Page 1

MOD 30ML™ Multiloop Controller Operation

General Operation and Setup using

1800R MOD 30ML™

Identity Module (Version 2)

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned by

MicroMod Automation or its suppliers.

i Information. Further reference for more detailed

information or technical details.

Page 3

MOD 30ML Operation

CONTENTS

CONTENTS

Page

SECTION 1 - INTRODUCTION

1.1 FEATURES.......................................................................................................................... 1-1

1.2 DESCRIPTION .................................................................................................................... 1-1

1.2.1 Functionality......................................................................................................................... 1-1

1.2.2 Configuration........................................................................................................................ 1-2

1.2.3 Operation ............................................................................................................................. 1-2

1.2.4 Process I/O .......................................................................................................................... 1-2

1.2.5 Communications (requires Application Builder Software suport) ......................................... 1-2

1.3 RELATED DOCUMENTATION............................................................................................ 1-3

1.4 VERSION IDENTIFICATION ............................................................................................... 1-4

SECTION 2 - SETUP

2.1 GENERAL PREPARATIONS............................................................................................... 2-1

2.2 DEVICE STATES................................................................................................................. 2-2

2.3 USING MEMORY MODULE ................................................................................................ 2-2

2.3.1 DOWNLOAD From Memory Module to Main Database ................................................... 2-2

2.3.2 UPLOAD From Main Database to Memory Module.......................................................... 2-3

2.4 DEVICE DISPLAYS ............................................................................................................. 2-3

2.5 TEMPLATE SETUP ............................................................................................................. 2-10

SECTION 3 - OPERATION

3.1 INTRODUCTION ................................................................................................................. 3-1

3.2 FRONT PANEL.................................................................................................................... 3-1

3.3 CONTROL KEYS................................................................................................................. 3-3

3.4 ALPHANUMERIC DISPLAYS.............................................................................................. 3-4

3.4.1 Line 1 and Line 2 Displays................................................................................................... 3-4

3.4.2 Line 3 Displays..................................................................................................................... 3-4

3.4.3 Line 4 Displays..................................................................................................................... 3-5

3.4.4 Line 5 Displays..................................................................................................................... 3-6

3.4.5 Line 6 Display ...................................................................................................................... 3-7

3.5 BAR DISPLAYS ................................................................................................................... 3-7

3.6 ALARM INDICATOR............................................................................................................ 3-7

3.7 UP / DOWN KEY OPERATION ........................................................................................... 3-8

3.7.1 Ramping .............................................................................................................................. 3-8

3.7.2 Data Entry............................................................................................................................ 3-8

3.8 SELECTING A CONTROL LOOP FOR DISPLAY ............................................................... 3-9

3.9 SINGLE LOOP OPERATION IN AUTOMATIC MODE ........................................................ 3-10

3.9.1 Single Loop Automatic Operation with Local Set-Point........................................................ 3-10

3.9.2 Single Loop Automatic Operation with Remote Set-Point.................................................... 3-11

3.9.3 Single Loop Automatic Operation with Ratio and Bias ........................................................ 3-12

3.9.4 Single Loop Automatic Operation with Feed Forward ......................................................... 3-13

3.10 SINGLE LOOP AUTO/MANUAL TRANSFER ..................................................................... 3-14

3.10.1 Control Loop with Reset....................................................................................................... 3-14

3.10.2 Control Loop without Reset.................................................................................................. 3-15

3.11 SINGLE LOOP OPERATION IN MANUAL .......................................................................... 3-16

3.12 CASCADE OPERATION ..................................................................................................... 3-17

3.12.1 Cascade Control, Slave in Manual....................................................................................... 3-17

3.12.2 Cascade Control, Slave in Auto ........................................................................................... 3-18

i

Page 4

MOD 30ML Operation

CONTENTS

CONTENTS (Cont’d)

Page

3.13 ALARMS............................................................................................................................... 3-19

3.13.1 Alarm Trip points .................................................................................................................. 3-19

3.13.2 Alarm Priority........................................................................................................................ 3-19

3.13.3 Monitoring and Acknowledging Alarms ................................................................................ 3-20

3.13.4 Alarm Display Viewing Sequence......................................................................................... 3-25

3.14 TUNING................................................................................................................................ 3-25

3.14.1 Password.............................................................................................................................. 3-25

3.14.2 Alarm Parameters ................................................................................................................ 3-26

3.14.2 Control Parameters .............................................................................................................. 3-27

3.15 STARTUP............................................................................................................................. 3-29

3.15.1 Startup Without Set-Point Tracking ...................................................................................... 3-29

3.15.2 Startup With Set-Point Tracking ........................................................................................... 3-29

APPENDIX A - EVENT CODES AND TRANSITIONS

A.1 EVENT TRANSITIONS (2-).................................................................................................. A-1

A.2 EVENT CODE, EXPANDED DESCRIPTION....................................................................... A-1

A.2.1 IF - Interface Block Events................................................................................................ A-1

A.2.2 SE - System Event Block Events ...................................................................................... A-3

A.2.3 LP - Loop Block Events..................................................................................................... A-3

A.2.4 ICN - ICN Communication Block Events........................................................................... A-3

A.2.5 MSC - MSC Communication Block Events ....................................................................... A-4

A.2.6 DIM - Digital Input Module Block Events........................................................................... A-4

A.2.7 DO, WDO, DDO - Digital Output Module Block Events .................................................... A-4

A.2.8 VCIM, TIM, CJIM, WRIM - Analog Input Module Block Events......................................... A-4

A.2.9 AOM - Analog Output Module Block Events ..................................................................... A-5

A.2.10 AI - Analog Input Block Events ......................................................................................... A-5

A.2.11 DI - Digital Input Block Events .......................................................................................... A-5

A.2.12 LN - Linearization Block Events ........................................................................................ A-5

A.2.13 PID - PID Block Events ..................................................................................................... A-5

A.2.14 PAD - Process Alarm Display Block Events...................................................................... A-6

A.2.15 AIN - Built-in Analog Input Block Events ........................................................................... A-6

A.2.16 AOUT - Built-in Analog Output Block Events .................................................................... A-6

ii

Page 5

MOD 30ML Operation

CONTENTS

ILLUSTRATIONS

Figure Page

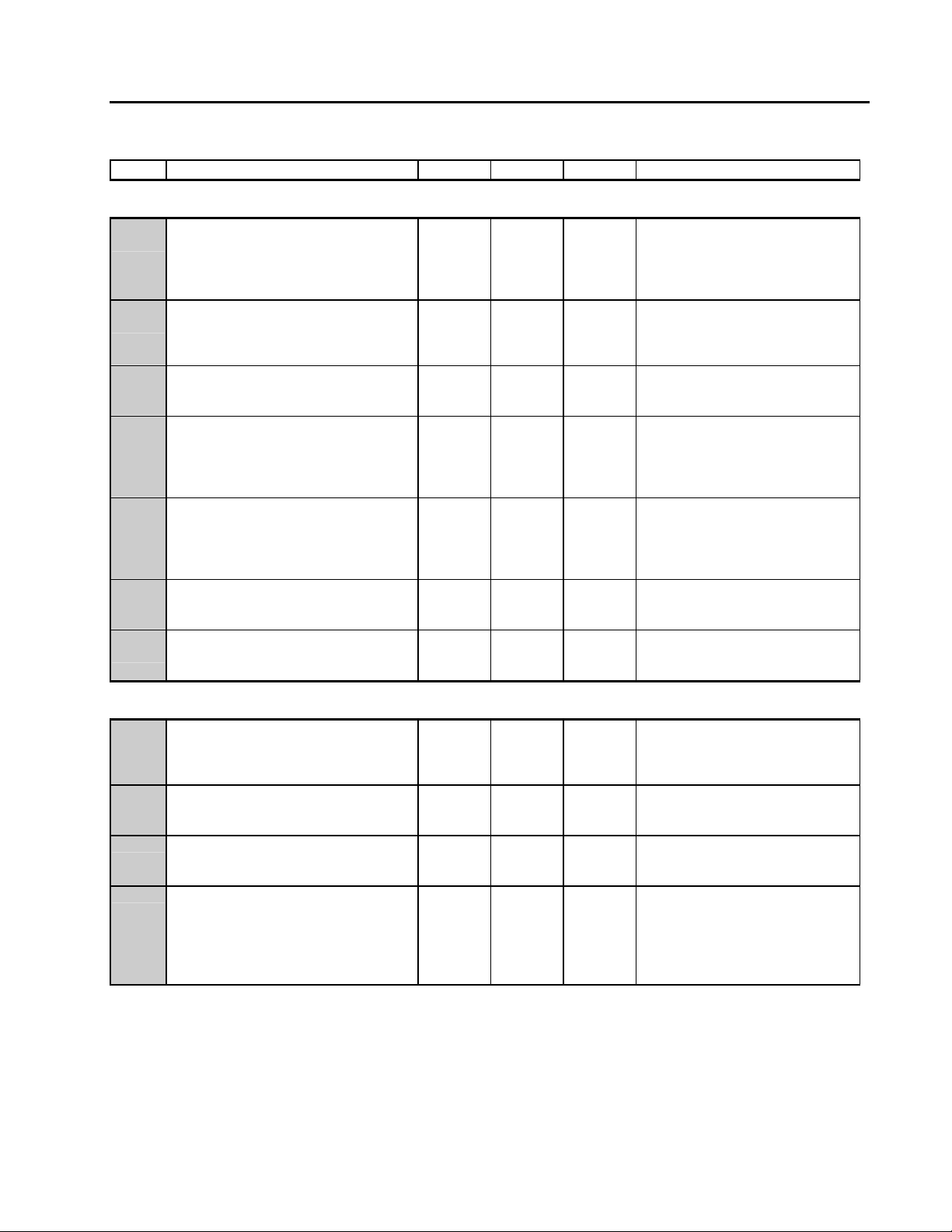

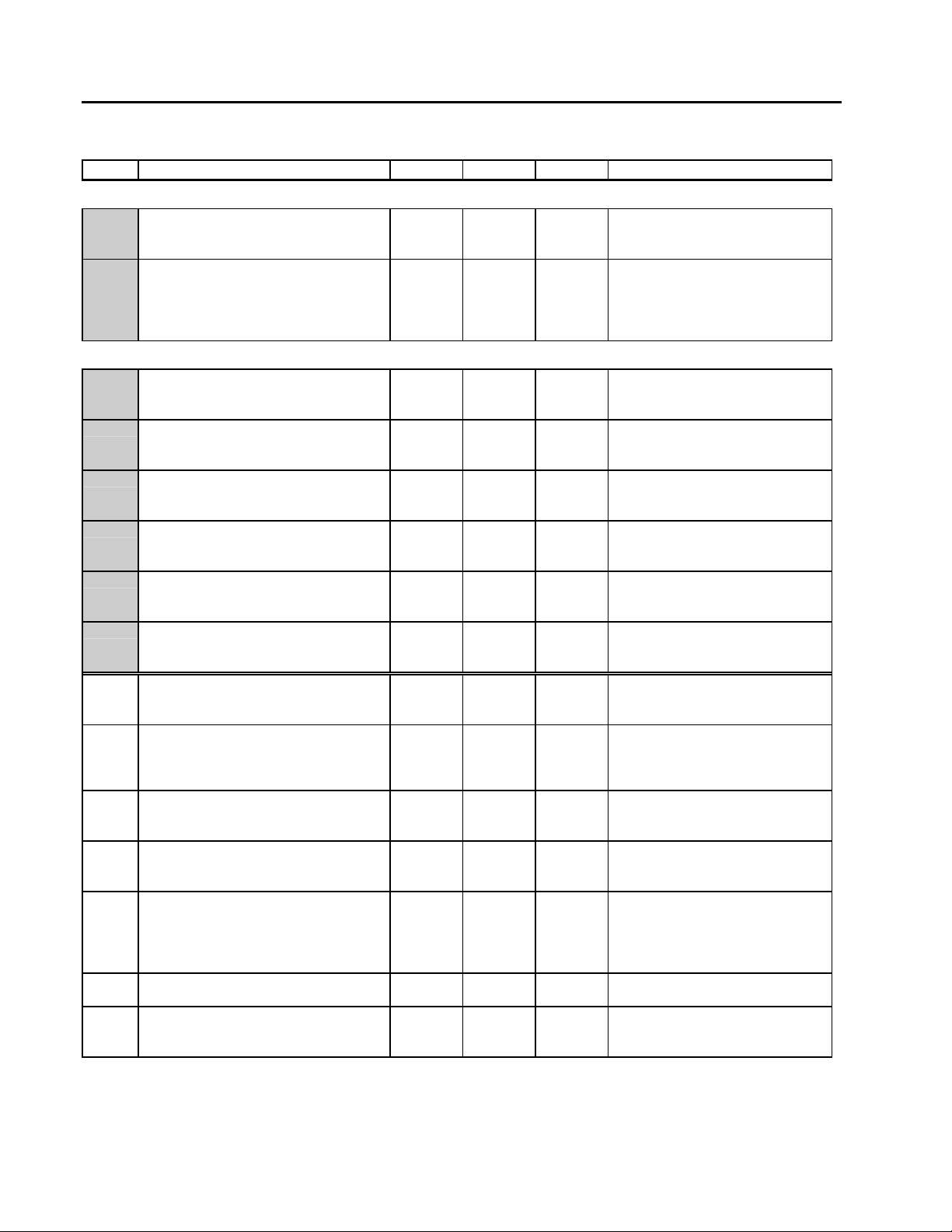

2-1 Display Resources ............................................................................................................... 2-3

2-2 Display Block (DISP), Edit display, page 1 .......................................................................... 2-7

3-1 Controller Front Panel .......................................................................................................... 3-2

TABLES

Table Page

2-1 Device Status....................................................................................................................... 2-4

2-2 Device Setup ....................................................................................................................... 2-7

2-3 Device I/O Status ................................................................................................................. 2-8

2-4 Device Events...................................................................................................................... 2-9

2-5 About This Device................................................................................................................ 2-9

2-6 Template Configuration........................................................................................................ 2-10

2-7 System Template Configuration........................................................................................... 2-11

2-8 User Compound Template Configuration............................................................................. 2-13

A-1 Event Transition Messages and Descriptions...................................................................... A-1

iii

Page 6

MOD 30ML Operation

CONTENTS

iv

Page 7

1.1 FEATURES

The following features are included with the basic instrument:

• Built-in single loop PID Control or Single Station Cascade Strategies,

• Two Isolated universal analog inputs standard

• Two analog outputs standard

The following features are options to the basic instrument:

• Up to 11 additional single point, individually isolated local process I/O

• Redundant, removable NOVRAM backs up configuration and current process parameters

The following features require the support of the instrument configuration software:

MOD 30ML Operation

INTRODUCTION

1

INTRODUCTION

• Serial communications: Instrument Communications Network, RS-232 and RS-485

Modbus standard

• Up to 100 additional discrete remote I/O points through a Remote I/O Interface module

• Logic, advanced and sequential control functions

• Display scripting functions

• Complete configuration control using graphics based blocks and connections

1.2 DESCRIPTION

This microprocessor based 3x6 multiloop controller is designed to meet your process control

needs whether you use it for loop indication or to implement advanced process strategies.

The controller can display and control continuous process variables such as temperature,

pressure, liquid level, or flow and has the ability to perform digital logic functions.

1.2.1 Functionality

The instrument provides continuous control functions such as PID, feedforward, set-point and

output tracking, external feedback, set-point and output limiting, in addition to logic and I/O

functions. As many as six PID or 4 cascade loops can be run in a single controller with a total

loop processing time of 250 milliseconds. Using on-board I/O, PID control loops can be

executed as fast as 100 milliseconds.

Using the configuration software for setup, the instrument can run Sequence Blocks based on

a drum programmer design with up to 100 inputs, 80 steps and 30 outputs per block; blocks

can be cascaded for larger sequences. Sequence Blocks allow forward and backward

stepping, unlimited branching and outputs configurable for any data type (discrete, floating

point, integer, time, date, ASCII or HEX).

The instrument has 64K of non-volatile RAM which contains the user database and all current

process and operating parameters. The optional Portable Memory Module provides 64K of

1-1

Page 8

MOD 30ML Operation

INTRODUCTION

redundant, removable non-volatile RAM which backs up the configured database and, if left

on the instrument during operation, current process data. Nonvolatile RAM memory has a

typical data retention of 10 years.

1.2.2 Configuration

Configuration of the instrument is accomplished via one of two methods. For applications

using single loop PID, single station cascade, feedforward and ratio/bias, canned strategies

and their faceplates are easily implemented through the instruments front face displays and

operator push buttons. Template configuration uses easy-to-read English prompts.

For more complex applications, beyond those offered with the basic instrument, configuration

is accomplished through the icon-based Application Builder Software which is used to create,

edit, save, download and document the data base in a graphic environment. Downloading

instrument configurations can be done via ICN, or via Modbus over RS-232 or a 4-wire RS485 network. This software is also used to prepare runtime operation files for a computer

using the ICN or Modbus protocol. Local display and operations can also be provided using

the 2021W Local Control Panel over the ICN.

1.2.3 Operation

The instrument can display and control a variety of process variables such as temperature,

pressure, flow, and liquid level. In addition to continuous display of the process variable for a

selected loop, the front panel display shows the operating set-point, control output, process

alarm indication, loop tag name, and status indication of control mode and set-point source.

Front panel keys provide for operational activities such as auto/manual switching,

remote/local set-point switching, manual output adjustment, process alarm and diagnostic

message acknowledgment, and enabling communication with a host device.

1.2.4 Process I/O

MODBUS

serial communications. Signal conditioning, fail-safe and power fail/recovery parameters may

reside in each individual module.

Analog I/O Modules

Analog input modules provide high-resolution signal conditioning performed in the module.

Process signals including RTD and thermocouple are connected directly to the rear terminations

without requiring transmitters or transducers for signal conversion. A single module supports all

thermocouple types with upscale burnout detection. Cold junction compensation is also provided.

One current input module type supplies isolated loop power for 2-wire transmitters. Other input

types include volt, millivolt, 2- and 3-wire RTD with upscale burnout detection and current input

Two isolated universal analog inputs and two current outputs

are standard. Each analog input can receive direct connection

of either milliamp (2-wire or non 2-wire), millivolt, volt, RTD

thermocouple or resistance. Inputs have full galvanic

isolation. Both analog outputs can be user set between span

limits of 0 and 50 milliamps.

In addition there can be up to eleven process I/O and

communication modules. Plug in modules include various

types of analog input, analog output, digital input, digital

output, Instrument Communication Network (ICN) and

1-2

Page 9

MOD 30ML Operation

without loop power. The analog output module supplies 4-20mA or 0-20mA. All analog I/O

modules are individually, optically isolated to 250Vrms continuous.

Digital I/O

Digital I/O is selected by the user through use of digital I/O modules. Options include both isolated

and non-isolated modules. Solid state relay versions offer high isolation voltage capability. Nonisolated modules are compatible with TTL logic levels and provide the ability to interface between

similar modules without the need for an external power supply. The Mechanical Relay output

module supports Form A, Form B and Form C relays.

Remote I/O (requires Application Builder Software support)

Remote I/O input and output modules expand the I/O capability to a total of 100 discrete points.

The module communicates over the Remote I/O Network, an RS-485 fieldbus which connects to

the instrument via a 2020N RIO module. The RIO module does not need to use a

communications position leaving those two positions open for communications modules. Refer to

IB-23C601.

1.2.5 Communications (requires Application Builder Software support)

Two serial communications channels on each instrument allow up to two independent

networks to function simultaneously. The first channel is built-in and is selectable for either

Instrument Communications Network (ICN), RS-232 Modbus or RS-485 Modbus. The second

channel uses an ICN, RS-232 Modbus or RS-485 (2-wire or 4-wire forms) module.

1.3 RELATED DOCUMENTATION

Information about this instrument and its configuration

can be found in:

INTRODUCTION

• IB-1800R-APP – Data Base Reference for MOD 30ML Functions

• IB-23G600 – Data Base Reference for Logic Functions - Book 1

• IB-23G602 – Data Base Reference for Logic Functions - Book 2

• IB-23G601 – Data Base Reference for Advanced Control Functions

• IB-23H141 – User’s Guide for Application Builder Software (2006S)

• IB-23H120 – User’s Guide for PC-30 Instrument Interface Software for MOD 30 and

MODCELL Instruments

Information about this instrument and its installation

• IB-1800R-INS – Installation, MOD 30ML

• IB-1800R-M30 – MOD 30 Replacement Installation, MOD 30ML

• IB-23C601 – Installation, Remote I/O Modules

can be found in:

1-3

Page 10

MOD 30ML Operation

INTRODUCTION

1.4 VERSION IDENTIFICATION

To verify the version level of the instrument, check the version number marked on the PROM

label of the identity module. The firmware version is a digit in the catalog number as follows:

Catalog Number Description for 2004P

MOD 30ML PANEL-MOUNT

Base Controller

Standard bezel

Narrow bezel (Foxboro replacement version)

Approvals

General Purpose

CE (European Community destinations only)

FM/CSA Class 1 Division 2 A,B,C,D

Power Supply

24V dc

85 to 265V ac

Enclosure

Standard terminations

Standard terminations, NEMA 4

Standard terminations, NEMA 4 with conformal

coating

Not Used 0

Design Model

General Purpose, FM/CSA approval

European Approval (CE Certification - for

European Community destinations)

Programming / Special Features

None

Sample Number 1800PZ10102C (Product is serialized)

Version number identification is also available in the *DEVICE* ABOUT displays as

described in setup Table 5.

06

1800RZ

1801RZ

07-08 09 10 11 12 13 14 15

10

12

21

0

1

0

3

4

A

B

S T D

1-4

Page 11

! CAUTION Be sure the process can be maintained in a safe condition before turning on

instrument power. The instrument may not be configured to meet the specific

requirements of the process until setup has been performed.

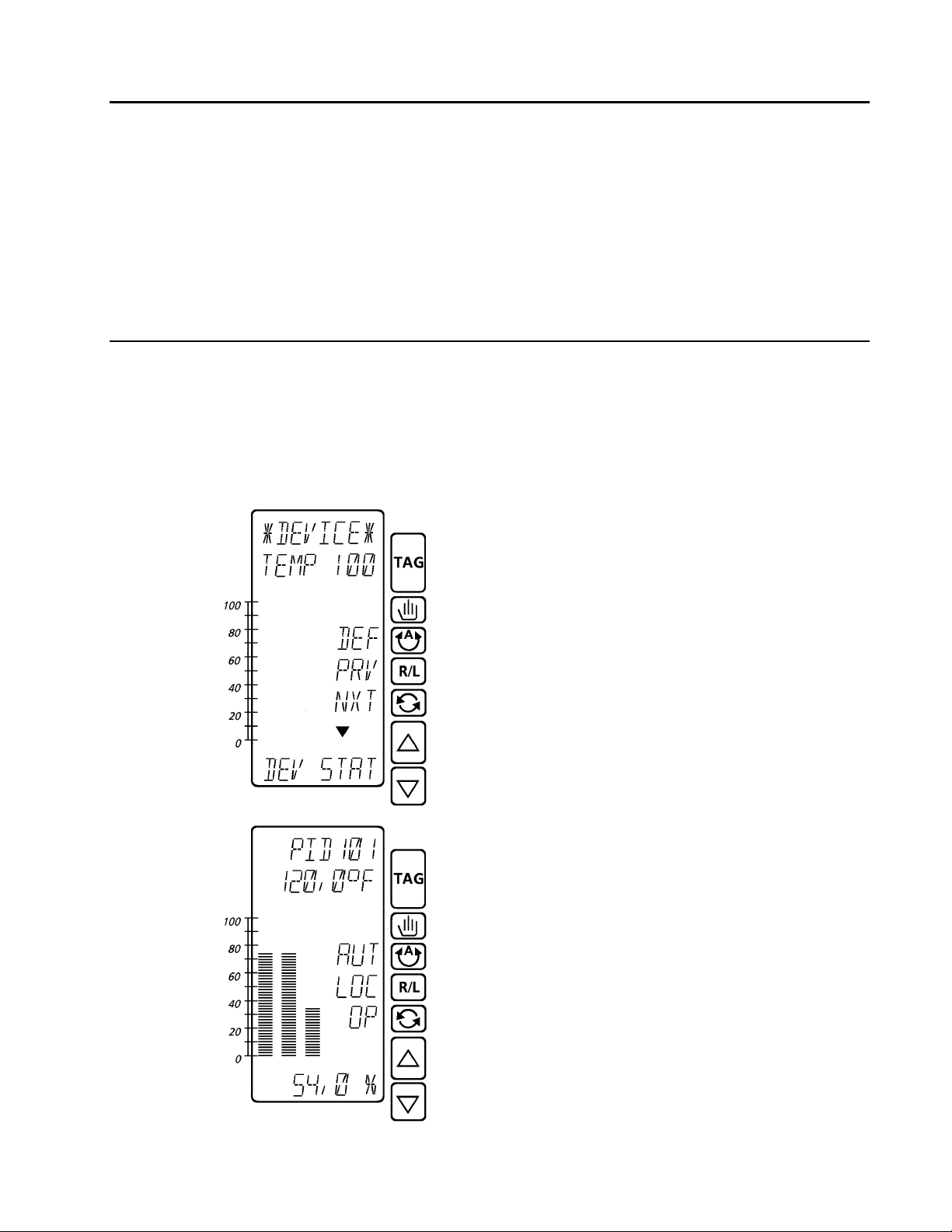

2.1 GENERAL PREPARATIONS

After installation is complete, begin setup by preparing the instrument as follows:

1. Set the SCRV/RUN switch under the front face to the RUN position. If a Memory Module is

present, see Using The Memory Module to load a database stored to a memory module.

2. At ac power source, turn on power to instrument. When power is on, the front panel

display illuminates showing either a default database (as shipped from factory) or some

other successfully loaded database.

MOD 30ML Operation

SETUP

2

SETUP

Default Database

If the instrument does not have a valid user database, the

first DEVICE display (device status entry point) will

appear and any diagnostic indications will be enabled.

The default device tag is TEMP 100.

The device display shows the state of the instrument on

line 3 (see Device States).

The keys labeled NXT (next step) and PRV (previous

step) move you through the entry points for the setup

tables while the down arrow ∇ indicates the down arrow

key can be used to enter a step

the instrument state is RUN, the TAG key will switch you

to the first user runtime display.

Valid User Database Loaded

If the instrument has a valid user database, the power up

display (Device, Previous or User) will appear and any

enabled diagnostics, such as for power up and power

down, will be indicated. You can prepare the instrument

for setup by acknowledging these diagnostics and

making any necessary adjustments to your operating

conditions from the user display (see Operation for

general operation).

Return to the DEVICE display by pressing and holding

the TAG key.

(see Device Displays). If

2-1

Page 12

MOD 30ML Operation

SETUP

3. Press the alarm key to get the list of unacknowledged and active

acknowledged alarms and diagnostics (Appendix A lists all reportable

diagnostics and events). Press the key labeled UAK to acknowlege the

alarm (changes to ACT). Press the alarm key again to view the next

4. If a previous shutdown condition exists, it must be acknowledged from the device status

shutdown displays (Step 1B of Device Status Table 1); otherwise, template configuration

and memory module downloads will fail.

alarm and repeat until the end where you can return to the device display

(see Alarms in Section 3.13).

2.2 DEVICE STATES

The instrument state is indicated by a three letter code on line 3 of the device displays.

Except for Local Hold, installation of a template will change the instrument state to Run.

DEF The Default state means the instrument has no valid user database and is running an

internal database to maintain communications and system activities.

HLD The Hold state indicates the instrument has a valid user database and is performing

overhead functions only - no loops are running.

LHD The Local Hold state indicates the SCRV/RUN switch is in SCRV and the instrument

is in the Local Hold state.

RUN The Run state means the instrument has a valid user database and is running that

database.

2.3 USING THE MEMORY MODULE

The backup memory module is used to maintain a mirror image of the 64K instrument

database. A small part of this image is reserved for shutdown information and serves as a

valuable diagnostic tool. The module may be write protected to protect shutdown and other

information.

2.3.1 DOWNLOAD From Memory Module to Main Database

Follow this procedure to load a database stored in a memory module.

1. Set Memory Module switches to "read/write" or "Read Only" and "Normal".

2. Power up the instrument.

The instrument automatically attempts a download from the memory module during

power-up. If the module database is 'good' (configured, version compatible, has valid

checksums, no ICN or comm port mismatch), the 'download on warm start' attribute is

YES and the instrument did not have a previous shutdown fault, the transfer will occur.

The download on warm start attribute allows a user to (for instance) write protect a

module with cold start values in it and have it download only on cold start.

2-2

Page 13

2.3.2 UPLOAD From Main Database to Memory Module

Follow this procedure to store a database to a memory module.

1. Set Memory Module switches to "read/write" and "module load".

2. Power up the instrument.

3. UPLOAD? is displayed by the instrument. To upload to the memory module, press either

the up or down arrows and press the key labeled ENT for enter. The default database is

run with instrument state equal to UPLOAD.

4. UPL DONE SET WP? is displayed by the instrument. The module is now loaded with the

instrument database. If you want to write protect the module, select YES and enter (UPL

DONE, WP DONE). Skip this command and go to the next step if you do not want to

write protect the module.

5. Power down the instrument. Instrument state cannot be changed until power is removed

and module switch is placed in "Normal".

6. Set Memory Module switches to "read/write" or "Read Only" and "Normal".

7. Power up the instrument.

2.4 DEVICE DISPLAYS

The device displays consist of the following main groups and related instrument information.

They are presented in the order they appear as you step through the top level of device

displays. Follow the steps as described in each table to view status information or change

how the instrument operates. Only Table 6 and its supporting setup tables are used to create

a runtime configuration.

DEVice STATus Table 1* State Commands, Shutdown information and

acknowledgement, Status Commands, Execution Times

and Current Time, Date and Day.

device SETUP Table 2 Communication Parameters and Password Entry.

device I/O status Table 3* Built-in and Single Point Input/Output Status, signal

values and Auto/Manual selection.

device EVENTS Table 4 List of events in the Event Queue. See Appendix A.

ABOUT this device Table 5 Current Version of Firmware and Display.

TEMPLATE Table 6* Load template defaults, Edit templates and Install

templates. See Template Setup.

* These require a Configure Password, if it is enabled, to gain entry.

* NOTE: Step levels changes are indicated by alternating numbers and letters. For

example, Step 1A is the first step down one level from Step 1. Shaded areas

alternate between significant subjects within the groups.

Use the keys labeled NXT (next step) and PRV (previous step) to move through the entry

points for the setup tables and use the down arrow ∇ key to enter the first step of each table.

MOD 30ML Operation

SETUP

2-3

Page 14

MOD 30ML Operation

SETUP

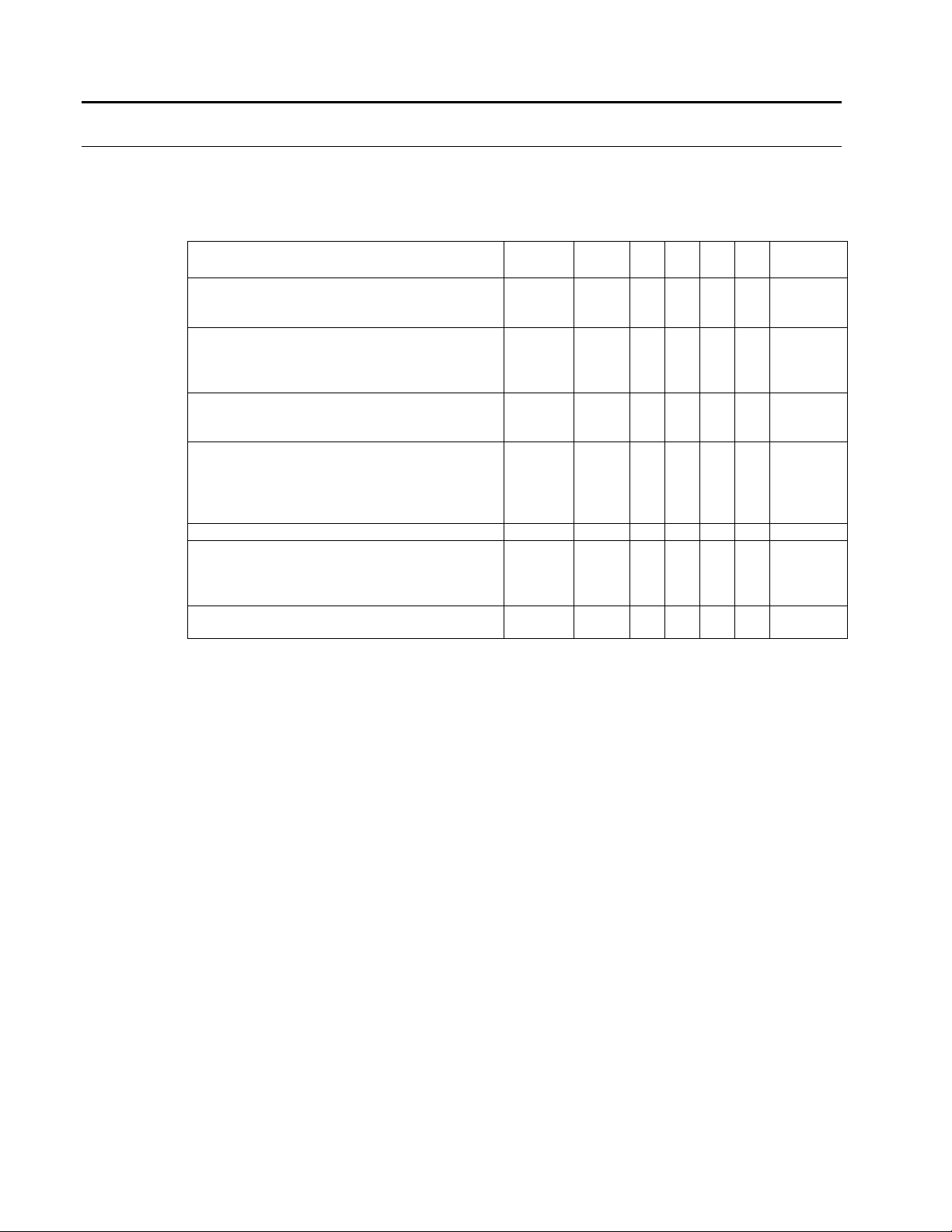

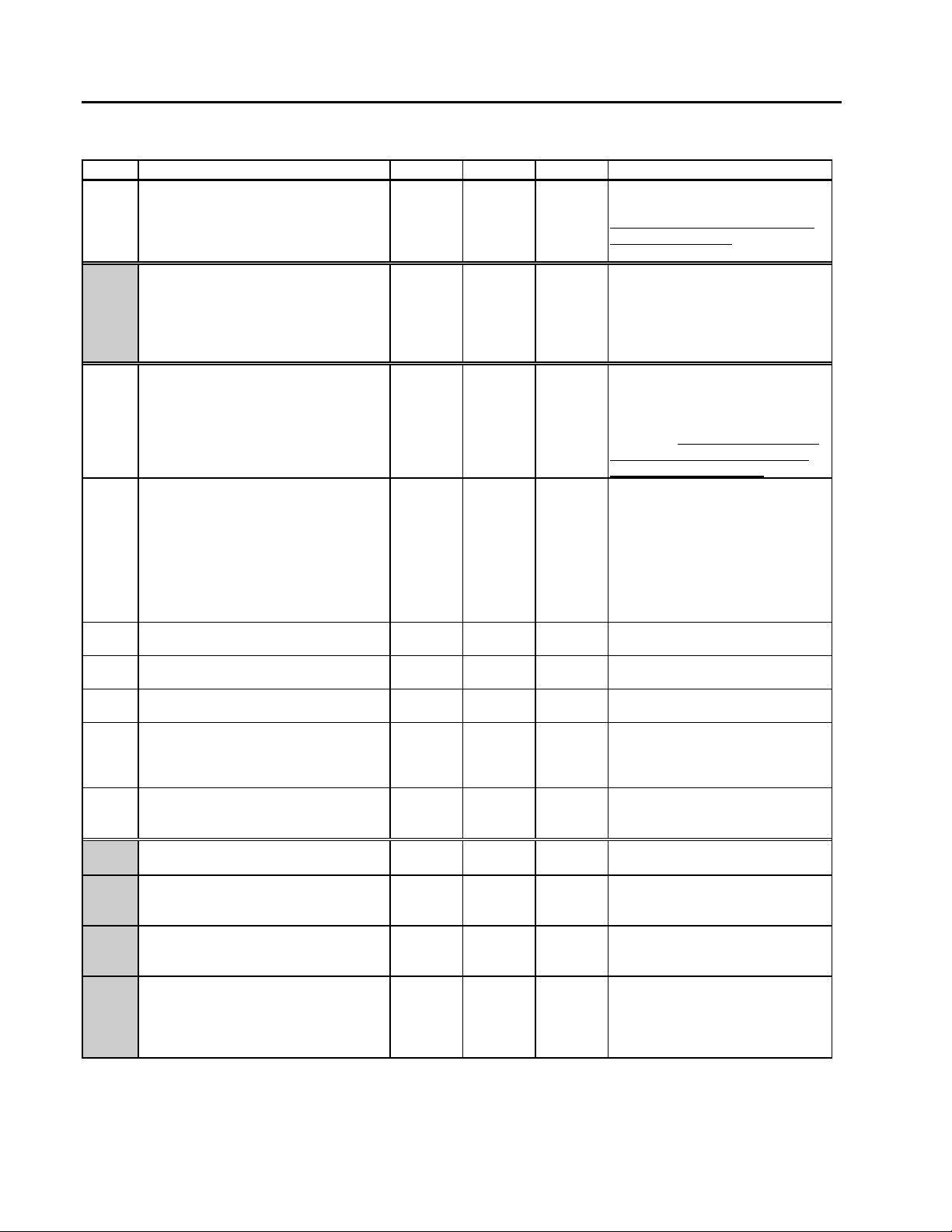

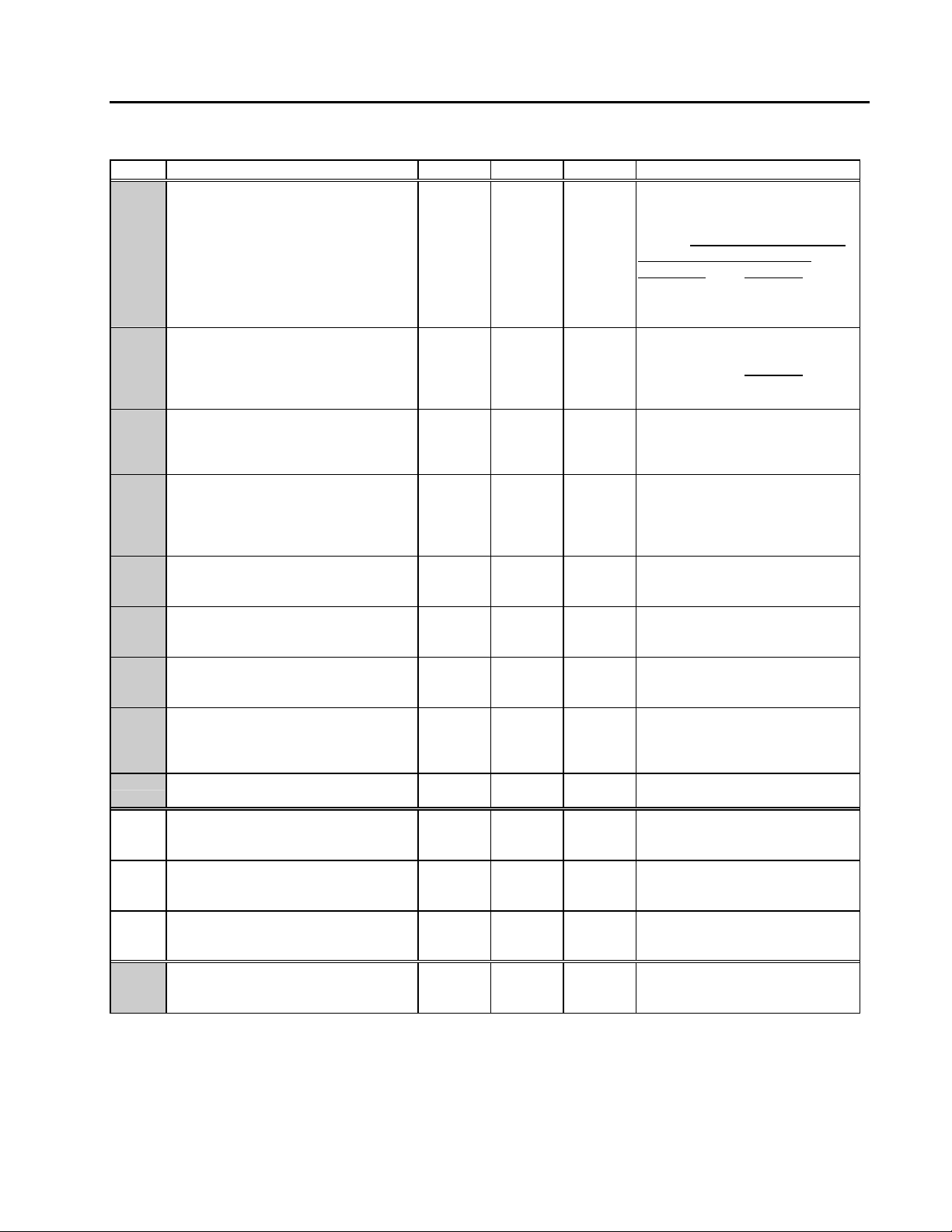

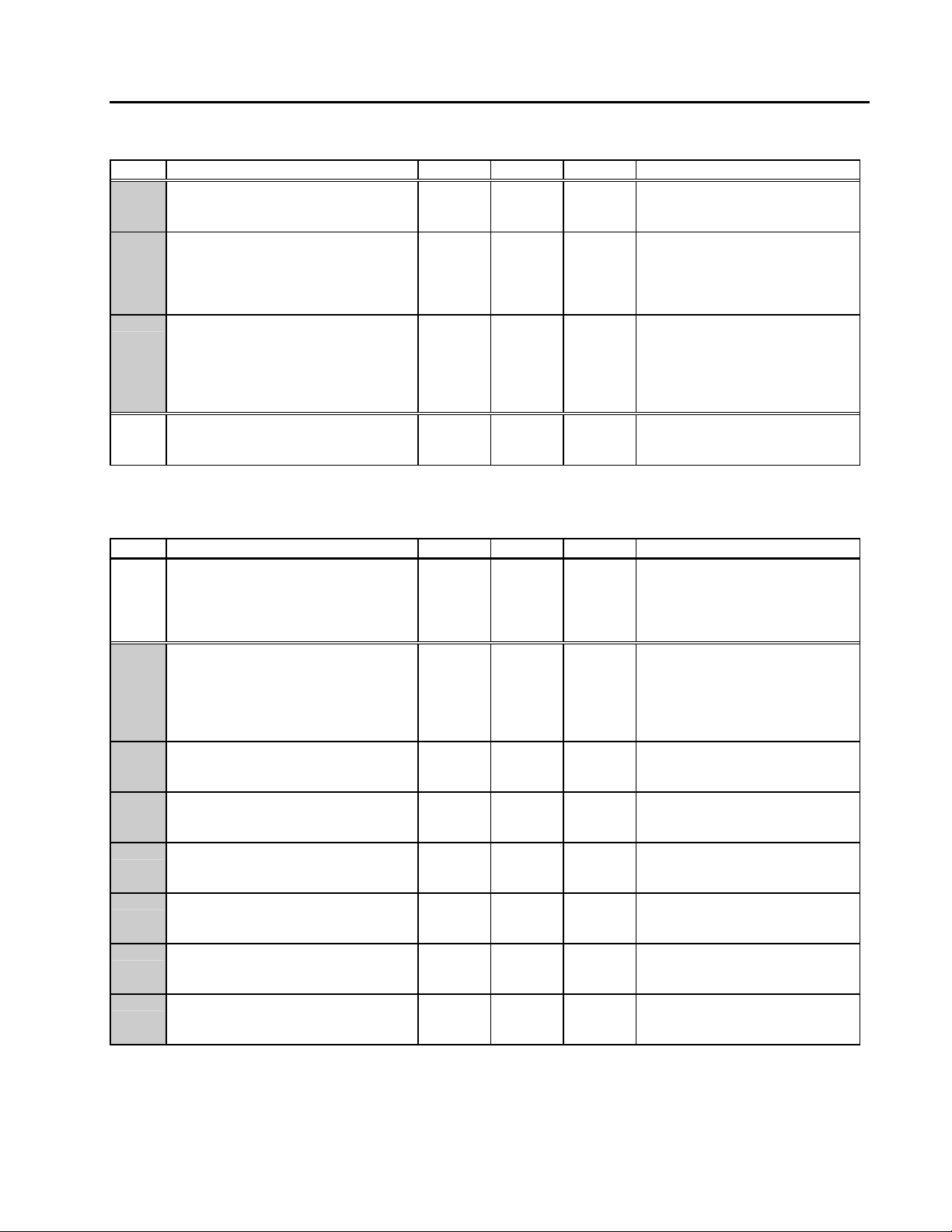

Table 1. Device Status

Step Step Description Line 1 Line 2 Line 6 Entry Description

1 Device Status

∇ moves down to Step 1A

NXT goes to Step 2 (Setup)

PRV goes to Step 6 (Template)

1A

Device Status State Command

∇ ∆ changes state on line 6

ENT enters device state

NXT, PRV change step

1B

Device Status Shutdown (Entry)

∇ moves down to Step 1B1.

1B1 Shutdown Page 1

NXT, PRV change step

1B2 Shutdown Page 2

NXT, PRV change step

1B3 Shutdown Page 3

NXT, PRV change step

1B4 Shutdown Page 4

NXT, PRV change step

1B5 Shutdown Page 5

∇ ∆ select YES/NO

NXT, PRV change step

1B6 Device Status Shutdown (Exit)

∆ moves up to Step 1B

NXT, PRV change step

1C Device Status Commands (Entry)

∇ moves down to Step 1C1

1C1 Clear Queue Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C2 Clear Maximum Scan Times

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C3 Global Acknowledge Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

*DEVICE* NOT CFGD

or

DEV TAG

DEV STAT INSTATE DEFAULT

DEV STAT SHUTDOWN NO

SYSPI 1 XXXXXXXX

SYSPI 2 HH:MM:SS MM/DD/YY

SYSPI 3 XXXXXXXX XXXXXXXX

SYSPI 4 XXXXXXXX XXXXXXXX

SYSPI 5 ACK SD NO

SYSPI 6 DEV STAT

DEV STAT COMMANDS

COMMANDS CLR Q NO

COMMANDS CLR MT NO

COMMANDS ACK ALL NO

DEV STAT

YES

See Table 2 for step 2 (Setup)

See Table 6 for step 6 (Template)

These steps are protected by the

CONFIG password. Enter proper

password, if used, to move down.

DEFAULT (DEF)

HOLD (HLD)

HOLD WST (Hold with Warm Start)

RUN (RUN)

RUN WST (Run with Warm Start)

see Device States.

Shutdown status is a debug tool

used to read specific instrument

registers. NO means no shutdown

is present. YES indicates a

shutdown. Record the information

on pages 1 to 5 and report them

when requesting a repair.

Line 1 can be: Sxrrrr where

x (shutdown) = Y (yes) or N (no) and

rrrr = WDOG (Watchdog),

SPI (Spurious interrupt),

BMCK (Bad main database checksum),

BDCK (Bad default database

checksum), BECK (Bad EEPROM

checksum), BRAM (Bad RAM), DMA

(DMA error), IOSO (IO Stack Overrun),

FPCF (Faceplate comm. failure).

Time and date of shutdown or

of acknowledge shutdown.

Record number.

Record number.

Yes acknowledges shutdown,

restarts instrument and clears

registers. If acknowledge fails,

instrument will not restart.

Use to clear system event queue.

Press ENT after selecting YES.

Use to clear maximum scan times

for all scan groups.

Press ENT after selecting YES.

Use to send global acknowledge

command causing all diagnostics,

alarms and notification/request

messages to be acknowledged.

Press ENT after selecting YES.

2-4

Page 15

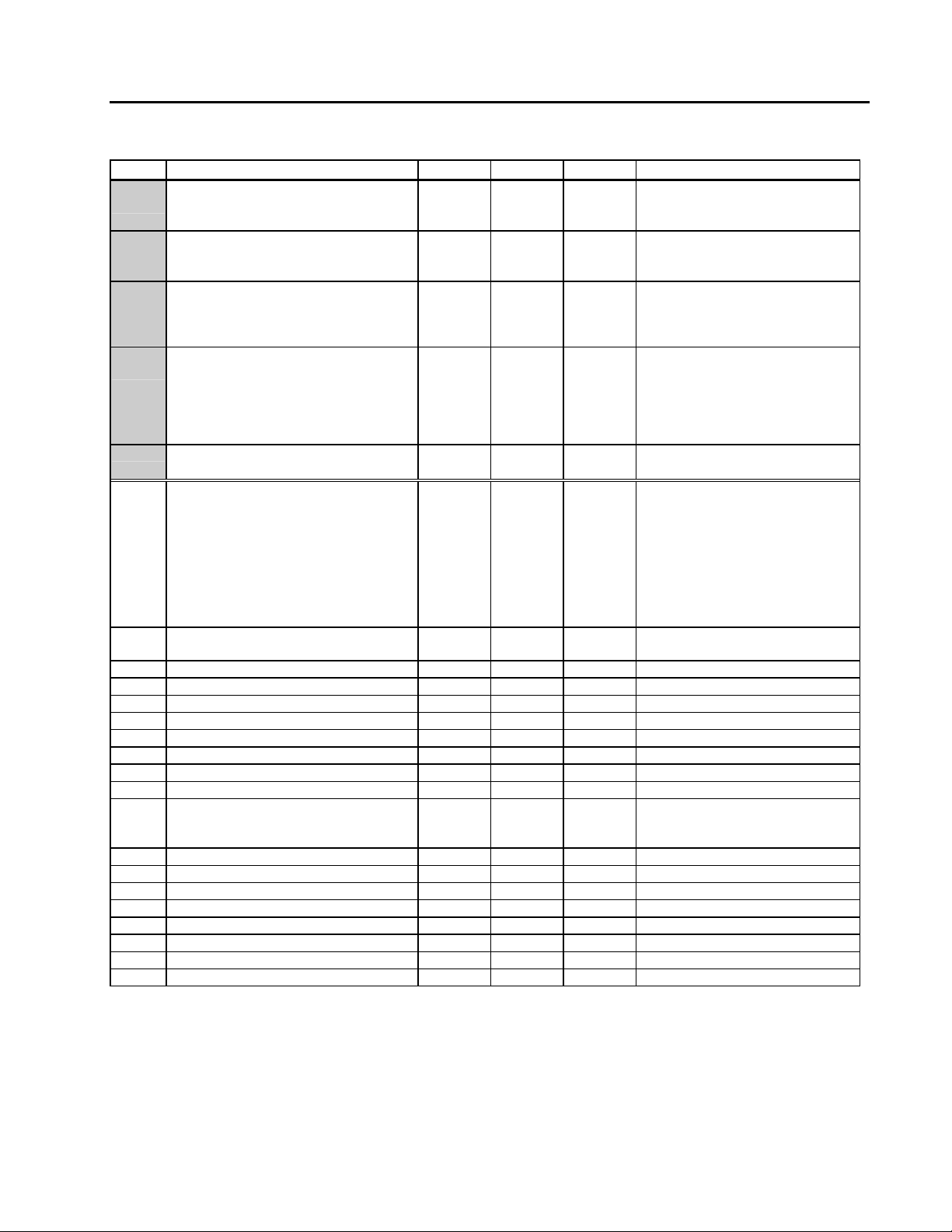

MOD 30ML Operation

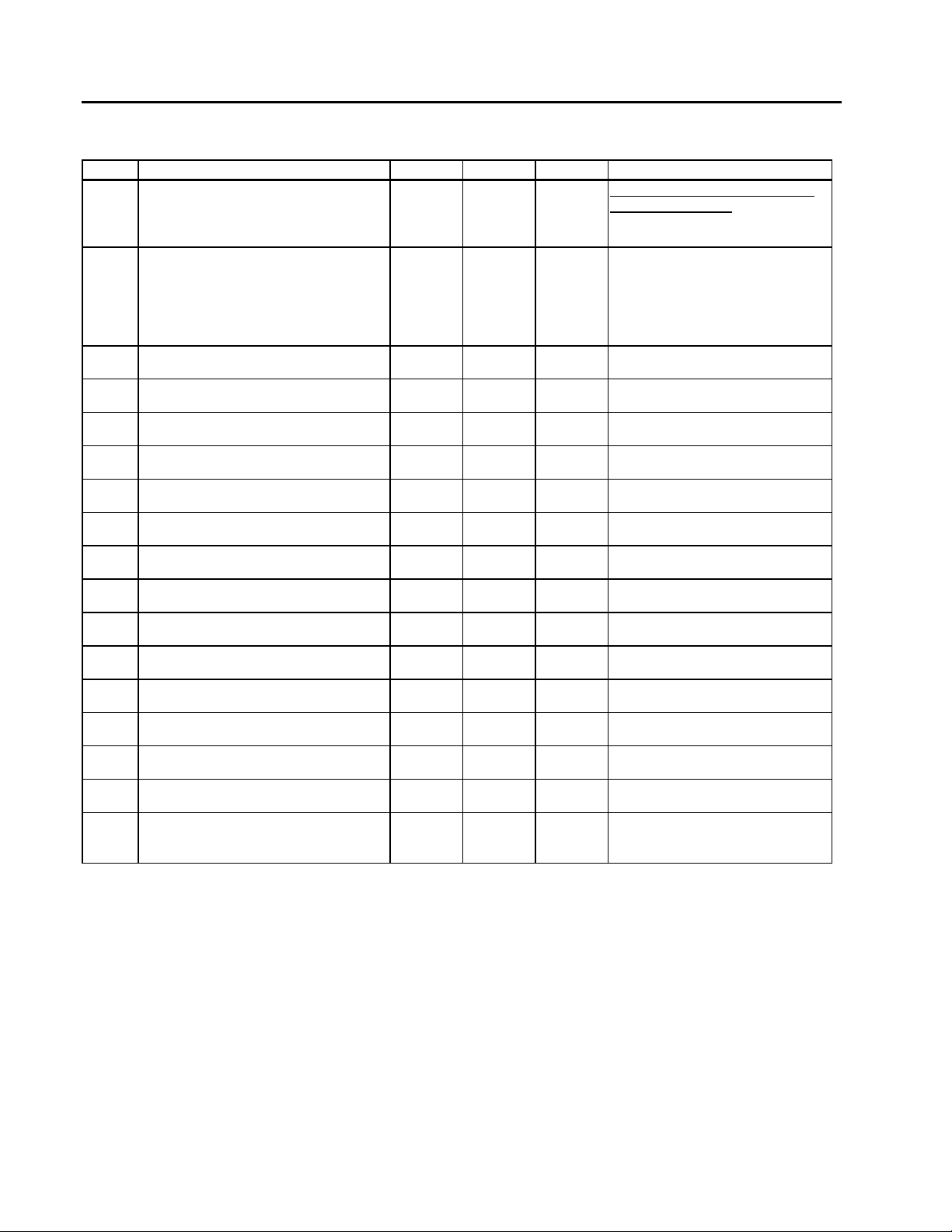

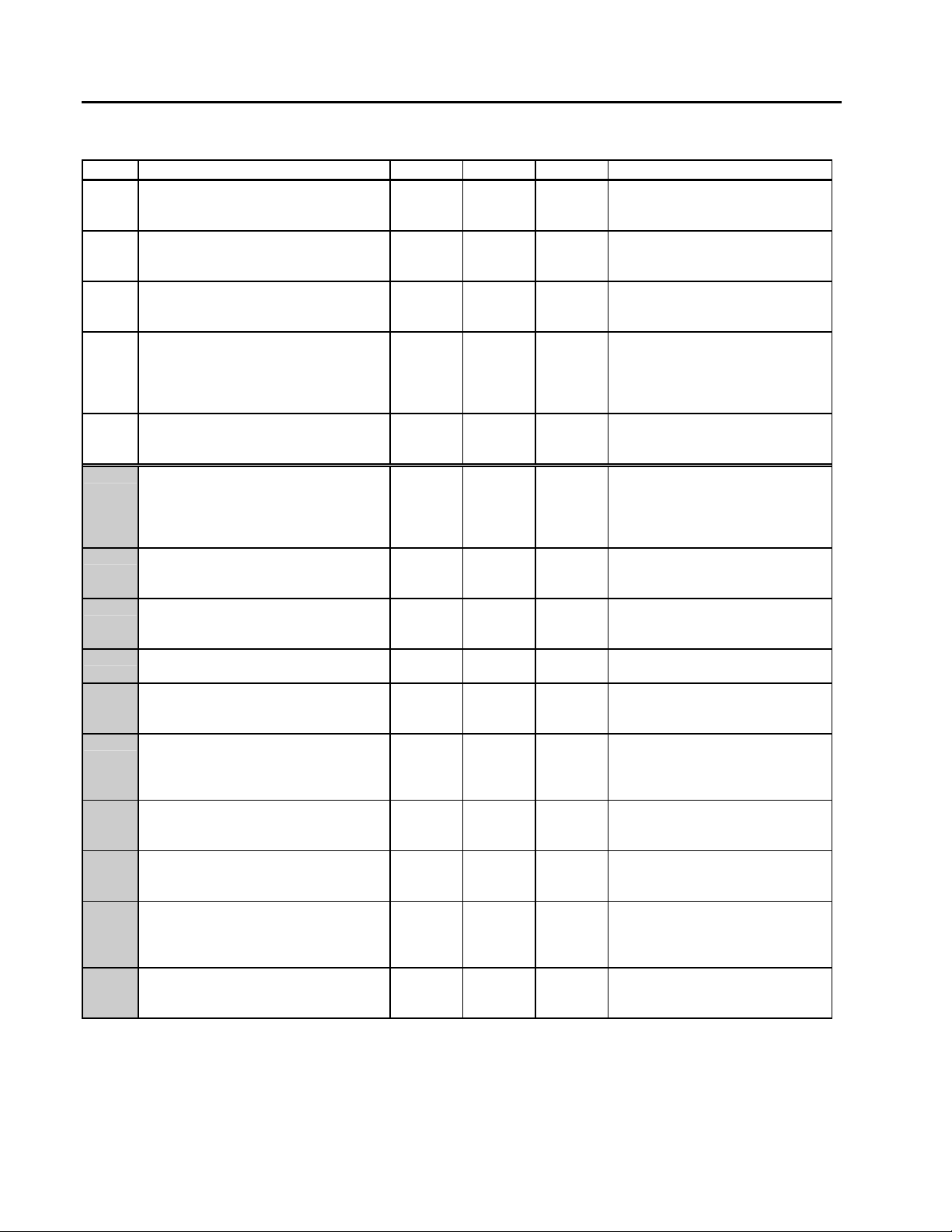

Table 1. Device Status (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

1C4 Reset Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C5 Kill Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C6 Delete Main Database Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C7 Restore Main Database Command

∇ ∆ select YES/NO, ENT enters.

NXT, PRV change step

1C8 Device Status Commands (Exit)

∆ moves up to Step 1C

1D Device Execution Times (Entry)

∇ moves down to Step 1D1

1D1 Scan 1 Execution Time

NXT, PRV change step

1D2 Scan 2 Execution Time

1D3 Scan 3 Execution Time

1D4 Scan 4 Execution Time

1D5 Scan 5 Execution Time

1D6 Scan 6 Execution Time

1D7 Scan 7 Execution Time

1D8 Scan 8 Execution Time

1D9 Scan 9 Execution Time

1D10 Scan 1 Filtered Execution Time

1D11 Scan 2 Filtered Execution Time

1D12 Scan 3 Filtered Execution Time

1D13 Scan 4 Filtered Execution Time

1D14 Scan 5 Filtered Execution Time

1D15 Scan 6 Filtered Execution Time

1D16 Scan 7 Filtered Execution Time

1D17 Scan 8 Filtered Execution Time

1D18 Scan 9 Filtered Execution Time

COMMANDS RESET NO

COMMANDS KILL NO

COMMANDS DEL MAIN NO

COMMANDS RES MAIN NO

COMMANDS DEV STAT

DEV STAT XTIMES

XTIMES T1 IMMED 0:00.000

XTIMES T2 IMMED 0:00.000

XTIMES T3 IMMED 0:00.000

XTIMES T4 IMMED 0:00.000

XTIMES T5 IMMED 0:00.000

XTIMES T6 IMMED 0:00.000

XTIMES T7 IMMED 0:00.000

XTIMES T8 IMMED 0:00.000

XTIMES T9 IMMED 0:00.000

XTIMES T1 FILTD 0:00.000

XTIMES T2 FILTD 0:00.000

XTIMES T3 FILTD 0:00.000

XTIMES T4 FILTD 0:00.000

XTIMES T5 FILTD 0:00.000

XTIMES T6 FILTD 0:00.000

XTIMES T7 FILTD 0:00.000

XTIMES T8 FILTD 0:00.000

XTIMES T9 FILTD 0:00.000

Use to complete tasks and then

perform a power-up.

Press ENT after selecting YES.

Use to perform an immediated

power-up.

Press ENT after selecting YES.

Use to mark the main database as

bad and set the instrument state to

DEFAULT.

Press ENT after selecting YES.

Use to mark the main database as

good (in case delete was issued by

mistake) and if verified as good will

attempt to set the instrument state

to RUN.

Press ENT after selecting YES.

Scan groups 1 through 5 are user

defined intervals for loops. The

fastest group has the highest

priority. The lower numbered group

has a higher priority if the interval is

the same.

Scan group 6 is a system group

Scan groups 7 to 9 are

communications groups.

Recent millisecond scan time for

the associated scan group.

“

“

“

“

“

“

“

“

Average millisecond scan time for

the associated scan group

(updates after group executes).

“

“

“

“

“

“

“

“

SETUP

2-5

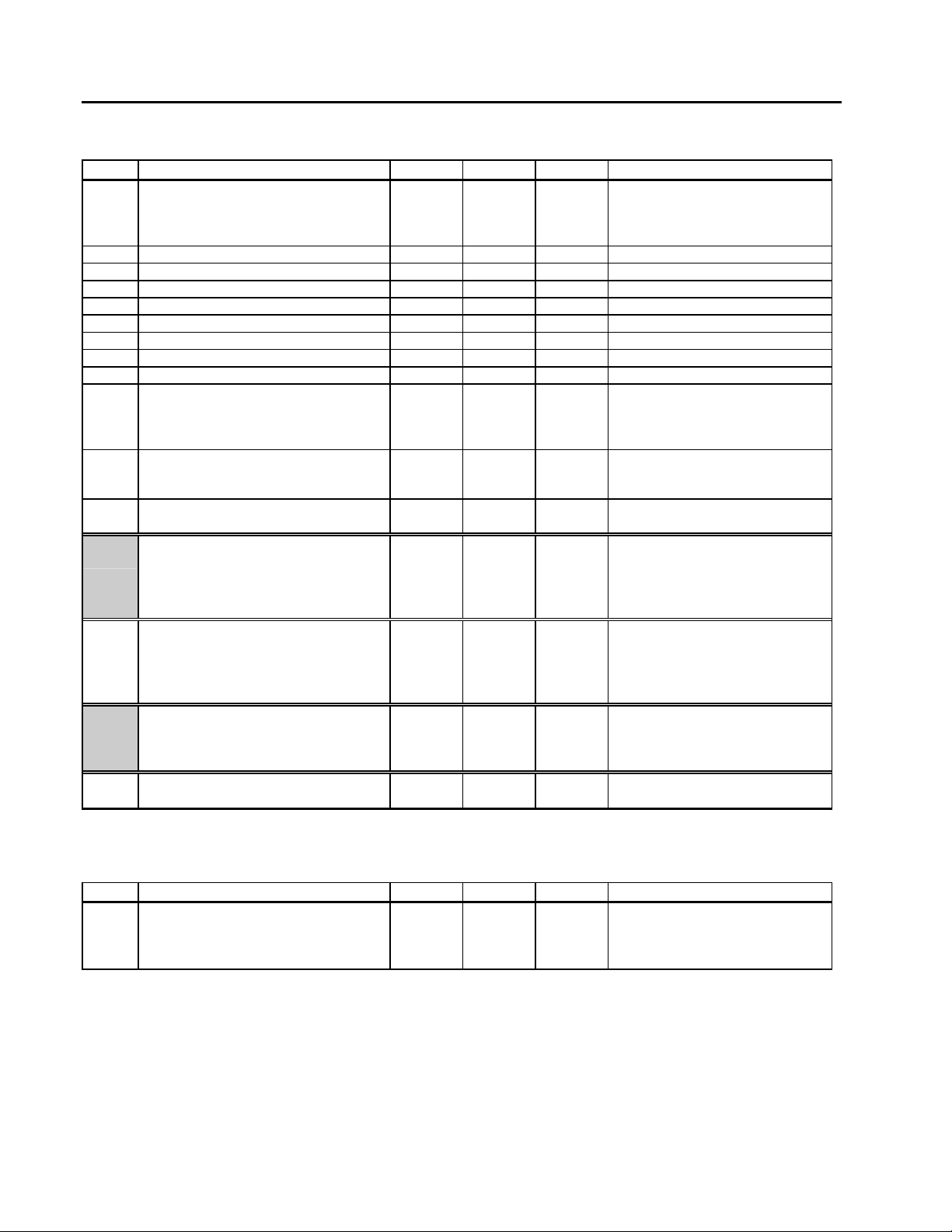

Page 16

MOD 30ML Operation

SETUP

Table 1. Device Status (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

1D10 Scan 1 Maximum Execution Time

1D11 Scan 2 Maximum Execution Time

1D12 Scan 3 Maximum Execution Time

1D13 Scan 4 Maximum Execution Time

1D14 Scan 5 Maximum Execution Time

1D15 Scan 6 Maximum Execution Time

1D16 Scan 7 Maximum Execution Time

1D17 Scan 8 Maximum Execution Time

1D18 Scan 9 Maximum Execution Time

1D19 Base Scan Time

1D20 Scan Idle Time

1D21 Device Status Xtimes (Exit)

∆ moves up to Step 1D

1E

1F

1G

1H Device Status (Exit)

Device Status Time

∇ ∆ changes a number

NXT, PRV flash to change position

ENT enters.

NXT, PRV change step

Device Status Date

∇ ∆ changes a number

NXT, PRV flash to change position

ENT enters.

NXT, PRV change step

Device Status Day

∇ ∆ changes day ENT enters.

NXT, PRV change step

∆ moves up to Step 1

XTIMES T1 MAX 0:00.000

XTIMES T2 MAX 0:00.000

XTIMES T3 MAX 0:00.000

XTIMES T4 MAX 0:00.000

XTIMES T5 MAX 0:00.000

XTIMES T6 MAX 0:00.000

XTIMES T7 MAX 0:00.000

XTIMES T8 MAX 0:00.000

XTIMES T9 MAX 0:00.000

XTIMES BASE SCN 0:00.050

XTIMES IDLE TM 0:00.039

XTIMES DEV STAT

DEV STAT TIME HH:MM:SS

DEV STAT DATE DD:MM:YY

DEV STAT DAY 3

DEV STAT *DEVICE*

Maximum millisecond scan time for

the associated scan group since

entering the current instrument

state.

“

“

“

“

“

“

“

“

Average millisecond of processor

time between base scan ticks.

00:00:00.050, unless

overconfigured.

Average millisecond of unused

processor time between base scan

ticks.

Current time. The instrument

maintains this time even when off.

Always keep set to current time.

Current date. The instrument

maintains this date even when off.

Always keep set to current date.

Current day (Sunday = 1, Saturday

= 7). The instrument maintains this

day even when off. Always keep

set to current day.

Table 2. Device Setup

Step Step Description Line 1 Line 2 Line 6 Entry Description

2 Device Setup

∇ moves down to Step 2A

NXT goes to Step 3 (I/O)

PRV goes to Step 1 (Status)

*DEVICE* NOT CFGD

or

DEV TAG

SETUP

See Table 3 for step 3 (I/O)

See Table 1 for step 1 (Status)

2-6

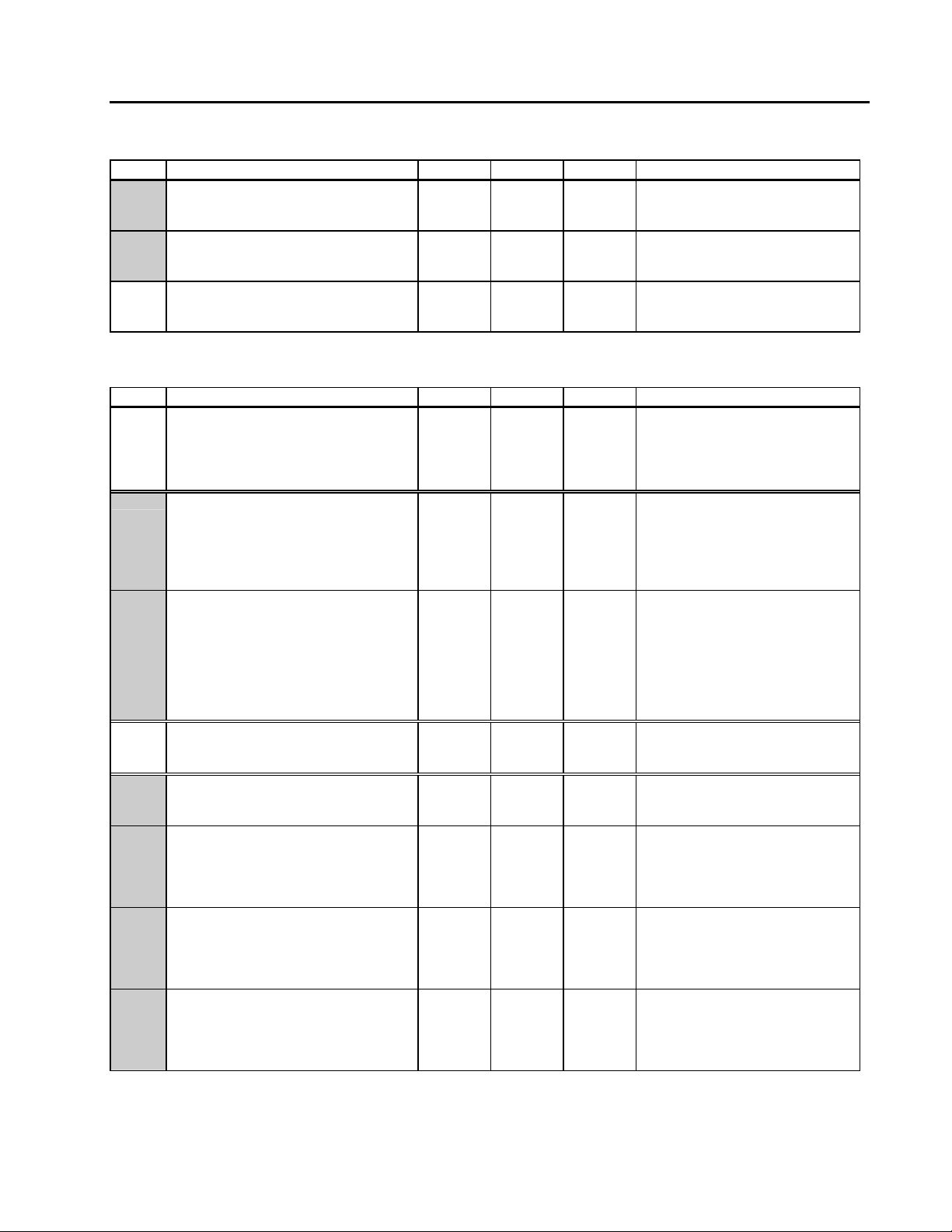

Page 17

MOD 30ML Operation

SETUP

Table 2. Device Setup (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

2A Setup Built-in Communications

∇ moves down to Step 2A1 if

jumper is on ICN or 2A3 if jumper

is on RS232, or RS485.

NXT, PRV change step

2A1 Set ICN Address

∇ ∆ changes number, ENT enters.

NXT, PRV change step

2A2 Set ICN Status Active

∇ ∆ selects YES/NO, ENT enters.

NXT, PRV change step

2A3 Set Modbus Address

∇ ∆ changes number, ENT enters.

NXT, PRV change step

2A4 Set Modbus Baud Rate

∇ ∆ changes rate, ENT enters.

NXT, PRV change step

2A5 Set Modbus Parity

∇ ∆ changes parity, ENT enters.

NXT, PRV change step

2A6 Set Modbus Stopbits

∇ ∆ changes stopbits, ENT enters.

NXT, PRV change step.

2A7 Set Modbus Status Active

∇ ∆ selects YES/NO, ENT enters.

NXT, PRV change step

2A8 Setup Communication (Exit)

∆ moves up to Step 2A.

2B Password

∇ moves down to Step 2B1

NXT, PRV change step

2B1 Password

∇ ∆ changes number, ENT enters

and changes step

2B2 Current Level

ENT goes to step 2B.

2C Setup Device (Exit)

∆ moves up to Step 2

NXT, PRV change step

NOTE: Built-in address cannot be changed if the ICN or MSC block's address within the Main Database is set to a specific number (not

set to "Any"). In order to change the address, the Main Database must first be deleted or a new Database must be downloaded which

has the ICN or MSC block's address configured to "Any".

SETUP BI COMM

BI ICN 1 ADDRESS 15

BI ICN 1 ENABLED

ENABLE?

BI MSC 1 ADDRESS 247

BI MSC 1 BAUDRATE 9600

BI MSC 1 PARITY NONE

BI MSC 1 STOPBITS 1

BI MSC 1 ENABLED

ENABLE?

SETUP

SETUP PASSWORD

PASSWORD 0

CURRENT LEVEL TUNE

SETUP *DEVICE*

NO

NO

Except for the address, built-in

communication parameters can be

changed while the instrument state

is RUN. Address changes require

that the instrument be in the

DEFAULT state (See Note) or with

port status set off after power up

and SCRV switch set (LHD or DEF

state).

ICN address can be 0 to 15. Can

be set when the instrument is in the

DEFAULT state (See Note

Communication jumper set on the

ICN position.

ENABLED = Active. To make

inactive, power up with SCRV

switch set. ENABLE? = Inactive.

Select YES to make it active.

Modbus address can be 1 to 247.

Can be set when the instrument is

in the DEFAULT state.

Communication jumper set on

RS232, or RS485 position.

150, 300, 600, 1200, 2400, 4800,

9600, 19200, 38400

None. Odd, Even

1, 2

ENABLED = Active. To make

inactive, power up with SCRV

switch set. ENABLE? = Inactive.

Select YES to make it active.

Enter a number to change access

to the instrument to None, Tune or

Configure.

NONE an invalid password.

TUNE tune access.

CONFIG configuration access.

).

2-7

Page 18

MOD 30ML Operation

SETUP

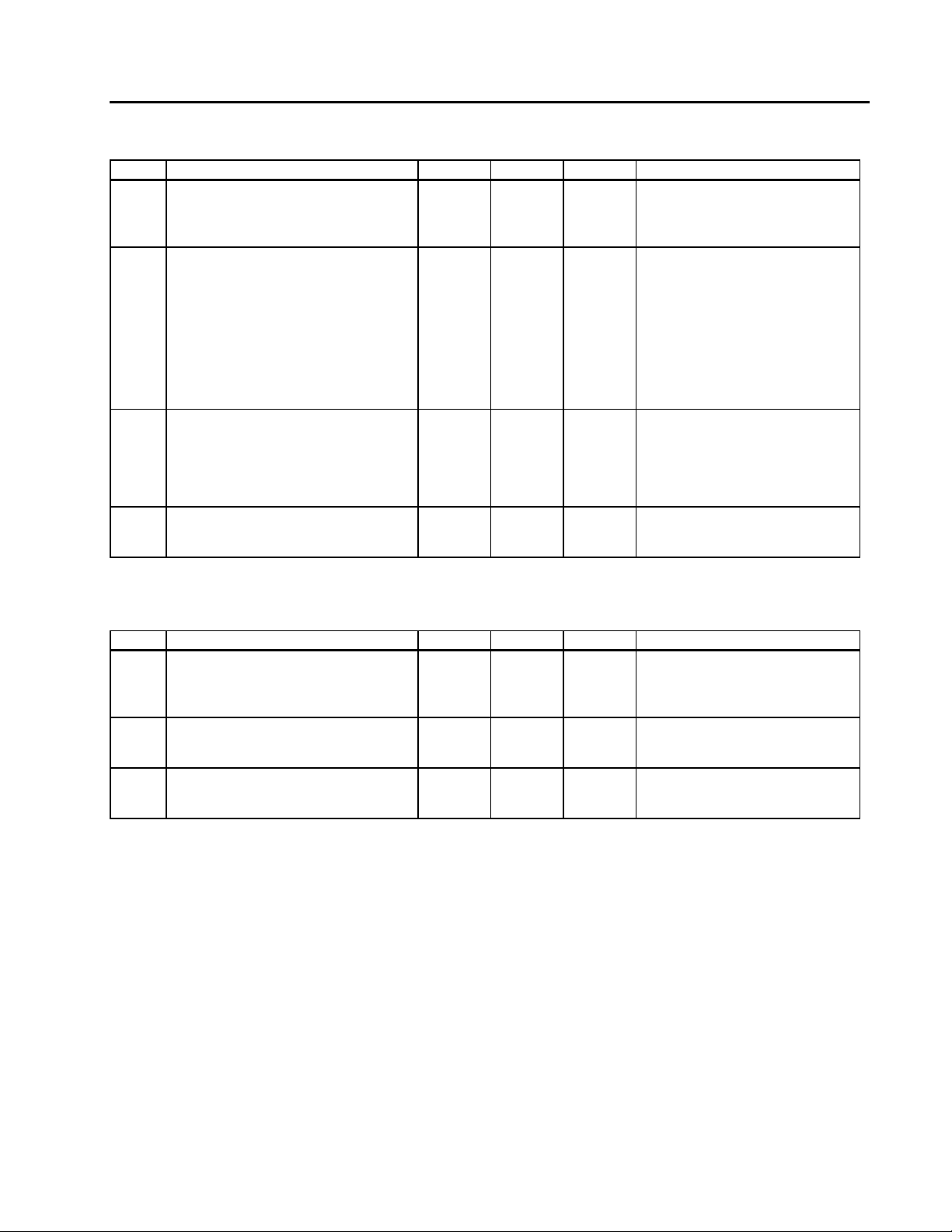

Table 3. Device I/O Status

Step Step Description Line 1 Line 2 Line 6 Entry Description

3 Device I/O

∇ moves down to Step 3A

NXT goes to Step 4 (Events)

PRV goes to Step 2 (Setup)

3A Built in Analog Input 1

AUT, MAN change mode

NXT, PRV change step

3B Built in Analog Input 2

Same as Input 1

3C Built in Analog Output 1

Same as Input 1

3D Built in Analog Output 2

Same as Input 1

3E Module Position 1

Same as Input 1

3F Module Position 2

Same as Input 1

3G Module Position 3

Same as Input 1

3H Module Position 4

Same as Input 1

3I Module Position 5

Same as Input 1

3J Module Position 6

Same as Input 1

3K Module Position 7

Same as Input 1

3L Module Position 8

Same as Input 1

3M Module Position 9

Same as Input 1

3N Module Position 10

Same as Input 1

3O Module Position 11

Same as Input 1

3P Device I/O (Exit)

∆ moves up to Step 3

NXT, PRV change step

*DEVICE* NOT CFGD

or

DEV TAG

BI AIN 1 UNCONFIG

or LABEL

BI AIN 2 UNCONFIG

or LABEL

BI AOUT1 UNCONFIG

or LABEL

BI AOUT1 UNCONFIG

or LABEL

S01 UNCONFIG

or LABEL

S02 UNCONFIG

or LABEL

S03 UNCONFIG

or LABEL

S04 UNCONFIG

or LABEL

S05 UNCONFIG

or LABEL

S06 UNCONFIG

or LABEL

S07 UNCONFIG

or LABEL

S08 UNCONFIG

or LABEL

S09 UNCONFIG

or LABEL

S10 UNCONFIG

or LABEL

S11 UNCONFIG

or LABEL

I/O *DEVICE*

I/O

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

& VALUE

These steps are protected by the

CONFIG password. Enter proper

password, if used, to move down.

Unconfigured or ‘module’ type and

value shown. Press manual key to

change line 3 to (MAN) and get ∇ ∆

keys. Change value from here.

Leave in auto (AUT) to get field

result.

“

“

“

“

“

“

“

“

“

“

“

“

“

“

2-8

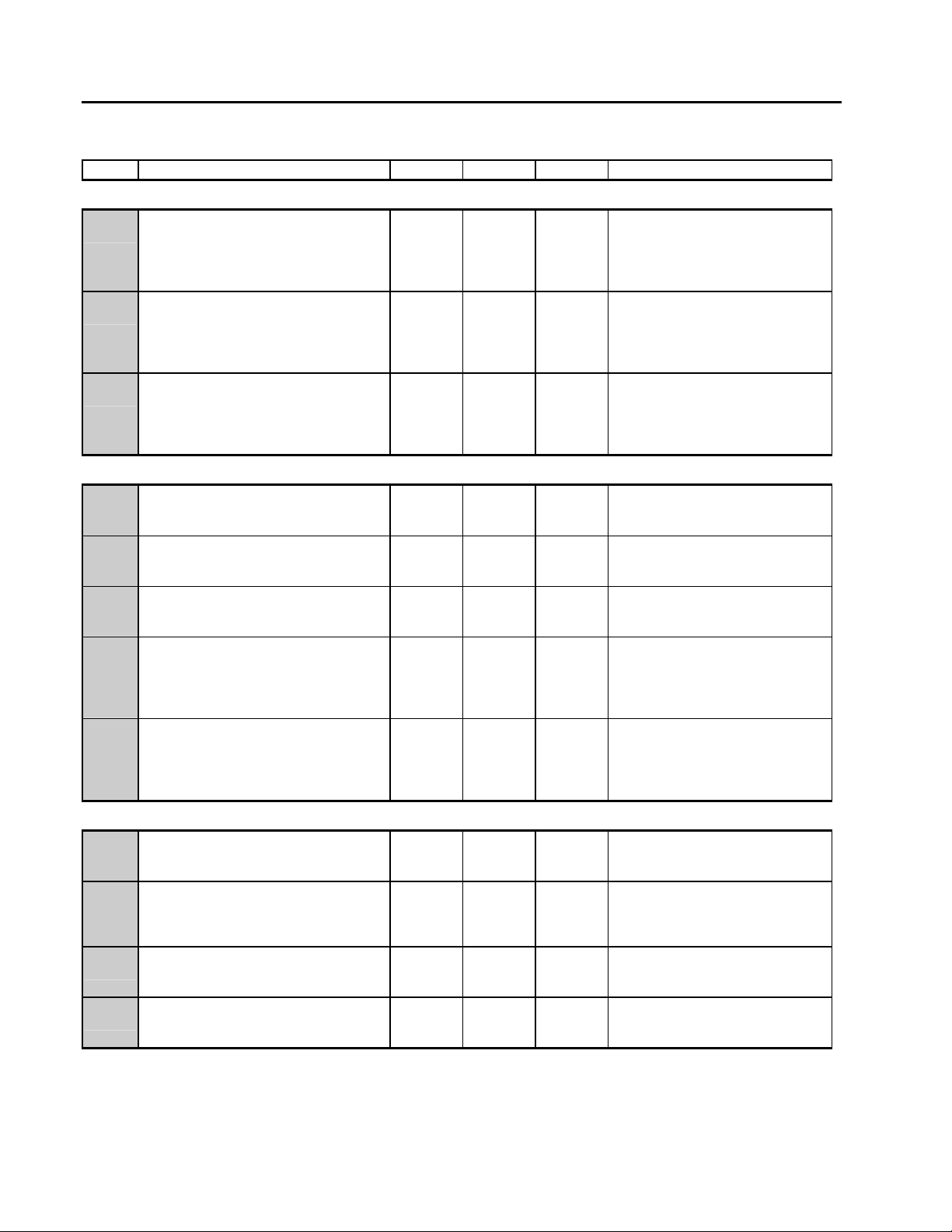

Page 19

MOD 30ML Operation

Table 4. Device Events

Step Step Description Line 1 Line 2 Line 6 Entry Description

4 Device Events (Entry)

∇ moves down to Step 4A

NXT goes to Step 5 (About)

PRV goes to Step 3 (I/O)

4A Block Event Codes

∆ show block event

∇ show event time and type

NXT, PRV change step

4B Block Event Codes (Cont’d)

∆ show block event

∇ show event time and type

NXT, PRV change step

4X Device Events (Exit)

∆ moves up to Step 4.

NXT, PRV change step

*DEVICE* NOT CFGD

INST IN

01/09/96

EVENT Q

01/01/96

EVENTS *DEVICE*

or

DEV TAG

RUN

08:29:34

CLEARED

08:00:00

EVENTS

IF 1

INFOONLY

SE 1

INFOONLY

Line 1 & 2 = event text, Line 3 =

event code, Line 6 = block type and

number. Example shown is

Interface block event (line 3 = code

137, Instrument in RUN state) at

date and time indicated on page 2

(line 3 = msec). See Appendix A

for block event code descriptions.

Use block type (line 6) and event

code (line 3) to find the description.

Same as above for System Event

block event (code 24). See

Appendix A for block event code

descriptions. Use block type (line

6) and event code (line 3) to find

the description.

SETUP

Table 5. About This Device

Step Step Description Line 1 Line 2 Line 6 Entry Description

5 About this Device (Entry)

∇ moves down to Step 5A

NXT goes to Step 6 (Template)

PRV goes to Step 4 (Events)

5A Firmware Version

∆ moves up to Step 5.

NXT, PRV change step

5B Display Version

∆ moves up to Step 5.

NXT, PRV change step

*DEVICE* NOT CFGD

or

DEV TAG

FW VERS I1A 1.0 ISA01

DISP VER 5.1

ABOUT

2-9

Page 20

MOD 30ML Operation

SETUP

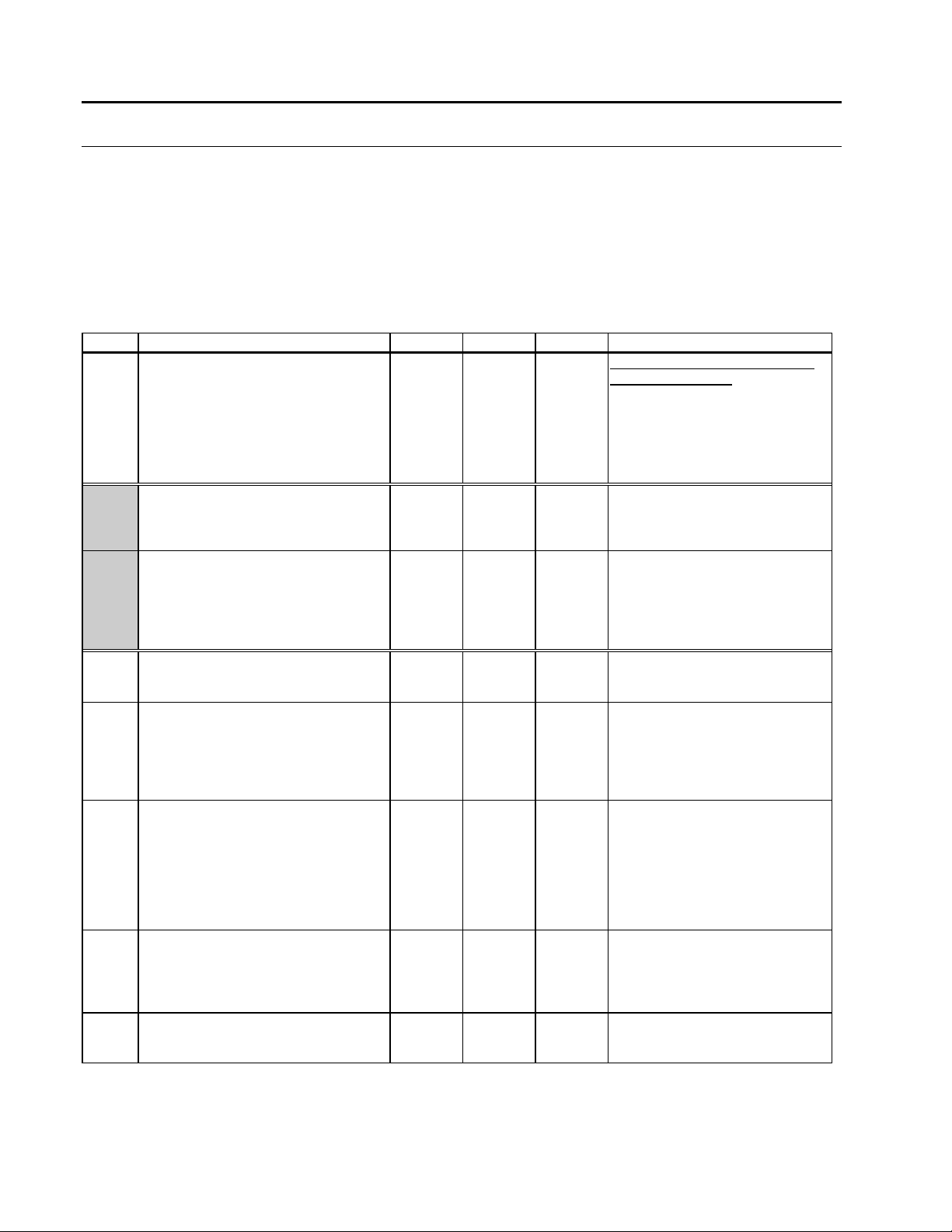

2.5 TEMPLATE SETUP

The general procedure for working with a new template configuration is to load defaults, edit

system parameters, edit first user compound, insert any new user compounds and then edit

them. After configuring compounds for single loop PID or Master Slave Cascade control, you

then install the database.

* NOTE INSERT places a new compound in the list AFTER the current compound.

DELETE deletes the current compound. The System compound cannot be

deleted.

Table 6. Template Configuration

Step Step Description Line 1 Line 2 Line 6 Entry Description

6 Device Templates

∇ moves down to Step 6A if

defaults are not loaded otherwise

move down to Step 6B.

NXT goes to Step 1 (Status)

PRV goes to Step 5 (About)

6A Load Template Defaults

∇ moves down to Step 6A1

NXT, PRV change step

6A1

6B Edit Template

6B1 System Compound List

6B2 First User Compound List

6B21 Verify Delete?

6B3 Compound List

Verify Loading Defaults

∇ ∆ select YES (press again ret-

urns you to Step 1 - Changes inst-

rument state & sends you back)

ENT loads defaults from YES and

changes to Step 6B..

∇ moves down to Step 6B1

NXT, PRV change step

∇ ∆ select List, Insert, Edit

ENT to insert (same as step 6B2)

or edit (Step 7A, Table 7).

NXT, PRV change step

∇ ∆ select List, Delete, Insert, Edit

ENT to insert or edit (Step 8A,

Table 8) or delete (Step 6B21).

NXT, PRV change step

∇ ∆ select YES, NO

ENT from NO (Step 6B2) or from

YES to delete (Step 6B3).

NXT, PRV change step

∆ moves up to Step 6B

NXT, PRV change step

*DEVICE* NOT CFGD

or

DEV TAG

LOAD DEFAULTS

VERIFY LOAD

EDIT TEMPLATE

CMP LIST *SYSTEM* LIST

CMP LIST CTAG01 LIST

VERIFY DELETE? NO

CMP LIST

TEMPLATE

These steps are protected by the

CONFIG password. Enter proper

password, if used, to move down.

If the message MAIN DB HAS NO

TEMPLATE appears, a database

loaded by the Application Builder is

present. This main database must

be deleted to access templates.

Use the default template as a

starting point for creation of a data

base. Default values are the basis

for what is shown here.

Defaults provide a System

Compound (Table 7 list defaults in

the line 6 column) and the CTAG01

Compound (Table 8 list defaults in

the line 6 column).

Select LIST to stay at current

compound list level.

Select INSERT to add a user

compound after system compound.

Select EDIT to access the system

compound.

Select LIST to access current user

compounds.

Select DELETE to remove the

current user compound.

Select INSERT to add a user compound after current compound.

Select EDIT to access the current

compound.

No = do not delete

Yes = delete compound

2-10

Page 21

MOD 30ML Operation

Table 6. Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

6C Install Template

∇ move down to 6C1

NXT, PRV change step

6C1 Installation of Template

∇ ∆ select YES (press again from

NONE returns you to Step 6C)

ENT loads template and displays

first runtime display.

6C2 Configuration Request Failed

ACK acknowledges failure

message and changes to Step 6B.

6D Template (Exit)

∆ moves up to Step 6

NXT, PRV change step

INSTALL TEMPLATE

INSTALL TYPE NONE

CONFIG REQUEST FAILED

TEMPLATE

Installation verifies and loads the

template making it the active

database (changes state to RUN).

Select NONE to exit installation.

Select INITCOLD to install and

RUN template using a cold start.

Select INITWARM to install and

RUN template using a warm start.

Data base verification failed

because of some inconsistency in

database or an active shutdown

condition. To ACK failure, go to

DEV STAT level and set ACK SD

to Yes (Step 1B5).

SETUP

Table 7. System Template Configuration

Step Step Description Line 1 Line 2 Line 6 Entry Description

7A System Device Tag

∇ ∆ change a character

NXT, PRV flash to change position

ENT enters new device tag.

NXT, PRV change step

7B System Scan Groups (Entry)

∇ moves down to Step 7B1

NXT, PRV change step

7B1 Scan Group 1 Interval

∇ ∆ changes interval, ENT enters

NXT, PRV change step

7B2 Scan Group 2 Interval

∇ ∆ changes interval, ENT enters

NXT, PRV change step

7B3 Scan Group 3 Interval

∇ ∆ changes interval, ENT enters

NXT, PRV change step

7B4 Scan Group 4 Interval

∇ ∆ changes interval, ENT enters

NXT, PRV change step

7B5 Scan Group 5 Interval

∇ ∆ changes interval, ENT enters

NXT, PRV change step

7B6 System (Tasks Exit)

∆ moves up to Step 7B

NXT, PRV change step

SYSTEM DEV TAG TEMP 100

SYSTEM SCANGRPS

SCAN GROUP 1 0:00.100

SCAN GROUP 2 0:00.000

SCAN GROUP 3 0:00.000

SCAN GROUP 4 0:00.000

SCAN GROUP 5 0:00.000

SYSTEM

Modify device tag using standard

set of characters. This tag identifies

instrument.

Scan groups 1 through 5 are user

defined intervals for loops. The

fastest group has the highest

priority. The lower numbered group

has a higher priority if the interval is

the same.

Set group scan interval.

(50ms to 50:00.000 Hrs)

Set group scan interval.

(0 to 50:00.000 Hrs)

Set group scan interval.

(0 to 50:00.000 Hrs)

Set group scan interval.

(0 to 50:00.000 Hrs)

Set group scan interval.

(0 to 50:00.000 Hrs)

2-11

Page 22

MOD 30ML Operation

SETUP

Table 7. System Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

7C System Passwords (Entry)

∇ moves down to Step 7C1

NXT, PRV change step

7C1 Tune Passwords

∇ ∆ changes number, ENT enters

NXT, PRV change step

7C2 Configure Passwords

∇ ∆ changes number, ENT enters

NXT, PRV change step

7C3 Access Timeout

∇ ∆ changes number, ENT enters

NXT, PRV change step

7C4 System (Passwords Exit)

∆ moves up to Step 7C

NXT, PRV change step

7D System Alarms (Entry)

∇ moves down to Step 7D1

NXT, PRV change step

7D1 Diagnostic Flash/Beep Rate

∇ ∆ change value, ENT enters

NXT, PRV change step

7D2 Diagnostic Flash

∇ ∆ change value, ENT enters

NXT, PRV change step

7D3 Diagnostic Beep

∇ ∆ change value

7D4 Minimum Low Alarm Priority

∇ ∆ change value, ENT enters

NXT, PRV change step

7D5 High Priority Process Alarm Flash/

Beep Rate

∇ ∆ change value, ENT enters

NXT, PRV change step

7D6 High Priority Process Alarm Flash

∇ ∆ change value, ENT enters

NXT, PRV change step

7D7 High Priority Process Alarm Beep

∇ ∆ change value, ENT enters

NXT, PRV change step

7D8 Low Priority Process Alarm Flash/

Beep Rate

∇ ∆ change value, ENT enters

NXT, PRV change step

7D9 Low Priority Process Alarm Flash

∇ ∆ change value, ENT enters

NXT, PRV change step

SYSTEM PASWORDS

TUNE PASSWORD 0

CONFIG PASSWORD 0

ACCESS TIMEOUT 0

SYSTEM

SYSTEM ALARMS

DIAGNSTC RATE FAST

DIAGNSTC FLASH OFF

DIAGNSTC BEEP ENABLE

MINIMUM LOW PRI 100

HIGH PRI RATE FAST

HIGH PRI FLASH OFF

HIGH PRI BEEP OFF

LOW PRI RATE SLOW

LOW PRI FLASH OFF

The passwords set here will restrict

access to tuning and configuration

features.

Enter a number required to access

tuning parameters.

Enter a number required to access

configuration parameters.

0-54 minutes; 0=infinite

The time in minutes that the tune

and configure access levels will

timeout and return to the operate

level after last keyboard activity.

Alarm indication rates apply to

light, display and beeper. Alarms

are: unacknowledged diagnostics,

high or low process and deviation

conditions, and input quality.

FAST = off 100msec, on 300 msec

SLOW = off 250msec, on 750msec

OFF = flashing is disabled

ENABLE = flash display (LED

always flashes for diagnostic)

OFF = beeping is disabled

ENABLE = beep for diagnostic

All process alarms with priority >=

this value (2 - 255) are considered

LOW priority for display purposes.

FAST = off 100msec, on 300 msec

SLOW = off 250msec, on 750msec

OFF = flashing is disabled

ENABLE = flash display on alarm

OFF = beeping is disabled

ENABLE = beep on alarm

FAST = off 100msec, on 300 msec

SLOW = off 250msec, on 750msec

OFF = flashing is disabled

ENABLE = flash display on alarm

2-12

Page 23

MOD 30ML Operation

Table 7. System Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

7D10 Low Priority Process Alarm Beep

∇ ∆ change value, ENT enters

NXT, PRV change step

7D11 System (Alarms Exit)

∆ moves up to Step 7D

NXT, PRV change step

7E System (System List Exit)

∆ moves up to Step 6B1

NXT, PRV change step

LOW PRI BEEP OFF

SYSTEM

SYSTEM

OFF = beeping is disabled

ENABLE = beep on alarm

Table 8. User Compound Template Configuration

Step Step Description Line 1 Line 2 Line 6 Entry Description

8A Tag ID String

∇ ∆ changes a character

NXT, PRV flash to change position

ENT enters new device tag.

NXT, PRV change step

8B Compound Type

∇ ∆ changes type

ENT requires verification (8B1).

NXT, PRV change step

8B1 Change Compound Type?

∇ ∆ changes value (a change from

YES to NO returns you to Step 8B)

ENT accepts YES

PRV returns to step 8A

8C Scan Group

∇ ∆ changes group, ENT enters.

NXT, PRV change step

8D Process Input (Entry)

∇ moves down to Step 8D1

NXT, PRV change step

8D1 Process Input Slot (location)

∇ ∆ changes slot, ENT enters

NXT, PRV change step

8D2 Process Input Type

∇ ∆ changes type, ENT enters

NXT, PRV change step

8D3 Process Input Filter

∇ ∆ change value, ENT enters

NXT, PRV change step

TAG ID STRING CTAG01

CTAG01 CMP TYPE SNGLLOOP

CHANGE TYPE? NO

CTAG01 SCAN GRP 1

CTAG01 PROC INP

PROC INP SLOT BI AIN 1

PROC INP INP TYPE VOLTS

PROC INP FILTER 0.00

Modify compound tag using

standard set of characters. This 8

character

compound (e.g. TIC-101).

Enter the type of compound to be

built: SNGLLOOP = Single loop or

MASTER C = Master compound.

MASTER C includes a SLAVE C

(the output of the master drives the

setpoint of the slave).

Verify change. If one single loop

compound exists, the one you are

in (CTAG01) will change to the

Master and another (CTAG02) will

be added as a Slave. Changing

from Master to single loop causes

both the master and slave

compounds to become single loop.

Enter a scan group (Task) number

(1 to 5) in which this compound is

to be executed.

Identify process input as NONE,

BI AIN 1, BI AIN 2 or module slot

S01- to S11- for input being

configured (use higher slot number

for double wide modules).

Select type as: VOLTS, MVOLTS,

CURRENT, RESIST, THRMOCPL

1 Slot: RTD2WIRE, CURRNT2W

2 Slots: RTD3WIRE, WIDERES

Built-in only: TC W/CJC, RTD

0 = no filtering (last sampled value

is the input value). Value = time in

minutes up to 100. Large filter

values tend to maintain the

previous input value.

ascii string identifies

SETUP

2-13

Page 24

MOD 30ML Operation

SETUP

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

Volt, Milliamp and Millivolt Inputs Only:

8D4

(V, mA)

8D5

(V, mA)

8D6

(V, mA)

Process Input Low Signal

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input High Signal

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Linearization

∇ ∆ change value, ENT enters

NXT, PRV change step

PROC INP LO SIGNL

1.00

4.00

0.00

PROC INP HI SIGNL

5.00

20.00

100.00

PROC INP LINEARZT LINEAR

0% value in input units.

Volts

milliamps

millivolts

100% value in input units.

Volts

milliamps

millivolts

LINEAR,

MOD SQRT modified square root,

MOD SQR modified square,

SQ ROOT square root, or

SQUARE

Resistance Inputs Only:

8D4

(Res.)

8D5

(Res.)

8D6

(Res.)

8D7

(Res)

8D8

(Res.)

Process Input Resistance Range

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Low Signal

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input High Signal

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Nominal Resistance

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Leadwire Resistance

∇ ∆ change value, ENT enters

NXT, PRV change step

PROC INP RES RNGE LOW

PROC INP LO SIGNL 0.00

PROC INP HI SIGNL 4000.00

PROC INP NOM RES 0.00

PROC INP LW RES 0.00

LOW (built-in = 0 to 55 ohms)

NORMAL (built-in = 0 to 430 ohms)

0% value in ohms.

100% value in ohms.

Resistance produced by RTD in

ohms at zero degrees Celsius.

Ranges are: 2-Wire module (0 to

4000), 3-Wire module (0 to 400),

BI AIN (0 to 430).

Leadwire resistance in ohms.

Values that cause the sum of the

leadwire resistance and the input to

exceed maximum resistance will

cause an overrange error.

Thermocouple Inputs Only:

8D4

(TC)

8D5

(TC)

8D6

(TC)

8D7

(TC)

Process Input Thermocouple Type

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Temperature Scale

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Zero

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Span

∇ ∆ change value, ENT enters

NXT, PRV change step

2-14

PROC INP TC TYPE TC TYPEK

PROC INP TEMPSCAL CELSIUS

PROC INP ZERO 0.00

PROC INP SPAN 1.00

Types are: B, E, J, K, N, R, S, T.

Celsius

Kelvin

Rankine

Farenheit

Specify zero calibration value in

result units.

One is nominal. Specify span

calibration value in result units.

Page 25

MOD 30ML Operation

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

RTD Inputs Only:

8D4

(RTD)

8D5

(RTD)

8D6

(RTD)

8D7

(RTD)

8D8

(RTD)

8D9

(RTD)

8D10

(RTD)

Process Input RTD Type

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Temperature Scale

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Resistance Range

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Nominal Resistance

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Leadwire Resistance

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Zero

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Span

∇ ∆ change value, ENT enters

NXT, PRV change step

PROC INP RTD TYPE PT3850

PROC INP TEMPSCAL CELSIUS

PROC INP RES RNGE LOW

PROC INP NOM RES 0.00

PROC INP LW RES 0.00

PROC INP ZERO 0.00

PROC INP SPAN 1.00

PT3850

PT3923

PT3902

PT3911

NI6270

Celsius

Kelvin

Rankine

Farenheit

LOW (built-in = 0 to 55 ohms)

NORMAL (built-in = 0 to 430 ohms)

Resistance produced by RTD in

ohms at zero degrees Celsius.

Ranges are: 2-Wire module (0 to

4000), 3-Wire module (0 to 400),

BI AIN (0 to 430).

Leadwire resistance in ohms.

Values that cause the sum of the

leadwire resistance and the input to

exceed maximum resistance will

cause an overrange error.

Specify zero calibration value in

result units.

One is nominal. Specify span

calibration value in result units.

All Inputs:

8D11 Process Input Display Format

∇ ∆ change value, ENT enters

NXT, PRV change step

8D12 Process Input Low Engineering Unit

∇ ∆ change value, ENT enters

NXT, PRV change step

8D13 Process Input High Engineering Unit

∇ ∆ change value, ENT enters

NXT, PRV change step

8D14 Process Input Engineering Unit

Label (not for TC or RTD)

∇ ∆ changes a character

NXT, PRV flash to change position

ENT enters new label.

NXT, PRV change step

PROC INP DISP FMT FLOAT 3

PROC INP LO ENGU 0.000

PROC INP HI ENGU 100.000

PROC INP EU LABEL

Float 0 = x

Float 1 = x.x

Float 2 = x.xx and so forth to

Float 6 = x.xxxxxx

0% value in engineering units.

100% value in engineering units.

Up to a 4 character label to appear

after process input value. Value

has precedence over label. First

character entered becomes

leftmost character.

SETUP

2-15

Page 26

MOD 30ML Operation

SETUP

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

Millivolt and Thermocouple Inputs Only:

8D14

(TC)

8D15

(TC)

Process Input CJC Source

∇ ∆ change value, ENT enters

NXT, PRV change step

Process Input Burnout

∇ ∆ change value, ENT enters

NXT, PRV change step

PROC INP CJC SRC NONE

PROC INP BURNOUT NONE

NONE, BI AIN 1, S01 TO S11

NONE - no burnout detection

DN SCALE - signal moves

downscale if burnout is detected.

UP SCALE. - signal moves upscale

if burnout is detected.

All Inputs:

8D16 Process Input Low Quality

∇ ∆ change value, ENT enters

NXT, PRV change step

8D17 Process Input High Quality

∇ ∆ change value, ENT enters

NXT, PRV change step

8D18 Process Input Quality Alarm

∇ ∆ change value, ENT enters

NXT, PRV change step

8D19 Process Input Quality Digital Output

∇ ∆ change value, ENT enters

NXT, PRV change step

8D20 Process Input Quality Priority

∇ ∆ change value, ENT enters

NXT, PRV change step

8D21 Process Input (Exit)

∆ moves up to Step 8D

NXT, PRV change step

8E Setpoint (Entry)

∇ moves down to Step 8E1

NXT, PRV change step

8E1 Setpoint Display Format

∇ ∆ change value, ENT enters

NXT, PRV change step

8E2 Remote Setpoint Input Setup (Entry)

∇ moves down to Step 8E2A

NXT, PRV change step

8E2A Remote Setpoint Slot Position

∇ ∆ change value, ENT enters

NXT, PRV change step

8E2B Remote Setpoint Input Type

∇ ∆ change value, ENT enters

NXT, PRV change step

8E2C Remote Setpoint Input Setup

Same as process value inputs.

8E2D Remote Setpoint Input Setup (Exit)

∆ moves up to Step 8E2

NXT, PRV change step

PROC INP LO QUAL -10.0

PROC INP HI QUAL 110.000

PROC INP QUAL ALM DISABLE

PROC INP QA D OUT NONE

PROC INP QA PRI 1

PROC INP

CTAG01 SETPT

SETPOINT DISP FMT FLOAT 3

REMOTE SETPOINT

REMSETPT SLOT NONE

REMSETPT INP TYPE VOLTS

REMSETPT

Result is set BAD if it goes below

this value.

Result is set BAD if it goes above

this value. High quality must be

higher than the low quality value.

Disable or Enable.

NONE or S01 to S11 location of

digital output module.

0 = suppress unacknowledge

1 to 255 = priority level.

Float 0 = x

Float 1 = x.x

Float 2 = x.xx and so forth to

Float 6 = x.xxxxxx

None, BI AIN 1, BI AIN 2, S01 to

S11

Select type as: VOLTS, MVOLTS,

CURRENT, RESIST, THRMOCPL

1 Slot: RTD2WIRE, CURRNT2W

2 Slots: RTD3WIRE, WIDERES

Built-in only: TC W/CJC, RTD

See Process Value input setup.

2-16

Page 27

MOD 30ML Operation

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

Steps 8E3A through F only presented when there is a remote setpoint input

8E3A Local Setpoint Enable

∇ ∆ change value, ENT enters

NXT, PRV change step

8E3B Setpoint Ratio

∇ ∆ change value, ENT enters

NXT, PRV change step

8E3C Setpoint Ratio Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8E3D Setpoint Bias

∇ ∆ change value, ENT enters

NXT, PRV change step

8E3E Setpoint Bias Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8E3F Setpoint Balance

∇ ∆ change value, ENT enters

NXT, PRV change step

LOCAL SETPOINT ENABLE

SETPOINT RATIO DISABLE

SETPOINT RATIO 1.000

SETPOINT BIAS DISABLE

SETPOINT BIAS 0.000

SETPOINT BALANCE AUTO RAT

Enable or Disable a local setpoint

value

Enable or Disable a remote

setpoint ratio value

Initial ratio value.

Auto balance calculation is:

(Active Setpoint - Bias) / Rem SP

Enable or Disable a remote

setpoint bias value

Initial bias value.

Auto balance calculation is:

Active Setpoint - (Rem SP * Ratio)

AUTO RAT, Ratio value calculated

to balance transition to remote.

STANDARD, Ratio and Bias use

the operator values.

AUTO BIA, Bias value calculated to

balance transition to remote.

Setpoint (Cont’d)

8E4 Setpoint Low Limit

∇ ∆ change value, ENT enters

NXT, PRV change step

8E5 Setpoint High Limit

∇ ∆ change value, ENT enters

NXT, PRV change step

8E6 Setpoint Restart Mode

∇ ∆ change value, ENT enters

NXT, PRV change step

8E7 Setpoint Initial Mode

∇ ∆ change value, ENT enters

NXT, PRV change step

8E8 Setpoint Restart Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8E9 Setpoint Restart Preset Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8E10 Setpoint Initial Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8E11 Setpoint Tracking

∇ ∆ change value, ENT enters

NXT, PRV change step

8E12 Setpoint (Exit)

∆ moves up to Step 8E

NXT, PRV change step

SETPOINT LO LIMIT 0.000

SETPOINT HI LIMIT 100.000

RESTART SP MODE PREVIOUS

INITIAL SP MODE LOCAL

RESTART SP VAL PREVIOUS

RESTART VALUE 0.0

INITIAL VALUE 0.0

SETPOINT TRACK DISABLE

COMPOUND

Setpoint values to the PID

algorithm are limited to this number

or above.

Setpoint values to the PID

algorithm are limited to this number

or below.

Previous (requires setting initial SP

Mode), Local or Remote

Local only for Master Controller.

Local or Remote

Local only for Master Controller.

Previous (enter an Initial Value) or

Preset (enter a Restart Value).

Enter restart value for setpoint.

Enter initial value for setpoint.

Enable or Disable

When active, setpoint tracks input

while in manual.

SETUP

2-17

Page 28

MOD 30ML Operation

SETUP

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

8F Control Type (Entry)

∇ moves down to Step 8F1

NXT, PRV go to 8F, 8D

8F1 Control Algorithm Type

∇ ∆ change value, ENT enters

NXT, PRV change step

Values are: ESPO, PMPO, EMPO,

EOEO, ESEO, EMEO, EOOE, EOPE,

EOEE, EOOO, OSOO, PSOO, ESOO,

OMOO, PMOO, EMOO, EOPO, PSPO

8F2 Control Action

∇ ∆ change value, ENT enters

NXT, PRV change step

8F3 Gain

∇ ∆ change value, ENT enters

NXT, PRV change step

8F4 Reset

∇ ∆ change value, ENT enters

NXT, PRV change step

8F5 Preact

∇ ∆ change value, ENT enters

NXT, PRV change step

8F6 Control Input Filter Type

∇ ∆ change value, ENT enters

NXT, PRV change step

8F7 Filter Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8F8 Control Manual Reset Balance Type

∇ ∆ change value, ENT enters

NXT, PRV change step

CTAG01 CONTROL

CONTROL ALGO TYP ESPO

CONTROL ACTION REVERSE

GAIN 0.01

RESET 0.01

PREACT 0.00

CONTROL FILTYPE NONE

FILTER 0.00

CONTROL MR TYPE NONE

Gain (1st Character):

O = Off

P = On Process

E = On Error

Reset (2nd Character):

O = Off

S = Standard

M = Micro-Scan

Pre-Act (3rd Character):

O = Off

P = On Process

E = On Error

Manual Reset (4th Character):

O = Off

E = Enabled

Reverse (output decreases as

process rises above setpoint),

Direct (output increases as process

rises above setpoint)

0.01 to 125.0

Proportional response in a fixed

gain controller.

0.01 to 125.0

Reset in repeats per minute.

0.00 = Off

0.07 to 32 preact time base value.

NONE = No low pass filter (last

sampled value is input value)

PRE AUTO = Preact Auto type low

pass filter based on derivative time

and task execution rate.

PRE USER = Filter time applied to

derivative (on process error) signal

before use in PID.

PROCUSER = Filter time applied

to process (on process error) signal

before use in PID.

Filter Time in minutes. Small

values maintain recent input and

large values maintain previous

input.

NONE = No manual reset balance.

PRCDLESS = Procedureless

manual reset (value recalculated

on a transfer to auto). Calculation

compares output and error signals

(MR = output - (gain * error).

2-18

Page 29

MOD 30ML Operation

Table 8. User Compound Template Configuration (Cont’d)

Step Step Description Line 1 Line 2 Line 6 Entry Description

8F9 Manual Reset Value

∇ ∆ change value, ENT enters

NXT, PRV change step

8F10 Feed Forward Compensation Input

(Entry)

∇ moves down to Step 8F10A

NXT, PRV change step

8F10A Feed Forward Compensation Input

Slot Position

∇ ∆ change value, ENT enters

NXT, PRV change step

8F10B Feed Forward Input Type

∇ ∆ change value, ENT enters

NXT, PRV change step

8F10C Feed Forward Input Setup

Same as process value inputs.

8F10D Feed Forward Input Setup (Exit)

∆ moves up to Step 8F10

NXT, PRV change step

8F11 Feed Forward Gain

∇ ∆ change value, ENT enters

NXT, PRV change step

8F12 Feed Forward Bias

∇ ∆ change value, ENT enters

NXT, PRV change step

8F13 Feed Forward Calculation

∇ ∆ change value, ENT enters

NXT, PRV change step

8F14 Output Mode Restart Value

(not used with MASTER C)

∇ ∆ change value, ENT enters

NXT, PRV change step

8F15 Initial Mode for Previous

∇ ∆ change value, ENT enters

NXT, PRV change step

8F16 Control Type (Exit)

∆ moves up to Step 8F

NXT, PRV change step

MR VAL 0.00

FEED FORWARD

FEED FWD SLOT NONE

FEED FWD INP TYPE VOLTS

FEED FWD

FF GAIN

FF BIAS

FF CALC ADD

RESTART MODE PREVIOUS

INITIAL MODE MANUAL

COMPOUND

Enter initial manual reset value

(-10.0 to 100.0 %) for proportional

only controllers.

Value to be added or multiplied to

output of PID.

None, BI AIN 1, BI AIN 2, S01 to

S11

Select type as: VOLTS, MVOLTS,

CURRENT, RESIST, THRMOCPL

1 Slot: RTD2WIRE, CURRNT2W

2 Slots: RTD3WIRE, WIDERES