Setup Guide. The installation order of these component s is significant, and should be done in the following sequence:

1. Set up the base PC. (See Section 3.1.)

2. Verify that the base PC is running the Windows 2000 Professional or Windows XP

Professional operating system. If the operating system is not already installed on the base PC,

install it at this time. (See Section 3.2.)

3. Install the optional Micro-DCI network interface board(s). This (or these) can be either a

DataLink Supervisor board, MicroLink Supervisor board, or a Red undant MicroLink Supervisor

board pair. Like the PC serial communications ports, Supervisor boards enable multiple

instruments to be networked together and connected to this base PC.

4. Install the hardware key. (See Section 3.3.1.)

5. Connect the Micro-DCI instruments to base PC. (See Section 3.3.2.)

6. Verify that Windows 2000 Professional Workstation or Windows XP Professional Workstation

has been properly configured to run Micro-Tools.

7. Install the Micro-Tools software. (See Section 3.4.)

3.1 Setting Up the Base PC

Connect all peripheral hardware units to the base PC, including the monitor, keyboard, mouse, and CDROM unit (if it is an external CD-ROM reader). Connect the base PC and all peripheral units to a power

source. See the instructions that are included with the PC for setting up these components.

Section 2.1 lists the minimum hardware requirements. Verify that all of the hardware components of the

base PC meet or exceed these hardware requirements. You can refer to the base PC's documentation to

verify these hardware requirements.

3.2 Verifying/Installing Windows® Workstation Software

Micro-Tools requires that the base PC is running Windows 2000 Professional, or Windows XP Professiona l

Workstation.

Note also that each of these versions of the Windows operating system is available in two different types: a

Workstation Version and a Server Version. Micro-Tools requires Windows Workstation software.

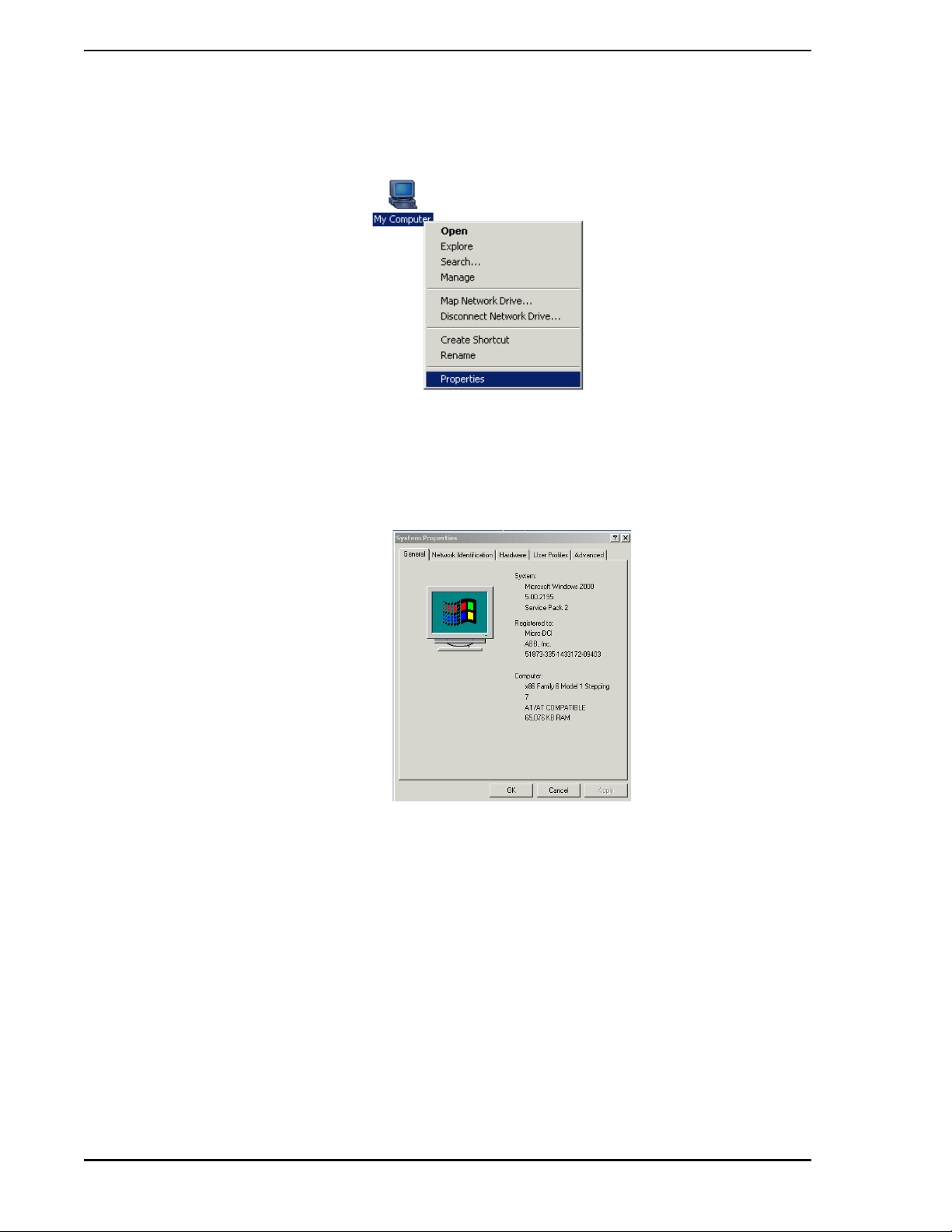

3.2.1 Verifying Version of Windows Workstation

Follow these steps to determine which version of Windows Workstation is running on the base PC:

• Locate the icon labeled My Computer on the Windows Desktop. With the mouse, right-click

Installation 5

Page 22

53MT6000 INSTRUCTION MANUAL

on this icon. The screen should appear as shown in Figure 3-1.

Figure 3-1. My Computer Icon and Menu

• From the drop-down menu that appears, select the Properties item. The System Properties

window will appear as shown in Figure 3-2.

Figure 3-2. System Properties Window

If the General tab is not selected, select it. The operating system version appears as shown in Figure 3-2.

Verify that Windows 2000 Professional, or Windows XP Professional is installed.

3.3 Hardware Installation

3.3.1 Installing the Hardware Key

A Hardware Key is supplied when one of the standalone versions of Micro-Tools is specified in the model

number (refer to Section 1.3).

The Micro-Tools software is licensed by MicroMod Automation Inc. The license is protected by a hardware

key (see Figure 3-3), which must be attached to the PC's parallel port. The hardware key does not interfere

with the operation of the parallel port. When installed, the hardware key provides a fe male connector allow-

6 Installation

Page 23

53MT6000 INSTRUCTION MANUAL

ing a parallel device to be attached to it. If a device (for example, a printer) is alr eady connected to the pa rallel port, remove the parallel cable connector, connect the hardware key to the port, and reconnect the

cable to the hardware key. Signals to and from the attached parallel device will be passed through the

hardware key. The hardware key must be installed for the Micro-Tools software to run.

Figure 3-3. Hardware Key for Use with Micro-Tools System Software

Installation of Micro-Tools software and licenses (Section 3.4) can proceed if the hardware key is not

attached; however, the Micro-Tools application will not start. Instead, a pop-up window will be displayed

which states:

Can't read hardware key.

Key must be attached to parallel port.

If the wrong hardware key is attached to the parallel port, a pop-up window will display the following message:

No valid Micro-Tools software license found.

If problems reading the hardware key persist, test the operation of the parallel port. This can be done by

attaching a printer to the port and attempting to print to it.

3.3.2 Connecting Micro-DCI Instruments to the Base PC

The connection necessary for this communication can be made in one of several ways:

• The computer's COM port can be connected directly to the mini-DIN configuration port on the

front of the controller, as described in Section 3.3.2.1.

• A COM port on the computer can be connected to one or more controllers via their DataLink

port using an RS232/485 Interface Terminal Board (ITB) that converts the RS-232 signals

used by the computer's COM port to the RS-485 signals used by the DataLink instruments.

This scheme is described in Section 3.3.2.2.

• If the computer contains a DataLink SUPERVISOR card, each card can be connected to one

or more controllers via their DataLink port (refer to Section 3.3.2.3).

• If the computer contains MicroLink SUPERVISOR cards, each card can be connected to a

MicroLink peer-to-peer network. If each stan dard M i croL ink SUPERVISOR card is paired with

a Redundant MicroLink SUPERVISOR card, the computer can communicate with one or two

redundant MicroLink networks.

Installation 7

Page 24

53MT6000 INSTRUCTION MANUAL

3.3.2.1 Connecting to a Single 53MC5 00 0 Co n trolle r

To connect a computer COM port on the computer to a single 53MC5000, all you need are:

• an available COM port on the computer

• a cable to connect the COM port with the mini-DIN configuration port on th e front of the

controller (behind the flip-down door below the display).

An appropriate cable is MicroMod Automation P/N 698B184U01. Six feet ( 1.8 m) in length, the cable has a

DIN connector on one end and a 9-pin connector on the other.

If your COM port requires a 25-pin connector, use one of these two options:

• buy an adapter locally to use the 9-pin cable

• order MicroMod Automation cable P/N 698B183U01; it has a 25-pin connector instead of a

9-pin connector

3.3.2.2 Connecting a COM Port to a DataLink Network

A COM port on the computer can be connected to a DataLink network using a special Interface Terminal

Board (ITB) (P/N 686B720U01) that converts the RS-232 signals used by the computer's COM port to the

RS-485 signals used by the DataLink instruments.

This connection scheme is illustrated in Figure 3-6. Note that this drawing shows how to connect the special RS-232/RS-485 ITB to the first 53MC5000 on the DataLink (both standard rear terminal block and

optional cord set rear connection are shown) . For de tails concerning the rest of the DataLink (which is

essentially a "daisy chain" of instruments), its termination, and suitable wire, consult the installation section

of the 53MC5000 instruction bulletin.

Note that Figure 3-6 shows a cable used to connect the ITB with a 53MC5000 having the cord se t o ption.

This cable is available in many lengths; the part numbers are shown in Table 1 of Figure 3-6.

3.3.2.3 Installing MicroLink or DataLink SUPERVISOR-PC Cards

To install the SUPERVISOR-PC cards, perform the following procedure:

1. Properly set the SUPERVISOR-PC card jumpers. All SUPERVISOR-PC cards are identical

when shipped. It is the installer's responsibility to check jumpers J3, J4 and J5; these jumpers

set the base address in the PC I/O address space. (Refer to Figure 3-2 for jumper terminal

locations and Table 3-1 on page 9 for jumper settings.)

2. Turn off power to the computer and install the cards. A maximum of four

SUPERVISOR-PC cards can be installed. Plug each card into any available ISA slot and

secure each card with a screw through its mounting bracket.

3. If a redundant MicroLink card is required, it must be installed in the slot immedi ately to the right

of the MicroLink SUPERVISOR card; connect the ribbon cable connecting the two cards into

J13.

8 Installation

Page 25

53MT6000 INSTRUCTION MANUAL

4. Connect the Instrument DataLink cable to th e T OP connector at the rear of the SUPERVISORPC card.

J

Figure 3-4. SUPERVISOR-PC Jumper Terminal Locations

Table 3-1. Selecting Supervisor Board Base Address With Jumpers J3, J4, and J5

Base

Address

300H AB AB AB

310H AB AB BC

380H AB BC AB

390H AB BC BC

3A0H BC AB AB

280H BC AB BC

290H BC BC AB

3.3.2.4 Connecting Micro-Tools to the DataLink Network

Once a DataLink SUPERVISOR card is installed in the computer, connect the SUPERVISOR card to the

DataLink network using the port provided on the card.

If your controllers have standard rear terminal connections, making this connection requires only one

cable. This cable has a 10-pin connector with a grounding lug on one end and five bare wires on the other.

Cables may be ordered using the part numbers shown in Table 2 in Figure 3-6.

1. Plug the 10-pin connector on the cable to the port at the top of the SUPERVISOR ca rd. This

connector is the key to insuring a proper installation.

J3 J4 J5

2. Connect the connector's grounding lug to the same ground as the DataLink instruments'

power common.

Installation 9

Page 26

53MT6000 INSTRUCTION MANUAL

3. The bare wire end of the 677B907 cable can be connected to the first controller's standard

rear terminal connector as shown in Figure 3-6.

If your controllers are equipped for optional rear cord sets, making this connection requires:

• The Communications ITB 686B622U01.

• A modular cable 677B943Uxx; this cable has a telephone-type modular connector on each

end. (See Table 1 in Figure 3-6 for part numbers and available cable lengths.)

If your controllers use optional cord sets, connect the bare wire end of the 677B907 cable to the terminals

on the communication ITB. Remove the resistors on the ITB as shown in Figure 3-6. Then connect a

677B943 modular cable to J1, J2 or J3 on the IT B an d to J10 o r J11 on the first instrument in the DataLink

as shown in Figure 3-6.

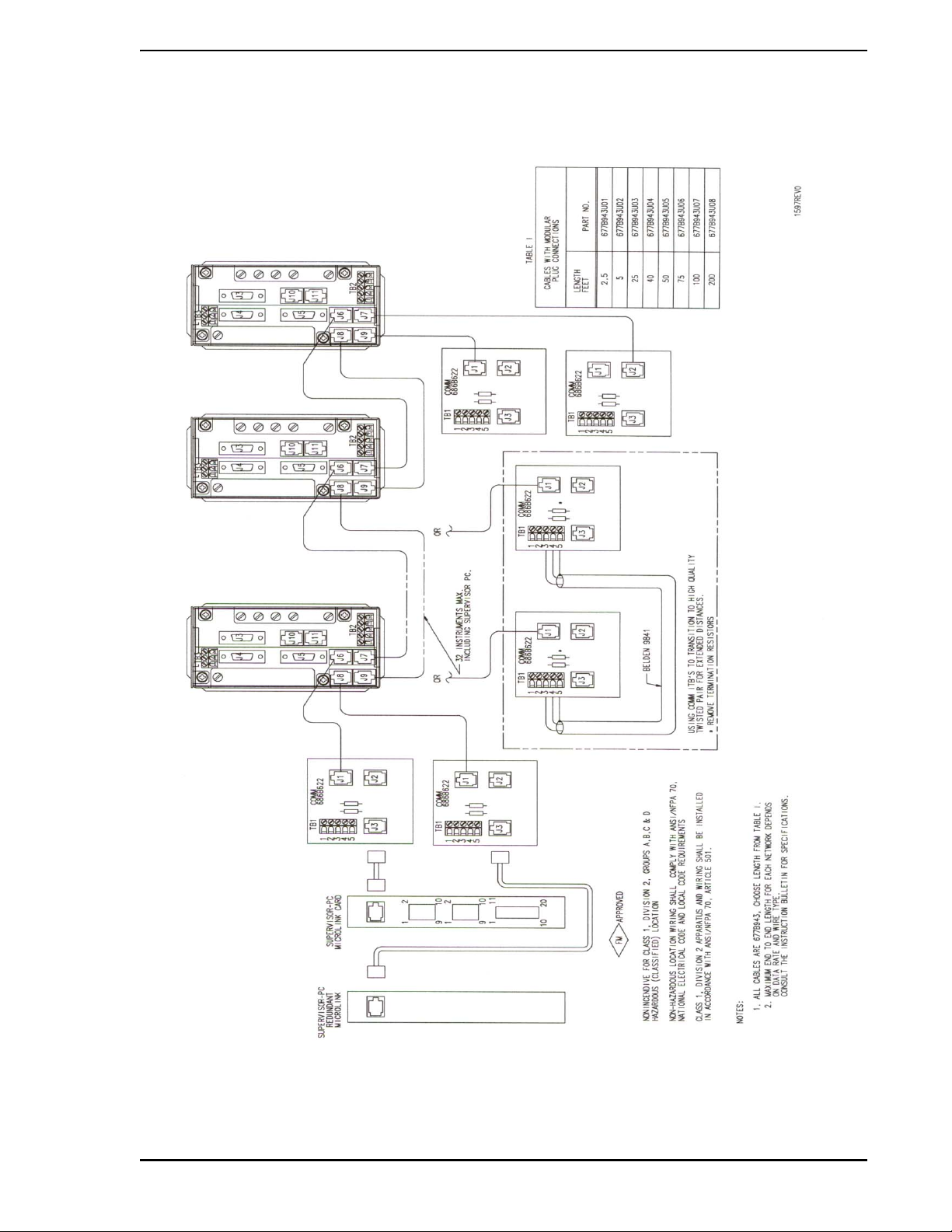

3.3.2.5 Connecting Micro-Tools to the MicroLink Network

Once a MicroLink SUPERVISOR card is installed in the computer, connect the SUPERVISOR card to the

MicroLink network. Making this connection requires:

• one modular cable to connect the MicroLink SUPERVISOR card to the Communications ITB.

Cable 677B943Uxx can be ordered in several lengths as shown in Table 1 in Figure 3-7.

• one communications ITB (Interconnection Terminal Board) P/N 686B622U01

• one modular cable is required to connect the Communication ITB to the fir st instrument on th e

MicroLink network. Cable 677B943Uxx can be ordered in several lengths as shown in Table 1

in Figure 3-7.

1. Plug one end of the 2.5 ft (.76 m) modular cable into the port at the top of the MicroLink

SUPERVISOR card.

2. Plug the other end of the same modular cable into J1, J2 or J3 on the Communications ITB.

Leave the resistors on the ITB (refer to the MicroLink Instruction Bulletin for resistor sizing).

The purpose of this ITB is to serve as a termination for the network.

3. Plug one end of a second modular cable (P/N 677B943) into one of the remaining unused

plugs (J1, J2 or J3) on the ITB.

4. Plug the other end of this second modular cable into J6 or J7 on the first controller on the

MicroLink network.

If you are using a Redundant MicroLink continue with the following steps.

5. Plug a third 2.5 ft (.76 m) modular cable pr ovided with the Red undant MicroLink option into th e

connector on the Redundant MicroLink Supervisor card.

6. Plug the other end of this third modular cable into J1, J2 or J3 on the second Communication

ITB provided. Leave the resistors on this ITB, also (refer to the MicroLink Instruction Bulletin

for resistor sizing).

7. Plug one end of the fourth modular cable (P/N 677B943) into one of the remaining unused

plugs (J1, J2 or J3) of the ITB.

8. Plug the other end of this fourth modular cable into J8 or J9 of the first controller on the

MicroLink network.

10 Installation

Page 27

53MT6000 INSTRUCTION MANUAL

Figure 3-5. Connecting the Computer’s COM Port to the DataLink

Installation 11

Page 28

53MT6000 INSTRUCTION MANUAL

Figure 3-6. Micro-Tools DataLink SUPERVISOR Card to DataLink Interconnection Diagram

(ID-53-1610)

12 Installation

Page 29

53MT6000 INSTRUCTION MANUAL

Figure 3-7. Micro-Tools MicroLink SUPERVISOR Card to MicroLink Interconnection Diagram

(ID-53-1597)

Installation 13

Page 30

53MT6000 INSTRUCTION MANUAL

3.4 Installing the Micro-Tools Software

Now the process of installing the Micro-Tools software can begin.

3.4.1 Pre-Setup Procedure

• Check that the Micro-Tools hardware security key is connected to the parallel port of the

computer.

• Have the software license key(s) ready.

• Power on the base PC and boot the Windows Workstation software.

• Log on to the Windows Workstation software with administrative privileges. You must have

administrative privileges or the installations process will not complete successfully.

• Close all Windows applications that are open, (such as Microsoft Word, Excel, Mail,

Scheduler, etc.).

3.4.2 Beginning Micro-DCI Master Setup

• Insert the Micro-DCI CD into the CD-ROM drive.

• If the CD-ROM drive is configured for automatic startup, the Micro-DCI Master Setup window

should open automatically . If the CD does not start automatica lly , click on the Windows START

button and select Run from the menu. Click the Browse button and navigate to the CD-ROM

drive and the setup.exe file. Once the path to the setup.exe file has been selected, click OK to

open the Micro-DCI Master Setup window.

• In the Micro-DCI Master Setup window, click on the Micro-Tools Setup button to begin the

Micro-Tools installation procedure and start the InstallShield Wizard.

3.4.3 Beginning Micro-Tools Installation

• When the InstallShield Wizard is loaded, the Micro-Tools System Setup window appears.

• Click Next to begin installing Micro-Tools.

If the Micro-DCI Communications Services are being installed for the first time, the setup routine

will prompt for them to be installed. Click on the "OK" button and prompts will appear for Section

3.4.4 through Section 3.4.9. Otherwise these items will be skipped and the installation process will

proceed to Section 3.4.10.

3.4.4 Micro-DCI Communications Services Setup

• The Micro-DCI Communications Services Setup window appears. Click on the Next button to

proceed.

14 Installation

Page 31

53MT6000 INSTRUCTION MANUAL

3.4.5 Micro-DCI Communication Services Location

•The Choose Destination Location window appears, which enables you to specify the drive

and directory where you want the Micro-DCI Communication Services installed. You can

accept the default path of C:\udci by clicking the Next button or you can change the

destination directory by clicking the Browse button.

• If you clicked the Browse button, enter both the drive and directory you want to use as the

destination directory in the Choose Directory field.

• Click the Next button.

• If the directory does not exist, Setup will ask you if it should be created. If this window

appears, click the Yes button.

•The Select Program Folder window appears. Select the program Folder you want the

program icons added to. The Micro-DCI Comm Services folder is selected by default as the

folder for the program icons. You can accept the default, select an existing program folder,

or type a new program folder.

• Click the Next button.

•A Setup window with a progress bar appears and the Micro-DCI files begin to install.

•The Enter Information window appears and prompts you to enter a maximum of eight

characters as a name for your entire Micro-DCI local system.

• Either accept the default name or enter a name and click the Next button.

✎ NOTE If this PC is a node on a Micro-PWC, the selected name will be

used to identify the Micro-DCI communication interface on this PC;

therefore this name must be unique from all other node names on

the network.

The progress bar then finishes updating and the Setup process continues.

3.4.6 Installing Data Access Objects (DAO)

• If DAO 3.5 is already present on the system, this phase of the installation will be bypassed.

• Micro-Tools uses Data Access Objects (DAO's) to store local databases. If Microsoft DAO 3.5

has not been previously installed, Micro-Tools instructs you to run the DAO Setup from the

Micro-DCI Master Setup menu. This may be done any tim e after the comp le tio n of the MicroTools installation.

3.4.7 Installing the Micro-DCI Communications Services & Program Folder

• The Micro-DCI Communications Services will be automatically installed. A window will pop up

to install these services.

• When the services are installed, the window will close and return you to the Main Micro-Tools

Setup.

• The Micro-DCI Communications Services Setup program then creates the Micro-DCI

Communications Services program folder and automatically adds the appropriate icons for

the Micro-DCI Communications Services product.

Installation 15

Page 32

53MT6000 INSTRUCTION MANUAL

3.4.8 Adding Micro-DCI Networks

If you would like to add Micro-DCI instrument networks, click on the Yes button when given the choice. The

Add Micro-DCI Networks window appears. Click the Next button.

• The Setup program then starts the Super32 Network Addition program which enables you to

add Micro-DCI network instruments to your system. This is a good time to add MicroDCI networks to your system since you need to reboot your PC after installing the Micro-Tools

software and after you install the Micro-DCI networks.

• The first Network Wizard window lets you select whether you are adding a netwo rk that

is connected to your system through a supervisor board (SUP) or tho ugh a COM port ( COM).

Select either SUP or COM. Then click the Next button.

• Enter a Network Name (up to a maximumm of 9 characters) in the Network Wizar d - Network

Attributes window and select a Network Position. Then click the Next button.

3.4.8.1 COM: PC Serial Com Port Network Addition

• The Network Wizard - Backup window appears. Click the Next button.

• The Network Wizard - Network Parameters window appears. The parameters

change depending on the type of network that is being installed.

• In the Network Wizard - Finish window, click the Finish button .

• A window appears confirming that the "Network was added successfully". Click the "ok" button

to proceed.

• If the network was added successfully, Super32 will ask if another network is to be added. If

so, repeat the above steps until all desired Micro-DCI networks h ave bee n adde d. An swer ing

No exits Super 32 and opens the Read-Me file in a Notepad window.

3.4.8.2 SUP: MicroDCI Supervisor Network Card

• The Network Wizard - Backup window appears. Select Master or Backup and then click the

Next button.

• The Network Wizard - Network Parameters window appears. Set the I/O Port Address to

agree with the address jumpers on the Supervisor Board. The parameters change depending

on the type of network that is being installed.

• After selecting the I/O Port Address, click the Next button.

• In the Network Wizard - Finish window, click the Finish button .

• A window appears confirming that the "Network was added successfully". Click the OK button

to proceed.

• If the network was added successfully, Super32 will ask if another network is to be added. If

so, repeat the above steps until all d esire d Micro- DCI ne tworks ha ve been ad ded. Answer ing

No exits Super 32 and opens the Read-Me file in a Notepad window.

• Close the Notepad window to continue.

3.4.9 Selecting the Target Location for the Micro-Tools System

•The MicroTools Target Location window appears, which enables you to specify the drive

and directory where you want Micro-Tools installed. You can accept the default path of

C:\MicroTools by clicking the Next button or you can change the destination directory by

clicking the Browse button.

16 Installation

Page 33

✎ NOTE If re-installing Micro-Tools, an information window alerts you that

the microtools.exe file already exists; click ok. If it exists in the

same location you are installing to, you can choose to overwrite the

file or keep the previous version.

• If you clicked the Browse button, enter both the drive and directory you want to use as the

destination directory in the Choose Directory field .

• If the directory does not exist, Setup will ask you if it should be created. If this window

appears, click the Yes button.

• Click the Next button.

•A Setup window with a progress bar appears and the files begin to install.

•The Select Program Folder window appears. Select the program Folder you want the

program icons added to. The MicroTools folder is selected by default as the folder for the

program icons. You can accept the default, select an existing program folder, or type a new

program folder.

• Click the Next button and follow the prompts until the installation is completed.

3.4.10 New Program Folder

• The Micro-Tools Setup program then creates the Micro-Tools program folder and

automatically adds the appropriate icons for the Micro-Tools product.

53MT6000 INSTRUCTION MANUAL

3.4.11 Integrating Into Super32

• Micro-Tools can be registered to be the default configuration program for MC5000 controllers

in the Super32 Micro-DCI network management utility.

• When asked if Micro-Tools should be integrated into Super32, select Yes to register MicroTools as the default configuration program or No to use the Super32's basic MC5000

configuration program.

3.4.12 Installing the Micro-Tools License Keys

• Setup will launch the Micro-DCI License Administration program to enter your license keys.

Skip this step by, closing the license window, if the license keys were previously installed.

•Select Add new license... from the License menu.

• In the License Administration dialog, type in your license information for each license key

one at a time. Be certain to enter all information exactly as it appears. Click Save and this

information will be verified and written to the license file. If the information entered is not

correct, a pop-up message box will appear and the information will have to be corrected.

The following license keys are used:

udci - licenses Micro-DCI Communication Services for 300 tags

udciunlim - licenses Micro-DCI Communication Services for unlimited tags

microtools -

microtools1 - supplied with basic functionality version

microtools2 - supplied with full functionality Micro-PWC add-on

microtools3 - supplied with full functionality stand-alone

Installation 17

Page 34

53MT6000 INSTRUCTION MANUAL

✎ NOTE Entry of the 20-character License Keys is not case-sensitive. The

spaces between characters is for legibility only and should NOT be

entered as part of the License Key.

• Repeat the above steps for each license key.

• When finished, select Exit from the File menu.

• At this point the Notepad application opens and a Micro-Tools Read Me file appears

containing Micro-Tools release information. When you have finished reading this document,

close Notepad.

• Setup will now ask if you want to restart the PC.

•Select Yes and then click the OK button to restart the PC.

• This completes the setup process.

18 Installation

Page 35

53MT6000 INSTRUCTION MANUAL

4.0 START-UP

4.1 Micro-Tools Startup

When 53MT6000 Setup is complete, the following Windows Menu Group is created:

Figure 4-1. MicroTools Windows Menu Group

The function of the icons contained in the Micro-Tools Menu Group are detailed below:

This menu item loads and begins running the Micro-T ools

application.

Provides on-line HELP information as an aid to resolving operational

problems.

Double-click on the Read Me icon for important information about

this software release.

Selecting this menu item removes the 53MT6000 software from the

system.

When Micro-DCI Communications Services has been installed successfully, the following Windows menu

group will be created:

Figure 4-2. Micro-DCI Communications Services Windows Menu Group

Start-up 19

Page 36

53MT6000 INSTRUCTION MANUAL

The function of the icons contained in the Micro-DCI Communications Services Menu Group are

detailed below:

The Micro-DCI DDE Server provides data in "tag.atom" format

to DDE clients such as Microsoft Excel.

Double-click on the License Admin icon to add or edit license

keys.

Double-click on the Read Me icon for important information

about this software release.

Super32 is the Micro-DCI network administration program used

to configure networks, instruments, tags, etc. Double-click this

icon to start Super32. For more information, see the 53SU6000

Configuration Guide, PN24828.

Double-clicking on the Uninstall Micro-DCI Communi ca ti on s

Services icon removes the 53SU6000 and all associated

components from the system.

20 Start-up

Page 37

53MT6000 INSTRUCTION MANUAL

5.0 OVERVIEW OF USER INTERFACE

Because the Micro-Tools software runs under the Microsof t Windows operating system, the po int-and-click

user interface with its menu bars, pop-up windows, radio buttons, and so on, should be familiar to many

users.

5.1 Starting the Micro-Tools Software

The setup program for the Micro-Tools software adds the Micro-Tools icon to a program group called

"Micro-Tools" by default. Clicking on the Micro-Tools icon starts the Micro-Tools application.

If Super32 is installed, Micro-Tools may also be started from within the Super32 window by clicking on a

controller icon.

5.2 The Micro-Tools Window

The Micro-Tools (Administrator) and Project Manager windows (Figure 5-1) are opened by clicking on the

Micro-Tools icon. The Administrator window includes the following:

• title bar with sizing controls

• menu bar

• status bar

• project toolbar

• application toolbars

If Micro-Tools is started by clicking on an "on-line" controller icon from within Super32, the Micro-Tools

(Administrator) and Database Editor windows (illustrated in Figure 5-1) are opened. The Administrator win-

dow includes the following:

• title bar with sizing controls

• menu bar

• status bar

• project toolbar

• application toolbars

Overview of User Interface 21

Page 38

project toolbar

53MT6000 INSTRUCTION MANUAL

application toolbar

title bar with sizing controls

menu bar

status bar

Figure 5-1. Micro-Tools Window

22 Overview of User Interface

Page 39

5.3 Toolbars

5.3.1 Project Toolbar

Project Selector Specify the default project to be configured using the Micro-

Project Manager Access project files for configuration.

Database Editor View and edit the Database.

53MT6000 INSTRUCTION MANUAL

Tools tools.

Flexible Control

Strategy

Control

Interconnection

Modules

F-TRAN Editor View, edit and compile F-TRAN Language for control,

F-TRAN Builder Use the information stored in the controller folder to build a

Download Download the configuration file to the specified controller.

Upload Upload a 53MC5000 configuration to the Micro-Tools

Graphically configure the Flexible Control Str ategy.

Graphically configure the Control Interconnection Modules.

display and sub-routine program files. Check the files for

errors.

downloadable 53MC5000 program.

computer.

On-line Configuration Directly configure the 53MC5000 in real-time.

Overview of User Interface 23

Page 40

53MT6000 INSTRUCTION MANUAL

5.3.2 Application Toolbar

The tools available on the Application Toolbar will vary with the operation being performed. Refer to the

Online Help for specific toolbar information.

5.4 Status Bar

The status bar at the bottom of the main Micro-Tools window contains an edit box, tool type field and displays the coordinates of the cursor position.

The edit box can be used to enter tool commands and location coordinates, permitting placement of graphical elements at exact locations when configuring func tion block diagrams an d other graphical obje cts. See

the Appendices for information on Tool Commands.

Another field in the status bar is used by some tools to show the tool type which is currently selected.

5.5 Cursor and Mouse Conventions

The shape of the cursor can vary, depending on the current activity or location. The cursor shapes in the

table below are representative.

The cursor and mouse in combination can be used in a variety of ways as shown in the table below. Note

that not all functions apply to every window.

✎ NOTE When referring to "left" and "right" mouse buttons, a right-handed

mouse button configuration is assumed.

Table 5-1. Cursor Status By Cursor Shape

Cursor Status Cursor Shape

In text entry box

On Help window “hot spot”

Dragging-and-dropping a file name

Standard cursor

(may appear different from the picture)

On project tables

The cursor and mouse in combination can be used in a variety of ways, as shown in the table below. Note

that not all functions apply to every window.

I

*

Û

✚

24 Overview of User Interface

Page 41

53MT6000 INSTRUCTION MANUAL

Table 5-2. Cursor/Mouse Functions

Function Action

select an item Position the cursor on the item, then click the left mouse button.

perform default

action for an item

display a list of

functions specific to

an item

drag-and-drop an

item

select a region Position the cursor at one corner of the region and press the left mouse

✎ NOTE Any time the instructions in this manual or in the Help system tell

Position the cursor on the item, then double-click the left mouse button.

Position the cursor on the item and click the right mouse button to display

the object menu.

Position the cursor on an item on the screen, then press the left mouse

button and hold while moving the mouse until the selected item is in the

desired location. Release the button.

button, then move the cursor until it is at the diagonally opposite corner of

the region. Release the mouse button.

you to click on an item, or to drag-and-drop an item, use the LEFT

mouse button, unless told otherwise.

5.6 Accessing On-Line Help

Many windows, such as pop-ups, provide a HELP button to access context-sensitive Help. For those windows without a HELP button, the

? button, available on the application toolbar, can be used to get Help.

You can also access the Help system using the Help item on the Micro-Tools window menu bar to display

the Help menu. The items on the menu provide access to Help in a variety of ways. "How to Use Help"

instructions are also accessible from this menu.

5.7 Specifying a Default Project

The first step in using most Micro-Tools tools is to specify a project, then to pick an item to create or edit. If

you plan to use several tools to work on the same project during a Micro-Tools session, it is advantageous

to use the drop-down combo-box on the Project Toolbar to specify a default. Once you have specified a

default, every selection window you open will list items relevant to that project.

If a default project has been specified, you can still use the open selection window to temporarily pick a different project, or you can quickly change the default.

Overview of User Interface 25

Page 42

53MT6000 INSTRUCTION MANUAL

26 Overview of User Interface

Page 43

53MT6000 INSTRUCTION MANUAL

6.0 THE MICRO-TOOLS PROJECT MANAGER

The Micro-Tools package is designed to be used to configure a whole project, not just a single database

(although configuration of an individual dat abase within a p roject is suppor ted). A project con sists o f all the

software resources needed to control an entire process, or a process area. The project management activities performed by the Micro-Tools software go on behind the scenes, keeping track of all the co nfiguration

work in the project, and where it is stored.

In addition to the project management activities that are transparent to you, there is also a PROJECT

MANAGER window, accessed from the Project Toolbar. This window makes it easy for you to view your

project and to access anything in your project or Micro-Tools library at any time.

The Micro-Tools Project Manager Window is shown in Figure 6-1. Note that the Project Manager consists