Page 1

Micro-DCI 4-Channel Indicator Totalizer

53IT5100B

Instruction Manual

Page 2

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

MicroMod Automation & Controls, Inc.

The Company

MicroMod Automation & Controls is dedicated to improving customer efficiency by providing the most cost-effective, application-specific

process solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design

and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional information.

Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process system

performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for any

other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation & Controls, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation & Controls, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed information

or technical details.

Page 3

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

INTRODUCTION ......................................................................................................................................... 1

1

1.1 PRODUCT OVERVIEW .............................................................................................................................. 1

1.2 SPECIFICATIONS ..................................................................................................................................... 6

2 INSTALLATION........................................................................................................................................... 9

2.1 INSPECTION ............................................................................................................................................ 9

2.2 LOCATION............................................................................................................................................... 9

2.3 MOUNTING.............................................................................................................................................. 9

2.3.1 General.......................................................................................................................................... 9

2.3.2 Mounting Procedure .................................................................................................................... 10

2.4 POWER & SIGNAL WIRING ..................................................................................................................... 13

2.4.1 Power Wiring ............................................................................................................................... 16

2.4.2 Field Signal Wiring ...................................................................................................................... 16

2.4.3 Datalink Communication ............................................................................................................. 17

2.5 FACTORY SET CALIBRATION .................................................................................................................. 17

2.6 GROUNDING ......................................................................................................................................... 17

3 DISPLAYS AND PUSH BUTTONS........................................................................................................... 19

3.1 OPERATOR DISPLAYS............................................................................................................................ 19

3.2 ALARM OVERLAY .................................................................................................................................. 22

3.2.1 Front Panel Pushbuttons............................................................................................................. 24

3.3 ENGINEERING MODE OVERLAYS ............................................................................................................ 25

3.3.1 Responding to the Prompt: KEY? ............................................................................................... 25

3.3.2 Displaying a Datapoint ................................................................................................................ 27

3.3.3 Altering a Datapoint..................................................................................................................... 28

4 CONFIGURATION PARAMETERS .......................................................................................................... 29

4.1 DATAPOINT TYPES ................................................................................................................................29

4.2 FACTORY STANDARD CALIBRATION........................................................................................................ 29

4.3 CONFIGURING THE DATABASE MODULES................................................................................................ 29

5 MAINTENANCE ........................................................................................................................................ 43

5.1 SERVICE APPROACH ............................................................................................................................. 43

5.2 PARTS REPLACEMENT........................................................................................................................... 43

5.3 CALIBRATION ........................................................................................................................................ 44

5.4 ERROR AND HARDWARE MALFUNCTION MESSAGES ................................................................................ 44

5.5 RESETTING THE INSTRUMENT ................................................................................................................ 44

5.6 PARTS LIST .......................................................................................................................................... 45

APPENDIX A: DISCRETE CONTACT OUTPUT CCO’S ................................................................................ 49

APPENDIX B : COMMUNICATIONS............................................................................................................... 53

APPENDIX C: DATABASE.............................................................................................................................. 60

Page 4

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

IMPORTANT NOTICE

All software, including design, appearances, algorithms and source code is copyrighted by MicroMod

Automation & Controls, Inc. and is owned by MicroMod or its suppliers.

Page 5

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

1 INTRODUCTION

1.1 Product Overview

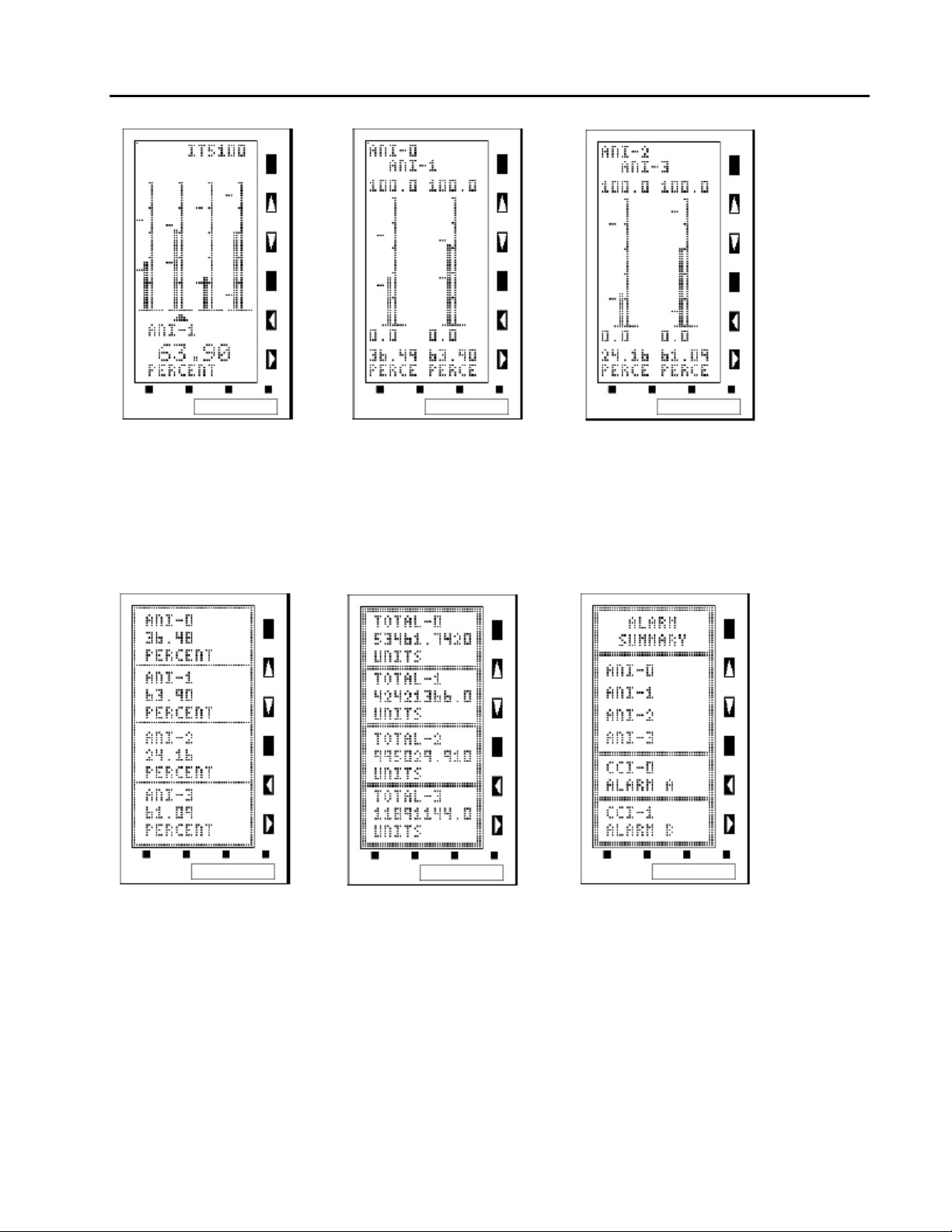

The 53IT5100B provides a suite of six operator displays to monitor process activity for up to four independent

process variables and also provides integration and totalization for each of the four process variables. The

displays are of three types: dynamic bar graph, digital readout, and alarm summary. There are three bar

graph displays, two digital readout displays, and one alarm summary display. These include:

Quad Bar Graph Display (Channels 1-4)

Two Dual Bar Graph Displays (Channels 1&2 and Channels 3&4)

Quad Process Digital Readout Display

Quad Totalizer Digital Readout Display

Alarm Summary Display.

The operator displays are paged forward or back, in the order given, by pressing the F2 (page forward) or the

F1 (page back) push button on the horizontal keypad of the instrument. The operator display suite is

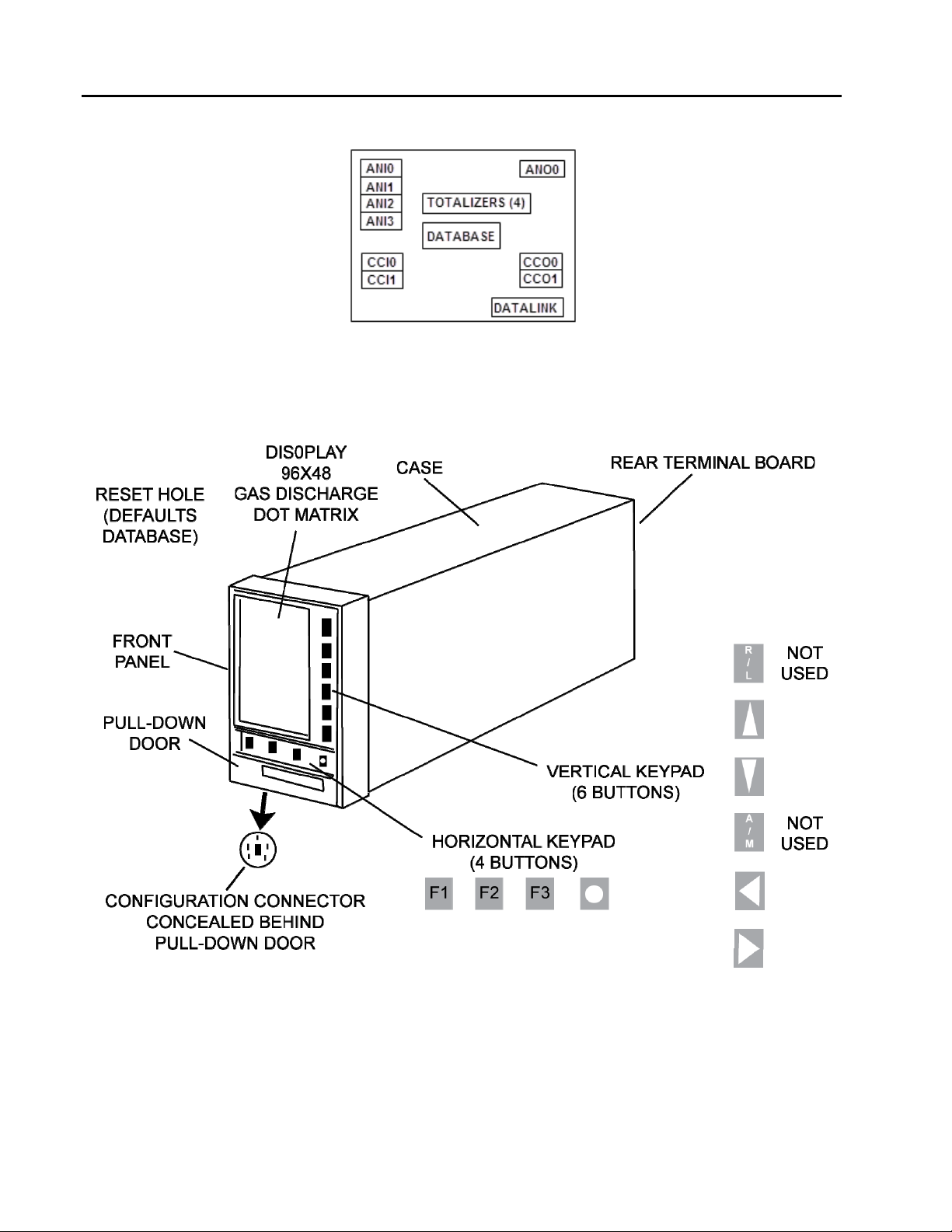

illustrated in Figure 1-1 and the instrument horizontal keypad is identified in Figure 1-2.

Quad Bar Graph Display (Channels 1-4) - all four channels are arrayed across the display as bar graphs

with the digital readout and measured units of a selected bar graph in the lower quadrant of the display. A bar

graph digital readout with measured units is selected with the F3 push button, which moves a pointer to the

base of each bar graph in the display every time it is pressed. In the illustration, upper and lower alarm limits

appear with each 50 segment vertical axis. The measured units and alarm limits are selectable entries, as

well as the mode of alarm reporting (e.g., High/Low, High only, Low only, High/Hi-Hi, Low/Lo-Lo, or none).

Dual Bar Graph Display (Channels 1&2) - two channels are arrayed across the display as bar graphs with

the digital readout and measured units of each channel appearing beneath its bar graph. The channel tag

names appear in the upper quadrant of the display. Each 50 segment vertical axis has a numeric range and

alarm limits. The tag names, vertical axis numeric range (zero and span), measured units, alarm limits, and

alarm mode are all selectable entries.

Dual Bar Graph Display (Channels 3&4) - is identical to Dual Bar Graph Display (Channels 1&2) except it

displays process activity from channels 3 and 4.

Quad Process Digital Readout Display - is a process activity digital readout of all four channels

that is refreshed every second. The display is divided vertically into four quadrants, each one dedicated to a

channel. Each channel readout has a tag name, numeric value, and measured units field. The tag names and

measured units are identical to those selected for the bar graph displays.

Quad Totalizer Digital Readout Display - is an integrator accumulator digital readout of each of the four

channels that is refreshed every second. The display is divided vertically into four sections, each one

dedicated to a channel. Each channel totalizer has a tag name, accumulated value, and totalizer measured

units field. The tag names and measured units are selectable entries.

Alarm Summary Display - presents six alarm states relevant to the four input channels and two contact

inputs. The display has four partitions with the uppermost containing the display title. The word ALARM in the

title flashes should an alarm condition occur with any one of the channel inputs or if a contact input is

activated indicating an alarm. The specific channel or contact input in the alarm state is also differentiated

from the rest of the display coincident with the ALARM banner flashing in the title of the display. The four

channel inputs are listed together in the second partition, and partitions three and four are occupied by the

two contact inputs. All six tag names for this display are selectable entries. There are also selectable entries

that define how each contact input display message is differentiated from the others to indicate an alarm

state.

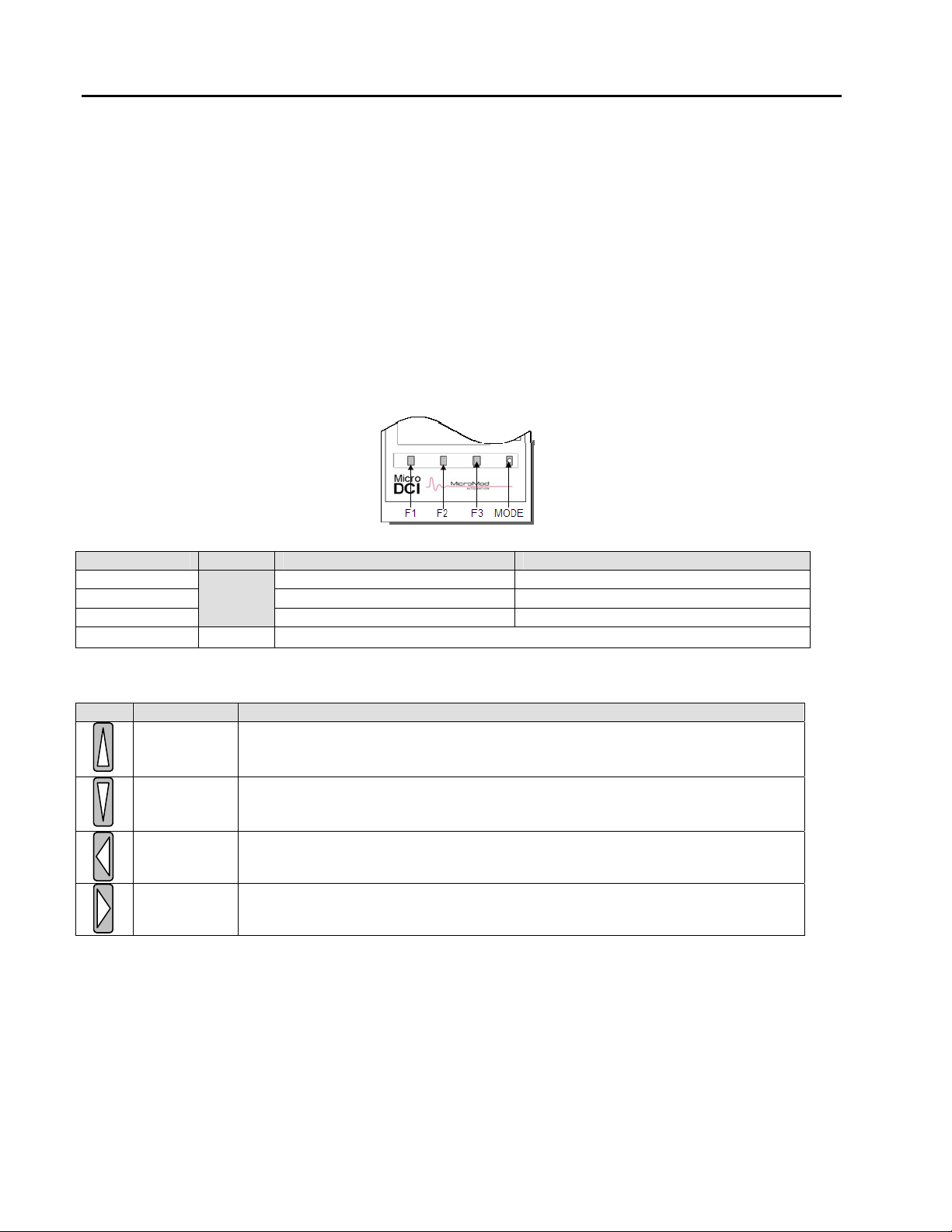

As shown in Figure 1-2, the 53IT5100 contains a graphical dot matrix display; horizontal and vertical keypads;

a MINI-DIN configuration port connector concealed behind the front panel pull-down door; terminals for signal

1

Page 6

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

input/output wiring and power wiring; and a compact instrument case that protects the instrument main

printed circuit board and internal power supply.

The display is a 96 X 48 gas discharge dot matrix, contrasted orange-on-black to enhance visibility and ease

of reading. The intensity is a range selectable entry from 0 to 7, with 0 being the brightest setting (see Table

4-10).

To the right of the display is the vertical keypad and directly beneath the display is the horizontal keypad.

Both keypads have functioning push buttons that are dependent on the instrument mode of operation which

can be either operator mode or engineering mode. Mode selection is made with the M

the horizontal keypad. Engineering mode is entered to make the necessary selections for the operator

displays and Datalink communications port; otherwise, the instrument is left in operator mode for process

applications. The vertical keypad is dedicated only to engineering mode functions and has no effect in

operator mode. Both keypads are described as follows:

Horizontal Keypad

ode push button on

Push Button Title Operator Mode Engineering Mode

F1

F2

F3

Title Engineering Mode

Ascending

Character umber, or symbol appears on

Select

Descending

Select

Shift Left

Shift Right

Mode Operator/Engineering mode select; Alarm reset.

er

Page back to previous display. Back to previous entry line function.

Page forward to next display. Pages the configure/display functions.

ter or display function. Moves Quad Bargraph pointer. Executes an en

Vertical Keypad

Displays one character at a time in ascending alphanumeric order; is

released when the desired character, n

the engineering mode data entry line.

Displays one character at a time in descending alphanumeric order; is

released when the desired character, n

the engineering mode data entry line.

data entry line each time this push button is pressed.

Shifts characters on engineering mode data entry line

position right each time this push button is pressed.

umber, or symbol appears on Charact

ering mode Shifts selected character one position left on the engine

one character

2

Page 7

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Quad Bar Graph (Chs. 1-4) Dual Bar Graph (Chs. 1&2) Dual Bar Graph (Chs. 3&4)

Quad Process Digital Readout Quad Totalizer Digital Readout Alarm Summary

Figure 1-1. Indicator/Totalizer Operator Displays

3

Page 8

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

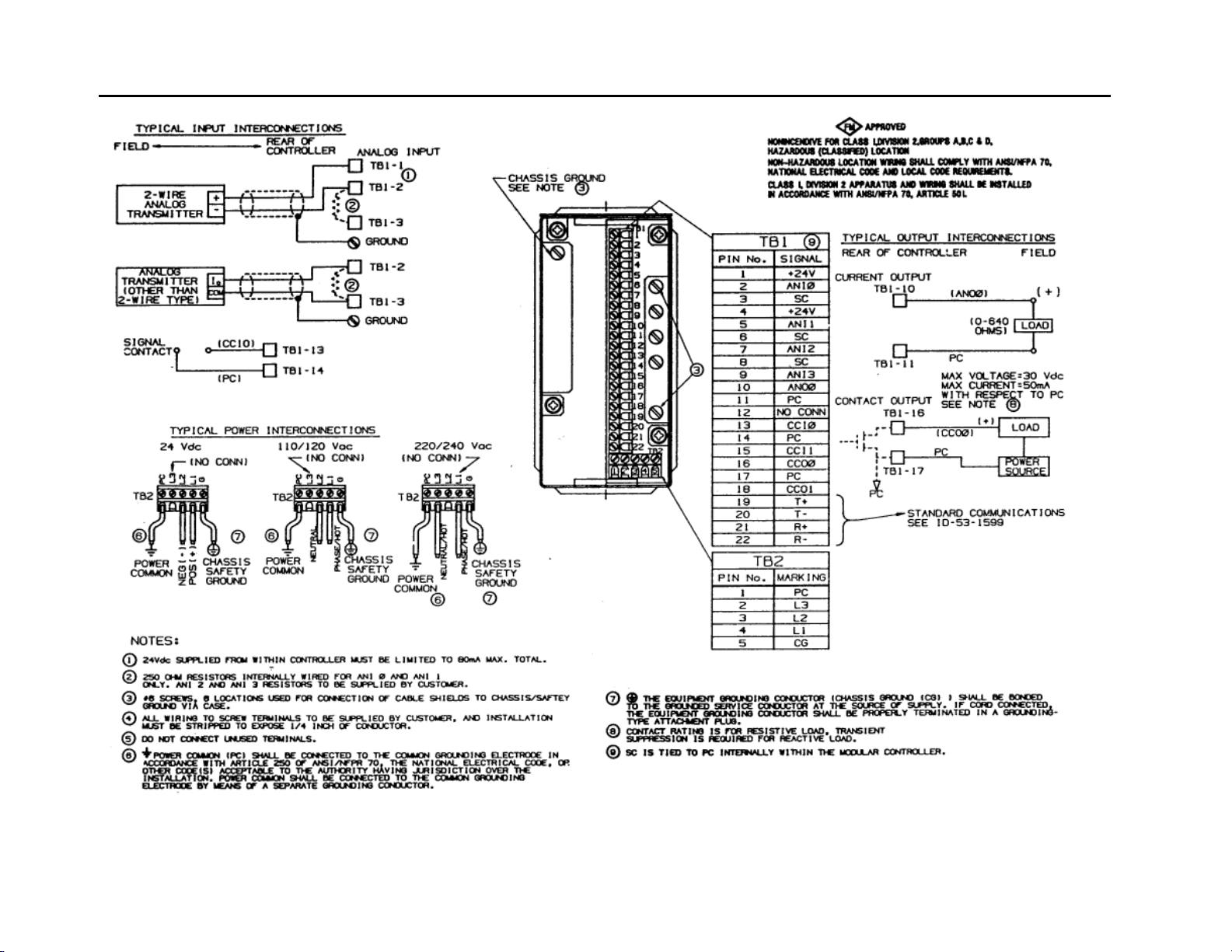

INPUT/OUTPUT DIAGRAM

4

Figure 1-2. Indicator/Totalizer Illustrated Overview

Page 9

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Setup of the 53IT5100B can be done using the buttons on the horizontal and vertical keypads. It can also be

done via the MicroTools configuration software package, Directly beneath the horizontal keypad and

concealed behind the front panel pull-down door is the RS-232 Configuration Port which accept the

configuration cable that provides interface between the instrument and MicroTools running on a personal

computer. The configuration functions within MicroTools are limited to loaded functions of the 53IT5100B

indicator/totalizer described in this manual.

The internal power supply provides power to the main board and output power for transmitters (24-26 V dc,

80 mA total available output for instrument and transmitters).

A simplified input/output diagram of the Indicator/Totalizer is provided in the upper left corner of

Figure 1-2. As illustrated in the figure, the instrument can accept four Analog Inputs (ANI0-3) which are

digitized as operands for firmware interpretation and execution (totalization). Each ANI has a square root

extractor and can accept linear or squared signals of 0-20 mA, 0-5 V, 4-20 mA, or 1-5 V. Any one of the four

analog inputs can be selected as the Analog Output (ANO0).

There are two contact inputs (CCI0 and CCI1 ) that have a closed recognition level of 1 V dc and open

recognition level of 4-24 V dc. Each CCI indicates an alarm state, for example, a CCI can have a closed

recognition level when a secondary pump is activated to support the primary pump in maintaining a proper

tank level.

The totalizers provide a running total of each ANI input. The totalizers are incremented in ascending order

every 0.05 seconds, but all four totalizers are refreshed on the display every second. Each ANI value can be

independently adjusted by a scaling factor before being summed to the running total. The totalizer measured

units, therefore, can differ from the process activity measured units as determined by the scaling factor

entries for each channel. Also available as selectable totalizer entries are rollover and dropout values. The

rollover value specifies a maximum positive value that causes the totalizer accumulator to reset to zero when

the actual total reaches this value. An output pulse is strobed to a 1 for one scan each time the actual total

reaches the rollover value. The dropout value specifies a minimum input value required to increment the

running total.

All of the selectable entries for the Indicator/Totalizer are parameter entries to the database. The database is

subdivided into modules composed of datapoints that are accessed by the instruction code as the instrument

performs its functions. The database allows instrument functionality to be refined to specific process

applications, as display attributes can be altered, input signal characteristics can be defined, each totalizer

accumulated value can be flagged, and the instrument can be configured to properly match Datalink network

communications requirements. A datapoint location is represented as an alphanumeric address, such as

C103, which is the location to enter the value for the ANI0 upper alarm limit that is displayed on the Quad Bar

Graph or Dual Bar Graph (Channels 1&2) displays. Datapoints are specified parenthetically in the illustration

call-outs of Section 3 where the displays are described in detail. There are also illustrated procedures

provided in Section 3 that show how a datapoint is displayed and configured. Definitions for all of the

Indicator/Totalizer datapoints are provided in Section 4 and listed in alphanumeric order in Appendix C.

External alarm buzzers can be activated with the contact outputs (CCO0 and CCO1). Capability limits of each

CCO are 50 mA maximum current flow when closed and 30 V dc maximum tolerance voltage when open.

Flagged conditions, such as Totalizer 0 (ANI0) rollover pulse activation, can be specified as selectable entries

in the CCO module of the database. Specific details for CCO database selections are described in Table 4-6

of Section 4, and typical circuit layouts for the CCOs are described in Appendix A.

Datalink is another independent serial communications connection for the Indicator/Totalizer. It provides a

permanent connection to an RS-485 multi-drop network through which a host computer can access the

instrument. The Datalink connection is made at TB1 of the rear terminal board, screw lugs 19 through 22.

5

Page 10

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

1.2 Model Number Breakdown

53IT51 __ __ B 2 1 A A A

Base Instrument

Power Requirements

AC (120/240V)

DC (24V)

Functional Requirements

Standard

Standard with Factory Configuration

Design Level

Enclosure Type

DIN 72 x 144 mm bezel

Main Rear Terminal Requirement

Standard

Chassis

Standard

Safety Classification

General Purpose

Conformal Coating

Standard

6

Page 11

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

1.3 Specifications

Item Specification(s)

Power

Range (as specified in model number) 22 - 26 V dc

Power Consumption (ac/dc operation) 36 VA maximum

Internal Power Supply:

Available Power Output for Transmitters

Output Ripple 200 mV p-p maximum

Analog Input (ANI0-3) Signals (all analog in-puts are referenced to signal common)

Quantity 4 (ANI0, ANI1, ANI2, and ANI3)

Signal Range 0 -5 V dc or 1 -5 V dc (0 -20 mA and 4 -20 mA dc respectively).

Input Impedance 1 megohm minimum for voltage inputs; value of ranging resistor

Measurement Accuracy ± 0.1% of span

Contact Input CCI0/1 Signals (are referenced to power common)

Quantity 2 (CCI0 and CCI1)

Type discrete input

Permitted Contact Resistance 100 ohm maximum

Open/Close Contact Duration for open recognition: 0.05 seconds minimum

Contact Recognition Level Closed

Contact Recognition Level Open 4 V dc to 24 V dc

Analog Output (ANO0) Signal (is referenced to power common)

Quantity 1 (ANO0)

Signal Range 0 -20 mA dc (4 -20 mA dc typically)

Load Range 0 - 750 ohms

Accuracy ± 0.2% of span

Switch Output (CCO0, CCO1) Signals (are referenced to power common)

Quantity 2 (CCO0 and CCO1)

Type

Configuration solid state equivalent of a single pole single throw, normally

Voltage 30 V dc maximum

Current 50 mA dc maximum

Datalink Communication

Sampling and Update Attributes

Program Scan Rate 0.05 seconds

Analog Input Signal Sampling Rate 0.05 seconds

Contact Input Signal Sampling Rate 0.05 seconds

Display Update 0.10 seconds

Output Signal Update 0.05 seconds

108 - 132 V rms

216 - 264 V rms

50/60 Hz

25 V dc ± 1 V dc @ 80 mA maximum, short circuit protected.

NOTE: The rear terminal board has the appropriate resistors

for ANI0 and ANI1.

for current signals.

for closed recognition: 0.05 seconds minimum

1 V dc maximum

solid state switch output

open or normally closed contacts referenced to common.

RS485, four wire, asynchronous; baud rates 300 to 28,800

7

Page 12

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Item Specification(s)

Environmental Characteristics

Controlled Environment Enclosed temperature controlled location (Class A and B per ISA-S71.01

Ambient Temperature Limits 4 -52°C (40 - 125°F)

Relative Humidity Limits 10 - 90% maximum

Temperature Effects on Accuracy ± 0.28% per 28°C (50°F) change from reference temperature 25°C (77°F)

Transient Immunity (all circuits) ANSI C37.90a - 1974/IEEE Std 472-974: Ring Wave: 1.5 MHz, 3 kV, 60

EMI Susceptibility SAMA PMC 33.1-1978: Class 3-abc: no effect at 30 V/m, at 27, 146, and

Enclosure Classification/Environment Panel Mounted Equipment: No enclosure rating. Designed to be installed

Shock 0.5g

Vibration SAMA PMC 31.1-1978; point-to-point constant displacement 0.05 in. (1.27

Drop and Topple SAMA PMC 31.1-1978; Tilt 30 degrees from horizontal and fall freely to a

Safety Classification General Purpose: Complies with ANSI/ISA S82.01-1988, Safety Standard

Physical Characteristics

Material of Construction:

1985)

pulses/s for 2.0 s

446 MHz

in a user provided panel or enclosure.

Rated for installation in a Pollution Degree 2 location per U.L. 5081989/Controlled Environment per CSA C22.2 No. 142-M1987. An indoor,

temperature controlled location (Control Room or Shop Floor) where

normally, only non-conductive pollution occurs; however, temporary

conductivity caused by condensation may be expected.

Location in environments more severe than those stated requires

supplementary protection

mm), 5 -14 Hz: 0.5 g, 14 - 200 Hz.

hard surface, all sides, front and back.

for Electrical and Electronic Test Measuring, Controlling and Related

Equipment; General Requirements and S82.03-1988 Safety Standard for

Electrical and Electronic Test, Measuring, Controlling and Related

Equipment; Electrical and Electronic Process Measurement and Control

Equipment.

FM Approved: Nonincendive for Class 1, Division 2, Groups A, B, C, & D,

Temperature Code T3C 160 ° C.

Case Steel, black enamel

Circuit Boards Glass epoxy

Bezel ULTEM 1000 (Polyethermide Resin) Flammability-UL94 5V

Dimensions 2.844W x 5.656H x 12.906L (inches) 73W x 144H x 329L (mm)

Flush Panel Mounting 0.125 inch - 1 inch thickness (3.2 mm - 25.4 mm)

Electrical Connections Screw type terminal block at rear of casework

Weight 5 lbs (2.3 kg)

Front Panel Display 96 x 48 dot addressable

Front Panel Push Buttons 10 membrane type switches

8

Page 13

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

2 INSTALLATION

2.1 Inspection

A list of all items in the shipment is attached to the shipping container. Inspect the equipment upon arrival for

damage that may have occurred during shipment. All damage claims should be reported to the responsible

shipping agent before installation is attempted. If damage is such that faulty operation is likely to result, the

MicroMod Customer Service Department should be notified.

Inspect the packing material before discarding it as a precaution to prevent loosing mounting hardware or

special instructions that may have been included with the shipment. Normal care in the handling and

installation of this equipment will contribute toward its satisfactory performance.

2.2 Location

The 53IT5100 is supplied with an enclosure designed specifically for indoor mounting. The installation site

selected should be dry, well lighted, and vibration free. The ambient temperature should be stable and

maintained within the specified minimum and maximum temperature limits listed in the Section 1,

specifications of this Instruction Bulletin.

The instrument can be supplied for use with a 24 V dc supply or 120, 220 and 240 V ac line service.

Instrument power requirements are given on the instrument data tag.

2.3 Mounting

2.3.1 General

It is normally not necessary to open the instrument case during installation. If the instrument must be removed

from the case, refer to Section 5 for details. Incorrect procedures may damage the instrument.

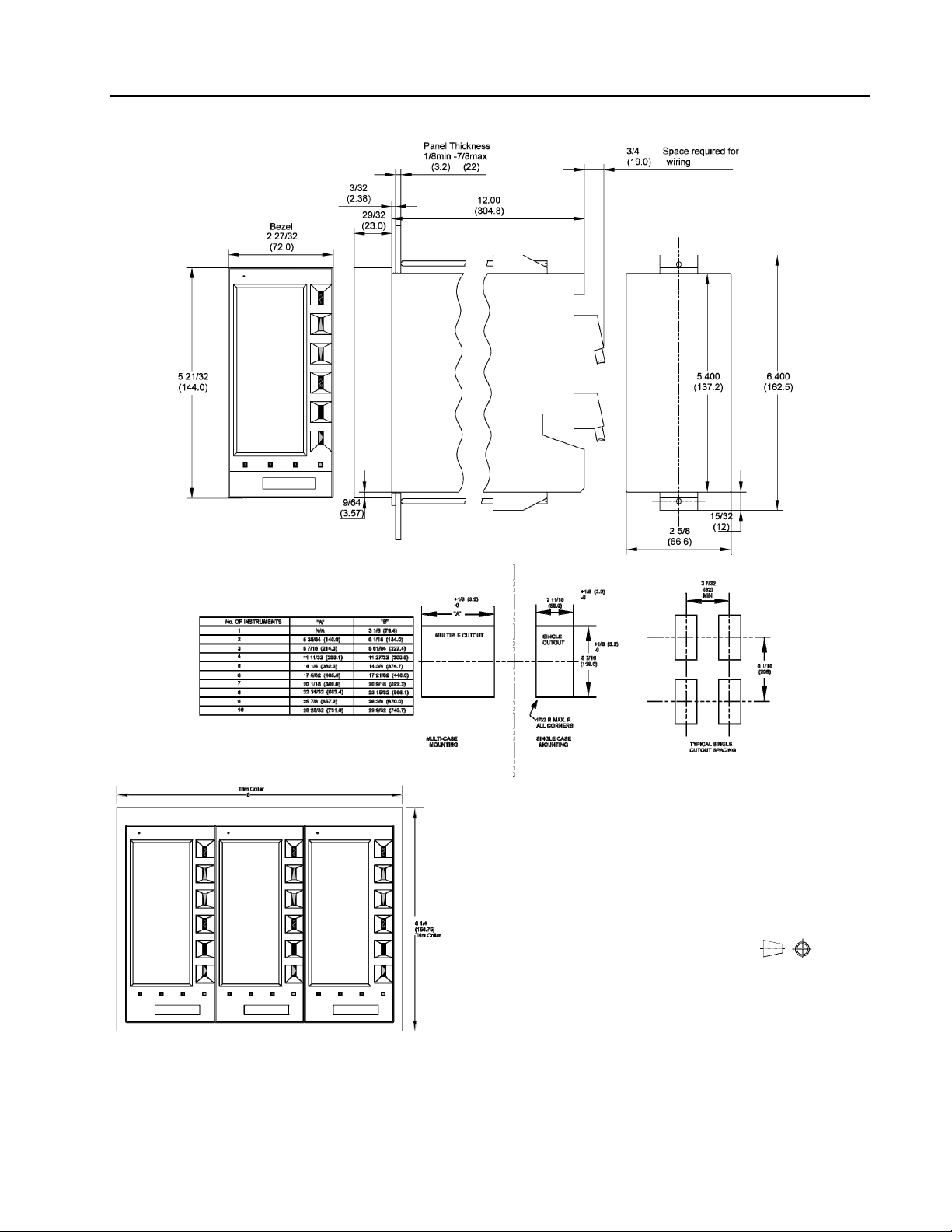

The instrument can be flush panel mounted, either as a single unit or side by side. Appropriate mounting

hardware is supplied. Outline dimensions and panel cut-out requirements for case mounting are shown in

Figure 2-1.

The dimensions given for spacing between instruments were selected on the basis of 1/8" thick panel

strength. Panel strength must be considered when multiple case mounting is required. As the panel cut-out

becomes longer it may be necessary to install supporting members. Because the panel area between

instrument rows becomes weaker as the cut-out becomes longer to the point where the panel offers very little

support. It is recommended that the 9 inch minimum center line dimension between horizontally mounted

rows be increased as the number of units increases, or that the panel strip be stiffened.

The rear of the instrument case must be supported to prevent panel distortion. Mount an angle iron or similar

member along the bottom of the cases as indicated in Figure 2-2. If the panel is to be moved the instrument

cases must be tied down to prevent damage.

If multiple mounted instruments are installed in a panel that tilts back, it may be necessary to support the

instruments so the panel does not sag. The downward weight should be supported by additional panel

supports and/or by increasing panel thickness.

9

Page 14

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

2.3.2 Mounting Procedure

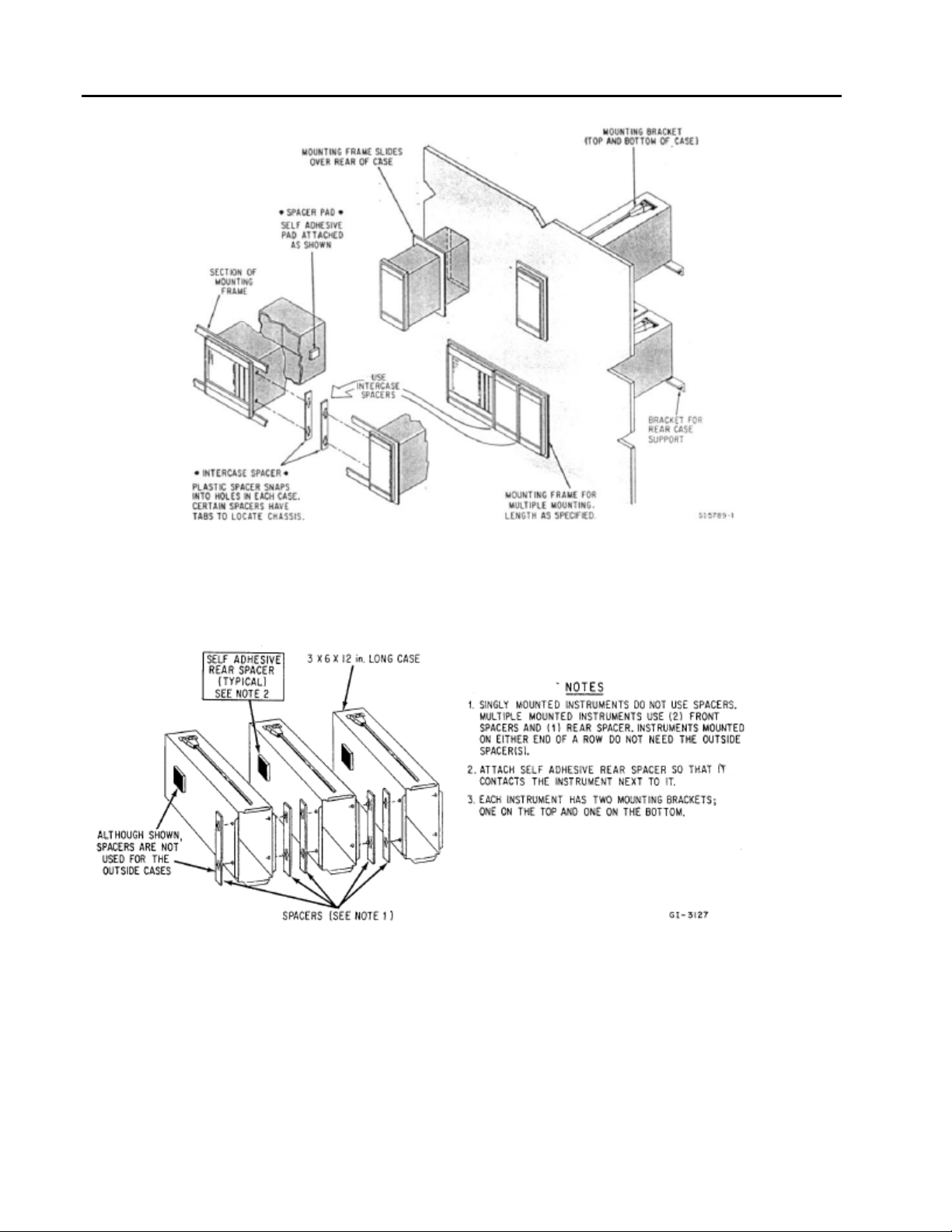

For single and multiple case mounting the instruments are furnished with a trim collar (mounting frame).

Figure 2-2 illustrates the installation and use of the trim collar (mounting frame). Trim collars (mounting

frames) are available in various sizes and are supplied to conform with the particular panel cut-out.

NOTE: Mounting brackets and trim collars (mounting frames) are packaged separately. Check the

shipment carefully to prevent loss of mounting hardware.

To install single or multiple mounted instruments in a prepared panel cut-out, proceed as follows:

1. Remove the through-case shipping bolt.

2. Slip the trim collar (mounting frame) over the rear of the case and slide it forward to the front of the

case.

3. Slide the instrument case through the panel opening.

a. Single mounting case - support the weight of the case and attach the top and bottom

mounting brackets. Tighten the bracket screws.

b. Multiple mounted cases - spacer bars and self-adhesive pads must be used between the

cases, as shown in Figure 2-3. Start the installation from the right (when facing the panel),

installing the spacers as each case is added. Also, as each case is positioned in place, install

and tighten the top and bottom mounting brackets. Each case must be tight against the

previous case.

NOTE: Spacers are not required on the outside of the right and left cases.

10

Page 15

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

NOTES:

1. DIMENSIONS ARE IN INCHES. DIMENSIONS IN BRACKETS (

) ARE IN MILLIMIETERS.

2. DIMENSIONS GUARANTEED ON CERTIFIED PRINTS ONLY.

3. CASE MOUNTING HARDWARE SUPPLIED UNLESS

OTHERWISE SPECIFIED.

4. THIS DRAWING IS THIRD-ANGLE PROJECTION AS SHOWN

5. UNLESS OTHERWISE INDICATED ALL TOLERANCES ARE ±

1/16 (1.6)

Figure 2.1 Outline Dimensions & Panel Cut-out Requirements

11

Page 16

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Figure 2-2. Single or Multiple Panel Mounting

Figure 2-3. Intercase Spacing

12

Page 17

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

2.4 Power & Signal Wiring

PREPARATORY: The 53IT5100B can be configured for one to four analog inputs (ANI0-3), one analog

output (ANO0), two control contact inputs (CCI0 and 1), two control contact outputs (CCO0 and 1) and

Datalink network interconnectivity. Therefore, prior to making electrical connections, the particular instrument

configuration should be determined with all assigned inputs and outputs identified to assure proper signal

routing.

Provisions for electrical interconnections are located at the rear of the instrument case. Under ideal conditions

shielded cable may not be required. In noisy locations all system input, output and power wiring should be

enclosed in electrical conduit. System interconnection cables (except for power cables) should be fabricated

from 2-wire shielded signal cable. Signal transmission distance should not exceed the limit specified for the

particular transmitter (refer to applicable technical literature provided for the respective device). Polarity must

be observed when connecting the remote transmitters to the instrument.

The instrument has a vertically mounted terminal strip (TB1) for signal interconnections and a horizontally

mounted terminal strip (TB2) for power wiring. Both terminal strips are located at the rear terminal board of

the instrument case.

SNAP-OUT TERMINAL CONNECTORS

Both terminal strips, TB1 and TB2, have removable plug-in connectors. The upper connector for TB1 has

screw lugs 1 through 12 and the lower connector has screw lugs 13 through 22. All of the screw lugs are on a

single connector for TB2. To remove a signal connector, grasp it securely on both sides with the thumb and

forefinger, rock it gently from top to bottom (not side to side) and pull it straight out. To remove the power

connector, grasp the sides firmly with the thumb and forefinger, rock it gently from side to side and pull

straight out.

NOTE: The screw lugs on the back of the instrument are designed for 12 – 24 AWG wire. It is

important that the wire be stripped to expose 1/2 inch of conductor before installation.

WARNING! Instruments that are powered from an ac line service constitute a potential

electric shock hazard to the user. Make certain that these system ac power lines are

disconnected from the operating branch circuit before attempting electrical interconnections.

13

Page 18

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

14

Figure 2-4. Controller Rear Power and Signal Terminal Boards

Page 19

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

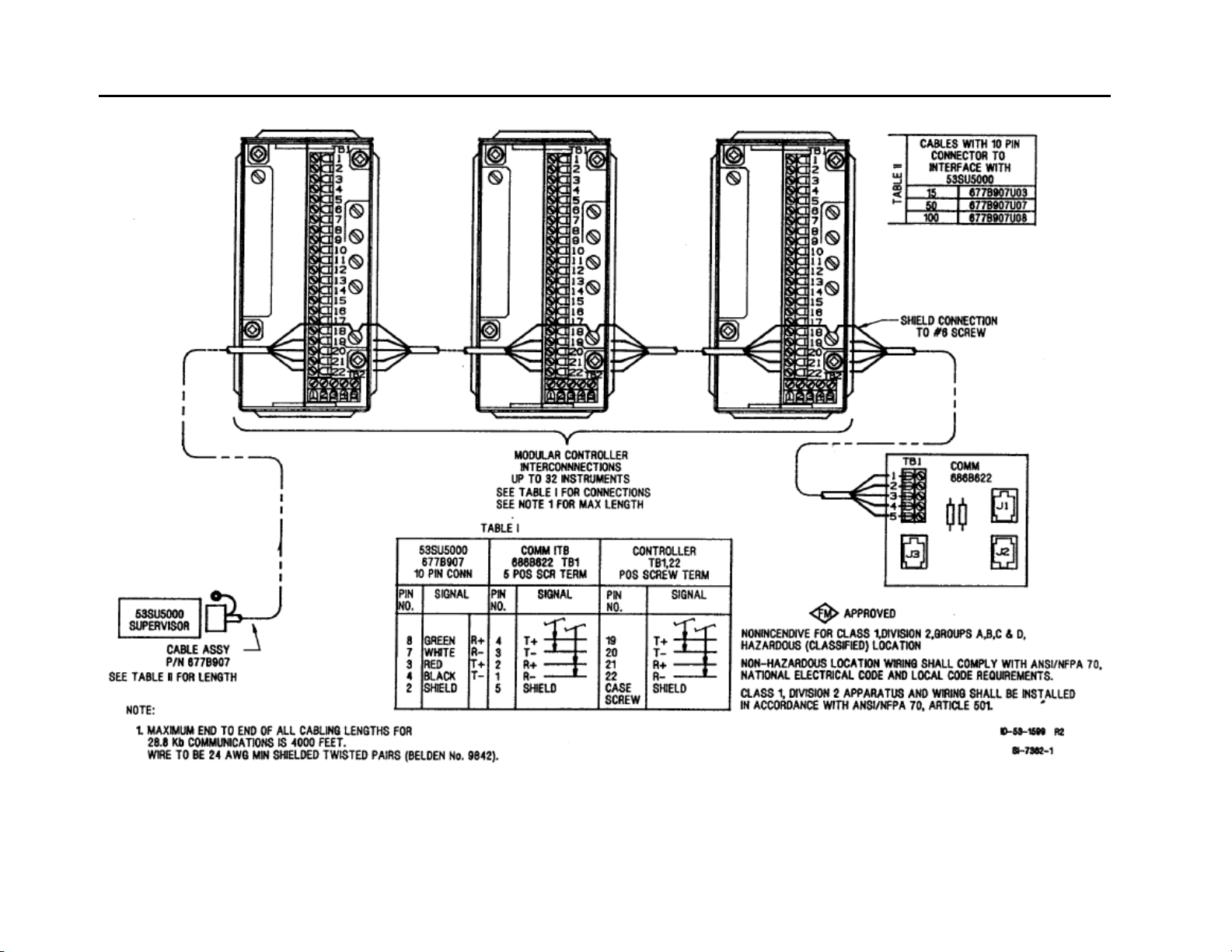

Figure 2-54. Datalink Installation Diagram

15

Page 20

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

2.4.1 Power Wiring

Refer to the instrument model number to verify the power input requirements:

53IT511nB21AAA – AC Power

53IT512nB21AAA – DC Power

2.4.1.1 DC Power

Reference Figure 2-4 and connect the remote 24 V dc power supply to the instrument as follows:

1.

Connect (+) input line, via remote SPST switch, to terminal L1.

2. Connect (-) input line to the system bus bar. The bus bar should be connected to a good earth

ground (#8 AWG wire is recommended). Individual wires should be run from the controller Power

Common (PC ) and Signal Common (SC ) terminals to the bus bar. The chassis should be grounded

by connecting terminal G to earth ground.

NOTE: Use of a common bus bar is recommended to minimize potential voltage differences that may

occur as the result of ground current loops, e.g., potential difference between separate signal grounds,

power grounds, etc.

2.4.1.2 AC Power

Reference Figure 2-4 and connect the specified line service (110-120, 220-240 V ac, 50 or 60 Hz) to the

trument as follows:

ins

1. Connect the phase or hot line L, via a remote power disconnect switch or circuit breaker, to terminal

L1.

2. Connect the neutral line N to terminal L2 for 110-120 V ac. Connect the neutral line N to terminal L3

for 220-240 V ac.

3. Connect Power Common to a good earth ground (#12 AWG wire is recommended). The instrument

case should be grounded by connecting terminal G to earth ground at the source of supply

(green/green-yellow ground).

All supply connections include surge protection rated at 275 V ac normal mode.

NOTE: To minimize possible interference, ac power wiring should be routed away from signal wiring.

2.4.2 Field Signal Wiring

2.4.2.1 Current/Voltage Input to AIN1 through AIN3

When the input signal is from a 4-20 mA current transmitter, a precision 250 ohms (+/-0.1%) resistor is

required. (The resistor tolerance is critical, as the resistor is used to accurately convert the current signal from

the transmitter, which is typically 4-20 mA, to a specified analog input voltage of 1 to 5 V dc). The back of the

rear terminal board has the appropriate resistors (R1 and R2, respectively) for ANI0 and ANI1. Resistor for

ANI2 and ANI3 are not supplied and must be installed as shown in the upper left corner of Figure 2-4. If the

input signal is already a voltage signal, its corresponding resistor should be removed.

2.4.2.2 Contact Input to CCI0 and CCI1

Separate contact input signals to CCI0 and CCI1 can be used for alarm inputs. One side of each

remote contact must be connected to power common as illustrated in Figure 2-4. Minimum opened

or closed recognition time for a remote contact must be 0.05 seconds.

2.4.2.3 Current Output from ANO0

A current output signal is available for re-transmission of one of the input signals ANI0 through

ANI3. Observe the proper polarity when connecting the output to another instrument.

2.4.2.4 Contact Outputs CCO0 and CCO1

Discrete contact outputs CCO0 and CCO1 are identified in Figure 2-4. Each discrete output is a

solid state switch with a rating of 30 V dc, 50 mA maximum. A CCO is referenced to power common.

When this contact is connected to an inductive load, an external arc suppression network is required

for contact protection.

16

Page 21

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

2.4.3 Datalink Communication

Datalink is an interrogator/responder serial interface capable of supporting 32 instruments on a single

network. It uses an RS485 physical interface. The Datalink wiring diagram for this instrument

is provided as Figure 2-5. Complete coverage of the Datalink is provided in the SUPERVISOR-PC

Instruction Bulletin 53SU5000.

2.5 Factory Set Calibration

Each unit contains individual factory set entries that calibrate the four analog inputs (ANI0 through ANI3) and

analog output (ANO0). There is a calibration sheet supplied with each instrument that should be retained for

future reference when the installation is completed. Reference Section 5.3 for additional information.

2.6 Grounding

Installations are expected to have access to an independent, high quality, noise-free point of earth reference.

The system should be connected by a dedicated, low resistance (less than one ohm) lead wire directly to the

installation’s point of earth reference. This ground reference is referred to as the Instrumentation Ground. If

an instrumentation ground reference does not exist in the installation, an earth ground electrode should be

established with an independent grounding rod or ground grid mesh.

17

Page 22

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

18

Page 23

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3 DISPLAYS AND PUSH BUTTONS

This section provides illustrations with item call-outs of the six operator displays, alarm overlays, and

engineering mode overlays. Where applicable, datapoints are identified parenthetically with the display item

call-outs. The datapoints are defined in Section 4. The front panel push button definitions are repeated in this

section from Section 1, because they are used in the engineering mode display overlay examples to enter a

key password, display a datapoint, and alter a datapoint.

3.1 Operator Displays

The Quad Bar Graph (Chs. 1-4), Dual Bar Graph (Chs. 1&2), Dual Bar Graph (Chs. 3&4), Quad Process

Digital Readout, Quad Totalizer Digital Readout, and Alarm Summary operator displays are illustrated in

Figures 3-1 through 3-6 respectively.

Alarm Index 0-3 and Alarm Dead Band 0-3 must alsobe configured:

ANI0 Alarm Index (B335) ANI0 Dead Band (C105)

ANI1 Alarm Index (B340) ANI1 Dead Band (C141)

ANI2 Alarm Index (B345) ANI2 Dead Band (C177)

ANI3 Alarm Index (B350) ANI3 Dead Band (C213)

Figure 3-1. Quad Bar Graph (Channels 1-4)

19

Page 24

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Figure 3-2. Dual Bar Graph (Channels 1 & 2)

20

Figure 3-3. Dual Bar Graph (Channels 3 & 4)

Page 25

53IT5100B Indicator/Totalizer

Figure 3-4. Quad Process Digital Readout

INSTRUCTION MANUAL

Figure 3-5. Quad Totalizer Digital Readout

21

Page 26

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3.2 Alarm Overlay

Figure 3-6. Alarm Summary

Any one of the six operator displays can have the upper quadrant of the display overlaid with an ALARM

indicator. An alarm indication warns of variation changes that exceed tolerance limits; the process may

require immediate attention. In the five illustrations of Figure 3-7, the process variable exceeded Alarm Limit 1

for ANI1. The five illustrations show how the alarm state would manifest itself on each operator display. The

alarm display for Dual Bar Graph (Chs. 3&4) is not illustrated, as the alarm banner appears in the identical

manner as shown in the illustration for Dual Bar Graph (Chs. 1&2).

In the Quad Bar Graph (Chs. 1-4) illustration of Figure 3-7, the alarm banner blinks from normal to reverse

video alternately with the ANI-1 graph scale (second from left). The ANI-1 graph scale does not appear in

reverse video, but disappears and reappears on the display. In the Dual Bar Graph (Chs. 1&2) illustration of

Figure 3-7, the alarm banner blinks from normal to reverse video alternately with the ANI-1 graph scale (on

the right of the display). The ANI-1 graph scale does not appear in reverse video, but disappears and

reappears on the display. The alarm banner in the Dual Bar Graph (Chs. 3&4) operator display (not shown)

would alternately blink from normal to reverse video; however, graph scales for channels 3 and 4 would be

unaffected.

In the Quad Process Digital Readout illustration of Figure 3-7, the alarm banner blinks from normal to reverse

video.

In the Quad Totalizer Digital Readout illustration of Figure 3-7, the alarm banner blinks from normal to reverse

video.

In the Alarm Summary illustration of Figure 3-7, the alarm banner and ANI-1 tag name blink from normal to

reverse video independent of one another.

The alarm banner blinking is stopped by pressing the Mode () push button on the horizontal keypad; the

alarm banner remains on the display, but does not blink, until the process variable returns to a value within

the alarm limit (passed dead band).

22

Page 27

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Figure 3-7. Alarm Overlays on the Operator Displays

23

Page 28

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3.2.1 Front Panel Pushbuttons

The front panel push buttons are repeated here from Section 1 because they are used in the engineering

mode display overlay examples to enter a key password, display a datapoint, and alter a datapoint.

To the right of the display is the vertical keypad and directly beneath the display is the horizontal keypad.

Both keypads have functioning push buttons that are dependent on the instrument mode of operation which

can be either operator mode or engineering mode. Mode selection is made with the Mode () push button

on the horizontal keypad. Engineering mode is entered to make the necessary selections for the operator

displays and to configure the Datalink port; otherwise, the instrument is left in operator mode for process

applications. The vertical keypad is dedicated only to engineering mode functions and has no effect in

operator mode. Both keypads are described as follows:

Horizontal Keypad

Push Button Title Operator Mode Engineering Mode

F1

F2

F3

Title Engineering Mode

Ascending

Character

Select

Descending

Character

Select

Shift Left

Shift Right

Mode Operator/Engineering mode select; Alarm reset.

Page back to previous display. Back to previous entry line function.

Page forward to next display. Pages the configure/display functions.

Moves Quad Bargraph pointer. Executes enter or display function.

Vertical Keypad

Displays one character at a time in ascending alphanumeric order; is released

when the desired character, number, or symbol appears on the engineering

mode data entry line.

Displays one character at a time in descending alphanumeric order; is released

when the desired character, number, or symbol appears on the engineering

mode data entry line.

Shifts selected character one position left on the engineering mode data entry

line each time this push button is pressed.

Shifts characters on engineering mode data entry line one character position

right each time this push button is pressed.

24

Page 29

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3.3 Engineering Mode Overlays

The engineering mode overlays are used to make the necessary parameter entry selections for the operator

displays and to configure the Datalink communications port. The entries are made to addressed datapoints

via the overlay single edit line at the bottom of the display. It should be noted that engineering mode has a 20

second timeout if it is accessed and its functions (e.g., configure or display) are not used.

3.3.1 Responding to the Prompt: KEY?

When the password prompt KEY? appears, it indicates a password was set in the MicroTools software. The

password can not be set via the front panel push buttons.

A password key is a maximum of 10 numeric characters (numbers 0-9 only). It does not impede display

functions in engineering mode but must be unlocked to perform configuration functions. A password key is

NOT SET FOR NEW INSTRUMENTS from the factory; therefore, if it is set, it must have been done locally.

The password must first be obtained from the originator before the procedure in Table 3-1 can be used to

access the engineering mode configuration function capabilities.

Table 3-1. Entering a Key Password

Step Press

Once

1

Shift

Result

Press to

Locate

Target

Char.

Result

Puts instrument in engineering mode.

2

3

F3

4

If DISPLAY appears instead of CONFIGURE, press 2.

Displays password query: KEY?

2

Puts first password number on entry line: KEY? .2.

5

.2Δ

6

7 Repeat step 6 until all of the password characters are entered.

.22Δ

2

2

8

F3

NOTE: Δ indicates Space

Shifts 2 and puts second password number on entry

line: KEY? .22.

Shifts 22 and puts third password number on entry

line: KEY? .222.

Enters the password key and displays the entry line:

POINT . The engineering mode configuration

function is now accessible for use.

25

Page 30

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

26

Figure 3-8. Engineering Mode Key Password Prompts

Page 31

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3.3.2 Displaying a Datapoint

The following procedure illustrates how to display the contents of datapoint C175, which is ANI2 Alarm Limit

1. Figure 3-9 contains supporting illustrations for the display procedure described in Table 3-2. (Notice in

these illustrations that ANI-2 Alarm Limit 1 is set at 80.)

Table 3-2. Procedure to Display a Datapoint

Step Press

Once

1

2

Shift

Result

Press to

Locate

If DISPLAY does not appear, press F2.

Target

Char.

Result

Puts instrument in engineering mode.

.CΔ

.C1Δ

.C17Δ

3

4

5

6

7

8 F3

9

F3

NOTE: Δ indicates Space

C

1

7

5

Displays entry line: POINT

Puts C on entry line: POINT .C.

Shifts C and puts 1 on entry line:

POINT .C1.

Shifts C1 and puts 7 on entry line:

POINT .C17.

Shifts C17 and puts 5 on entry line:

POINT .C175.

Enters address to display datapoint contents.

The address with the contents are displayed as

follows: C175 80.0000

Returns instrument to operator mode.

Figure 3-9. Displaying a Datapoint

27

Page 32

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

3.3.3 Altering a Datapoint

The procedure in Table 3-3 illustrates how to alter the contents of datapoint

C175, which is ANI2 Alarm Limit 1, from 80 to 90. Figure 3-10 is provided to

show the maximum input character length for the engineering mode edit line.

The edit line can accept ten characters. The full ten character field is used

primarily for the A type datapoint text strings (tag names). Reference Table

4-1 in Section 4 for information about the datapoint types. Note that in Figure

3-10, the PO is residual from the prompt POINT and that the character field

string starts with 1 and ends with 0 (underlined in the figure) to illustrate 10

characters.

Table 3-3. Procedure to Alter a Datapoint

Step Press

Once

1

2

3 F3 Displays entry line: POINT

4

5

6

7

8 F3

9

Hold

10

11

12 F3

13

NOTE:

Shift

Result

Puts instrument in engineering mode.

.CΔ

.C1Δ

.C17Δ

locator

.9Δ

Δ indicates Space

•

Press to

Locate

If CONFIGURE does not appear, press F2.

Target

Char.

C Puts C on entry line: POINT .C.

1

7

5

9

0

Result

Shifts C and puts 1 on entry line:

POINT .C1.

Shifts C1 and puts 7 on entry line:

POINT .C17.

Shifts C17 and puts 5 on entry line:

POINT .C175.

Enters address to display datapoint contents.

The address with the contents are displayed as

follows: C175 80.0000

C175 contents shifted right; only the locator

point remains on the entry line: C175 .

Puts 9 on entry line: C175 .9.

Shifts 9 and puts 0 on entry line:

C175 .90.

Enters the value 90 in datapoint C175.

Returns instrument to operator mode.

Figure 3-10. Entry Line

Ten Character Field

28

Page 33

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

4 CONFIGURATION PARAMETERS

The configuration parameters provide the latitude to define the instrument’s personality attributes, so that

while still functioning within its designed specifications, it can perform application requirements with greater

refinement. Typical configuration parameters are the instrument’s indicator zero point and span, the display

tag names, engineering units of the displayed process value, and alarm limits, etc. IT IS NOT NECESSARY

TO DEFINE ALL OF THE CONFIGURATION PARAMETERS, as commonly used preset values may not

have to be altered and certain parameter selections eliminate others.

Although all resident in a memory database as datapoints, the configuration parameters are clustered into

modular groups that may have specific hardware identities (e.g., the ANI, ANO, CCI, and CCO circuits

illustrated in Figures 4-1 through 4-4), or may represent software controlled functions that are not specific to

any one hardware element.

4.1 Datapoint Types

A parameter can be any one of five data types. Each data type represents a specific data format:

integers, alphanumeric text strings, etc. A database module containing multiple parameters can

have a mix of data types. The data types are defined in Table 4-1 as follows:

Table 4-1. Datapoint Types

Type Byte

Size

L 1 Bit Represents a single binary bit that can have the value of 0 or 1.

B 1 Represents a positive integer with values from 0 to 255.

C 3 Represents a real analog (floating point) value that has a resolution of one part in

H 5 Represents a high precision analog (floating point) value that has a resolution of

A 10 Represents a text string that can be 10 characters long.

4.2 Factory Standard Calibration

The instrument is shipped from the factory configured with all parameters set to the default values. The

default values are listed in the parameter tables under the heading Default. The gray-tone shading in a

default cell of a parameter indicates the contents of the datapoint are left unchanged after the database is

returned to the default condition using the procedure described in Section 5.5. Examples of datapoints

unaltered by default are the Calibrate Zero and Calibrate Span parameters which are factory set.

4.3 Configuring the Database Modules

The datapoints in the database modules must be changed to reflect required alterations in the factory

standard configuration or when the instrument is re-configured. There are generally four datapoint parameter

types contained in the eight database modules. The parameter types affect Datalink communications, display

indications, input-output signals, and alarm conditions. The eight database modules are described in Table 4-

2. Although it is not an absolute criterion, it is assumed the modules will be configured in the table Item order;

however, if the instrument is to be connected to a Datalink network, item 7, Communication Module, should

be configured first. By configuring the Communication Module first, the instrument can function on the

Datalink and the remaining datapoint values can be entered via the Datalink interrogator (master). Reference

the applicable instruction bulletin (e.g., IB 53HC3300, IB53WS5000, or IB 53SU5000) for the procedure.

Table 4-2 is also a pointer to the descriptions of the database modules; the descriptions are presented

as Tables 4-3 through 4-10. (The gray tone shading in the default cell of a datapoint indicates the datapoint

contents are left unchanged after default. See Section 5.5 for the default procedure.)

Format

32,768 (15 bits) and a dynamic range of ± 10

one part in 2 billion (31 bits) and a dynamic range of ± 10

38 .

38 .

29

Page 34

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-2. Database Modules

Item Title Purpose See

Table

1 Analog Input Module This module is used to configure the voltage input

characteristics (e.g., input voltage range) and how the input

signal is interpreted (linear or square root representation).

2

Analog Output Module

3 Contact Input Module This module allows the action of the CCIs to be reversed

4 Contact Output

Module

5 Alarm Module The primary purpose of this module is to set the instrument’s

6 Totalizer Module The totalizers provide the sum of each analog input (ANI0-3).

7 Communication

Module

8 System Module This module is used to set the instrument tag name and the

The primary purpose of this module is to set the 0 - 20 mA

output signal relative to the displayed percent output.

(normally a closed contact = 1, but can be change to = 0).

This module allows the action of a CCOs to be reversed

(normally a closed contact = 1, but can be changed to = 0).

Alarm Index mode, Alarm Limits 1 & 2, and Alarm Dead

Band.

This module is used to set input scaling factors, rollover and

dropout values, and to define display tags for each totalizer.

This module is used to configure the Datalink port

parameters (e.g., baud rate, parity selection, etc.).

4-10

display brightness.

4-3

4-4

4-5

4-6

4-7

4-8

4-9

30

Page 35

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-3. Analog Input (ANI) Module

Purpose: This module is used to configure input voltage characteristics (e.g., input voltage range), and how the

input signals are interpreted (linear or square root representation).

Title Symbol ANI Datapoint Default Attribute

Analog

Input

(Display

Only)

Engineering

Span

Engineering

Zero

Digital Filter

Index

0 - 5 V Input

Square

Root

Signal

Calibrate

Zero

Calibrate

Span

Tag Name

Engineering

Units

ANI0

ANI1

ANI2

ANI3

SPAN0

SPAN1

SPAN2

SPAN3

ZERO0

ZERO1

ZERO2

ZERO3

DFILT0

DFILT1

DFILT2

DFILT3

NOBIAS0

NOBIAS1

NOBIAS2

NOBIAS3

SQRT0

SQRT1

SQRT2

SQRT3

CIZ0

CIZ1

CIZ2

CIZ3

CIS0

CIS1

CIS2

CIS3

AITAG0

AITAG1

AITAG2

AITAG3

AIEU0

AIEU1

AIEU2

AIEU3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

ANI0

ANI1

ANI2

ANI3

H000

H001

H002

H003

C256

C257

C258

C259

C276

C277

C278

C279

B269

B270

B271

B272

L416

L417

L418

L419

L440

L441

L442

L443

B263

B264

B265

B266

C296

C297

C298

C299

A224

A225

A226

A227

A298

A299

A300

A301

0

0

0

0

100

100

100

100

0

0

0

0

3

3

3

3

0

0

0

0

0

0

0

0

ANI-0

ANI-1

ANI-2

ANI-3

PERCENT

(ALL)

This is the value in engineering units of the

measured input after all signal conditioning

has been applied.

This determines the upper range the analog

input represents in engineering units. The

upper range value equals Engineering Zero

plus Engineering Span.

This is the lower range value.

This controls a first order filter that is applied

to the input signal. The time constant is

entered as an index value as follows:

0 -No Smoothing (no effect)

1 -0.05 s

2 - 0.1 s

3 - 0.3 s

4 - 0.7 s

5 - 1.5 s

Setting this parameter to 1 indicates the input

range is from 0 -5 volts (0 -20 mA). 0

indicates the input range is from 1 -5 volts (4 20 mA).

When a 0, it indicates the analog input signal

should be interpreted linearly.

When 1, it indicates the analog input signal

should be interpreted as a square root

representation of the value. When square root is

selected, input signals less than 1% (10% input

range) forces the input to its zero value.

This is the calibration zero adjustment. This

parameter is factory set and should not need

adjustment under normal operation.

See Section 5.3 for adjustment.

This is the calibration span adjustment. This

parameter is factory set and should not

need adjustment under normal operation.

See Section 5.3 for adjustment.

an assignable 10 character name for the analog

input (ANI-0, ANI-1, ANI-2, ANI-3).

assignable for units of measure the ANI

represents (e.g., GPM for gallons/minute).

6 - 3.1 s

7 - 6.3 s

8 -12.7 s

9 -25.5 s

10 -51.1 s

11 - 102 s

12 - 205 s

13 - 410 s

14 - 819 s

15 -1638 s

31

Page 36

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Figure 4-1. ANI0-3 Figure 4-2. ANO0

NOTE: These figures are graphical representations of the signal conditioning that occurs on the

instrument main board. They are provided for reference purposes only.

32

Page 37

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-4. Analog Output (ANO) Module

Purpose: The primary purpose of this module is to set the 0 - 20 mA output signal relative to the

displayed percent and to select the analog input signal (ANI0-3) that is to be routed to the analog

output (ANO0).

Title Symbol ANO0

Datapoint

Analog Output

(Display Only)

Analog Output

Source

0 -20 mA

Output

Calibrate Zero COZ0 B267

Calibrate

Span

Tag Name AOTAG0 A244 ANO0 The assignable 10 character name for ANO0.

ANO0 C000 0 The value in this datapoint represents the

OZBASE0 L472 0

COS0 C300

B100 0 This parameter determines which analog input

Default Attribute

percent of output to be generated by hardware

(e.g., 100% output = 20 mA).

(ANI0-3) is routed to the analog output (ANO0).

The routing index values are as follows: 0 =

ANI0 →ANO0, 1 = ANI1 →ANO0 2 = ANI2

→ANO0, 3 = ANI3 →ANO0

When a 0, the percentage output generates a 4

-20 mA signal. When set to 1 , the percentage

output generates a 0 -20 mA signal.

These parameters are factory set and should

not need adjustment under normal operation.

See Section 5.3 for adjustment.

Figure 4-3. CCI0/1 Figure 4-4. CCO0/1

NOTE: These figures are graphical representations of the signal conditioning that occurs on the

instrument main board. They are provided for reference purposes only.

33

Page 38

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-5. Contact Input Module (CCI)

Purpose: This module allows the action of the CCIs to be reversed (normally a closed contact = 1, but can be

changed to = 0).

Datapoin

Title Symbol CCI

Contact

Input

(Display

Only)

CCI0

CCI1

CCI0

CCI1

t Default Attribute

L000

L001

0

0

When open, a 4 -24 V dc input signal = 0 when IINV =

0.

When open, a 4 -24 V dc input signal = 1 when IINV =

1.

When closed, a < 1 V dc input signal = 1 when IINV = 0.

When closed, a < 1 V dc input signal = 0 when IINV = 1.

Contact

Input

Invert

Display

Message

Tag

Name

Display

Mode

Alarm

Enable

Contact Input = 0 1 0 1

Display Mode

Display Mode

= 0

= 1

IINV0

IINV1

CCI0

CITAG0

CITAG1

SMA

SMB

SAA

SAB

CCI0

CCI1

CCI1

CCI0

CCI1

CCI0

CCI1

CCI0

CCI1

10 character

message.

No message blinking and no Alarm Banner blinking.

Frst half (5

characters) of 10

character

message

sequence.

No message blinking and no Alarm Banner blinking.

L264

L265

A055

A056

A262

A263

L352

L353

L368

L369

Alarm Enable = 0 Alarm Enable = 1

10 character

message in

reverse video.

Second half (5

characters) of

10 character

message

sequence.

0 0 As shown above, it reverses the action of the CCI

datapoint.

ALARM A

ALARM B

CCI-0

CCI-1

0 0

0 0

The messages for CCI0 and CCI1, respectively, on the

Alarm Summary display.

It is an assignable 10 character name for the contact

control input.

Display Mode, Alarm Enable, and Contact Input interact

to alter the two five character segments of the Display

Messages (A055 and A056) as shown in the table that

follows:

10 character

message.

First half (5

characters) of

10 character

message

sequence.

10 character message blinking in

reverse video with Alarm Banner

also blinking. (After pressing

Mode push button, 10 character

message appears in reverse

video.)

Second half (5 characters) of 10

character message blinking with

Alarm Banner blinking. (After

pressing Mode push button, 5

character message remains, but

stops blinking.)

34

Page 39

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-6. Contact Output Module (CCO)

Purpose: This module allows the action of the CCOs to be reversed (normally a closed contact =

1, but can be changed to = 0) and is used to select the signal or condition that activates the CCO.

Title Symbol CCO Data-point Default Attribute

Contact

Output

(Display

Only)

Contact

Output

Invert

Control

Contact

Output

Source

Tag

Name

CCO0

CCO1

OINV0

OINV1

COTAG0

COTAG1

CCO0

CCO1

CCO0

CCO1

CCO0

CCO1

CCO0

CCO1

L024

L025

L288

L289

B101

B102

A280

A281

0

0

0

0

110

134

CCO-0

CCO-1

If CCO = 0 and OINV = 0, then it is open.

If CCO = 0 and OINV = 1, then it is closed.

If CCO = 1 and OINV = 0, then it is closed.

If CCO = 1 and OINV = 1, then it is open.

As shown above, it reverses the action of the

CCO datapoint.

This parameter selects the signal or condition

that activates the CCO. The routing index

values

are as follows:

110 Channel 0 Alarm A (PA10).

111 Channel 0 Alarm B (PA20).

134 Channel 1 Alarm A (PA11).

135 Channel 1 Alarm B (PA21).

158 Channel 2 Alarm A (PA12).

159 Channel 2 Alarm B (PA22).

182 Channel 3 Alarm A (PA13).

183 Channel 3 Alarm B (PA23).

0 Contact Input 0 (CCI0).

1 Contact Input 1 (CCI1).

224 Totalizer 0 Rollover Pulse (TMP0).

225 Totalizer 1 Rollover Pulse (TMP1).

226 Totalizer 2 Rollover Pulse (TMP2).

227 Totalizer 3 Rollover Pulse (TMP3).

65 Horn - latches the OR function of all

alarms (8 process alarm bits and 2 contact

input alarms).

99 Non-latched OR function of all alarms (8

process alarm bits and 2 contact input

alarms). It is cleared when the last alarm goes

away.

An assignable 10 character name for the

contact control output.

35

Page 40

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-7. Alarm Module

Purpose: The primary purpose of this module is to set the instrument’s Alarm Index mode, Alarm

Limits 1 & 2, and Alarm Dead Band.

Title Symbol CCO Data-point Default Attribute

This parameter defines the Alarm Active (PA1 &

PA2) interpretation of the two Alarm Limits (PL1

& PL2). It is entered into the datapoint as an

index value (0-5 ) as follows (n = 0-3 and

correlates with ALRM0 through ALRM3):

0 PA1n: high when PV> PL1n

PA2n: low when PV< PL2n

1 None

2 PA1n: high when PV> PL1n

PA2n: not affected

3 PA1n: not affected

PA2n: low when PV< PL1n

4 PA1n: high when PV> PL1n

PA2n: hi-hi when PV> PL2n

5 PA1n: low when PV< PL1n

PA2n: lo-lo when PV< PL2n

Examples are provided as follows:

Alarm

Index

AIX0

AIX1

AIX2

AIX3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

B335

B340

B345

B350

1

1

1

1

Alarm Examples:

B335 PV PL1

(C103)

0 >60 60 high Alarm Llimit 1 is set for 60: PV > 60 = high Alarm.

0 <40 40 low Alarm Limit 2 is set for 40: PV < 40 = low Alarm.

2 >60 60 high Alarm Limit 1 is set for 60: PV > 60 = high Alarm.

2 <40 40 N/A Alarm Limit 2 is set for 40: PV < 40 = no alarm.

3 >60 60 N/A Alarm Limit 1 is set for 60: PV > 60 = no alarm.

3 <40 40 Low

4 >60 60 high Alarm Limit 1 is set for 60: PV > 60 = high Alarm.

4 <70 70 hi-hi Alarm Limit 2 is set for 70: PV > 70 = hi-hi Alarm.

5 >40 40 low Alarm Limit 1 is set for 40: PV < 40 = low Alarm.

5 <30 30 low-low Alarm Limit 2 is set for 30: PV < 30 = lo-lo Alarm.

PL2 (C104) Alarm Notes

low Alarm Limit 2 is set for 40: PV < 40 = low

Alarm.

36

Page 41

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-7. Alarm Module (continued)

Purpose: The primary purpose of this module is to set the instrument’s Alarm Index mode, Alarm

Limits 1 & 2, and Alarm Dead Band.

Title Symbol CCO Data-point Default Attribute

Alarm A

(Display

Only)

Alarm B

(Display

Only)

Alarm

Limit 1

Alarm

Limit 2

Alarm

Dead

Band

PA10

PA11

PA12

PA13

PA20

PA21

PA22

PA23

PL10

PL11

PL12

PL13

PL20

PL21

PL22

PL22

ADB0

ADB1

ADB2

ADB3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

ALRM

0

ALRM

1

ALRM

2

ALRM

3

L110

L134

L158

L182

L111

L135

L159

L183

C103

C139

C175

C211

C104

C140

C176

C212

C105

C141

C177

C213

0

0

0

0

0

0

0

0

100

100

100

100

0

0

0

0

2

2

2

2

When active, it indicates one of the four PA1

conditions (PA10-PA13) specified in its

respective

Alarm Index (AIX0-AIX3) has an alarm indication

as determined by the index value (0-5) that was

entered for the Alarm Index.

When active, it indicates one of the four PA2

conditions (PA20-PA23) specified in its

respective

Alarm Index (AIX0-AIX3) has an alarm indication

as determined by the index value (0-5) that was

entered for the Alarm Index.

These parameters are the points in engineering

units at which the alarms are triggered.

This parameter sets the activation/deactivation

gap for the alarm. This value in engineering units

defines an area of hysteresis at the alarm point.

37

Page 42

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-8. Totalizer Module

Purpose: The totalizers provide a running total of each analog input (ANI0-3). This module is

used to set input scaling factors, rollover and dropout values, and to define display tags for each

totalizer.

Title Symbol TM Datapoint Default Attribute

Tag

Name

Eng.

Units

Scale

Factor

TMTAG0

TMTAG1

TMTAG2

TMTAG3

TMEU0

TMEU1

TMEU2

TMEU3

TMF0

TMF1

TMF2

TMF3

TM0

TM1

TM2

TM3

TM0

TM1

TM2

TM3

TM0

TM1

TM2

TM3

A092

A094

A096

A098

A093

A095

A097

A099

C318

C320

C322

C324

TOTAL-0

TOTAL-1

TOTAL-2

TOTAL-3

UNITS

UNITS

UNITS

UNITS

16666

16666

16666

16666

These are assignable 10 character names that

appear on the totalizer display.

These are assignable 10 character names that

appear on the totalizer display as the engineering

units of measure.

The value of the input is multiplied by this

parameter prior to being summed to the running

total. The parameter is used for both scaling and

time interval integration. For example, if ANI0 is in

M gallons/day, in order to totalize in K gallons the

scale factor (SF) would be:

SF = [Units Conversion] X [Time Base Conversion]

SF = [1000 K gal / M gal] X [(1 day/24 hrs) X (1

hr/60 mins) X (1 min/60 sec) X (1 sec/sample)] =

1000/86400 = 0.01157

NOTE: The time between totalizer updates is

one second.

The default value of 16666 uses the scale factor

for time interval integration. Due to the internal

timing of the instrument, a scale factor of 16666 will

cause the rollover total to occur once every minute.

Rollover

Value

Dropout

Value

Reset

38

TMM0

TMM1

TMM2

TMM3

TMD0

TMD1

TMD2

TMD3

TMR0

TMR1

TMR2

TMR3

TM0

TM1

TM2

TM3

TM0

TM1

TM2

TM3

TM0

TM1

TM2

TM3

H048

H049

H050

H051

C319

C321

C323

C325

L232

L233

L234

L235

1000000

1000000

1000000

1000000

0

0

0

0

0

0

0

0

Specifies the maximum value of the totalizer.

When the total reaches this value it is reset to

0.0; however totalizing continues. This value

must be a positive number.

When the input value is less than this value, no

change in the total occurs.

This parameter acts like a momentary switch.

When this parameter is set to 1 the total is forced

to 0.0 and then this parameter is reset to 0.

Page 43

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-8. Totalizer Module (continued)

Purpose: The totalizers provide a running total of each analog input (ANI0-3). This module is

used to set input scaling factors, rollover and dropout values, and to define display tags for each

totalizer.

Title Symbol TM Datapoint Default Attribute

Actual

Total

(Display

Only)

Output

Pulse

TO0

TO1

TO2

TO3

TMP0

TMP1

TMP2

TMP3

TM0

TM1

TM2

TM3

TM0

TM1

TM2

TM3

H032

H033

H034

H035

L224

L225

L226

L227

0

0

0

0

0

0

0

0

This parameter indicates the integer value of the

total accumulation.

This value is pulsed to a 1 for one scan each

time the actual total reaches the rollover value.

39

Page 44

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-9. Communication Module

Purpose: This module is used to configure the Datalink port parameters (e.g., baud rate, parity

selection, etc.).

Title Symbol Datapoint Default Attribute

It identifies the address of this instrument on the

Instrument

Address

Baud Rate BR B002 253

No Parity CP L256 0

No Byte

Stuffing

Datalink

Disable

IA B001 0

CB L258 0

DLD L257 0

Datalink network. Each unit connected to the Datalink

network must have its own unique address. Valid

addresses are from 0 -31.

This datapoint value designates the baud rate (data

transfer rate) of the Datalink network. The baud rate

must be the same for all of the instruments connected to

the same Datalink network. Datapoint values and their

corresponding baud rates are as follows:

Value Baud Rate Value Baud Rate

255 28800 9 28800

254 14400 8 14400

N/A N/A 7 19200

253 9600 6 9600

250 4800 5 4800

244 2400 4 2400

232 1200 3 1200

208 600 2 600

160 300 1 300

N/A N/A 0 110

This datapoint indicates if parity generation and

checking should be turned on or off. It is set to 0 for

even parity serial byte protocol. It is set to 1 for no parity

protocol.

When set to a 1, this datapoint disables the standard

communication protocol feature which inserts a 00

(NUL) byte after every 7EH (SOH) that is not the

beginning of a message. (This permits user written

communications software to determine the number of

bytes to expect in a response message.) It must be set

to 0 when using the Micro-DCI communications

software or equipment.

When set to 0 , it permits full Datalink communication

capabilities. When set to 1, it disables Datalink

communication capabilities.

40

Page 45

53IT5100B Indicator/Totalizer

INSTRUCTION MANUAL

Table 4-10. System Module

Purpose: This module is used to set the instrument tag name and the display brightness.