Page 1

INSTRUCTION MANUAL

PC Configuration Software, Controllers

53HC2600

Release 4.0

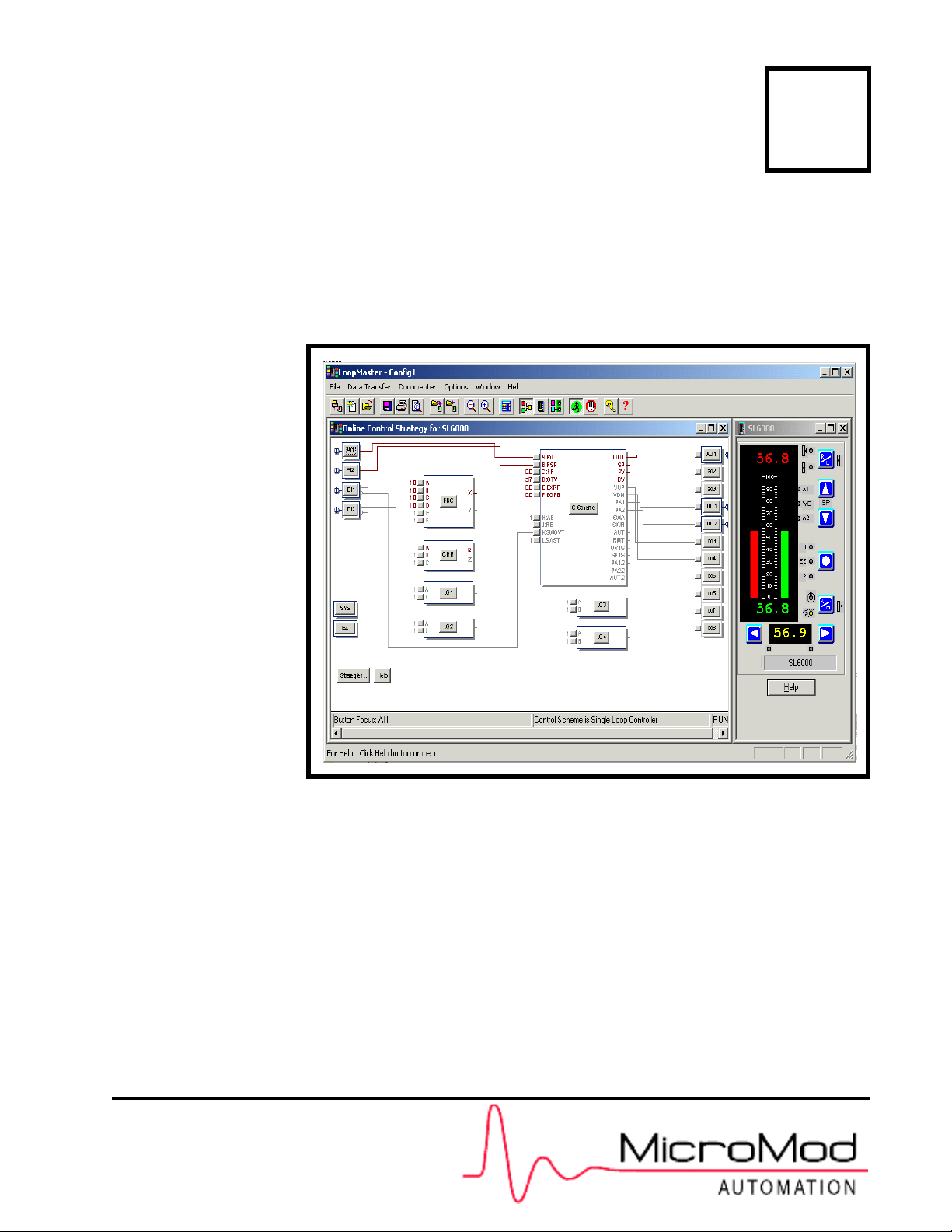

LoopMaster™ SL6000 CONFIGURATION TOOLKIT

PN26003 Rev. 1

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most ost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

∆ Warning. An instruction that draws

attention to the risk of injury or death.

❢ Caution. an instruction that draws

attention to the risk of the product,

process, or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

✎Note. Clarification of an instruction

or additional information.

i Information. Further reference for

more detailed information or

technical details.

Licensing, Trademarks and Copyrights

Easy-Tune, LoopMaster, and Micro-Mite are trademarks of MicroMod Automation, Inc. Micro-DCI is a registered trademark of

MicroMod Automation, Inc.

All other trademarks are the property of their respective owners.

Copyright 2005 MicroMod Automation Inc. [October 2005]

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted.

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions

of high pressure and/or temperature.

4. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

5. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and

source codes, is copyrighted by MicroMod Automation, Inc.,

and is owned by MicroMod Automation or its suppliers.

Page 3

53HC2600 INSTRUCTION MANUAL

TABLE OF CONTENTS

READ FIRST ...............................................................................vii

1.0 - INTRODUCTION ...................................................................1

1.1 LoopMaster™................................................................................................1

1.2 What You Will Need.......................................................................................1

1.3 About This Manual.........................................................................................2

1.4 Text Conventions Used In This Manual.........................................................2

1.5 SL6000 Configuration Toolkit Model Numbers ..............................................3

2.0 - INSTALLATION.....................................................................5

2.1 Installing LoopMaster ....................................................................................5

2.1.1 To Install LoopMaster for Windows 3.1 or Windows 95/98...............5

2.1.2 What Gets Installed..........................................................................6

2.1.3 To Install LoopMaster for Windows 2000 Professional/Windows XP

Professonal................................................................................7

2.1.4 Hardware Installation.......................................................................8

2.1.4.1 Installing the Hardware Key...........................................8

2.1.5 LoopMaster Software Installation.....................................................9

2.2 Uninstalling LoopMaster Under Windows 3.1 or

Windows 95.......................................................................................13

2.3 Uninstalling LoopMaster Under Windows 2000 Professional or Windows XP

Professional.............................................................................................14

2.3.1 Removing the LoopMaster Software..............................................14

2.3.1.1 Method 1......................................................................14

2.3.1.2 Method 2......................................................................15

3.0 - GUIDED TOUR....................................................................17

3.1 Starting LoopMaster....................................................................................17

3.1.1 To start LoopMaster........................................................................17

3.2 Online Or Offline?........................................................................................17

3.3 Offline Configuration....................................................................................18

3.4 Tagname......................................................................................................18

3.5 The Strategy Assistant.................................................................................18

3.6 Main LoopMaster Window...........................................................................19

3.7 Control Strategy Window.............................................................................19

3.8 Typical Offline Parameter Value Change.....................................................20

3.8.1 Changing the AI Input Base ...........................................................20

3.8.2 Changing the AI Digital Filtering.....................................................20

3.8.3 Adding DOCUMENTER Information ..............................................21

3.9 Viewing the DOCUMENTER Report............................................................22

3.10 Saving the Configuration ...........................................................................24

3.11 Changing Function Block Connections......................................................24

Contents i

Page 4

53HC2600 INSTRUCTION MANUAL

3.12 Configuring the FNC Block........................................................................26

3.13 Using the Interactive Training Screens......................................................27

4.0 - ONLINE CONFIGURATIONS..............................................31

4.1 LoopMaster Online..................................... ... .... ... ... ... .................................31

4.2 Connecting A Micro-Mite Controller To Your PC..........................................31

4.3 Multi-Drop Network Connections.................................................................31

4.4 Starting An Online Configuration.................................................................36

4.4.1 Online or Offline? ...........................................................................36

4.4.2 Select a Controller..........................................................................36

4.4.3 Main LoopMaster Window with Front Panel Window.....................37

4.4.4 Typical Online Parameter Value Change .......................................38

4.4.4.1 Changing the AI Input Base Online..............................39

4.4.4.2 Changing the AI Digital Filtering Online.......................39

4.4.4.3 Documenter Supplementary Information ................. ....39

4.4.5 Changing Function Block Connections Online...............................39

4.4.6 Configuring the FNC Block Online .................................................41

4.4.6.1 Using the Interactive Training Screens Online.............42

4.5 Uploading a Controller Configuration To a File............................................43

4.6 Downloading a File to a Controller ..............................................................44

5.0 - USING THE DOCUMENTER .............................................. 47

5.1 Documenter Report.................................... ... .... ... ... ... .... ... ... ... ... .................47

5.1.1 Documenter Fonts..........................................................................47

5.1.2 Header and Footer.........................................................................47

5.1.3 Margins...........................................................................................47

5.1.4 Title Page.......................................................................................47

5.1.4.1 Documenter Title......... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....48

5.1.4.2 Documenter Function Block Overview.........................48

5.1.5 Parameter Listing Pages................................................................48

5.1.5.1 Parameter Listing Format ............................................48

5.1.6 Rear Connection Diagrams............................................................48

6.0 - ADVANCED TOPICS .......................................................... 49

6.1 How to Start An Online Configuration Directly.............................................49

6.2 How To Start An Offline Configuration Directly............................................49

6.3 LoopMaster File Format .......... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....50

6.3.1 [Info] Section ..................................................................................50

6.3.2 [Documenter] Section.....................................................................50

6.3.3 [Database] Section.........................................................................52

6.4 Downloading A File......................................................................................52

6.4.1 Download Selectivity......................................................................52

6.5 Strategy Assistant Start Base File ...............................................................52

ii Contents

Page 5

53HC2600 INSTRUCTION MANUAL

7.0 - TROUBLESHOOTING ........................................................55

7.1 SERIAL.386 File Installation Instructions ....................................................55

7.2 Documenter Problems.................................................................................56

7.3 Display Problems.........................................................................................56

7.3.1 THREED.VBX Display Problems ...................................................57

7.4 COM Port Selection................. ... ... ... .... ... ... ... .... ... ... ... .................................57

8.0 - MICRO-MITE CONTROLLER OPTIONS............................59

8.1 Connecting the Option Modules.................................... .... ... ... ... .... ... ... ... ... .59

8.2 Communications Module.............................................................................59

8.3 2DI/2DO Option Module ..............................................................................59

8.4 Universal Ananlog Input Module..................................................................60

Appendix A - GLOSSARY OF TERMS ......................................61

Appendix B - DATABASE CROSS REFERENCE ..................... 63

Appendix C - MENUS AND TOOLBAR BUTTONS ................... 75

LIST OF FIGURES

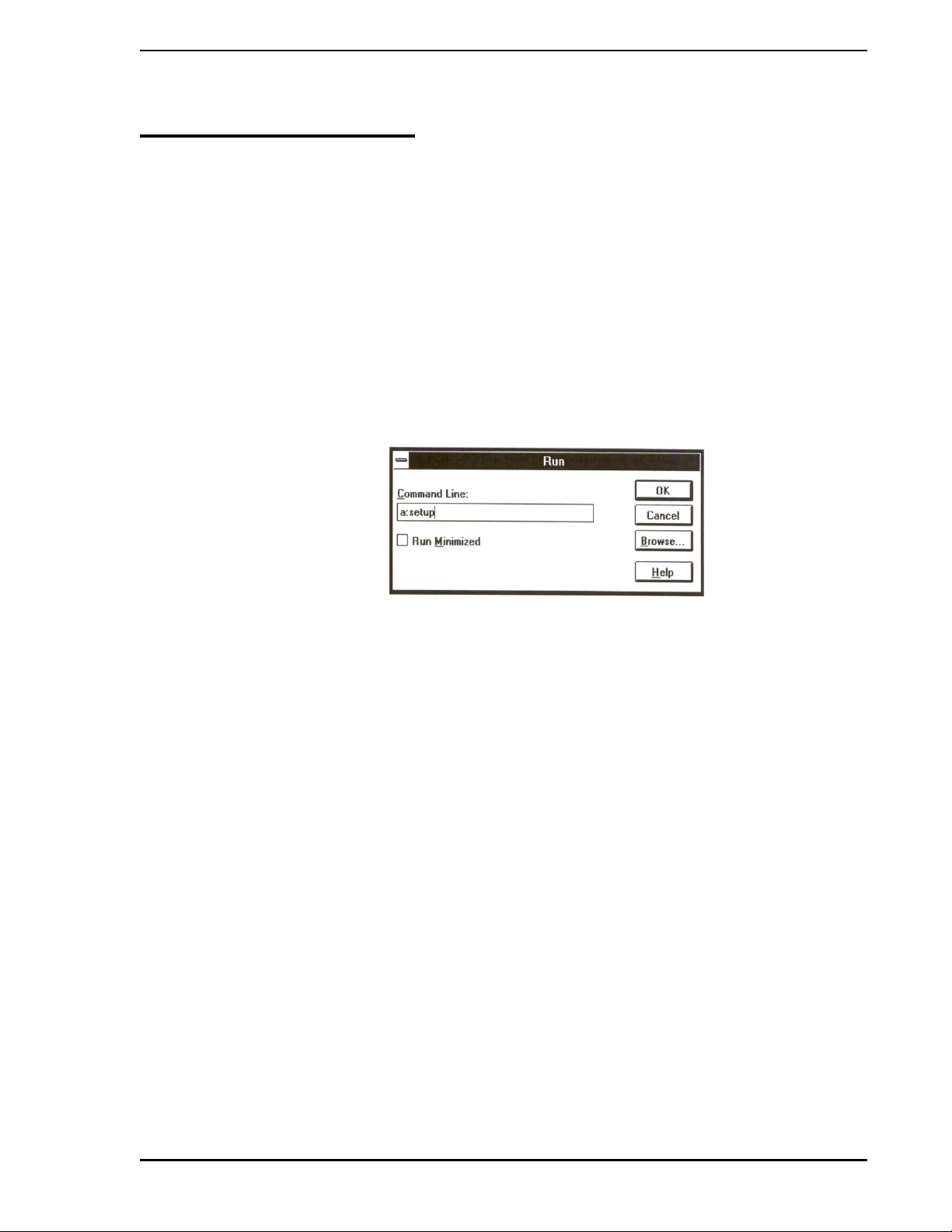

Figure 2-1. Run Dialog Box .................................... ... ... ......................................5

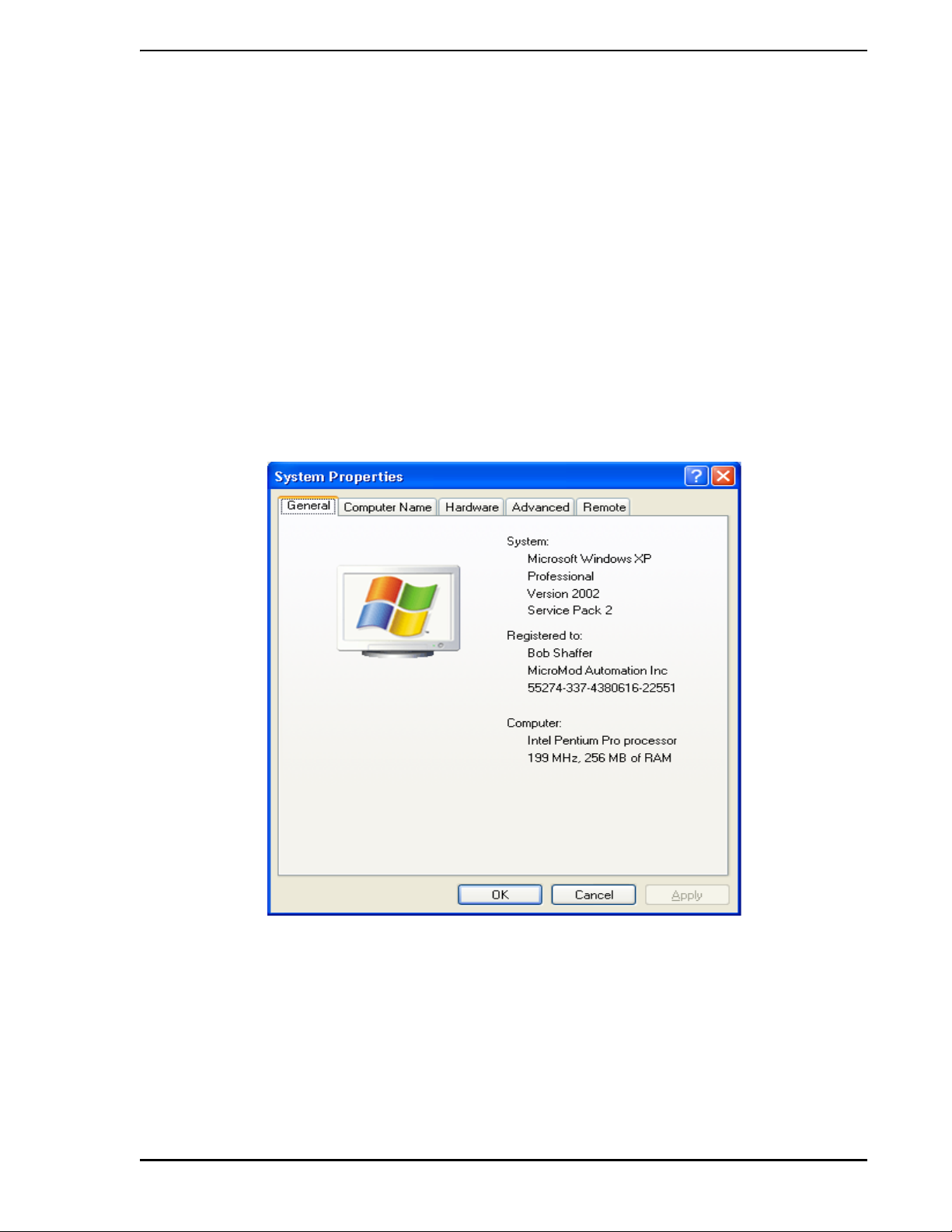

Figure 2-2. System Properties Window, General Tab Displayed ........................7

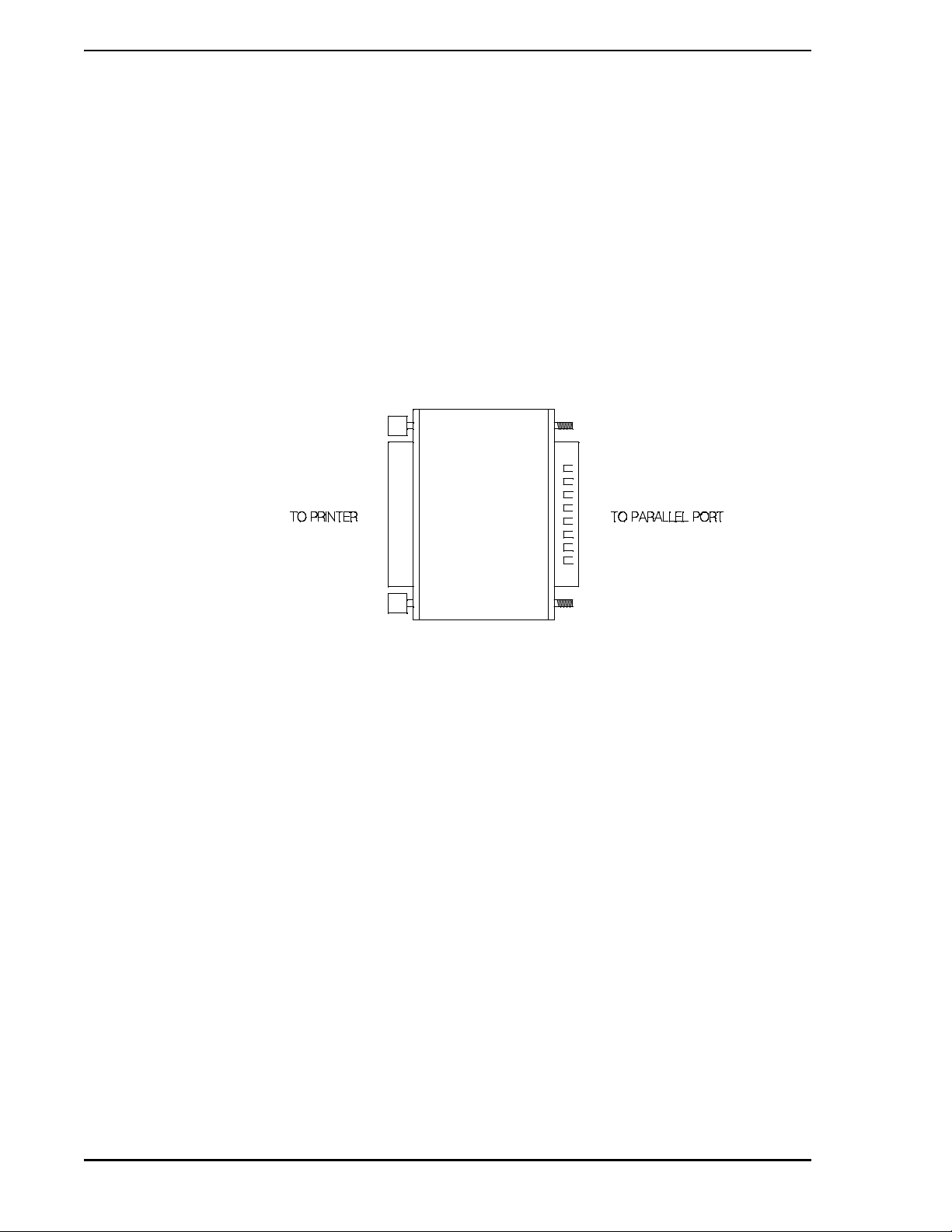

Figure 2-3. Hardware Key for Use with LoopMaster System Software ..............8

Figure 2-4. Menus for Uninstalling LoopMaster Software, Method 1 ................14

Figure 2-5. Uninstalling LoopMaster Software, Method 2 .................................15

Figure 3-1. The Online or Offline? Dialog Box ........................... ... ... .... ... ... ... ... .17

Figure 3-2. Creating a New Offline Configuration ...................................... .......18

Figure 3-3. Main LoopMaster Window - Example ............................................19

Figure 3-4. Standard AI Dialog Box ........................ ... ... ... ... .... ... ... ... .... ... ... ... ... .20

Figure 3-5. Adding Information for the Documenter Report .............................21

Figure 3-6. Documenter Report, Sample First Page ........................................22

Figure 3-7. Documenter Report, Last Page, Rear Connections Example ........23

Figure 3-8. Selecting the C Scheme A Input Button .........................................25

Figure 3-9. Connection Drawing Example, FNC Output X Source ...................25

Figure 3-10. Connection Drawing Example, AI1 Source ..................................26

Figure 3-11. Equation Constant Configuration Example ...................................27

Figure 3-12. Sample Control Scheme Window ................................................28

Figure 3-13. SAMPLE.cn1.Output1 Dialog Window ......................................... 28

Figure 4-1. RS-232 Single Controller Cabling .................................................. 32

Figure 4-2. Datalink Cabling ................................................................ ... ... ... ... .33

Figure 4-3. RS-232/485 Cable ...................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .34

Figure 4-4. ITB Track Clearances .................................................... .......... .......35

Contents iii

Page 6

53HC2600 INSTRUCTION MANUAL

Figure 4-5. Online or Offline? Dialog Box ............................................ ............. 36

Figure 4-6. Select a Controller Dialog Box ....................................................... 37

Figure 4-7. Control Strategy Window and Front Panel Window .......................37

Figure 4-8. Online Standard AI Dialog Box .......................................................38

Figure 4-9. FNC Function Block, A Input Selected .... .......................................40

Figure 4-10. FNC Function Block, Connection Example ..................................41

Figure 4-11 . Function Block Equations Dialog Window ....................................41

Figure 4-12. Control Scheme Dialog Window ..................................................42

Figure 4-13. SL6000.cn1.Output1 Dialog Window ...........................................42

Figure 4-14. Upload Dialog Window .................................................................44

Figure 4-15. Upload From Controller Window ........................ .......................... 44

Figure 4-16. Download to Controller Window ............................ .......................45

Figure 6-1. LoopMaster Properties Dialog Box .. .... ... ... ... .... ... ...... ... .... ... ... ... ....49

Figure 8-1. Micro-Mite Controller Connectors ..................................................59

Figure B-1. Accessing the SL6 Database Dialog Box ......................................63

Figure B-2. Manual Write to SL6 Database Dialog Box ....................................63

Figure C-1. LoopMaster Menu and Button Overview .......................................75

List of Tables

Table 2-1. Files installed In LoopMaster Directory.............................................. 6

Table 6-1. Info Section Variables...................................................................... 50

Table 6-2. Documenter Section Variables ........................................................ 50

Table B-1. Prompt-to-Datapoint Number Cross Reference List........................ 64

iv Contents

Page 7

READ FIRST

∆ WARNING: INSTRUCTION MANUALS

53SU6000 INSTALLATION AND SETUP GUIDE

Do not install, maintain, or operate this equipment

without reading, understanding and following the proper

MicroMod Automation Inc. instructions and manuals,

otherwise injury or damage may result.

Read these instructions before starting installation;

save these instructions for future reference.

RETURN OF EQUIPMENT

All Flowmeters and/or Signal Converters being returned

to the factory for repair must be free of any hazardous

materials (acids, alkalis, solvents, etc.). A Material Safety

Data Sheet (MSDS) for all process liquids must

accompany returned equipment. Contact the factory for

authorization prior to returning equipment.

Contacting MicroMod Automation Inc.

Should assistance be required with any MicroMod Automation Inc. product, use the follo wing contact

information.

Telephone:

MicroMod Automation Inc., Rochester NY:

Phone: 1 (585) 321-9200

Fax: 1 (585) 321-9291

MicroMod Automation Inc., Southampton, PA:

Phone: 1 (215) 355-4377

Fax: 1 (215) 355-4378

E-Mail:

support@micmod.com

Read First vii

Page 8

53SU6000 INSTALLATION AND SETUP GUIDE

viii Read First

Page 9

53HC2600 INSTRUCTION MANUAL

1.0 INTRODUCTION

1.1 LoopMaster™

Thank you for purchasing the 53HC2600 LoopMaster™ SL6000 Configuration Toolkit!

LoopMaster is the graphical configuration package for the 53SL6000 Micro-Mite controller. LoopMaster

produces Micro-Mite controller configurations, saves them to files, sends them to a Micro-Mite controller,

and documents the configuration in a comprehensive report.

LoopMaster contains time-saving features like the Strategy Assistant to help you get started, interactive

training screens to explain parameters and guide you through configuration dialogs (see dialog in Appendix A, Glossary of Terms), and an integrated Documenter to automatically generate a complete configuration report. On-the-spot assistance is available; click the Help button to view the help screen related to

your current situation.

1.2 What You Will Need

To use LoopMaster with Windows® 3.1 or Windows® 95, you will need:

•Microsoft

• Pointing device (mouse, trackball, etc.).

• 4 megabytes of RAM.

®

Windows 3.1 or Windows 95.

• 3 megabytes of free disk space.

• VGA 640 x 480 display (16-color preferred) or higher.

• One COM port available.

• 3.5” disk drive for the LoopMaster installation diskette.

To use LoopMaster with Windows 2000 Professional or Windows XP Professional, you will need:

• A personal computer (PC) that meets the minimum require ments for running the chosen

Windows operating system.

• The Windows 2000 Professional or Windows XP Professional SP2 software.

• A CD-ROM drive for the LoopMaster installation CD-ROM.

• Pointing device (mouse, trackball, etc.).

• VGA 640 x 480 display (256-color preferred) or higher.

• A 3.5 inch floppy disk drive for small capacity removable storage.

• A parallel port for printing and hardware key inst allation.

• A full size ISA bus slot is required for each installed Supervisor card.

Introduction 1

Page 10

53HC2600 INSTRUCTION MANUAL

1.3 About This Manual

This manual provides information to install and use the LoopMaster SL6000 Configuration Toolkit.

It is assumed that you are familiar with Microsoft Windows™ and have a basic knowledge of process con-

trol terminology. If you are not familiar with Windows, try running the Windows Tutorial, which can be

accessed using the menues available from the Start button; for example, on a Windows XP Professional

system, select the sequence Start > All Programs > Accessories > Tour Windows XP to initiate the

tutorial.

Section 1.

Introduction

Section 2.

Installation

Section 3,

Guided Tour

Section 4.

Online Configurations

Section 5.

Using The Documenter

Section 6.

Advanced Topics

Section 7.

Troubleshooting

Section 8.

Micro-Mite Controller Options

Appendix A.

Glossary of Terms

Provides a LoopMaster overview and minimum system

requirements.

Provides step-by-step in structions to inst all LoopMaster onto

your system.

How to start LoopMaster and create a simple offline

configuration.

How to connect a Micro-Mite controller to your personal

computer and Micro-Mite controller Datalink cabling. Also,

how to develop an online configuration and download a

configuration file to a Micro-Mite controller.

Customizing the Documenter Report and what the

Documenter does.

Command line options, LoopMaster file format, specific

information about downloading files.

A list of potential problems and their remedies.

Information on supporting Micro-Mite controller option

modules in LoopMaster.

Contains a brief description of unique LoopMaster terms.

Appendix B.

Database Cross Reference

Appendix C.

Menus and Toolbar Buttons

Provides a prompt-to-datapoint location number cross

reference list.

Provides a quick reference that describes the purpose of

each menu command and toolbar button.

1.4 Text Conventions Used In This Manual

File > Print indicates access File on the Main Menu bar and select Print from the pull-down menu.

2 Introduction

Page 11

53HC2600 INSTRUCTION MANUAL

1.5 SL6000 Configuration Toolkit Model Numbers

Refer to the product data sheet or data tag for the model number of the product furnished. The details of a

specific number are as follows:

53 HC26 0 A _ 0

Controllers

Design Designator

System Type

Windows 3.1 or Windows 95 Standalone 0

Windows 2000 Pro/XP Pro Standalone 1

Add-on to existing hardware security device 2

Reserved 0

Design Level A

Interface

None 0

RS-232 (Cable only: 9 Pin D to SL6000 RS-232 Module) 1

RS-232 (Cable and Communications Module) 2

RS-485 (Cable and RS-232 to RS-485 converter) 3

Media Type

None 0

3.5 inch, 1.44 MB diskette 1

CD-ROM 2

Introduction 3

Page 12

53HC2600 INSTRUCTION MANUAL

4 Introduction

Page 13

53HC2600 INSTRUCTION MANUAL

2.0 INSTALLATION

2.1 Installing LoopMaster

The LoopMaster setup utility installs the program, help file, and the necessary support files onto your hard

drive.

2.1.1 To Install LoopMaster for Windows 3.1 or Windows 95/98

1. Insert the LoopMaster diskette into the flop p y driv e.

2. From Program Manager, click on the File menu and select Run.

3. In the Run dialog (Figure 2-1), type a:setup and click OK. Type b:setup if installing from

the b: drive. The LoopMaster splash screen will appear while Setup initializes.

Figure 2-1. Run Dialog Box

4. Setup asks if you want to install LoopMaster onto your hard drive. Click Yes.

5. Depending on your hardware, Setup may make some suggestions. Click OK after reading

any suggestions.

6. Setup asks for the destination drive and directory. Type in the drive and subdirectory where

you want Setup to install all LoopMaster files. If the subdirectory does not exist, Setup will

create it for you. LoopMaster uses a straightforward subdirectory tree where all files are

installed into the same subdirectory.

7. If a warning message appears indicating your system has an old version of SERIAL.386

installed in the Windows System subdirectory, click OK. If the warning message does not

appear , it indicates your SERIAL.386 file is at an acceptable version or it is not used by your

system; proceed to step 9.

✎ NOTE Ignore step 3 of the Microsoft instructions, where it states the

WG1001 disk should be inserted into the floppy drive.

8. Microsoft’s instructions to install the SERIAL.386 file appear on the monitor . A copy of these

instructions is provided in Section 7.0, TROUBLESHOOTING. Do not remove the LoopMaster

diskette from its drive. Follow the Microsoft instructions provided in Section 7.0 to install the

SERIAL.386 file.

Installation 5

Page 14

53HC2600 INSTRUCTION MANUAL

9. After all the files are installed, Setup adds five icons to the LoopMaster program group. Setup

also creates the group if it does not exist.

• LoopMaster icon

• LoopMaster Help icon

• Readme icon

• Uninstall icon

• Documents icon

10. Before starting LoopMaster, double-click on the Readme icon to view up-to-date information

on this version.

This completes the LoopMaster installation. Section 3.0 provides a brief guided to ur of LoopMaster.

2.1.2 What Gets Installed

All of the LoopMaster files are installed into the same subdirectory. Here are the files installed onto your

drive.

Table 2-1. Files installed In LoopMaster Directory

File Description

LOOPMSTR.EXE LoopMaster Program file

LOOPMSTR.HLP LoopMaster Help file

WSUP31.DLL MicroMod Automation Inc. Communications Dynamic

Link Library (.DLL)

WSUP.INI .INIfile required by WSUP31.DLL

LMTRAIN.TXT LoopMaster training screens text file

UIM.TXT Universal Input Module text file

README.TXT Additional information text file

SPIN.VBX Spin button .VBX control

ANIBRT.VBX Pushbutton .VBX control

THREED.VBX Assorted .VBX controls

SS3D2.VBX 3D drop-down list box .VBX control

START.S6D Strategy Assistant start base file

GAUGE.VBX Gauge .VBX control

In addition to these files, the LOOPMSTR.INI file is created when you run LoopMaster for the first time.

This file will be located in your Windows directory.

6 Installation

Page 15

53HC2600 INSTRUCTION MANUAL

2.1.3 To Install LoopMaster for Windows 2000 Professional/Windows XP Professonal

1. Set up the Base PC by connecting all peripheral hardware units to the base PC, including the

monitor, keyboard, mouse, and CD-ROM unit (if it is an external CD-ROM unit). Connect the

base PC and all peripheral units to a power sour ce. See the instructions that are included with

the PC for setting up these components.

2. Verify or install the Windows operating system software. For installations performed after

October 2005, LoopMaster requires that the base PC is running Windows 2000 Professional

or Windows XP Profession SP2.

NOTE: Existing installations on a base PC running Windows NT 4.0 will continue to work.

Locate the button labeled START at the bottom left of the base PC monitor scr een and click it.

Right-click on the My Computer menu item, then click on the View System Information

option. The version information for the system will be displayed on the General tab of the

resulting pop-up window (see Figure 2-2).

Figure 2-2. System Properties Window, General Tab Displayed

Verify that either Windows 2000 Pro fessional or Windows XP Professional SP2 is inst alled. If

the information on this window indicates that the op erating system is Windows 95 or Windows

NT Server, then you must install Windows 2000 Professional or Windows XP Professional at

this time. If you need to install Windows 2000 Professional or Windows XP Professional,

follow the instructions included with the ap pr op r iate op er at ing syste m .

Installation 7

Page 16

53HC2600 INSTRUCTION MANUAL

2.1.4 Hardware Installation

2.1.4.1 Installing the Hardware Key

A “Hardware Key” is supplied when the standalone version is specified in the model number.

The LoopMaster software is licensed by MicroMod Automation Inc. The license is protected b y a hardware

key, shown in Figure 2-3, which must be attached to the PC’s parallel port. The hardware key does not

functionally compromise the parallel port. When installed, the hardware key provides a female connecto r

allowing a parallel device to be attached to it. If a device (for examp le, a printer) is already connected to th e

parallel port, remove the parallel cable co nnector, connect the hardware key to the port, and reconnect the

cable to the hardware key. Signals to and from the attached parallel device will be passed through the

hardware key. The hardware key must be installed for the LoopMaster software to run.

Figure 2-3. Hardware Key for Use with LoopMaster System Software

Installation of LoopMaster software and licenses can proceed if the hardware key is not att ached; however ,

no LoopMaster windows can be opened. Instead, a pop-up window will be displayed which states:

Can’t read hardware key.

Key must be attached to parallel port.

If the wrong hardware key is attached to the parallel port, a pop-up window will display the following message:

No valid LoopMaster software license found.

If problems reading the hardware key persist, test the operation of the parallel port. This can be done by

attaching a printer to the port and attempting to print to it.

8 Installation

Page 17

53HC2600 INSTRUCTION MANUAL

2.1.5 LoopMaster Software Installation

Now the process of installing the LoopMaster software can begin .

1. Pre-Setup Procedure

• Check that the LoopMaster hardware key is connected to the parallel port of the com-

puter.

• Have the LoopMaster license key ready.

• Turn on power to the base PC and boot the Windows operating system software.

• Log on to the Windows operating system software with administrative privileges. Y ou must

have administrative privileges or the installation process will not complete successfully.

• Close any open Windows applications (for example, Microsoft Word, Excel, Mail, Sched-

uler , etc.).

2. Beginning Micro-DCI Master Setup

• Insert the Micro-DCI CD into the CD-ROM drive.

• Open Explorer and select the drive letter of the CD-ROM drive.

• In the root directory of the CD-ROM, double click on the setup.exe file.

• In the Micro-DCI Master Setup, click on the LoopMaster Setup button.

3. Beginning LoopMaster Installation

• The InstallShield Wizard is loaded and then the LoopM aster System Setup window

appears.

• Click Next to begin installing the LoopMaster.

• Click the OK button if a font-size information window opens.

✎ NOTE If the Micro-DCI Communications Services are being installed for

the first time, the setup routine will prompt for them to be installed.

Click on the OK button and prompts will appear for Items 4 through

9. Otherwise these items will be skipped and the installation

process will proceed to item 10.

4. The Micro-DCI Communication Services

• The Micro-DCI Communication Services Setup window appears. Click on the Next button

to proceed.

5. Micro-DCI Communication Services Location

•The Choose Destination Location window appe ars, which enables you to sp ecify the drive

and directory where you want the Micro-DCI Communication Services installed. You can

accept the default path of C:\udci by clicking the Next button, or you can change the

destination directory by clicking the Browse button.

• If you clicked the Browse button, enter both the drive and directory you want to use as the

destination directory in the Choose Directory field.

• Click the Next button.

• If the directory does not exist, Setup will ask you if it should be created. If this window

appears, click the Yes button.

Installation 9

Page 18

53HC2600 INSTRUCTION MANUAL

•The Select Program Folder window appears. Select the program Folder you want the pro-

gram icons added to. The Micro-DCI Comm Services folder is selected by default as the

folder for the program icons. You can accept the default, select an existing program fold er,

or type a new program folder.

• Click the Next button.

•A Setup window with a progress bar appears and the Micro-DCI files begin to install.

•The Enter Information window appears and prompts you to enter a maximum of eight-

characters as a name for your entire Micro-DCI local system.

• Either accept the default name or enter a name and click the Next button.

✎ NOTE If this PC is a node on a Micro-PWC network, the selected name

will be used to identify the Micro-DCI communication interface on

this PC; therefore this name must be unique from all ot he r no de

names on the Micro-PWC global network.

The progress bar then finishes updating and the Setup process continues.

6. Installing Data Access Objects (DAO)

• The LoopMaster uses Data Access Objects (DAO’s) to store local databases. If Microsoft

DAO 3.5 has not been previously installed, LoopMaster launch es the Dat aAccess Objects

(DAO) SDK Setup window. This program is only installed the fir st time then LoopMa ster is

installed on your PC.

• Click the Next button and DAO Setup will copy about 25% of the files, then close and

return to the Main LoopMaster Setup program. It is correct that on ly about 25% of th e files

are copied. These are the only files required.

• If DAO 3.5 is already present on the system, Item 5 will be bypassed and the setup program will perform Item 6.

7. Installing Micro-DCI Services and Program Folder

• The Micro-DCI Services will be automatically installed. A window will pop up to install

these services.

• When the services are installed, the window will close and return you to the Main LoopMaster Setup.

• The Micro-DCI Communications Services Setup program then creates the Micro-DCI

Communications Services program folder and automatically adds the appropriate icons

for the Micro-DCI Communications Services product.

8. Installing Micro-DCI Communications Services License Key

Setup will launch the Micro-DCI License Administration program to enter your license keys.

License keys must be added one at a time.

•Select Add new license... from the License menu.

• In the License Administration dialog, type in your license information for one license key.

Be certain to enter all information exactly as it appears. Click Save and this information

will be verified and written to the license file. If the information entered is not correct, a

pop-up message box will appear and the information will have to be corrected.

10 Installation

Page 19

53HC2600 INSTRUCTION MANUAL

The following license keys may be provided:

udci - licenses MIcro-DCI Communication Services for 300 tags

udciunlim - licenses MIcro-DCI Communication Services for unlimited tags

loopmaster - licenses the LoopMaster product features

✎ NOTE Entry of the License Keys is not case-sensitive.

•Select Exit from the File menu when finished.

9. Adding Micro-DCI Networks

If you would like to add Micro-DCI instrument networks, click on the Yes button when given the

choice. The Add Micro-DCI Networks window appears. Click the Next button.

• The Setup program then start s the Super32 p rogram, which is a L oopMaster program that

enables you to add Micro-DCI network instruments to your system. This is a good time to

add Micro-DCI networks to your system since you need to reboot your PC after installing

the LoopMaster software and after you install the Micro-DCI networks.

• The first Network Wizard window lets you select whether you are adding a network that is

connected to your system through a supervisor board (SUP) or though a COM port

(COM). Select either SUP or COM, then click the Next button.

• In the Network Wizard - Network Attributes window, enter a Network Name (up to 9 char-

acters) and select a Network Position, then click the Next button.

•The Network Wizard - Backup window appears. Select Master or Backup, and then click

the Next button.

•The Network Wizard - Network Parameters window appears. If SUP was selected in the

first Network Wizard window, set the I/O Port Addres s to agree with the address jumpers

on the Supervisor Board. The parameters change depending on the type of network that

is being installed.

• After selecting the I/O Port Address (if required), click the Next button.

• In the Network Wizard - Finish window, click the Finish button.

• A window appears confirming that the Network was added successfully. Click the

OK button to proceed.

• If the network was added successfully, Super32 will ask if another network is to be added.

If so, repeat the above steps until all desired Micro-DCI networks have been added.

Answering No exits Super 32 and opens the Read-Me file in a Notepad window.

• When the Read-Me file window is closed, a window appears asking if the the computer

should be rebooted for the system to recognize the newly added SUP Micro-DCI networks. Click the No button at this time.

10. LoopMaster System Target Location

•The LoopMaster Target Location window then appears, which enables you to specify the

drive and directory where you want the LoopMaster installed. You can accept the default

path of C:\LoopMaster by clicking the Next button or you can change the destination

directory by clicking the Browse button.

Installation 11

Page 20

53HC2600 INSTRUCTION MANUAL

• If you clicked the Browse button, enter both the drive and directory you want to use as the

destination directory in the Choose Directory field.

• If the directory does not exist, Setup will ask you if it should be created. If this window

appears, click the Yes button.

• Click the Next button.

•The Setup window progress bar reactivates and the Micro-DCI files begin to install.

11. Installing the LoopMaster license key

Setup will launch the Micro-DCI License Administration window to enter your license keys.

• If the loopmaster license key was entered during Item 8, it need not be entered again.

Close the window by clicking on the close button in the upper right-hand corner of the window.

✎ NOTE If the Micro-PWC software has been installed, the Micro-PWC

Maintenance Utility window will appear instead of the Micro-DCI

License Administration window

• If the LoopMaster License Key has not been entered previously, select Add new

license... from the License menu.

• In the License Administration dialog, type in your license information for one license key.

Be certain to enter all information exactly as it appears. Click Save and this information

will be verified and written to the license file. If the information entered is not correct, a

pop-up message box will appear and the information will have to be corrected.

The following license key is used:

loopmaster - licenses all product features

• When finished, select Exit from the File menu.

12. Select Program Folder

The Select Program Folder window appears. Se lect the program Folder you want the progr am

icons added to. The LoopMaster folder is selected by default as the folder for the program

icons. You can accept the default, select an existing program folder, or type a new progra m

folder.

• Click the Next button.

13. New Program Folder

• The LoopMaster Setup program then creates the LoopMaster program folder and auto-

matically adds the appropriate icons for the LoopMaster product.

14. Integrating Into Super32

• LoopMaster can be registered to be the default configuration program for SL6000 control-

lers in the Super32 Micro-DCI network management utility.

• When asked if LoopMaster should be integrated into Supe r32, select Yes to register Loop-

Master as the default configuration program or No to use the Super32’s basic SL6000

configuration program.

15. Finishing the Installation

12 Installation

Page 21

53HC2600 INSTRUCTION MANUAL

• When the Installation is Complete window appears, click on the OK button.

• At this point the Notepad application opens and a LoopMaster Read Me file appears

containing LoopMaster release information. When you have finished reading this document, close Notepad using the Close button in the upper right-hand corner of the window.

• Any windows remaining open may be closed, if desired, using the Close button in the

upper right-hand corner.

• When the Read-Me file window is closed, a window appears asking if the the computer

should be rebooted. Click the Yes button to have the system recognize the new software.

• This completes the setup process.

2.2 Uninstalling LoopMaster Under Windows 3.1 or Windows 95.

Use this procedure to remove the LoopMaster software and its associated files from your system.

1. Delete the LOOPMSTR subdirectory. This is the subdirectory where Setup installed

LOOPMSTR.EXE and all associated files. Deleting this subdirectory tree pur ges mo st of

LoopMaster from your system.

2. If LOOPMSTR was ever started, LoopMaster created an INI file in your Windows directory.

Delete LOOPMSTR.INI from your Windows directory.

3. Since it is possible to store LoopMaster database files anywhere on your system, delete any

*.S6D files not in the LOOPMSTR directory.

4. From Program Manager, select and minimize the LoopMaster group, then press the Delete

key. It is not necessary to delete each individual icon to delete the group.

Installation 13

Page 22

53HC2600 INSTRUCTION MANUAL

2.3 Uninstalling LoopMaster Under Windows 2000 Professional or Windows XP Professional

2.3.1 Removing the LoopMaster Software

There are two ways to remove the LoopMaster software and its associated files from your system.

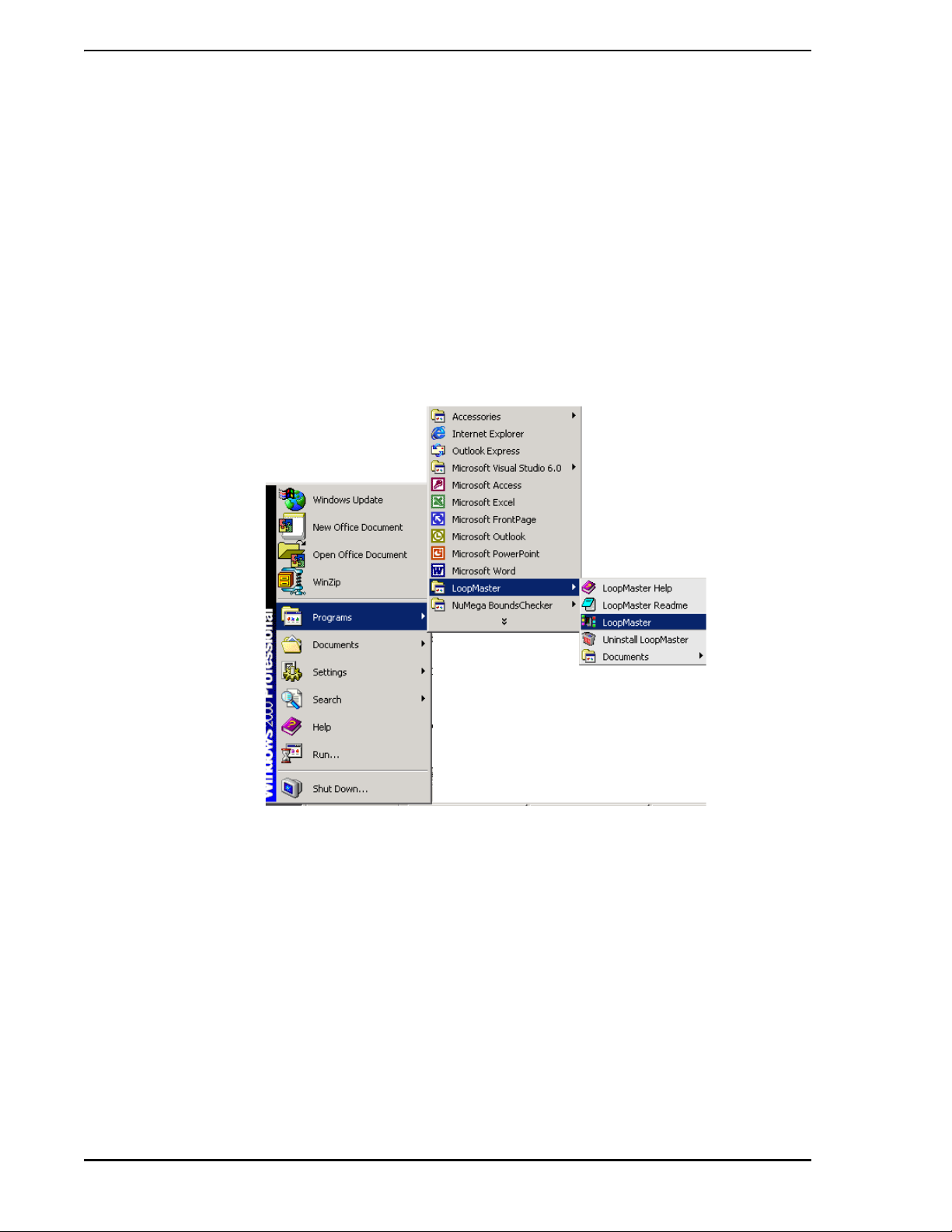

2.3.1.1 Method 1

1. Click the START button.

2. Select this sequence of menu items: PROGRAMS > LOOPMASTER > UNINSTALL

LOOPMASTER. (See menus illustrated in Figure 2-4.)

14 Installation

Figure 2-4. Menus for Uninstalling LoopMaster Software, Method 1

Page 23

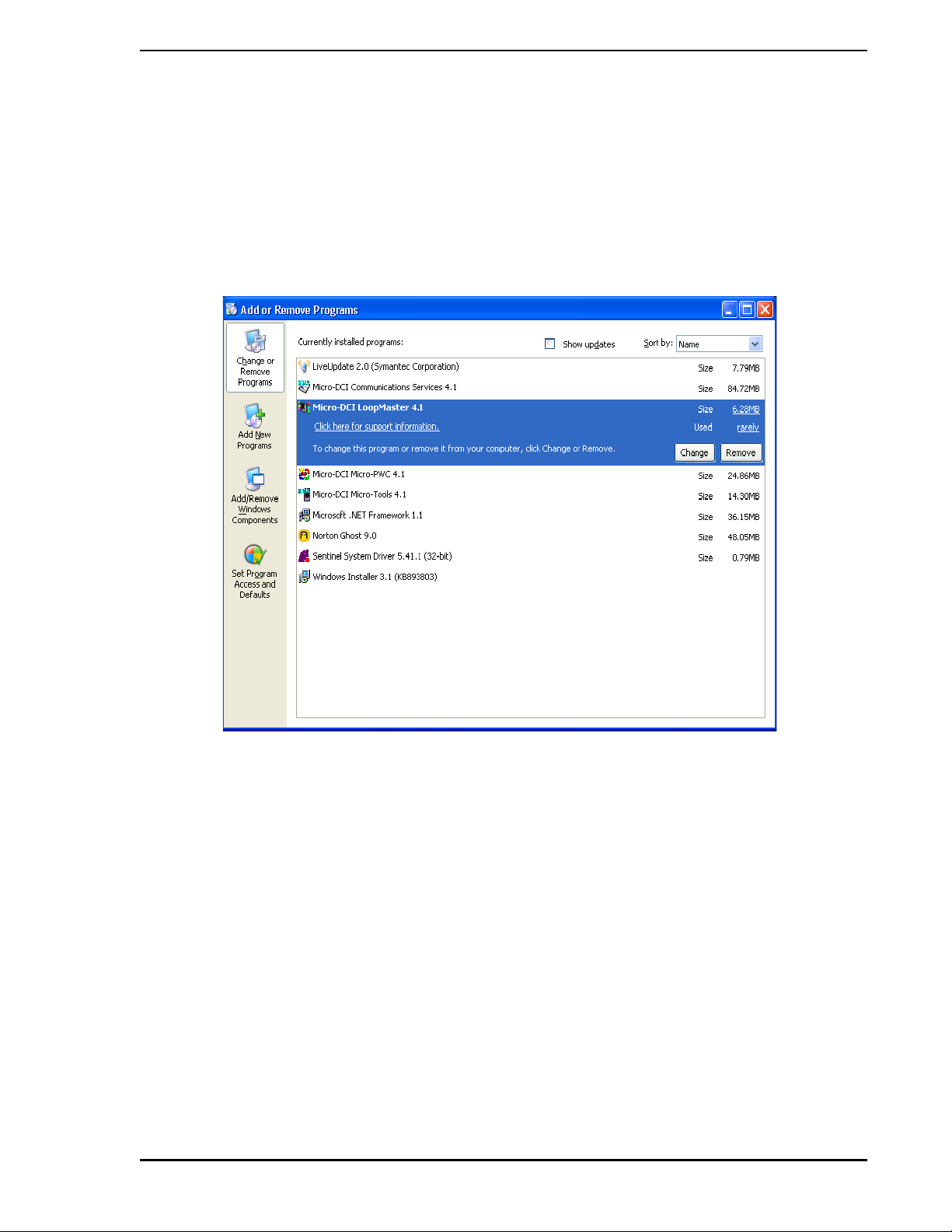

2.3.1.2 Method 2

1. Click on the START butt on.

2. Select CONTROL P ANEL.

3. Double-click on the ADD OR REMOVE PROGRAMS icon.

4. Select the item (LoopMaster) to uninstall, as illustrated in Figure 2-5.

5. Click on the CHANGE OR REMOVE PROGRAMS button to begin the uninstall proced ur e.

53HC2600 INSTRUCTION MANUAL

Figure 2-5. Uninstalling LoopMaster Software, Method 2

Installation 15

Page 24

53HC2600 INSTRUCTION MANUAL

16 Installation

Page 25

53HC2600 INSTRUCTION MANUAL

3.0 GUIDED TOUR

3.1 Starting LoopMaster

In this section, we will take a brief tour through LoopMaster and generate a simple offline configuration.

3.1.1 To start LoopMaster

1. From Program Manager, double-click on the LoopMaster icon. The main LoopMaster window

will be drawn while the application initializes.

✎ NOTE If a warning message appears indicating LoopMaster de tected a

faulty version of THREED.VBX, the startup will terminate. If this

message appears, see Section 7.3.1, THREED.VBX Display

Problems.

2. The opening dialog displays version, copyright and trademark information. Click OK.

✎ NOTE For display problems, see Section 7.3, Display Problems.

To help you get started, LoopMaster presents a few dialogs. These startup dialogs help you open the

desired configuration.

3.2 Online Or Offline?

The Micro-Mite controller is configured by setting up its configuration database. LoopMaster provides two

ways to set up a configuration database:

• Offline Configuration: Develop the configuration database in personal computer memory

and save it to a file, then download the entire database into Micro-Mite memory.

• Online Configuration: Connect a Micro-Mite controller to your personal computer and

manipulate its database through this connection.

In addition to storing the Micro-Mite controller database, offline configurations can also store transmitter

tagnames and other rear connection information. This additional information is used to produce a more

complete configuration report. Use of offline configurations is therefore recommended whenever possible.

Figure 3-1. The Online or Offline? Dialog Box

Guided Tour 17

Page 26

53HC2600 INSTRUCTION MANUAL

To create a new offline configuration:

1. In the Online or Offline? dialog, click on the Offline: Develop configurat ion in memory radio

button.

2. Click OK.

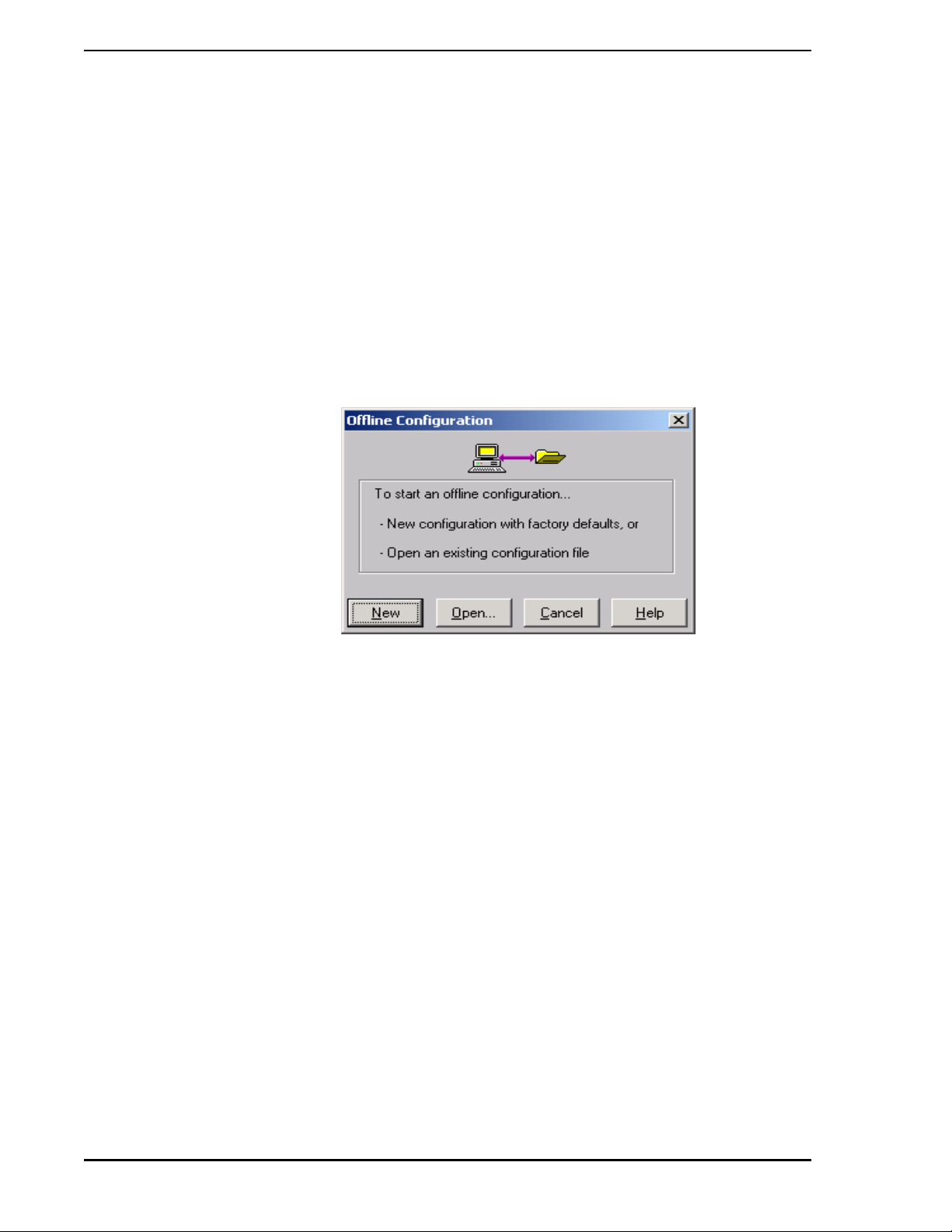

3.3 Offline Configuration

Since offline configurations can be developed without a controller, you can start with a brand new configuration of factory defaults, or edit one that was previously created. For this example, we will create a new

configuration.

Click on New to start a new offline configuation where all parameters are loaded with the factory default

settings.

Figure 3-2. Creating a New Offline Configuration

3.4 Tagname

LoopMaster uses the instrument tagname and the filename to uniquely identify a configuration. LoopMaster often shows the tagname in the title bar, so it is important to enter a descriptive tagname.

Type SAMPLE as the tagname, then click OK.

3.5 The Strategy Assistant

The Strategy Assistant contains eight commonly used control strategies. A strategy is a complete configuration from inputs to outputs. When you select one of the eight preconfigured strategies, the Strategy

Assistant automatically changes parameter s and function blo ck connections for you. You may then edit the

configuration to suit your specific process.

For this example, click on Single Station Cas cade Controller, then click OK.

18 Guided Tour

Page 27

53HC2600 INSTRUCTION MANUAL

3.6 Main LoopMaster Window

The Title Bar, Main Menu and Toolbar go across the top of the main window, and the Main Status Bar runs

along the bottom. Inside is the Control Strategy Window entitled Offline Control Strategy for SAMPLE.

Tit le Bar

Main Menu

Toolbar

Control Strategy

Window

Main Status Bar

Figure 3-3. Main LoopMaster Window - Example

3.7 Control Strategy Window

The Control Strategy Window provides a function block overview, showing inputs on the left and outputs on

the right. This window has its own title bar across the top, and its own status bar along the bottom. This

status bar reminds you that the Control Scheme is Cascade Controller, and the OFFL indicates that this is

an offline configuration.

Function blocks are drawn as standard Windows pushbuttons with an extra outline and drop shadow. For

example, input blocks are AI1, DI2, etc. Output blocks are AO1, DO2, etc. Internal blocks are FNC, CHR,

C Scheme, etc. There are two stand-alone blocks: System and EZ Tune.

There are two other buttons in this window: Strategies... and Help. The Strategies... button opens the

Strategy Assistant dialog. The Help button opens the LoopMaster help screen for this window.

Move the mouse around the Control Strategy Window. When the mouse moves over a button, the Main

Status Bar displays a FlyBy message. Look to the Main Status Bar for messages.

Guided Tour 19

Page 28

53HC2600 INSTRUCTION MANUAL

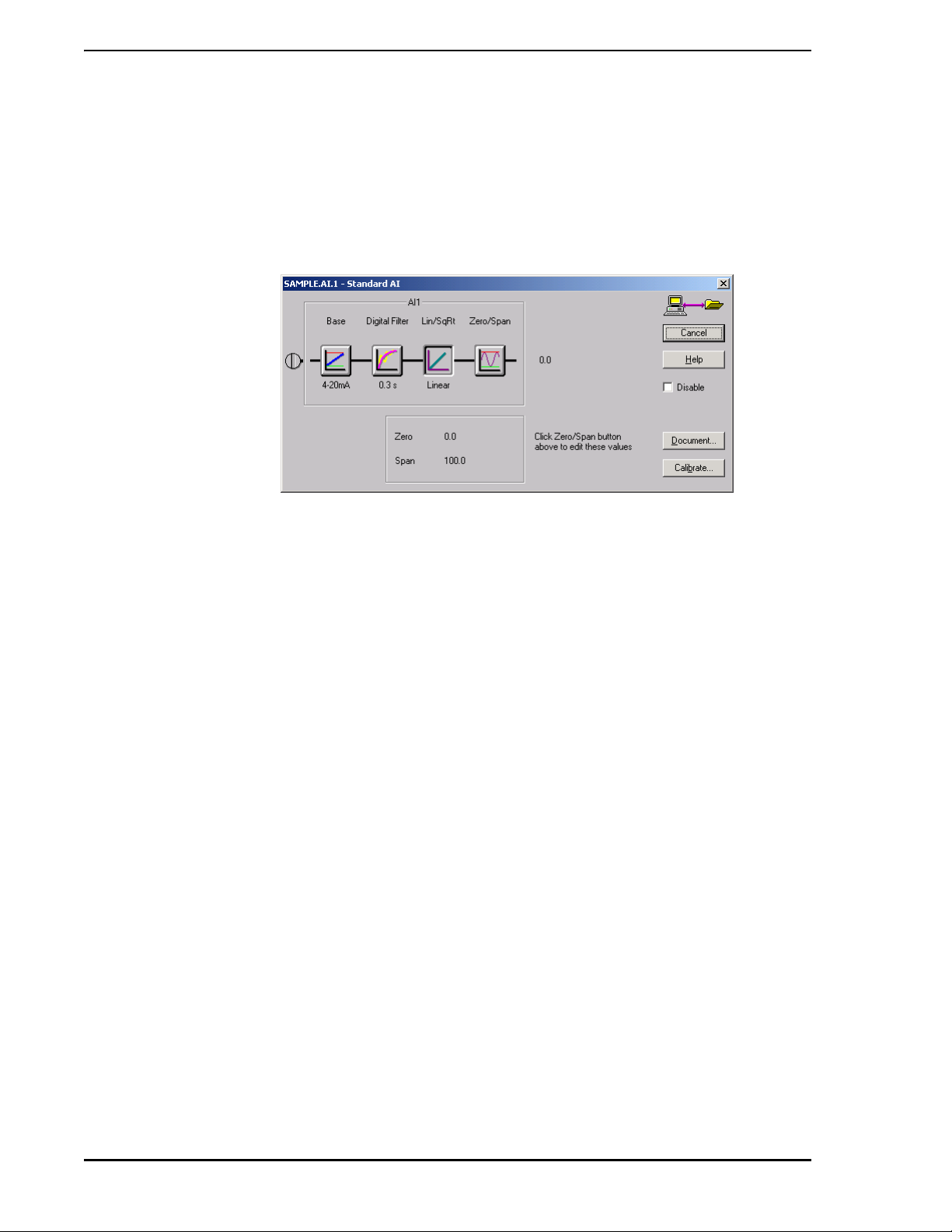

3.8 Typical Offline Parameter Value Change

To configure a function block’s parameters, click on its button. We’ll start by configuring the first analog

input.

1. Click on AI1.

2. The Standard AI dialog opens, as shown in the example in Figure 3-4.

Figure 3-4. Standard AI Dialog Box

The dialog title shows the tagname, and the function block mnemonic found in the Micro-Mite controller.

This dialog is laid out to show signal flow through the analog input block, starting at the screw on the left,

flowing through the AI1 block, and producing the analog value.

When the dialog was first displayed, the button in the upper right corner was Cancel. Clicking the Cancel

button in any LoopMaster dialog leaves the configuration unchanged. Pressing the ESC key is the same

as clicking on Cancel.

3.8.1 Changing the AI Input Base

Setup the AI1 function block for a 0-20 mA input source:

1. Click on the Base button. The picture inside the button, and the text below th e button, change

between 0-20 mA and 4-20 mA configurations.

2. Change the input base to 0- 20 mA.

The AI1 Base parameter chang ed as soon as you clicked it s button . No tice the Cancel button changed to

Close because the configuration database changed while this dialog was open.

Try clicking on the Lin/SqRt button. The picture insid e and the text below the button change between

Linear and SqRoot. Set it back to Linear.

3.8.2 Changing the AI Digital Filtering

The Micro-Mite controller AI blocks are capable of smoothing input noise with a digital filter. Apply a small

amount of filtering by setting the digital filter to 1.5 seconds:

1. Click on the Digital Filter button and the Digital Filter dialog pops up.

2. Click on the down arrow to drop down the list of selections. Use the scroll bar to see other

entries in the list. Select 1.5 s.

3. Click OK to close this dialog and change the Digital Filter setting.

20 Guided Tour

Page 29

53HC2600 INSTRUCTION MANUAL

When you click OK, LoopMaster writes all the parameters in the dialog to the configuration database.

You’ll see your change in the Standard AI dialog because the text below the Digital Filter button now

reads 1.5 s. Leave the Standard AI dialog open for one more step.

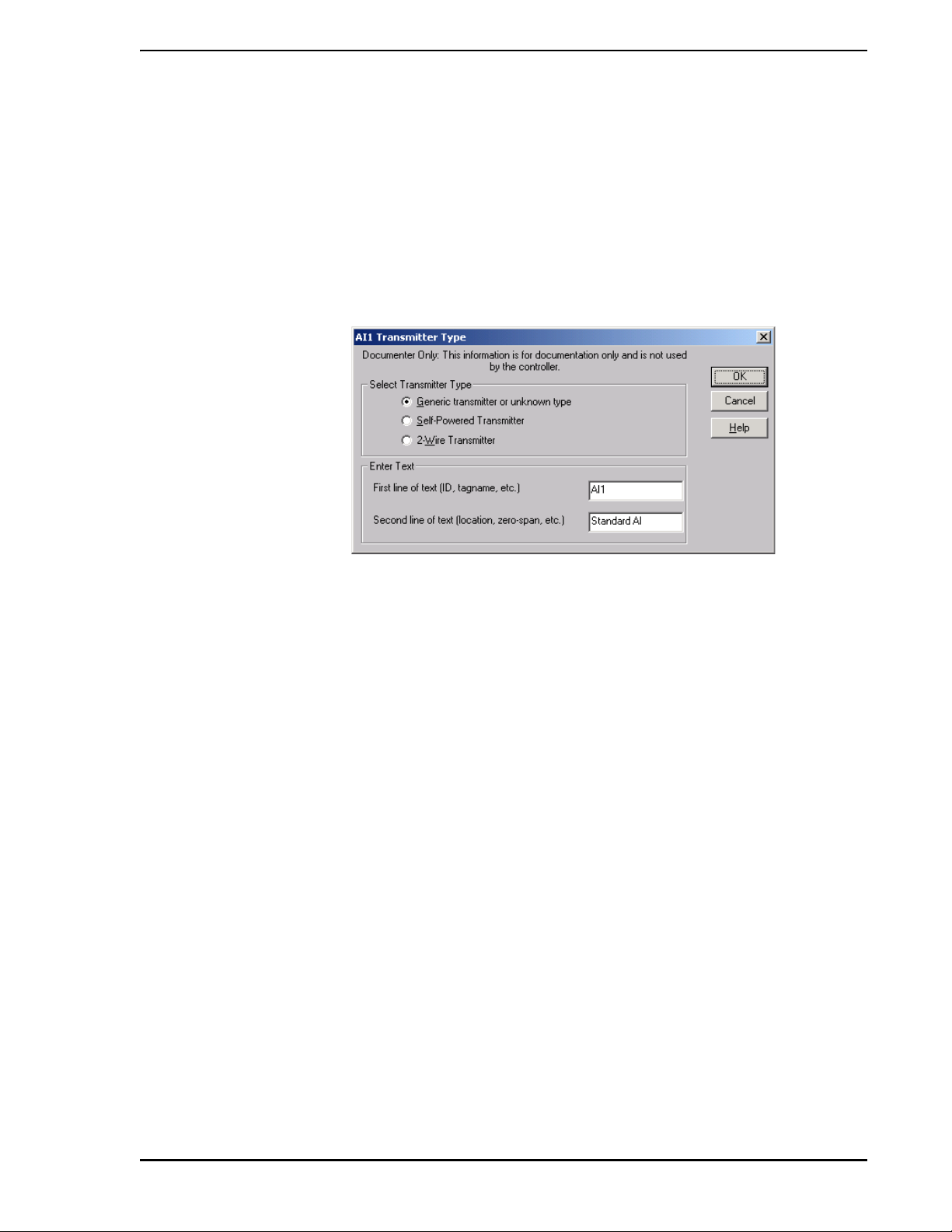

3.8.3 Adding DOCUMENTER Information

Since this is an offline configuration, we can take advantage of storing additio nal information for the

Documenter Report.

1. Click on the Doc Info... button to enter information for the Documenter Report.

Figure 3-5. Adding Information for the Documenter Report

You can select the type of transmitter connected to this AI. The wiring changes, depending upon the transmitter type. (Leave the Generic radio button on.)

The Documenter Report has a Rear Connections Diagram showing how the I/O connectors are wired. The

First line and Second line of text will be used to label this input connection. Type in the text as shown and

click OK. This information is used by the LoopMaster Documenter to enhance the rear connections diagrams.

In the Standard AI dialog, click Close to close this dialog.

This completes the configuration of the first analog input. In the next section, we’ll view the Documenter

Report and see where the Doc Info text appears.

Guided Tour 21

Page 30

53HC2600 INSTRUCTION MANUAL

3.9 Viewing the DOCUMENTER Report

Since the Documenter Report is automatically generated using the File > Print command, we can u se the

Windows print previewing capability to view the Documenter Report.

1. Select Print Preview... from the File menu, or click on the print preview toolbar button.

Print Preview toolbar button.

The first page of the Documenter is displayed with title and function block overview.

22 Guided Tour

Figure 3-6. Documenter Report, Sample First Page

Page 31

53HC2600 INSTRUCTION MANUAL

2. Click on Next Page to advance to the next page in the Documenter Report. This is a

parameter listing page.

Following the title page is a complete list of parameters involved in this configuration.

Parameters are grouped in the same order as they appear in the controller.

3. Continue to click on Next Page until the button grays out when you reach the last page.

The last page of this Documenter Report is a rear connections diagram. The top half shows

the back of the controller, and the bottom half details connections to the Standard I/O

Connector.

Figure 3-7. Documenter Report, Last Page, Rear Connections Example

4. Click on Zoom In and use the scroll bar to get a closer look at Standard I/O Connector

diagram on the bottom. This diagram details the wiring to the I/O conn ector and shows the

Guided Tour 23

Page 32

53HC2600 INSTRUCTION MANUAL

information you entered for AI1.

✎ NOTES The wiring of AI1 changes, depending upon the type of transmitter

you selected. The text you entered earlier labels this connection.

By using the Doc Info... button, you can create informative and

valuable configuration reports.

The final appearance of your Documenter Report dep ends upon the

installed Windows Printer Driver . Make sure you have the latest

driver for your printer. Use the Program Manager Control Panel,

Printers icon to install new drivers.

5. Click Close to go back to the Control Strategy Window.

Many aspects of the Documenter Report can be customized from the Documenter menu. For more information, see Section 5.0, USING THE DOCUMENTER.

3.10 Saving the Configuration

1. To save this configuration to disk, select Save from the File menu, or click on the Save toolbar

button that looks like a disk:

The Save toolbar button.

2. Since this is the first time this configuration has been saved, the standard Windows Save As

dialog pops up.

3. For the File Name, type in TOUR, then click OK.

LoopMaster automatically adds the .S6D filename extension, then writes the configuration

database and the Documenter information to disk under the filename TOUR.S6D.

The .S6D files created by LoopMaster are text files which can be viewed by a text editor. For more infor-

mation on the format of these files, see Section 6.3, LoopMaster File Format.

3.11 Changing Function Block Connections

Configurable function block connections have a small button on the left side of the function block. Use

these input buttons to view all possible sources for the input, and to change the connection.

In our example, let’s say PV requires a +25 engineering units offset. We’ll use the FNC function block to

add 25 to AI1:

24 Guided Tour

Page 33

53HC2600 INSTRUCTION MANUAL

1. Click on the C Scheme A input button as shown in Figure 3-8.

Figure 3-8. Selecting the C Scheme A Input Button

2. The Input Selection dialog shows the currently selected source as Analog Input AI1. Change

the PV input to come from FNC:

3. In the Input Selection dialog, click on the down arrow button to view the list of possible

sources.

4. Select FNC Output X.

5. Click OK. The connection is now drawn from the FNC X output to the C Scheme A input, as

illustrated in Figure 3-9.

Figure 3-9. Connection Drawing Example, FNC Output X Source

Guided Tour 25

Page 34

53HC2600 INSTRUCTION MANUAL

6. There are four analog inputs and two digital inputs to the FNC block. Connect AI1 to FNC

input A:

7. Click on the FNC A input button which is on the left of the FNC block next to input A.

8. In the Input Selection dialog for FNC Input A, click on the down arrow to drop down the list.

9. Click on Analog Input AI1, then click OK. A connection is drawn from AI1 to FNC input A, as

illustrated in fig.

Figure 3-10. Connection Drawing Example, AI1 Source

10. Click on the Save toolbar button to save these changes to disk. Your changes will be written

to the same file TOUR.S6D.

3.12 Configuring the FNC Block

The FNC function block contains nine mathematical equations and can operate on up to four analog inputs

(A through D) and two digital inputs (E and F). To configure the FNC equation and constants:

1. Click on the FNC button to open the FNC dialog. This dialog shows th e analog in put sources,

digital input sources, the selected equation, and the six equation constants.

2. The Equations section lists the nine equations supported by the FNC block. Click on the

Algebraic radio button and the equation is drawn as a mathematical formula.

3. Fill in the Equation Constants as shown in Figure 3-11.

26 Guided Tour

Page 35

53HC2600 INSTRUCTION MANUAL

Figure 3-11. Equation Constant Configuration Example

4. Click OK to write the changes into the configuration database.

5. Save the modified database by clicking on the disk toolba r button, or by selecting File > Save.

Your new configuration database replaces the old one in TOUR.S6D.

3.13 Using the Interactive Training Screens

The LoopMaster interactive training screens enable you to configure a da t abase while you learn ab out the

parameters. These screens explain parameters in plain language and provide step-by-step instructions on

how to configure the Micro-Mite controller.

In this section, we will use the interactive training screens to configure the control output.

Guided Tour 27

Page 36

53HC2600 INSTRUCTION MANUAL

1. Click on the C Scheme button to open the Control Scheme dialog. This dialog shows the

selected control scheme, control switches, and a graphical representation of the Control

Scheme block (Figure 3-12).

Figure 3-12. Sample Control Scheme Window

2. Since the current control scheme is Cascade Contro l, both cn1 and cn2 loops are shown. To

configure the control output of cn1, click on Output1 to display the SAMPLE.cn1.Output1

dialog (Figure 3-13).

3. The SAMPLE.cn1.Output1 dialog shows the Output Parameters. The yellow box (at the top of

the window) is an interactive training screen, and the parameters are shown in the Output

28 Guided Tour

Figure 3-13. SAMPLE.cn1.Output1 Dialog Window

Page 37

53HC2600 INSTRUCTION MANUAL

4. Parameters section below it. The interactive training screens explain the meaning of each

parameter, then prompt you for an action to configure it.

• The first screen explains the RSW reverse switch. Notice in the Output Parameters sec-

tion that the RSW box is checked. Click No and you’ll see the RSW box become

unchecked.

• The next screen states that RSV (reverse valve) can invert the output signal. Click Yes to

invert the output and watch the RSV box become checked.

• The next screen explains the OH (output high) parameter. In this screen, an edit box and

a Next button appear because you are promp ted to enter a value. Do uble-click in this edit

box and type in the value 90. Click Next. The OH parameter changes from 100.0 to 90.0.

• The next screen explains the OL parameter and displays its current value in the edit box.

We will accept this value and click Next.

• Since HML is a switch, the Yes and No buttons appear again. Answering Yes turns HML

on, while No sets HML to off. Click Yes.

• For the next three screens, accept the current values by clicking Next in each screen.

Y o u’ve reached the end of the tr aining screens. The traini ng screens only write values into

the dialog, so you must click OK to write your changes into the configuration database, or

click Cancel to abandon any changes made through the training screens.

5. Click OK and all the changes made in this dialog are written into the configuration database.

6. In the Control Scheme dialog, click Close.

Interactive training screens read their text from the LMTRAIN.TXT file. This file must be locate d in the

same subdirectory as LOOPMSTR.EXE. A dialog that uses training screens loads all it s training screen text

just before the dialog is displayed. This file has the same format as a standard Windows .INI file.

The interactive training screens explain parameters in plain language and provide a step-by-step method

of configuring parameters. Once you become familiar with Micro-DCI terminology, you can edit parameters directly in the dialog.

In this Guided Tour we introduced several LoopMaster concepts, created an offline configuration, and

saved it to a file. In the next section, we will download an offline file into a Micro-Mite controller.

Guided Tour 29

Page 38

53HC2600 INSTRUCTION MANUAL

30 Guided Tour

Page 39

53HC2600 INSTRUCTION MANUAL

4.0 ONLINE CONFIGURATIONS

4.1 LoopMaster Online

Before LoopMaster can be operated online, you must make a physical communications connection

between the personal computer an d a con tr olle r or controller network. The simplest communications connection for a single Micro-Mite controller is to cable a personal computer COM port to the RS-232 module

on the back of the controller.

Cabling a personal computer to a network of Micro-Mite controllers requires a personal computer COM

cable, controllers with RS-485 modules, an RS-232/485 Interconnection Terminal Board (ITB), four wire

twisted pair shielded controller interconnecting cables, and a Communications ITB. This section provides

the procedures to make these connections, as well as operating procedures to start an online configuration, to upload a configuration from a Micro-Mite controller, and to download a configuration file to a

Micro-Mite controller.

4.2 Connecting A Micro-Mite Controller To Your PC

Y o ur personal co mputer communicates to a Micro-Mi te controller th rough one of it s COM p orts. In order to

communicate, both the personal computer and the Micro-Mite controller must have identical communication settings. This means the baud rate and parity must be the same in the controller and the personal

computer (e.g., 9600 baud, even parity).

LoopMaster stores the communication settings in the LOOPMSTR.INI file. The Micro-Mite controller

stores its communication settings in the conF-SYS menu. As shown in Figure 4-1, the communications

cable (698B239U01) is connected from the personal computer to the RS-232 module of the Micro-Mite

controller. Included in the illustration is a cable drawing that can be used to fabricate your own cable, if

necessary. Maximum cable length should not exceed 50 feet (15.2 meters).

4.3 Multi-Drop Network Connections

Y o ur personal computer co mmunicates to an addressed Micr o-Mite controller on a Datalink through o ne of

its COM ports via an RS-232/485 ITB. As shown in Figure 4-2, the personal computer COM port is connected to the ITB J1 with cable 698B240U01. The ITB acts as an RS-232/RS485 (422) signal converter.

The signals are daisy-chained to each controller with four wire twisted pair shielded cables (24 AWG minimum, Belden number 9842 or equivalent).

Maximum end-to-end distance of all cabling lengths for 28.8 Kb communications is 4000 feet (1219

meters). The network is terminated with the Communications ITB. An RS-232/485 ITB cable drawing is

provided as Figure 4-3 should it be necessary to fabricate your own cable.

The maximum allowable number of controllers on the network is 32 (0-31). All network communications

queries are initiated by the personal computer. Micro-Mite controllers on the Datalink do not initiate a session or communicate with each other.

Online Configurations 31

Page 40

53HC2600 INSTRUCTION MANUAL

The RS-232/485 and Communications ITBs should be mounted on 2.90 inch (73.7 mm) track. Clearance

specifications for ITB track mounting are provided in Figure 4-4.

32 Online Configurations

Figure 4-1. RS-232 Single Controller Cabling

Page 41

53HC2600 INSTRUCTION MANUAL

Figure 4-2. Datalink Cabling

Online Configurations 33

Page 42

53HC2600 INSTRUCTION MANUAL

Figure 4-3. RS-232/485 Cable

34 Online Configurations

Page 43

53HC2600 INSTRUCTION MANUAL

Figure 4-4. ITB Track Clearances

Online Configurations 35

Page 44

53HC2600 INSTRUCTION MANUAL

4.4 Starting An Online Configuration

To start the LoopMaster software:

1. From Program Manager, double-click on the LoopMaster icon. The main LoopMaster window

will be drawn while the application initializes.

✎ NOTE If a warning message appears indicating LoopMaster de tected a

faulty version of THREED.VBX, the startup will terminate. If this

message appears, see Section 7.3.1, THREED.VBX Display

Problems.

2. The opening dialog displays version, copyright and trademark information. Click OK.

✎ NOTE For display problems, see Section 7.3, Display Problems.

To help you get started, LoopMaster presents a few dialogs. These startup dialogs help you open the

desired configuration.

4.4.1 Online or Offline?

1. When the Online or Offline dialog appears, select Online and click OK.

Figure 4-5. Online or Offline? Dialog Box

If LoopMaster is already invoked, an alternate method to initiate an online session is by clicking on the

Online toolbar button.

The Online toolbar button.

During an online session, your personal computer can manipulate the Micro -Mite controller database

through either one of the connections described previously in this book section (direct or via a Datalink).

4.4.2 Select a Controller

A controller address must be specified whether the Micro-Mite controller connection is direct to the personal computer or via a Datalink. The controller baud rate and parity selections must match your personal

computer COM port settings. In the example shown, controller 0 is being connected to COM port 2 of the

personal computer.

36 Online Configurations

Page 45

53HC2600 INSTRUCTION MANUAL

When the Select the Controller dialog appears, select a COM port, and a controller

address, then click OK. (The controller tagname [for ex ample, SL6000] originally assigned

to the controller appears last in the dialog.)

Figure 4-6. Select a Controller Dialog Box

4.4.3 Main LoopMaster Window with Front Panel Window

The main window appears, which contains the Control Strategy for SL6000 window. The controller Front

Panel window is invoked by clicking on the Front Panel toolbar button. The Front Panel Window is then

positioned to the right of the main window with a click and drag maneuver. All of the window displays are

then sized to give the compact presentation shown.

Front Panel toolbar button.

Tit le Bar

Main Menu

Toolbar

Control

Strategy

Window

Main Status

Bar

Figure 4-7. Control Strategy Window and Front Panel Window

Online Configurations 37

Page 46

53HC2600 INSTRUCTION MANUAL

As in offline operation, the online Control Strategy Window provides a function block overview, showing

inputs on the left and outputs on the right. This window has its own title bar across the top and its own status bar along the bottom. The status bar reminds you that the Control Scheme is a Single Loop Controller,

and RUN indicates that this is an online configuration.

The function blocks are drawn as standard Windows push buttons with an extra outline and drop shadow.

Input blocks are AI1, DI2, etc. Output blocks are AO1, DO2, etc. Internal blocks are FNC, CHR, C Scheme,

etc. There are two stand-alone blocks, System and EZ Tune.

✎ NOTE Note that any changes made to the controller parameter values

presented in dialog boxes with a Cancel/Close button take

immediate effect, and can therefore significantly alter proc e ss

operation. Parameter values presented in dialogs with an OK

button take affect only after you click on OK.

There are two other buttons in this window: Strategies... and Help. The Strategies... button opens the

Strategy Assistant dialog. To change from a Single Loop Controller to a different control strategy, click on

this button. The eight control strategies appear. Select the radio button next to a control strategy and click

OK to load that preconfigured strategy. The Strategy Assistant automatically changes parameters and

function block connections for you. You may then edit the configuration to suit your specific needs.

The Help button opens the LoopMaster help screen for this window. Move the mouse around the Control

Strategy window. When the mouse moves over a button, the Main Status Bar displays a FlyBy message.

See the Main Status Bar for messages.

✎ NOTE For information regarding the Micro-Mite controller front panel push

button functions and the engineer mode display, reference the

53SL6000 Controller Instruction Bulletin.

If your baud rate is 9600 or higher, then all of the push buttons on the front panel display should be functional. To activate a front panel push button, move the mouse pointer to the button and click on it. Click

and hold the mouse pointer on a push button to simu late pressing a real push button for an extended time,

to move the setpoint up or down, for example. If the Mode push button is pressed for an extended time,

the engineer mode display panel will be activated on the controller and will function as though the controller front panel push buttons were actually being manipulated in engineer mode.

4.4.4 Typical Online Parameter Value Change

To configure a function block’s parameters, click on its button. We’ll start by configuring the first analog

input.

1. Click on AI1. The Online Standard AI dialog (Figure 4-8) opens.

38 Online Configurations

Figure 4-8. Online Standard AI Dialog Box

Page 47

53HC2600 INSTRUCTION MANUAL

✎ NOTES Because this dialog has a Cancel/Close button, each parameter

value change immediately takes affect in the controller.

Clicking on the Cancel button in online operation causes that dialog

to end before the changes can be entered.

Pressing the ESC key is the same as clicking on Cancel.

The dialog title shows the tagname, and the function block mnemonic found in the Micro-Mite controller.

This dialog is laid out to show signal flow through the analog input block, starting at the screw on the left,

flowing through the AI1 block, and producing the analog value.

4.4.4.1 Changing the AI Input Base Online

Setup the AI1 function block for a 0-20 mA input source:

1. Click on the Base button. The picture inside the button, and the text below the button, change

between 0-20 mA and 4-20 mA configurations.

2. Change the input base to 0-20 mA. The AI1 Base parameter changed as soon as you clicked

its button.

Notice the Cancel button changed to Close because the controller database changed while

this dialog was open.

3. Try clicking on the Lin/SqRt button. The picture inside and the text below the button change

between Linear and SqRoot.

4. Set it back to Linear.

4.4.4.2 Changing the AI Digital Filtering Online

The Micro-Mite controller AI blocks are capable of smoothing inp ut noise with a digital filter. Apply a small

amount of filtering by setting the digital filter to 1.5 seconds:

1. Click on the Digital Filter button and the Digital Filter dialog pops up.

2. Click on the down arrow to drop down the list of selections. Use the scroll bar to see other

entries in the list. Select 1.5 s.

3. Click OK to close this dialog and change the Digital Filter setting.

4.4.4.3 Documenter Supplementary Information

Since this is an online configuration, additional information regarding the input transmitter type cannot be

stored for the Documenter Report; therefore, the selection Doc Info... appears as a graytone in the dialog

box. (To add this information, the online configuration must first be uploaded and saved as an of fline .S6D

file, then added in offline operation as describe d in Section 3.8.3, Adding DOCUMENTER Information. As

in offline operation, however , the Documenter report can still be viewed with the Print Preview toolbar bu tton.)

4.4.5 Changing Function Block Connections Online

Configurable function block connections have a small button on the left side of the function block. Use

these input buttons to view all possible sources for the input and to change the connection.

As in the offline example, assume PV requires a +25 engineering unit offset. We’ll use the FNC function

block to add 25 to AI1.

Online Configurations 39

Page 48

53HC2600 INSTRUCTION MANUAL

Figure 4-9. FNC Function Block, A Input Selected

✎ NOTE Altering function block connections causes the controller to stop. In

the stop state, all of the controller output s are he ld where they wer e

when the stop state was entered. To resume control acti on, click on

the toolbar Run button.

1. Click on the C Scheme A input button as shown in Figure 4-9.

2. The Input Selection dialog shows the currently selected source as Analog Input AI1. To

change the PV input to come from FNC:

a. In the Input Selection dialog, click on the down arrow button to view the list of possible

sources.

b. Select FNC Output X.

c. Click OK. The connection is now drawn from the FNC X output to the C Scheme A input

and the controller stops.

3. There are four analog inputs and two digital inputs to the FNC block. To connect AI1 to FNC

input A:

a. Click on the FNC A input button which is on the left of the FNC block next to input A.

b. In the Input Selection dialog for FNC Input A, click on the down arrow to drop down the list.

c. Click on Analog Input AI1, then click OK. A connection is drawn from AI1 to FNC input A,

as illustrated in Figure 4-10.

40 Online Configurations

Page 49

53HC2600 INSTRUCTION MANUAL

Figure 4-10. FNC Function Block, Connection Example

4.4.6 Configuring the FNC Block Online

The FNC function block contains nine mathematical equations and can operate on up to four analog inputs

(A through D) and two digital inputs (E and F). Use this procedure to configure the FNC equation and constants:

1. As in offline operation, click on the FNC button to open the FNC dial og. This dialog shows the

analog input sources, digital input sources, the selected equation, and the six equatio n

constants.

2. The Equations section lists the nine equations supported by the FNC block. Click on the

Algebraic radio button and the equation is drawn as a mathematical formula.

3. Fill in the Equation Constants as shown in Figure 4-11.

4. Click OK to write the changes into the controller database.

Figure 4-11. Function Block Equations Dialog Window

Online Configurations 41

Page 50

53HC2600 INSTRUCTION MANUAL

4.4.6.1 Using the Interactive Training Screens Online

As in offline operation, the LoopMaster interactive training screens enable you to configure a controller

database online while you learn about the parameters. These screens explain parameters in plain language and provide step-by-step instructions on how to configure the Micro-Mite controller.

In this section, we will use the interactive training screens to configure the control output.

1. Click on the C Scheme button to open the Control Scheme dialog. This dialog shows the

selected control scheme, control switches, and a graphical representation of the Control

Scheme block (Fig).

Figure 4-12. Control Scheme Dialog Window

2. Since the current control scheme is Single Loop Contr ol, only the cn1 loop is shown. To

configure the control output of cn1, click on Output1. The SL6000.cn1.Output1 dialog window

(Figure 4-13) is displayed.

42 Online Configurations

Figure 4-13. SL6000.cn1.Output1 Dialog Window

Page 51

53HC2600 INSTRUCTION MANUAL

The SL6000.cn1.Output1 dialog shows the Output Parameters. The yellow box is an

interactive training screen, and the parameters are shown in the Output Parameters section

below it. The interactive training screens explain the mean ing of each parameter, then prompt

you for an action to configure it.

3. The first screen explains the RSW reverse switch. Notice in the Output Parameters section,