Page 1

Supplement to

Instruction Bulletin

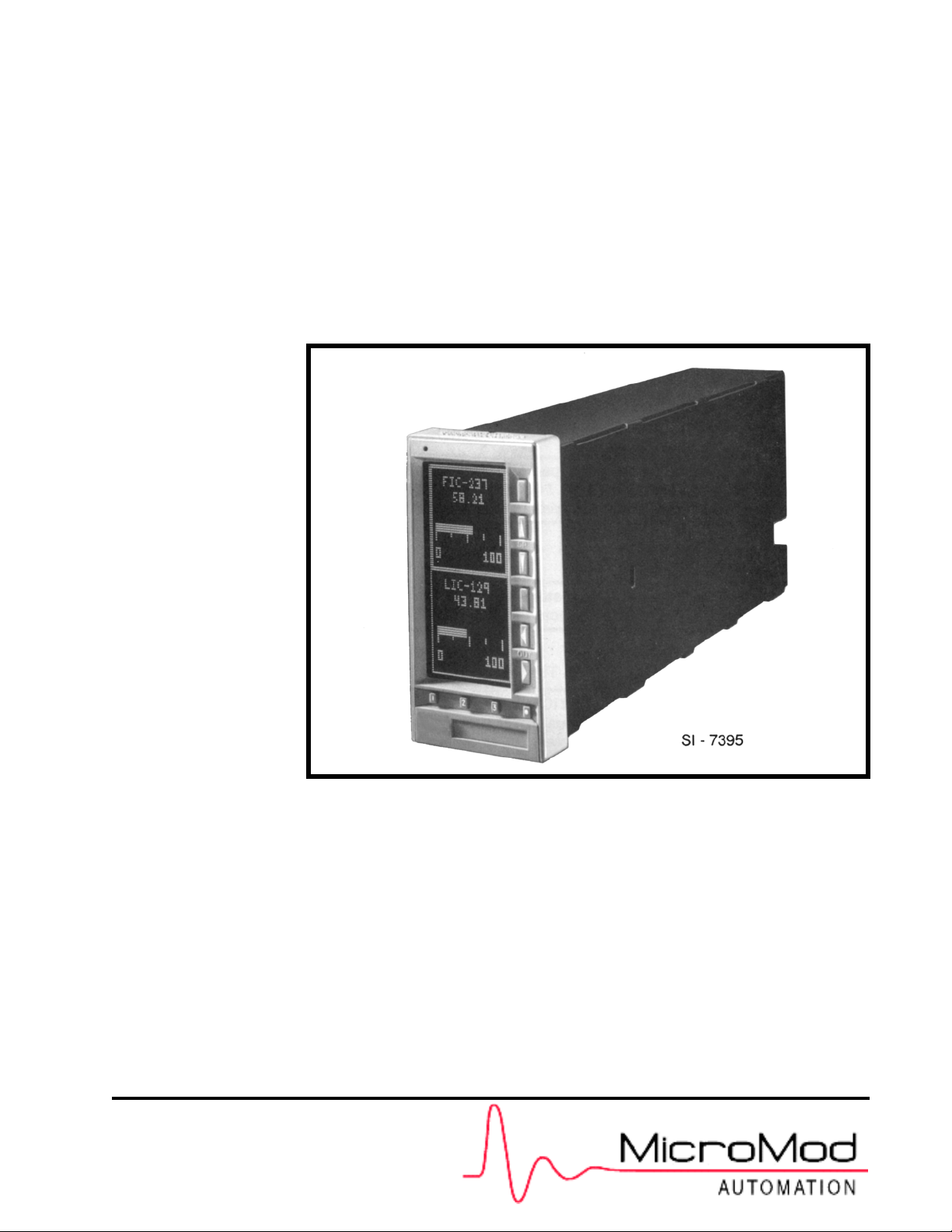

Micro-DCI

53ML5100A

53ML5100 MANUAL LOADING STATION REV. 1 FIRMWARE

®

PN24698 Rev. 1

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

∆ Warning. An instruction that draws

attention to the risk of injury or death.

❢ Caution. An instruction that draws

attention to the risk of the product,

process, or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, re sult in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipmen t. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

✎ Note. Clarification of an instruction

or additional information.

i Information. Further reference for

more detailed information or

technical details.

Licensing, Trademarks and Copyrights

Micro-DCI is a registered trademark, and MicroLink is a trademark of MicroMod Automation, Inc.

All other trademarks are the property of their respective owners.

© 2005 MicroMod Automation, Inc. (April 2005)

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted.

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions

of high pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and

source codes, is copyrighted by MicroMod Automation, Inc.,

and is owned by MicroMod Automation or its suppliers.

Page 3

Proportional Speed Floating Controller

TABLE OF CONTENTS

1.0 - APPLICABLE DOCUMENTATION........................................1

1.1 SCOPE OF CHANGES .................................................................................1

2.0 - INSTALLATION PROCEDURES...........................................3

3.0 - CONFIGURATION REQUIREMENTS...................................5

4.0 - DATALINK COMMUNICATIONS...........................................7

4.1 Protocol .........................................................................................................8

4.1.1 Message Types................................................................................9

4.1.2 COMMUNICA TION TRANSACTION EXAMPLES.........................10

4.2 CALCULATING DATA ADDRESSES .......................................................... 11

4.3 SOFTWARE CHARACTERISTICS .............................................................13

4.4 HARDWARE CHARACTERISTICS.............................................................13

4.5 INITIALIZATION MESSAGE........................................................................13

List of Figures

Figure 2-1. Datalink Installation Diagram ............................................................4

List of Tables

Table 3-1. Communication Module..................................................................... 5

Table 4-1. Message Field Definitions.................................................................. 8

Table 4-2. Controller Memory Address Scheme............................................ ... 11

Contents 1

Page 4

Proportional Speed Floating Controller

2 Contents

Page 5

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

1.0 APPLICABLE DOCUMENTATION

The information contained in this supplement is applicable to the Micro-DCI® Instruction Bulletin

53ML5100A, Manual Loading Station.

1.1 SCOPE OF CHANGES

The 53ML5100 Manual Loading Station now has Datalink capabilities as a result of Revision 1 to the firmware EPROM. In a Datalink network, nodes communicate as responders to host personal co mputer queries. The host personal computer functions as the interrogator and acts as the central control point for the

Datalink network. A maximum of 32 addressable nodes can be connected to a Datalink network. With this

firmware revision, a 53ML5100 Manual Loading Station can function as a node instrument on the Datalink

network.

✎ Note Numbers used in this document that are expressed in hexadecimal

notation (base 16) are identified with a subs crip t

number.

after the

H

Applicable Documentation 1

Page 6

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

2 Applicable Documentation

Page 7

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

2.0 INSTALLATION PROCEDURES

Reference Micro-DCI Instruction Bulletin 53ML900, Upgrading the 53ML5100 Manual Loading Station, for

instructions on installing the new EPROM on the main board.

Datalink is an interrogator/responder serial interface capable of supporting 32 instruments on a single network. It uses an RS485 physical interface. See the Datalink wiring diagram for this instrument in

Figure 2-1.

The interface for connecting the 53ML5100 Manual Loading Station to a Datalink network is via the rear

terminal board (TB1), pins 19 through 22 (T+, T-, R+, and R-).

The Datalink interface requires four conductors: a transmit pair (T+, T-) and a receive pair (R+, R-). The

voltage levels of each conductor pair conform to the EIA RS-4 22/485 standard. In accordance with this

standard, the overall Datalink network distance is limited to 4000 feet when #24 AWG twisted pair wire is

used to interconnect the nodes. Adapters are available to convert RS-422/485 to RS-232 or 20 mA current

loops.

Installation Procedures 3

Page 8

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4 Installation Procedures

Figure 2-1. Datalink Installation Diagram

Page 9

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

3.0 CONFIGURATION REQUIREMENTS

See Table 3-1, Communication Module, Column 3 (Set Up) for the appropriate configuration values.

Table 3-1. Communication Module

Title

Address

Baud

Rate

Datapoint

B01 Select

B02 Select

Set Up Default Attribute

Address

a

Baud

Rate

0

253

It identifies the address of this instrument on the Datalink

network. Each unit connected to the Datalink network must

have its own unique address. Valid addresses are from 0-31.

This datapoint value designates the baud rate of the Datalink

network. The baud rate must be the same for all of the

instruments connected to the same Datalink network.

Datapoint values and their corresponding baud rates are as

follows:

Value Baud Rate OR Value Baud Rate

255 28800

254 14400

N/A N/A

253 9600

250 4800

244 2400

232 1200

9

8

7

6

5

4

3

28800

14400

19200

9600

4800

2400

1200

No

Parity

No Byte

Stuffing

Datalink

Disable

L256

L258

L257

0 0

0 0

0 0

208 600

160 300

N/A N/A

2

1

0

600

300

110

This datapoint indicates if parity generation and checking

should be turned on or off. It is set to 0 for even parity serial

byte protocol. It is set to 1 for no parity protocol.

When set to a 1, this datapoint disables the standard MicroMod

communication protocol feature whic h inse r ts a 00 (NUL) byte

after every 7E

(SOH) that is not the beginning of a message.

H

(This permits user-written communications software to

determine the number of bytes to expect in a response

message.) It must be set to 0 when using MicroMod

communications software or equipment.

When set to 0, it permits full Datalink communication

capabilities.

When set to 1, it disables Datalink communication capabilities.

Configuration Requirements 5

Page 10

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

6 Configuration Requirements

Page 11

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.0 DATALINK COMMUNICATIONS

Datalink communications capabilities are now provided in the 53ML5100 Manual Loading Station.

Datalink Information in this supplement can also be applied to the existing configuration port binary mode

as follows:

1. The configuration port data rate is still 9600 baud, with 8 data bits, and no parity.

2. The configuration port powers up in standard mode suitable for use with the HHC, but is

switched to binary mode by sending the following four character sequence:

Sent 03

Echoed 0DH 0AH 1BH 20H 0EH 20H 15

✎ Note Numbers used in this section that are expressed in hexadecimal

After echoing the 15H character , the instrument switches to binary mode and is able to process

binary communications messages from that time on. (Characters sent af ter the 15

the 15

echo are ignored.)

H

3. Once the configuration port switches to binary mode, it remains in that mode as long as the

connection is maintained. The connection is maintained by sending a character at least once

every 30 seconds. If 30 seconds elapse without a character being received by the instrument

through the configuration port, the port returns to standard mode.

1BH 0EH 15

H

notation (base 16) are identified with a sub script

H

H

after the number .

H

and before

H

4. When in binary mode, the configuration port responds to all messages regardless of the

address to which they are directed.

Datalink Communications 7

Page 12

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.1 Protocol

The Datalink protocol requires the host persona l comp u t er to initiate all transactions. There are two basic

categories for all of the Datalink message types: Interrogate, which is used to read data from an

addressed instrument, and Change, which is used to alter a value in an addressed instrument. The

addressed instrument decodes the message and provides an appropriate response. The protocol definitions for the Datalink message types are provided in Table 4-1.

Table 4-1. Message Field Definitions

Symbol Title Definition

SOH Start of Header This character, 7E, denotes the beginning of a message.

CMD Command Is the operation to be performed or a description of the message

that follows the Command-I.A. byte. The Command-I.A. byte has

two fields: the Command field (3 bits), and the I.A. field (5 bits).

There are five commands: Interrogate, Change, Change Bits ,

Acknowledge, Response. The commands are covered in Section

4.1.1, Message Types.

I.A. Controller Address The address of the instrument responding to the transaction. It must

be within a range of 00-1F (00-31 decimal).

NUM Number The number of data bytes transferred or requested. The NUM must

be in a range of 00-32 decimal.

LO-ADD Lower Address Bits The least significant 8 bits of a 16 bit instrument address.

HI-ADD Higher Address Bits The most significant 8 bits of a 16 bit instrument address.

DATA An 8 bit data byte.

XXXX Represents a variable number of data bytes.

MASK An 8 bit byte where each bit, called a flag, is dedicated to an event

that is permitted or prohibited, depending on the flag setting.

If the flag is set to 0, the event is permitted.

If the flag is set to 1, the event is prohibited.

STATE Represents the bit settings of a particular byte: which bits are set

to 1, and which bits are set to 0.

LRC Longitudinal

Redundancy

Character

Is a character written at the end of the message that represents the

byte content of the message and is checked to ensure data was not

lost in transmission. It is the sum of all bytes Modulo 256 of the

message not including the SOH character or its own bi t settings

(LRC).

8 Datalink Communications

Page 13

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.1.1 Message Types

The types of messages that are sent between the host personal computer and a Datalink network instrument are formatted as follows:

HOST PERSONAL COMPUTER TO INSTRUMENT:

1. INTERROGATE - This message requests up to 20H (32 decimal) consecutively stored bytes,

beginning at the specified memory address location of the addressed instrument.

01111110 E0

2. CHANGE - This message sends up to 20

instrument.

+ I.A. NUM LO ADD HI ADD LRC

H

(32 decimal) bytes of new data to the addressed

H

01111110 A0

+ I.A. NUM LO ADD HI ADD Data 1 XXXXXXXXX Data N LRC

H

3. CHANGE BITS - This message alters only the specified bits of the specified bytes in the

addressed instrument. (NUM = 2n)

01111110 C0

+ I.A. NUM LO ADD HI ADD Mask 1 State 1 XXXX Mask N

H

State N LRC

4. ACKNOWLEDGE - This message signals the addressed instrument that its last echoed

change message was received correctly; the instrument then performs the change requested.

01111110 80

+ I.A.

H

INSTRUMENT TO HOST PERSONAL COMPUTER:

1. RESPONSE - This message furnishes the data requested by the INTERROGATE command

of the host personal computer. It is also used to echo back the previous CHANGE message of

the host personal computer.

01111110 20

+ I.A. NUM LO ADD HI ADD Data 1 XXXXX Data N LRC

H

Datalink Communications 9

Page 14

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.1.2 COMMUNICATION TRANSACTION EXAMPLES

Transaction A Example

Host personal computer requests 9 bytes of data beginning at hexadecimal memory address 1000

from

H

the instrument which has Datalink address 03.

1. Host personal computer sends INTERROGATE message.

01111110 11100011 00001001 00000000 00010000 11111100

SOH Command NUM LO ADD HI ADD LRC

+ I.A.

2. Instrument sends RESPONSE message.

01111110 00100011 00001001 00000000 00010000 XXXXX XXXXX XXXXX LRC

SOH Command NUM LO ADD HI ADD Data 1..............Data 9

+ I.A.

Transaction B Example

Host personal computer sends two bytes of new data to be loaded into the instrument at Datalink address

03 beginning at hexadecimal memory address 1000

.

H

1. Host personal computer sends CHANGE message.

01111110 10100011 00000010 00000000 00010000 00001000 00001100 11001001

SOH Command NUM LO ADD HI ADD Data 1 Data 2 LRC

+ I.A.

2. Instrument sends RESPONSE message.

01111110 00100011 00000010 00000000 00010000 00001000 00001100 01001001

SOH Command NUM LO ADD HI ADD Data 1 Data 2 LRC

+ I.A.

3. Host personal computer sends ACKNOWLEDGE message.

01111110 10000011

SOH Command

+ I.A.

4. Instrument performs the change requested at end of the current program scan.

10 Datalink Communications

Page 15

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.2 CALCULATING DATA ADDRESSES

If communications software must be generated to accommodate unique Datalink applications requirements, then the instrument memory address scheme must be known for pro per data bit (e.g., L datapoint s)

and data byte (e.g., B, C, H, and A datapoints) memory location determination.

✎ Note Hexadecimal (base 16) numbers used in this section are identified

with a subscript

This memory address scheme applies only if a 6 is in memory address location 8002

location 8002

must be read and if it contains a 6, then the address scheme that is described in Table 4-2

H

should be applied for this instrument.

Table 4-2. Controller Memory Address Scheme

after the number.

H

. Memory address

H

Data

Type

B200

L500

C600

Base

Memory

Address

H

H

H

Byte

Size

1

1 Bit

3

Data Format Address Calculation Algorithm

Represents a positive integer with values

from 0 to 255.

A single binary bit with a logical value of 0

or 1. L datapoints are packed 8 to a byte.

Represents floating point values that have

a resolution of one part in 3 2,768 ( 15 b i ts)

and a dynamic range of ± 10

38

.

The first two bytes represent a 2’s

complement notation in fractional form (2

n

) whose absolute value is between 0.5

and 0.9999.

The third byte is the power of 2 in 2’s

complement notation.

Floating point example:

64

00H 07H = 100D (Decimal)

H

64

= 01 10 0100, fractional bina ry weights

H

left to right are 0 = 2’s complement

positive,

-1

1 = 2

= 1/2 = 0.5, 1 = 2-2 = 1/4 = 0.25,

0=0, 0=0, 1 = 2

-5

= 1/32 = 0.03125, 0=0,

and 0=0.

64

= 0.5+0.25+0.03125 = 0.78125.07H =

H

128

. 128D X 0.78125D = 100.

D

Address = B Base + (B Number)

= 200

+ (B Number)

H

Address example: B012 location

= 200

+ 12D = 200H + CH = 20C

H

Address = L Base + (L Number/8)

= 500

+ (L Number/8)

H

Remainder = bit position in byte

Address example: L014 location

= 500

+ 14/8 = 501H, bit 6

H

(remainder).

Address = C Base + (3 X C Number)

= 600

+ (3 X C Number)

H

Address example: C011 location

600

+ (3 X 11) = 600H + 33D

H

-

= 600

+ 21H = 621H.

H

H

Datalink Communications 11

Page 16

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

Table 4-2. Controller Memory Address Scheme (Continued)

Data

Type

HF00

Base

Memory

Address

H

Byte

Size

5

Data Format Address Calculation Algorithm

Represents high precision floating point

values that have a resolution of one part in

2 billion (31 bits) and a dynamic range of

38

± 10

.

The first four bytes represent a 2’s

complement notation in fractional form

-n

(2

) whose absolute value is between 0.5

and 0.9999.

The fifth byte is the power of 2 in 2’s

complement notation. Floating point

example: 9C

00H 00H 00H 07H = -100.

H

The 2’s complement notation bit in the

9 = 1 (1001) indicating a negative number;

therefore, 9C must be re-complemented.

9C = 1001 1 10 0, change 1’ s to 0 ’ s and 0’ s

to 1’s = 0110 0011 and add 1= 0110 0100

(64

). Fractional binary weights left to

H

right for 0110 0100 are 0 = 2’s

complement positive, 1 = 2

-2

1 = 2

= 1/4 = 0.25, 0=0, 0=0,

-5

1= 2

= 1/32 = 0.03125, 0=0, 0=0.

6

= 0.5 + 0.25 + 0.03125 = 0.78125.

H

07

=128D, 128D X 0.78125D = 100.

H

-1

= 1/2 = 0.5,

A negative sign is assigned (-100)

because the original 2’s complement

binary bit in the 9 (1001) of 9C was set

indicating a negative number.

Address =

= F00

Base + (5 X H Number)

H

+ (5 X H Number)

H

Address example: H001 location

F00

+ (5 X 1) = F00H + 5D = F00H

H

+ 5

= F05H.

H

A (F)* 1400

10 (A)

H

5 (F)*

The A data format represents text strings

that are 10 characters long.

The F data format represents text strings

that are 5 characters long.

*F data types are 5 bytes long and are mapped onto A data types.

12 Datalink Communications

Address = A Base + (10 X Number)

= 1400

+ (10 X Number)

H

Address example: A015 location

1400

1400

+ (10 X 15) =

H

+ 150D = 1400H + 96H

H

1496

. (For A data type.)

H

Address = F Base + (5 X Number)

= 1400

+ (5 X Number)

H

(For F data type within A database.)

Page 17

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

4.3 SOFTWARE CHARACTERISTICS

1. Transparency Rule - whenever 7E hexaecimal is transmitted as anything other than SOH,

a 00 byte will be inserted directly following it (byte stuffing).

2. All transactions are initiated by the host personal computer.

3. All instruments begin their response within 10 ms after th e end of the transmission by the host

personal computer; otherwise, a faulty transmission may be assumed.

4. Illegal messages received by the instruments are ignored.

5. The maximum number of data bytes per message is 20

4.4 HARDWARE CHARACTERISTICS

1. Transmission Speed - standard rates are 110 - 28800 baud.

2. Asynchronous by character.

3. A character is:

1 Start bit.

8 Data bits - the Least Significant Bit (LSB) is transmitted first.

1 Even Parity bit.

1 Stop bit.

(32 decimal).

H

4. The line is 4-wire, shielded twisted pair, type RS-422/485.

4.5 INITIALIZATION MESSAGE

If datapoints A188 and A189 are configured to NON-NULL values, their contents will be transmitted onto

the Datalink network at reset/power-up. Prior to transmitting, a delay based on the unit’s instrument

address is observed. There is a one second delay between the transmission of datapoint A188 and

datapoint A189 contents. Datapoints A188 and A189 can be configured as two NULL TERMINATED

strings up to 10 characters each. For example, to initialize a Hayes-compatible modem to Auto Answer,

datapoint A188 would be configured through the faceplate push buttons to appear as follows:

This seven-character string is an Auto Answer command that direct s the mo dem to respond to calls on the

fourth ring. It is an AT command that loads the modem S0 register with a 4 to indicate a modem response

on the fourth ring. Any value other than 0 in this modem register activates Auto Answer. The NULL

TERMINATING values are automatically propagated into the remainder of the datapoint field by the controller. Datapoint A189 can be left at all NULL VALUES for this operation.

A188 LATS0=4

C

R

Datalink Communications 13

Page 18

53ML5100A Manual Loading Station

Supplement to the Instruction Bulletin

14 Datalink Communications

Page 19

Page 20

The Company’s policy is one of continuous product improvement and the

right is reserved to modify the information contained herein without notice, or

to make engineering refinements that may not be reflected in this bulletin.

Micromod Automation assumes no responsibility for errors that may appear

in this manual.

© 2005 MicroMod Automation, Inc. Printed in USA

MicroMod Automation, Inc.

75 Town Centre Drive

Rochester, NY USA 14623

Tel. 585-321-9200

Fax 585-321-9291

www.micromodautomation.com

Loading...

Loading...